Patents

Literature

994results about How to "Good transmission effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

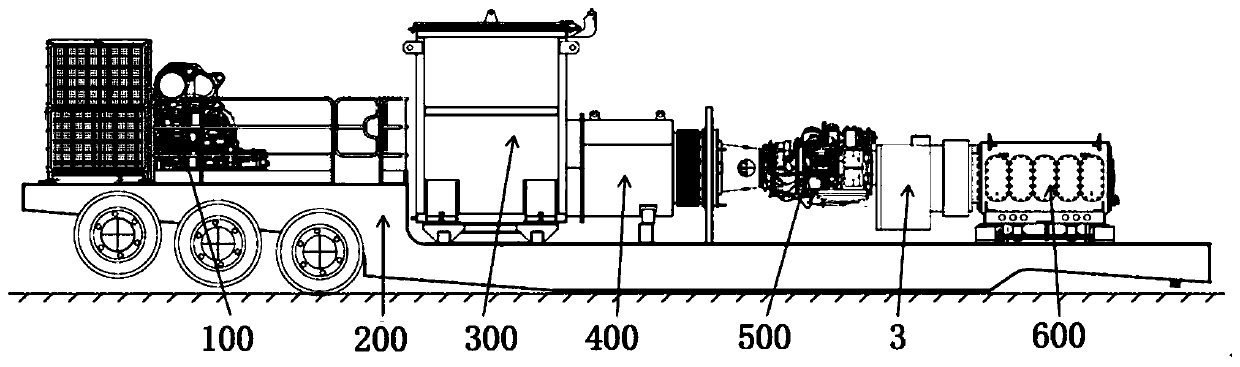

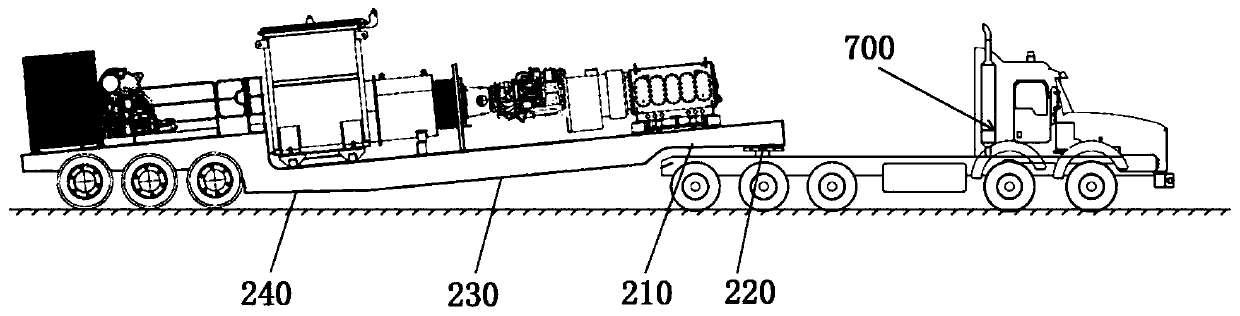

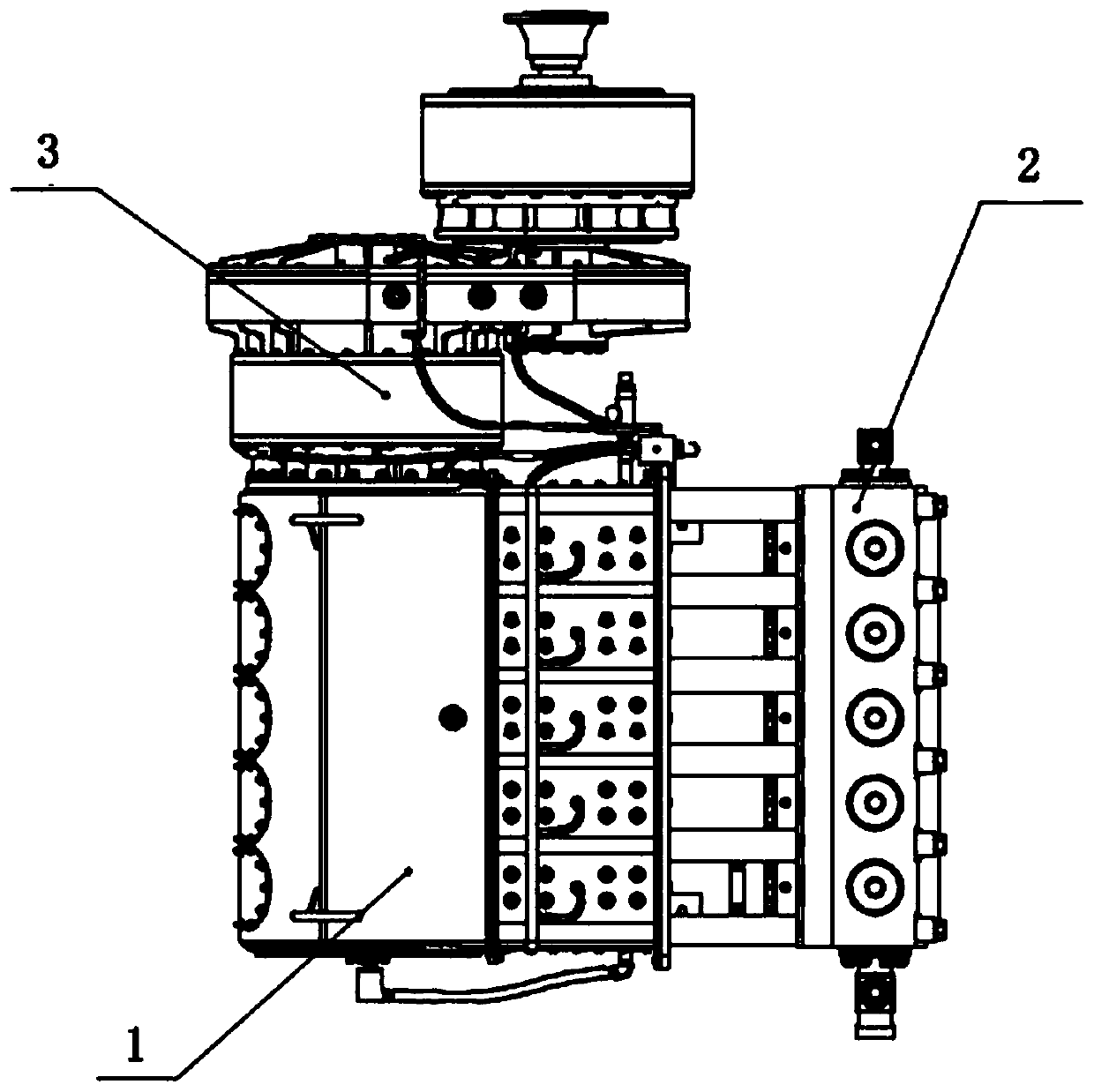

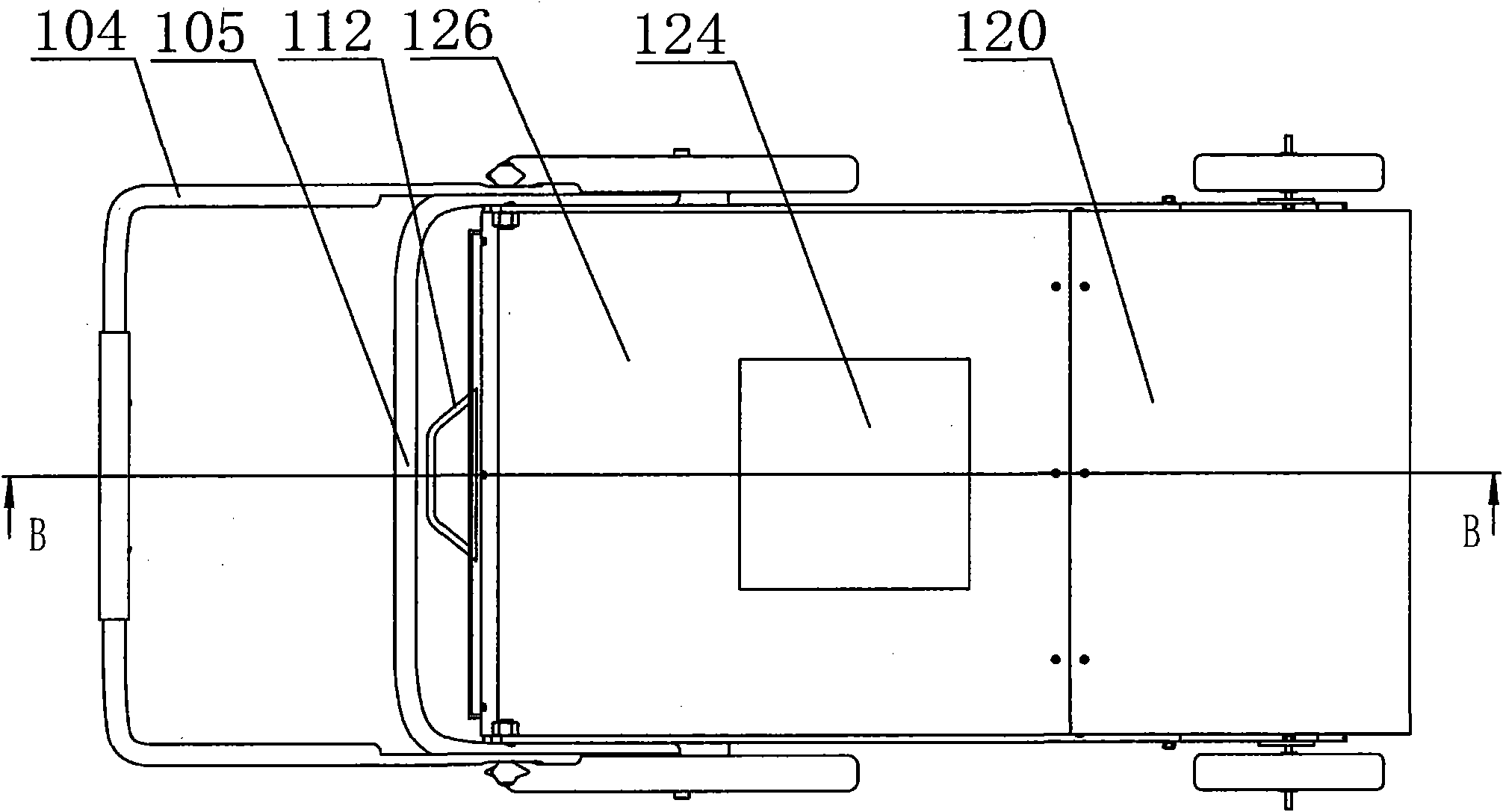

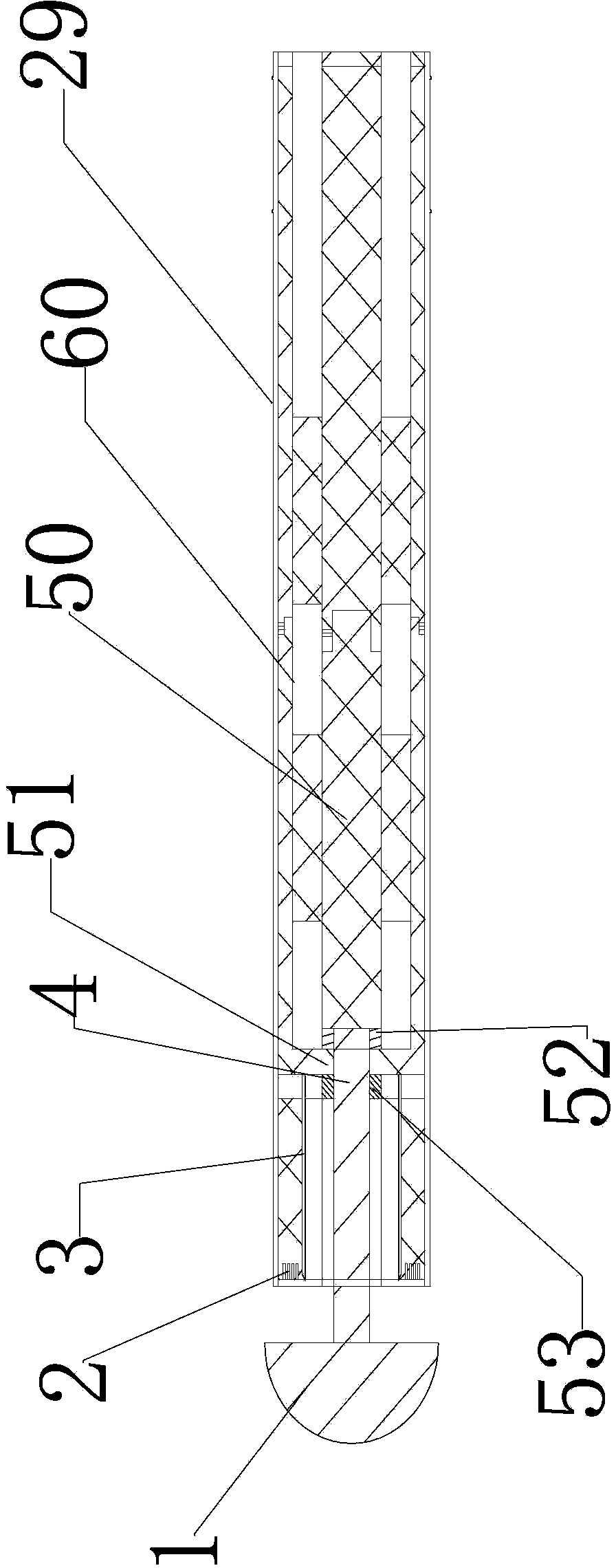

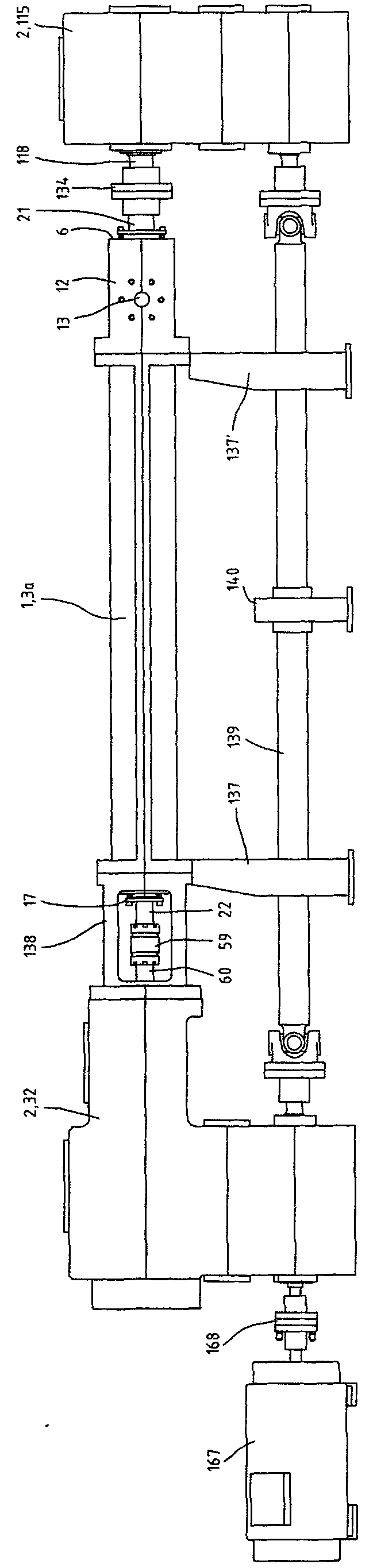

Semitrailer-mounted turbine fracturing equipment

PendingCN110485984AReduce weightLower center of gravityPositive displacement pump componentsFlexible member pumpsOperational costsGravity center

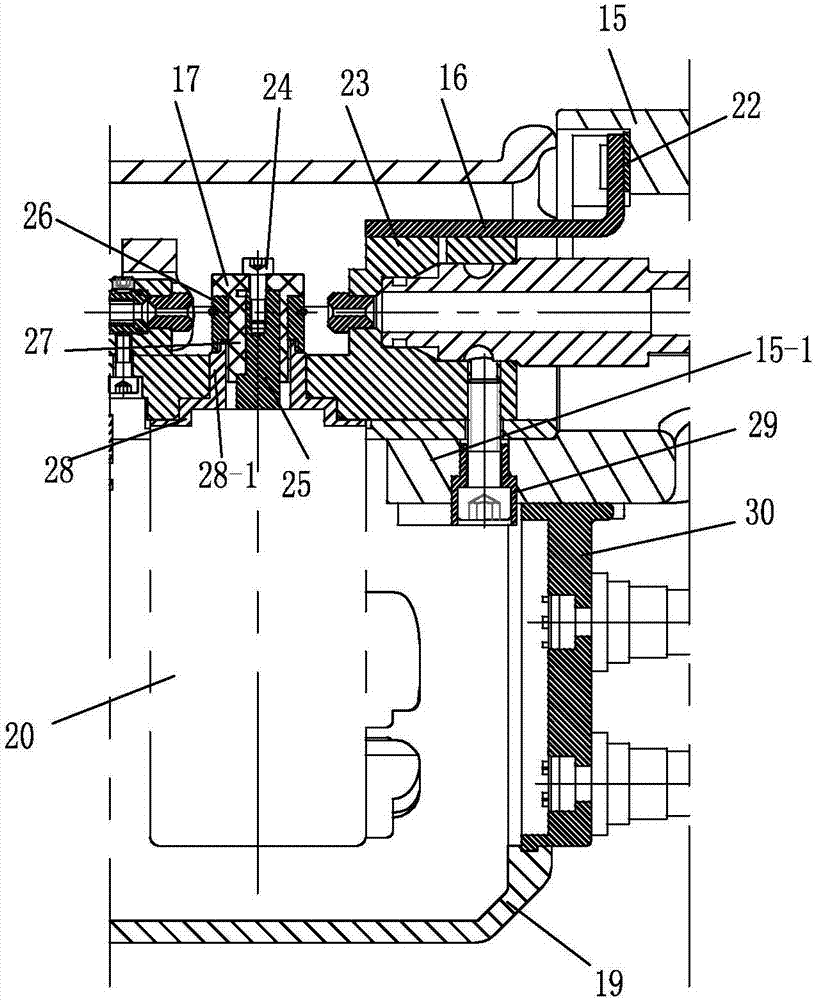

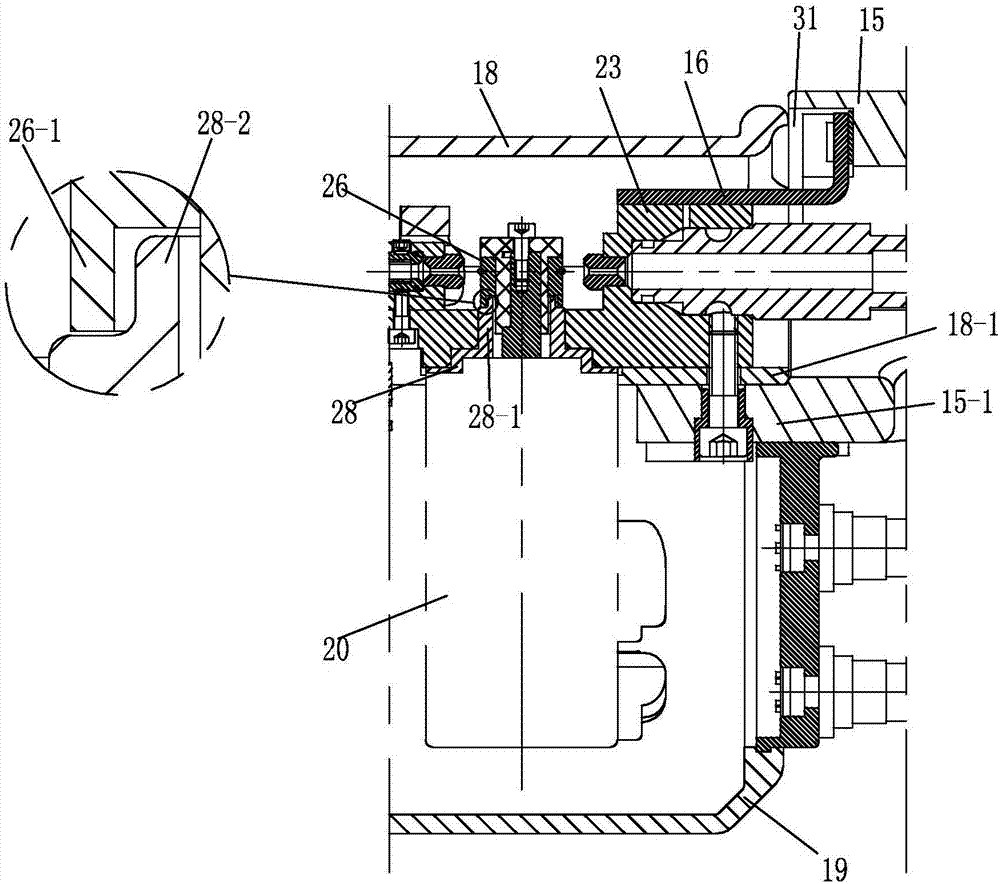

The invention discloses semitrailer-mounted turbine fracturing equipment. Straight-line connection and special chassis design of the whole equipment can double reduce center of gravity of the equipment, stability and safety are better ensured, the structure is simpler, the investment cost and the operation cost are lowered, risks of the whole breakdown of fracturing sites are reduced, transmissionis better, and the semitrailer-mounted turbine fracturing equipment is suitable for continuous operation working conditions with long time and large load. By improving a plunger pump, optimization ofrotating center distances of a crank throw and a crankshaft makes rated power input of the crank throw and the crankshaft increase to 5000-7000 hp, optimization of the transmission ratio of an integrated reduction gearbox on the plunger pump makes the maximum input speed of the integrated reduction gearbox reach 16000 rpm, and ultra-high speed enables reduction gearboxes to be directly connectedwith a turbine engine so as to the solve the problems that turbine fracturing equipment slows down depending on the two reduction gearboxes, and weight of the whole semitrailer is reduced, and boundary dimension of the semitrailer-mounted turbine fracturing equipment is reduced.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

