Patents

Literature

956results about How to "Uniform surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

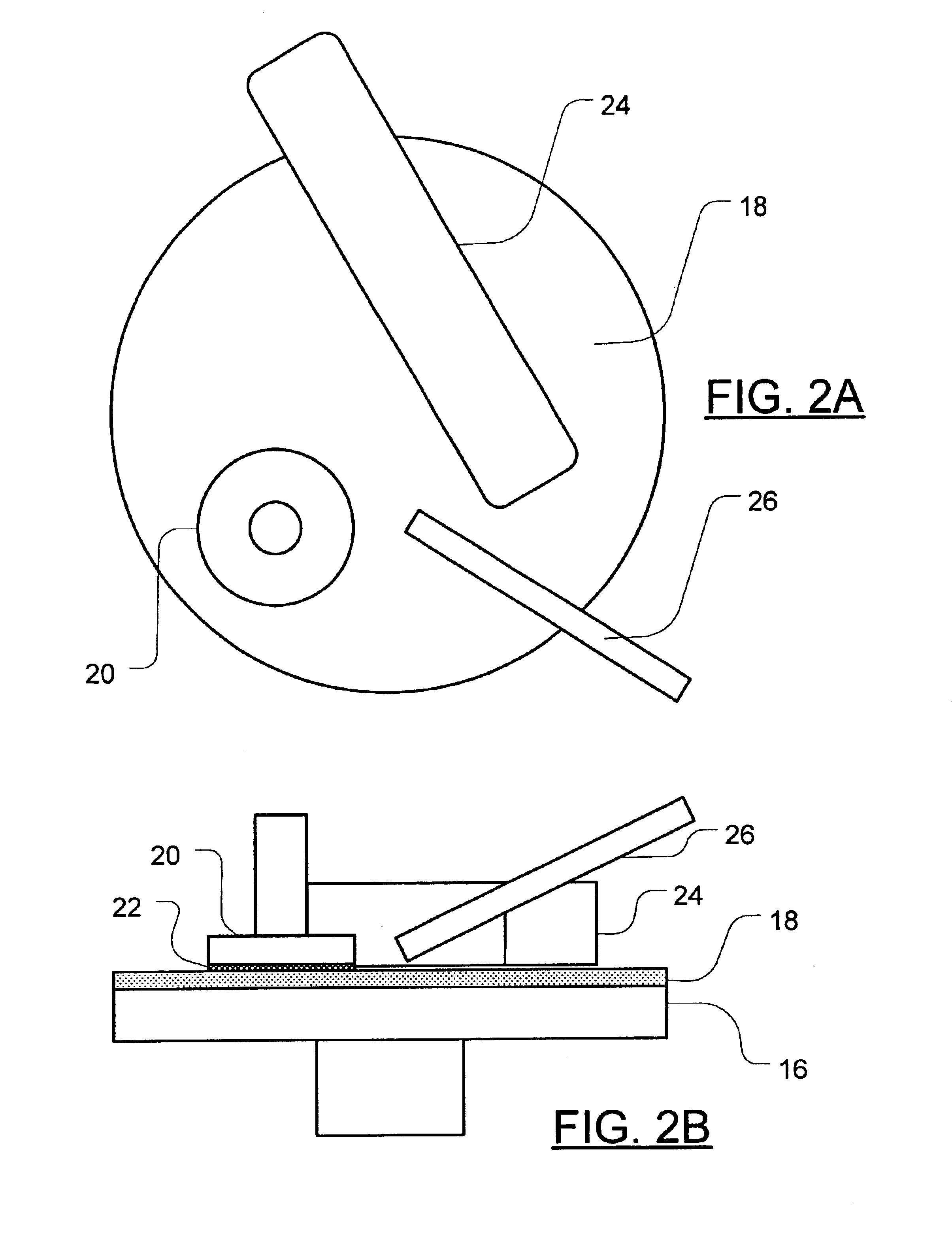

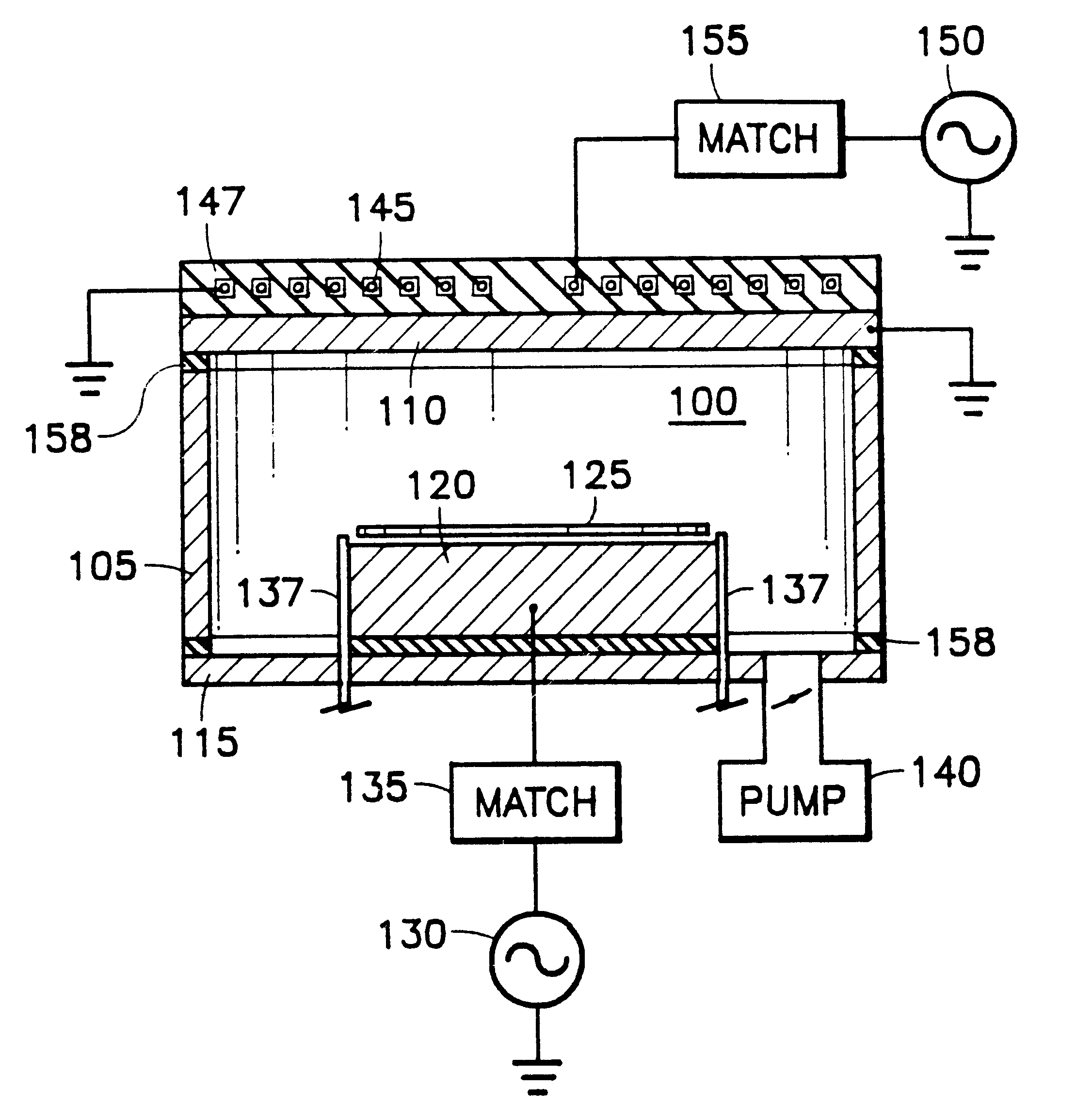

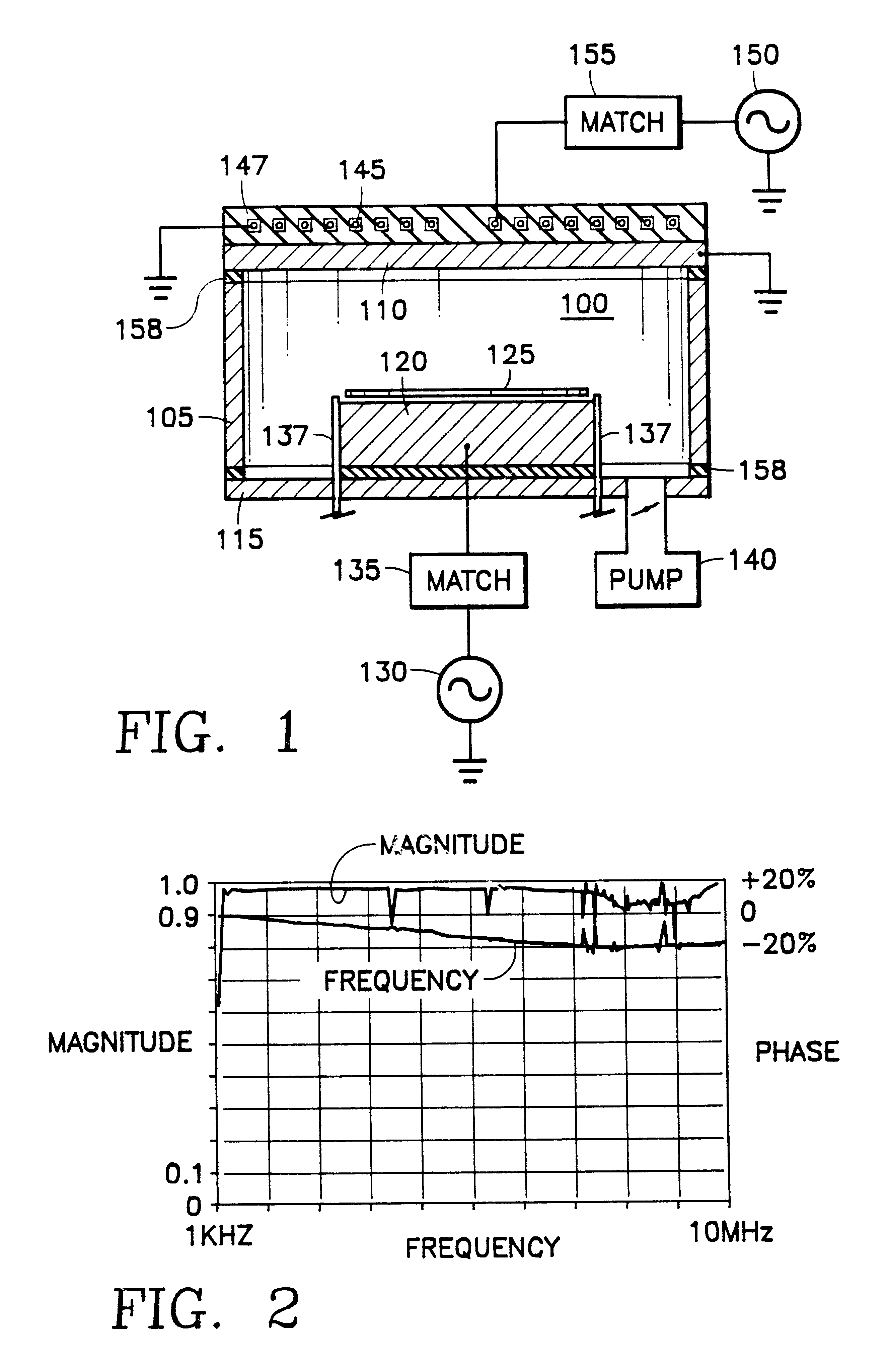

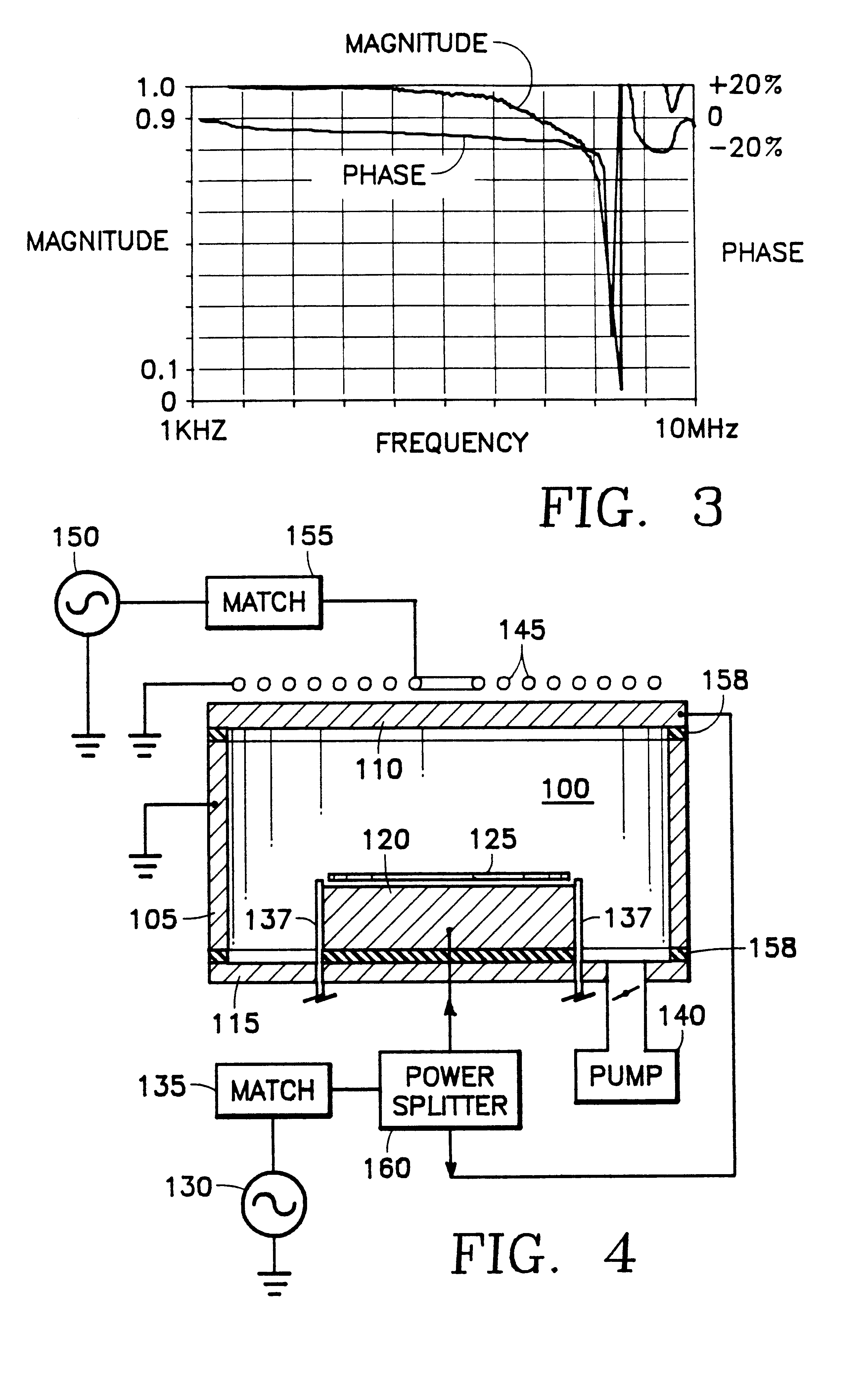

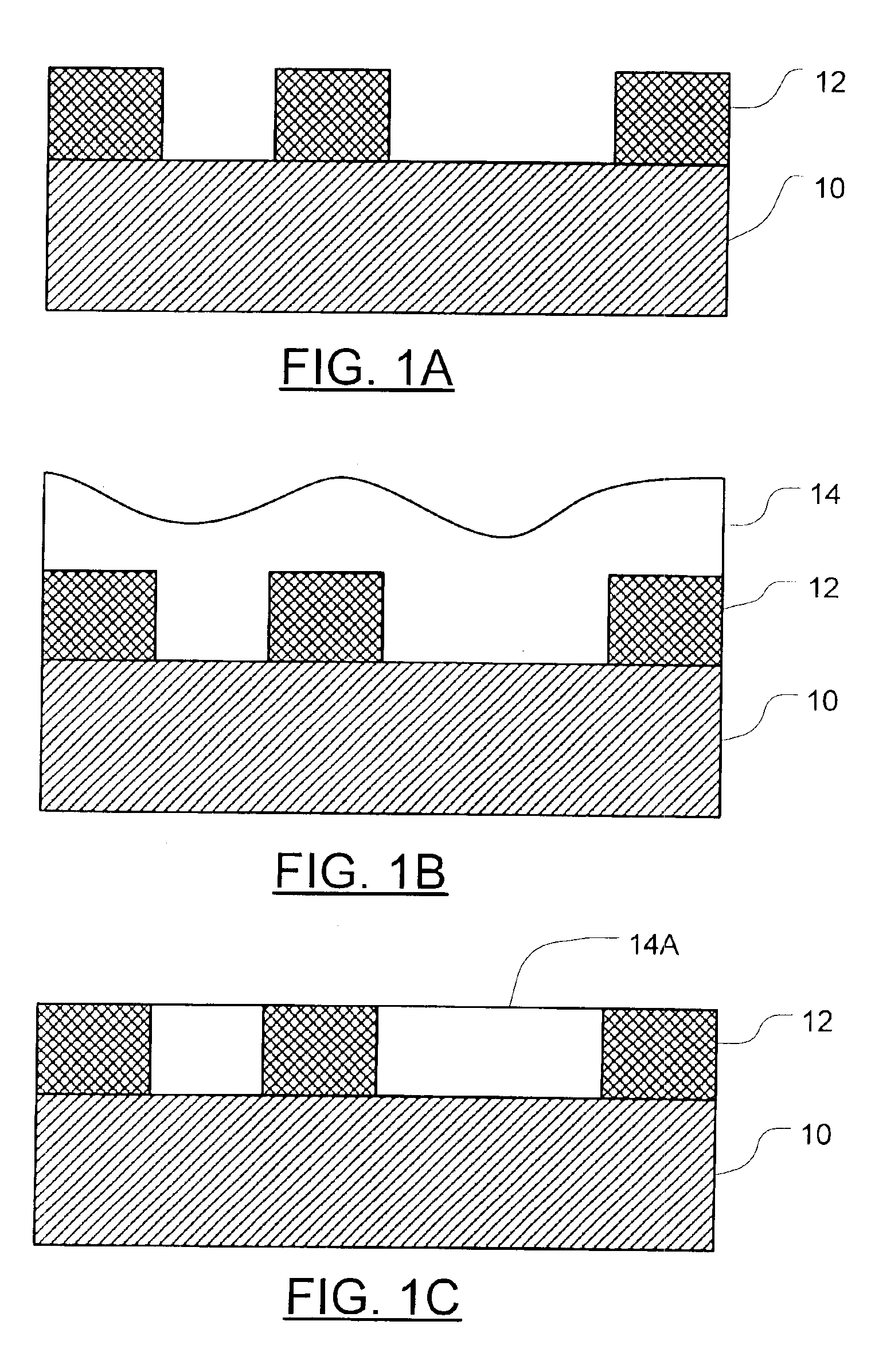

Parallel plate electrode plasma reactor having an inductive antenna and adjustable radial distribution of plasma ion density

InactiveUS6054013AMinimize interactionAvoid flowElectric discharge tubesSemiconductor/solid-state device manufacturingParallel plateThree dimensional shape

There is disclosed a plasma reactor for processing a semiconductor workpiece such as a wafer, including a chamber having an overhead ceiling with a three-dimensional shape such as a hemisphere or dome. The reactor further includes an inductive antenna over the ceiling which may be conformal or nonconformal in shape with the ceiling. The ceiling may be a semiconductor material so that it can function as both a window for the inductive field of the antenna as well as an electrode which can be grounded, or to which RF power may be applied or which may be allowed to float electrically. The reactor includes various features which allow the radial distribution of the plasma ion density across the wafer surface to be adjusted to an optimum distribution for processing uniformity across the wafer surface.

