A natural fiber dry packaging system

A natural fiber and packaging system technology, applied in packaging, fiber processing, textiles and papermaking, etc., can solve problems such as low production efficiency, unfavorable packaging, and long drying time, so as to increase loading capacity, facilitate compaction, and accelerate drying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

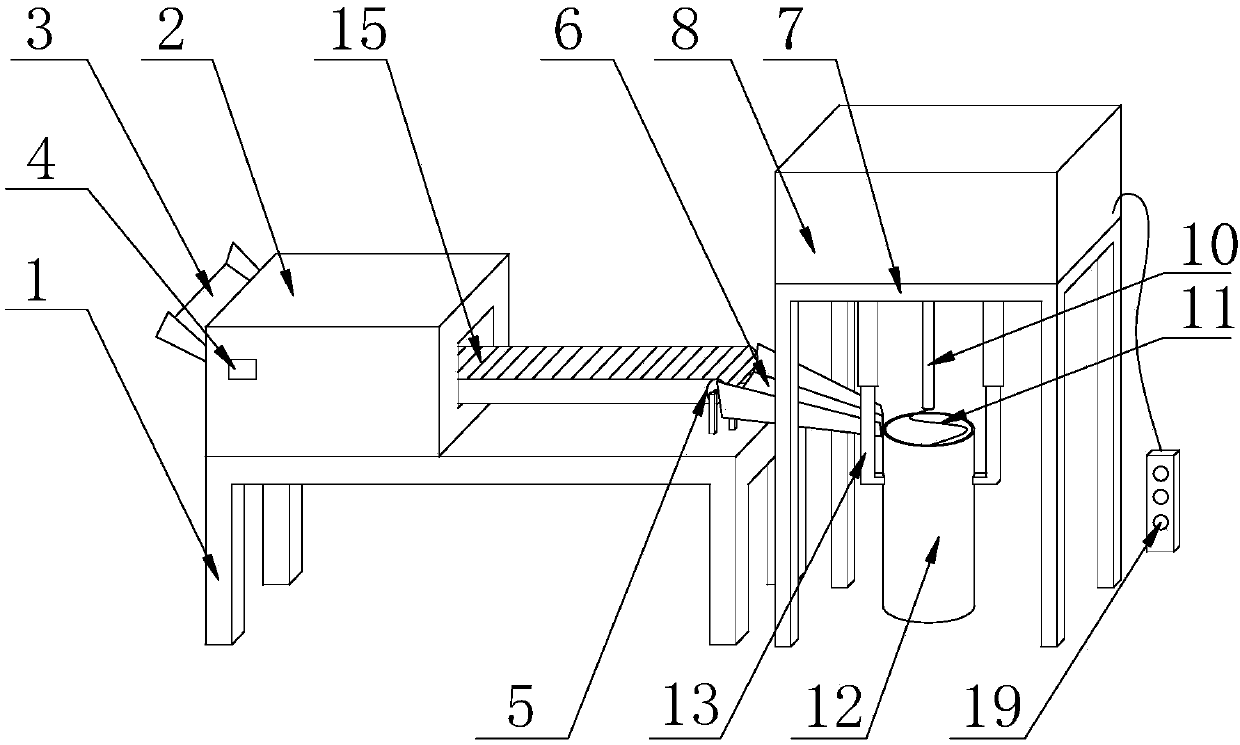

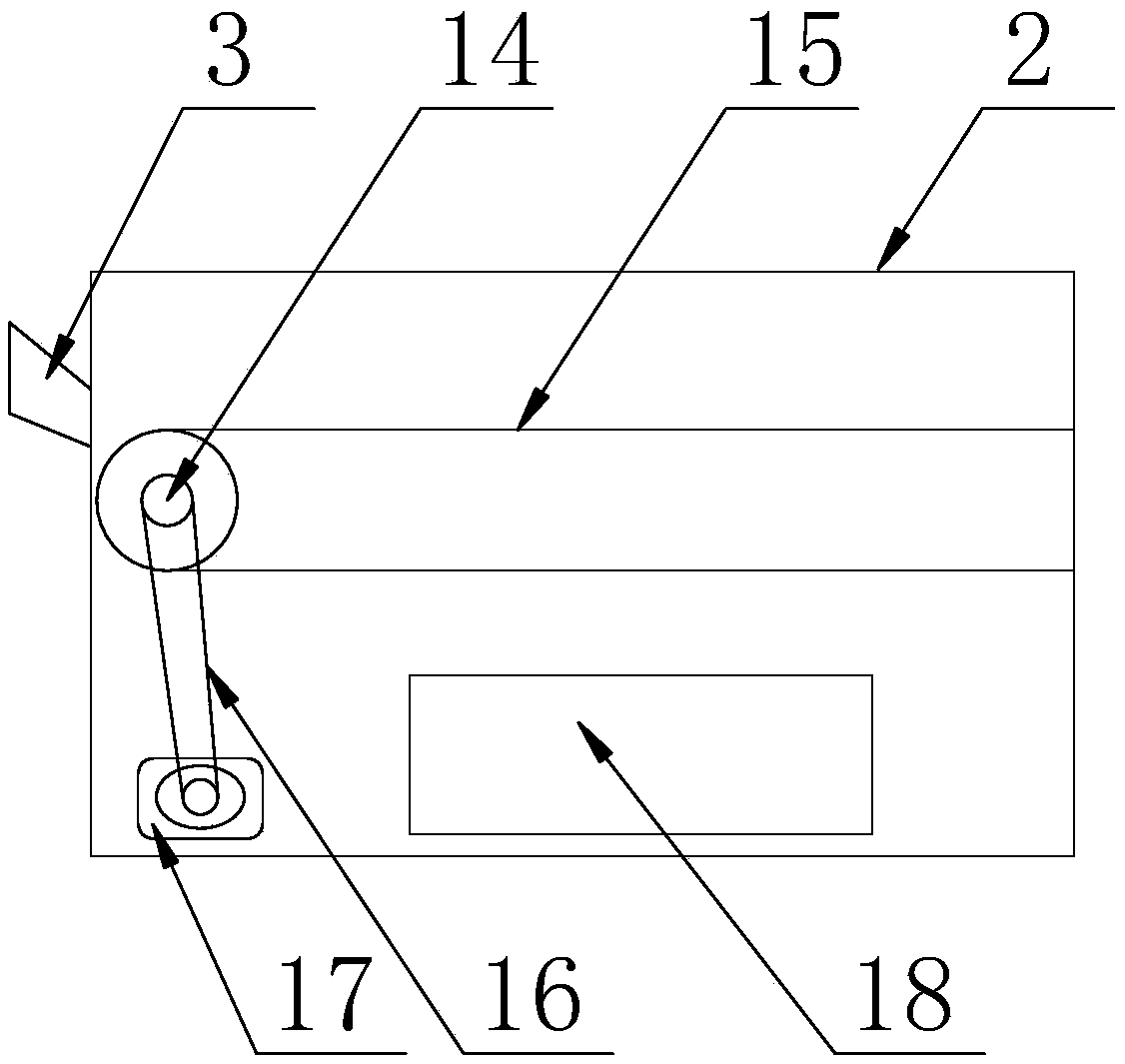

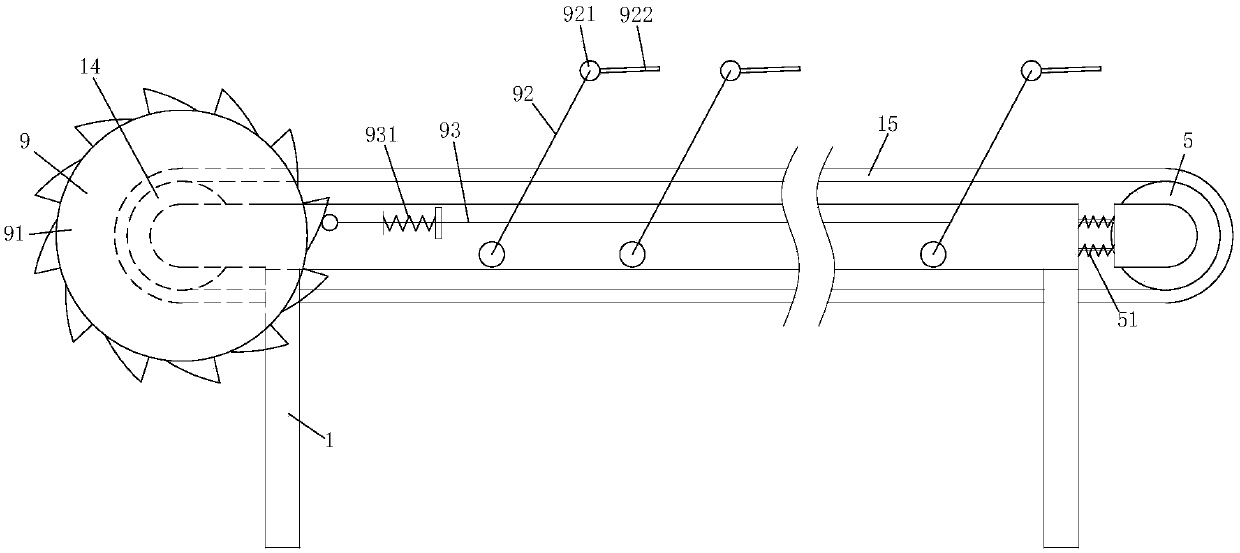

[0022] As an embodiment of the present invention, the conveyor belt 15 is a steel wire mesh material member, which not only facilitates the passage of hot air, but also avoids winding natural fibers on the conveyor belt 15 .

[0023] As an embodiment of the present invention, the cross section of the auger 11 is circular, and the screw diameter of the auger 11 decreases sequentially from top to bottom, which is beneficial to the sufficient compaction of natural fibers.

[0024] As an embodiment of the present invention, when the rocker 92 is at the extreme position, the conveyor belt 15 does not contact the base 1 , which can avoid the generation of noise and prevent the rocker 92 from being damaged.

[0025] As an embodiment of the present invention, the elastic member 51 is one of a spring, an elastic air bag, a pneumatic telescopic rod and elastic rubber.

[0026] During work, wet natural fibers are put into the drying box 2 from the feed port 3, and the natural fibers fall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com