Patents

Literature

190results about How to "Shorten migration distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

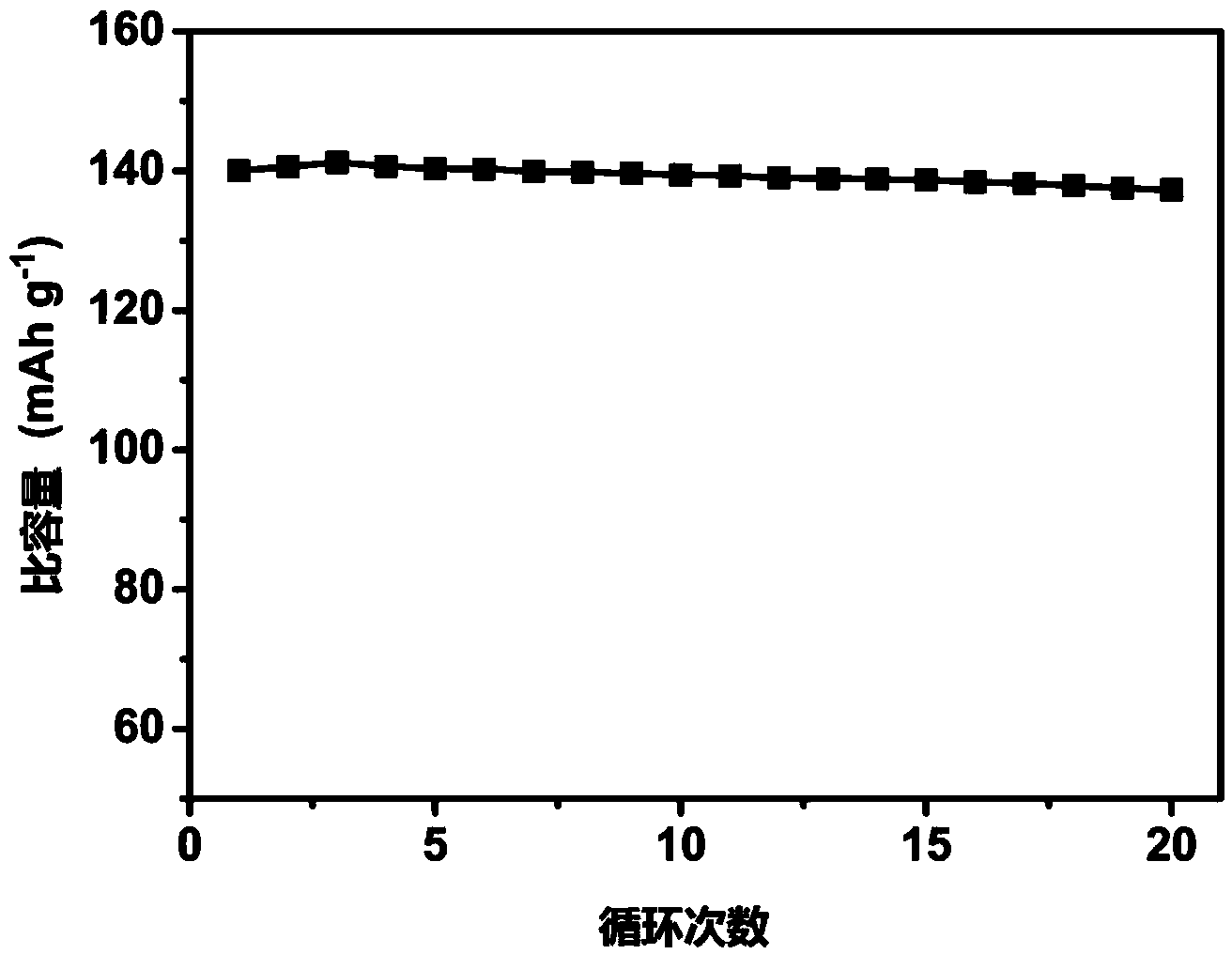

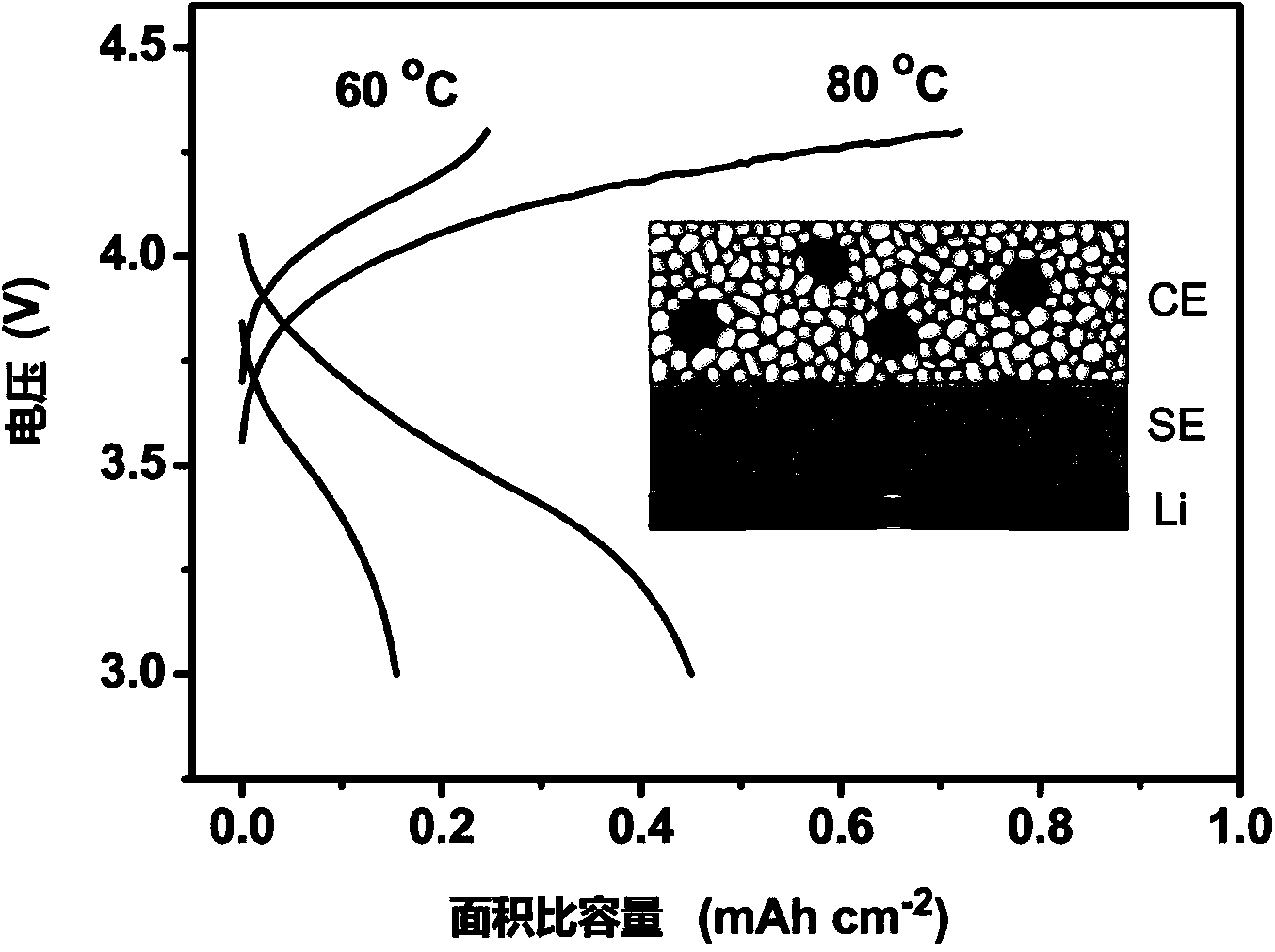

Composite positive electrode of lithium ion battery as well as preparation method and application to all-solid-state battery thereof

ActiveCN103956458AShorten migration distanceIncrease energy densityCell electrodesSecondary cellsSolid state electrolyteTin dioxide

The invention discloses a composite positive electrode of a lithium ion battery as well as a preparation method and application to an all-solid-state battery thereof. The composite positive electrode of the lithium ion battery comprises a positive active material, inorganic solid electrolyte and a conductive oxide additive, wherein the positive active material is any one of lithium cobaltate, lithium manganate, lithium iron phosphate and nickel-cobalt-manganese ternary material; the inorganic solid electrolyte is at least one of lithium borate, lithium metaborate and lithium fluoride; the conductive oxide additive is any one of indium tin oxide, indium oxide, tin dioxide, zinc oxide, nickel oxide and ferroferric oxide. The method comprises the steps of (1) mixing the positive active material, the inorganic solid electrolyte and the conductive oxide additive, carrying out ball milling, drying, and carrying out tabletting to obtain a ceramic piece; and (2) sintering the ceramic piece to obtain the composite positive electrode. The composite positive electrode is good in mass ratio capacity, area ratio capacity and cycle performance, can be used for preparing the all-solid-state lithium ion battery, and can be used at high temperature.

Owner:TSINGHUA UNIV

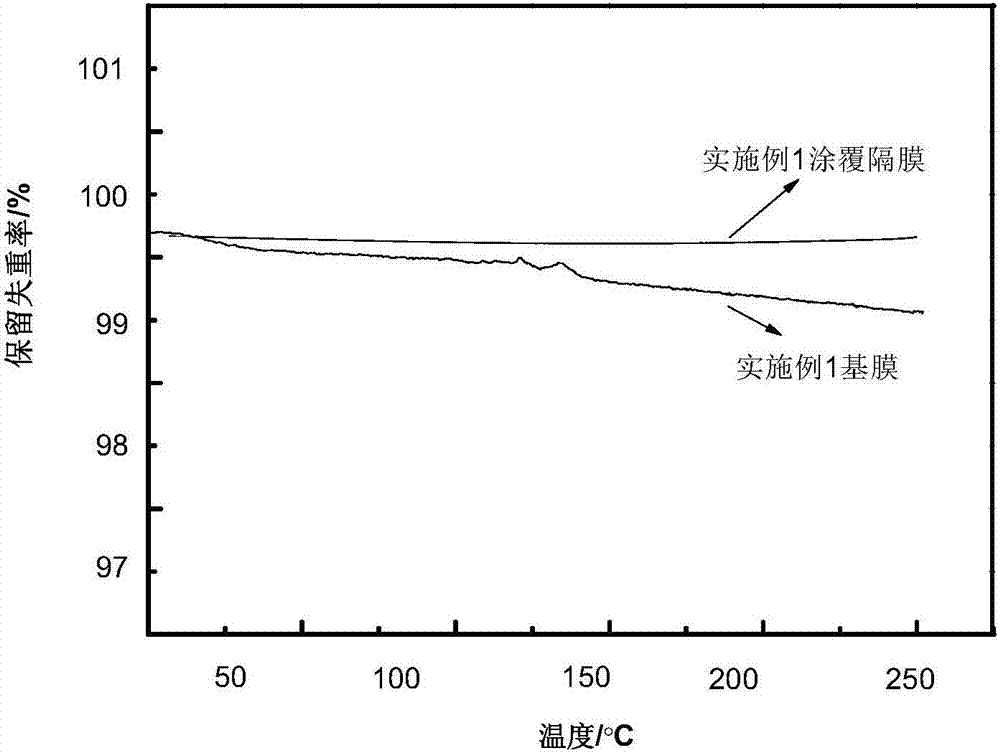

Non-woven ceramic membrane with excellent closed-pore performance for lithium ion battery and technology

ActiveCN103199209AReduce the temperatureSlow down the degree of electrochemical reactionCell component detailsCeramic coatingPore diameter

The invention provides a non-woven ceramic membrane with excellent closed-pore performance for a lithium ion battery. The non-woven ceramic membrane comprises a non-woven base material and coatings with the closed-pore performance. The non-woven ceramic membrane is characterized in that the coatings with the closed-pore performance are uniformly coated on the two surfaces of the non-woven base material, the thickness of the non-woven ceramic membrane for the lithium ion battery is 30-50mu m, the porosity of the non-woven ceramic membrane is 40-60%, the average pore diameter of the non-woven ceramic membrane is 0.1-0.5mu m, the closed-pore temperature of the non-woven ceramic membrane is 120-130 DEG C, and the membrane rupture temperature of the non-woven ceramic membrane is 300-500 DEG C. The invention also provides a preparation technology of the non-woven ceramic membrane with the excellent closed-pore performance for the lithium ion battery. The non-woven ceramic membrane has the advantage that the disintegration or explosion of the battery is not easy cause; the adhesive power between the ceramic coating and the base material is increased, and no powder falls off the surface of the membrane under the conditions of bending, rubbing and the like; the consistency of the membrane thickness is substantially improved; and the non-woven ceramic membrane has good high temperature resistance performance, high ion penetrability, low resistance and stable electrochemical property.

