Patents

Literature

70results about How to "Uniform surface topography" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

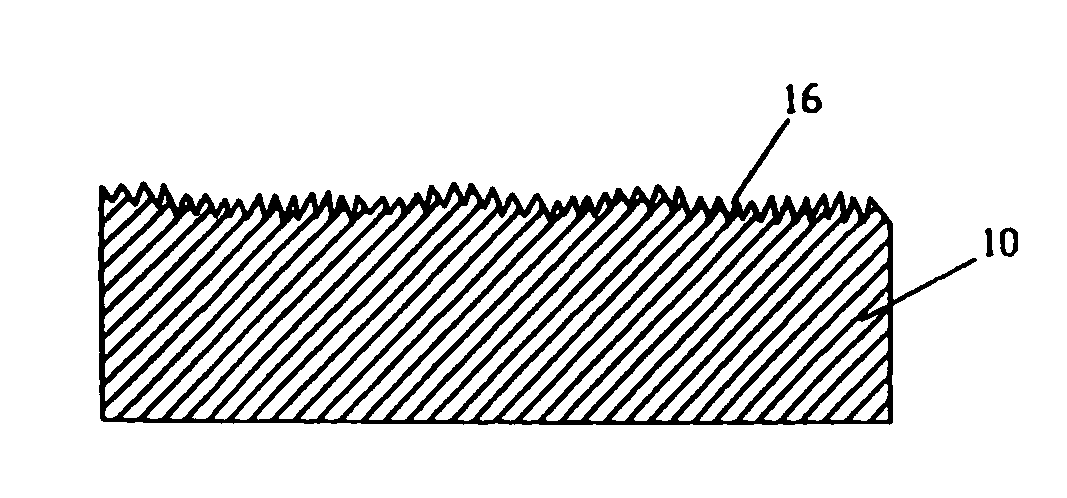

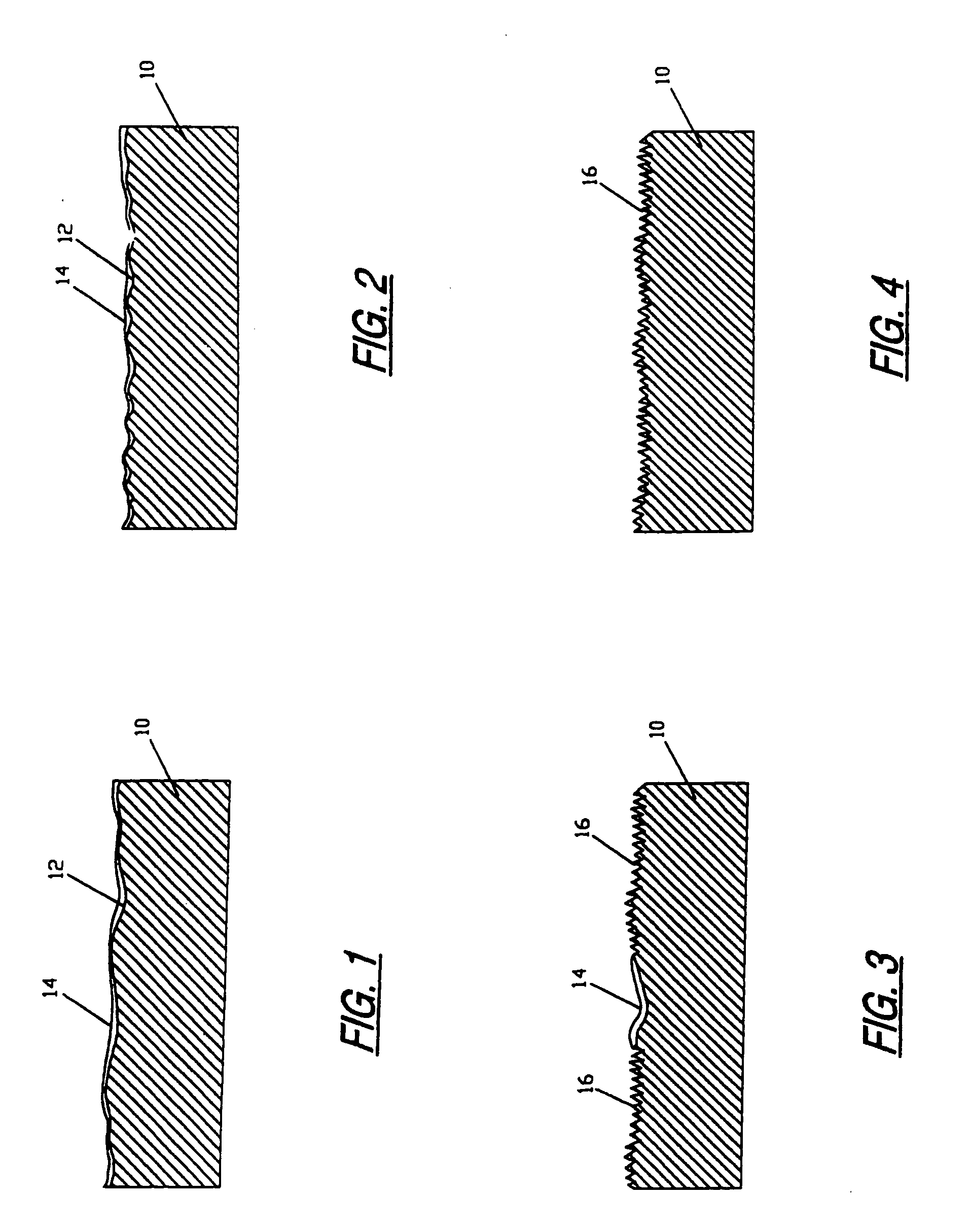

Implant surface preparation

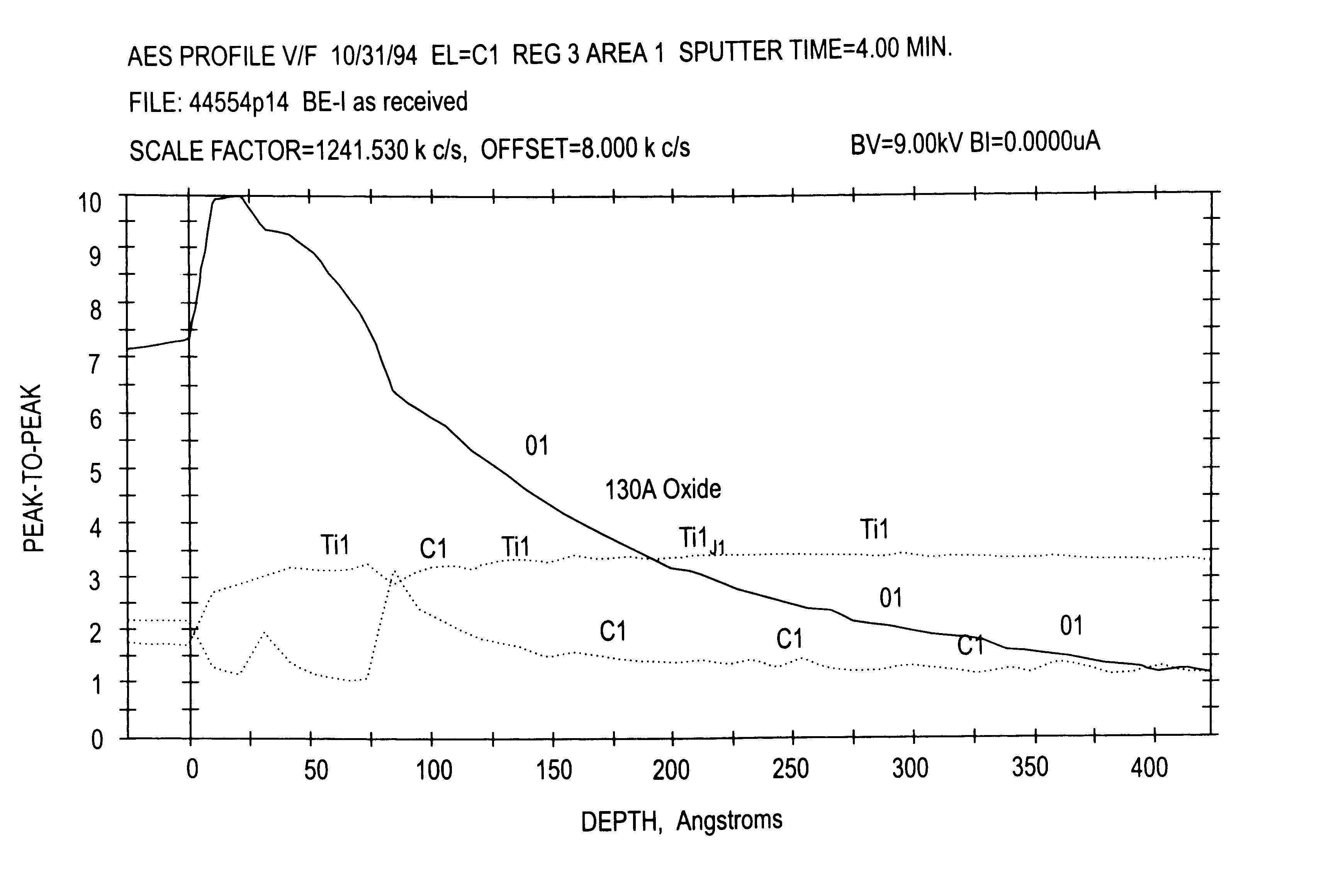

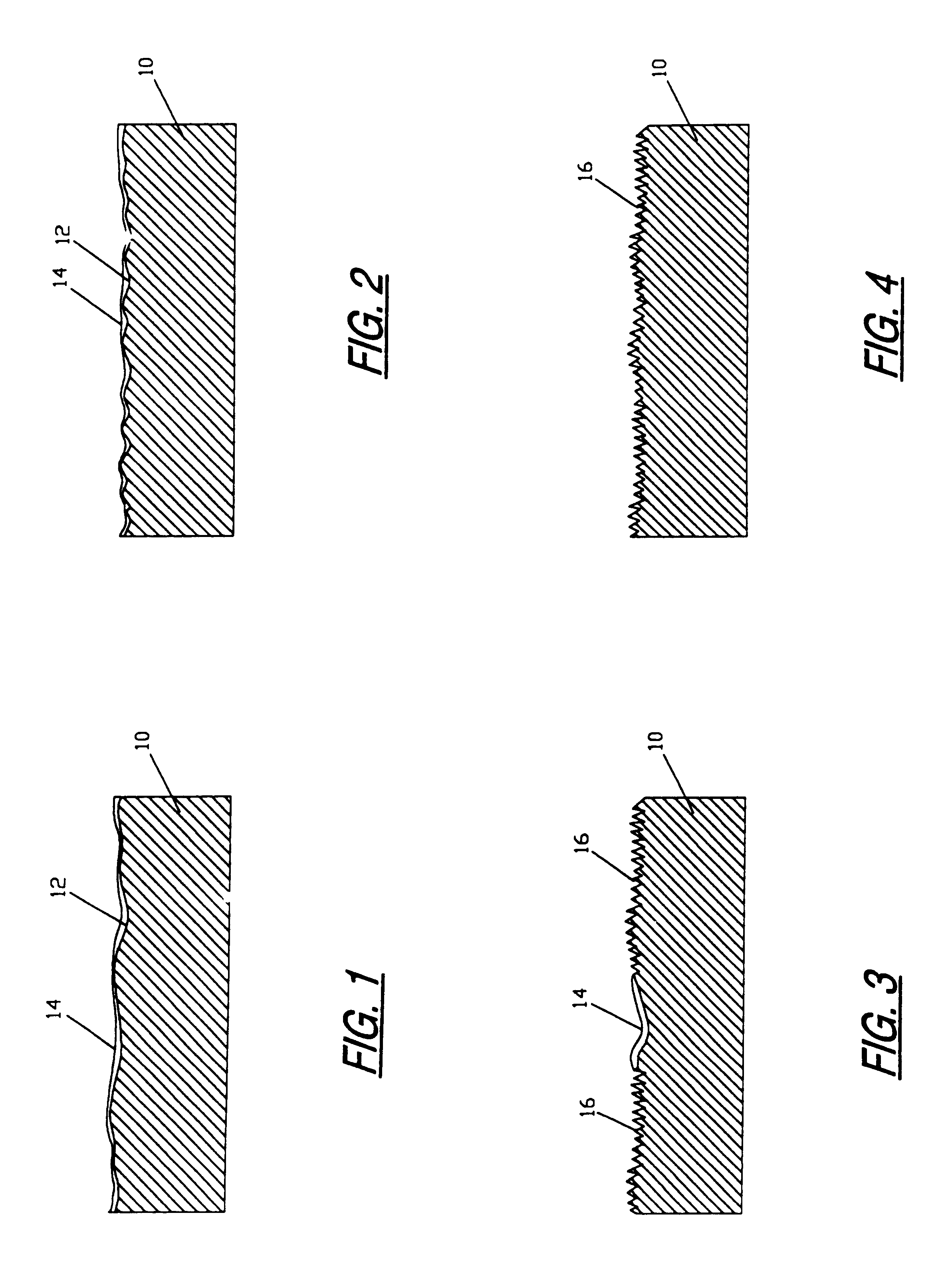

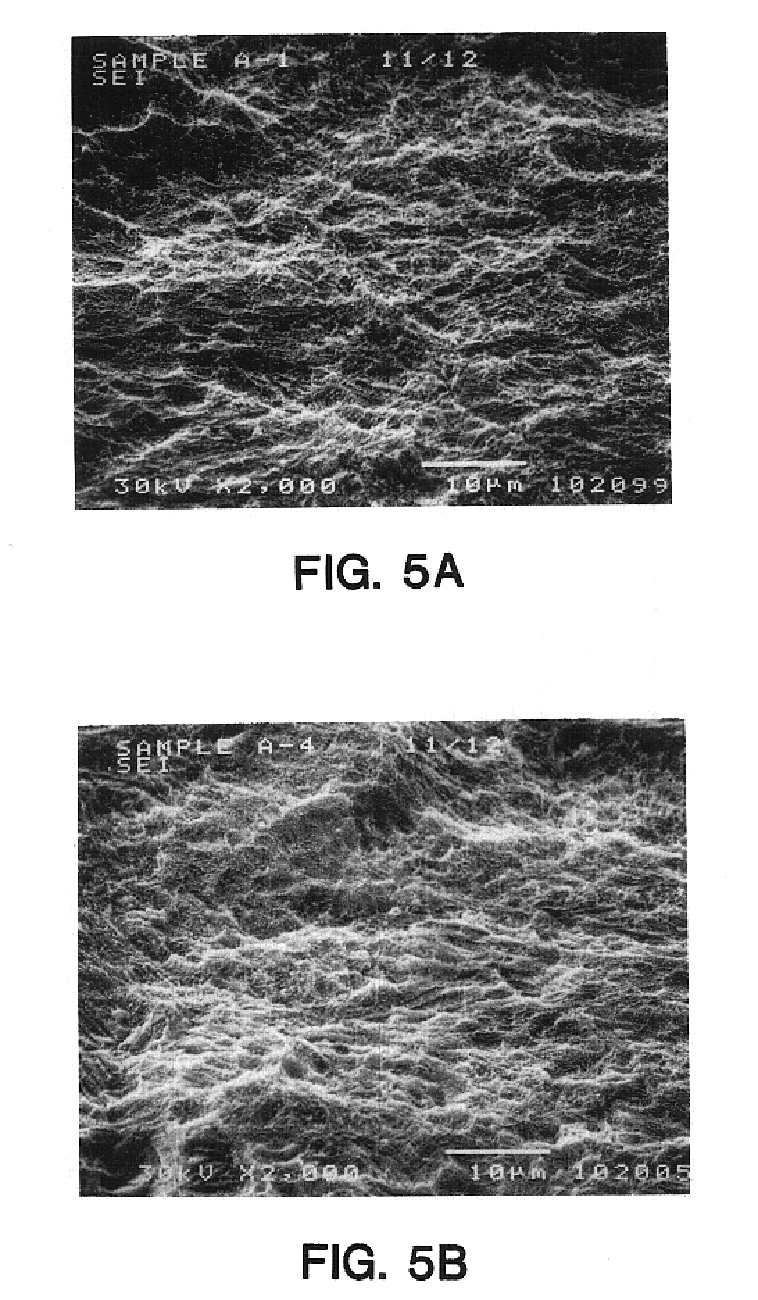

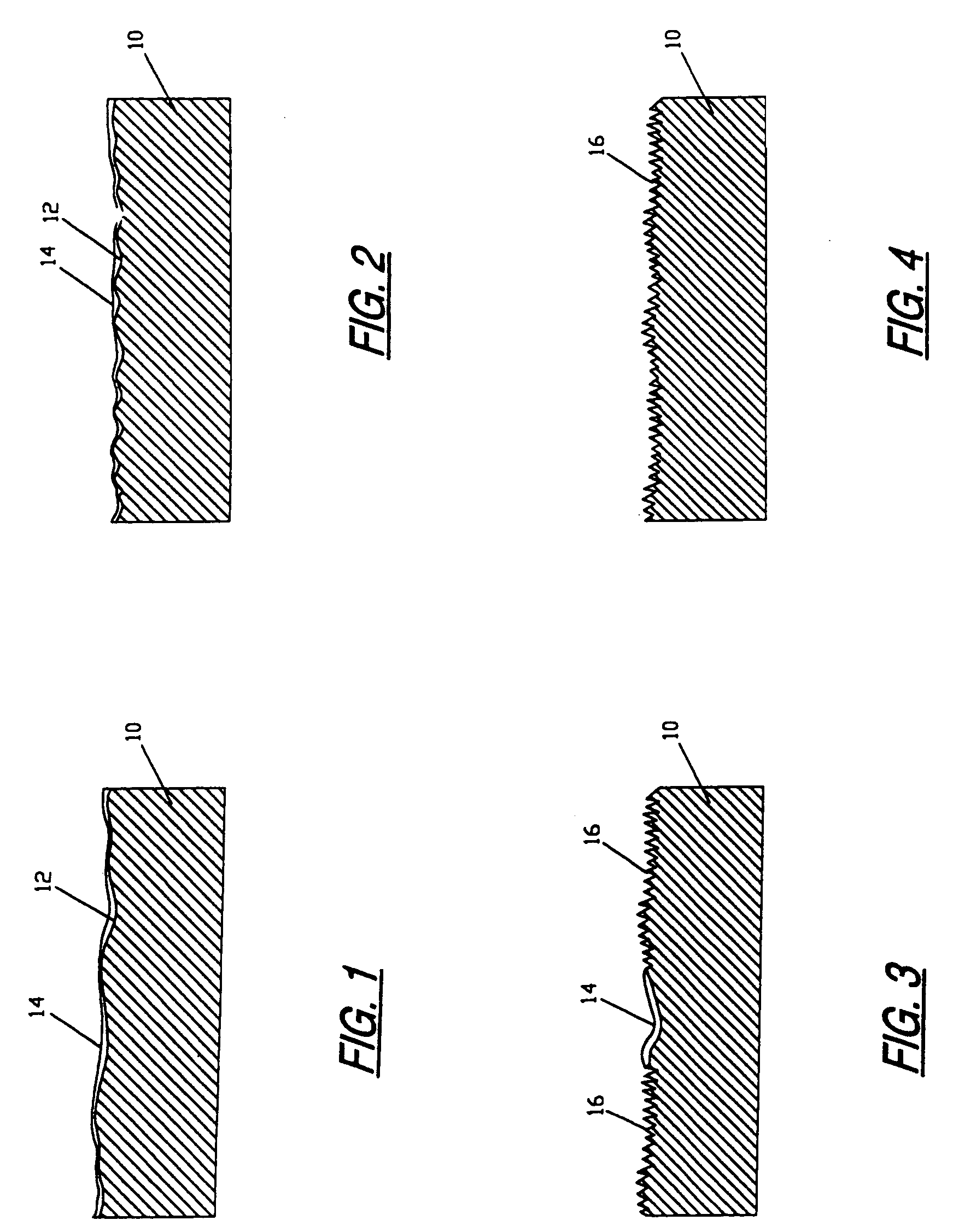

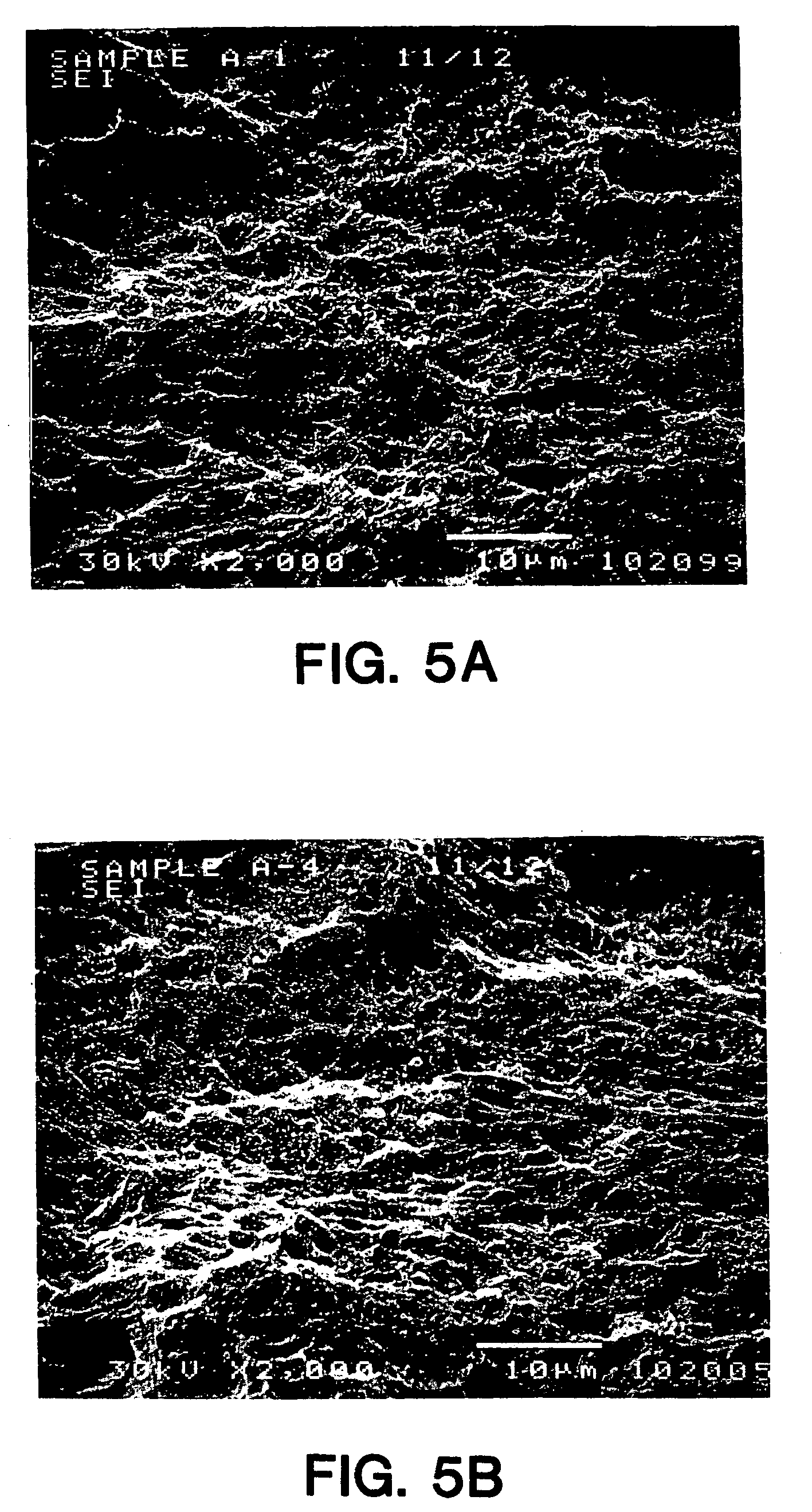

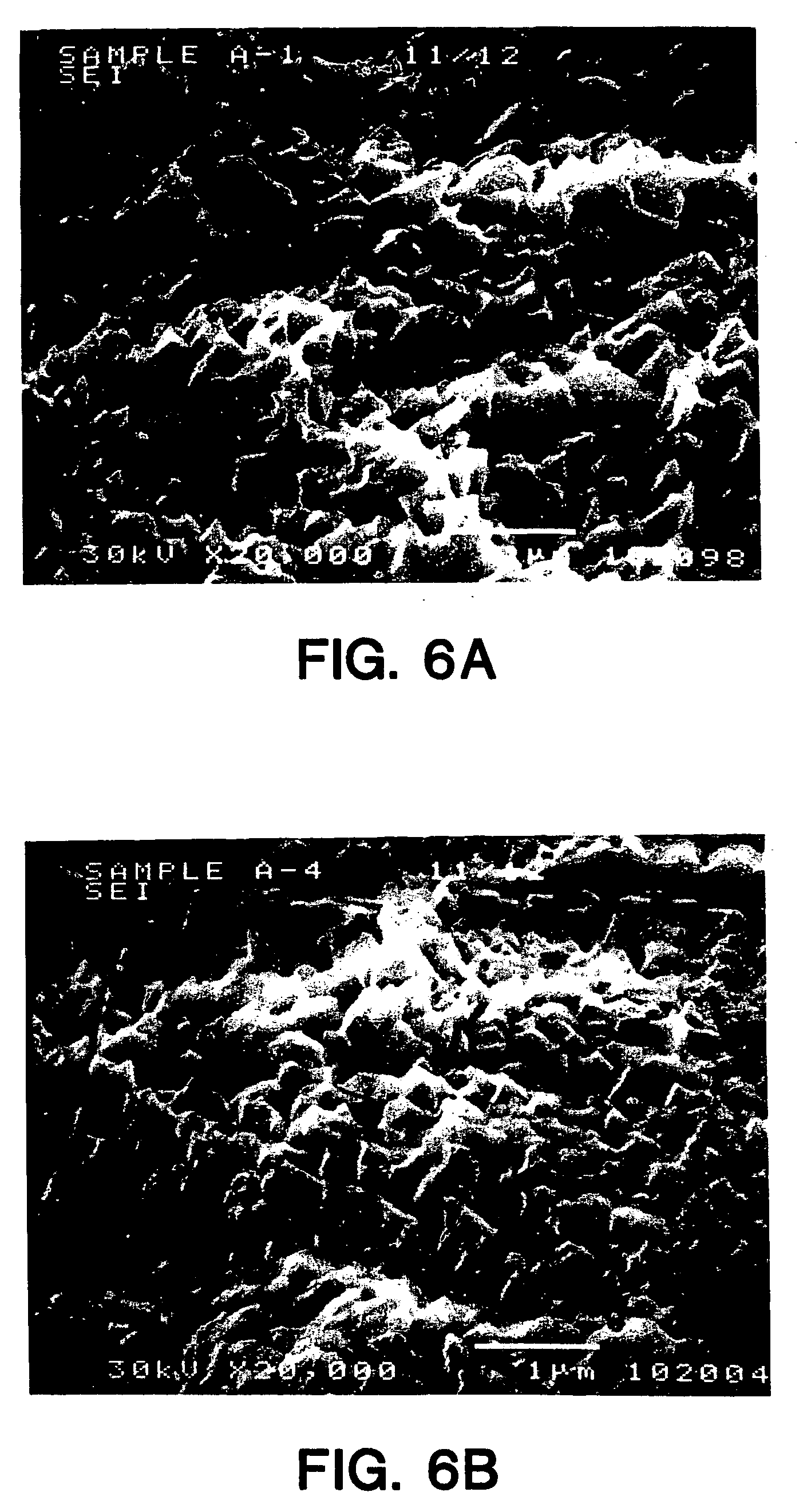

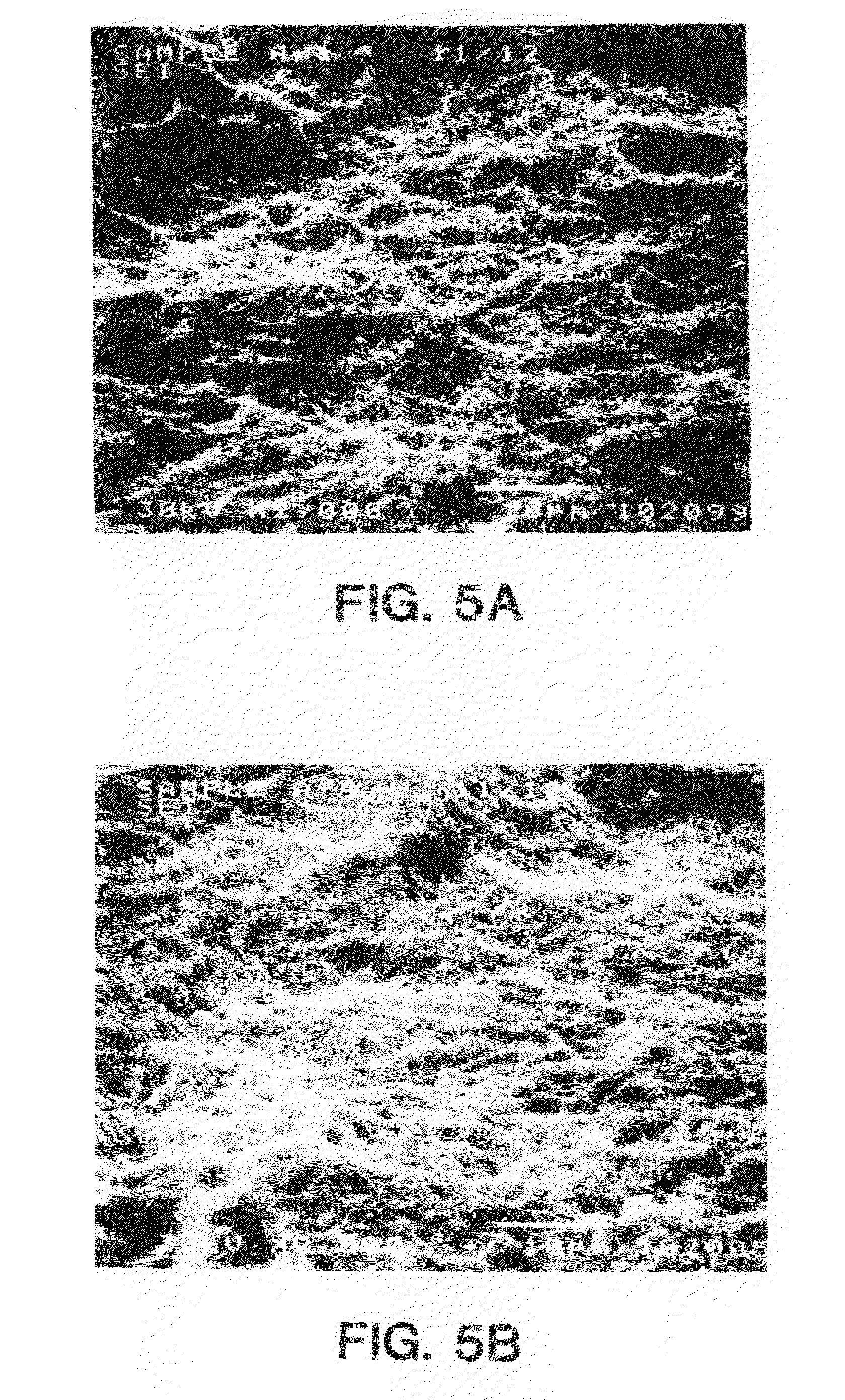

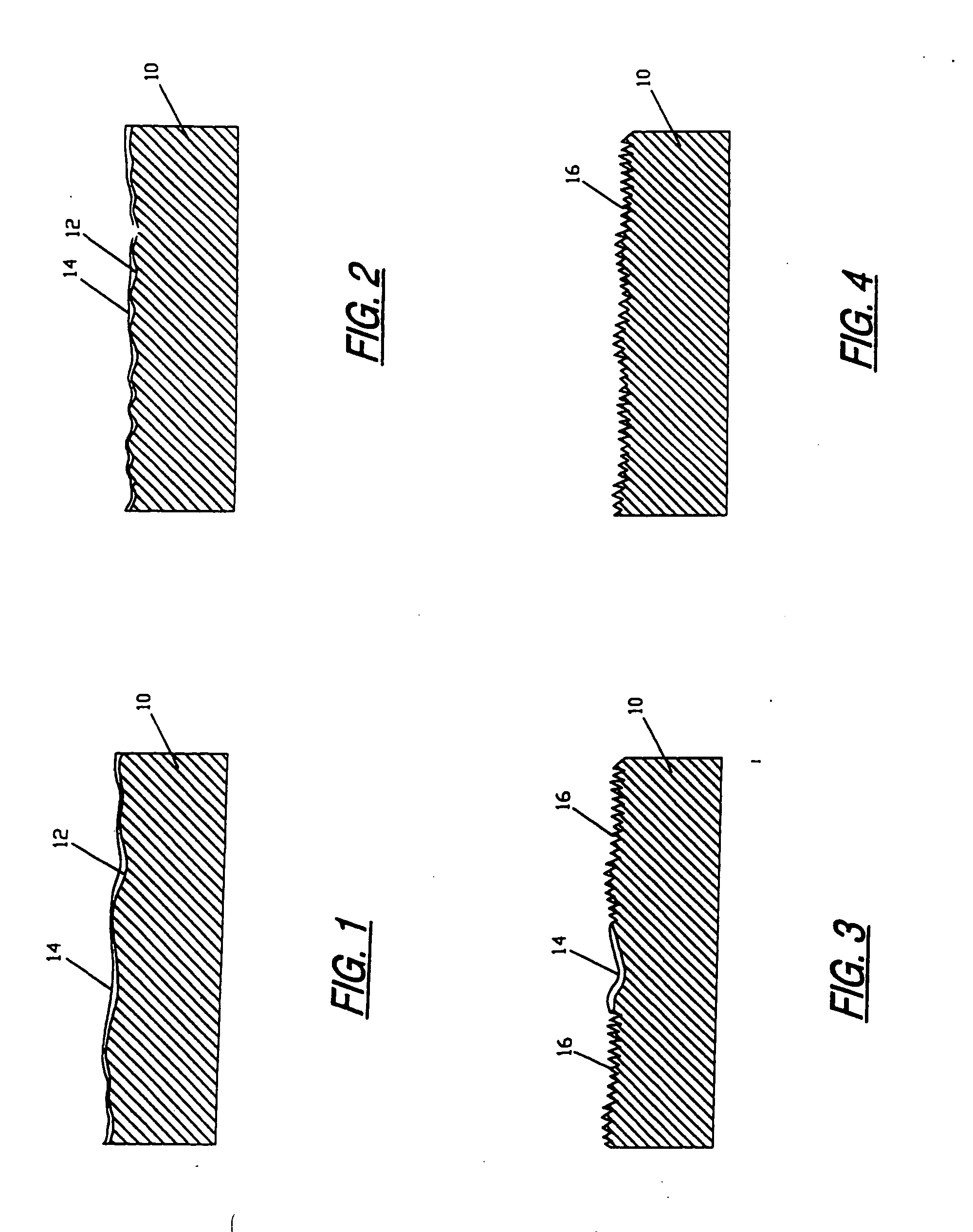

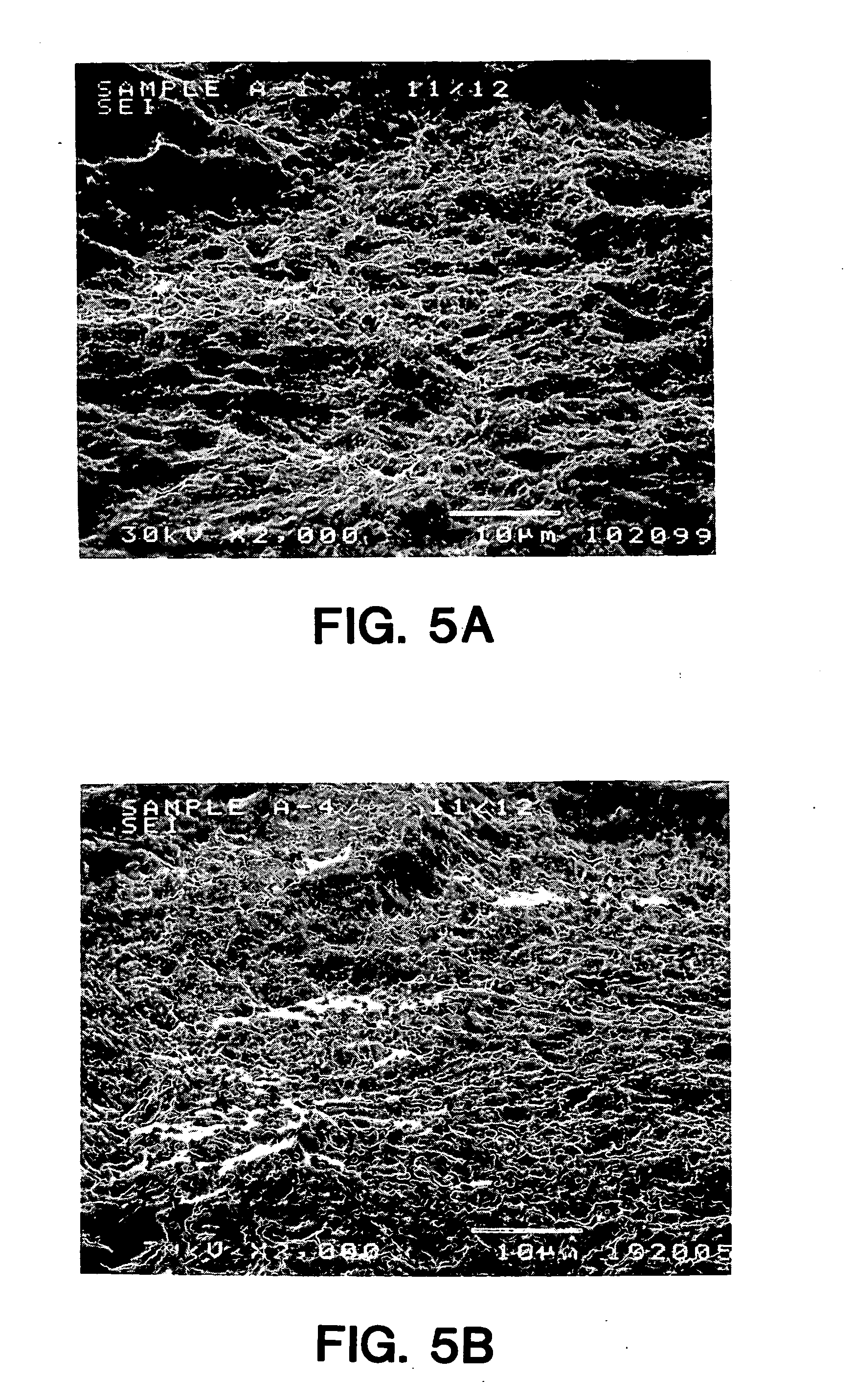

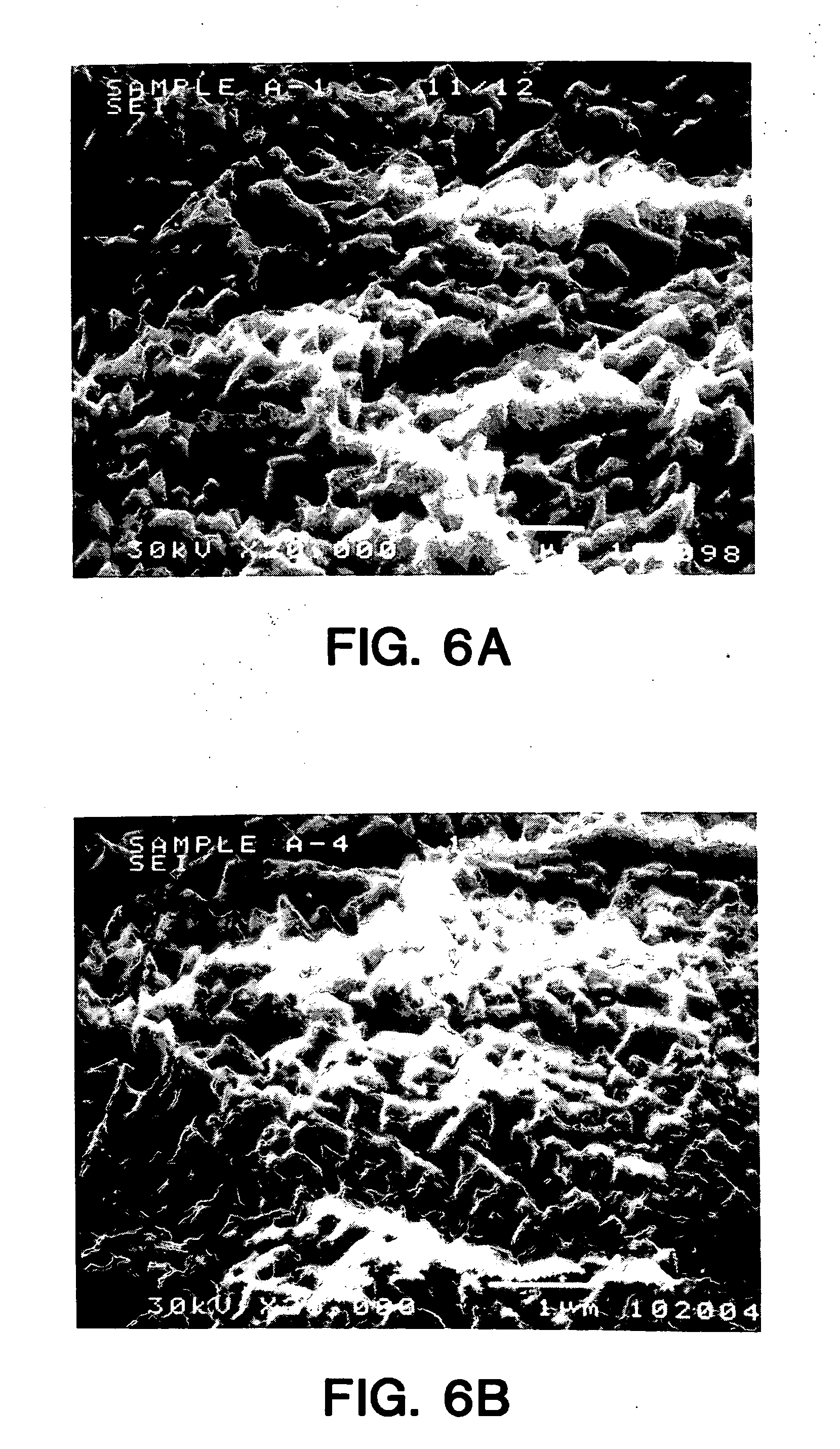

InactiveUS6969474B2Uniform roughnessUniform surface topographyDental implantsImpression capsTitaniumOxygen

The surface of a device that is surgically implantable in living bone is prepared. The device is made of titanium with a native oxide layer on the surface. The method of preparation comprises the steps of removing the native oxide layer from the surface of the device and performing further treatment of the surface substantially in the absence of unreacted oxygen.

Owner:BIOMET 3I LLC

Implant surface preparation

InactiveUS20050263491A1Uniform roughnessUniform surface topographyDental implantsDecorative surface effectsTitaniumOxygen

The surface of a device that is surgically implantable in living bone is prepared. The device is made of titanium with a native oxide layer on the surface. The method of preparation comprises the steps of removing the native oxide layer from the surface of the device and performing further treatment of the surface substantially in the absence of unreacted oxygen.

