Patents

Literature

1093results about How to "Solve the problem of longevity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

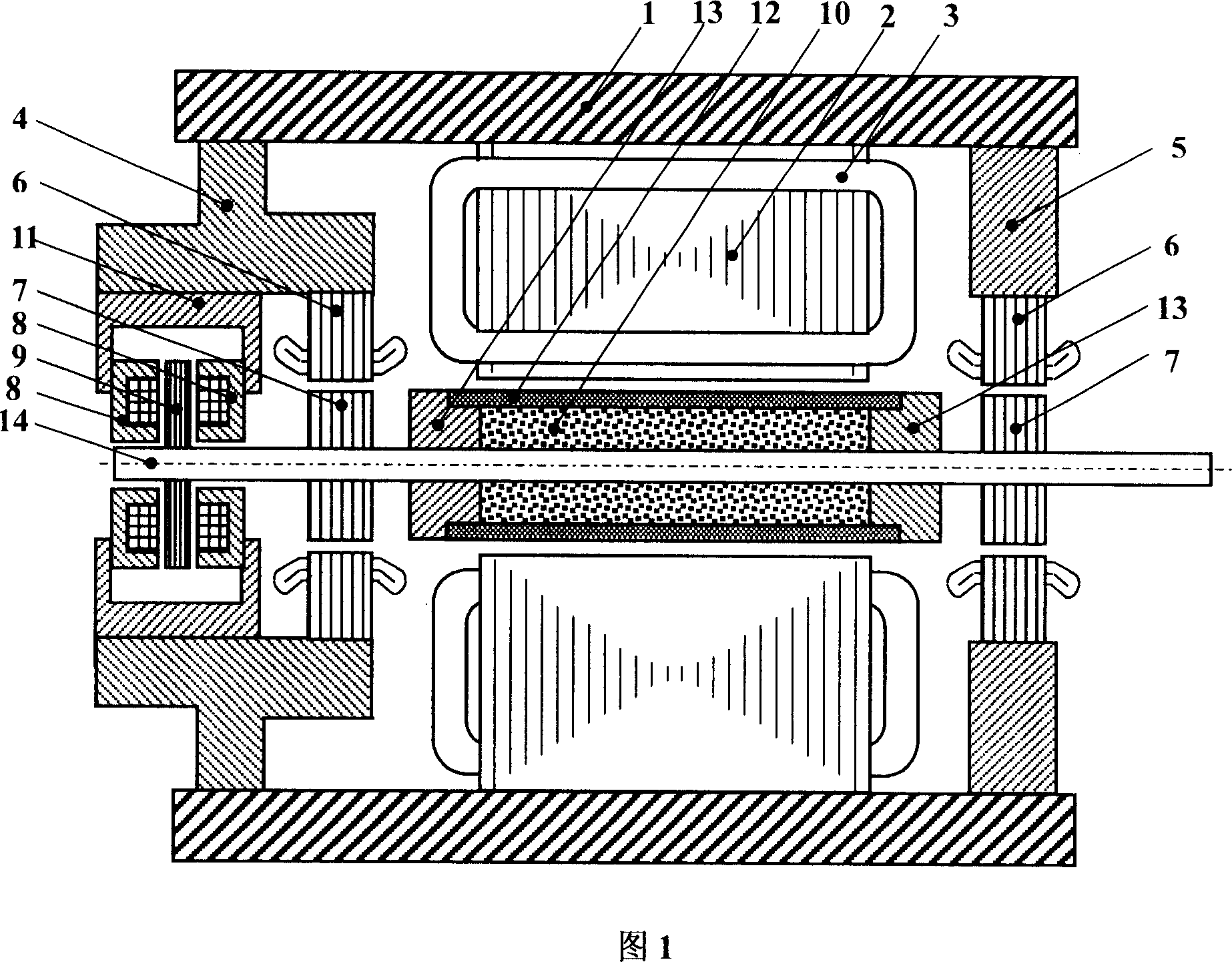

Mechanical two-degree-of-freedom controllable loading machine

InactiveCN101892680AArbitrary outputImplement the loading actionMechanical machines/dredgersEngineeringDegrees of freedom

The invention discloses a mechanical two-degree-of-freedom controllable loading machine. A bucket turning crank-link mechanism consists of two four-bar mechanisms which are connected in series with each other; a loading arm driving mechanism is a crank-rocker mechanism; the three cranks are driven by three controllable motors respectively; any track output of an output end is realized in a working space by programming; and turning of a bucket is matched with lifting of the arm of the loading machine, and actions such as attitude keeping, adjusting and the like are realized by programming a control motor. The mechanical two-degree-of-freedom controllable loading machine can overcome the defects of simple action and difficult control of the traditional mechanical loading machine, and also can overcome the defects of high requirement on a hydraulic element, easy oil leakage, low reliability and the like of the hydraulic loading machine.

Owner:GUANGXI UNIV

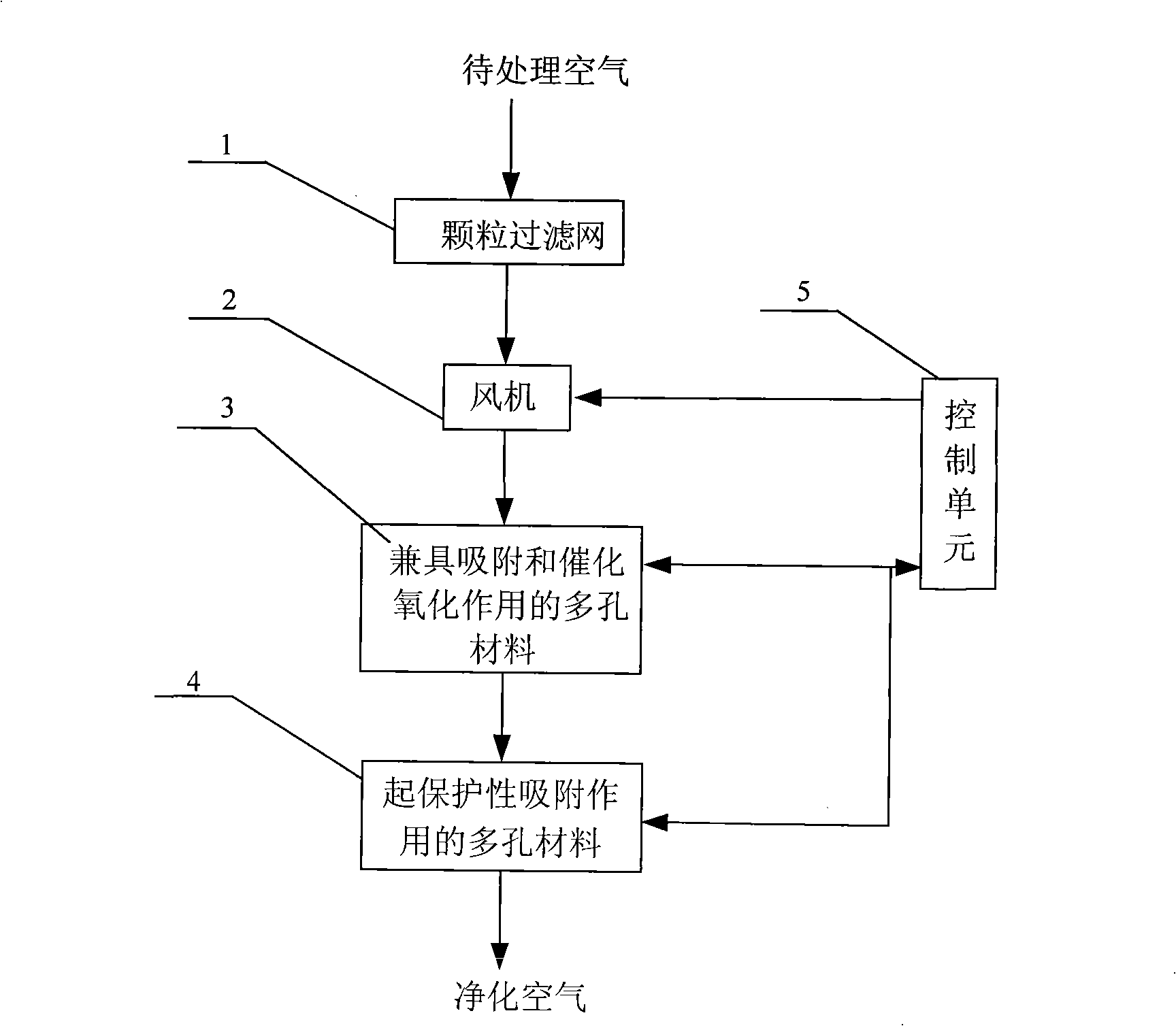

Air purification method combined of adsorption and heat catalytic oxidation regeneration in situ

InactiveCN101314101ASolve the problem of longevitySolve operational problemsDispersed particle filtrationCarbon dioxideCatalytic effect

The invention discloses a method for purifying air by combining adsorption and in-situ heat catalytic oxidation regeneration. The method uses a porous material with adsorption and catalysis functions and a porous material with protective adsorption to adsorb low concentration of formaldehyde and benzene series in the air; when the adsorption of the porous material approaches to saturation, electrical heating is started to activate the catalytic activity of the porous material with the adsorption and catalysis functions, thereby catalytically oxidizing the formaldehyde and the benzene series which are adsorbed on the surface of the porous material into carbon dioxide and water; at the same time, the adsorption capability of the porous material is regenerated; the regenerated porous material is reused for adsorption; thus air purification can be realized through the circulation. The method has the advantages of high efficiency, energy conservation, low cost, no secondary pollution and so on. The method is suitable for purifying air containing the low concentration formaldehyde and the benzene series in a building, a cabin or other restricted spaces.

Owner:BEIHANG UNIV

High chromium cast iron self protective build-up welding cored welding wire and its usage

InactiveCN1714986ARealize direct surfacingOverlay welding wear-resistant and corrosion-resistantArc welding apparatusWelding/cutting media/materialsHigh carbonManganese

The self-protective high chromium cast iron cored build-up welding wire has metal powder core comprising nickel powder 6-8 wt%, middle carbon manganese iron 8-10 wt%, No. 45 ferrosilicon 9-12 wt%, high carbon ferrochromium 65-75 wt%, metal Cr powder 18-21 wt%, ferromolybdenum 5-7 wt% and Al-Mg powder 1.5-2.5 wt%, and with one welding wire filling amount of 0.49-0.53. The present invention makes it possible to use the welding wire in submerged arc welding without needing added flux and protecting gas, results in raised comprehensive welding performance and raised welding quality, and may be applied widely in build-up welding field requiring high antiwear, anticorrosive and anticracking performance.

Owner:XIANGTAN UNIV

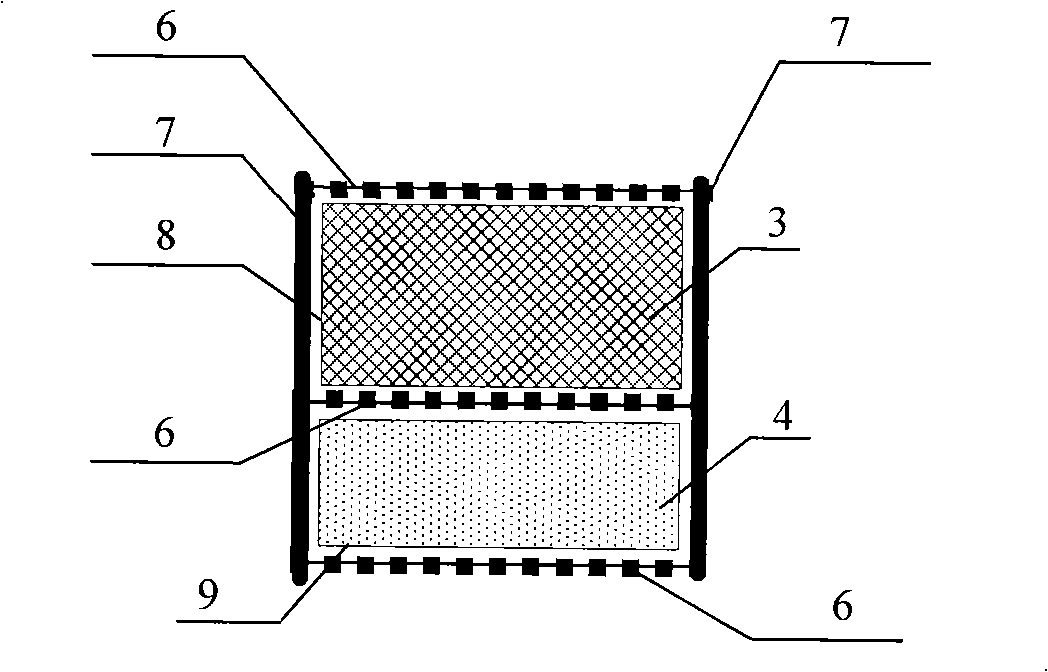

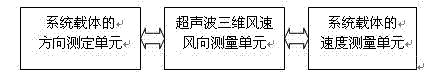

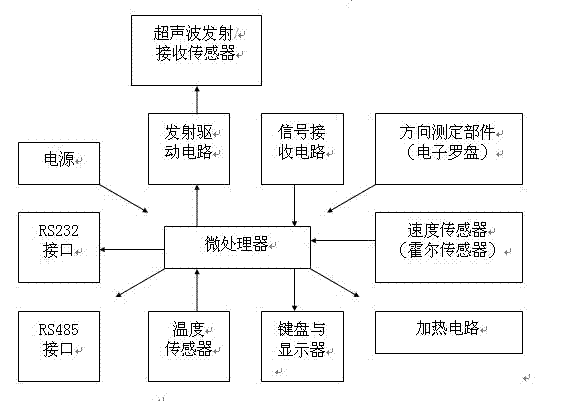

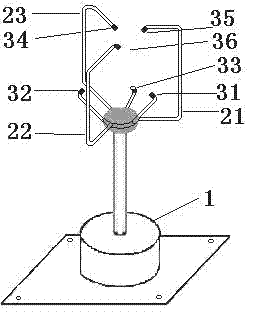

Mobile ultrasonic anemoclinograph and method for measuring wind speed and direction

InactiveCN102175887ASolve the technical problems that cannot meet the wind speed and direction measurement in mobile situationsSolve the technical problem that the position data cannot be obtained accuratelyIndication/recording movementFluid speed measurementUltrasonic sensorEngineering

The invention provides a mobile ultrasonic anemoclinograph and a method for measuring wind speed and direction, wherein the device comprises an ultrasonic wind speed and direction measuring unit, a mobile system carrier speed measuring unit and a system direction measuring unit; the wind speed and direction measuring unit comprises a base, a control circuit board, six measuring arms and six ultrasonic transmitting / receiving sensors; the measuring arms are connected to the base and in an included angle at 60 degrees in turn; each measuring arm is provided with an ultrasonic sensor; the speed and direction measuring unit of the system carrier comprises a speed sensor and a direction measuring component; simultaneously, the invention further provides a method for measuring the wind speed anddirection in actual environment under a mobile condition by ultrasonic, wherein the method comprises the steps of: measuring the wind speed and direction parameters under the mobile condition by the ultrasonic wind speed and direction measuring unit; combining the measured moving speed and direction parameters of the system carrier; and calculating the measured wind speed and direction parametersin actual environment of the system under a mobile condition.

Owner:兴化市华伦达铸钢有限公司

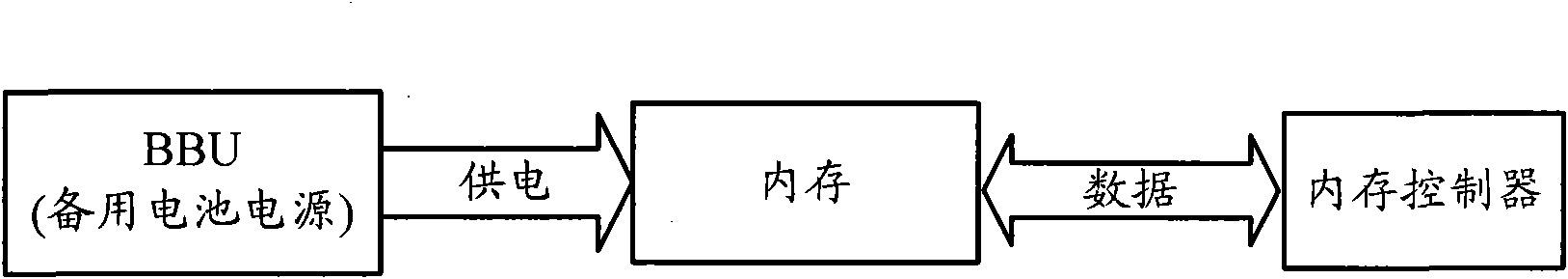

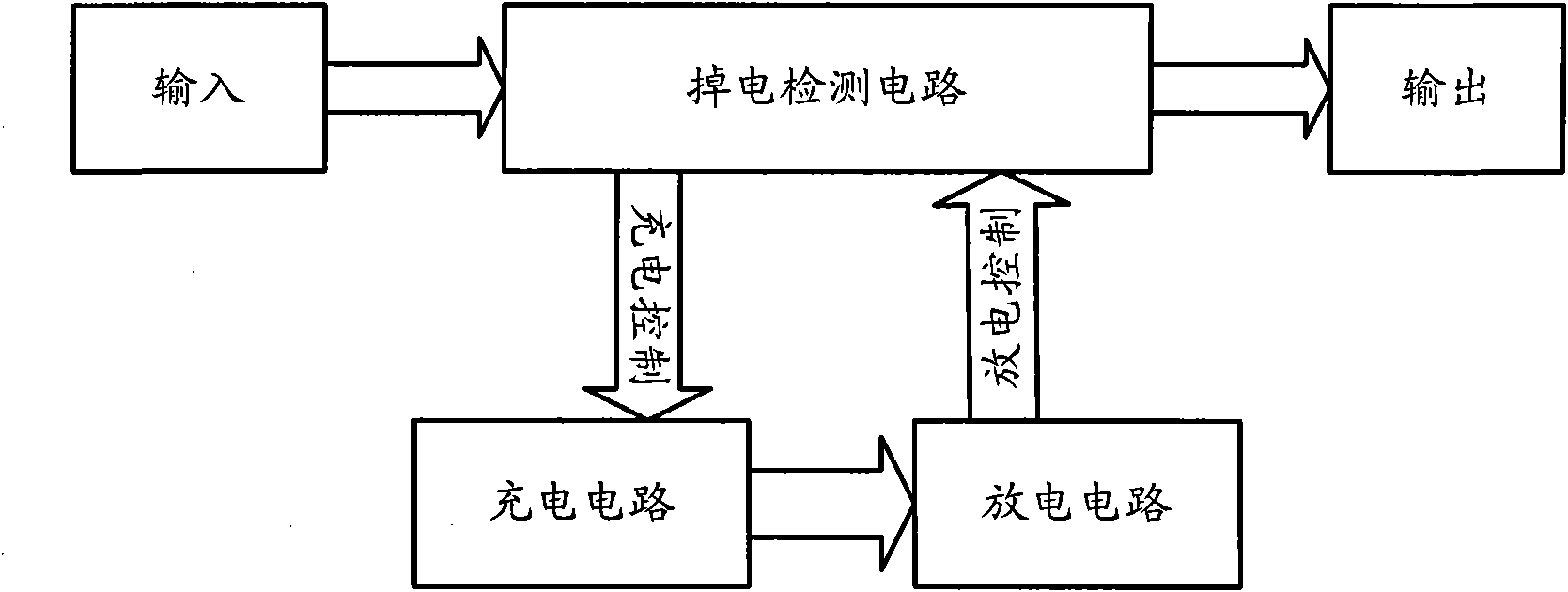

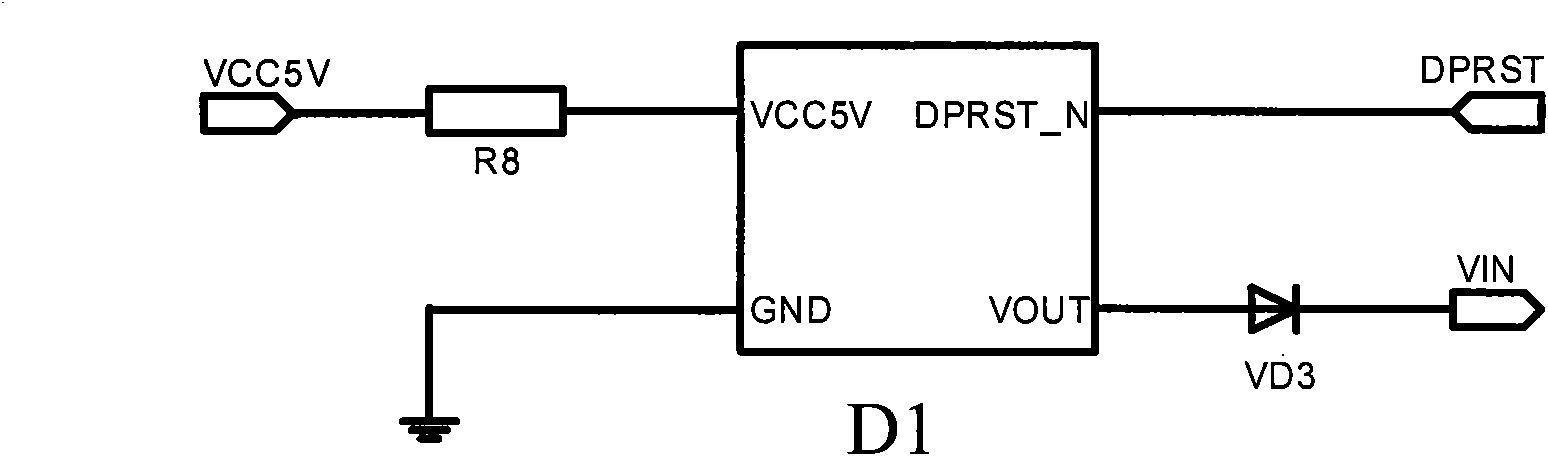

Circuit power fail safeguard device and protection method thereof

ActiveCN101667748ASolve the costSolve the problem of longevityBatteries circuit arrangementsCurrent/voltage measurementElectricityInternal memory

The invention discloses a circuit power fail safeguard device and a protection method thereof. The device comprises a power fail detection circuit, a charging circuit and a discharging circuit, wherein the power fail detection circuit is connected with a circuit to be detected and is used for detecting whether the circuit to be detected has the phenomenon of power failure; the charging circuit isconnected with the power fail detection circuit and is used for storing electrical energy; and the discharging circuit is respectively connected with the charging circuit and the circuit to be detected and is used for supplying power for the circuit to be detected when the circuit to be detected has the phenomenon of power failure. The invention overcomes the defects of high cost and short service life caused by using a stand-by battery, and simultaneously expands the protection range and increases the protection for cache data and register data of a memory controller, thus being capable of supplying power for an internal memory and an internal memory controller under the condition that equipment suddenly have power down phenomenon, and ensuring the equipment to completely store the processed data and the related status messages. In addition, the invention also has the advantages of simple circuit, low cost, short charging time, high efficiency, small volume and long service life.

