Lithium battery positive electrode material surface transmission efficiency regulation and control method and obtained positive electrode material

A technology for positive electrode materials and transmission efficiency, applied in the direction of battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of poor stability, poor sustainability, and incompatibility of the coating layer, and achieve the elimination of interface incompatibility , easy commercial application, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for controlling the surface transmission efficiency of a lithium battery positive electrode material, comprising the following steps:

[0031] S1. Weigh 0.01g of PEG and 0.01g of PANI and fully dissolve in 4mL of NMP solvent to form a transparent mixed solution;

[0032] S2, adding 1 g of NCM811 to the mixed solution to prepare a suspension;

[0033] S3. The suspension is heated and stirred until uniform, and baked in an oven at 110°C. After the solvent is completely evaporated, a black dry powder is obtained, which is the final coated positive electrode material.

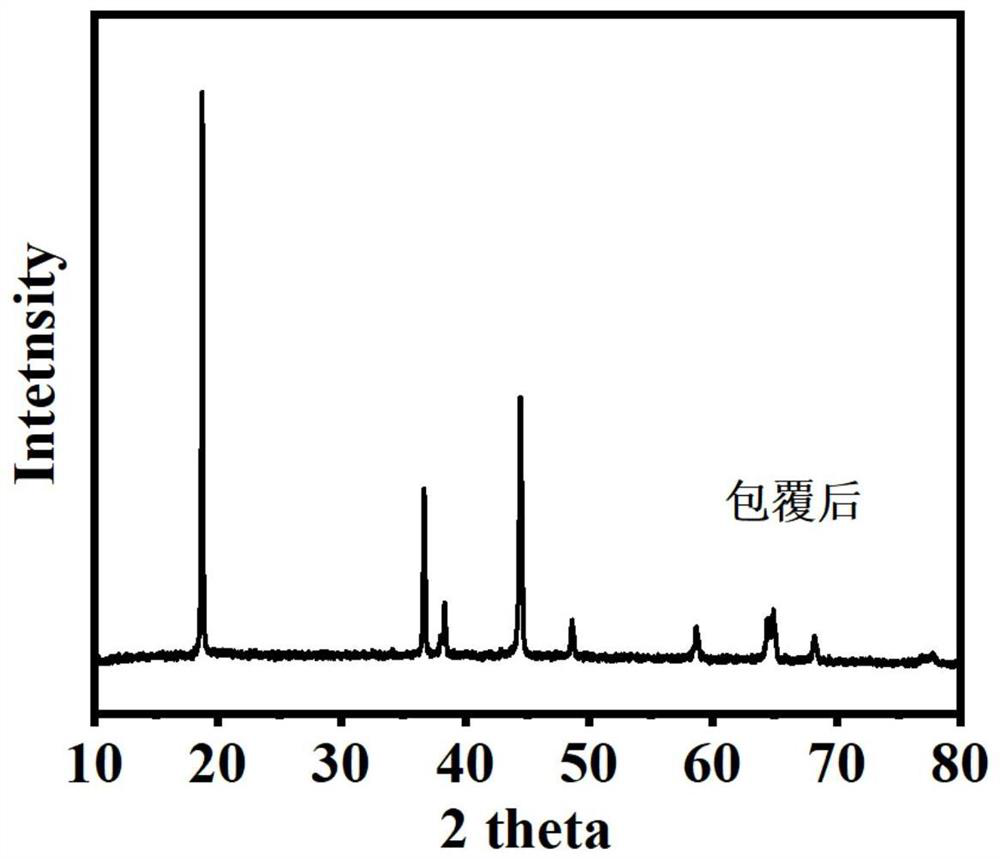

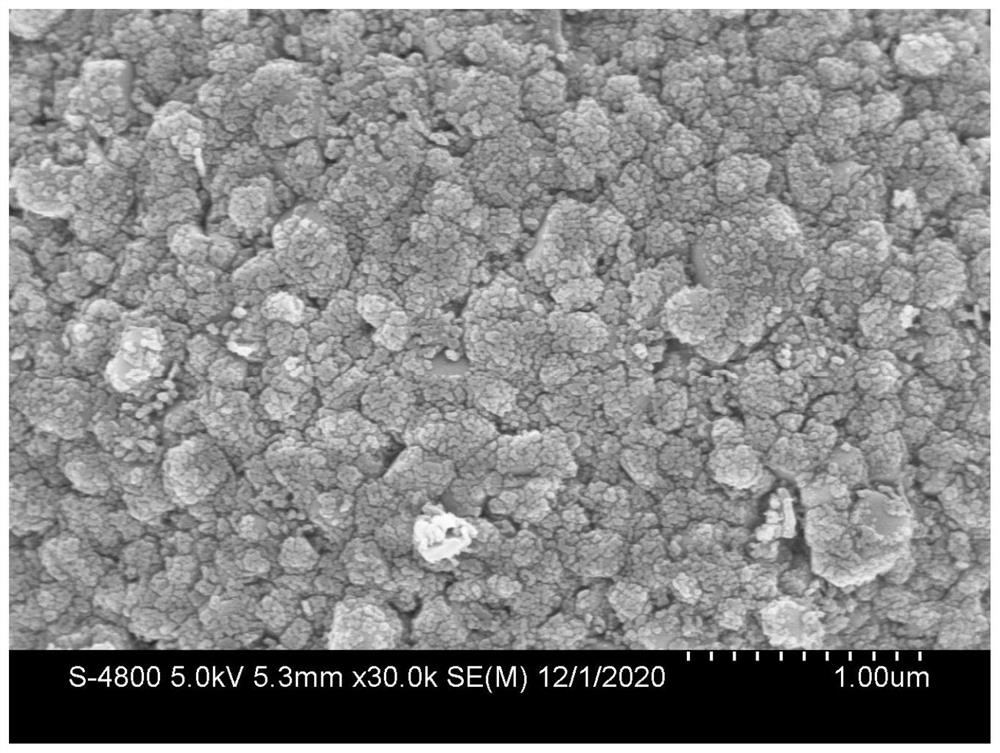

[0034] Such as figure 1 As shown, the XRD test shows that the positive electrode material prepared in Example 1 still retains the original crystal structure. Such as figure 2 As shown, the SEM test shows that the surface of the positive electrode material has a polymer composite coating layer, and the coating structure is compact and complete, and there is no obvious layering or sub-regional int...

Embodiment 2

[0036] A method for controlling the surface transmission efficiency of a lithium battery positive electrode material, comprising the following steps:

[0037]S1. Weigh 0.015g of PANI and 0.01g of PVP into 4mL of NMP and ultrasonically form a transparent mixed solution;

[0038] S2, 1g of LiFePO 4 Add to the mixed solution to configure the suspension;

[0039] S3. Stir evenly with a magnetic stirrer, then heat the suspension to volatilize all the solvent, and finally obtain dry powder, which is the coated positive electrode material.

Embodiment 3

[0041] A method for controlling the surface transmission efficiency of a lithium battery positive electrode material, comprising the following steps:

[0042] S1. Weigh 0.01g of PEG and 0.02g of PA and fully dissolve them in 4mL of absolute ethanol to form a transparent mixed solution;

[0043] S2, adding 1 g of NCM622 to the mixed solution to configure a suspension;

[0044] S3. Using a magnetic stirrer to heat and stir evenly until the solvent in the mixed solution is evaporated to dryness to obtain dry powder, which is ground to obtain the final coated positive electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com