Owner:BIOMET 3I LLC

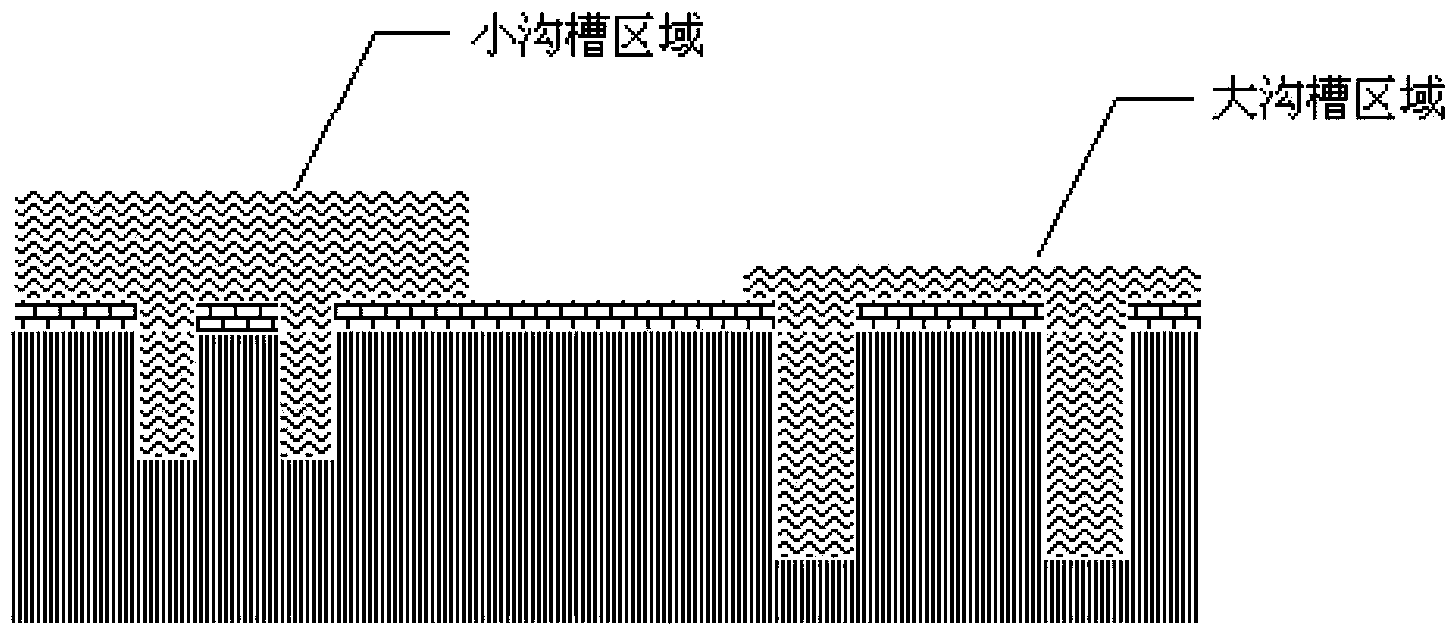

Method for flattening deep grooves with different structures

ActiveCN104347346AEffective protectionAvoid contactSemiconductor/solid-state device manufacturingProcess windowSilicon chip

The invention discloses a method for flattening deep grooves with different structures. The method comprises the following steps of 1) depositing a barrier layer on a silicon substrate; 2) depositing a photoresist on the barrier layer, performing development, and etching the barrier layer to expose the silicon substrate in which a groove needs to be etched in the subsequent flow; 3) etching graphs of the deep grooves with different widths and depths on the silicon substrate; 4) filling the deep grooves of silicon by using selective epitaxial growth; 5) depositing a polycrystalline silicon buried layer on a silicon chip, wherein the polycrystalline silicon buried layer covers the surface of the whole silicon chip; 6) removing polycrystalline silicon above the barrier layer. The method has the advantages that 1) the barrier layer can be effectively protected, and a process window is added; 2) the process can be more accurately controlled in an end point detection mode by utilizing film conversion between the polycrystalline silicon and the barrier layer; 3) the surface appearance is uniform, the defects can be avoided, and the yield is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