Owner:ZTE CORP

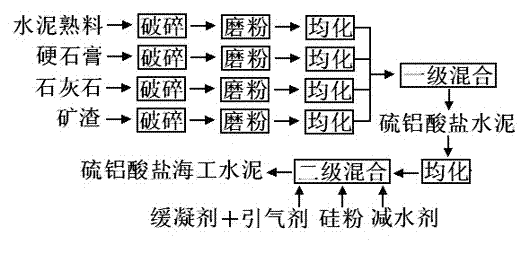

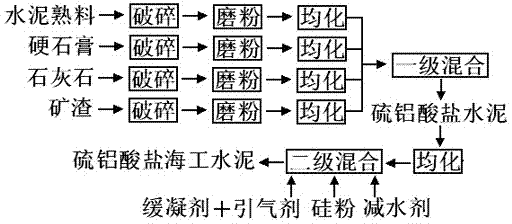

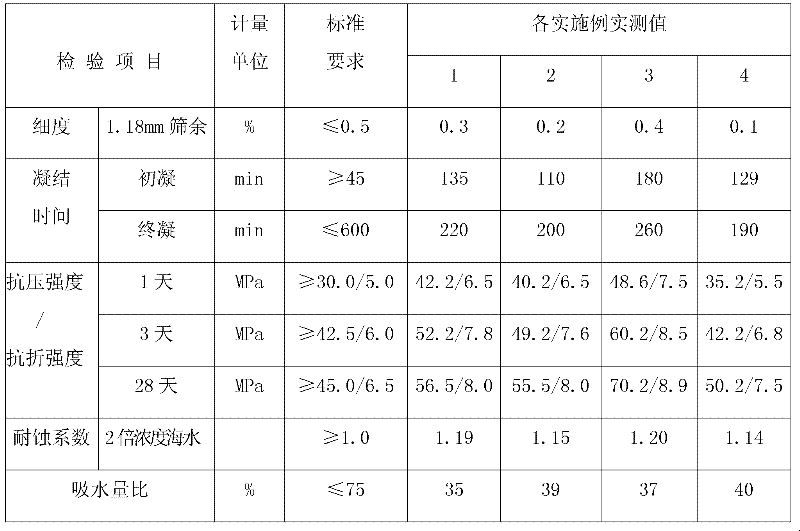

Sulphoaluminate maritime work cement and preparation method thereof

The invention discloses sulphoaluminate maritime work cement and a preparation method thereof. The sulphoaluminate maritime work cement comprises the following main raw materials in parts by weight: 50-80 parts of cement clinker, 8.0-20 parts of anhydrite, 0-30 parts of limestone, 0-30 parts of slag, 0.1-0.5 part of water reducing agent, 0.001-0.005 part of air entraining agent, 0.1-0.5 part of retarder and 2-5 parts of silicon powder. The preparation method comprises the following steps of: respectively smashing, grinding and homogenizing the sulphoaluminate cement clinker, the anhydrite, the limestone and the slag; then, burdening at a ratio, and evenly mixing; adding the water reducing agent, the air entraining agent, the retarder and the silicon powder; and mixing and homogenizing to obtain the product. The concrete mixed by the sulphoaluminate maritime work cement has the advantages of small bleeding rate and high slurry viscidity. The slurry has strong covering and supporting action on aggregate. The concrete keeps good homogeneity and has the advantages of hard and quick early strength, continuously-increased later strength, good slurry structure compactness and high volume stability and is convenient to use and operate for constructing.

