Patents

Literature

206 results about "Oleamide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

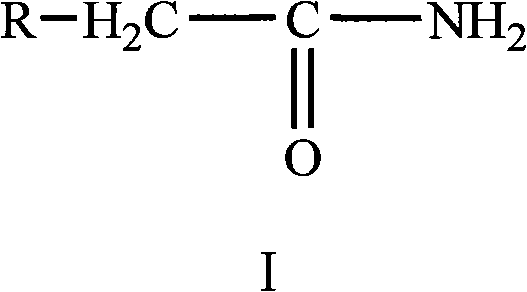

Oleamide is an organic compound with the formula CH₃(CH₂)₇CH=CH(CH₂)₇CONH₂(. It is the amide derived from the fatty acid oleic acid. It is a colorless waxy solid and occurs in nature. Sometimes labeled as a fatty acid primary amide (FAPA), it is biosynthesized from N-oleoylglycine.

Completely degradable temporary plug for oil-gas well fracturing and preparation method thereof

PendingCN111997560AReduce degradationReduce riskFluid removalConjugated synthetic polymer artificial filamentsSpinningLactide

The invention relates to the field of fracturing engineering in the oil and gas field development process, and particularly discloses a completely degradable temporary plug for oil-gas well fracturingand a preparation method thereof. The completely degradable temporary plug is prepared from polyglycolic acid, poly (L-lactide-epsilon-caprolactone), polycaprolactone, silicon dioxide, a flexibilizer, a water-blocking agent, oleamide, starch, chitosan and other materials; the completely degradable material is decomposed into carbon dioxide and water, and the degradation speed can be adjusted according to the temperature of a fracturing interval and required time, so that the applicability of temporary plugging is improved; a finished product is directly obtained by adopting a five-step process of melting, spinning, weaving, cutting and drying, so that industrial production is facilitated; compared with the existing polylactic acid temporary plugging particles and temporary plugging balls,the completely degradable temporary plugging has the advantages that the process is simple, the fracturing cost is effectively reduced, the temporary plugging pressure-bearing strength is greatly enhanced, the fracturing effect is improved, and the yield after fracturing measures is greatly increased.

Owner:山东科兴化工有限责任公司

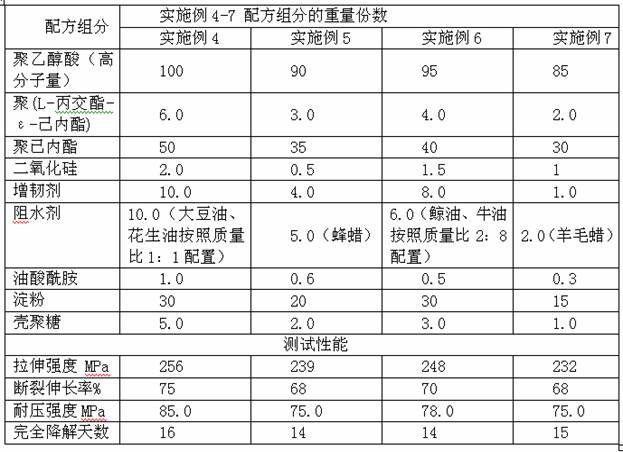

Polyvinyl alcohol wire for fused deposition molding and processing method of polyvinyl alcohol wire

ActiveCN104448641AImprove thermal stabilityImproved melt processabilityPolymer sciencePolyvinyl alcohol

The invention relates to a preparation method of high polymer materials, and particularly relates to a polyvinyl alcohol wire for fused deposition molding and a processing method of the polyvinyl alcohol wire. The polyvinyl alcohol wire comprises the following raw materials in parts by weight: 100 parts of polyvinyl alcohol resin, 20-40 parts of a plasticizer, 0.5-2 parts of an antioxidant, 5-10 parts of a heat stabilizer, 0.2-1 part of a lubricating agent and 0.1-0.5 part of an anti-blocking agent, wherein the anti-blocking agent is one of oleamide and erucyl amide. The polyvinyl alcohol wire disclosed by the invention has the advantages of high heat stability, good melt processing property, excellent mechanical property, stable wire diameter, good water solubility, simple production process, high efficiency and low cost.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

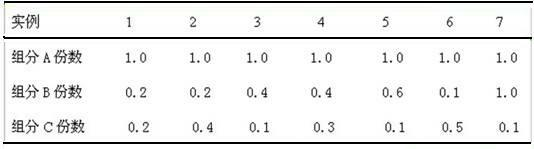

a diesel fuel additive

ActiveCN102277212AAvoid emulsificationObvious anti-emulsification effectLiquid carbonaceous fuelsFuel additivesEmulsionOil additive

The invention relates to a diesel fuel additive for improving diesel fuel performances. The diesel fuel additive is a dual-purpose additive mixture which can be utilized as a diesel fuel anti-wear agent and a diesel fuel emulsion inhibitor. The diesel fuel additive for improving diesel oil performances comprises components of A) tall oil fatty acid, B) oleamide, and C) naphthenic acid imidazoline, wherein a weight ratio of the component A to the component B to the component C is 100: (5 to 100): (5 to 50) and the component A, the component B and the component C can be respectively added directly into diesel fuel for use. The component A, the component B and the component C also can be mixed into a lubricant additive and then the lubricant additive is added into diesel fuel, wherein an additive amount is in a range of 50 to 300 mg / kg. The diesel fuel additive for improving diesel fuel performances has prominent substantive characteristics and remarkable improvements that 1, the diesel fuel additive can improve lubricity of diesel fuel and thus can be utilized as a diesel fuel anti-wear agent; and 2, the diesel fuel additive has obvious anti-emulsification effects on diesel fuel, can inhibit emulsification of diesel fuel and can be utilized as a diesel fuel emulsion inhibitor for use.

Owner:CHINA PETROLEUM & CHEM CORP

Matt villus waxy feel finishing agent used for synthetic leather and preparation method thereof

The invention discloses a matt villus waxy feel finishing agent used for synthetic leather, composed of the following components by parts by weight: 30-40 parts of resin, 20-30 parts of DMF, 20-30 parts of butyl acetate, 4-5 parts of silicon dioxide colour-changing powder, 1-4 parts of modified amine siloxane, 1-3 parts of oleamide, 3-5 parts of polyurethane colour pearl and 1-2 parts of flatting agent. The invention also discloses a preparation method of matt villus waxy feel finishing agent used for synthetic leather. All the components in the matt villus waxy feel finishing agent used for synthetic leather coordinate and act combinedly, matt extinction effect of synthetic leather after treatment of the invention is good, villus feel is excellent, leather surface effect is strong, and handfeel and oil waxy effect are good.