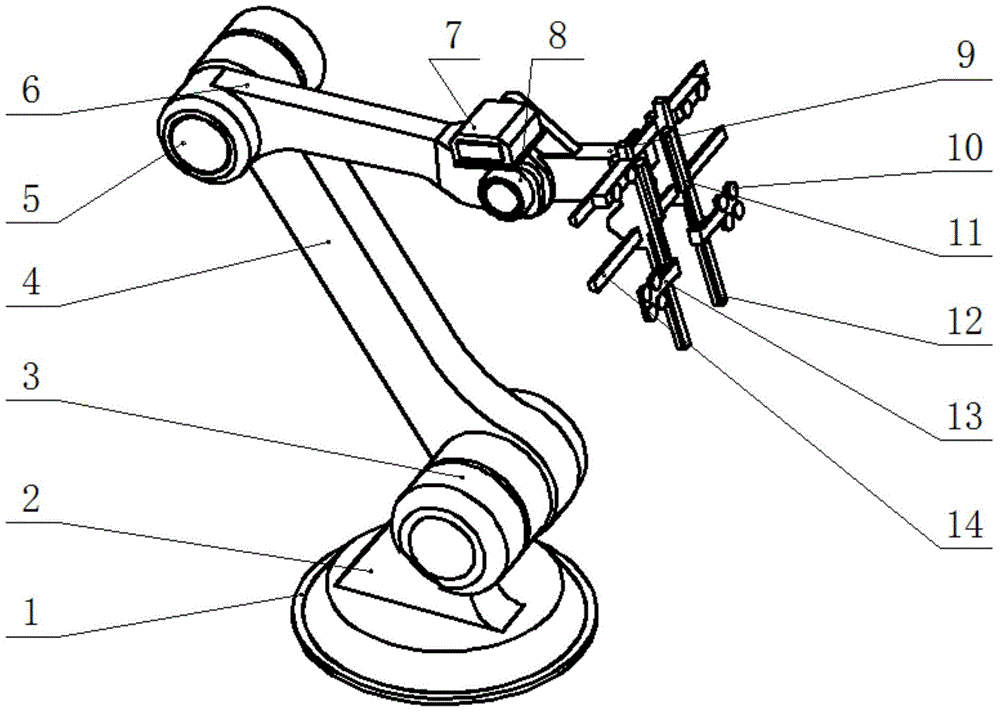

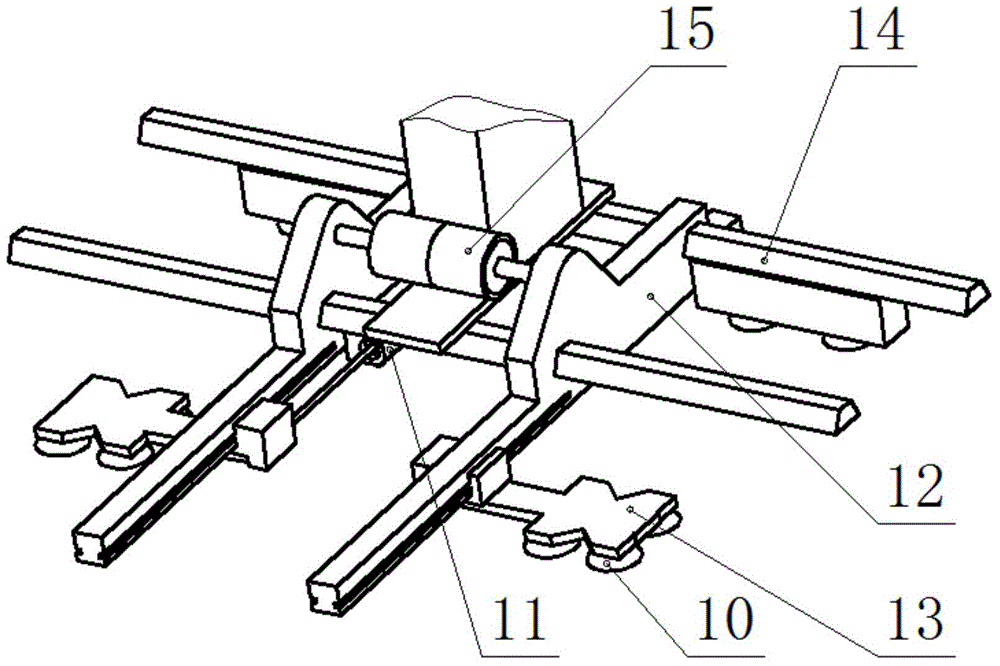

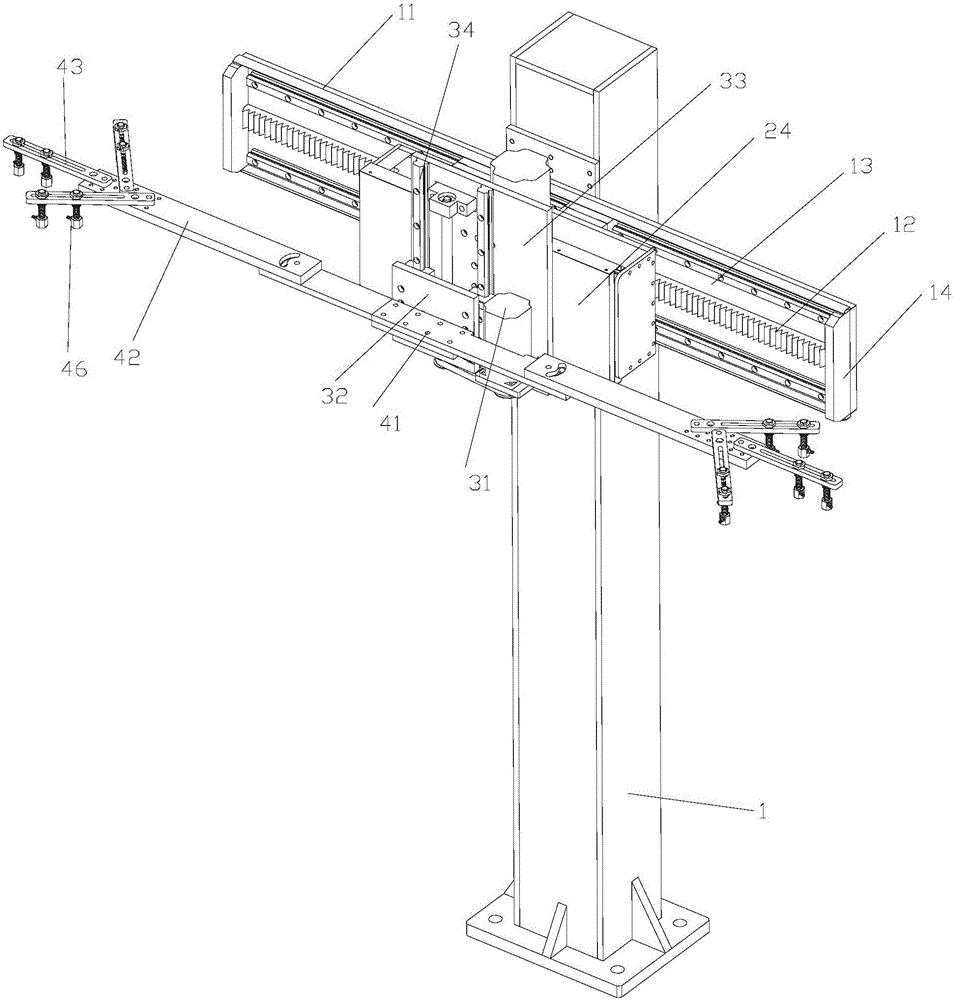

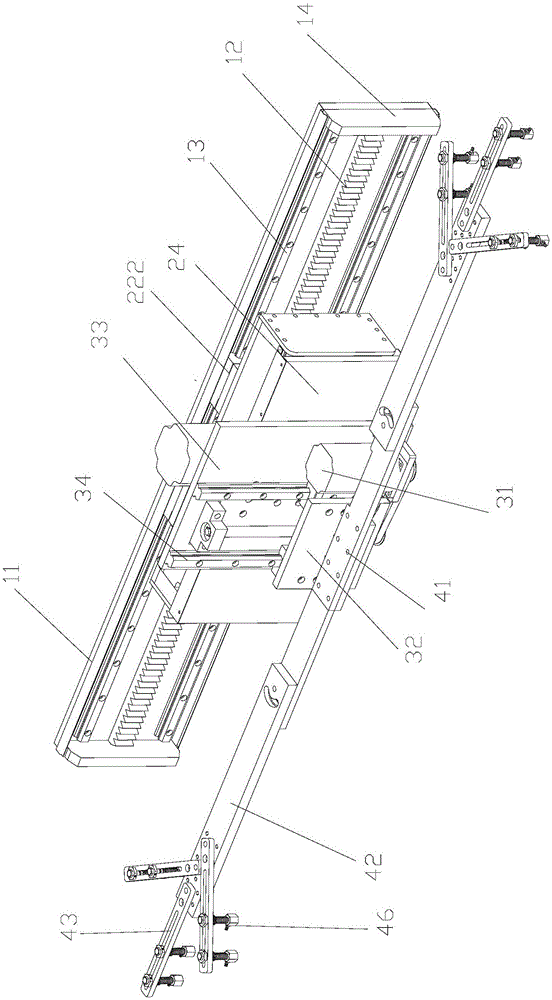

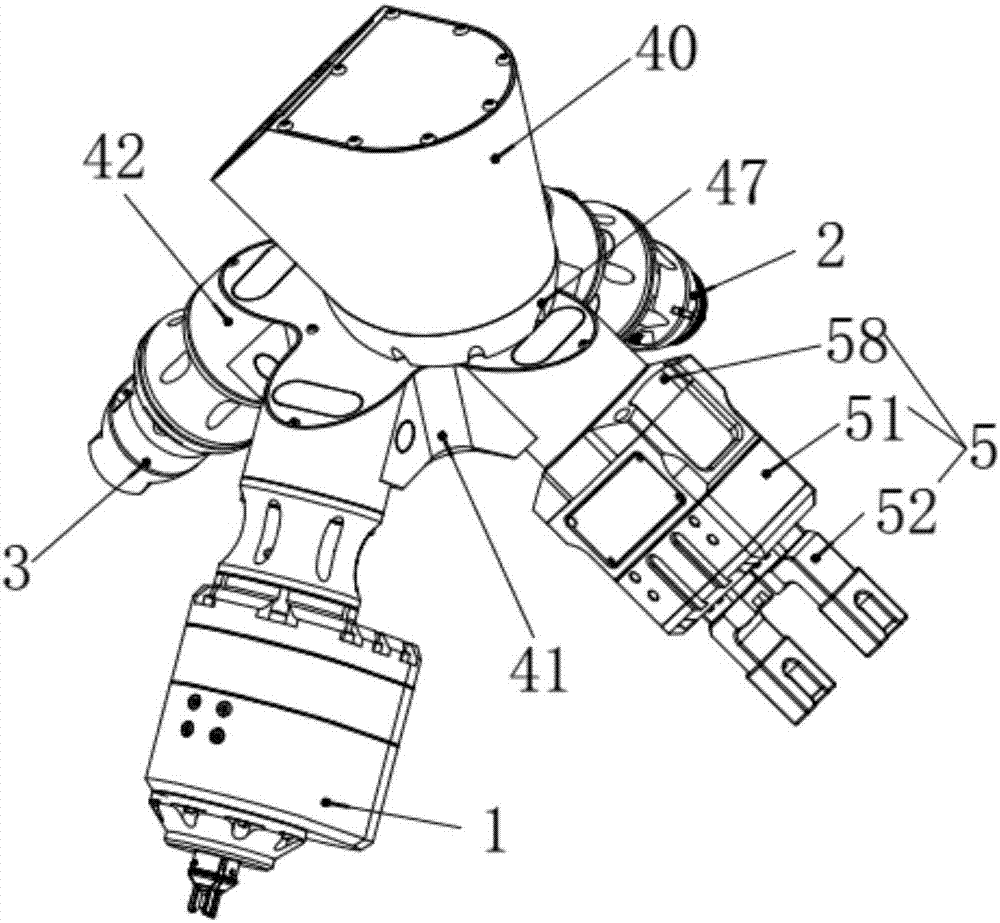

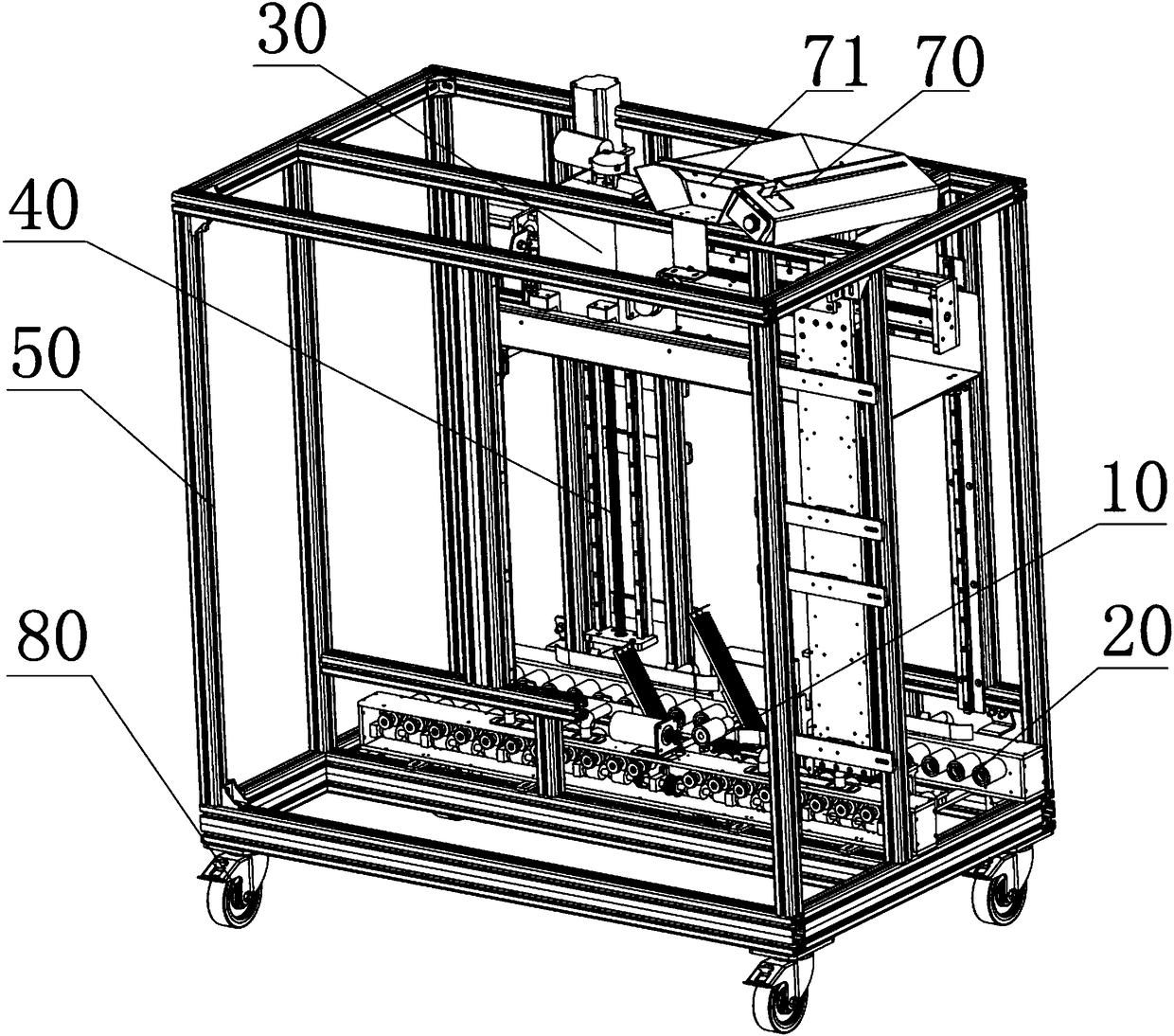

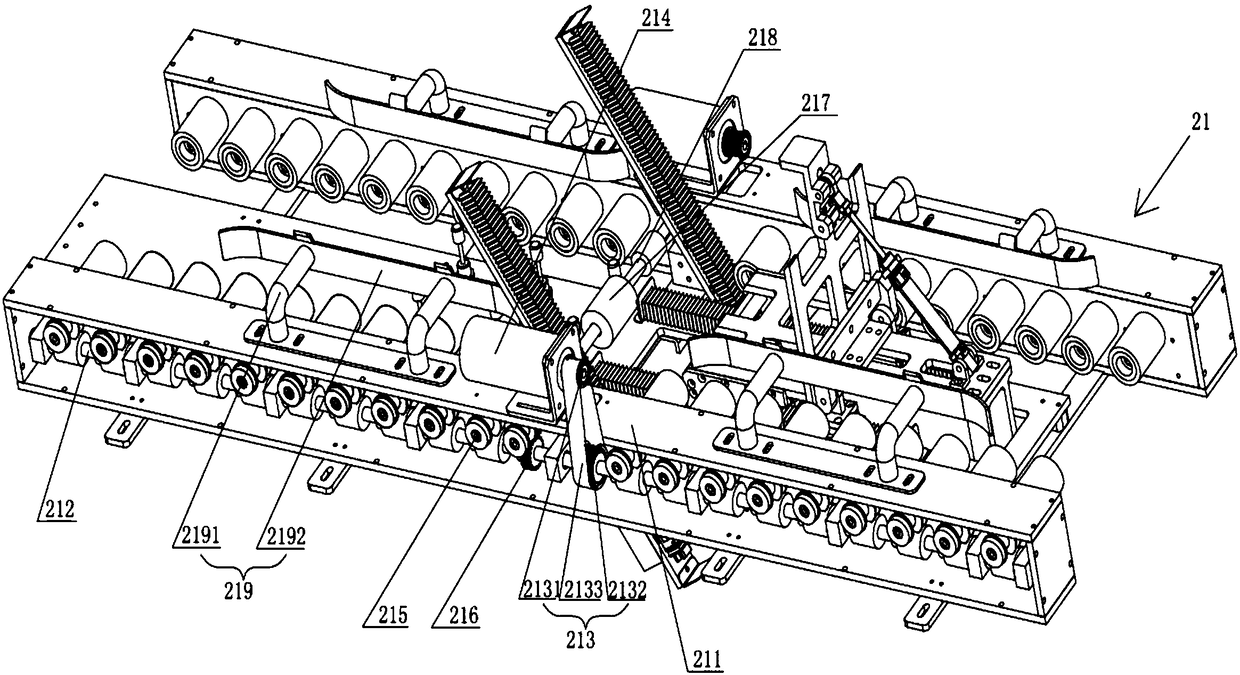

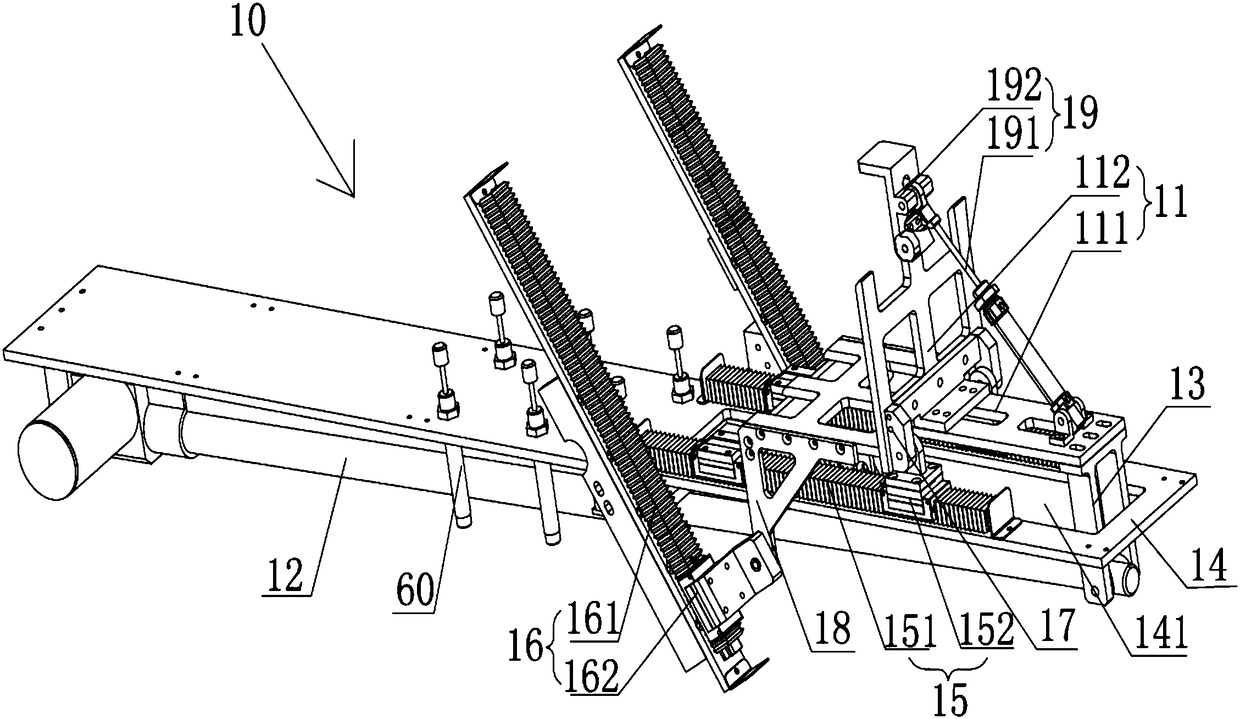

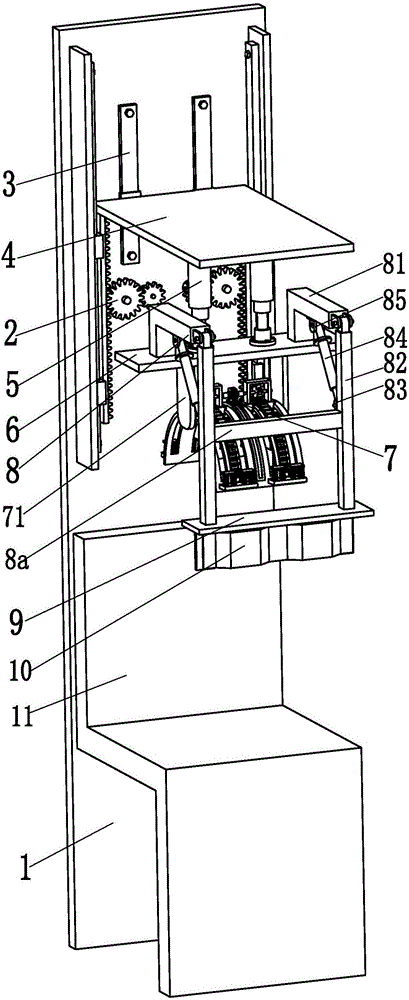

Glass carrying and stacking manipulator

InactiveCN104310069AEasy to grabGood transmission effectCharge manipulationStacking articlesHydraulic motorRotary stage

The invention discloses a glass carrying and stacking manipulator, and belongs to the field of production equipment. The manipulator consists of a fixed base, a rotating pedestal, a large movable arm, a small movable arm, a tail movable arm, fixed sliding rails, adjustment sliding rails, sucker sliding frames, suckers, a vacuum air pump, a transverse adjustment cylinder, longitudinal adjustment cylinders, a hydraulic motor I, a hydraulic motor II and a servo motor, wherein the rotating pedestal is mounted in the fixed base; the large movable arm is hinged to the rotating pedestal through the hydraulic motor I; the small movable arm is hinged to the large movable arm through the hydraulic motor II; the tail movable arm is hinged to the small movable arm through the servo motor; the fixed sliding rails are fixedly connected with the end face of the tail movable arm; the adjustment sliding rails are arranged on the fixed sliding rails; the transverse adjustment cylinder is arranged on the rear part of the tail movable arm; the sucker sliding frames are arranged on the adjustment sliding rails; the longitudinal adjustment cylinders are arranged on the inner sides of the adjustment sliding rails; the suckers are arranged on the adjustment sliding rails and the sucker sliding frames. The manipulator can be used for efficiently and safely carrying and stacking glass instead of a worker.

Owner:曹磊

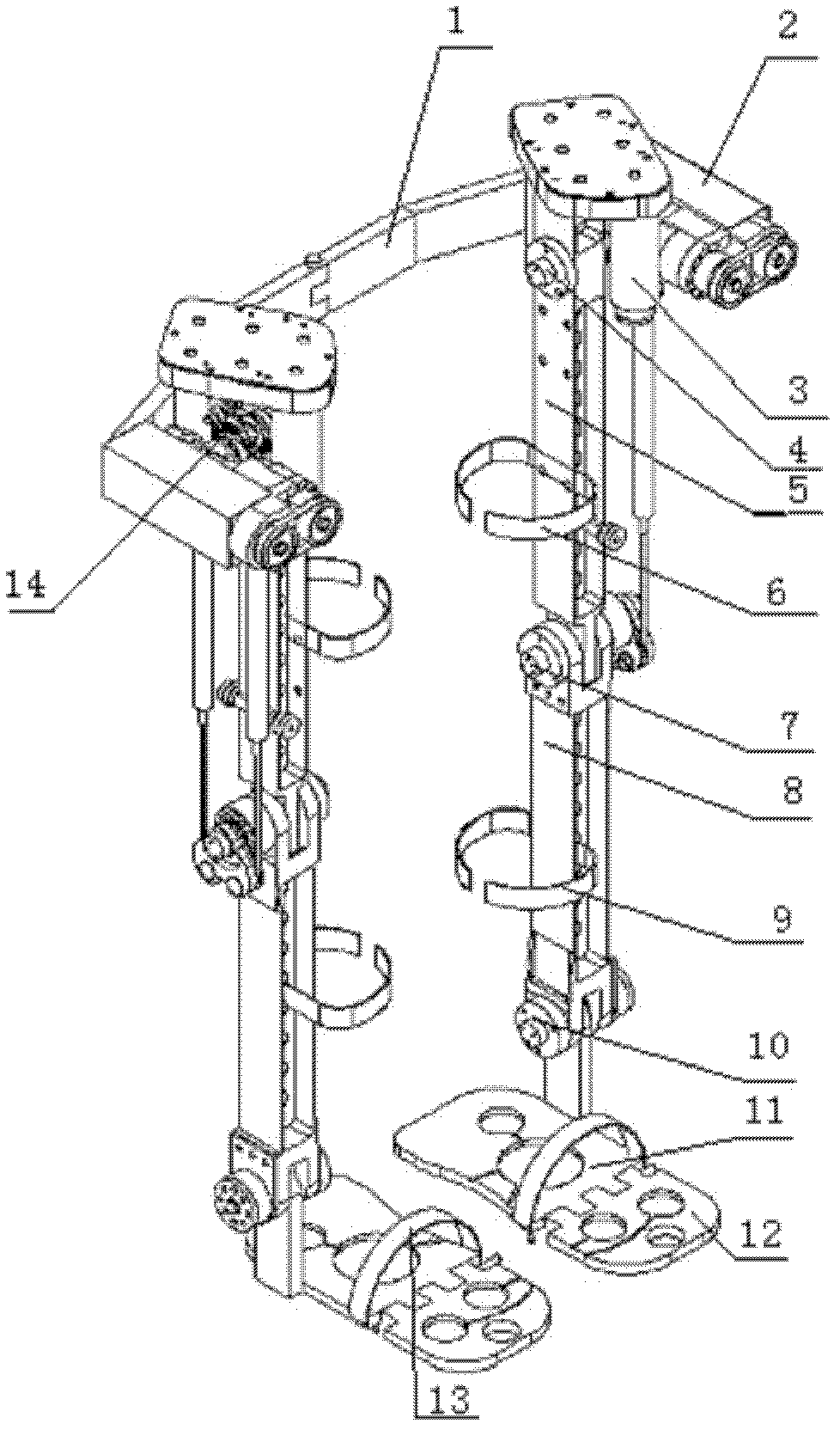

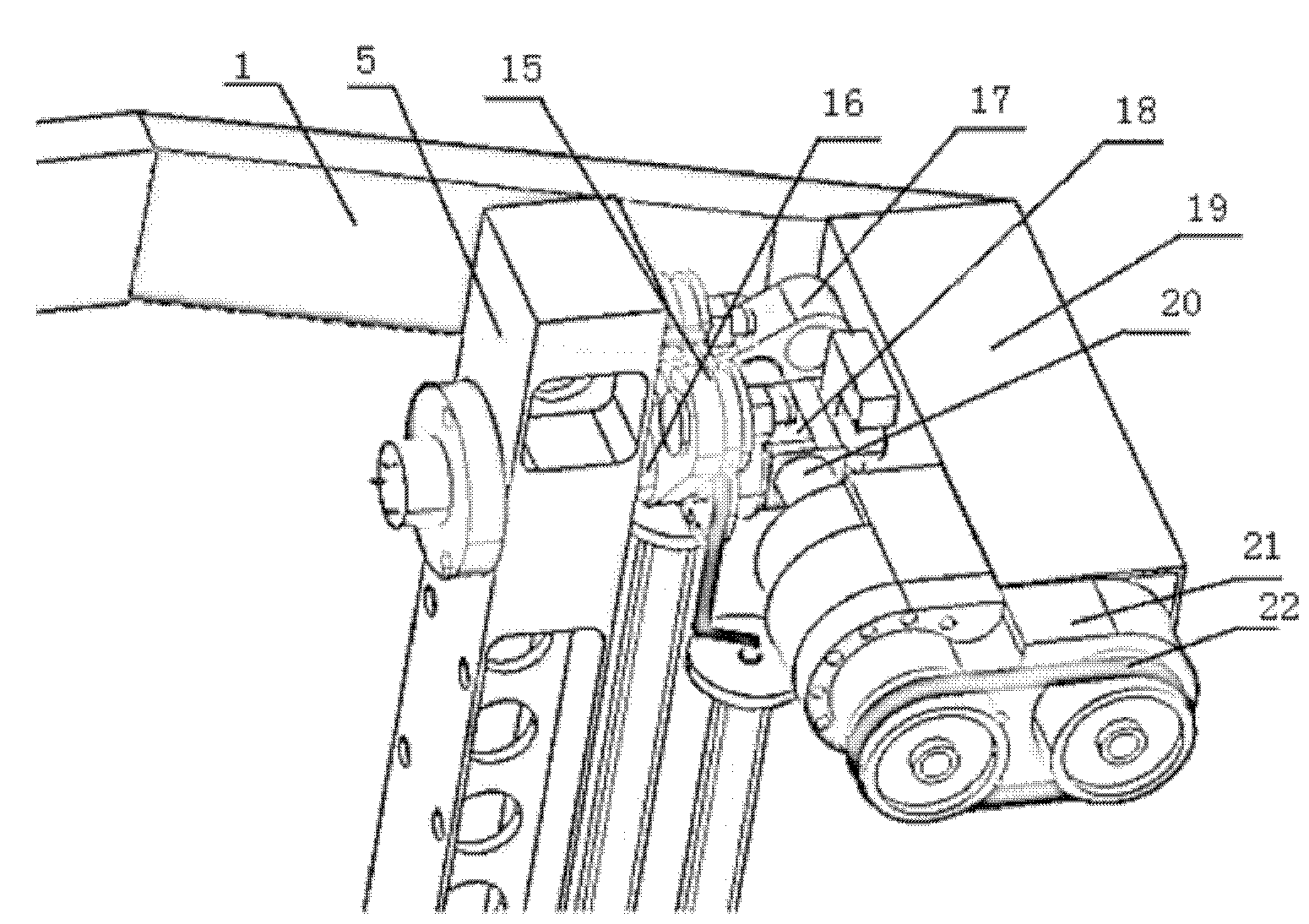

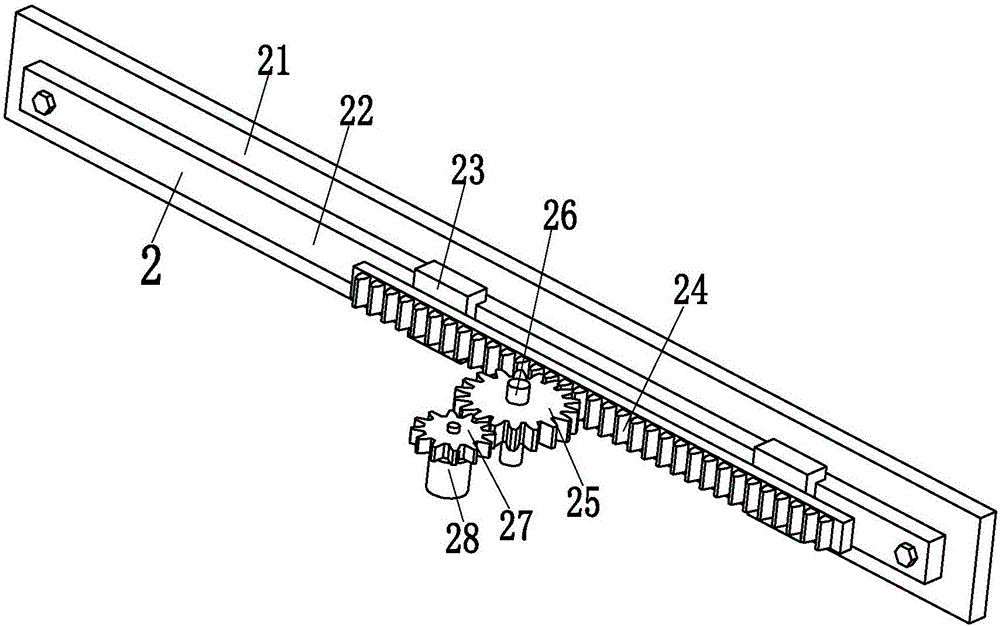

Line angle driving lower limb walking aid

InactiveCN102247260AConvenient lifeAchievement of abduction and adductionWalking aidsThighMuscles of the hip

The invention relates to a line angle driving lower limb walking aid. The walking aid comprises bilaterally symmetrical waist support brackets, thigh support rods, shank support rods, feet support plates, first hip joint revolute pairs, second hip joint revolute pairs, knee joint revolute pairs, ankle joint revolute pairs, abduction and adduction driving mechanisms, flexion and extension driving mechanisms, thigh fastening straps and shank fastening straps. The walking aid has the following advantages: the walking aid has a scientific and reasonable structure design, can assist patients with paralysis of lower limbs to stand and walk, is stable in operation and reliable in support, is easy to produce and has low cost.

