Patents

Literature

749results about How to "Achieve vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

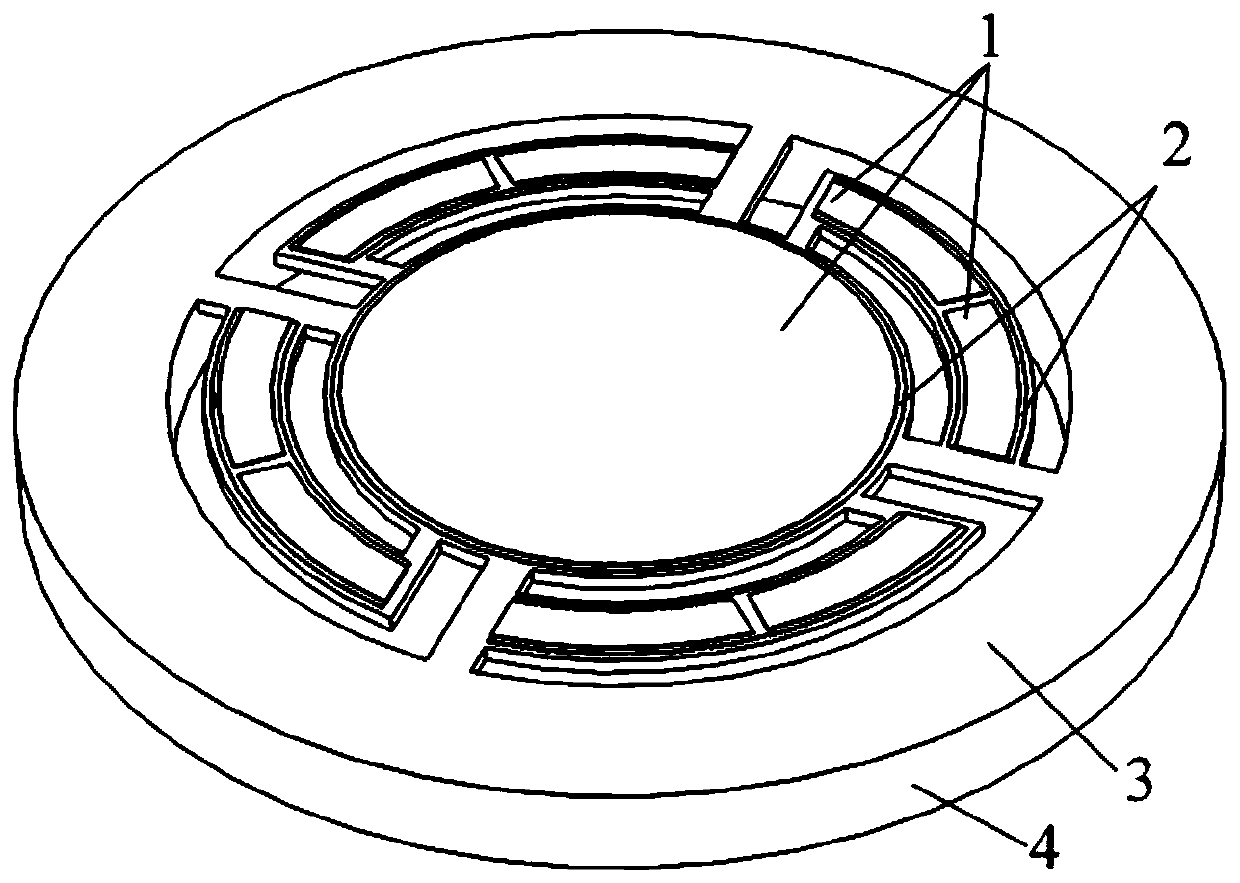

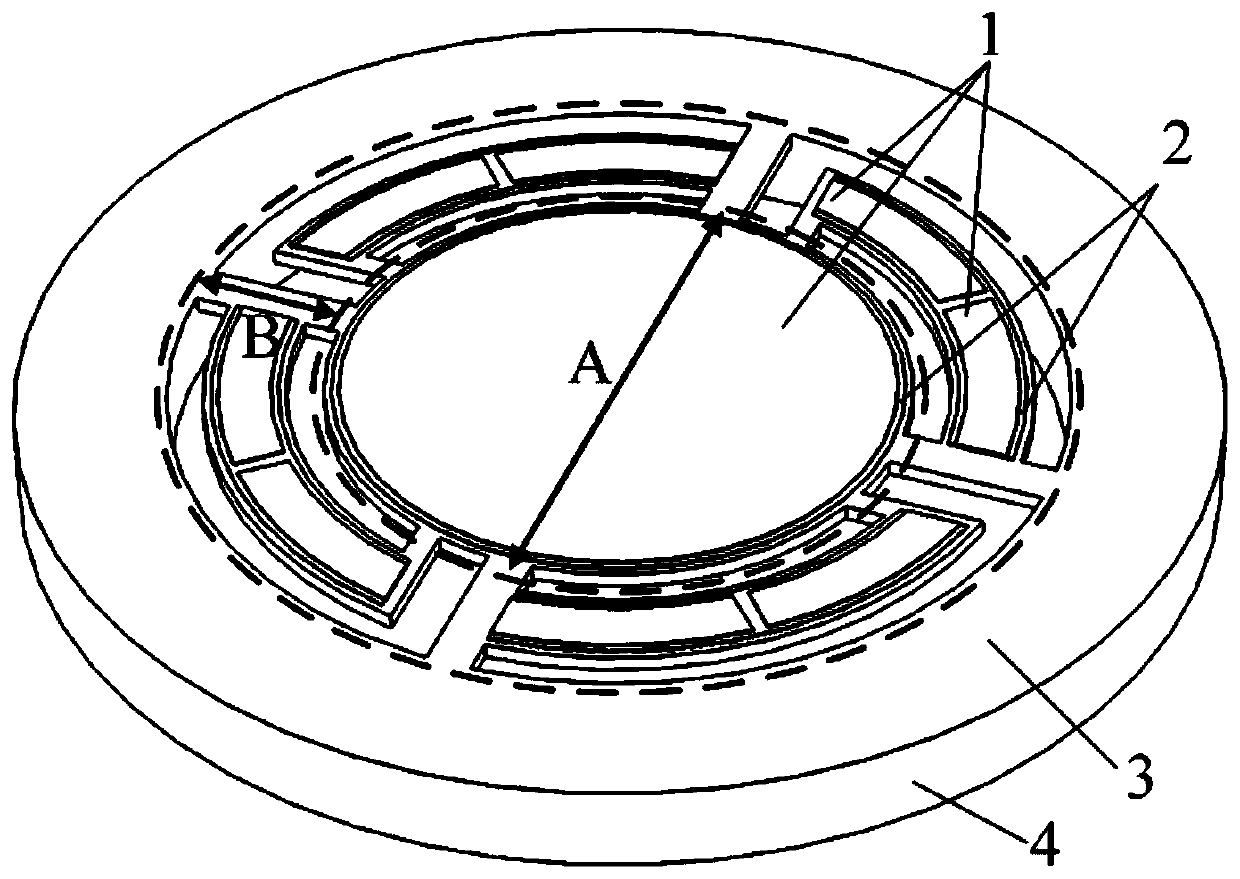

Concrete pumping equipment and arm support state control system thereof

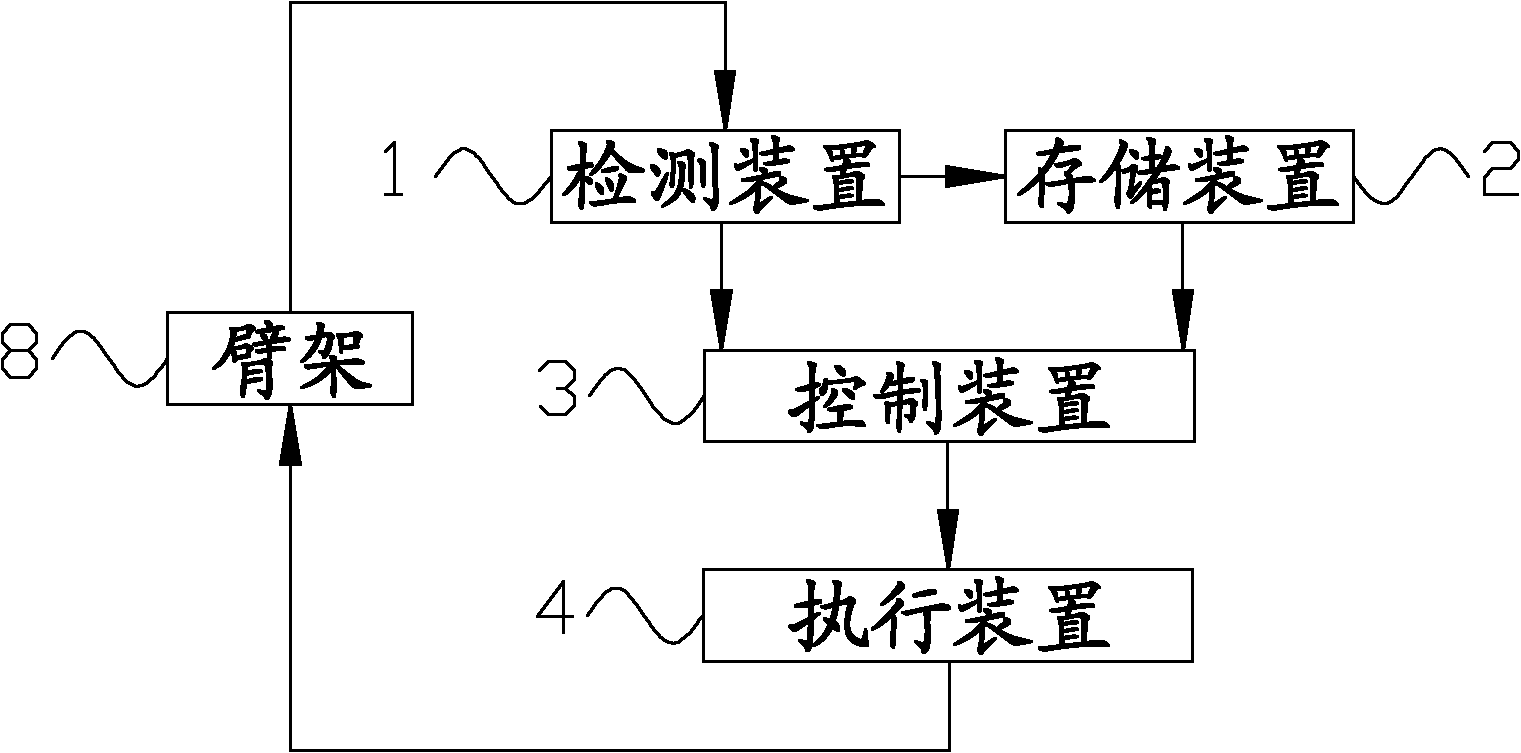

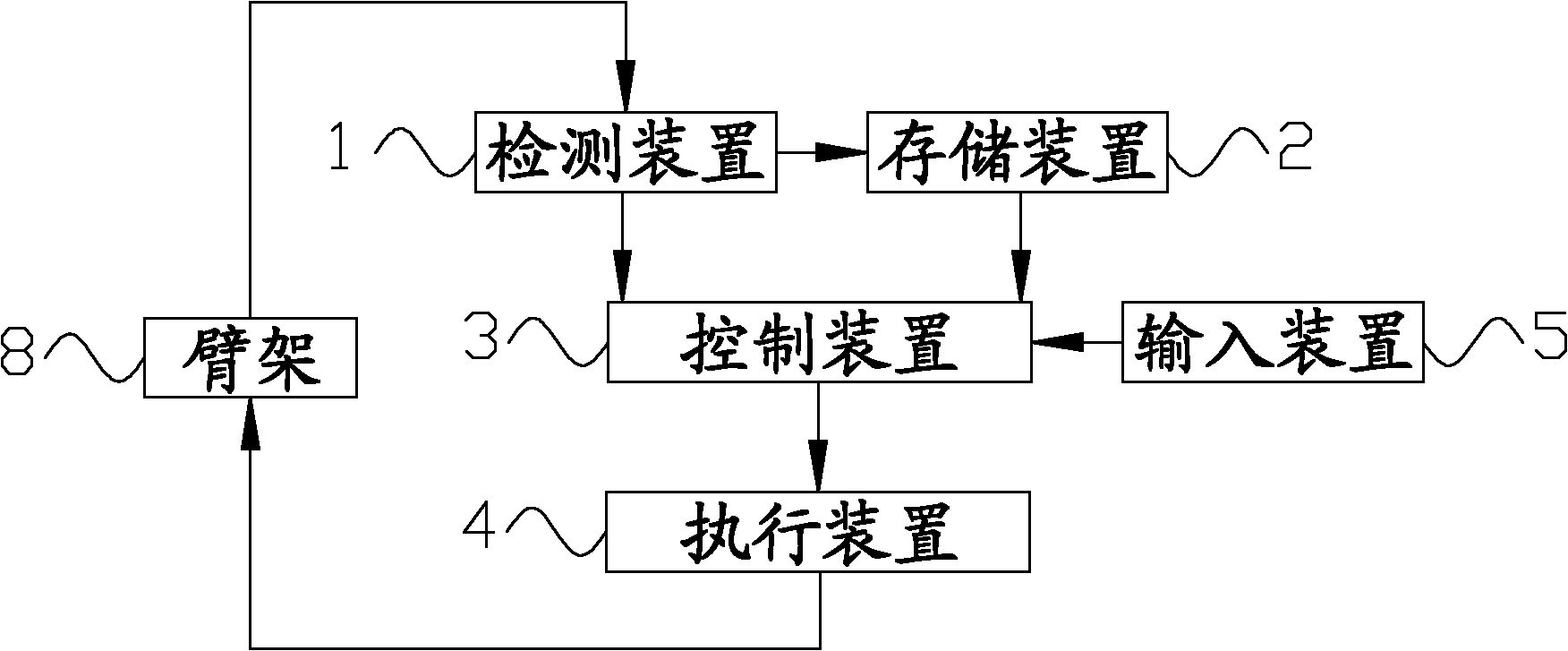

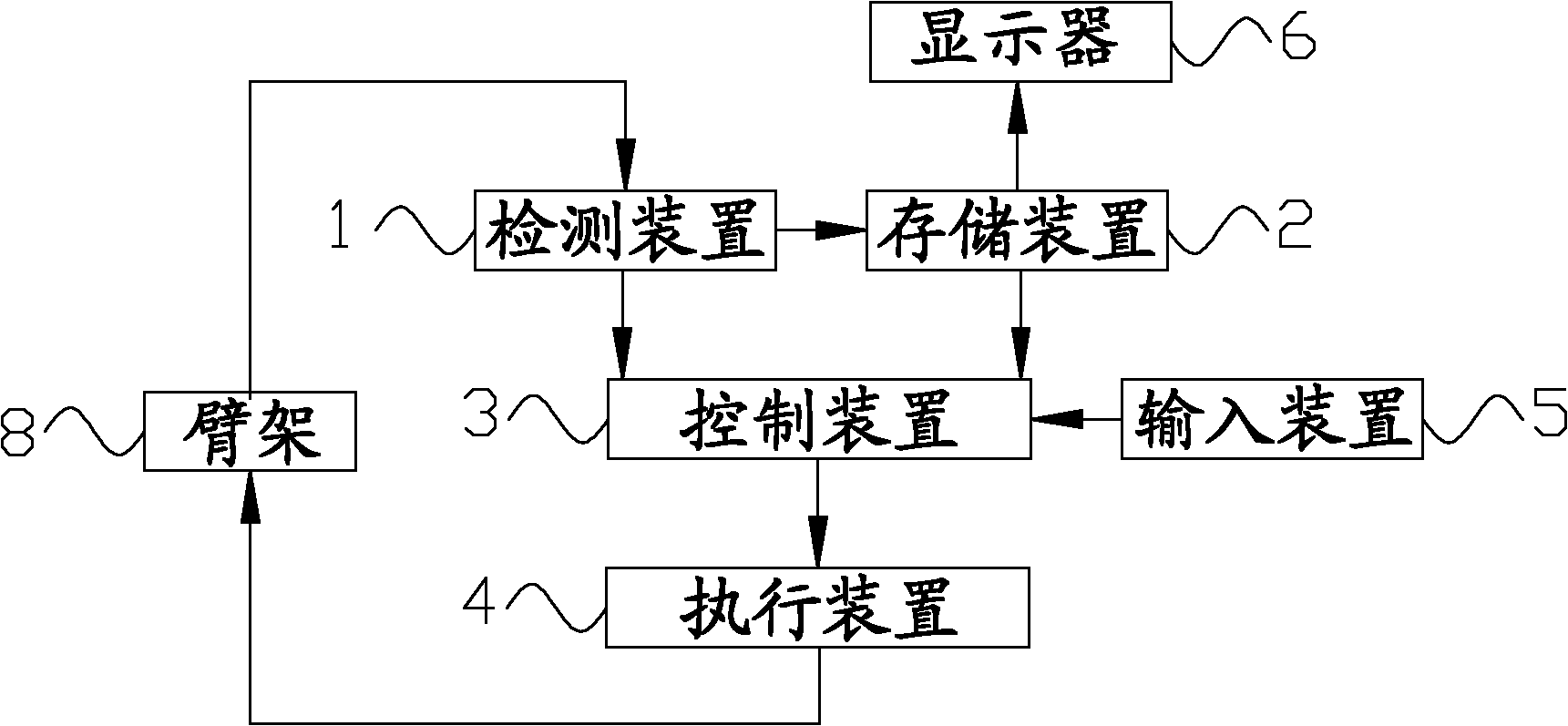

ActiveCN102108790AEasy to controlAchieve vibrationElectric programme controlPumpsControl systemTime delays

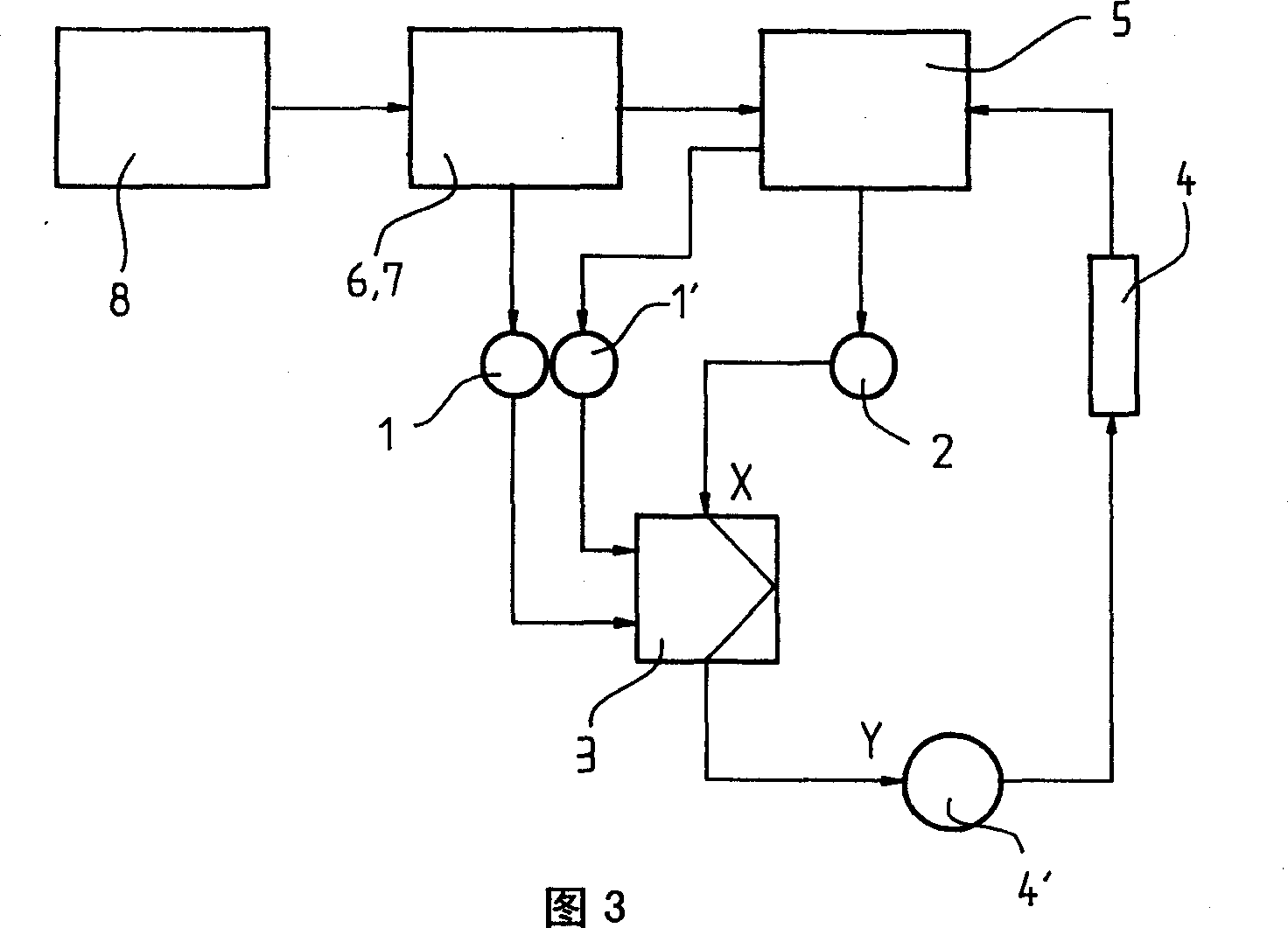

The invention discloses an arm support state control system, which comprises a detection device (1), a storage device (2), a control device (3) and an actuating device (4), wherein the detection device (1) is used for detecting the position state and vibration state of an arm support (8) of concrete pumping equipment to obtain a position state signal and a vibration signal; the storage device (2) is used for storing the vibration signal to obtain the periodical vibration signal of the arm support (8); the control device (3) is used for receiving the position state signal, the vibration signal and the periodical vibration signal and obtaining a control instruction according to a preset arm support vibration range, a preset advanced regulation time and a preset control policy; and the actuating device (4) is used for changing the state according to the control instruction and controlling the arm support (8) to act the preset arm support vibration range. The arm support state control system provided by the invention can avoid control error caused by time delay in the detection process of the detection device and the actuating process of the actuating device, absorb vibration in time and improve the operation convenience of the arm support. The invention also discloses concrete pumping equipment.

Owner:SANY AUTOMOBILE MFG CO LTD

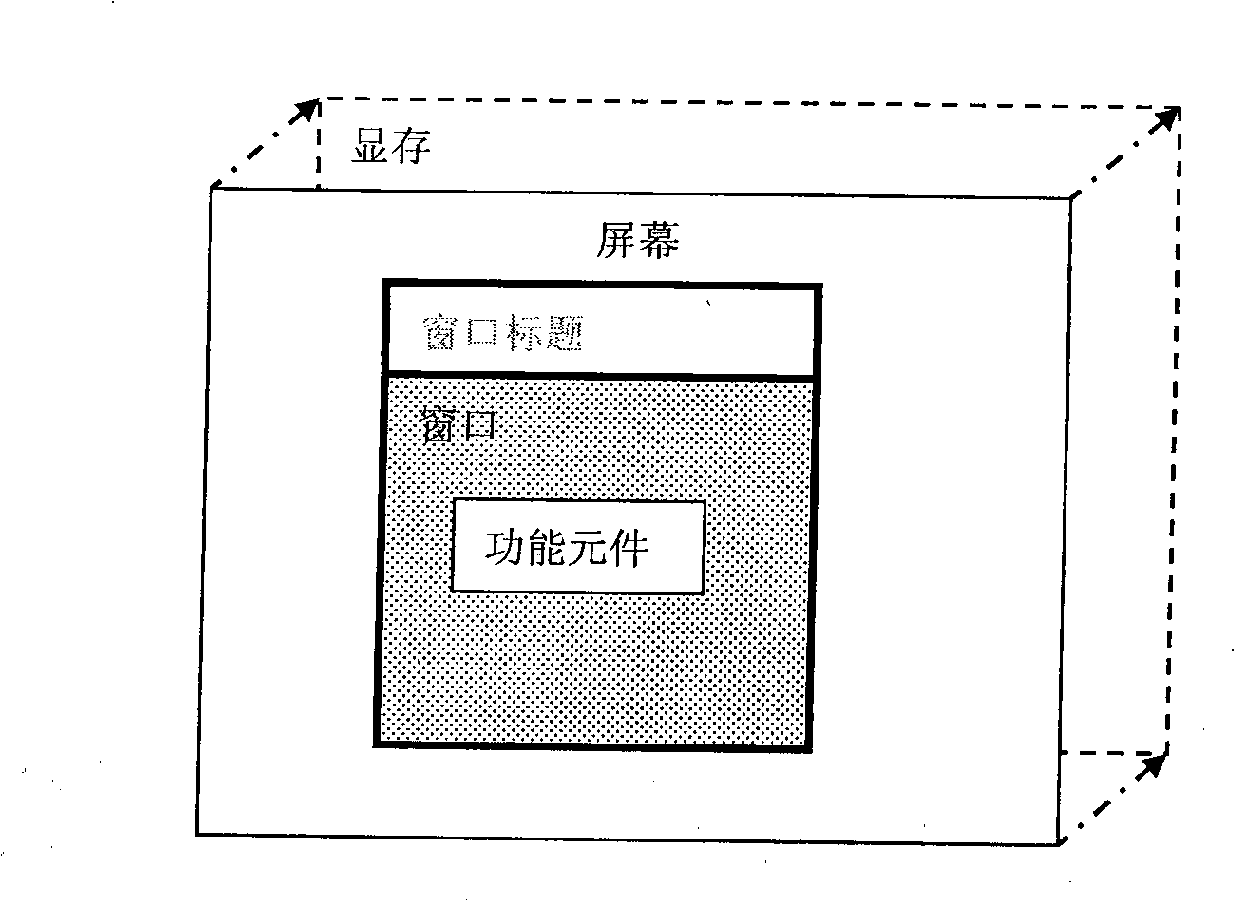

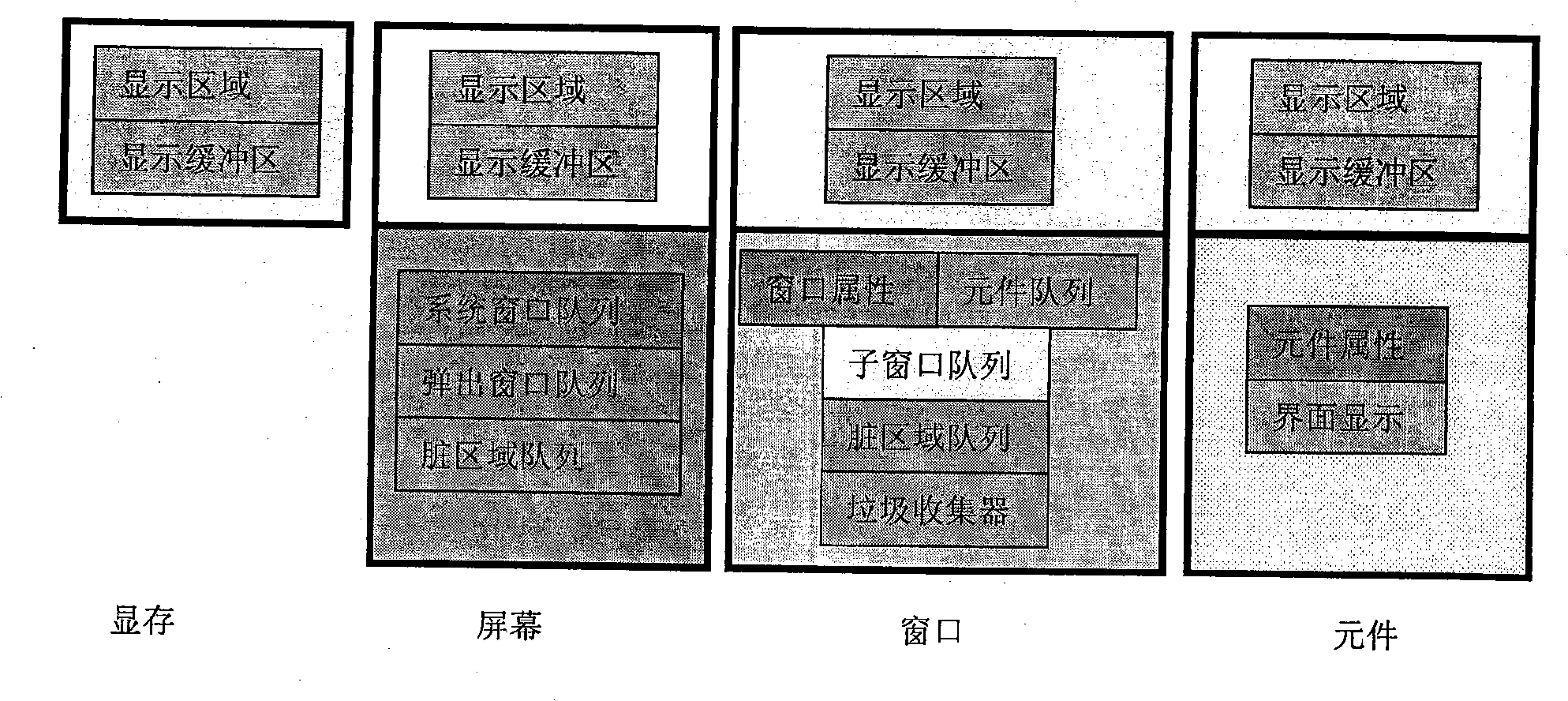

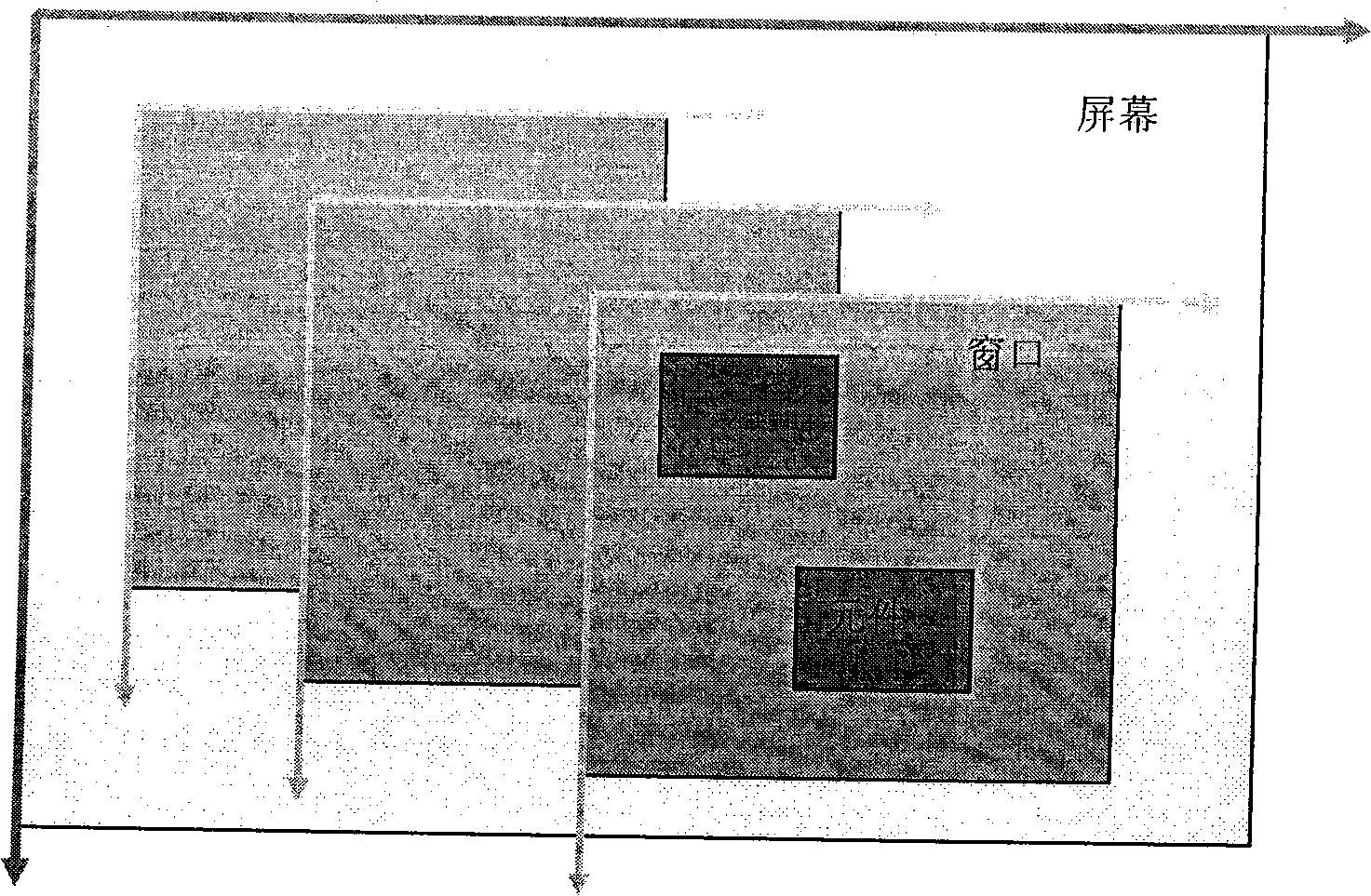

Multi-window manager of embedded graph system

ActiveCN101493751AEasy to transplantImprove portabilitySpecific program execution arrangementsInput/output processes for data processingGraphicsInformation processing