Owner:JIANGSU BAOZE POLYMER MATERIAL

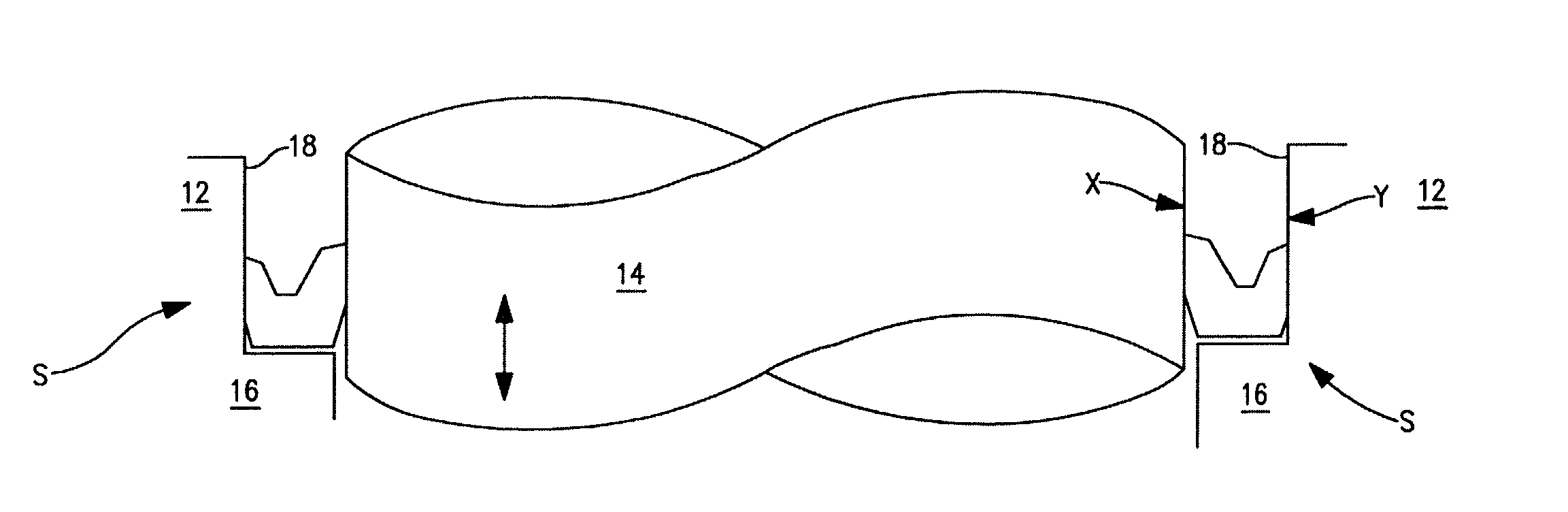

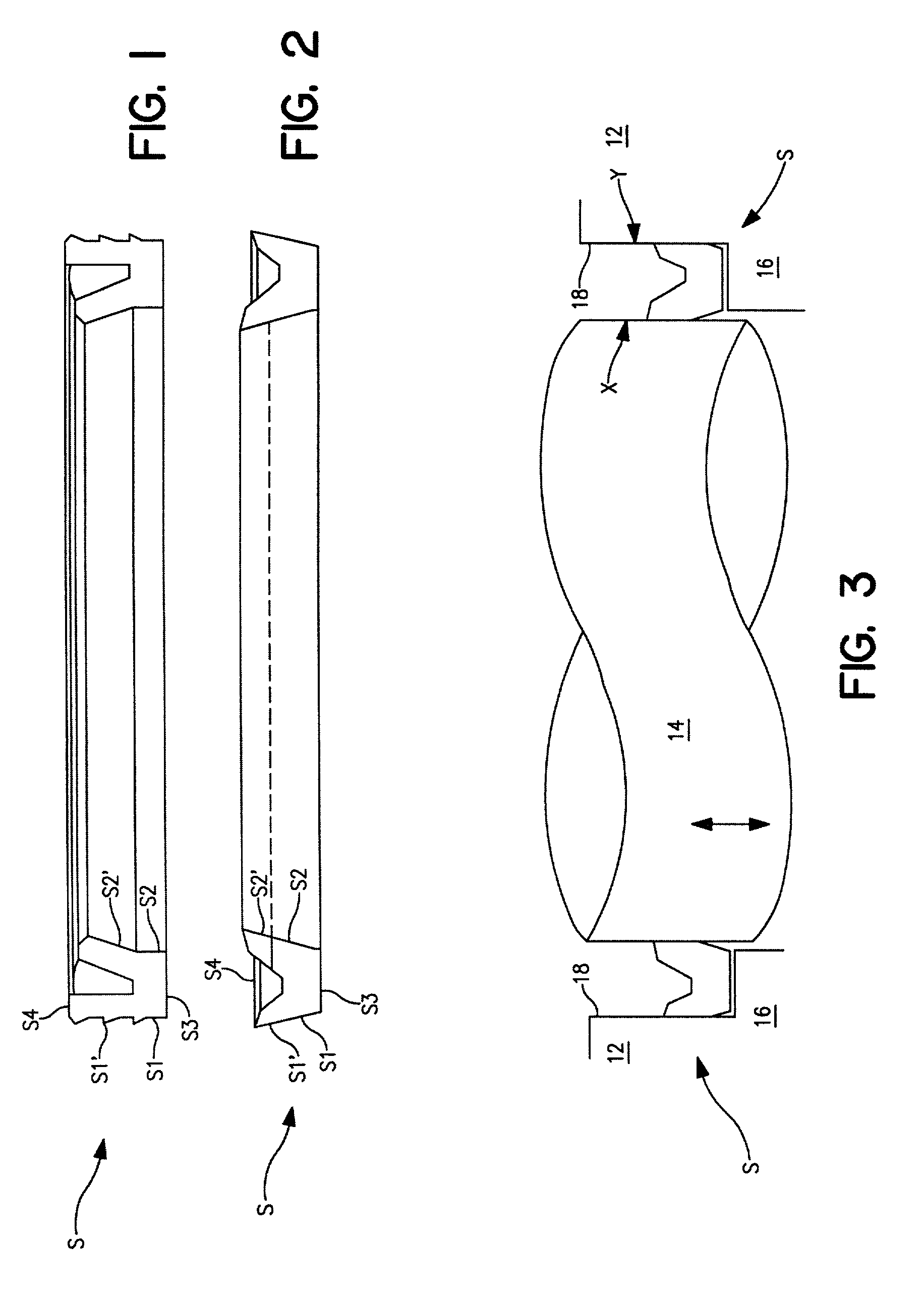

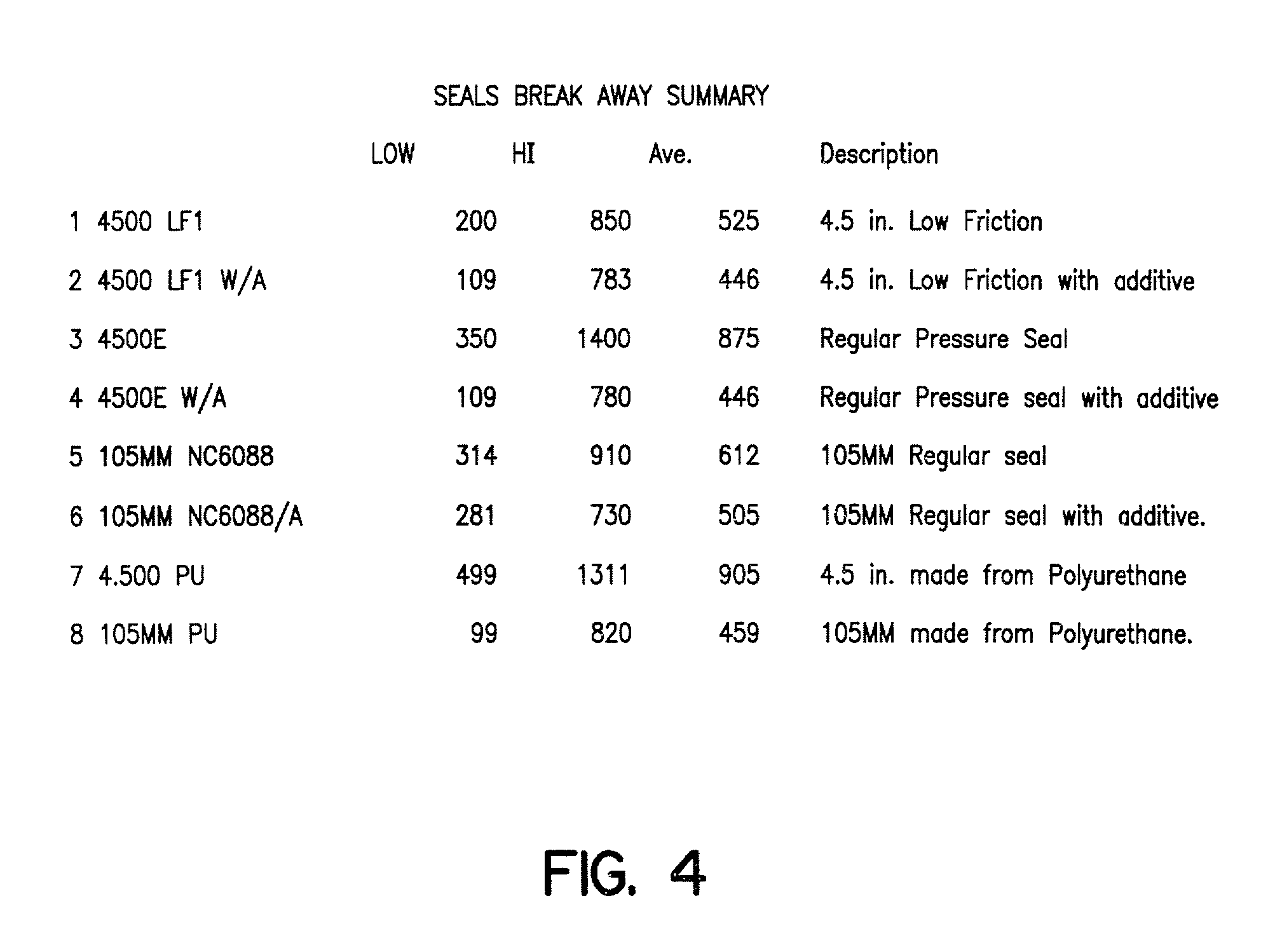

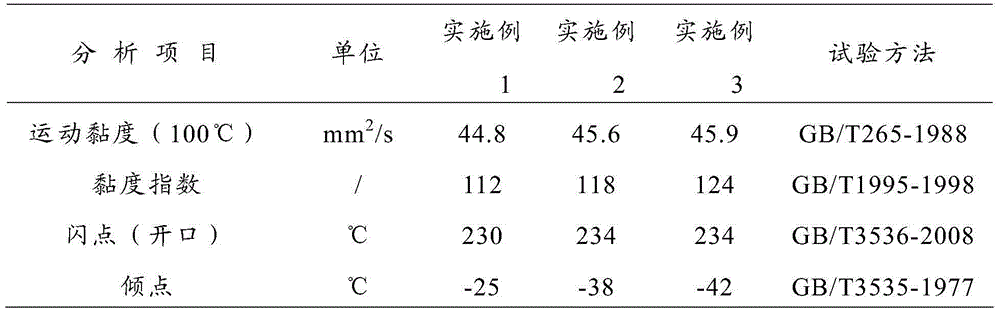

Low friction fluid seal device with additive to rubber compound

InactiveUS7021633B2Excellent abrasion resistanceImprove surface toughnessEngine sealsCompound aLow speed

A fluid seal device for use in sealing an annular space between an internal surface of a cylinder and a member therein having an outer cylindrical surface and being formed at least in part from rubber. An oleamide additive is included in the rubber compound comprising about 1.0%–5.0% by weight of oleamide. The oleamide additive to the rubber of the fluid seal device results in a reduced coefficient of friction and low speed vibration as well as enhanced abrasion resistance.

Owner:GORMAN

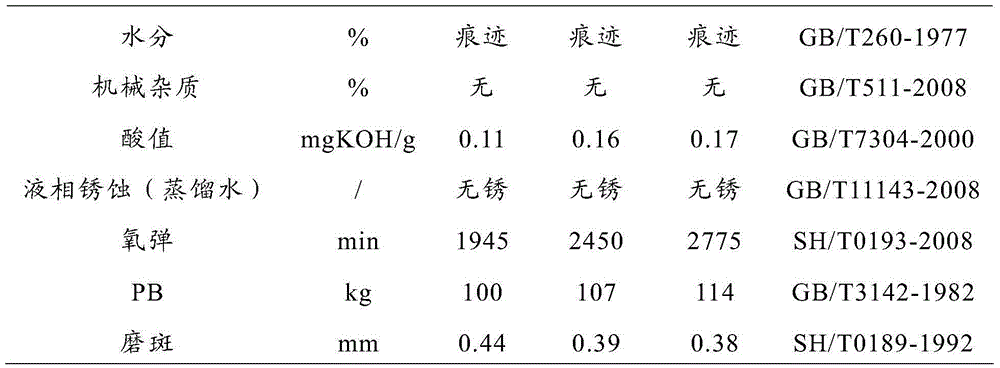

Lubricating oil composition used in rotary screw rod air compressor and preparation method thereof

ActiveCN103981005AImprove protectionImprove antioxidant capacityLubricant compositionBenzoic acidButylated hydroxytoluene

The invention provides a lubricating oil composition used in a rotary screw rod air compressor. The lubricating oil composition comprises the following components in percentage by mass: 0.1-3.0% of antioxidant, 0.01-1.5% of metal antirust agent, 0.01-1.5% of metal deactivating agent, 0.5-3.0% of anti-wear reagent at extreme pressure, 0.1-2.0% of pour point depressant, 10-500ppm of defoaming agent and the balance of hydrofined mineral oil, wherein the antioxidant is one or more of 2,6-ditertiary butyl p-cresol, phenyl-alpha-naphthylamine, dialkyl diphenylamine, butyl octyl diphenylamine and 3,5-ditertbutyl-4-hydroxy hydroxyl acetic acid ester; the metal deactivating agent is one or more of benzotriazole, a derivative of benzotriazole, thiadiazole and a derivative of thiadiazole; the metal antirust agent is one or more of long-chain carboxylic acid, alkyl benzoic acid, oleamide, oleoyl amino acid, benzotriazole and derivative of benzotriazole. The invention further provides a preparation method of the lubricating oil composition.

Owner:KASONG SCI & TECH

Aurum-ferric oxide/titanium dioxide nano-catalyst and preparation method thereof

InactiveCN101612582AThe size is easy to controlSize and shape are easy to controlDispersed particle separationCatalyst activation/preparationNano catalystDecomposition

The invention relates to an aurum-ferric oxide / titanium dioxide nano-catalyst and a preparation method thereof, in particular to an Au nano-catalyst. The invention provides the aurum-ferric oxide / titanium dioxide nano-catalyst which has better heat stability and higher activity, and the preparation method thereof. The aurum-ferric oxide / titanium dioxide nano-catalyst has the general formula of Au-Fe3O4 / TiO2. The preparation method comprises: 0.5-1.5g of H AuCl4 is added into 100ml of chloroform solution]; then, 10-30ml of oleamide is added into the solution and 0.25-0.75g of tert-butyl amine borane is added into the solution so that Au nano-particles can be obtained; after that, the Au nano-particles and acetylacetone iron are added into oleic acid oleamide solution for reaction so that Au-Fe3O4 nano-particles can be obtained, and the mother liquid is reserved for standby application; the mother liquid is added with 0.05-1.6ml of titanium 4-butanol, and solid product can be obtained after decomposition; and the solid product is calcined, and the aurum-ferric oxide / titanium dioxide nano-catalyst is obtained.