Owner:广西云燕特种水泥建材有限公司

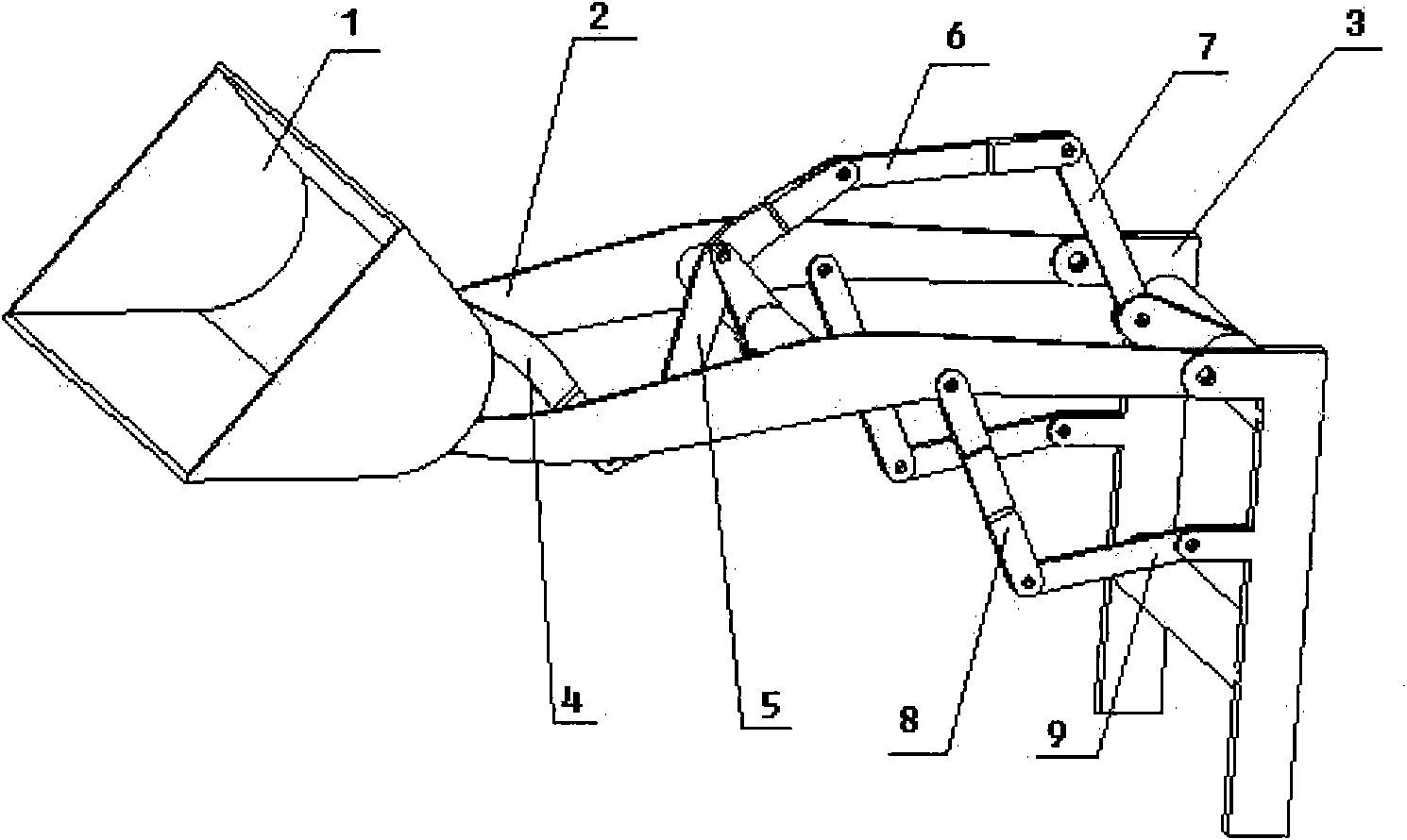

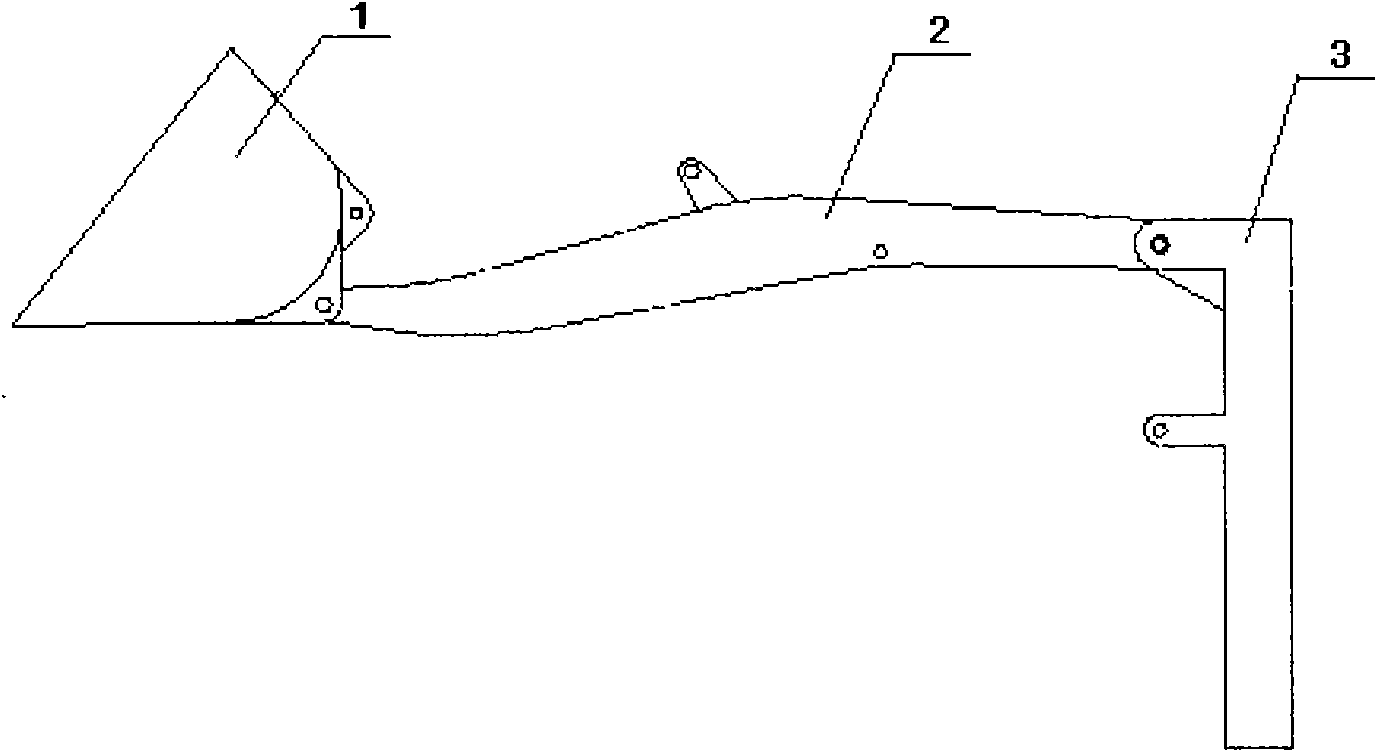

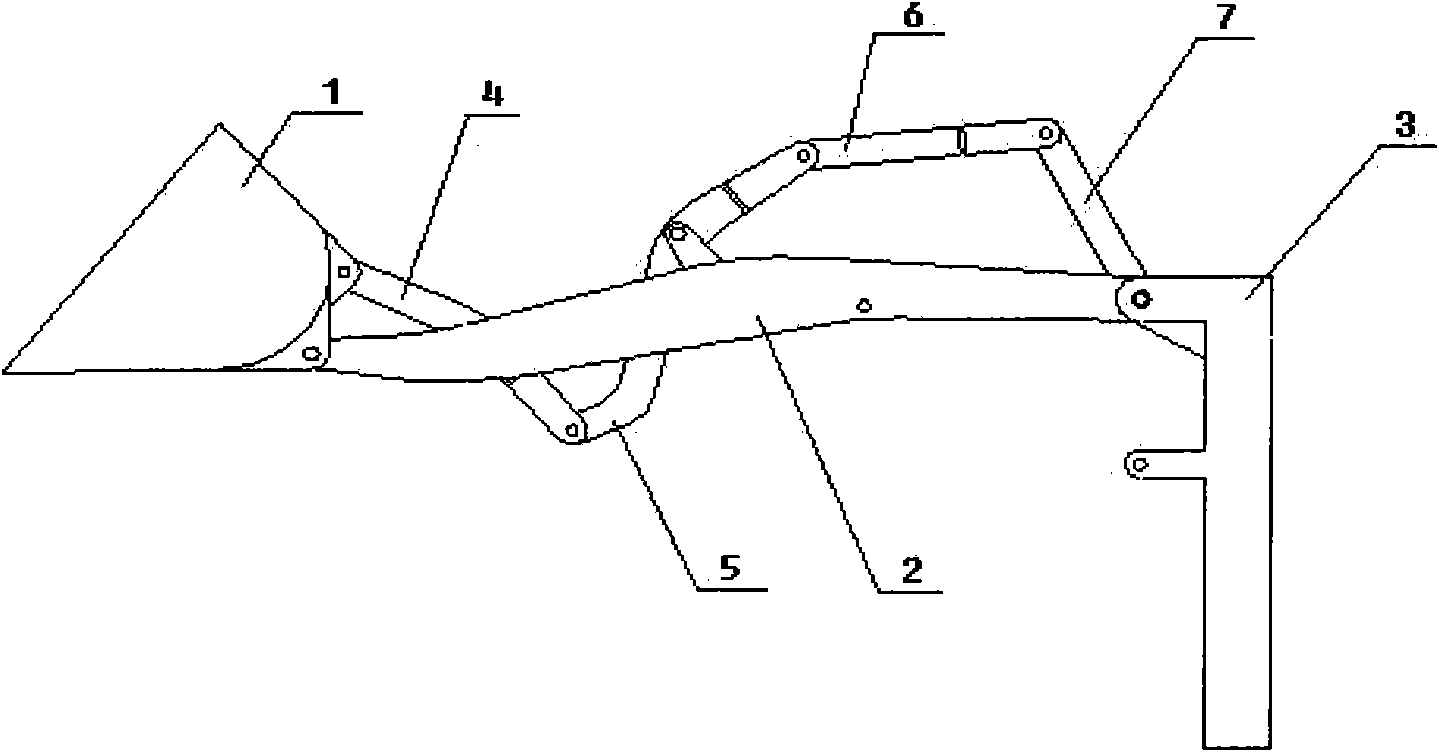

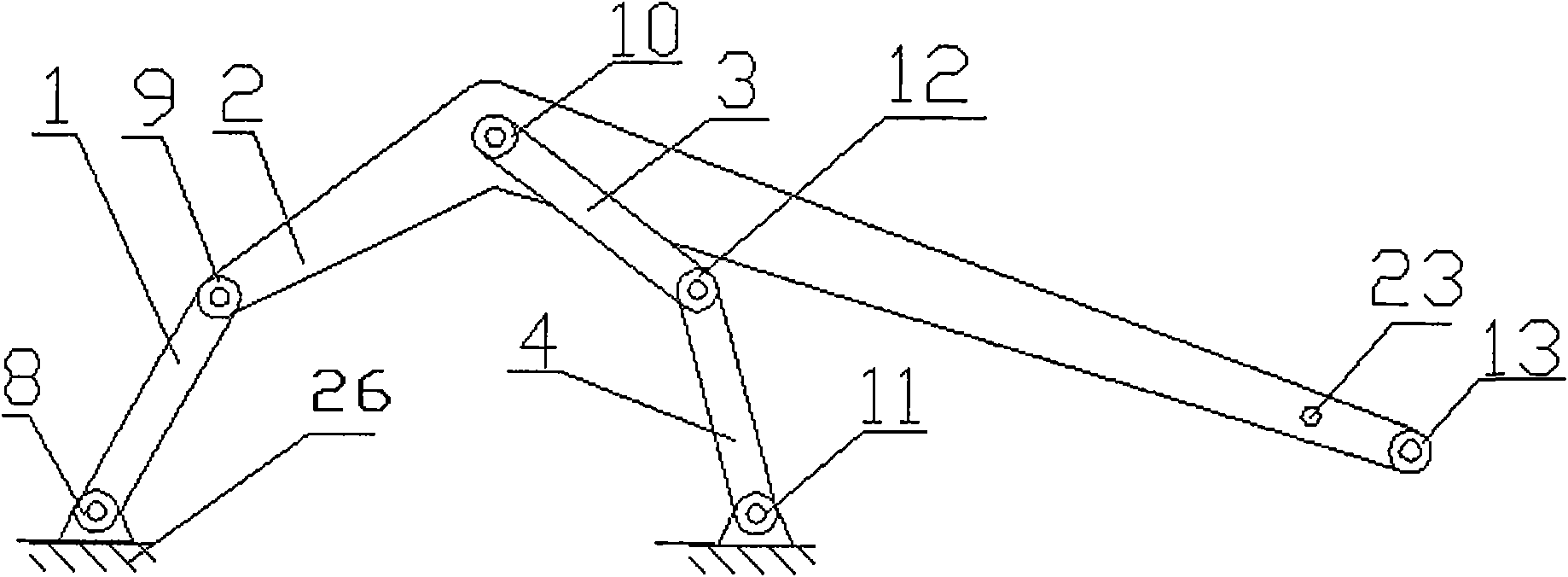

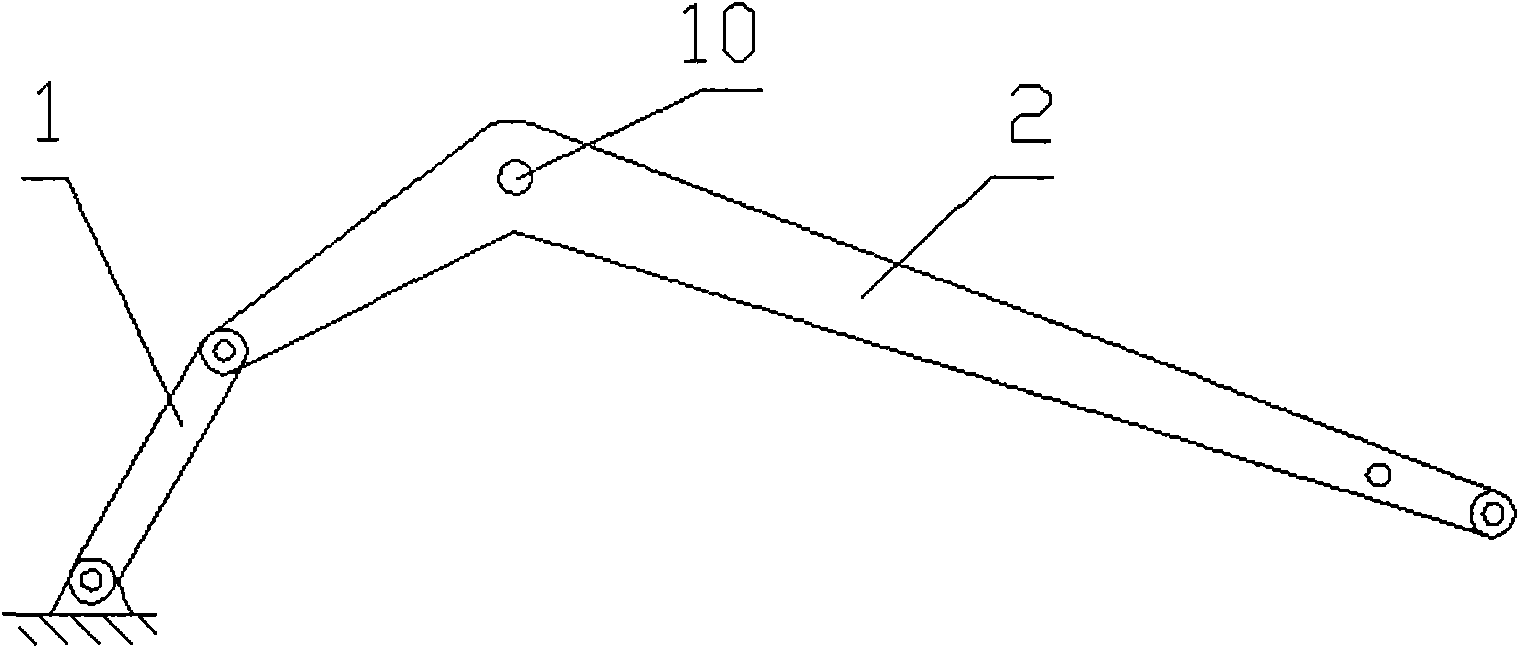

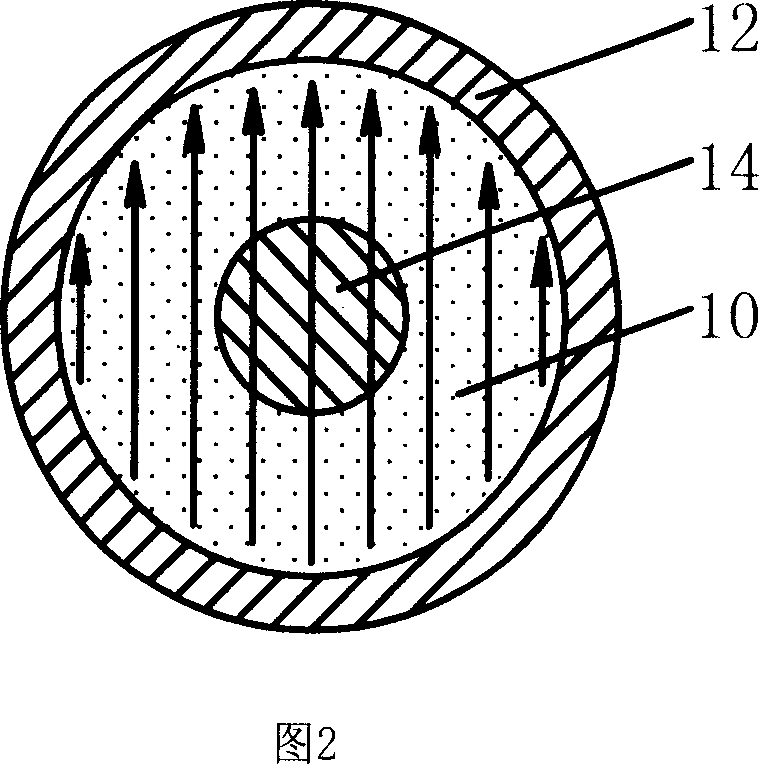

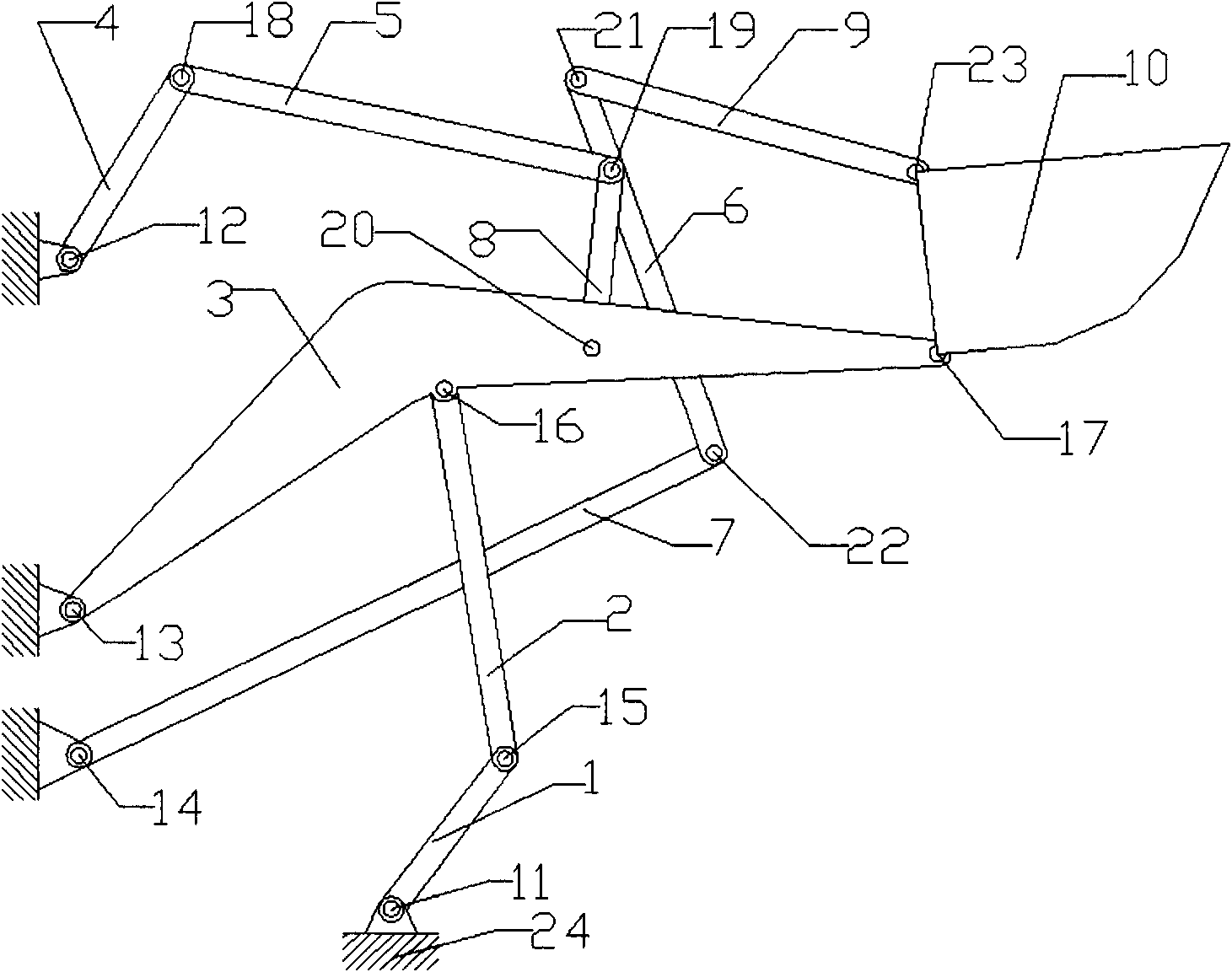

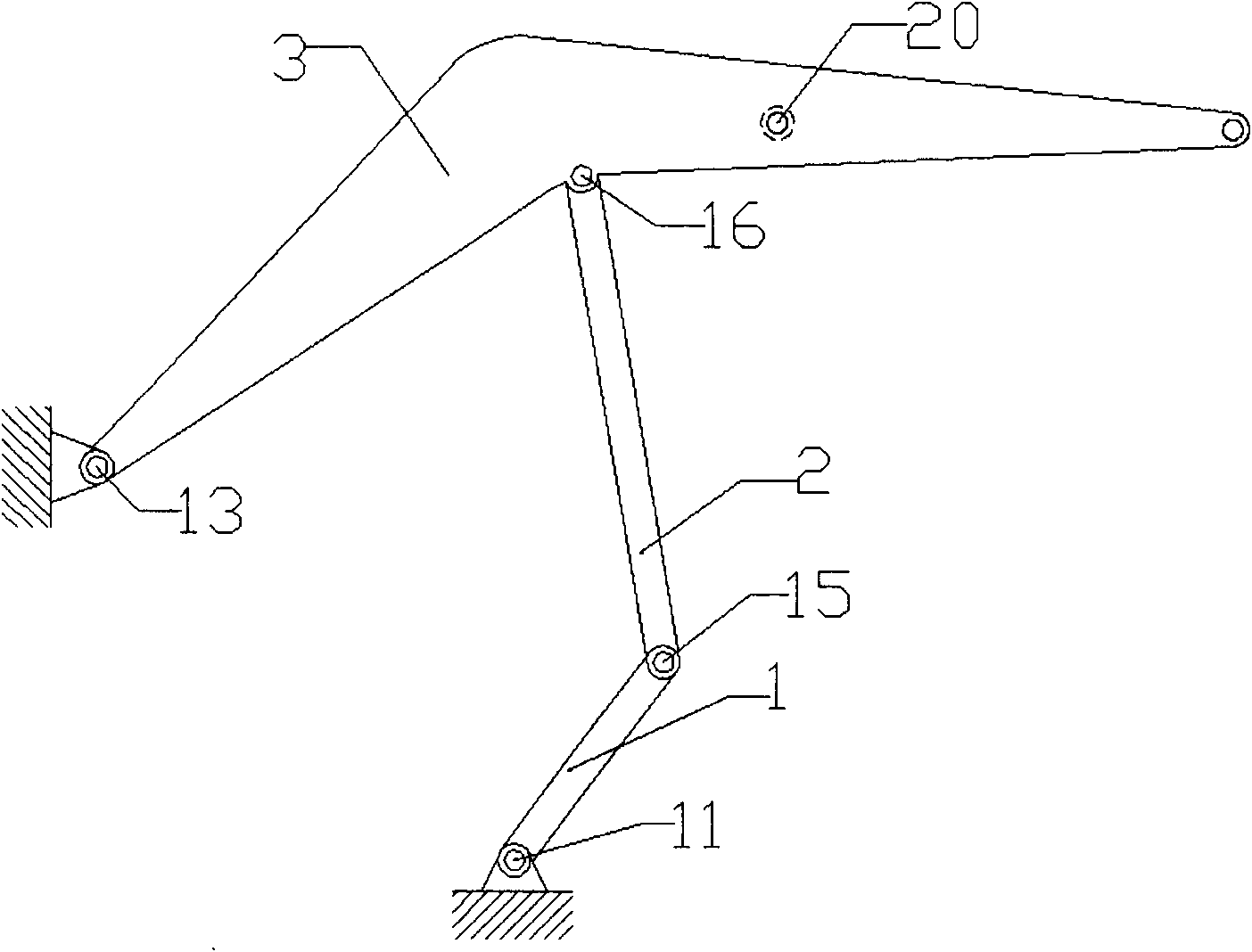

Excavating mechanism of controllable planar three degree of freedom

InactiveCN101666104AReduce weightIncrease digging speedMechanical machines/dredgersThree degrees of freedomSingle degree of freedom

The invention relates to an excavating mechanism of controllable three degree of freedom, comprising an excavating arm, a bucket turning-over mechanism, a backhoe bucket and a stand. The excavating arm is a mechanism of controllable planar two degree of freedom, wherein one end of a driving rod (1) of the mechanism is hinged together with a driven rod (2) through a hinge hole (9), and the other end is hinged on the stand (26) through a hinge hole (8); one end of a driving rod (4) is hinged together with a transmitting rod (3) through a hinge hole (12), and the other end is hinged on the hingehole (11) of the stand (26); and the driven rod (2) is a curved rod which is provided with a hinge hole (10) on the middle curved part and is hinged together with the transmitting rod (3). The invention solves the problems that the traditional mechanical excavating mechanism of single degree of freedom acts simply and the hydraulic excavating mechanism is easy to leak oil.

Owner:GUANGXI UNIV

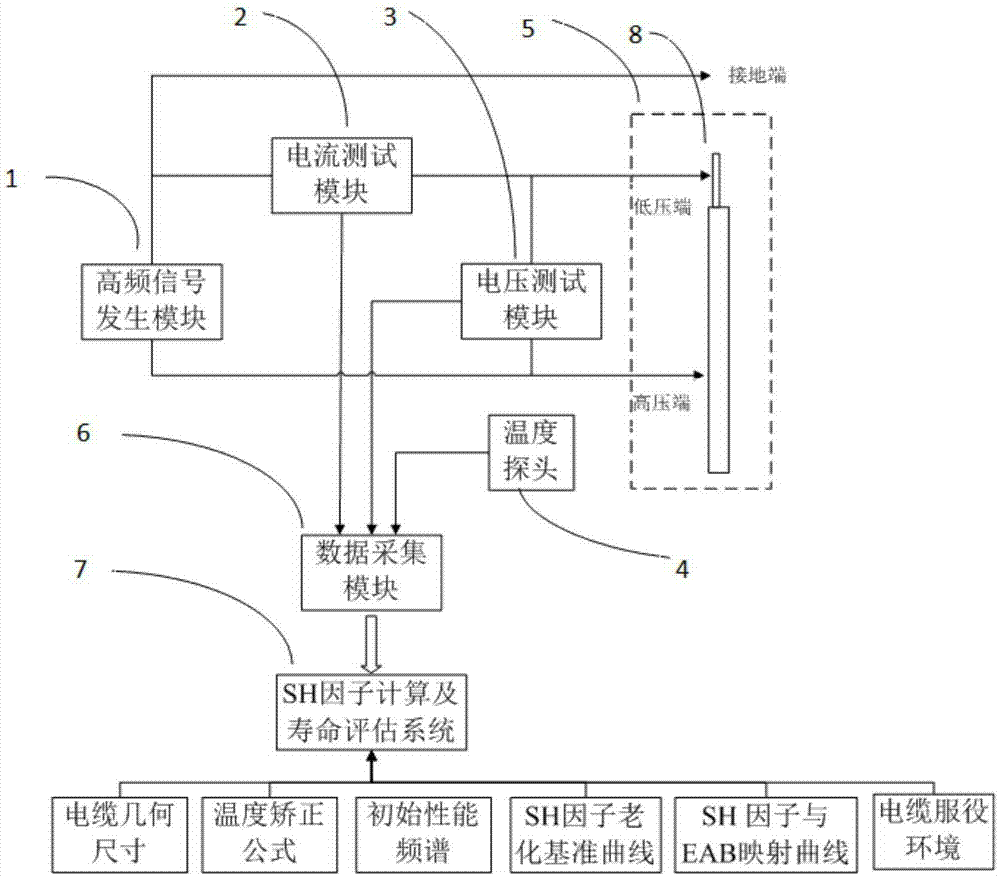

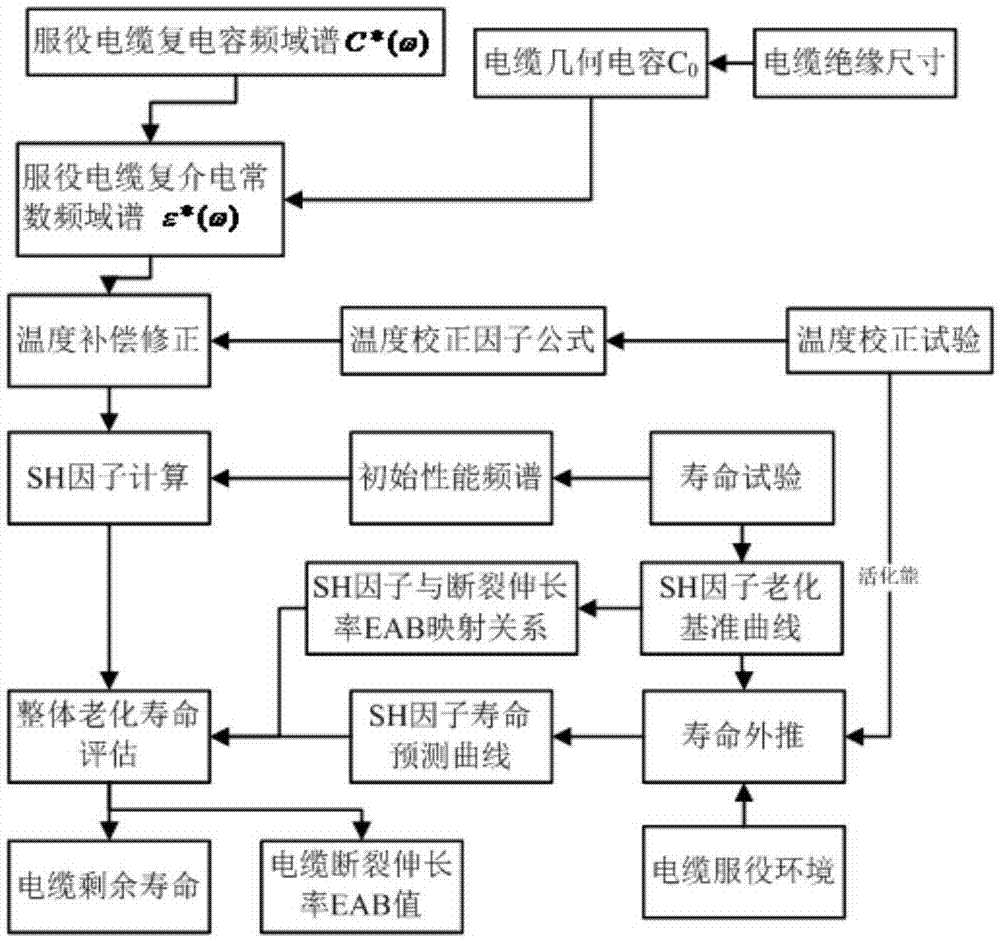

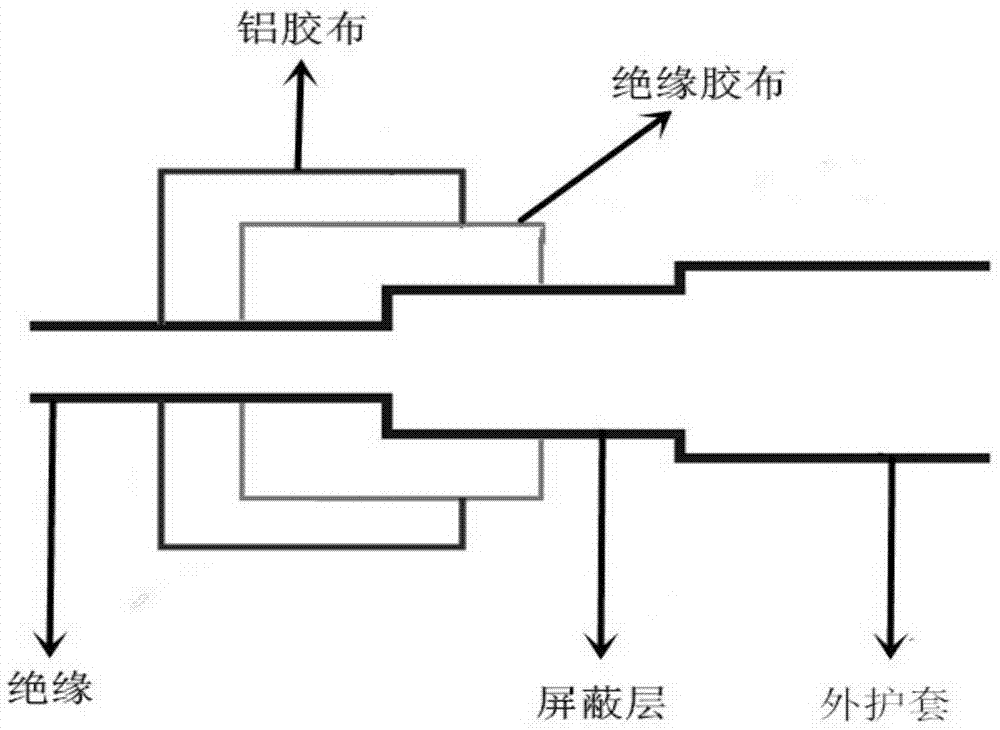

Frequency domain test and analysis system and method for cable overall ageing life evaluation

ActiveCN106855605AAccurate aging stateSolve the problem of longevityTesting dielectric strengthResistance/reactance/impedenceCapacitanceFrequency spectrum

The invention belongs to the technical field of cable nondestructive test and life evaluation and specifically relates to frequency domain test and analysis system and method for cable overall ageing life evaluation. A data acquisition module collects voltage and current response of a cable under actions of AC signals in different frequencies, and calculates cable complex capacitance spectrum and dielectric spectrum; according to temperature signals measured by a temperature probe, the dielectric spectrum calculated based on the test data is subjected to temperature correction treatment by calling temperature compensation factor of the cable in such material stored in the system to obtain a corrected frequency domain curve under a reference temperature; and an SH factor calculation and life evaluation system calculates an SH factor value for reflecting a current state of the cable according to the corrected dielectric spectrum curve, and extrapolates residual life of the cable under the current service condition and a current EAB (elongation at break ) value according to curve information recorded in the system. The system can realize in-service inspection and life evaluation of the on-site in-service cable.