Owner:APPLIED MATERIALS INC

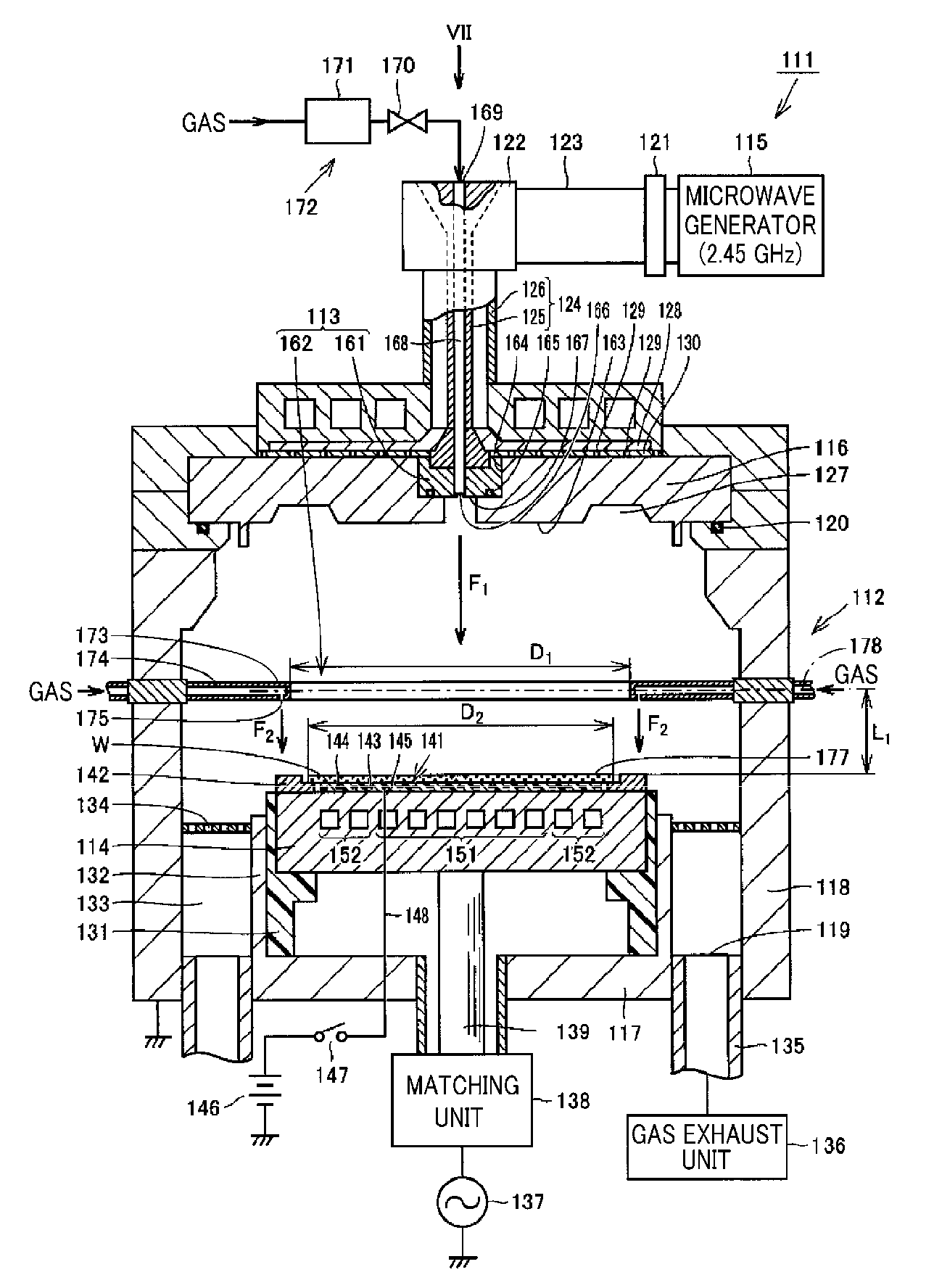

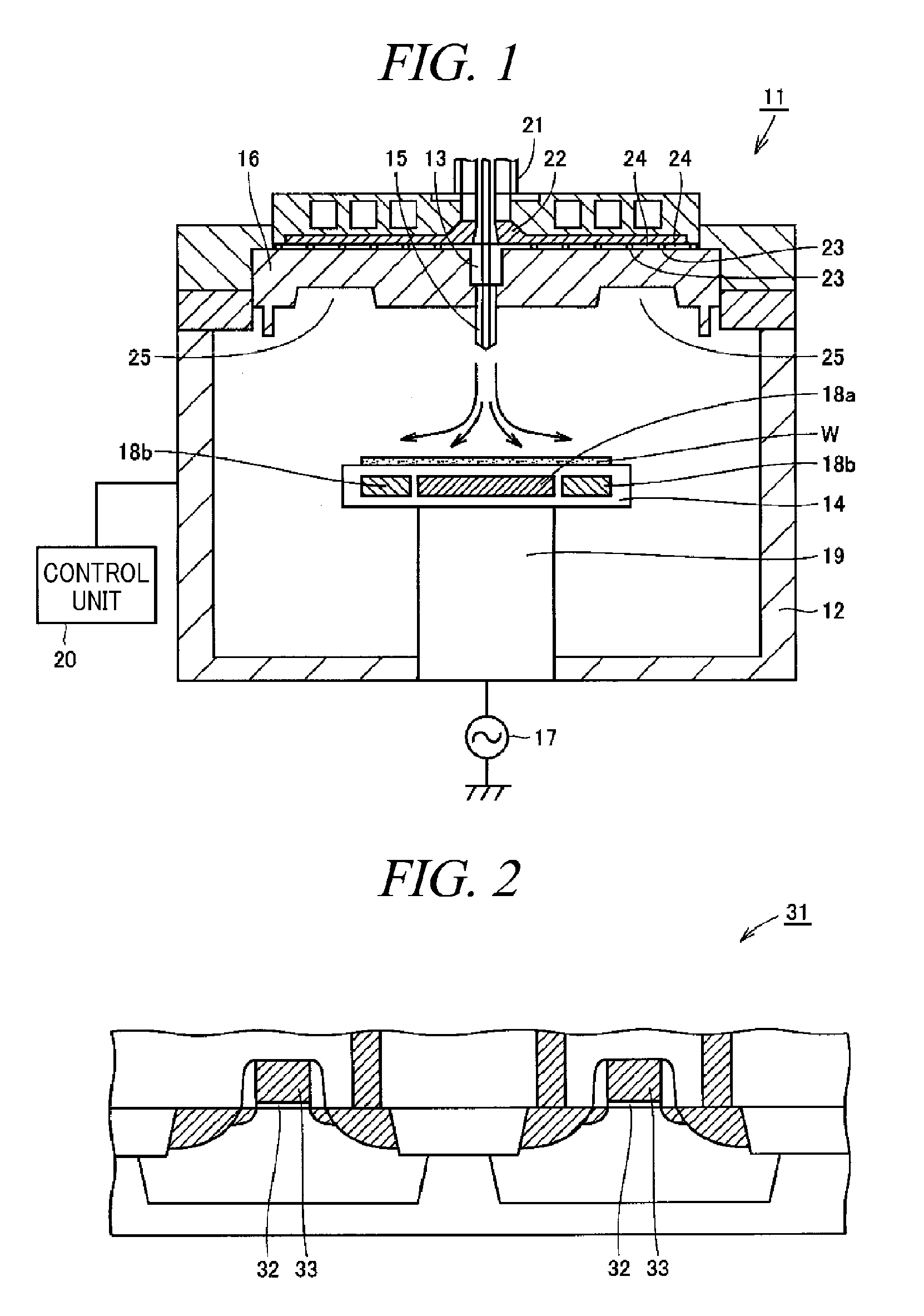

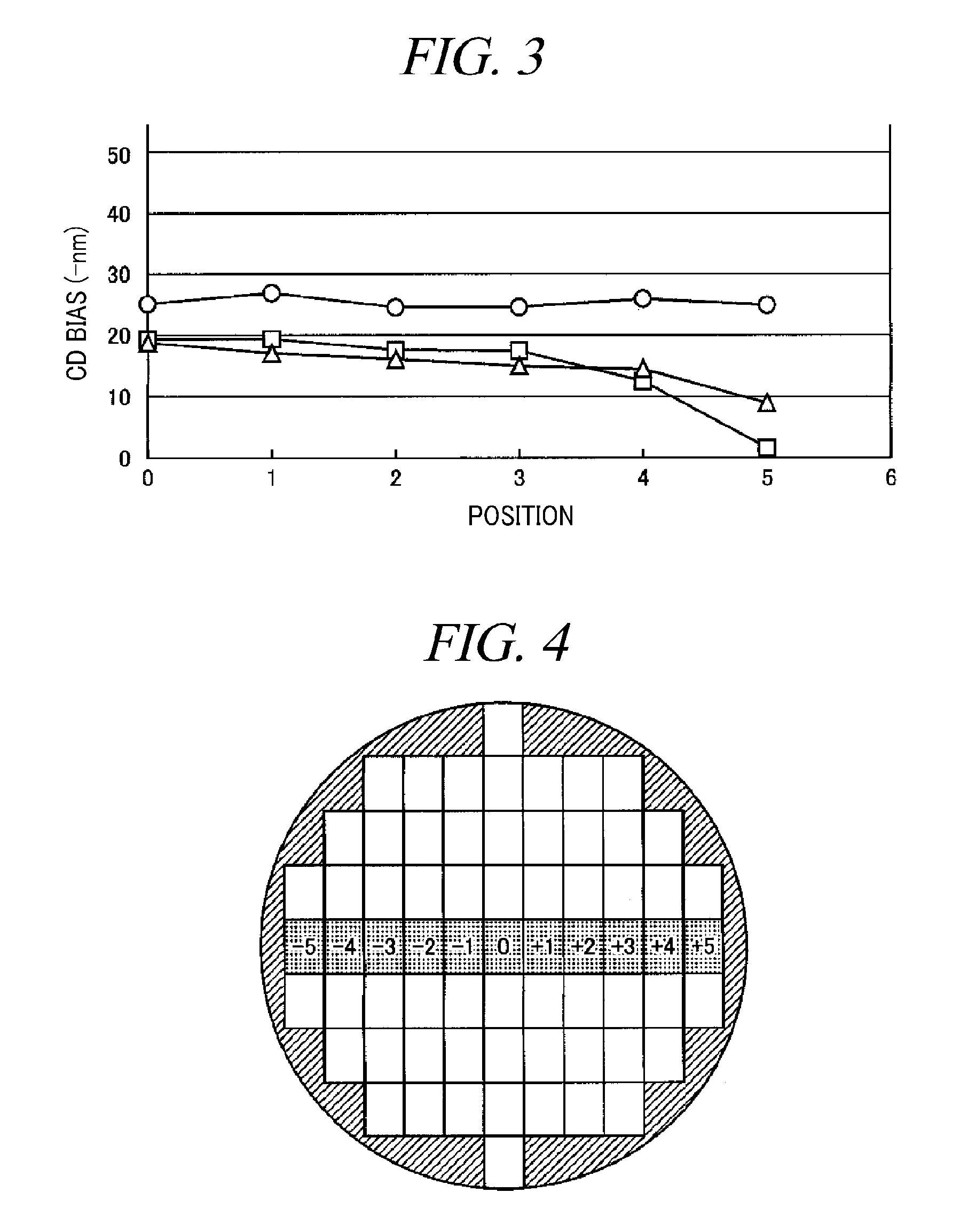

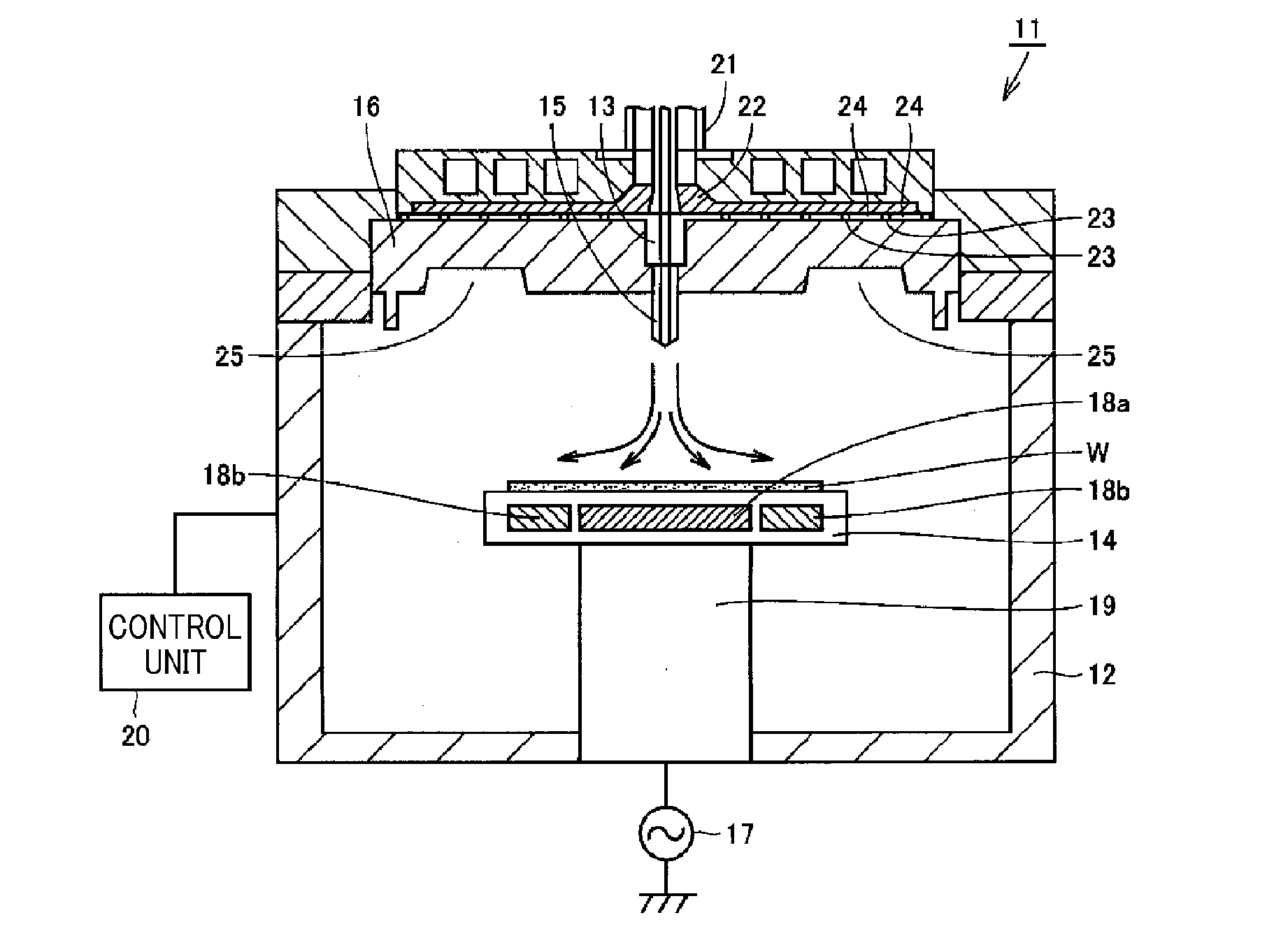

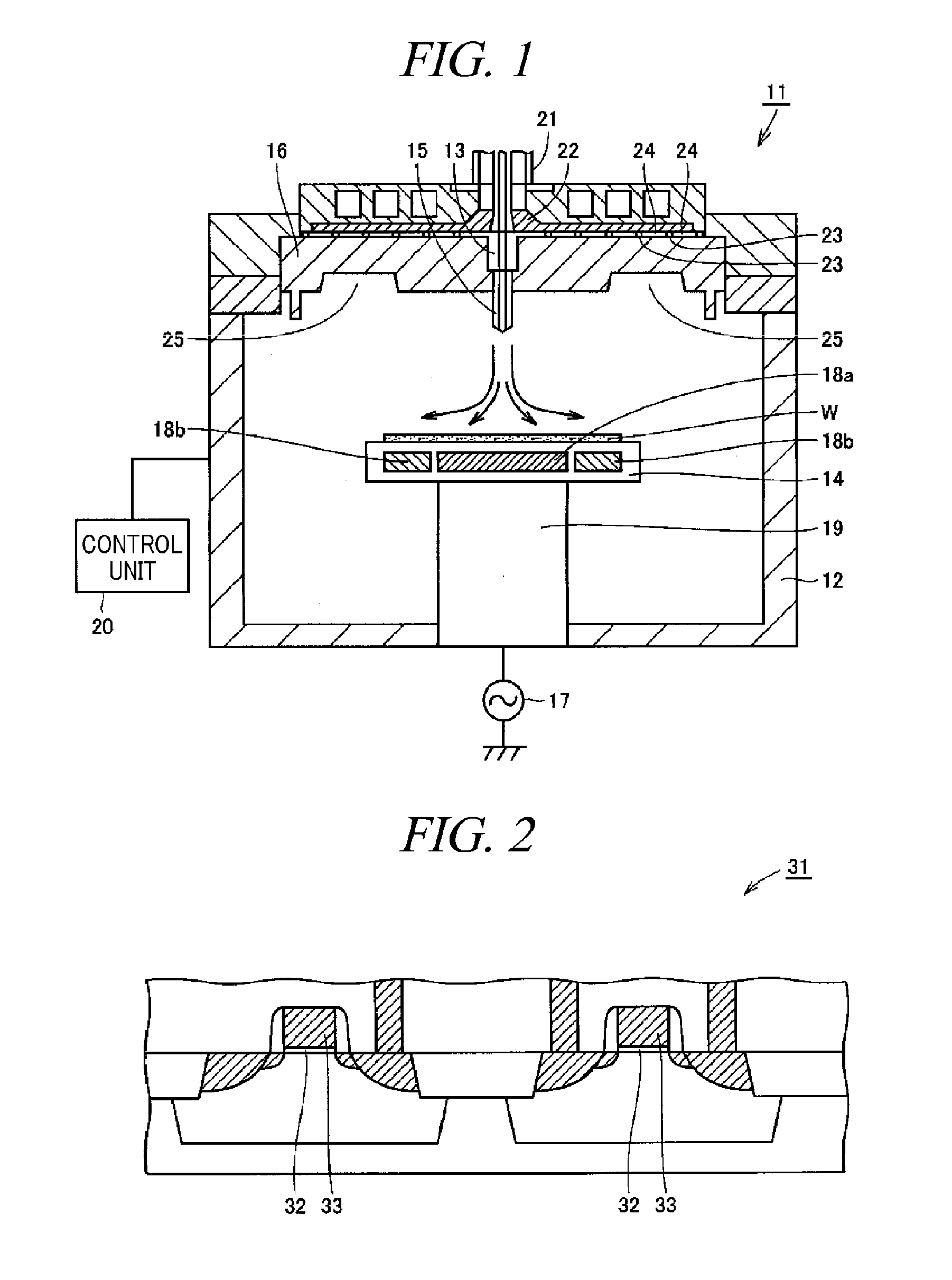

Plasma etching apparatus and plasma etching method

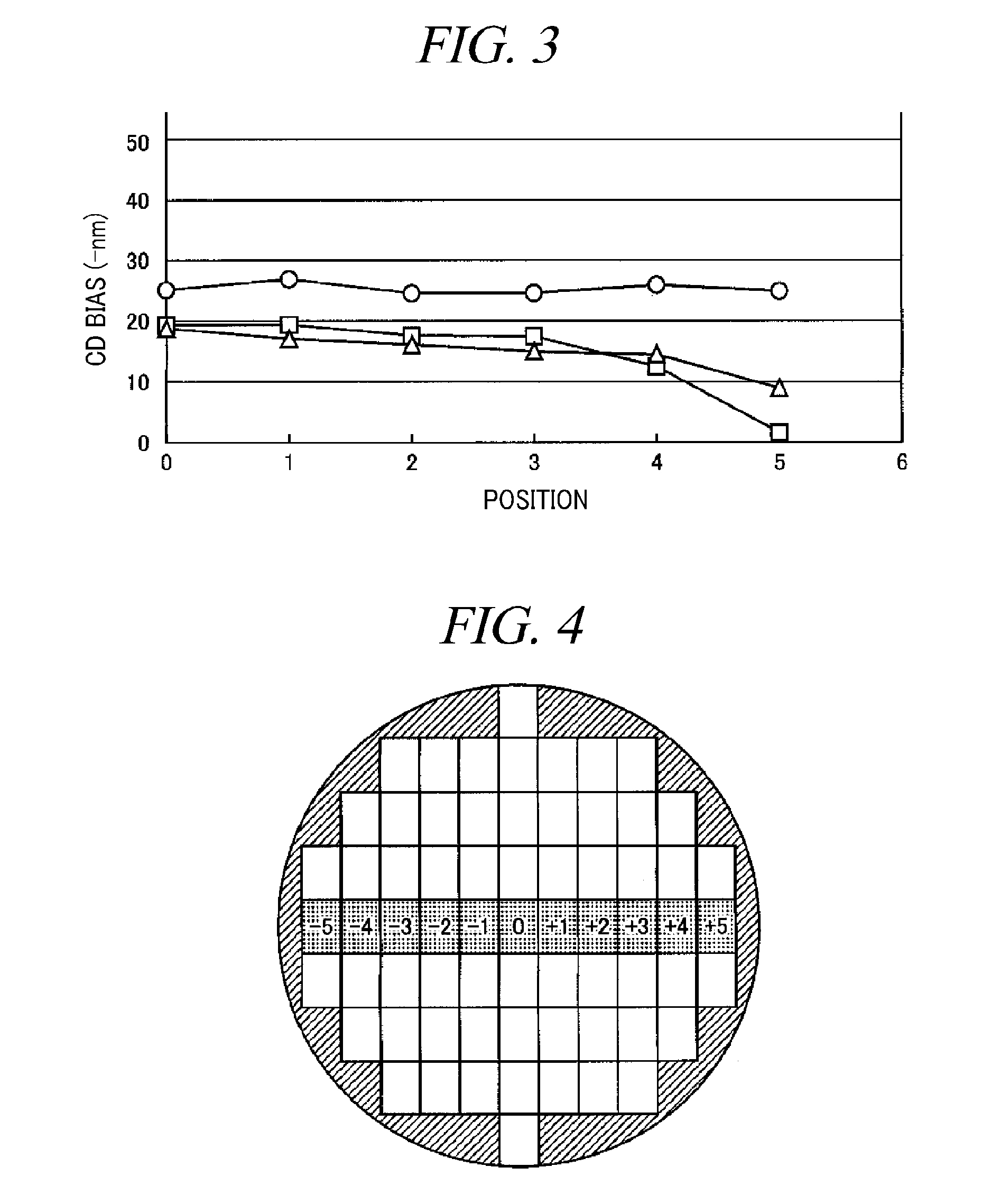

ActiveUS9263298B2Easy to controlUniform surfaceElectric discharge tubesDecorative surface effectsEngineeringGas supply

A plasma etching apparatus 11 includes a mounting table that holds a semiconductor substrate W thereon; a first heater 18a that heats a central region of the semiconductor substrate W held on the mounting table 14; a second heater 18b that heats an edge region around the central region of the semiconductor substrate W held on the mounting table 14; a reactant gas supply unit 13 that supplies a reactant gas for a plasma process toward the central region of the semiconductor substrate W held on the mounting table 14; and a control unit 20 that performs a plasma etching process on the semiconductor substrate W while controlling the first heater 18a and the second heater 18b to heat the central region and the edge region of the processing target substrate W held on the mounting table 14 to different temperatures.

Owner:TOKYO ELECTRON LTD

Plasma etching apparatus and plasma etching method

ActiveUS20120012556A1Improve uniformityEasy to controlElectric discharge tubesDecorative surface effectsEngineeringSemiconductor

A plasma etching apparatus 11 includes a mounting table that holds a semiconductor substrate W thereon; a first heater 18a that heats a central region of the semiconductor substrate W held on the mounting table 14; a second heater 18b that heats an edge region around the central region of the semiconductor substrate W held on the mounting table 14; a reactant gas supply unit 13 that supplies a reactant gas for a plasma process toward the central region of the semiconductor substrate W held on the mounting table 14; and a control unit 20 that performs a plasma etching process on the semiconductor substrate W while controlling the first heater 18a and the second heater 18b to heat the central region and the edge region of the processing target substrate W held on the mounting table 14 to different temperatures.

Owner:TOKYO ELECTRON LTD

Leveler compounds

ActiveUS7128822B2No suppressed local platingOverplating is reduced or substantially eliminatedOrganic chemistrySpray nozzlesCopper platingMetal

Compounds that function to provide level or uniform metal deposits are provided. These compounds are particularly useful in providing level copper deposits. Copper plating baths and methods of copper plating using these compounds are also provided. These baths and methods are useful for providing a planarized layer of copper on a substrate having small apertures. The compositions and methods provide complete fill of small apertures with reduced void formation.