Owner:TIANJIN UNIV OF SCI & TECH

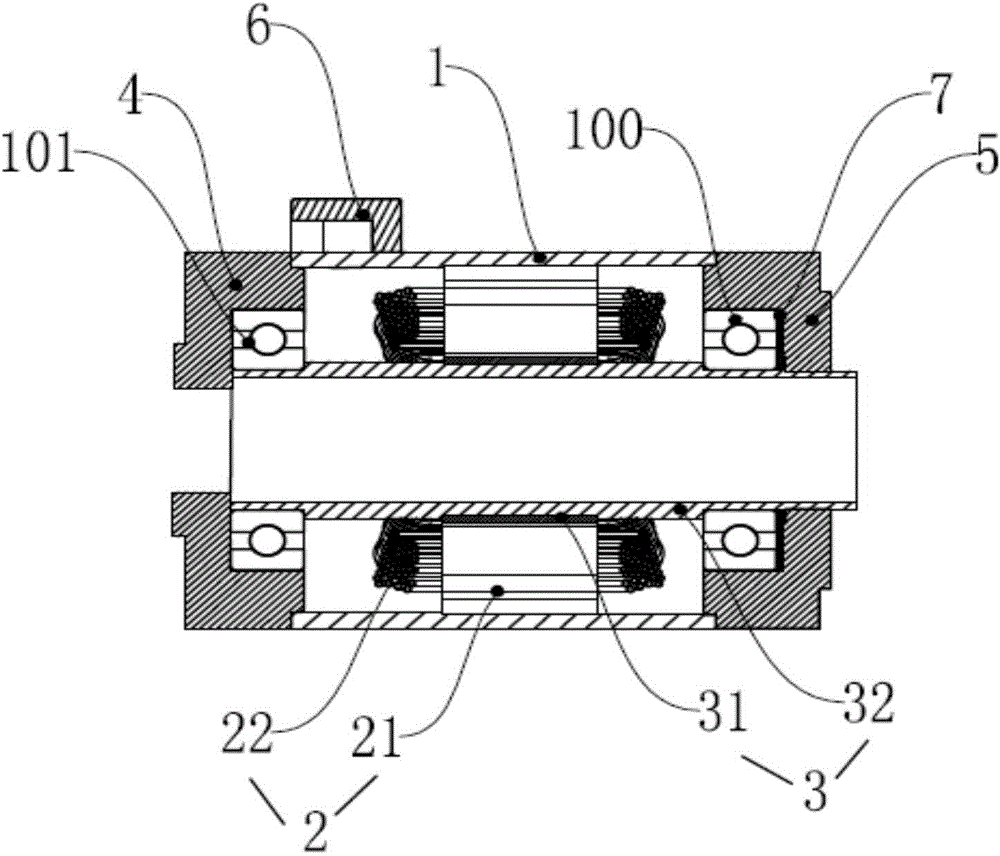

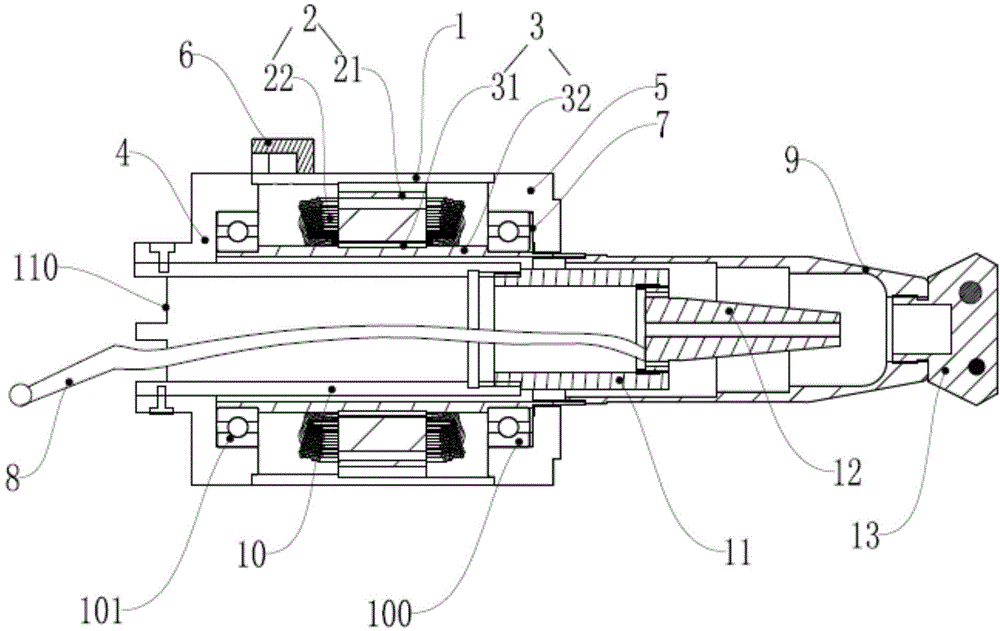

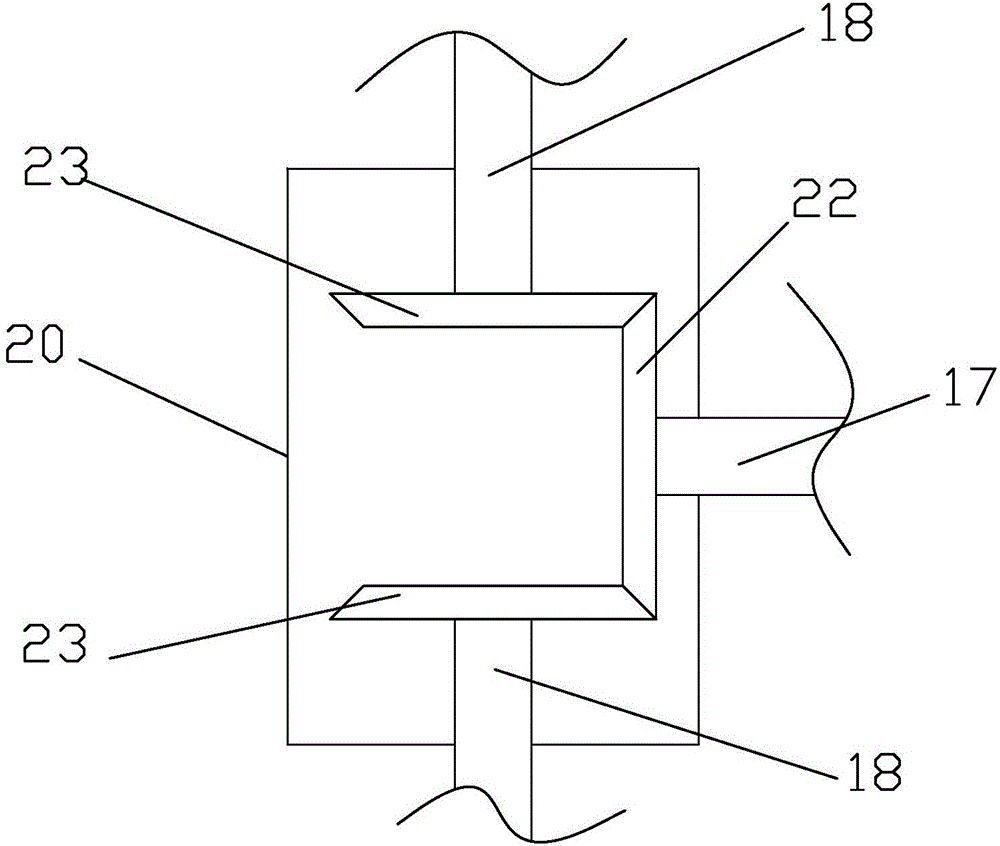

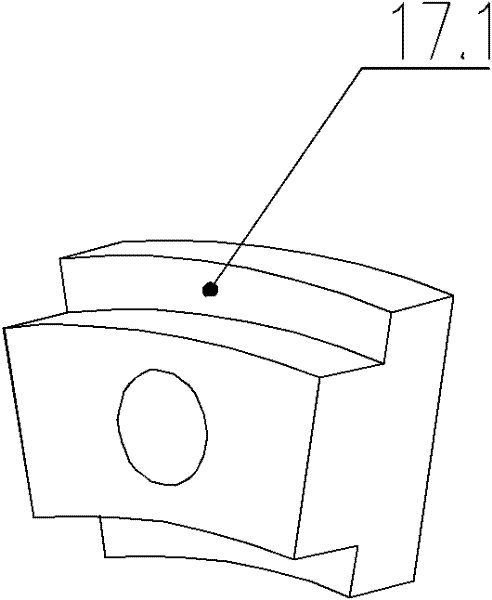

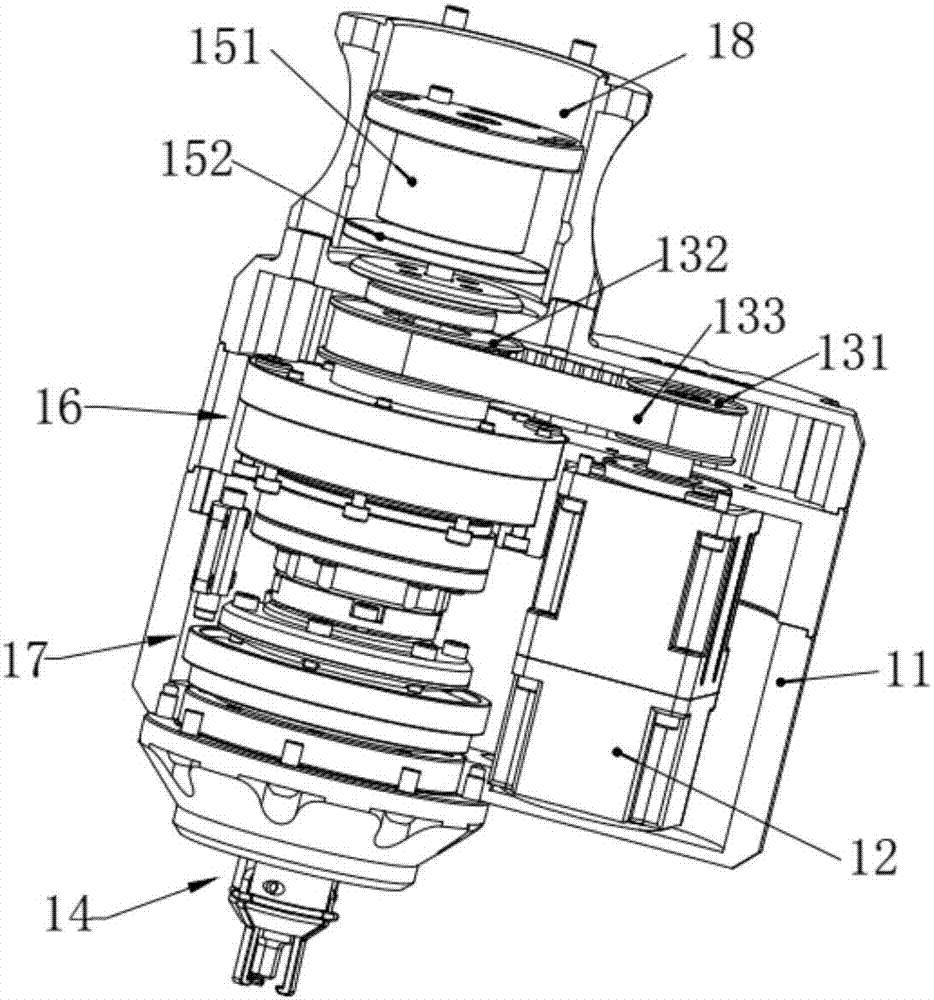

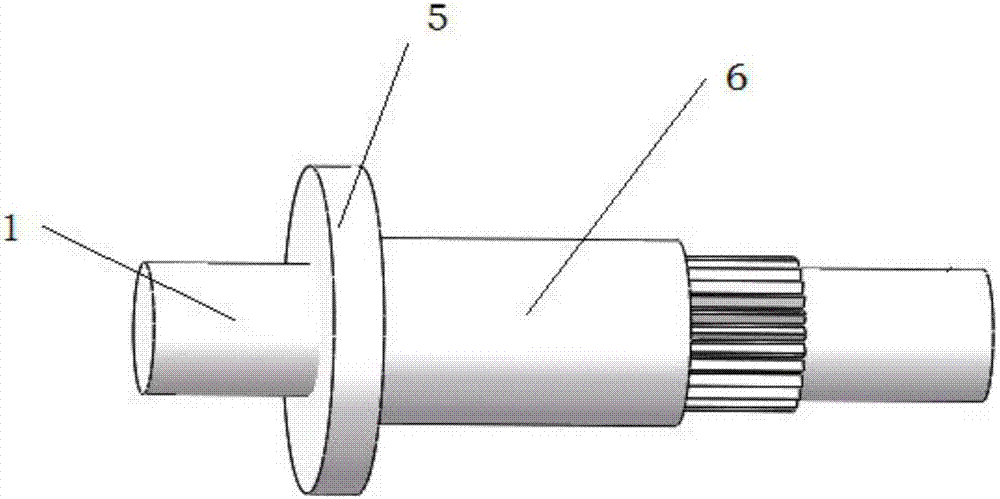

Hollow motor

InactiveCN104600902AReduce transmission ring damageGood transmission effectMechanical energy handlingSupports/enclosures/casingsStatorEngineering

A hollow motor comprises a shell, a stator assembly, a rotor assembly, a rear cover and a front cover; the stator assembly comprises a coil former and magnetic steel; the stator assembly comprises a rotor shaft and a hollow shaft; the hollow shaft passes through and is fixed in the rotor shaft; the coil former is located between the rotor shaft and the shell; the front cover is connected with the front end of the hollow shaft by means of a front bearing; and the rear cover is connected with the rear end of the hollow shaft by means of a rear bearing. The hollow shaft is directly connected with a transmission structure; compared with the present synchronous belt or the gear driving manner, the hollow motor is capable of reducing damages in a transmission process, good in transmission effect, simple in structure, less in quantity of parts and low in cost; the stability of the hollow shaft during transmission is guaranteed by means of the dual bearings, so that the stability of the transmission mechanism during transmission can be guaranteed.

Owner:广东韦达尔传媒有限公司 +1

Full-automatic intelligent rubbish bin and control method thereof

InactiveCN106241103ASimple structureInnovative designWaste collection and transferRefuse receptaclesAutomatic controlControl system

The invention discloses a full-automatic intelligent rubbish bin. The full-automatic intelligent rubbish bin comprises a bin body, a rubbish throwing inlet, an automatic sorting device and a rubbish cavity. A control system is arranged in the bin body. The control system comprises a controller, a sensing device, a detection device, a verification and identification device, a voice broadcasting device and an operating screen. The sensing device, the detection device, the verification and identification device, the voice broadcasting device and the operating screen are all connected with the controller. The full-automatic intelligent rubbish bin is simple in structure, novel in design and capable of achieving full-automatic control. Using difficulty of users can be lowered, and meanwhile working efficiency of cleaning staff can be effectively improved. According to the control method, the controller is used for controlling the sensing device, the detection device, the verification and identification device, the voice broadcasting device, the operating screen and the automatic sorting device, and thus rubbish can be sorted automatically. Useful rubbish can be separated from unrecyclable rubbish more easily, rubbish treatment cost is reduced, and pollution caused in the sorting recovery processing of the rubbish can be reduced or avoided.

Owner:浙江融家科技有限公司

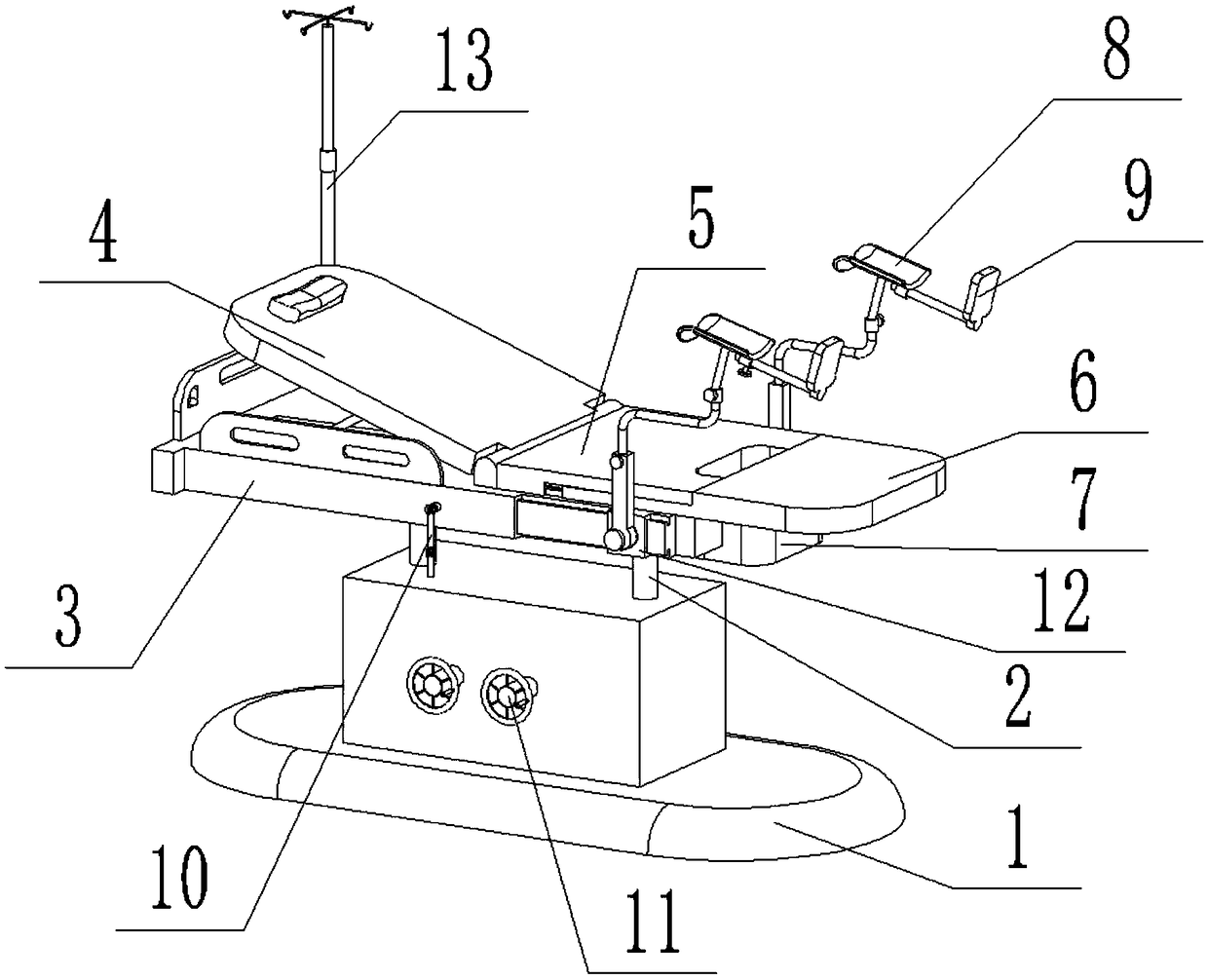

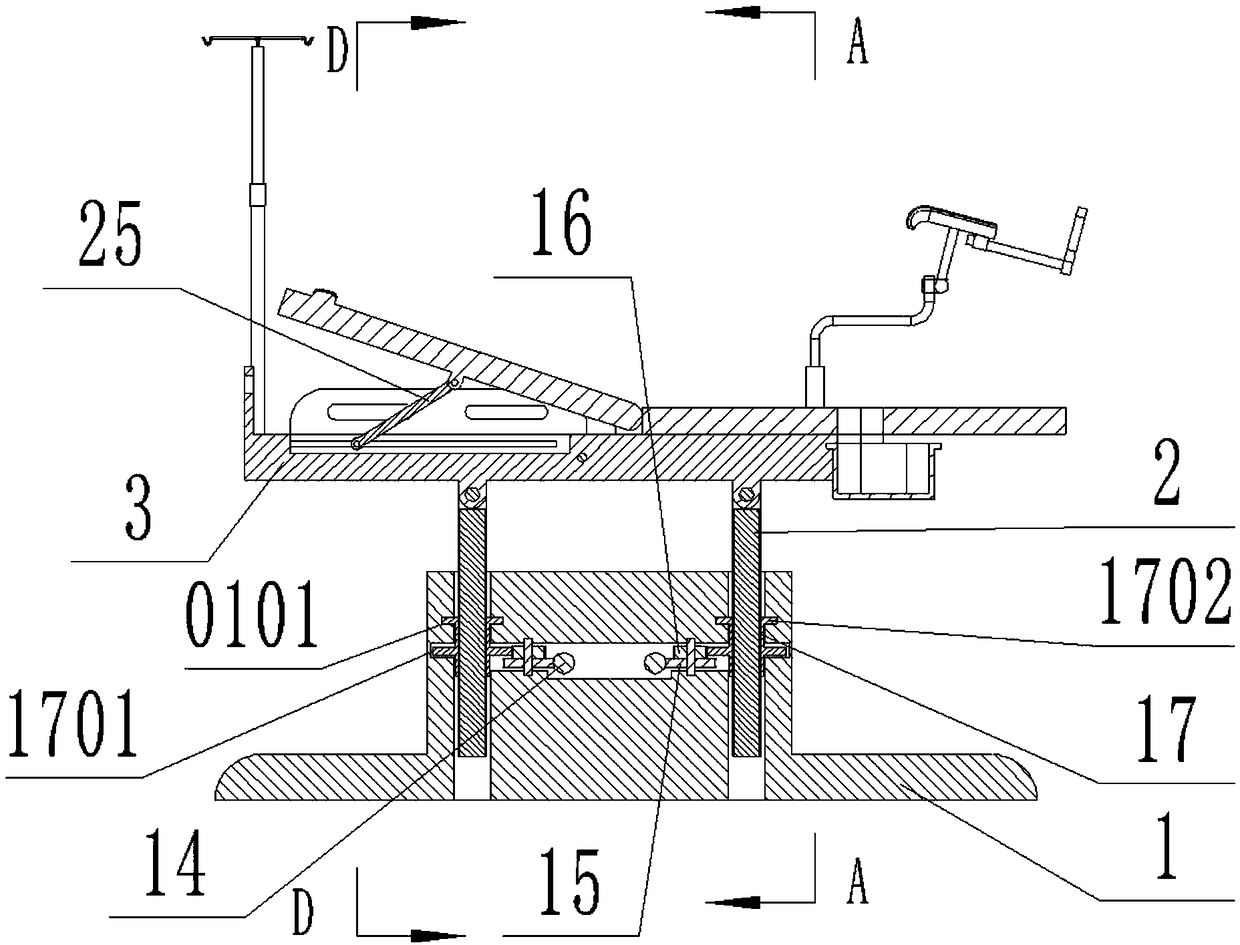

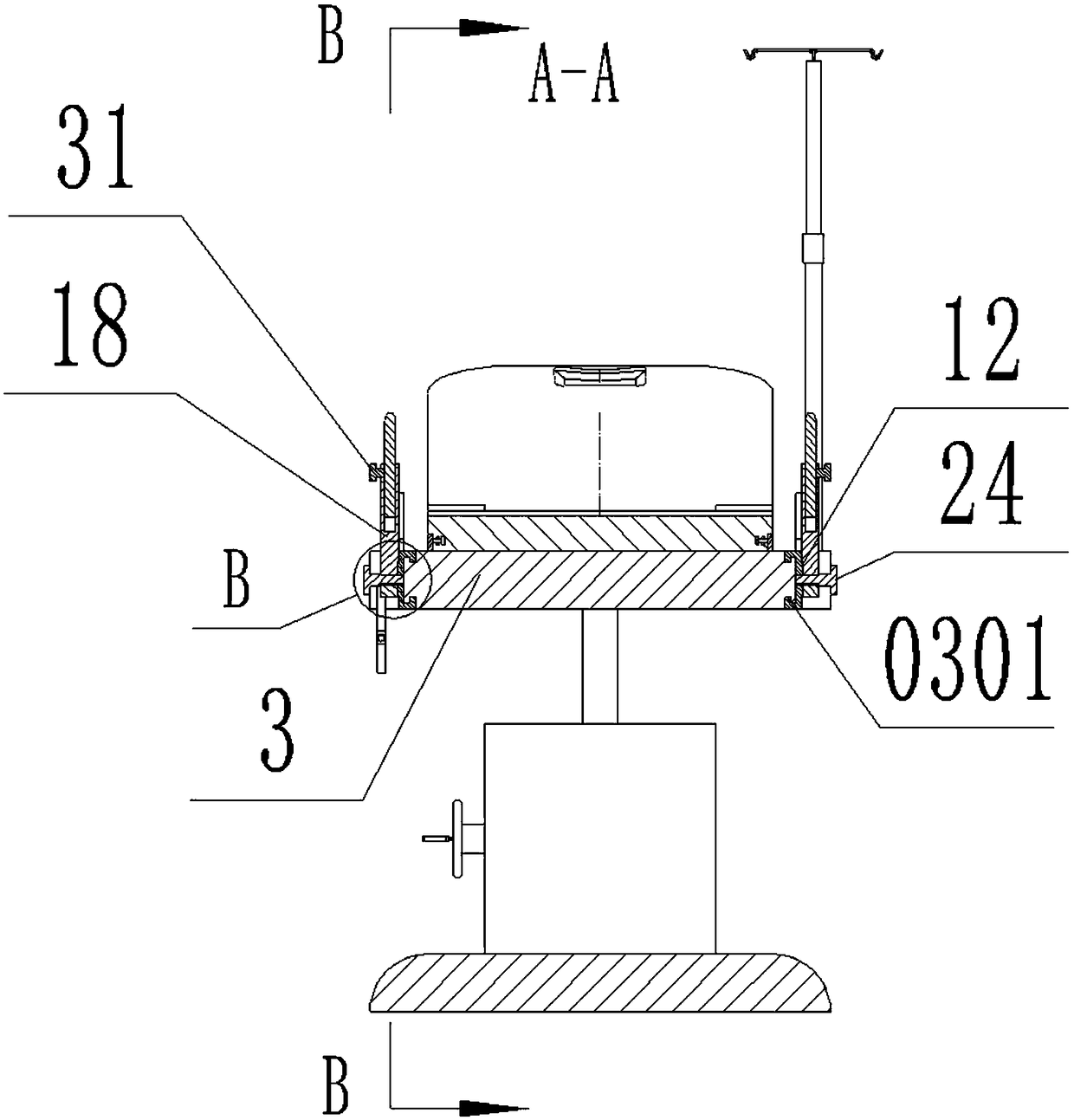

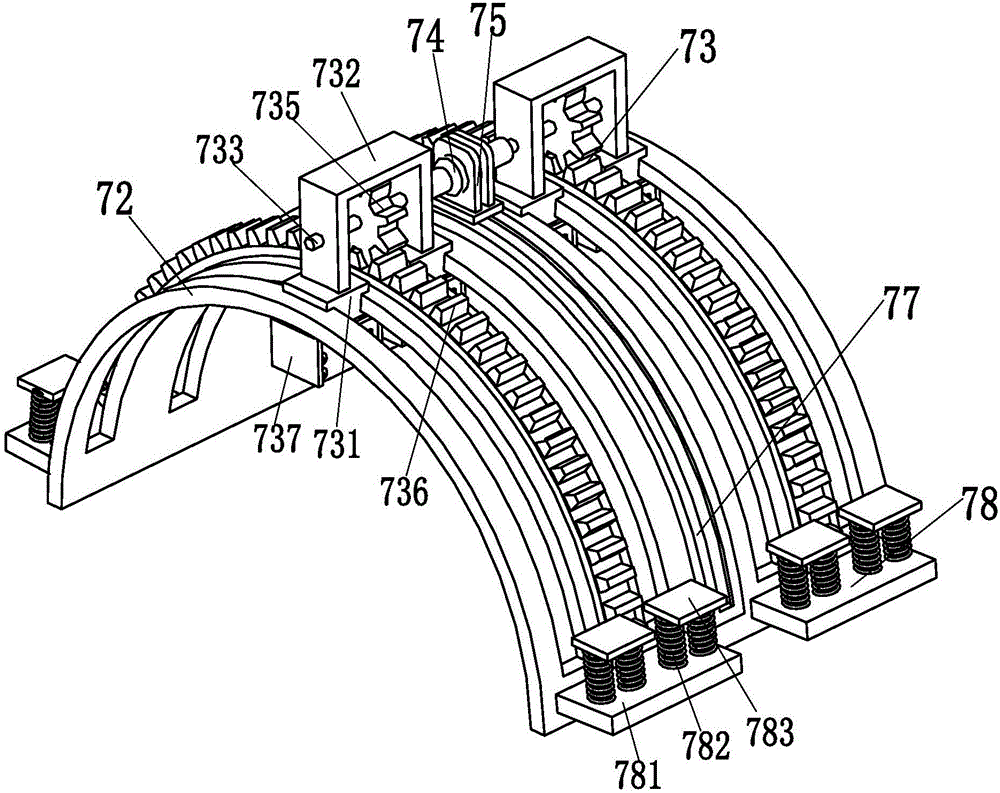

Convenient-to-adjust special bed for department of gynaecology and obstetrics

ActiveCN108938296AImprove practicalityEasy to operateOperating tablesMedical transportSpecial bedObstetric history

The invention provides a convenient-to-adjust special bed for the department of gynaecology and obstetrics. The bed comprises a base, a ring platform and a telescopic adjusting rod locking nut; the tops of two lifting rods are connected with a bed body; three short guiding wheels are arranged on the parts, located on the inner sides of the front and rear end faces of a mattress, of leg parts; a sewage bucket clamping groove is formed in the right side of the bed body, and a sewage bucket is clamped in the sewage bucket clamping groove; each of both left and right sides of the right portion ofthe bed body is slidably connected with a translation sliding block; a rotary adjusting rod is axially connected with the outer side of each translation sliding block; a rotary adjusting rod fixing screw is in threaded connection with each translation sliding block. By adopting a double lifting and lowering rod structure, the height of the bed body can be lifted and lowered, the tilting angle of the bed body can be adjusted, the operation is convenient, the adjustment is simple, multiple functional adjustments can be achieved by adopting multiple kinds of adjusting mechanisms, the practicability is higher, and the adjusting effect is better.

Owner:西安欧氧生物科技有限公司

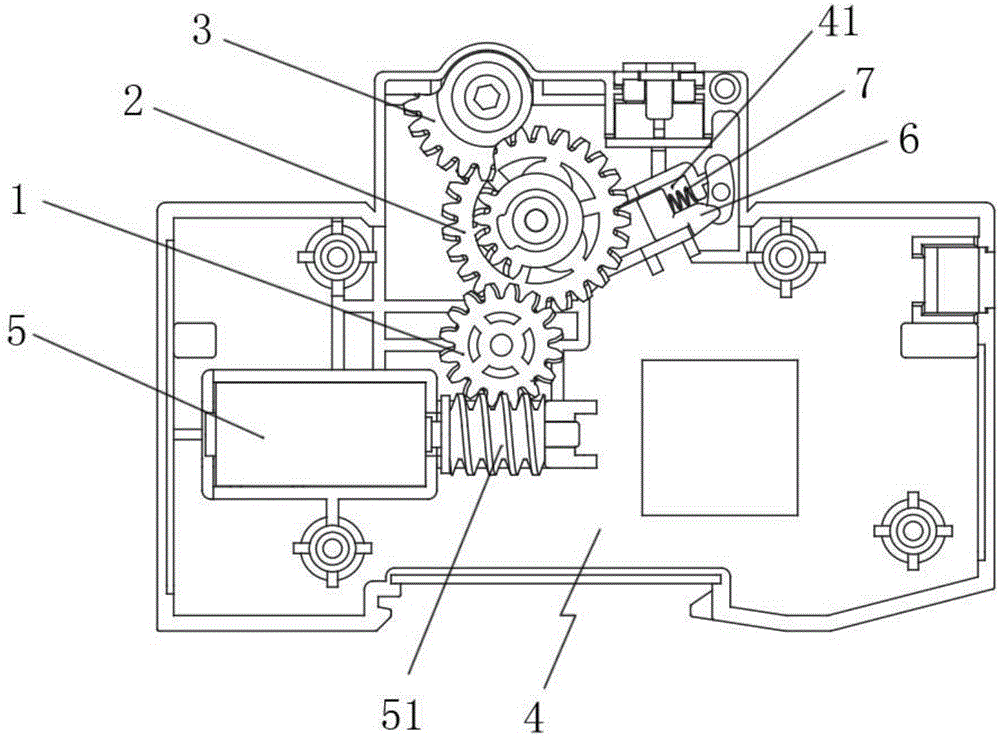

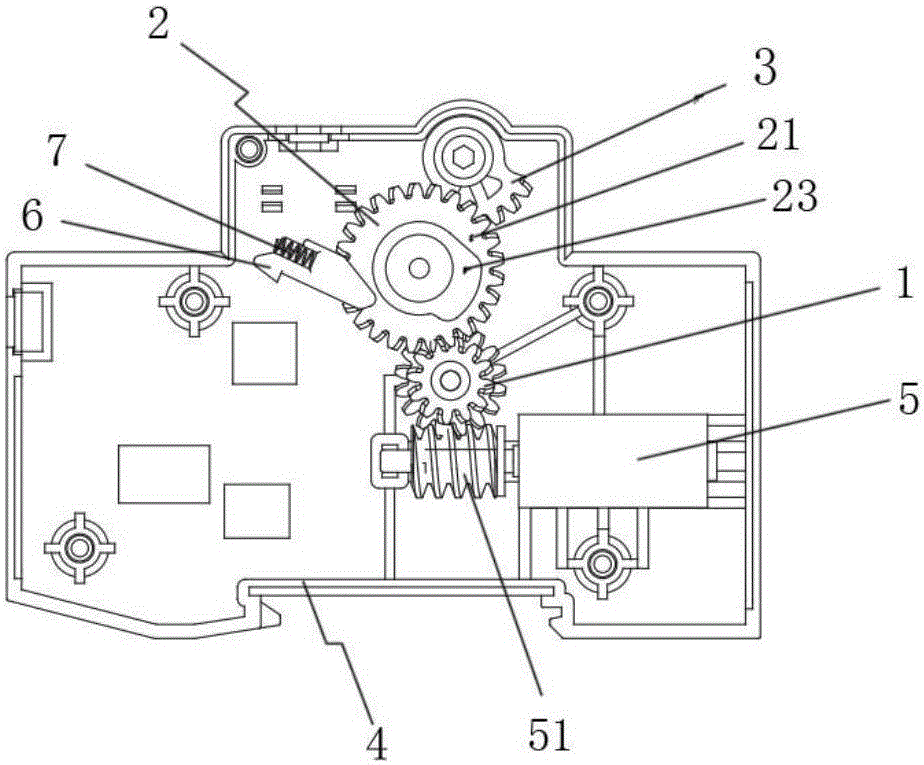

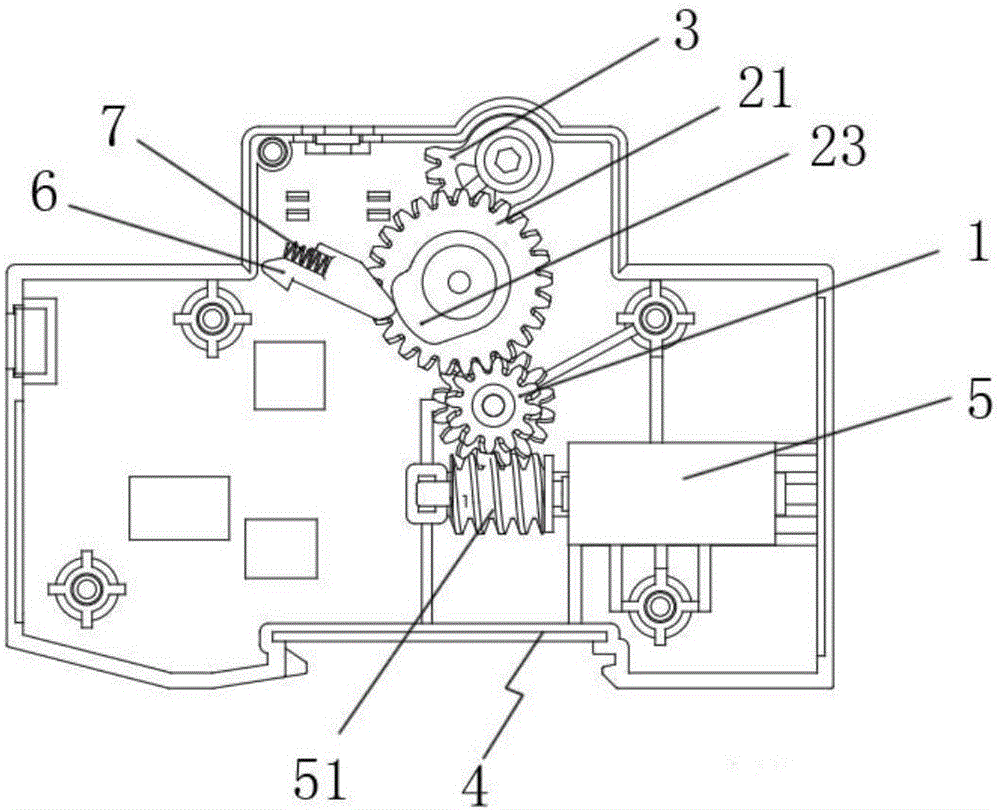

Automatic reclosing lock device of breaker

ActiveCN106356263ANo shakingSolve the unstable transmissionProtective switch operating/release mechanismsDrive motorEngineering

The invention provides an automatic reclosing lock device of a breaker. The automatic reclosing lock device comprises a drive motor, a linkage tripping mechanism, a transmission gear mechanism and a breaker handle mechanism, wherein the transmission gear mechanism comprises a first transmission gear, a second transmission gear and a third transmission gear which are adjacently meshed with one other, a cam portion of the second transmission gear can drive a push rod to shift a tripping rod, so as to quickly separate the breaker, the second transmission gear can drive an incomplete gear to rotate continuously, and the incomplete gear and the third transmission gear are in mesh transmission to drive a handle to switch on automatically through a linkage rotation shaft. The automatic reclosing lock device has the advantages of being reliable in transmission, strong in stability and capable of enabling the second transmission gear not to be prone to shaking or rising; thus, the automatic reclosing lock device can avoid the problem of tripping clamping stagnation or tripping slide when being matched with a linkage tripping part, the use performance of a product is favorably improved, and the service life of the product is favorably prolonged.