Owner:RES INST OF NUCLEAR POWER OPERATION +1

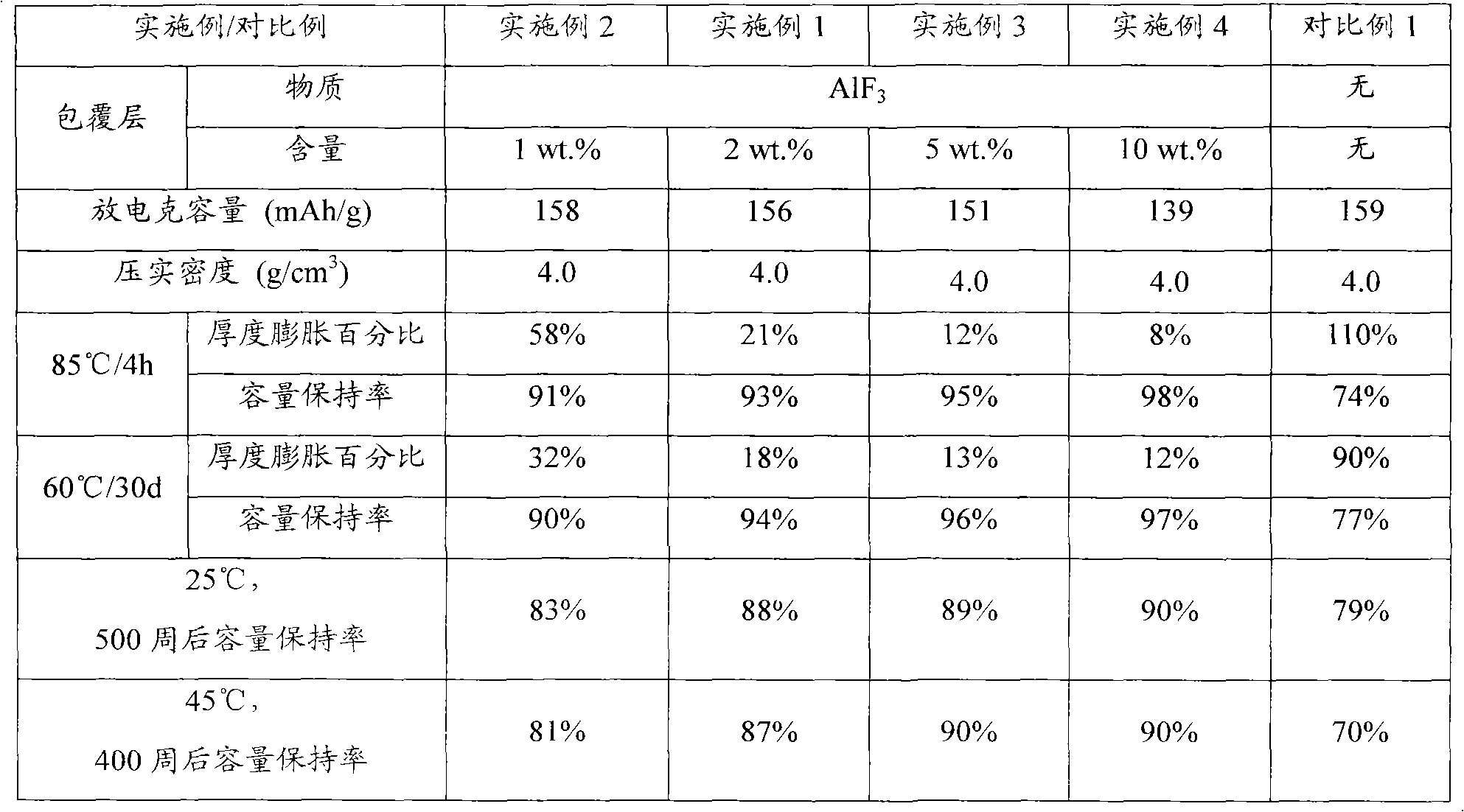

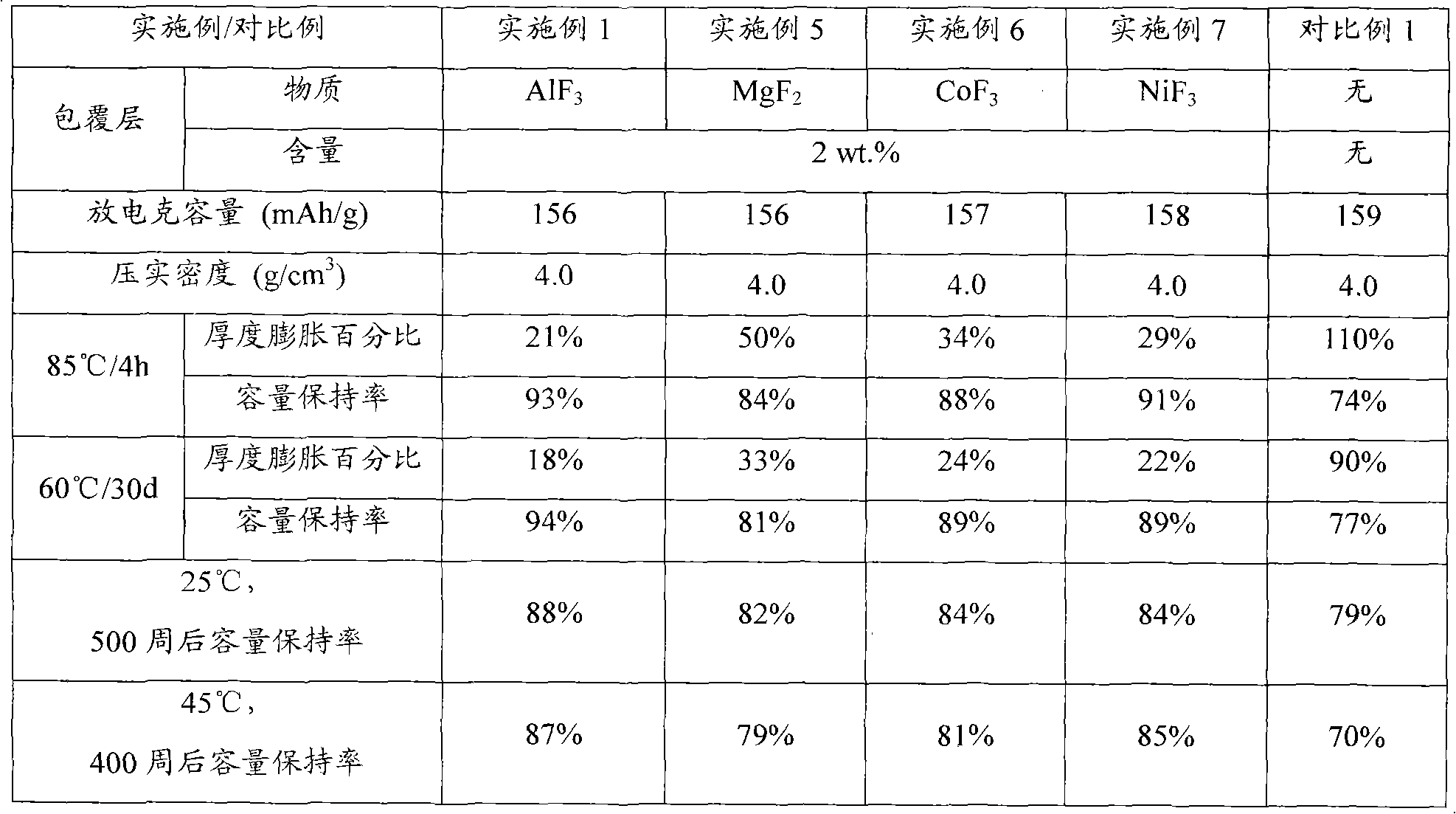

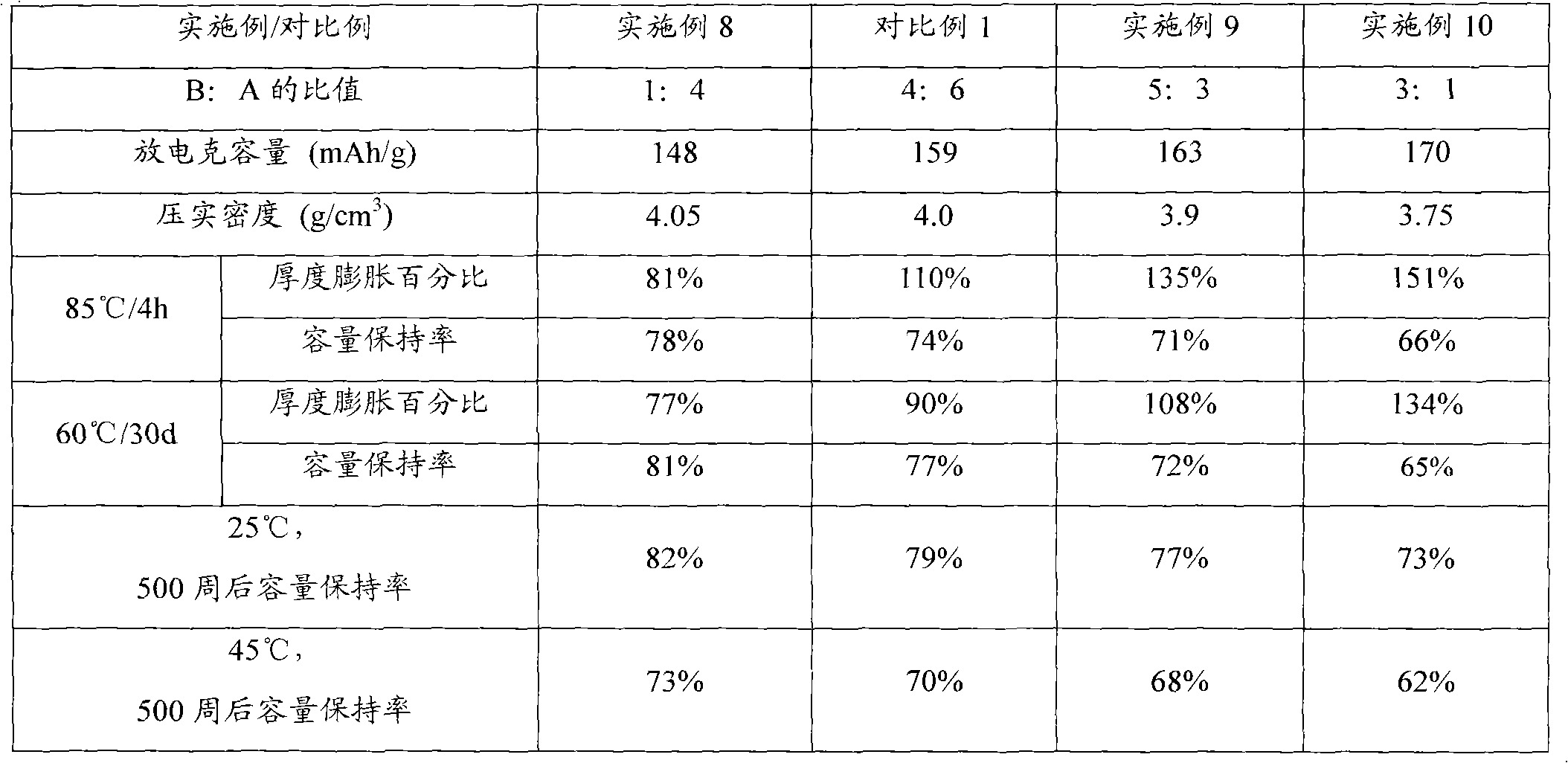

Lithium ion secondary battery and anode thereof

ActiveCN102569722ASolve the problem of longevityImprove physical stabilityCell electrodesSecondary cellsHigh temperature storageMass ratio

The invention provides a high-energy-density lithium ion secondary battery. The lithium ion secondary battery mainly comprises an anode, a cathode, an isolating film, electrolyte and a packaging bag, wherein a positive active material is a mixed material of a lithium cobaltate series active substance A and a high-nickel ternary active substance B; the positive active material is subjected to surface coating treatment of a metal fluoride MeFx (Me is one of Al, Mg, Co and Ni) after mixing; and the mass ratio of the active substance B to the active substance A is between 0.25 and 3.0, and the compacted density is more than or equal to 3.8g / cm<3>. The lithium ion secondary battery has the characteristics of high capacity, high compacted density, high working voltage and good cycle performance at a voltage more than or equal to 4.25V, and the problem that the battery generates a gas during high-temperature storage is solved at the same time.

Owner:NINGDE AMPEREX TECH

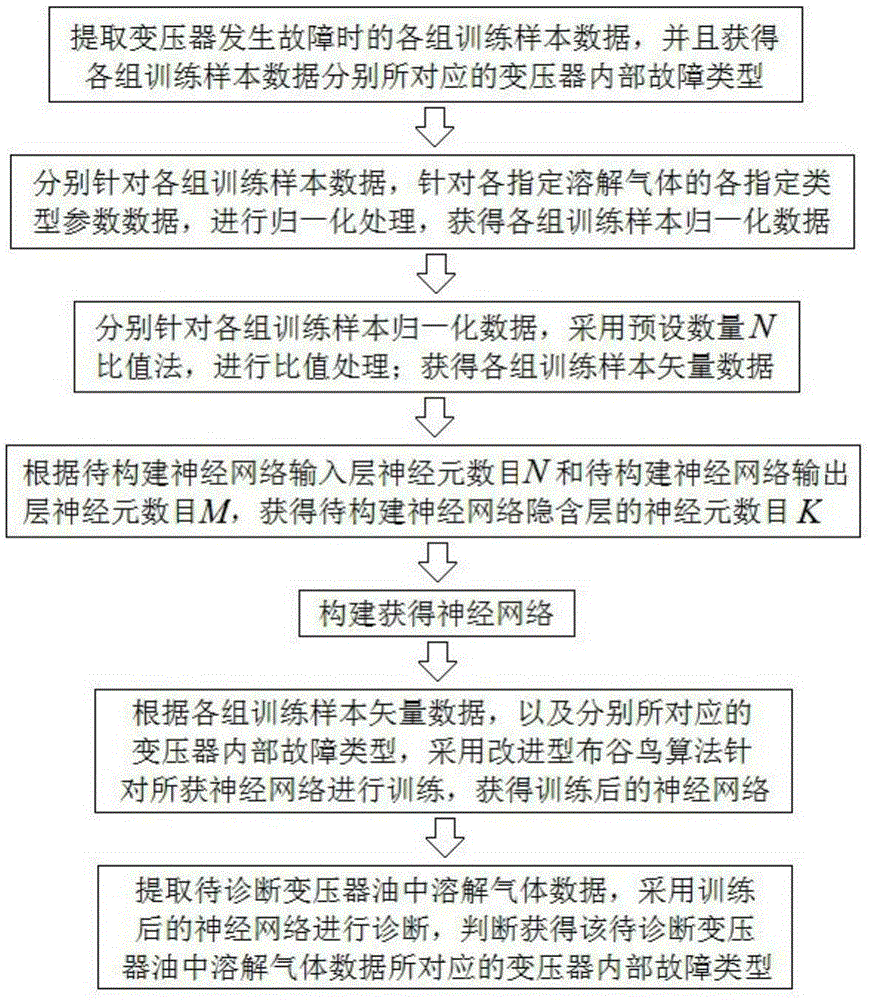

Transformer fault diagnosis method based on neural network

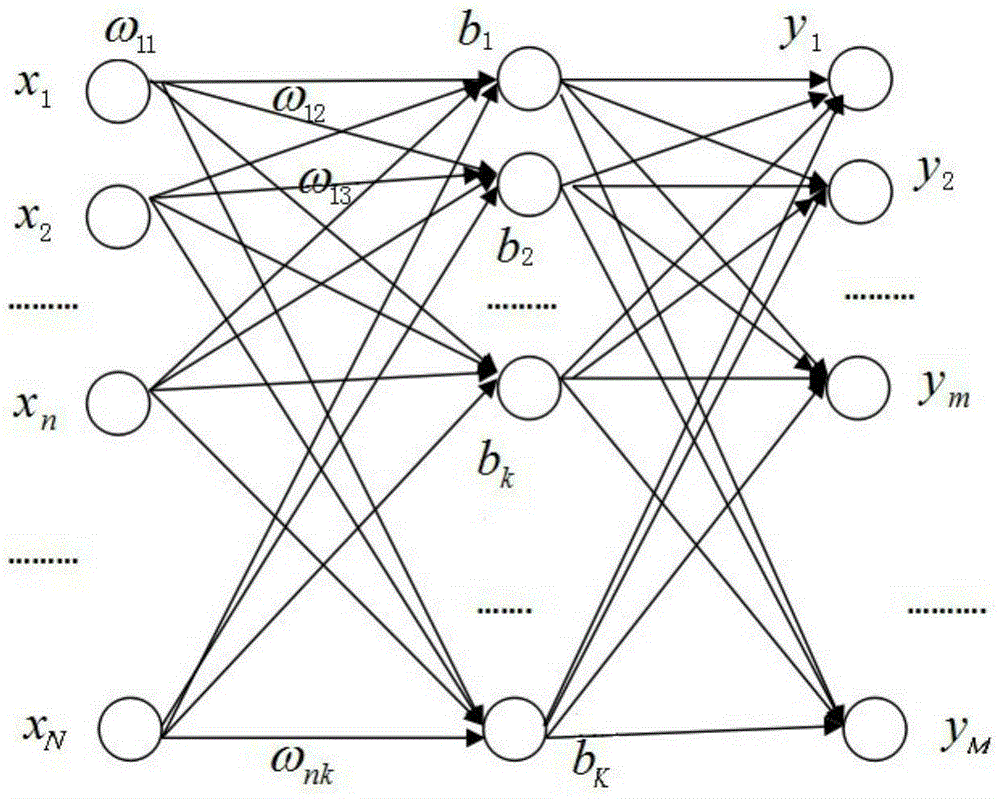

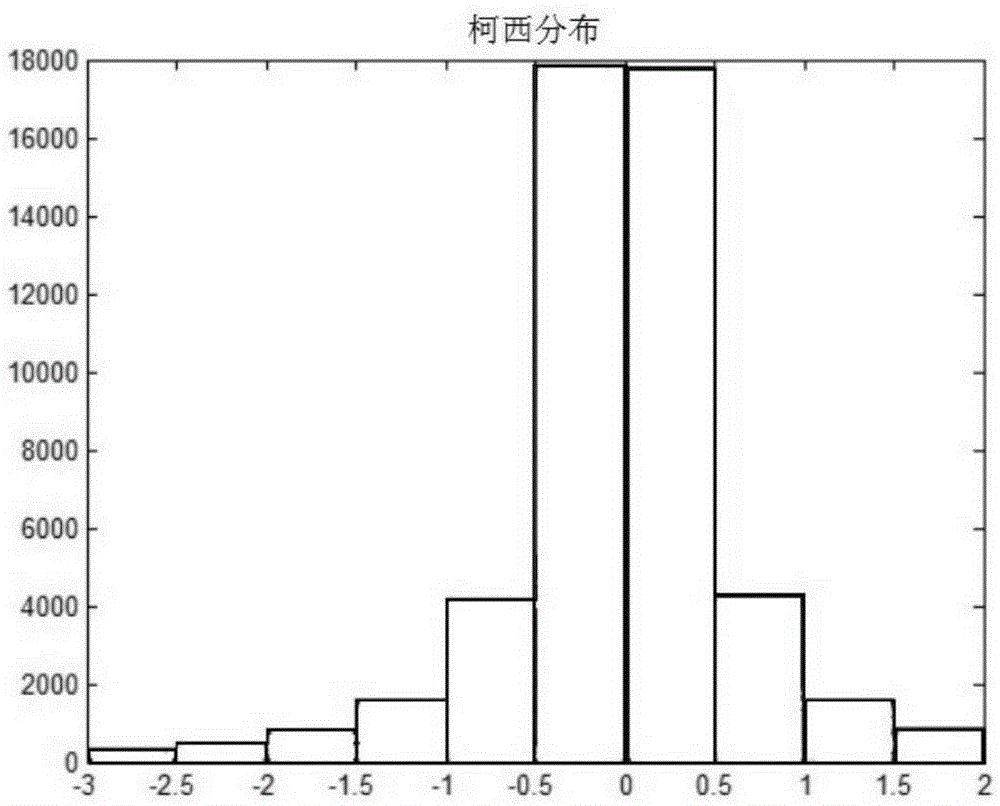

ActiveCN105353255ASolve the local convergence problemFast convergenceElectrical testingBiological neural network modelsHidden layerNerve network

The invention relates to a transformer fault diagnosis method based on a neural network. The method comprises the following steps: analyzing fault reasons, and extracting a sample set of dissolved gas in transformer oil and a corresponding a fault type inside a transformer; determining the number of Neurons in a neural network hidden layer according to experience and a successive optimization searching method, and building a neural network; adopting an improved Cuckoo optimization algorithm to train the neural network; and finally utilizing the trained neural network to diagnose a fault of the transformer. The entire design method has the characteristics of high search precision and high global search capability, and effectively improves the accuracy of fault diagnosis for a transformer.

Owner:NANJING UNIV OF POSTS & TELECOMM

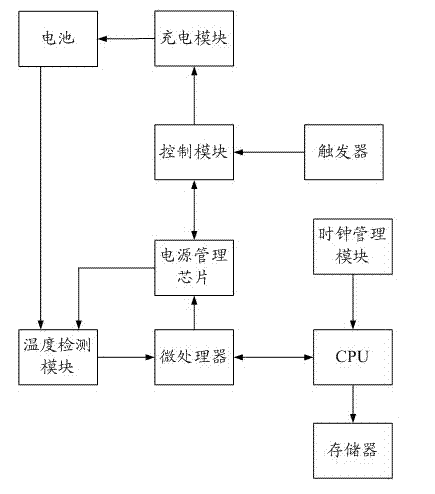

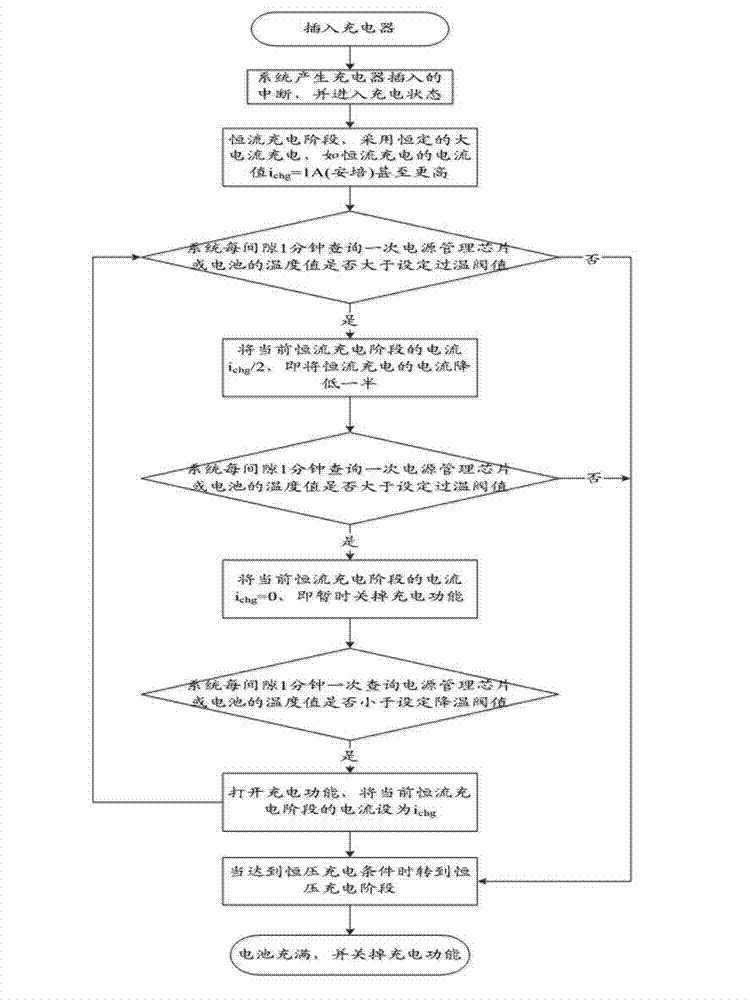

System and method for reducing heating value in mobile terminal charging

ActiveCN103166202ASolve the problem of longevityTroubleshooting Battery DamageEmergency protective circuit arrangementsCharge currentMobile phone

The invention discloses a system and a method for reducing a heating value in mobile terminal charging. The method includes the steps that A, a clock management module sends temperature detection signals every other cycle, and a central processing unit (CPU) carries out temperature detection according to the temperature detection signals; B, an obtained temperature value is compared with an over-temperature threshold value of a battery and a power management chip in a memorizer by the CPU, and if the temperature value exceeds the over-temperature threshold value, charging currents are reduced; and C, the CPU detects the temperature of the battery and the power management chip after a cycle interval through a microprocessor, and if the temperature exceeds the over-temperature threshold value, the power management chip is controlled through the microprocessor to close a charging function. According to the system and the method, the heating value of a mobile phone in the charging process can be reduced, if the heating value of the mobile phone reaches the threshold value, the current value of constant current charging is halved, and if the temperature is not reduced below a prewarning value yet, the charging function is closed. Until the temperature of the mobile phone returns to be in a normal temperature, the charging function is opened again. According to the system and the method, not only is the temperature of the mobile phone in the charging process is reduced, but also safety of the mobile phone in the charging process is further improved.

Owner:SHENZHEN TRANSSION HLDG CO LTD

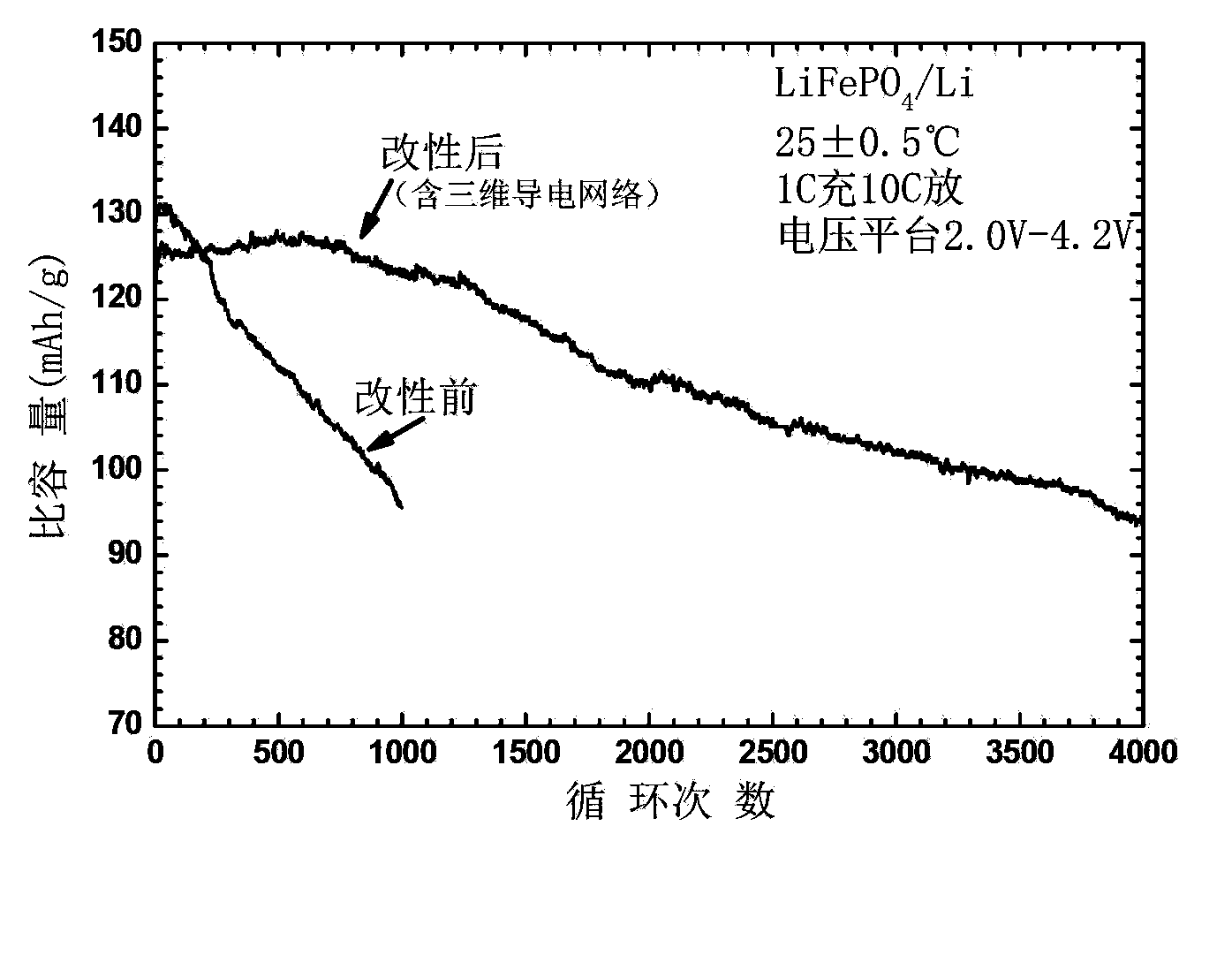

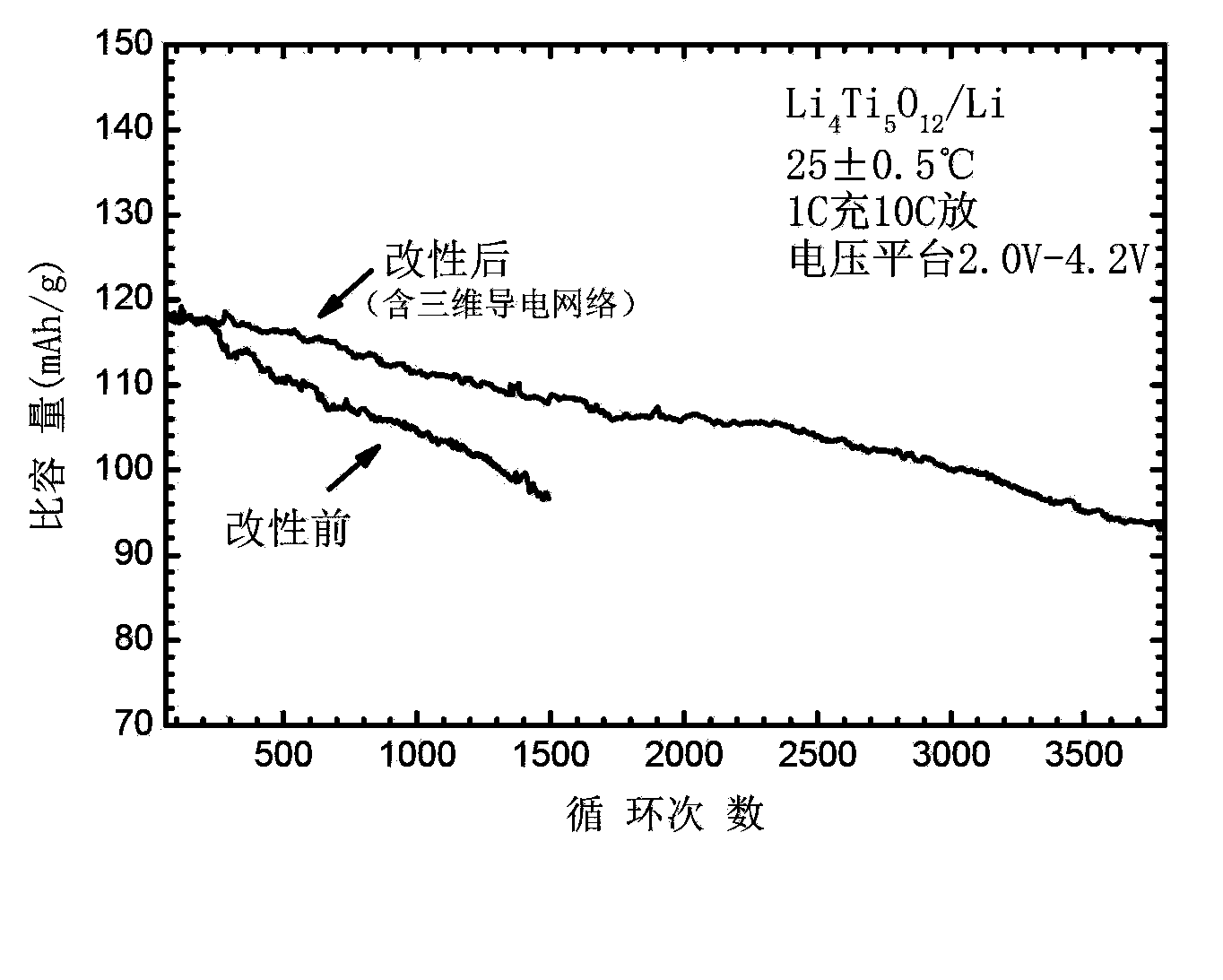

Lithium ion battery nano composite positive-negative electrode material containing three-dimensional conductive network as well as preparation method thereof

InactiveCN103545525AEvenly dispersedHigh mechanical strengthCell electrodesSecondary cellsConductive materialsSurface-active agents

The invention discloses a lithium ion battery nano composite positive-negative electrode material containing a three-dimensional conductive network as well as a preparation method thereof. Technical key point is that the three-dimensional conductive network is built by comprehensively using a modified and dispersed one-dimensional conductive nano material with great slenderness ratio and high strength and a zero-dimensional nano conductive material under action of a binding agent, so that mechanical strength and processing performance of the positive-negative electrode material of the lithium ion battery as well as transmissibility of electrons among particles are improved, and therefore, a problem that the typical lithium ion battery electrode material is poor in great multiplying power performance and short in cycle life is solved. The preparation method of the lithium ion battery nano composite positive-negative electrode material comprises the following steps: firstly, adding the one-dimensional conductive nano material into water or an organic solvent containing a surfactant for ultrasonic treatment and stirring treatment so as to sufficiently disperse one-dimensional conductive nano material; and then, respectively adding the dispersing liquid into a zero-dimensional conductive agent, a binding agent and the positive-negative electrode material for ultrasonically stirring and stirring for a certain time at a high speed to obtain the lithium ion battery nano composite positive-negative electrode material containing the three-dimensional conductive network.