Owner:CHINA HAISUM ENG

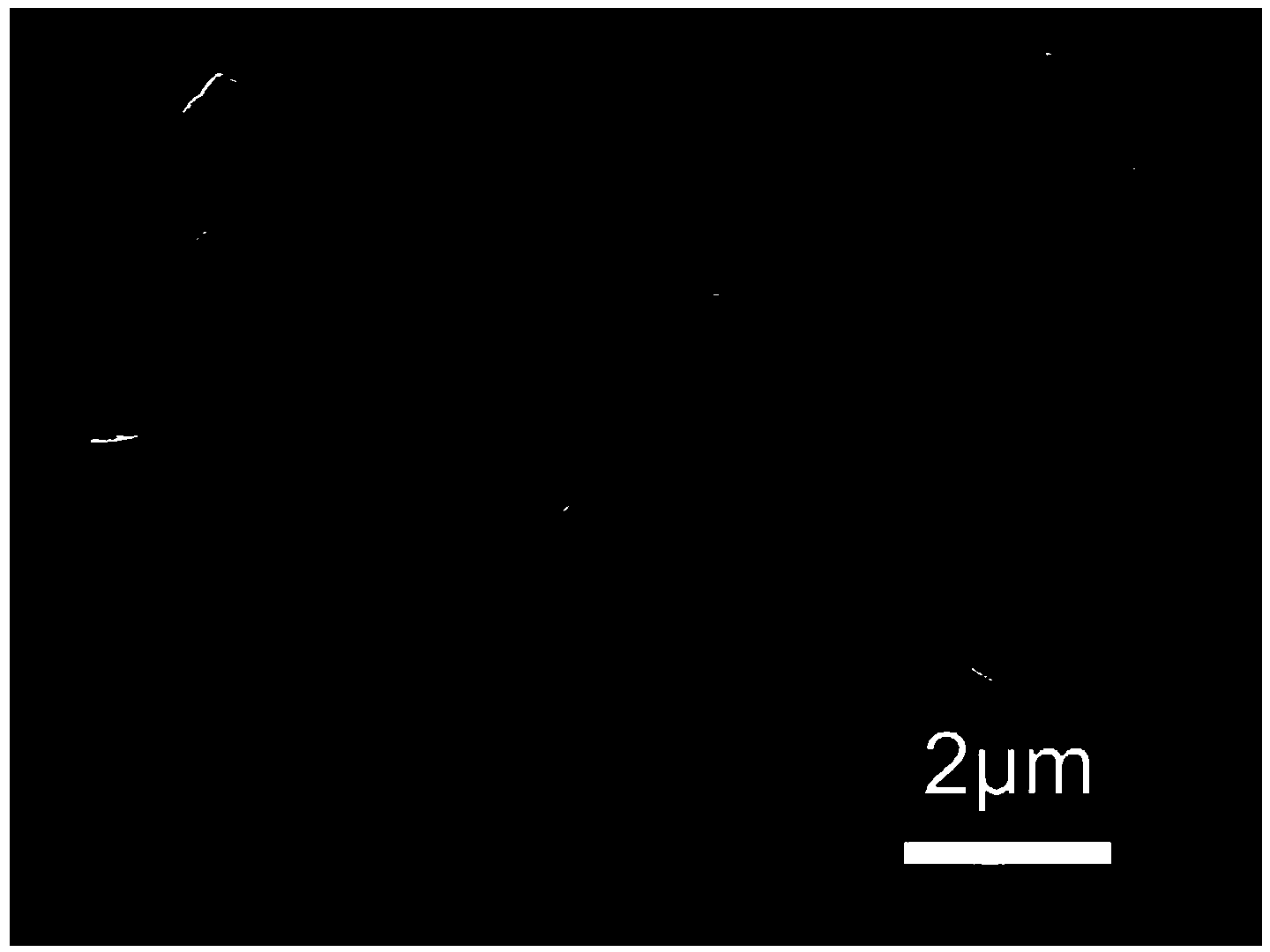

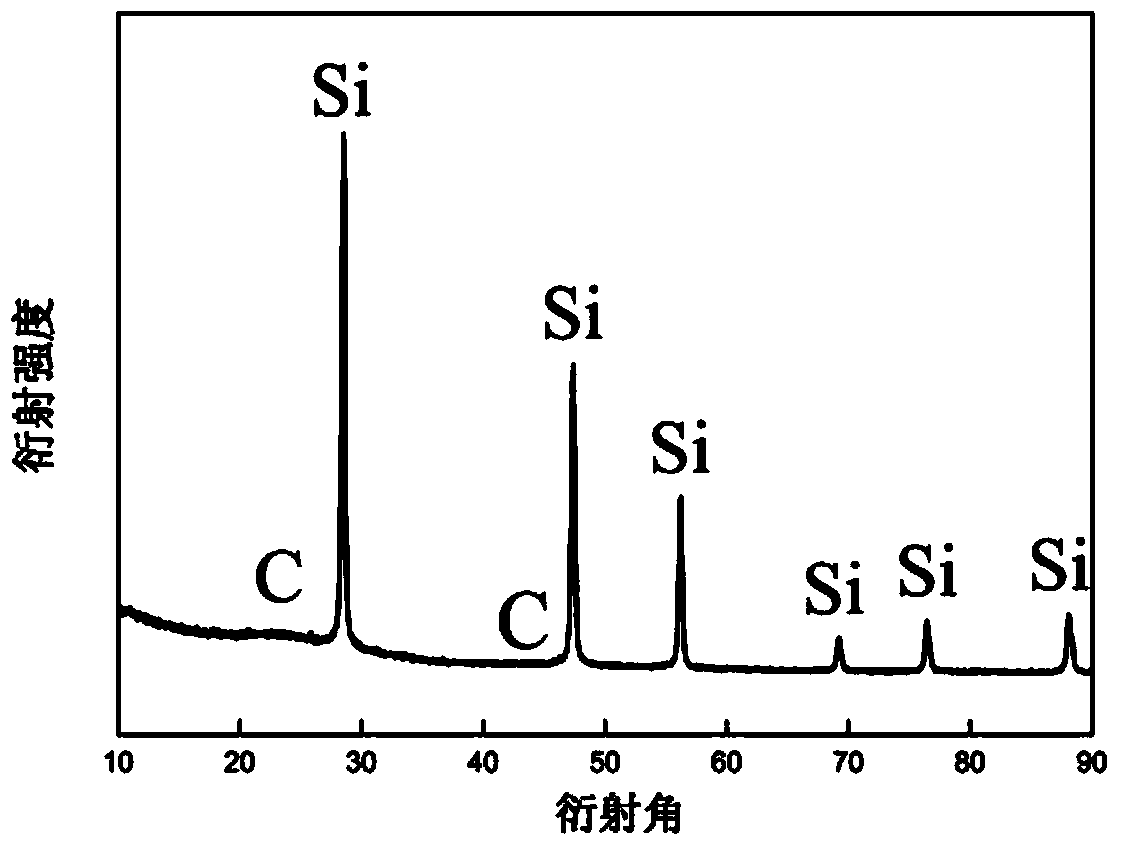

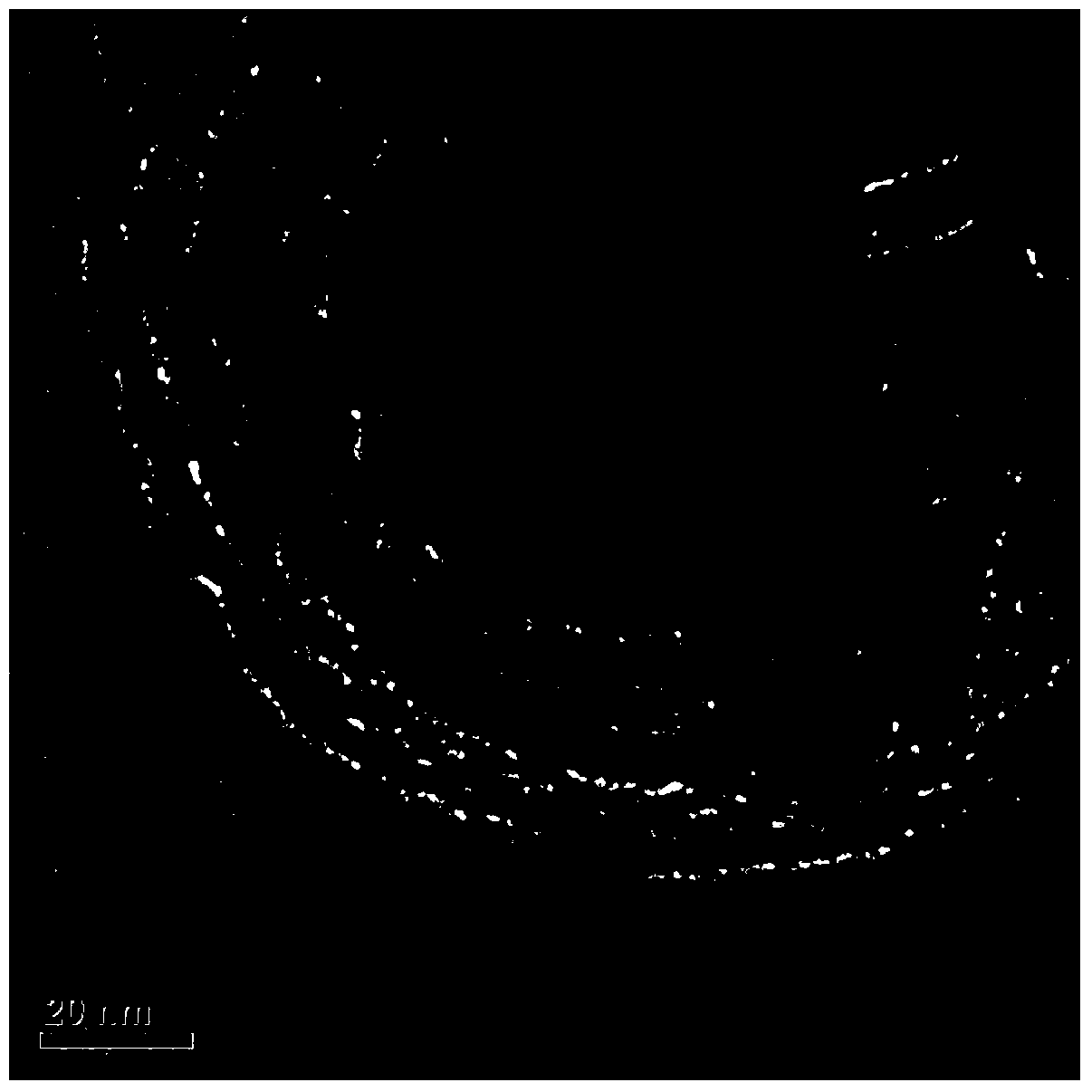

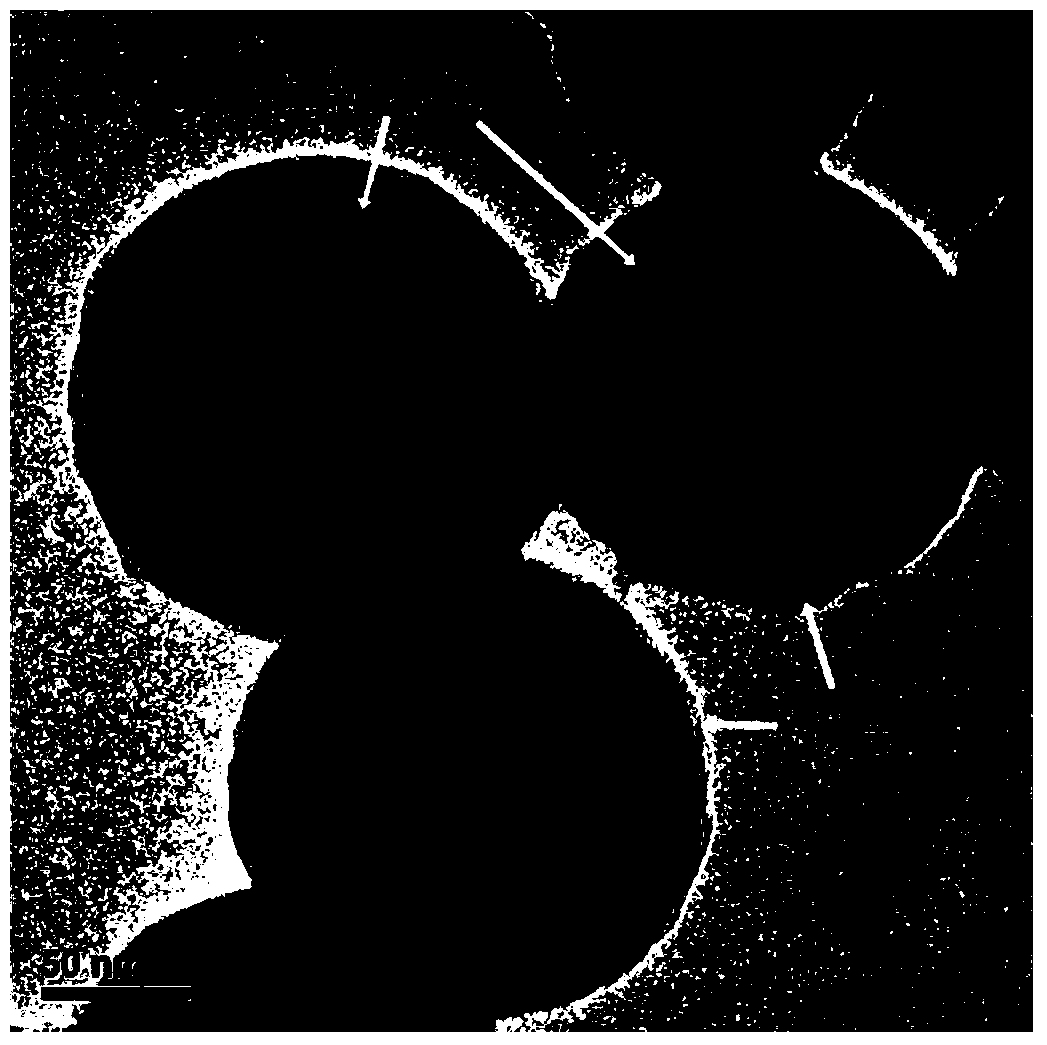

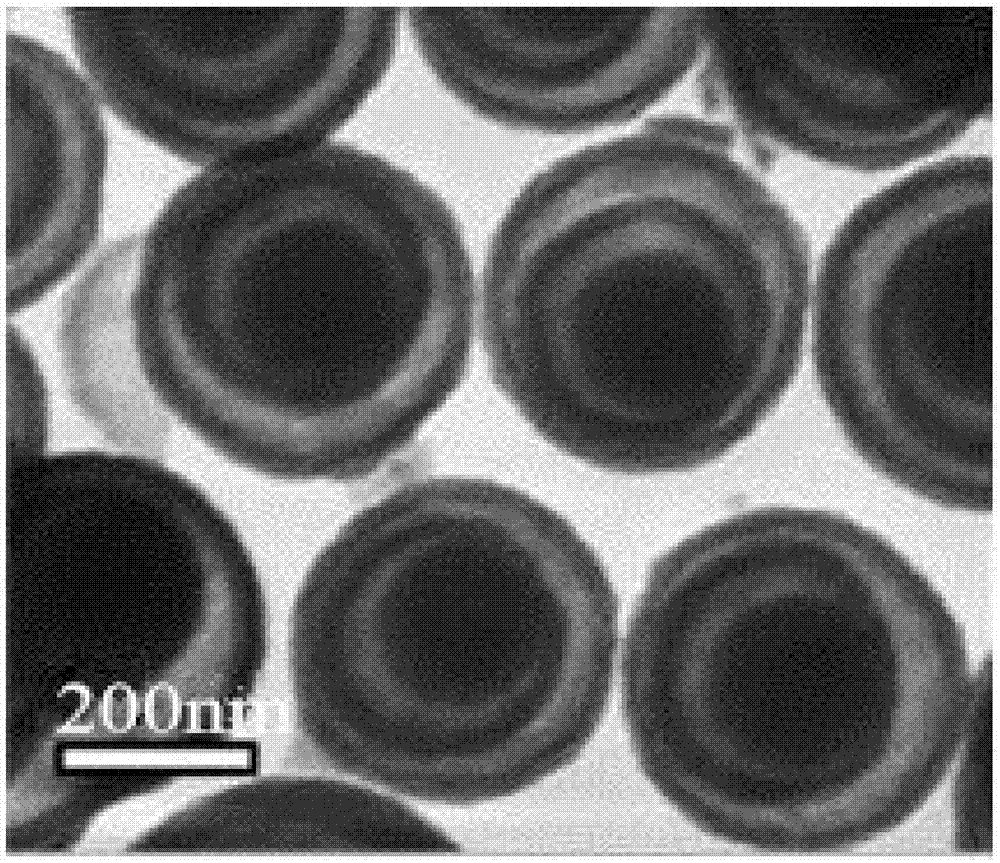

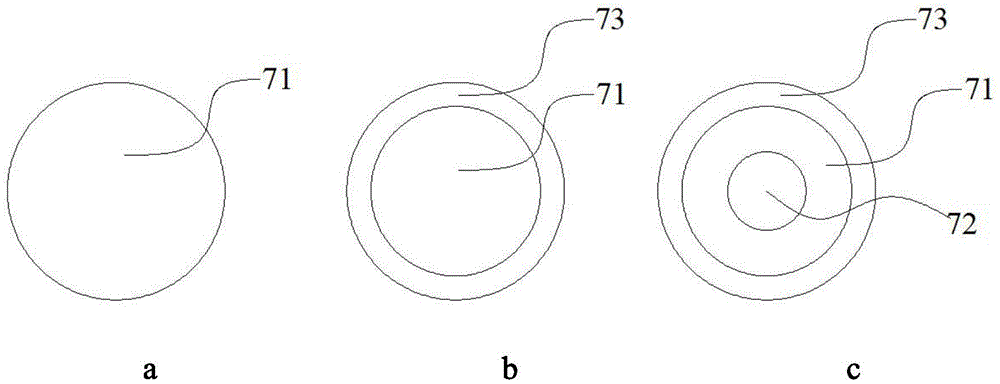

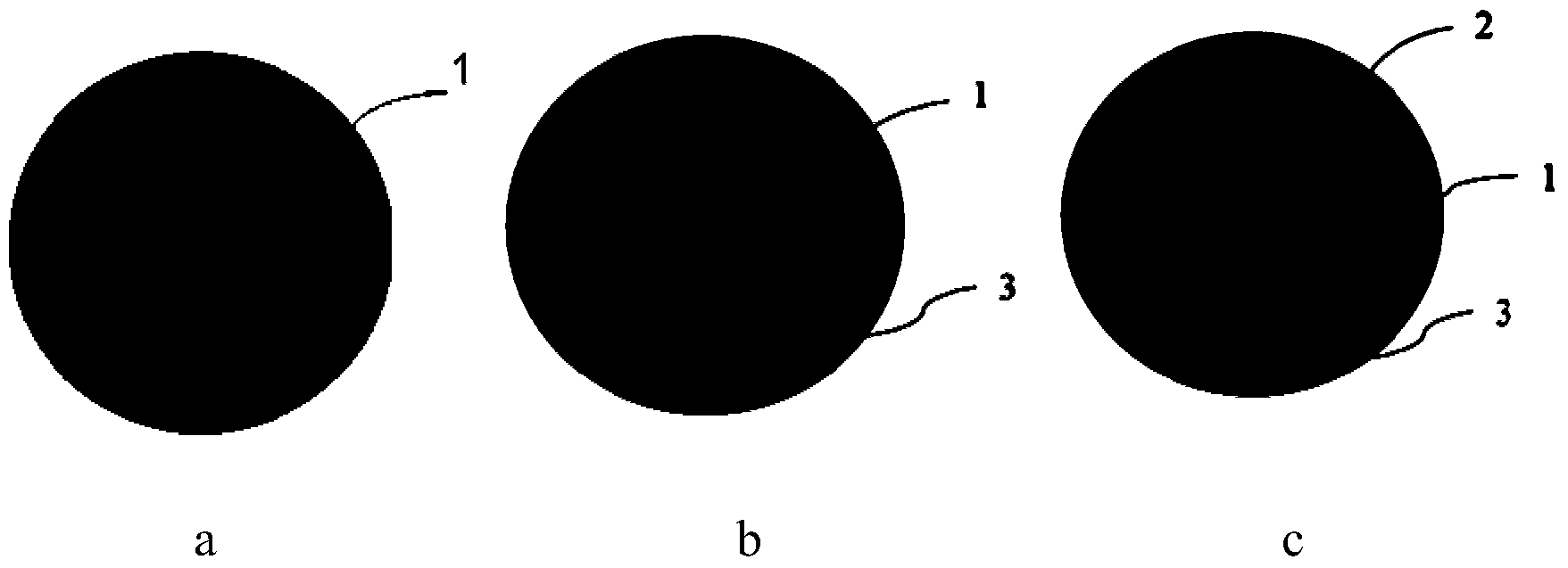

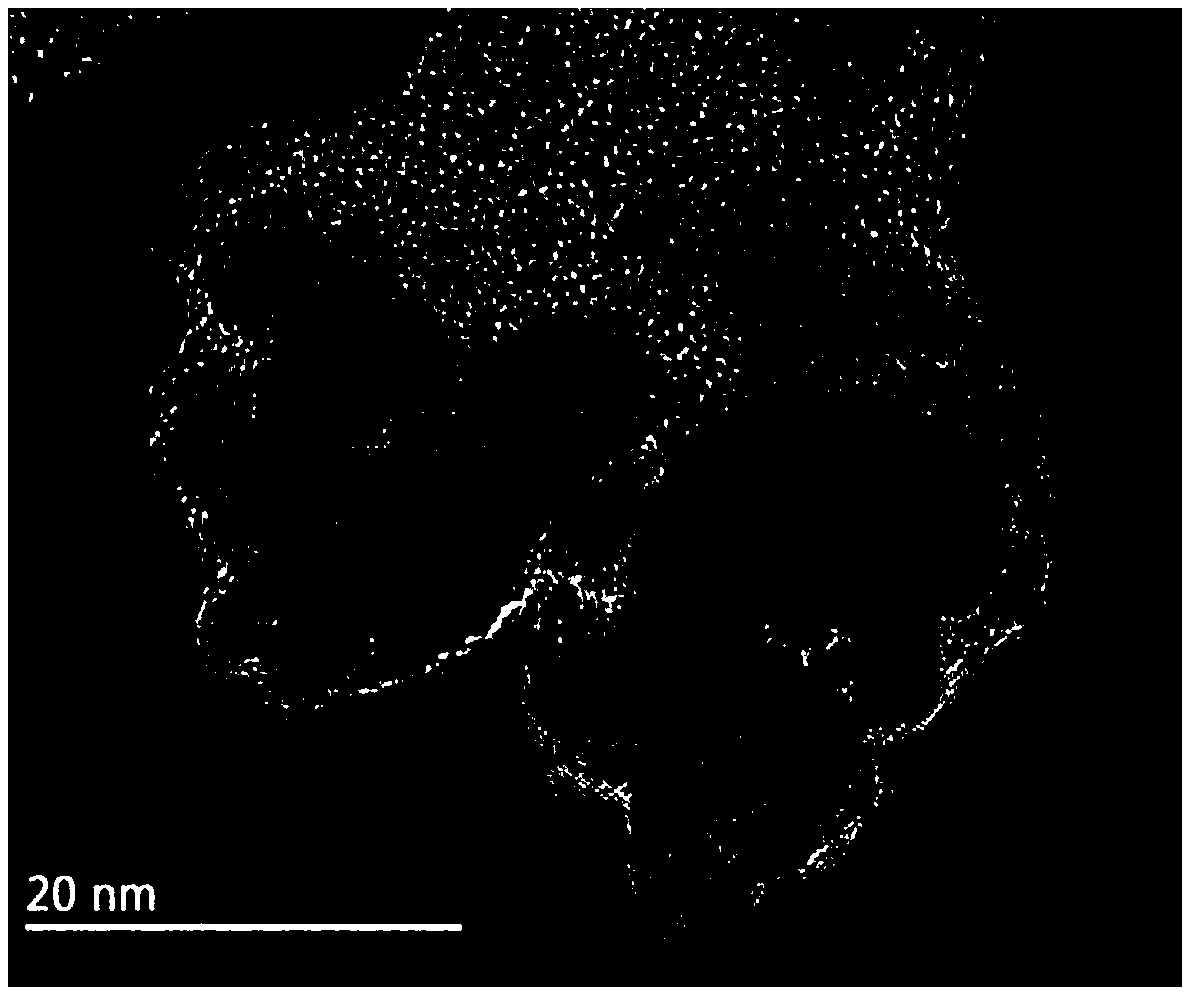

Anode material for double-shell capsule-shaped silicon-based lithium-ion battery and preparation method of anode material

InactiveCN104319401AHigh specific capacityImprove conductivityMaterial nanotechnologyCell electrodesNano siliconCarbonization

The invention discloses an anode material for a double-shell capsule-shaped silicon-based lithium-ion battery and a preparation method of the anode material. In the material, a nano-silicon nuclear is coated by a double-layer carbon shell; a certain space exists between the silicon nuclear and an inner-layer carbon shell. According to the preparation method, the material disclosed by the invention can be obtained by taking a capsule-shaped structural silicon dioxide-coated silicon nano-composite material as a template, performing pyrolysis on an organic carbon source to coat the inner surface and the outer surface of the template silicon dioxide, performing high-temperature carbonization under an inert atmosphere, and finally, etching the silicon dioxide template. According to the material, the first lithium embedding capacity is 3,125 mAh / g; the specific capacity can still be kept at 1,161mAh / g after 30-time repeated charge-discharge cycles. The preparation method provided by the invention is simple in process and environmentally friendly; industrial production is easy to realize.

Owner:SHANGHAI JIAO TONG UNIV

Method for quickly generating lamination flexible package lithium ion battery

ActiveCN106099202ADischarge fullyRestructuring and StabilityFinal product manufactureSecondary cells charging/dischargingSurface reactionPole piece

The invention belongs to the technical field of lithium ion batteries and particularly relates to a method for quickly generating a lamination flexible package lithium ion battery. The method comprises a stage of forming a solid electrolyte phase interface film and a stage of discharging formation gas. The main theoretical foundation is that the solid electrolyte phase interface film is mainly formed at the initial stage of formation charging, accompanied with the discharging of the formation gas. The formation of an SEI film is subjected to the influences of current density and temperature and the like. Under a small current density, first organic lithium salt is formed on the surface of a cathode and then inorganic lithium salt is formed, so that the formed SEI film is denser, and ingredients are more stable. At this stage, a high-pressure pressurization formation mode is adopted, the reaction activity can be increased, the reaction is accelerated, battery surface pressure is increased, the ionic migration distance can be shortened, and formation efficiency and pole piece surface reaction consistency are improved. Compared with a conventional formation process, according to the method, the formation time is shortened, the formed SEI film is denser and more stable, and the method can be widely applied to industrial production.

Owner:CAMEL GRP NEW ENERGY BATTERY CO LTD

Granular electrode catalyst stuffing for 3D electrode reactor and its preparing method

InactiveCN1986434ALow ashLarge specific surface areaOther chemical processesWater/sewage treatment by electrochemical methodsFilm-coated tabletWater quality

The present invention is granular electrode catalyst stuffing for 3D electrode reactor and its preparation process. The electrode catalyst stuffing consists of modified active carbon 60-70 wt% and film coating active carbon 40-30 wt%. The modified active carbon is prepared with active carbon through acid or alkali modification, oxidizing modification and metal supporting modification; and the film coating active carbon is prepared with active carbon through acid or alkali modification and soaking in cellulose acetate solution. The 3D granular electrode stuffing is used in waste water treatment, and has the advantages of great adsorption capacity, fast reaction speed, stable treating effect, etc.

Owner:NANJING UNIV OF TECH

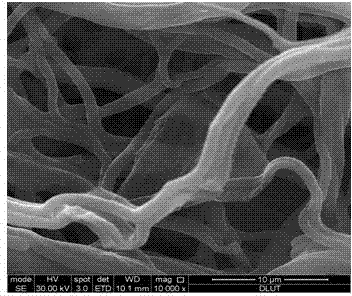

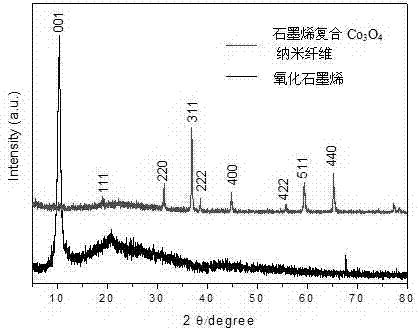

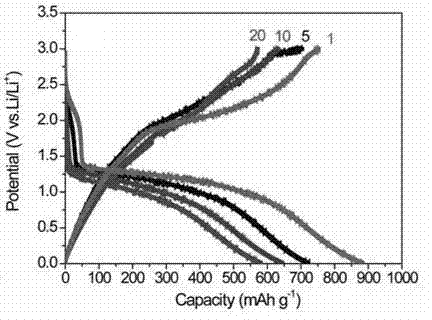

Graphene composite transition metal oxide nanofiber lithium ion battery electrode material and preparation method thereof

InactiveCN102931408AQuick releaseShorten migration distanceMaterial nanotechnologyCell electrodesLithium-ion batteryMaterials science

The invention discloses a graphene composite transition metal oxide nanofiber lithium ion battery electrode material and a preparation method thereof. The composite electrode material combines a function of a graphene laminated structure for embedding and binding transition metal oxide nanoparticles, a function of a micropore tunnel structure interconnected in graphene composite transition metal oxide nanofiber for quickly embedding and taking off lithium ions and a function of three-dimensional space structures wound with each other among nanofibers and used for effectively releasing greatly-changed stress when the volume in an electrode membrane is expanded or contracted. Due to the integration of the three functions, the volume effect of the transition metal oxide material in the process of embedding / taking off the lithium ions can be effectively restrained and buffered, the loss of the irreversible capacity can be reduced, and then, the capacity and the cycling stability performance of a lithium ion battery are further improved.