Owner:SHIPLEY CO LLC

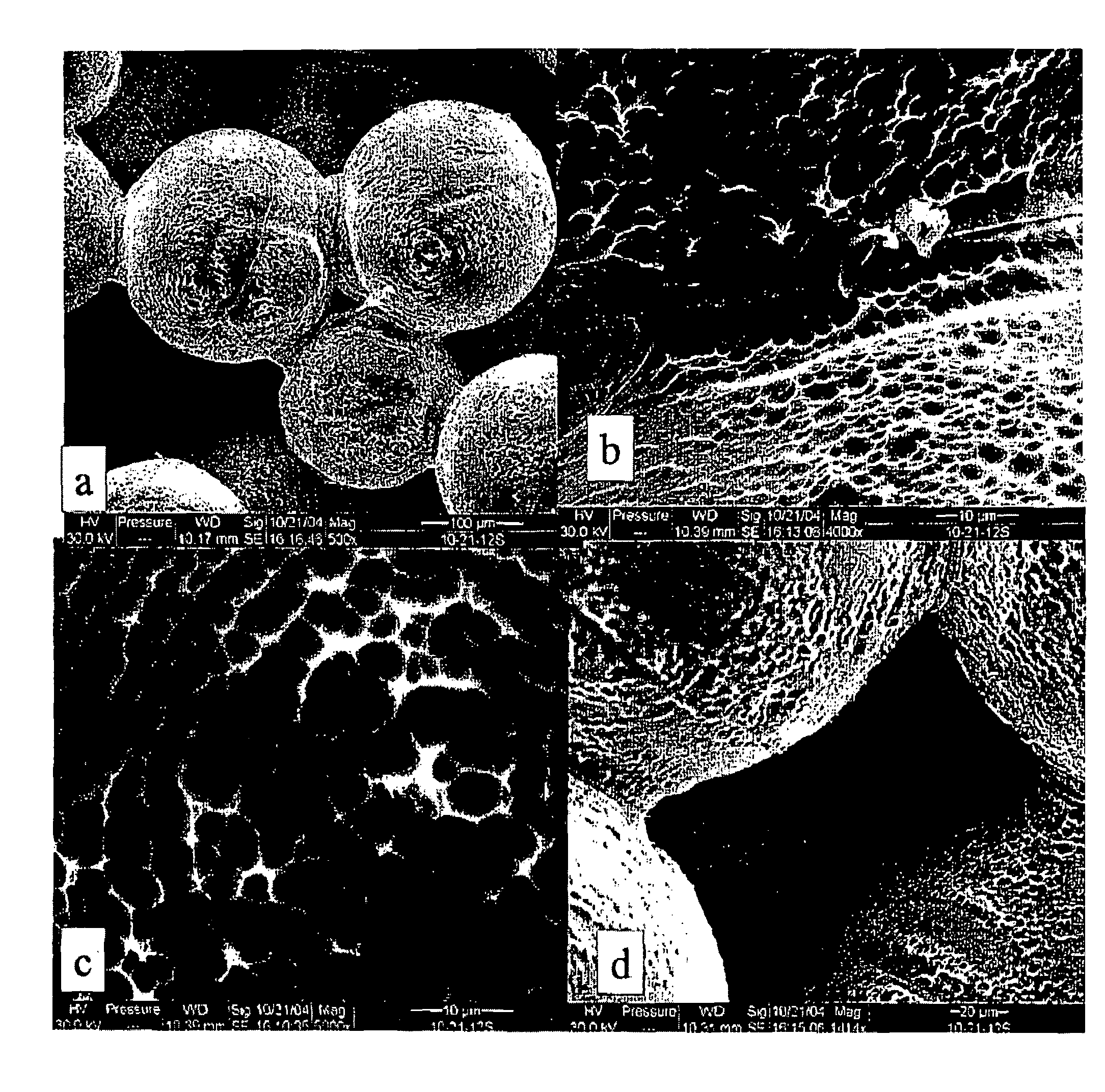

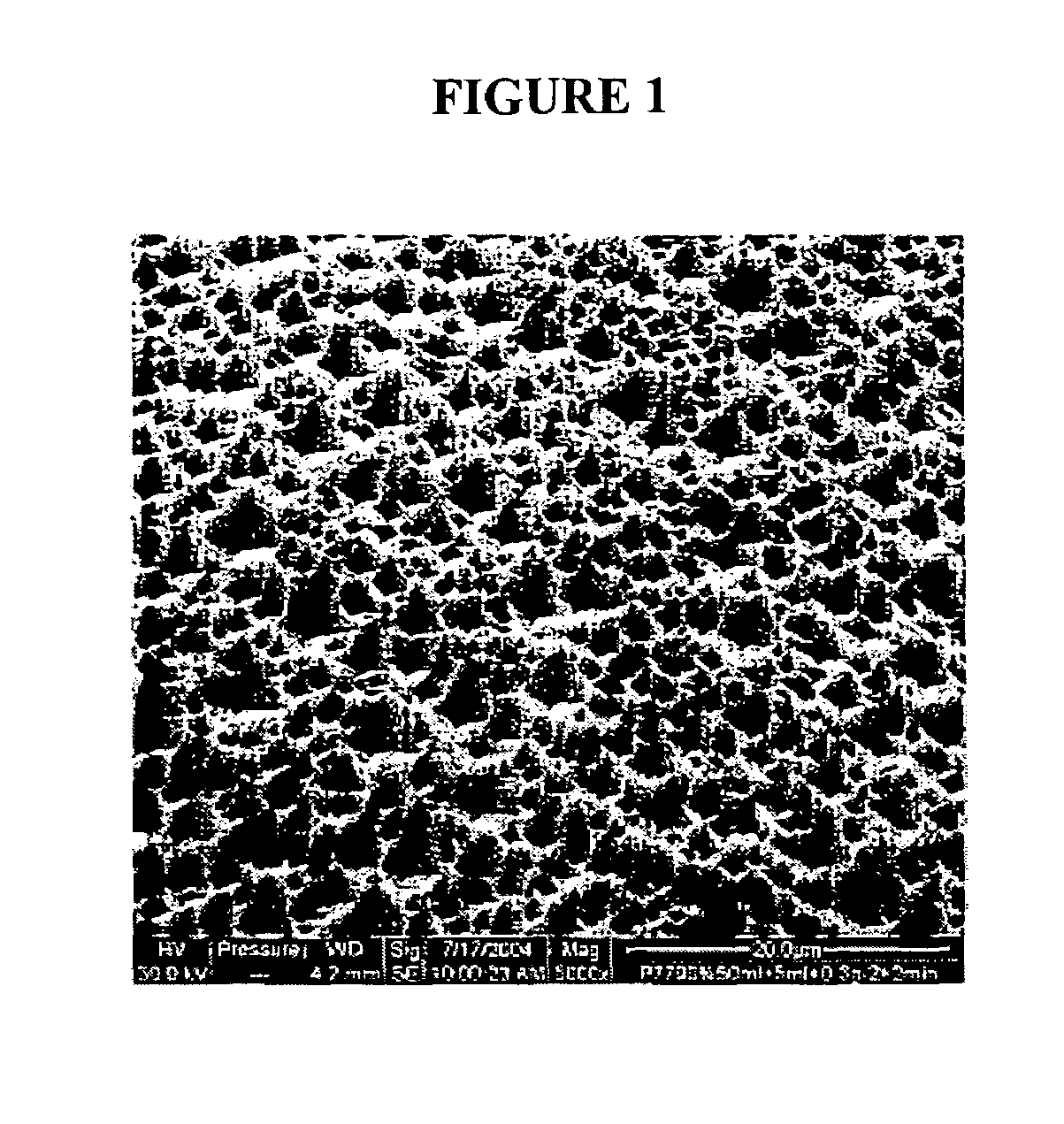

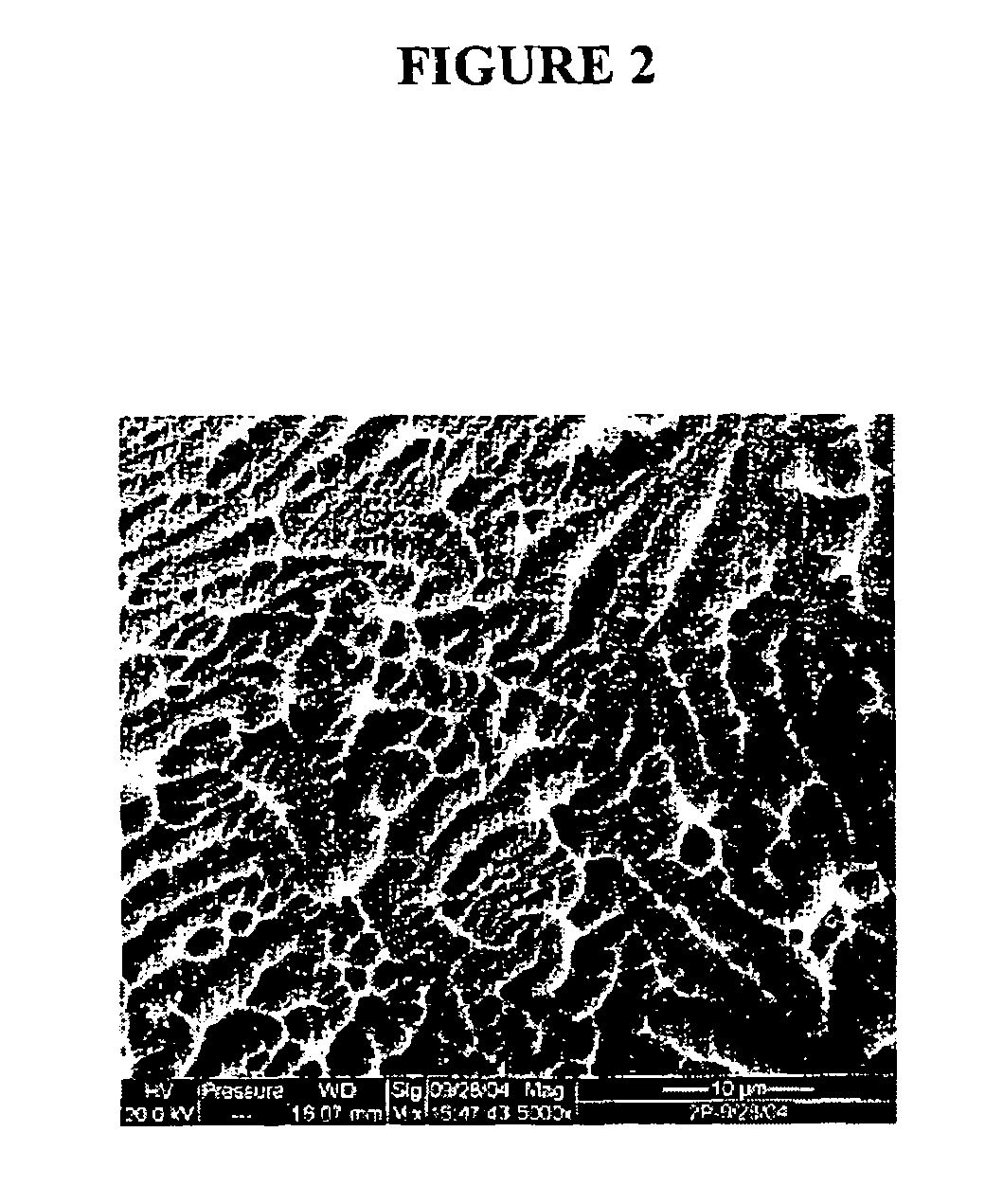

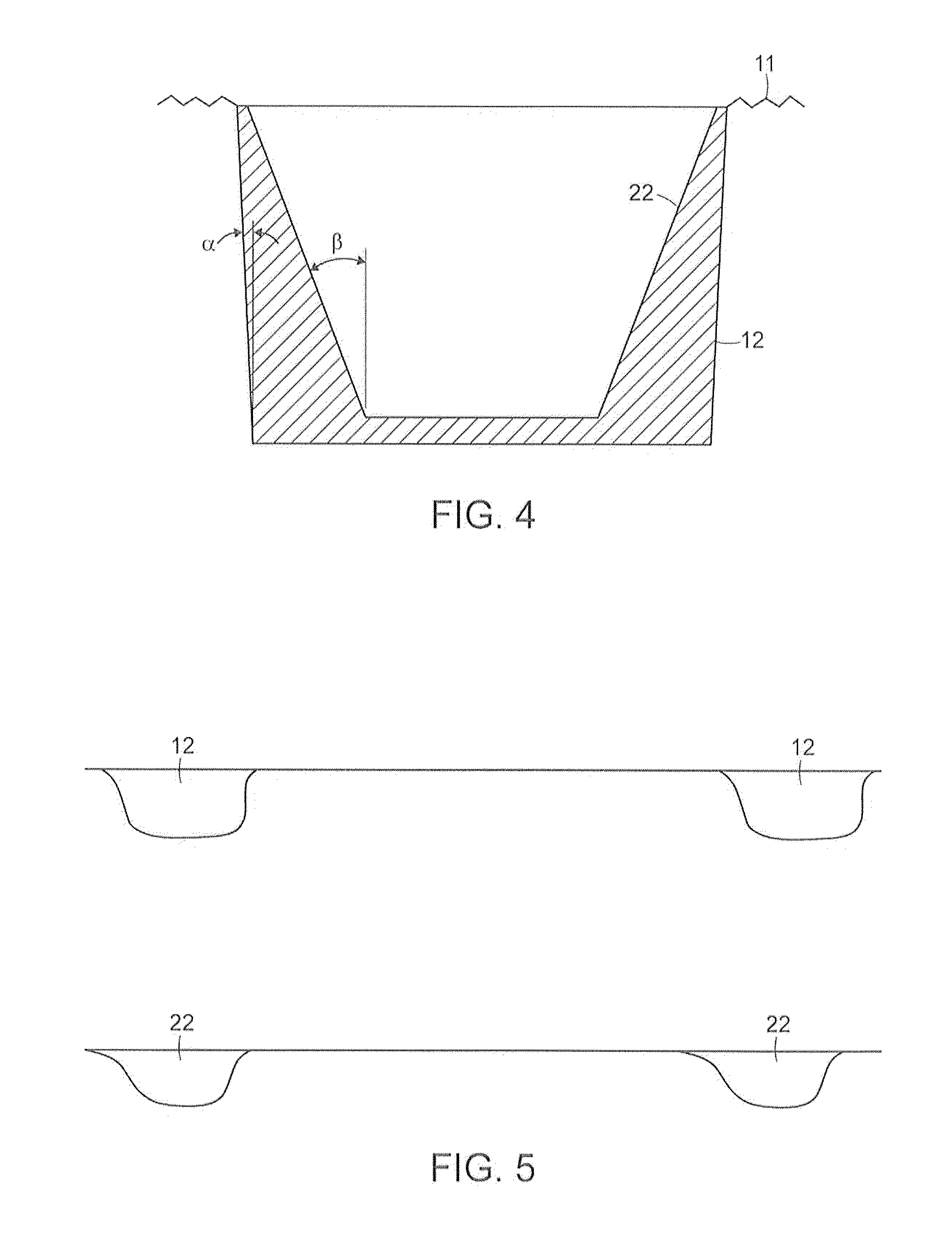

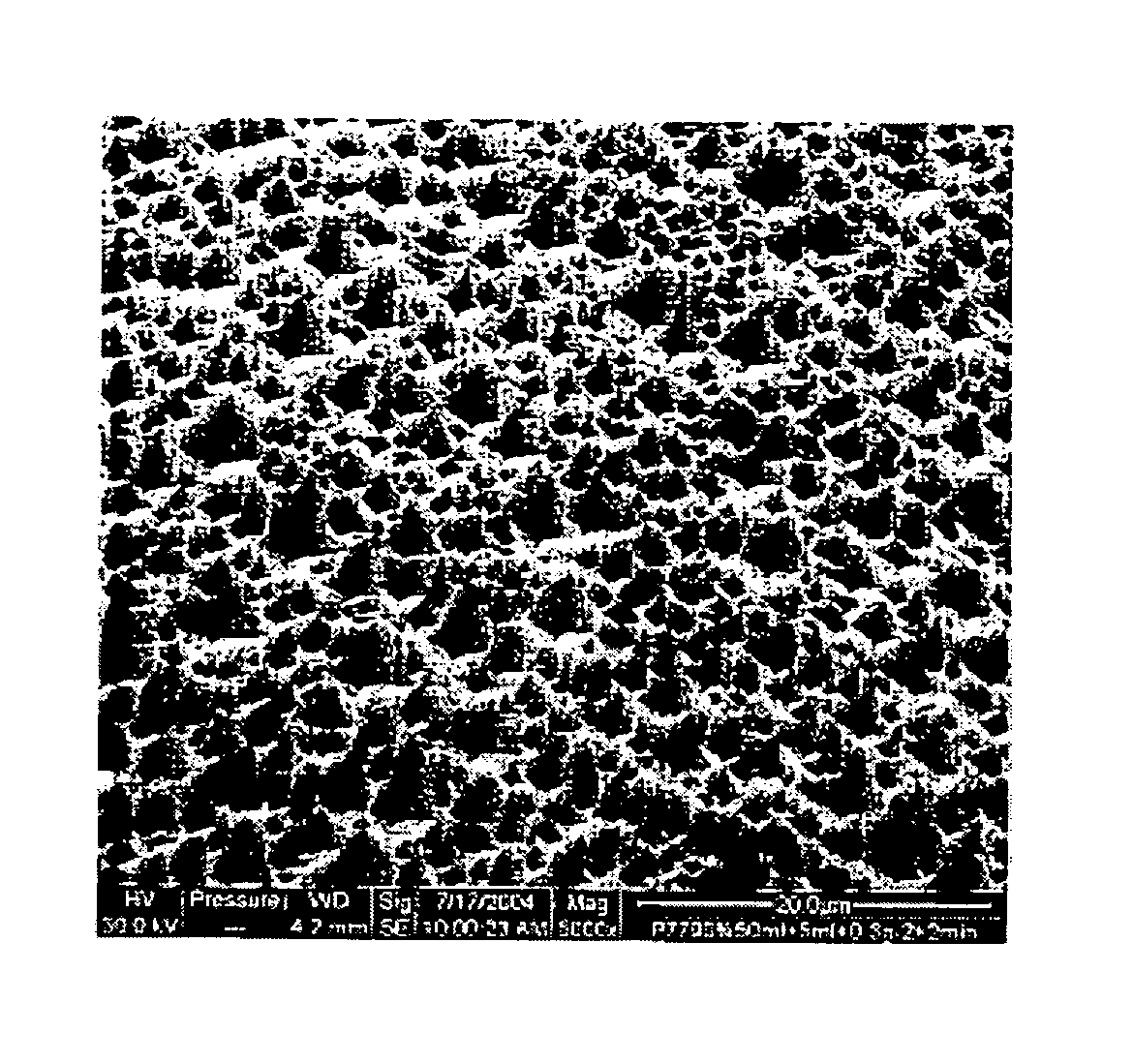

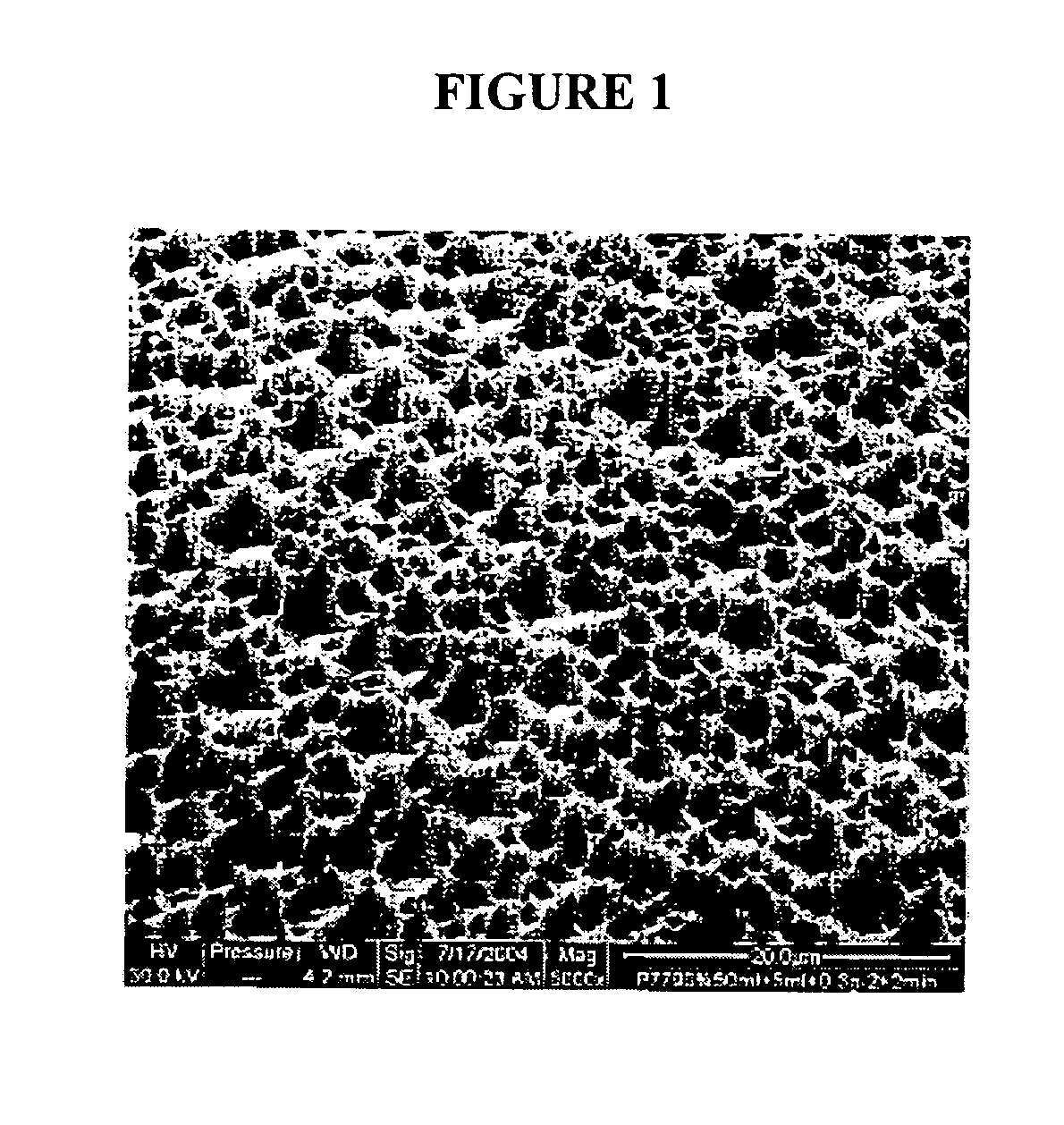

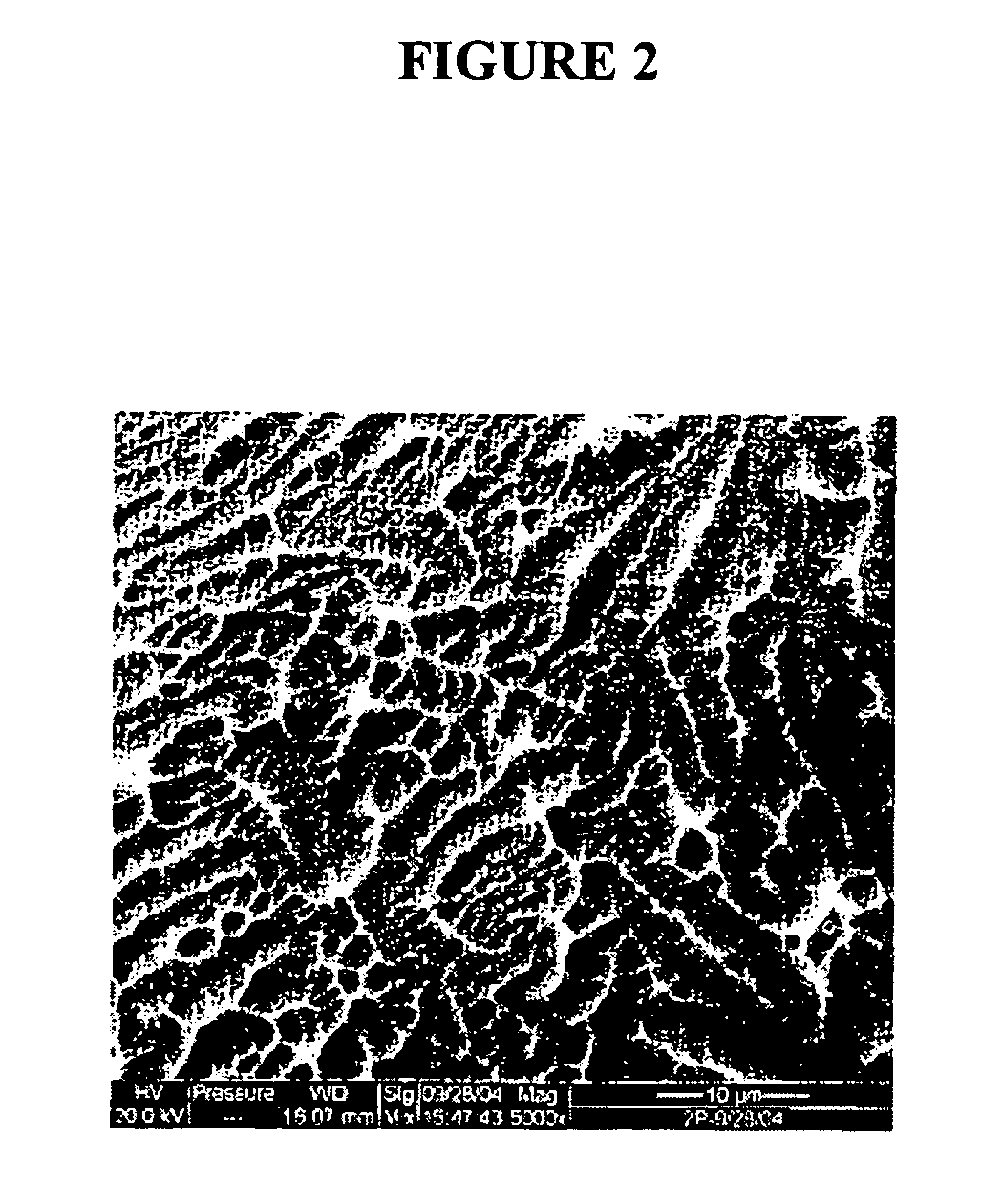

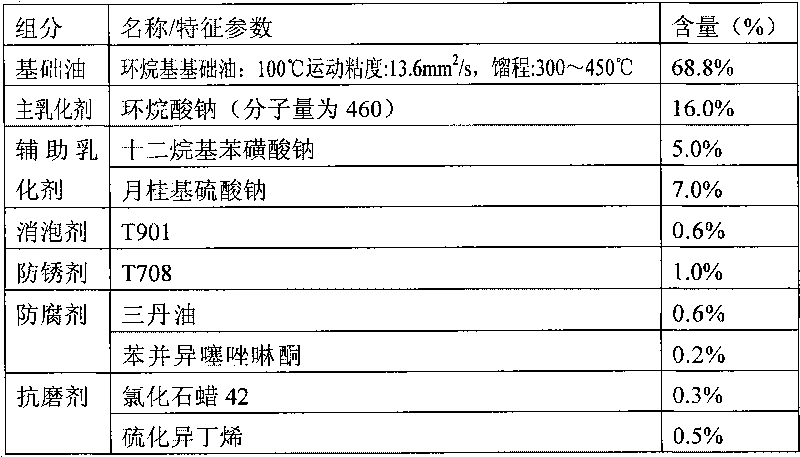

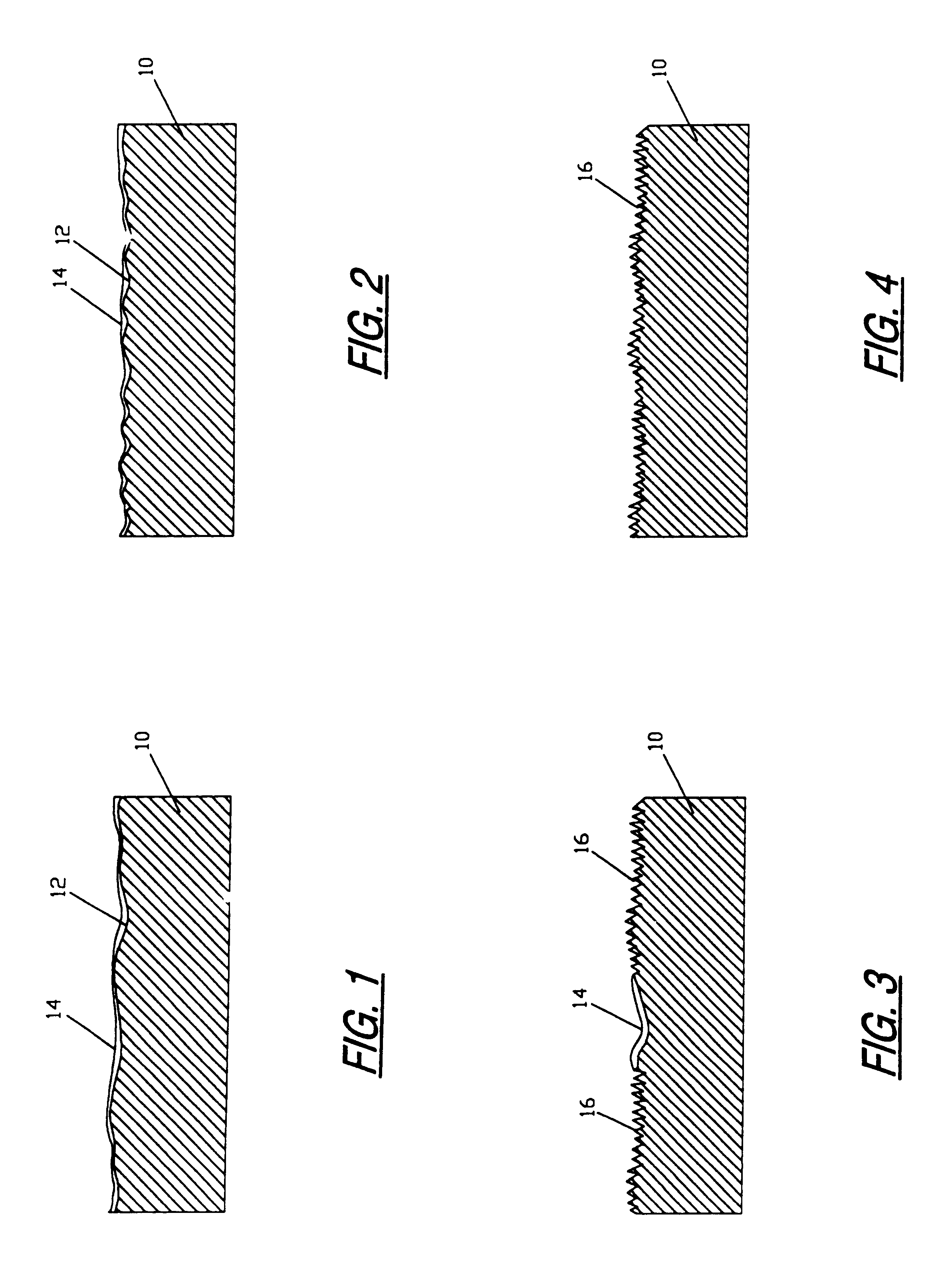

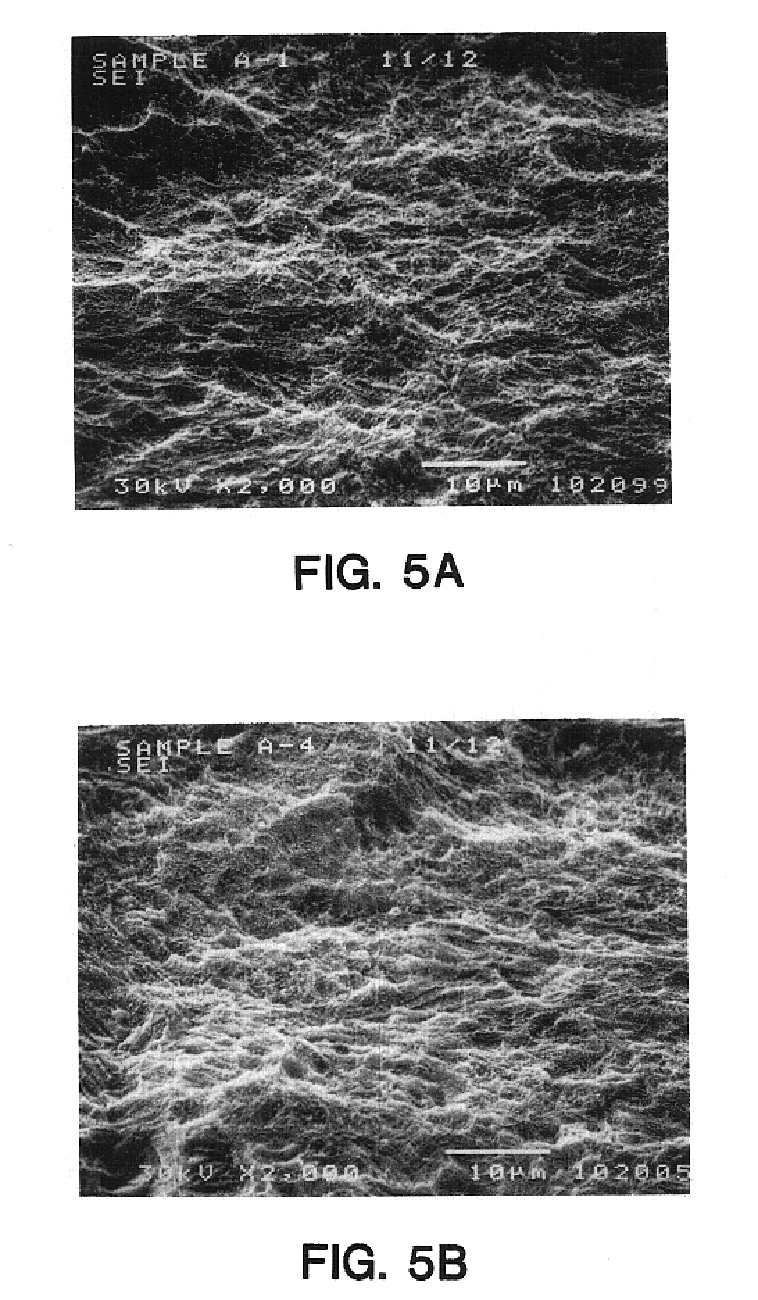

Implants with textured surface and methods for producing the same

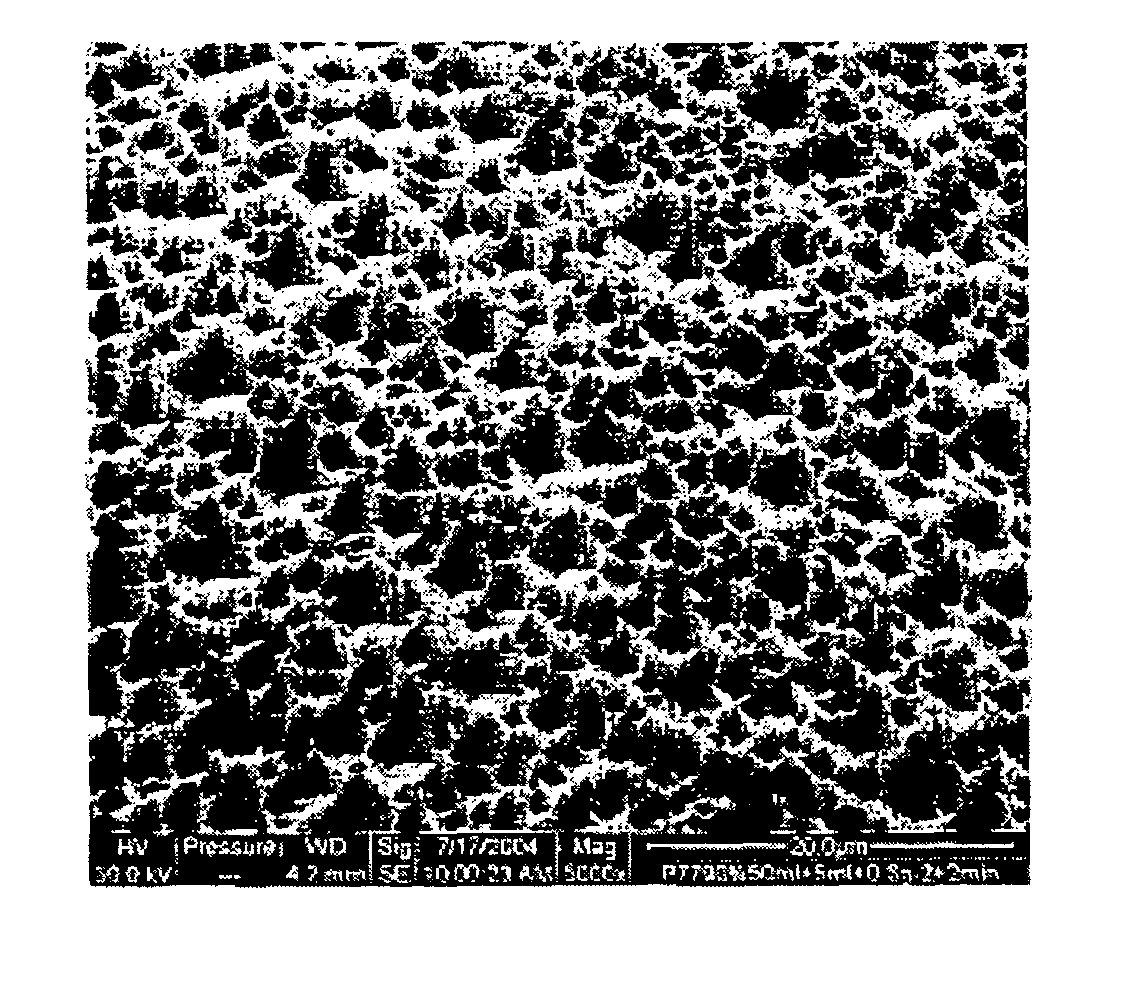

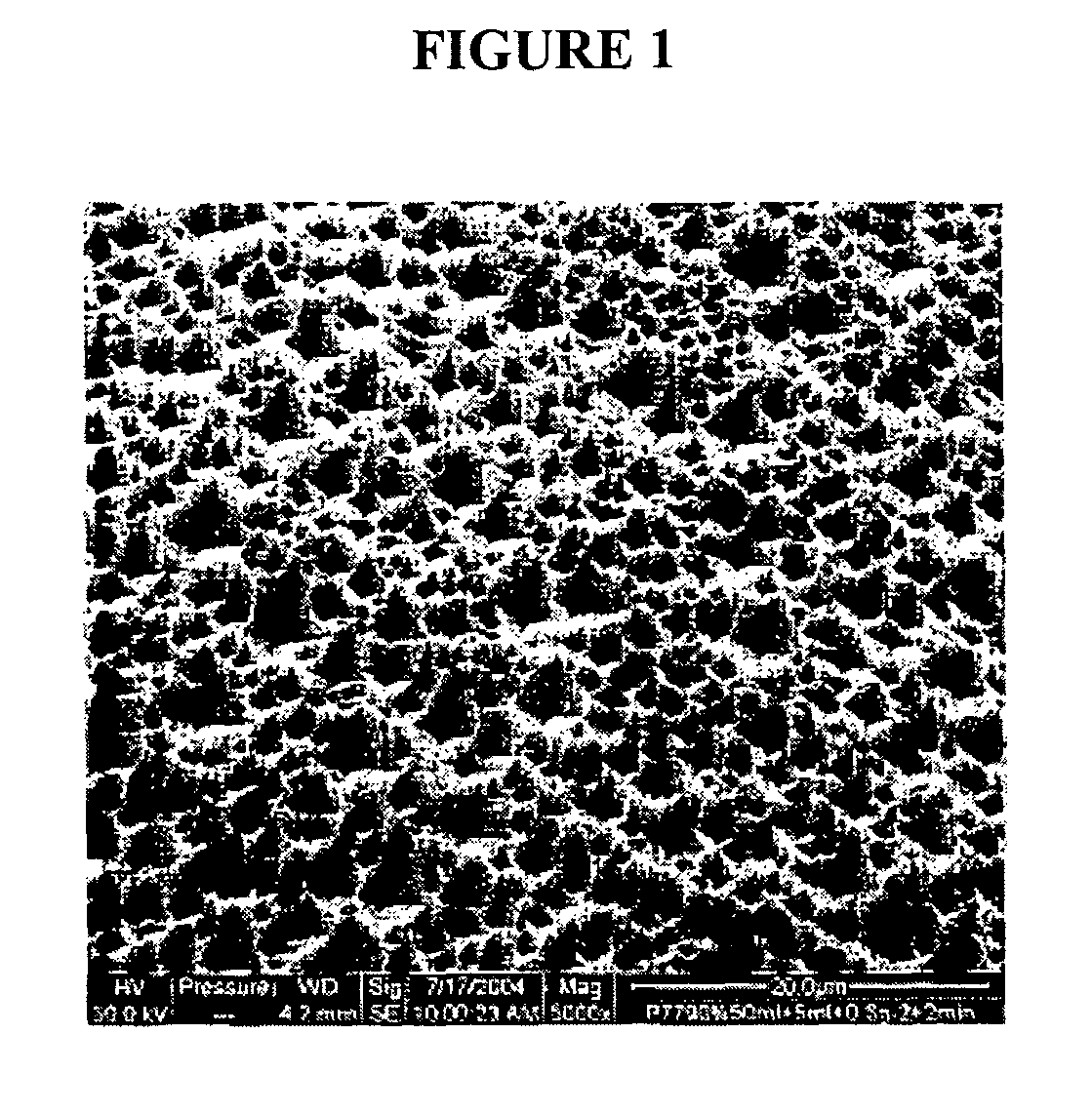

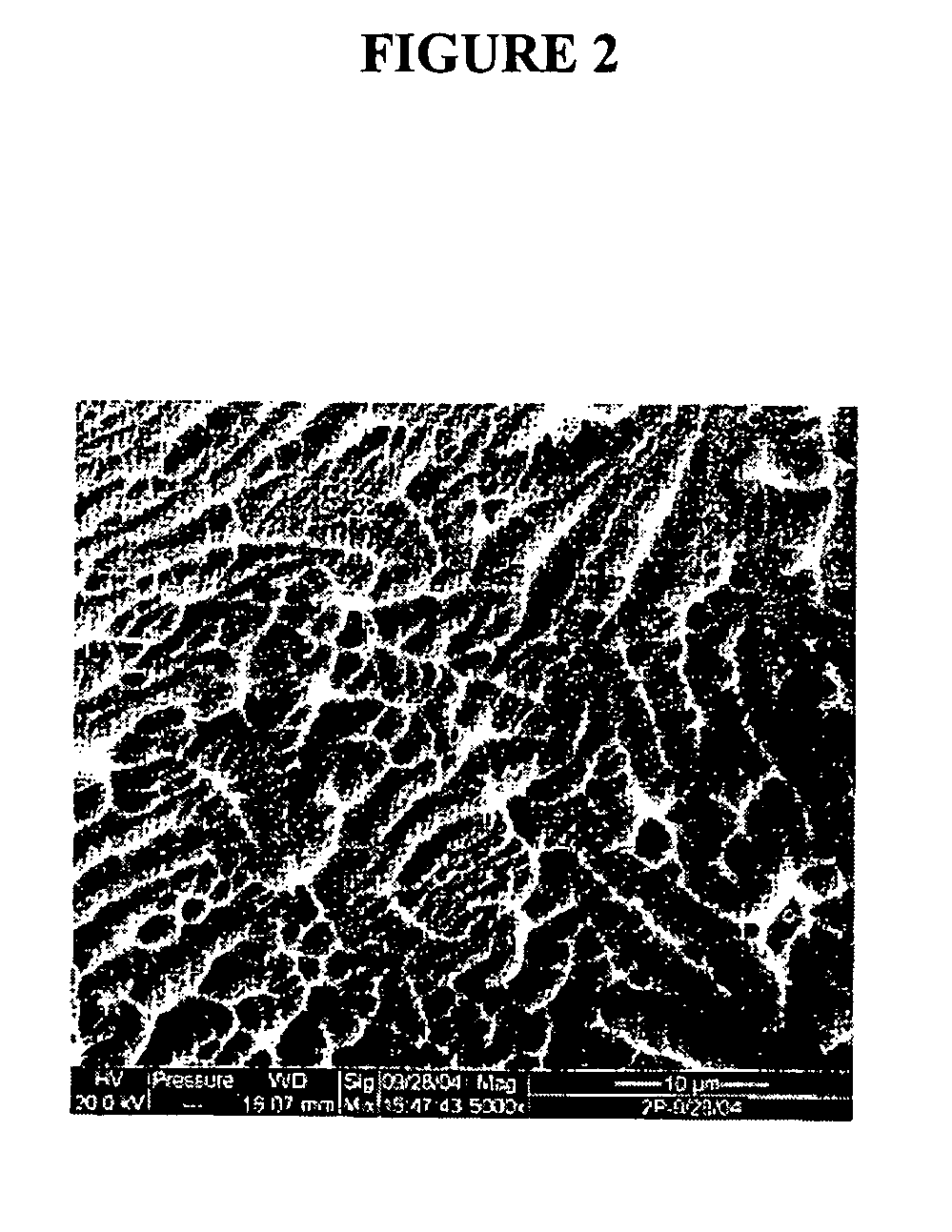

ActiveUS7368065B2High retention rateConvenient coatingImpression capsDecorative surface effectsMicrometerChloride

Compositions and methods are provided for preparing a metal substrate having a uniform textured surface with a plurality of indentations with a diameter in the nanometer and micrometer range. The textured surface is produced by exposing the substrate to an etching fluid comprising a hydrohalic acid and a mixture of a hydrohalic acid and an oxyacid, a chloride containing compound, and an oxidant. The etching solution can be used at ambient temperature. This textured surface enhances adherence of coatings or cells onto the textured surface, improves the retention of proteins on the surface, and encourages bone in-growth.