Owner:ZHEJIANG ZHONGFU ELECTRIC

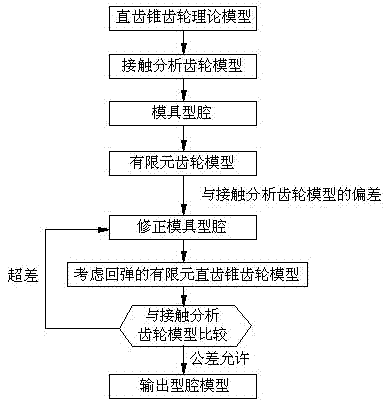

Control method for tooth shape size precision of cold forming straight bevel gear

InactiveCN102728646AGuaranteed dimensional accuracyIncrease contactShaping toolsExtrusion profiling toolsTheory modelCold formed

The present invention discloses a control method for tooth shape size precision of a cold forming straight bevel gear. The method comprises: 1) establishing a contact analysis gear model according to a gear theory model; 2) generating a mold cavity; 3) determining a finite element gear model after considering resilience; 4) comparing the finite element gear model with the contact analysis gear model to obtain model deviation; 5) correcting the mold cavity, and carrying out finite element calculation to obtain a new finite element straight bevel gear model; 6) comparing the finite element straight bevel gear model with the contact analysis of gear model, carrying out outputting if the size precision requirement is met, otherwise determining the deviation between the finite element straight bevel gear model and the contact analysis of gear model; and 7) repeated performing the steps of 5) and 6) until the size precision requirement is met. According to the present invention, the size of the cold forming mold cavity of the straight bevel gear is determined after the shape correcting, the material and the mold of the tooth shape after resilience are considered, such that the tooth shape size precision of the straight bevel gear is ensured, and it is ensured that excellent contact and transmission effects of the straight bevel gear after cold forming can be directly met without mechanical processing.

Owner:CHONGQING UNIV OF TECH

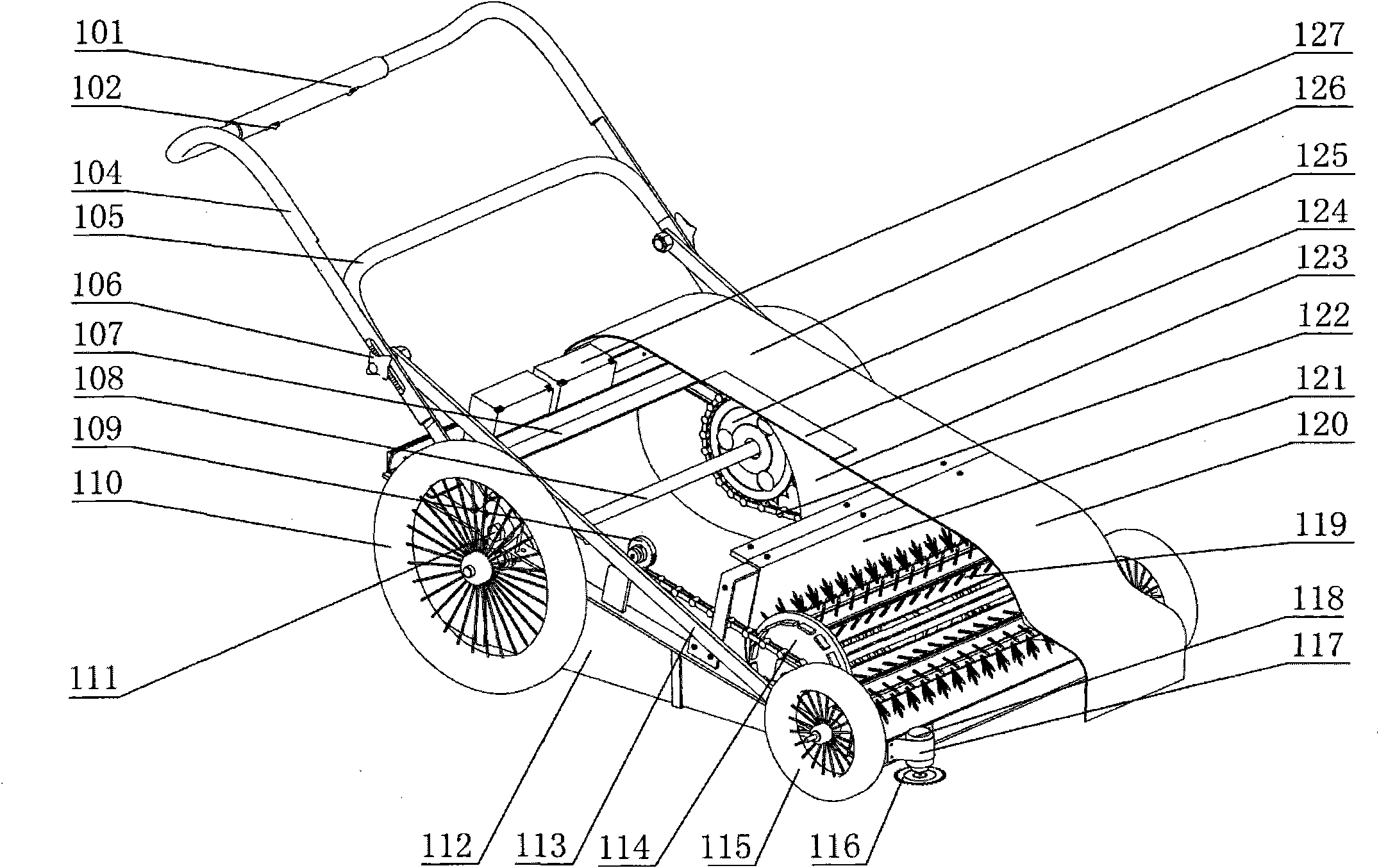

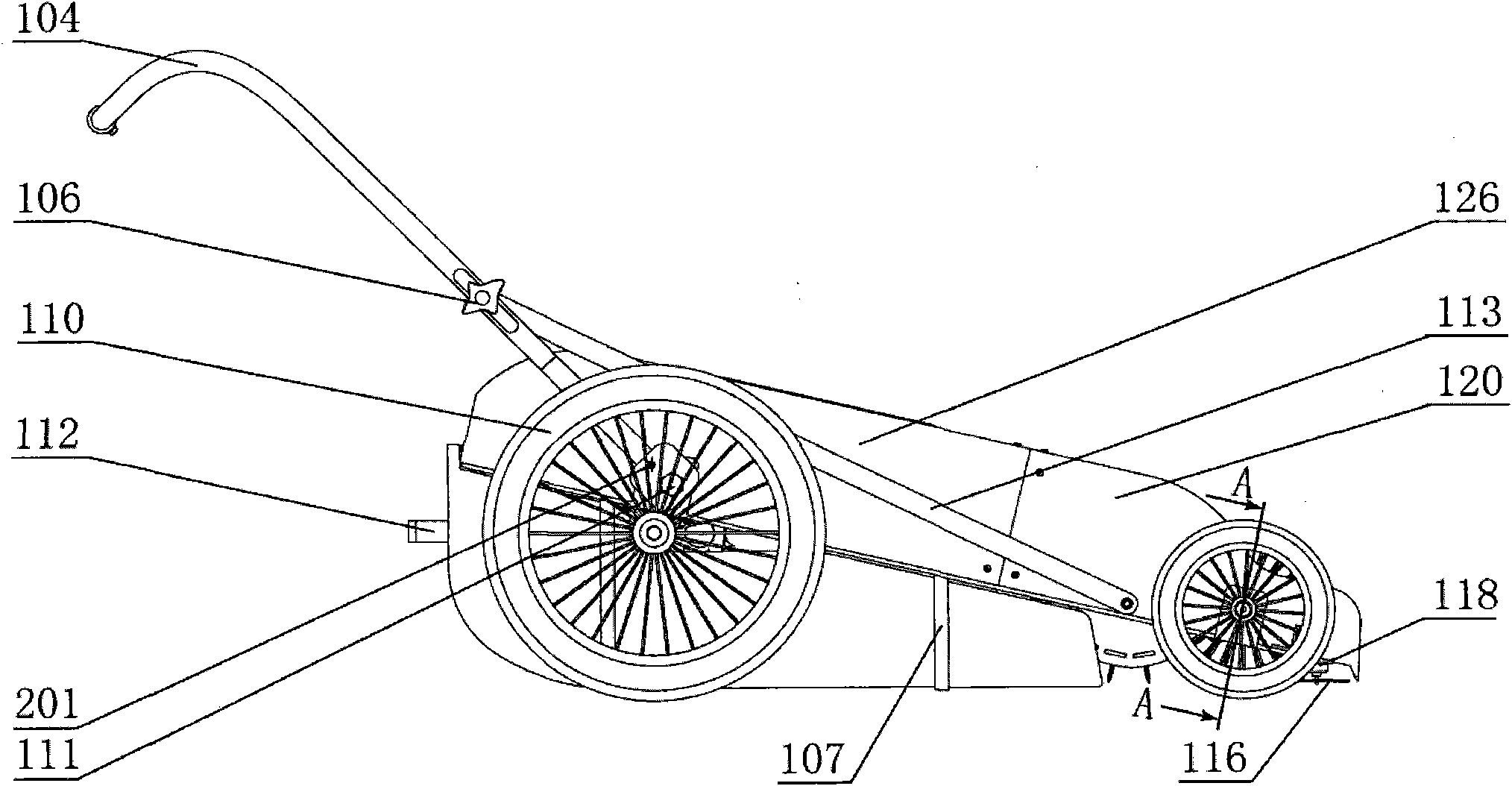

Vehicle for cleaning leaves of lawn

The invention discloses a vehicle for cleaning leaves of a lawn, comprising a vehicle body and a main collecting device, wherein a plurality of rows of elastic rolling needles are circumferentially distributed on a roller of the main collecting device. When the roller rotates, the elastic rolling needles prick garbage, such as leaves, and the like on the lawn and interact with harrows arranged at intervals with the rolling needles while the roller rotates to ensure that the garbage, such as leaves, and the like falls into a collecting box so as to complete the cleaning of the leaves. In the invention, because the people-pushing kinetic energy is adopted, and the garbage, such as leaves, and the like is efficiently and conveniently collected through the roller circumferentially and uniformly provided with the elastic rolling needles and the stagger falling harrows, the vehicle is pure mechanical, has no energy consumption and no noise, protects the environment and saves the energy. Furthermore, in order to ensure that the cleaning vehicle adapts the environment of the lawn more strongly and has wider application range, a motor as an auxiliary power is skillfully installed in the roller without influencing the main power so as to deal with the landform or the condition inconvenient for pushing by hands.

Owner:SOUTH CHINA UNIV OF TECH

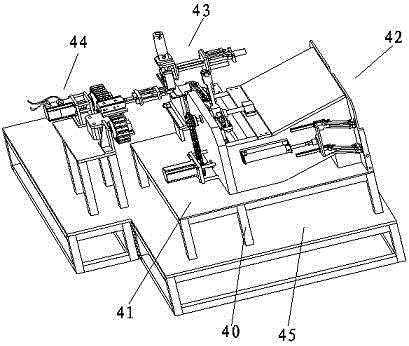

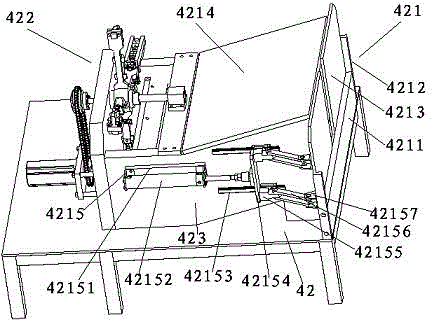

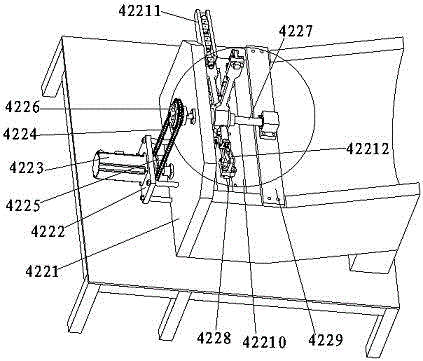

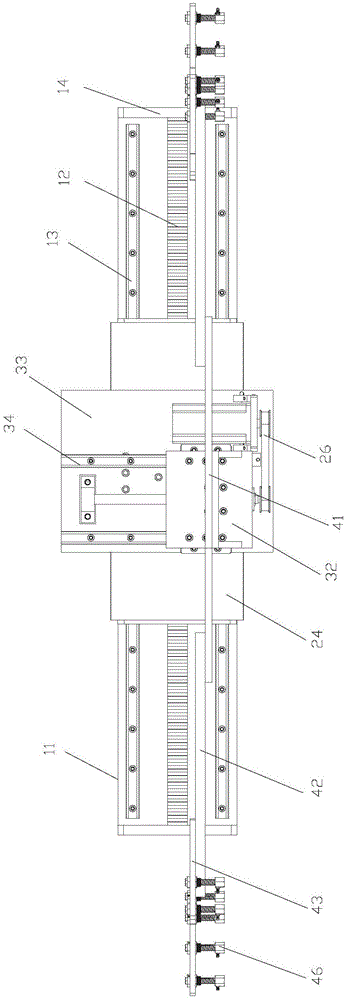

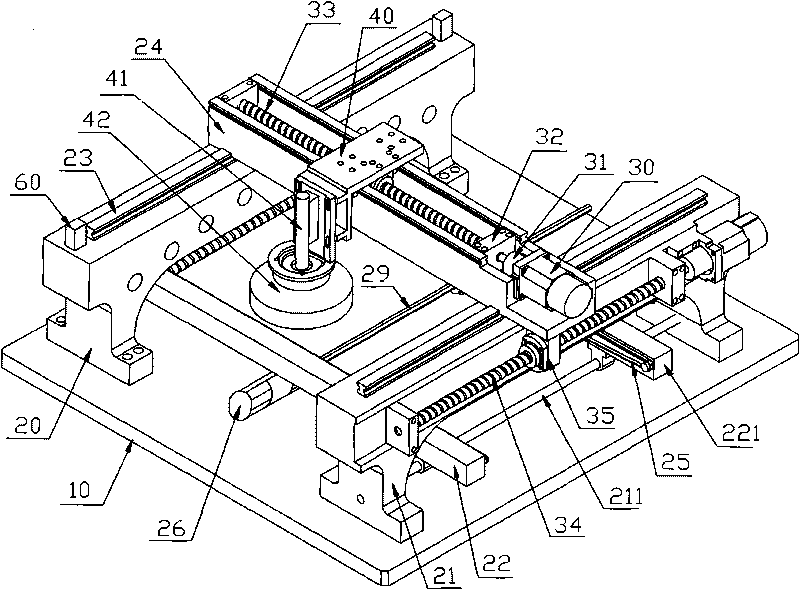

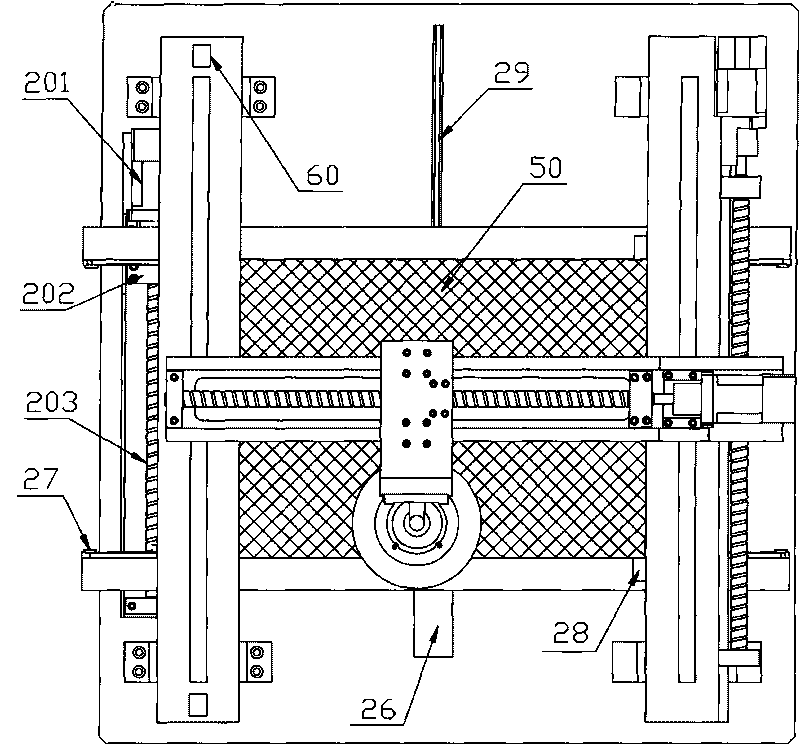

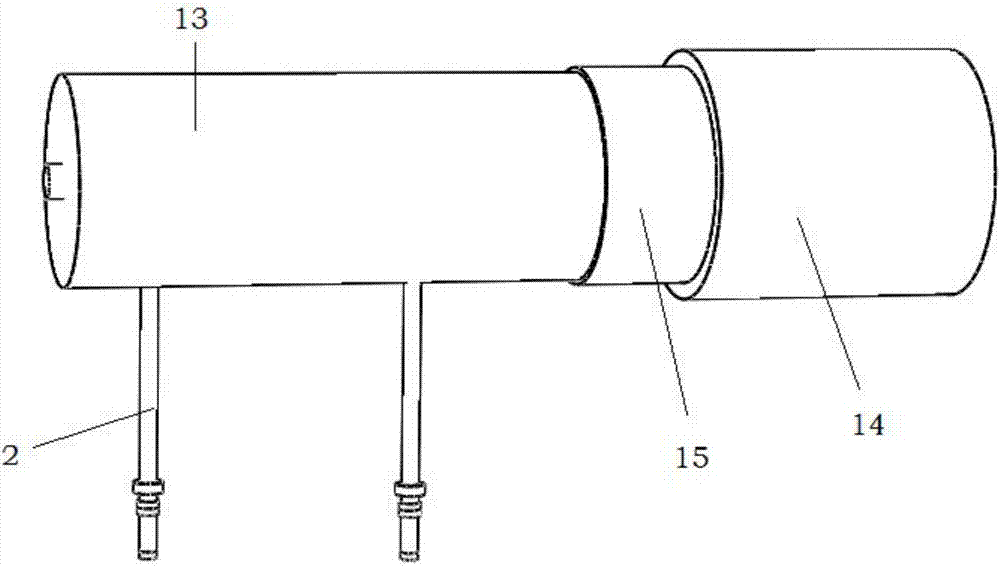

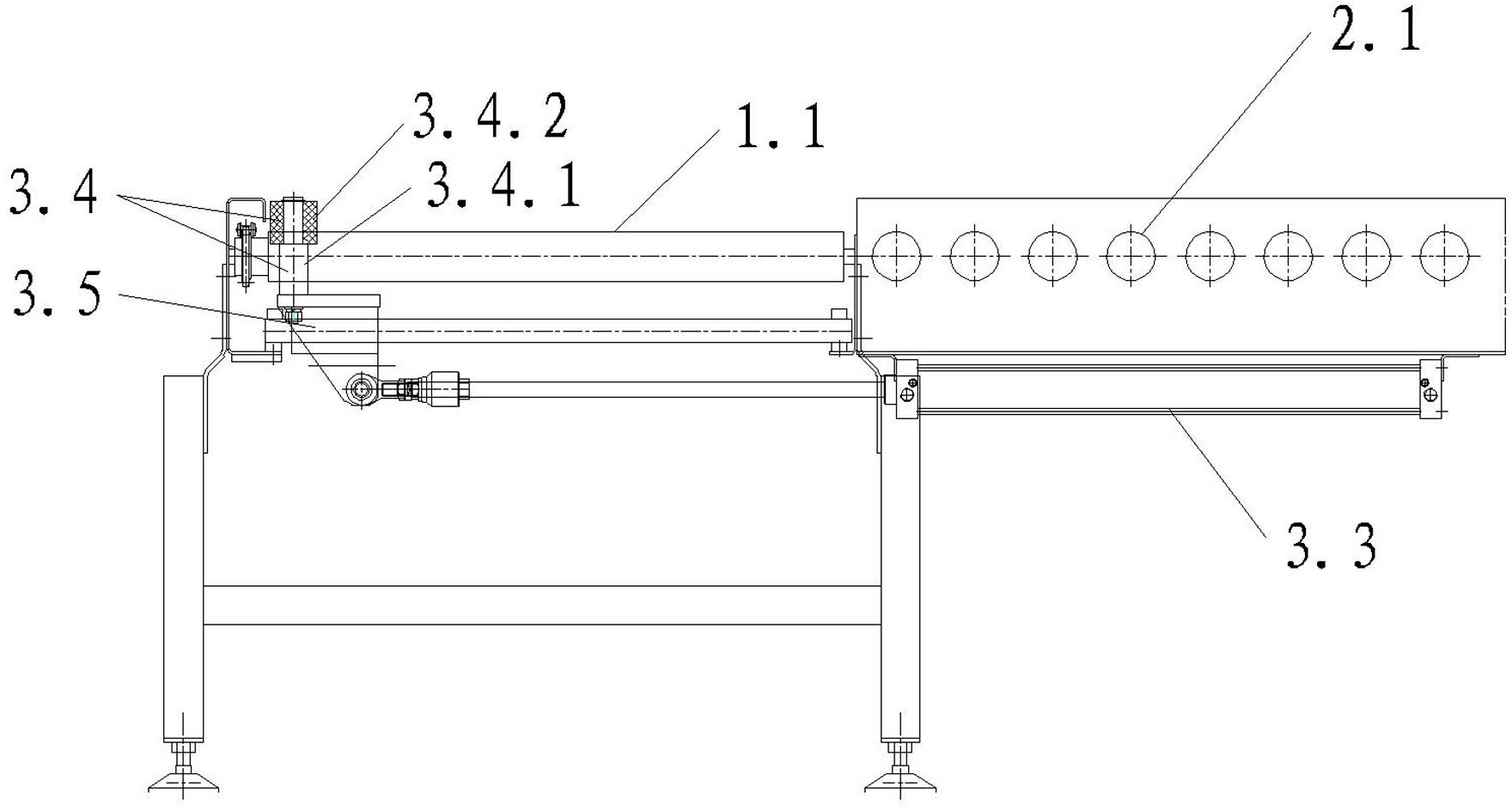

Shell conveying mechanism of electronic drain valve controller assembly machine

The invention discloses a shell conveying mechanism of an electronic drain valve controller assembly machine. The shell conveying mechanism of the electronic drain valve controller assembly machine comprises a mounting bottom plate fixed to a rack, wherein a shell feeding mounting bracket is fixed to the upper plane of the mounting bottom plate; a shell feeding mounting plate is mounted on the shell feeding mounting bracket; a shell feeding device and a shell taking device are mounted on the upper plane of the shell feeding mounting plate; the shell taking device is positioned on one side of the shell feeding device; a shell moving device is arranged on the mounting bottom plate on one side of the shell taking device; the shell feeding device comprises a feeding guide groove; a rectangular open groove is formed in the upper end of the side wall of the feeding guide groove; the feeding guide groove is provided with an inclined end and a horizontal end; the inclined end of the feeding guide groove is provided with an opening-closing component; and the horizontal end of the feeding guide groove is provided with a feeding component. According to the shell conveying mechanism, through the manner, the conveying effect is good, the abrasion of workpieces is small, the production efficiency is greatly improved, and the production cost is reduced.

Owner:JIANGSU PROVINCE SINGE IRRIGATION & DRAINAGE EQUIP

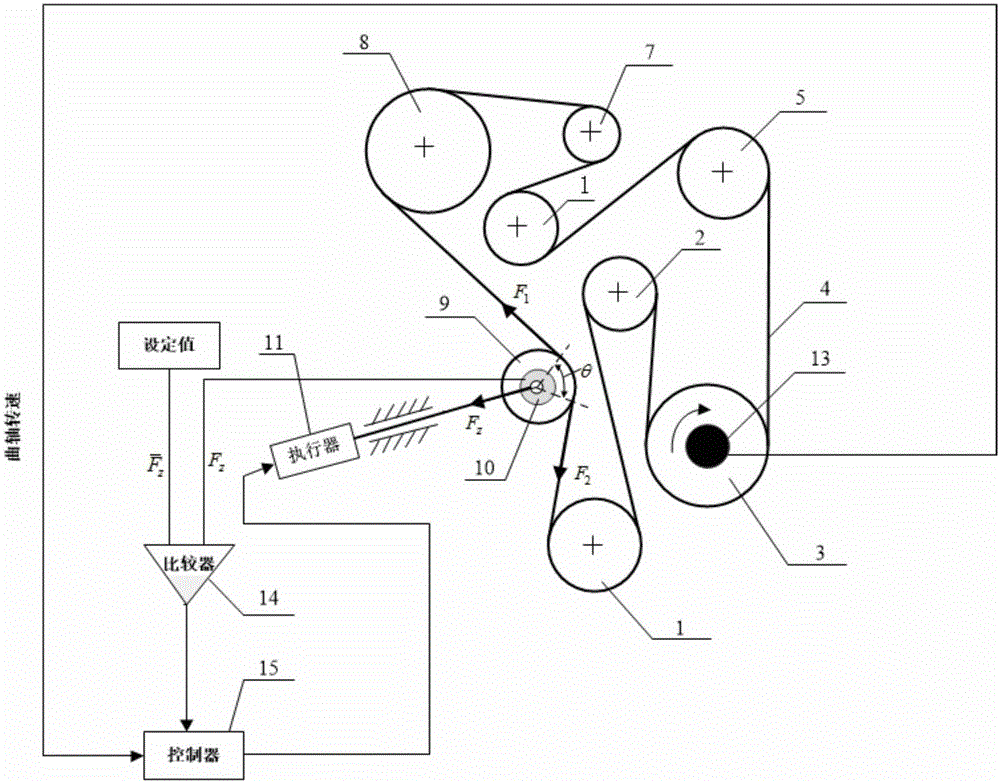

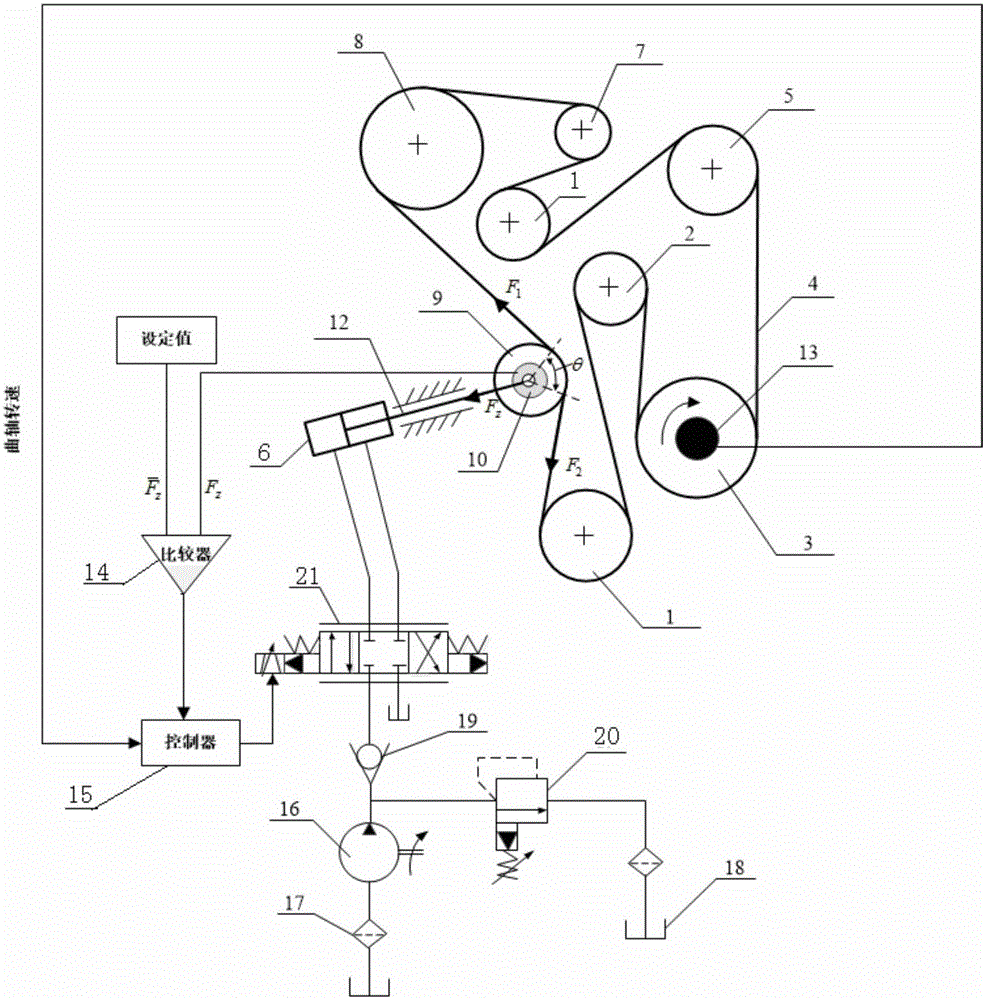

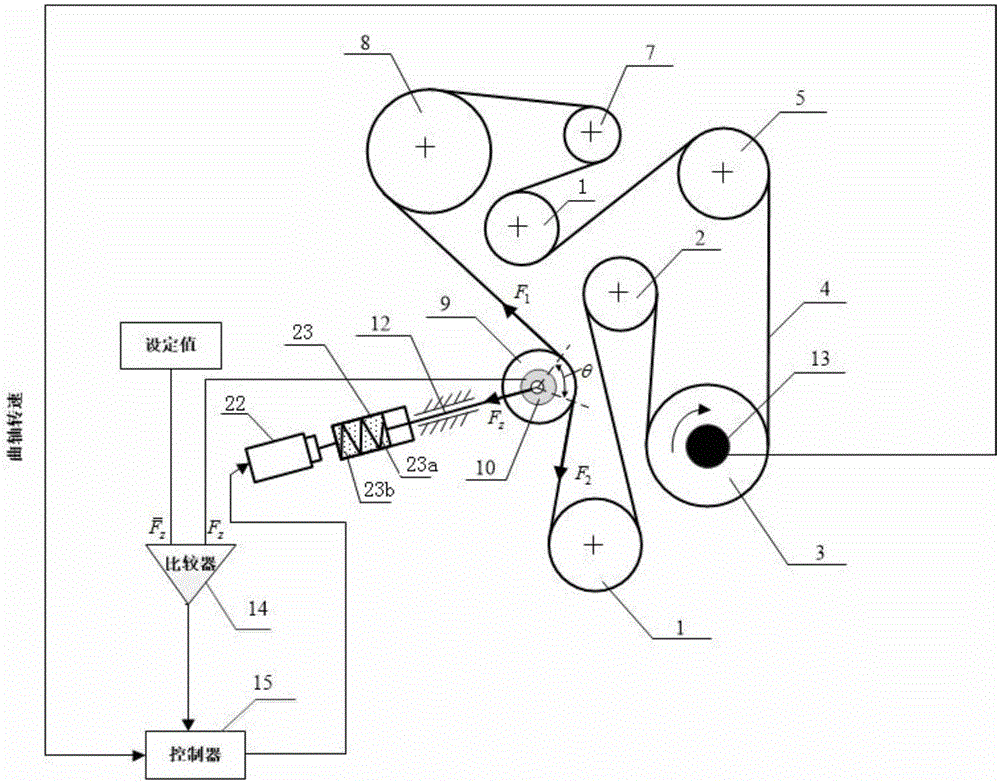

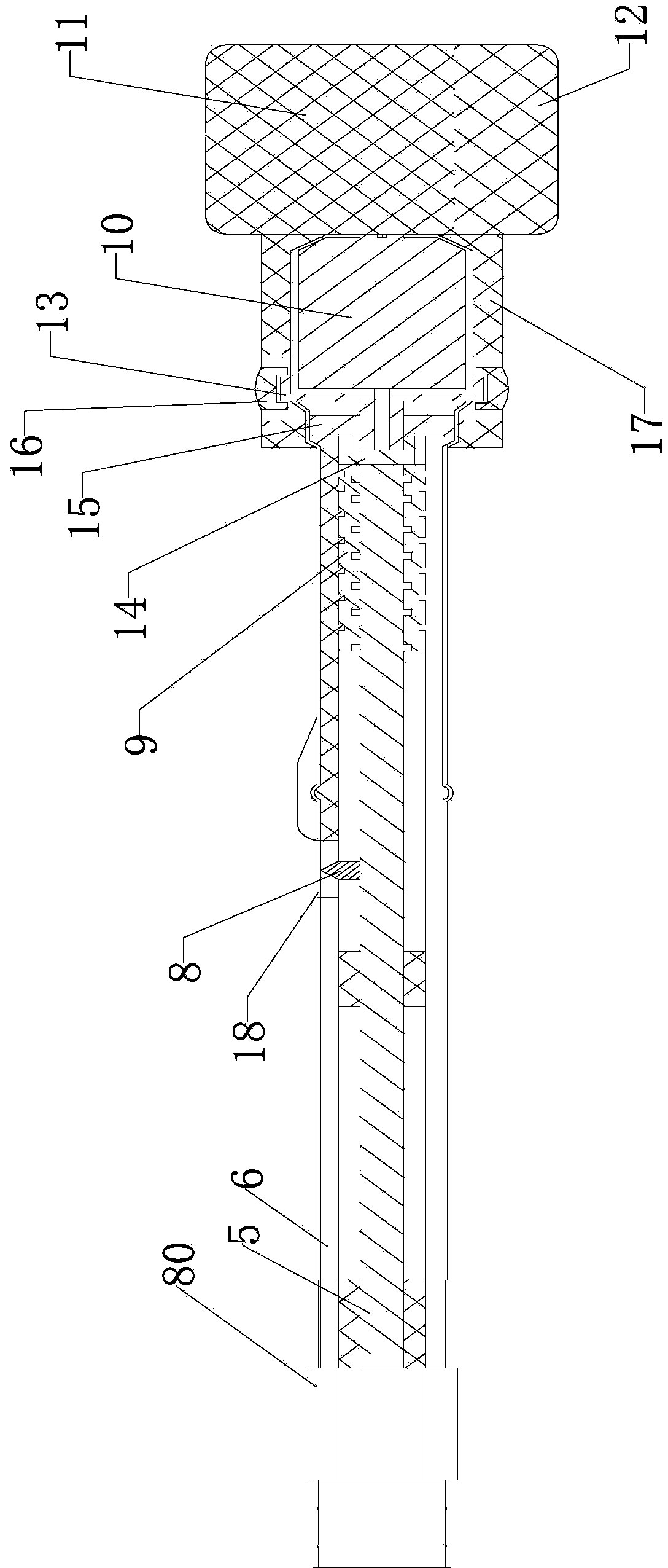

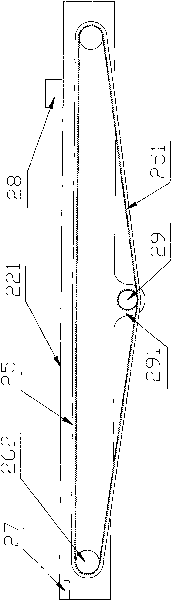

Tension adjusting device for self-adaptive engine front end accessory gear train

InactiveCN105179083AExtended service lifeGood transmission effectGearingMachines/enginesElectricityControl system

The invention discloses a tension adjusting device for a self-adaptive engine front end accessory gear train. The tension adjusting device comprises the engine front end accessory gear train and a belt tension control system. The belt tension control system comprises a piezoelectric sensor, an angle encoder, a comparator, a controller and an actuator. When the rotation speed of a crankshaft of an engine is zero, a tensioning wheel is in the preset position where the belt tension is smaller all the time; when the engine is started, the rotation speed of the crankshaft is gradually increased from zero, and the controller immediately controls the actuator to act, so that the tensioning wheel moves to the preset position where the belt tension is larger; and after the rotation speed of the crankshaft is stable, a tension value obtained by the piezoelectric sensor is compared with a preset tension value through the comparator, then the controller controls the actuator to act to adjust the position of the tensioning wheel so that the tension can be kept in a constant state. According to the tension adjusting device, the rotation speed of the crankshaft of the engine and the dynamic tension applied to the ribbed belt can be measured in real time, and the position of the tensioning wheel can be adjusted actively, so that the purpose that the tension of the belt is adjusted according to the running state of the self-adaptive engine is achieved.

