Patents

Literature

293results about How to "Solve cleaning difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

All-in-one machine for shell fabric washing and drying

ActiveCN103409960ASimple structureWash and rinse thoroughlyTextile treatment machine partsDrive motorWater washing

The invention provides an all-in-one machine for shell fabric washing and drying, and belongs to the technical field of machines. The all-in-one machine solves the technical problems that shell fabric is incapable of being washed, dried and collected at one time after being woven. The all-in-one machine for shell fabric washing and drying comprises a base, wherein the base is provided with a washing box; the box body of the washing box is partitioned into a washing tank and a bleaching tank through a partition board in the middle part of the washing box; two ends of the washing box are respectively provided with a shell fabric inlet I and a shell fabric outlet II; the inner wall of the washing box is provided with a washing roller I and a washing roller II which are parallel to each other; the washing roller I and the washing roller II are both positioned in the washing tank; the washing roller I is driven by a driving motor I; the base is further provided with a drying box; a shell fabric collecting device is arranged between the drying box and the base; the base is further provided with a shell fabric collecting box. The all-in-one machine has the advantages that the shell fabric can be washed, dried, collected and the like at one time.

Owner:ZHEJIANG HUAYUAN TEXTILE

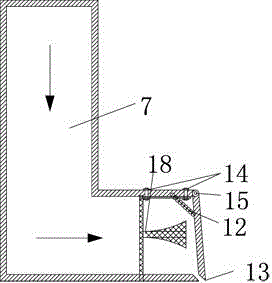

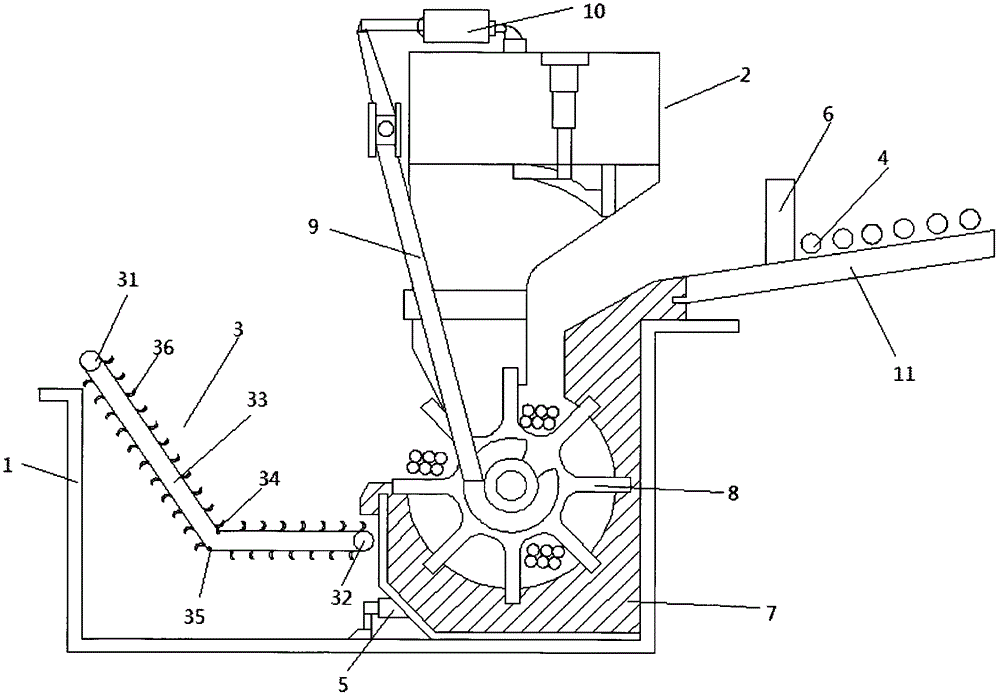

Grating garbage removing device for sewage treatment

ActiveCN107185280ASolve problems that require manual workImprove work efficiencySpecific water treatment objectivesTreatment involving filtrationGratingCoupling

The invention discloses a grating garbage removing device for sewage treatment. The device comprises a fixing box, a first motor is fixedly connected to the bottom of the fixing box through a support, and the output shaft of the first motor is fixedly connected with a first belt pulley through a coupling; a second belt pulley is connected to the surface of the first belt pulley through belt transmission, and a rotating shaft penetrates the middle portion of the second belt pulley; a threaded rod is fixedly connected to the top end of the rotating shaft, a sleeving pipe is connected to the surface of the threaded rod in a threaded mode, and a filtering plate is connected to the top end of the sleeving pipe through a movable part in a rotating mode. The invention relates to the technical field of sewage treatment. By means of the grating garbage removing device for the sewage treatment, the problem that currently, garbage on a grating for sewage treatment needs treating by labor is solved, the working efficiency of the sewage treatment equipment is improved, the work amount of people is reduced, the workload of people is relieved, the mechanical cleaning effect is good, and an influence on the sewage treatment is avoided.

Owner:SHANDONG LANCHUAN ENVIRONMENTAL PROTECTION CO LTD

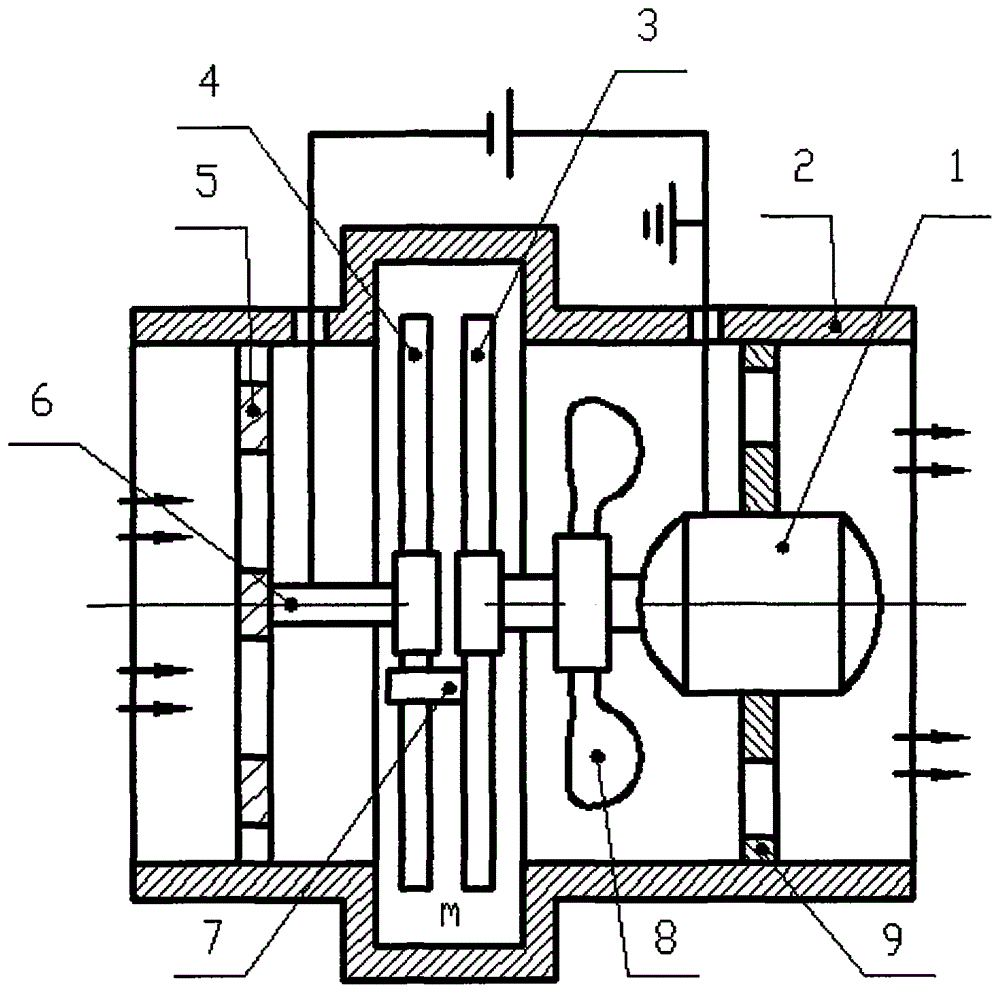

Airflow blow and suction vibration cleaning method and device of engine cylinder cover

ActiveCN101865029AGet over stuckOvercoming the Difficulty of Depositing in Narrow Cavity BendsMachines/enginesEngine componentsEngineeringContract type

The invention relates to airflow blow and suction vibration cleaning method and device of an engine cylinder cover. The device comprises a Venturi tube. Air outlet pipelines are arranged in the expanding section and / or shrinkage section of the Venturi tube; the air outlet pipelines are communicated with an intake pipe; and the air outlets of the air outlet pipelines face the media flowing direction of the Venturi tube. By utilizing the device, two-direction alternate blow and suction cleaning is realized on box parts, such as the engine cylinder cover and the like, the problem that aluminium skimming jam and deposit at contracted type cavity bends, caused by the unidirectional characteristic of the traditional cleaning process, is solved, the cleaning problem of the aluminium skimmings iseffectively solved, and the cleanness demand of the product is satisfied.

Owner:DONGFENG PEUGEOT CITROEN AUTOMOBILE

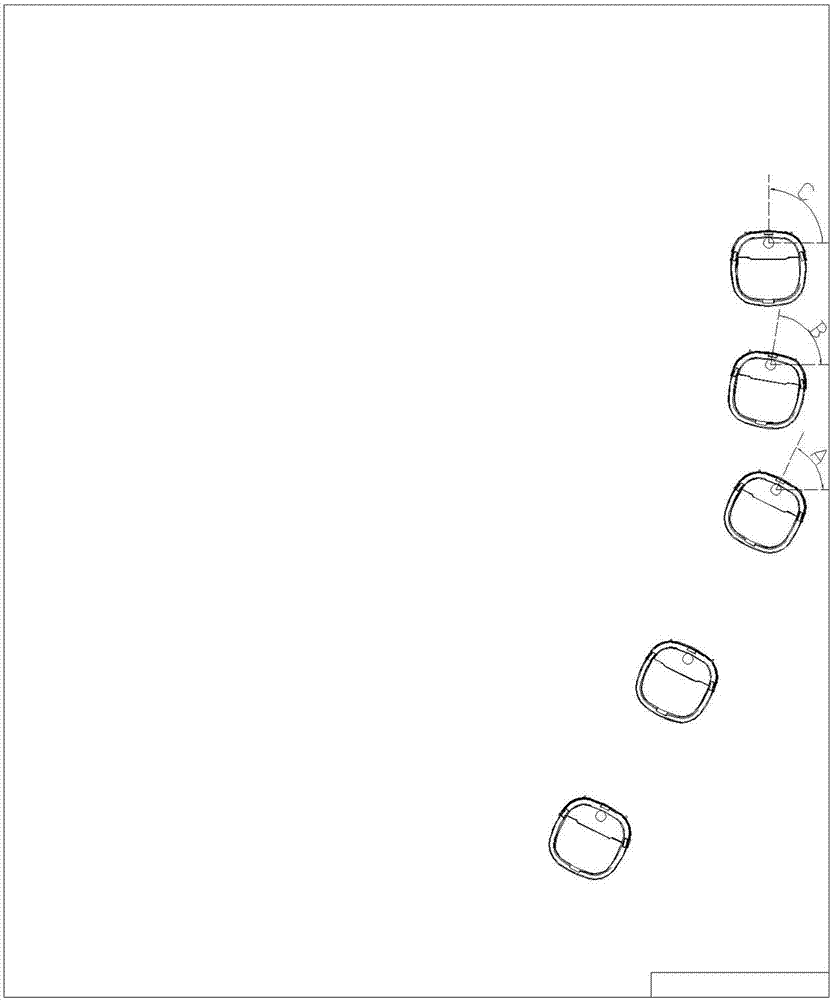

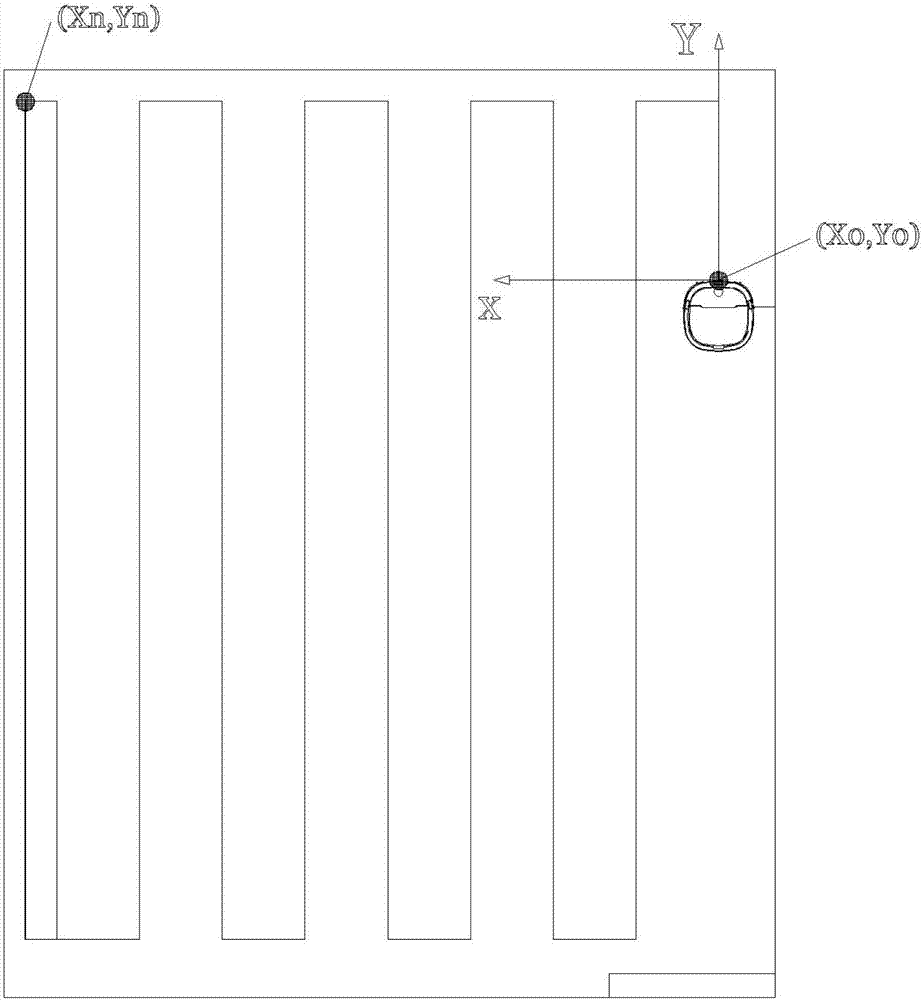

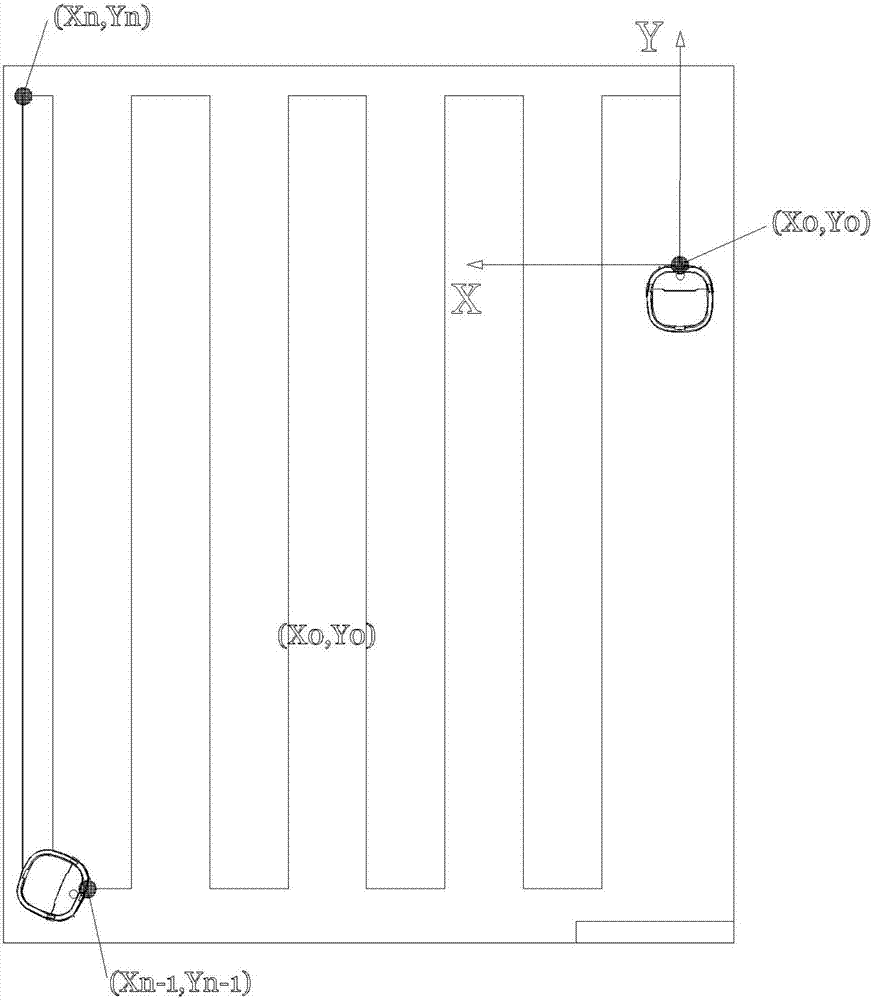

Intelligent cleaning device and grid path working method thereof

ActiveCN106970623AImprove cleaning efficiency and coverageAvoid improper cleaningPosition/course control in two dimensionsVehiclesGyroscopeComputer module

The invention provides an intelligent cleaning device and a grid path working method thereof. The cleaning device comprises a primary Chinese character gong-shaped cleaning mode, a secondary Chinese character gong-shaped cleaning mode and a wall-following cleaning mode. A gyroscope module transmits angle signals of the intelligent cleaning device and a wall body to a driving module. The driving module controls a walking module to finish grid-type cleaning. Thus, high cleaning rate can be ensured; overlapping rate of the cleaning is reduced; and compared with the former cleaning methods, the provided method has quite good effects.