Owner:DEPUY PROD INC

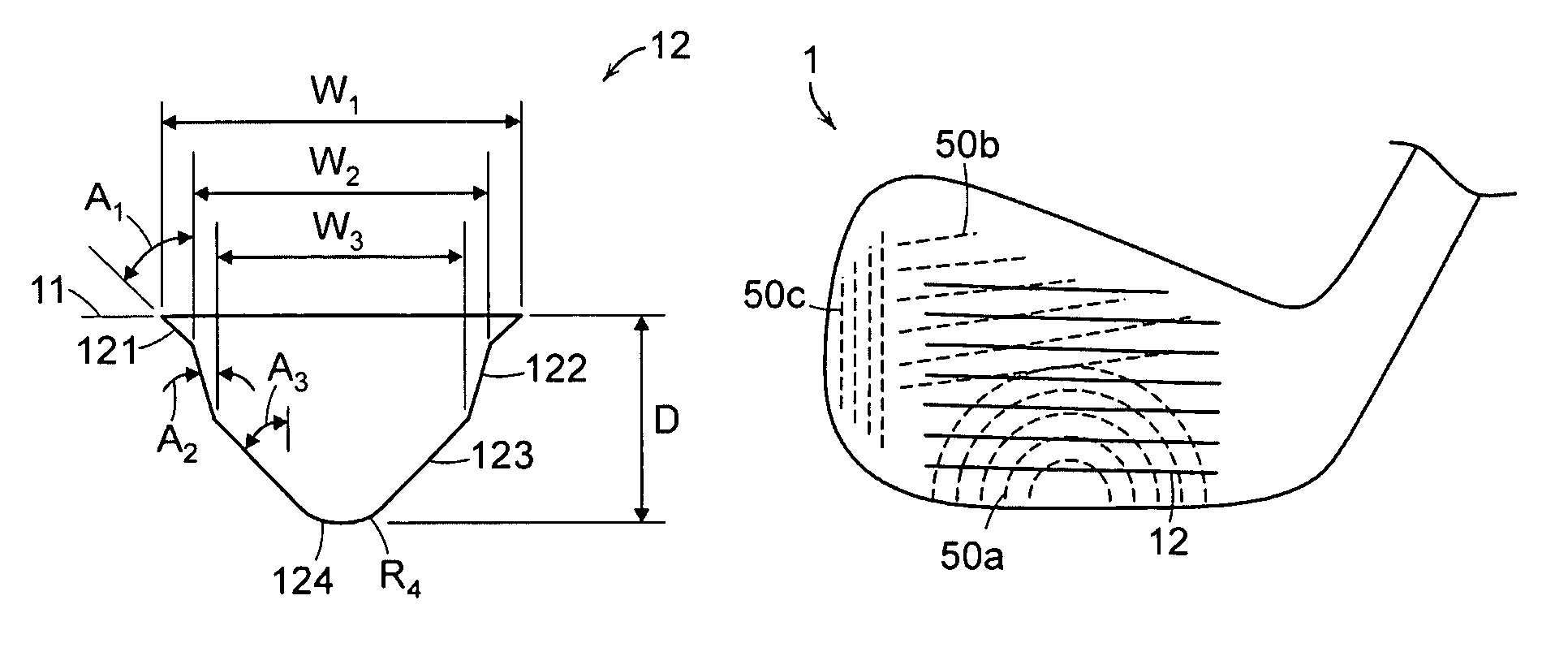

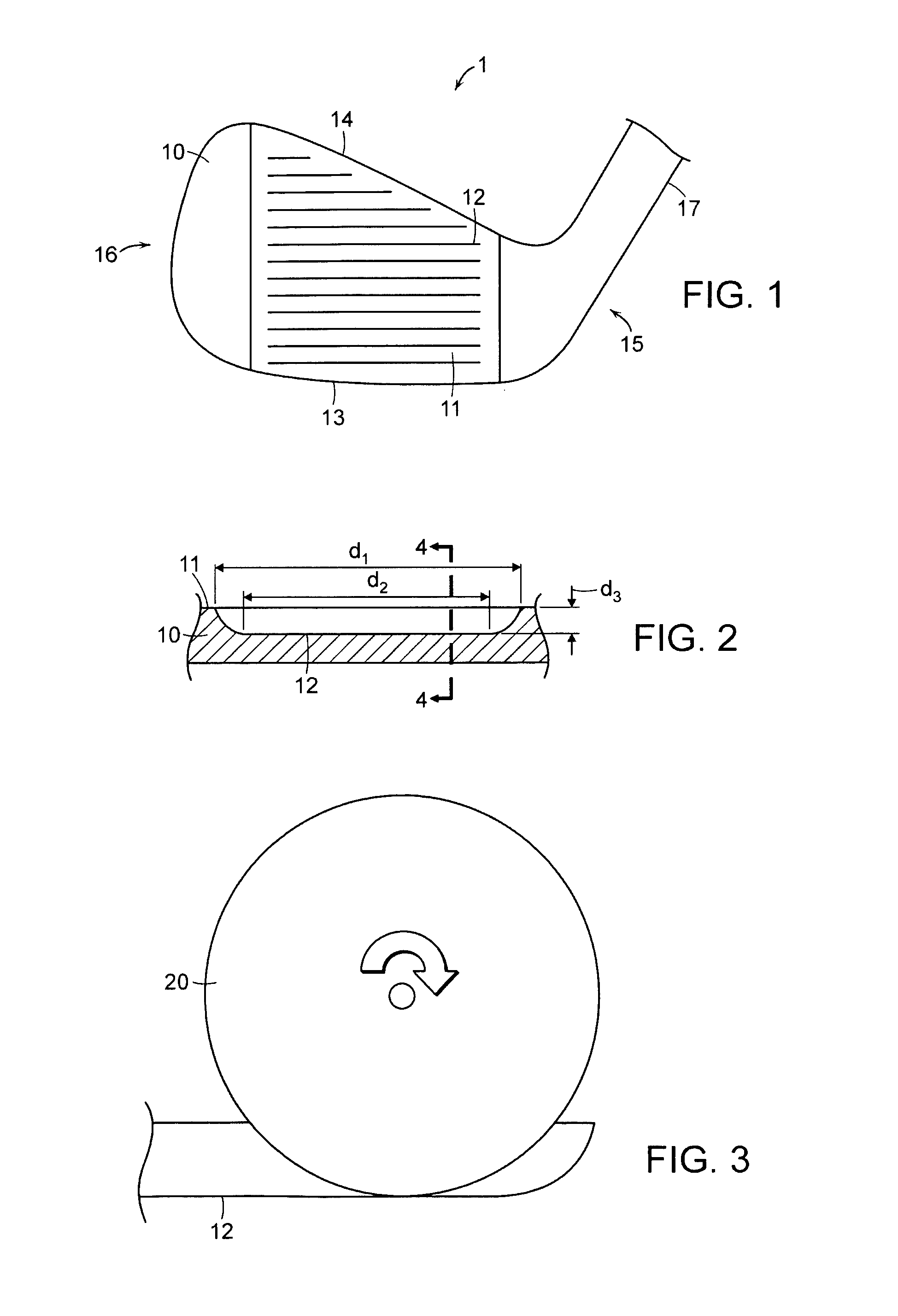

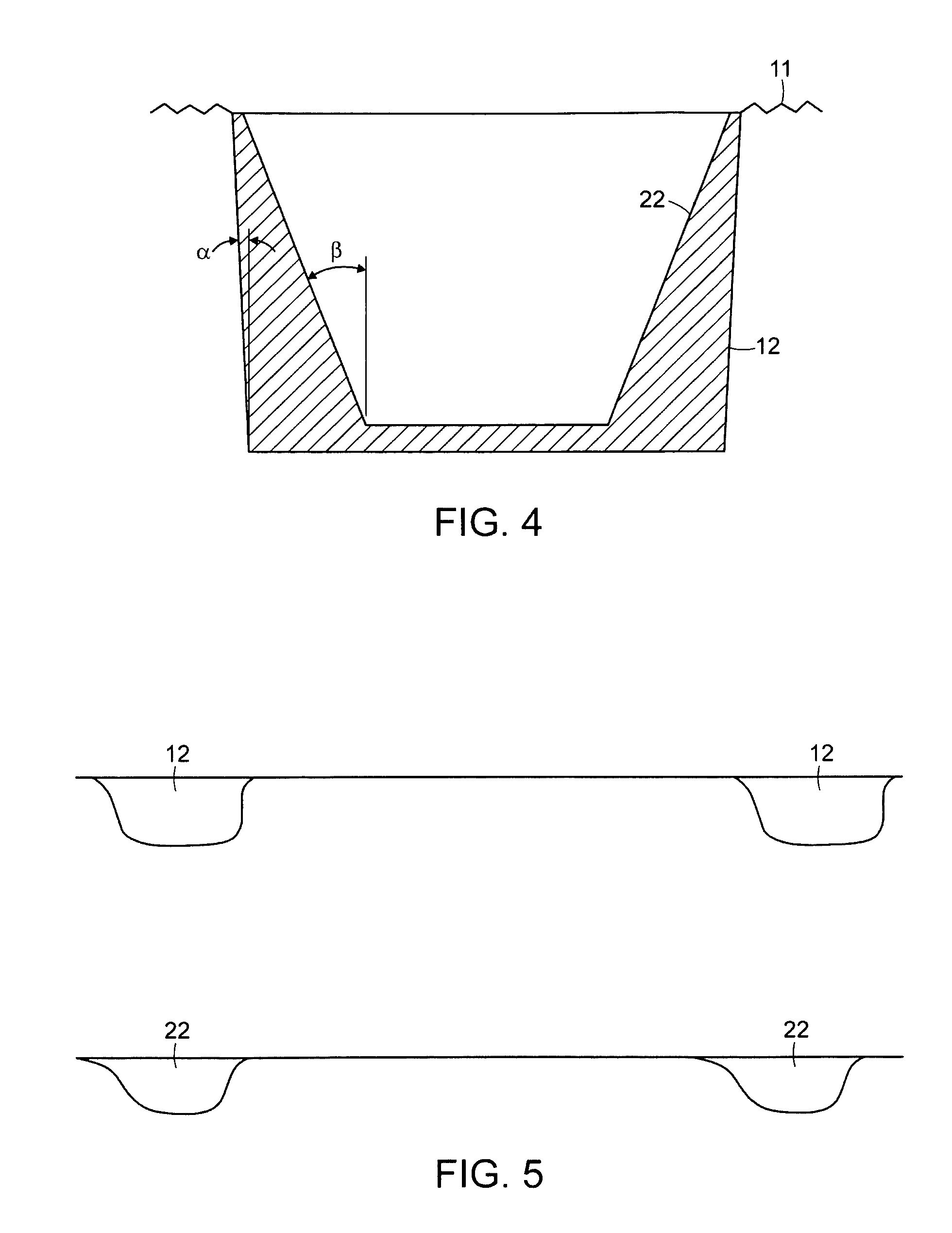

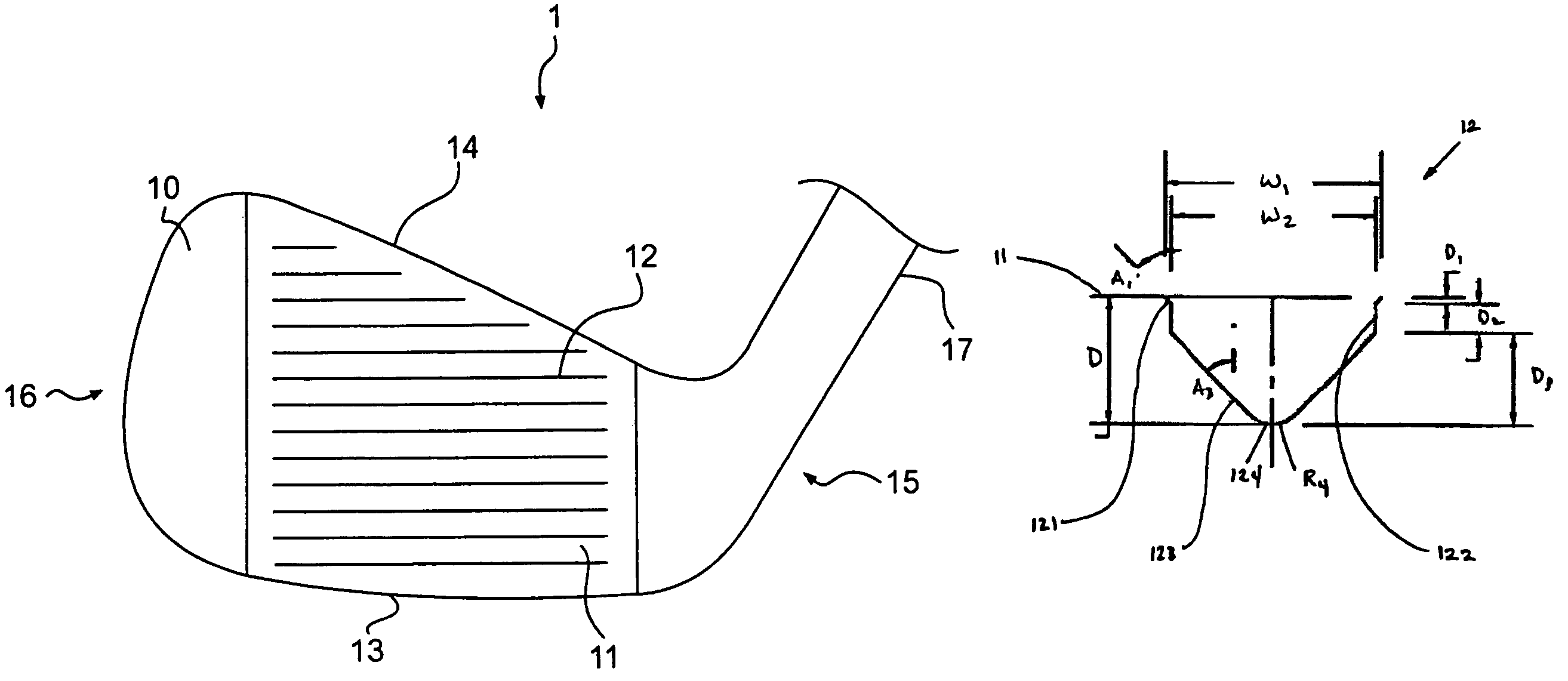

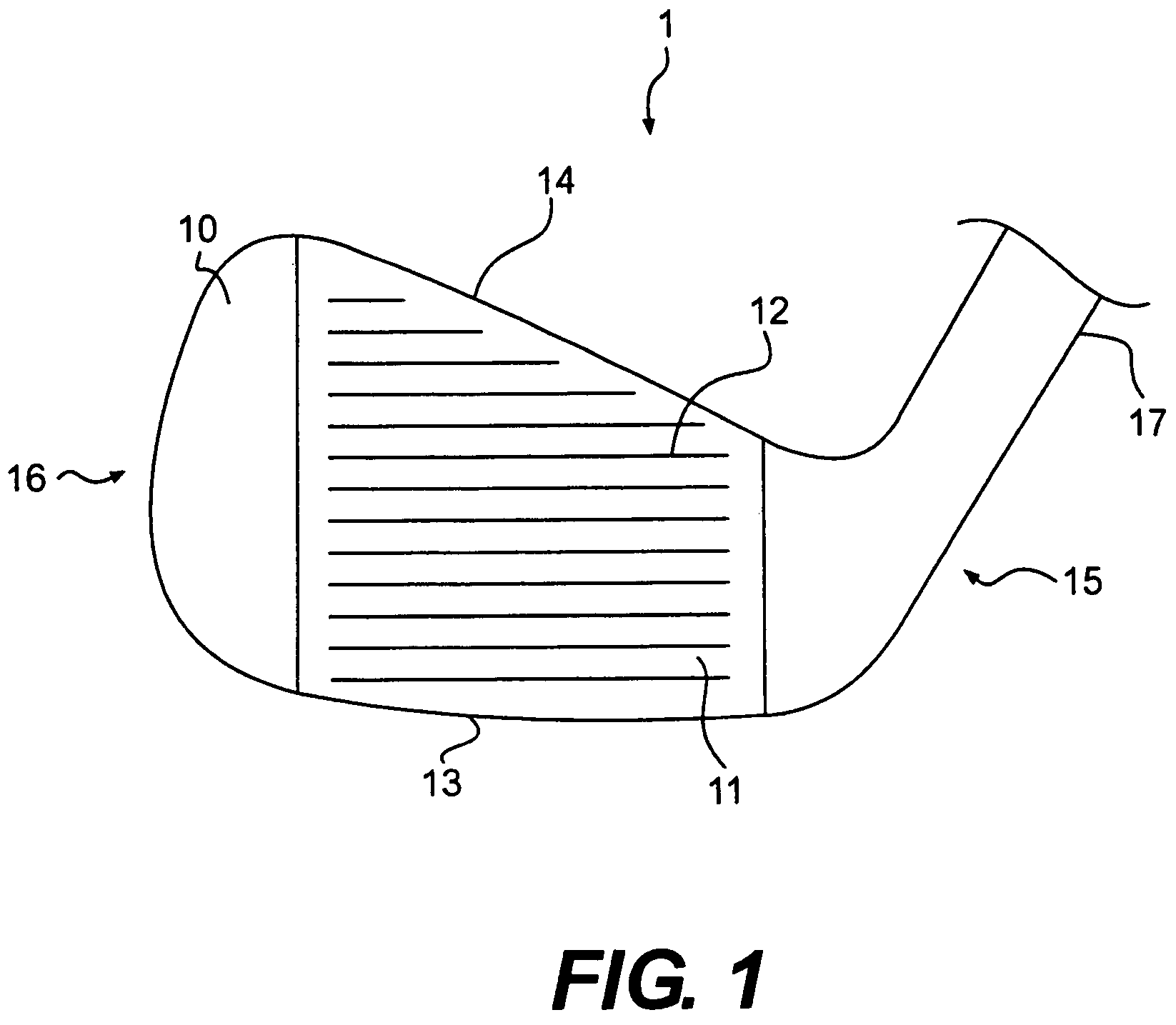

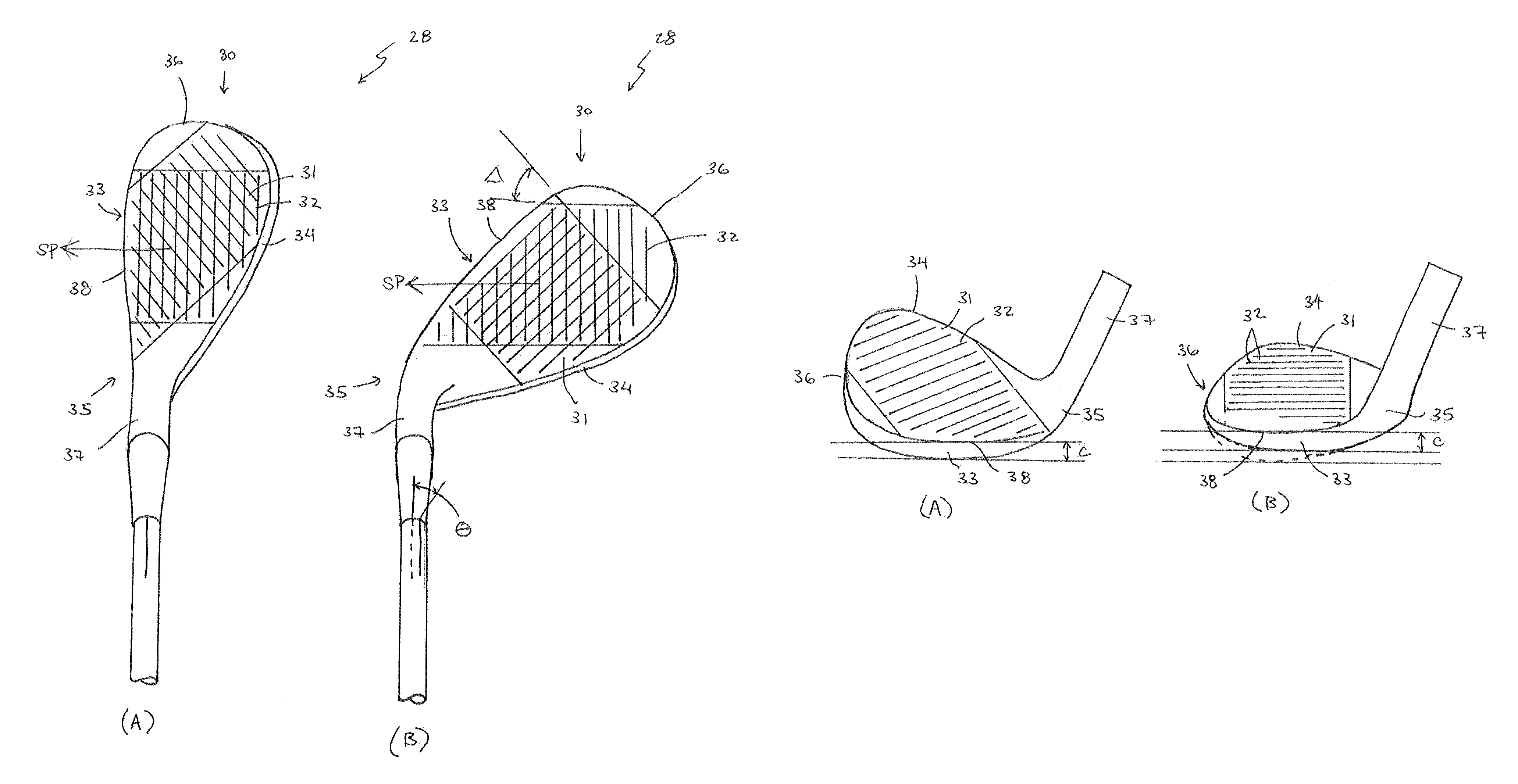

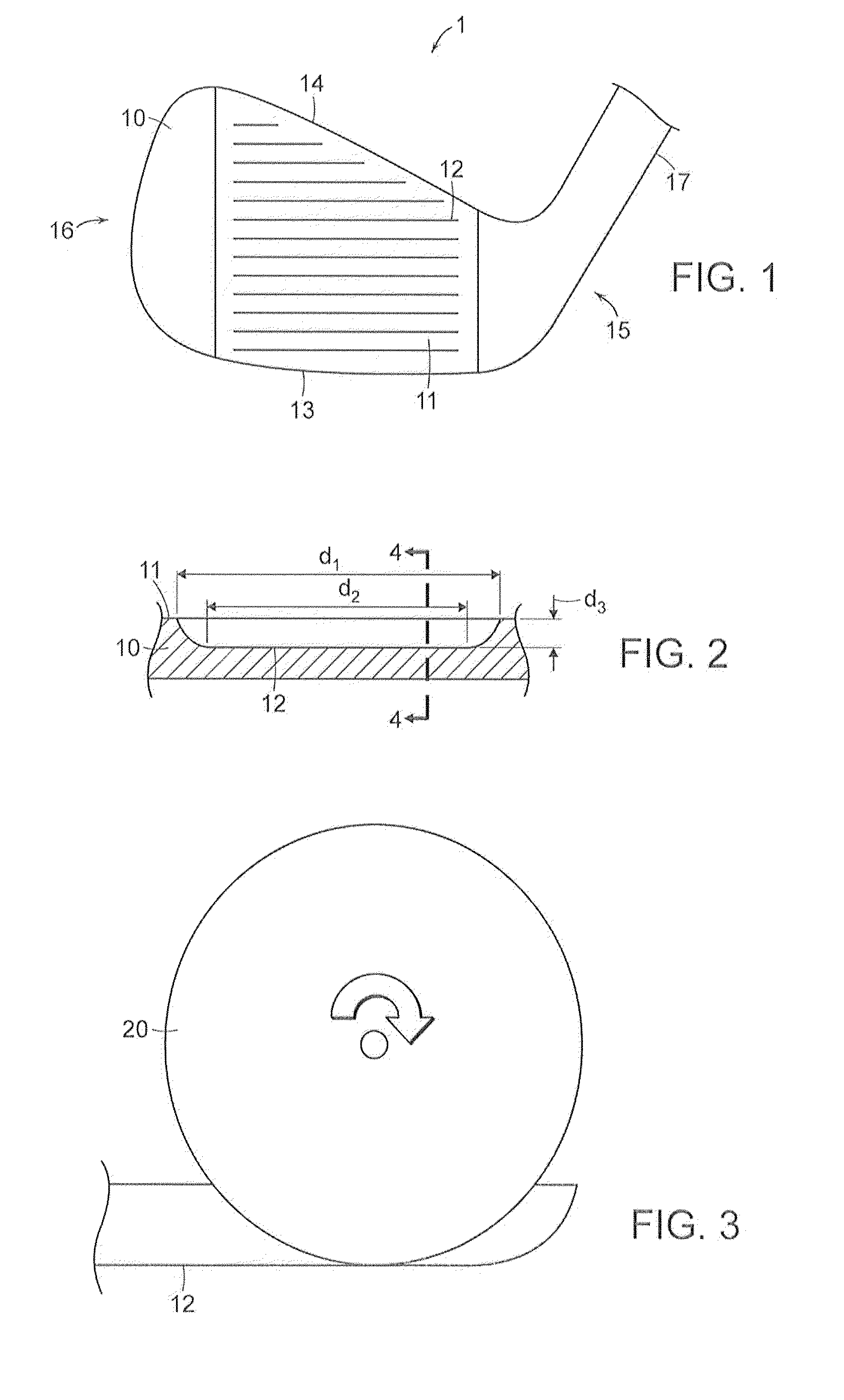

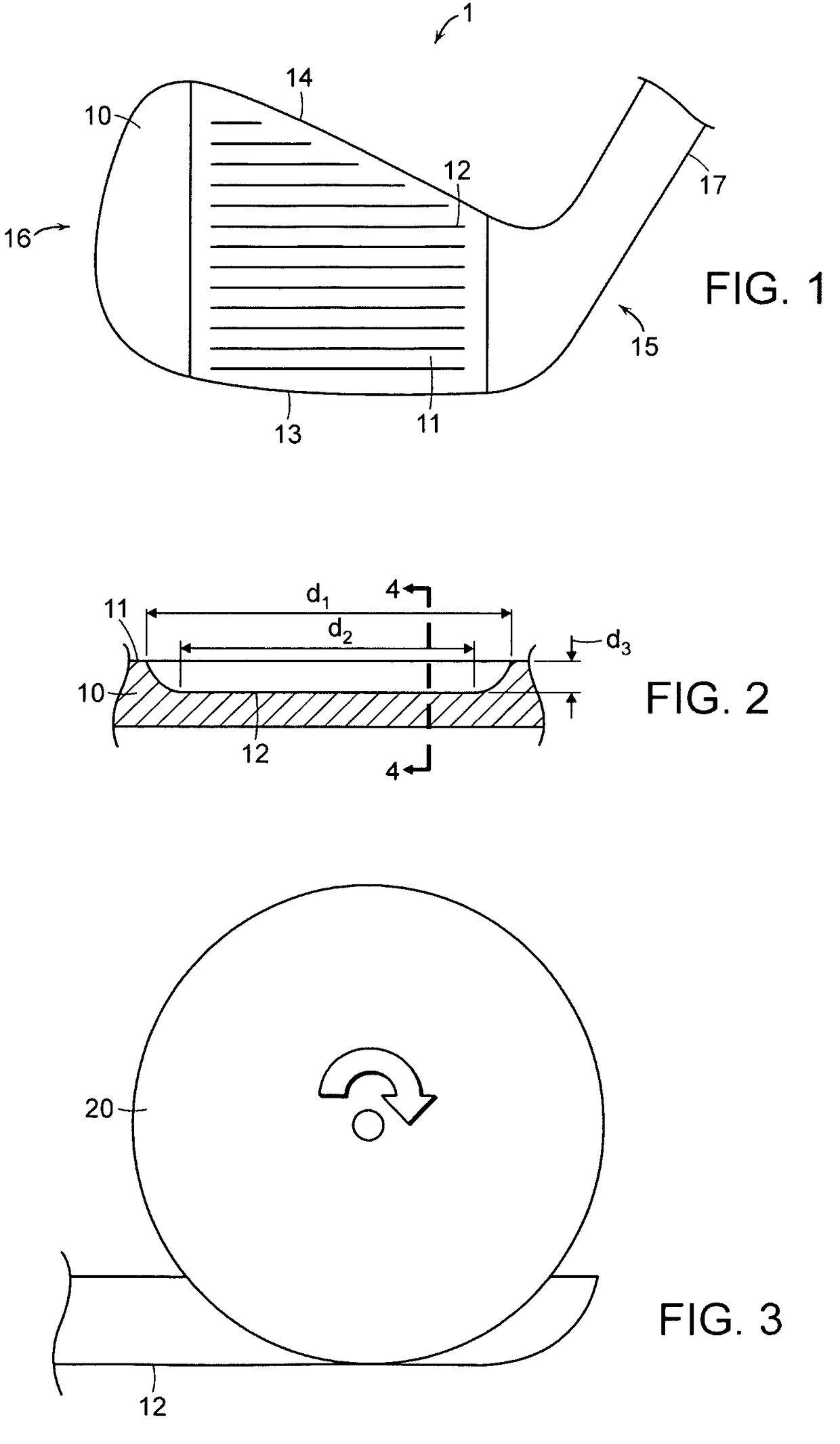

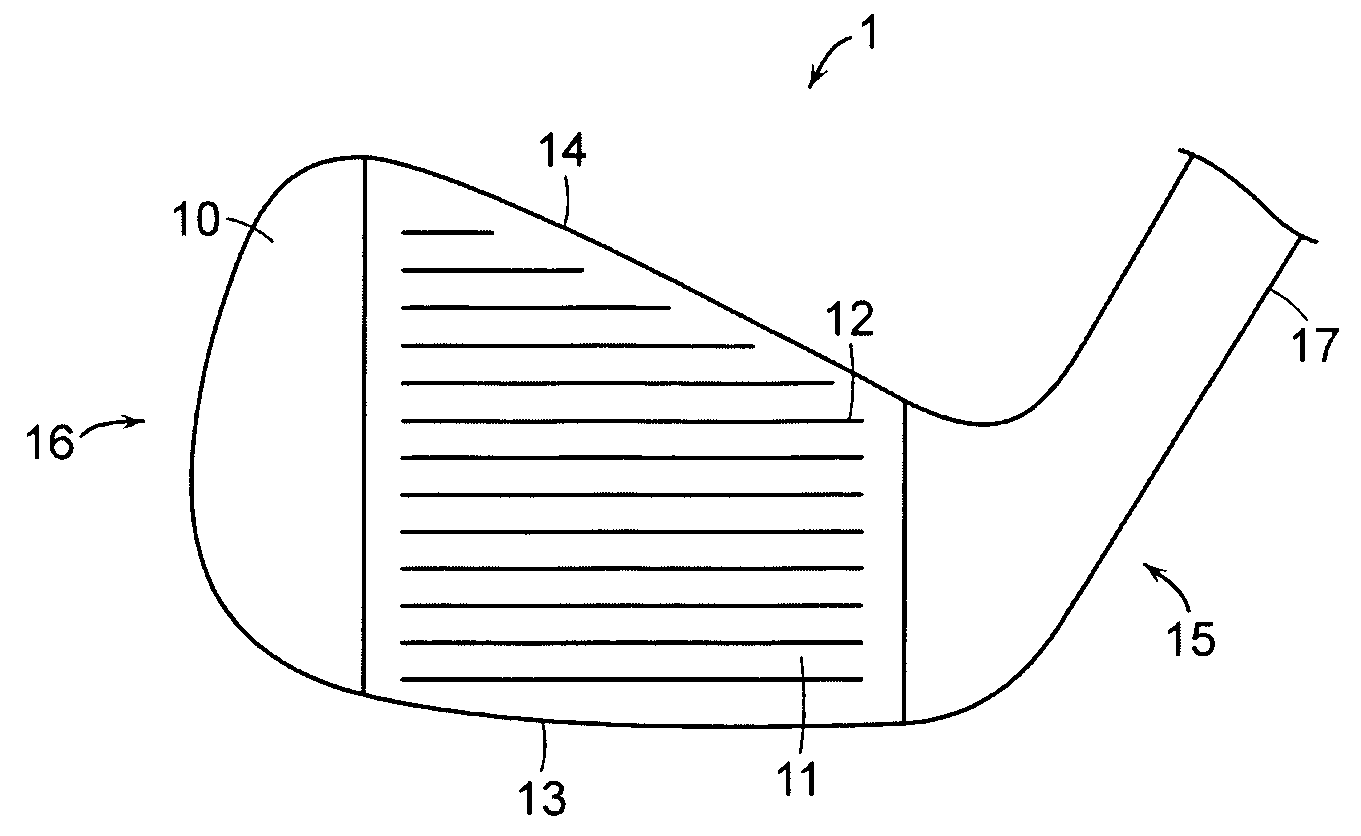

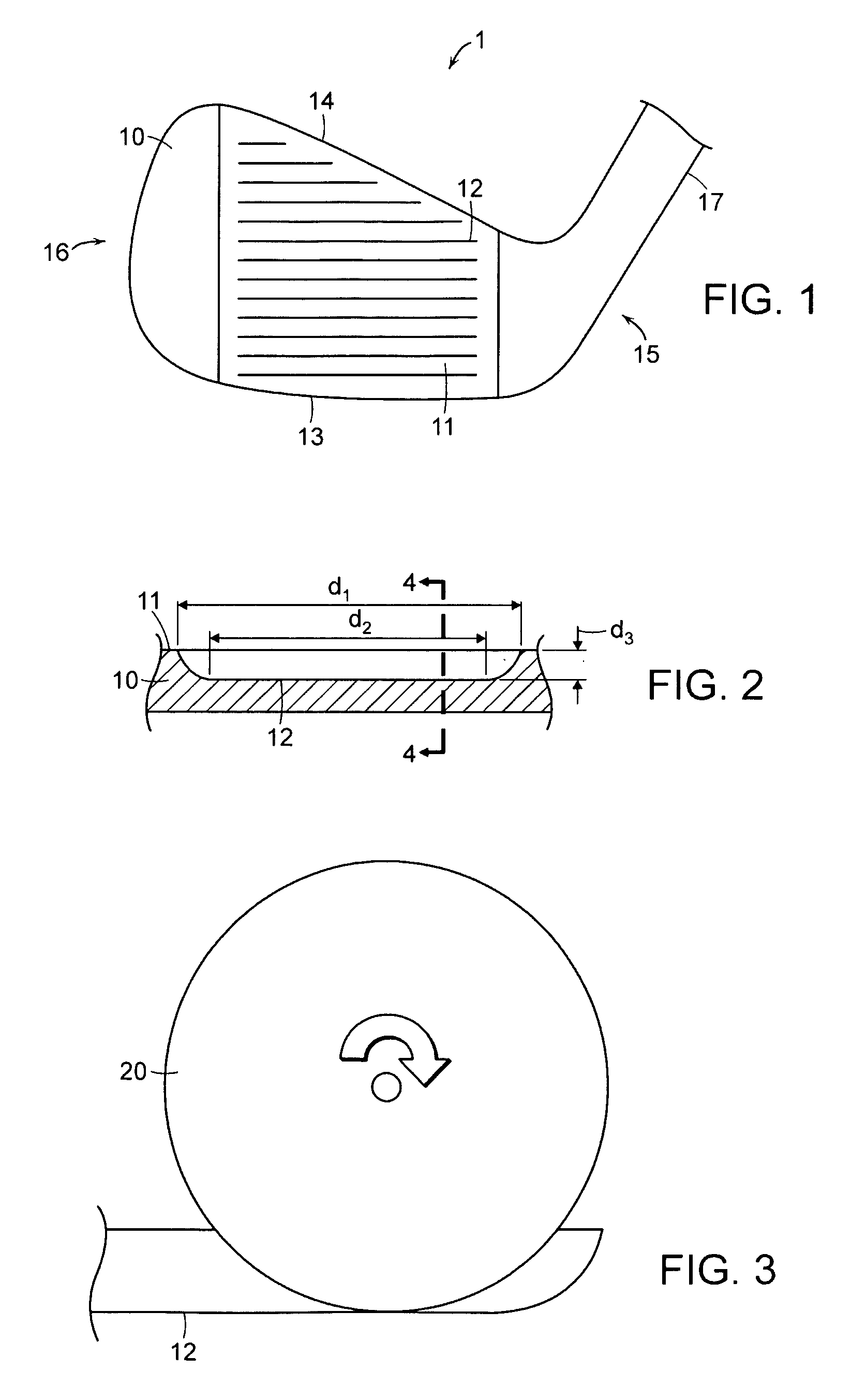

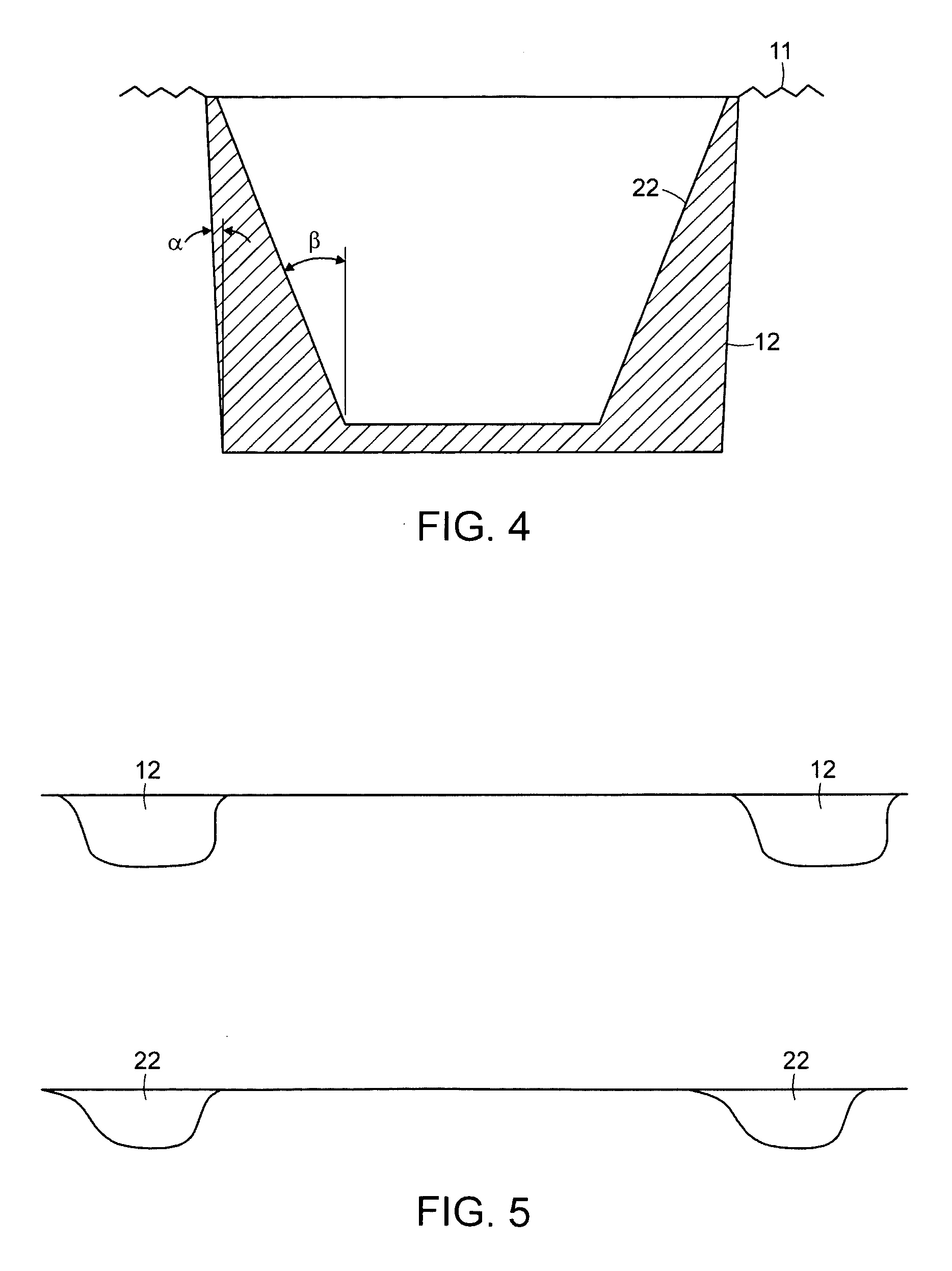

Golf club head having a grooved and textured face

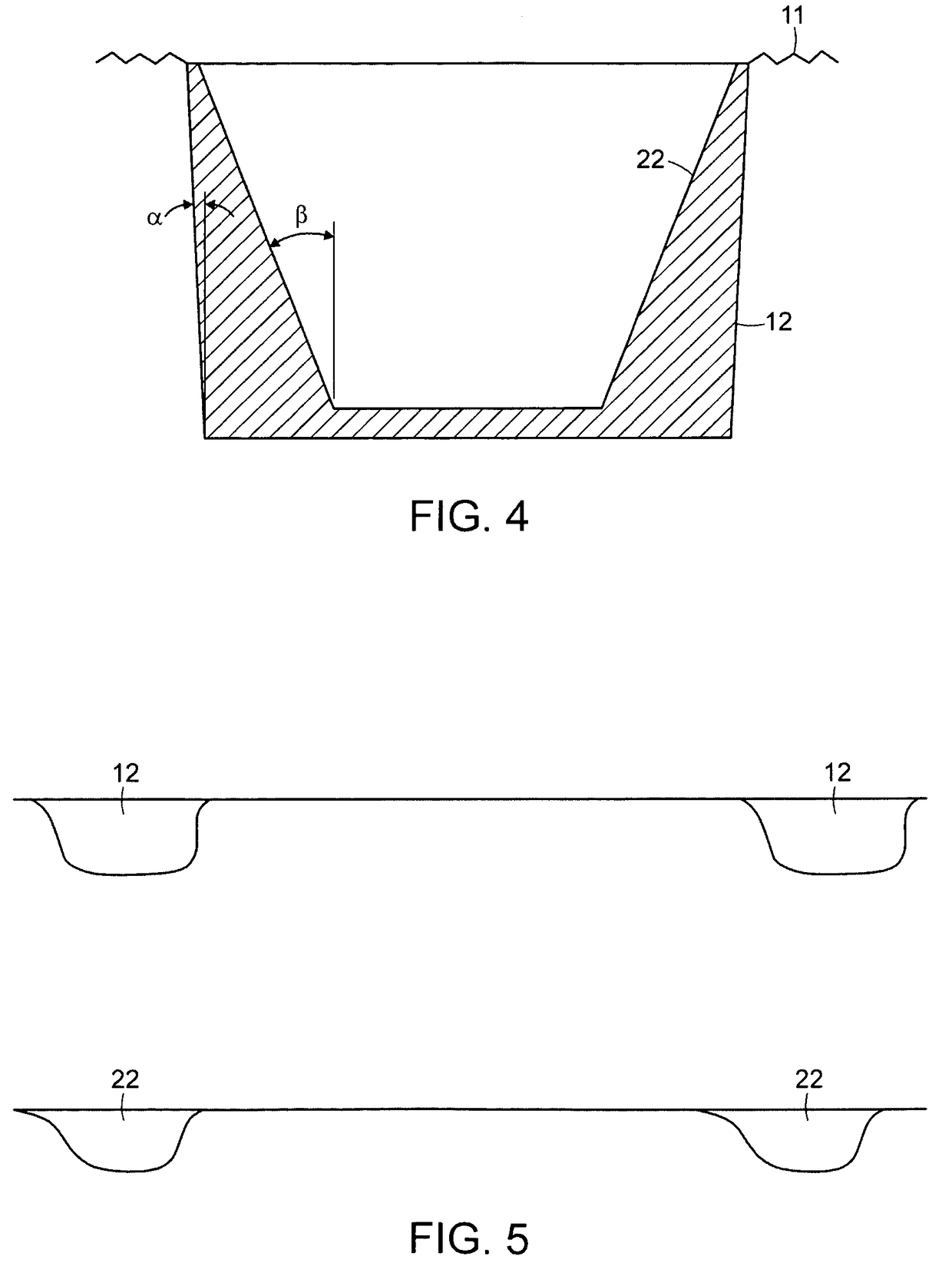

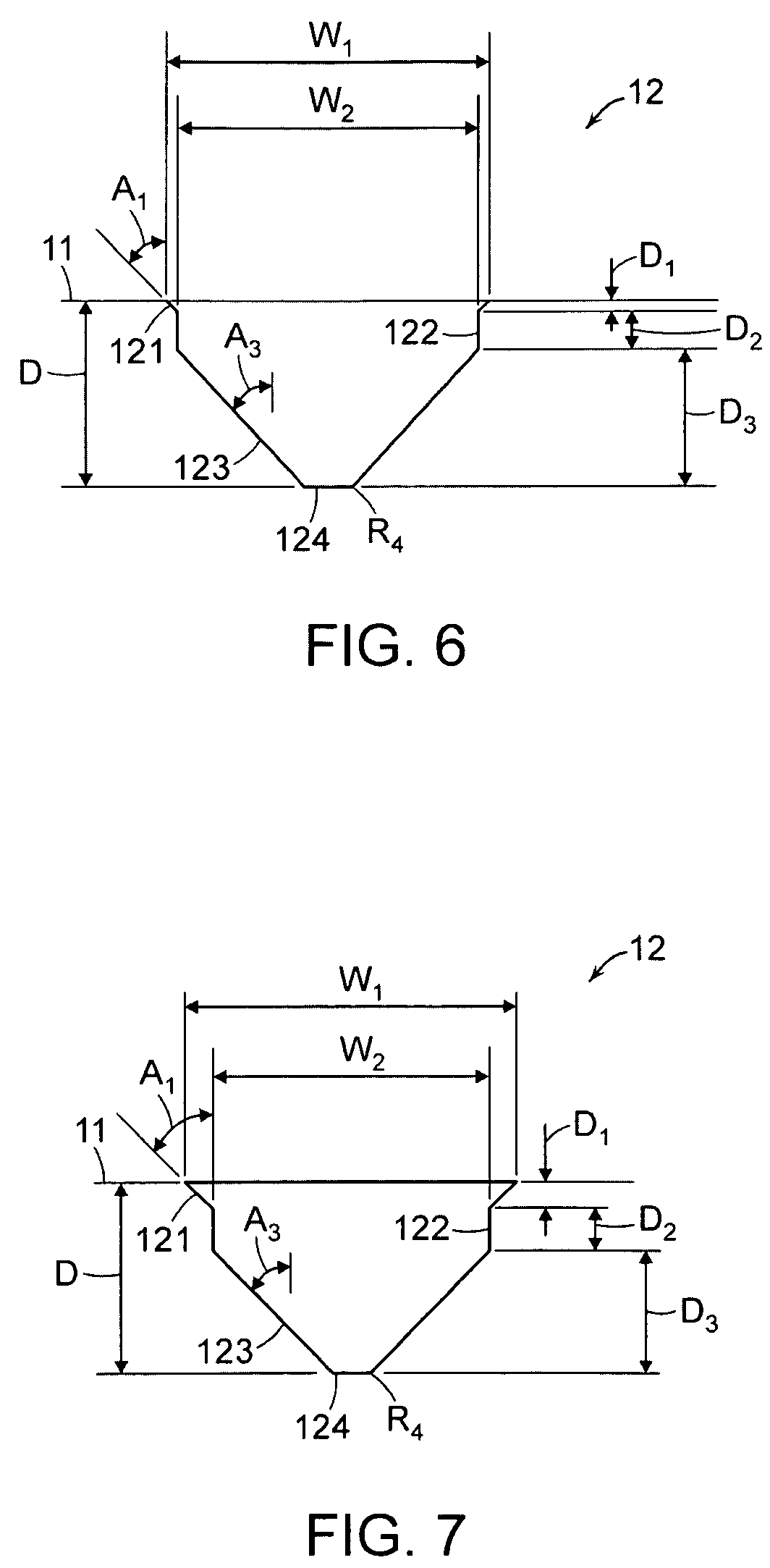

The present invention is directed to a golf club head with an improved striking surface. The grooves are machined into the strike surface with tight tolerances. The grooves have sharp edges, radiused ends, and a draft angle between about 2° and 12°. The striking face is machined such that it has a uniform texture with a roughness of more than 40 Ra. The face may be selectively textured to enhance certain shots that the golfer may perform. This may include providing a plurality of distinct sets of texturing to accommodate a plurality of different shots. The grooves may contain a plurality of portions, including a radiused or angled portion, a portion having substantially parallel walls, a portion having a v-shape, and a curved portion. The grooves may also be characterized by various dimensions, including draft angle, inclusive side wall angle, width, depth, cross-sectional area, spacing, and pitch ratio.

Owner:ACUSHNET CO

Golf club head groove configuration

ActiveUS7568983B2Facilitate cleaning sand and dirt and other debrisTighter draft anglesGolf clubsRacket sportsEngineeringGolf Ball

The present invention is directed to a golf club head with an improved striding surface. The grooves are machined into the strike surface with tight tolerances. The grooves have sharp edges, radiused ends, and a draft angle between about 2° and 12°. The striking face is machined such that it has a uniform texture with a roughness of more than 40 Ra. The grooves may contain a plurality of portions, including a radiused or angled portion, a portion having substantially parallel walls, a portion having a v-shape, and a curved portion.

