Patents

Literature

980results about How to "Solve wear and tear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

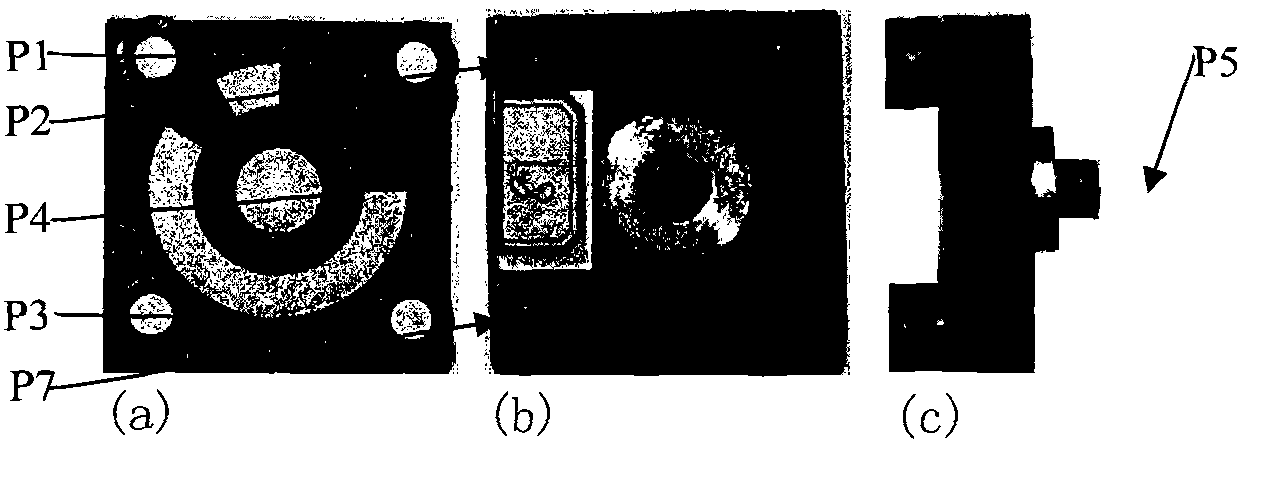

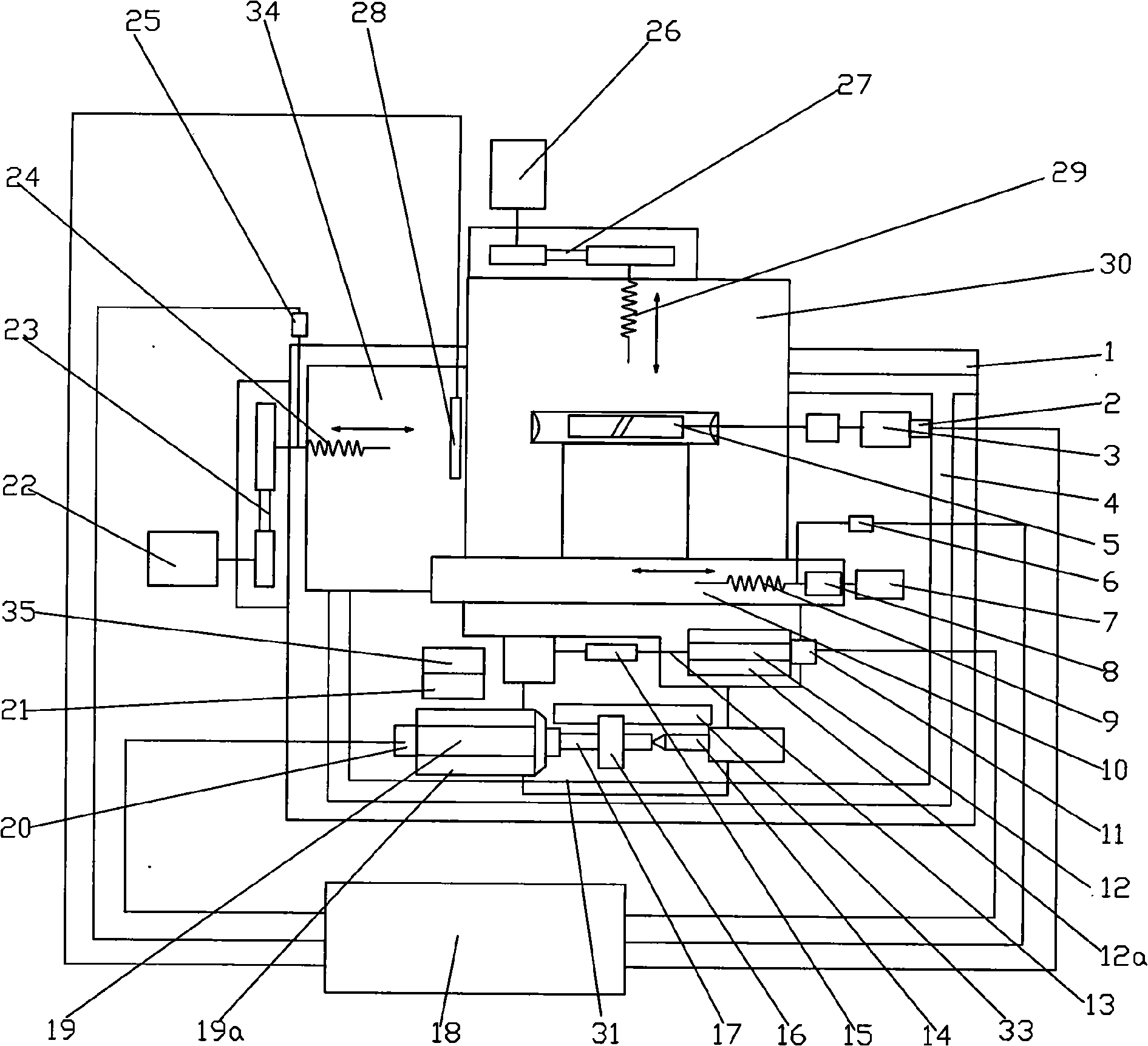

Single order high precision large-sized object three-dimensional digitized measurement system and measurement method thereof

InactiveCN101509763ASolve workpiece wearAddressing Probe Operational LimitationsUsing optical meansIntelligent designStimulus detection

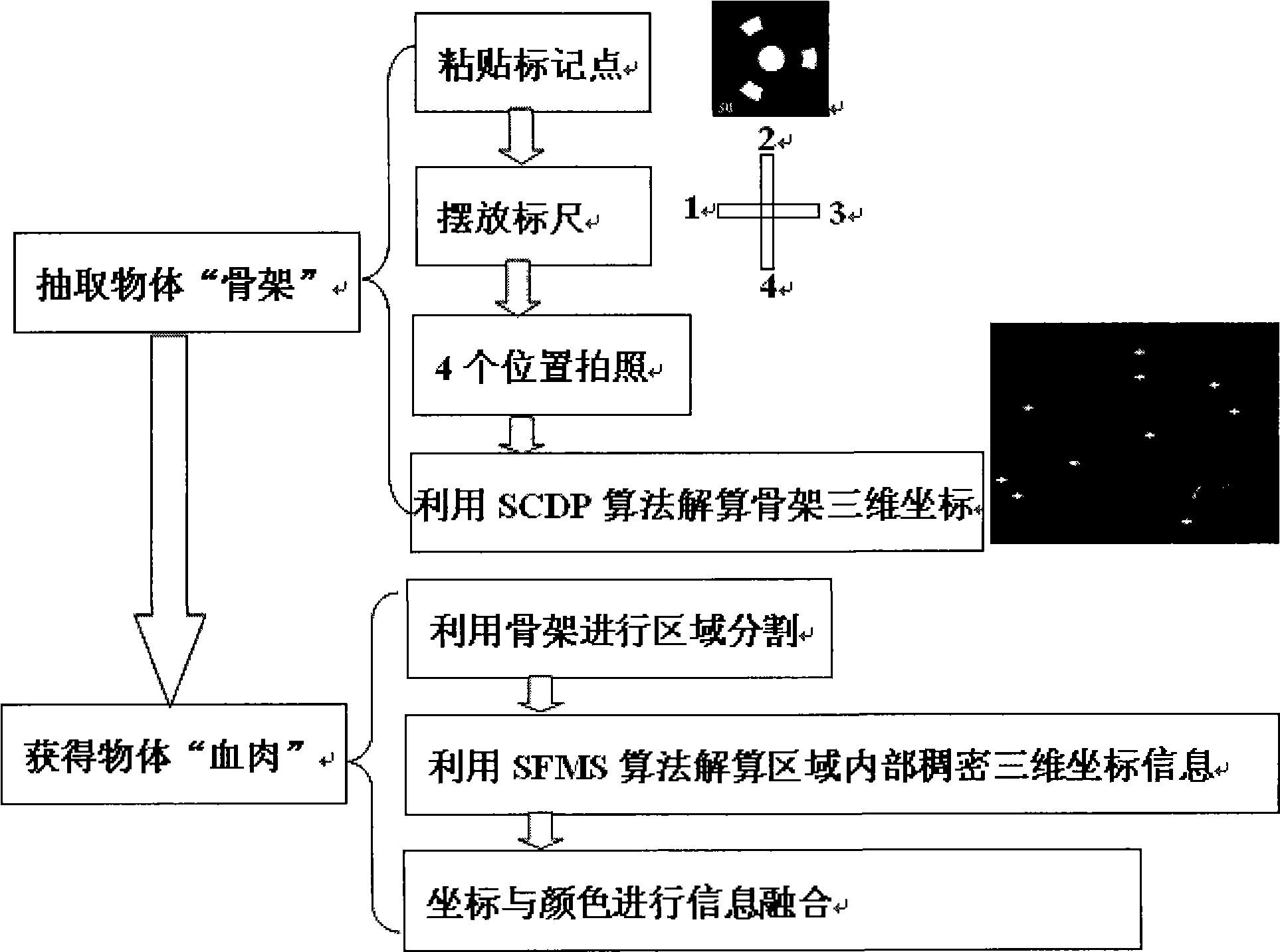

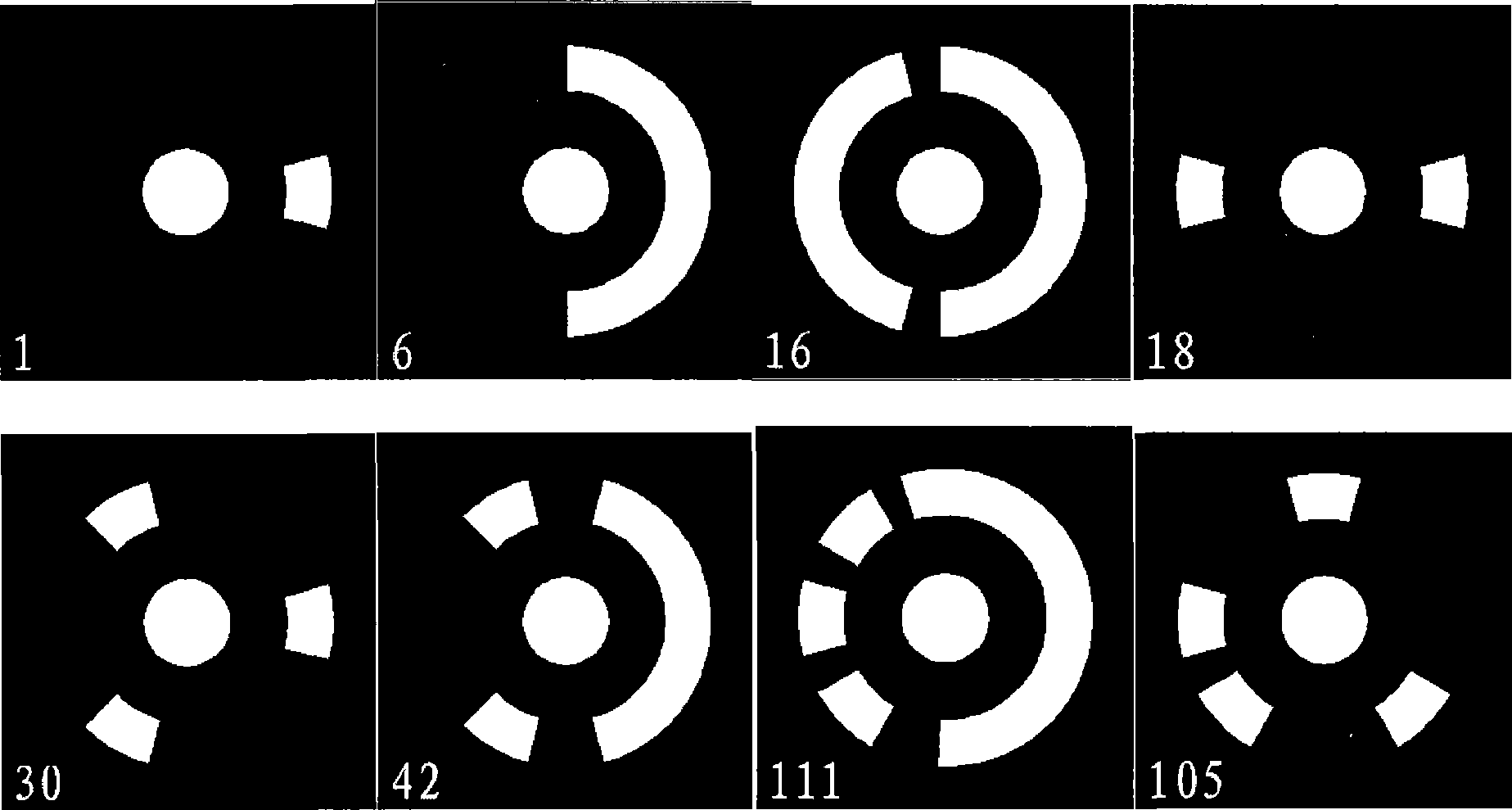

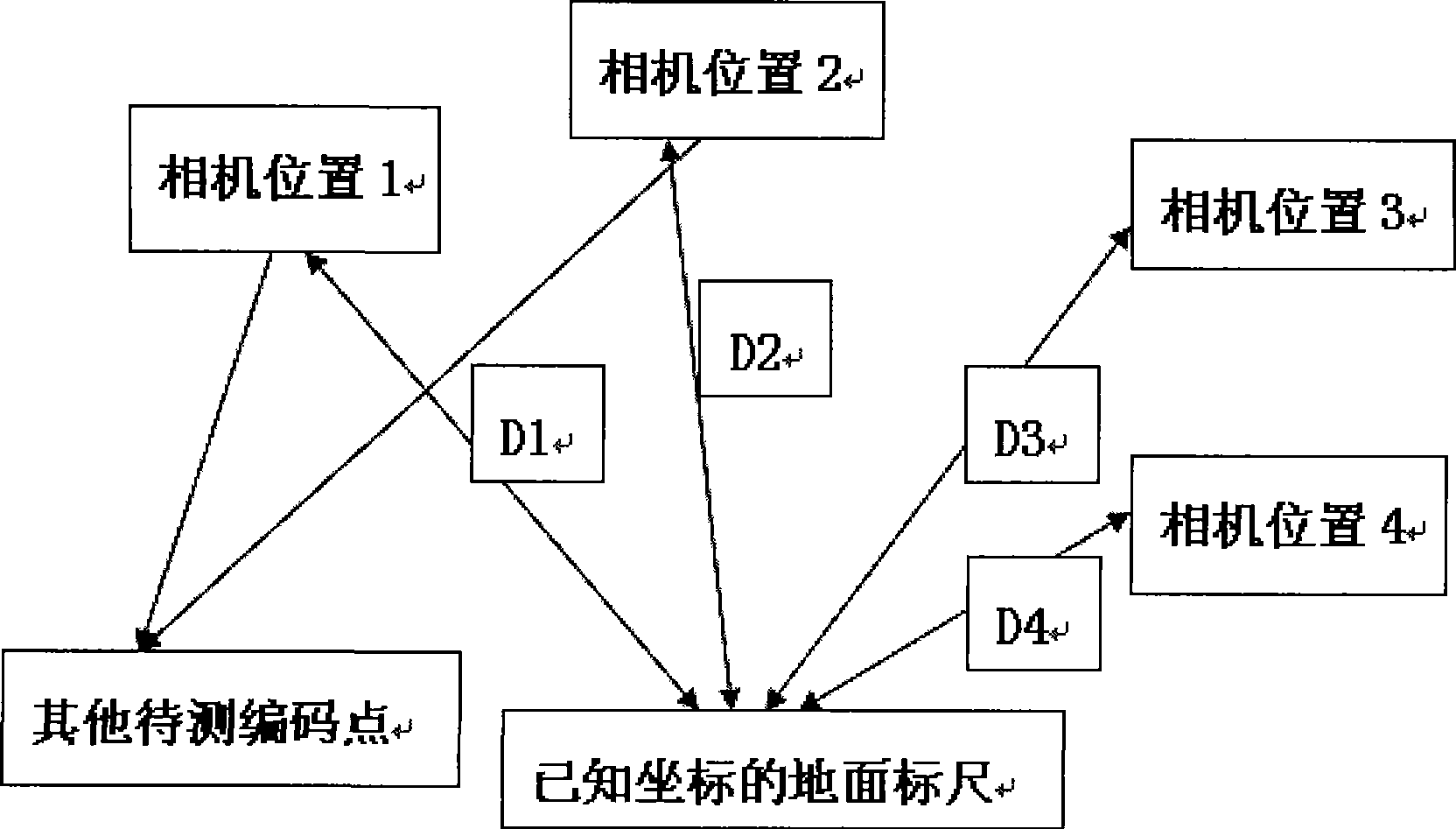

The invention belongs to the field of image processing and pattern recognition and relates to a three-dimensional digital measurement method of a monocular high accuracy large-scale object. The method needs to attach a digital solid coding marking point at the key dimensional part of an object to be measured and put a cross target on which a coding marking point is attached beside the object, and the coding marking point can show the framework information of the object. A high accuracy digital camera is adopted first to collect images at four positions of the object to be measured; then an SCDP (Single Camera Different Position) method proposed by the invention is applied to obtain precision three-dimensional coordinate of the framework coding marking point, a space is divided into a plurality of sub-areas; inside the sub-areas, an SFMS (Shape From Multi Shading) method proposed in the invention is adopted to obtain the corresponding three-dimensional coordinate of each pixel point of images; and by combining with the color information of the coordinate, a color three-dimensional digital model of the object is consequently obtained to provide data foundation for the subsequent intelligent design. The SCDP and the SFMS method proposed in the invention enrich the basic theory of three-dimensional visualization measurement, lay a foundation for the monocular three-dimensional visualization detection theory and boost the level of Chinese manufacturing industry.

Owner:TIANJIN POLYTECHNIC UNIV

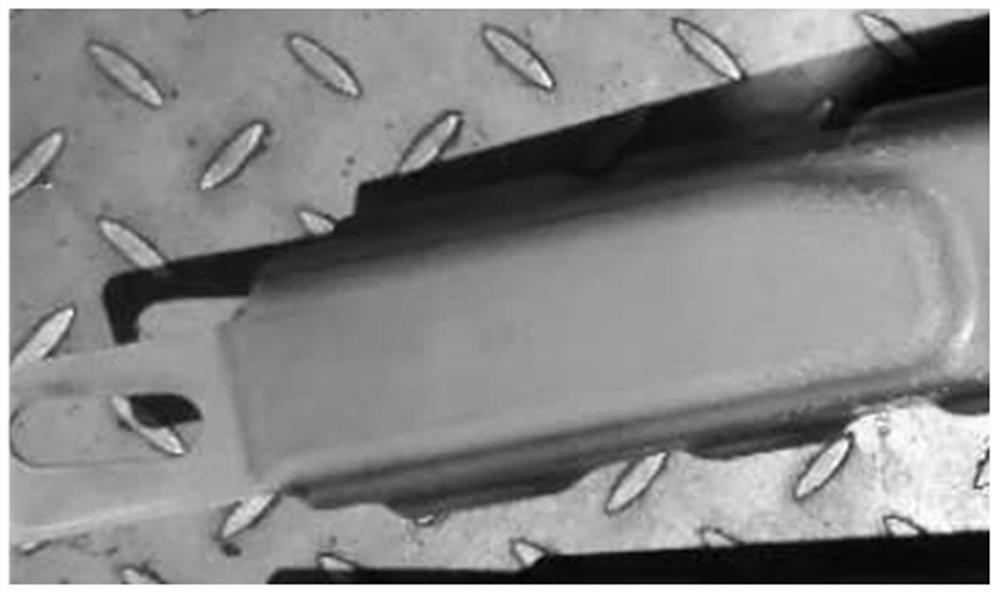

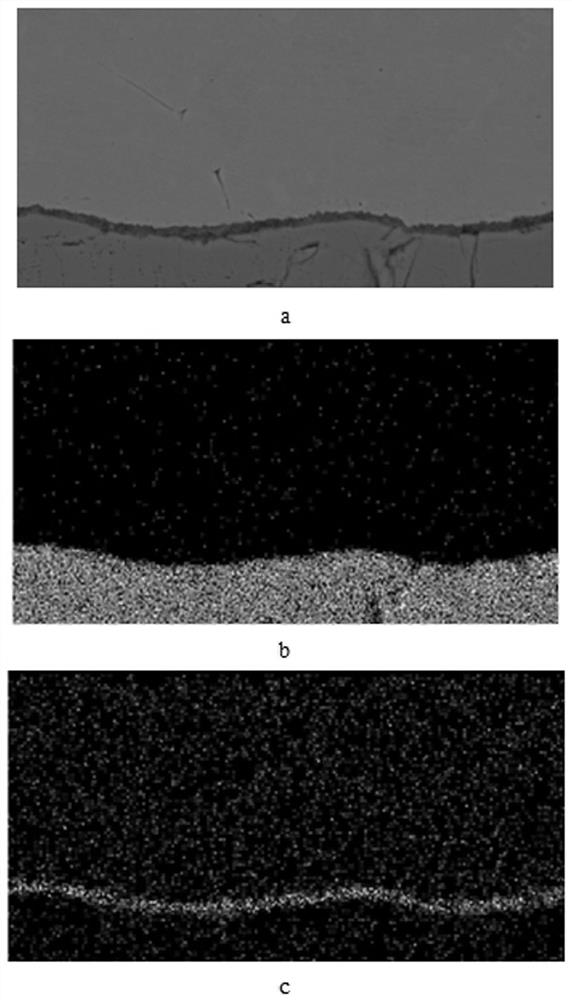

Method for preparing tungsten carbide abrasion resistant composite coating by penetration brazing method

ActiveCN101637838AHigh bonding strengthFast heat conductionSoldering apparatusWelding/soldering/cutting articlesEpoxyBond interface

The invention relates to a method for preparing tungsten carbide abrasion resistant composite coating by a penetration brazing method, belonging to the field of coating preparation in materials processing engineering. The invention comprises the following steps: (1) pasting coating metal powder cloth containing tungsten carbide-cobalt (WC-Co), nickle (Ni) and chromium (Cr) mixed powder on a metalsubstrate by using epoxy resin bonding agent; (2) preparing welding material metal powder cloth from BNi-2 brazing material and pasting the welding material metal powder cloth on the coating metal powder cloth obtained in the step (1); and (3) carrying out penetration brazing in a vacuum furnace to form a metallurgical bonded interface. The tungsten carbide abrasion resistant composite coating canbe applicable to protection of mechanical elements in the field of generating plant, petroleum, aviation, food, plastics and the like.