Owner:杭州匠龙机器人科技有限公司

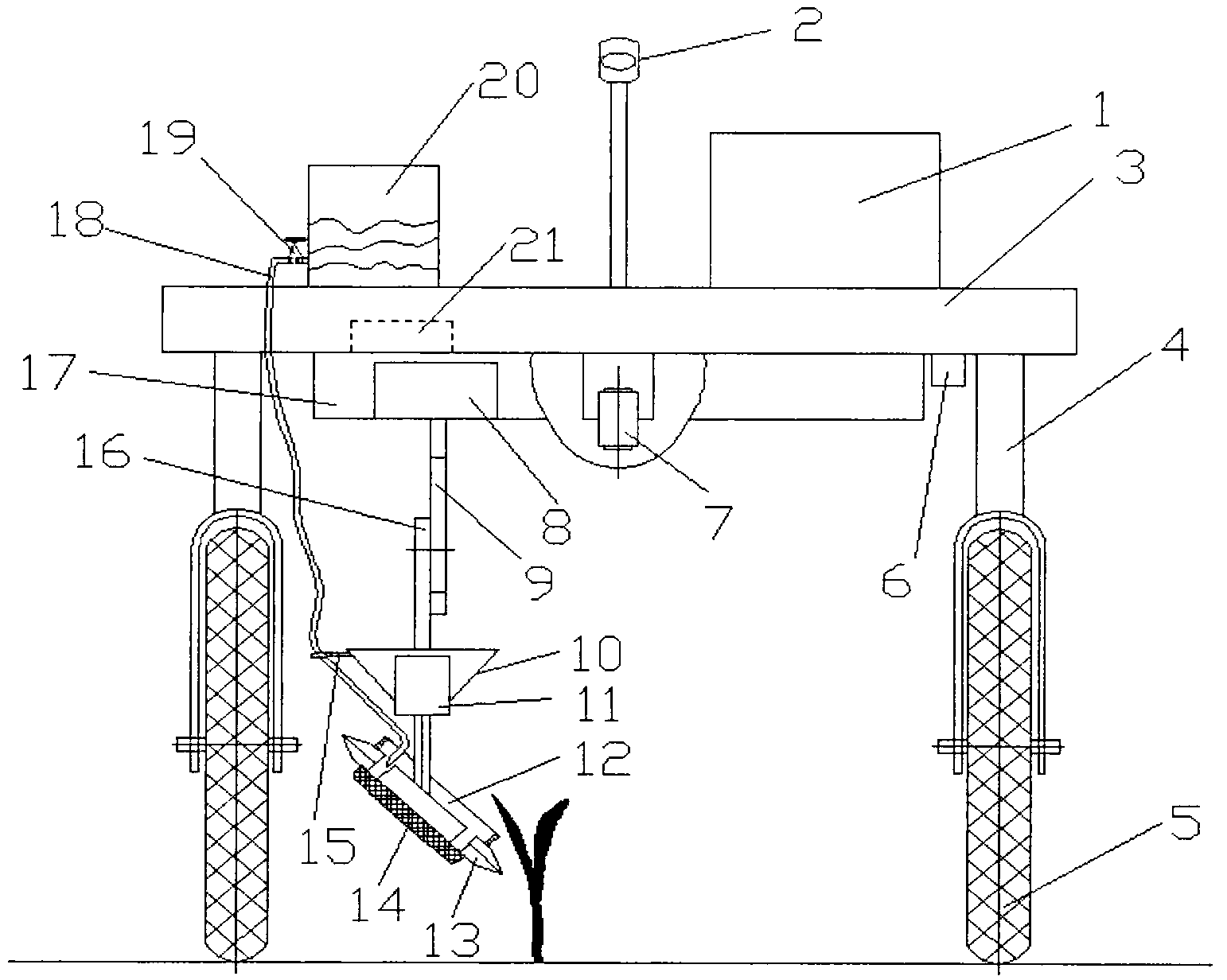

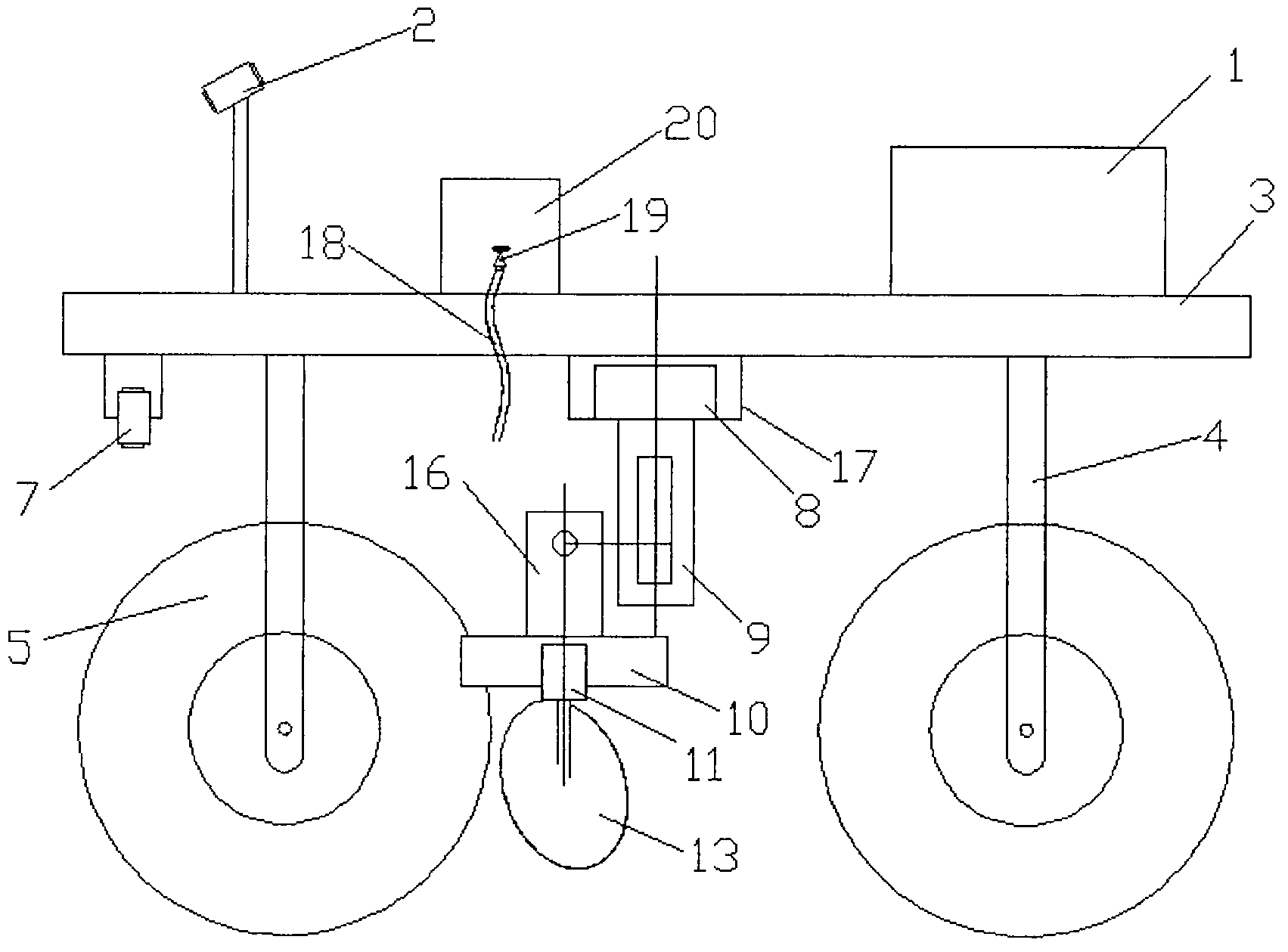

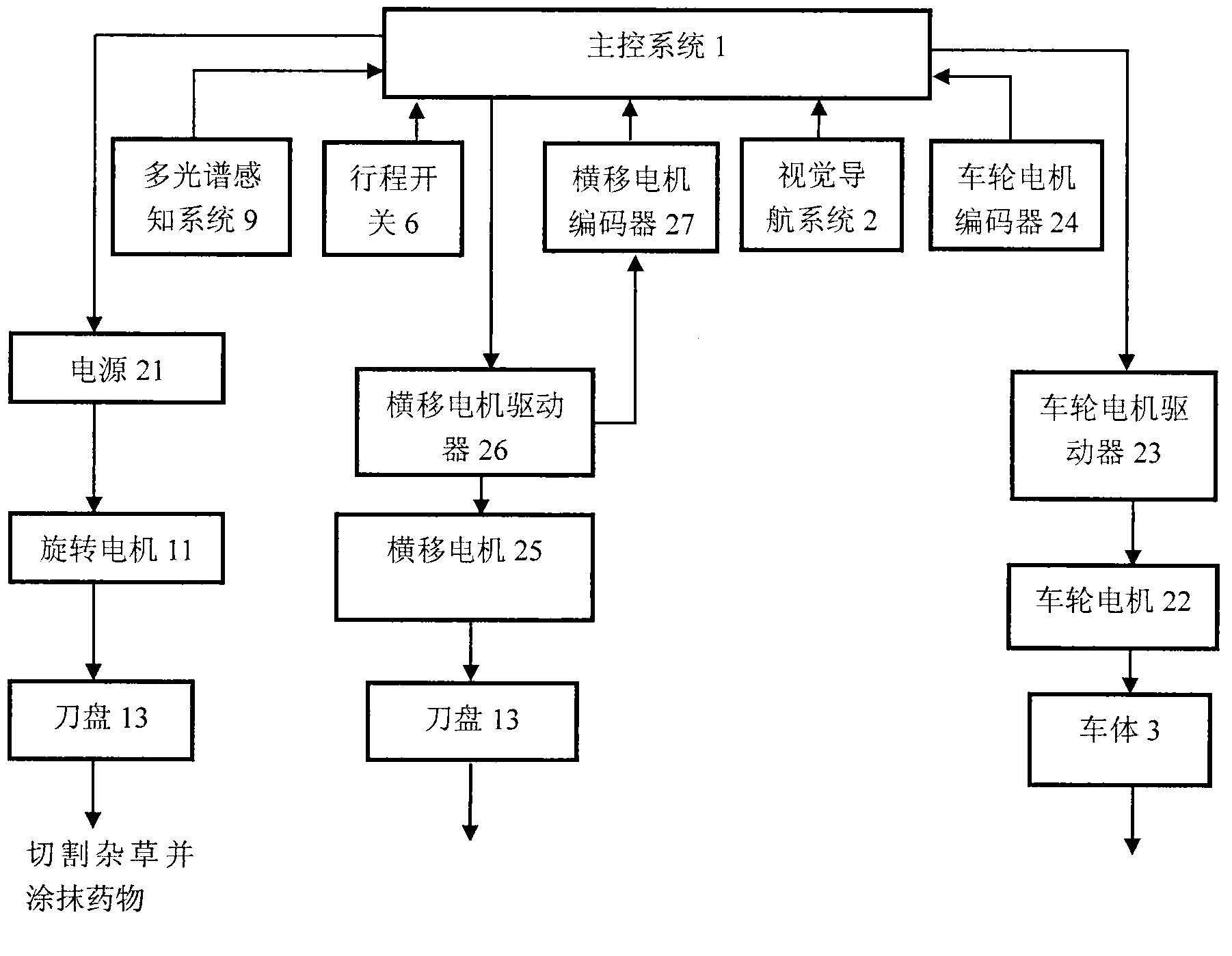

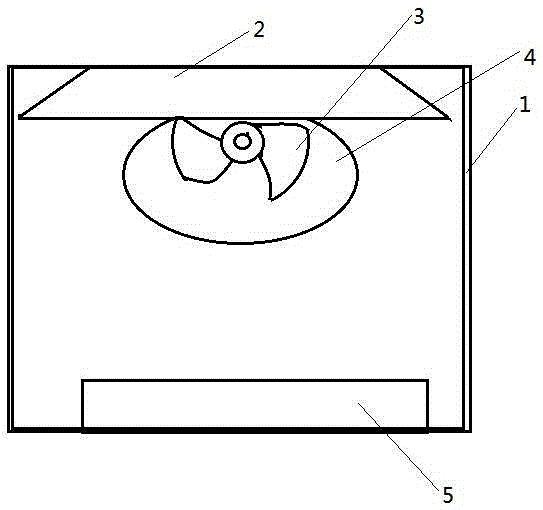

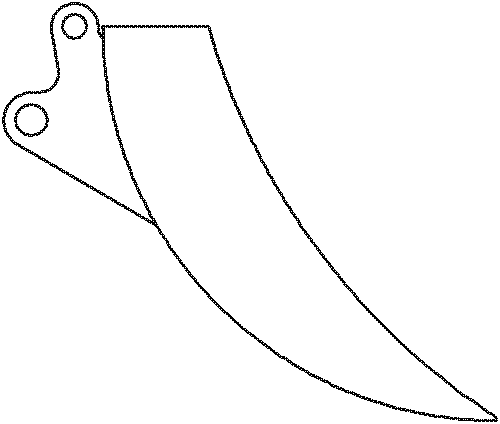

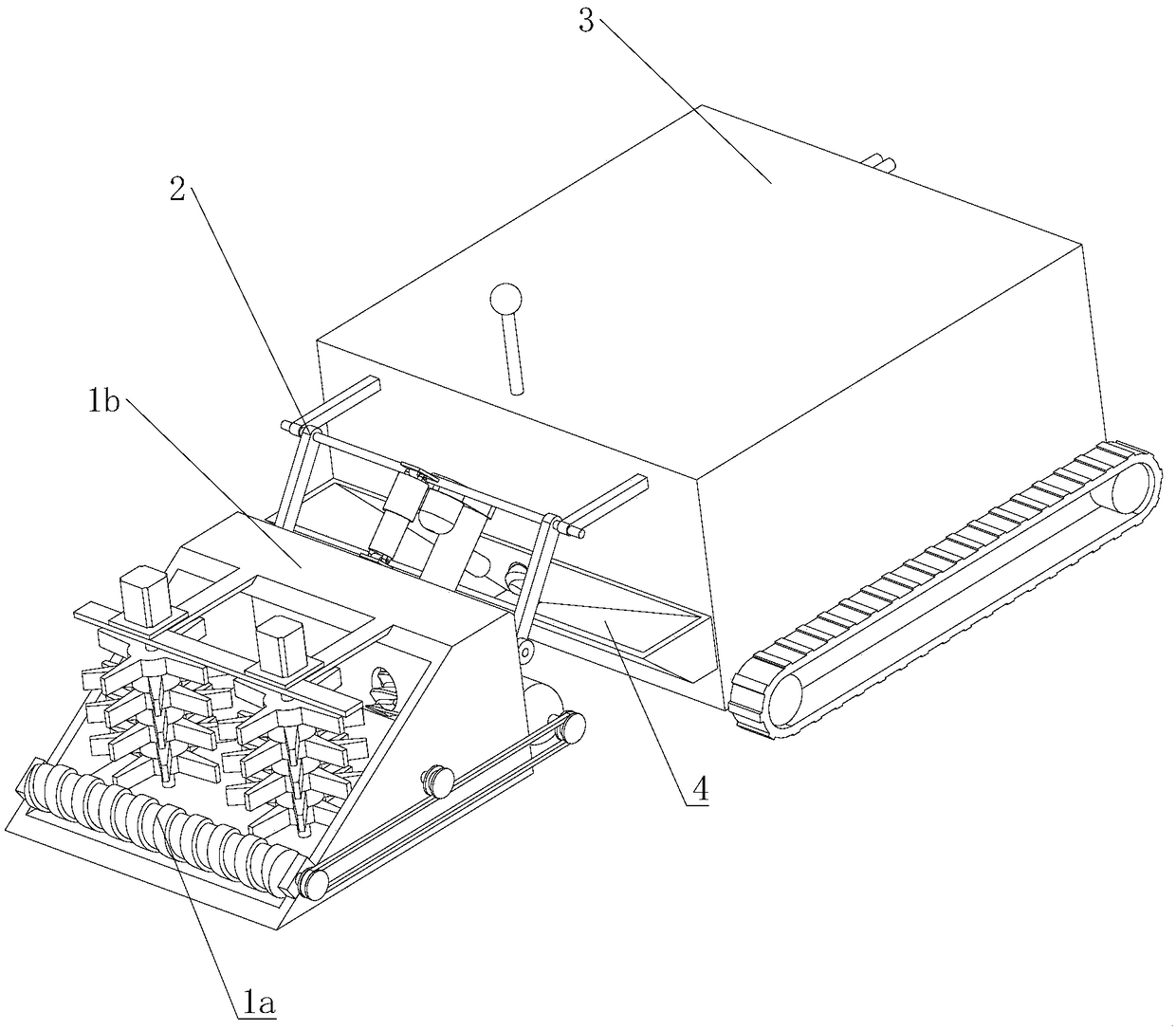

Multispectral vision based efficient weeding robot

The invention discloses a multispectral vision based efficient weeding robot comprising a travelling car, a transverse connecting device, a weeding cutting device and a master control system, wherein the transverse connecting device, the weeding cutting device and the master control system are arranged on the travelling car and are connected with each other. The multispectral vision based efficient weeding robot is capable of rapidly and effectively recognizing farmland weeds, strong in real-time property and suitable for actual field work; the weed clearing works inside and outside a row are simultaneously finished through the combination of a simple cutting structure and a pesticide spraying way, not only is the load of the travelling car reduced, but also the weeds can be thoroughly cleared, the weeding efficiency is high, and the problem for clearing the weeds inside and outside the row is effectively solved; and due to the adoption of a derusting device, the work efficiency of a cutting tool is increased effectively, the service life of the cutting tool is prolonged, and the comprehensive performance of the weeding robot is improved.

Owner:NORTHWEST A & F UNIV

Dust remover of air conditioner

InactiveCN105268694AGood dust removal effectImprove the effectCleaning using gasesComputer caseEngineering

The invention discloses a dust remover of an air conditioner. The dust remover comprises a case, a dust suction device, a fan, a dust accumulation bag and a control device, wherein the dust suction device is arranged on the top of the case, the fan is arranged behind the dust suction device, the dust accumulation bag is arranged below the dust suction device, and both the dust suction device and the fan are connected with the control device. According to the dust remover of the air conditioner, the fan continuously rotates, so that dust in the air conditioner is blown, and then the blown dust is sucked by the dust suction device and then falls into the dust accumulation bag, so that a good cleaning effect on the air conditioner is achieved, a person does not need to climb high to clean the air conditioner, the operation safety of the air conditioner is increased, and the problem of difficulty in cleaning the air conditioner is preferably solved.

Owner:苏州腾辉环保科技有限公司

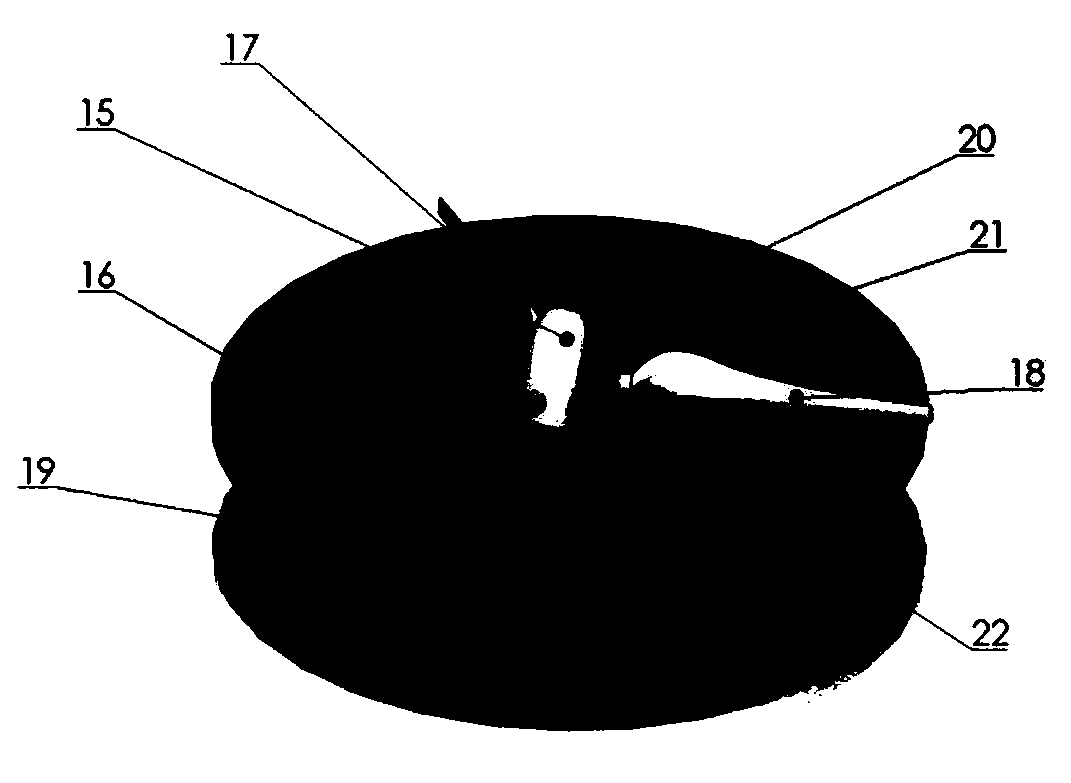

Novel ocean energy self-cleaning type power generating buoy

ActiveCN109292043ASolve energy supply difficultiesReal-time cleaningBuoysCleaning using toolsBuoySeawater

The invention discloses a novel ocean energy self-cleaning type power generating buoy. A wind-photovoltaic integrated generating assembly is mounted at the upper end of a buoy lamp by a base. A cabinbody is connected to the lower end of the buoy lamp. The wind-photovoltaic integrated generating assembly comprises a wind generator set and a modularization photovoltaic generator set. The modularization photovoltaic generator set is divided into three areas. Rotor blades of the wind generator set are mounted on the upper surface of a photovoltaic generating panel of the photovoltaic generator set. A dedusting device is mounted in each rotor blade. The dedusting devices face the generating panel of the photovoltaic generator set. The wind generator set and the photovoltaic generator set respectively convert wind energy and solar energy into electric energy to power the buoy together. A tension leg mooring system with double-permeable pendant plates fixes the buoy to seawater. The day andnight alternation working mode is adopted, the rotor blades with dedusting brushes of the wind generator clean the photovoltaic generating panel during rotating, and therefore light transmittance of the photovoltaic generating panel is guaranteed. The tension leg mooring system with the double-permeable pendant plates guarantees that the buoy can work stably in the severe environment.

Owner:JIANGSU UNIV OF SCI & TECH

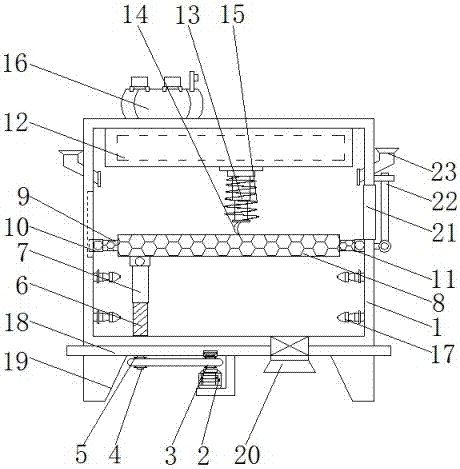

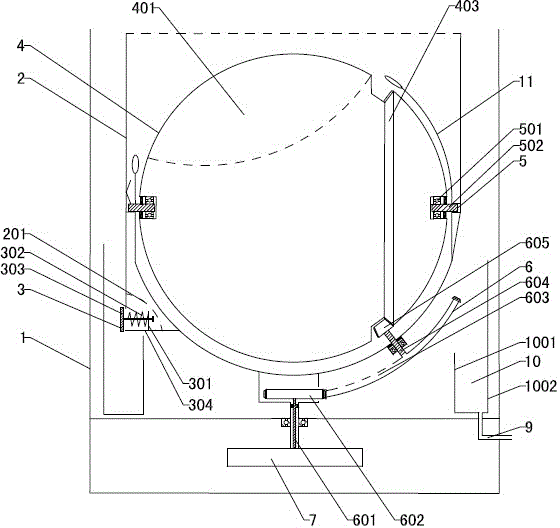

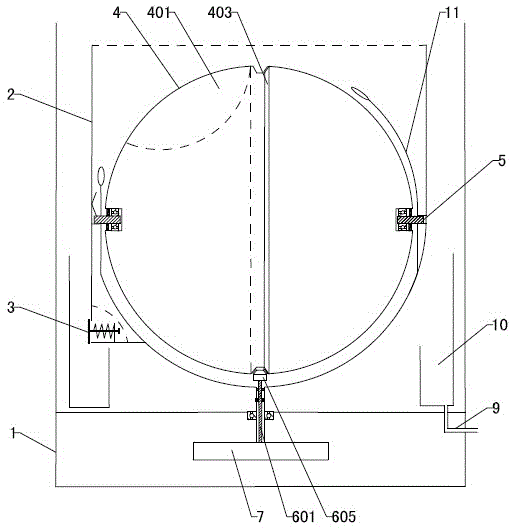

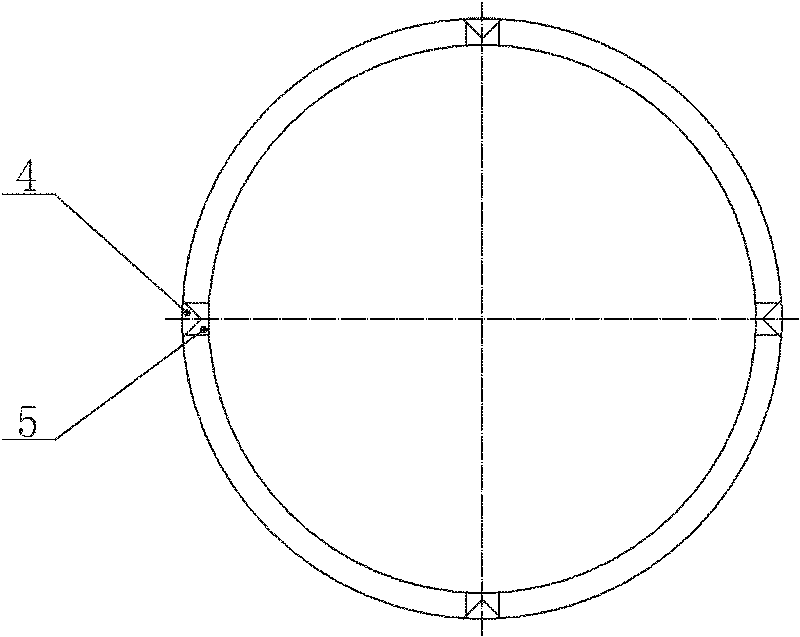

Rolling ball type washing machine

InactiveCN103603168ASolve the problem of inconvenient pick and placeCompact structureOther washing machinesWashing machine with receptaclesImpellerBall type

The invention relates to a rolling ball type washing machine belonging to the field of washing equipment, and particularly relates to a rolling ball type washing machine with a spherical washing drum. A rolling ball (4) is a spherical shell provided with a fetching hole (401) in the top and can rotate in an inner drying cylinder (2) by taking a horizontal central axis as a rotating shaft, and the rolling ball (4) and the inner drying cylinder (2) can synchronously rotate through a power device (7) by taking a central shaft in the vertical direction as a rotating shaft; one side of the lower part of the inner drying cylinder (2) is provided with a water outlet (201) where a centrifugal starting / stopping device (3) is arranged, the circumference below the inner drying cylinder (2) is provided with an annular water receiving tank (10) with an upper opening, and one side of the water receiving tank (10) is connected with a water outlet pipe (9). The rolling ball type washing machine is capable of realizing rolling type washing by using the rolling ball, good in washing effect and capable of saving water and reducing the dosage of detergents; due to the combination of a centrifugal drainage way of the water outlet of the inner drying cylinder, the problem of secondary pollution to clothes is thoroughly solved, and the rolling ball type washing machine can be conveniently changed to work in an impeller washing way.

Owner:张安达

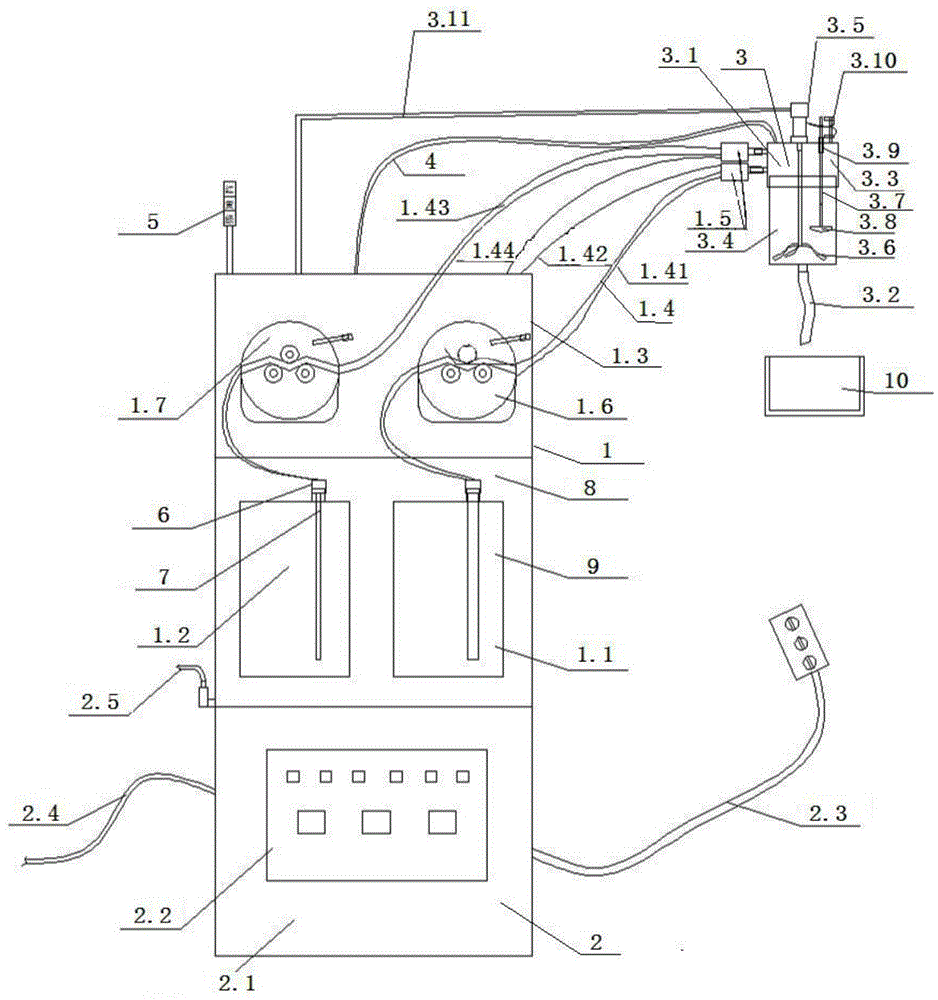

Glue feeding system with automatic glue proportioning function

InactiveCN104014460AGood economic and social benefitsEasy curingLiquid surface applicatorsCoatingsEngineeringLower limit

The invention discloses a glue feeding system with an automatic glue proportioning function. The glue feeding system comprises an AB glue mixing machine, a control device and an AB glue mixing and discharging device, wherein the control system comprises a control cabinet and a control system; the control cabinet is connected with a control switch, an input power source and an input air source respectively; the control device is connected with the signal receiving end of the AB glue mixing machine which comprises an A glue bucket, an B glue bucket and an AB glue output unit; the AB glue mixing and discharging device comprises an AB glue amount control box and a glue discharge head rubber pipe; the AB glue amount control box comprises an upper glue box and a lower glue box which are fastened together; and the upper glue box is provided with a stirring motor, a stirring head, a floating block connecting rod, floating blocks, a guide shaft, an upper limiting sensor and a lower limiting sensor. By the glue feeding system, the problems that manual glue proportioning is frequent and the work efficiency is low due to manual glue stirring are solved; the requirement for automatically feeding glue as required is met; cleaning liquid for a pipeline cleaning device is designed for cleaning pipelines, so as to prevent residual A glue and B glue in the pipeline from blocking the pipeline; and thus the glue feeding system has good economical and social effects.

Owner:WUHAN MINHUI AUTOMOTIVE PARTS

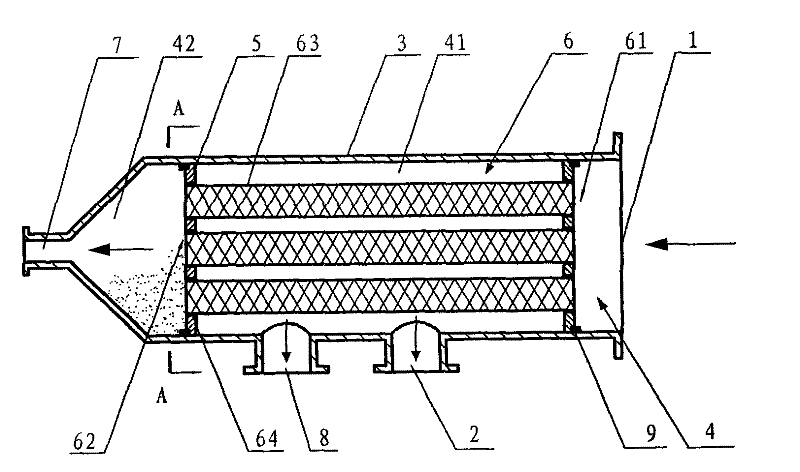

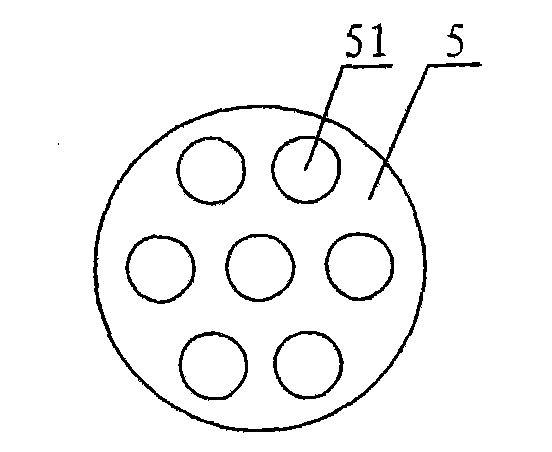

Dismountable cross-flow type filter for liquid with high viscosity

InactiveCN102225263AImprove filtration efficiencySolve the filtering problemFilter regenerationStationary filtering element filtersVena contracta diameterEngineering

The invention discloses a dismountable cross-flow type filter for liquid with high viscosity, comprising a filter housing which has a stock solution inlet and a filtered clear liquid outlet. A filter chamber is provided in the filter housing; the stock solution inlet is arranged on one end of the filter housing, and the filtered clear liquid outlet is arranged on the external surface of the filter housing; the stock solution inlet and the filtered clear liquid outlet both communicate with the filter chamber; orifice plates are provided in the filter chamber, dividing the filter chamber into a filtering processing zone and a raffinate storage zone; installing holes are provided in the two orifice plates to fix a filter tube system which is fixed between the two orifice plates; an inlet of the filter tube system is connected with the stock solution inlet and an outlet of the filter tube system is connected with the raffinate storage zone; the raffinate storage zone is provided with a residue discharge outlet; a compression gauge interface communicating with the raffinate storage zone is also provided in the filter housing. The invention enables the problem in filtering liquid with high viscosity to be effectively solved. A cross-flow structure enables the problem in discharging stock solution residues on-line to be effectively solved, and a dismountable structure enables the difficulty in cleaning to be effectively overcome.

Owner:QINGDAO UNIV

Hole cleaning device for spun-digging pile hole and construction method thereof

The invention discloses a hole cleaning device for a spun-digging pile hole and a construction method thereof. The hole cleaning device comprises a cylindrical hole cleaning device casing pipe with a water filtering hole, a slag extracting pump, a filter screen, a center slag discharge hole, a first slag outlet, a second slag outlet, a compressed gas pipeline, a foaming agent pipeline, a sediment collection chamber, a steel plate, a spring, a rubber sheet, a fastening bolt, a rotating bolt, a compressed gas outlet, a foaming agent outlet, a gas flow dividing body, a blocking device, a filter screen fastening bolt, a round insertion rod, a filter screen rotating bolt, a steel cable, a guide wheel and a fixed shaft. The construction method comprises the following construction steps: 1, arranging the hole cleaning device for the spun-digging pile hole at the end part of a rotary drill rod; 2, inserting the hole cleaning device for the spun-digging pile hole to the bottom of the pile hole and fixing the hole cleaning device for the spun-digging pile hole after rotating the hole cleaning device for the spun-digging pile hole by a plurality of circles at a low speed; 3, inputting compressed gas to the compressed gas pipeline and simultaneously inputting a foaming agent; 4, starting the slag extracting pump to extract slags; 5, repeatedly circulating the operation to complete slag removal, pulling out the hole cleaning device to discharge the slags. The hole cleaning device for the spun-digging pile hole and the construction method thereof have the advantages of low manufacturing and use cost and high slag removing and hole cleaning efficiency and solve the problem of difficulty in removal of the sediments of a mechanical hole and particularly a spun-dug mechanical form.

