Patents

Literature

33results about How to "Excellent high rate charge and discharge performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

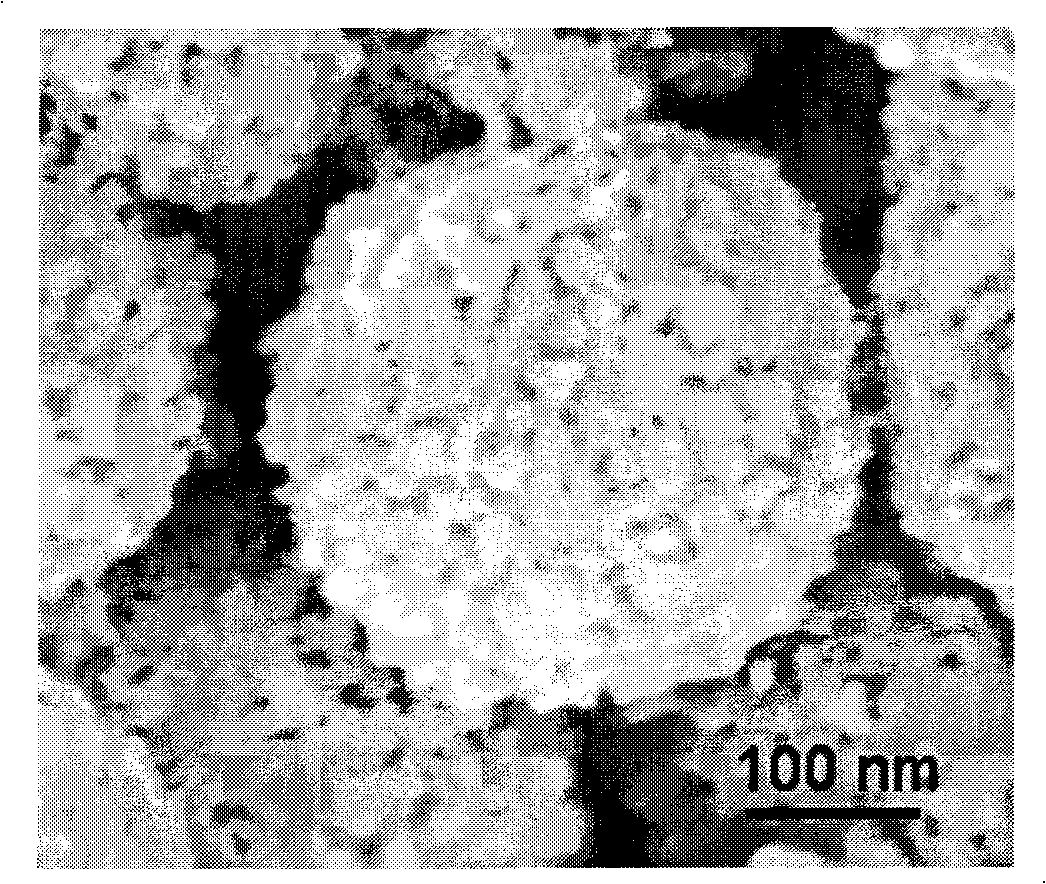

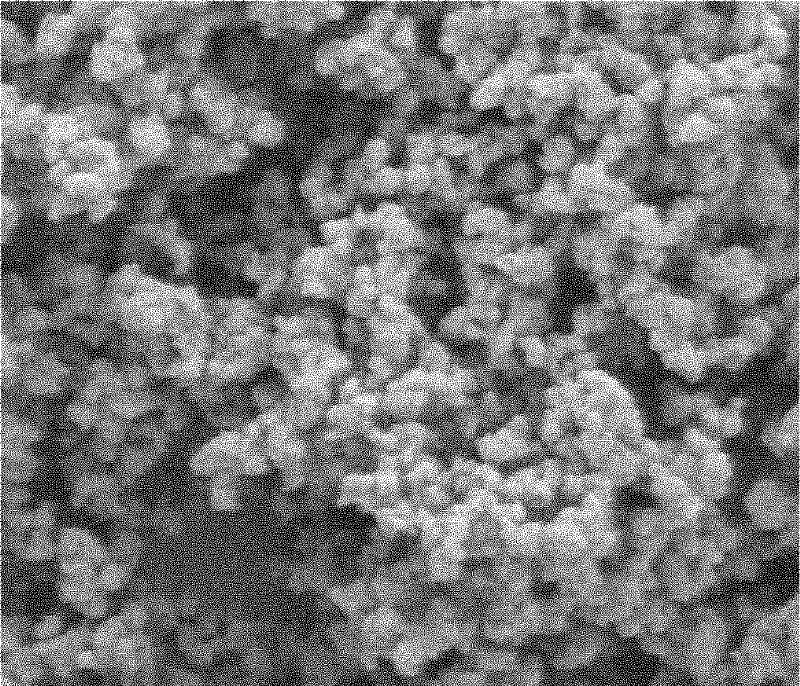

Titanium dioxide/graphene nanocomposite material and preparation method and application thereof

InactiveCN102569761AShape is easy to controlControllable surface structureCell electrodesGraphene nanocompositesHigh energy

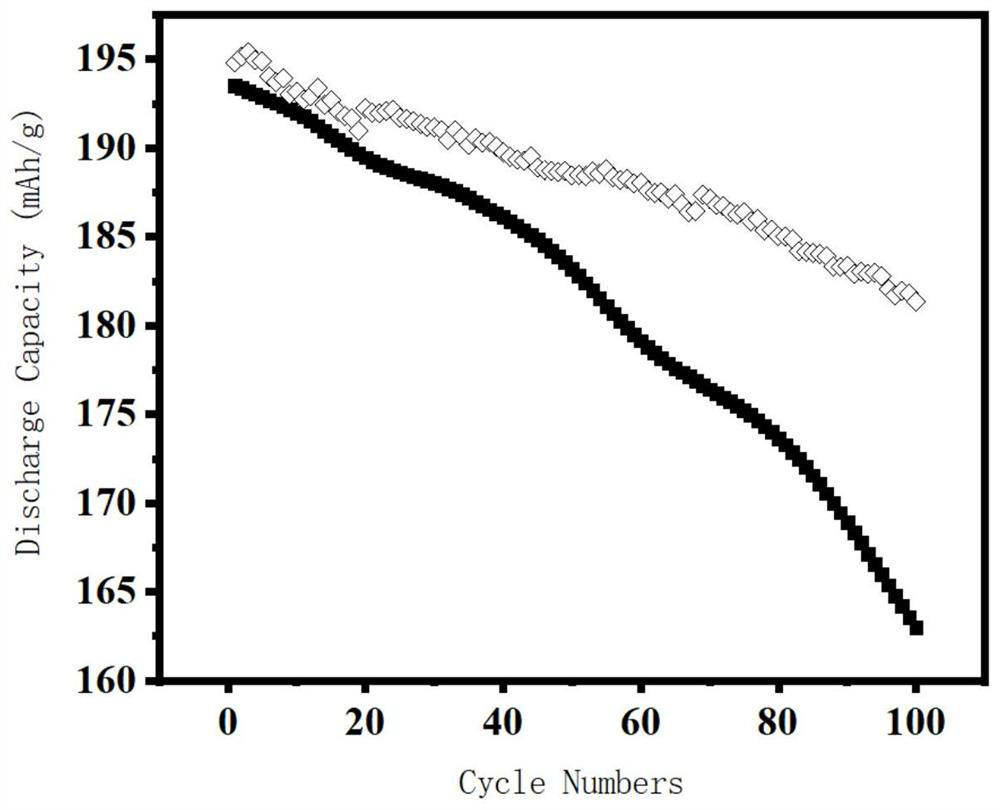

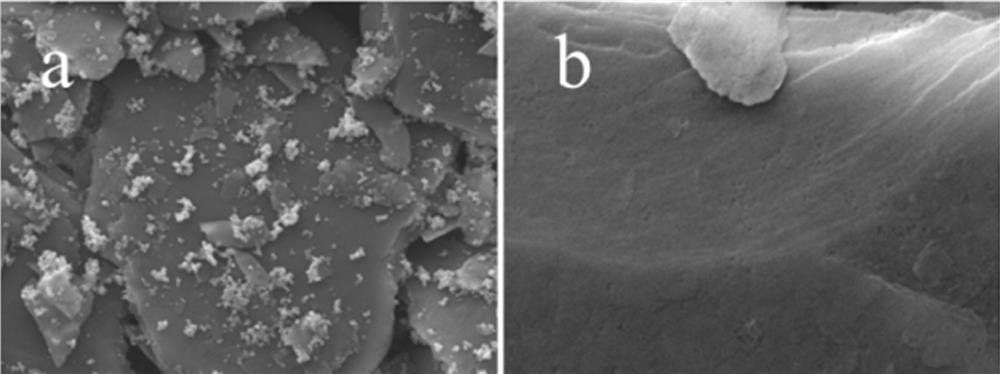

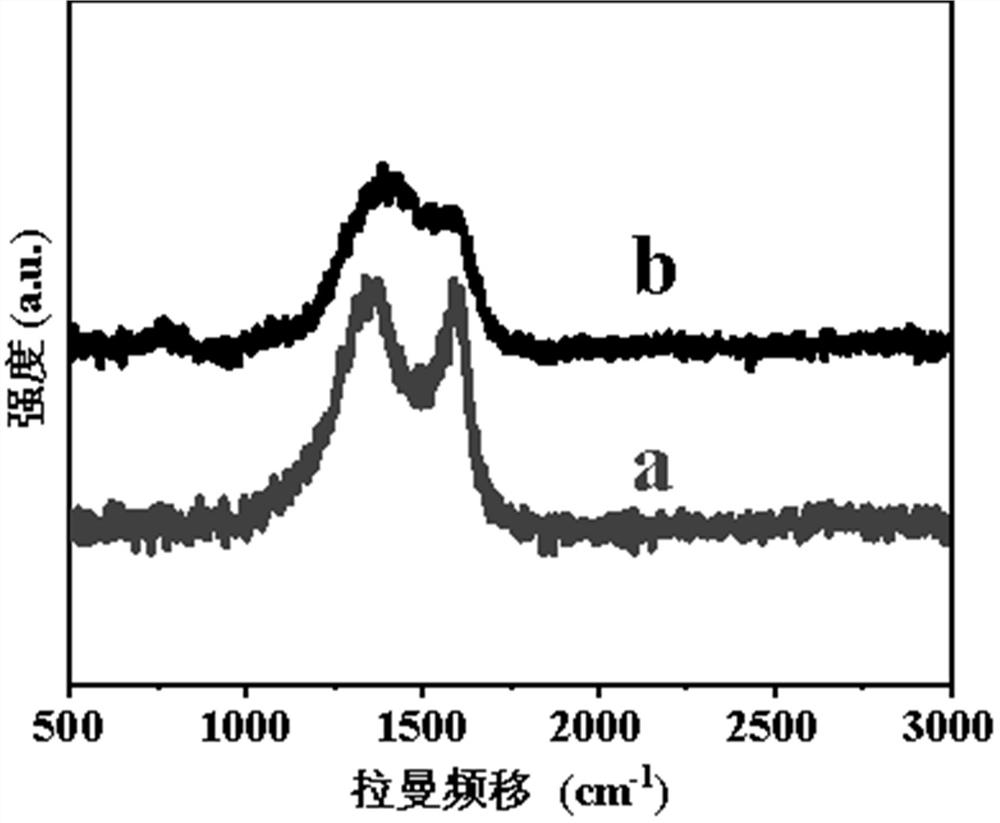

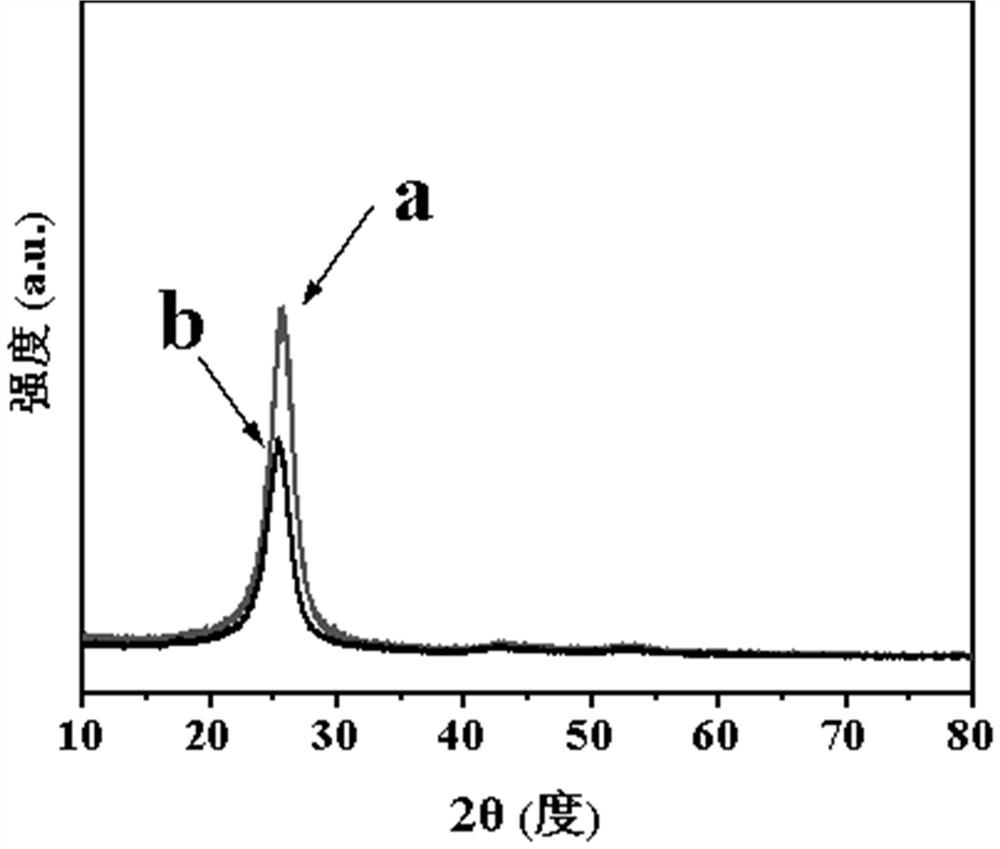

The invention relates to a titanium dioxide / graphene nanocomposite material, a preparation method of the nanocomposite material and application of the nanocomposite material in the field of energy source and cleaning environment. The graphene accounts for 1-25wt% and the balance is titanium dioxide. Morphology of the titanium dioxide is a mesoporous structure or a structure with a dominant high energy surface, and titanium dioxide is scattered uniformly on the surface of graphene. According to the invention, by adopting a titanium source and graphene as initial materials, and water or organic solvents as reaction solvents, the nanocomposite material with titanium dioxide with the mesoporous structure or a titanium dioxide nano sheet with the dominant high energy surface compounded with graphene can be obtained through hydrothermal synthesis or a hydrolysis reaction. The invention can be carried out in an aqueous solution system and the crystallinity of the product is high. The composite material can be applied to a cathode material of a power ion battery, has a higher charge-discharge capacity, is excellent in high current charge and discharge, stable in circulating performance, has very good photocatalytic performance and can be used to light degradation of organic pollutants and water photolysis for preparing hydrogen.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

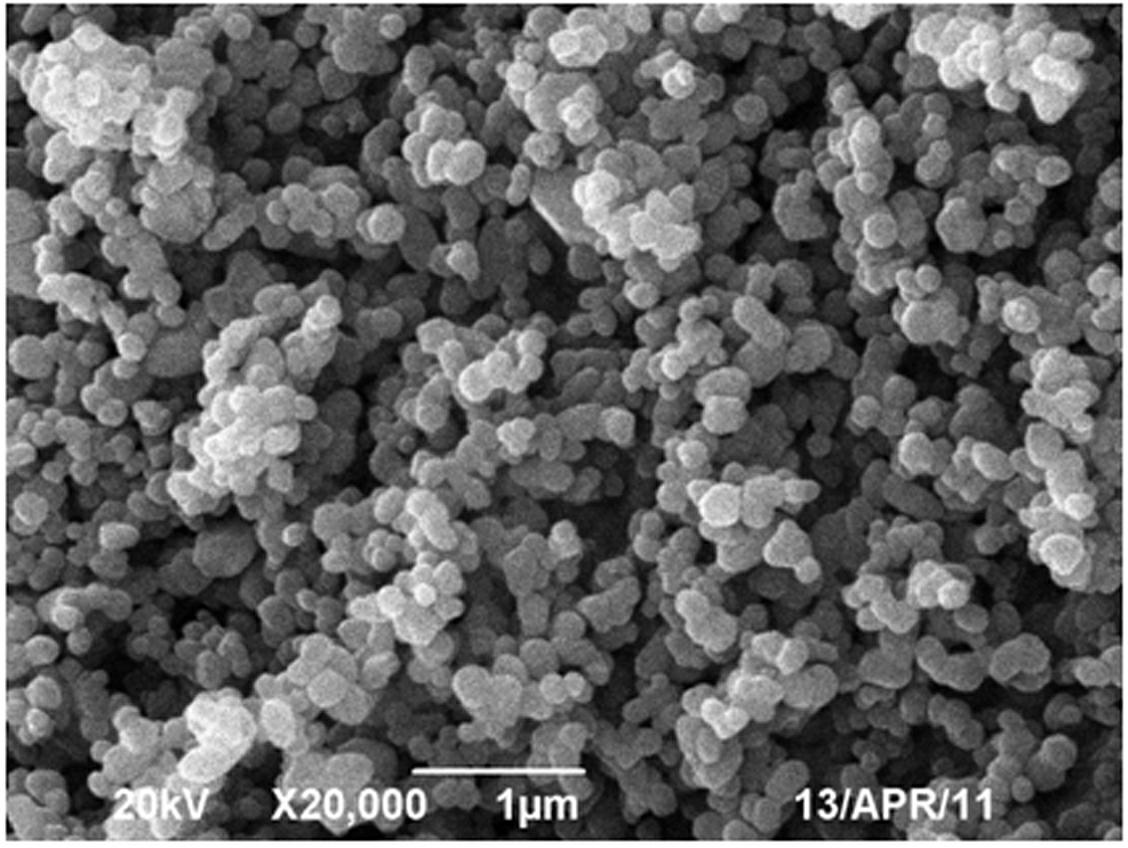

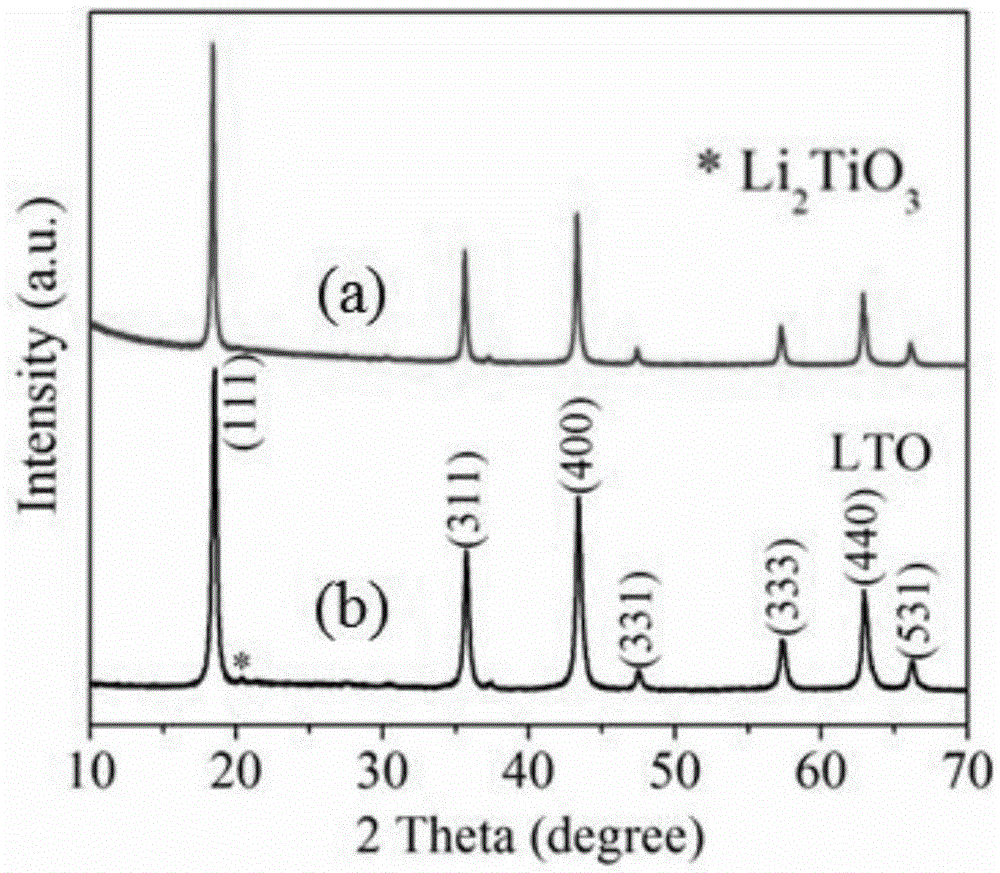

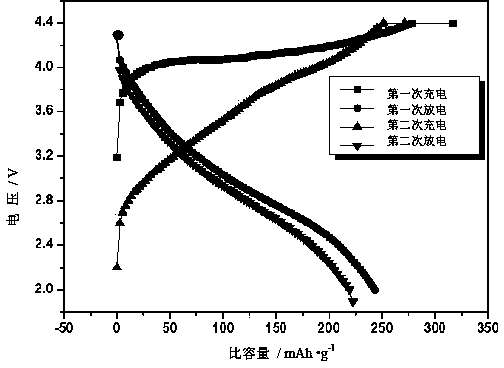

Method for preparing lithium titanate cathode material of lithium ion battery

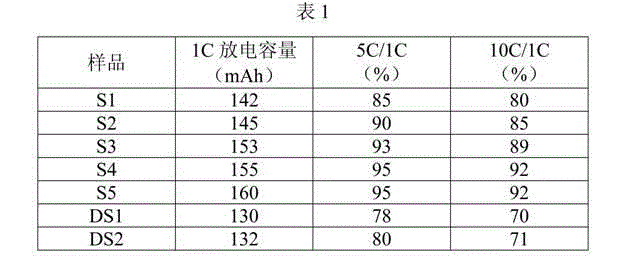

InactiveCN101409341AExcellent high rate charge and discharge performanceElectrode manufacturing processesHigh rateLithium hydroxide

The invention discloses a preparation method of a lithium titanate cathode material for a lithium ion battery. Titanium dioxide colloid is taken as an initial raw material; the titanium dioxide colloid and lithium hydroxide are added to a mixture of water and ethanol while stirring, then the obtained solution is transferred to a hydrothermal reaction kettle for hydrothermal ion exchange reaction at 150-200 DEG C for 10-18h, the reacted solution is naturally cooled to room temperature, then filtered to obtain white precipitate; the obtained precipitate is placed in a muffle furnace with the temperature of 350-600 DEG C for 1-3h heat treatment to obtain the lithium titanate cathode material used in the lithium ion battery. The lithium titanate cathode material which is used in the lithium ion battery and synthesized by the method has stable discharge specific capacity of 125mAh / g at the rate of 20C (3.5A / g), and has good high-rate charge and discharge performance.