Owner:CHONGQING UNIV

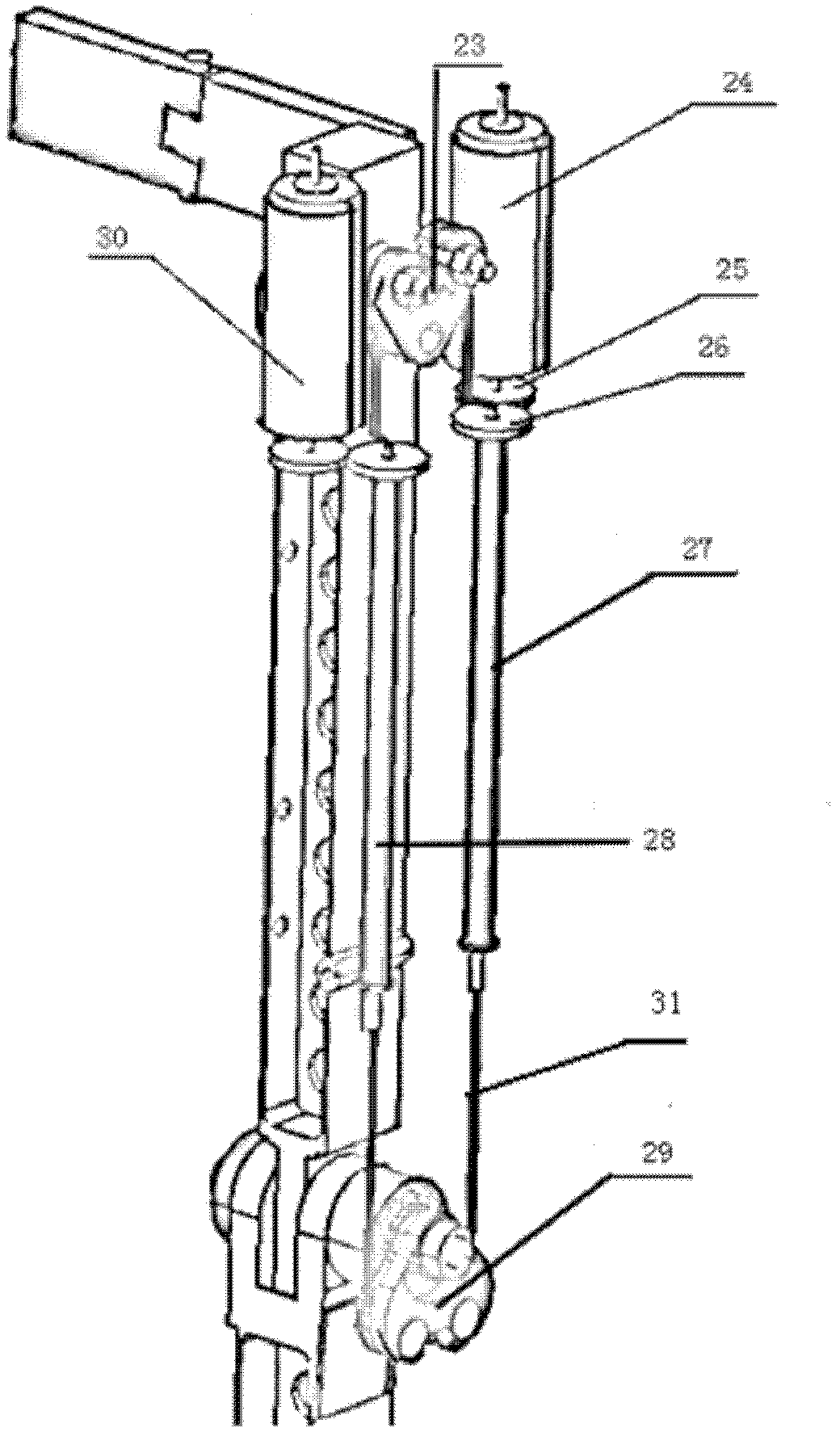

Electric stapler

ActiveCN103784175ASimple structureImprove practicalityEndoscopic cutting instrumentsSurgical staplesEngineeringActuator

The invention discloses an electric stapler comprising an osculating mechanism and a drive actuator. The drive actuator comprises a rear drive mechanism and a front actuator connected through a quick connection mechanism. The rear drive mechanism comprises a rear pipe, a rear push pipe, and a rear central rod; the rear push pipe is disposed inside the rear pipe and can be driven to screw back and forth; the rear central rod is disposed at the center of the rear push pipe and can be driven to screw back and forth. The front actuator comprises a front pipe, a front push pipe, and a front central rod; the front push pipe is disposed inside the front pipe and can be driven to screw back and forth; the front central rod is disposed inside the front push pipe and can be driven to screw back and forth. The quick connection mechanism comprises a sleeve, first grooves and ribs, and second grooves and ribs; the front and rear pipes are fixedly connected through the sleeve; the first grooves and ribs are arranged on opposing faces of the front and rear push pipes correspondingly; the second grooves and ribs are arranged on the opposing faces of the front and rear central rods correspondingly. The electric stapler is simple in structure and highly practicable, an osculating head can be changed fast, the rear of the stapler can be reused, and usage cost can be reduced.

Owner:TIANJIN RAPID PRECISION MACHINERY TECH RES & DEV

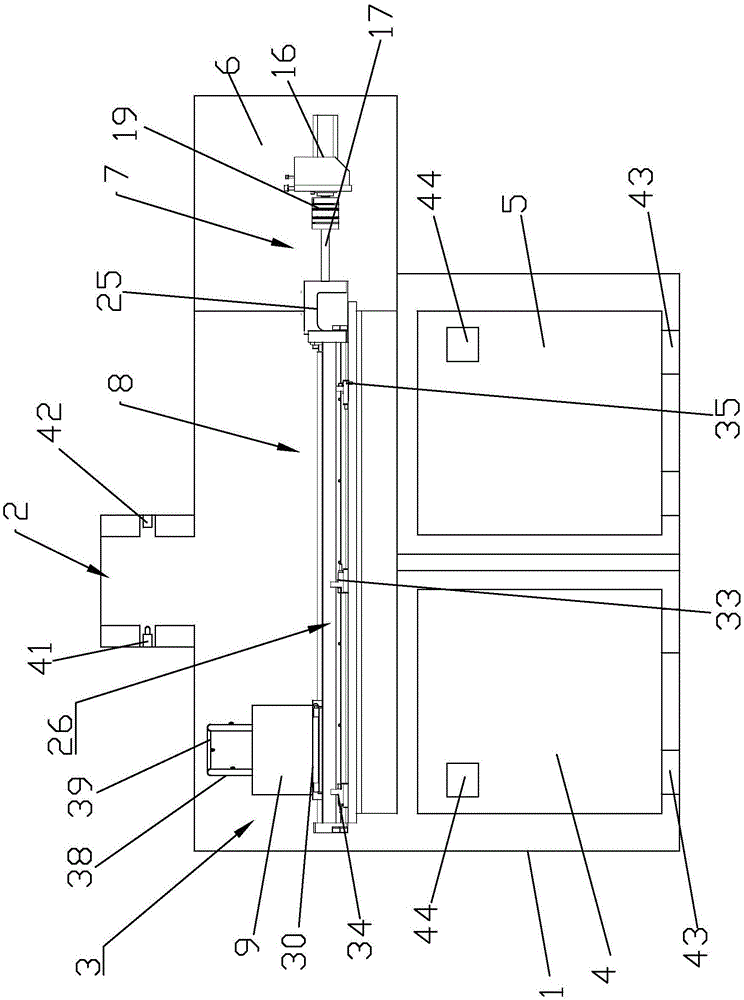

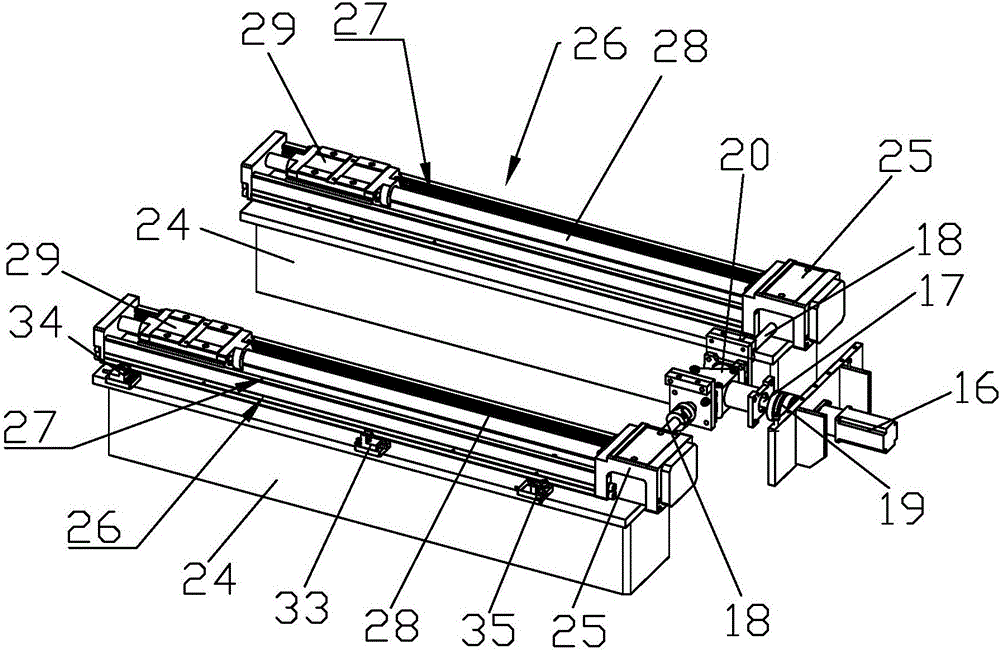

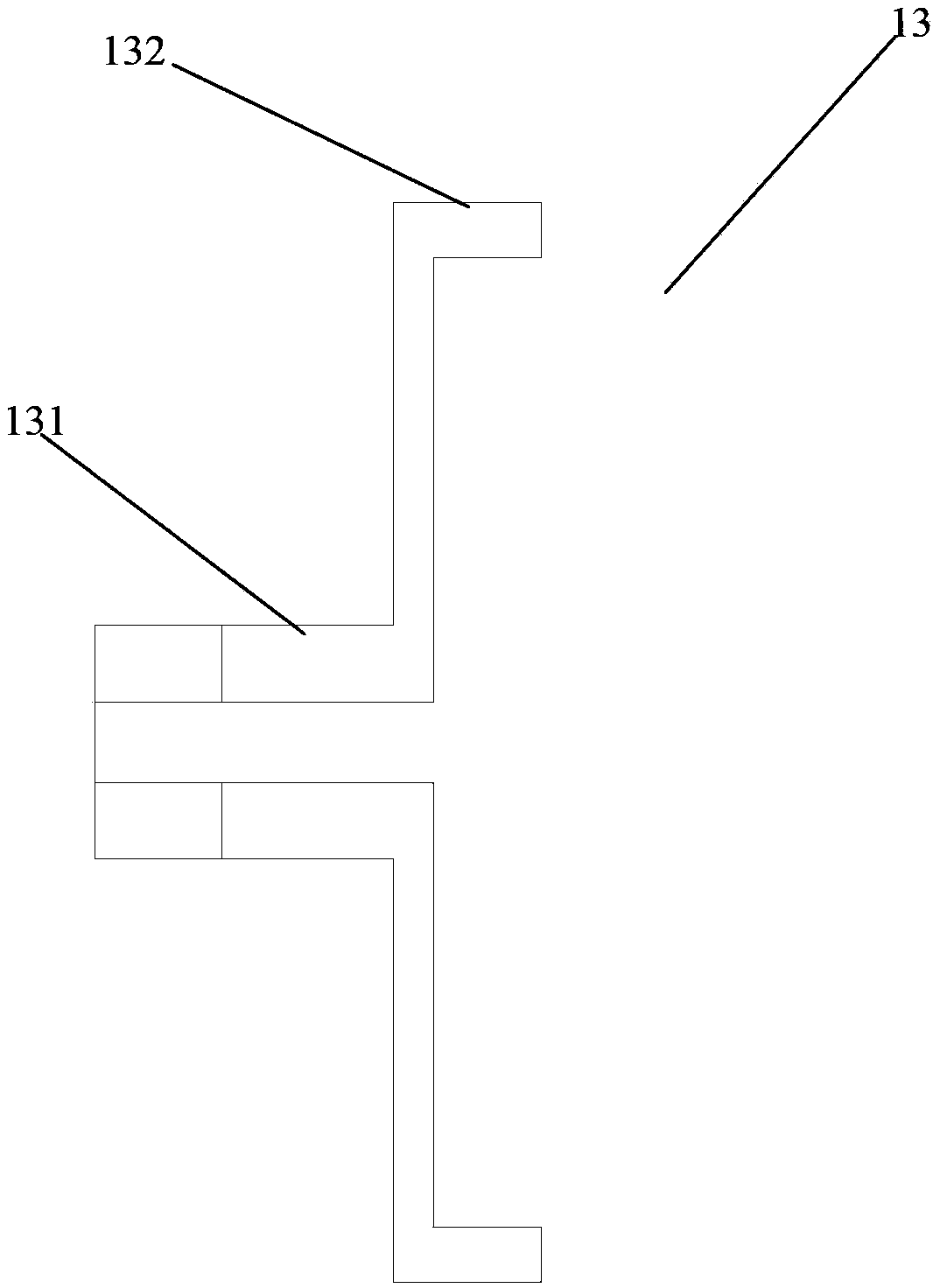

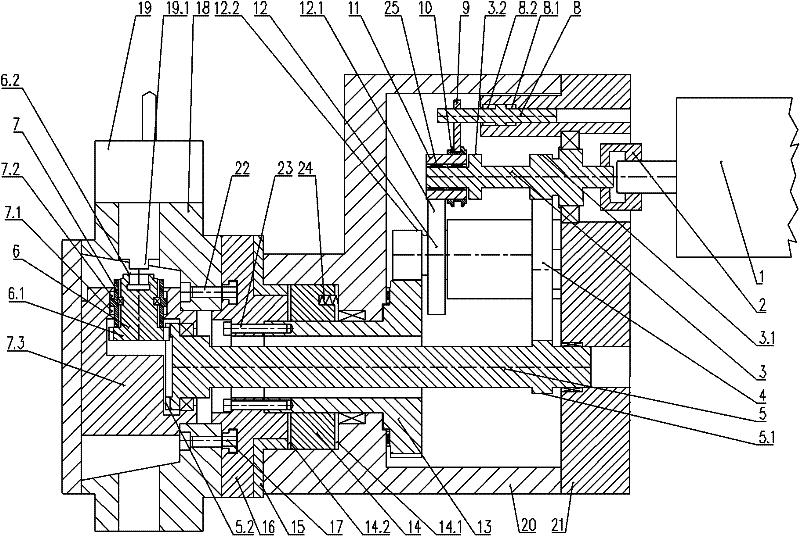

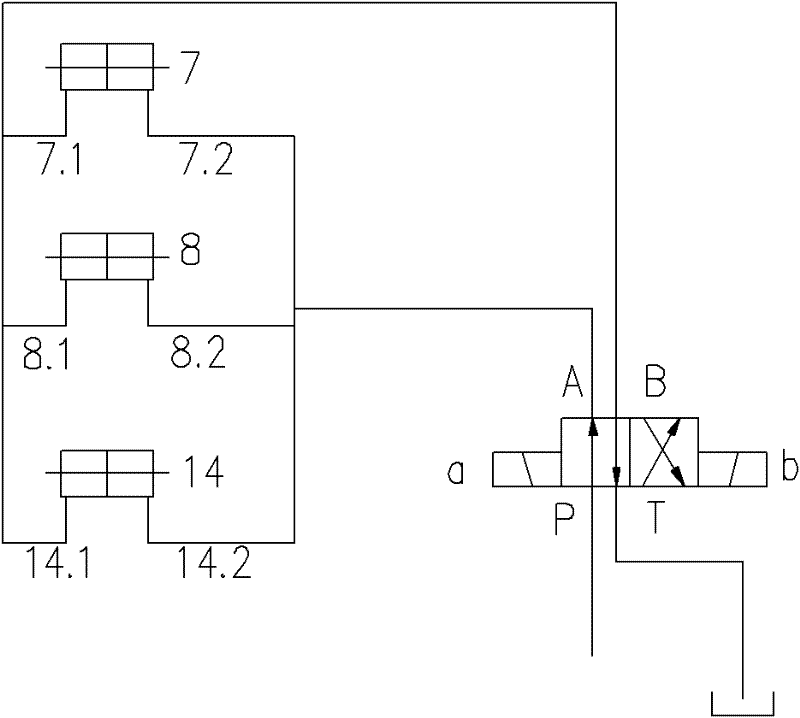

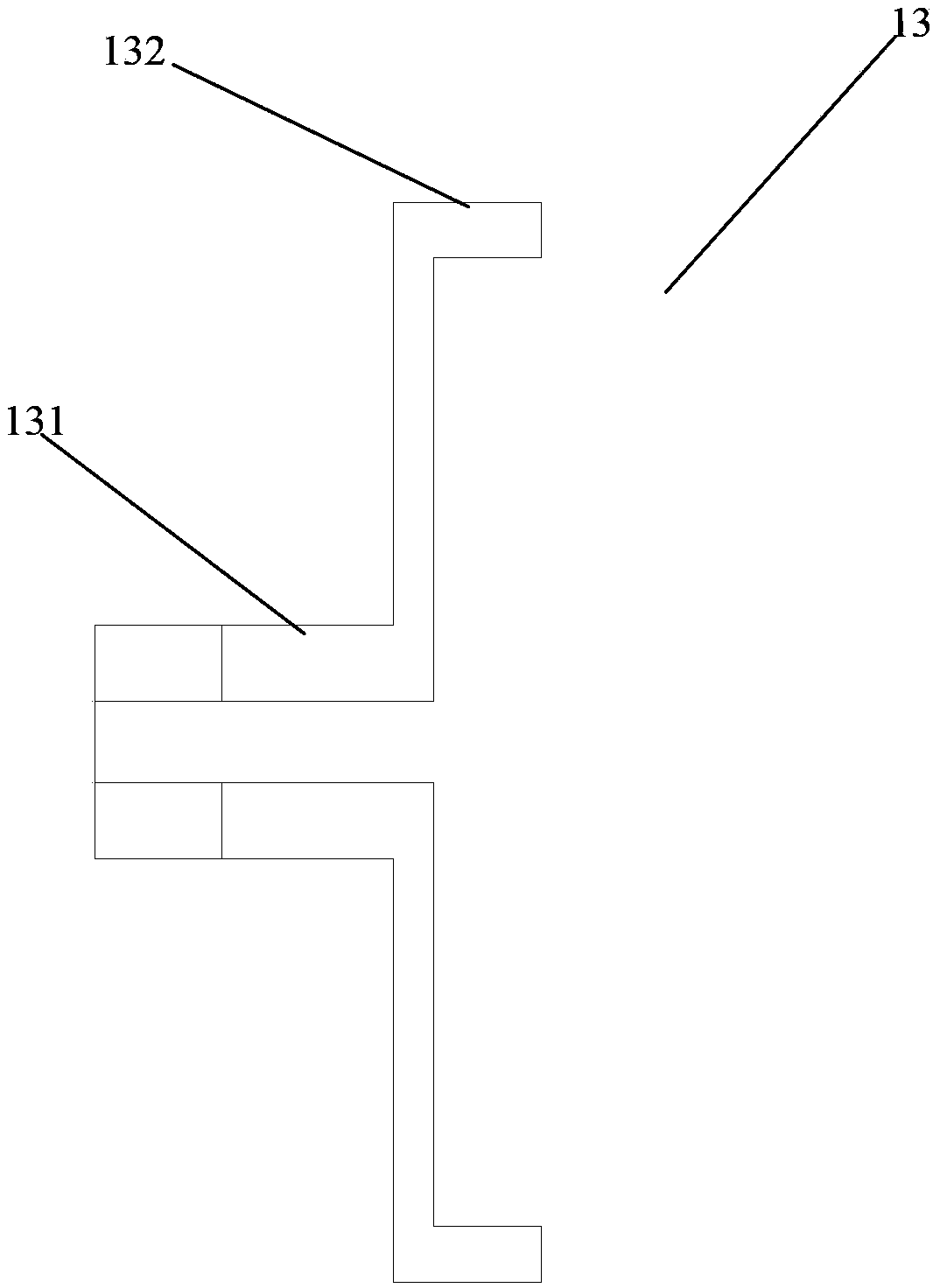

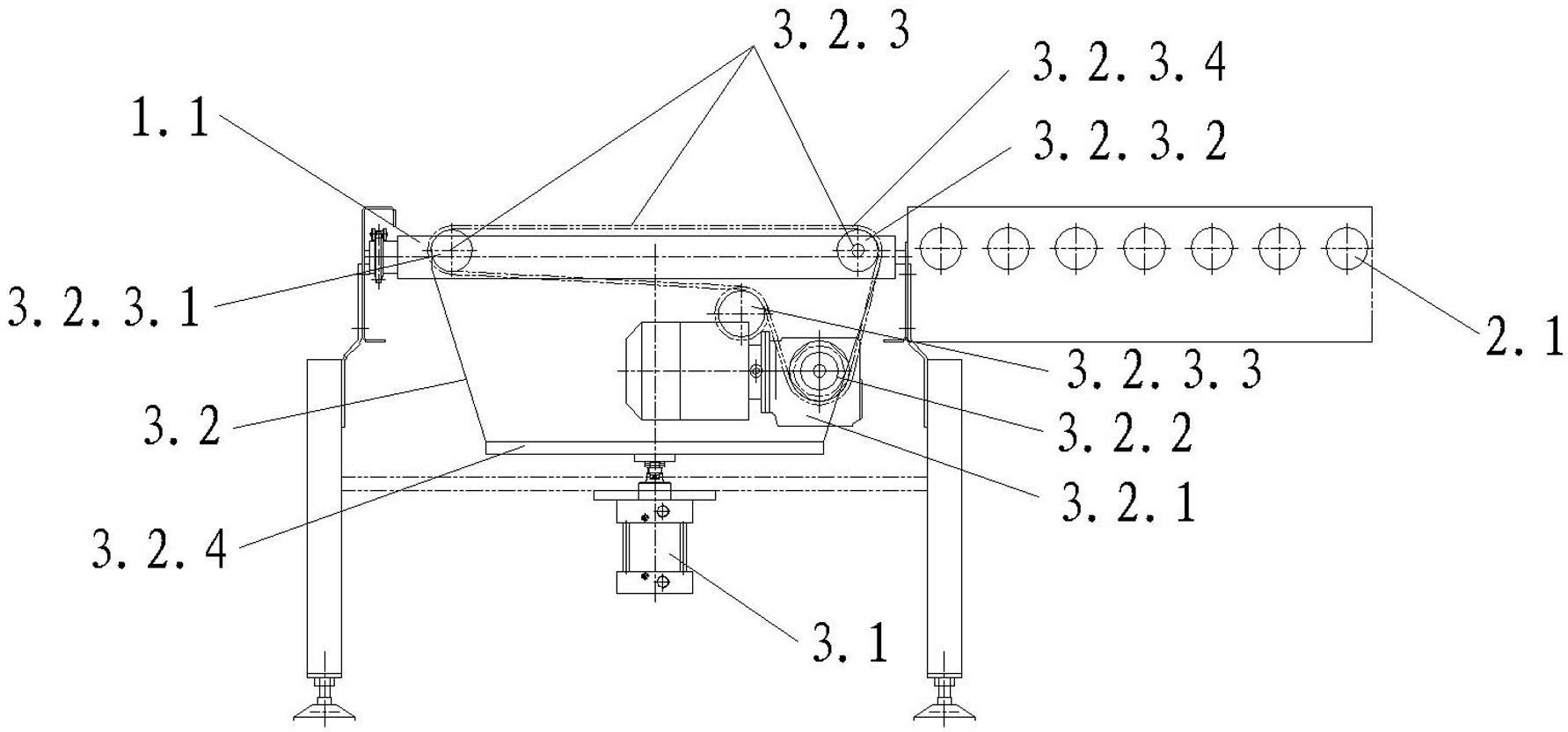

Single servo power tool rest

ActiveCN102172778AImplementation driveGood transmission effectPrecision positioning equipmentFeeding apparatusNumerical controlGear wheel

The invention relates to the field of tool rests for numerical control machines, particularly to a single servo power tool rest in which a single servo motor simultaneously drives indexing of a cutter head and drives power tools, solving the problems of transmission, power switching and the like of the tool rest. The single servo power tool rest is provided with a cutter head, a tool rest case body and a backseat cover, wherein the cutter head is used for installing a tool apron, and the backseat cover is arranged at one end of the tool rest case body; the other end of the tool rest case body is sequentially provided with a fixed fluted disc and a movable fluted disc; one ends of the fixed fluted disc and the movable fluted disc extend into the tool rest case body, the fixed fluted disc is fixed on the tool rest case body, and the outer end of the movable fluted disc which can rotate in the tool rest case body is connected with the cutter head; and a first rotating shaft, a second rotating shaft and a third rotating shaft are arranged in the tool rest case body. The indexing of the cutter head and the driving state switching of the tools are realized through the controlling of a hydraulic transmission system, the hydraulic transmission system controls the flow direction of hydraulic pressure by a reversing valve so as to realize the meshing and separation of an inner gear and a first shaft gear, the locking and detachment of locking fluted discs, and the meshing and separation of drive parts of the power tools.