Owner:FUJIAN YONGQIANG SOIL

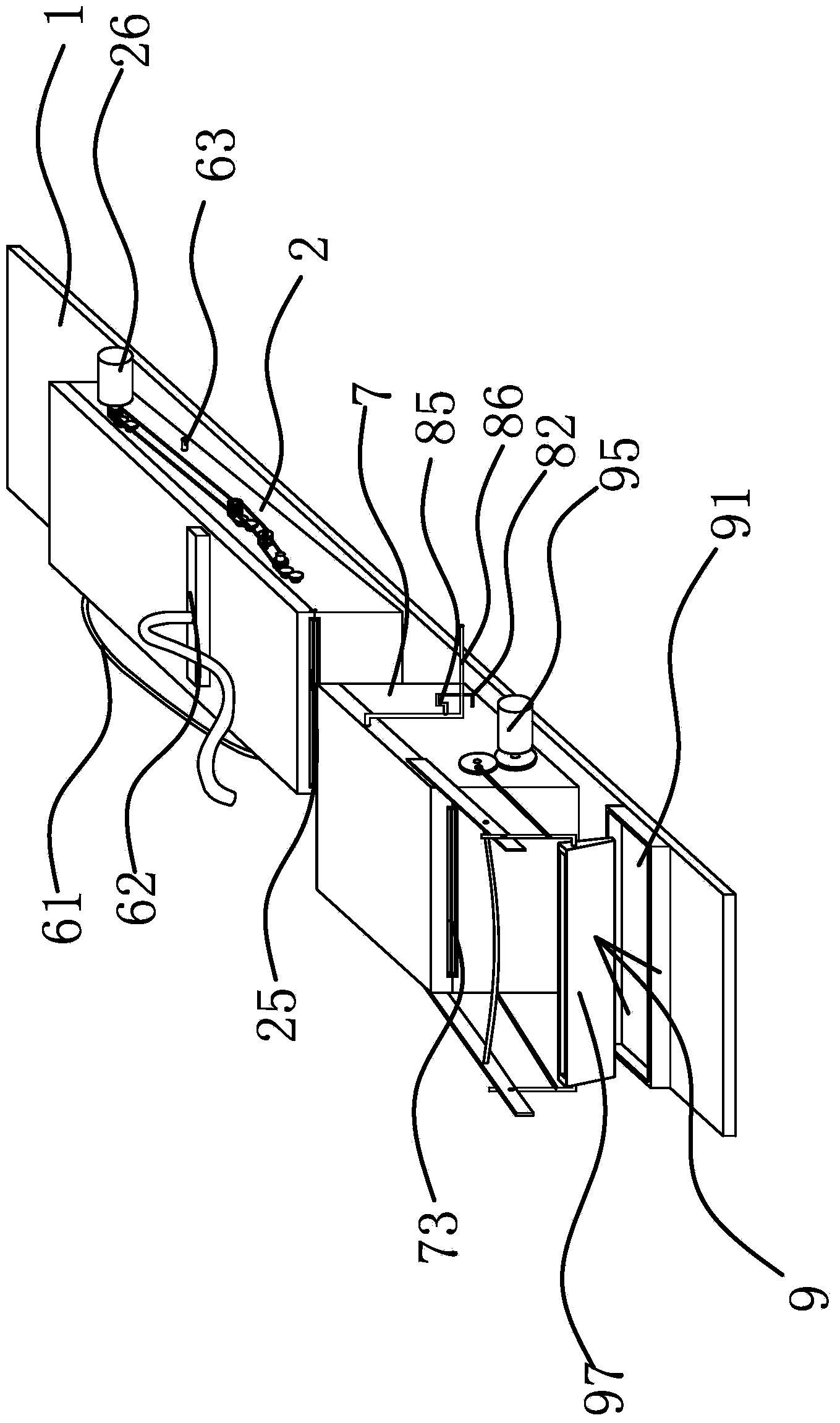

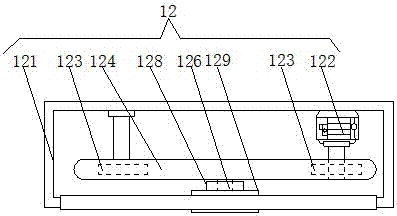

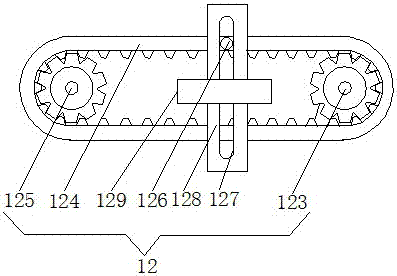

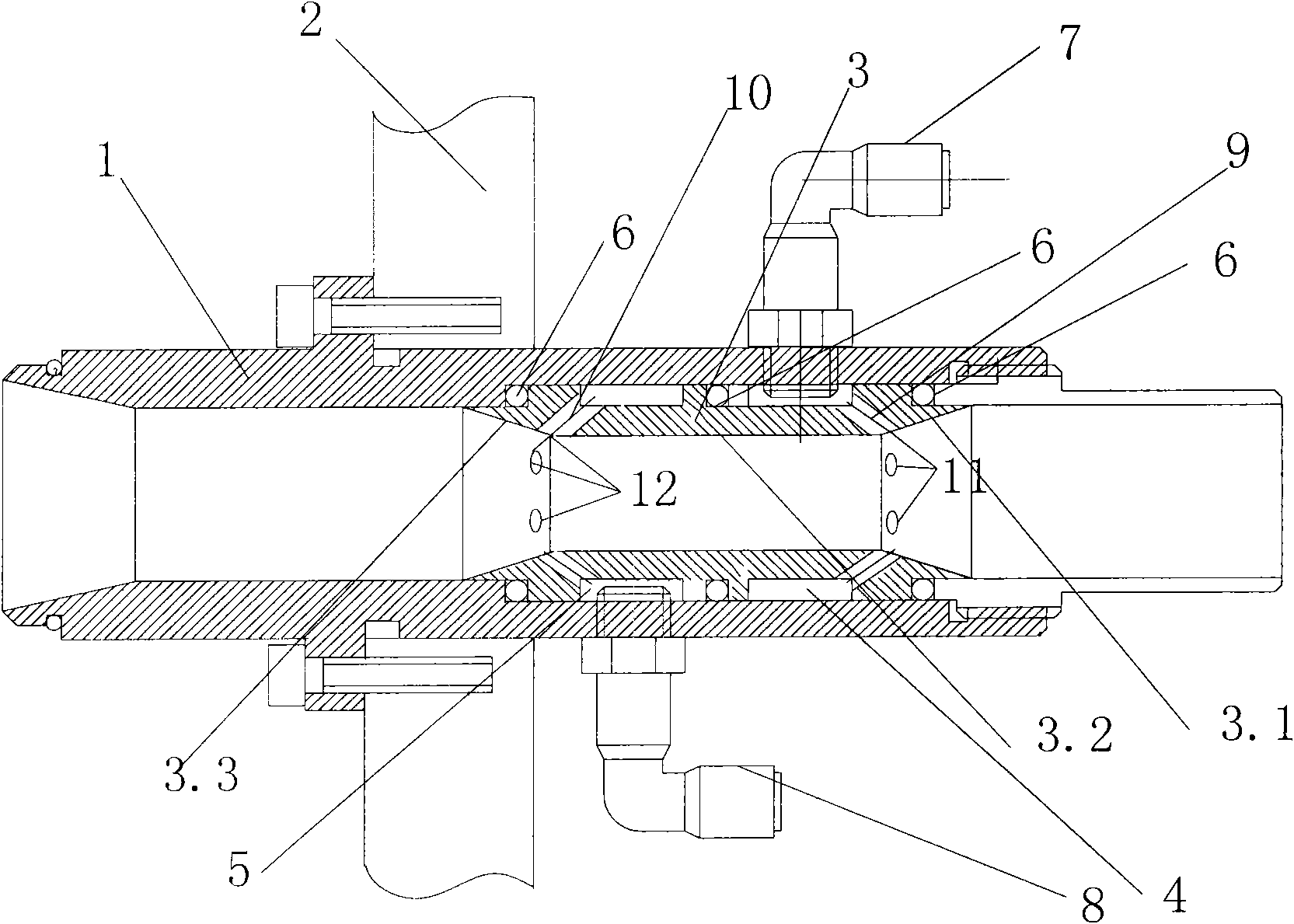

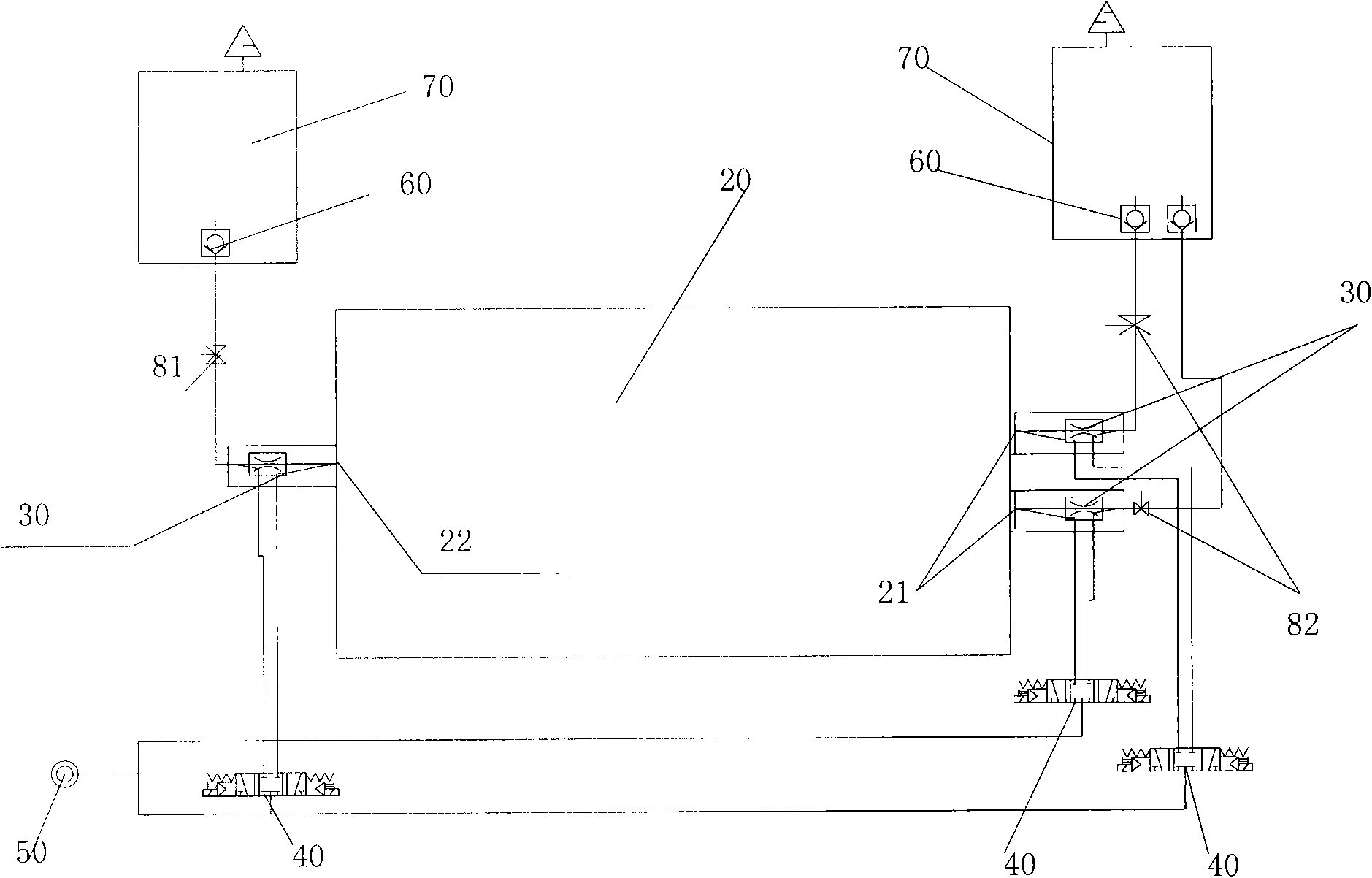

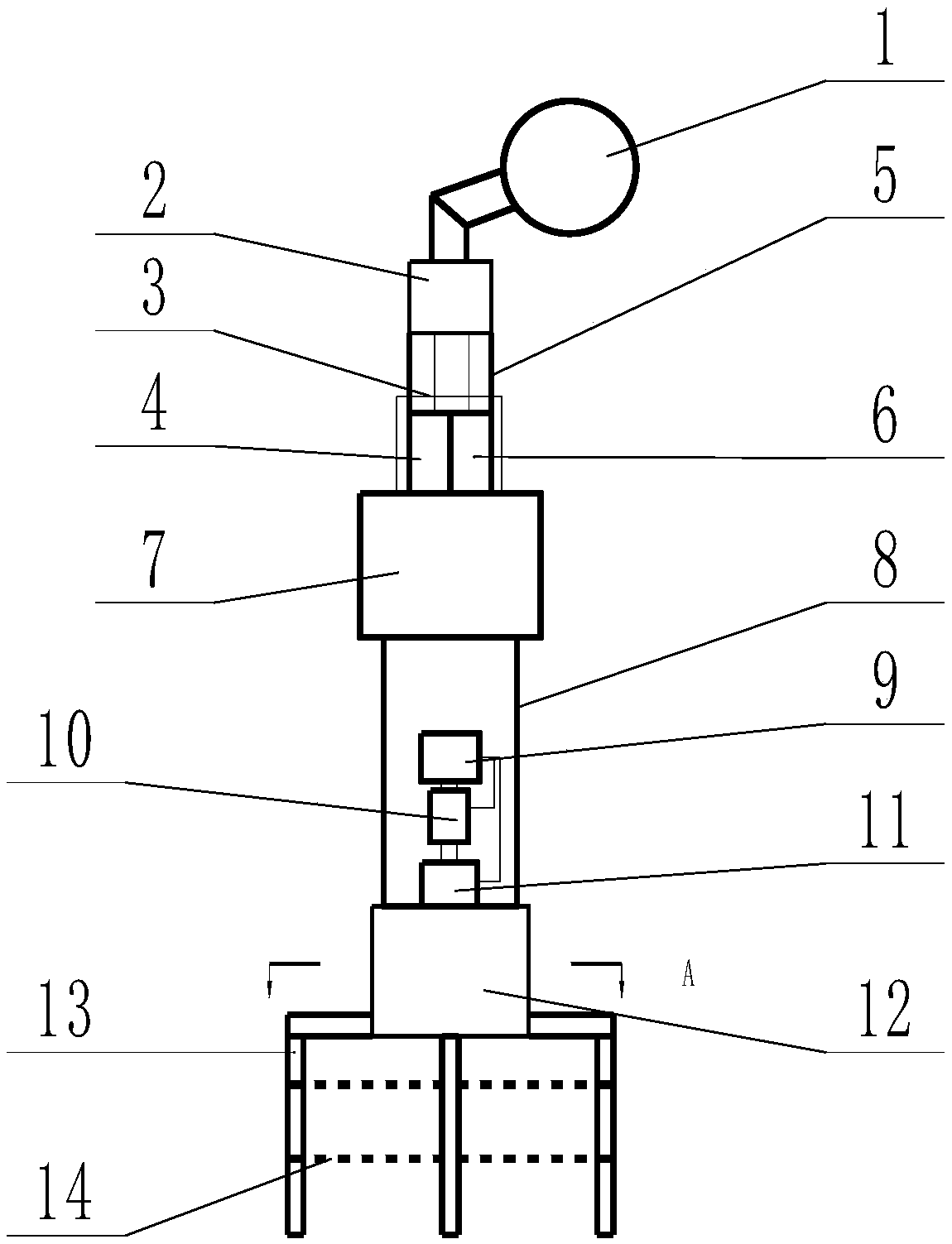

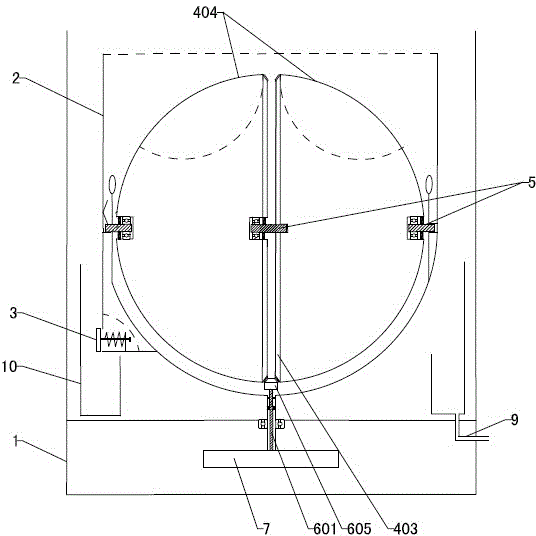

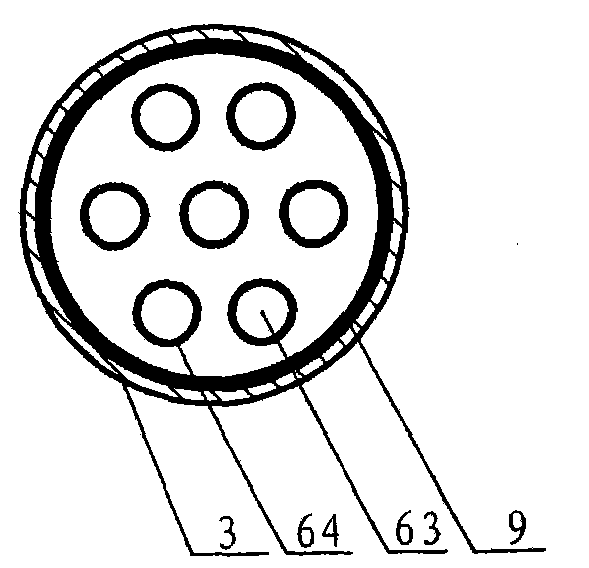

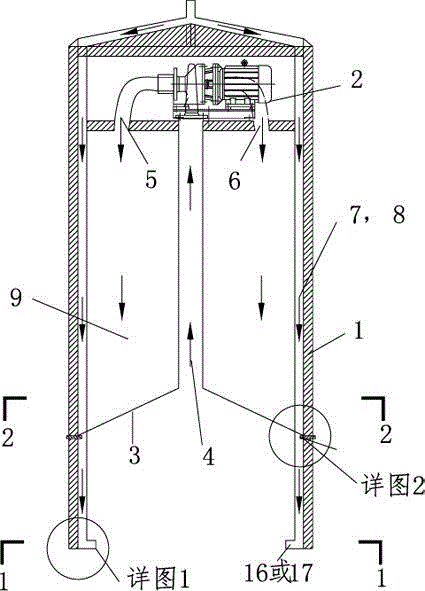

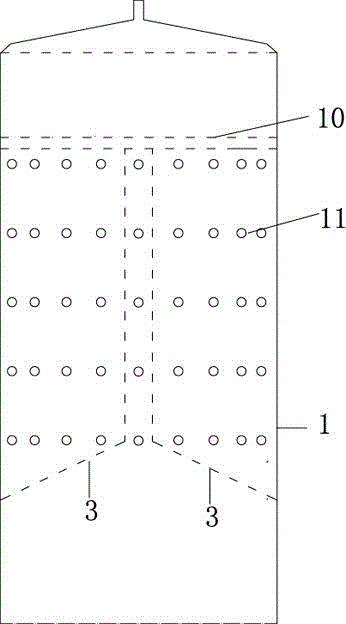

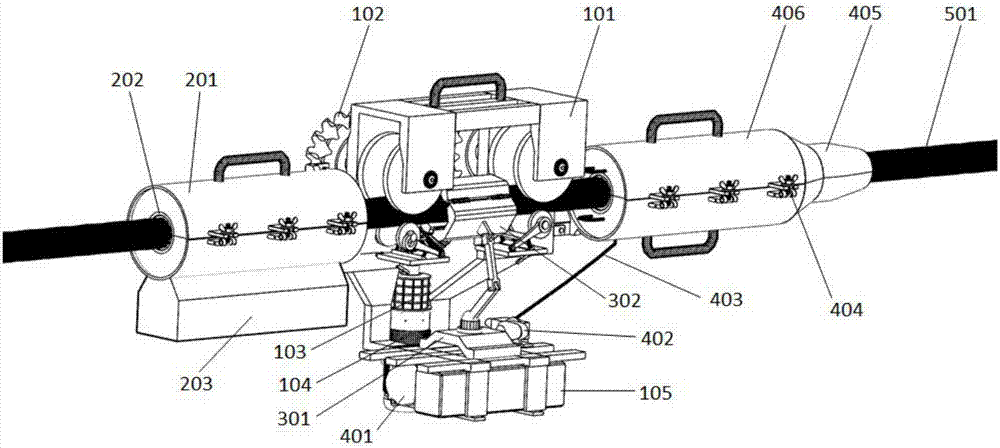

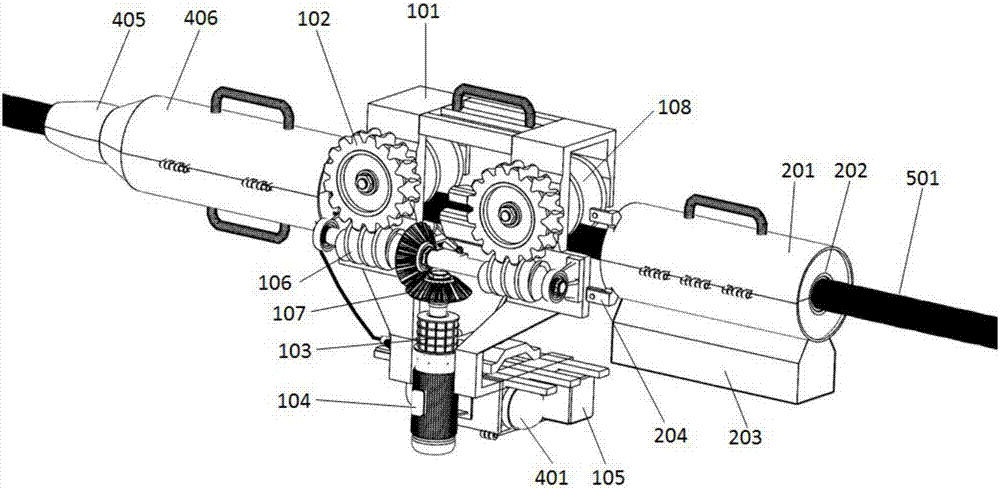

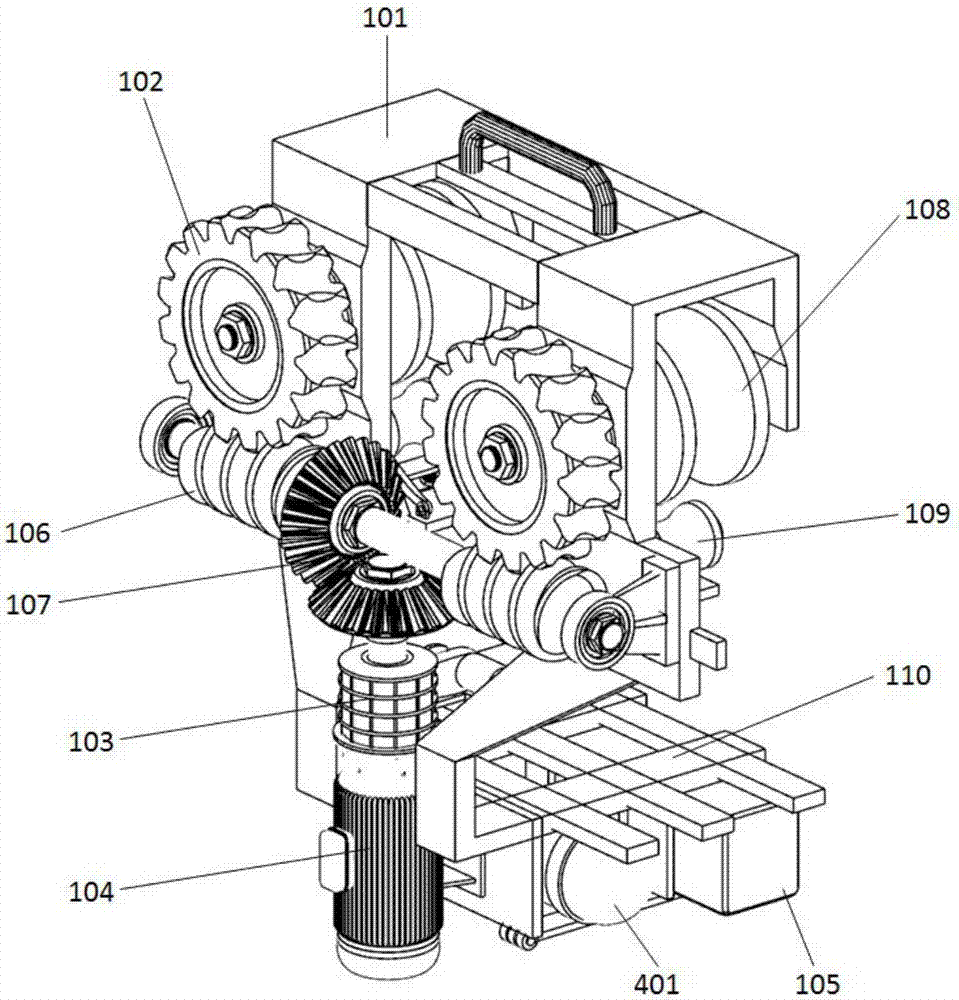

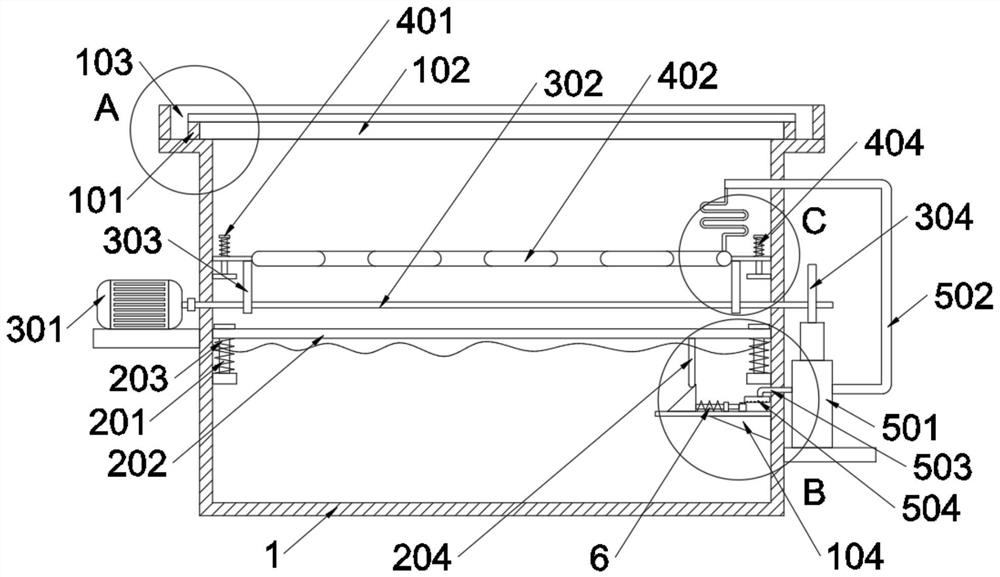

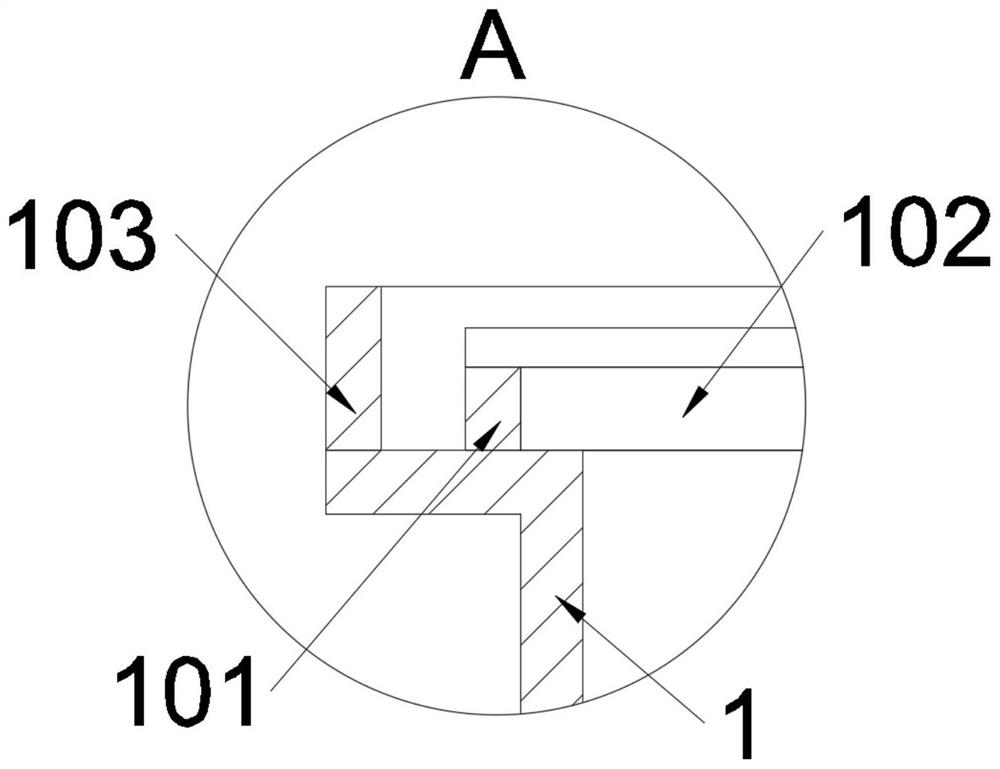

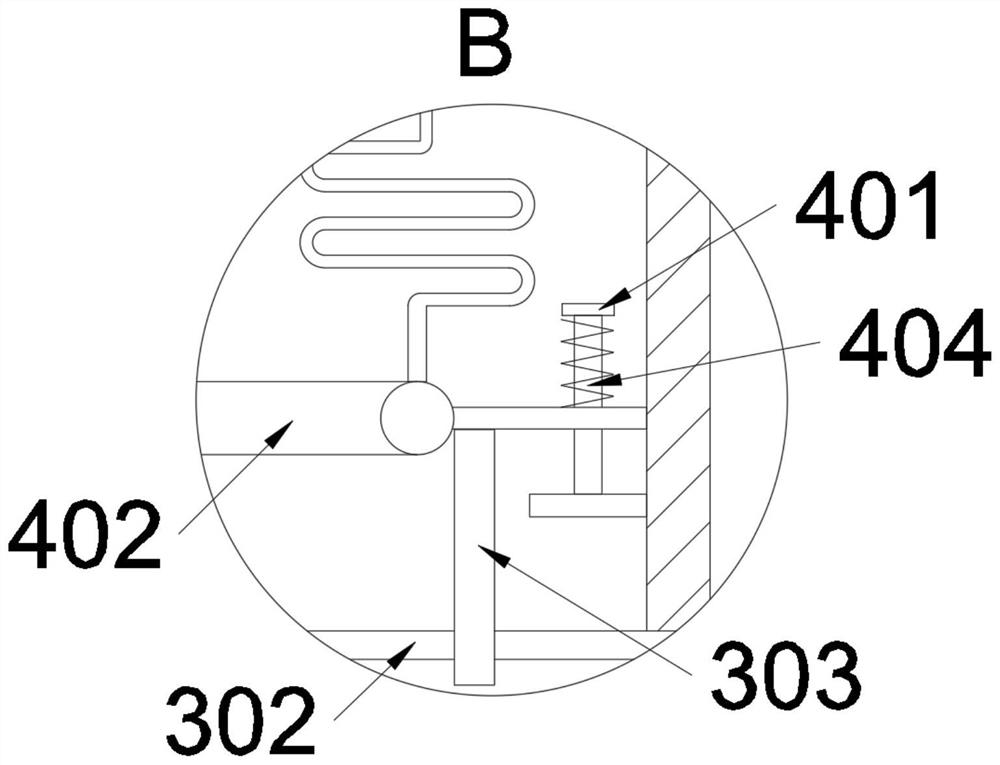

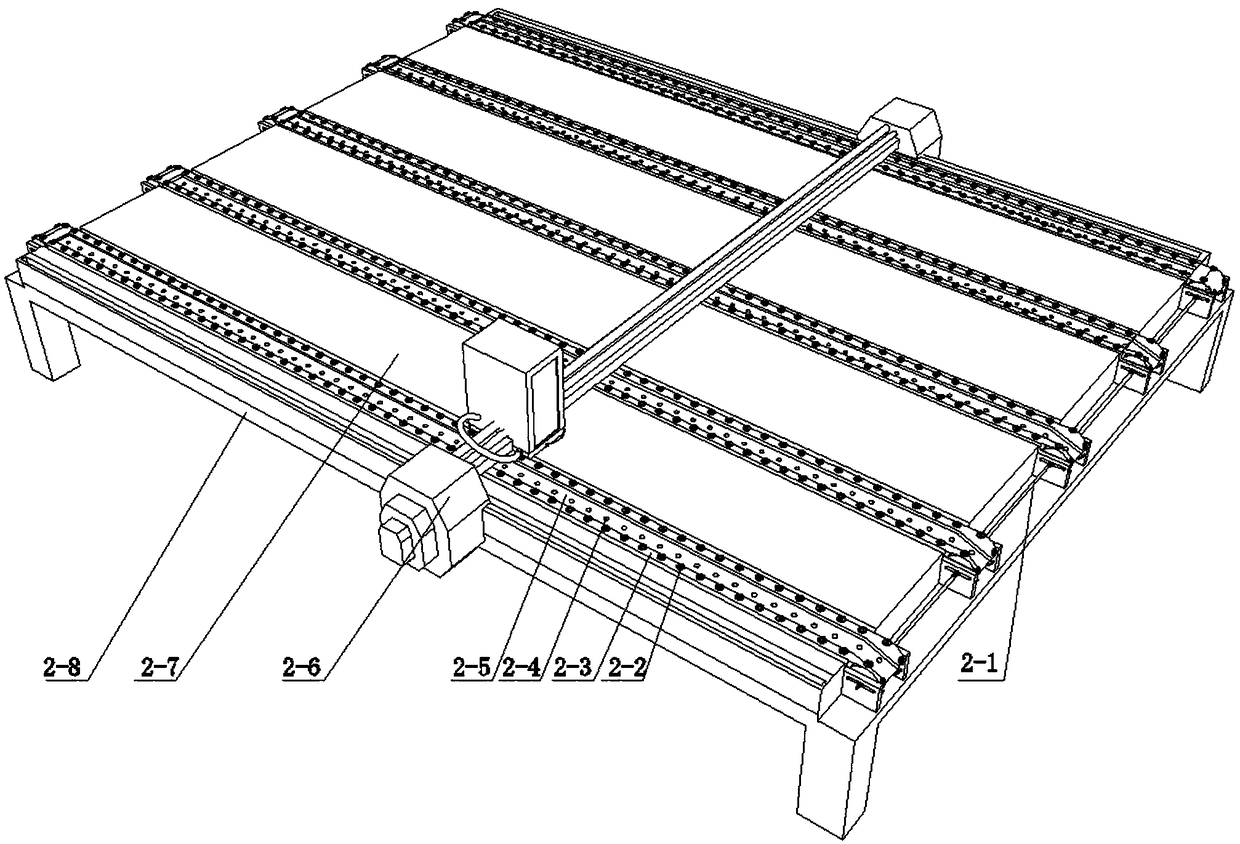

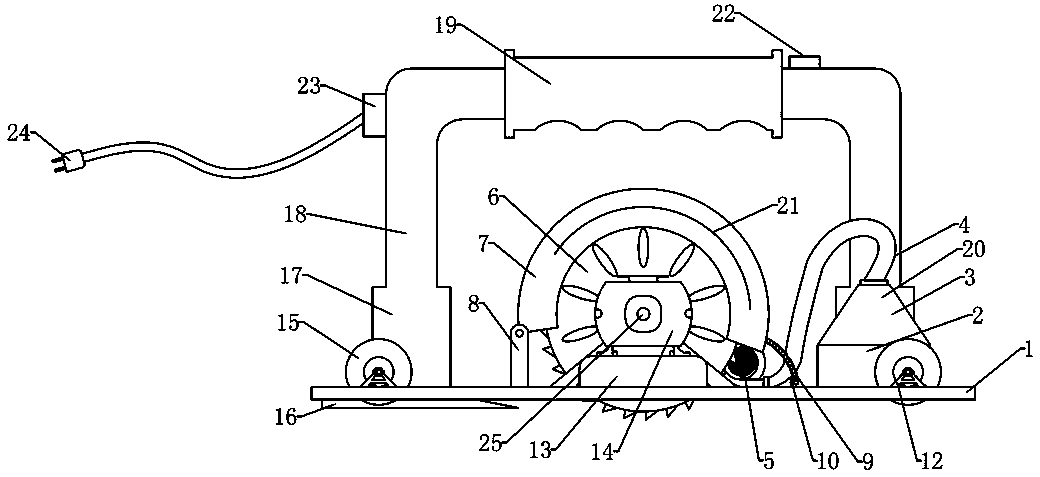

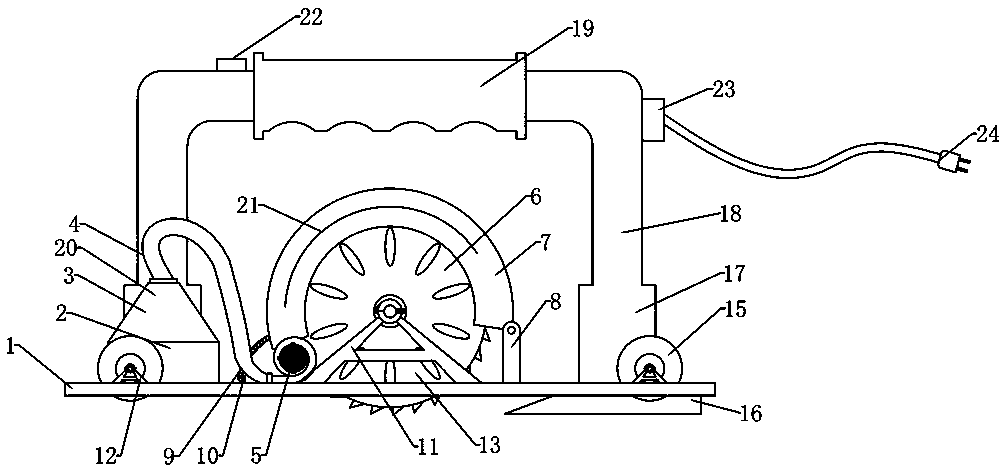

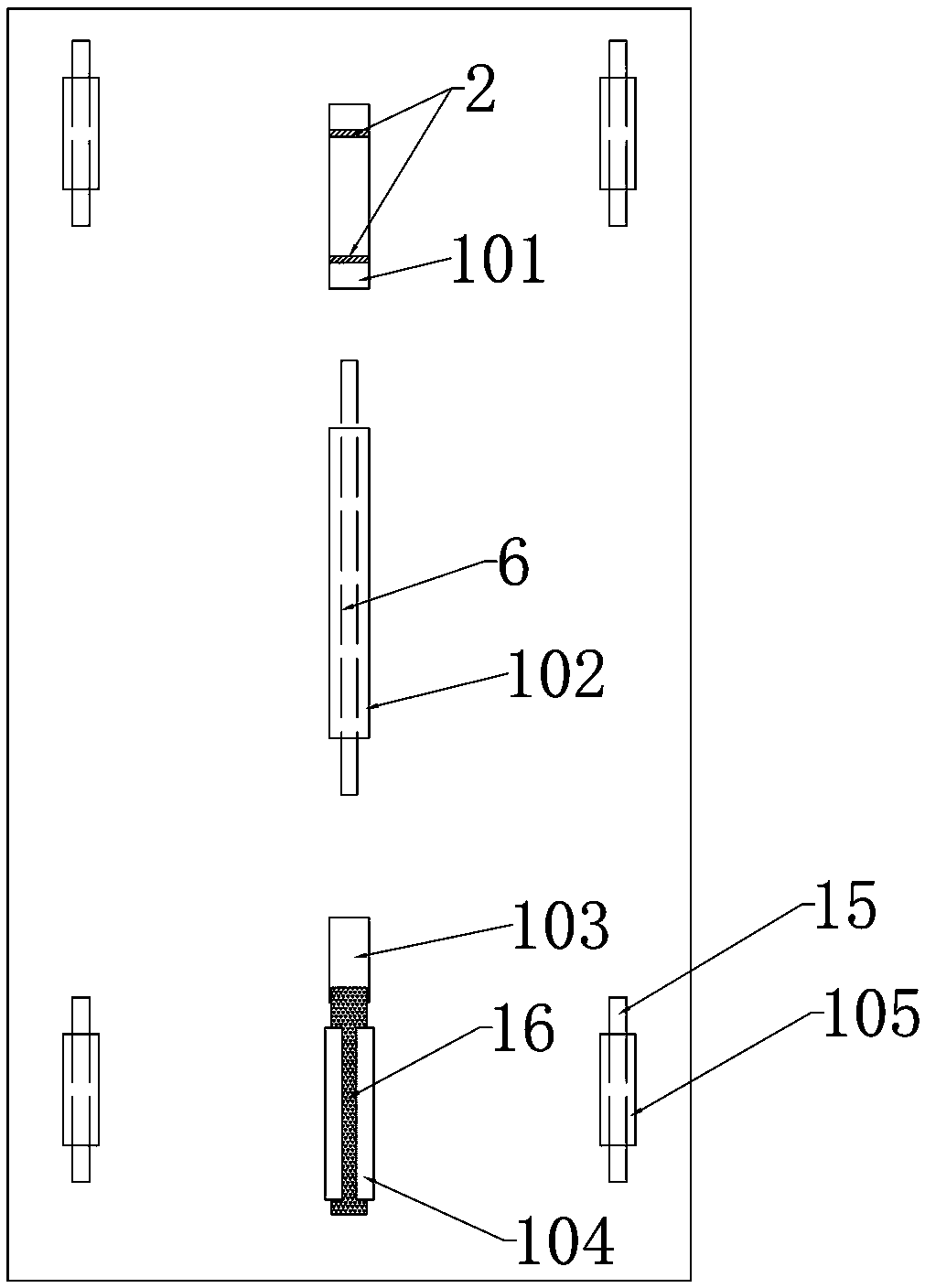

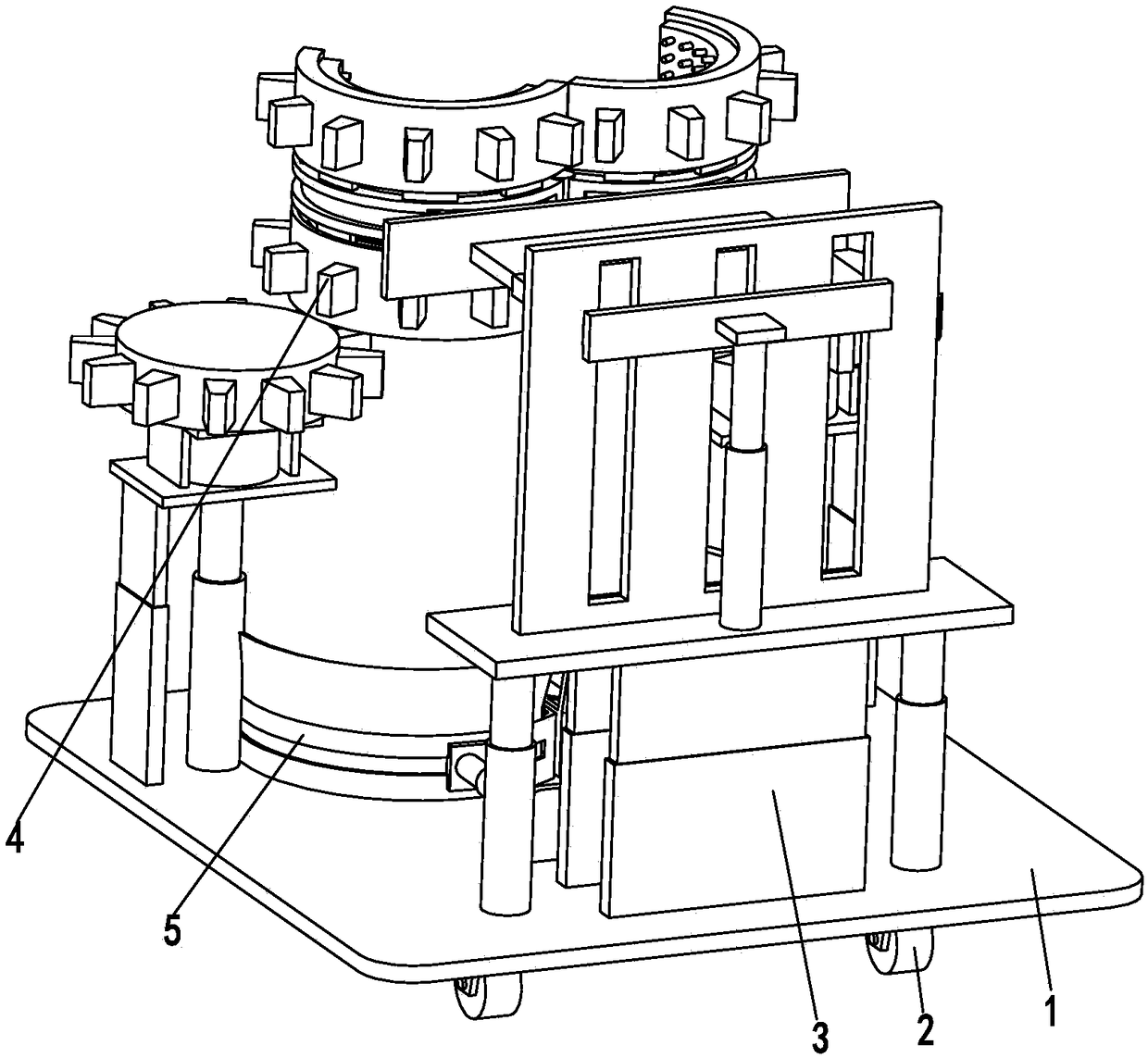