Owner:SHANGHAI JIAO TONG UNIV +1

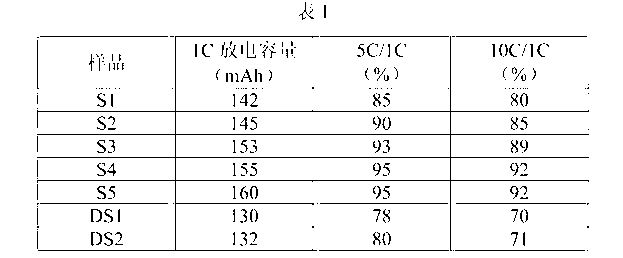

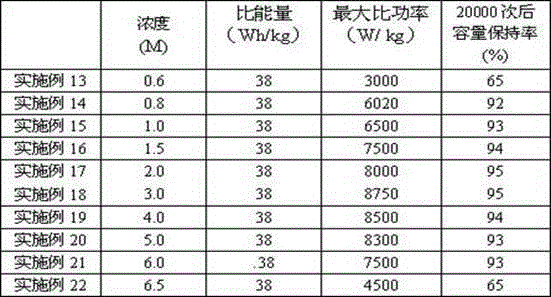

Carbon compound cathode material for ultracapacitor battery

InactiveCN101740230AGood lithium ion intercalation/extraction cycle performanceExcellent Capacitive Energy Storage PerformanceElectrolytic capacitorsFiberCapacitance

The invention discloses a carbon compound cathode material for an ultracapacitor battery, comprising a nuclear layer and a shell layer, wherein the shell layer accounts for the total weight of 10-40 percent; the nuclear layer is made of graphite materials subjected to surface nanometer treatment; and the shell layer is made of a porous carbon material. The surface nanometer treatment of the nuclear layer is to form a nano carbon fiber, a cabon nanotube or a nano hole on the surface of natural graphite, artificial graphite or an in intermediate phase carbon microsphere material in situ; and the porous carbon material comprises a three-dimensional structure that millipores are distributed on a carbon organism. Metal elements are doped in the shell layer. The component formula is reasonable; the prepared material has the nuclear and shell structures in which the metal elements are doped; meanwhile, the invention has favorable characteristics of energy accumulation by using double electric layers and lithium ion stripping / embedding, can effectively improve the high multiplying power and the power density of a lithium ion battery, meets the double requirements of the ultracapacitor battery on energy accumulation by using the lithium ion and double electric layers of the cathode material, can be used as a cathode of a high-performance lithium ion battery, and has favorable high multiplying power charge-discharge performances and industrial prospect.

Owner:CENT SOUTH UNIV +1

Method for preparing nano-graphite with electric arc method

InactiveCN104609408ASmall sizeShort migration pathMaterial nanotechnologyHigh rateElectric arc furnace

The invention provides a method for preparing nano-graphite with an electric arc method. Graphite rods are taken as two poles of an electric arc furnace, electric arc discharge is performed under the high-current and helium atmosphere, a graphite rod of the positive pole is continuously consumed in the electric arc discharge process, and graphite can be obtained in an inner wall area of a reaction chamber. The graphite prepared with the method has a smaller size, the migration path of lithium ions is short when the graphite is used as a lithium ion battery anode material, and accordingly, the graphite has excellent high-rate charge-discharge performance.

Owner:北京清大际光科技发展有限公司

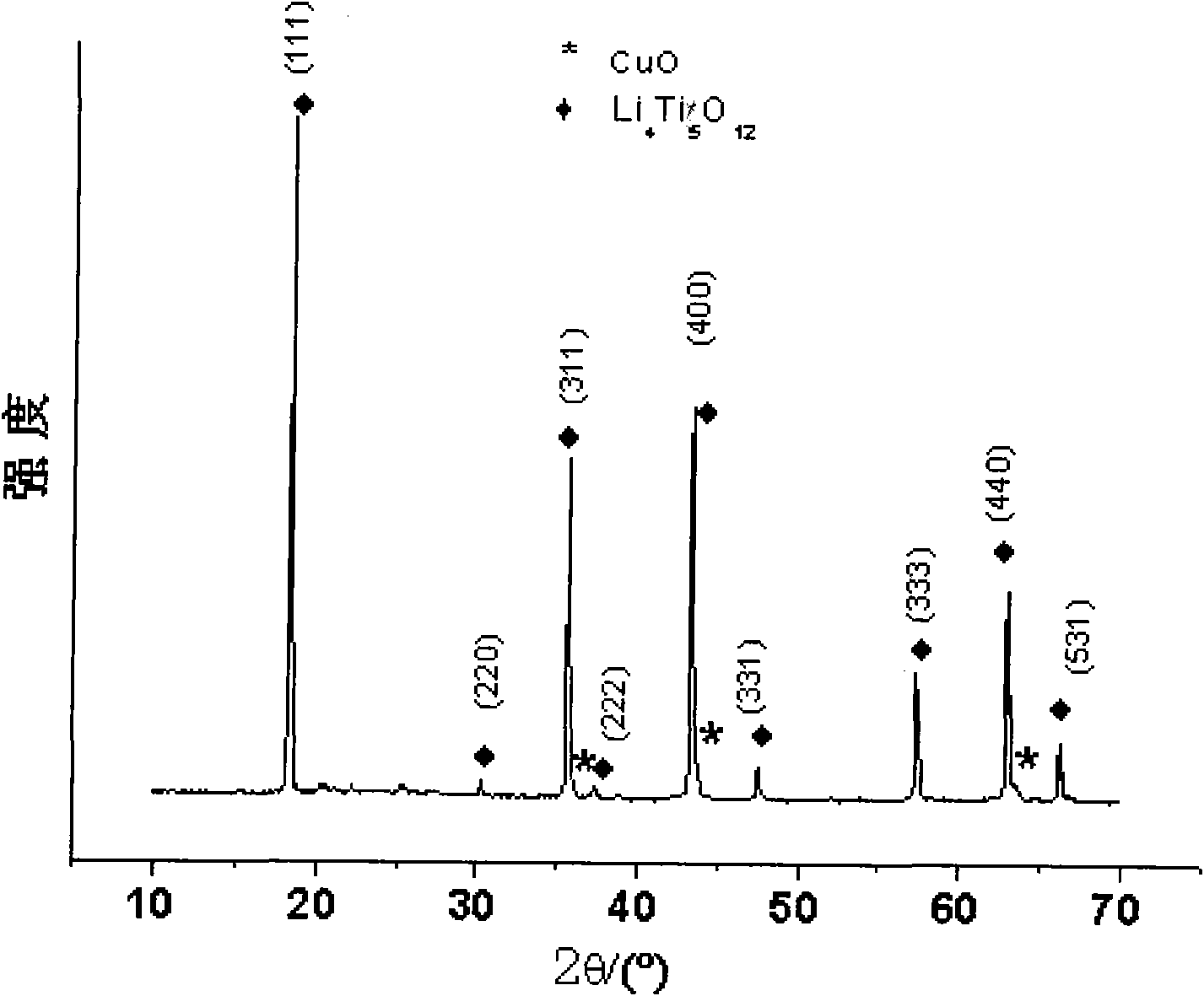

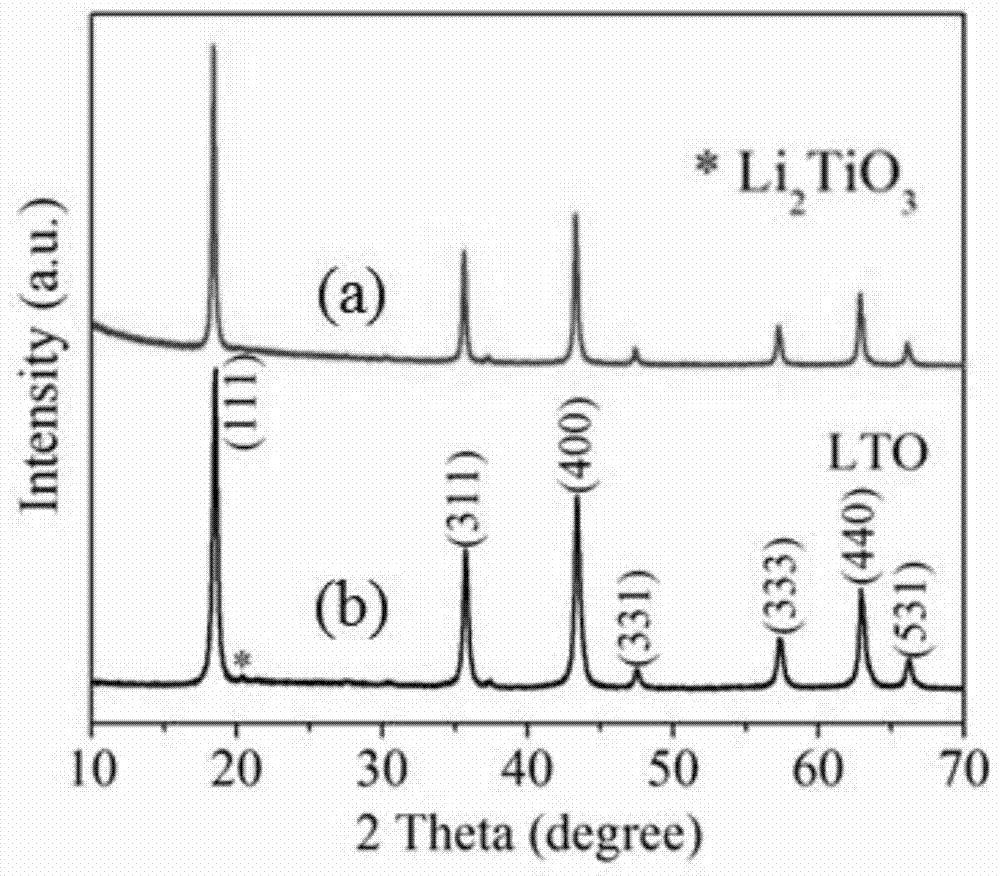

Preparation method of lithium titanate composite negative electrode materials used by lithium ion batteries

The invention discloses a preparation method of lithium titanate composite negative electrode materials used by lithium ion batteries, which is characterized in that the method comprises the following steps: proportionally mixing Li2CO3 powder and TiO2 powder; then, adding organic solvents into the mixture to be simultaneously prepared into paste materials; drying the paste materials after ball milling; raising the temperature; preserving the temperature; carrying out ball milling after cooling to obtain Li4Ti5O12; adding Li4Ti5O12 into metal compounds to simultaneously carry out ball milling; and then, completing the preparation through drying, temperature rising, temperature preservation, cooling and fine grinding. The lithium titanate of the composite negative electrode materials of the lithium ion batteries prepared by the method of the invention can adopt a general formula of Li4Ti5O12 / MOx, wherein x is 1 when M is Cu, and x is 0 when M is Ag. The lithium titanate can be used as the negative electrode materials of the lithium ion batteries, and has the advantages of good fast charging and discharging capability, high safety performance, no pollution and excellent large-magnification charging and discharging performance. The invention is applicable to industrial production, and can be applied to the fields of electric automobiles, energy storing equipment and electric tools.

Owner:HEFEI UNIV OF TECH

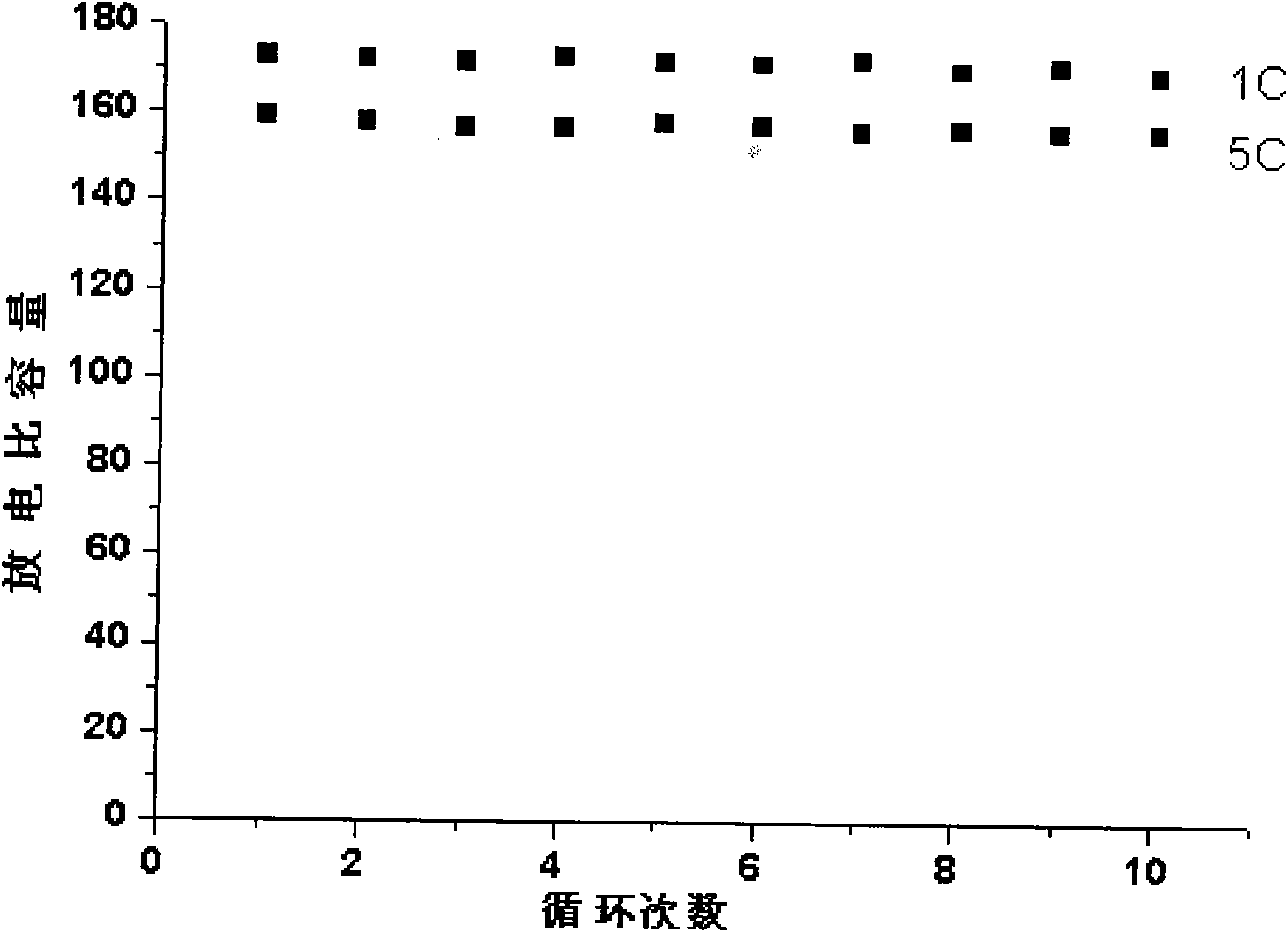

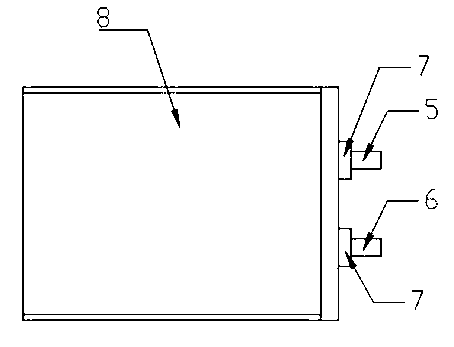

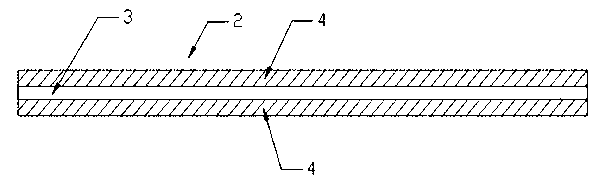

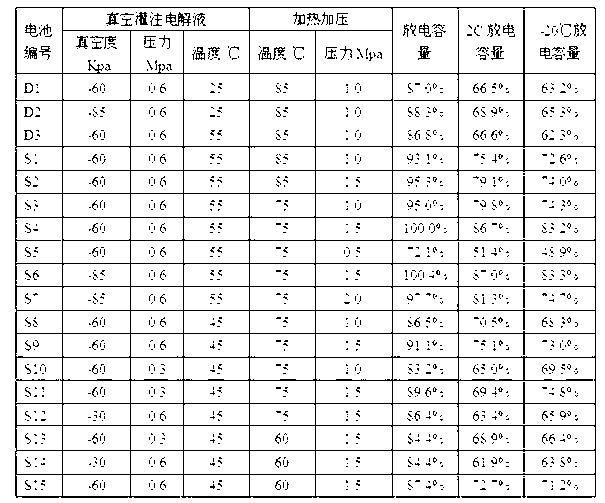

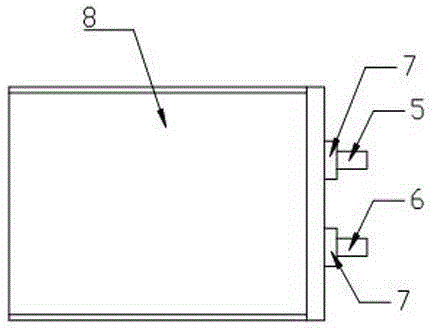

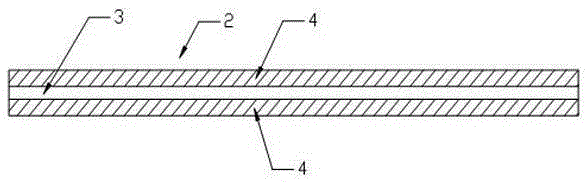

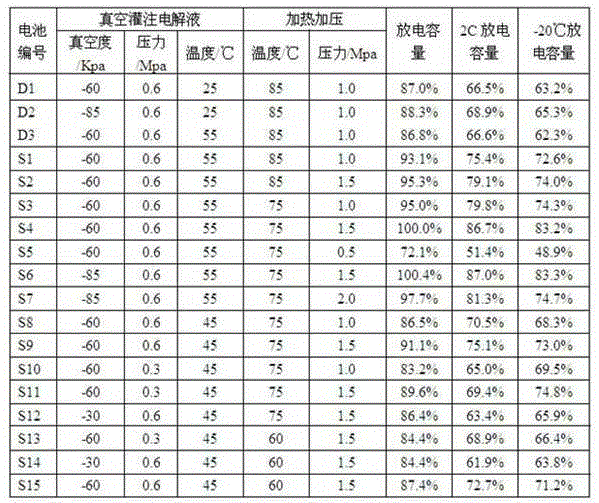

Manufacturing method of lithium ion battery containing gel electrolyte

ActiveCN103000956AEasy to prepareImprove ionic conductivityFinal product manufactureElectrolyte accumulators manufactureElectrolytic agentElectrical battery

The invention belongs to the technical field of a lithium ion battery, and particularly relates to a manufacturing method of a lithium ion battery containing gel electrolyte. The manufacturing method comprises the steps of preparation of a micro-pore isolating diaphragm plate, preparation of a cell, pouring of the electrolyte, after-treatment and the like. Compared with the prior art, the manufacturing method provided by the invention adopts a two-step method to polymerize gel; a good cathode pole sheet / electrolyte interface and a good anode pole sheet / electrolyte interface are formed on the cell by a pre-gelling step; in a formation process, a cathode activity material and an anode activity material can be sufficiently activated; the lithium ion battery is pressurized in a heating process after the formation is completed, so that air bubbles generated in the formation process of the battery and existing between the cathode pole sheet / electrolyte interface and the anode pole sheet / electrolyte interface can be removed; and an interface gap can be smaller, thereby being beneficial to the generation of the cathode pole sheet / electrolyte interface and the anode pole sheet / electrolyte interface. Therefore, the battery has better electrochemical performance.

