Patents

Literature

3018results about How to "Easy to grab" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for facilitating the execution of law enforcement duties and enhancing anti-terrorism and counter-terrorism capabilities

ActiveUS8742934B1Easy to grabAvoid prolonged useData processing applicationsDigital data processing detailsElectronic systemsComputer science

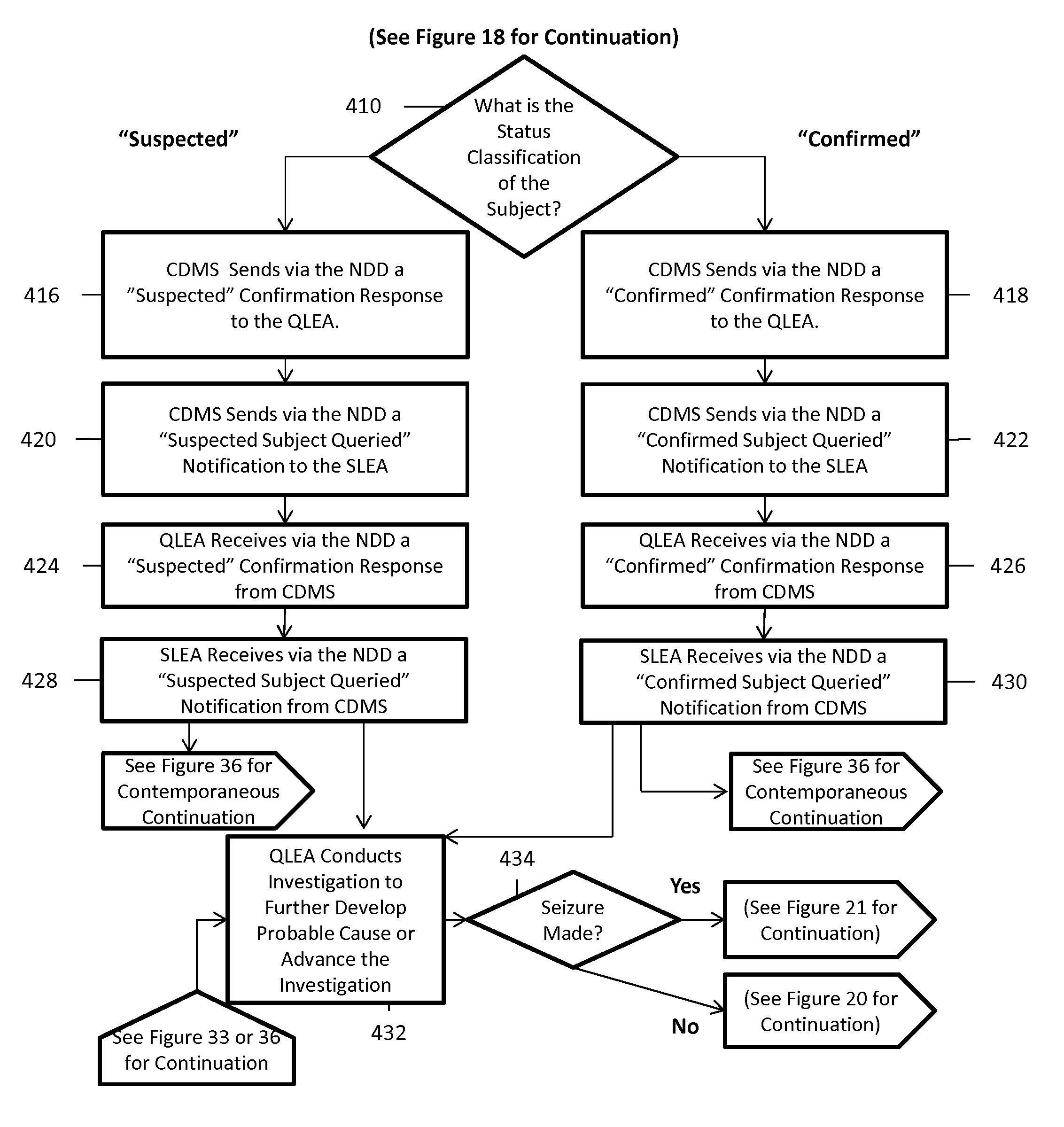

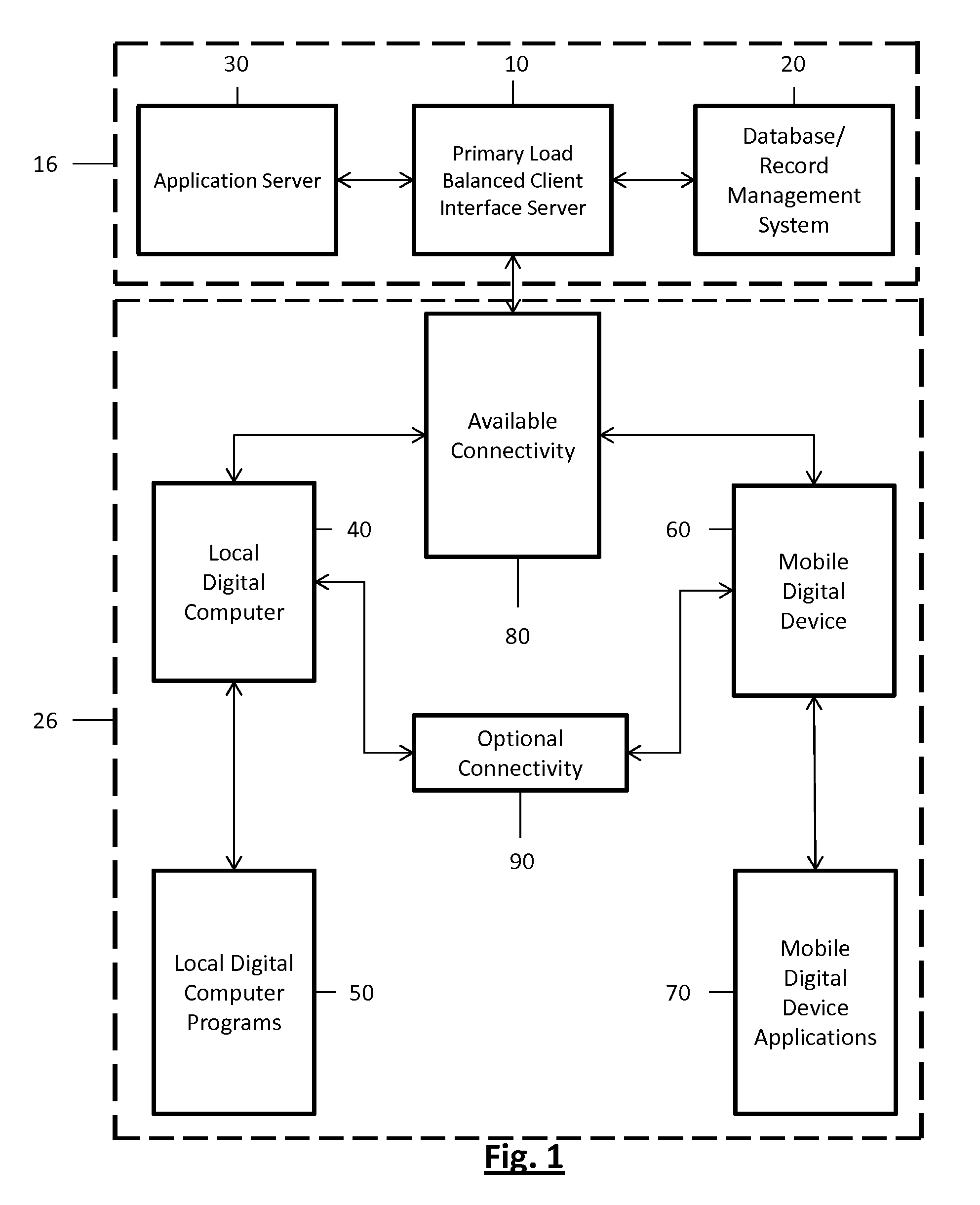

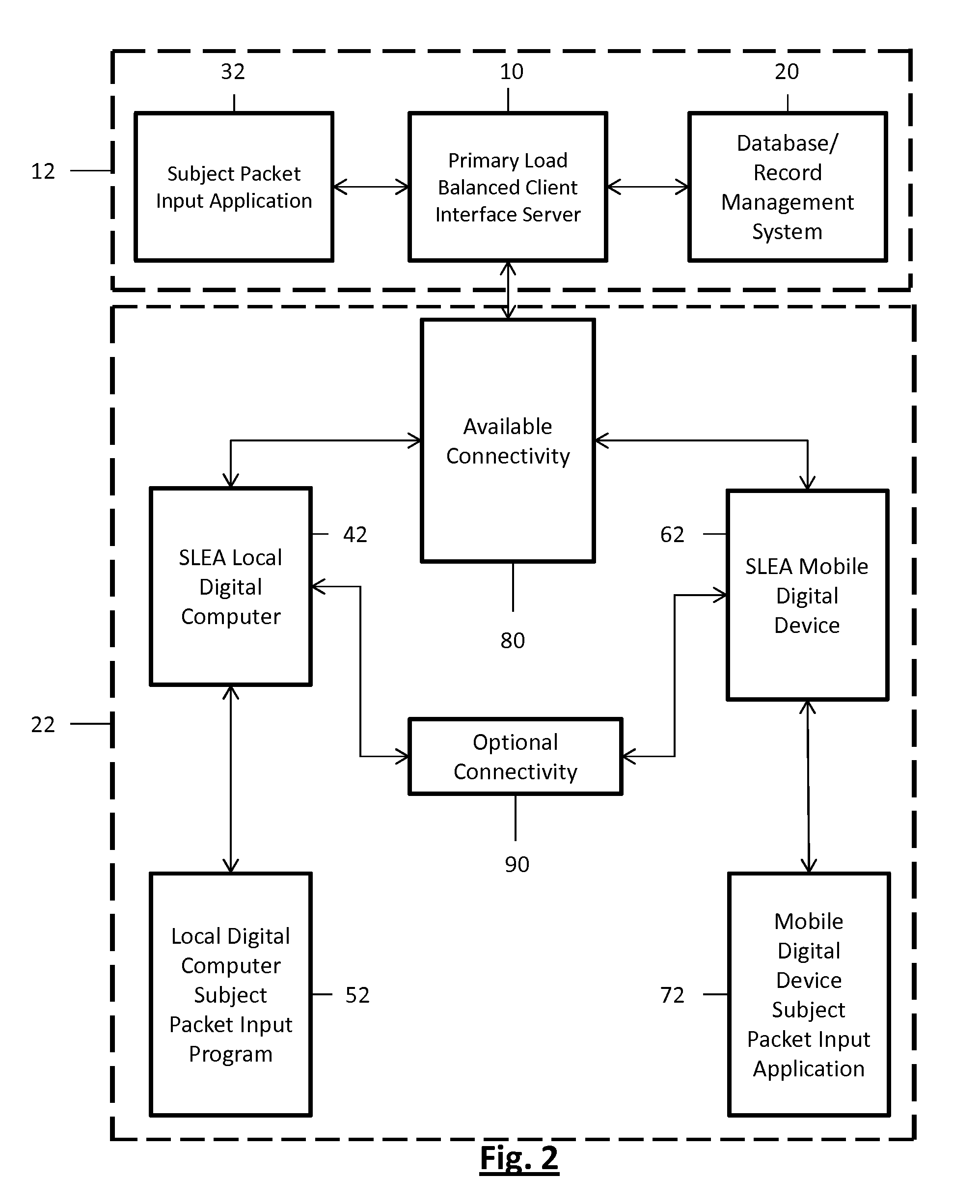

A system and method for facilitating the execution of law enforcement duties and enhancing anti-terrorism and counter-terrorism capabilities is disclosed. More particularly, according to one aspect of the invention, an electronic system and associated method is configured to facilitate the performance of law enforcement duties by quasi-instantaneously providing actionable intelligence to its users, such as front-line law enforcement officers, in response to a real-time query. According to another aspect of the invention, a system implements a set of automated status classifications for subjects with suspected or confirmed involvement in criminal and / or terrorist activities. The status classifications specifically and concisely establish the subject's involvement in criminal and / or terrorist activities. According to yet another aspect of the invention, a system executes a streamlined electronic process for asset forfeiture actions so as to ensure that criminal and / or terrorist assets are efficiently and effectively seized.

Owner:SUBJECT PACKET SOLUTIONS LLC

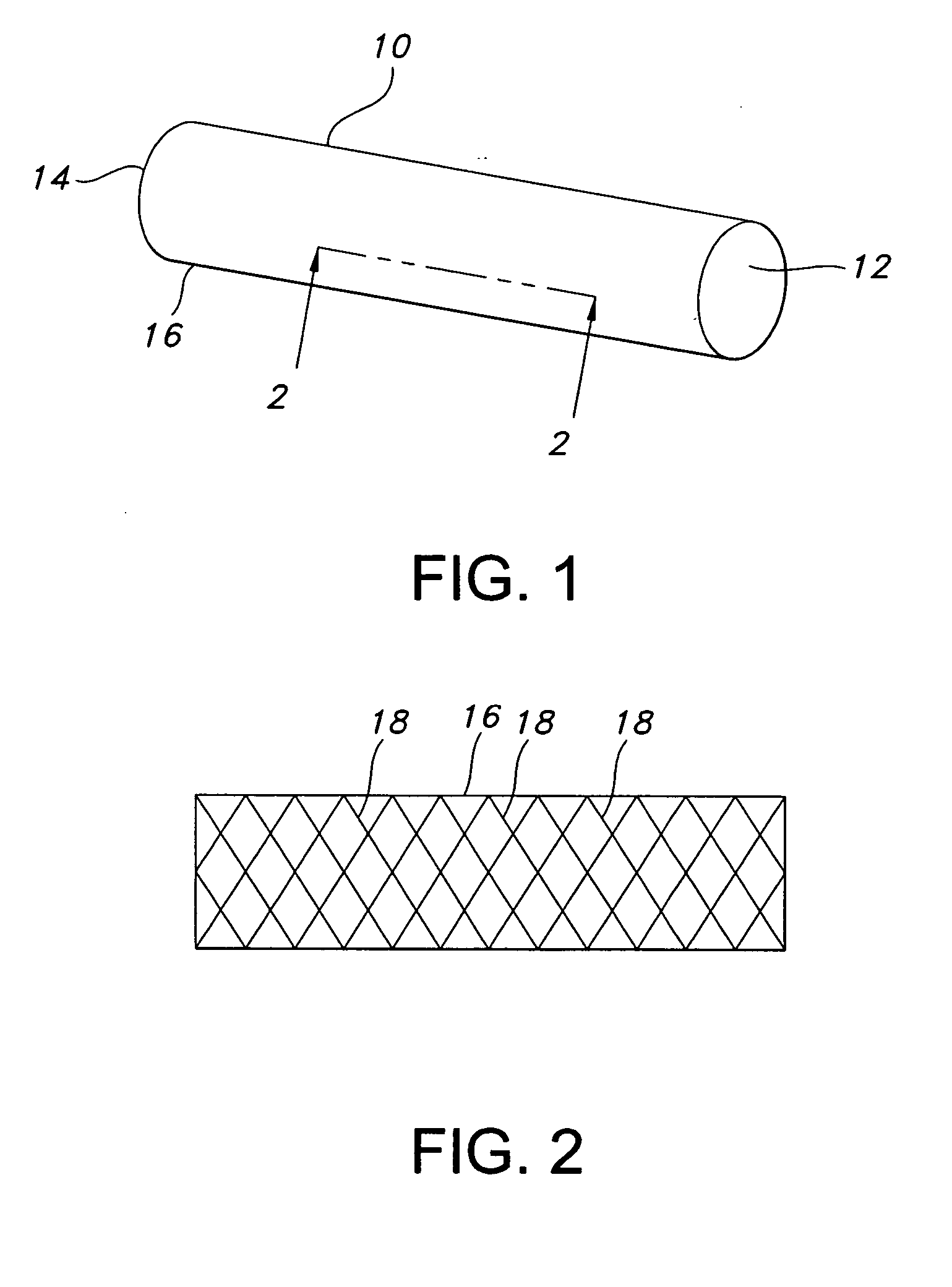

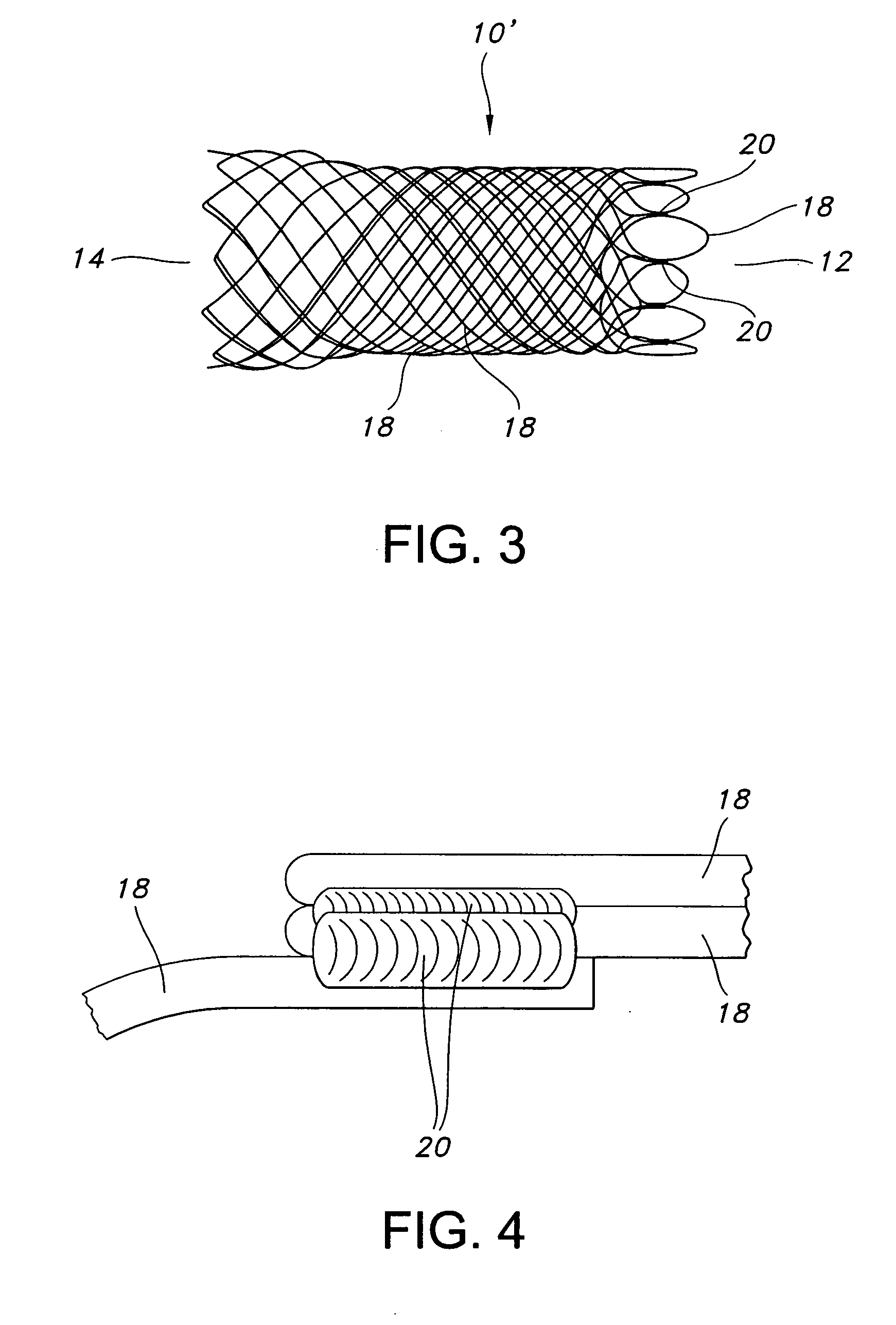

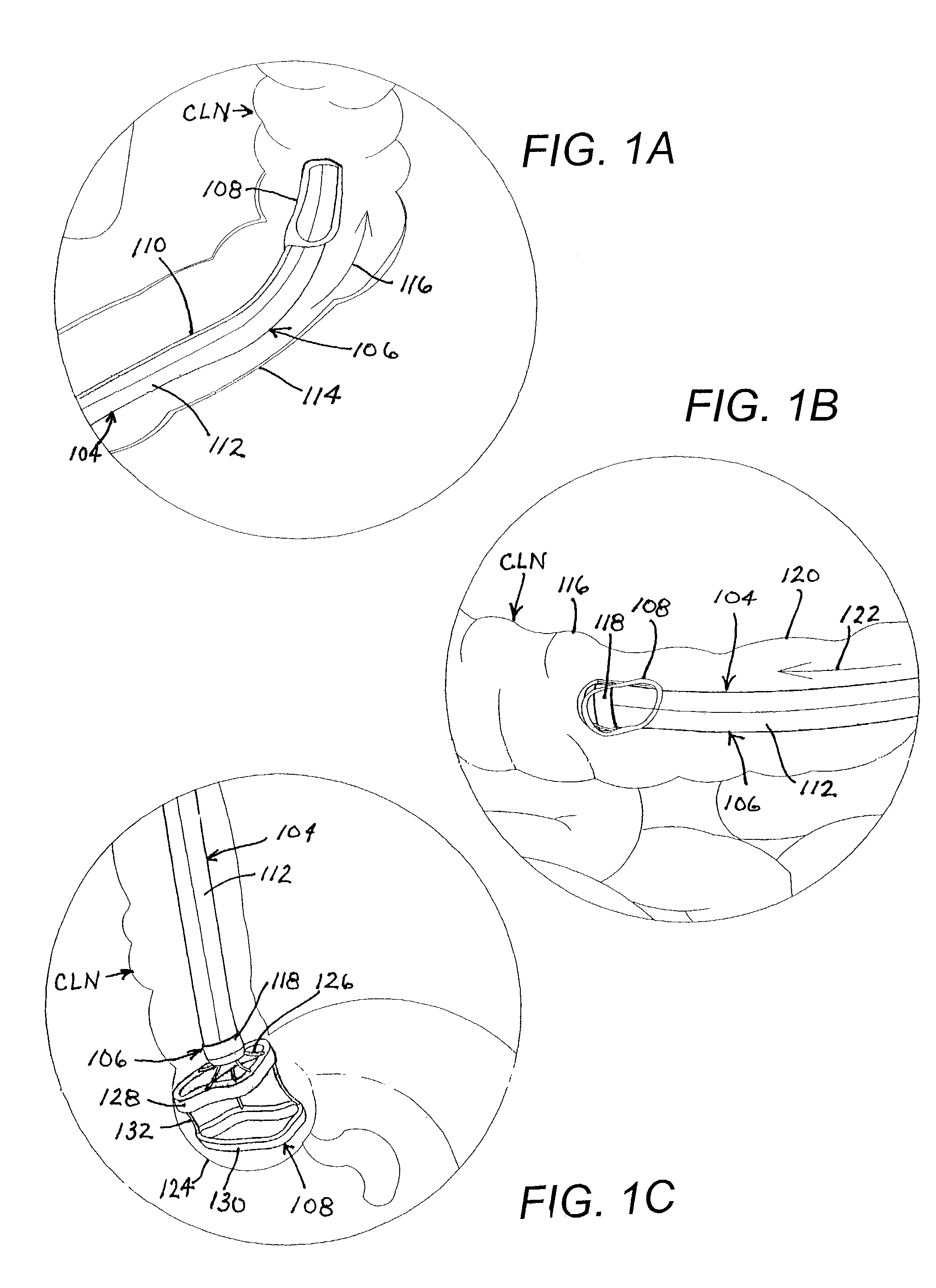

Method for reducing stent weld profiles and a stent having reduced weld

InactiveUS20050256563A1Easy to captureEasy to grabOrnamental textile articlesWelding/cutting auxillary devicesWire rodInsertion stent

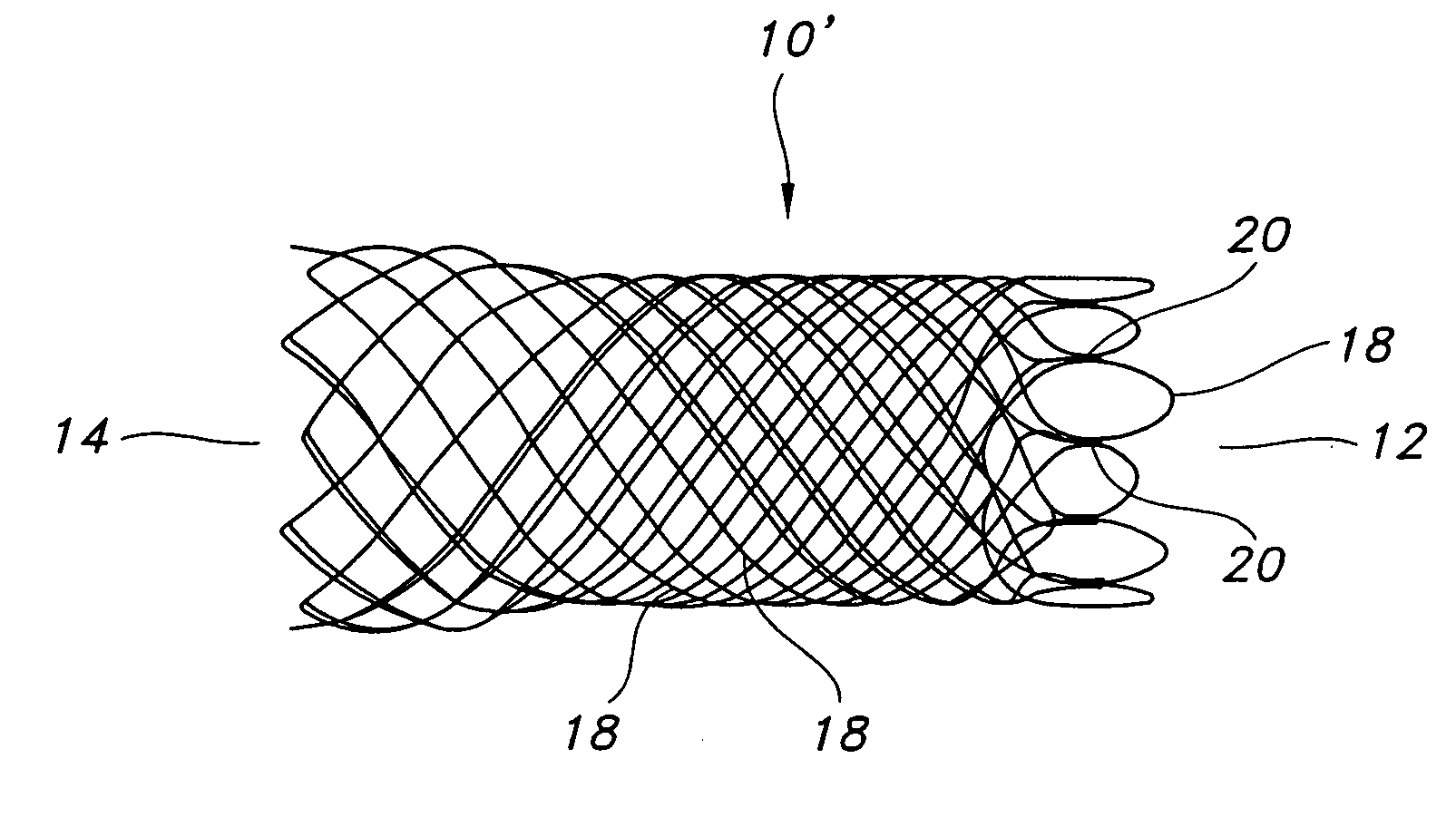

A method for making an implantable stent includes the steps of (i) providing a plurality of elongate stent wires; (ii) forming said wires into a hollow tubular structure having opposed first and second open ends; (iii) terminating said wires at the second end; (iv) aligning the wires at the second end into a plurality of mated adjacent wires to define a plurality of abutting regions; (v) welding the mated adjacent wires to one and the other at the abutting regions to define a plurality of welds; and optionally (vi) chemically or electro-chemically removing a portion of the welds. The method may further include the steps of (a) extending at least one of the mated stent wires to provide an extended stent wire; (b) looping the extended stent wire so the extended end abuts a proximal pair of stent wires; and (c) welding the extended and looped wire to the proximal pair of wires. The step of looping may include the forming of the wire into a equilaterally arched loop having an apex, but not having other sharp bends.