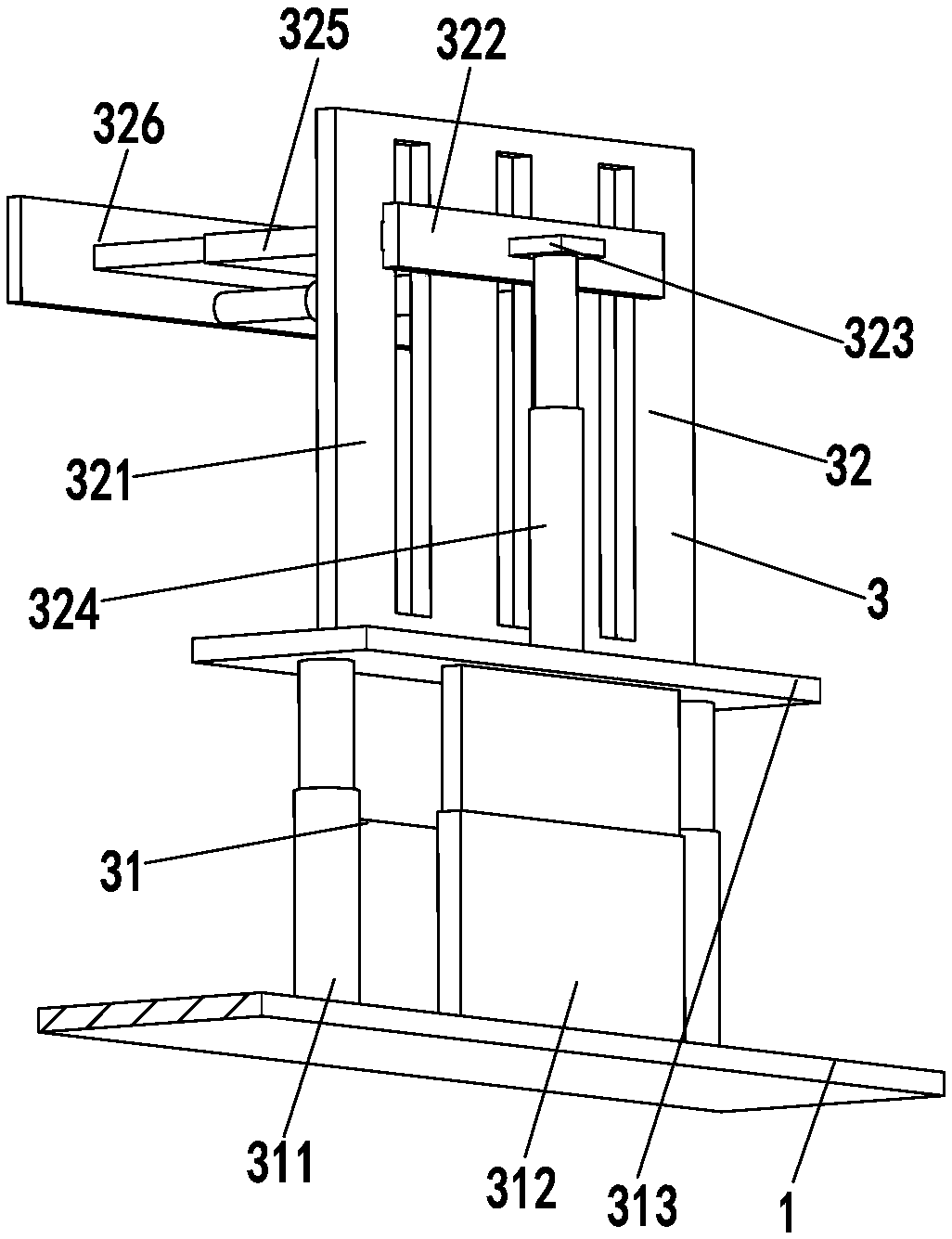

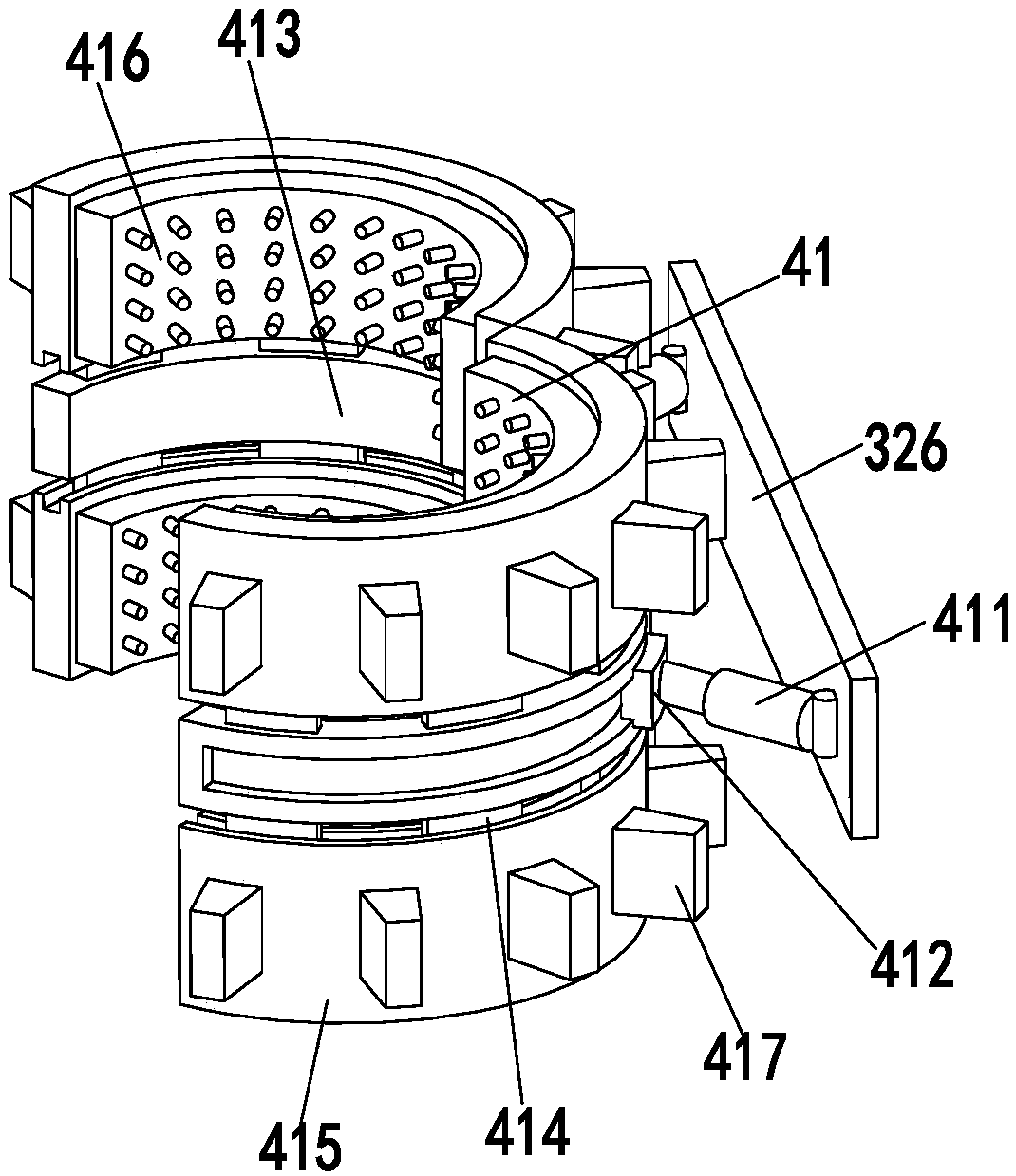

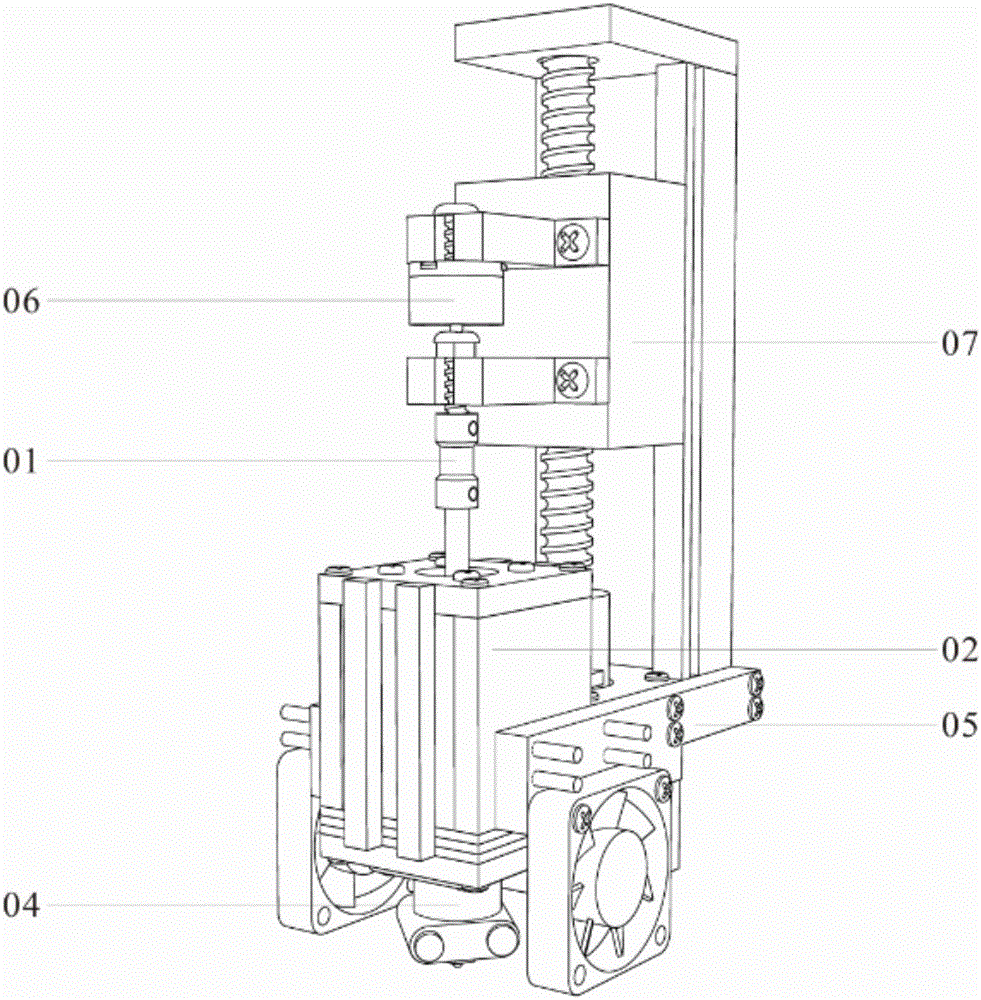

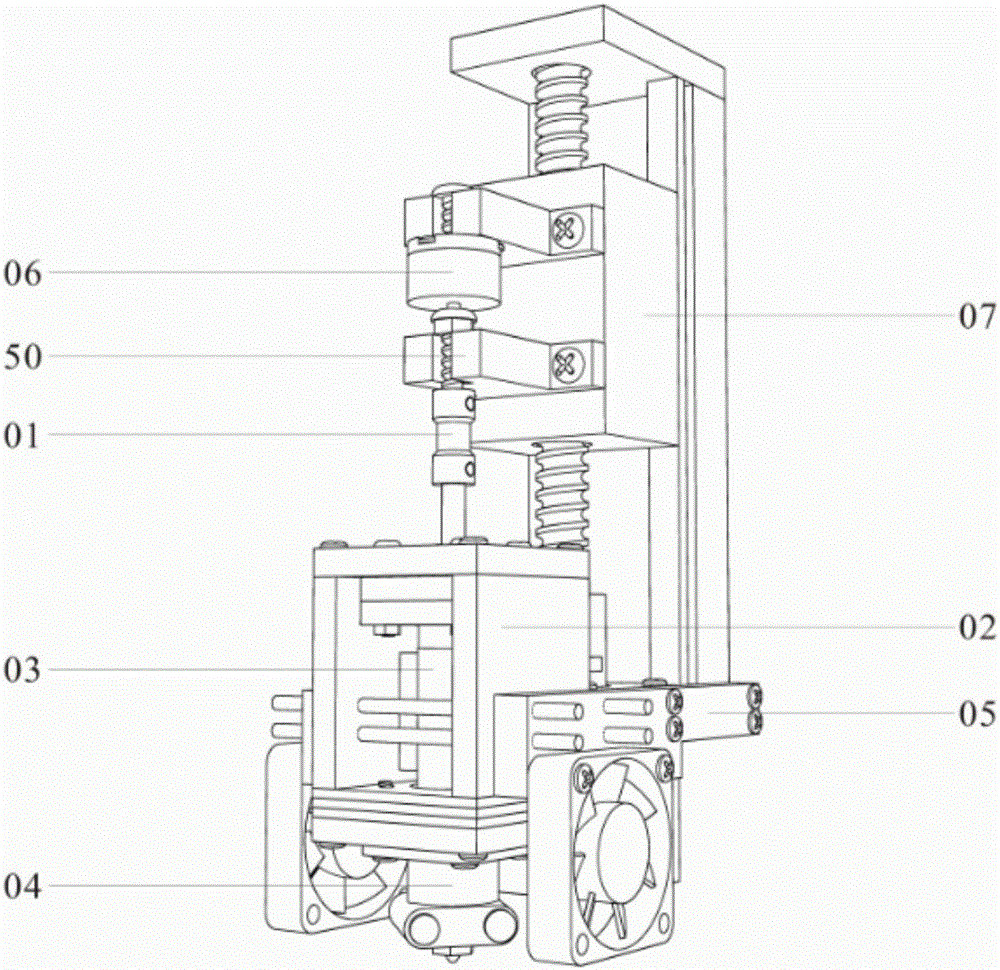

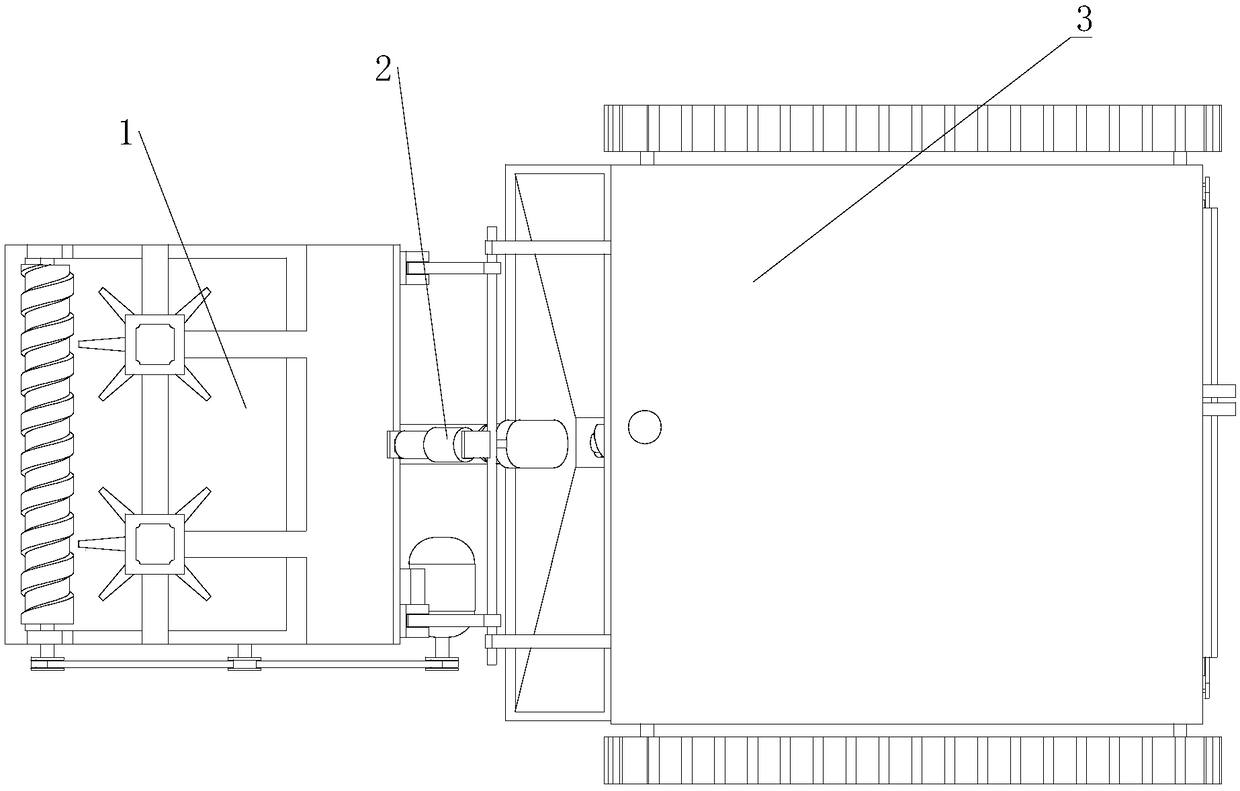

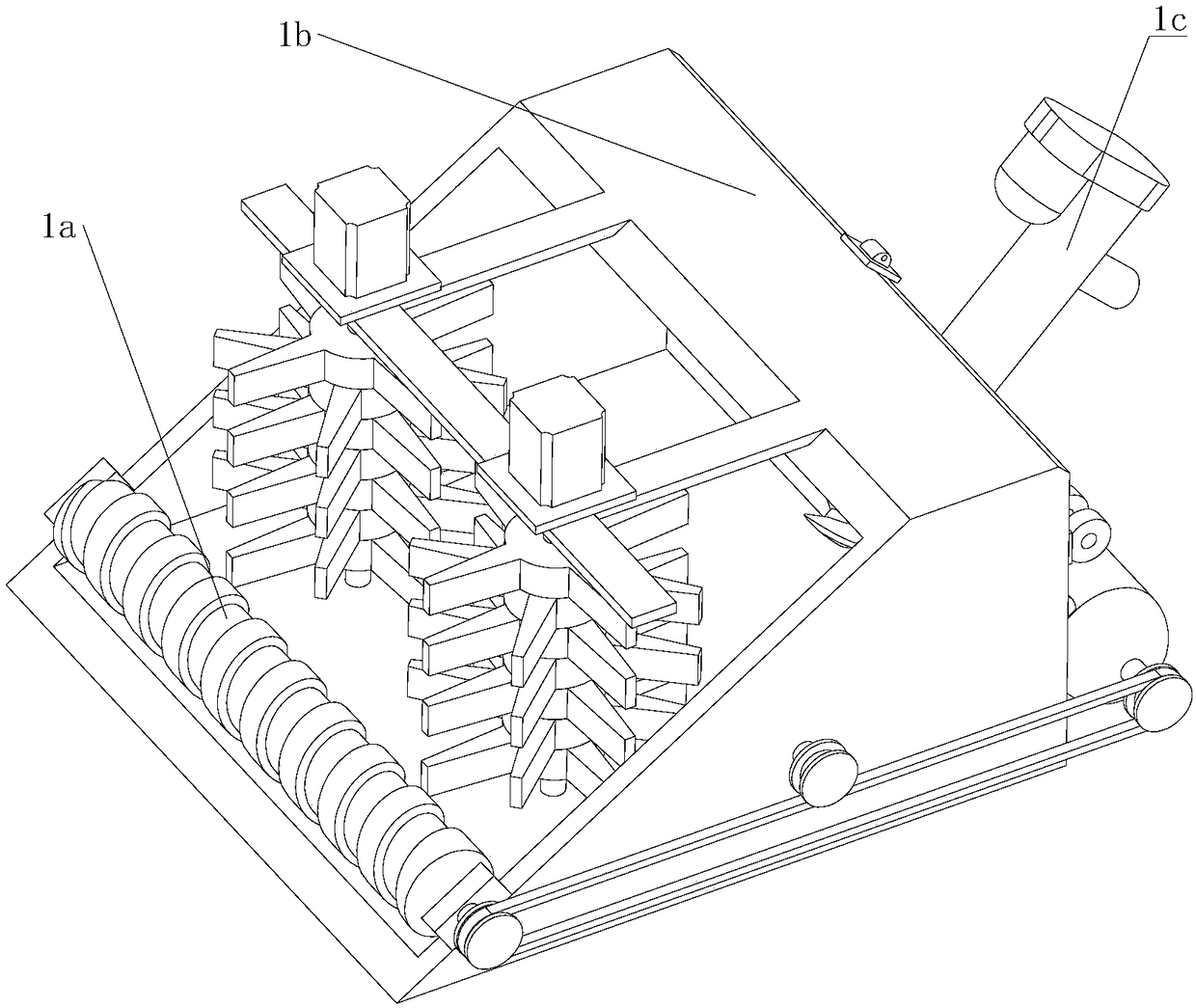

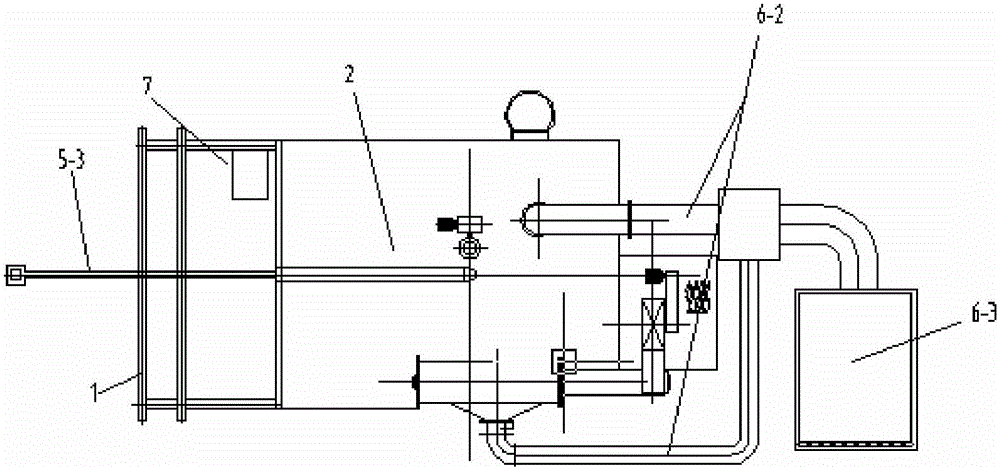

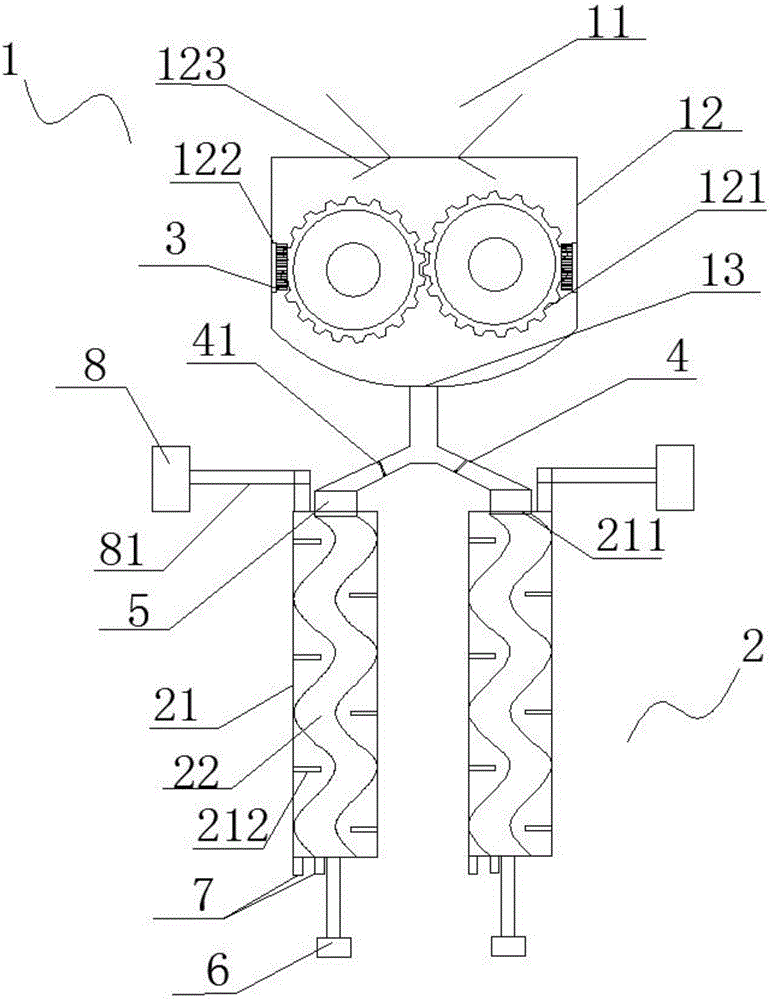

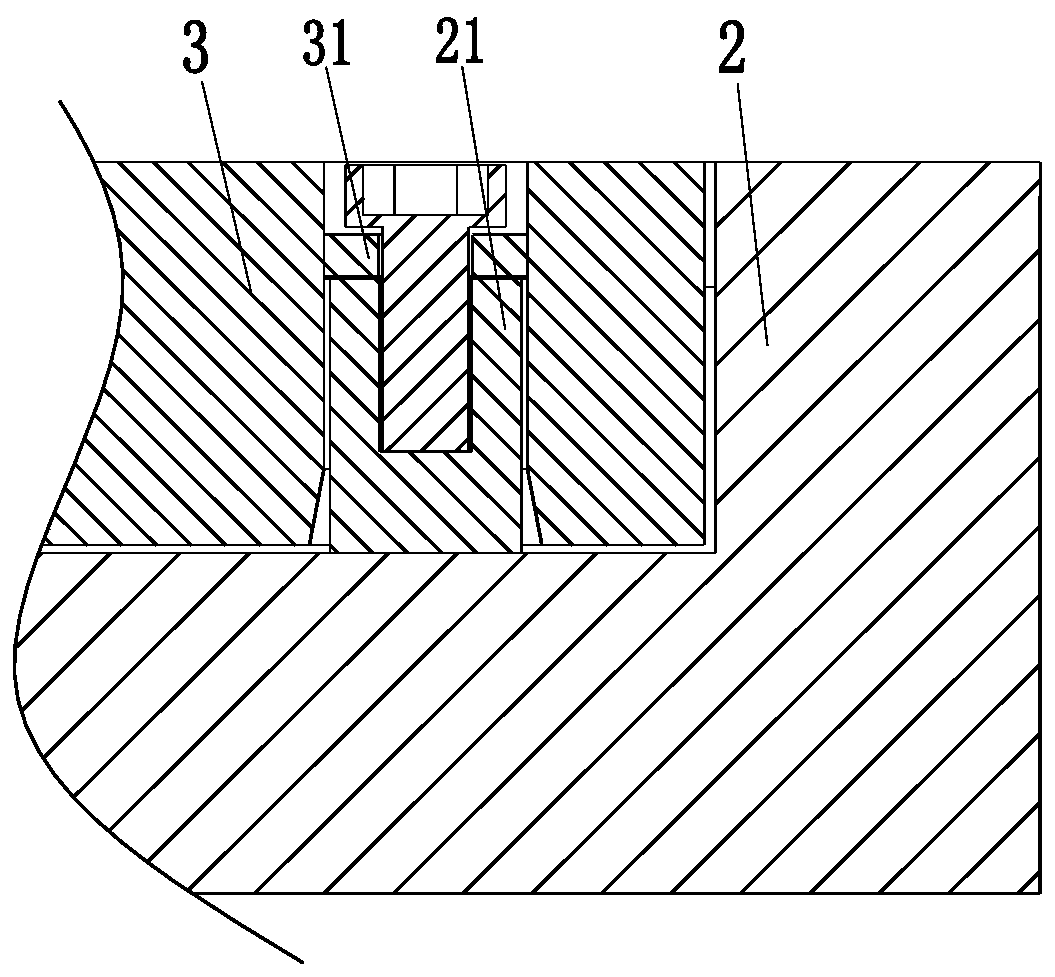

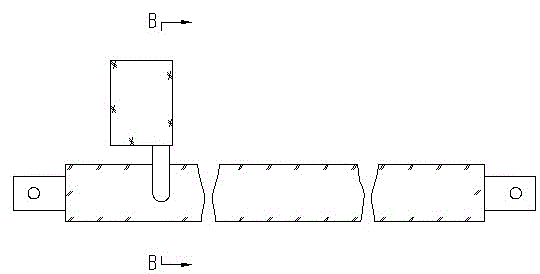

Crane steel wire rope complete lubricating integrated machine

ActiveCN107200271ASolve cleaning difficultiesSolving Grease Lubrication ProblemsLubrication elementsLoad-engaging elementsEngineeringSteel rope

The invention discloses a crane steel wire rope complete lubricating integrated machine comprising a power module, a waste oil removing module, a steel wire rope flaw detection module which a steel wire rope grease injection lubricating module which are arranged on a crane steel wire rope. The power module is arranged on the crane steel wire rope and can move along the crane steel wire rope. The waste oil removing module and the steel wire rope grease injection lubricating module are arranged on the front side and the rear side of the power module correspondingly and connected with the power module. The steel wire rope flaw detection module is fixed to the power module. The power module provides power for the whole lubricating integrated machine. Under the drive of the power module, the steel wire rope waste oil removing module, the steel wire rope flaw detection module and the steel wire rope grease injection lubricating module achieve the functions of themselves when moving on the steel wire, and therefore lubricating maintenance and flaw detection for the steel wire rope are achieved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