Owner:XIAMEN UNIV

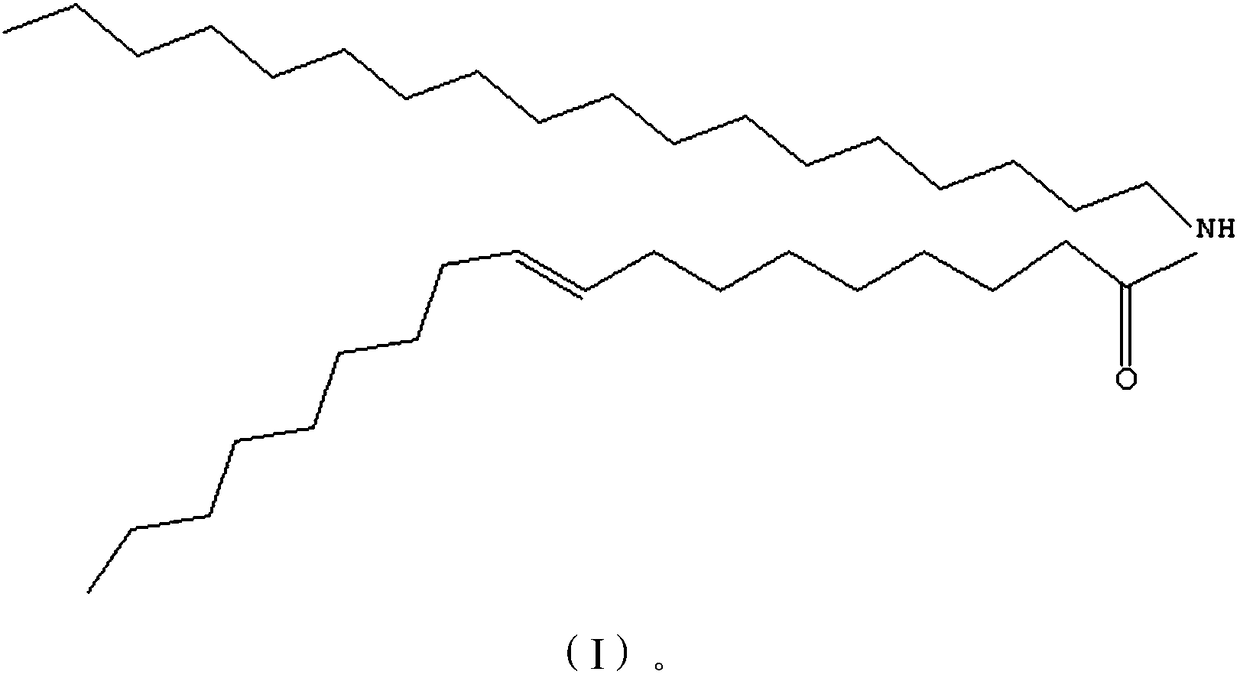

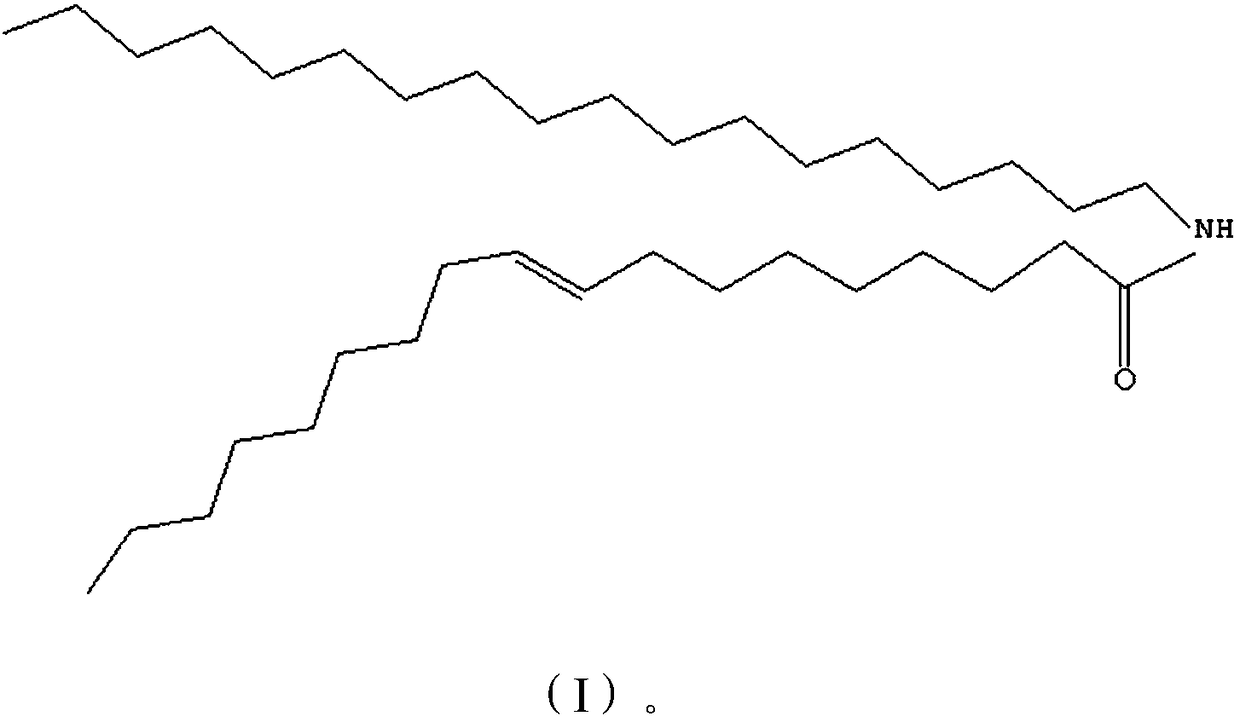

Octadecyl oleamide, preparation method and application thereof

InactiveCN109336780AHigh synthetic conversion rateReduce energy consumptionOrganic compound preparationCarboxylic acid amides preparationAntistatic agentTemperature resistance

The invention discloses octadecyl oleamide and preparation thereof. The octadecyl oleamide has a structure shown by the general formula (I) in the specification. The octadecyl oleamide provided by theinvention is a plastic additive which is multifunctional, high-efficiency, high-temperature resistant, low-migration and wide in range of application, can be used as one or more of an anti-blocking agent, a slipping agent, an antistatic agent, a heat stabilizer, a release agent and an anti-wear agent in plastics, and has the effects of lubricating an opening and improving the properties of a plastic product, such as scratch resistance, wear resistance, static electricity resistance, high-temperature resistance and the like.

Owner:广州禾工材料科技有限公司

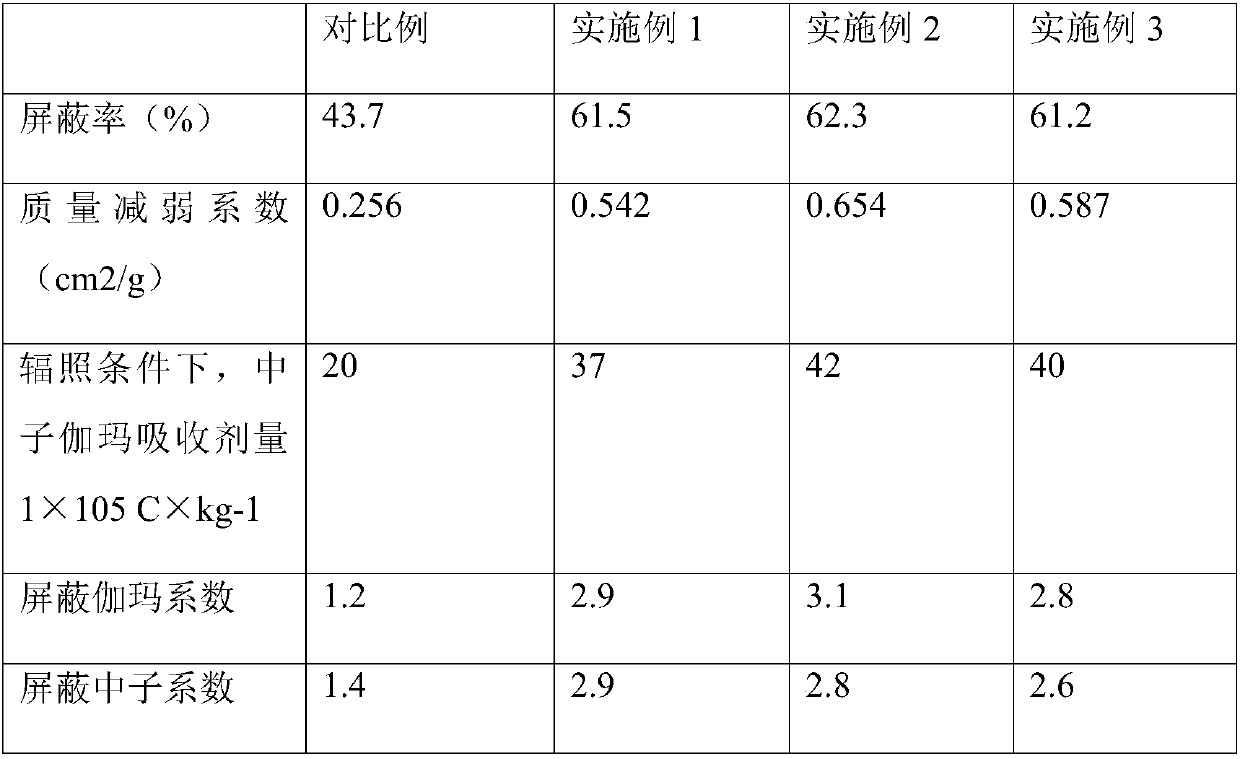

Composite particle material and radiant panel for shielding neutron gamma radiation by high strength

PendingCN107722425AImprove adhesionTotal reflectionSynthetic resin layered productsShieldingFiberColemanite

The invention discloses a composite particle material and a radiant panel for shielding neutron gamma radiation by high strength, and relates to the technical field of radiation-shielding plates. Thecomposite particle material comprises, by mass, 26-33% of high-density polyethylene, 2.2-2.7% of polyvinyl alcohol, 10-12% of lead sand, 2.9-4.0% of boron carbide powder, 1.2-1.5% of polyethylene wax,1.7-2.3% of coupling agents, 0.6-1.2% of colemanite, 1.1-1.4% of aluminum hydroxide, 1.0-1.2% of carbon fibers, 2.1-2.3% of 2, 6-butylated hydroxytoluene, 0.6-1.1% of oleamide, 0.6-0.9% of powdered aluminum and the balance samarium powder and tungsten powder.

Owner:镇江奥特氟科技有限公司

Oleamide sodium type phosphorite floatation agent and preparation method thereof

The invention relates to a phosphorite flotation agent, and in particular relates to an oleamide sodium type phosphorite flotation agent and a preparation method thereof. The preparation method comprises the following steps of: carrying out an amidation reaction on oleic acid and diethanol amine, wherein the mol ratio of the oleic acid to the diethanol amine is 1: 1; and meanwhile, carrying out a saponification reaction on unreacted fatty acid in an amidation reactant and a 30% sodium hydroxide solution, wherein the iodine value of plant oleic acid is more than 110. When the phosphorite flotation agent is used, the produced oleamide, sodium type floatation agent as well as surfactant Twen series and long-chain alkyl sodium sulfonate are compounded in a certain proportion. Compared with the traditional conventional flotation agent, the phosphorite flotation agent provided by the invention has a better flotation effect, the mineral separation comprehensive efficiency is obviously improved, and the raw materials are available, the price is low, a synthetic route is simple, safe and reliable, and the abundant low-grade phosphorite resource in China can be fully utilized.

Owner:YUEYANG BAILI IND GREASE

Aliphatic amine ester boride lubricating oil additive and preparation method thereof

The invention discloses an aliphatic amine ester boride lubricating oil additive and a preparation method thereof. The method comprises the following steps: putting methyl oleate and triethanolamine in a container, reacting under the conditions of the temperature of 90 DEG C and the pressure of 80mmHg for 4-5 hours, adding oleic acid and reacting, and obtaining oleamide; mixing the oleamide and phosphorus pentasulfide and dodecanol, continuously cyclically introducing ammonia gas at high pressure, reacting at the temperature of 170-180 DEG C for 4-5 hours, and obtaining an aliphatic amine ester mixture; mixing aliphatic amine ester and boric acid, reacting under the conditions of the temperature of 100 DEG C and the pressure of 230mmHg for 4-5 hours, reducing the pressure to 30mmHg, and reacting; and reducing the temperature, filtering and obtaining the aliphatic amine ester boride lubricating oil additive. A novel low-sulfur low-phosphorus high-efficiency and boron nitride structure-containing aliphatic amine ester boride lubricating oil additive is prepared through continuous cyclic introduction of ammonia gas in a three-step reaction and a two-step pressure reduction method, and the prepared product has excellent wear resistance, antifriction property and oxidation resistance, the production method is simple, the cost is low, and the product structure is stable.

Owner:王严绪

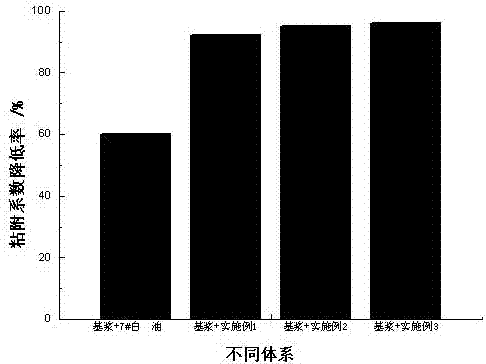

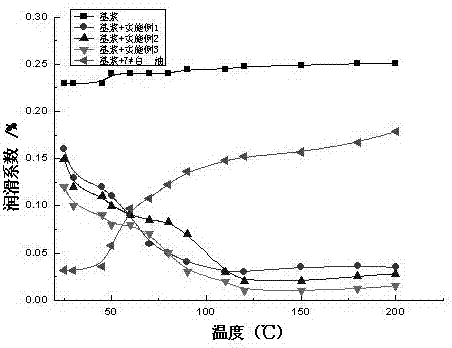

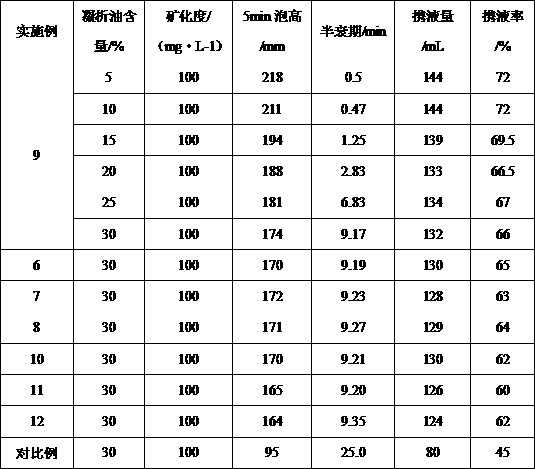

Thermo-sensitive and controllable-release lubricant used for well drilling fluid and preparation method for lubricant

The invention relates to the technical field of well drilling fluid lubricants, and especially relates to a thermo-sensitive and controllable-release lubricant used for a well drilling fluid and a preparation method for the lubricant. According to the lubricant, an interface synergistic effect of a composite surfactant and nano particles is adopted to control emulsion stability, a thermo-sensitive polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer (PEO-PPO-PEO block copolymer) is added to control the release speed of the lubricant, and the lubricant has the characteristics of high lubricating performance, persistent usage, a temperature controllable release and the like. The thermo-sensitive and controllable-release lubricant used for the well drilling fluid comprises the following components, in percent by mass: 15-25% of white oil, 10-20% of oleamide, 3-6% of the PEO-PPO-PEO block copolymer, 2-5% of nano calcium carbonate, 3-5% of polyoxyethylene sorbitan fatty acid ester, 1-3% of sorbitan fatty acid ester, 0.1-0.5% of an antifoaming agent, and the balance of water.