Owner:DONGGUAN AMPEREX TECH

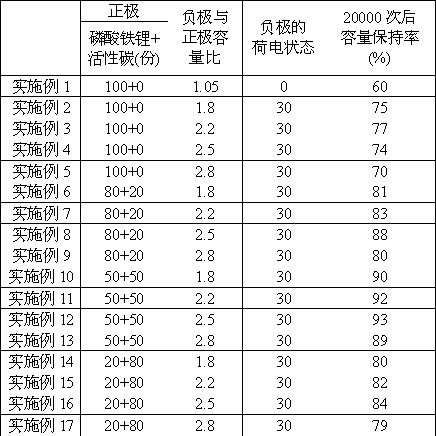

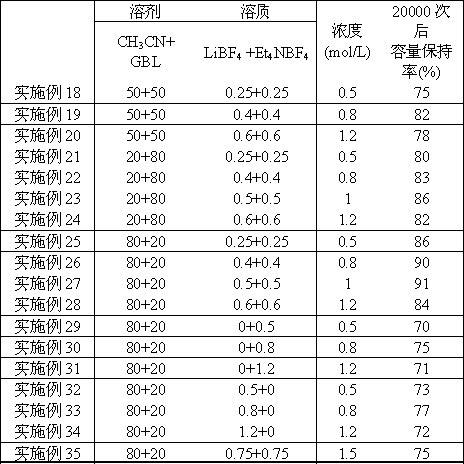

Chemical power supply

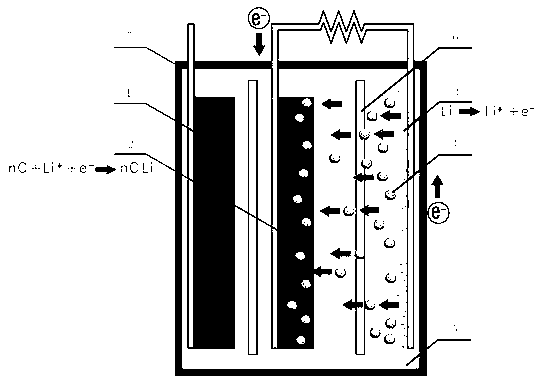

InactiveCN102842703AGood charge and discharge performanceLong cycle lifeElectrolytic capacitorsCell electrodesLithium electrodeSupercapacitor

The invention provides a chemical power supply. The chemical power supply comprises an anode, a cathode, an isolation film and electrolyte, and is characterized by being formed by mixing a lithium ion battery and the inner part of a super capacitor, wherein the cathode is subjected to the pre-doping lithium process, so that the SOC (State of Charge) of the cathode is 30%. According to the chemical power supply, particularly the lithium titanate-based chemical power supply provided by the invention, not only is high-multiplying power charging and discharging performance good, also the cycle service life is long, the internal resistance can not be increased, and the gas expansion can be occur after the long-term use of the chemical power supply, the safety is high, and the circulation performance and the power performance are good, so that the chemical power supply has wide application field.

Owner:SHANGHAI AOWEI TECH DEV

Preparation method of lithium titanate material, lithium titanate material, and lithium ion battery

InactiveCN102842706AImprove high rate charge and discharge performanceExcellent high rate charge and discharge performanceCell electrodesSecondary cellsPower batteryHigh rate

The invention provides a preparation method of a lithium titanate material, the lithium titanate material, and a lithium ion battery. The preparation method comprises the steps that: a mixture containing a lithium source and a nickel source is subjected to primary ball milling; the mixture is calcined, such that a precursor is obtained; the precursor is mixed with a titanium source, and the mixture is subjected to secondary ball milling; and the mixture is calcined in an inert or reductive atmosphere, such that the lithium titanate material is obtained. With the method, the prepared lithium titanate material has excellent rate discharge performance, and is especially suitable to be applied in fields such as power batteries which require high-rate charging and discharging.

Owner:BYD CO LTD

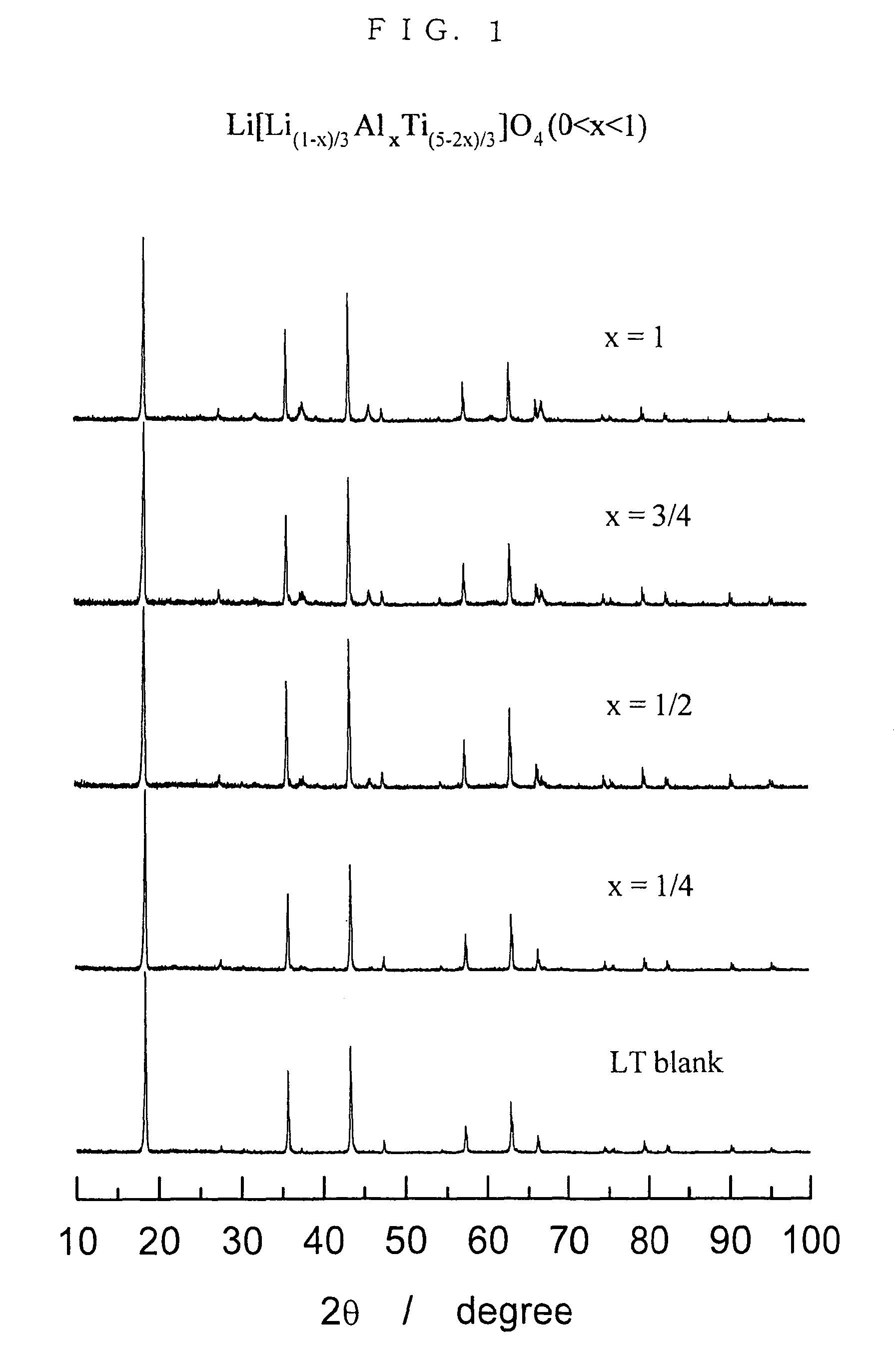

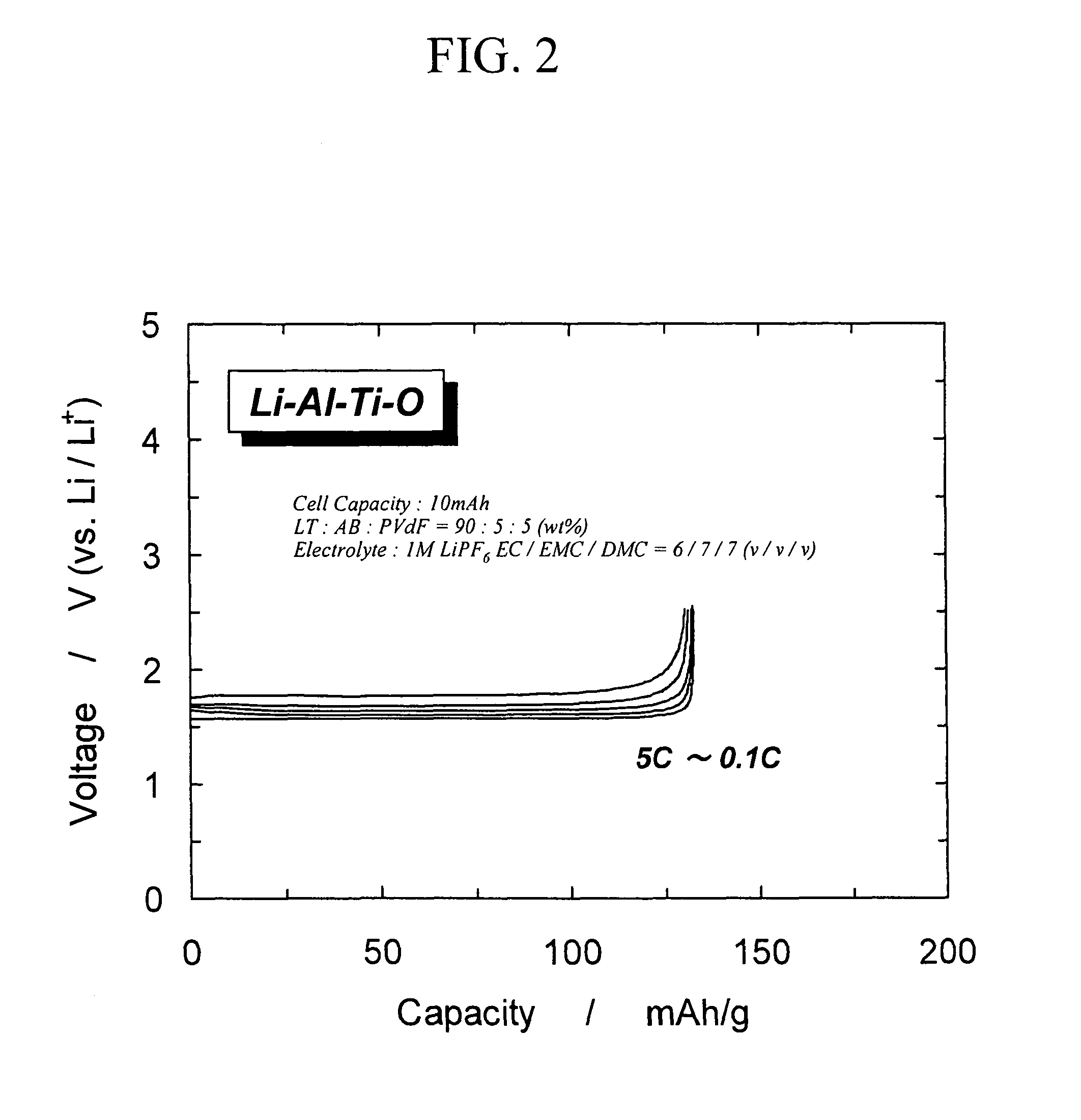

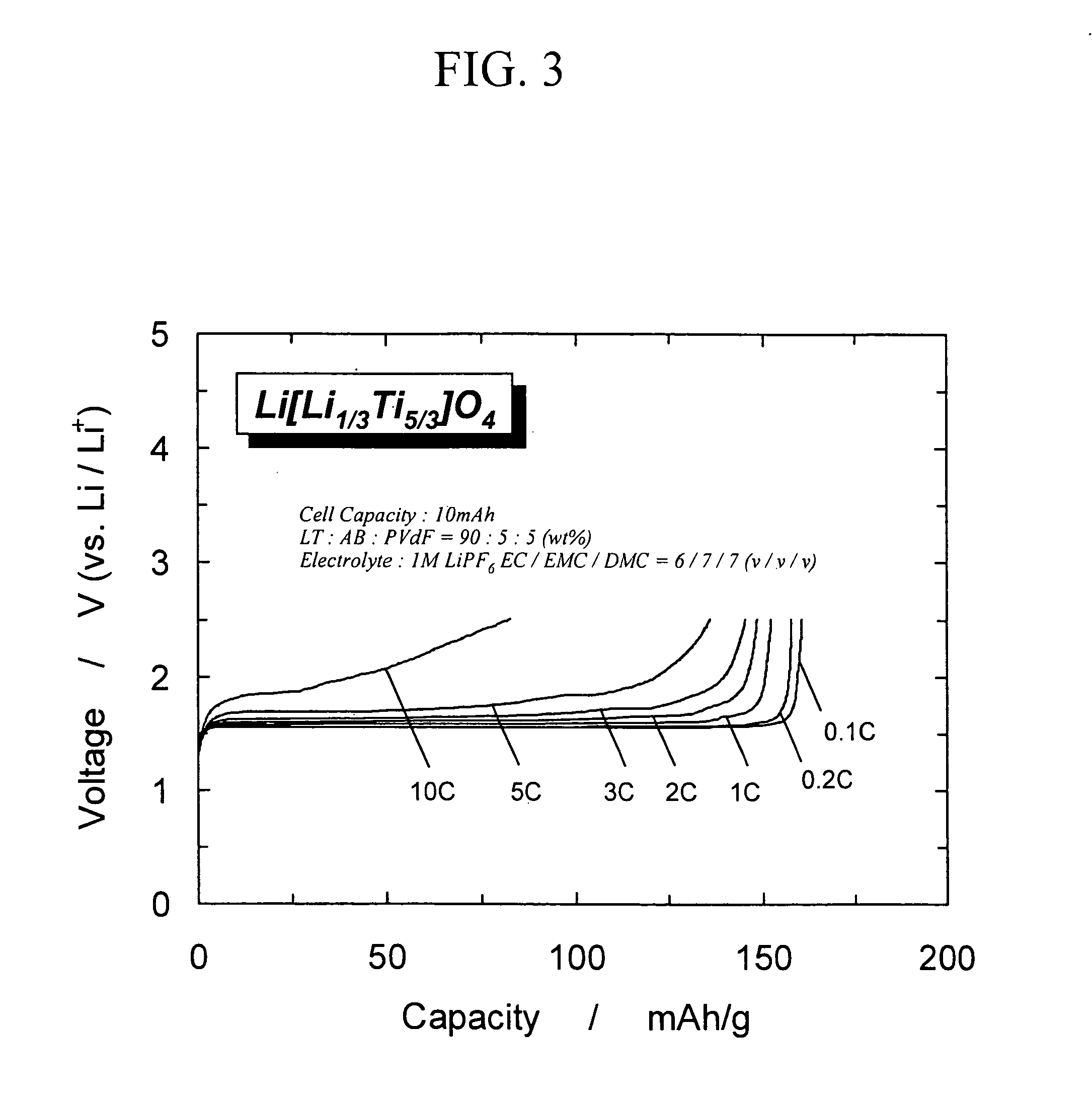

Active Material for Lithium Ion Battery Having A1-Containing Lithium Titanate and Lithium Ion Battery

