Oleamide type floating agent and preparation method thereof

An oleic acid amide type, flotation agent technology, applied in the field of flotation agents, can solve the problems of poor selectivity, low normal temperature flotation index, etc., and achieve the effects of reducing beneficiation cost, improving comprehensive efficiency of beneficiation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

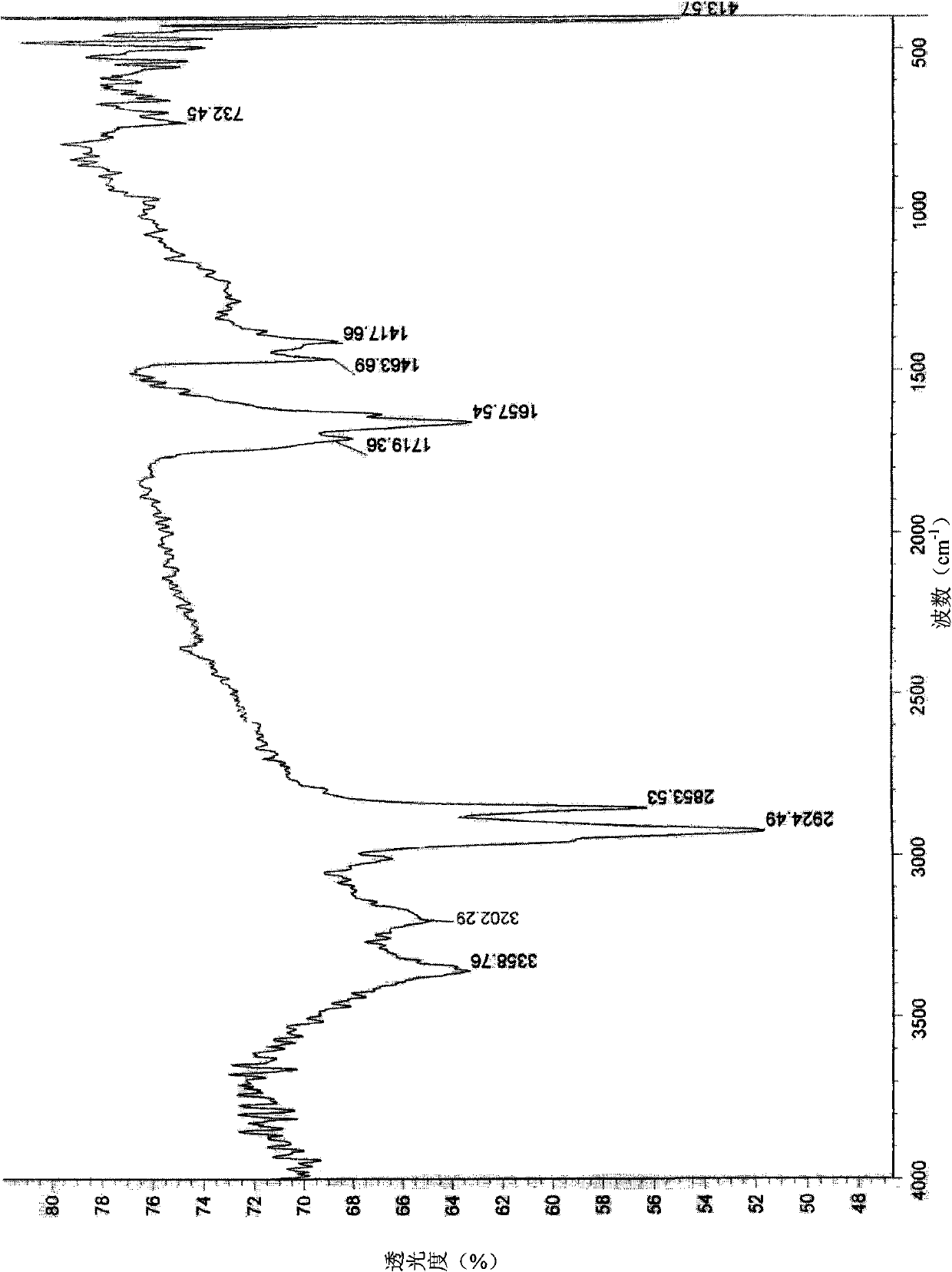

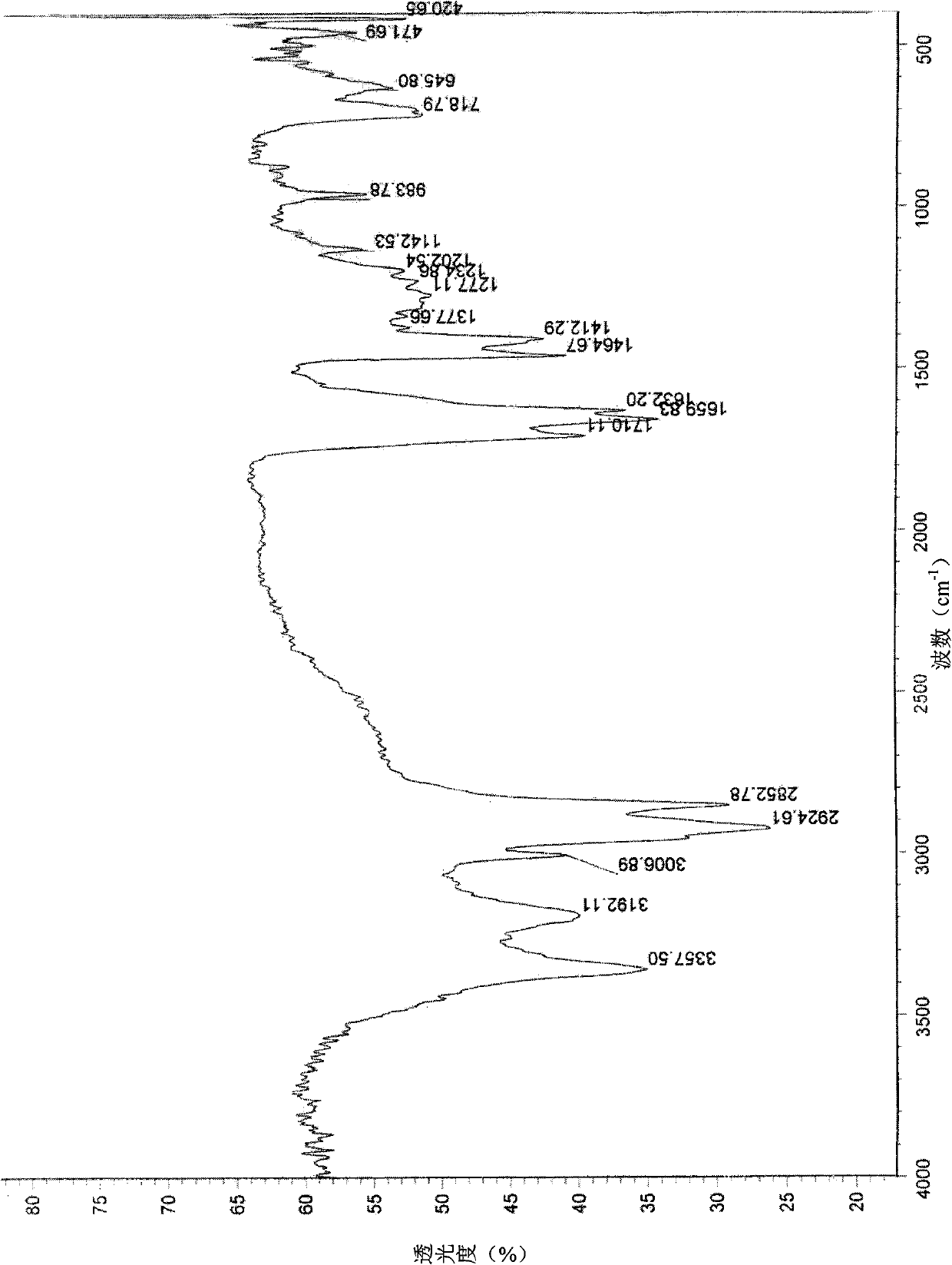

Image

Examples

Embodiment 1

[0030] (1) Synthesis of α-chlorooleic acid amide

[0031] ①Weigh 500g of soybean oleic acid and put it in a three-necked flask, plug one end with a stopper with a glass tube (through chlorine gas) (the glass tube is inserted into the bottom of the flask), and connect the exhaust gas with a drying tube at the other end, and use sodium hydroxide for the exhaust gas. Absorb, keep the device airtight. Add a small amount of red phosphorus 1-2g as a catalyst, pass chlorine gas under mechanical stirring, adjust the chlorine gas flow rate to 80ml / min with a pressure reducing valve and a flowmeter, and control the temperature to react at 110°C for 10 hours. The product was then filtered under reduced pressure at about 130 °C to remove the mixed HCl gas and excess Cl 2 gas to obtain the desired α-chlorooleic acid.

[0032] ② Take 500mL of α-chlorooleic acid in a 1000mL three-necked flask (with a water separator), add 4.5g of silica gel (200-250 mesh) as a catalyst, and place the three...

Embodiment 2

[0036] (1) Synthesis of α-chlorooleic acid amide