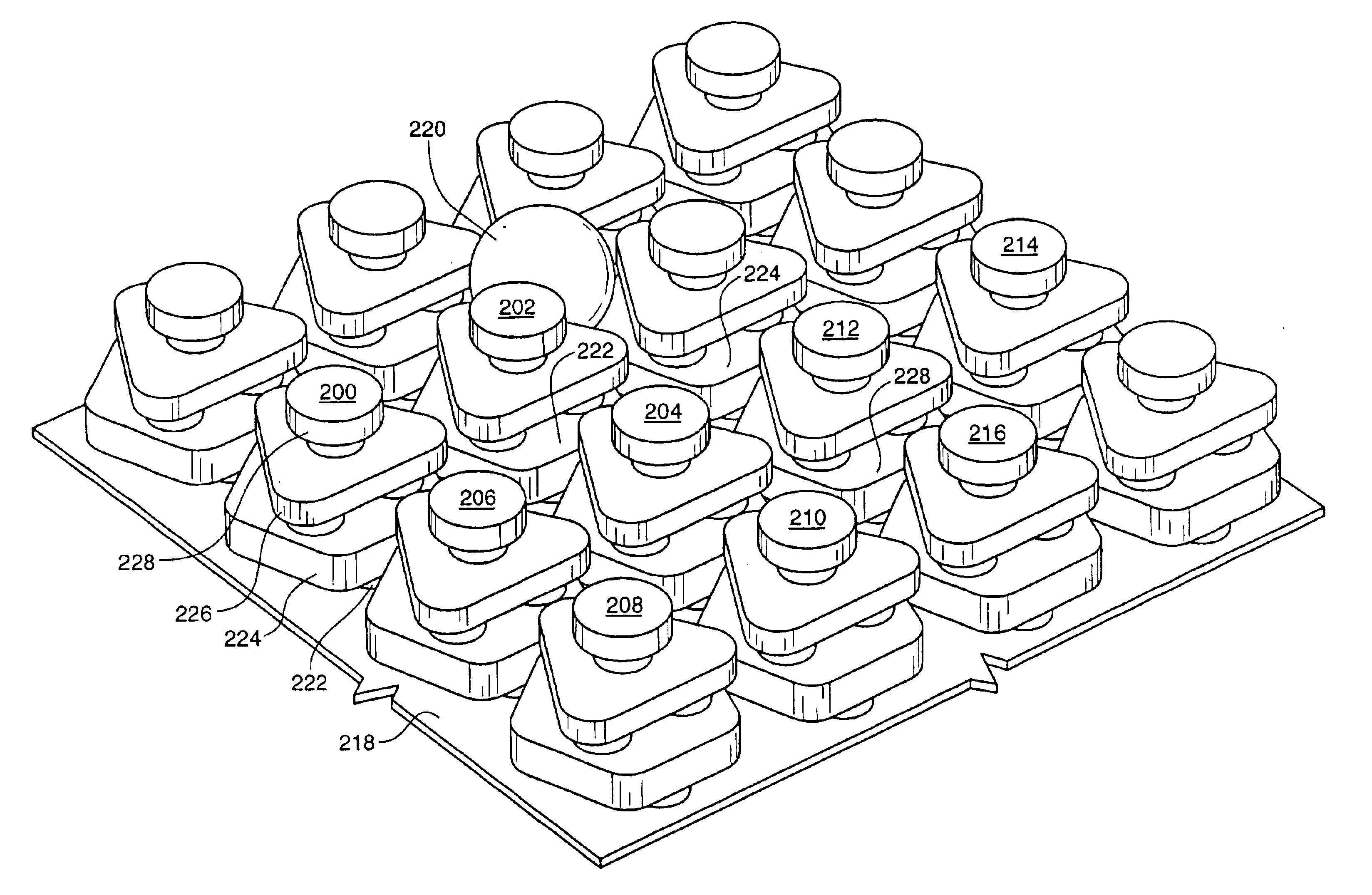

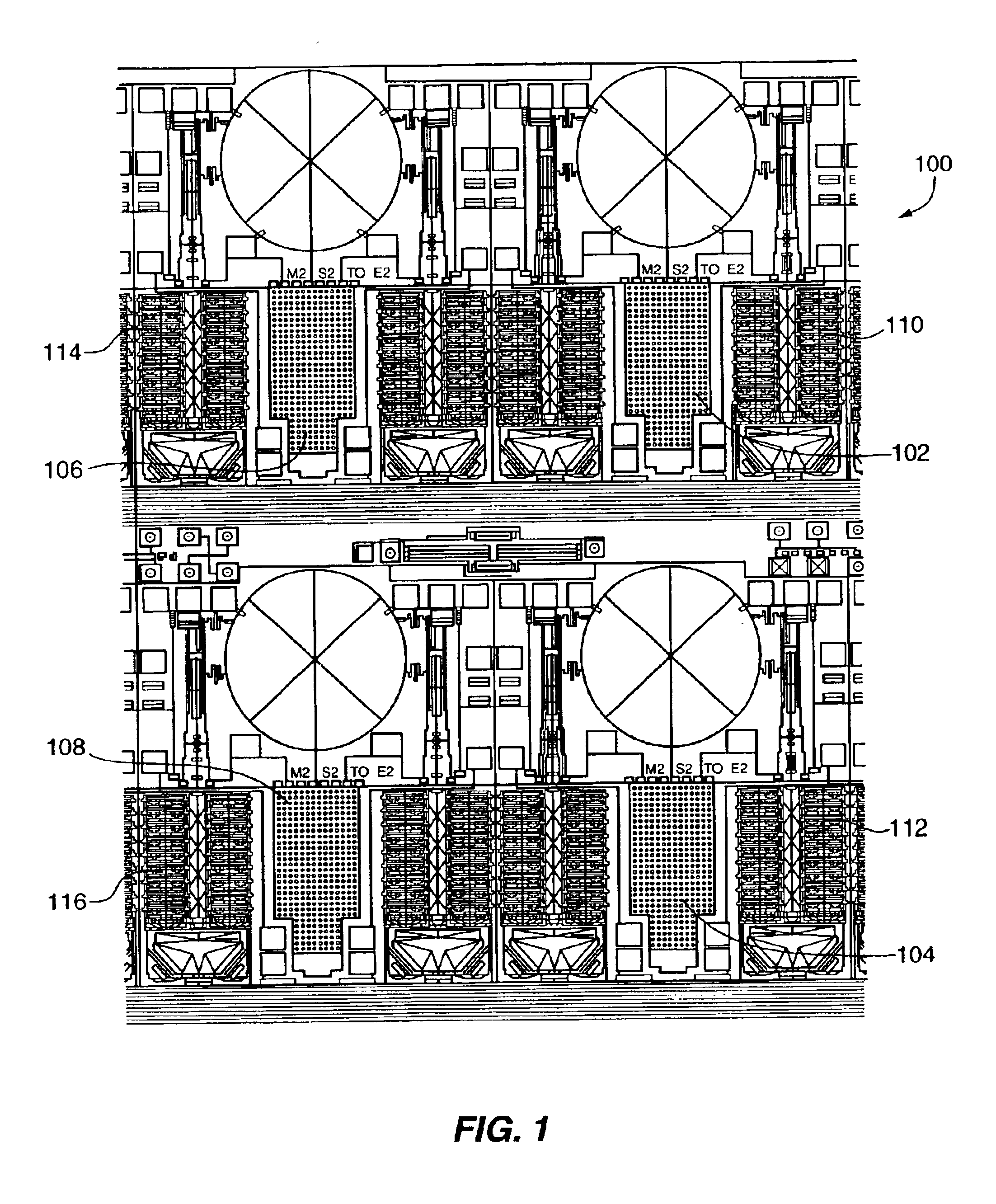

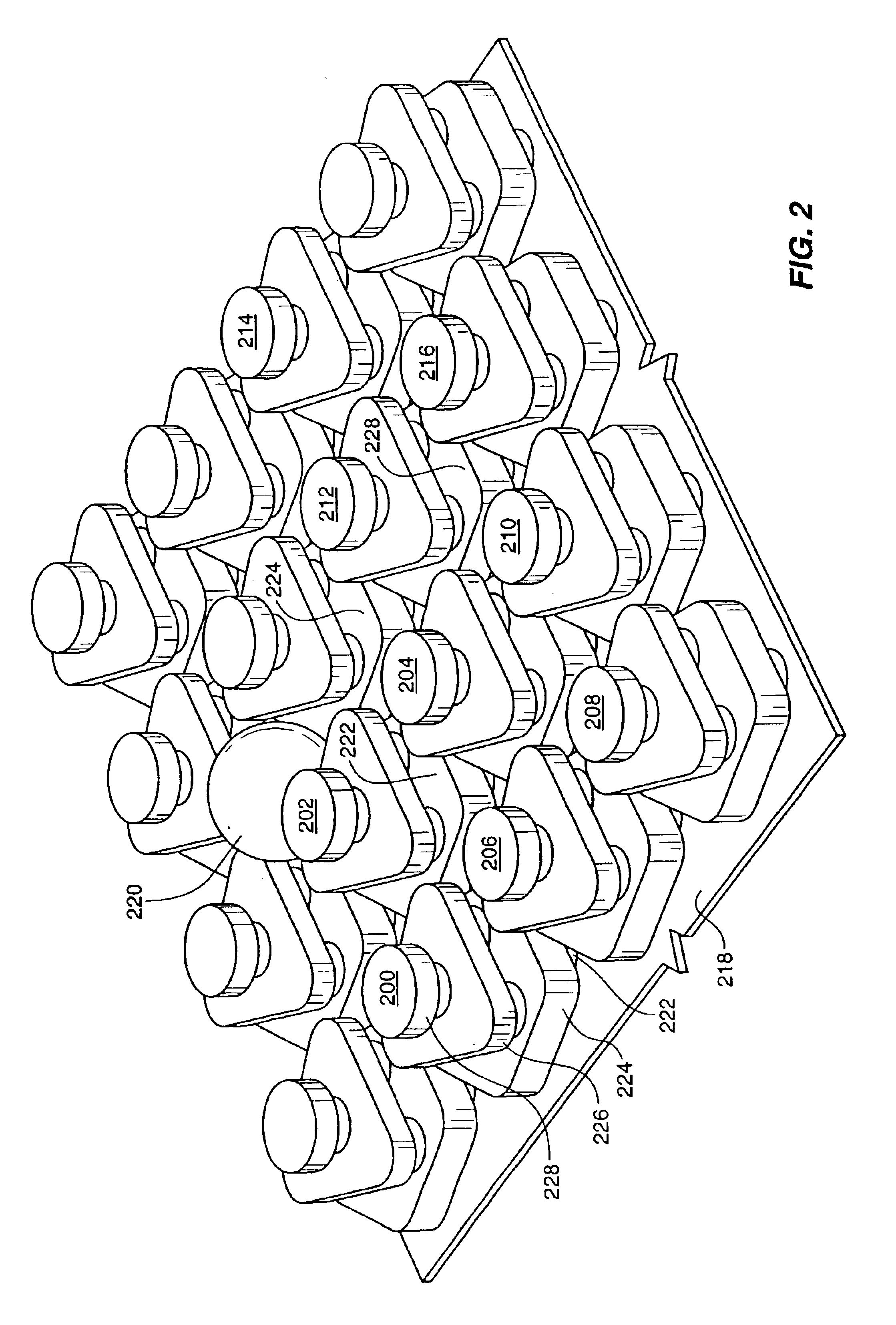

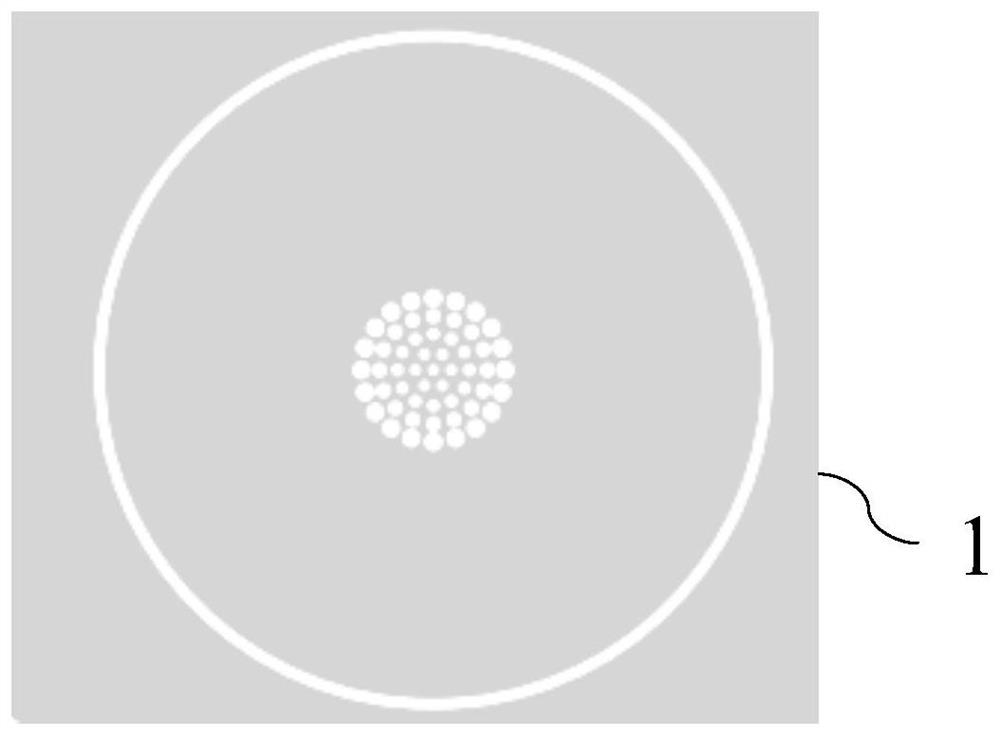

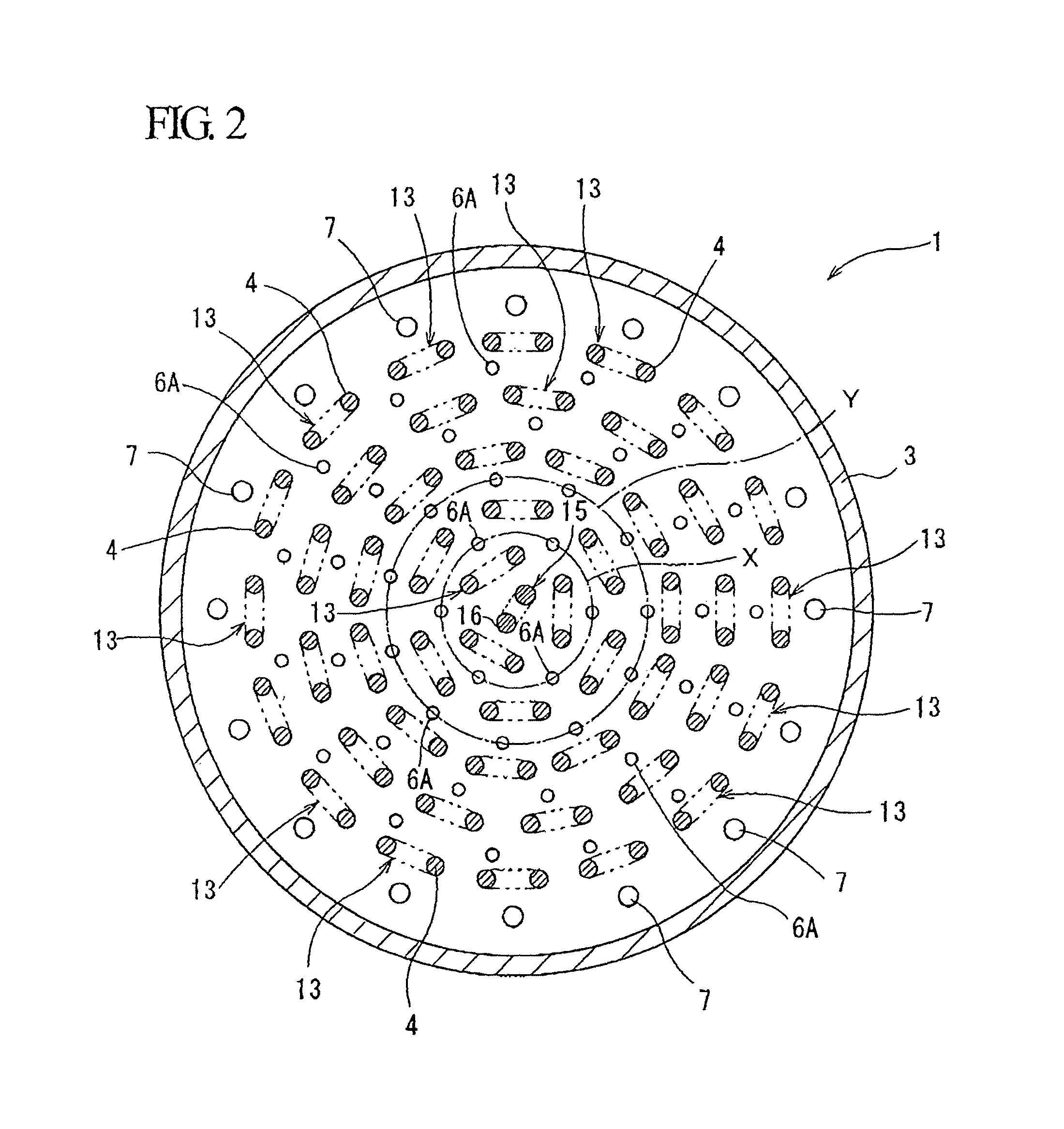

Particle filter for microelectromechanical systems

InactiveUS6875257B2Uniform surface topographyPrevent undesired characteristicCombination devicesPaper/cardboard articlesMultiple dimensionFilter system

A particle filter for microelectromechanical systems is provided that includes a particle trap formed on a substrate material. The particle trap includes an array of multidimensional geometric structures in an adjacent relationship. The geometric structures further define a plurality of multidimensional voids therebetween for trapping particles therein. The individual multidimensional geometric structures are formed by a plurality of vertically interconnected geometric shapes to define different configurations of voids between the adjacent geometric structures. In one embodiment of the filter system, an electrical bias is applied to the array of multidimensional geometric structures to facilitate attracting and trapping of particles in the filter.

Owner:NEOPHOTONICS CORP

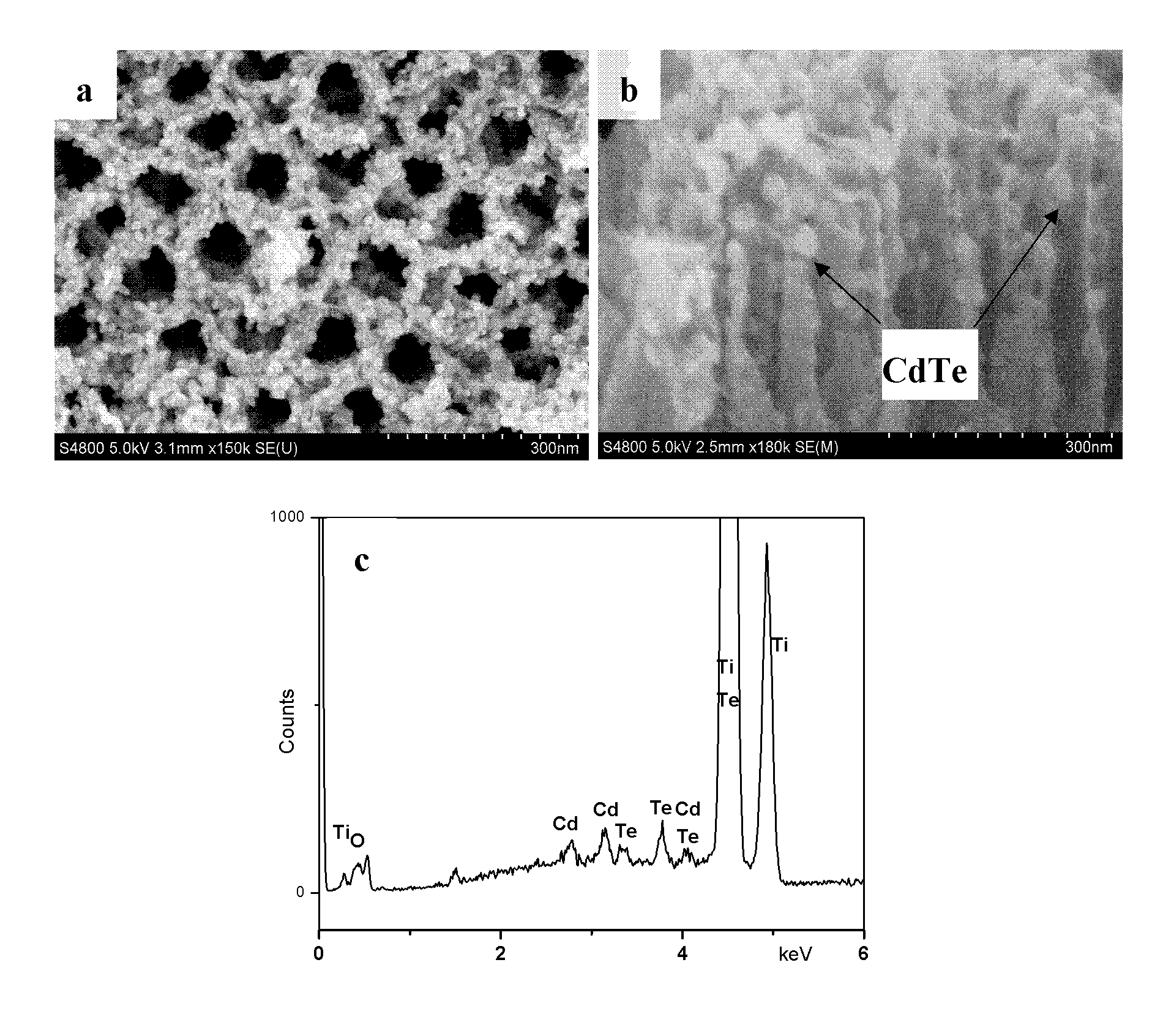

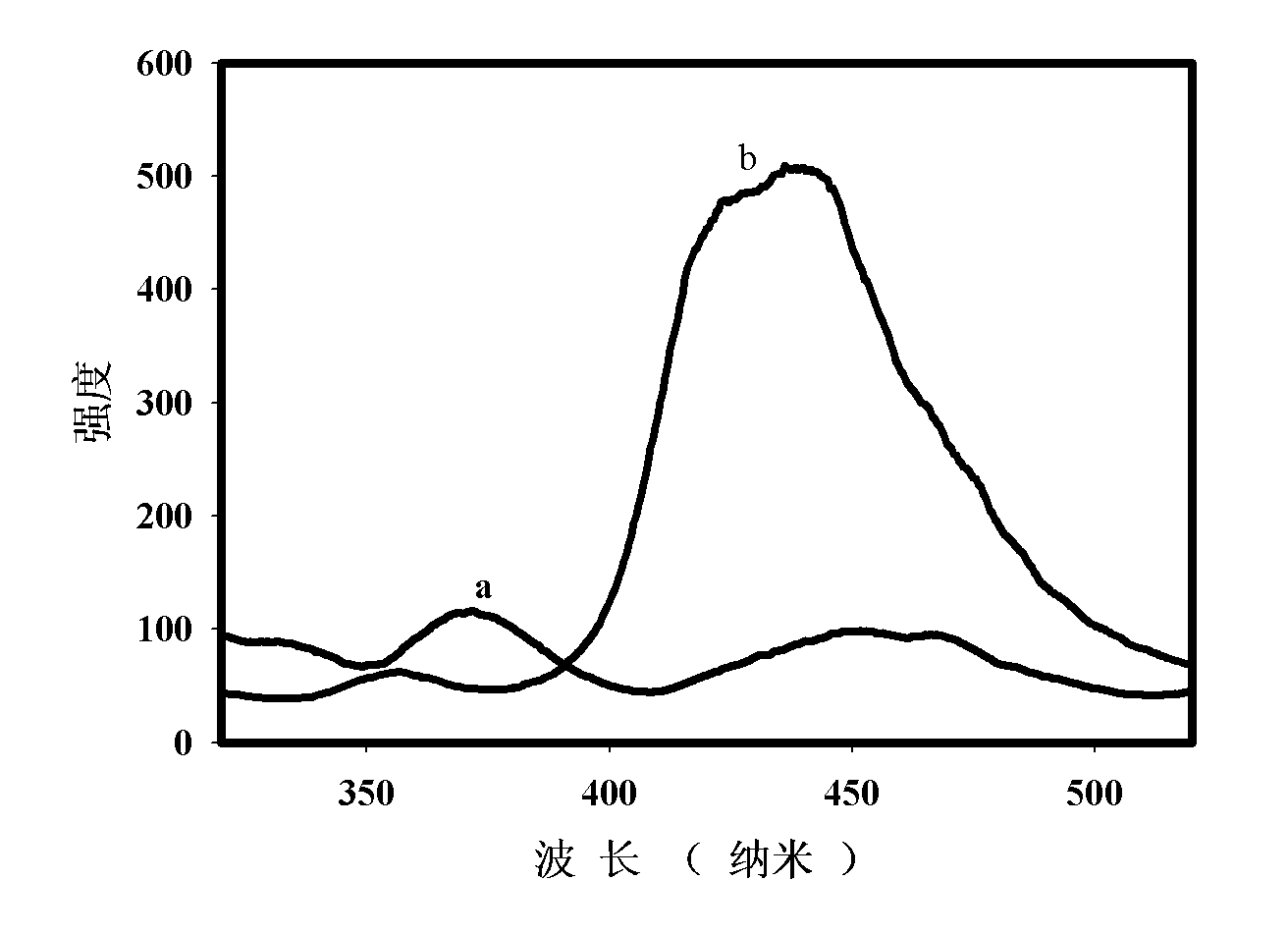

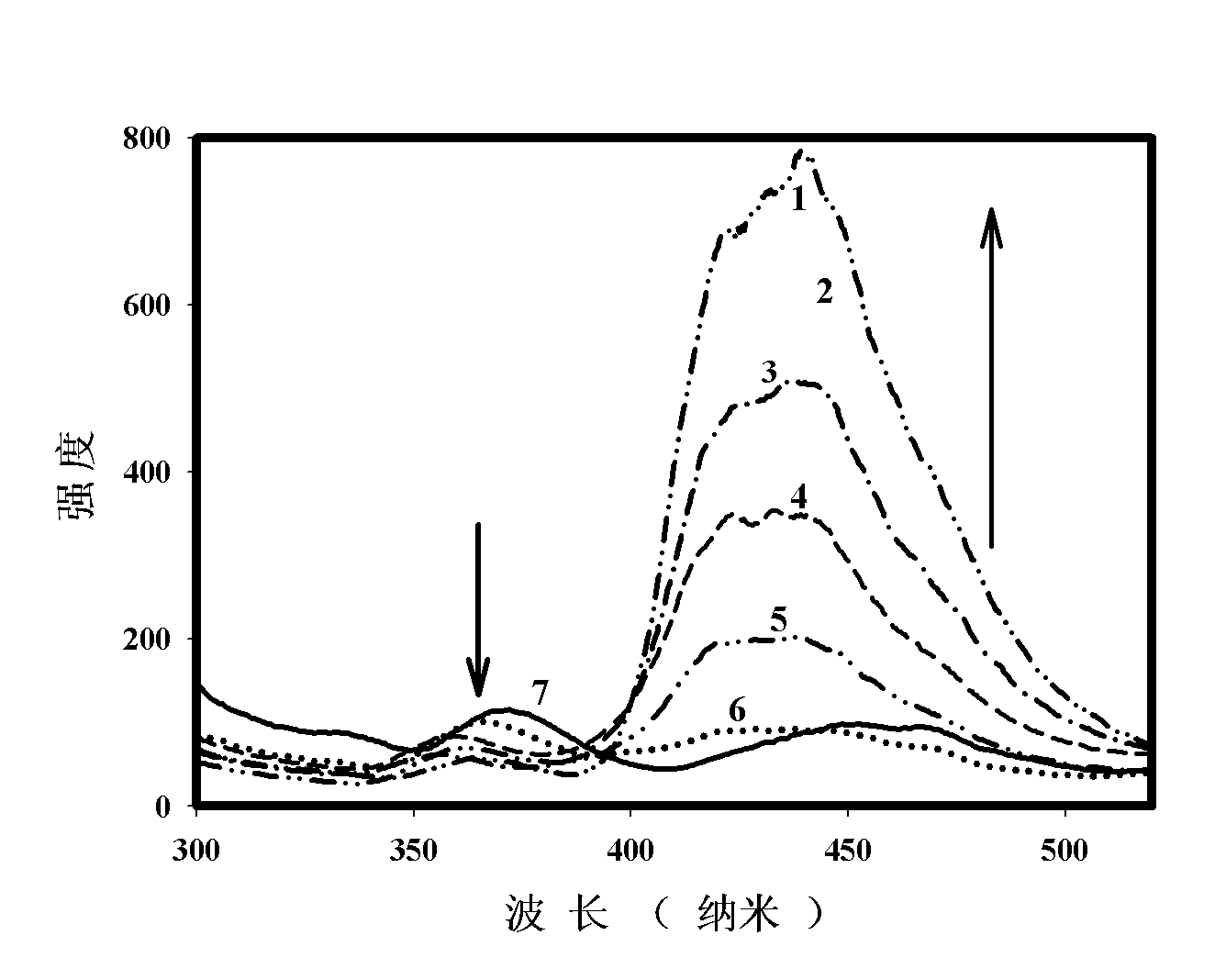

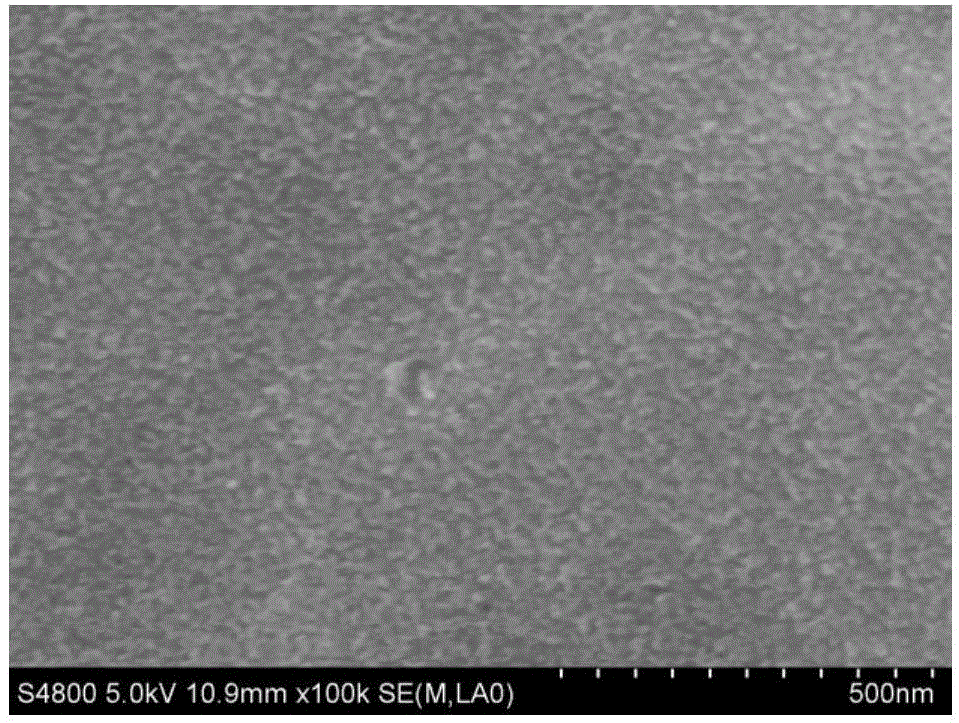

Optical sensor for fast detecting polycyclic aromatic hydrocarbon type contaminants and preparation and application thereof

InactiveCN101846627ASimple preparation stepsLow costFluorescence/phosphorescencePolycyclic aromatic hydrocarbonFluorescence

The invention relates to an optical sensor for fast detecting polycyclic aromatic hydrocarbon type contaminants. A TiO2 nanometer tube array with CdTe quantum dots decorated on the surface and inside the TiO2 nanometer tube array is used as the optical sensor for detecting the polycyclic aromatic hydrocarbon type contaminants, and the dimension of the CdTe quantum dots is between 5 and 25 nm. When the composite material is used as a sensing element, the detection on the polycyclic aromatic hydrocarbon type persistent organic contaminants can be realized. Through the method of the invention, the inventor successfully expands the application of the fluorescence performance of the CdTe quantum dots to a range lower than 450 nm for the first time. The sensing element has the advantages of simple manufacture step, low cost, stable physical and chemical property and portability, so the sensing element can be used as the optical sensor for fast, efficiently and quantitatively detecting the polycyclic aromatic hydrocarbon type contaminants in the environment.

