High-speed milling cutter designing method for suppressing unevenness in forced vibration wear of cutter teeth

A technology of forced vibration and design methods, applied in computing, manufacturing tools, special data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

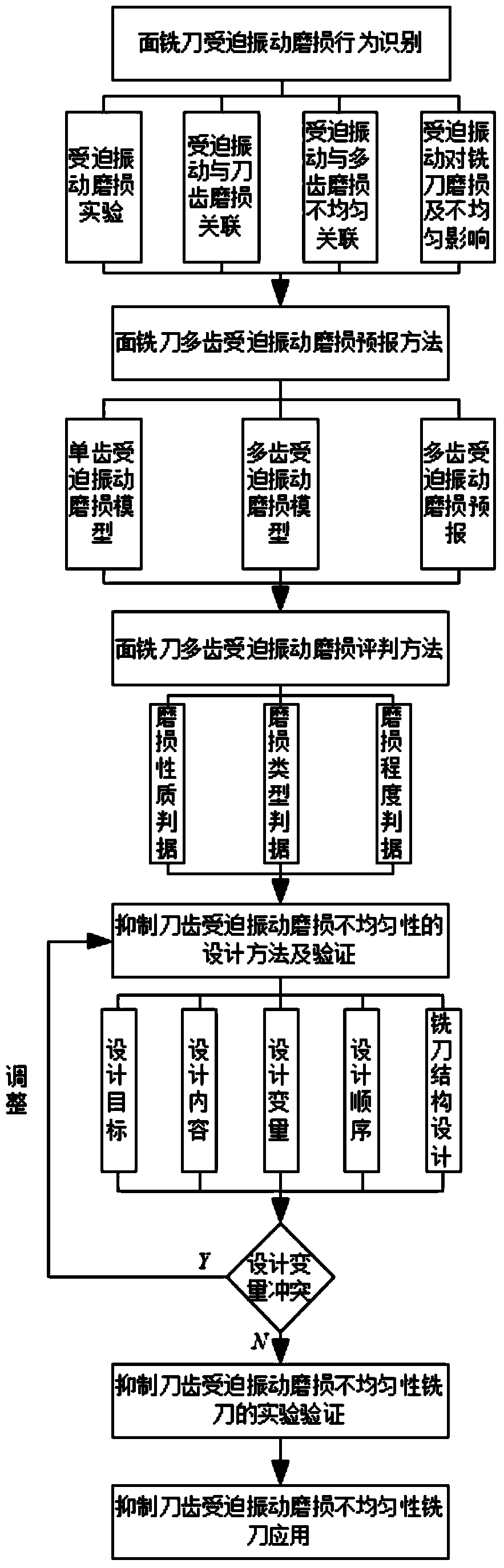

[0098] The specific steps of a high-speed milling cutter design method for suppressing the unevenness of forced vibration and wear of cutter teeth in this embodiment are as follows:

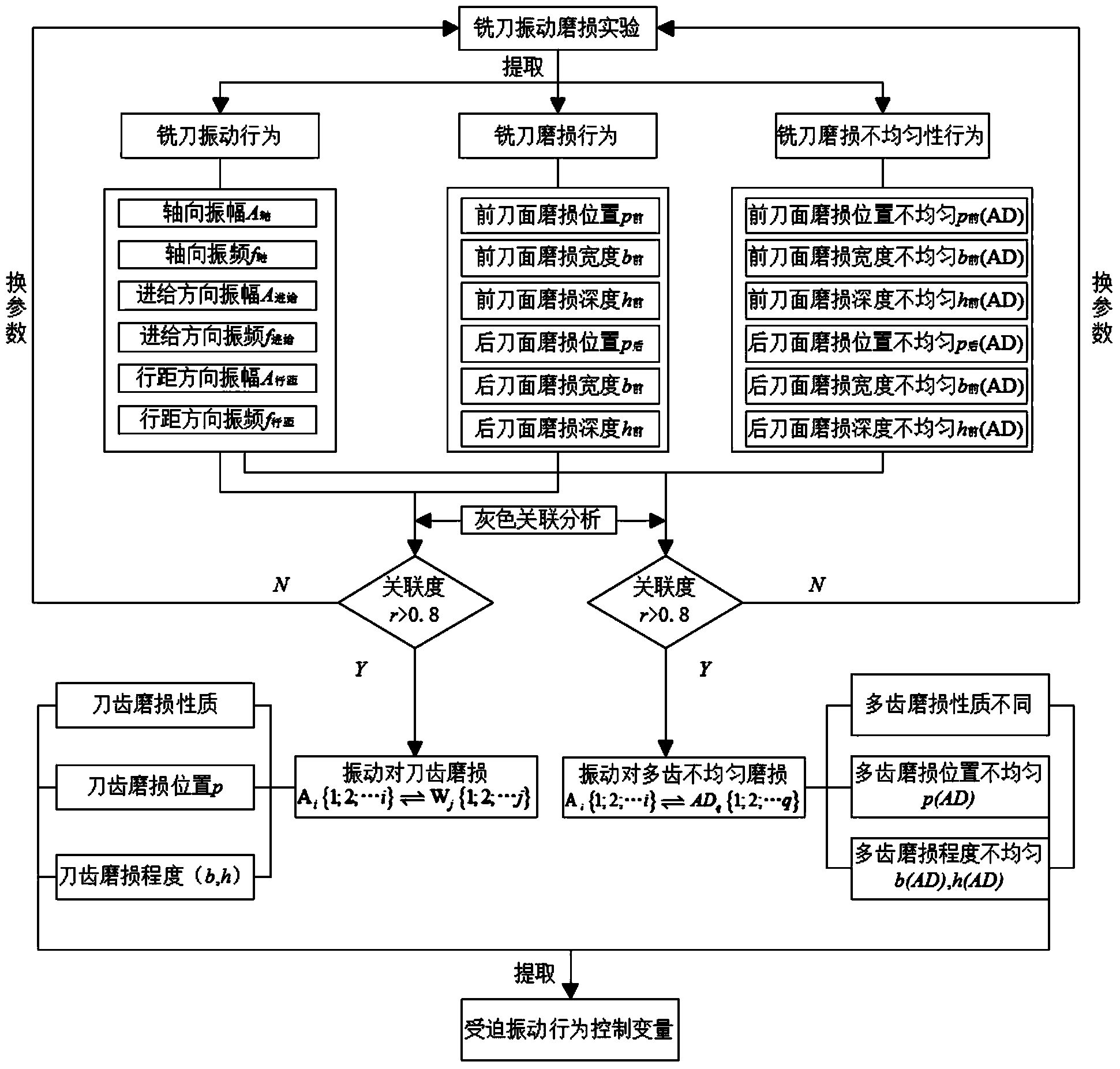

[0099] 1. Identification method of forced vibration wear of milling cutter

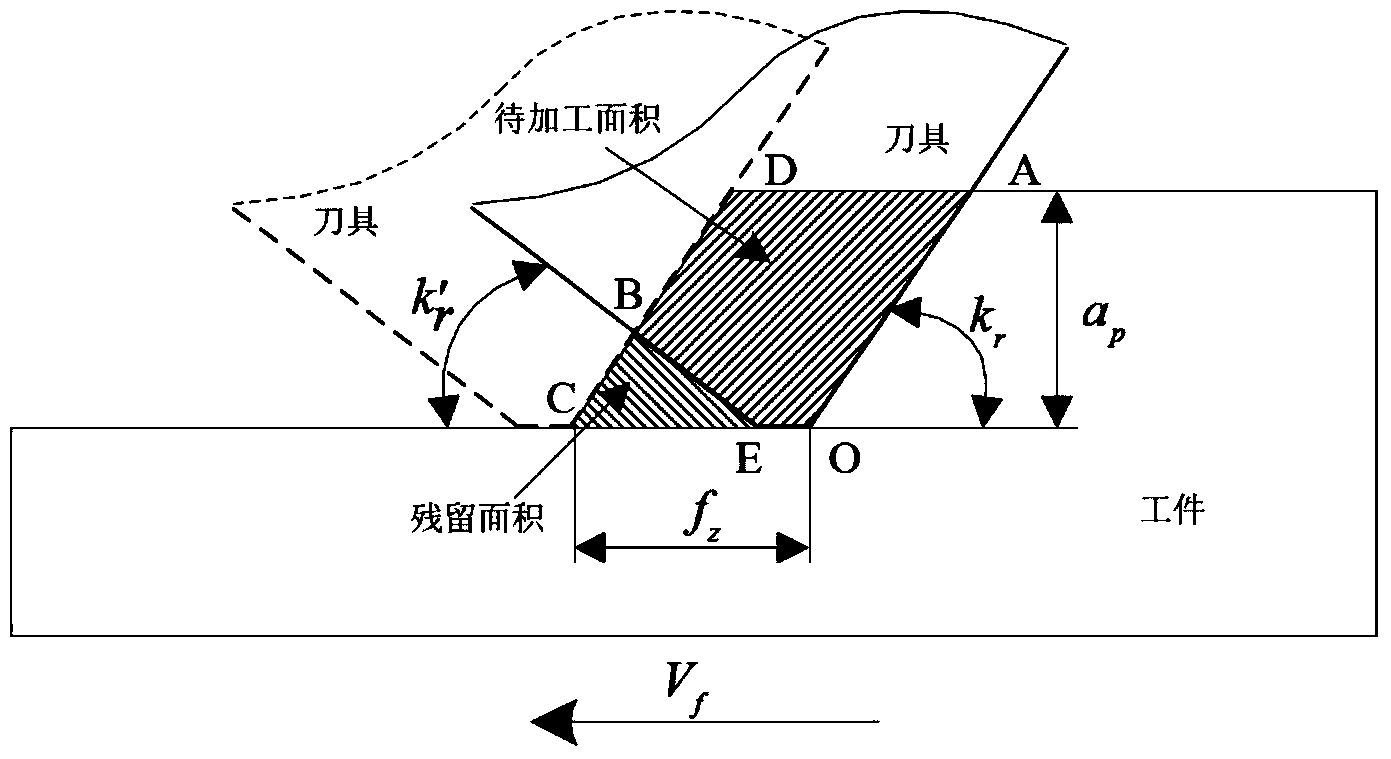

[0100] Due to the forced vibration of the process system in the milling process, as the cutting process continues, due to the mutual contact between the tool and the workpiece, the tool and the chips; they move with each other at a certain linear speed, and the vibration generates displacement at the same time, forming a process that accompanies the tool cutting process. The dynamic wear process, that is, the dynamic characteristics of the forced vibration of the milling cutter.

[0101] The forced vibration of the milling cutter will cause the forced vibration wear of the milling cutter t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com