[0037] Get the alpha-chlorooleic acid of 1000mL (the preparation of alpha-chlorooleic acid is with embodiment 1, but vegetable oleic acid adopts rapeseed oleic acid) in the there-necked flask (with water separator) of 2000mL, add 10g silica gel As a catalyst, the three-necked flask was heated on an oil bath, the temperature was raised to 160°C, and ammonia gas was introduced at a rate of 100L / h, and the reaction was carried out for 12h to obtain a brown-black paste product α-chlorooleic acid amide.

[0038] (2) Synthesis of oleic acid amide

[0039] Take 1000mL of soybean oleic acid in a 2000mL three-necked flask (with a water separator), add 10g of silica gel as a catalyst, heat the three-necked flask on an oil bath, heat it up to 160°C, and feed it at a speed of 100L / h Ammonia, reacted for 12h to obtain oleic acid amide as a brown-black paste.

Embodiment 3

[0041] (1) Synthesis of α-chlorooleic acid amide

[0042] Get the α-chlorooleic acid of 1000mL (the preparation of α-chlorooleic acid is the same as Example 1) in the there-necked flask (with a water separator) of 2000mL, add 10g of silica gel as a catalyst, and place the there-necked flask in an oil bath Heating on the pot, heating up to 170°C, feeding ammonia gas at a rate of 100L / h, and reacting for 10h to obtain α-chlorooleic acid amide as a brown-black paste product.

[0043] (2) Synthesis of oleic acid amide

[0044] Take 1000mL of soybean oleic acid in a 2000mL three-necked flask (with a water separator), add 10g of silica gel as a catalyst, heat the three-necked flask on an oil bath, heat it up to 170°C, and feed it at a speed of 100L / h. Ammonia, reacted for 10h to obtain oleic acid amide as a brown-black paste.

[0045] Alpha-chlorooleic acid amide and oleic acid amide flotation agent prepared in Example 1 are respectively used for flotation of a certain refractory ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com