Owner:ACUSHNET CO

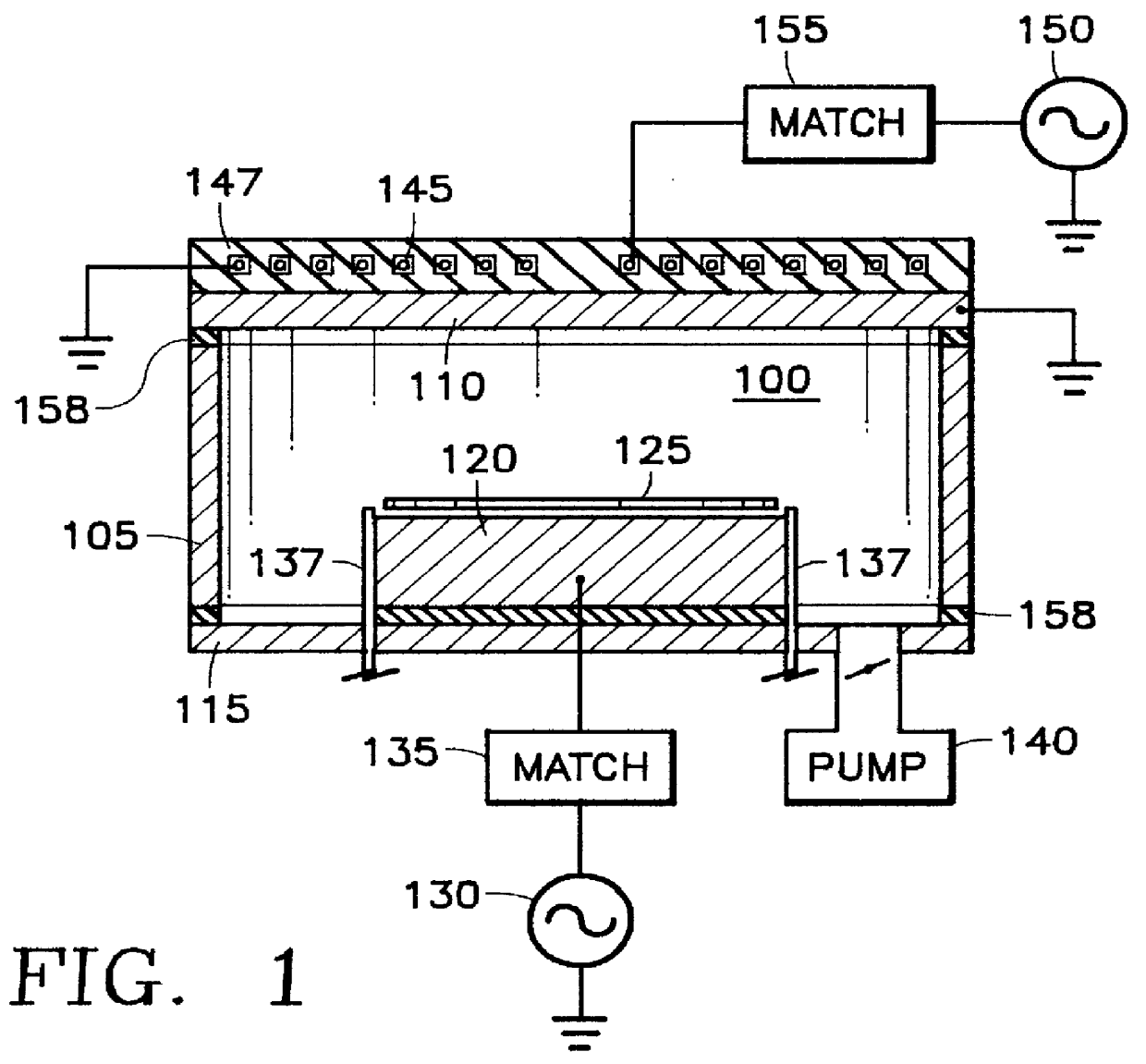

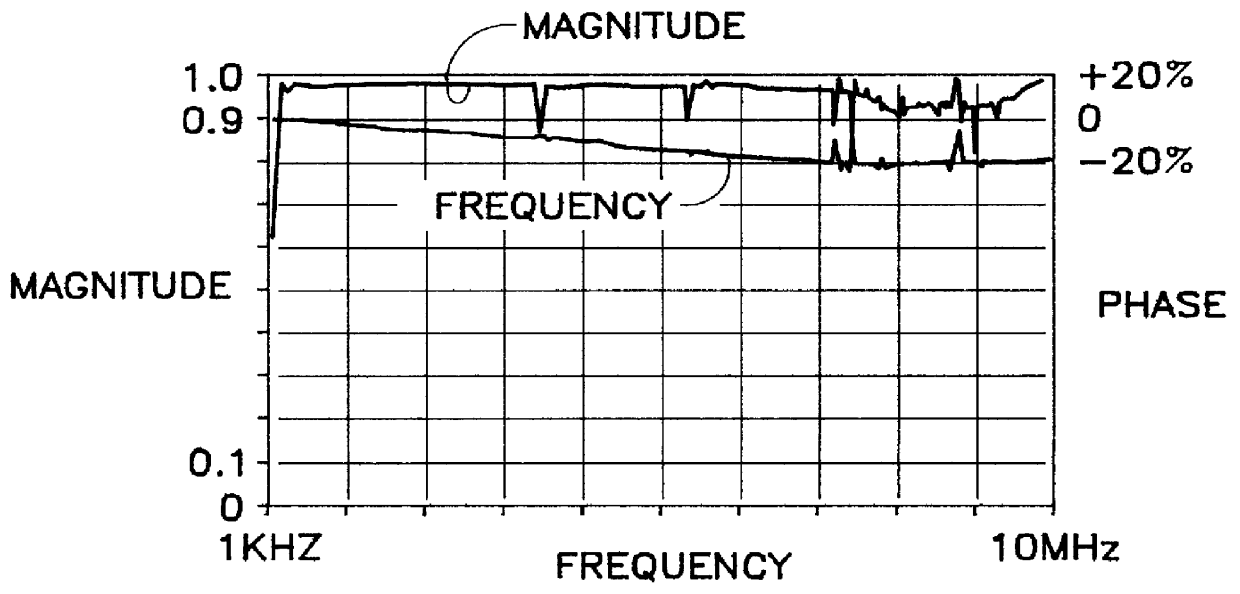

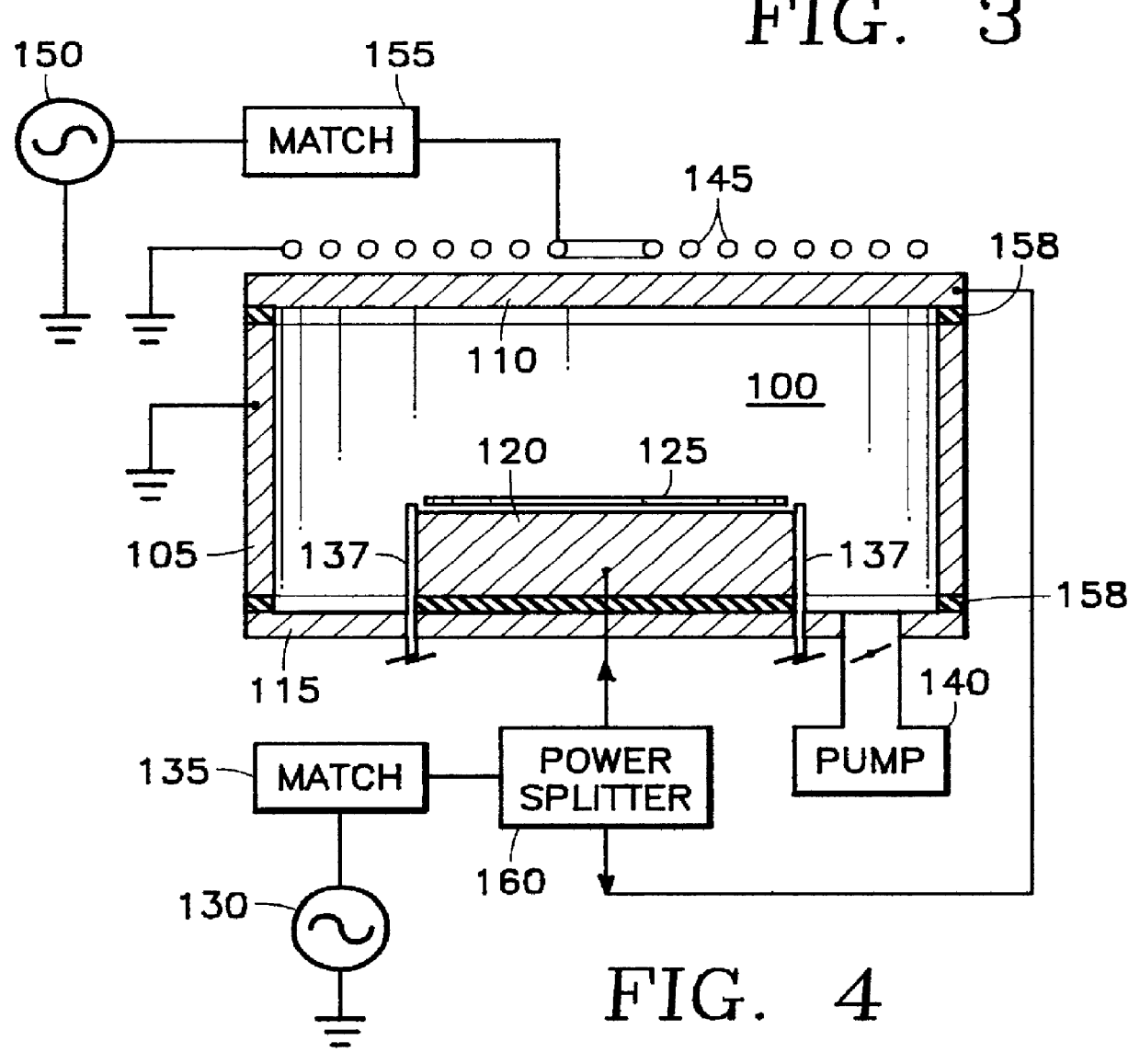

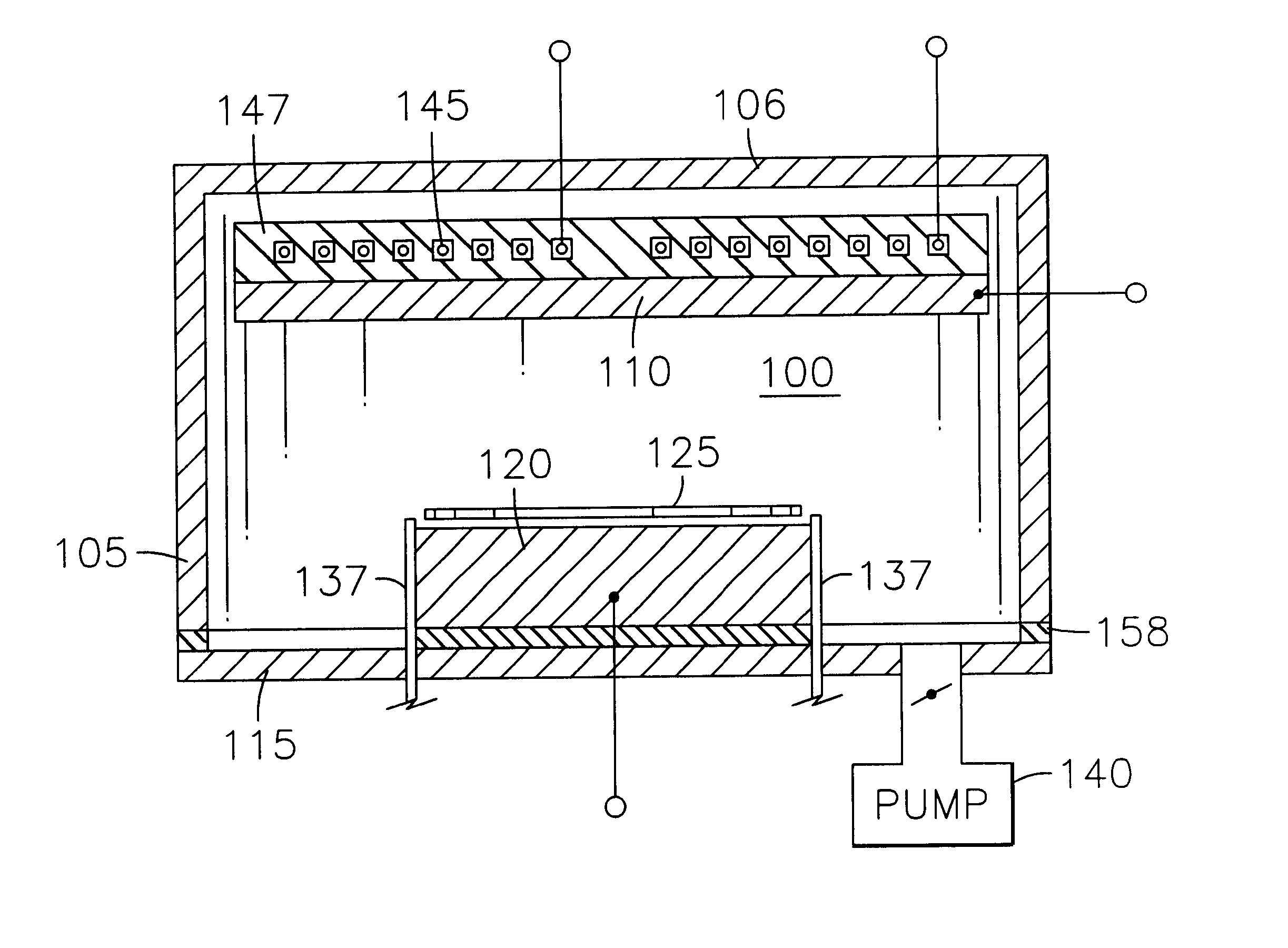

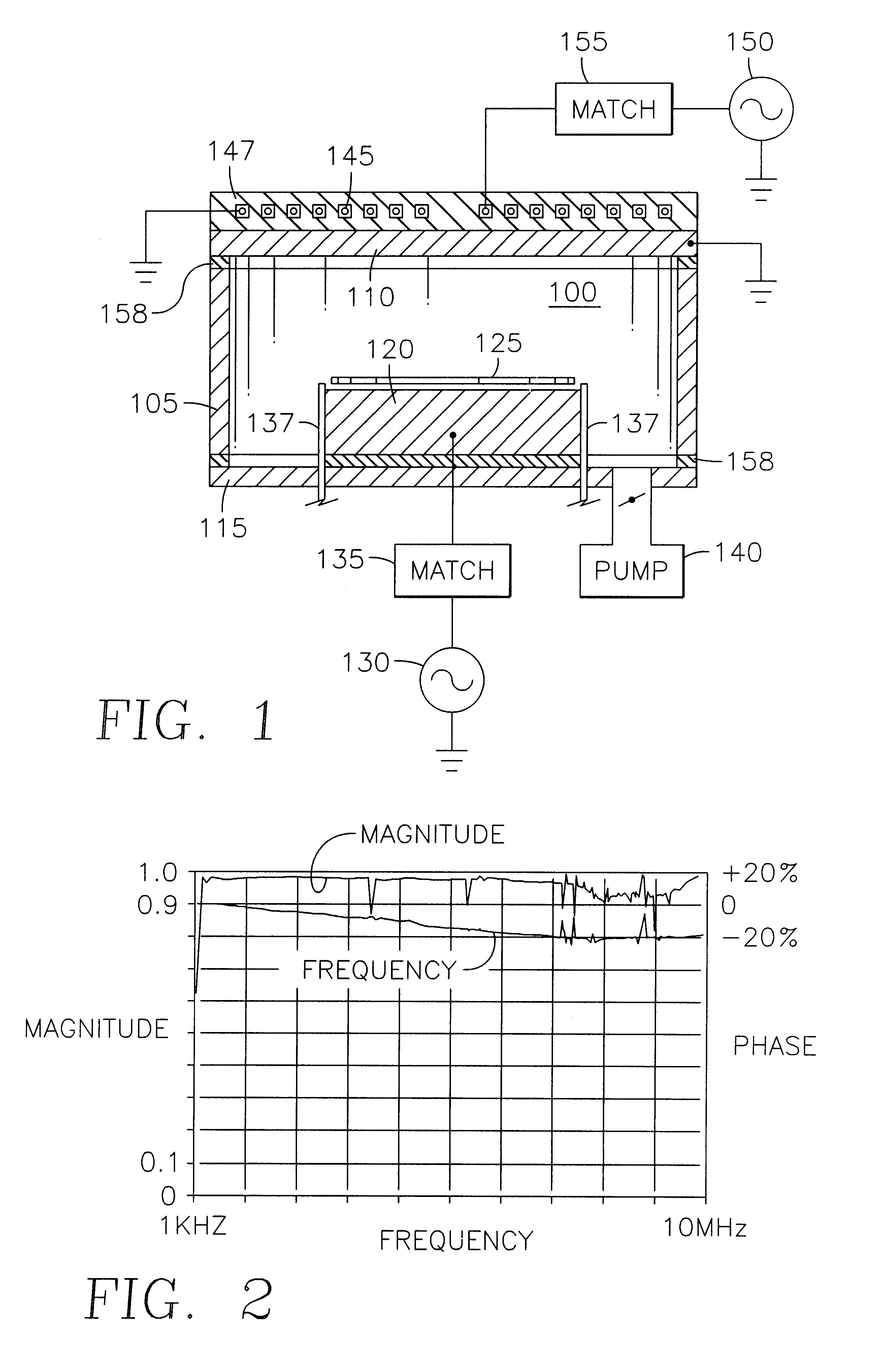

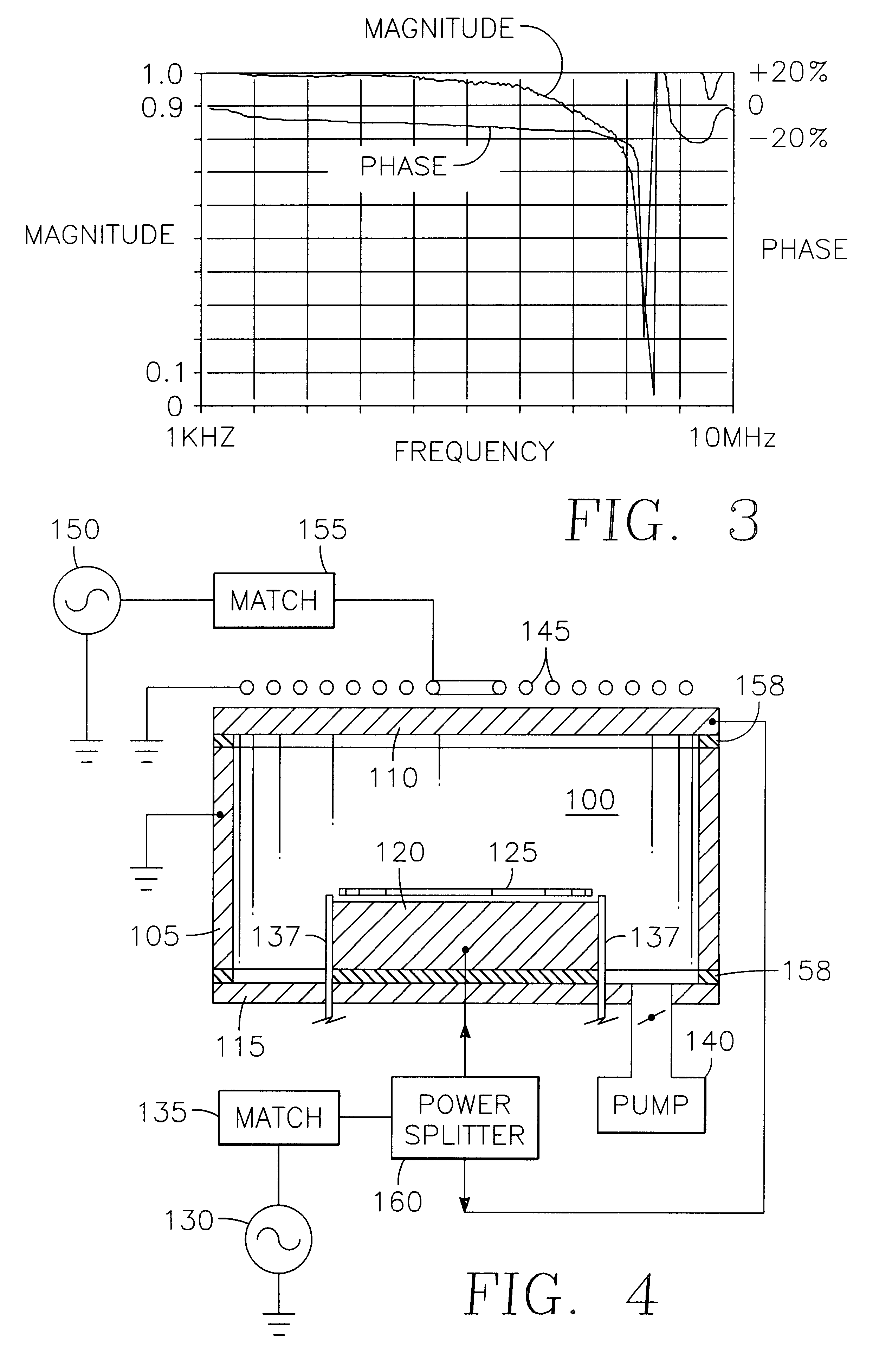

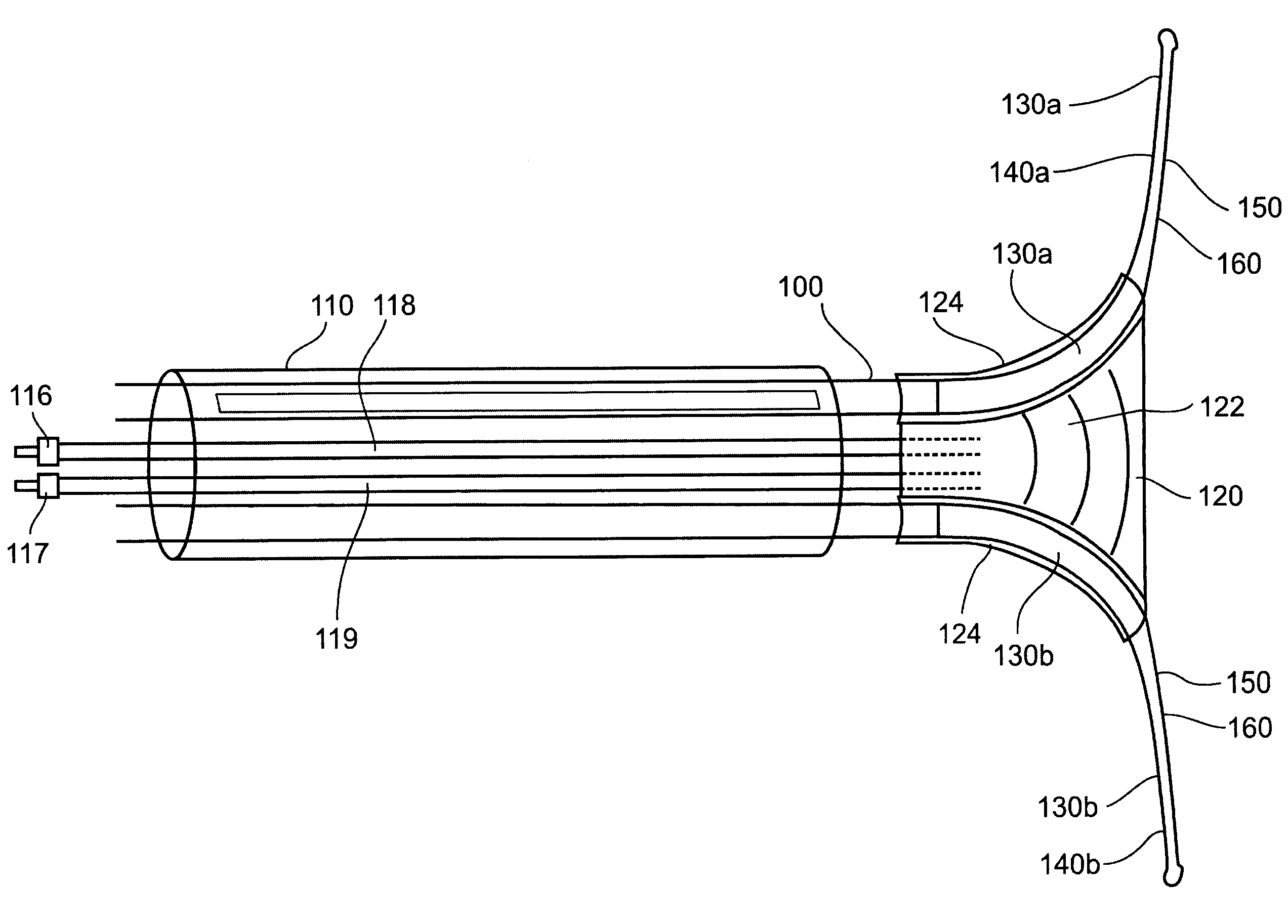

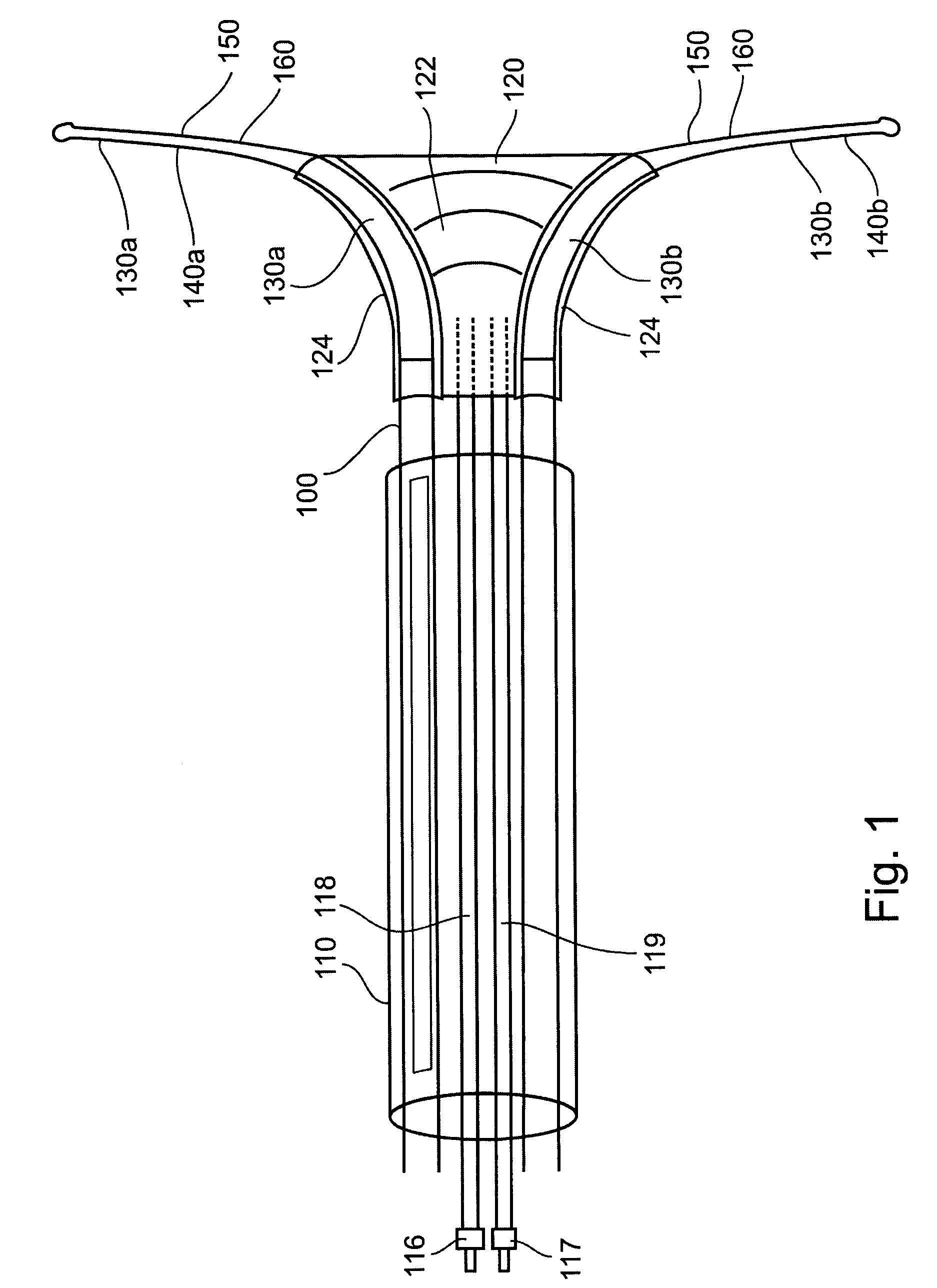

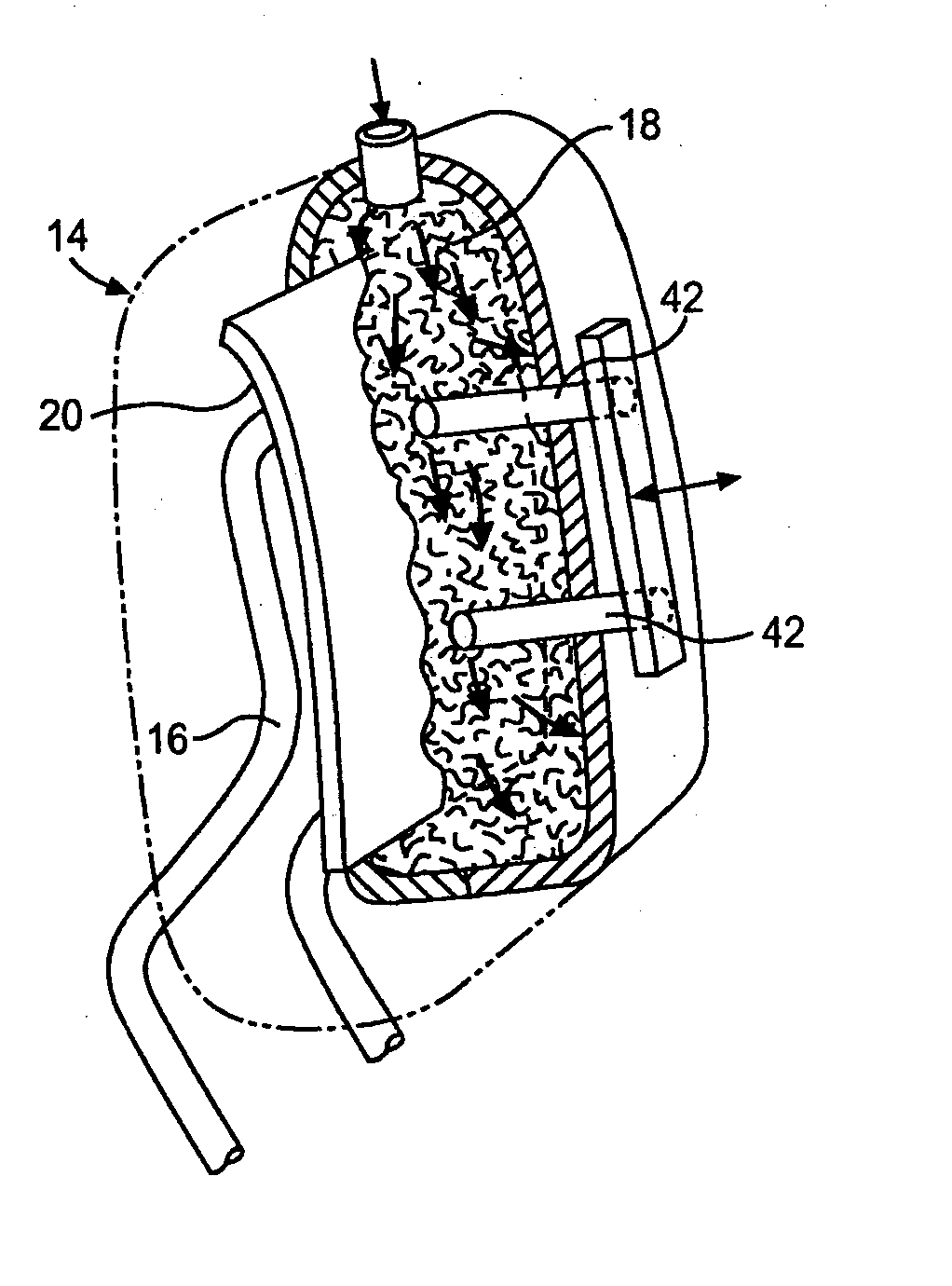

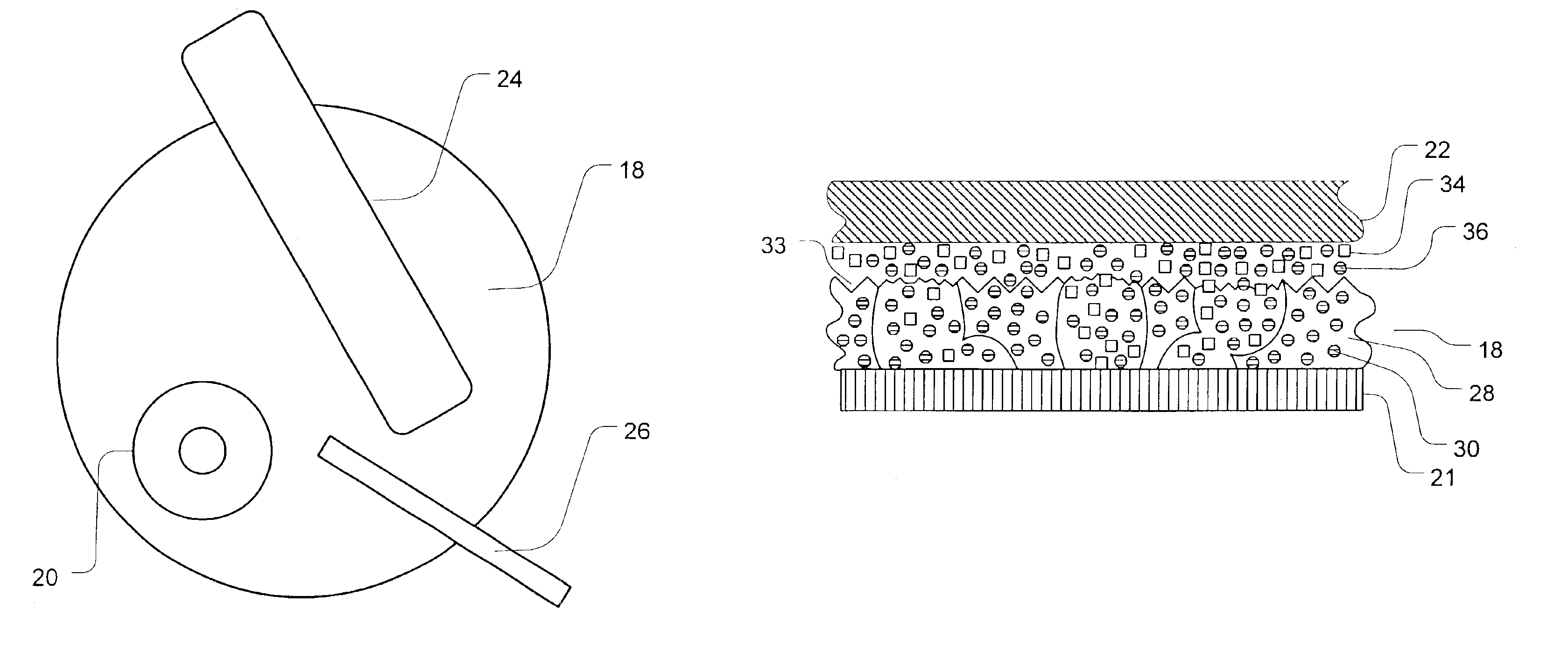

Plasma reactor having an inductive antenna coupling power through a parallel plate electrode

InactiveUS6623596B1Minimize interactionAvoid flowDough treatmentElectric discharge tubesParallel plateElectricity

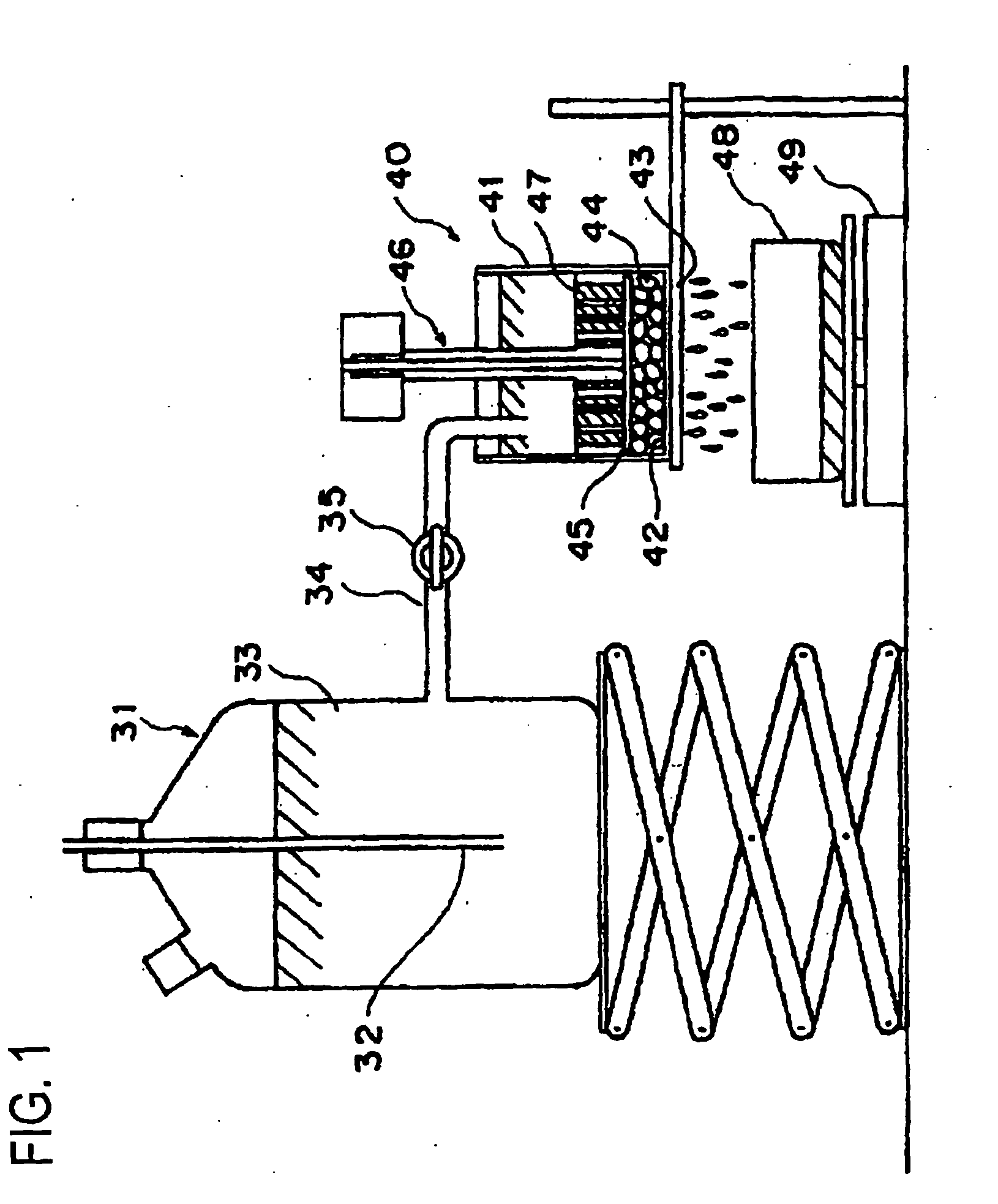

A plasma reactor for processing a workpiece includes a reactor enclosure defining a processing chamber, a base within the chamber for supporting the workpiece during processing thereof, a semiconductor window electrode overlying the base, a gas inlet system for admitting a plasma precursor gas into the chamber, an electrical terminal coupled to the semiconductor window electrode, an inductive antenna adjacent one side of the semiconductor window electrode opposite the base for coupling power into the interior of said chamber through the semiconductor window electrode.

Owner:APPLIED MATERIALS INC

Golf club head having a grooved face

The present invention is directed to a golf club head with an improved striking surface. The grooves are machined into the strike surface with tight tolerances. The grooves have sharp edges, radiused ends, and a draft angle between about 2° and 12°. The striking face is machined such that it has a uniform texture with a roughness of more than 40 Ra. The face may be selectively textured to enhance certain shots that the golfer may perform. This may include providing a plurality of distinct sets of texturing to accommodate a plurality of different shots. The grooves may contain a plurality of portions, including a radiused or angled portion, a portion having substantially parallel walls, a portion having a v-shape, and a curved portion. The grooves may also be characterized by various dimensions, including draft angle, inclusive side wall angle, width, depth, cross-sectional area, spacing, and pitch ratio.