Owner:中石化石油工程技术服务有限公司 +2

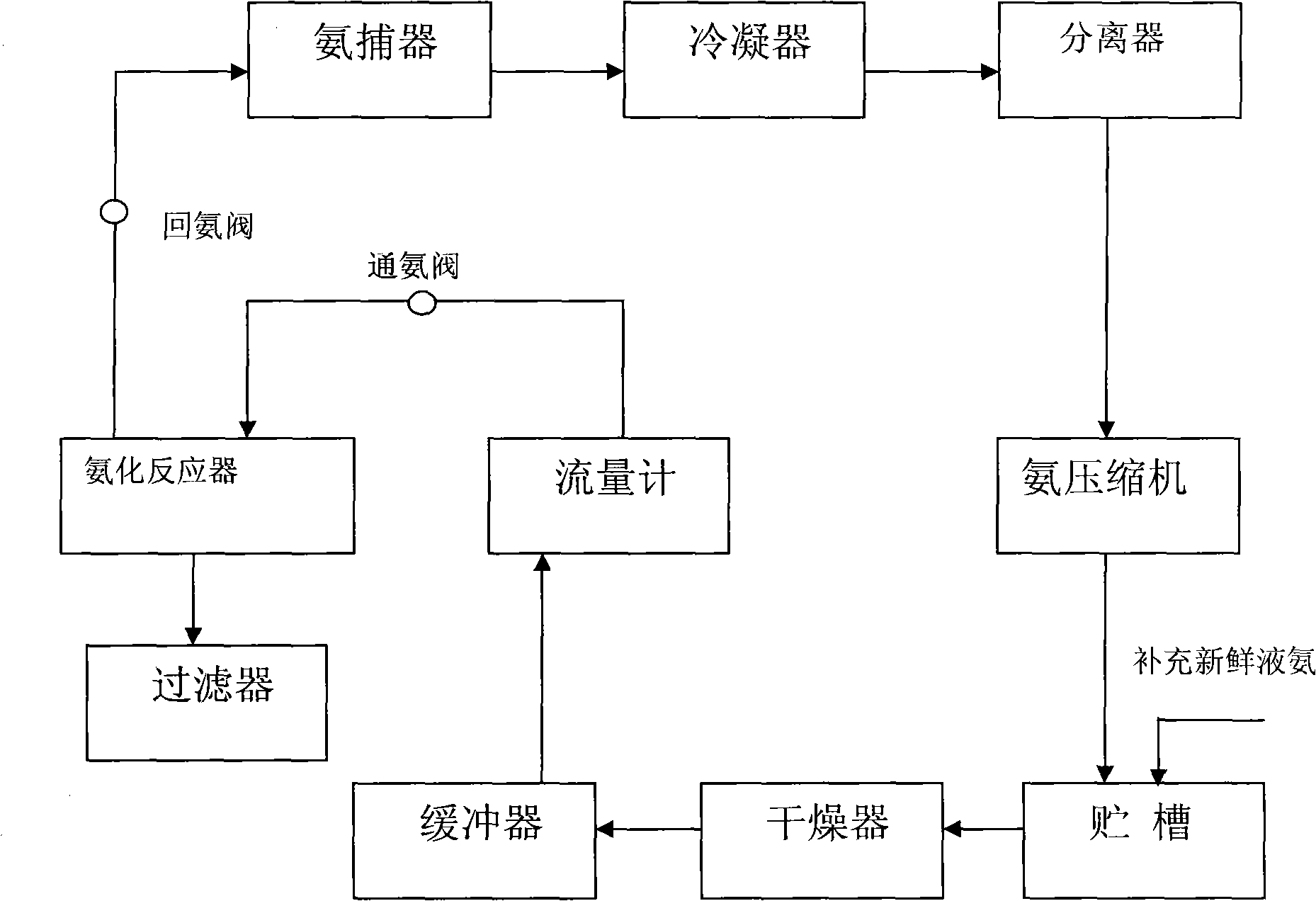

Method for synthesizing primary fatty acid amide and device of ammonia gas recovery and circulation

ActiveCN101289413AHigh aspect ratioEvenly distributedOrganic compound preparationCarboxylic acid amides preparationReaction temperatureAcid value

The invention discloses a synthetic method of a primary fat amide and an ammonia recovery and cycle device thereof. The steps of the synthetic method of the primary fat amide are as follows: a fatty acid and the ammonia are taken as raw materials, and an amination is carried out by the catalysis of a catalyst at the reaction temperature of 160 DEG C to 210 DEG C, the reaction pressure is 0.1 to 0.4 MPa, the ammonia gas flow is 0.5 to 3.0m<3> / h and the reaction time is 8 hours to 26 hours; samples are taken out to analyze until the acid value of the free fatty acid is qualified (the acid value is less than 1.0 mgKOH / g); and the catalyst is filtered and separated by a filter, so as to obtain the primary fat amide. The ammonia recovery and cycle device consists of an ammoniation reactor, an ammonia arrestor, a condenser, a separator, an ammonia compressor, a tank, a dryer, a buffer, a flow meter and the filter. The method and the device lead the consumption of the ammonia per ton to be less than 110 kg, which is greatly lower than the ammonia consumption of the traditional technology (more than 1200 kilograms per ton), and the consumption of the ammonia per ton is close to the theoretical consumption, and a clean production can be realized. The synthetic method for the primary fat amide and the ammonia recovery and cycle device thereof are suitable for oleamide, erucyl amide, stearic amide, behenamide, lauramide, palm acid amide, peanut acid amide and 12-hydroxy stearic amide.