Owner:BOSTON SCI SCIMED INC

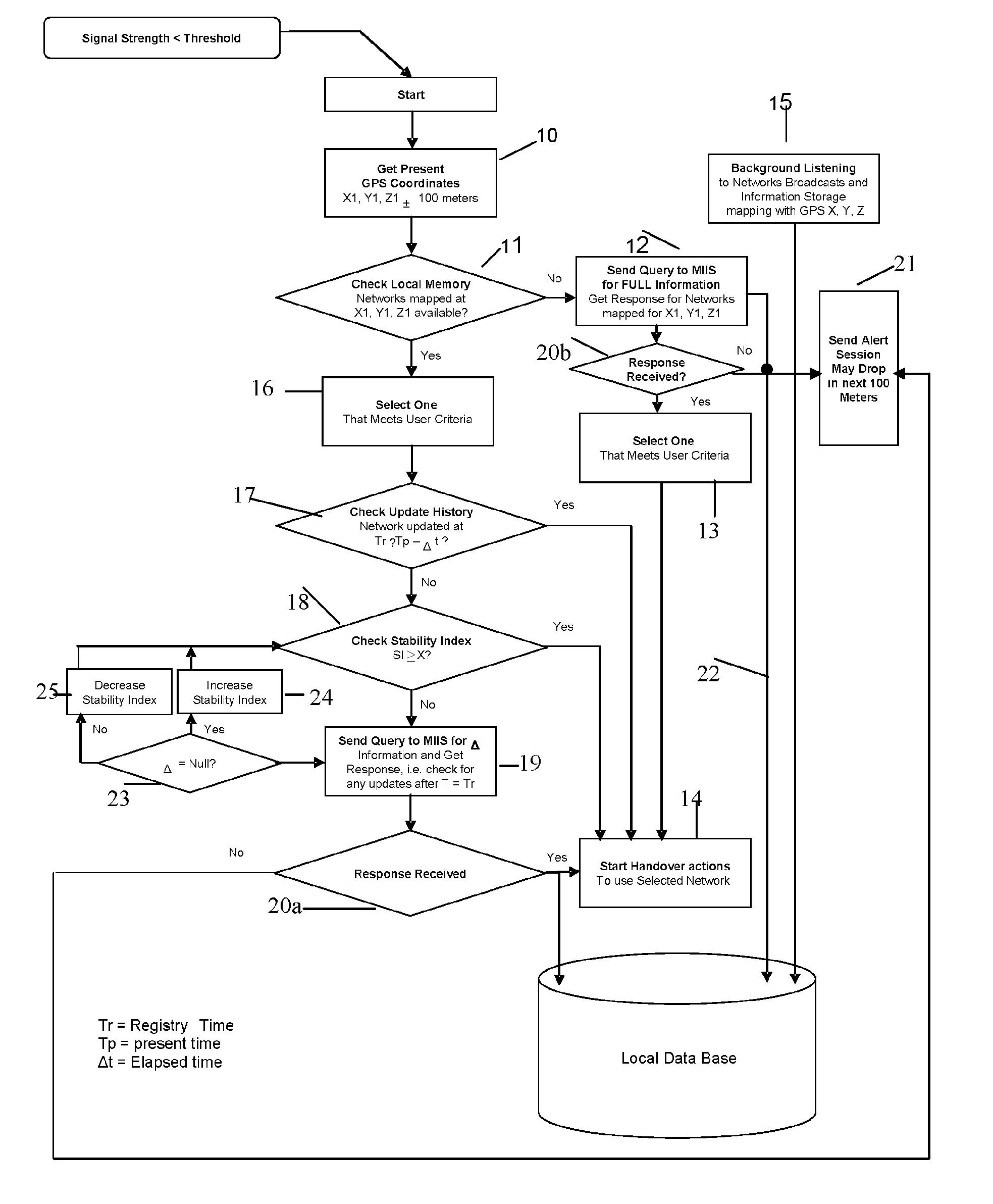

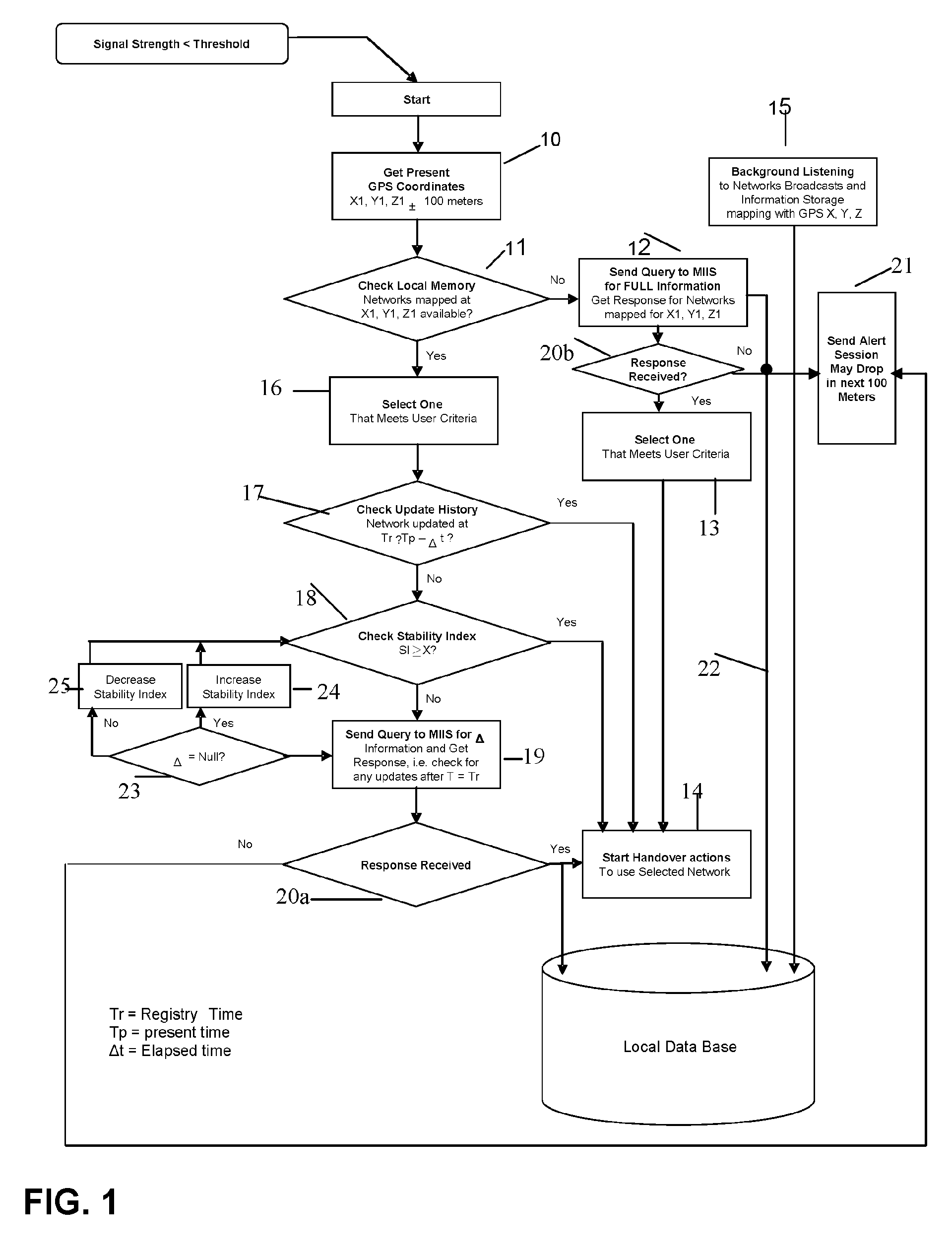

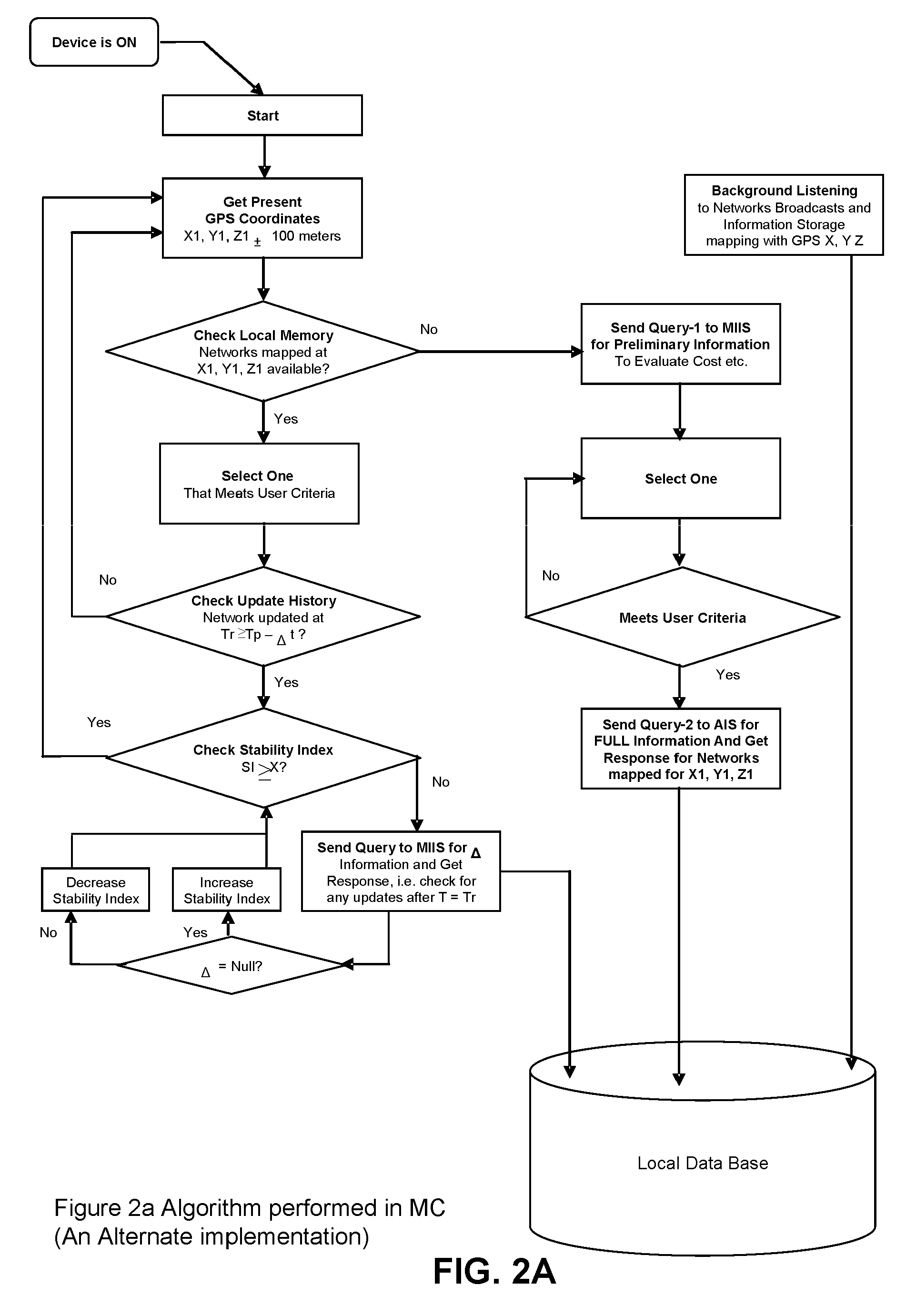

IP network information database in mobile devices for use with media independent information server

ActiveUS20070041344A1Easy to grabExcessive trafficAssess restrictionMultiple digital computer combinationsRelevant featureNetwork data

A mobile device receives wireless network information from a MIIS (Media Independent Information Server), and builds its own database of existing networks with their associated characteristics, appropriately mapped with GPS (Global Positioning Satellite) coordinates or other appropriate form of geographical location identifying information. Consequently, the mobile device becomes “smart” over time through the learning process of first attempting to utilize its own developed database and, only if such database information falls short, making a remote query to a MIIS to get required information for session continuity and performing handovers. The mobile device may store the information received from the MIIS in its own local database together with a time-stamp. Each time the mobile device needs to get updated or new information, it sends a request to the MIIS along with the time-stamp appended to the request. In this way, the mobile device is sent only the information that it does not already have stored in its database.