Owner:DALIAN OCEAN UNIV +1

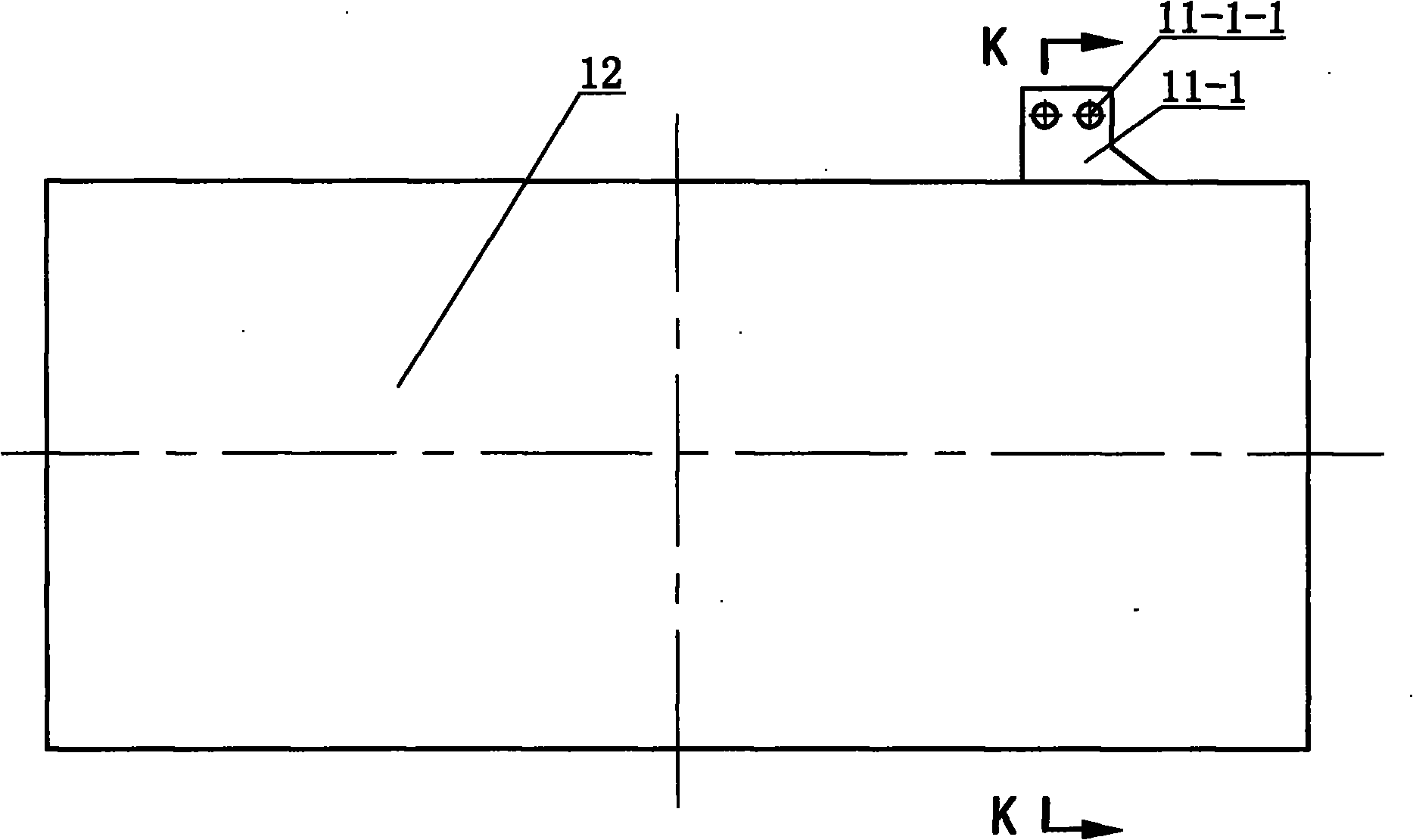

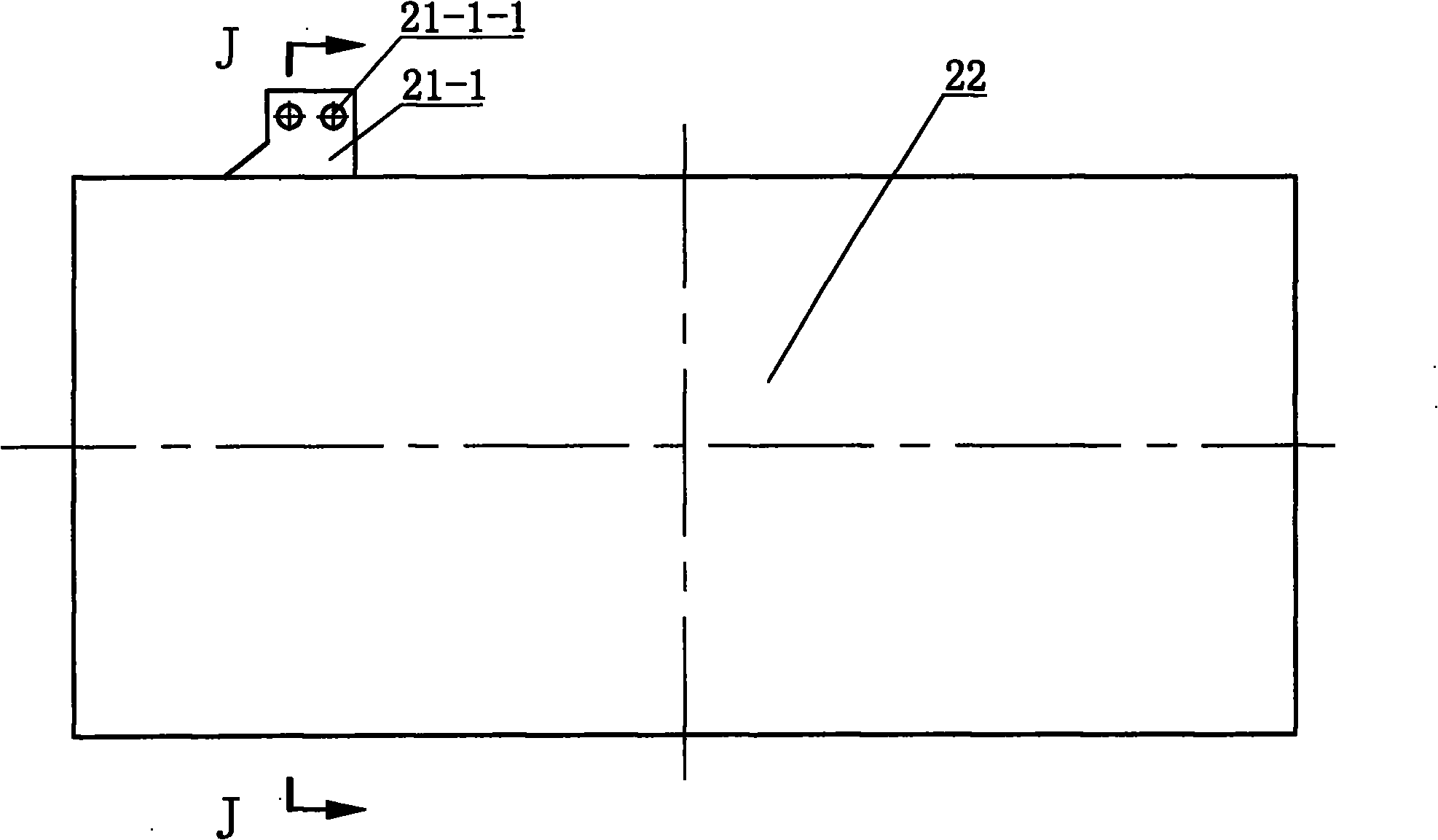

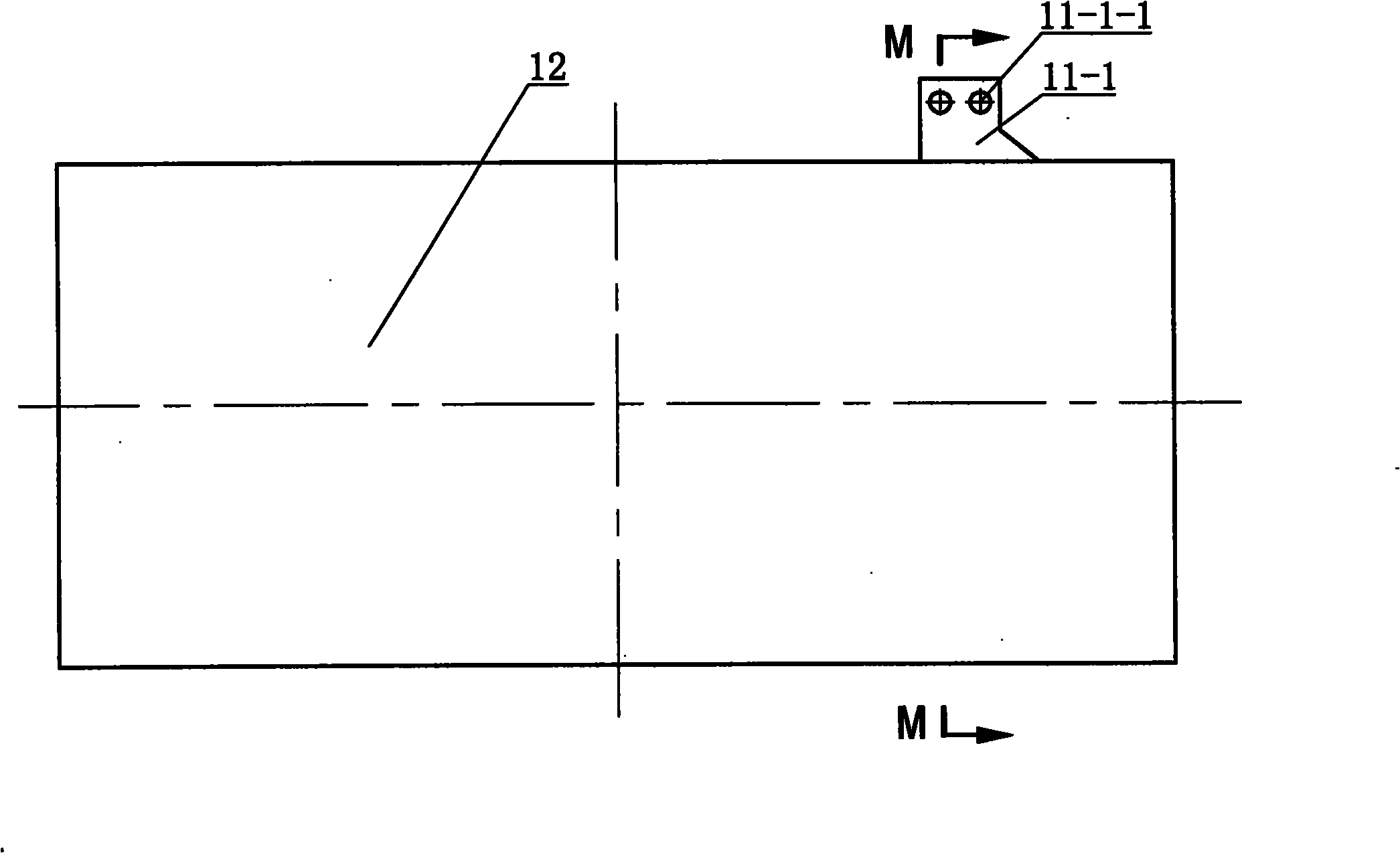

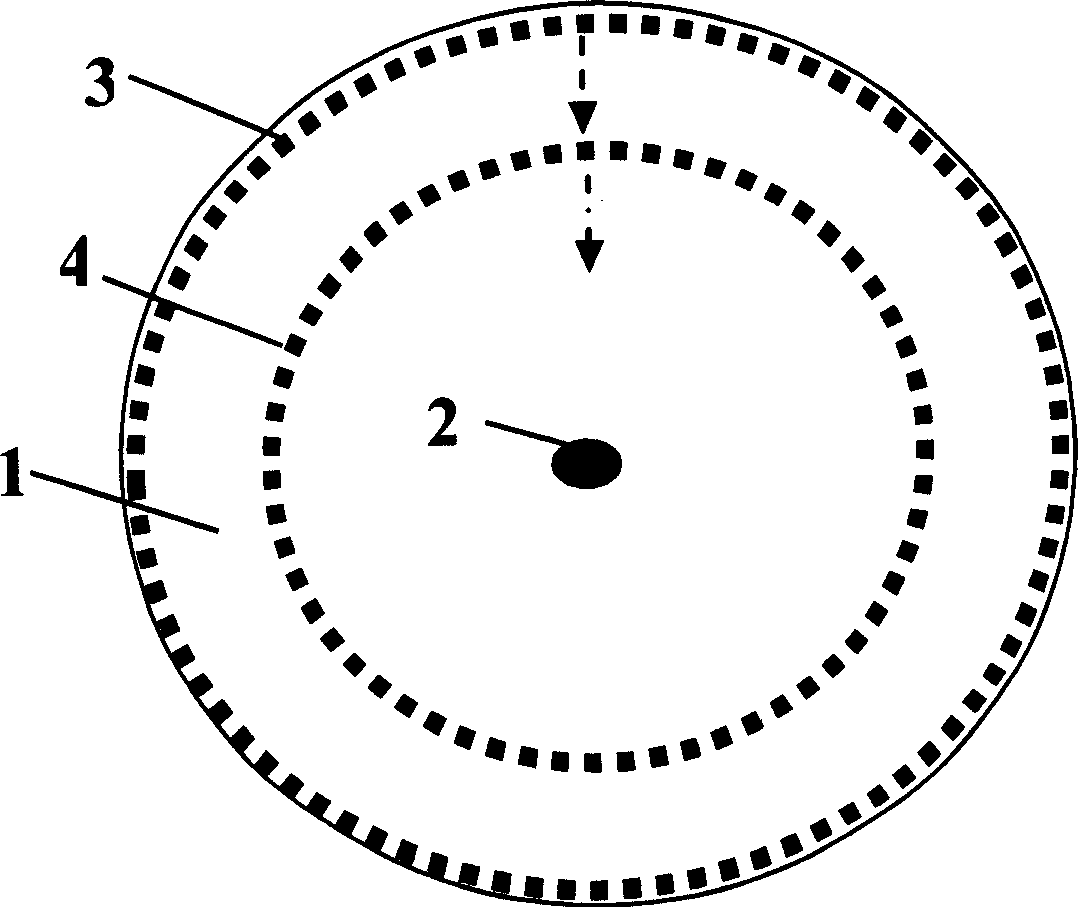

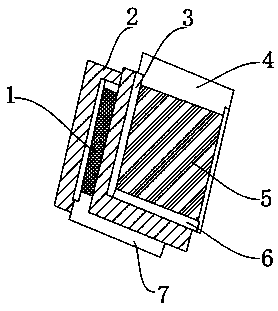

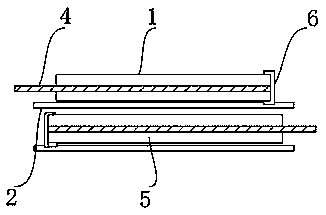

Positive electrode piece, negative electrode piece of lithium ion capacitance battery and manufacture method of two electrode pieces thereof

InactiveCN101807683ALarge specific surface areaImprove conductivityCell electrodesLithiumCapacitance

The invention relates to a positive electrode piece, a negative electrode piece of a lithium ion capacitance battery and a manufacture method of two electrode pieces thereof. The positive electrode piece of the lithium ion capacitance battery is characterized in that a positive electrode substrate (11) is an aluminum foil, an active carbon layer (13) is respectively clamped between the positive electrode substrate (11) and positive electrode material layers (12) arranged at both sides of the positive electrode substrate (11), and the active carbon layers (13) and the positive electrode material layers (12) form a positive electrode coating layer (14). The negative electrode piece of the lithium ion capacitance battery is characterized in that a negative electrode substrate (21) is a copper foil, an active carbon layer (23) is respectively clamped between the negative electrode substrate (21) and negative electrode material layers (22) arranged at both sides of the negative electrode substrate (21), and the active carbon layers (23) and the positive electrode material layers (22) form a negative electrode coating layer (24). The invention also provides the manufacture method of the two electrode pieces: the positive electrode piece and the negative electrode piece. The invention has the advantages of small size, low cost, fast charging (the charging time is only five minutes), high safety, simple manufacture method and high efficiency.

Owner:CHANGZHOU ZHOUNA NEW ENERGY TECH

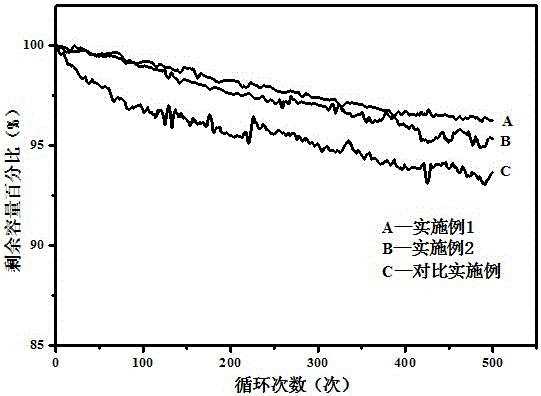

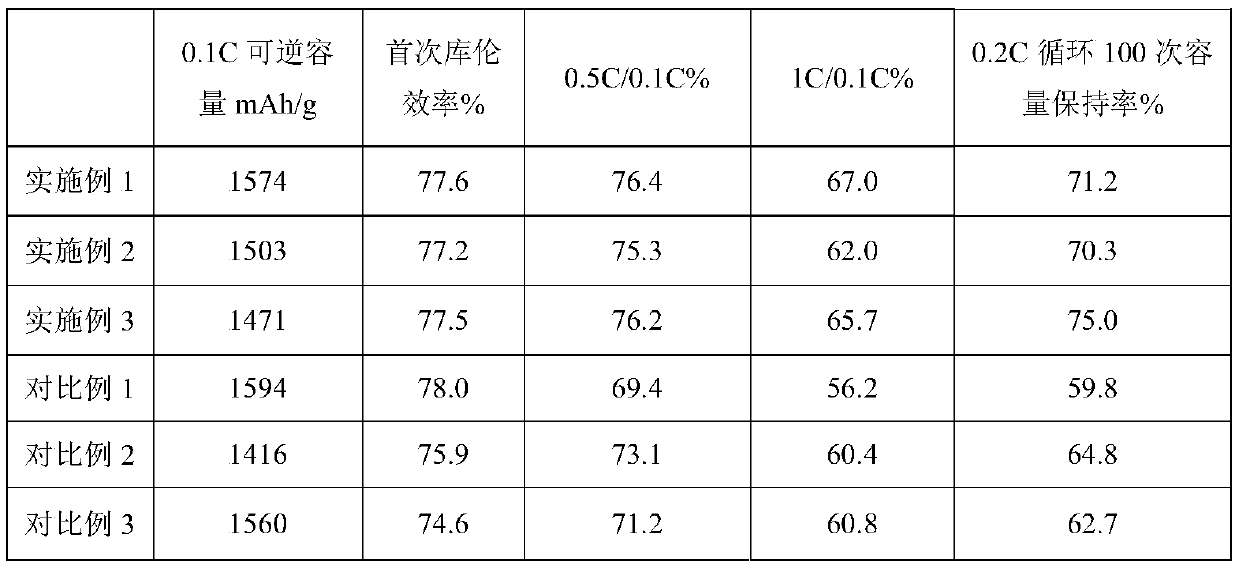

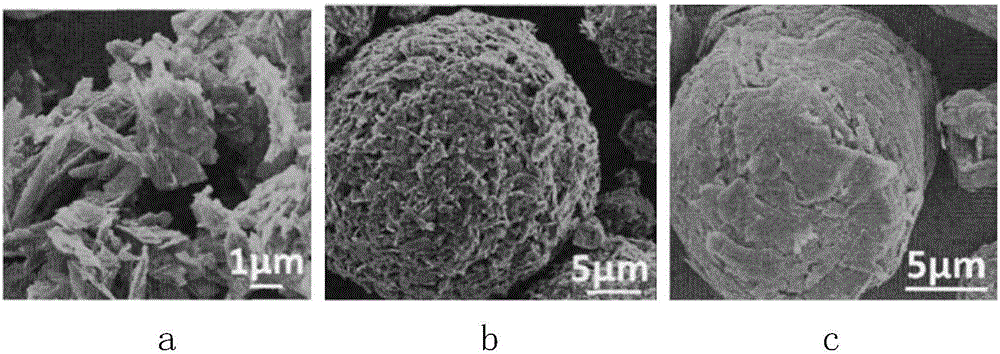

Lithium-ion battery silicon monoxide negative electrode material, preparation method and application thereof

ActiveCN110767877AShorten migration distanceImprove poor conductivitySecondary cellsNegative electrodesSilicon monoxideChemical physics

The invention relates to a lithium-ion battery silicon monoxide negative electrode material, and a preparation method and application thereof. A method for improving rate performance and cycle performance of the lithium-ion battery silicon monoxide negative electrode material includes the following steps: S1: crushing silicon monoxide to silicon monoxide particles having a particle size of 100 to800 nm; S2: after mixing the silicon monoxide particles, a conductive agent, an organic carbon source, and a solvent to obtain a slurry, performing granulation to obtain spherical silicon monoxide secondary particles having a particle size of 4 to 8 [mu]m; S3: pyrolyzing the silicon monoxide secondary particles; and S4: performing secondary coating on pyrolyzed silicon monoxide secondary particlesto obtain the silicon monoxide negative electrode material. In the invention, pulverization, secondary granulation, pyrolysis, and secondary coating processing are performed on the silicon monoxide,on the basis of retaining original first-time coulombic efficiency to a large extent, thereby shortening a lithium-ion diffusion path, improving lithium-ion conductivity, limiting lithium-ion volume expansion, and having better rate performance and cycle performance.

