Quick-charging and safe low-temperature lithium ion battery and manufacturing method thereof

A lithium-ion battery, fast charging technology, applied in the direction of non-aqueous electrolyte battery electrodes, secondary batteries, battery electrodes, etc., can solve problems such as limited degree, to improve compaction density and surface density, increase contact area, reduce migration effect of distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

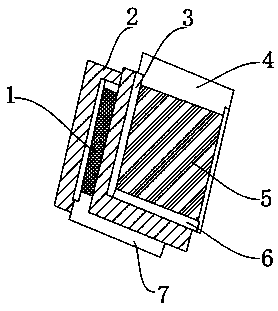

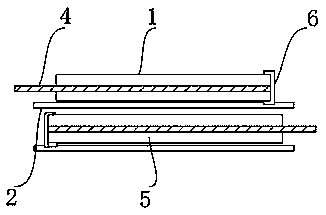

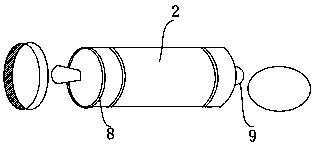

[0037] Such as figure 1 , 2 , 3, a fast-charging and safe low-temperature lithium-ion battery, the lithium-ion battery is mainly composed of a positive electrode sheet, a negative electrode sheet, a ceramic diaphragm, a high-low temperature electrolyte and a battery case, and the low temperature is less than -45°C , the high-rate fast charging refers to the charging performance at different rates under different temperature conditions; The combination of positive electrode sheet, ceramic diaphragm, negative electrode sheet and ceramic diaphragm is formed by winding; the ceramic diaphragm 2 is located between the positive electrode sheet 9 and the negative electrode sheet 8; the positive electrode sheet 9 includes nano-microporous carbon-coated aluminum mesh 7, nano-micro The surface of the hole carbon-coated aluminum mesh 7 is provided with a positive electrode coating 1; the negative plate 8 includes a nano-microporous copper mesh 4, and the surface of the nano-microporous c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com