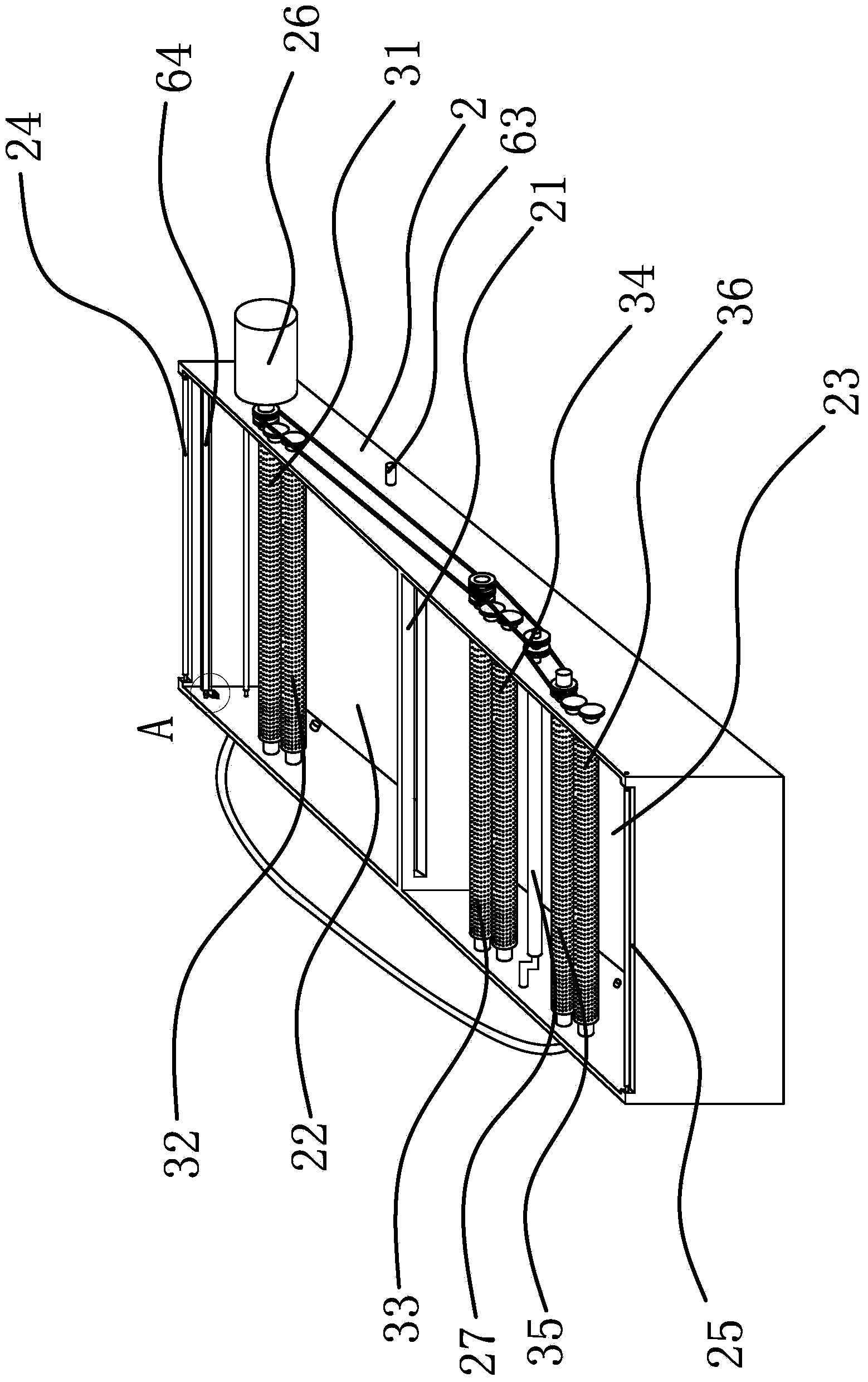

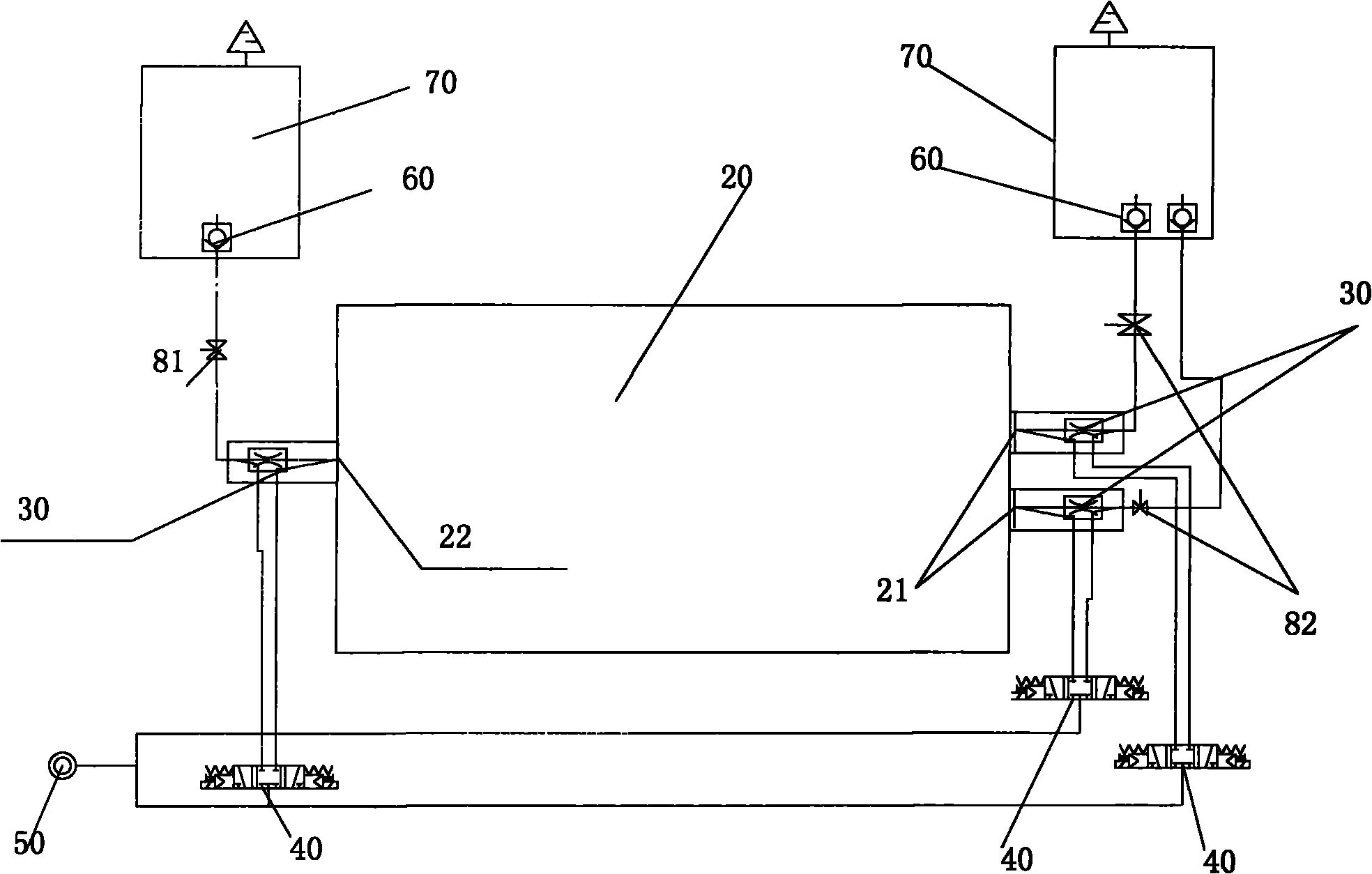

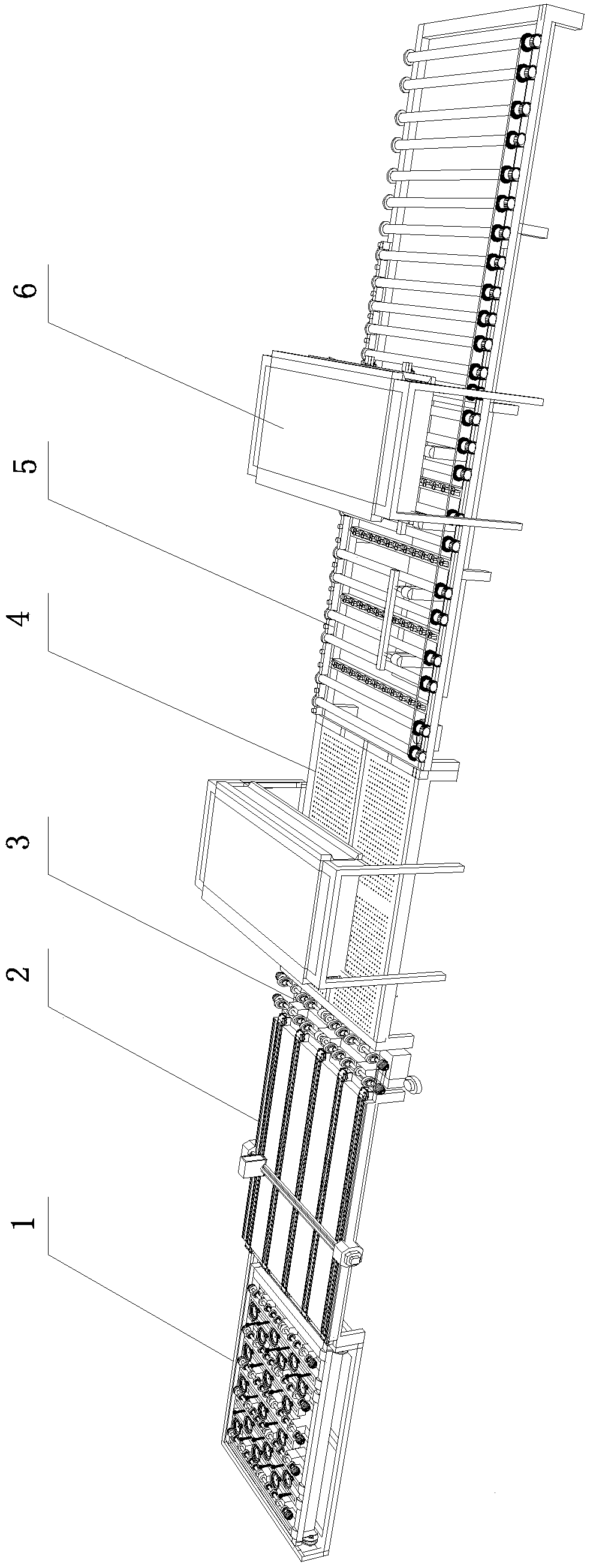

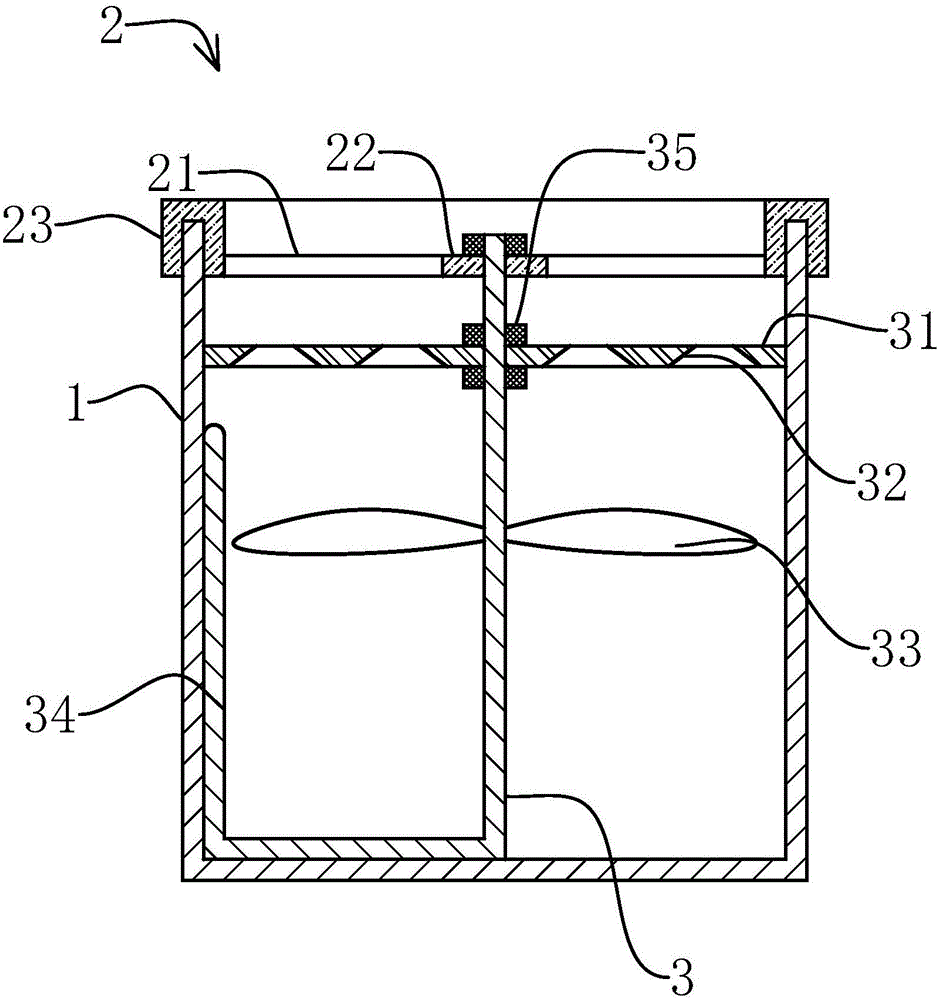

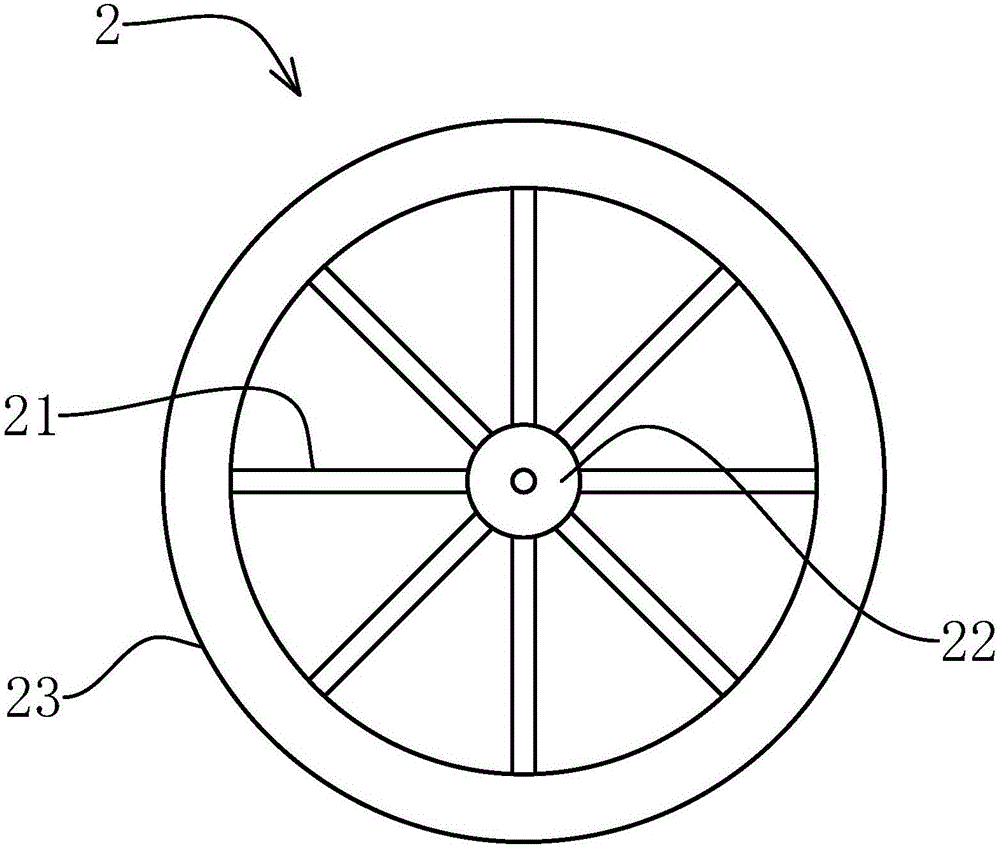

Oxidation washing system equipment based on new resin material treatment

ActiveCN111773854ASolve cleaning difficultiesImprove sealingUsing liquid separation agentSpraying apparatusReciprocating motionMaterials processing

The invention provides oxidation washing system equipment based on new resin material treatment, relates to the technical field of resin material processing, and solves the problems that when gas is filtered, spraying filtration is realized only through a single spraying structure, and linkage movement of multiple filtering structures cannot be realized through structural improvement. In addition,the seepage phenomenon is likely to occur in the spraying and filtering process, and temporary collection cannot be achieved when seepage occurs. The oxidation washing system equipment based on new resin material treatment comprises a box body, the box body is filled with liquid, and a vibration cleaning structure is installed in the box body. A shifting block is in contact with a spray pipe, andthe spray pipe is in an up-and-down reciprocating motion state when the shifting block rotates along with a rotating shaft, so that further diffusion of water mist sprayed by the spray pipe is realized.

Owner:山东仲宜复合材料有限公司

Full-automatic glass slitting and edge-grinding assembly line

PendingCN108943422ALow processing and production costsHigh degree of automationWorking accessoriesStone-like material working toolsTime efficientWater resources

The invention relates to a full-automatic glass slitting and edge-grinding assembly line. The assembly line is sequentially provided with a full-automatic glass loading machine, a full-automatic glasscutting machine, an automatic glass breaking table and a full-automatic glass edge grinding machine in the moving direction of glass. The assembly line can achieve the effects of full-automatic glassloading, feeding, cutting, breaking and edge grinding, the trouble of manual glass loading, manual cutting, manual breaking and manual edge grinding is avoided, moreover, the production environment protection efficiency of workers in each link is improved, machining of the glass is finer, the resource waste is reduced by utilizing recycling of the water resources, meanwhile, the equipment is protected, the automation degree is high, the production efficiency is high, the product percent of pass is high, the labor is saved, the time is saved, the glass slitting cost is reduced, and the safetyis high.

Owner:鹏凯(天津)玻璃有限公司

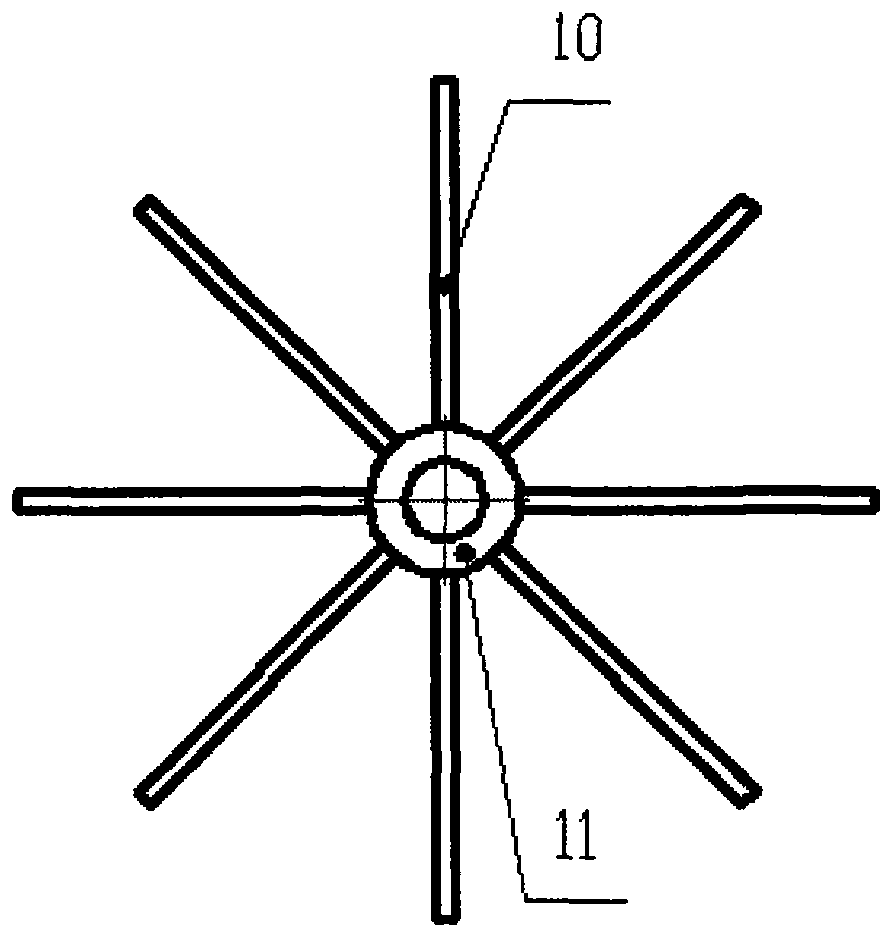

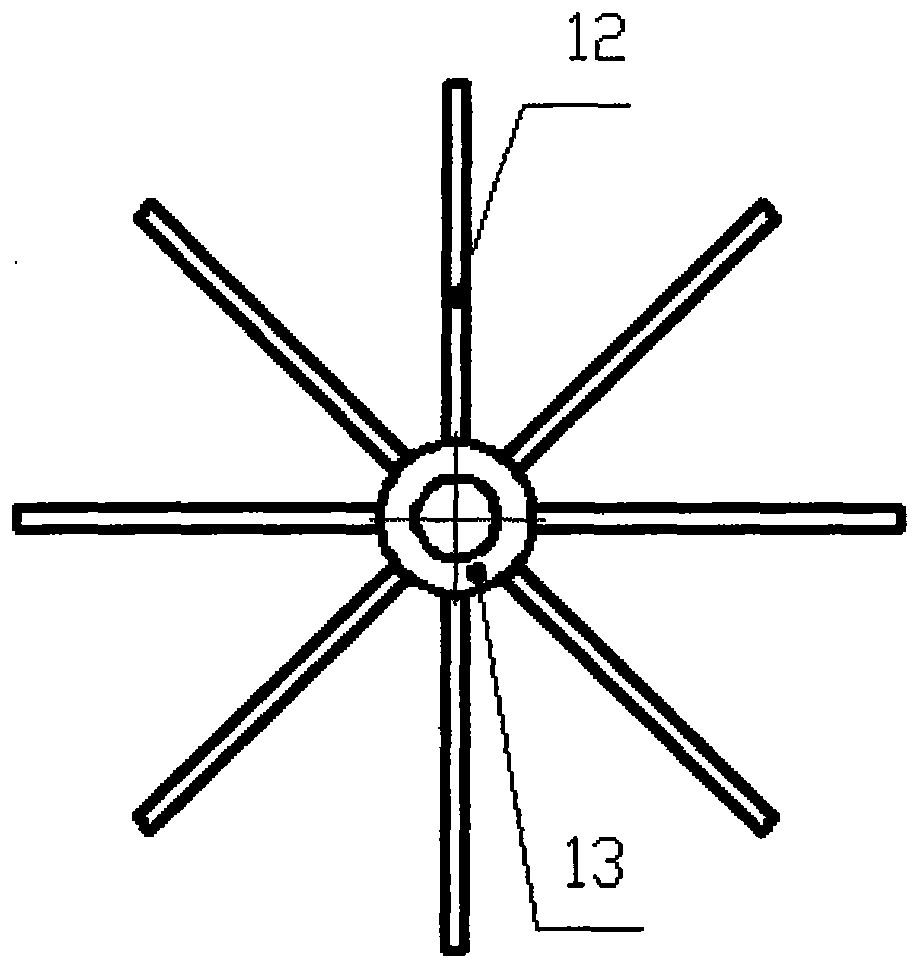

Centrifugal static lampblack removal device

InactiveCN105080719AImprove smoke removal effectReduce accumulationDomestic stoves or rangesLighting and heating apparatusEngineeringFan blade

The invention discloses a centrifugal static lampblack removal device. The centrifugal static lampblack removal device comprises a motor, a channel, an anode and a cathode. The anode is grounded. The cathode is connected with a negative high voltage power supply. The anode is of a disc structure composed of oil throwing strips and an anode jacket, and more than one oil throwing strip is evenly distributed on the anode jacket in a radial manner. The cathode is of a disk structure composed of barb wires and a cathode jacket, and more than one barb wire is evenly distributed on the cathode jacket in a radial manner. The anode is installed at the left end of a main shaft of the motor through the anode jacket. The cathode is installed at the right end of a positioning shaft through the cathode jacket, and can rotate around the positioning shaft. The anode and the cathode are connected through a pusher dog. Fan blades are installed at the positions, located the right side of the anode, of the main shaft of the motor. An oil collecting tank is formed in the position, corresponding to the anode and the cathode, of the channel. Because the deoiling mode that the motor is adopted for driving the anode and the cathode to throw oil at a high speed, the centrifugal static lampblack removal device has the beneficial effects of being good in oil removal effect, low in using cost at the later period, small in workload of maintenance and the like; the problem that electrode plates of a static lampblack removal device are difficult to clean is solved; and the centrifugal static lampblack removal device has the popularization value.

Owner:吴建初

Floor seam beautifying removing device

The invention discloses a floor seam beautifying removing device, which includes a device carrying plate, a cutting mechanism, a heating mechanism, a guide rod as well as a handle, a power connector and a switch. The floor seam beautifying removing device is characterized in that the cutting mechanism is located in the middle of the upper side of the device carrying plate, the heating mechanism islocated at the front end of the upper side of the device carrying plate, and the guide rod is located at the rear end of the lower side of the device carrying plate; the cutting mechanism includes acutting wheel, a driving motor and a transmission mechanism, a rotating shaft of the cutting wheel is connected with the driving motor through the transmission mechanism in a transmission mode; and the heating mechanism includes a heating box, a conical air supply outlet and an air blower, the conical air supply outlet is located on the upper side of the heating box and is connected as a whole ina sealed mode, and the air blower is connected with a port of the conical air supply outlet through a ventilation pipeline. According to the floor seam beautifying removing device, manual work can bereplaced to remove a solidified seam beautifying agent in gaps of a floor in one time, and people conveniently removes the floor and replaces the seam beautifying agent.

Owner:郑州宏拓电子技术有限公司

Pipeline outer wall processing device and pipeline processing technology thereof

ActiveCN108723016AEnsure personal safetyImprove work efficiencyHollow article cleaningWorking environmentEngineering

The invention relates to a pipeline outer wall processing device and a pipeline processing technology thereof. The pipeline outer wall processing device comprises a bottom plate, walking wheels, a position adjusting device, a cleaning device and a collecting device. The walking wheels are mounted at the lower end of the bottom plate, and the position adjusting device is installed at the upper endof the bottom plate. The cleaning device is mounted on the side wall of the position adjusting device, the collecting device is disposed below the cleaning device, and the collecting device is mountedon the bottom plate. The pipeline outer wall processing device solves the difficult problems that in the existing cleaning process of an indoor vertical pipeline outer wall, the difficulty of cleaning is high, labor cost is high, potential safety hazard exists, the labor intensity is high, the work efficiency is low and the cleanness of the working environment is poor; and the function of automatic cleaning of the indoor vertical pipeline outer wall can be realized, and the pipeline outer wall processing device has the advantages of convenient cleaning, low labor cost, high safety degree, lowlabor intensity, high work efficiency, high cleanliness of the working environment and the like.

Owner:无锡市治宇百通投资管理有限公司

Abalone shell calcium complement agent and its prepn. method

ActiveCN1903219AIncrease added valueReduce pollutionOrganic active ingredientsMetabolism disorderProtecting eyeSodium hypochlorite solution

A Ca supplement for increasing bone density and protecting eye and liver is prepared from the shell of abalone through washing with the solution of sodium hypochlorite and pulverizing to obtain powder.

Owner:大连海宝生物技术有限公司

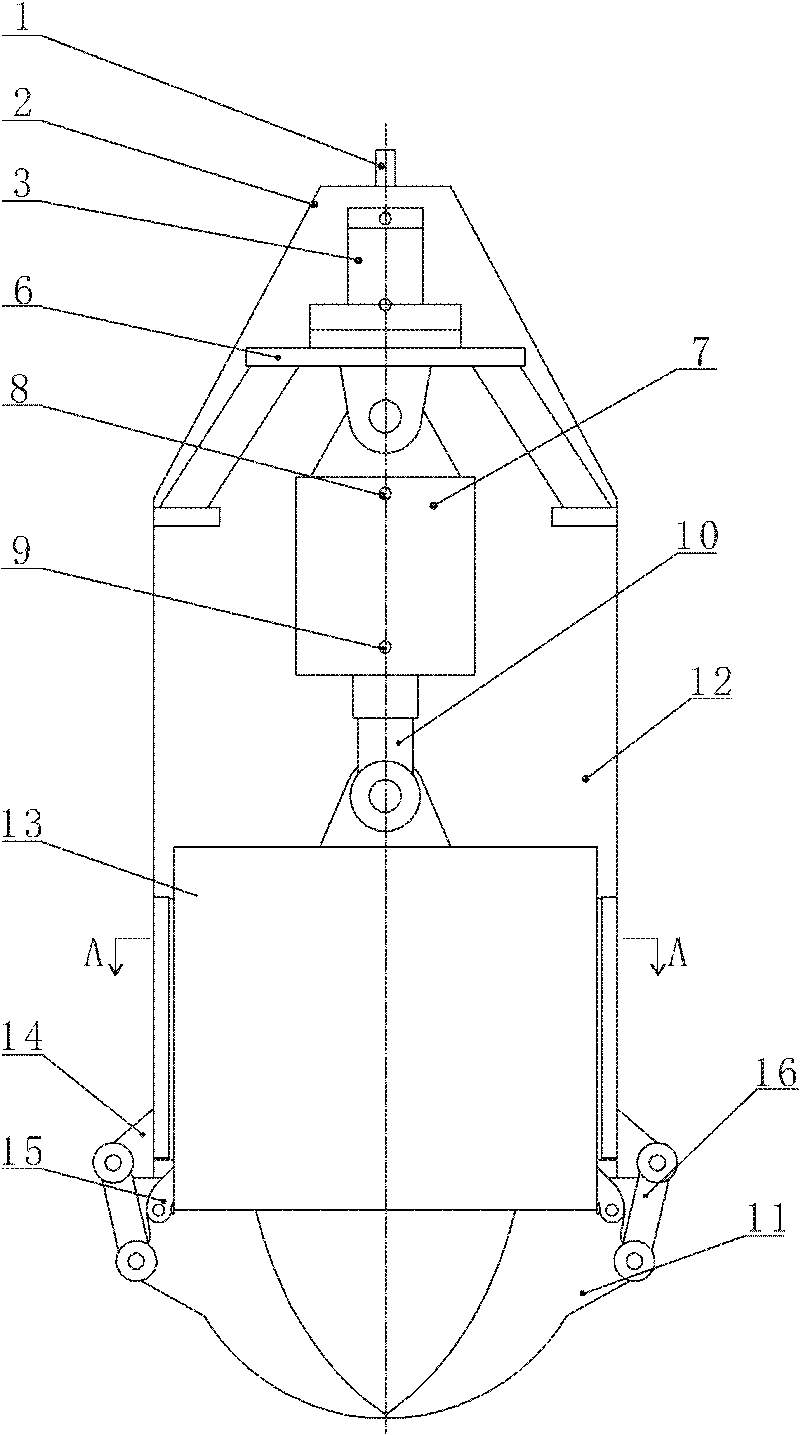

Sludge vibration grab bucket

ActiveCN101761132AEasy to grabEasy accessSoil-shifting machines/dredgersSewer systemsSludgeWater well

The present invention discloses a sludge vibration grab bucket, which relates to a device mainly used for grabbing sludge under the wells of the municipal pipe network drainage system. A cylinder is fixedly arranged in a grab bucket cradle, and a cylinder piston is connected with a grab mechanism. Sludge and scum in wells can be conveniently grabbed by the grab mechanism driven by the cylinder. A pneumatic vibrator is arranged in the grab bucket cradle, and auxiliary vibration force can be transferred to the tip of a grab bucket shovel, which is convenient for the grab bucket shovel to get in dirt blocks. Dry dirt blocks are effectively cleared. A link mechanism fitting with the lotus-shaped grab bucket shovel is arranged upside down. The present invention has the advantages of reasonable running path, little interference, convenient grab, safe and efficient use, time saving and labour saving. The problem for clearing sludge under wells is effectively solved.

Owner:SAFECLEEN TECH

Improved type sewage treatment filter barrel

InactiveCN105964030AAvoid entanglementAvoid gatheringHollow article cleaningStationary filtering element filtersWater flowPulp and paper industry

The invention provides an improved filter cartridge for sewage treatment, which belongs to the field of sewage treatment devices. The utility model solves the problem that the mesh of the existing filter cylinder is easily entangled with silk dirt. The improved filter cartridge for sewage treatment includes a cylindrical filter cartridge with an opening at the top, and both the wall and the bottom of the cartridge are made of metal mesh, and a hanger. The hanger includes several hanging rods arranged radially along the wall of the cartridge. The inner end of the hanging rod is jointly connected with a support plate, and also includes a movable shaft coaxially arranged with the cylinder wall. Between them, the spiral fan blade is set close to the bottom of the cylinder, and can drive the spiral fan blade to rotate around the movable shaft through the water flow, and drive the blade to rotate. The bottom end of the movable shaft is connected with an L-shaped cleaning rod, and the cleaning rod is respectively attached to the bottom of the cylinder The inner side and the inner side of the cylinder wall are set. The filter cartridge can avoid entanglement of filamentous dirt.