Owner:HUNAN UNIV

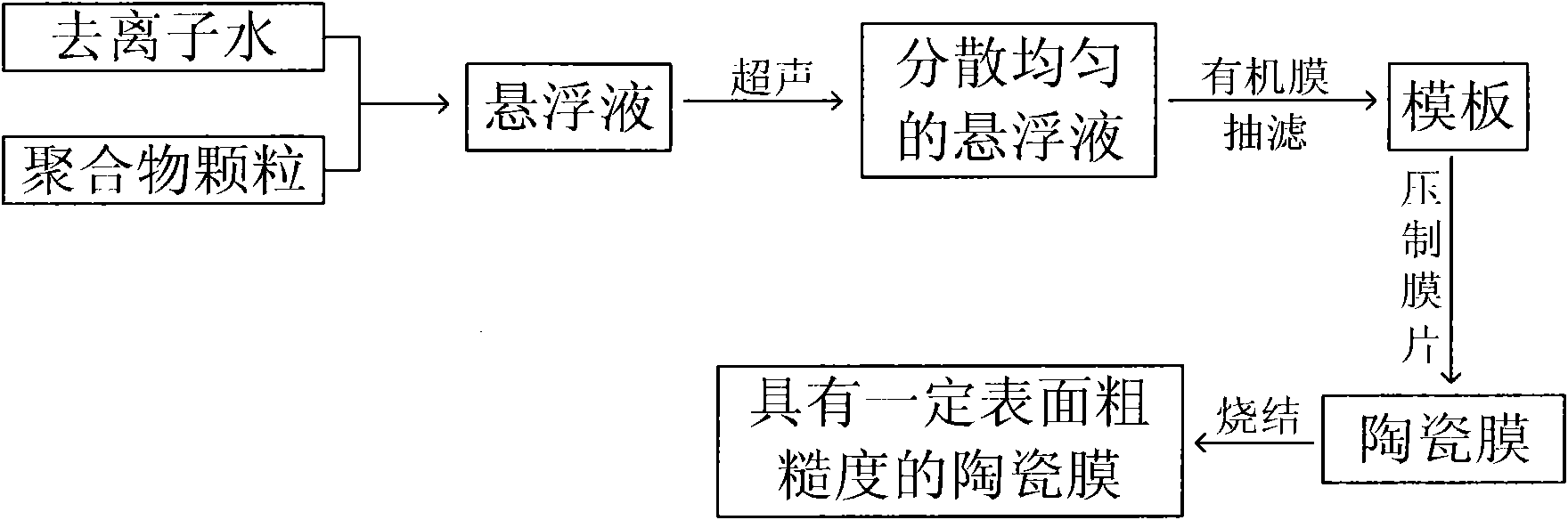

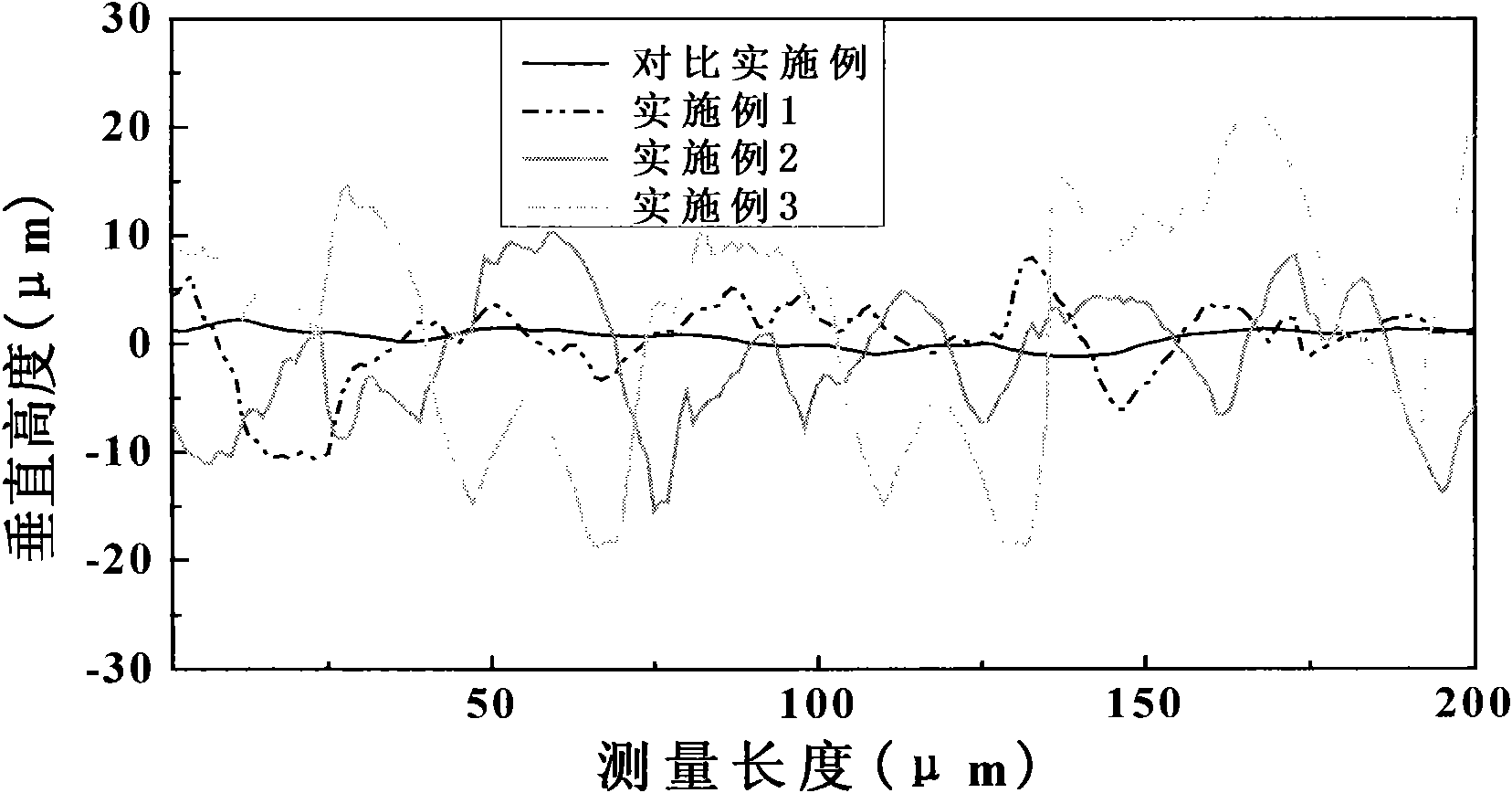

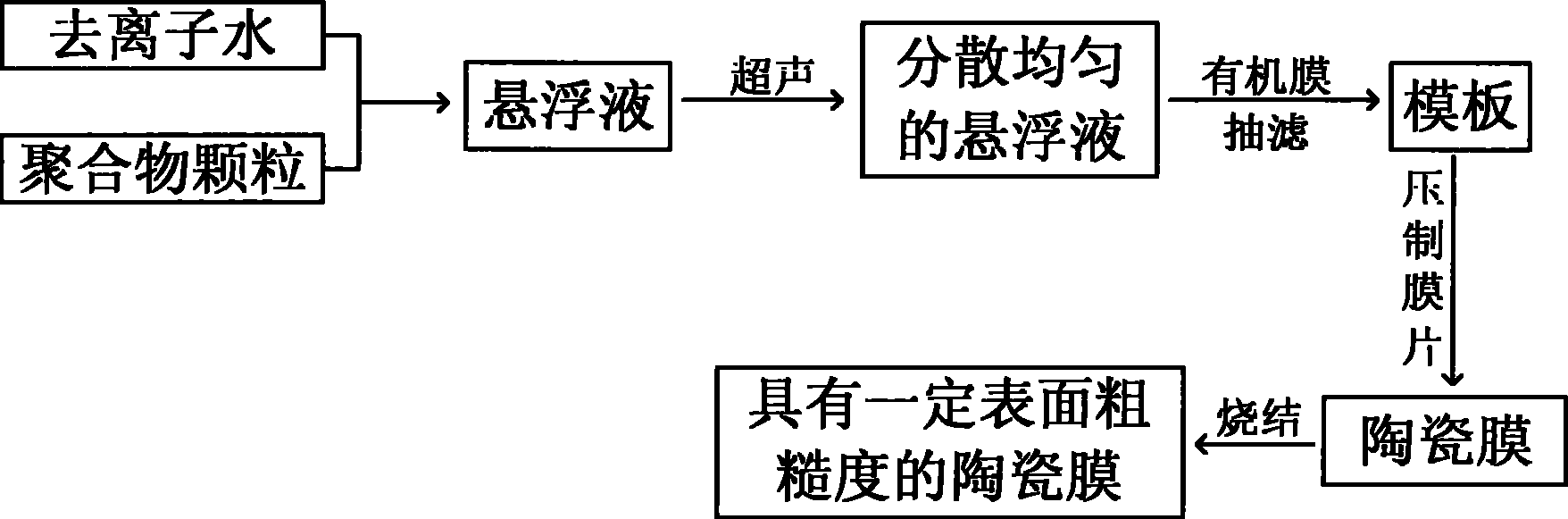

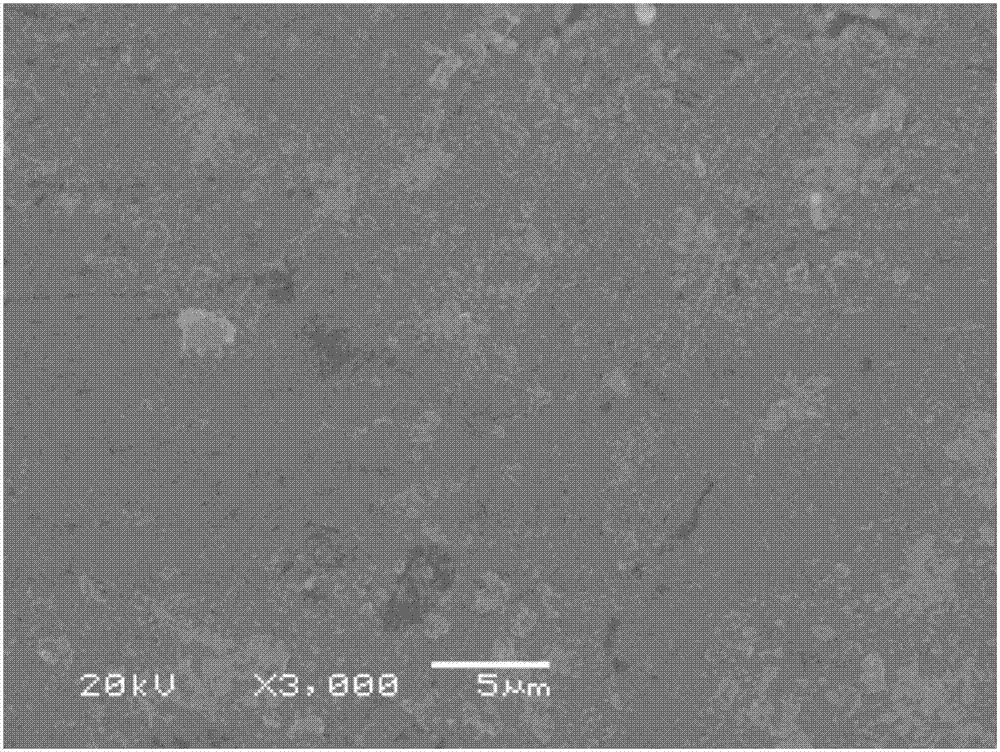

Preparation method of ceramic membrane with different surface roughness

ActiveCN101851100AFast preparationSimple procedureCeramic shaping apparatusSurface roughnessCeramic membrane

The invention belongs to the field of new material preparation, in particular to a preparation method of ceramic membranes with different surface roughness. The preparation method of the invention comprises the following steps: using de-ionized water and polymer particles for preparing suspension liquid; carrying out ultra audible sound treatment on the suspension liquid in an ultrasonic instrument for uniformly dispersing the polymer particles; then, using an organic membrane as a filter membrane; carrying out suction filtration on the suspension liquid so that a layer of polymer particles is uniformly deposited on the surface of the organic membrane; then, placing the organic membrane on the bottom of a mold; adding ceramic powder bodies containing bonding agents into the mold; using a pelleting press for pressing the powder bodies into blanks at certain pressure; and finally, placing the pressed blanks into a furnace to be sintered at a high temperature to obtain the ceramic membrane with certain surface roughness. The method of the invention is simple, and the size of the polymer particles can be fast regulated for fast prepare the ceramic membrane with different surface roughness and uniform surface shape and appearance. The method is also applicable to the preparation of other inorganic materials with different surface roughness.

Owner:NANJING UNIV OF TECH +1

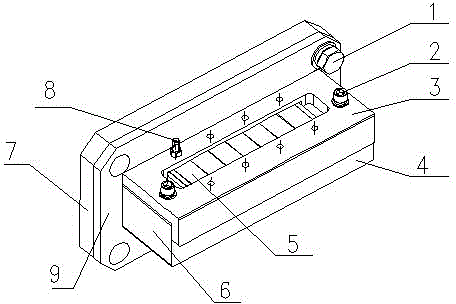

Extruder mouth-type plate, use method and extruder adopting mouth-type plate

The invention relates to an extruder mouth-type plate and an extruder adopting the same. The extruder mouth-type plate comprises a mouth-type seat fixed to an extruder head, a supporting beam born by the mouth-type seat, and two or more relatively movable adjusting blocks connected to the supporting beam, wherein the mouth-type seat, the supporting beam and the adjusting blocks form an extrusion hole. Compared with the prior art, the problems of difficult complicated design and processing and high manufacturing cost of an extruder head of a conventional extruder are solved, the design of the mouth-type plate which is easy to design, simple to process and convenient to modify is adopted, the adjustable extrusion hole is formed by the mouth-type seat, the supporting beam and the adjusting blocks, a plurality of different runners and the outlet-shaped mouth-type plate can be configured through the extruder head of a set of extruder for extrusion molding of products with different raw materials, different flow parameter requirements and different product shapes and sizes, the extruder is multifunctional, the design and processing costs of the extruder are reduced, and the equipment purchasing costs of manufacturers are reduced.

Owner:CHINA RUBBER RESOURCE REGENERATION QINGDAO

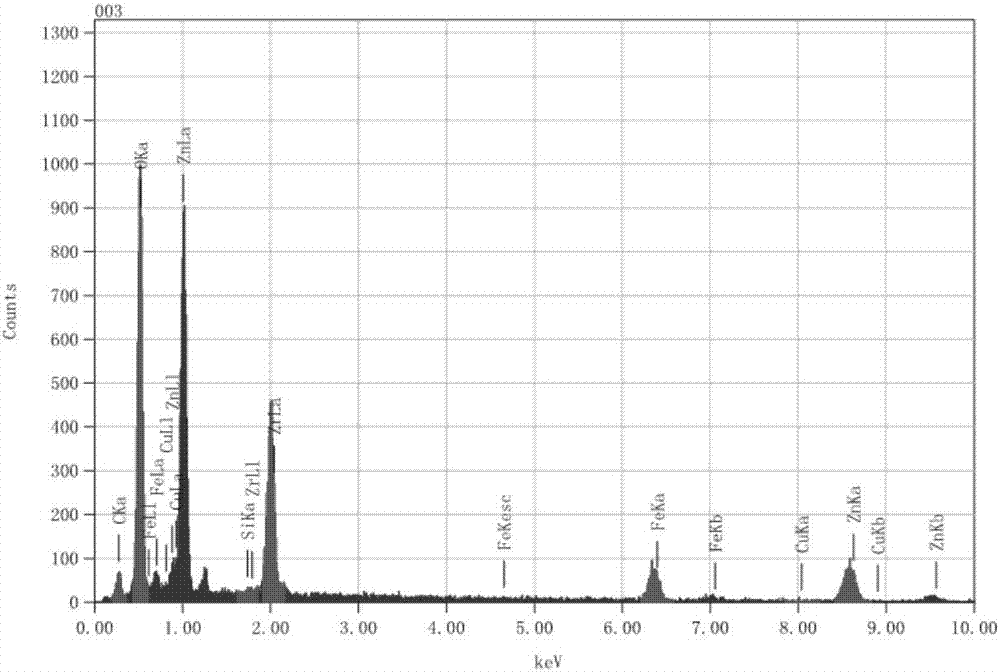

Method for acquiring vitrification-silane compound modification layer on surface of steel body and modification liquid

InactiveCN106967969AReduce usageAvoid eutrophication pollutionMetallic material coating processesManganeseChemical conversion

The invention provides a method for acquiring a vitrification-silane compound modification layer on a surface of a steel body and a modification liquid. The preparation method is carried out according to the following steps that firstly, silane coupling agent pre-hydrolysate subjected to acid environment prehydrolysis treatment is added into the vitrification modification liquid, then, under the room temperature condition, a pre-treated steel base body is immersed for 0.5-1 h in the vitrification liquid, and the compound modification layer containing copper, iron, manganese, zirconium and zinc can be acquired on the surface of the steel. According to the preparation method, the chemical conversion coating technology is adopted, the method is suitable for large complex curved parts, and moreover, use of heavy metal ions, such as Cr<6+> with relatively high toxicity is avoided in the modification liquid; and the method does not have the defect that a phosphate conversion coating technology pollutes water seriously. The modification layer acquired through the method is uniform in appearance and excellent in decay resistance.

Owner:HARBIN ENG UNIV

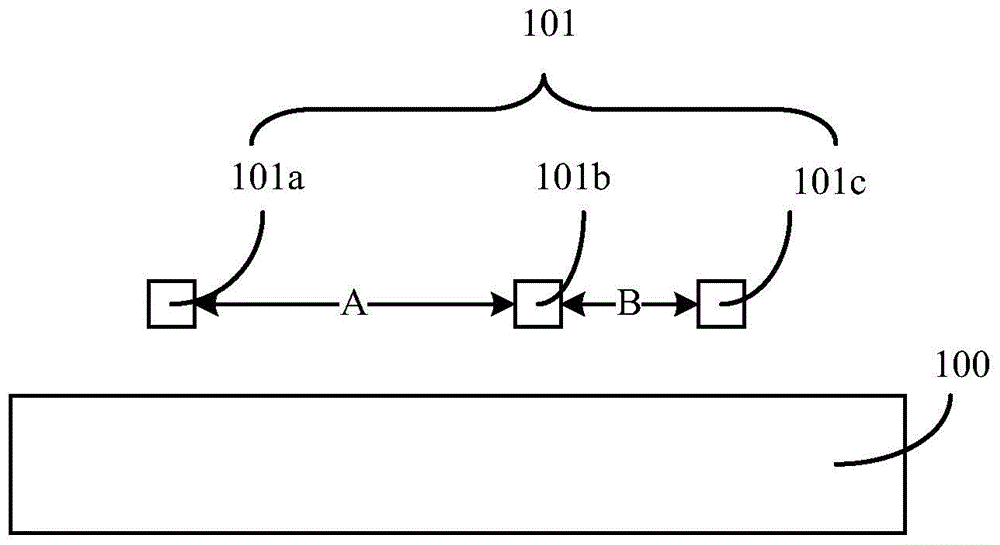

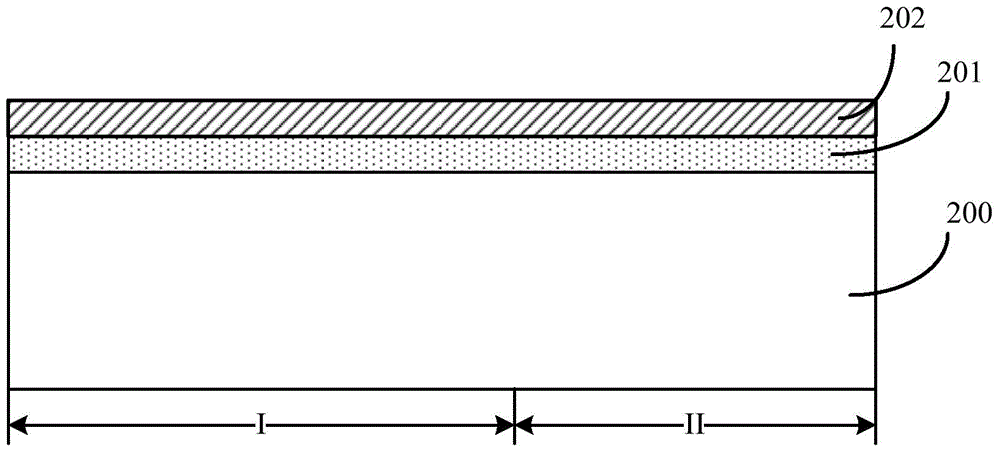

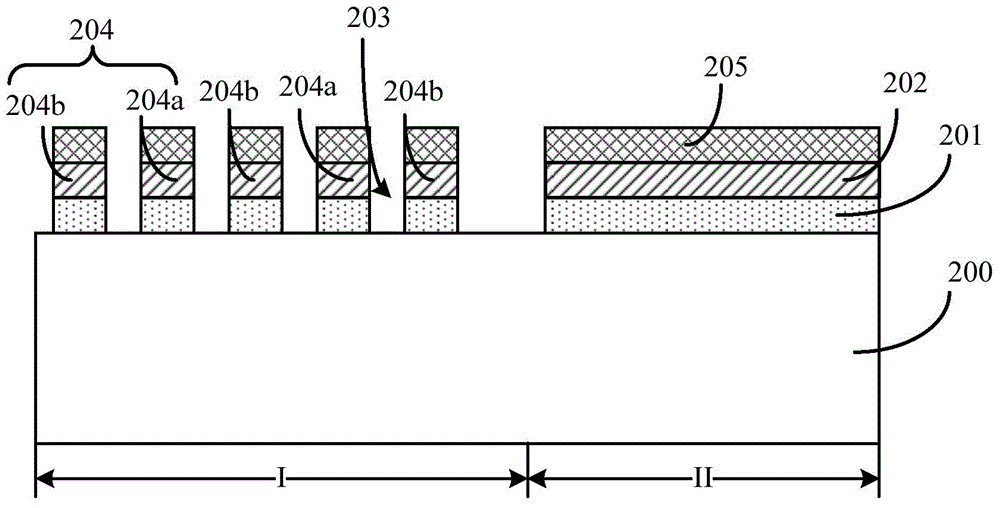

Formation method of semiconductor device

ActiveCN105097525AUniform temperature and atmosphere distributionUniform surface topographyNanoinformaticsSemiconductor/solid-state device manufacturingPhysicsNanometre

A formation method of a semiconductor device comprises the steps of providing a substrate, wherein the substrate possesses a first area, a sacrificial layer is arranged on the surface of the substrate, and a semiconductor layer is arranged on the surface of the sacrificial layer; forming at least three adjacent first grooves in the semiconductor layer and the sacrificial layer of the first area, wherein the first grooves expose out of the surface of the substrate, the semiconductor layer between the first grooves forms at least two parallelly arranged nano wires, the distances between the adjacent nano wires are same, and the nano wires comprise the device nano wires and the pseudo nano wires; removing the sacrificial layer at the bottoms of the nano wires to enable the nano wires to suspend above the substrate; after the sacrificial layer of the first area is removed, carrying out a first time annealing process to enable the cross-sections of the nano wires to be circular; after the first time annealing process, removing the pseudo nano wires. The morphology and performance of the formed semiconductor device are improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

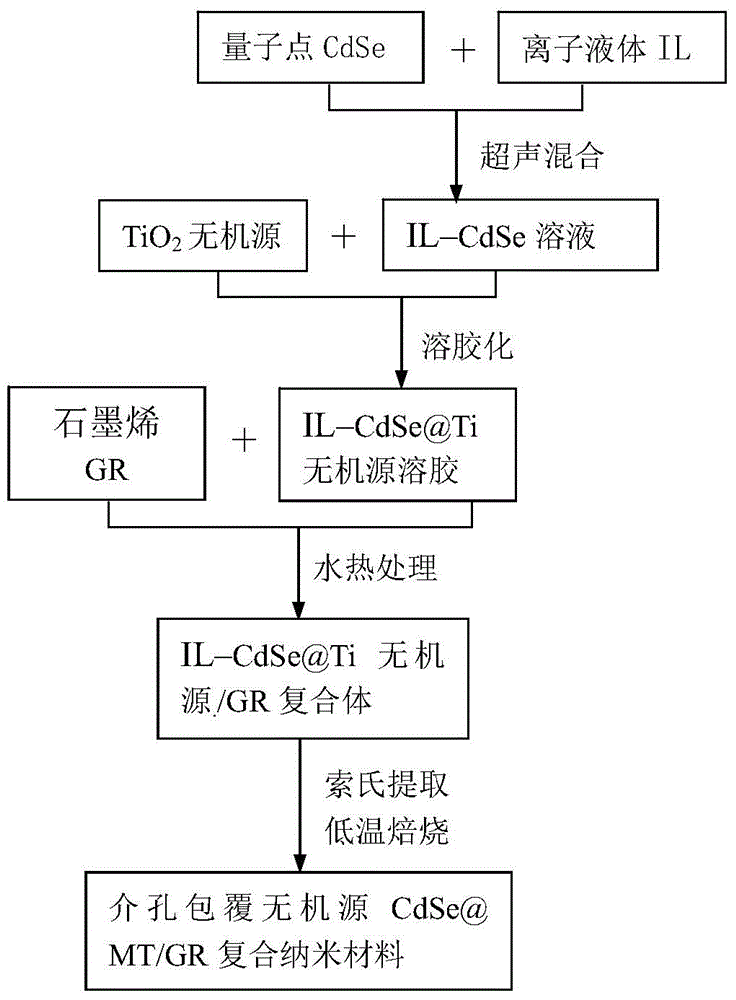

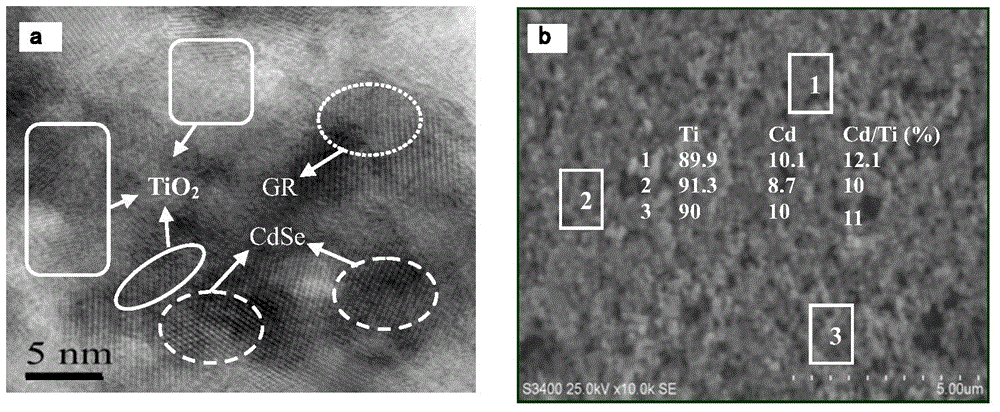

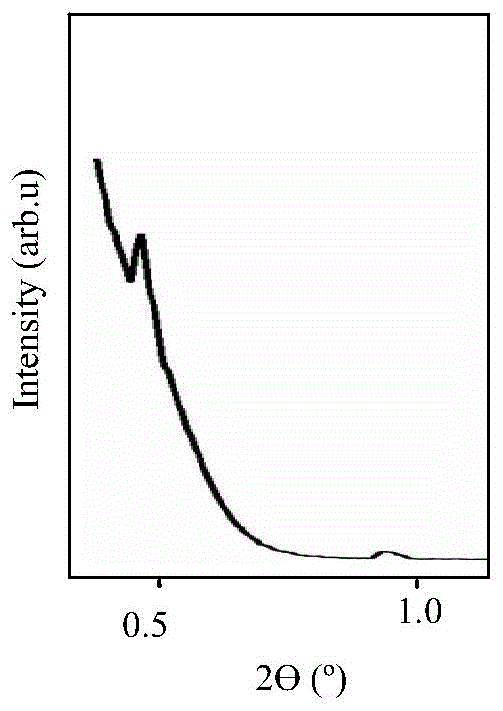

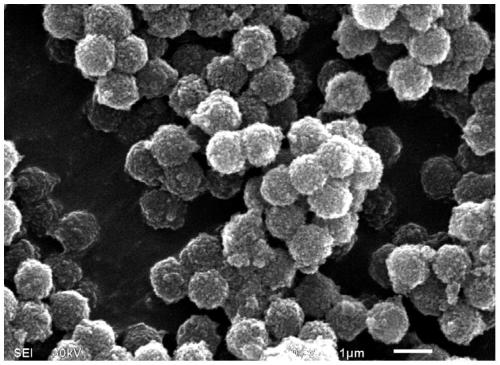

Quantum dot-sensitized graphene base mesoporous coating CdSe @ MT/GR visible light-catalyzing composite nanometer material and preparation method thereof

ActiveCN104588044AReduce the cost of degradation treatmentCalcination temperature is lowMaterial nanotechnologyPhysical/chemical process catalystsQuantum dotCvd graphene

The invention relates to a quantum dot-sensitized grapheme base mesoporous coating CdSe @ MT / GR high-performance visible light-catalyzing composite nanometer material and a preparation method thereof. According to the invention, CdSe@MT is loaded in to a graphene base by adopting a functionalized ionic liquid self-assembling method through a hydrothermal process, a soxhlet extraction and a low-temperature heating treatment. The preparation method disclosed by the invention has the outstanding characteristics that a quantum dot-sensitized graphene base mesoporous coating CdSe @ MT / GR high-performance visible light-catalyzing composite nanometer material with a novel structure and good physical and chemical properties is prepared by using a functionalized ionic liquid self-assembling method, so as to provide a new way for TiO2-type light-catalyzing material application studies. The preparation method is simple in process and easy to industrially produce. The prepared mesoporous nanometer material has large specific surface area, even pore size distribution and good visible light-catalyzing performance.