Owner:乳源东阳光新能源材料有限公司

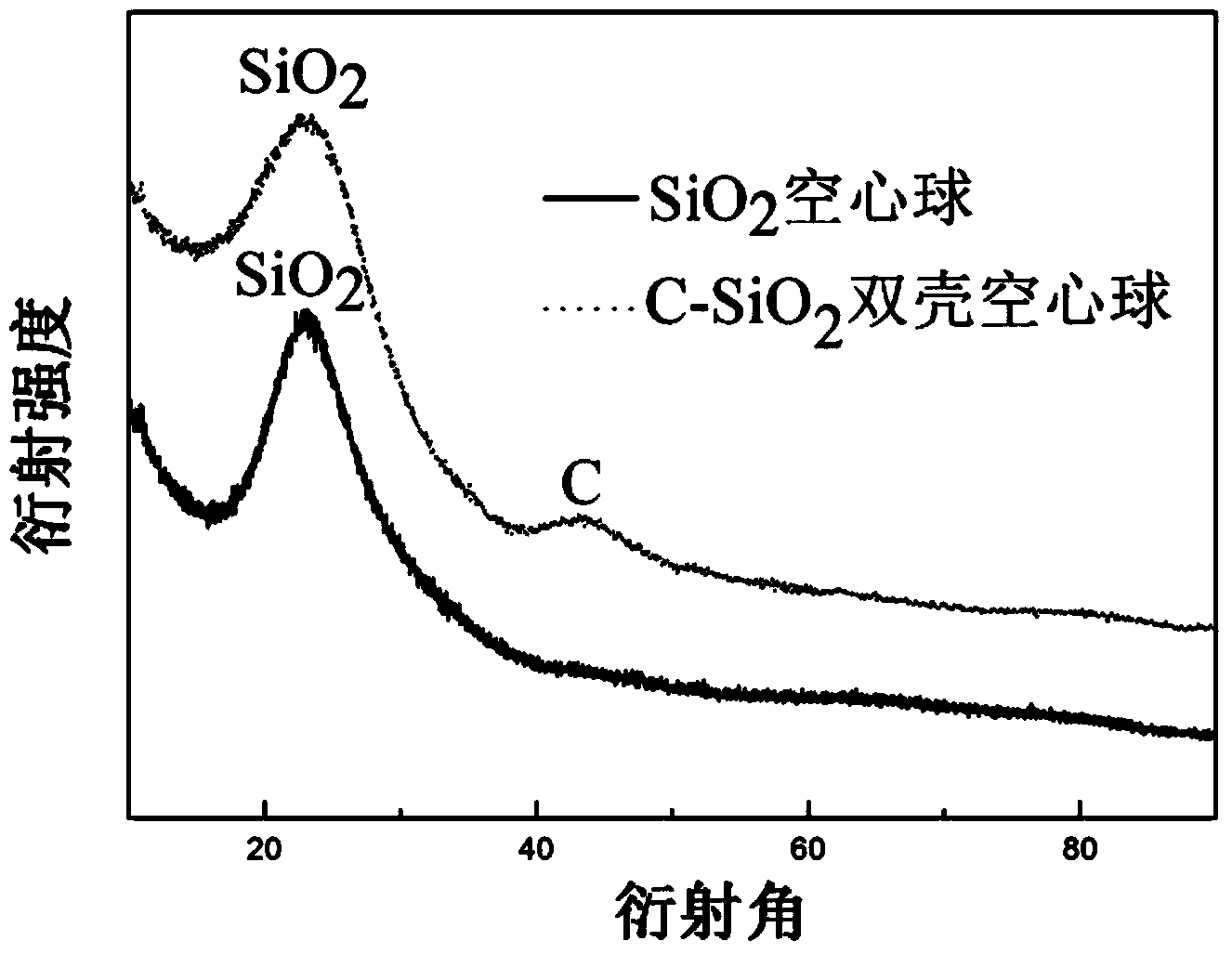

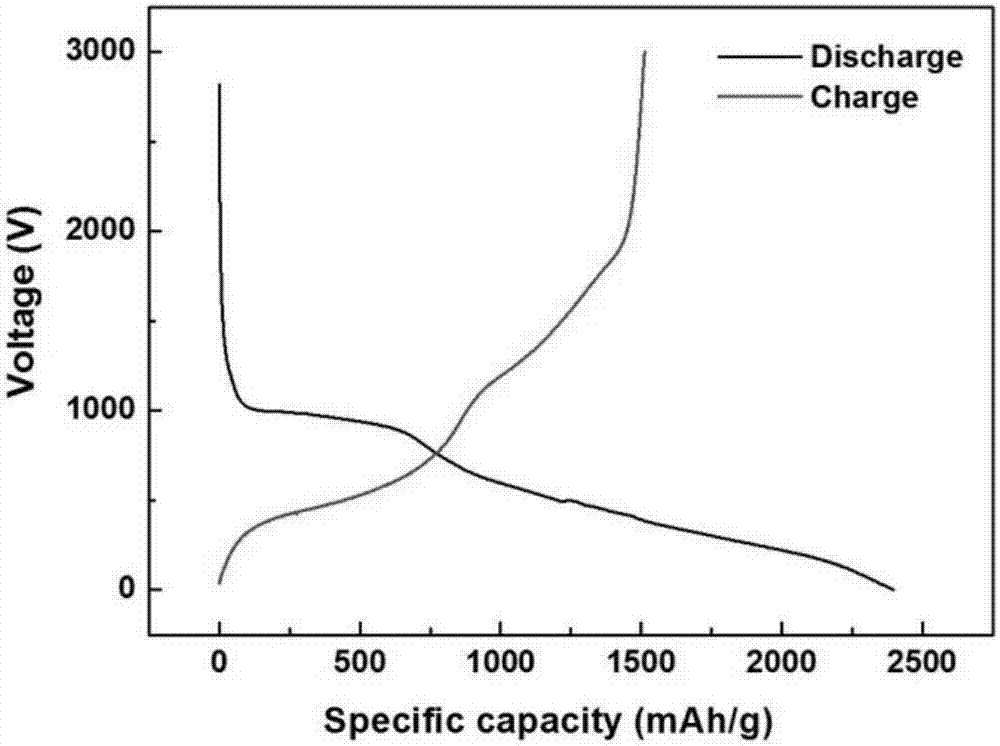

Lithium ion battery cathode material and preparation method thereof

InactiveCN103682272AImprove conductivityImprove stabilityMaterial nanotechnologyCell electrodesSurface-active agentsSilicon dioxide

The invention discloses a lithium ion battery cathode material and a preparation method of the lithium ion battery cathode material. In the lithium ion battery cathode material, silicon dioxide is in a spherical hollow structure, and the surface of the silicon dioxide is uniformly coated with carbon to form a carbon-silicon dioxide double-shell hollow sphere. The preparation method is characterized in that 3-aminopropyl triethoxysilane and tetraethoxysilane are adopted as silicon sources, and the hollow silicon dioxide is prepared by adopting a surface active agent soft template method; then the silicon dioxide hollow sphere is coated with organic carbon source through a pyrolysis way, and the silicon dioxide hollow sphere is carbonized at a high temperature under the inert atmosphere to obtain the lithium ion battery cathode material. The primary lithium embedding capacity of the material is 1394mAh / g, and the specific capacity can still be maintained at 498mAh / g after the material is repeatedly charged and discharged for 20 times. The preparation method is simple in process, environmentally friendly and easy for realizing the industrialized production.

Owner:SHANGHAI JIAO TONG UNIV

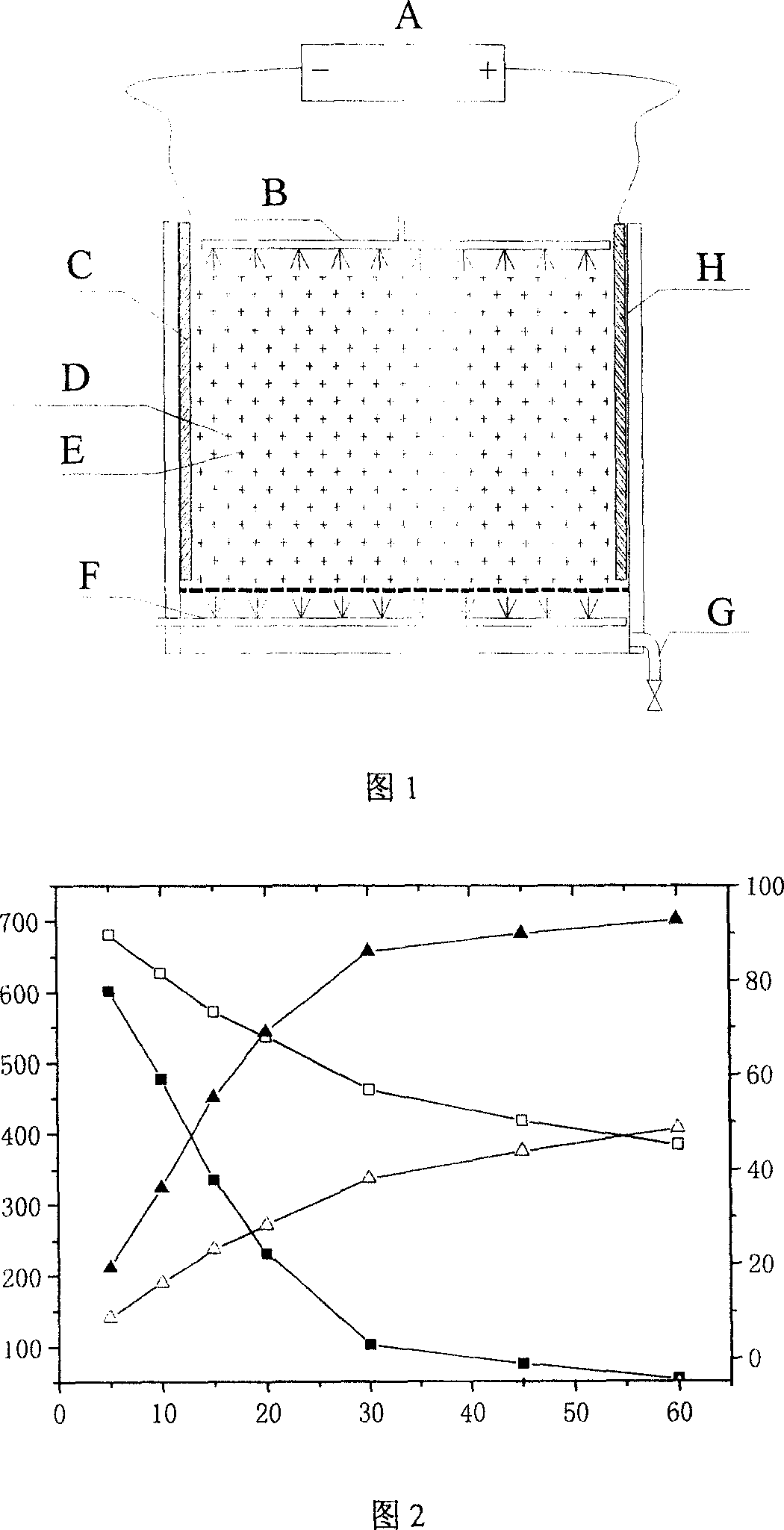

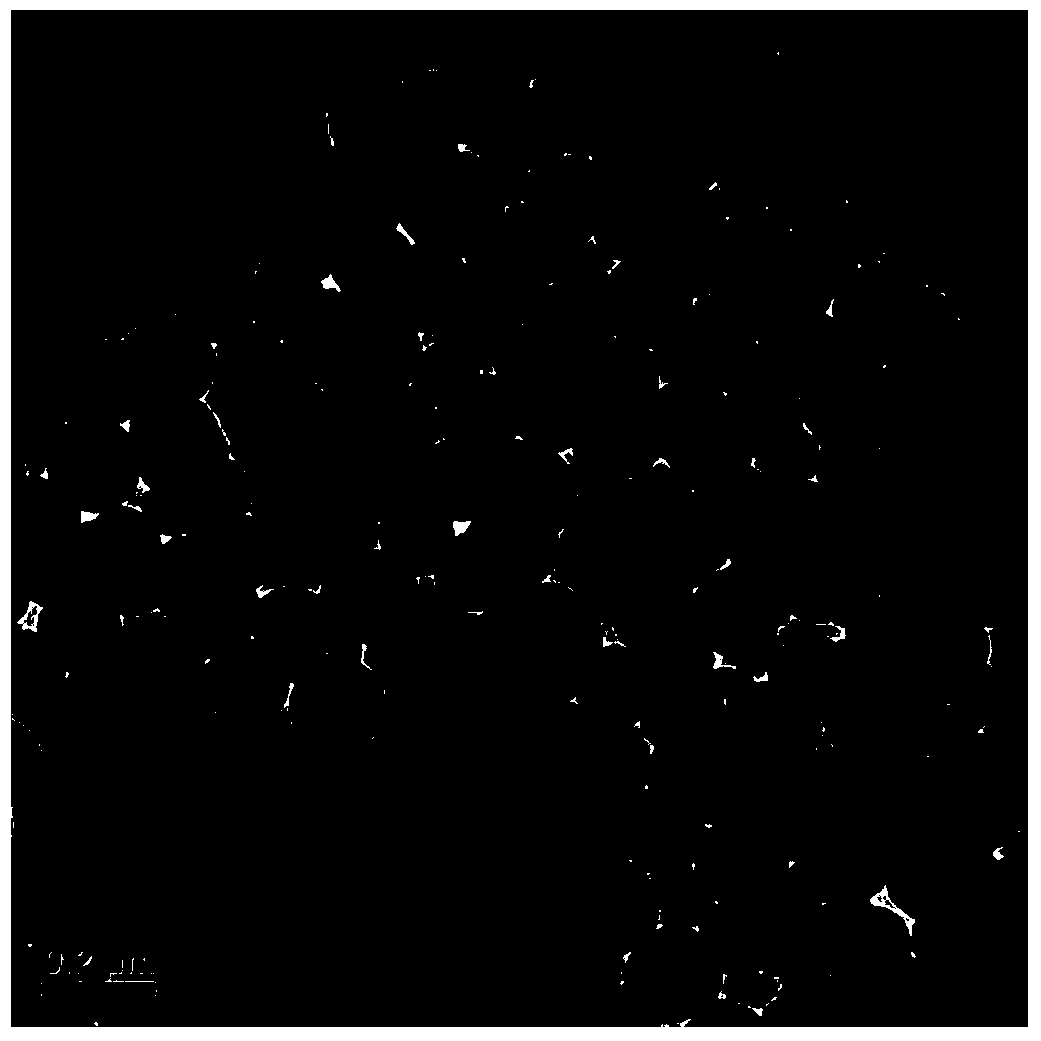

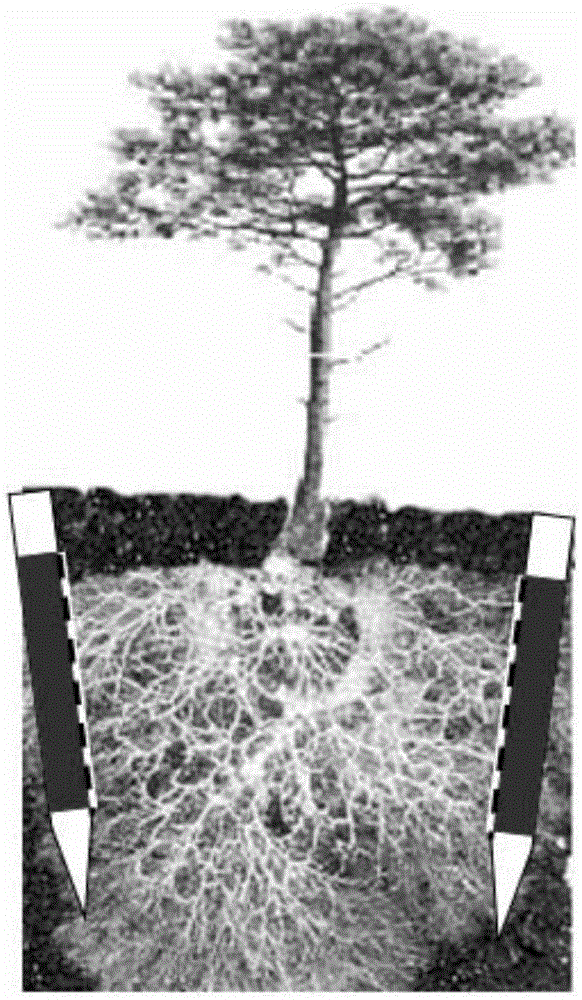

Method of electrodynamics for quick restoring soil polluted by heavy metal in situ

InactiveCN1695835AGood dissolution effectShorten migration distanceContaminated soil reclamationProcess regionSoil heavy metals

An electrodynamic method for fasthy in-situ repairing the pollated soil includes inserting a collecting electrode at one end of the region to be treated, inserting the working electrode in the region in array mode, and sequentially applying a DC field between the collecting electrode and the working electrodes changed from far end to near end for moving the pollutants, so cleaning the region.

Owner:SHANGHAI JIAO TONG UNIV

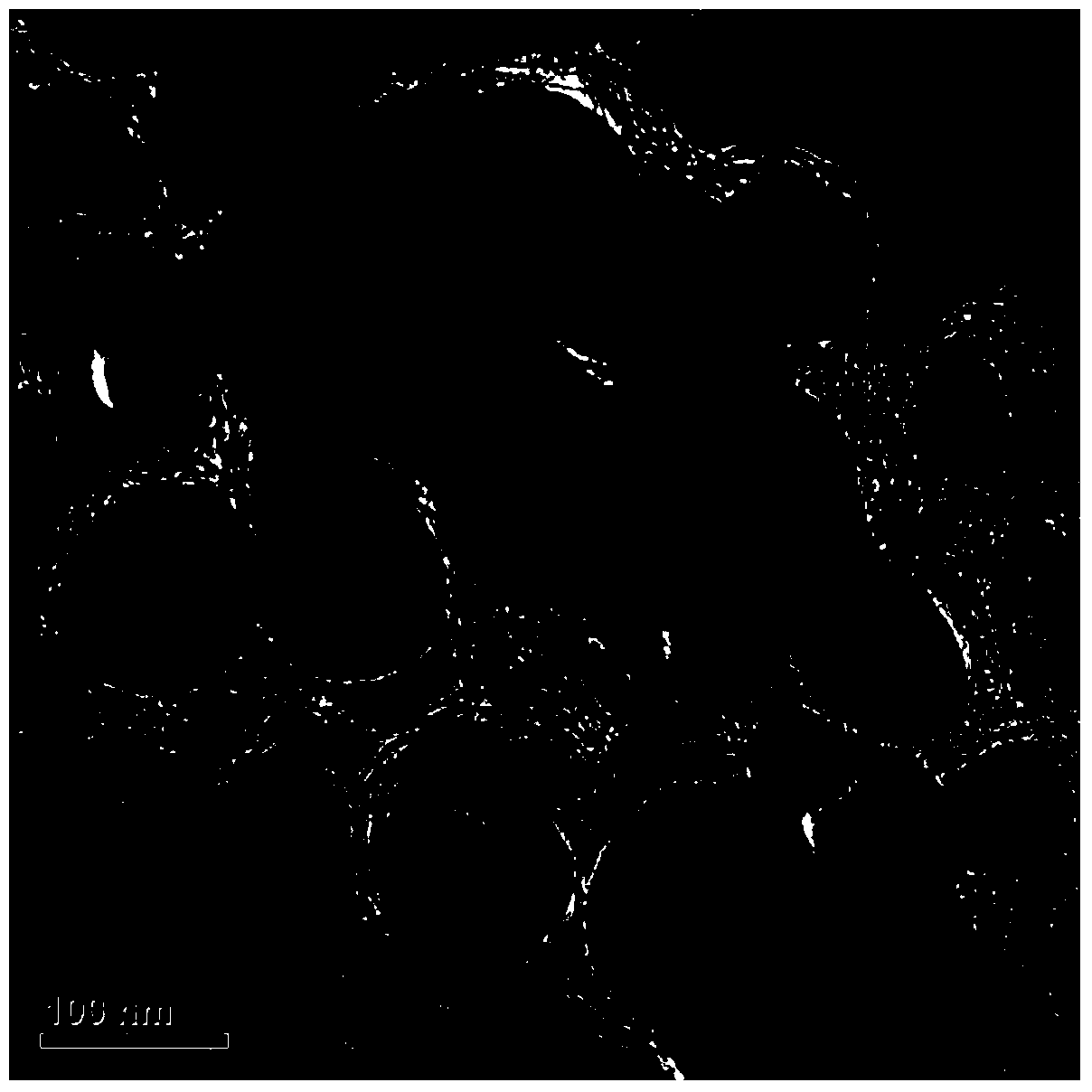

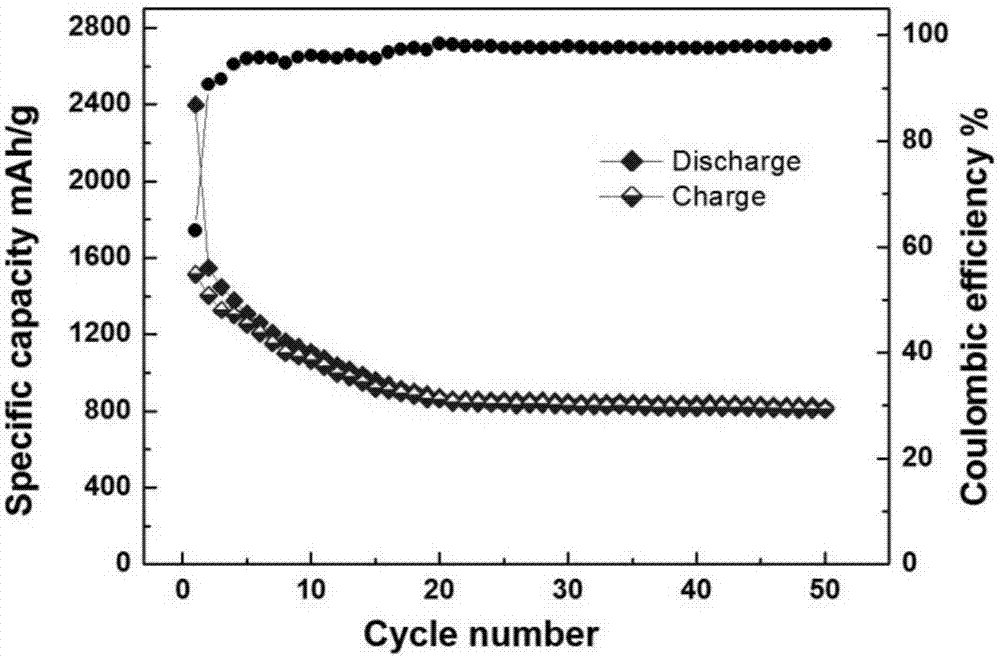

Egg-shaped dual-carbon shell layer tin-based negative electrode material of lithium ion battery and preparation method for negative electrode material