Owner:TELCORDIA TECHNOLOGIES INC

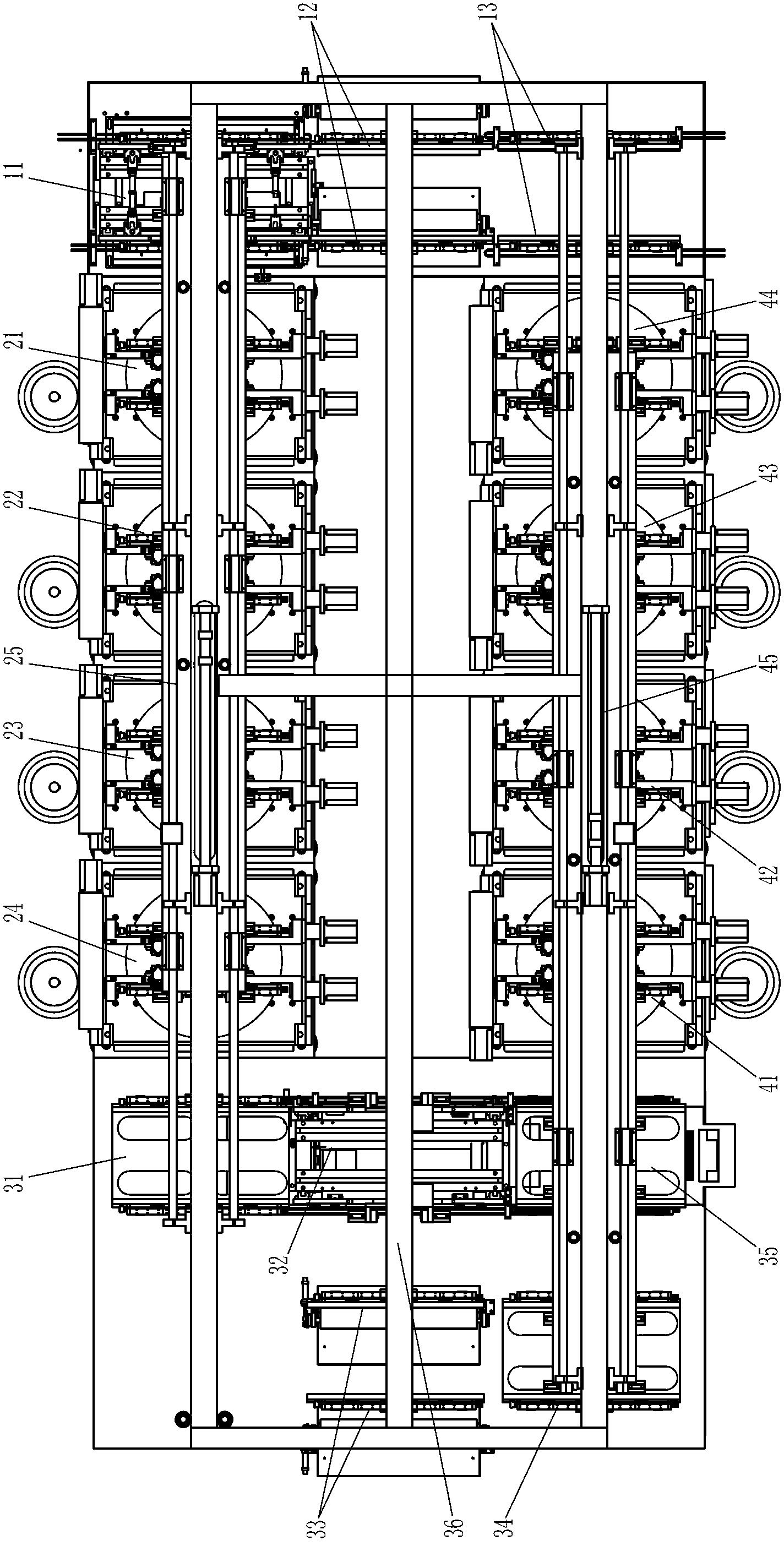

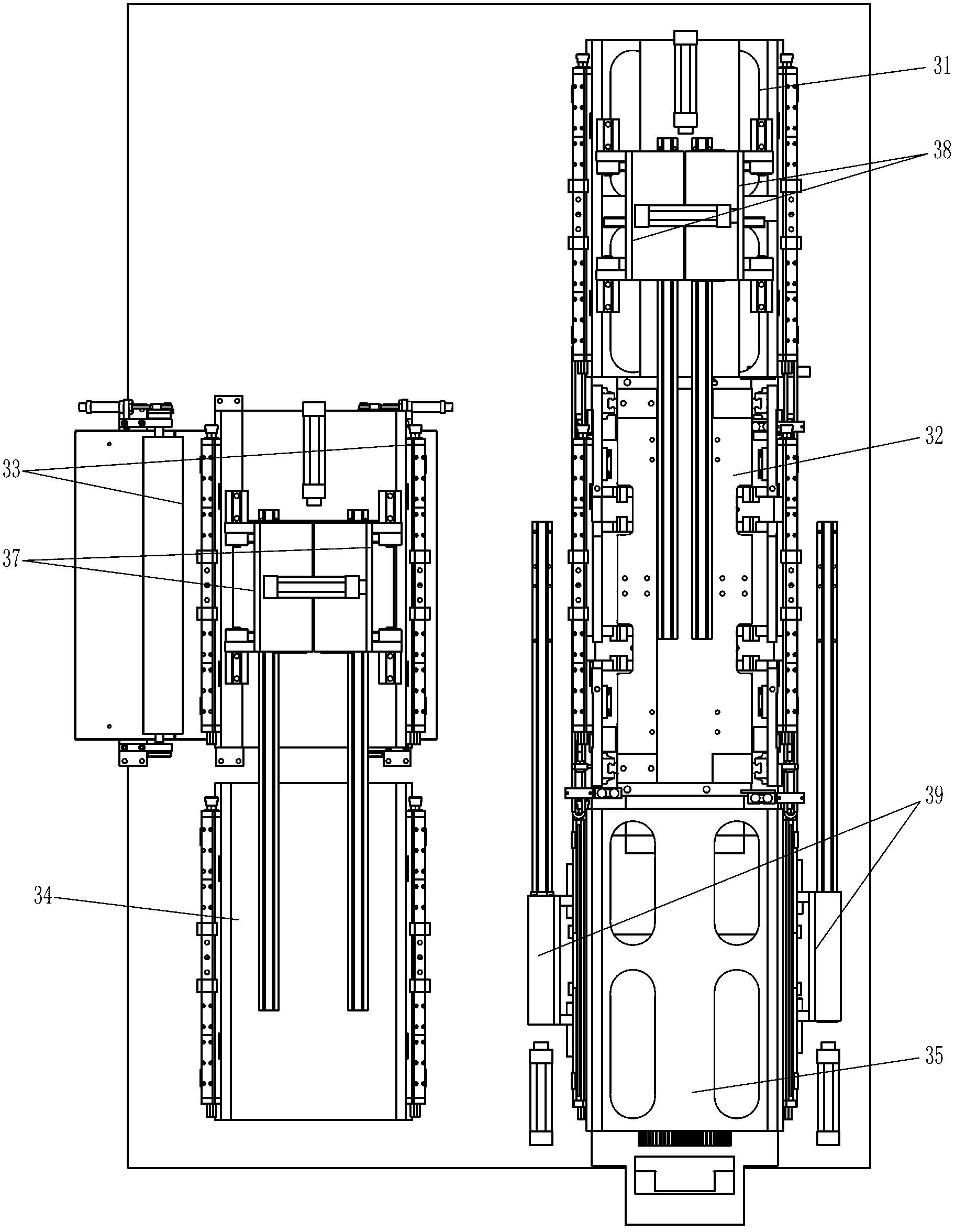

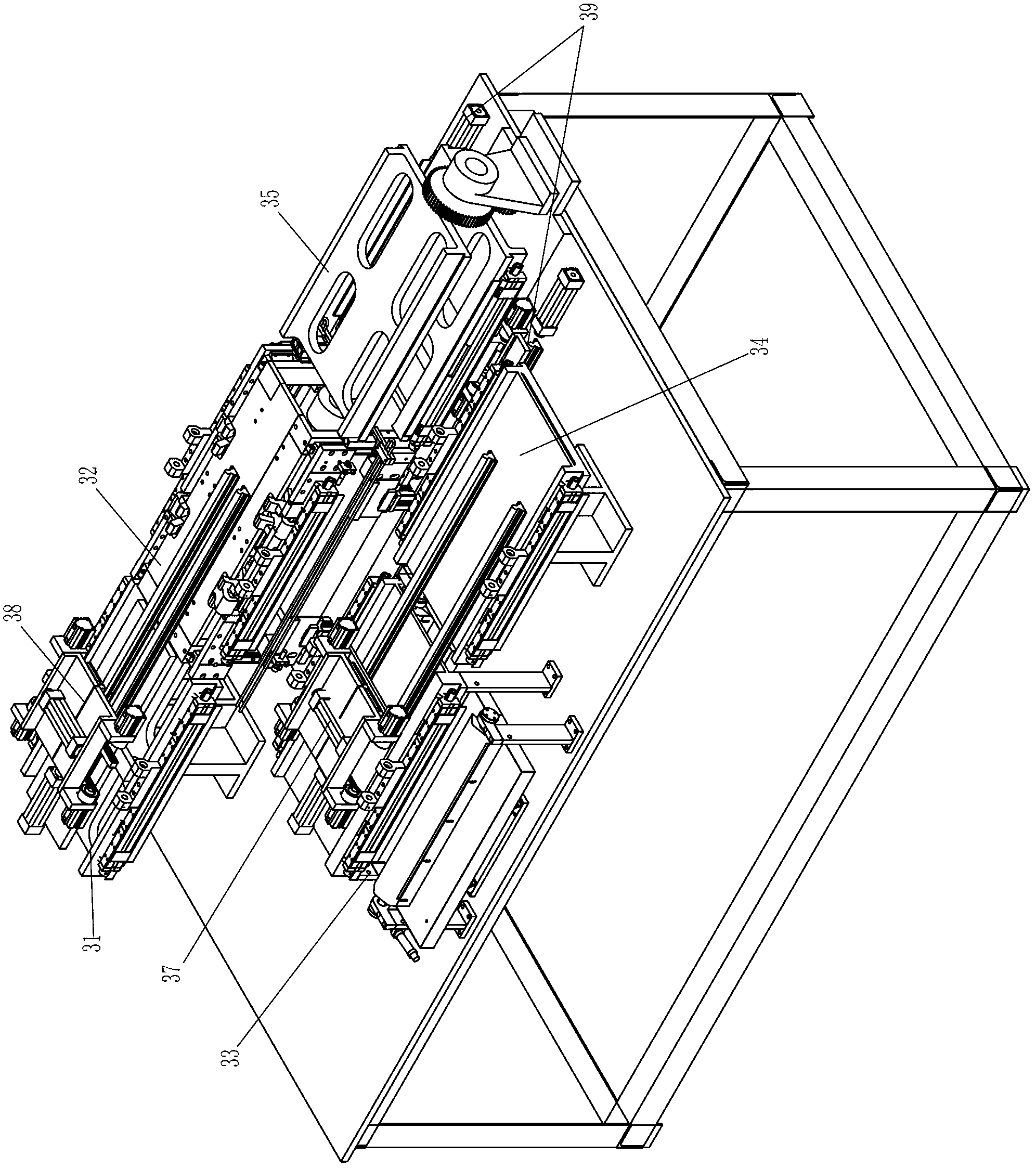

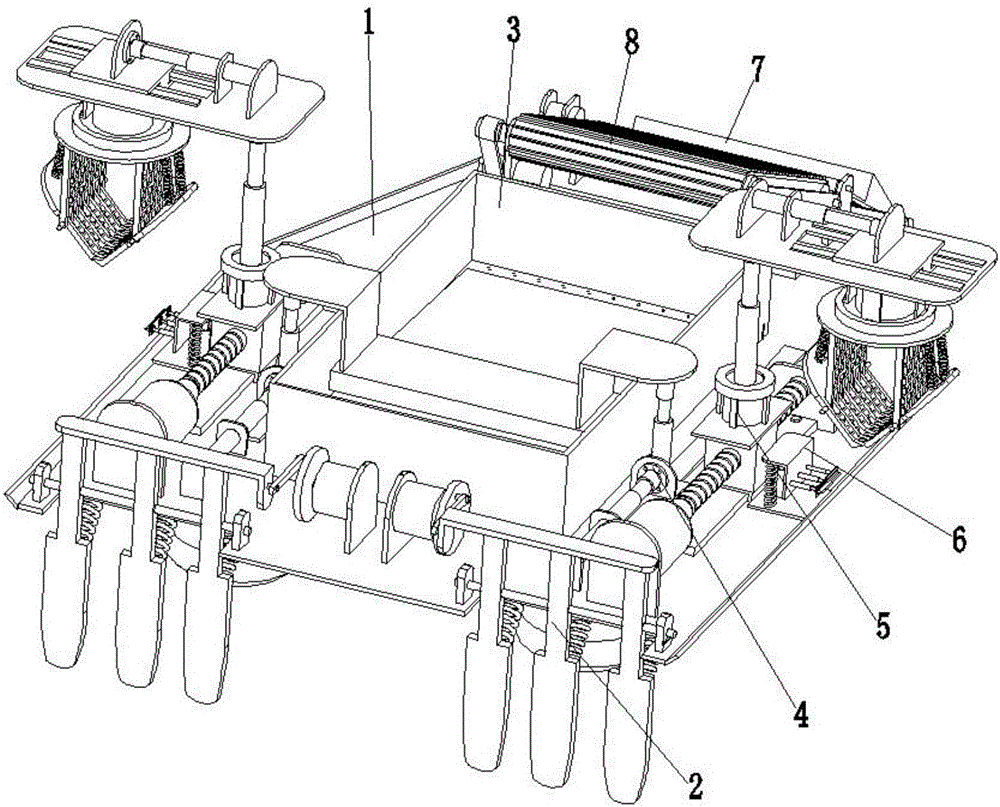

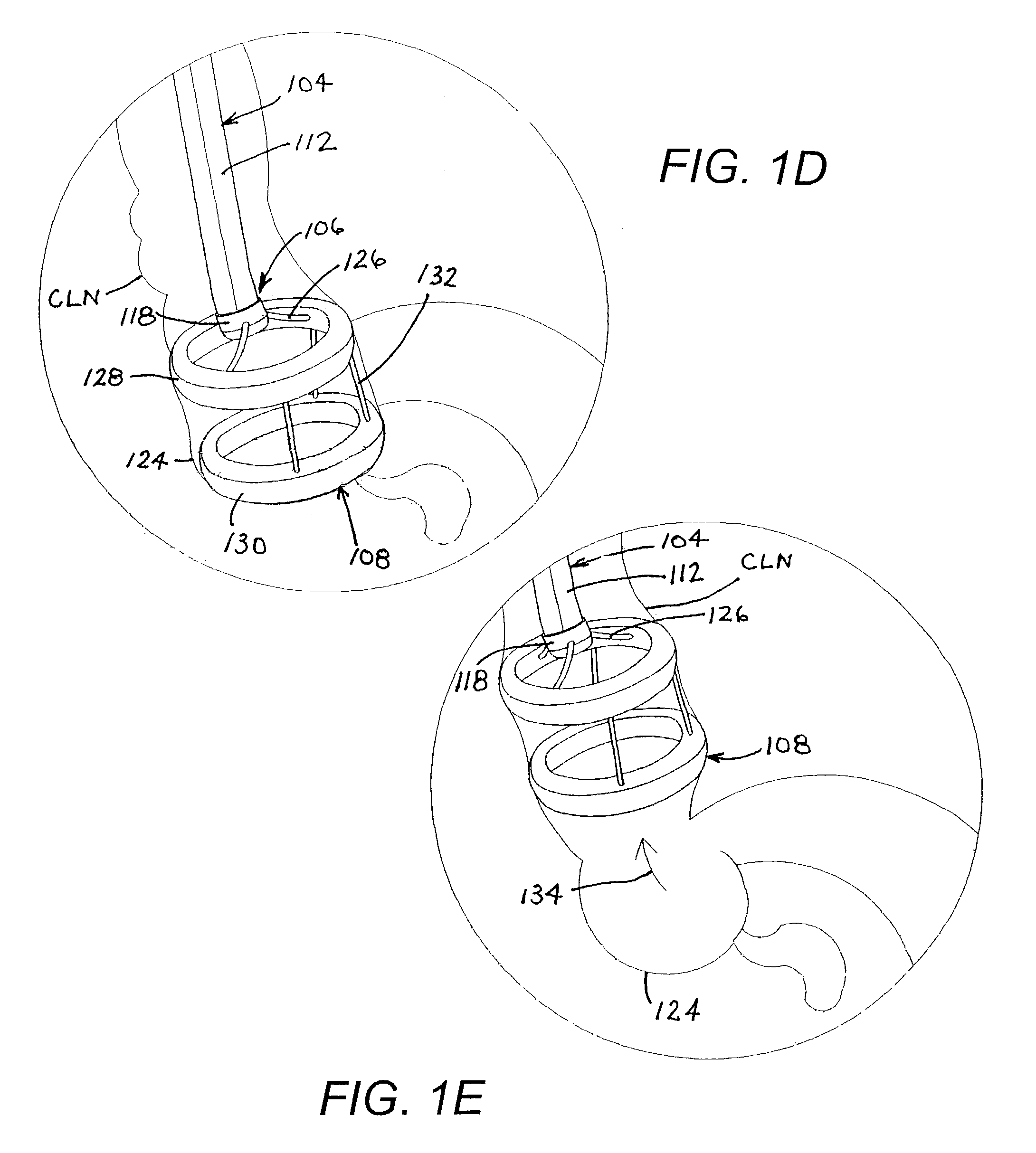

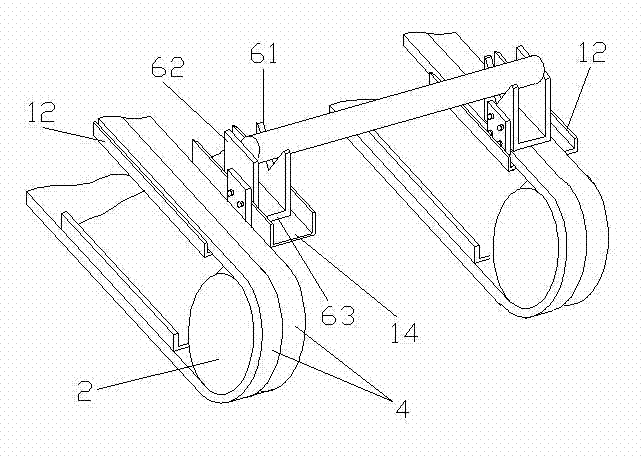

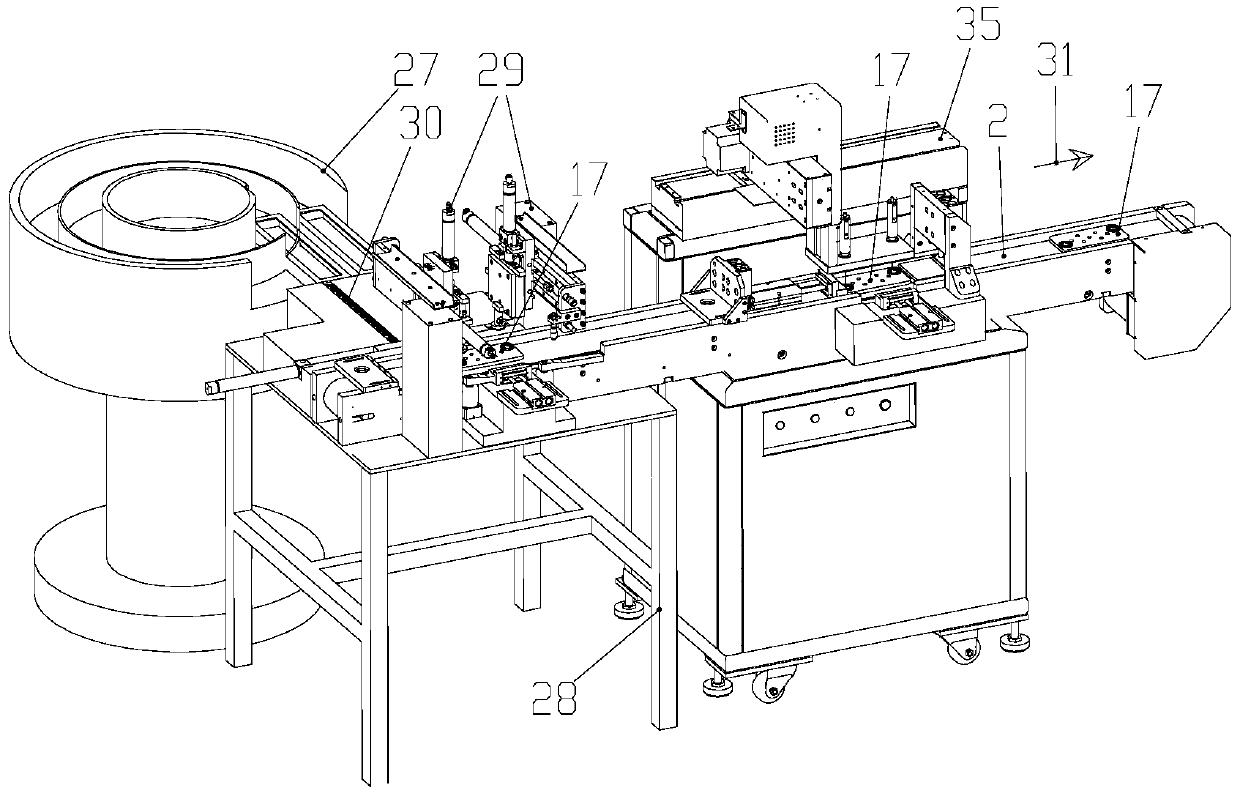

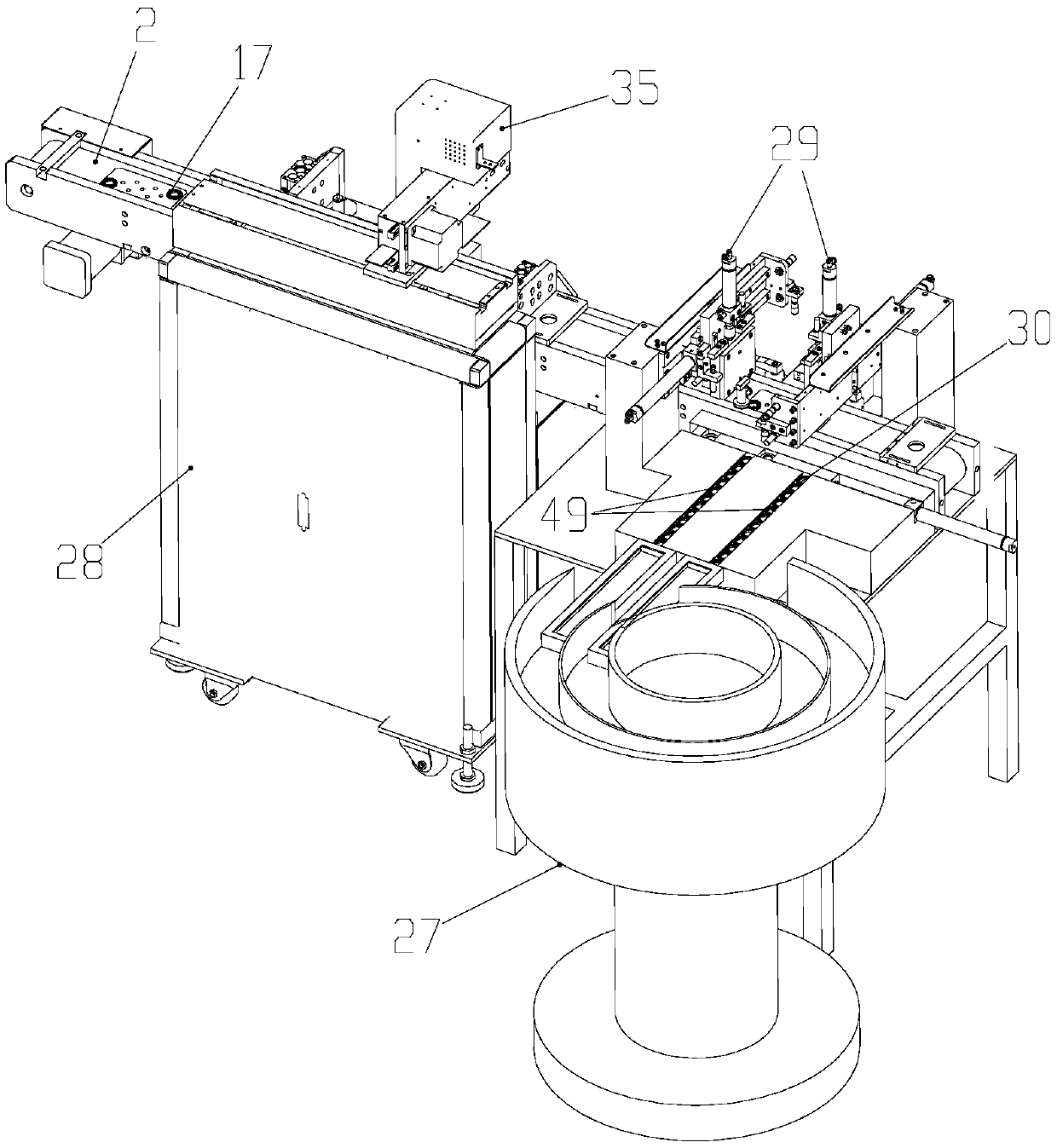

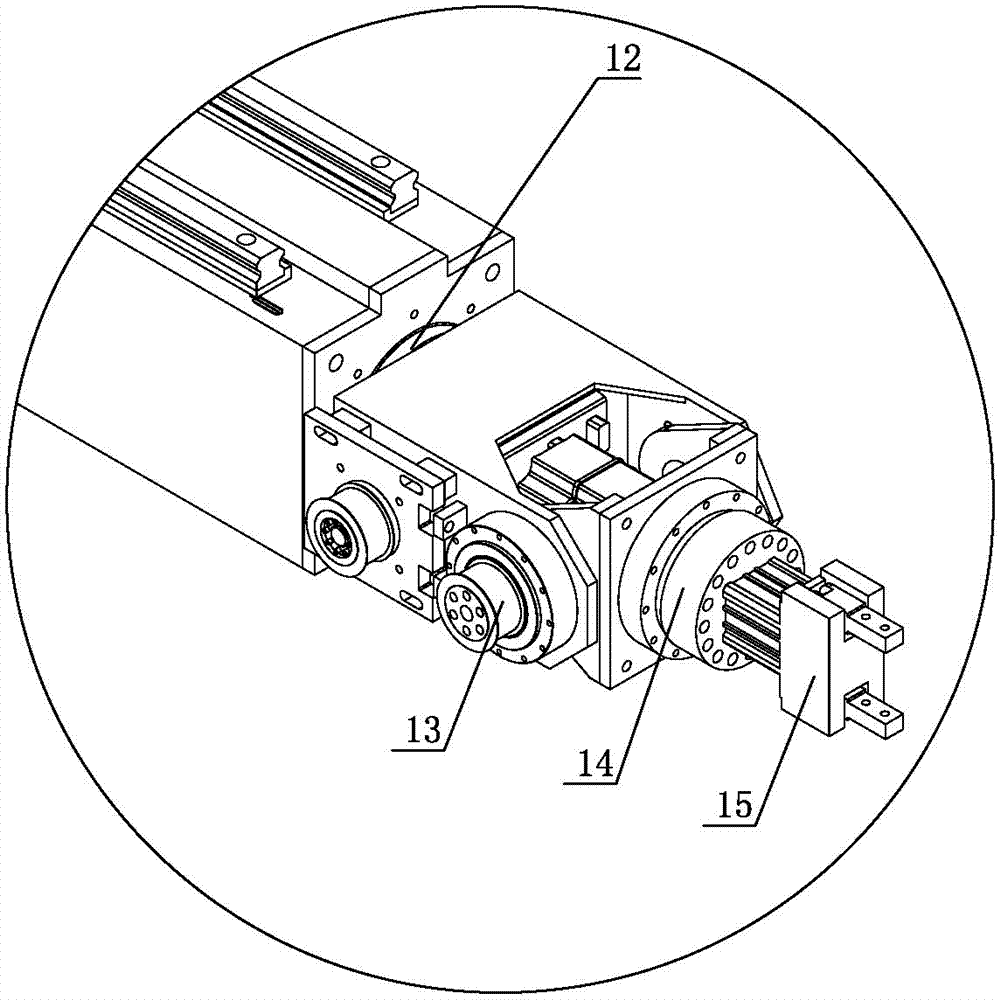

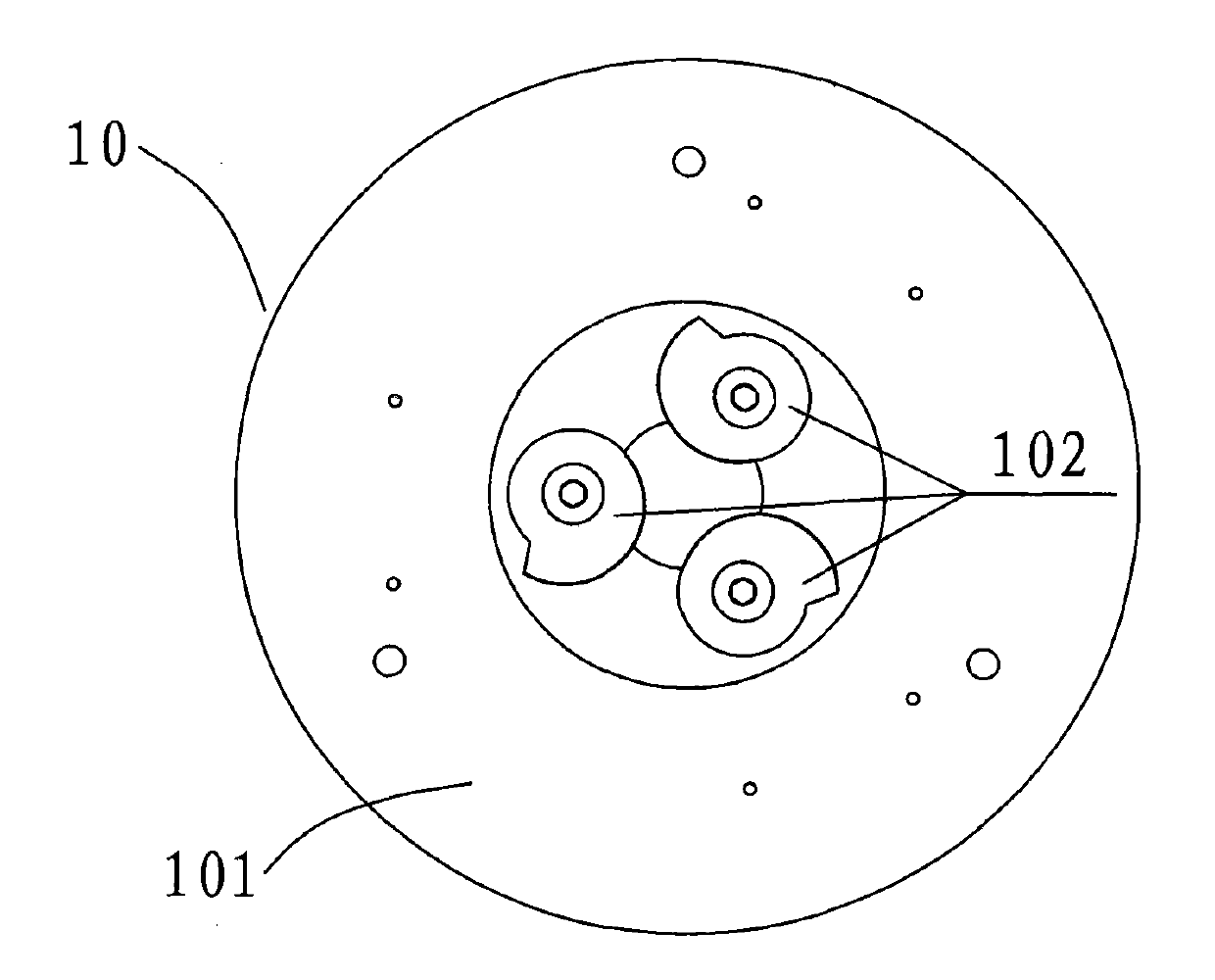

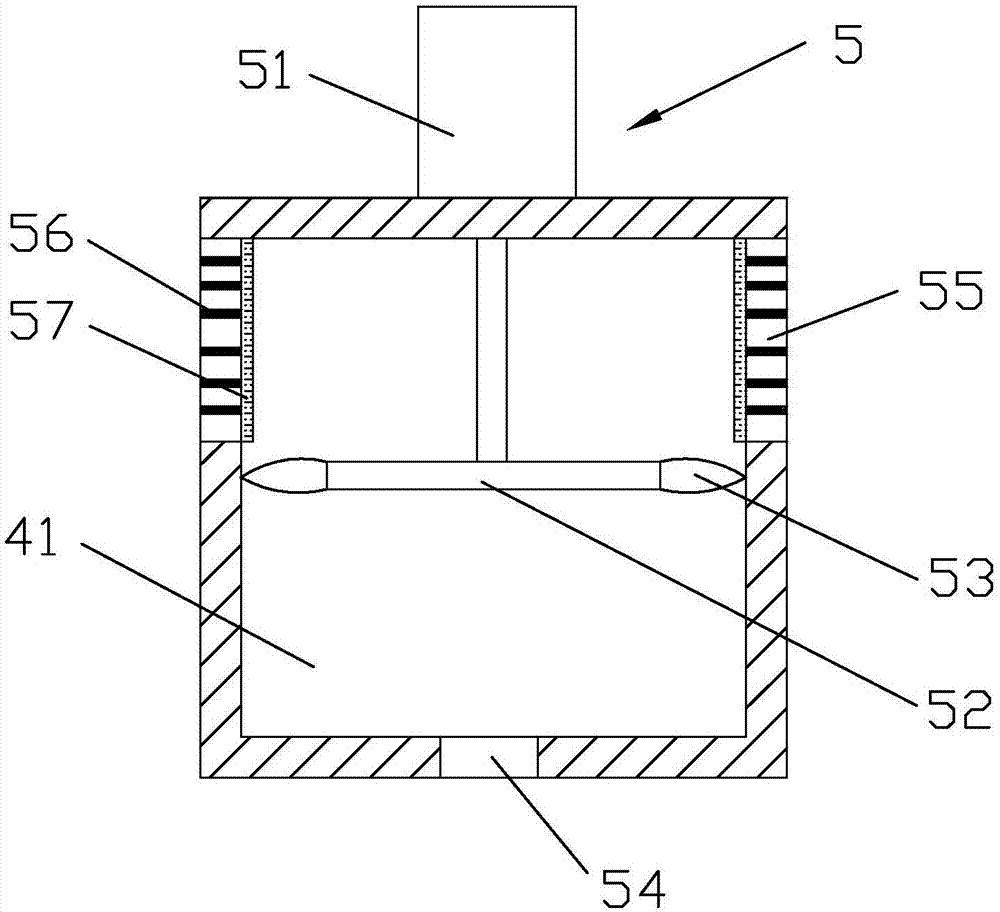

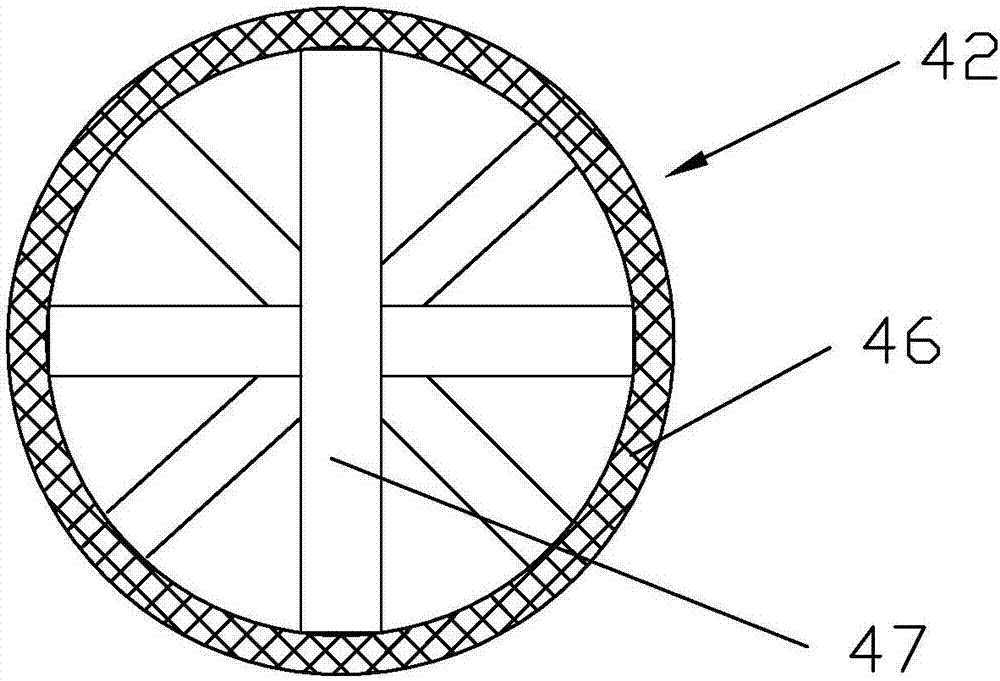

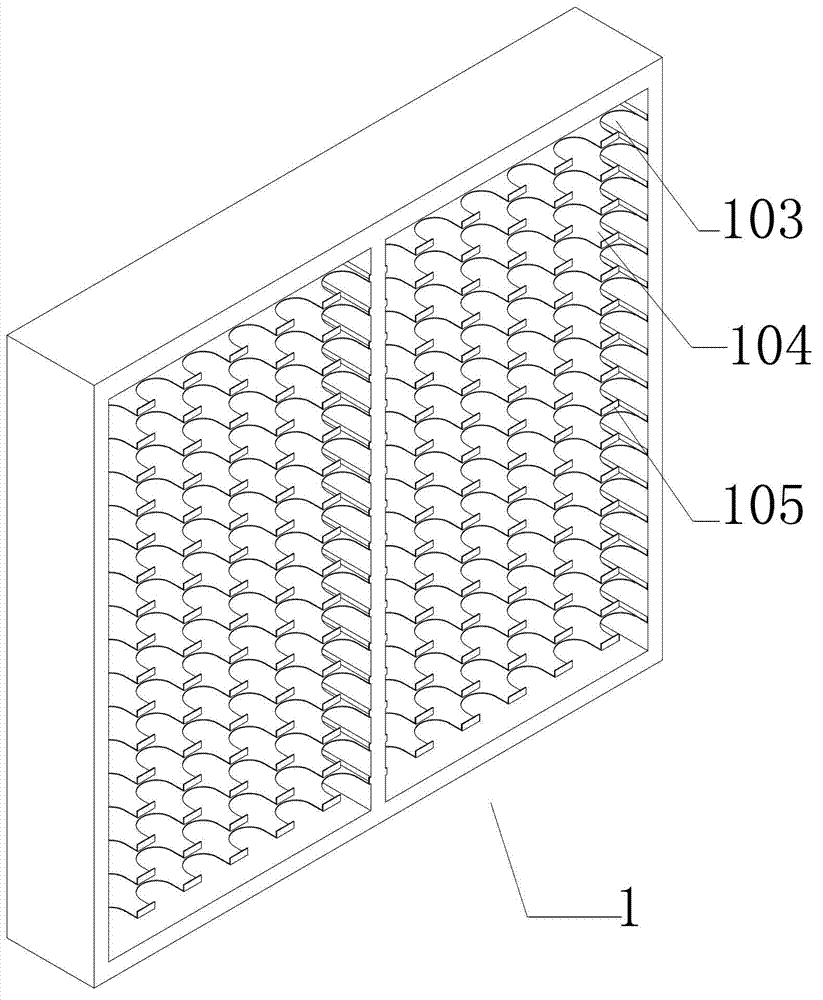

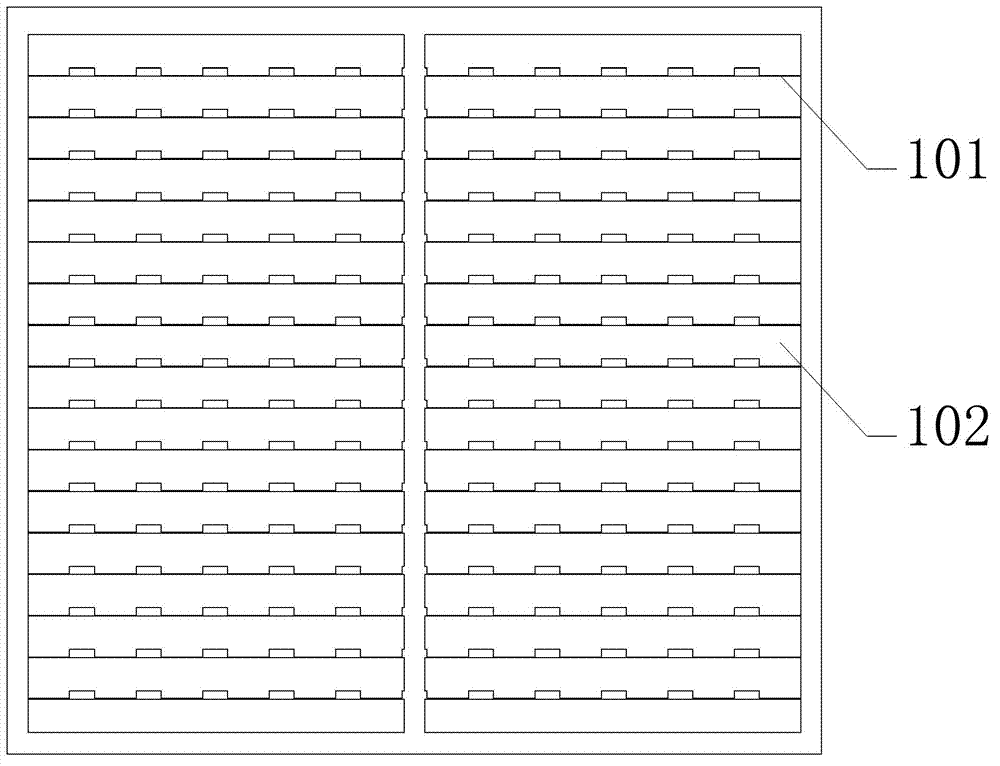

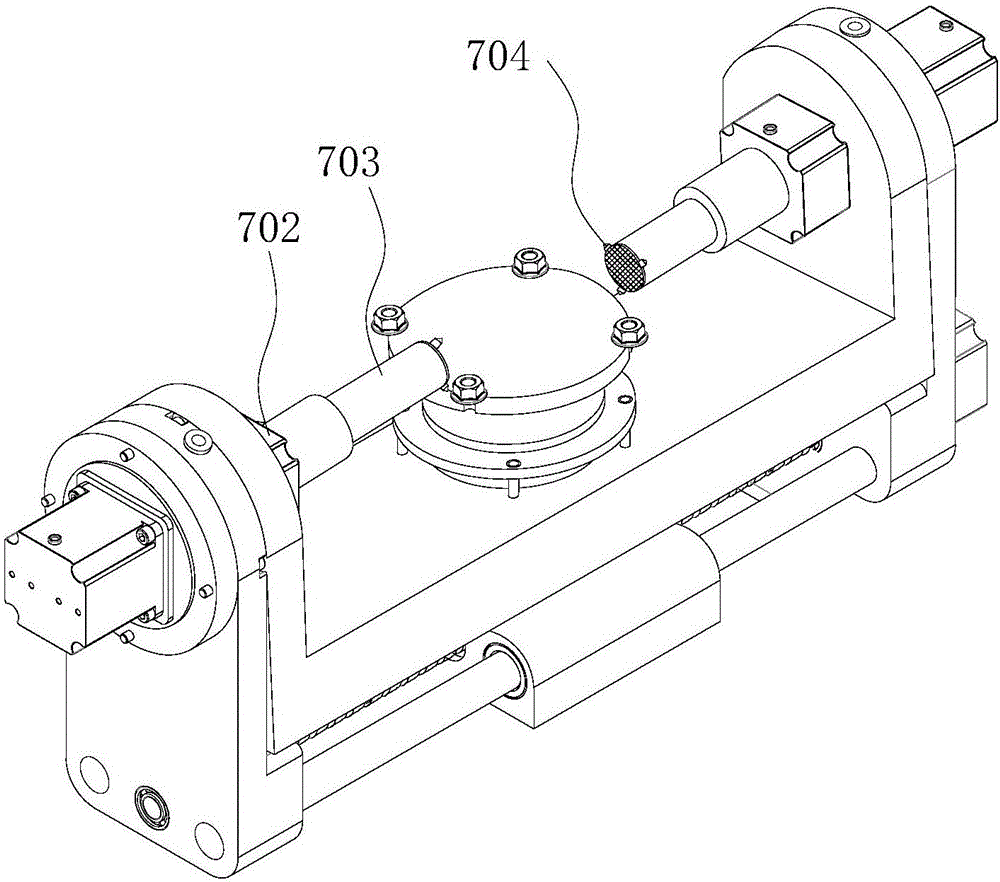

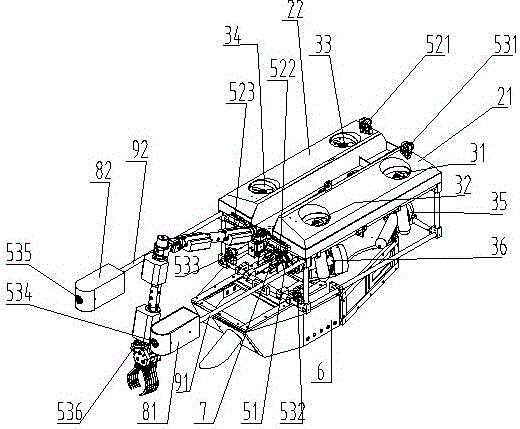

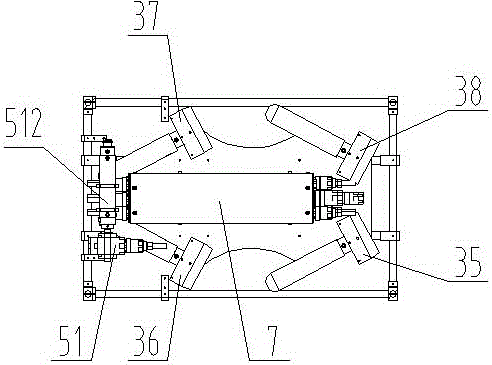

Automatic crystal blank polishing and burnishing system and docking mechanism thereof

ActiveCN103072059AExcellentExcellent efficiencySpherical surface grinding machinesGrinding work supportsEngineeringTransfer mechanism

The invention discloses a docking mechanism, comprising a docking machine frame, wherein a docking position, a switching position, a powder soaking position and a transition position are arranged on the docking machine frame; the docking bracket is fixedly mounted in the docking position, a docking component is arranged on the docking bracket, and the docking component comprises an upper sliding fixture seat and a lower fixed fixture seat; a switching bracket is arranged in the switching position, the switching bracket is driven by a switching bracket driving device to rotate around a horizontal shaft, and an upper fixture fixing part and a lower fixture fixing part are arranged on the switching bracket; a powder soaking component is arranged in the powder soaking position; a first fixture placement rack is arranged in the transition position; and the docking mechanism also comprises a first front-and-back transfer mechanism and a second front-and-back transfer mechanism. The invention also discloses an automatic crystal blank polishing and burnishing system adopting the docking mechanism. According to the technical scheme, the docking precision and the bonding firmness of crystal blanks are guaranteed, the docking working position is reasonable in structure, and the docking efficiency and the processing efficiency of the whole automatic polishing and burnishing system are improved.

Owner:虞雅仙

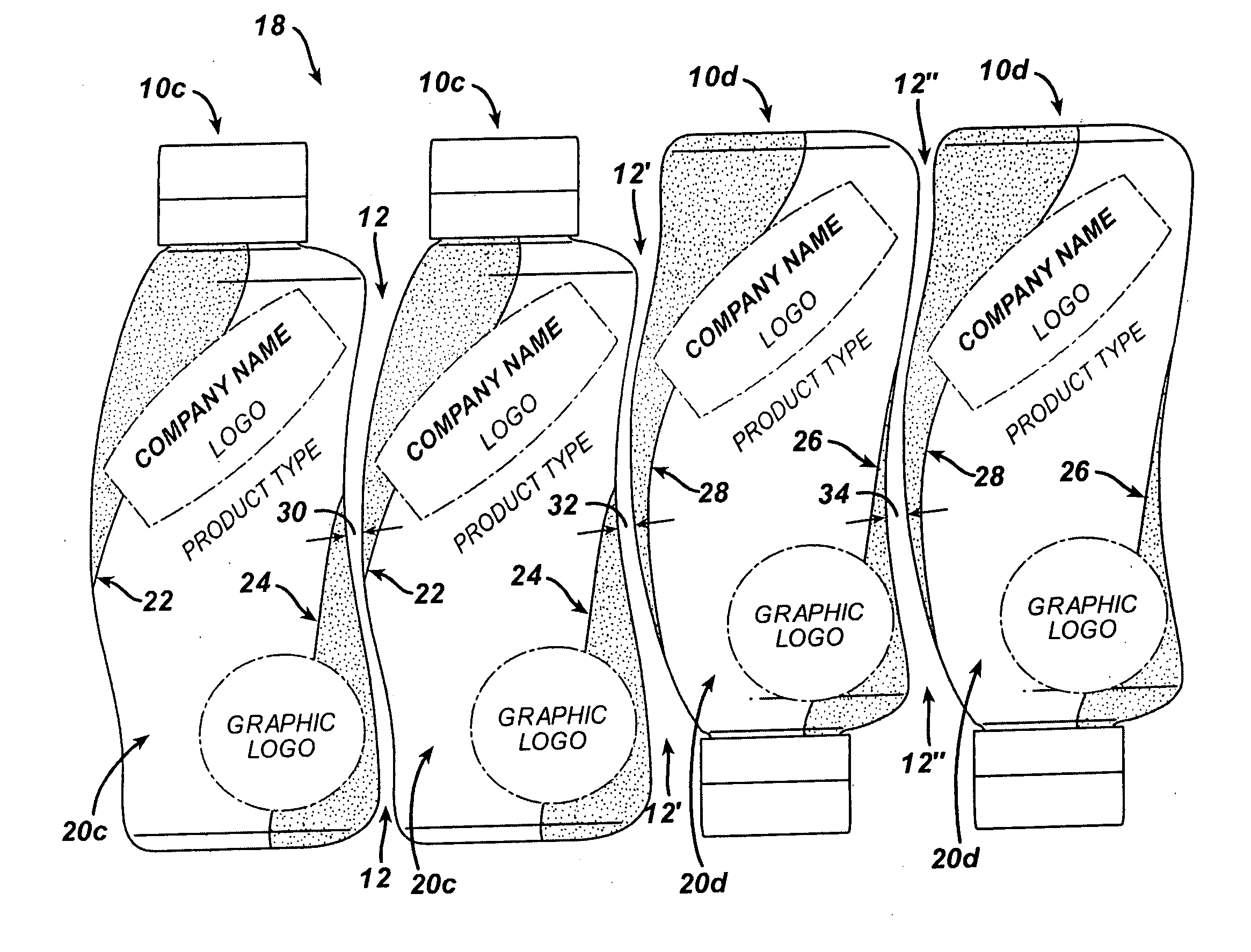

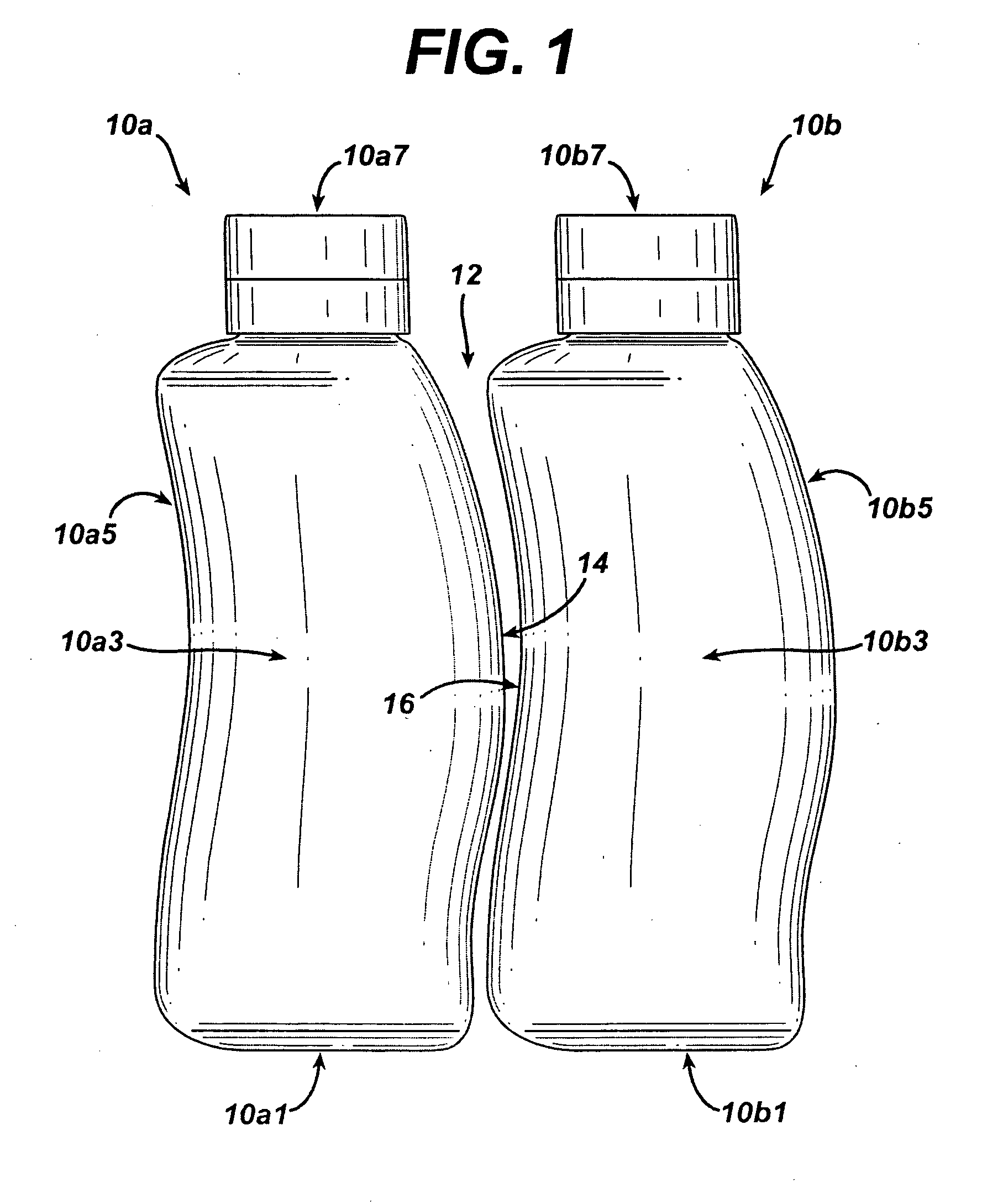

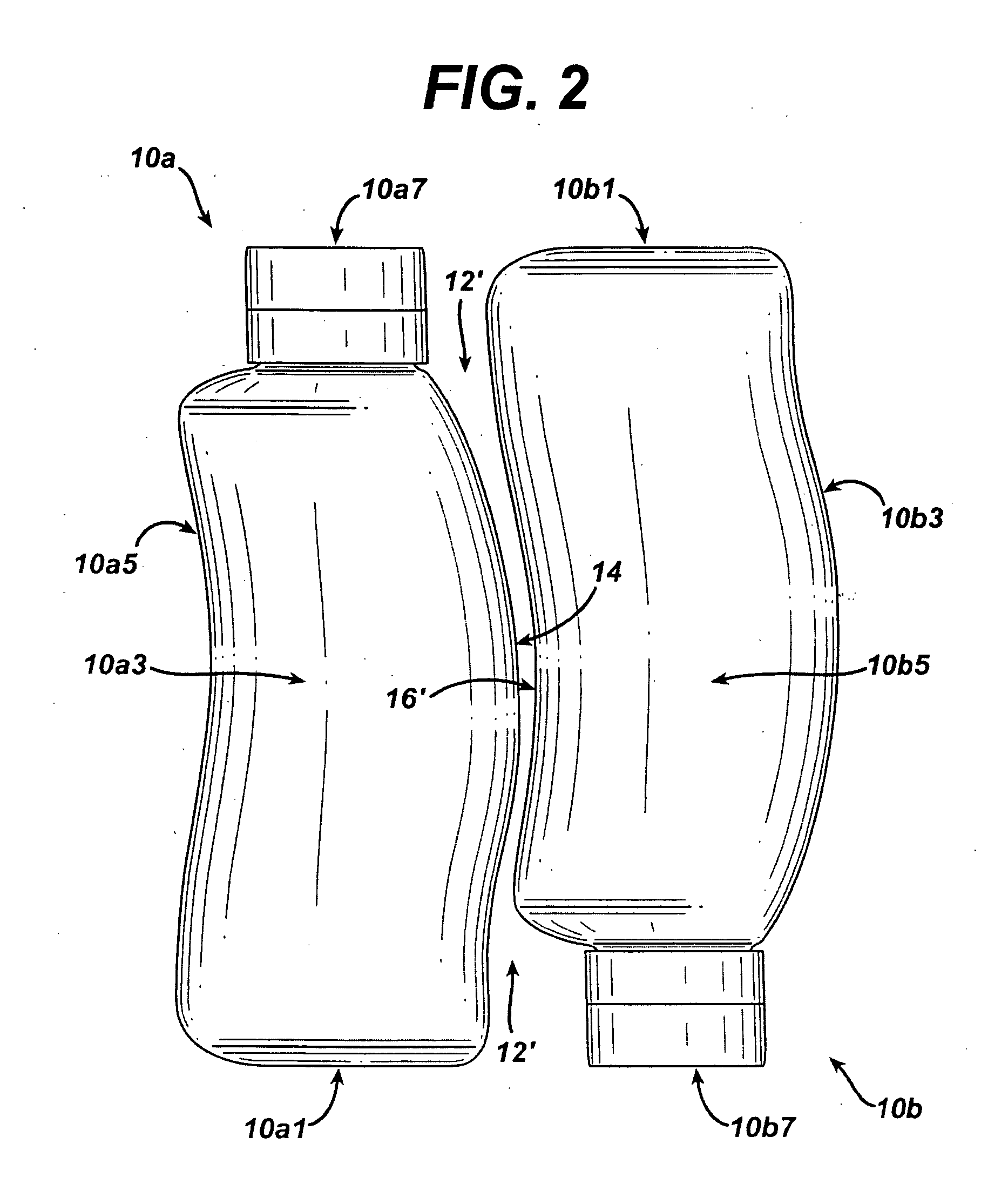

Packaging with continuing labels

The invention is directed to a package having a continuing label. The continuing label has at least one portion that is a continuation of a label on an adjacent package. The package of this invention can stand right side up or upside down and when displayed in a group creates a billboard or poster-like appearance.