Owner:WENZHOU QIBANG ENVIRONMENTAL PROTECTION TECH

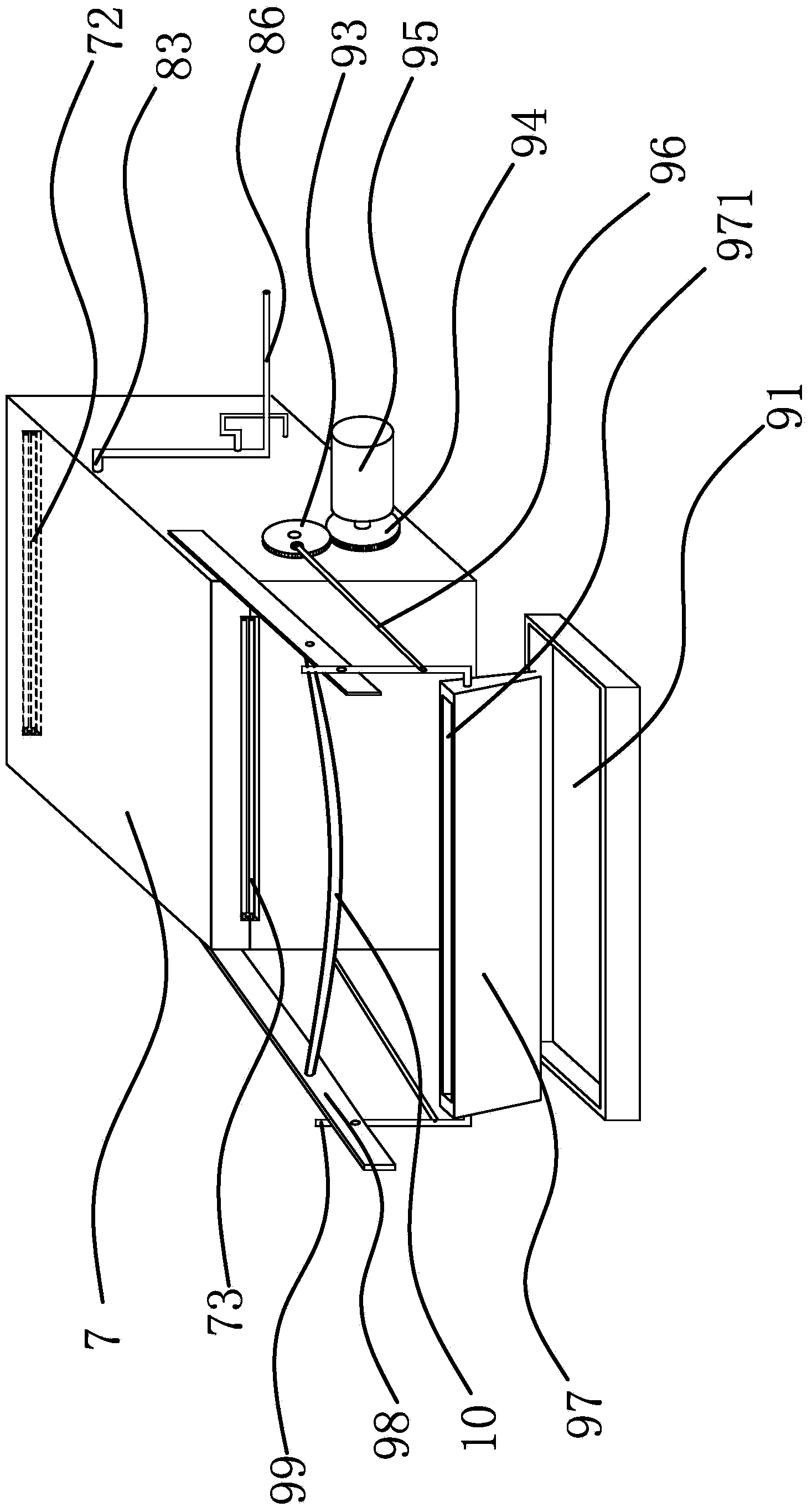

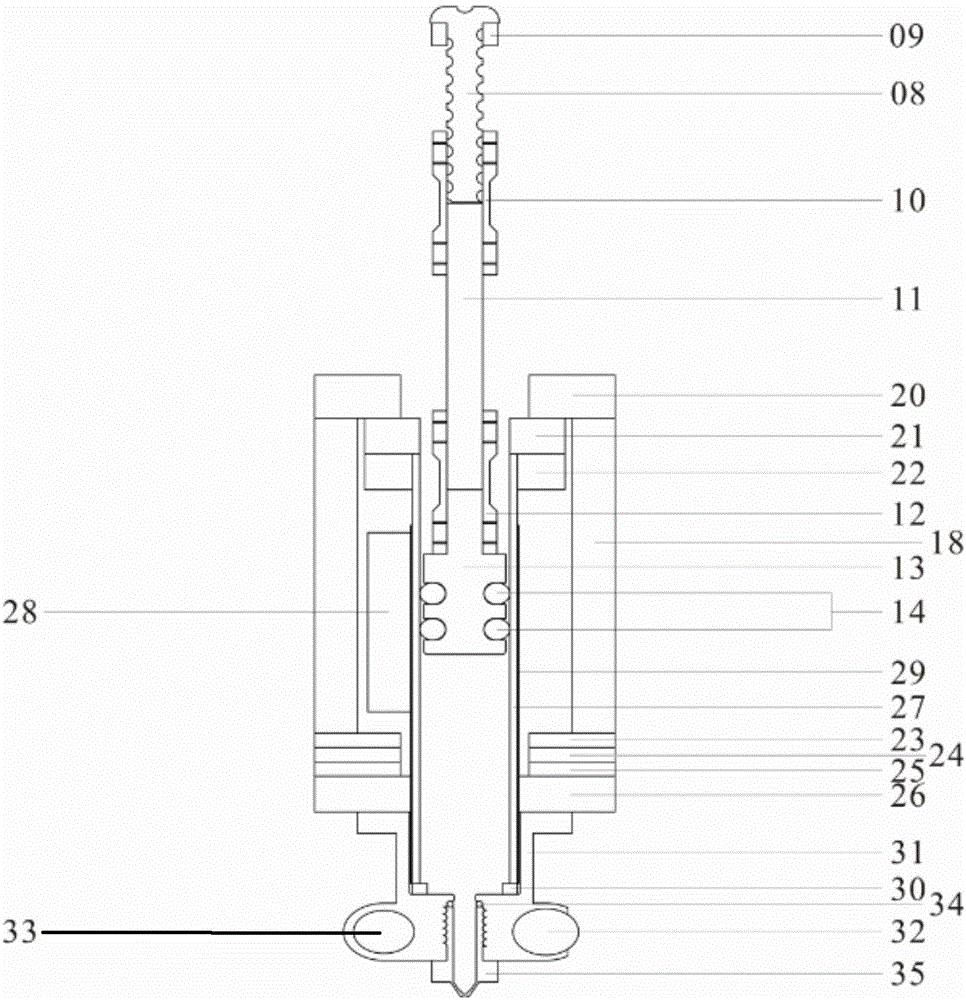

3D printing head with pressure sensing high-temperature-resisting pulp

InactiveCN106426922AFix damageKeep abreast of stressAdditive manufacturing apparatusManufacturing auxillary operationsPressure senseLinear displacement

The invention provides a 3D printing head with pressure sensing high-temperature-resisting pulp. The 3D printing head is arranged on a three-shaft linkage platform and comprises a storage module and a discharging module. The storage module is located in a heat isolation bin module. The heat isolation bin module is a cuboid bin, and each of an upper bin plate and a lower bin plate of the heat isolation bin module is provided with a through hole. The lower end of the storage module is connected with the discharging module through the through hole of the lower bin plate, wherein the discharging module is located below the heat isolation bin module. The spraying direction of the storage module points at the printing plane of the three-shaft linkage platform. The upper end of the storage module is connected with the lower end of an extrusion push rod module through the through hole of the upper bin plate. The upper end of the extrusion push rod module is connected with a linear displacement mechanism module doing the vertical movement through a pressure sensing module. According to the 3D printing head, the pressure is detected according to the extrusion force of the push rod on a pressure sensor, and the problem of damage on equipment due to continuous extrusion in a plugging state is effectively solved; and meanwhile, the discharging module and the storage module are simple in structure and easy to detach, and the problem that the 3D printing head is difficult to maintain and clean is effectively solved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Robot for removing sludge of rainwater pipeline

The invention relates to the field of rainwater pipeline cleaning, and in particular to a robot for removing sludge of a rainwater pipeline. The robot for removing sludge of the rainwater pipeline comprises a steel wire rope spool and a robot main body, wherein the robot main body comprises a controller, a sludge shoveling component, a connecting component, a moving component and a storage component; the sludge shoveling component is arranged at the front end of the robot main body; the moving component is hinged with the sludge shoveling component by virtue of the connecting component; the storage component is arranged in the moving component; the sludge shoveling component comprises a shovel for shoveling off the sludge and a roller component for crushing the sludge; the roller componentis arranged in the shovel; by virtue of the sludge shoveling component, garbage of the sludge in the rainwater pipeline can be shoveled into the shovel, the shoveled garbage can be pushed to the inlet end of a first lifting component by virtue of the roller component in the shovel, and such garbage as the sludge and the like can be stored in a storage box by virtue of the first lifting componentand a second lifting component; and the robot main body is drawn to the ground by virtue of a steel wire rope when the storage box is full of sludge or garbage, so that the sludge or garbage is pouredoff.

Owner:南通市金润市政工程有限公司

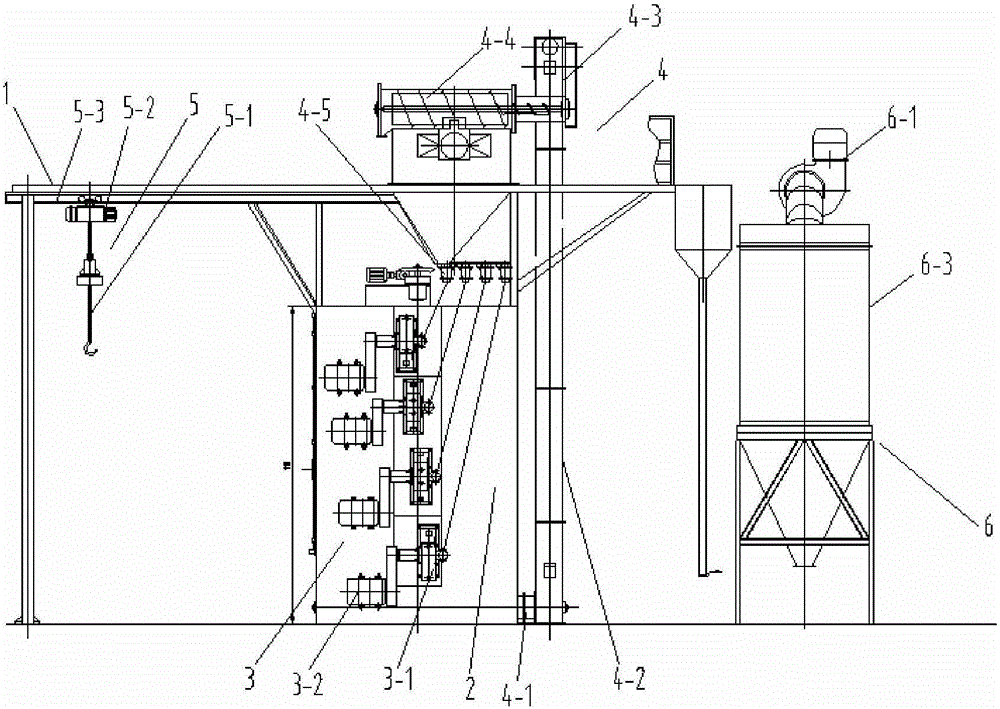

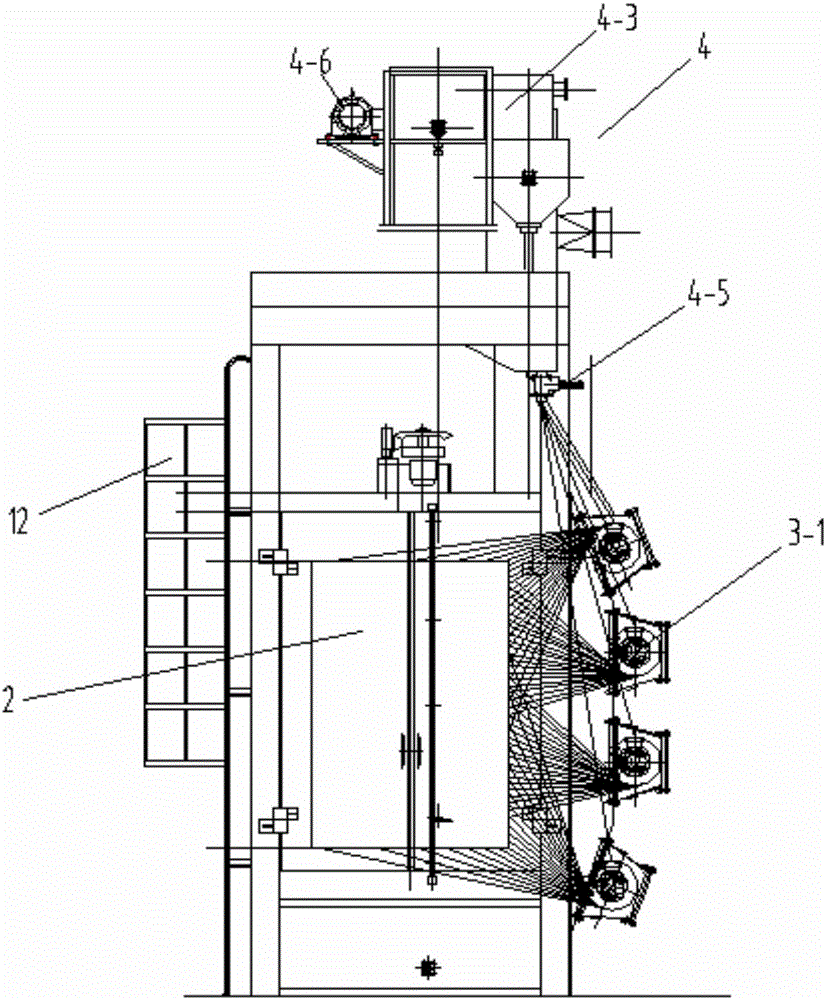

Shot blasting rust removal device for buoy accessories

InactiveCN106041747AEasy to operateVersatileAbrasive feedersAbrasive machine appurtenancesControl systemElectrical control

A shot blasting rust removal device for buoy accessories comprises a rack, a shot blast cleaning chamber, a blast wheel assembly, a shot-sand distributing system, a lifting hook system, a dust removal system and an electrical control system. The shot blasting rust removal device for buoy accessories is structurally characterized in that the shot-sand distributing system for shot-sand distributing and supplying is borne on the top layer of the rack, the shot blast cleaning chamber is located below the shot-sand distributing system, an outlet of the shot-sand distributing system is connected with an inlet of the blast wheel assembly for carrying out shot blasting work treatment, an inlet of the shot-sand distributing system communicates with a pipeline extending downwards, and a shot-sand conveyor for sucking materials from the outside is arranged at the tail end of the pipeline. The shot blasting rust removal device for buoy accessories has the characteristics of being high in automation degree, capable of achieving pipeline operation, high in production efficiency, good in rust removal quality, low in cost and little in environment pollution.

Owner:交通运输部南海航海保障中心湛江航标处

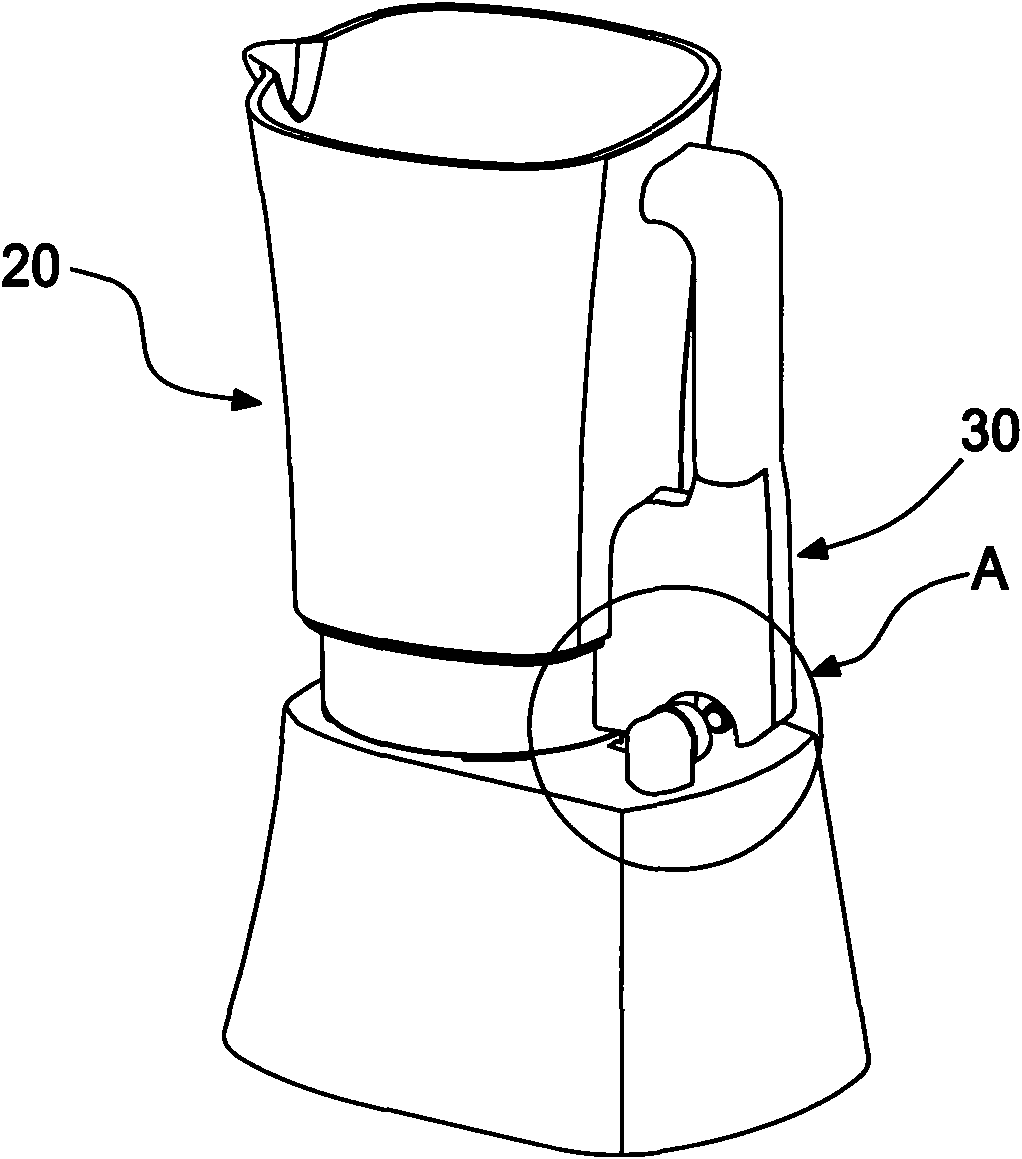

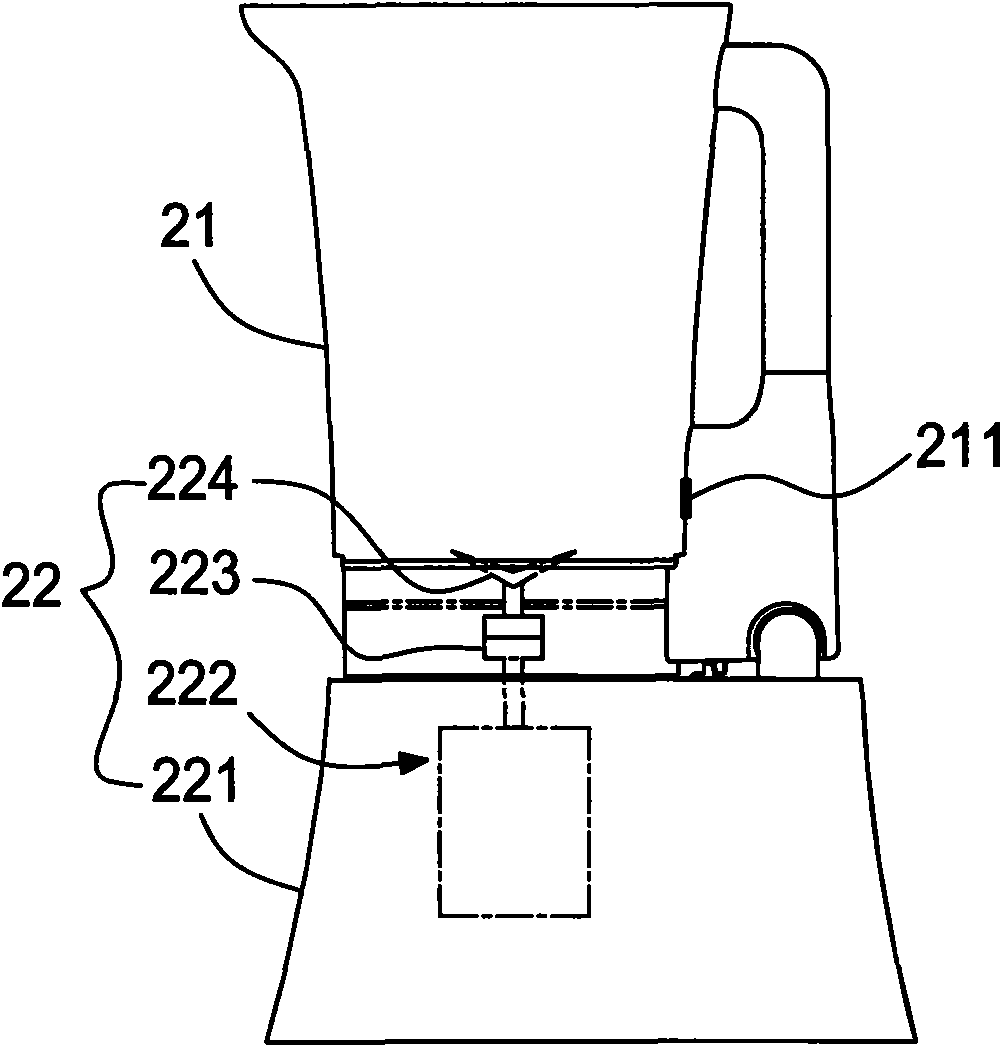

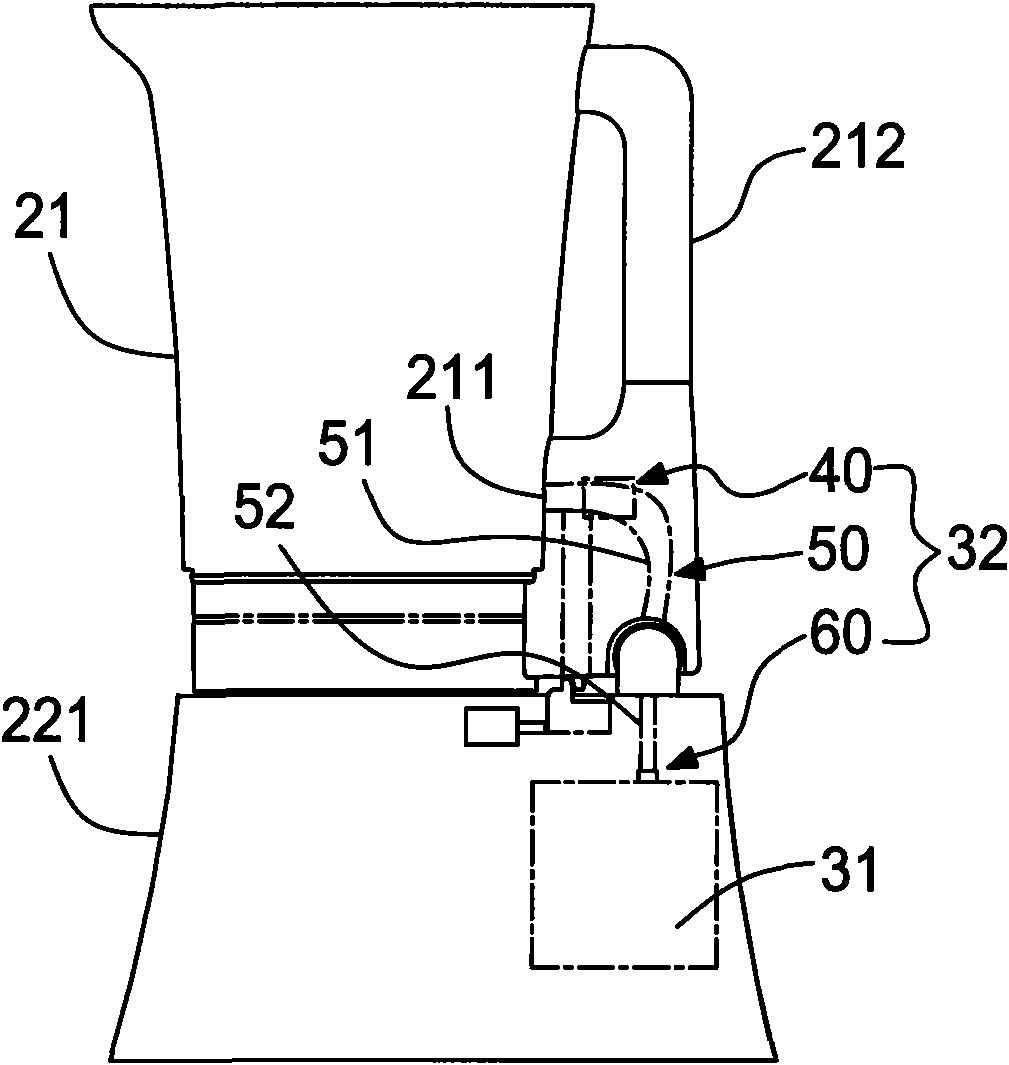

Steam heating type soybean milk grinder

ActiveCN101862124ASolve cleaning difficultiesOvercome operabilityBeverage vesselsMilk substitutesProcess engineeringSteam generation

The invention relates to a soybean milk grinder, in particular to a steam heating type soybean milk grinder. The soybean milk grinder comprises a drink making system and a steam heating system, wherein the drink making system comprises a milk making cup and a drink making device for making the drink in the milk making cup; the steam heating system comprises a steam generation container and a pipeline conveying device which is connected with the milk making cup and the steam generation container, wherein the milk making cup is provided with a pipeline port which is formed under the liquid level of the milk making cup; the output end of the pipeline conveying device is connected with the pipeline port, while the input end is connected with the steam generation container; in addition, the soybean milk grinder also comprises a control device, wherein the control device comprises a water supply module and a steam supply module; the water supply module is used for controlling the pipeline conveying device to convey the liquid in the milk making cup into the steam generation container; and the steam supply module is used for controlling the pipeline conveying device to convey the steam produced by the steam generation container into the milk making cup. The soybean milk grinder simultaneously overcomes the technical problems of difficult water adding operation and complex pipeline structure in the prior art and has obvious improvement.

Owner:MIDEA GRP CO LTD

Heat exchanger pipeline galvanizing groove

InactiveCN104404425AUniform feedingThe product processing effect is the sameHot-dipping/immersion processesSteel tubeSlag

The invention discloses a heat exchanger pipeline galvanizing groove. The galvanizing groove comprises a groove body, a frame, a conveying device and a fluted disc; the frame, conveying device, and the fluted disc are arranged in the groove body, the fluted disc is arranged under the frame, a feed guide rail is arranged above the right side of the fluted disc, a control brake is arranged on the feed guide rail, a material bearing guide rail is arranged on the rotation shaft of the fluted disc, a zinc pot is arranged under the fluted disc; a control motor is arranged on the frame, the control motor is connected to a material-pushing rod, and the inclined opening arranged in the lower left part of the zinc port is provided with a slag removing shovel. A control brake is arranged on the feed guide rail, and is used to control the number of steel pipes that enter the fluted disc so that the tooth removing treatment can be carried out on one steel pipe at a time. The material feeding is even, and the processing effect on each steel pipe is the same. The slag removing shovel can eliminate the residues on the bottom of the groove body in time so as to avoid the long-term accumulation of the residues, and thus the cleaning becomes easier. The conveying belt is also provided with a plurality of material-clamping hooks that can individually convey the steel pipes, the steel pipes are individually transported, and thus the post-treatment on the steel pipes becomes easier.

Owner:WUXI YUDA HEAT EXCHANGER

Crushing and screening device

ActiveCN106311392AIncrease centrifugal forceImprove sievingSievingGas current separationEngineeringAir compressor

The invention provides a crushing and screening device. The crushing and screening device comprises a crushing part and two screening parts. A pair of rollers is arranged in a crushing cavity. Fixing plates are arranged on the inner walls of the two sides of the crushing cavity. Bristles are arranged on the fixing plates. Each screening part comprises a sleeve and an S-shaped screening cylinder which is arranged in the sleeve. The lower end of each S-shaped screening cylinder is connected with a rotating motor. Each S-shaped screening cylinder communicates with the corresponding sleeve through a plurality of screening holes which are formed in the side wall of the S-shaped screening cylinder. A plurality of barrier strips are arranged on the two sides of the inner wall of each sleeve in a vertically-staggered mode. According to the crushing and screening device, the S-shaped screening cylinders are matched with the rotating motors, so that centrifugal force is increased, and screening efficiency is effectively improved; in addition, the crushing and screening device has excellent self-cleaning performance, the bristles can remove materials adhering to the pair of rollers during work, the barrier strips can continuously flip the S-shaped screening cylinders along with rotation of the rotating motors, and the screening holes are effectively prevented from being blocked; and furthermore, air compressors are arranged, so that the cleaning effect is good, and the problem that a screening device is difficult to clean is effectively solved.