InactiveCN107369819AHigh specific capacityImprove conductivityMaterial nanotechnologyCell electrodesTin dioxideCarbonization

The invention provides an egg-shaped dual-carbon shell layer tin-based negative electrode material of a lithium ion battery and a preparation method for the negative electrode material. The egg-shell-shaped dual-layer carbon-coated stannic oxide nanocomposite comprises a porous stannic oxide sphere kernel and a dual-layer carbon shell for coating the surface of the porous stannic oxide sphere kernel, and a hollow layer exists between the two parts; the preparation method comprises the steps of preparing the egg-shell-shaped silicon dioxide-coated porous stannic oxide sphere nanocomposite by adopting a surfactant soft template method, and then attaching an organic pyrolytic carbon raw material on the surface of the nanocomposite, and performing a hydrothermal reaction and then carrying out condensation polymerization and carbonization to obtain the egg-shell-shaped carbon-silicon dioxide-carbon-coated stannic oxide sphere nanocomposite, and finally, performing etching by adopting a sodium hydroxide alkali solution to obtain the egg-shell-shaped dual-layer carbon-coated stannic oxide nanocomposite. Finally, the invention provides the tin-based negative electrode material of the lithium ion battery with nanometer scale, high conductivity and capability of effectively suppressing the volume effect of stannic oxide, and a preparation method for the negative electrode material.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

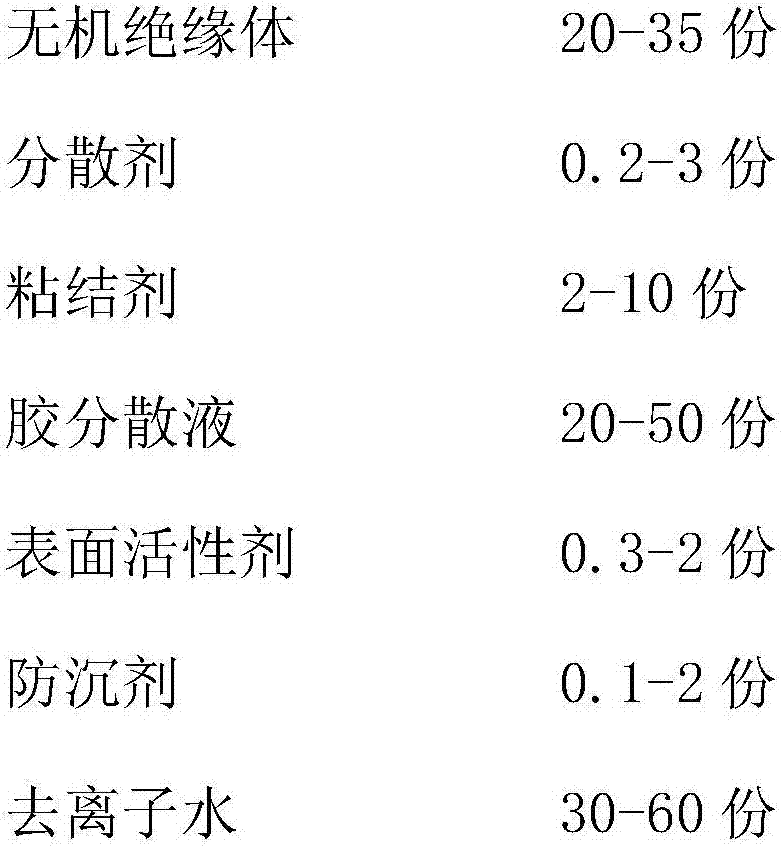

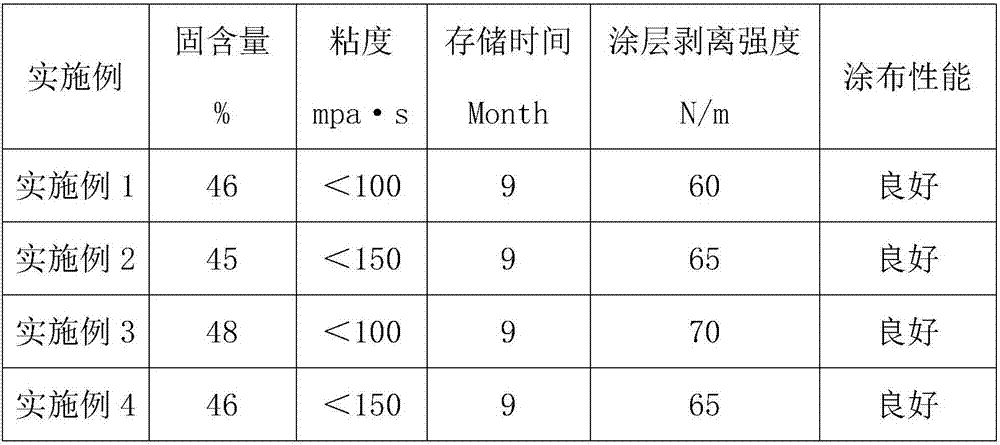

Waterborne slurry used for coating lithium ion battery diaphragm and preparation method for waterborne slurry

InactiveCN106997940AEasy to makeReduce pollutionCell seperators/membranes/diaphragms/spacersLow speedSlurry

The invention provides waterborne slurry used for coating a lithium ion battery diaphragm and a preparation method for the waterborne slurry. The waterborne slurry is prepared from the components of 20-35 parts of inorganic ceramic powder, 0.2-3 parts of dispersing agent, 2-10 parts of binder, 20-50 parts of adhesive dispersion liquid, 0.3-2 parts of surfactant, 0.1-2 parts of anti-settling agent and 30-60 parts of deionized water. The preparation method comprises the steps of adding the inorganic ceramic powder, the dispersing agent, the anti-settling agent and the deionized water into a dispersing machine based on proportion to be subjected to high-speed dispersion for 1-3h, and then adding the binder, the adhesive dispersion liquid and the surfactant to be subjected to low-speed dispersion for 0.5-2h and then enabling the obtained mixture to be sieved by a 200-mesh screen to obtain slurry; and finally uniformly coating the surface of a base diaphragm of the diaphragm with the slurry by using a coating machine, and drying the diaphragm. The waterborne slurry can be manufactured favorably, and also has the dual advantages of reduction of thermal shrinkage by virtue of the ceramic diaphragm, improvement of electrolyte wettability, and improvement of lithium ion battery interface and cycling performance due to the gummed diaphragm, and the like.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

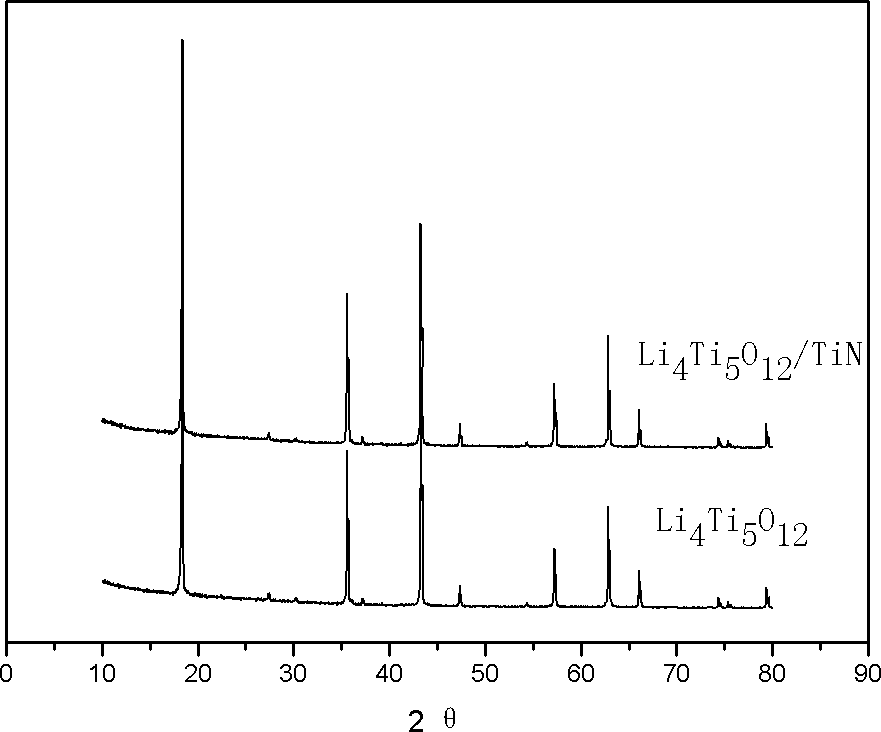

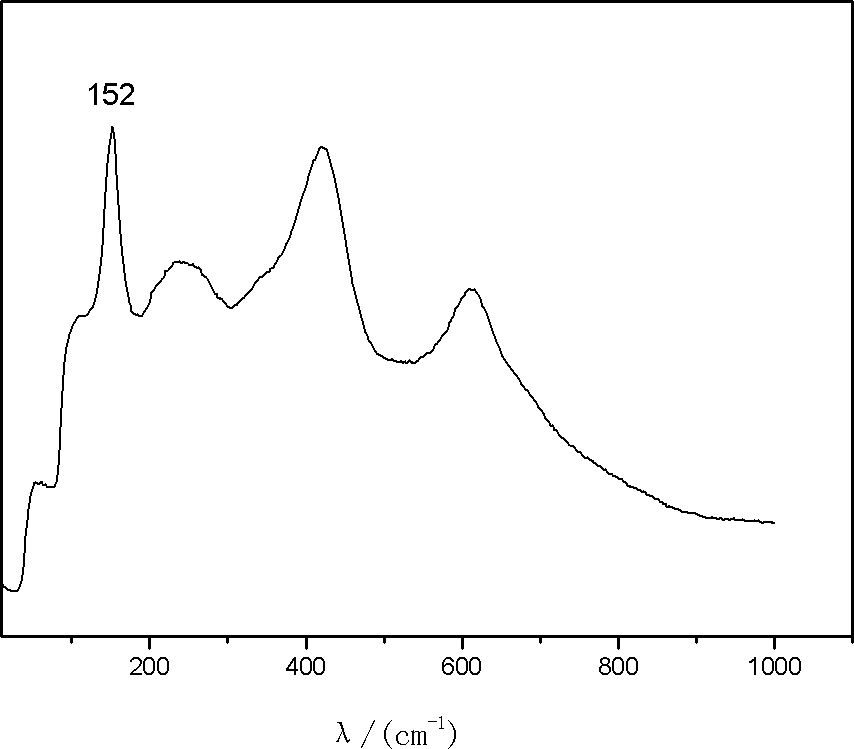

Anode material for lithium ion battery and preparation method thereof

InactiveCN102354748AImprove conductivityImprove high current charge and discharge performanceCell electrodesTitanium compoundsLithium electrodeLithium battery

The invention discloses a preparation method of an anode material for a lithium ion battery, which comprises the following steps of: mixing titanium dioxide with lithium carbonate to be ball-milled evenly, carrying out heat preservation for 10-180 minutes at the temperature of 750-850 DEG C and cooling to obtain lithium titanate; and mixing the lithium titanate with a solid-state nitrogen source compound to be calcined with the protection of protective gas, and obtaining the anode material for the lithium ion battery after reaction. In the step of preparing the lithium titanate, the time for heat preservation of raw materials at high temperature is greatly shortened, the aggregation of material particles caused by long-time ignition is avoided, the particle size of the lithium titanate is greatly reduced, and the modification area of TiN after the lithium titanate is nitrided is increased, so that the conductivity performance of the prepared anode material for the lithium ion battery is improved. In addition, due to the reduction of the particle size of the lithium titanate, the migration distance of lithium ions in a charge-discharge process of the lithium ion battery is reduced, and thus the large current charge-discharge performance of the anode material for the lithium ion battery is improved.

Owner:SUZHOU UNIV

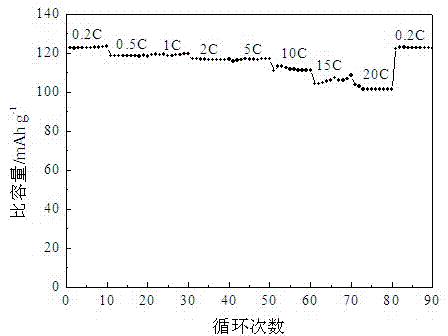

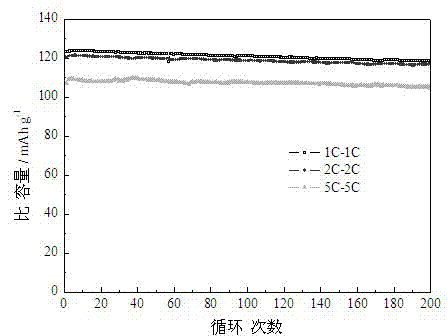

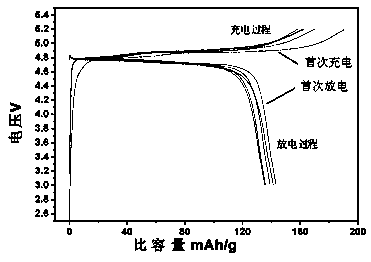

Preparation method of high-voltage nickel lithium manganate cathode material with porous morphology

A preparation method of a high-voltage nickel lithium manganate cathode material with porous morphology belongs to the field of material synthesis technology. The method is as below: calcining manganese salt at 200-800 DEG C for 3-10 h to obtain a porous manganese oxide A; weighing a lithium source, a nickel source and the manganese oxide A according to a molar ratio of Li:Ni:Mn=1-1.1:0.5:1.5, and mixing the three to obtain a precursor; putting the precursor in a muffle furnace air atmosphere, pre-sintering at 300-500 DEG C for 3-8 h, heating to 700-1000 DEG C and calcining for 8-20 h to obtain the nickel lithium manganate material. The particles of the nickel lithium manganate cathode material prepared by the invention have a porous structure and controllable morphology. The apertures in the porous nickel lithium manganate can buffer changes in structural stress and volume caused by lithium de-intercalation, enhance cycle performance, shorten transmission distance of lithium ions, increase the contact area of the electrode and an electrolyte and improve multiplying power performance, thereby gaining excellent multiplying power performance and cycle performance.

Owner:南京时拓能源科技有限公司

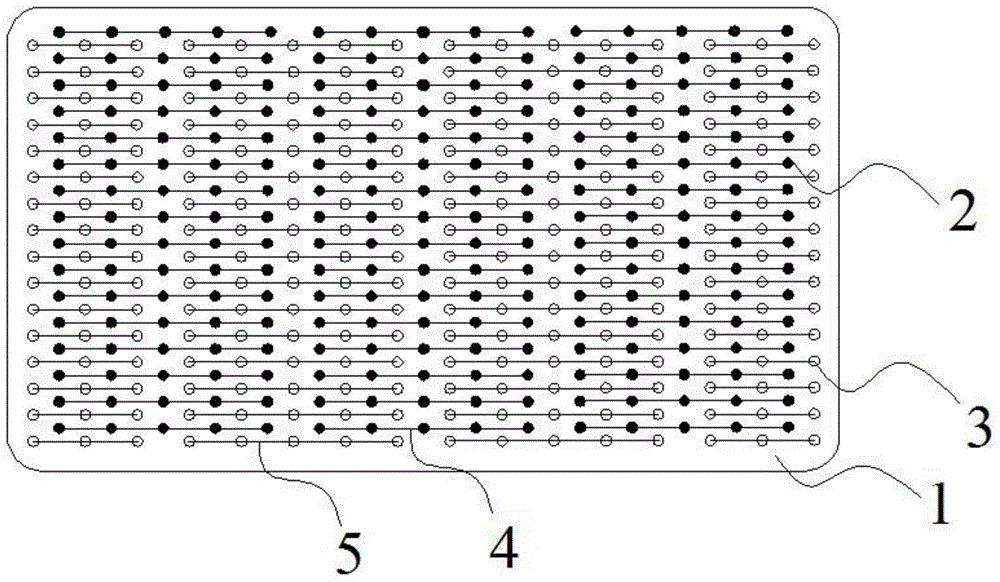

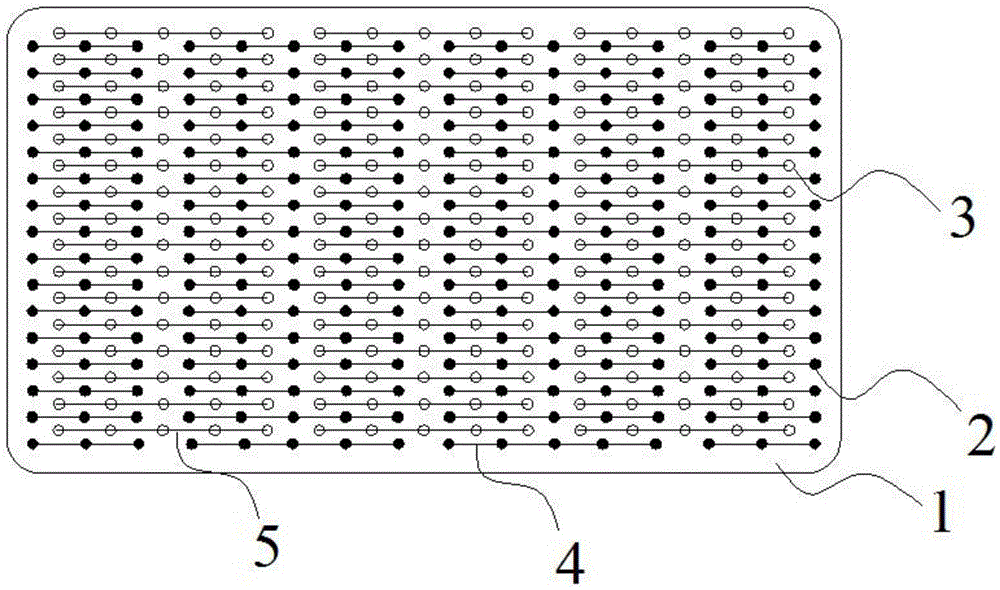

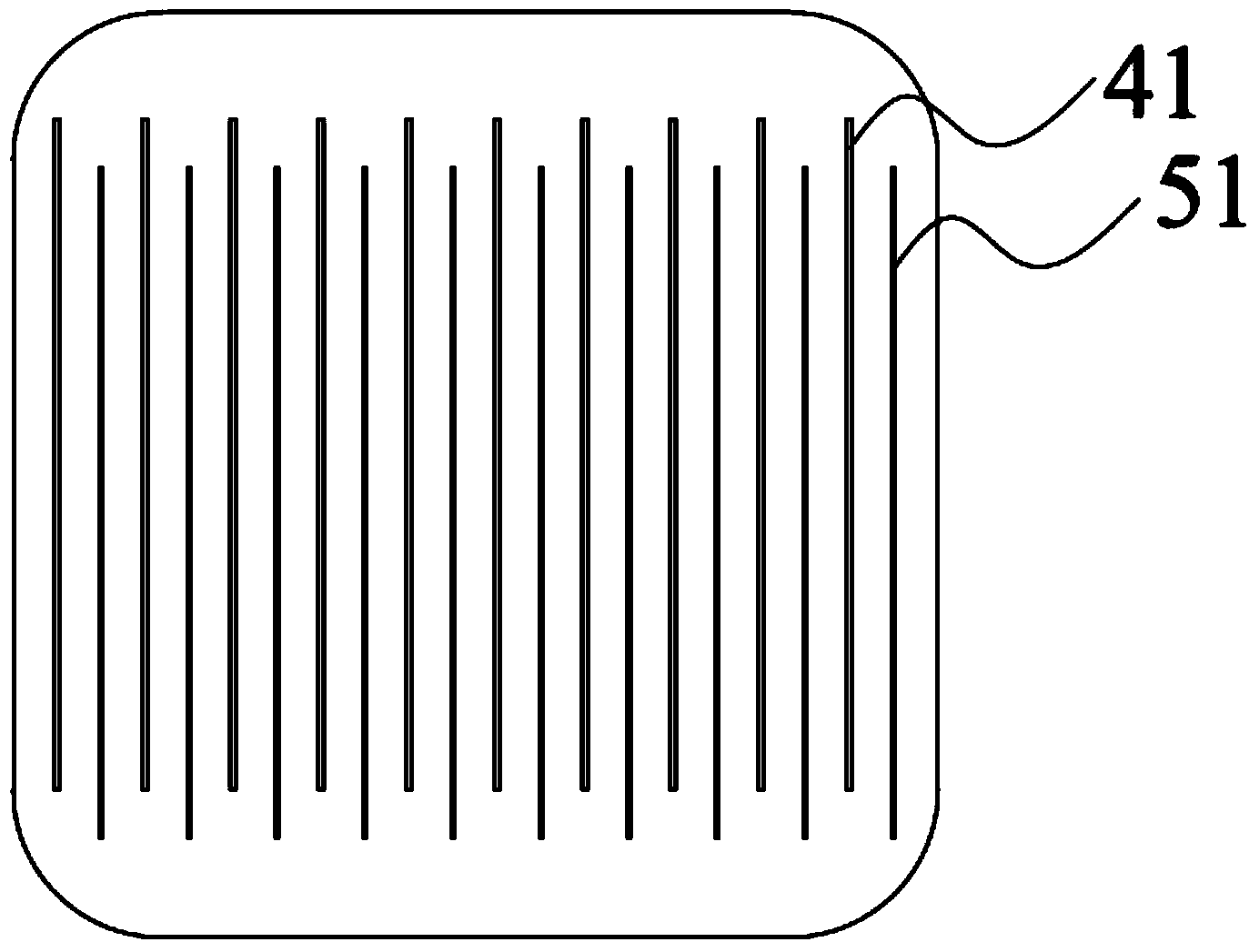

Main-grid-free efficient back-contact solar battery and assembly and manufacturing technology thereof