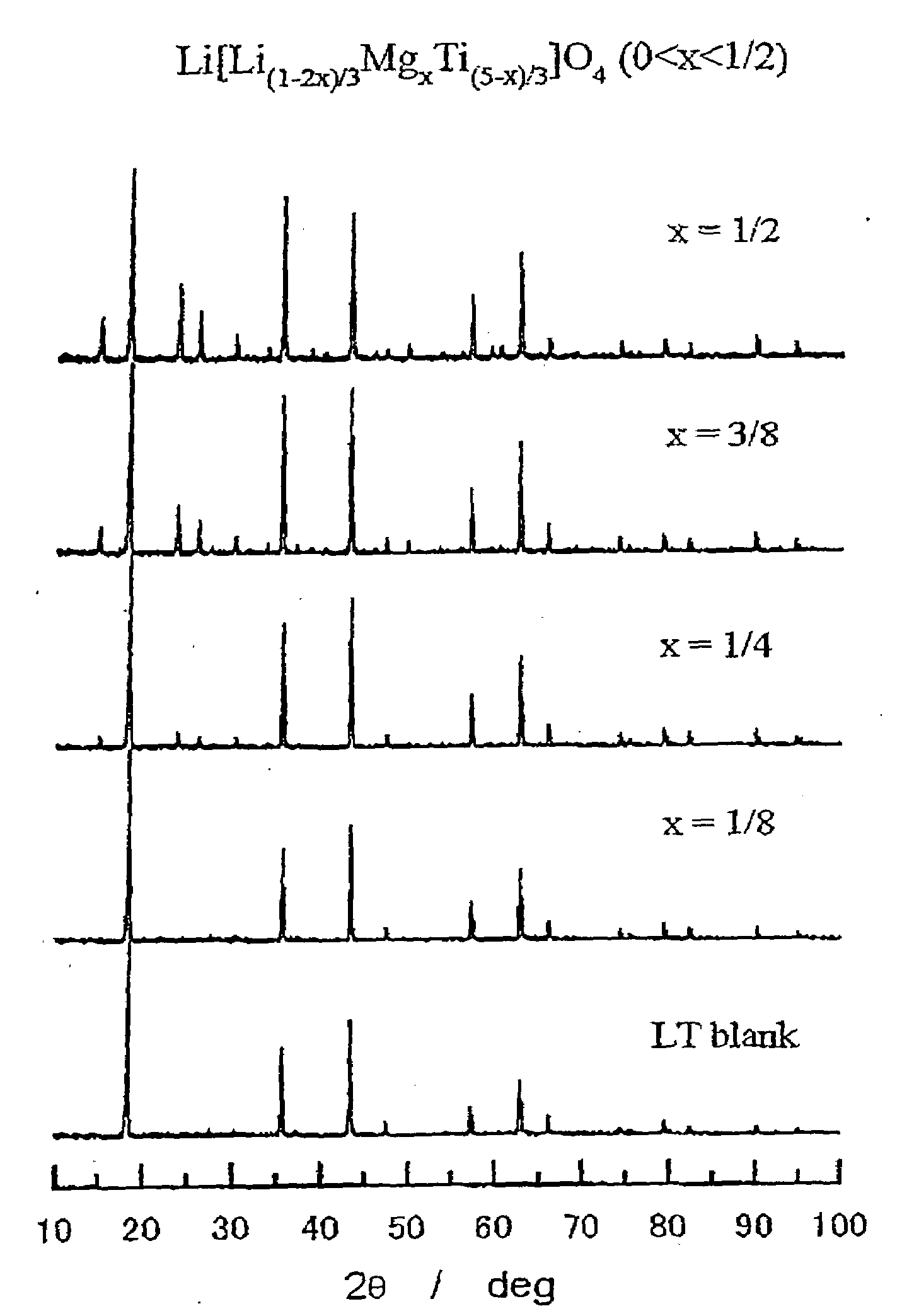

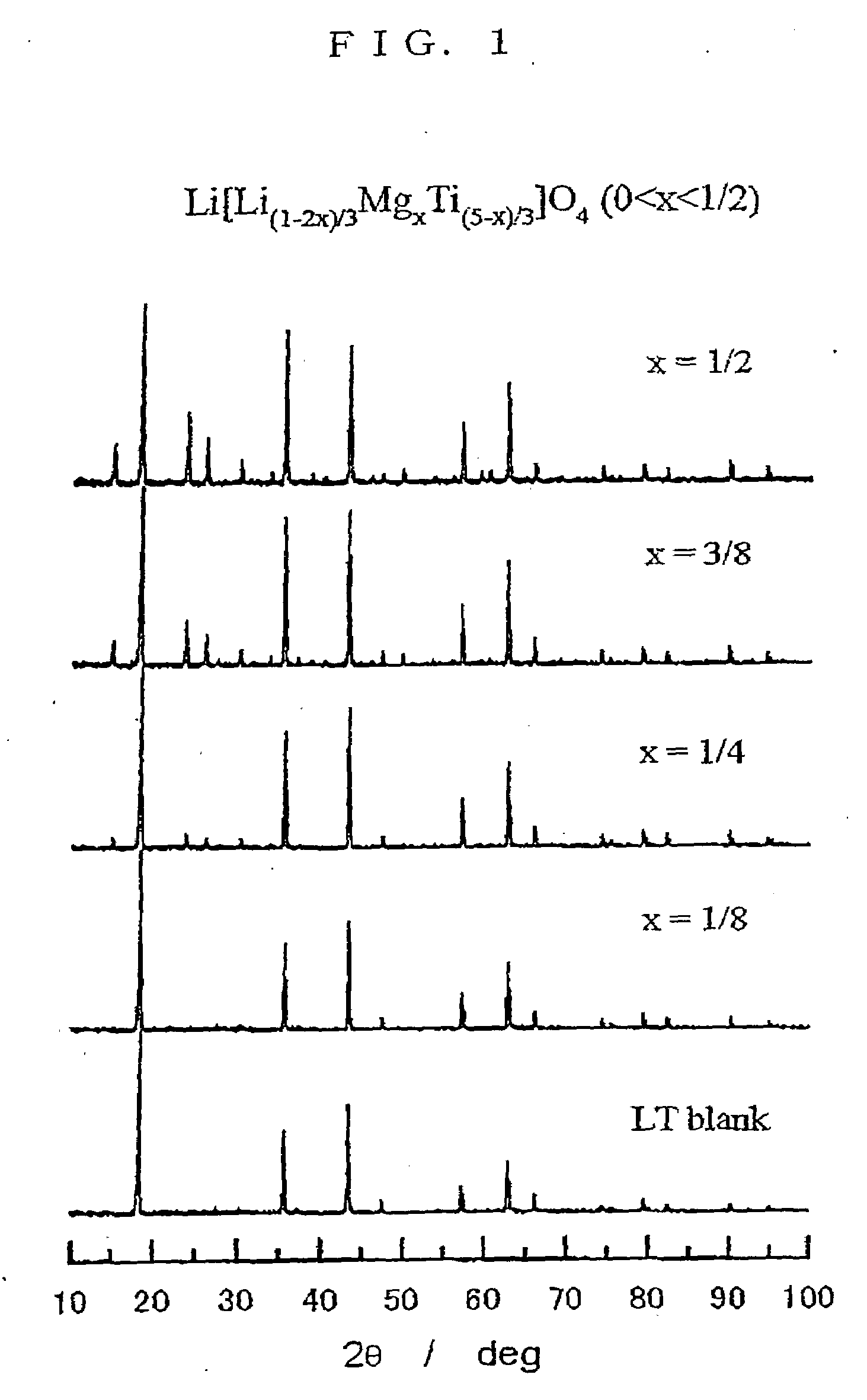

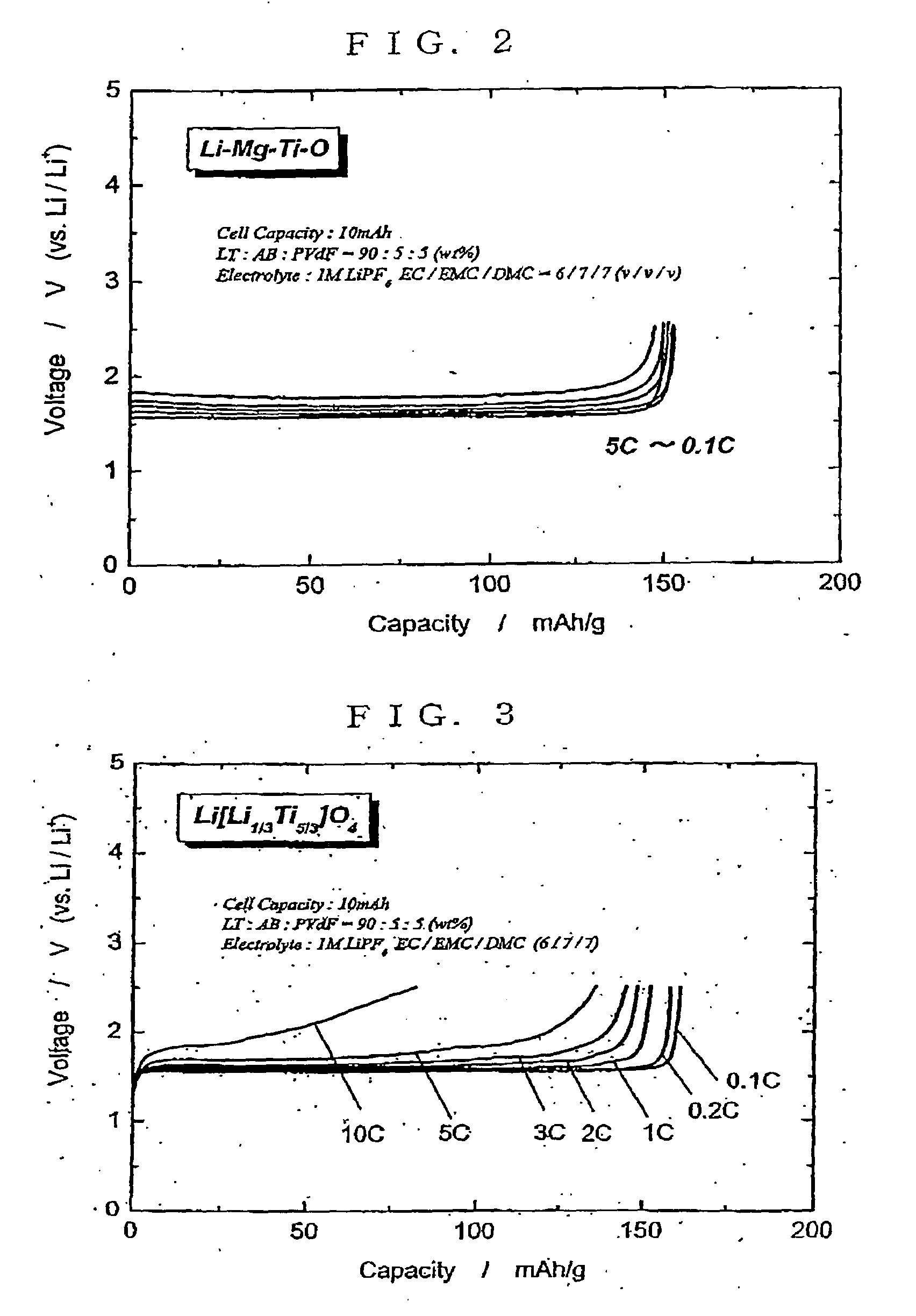

ActiveUS20090127503A1Excellent high rate chargeImprove discharge performanceThermoelectric device with peltier/seeback effectCell electrodesHigh ratePhysical chemistry

It is an object of the present invention to provide an active material for lithium ion battery capable of producing a lithium ion battery having an excellent high rate charge and discharge performance and a lithium ion battery having an excellent high rate charge and discharge performance.The present invention provides an active material for lithium ion battery represented by a composition formula: Li[Li(1-x) / 3AlxTi(5-2x) / 3]O4 (0<x<1) in which a part of the element of lithium titanate is substituted with Al, and a lithium ion battery using this active material as a negative electrode active material.

Owner:GS YUASA INT LTD

Method for preparing anode material lithium vanadium phosphate by adopting quenching

InactiveCN102386407AImprove conductivityImproved magnification performanceCell electrodesHigh energyBall mill

The invention relates to a method for preparing anode material lithium vanadium phosphate by adopting quenching, which comprises the following steps: mixing a lithium source compound, a vanadium source compound, a phosphorus source compound and a fluoride at a molar ratio of lithium : vanadium : phosphorus : fluorine = (1-1.05):1:1:1, adding a carbon source at a molar ratio of the carbon source : the vanadium source compound = 1:1-10:1, performing high-energy ball-milling for uniform mixing to obtain a precursor mixture, drying the precursor mixture, placing the dried precursor mixture in a non-oxidizing atmosphere and heating to 500-1000 DEG C, performing constant-temperature calcination for 0.5-48 h, rapidly transferring the high-temperature powder to a low-temperature medium (-209-40 DEG C), and allowing rapid quenching for a period from 1 min to 1 h to obtain lithium vanadium phosphate powder. The lithium vanadium phosphate powder prepared by using the quenching method provided by the invention has nano size, uniform particle size distribution, and excellent large-multiplying factor charging / discharging performance.