The invention discloses a multi-window managing system and a method used for an embedded system. The system comprises an information processing module for carrying out front-end operation used for processing the user information and outputting the change information of a window basic module area in a dirty area queue way, and a picture refresh module for carrying out back-end operation used for analyzing the transmitted dirty area queue and transmitting newest module area information to a screen display buffer area to complete display refresh. As the invention adopts a layered refresh method and an optimized dirty area queue algorithm to minimize the refresh operation calculation and supports a window junk collector, the invention has higher efficiency; and as a double-buffer display mechanism is adopted, the splash problem in picture refresh is avoided; therefore, the invention has better display effect.

Owner:上海步科自动化股份有限公司

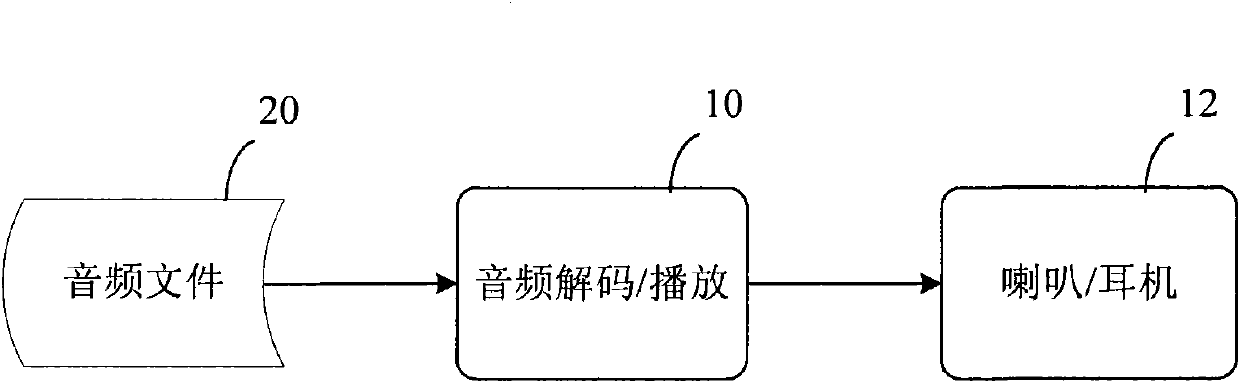

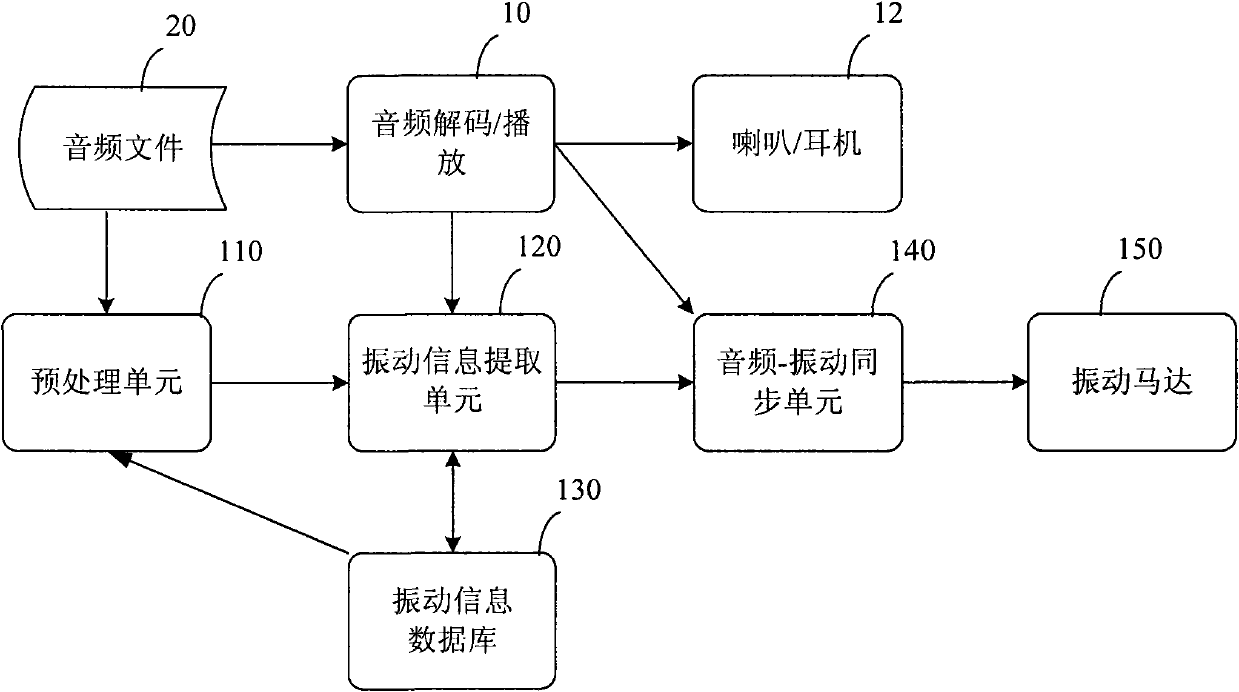

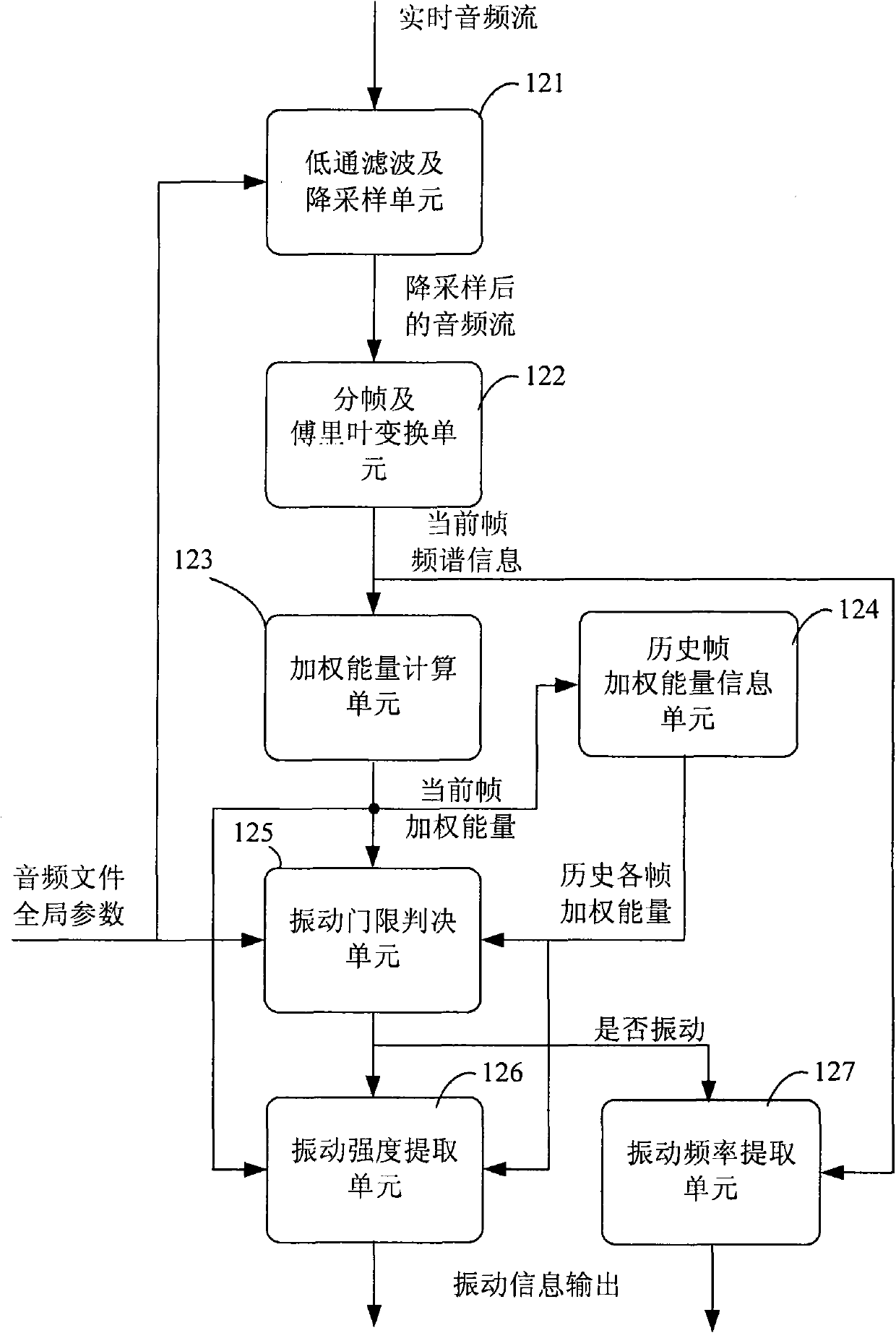

Method and device for extracting vibration information from audio file and vibrating device

ActiveCN102024481AAchieve vibrationRecord information storageSubstation equipmentVibration controlFrequency conversion

The invention relates to a method and a device for extracting vibration information from an audio file and a vibrating device. The method and the device can acquire vibration control information such as vibration starting time, vibration ending time, vibration strength and vibration frequency from a decoded audio stream by time-to-frequency conversion, weighted energy calculation using frequency as a weight, energy-based vibration threshold determination and other steps. The vibration device can drive the vibration motor of a mobile phone on the basis of the vibration information, so that themotor can vibrate with music played for rendering music playing effect.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

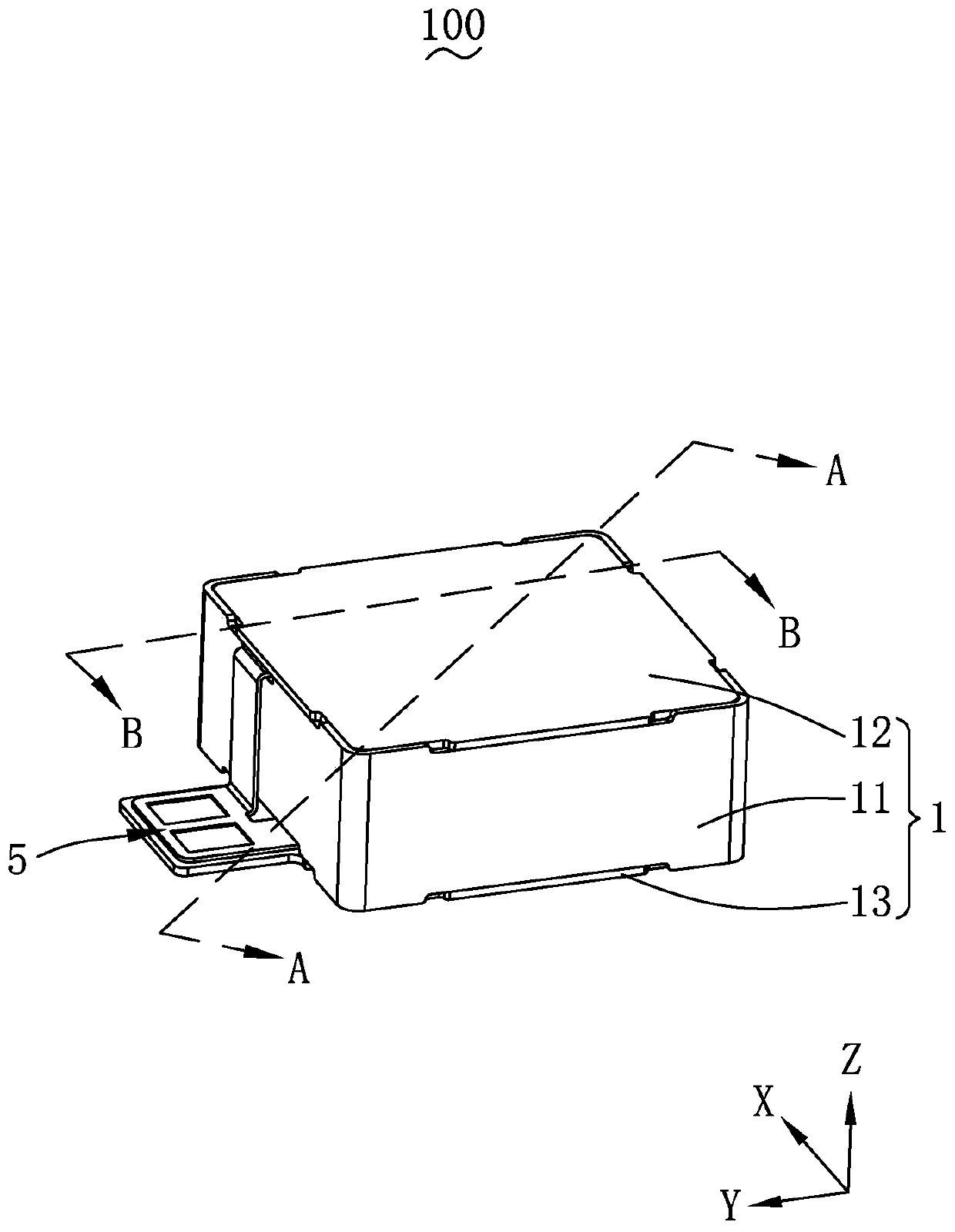

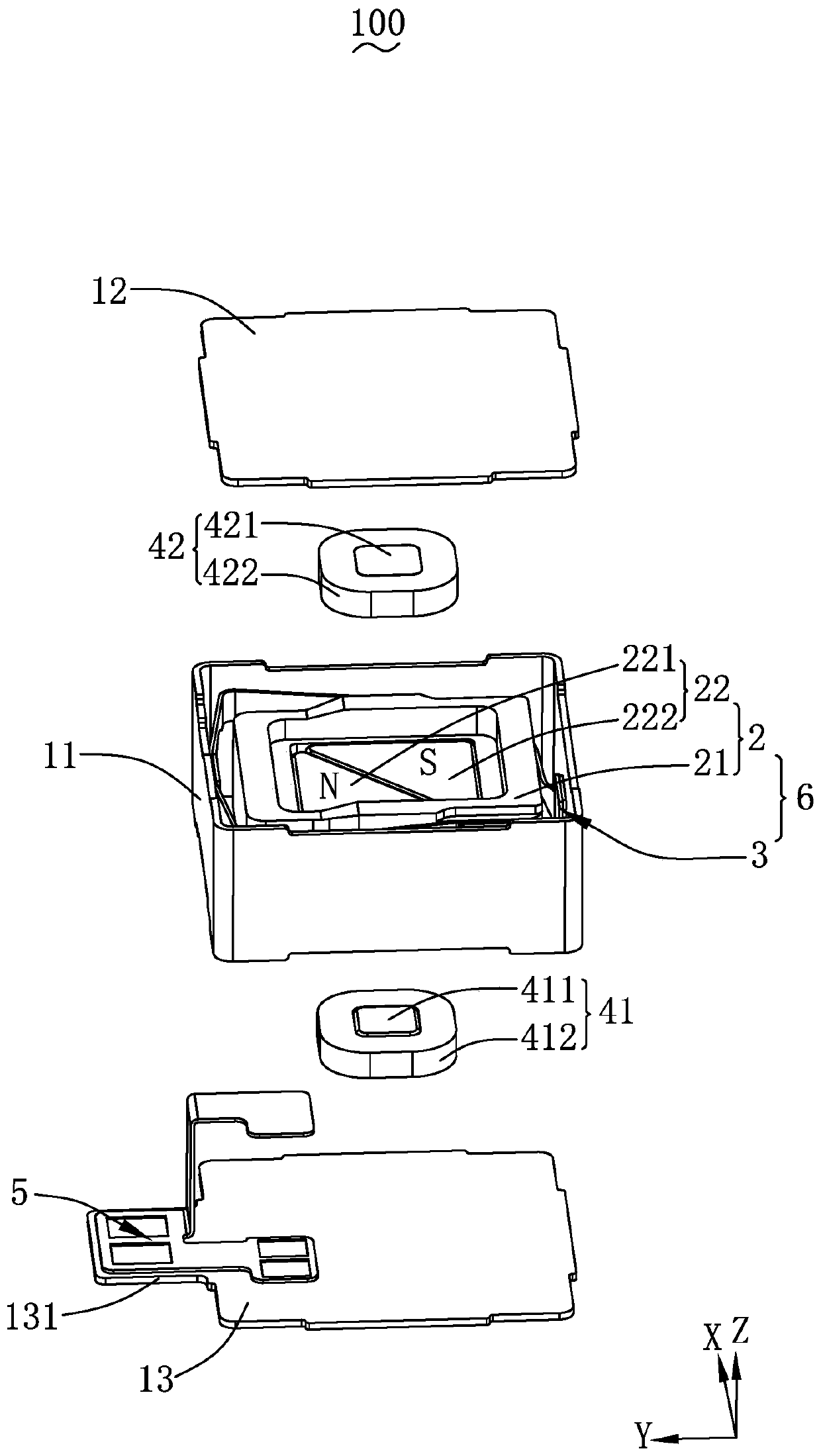

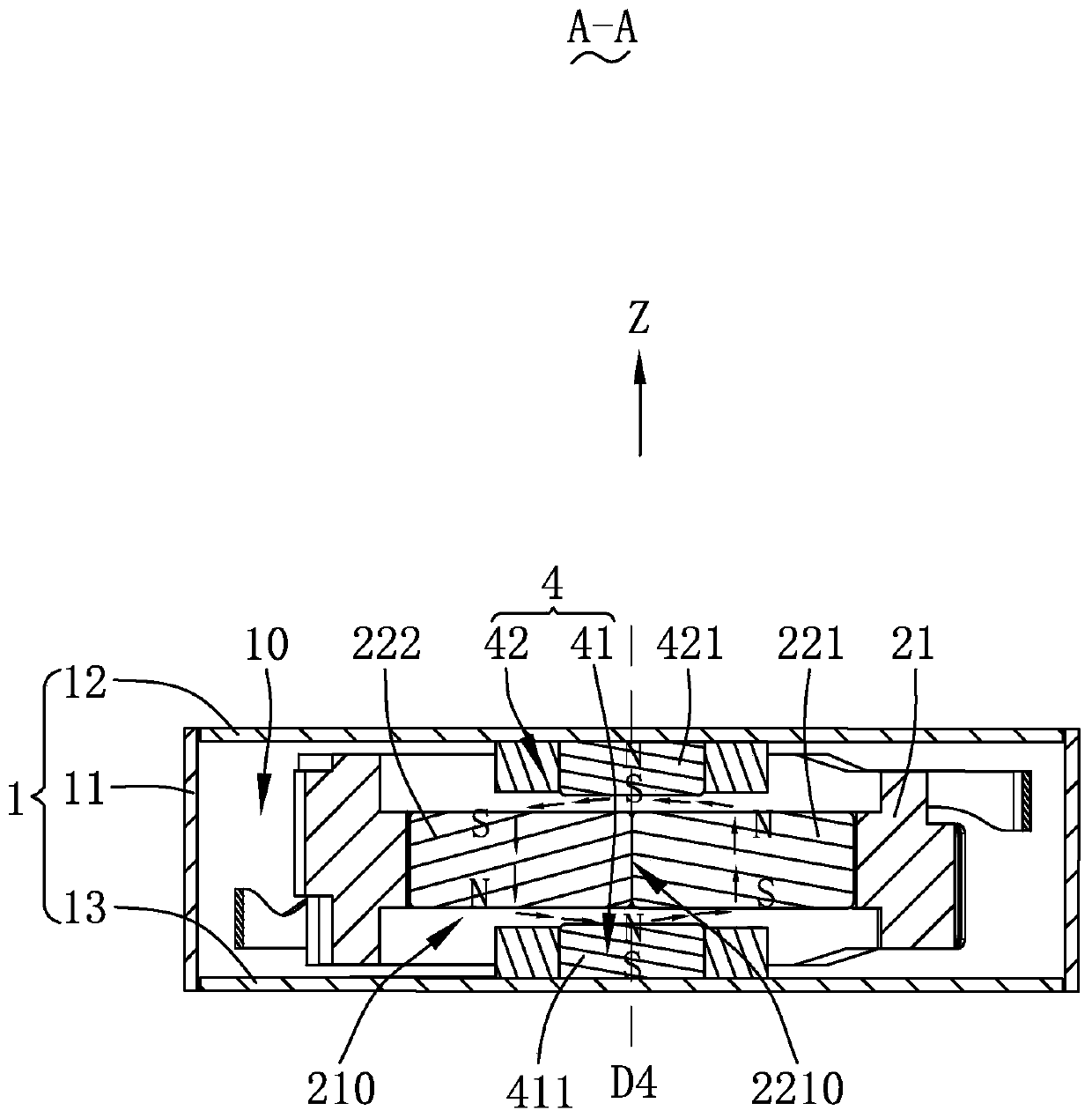

Vibration motor

ActiveCN110266171AAchieve vibrationImprove the vibration effectReciprocating/oscillating/vibrating magnetic circuit partsElectric machineMagnetization

The invention provides a vibration motor, which comprises a base, a vibration unit, an elastic member and a coil assembly, wherein the vibration unit comprises a mass block and magnetic steel; the vibration unit comprises the mass block supported on the elastic element and the magnetic steel fixed on the mass block and arranged opposite to the coil assembly; the magnetization direction of the magnetic steel is a thickness direction; a drive signal is applied to the coil assembly; the elastic member supports vibration of the vibration unit along the direction vertical to the magnetization direction; and the vibration unit vibrates along any one of a first vibration direction vertical to the magnetization direction, a second vibration direction vertical to the magnetization direction and vertical to the first vibration direction and a third direction in a plane in which the first vibration direction and the second vibration direction are located through adjusting the drive signal. Compared with the related technology, the vibration motor provided by the invention has the advantages that multidirectional vibration is achieved and the vibration effect is good.