Owner:CONOPCO INC D B A UNILEVER

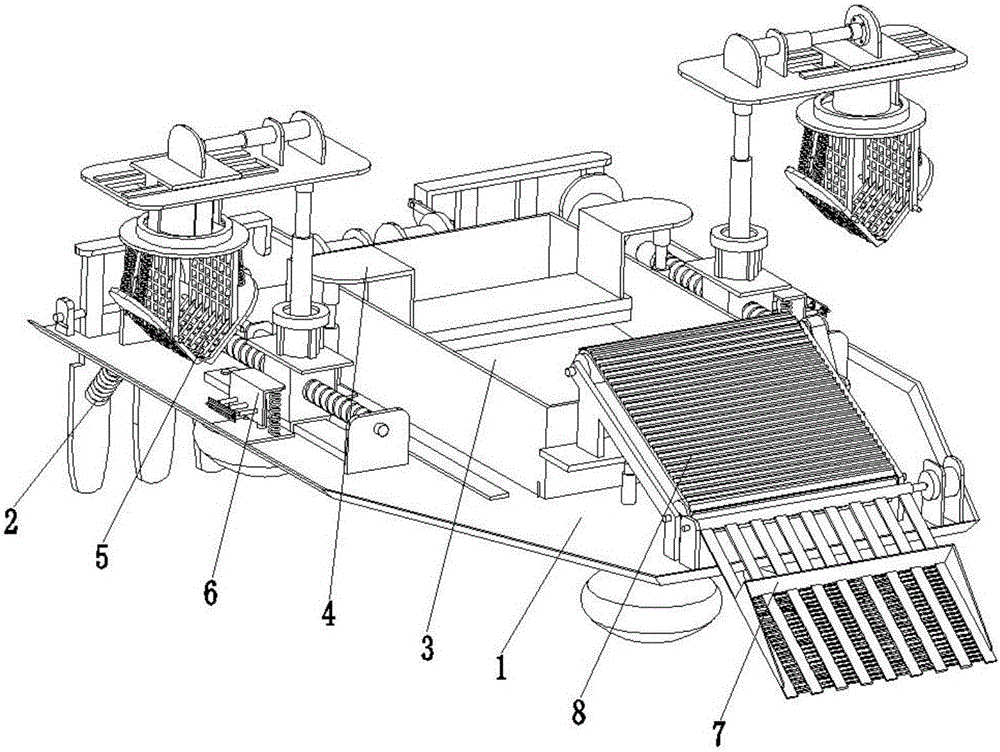

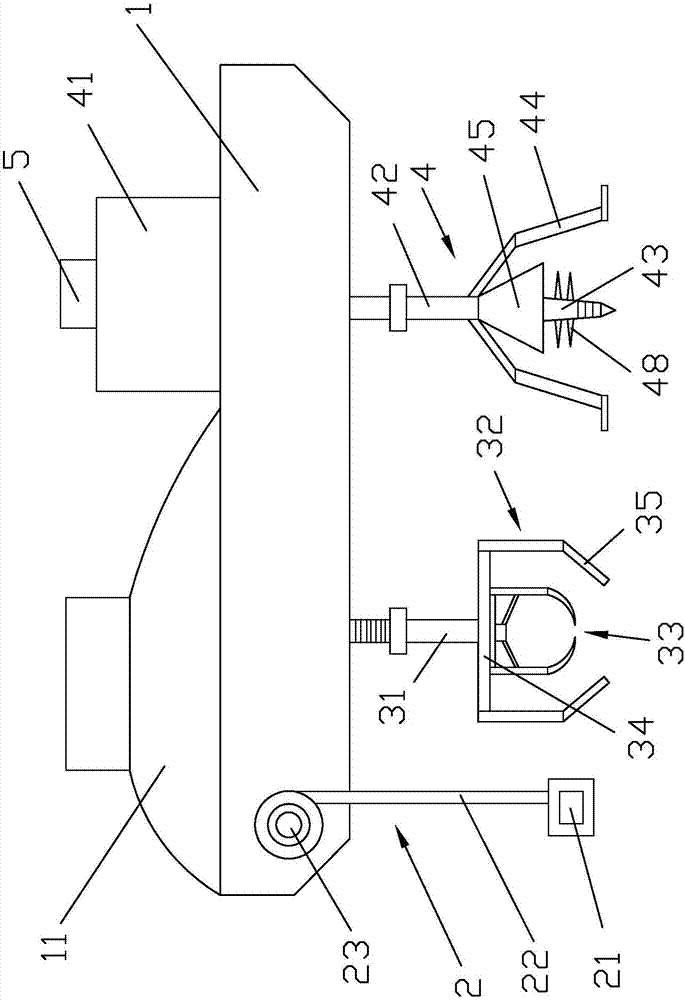

Environment-friendly type river and lake controlling and cleaning equipment

ActiveCN106759196APlay a dredging roleKeep water cleanWater cleaningWaterborne vesselsCompression deviceWater quality

The invention relates to environment-friendly type river and lake controlling and cleaning equipment. The environment-friendly type river and lake controlling and cleaning equipment comprises a boat body, power devices, a storage slot, a compression device, movable gripping devices, cut-off devices, a salvaging device and a conveying device, wherein the power devices are symmetrically mounted at the left side and the right side behind the boat body separately along the longitudinal central axis of the boat body; the compression device is positioned above the storage slot; the movable gripping devices are separately positioned at the left side and the right side of the compression device; the cut-off devices are positioned at the outer sides of the movable gripping devices; the salvaging device is positioned in front of the boat body; and the conveying device is positioned between the salvaging device and the storage slot. The environment-friendly type river and lake controlling and cleaning equipment integrates the functions of floating force adjusting, water-surface travelling, waste compacting, aquatic plant gripping, garbage salvaging, garbage conveying and the like, realizes the functions of eliminating aquatic plants in rivers and lakes as well as floating waste on the water surface, achieves the effect of dredging the rivers and the lakes, keeps water in the rivers and the lakes clean, is high in integral mechanical degree, is complete in function and is high in operating efficiency.

Owner:广东祥实建设有限公司

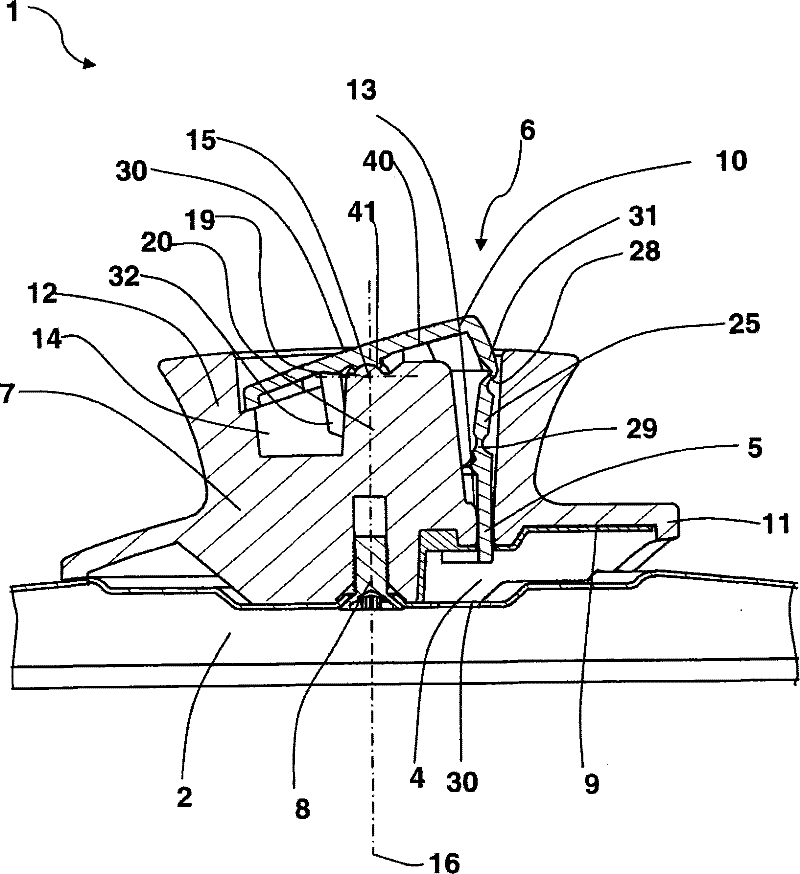

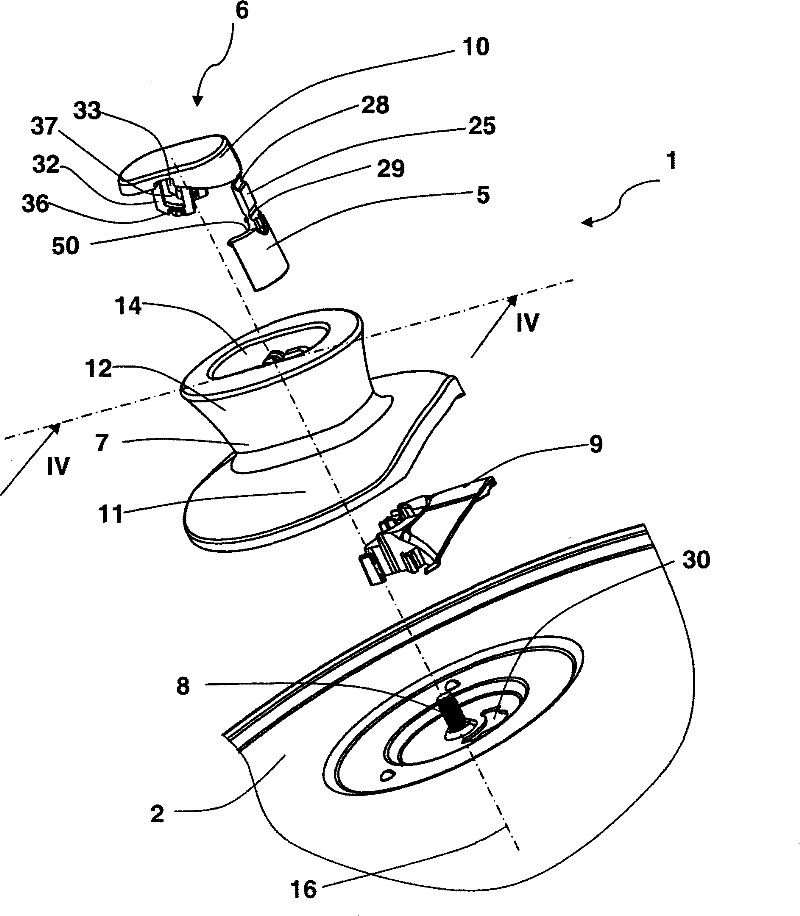

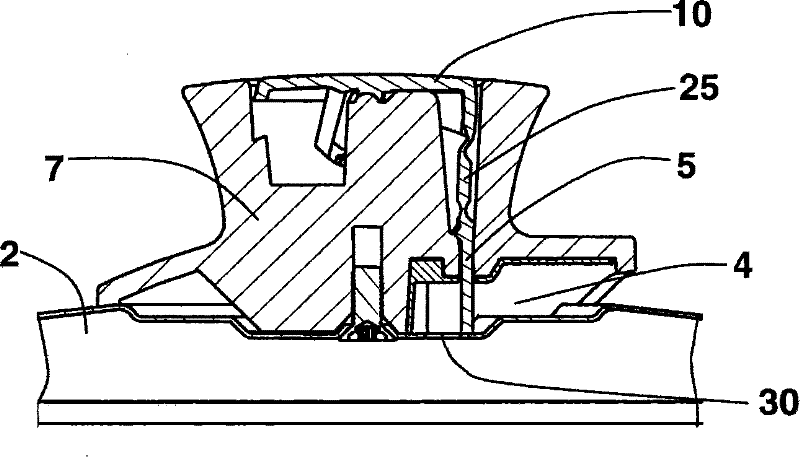

Exhaust devices for kitchen utensil lids

InactiveCN101305890BSmall footprintEasy to grabCooking-vessel lids/coversEngineeringMechanical engineering

The invention relates to a venting device (1) for a lid (2) of a kitchen utensil, comprising: a knob (7) comprising a gripping portion (12) and adapted to be fixed to said lid (2) and capable of a base (11) delimiting an exhaust duct (4); and an exhaust regulating device (6) comprising a valve plug (5) movable in said knob (7) and a control device for the valve plug (5) (10), the valve plug (5) can move between a position for closing the exhaust duct (4) and at least one open position for exhausting, the control device (10) is arranged on the The grip part (12) of the button (7) is accessible by the user and can be manipulated by simple axial pressing, wherein the manipulation device (10) is a rotatably mounted joystick, And the valve plug (5) can translate in the button (7).

Owner:SEB SA

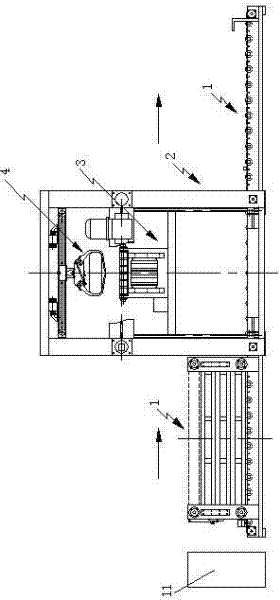

Stacking machine

InactiveCN102358519AStabilize the palletizing processReliable palletizing processStacking articlesStack machineMaterial resources

The invention relates to a stacking machine of bagged objects, comprising a stacking device, a tray lifting, propelling and conveying device, a mechanical arm and a bag supporting device, wherein the tray lifting, propelling and conveying device consists of a tray feeding device and an out-stacking conveying device; the stacking device is arranged between the tray feeding device and the out-stacking conveying device; the stacking device is in transmission connection with the mechanical arm; the bag supporting device is arranged at one side of the stacking device; the tray feeding device comprises a rack, a conveying frame, a lifting mechanism, a lifting beam and a pushing rod; the mechanical arm comprises a rotating motor, a plurality of grabbing fingers and a grabbing palm, the grabbing palm is fixedly provided with a driving cylinder which is provided with a piston rod in transmission connection with one rotating shaft on the grabbing palm through a rotating block, and each rotatingshaft is fixedly provided with a plurality of the grabbing fingers. The stacking machine provided by the invention is simple in structure, smooth in action, capable of continuously finishing stackingwork of the bagged objects in the automatic production process, saving in manpower and material resources and high in stacking efficiency.

Owner:溧阳市元创智能设备有限公司

Facilitating searches through content which is accessible through web-based forms

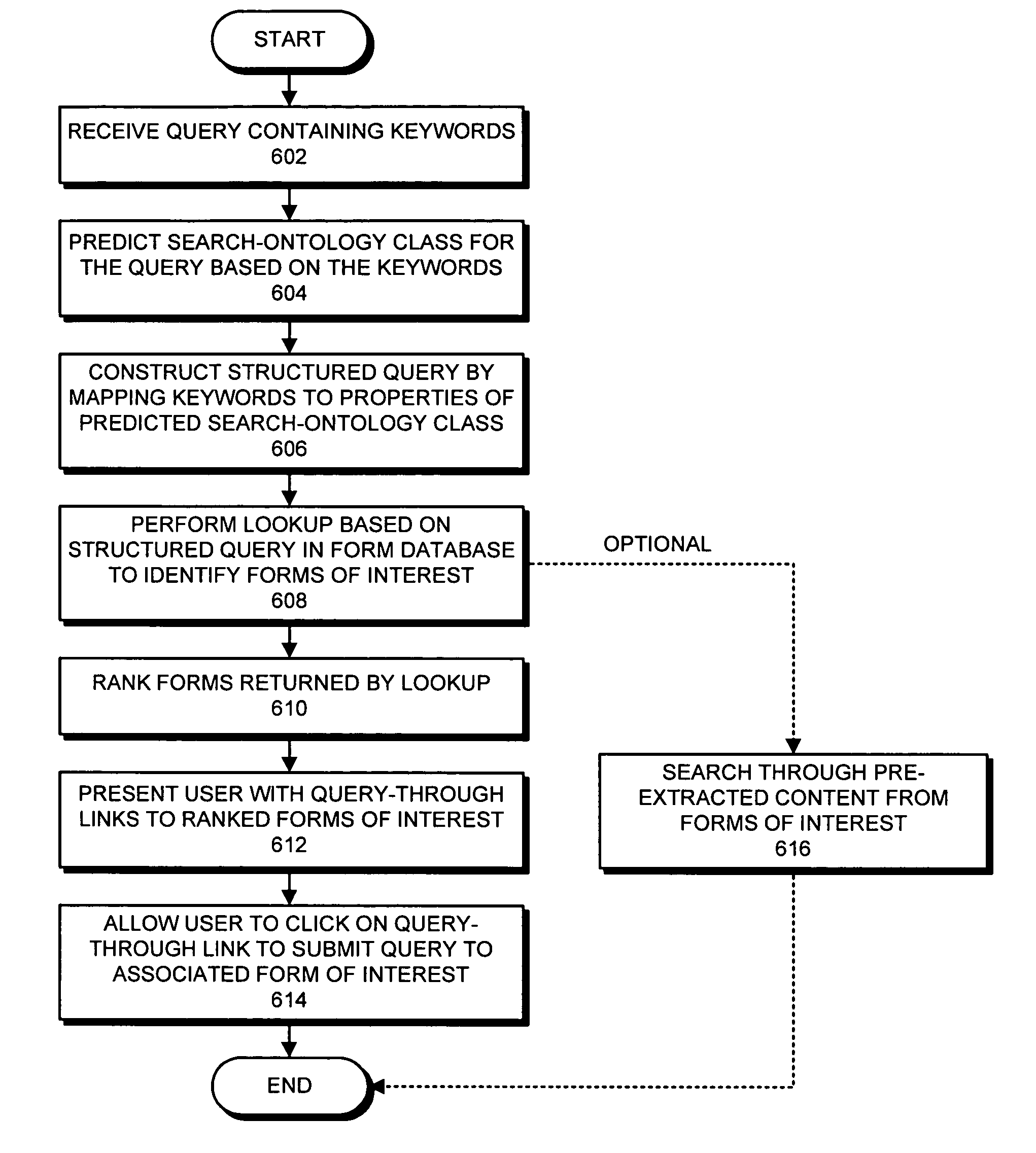

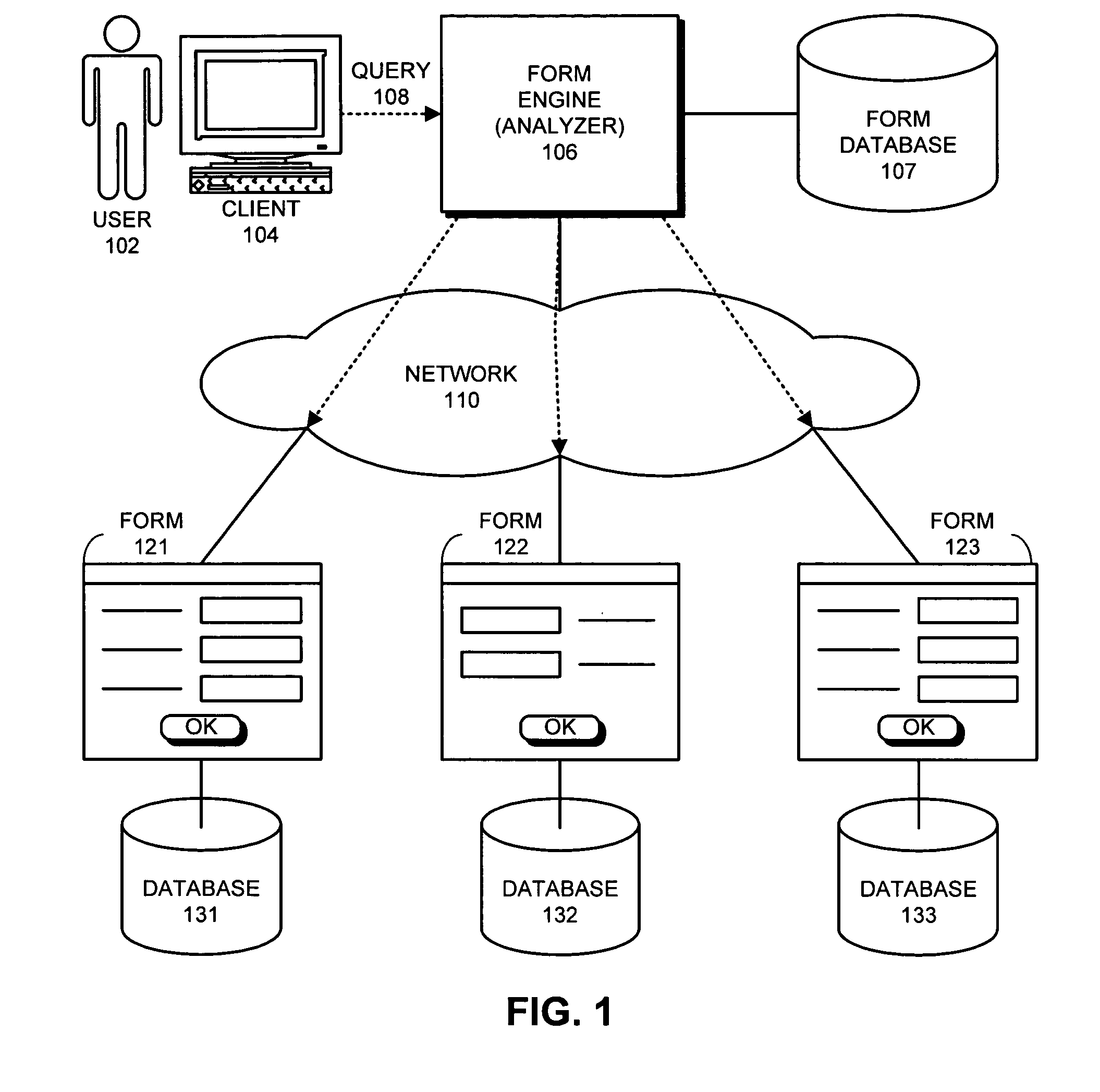

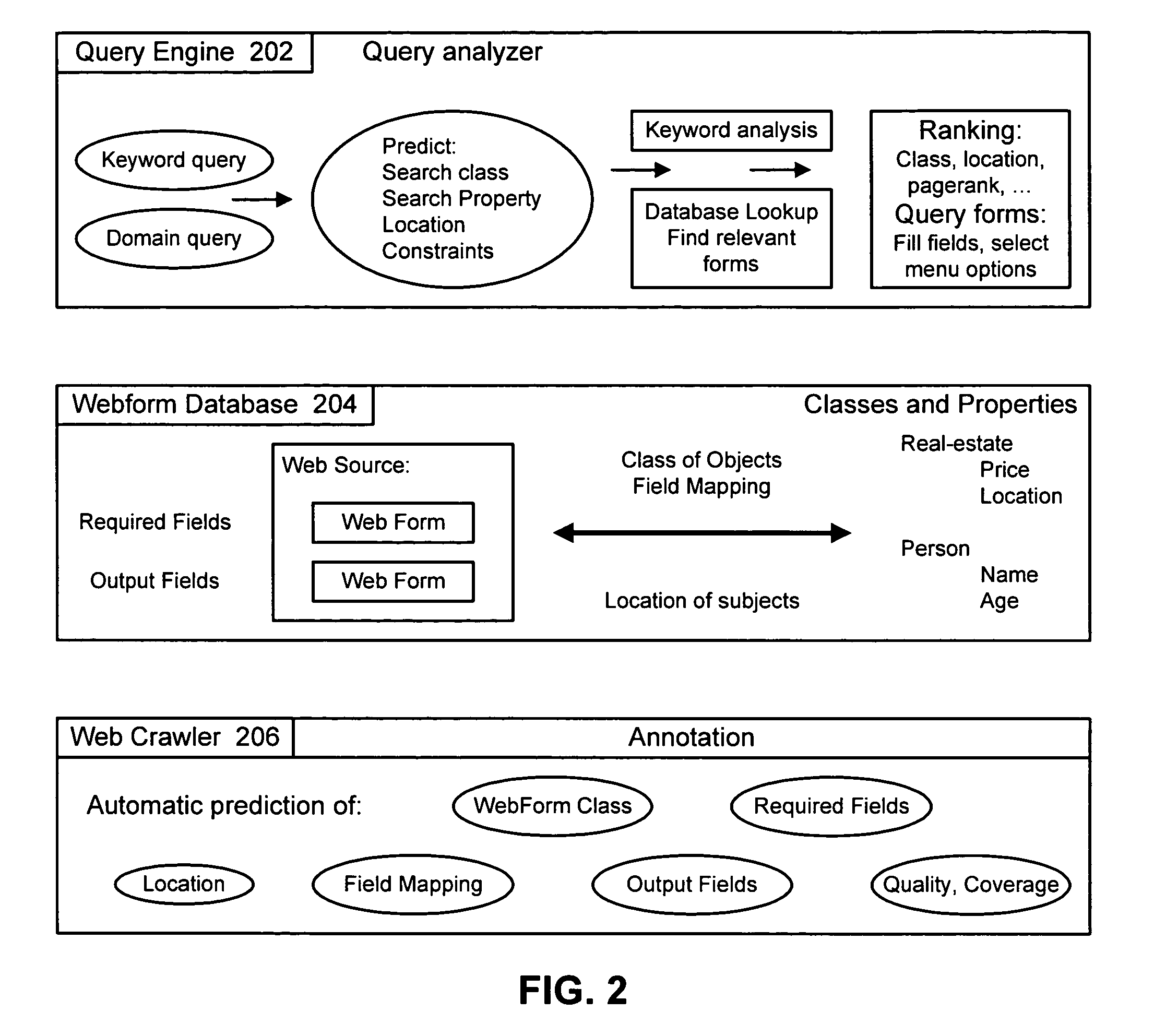

ActiveUS7739258B1Easy to grabFacilitate subsequent searchesWeb data indexingDigital data processing detailsWeb siteDocumentation

One embodiment of the present invention provides a system that facilitates crawling through web-based forms to gather information to facilitate subsequent searches through content which is accessible though the web-based forms. During operation, the system first obtains web-based forms to be searched. Note that the system can obtain these web-based forms from a number of sources. For example, the system can crawl through web sites to identify web-based forms, the system can receive manually provided web-based forms, or the system can find web-based forms through methods other than crawling. Next, the system creates database entries for the identified forms. This involves obtaining and storing metadata describing the identified forms into database entries and then storing these database entries in a form database to facilitate searches through content which is accessible through the identified forms. Note that this form database can include a web index and associated documents, which can be used to facilitate web search queries that return both ordinary documents and documents that result from form queries.

Owner:GOOGLE LLC

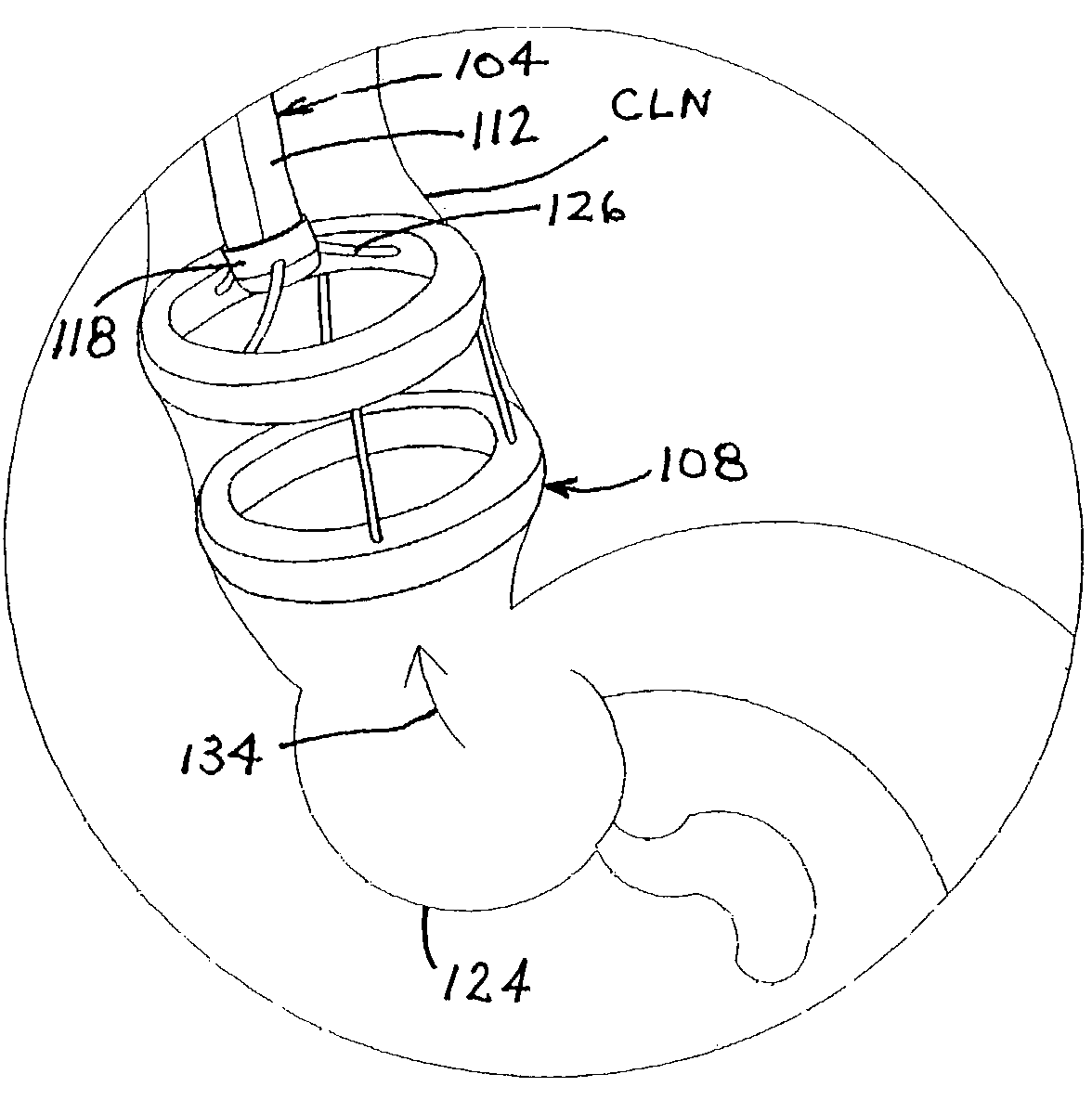

Endoscopic retractor instrument and associated method

An endoscopic retractor instrument assembly includes a balloon having a pair of expandable or inflatable end portions and at least one expandable or inflatable spacer portion connecting the end portions to one another. A fastener is provided for securing the balloon to a distal end of an endoscopic insertion member, with the balloon being disposed in a collapsed configuration along an outer surface of the endoscopic insertion member. An inflation element is operatively coupled with the balloon for enabling an inflating of the balloon from the collapsed configuration to an expanded use configuration in which the spacer portion pushes the end portions apart from one another and in which the balloon extends at least partially in a distal direction away from the distal end of the endoscopic insertion member for spreading internal tissues of a patient to facilitate access to the tissues via the endoscopic insertion member.