Owner:CENT SOUTH UNIV

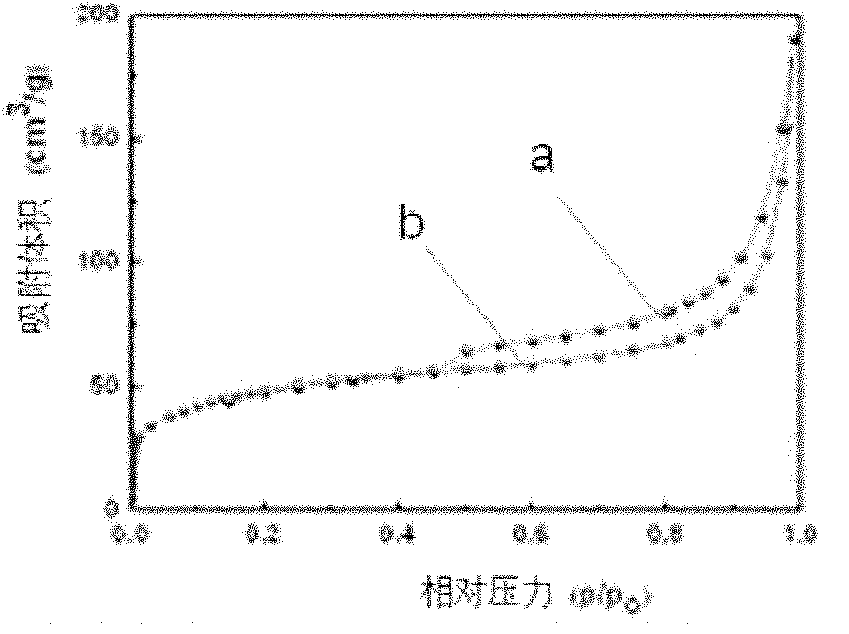

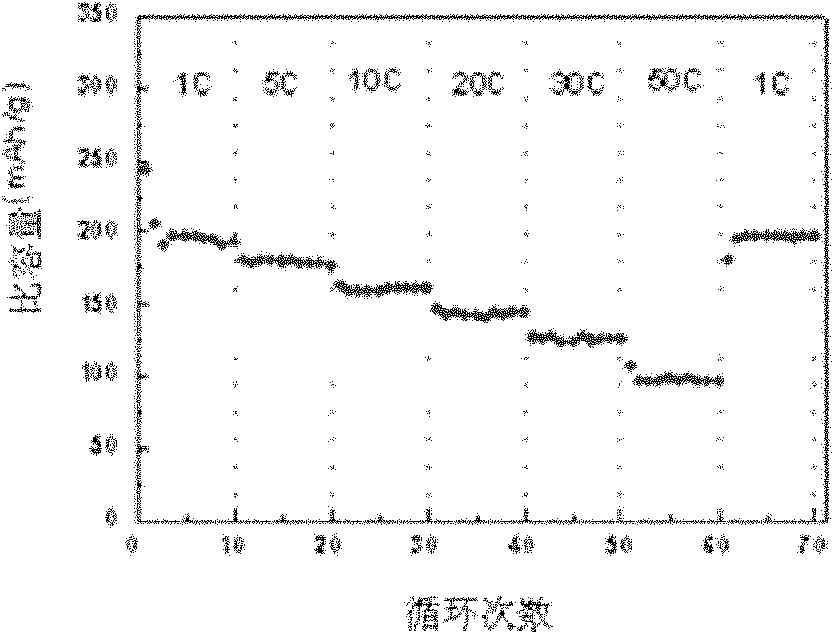

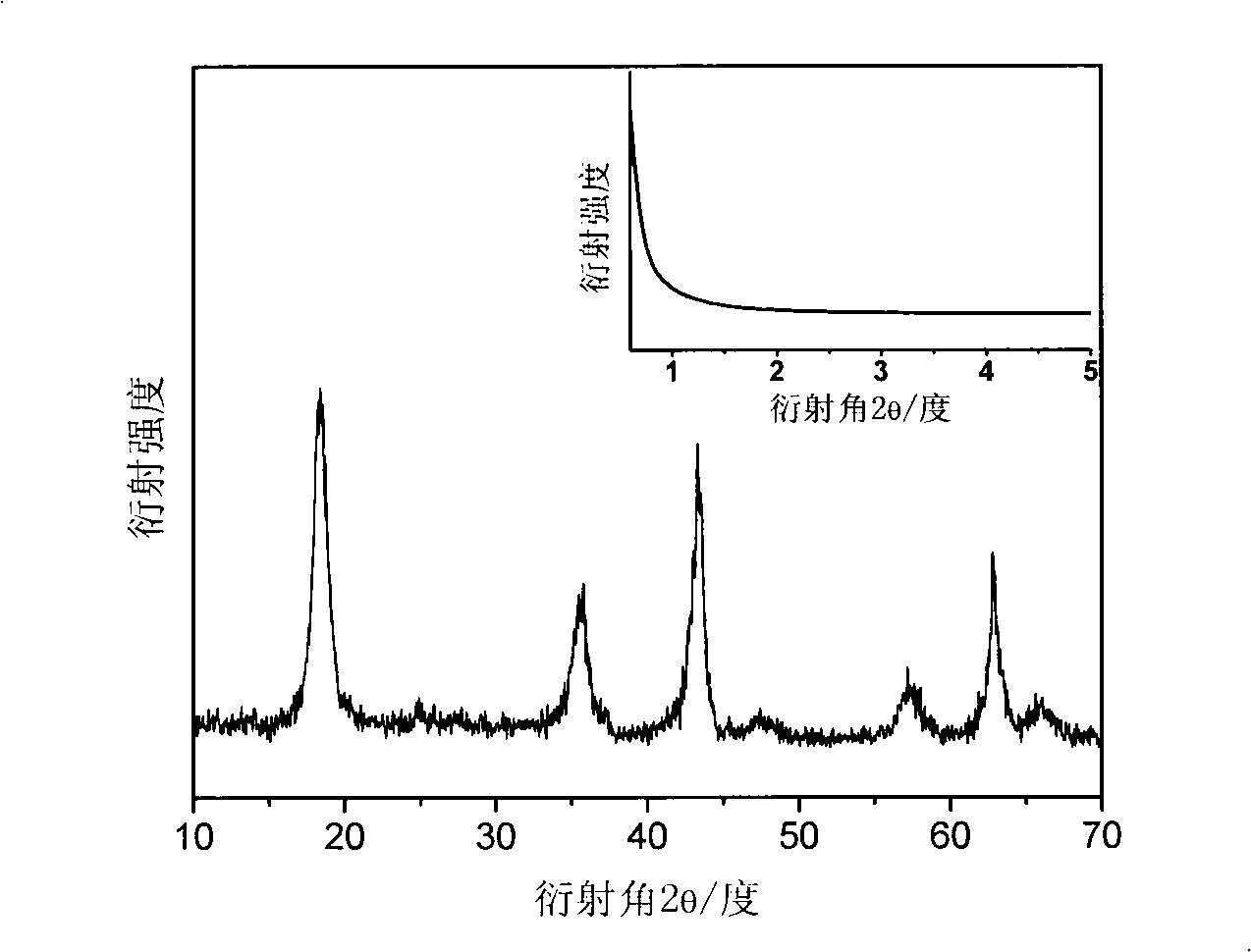

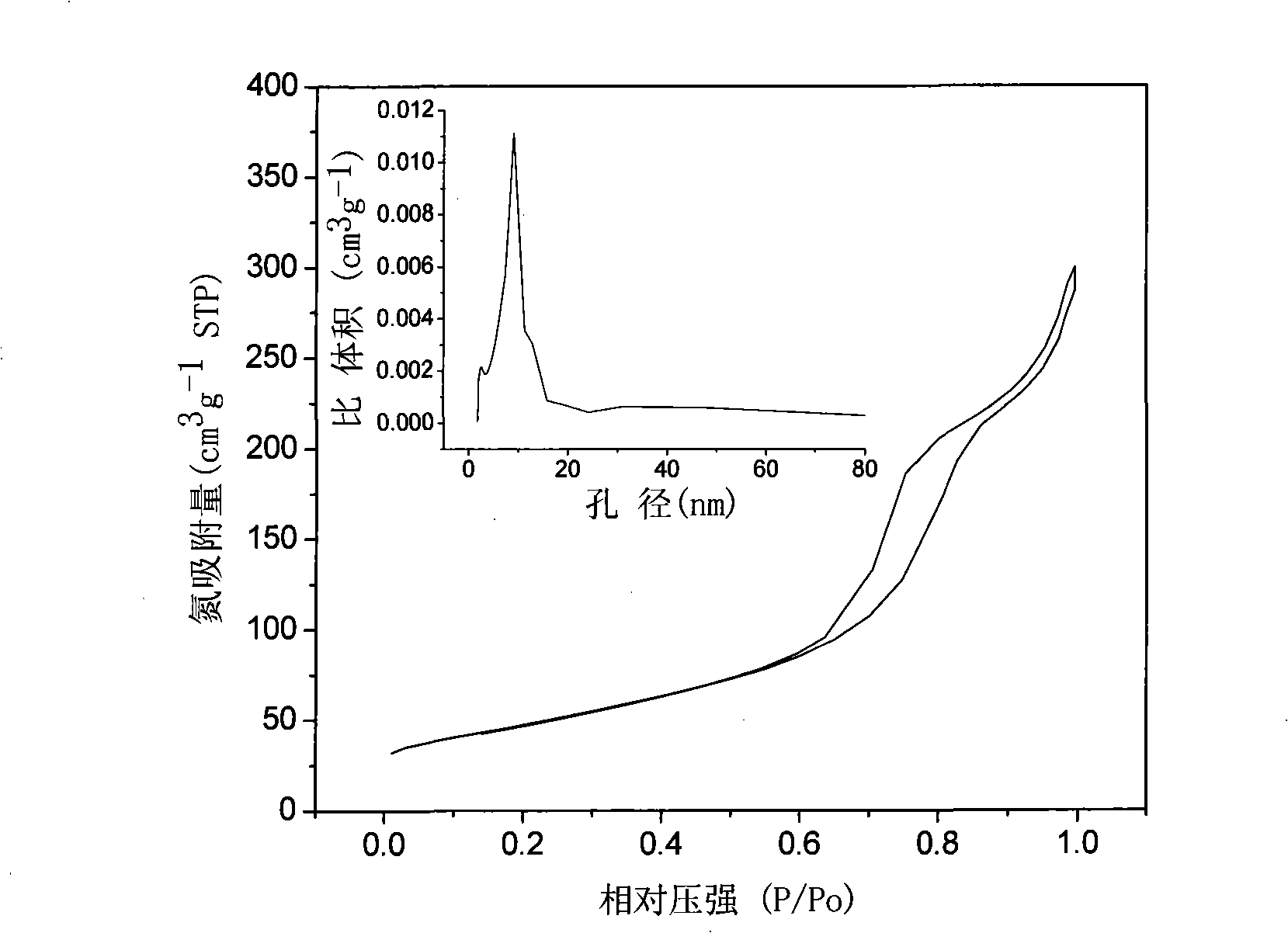

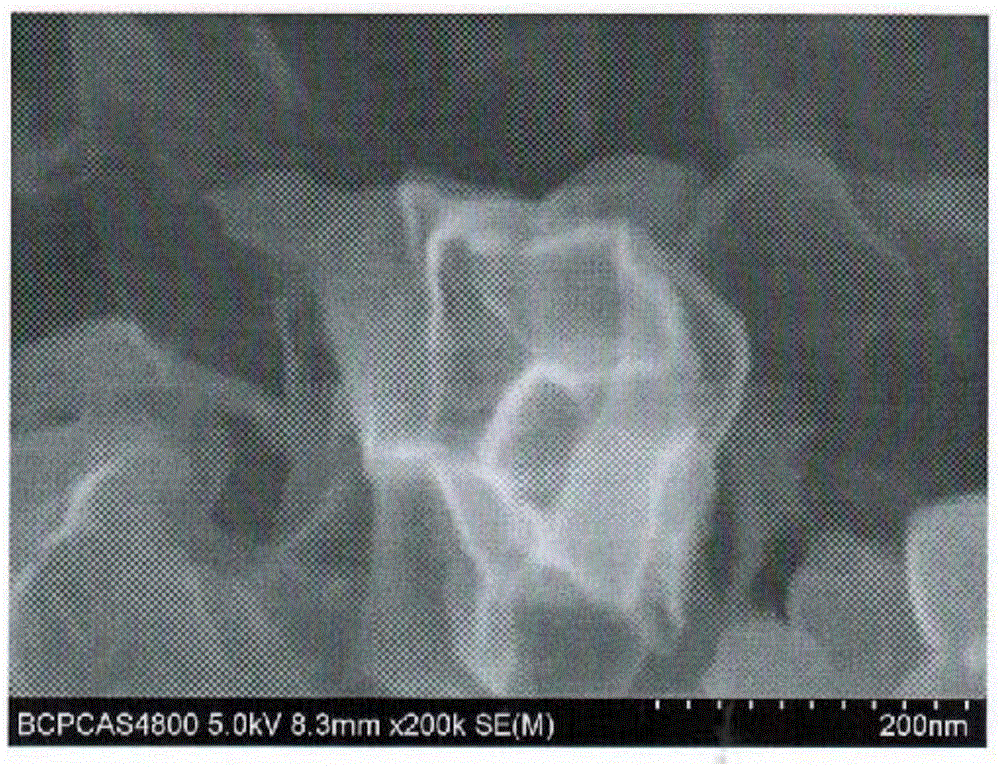

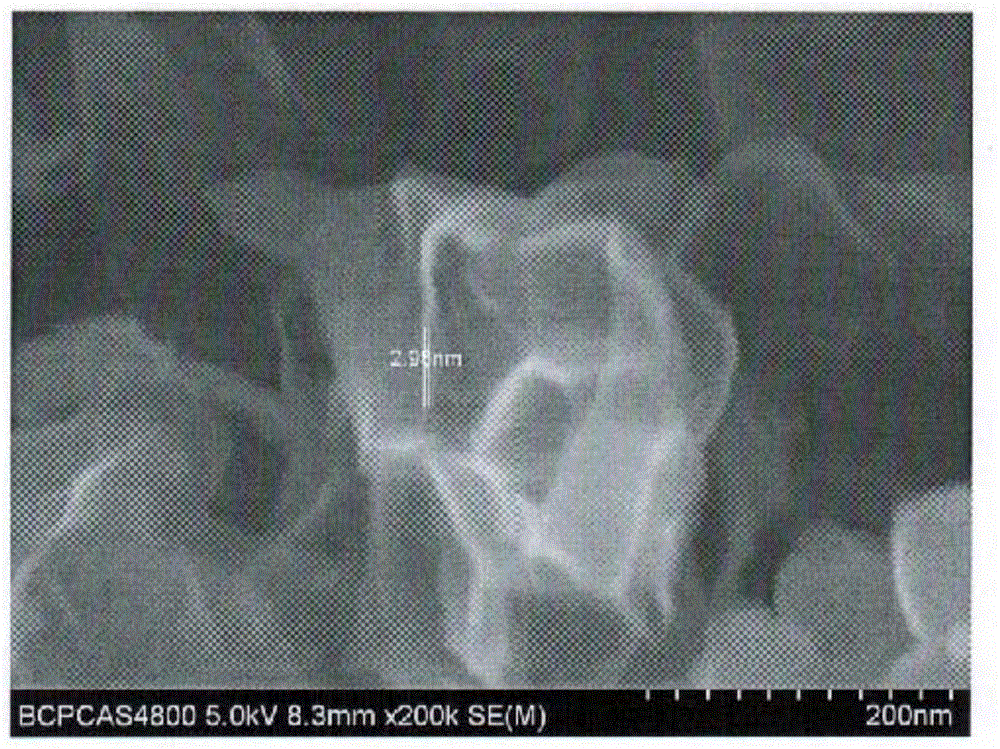

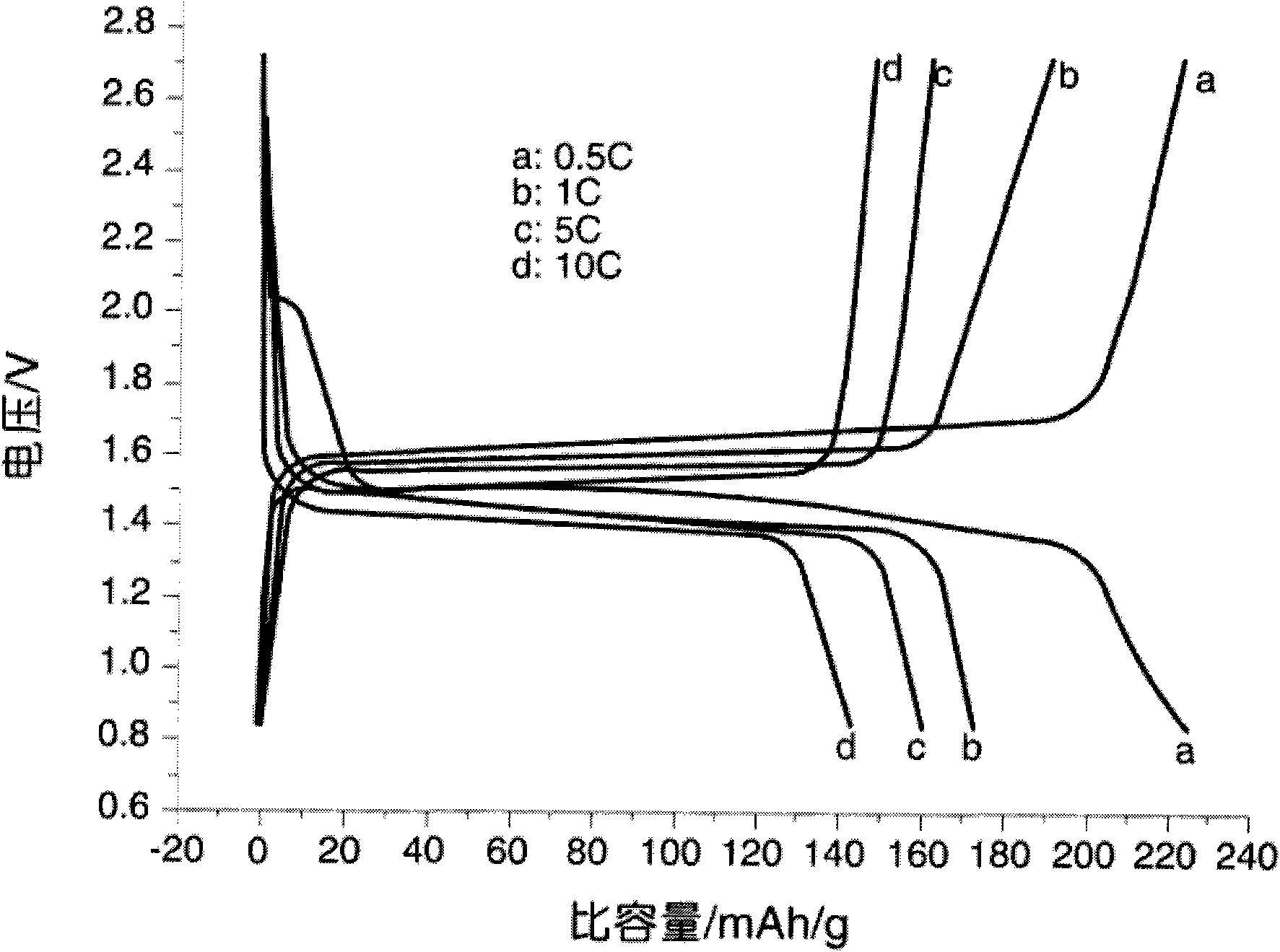

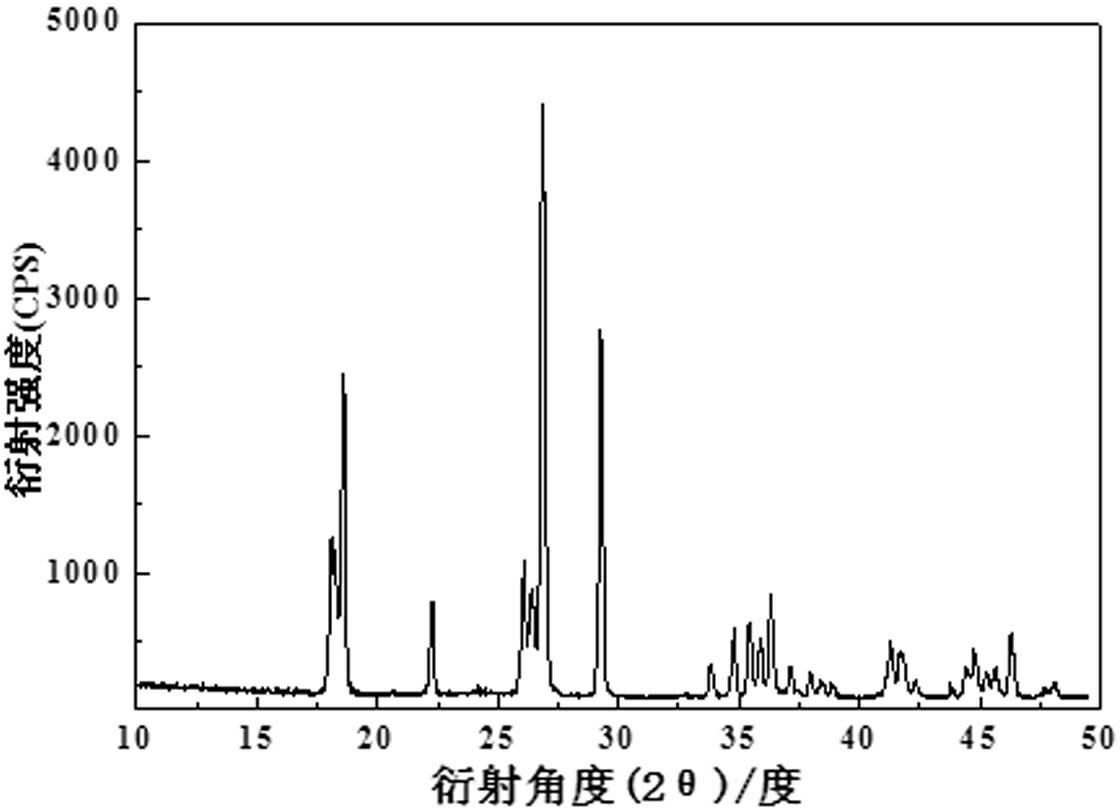

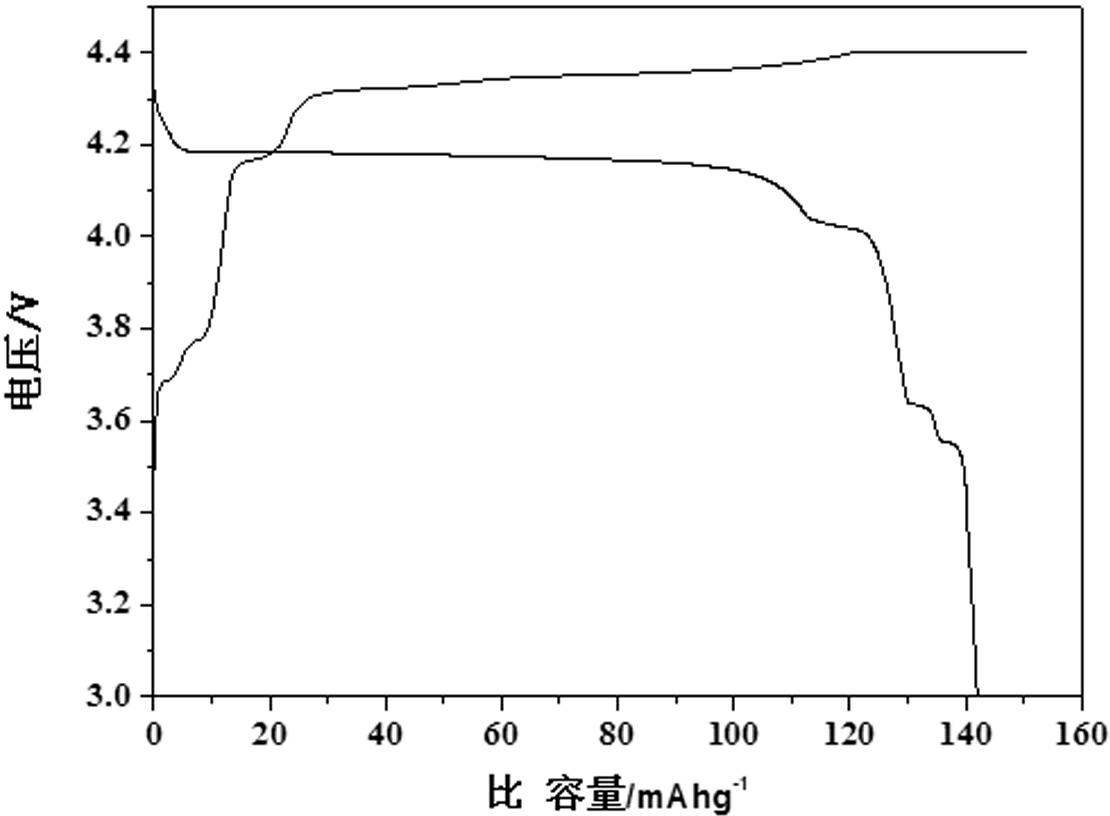

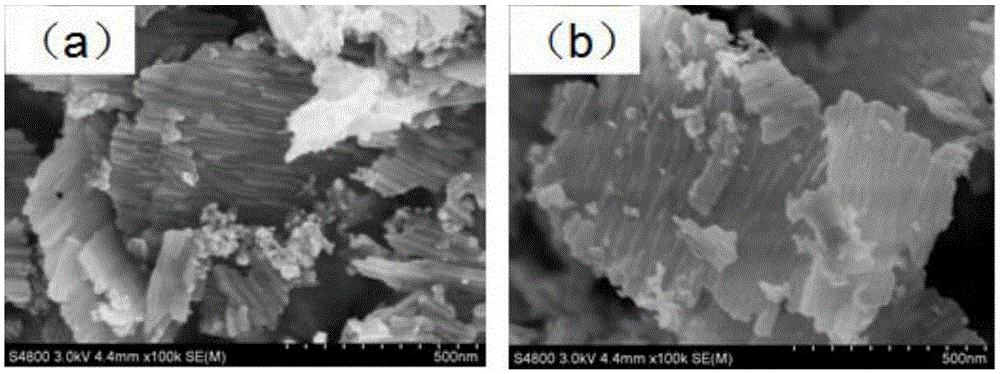

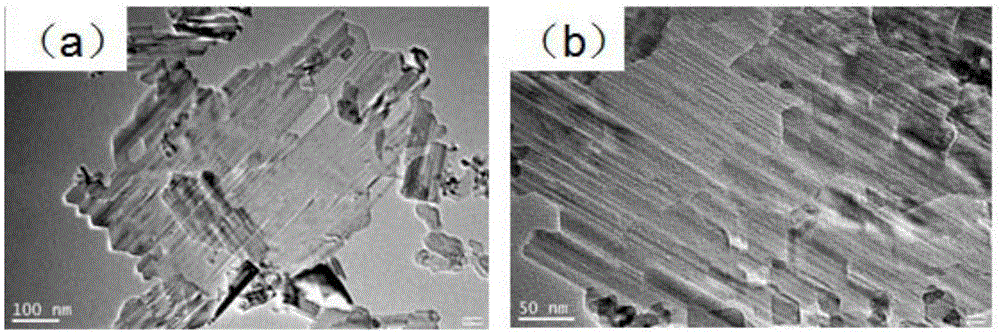

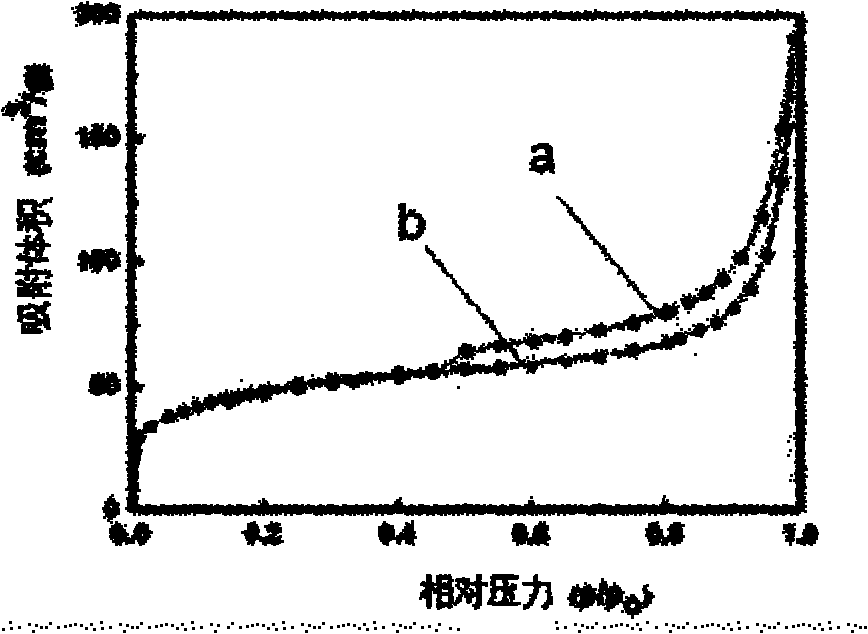

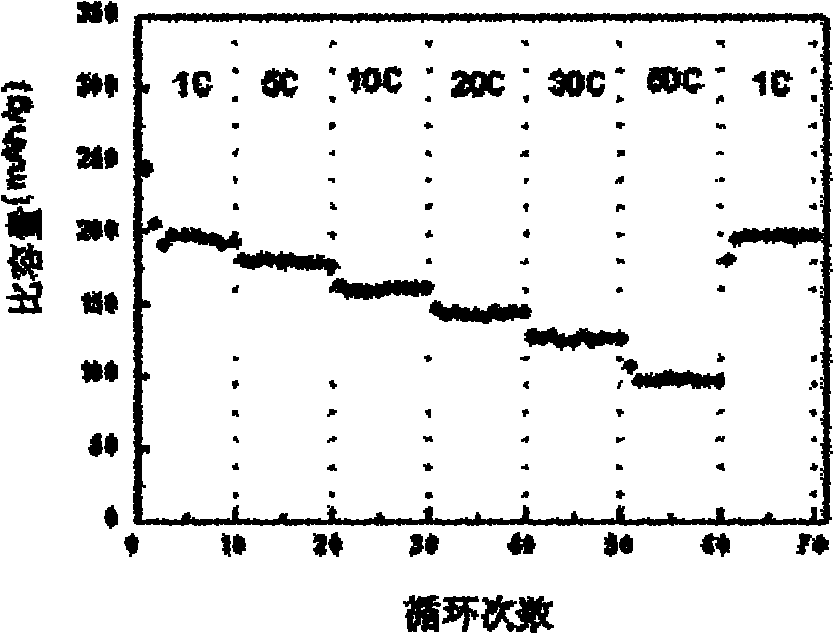

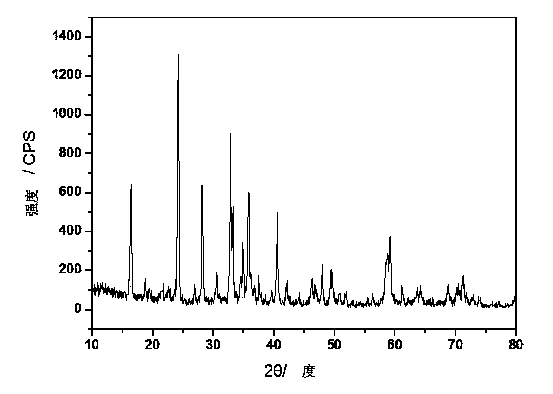

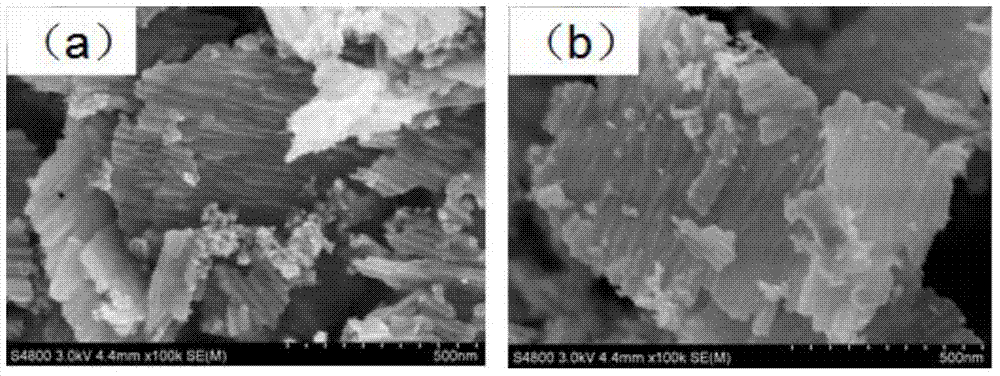

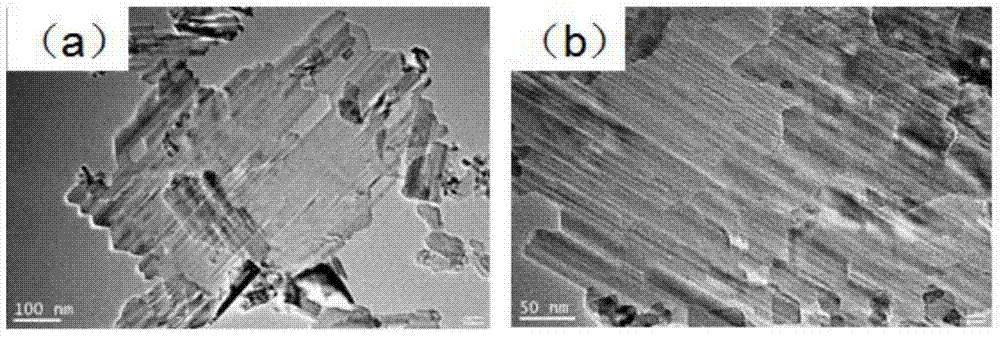

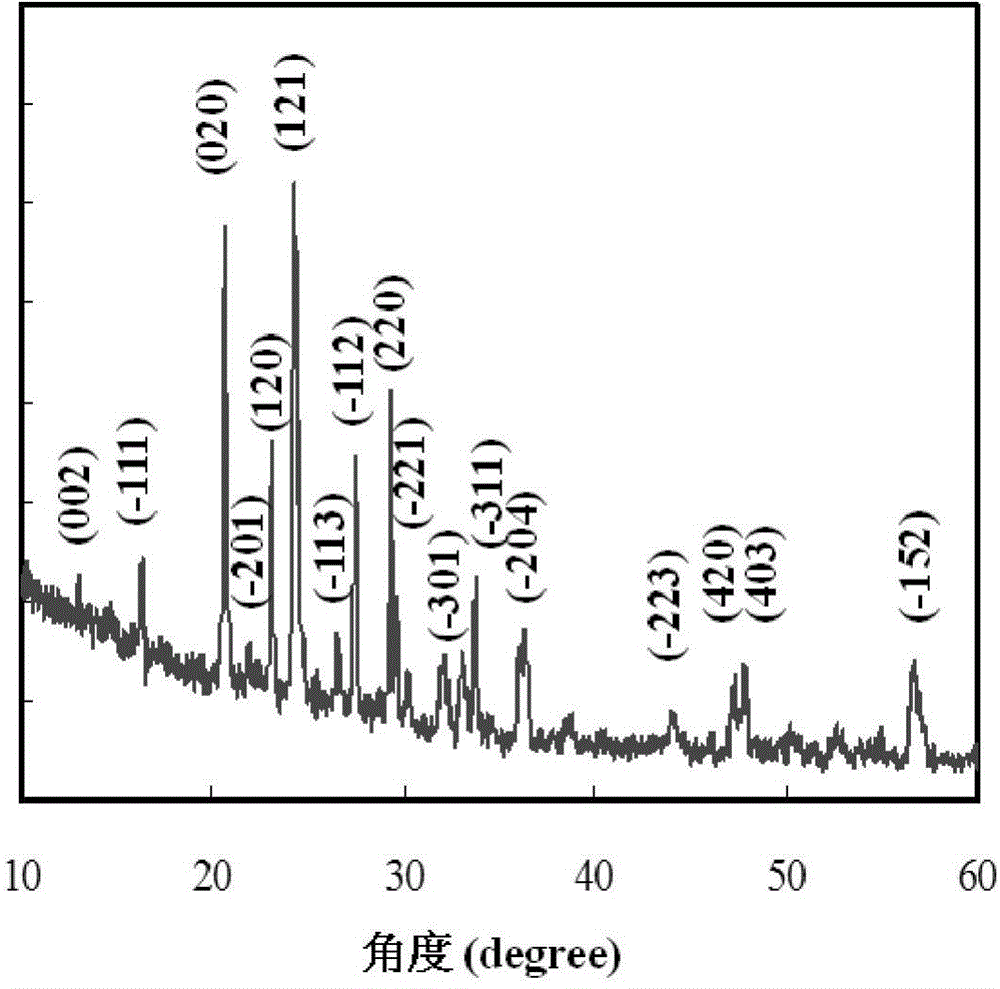

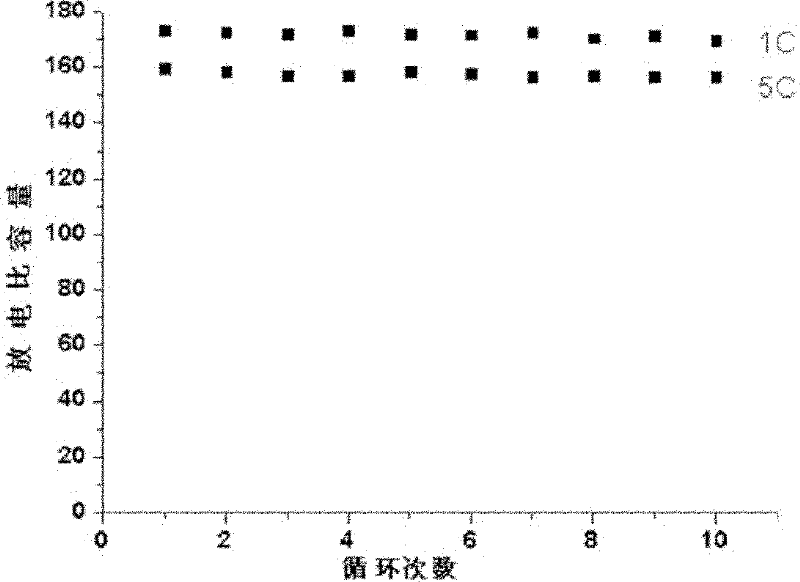

Preparation method for ultra-thin Li4Ti5O12 nanosheet assisted by surfactant, and use method for ultra-thin Li4Ti5O12 nanosheet in lithium battery and sodium battery

ActiveCN105390690AExcellent high rate charge and discharge performanceMaterial nanotechnologyAlkali titanatesAir atmosphereHigh rate

The invention relates to a preparation method for an ultra-thin Li4Ti5O12 nanosheet assisted by a surfactant, and a use method for the ultra-thin Li4Ti5O12 nanosheet in a lithium battery and a sodium battery, and belongs to the fields of electrochemical power supply and energy storage. According to the preparation method, a three block-polyether type surfactant is initially used to assist a hydrothermal method to synthesize a lithium titanate precursor, and then the lithium titanate precursor is sintered under an air atmosphere to obtain an ultra-thin nanosheet-shaped Li4Ti5O12 electrode material with the thickness of 3-10 nm; the synthesized ultra-thin nanosheet-shaped Li4Ti5O12 material takes metal lithium and metal sodium as negative electrodes to prepare a lithium ion battery and a sodium ion battery respectively; and the prepared ultra-thin nanosheet-shaped Li4Ti5O12 material is excellent in the high rate capability, high in specific capacity, can be widely applied to the lithium ion batteries required by various portable electronic equipment and various electric vehicles, and the lithium ion batteries for the related energy storage, and can be used for the lithium ion batteries with excellent performance as well.

Owner:HEFEI UNIV OF TECH

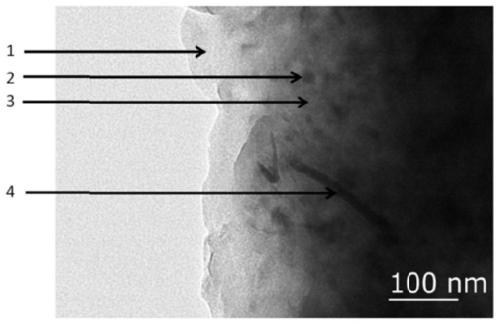

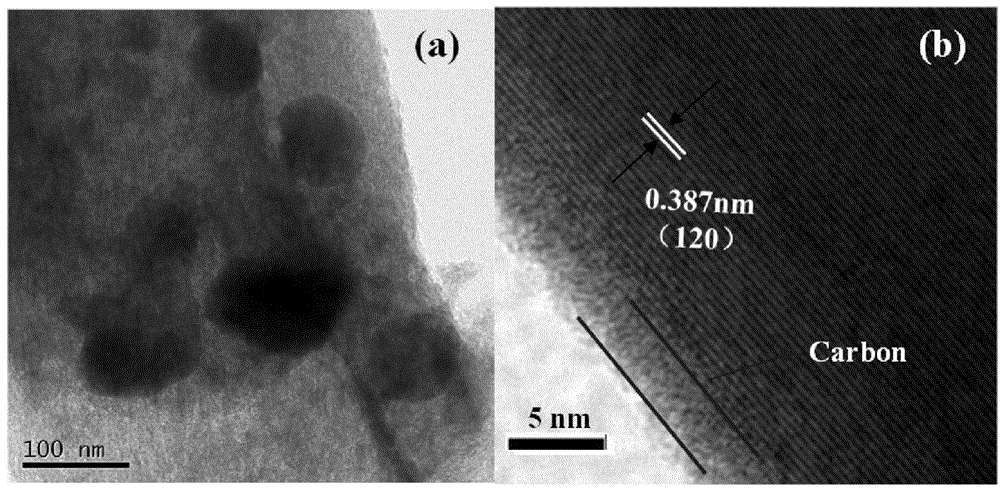

Silicon-carbon negative electrode material for lithium ion battery and preparation method