Owner:JIANGXI HENGDA HI TECH CO LTD

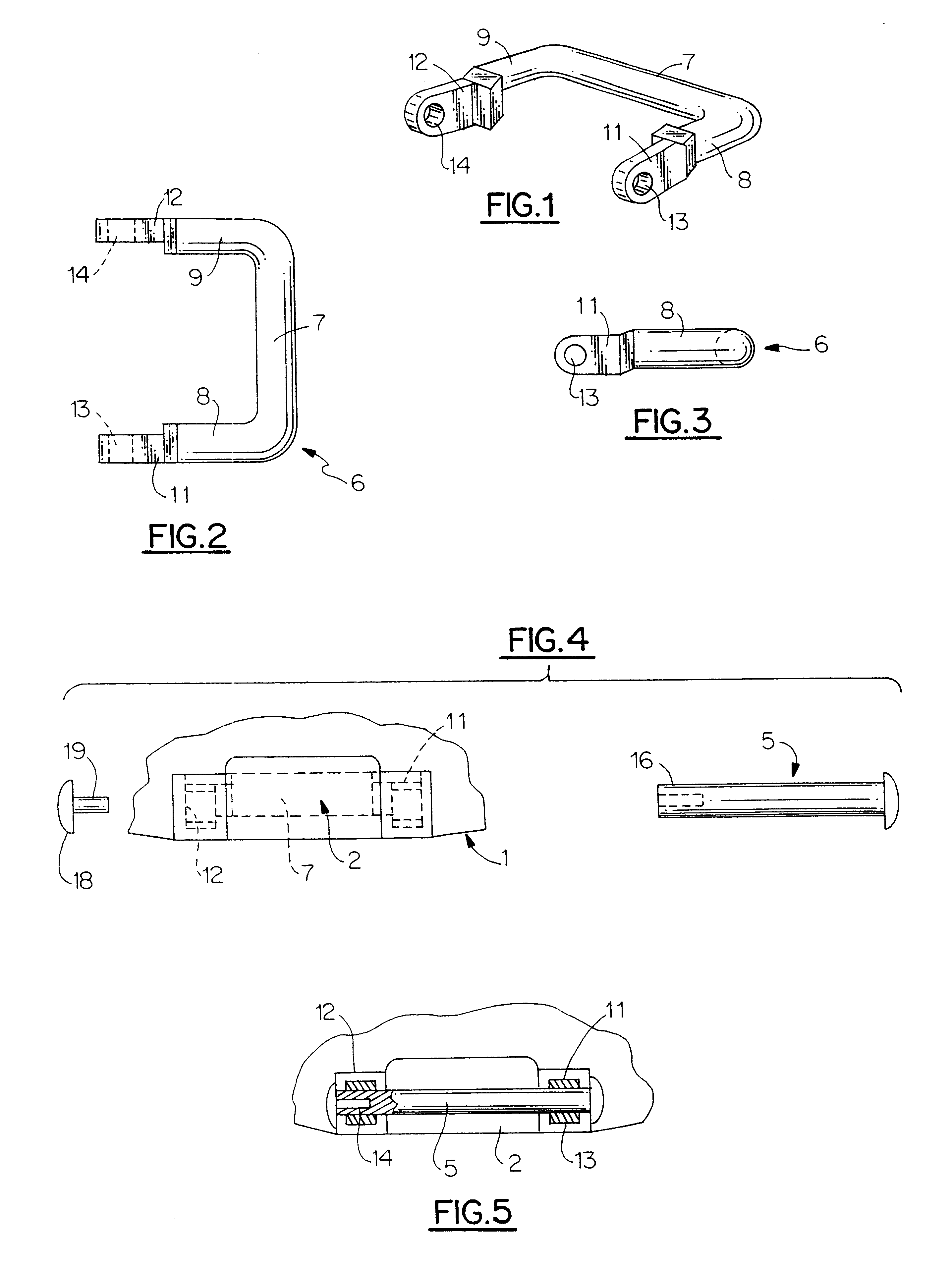

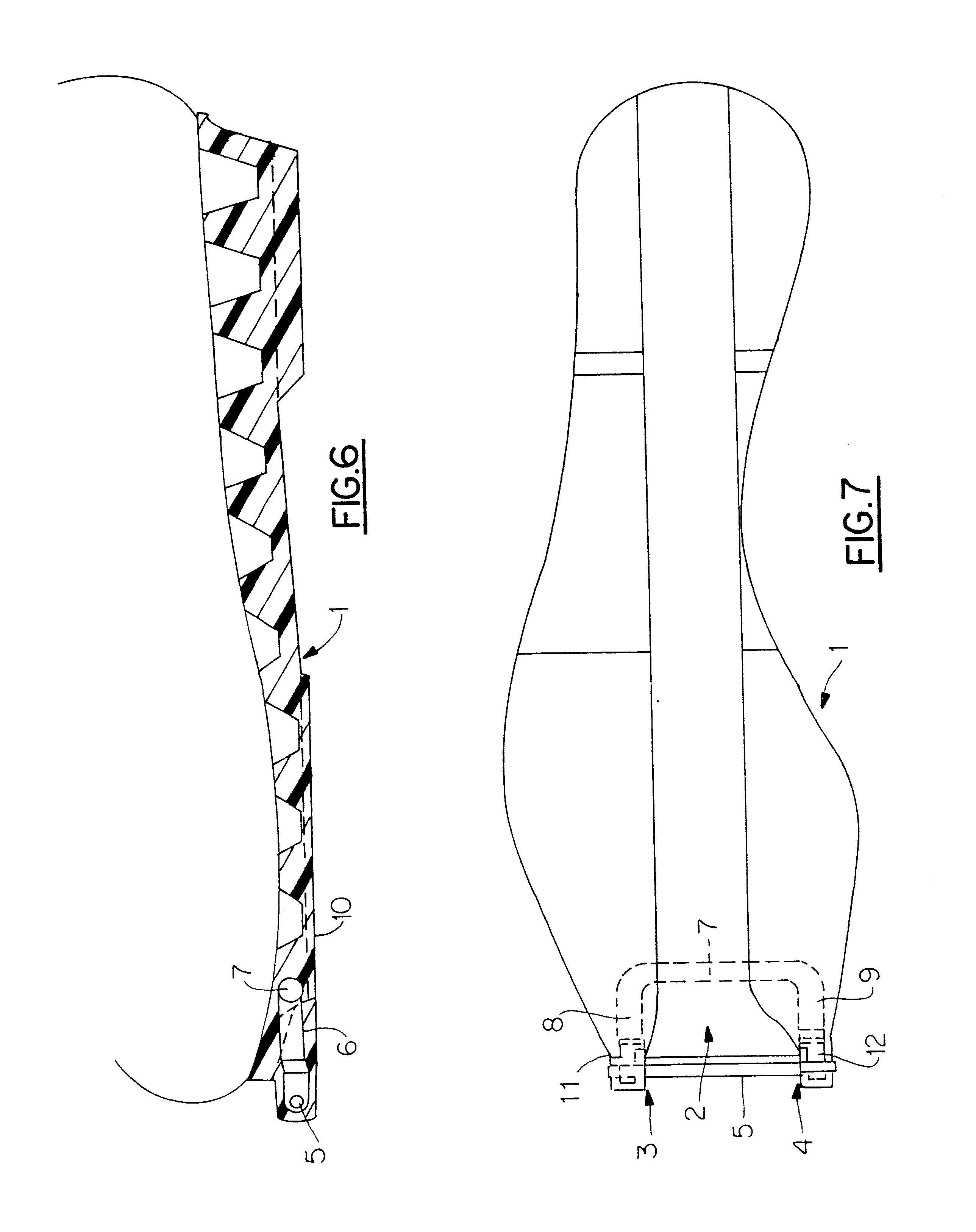

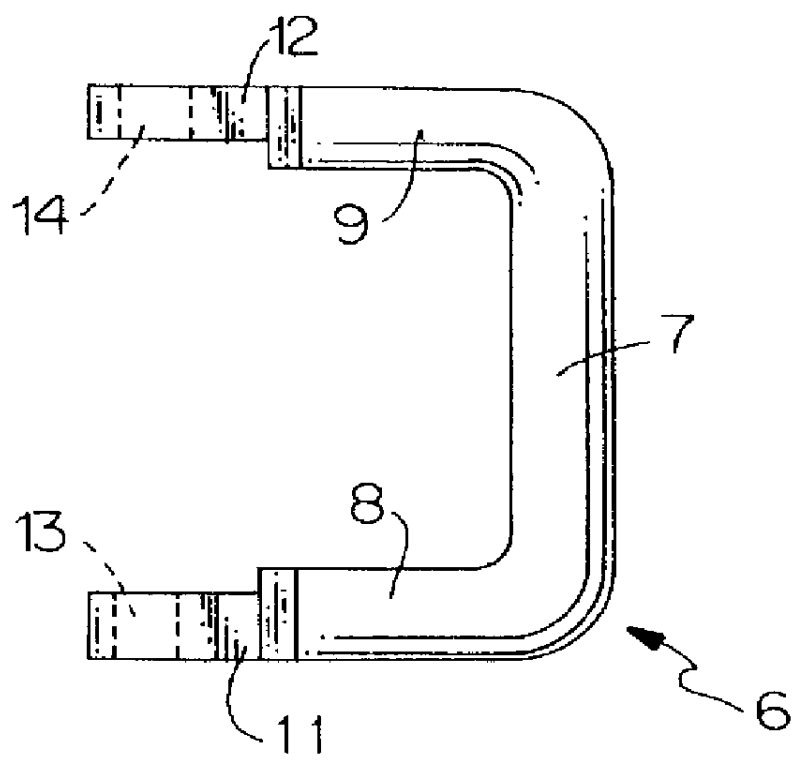

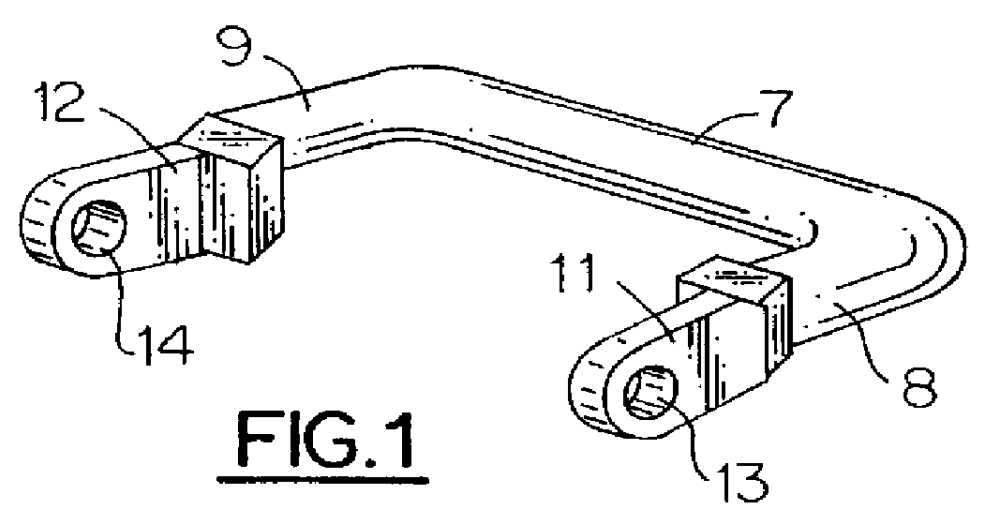

Footwear with a releasable pin for use in gliding sports

Owner:SKIS ROSSIGNOL

Multifunctional crown block piston rod

InactiveCN102384266AAddressing Early Fatigue FracturesSolve wear and tearSolid state diffusion coatingPiston rodsBiochemical engineeringStress relief

The invention provides a multifunctional crown block piston rod. A piston is arranged on a piston rod, the piston rod and the piston are of an integral structure, the piston rod is made of 38CrMoA1A steel, and the production process of the piston rod is as follows: blank-forging-normalizing-rough turning-tempering-semi finish turning-stress relief annealing-grinding-ion nitriding-polishing. The piston rod provided by the invention has high strength and rigidity and good wear resistance and fatigue resistance, so that the problem that the piston rod is easy to be fatigue to break and easy to wear in the early stage can be solved, and the service life of the piston rod is prolonged greatly and can be longer than 18 months.

Owner:贵阳白云高原紧固件有限公司

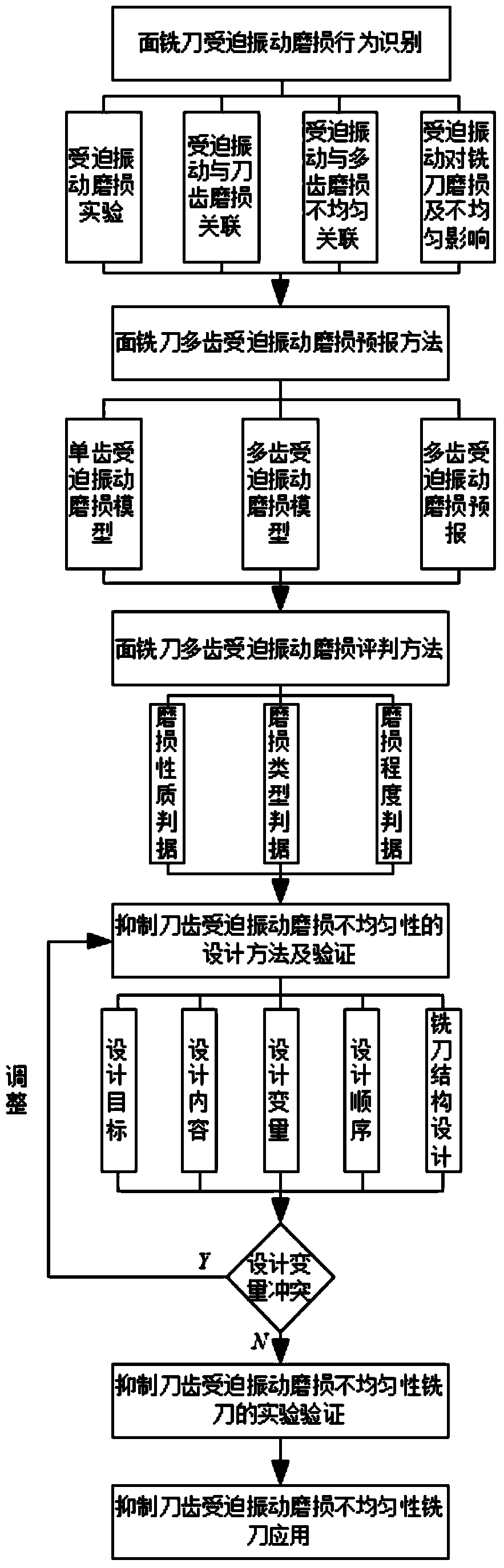

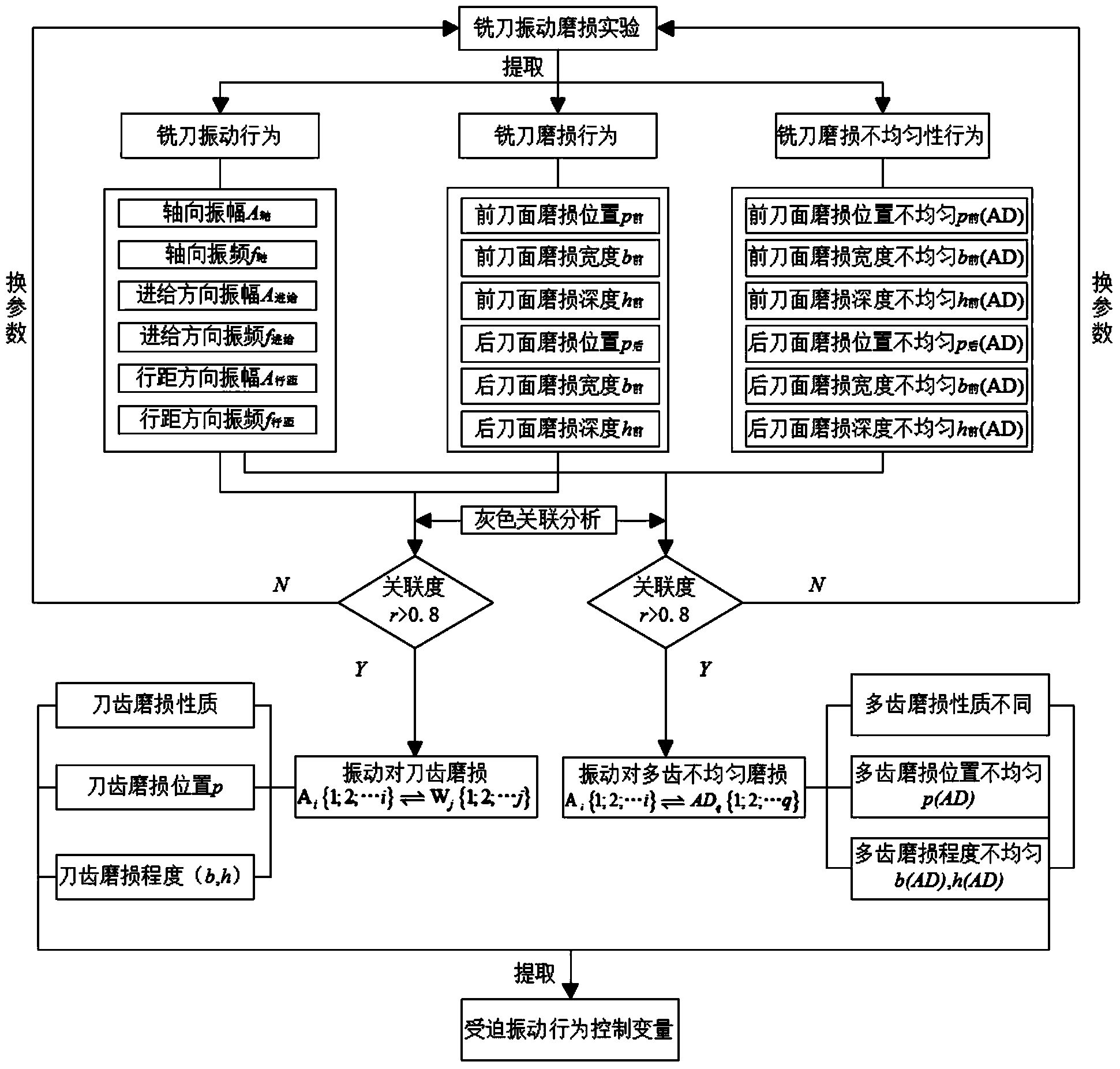

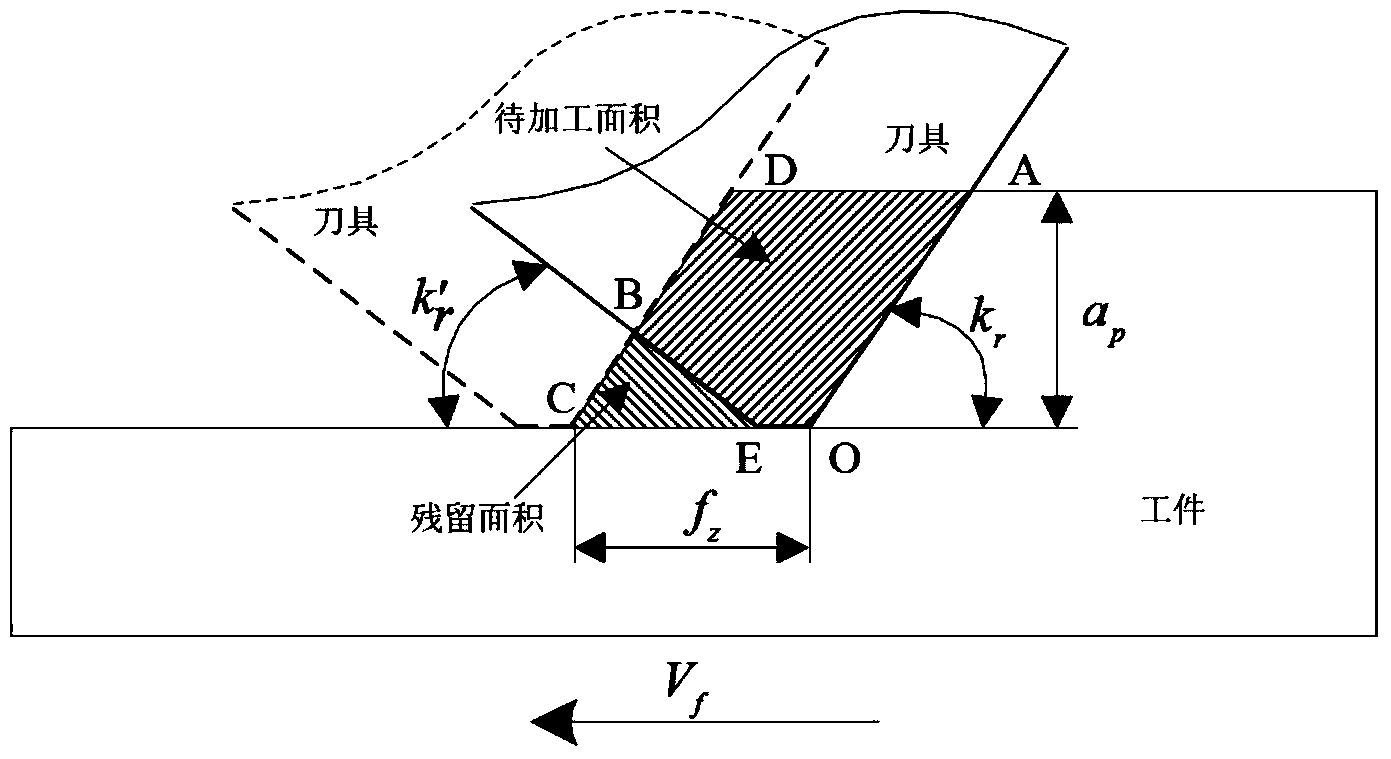

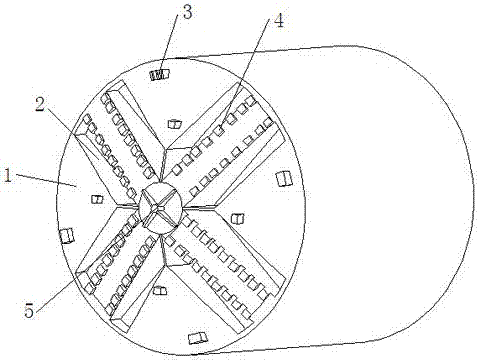

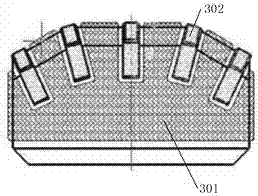

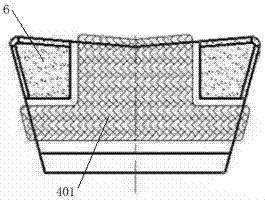

High-speed milling cutter designing method for suppressing unevenness in forced vibration wear of cutter teeth

ActiveCN103761386AReduce unevennessSolution to short lifeStapling toolsSpecial data processing applicationsTooth wearMilling cutter

The invention discloses a high-speed milling cutter designing method for suppressing unevenness in forced vibration wear of cutter teeth, and belongs to the technical field of cutters. The high-speed milling cutter designing method particularly includes providing a process for identifying forced vibration wear behavior of a milling cutter by the aid of correlation characteristics of forced vibration of the high-speed face milling cutter and wear behavior of the cutter teeth; building a multi-tooth forced vibration wear model of the milling cutter and providing a process for predicting and judging forced vibration wear and uneven wear of the milling cutter. The high-speed milling cutter designing method has the advantages that a process for controlling the uneven wear of the milling cutter and a process for designing the milling cutter are provided, so that the problem of design conflicts among multi-tooth wear positions, wear areas and wear depth control variables of an existing milling cutter can be solved, the milling cutter with the diameter of 63mm can be designed by the high-speed milling cutter designing method, the unevenness in forced vibration wear of the cutter teeth for cutting No.45 steel at high speeds can be effectively suppressed, and the high-speed milling cutter designing method is used for designing milling cutters.

Owner:HARBIN UNIV OF SCI & TECH

Single-wheel dual-brake electronic transmission brake system of aircraft, capable of choosing braking manner

InactiveCN106114829AIncrease energy levelsExtended service lifeBraking action transmissionAircraft brake actuating mechanismsElectronic transmissionCarbon composites

The invention relates to a single-wheel dual-brake electronic transmission brake system of an aircraft, capable of choosing a braking manner. A brake antiskid control system is formed by an aircraft wheel speed sensor, a control box and an electro-hydraulic servo valve; a brake control system is formed by a braking instruction sensor, the control box and the electro-hydraulic servo valve. The electro-hydraulic servo valve responds to an electric current control signal of the control box to output and adjust the braking pressure outputted to a braking aircraft wheel; braking selection is realized through a hydraulic control valve; a hydraulic braking valve is replaced with the braking instruction sensor; and the electro-hydraulic servo valve is a positive gain valve. The single-wheel dual-brake electronic transmission brake system disclosed by the invention is suitable for a single-wheel dual-brake aircraft wheel using a carbon brake; the requirements for selective brake use of the single-wheel dual-brake aircraft wheel can be met, and the using conditions of a carbon disk is adjusted, so that the good characteristics of wear resistance of a carbon-carbon composite friction material can be fully exerted, the difficult problems that a conventional single-wheel single-brake carbon brake disk is high in wear and short in service life are effectively solved, the service life of the carbon disk is prolonged, and the economic benefits of the carbon disk are improved.