Owner:GRANIT MEDICAL INNOVATION

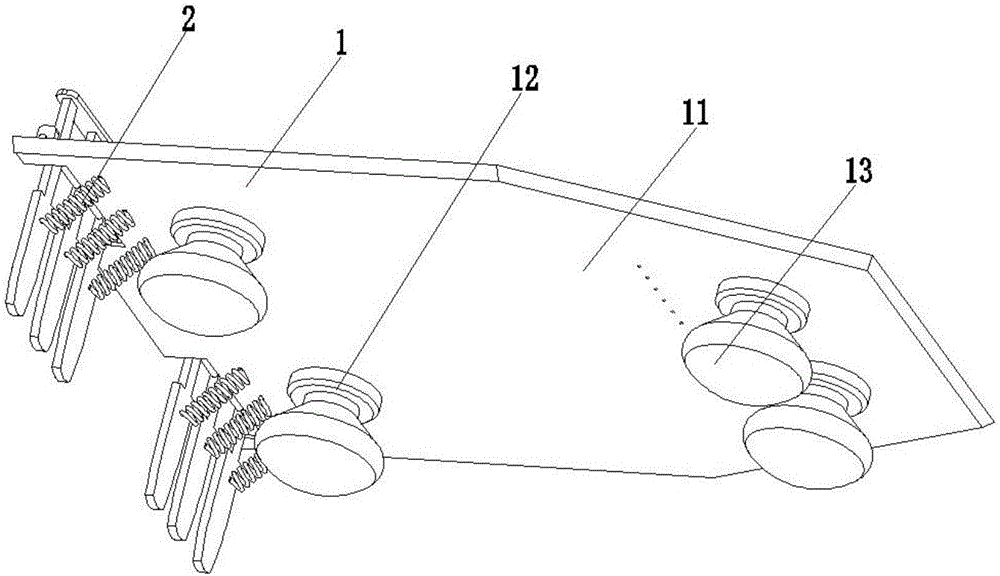

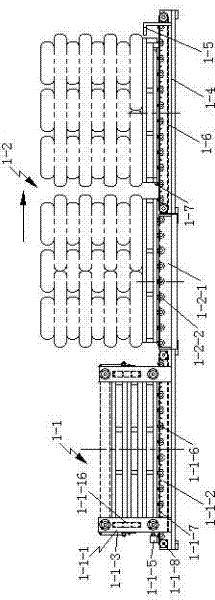

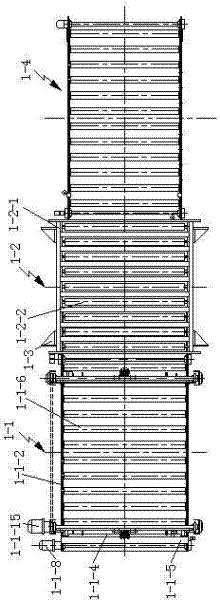

Bar material conveying device

ActiveCN102897478AStable supportStable positionConveyorsConveyor partsEngineeringMechanical engineering

The invention relates to a bar material conveying device which comprises a horizontal conveying machine. The horizontal conveying machine comprises at least one conveying set formed from a driving assembly and a band type dragging assembly, wherein as least one row of bar bases in the direction of conveying are arranged on the band type dragging assembly, the bar bases comprise supporting plates perpendicular to the annular surface of the band type dragging assembly, and the outer ends of the supporting plates are provided with concave type supporting parts sunk in the direction of the band type dragging assembly. The bar material conveying device provided by the invention is provided with multiple bar bases used for bearing bars, the concave type supporting parts are arranged on the bar bases, so that the positions of the bars in the direction of conveying are stabilized, a certain space is also left below the bars to be conveniently captured by mechanical arms, and the capture accuracy is increased by stabilizing the positions of the bars at the same time.

Owner:TATUNG GEAR KUNSHAN

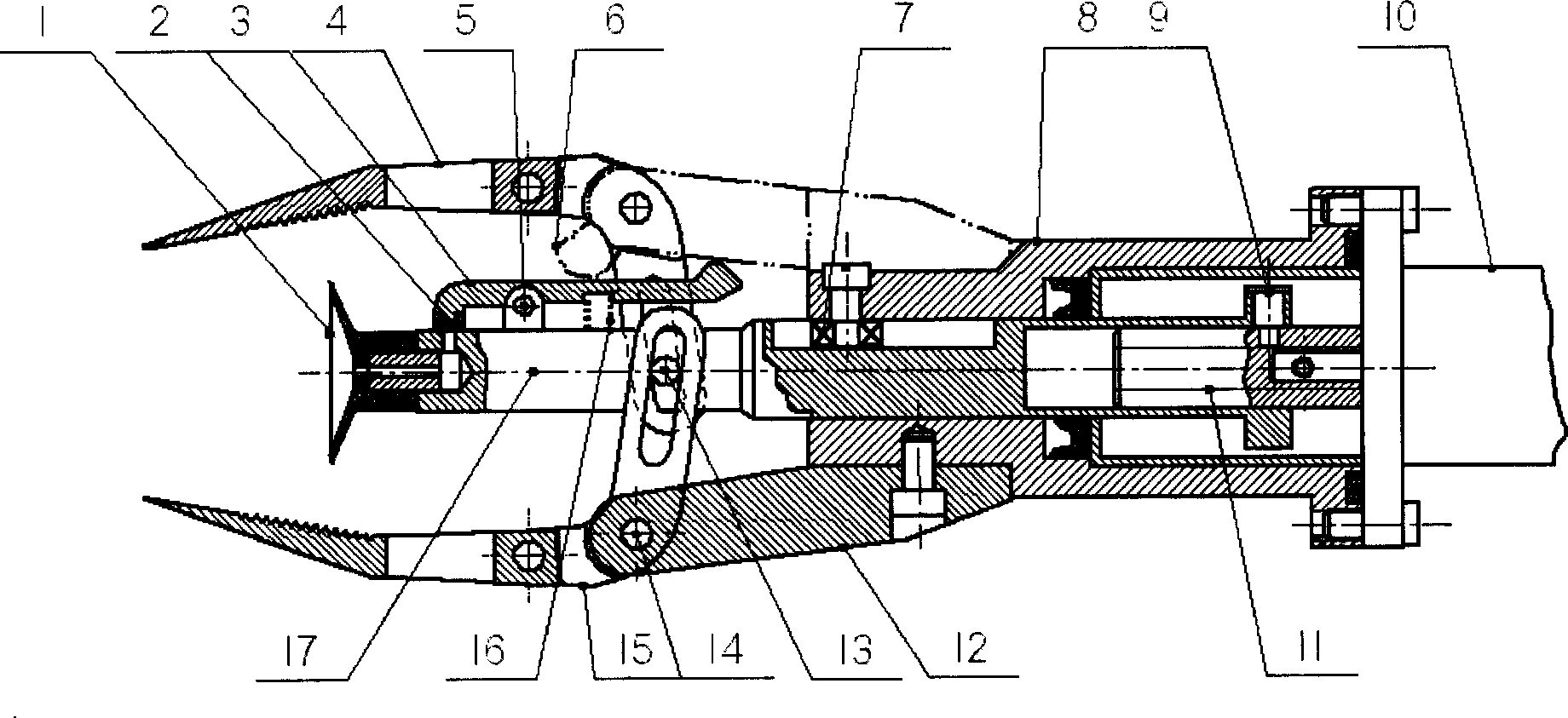

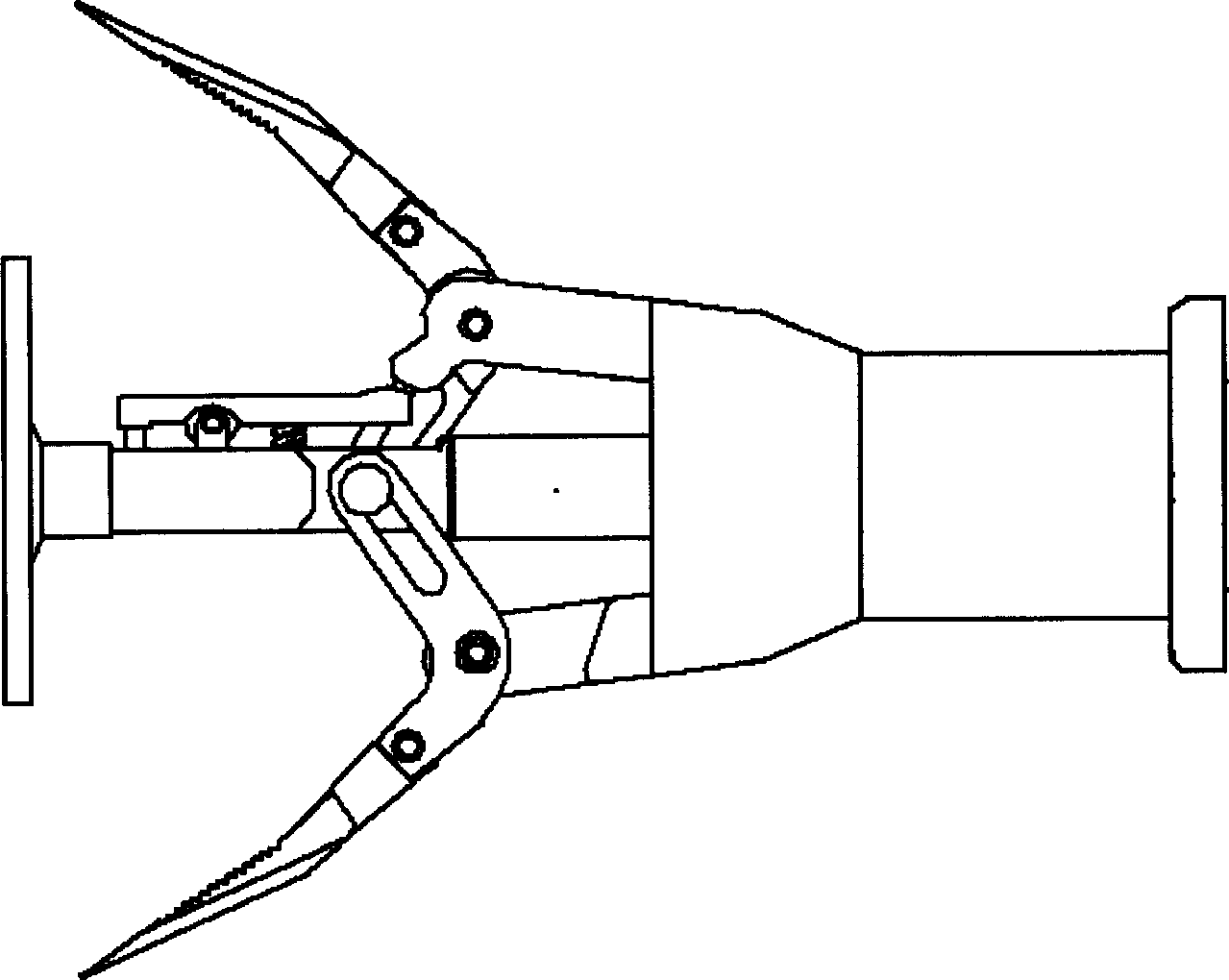

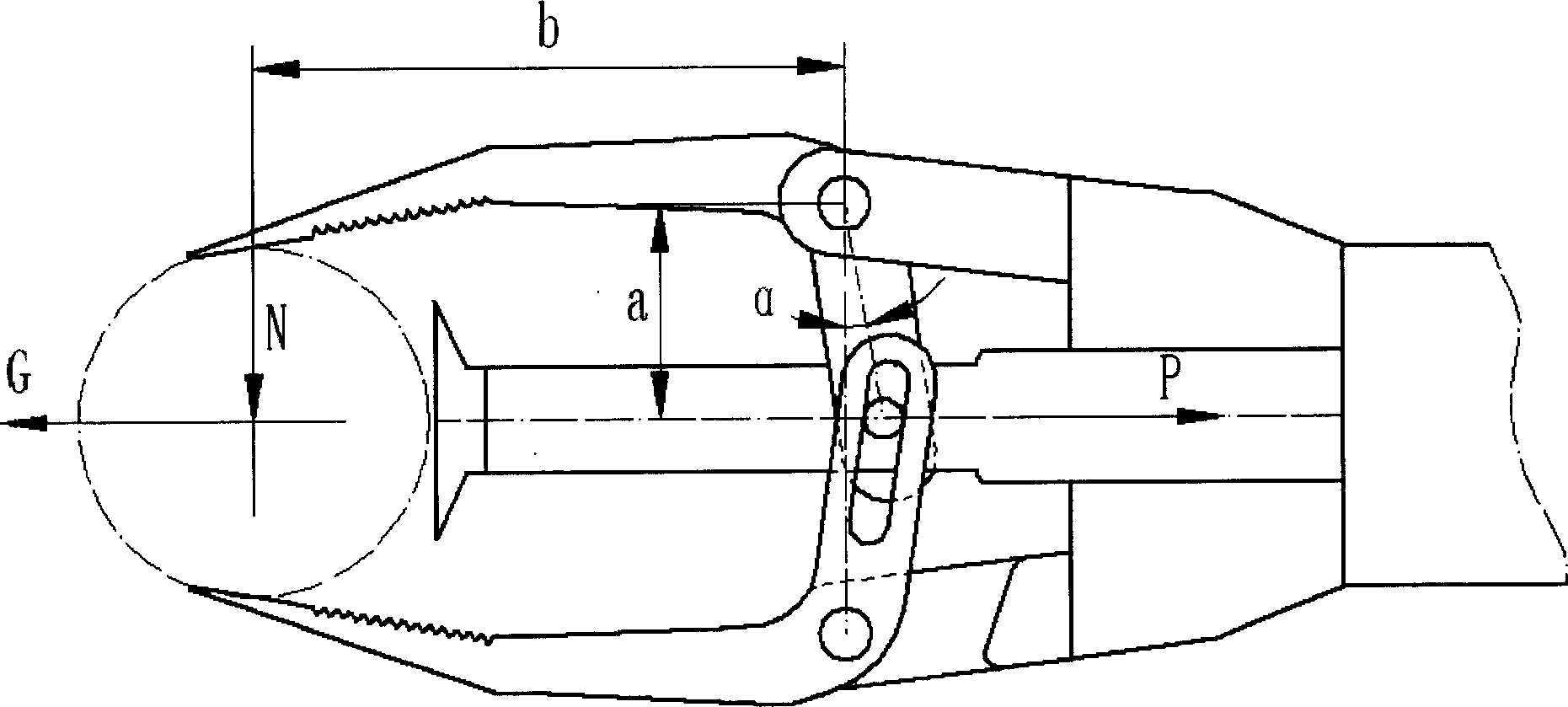

Grasp and suction dual-functional underwater electric manipulator

InactiveCN1883888AGive full play to multiple functionsCrawl to solveGripping headsForeign matterUnderwater

The invention involves submarine manipulator with clamping and suctioning functions. The manipulator mainly consists of the suction disc, pressure-relieving cushion, supporting rod, clamping fingers, spindle 1, stopper for clamping finger seat, guide bearing, clamp seat, pulling nail, motor, transmission screw, clamping finger seat, spindle 2, spindle 3, clamping finger arm, pressing spring and transmission shaft. The motor spindle is fixed to the transmission screw through pins. The clamp seat and the clamping finger seat are stationary. The motor and the transmission are connected with the pulling nail through a helix trough. One end of the clamping arm is connected to the clamping finger seat through the spindle and can rotate around the central line of the spindle. The other end is connected to the spindle 2 through a sliding trough. The spindle 2 and the transmission spindle are fixed into a whole structure, so the clamping and opening motion of the clamping fingers are realized. The supporting rod is connected to the transmission spindle through the spindle 1, and thus forming a level mechanism. As the transmission spindle reaches a certain position, under the joint action of the extruding block on the supporting rod and the stopper on the clamping finger seat, one end of the supporting rod is lifted. So the negative pressure cavity in the suction disc is depressurized. With this invention, the problem of picking up various kinds of objects with a single mechanism is solved, fully exerting the multi-functions which one single mechanism possesses, characterized by being light in weight, compact, practicability, reliable seal and convenience.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

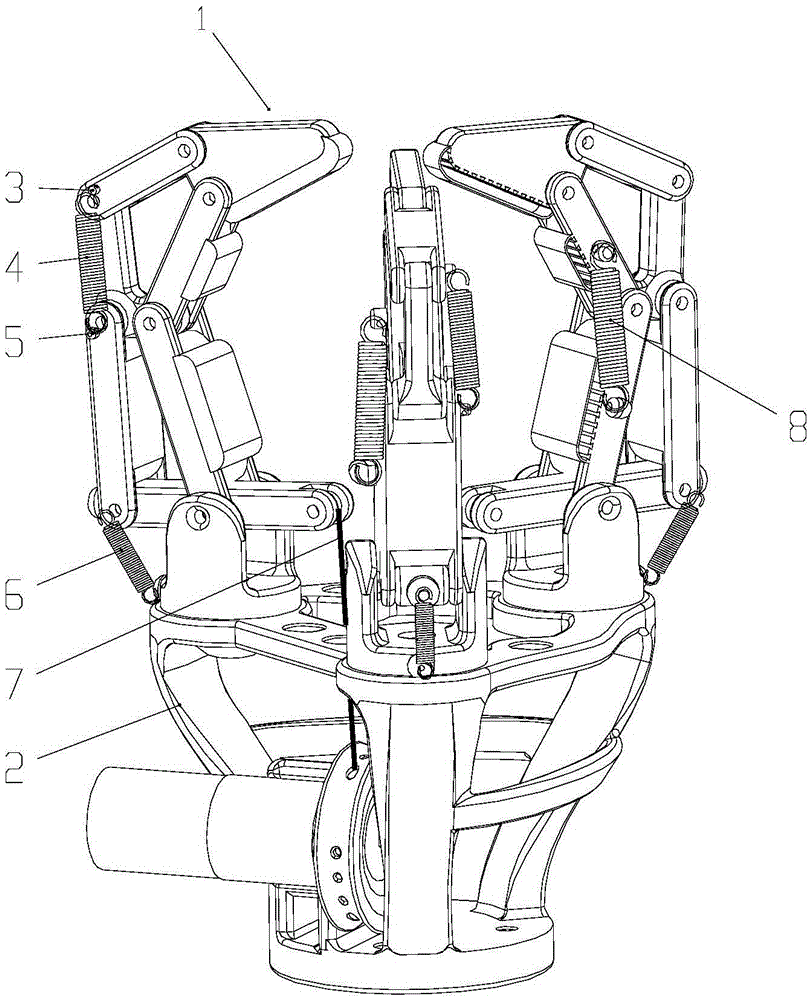

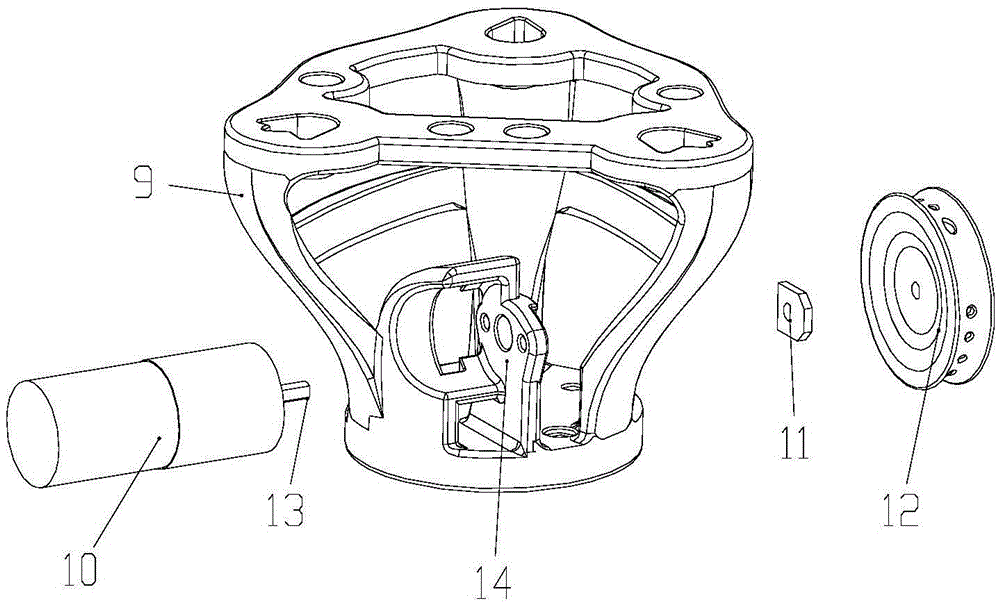

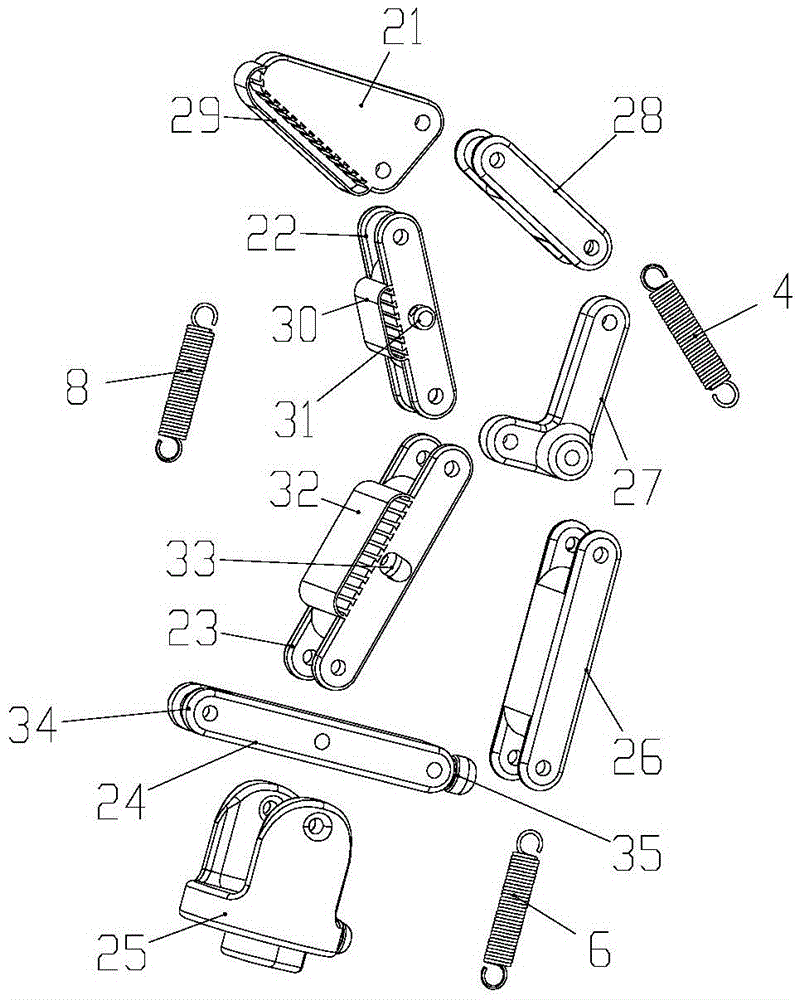

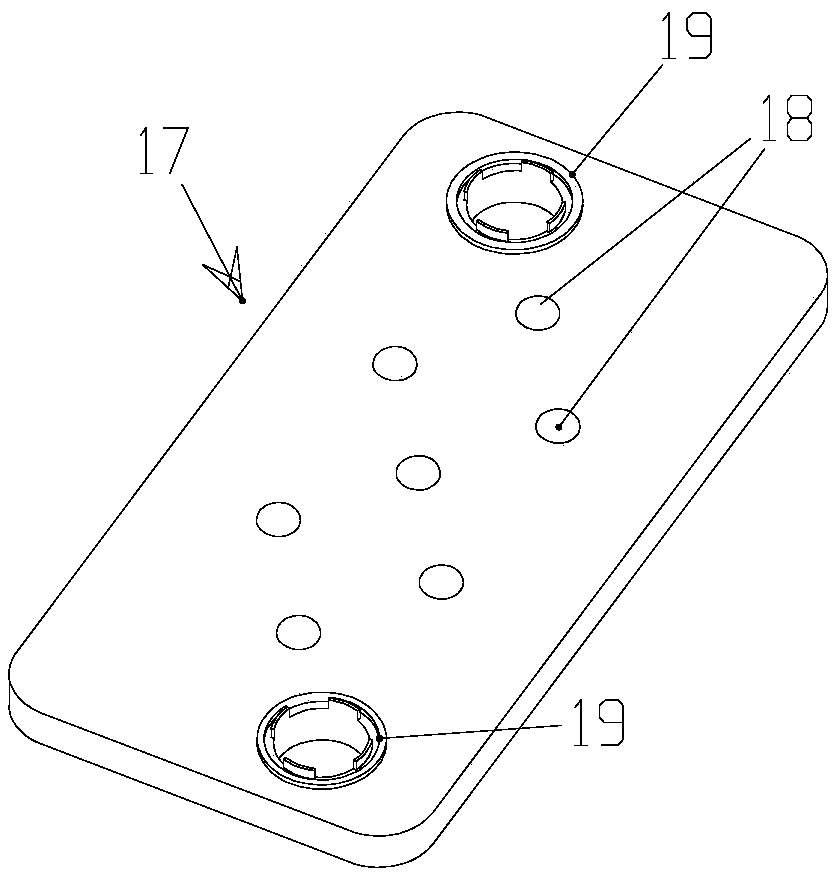

Flexible self-adaption under-actuated robot hand

ActiveCN105563513AGuaranteed crawlGuaranteed crawling workProgramme-controlled manipulatorGripping headsRobot handWinch

The invention relates to a hand, in particular to a flexible self-adaption under-actuated robot hand. The flexible self-adaption under-actuated robot hand comprises fingers and a wrist; the wrist includes a skeleton, a direct-current motor, a potentiometer and a winch; the direct-current motor is fixedly connected to a motor mounting surface of the skeleton; the potentiometer is fixedly connected to a potentiometer mounting surface of the skeleton by penetrating through an output shaft of the motor; the winch is fixedly connected to the tail end of the output shaft of the motor; multiple fingers are provided; and the fingers are embedded in clamping grooves of the skeleton or multiple clamping grooves through convex blocks of rotating bodies. The flexible self-adaption under-actuated robot hand is assembled at the tail end of an industrial robot for assisting mechanical assembly or mechanical manufacturing process and finishing automatic workpiece loading / unloading; and the fingers can flexibly adapt to geometric shapes of products, and realize automatic adjustment according to the geometric shapes of workpieces to realize stable grabbing.

Owner:华粹智能装备有限公司

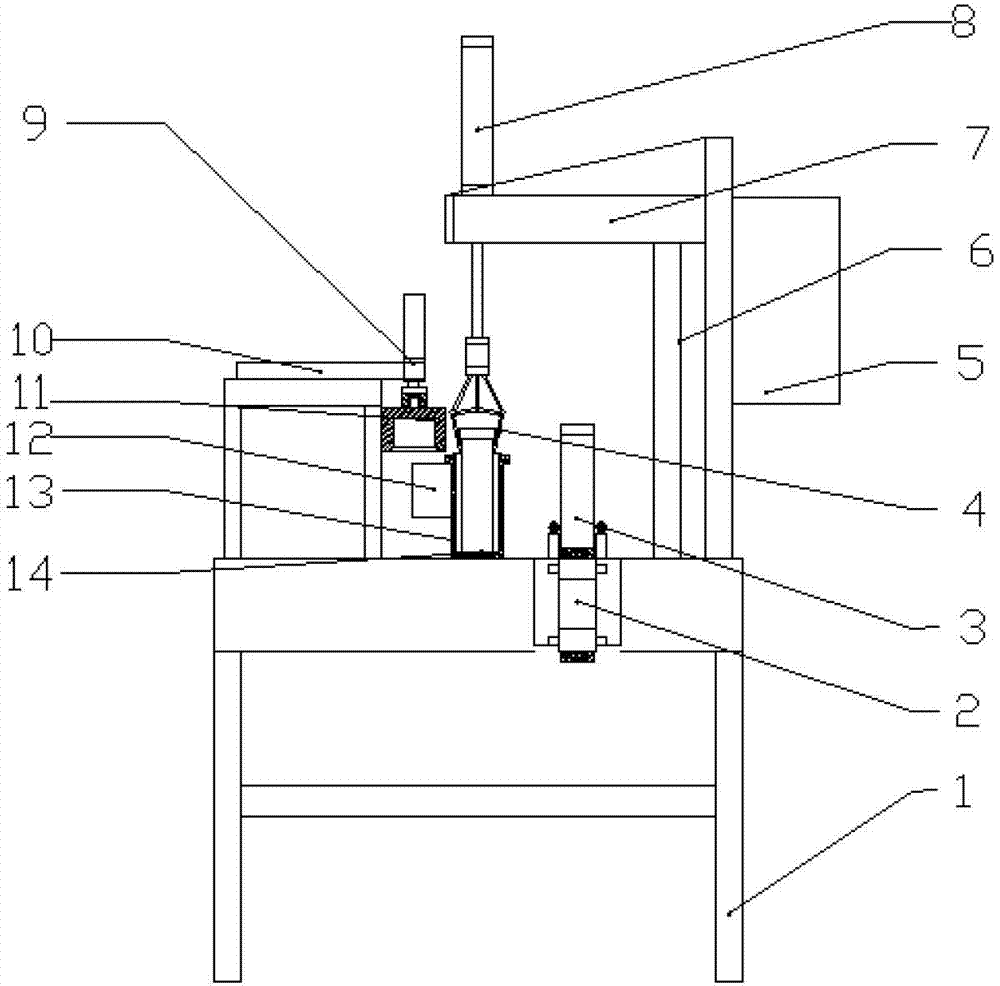

Automatic assembling and smearing equipment of cover plate of speed reducer

ActiveCN105499968ASimple actionImprove reliabilitySpraying apparatusVehicle componentsReduction driveEngineering

The invention relates to automatic manufacturing equipment and particularly relates to automatic assembling and smearing equipment of a cover plate of a speed reducer. The automatic assembling and smearing equipment of the cover plate of the speed reducer comprises a worktable, a conveyor belt for conveying the cover plate of the speed reducer, a charging mechanical arm for grasping a plane bearing, a three-coordinate smearing mechanism for realizing track smearing, a No.1 tool clamp used for fixing the cover plate of the speed reducer, a No.2 tool clamp used for fixing the cover plate of the speed reducer, and a vibration disc for realizing sorted charging of the plane bearing; a material loading plate is movably connected with the tail end of a feeding rail of the vibration disc; the material loading plate is provided with a material loading hole matched with the plane bearing; and one end of the material loading plate is connected with a transverse pushing air cylinder. The invention aims at providing the automatic assembling and smearing equipment of the cover plate of the speed reducer, which is used for assembling the plane bearing to the cover plate of the speed reducer, and is used for finishing smearing of lubricating grease on the surface of the plane bearing at the same time; and the automatic assembling and smearing equipment has relatively high smearing efficiency.