Owner:安徽中扬新材科技有限公司

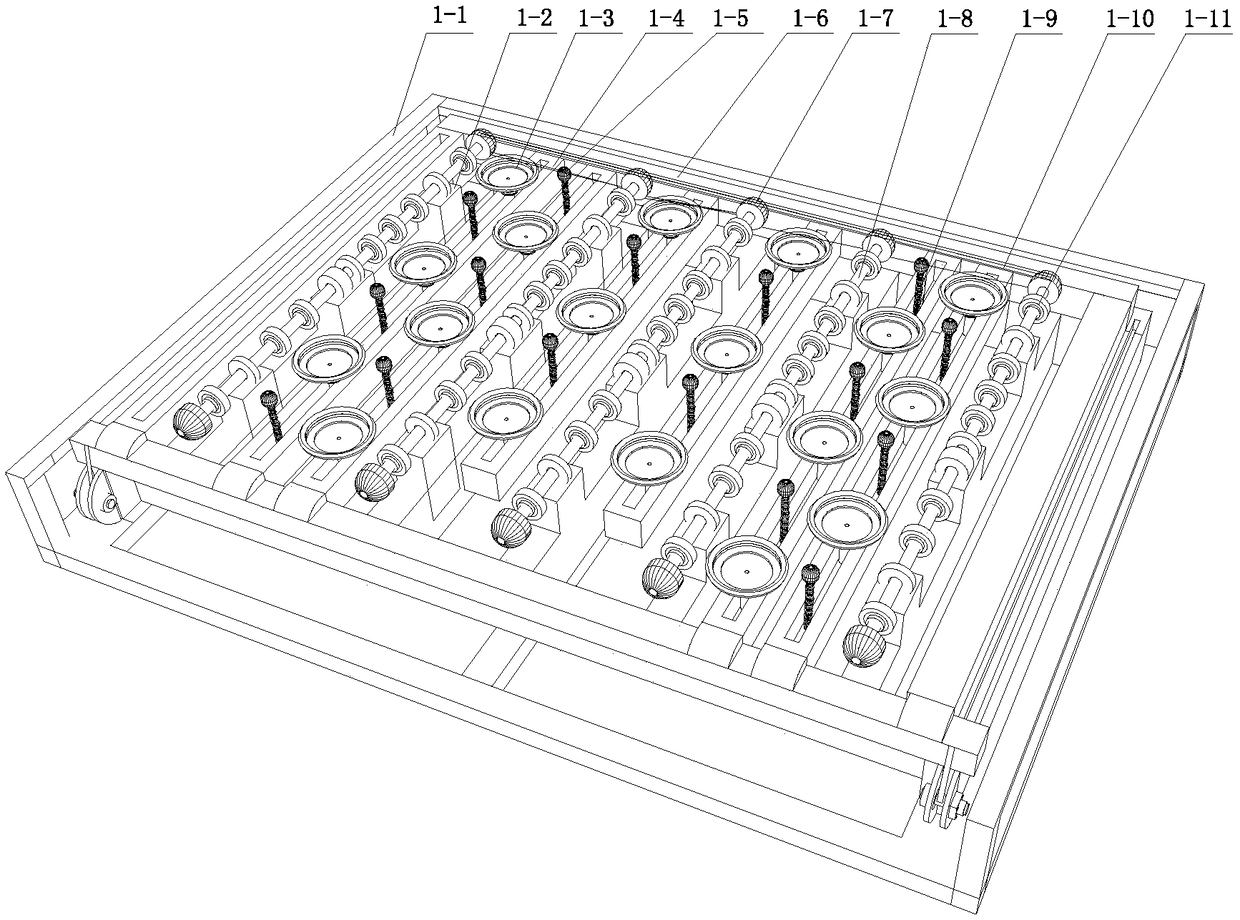

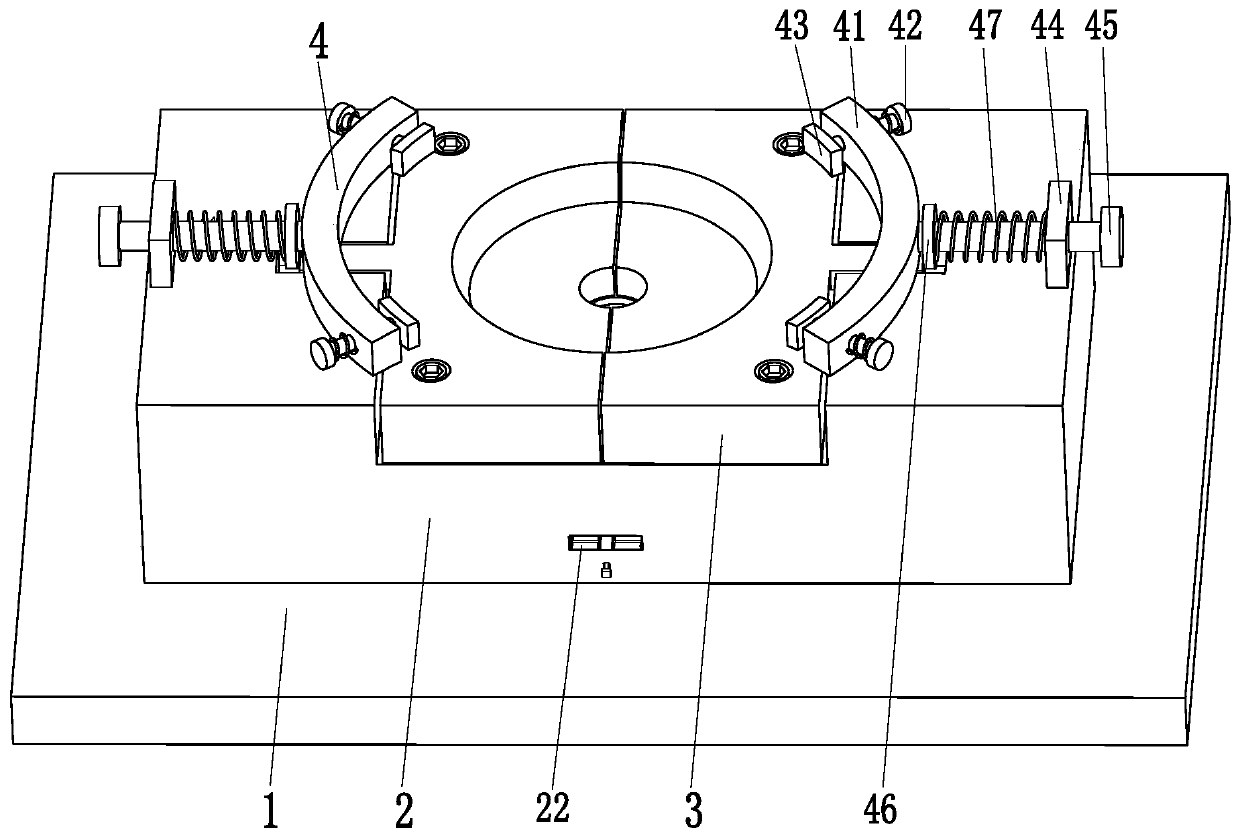

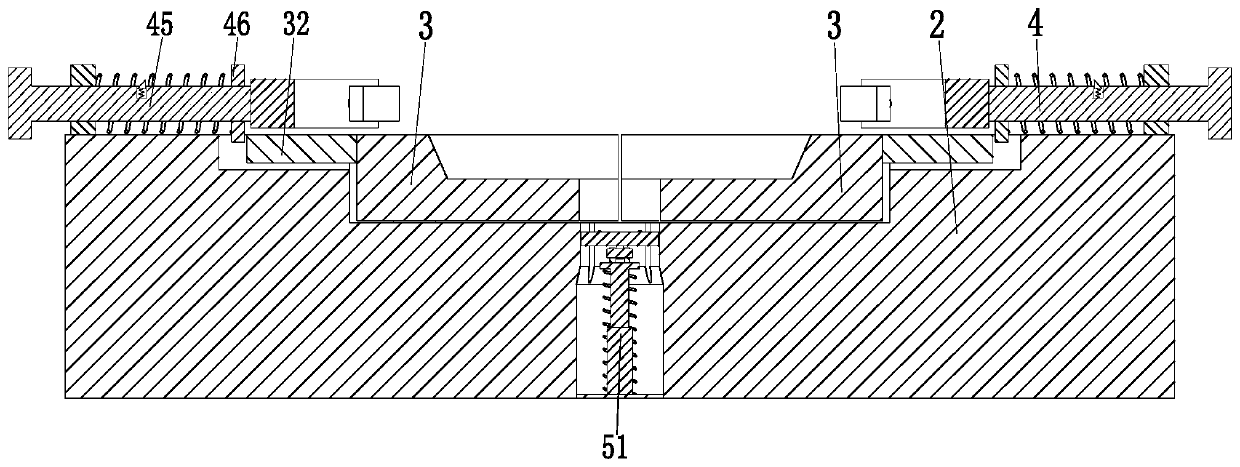

Supporting mold of disk-shaped aluminum pressure casting

ActiveCN110479866ASolve cleaning difficultiesImprove stamping effectShaping toolsPerforating toolsPressure castingEngineering

The invention relates to a supporting mold of a disk-shaped aluminum pressure casting. The supporting mold of the disk-shaped aluminum pressure casting comprises a bottom plate, a supporting base, lower dies, positioning mechanisms and a conveying mechanism; the supporting base is arranged on the upper end face of the middle part of the bottom plate; the supporting base is of a U-shaped structure;two lower dies are arranged in the U-shaped structure of the supporting base; the lower dies are arranged symmetrically; a square groove is formed on each of the left side wall and the right side wall of the U-shaped structure of the supporting base; one positioning mechanism is distributed on the outer side of the upper end of each lower die; the positioning mechanism is arranged at the top of the outer end of the supporting base; and the conveying mechanism is arranged in a round hole of the supporting base. The supporting mold of the disk-shaped aluminum pressure casting can solve the problems that the common die only can perform pressure casting on one type of product and has low applicability when a round aluminum plate is subjected to pressure casting at present, the pressure casting effect of the aluminum plate is bad due to low manual alignment precision on the aluminum plate when the aluminum plate is placed on the lower die as well as the punched waste is difficult to recover when the aluminum plate is subjected to punching treatment can be solved.

Owner:TAIZHOU TIANCHENG MOLD MFG

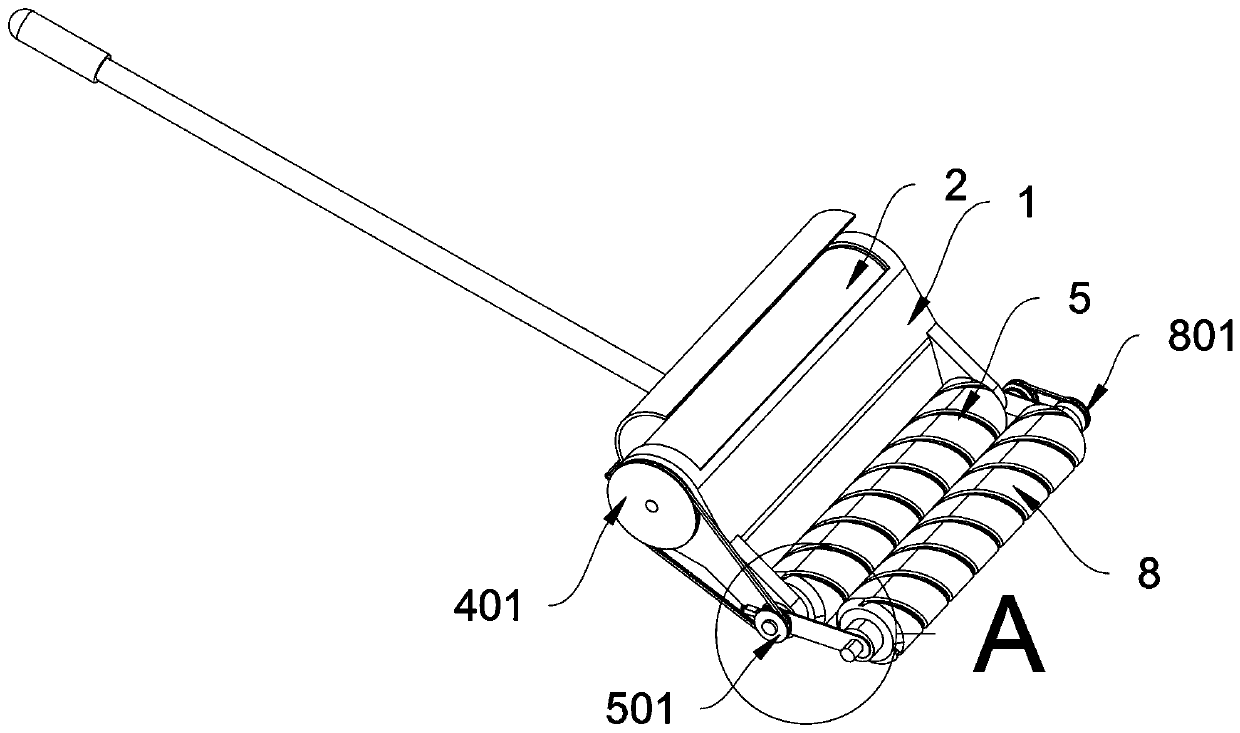

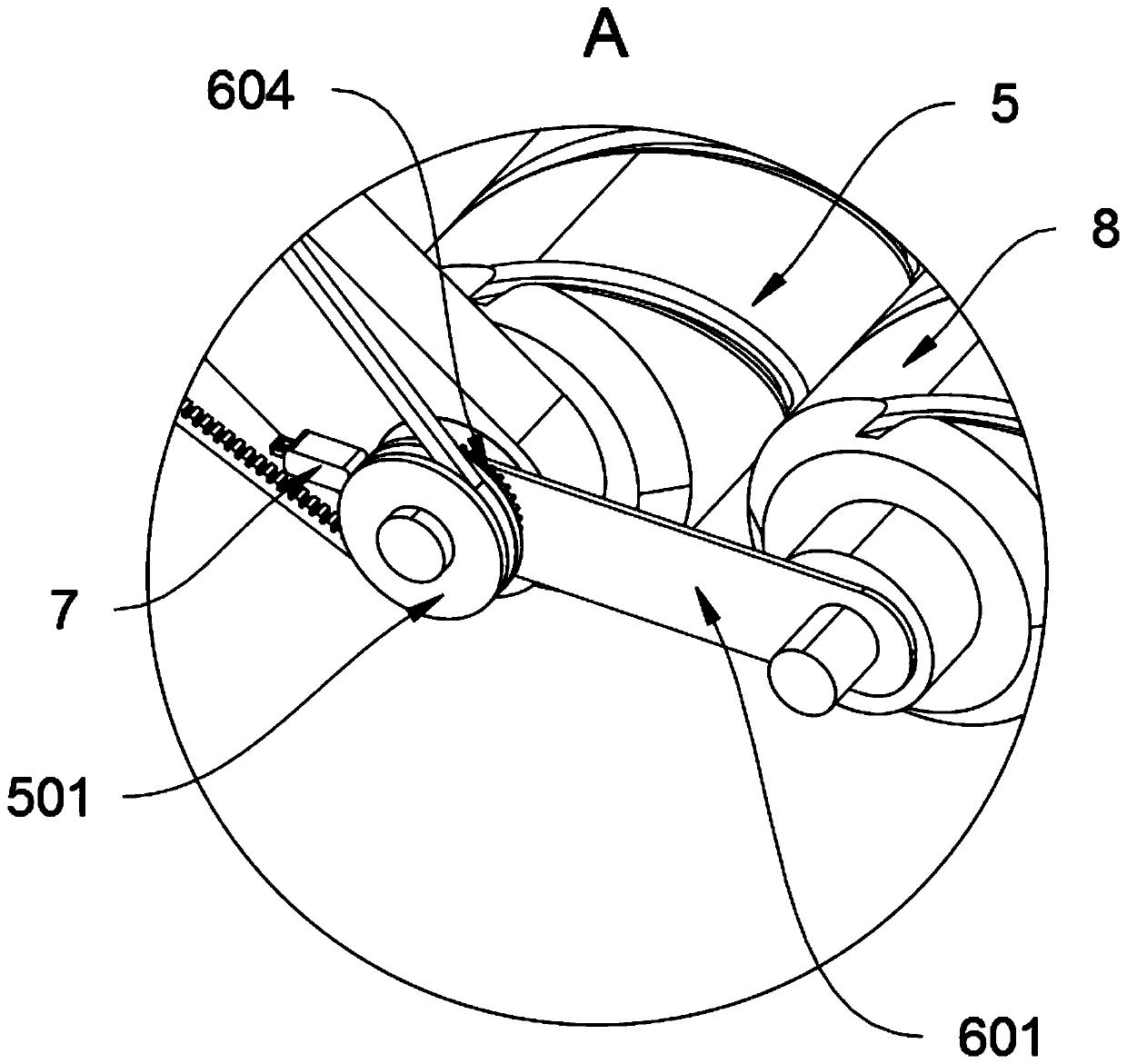

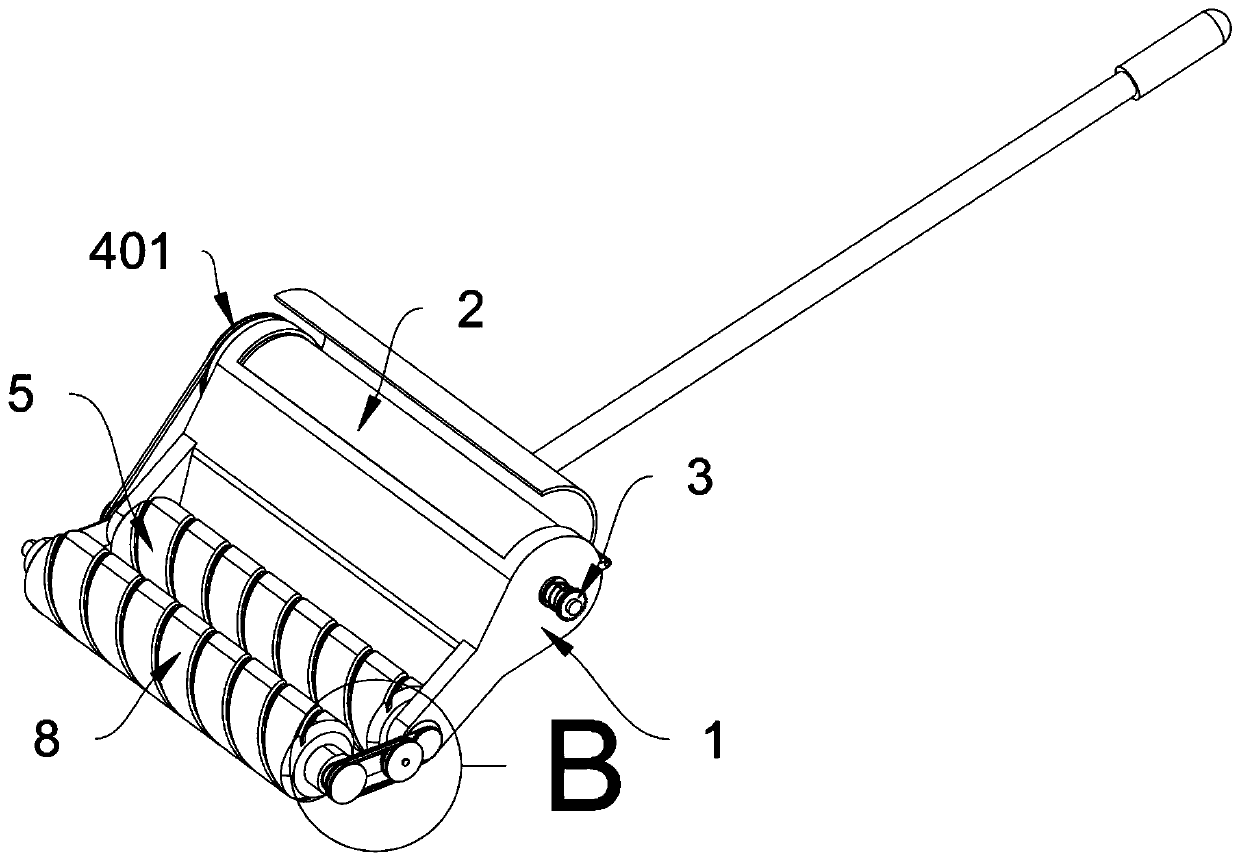

Coating device for mold release agent

ActiveCN110694868AAvoid runningReasonable structureLiquid surface applicatorsRotary stirring mixersEngineeringMechanical engineering

The invention provides a coating device for a mold release agent and relates to the field of coating devices. The problems are solved that when dipped, the coating easily drips on the ground, cleaningis difficult, and cleaning and coating cannot be conducted at the same time. The coating device for the mold release agent comprises a main device base and a rotation connection base; a storage barrel is rotatably connected into the main device base, and a positioning structure is welded to the storage barrel; a stirring shaft is rotatably connected into the main device base and the storage barrel. Through linkage arrangement of a painting roller and the stirring shaft, raw materials in the storage barrel can be stirred during printing, and compared with existing devices, the device is more reasonable in structure and higher in practicability; through linkage arrangement of the painting roller and a cleaning roller, when rotating clockwise, the painting roller can drive the cleaning roller to rotate anticlockwise, and accordingly dust and debris on planks can be removed. Compared with the existing devices, the device can avoid the situation that since the dust and debris are attachedto the painting roller, cleaning is difficult.

Owner:NANJING YUZHI INTELLIGENT TECH CO LTD

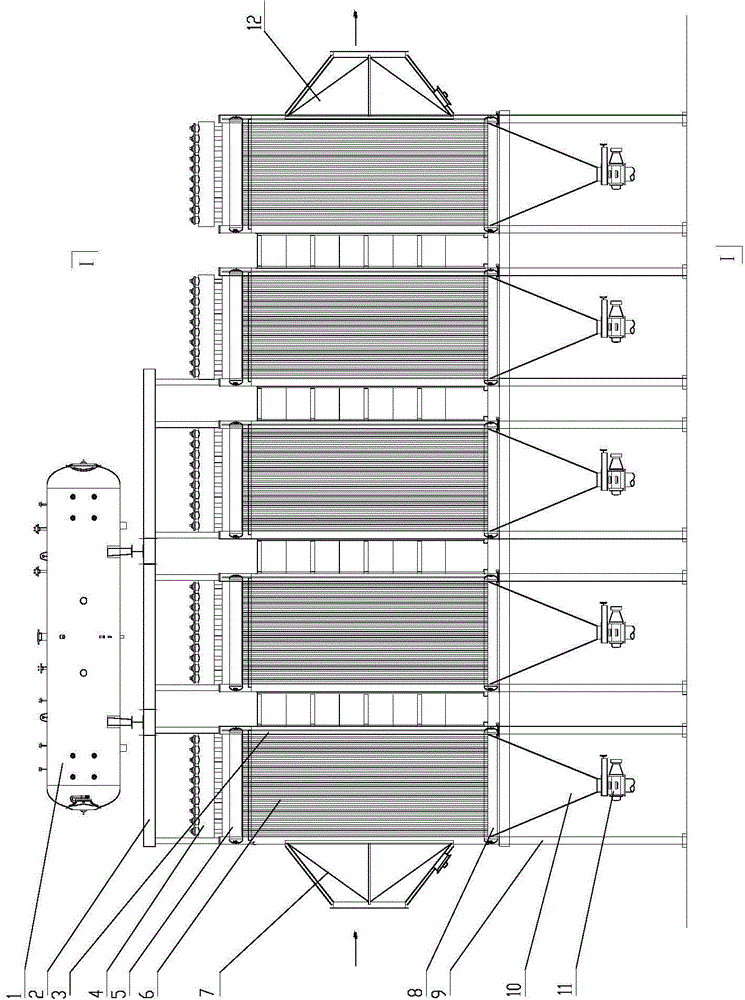

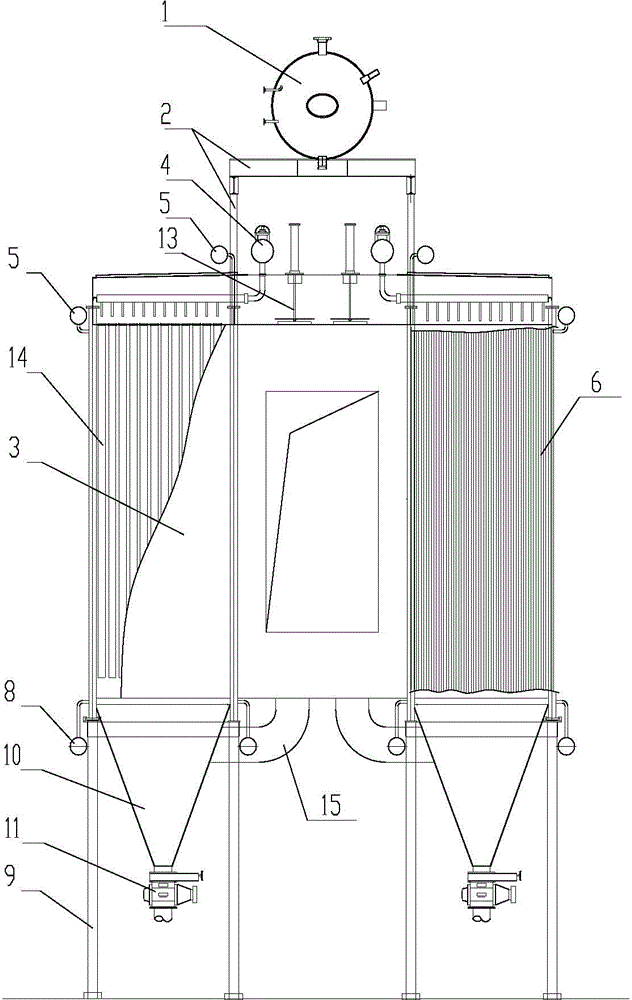

Waste heat recycling type deduster

The invention provides a waste heat recycling type deduster which is used for recycling waste heat of high-temperature flue gases. The waste heatrecycling type deduster comprises a plurality of box bodies connected in sequence, high-temperature flue gas flow channels are formed in the box bodies, and a plurality of filter devices for filtering flue gases are vertically arranged in each high-temperature flue gas flow channel; water cooling devices are respectively arranged on the outer walls of the box bodies, and the water cooling devices on the outer walls of the box bodies exchange heat with high-temperature flue gases flowing in the box bodies, and heat recycling devices are respectively connected to the water cooling devices so as to recycle the heat generated after the heat is exchanged between the water cooling devices and the high-temperature flue gases. The waste heatrecycling type deduster not only can remove dust, but also can recycle heat in the high-temperature flue gases at the same time.

Owner:BERIS ENG & RES CORP

Manufacturing method for casting branch oilway in body of diesel engine

The invention relates to the technical field of a diesel engine, in particular to a manufacturing method for casting an branch oilway in a body of the diesel engine. The manufacturing method comprises the following steps of: a, cutting out a seamless steel tube with required length and welding a round bar steel on a lower part of the seamless steel tube; b, performing tin plating on the seamless steel tube welded with the round bar steel; c, manufacturing a core, and filling zircon precoated sand into the seamless steel tube; d, after the core is manufactured, putting the core and a mould into a furnace for baking, wherein the baking temperature is between 150-180 DEG C and the baking time is between 3-7 hours; and e, when the core is installed, installing one end of the core of the branch oilway in a core seat on a core of a main oilway and installing the other end of the core in a core seat on a core of a thrust camshaft seat, filling paper and other substances into reserved gaps of the top ends of the core seats, and levelling by newly-mixed resin sand. The manufacturing method provided by the invention is used to avoid air hole generation and the like caused by rusting of the seamless steel tube and higher moistures in red sand mud and cleaning difficulty caused by iron penetrating into the branch oilway, adhesion of a ceramic pipe and other phenomena.

Owner:CRRC QISHUYAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com