Owner:XIAN AVIATION BRAKE TECH

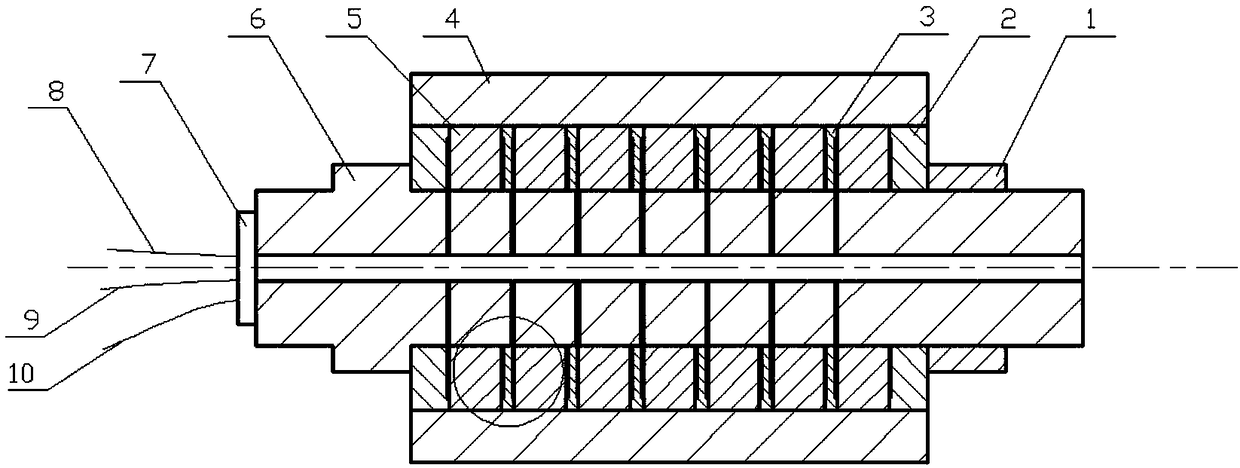

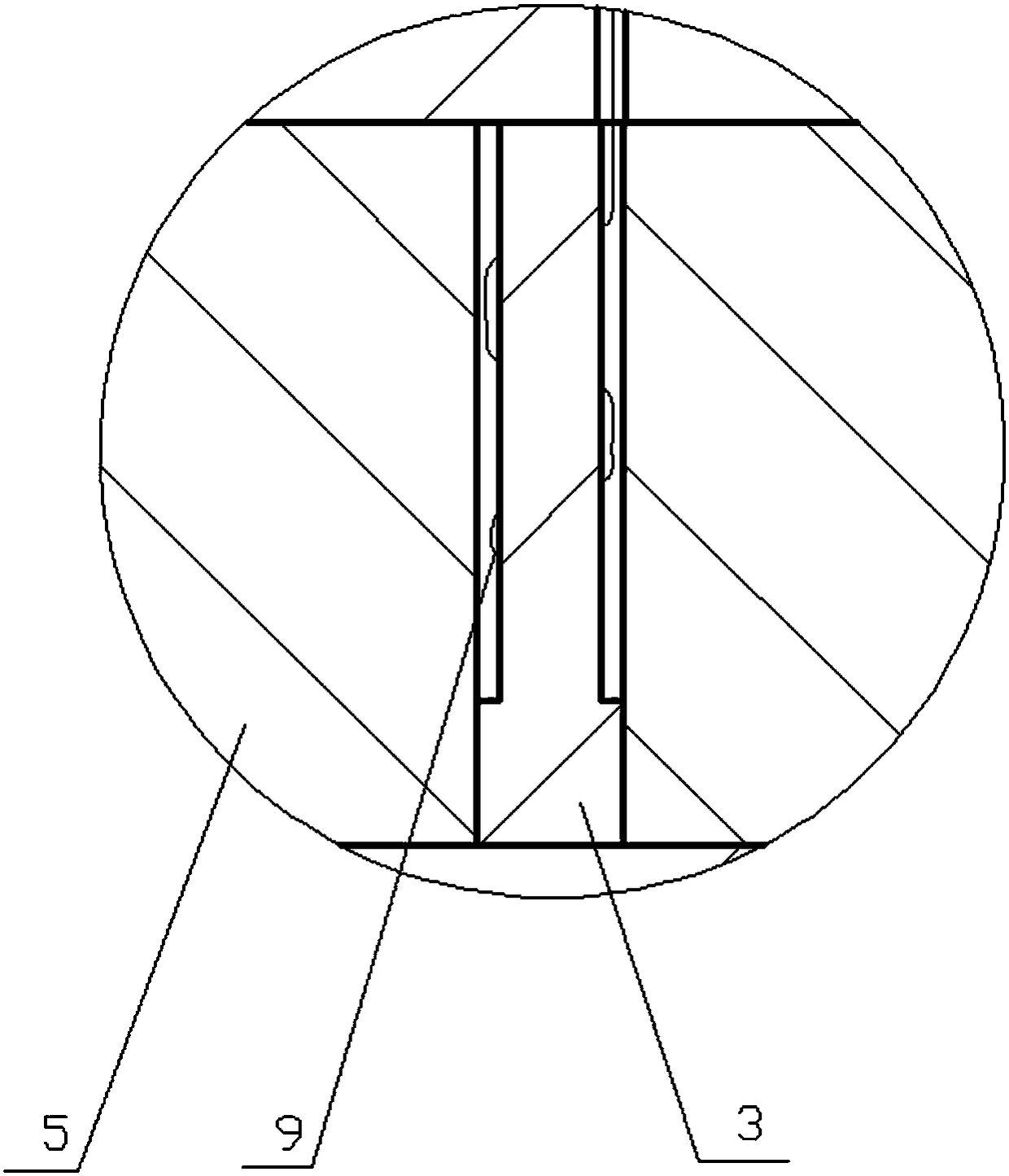

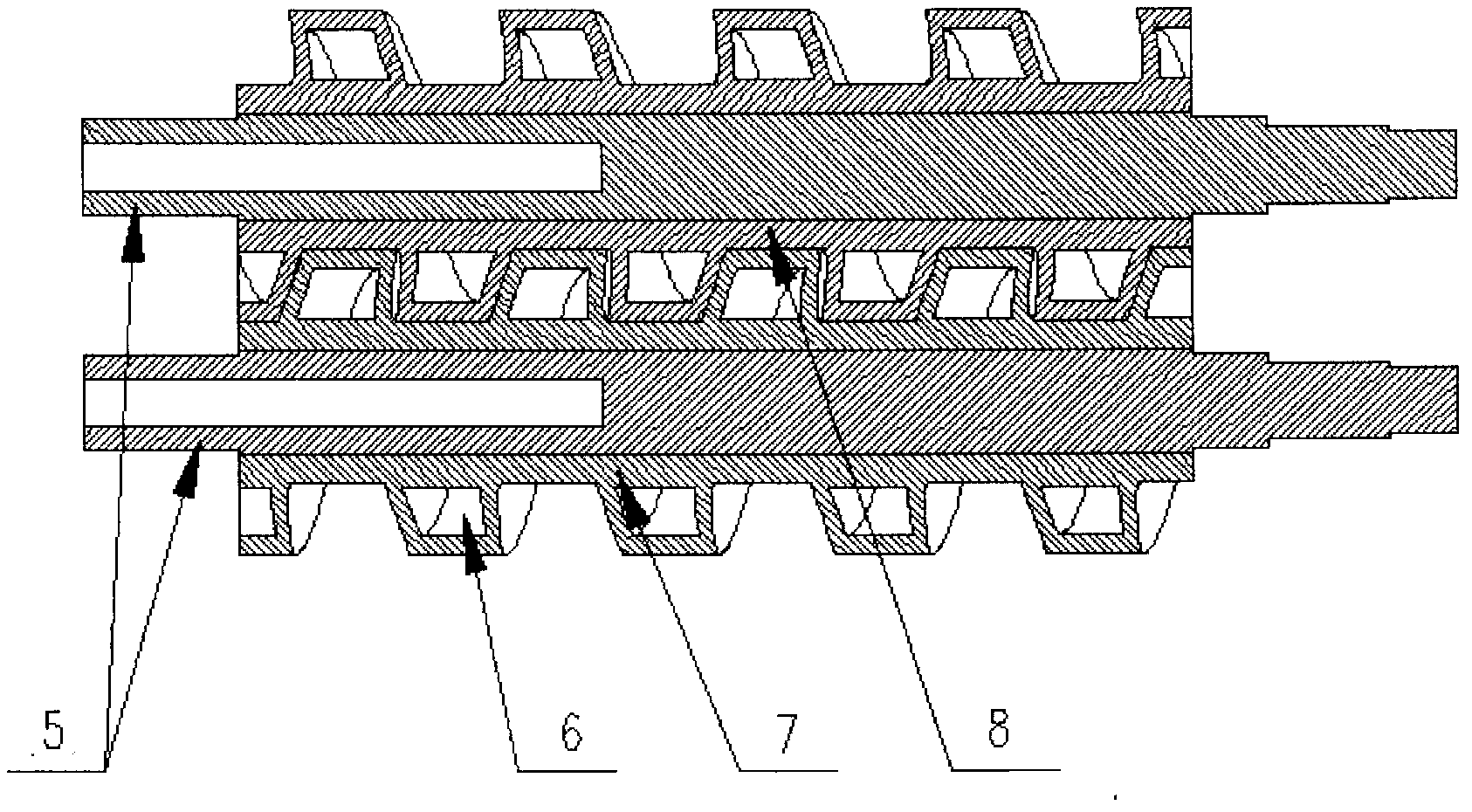

Sectionalized flexible roll convexity regulation and control roller

ActiveCN108372204AIncreased roll stiffnessHeating evenlyRollsMetal rolling arrangementsHoneycombEngineering

The invention discloses a sectionalized flexible roll convexity regulation and control roller. The sectionalized flexible roll convexity regulation and control roller is mainly characterized in that an axial center through hole is formed in a roll core, one or a plurality of parallel ring-shaped electromagnetic rods are arranged on the roll core, axial through holes are regularly formed in the ring-shaped electromagnetic rods to be similar to 'honeycombs' in the appearance, a bundle of wires penetrates each axial through hole, two ends of each bundle of wires are individually connected with power sources by slide rings, signals can be independently fed by each bundle of wires, a groove is formed in the inner peripheral surface of each electromagnetic rod, a temperature sensor is arranged in each groove, an insulating support ring is arranged between every two corresponding electromagnetic rods, grooves are formed in two end surfaces of each insulating support ring, two shaft sleeve endcovers are arranged on the outer sides of the electromagnetic rods at two ends of the roll core, one of the shaft sleeve end covers is positioned by shaft shoulders, the other shaft sleeve end coveris connected onto the roll core in a threaded manner, grooves are formed in the end surfaces, which are adjacent to the corresponding electromagnetic rods, of the two shaft sleeve end covers, cylindrical roll sleeves are arranged on the outer peripheral surfaces of the electromagnetic rods, the insulating support rings and the shaft sleeve end covers, and a slide ring is arranged on the top of theend, which is provided with a boss, of the roll core. The sectionalized flexible roll convexity regulation and control roller has the advantages of high plate shape regulation and control ability, roller stiffness and regulation and control speed.

Owner:YANSHAN UNIV

Pipe jacking construction technology through water-mud balance

The invention discloses a pipe jacking construction technology through water-mud balance. The pipe jacking construction technology comprises the steps of construction preparation, equipment mounting and debugging, pipe jacking machine out of a hole, pipe section jacking construction, intermediate jacking station jacking construction, main top jacking and the like, and circulation is conducted till jacking is finished. Through the construction technology, construction is conducted especially aiming at the specific soil texture of the pipe jacking construction technology, the operation difficulty is greatly reduced, the maximum amount of excavation is increased, the construction technology is easy, the construction progress is quick, the construction difficult problems such as ground subsidence are controlled within the range stipulated by standards, and the construction technology is suitable for being applied and popularized.

Owner:ZHEJIANG BAOTIAN ENVIRONMENT CONSTR CO LTD

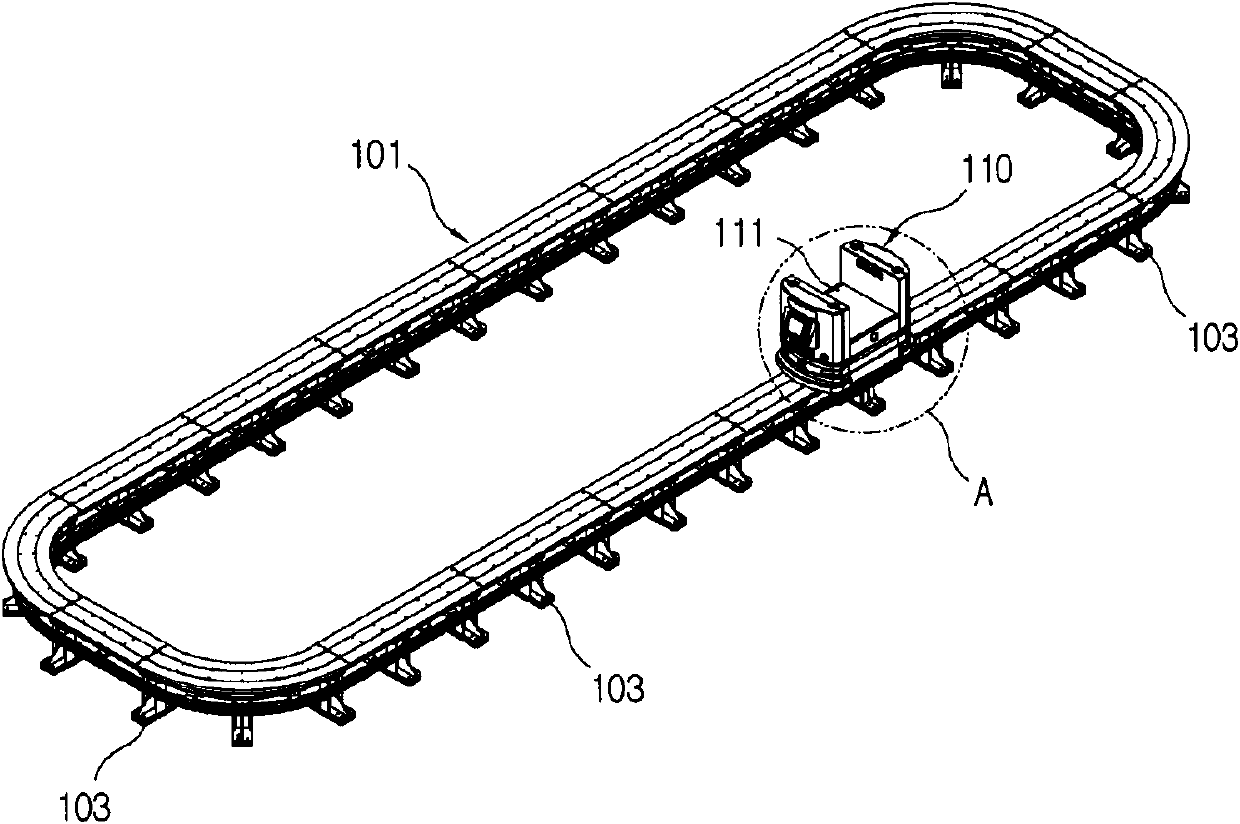

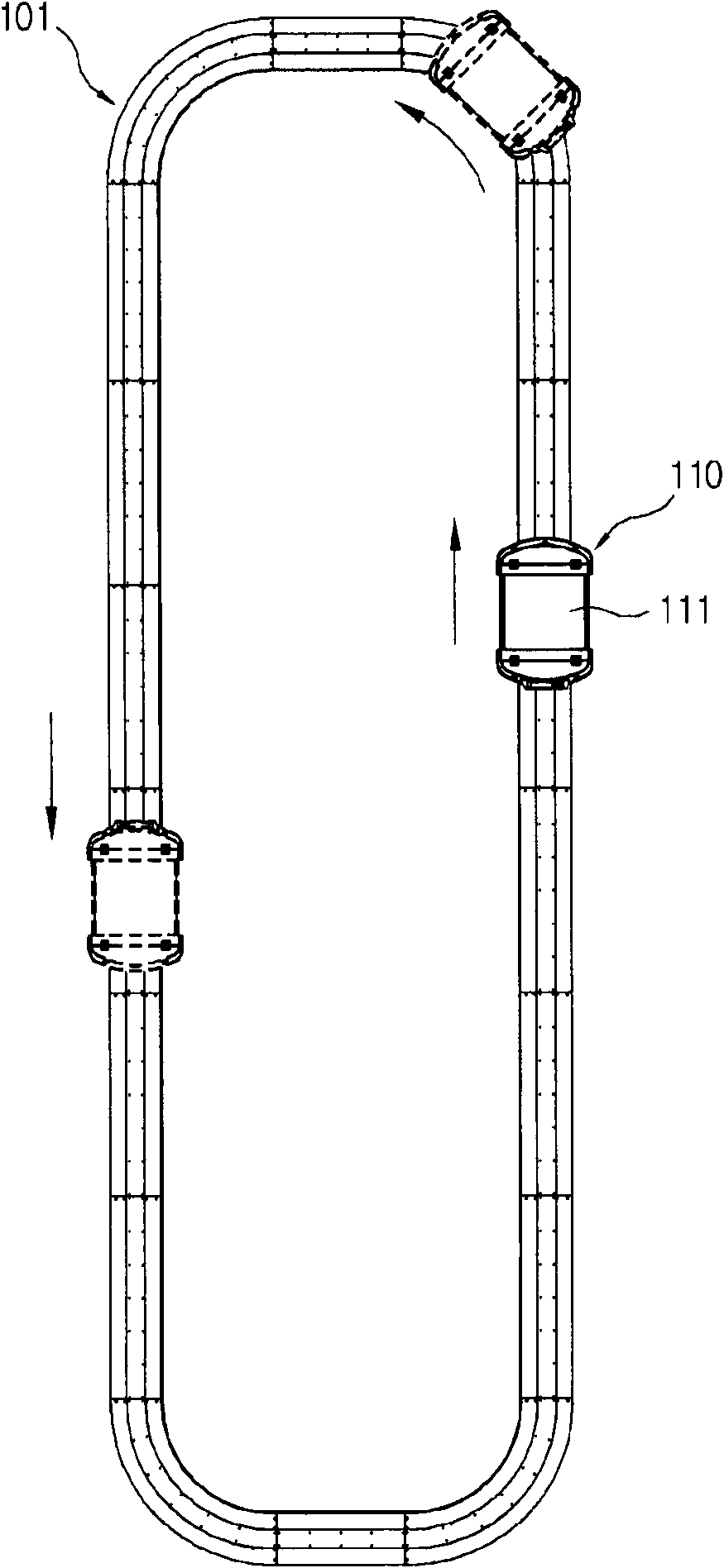

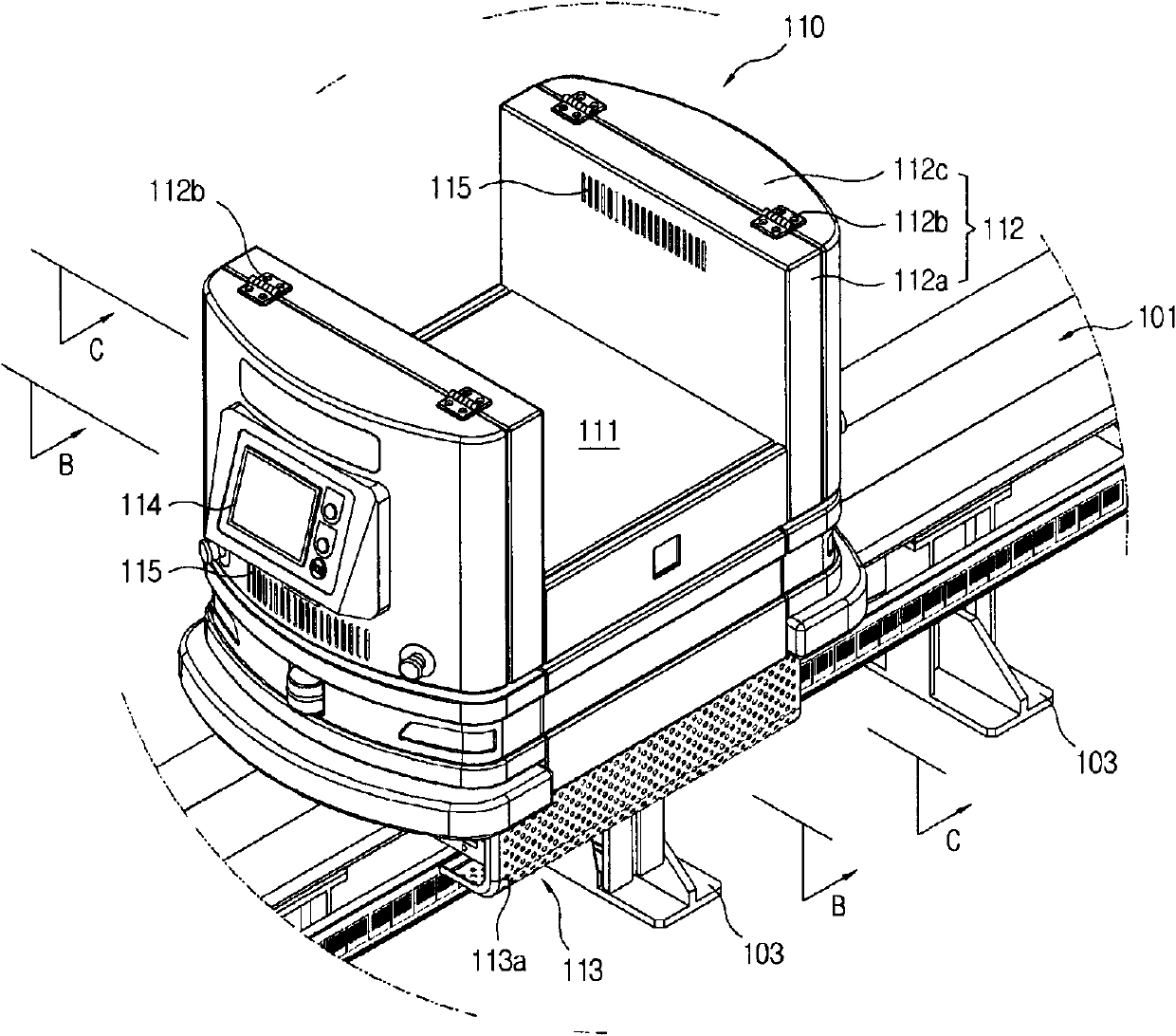

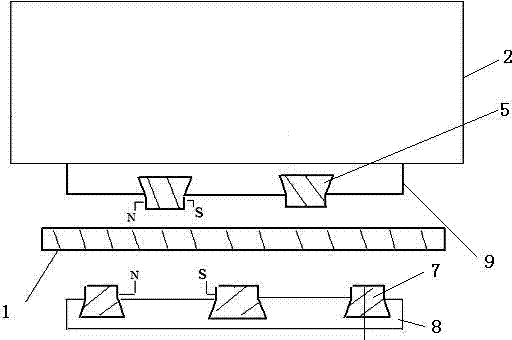

Magnetic levitation transferring system

InactiveCN102030192AStable structureAvoid vibrationNon-mechanical conveyorsNoise generationTransfer system

The present invention provides a magnetic levitation transferring system which comprises the following components: a loading unit which is loaded with object; a body transferring unit while the loading unit is coupled to the body transferring unit at one side; a rail which forms a line for transferring the body transferring unit; a levitating unit which is connected with the body transferring unit and causes the body transferring unit to levitate to a preset height relatively to the rail; a pushing unit which is connected with the body transferring unit and provides a pushing force for transferring the body transferring unit levitated by the levitating unit along the line of the rail; and a non-contact power source which receives power through a non-contact mode and supplies power for at least one in the levitating unit and the pushing unit. Through the configuration, a magnetic levitation technique is adopted in transferring object as one of the non-contact techniques thereby settling the problems of assembly damage caused by wearing and abrasion, noise generation and particle generation. Furthermore the power is supplied stably and safely while the object is transferred with a high speed.

