Nanoporous films and method of manufacturing nanoporous films

A nano-porous and nano-technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of separation membrane life barrier, separation performance decline, membrane fouling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

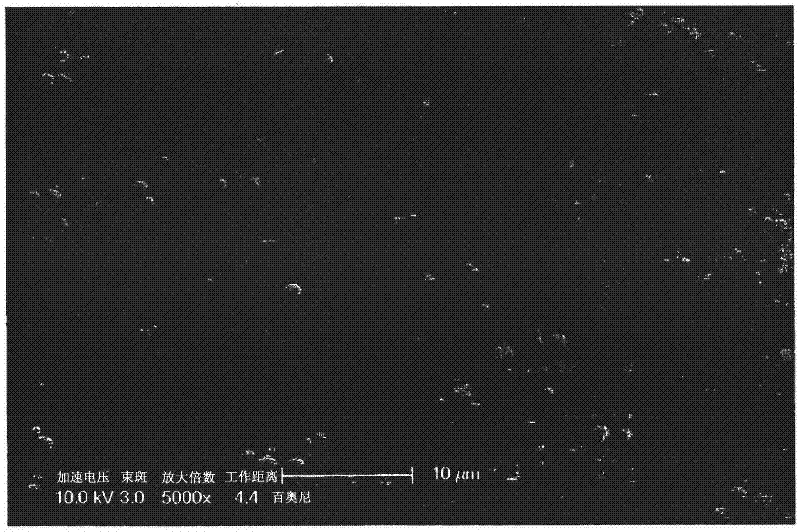

[0065] Preparation Example 1 Preparation of carbon nanotube-silver composite

[0066] Put 0.3g thin multi-walled carbon nanotubes (nanotechnology, thin multi-walled carbon nanotubes CNT tube grade) in a 500ml round bottom flask, then add 280ml ethylene glycol (EG) into the round bottom flask for reaction device. Install a stirrer and stir for 30 minutes, then put the reactor into an ultrasonic cleaning machine, and perform ultrasonic treatment for 3 hours with ultrasonic waves, so that the carbon nanotubes are dispersed in ethylene glycol. At this time, the temperature of the reactor was controlled not to exceed 50°C. After the ultrasonic treatment, reinstall the stirrer, and connect the thermometer and the cooling condenser. While stirring the reactor, add 1.68g of PVP (polyvinylpyrrolidone, manufacturing company: Fluka, average molecular weight (Mw): 40,000) and 5.6ml of oleamide (Oleylamine), then add 1.102g of silver nitrate (Silver Nitrate; AgNO 3 ). Connect a vacuum...

preparation example 2

[0067] Preparation Example 2 Preparation of Carbon Nanotube-Cobalt Composite

[0068] 0.3 g of carbon nanotubes (Hanwha Nanotech, CM-95) were placed in a 500 ml round bottom flask, and then 128 ml of triethylene glycol (TEG) was added into the reactor. Install a stirrer and stir for 30 minutes, then put the reactor into an ultrasonic cleaning machine, and perform ultrasonic treatment for 3 hours with ultrasonic waves to disperse the carbon nanotubes. At this time, the temperature of the reactor was controlled not to exceed 50°C. After the ultrasonic treatment, reinstall the stirrer, and connect the thermometer and the cooling condenser. While stirring the reactor solution, 4.26ml polyethylene glycol monomethyl ether (MPG, CH3(OCH 2 CH 2 )nOH, n=4-5, Hannong Chemical, trade name: MPG) was added into the flask reactor, and then 3.48g cobalt acetylacetonate was added. Connect a vacuum pump to the reactor to remove the air inside the reactor and replace it with nitrogen. Then...

preparation example 3

[0069] Preparation Example 3 Preparation of Carbon Nanotube-Cobalt Composite

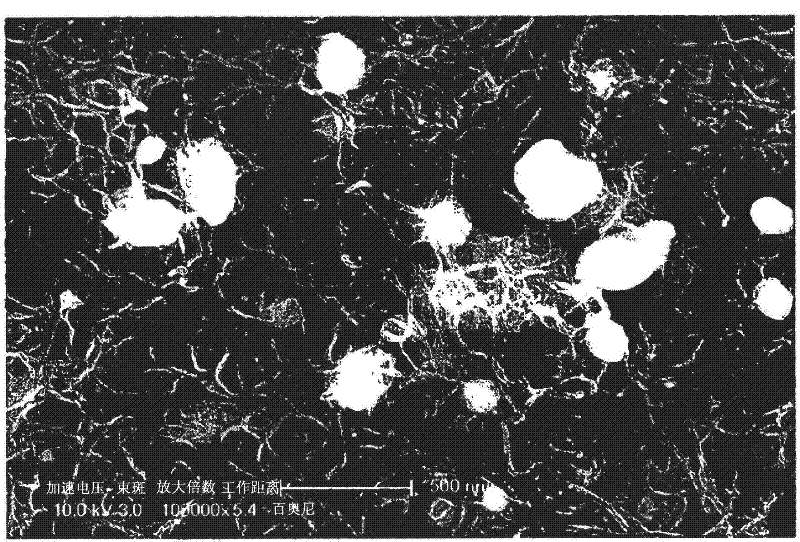

[0070] Except that the metal salt was replaced by 4.04 g of copper acetylacetonate, other conditions were carried out under the same conditions as in Example 2, so as to obtain a carbon nanotube-copper composite. As a result of analyzing the carbon nanotube-copper composite with a scanning electron microscope (SEM), it was confirmed that the copper particles were nearly spherical and uniformly dispersed with a constant size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com