Owner:ACUSHNET CO

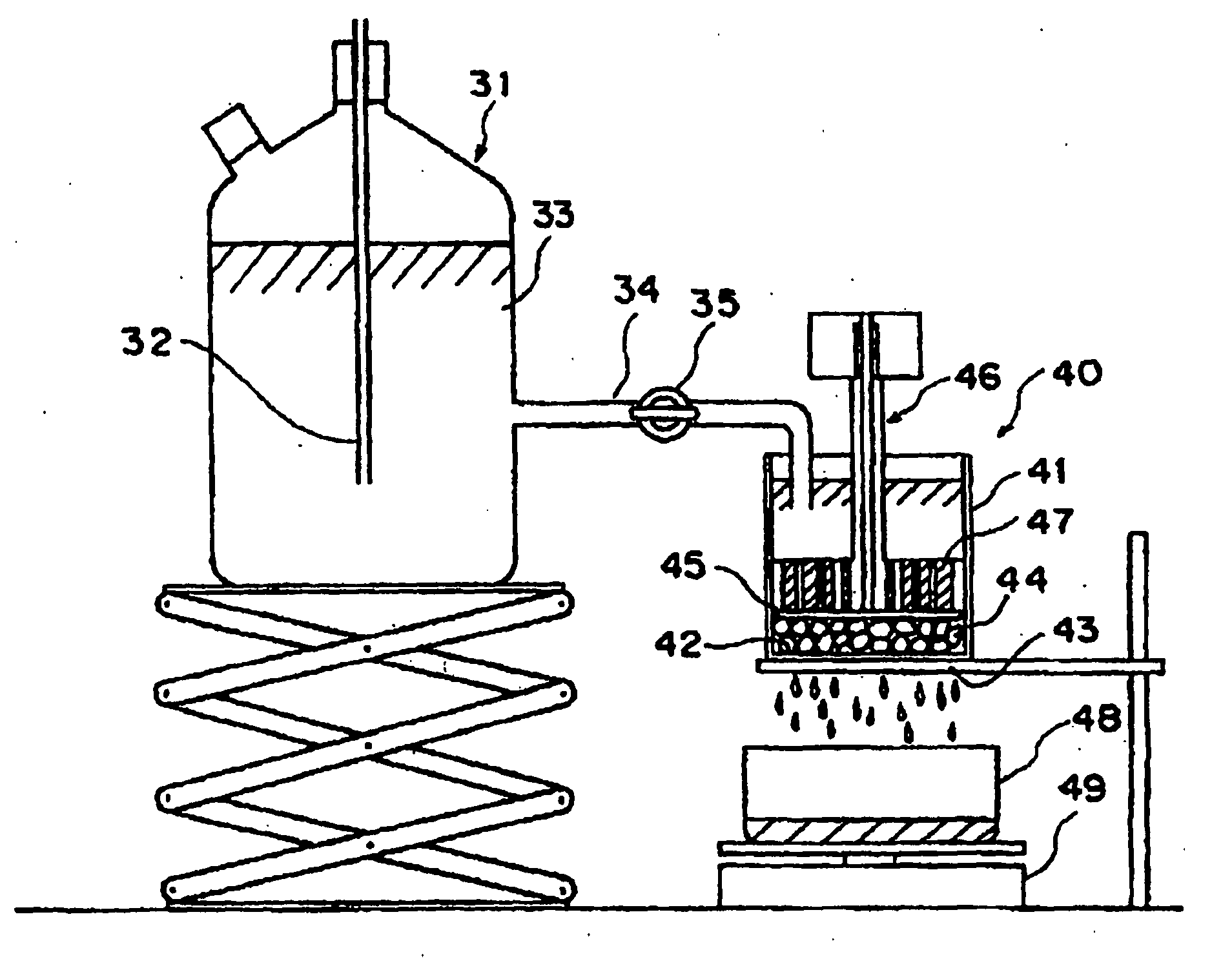

Method for production of modified water absorbent resin

InactiveUS20090298963A1Improve production efficiencyOutstanding propertyAbsorbent padsBandagesWater solublePolymer chemistry

This invention is to provide a method for producing a modified water absorbent resin excelling in water absorbing properties. This invention relates to a method for producing a modified water absorbent resin, which comprises a) mixing a water absorbent resin and a water-soluble radical polymerization initiator or a heat-degradable radical polymerization initiator without addition of an ethylenically unsaturated monomer and b) irradiating the resultant mixture with active energy rays. The method is particularly capable of exalting the absorbency against pressure and the saline flow conductivity.

Owner:NIPPON SHOKUBAI CO LTD

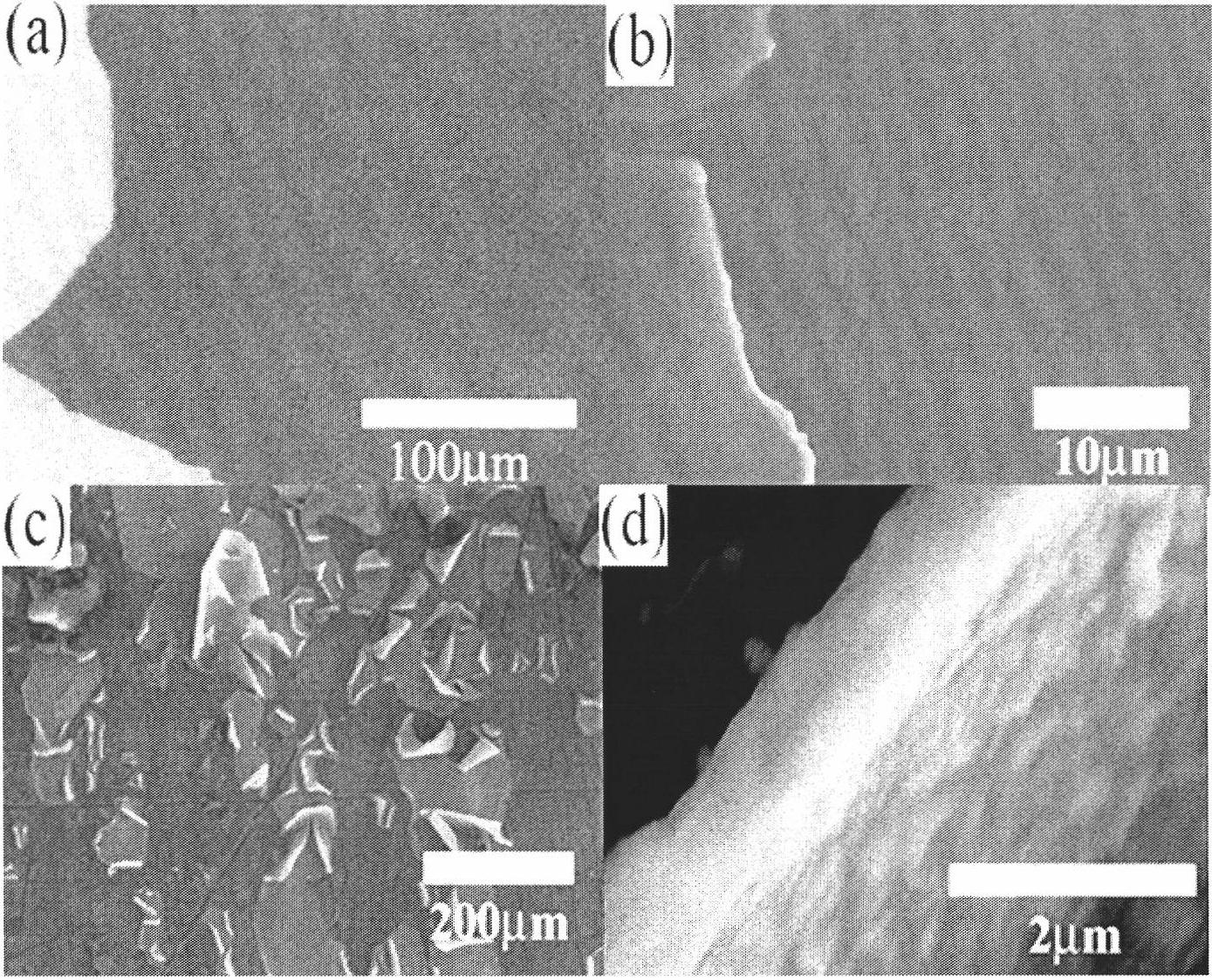

Implants with textured surface and methods for producing the same

ActiveUS7901462B2High retention rateConvenient coatingDental implantsBone implantHydrogen halideChloride

Compositions and methods are provided for preparing a metal substrate having a uniform textured surface with a plurality of indentations with a diameter in the nanometer and micrometer range. The textured surface is produced by exposing the substrate to an etching fluid comprising a hydrogen halide acid and / or an oxyacid, a chloride containing compound, and an oxidizing agent. The etching solution can be used at ambient temperature without damaging the metal elements on the substrate surface. This textured surface enhances adherence of coatings or cells onto the textured surface, improves the retention of proteins on the surface, and encourages bone in-growth.

Owner:DEPUY PROD INC

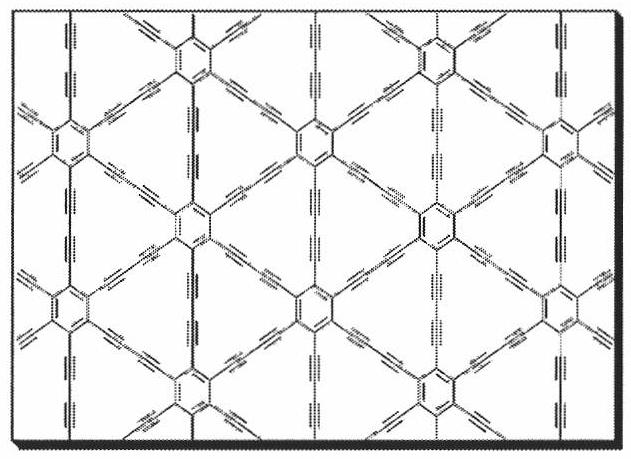

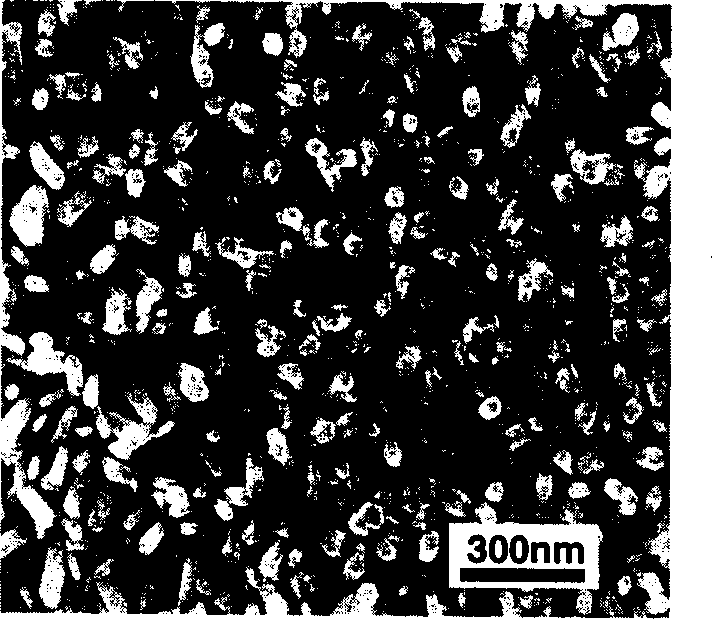

Method for preparing graphite alkyne film

The invention discloses a method for preparing a graphite alkyne film. The method comprises that: a copper sheet or any one substrate the surface of which is covered with a copper film layer is used as a substrate; 6-alkynyl-benzene is subjected to coupling reaction in a solvent under the catalytic action of the copper to obtain the graphite alkyne film on the surface of the substrate. The method for preparing the graphite alkyne film, which is provided by the invention, has simple and convenient process, and can carry out large-scale preparation of the graphite alkyne film on the surface of the copper sheet or the substrate any surface of which is covered with the copper. The electrical conductivity of the graphite alkyne film is 2.516*10-4S / m. The film has uniform surface, can exist stably in the air, is a semiconductor with similar performances with silicon, and has potential application prospect in the fields of catalysis, electron, semiconductor, energy, material and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Golf club head with varying face grooves

The present invention is directed to a golf club head with an improved striking surface. Grooves are machined into the strike surface with tight tolerances. The grooves have sharp edges, radiused ends, and a draft angle between about 2° and 12°. The striking face is machined such that it has a uniform texture with a roughness of more than 40 Ra. The grooves may contain a plurality of portions, including a radiused or angled portion, a portion having substantially parallel walls, a portion having a v-shape, and a curved portion. The grooves may also be characterized by various dimensions, including draft angle, inclusive side wall angle, width, depth, cross-sectional area, spacing, and pitch ratio. Preferred values for these dimensions are provided. A golf club head having a variety of groove types and a set of golf clubs with grooves varying among the individual clubs of the set are also disclosed.

Owner:ACUSHNET CO

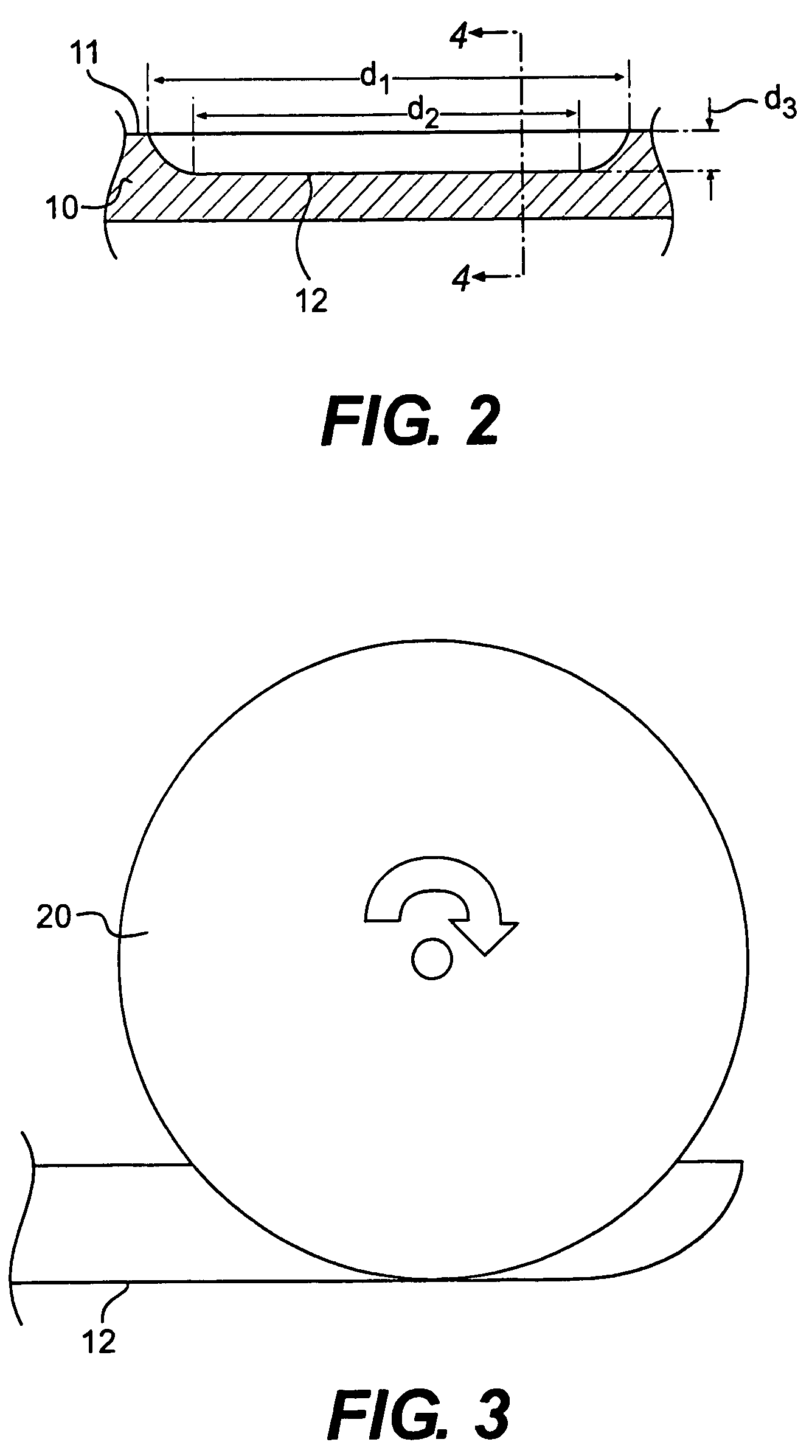

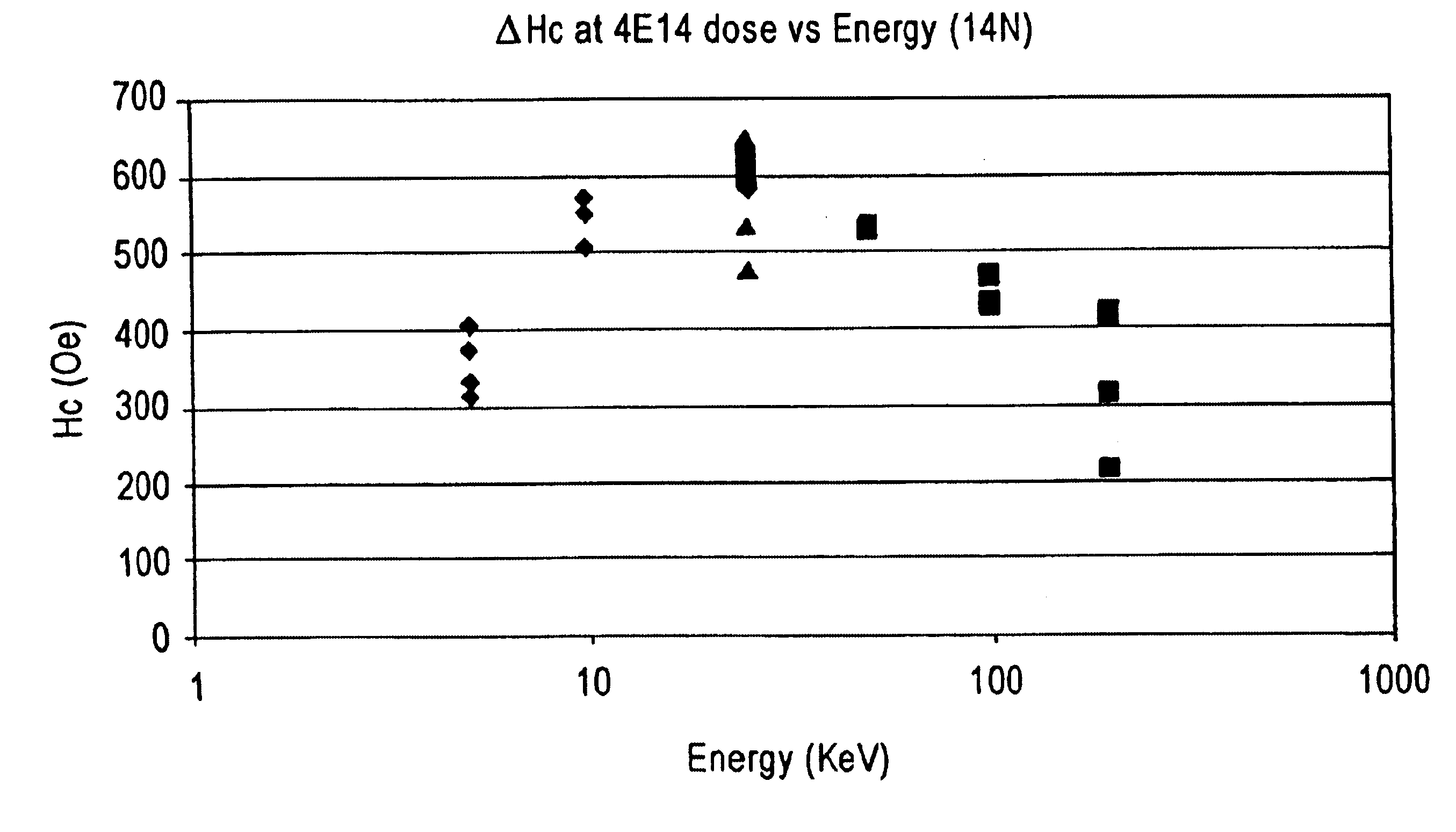

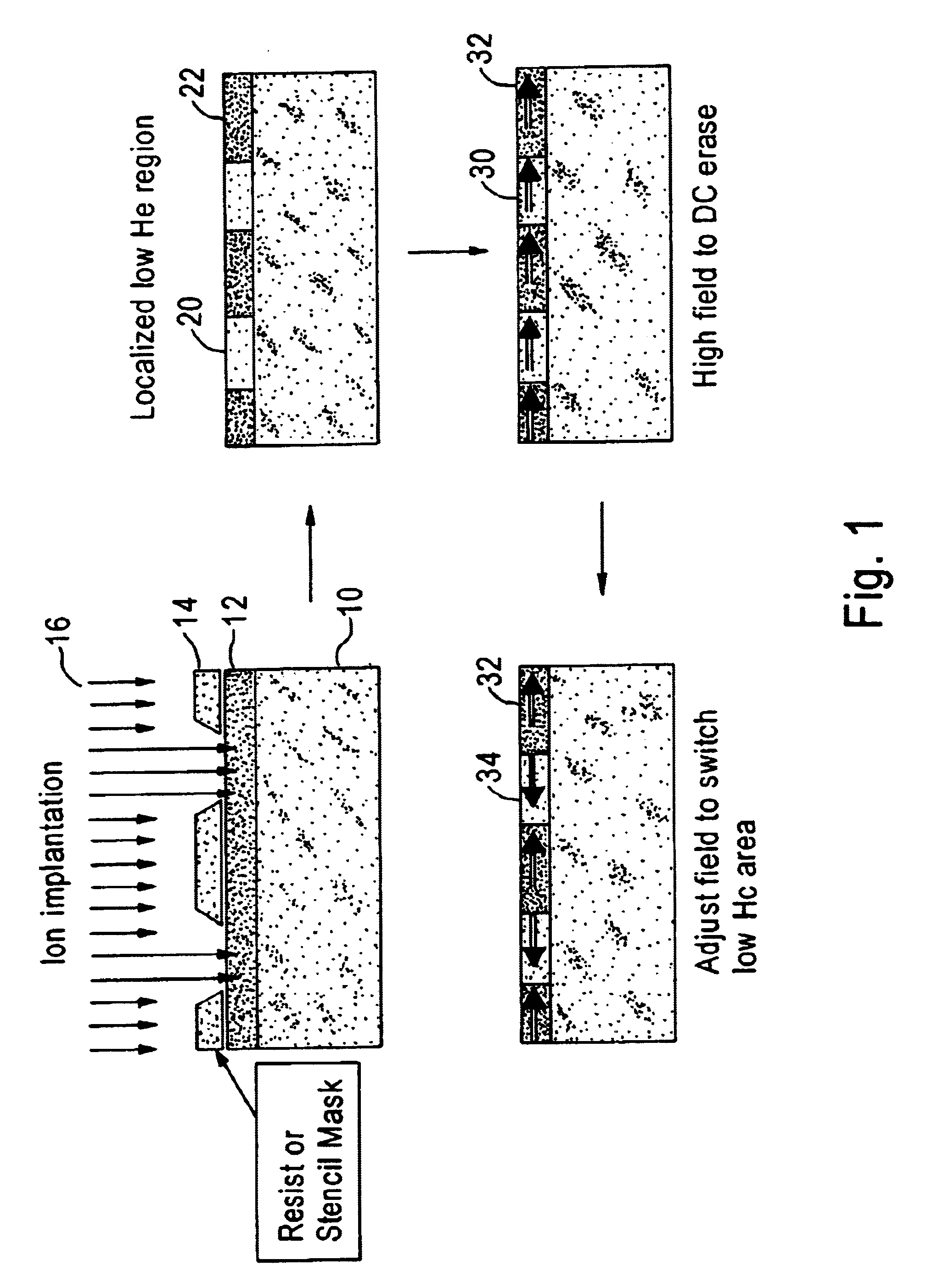

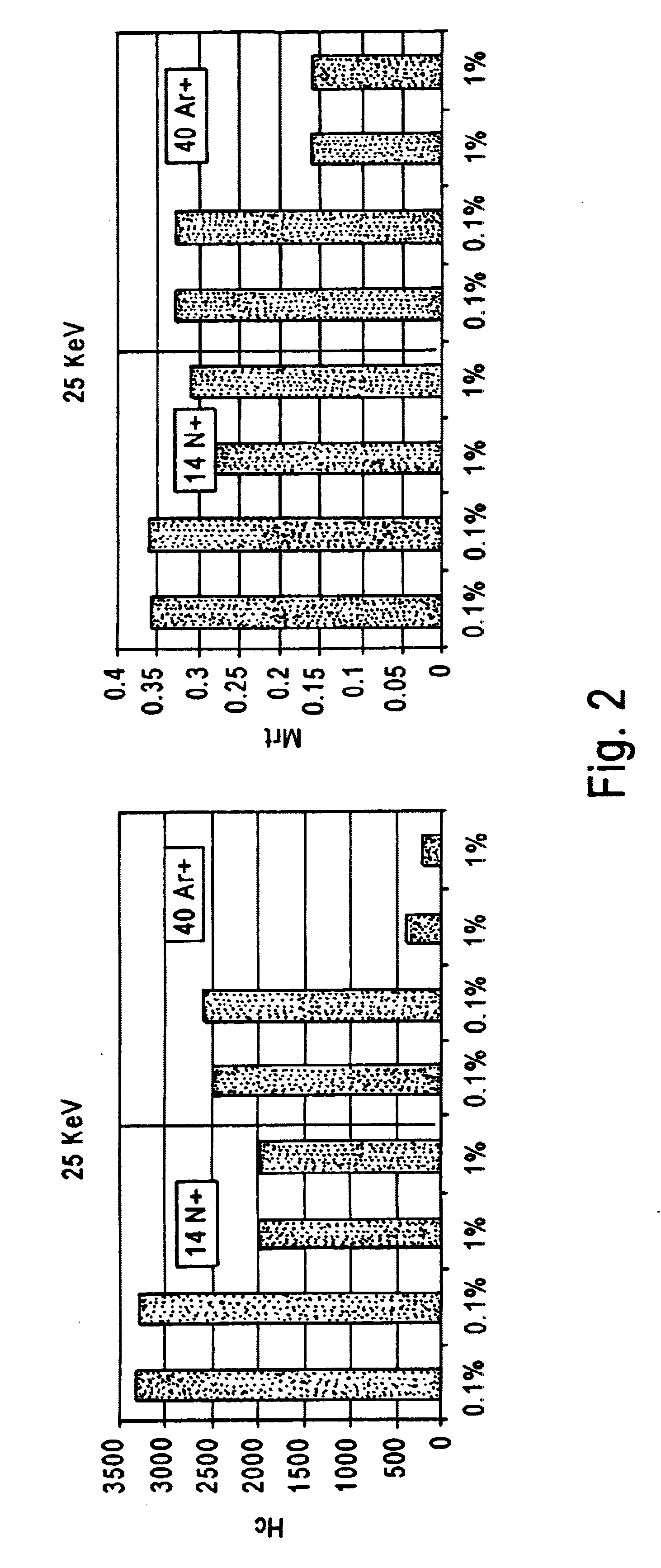

Patterning longitudinal magnetic recording media with ion implantation

InactiveUS6864042B1Increased areal recording densityUniform surfaceNanoinformaticsPatterned record carriersIon bombardmentTopography

A magnetic recording medium is formed with a distribution of low coercivity regions functioning as a transition pattern for servo information capable of being sensed by a read / write head by exposing a masked magnetic layer to ions to change the coercivity of the exposed magnetic layer without substantially affecting the topography of the magnetic layer.Embodiments of the present invention include forming a series of substantially radially extending low coercivity regions used to divide the magnetic layer into a plurality of sectors comprising substantially concentric circumferentially extending data tracks by exposing a masked magnetic layer having a high coercivity, i.e. from about 2000 Oe to about 10000 Oe, to one or more heavy atom ion bombardments of gaseous ions, e.g. argon ions, at a dose of about 1×1013 atoms / cm2 to about 9×1015 atoms / cm2 having an implantation energy of about 10 KeV to about 50 KeV.

Owner:SEAGATE TECH LLC

Implants with textured surface and methods for producing the same

ActiveUS20060289388A1High retention rateConvenient coatingImpression capsDecorative surface effectsMicrometerChloride

Compositions and methods are provided for preparing a metal substrate having a uniform textured surface with a plurality of indentations with a diameter in the nanometer and micrometer range. The textured surface is produced by exposing the substrate to an etching fluid comprising a hydrohalic acid and a mixture of a hydrohalic acid and an oxyacid, a chloride containing compound, and an oxidant. The etching solution can be used at ambient temperature. This textured surface enhances adherence of coatings or cells onto the textured surface, improves the retention of proteins on the surface, and encourages bone in-growth.

Owner:DEPUY PROD INC

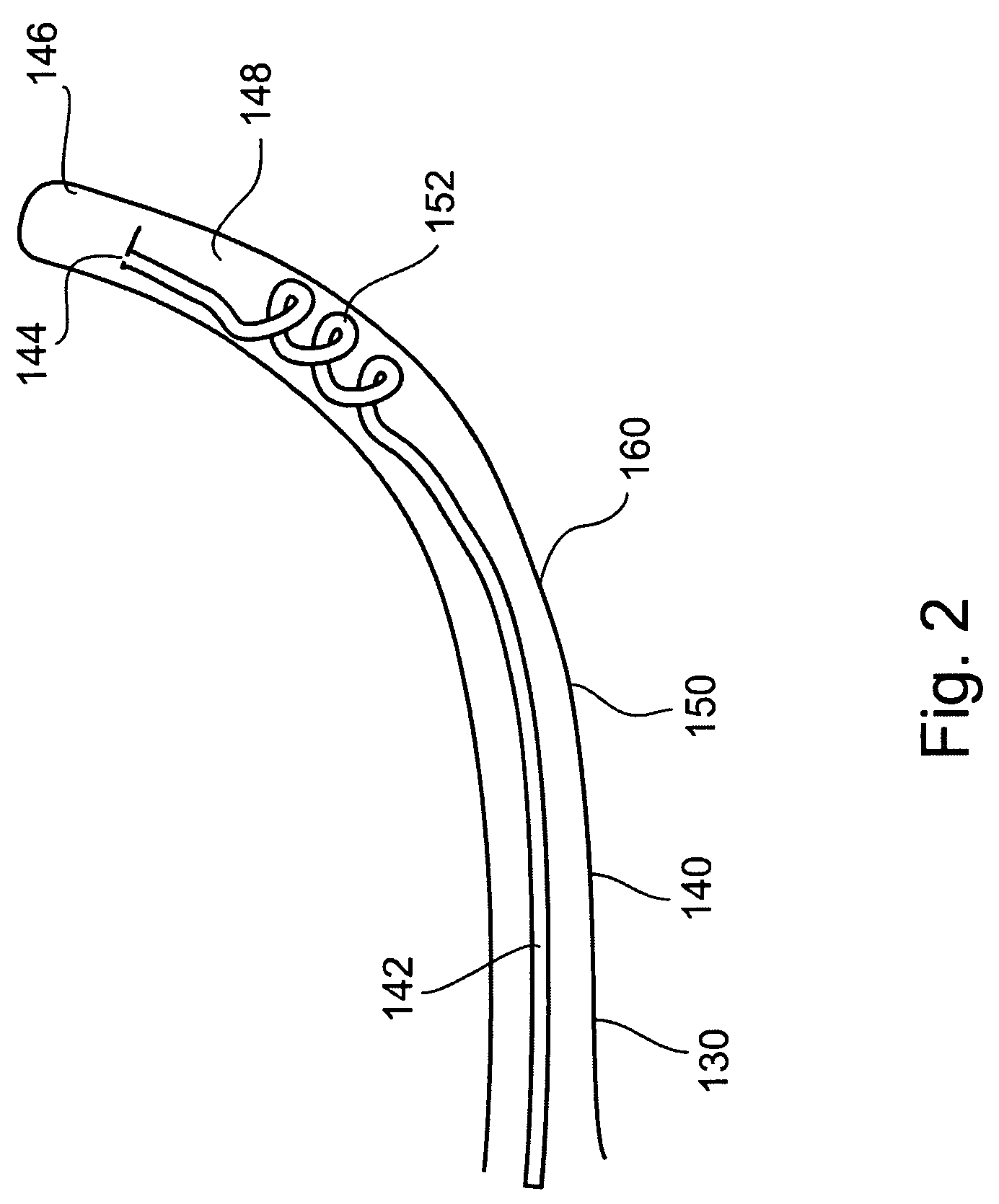

Endometrial ablation device and method

A device for uniform ablation of the endometrium comprises a transparent inflatable coolable balloon, flexible cryoprobes operable to be advanced into the uterine cornuae, an applicator operable to deliver balloon and cryoprobes to and from the uterine cavity, and optional channels for a hysteroscope and a light source, enabling observation of the uterine cavity during device insertion and observation of the endometrium during various stages of the ablation process.

Owner:GALIL MEDICAL

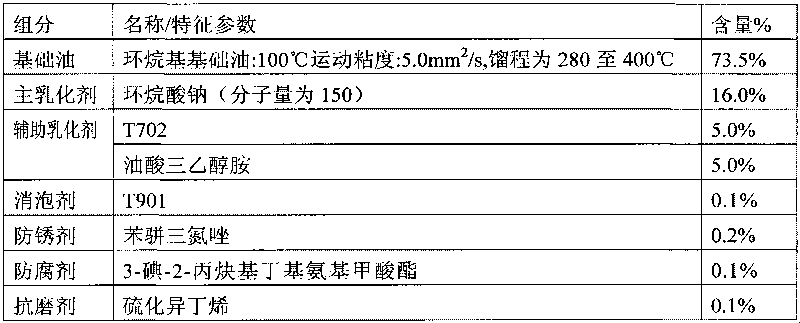

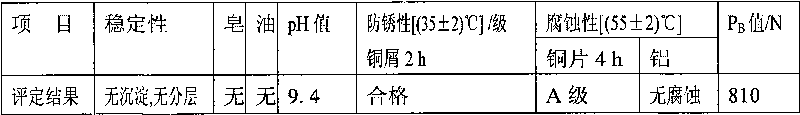

Water-based copper and aluminum wiredrawing oil composite and preparation method thereof

The invention relates to an oil-based lubricating composite and a preparation method thereof, in particular to a water-based copper and aluminum wiredrawing oil composite and a preparation method thereof. The water-based copper and aluminum wiredrawing oil composite comprises base oil, an emulsifier, an auxiliary emulsifier, a defoaming agent, a rust-proof agent, an antiseptic and an antiwear agent. The preparation method comprises the following steps of: configuring the water-based copper and aluminum wiredrawing oil composite into 3 percent to 45 percent water-based emulsion according to weight percentage; and spraying the water-based emulsion into a wiredrawing die cavity in the copper and aluminum wiredrawing process. The water-based copper and aluminum wiredrawing oil composite has the advantages of excellent lubricating property, great optimal light stability and storage stability, low cost, good cooling effect, fast heat transfer, little temperature increase in the using process, difficult combustion and easy cleaning and ensures the safety of the service environment; and in addition, a copper wire and an aluminum wire drawn by the method have the advantages of uniform wireshape, bright surfaces, difficult corrosion, good ultraviolet and storage stability and good stability.