Owner:SFA ENG CORP

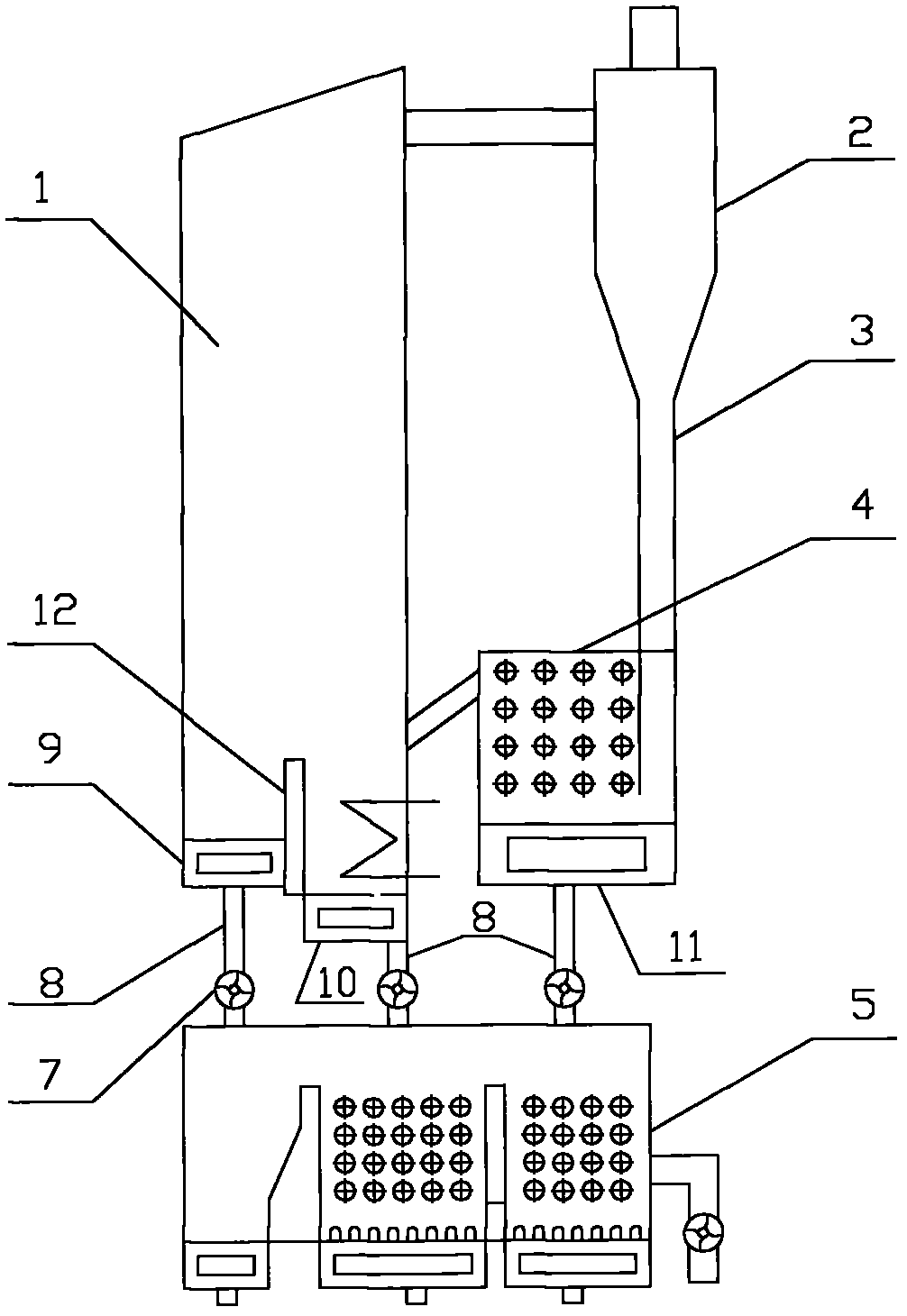

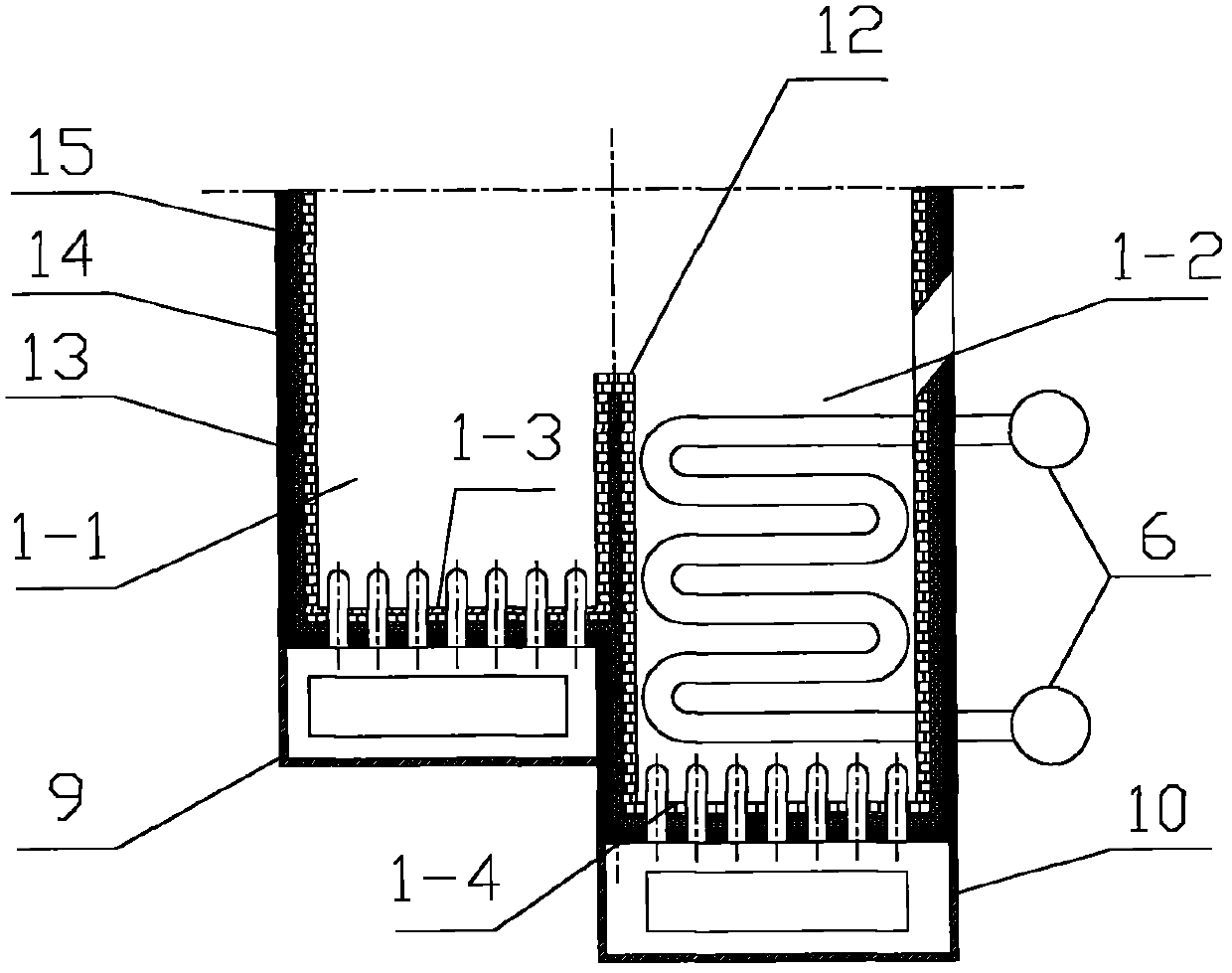

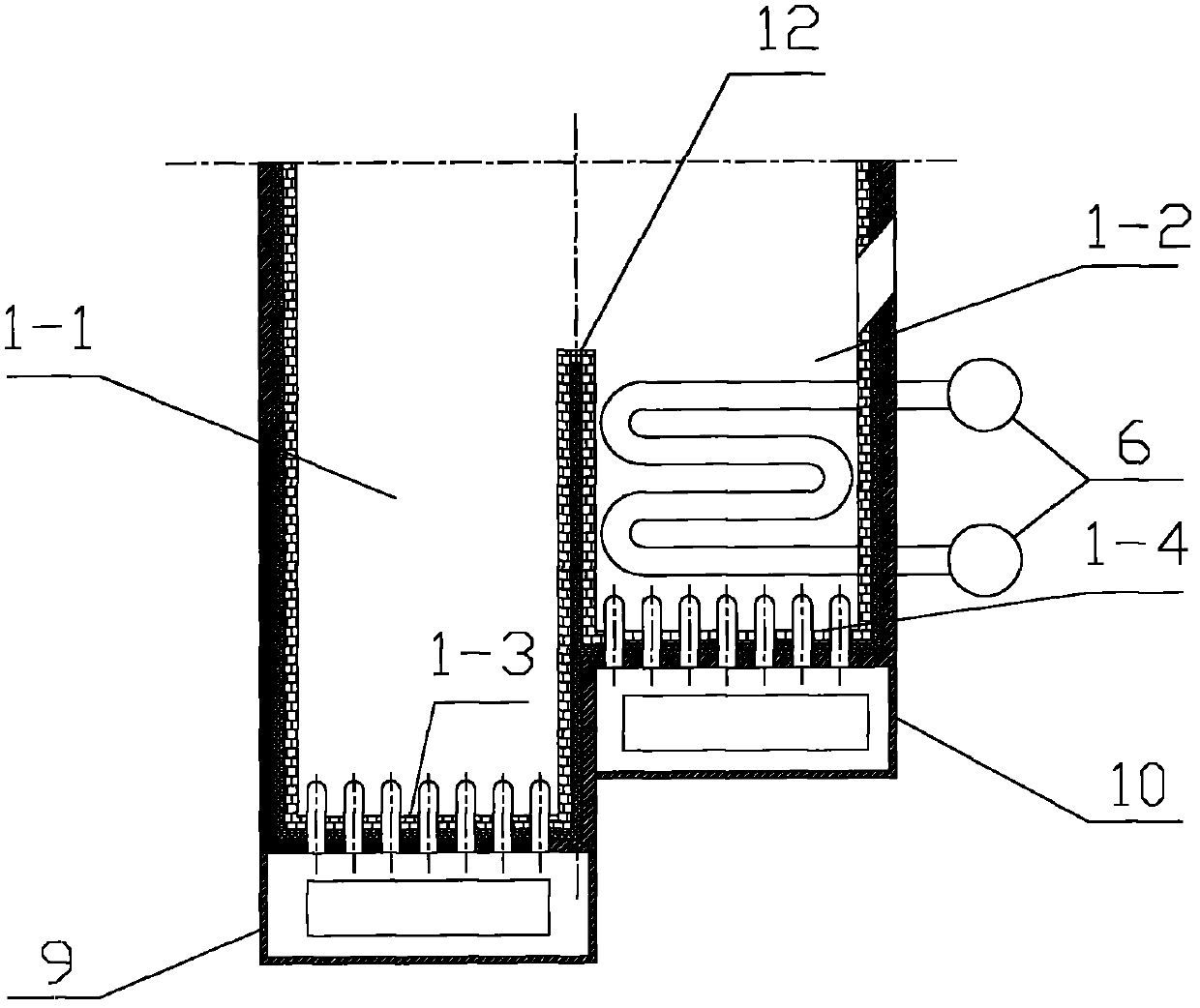

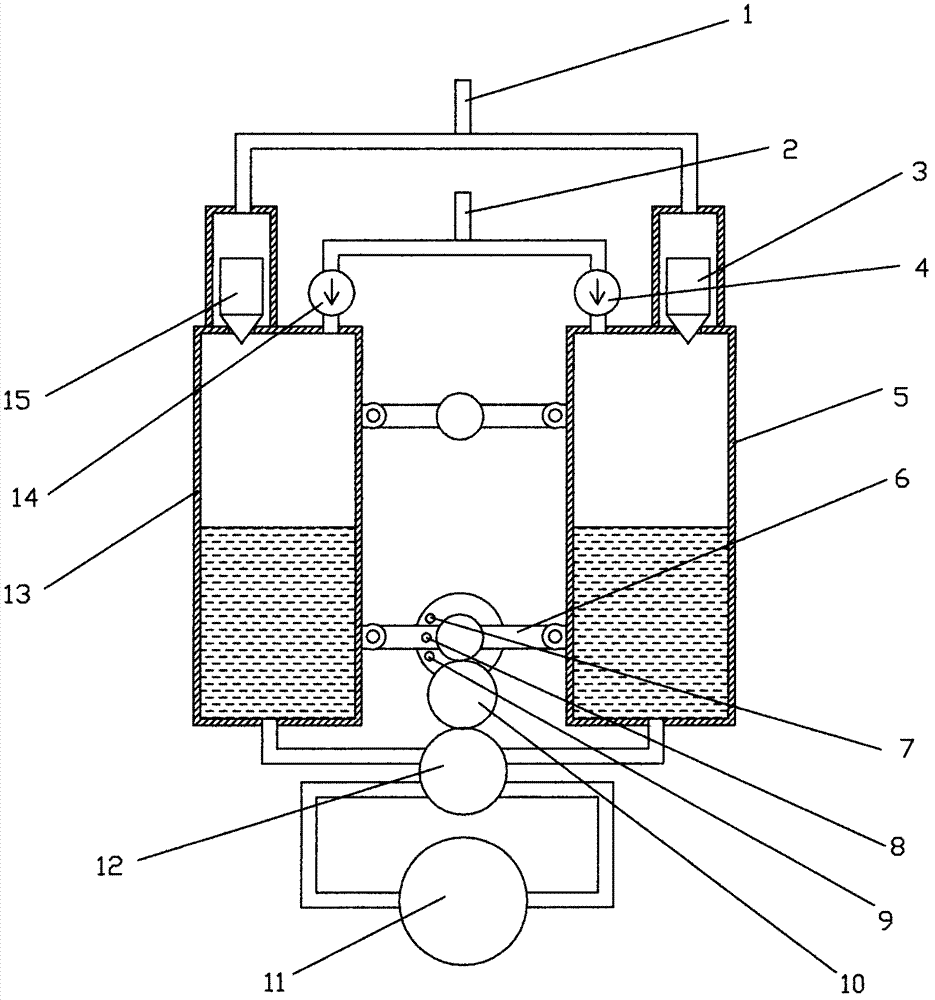

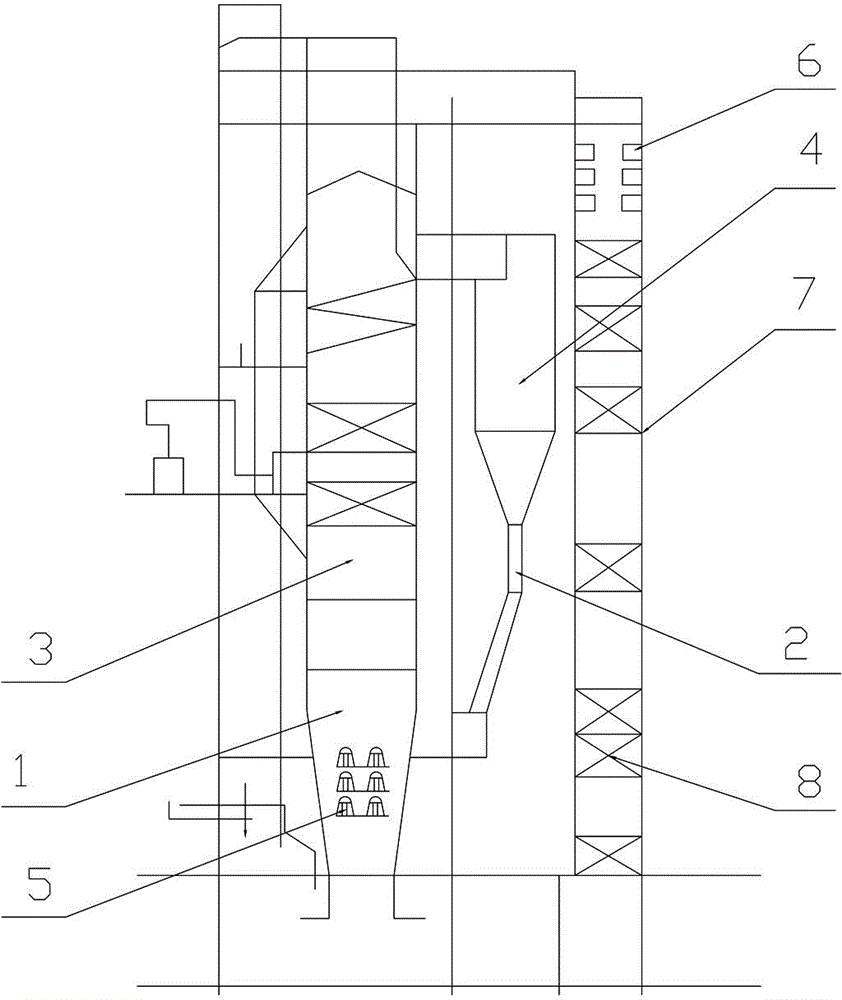

Circulating fluidized bed boiler device using low calorific value coal gangue for post ignition

InactiveCN101995016ASolve wear and tearSolving Adaptive ProblemsFluidized bed combustionApparatus for fluidised bed combustionCombustion systemCombustion

The invention discloses a circulating fluidized bed boiler device using low calorific value coal gangue for post ignition, and belongs to a combustion system of a coal fired boiler. The device mainly comprises a hearth, a cyclone separator, a riser, a circulating ash heat exchanger, a header, a fluidized bed slag cooler and the like. The device is characterized in that: heat exchange and combustion are separated; the combustion is performed in a heat insulation region; a heating surface is arranged in a fluidized bed with finer particles; the device comprises a fine particle fluidized bed, a circulating ash heat exchanger and a fluidized bed slag cooler; the bottom part of the hearth is divided into two fluidizing regions; the flow direction of the bed material between the two fluidizing regions is changed by changing the fluidizing air parameter and slag discharge of the two fluidizing regions so as to fulfill the aim of adjusting the bed temperature; and both the hearth and the circulating ash heat exchanger are communicated with the fluidized bed slag cooler, so that the ash and the slag of the fluidized bed slag cooler can be independently discharged to greatly improve the adaptability of the boiler to fuels. The device has the main advantages of burning the fuels such as coal gangue with a low calorific value and the like and solving the problem of heavy wearing of the heating surface well.

Owner:CHONGQING UNIV

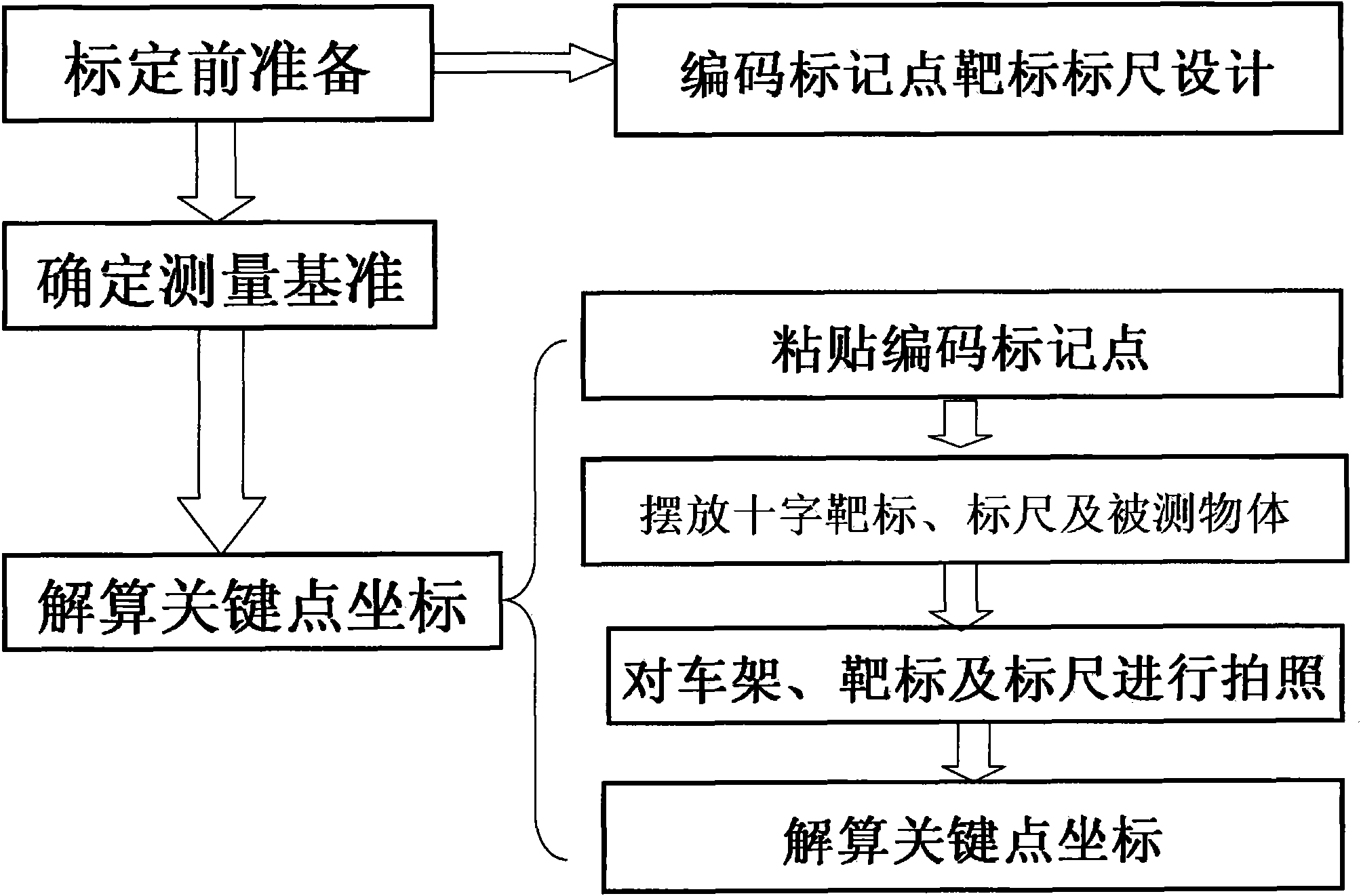

Method for measuring key point of car frame based on coding points and computer vision

The invention belongs to the field of reverse engineering, in particular to a method for measuring a key point of a car frame based on coding points and computer vision. The method comprises the following steps of: sticking a digital three-dimensional coding mark point to a key position of the car frame, placing a cross target and a scale stuck with coding mark points near an object, and firstly acquiring pictures of the object to be measured in different directions by using a high-precision digital camera; calculating three-dimensional coordinates corresponding to certain pixel points of the mark point through the acquired pictures; and acquiring the coordinate information of the key point of the car frame by combining an algorithm through the acquired pictures and the three-dimensional coordinate information of the marker point so as to provide data basis for subsequent car frame matching. The method for measuring the key point of the car frame enriches the three-dimensional vision measurement basic theory, lays the foundation for the reverse engineering and the three-dimensional vision detection theory, and improves the manufacture level in China.

Owner:TIANJIN POLYTECHNIC UNIV

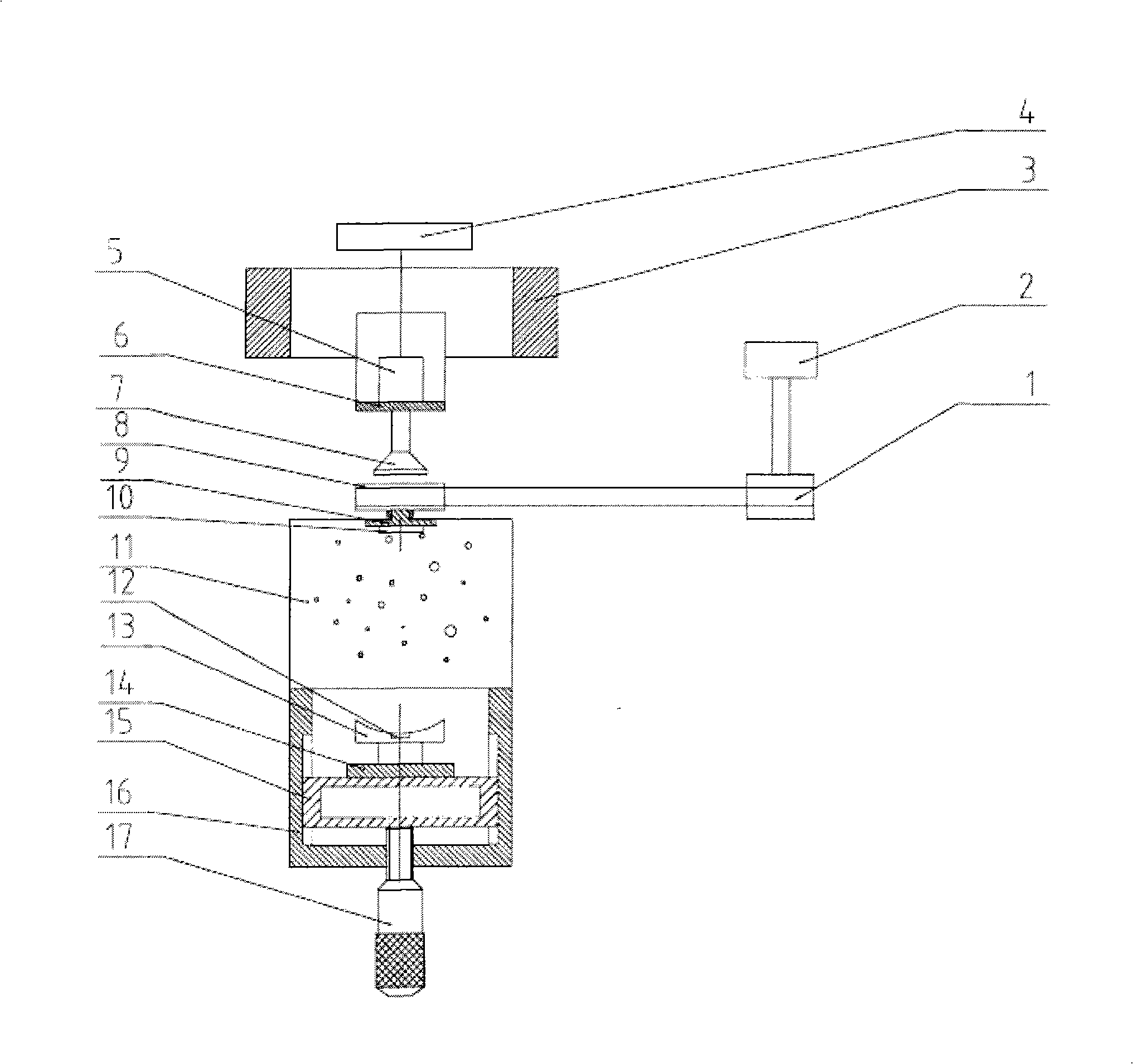

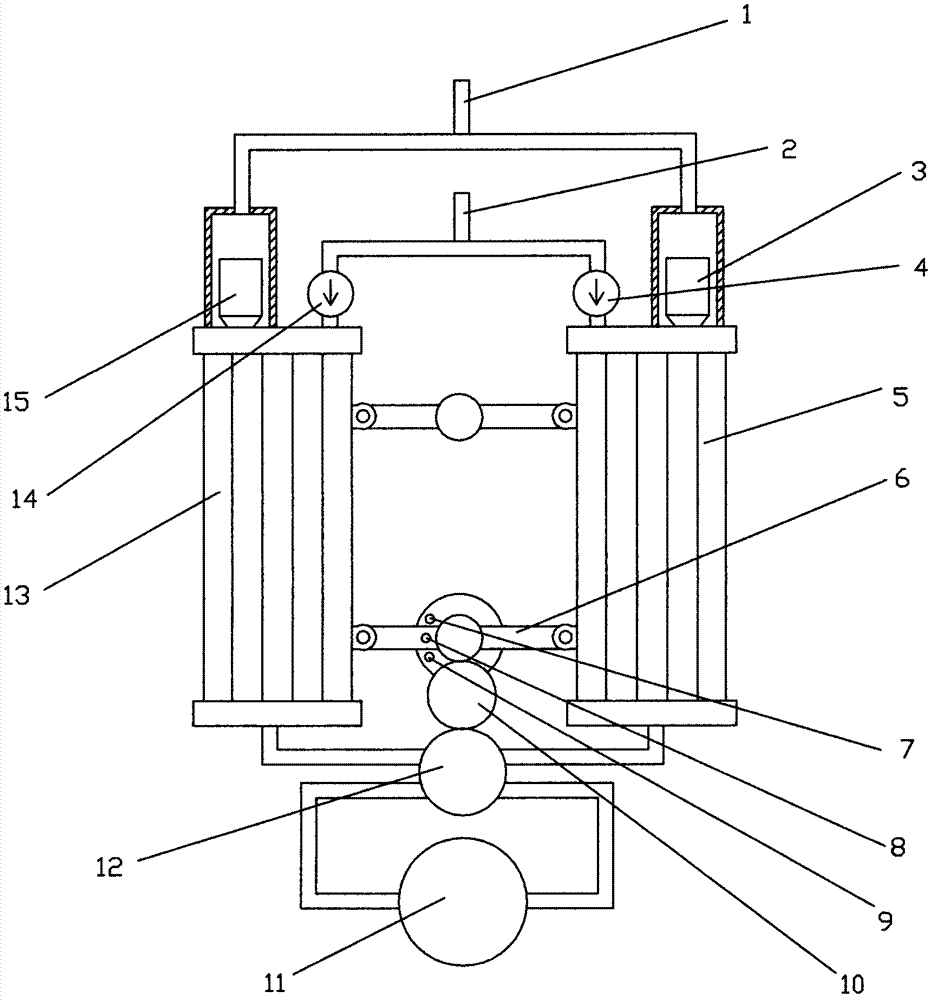

Sound suspending polissoir for nanometer mechanics characterization sample

InactiveCN101344468AAchieve removalGood dispersionPreparing sample for investigationUltrasonic sensorTest sample

The invention discloses an acoustic levitation polishing machine of mechanically representing nano test samples and comprises a machine frame, a pulse power source, a holding fixture that is used for clamping a working piece to be processed, an ultrasonic energy transducer, a container that is used for storing polishing liquid, an ultrasonic reflecting end, and a tuning mechanism that is used for adjusting the distance between the ultrasonic reflecting end and the ultrasonic energy transducer. The ultrasonic energy transducer, the container and the tuning mechanism are all arranged above the machine frame, the pulse power source is connected with the ultrasonic energy transducer, the container is arranged under the ultrasonic energy transducer, the holding fixture is arranged above the container and is connected with a belt wheel actuating mechanism, and the ultrasonic reflecting end is arranged under the container, coordinated with the ultrasonic energy transducer and connected with the tuning mechanism. The invention provides an acoustic levitation polishing machine of the mechanically representing nano test samples with good applicability and well polishing effect.