ActiveCN104576778AReduce the difficulty of serial connectionLow costFinal product manufacturePhotovoltaic energy generationElectricityFill factor

The invention relates to the field of solar batteries, in particular to a main-grid-free efficient back-contact solar battery and assembly and a manufacturing technology of the main-grid-free efficient back-contact solar battery and assembly. The main-grid-free efficient back-contact solar battery comprises a solar battery piece and an electric connection layer. The backlight surface of the solar battery piece is provided with an electrode P and an electrode N, wherein the electrode P is connected with a P-type doped layer, and the electrode N is connected with an N-type doped layer. The solar battery is characterized in that the electric connection layer comprises a plurality of conductive fine grid lines, the conductive fine grid lines are partially connected with the electrode P on the backlight surface of the solar battery piece, and the remaining conductive fine grid lines are connected with the electrode N on the backlight surface of the solar battery piece. The conductive fine grid lines are each of a multi-segment structure. The main-grid-free efficient back-contact solar battery and assembly and the manufacturing technology of the main-grid-free efficient back-contact solar battery and assembly have the advantages that the usage amount of silver paste is reduced, and the cost is lowered; as the multi-segment conductive fine grid lines are arranged, series resistance is lowered, and the transmission distance of fill factors is shortened; efficiency is improved, and meanwhile the stress on the battery piece by the conductive fine grid lines can be effectively reduced.

Owner:JOLYWOOD SUZHOU SUNWATT

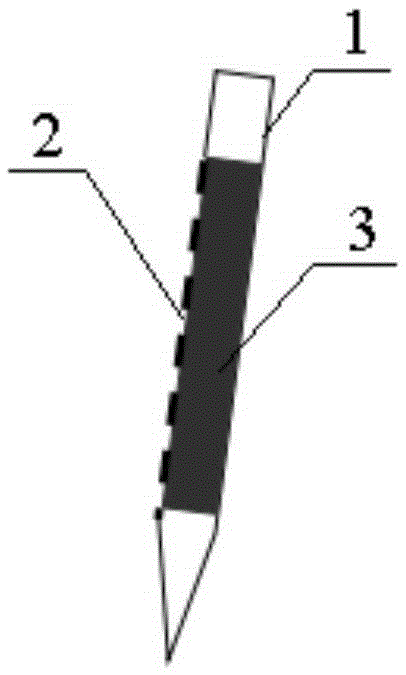

Fertilization rod and using method thereof

InactiveCN105248023ARegulating the rate of extravasationIncrease profitFertiliser distributersAgriculture gas emission reductionFruit treeOrnamental tree

The invention discloses a fertilization rod and a using method thereof. The fertilization rod is composed of a rod body and fertilizer. An opening is formed in the upper portion of the rod body. The bottom of the rod body is sealed. A plurality of thin holes are formed in one side of the rod body, and the interior of the rod body is filled with the fertilizer. The using method includes the following steps that the fertilization rod is inserted or wedged into soil around a water drip of a tree, the side with the holes faces the direction of a trunk, and the depth is commonly 20-30 cm. The fertilizer applying method is easy and convenient to operate, and the fertilization rod can be reused many times. Nutrients needed by plants are supplied in a full-thickness and full-time mode, the advantages of slow release, environmental friendliness and high fertilizer utilization rate are achieved, and the fertilization rod and the using method of the fertilization rod can be widely used for fruit trees, vines, ornamental trees and shrubs, potted flowers, bonsai plants and the like. Nutrient leaching loss is reduced, full-thickness and full-time nutrient supply is achieved, application is performed one time, and the fertilizer utilizing rate is increased. Labor force is saved, fertilizer invested cost is effectively reduced, the fertilizer utilizing rate is increased, and the effect of reducing nutrient leaching loss is especially obvious when the fertilization rod is used in sandy soil and soil low in organic matter content.

Owner:HEILONGJIANG ZHONGNONG XINXIN AGRI TECH DEV CO LTD +1

Preparation method of lithium iron phosphate/double carbon layer coated composite material

InactiveCN106848222AGood size controlPrimary particle size is smallCell electrodesCarbon layerSolvent

The invention provides a preparation method of a lithium iron phosphate / double carbon layer coated composite material. The preparation method comprises the following steps of: S1, preparing an iron source, a phosphorus source and a lithium source in a certain ratio of amount of substance, adding a reducing agent to stir, then adding mesoporous carbon, and performing ultrasonic stirring; S2, transferring a mixed liquid prepared in the S1 to a reaction kettle, performing a hydrothermal reaction, reducing the temperature to room temperature after reaction, and washing, blowing and drying the reaction product to obtain a composite material; S3, putting the composite material in a tubular furnace for first time high-temperature calcining, cooling the composite material and taking out the same, and washing and drying the same; and S4, dissolving an additive in absolute ethyl alcohol, adding the composite material prepared in the S3, stirring the mixture to prepare a second mixed liquid, putting the second mixed liquid in an oven to be dried, fully evaporating a solvent, putting the obtained product under protection of inert gas for second time high-temperature calcining, and cooling, washing and drying the product to obtain the secondarily granulated lithium iron phosphate / double carbon layer coated composite material.

Owner:OPTIMUM BATTERY CO LTD

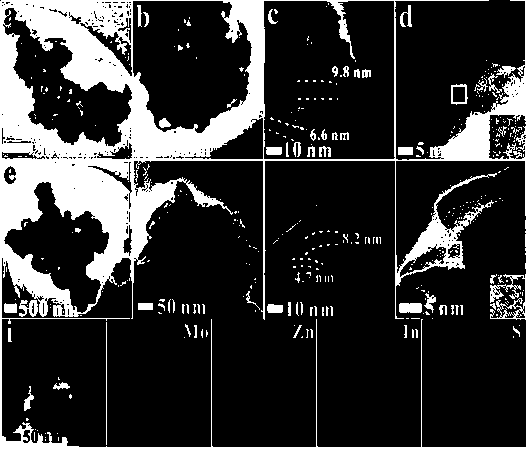

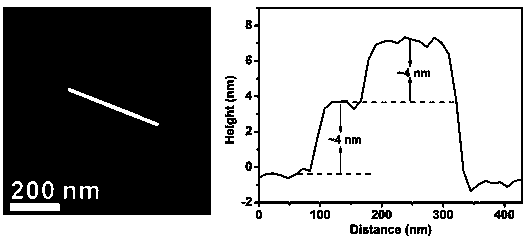

Molybdenum-doped zinc indium sulfide (ZnIn2S4) hollow hierarchical structure photocatalyst applied to photocatalytic water splitting for hydrogen production, and preparation method thereof

ActiveCN110694648AAvoid excessive consumptionImprove controllabilityMaterial nanotechnologyCatalyst activation/preparationPhotocatalytic water splittingActive agent

The invention discloses a molybdenum-doped ZnIn2S4 hollow hierarchical-structure photocatalyst applied to photocatalytic water splitting for hydrogen production, belonging to the field of photocatalyst preparation and application. According to the invention, molybdenum powder serves as a molybdenum source, and the molybdenum-doped ZnIn2S4 hollow hierarchical-structure photocatalyst is prepared through a one-step solvothermal method. The method does not use a template agent or a surfactant, is simplified in preparation steps, and avoids excessive consumption of raw material and energy; preparation process is simple, and the raw materials are widely available; and the efficient photocatalyst is designed, regulated and controlled from the two aspects of structure and composition, so the economic benefit of photocatalysis is expected to be remarkably improved, and the industrialization process of photocatalysis is promoted.

Owner:FUZHOU UNIV

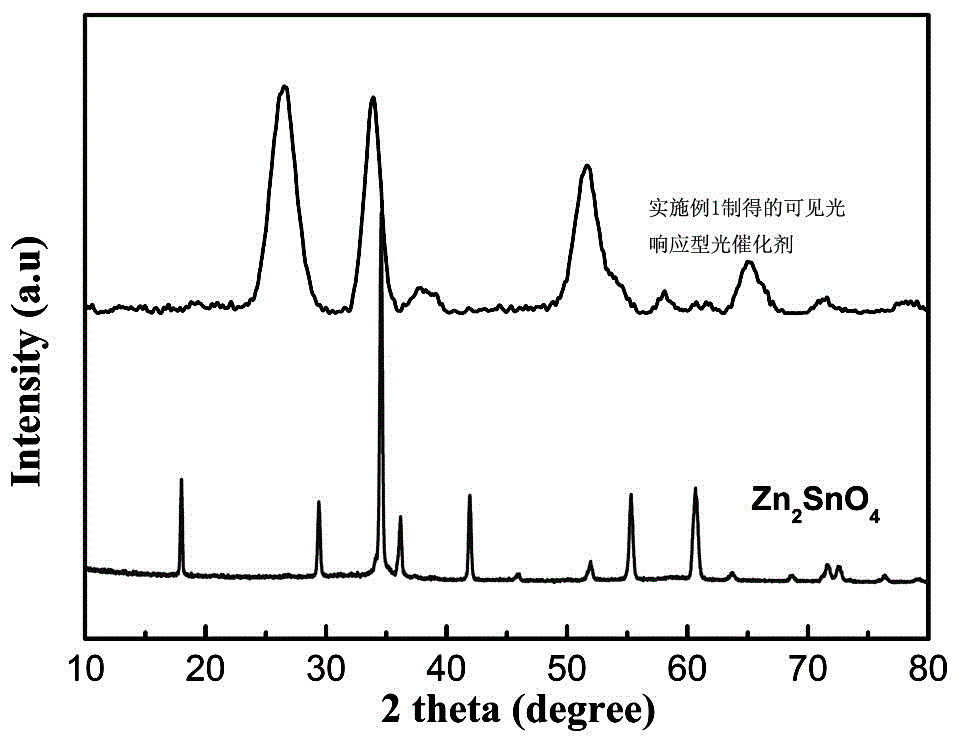

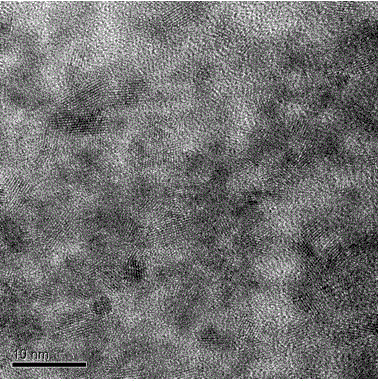

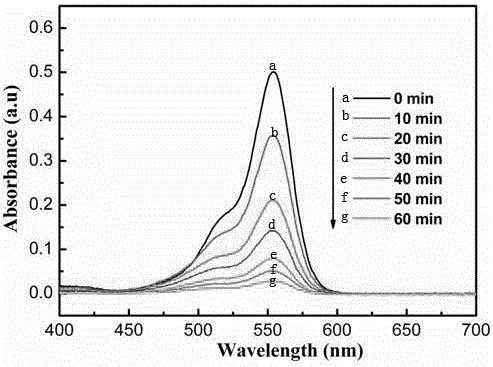

Method for preparing visible-light response photocatalyst by utilizing nano Zn2SnO4

ActiveCN106512978AHigh purityEasy to operateWater/sewage treatment by irradiationWater contaminantsAbsorption capacityNanostructure

The invention discloses a method for preparing a visible-light response photocatalyst by utilizing nano Zn2SnO4. The method comprises a step of preparing a solvent thermal product, a step of preparing Zn2SnO4 nano powder, a step of preparing a turbid liquid, a step of preparing a hydrothermal reaction product and a step of preparing the visible-light response photocatalyst. According to the method disclosed by the invention, a synthesis process is simple and convenient, impurities introduced by follow-up processes such as high-temperature calcining and ball-milling and structure defects are avoided, operations are easy, and purity of products synthesized by reaction is high. The visible-light response photocatalyst synthesized by the method is a nano structure, is small in crystalline grain, and has a mesoporous structure and a relatively great surface area, so that light absorption capacity of the visible-light response photocatalyst is strengthened; and meanwhile, a migration distance of light-generated electrons is shortened, and recombination probability of light-generated electrons and electron-hole pairs is reduced.

Owner:LUOYANG INST OF SCI & TECH

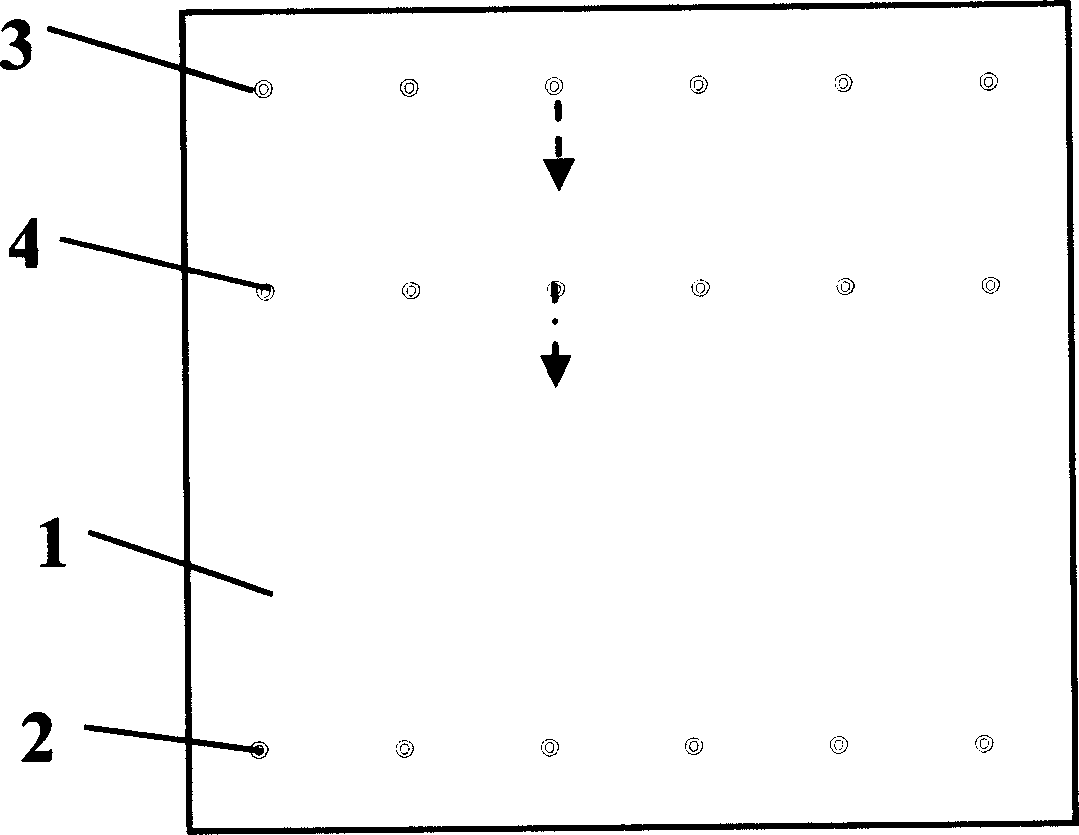

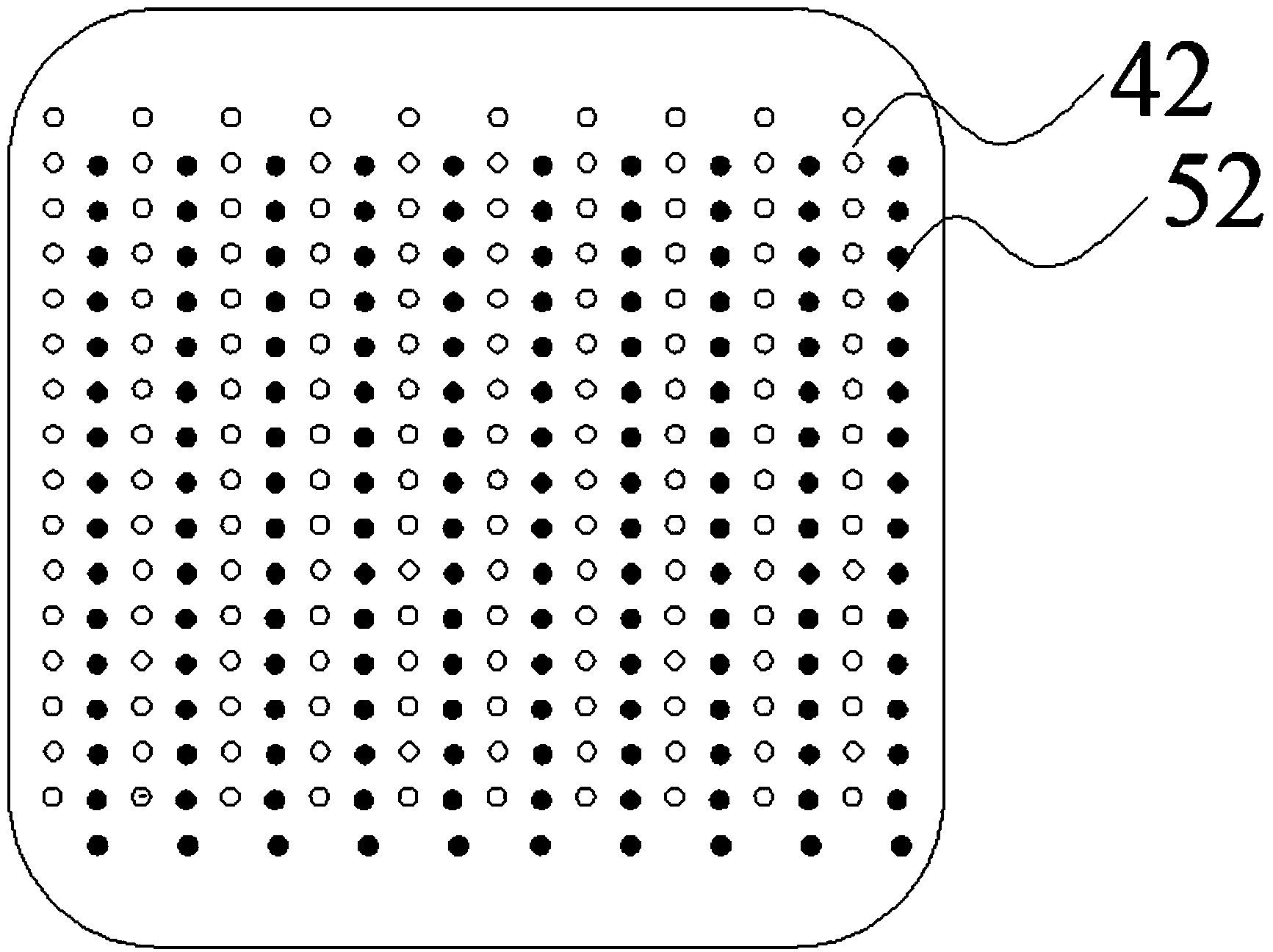

Main-grid-free high-efficiency back contact solar battery module, assembly and preparing process

ActiveCN104253169AReduce dosageReduce usageFinal product manufacturePhotovoltaic energy generationP type dopingElectrical battery

The invention relates to the field of solar batteries, in particular to a main-grid-free high-efficiency back contact solar battery module, an assembly and a preparing process. The solar battery module comprises a battery piece and an electric connecting layer, wherein the back light side of the battery piece is provided with an electrode P connected with a P type doping layer and an electrode N connected with an N type doping layer. The solar battery module is characterized in that the electric connecting layer comprises a penetrating hole and a conducting wire, the conducting wire is respectively arranged at the front side and the back side of the electric connecting layer, the front side conducting wire is electrically connected with any one electrode, the back side conducting wire is electrically connected with the other electrode through conducting media in the through hole, and the electric connecting layer is made of insulation materials. The solar battery module, the assembly and the preparing process have the beneficial effect that the low-cost hidden-crack-resistant high-efficiency and high-stability solar battery assembly capable of preventing emitting electrode P and emitting electrode N short circuit is provided.