Owner:南京宏德纳米材料有限公司

Alkali-activated slag powder geopolymer mortar for structure reinforcement and preparation method thereof

The invention discloses alkali-activated slag powder geopolymer mortar for structure reinforcement and a preparation method thereof. The alkali-activated slag powder geopolymer mortar for structure reinforcement is prepared from, by weight, 150-210 parts of slag powder, 0-60 parts of fly ash, 400-700 parts of sand, 190-240 parts of water glass and 25-50 parts of solid sodium hydroxide. The preparation method comprises the following steps that the slag powder, the fly ash and the sand are mixed to be uniform according to the proportions; solid sodium hydroxide particles are dissolved in the corresponding amount of the water glass according to the proportion; sodium hydroxide-dissolved water glass is added into well-mixed dry materials, and stirring is conducted continuously to be uniform; the well-stirred alkali-activated slag powder geopolymer mortar is used for building structure reinforcement; the alkali-activated slag powder geopolymer mortar has high compressive strength, good adhesive property with concrete and fiber cloth materials and a wide fluidity range and can adapt to the situation of reinforcing building structures through a fiber cloth bonding method or a grouting pouring method.

Owner:SHANGHAI JIUJIAN REINFORCEMENT TECH

Refractory castable for kilneye and kiln head cover of rotary kiln

The invention discloses a refractory castable for a kilneye and a kiln head cover of a rotary kiln, comprising 50-60 parts of refractory aggregate, 28-39 parts of refractory micro powder, 5-8 parts of oxide micro powder, 4-6 parts of bonding agent and 1.56-2.8 parts of additive, wherein the granularity of the refractory aggregate is 1-8mm, the granularity of the refractory micro powder is less than 1.0mm, the granularity of the oxide micro powder is less than 5mum, and the granularity of the bonding agent is less than 0.088mm. The refractory castable adopts the complex phase technology, has good balance in notably improving mechanical strength, wearing resistance and thermal shock resistance of the material, enables the castable to obtain excellent comprehensive performance, and effectively solves the problems that the prior refractory castable for the kilneye and the kiln head cover of the rotary kiln is easy to wear, has bad thermal shock resistance or lower strength and short service life.

Owner:LUOYANG INST OF SCI & TECH +1

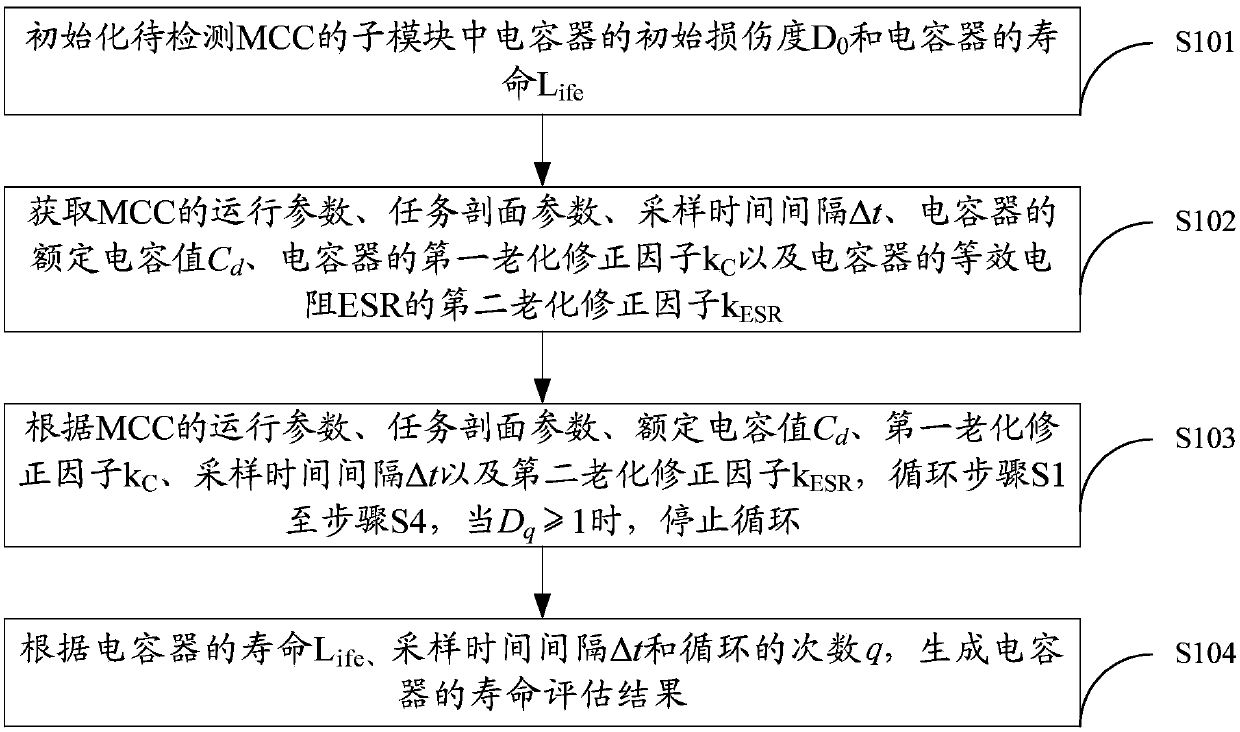

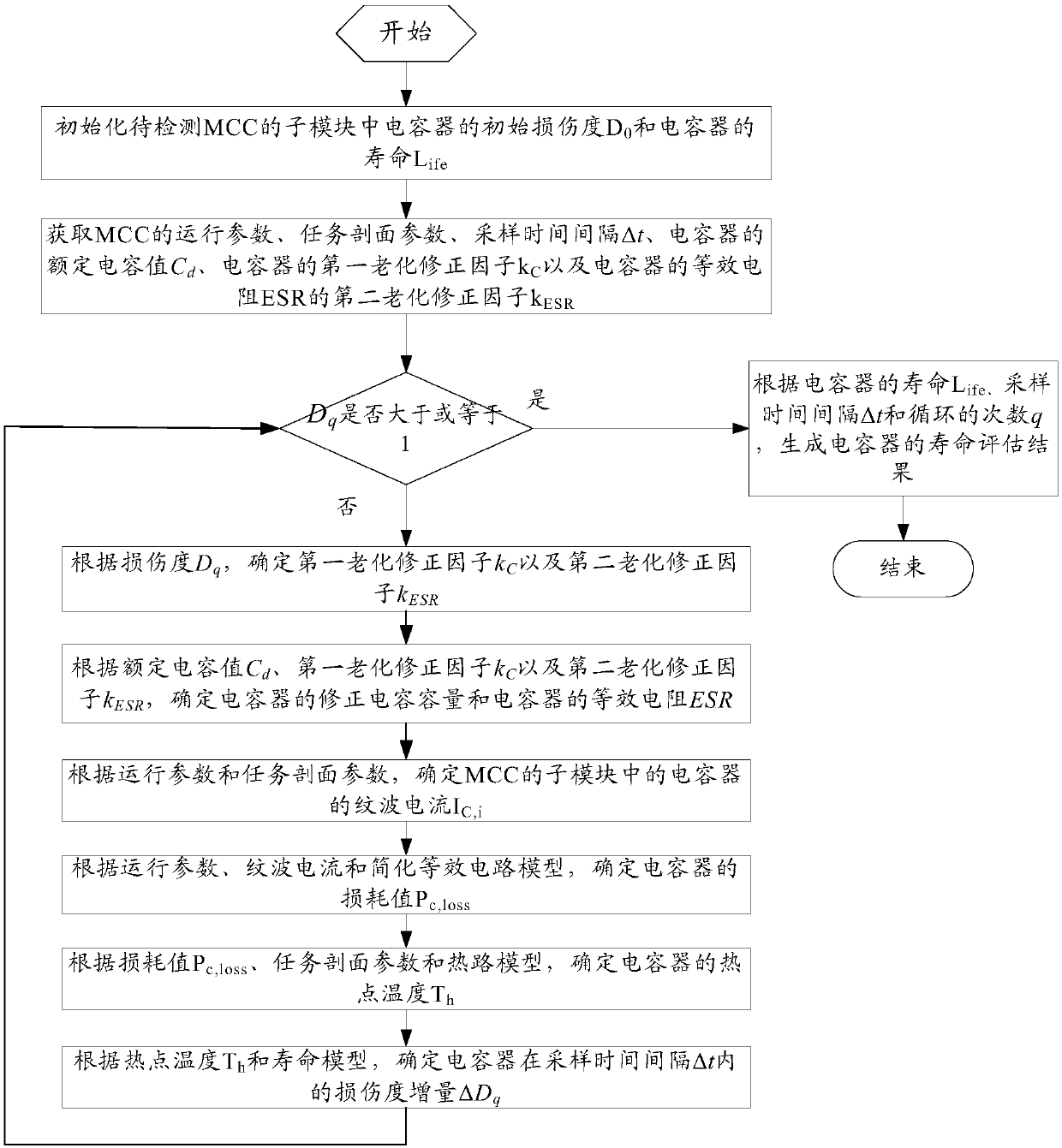

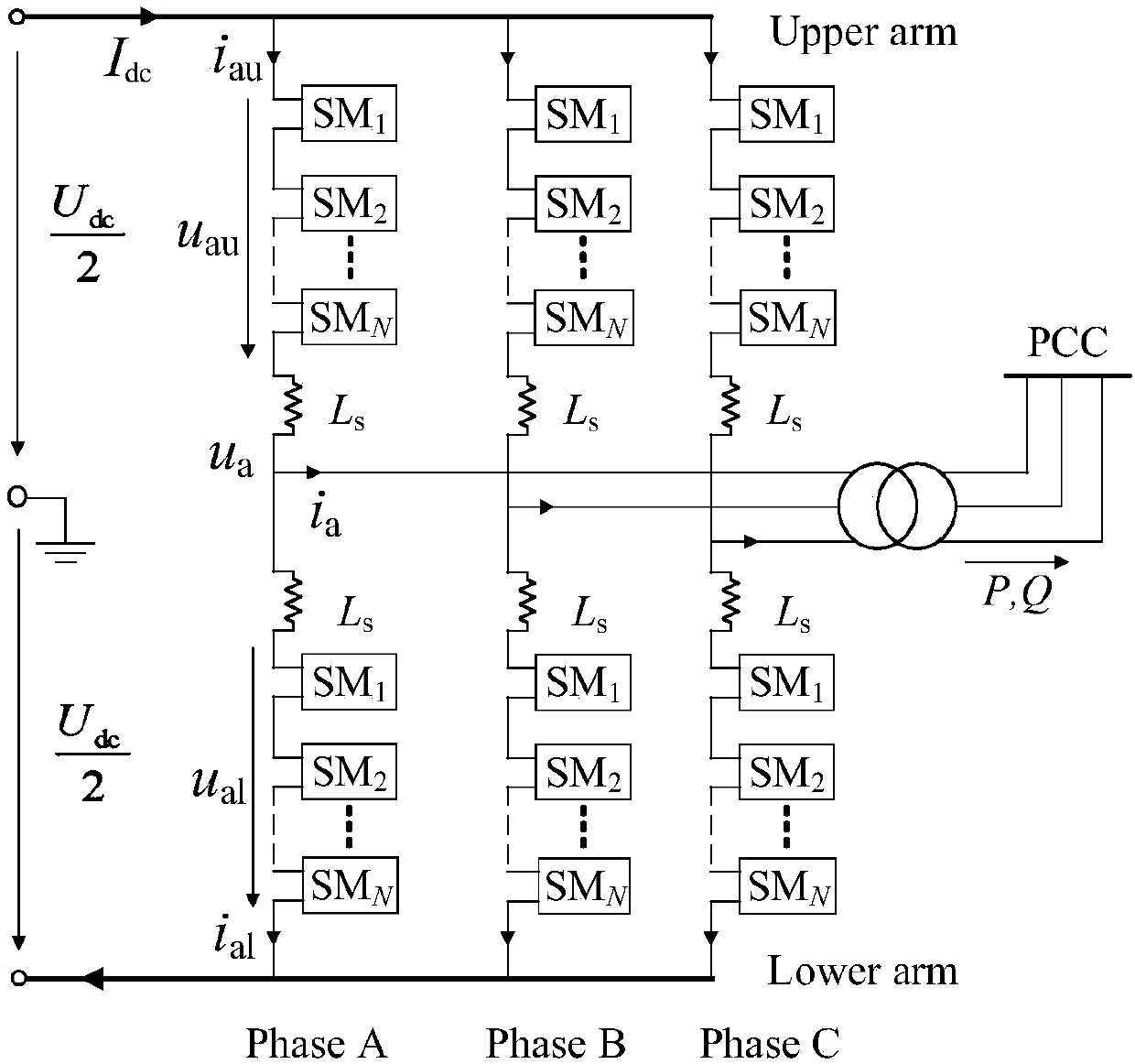

Service life evaluating method and device for sub-module capacitor of modular multi-level converter

The embodiment of the invention provides a service life evaluating method and device for a sub-module capacitor of a modular multi-level converter, and relates to the technical field of power transmission. The problem that the service life of the capacitor in the MMC cannot be accurately analyzed in the prior art is solved. The method comprises the steps that the initial damage degree and servicelife of the capacitor in a sub-module of the MCC are initialized; the operating parameter of the MCC, a task profile parameter, sampling time interval delta t, the rated capacitance value Cd of the capacitor, the first aging correction factor kC of the capacitor, and the second aging correction factor kESR of an equivalent resistor ESR of the capacitor are acquired; the steps from S1 to S4 are circulated; if Dq is greater than or equal to 1, circulation is stopped; and the service life evaluation result of the capacitor is generated according to the service life Life of the capacitor, the sampling time interval delta t and the number of times q of circulation. The method and device are used for calculating the damage degree of the capacitor in the MMC.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD

SiC-Si3N4 high temperature ceramic furnace bottom plate for annular furnace and preparation method thereof

InactiveCN102795859AImprove creep resistanceHigh temperature strengthThermal dilatationTemperature resistance

The invention relates to a SiC-Si3N4 high temperature ceramic furnace bottom plate for an annular furnace and a preparation method thereof; the preparation method comprises the following steps: on a basis of a total weight part of 100 parts, weighing 25-75 parts of Si powder and the balance of SiC powder; adding 3-8 parts of a sintering aid and 4-9 parts of a binder, wherein the sintering aid is Y2O3, or a mixture of Y2O3 and Al2O3; performing material mixing, molding, sintering, silicon immersion, and machining to prepare the SiC-Si3N4 high temperature ceramic furnace bottom plate for an annular furnace. The preparation method is simple in process and low in cost, and the obtained product has the characteristics of high temperature resistance, good creep resistance, large high-temperature strength, good thermal shock resistance, and the like, can meet working condition requirements for annular furnace production, and can effectively solve the problems of poor high temperature resistance of metal furnace bottom plates, furnace bottom plate bending deformation due to a large material high-temperature creep rate, furnace bottom plate cracking damage due to a large material thermal expansion rate, and low service life.

Owner:湖北红花高温材料股份有限公司

Manufacture method of functional refractory for steelmaking

InactiveCN1413951AShort production processImprove physical and chemical propertiesMolten stateSteelmaking

A functional refractory for smelting steel is prepared from one or more inorganic materials through mixing, smelting and casting. Its advantages are simple process, low cost, long service life and high smelting temp (1800-3200 deg.C).

Owner:ZHEJIANG ZILI HIGH TEMPERATURE TECH CO LTD

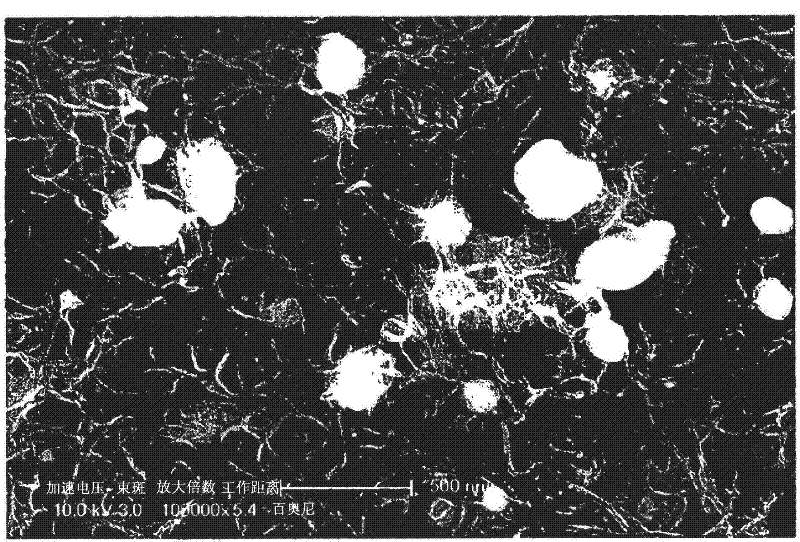

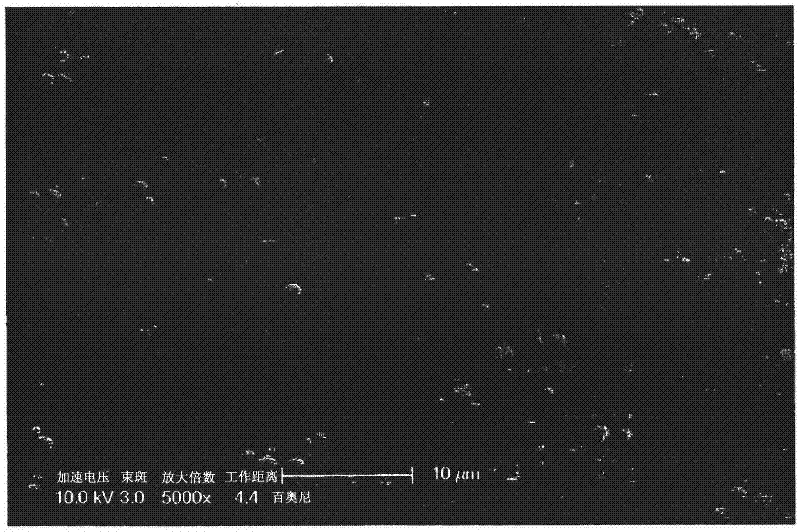

Nanoporous films and method of manufacturing nanoporous films

The invention provides a carbon nano-structure-metal complex nano porous film coating on both sides of a membrane support having micro or nano-porous carbon and a manufacturing method thereof. The method comprises dispersing the carbon nano-structure-metal complex and coating on both sides of a separated membrane support in the presence of surface active agent; performing thermal treatment to the coated separated membrane support and welding the melt to the separated membrane support. According to the carbon nano-structure-metal complex nano porous film, the metal of the carbon nano-structure-metal complex is nanometer to hundreds of nanometer level, thus can be melted at low temperature.

