Sludge vibration grab bucket

A grab and sludge technology, applied in waterway systems, earth movers/excavators, water supply devices, etc., can solve the problems of low efficiency, poor adaptability, high cost of transporting sludge, etc., and achieve reasonable running track, safe and efficient use , Grab the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

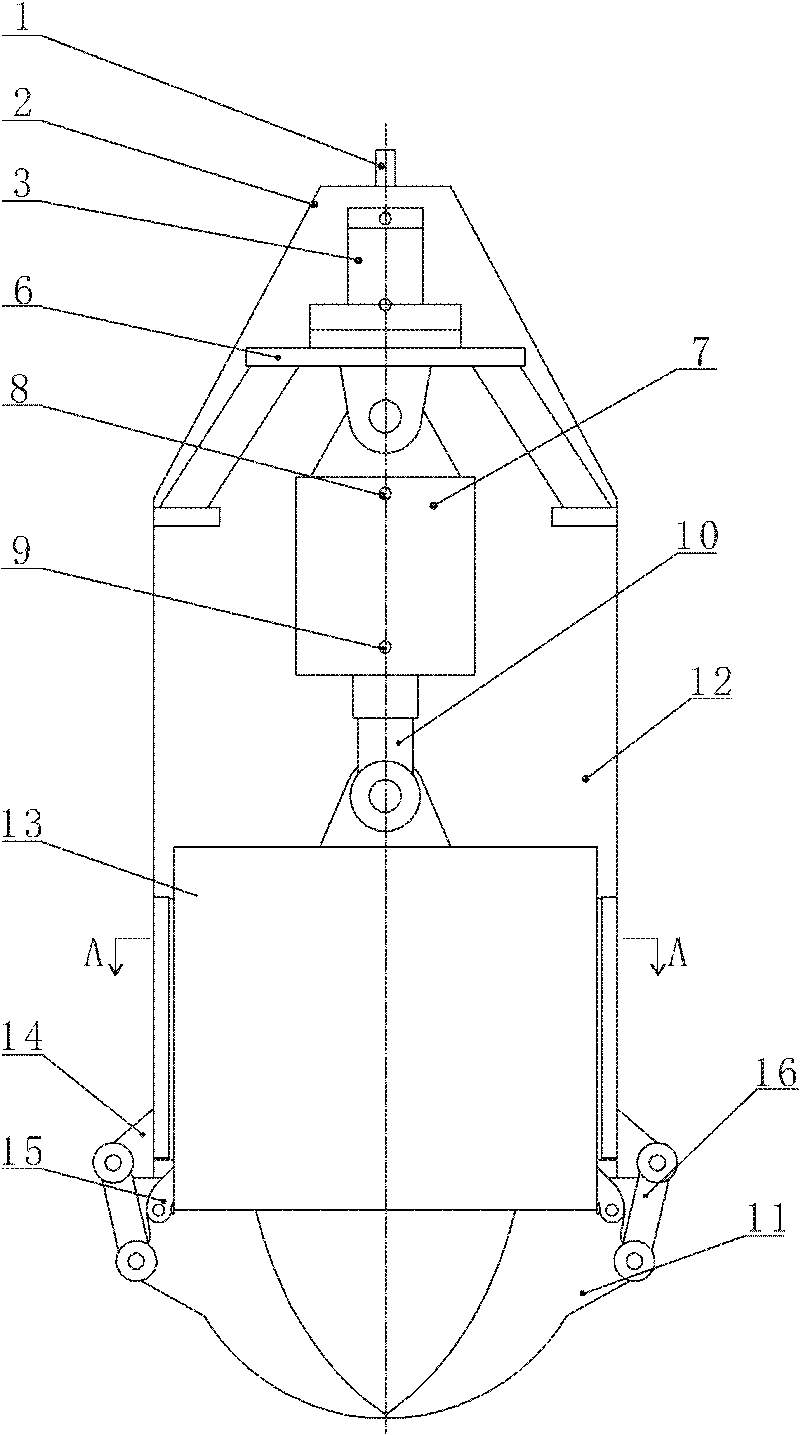

[0011] A sludge vibrating grab. A cylinder 7 is fixedly installed in a grab hanger 2, and a cylinder piston 10 is connected with a grabbing mechanism.

[0012] In the grabbing mechanism, at least two connecting rod supports 14 are arranged under the grab outer cylinder 12, and the connecting rod supports 14 are hinged with the grab shovel 11 through the connecting rod 16; There are at least two grab shovel rings 15, and the grab shovel ring 15 is hinged with the grab shovel 11; In actual operation, according to different application occasions, there can be two grab shovels or three or four grab shovels, and even precision machining can be used to make the grab shovels 11 closed when they are closed, which can be used Good at picking up smaller objects, such as dry sand.

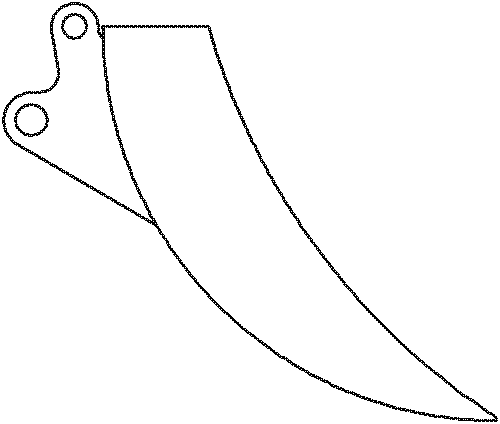

[0013] The grab shovel 11 is in the shape of an inverted lotus petal, and two hinge holes are arranged on the support at the root. The gap between the two hinge holes can be regarded as a side of the link m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com