Owner:JISHOU UNIVERSITY

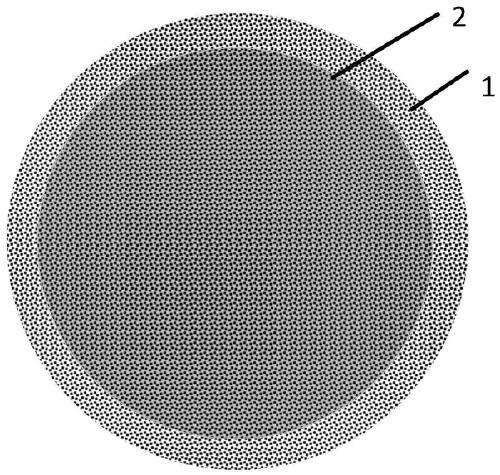

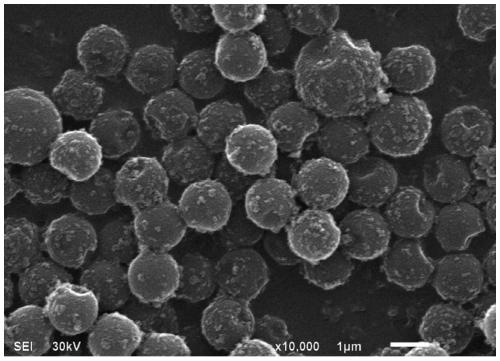

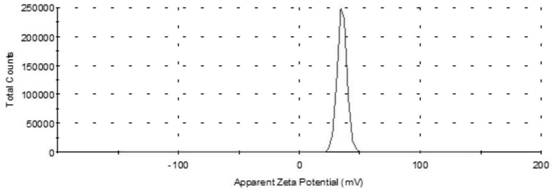

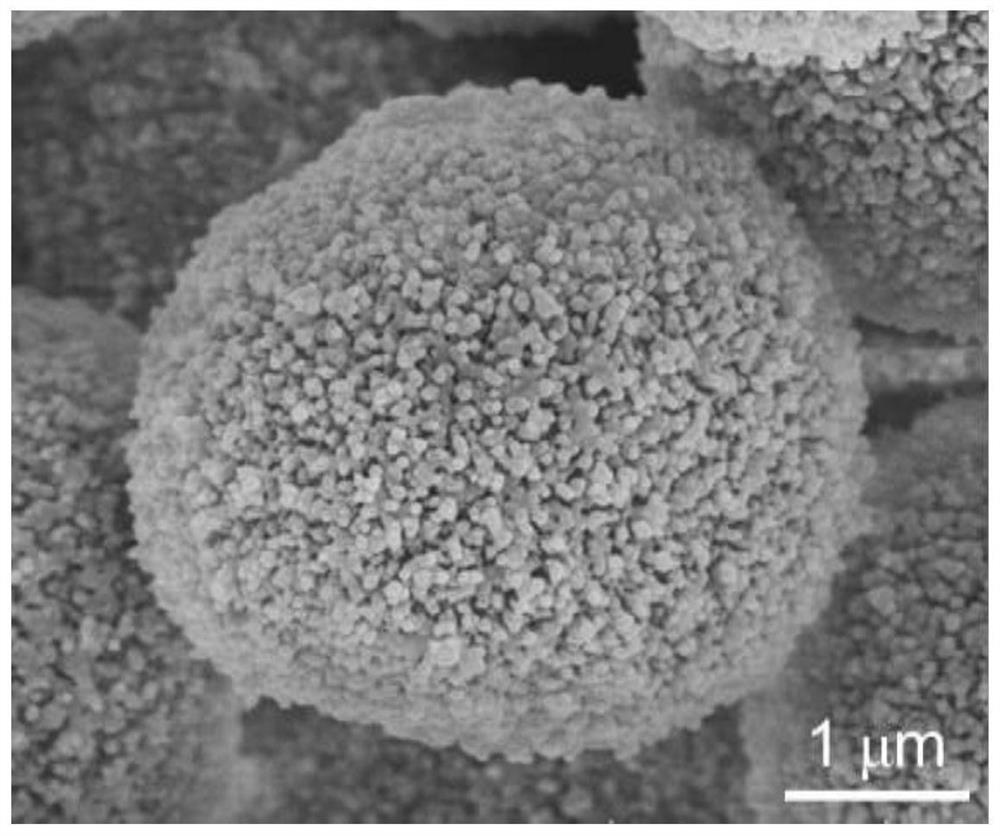

Immunomagnetic beads and preparation method thereof

ActiveCN110343218AIncrease coverageImprove structural stabilityInductances/transformers/magnets manufactureDiamagnetic/paramagnetic materialsPolystyrene microsphereImmunomagnetic bead

The invention provides immunomagnetic beads and a preparation method thereof. The preparation method comprises the following steps: swelling polystyrene microspheres; synthesizing magnetic composite microspheres at high temperature and high pressure; carrying out acid dissolution to remove exposed magnetic particles on the surfaces of the magnetic composite microspheres; and carrying out surface cross-linking modification on the magnetic composite microspheres. The immunomagnetic beads prepared by the method disclosed by the invention are uniform in particle size, good in magnetic responsiveness, stable in structure and consistent in magnetic content.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

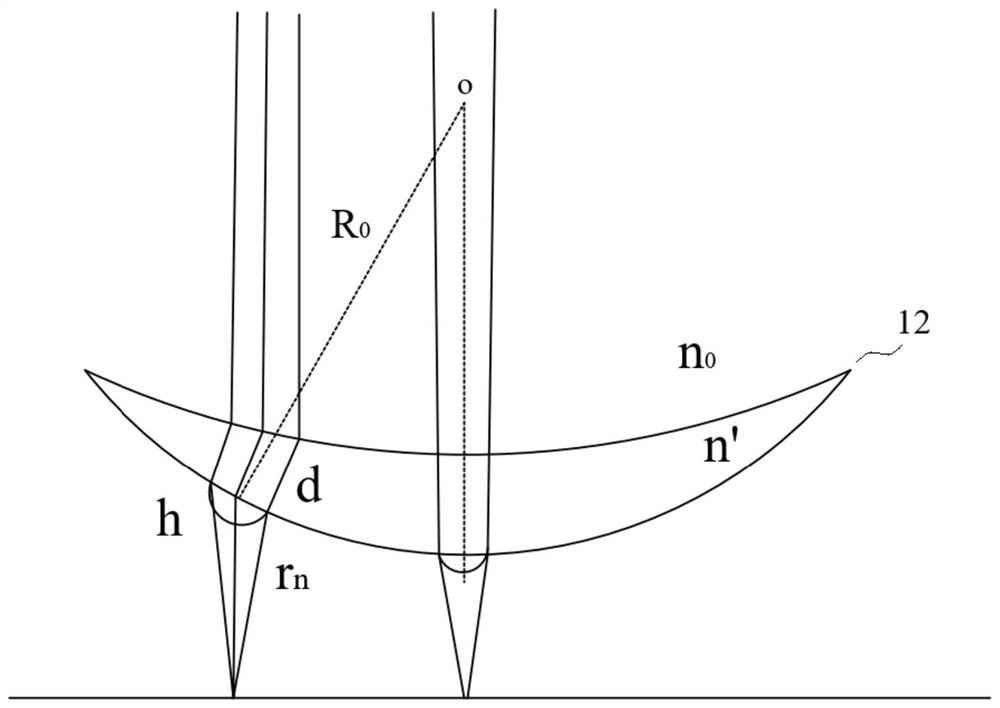

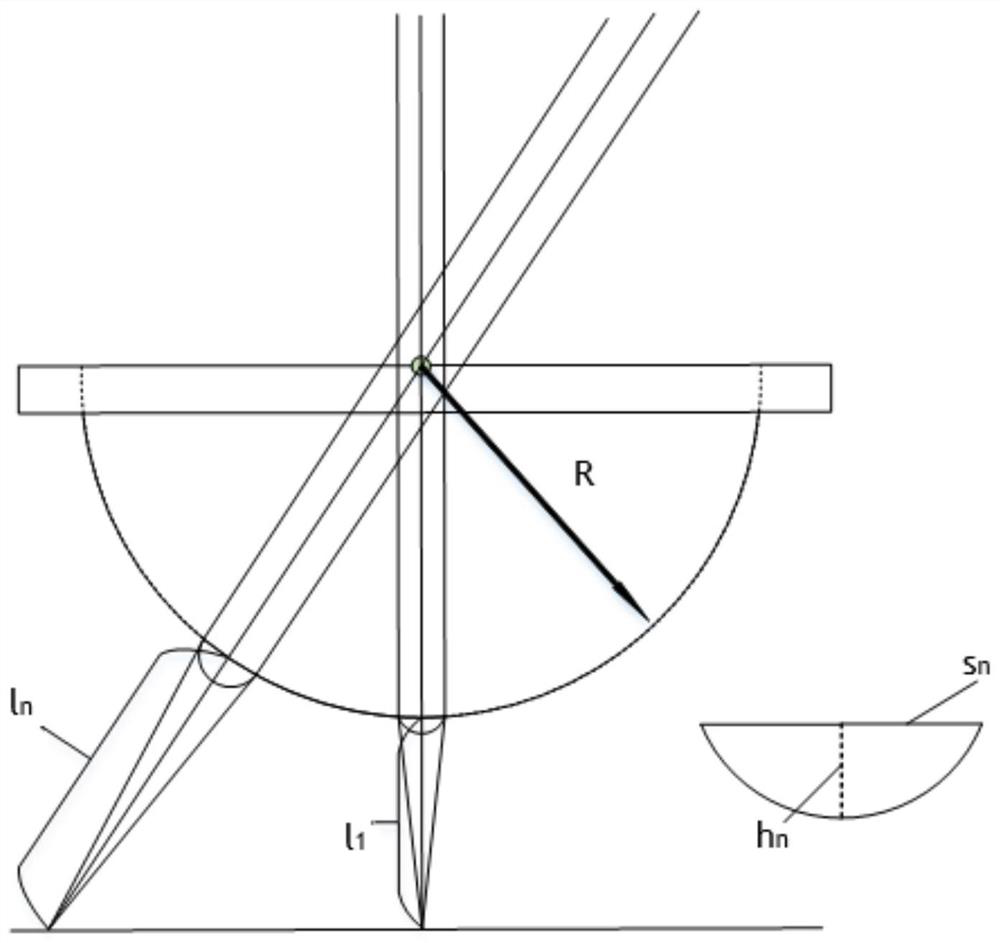

Curved fly's-eye lens and preparation method thereof

InactiveCN113126188AImprove machining accuracyPrecisely control the radius of curvaturePhotosensitive material processingLensPolymeric surfaceImage resolution

The invention provides a curved fly's-eye lens and a preparation method thereof. The curved fly's-eye lens comprises an upper concave surface and a lower concave surface, light vertically enters from the upper part of the concave surface of the curved fly's-eye lens and is transmitted to the lower concave surface from the upper concave surface; the lower concave surface is provided with sub-eye lenses, transmission light rays at different angles pass through the optical center of each stage of sub-eye lens, and then the focus of each stage of fly's-eye lens falls on the plane of the detector. The micro-lens pattern on the silicon wafer substrate is transferred to the polymer layer by adopting the hot-pressing process, the pressure is uniformly applied to the surface of the polymer, the sub-eye vector height is uniform, and the size of the sub-eye vector height can be controlled by controlling the preset hot-pressing thickness; the curvature radius of the deformation of the film is accurately controlled according to the linear relationship between the deformation of the PDMS film and the atmospheric pressure; the lens is prepared by adopting an ultraviolet curing process, the time is short, the efficiency is high, the repeatability is good, and the surface appearance is uniform; the variable-curvature quartz glass is adopted, and the meniscus fly's-eye lens is prepared during ultraviolet curing, so that the influence of spherical aberration and aberration is reduced, and the resolution is improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

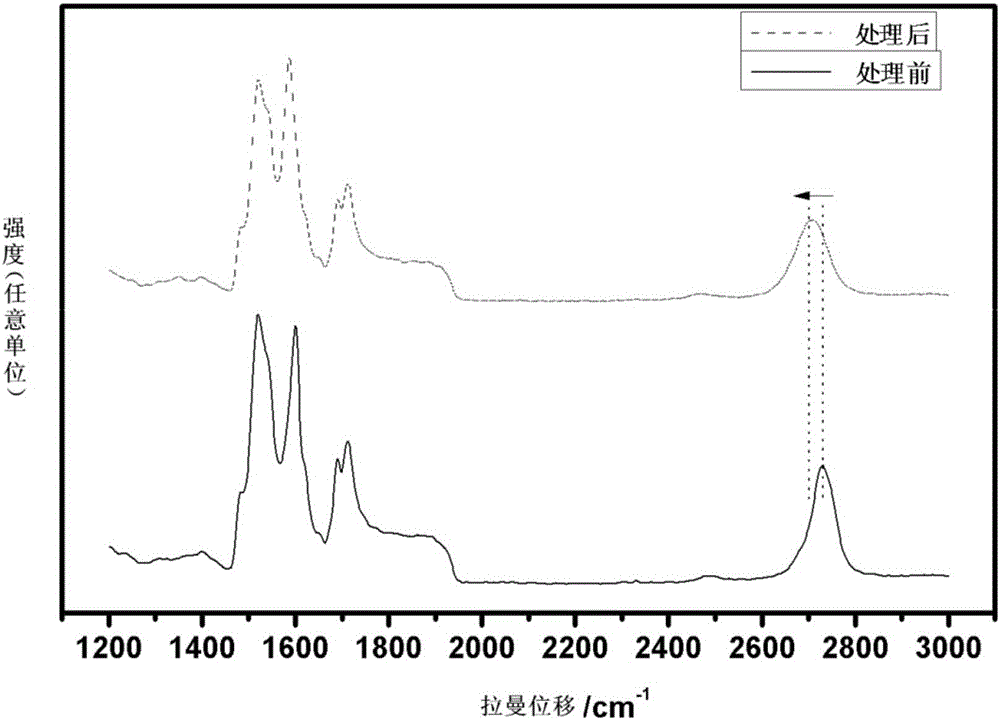

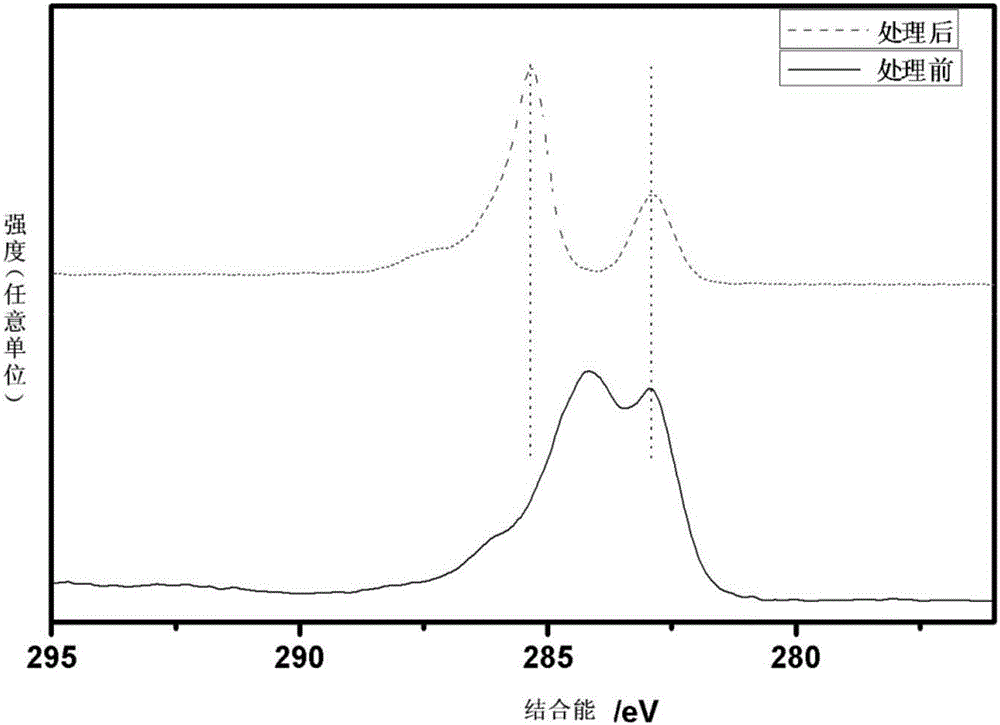

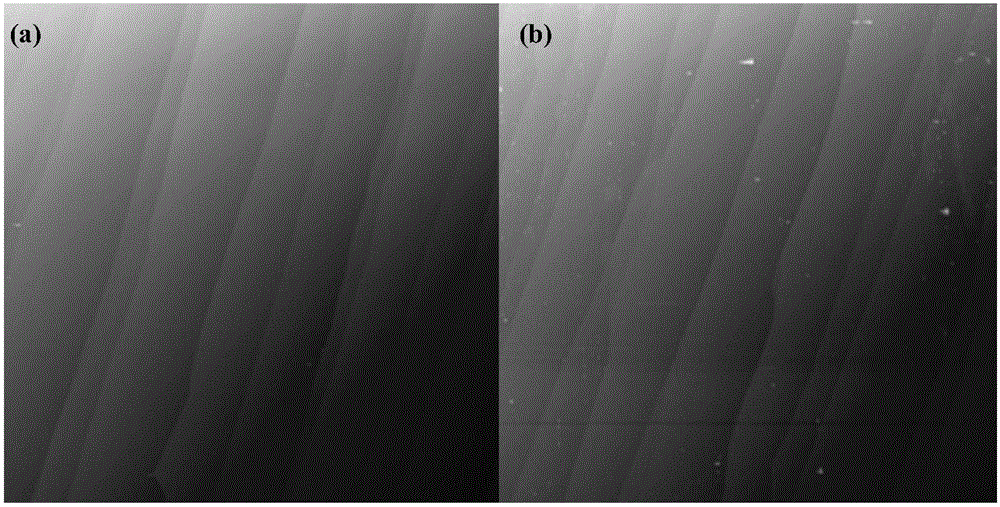

Photoelectrochemical etching method for removing SiC substrate epitaxial graphene buffer layer

InactiveCN105845552AImprove securityUniform surface topographySemiconductor/solid-state device manufacturingSic substrateIndium

The invention relates to a photoelectrochemical etching method for removing an epitaxial graphene buffer layer on a SiC substrate, comprising the following steps: (1) connecting a SiC substrate epitaxial graphene wafer to metal indium as a working electrode; using a saturated calomel electrode or The silver / silver chloride electrode is used as the reference electrode, the platinum electrode is used as the counter electrode, and the KOH solution is used as the etching solution; the working electrode, the reference electrode and the counter electrode are placed in the etching solution, and a three-electrode system is assembled; (2 ) Irradiate the three-electrode system with ultraviolet light, and control the electrolytic current density to 1.0-2.0mA / cm 2 , the buffer layer can be removed by photoelectrochemical etching on the SiC substrate epitaxial graphene buffer wafer. By optimizing the process parameters in the method of the invention, the buffer layer can be completely removed, and a graphene material with a uniform surface can be obtained.

Owner:SHANDONG UNIV

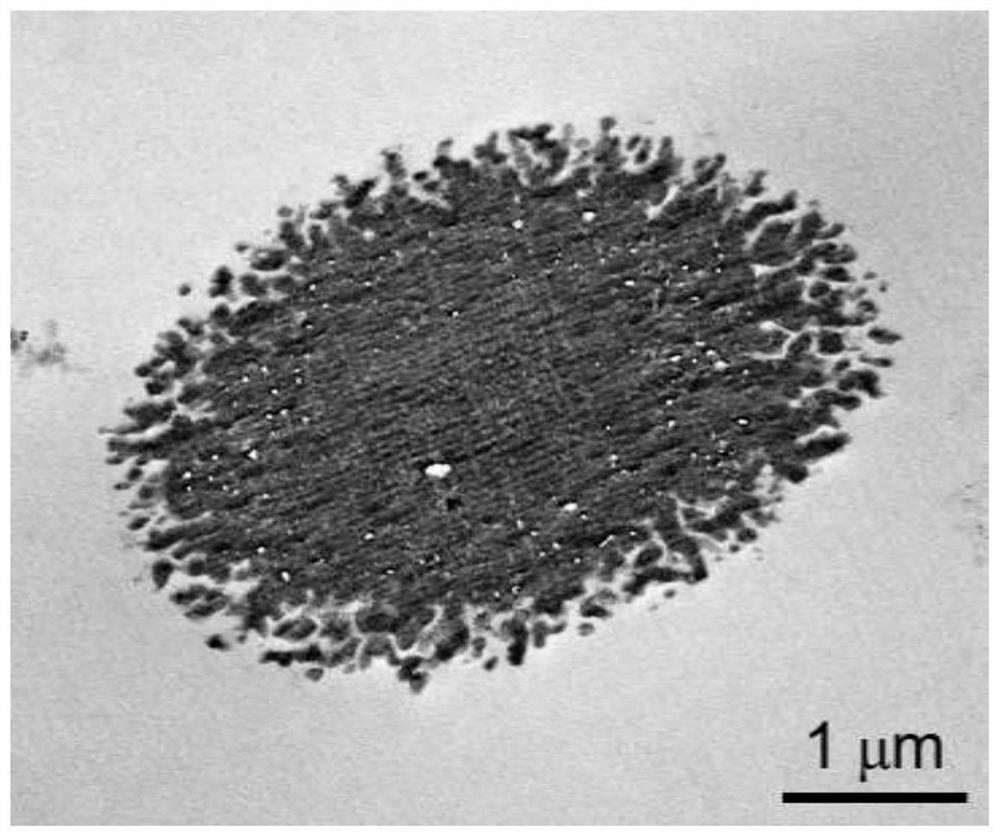

Ion exchange polymer microsphere and synthesis method thereof

PendingCN114805657AThe reaction process is simpleExperimental conditions are simpleMicroballoon preparationMicrocapsule preparationIon exchangeHydrophilic polymers

The invention relates to an ion exchange polymer microsphere and a synthesis method thereof. The microsphere has a micron size, is internally composed of a hydrophobic polymer, and has a solid and compact structure; and the outer part is composed of a charged hydrophilic polymer and has a nano-porous structure. By changing the types of the hydrophobic polymer and the charged hydrophilic polymer, the chemical components and the surface appearance of the microspheres can be regulated and controlled. The microspheres have uniform size and morphology, the preparation method is simple, large-scale production is easy, and the microspheres have wide industrial application value. The ion exchange polymer microsphere with the micro-nano hierarchical heterostructure has great value in adsorption and separation of various molecules, ions and particles, and is expected to be applied to the fields of medicine purification, food detection, environmental governance and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

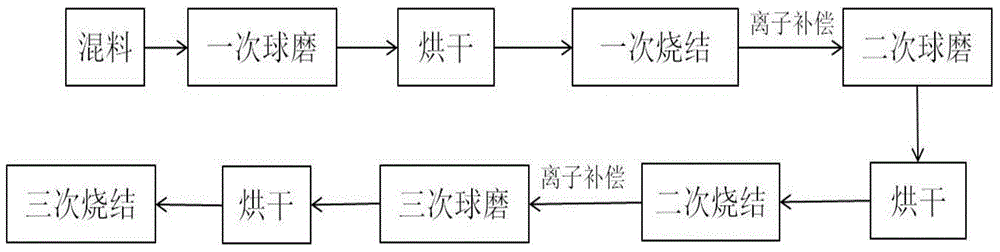

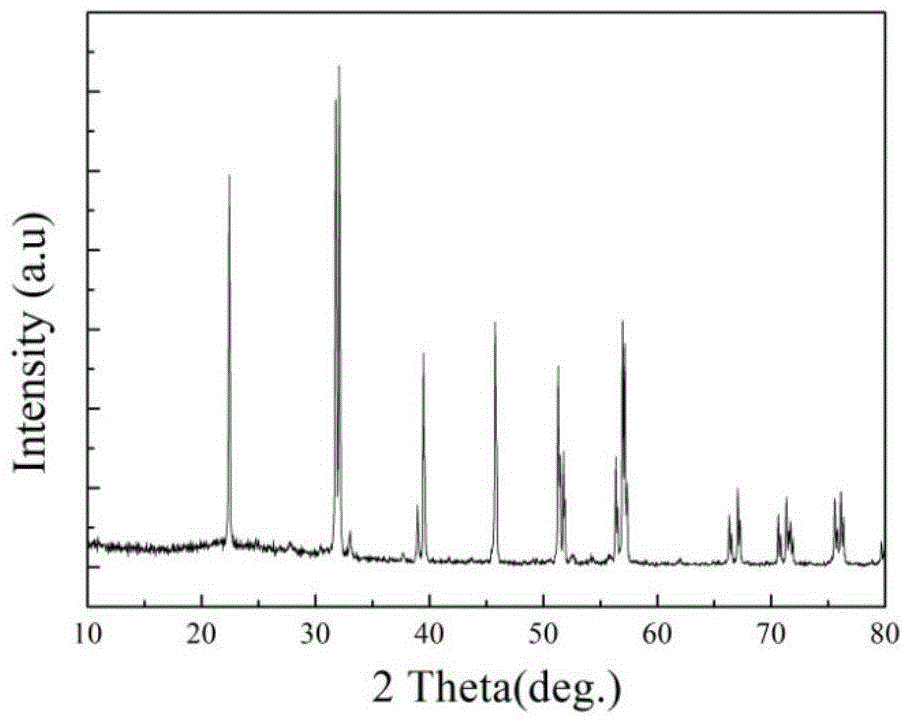

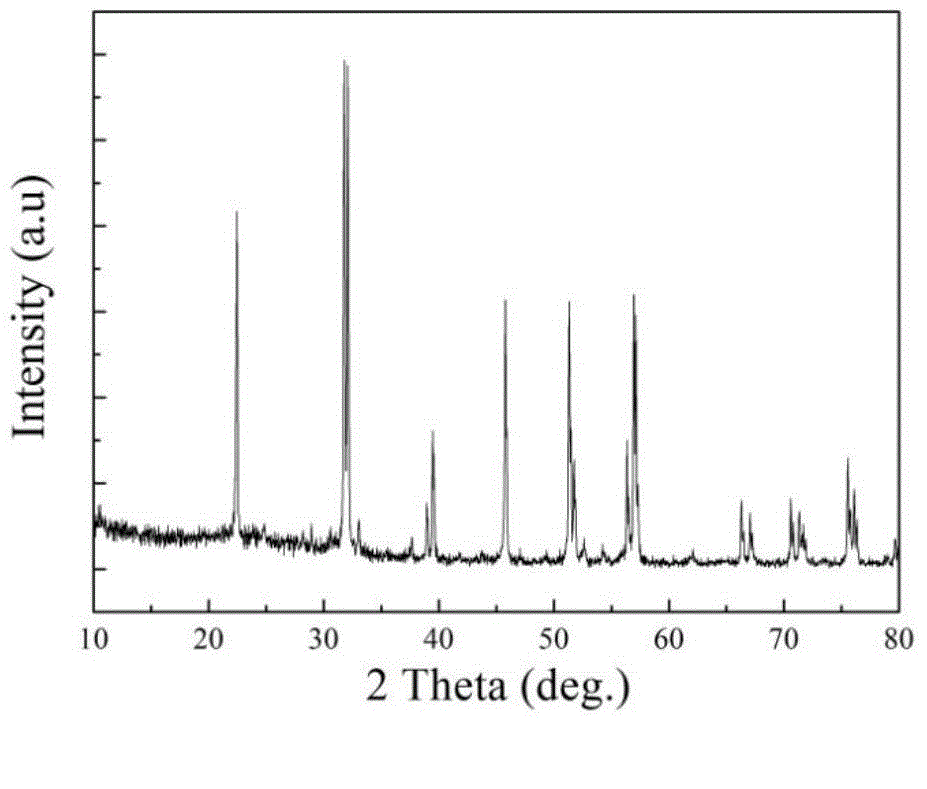

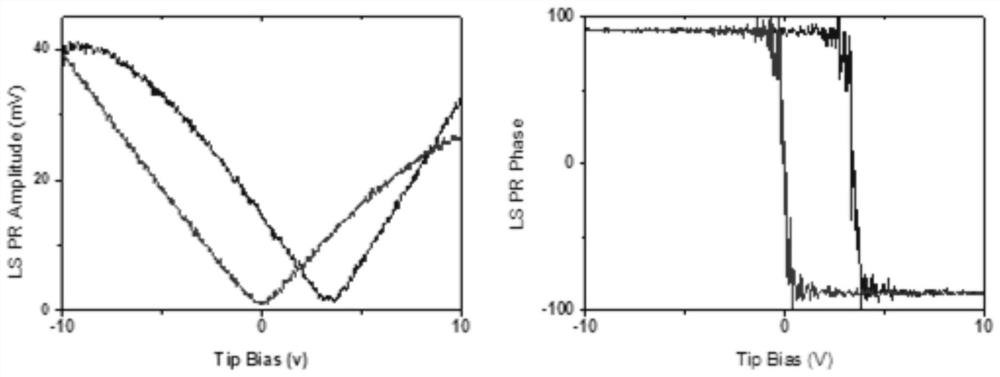

Preparation method of single pure-phase bismuth ferrite material based on ionic compensation

InactiveCN104961162ASolve technical problems of composition segregationReduce the ratioIron compoundsRoom temperatureIron oxide

The invention provides a preparation method of a single pure-phase bismuth ferrite material based on ionic compensation, which belongs to the field of ceramic material preparation. Firstly, a bismuth ferrite ceramic reaction mixture is prepared and then is dried for presintering for the first time; then 0.3 to 0.7wt percent of bismuth oxide is added through secondary ball milling for ionic compensation, and drying is performed for presintering for the second time; 0.2 to 0.4wt percent of bismuth oxide is added through third ball milling for ionic compensation, drying is performed for presintering for 0.5 to 1.5 h at 810 to 835 DEG C, and natural cooling is performed to room temperature along with a furnace, so as to obtain the single pure-phase bismuth ferrite material. According to the preparation method, the bismuth oxide and ferric oxide are used as raw materials, and three-step sintering and twice ionic compensation are adopted to prepare the single pure-phase bismuth ferrite material, so as to solve the technical problem of composition segregation caused by volatile bismuth oxide in the preparation process of bismuth ferrite and prepare the single pure-phase bismuth ferrite material.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Non-uniform curved surface fly-eye lens and preparation method thereof

ActiveCN112578484APrecisely control the radius of curvatureImprove machining accuracyLensOphthalmologyEye lens

The invention provides design of a non-uniform curved surface fly-eye lens and a preparation method of the same. The method comprises the steps of: setting sub-eyes, with different calibers and vectorheights, of all levels on the curved surface fly-eye lens, and acquiring different sub-eye focal lengths of all levels; enabling light to enter from the plane end of the curved surface fly-eye lens and exit from the curved surface end, wherein light at different angles passes through the optical center of the sub-eye, so that all light refraction focuses fall on the same plane; and taking the central sub-eye through which light enters in a manner of being perpendicular to the plane end of the curved surface fly-eye lens as a primary sub-eye. The non-uniform curved surface fly-eye lens is prepared by utilizing twice air pressure assistance and an ultraviolet curing process, the time is short, the efficiency is high, the repeatability is good, and the surface appearance is uniform.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Implant surface preparation

InactiveUS20080135521A1Uniform roughnessUniform surface topographyDental implantsDecorative surface effectsTitaniumOxygen

The surface of a device that is surgically implantable in living bone is prepared. The device is made of titanium with a native oxide layer on the surface. The method of preparation comprises the steps of removing the native oxide layer from the surface of the device and performing further treatment of the surface substantially in the absence of unreacted oxygen.

