Ion-selectivity composite membrane as well as preparation method and application thereof

An ion-selective, composite diaphragm technology, applied in electrical components, electrochemical generators, circuits, etc., can solve the problems of hindering the commercialization of lithium-sulfur batteries, irreversible capacity loss, low coulomb efficiency, etc., and is conducive to large-scale production. , avoid the shuttle effect, improve the effect of migration number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

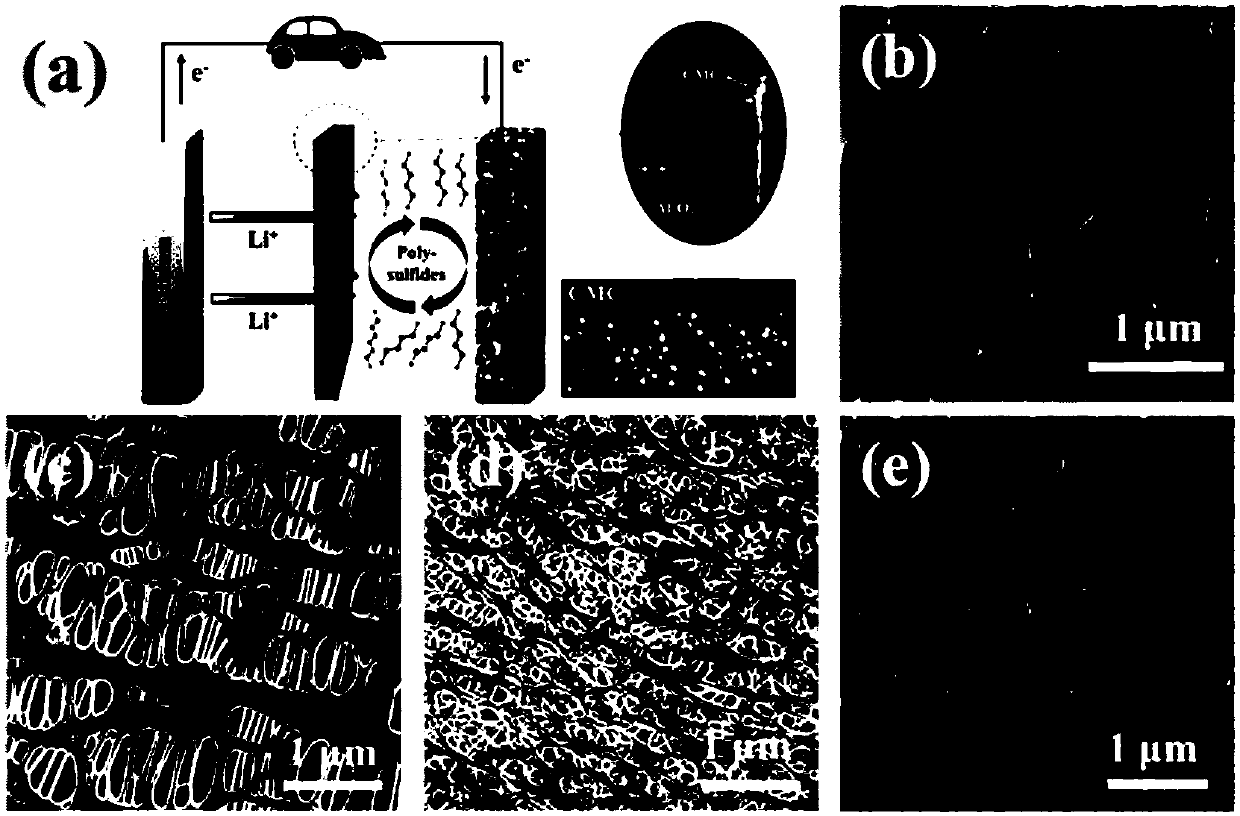

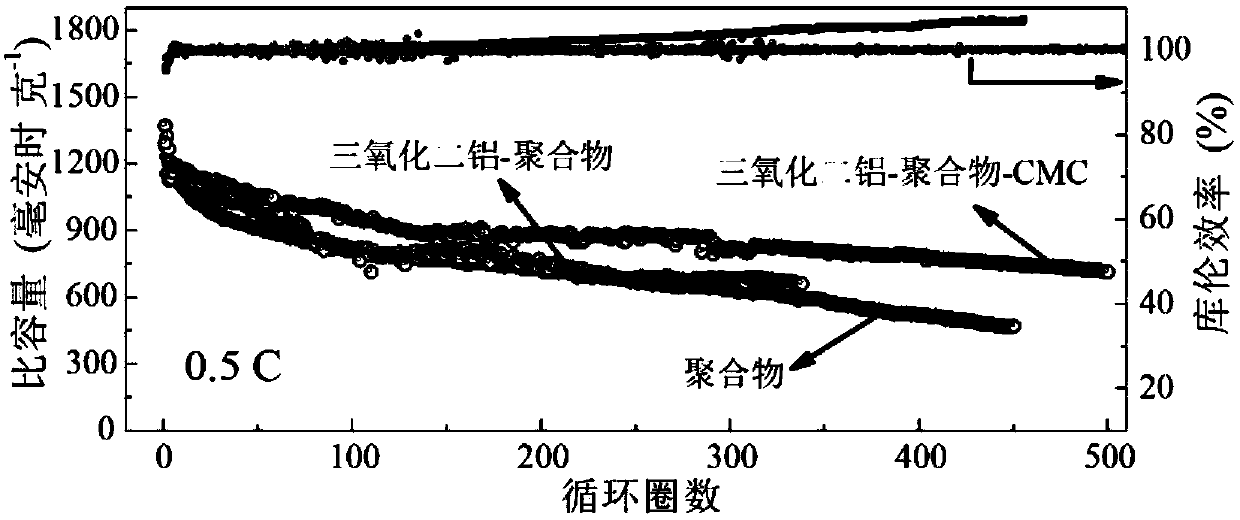

[0039] Example 1: Preparation of ion-selective composite diaphragm and lithium-sulfur battery

[0040] A kind of ion-selective composite diaphragm, comprises the sodium carboxymethyl cellulose (CMC) coating that is coated on diaphragm positive pole side, is coated on the Al of diaphragm negative pole side 2 o 3 The coating and the polymer porous layer in the middle, the thickness of the polymer porous layer is 12 μm, the thickness of the CMC coating is 10 μm, Al 2 o 3 The thickness of the coating was 4 μm.

[0041] The preparation method of described ion-selective composite diaphragm is as follows:

[0042] A. Select single-sided Al prepared by industrial coating method 2 o 3 a diaphragm with a polymer layer on the other side;

[0043] B. Dissolve CMC in H 2 In the mixed solvent of O and organic solvent, stir 12h, make CMC be uniformly dispersed in solvent;

[0044] C. Transfer the uniformly dispersed CMC glue solution to the diaphragm of the film-coated plate, and app...

Embodiment 2

[0054] Example 2: Preparation of ion-selective composite diaphragm and lithium-sulfur battery