Owner:AAC TECH PTE LTD

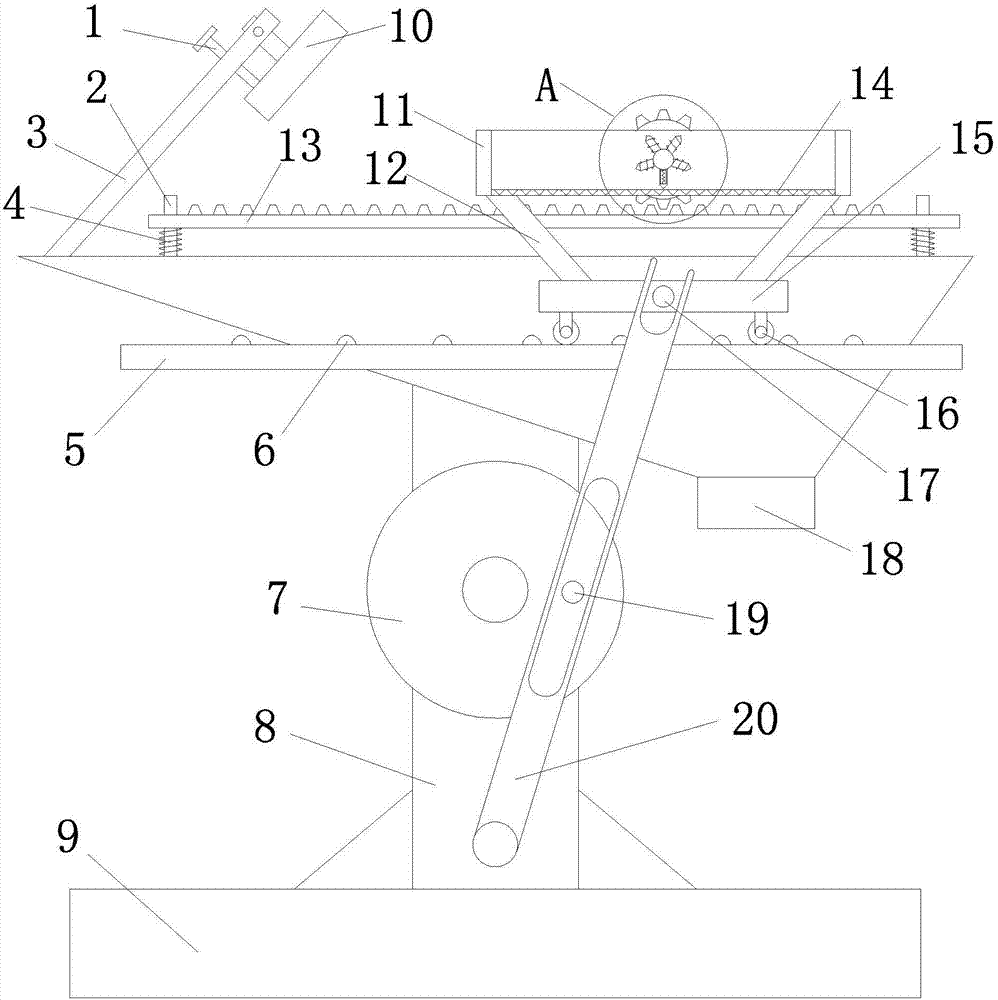

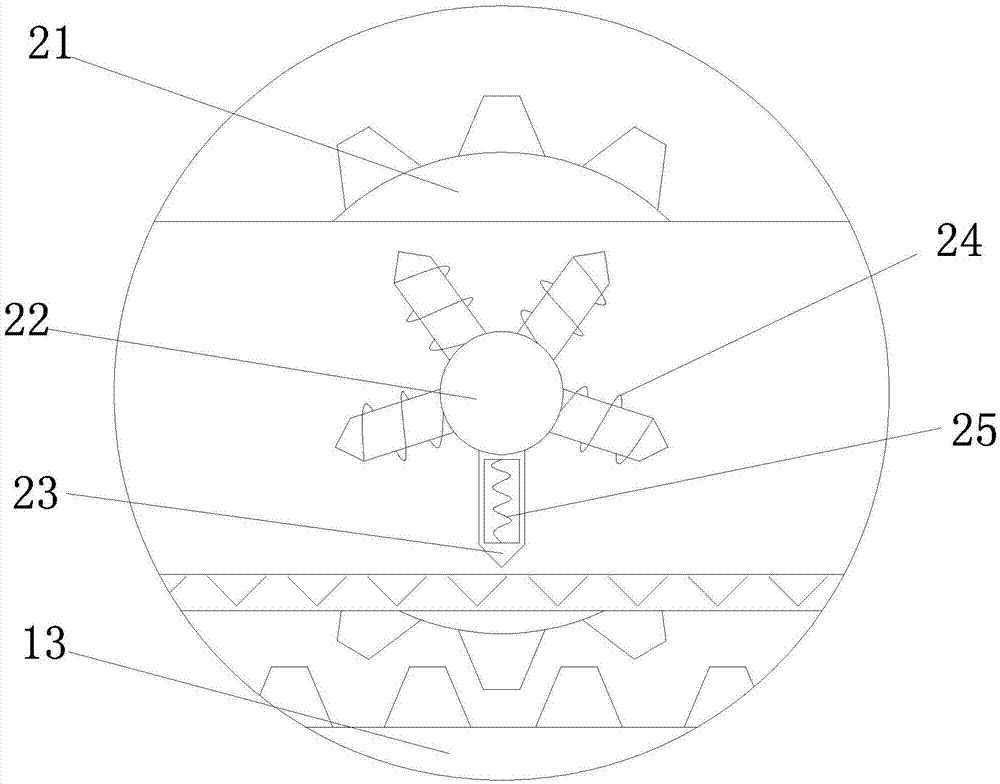

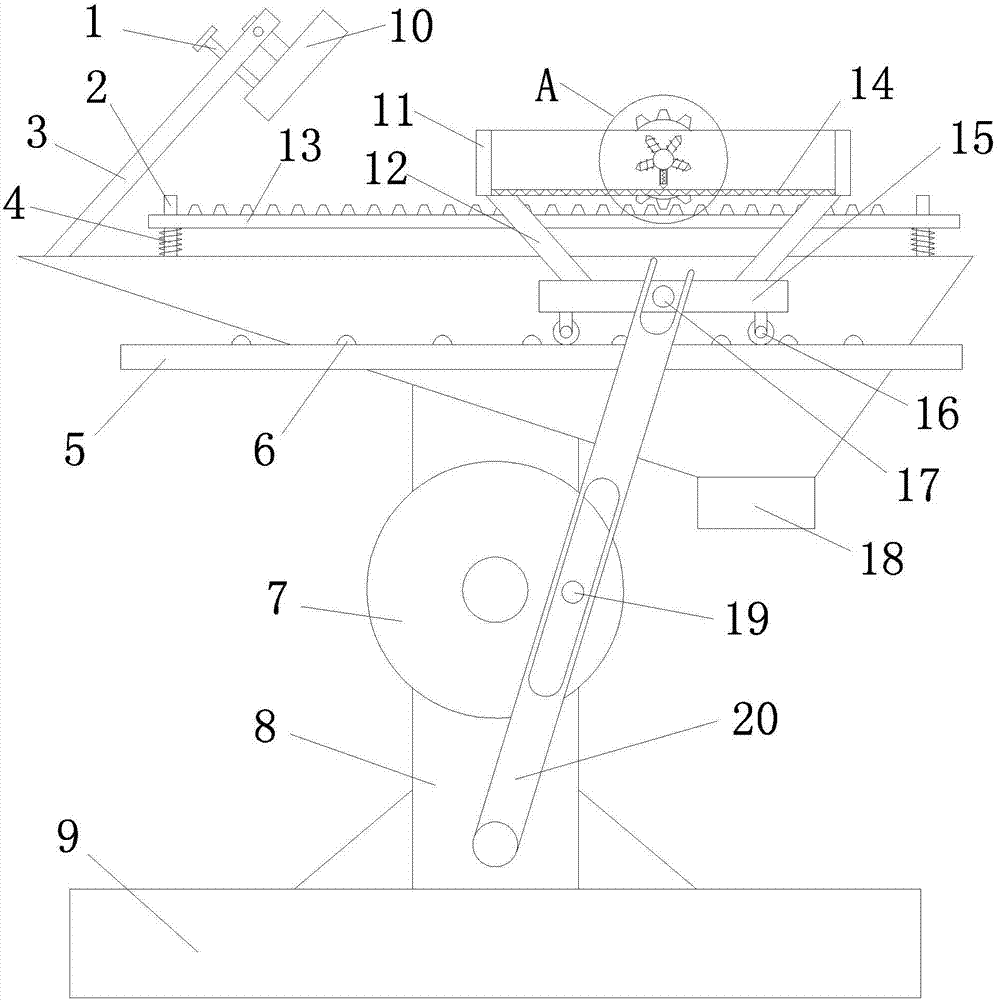

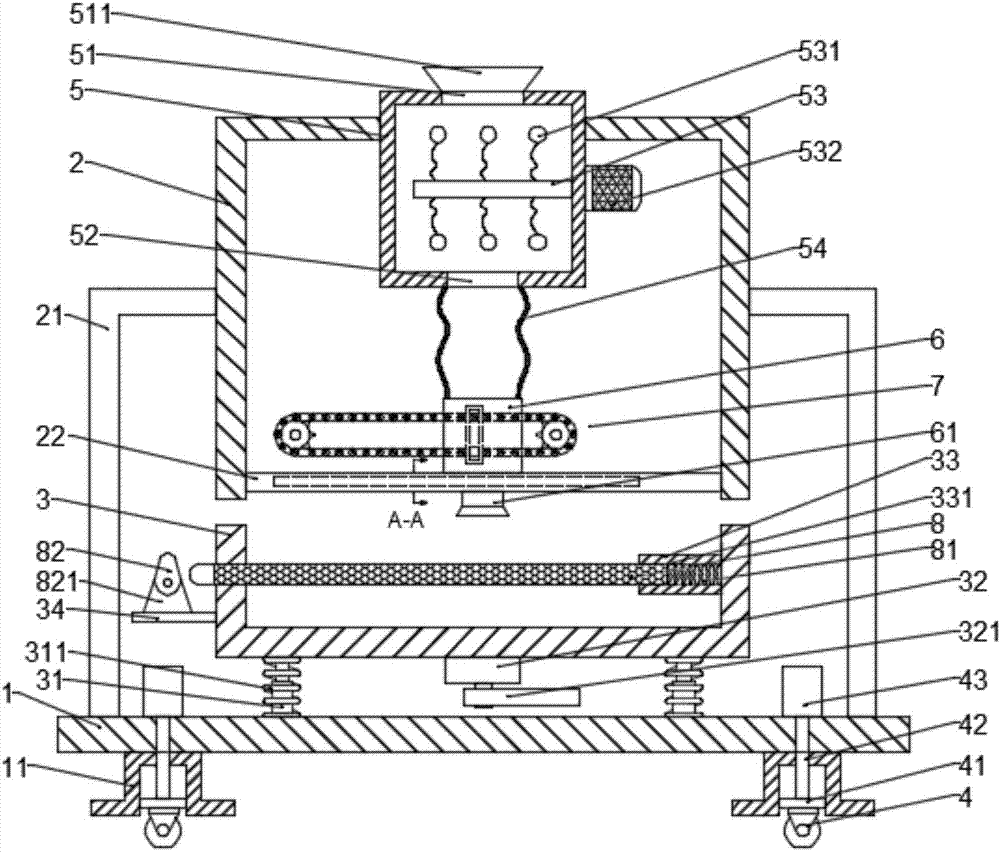

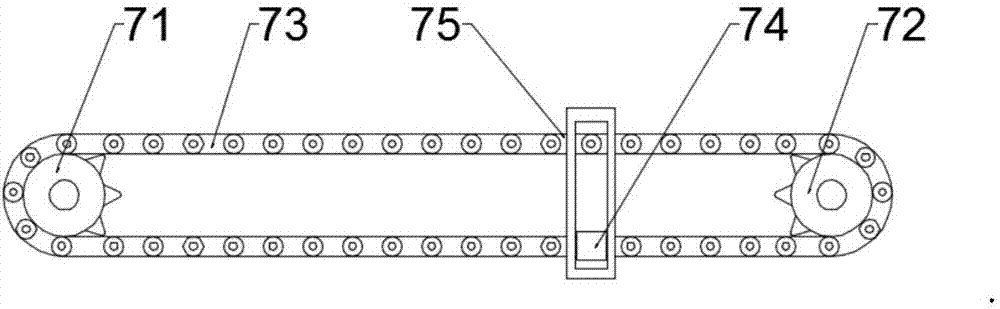

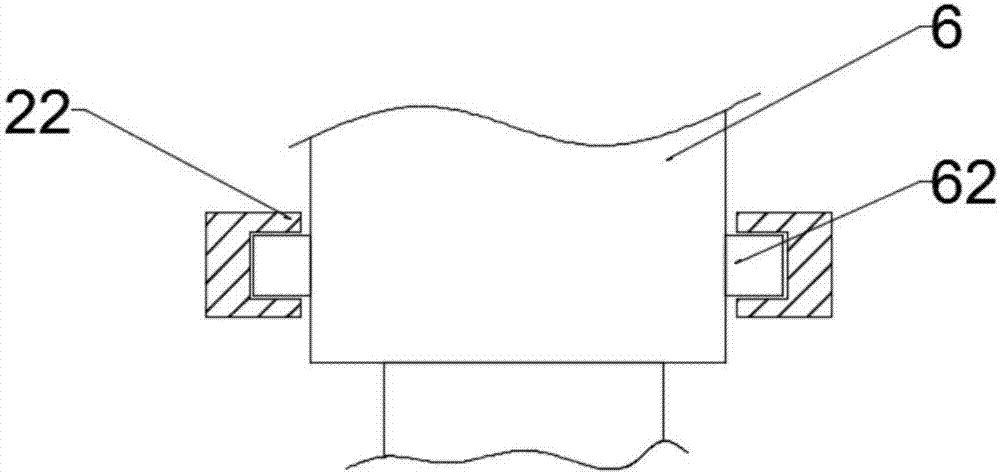

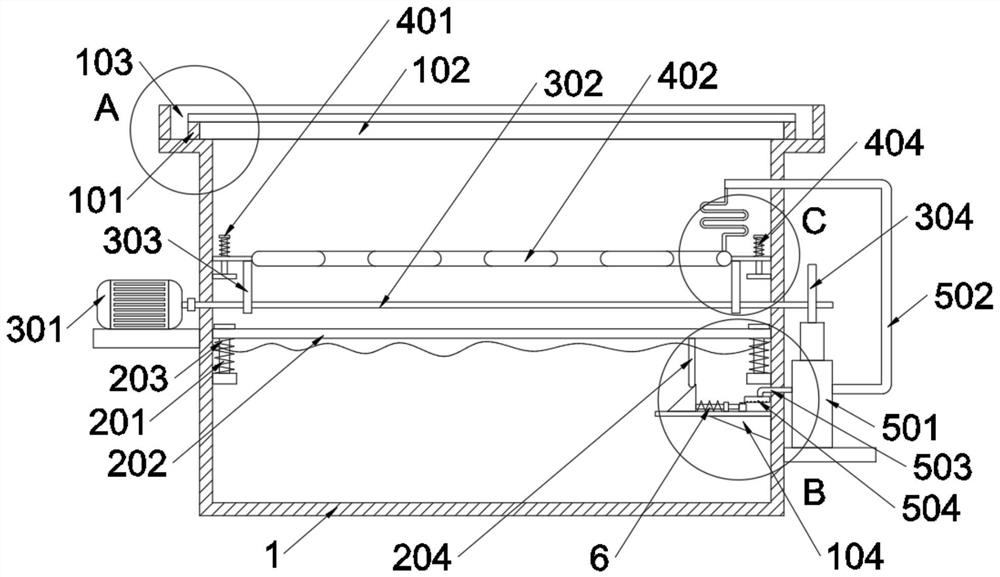

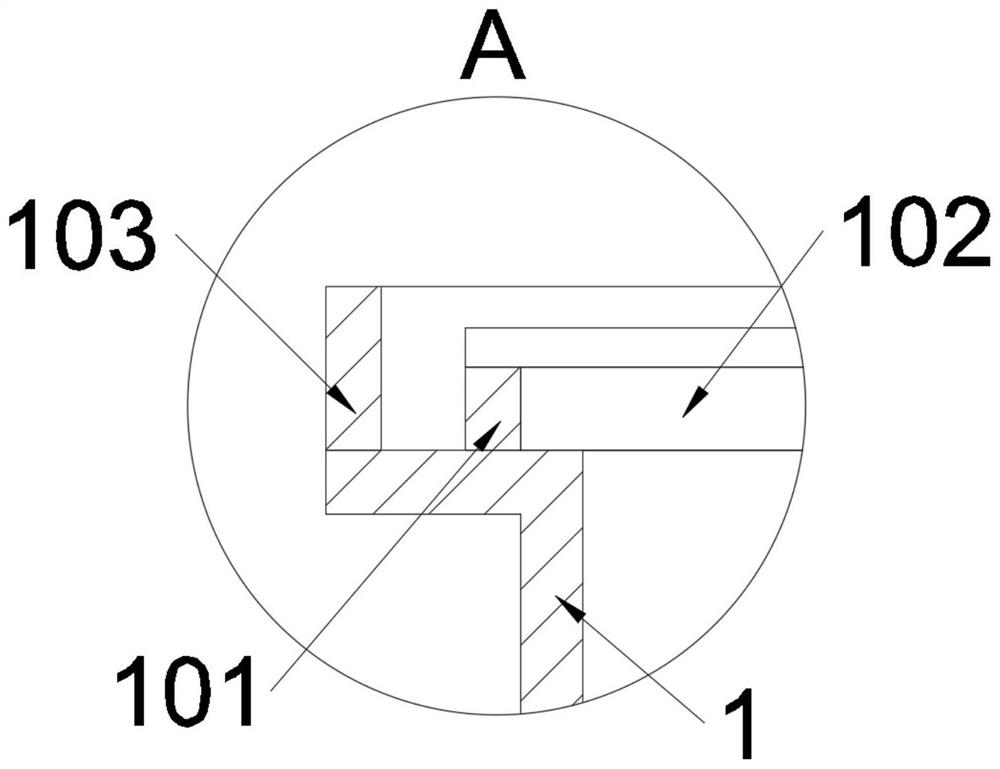

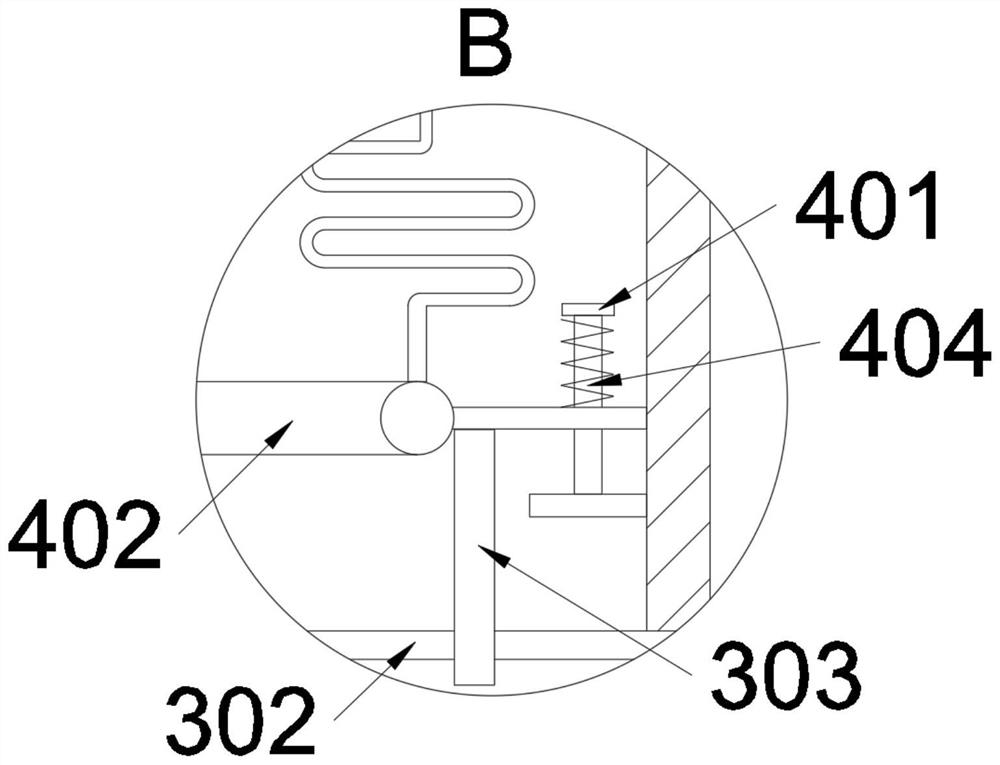

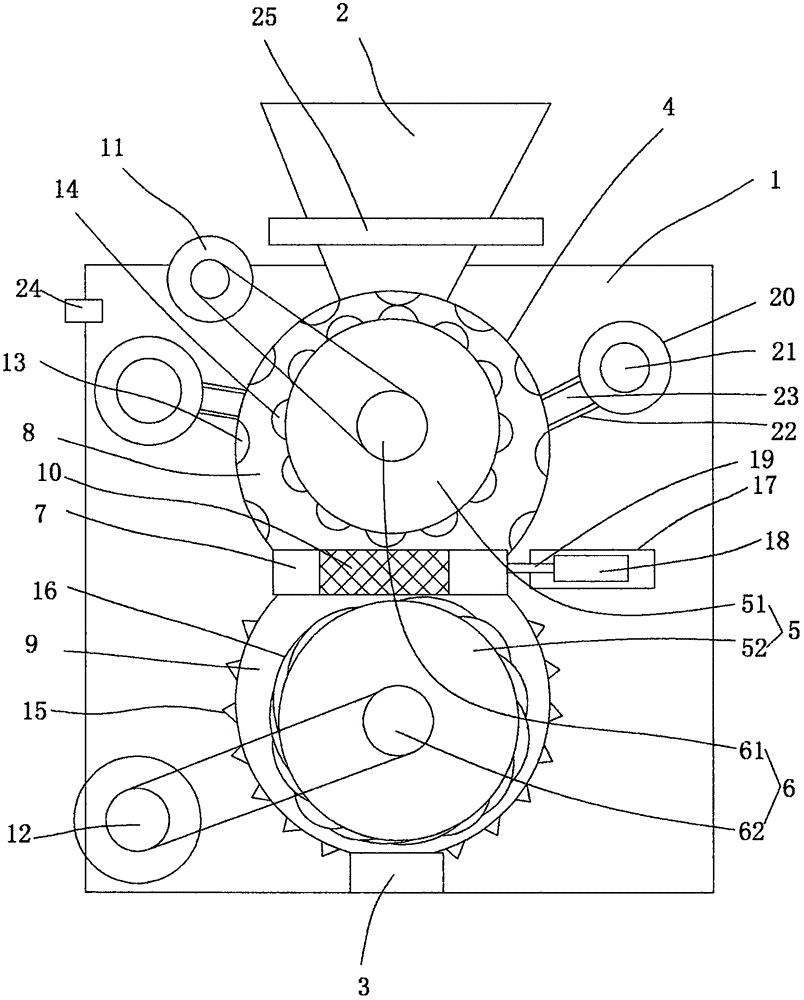

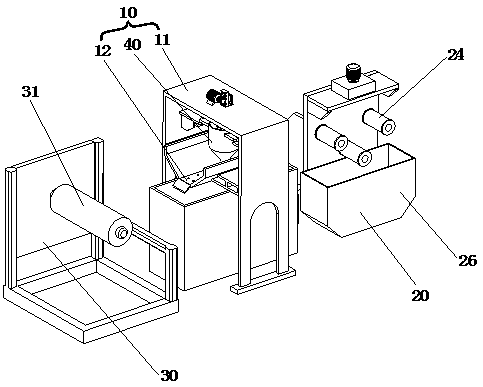

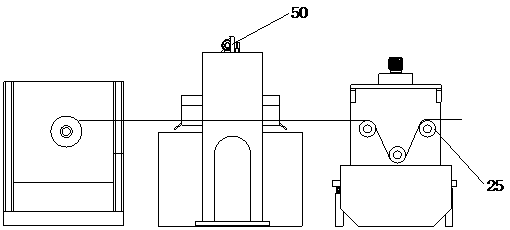

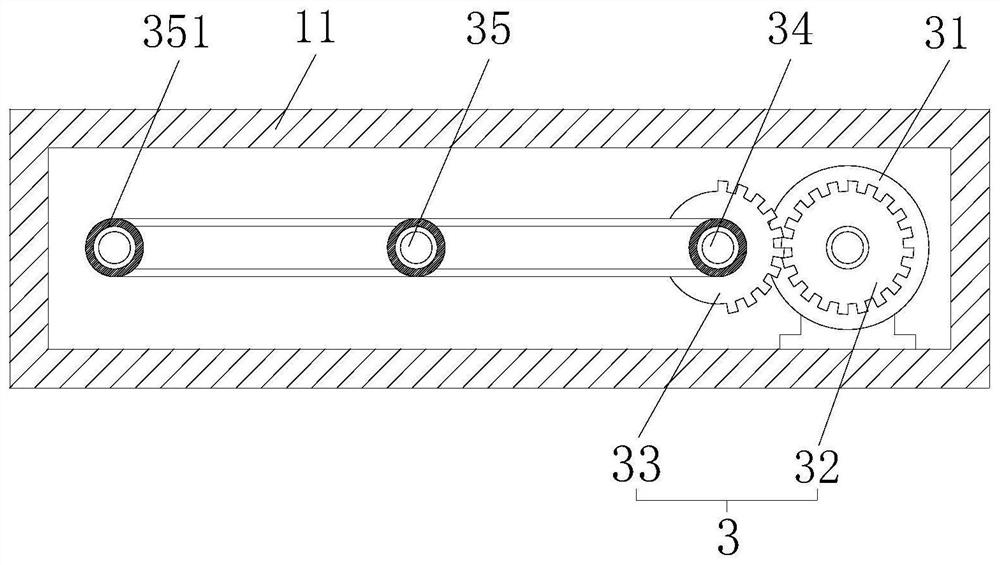

Vibration screening machine

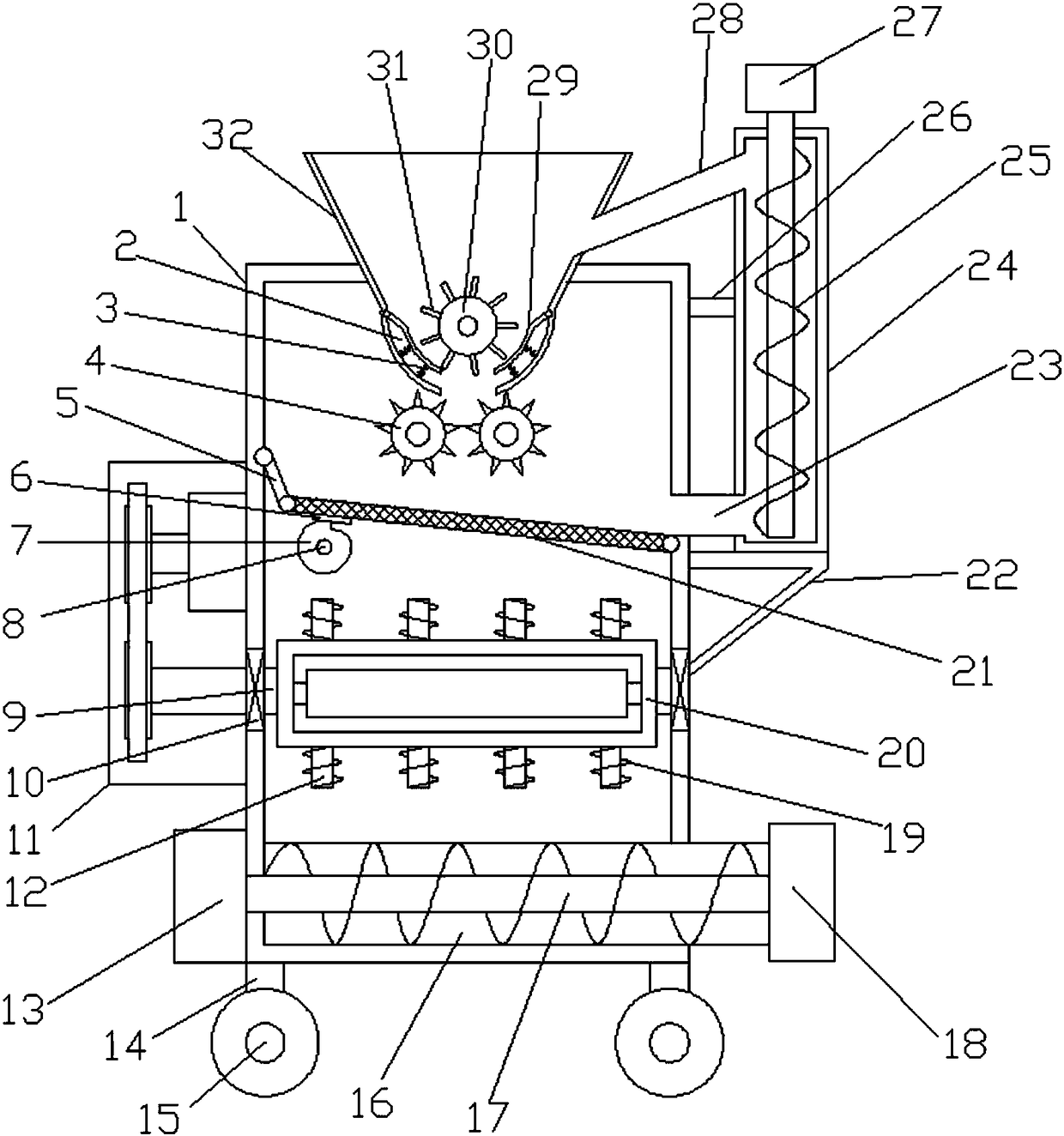

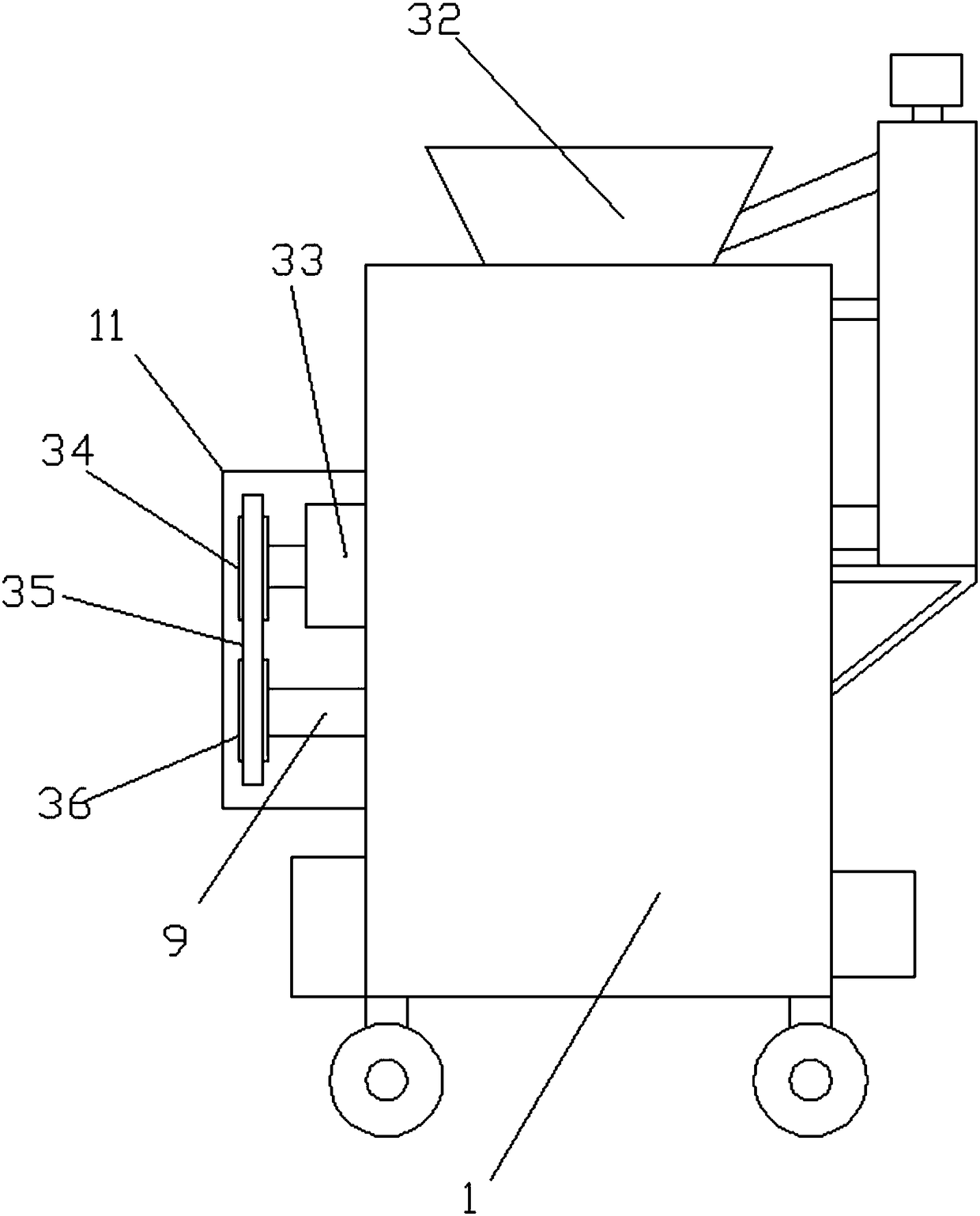

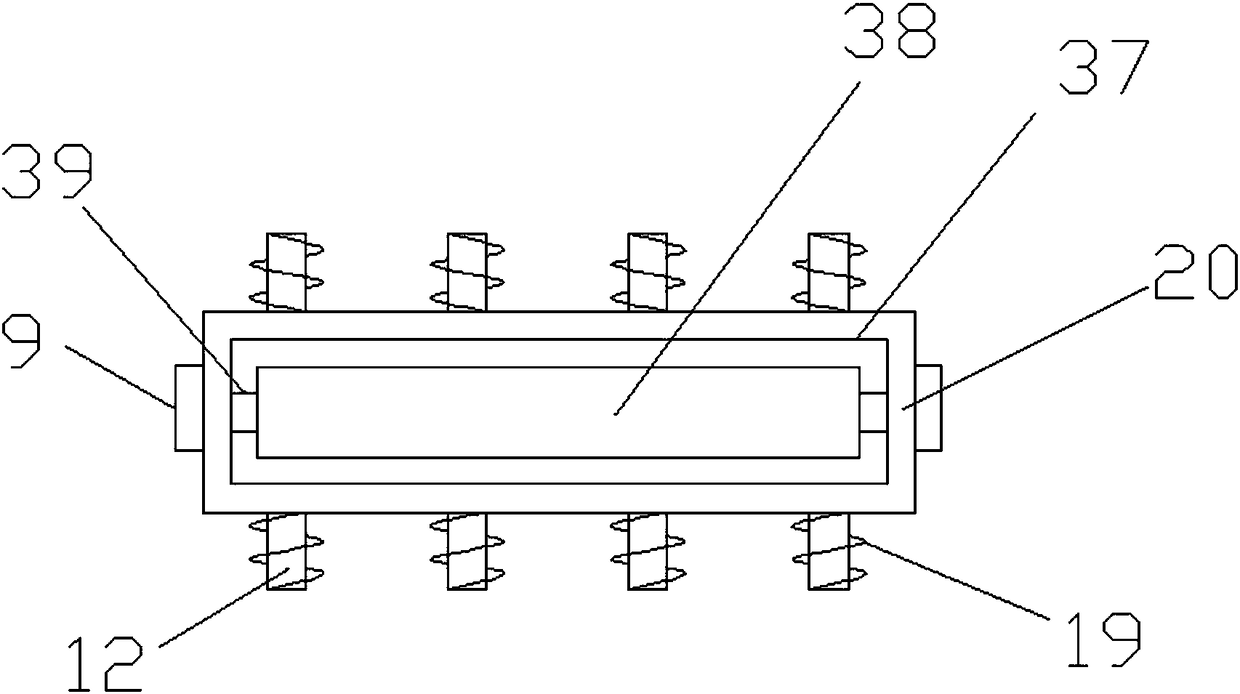

ActiveCN107999387ASimple structureImprove screening efficiencySievingScreeningMotor driveSlide plate

The invention discloses a vibration screening machine. The vibration screening machine comprises a base, a hopper is connected to the top of the base through a vertical rod, a mounting frame is arranged above the hopper, and the inner wall of the mounting frame is connected with a screen and rotationally connected with a rotating shaft. The vibration screening machine is simple in structure, a motor drives a rotating plate to rotate, the rotating plate drives a swinging rod to swing through a second fixing pin, then the swinging rod drives a sliding plate to move left and right through a firstfixing pin, the sliding plate drives the mounting frame and the screen to move left and right through supporting rods so that materials on the screen can shake, the screening efficiency is improved accordingly, idler wheels make contact with arc blocks intermittently when the sliding plate moves so that vertical vibration of the sliding plate can be achieved, vibration of the mounting frame is achieved accordingly, and the screening efficiency is further improved; meanwhile, when the mounting frame moves, a gear and a rack are engaged, stirring rods are driven by the rotating shaft to rotate,the materials can not only be spread but also be heated for moisture removal, and by means of springs, the effect that the gear is engaged with the rack all the time when the mounting frame is vibrated up and down can be ensured.