Owner:江西威科油脂化学有限公司

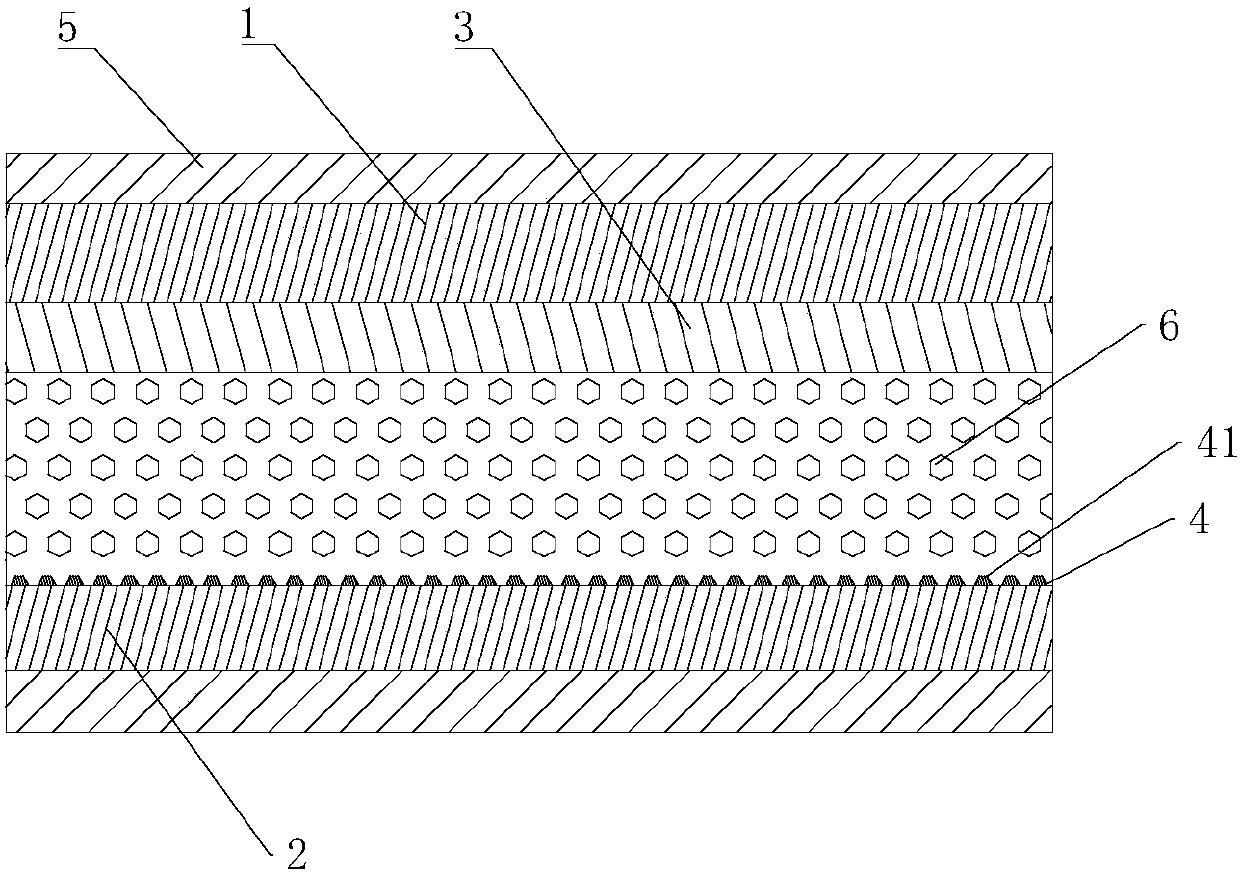

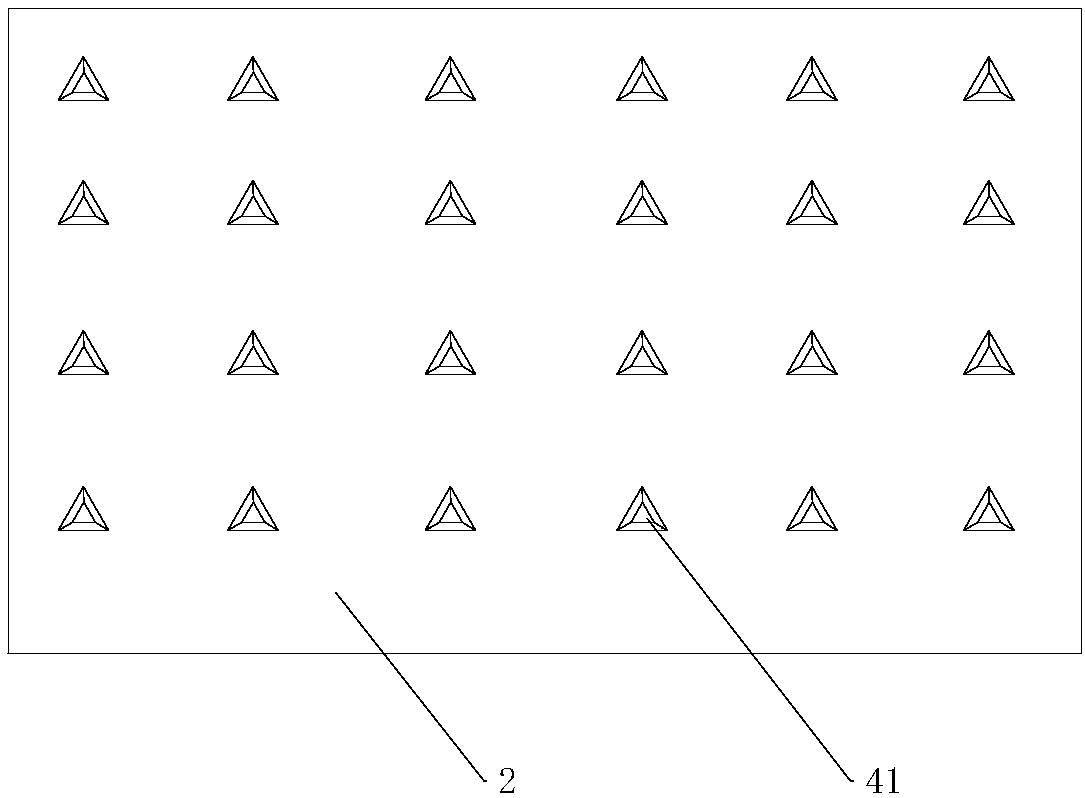

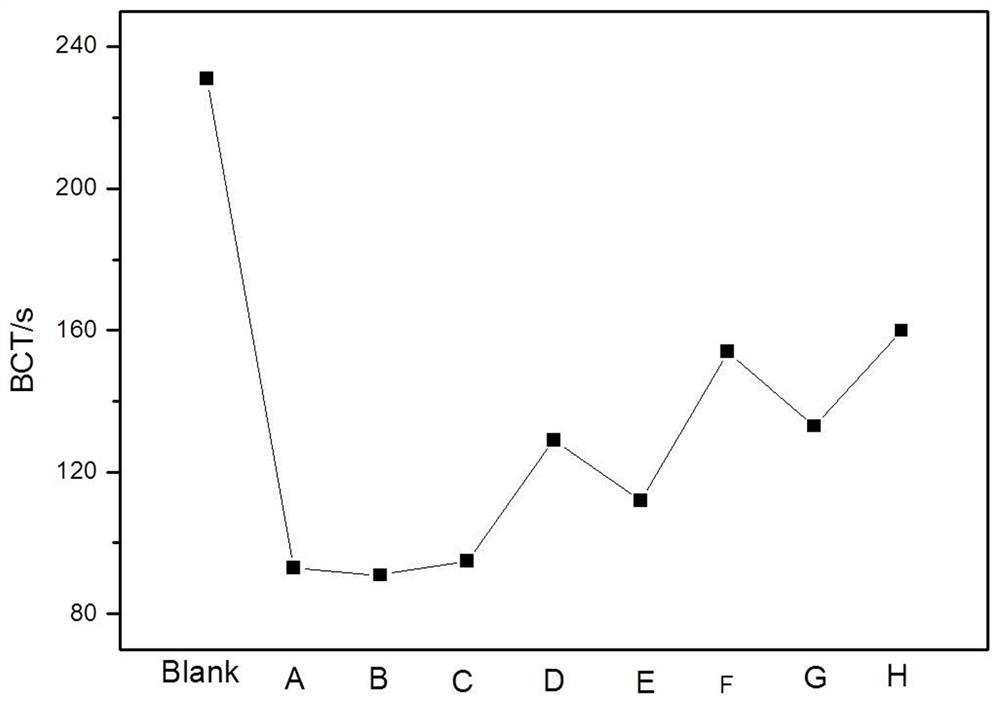

Degradable chitosan-based composite hemostatic film

ActiveCN112717194AMeet the mechanical performance requirementsStrong humidityAbsorbent padsCoatingsFiberPolyethylene glycol

The invention discloses a degradable chitosan-based composite hemostatic film which comprises a base material layer and a functional layer, and is characterized in that the base material layer is degradable fiber cloth; the functional layer is composite hydrogel prepared from modified chitosan, polyethylene glycol 2000, gelatin, xanthan gum, Ag / Fe2O3 magnetic nanoparticles, forged ophicalcitum and oleamide, and the functional layer is combined with the base material layer through polydopamine. The degradable chitosan-based composite hemostatic film provided by the invention has the advantages of softness, air permeability, high safety, good mechanical properties, strong water absorption and retention capacity, capability of being tightly attached to a wound, easiness in stripping, hemostasis, good anti-infection effect and no side effect of vascular embolism.

Owner:HENAN YADU IND

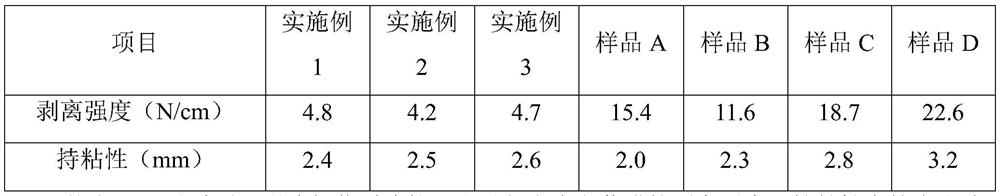

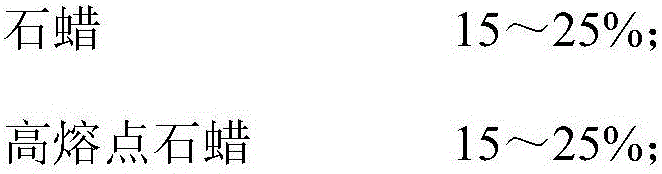

High-dimensional shape hard alloy forming agent and material mixing process thereof

ActiveCN106077616AReduce difficulty of removalStable removalTransportation and packagingMetal-working apparatusAlkaneDesorption