Owner:BIONEER

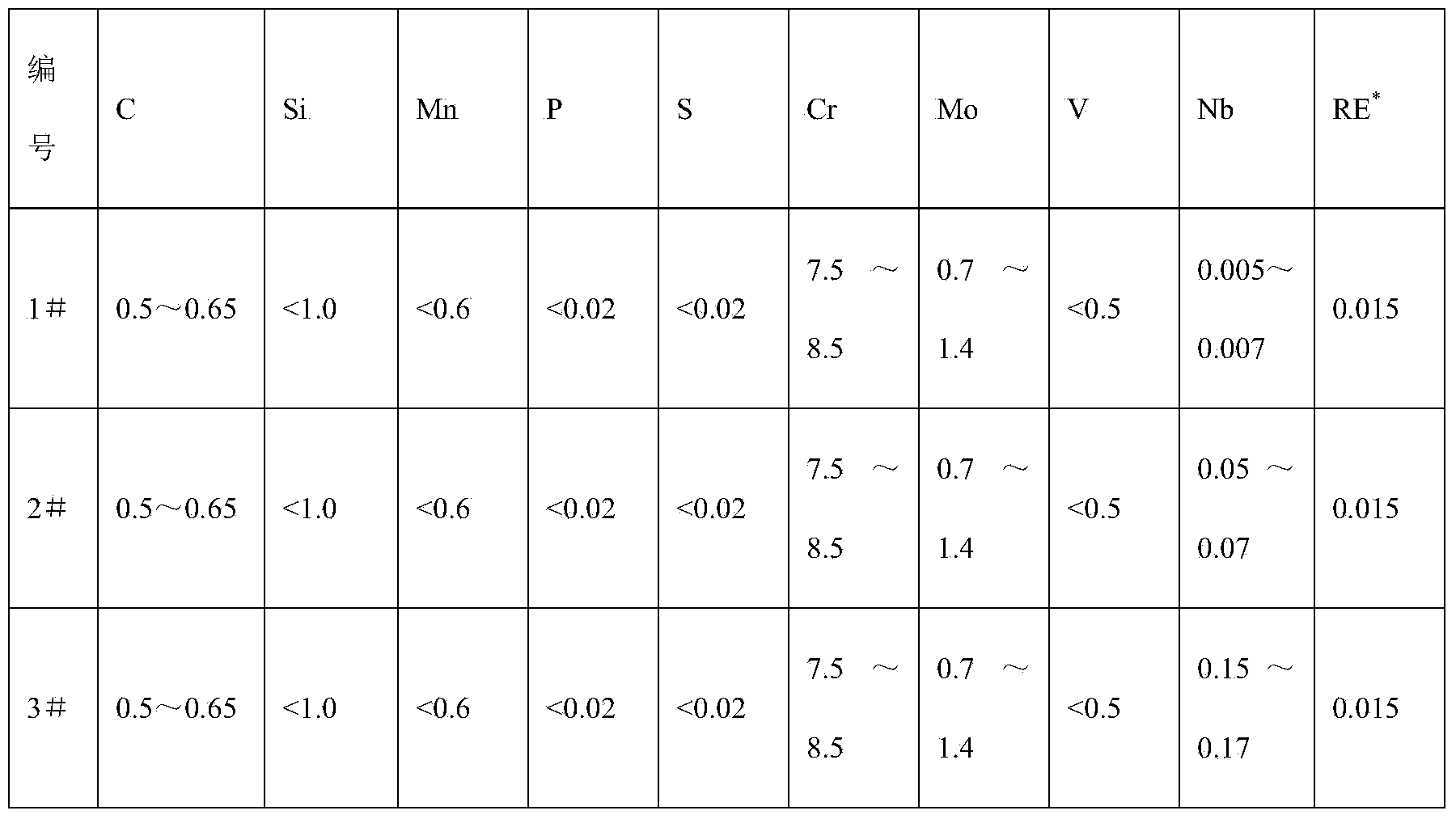

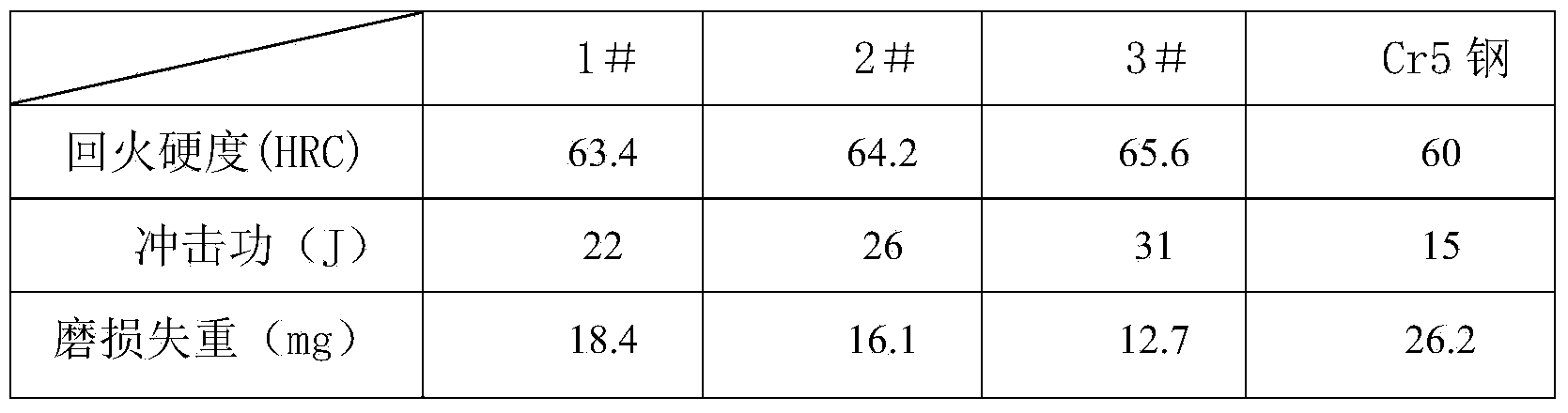

Improved Cr8 steel roll and preparation method thereof

The invention discloses an improved Cr8 steel roll and a preparation method thereof. Based on the Cr5 steel, the Cr8 steel roll also comprises microalloying Nb and RE, wherein Nb is mainly used for refining the crystalline grain, and RE is mainly used for purifying molten steel. The Cr8 steel roll comprises the following components: 0.50-0.65% of C, less than or equal to 1.0% of Si, less than or equal to 0.60% of Mn, less than or equal to 0.020% of S, less than or equal to 0.020% of P, 7.5-8.5% of Cr, 0.70-1.40% of Mo, less than or equal to 0.50% of V, 0.005-0.20% of Nb, 0.003-0.02% of RE, and the balance of Fe and impurities. By combining solidification refining, deformation recrystalization refining and thermal treatment refining, the method refines the tissue of a high chrome ledeburite die steel and obtains fine plate martensite with the length less than 30micron and width less than 0.5micron. Due to rare earth modification, carbide segregation is reduced, and the morphology of the included foreign substances and eutectic carbide is improved. Due to the adoption of proper thermal treatment technology, compared with Cr5 steel, the Cr8 steel roll not only has higher toughness, but also improves the abrasion performance, and greatly prolongs the service life.

Owner:UNIV OF SCI & TECH BEIJING

Integrated permanent magnet rotor magnetic suspension high speed motor

InactiveCN1945940ASolve the quality balance problemSimple manufacturing processSynchronous machines with stationary armatures and rotating magnetsPermanent magnet rotorCoupling

An integral permanent magnet rotor magnetic suspension high speed motor includes a shell, right and left covers, a stator core, a stator winding, a magnet rotor, a shaft, an axial magnetic suspension bearing and right and left radial magnetic suspension bearings, in which, the magnet rotor is set on the shaft of the motor, the stator core is mounted on the internal wall and surrounding the rotor, the stator winding is inserted in the core tank, the right and left covers are fixed at either end of the shell at both sides of the stator core, a right radial magnetic suspension bearing is set between the shaft and the right cover, the left radial suspension bearing and the axial bearing are mounted between the shaft and the left cover and the axial bearing is set at the end of the shaft, the other end of the shaft is connected with the drive device by a coupling and the magnet rotor is an integer structure.

Owner:SHENYANG POLYTECHNIC UNIV

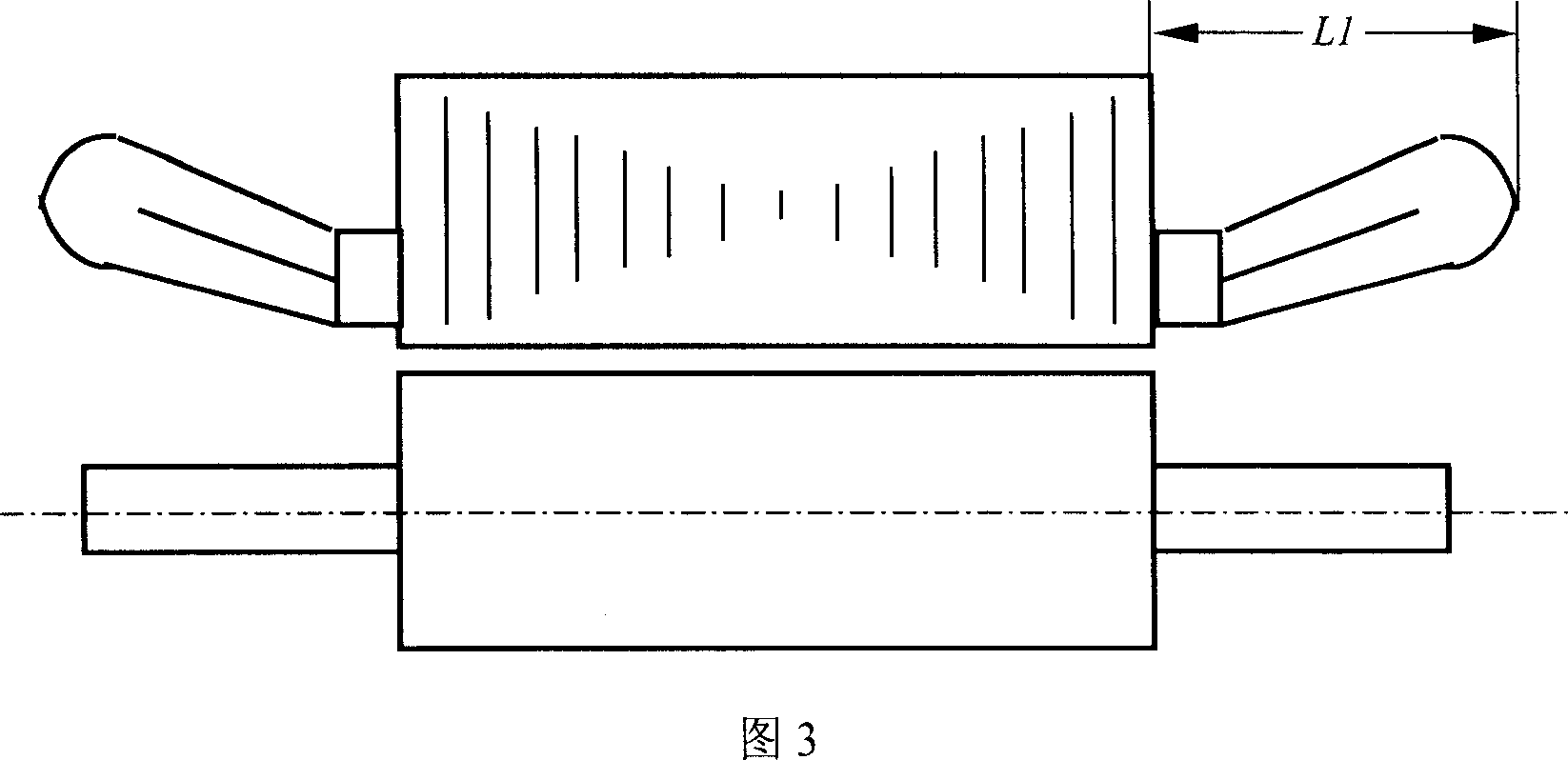

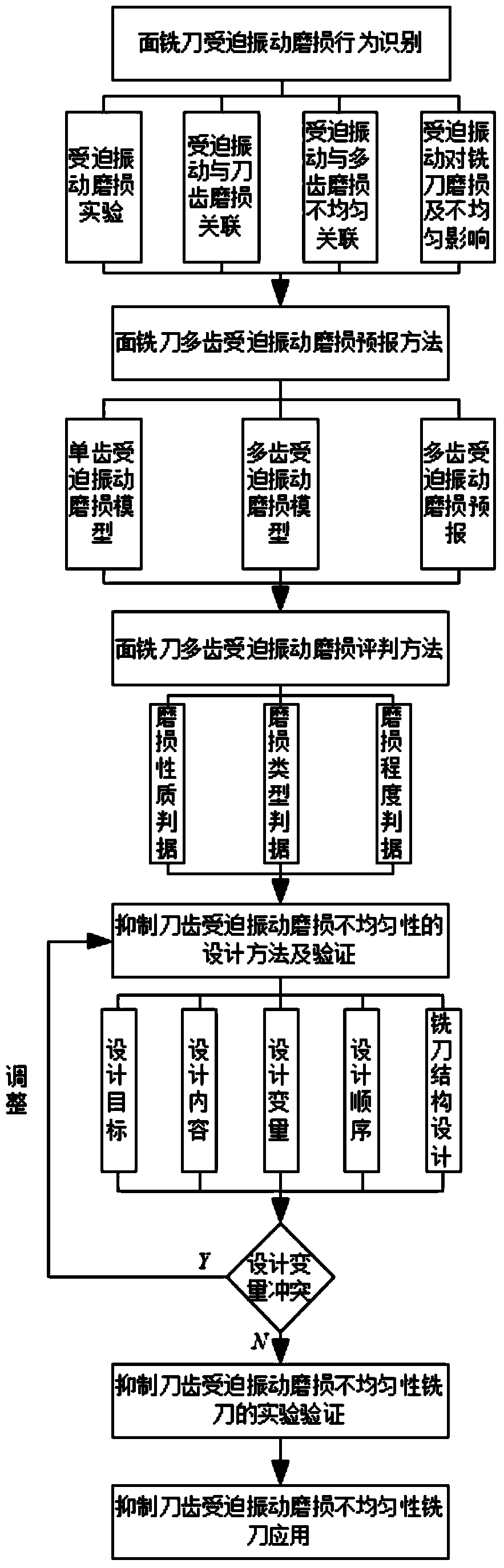

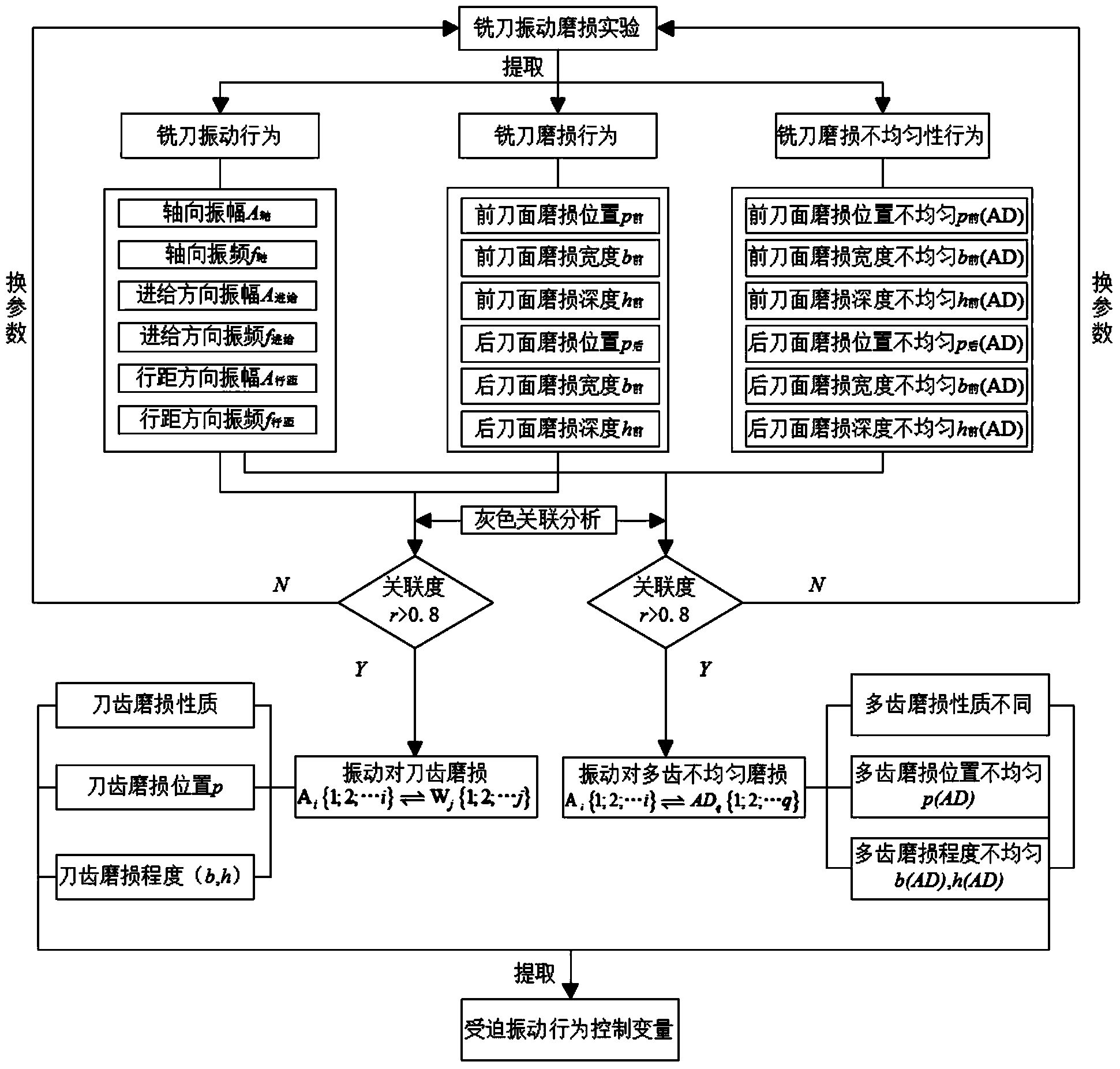

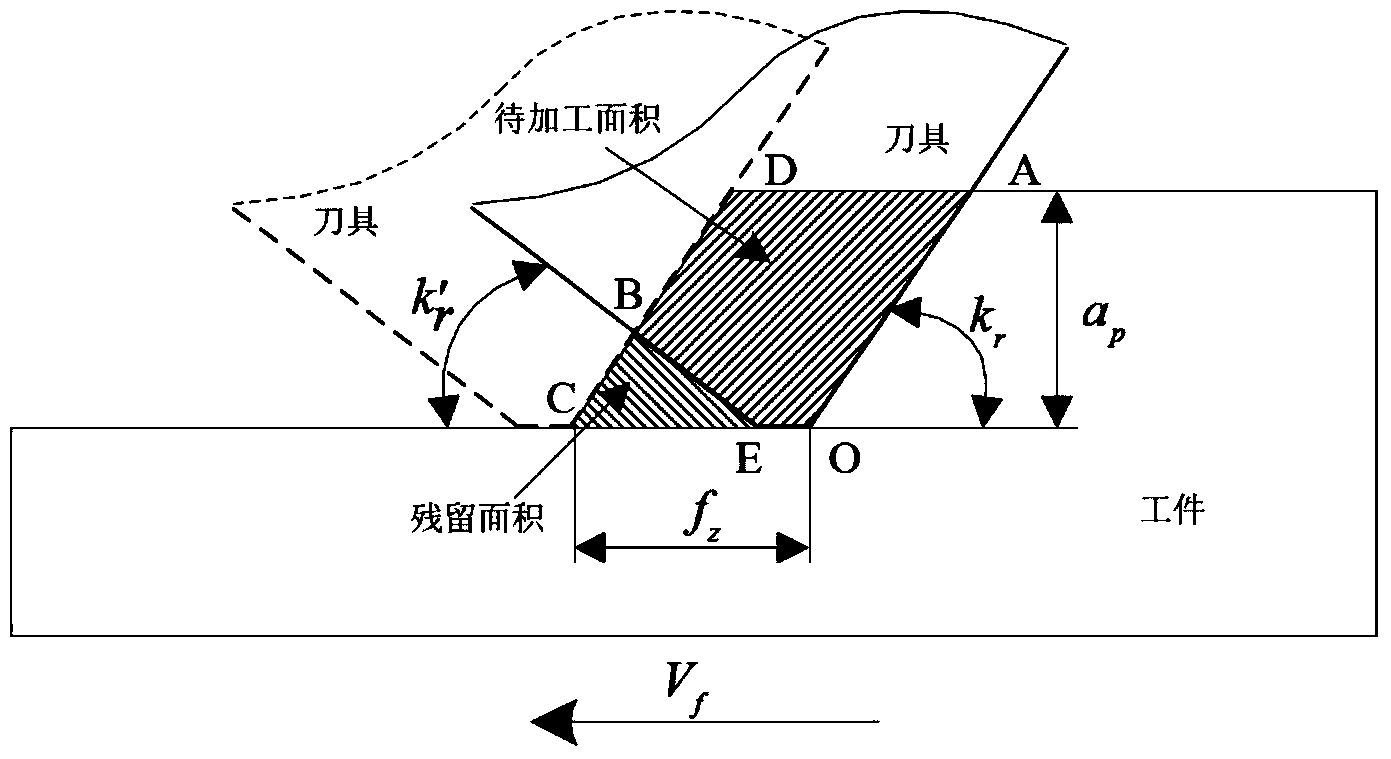

High-speed milling cutter designing method for suppressing unevenness in forced vibration wear of cutter teeth

ActiveCN103761386AReduce unevennessSolution to short lifeStapling toolsSpecial data processing applicationsTooth wearMilling cutter

The invention discloses a high-speed milling cutter designing method for suppressing unevenness in forced vibration wear of cutter teeth, and belongs to the technical field of cutters. The high-speed milling cutter designing method particularly includes providing a process for identifying forced vibration wear behavior of a milling cutter by the aid of correlation characteristics of forced vibration of the high-speed face milling cutter and wear behavior of the cutter teeth; building a multi-tooth forced vibration wear model of the milling cutter and providing a process for predicting and judging forced vibration wear and uneven wear of the milling cutter. The high-speed milling cutter designing method has the advantages that a process for controlling the uneven wear of the milling cutter and a process for designing the milling cutter are provided, so that the problem of design conflicts among multi-tooth wear positions, wear areas and wear depth control variables of an existing milling cutter can be solved, the milling cutter with the diameter of 63mm can be designed by the high-speed milling cutter designing method, the unevenness in forced vibration wear of the cutter teeth for cutting No.45 steel at high speeds can be effectively suppressed, and the high-speed milling cutter designing method is used for designing milling cutters.