Owner:ZHEJIANG UNIV OF TECH

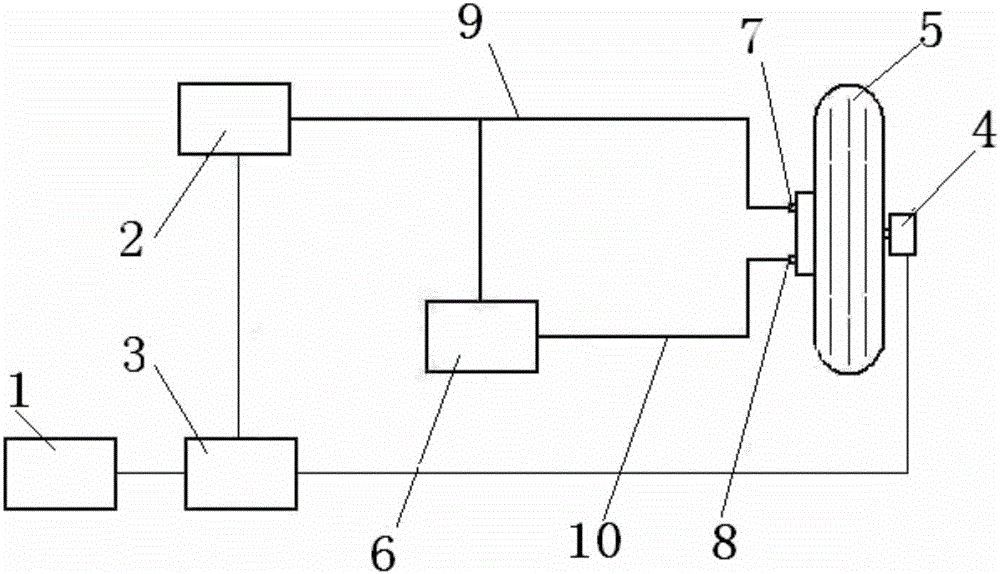

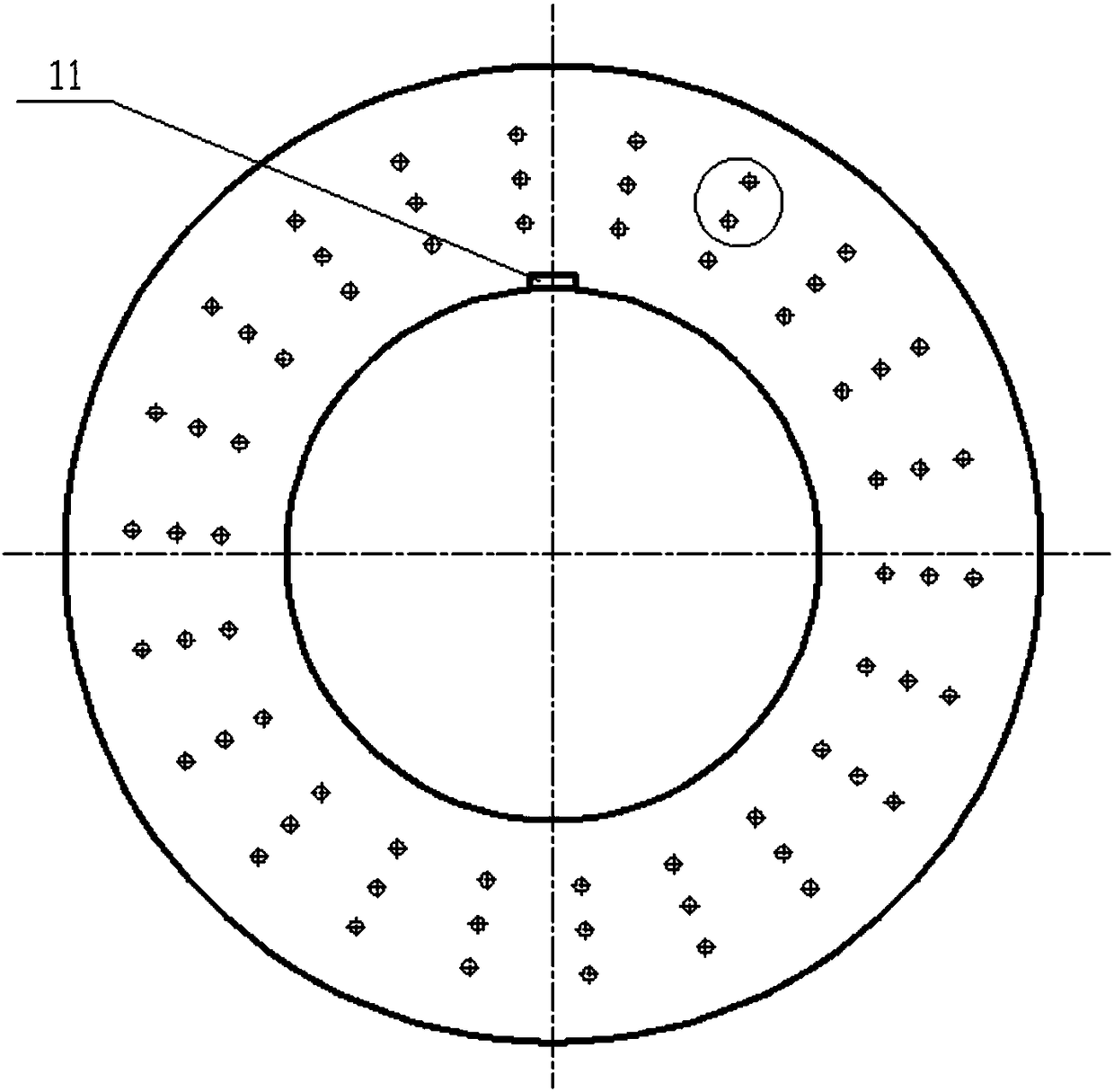

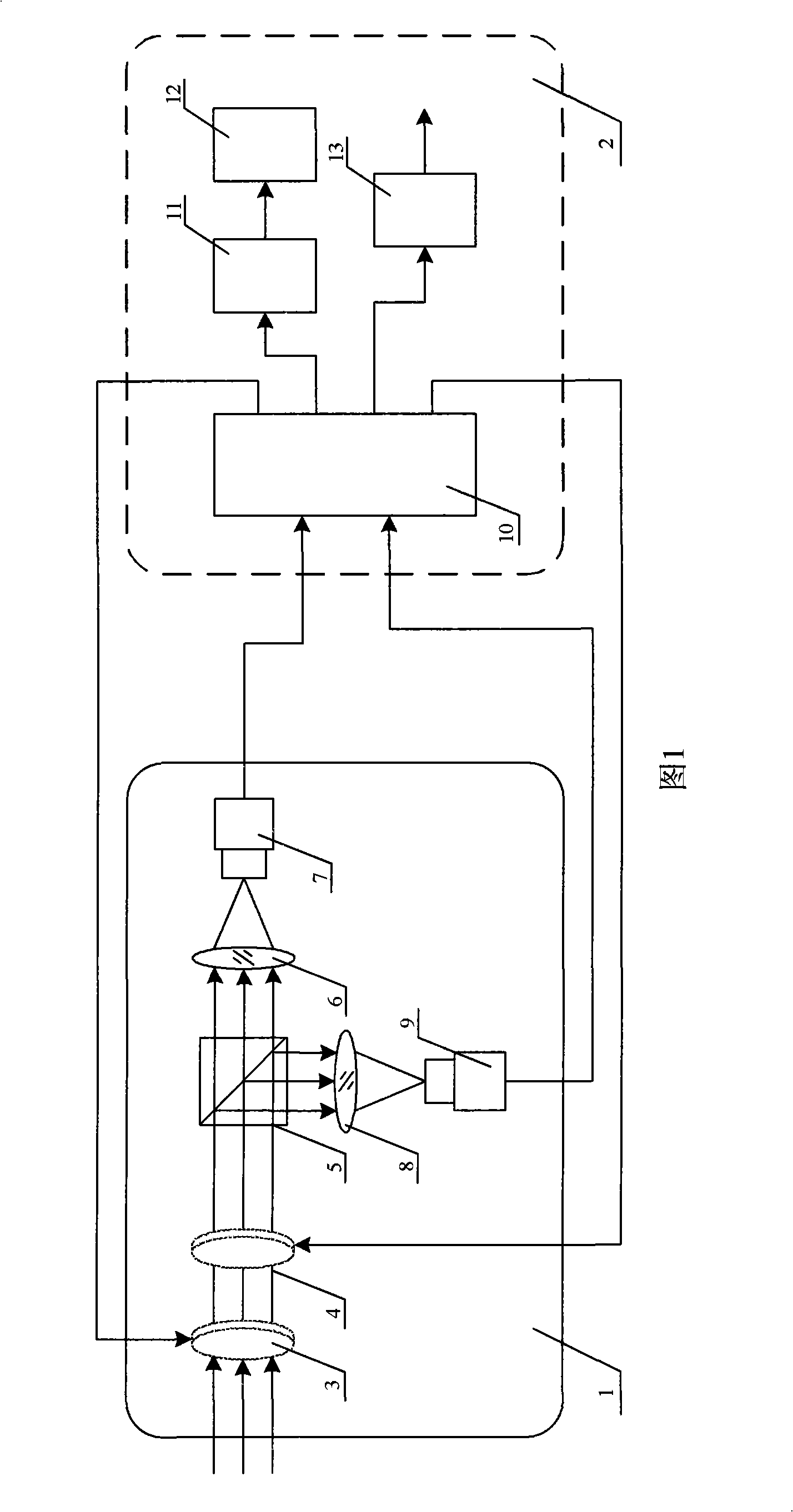

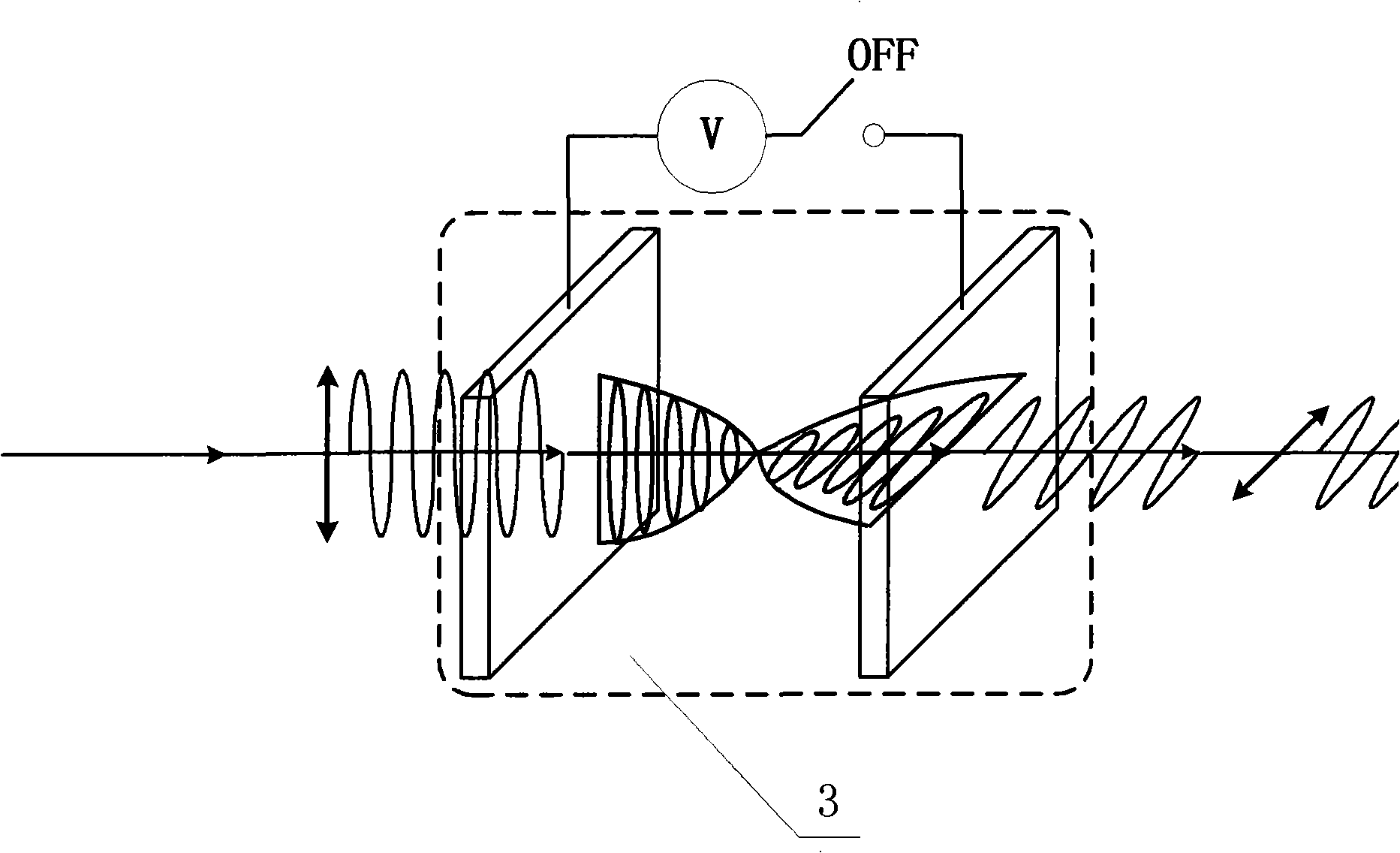

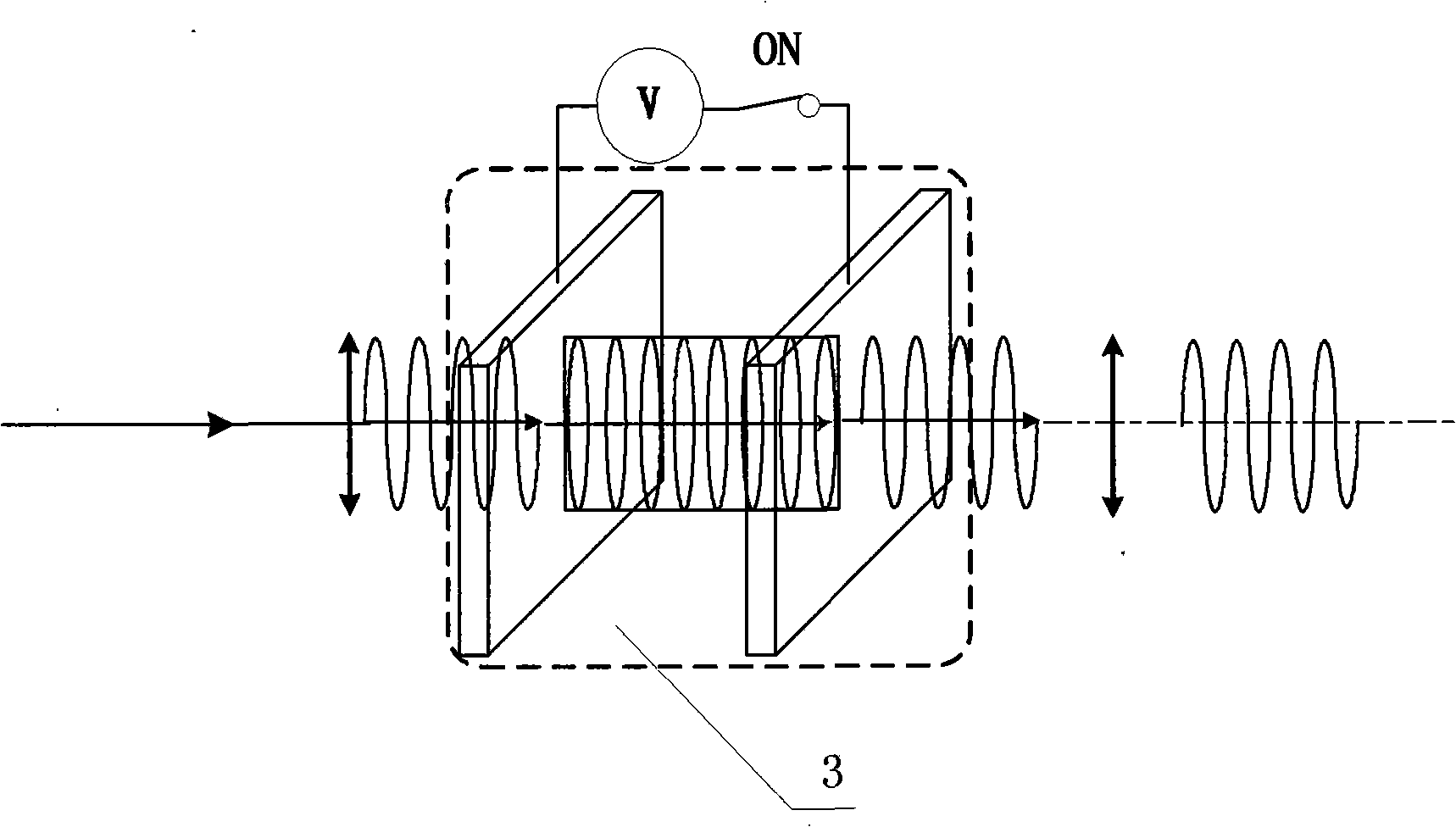

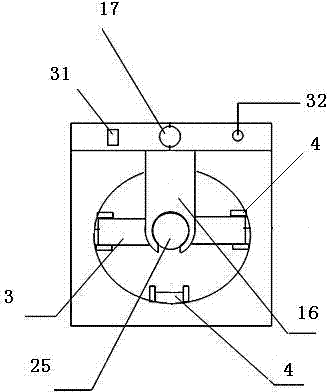

Embedded type polarization state measuring instrument based on LCD

InactiveCN101303256ASolve wear and tearOvercoming Vibration Source ProblemsLight polarisation measurementNon-linear opticsMeasuring instrumentBeam splitting

The present invention relates to an embedded polarization state measuring apparatus, which is composed of a detection unit (1), liquid crystal type adjustable-phase delayer(s) (3, 4), a polarization beam-splitting prism (5), a collective lens (6), a photo detector (7) arranging in a shaft of a first part of the detection unit (1); a collective lens (8) and a photo detector (9) arranging in a shaft of a second part being orthogonal with the first part; a control unit (2) containing a signal-collection and liquid crystal control module (10), a data treatment module (11), a display module (12) and a RS232 serial port (13). By means of replacing rotational wave sheet by the liquid crystal type adjustable-phase delayer, It is able to control polarization state of incident light and measure Stokes parameter for real time quantity of polarization state accurately, and to overcome mechanical vibration problem; it is used for collimation of optical element(s), measurement of optical phase delay, material representation, medicament development, communication equipment, ellipse polarization instrument and spectrum application as well as space optical communication.

Owner:CHANGCHUN UNIV OF SCI & TECH

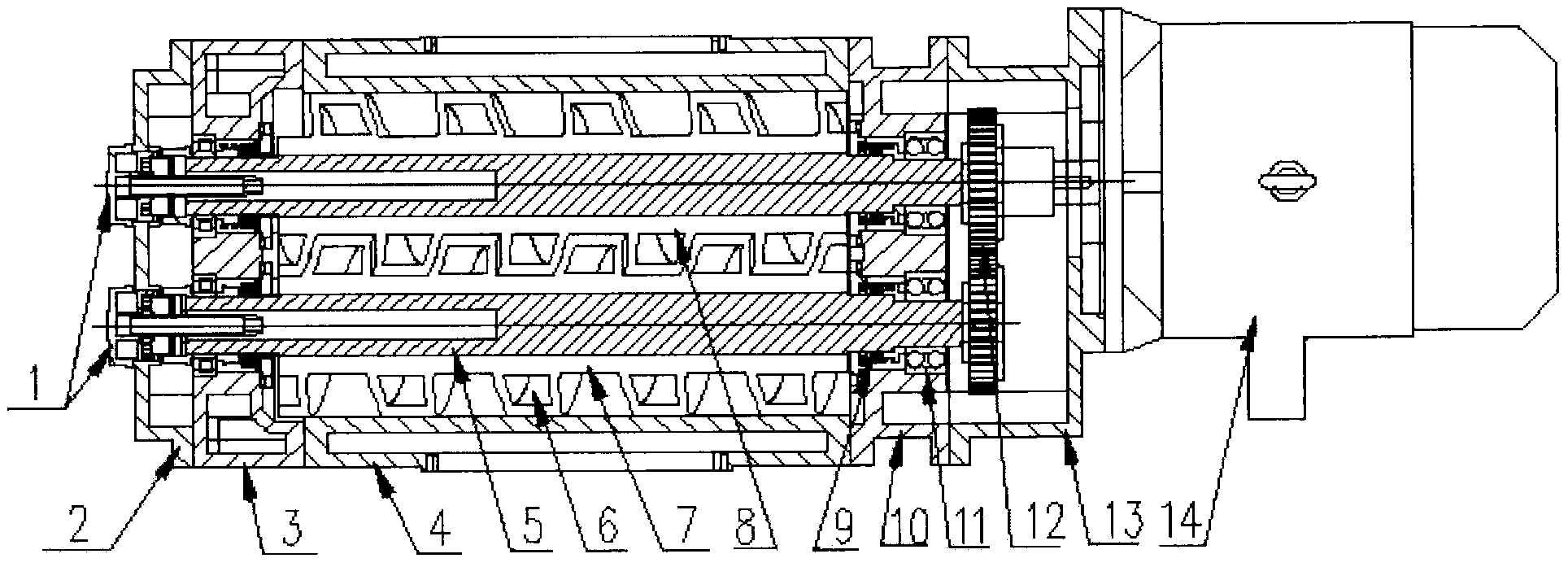

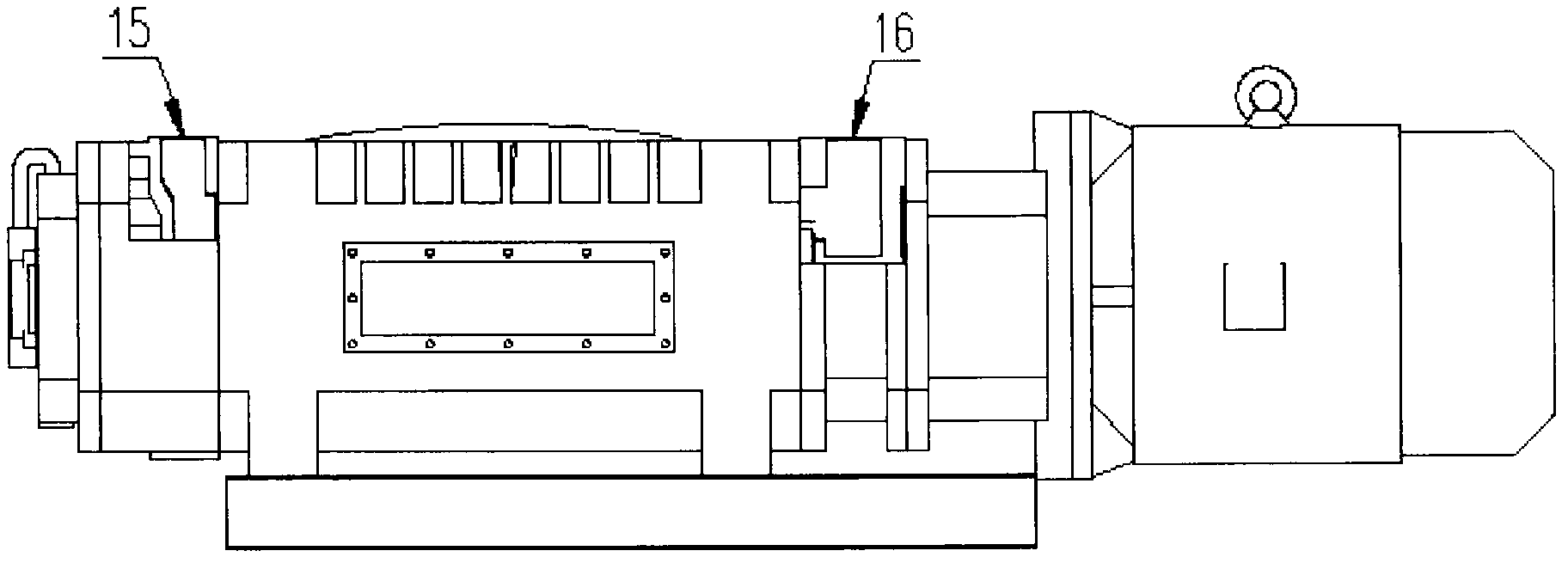

Zero-drive chain digital control gear hobbing machine

InactiveCN101298106AGuaranteed stabilityNo vibrationFeeding apparatusGear-cutting machinesHobbingGear wheel

The invention discloses a numberical control hobbing machine with zero transmission, which comprises a machine body, a main shaft system, a hobbing cutter feeding and angle adjusting system and a control system; the main shaft system comprises a functional part of a hobbing cutter main shaft and a functional part of work-piece main shaft part; the functional part of the hobbing cutter main shaft is an integration of the rotator of the servo motor I and the hobbing cutter main shaft, and the functional part of the work-piece main shaft is an integration of the rotator of the servo motor II and the work-piece main shaft. The numberical control hobbing machine of the invention can remove the manufacturing errors of transmission component of generating motion and the influence on gear process caused by space and assembly error, is able to greatly improve process accuracy and process speed of machine tool. The numberical control hobbing machine of the invention has simple structure, is able to improve overall rigidity of machine tool, solves the wearing problem caused by mechanical transmission chain, improves the retentivity of precision, causes the hobbing speed to be higher than the numberical control hobbing machine with traditional structure, shortens milling time as well as based on which, the hobbing machine is provided with the machine tool conditions required by dry type hobbing through adopting a series of matching technical measures.