Owner:MEISEN IND TECH CO LTD

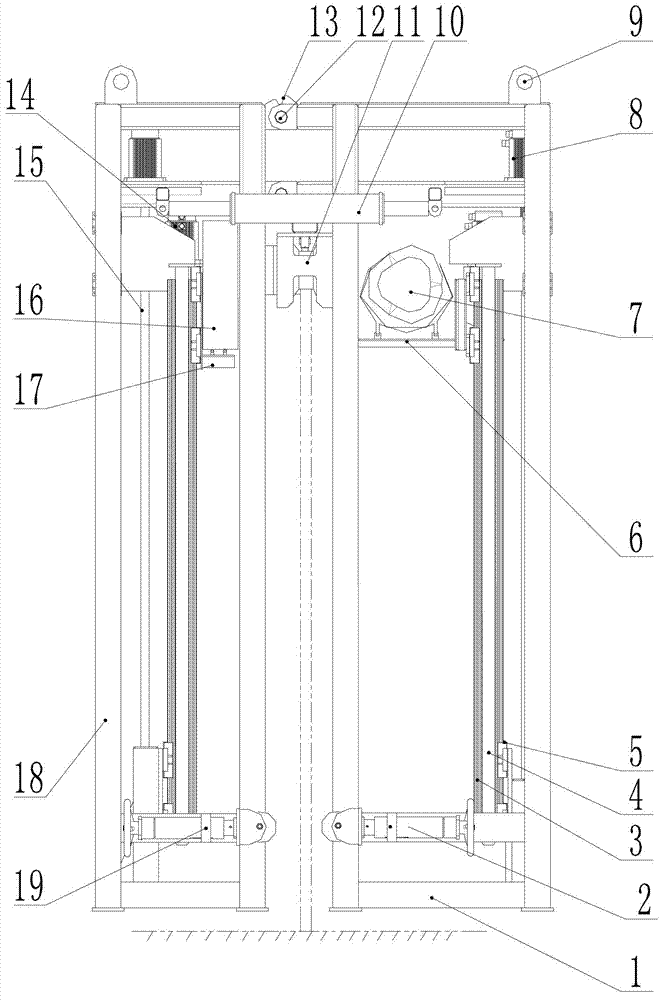

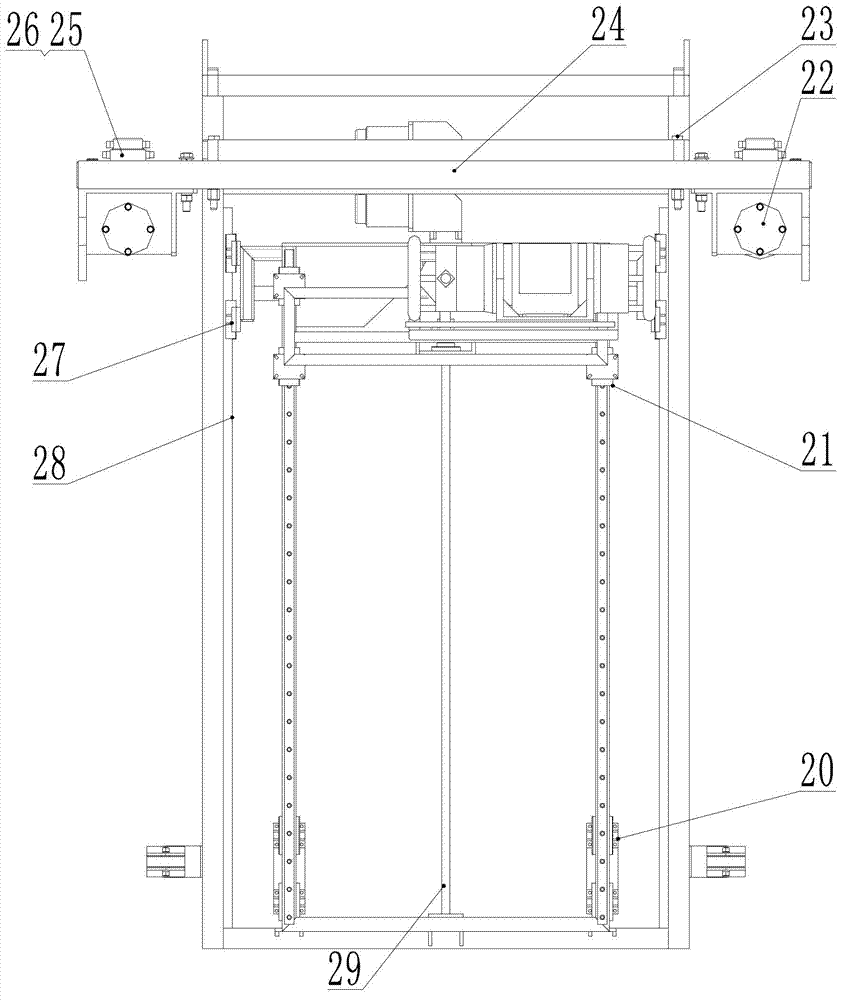

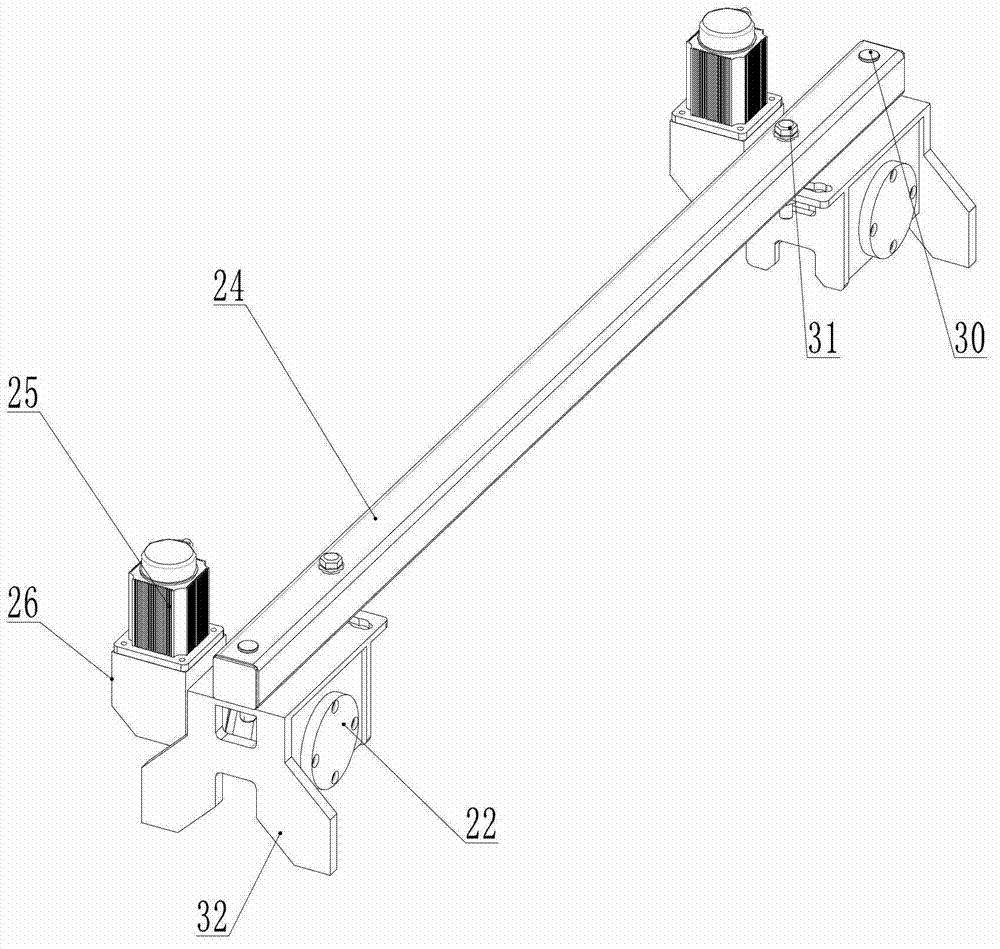

X-ray digital nondestructive detection device and method of welding seam of storage tank

ActiveCN103196928AReliable completionObjective completionMaterial analysis by transmitting radiationDigital imagingStructural engineering

The invention relates to an X-ray digital nondestructive detection device of a welding seam of a storage tank, and a detection method using the same, and mainly solves the problems of high flaw detection cost and influence on detection quality in the conventional X-ray film method. The device comprises a riding seat type gantry rack, movement guide mechanisms, a transverse movement mechanism, longitudinal movement mechanisms and a digital imaging system, wherein the riding seat type gantry rack consists of an outer rack and an inner rack; a mechanical buffer is arranged between the inner rack and the outer rack; the transverse movement mechanism is arranged at the upper end of the outer rack; two movement guide mechanisms are respectively arranged on the lower parts of the outer rack and the inner rack; and a longitudinal movement mechanism is respectively arranged on the opposite inner sides of the inner rack and the outer rack. The digital nondestructive detection on the welding seam of 0 to 3m through a digital imaging device and an X-ray flaw detector is realized by using each mechanism in the device and using a synchronization telescoping driving control method. The method is high in degree of automation, high in positioning accuracy and high in imaging speed; and the x-ray digital nondestructive detection on the welding seam of the storage tank can be reliably, objectively and accurately accomplished.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Construction solid waste multistage treatment device

The invention discloses a construction solid waste multistage treatment device. The construction solid waste multistage treatment device comprises a treatment box, wherein a servo motor is arranged onone side of the treatment box, an output shaft of the servo motor is fixedly provided with a first rotating shaft, the first rotating shaft is fixedly provided with a first belt wheel, the first beltwheel is in transmission connection with a second belt wheel, the second belt wheel is fixedly provided with a second rotating shaft, a smashing rod is fixed on the second rotating shaft, the smashing rod is located in the treatment box, a first gear is fixed to the first rotating shaft, the first gear is in transmission connection with a second gear, the second gear is fixed on a third rotatingshaft, a first grinding roller and a second grinding roller are fixed on the first rotating shaft and the third rotating shaft respectively, the first grinding roller and the second grinding roller are located in the treatment box, a screen is arranged below the smashing rod, and a vibrating mechanism is arranged on one side of the screen. According to the structure, waste crushing, screening andgrinding multistage treatment are realized, the working efficiency is high, and the treatment quality is good.

Owner:上海达人建设科技集团有限公司

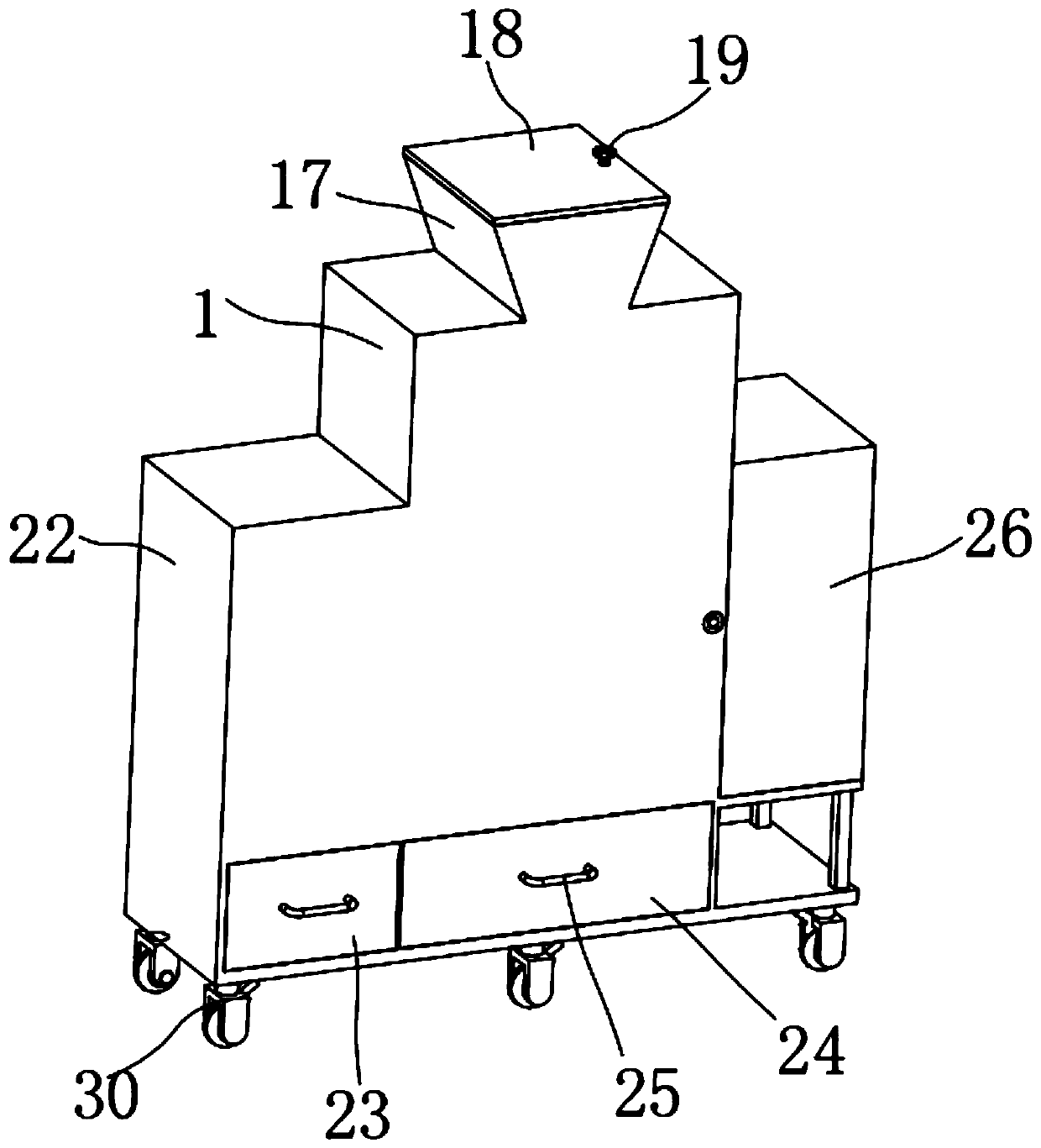

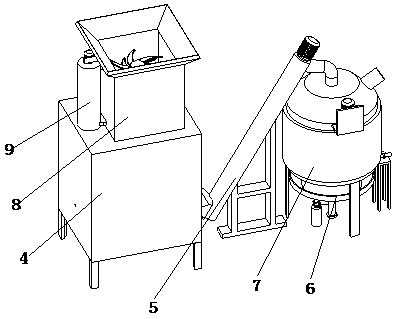

Efficient sand screening device with conveying frame

InactiveCN107457044AAchieve vibrationAvoid affecting screening efficiencySievingScreeningScreening effectMechanical engineering

The invention discloses a high-efficiency sand screening device with a conveying frame, which comprises a conveying frame, a sand screening frame and a base arranged from top to bottom; Lifting rollers are provided; the conveying frame is connected to the base through a bracket, a feeding frame is embedded on the top plate of the conveying frame, and a breaking hammer is arranged in the feeding frame; U-shaped Guide rails, a hollow movable block is arranged between the U-shaped guide rails on both sides, and a left and right reciprocating mechanism is arranged on the inner side of the movable block to drive it to move; High drive mechanism. The sand screening device of the present invention can effectively solve the problems of sand agglomeration and concentrated accumulation, and improve the sand screening efficiency; meanwhile, the setting of multi-directional vibration can effectively improve the sand screening effect.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

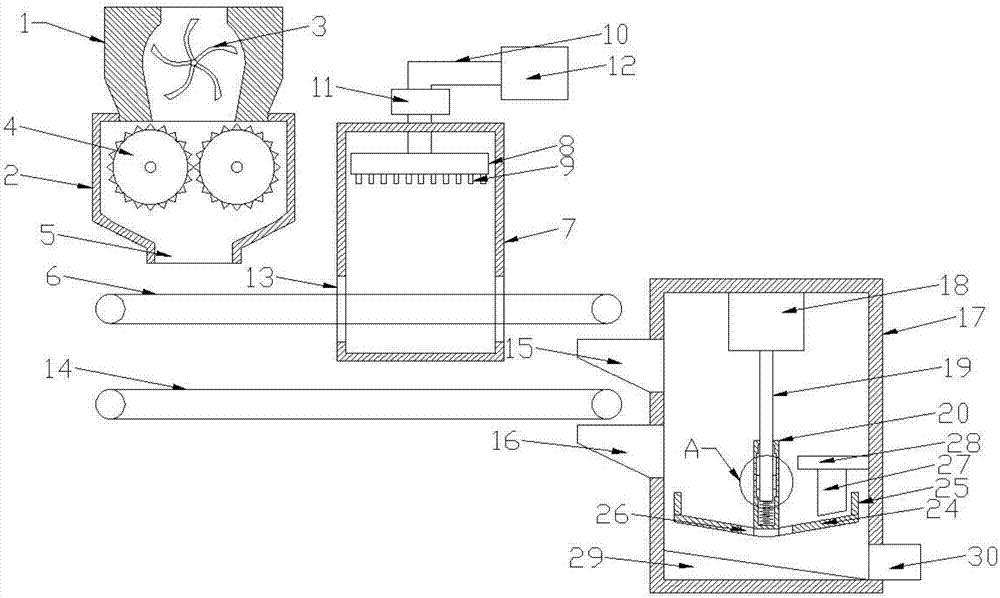

Efficient harmless treatment device for medical waste

InactiveCN108405054ACleverly structuredReasonable arrangementMedical waste disposalGrain treatmentsMedical wasteEngineering

The invention discloses an efficient harmless treatment device for medical waste. The efficient harmless treatment device comprises a shell; a feeding hopper is arranged at the top of the shell; an arc-shaped groove is formed in the bottom of the feeding hopper; a rotating roller is arranged at the circle center position of the arc-shaped groove; scraping plates are arranged on the rotating roller; supporting plates are arranged in the arc-shaped groove in bilateral symmetry; the top ends of the supporting plates are hinged to the left inner wall and the right inner wall of the arc-shaped groove; the lower sides of the supporting plates are supported on the inner wall of the arc-shaped groove through a plurality of compression springs; the supporting plates are connected to the scraping plates on the two sides of the rotating roller in an abutting mode to seal the feeding hopper; a pair of crushing rollers are arranged at the position, corresponding to the position below the feeding hopper, in the shell; crushing teeth are uniformly arranged on the crushing rollers; and a screen is arranged at the position, corresponding to the position below the crushing rollers, in the shell andis obliquely arranged in a downward sloping mode. The efficient harmless treatment device for the medical waste has the advantages that the structure set is ingenious, the layout is reasonable, harmless treatment of animals can be realized, the discharging effect is good, and the efficiency is high.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