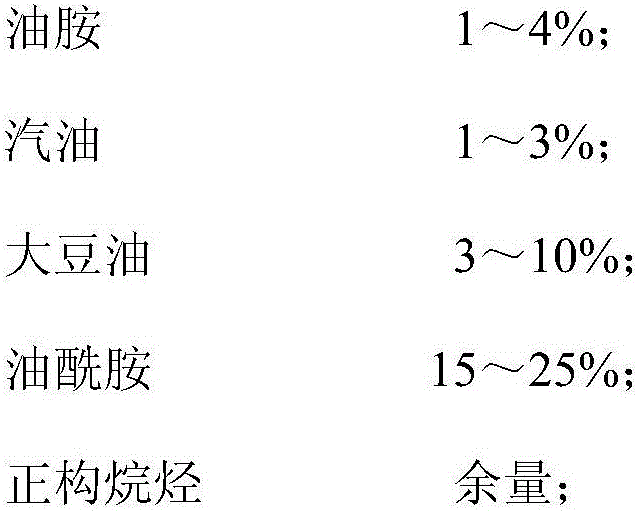

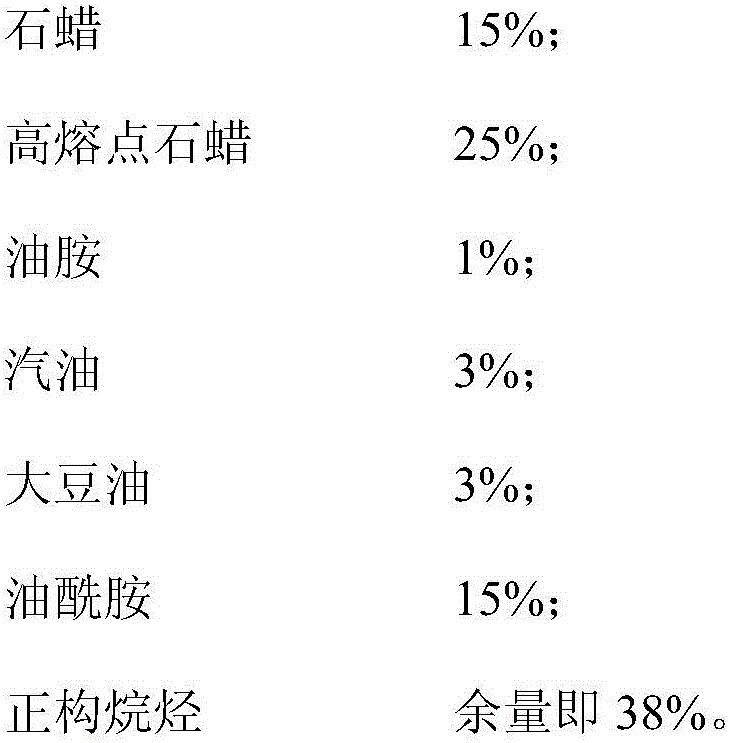

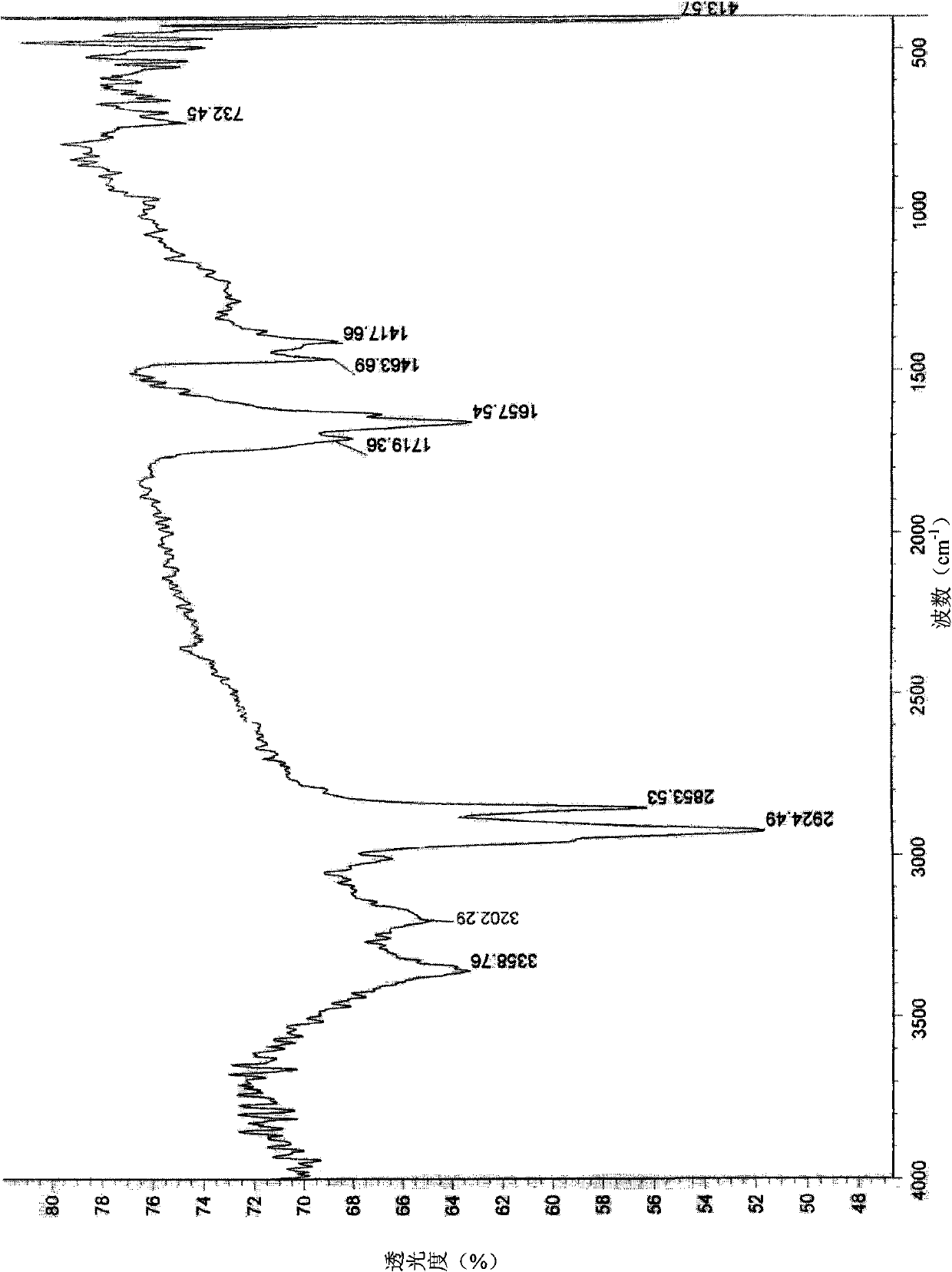

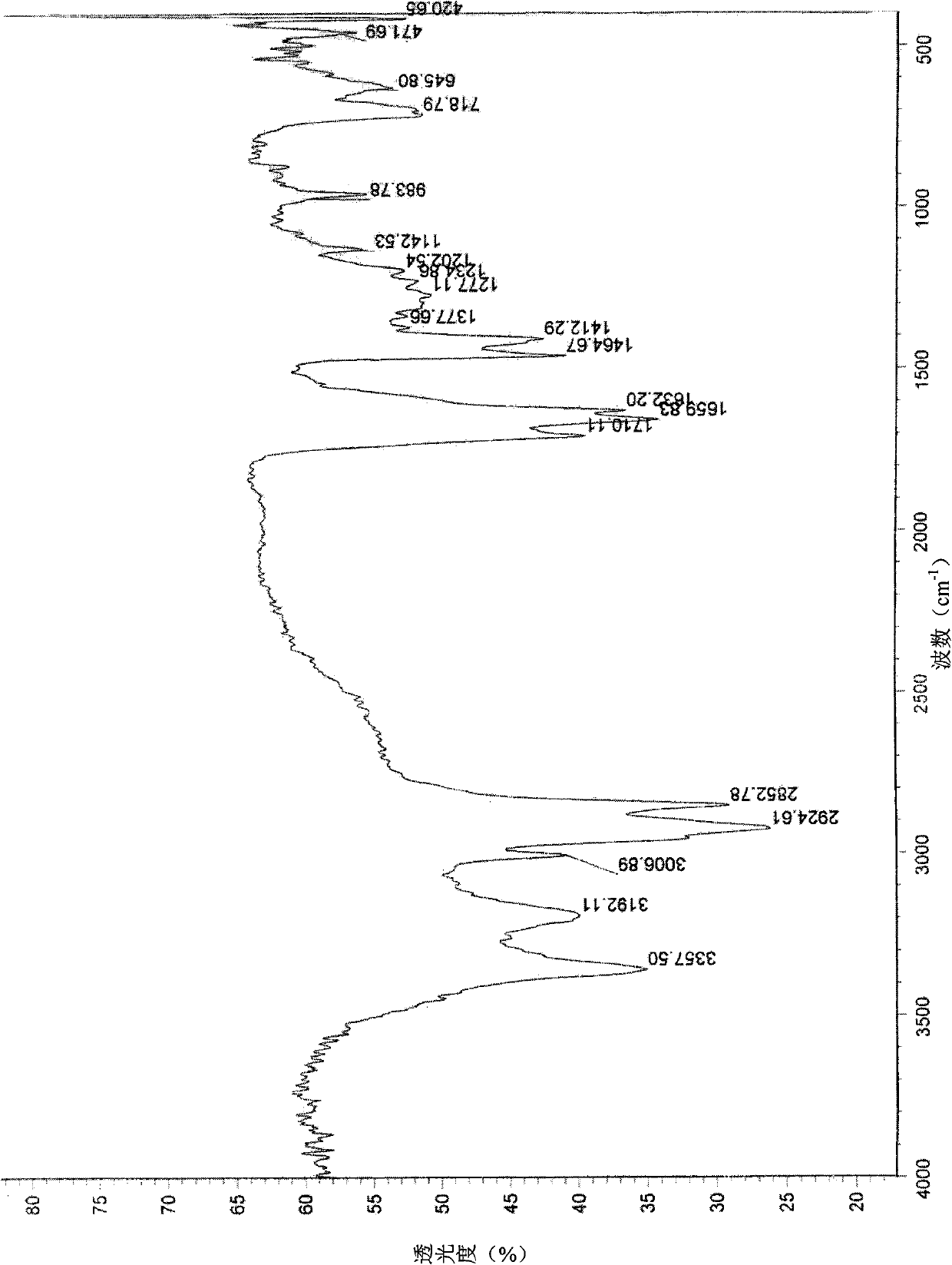

The invention discloses a high-dimensional shape hard alloy forming agent and a material mixing process thereof. The high-dimensional shape hard alloy forming agent is prepared from the following components in percentage by weight: 15 to 25 percent of paraffin, 15 to 25 percent of high melting-point paraffin, 1 to 4 percent of oleylamine, 1 to 3 percent of gasoline, 3 to 10 percent of soybean oil, 15 to 25 percent of oleamide and the balance of n-alkanes. According to the high-dimensional shape hard alloy forming agent and the material mixing process thereof disclosed by the invention, by selecting proper components and proportion, an extrusion material is enabled to simultaneously have suitable plastic deformation capacity and higher dimensional shape, and the control precision about screw pitches of the front end and the rear end of a product is high; the extrusion material is enabled to have high toughness and can bear the torsion in the extrusion process, thereby eliminating extrusion cracks; the forming agent is stable in desorption, and cracks generated in the drying in the shade and presintering process are avoided.

Owner:厦门金鹭硬质合金有限公司

PET (polyethylene glycol terephthalate) fiber/polyimide fiber composite sound absorbing cotton and preparation method of PET fiber/polyimide fiber composite sound absorbing cotton

InactiveCN102965846AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsSound producing devicesFiberPolymer science

The invention discloses PET (polyethylene glycol terephthalate) fiber / polyimide fiber composite sound absorbing cotton, which is prepared from the following ingredients in parts by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of polyimide fibers, 10 to 15 parts of emulsifying agents OP-15, 5 to 10 parts of peregal O-10, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of SBS (styrene butadiene styrene block polymer), 15 to 20 parts of nanometer dolomite powder, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of dibutyl phthalate, 4 to 6 parts of triethyl phosphate, 2 to 3 parts of ethylene bis oleamide, 1 to 2 parts of tetraisopropyl di(dioctylphosphate) titanate, 2 to 3 parts of calcium stearate, 1 to 2 parts of lead sulfate tribasic, 0.5 to 1.5 parts of anti-aging agents MB and 1 to 2 parts of antioxidants 1010. The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

Oleamide type floating agent and preparation method thereof

InactiveCN101767063AHigh selectivityImprove beneficiation efficiencyOrganic compound preparationCarboxylic acid amides preparationVegetable oilOleic Acid Triglyceride

The invention relates to an oleamide type floating agent and a preparation method thereof. The oleamide type floating agent is prepared by vegetable oil acids and ammonia gas, wherein the molar ratio of the vegetable oil acids and the ammonia gas is 1 to 2-3, or the oleamide type floating agent also comprises chlorine gas, wherein the molar ratio of the vegetable oil acids, the chlorine gas and the ammonia gas is 1 to 2-3 to 2-3. The method comprises the following steps: 1) preparing the vegetable oil acids, the chlorine gas and the ammonia gas; 2) taking the vegetable oil acids to be put in a container, adding a catalyst, and continuously adding the chlorine gas to obtain a pha-chloro oil acid; 3) taking the pha-chloro oil acid obtained in step 2) to be put in the container, adding the catalyst, adding the ammonia gas, heating stirring for raising temperature, and continuously reacting for10-12 hours. Compared with conventional higher fatty acids, the oleamide type floating agent significantly improves the selectivity of phosphorus, has the better flotation effect, and significantly improves the comprehensive efficiency of mineral processing. The oleamide type floating agent has the advantages of easy obtaining of materials, low cost and simple synthetic route, and reduces the cost of mineral processing.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Preparation of oily anti-blocking agent and application method

InactiveCN106518323AReduce dosageLow costLayered/coated fertilisersFertilizer mixturesNitro compoundAnticaking agent

Disclosed is an oily anti-blocking agent. The oily anti-blocking agent is prepared from, by mass, 40-60 wt% of palm oil, 20-40 wt% of oleic acid, 5-20 wt% of oleamide, 5-20 wt% of phosphate, and 2-10 wt% of potassium stearate; a preparation method of the oily anti-blocking agent comprises the steps of heating the raw materials to 80-110 DEG C, mixing and uniformly stirring the raw materials, and cooling the raw materials to an indoor temperature; an application method of the oily anti-blocking agent comprises the steps of heating the oily anti-blocking agent to 70-110 DEG C, dropping the oily anti-blocking agent to a compound fertilizer with the temperature of 50-60 DEG C after the oily anti-blocking agent is melted, fully wrapping the oily anti-blocking agent into particle surface of the fertilizer through a wrap machine, wherein 0.5-2.0 kg of the oily anti-blocking agent is added into per ton of the compound fertilizer. According to the preparation of oily anti-blocking agent and the application method, operation is simple, industrialized production is easy, use amount is small, and cost is low; meanwhile, the oily anti-blocking agent is easy to degrade, free of pollution, good in anti-blocking effect, and is capable of making an anti-blocking rate of granulous nitro-compound fertilizer reach 90% or above.

Owner:YANSHAN UNIV

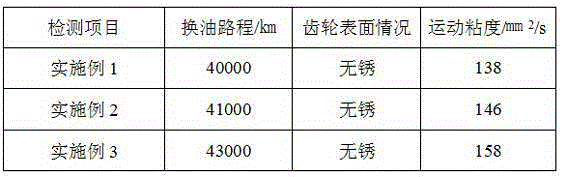

Formulation for gear oil for automobile transmission

ActiveCN105255565AImprove rust resistancePlay a lubricating effectAdditivesSulfite saltButylated hydroxytoluene

The invention discloses a formulation for gear oil of an automobile transmission and relates to the field of automobile lubrication oil. The formulation for the gear oil of the automobile transmission comprises, by mass, 76-80% of hydrogenated basic oil, 2.6-4.3% of sodium sulfite, 2.6-4.7% of dodecylbenzene sodium carbonate, 0.7-1.6% of butylated hydroxytoluene, 1.9-2.6% of potassium borate, 5.7-8.2% of dimethione and 4.8-6.1% of oleamide. Compared with common gear oil, the gear oil has the better extreme pressure anti-wear property and higher oxidation resistance.