Owner:SHENYANG MACHINE TOOLGRP RES & DESIGN INST CO LTD SHANGHAI BRANCH

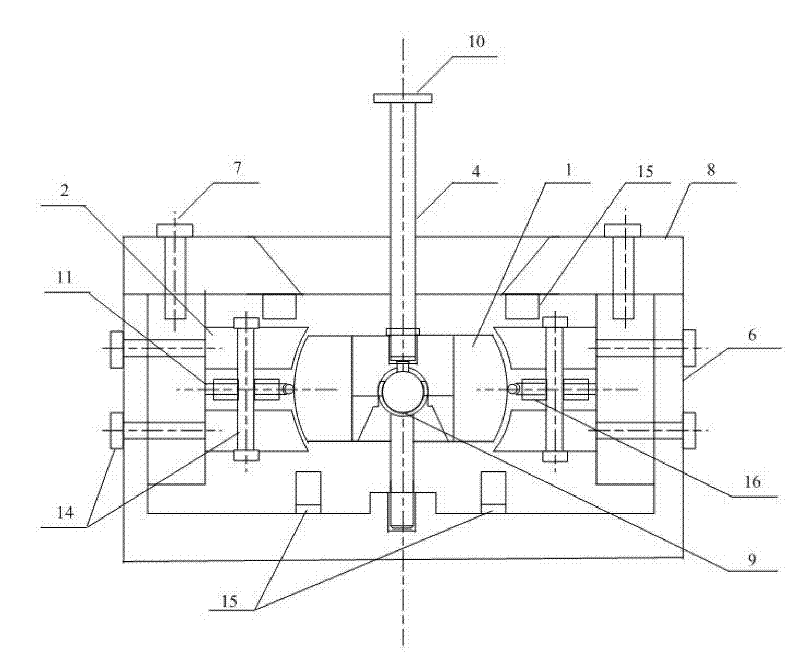

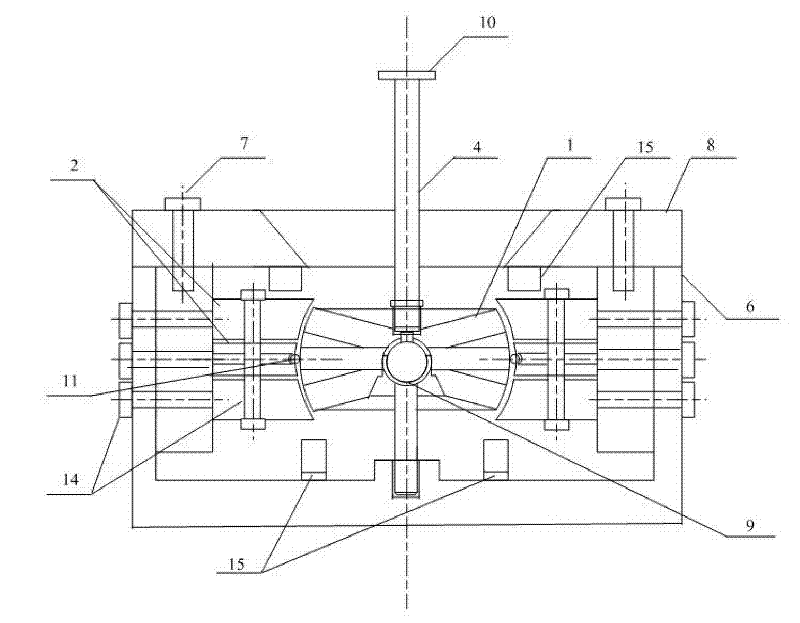

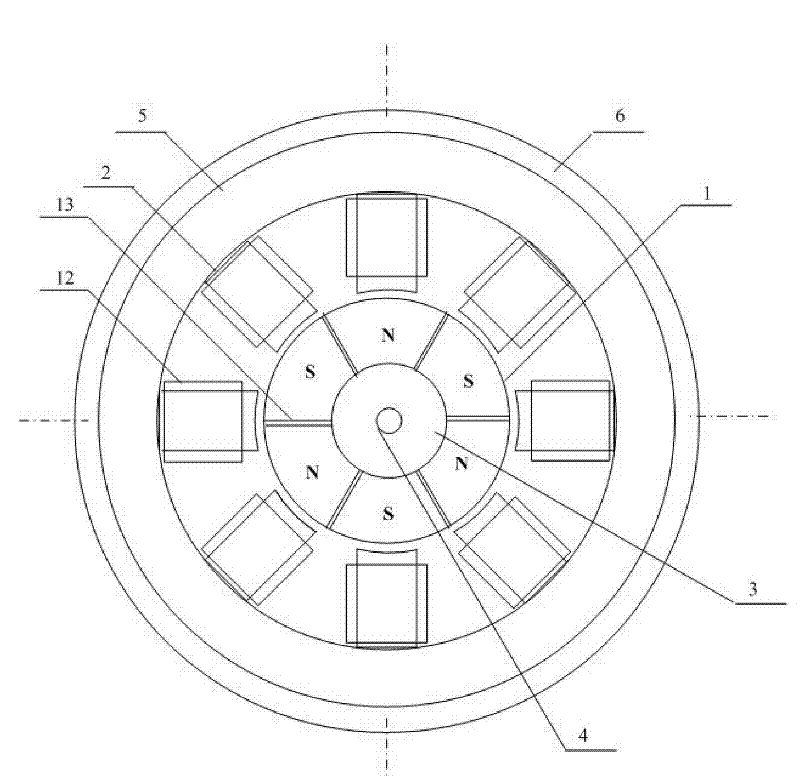

Permanent-magnet rotor deflection-type three-degree-of-freedom motion motor

ActiveCN102480253ASolve wear and tearSolve problems such as poor torque output capabilityMagnetic holding devicesPermanent magnet rotorLoop control

The invention provides a permanent-magnet rotor deflection-type three-degree-of-freedom motion motor, which relates to the technical field of permanent-magnet rotor motors. The motion motor is characterized in that magnetism isolating sheets and permanent magnets consisted of non-magnetic-conduction materials are distributed on the outer side of the inner core of the rotor. N-poles and S-poles are distributed in a staggered way and the outlines of the permanent magnets are spherical. At least two layers of magnetic pole iron cores are provided on the rotor of the periphery. Stator magnetic pole loops are provided on the magnetic pole iron cores. An output shaft is rigidly connected with center of the stator, the center of an outer housing overlaps with center of the rotor and the rotor is supported by a circular ball bearing fixed on the stator. The stator is provided with a transducer for detecting the position and the speed of the rotor so as to realize closed-loop control of the motor. The motion motor of the invention solves the problems of the three-degree-of-freedom motion motor in the prior art, including heavy abrasion, poor torque output capacity and the like. The motion motor of the invention is relatively simple in structure, easy to control, high in mechanical integration level, small in abrasion, strong in torque output capacity, and excellent in static and dynamic performance. In addition, the motion motor can realize suspension control.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

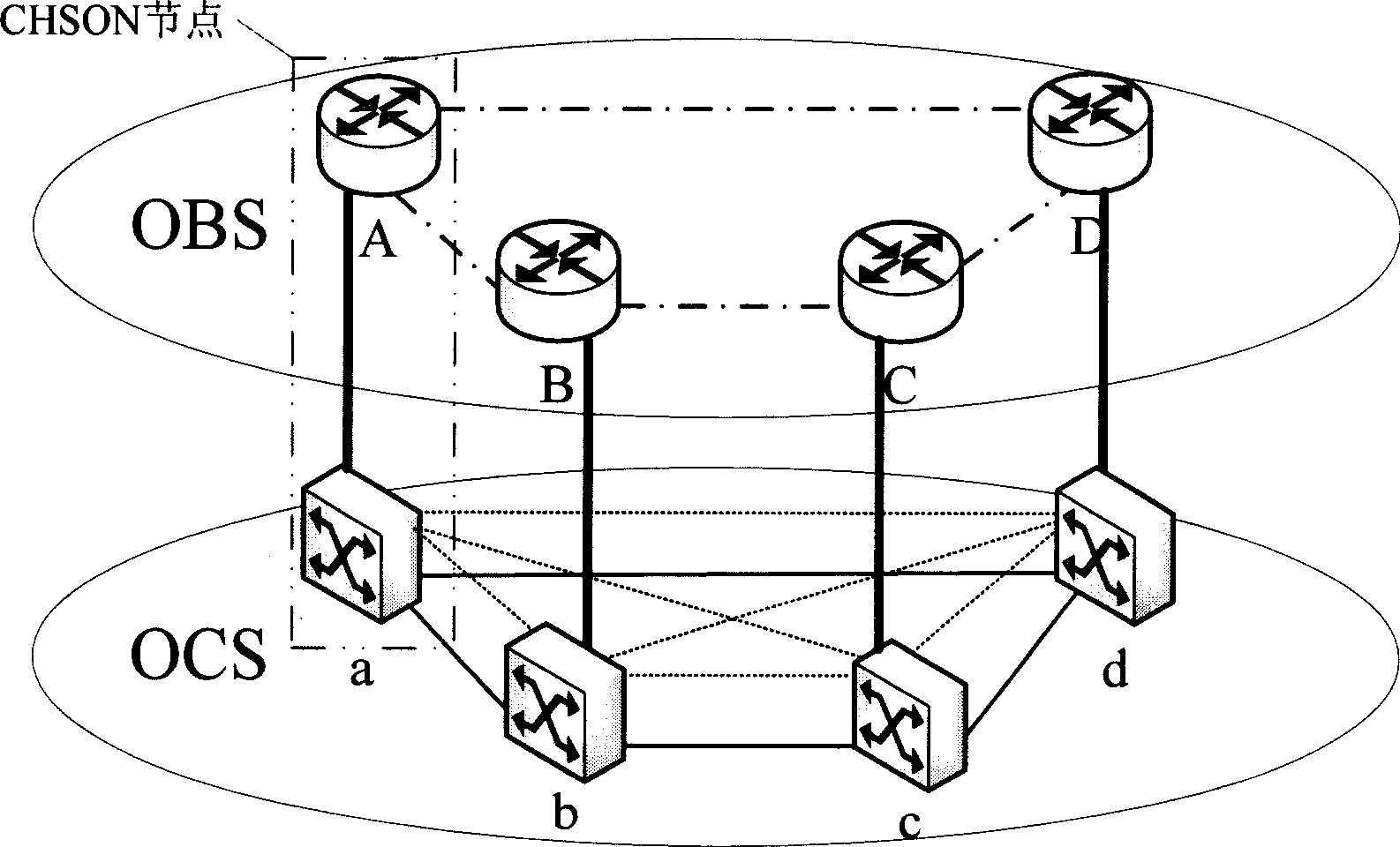

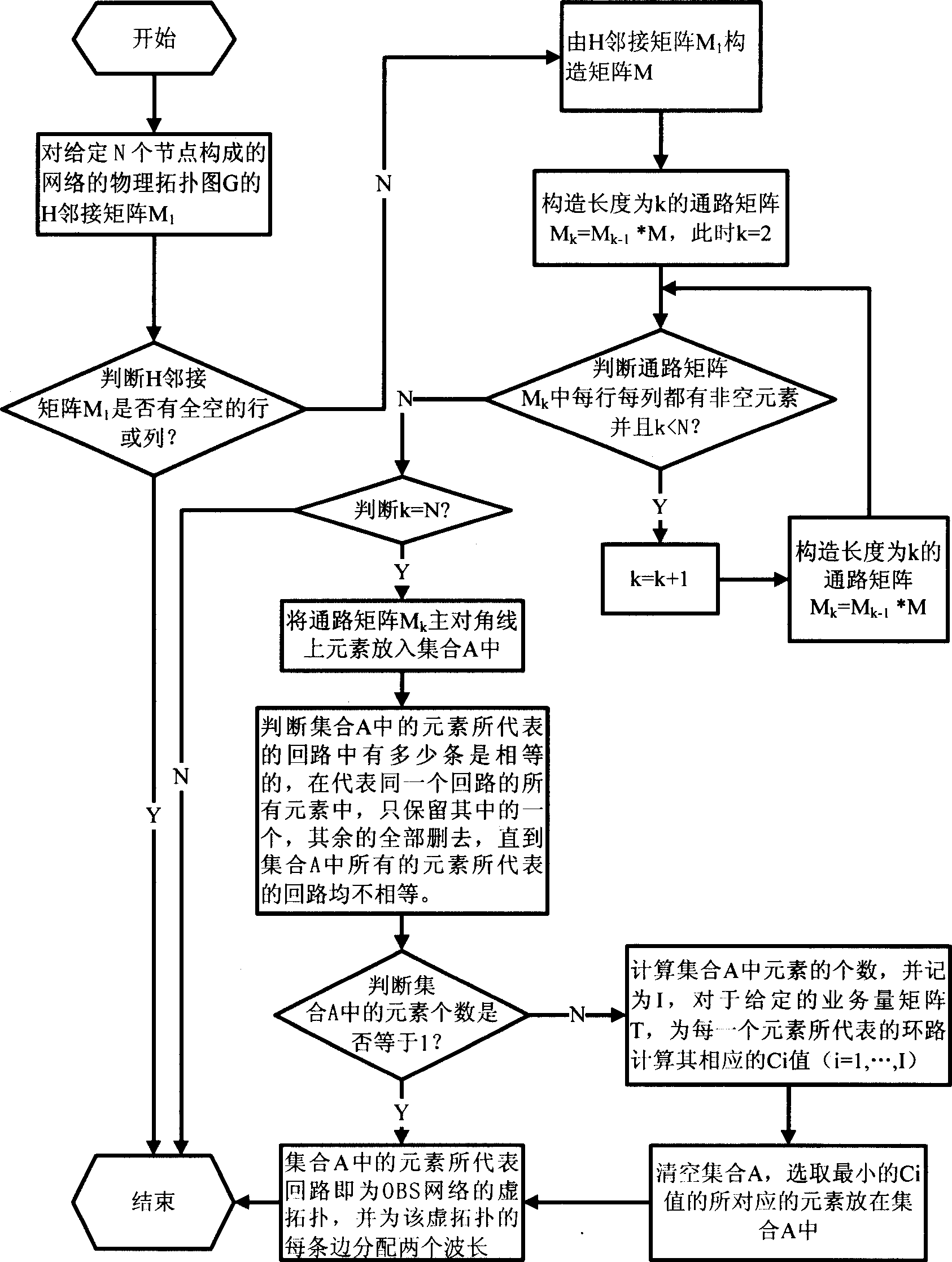

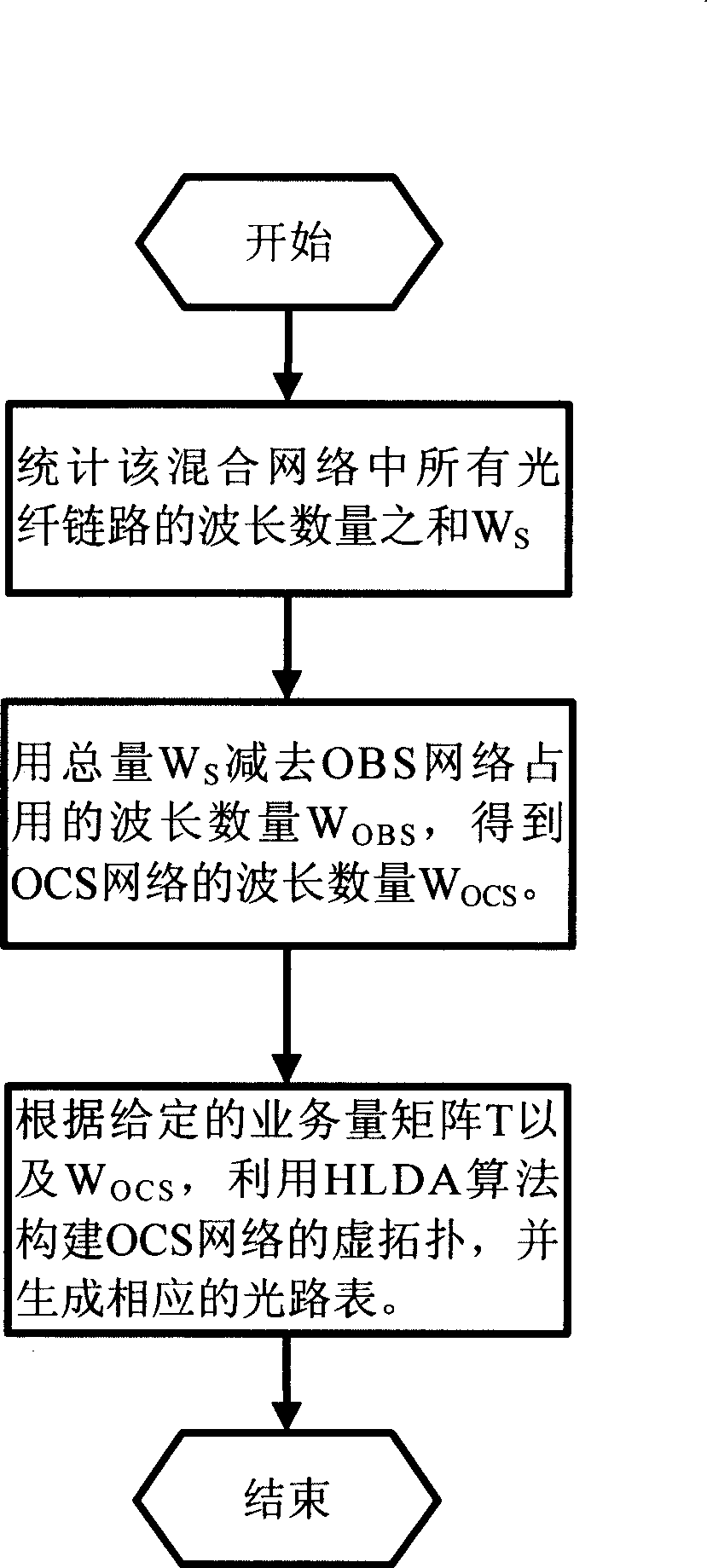

Construction method for hybrid switching optical network based on loop circuit

InactiveCN101370312AMeeting Communication NeedsSimple methodMultiplex system selection arrangementsRing-type electromagnetic networksMostly TrueStructure of Management Information

The invention provides a mixed ASTN construction method, which effectively combines OCS and OBS two exchange modesby constructing network to form a ring topological structure OBS network and OCS network combination, making majority service to reach target node via one hop. The method satisfies communication need of network of most conditions. When network service changes in a small range, service Optical path can not bear will continue to transmit along ring topology in OBS exchange style. The inventive networking technology is more simple and effective, network performance worsening degree is small arising from network dynamic change, network operation is more stable and possesses relatively high communications capability; furthermore, network algorithm realization is less difficult and practical.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

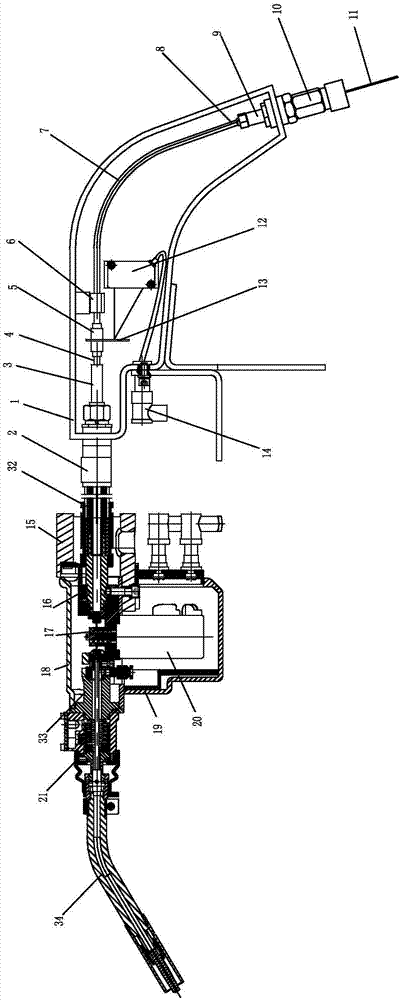

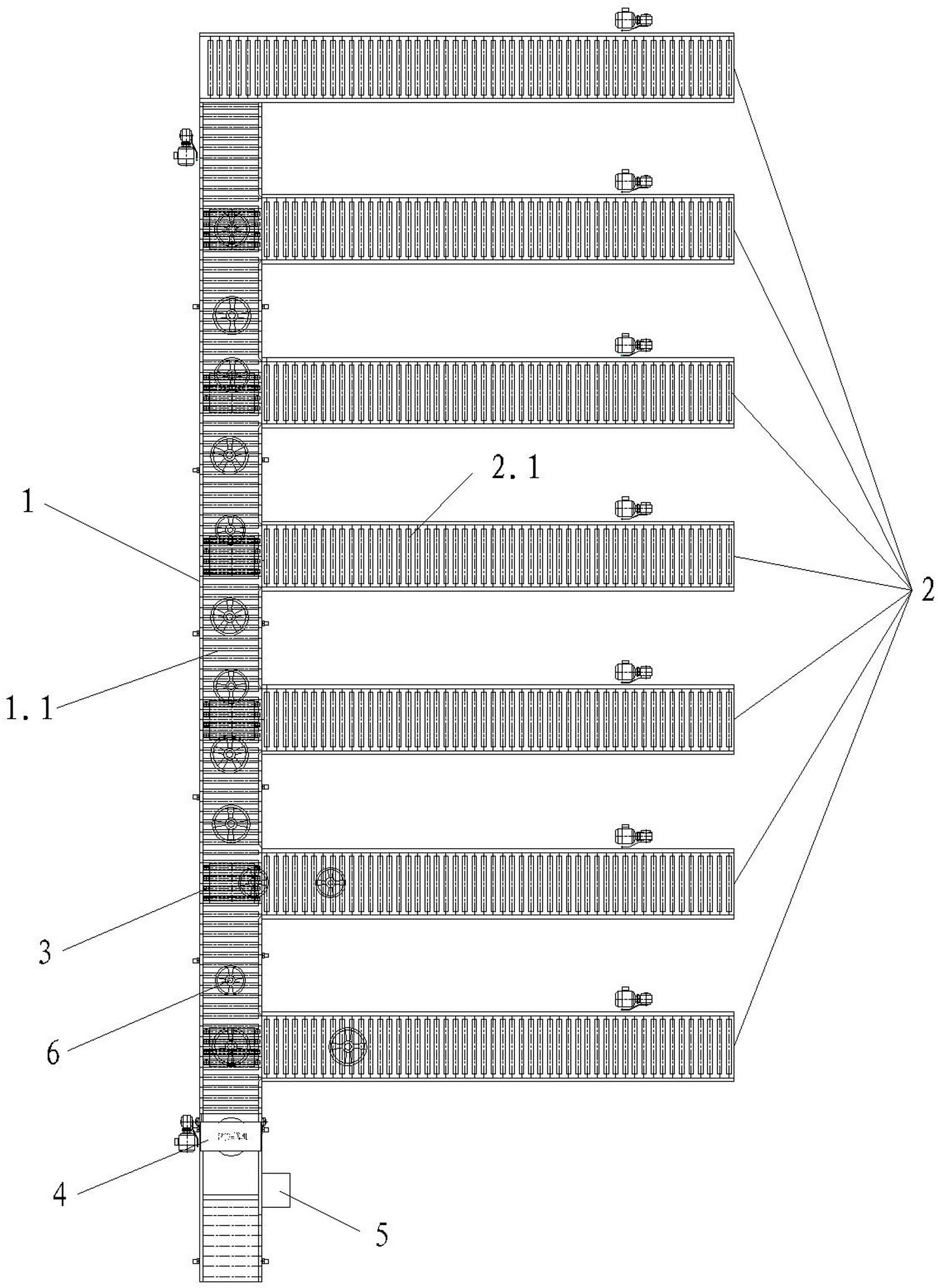

Servo wire feeding device for automatic welding robot

ActiveCN107160010AReduce impactEasy to useWelding/cutting auxillary devicesAuxillary welding devicesWire wheelEngineering

The invention relates to the technical field of welding robots and provides a servo wire feeding device for an automatic welding robot. The servo wire feeding device has a good insulation effect and has functions of dust prevention and chip prevention. The servo wire feeding device comprises a servo wire feeding welding gun body and a linear buffer connected with the tail end of the servo wire feeding welding gun body through a conducting wire cable. The servo wire feeding welding gun body comprises a welding gun shell, a gun nozzle assembly mounted on the front side of the welding gun shell, servo wire feeding motors, wire feeding wheels and a bottom flange, the servo wire feeding motors and the wire feeding wheels are installed in the welding gun shell through a sky beam and a wire drawing base, and the bottom flange is installed on the rear side of the welding gun shell; insulation structures are arranged between the servo wire feeding motors and the wire drawing base, between the wire feeding wheels and the servo wire feeding motors, between the sky beam and the bottom flange, between the wire drawing base and a front flange support, and between a lower housing and the wire drawing base; key groove connecting structures are arranged between the servo wire feeding motors and a wire wheel locating sleeve, and between the wire wheel locating sleeve and the wire feeding wheels; dust prevention structures are arranged between the wire feeding wheels and the wire feeding motors, between the sky beam and the bottom flange, and between the wire feeding motors and the wire drawing base.

Owner:HANGZHOU KAIERDA ROBOT TECH CO LTD

Novel connecting-rod type mechanical arm

InactiveCN105014661AReduce layout requirementsBig work scheduleProgramme-controlled manipulatorMetal-working feeding devicesPunch pressRobot hand

The invention discloses a novel connecting-rod type mechanical arm. The mechanical arm comprises a rack, a horizontal moving assembly arranged on the rack, a lifting assembly and a material taking assembly. The horizontal moving assembly comprises a first horizontal motor, a first horizontal carrying plate, a second horizontal motor and a second horizontal carrying plate, wherein the second horizontal carrying plate is connected with the first horizontal carrying plate in a sliding mode, the first horizontal motor drives the first horizontal carrying plate to move horizontally, and the second horizontal motor drives the second horizontal carrying plate to move horizontally. The lifting assembly is arranged on the second horizontal carrying plate and comprises a lifting motor and a lifting carrying plate connected with the lifting motor in a transmission mode, and the lifting motor drives the lifting carrying plate to ascend and descend. The material taking assembly comprises a mechanical arm body arranged on the lifting carrying plate and at least one suction foot arranged on the mechanical arm body, wherein each suction foot is provided with a vacuum sucker or an electromagnet assembly. The novel connecting-rod type mechanical arm is simple in structure, the cost is low and the requirement for arrangement of a die and a punch press is low and capable of effectively improving the integral production efficiency of products and lowering production cost.

Owner:YIHE PRECISION IND SUZHOU

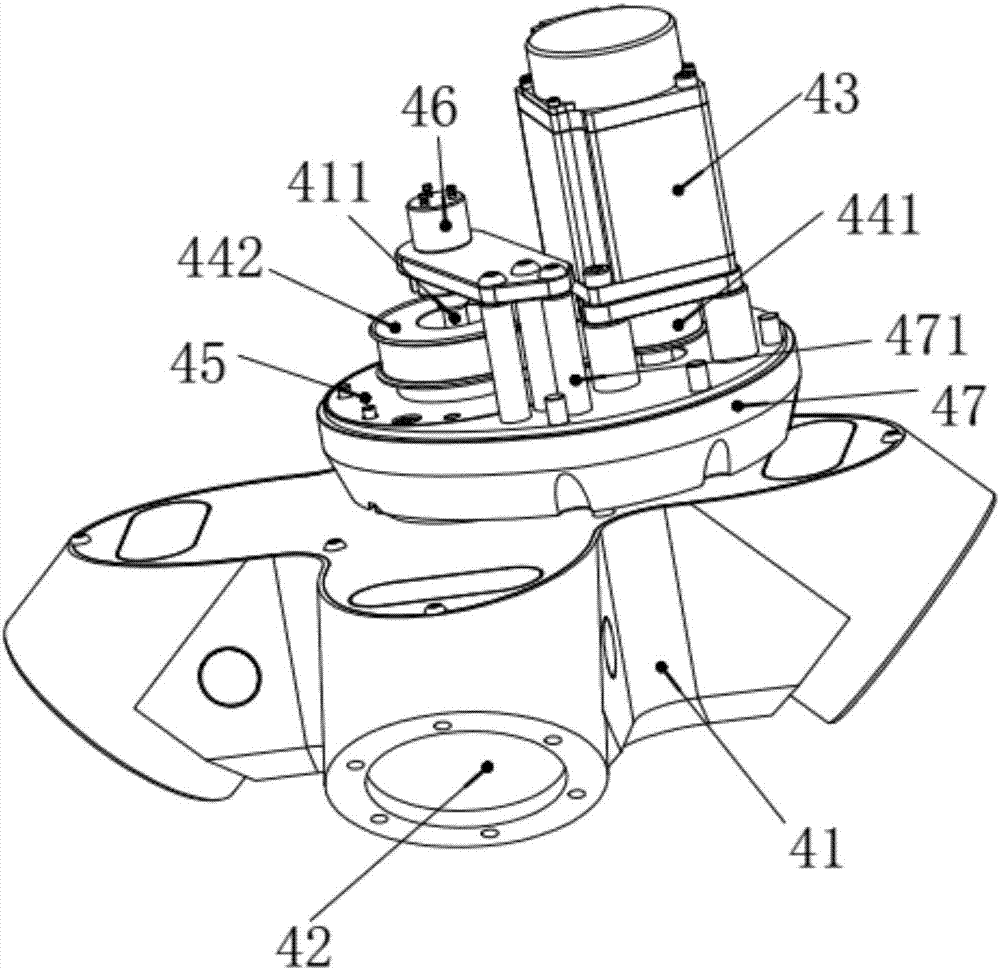

Manipulator used for disassembling and assembling radioactive source standard liquid target

PendingCN107972054ARapid responseImprove work efficiencyGripping headsMetal working apparatusRadiation injuryManipulator

The invention belongs to the technical field of industrial robots and in particular relates to a manipulator used for disassembling and assembling a radioactive source standard liquid target. The manipulator used for disassembling and assembling the radioactive source standard liquid target comprises a rotating mechanism connected with a robot main body, wherein a rotating part is arranged on therotating mechanism, a plurality of rotating heads are molded on the rotating part, and a screw and bolt disassembling manipulator, a workpiece clamping manipulator, a sealing ring drawing manipulatorand a sucking disc manipulator are respectively arranged on the rotating heads; and a control mechanism, a transmission mechanism, a speed reducing mechanism and an angle sensor are arranged inside the rotating mechanism, and the angle sensor is connected with the rotating part. The manipulator provided by the invention is used for disassembling and assembling a structure of the radioactive sourcestandard liquid target, so as to replace a radioactive source inside, the whole course can be automatically carried out by a robot, manual intervention operation can be carried out at any time, reaction is sensitive, working efficiency is high, and a person does not need to replace the radioactive source in person, so that the problem that radiation injury is caused when the radioactive source ismanually replaced is solved.

Owner:浙江梵煜电子科技有限公司

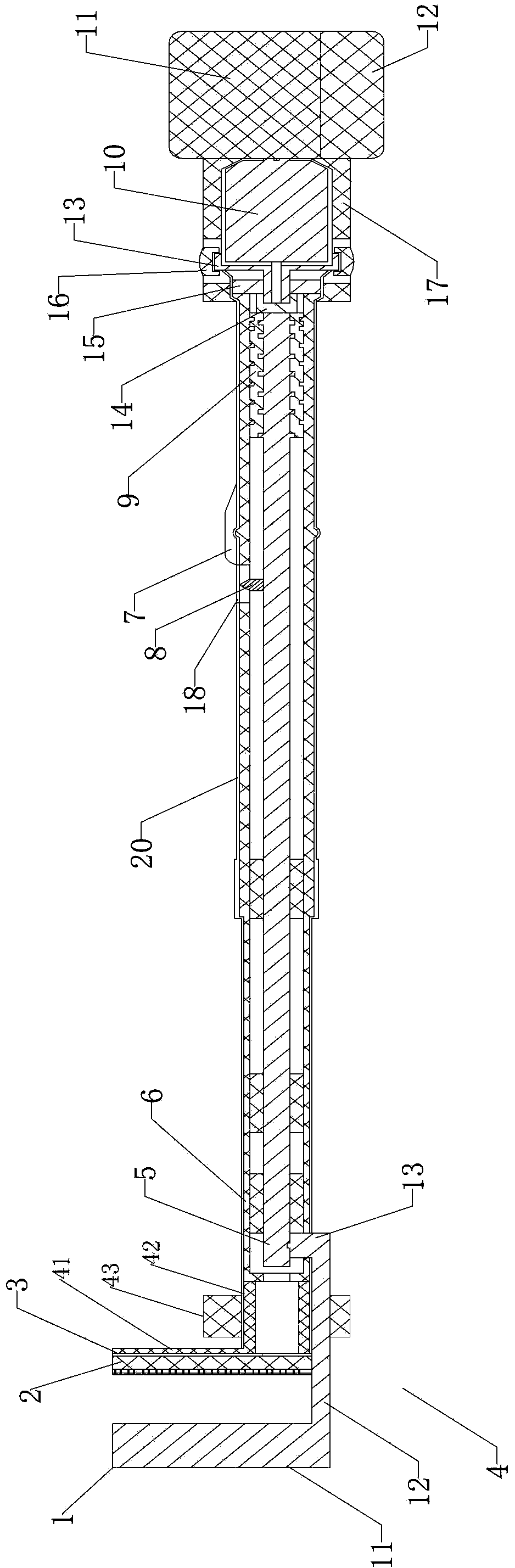

Electric linear anastomat

ActiveCN103829982ASimple structureImprove practicalityIncision instrumentsSurgical staplesEngineeringShape Nail

The invention discloses an electric linear anastomat which comprises an osculating mechanism and a driving and executing mechanism, wherein the driving and executing mechanism comprises a tube body, a push tube which is arranged inside the tube body and capable of being driven to precess back and forth, and a center rod which is arranged at the center of the push tube and capable of being driven to precess back and forth, and the osculating mechanism comprises an L-shaped nail abutting base which is in transmission connection with the center rod and capable of moving back and forth only, and an L-shaped nail pushing component which is in transmission connection with the push tube and capable of moving back and forth only. The electric linear anastomat is simple in structure, highly practical, capable of achieving adjustment and percussion by means of one motor and reducing machining cost, convenient to control, and capable of improving the using effect. Due to the fact that percussion is achieved with the motor, the difference caused by manual percussion is avoided. Due to the additional arrangement of a feedback window, visual feedback is provided, the success rate is increased, and the operation effect is improved.