Owner:HARBIN UNIV OF SCI & TECH

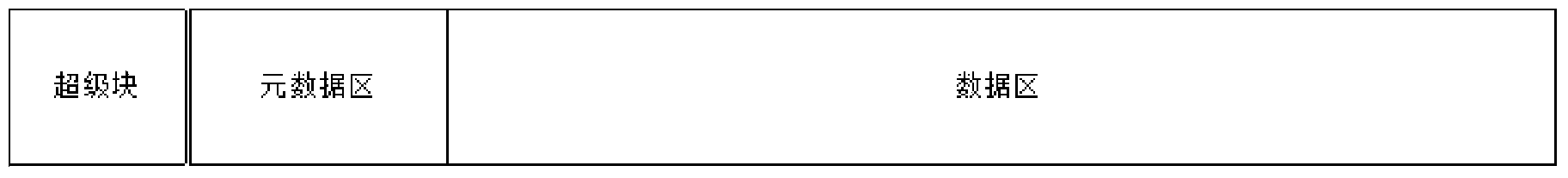

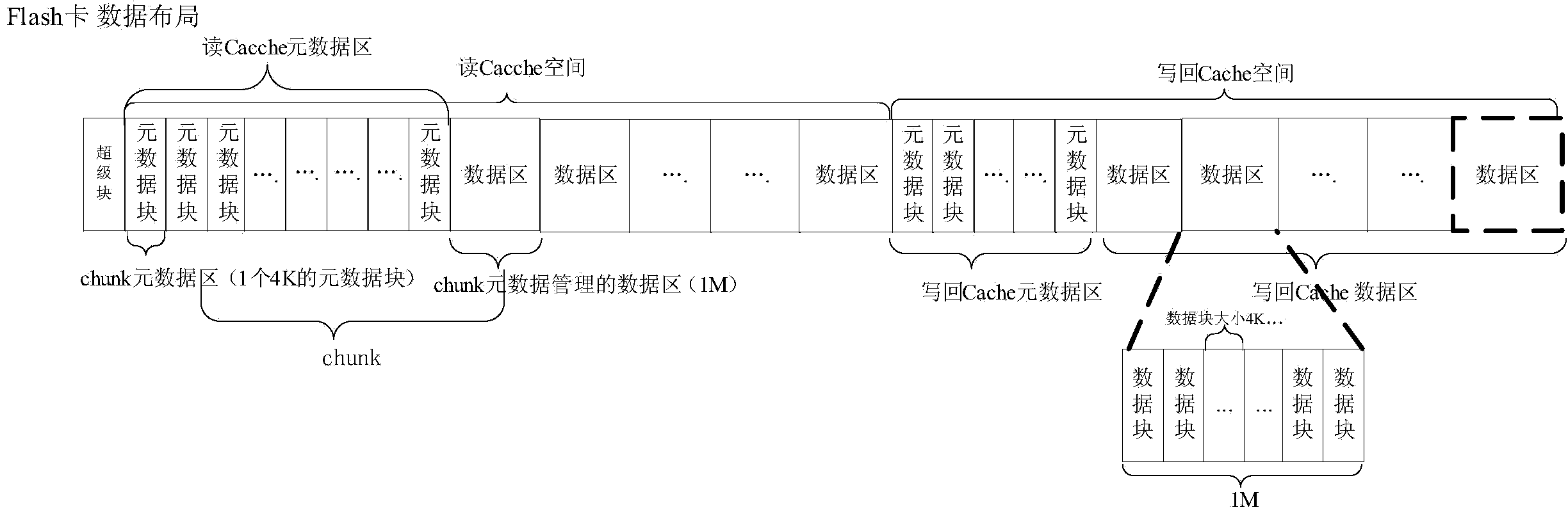

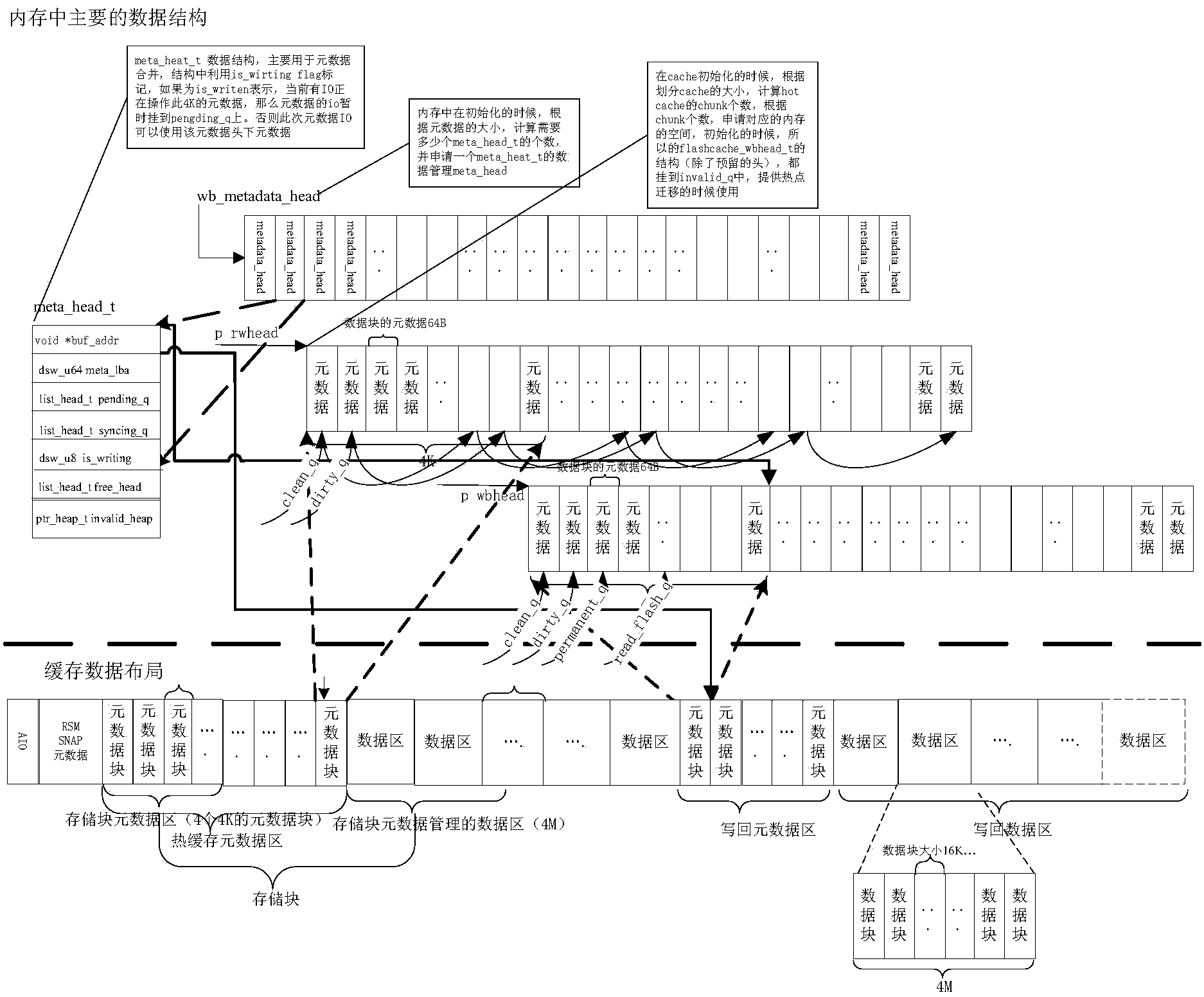

Method and device for writing data into cache

ActiveCN104238962AIncrease the probability of mergingSolve the problem of longevityInput/output to record carriersMemory adressing/allocation/relocationDatabaseMetadata

The embodiment of the invention relates to a method and a device for writing data into a cache. The method comprises the following steps: receiving a writing IO request command, wherein the command comprises metadata of data to be written; acquiring a first metadata set, and judging whether remaining free blocks exist in the first metadata set or not; if so, writing the metadata of the data to be written into one of the remaining free blocks, and writing the metadata of the data to be written into metadata blocks which correspond to the first metadata set; otherwise, judging whether remaining free blocks exist in a second metadata set or not, acquiring the second metadata set if the remaining free blocks exist in the second metadata set, and writing the metadata of the data to be written into one of the remaining free blocks of the second metadata set; writing the metadata of the data to be written into metadata blocks which correspond to the second metadata set. By adopting the method and the device, the problem of influence on the service life of Flash due to frequent writing of the metadata into the Flash can be solved.

Owner:HUAWEI CLOUD COMPUTING TECH CO LTD

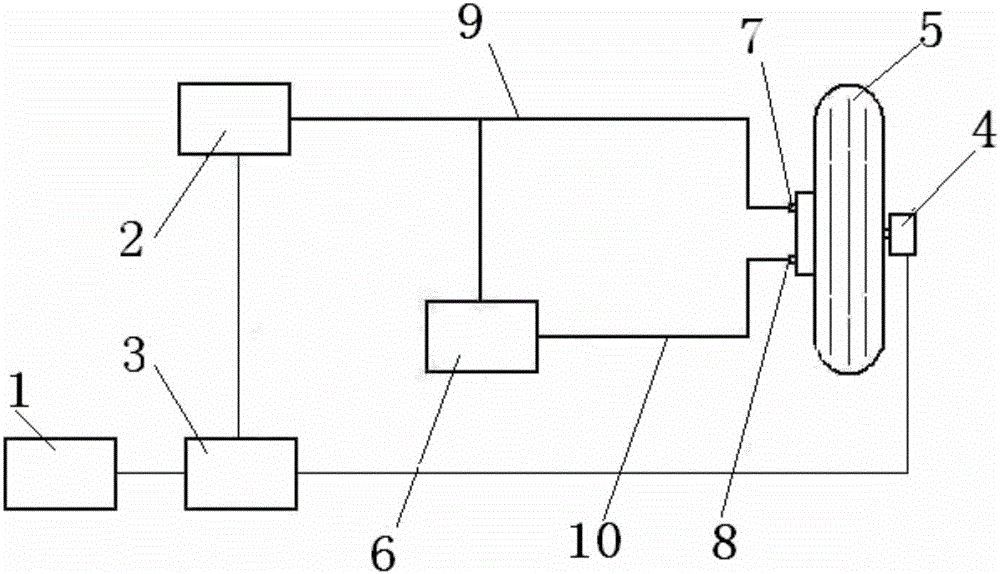

Single-wheel dual-brake electronic transmission brake system of aircraft, capable of choosing braking manner

InactiveCN106114829AIncrease energy levelsExtended service lifeBraking action transmissionAircraft brake actuating mechanismsElectronic transmissionCarbon composites

The invention relates to a single-wheel dual-brake electronic transmission brake system of an aircraft, capable of choosing a braking manner. A brake antiskid control system is formed by an aircraft wheel speed sensor, a control box and an electro-hydraulic servo valve; a brake control system is formed by a braking instruction sensor, the control box and the electro-hydraulic servo valve. The electro-hydraulic servo valve responds to an electric current control signal of the control box to output and adjust the braking pressure outputted to a braking aircraft wheel; braking selection is realized through a hydraulic control valve; a hydraulic braking valve is replaced with the braking instruction sensor; and the electro-hydraulic servo valve is a positive gain valve. The single-wheel dual-brake electronic transmission brake system disclosed by the invention is suitable for a single-wheel dual-brake aircraft wheel using a carbon brake; the requirements for selective brake use of the single-wheel dual-brake aircraft wheel can be met, and the using conditions of a carbon disk is adjusted, so that the good characteristics of wear resistance of a carbon-carbon composite friction material can be fully exerted, the difficult problems that a conventional single-wheel single-brake carbon brake disk is high in wear and short in service life are effectively solved, the service life of the carbon disk is prolonged, and the economic benefits of the carbon disk are improved.

Owner:XIAN AVIATION BRAKE TECH

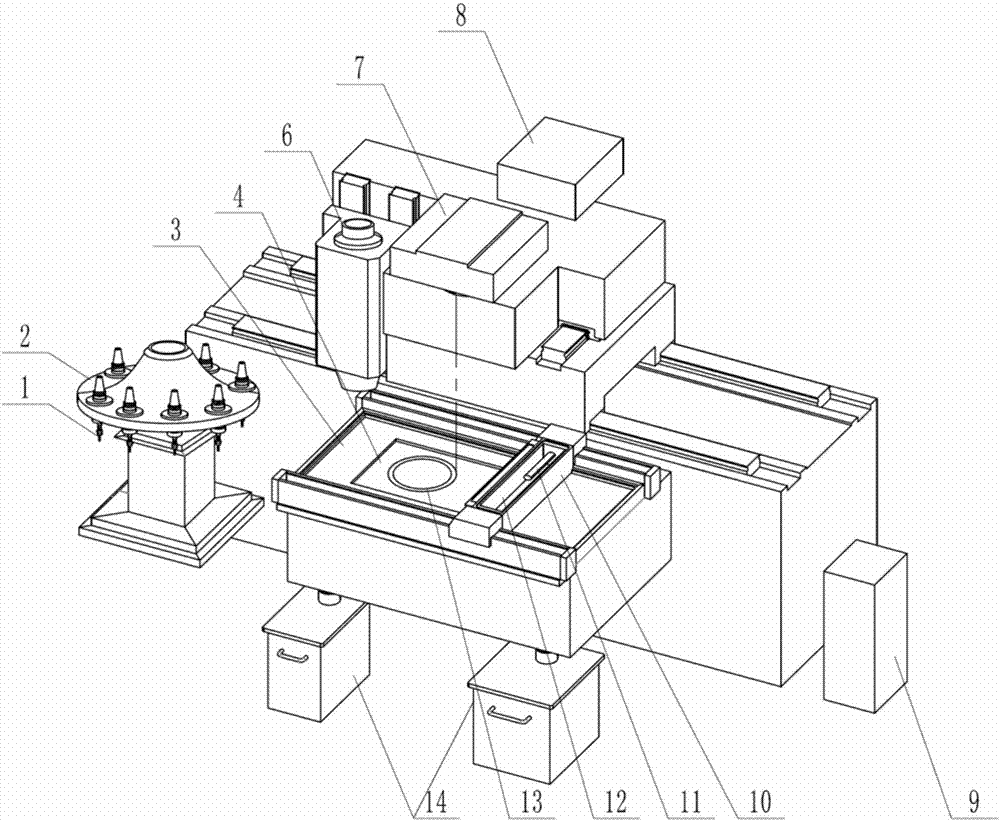

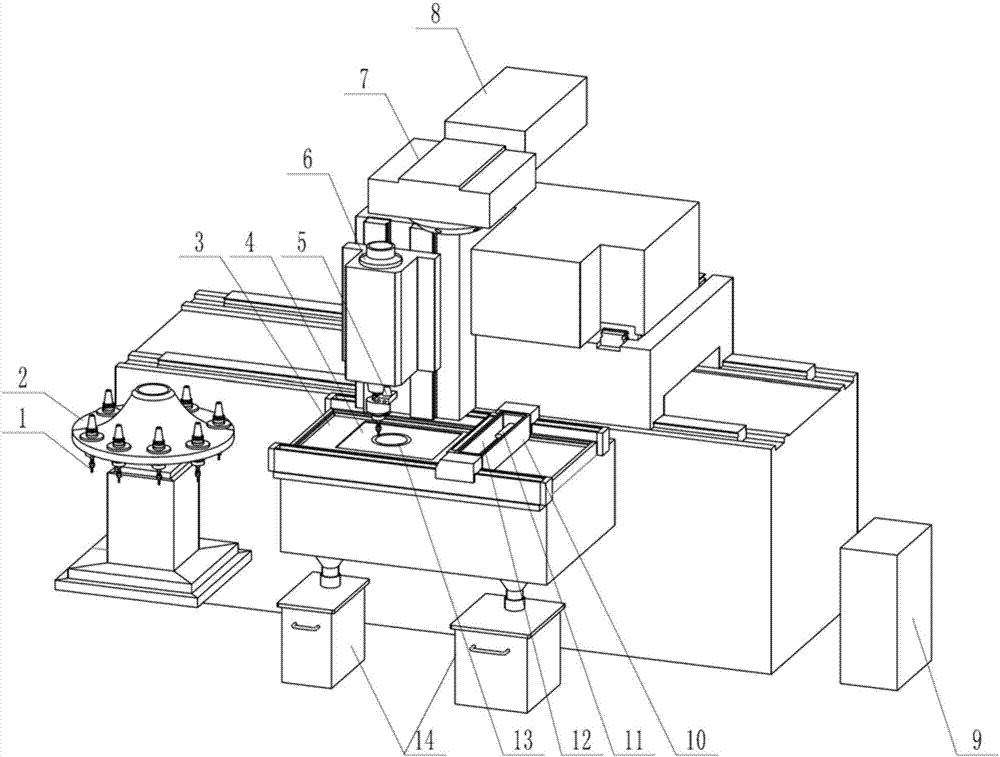

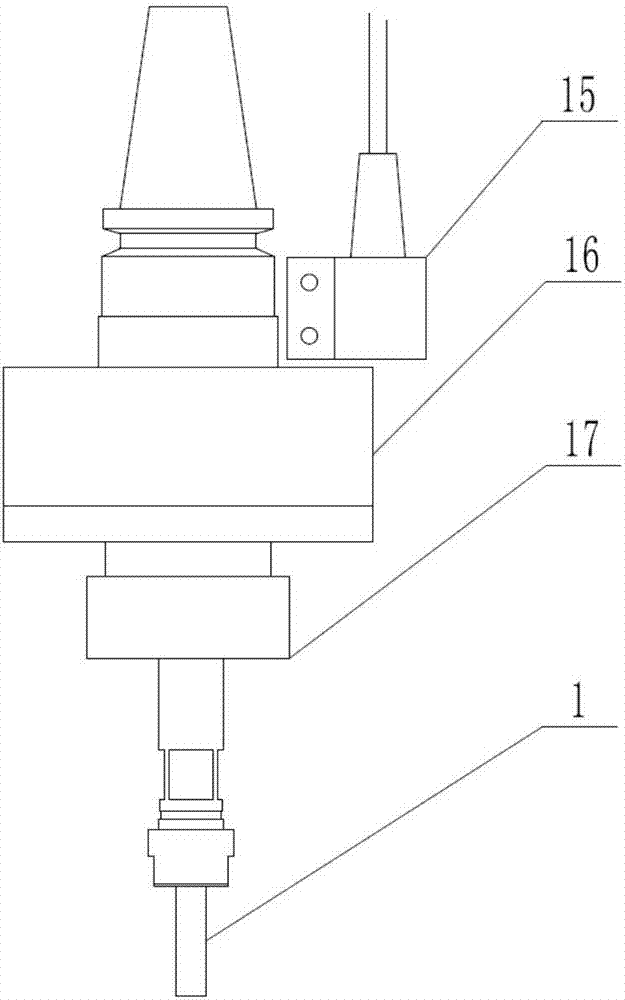

Equipment for applying ultrasonic cutting to powder laying type additional and subtractive composite manufacturing and machining method

InactiveCN107052340AExtended service lifeSolve the problem of longevityAdditive manufacturing apparatusIncreasing energy efficiencyLaser scanningEngineering

The invention relates to the field of additional and subtractive manufacturing, in particular to equipment for applying ultrasonic cutting to powder laying type additional and subtractive composite manufacturing and a machining method. A workbench is horizontally installed in the middle position of the front portion of a lathe bed. A molding cavity is formed in the workbench and can move up and down in the vertical direction. A base plate can be installed in the molding cavity. Additional and subtractive composite manufacturing is carried out on the base plate. A powder laying device is installed on the workbench and located at one end of the workbench. A laser generator and a laser screening system are fixed to the position over the front portion of the lathe bed. A powder supply device is located on the outer side of the lathe bed. A magazine tool is located on one side of the front portion of the lathe bed. A tool is installed in the magazine tool. A main shaft is installed on the front portion of the lathe body, and can slide along sliding rails in the X,Y and Z directions. During additional manufacturing, the main shaft is located at one end of the workbench. During subtractive machining, the main shaft moves to the position over the workbench. The tool is installed on the lower portion of the main shaft, and an ultrasonic cutting device is installed between the tool and the main shaft. A powder recycling device is arranged on the lower portion of the workbench.

Owner:DALIAN UNIV OF TECH

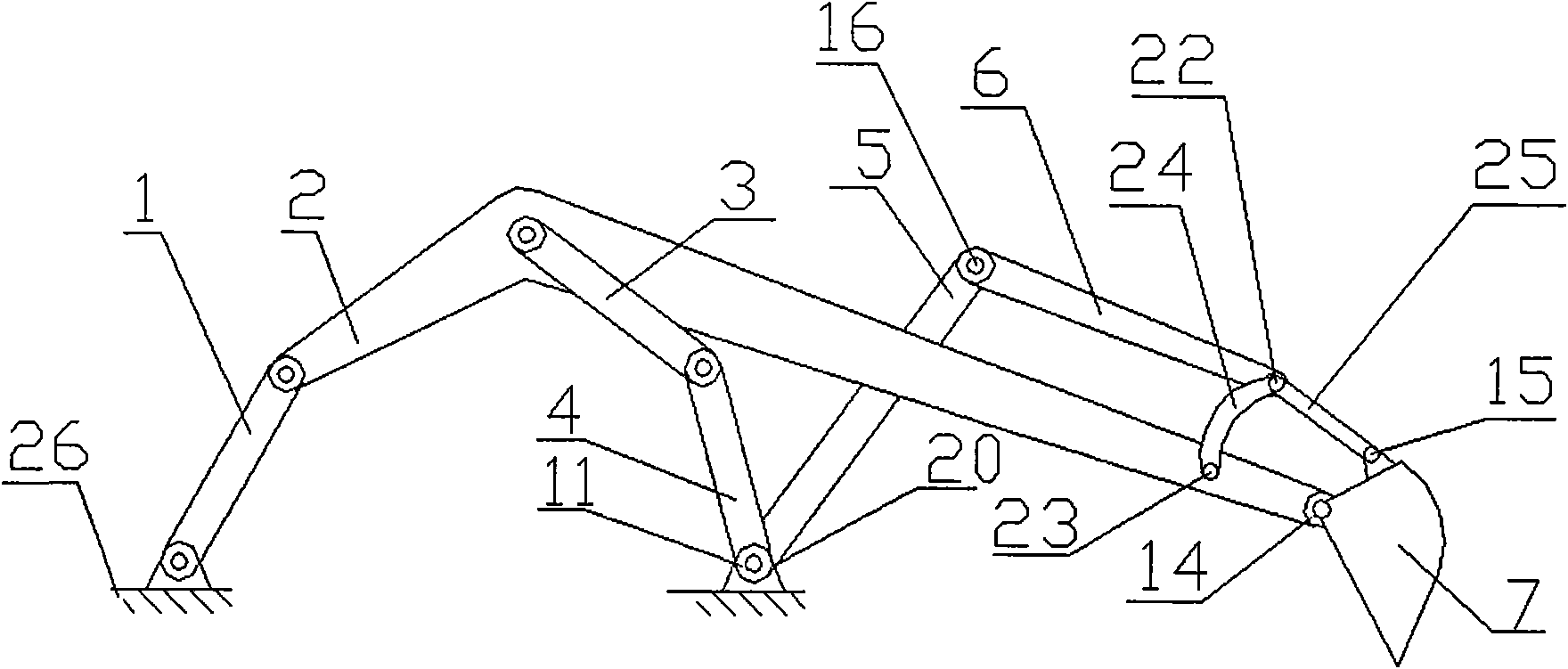

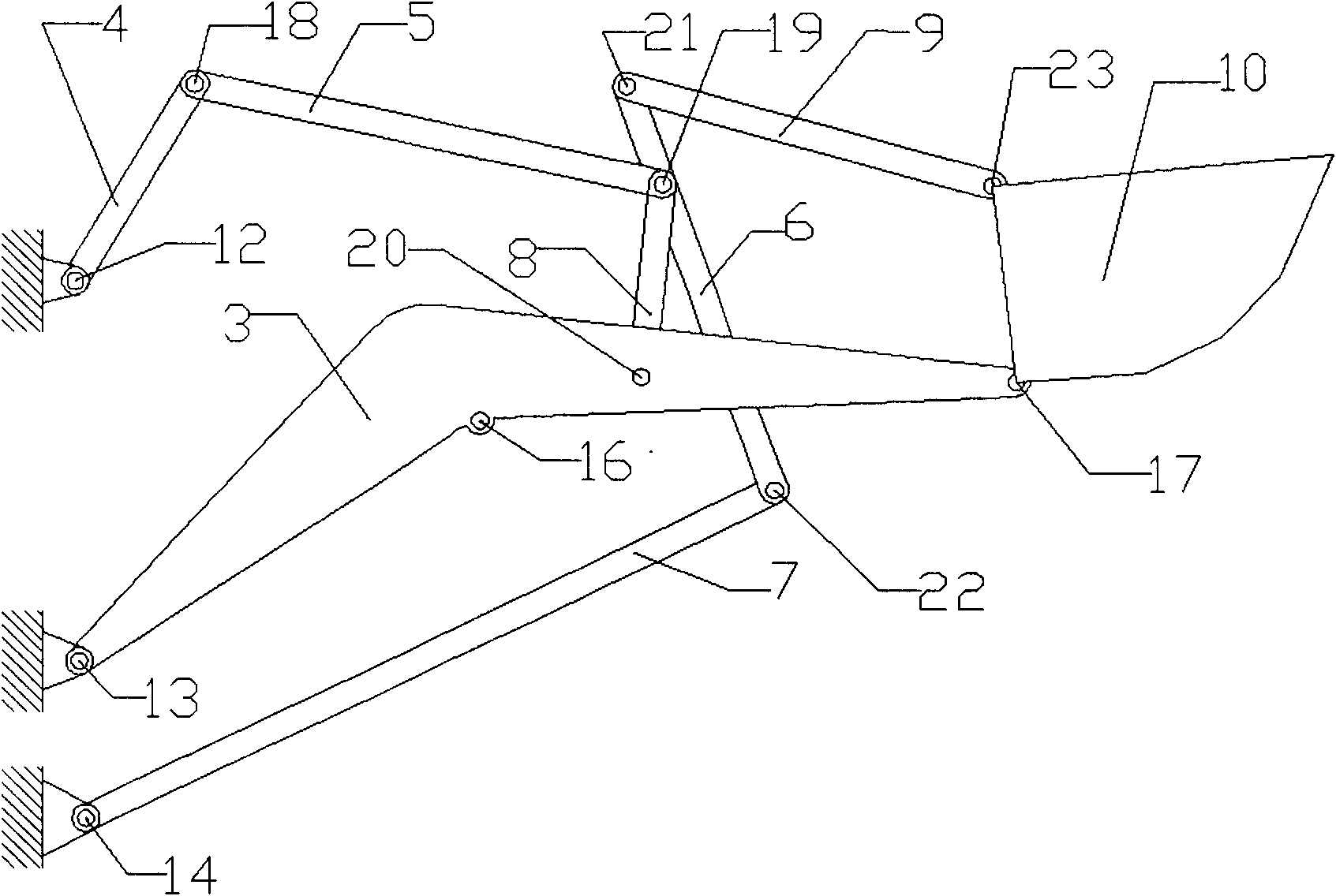

Planer multiple degree of freedom controllable loading mechanism

InactiveCN101899846AGuaranteed levelPrevent crossingMechanical machines/dredgersRolloverSingle degree of freedom

The invention relates to a planer multiple degree of freedom controllable loading mechanism. The raise-rise arm of the loading mechanism is a planer single degree of freedom controllable mechanism, wherein one end of the raise-rise arm is hinged on the chassis, and the other end is hinged a bucket; and a bucket rollover mechanism is linked between the bucket and the chassis. By using the invention, the problem that the hydraulic system of the traditional hydraulic loading machine has high demand on parts and short service life and leaks oil, etc can be solved.