Owner:HANGZHOU POLYTECHNIC

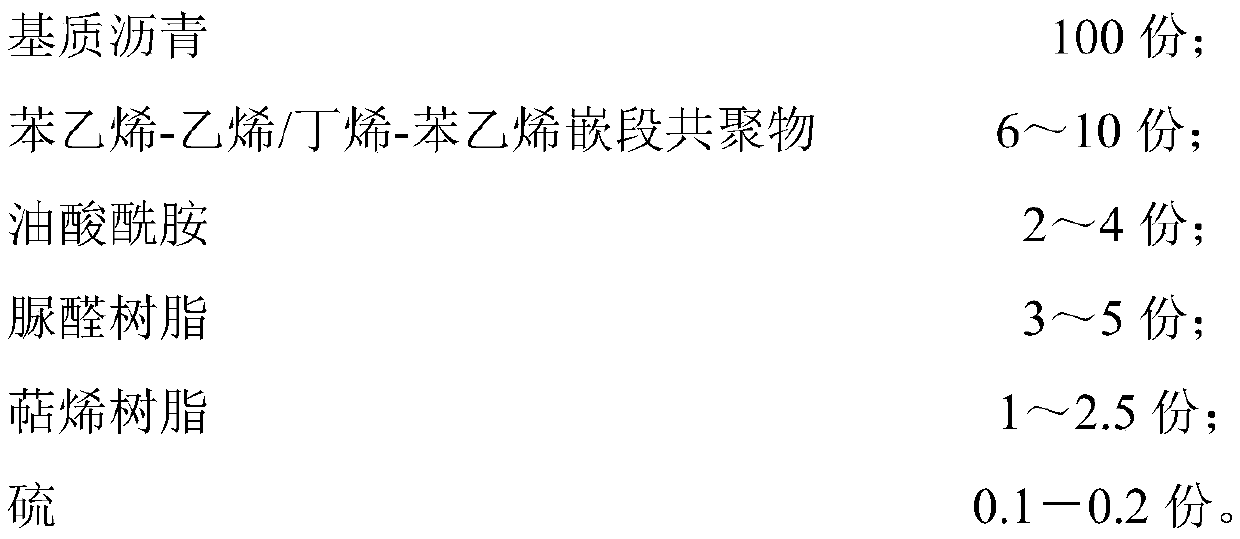

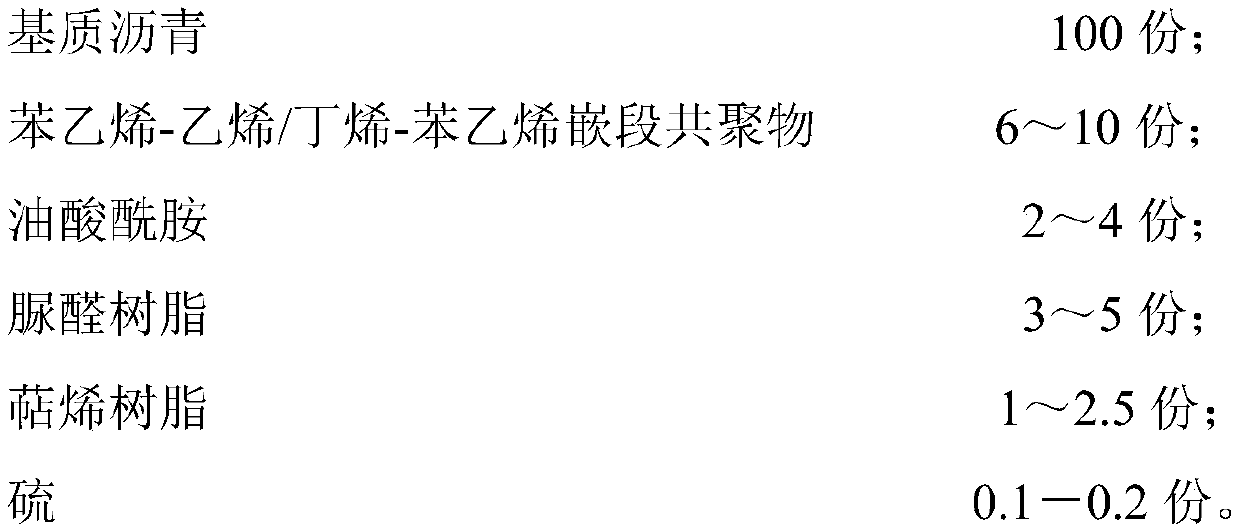

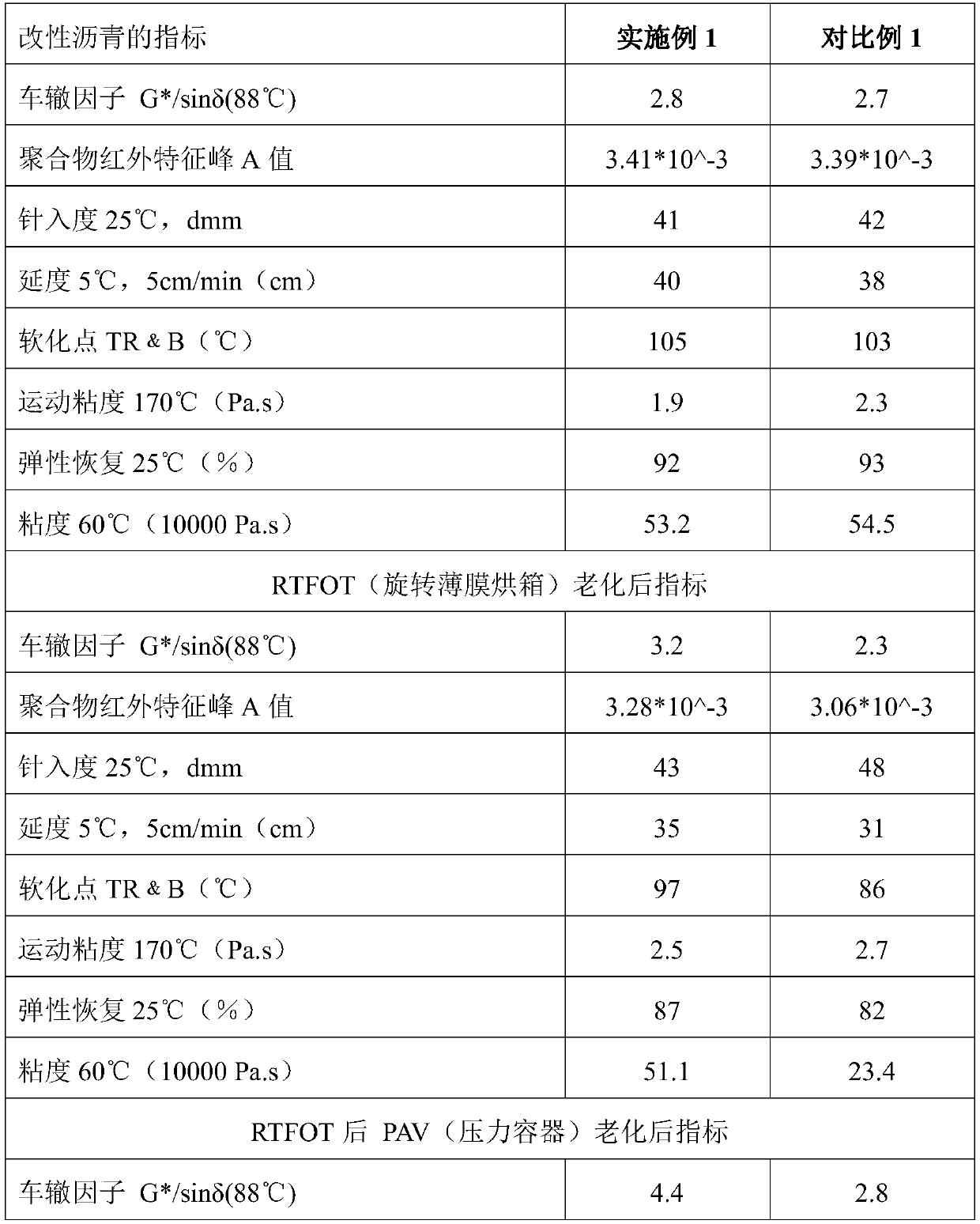

Modified asphalt for warm-mixed thin overlay and preparation method and application thereof

InactiveCN111205663AHigh viscosityGood anti-scatter performanceBuilding insulationsPolymer scienceActive agent

The invention relates to modified asphalt for a warm-mixed thin overlay and a preparation method and application thereof. The modified asphalt is prepared from the following raw material components: matrix asphalt, a styrene-ethylene / butylene-styrene block copolymer, oleamide, urea resin, terpene resin and sulfur. Compared with the prior art, the styrene-ethylene / butylene-styrene block copolymer and the urea resin are introduced into the asphalt composition, and the anti-aging agent or stabilizer terpene resin and sulfur are further added, so that the bonding strength between asphalt and aggregate is improved, the high-viscosity asphalt composition is ensured to have extremely excellent water loss resistance, and the warm-mixed thin overlay can still have good anti-scattering performance and anti-aging performance after being used for many years; and meanwhile, oleamide is added to achieve the effect of a surfactant, and it can be guaranteed that the modified asphalt special for the warm-mixed thin overlay has good workability in the construction process.

Owner:成都交通投资集团有限公司

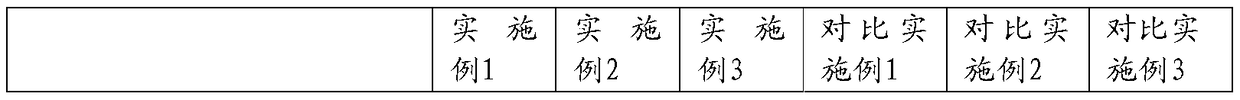

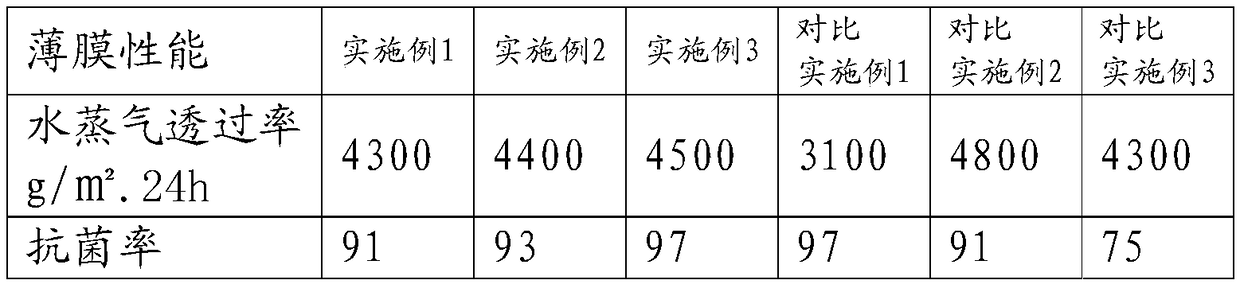

Antibacterial breathable plastic masterbatch and preparation method and application thereof

The invention relates to antibacterial breathable plastic masterbatch and a preparation method thereof. The masterbatch includes, by weight, 15-25% of metallocene linear low-density polyethylene, 50-70 parts of low density polyethylene, 5-8 parts of isotactic polypropylene, 3-6 parts of a dimethylsiloxane-diphenyl siloxane block copolymer, 40-48 parts of inorganic micropowder, 2-5 parts of nanometer bamboo-fragrance charcoal micropowder, 0.2-0.4 part of polyphthalamide, 0.1-0.2 part of a silicate silver-loaded inorganic antibacterial agent, 0.5-2 parts of glyceryl trimyristate, 0.3-0.8 part ofstearyl alcohol, 0.1-0.5 part of oleamide, 0.5-1 part of an antioxidant, 1-1.5 parts of liquid paraffin and 1-2 parts of glycerol monostearate. The masterbatch has excellent mechanical properties, integrates antibacterial performance and breathability, and has environmentally friendly raw materials, low preparation energy consumption, low cost and high single output. A plastic film processed fromthe masterbatch is of extremely high application value in the fields of diapers, sanitary napkins, medical surgical gowns, and the like.

Owner:泉州联盛新材料科技有限公司

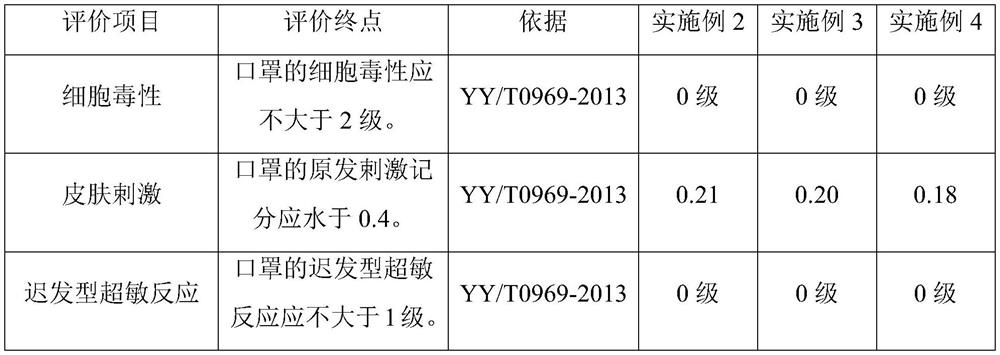

Antibacterial and odor-resistant spun-bonded non-woven fabric, planar mask with spun-bonded non-woven fabric and manufacturing method of planar mask

ActiveCN112064207AStrengthen antibacterial and deodorizing effectIncrease contentConjugated synthetic polymer artificial filamentsNon-woven fabricsLinear low-density polyethylenePolymer science

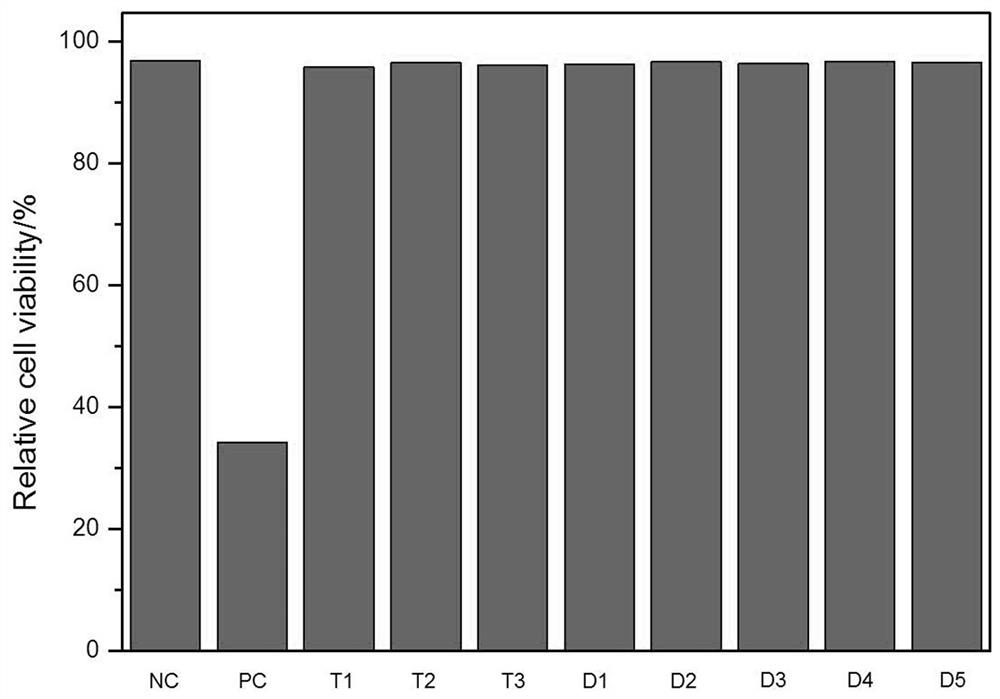

The invention discloses antibacterial and odor-resistant spun-bonded non-woven fabric, a planar mask with the spun-bonded non-woven fabric and a manufacturing method of the planar mask. The antibacterial and odor-resistant spun-bonded non-woven fabric is prepared from the following raw materials in parts by weight: 75-85 parts of polypropylene, 15-19 parts of metallocene catalyzed linear low density polyethylene, 2-2.5 parts of mesoporous silica, 3-4 parts of sepiolite powder, 1.2-1.4 parts of dichlorophenyl imidazole dioxolane, 2.2-2.6 parts of avermectin, 1-1.6 parts of maleic anhydride grafted polypropylene, 1-1.5 parts of oleamide, 1.5-2 parts of erucyl amide, 1-1.5 parts of a heat stabilizer and 3-5 parts of polypropylene cooling masterbatch. The antibacterial and odor-resistant spun-bonded non-woven fabric has good antibacterial and odor-resistant effects, is particularly suitable for being applied to masks, and has excellent microbial indexes, cytotoxicity, skin irritation, delayed hypersensitivity and other performance indexes.