Owner:CHONGQING UNIV

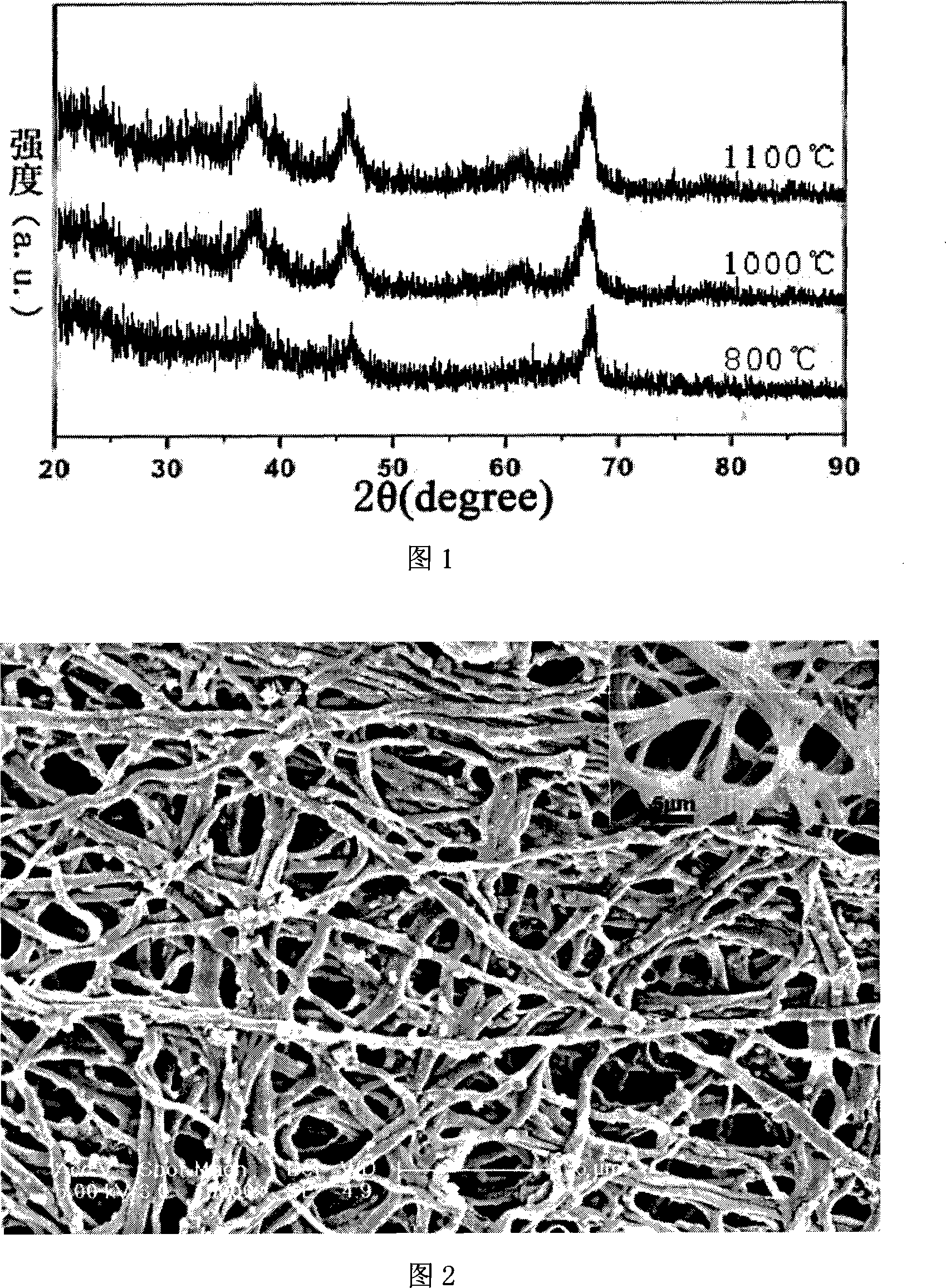

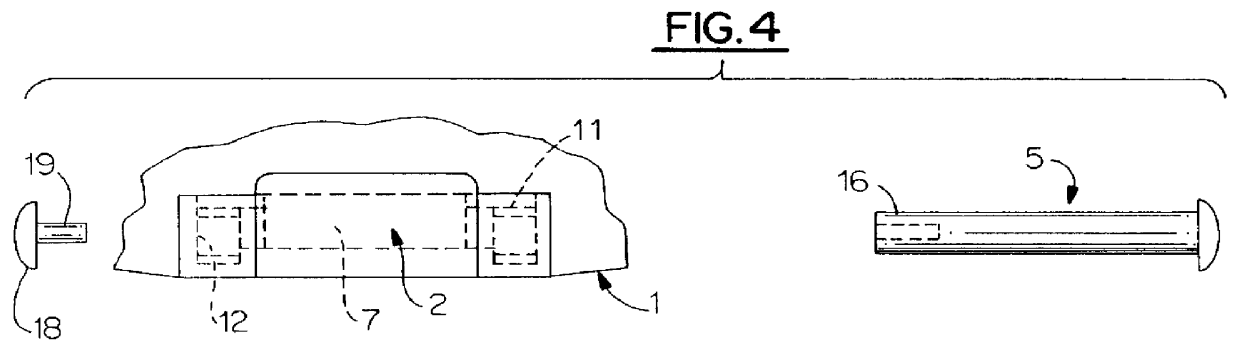

Method for preparing classifying porous aluminum oxide nano heat insulating material

InactiveCN101100307AReduce heat transferSmall coefficient of thermal expansionNanostructure manufactureChemical industryCeramic sinteringEGG SHELL MEMBRANE

This invention relates to the production of classified porous alumina nanometer thermal insulating material, based-on biological templet synthesis technique, by using waste egg shell membrane as raw material. First, the membrane is pretreated by separation and washing, followed by dipping in prodromal liquid aluminium salt solution, then oxidized burnt, forming alumina nanometer material in situ under the effect of biological templet. This invention has advantages of: simple process, low cost, being able to control the granule size and aperture dimension by regulating the burning temperature and speed of stepping-up temperature. The product has advantages of small heat conductivity, low expansion coefficient, well property of anti-heat shock, able to be used in field of metallurgical industry, ceramic furnace as excellent heat insulation refractory.

Owner:SHANGHAI JIAO TONG UNIV

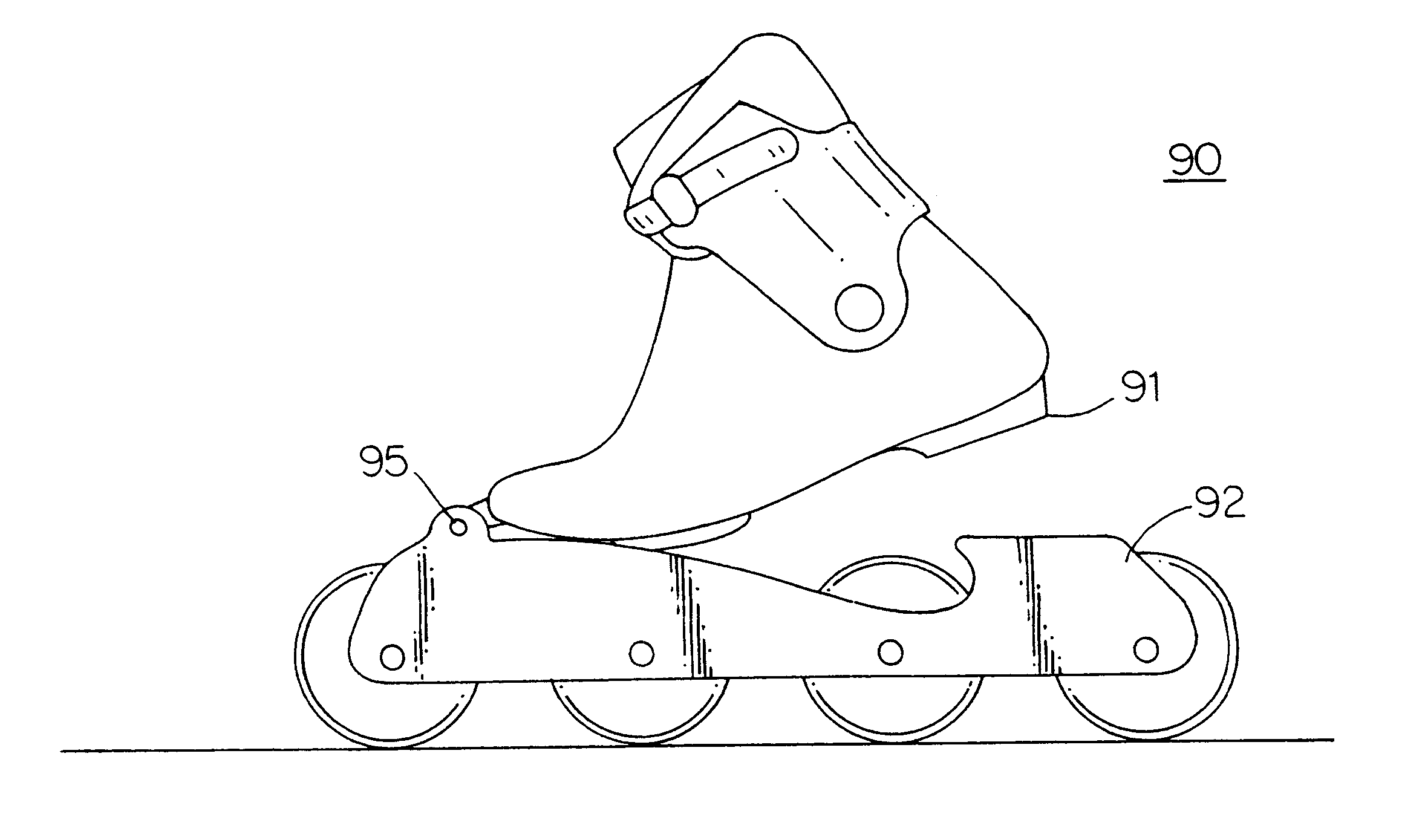

Footwear with a releasable pin for use in gliding sports

PCT No. PCT / FR96 / 00859 Sec. 371 Date Nov. 17, 1997 Sec. 102(e) Date Nov. 17, 1997 PCT Filed Jun. 7, 1996 PCT Pub. No. WO96 / 41547 PCT Pub. Date Dec. 27, 1996A boot suitable for use in association with various sports related gliding devices having a stirrup embedded in the sole of the boot containing a pair of opposed arms for removably supporting a pin therebetween.

Owner:SKIS ROSSIGNOL

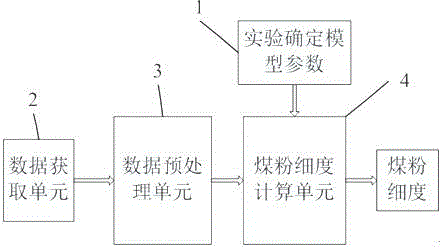

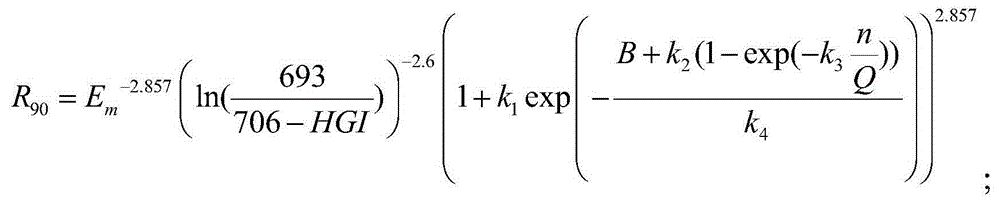

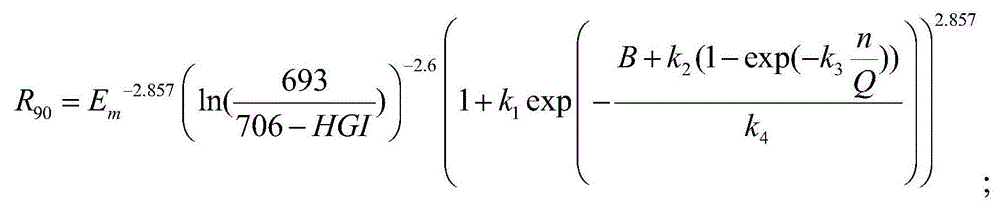

Coal mill pulverized coal fineness online monitoring method

The invention discloses a coal mill pulverized coal fineness online monitoring method; according to a pre-established model, during running, the coal mill dynamic separator revolving speed, the coal mill inlet primary air volume, the coal feeder coal-feeding quantity, the coal mill current, the coal Hardgrove grindability index and other parameters are acquired through a DCS system for estimating the fineness of current pulverized coal, and the reference is provided for the operation of a pulverizing system; the online monitoring method is used in the pulverized coal furnace pulverizing system, the outlet pulverized coal fineness can be monitored, and the economy is better compared with that of a system without monitoring the fineness; the method only utilizes DCS data, fire coal daily records and other related records in existing operation data, has no need of special sampling and measuring devices, is simple and practical, and avoids the problems of abrasion and blocking of sampling and measuring devices in an existing pulverized coal fineness physical measurement method.

Owner:STATE GRID CORP OF CHINA +3

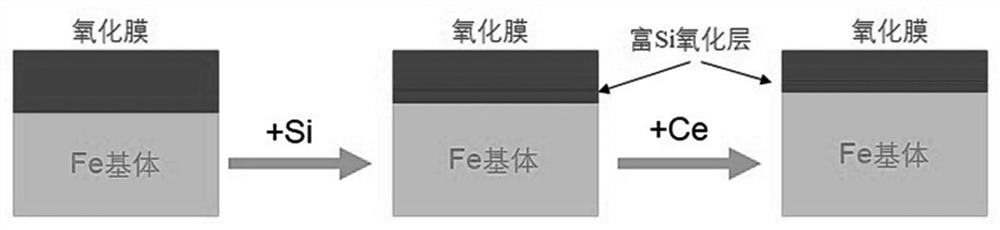

Hot stamping forming steel added with Ce alloy and hot stamping forming technology

The invention belongs to the technical field of steel preparation and particularly relates to hot stamping forming steel added with Ce alloy and a hot stamping forming technology. The hot stamping forming steel added with Ce alloy comprises the following chemical compositions in percentage by mass: 0.22-0.40% of C, 1.0-2.5% of Mn, 1.2-2.0% of Si, 0.05-0.5% of Al, 1.2-2.5% of Cr, less than 0.6% ofMo, less than 0.1% of Nb, less than 0.15% of V, 0-0.1% of Ti, 0-0.01% of B, 0.01-0.03% of P, less than 0.004% of O, less than 0.002% of S, 0.03-0.08% of Ce, less than 0.01% of Ca, less than 0.01% of Mg and the balance of Fe and unavoidable impurities. The hot stamping forming steel adopts brand new composition design and a conventional production process for production and hot stamping. Through changing the thickness and structure of oxidized scale during the heating and stamping process of hot forming steel, the problem about falling of the hot forming steel during the heating and stamping process is solved, and finally, a thin oxide layer with a stable and dense structure is formed on the surface of a stamping component, so that the problem that a die is worn because the oxide layer of the hot stamping steel falls off is solved, at the same time, shot blasting treatment is also avoided, and the hot stamping forming steel has the direct coating application condition and does not pollute the environment.

Owner:LIAONING INST OF SCI & TECH

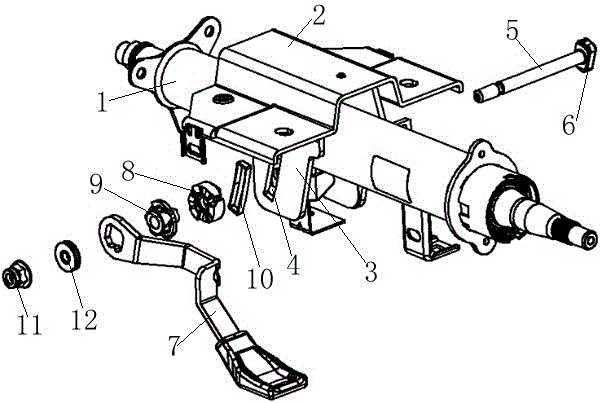

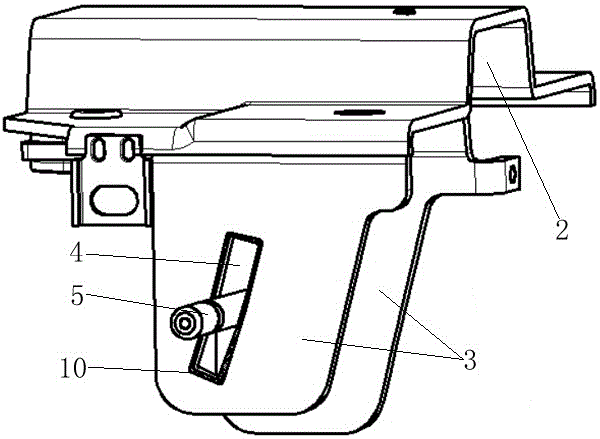

Angle adjusting mechanism of steering tubular column

The invention relates to an angle adjusting mechanism of a steering tubular column. The angle adjusting mechanism comprises the steering tubular column, an adjusting bracket and an adjusting rod, wherein a bracket is fixedly connected onto the steering tubular column; a through hole is formed in the bracket; the adjusting bracket is provided with two side plates; first strip-shaped holes are formed in the two side plates; the bracket is located between the two side plates; the adjusting rod penetrates through the through hole and the two first strip-shaped holes; a locking structure is arranged on the adjusting rod; each first strip-shaped hole is provided with an elastic lining; each elastic lining is provided with a second strip-shaped hole; one end of each second strip-shaped hole in the length direction is a large-width end, and the other end of each second strip-shaped hole is a small-width end; the width of each second strip-shaped hole is gradually reduced from the large-width end to the small-width end; the adjusting rod penetrates through the two second strip-shaped holes; and the diameter of the adjusting rod is greater than the width of the small-width end of each second strip-shaped hole. With the adoption of the angle adjusting mechanism of the steering tubular column, an abrasion problem caused by the fact that the steering tubular column is adjusted can be solved, and noises caused by the fact that the steering tubular column is adjusted can also be reduced, so that the reliability and the comfort are improved when the steering tubular column is adjusted.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