Owner:BIOMET 3I LLC

Implant surface preparation

InactiveUS20070108162A1Increase processEnhanced bondingDental implantsImpression capsImplant surfaceTitanium

The surface of a device that is surgically implantable in living bone is prepared. The device is made of titanium with a native oxide layer on the surface. The method of preparation comprises the steps of removing the native oxide layer from the surface of the device and performing further treatment of the surface substantially in the absence of unreacted oxygen.

Owner:BIOMET 3I LLC

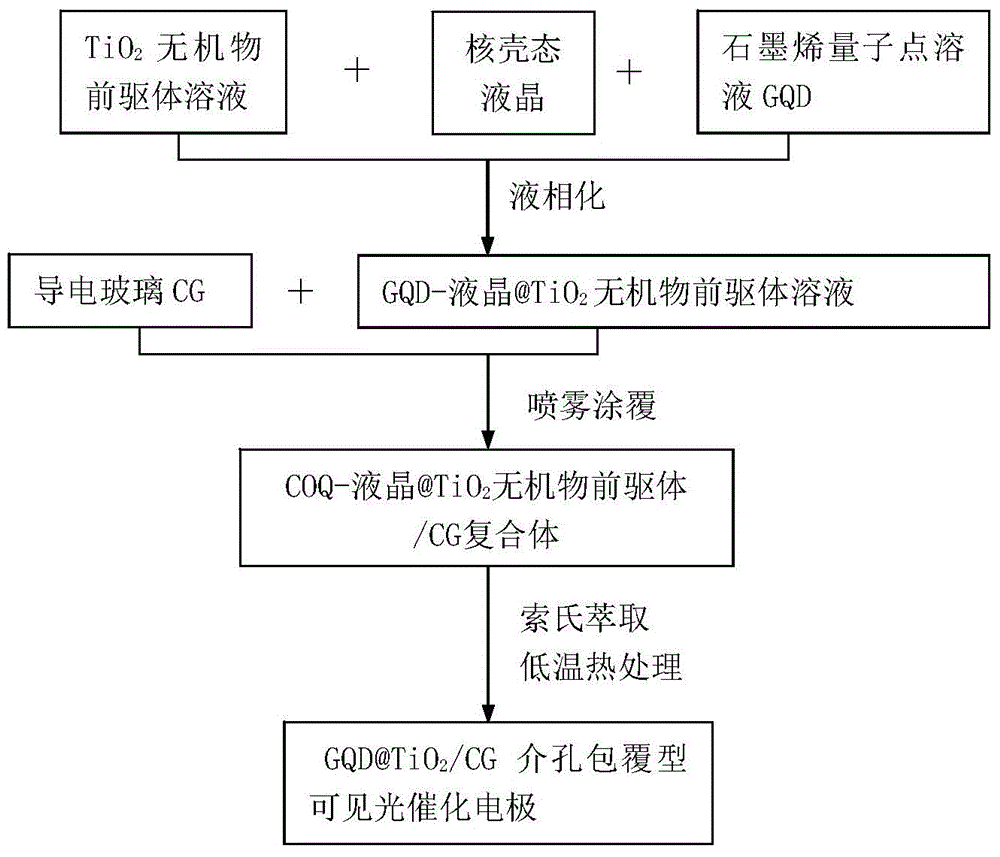

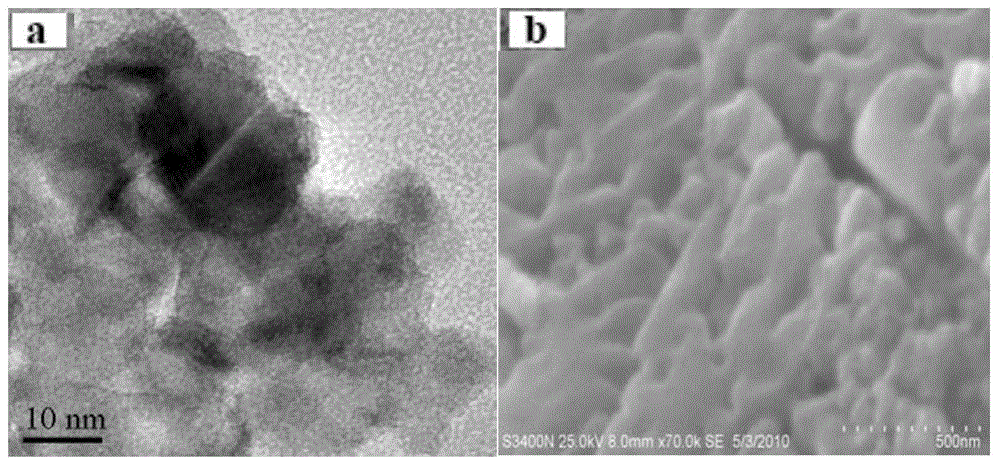

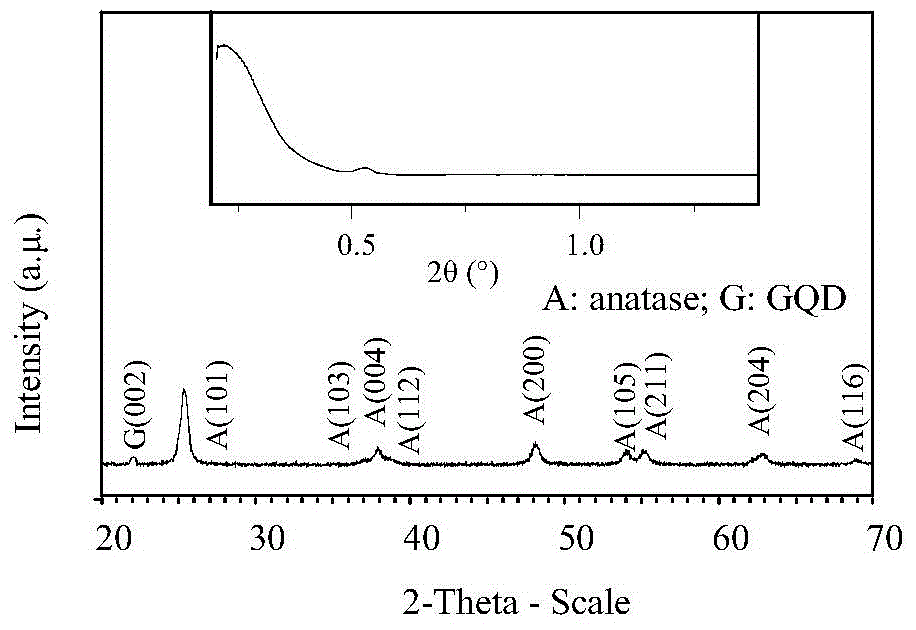

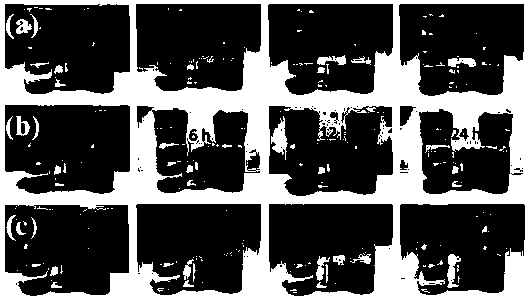

GQD (graphene quantum dot) sensitized mesoporous Ti coated type GQD@TiO2/CG (conductive glass) visible light catalytic electrode and preparation technology thereof

ActiveCN104549187ALarge specific surface areaHas a mesoporous coating structurePhysical/chemical process catalystsWater/sewage treatment by irradiationIn situ polymerizationSpray coating

The invention relates to a GQD (graphene quantum dot) sensitized mesoporous Ti coated type GQD@TiO2 / CG (conductive glass) visible light catalytic electrode and a preparation technology thereof. A core-shell liquid crystal synthesized with an in situ polymerization technology is adopted as a template to prepare the visible light catalytic GQD@TiO2 / CG electrode through spray deposition, Soxhlet extraction and low-temperature heat treatment. The method has the outstanding characteristics as follows: the GQD sensitized mesoporous Ti coated type GQD@TiO2 / CG with a novel structure and visible light catalytic capacity is prepared with a spray coating technology and a core-shell liquid crystal template method, and a new approach is provided for application research of porous material supported mesoporous doped TiO2 photocatalytic materials. The process is simple, industrial production is easy, and the prepared efficient gas diffusion photoelectrode mesoporous material supported composite nanomaterial has high electrical conductivity, large specific surface area and uniform pore size distribution.

Owner:JISHOU UNIVERSITY

Ion-selectivity composite membrane as well as preparation method and application thereof

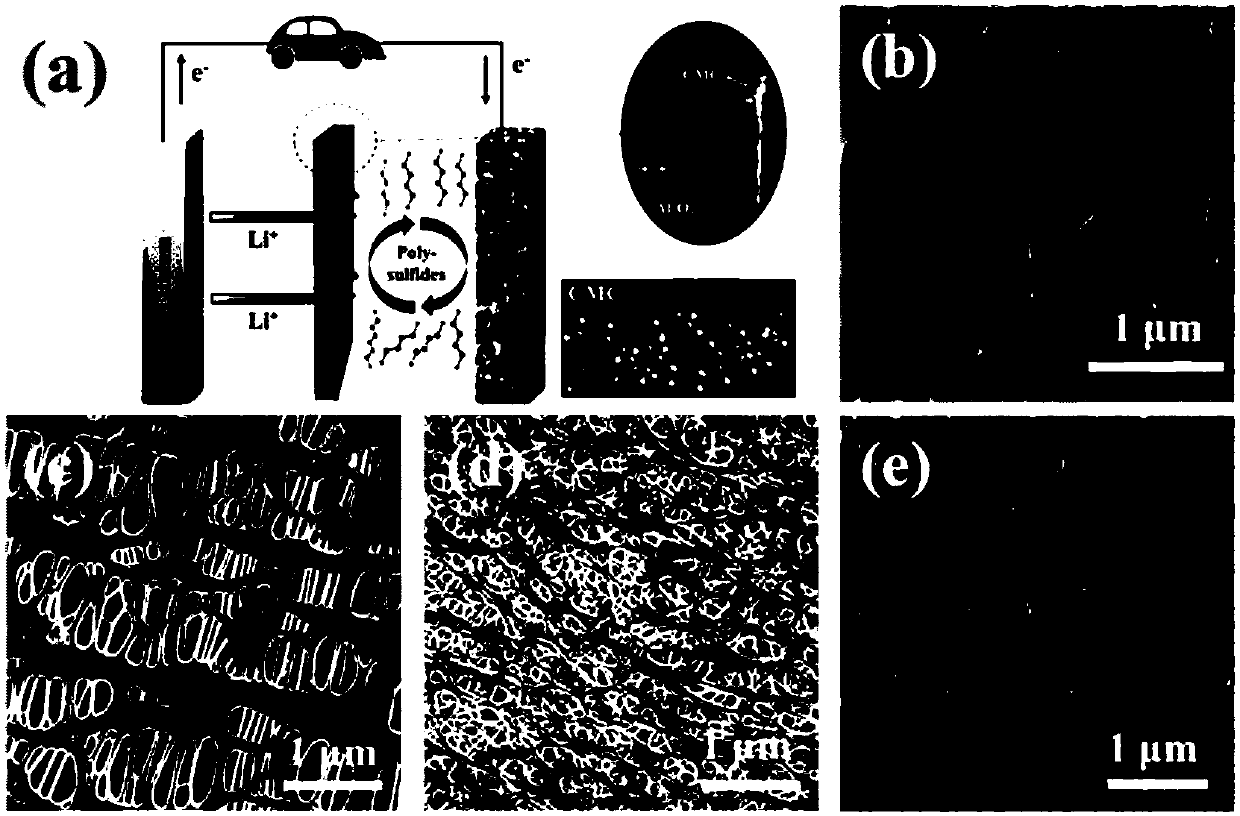

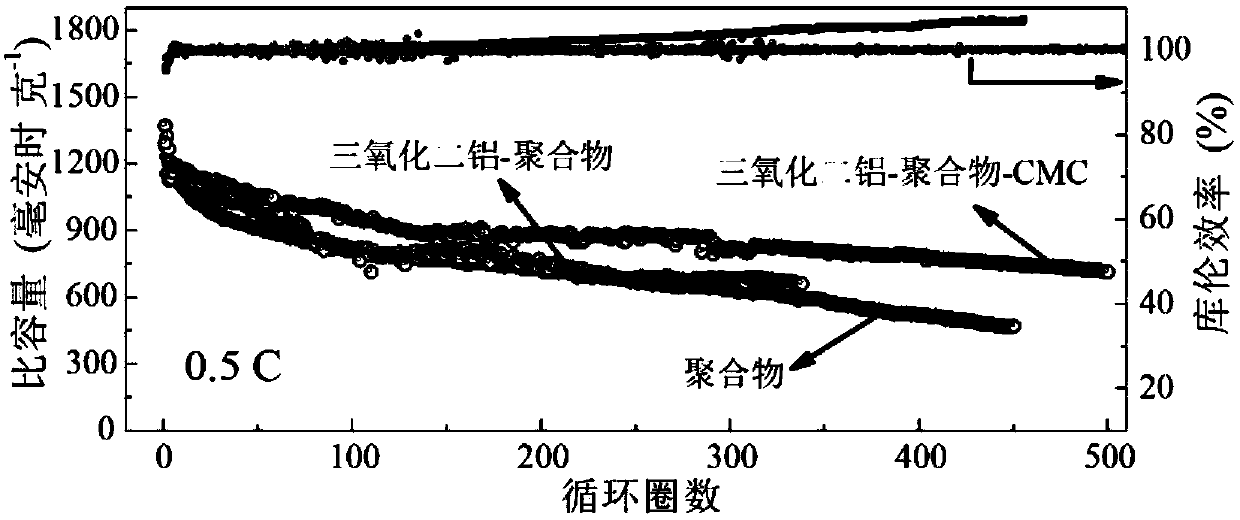

ActiveCN109599524AShorten migration distanceInhibit migrationSecondary cellsCell component detailsCarboxymethyl celluloseCeramic coating

The invention discloses an ion-selectivity composite membrane. The ion-selectivity composite membrane comprises a polymer porous layer, a sodium carboxymethyl cellulose coating and an inorganic ceramic coating, wherein the sodium carboxymethyl cellulose coating and the inorganic ceramic coating are separately coated on the two sides of the polymer porous layer. The invention also provides a preparation method of the ion-selectivity composite membrane and application of the ion-selectivity composite membrane to lithium batteries. According to the ion-selectivity composite membrane disclosed bythe invention, shuttling of polysulfide ions and production of lithium dendrite can be effectively inhibited.

Owner:SUZHOU DISIFU NEW ENERGY TECH CO LTD

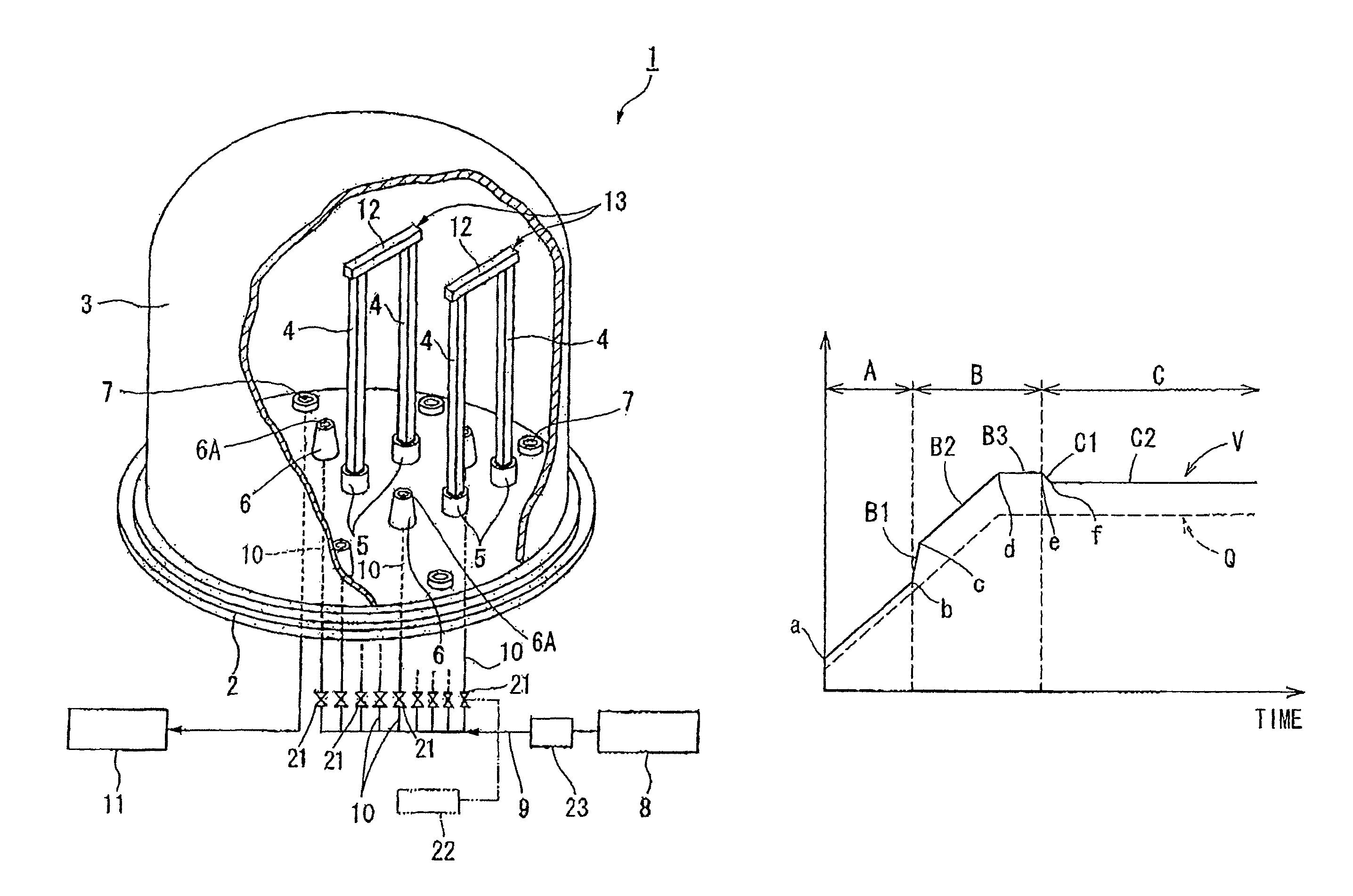

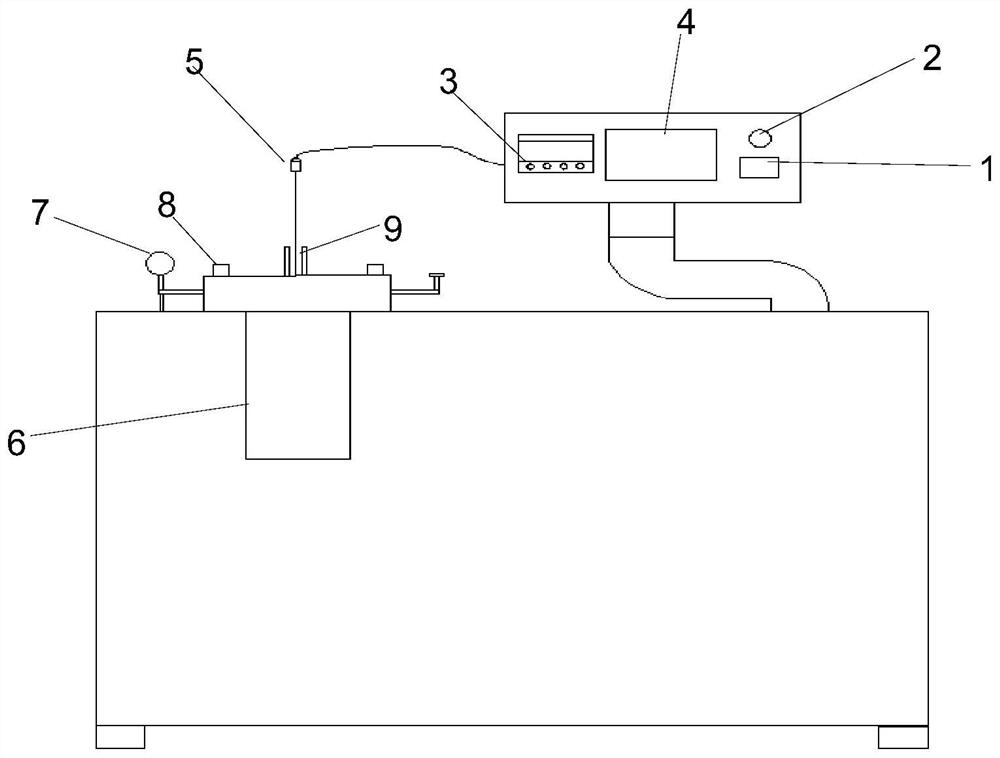

Method for manufacturing polycrystalline silicon

ActiveUS8043660B2Uniform surface topographyEfficient growth processVacuum evaporation coatingSputtering coatingRough surfacePolycrystalline silicon

A method for manufacturing polycrystalline silicon with high quality by effectively preventing undesired shape such as giving an rough surface to silicon rods or an irregularity in diameter of the silicon rods. The method for manufacturing polycrystalline silicon includes: an initial stabilizing step of deposition wherein a velocity of ejecting the raw material gas from the gas ejection ports is gradually increased; the shaping step wherein first the ejection velocity is increased at a rate higher than that in the stabilizing step and then the ejection velocity is gradually increased at a rate lower than the previous increasing rate; and a growing step wherein, after the shaping step, the ejection velocity is made slower than that at the end of the shaping step until the end of the deposition.

Owner:HIGH-PURITY SILICON CORP

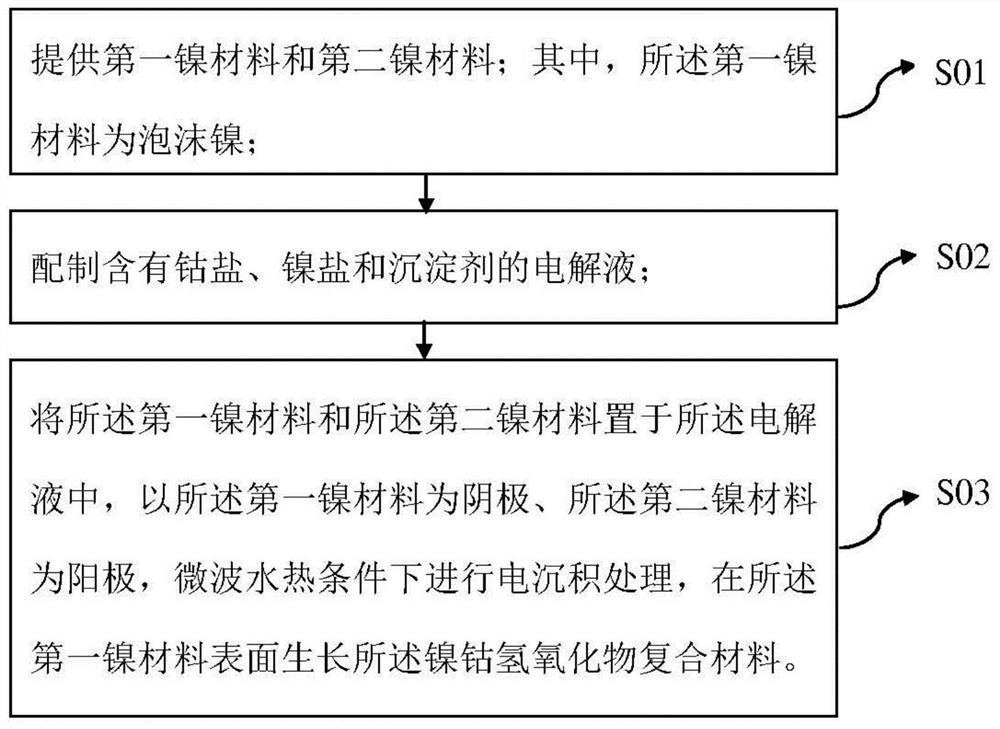

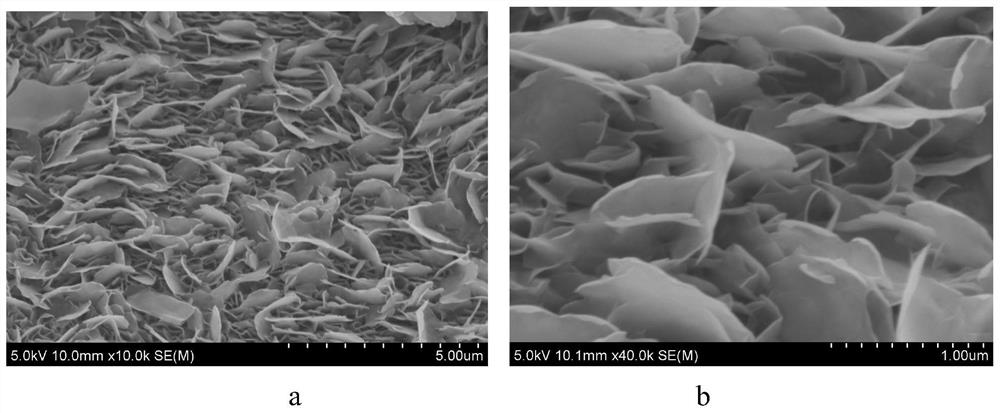

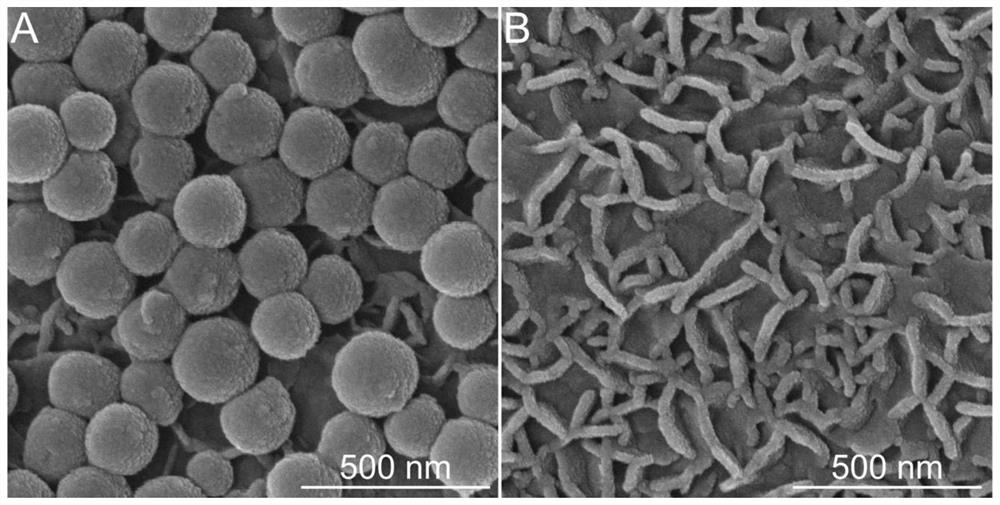

Nickel-cobalt hydroxide composite material, preparation method thereof and supercapacitor

ActiveCN112820554AUniform surface topographySimple structureHybrid capacitor electrodesHybrid/EDL manufactureGalvanic depositionComposite material

The invention belongs to the technical field of nano materials, and particularly relates to a nickel-cobalt hydroxide composite material, and a preparation method thereof and a supercapacitor. The preparation method of the nickel-cobalt hydroxide composite material comprises the following steps: providing a first nickel material and a second nickel material, wherein the first nickel material is foamed nickel; preparing an electrolyte containing cobalt salt, nickel salt and a precipitator; and placing the first nickel material and the second nickel material in the electrolyte, wherein the first nickel material serves as a cathode, the second nickel material serves as an anode, electro-deposition treatment is carried out under the microwave hydrothermal condition, and the nickel-cobalt hydroxide composite material grows on the surface of the first nickel material. The preparation method is accurate and stable in reaction condition, and the prepared nickel-cobalt hydroxide composite material is uniform in surface appearance and rich in structure and has good specific capacitance and cycle performance when being used as an electrode material, so that the nickel-cobalt hydroxide composite material has good application prospects in supercapacitors.