Owner:PETROCHINA KARAMAY PETROCHEMICAL CO LTD

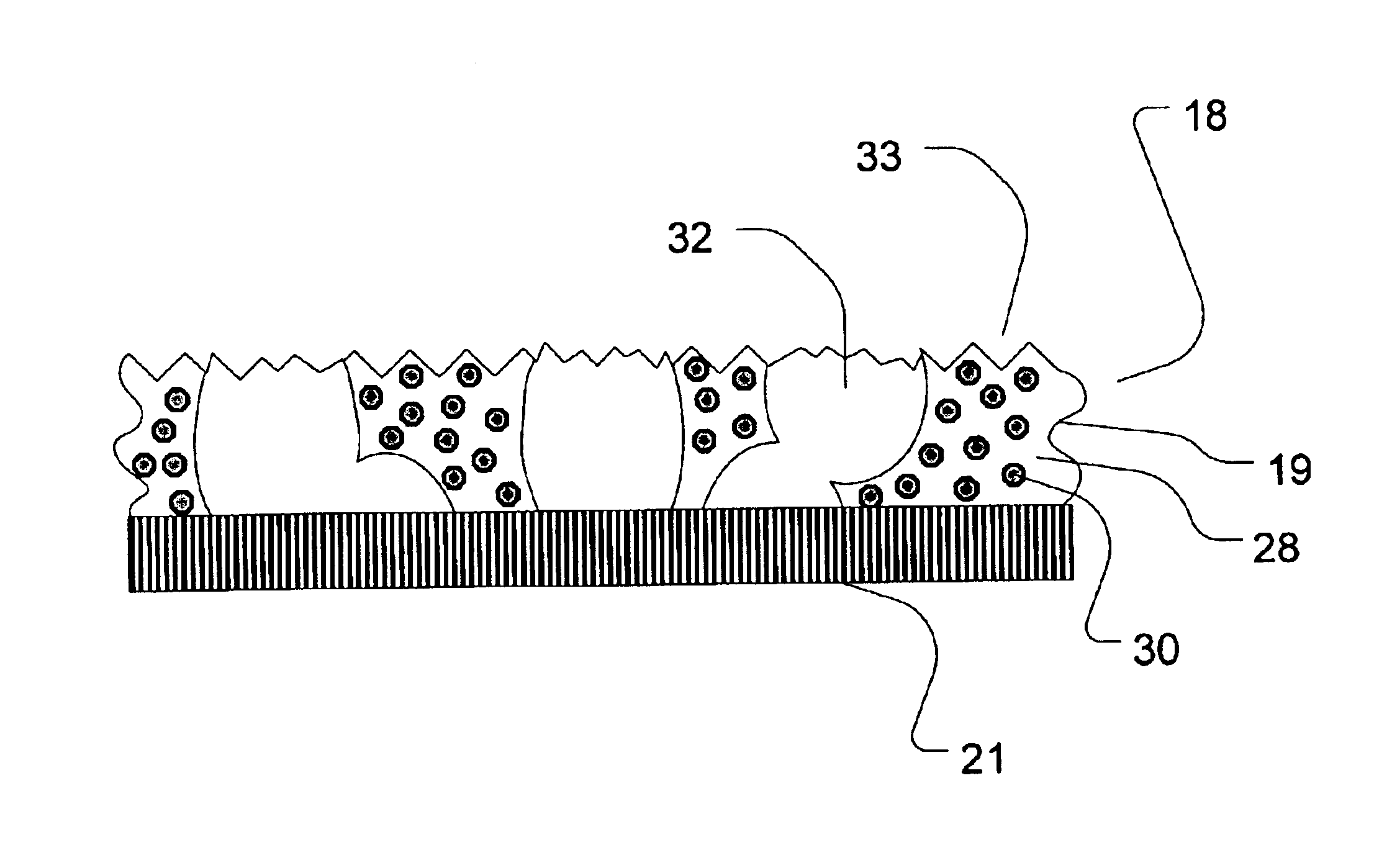

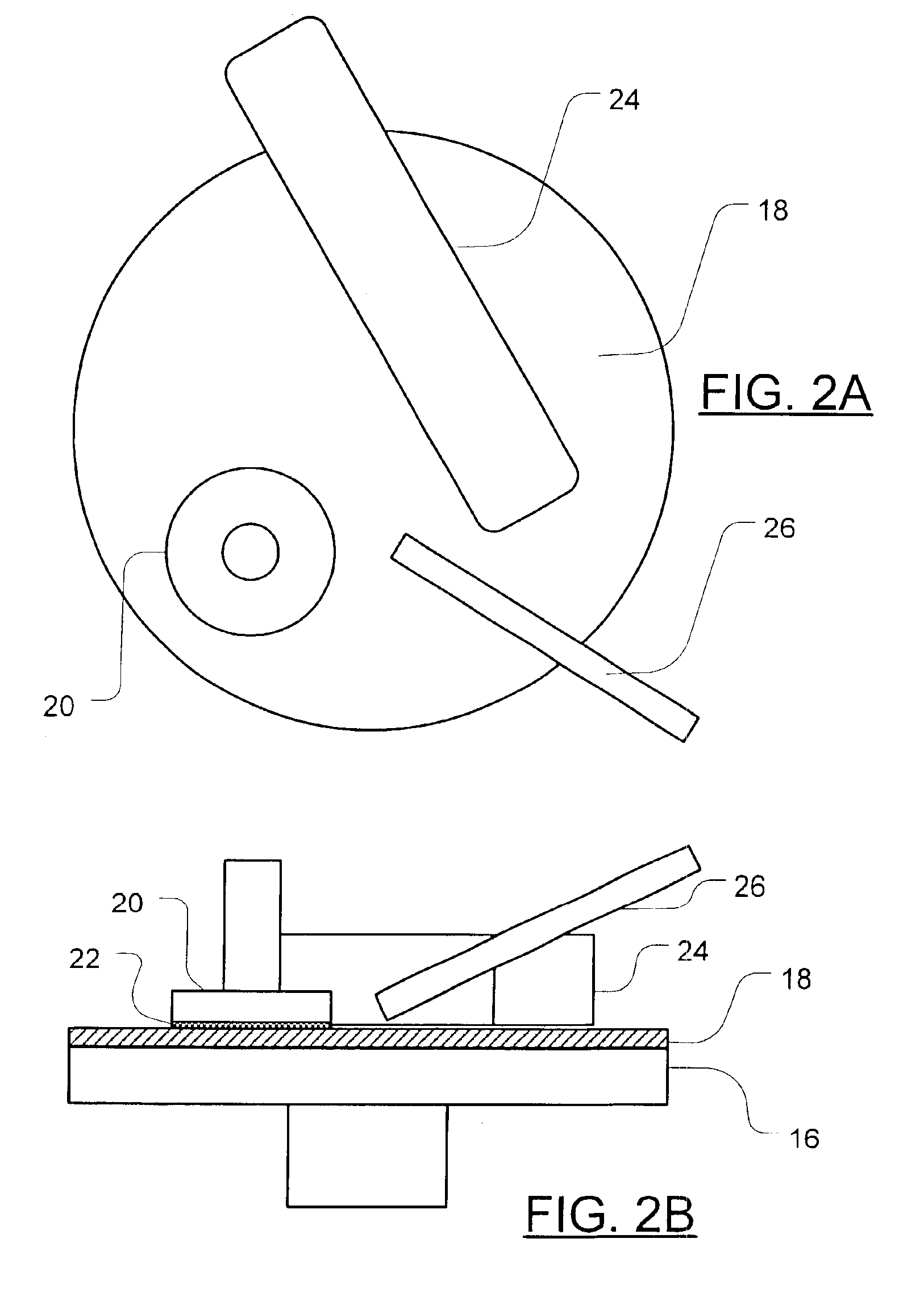

Method of manufacturing a fixed abrasive material

InactiveUS7066801B2Low costImprove throughputRevolution surface grinding machinesTransportation and packagingPolymer chemistryOpen cell

Provided is a method for manufacturing a fixed abrasive material suitable for use in CMP planarization pads from an aqueous polymer dispersion that also includes abrasive particles that involves frothing the polymer dispersion, applying the froth to a substrate, mold or carrier and curing the froth to form a fixed abrasive material having an open cell structure containing between about 5 and 85 wt % abrasive particles and a dry density of about 350 kg / m3 to 1200 kg / m3.

Owner:DOW GLOBAL TECH LLC +1

Ultra-fine highly effective anion powder material and its preparation method

The invention relates to an ultrafine high-effect negative ion powder material, which comprises: 60~95% natural negative ion releasing material, 2~30% activated material, and 3~25% energy transfer material. Wherein, using dry way and wet way to ultrafine break the material and obtain the product. This material increases the ion releasing ability more than twenty times to pure natural tourmalin and three times to the material theoretic value, and has high far-infrared radiation function without toxin.

Owner:深圳市金士吉康复用品科技有限公司

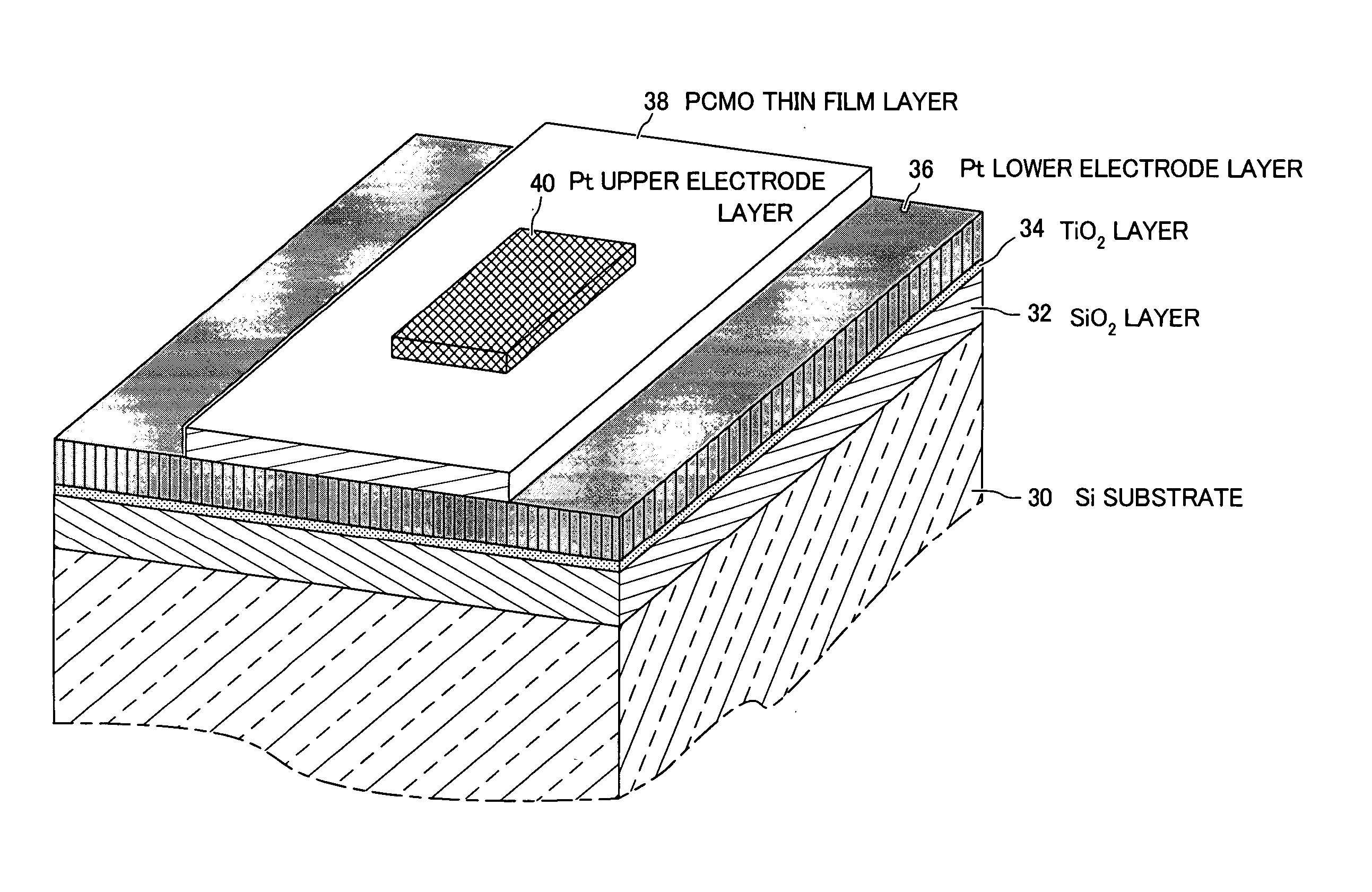

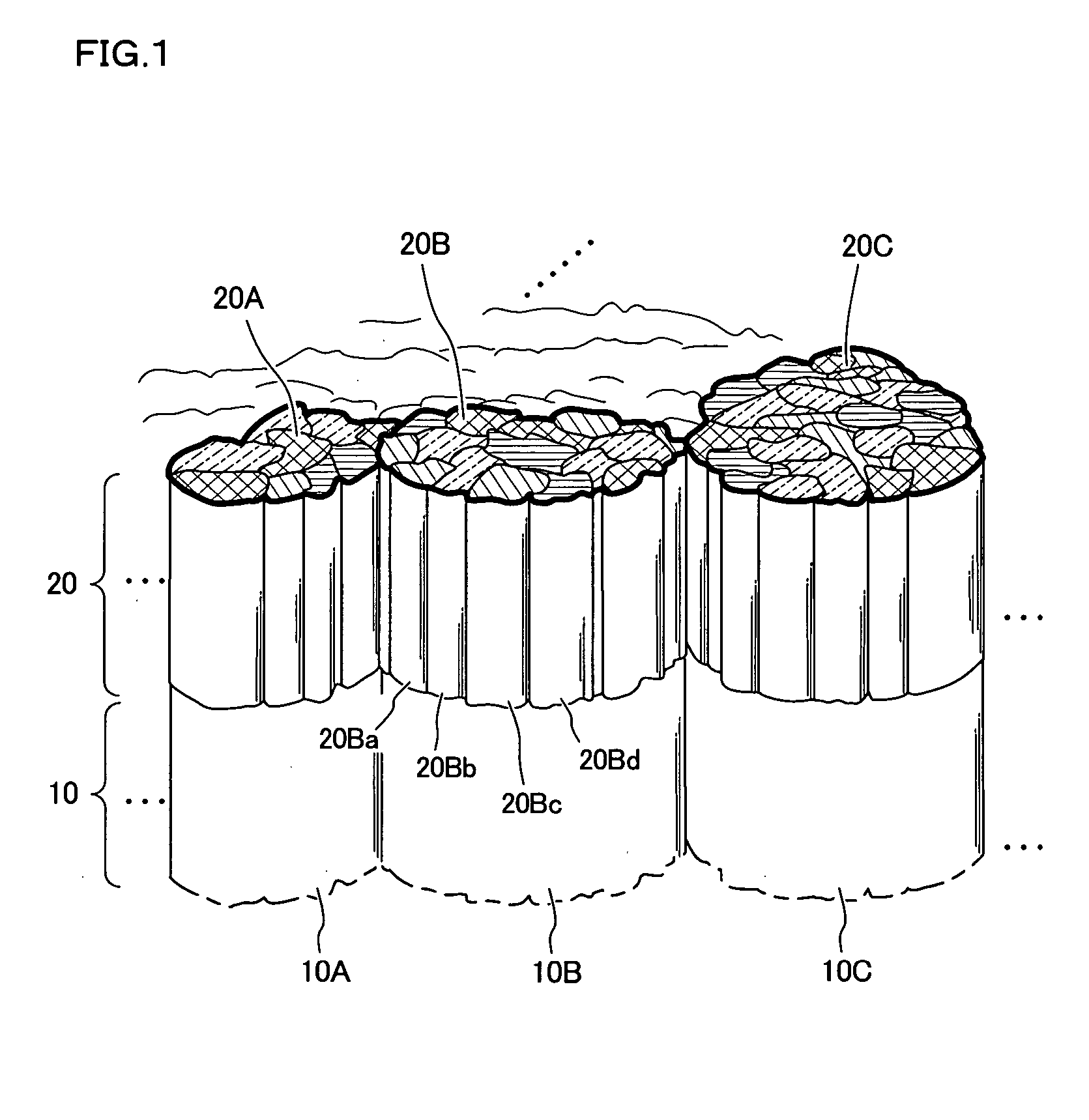

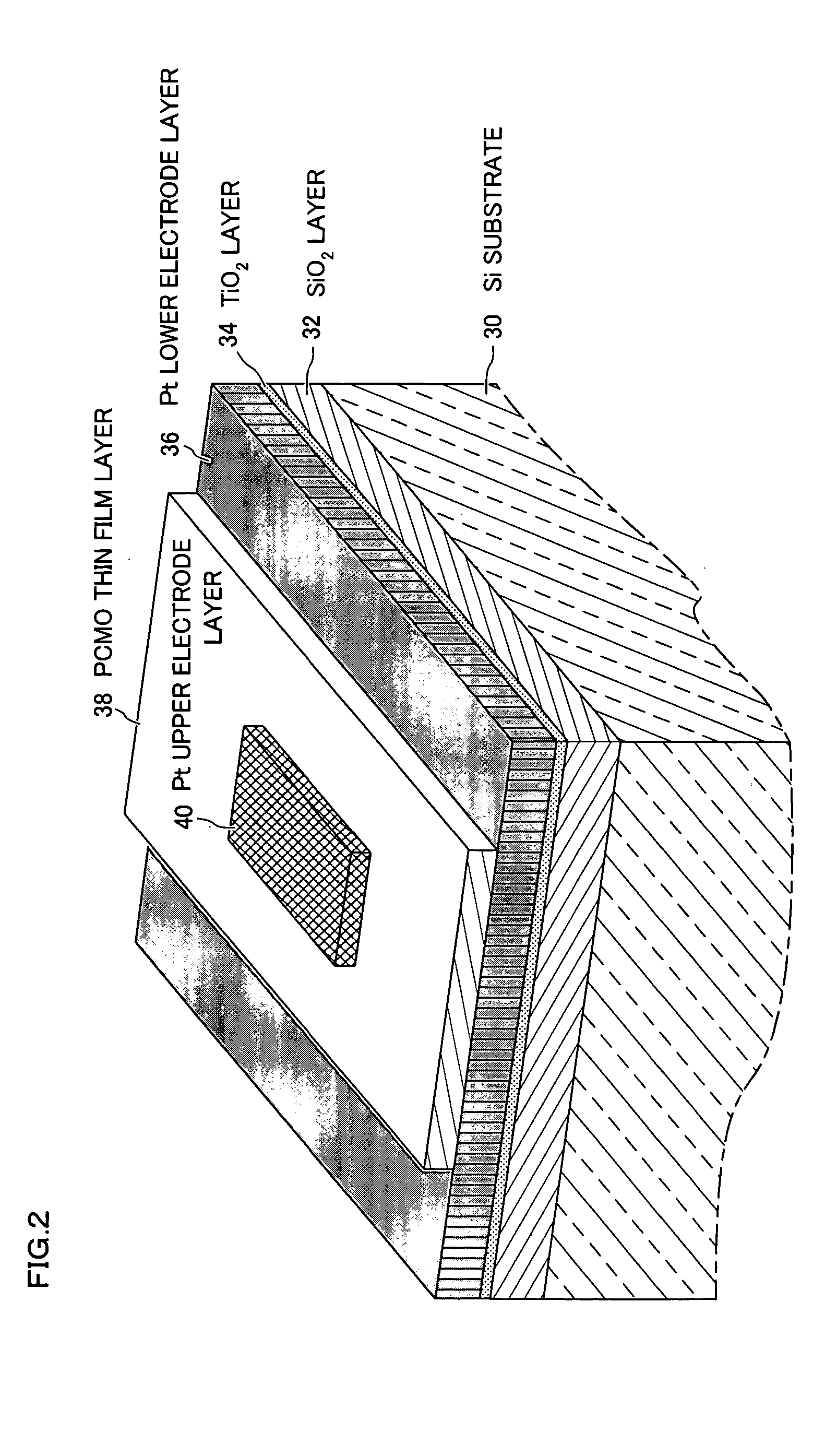

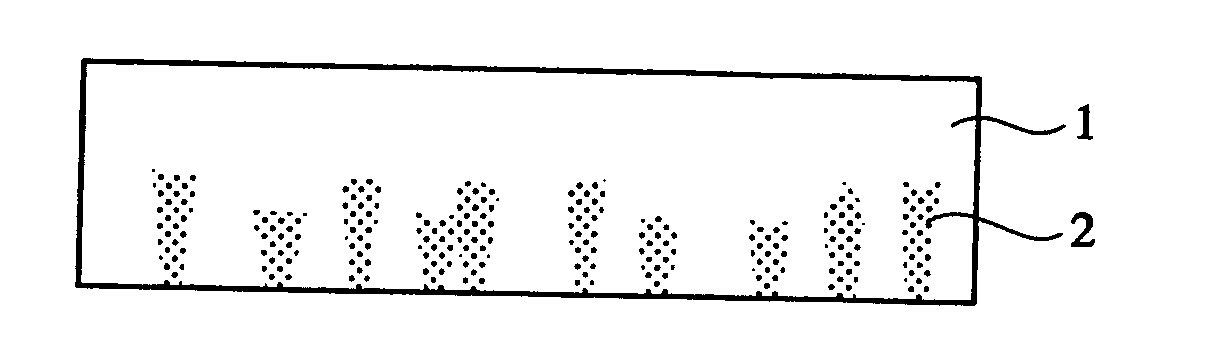

EPIR device and semiconductor devices utilizing the same

InactiveUS20050040482A1Improve batch productivityHigh in practical utilityTransistorNanoinformaticsSemiconductorSubstrate surface

There is provided an EPIR device which is excellent in mass productivity and high in practical utility. The EPIR device includes a lower electrode layer, a CMR thin film layer and an upper electrode layer which are laminated in this order on any of various substrates. A Pt polycrystal thin film 10 forming the lower electrode layer includes columnar Pt crystal grains 10A, 10B, 10C, . . . and over 90% of these crystal grains is oriented to a (1 1 1) face. Columnar PCMO crystal grain groups 20A, 20B, 20C, . . . are respectively locally grown epitaxially on the respective outermost surfaces of the Pt crystal grains 10A, 10B, 10C, Then, the crystal faces of the crystal grains included in the PCMO crystal grain groups 20A, 20B, 20C, . . . and vertical in the substrate surface normal direction are any one of (1 0 0)p, (1 1 0)p and (1 1 1)p planes.

Owner:XENOGENIC DEV LLC

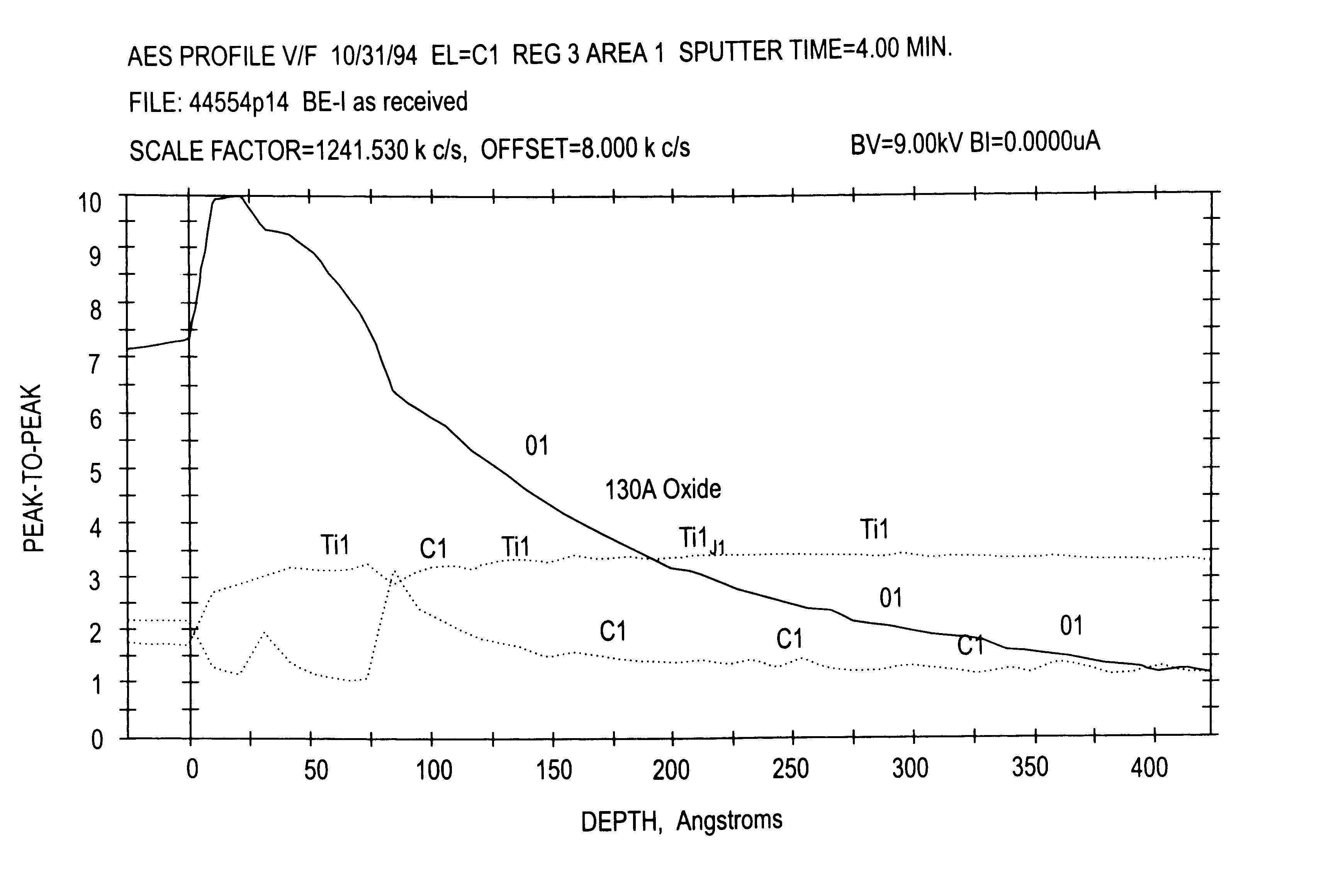

Implant surface preparation

InactiveUS6969474B2Uniform roughnessUniform surface topographyDental implantsImpression capsTitaniumOxygen

The surface of a device that is surgically implantable in living bone is prepared. The device is made of titanium with a native oxide layer on the surface. The method of preparation comprises the steps of removing the native oxide layer from the surface of the device and performing further treatment of the surface substantially in the absence of unreacted oxygen.

Owner:BIOMET 3I LLC

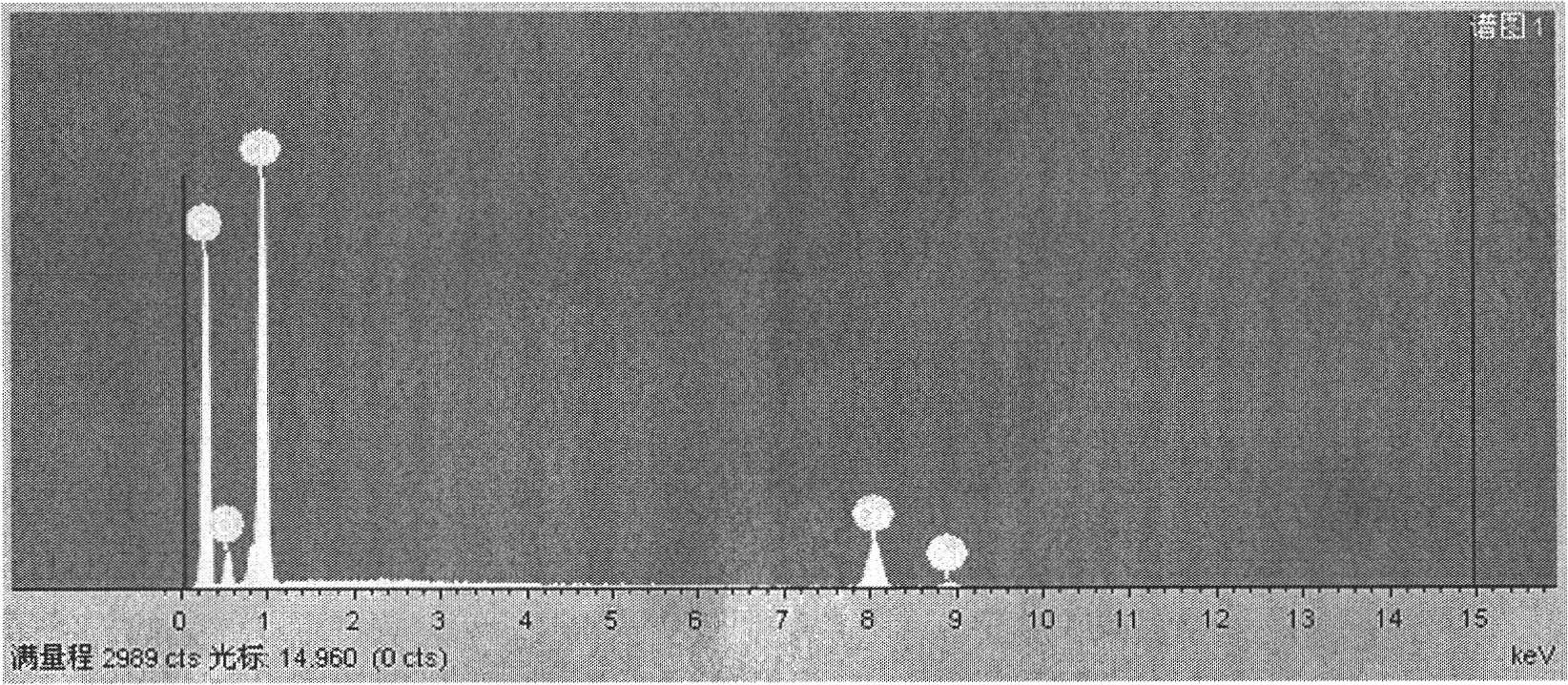

Surface protection of neodymium iron boron permanent-magnet material

ActiveCN101029389AImprove bindingUniform surfaceMetallic material coating processesTectorial membraneBoron

A surface protection technology of neodymium-ferrous-boron permanent magnetic material is carried out by grinding for neodymium-ferrous-boron permanent magnetic material, degreasing while removing oil, removing rust while acid cleaning, activating acid liquid, putting it into black liquid or blue liquid, chemically coating and forming into blue-black or dark blue protection film. It has excellent combination and anti-corrosion performances.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

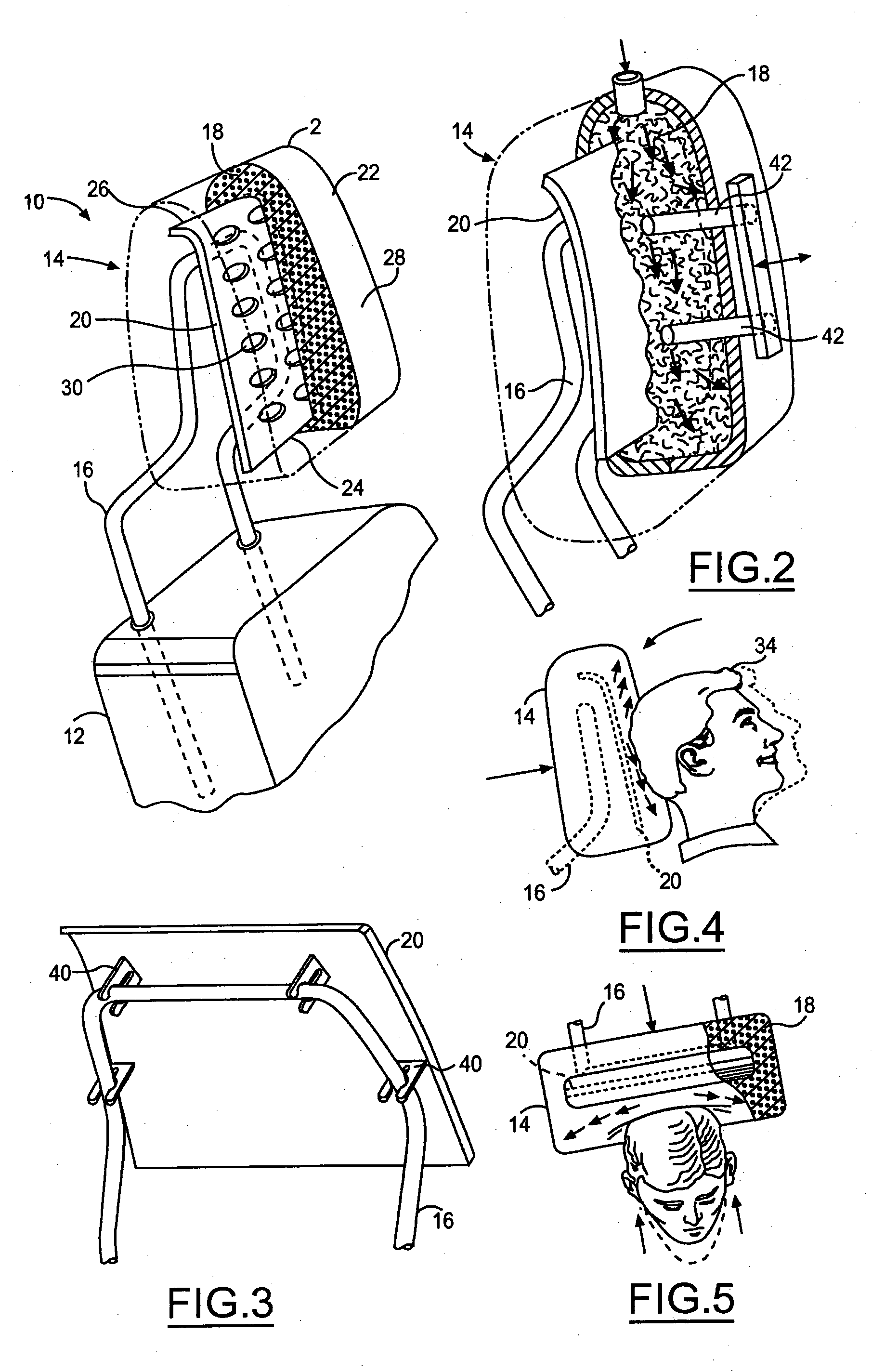

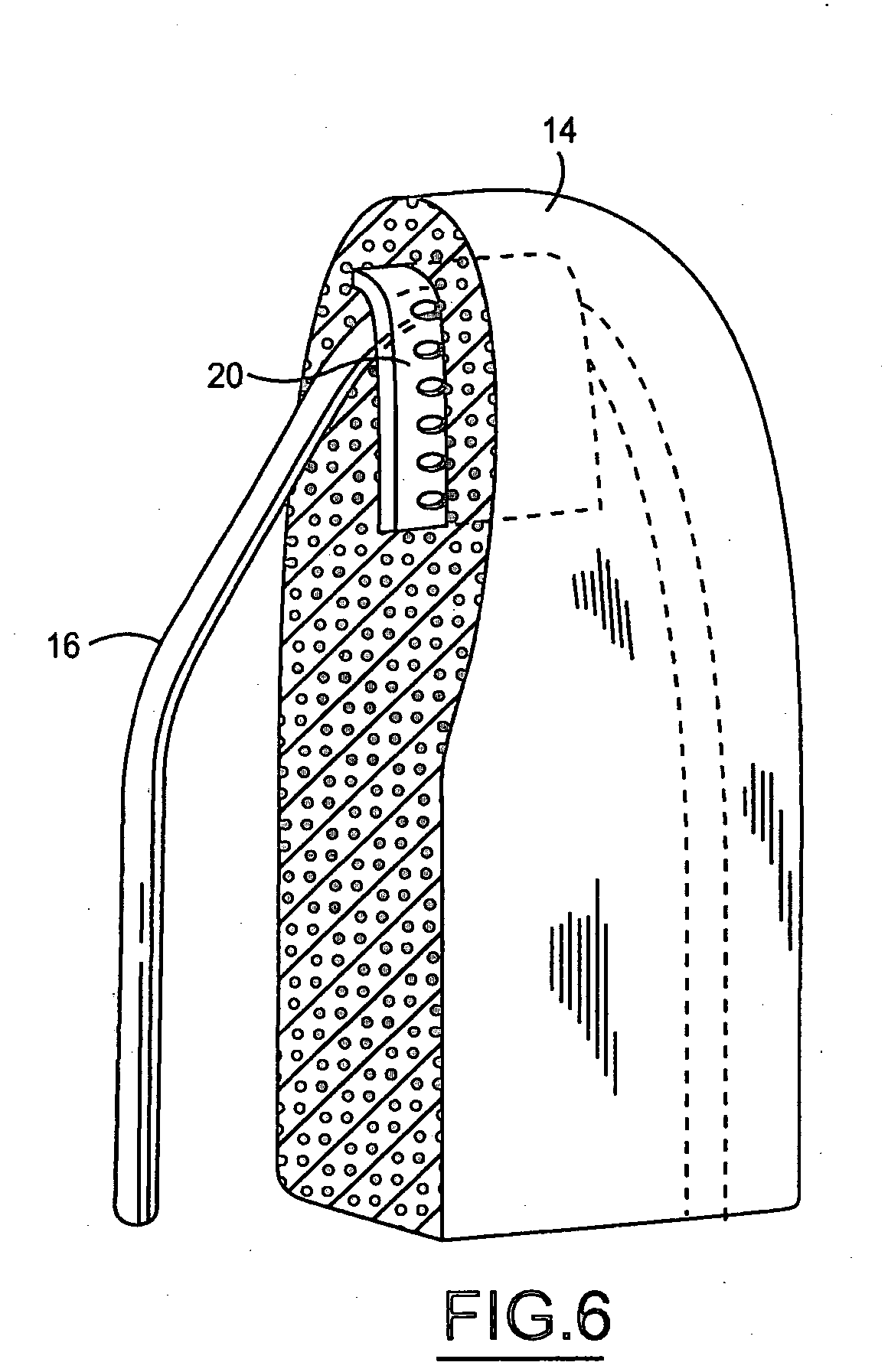

Energy management head restraint insert

InactiveUS20050127734A1Neck injury can be reducedMeet the regulationVehicle seatsOperating chairsEngineeringHead restraint

An head restraint with an insert on seats in motor vehicles whereby said head restraint controls occupant's head acceleration and reduces neck loading in cases of impact. This head restraint comprises a post of any shape inserted into a seatback, foam of a desired thickness, an insert sized to cover a majority of the surface area on the front face and top of said head restraint, and a trim cover. Alternatively, the head restraint may be of integral design without posts. The insert is meant to float within foam in the head restraint and one can use clips or locating pins during manufacturing to obtain desired floating effect.