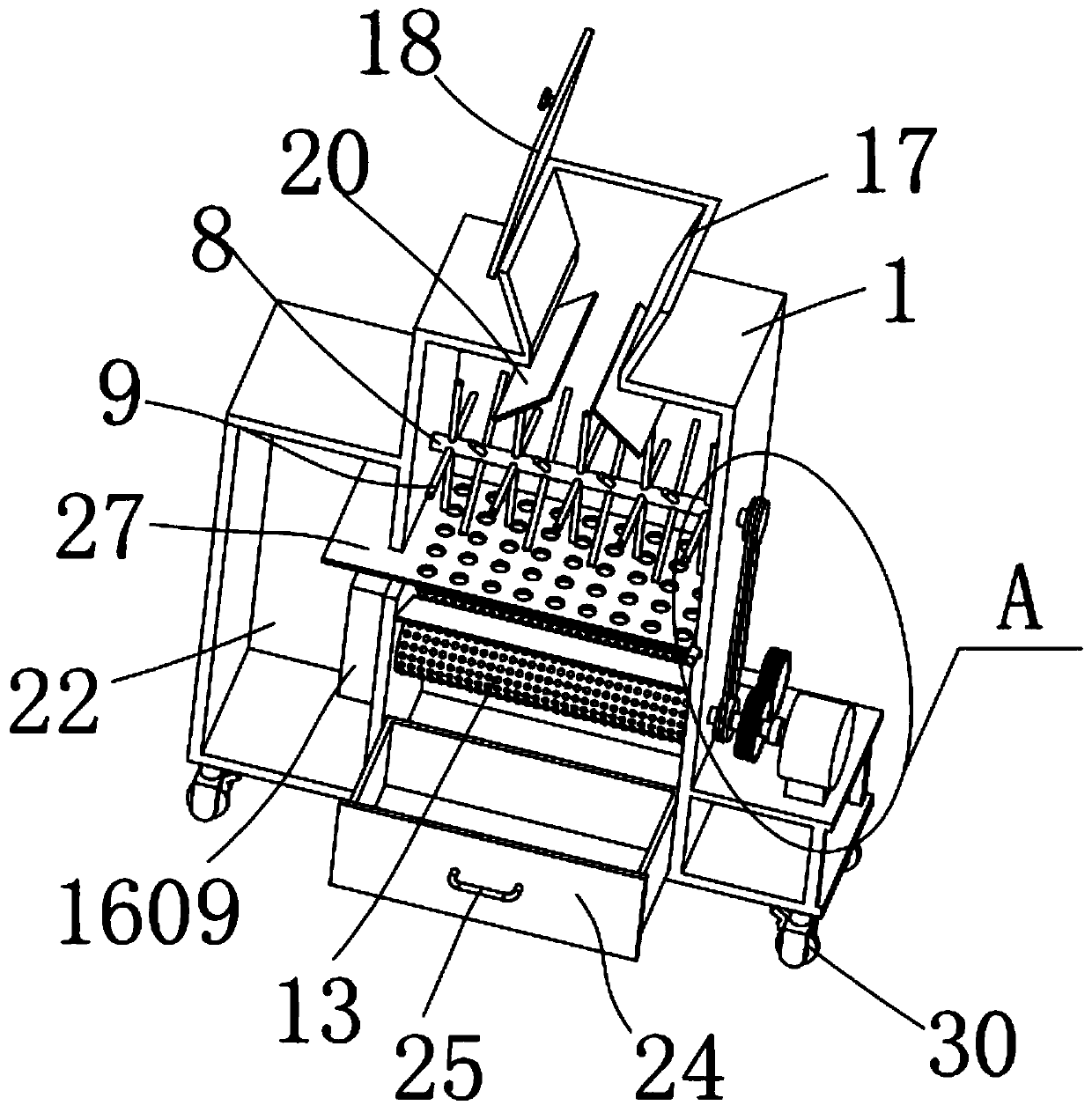

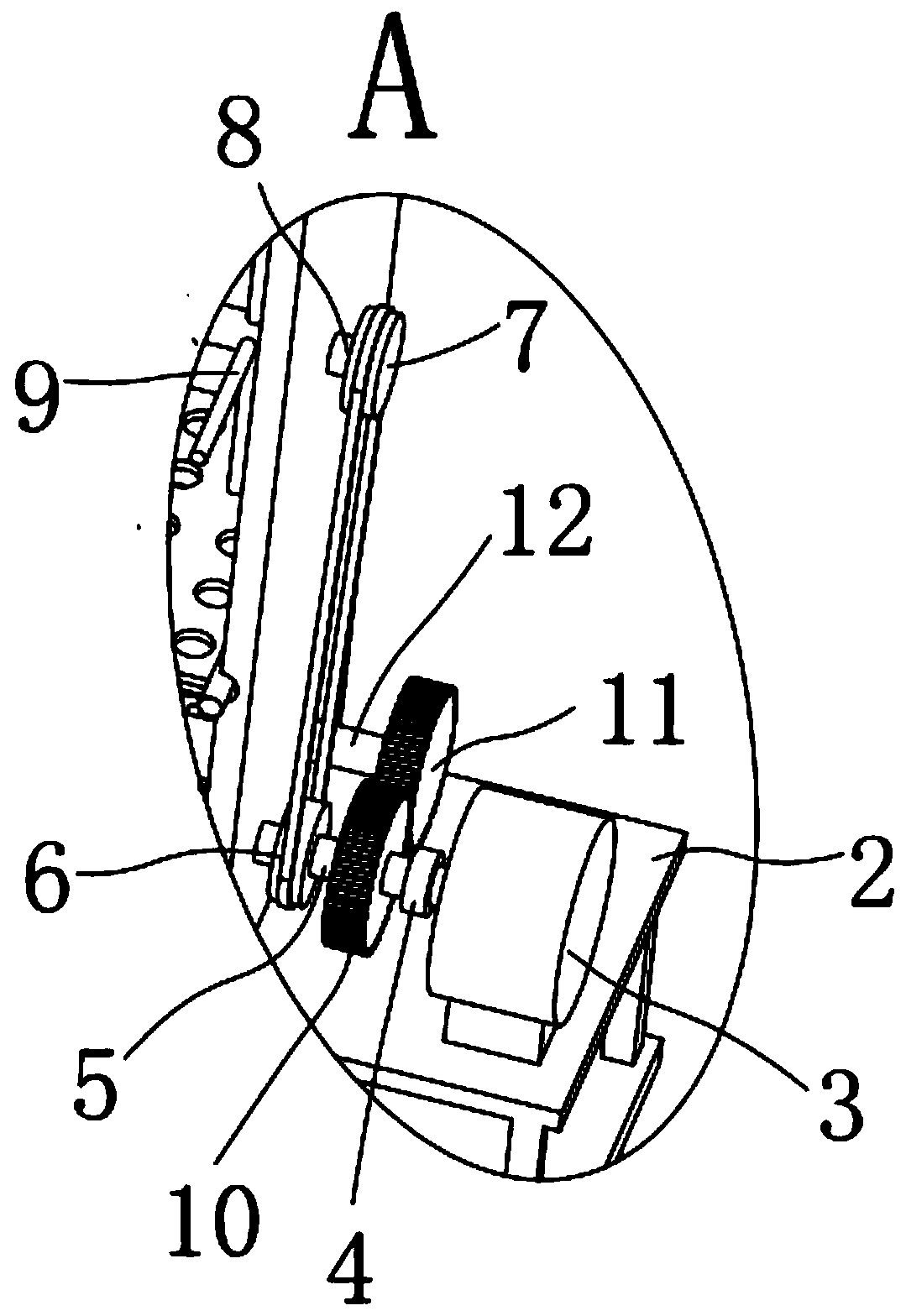

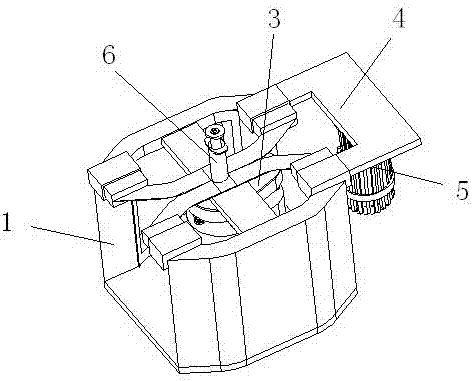

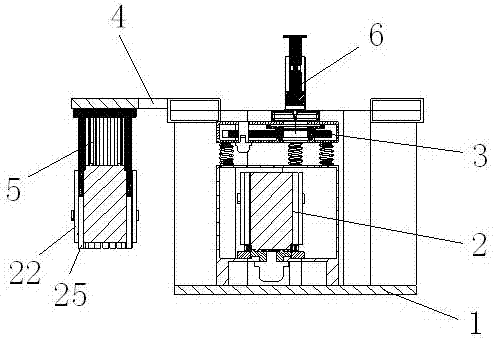

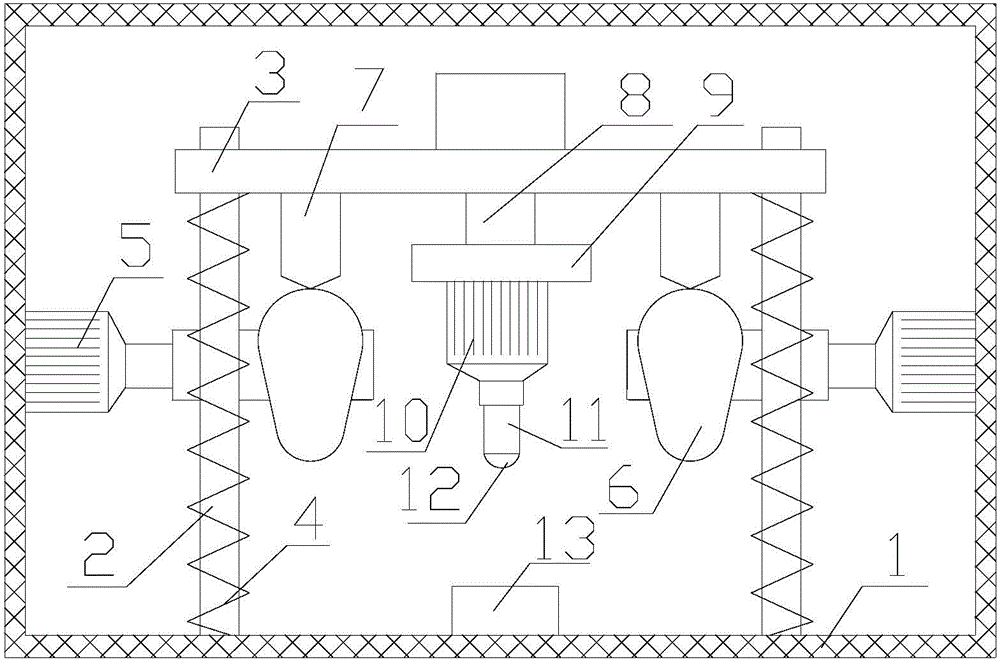

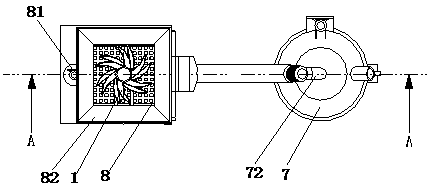

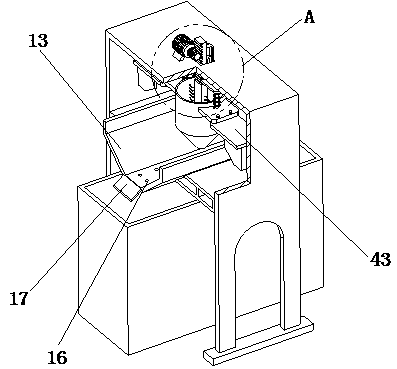

Medical portable syringe needle recoverer for clinical usage

ActiveCN107485765AEasy to useHigh degree of automationInfusion needlesSyringe needleBiomedical engineering

The invention discloses a medical portable syringe needle recoverer for clinical usage. The recoverer includes a splint device, a syringe needle pulling device and a syringe needle collecting device, wherein the splint device includes a rack base, two support plates symmetrically arranged above the rack base and two splint fixing mechanisms which are symmetrically and fixedly arranged on the inner sides of the upper portions of the two support plates respectively and used for fixing and clamping a needle cap in a syringe needle assembly; the rack base is successively provided with the syringe needle pulling device and the syringe needle collecting device which are positioned under the two splint fixing mechanisms from top to bottom, the syringe needle pulling device is used for clamping and pulling out a metal syringe needle fixedly inserted in the bottom of the needle cap, and the syringe needle collecting device is used for collecting the metal syringe needles pulled out by the syringe needle pulling device. The medical portable syringe needle recoverer for the clinical usage has the advantages of being small in overall occupied space, convenient to carry, high in automation degree, convenient to operate and use, environment-friendly and capable of well recovering the medical syringe needles alone.

Owner:李奇元

Straw crushing and mixing device for breeding

The invention discloses a straw crushing and mixing device for farming, which comprises a feeding hopper, a crushing box and a mixing box; several cutting blades are installed in the feeding hopper; A horizontal straw conveyor belt is installed below the feeding port, an atomization box is arranged on the right side of the crushing box, and a horizontal feed conveyor belt is arranged below the straw conveyor belt; the lower end of the rotating shaft covers A sleeve is provided, a vertical spring is fixed at the lower end of the rotating shaft, and a vertical chute is provided on the inner wall of the sleeve; a receiving tray is fixed at the lower end of the sleeve; the crushed straw surface There is water vapor attached to it, which can adhere to the feed during mixing, and evenly mix the feed with straw fragments to ensure the mixing ratio of feed and straw; the feeding tray can also move up and down while rotating, so as to realize the vibration of the feeding tray and shake the raw materials. Fall, to facilitate the whereabouts of materials.

Owner:刘志坚

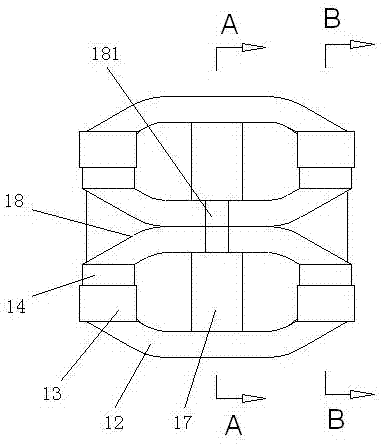

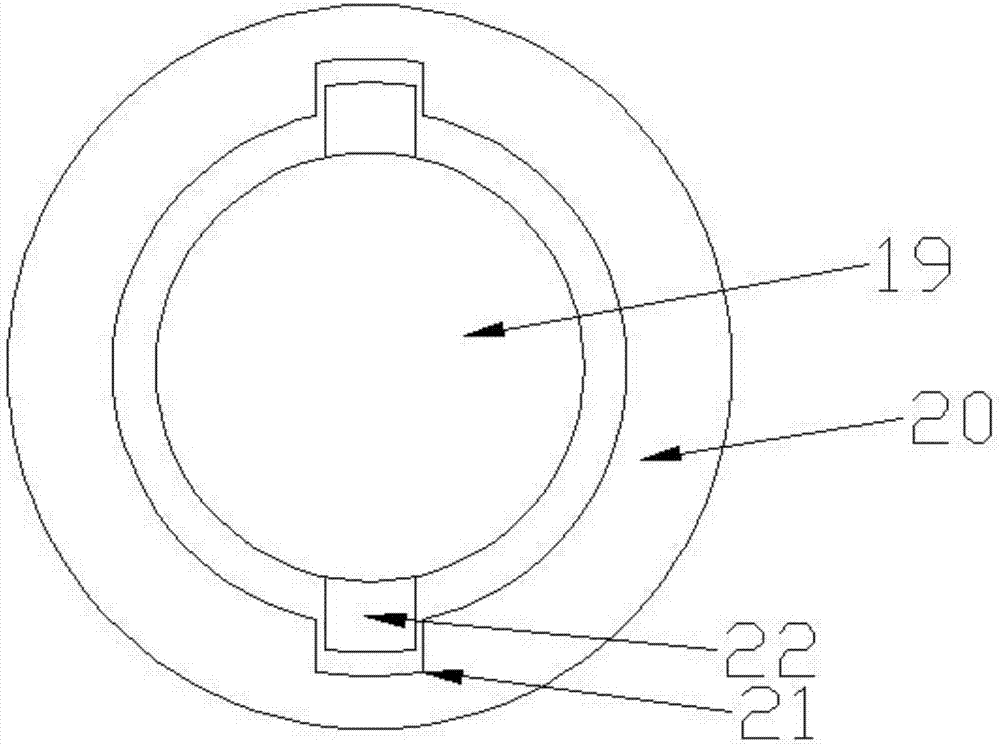

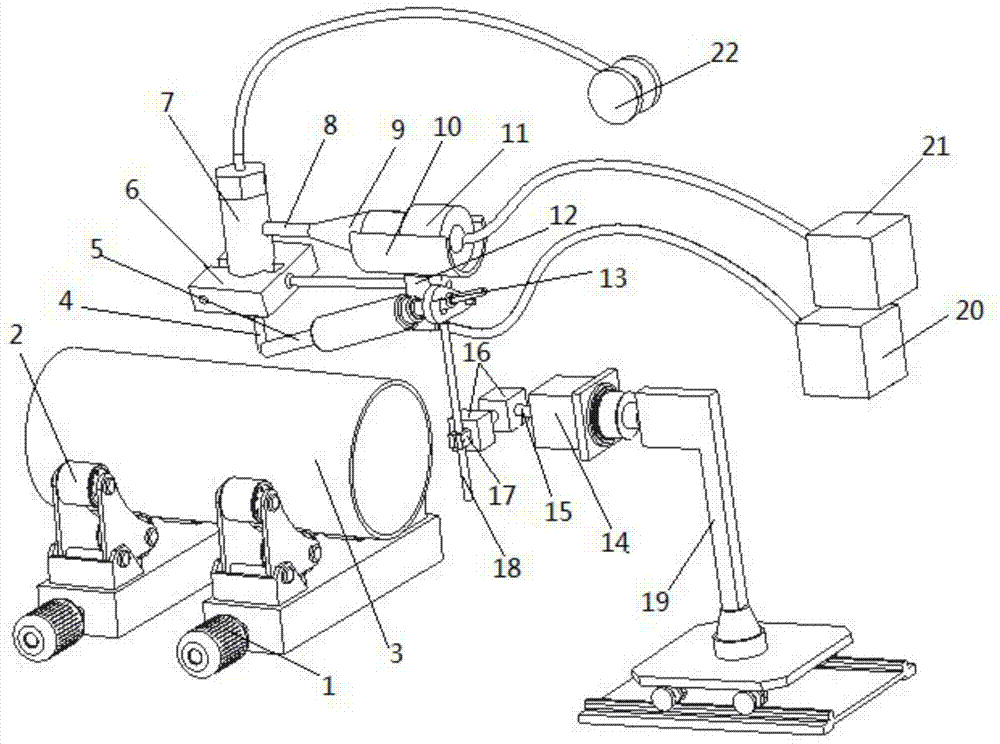

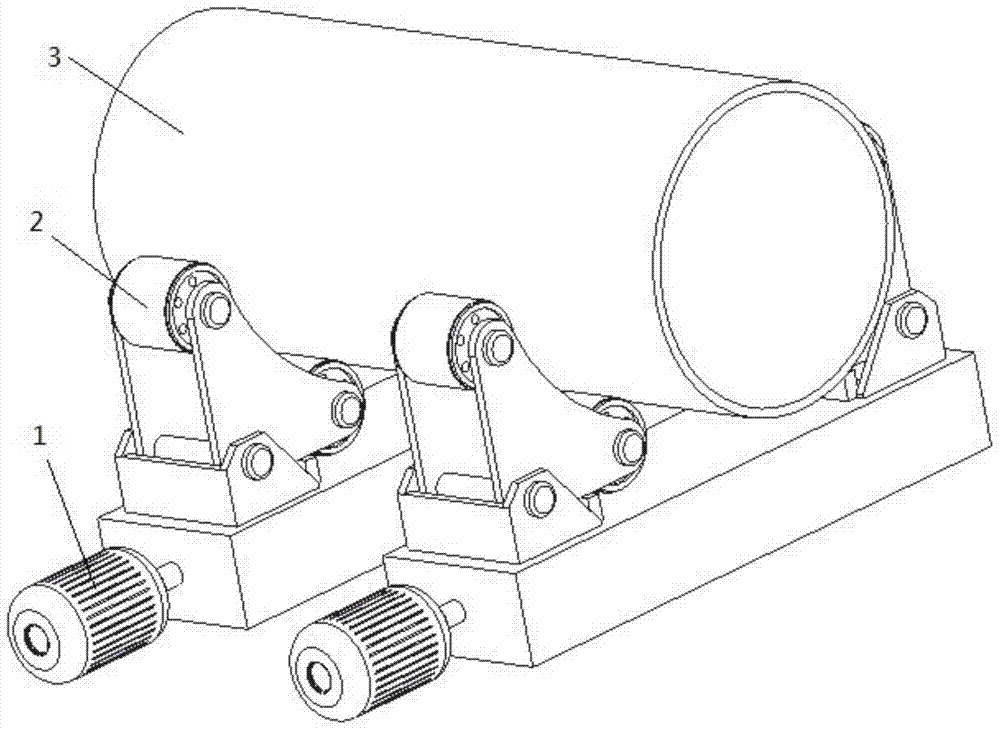

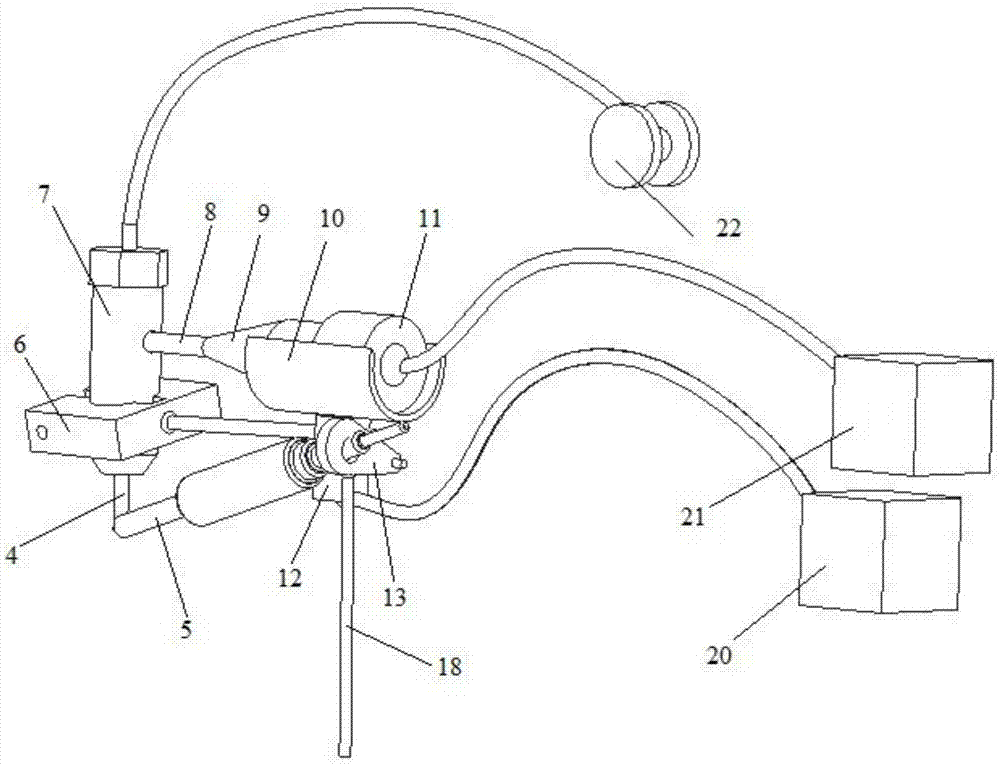

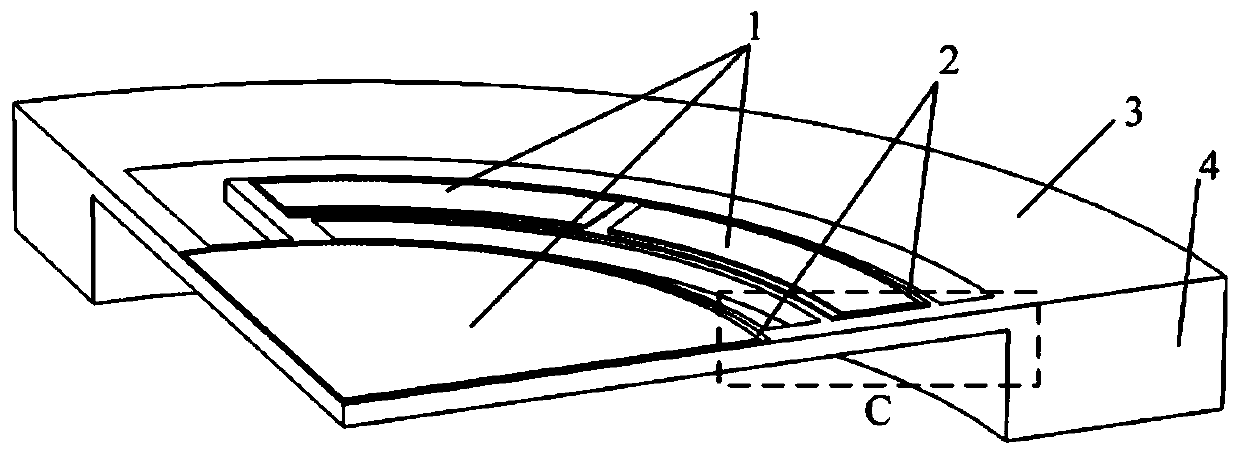

Device and method for welding high steel grade and large wall thickness pipeline steel

The invention discloses a device and a method for welding high steel grade and large wall thickness pipeline steel. The device for welding the high steel grade and large wall thickness pipeline steel is mainly composed of a work platform controller 1, an idler wheel support 2, a work piece 3, a welding gun 5, a wire feeding nozzle 7, an ultrasonic tool head 8, an amplitude variation pole 9, an ultrasonic transducer 11, a welding power source 20, an ultrasonic generator 21, a wire feeding mechanism 22, an oscillator 14, a transmission shaft 15, an angle adjustor 16 and the like. The method for welding the high steel grade and large wall thickness pipeline steel includes: (1) placing the work piece on the idler wheel support, and starting the work platform controller; (2) setting welding voltage and a welding current, turning on the welding power source, and starting the ultrasonic generator after an electric arc is stabilized; (3) adjusting angles of the welding gun through the angle adjustor; (4) starting the oscillator, and driving the welding gun to swing back and forth through entrance and exiting movements of the transmission shaft; (5) starting the wire feeding mechanism, and staring automatic welding. The device and the method for welding the high steel grade and large wall thickness pipeline steel achieve high welding quality, good weld joint formation, and a high welding joint microstructure constituent homogenization degree, and have a broad market application prospect.

Owner:SOUTHWEST PETROLEUM UNIV

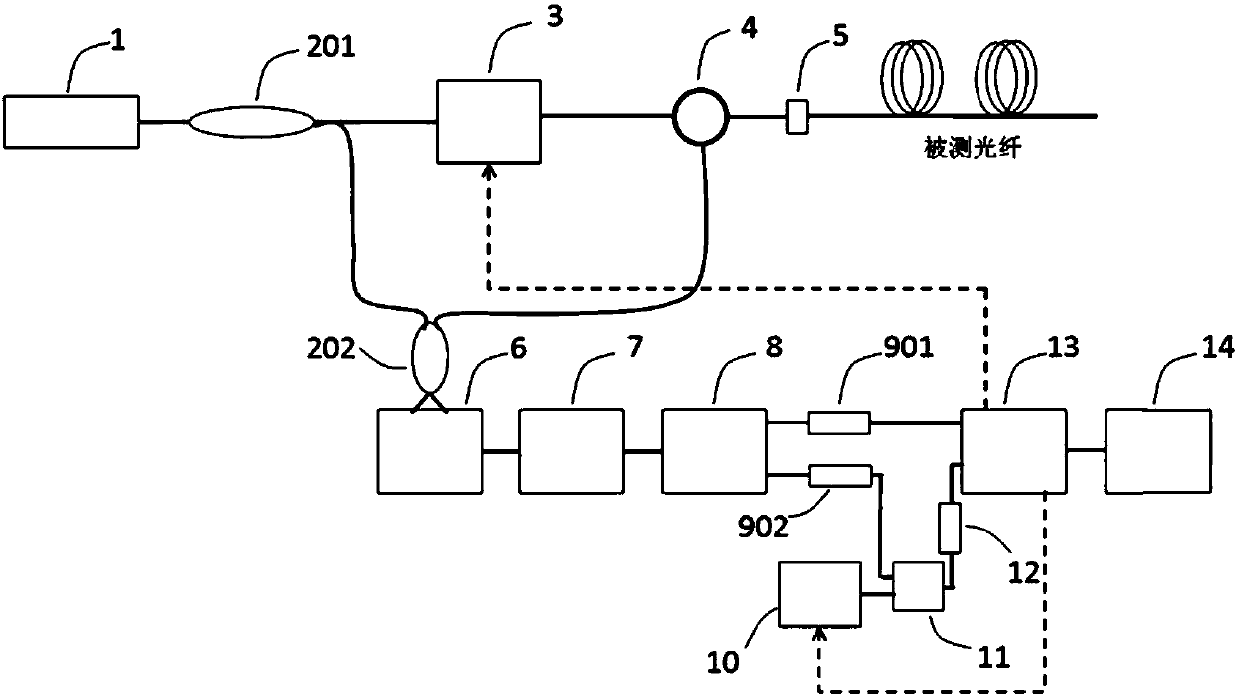

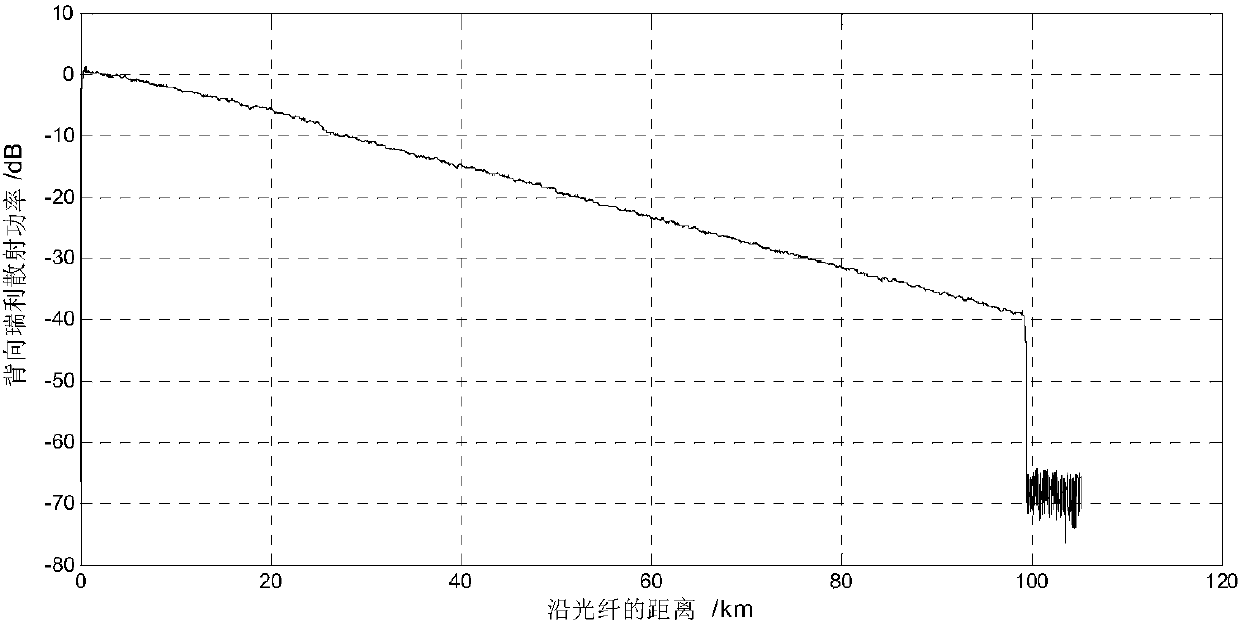

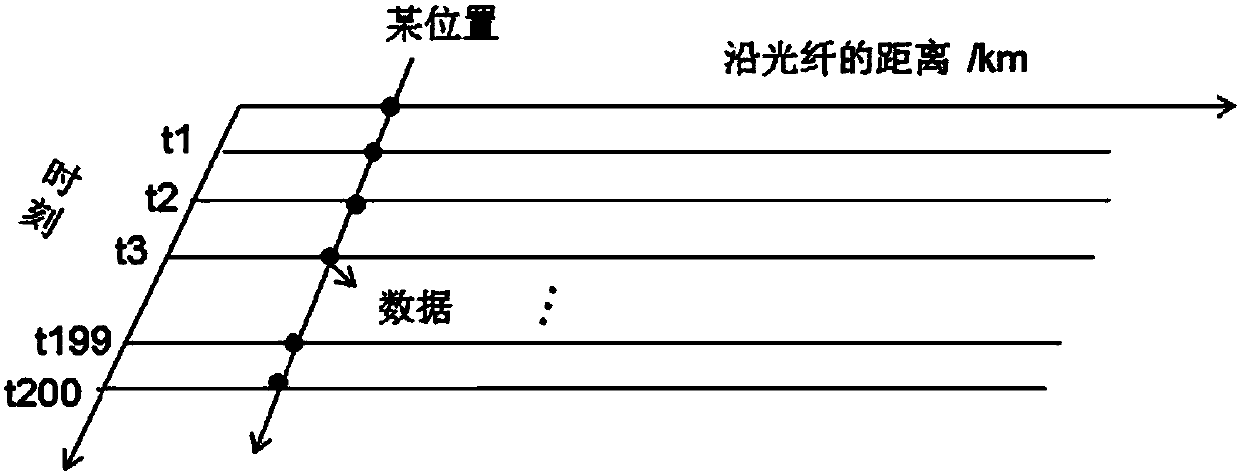

Distributed type fiber sensing device based on signal reusing perception and demodulation

ActiveCN107560644AAchieve attenuationAchieve vibrationConverting sensor output opticallyFiber couplerRayleigh scattering

The invention provides a distributed type fiber sensing device based on signal reusing perception and demodulation, comprising a laser, a first fiber coupler, a second fiber coupler, a light pulse modulator, a fiber annular device, an optical interface, a balance photoelectric detector, a low noise amplifier, a power divider, a first filter, a second filter, a frequency synthesizer, a mixer, a lowpass filter, a data collecting and processing module, and a computer. The feature that rayleigh scattering signals and Brillouin scattering signals can be generated at the same time is taken into consideration, and by means of the balance photoelectric detector, the rayleigh scattering signals and Brillouin scattering signals of the detection light pulse, generated in the detected fiber are simultaneously converted into radiofrequency signals of the corresponding frequency or frequency range. The rayleigh scattering signals and the Brillouin scattering signals are separated by means of the power divider and a band pass filter. The separated rayleigh scattering signals and the Brillouin scattering signals are accessed to the data collecting and processing module. The attenuation, vibration, and monitoring and displaying of the temperature and strain information of the fiber can be realized.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +3

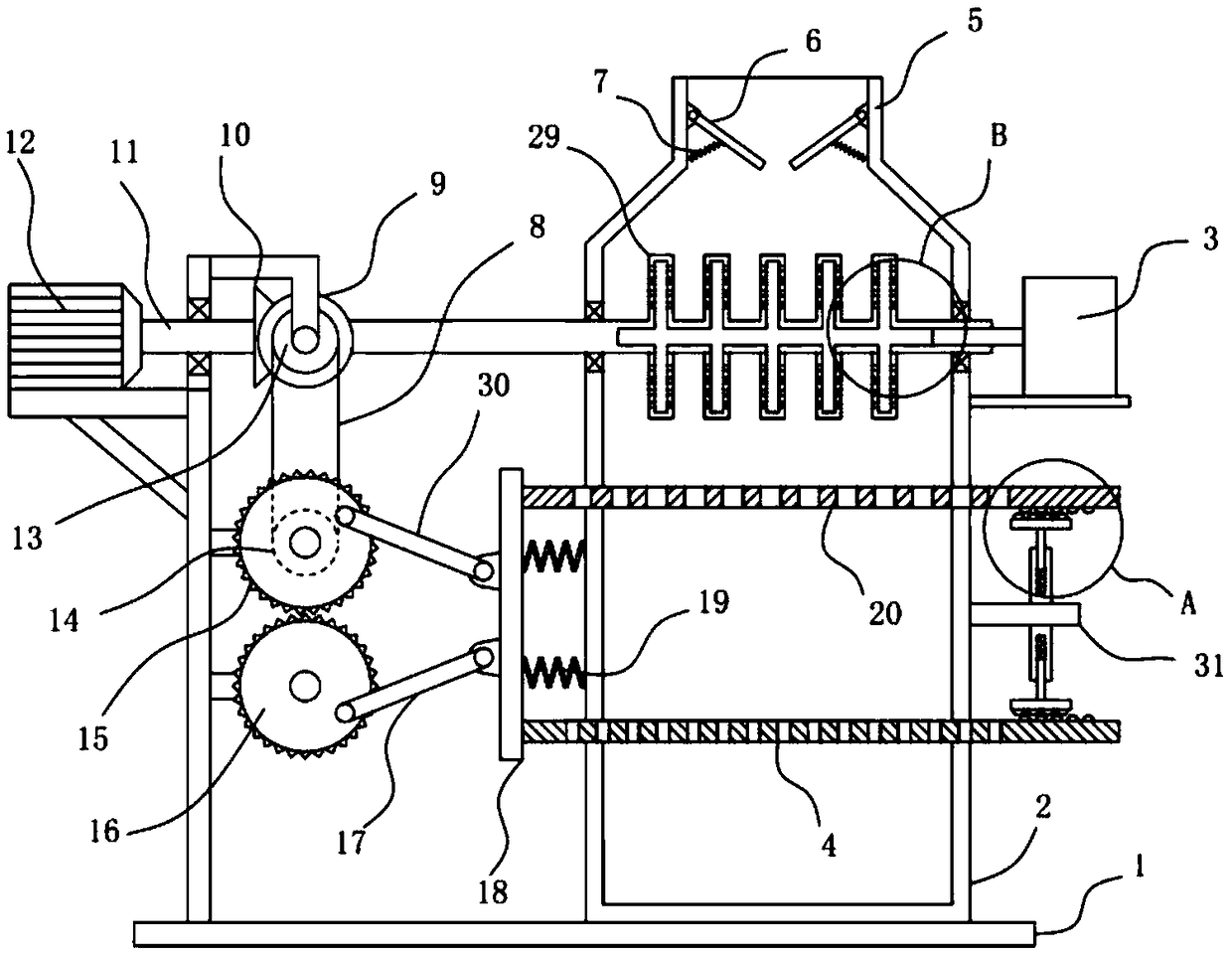

Novel self-chip-removal machine tool

InactiveCN104889445ASmooth chip removalFast Chip EvacuationFeeding apparatusDriving apparatusEngineeringCam

The invention provides a novel self-chip-removal machine tool. The cutting efficiency is effectively improved through vibrating drilling, and the novel self-chip-removal machine tool is smooth in chip removal and high in chip removal speed. A guide rod is arranged on the machine frame. An upper supporting plate is connected to the periphery of the guide rod in a vertical sliding and sleeving mode. The two ends of each spring are fixedly connected to the upper supporting plate and a machine frame respectively. A first drive device is arranged on the machine frame. A cam mechanism comprises a cam and a driven rod. The cam is connected to the periphery of an output shaft of the first drive device in a sleeving mode and is driven by the first drive device to rotate. One end of the driven rod is arranged on the upper supporting plate, and the other end of the driven rod abuts against the cam. A second drive device is arranged on the upper supporting plate and can drive a lower supporting plate to move in the axial direction of the guide rod. A third drive device is arranged on the lower supporting plate and can drive a drilling assembly to rotate. A drill stem is connected with an output shaft of the third drive device. A drill bit is arranged on the side, away from the third drive device, of the drill stem. The novel self-chip-removal machine tool is used for arranging a clamping piece on the machine frame, wherein the clamping piece is used for clamping workpieces.