ActiveCN111180713AHigh specific capacityPromote circulationMaterial nanotechnologyNegative electrodesCarbon coatingNano silicon

The invention belongs to the field of lithium ion battery negative electrode materials and electrochemistry, and particularly relates to a silicon-carbon negative electrode material for a lithium ionbattery and a preparation method thereof. The negative electrode material is of a core-shell structure, wherein the core is nano silicon, cracked carbon and a single-walled carbon nanotube, and the shell is a carbon coating layer formed by vapor deposition; the particle size of the nano silicon is 5-100 nm; the softening point of cracked carbon is less than 300 DEG C, and the residual carbon rateis more than 40%; the diameter of the single-walled carbon nanotube is 5-20 nm, preferably 5-10 nm; the tube length is 30 to 500 nm, preferably 30 to 100 nm; and the thickness of the carbon coating layer is 10-200 nm. The preparation method comprises the following steps: (1) carrying out homogeneous compounding on a cracked carbon precursor and the single-walled carbon nanotube; (2) depositing nano silicon CVD in the cracked carbon; (3) carrying out mechanical shaping; and (4) carrying out carbon coating. The silicon-carbon negative electrode material prepared by the method is simple in process, excellent in performance and environment-friendly.

Owner:MAANSHAN KEDA PURUI ENERGY TECH CO LTD +2

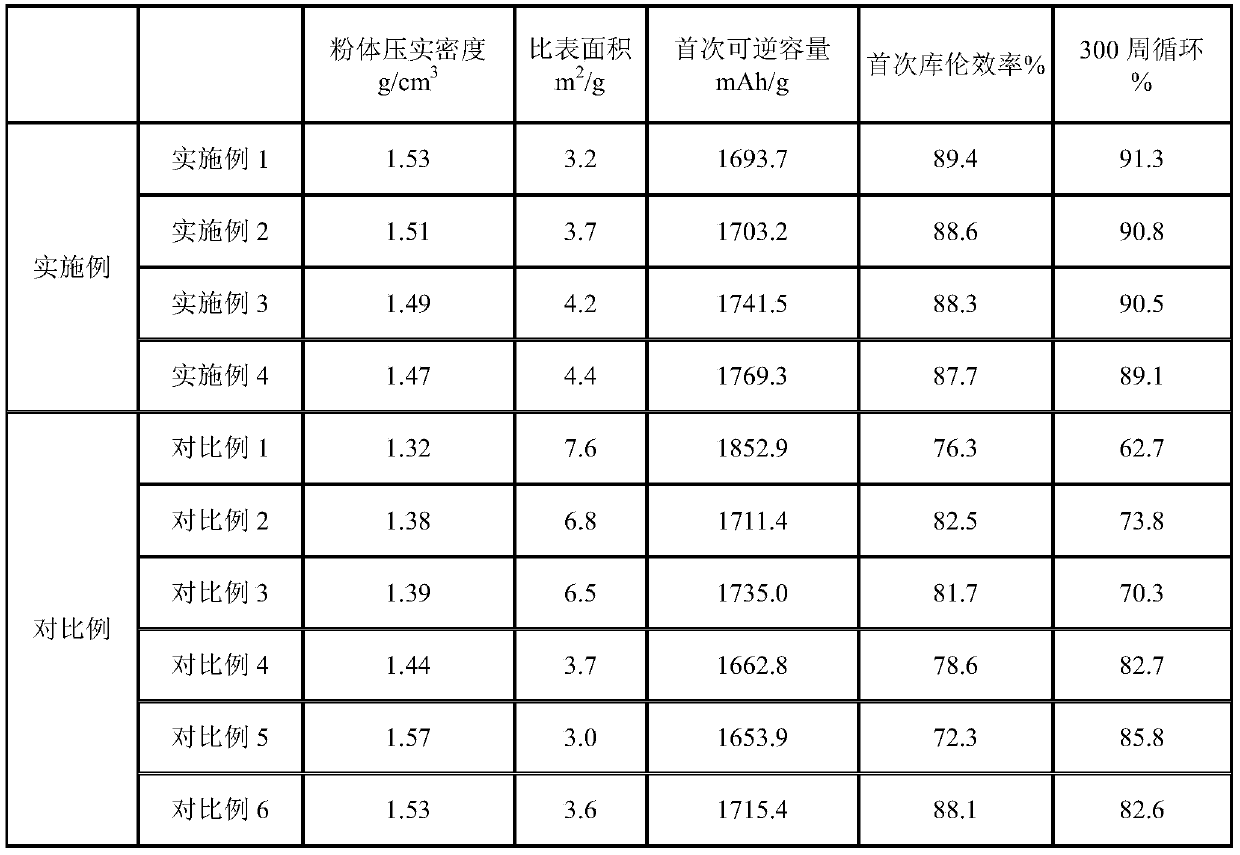

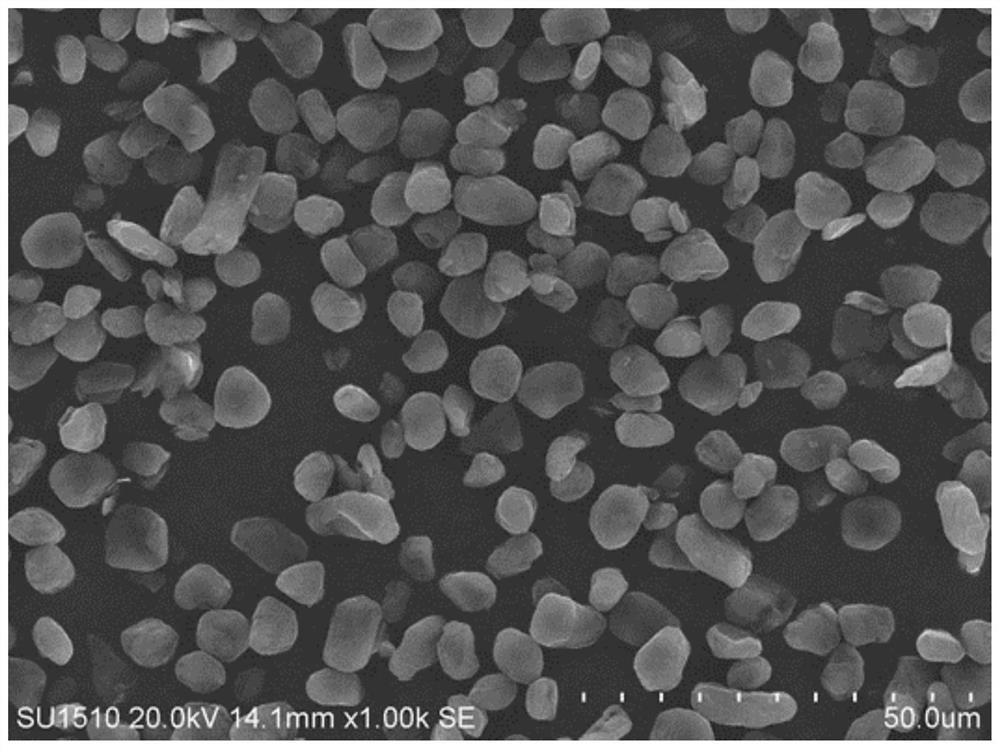

Negative plate and lithium ion battery comprising same

PendingCN114122329AImprove the disadvantage of poor cycle performanceFast transferNegative electrodesSecondary cellsPhysical chemistryLithium-ion battery

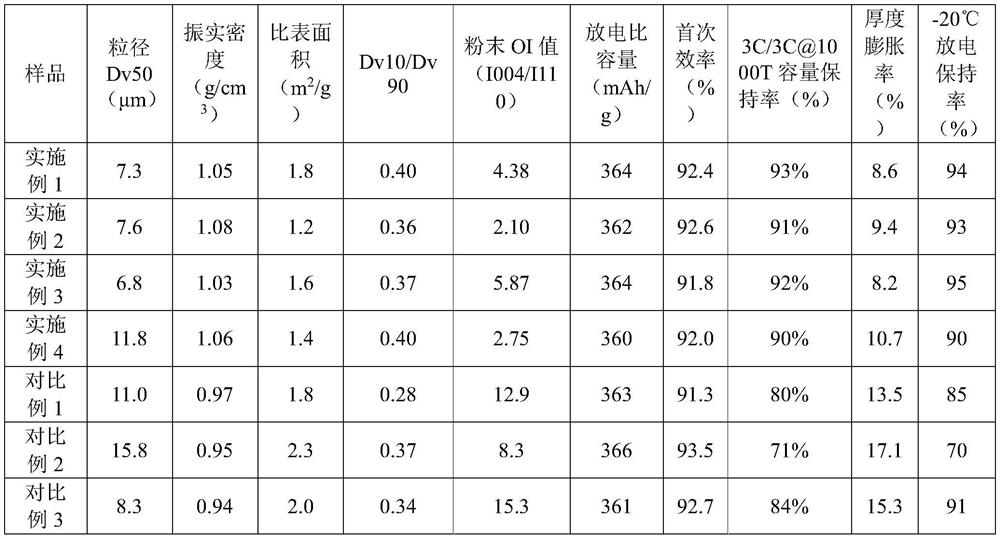

The invention provides a negative plate and a lithium ion battery comprising the same. The negative plate contains a negative active material, and the negative active material has the following characteristics: the particle size distribution Dv10 / Dv90 is greater than 0.35; the specific surface area is 2-3m < 2 > / g; and the tap density is 1.0-1.3 g / cm < 3 >. The high-rate charge-discharge performance of the negative plate is excellent, the low-temperature charge-discharge polarization of the negative plate is smaller, the start-stop / HEV lithium ion battery has excellent performance in low-temperature high-rate charge-discharge, and the application prospect of the negative plate is wide.