Owner:山西中来光能电池科技有限公司

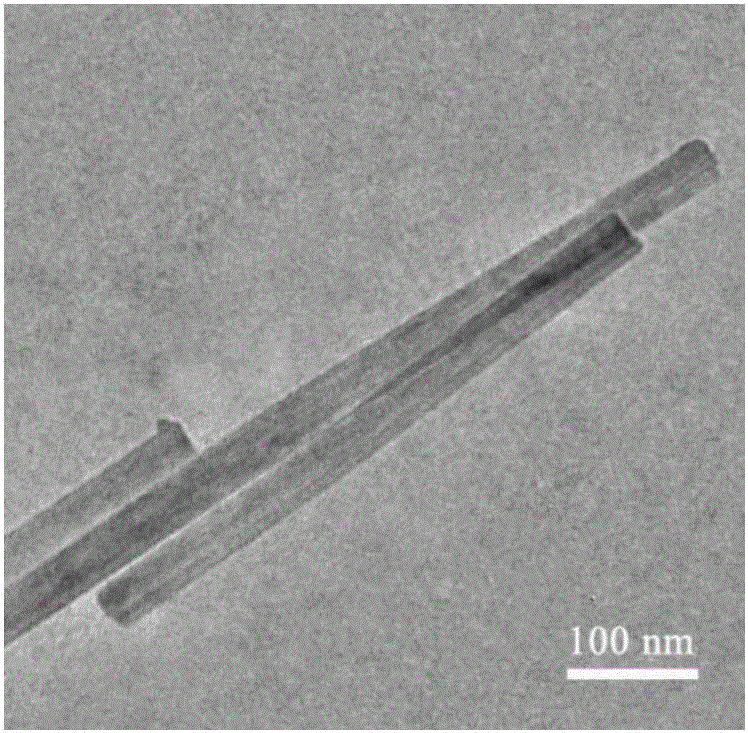

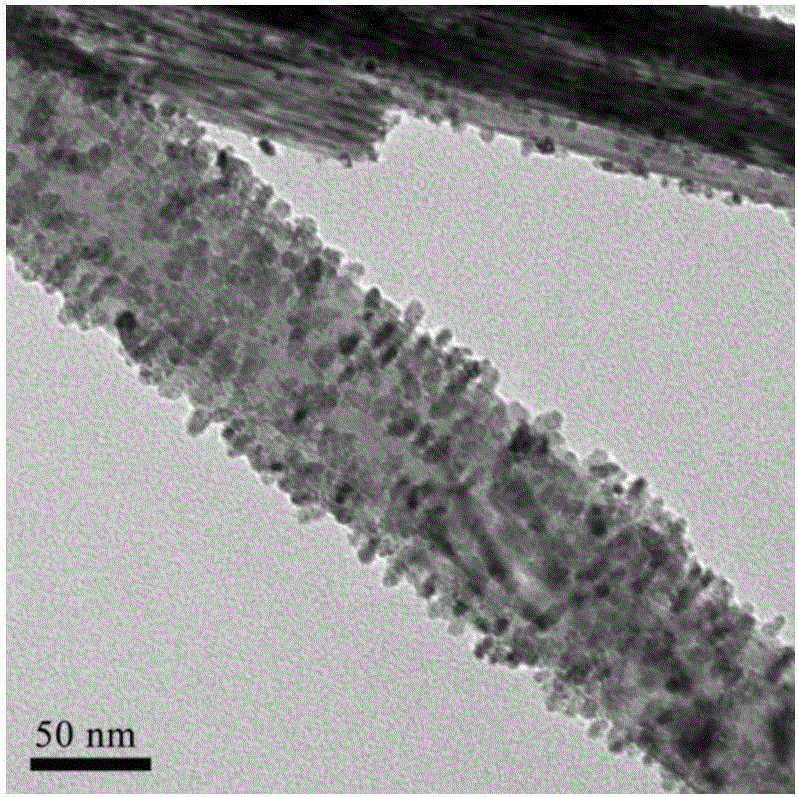

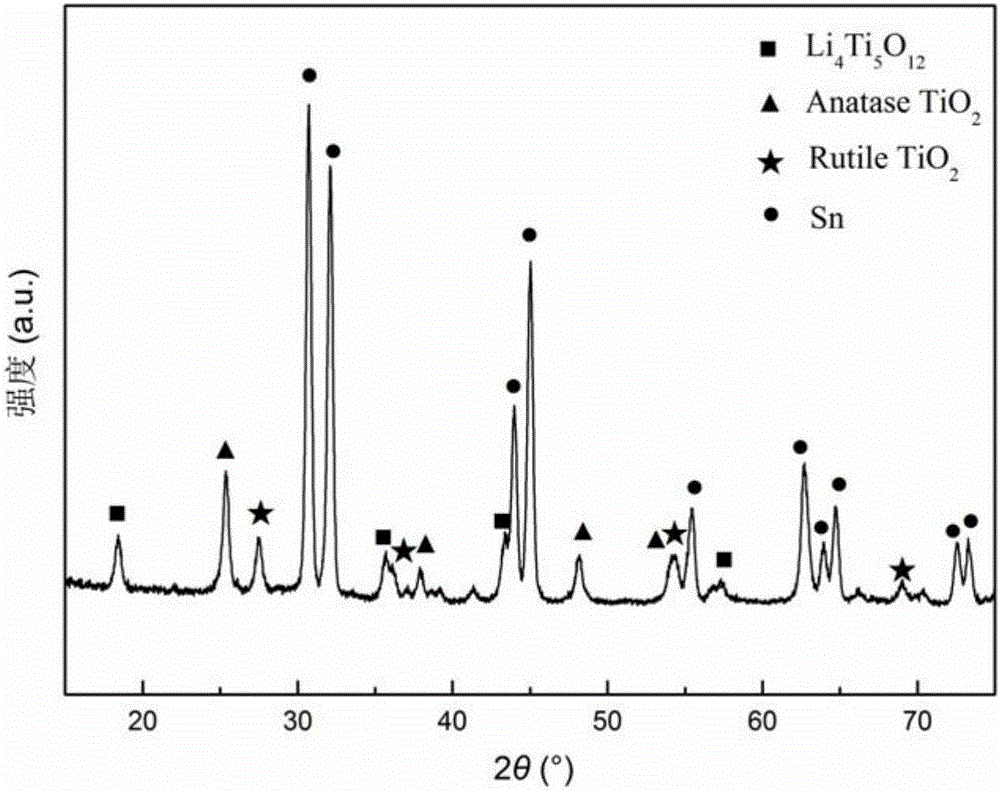

Carbon-coated Li4Ti5O12-TiO2/Sn nanocomposite and preparation and application thereof

InactiveCN105206815ASmall volume changeHigh specific capacityMaterial nanotechnologyCell electrodesFast chargingSize change

The invention belongs to the technical field of preparation and application of nano materials and particularly relates to a carbon-coated Li4Ti5O12-TiO2 / Sn nanocomposite and preparation and application thereof. The carbon-coated Li4Ti5O12-TiO2 / Sn nanocomposite is composed of 19wt%-65wt% of Li4Ti5O12, 11wt%-57wt% of TiO2, 23wt%-49wt% of Sn and 1wt%-24wt% of a carbon coating layer. The carbon-coated Li4Ti5O12-TiO2 / Sn nanocomposite gives play to synergistic effects of the carbon coating layer with functions of electronic conductivity improvement and ion permeability improvement, the metal Sn with high specific capacity and a one-dimensional nano Li4Ti5O12-TiO2 substrate with small size change in an electrochemical lithium intercalation process, shows excellent electrochemical performances and has a promising application prospect in fields of lithium ion batteries in fast-charge electronic products, electric vehicles and the like.

Owner:TSINGHUA UNIV

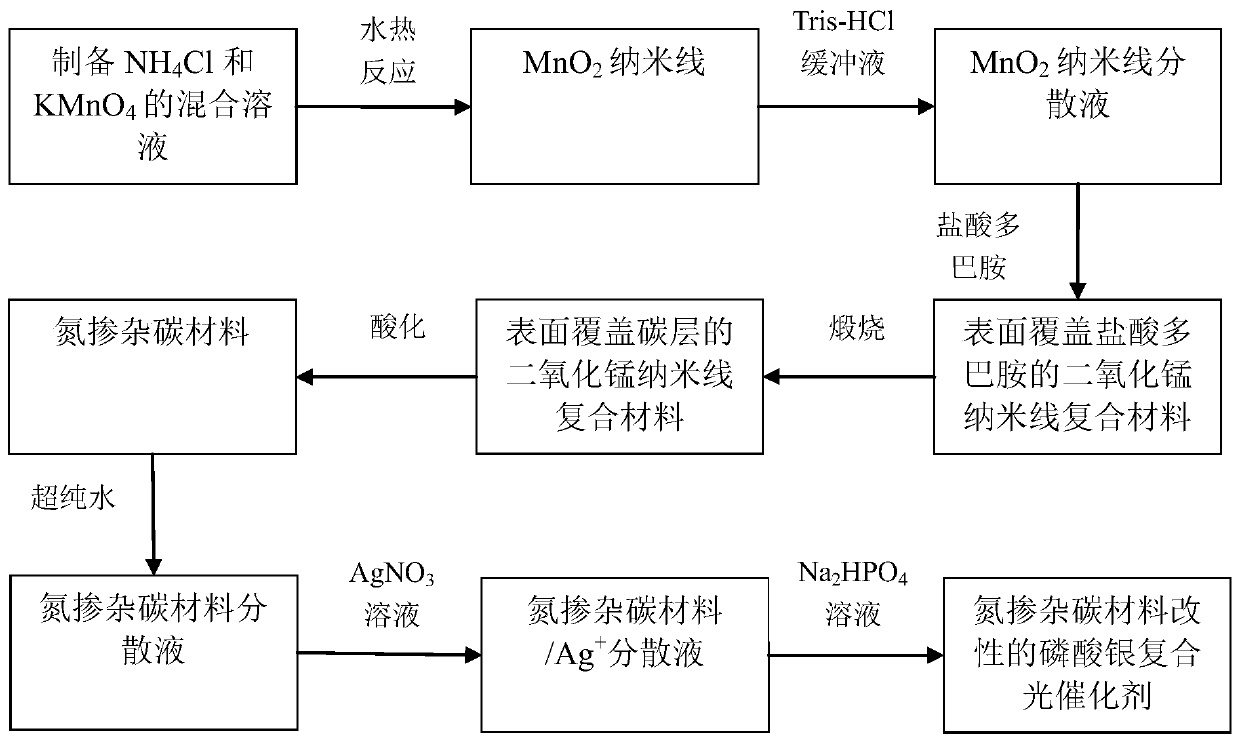

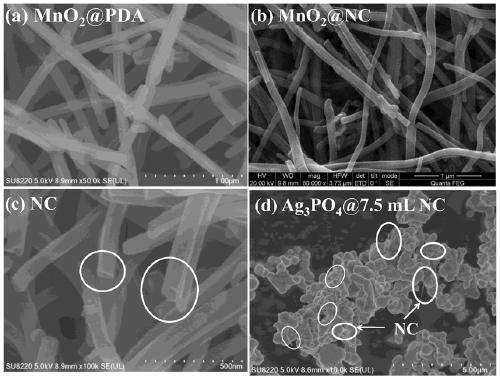

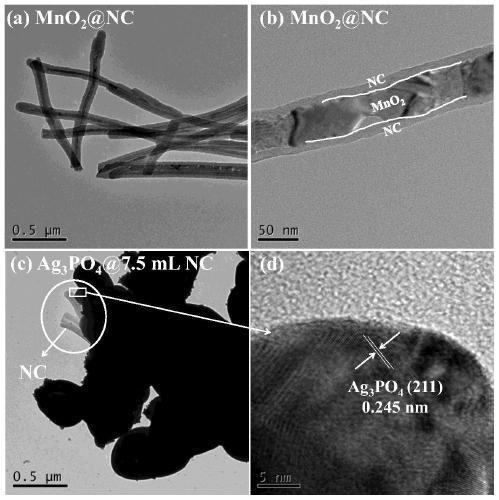

Nitrogen-doped carbon material modified silver phosphate composite photocatalyst, preparation method and application thereof

ActiveCN111389449AImprove conductivityImprove photocatalytic efficiencyPhysical/chemical process catalystsWater/sewage treatment by irradiationSilver phosphateVisible light photocatalytic

The invention discloses a nitrogen-doped carbon material modified silver phosphate composite photocatalyst, a preparation method and application thereof. The silver phosphate composite photocatalyst comprises a nitrogen-doped carbon material, and silver phosphate particles are loaded on the nitrogen-doped carbon material. The preparation method comprises the following steps: preparing the nitrogen-doped carbon material into a nitrogen-doped carbon material dispersion liquid, adding an Ag<+> solution to prepare a nitrogen-doped carbon material / Ag<+> dispersion liquid, and adding an HPO4<2-> solution to prepare the silver phosphate composite photocatalyst. The silver phosphate composite photocatalyst disclosed by the invention has the advantages of high photo-induced electron-hole pair separation efficiency, strong light corrosion resistance, strong photocatalytic activity and the like, is a novel efficient visible light photocatalyst, can be widely applied to removal of organic pollutants in the environment, and has very high use value and very good application prospect. The preparation method of the silver phosphate composite photocatalyst has the advantages of simple process, operation method, low cost, greenness, no pollution and the like, is suitable for large-scale preparation, and is beneficial to industrial application.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Carbon nitride-supported molybdenum nitride nanoparticle photocatalyst, and preparation method and application thereof

InactiveCN108786888AEasy to separateEasy constructionPhysical/chemical process catalystsHydrogen productionPhotocatalytic water splittingDecomposition

The invention discloses a carbon nitride-supported molybdenum nitride nanoparticle photocatalyst, and a preparation method and an application thereof. The preparation method comprises the steps: firstly, preparing ultra-thin precursors of CN and Mo2N, and then preparing a Mo2N aqueous solution and a CN ethanol dispersion solution; and then dropping the CN ethanol dispersion solution into the Mo2Naqueous solution in a 70 DEG C oil bath, stirring and mixing, then centrifuging, washing and drying to obtain the carbon nitride-supported molybdenum nitride nanoparticle photocatalyst. The photocatalyst has the advantages of wide light absorption range, property of high decomposition of water to produce hydrogen, low electrical resistivity, fast current carrier transfer ability, high photogenerated current carrier separation ability, low current carrier recombination rate, good hydrogen evolution circulation stability and the like, is used for photocatalytic decomposition of water to producehydrogen, and has the highest hydrogen production rate reaching 0.89 [mu]mol.g<-1>.h<-1>. The preparation method has the advantages of simple operation, low cost and non-toxic used raw materials, andconforms to production of the concept of environmental protection.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

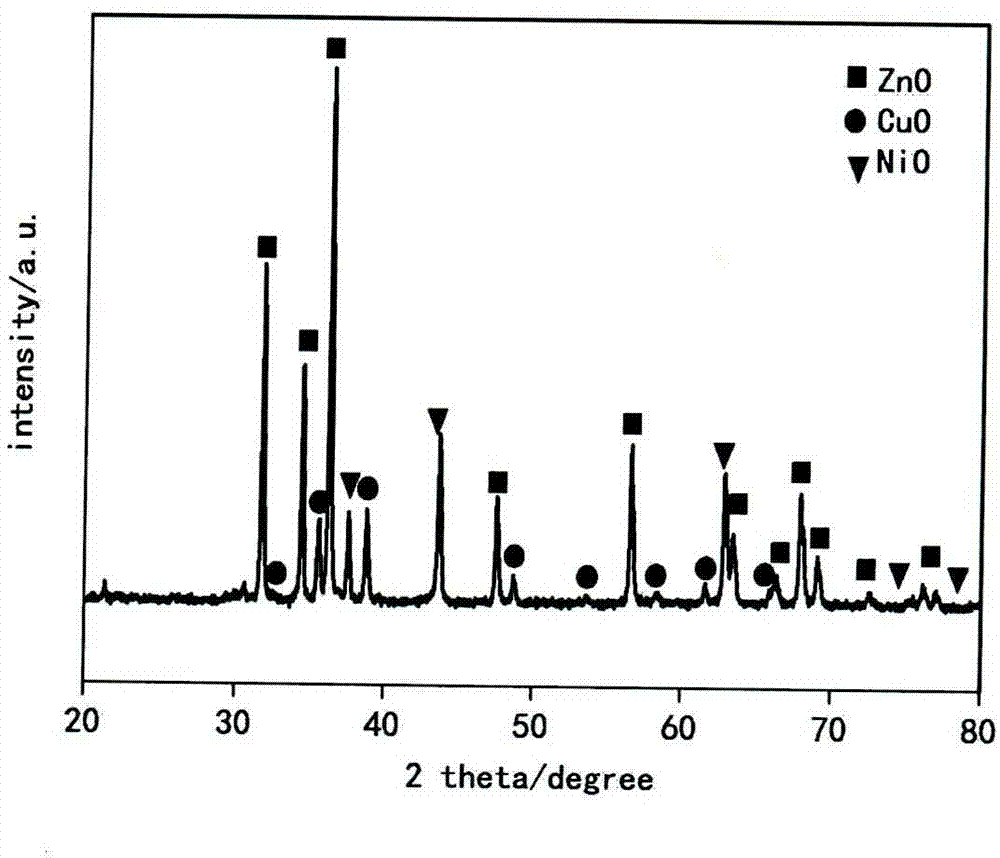

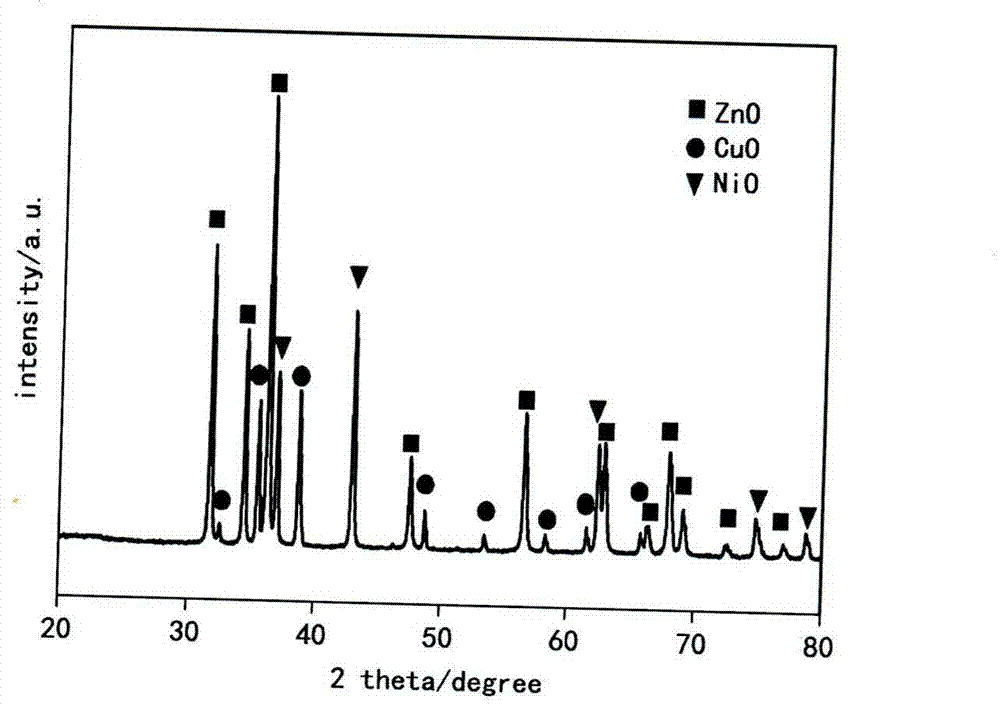

Preparation method of multiple-duct composite metal oxide

InactiveCN103111301ALow costEasy to operateMetal/metal-oxides/metal-hydroxide catalystsOxideCitric acid

The invention discloses a preparation method of a multiple-duct composite metal oxide. The preparation method comprises the following steps of: adding metal salt and citric acid to a surfactant or a segmented copolymer which is taken as a soft template and a brine shrimp egg shell which is taken as a hard template;, and stirring to obtain wet gel; drying the wet gel in a drying box, and calcining the dried gel in a muffle to obtain the multiple-duct composite metal oxide. The preparation method is low in cost, simple in process, easy to control and good in repeatability, ensures that pore size distribution is uniform and pore walls are communicated with one another, and can be widely applied to the fields of catalysis, fuel batteries and electrode materials.