Owner:怡佳(福建)卫生用品股份有限公司

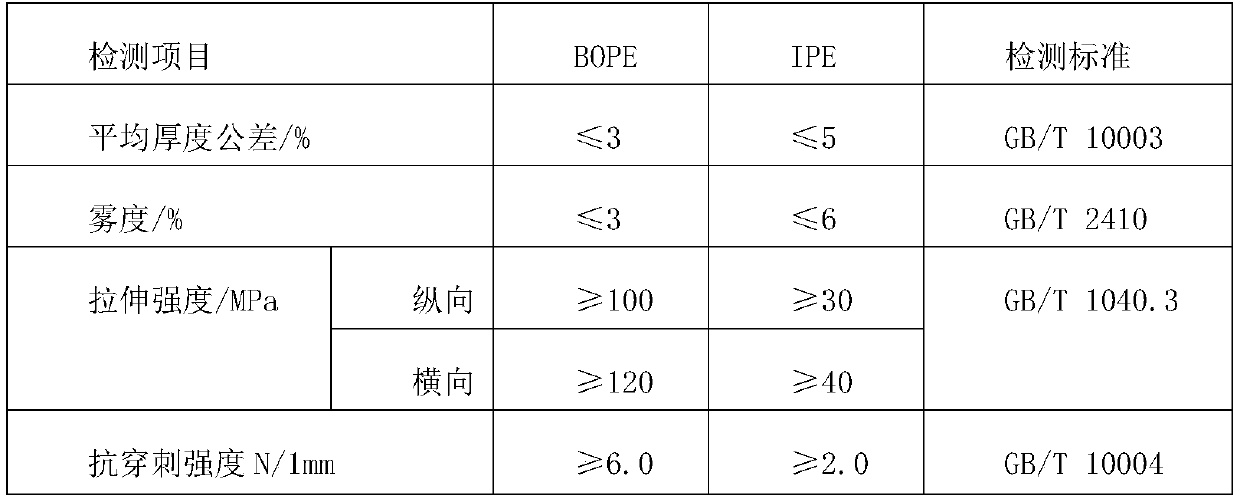

BOPE film and preparation method thereof

InactiveCN110450490AHigh molecular weight orientationHigh crystallographic orientationSynthetic resin layered productsLaminationSurface layerMaterials science

The invention relates to a BOPE film and a preparation method thereof. The BOPE film has a three-layer structure composed of a core layer, an upper surface layer, and a lower surface layer. The core layer is composed of 1 to 3 wt.% of antistatic master batch and 97 to 99 wt.% of M-LLDPE. The upper surface layer is composed of 2 to 4 wt.% of antistatic master batch and 96 to 98 wt.% of M-LLDPE. Thelower surface layer is composed of 3 to 5 wt.% of anti-sticky master batch and 95 to 97 wt.% of M-LLDPE. The antistatic master batch is a blend of ethyoxyl amine, glycerol monostearate, and M-LLDPE.The anti-sticky master batch is a blend of oleamide and M-LLDPE. Compared with a polyethylene film produced by a conventional blowing / casting method, the physical properties of prepared BOPE film aregreatly improved; the transparency is high, the heat seal property is good, and the vertical / horizontal tensile strength is excellent. The key performances are maintained, when the thickness is reduced by 50%, compared with other polyethylene films.

Owner:ANHUI GUOFENG PLASTIC

Pass box prepared from recycled and modified waste PE plastic woven bags and preparation method thereof

The invention discloses a pass box prepared from recycled and modified waste PE plastic woven bags and a preparation method thereof. The pass box is prepared from the following raw materials by weight: crushed waste PE plastic woven bags, HDPE, polybutyl rubber particle, PP-g-MAH, oleamide, glass fiber, fatty acid ester, calcium stearate, active calcium carbonate, glycol, white carbon black, octadecylamine, flexibilizer, silicone powder, dioctyl adipate, polyvinyl alcohol and acetone. According to the invention, the waste HDPE PE plastic woven bags are utilized in the formula, so product cost is greatly reduced; the preparation method is simple, can easily realize industrial production and effectively overcomes the problems of environmental pollution and waste of resources caused by waste and old plastic; the prepared pass box has high notch impact strength, bending strength and hardness; and with the method provided by the invention, the qualified pass box can be effectively prepared, operation process is simple, and large-scale production can be conveniently carried out.

Owner:SUZHOU DINGLI PACKAGING

Pass box prepared from recycled and modified waste PP plastic woven bags and preparation method thereof

The invention discloses a pass box prepared from recycled and modified waste PP plastic woven bags and a preparation method thereof. The pass box is prepared from the following raw materials by weight: crushed waste PP plastic woven bags, HDPE, PVC resin, PP-g-MAH, oleamide, glass fiber, bis(stearoyloxy)propoxy borate, glycerol, active calcium carbonate, glycol, flexibilizer, a coupling agent, octadecylamine, silicone powder, ethylene-vinyl acetate copolymer and acetone. The preparation method for the pass box is simple and can be easily implemented; the mechanical properties and processing properties of the prepared pass box meet requirements; meanwhile, since the waste PP plastic woven bags are used as the raw material, cost is low, good economic benefits are obtained, and reasonable utilization of resources and environmental protection are benefited.

Owner:SUZHOU DINGLI PACKAGING

Condensate-oil-resistant, salt-resistant and temperature-resistant foam scrubbing agent and preparation method thereof

InactiveCN111139050AHigh fluid carrying capacityIncrease the lengthDrilling compositionChloroacetic acidsErucyl amide

The invention discloses a condensate-oil-resistant, salt-resistant and temperature-resistant foam scrubbing agent and a preparation method thereof. The condensate-oil-resistant, salt-resistant and temperature-resistant foam scrubbing agent is composed of the following components in percentages by weight: 8%-22% of cocamidopropyl dimethyl tertiary amine, 3%-12% of oleamide propyl dimethyl tertiaryamine, 3%-15% of erucyl amide propyl dimethyl tertiary amine, 3%-18% of chloroacetic acid, 8%-22% of liquid caustic soda and 6%-20% of organic solution, with the balance being water. According to theinvention, through selection and specific proportion design of raw materials, the liquid carrying capacity of the foam scrubbing agent is still high under the condition of high condensate oil content;meanwhile, the liquid carrying capacity cannot be reduced along with increase of the condensate oil content; and the problem that a conventional foam scrubbing agent cannot simultaneously meet the requirements for high temperature resistance, salt resistance and condensate oil resistance is solved.

Owner:PETROCHINA CO LTD

Antifouling coating for marine net wire and preparation method of antifouling coating

ActiveCN110724424AImprove adhesionGood weather resistanceAntifouling/underwater paintsPaints with biocidesThioketonePhosphate

The invention relates to the field of materials science, and discloses an antifouling coating for a marine net wire and a preparation method of the antifouling coating aiming at the problem of low flexibility and bactericidal activity of a matrix resin. The antifouling coating comprises the following components in percent by mass: 2-5% of modified nano zinc oxide, 2-7% of P-aminobenzoic acid, 2-7%of sodium benzoate, 2-7% of copper pyrithione, 2-7% of SeaNine211, 3-12% of oleamide, 0.5-2% of phytic acid, 2-6% of ZH 6900-20X, and the balance poly acrylic acid composite resin. A quaternary noveldiisobutylene / n-pentyl acrylate / styrene / isobornyl methacrylate copolymer resin is synthesized, the synthesized multi-polyethylene resin has excellent flexibility, and has good adhesion and weather resistance to a net wire, the anti-fouling ability is significantly improved, the environmental pollution and aquaculture maintenance cost are reduced, and the yield and quality of seafood aquaculture are relatively greatly improved.

Owner:ZHEJIANG OCEAN UNIV

Antibacterial plastic and preparation method thereof

The invention belongs to the technical field of functional polymer materials, and especially discloses an antibacterial plastic and a preparation method thereof. The antibacterial plastic is preparedfrom the following raw materials in parts by weight: 90-95 parts of plastic granules, 10-13 parts of glass fibers, 0.5-0.7 parts of oleamide, 0.4-1 parts of a calcium-zinc stabilizer, 0.2-0.8 parts ofa nano-silver antibacterial agent and 0.2-0.5 parts of an antioxidant. The preparation method comprises the following three steps: S1, stirring the plastic granules, the glass fibers, the oleamide, the antioxidant and the calcium-zinc stabilizer in a high-speed stirrer at the speed of 1500 rpm for 10-15 minutes, and discharging the mixture after the mixture is uniform, so as to obtain a mixed material; S2, putting the mixed material into a reactor, performing heating to 130-140 DEG C while stirring, adding a nano-silver antibacterial agent, and continuously heating and stirring for 10-20 minutes to obtain an antibacterial mixed material; and S3, cooling and stirring the antibacterial mixed material obtained in the step S3 until the temperature of the material is 50-80 DEG C, then adding the material into a double-screw extruder, and carrying out extrusion molding to obtain the antibacterial plastic.

Owner:中山市海辉塑胶制品有限公司

Cleaning agent for machine tools

A cleaning agent for machine tools is prepared from the following raw materials, by weight, 6-9 parts of amino trimethylene phosphonic acid, 3-6 parts of oleamide, 3-5 parts of a surfactant, 4-7 parts of sodium tripolyphosphate, 3-8 parts of soda ash, 6-11 parts of ethylene diamine tetraacetic acid, 4-8 parts of straight-chain paraffin, 4.5-10 parts of a rust remover, 3.2-7 parts of sodium dodecyl sulfate, 2.5-6 parts of monoethanolamine and 4.1-8.6 parts of sorbitan fatty acid ester. The invention has the following beneficial effects: the cleaning agent has high cleaning efficiency, can be used to clean machine tools cleanly and rapidly and has low causticity to equipment so as to prolong service life of machine tools.

Owner:QINGDAO QIYUAN ZHENDONG ELECTRIC

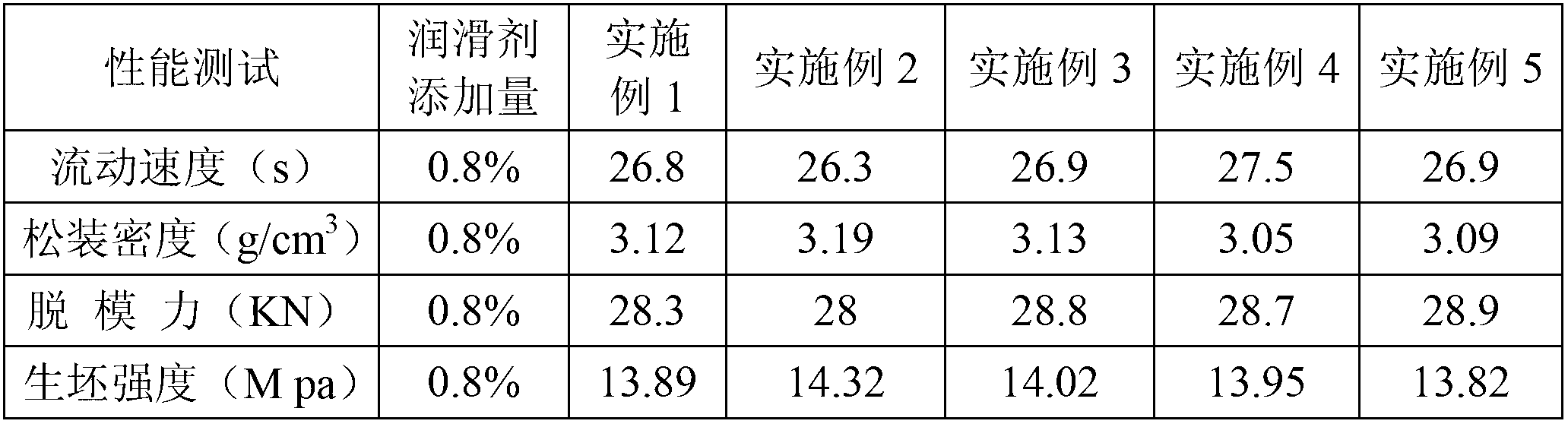

Special powder metallurgy lubricant for stainless steel and preparation method thereof

The invention relates to a special powder metallurgy lubricant for a stainless steel and a preparation method thereof, and belongs to the technical field of additives for powder metallurgy materials. According to the special powder metallurgy lubricant for the stainless steel and the preparation method thereof, provided by the invention, a stearate, a vinyl-based distearic amide and an oleamide are adopted as the raw materials, the raw materials are uniformly mixed and heated to reach a certain temperature, and then the mixture is cooled, grinded, crushed and screened, thus obtaining the finished product of the special powder metallurgy lubricant for the stainless steel. The special powder metallurgy lubricant for the stainless steel, provided by the invention, is suitable for being used for pressing powders of stainless steels 304 and 316; and the special powder metallurgy lubricant is low in capacity of pressing and demoulding, low in production cost and high in production efficiency, and can ensure the safety of a mould in use.

Owner:曾锐

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com