Owner:ZHUHAI COSMX BATTERY CO LTD

Method for preparing lithium titanate cathode material of lithium ion battery

InactiveCN101409341BExcellent high rate charge and discharge performanceElectrode manufacturing processesHigh rateLithium hydroxide

The invention discloses a preparation method of a lithium titanate cathode material for a lithium ion battery. Titanium dioxide colloid is taken as an initial raw material; the titanium dioxide colloid and lithium hydroxide are added to a mixture of water and ethanol while stirring, then the obtained solution is transferred to a hydrothermal reaction kettle for hydrothermal ion exchange reaction at 150-200 DEG C for 10-18h, the reacted solution is naturally cooled to room temperature, then filtered to obtain white precipitate; the obtained precipitate is placed in a muffle furnace with the temperature of 350-600 DEG C for 1-3h heat treatment to obtain the lithium titanate cathode material used in the lithium ion battery. The lithium titanate cathode material which is used in the lithium ion battery and synthesized by the method has stable discharge specific capacity of 125mAh / g at the rate of 20C (3.5A / g), and has good high-rate charge and discharge performance.

Owner:SHANGHAI JIAO TONG UNIV +1

Titanium dioxide/graphene nanocomposite material and preparation method and application thereof

InactiveCN102569761BShape is easy to controlEvenly dispersedCell electrodesGraphene nanocompositesHigh energy

The invention relates to a titanium dioxide / graphene nanocomposite material, a preparation method of the nanocomposite material and application of the nanocomposite material in the field of energy source and cleaning environment. The graphene accounts for 1-25wt% and the balance is titanium dioxide. Morphology of the titanium dioxide is a mesoporous structure or a structure with a dominant high energy surface, and titanium dioxide is scattered uniformly on the surface of graphene. According to the invention, by adopting a titanium source and graphene as initial materials, and water or organic solvents as reaction solvents, the nanocomposite material with titanium dioxide with the mesoporous structure or a titanium dioxide nano sheet with the dominant high energy surface compounded with graphene can be obtained through hydrothermal synthesis or a hydrolysis reaction. The invention can be carried out in an aqueous solution system and the crystallinity of the product is high. The composite material can be applied to a cathode material of a power ion battery, has a higher charge-discharge capacity, is excellent in high current charge and discharge, stable in circulating performance, has very good photocatalytic performance and can be used to light degradation of organic pollutants and water photolysis for preparing hydrogen.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Active material for lithium ion battery having Al-containing lithium titanate and lithium ion battery

ActiveUS7879265B2Excellent high rate charge and discharge performanceThermoelectric device with peltier/seeback effectCell electrodesHigh rateCharge and discharge

It is an object of the present invention to provide an active material for lithium ion battery capable of producing a lithium ion battery having an excellent high rate charge and discharge performance and a lithium ion battery having an excellent high rate charge and discharge performance. The present invention provides an active material for lithium ion battery represented by a composition formula: Li[Li(1-x) / 3AlxTi(5-2x) / 3]O4 (⅛≦x<1) lithium titanate is substituted with Al, and a lithium ion battery using this active material as a negative electrode active material.

Owner:GS YUASA INT LTD

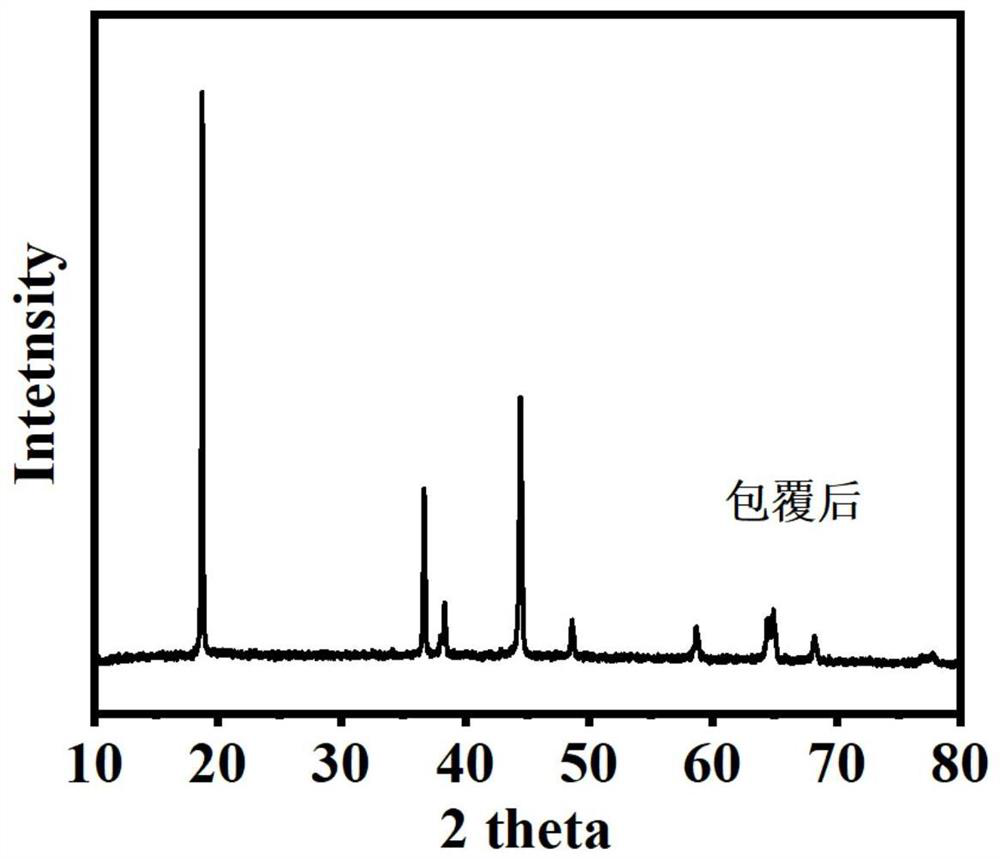

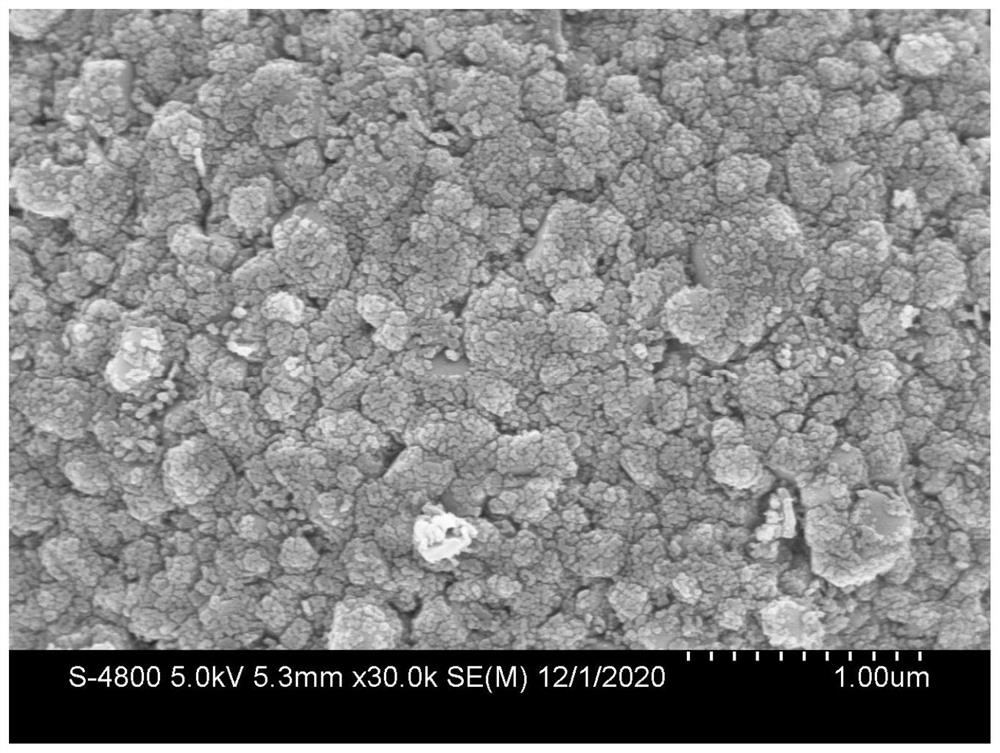

Lithium battery positive electrode material surface transmission efficiency regulation and control method and obtained positive electrode material

InactiveCN112563504AEliminate the disadvantages of incompatibilityAchieve firmnessFinal product manufactureCylindrical casing cells/batteryPhysical chemistryPolymer composites

The invention discloses a lithium battery positive electrode material surface transmission efficiency regulation and control method and an obtained positive electrode material. The method comprises the following steps: S1, uniformly mixing two or more polymers according to a certain ratio to obtain a polymer mixed solution; S2, dispersing a lithium battery positive electrode material into the polymer mixed solution to obtain a suspension; and S3, heating the suspension, and drying a powder to obtain the final polymer-coated lithium battery positive electrode material. A polymer composite coating layer is formed on the surface of the positive electrode material, the elasticity of the polymer and a cross-linking property between two or more polymers are utilized, a defect of interface incompatibility is eliminated while multiple electron / ion channels are constructed, the compactness and completeness of a coating structure are realized, and different polymers are coated so that electron / ion transmission efficiency of an interface can be regulated and controlled. The method is simple, convenient, low in cost and high in raw material selectivity. Universality is high, and a commercial application is easy.

Owner:北京理工大学重庆创新中心 +1

Method for preparing composite carbon cathode material for super-capacitor battery

InactiveCN101763944BGood lithium ion intercalation/extraction cycle performanceExcellent Capacitive Energy Storage PerformanceElectrolytic capacitorsChemical platingElectrical battery

The invention relates to a high-rate lithium-ion battery and a method for preparing a composite carbon cathode material for a super-capacitor battery. The method comprises the following steps: coating a surface-nano-crystallized core with a porous carbon coat provided with macro-pore / meso-pore / micro-pore three-dimensional layer pores; doping metal particles on the surface of the coat; and carrying out low-potential treatment, wherein the three steps are sequentially achieved by a template-based method, a combined method comprising dipping, chemical plating and physical mixing, and an electrochemical method of lithium pre-doping respectively. The process of the invention has the advantages of simple method and convenient operation; the prepared material has a core-coat structure and doped metallic elements, and meanwhile, the material has good performance in double-layer electric energy storage and lithium-ion intercalation and de-intercalation energy storage and effectively improves the high-rate performance and power density of the lithium-ion battery; the material meets the requirements of super-capacitor batteries in both the lithium-ion energy storage and double-layer electricenergy storage of the cathode material; accordingly, the material can be used as the cathode of a high-performance lithium-ion battery; and the material has good performance in high-rate charging / discharging, so the material has a good prospect for industrialization.

Owner:CENT SOUTH UNIV +1

Needle coke regulated and controlled by transition metal as well as preparation and application of needle coke

PendingCN114725377AIncrease the active siteImprove distributionSecondary cellsNegative electrodesCokeEnergy storage

The invention discloses a preparation method of transition metal regulated and controlled needle coke and application of the transition metal regulated and controlled needle coke in a lithium ion battery, the transition metal regulated and controlled needle coke is prepared by the following steps: by taking coal-based needle coke as a substrate, activating the coal-based needle coke, performing hydrothermal mixing treatment on the activated coal-based needle coke and transition metal salt, and performing simple roasting to modify the surface by metal, thereby obtaining the transition metal regulated and controlled needle coke. And metal on the surface is removed through low-concentration acid pickling to obtain the high-performance electrode material. The method disclosed by the invention is simple in preparation process, safe, effective and short in operation time, shows excellent cycle performance and rate charge-discharge performance as a lithium ion battery negative electrode material, and has a wide application prospect in the field of energy storage.

Owner:TAIYUAN UNIV OF TECH

A kind of cathode material of lithium ion battery and preparation method thereof

The invention provides a positive electrode material for a lithium ion battery, the positive electrode material comprises a positive electrode active material, the structural formula of the positive electrode active material is Li2+xMSi1-xNxO4, wherein, M is selected from Mn, Fe or Mn1-yFey, N Selected from Ti, Cr or Ti1-zCrz, 0.01<x≤0.5, 0<y<1, 0<z<1. At the same time, the present invention also provides a preparation method of the above positive electrode material. The preparation method of the present invention has a simple process, and the prepared positive electrode material has excellent performance, stable structure, high specific capacity, coulombic efficiency and good cycle performance, and also has excellent high rate charge and discharge performance.

Owner:BYD CO LTD

A Surfactant-Assisted Ultrathin Li 4 ti 5 o 12 Preparation method of nanosheets and method of use thereof in lithium batteries and sodium batteries

ActiveCN105390690BExcellent high rate charge and discharge performanceMaterial nanotechnologyAlkali titanatesMetallic lithiumElectrical battery

The invention relates to a preparation method for an ultra-thin Li4Ti5O12 nanosheet assisted by a surfactant, and a use method for the ultra-thin Li4Ti5O12 nanosheet in a lithium battery and a sodium battery, and belongs to the fields of electrochemical power supply and energy storage. According to the preparation method, a three block-polyether type surfactant is initially used to assist a hydrothermal method to synthesize a lithium titanate precursor, and then the lithium titanate precursor is sintered under an air atmosphere to obtain an ultra-thin nanosheet-shaped Li4Ti5O12 electrode material with the thickness of 3-10 nm; the synthesized ultra-thin nanosheet-shaped Li4Ti5O12 material takes metal lithium and metal sodium as negative electrodes to prepare a lithium ion battery and a sodium ion battery respectively; and the prepared ultra-thin nanosheet-shaped Li4Ti5O12 material is excellent in the high rate capability, high in specific capacity, can be widely applied to the lithium ion batteries required by various portable electronic equipment and various electric vehicles, and the lithium ion batteries for the related energy storage, and can be used for the lithium ion batteries with excellent performance as well.

Owner:HEFEI UNIV OF TECH

Preparation method of high-performance lithium ion power battery/porous carbon composite positive electrode material

InactiveCN104466181AImprove cycle lifeLarge rate charge and discharge characteristicsCell electrodesSecondary cellsPorous carbonEthylic acid

The invention discloses a preparation method and application of a high-performance lithium ion power battery / porous carbon composite positive electrode material. The preparation method comprises the following steps: performing refluxing on porous carbon with nitric acid at 40-60 DEG C for 0.5-2 hours; adding lithium carbonate / lithium nitrate / lithium acetate, ammonium metavanadate, ammonium dihydrogen phosphate and citric acid into a reactor according to the mole ratio of 3 to 2 to 3 to (1-3), adding a proper amount of deionized water and ethyl alcohol, stirring by a magnetic stirrer for 10-30 minutes, then adding porous carbon, further stirring for 10-15 minutes, carrying out ultrasonic treatment for 5-10 minutes, and drying at 50-80 DEG C for 2-3 hours; and forging the obtained powder in a N2 atmosphere tubular furnace at 700-900 DEG C for 4-6 hours, thereby obtaining the Li3V2(PO4)3 / porous carbon composite material. The preparation technology is simple, the cost is low, the energy consumption is low, the reproducibility is good, and the high-performance lithium ion power battery / porous carbon composite positive electrode material can be produced on a large scale, and conforms to the environment requirement.

Owner:FUJIAN NORMAL UNIV

A negative electrode material for a lithium-ion battery, a preparation method thereof, and a lithium-ion battery

ActiveCN102569788BStable structureImprove performanceCell electrodesSecondary cellsPhysical chemistryBattery cell

Owner:BYD CO LTD

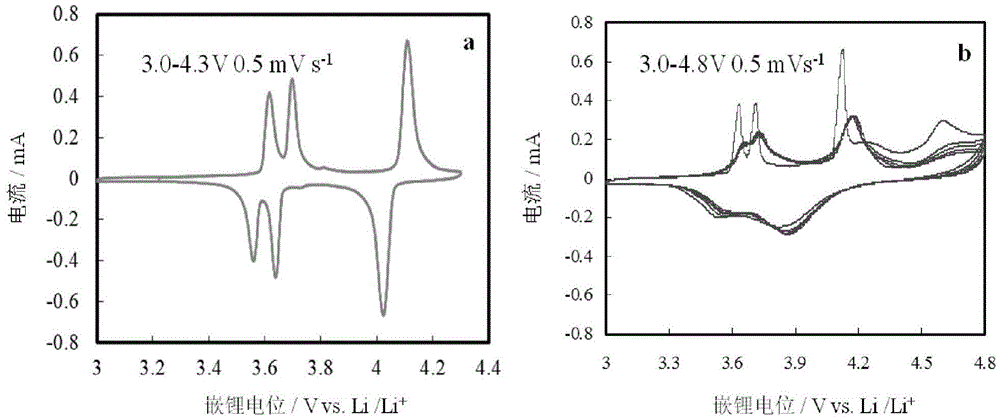

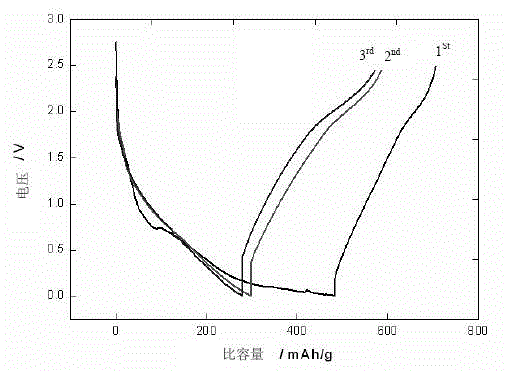

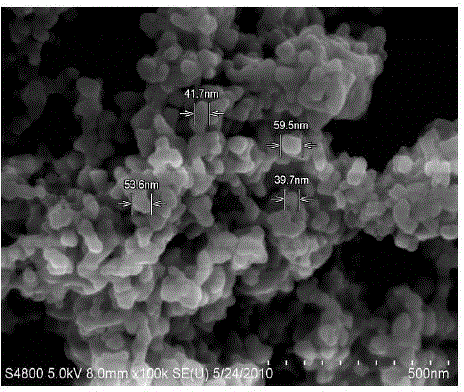

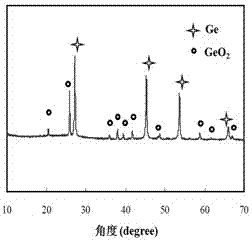

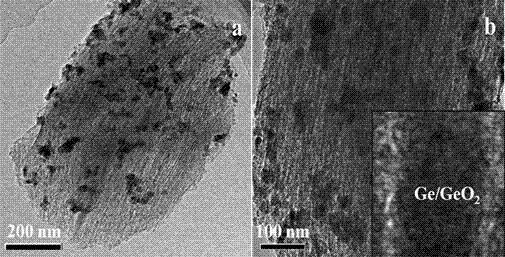

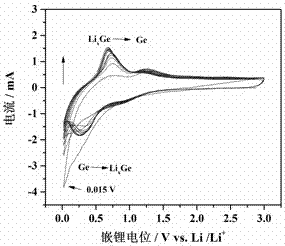

ge/geo for lithium-ion batteries 2 ‑Mesoporous carbon composite electrode material preparation and application

ActiveCN105070891BLarge rate charge and discharge characteristicsImprove cycle lifeSecondary cellsNon-aqueous electrolyte accumulator electrodesLithium-ion batteryLithium electrode

The invention belongs to the field of lithium ion battery material science, and particularly relates to a preparation method of a Ge / GeO2-mesoporous carbon composite electrode material with high performance and an application of the Ge / GeO2-mesoporous carbon composite electrode material. The method comprises the following steps: refluxing mesoporous carbon with nitric acid at 50-70 DEG C for 0.5-2 hours; dispersing a germanium salt into a proper amount of ethanol, and stirring the germanium salt with a magnetic stirrer for 5-20 minutes; adding the mesoporous carbon, further stirring for 5-20 minutes, ultrasonically treating for 5-10 minutes, and drying the solution at 50-70 DEG C for 2-4 hours; burning the obtained powder in an N2 atmosphere tube furnace at 600-800 DEG C for 2-6 hours, so as to obtain the Ge / GeO2-mesoporous carbon composite material. The prepared composite material is assembling into a lithium ion battery, with the material as a cathode of the battery, and the material doped with a compound as an anode of the battery. The technology is simple and convenient, available in raw materials, good in repeatability and free of obvious pollutant emission, and the Ge / GeO2-mesoporous carbon composite electrode material can be massively produced, and conforms to the environmental requirements.