Owner:GUANGXI UNIV

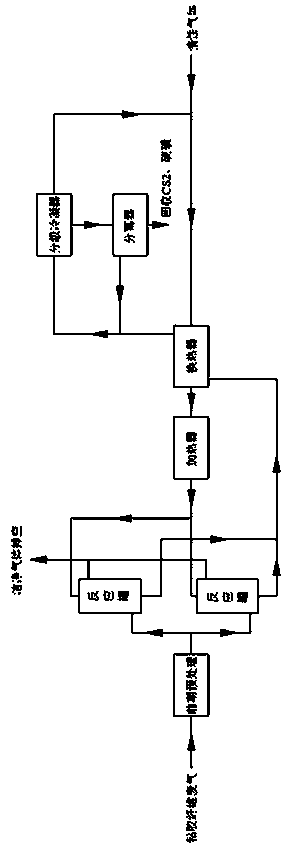

Recycling treatment method of CS2 and H2S in waste gas in production of viscose fiber

InactiveCN103721524ANo emissionsSolving Corrosion ProblemsCarbon disulfideDispersed particle separationDesorptionSorbent

The invention relates to a recycling treatment method of CS2 and H2S in waste gas in production of viscose fiber. The recycling treatment method comprises the four steps of pretreatment at the early stage, enrichment and thickening, desorption and regeneration and separation and recycling. The recycling treatment method particularly comprises the following steps: in the process of pretreatment at the early stage, carrying out dust removal, cooling and drying treatment on the waste gas; in the enrichment and thickening process, carrying out absorption and catching on two types of gases in a concentration-reaction tank filled with an absorbing agent; in the desorption and regeneration process, carrying out stepwise desorption on CS2 and H2S by adopting selected inert gas; and in the separation and recycling process, extracting CS2 and H2S respectively by adopting a fractional condenser. The recycling treatment method solves the problems that the equipment adopting steam as a desorbing carrier is corroded, the microporous surface of active carbon is calcified, and drying is needed after desorption and regeneration, and has the advantages that no waste gas is discharged, the service life of the absorbing agent is prolonged and high-efficiency and environmentally-friendly effects are achieved and the like.

Owner:石家庄科英化工技术有限公司

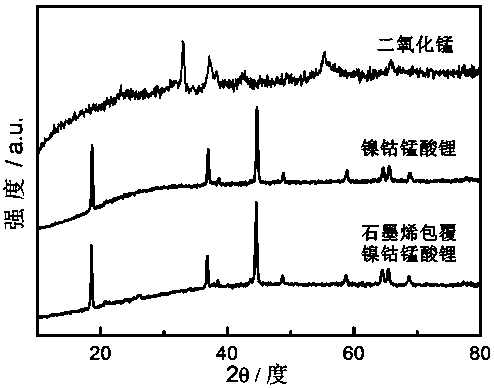

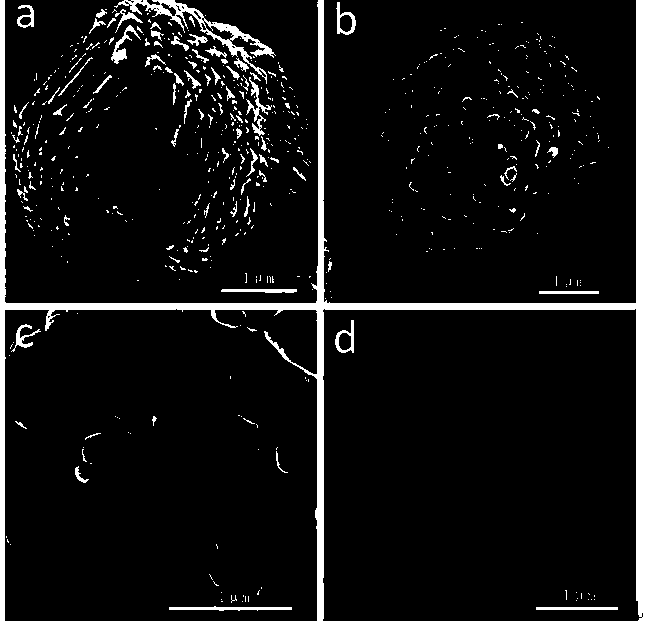

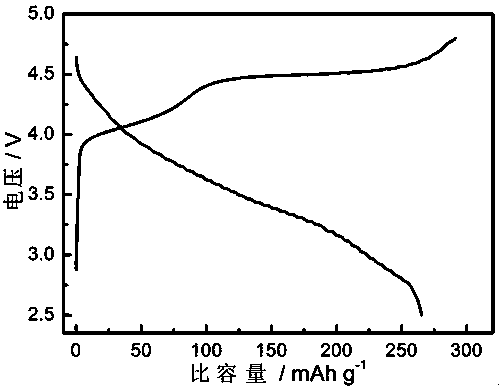

Preparation method of graphene-coated lithium nickel cobalt manganate composite material

The invention discloses a preparation method of a graphene-coated lithium nickel cobalt manganate composite material. The method comprises the following steps of preparing graphene with properties ofeasy separation, high water dispersity and high electrical conductivity in a green and efficient manner by combination of a water phase "intercalation-expansion-oxidization" method and a gamma-ray irradiation reduction technology; by adopting a high-temperature calcining method and by taking spherical manganese dioxide as a template, skillfully preparing a spherical ternary material which has a hollow structure and is formed by nanometer lithium nickel cobalt manganate primary particles, and performing surface modification treatment on the spherical ternary material; and further controlling proper conditions to enable graphene to be uniformly and firmly coated on the surface of lithium nickel cobalt manganate to obtain the target composite material. The raw materials involved in the invention are low in cost, the preparation process is high in controllability, and adopted water or an ethyl alcohol solvent is environment friendly; the composite material is excellent in electrochemical performance; the specific capacity can be as high as 265 mAh g<-1>; and after 500 cycles, the capacity retention rate can be 86%, so that the composite material can be widely applied to the lithium ionbattery and other electrochemical energy storage devices.

Owner:FUDAN UNIV

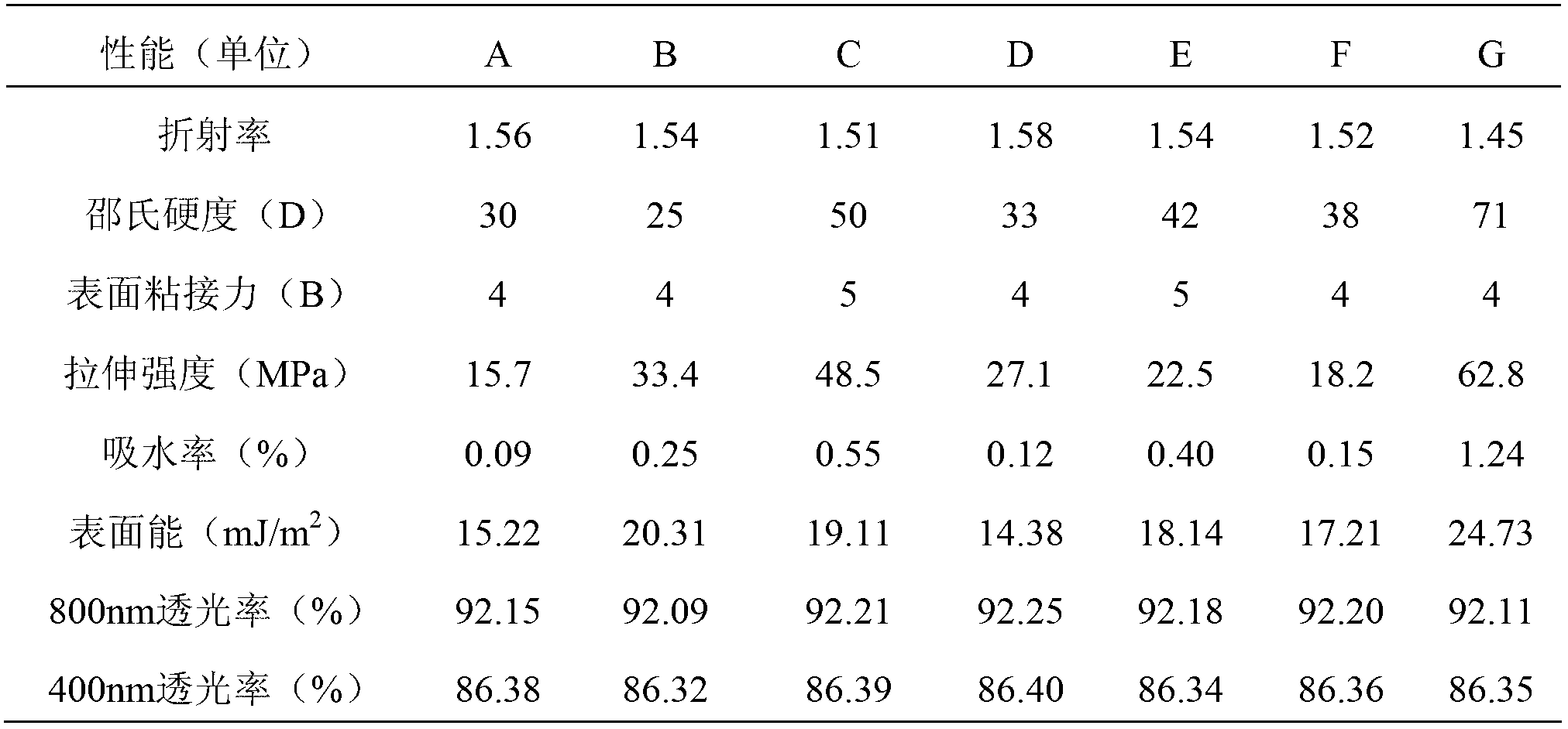

Method for preparing organosilicone hybrid resin and power type encapsulating material for light-emitting diodes (LED) thereof and application

ActiveCN102702532AEasy to prepareRaw materials are environmentally friendlyPlastic/resin/waxes insulatorsCoatingsEpoxyAdhesive

The invention discloses a method for preparing organosilicone hybrid resin and a power type encapsulating material for light-emitting diodes (LED) thereof and application. According to the method, the organosilicone hybrid resin containing three functional groups of an epoxy group, a fluorin group and a phenyl group is prepared by a cohydrolysis condensation method, and the content of each group in the resin is optimized by controlling the ratios of fluoro alkyl silicane, epoxy alkyl silicane and phenyl silicane, so that the resin is applied to the power type encapsulating material for the LEDs. The prepared encapsulating material has the advantages of epoxy resin and organosilicone, has high performance of high light transmittance and refractive index, low hygroscopicity, high mechanical property and ageing-resistant performance and the like, and the problems of low light output rate, short service life and the like of the LEDs due to dropping caused by low bonding strength and poor mechanical property of the ordinary organosilicone material for encapsulating LEDs are solved. The method for preparing the organosilicone hybrid resin and the power type encapsulating material for the LEDs is simple, and raw materials are readily available and environment-friendly; and the organosilicone hybrid resin can also be used as the raw materials to be applied to processing and preparation of optical lens materials, photovoltaic conversion materials, integrated circuit encapsulating materials, insulating materials, coating materials, adhesives and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Refractory castable for rotary kiln mouth and kiln head hood

The invention provides a refractory castable for a rotary kiln mouth and a kiln head hood. The refractory castable comprises the following components in parts by weight: 40-50 parts of aggregate, 25-40 parts of fine powder, 6-15 parts of oxide micro powder, 1-3 parts of binding agent and 2-2.5 parts of additives, wherein the aggregate is composed of 30 parts of special-grade alumina, 10 parts of corundum, 30 parts of mullite, 15 parts of andalusite and 15 parts of spinel; the fine powder is composed of 60 parts of zirconite powder and 40 parts of silicon carbide powder; the oxide micro powder comprises aluminum oxide micro powder; the binding agent is calcium aluminate cement in which the content of aluminum oxide is 80%; and the additives are composed of 30 parts of metal aluminum powder, 30 parts of organic anti-explosion fibers, 30 parts of sodium hexametaphosphate and 10 parts of heat-resistant steel fibers.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

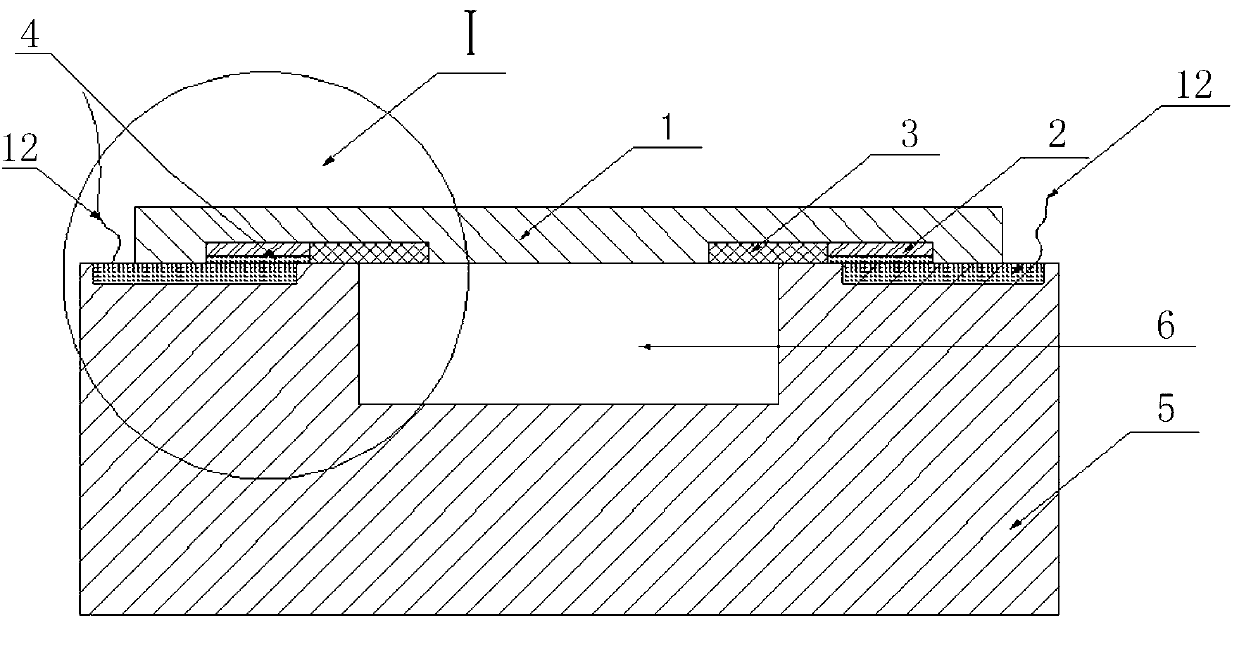

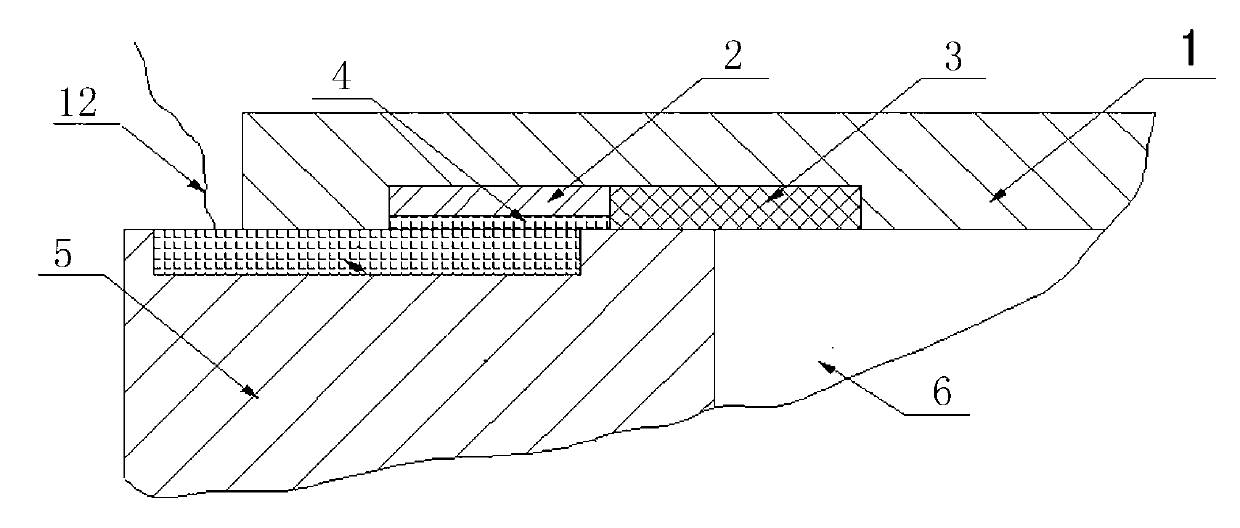

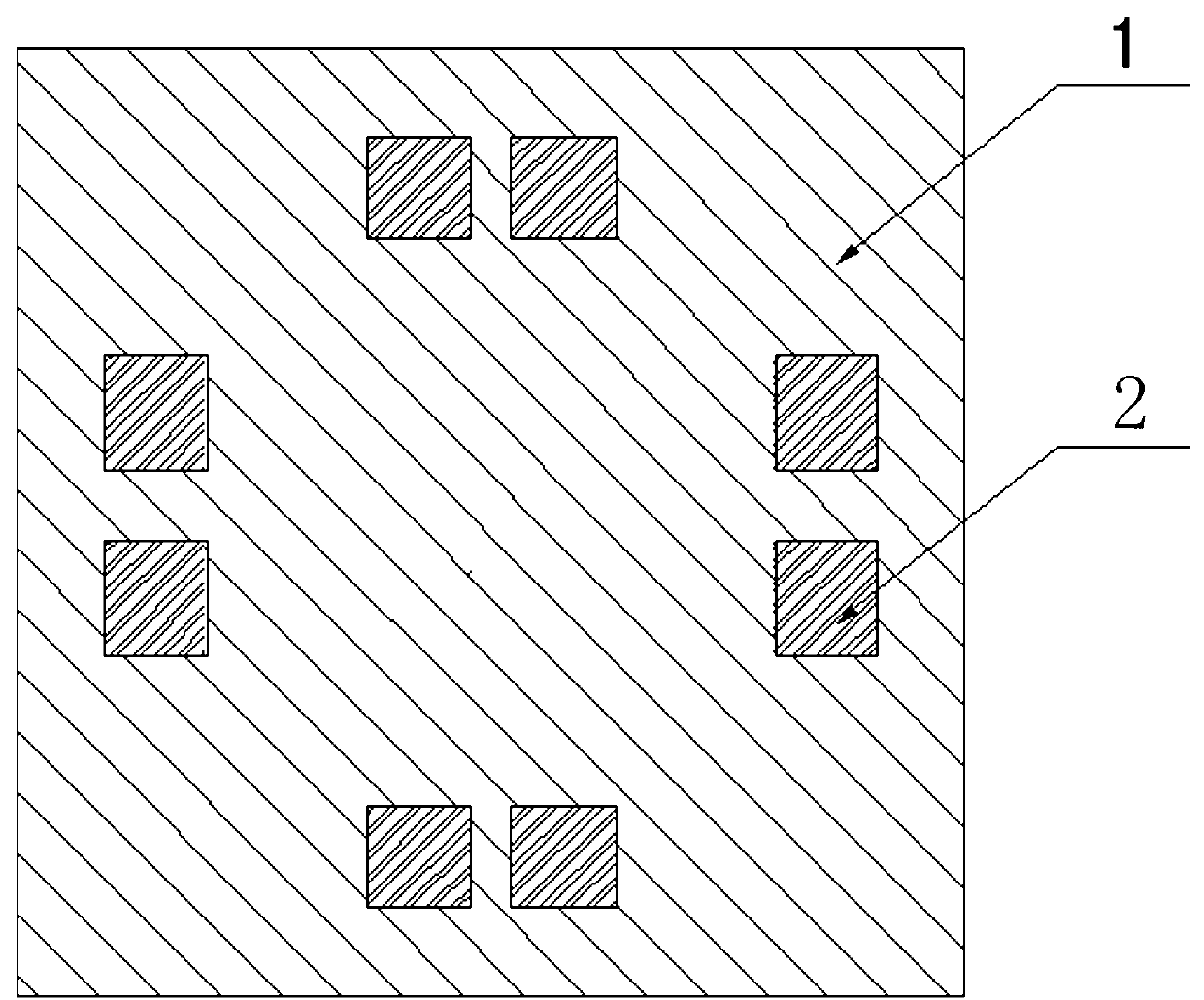

Hidden-type MEMS pressure sensor sensitive chip and manufacturing method thereof

InactiveCN103344374AGuaranteed tightnessMeet basic performance requirementsFluid pressure measurement using ohmic-resistance variationDecorative surface effectsMems pressure sensorHemt circuits

The invention relates to a sensitive chip of a pressure sensor, in particular to a hidden-type MEMS pressure sensor sensitive chip and a manufacturing method thereof. According to the hidden-type MEMS pressure sensor sensitive chip and the manufacturing method, the problem that component performance and service life of an existing silicon piezoresistive pressure sensor are not ideal is solved. The hidden-type MEMS pressure sensor sensitive chip comprises an SOI wafer component layer (1) and a glass substrate (5), wherein the SOI wafer component layer (1) is formed by the practice that a substrate layer of an SOI wafer is etched in an etching process based on a stopping layer, and the BOX layer of the SOI wafer is taken as the stopping layer. Four voltage dependent resistors of the Wheatstone bridge including R1, R2, R3 and R4, eight doping wires (3) and eight connection anchor points (2) are manufactured on the SOI wafer component layer (1). The hidden-type MEMS pressure sensor sensitive chip and the manufacturing method are reasonable in design, the manufacture hidden-type MEMS pressure sensor sensitive chip overcomes influences of external environment factors on a component circuit, the defect that component performance is reduced due to thermal mismatch of materials is eliminated, and service life of components is prolonged.

Owner:山西傲维光视光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com