Owner:TIANJIN RAPID PRECISION MACHINERY TECH RES & DEV

Belt driving device of online detection device

InactiveCN101758995AAvoid defectsGood transmission effectConveyorsMaterial analysis by optical meansSpecial designEngineering

Owner:苏州德天光学技术有限公司

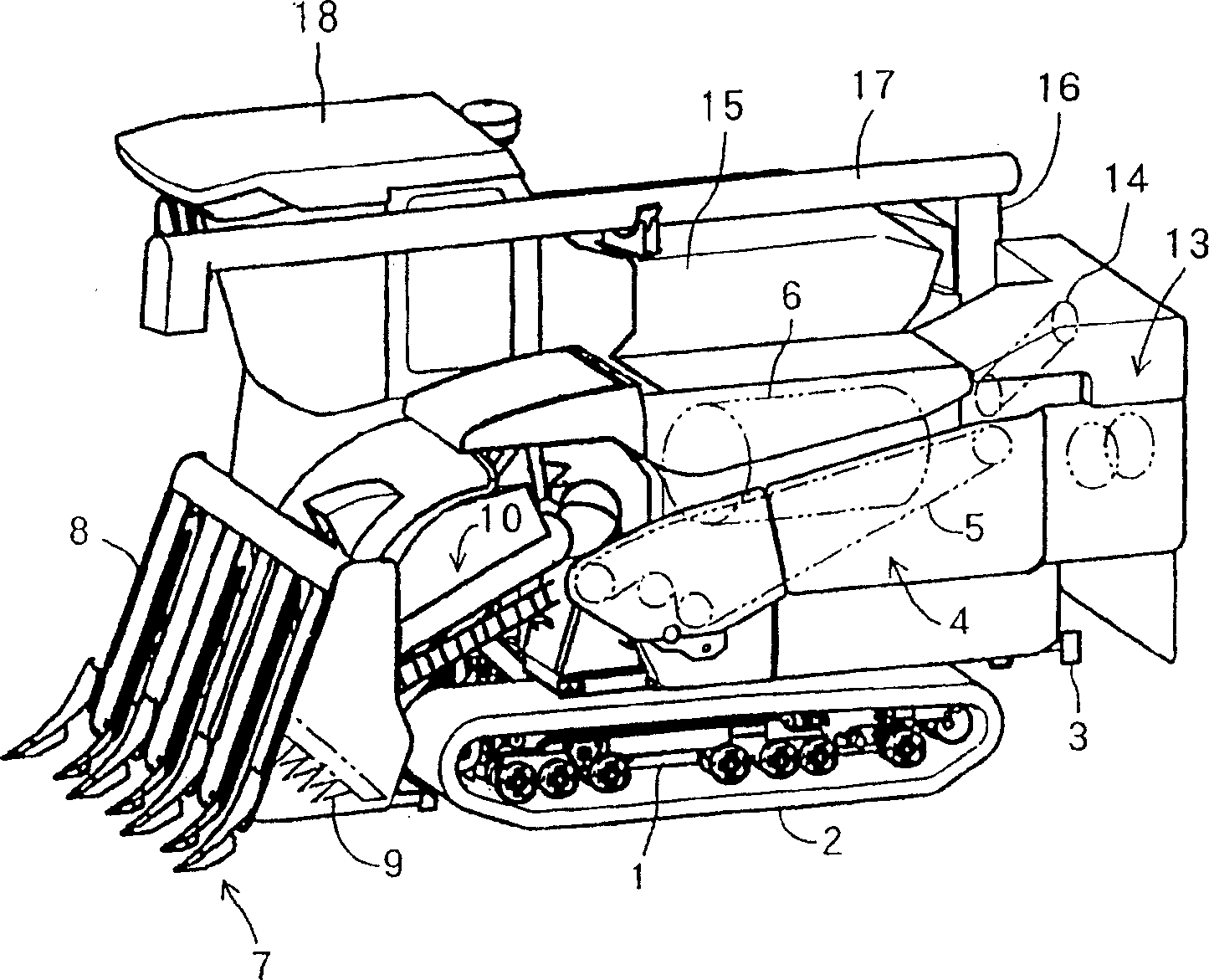

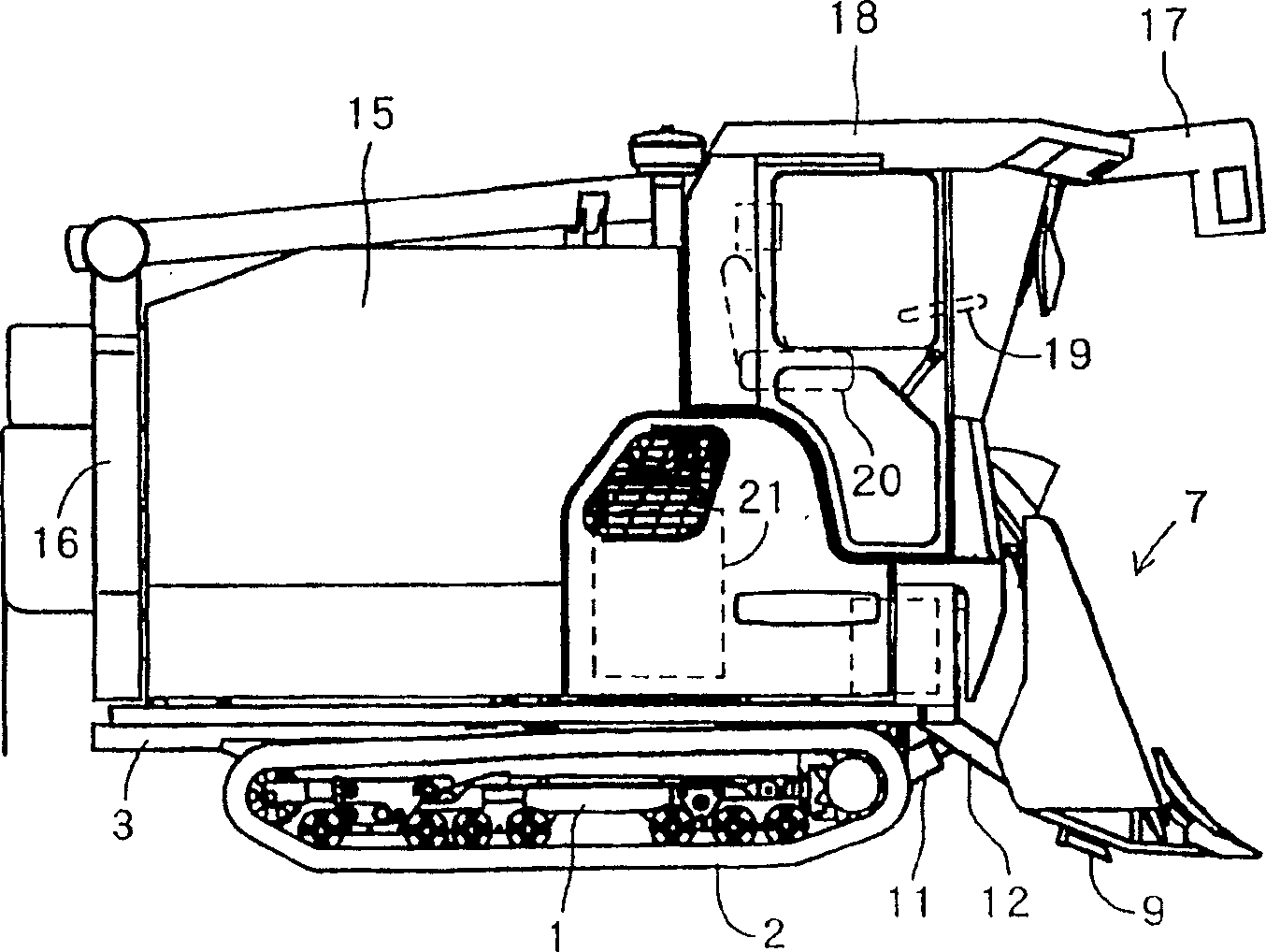

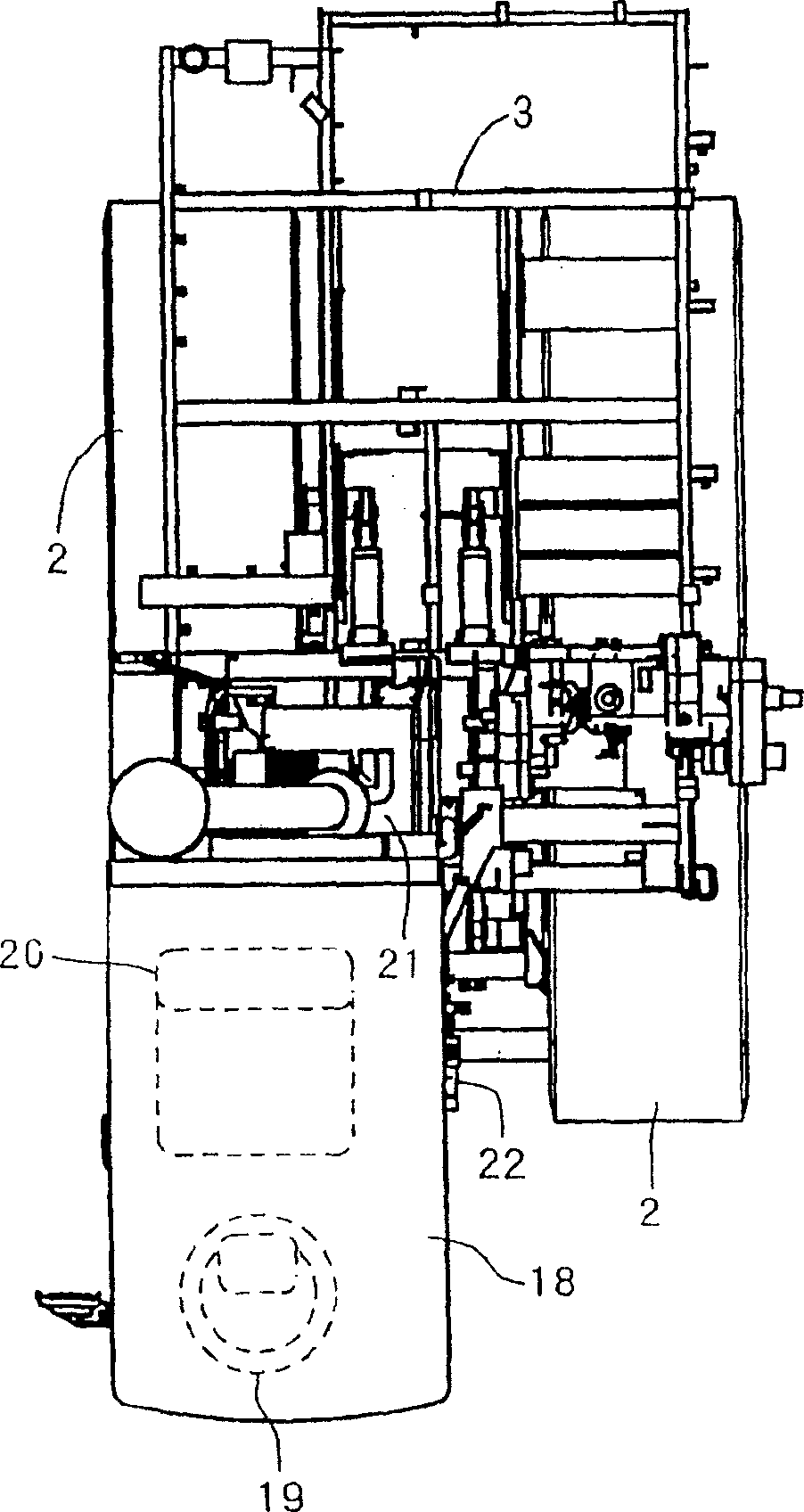

Combine

InactiveCN1668184AReduced power transmission efficiencyReduce drive speedMowersGearing controlEngineeringTransmission loss

A combine for driving a traveling section (2) by transmitting the power of an engine (21) to a transmission case (22) provided with a traveling speed change mechanism (40), characterized in that the power of the engine (21) is transmitted to a counter case (25) in order to drive a threshing section (4) by a substantially constant rotational output and the speed change output from the traveling speed change mechanism (40) is transmitted to the counter case (25) in order to drive a reaping section (7) at a speed synchronous with the vehicle speed, and the counter case (25) is arranged such that the reaping section (7) is driven at a substantially constant speed by a substantially constant rotational output from the counter case (25). The counter case (25) for driving the threshing section (4) at a constant speed can also drive the reaping section (7) at a speed synchronous with the vehicle speed or at a substantially constant speed, and the reaping section (7) can be driven at a constant speed utilizing a part of the driving system of the threshing section (4), resulting in simplification of driving structure of the reaping section (7), or the like and reduction of transmission loss.

Owner:YANMAR CO LTD

Stable printing paste robot and control method thereof

ActiveCN108071237AFunction increaseHigh printing efficiencyBuilding material handlingManipulatorBrickMechanical equipment

The invention discloses a stable printing paste robot and a control method thereof, and relates to the technical field of mechanical equipment. The stable printing paste robot comprises a turnover mechanism, a transport mechanism, a sizing mechanism, a lifting mechanism, and a support frame; the turnover mechanism is arranged in the lower part of the interior of the support frame; the turnover mechanism is used for turning over wall tiles; the transport mechanism is arranged in the lower part of the interior of the support frame; the transport mechanism comprises two conveying units; the conveying units are separately arranged at both sides of the turnover mechanism and used for conveying the wall bricks after printing paste; the sizing mechanism is arranged in the support and is located above the turnover mechanism; the lifting mechanism is vertically arranged in the support frame; and the lifting mechanism can realize the lifting of the sizing mechanism in the vertical direction. Thestable printing paste robot can ensure that the bottom surface height of the wall tiles after turning over is the same every time and can be applied to printing paste process of wall tiles with different specifications.

Owner:HUAWAY IOT TECH

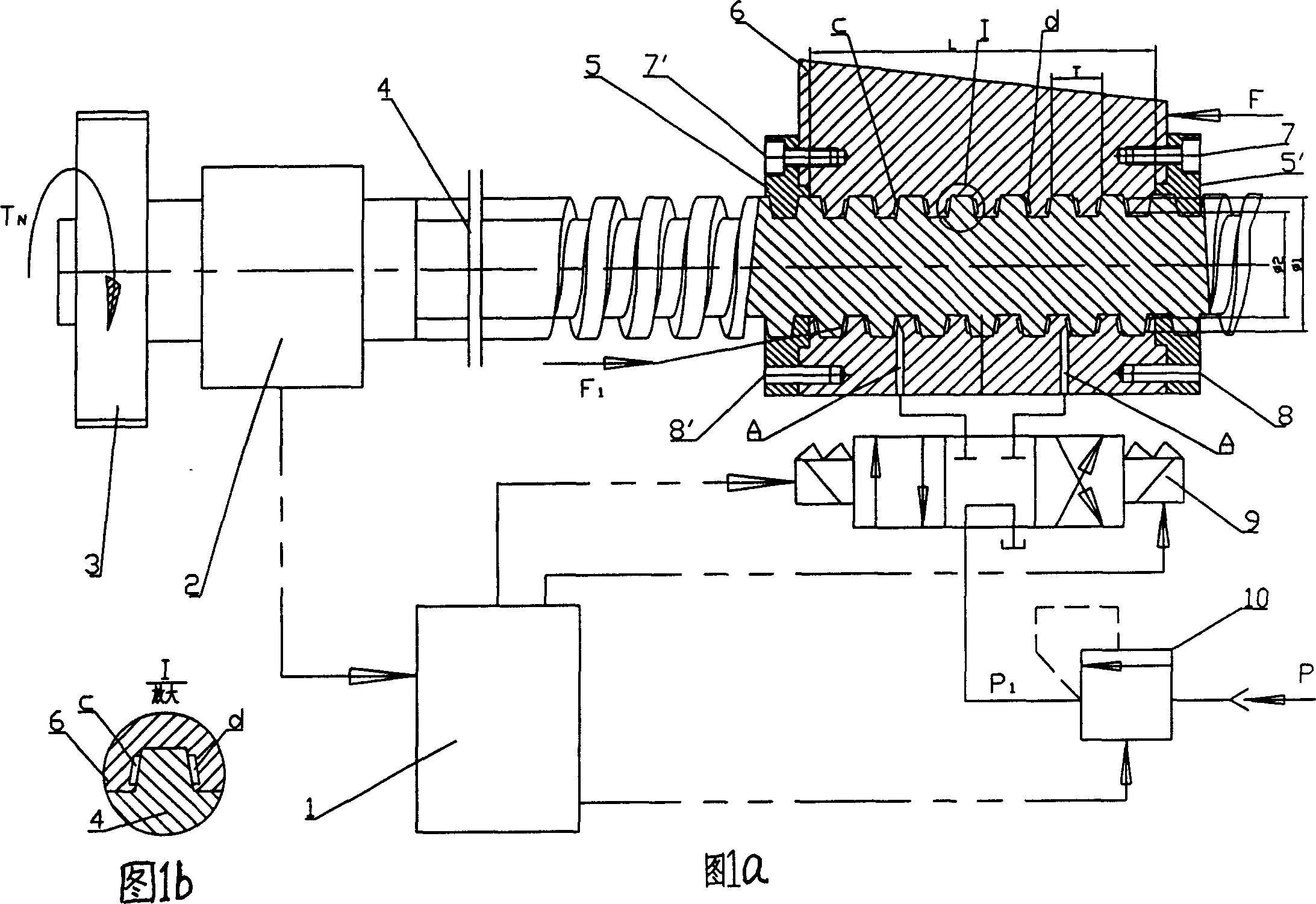

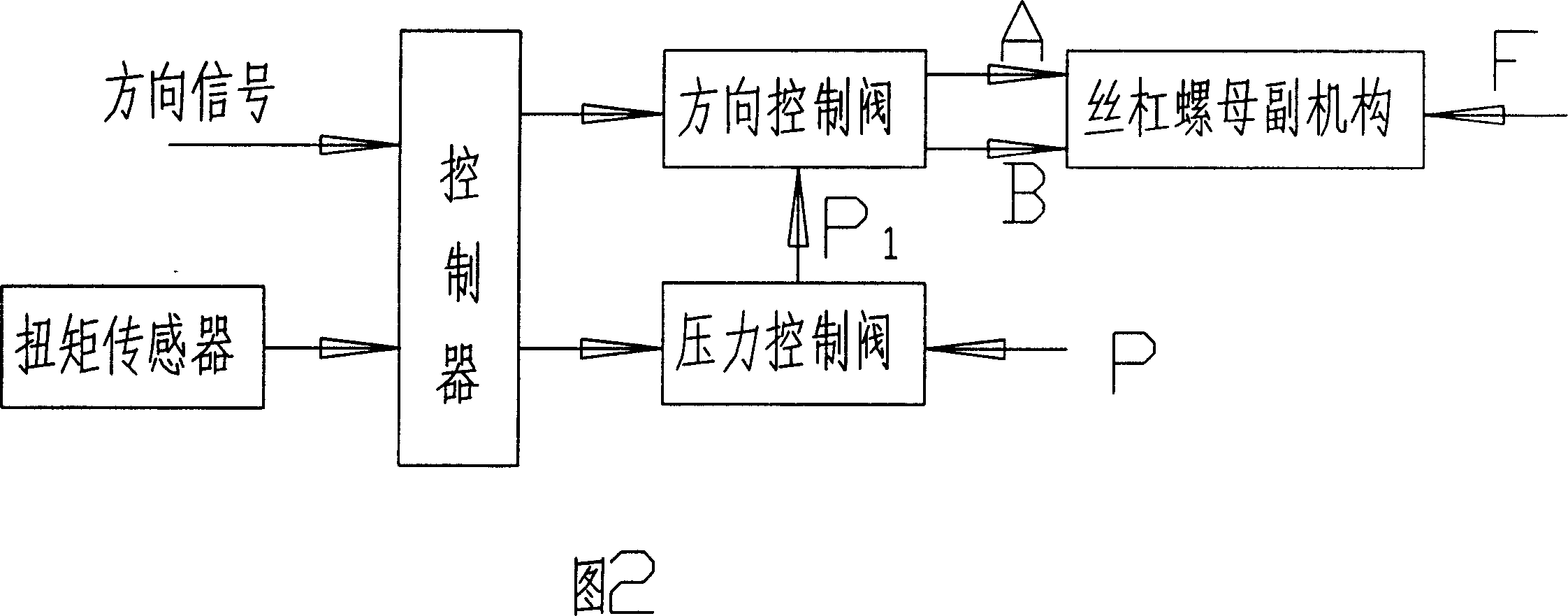

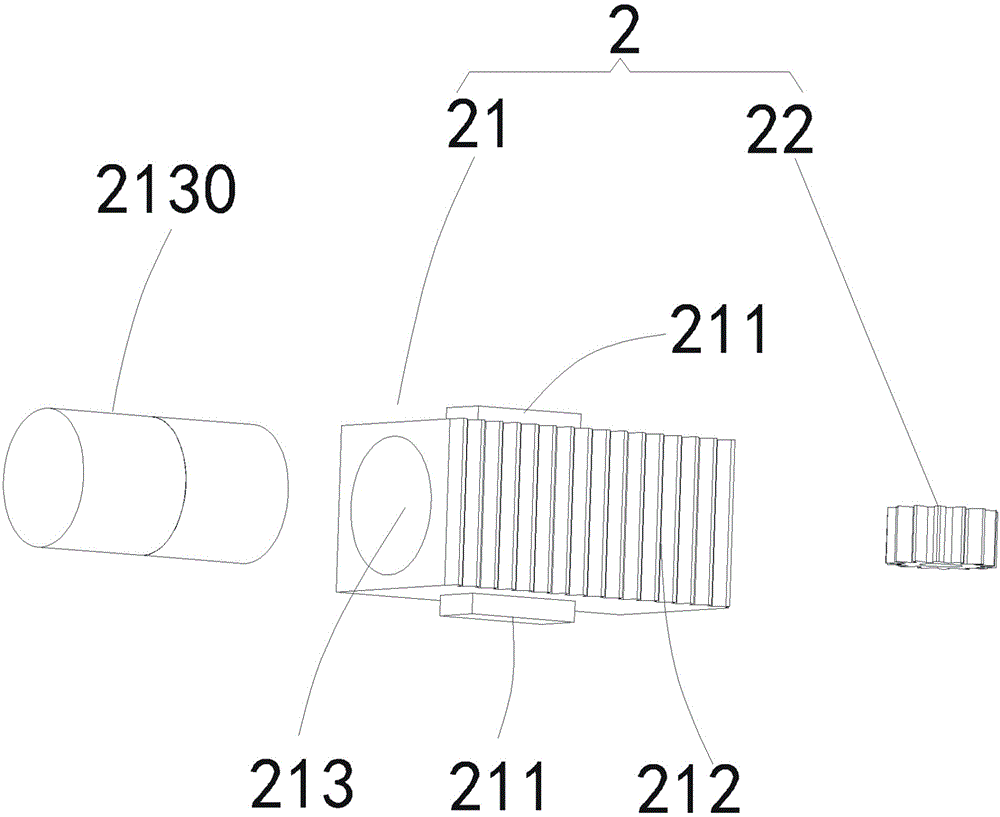

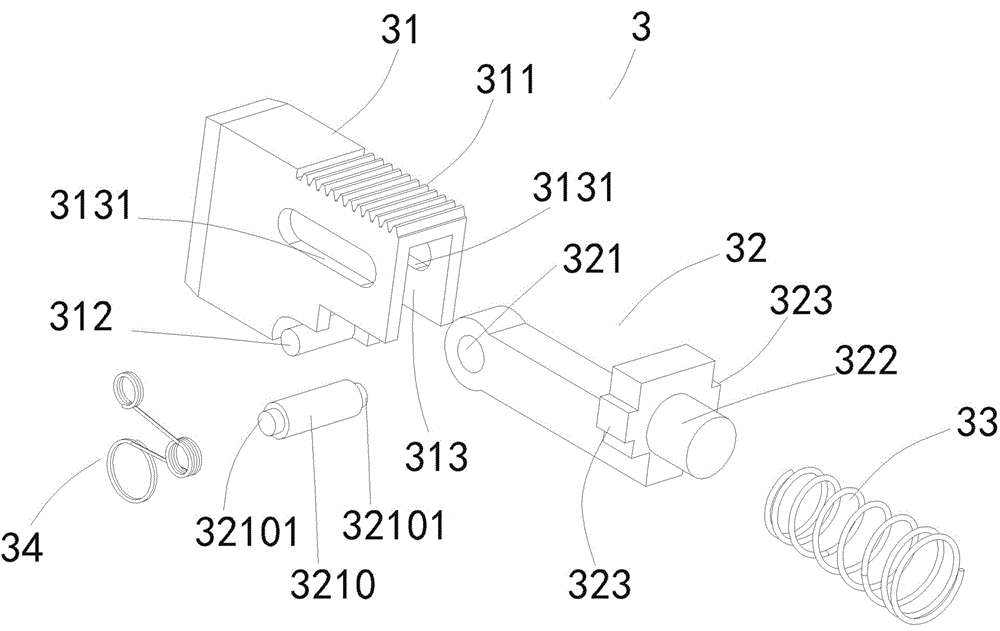

Lead screw nut pair transmission control device and method, nut subassembly processing method

InactiveCN101059165AReduce rigid contact pressureWon't breakGearingGear lubrication/coolingTorque sensorHydraulic control

Lead-screw nut vice transmission control device and the method and the processing method of nut components, the torque sensor in hydraulic control device of control device changes the torque transmitted by lead-screw into signals and transmits the signals to controller, the controller sends the oil duct reversing control signals on the three-position four-way magnetic reversing solenoid valve, the controller controls the output mouth pressure of pressure control valve which is transmitted on the side surface contacted with nut and lead-screw through two pipelines, the screw thread two sides of nut is opened with two spiral oil-storing grooves which are sealed and formed by two end covers of nut two ends and the surface contacted with nut and lead-screw; the control method is: the controller controls the output mouth pressure of pressure control valve to make it is less than or equal with 8TN / ((phi12-phi22)L), the processing method is: first assembling the nut and two end covers into one unit, processing screw thread on the inner hole surface of nut and two end covers, then processing two spiral oil-storing grooves on the screw thread two sides of nut, last assembling the nut and two end covers into one unit.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

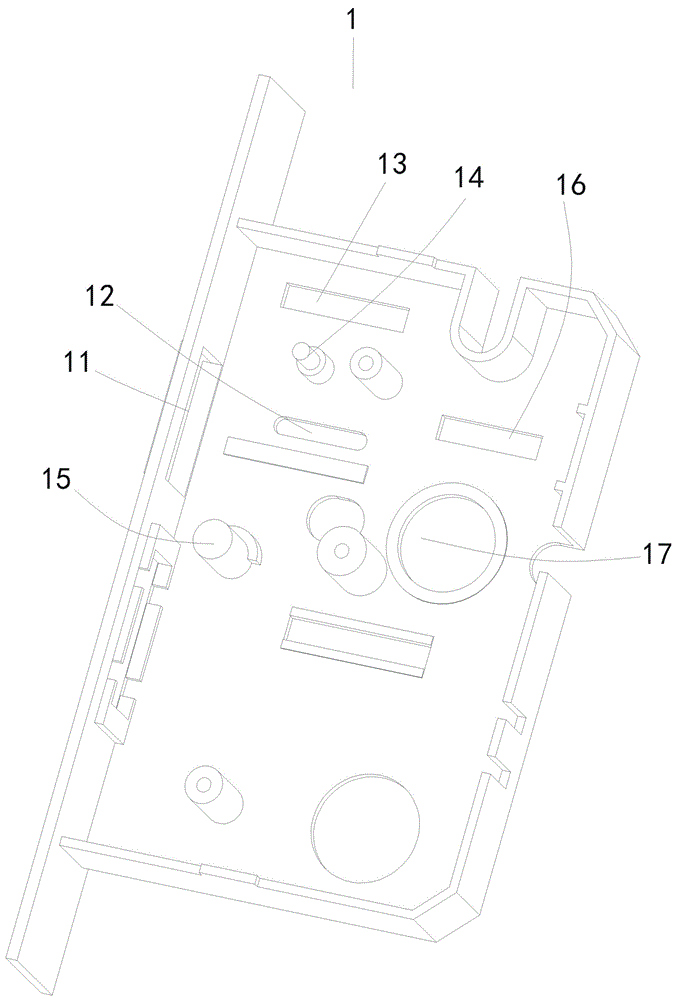

Magnetic silent lock body

ActiveCN104314381AEasy to useGood transmission effectNon-mechanical controlsEngineeringTorsion spring

The invention relates to a hardware door lock fitting, and discloses a magnetic silent lock body. The magnetic silent lock body is provided with a box bottom assembly, a driving assembly, a deadbolt assembly, a buckling box assembly and a handle stirrer, wherein the driving assembly consists of a slide block, a gear and a three-circle torsion spring; the deadbolt assembly consists of a deadbolt, a deadbolt pull rod and a reset spring; the top of the deadbolt is provided with a rack B; the box bottom assembly is provided with a gear positioning column; the slide block is provided with a rack A and a magnet positioning hole; the deadbolt is provided with a rack B; a magnet B is arranged in the buckling box assembly; the magnet A is fixedly embedded into the magnet positioning hole in the slide block; the slide block is arranged in the box bottom assembly; the gear passes through the gear positioning column, and is meshed with the rack A and the rack B simultaneously. During door closing, the deadbolt extends outwards under the same-pole repellant force of the magnet A and the magnet B. The movement of the lock body is driven by the gear and the racks, and the overall movement process is stable and reliable without collision, so that the use handfeel of the lock body is improved, and a silencing effect is achieved.

Owner:GUANGDONG MINGMEN LOCKS IND

AR (Augmented Reality) or VR (Virtual Reality) headset equipment based on virtual reality technology

InactiveCN106669144AImprove experienceSmooth transmissionInput/output for user-computer interactionVideo gamesHydraulic cylinderVirtual technology

The invention relates to AR (Augmented Reality) or VR (Virtual Reality) headset equipment based on a virtual reality technology. The AR or VR headset equipment comprises a mounting plate, wherein two hoisting adjusting mechanisms and two linear guide rails are symmetrically mounted above a front side face of the mounting plate; two height adjusting hydraulic cylinders are symmetrically mounted at the lower end of an adjusting plate; a supporting plate is mounted at the tops of the two height adjusting hydraulic cylinders through flanges; a cold and warm air blowing system is mounted at the lower end of the supporting plate; two angle adjusting branch chains are symmetrically mounted on left and right sides of the upper end face of the supporting plate; a transverse rod is arranged between the two angle adjusting branch chains; a fixed plate is mounted at the lower ends of the two angle adjusting branch chains; an adjustable experiencing device is mounted at the lower end of the fixed plate; and a physical therapy chair is mounted below the front side face of the mounting plate. According to the AR or VR headset equipment, cold and hot air can be automatically and cyclically blown out when a user has AR or VR experience, a visual watching angle can be manually adjusted and a back magnetic physical therapy function can be realized; and the visual experience effect of the user is greatly improved and the AR or VR headset equipment has a wide applicable range and abundant functions.