Owner:蚌埠市金林数控机床制造有限公司

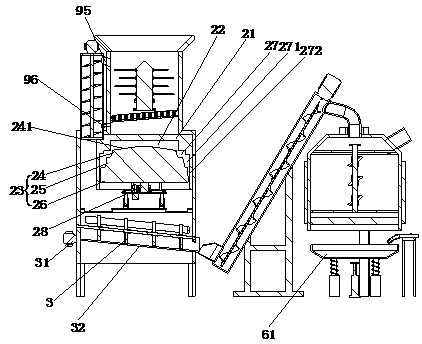

Enzymolysis device for polypeptide production

InactiveCN110938540AEasy to GrindHigh extraction rateBioreactor/fermenter combinationsBiological substance pretreatmentsSpray nozzleProcess engineering

The invention discloses an enzymolysis device for polypeptide production, and belongs to the technical field of bioengineering. The device includes a raw material crushing mechanism, a multi-stage grinding mechanism, a homogenizing and mixing mechanism, a grinding box, an auger feeder, a filtering and drying mechanism and an enzymolysis tank; the top of the grinding box is provided with a crushingbox, the top of the crushing box is provided with a material guide hopper, the material guide hopper is provided with screening holes, and the side of the crushing box is provided with a large particle secondary crushing component; and the multi-stage grinding mechanism includes a grinding shell, a multi-stage grinding block and a rotating component, and a grinding chamber is arranged in the bottom of the grinding shell. The device has the following beneficial effects: raw materials can be automatically crushed through the raw material crushing mechanism, and the raw material particles that are not completely crushed can be conveyed into the crushing box again under the action of the large particle secondary crushing component, a drying basin can be shaken through the filtering and dryingmechanism, and under the action of spray drying by a spray nozzle, a peptide concentrate in the drying basin can be spray dried.

Owner:谢双

Multistage chemical material screening and treatment device

InactiveCN109046929ARealize left and right reciprocating motionAchieve secondary screeningSievingScreeningRelative displacementReciprocating motion

The invention discloses a multistage chemical material screening and treatment device and relates to the technical field of chemical devices. The multistage chemical material screening and treatment device comprises a bearing frame, wherein a screening barrel is fixedly mounted on the bearing frame; feeding tubes are mounted at the upper end of the screening barrel; a driving motor is fixedly mounted on the bearing frame; a driving belt pulley is coaxially fixed on a driven bevel gear; and the left end of a pull rod II and the left end of a pull rod I are separately hinged on the front surfaceof a driving gear and the front surface of a driven gear in an eccentric manner. The multistage chemical material screening and treatment device separately pulls the pull rod II and the pull rod I byvirtue of the driving gear and the driven gear which are in meshing connection, thereby realizing the left and right reciprocating motion of a second screening plate and a first screening plate, andrealizing the second-stage screening of chemical materials. The relative displacement between protruding blocks I and protruding blocks II realizes the vibration of the second screening plate and thefirst screening plate so as to improve the screening efficiency. Rotating tubes can rotate to scatter the chemical materials, and the hot air sprayed from air outlets can dry the chemical materials toavoid the bonding of the chemical materials so as to ensure great improvement in subsequent screening efficiency.

Owner:福州市长乐区巧通工业设计有限公司

Soil vibration measuring method and soil detection device

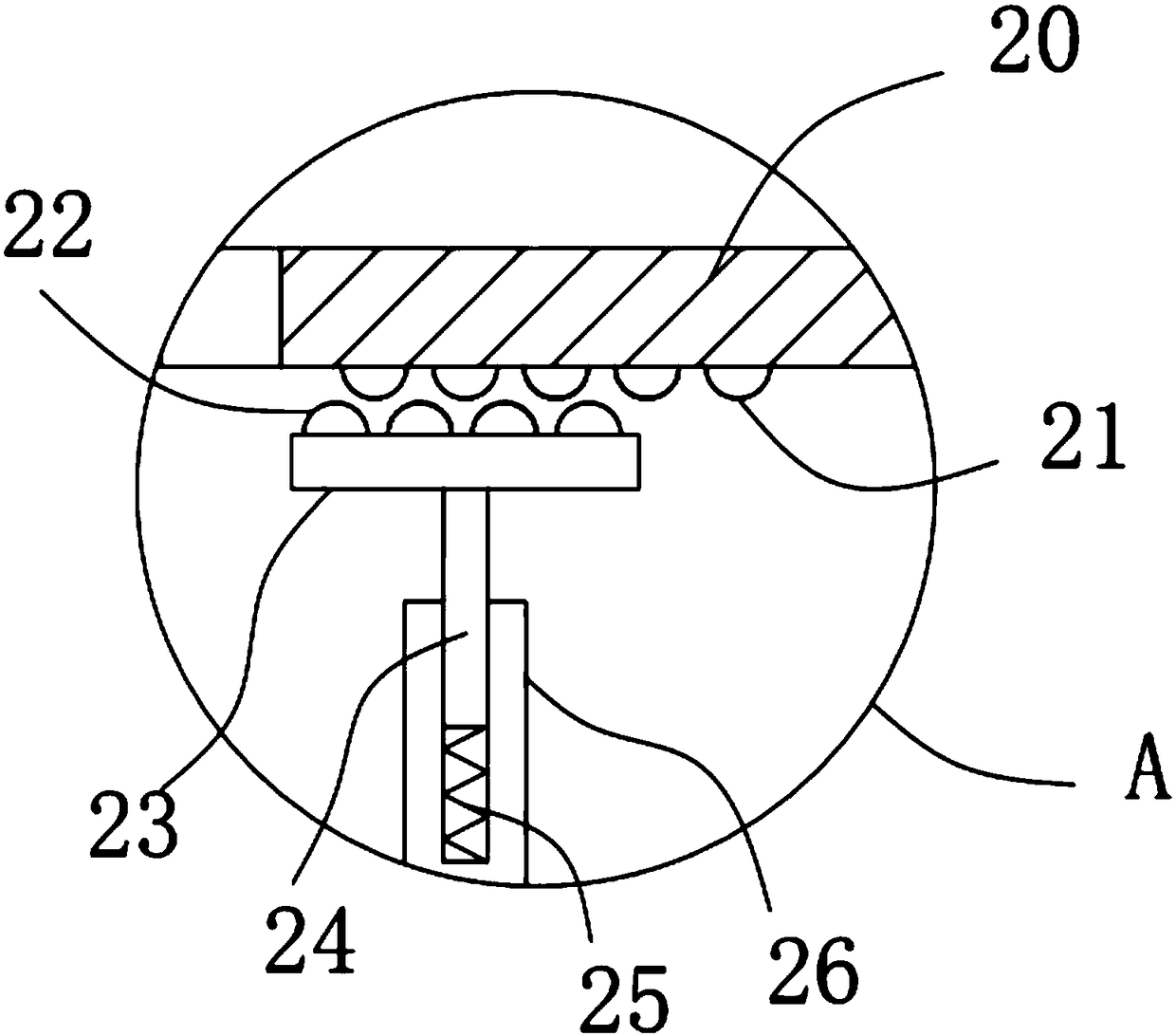

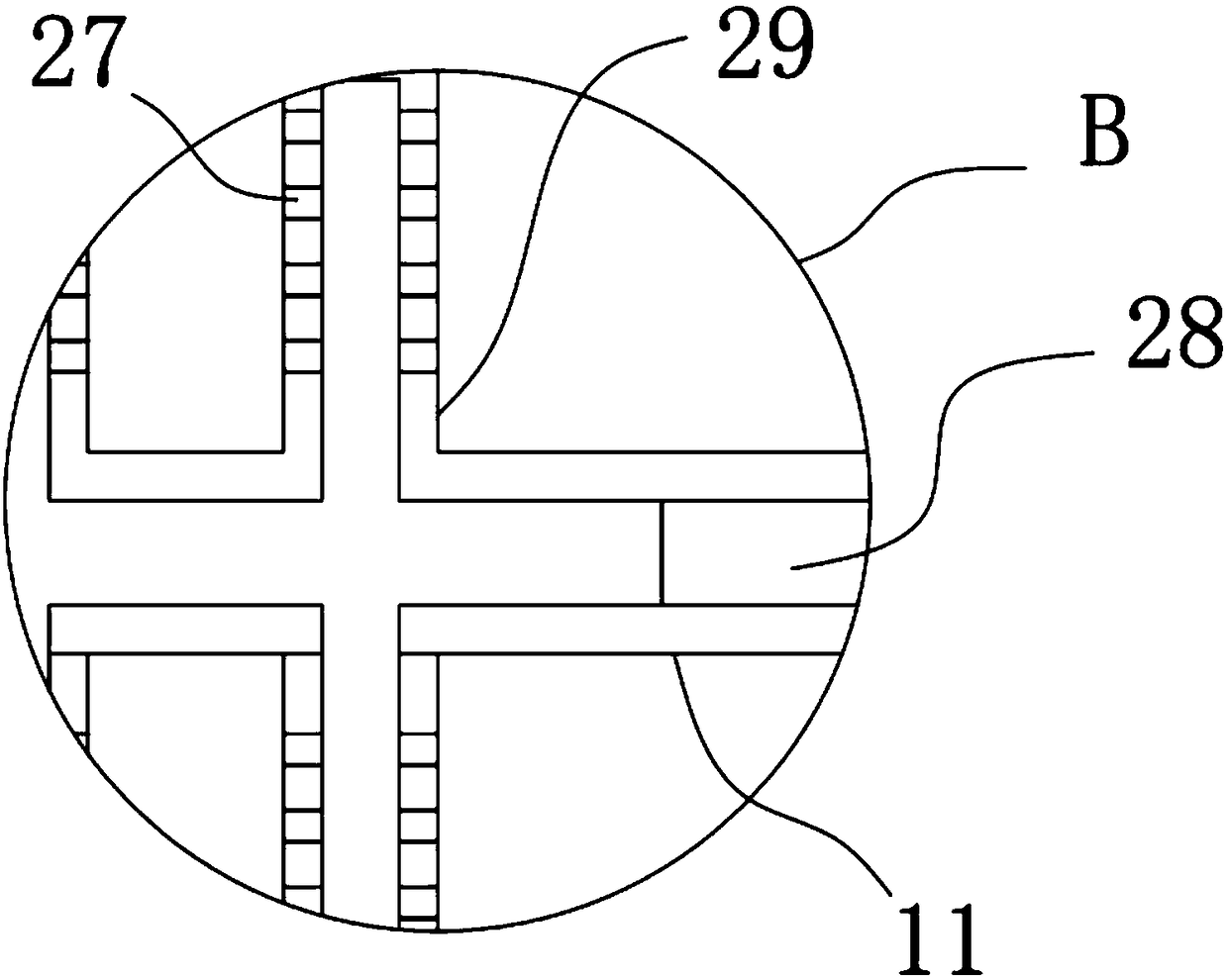

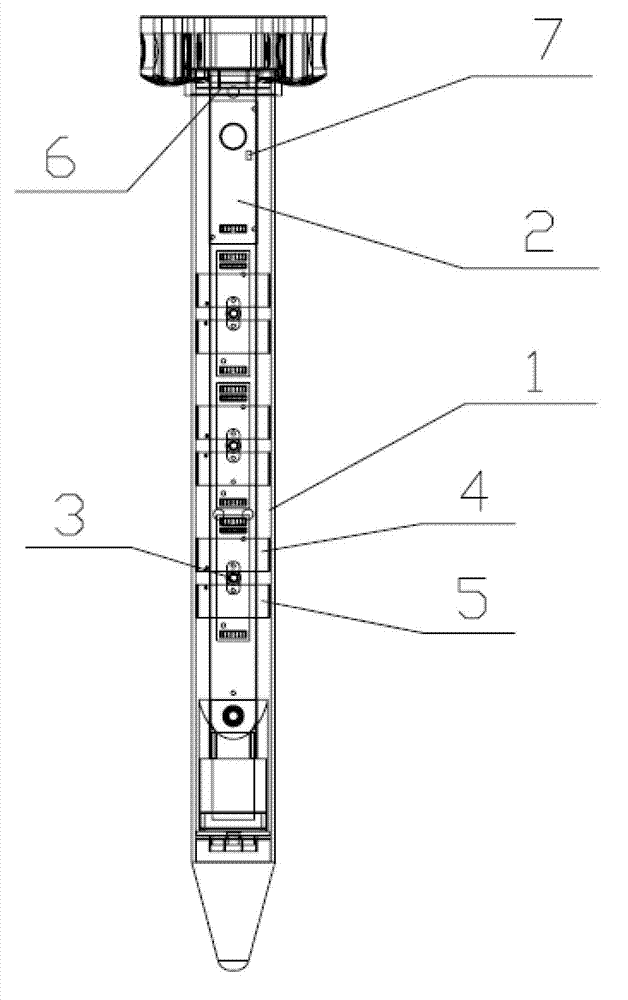

ActiveCN102879545AAchieve vibrationEnable mobilitySubsonic/sonic/ultrasonic wave measurementEarth material testingElectricityInformation processing

The invention relates to a soil vibration measuring method. The soil vibration measuring method comprises the steps of embedding a gravity sensor into the soil and sending data measured by the gravity sensor to an external information processing device by a signal sending device. The invention further relates to a soil detection device comprising a cylindrical body, wherein the cylindrical body is embedded into the soil; the gravity sensor and the signal sending device are arranged on the cylindrical body; the gravity sensor is electrically connected with the signal sending device; the gravity sensor is used for detecting the occurring vibration or movement and simultaneously converting the detected signal into data of the occurring vibration or movement; and the signal sending device is used for sending the data to the external information processing device. According to the soil vibration measuring method and the soil detection device, with the adoption of the gravity sensor, the measurement on the soil vibration is realized, and the early warning information and the data analysis can be provided effectively in advance; and meanwhile, as the gravity sensor is arranged on the soil detection device, not only is the early warning information provided, but also the function of the soil detection device can be further improved.

Owner:BEIJING ANSAIBO TECH

Road repairing device

The invention belongs to the technical field of pavement repairing devices, Specifically, the invention relates to a road repairing device, comprising a frame, a traveling wheel, a puncture unit, a crushing unit, a stuffing box and a rolling roller, wherein the puncture unit is installed on the frame, and the puncture unit is used for knocking the edge of the damaged pavement to determine the range of the damaged pavement, and simultaneously avoiding damage to the intact pavement during the repairing process; The crushing unit is installed on the vehicle frame, the crushing unit is located behind the puncture unit, and the crushing unit is used for completely crushing the damaged road surface knocked by the puncture unit; The stuffing box is used for adding asphalt to the pavement to be repaired after being crushed by the crushing unit according to the actual needs and repairing the pavement again; The rolling roller is installed under the vehicle frame, the rolling roller is located behind the stuffing box, and the rolling roller is used for rolling the pavement and repairing the pavement. The invention greatly improves the repairing efficiency, and at the same time, the crushed asphalt is heated and reused, thereby reducing the cost.

Owner:南京天方市政工程有限公司

Dual resonant mode coupled micro-mechanical piezoelectric ultrasonic transducer

PendingCN110052391AImprove emission sensitivityHigh bandwidthMechanical vibrations separationHigh level techniquesCantileverFrequency difference

The invention discloses a dual resonant mode coupled micro-mechanical piezoelectric ultrasonic transducer. The transducer is provided with a substrate, a structure layer, a bottom electrode, a piezoelectric layer and an upper electrode. The working principle of the transducer is to realize the conversion of mechanical energy to electrical energy or electrical energy to mechanical energy through using positive and negative piezoelectric effects. According to the micro-mechanical piezoelectric ultrasonic transducer, two parts with opposite stress symbols of the diaphragm are divided into an inner region and an outer region on the structural layer, wherein the inner region adopts a boundary fixed supported film vibration mode, and the outer region adopts a single-end fixed supported cantilever beam vibration mode. The resonance frequency of the external cantilever beam is adjusted through changing the geometrical size of the external cantilever beam, so that the transducer is selectivelyrealized that (1) when the resonance frequency of the inner membrane and the resonance frequency of the external beam are the same, the emission sensitivity of the transducer can be improved; (2) whenthe resonance frequency difference between the inner membrane and the external beam is within the -3dB, the bandwidth of the transducer can be increased; and (3) when the resonance frequency difference between the inner membrane and the external beam is large, double-resonance frequency vibration can be realized.

Owner:ZHEJIANG UNIV

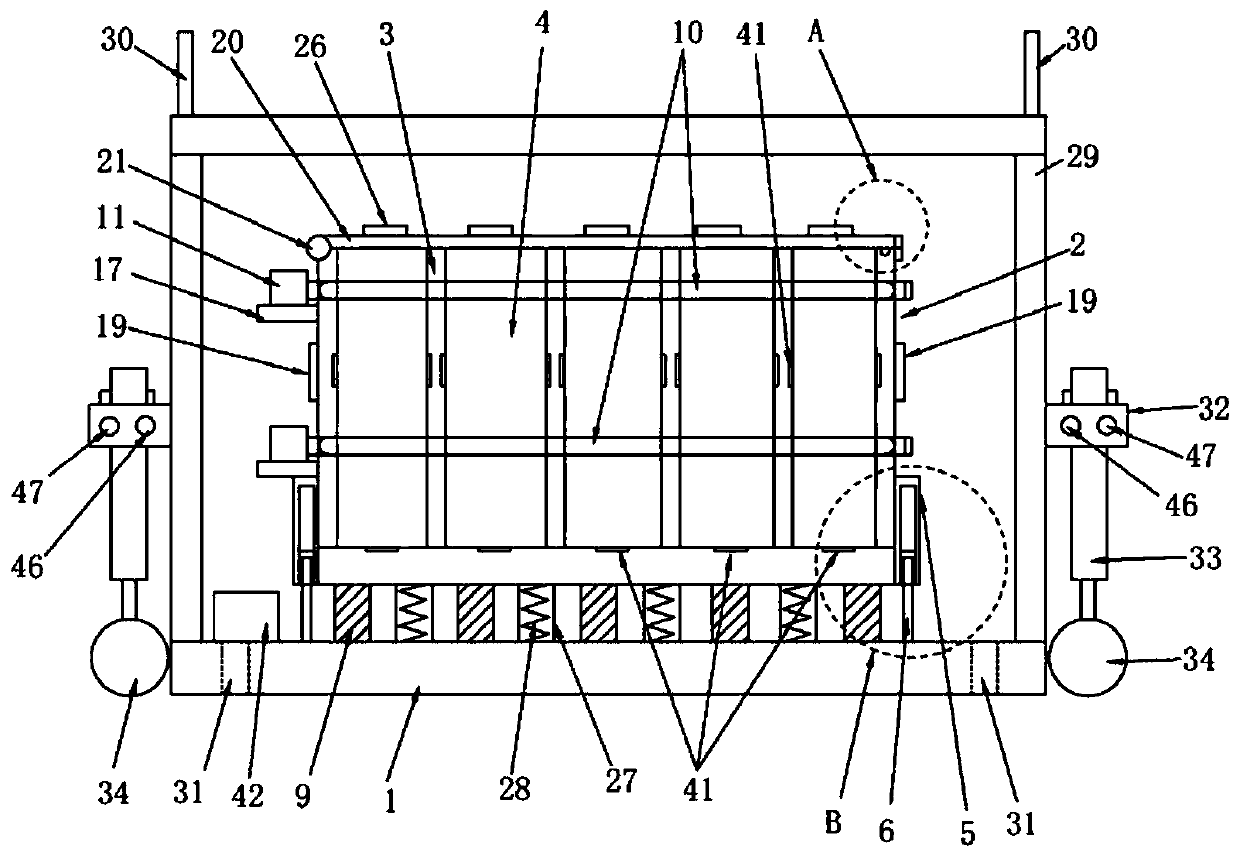

Civil engineering structure anti-vibration test device

InactiveCN108956071AAdjustable angleAdjustable distanceVibration testingVibration amplitudeEngineering structures

The invention relates to a civil engineering structure anti-vibration test device, which comprises an experiment box, wherein an opening is formed in the bottom surface of the experiment box, a base is arranged under the experiment box, the bottom surface of the experiment box is fixedly mounted on the top surface of the base, a strip-shaped through groove is formed in the top surface of the experiment box, observation windows are formed in front and rear sides of the experiment box, the inner walls of the observation windows are fixedly provided with transparent tempered glass, the top surface of the base is fixedly provided with a buffer plate, the buffer plate is located in the experiment box, a transverse installation plate is arranged above the buffer plate, the bottom surface of theinstallation plate and the top surface of the buffer plate are fixedly connected by means of a plurality of vertical buffer rods. The civil engineering structure anti-vibration test device is reasonable in structural design and convenient to use, can conveniently adjust an angle of a fan so as to adjust an air blowing angle, can adjust the distance between the fan and a test piece, can realize one-way vibration by means of one motor, can further realize multi-directional simultaneous vibration, and can adjust the magnitude of vibration amplitudes, thereby being capable of simulating the actualenvironment and improving the precision of test data.

Owner:XINXIANG UNIV

Oxidation washing system equipment based on new resin material treatment

ActiveCN111773854ASolve cleaning difficultiesImprove sealingUsing liquid separation agentSpraying apparatusReciprocating motionMaterials processing

The invention provides oxidation washing system equipment based on new resin material treatment, relates to the technical field of resin material processing, and solves the problems that when gas is filtered, spraying filtration is realized only through a single spraying structure, and linkage movement of multiple filtering structures cannot be realized through structural improvement. In addition,the seepage phenomenon is likely to occur in the spraying and filtering process, and temporary collection cannot be achieved when seepage occurs. The oxidation washing system equipment based on new resin material treatment comprises a box body, the box body is filled with liquid, and a vibration cleaning structure is installed in the box body. A shifting block is in contact with a spray pipe, andthe spray pipe is in an up-and-down reciprocating motion state when the shifting block rotates along with a rotating shaft, so that further diffusion of water mist sprayed by the spray pipe is realized.