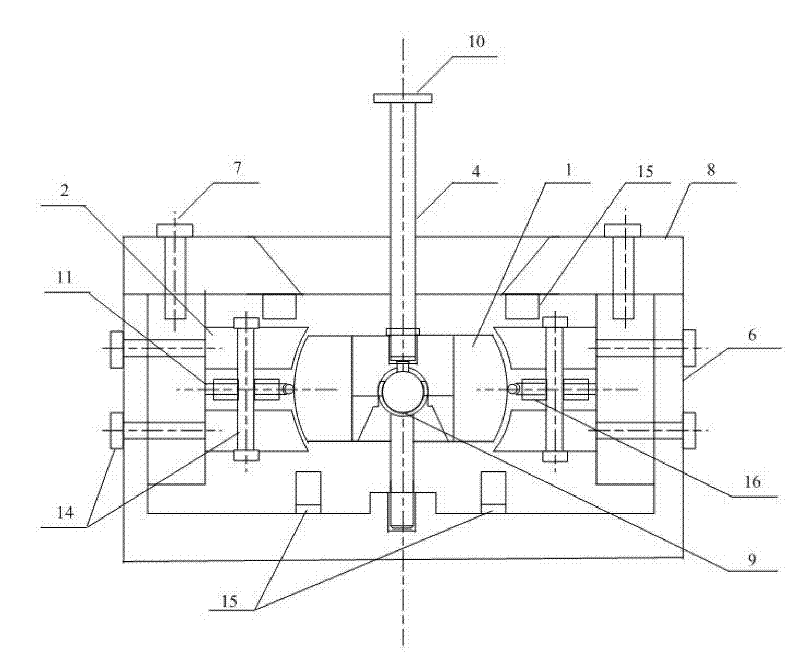

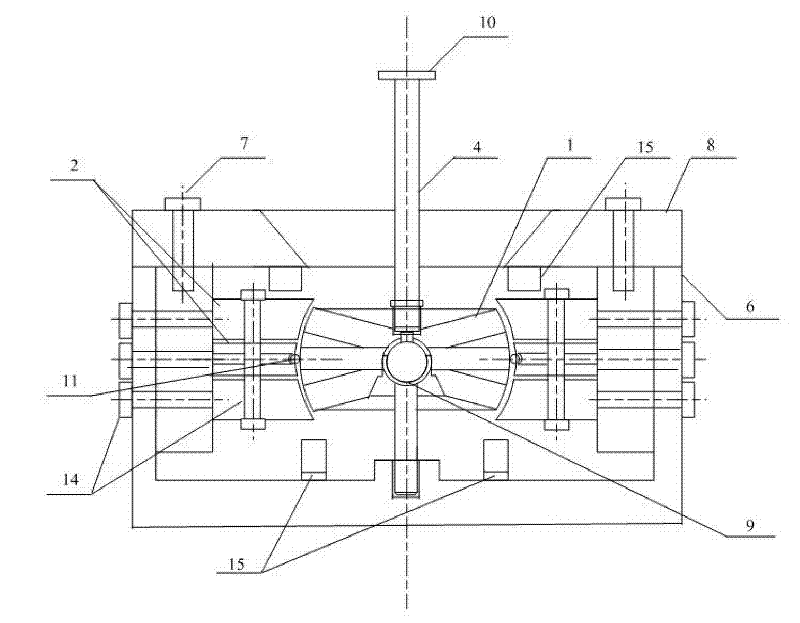

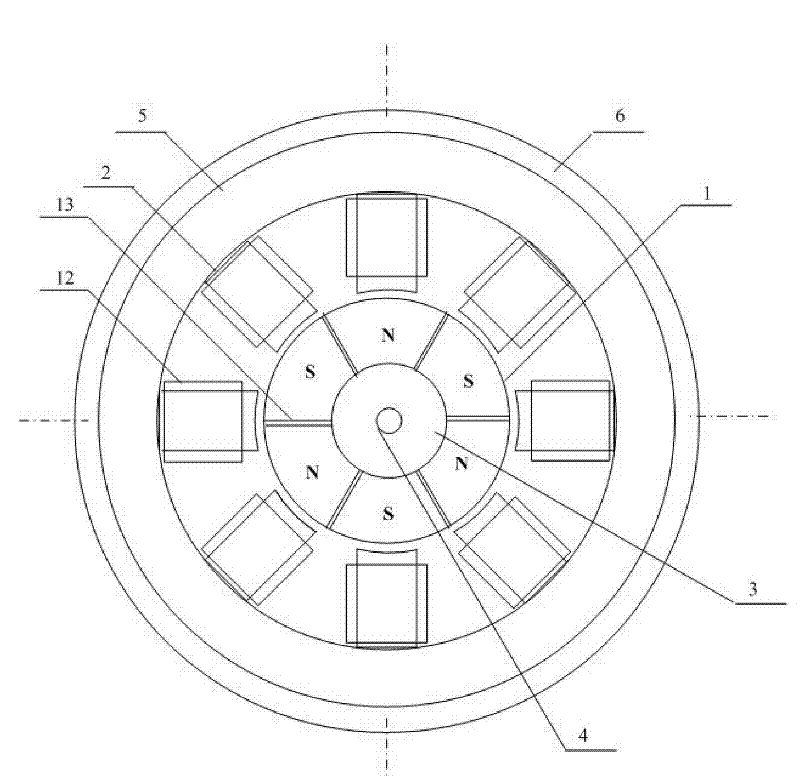

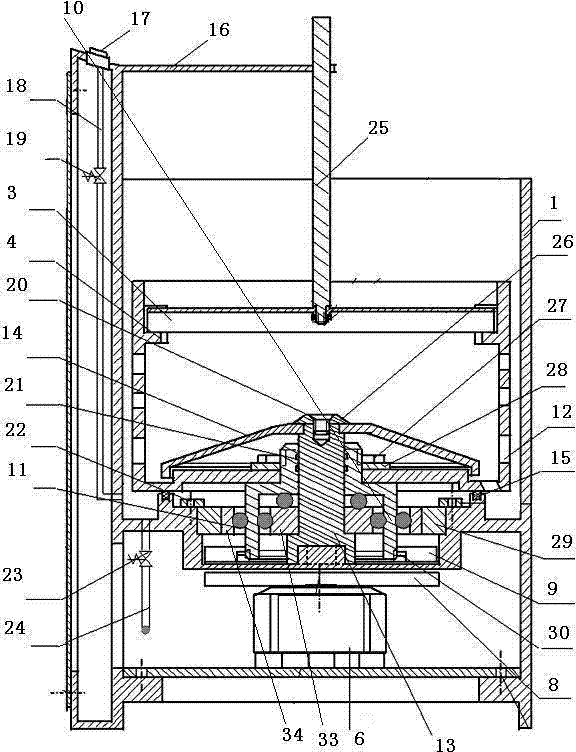

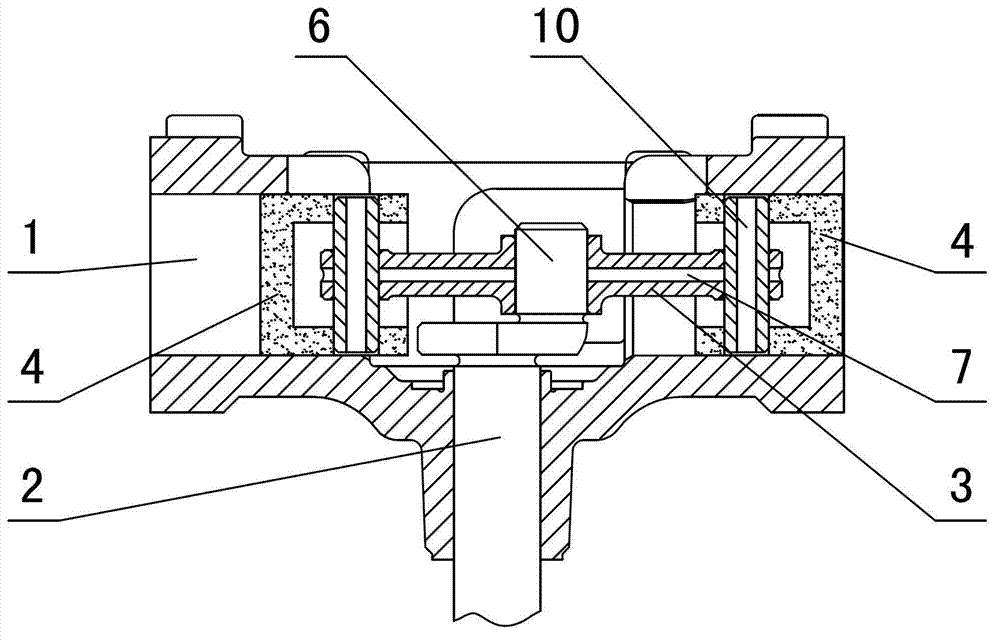

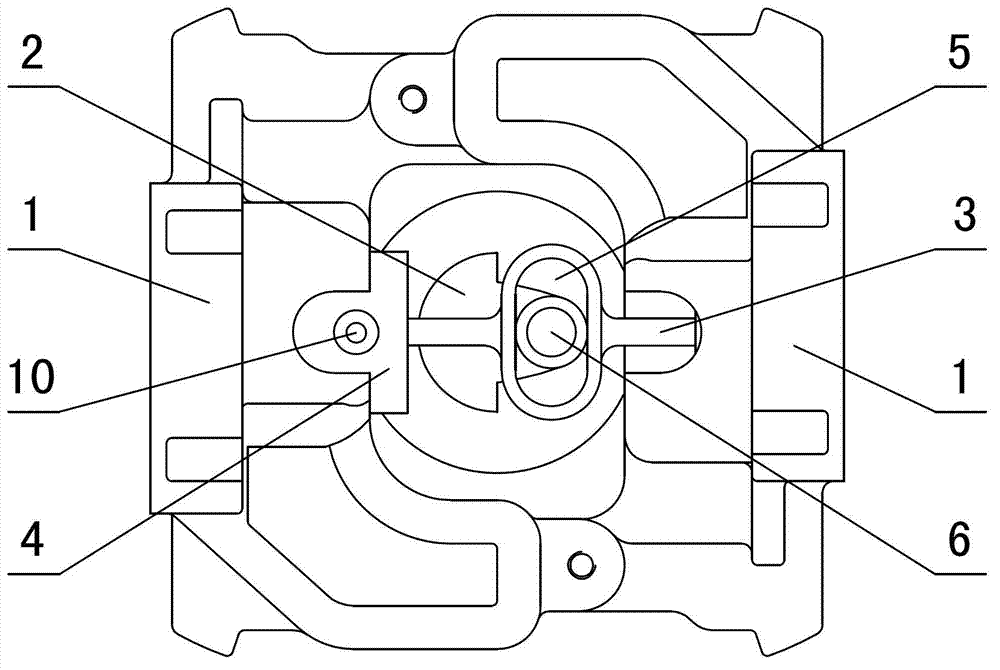

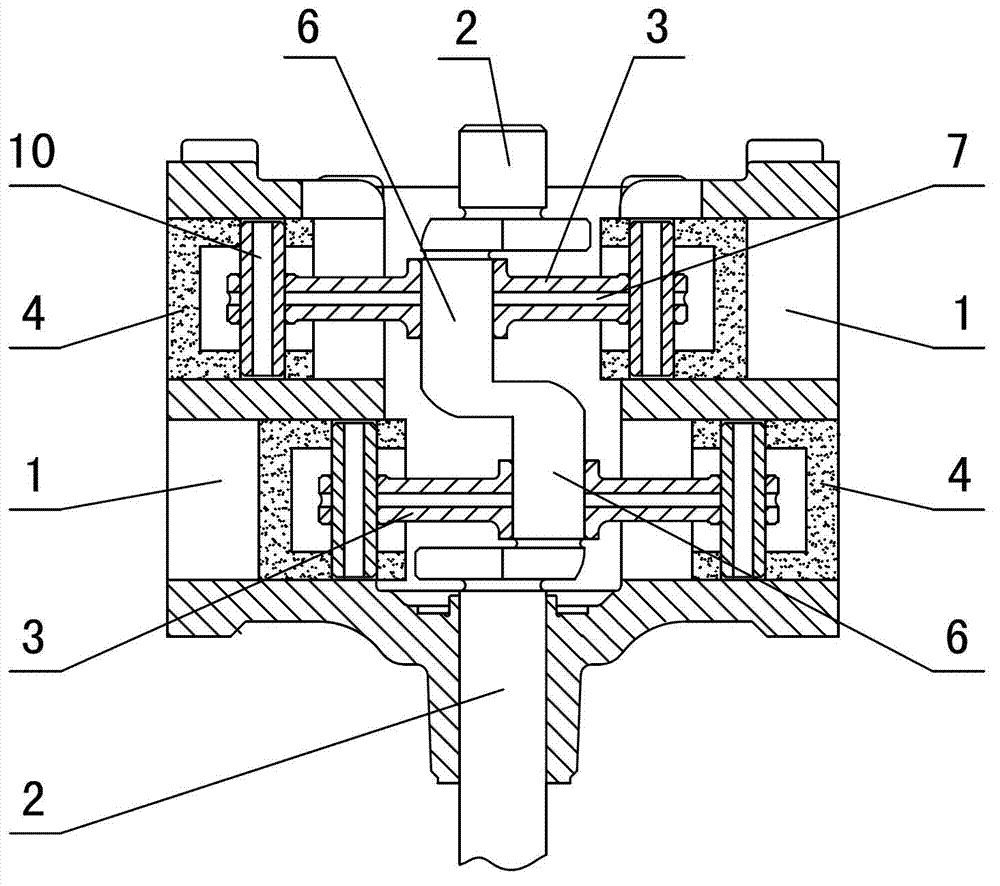

Permanent-magnet rotor deflection-type three-degree-of-freedom motion motor

ActiveCN102480253ASolve wear and tearSolve problems such as poor torque output capabilityMagnetic holding devicesPermanent magnet rotorLoop control

The invention provides a permanent-magnet rotor deflection-type three-degree-of-freedom motion motor, which relates to the technical field of permanent-magnet rotor motors. The motion motor is characterized in that magnetism isolating sheets and permanent magnets consisted of non-magnetic-conduction materials are distributed on the outer side of the inner core of the rotor. N-poles and S-poles are distributed in a staggered way and the outlines of the permanent magnets are spherical. At least two layers of magnetic pole iron cores are provided on the rotor of the periphery. Stator magnetic pole loops are provided on the magnetic pole iron cores. An output shaft is rigidly connected with center of the stator, the center of an outer housing overlaps with center of the rotor and the rotor is supported by a circular ball bearing fixed on the stator. The stator is provided with a transducer for detecting the position and the speed of the rotor so as to realize closed-loop control of the motor. The motion motor of the invention solves the problems of the three-degree-of-freedom motion motor in the prior art, including heavy abrasion, poor torque output capacity and the like. The motion motor of the invention is relatively simple in structure, easy to control, high in mechanical integration level, small in abrasion, strong in torque output capacity, and excellent in static and dynamic performance. In addition, the motion motor can realize suspension control.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

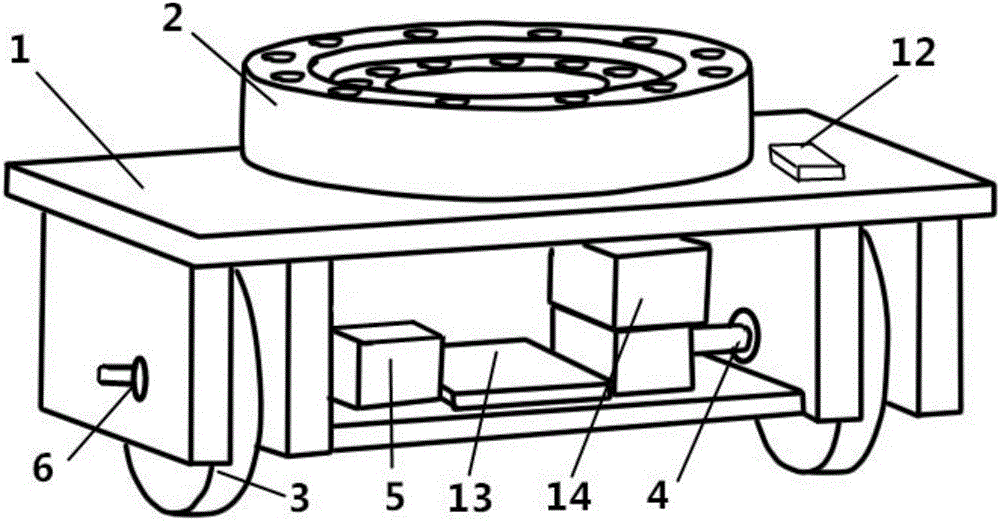

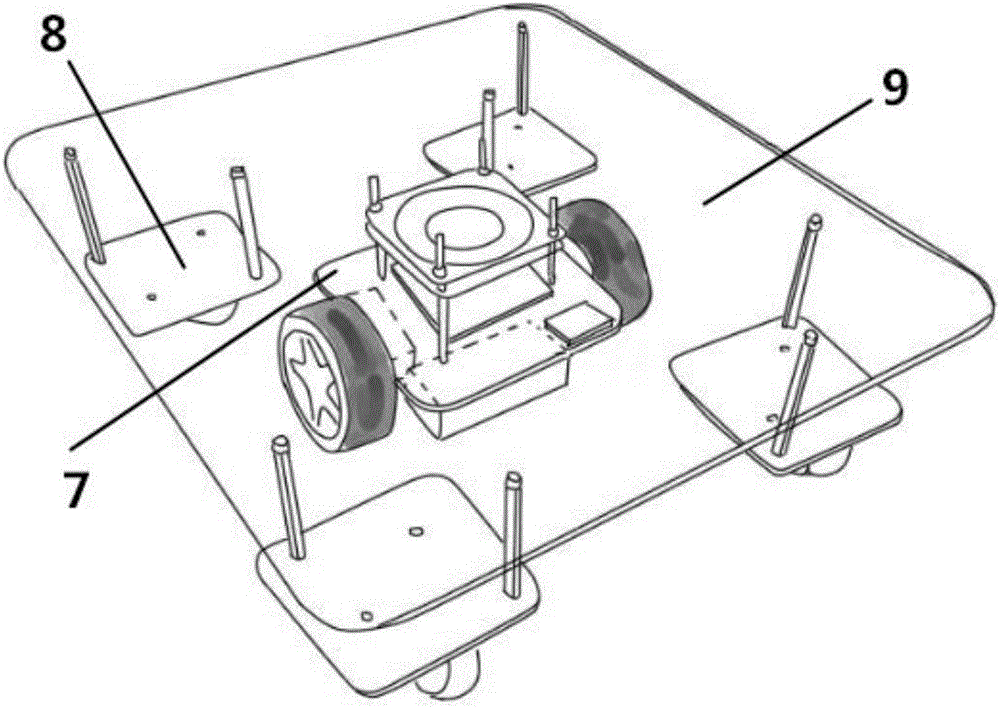

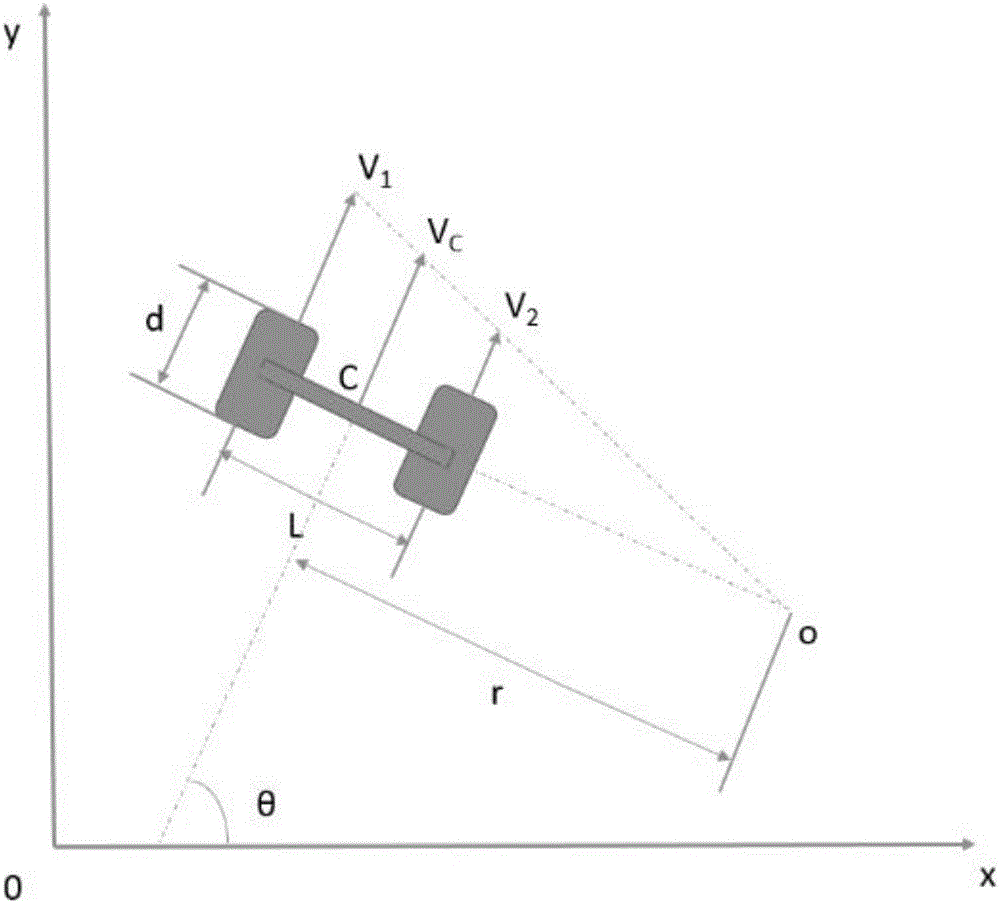

Angle-controllable power differential omnidirectional wheel, and control method and omnidirectional moving platform thereof

InactiveCN106379409ALow costEasy to maintainNon-deflectable wheel steeringVehiclesHeavy equipmentAzimuth

The invention discloses an angle-controllable power differential omnidirectional wheel, and a control method and an omnidirectional moving platform thereof, and relates to the technical field of machinery manufacturing and assembly and intelligent control. The angle-controllable power differential omnidirectional wheel comprises a wheel frame main body, a rotary support bearing, two wheels, two elastic shaft couplers, two speed reducing motors, a gyroscope and a controller. According to the control method of the omnidirectional wheel, the rotating speed of two wheels is subjected to closed loop control so that the practical azimuthal angle of the omnidirectional wheel tracks the expected value; the flexible steering is realized; the cost is low; the omnidirectional moving requirements of the heavy equipment or cargo transportation can be met. The omnidirectional platform comprises the omnidirectional wheel and a platform bottom plate connected with the omnidirectional wheel through the rotary support bearing; the non-steering flexible movement of the platform bottom plate is realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Liquid piston compressor

InactiveCN103195684AResolve frictionSolve wear and tearPositive displacement pump componentsPositive-displacement liquid enginesEngineeringCheck valve

The invention discloses a liquid piston compressor, which comprises a cylinder, pressure transmission liquid, a pump, a check valve, a buoyancy check valve, a selector valve, a lever and a transmission mechanism; the liquid piston compressor adopts the pump to drive the liquid to rise or drop in the cylinder, so that the conventional piston movement is replaced for realizing the suction and the exhaust of the cylinder; as the friction between the liquid piston and the cylinder wall is much smaller than the friction of a solid piston against the cylinder wall, the efficiency is improved and the service life is prolonged; besides, the liquid piston and the cylinder can be fabricated to be a parallel structure with a plurality of tiny pipes, so that the problem in the conventional cylinder that heat dissipation is difficult to carry out due to high cylinder diameter is solved; and the production cost is lower.