Owner:苏州峘一自动化有限公司

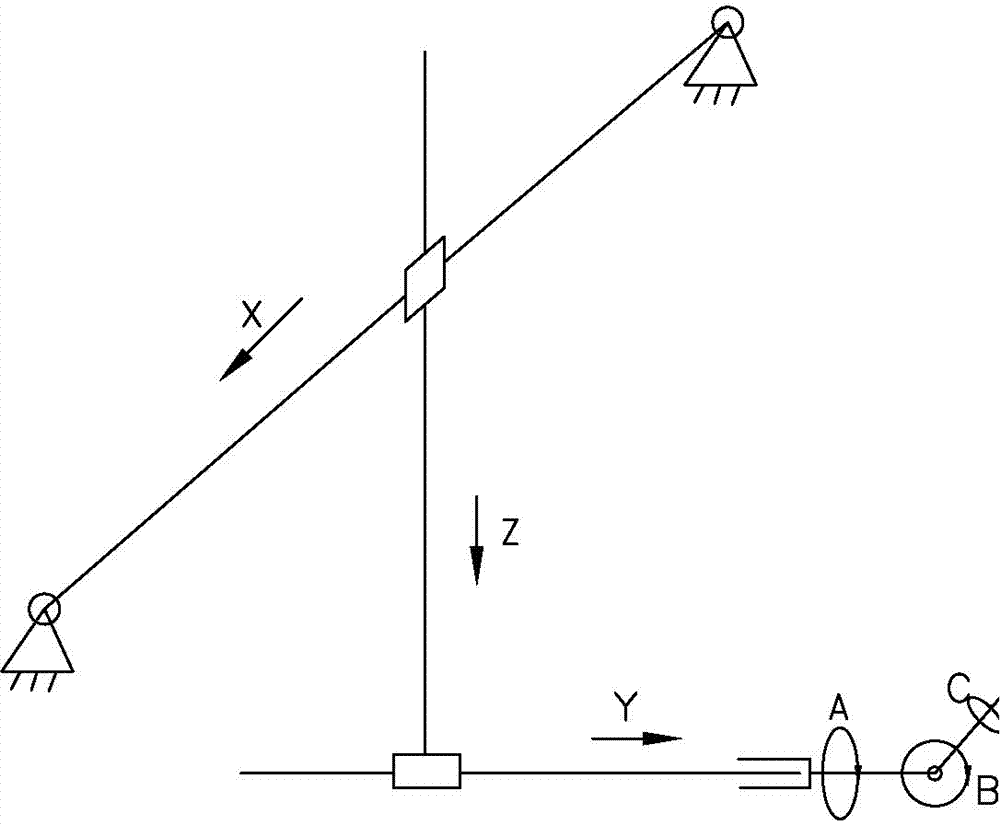

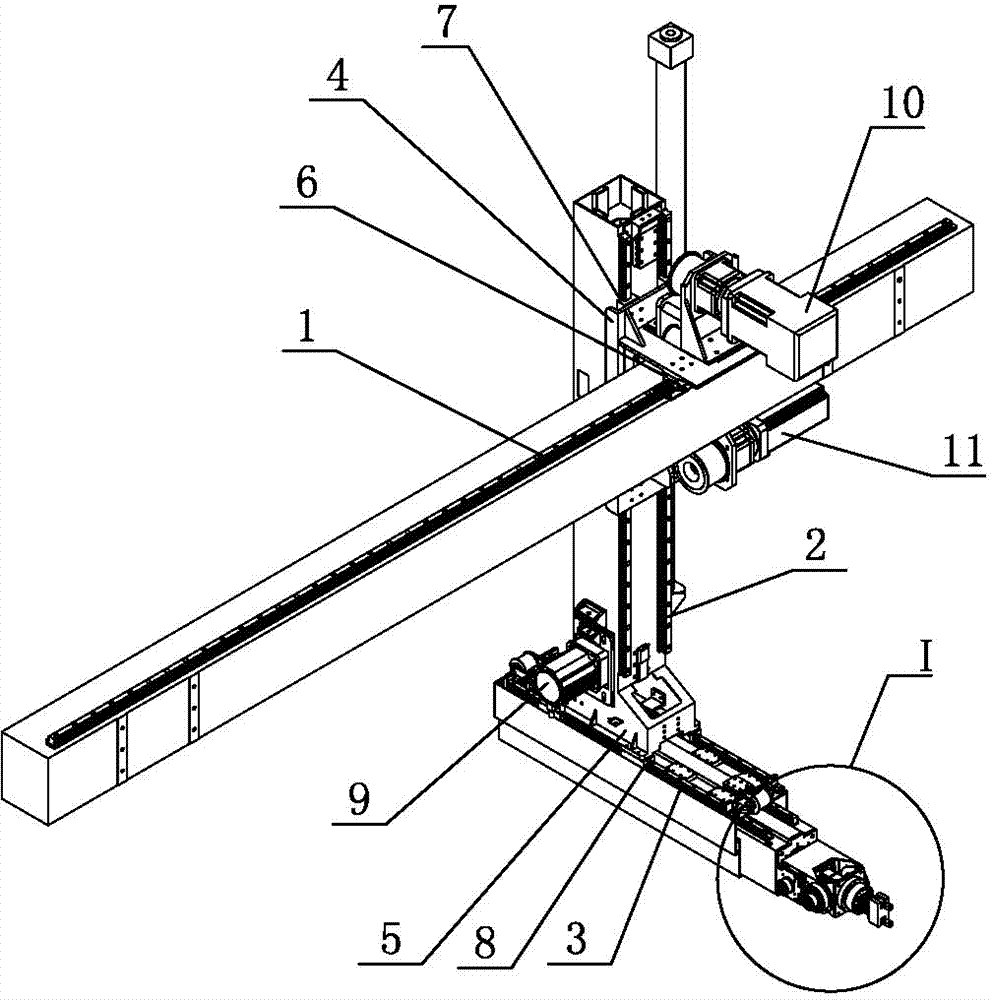

Six-axis bending robot

ActiveCN103538060APrecise positioningEasy to grabProgramme-controlled manipulatorClassical mechanicsEngineering

The invention relates to a six-axis bending robot in the technical field of mechanical processing. The six-axis bending robot comprises an X-axis guide rail, a Y-axis guide rail and a Z-axis guide rail which are perpendicular to one another, the X-axis guide rail is fixedly connected with a machine body, and vertically connected with the Z-axis guide rail through a slider I, an X-direction slider guide rail and a Z-direction slider guide rail in relatively sliding connection with the X-axis guide rail and the Z-axis guide rail are arranged on the slider I respectively, a slider II is fixedly arranged at the lower end of the Z-axis guide rail, a Y-axis slider guide rail in slidable connection with the Y-axis guide rail is fixedly arranged on the slider II, an A shaft is rotatably connected at the front end of the Y-axis guide rail, a B shaft perpendicular to the A shaft is rotatably connected on the A shaft, a C shaft perpendicular to the B shaft is rotatably connected on the B shaft, a tail end executing mechanism is arranged at the front end of the C shaft, an X-axis driving mechanism and a Z-axis driving mechanism which drive the slider I to horizontally move along an X shaft and a Z shaft respectively are arranged on the slider I, a Y-axis driving mechanism is arranged on the slider II, and a rotary driving device is arranged on each of the A shaft, the B shaft and the C shaft. By the structure, the six-axis bending robot is accurate and flexible to act and high in working efficiency in the process of continuous plate material bending processing.

Owner:扬州恒佳机械有限公司

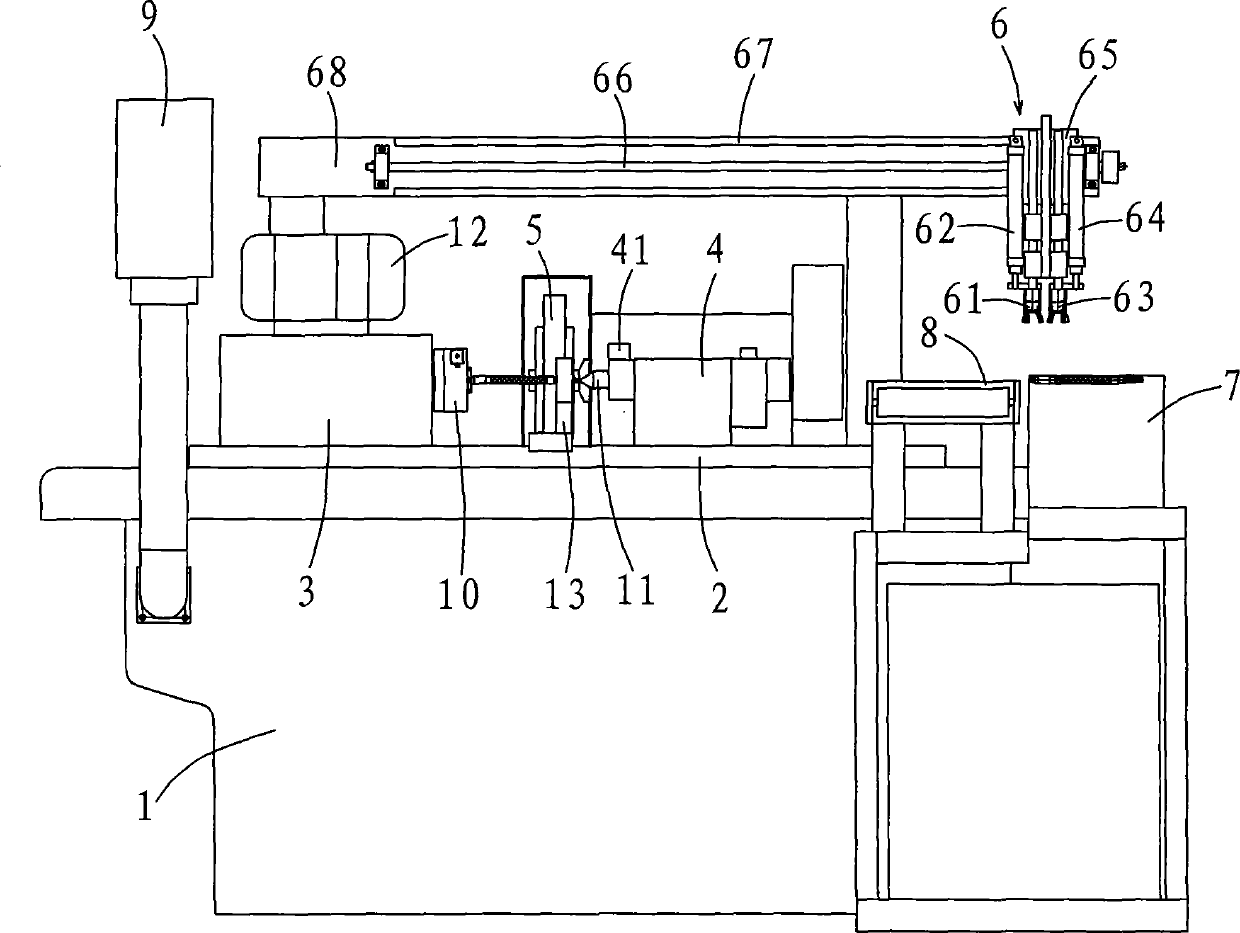

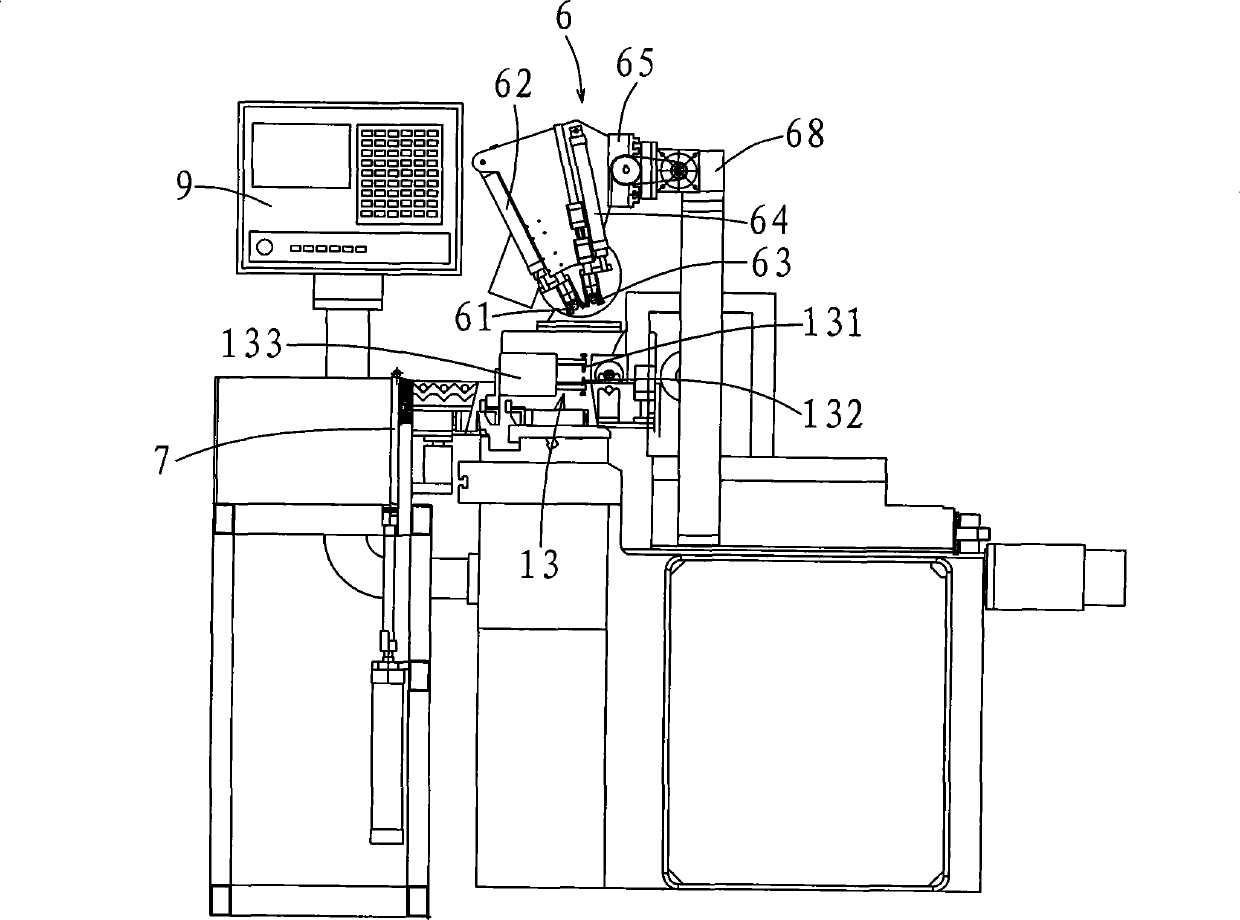

Fully-automatic grinder

InactiveCN103962901AHigh degree of automationReduce labor intensityRevolution surface grinding machinesGrinding feed controlNumerical controlMulti machine

The invention relates to a fully-automatic grinder comprising a base, a workbench, a headstock, a tailstock, a grinding wheel mechanism, a feeding and discharging manipulator, an automatic feeding mechanism, an automatic discharging mechanism and a numerical control device. A chuck and a centre are arranged on opposite faces of the headstock and the tailstock respectively and concentrically. The feeding and discharging manipulator comprises a taking pneumatic gripper, a taking cylinder, a putting pneumatic gripper, a putting cylinder, a guide slide fixing frame, a ball screw, a linear guide rail and a guide rail bracket, the taking pneumatic gripper, the taking cylinder, the putting pneumatic gripper and the putting cylinder are all mounted on the guide slide fixing frame, the taking pneumatic gripper and the putting pneumatic gripper are arranged at an included angle forward and backward and arranged parallelly leftward and rightward, and the guide slide fixing frame is in sliding fit with the ball screw and the linear guide rail. The grinder is high in automation degree, the whole process of feeding, discharging, clamping, machining, on-line measurement and the like of workpieces is completed automatically through the numerical control device, one-man multi-machine operation can be realized, production efficiency and production quality are improved, and labor intensity and production cost of workers are lowered.

Owner:JIAHE TOOLS

Lake silt clearing device and method

ActiveCN107059970AAvoid the phenomenon of poor graspingImprove crawling efficiencyMechanical machines/dredgersEngineeringSilt

The invention mainly discloses a lake silt clearing device and method. According to the technical scheme, the lake silt clearing device comprises a boat body, a detection device, a grabbing device and a silt sucking device; the detection device comprises a detector, an ascending and descending rope and a winching device, and the detector is wound on the winching device through the ascending and descending rope; the grabbing device comprises an ascending and descending rod, a first grab bucket and a second grab bucket, the ascending and descending rod is connected with the first grab bucket, and the second grab bucket is located inside the first grab bucket; and the silt sucking device comprises a silt collection bin, a centrifugal type silt pump, a silt sucking pipe, a drill and a support frame, the silt sucking pipe is connected with the silt collection bin through the centrifugal type silt pump, the support frame is fixed to the outer side of the lower end of the silt sucking pipe, and the silt sucking pipe is internally provided with an enclosed motor connected with the drill. By means of the lake silt clearing device and method, the mode that grabbing and silt sucking are combined is adopted for disposing silt at the bottom of a lake; different types of disposal can be conducted according to the practical conditions of soil at the bottom of water; damage and blockage of the clearing device caused by hard objects are avoided; and the lake silt clearing device is high in clearing efficiency and long in service life.

Owner:ZHEJIANG SHUANGLIN PLASTIC MACHINERY

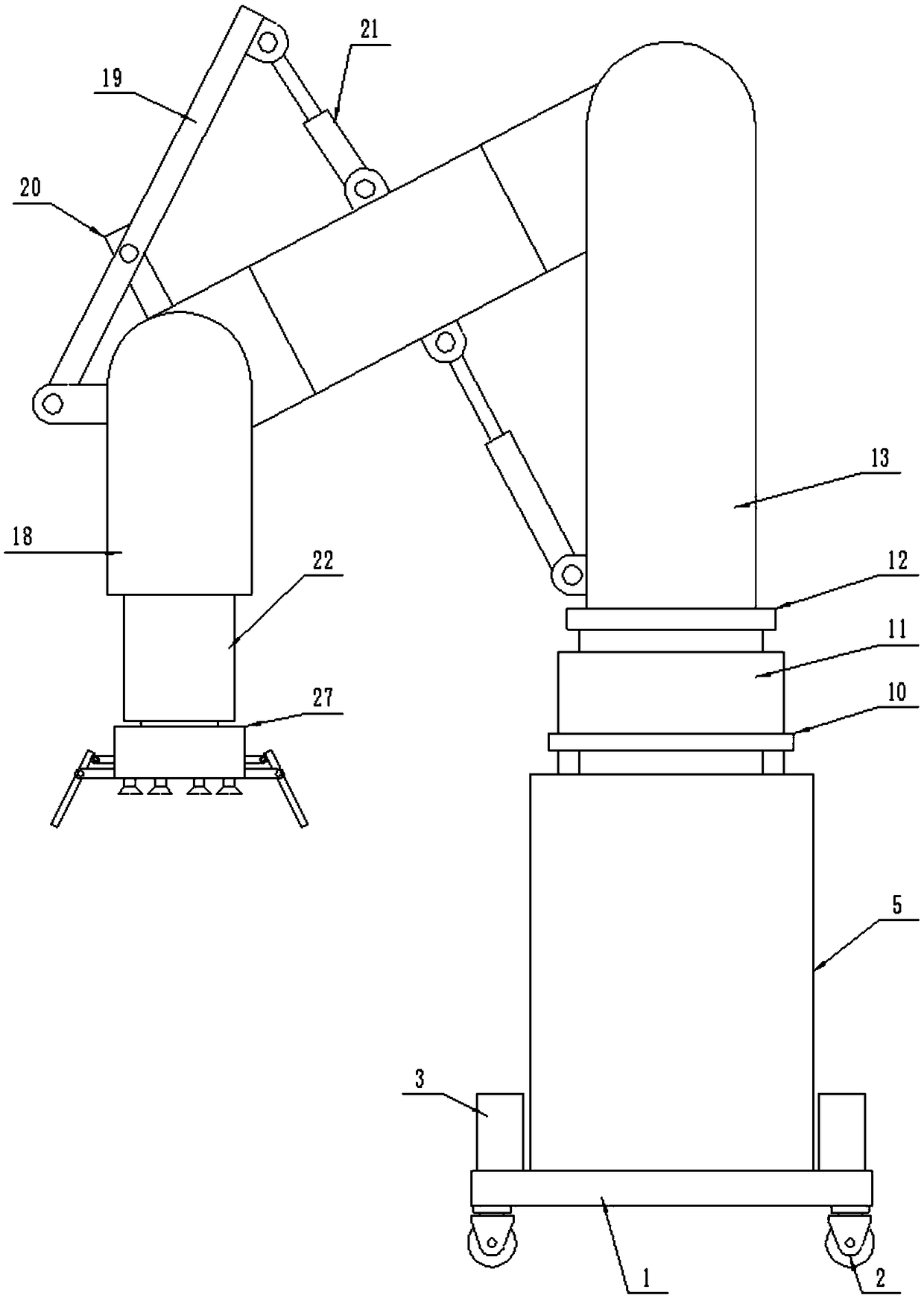

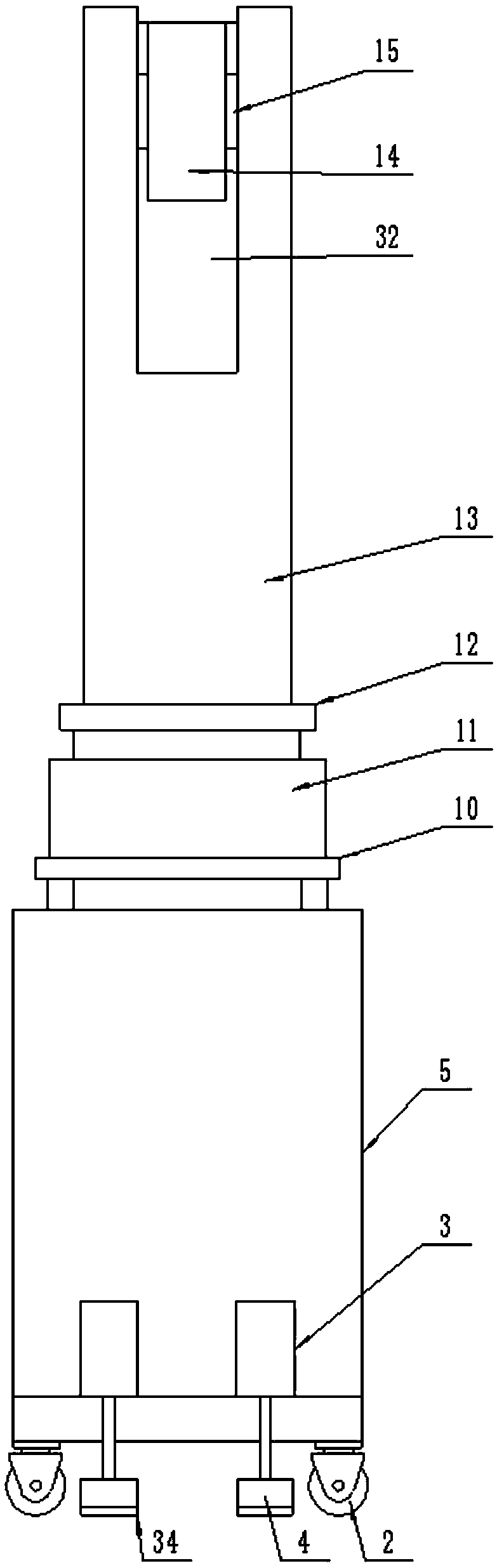

Height-adjustable stacking mechanical arm

InactiveCN108818507AEasy to grabStop fallingProgramme-controlled manipulatorGripping headsHydraulic cylinderEngineering

The invention discloses a height-adjustable stacking mechanical arm comprising a base, a lifting mechanism, an angle regulation mechanism and a clamping mechanism. Universal wheels are arranged at thelower end of the base. A parking cylinder is arranged at the upper end of the base. A parking fixed block is installed at the telescopic end of the parking cylinder. The lifting mechanism comprises arectangular shell, a lifting hydraulic cylinder, a first lifting push plate, a guide sleeve, a guide rod and a second lifting push plate. The angle regulation mechanism comprises a hydraulic rotationoil cylinder, a rotation base, a supporting arm, a first pitching arm, a first rotating shaft, a first bearing, a first pitching regulation hydraulic cylinder, a second rotating shaft, a second pitching arm, a second bearing, a regulation lever, a lever support, a second pitching regulation hydraulic cylinder, a rotation shell, a stepping motor, a rotation bearing, a drum and a turning plate. Theclamping mechanism comprises a clamping shell, a two-way cylinder and a hinge plate. Multiple vacuum suction cups are arranged at the lower end of the clamping shell. The height-adjustable stacking mechanical arm has the beneficial effects of being simple in structure and high in practicability.

Owner:吴晓蝶

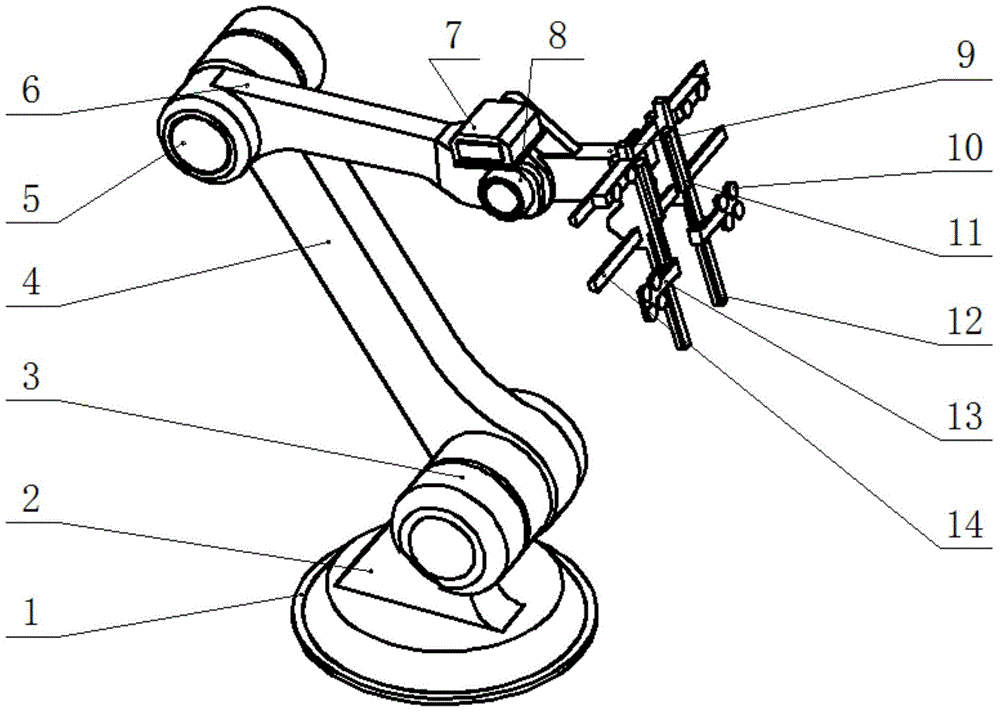

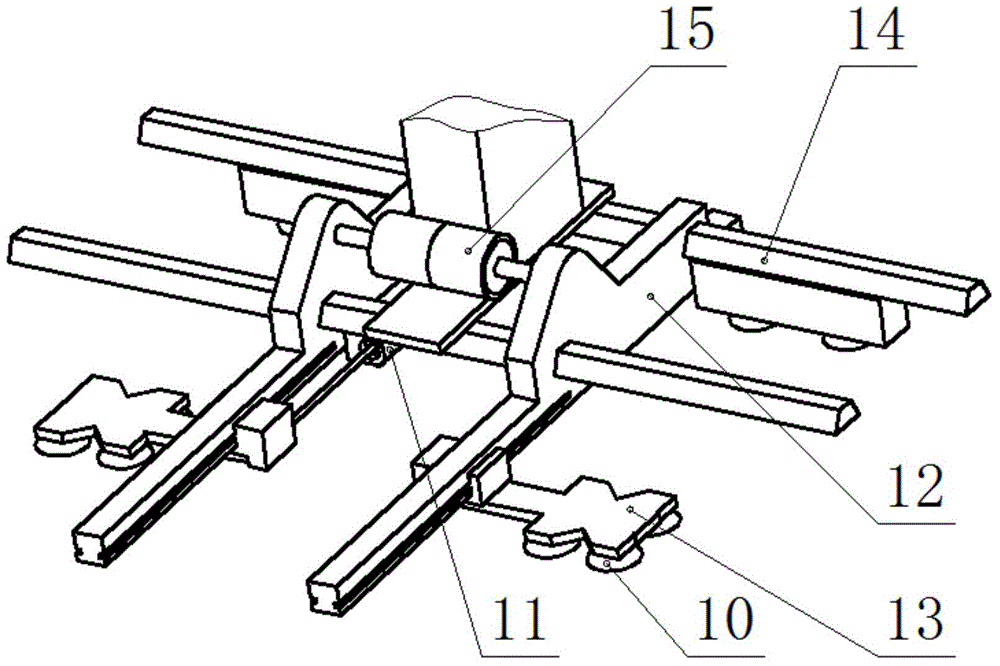

Glass carrying and stacking manipulator

InactiveCN104310069AEasy to grabGood transmission effectCharge manipulationStacking articlesHydraulic motorRotary stage

The invention discloses a glass carrying and stacking manipulator, and belongs to the field of production equipment. The manipulator consists of a fixed base, a rotating pedestal, a large movable arm, a small movable arm, a tail movable arm, fixed sliding rails, adjustment sliding rails, sucker sliding frames, suckers, a vacuum air pump, a transverse adjustment cylinder, longitudinal adjustment cylinders, a hydraulic motor I, a hydraulic motor II and a servo motor, wherein the rotating pedestal is mounted in the fixed base; the large movable arm is hinged to the rotating pedestal through the hydraulic motor I; the small movable arm is hinged to the large movable arm through the hydraulic motor II; the tail movable arm is hinged to the small movable arm through the servo motor; the fixed sliding rails are fixedly connected with the end face of the tail movable arm; the adjustment sliding rails are arranged on the fixed sliding rails; the transverse adjustment cylinder is arranged on the rear part of the tail movable arm; the sucker sliding frames are arranged on the adjustment sliding rails; the longitudinal adjustment cylinders are arranged on the inner sides of the adjustment sliding rails; the suckers are arranged on the adjustment sliding rails and the sucker sliding frames. The manipulator can be used for efficiently and safely carrying and stacking glass instead of a worker.