Owner:山东仲宜复合材料有限公司

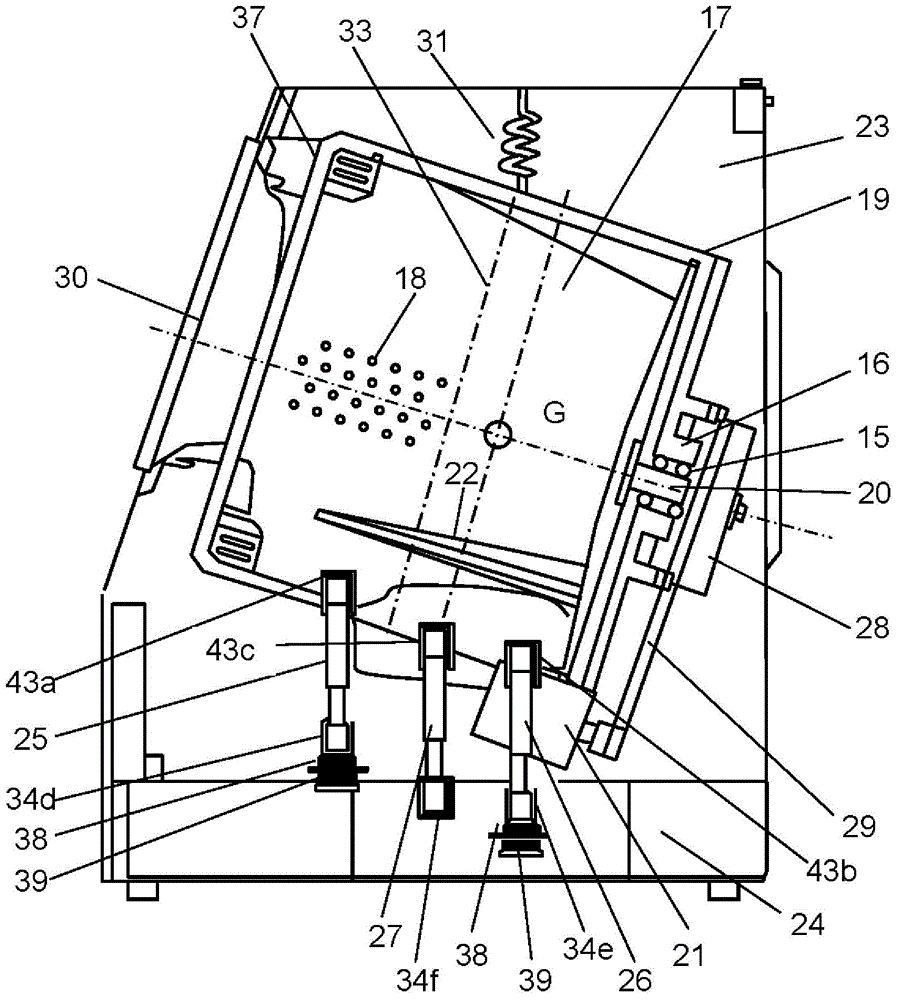

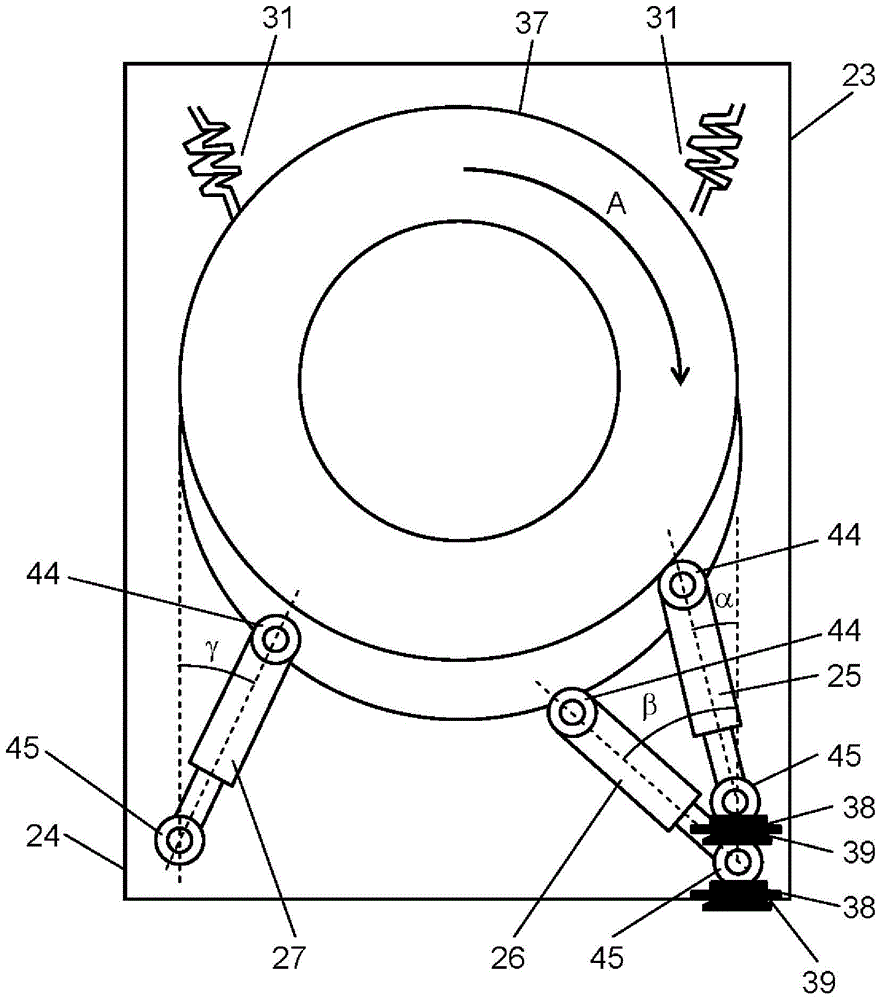

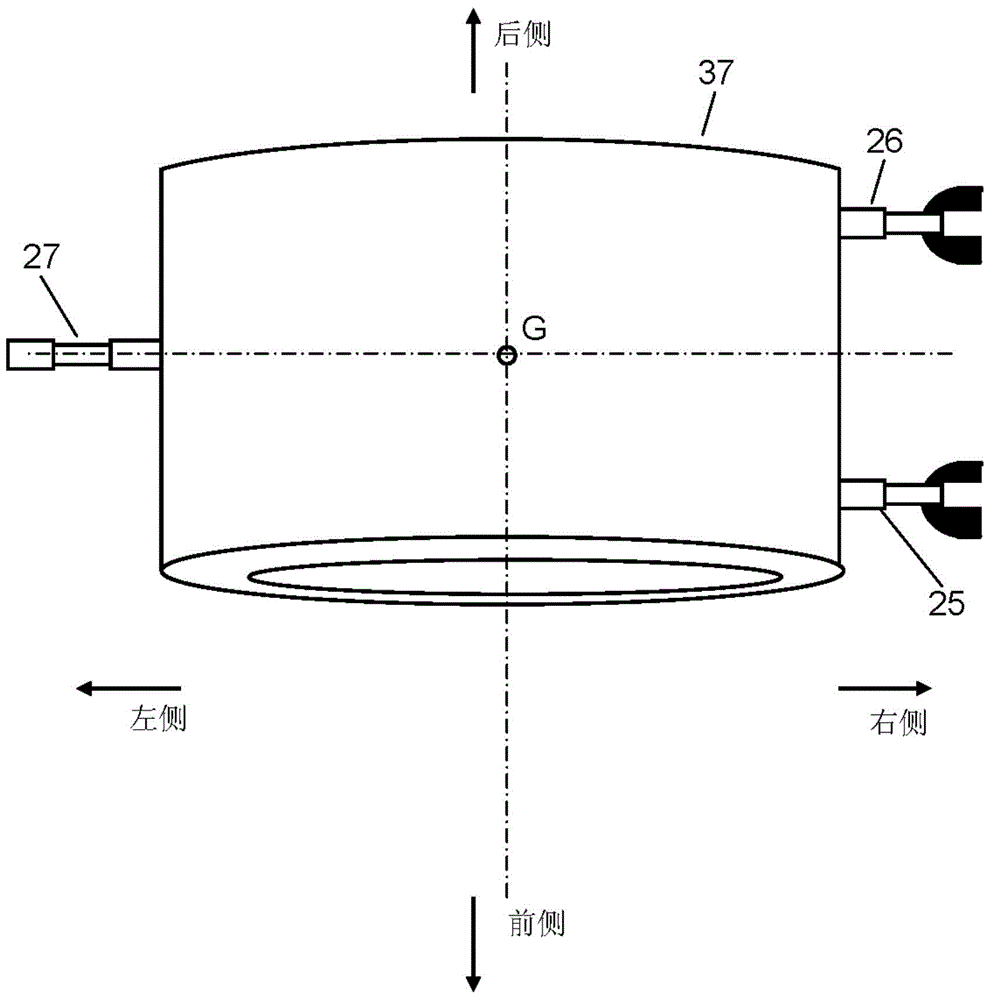

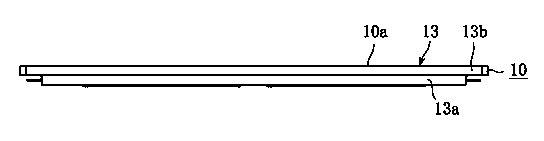

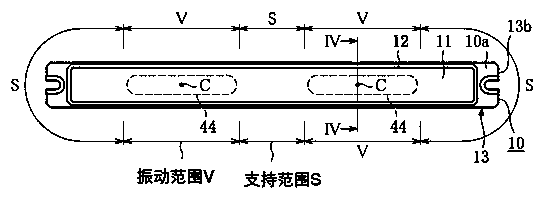

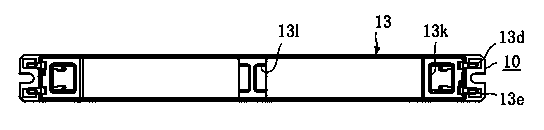

Front-loading-type Washing Machine

ActiveCN104420116AAchieve vibrationOther washing machinesWashing machine with receptaclesEngineeringFront loading

Multiple vibration isolating dampers have at least a first vibration isolating damper which is disposed in a direction in which a rotary drum is rotated during a spin-drying process and is arranged at a position close to a front surface side from a center of gravity of a water tub unit. In addition, the multiple vibration isolating dampers have at least a second vibration isolating damper which is disposed in the direction in which the rotary drum is rotated during the spin-drying process and is arranged at a position close to a rear surface side from the center of gravity of the water tub unit. In addition, the multiple vibration isolating dampers have at least a third vibration isolating damper which is arranged on an opposite side to the direction in which the rotary drum is rotated during the spin-drying process.

Owner:PANASONIC CORP

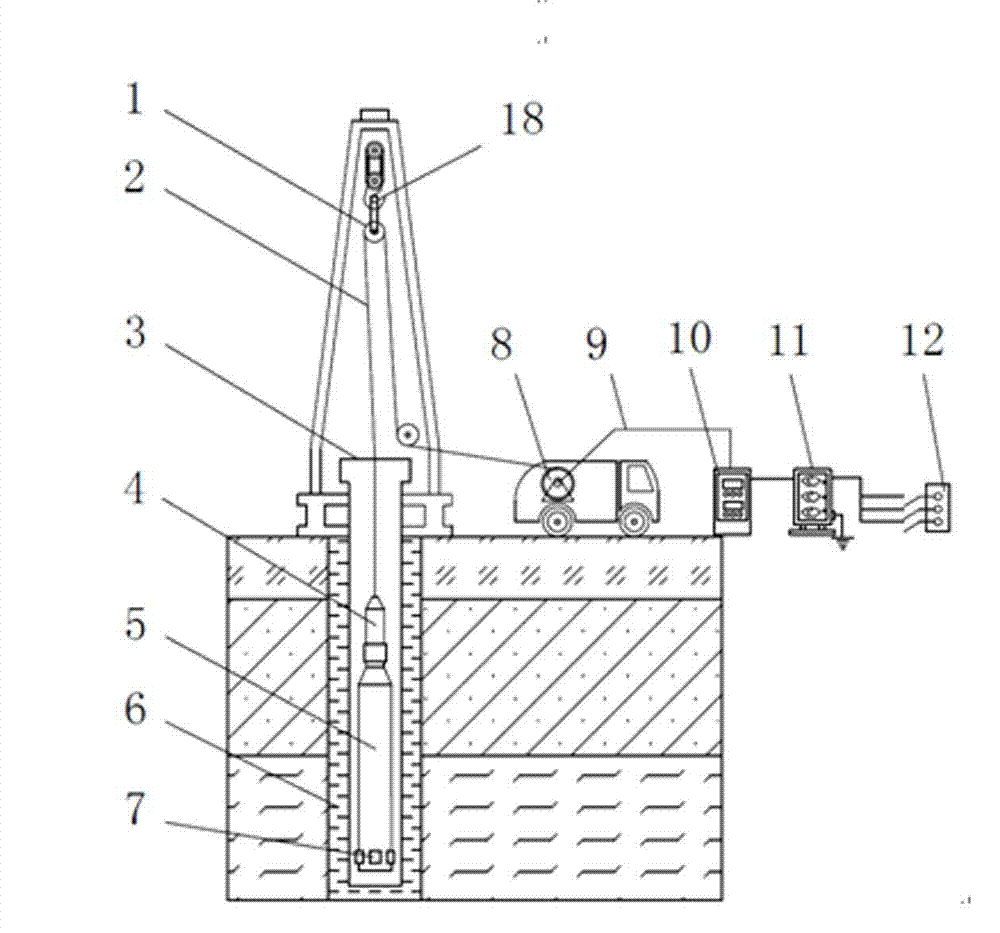

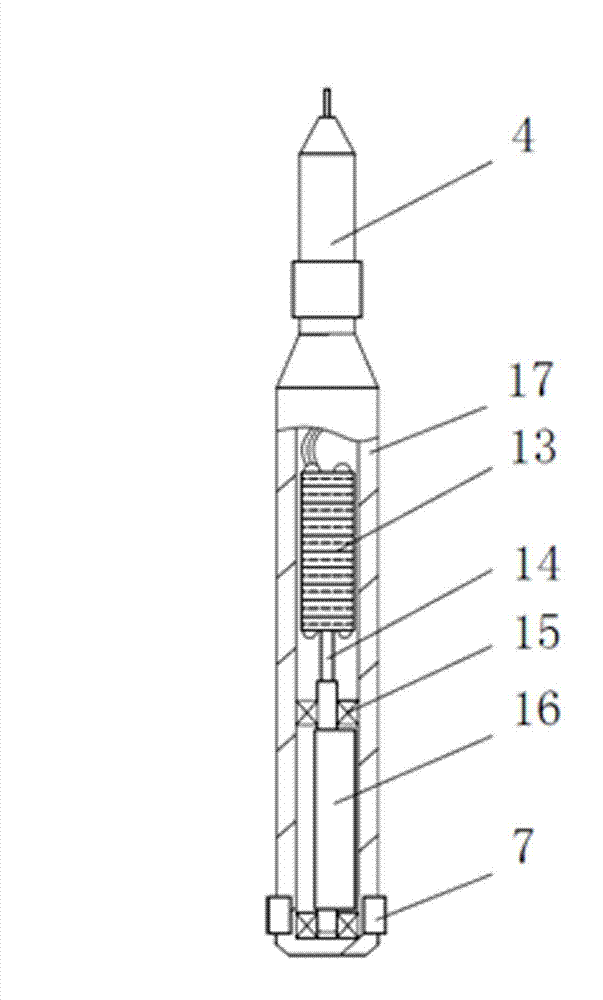

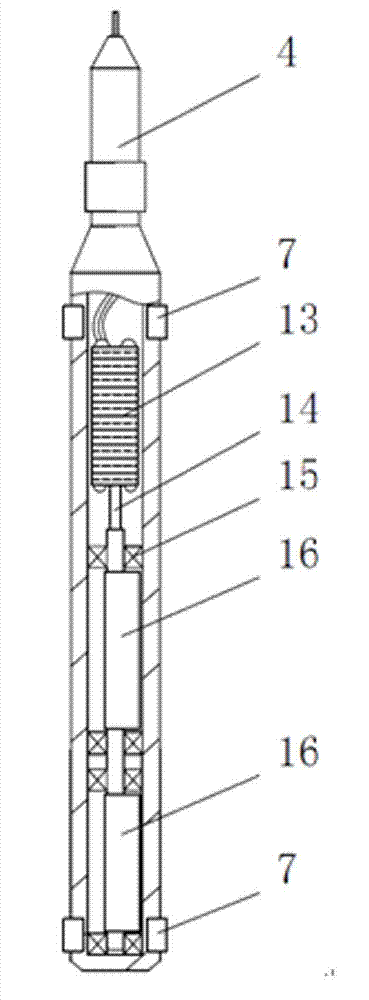

Vibration well cementation device and vibration well cementation method

The invention discloses a vibration well cementation device and a vibration well cementation method. The vibration well cementation device mainly comprises a cable, a transformer and a vibrator. The vibration well cementation method includes demounting a cement head after well cementation slurry is replaced and pressing is finished, and extending the vibrator and the cable into a casing; starting the transformer and the vibrator to vibrate in an appointed well depth; letting the vibrator to go up or down as vibrating; stopping vibration of the vibrator and lifting the vibrator out of a well mouth when initial solidification time of cement slurry of a vibrating layer is up. Under the condition of having no influence on conventional well cementation process, annulus cement slurry is vibrated within the full range of the casing by a manner of transmitting vibration wave and beating the casing during cementation, flowing deformation characteristics of the cement slurry are improved, and well cementation quality is improved.

Owner:CHINA PETROCHEMICAL CORP +1

Flat horn

ActiveCN103618979AUnbalanced controlAchieve ultra-thinPlane diaphragmsFrequency/directions obtaining arrangementsVibrating membraneSound wave

The invention relates to a flat horn including a supporting framework. The flat horn is characterized in that at least one sounding unit is disposed along the axial direction of the supporting framework; each the sounding unit is composed of a plane vibrating membrane emitting sound waves through vibration, a frame body mounted along the periphery of the plane vibrating membrane, and a drive device driving the plane vibrating membrane according to a sound signal; and two side edges of an open groove disposed in the supporting framework respectively have a non-contact space, each the non-contact space is a corner cut disposed in the bottom, along an outside edge, of the open groove disposed in the supporting framework, and the frame body mounted along the periphery of the plane vibrating membrane is adhered to the open groove disposed in the supporting framework. The flat horn has good output frequency characteristic, can achieve an ultrathin structure in condition of large input power, and the sound propagation has the directional property of being forward.

Owner:谭菊花

Layered grinding equipment

The invention discloses layered grinding equipment. The layered grinding equipment comprises a shell body which is provided with a feeding inlet, a discharging outlet and a grinding and pressing channel. The grinding and pressing channel is internally provided with grinding and pressing rollers, and rotating shafts connected with the grinding and pressing rollers, and a partition plate is arranged in the middle of the grinding and pressing channel. The direction of the partition plate is the same as that of the grinding and pressing channel. The grinding and pressing channel is divided into an upper grinding cavity and a lower grinding cavity through the partition plate. Screen nets are uniformly arranged on the partition plate. The grinding and pressing rollers comprise the upper-layer grinding and pressing roller and the lower-layer grinding and pressing roller. The rotating shafts comprise the upper-layer rotating shaft and the lower-layer rotating shaft. The feeding inlet communicates with the upper grinding cavity. The discharging outlet communicates with the lower grinding cavity. The shell body is provided with an upper driving motor and a lower driving motor. According to the layered grinding equipment, the structure is simple, operation is convenient, grinding is conducted through the up-down two-layer structure, and the situation of insufficient grinding can be effectively avoided; accordingly, regrinding is avoided, human and material resources are saved, and the machining cost is greatly reduced; and the using stability is good, the applicability is high, and the practicality is good.