Owner:FUJIAN NORMAL UNIV

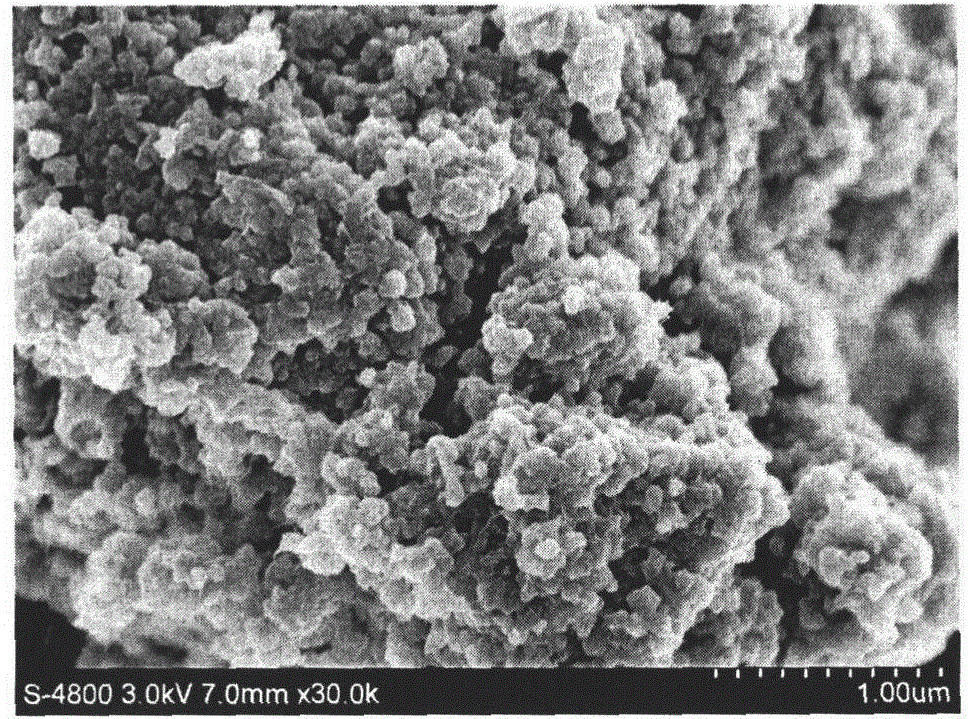

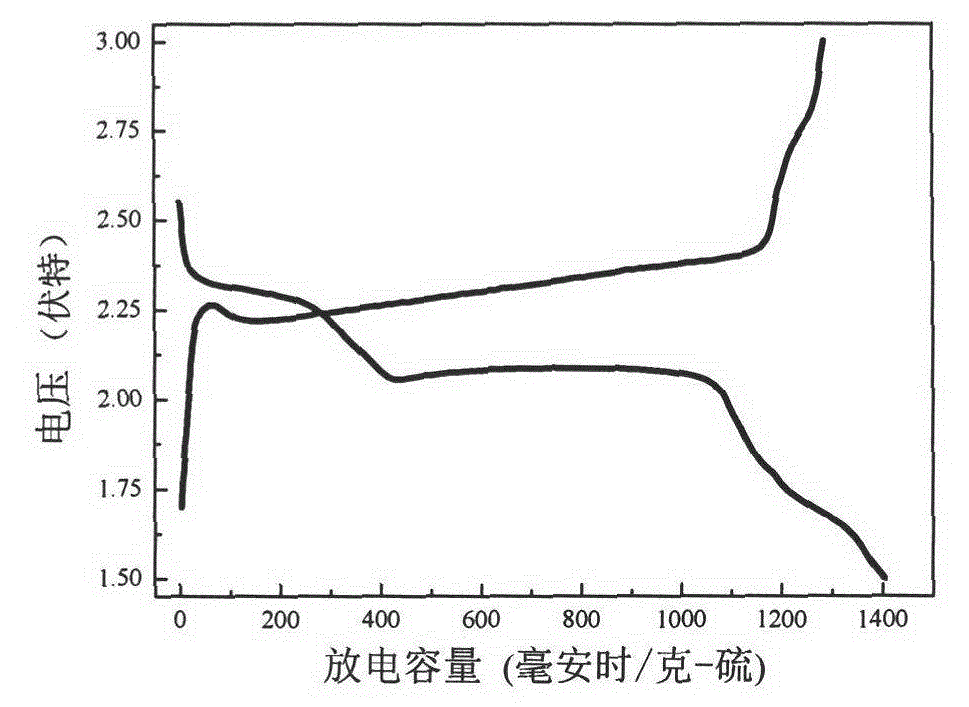

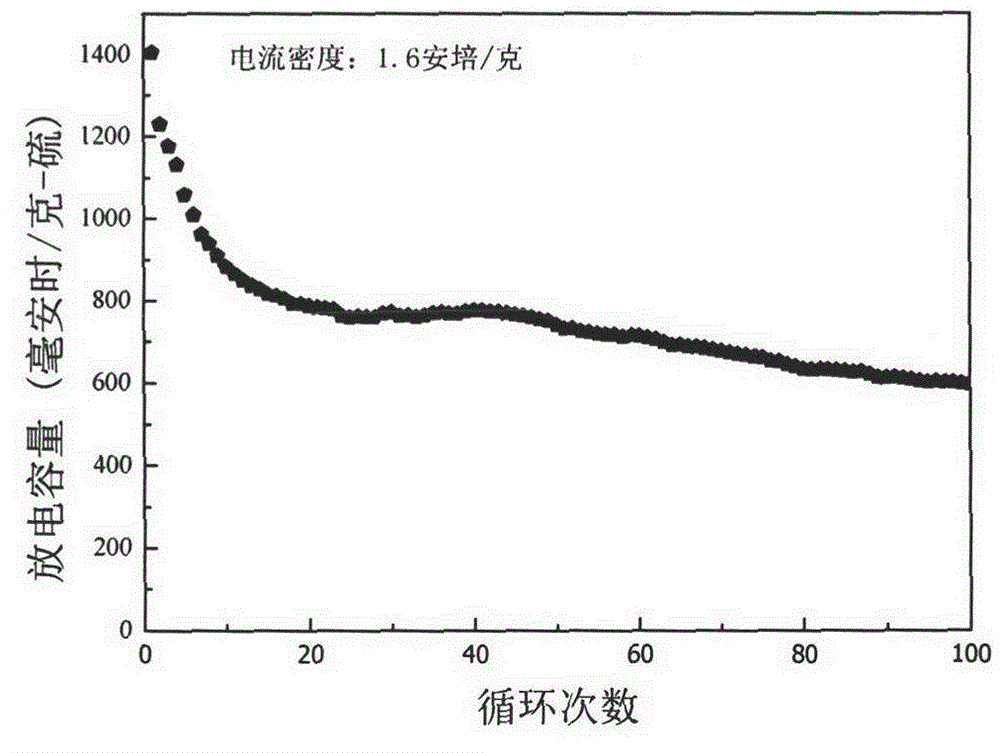

Lithium battery with polymer-coated sulfur/carbon composite material as anode

InactiveCN102447113BImprove cycle performanceImprove conductivityCell electrodesSecondary cellsCarbon compositesLithium-ion battery

The invention relates to a lithium battery with a polymer-coated sulfur / carbon composite material as an anode. According to the invention, sublimed sulfur or sulfur powder and a conductive carbon material are mixed according to a mass ratio of 3:7-8:2; the mixture is subject to ball milling, such that a sulfur / carbon composite material is obtained; the composite material is dispersed in a solution, and a polymer monomer is added to the solution; under a low temperature and the protection of inert gas, an oxidizing agent is added for initiating polymerization; the material is centrifuged, washed, and dried; the obtained polymer-coated elemental sulfur / carbon composite material, acetylene black and PTFE are mixed; a dispersant is added to the mixture, and the mixture is sufficiently mixed by stirring; the mixture is rolled into a sheet, and is vacuum-dried under a temperature of 55 DEG C, such that an electrode sheet is obtained. The prepared electrode sheet is adopted as an anode, metal lithium is adopted as a cathode, and a solvent type organic solution system containing 0.2mol / L of a waterless lithium nitrate additive is adopted as electrolyte, and a battery is assembled. With the electrode material, the assembled lithium battery is advantaged in high specific capacity, good circulation stability, and excellent heavy-current charge / discharge performances. The preparation method is advantaged in simple process, low cost, and good repeatability.

Owner:NANKAI UNIV

Lithium titanate-based chemical power supply

ActiveCN103050732BExcellent high rate charge and discharge performanceImprove cycle lifeCell electrodesSecondary cellsMagnificationCharge discharge

The invention provides a lithium titanate-based chemical power supply which consists of an anode, a cathode, a diaphragm and an electrolyte and is characterized in that the anode and the cathode respectively consist of active substances and current collectors, wherein the cathode active substance is lithium titanate, the capacity of the anode active substance is excessive, and the capacity ratio of the anode active substance to the cathode active substance is between (1.1:1)-(4:1). The lithium titanate-based chemical power supply has the advantages of excellent large-magnification charging-discharging performance, long cycling life, high safety and good cycling performance, so that the chemical power supply has wider application field.

Owner:SHANGHAI AOWEI TECH DEV

A kind of manufacturing method of lithium ion battery containing gel electrolyte

ActiveCN103000956BEasy to prepareImprove ionic conductivityFinal product manufactureElectrolyte accumulators manufactureElectrolytic agentLithium-ion battery

The invention belongs to the technical field of lithium-ion batteries, and in particular relates to a method for manufacturing a lithium-ion battery containing a gel electrolyte, the method comprising: preparation of a microporous isolation membrane, preparation of a battery cell, filling of the electrolyte and post-treatment and other steps. Compared with the prior art, the present invention adopts a two-step method to polymerize the gel. Through the pre-gelation step, the cell forms a good cathode electrode / electrolyte interface and an anode electrode / electrolyte interface. During the formation process, the cathode is activated The material and the anode active material are fully activated, and the battery is heated while pressurized after formation, which can eliminate the bubbles generated during the formation process of the battery and exist between the cathode electrode / electrolyte interface and the anode electrode / electrolyte interface. Making the interface gap smaller is more conducive to the formation of a good cathode electrode sheet / electrolyte interface and anode electrode sheet / electrolyte interface, so that the battery has more excellent electrochemical performance.

Owner:DONGGUAN AMPEREX TECH

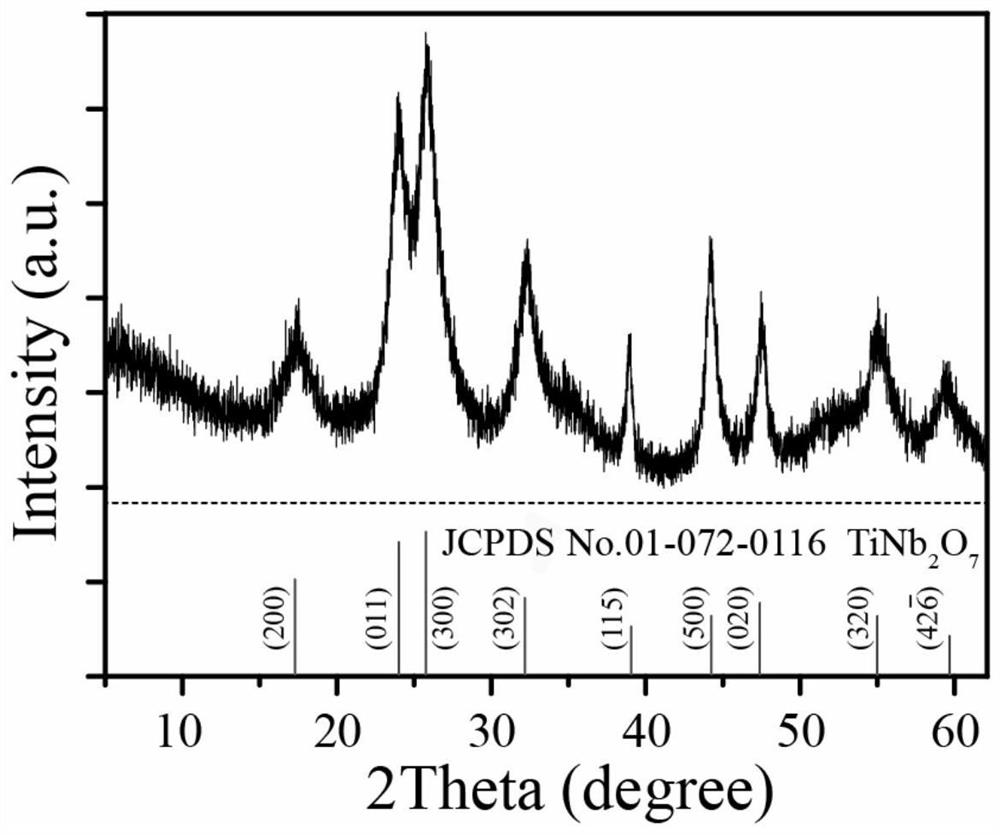

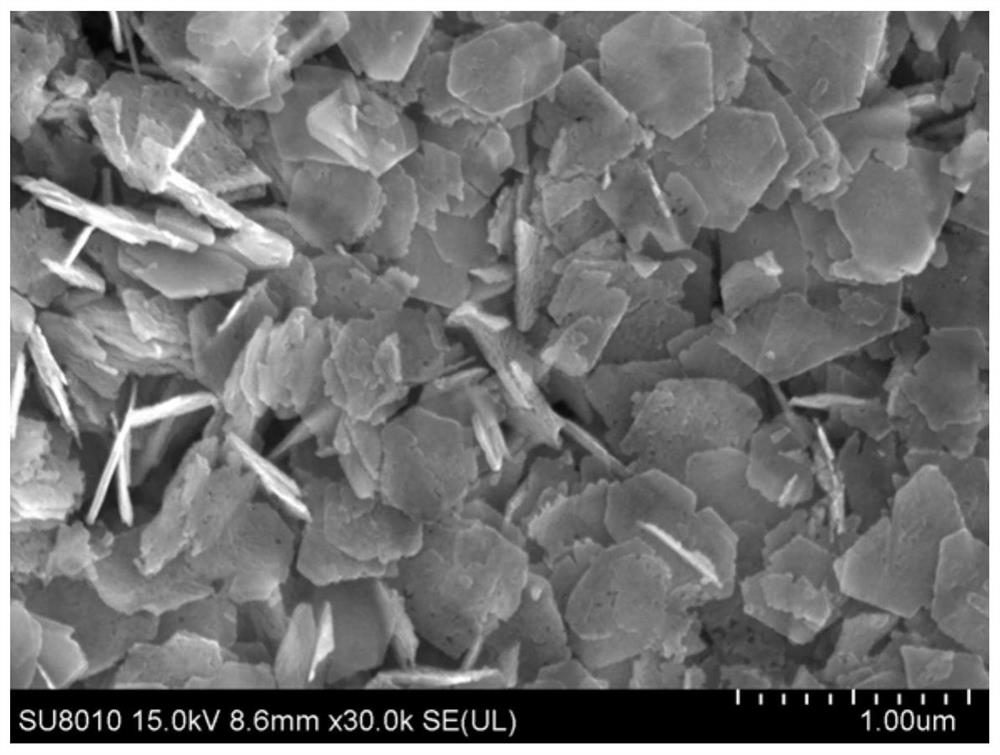

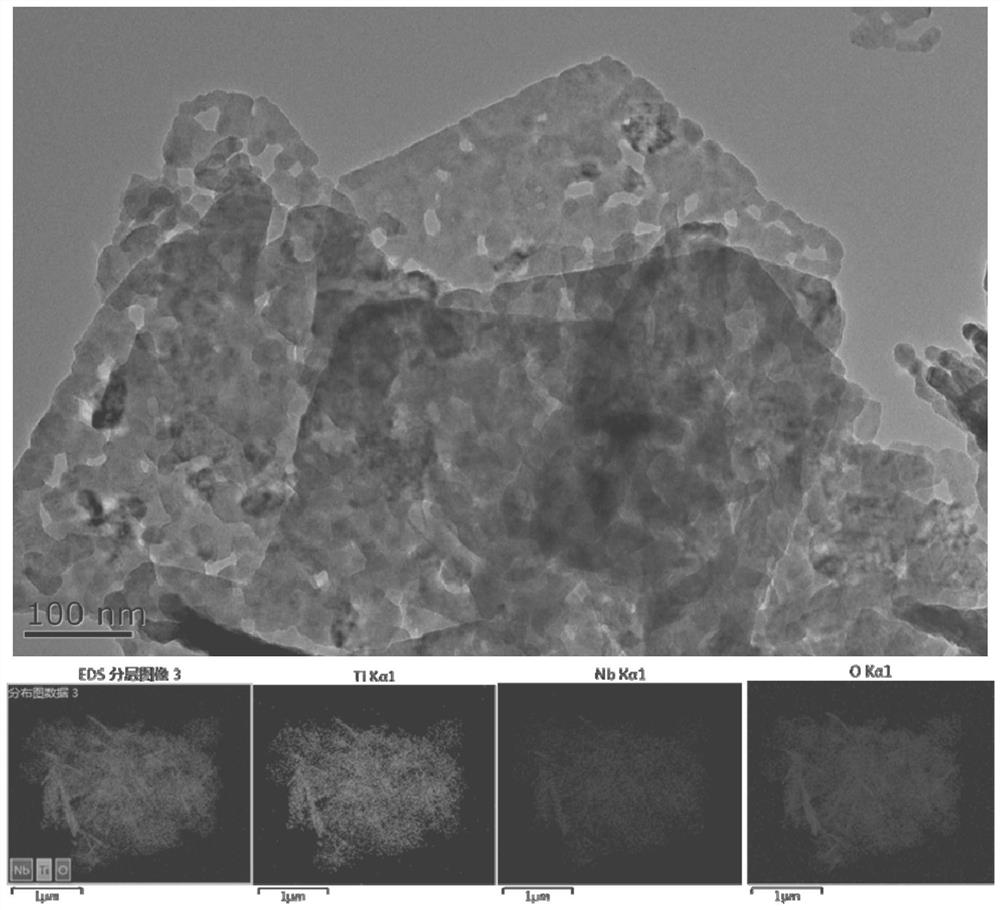

A kind of porous sheet tinb for negative electrode of lithium ion battery 2 o 7 Preparation methods of nanocrystals

ActiveCN110156081BIncrease contact areaImprove electrochemical performanceMaterial nanotechnologySecondary cellsElectrolytic agentHexamethylenetetramine

A kind of porous thin TiNb for negative electrode of lithium ion battery 2 o 7 The invention discloses a method for preparing nanocrystals, and relates to the technical field of preparation of negative electrode materials for lithium ion batteries. Firstly, titanium source and niobium source are added to the mixed solution of ethylene glycol and isopropanol in a certain proportion, then hexamethylenetetramine is added to mix and stir evenly, then the reaction solution is placed in the reaction vessel for reaction, and finally post-treated Porous and flake TiNb 2 o 7 Nanocrystalline anode materials. The preparation method of the present invention is simple, and the repeatability of the experiment is high; the prepared negative electrode material is in the shape of nano flakes, the flake size is 300-600nm, the thickness is 10-30nm, and has a large specific surface area and porosity, which is beneficial to the electrolyte solution. Permeation and transport of lithium ions, thereby improving the electrochemical performance of the material. As a lithium-ion battery negative electrode, it has high reversible capacity and first-time efficiency, excellent high-rate charge-discharge performance and excellent rate cycle performance.

Owner:HEFEI UNIV

Preparation method of lithium titanate material, lithium titanate material, and lithium ion battery

InactiveCN102842706BImprove high rate charge and discharge performanceExcellent high rate charge and discharge performanceCell electrodesSecondary cellsPower batteryHigh rate

The invention provides a preparation method of a lithium titanate material, the lithium titanate material, and a lithium ion battery. The preparation method comprises the steps that: a mixture containing a lithium source and a nickel source is subjected to primary ball milling; the mixture is calcined, such that a precursor is obtained; the precursor is mixed with a titanium source, and the mixture is subjected to secondary ball milling; and the mixture is calcined in an inert or reductive atmosphere, such that the lithium titanate material is obtained. With the method, the prepared lithium titanate material has excellent rate discharge performance, and is especially suitable to be applied in fields such as power batteries which require high-rate charging and discharging.

Owner:BYD CO LTD

Method for preparing composite anode material of super capacitor lithium titanate

ActiveCN102024574BUniform particle distributionGood fast charge and discharge capabilityElectrolytic capacitorsRoom temperatureBall mill

The invention provides a method for preparing a composite anode material of super capacitor lithium titanate, which is used for solving the problems that the negative electrode material of the super capacitor, which is prepared according to the existing method for preparing the negative electrode material of the super capacitor, has insufficient property, pollution and the like. The preparing method comprises the following steps: A, respectively weighing Li2CO3 powder, TiO2 powder and a proper amount of dispersing agent based on mass ratio of each element in Li4Ti5O12; B, mixing the raw materials in a mixing tank, placing the mixture in a ball mill for ball-milling, drying the materials subject to the ball-milling, sintering, and cooling to room temperature; and C, adding CuO to the cooled materials, wherein the weight of the CuO is equal to 3-6% of that of the cooled materials, carrying out ball-milling, drying, sintering, cooling to room temperature, porphyrizing and drying to obtain the composite anode material. The method for preparing the composite negative electrode material of the super capacitor lithium titanate has the advantages of simple technology, high material property, no pollution, and high cyclical stability.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com