[0055] A kind of ion-selective composite diaphragm, comprises the sodium carboxymethyl cellulose (CMC) coating that is coated on diaphragm positive electrode side, is positioned at the Al of negative electrode side 2 o 3 The coating and the polymer porous layer in the middle, the thickness of the polymer porous layer is 12 μm, the thickness of the CMC coating is 2 μm, Al 2 o 3 The thickness of the coating was 4 μm.

[0056] The preparation method of described ion-selective composite diaphragm is as follows:

[0057] A. Select single-sided Al prepared by industrial coating method 2 o 3 a diaphragm with a polymer layer on the other side;

[0058] B. Sodium carboxymethyl cellulose (CMC) was dissolved in H 2 Mixed solvent of O and organic solvent, stir 12h, make CMC evenly disperse in solvent;

[0059] C. Transfer the uniformly dispersed CMC glue solution to the diaphragm of the...

Embodiment 3

[0069] A kind of ion-selective composite diaphragm, comprises the sodium carboxymethyl cellulose (CMC) coating that is coated on diaphragm positive pole side, is coated on the Al of negative pole side 2 o 3 The coating and the polymer porous layer in the middle, the thickness of the polymer porous layer is 12 μm, the thickness of the CMC coating is 2 μm, Al 2 o 3 The thickness of the coating was 4 μm.

[0070] The preparation method of described ion-selective composite diaphragm is as follows:

[0071] A. Select single-sided Al prepared by industrial coating method 2 o 3 a diaphragm with a polymer layer on the other side;

[0072] B. Sodium carboxymethyl cellulose (CMC) was dissolved in H 2 Mixed solvent of O and organic solvent, stir 12h, make CMC evenly disperse in solvent;

[0073] C. Transfer the uniformly dispersed CMC glue solution to the diaphragm of the film-coated plate, and use the scraper method to coat the composite diaphragm with a uniform coating, and cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com