Owner:曹磊

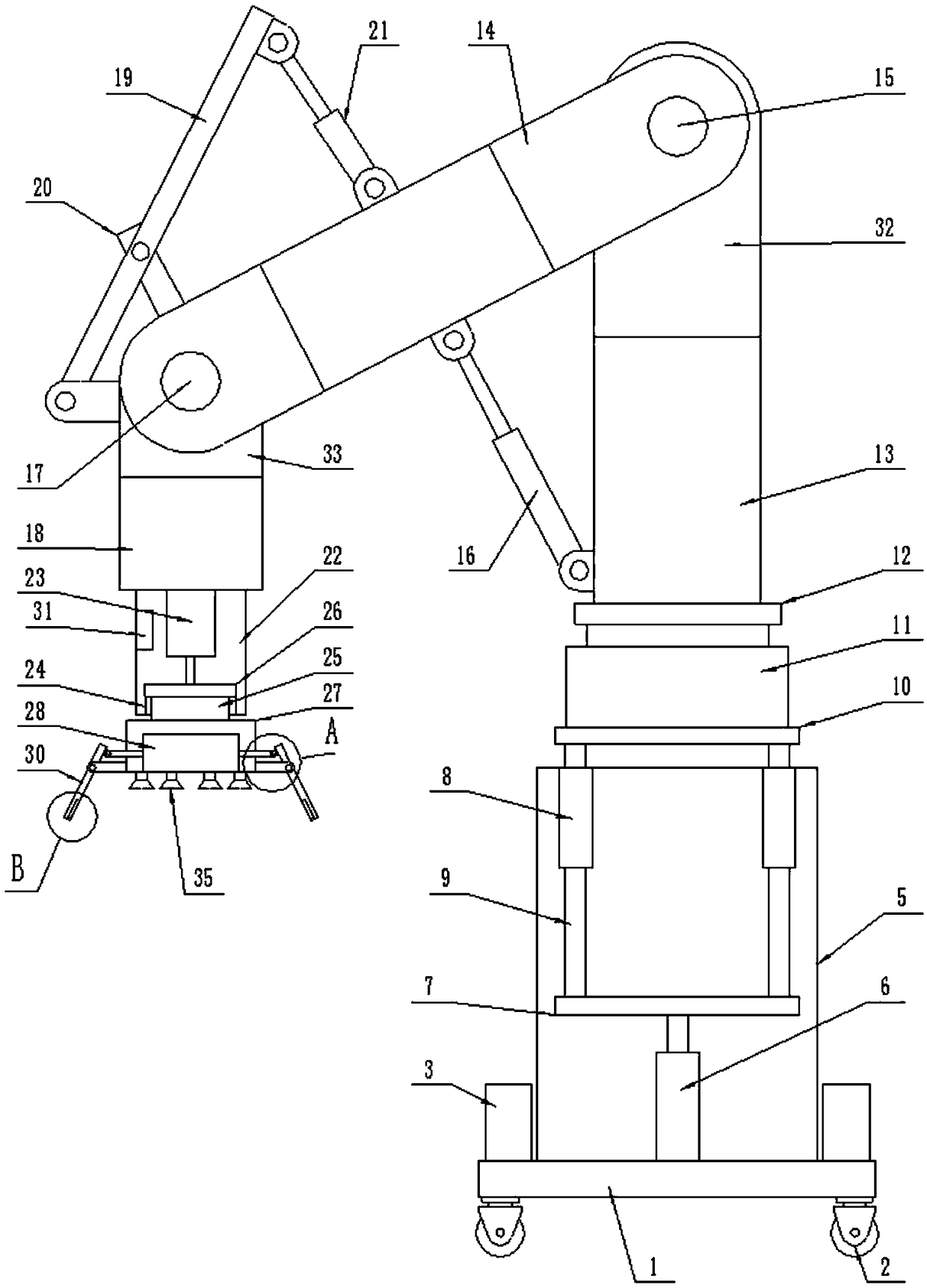

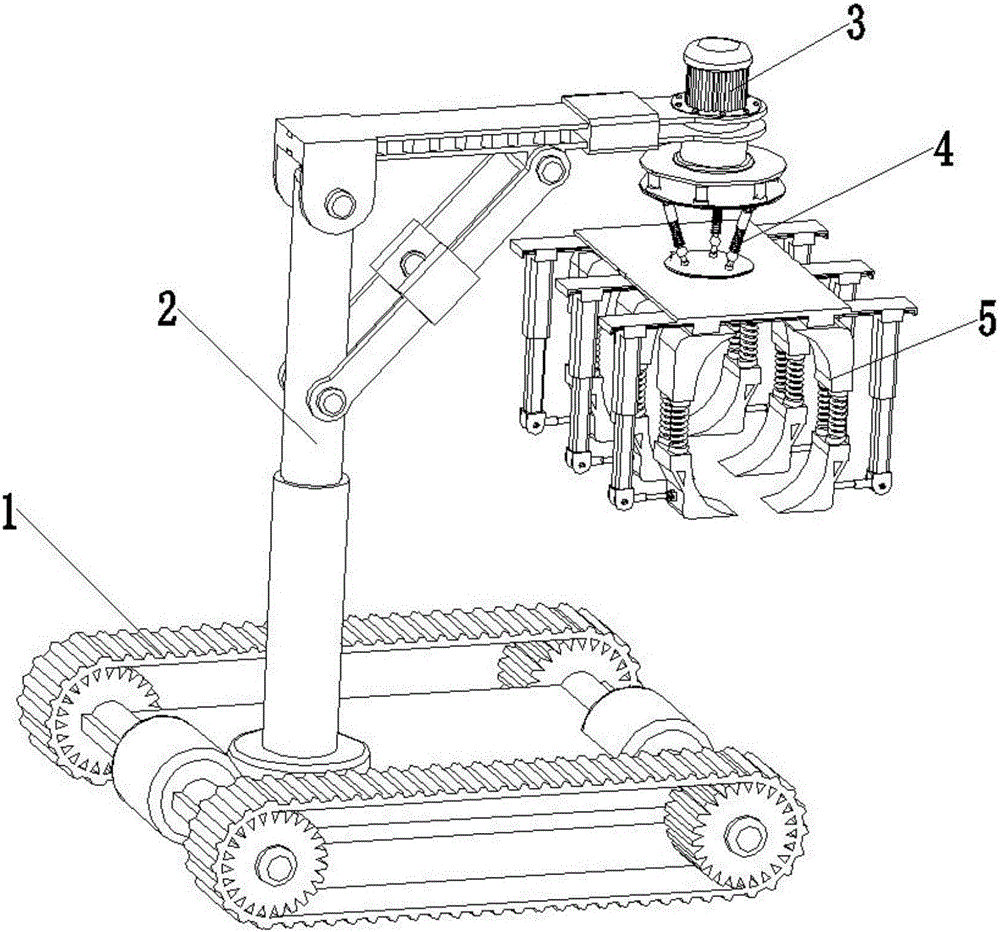

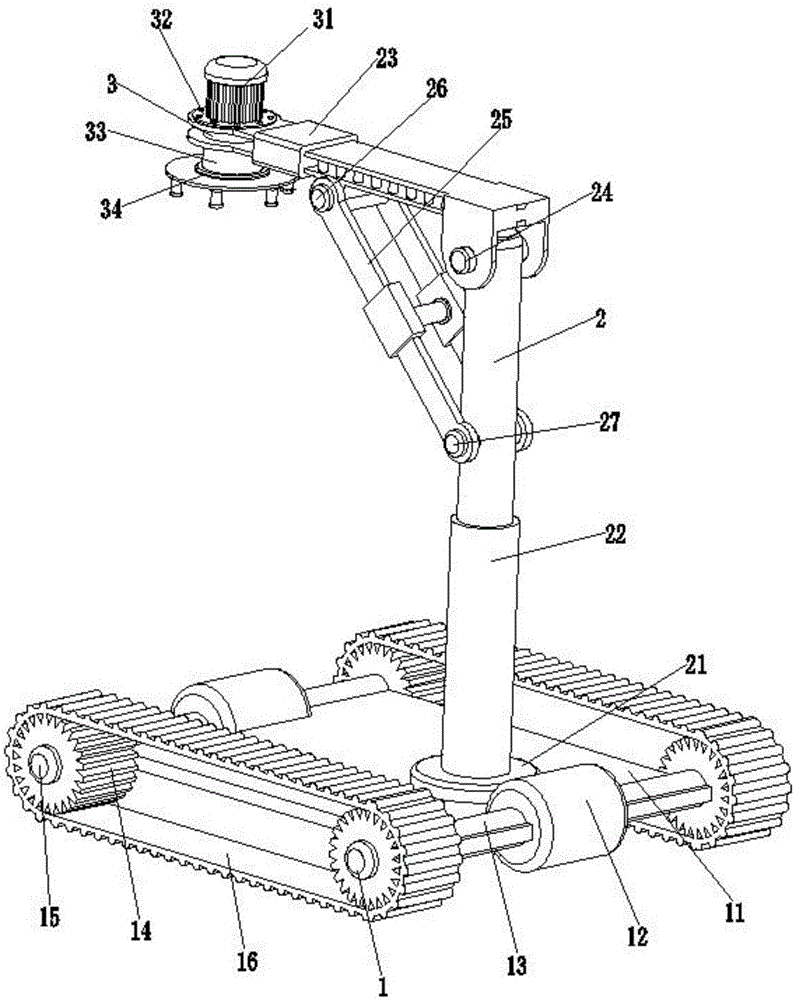

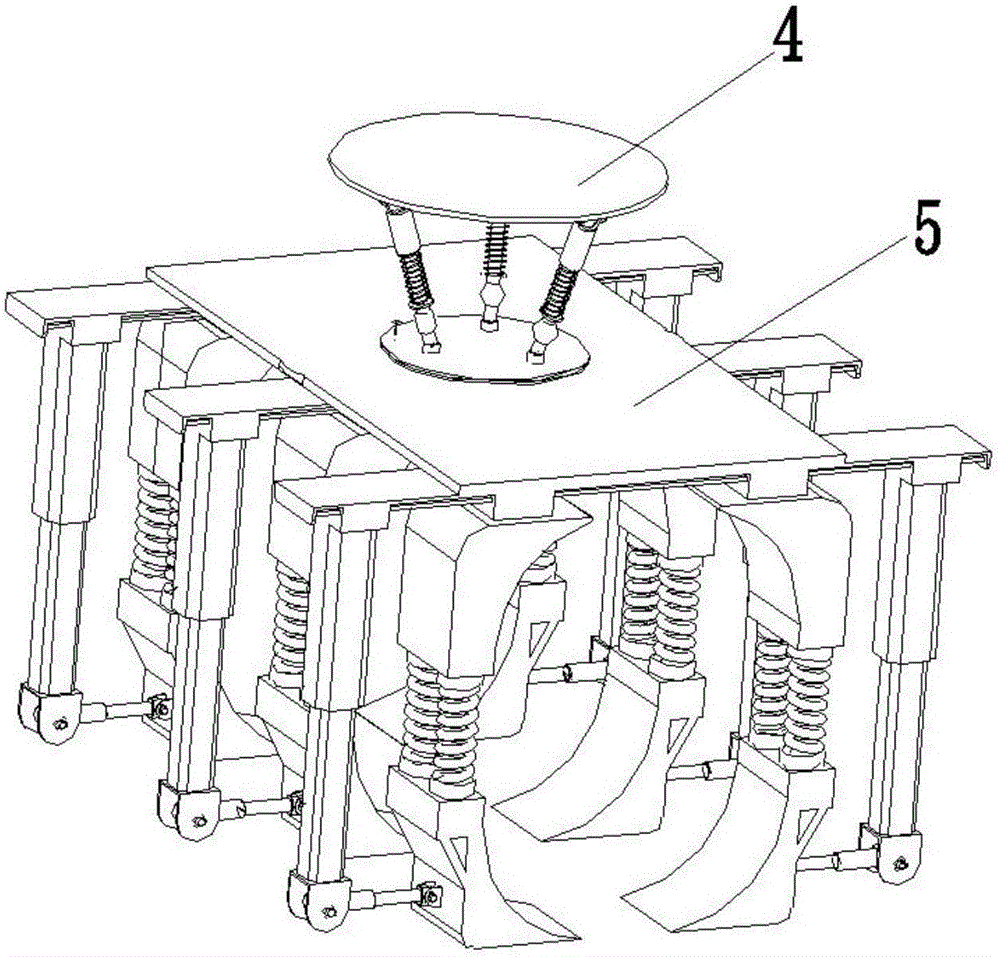

Hydraulic engineering pipe fitting stacking industrial robot

InactiveCN105904432AHigh degree of automationImprove work efficiencyProgramme-controlled manipulatorGripping headsThree degrees of freedomPipe fitting

The invention relates to a hydraulic engineering pipe fitting stacking industrial robot. The hydraulic engineering pipe fitting stacking industrial robot comprises a traveling device, an adjustable support, a rotary device, a three-degree-of-freedom parallel mechanism and a clamping device; the adjustable bracket is located on the rear upper side of the traveling device; the rotary device is located in the front end position of the adjustable support, and is fixedly connected with the adjustable support; the three-degree-of-freedom parallel mechanism is located between the rotary device and the clamping device; the upper end of the three-degree-of-freedom parallel mechanism is connected with the rotary device; and the lower end of the three-degree-of-freedom parallel mechanism is connected with the clamping device. The hydraulic engineering pipe fitting stacking industrial robot can realize a series of operation including grabbing, carrying and stacking of water conservancy and hydropower pipelines, is high in automation degree and stable and flexible in motion, solves such problems as high manual carrying operation cost, low efficiency and high dangerousness, the horizontal interval and vertical interval of the clamping device are adjustable, thereby facilitating grabbing of the water conservancy and hydropower pipelines with different diameter sizes, grabbing and stacking are convenient and rapid, clamping is stable and firm in the carrying process, slipping is not easy to occur, and the safety is good.

Owner:陈薇

Full-automatic stack room

The invention discloses a full-automatic stack room which comprises bookshelves, roadway conveying mechanisms and an automatic terminal. Each bookshelf is provided with layer partition plates, each roadway conveying mechanism is provided with a horizontal rail, a vertical rail is disposed on each horizontal rail, a manipulator rail which is perpendicular to each horizontal rail and each vertical rail is disposed on each vertical rail, and a manipulator is disposed on each manipulator rail. Significant improvements include that book fetching and returning manipulators are in butt joint with a book conveying platform, and the book conveying platform is connected with the automatic terminal. The full-automatic stack room can have multiple functions of storage, borrowing, returning, classification, temporary storage and the like of books, and has wider adaptability and more flexible expansibility as compared with a full-automatic closed shelf stack room with basic functions of storage, borrowing and returning.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

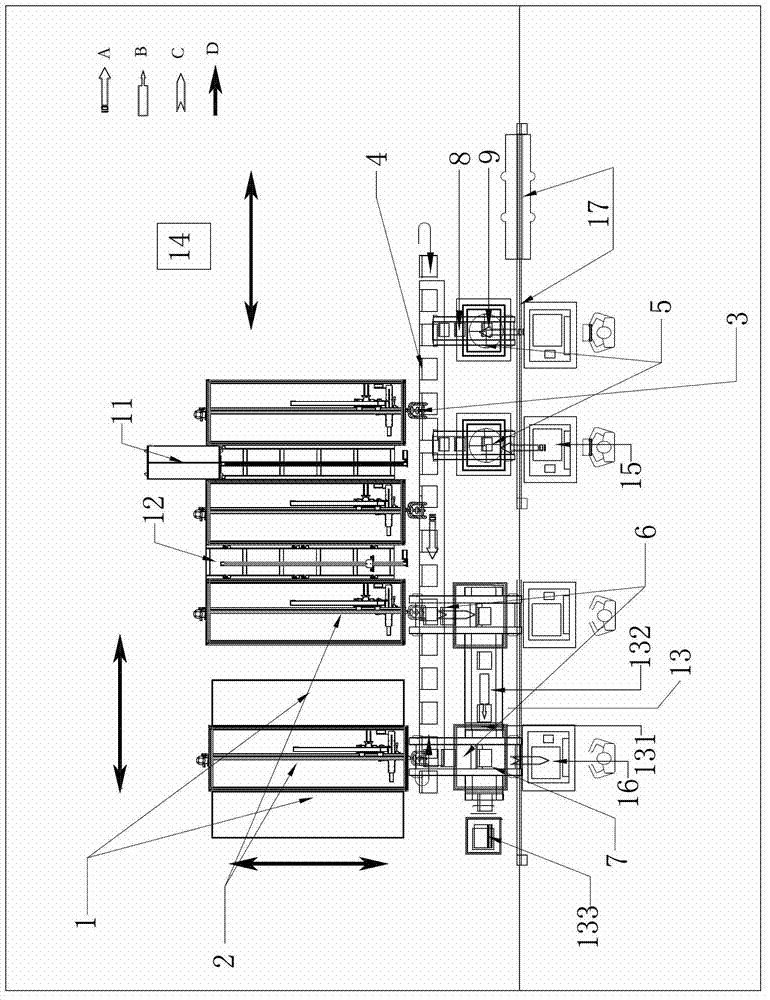

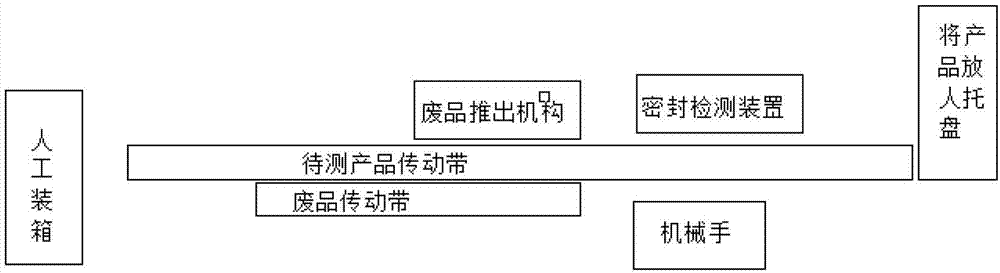

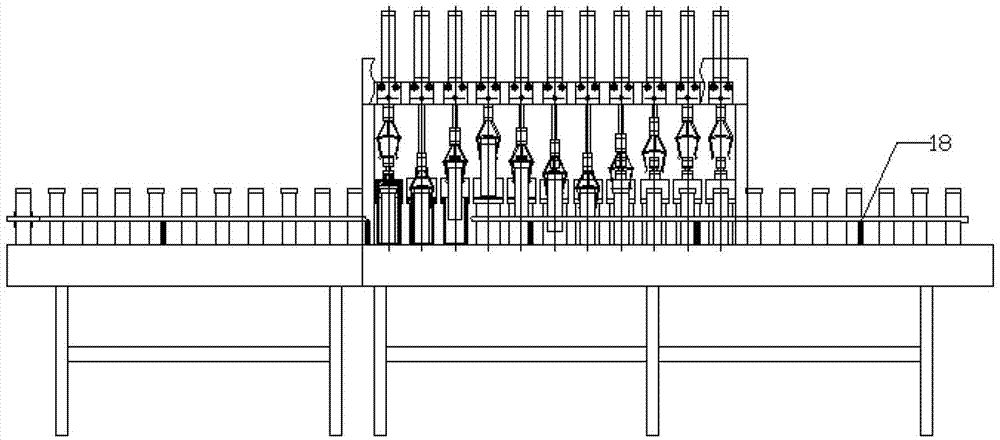

Seal detecting production line

InactiveCN103196636ANot destroyedEasy to grabMeasurement of fluid loss/gain rateProduction lineProgrammable logic controller

The invention discloses a seal detecting production line. The seal detecting production line comprises a working platform, a conveying belt for products to be tested, a waste conveying belt, a seal detecting device, a mechanical arm, and a waste pushing mechanism. The mechanical arm is used for grabbing the products to be tested and enabling the products to be tested to pass in and out the seal detecting device. The waste pushing mechanism is used for enabling tested sub-quality products to be pushed into the waste conveying belt from the conveying belt for the products to be tested. The seal detecting production line enables the mechanical arm, the simple seal detecting device, and the product conveying belt to be combined together in an organic mode, a programmable logic controller (PLC) is utilized for controlling a working time sequence of each unit, and automation degree and system reliability are improved. The products to be tested can be effectively protected form being damaged, grabbing of the mechanical arm depends on the opening and the closing of an executor at the tail end, and the mechanical arm not only is suitable for grabbing canning products, box-packed products, and bottled products, but also can be used for grabbing bagged products, and is strong in generality.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

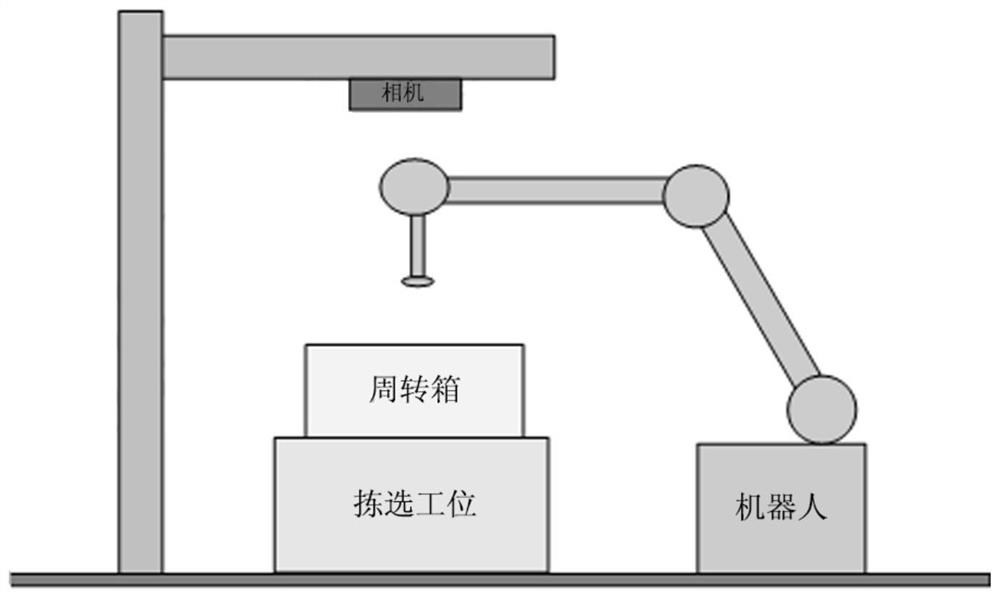

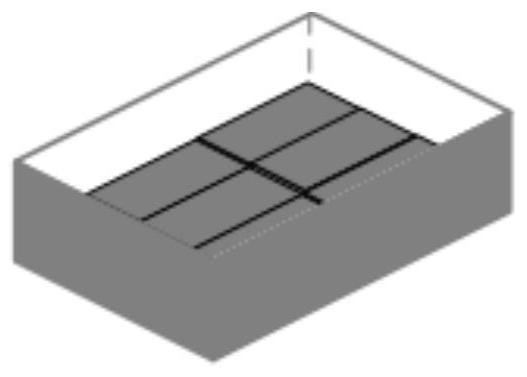

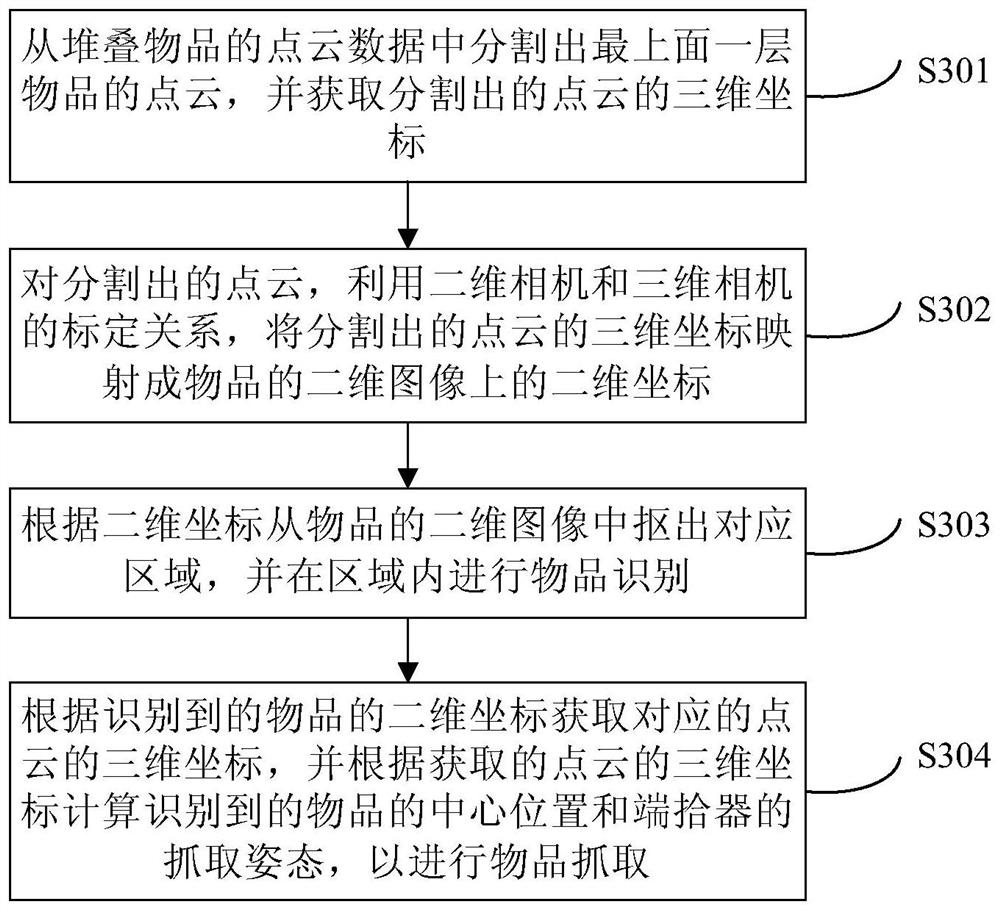

Sequential grabbing method and device for stacked articles

PendingCN111754515AAccurate identificationEasy to grabImage enhancementImage analysisPoint cloudComputer graphics (images)

The invention discloses a sequential grabbing method and device for stacked articles, and relates to the technical field of computers. One specific embodiment of the method comprises the following steps: segmenting point cloud of an article on the uppermost layer from point cloud data of stacked articles, and acquiring three-dimensional coordinates of the segmented point cloud; for the segmented point cloud, mapping three-dimensional coordinates of the segmented point cloud into two-dimensional coordinates on a two-dimensional image of the object by utilizing a calibration relationship betweena two-dimensional camera and a three-dimensional camera; digging out a corresponding area from the two-dimensional image of the article according to the two-dimensional coordinates, and identifying the article in the area; and acquiring three-dimensional coordinates of the corresponding point cloud according to the identified two-dimensional coordinates of the article, and calculating the identified central position of the article and the grabbing posture of the tooling according to the acquired three-dimensional coordinates of the point cloud so as to grab the article. According to the method, article identification and article position determination can be accurately carried out, so that article grabbing is more accurate, convenient and efficient, and the collision probability during article grabbing is reduced.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

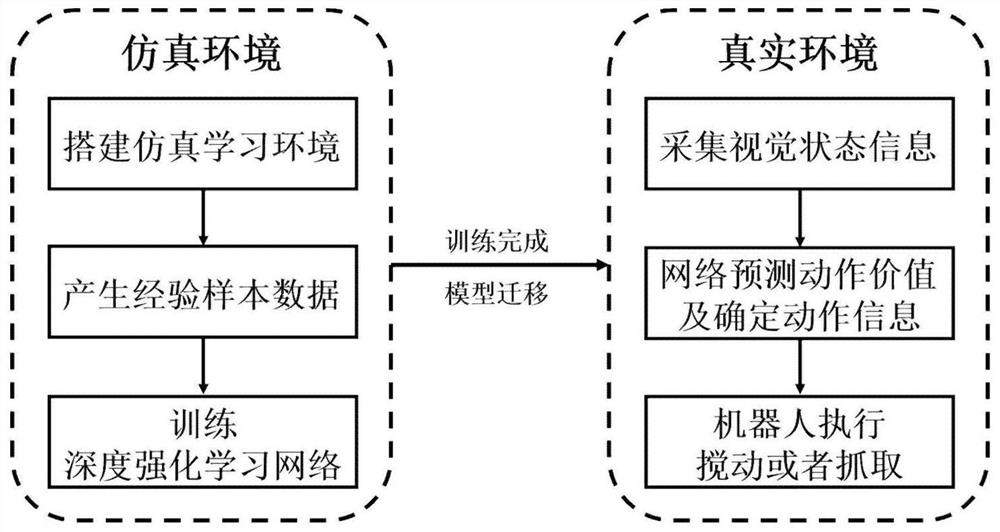

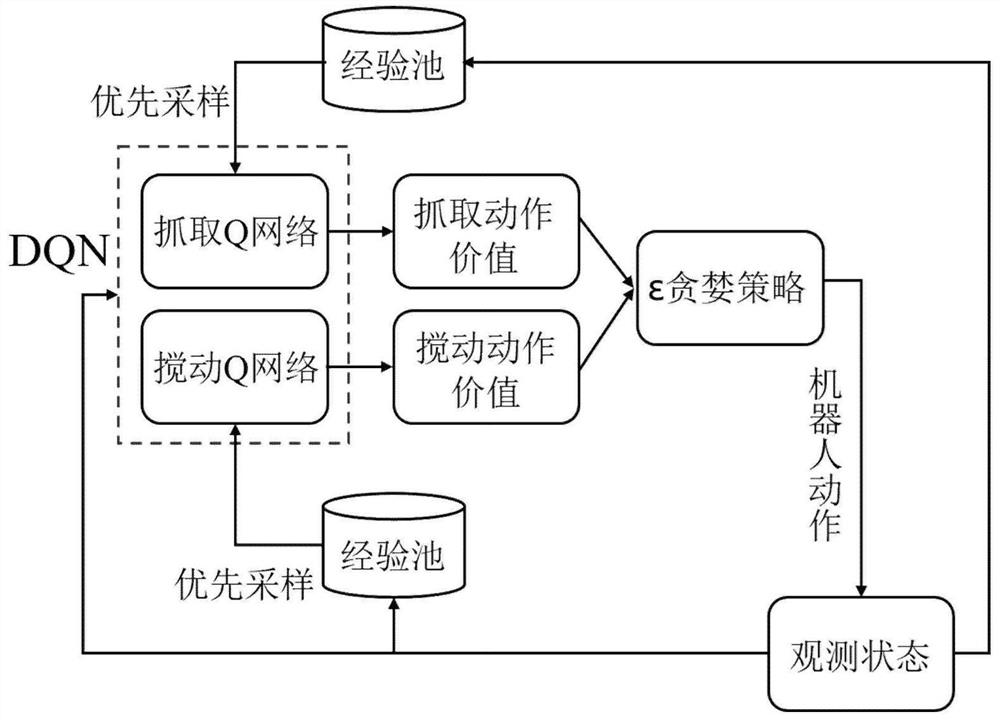

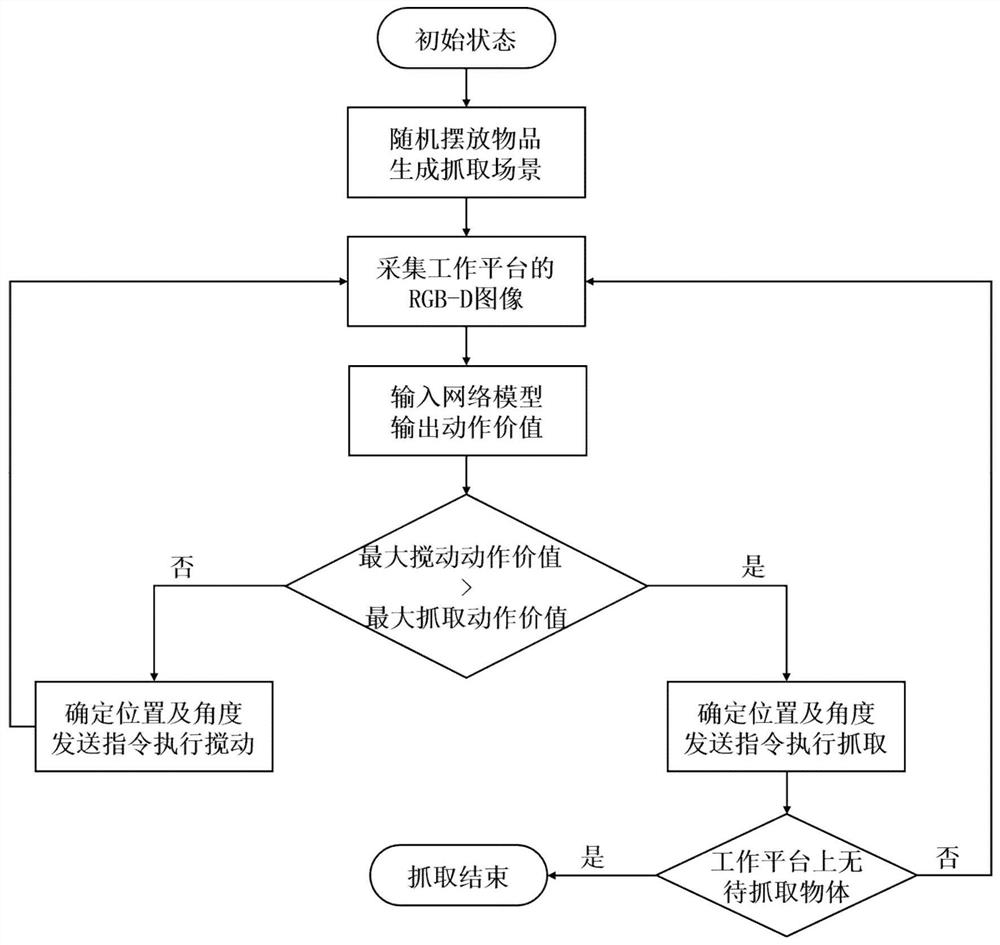

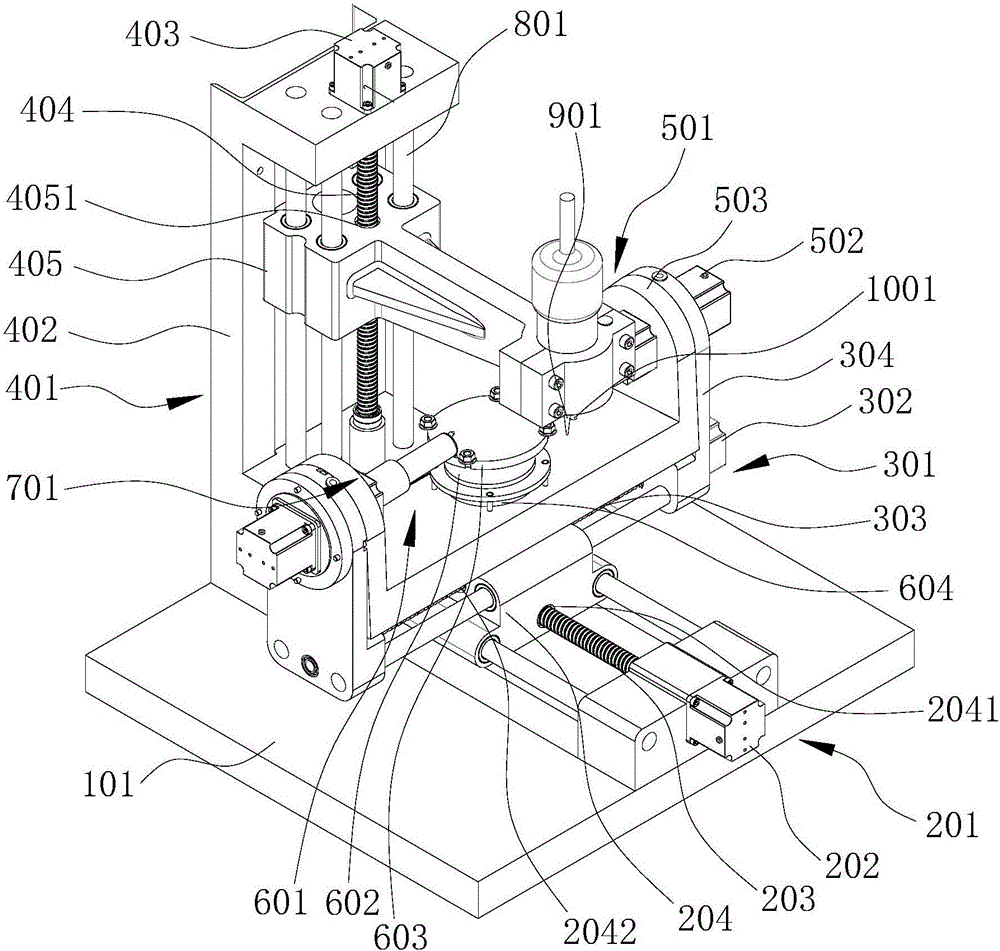

Robot stirring and grabbing combination method based on deep reinforcement learning

ActiveCN112102405AReduce the cost of trainingIncrease training speedGeometric CADProgramme-controlled manipulatorEngineeringNetwork model

The invention discloses a robot stirring and grabbing combination method based on deep reinforcement learning. The robot stirring and grabbing combination method comprises the following steps: building a robot stirring and grabbing execution platform in a real environment and a robot stirring and grabbing execution platform in a simulation environment respectively; modeling a stirring and grabbingprocess of the robot into a Markov process, and constructing a state space, an action space and a reward function; constructing a robot stirring and grabbing learning framework based on deep reinforcement learning and a deep reinforcement learning network; then, repeatedly carrying out stirring and grabbing action attempts on the simulation platform, collecting experience sample data, and carrying out self-supervised training on the deep reinforcement learning network according to the Markov process; and finally, migrating the trained network model to a real environment, and carrying out actual training on the robot in the real environment. When facing a random grabbing scene and a novel grabbing object, the robot can sense and analyze the scene and decide to execute a stirring or grabbing action, an action position and an action direction.