Owner:盛寅寅

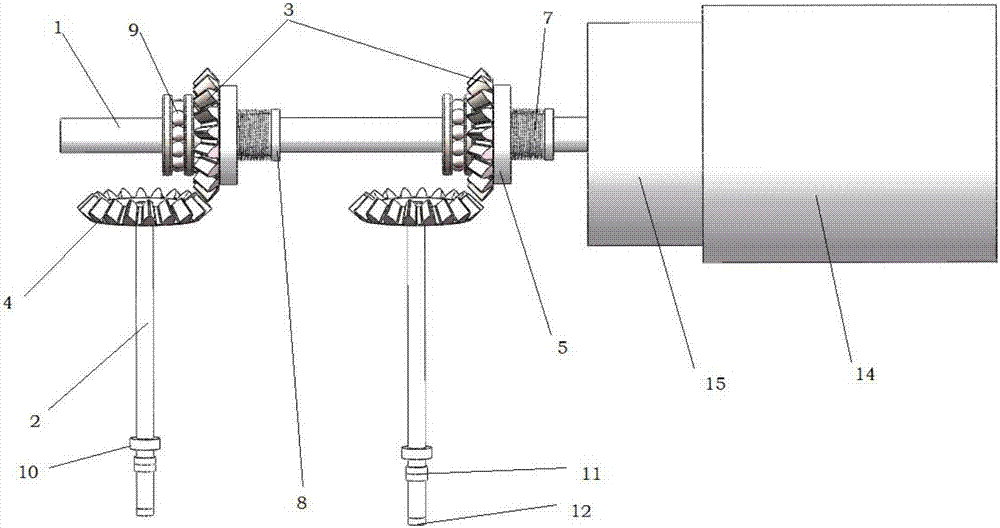

Flexible transmission double-bolt screwing device

InactiveCN107414468AGood transmission effectMomentary Torque Overload ProtectionMetal working apparatusDrive shaftCoupling

The invention discloses a flexible transmission double-bolt screwing device. The flexible transmission double-bolt screwing device comprises a driving shaft, driven shafts, driving bevel gears, driven bevel gears, a friction ring, a sleeve, a spring, an adjusting ring, a thrust bearing, torque sensors, couplings, bolt gun heads, an outer cover, a motor and a speed reducer. The driving shaft is sleeved with the two driving bevel gears. The back faces of the driving bevel gears make contact with one end face of the friction ring. The thrust bearing is fixedly connected to the driving shaft. The front faces of the driving bevel gears make contact with the thrust bearing. The friction ring and the sleeve are arranged on the driving shaft in a sleeving mode. The other end face of the friction ring is fixedly connected with the sleeve. The spring is arranged on the sleeve in a sleeving mode and is further located between the friction ring and the adjusting ring. The other end of the driving shaft is connected with one end of the outer cover through a bearing. The other end of the outer cover is fixedly connected with a speed reducer shell. The driven bevel gears which are engaged with each other are installed below the two driving bevel gears. The driven shafts are provided with the corresponding torque sensors. The driven shafts are connected with shafts with the bolt gun heads through the couplings.

Owner:重庆都英科技有限公司

Automobile wheel hub sorting apparatus

InactiveCN102303022AReduce labor intensityImprove sorting efficiencySortingNetwork connectionAssembly line

The present invention discloses an automobile wheel hub sorting apparatus. The automobile wheel hub sorting apparatus comprises a longitudinal assembly line, a plurality of transverse assembly lines, a plurality of reversing apparatuses, an intelligent camera and a controller, wherein the longitudinal assembly line is connected with an automobile wheel hub main assembly line, the transverse assembly lines are connected with the longitudinal assembly line, and are provided for conveying sorted automobile wheel hubs, the reversing apparatuses arranged on the connection position of the longitudinal assembly line and the transverse assembly lines, and are provided for conveying the automobile wheel hubs on the longitudinal assembly line to the transverse assembly lines, the intelligent camera can store the information of the automobile wheel hubs with different types, and can perform a comparison between the information of the shot automobile wheel hub and the stored information of the automobile wheel hubs with different types. The intelligent camera is arranged on an input end of the longitudinal assembly line. The controller forms an electric connection with the longitudinal assembly line, the transverse assembly lines and the reversing apparatuses. The controller is connected with the intelligent camera through network. The automobile wheel hub sorting apparatus has characteristics of small work intensity and high sorting efficiency. With the automobile wheel hub sorting apparatus provided by the present invention, the error is not easy to be generated during the sorting process.

Owner:NINGBO SAIENSI INTELLIGENT TECH

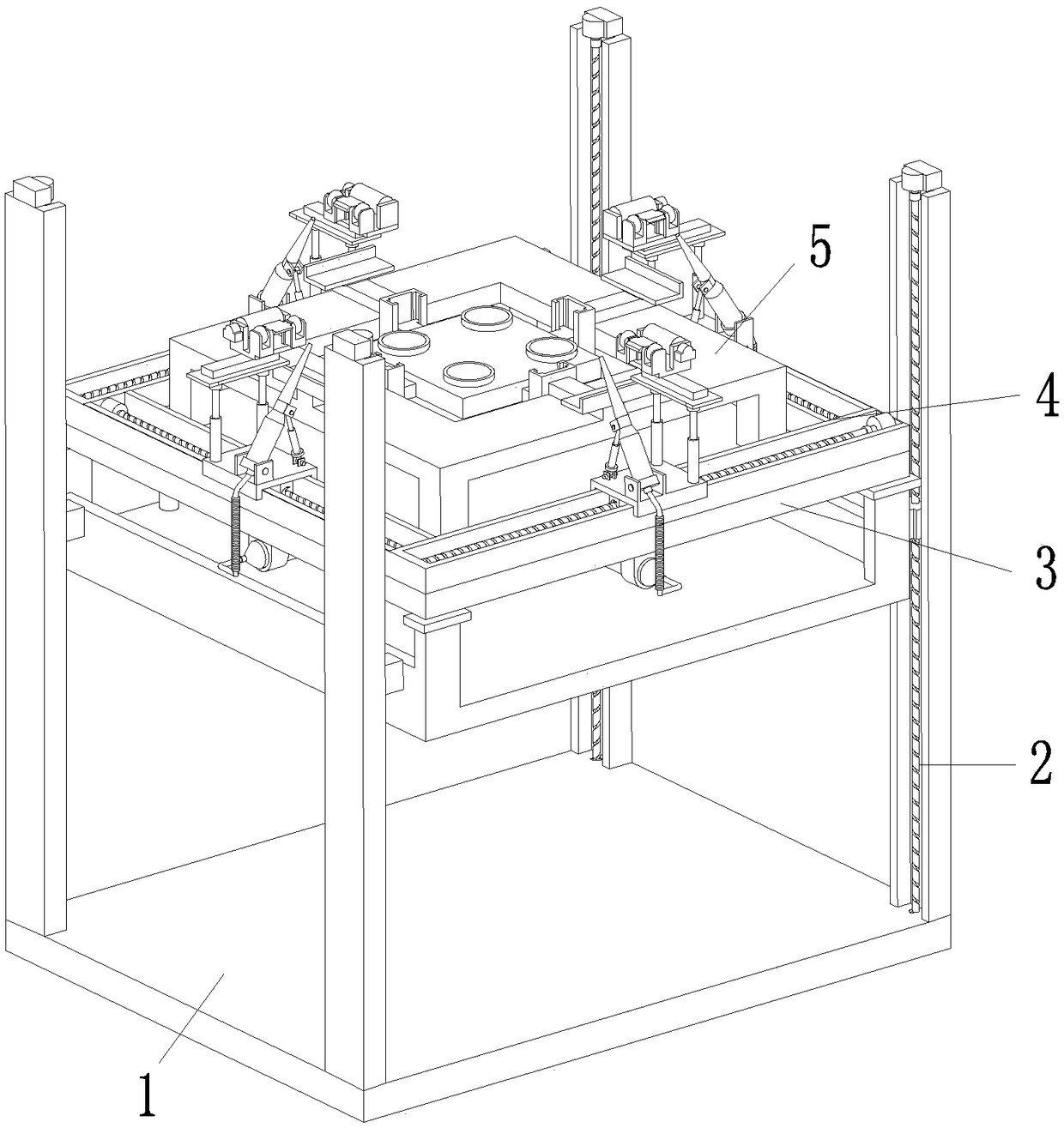

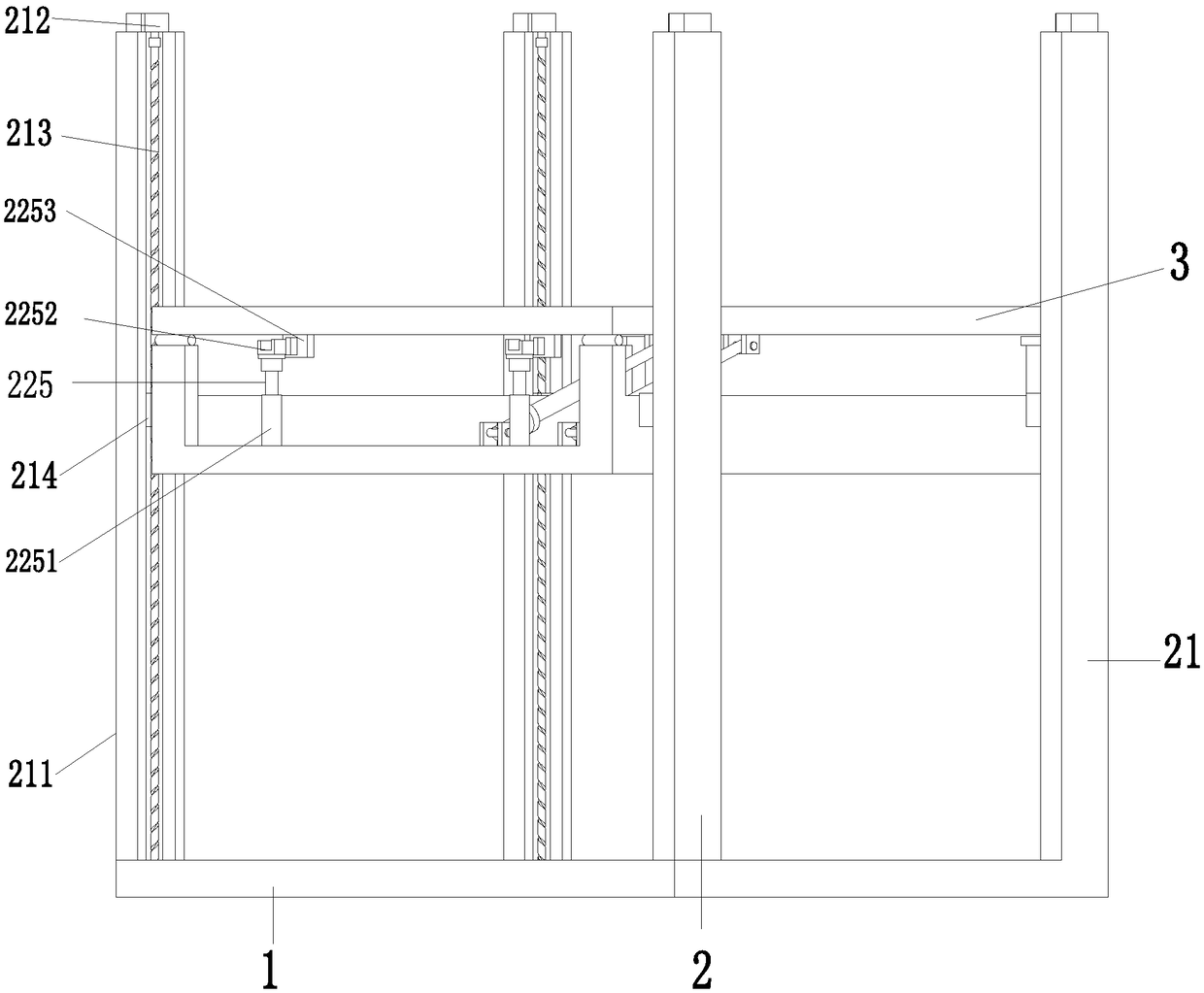

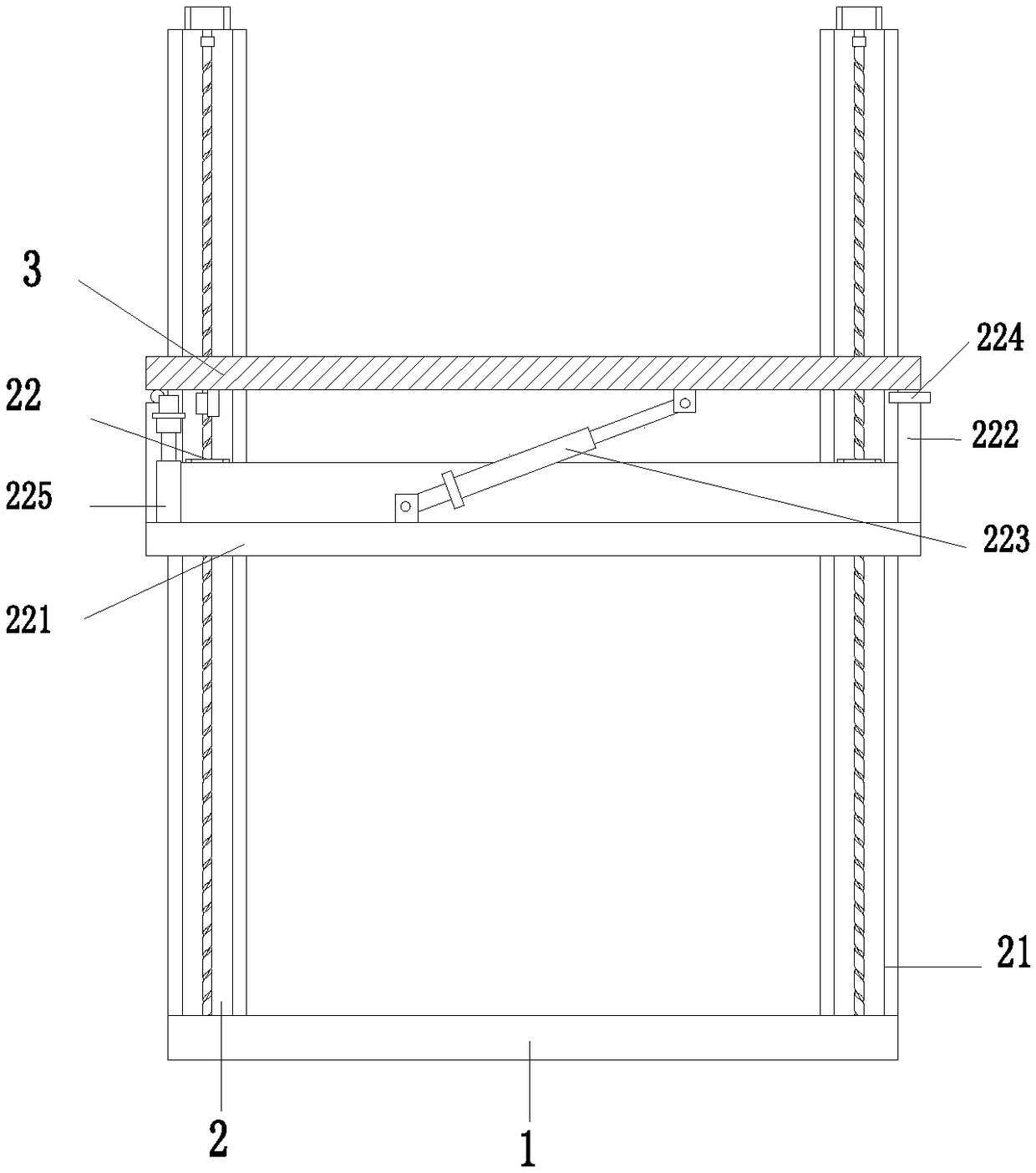

Automatic mounting equipment and method of aluminum-plastic panel

ActiveCN109057284AReduce manual operationsImprove work efficiencyBuilding constructionsUltimate tensile strengthSealant

The invention relates to automatic mounting equipment and method of an aluminum-plastic panel. The automatic mounting equipment comprises a bottom plate, an adjusting device, a fixed plate, four glueinjection devices and a clamping device. The adjusting device is mounted at the upper end of the bottom plate, and the fixed plate is mounted at the upper end of the adjusting device. The four glue injection devices are evenly mounted on the outer side of the upper end of the fixed plate, the clamping device is mounted on the inner side of the upper end of the fixed plate, and the clamping deviceis located among the four glue injection device. According to the automatic mounting equipment and method of the aluminum-plastic panel, the problems that the aluminum-plastic panel is usually mountedmanually in the existing aluminum-plastic panel mounting and glue injection process; during mounting and glue injection, a worker needs to work in the air, due to the fact that the operation space isnarrow, the worker cannot mount the aluminum-plastic panel on a ceiling and a wall easily, and potential safety hazards are possibly caused by improper operation in long-time aloft work; in the manual glue injection process, the glue injection amount is hard to control, redundant sealant cannot be removed in time when too much glue is injected, the operation difficulty is large, the labor intensity is large, and the work efficiency is low can be solved.

Owner:安徽利凌建筑材料科技有限公司

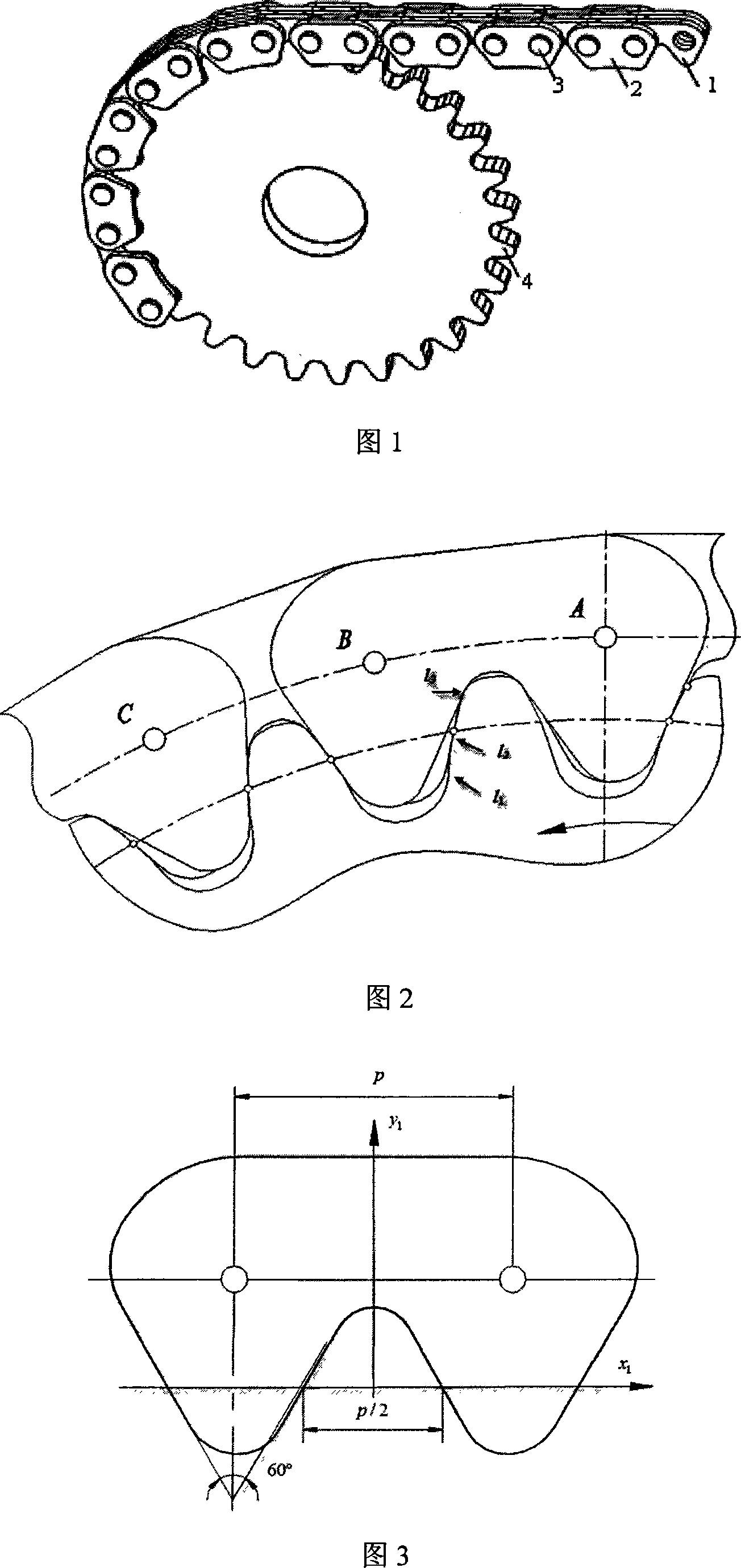

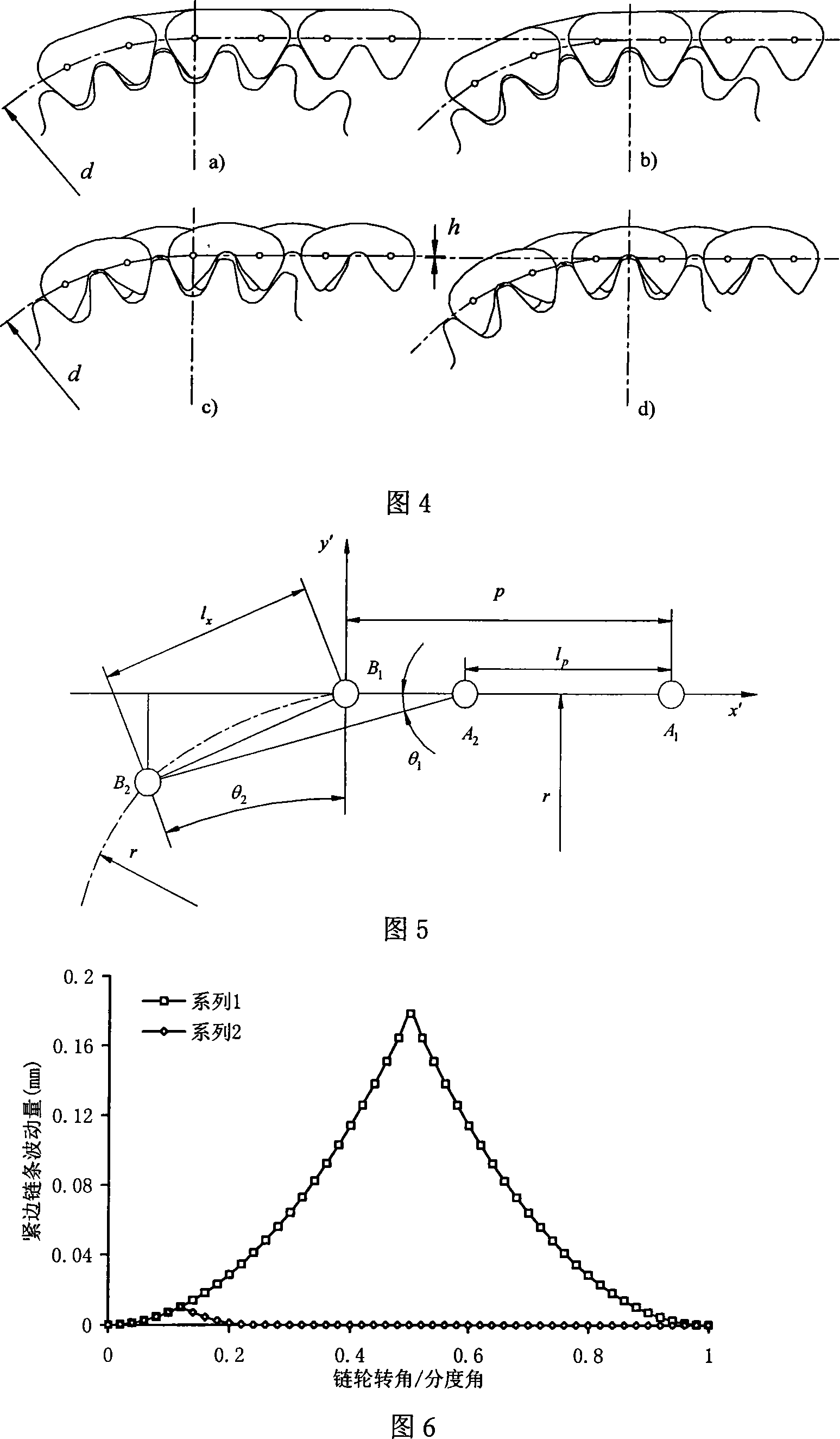

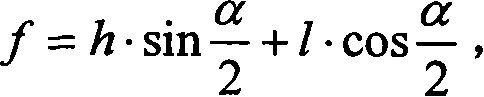

High speed transmission toothed chain and chain wheel

InactiveCN101101049AEliminate position changesEliminate lateral movementGearingPortable liftingLow noiseSprocket

This invention discloses high speed driving toothed chain and chain wheel. The inner and outer tooth profile of tooth link joint can be joggled with gear tooth of chain wheel. The link joint inner tooth profile is first joggled with chain wheel gear tooth. With chain wheel rotating, the link joint inner and outer tooth profile are joggled with chain wheel at the same time. At last, outer tooth profile is located on the gear tooth of chain wheel. The chain wheel single tooth single side tooth profile line is composed of transition curve, involute and correcting involute. The inner profile of inverted tooth chain link joint is convex in respect to outer profile. This invention has low shock and low noise.

Owner:SHANDONG UNIV

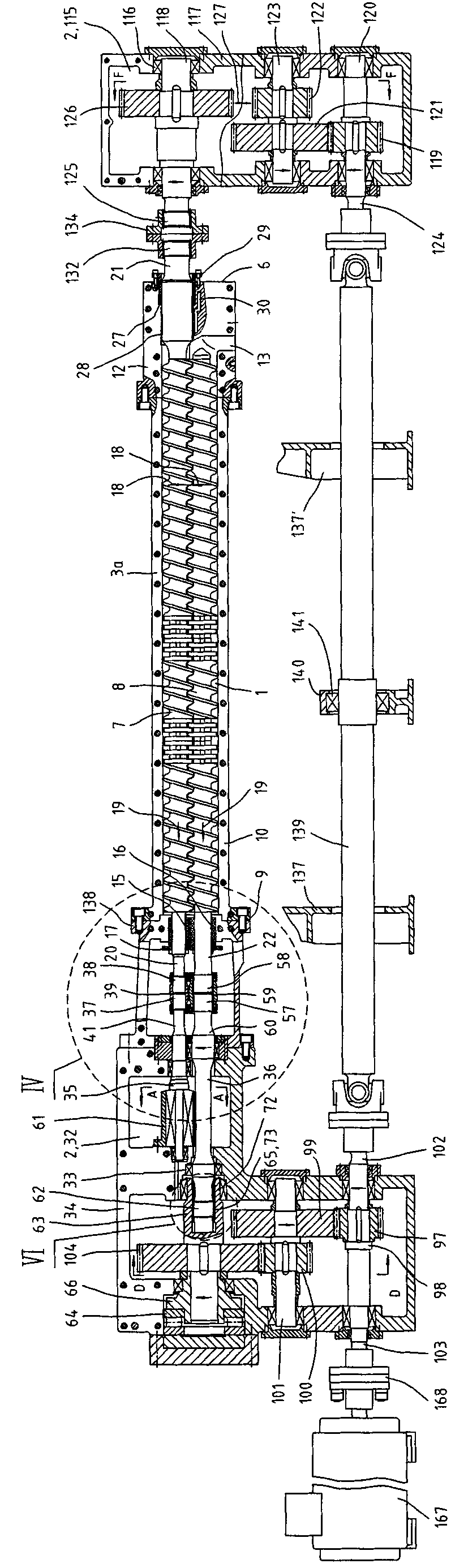

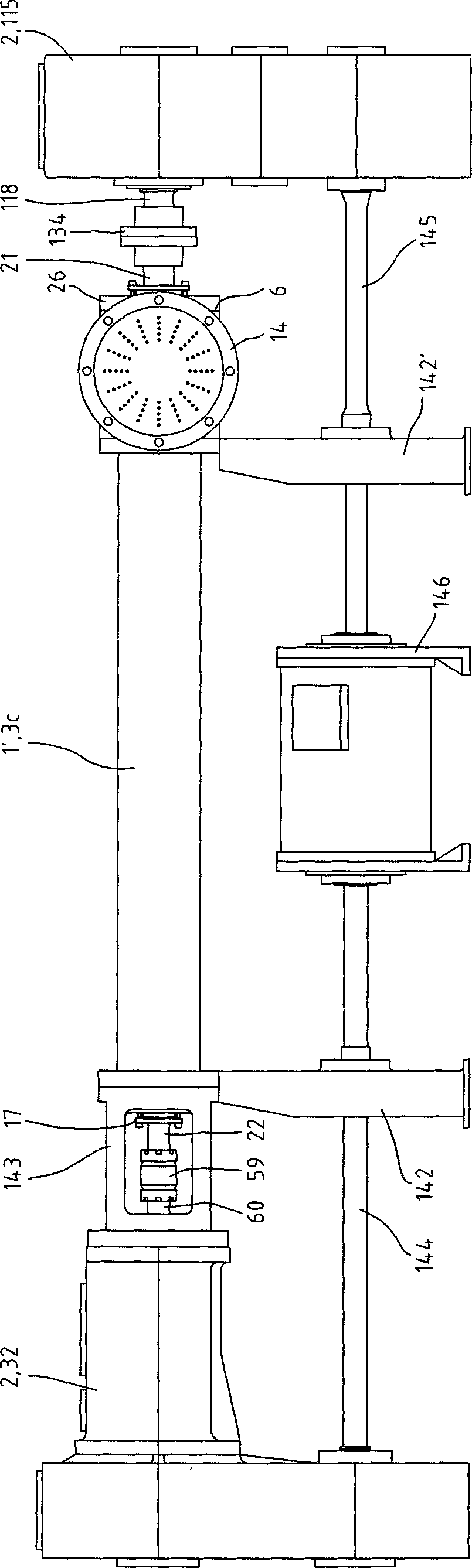

Parallel co-rotating intermeshing twin-screw extruder

The invention discloses a parallel co-rotating intermeshing twin-screw extruder used for compounding or compounding extrusion of plastic materials such as plastic. The parallel co-rotating intermeshing twin-screw extruder comprises a parallel co-rotating intermeshing twin-screw continuous compounding or compounding extrusion device, a tail side transmission case, a head side transmission case, and at least one motor; the parallel co-rotating intermeshing twin-screw continuous compounding or compounding extrusion device comprises an integral or a combined type housing; the housing comprises two cavities which are parallel in longitudinal direction and are intercross along longitudinal direction; each cavity is provided with a pair of co-rotating intermeshing screws, one of the co-rotating intermeshing screws is protruded out of the head end and the tail end of the housing respectively, the forward protruded end is driven to rotate by the head side transmission case, and thrust supporting of the backward protruded end is realized by the tail side transmission case reelingly in longitudinal direction i.e. in axial direction; the other co-rotating intermeshing screw is protruded out of the tail end of the housing, and thrust supporting and driving of the backward protruded end is realized by the tail side transmission case reelingly in longitudinal direction i.e. in axial direction, so that torque density is capable of exceeding 10Nm / cm<3> economically and serviceably, and is capable of exceeding 20Nm / cm<3> significantly.

Owner:陈克俭

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com