Automatic assembling and smearing equipment of cover plate of speed reducer

A reducer and cover plate technology, applied in the field of automated manufacturing equipment, can solve the problems of affecting the quality of the reducer, low efficiency of manual operation, waste of human resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

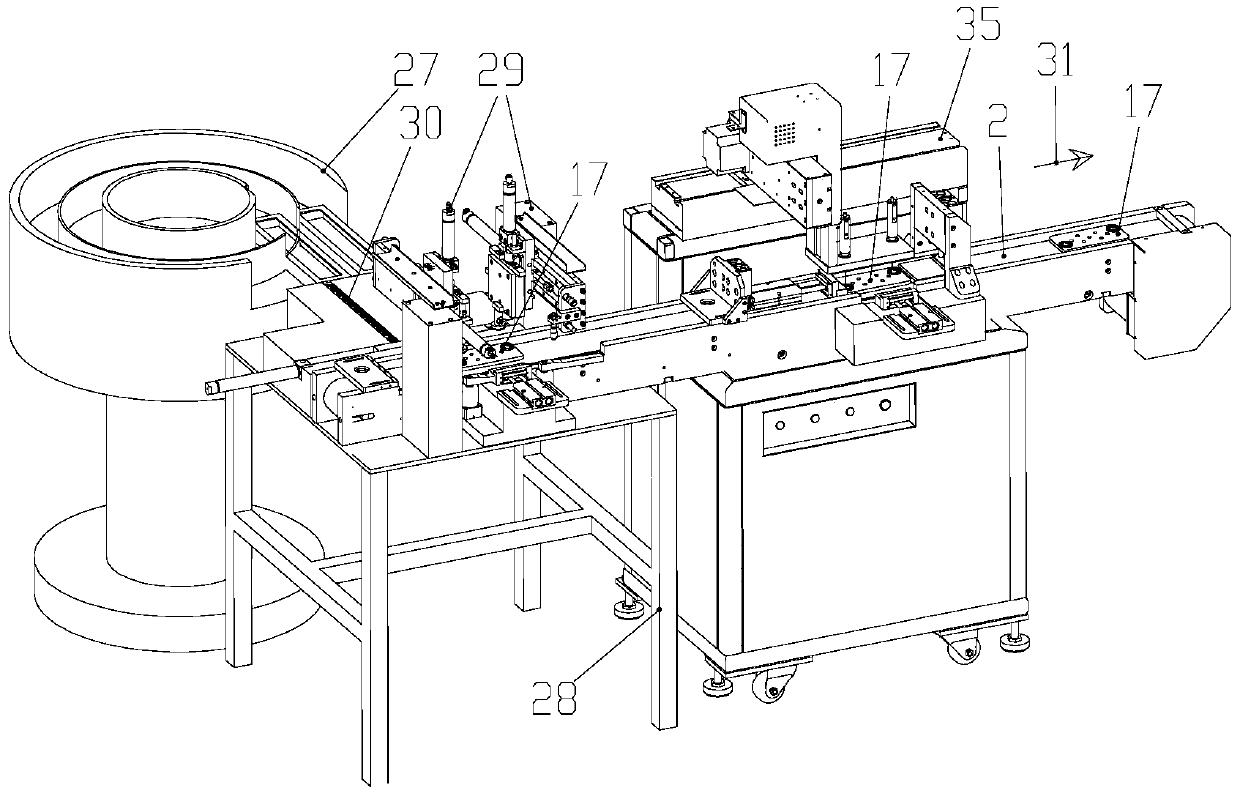

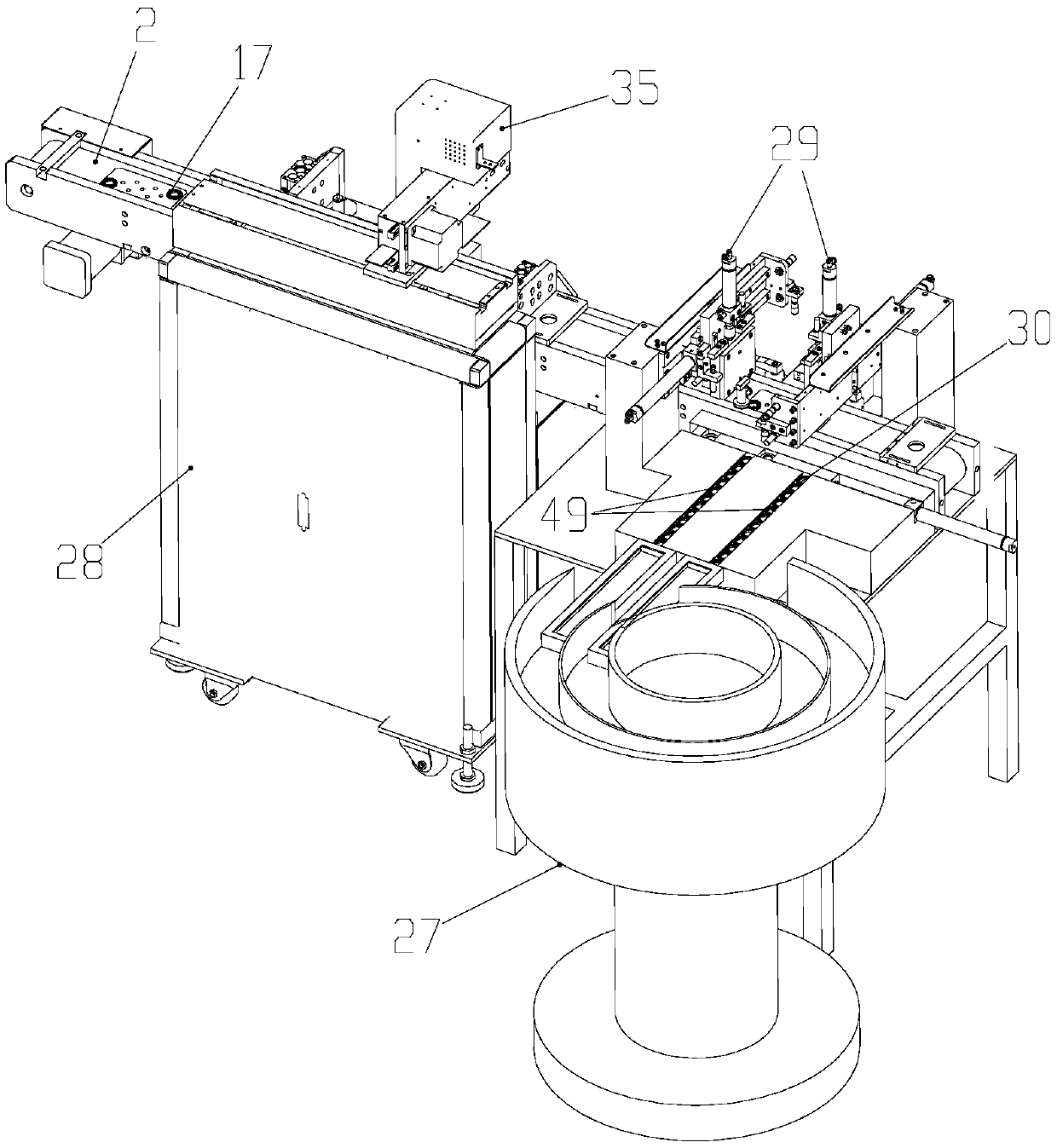

[0036] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention provides an automatic assembly and coating equipment for the reducer cover plate, which has good manufacturability, adopts the automatic unmanned operation of the assembly line, and is used to