Owner:陕西阿姑农业发展有限公司

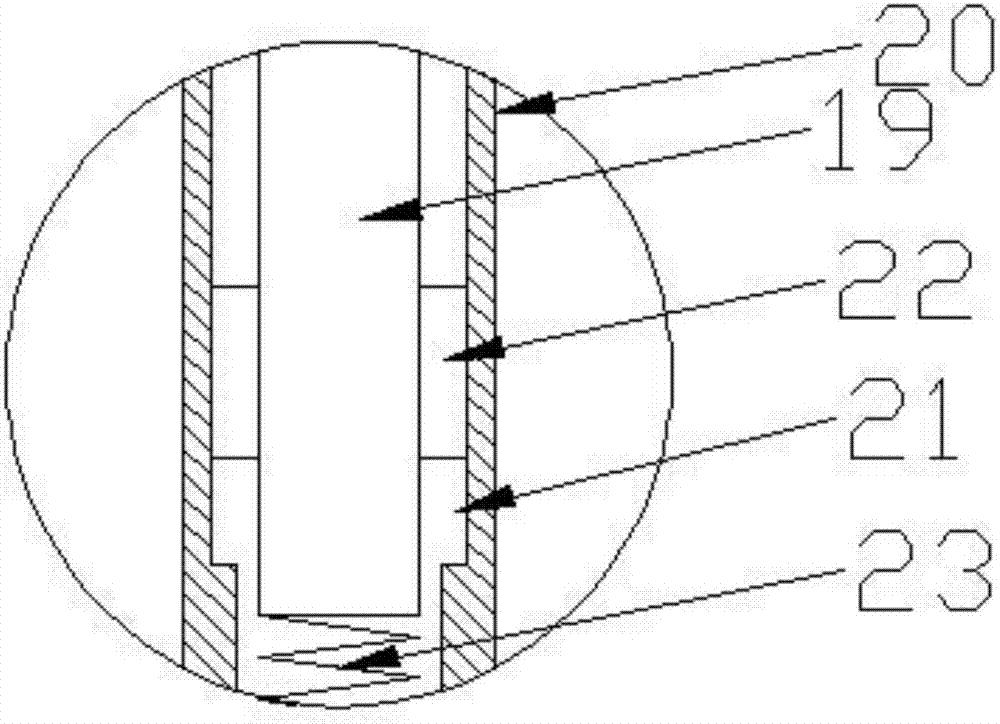

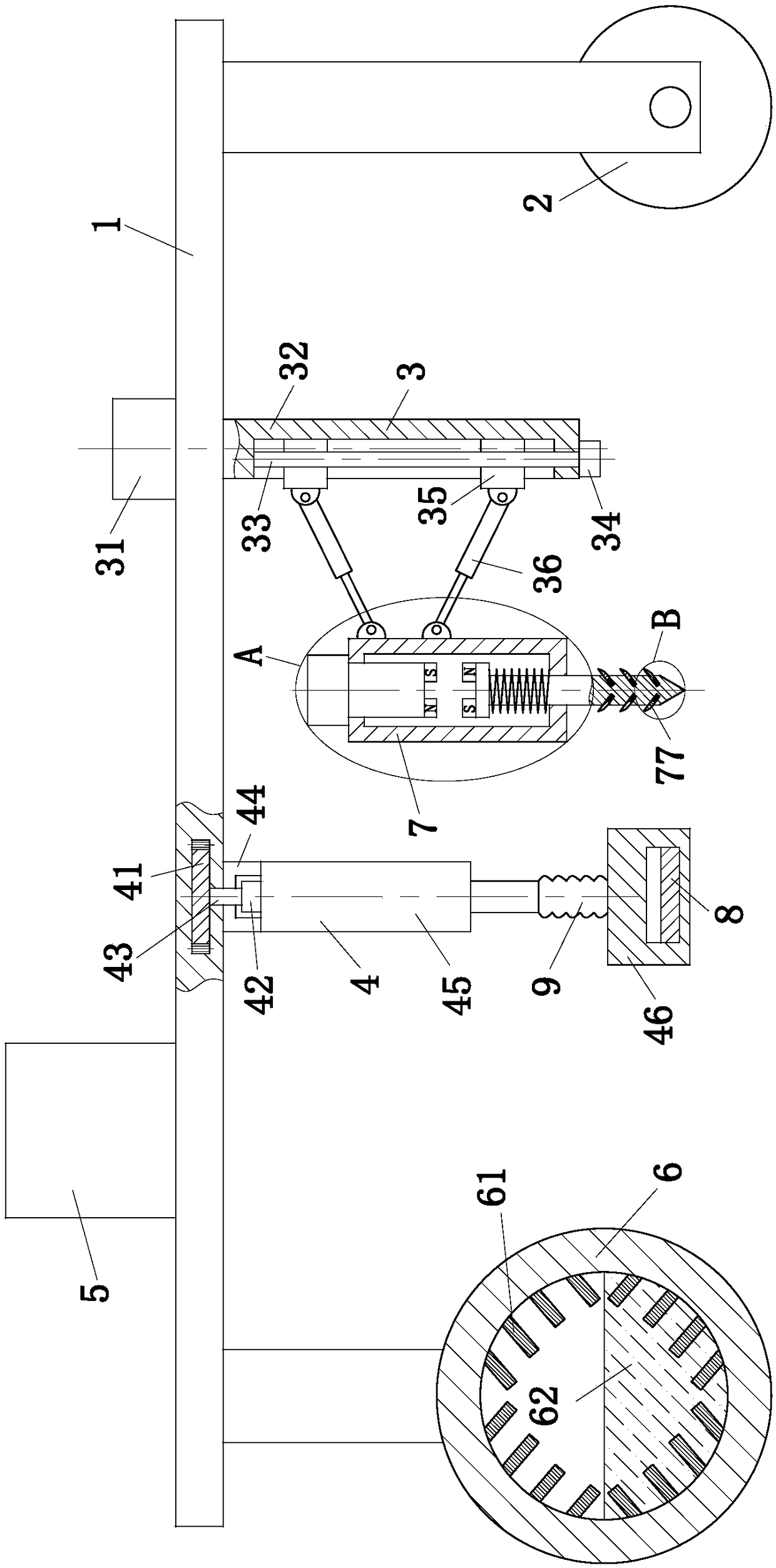

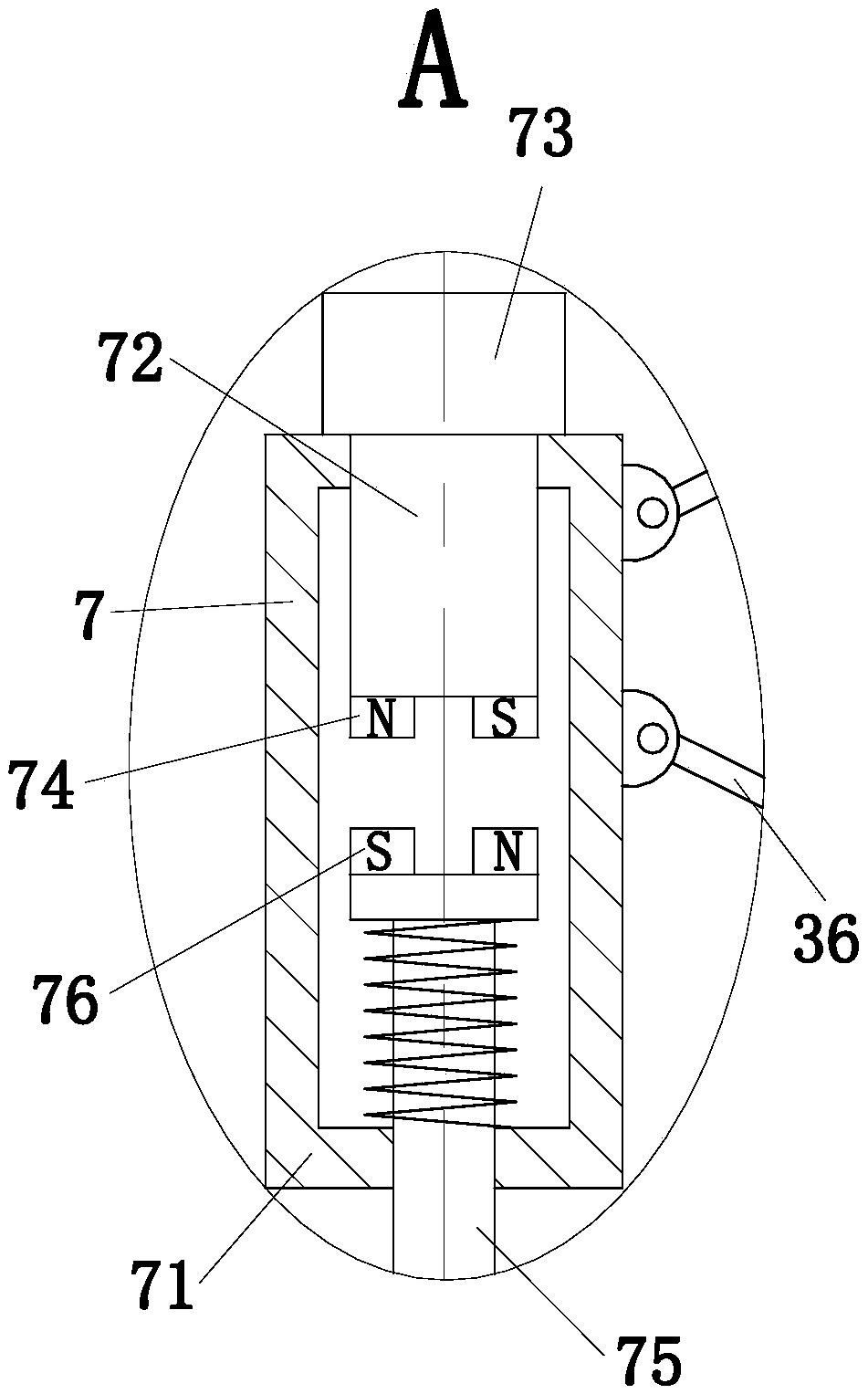

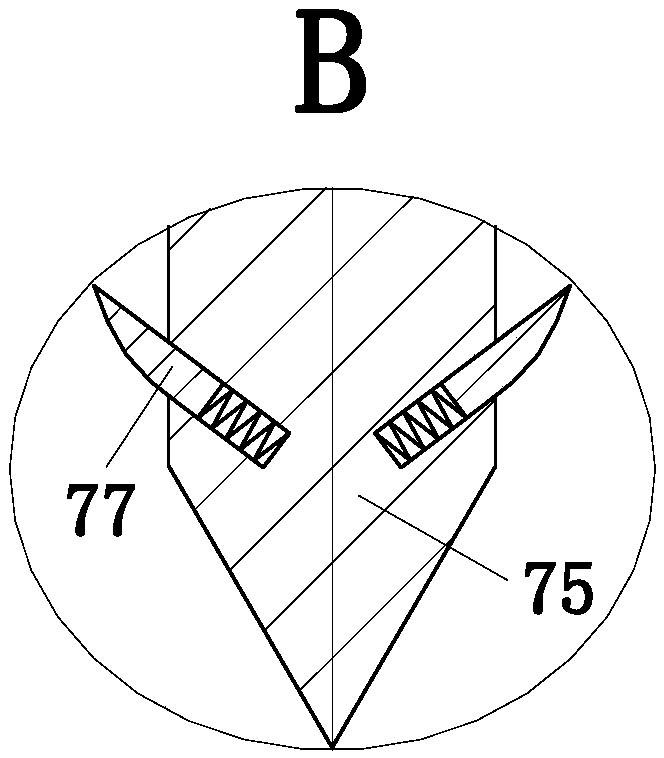

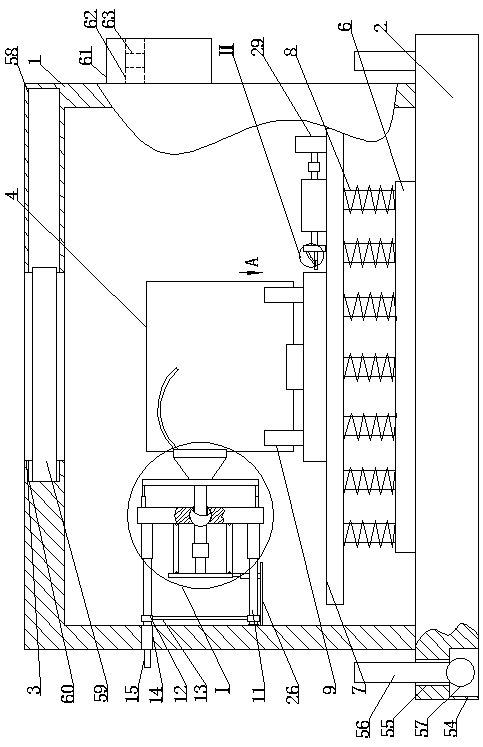

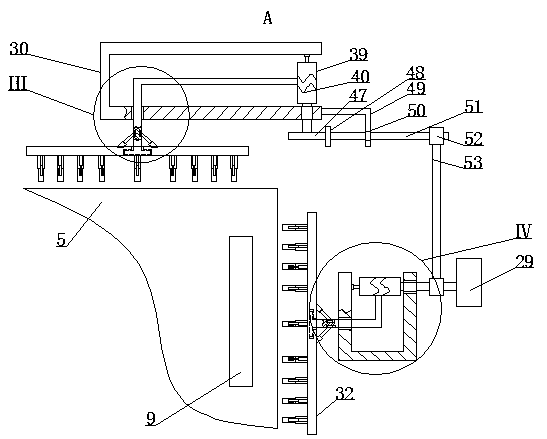

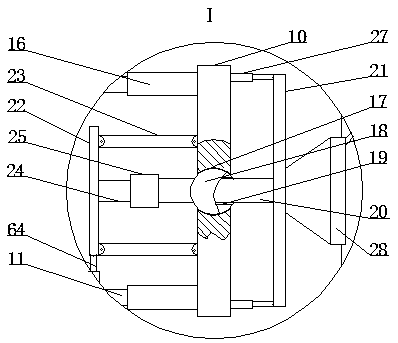

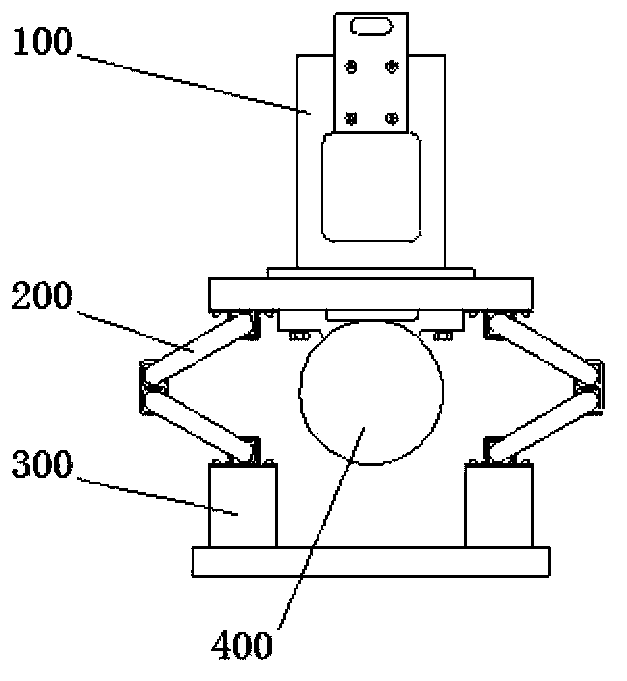

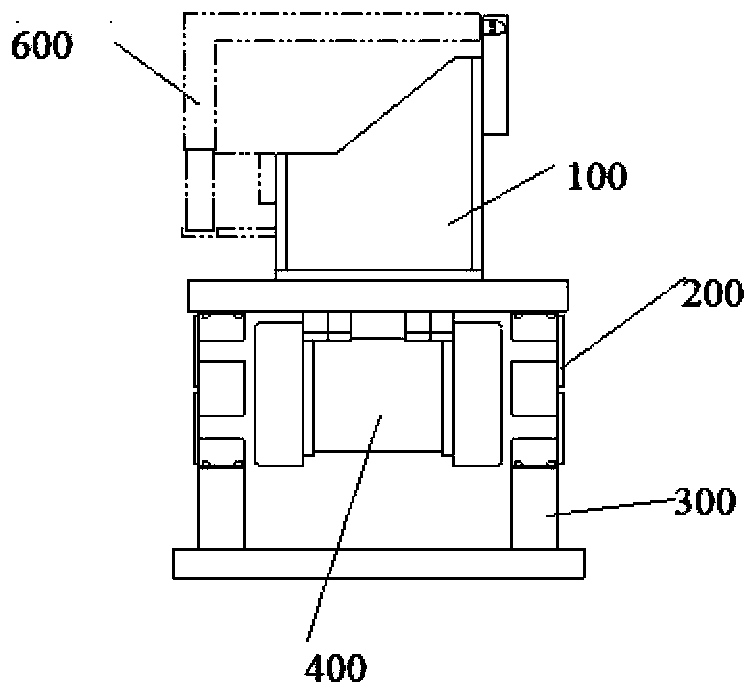

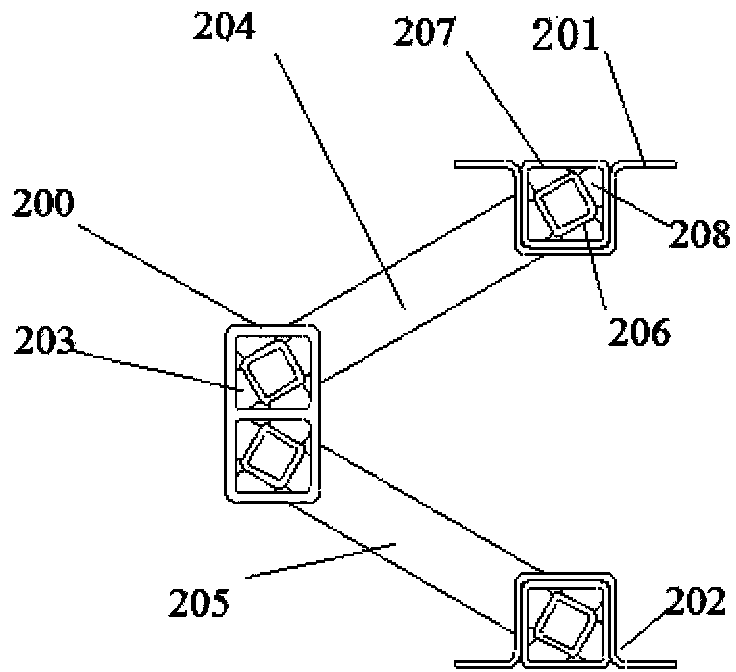

Vibration test simulator for levitation sensor of high-speed maglev train

The invention discloses a vibration test simulator for a levitation sensor of a high-speed maglev train. The vibration test simulator is used for a vibration test on the levitation sensor of the high-speed maglev train and mainly composed of a sensor mounting base (100), damping devices (200), a base (300) and a vibration motor (400). The upper portion of the sensor mounting base is used for mounting of the levitation sensor, and the vibration motor is arranged on the lower portion of the sensor mounting base. The damping devices are arranged between the sensor mounting base and the base and located on the four corners of the sensor mounting base respectively. Each damping device is composed of two independent square casing connection joints at the two ends, a parallel-connection square casing connection joint in the middle and supporting rods supported between the square casing connection joints. While achieving vibration of the levitation sensor, the vibration test simulator adjusts the shock insulating effect through the damping devices to simulate the shaking working conditions of the sensor more finely.

Owner:SOUTHWEST JIAOTONG UNIV

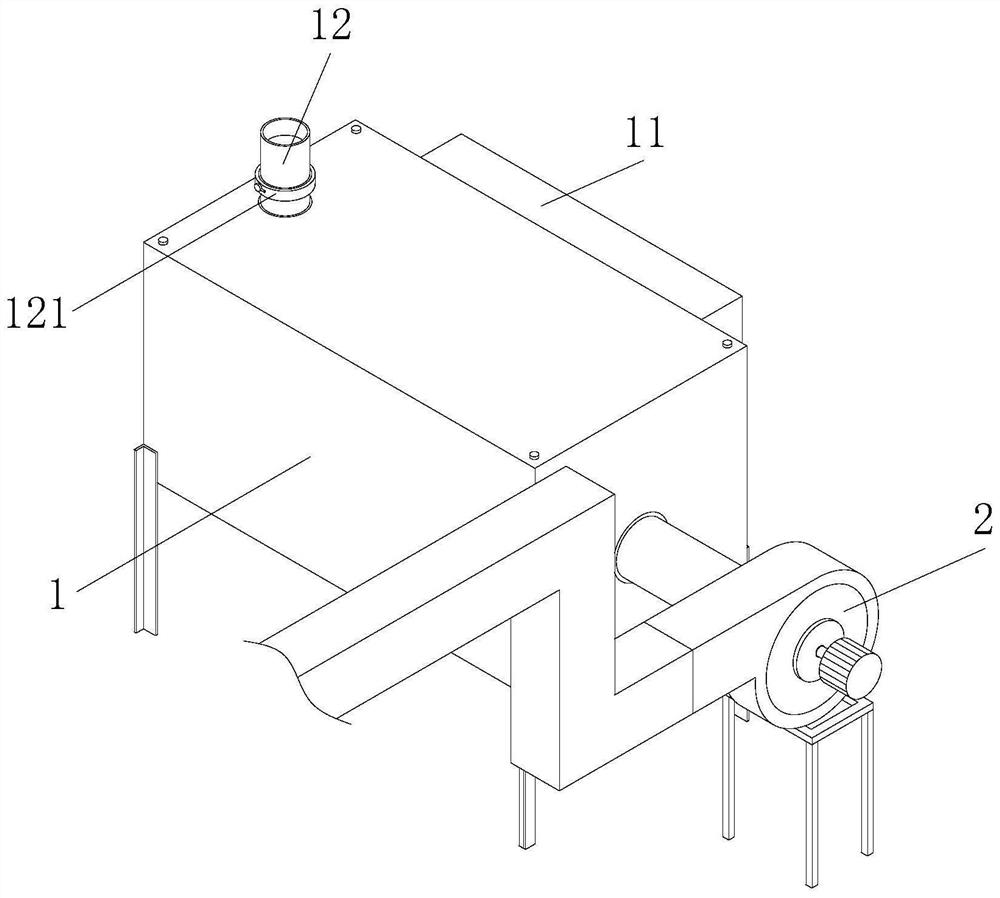

Automatic lubricating equipment for textile yarns

The invention discloses automatic lubricating equipment for textile yarns, and belongs to the technical field of textile equipment. The equipment comprises a lubricating assembly, a residual liquid removing assembly and a bearing frame, an upper winding roller is arranged on the bearing frame, the lubricating assembly comprises an oil outlet component, a gantry frame and a bearing platform, the oil outlet component comprises a heating cylinder, a buffer part, an oil outlet hopper, a limiting disc and a lifting part, the oil outlet hopper communicates with the interior of the heating cylinder,the bottom of the oil outlet hopper is provided with an oil outlet hole, and the bottom of the limiting disc is provided with a curve chamfer. Lubricating operation for the yarns can be achieved through the lubricating assembly, residual lubricating oil stuck on the yarns can be removed through the residual liquid removing assembly, lubricating oil can be vibrated through a vibration component, anair blower can be matched with the vibration component, and lubricating oil stuck on the yarns can fall down to an oil storage tank.

Owner:扬州金晟华线业有限公司

Smoke dust removal equipment for waste incineration

InactiveCN112007449AAchieve vibrationAvoid cloggingDispersed particle filtrationLighting and heating apparatusFiltrationElectric machine

The invention provides smoke dust removal equipment for waste incineration. The smoke dust removal equipment comprises a dust collecting box, a dust suction fan is arranged in front of the dust collection box, a first filter screen, a second filter screen and a third filter screen are arranged on the inner side of the dust collecting box, a protective cover is arranged on one side of the dust collecting box, an anti-blocking assembly is arranged on the inner side of the protective cover, the anti-blocking assembly comprises a driving motor, a straight gear is arranged on an output shaft of thedriving motor, one side of the straight gear is engaged with a sector gear, one side of the sector gear is provided with a first rotating shaft and two second rotating shafts, one end of the first rotating shaft and one ends of the second rotating shafts are each provided with a connecting block, one side of each connecting block is provided with a connecting rod, and one end of each connecting rod is provided with a beating ball. Through the dust suction fan, the first filter screen, the second filter screen and the third filter screen, multi-stage filtration of dusty air is achieved, vibration of the filter screens is achieved through the anti-blocking assembly, the filter screens can be effectively prevented from being blocked, and the dust removal effect is improved.

Owner:浙江万源环保机械科技有限公司

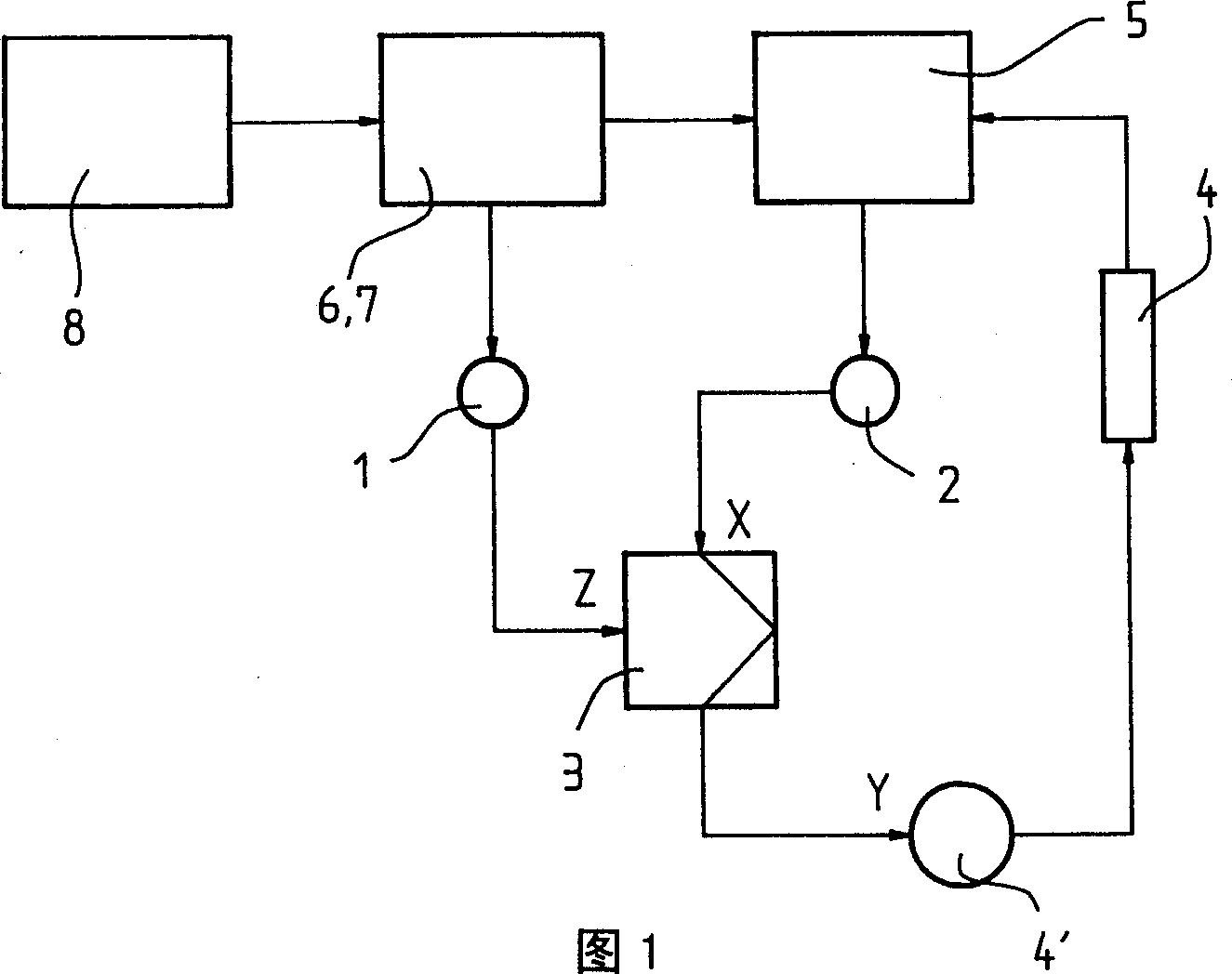

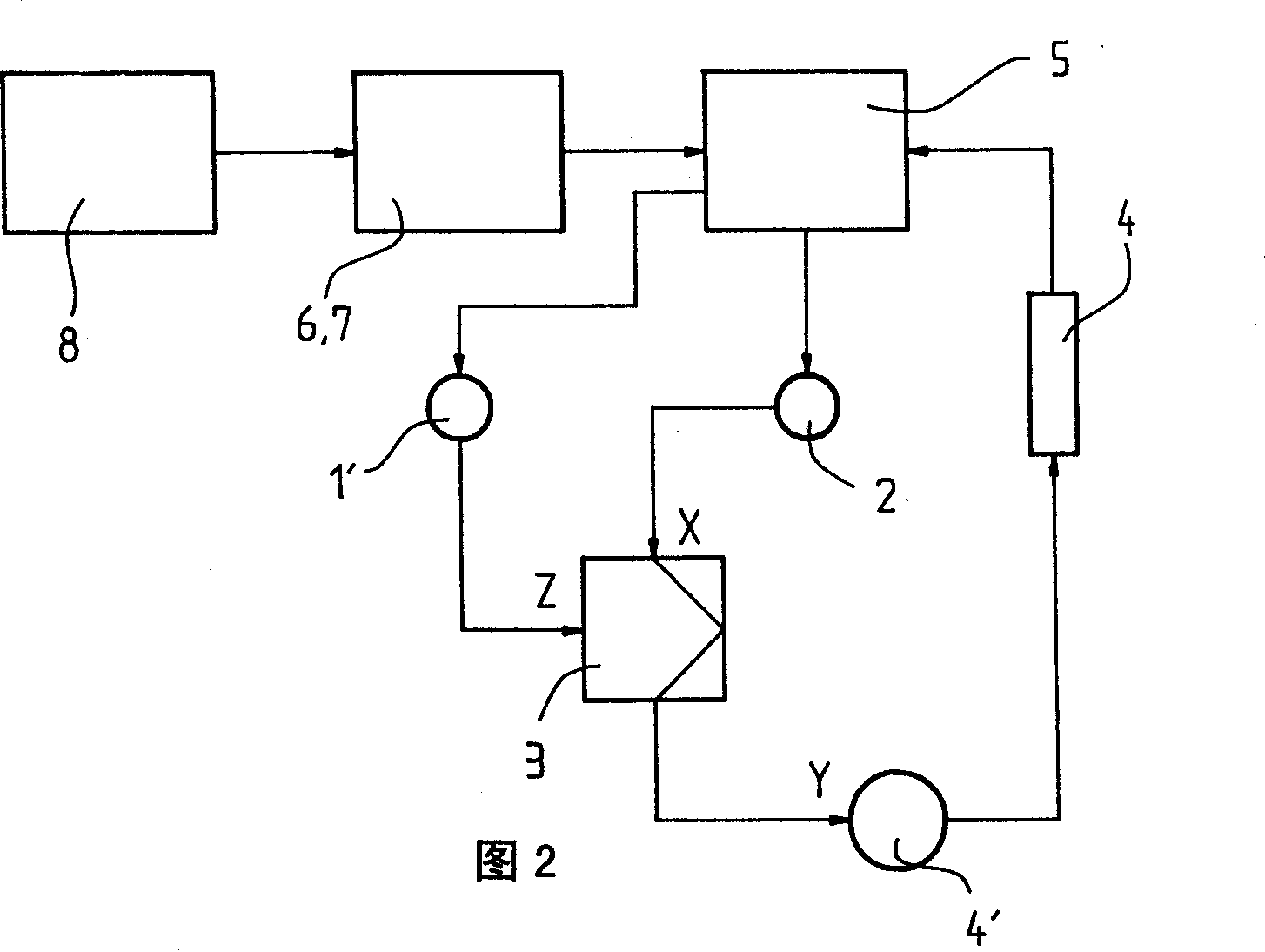

Method and system for compensating shock of elevator car

The present invention relates to a method and system for compensating vibrations in an elevator car (5), which elevator car (5) is guided on at least one guiderail (7), vibrations being detected by at least one first sensor (1, 1') at a source of disturbance (8), vibrations being detected by at least one second sensor (2) at the affected point on the elevator car (5), the detected vibrations being interpreted by a controlling means (3), a compensating mass 4 being systematically activated by the controlling means (3), and detected vibrations being neutralized by a.compensating force of opposite sign and equal amount.

Owner:INVENTIO AG

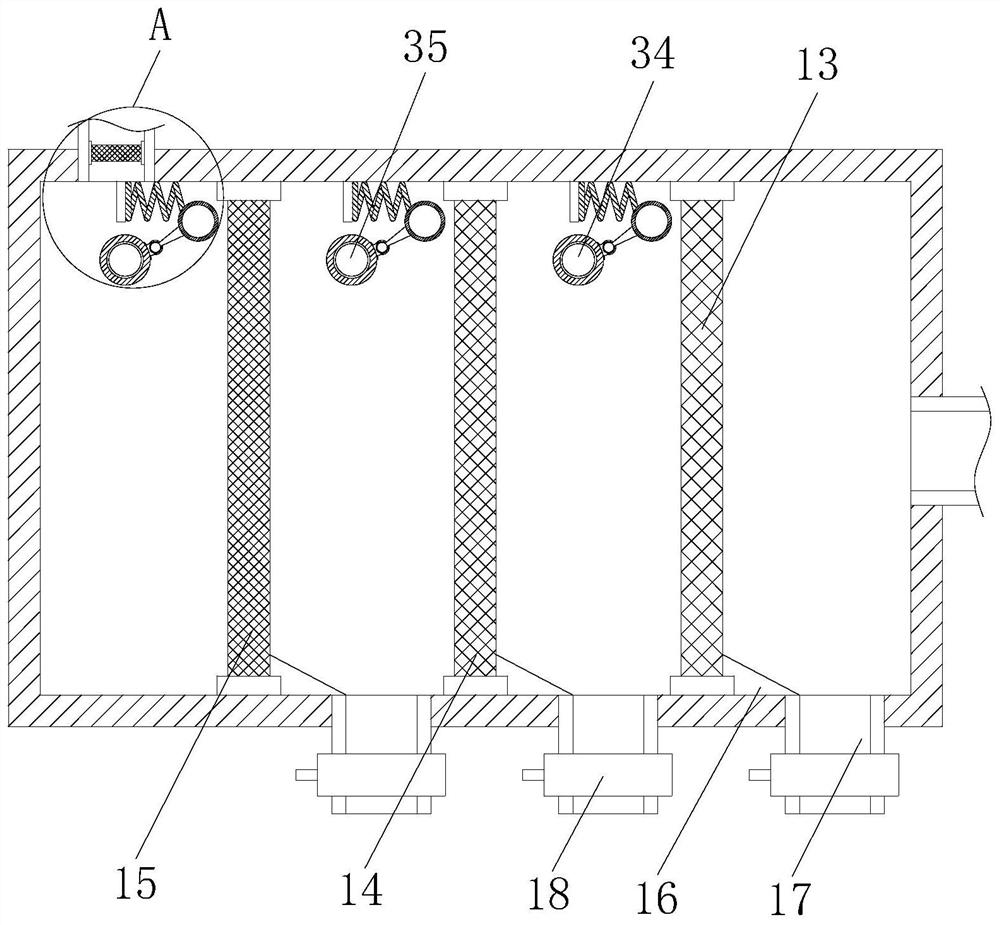

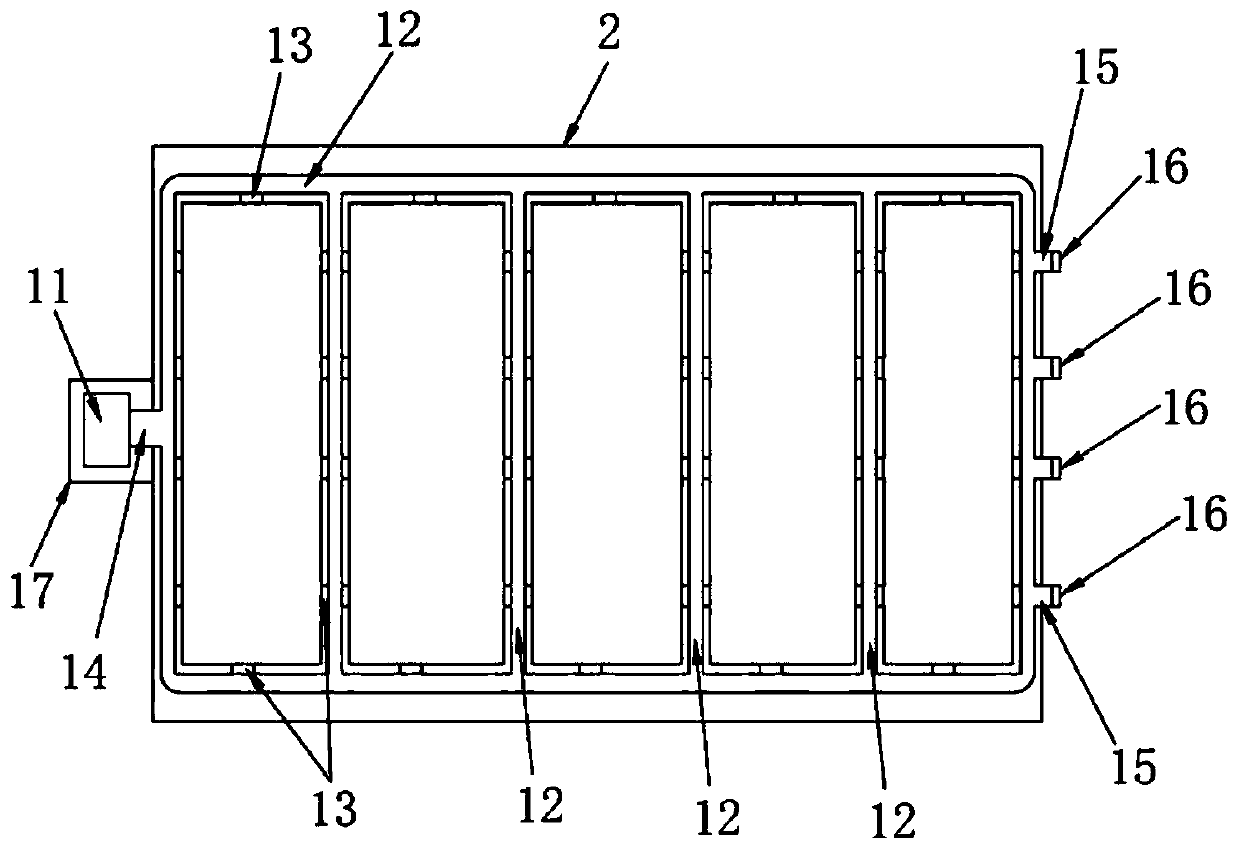

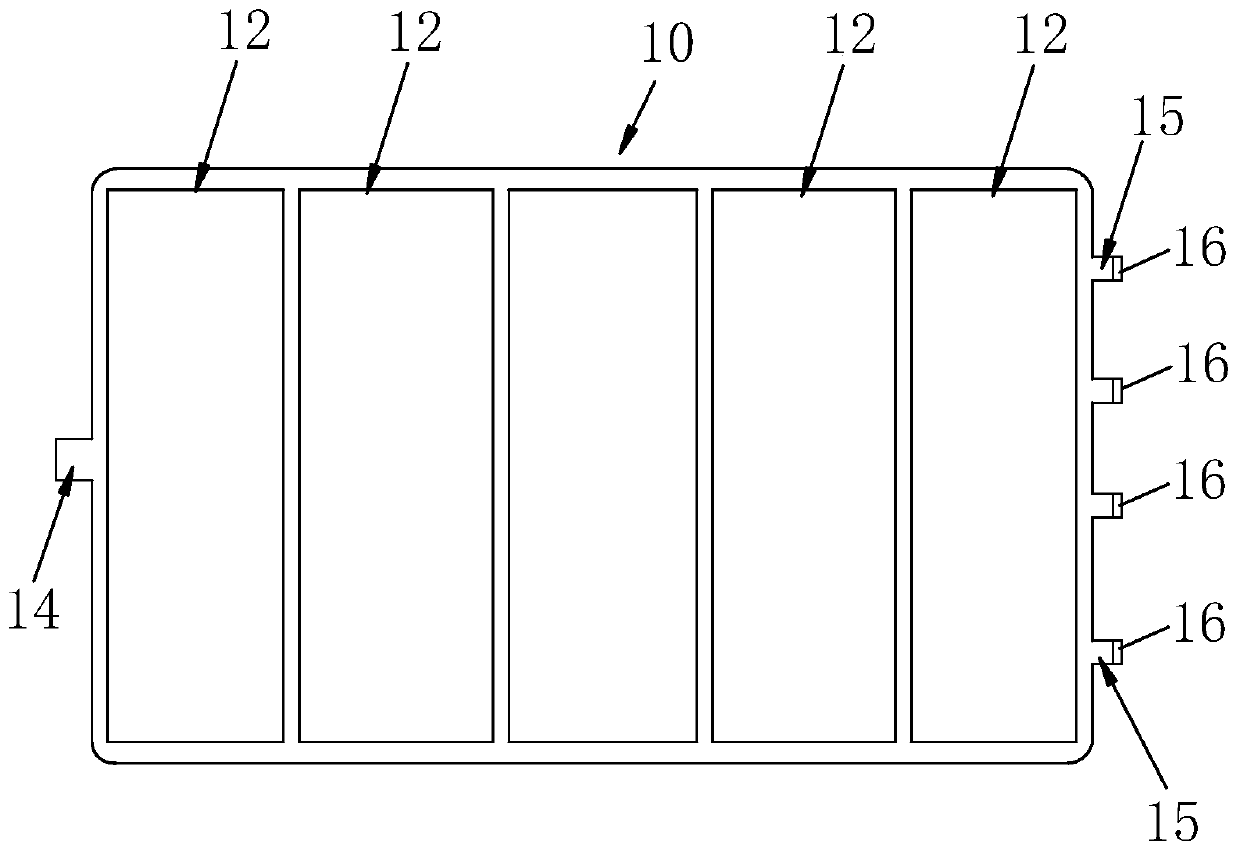

Heat dissipation type vibration-proof new energy battery device

InactiveCN110061163ARealize moving up and downEffective flow throughBattery isolationSecondary cellsElastic componentNew energy

The invention relates to the technical field of batteries, in particular to a heat dissipation type vibration-proof new energy battery device. The heat dissipation type vibration-proof new energy battery device comprises a base, wherein a box is arranged on the base; the box is internally provided with a plurality of spacer plates in a uniformly-spaced mode from left to right, and a battery cavityis formed between every two adjacent spacer plates; fixed blocks are arranged on two sides of the box respectively, and sliding supporting plates are arranged on two sides of the base respectively; aplurality of elastic blocks are arranged at the bottom of the box in the uniformly-spaced mode, and an elastic component is arranged between every two adjacent elastic blocks; the box is provided with two groups of heat dissipation components at intervals from top to bottom, and each annular sleeve is arranged on the periphery of the corresponding battery cavity in a sleeving mode respectively; an air suction nozzle is arranged at one end of a heat dissipation sleeve, an air suction port of a micro air suction machine is communicated with the air suction nozzle, a plurality of air inlet nozzles are arranged at the other end of the heat dissipation sleeve, and each air inlet nozzle is provided with a filter screen. According to the heat dissipation type vibration-proof new energy battery device, the vibration can be reduced, the stability is high, and a vibration-proof effect is achieved; the ventilation effect and heat dissipation effect can be improved, and the annular sleeves are prevented from being blocked by dust to influence the heat dissipation effect.

Owner:GUANGDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com