Owner:LEAR CORP

Parallel-plate electrode plasma reactor having an inductive antenna and adjustable radial distribution of plasma ion density

InactiveUS6524432B1Minimize interactionAvoid flowElectric discharge tubesSemiconductor/solid-state device manufacturingSemiconductor materialsParallel plate

There is disclosed a plasma reactor for processing a semiconductor workpiece such as a wafer, including a chamber having an overhead ceiling with a three-dimensional shape such as a hemisphere or dome. The reactor further includes an inductive antenna over the ceiling which may be conformal or nonconformal in shape with the ceiling. The ceiling may be a semiconductor material so that it can function as both a window for the inductive field of the antenna as well as an electrode which can be grounded, or to which RF power may be applied or which may be allowed to float electrically. The reactor includes various features which allow the radial distribution of the plasma ion density across the wafer surface to be adjusted to an optimum distribution for processing uniformity across the wafer surface.

Owner:APPLIED MATERIALS INC

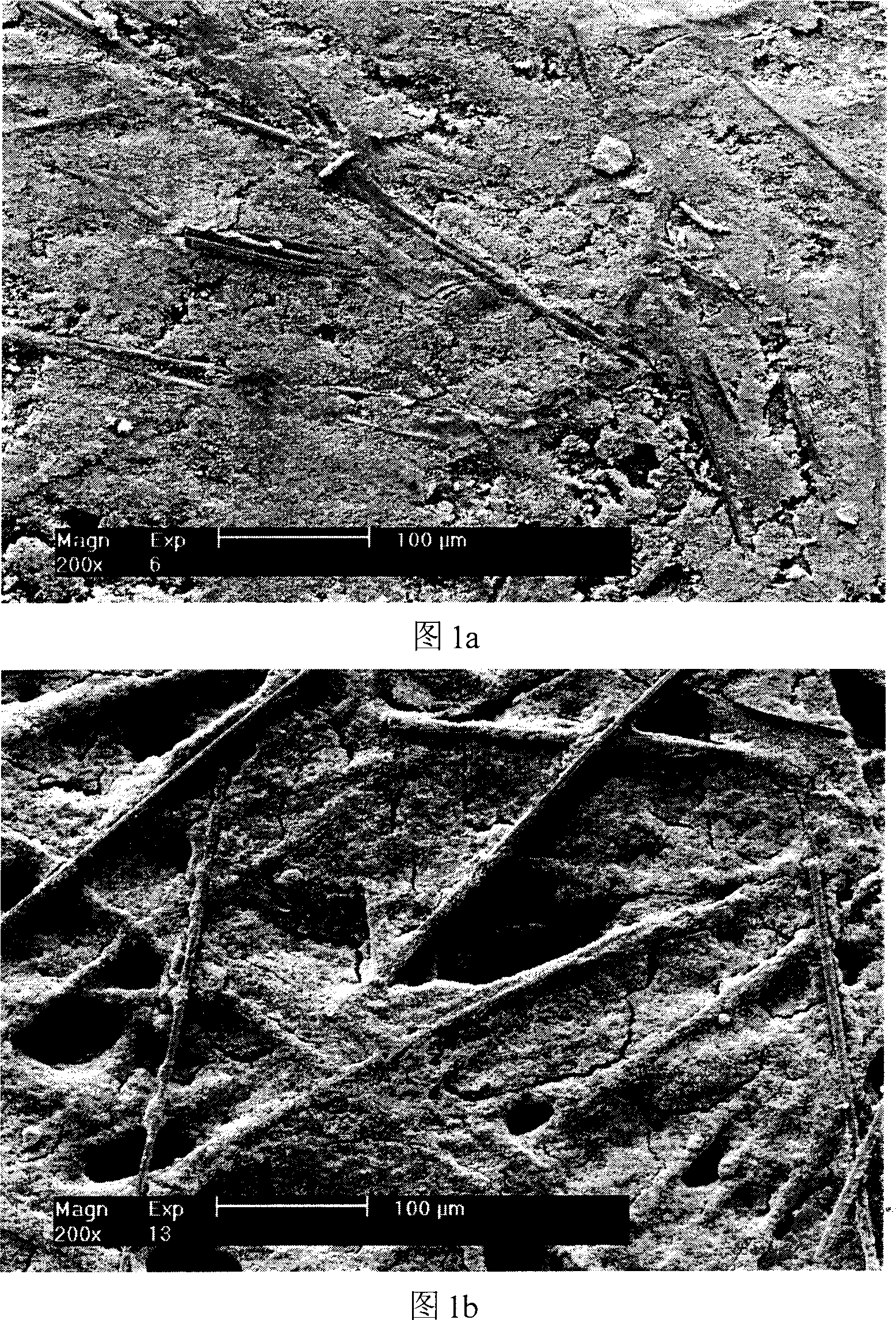

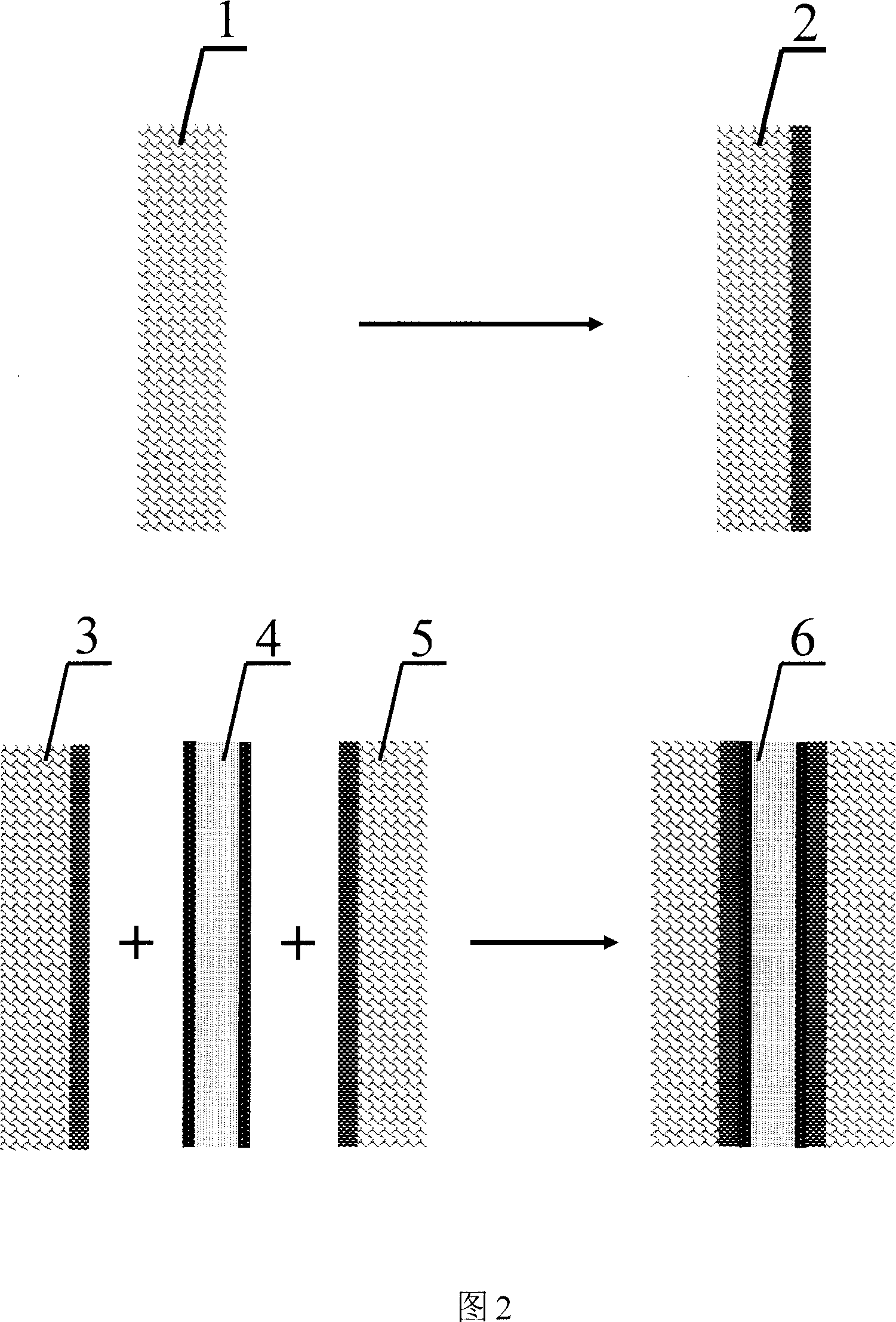

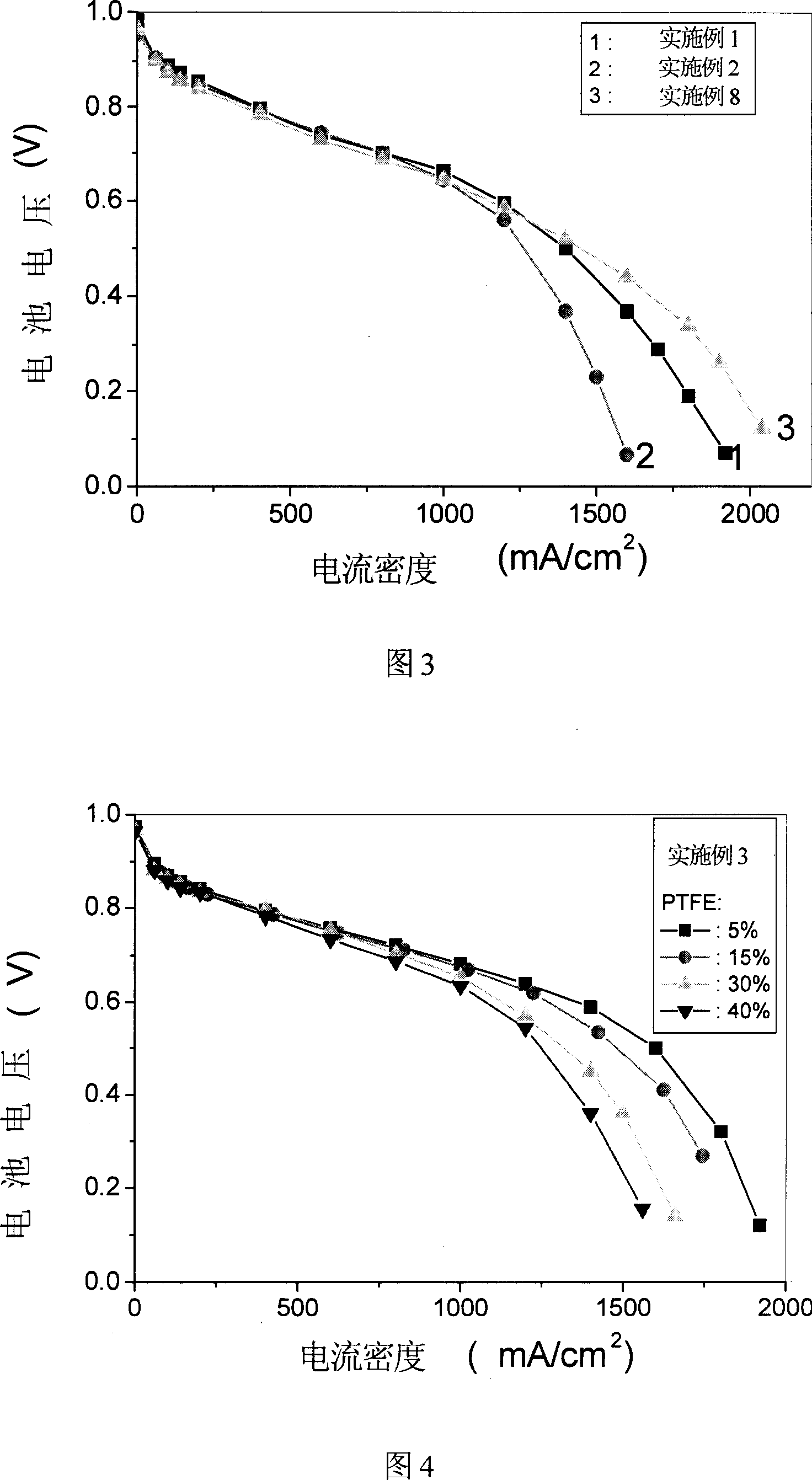

Gas diffusion layer for proton exchanging film fuel cell and its preparing method

InactiveCN1988225ALight weightUniform surfaceFinal product manufactureCell electrodesFiberHydrophile

This invention relates to a gas diffusion layer used in proton exchange film fuel cells and its preparation method, in which, the gas diffusion layer includes a multihole supporting layer and a microhole layer, the multihole supporting layer is a net and porous structure, the microhole layer is composited on the surface of the porous supporting layer closing to the catalyzed layer and covers the surface of the large hole and fiber dense region of the supporting layer uniformly but not penerates into the inside of the supporting layer, which applies a drying method to prepare a gas diffusion layer used in proton exchange membrane fuel cells, and polymr 1 and 2 containing FI is either a same kind or different, and the hydrophile / hydrophobic degree of the two layers is adjustable, so the gas diffusion layer structure is matched with the running condition of the fuel cell and discharges water more easily.

Owner:SUNRISE POWER CO LTD

Golf club head with varying face grooves

The present invention is directed to a golf club head with an improved striking surface. Grooves are machined into the strike surface with tight tolerances. The grooves have sharp edges, radiused ends, and a draft angle between about 2° and 12°. The striking face is machined such that it has a uniform texture with a roughness of more than 40 Ra. The grooves may contain a plurality of portions, including a radiused or angled portion, a portion having substantially parallel walls, a portion having a v-shape, and a curved portion. The grooves may also be characterized by various dimensions, including draft angle, inclusive side wall angle, width, depth, cross-sectional area, spacing, and pitch ratio. Preferred values for these dimensions are provided. A golf club head having a variety of groove types and a set of golf clubs with grooves varying among the individual clubs of the set are also disclosed.

Owner:ACUSHNET CO

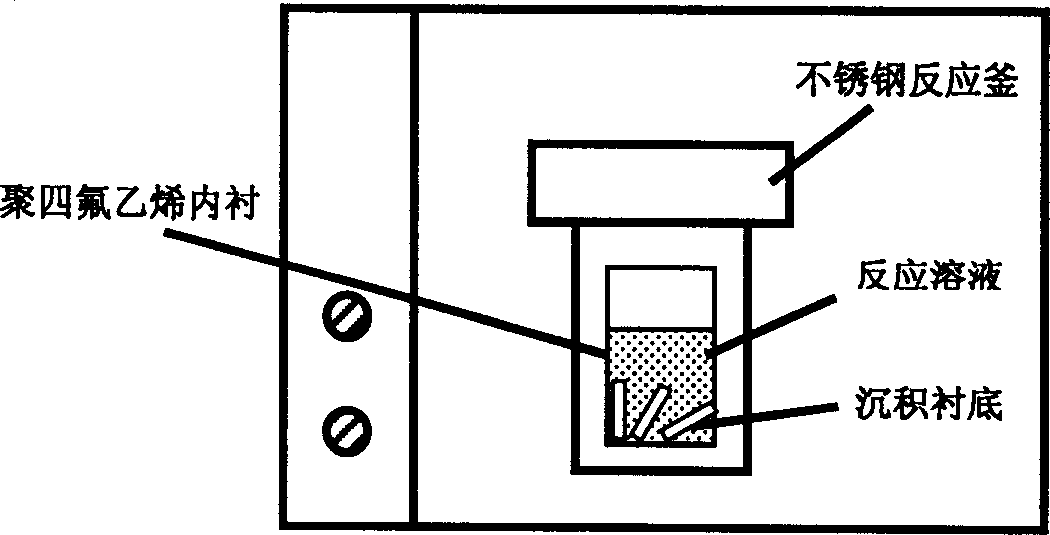

Oriented ZnO nanorod or nanowire film and preparation process thereof

InactiveCN1763263AHigh crystallinityGood orientationPolycrystalline material growthFrom normal temperature solutionsHydrothermal depositionZinc

The present invention relates to directional nanometer zinc oxide stick or linear film and its preparation process, and belongs to the field of low-dimensional nanometer film material technology. The present invention adopts hydrothermal deposition process, in which zinc salt solution in molar concentration 1-25 mM and amine surfactant solution are mixed homogeneously and set inside stainless steel reactor with PTFE lining, substrate of glass, polymer, inorganic metal, non-metal or other material and with directional texture ZnO crystal seed is set inside the lining, so as to react at 50-150 deg.c for 1-6 hr. After cooling naturally, directionally grown and high crystallized ZnO nanometer stick array film or nanometer stick of diameter 10-500 nm may be form. The process has low synthesis temperature and easy control, and the grown ZnO film is well directional. The present invention is suitable for industrial production of directional nanometer ZnO stick or film.

Owner:TSINGHUA UNIV

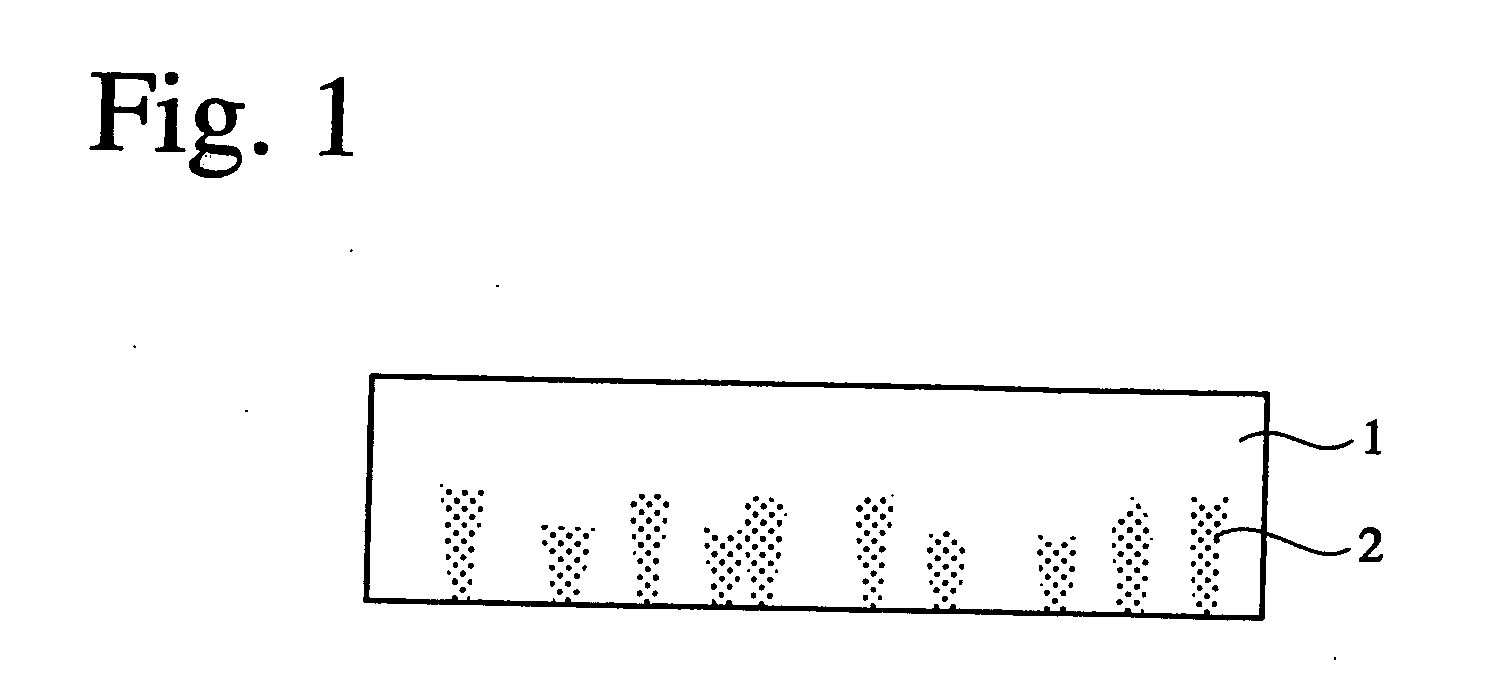

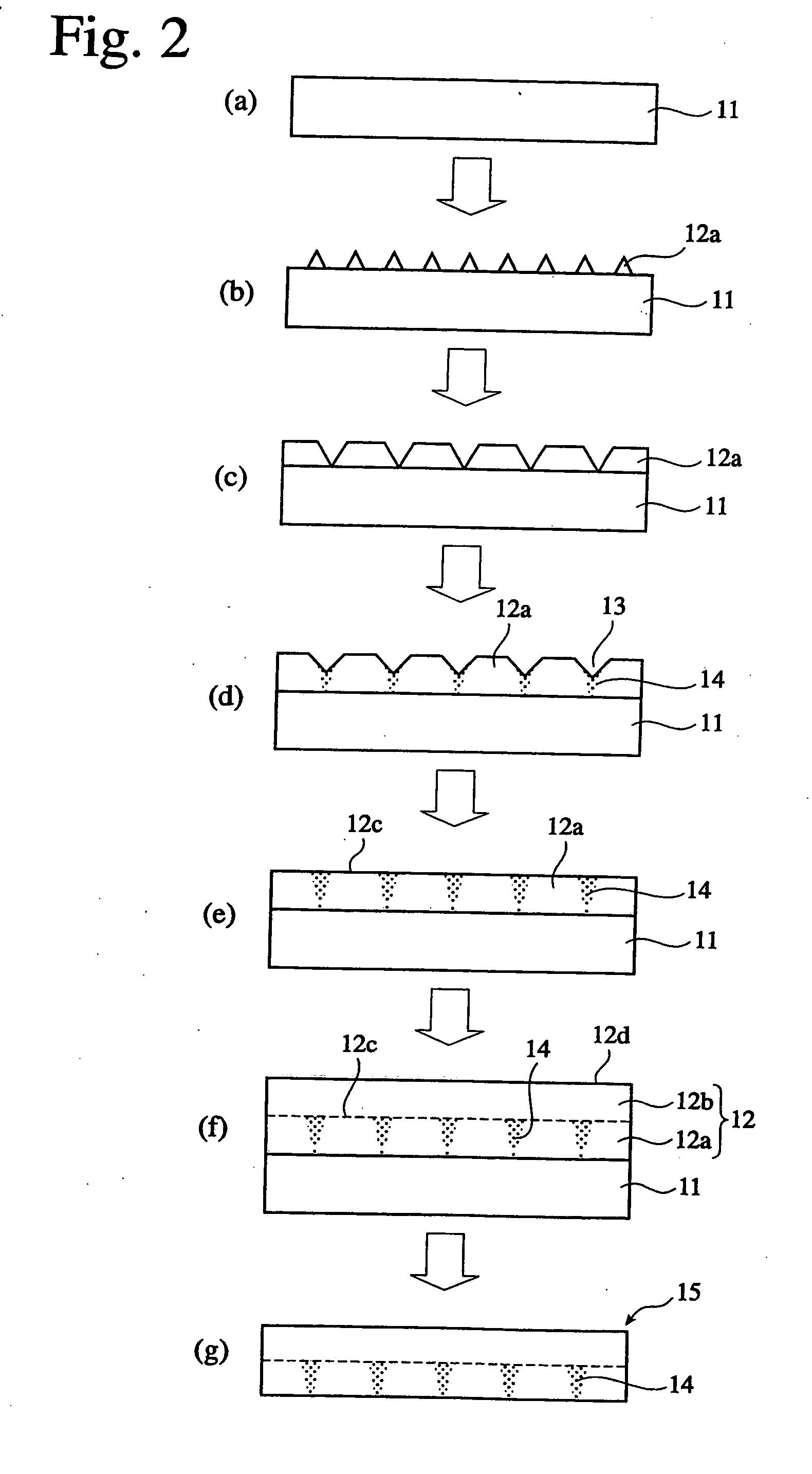

III-V nitride semiconductor substrate and its production method

ActiveUS20050048685A1Low dislocation densityReduce variationPolycrystalline material growthFrom solid stateIntermediate stageCharge carrier

A self-supported III-V nitride semiconductor substrate having a substantially uniform carrier concentration distribution in a surface layer existing from a top surface to a depth of at least 10 μm is produced by growing a III-V nitride semiconductor crystal while forming a plurality of projections on a crystal growth interface at the initial or intermediate stage of crystal growth; conducting the crystal growth until recesses between the projections are buried, so that the crystal growth interface becomes flat; and continuing the crystal growth to a thickness of 10 μm or more while keeping the crystal growth interface flat.

Owner:SUMITOMO CHEM CO LTD

Materials and methods for chemical-mechanical planarization

InactiveUS6910951B2Low costImprove throughputGrinding drivesBelt grinding machinesDevice materialMaterial removal

Provided are materials and methods for the chemical mechanical planarization of material layers such as oxide or metal formed on semiconductor substrates during the manufacture of semiconductor devices using a fixed abrasive planarization pad having an open cell foam structure from which free abrasive particles are produced by conditioning and combined with a carrier liquid to form an in situ slurry on the polishing surface of the planarization pad that, in combination with relative motion between the semiconductor substrate and the planarization pad, tends to remove the material layer from the surface of the semiconductor substrate. Depending on the composition of the material layer, the rate of material removal from the semiconductor substrate may be controlled by manipulating the pH or the oxidizer content of the carrier liquid.

Owner:DOW GLOBAL TECH LLC

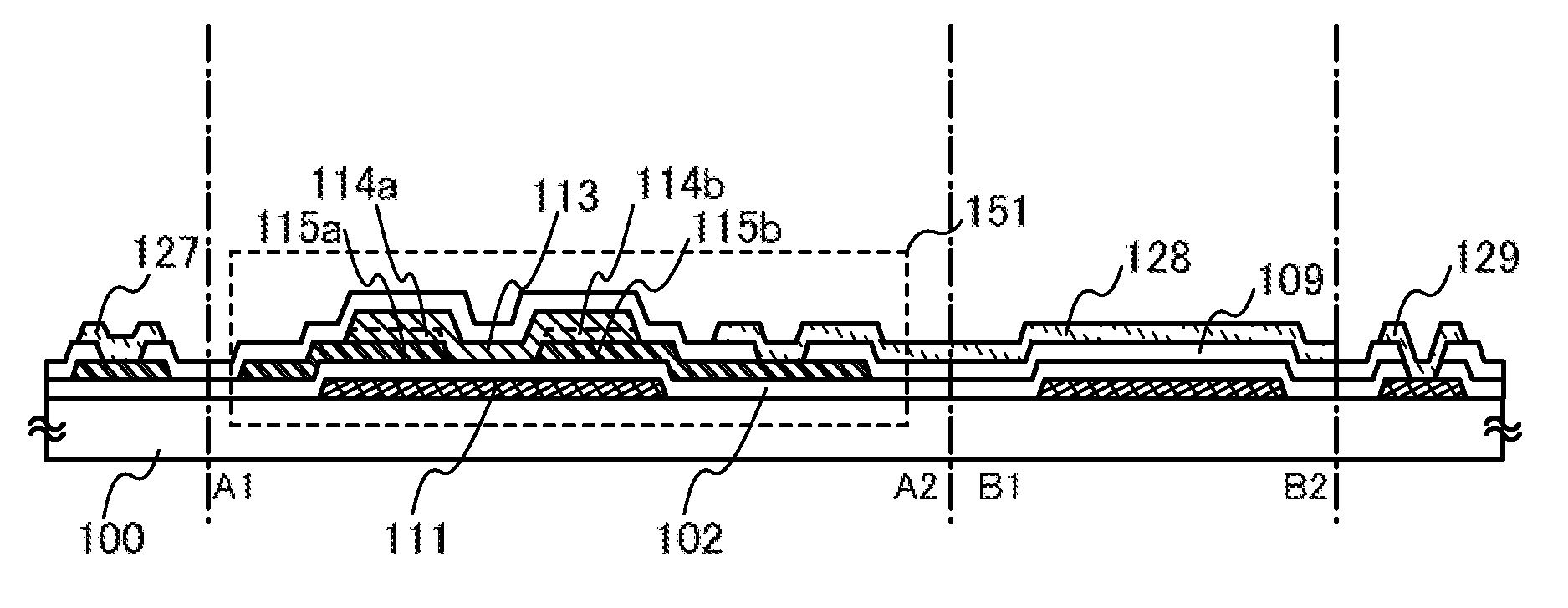

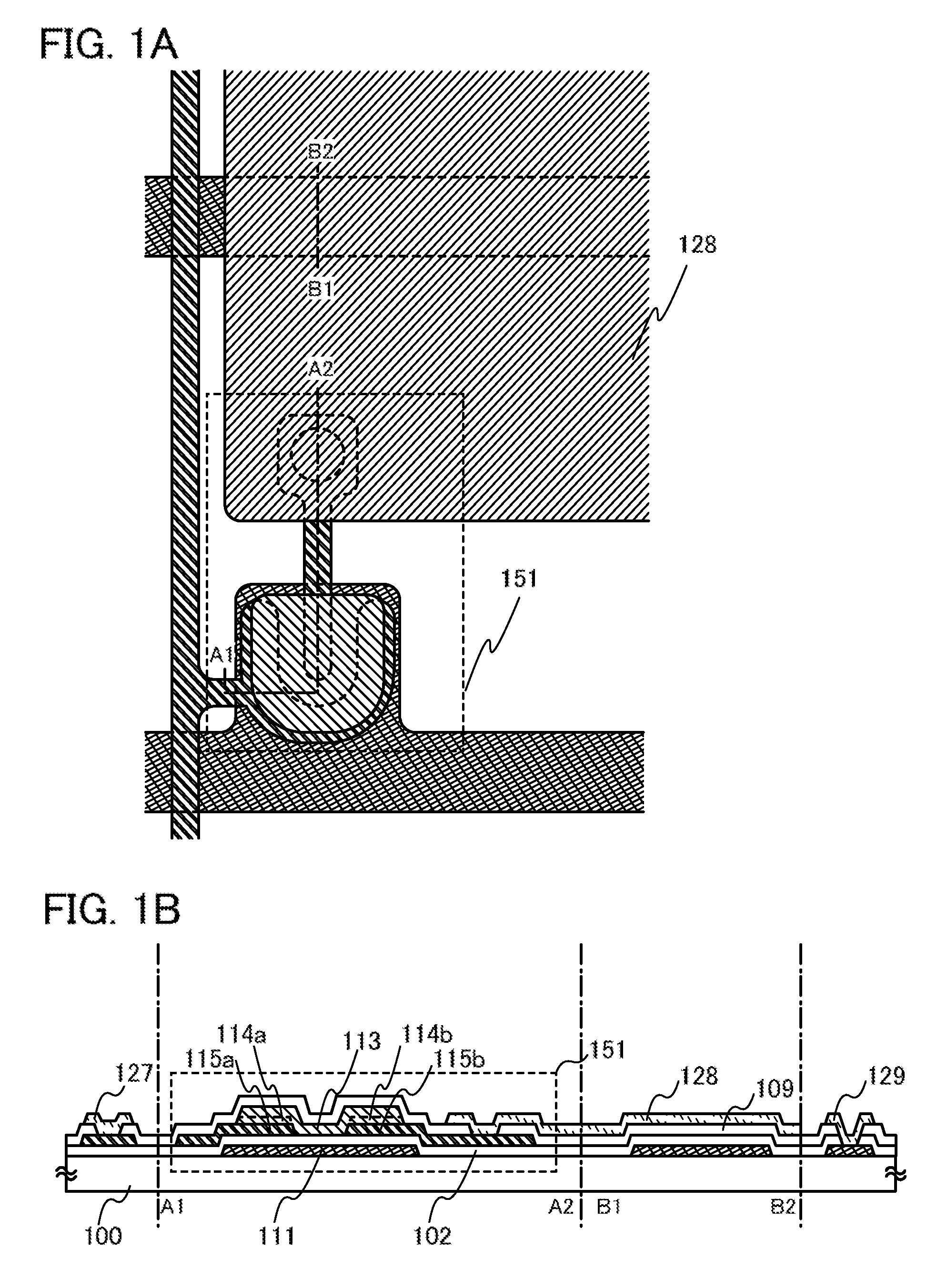

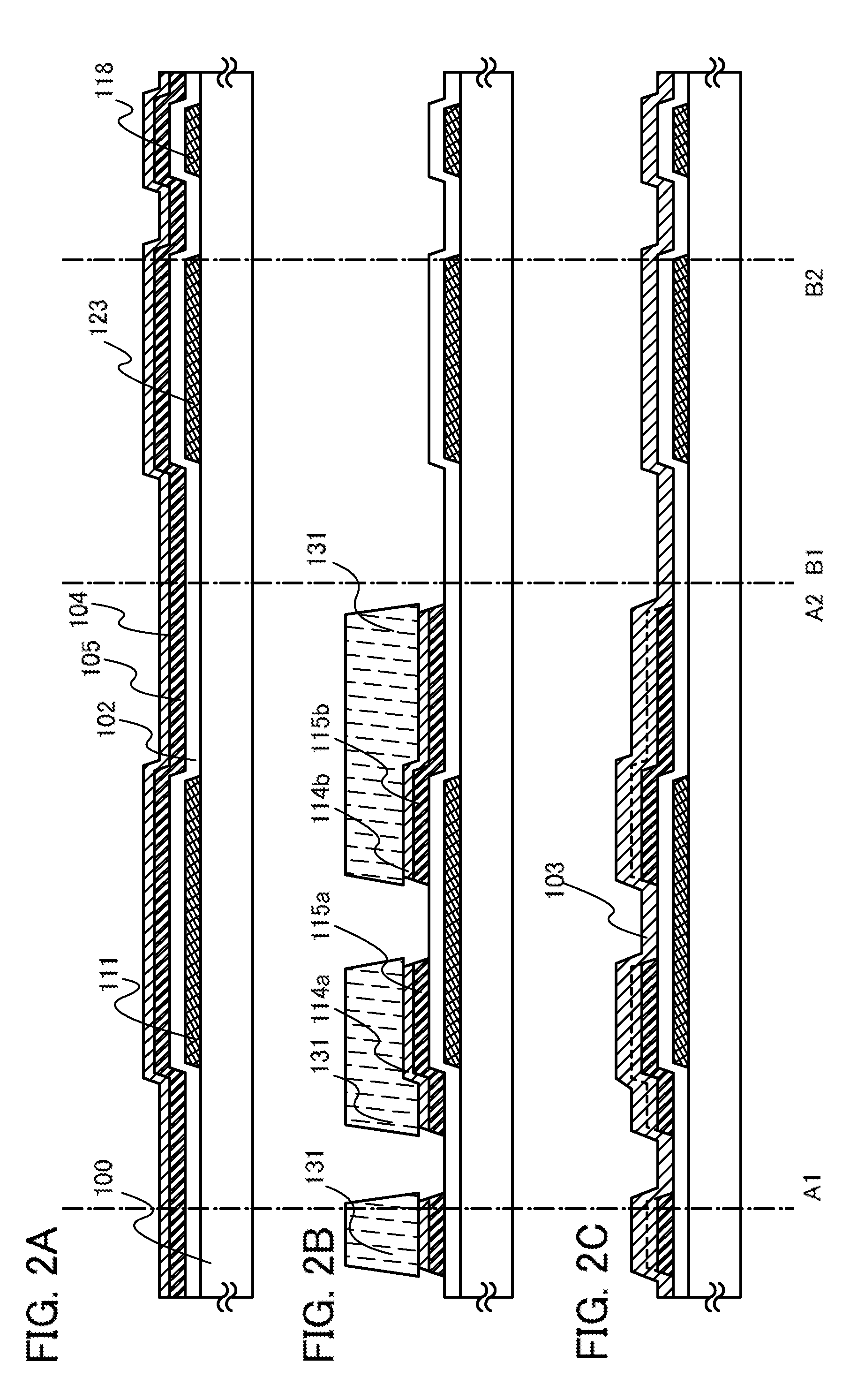

Semiconductor device and manufacturing method thereof

ActiveUS20100163866A1Easy to makeSolve the lack of reliabilityTransistorElectroluminescent light sourcesSemiconductor packageContact resistance

One of factors that increase the contact resistance at the interface between a first semiconductor layer where a channel is formed and source and drain electrode layers is a film with high electric resistance formed by dust or impurity contamination of a surface of a metal material serving as the source and drain electrode layers. As a solution, a first protective layer and a second protective layer including a second semiconductor having a conductivity that is less than or equal to that of the first semiconductor layer is stacked successively over source and drain electrode layers without exposed to air, the stack of films is used for the source and drain electrode layers.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com