Owner:SOUTHEAST UNIV

Five-axis linkage laser cutter

InactiveCN106799545AImprove work efficiencyWill not affect machining accuracyWelding/cutting auxillary devicesAuxillary welding devicesDrive motorEngineering

The invention discloses a five-axis linkage laser cutter which comprises a laser, optical fiber, a laser head and a five-axis machining platform; the five-axis machining platform comprises a platform base, a Y-axis movement module, an X-axis movement module, a Z-axis lifting module, an A-axis rotation module, a C-axis rotation module and a turnover module. Power output shafts of turnover module driving motors of the turnover modules are connected with connection surfaces of expansion rods, and contact surfaces of the expansion rods clamp the two sides of a workpiece, so that accuracy control on a turnover angle of the circular arc or spherical workpiece can be realized through the turnover module driving motors; and the turnover modules are arranged at the two ends of a rotating axis of an A shaft, so that the workpiece does not deviate in the X axis, Y axis, Z axis or C axis direction, the machining after the workpiece is turned over is facilitated, the working efficiency of the laser is improved, and the influence on the machining accuracy due to the fact that the workpiece is turned over is reduced.

Owner:PUTIAN UNIV

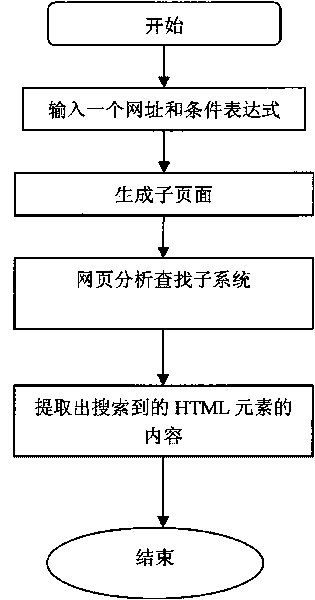

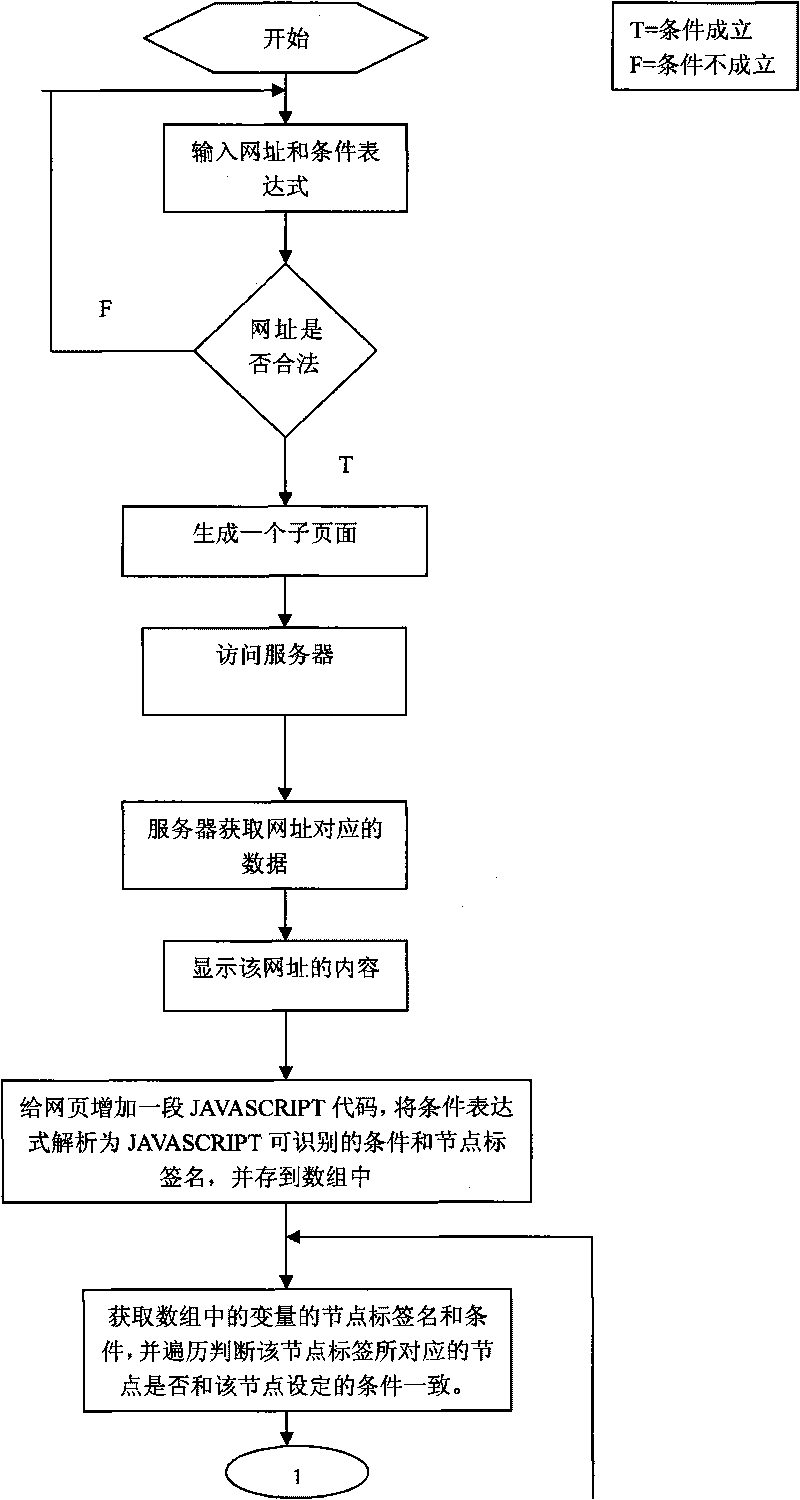

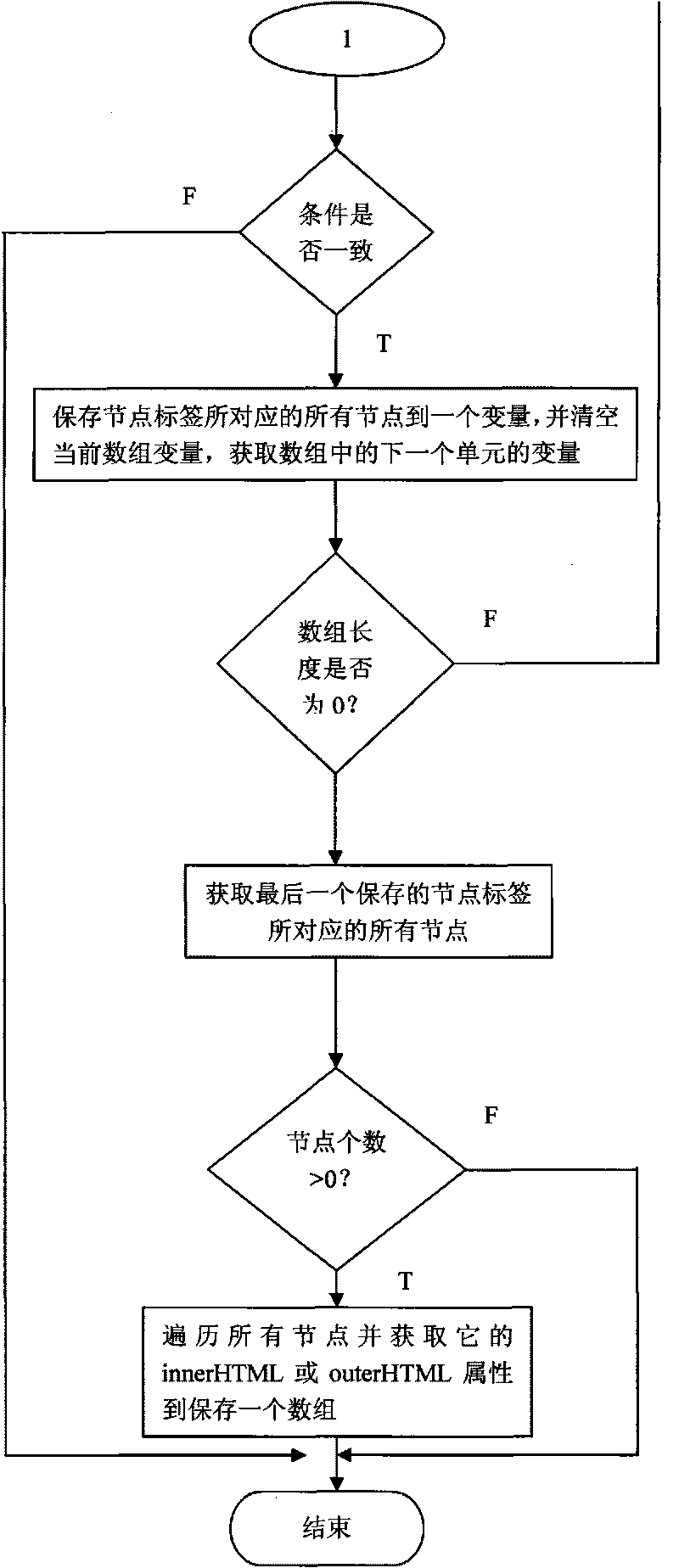

Universal method for capturing webpage contents of any webpage

InactiveCN101763425AEasy to grabImprove efficiencyNatural language data processingSpecial data processing applicationsArray data structureUser input

The invention discloses a universal method for capturing webpage contents of any webpage, which belongs to the technical field of networks. The technical scheme is a universal method for capturing webpage contents of any webpage. The method comprises the following steps: inputting the captured websites and conditional expressions, creating a subpage and transmitting the websites and the conditional expressions to the subpage by a user; requesting a server, acquiring all contents of webpages of the websites and embedding a segment of javascript program into the webpage contents by the subpage; converting the conditional expressions into an array variable, traversing the array and finding out all nodes according with the conditions by the javascript program; and acquiring inner HTML(Hypertext Markup Language) or outer HTML(Hypertext Markup Language) attribute value of all nodes and further acquiring corresponding webpage contents by the javascript program. The method can ensure that the user can capture any content of the webpages by only simply modifying the conditional expressions without writing a code for analyzing the webpage contents aiming at each web page.

Owner:SUZHOU CODYY NETWORK SCI & TECH

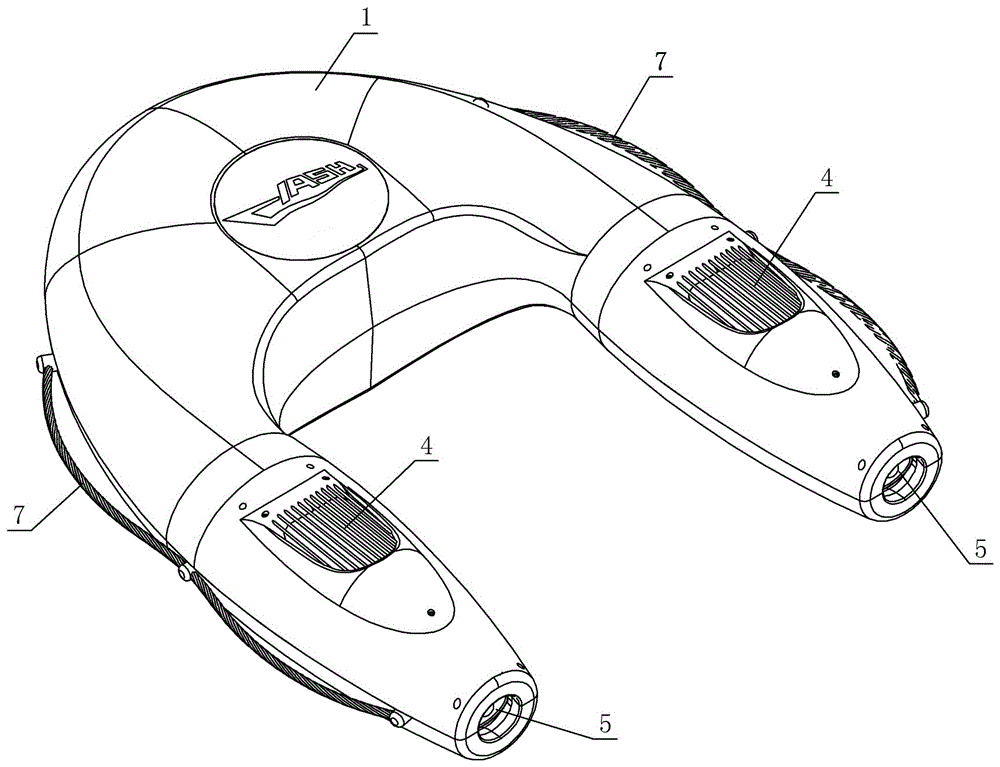

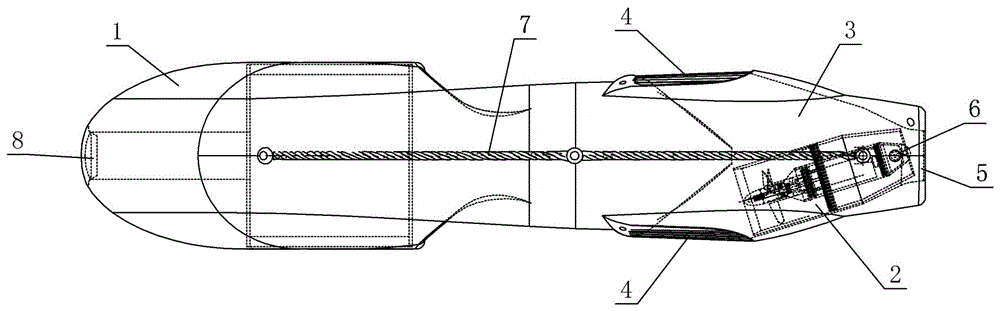

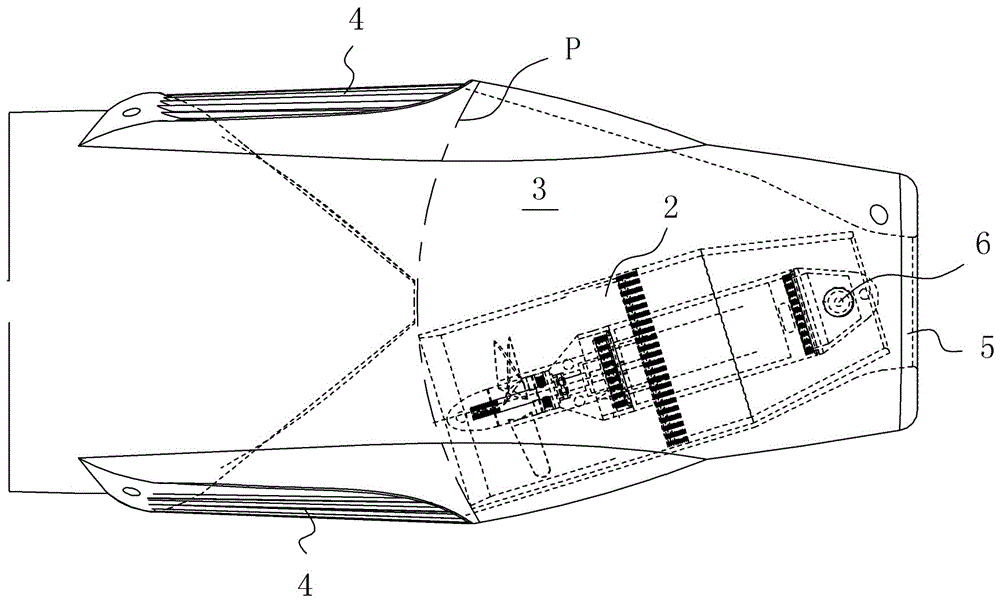

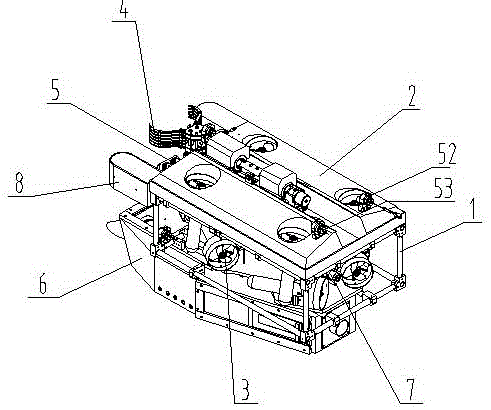

Heat-preservation power life buoy

InactiveCN106379500ASmall sizeShallow draftLife-buoysPropulsive elementsPropellerSurvival probability

The invention relates to a heat-preservation power life buoy. A life buoy body is in a U shape; a heating device, a propeller for providing power, and a remote controller for controlling the life buoy to move are arranged on the life buoy body; the life buoy body and an engine compartment on the life buoy body are arranged symmetrically; the propeller is rotatably arranged in the engine compartment. When a person fall into a river, a rescuer puts the life buoy body into water, and then controls the life buoy to move to a position where the person is located through the remote controller, so that the person who falls into the river can be quickly and conveniently rescued, and meanwhile, the temperature of the person who falls into the river can be recovered through the heating device of the life buoy; through the arrangement of the engine compartment and the propeller, any one face of the life buoy can be placed on water, so that the life buoy moves. With the use of the life buoy, the rescuing speed can be greatly improved, the person who falls into the river is protected, and the safety and the survival probability are improved.

Owner:珠海蓝创科技有限公司

Manipulator backpack type underwater robot

A manipulator backpack type underwater robot is composed of a main body frame, a buoyancy block system, a multi-joint manipulator, a collection box system, a control cabinet, an auxiliary adjusting buoyancy block system, a propeller system and a shooting and illuminating system. The whole manipulator backpack type underwater robot is arranged in a horizontal compressed mode, and continuous operation is facilitated; the eight-propeller power system is adopted so that the robot can reach a working zone more conveniently and rapidly; through the auxiliary adjusting buoyancy block system and extension-length-adjustable push-pull rods matched with the auxiliary adjusting buoyancy block system, the robot can adapt to the complex underwater working environment; the shooting and illuminating system similar to binocular vision is adopted for the working zone, so that the working zone is more tridimensional and visual, and the manipulator can perform operation conveniently and accurately; the multi-joint design is adopted for the manipulator, so that the manipulator is more flexible and can grab and place objects more conveniently, and the working range is relatively enlarged; and the manipulator can be folded or unfolded, so that the space utilization rate is improved.

Owner:远洋探海机器人东台有限公司

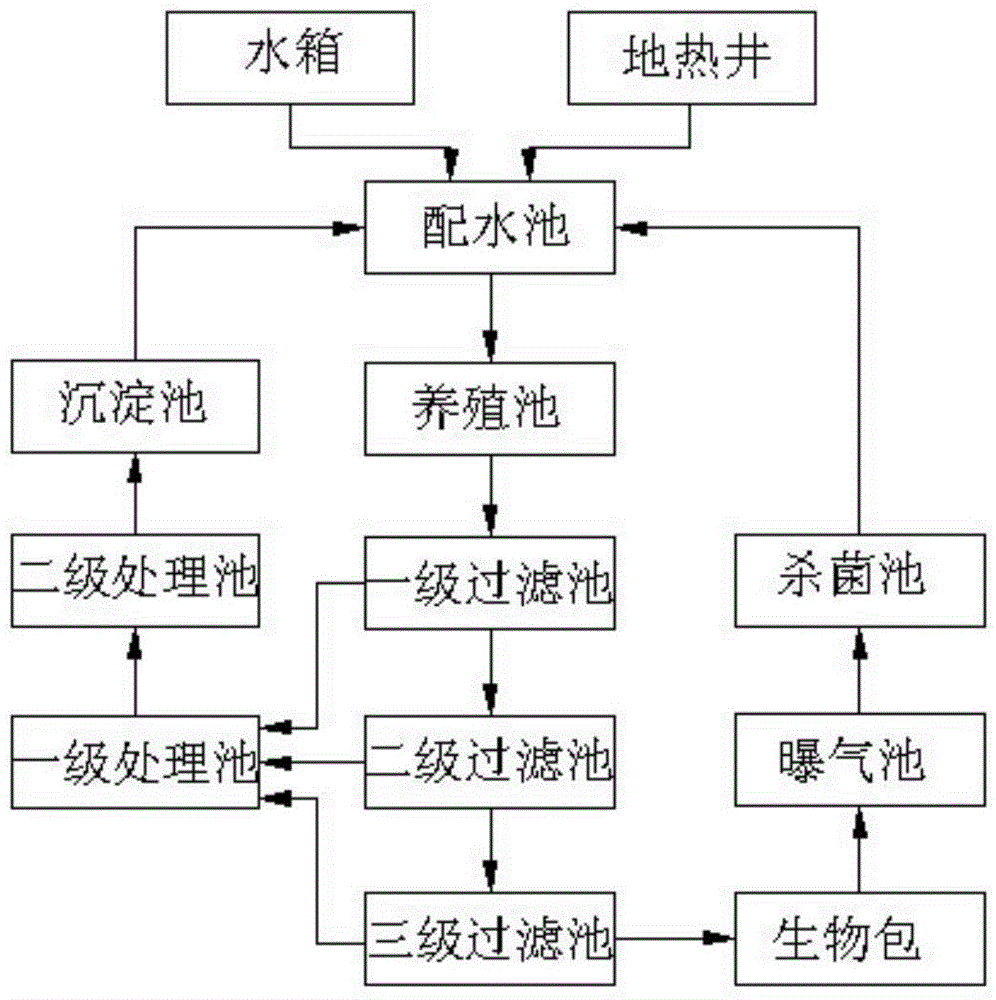

Ecological cycling freshwater aquaculture method

InactiveCN105638515ACompact structureEasy to manageClimate change adaptationPisciculture and aquariaEcological environmentWater source

The invention provides an ecological cycling freshwater aquaculture method. The method comprises: preparing a culture water source, supplying water to culture ponds, filtering water, and treating sewage. The plurality of culture ponds are arranged from left to right in sequence to form a culture pond group. The culture ponds in the culture pond group are connected in parallel, and form a recirculating aquaculture system with a filter tank, a treating pond, a settling pond, a biological package, an aeration tank, and a sterilization pond. Using the ecological cycling freshwater aquaculture method, water of the whole system forms virtuous cycle, and is suitable for growth of freshwater fishes and shrimps, and zero discharge of aquaculture wastewater is realized, and water resource is saved. The ecological cycling freshwater aquaculture method has obvious ecological environment benefits, and meets the sustainable development strategy of the country.

Owner:天津市滨海新区塘沽金岛养殖有限公司

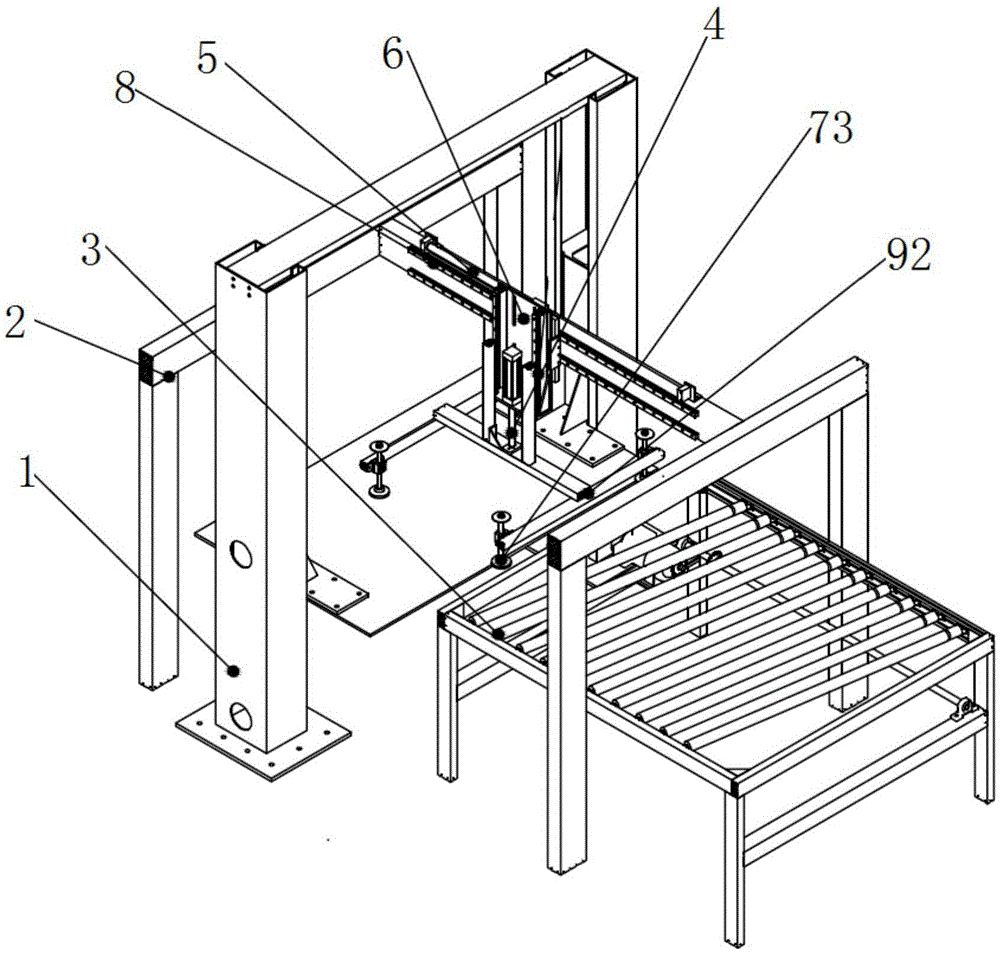

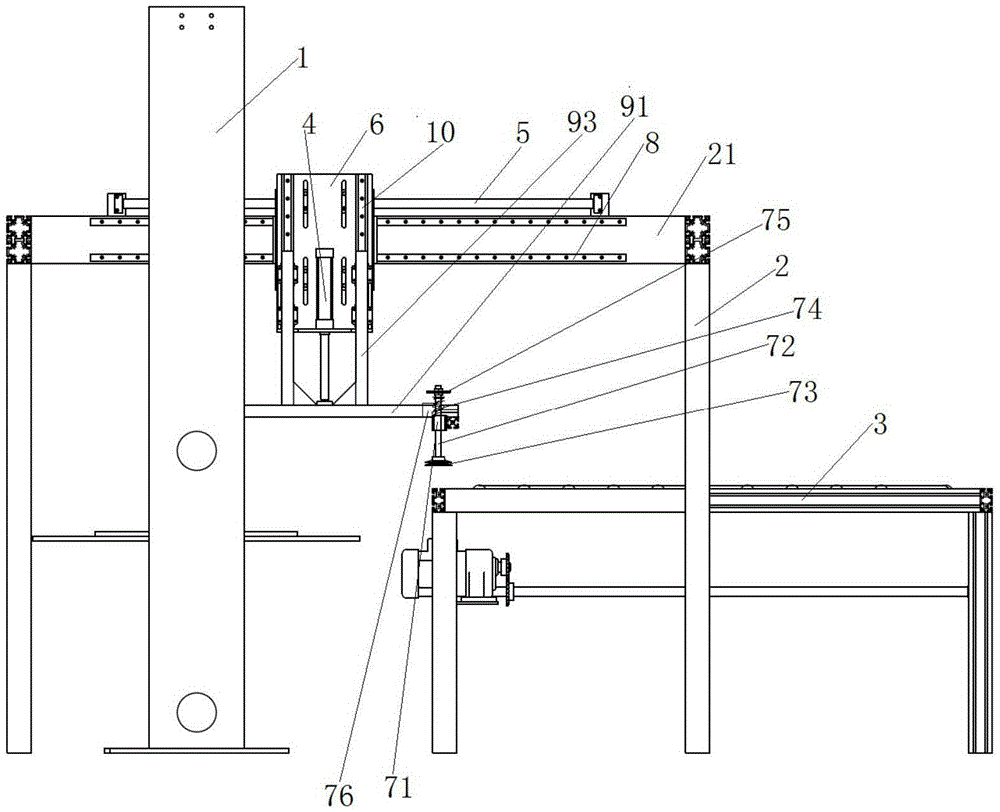

Loading device for floor production line

InactiveCN105540259AReduced gripping strokesReduce crawl timeConveyorsConveyor partsProduction lineBraced frame

The invention discloses a loading device for the floor production line. The loading device comprises a loading manipulator and a hydraulic lift platform which can ensure that a material is lifted to the original position in height after each raw material is grabbed, wherein a roll conveyor is arranged behind the hydraulic lift platform; the loading manipulator comprises a support frame formed by a cross beam arranged in the front-back direction and landing legs fixed at two ends of the cross beam, and the landing legs are located on the front side and the rear side of the hydraulic lift platform; a rodless cylinder is fixedly mounted on the top surface of the cross beam, a mounting plate is fixedly mounted on a cylinder slider of the rodless cylinder, a lifting cylinder is perpendicularly mounted on the mounting plate, and the manipulator is mounted at the tail end of a telescopic rod of the lifting cylinder. The loading device is simple in structure, convenient to operate and low in manufacturing and maintaining cost, the loading interval time is greatly shortened, the manipulator can grab one raw material once, and the condition that normal work of the follow-up process during automatic production is affected by the fact that the manipulator grabs multiple plates once is avoided.

Owner:JIANGSU HAOLIN AUTOMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com