Owner:时剑

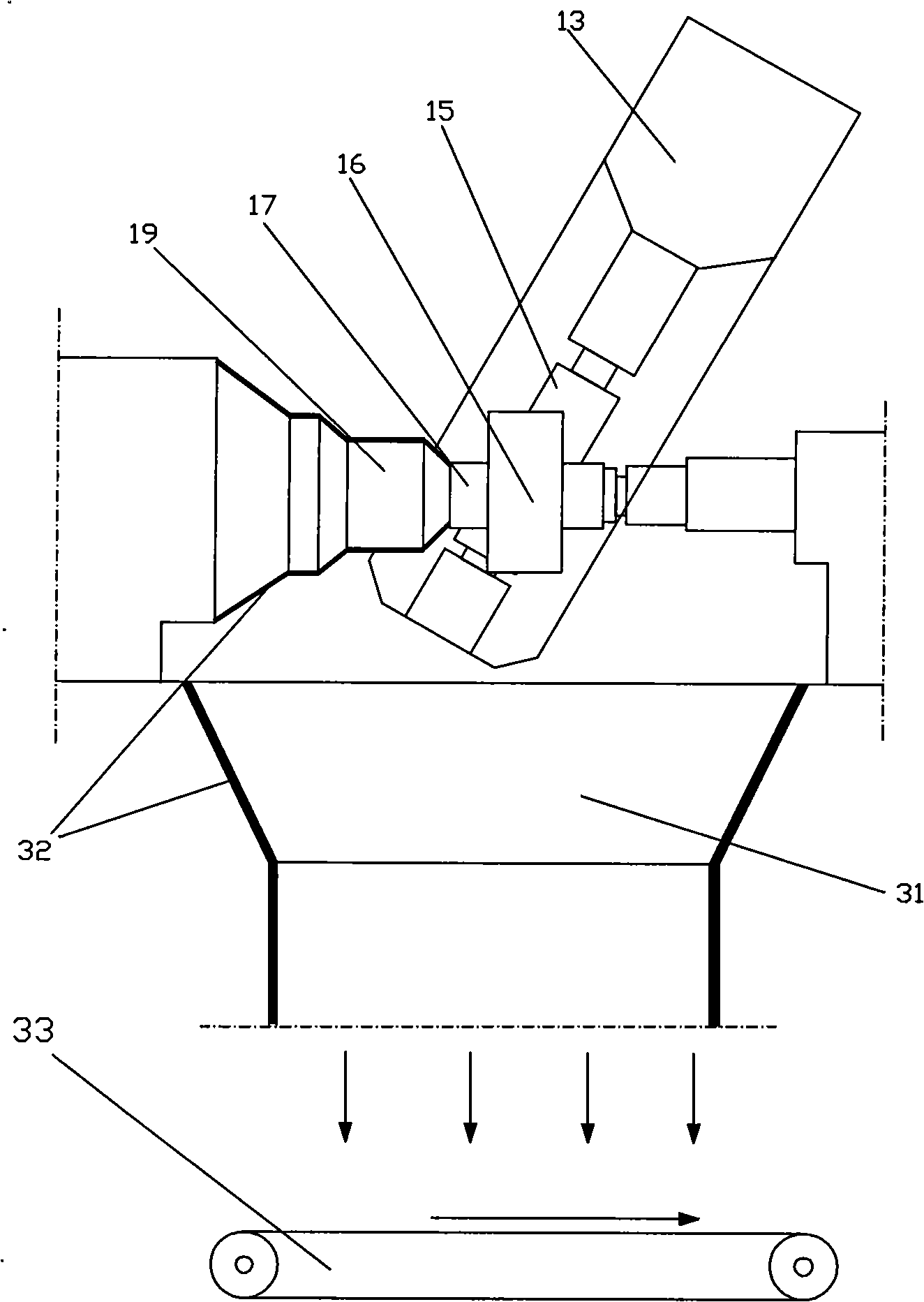

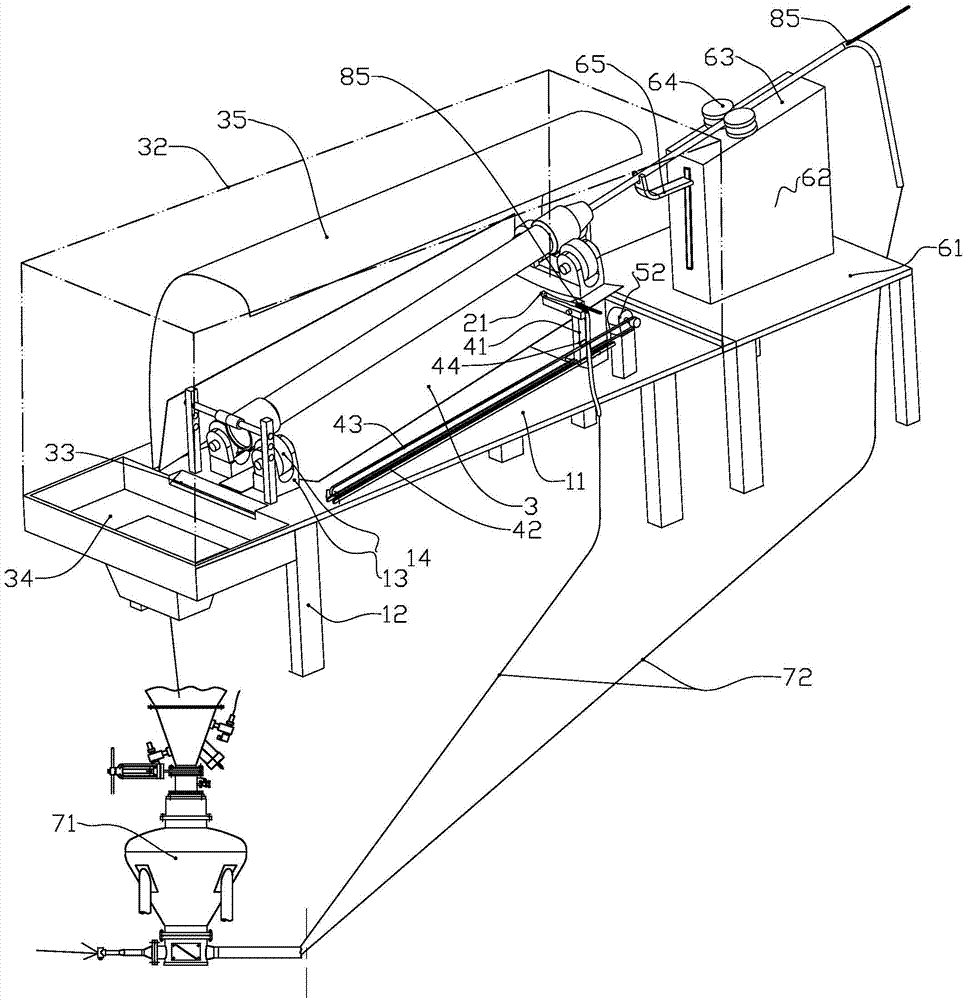

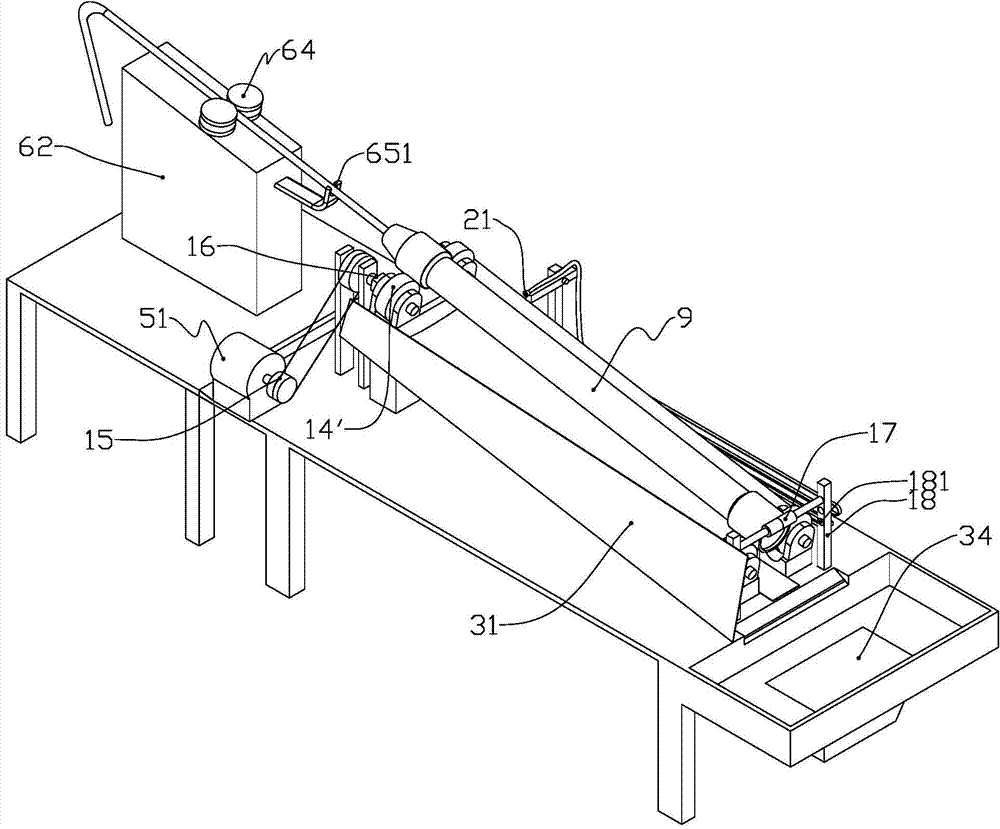

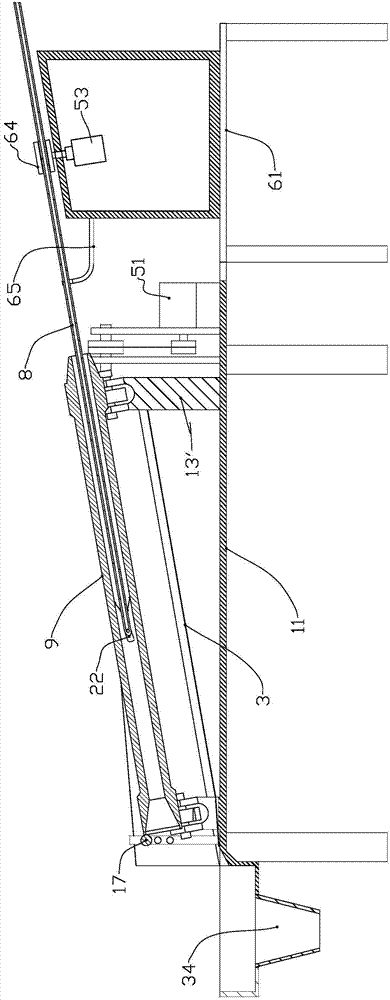

Shot-blasting intensifying and cleaning device for inner and outer walls of petroleum drilling rod

ActiveCN104493727AAchieve cleaning effectAchieve reinforcementAbrasive machine appurtenancesAbrasive blasting machinesDrive wheelCoupling

The invention discloses a shot-blasting intensifying and cleaning device for inner and outer walls of a petroleum drilling rod. The device comprises a supporting part, a driving power part and a pneumatic shot-blasting part, wherein supporting legs are arranged at four corners of a platform; two mounting seats are fixedly arranged on the platform; the height of each mounting seat is larger than the height of the other mounting seat; the tops of one of the two mounting seats are inclined; a pair of supporting wheels which can support one drilling rod is arranged on the top of each mounting seat; the drilling rod is in an inclined state; one supporting wheel is connected to a belt pulley by virtue of a universal coupling; the belt pulley is driven by a first motor by virtue of belt drive; a rubber layer covers the surface of the supporting wheel serving as a driving wheel; and the first motor, a second motor and a third motor form a driving part. The inner wall of the drilling rod is cleaned and intensified, so that the wear resistance and strength of the inner wall are effectively improved, and the wear problem generated in the process of contacting the inner wall of the traditional drilling rod and sand is solved.

Owner:山东阳谷天岳钻具有限公司

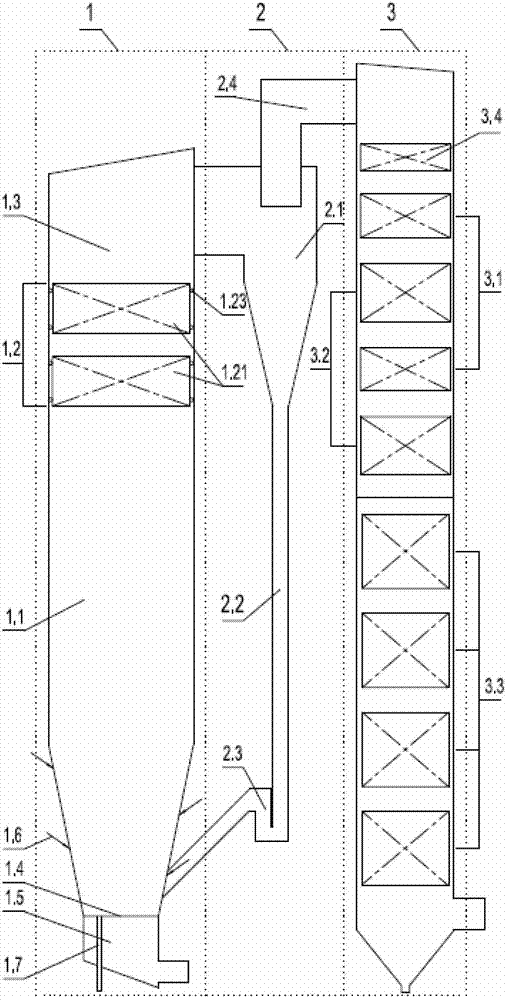

Circulating fluidized bed boiler

InactiveCN104315505AReasonable structureEasy to replaceFluidized bed combustionSolid removalSuperheaterCirculating fluidized bed boiler

The invention relates to a circulating fluidized bed boiler, belongs to the field of mechanized equipment, and particularly relates to a circulating fluidized bed boiler. The circulating fluidized bed boiler comprises a boiler chamber and a returning charge device and is successively provided with a combustion chamber, a cyclone separator and a rear smoke channel from front to back, wherein the hearth is a full-suspended water wall; an air distribution plate of the water wall is uniformly provided with an air cap; a high-temperature superheater is suspended above the rear smoke channel; a low-temperature superheater, a coal economizer and an air preheater are of support structures; the boiler is of an all-steel frame structure; and four rows of stand columns are arranged backward in front of the boiler. The circulating fluidized bed boiler is characterized in that the air cap is changed to be a small bell jar type air cap; and the upper end of the air cap is connected with an air cap head through a clamp cover. The circulating fluidized bed boiler is reasonable in structure and easy in replacing of the air cap, completely solves the problems of air cap abrasion and air chamber ash, is stable in air feeding and returning charge operation, and can ensure stable operation of the whole combustion system.

Owner:SHAANXI QIYUAN TECH DEV

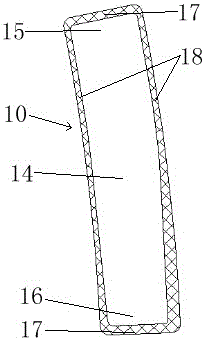

Metal flexible cloth for metal surface modification and preparation method thereof

The invention relates to a special metal flexible cloth for the preparation of a coating with high temperature and corrosion resisting and a preparation method thereof. The metal flexible cloth can be used for the protection of mechanical parts in fields, i.e. a power station, petroleum, aviation, food, plastic, and the like. The metal powder cloth is prepared by adding a forming agent and a bonding agent into the mixed power of metals, i.e. WC-Co, Ni, Cr, and the like, and the cloth patch can be bonded on a metal base body by an organic bonding agent to form a thicker protective layer with abrasion resistance, high temperature resistance and corrosion resistances by being metallurgically combined with the metal base body in a penetration brazing way. The coating has good heat conductivity, corrosion resistances and impact resistance, and wrapped parts can recover the original mechanical property of base materials through heat processing, thereby, the costing can be suitable for the recovery of pieces with heterogeneous surfaces and especially suitable for the recovery of a curved surface, a folded surface, a helical surface, and the like. The invention an solve the problems of the high temperature corrosion and the abrasion of parts with serious abrasion and heat resistance in mechanical equipment and power station equipment, decreases the times of stopping production for overhauling and enhances the economic benefits.

Owner:JIANGXI HENGDA HI TECH CO LTD

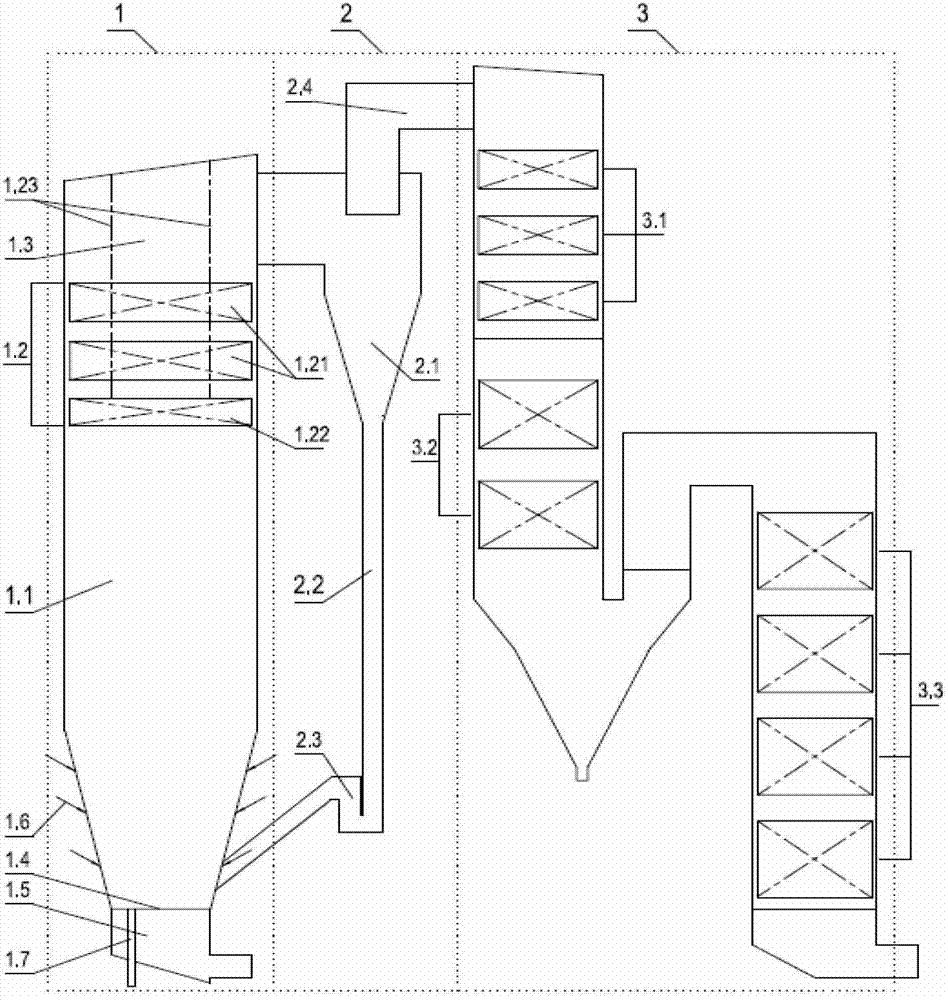

Semi-tower type medium-temperature separation biomass circulating fluidized bed boiler

ActiveCN102777895AAvoid low loadAvoid the problem of too low bed temperature under the condition of fuel changeFluidized bed combustionApparatus for fluidised bed combustionAir preheaterCombustion

The invention relates to a semi-tower type medium-temperature separation biomass circulating fluidized bed boiler, composed of a front shaft, a middle gas-solid separating and recycled material returning unit, and a tail flue, wherein the front vertical well comprises a hearth, a convection shaft and a smoke reversing chamber; the middle gas-solid separating and recycled material returning unit comprises a gas-solid separating device, a returning riser and a returning device; a super-heater, an economizer and an air pre-heater are arranged along a smoke flowing direction in the tail flue; a lower portion of the hearth is provided with 2 to 3 layers of secondary air along a height direction; an upper portion of the hearth is provided with a convection heated surface in the convection shaft; the hearth, the convection shaft, the smoke reversing chamber, the gas-solid separating device, the returning riser and the returning device compose a main circulation loop. According to the invention, adaptability of fuels is wide; combustion efficiency is high; abrasion and corrosion for the heated surface is poor; temperature of the smoke at an inlet of the gas-solid separating device is within a range of 400-750 degrees centigrade so as to effectively prevent slagging, slag hanging, dusts gathering, ashes blocking, bed materials blocking and returning device blocking in the boiler.

Owner:武汉和信益科技有限公司

Full-automatic shaftless magnetic mop washer

InactiveCN102920411AAvoid Radial WobbleSolve wear and tearCarpet cleanersFloor cleanersMagnetBearing wear

The invention relates to a home appliance, in particular to a full-automatic shaftless magnetic mop washer. The washer comprises a barrel which is internally provided with a rotary cylinder. A cloth bracket for placing cloth is placed on the rotary cylinder. A driven magnet is arranged at the bottom of the rotary cylinder. A driving magnet driven by a motor is arranged outside the bottom of the barrel. The motor and the cloth rotary cylinder are separated, shaftless and transmitted by a magnetic force. The motor is not suitable for being overheated during long time washing and is likely to burn away, and meanwhile, the problem of bearing wear during long time use is solved and the hidden danger of water leakage caused by large wearing capacity of the bearing is overcome, so that the service life of the device is prolonged. The full-automatic shaftless magnetic mop washer washes at one time, and is good in washing effect, time-saving, simple and convenient in transmission mechanism and easy to maintain.

Owner:STATE GRID CORP OF CHINA +3

Heat pipe internal cooling dry type screw rods vavuum pump

InactiveCN103267015AImprove cooling effectReduce surface temperatureRotary piston pumpsRotary piston liquid enginesCooling chamberEngineering

The invention relates to a vacuum obtaining apparatus, namely a dry type screw rods vavuum pump that designs two screw rods into hollow and employs the heat pipe internal cooling method. In the heat pipe internal cooling dry type screw rods vacuum pump provided by the invention, the screw rods are made into hollow; the internal of the screw rods are cooling chambers, which is convenient for cooling the screw rods, taking away the heat generated by the screw rods, therefore the surface temperature of the screw rods is reduced, the problem of medium solidification carbon formation generated in the process of pumping the medium by the screw pump is solved, and service life of the screw rods are greatly improved.

Owner:威海智德真空科技有限公司

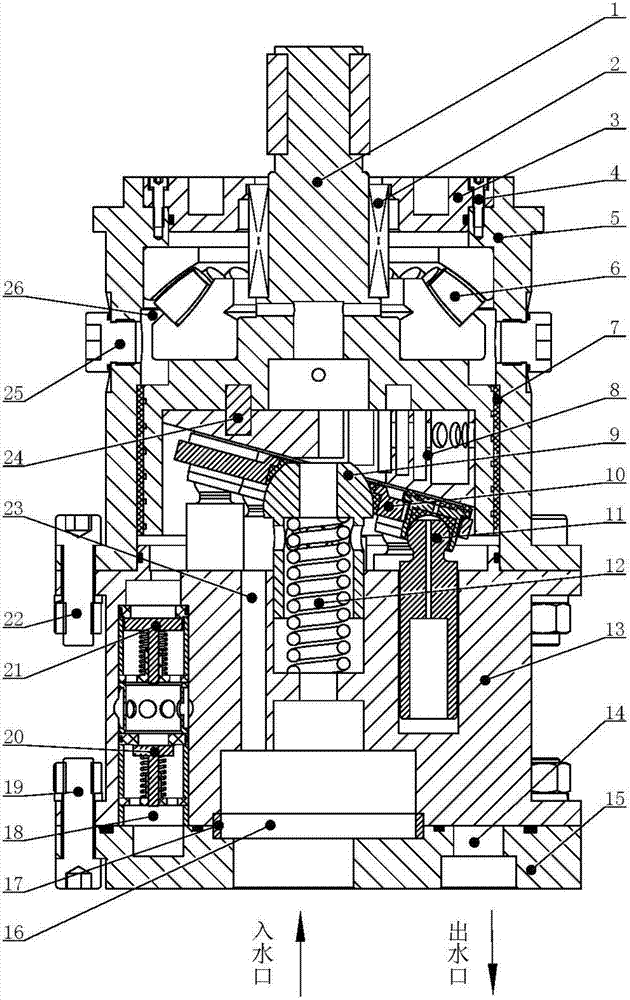

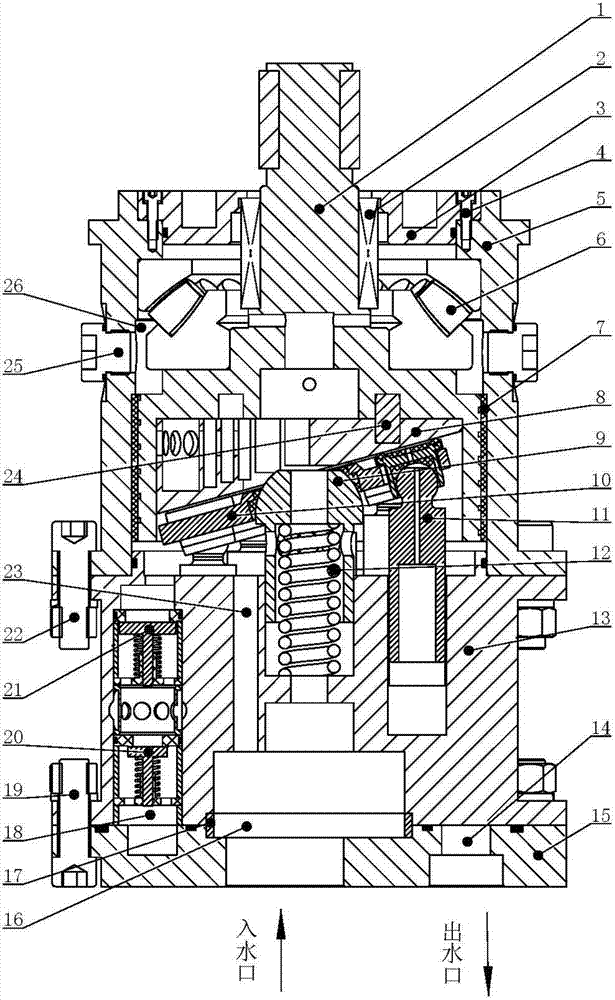

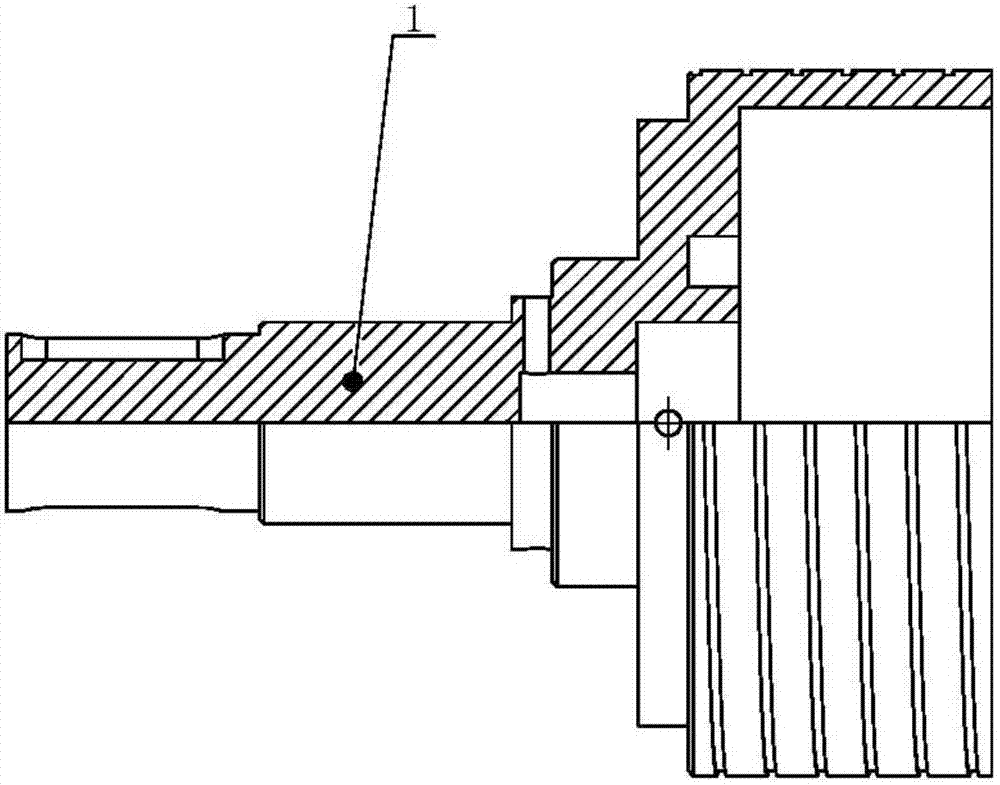

Fully water-lubricated valve distribution plunger pump

ActiveCN102734109AReduce volumeLower thermal equilibrium temperaturePositive displacement pump componentsPositive-displacement liquid enginesHydraulic pumpEngineering

The invention discloses a fully water-lubricated valve distribution plunger pump which comprises a pump main body, a rotary unit, a supporting unit and a plunger distribution unit, wherein the pump main body comprises a cavity, and a water inlet and a water outlet which are communicated with the cavity; the rotary unit comprises a rotation spindle one end of which is arranged in the cavity of the pump main body; the supporting unit consists of an axial supporting unit and a radial supporting unit; the plunger distribution unit consists of a distribution valve assembly and a plunger shoe assembly, the plunger shoe assembly does periodic movement under the rotation of the rotation spindle, thus driving the on and off of valves in the distribution valve assembly, and leading a fluid to flow into the cavity from the water inlet or a fluid in the cavity to be discharged from the water outlet so as to realize flow distribution; a helical groove is arranged on the peripheral surface where the rotation spindle and the radial supporting unit are matched, and the pumping action of the helical groove leads the fluid to circularly flow in the cavity at two end surfaces of the rotation spindle. The fully water-lubricated valve distribution plunger pump fully utilizes the spaces of the shell and the spindle, and the radial sliding bearing design greatly improves the bearing capability of the spindle, and extends the service life of the hydraulic pump.

Owner:WUHAN HUAXI HYDRAULIC +1

Single-drive multi-cylinder compressor structure

ActiveCN102777343ASolve efficiency problemsSolve the vibrationPositive displacement pump componentsMulti-stage pumpsEngineeringMechanical engineering

The invention discloses a single-drive multi-cylinder compressor structure. The structure comprises a crank shaft and cylinders, wherein the cylinders are arranged on the radial direction of the crank shaft and are driven by the crank shaft, the number of the cylinders is even, the cylinders are arranged on two opposite sides of the crank shaft in pairs, the central axis of the same pair of cylinders and the central axis of the crank shaft are arranged in the same plane, the crank shaft is connected with pistons which are arranged on the same pairs of cylinders through a linear three-hole connecting rod, a chute which is vertical to the three-hole connecting rod is arranged in the center of the three-hole connecting rod, and the crank shaft is connected with the interior of the chute in a sliding mode. By the aid of the compressor structure, problems that in existing refrigerating compressors of the prior art, working efficiency is low, the vibration is large, the noise pollution is serious, piston pins are abraded and the service life is short are solved. The compressor structure has the advantages of being stable in operation, low in noise and long in service life. The compressor structure has high usage value and is suitable to various compressors.

Owner:HANGZHOU QIANJIANG REFRIGERATION COMPRESSOR GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com