Owner:SHENZHEN UNIV

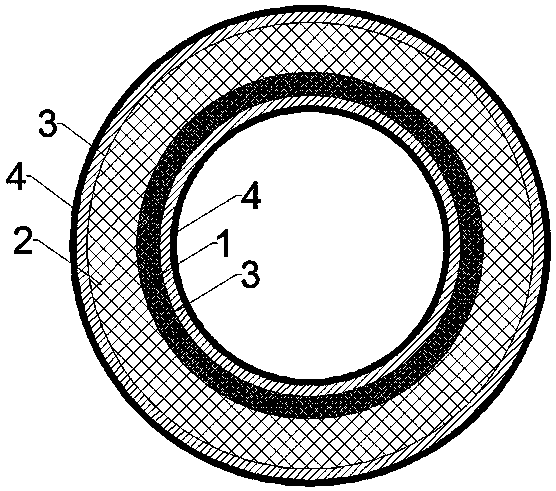

Anti-corrosion silicon core pipe

InactiveCN109655983AGood antibacterial effectGood hygroscopicityFibre mechanical structuresFiberMoisture absorption

The invention relates to an anti-corrosion silicon core pipe, which comprises an inner layer and an outer layer. The outer surface of the outer layer and the inner surface of the inner layer are provided with anti-corrosion protective layers respectively. Each anti-corrosion protective layer comprises 74.5-80wt% of high density polyethylene, 7-15wt% of activated carbon fibers, 6-15wt% of antibacterial microcapsules and 2-3.5wt% of a dispersing agent. The silicon core pipe is provided with the anti-corrosion protective layers which are provided with the antibacterial microcapsules with garlic essential oil or mustard essential oil serving as a core material. The garlic essential oil or mustard essential oil has great antibacterial effects and is capable of effectively inhibiting growth of microorganisms such as mildew to protect the silicon core pipe; further, the garlic essential oil or mustard essential oil has certain irritation, so that probability that small animals bite the pipe can be lowered; in addition, the anti-corrosion protective layers are further provided with magnesium sulfate solution loaded activated carbon fibers with great moisture absorption performance, so thatsurroundings of the silicon core pipe can be kept dry, a growth environment of the microorganisms such as mildew is destroyed, growth of the microorganisms such as mildew is reduced, and the siliconcore pipe is protected from being corroded by the microorganisms.

Owner:JIANGSU NOBEL PLASTICS CO LTD

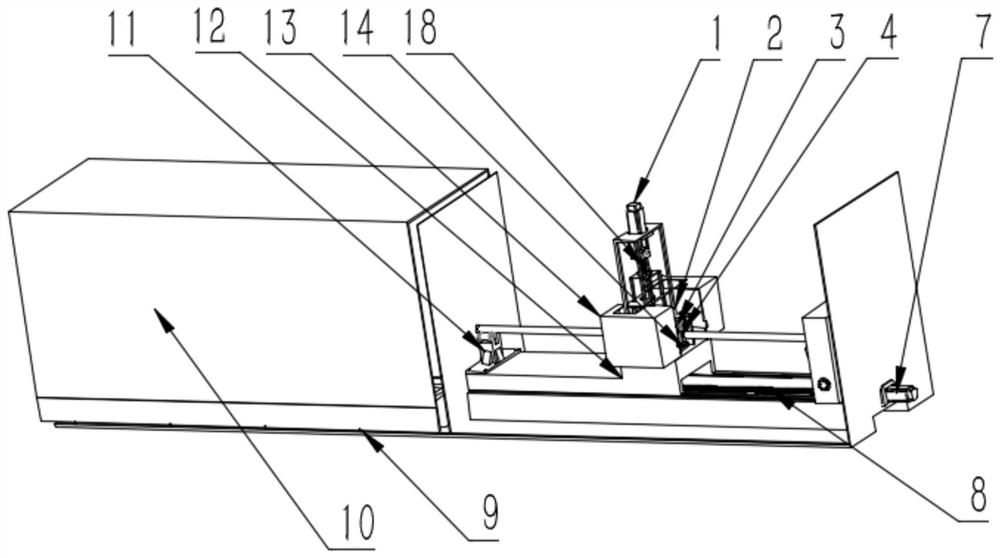

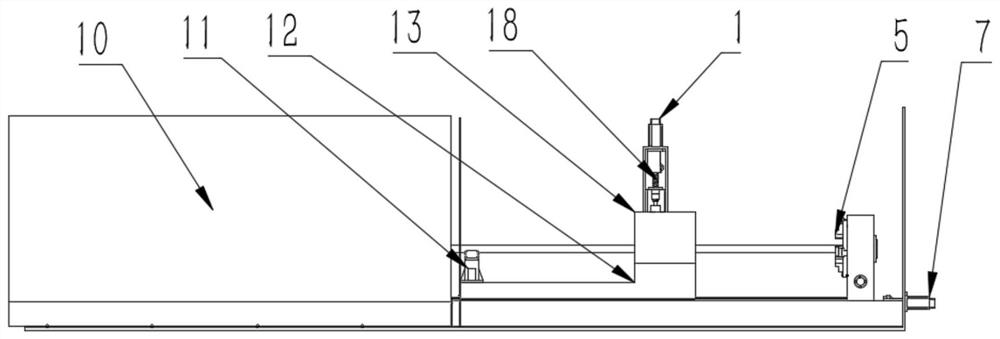

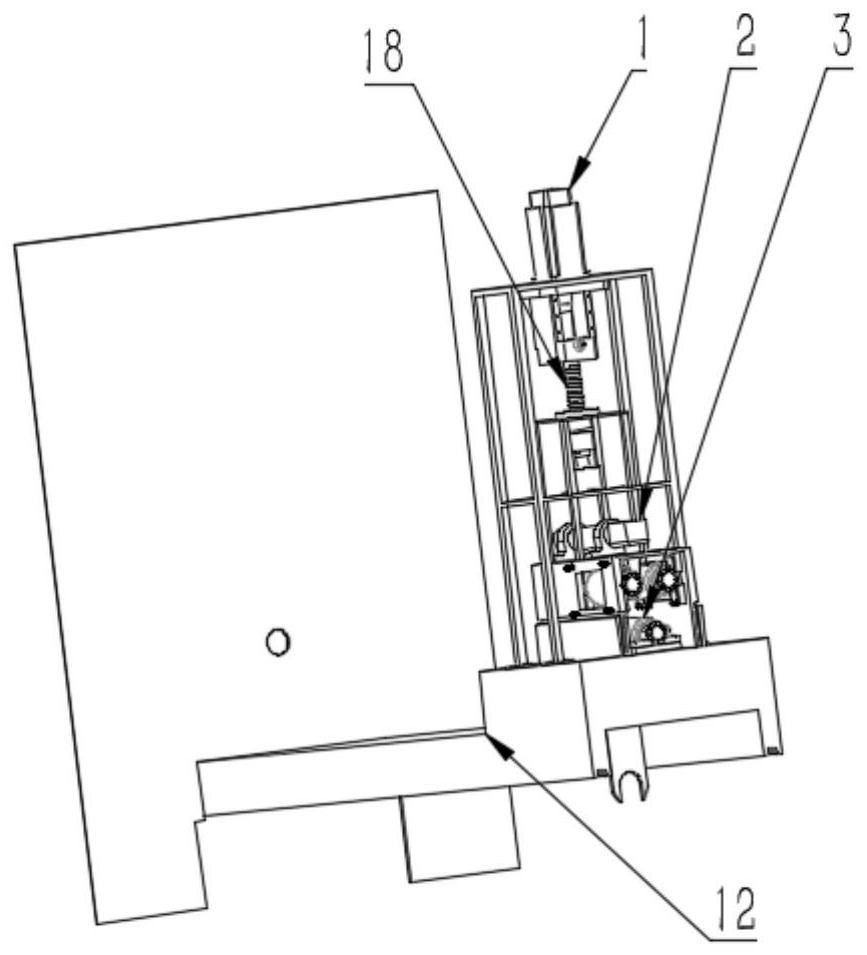

Device for forming bimetal composite pipe by spinning semisolid metal powder on outer wall of steel pipe

ActiveCN112077322AUniform spinningImprove spinning efficiencyAdditive manufacturing apparatusLiquid surface applicatorsSpinningSemi solid

The invention relates to a device for forming a bimetal composite pipe by spinning semisolid metal powder on the outer wall of a steel pipe. The device comprises a feeding device, a clamping device, spinning rollers, a hot melting head, a motor, a lifting device, a workbench, a buffer bearing pack, a tailstock supporting device and a heat preservation device. By adopting the three spinning rollers, the spinning efficiency is improved, meanwhile, uniform stress is guaranteed, and semisolid powder is uniformly spun on the outer wall of a metal pipe. The spinning rollers are designed to be taper,so that the forming resistance of a spinning device in the axial moving process can be effectively reduced, and it is guaranteed that the outer wall of the steel pipe is evenly covered with semisolidpowder. The lifting device is additionally arranged and can be adjusted according to different pipe diameters so as to machine different metal pipes. A spring is additionally arranged at the bottom of a first bearing seat, so that rigid impact between the steel pipe and the spinning rollers in the spinning process is avoided and reduced, and the surface appearance and the structure uniformity ofa spinning layer are guaranteed. In addition, the device is driven by the motor, and a lead screw is used for driving a frame to axially horizontally move at constant speed.

Owner:沧州赛腾管道工程有限公司

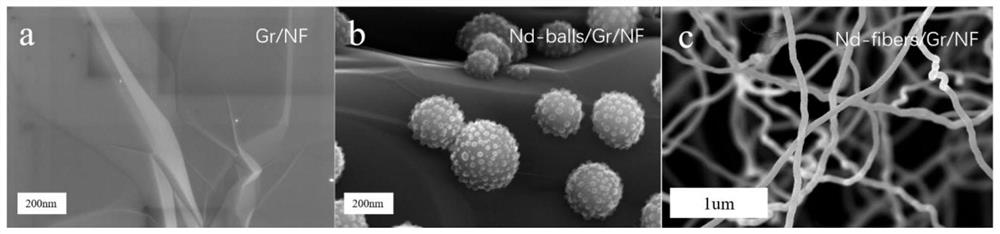

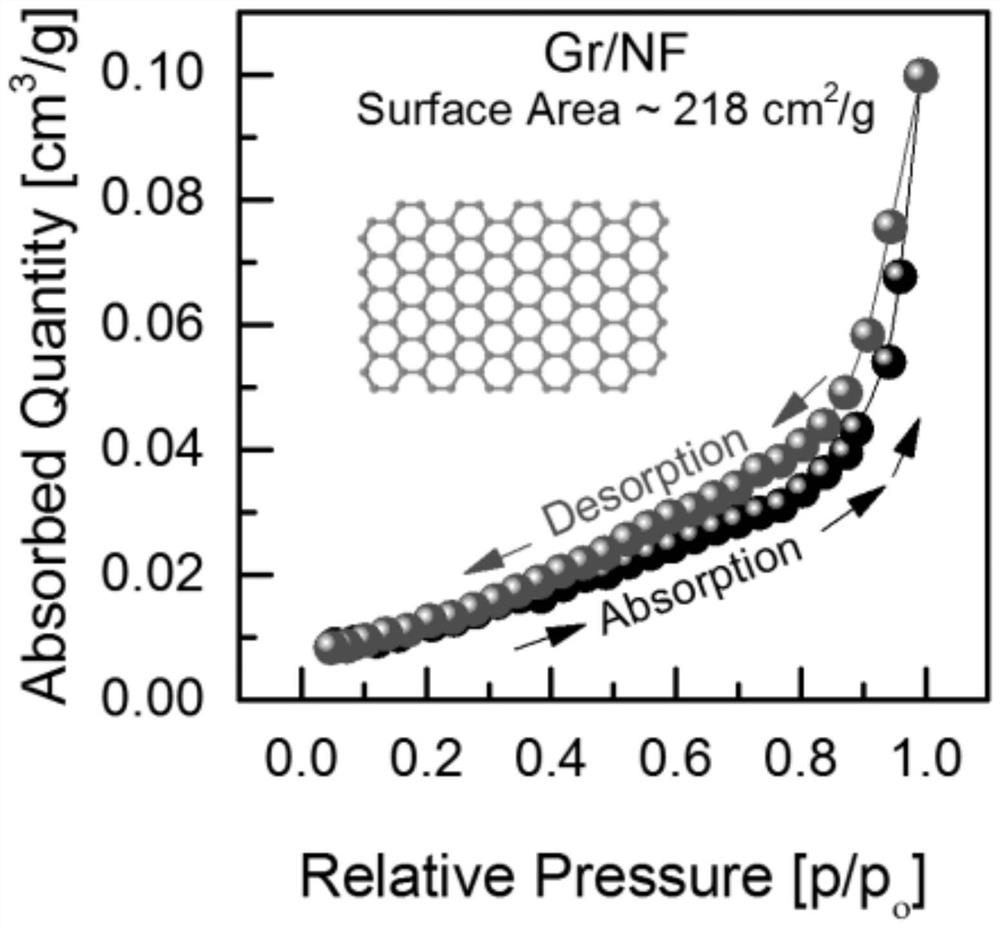

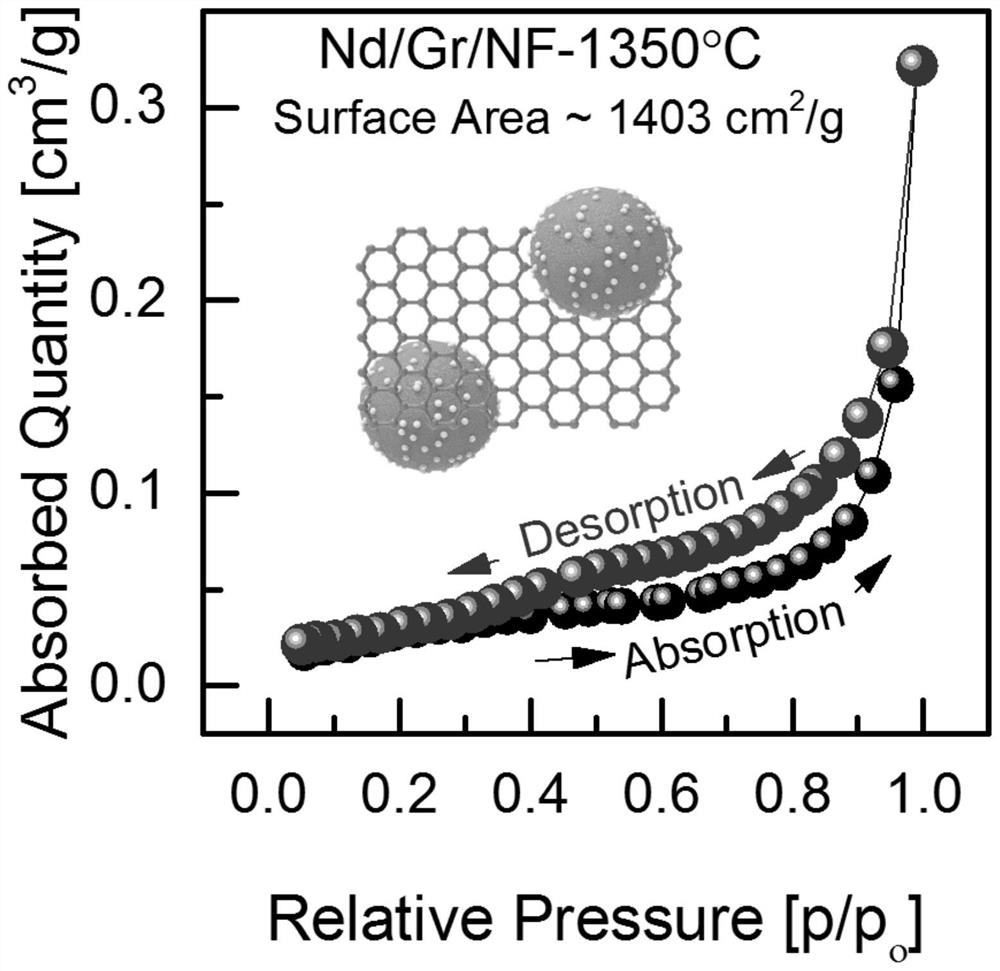

Nd-graphene composite material and preparation method and application thereof

ActiveCN113046720AAvoid stackingFully spreadCell electrodesGrapheneRare-earth elementChemical vapor deposition

The invention provides an Nd-graphene composite material and a preparation method and application thereof. The preparation method of the composite material comprises the following steps that S1, graphene is grown on the surface of a foamed nickel substrate by using a chemical vapor deposition method to obtain a graphene foamed nickel material; and S2, an Nd elementary substance is prepared on the graphene surface of the graphene foamed nickel material to obtain the Nd-graphene composite material. According to the preparation method, the foamed nickel is adopted as the substrate, the foamed nickel is a conductive 3D porous material which is low in cost and good in performance, the foamed nickel can play a role in a framework when being used as the substrate, graphene stacking can be avoided through the foamed nickel, and graphene can be fully spread; and meanwhile, neodymium in neodymium fluoride is a rare earth element, and due to the unique property of neodymium 4f electrons, the neodymium fluoride is combined with an electrocatalyst, so that the electrochemical catalysis efficiency of hydrogen evolution reaction, oxygen evolution reaction, oxygen reduction reaction and the like is remarkably improved. The material prepared by the invention has a self-supporting structure, and no binder is needed in use.

Owner:JIANGXI UNIV OF SCI & TECH +1

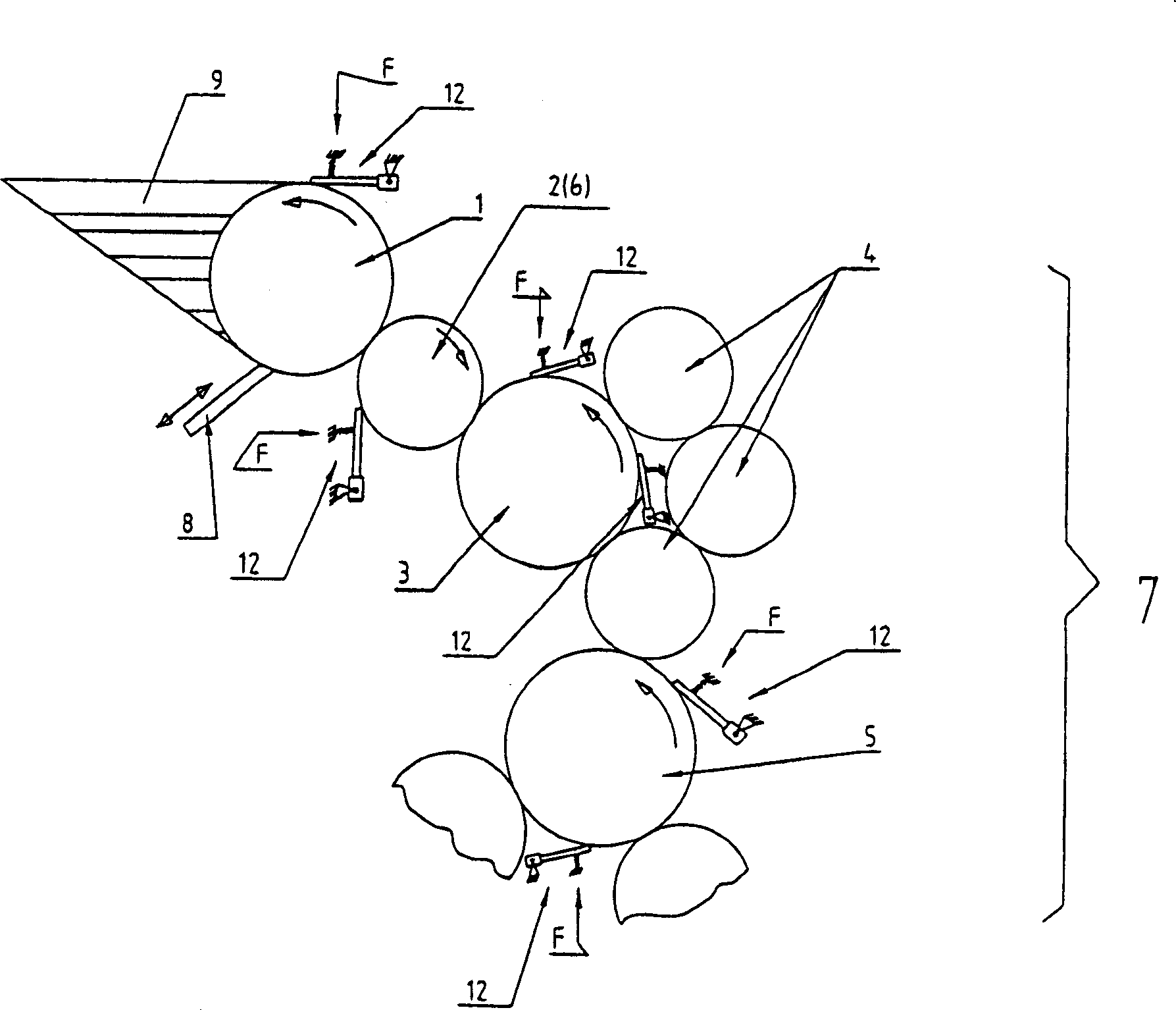

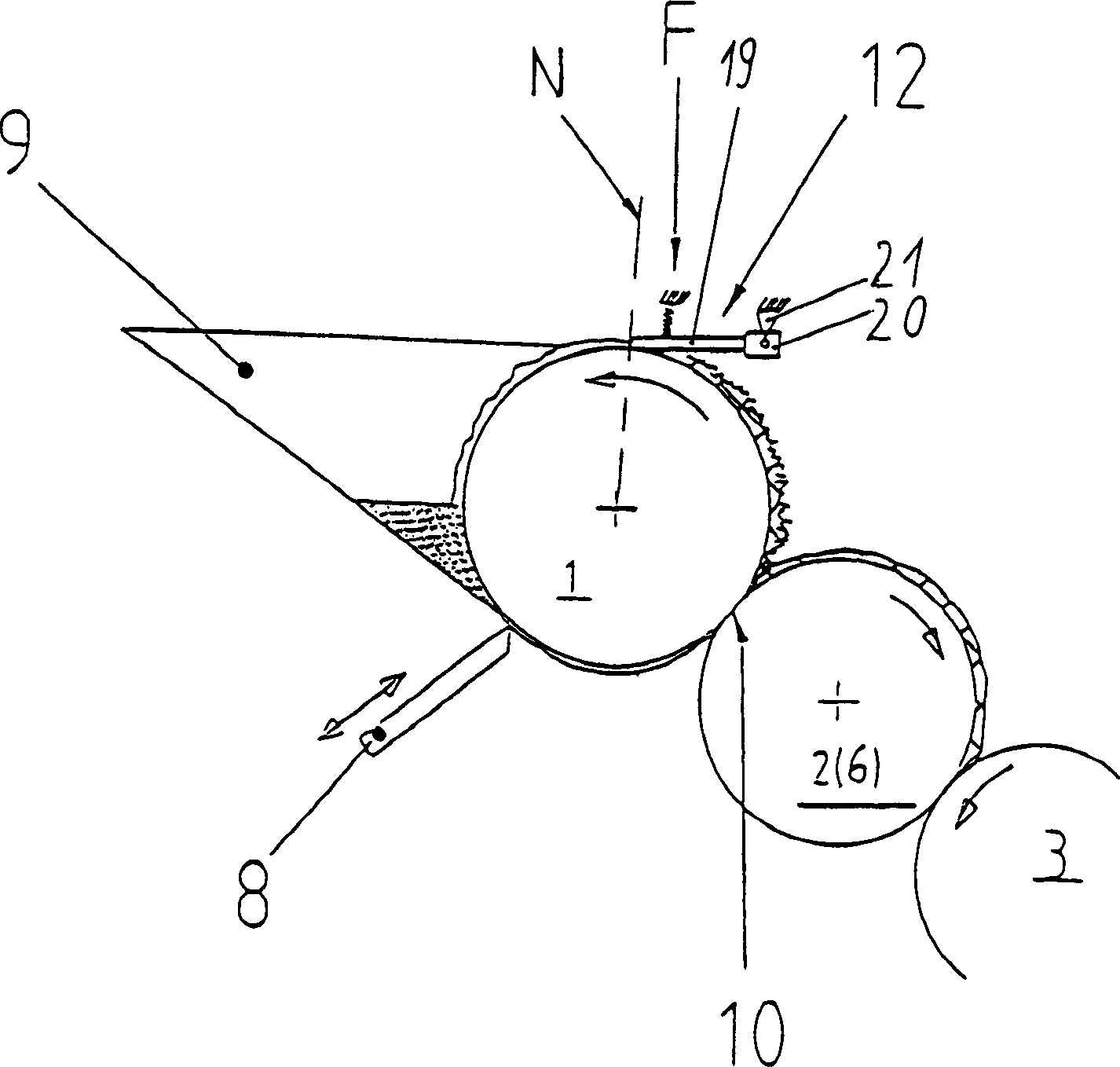

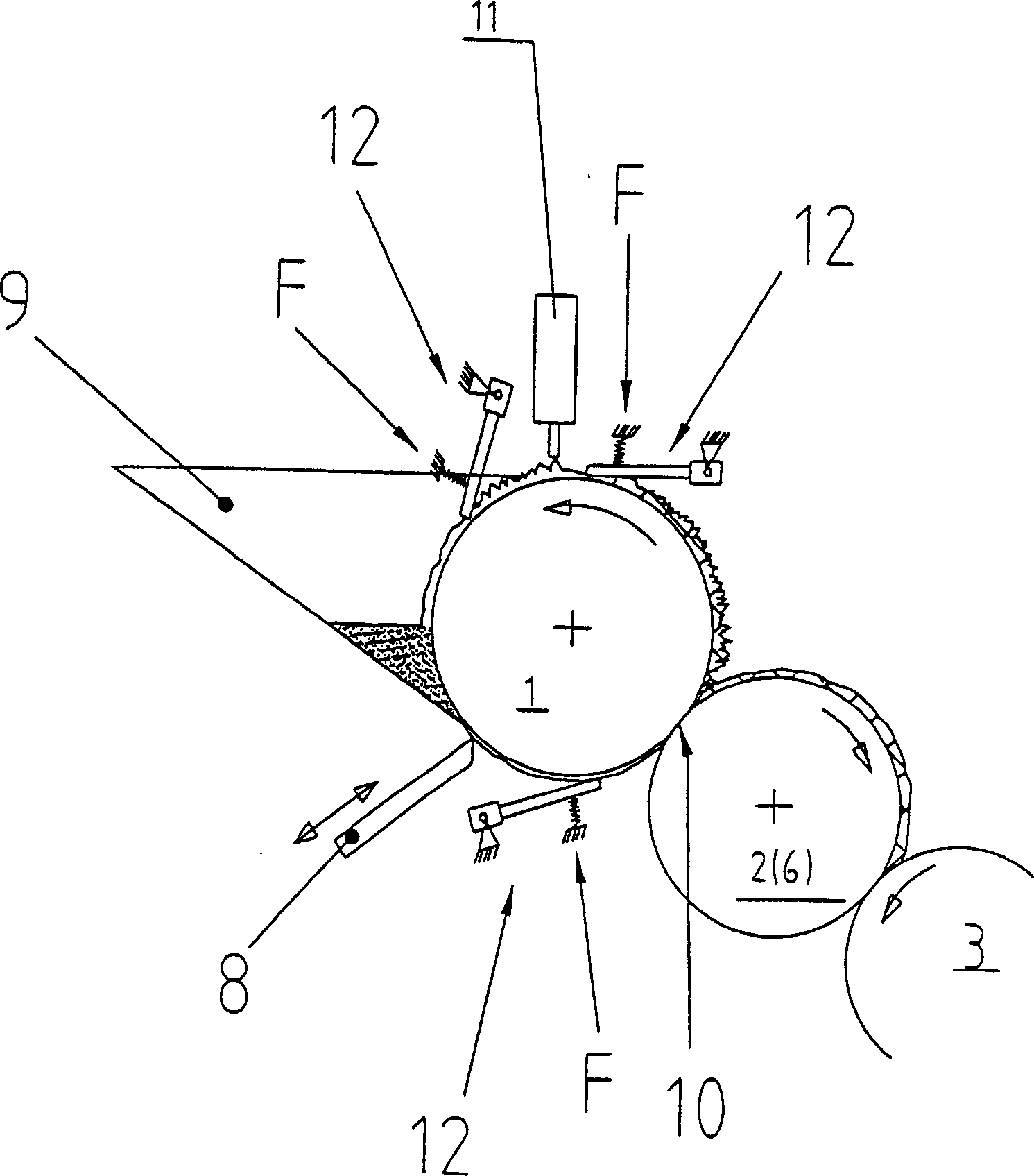

Dosing system for inking up rollers in printing machine

InactiveCN1426353AThe change in density is reducedQuality improvementPrinting press partsEngineeringPrinting press

The invention relates to a dosing system for inking up rollers in a printing machine. The aim of the invention is to create a dosing system which achieves, with a low level of complexity, a uniform and steady ink guidance on a roller surface and which noticeably improves the printing quality. To these ends, the invention provides that a coating device (12) is, in the rotational direction of a roller, engageably arranged on the outer surface of the roller (1), preferably after a contact zone (10) in which an ink separation occurs.