Owner:YANSHAN UNIV

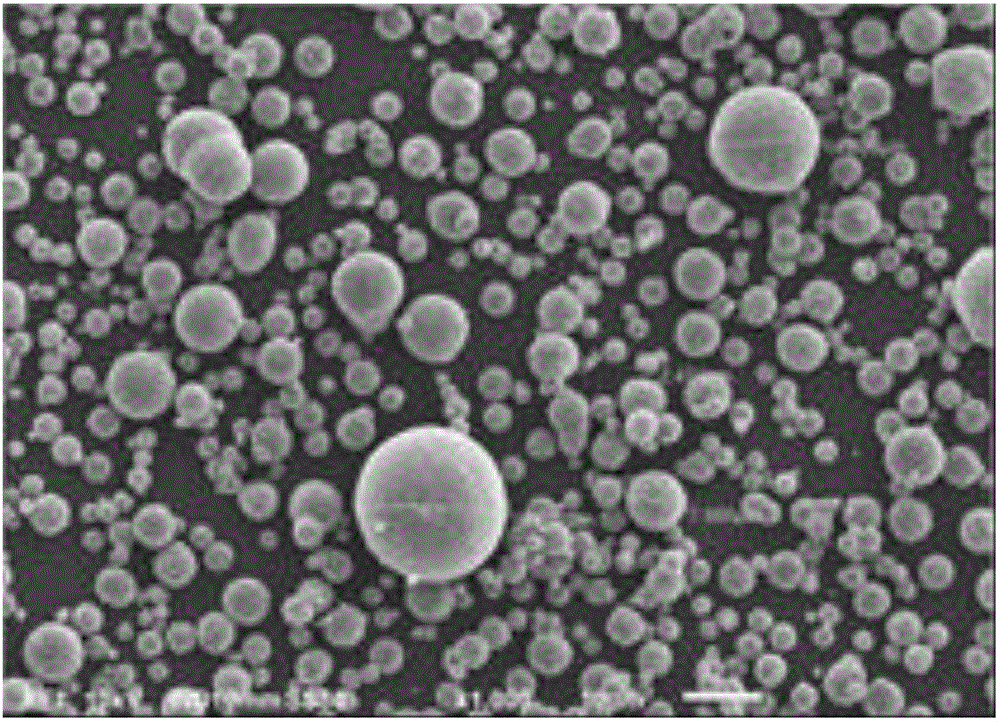

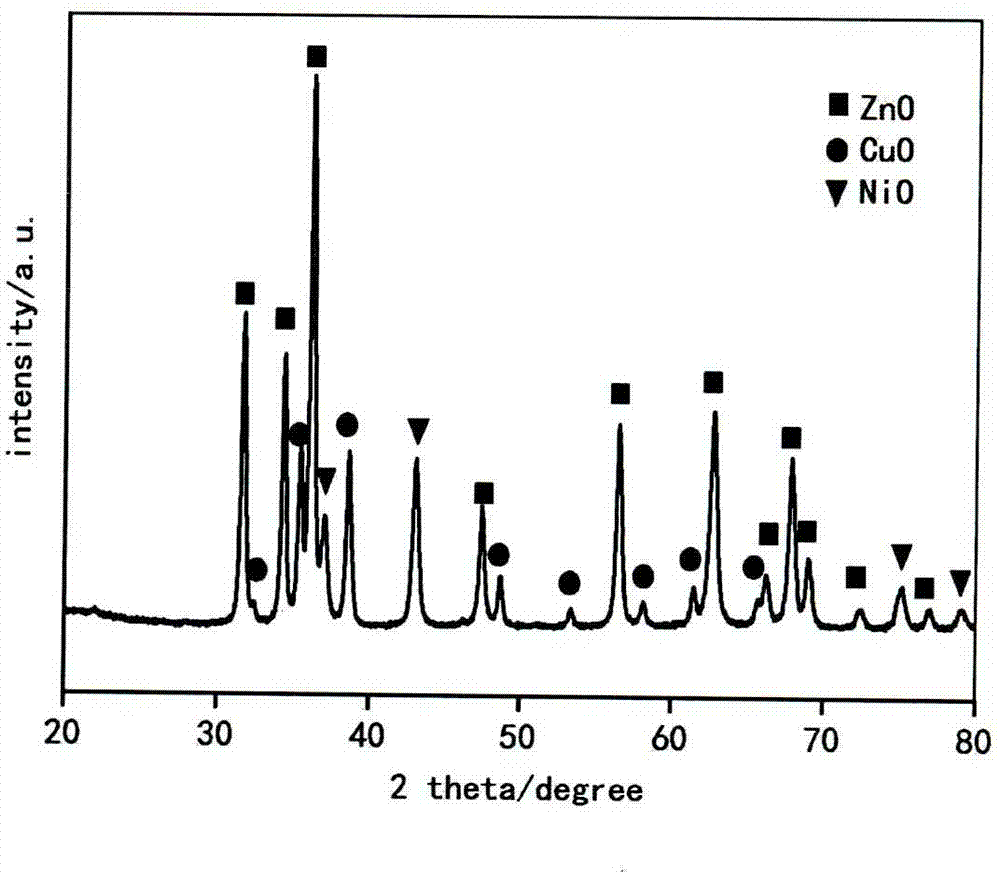

Preparation method of ternary layered positive electrode material for sodium ion battery

ActiveCN108539141AImprove performanceSimple preparation processCell electrodesSecondary cellsSlurrySodium-ion battery

The invention provides a preparation method of ternary layered positive electrode material for a sodium ion battery. The preparation method comprises the following steps: mixing sodium carbonate, manganese monoxide, ferrous oxide and nickel oxide according to a given ratio, adding deionized water, preparing the mixture slurry with a solid content of 30 to 45 percent, ball milling, obtaining a uniformly-mixed raw material with small particles, obtaining a precursor in an atomizing manner, wherein the precursor consists of spherical particles formed by clustering small particles, calcining the spherical particles at high temperature, preserving the heat for a given time, cooling, and obtaining the needed NaMn1-x-yFexNiyO2(x is greater than 0 and less than 0.5, and y is greater than 0 and less than 0.5) positive electrode material. The ternary layered positive electrode material for the sodium ion battery synthesized in the invention has the spherical particle appearance characteristic and nano porous internal structure, so that the transport distance of the sodium ions between the interior of a material lattice and electrolyte can be reduced, and the electrochemical performance of the material can be improved.

Owner:浙江钠创新能源有限公司

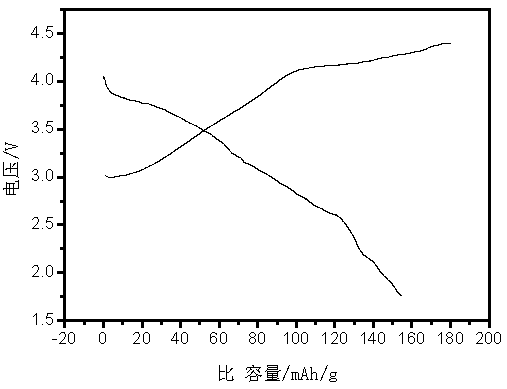

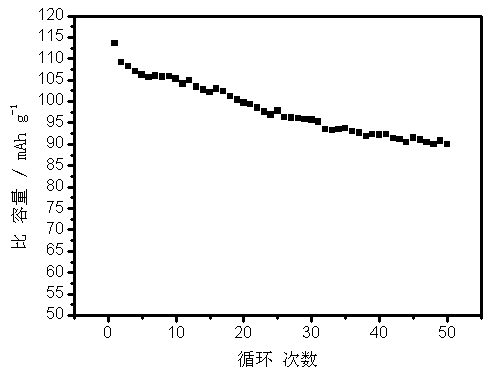

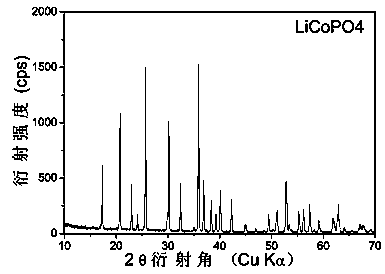

Synthetic method for cathode material lithium cobaltous phosphate used for lithium ion batteries

InactiveCN103413918AShorten migration distanceHigh rate characteristicsMaterial nanotechnologyCell electrodesO-Phosphoric AcidLithium hydroxide

The invention discloses a synthetic method for a cathode material lithium cobaltous phosphate used for lithium ion batteries. The method comprises a step of dissolving cobaltous acetate in deionized water to prepare an aqueous solution of the cobaltous acetate; a step of dissolving lithium hydroxide and sucrose in deionized water to prepare a lithium hydroxide / sucrose mixed solution; a step of adding phosphoric acid in deionized water to prepare a phosphoric acid solution; a step of adding the phosphoric acid solution into the aqueous solution of the cobaltous acetate to obtain a burgundy emulsion, stirring uniformly, adding the lithium hydroxide / sucrose mixed solution into the burgundy emulsion, mixing uniformly, and adding nitric acid to obtain a precursor solution; a step of subjecting the precursor solution under stirring to spray drying to obtain a precursor of lithium cobaltous phosphate powder; and a step of subjecting the precursor of the lithium cobaltous phosphate powder to vacuum calcination at 600-750 DEG C for 16-26 h to obtain the cathode material lithium cobaltous phosphate with a spherical porous structure and a high specific capacity.

Owner:SHANGHAI INST OF TECH

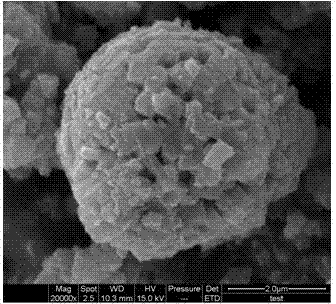

Three-dimensional porous nanocarbon composite lithium manganate spherical positive electrode material and preparation method thereof

InactiveCN103904322AExcellent high temperature cycle performanceExcellent high rate charge and discharge performanceCell electrodesSecondary cellsMicrosphereManganate

The invention discloses a three-dimensional porous nanocarbon composite lithium manganate spherical positive electrode material and a preparation method thereof. The preparation method comprises the following steps of adsorbing Mn<2+> ions onto a carbonyl (-COH-) group in a microgel three-dimensional macromolecular network by adopting poly(acrylamide, acrylic acid) microgel spheres as a template; increasing the pH value of the poly(acrylamide, acrylic acid) microgel spheres so as to in-situ hydrolyze the Mn<2+> ions to generate Mn(OH)2 crystal nucleus, depositing the Mn(OH)2 crystal nucleus into a space formed by the three-dimensional macromolecular network to form nano composite polymer microspheres; placing the obtained nano composite polymer microspheres into a tubular furnace to be calcined at a high temperature in an inert gas atmosphere to prepare the three-dimensional porous nanocarbon composite lithium manganate spherical positive electrode material. The positive electrode material has the advantages of excellent high-temperature cycling performance, large multiplying power charging-discharging performance and the like, and can be widely applied to the production of a lithium battery.

Owner:XIANGTAN UNIV

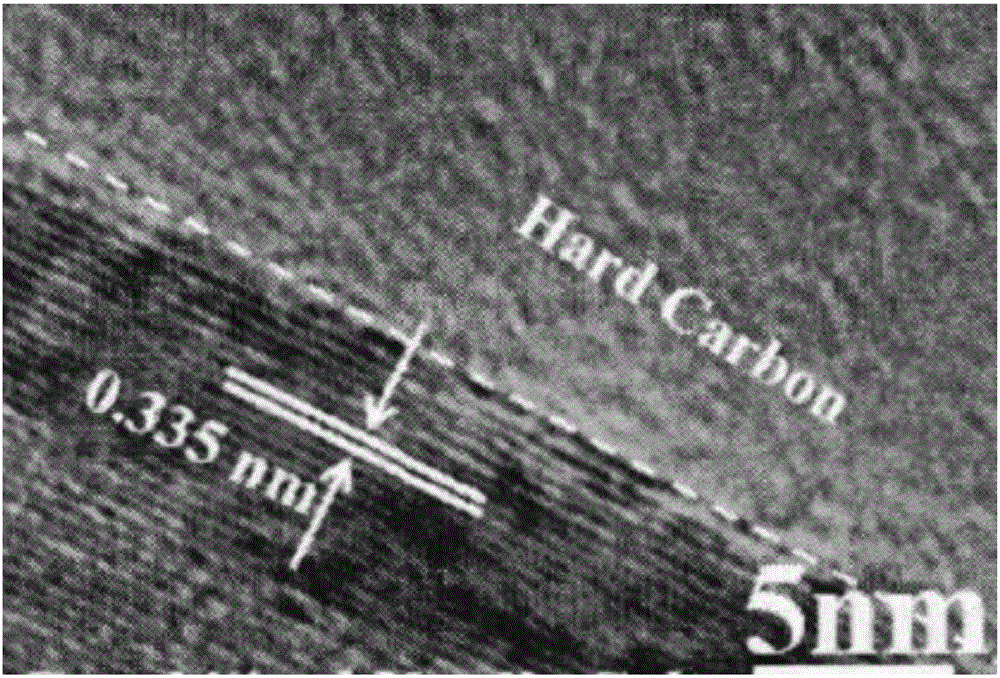

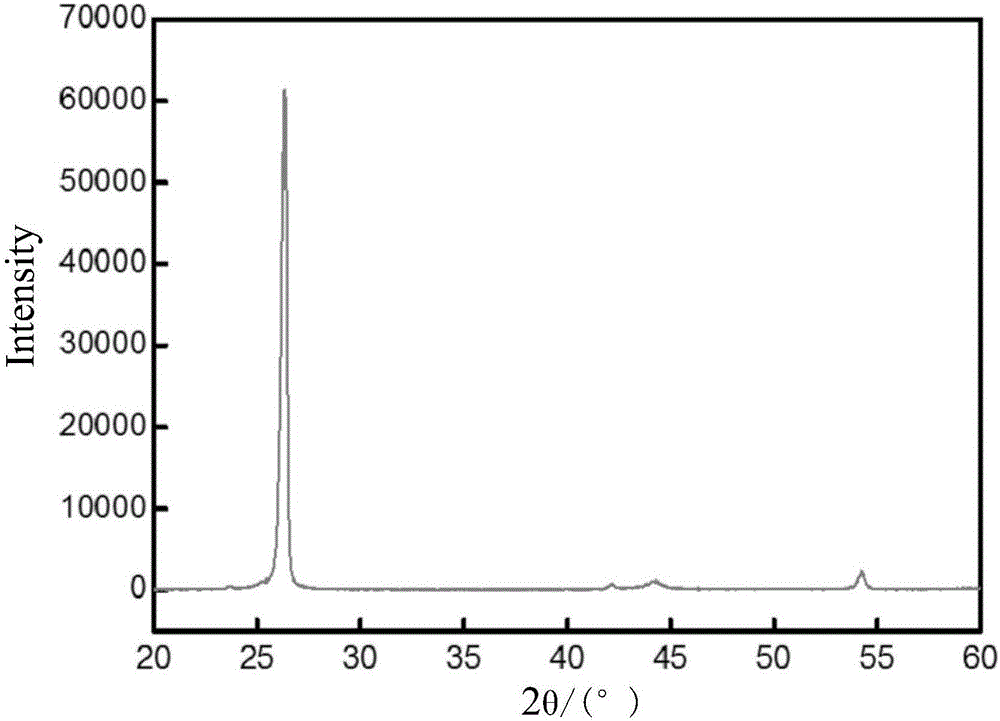

Preparation method of graphitized carbon negative electrode material

PendingCN106848258AIncrease electron densityImprove electronic conductivityCell electrodesGrapheneSucroseMetallurgy

The invention provides a preparation method of a graphitized carbon negative electrode material. The preparation method comprises the following steps: 1) calcining fatty acid in a nitrogen atmosphere at the temperature of 600-800 DEG C for 6-8h and cooling, so as to obtain amorphous carbon; 2) calcining the amorphous carbon in a nitrogen atmosphere at the temperature of 2,500-2,800 DEG C for 4-6h and cooling, so as to obtain graphitized carbon; 3) dispersing the graphitized carbon and a certain amount of nitrogenous polymers into anhydrous ethanol, uniformly mixing the mixture, atomizing to form balls and collecting precursors with a cyclone separator; 4) carbonizing the precursors in a nitrogen atmosphere at the temperature of 800-1,000 DEG C for 2-4h and cooling, so as to obtain porous graphitized carbon; 5) dispersing the porous graphitized carbon and a certain amount of sucrose into deionized water, uniformly mixing the mixture and performing air blast drying on the mixture at the temperature of 120-150 DEG C; carbonizing the mixture in a nitrogen atmosphere at the temperature of 800-1,000 DEG C for 2-3h and cooling, so as to obtain N-doped carbon-coated porous graphitized carbon.

Owner:OPTIMUM BATTERY CO LTD

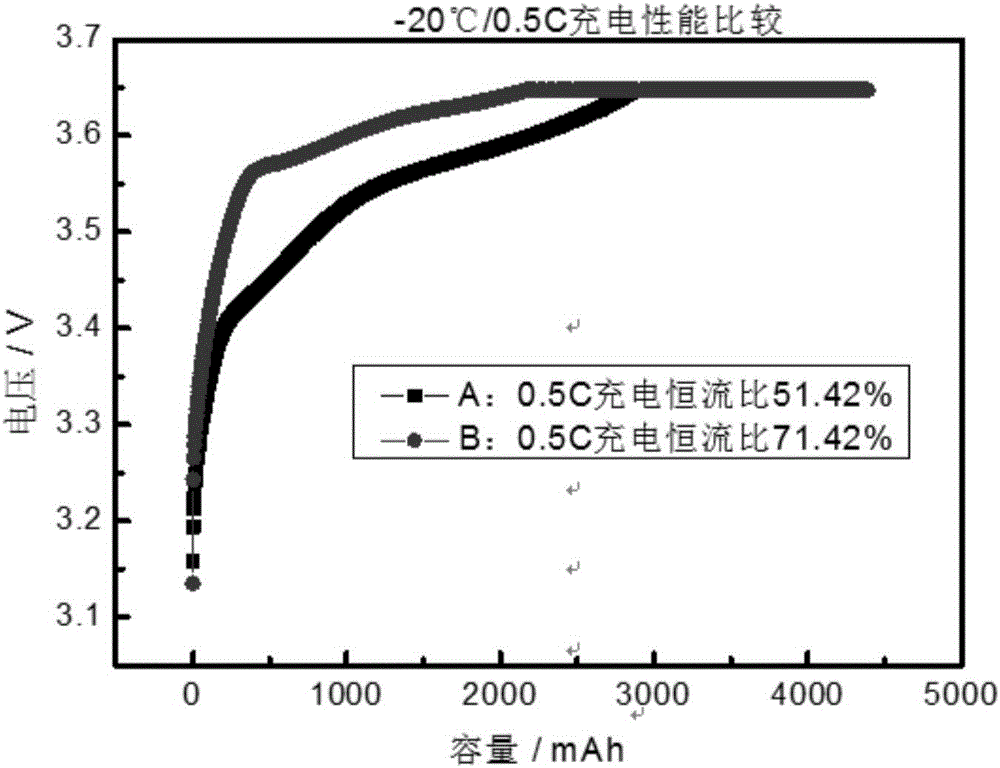

Quick-charging and safe low-temperature lithium ion battery and manufacturing method thereof

InactiveCN111370752AIncrease contact areaEliminate the "partition wall effect"Final product manufactureSecondary cellsInternal resistanceFast charging

The invention discloses a quick-charging and safe low-temperature lithium ion battery and a manufacturing method thereof. The battery is prepared by putting a dry battery cell into a shell, injectingelectrolyte, forming, sealing and grading capacity, and the dry battery cell is formed by winding a positive plate, a ceramic diaphragm, a negative plate and a ceramic diaphragm. The positive / negativeelectrode active substance is secondary micron particles formed by primary nanoparticles, and the nanoscale particles can effectively shorten the migration distance of lithium ions and improve the migration speed of the lithium ions in the charging and discharging process of the battery. Meanwhile, the multiple tabs led out from the positive and negative plates of the dry battery cell are gathered and then are welded with the planar metal sheet current collector to form a full tab. The internal resistance and the temperature rise of the battery in the charging process are effectively reduced,the problem of high-rate quick charging of the battery is solved, the high-current charging and discharging performance of the battery is improved, and the safety stability and the low-temperature electrochemical performance of the battery are also improved.

Owner:LONG POWER SYST NANTONG CO LTD

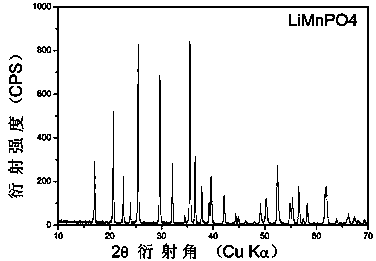

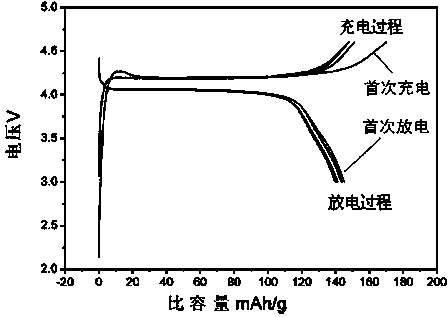

Synthetic method for cathode material nano lithium manganese phosphate for lithium ion batteries

InactiveCN103413940AShorten the timeImprove electrochemical performanceCell electrodesO-Phosphoric AcidLithium hydroxide

The invention discloses a synthetic method for a cathode material nano lithium manganese phosphate for lithium ion batteries. The method comprises a step of dissolving phosphoric acid in deionized water to obtain a phosphoric acid solution, and adding PEG 400 under stirring to obtain a phosphoric acid / PEG 400 mixed solution; a step of dissolving lithium hydroxide in deionized water to obtain an aqueous solution of the lithium hydroxide, and adding the aqueous solution of the lithium hydroxide under stirring into the phosphoric acid / PEG 400 mixed solution to obtain a white emulsion; and a step of dissolving manganese sulfate in deionized water to prepare a manganese sulfate solution, adding the manganese sulfate solution under stirring into the white emulsion to obtain a precursor emulsion, adding the precursor emulsion in a microwave reactor to perform a microwave reaction at 140-180 DEG C for 5-20 min, and then centrifuging, washing and drying to obtain the cathode material nano lithium manganese phosphate for the lithium ion batteries. The synthetic method can effectively avoid particle agglomeration and products produced have uniform particle sizes, uniform shapes and stable charge-discharge properties.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com