assemble the planar bearing on the reducer cover plate, and install it on the planar bearing Grease is applied to the surface of the reducer, and the invention provides an automatic assembly and application equipment for the cover plate of the reducer. The assembly speed is fast, the application effect is good, and unmanned operation is realized.

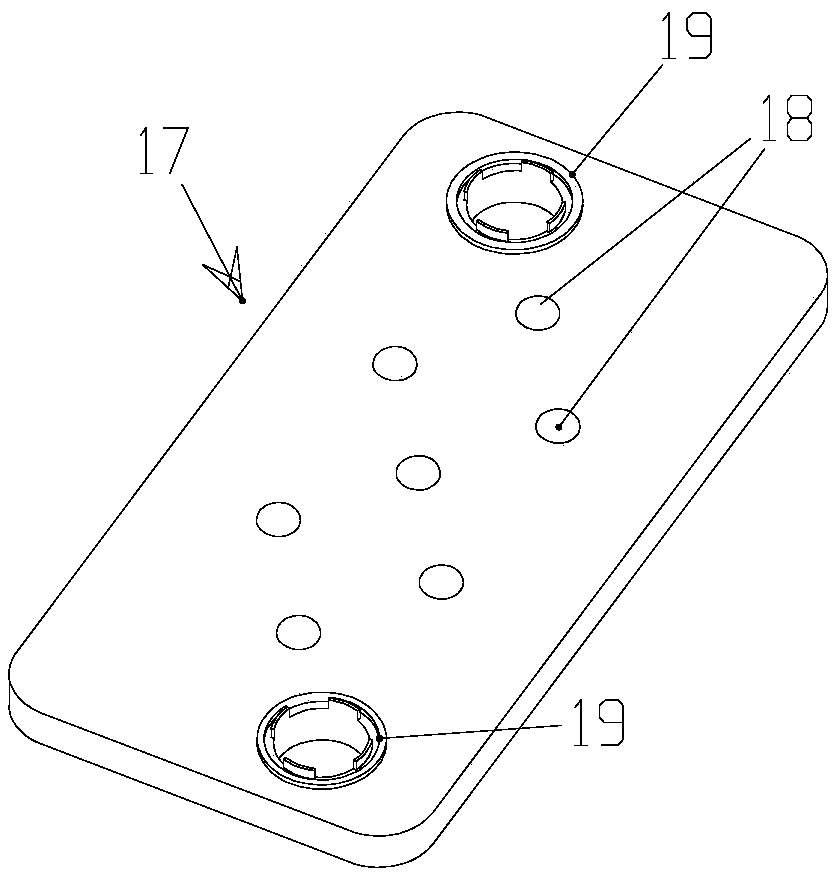

[0037] figure 1 It is a schematic diagram of the structure of the automobile reducer cover plate, figure 2 It is a structural schematic diagram of a specific embodiment of the automatic assembly and coating equipment of the reducer cover plate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com