Owner:MAN ROLAND MASCHINEN AG

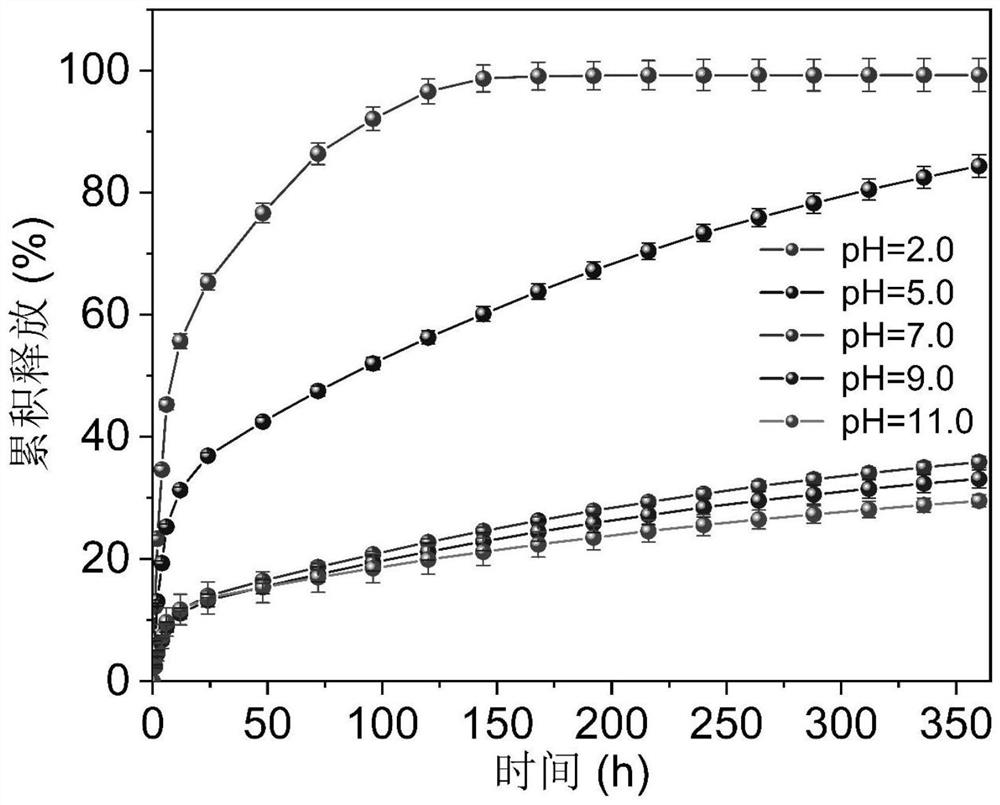

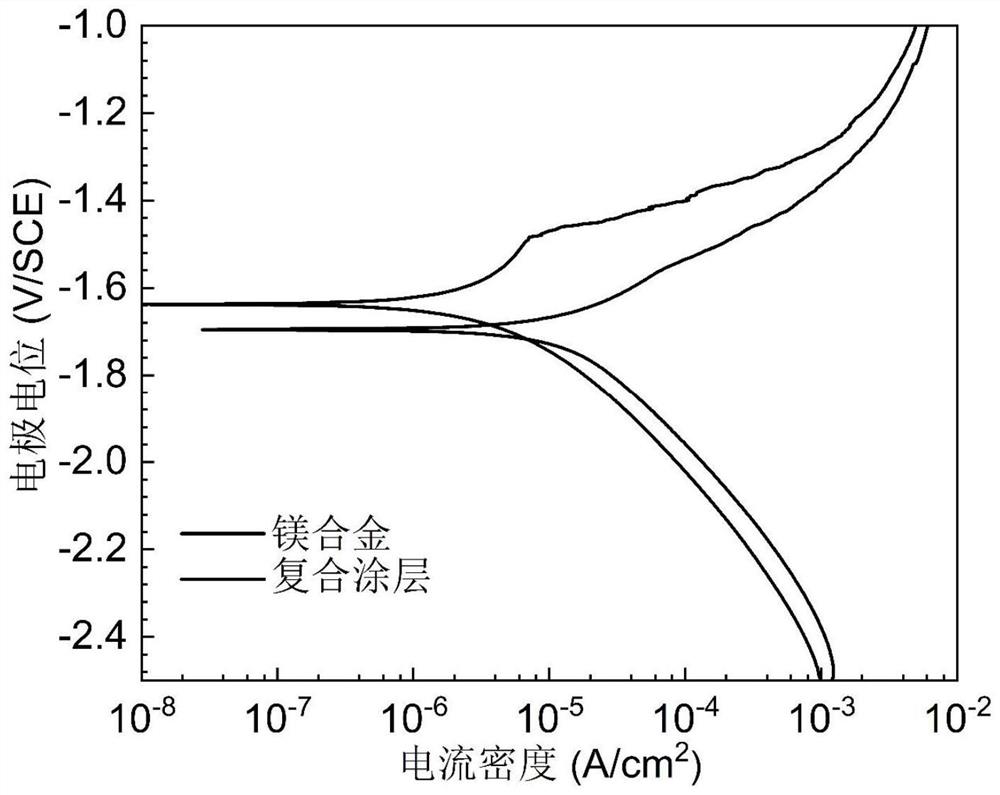

Preparation method of degradable orthopedic implant material capable of dual self-healing and controllable drug release

ActiveCN114504676APromotes self-healingExcellent corrosion protectionTissue regenerationCoatingsORTHOPEDIC IMPLANT MATERIALMg alloys

The invention discloses a preparation method of a degradable orthopedic implant material capable of dual self-healing and controllable drug release. According to the material, hyaluronic acid and polyethyleneimine intrinsic self-healing polymer coatings are assembled on the surface of magnesium alloy layer by layer, mesoporous silica nanoparticles serve as a carrier nano platform of the coating composite stimulation-responsive drug-loaded nanocapsule, a small molecule corrosion inhibitor paeonol can be embedded, and the outermost layer is coated with polydopamine macromolecules. The orthopedic implant material has good functions of self-healing, corrosion protection, drug controlled release and the like at the same time. A coating on the surface of the magnesium alloy implant material is uniform, compact and high in binding force. The drug-loading nanocapsule is high in drug loading capacity, and drug release kinetics can be regulated and controlled.

Owner:SOUTHEAST UNIV

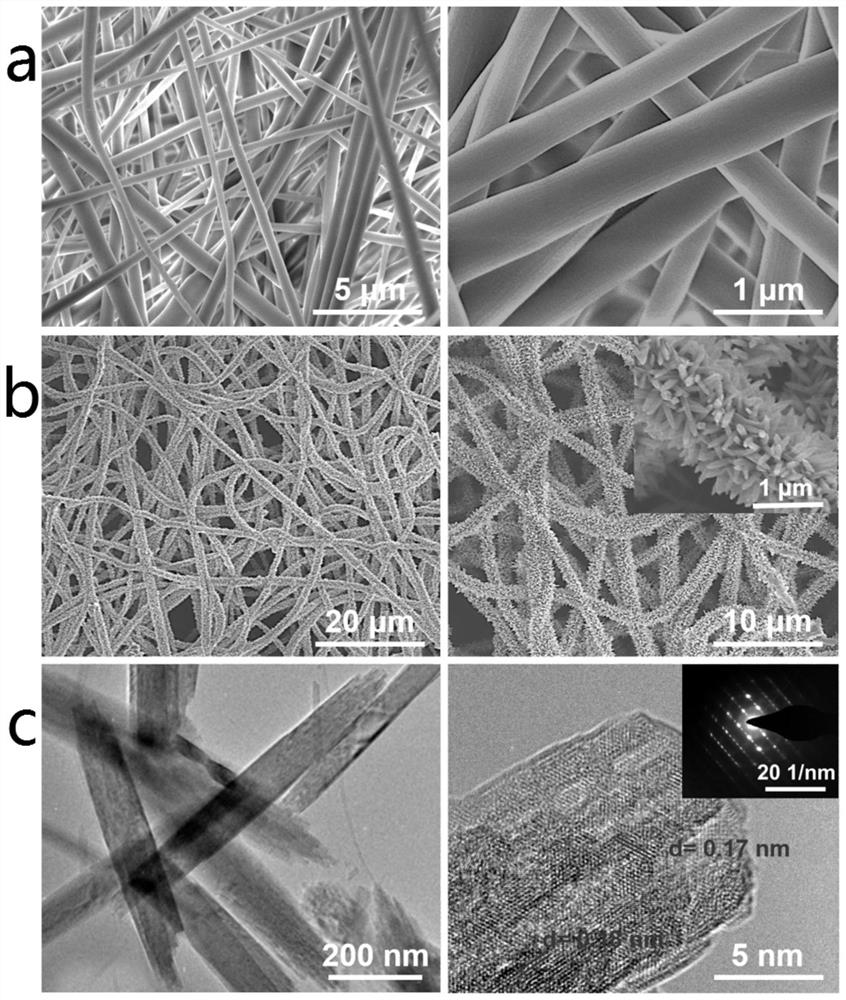

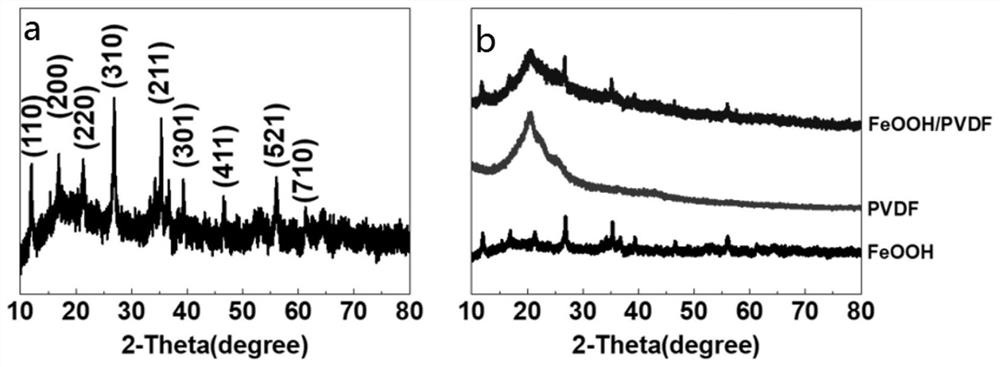

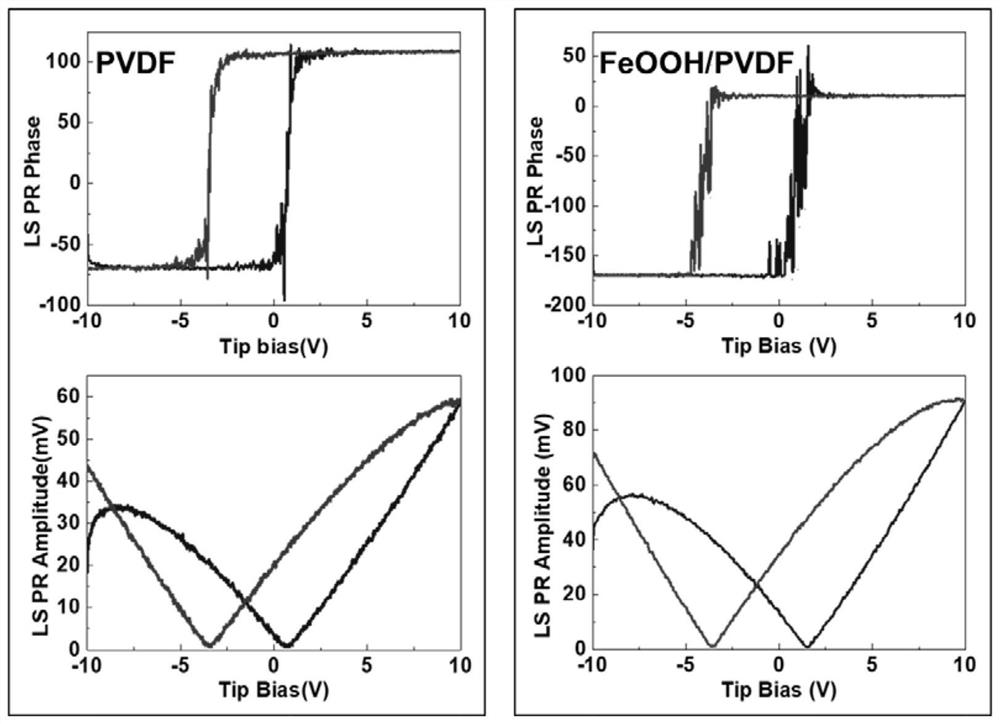

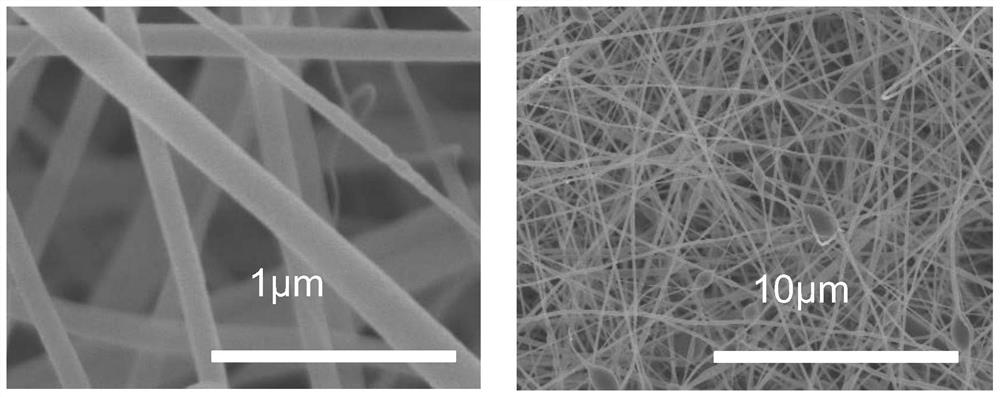

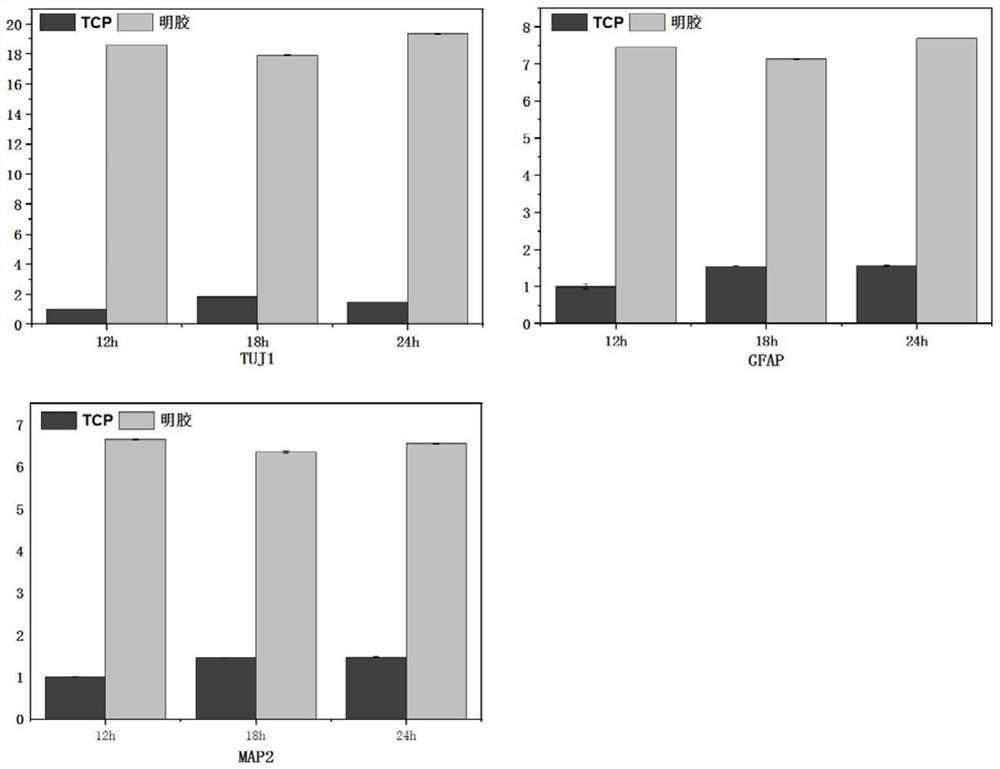

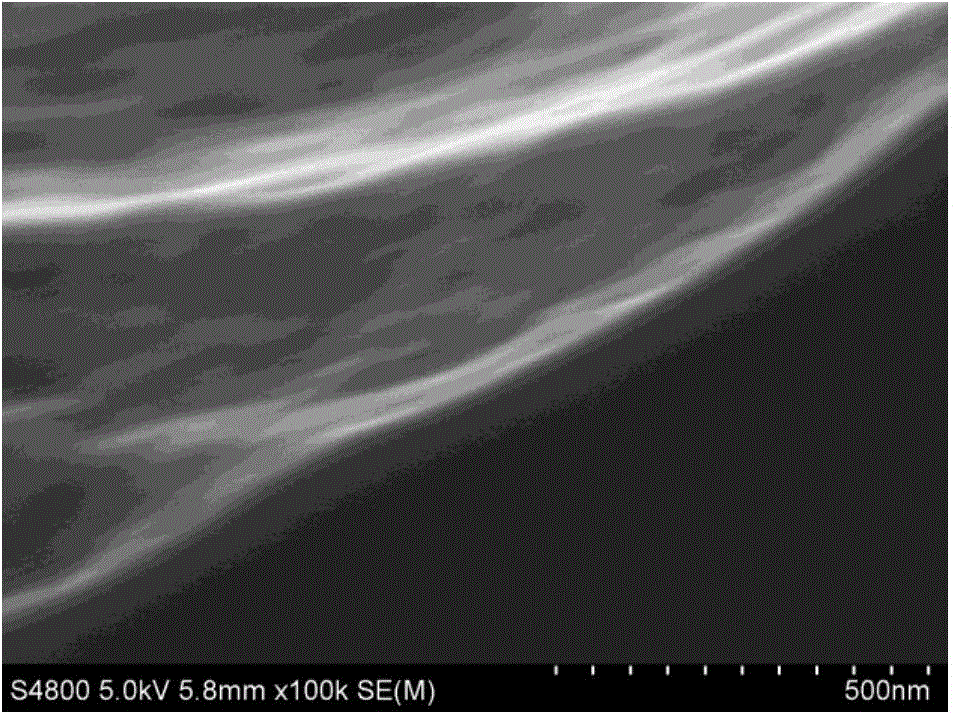

FeOOH/PVDF (Polyvinylidene Fluoride) fiber scaffold as well as preparation method and application thereof

ActiveCN113373595AGood biocompatibilityLarge specific surface areaCulture processElectro-spinningFiberNerve cells

The invention provides a preparation method of a FeOOH / PVDF (Polyvinylidene Fluoride) fiber scaffold. The preparation method of the FeOOH / PVDF fiber scaffold comprises the following steps of dissolving PVDF powder in a mixed solvent of acetone and N, N-dimethylformamide to prepare a PVDF solution, then carrying out electrostatic spinning to obtain a fiber membrane, and then drying to obtain a PVDF fiber membrane; and transferring a mixed solution of ferric chloride hexahydrate and sodium nitrate and the PVDF fiber membrane into a reaction kettle for hydrothermal reaction, and washing and drying a product to obtain the FeOOH / PVDF fiber scaffold. The FeOOH in the FeOOH / PVDF fiber scaffold obtained by the preparation method is rod-shaped, the length is about 800 to 900 nm, the width is about 100 nm, and the crystal form is beta form; and the FeOOH is loaded on the surface of the PVDF fiber. The FeOOH / PVDF fiber scaffold can be used as a medical material for inducing mesenchymal stem cells to differentiate into nerve cells. According to the FeOOH / PVDF fiber scaffold as well as the preparation method and the application thereof provided by the invention, the FeOOH / PVDF fiber membrane is designed and prepared by utilizing an electrostatic spinning technology and a hydrothermal reaction process, the preparation method is simple, and reaction conditions are easy to realize; and the obtained scaffold is uniform in surface appearance, has good piezoelectricity, and can induce rBMSCs neural differentiation in a wireless stimulation mode.

Owner:UNIV OF JINAN

Preparation method of degradable piezoelectric fiber stent and product thereof

ActiveCN113413488AGood biocompatibilityUniform surface topographyElectro-spinningTissue regenerationElectrospinningNeural tissue engineering

The invention belongs to the technical field of medical material preparation, and provides a preparation method of a degradable piezoelectric fiber stent and a product thereof. The preparation method of the degradable piezoelectric fiber stent comprises the following steps: preparing a gelatin solution, performing electrostatic spinning to prepare a fiber membrane, and drying to obtain a gelatin fiber membrane; placing the gelatin fiber membrane in glutaraldehyde saturated steam for normal-temperature crosslinking, and drying to obtain the degradable piezoelectric fiber stent. The preparation method provided by the invention adopts electrostatic spinning and chemical crosslinking modes for preparation, the method is simple, and reaction conditions are easy to realize. The prepared degradable piezoelectric fiber membrane stent can induce neural differentiation of neural stem cells in a wireless stimulation mode, and has important significance in clinical and nervous tissue engineering.

Owner:UNIV OF JINAN

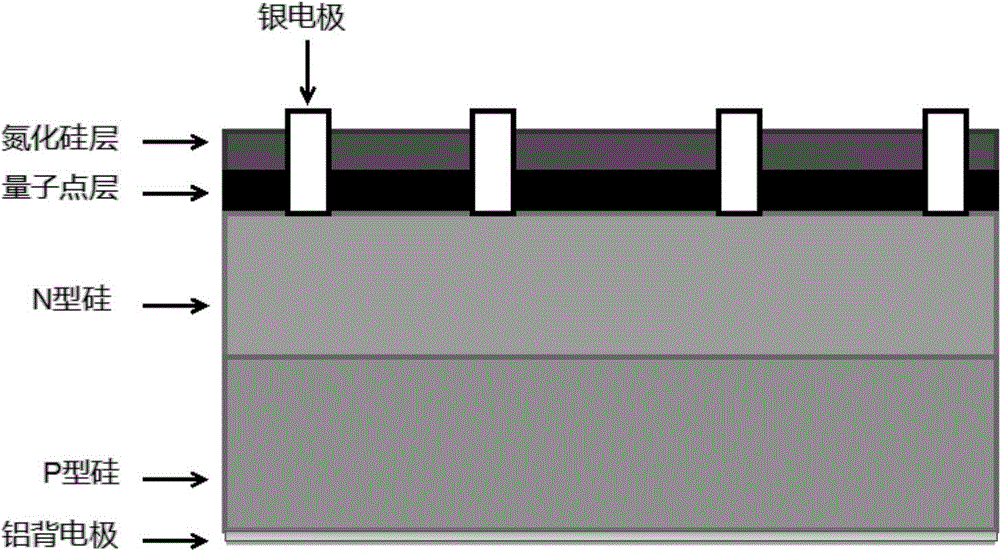

Preparation method of QDs/Si heterojunction composite crystalline silicon wafer having high quantum efficiency

InactiveCN104600154AUniform surface topographyImprove stabilityFinal product manufactureSemiconductor devicesHeterojunctionQuantum efficiency

The invention discloses a preparation method of QDs / Si heterojunction composite crystalline silicon wafer having high quantum efficiency, and application thereof. The preparation method of QDs / Si heterojunction composite crystalline silicon wafer having high quantum efficiency uses chemical liquid phase deposition to uniformly grow a semiconductor quantum dot layer having broad-band gaps on the surface of the crystalline silicon, and then forms QDs / Si heterojunction after being subsequently processed. The quantum dot layer can not only modulate the energy gap of the composite crystalline silicon battery, but also the unique quantum confinement effect of the quantum dot can greatly and effectively increase the quantum efficiency of the crystalline silicon battery piece as well as the minority carrier lifetime, thereby increasing the overall photoelectric converting efficiency of the battery piece. The preparation method of QDs / Si heterojunction composite crystalline silicon wafer having high quantum efficiency, and application thereof also have the advantages that: 1, the technical condition is simple and easy to operate; 2, the equipment is simple and applicable to industrial mass production; 3, raw materials are easily obtained and low cost. Additionally, no poisonous or harmful substance is produced in the production process. The crystalline silicon piece is monocrystalline silicon piece, polycrystalline silicon piece, noncrystalline silicon piece, or microcrystalline silicon piece.

Owner:SHANGHAI NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com