Patents

Literature

76 results about "Oleic acid amide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antistatic biaxially oriented polypropylene composition and its preparation method

This invention relates to antistatic biaxially oriented polypropylene (BOPP) combination, using polypropylene as material and including opening agent, smoothness agent, antistatic agent, antioxidant, processing and heat stabilizer, wherein the antistatic agent is glycerin fatty acid ester or two ester, polyethylene glycol ester, amides and / or ethyl amines, the anti-adhesion agent is a series of silicon dioxide inorganic matters or crosslinked polysiloxane particles, the opening agent is the synthesized silicon dioxide or silicates, calcium stearate, the smoothness agent is oleic acid amide, erucic acid amide and / or silicone, and the primary and secondary antioxidants are phosphite stabilizing agent and hindered amine antioxidant. The preparation method includes adding antistatic agent, etc. additives in granulation part, and adding them into PP, mixing, and melting and granulating to obtain the BOPP antistatic resin, or pre-preparing antistatic anti-adhesion smoothness masterbatch by various components. This invention keeps the original performances of BOPP with a lower volume of auxiliaries, and obtain good performances of antistatic property, anti-adhesion, and smoothness.

Owner:SINOPEC YANGZI PETROCHEM

Blow molded polyvinyl alcohol membrane and production method thereof

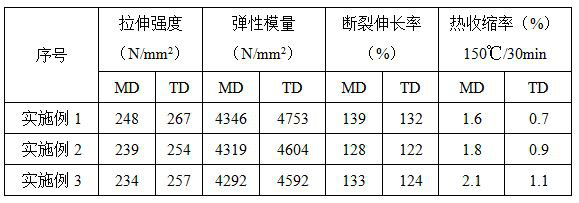

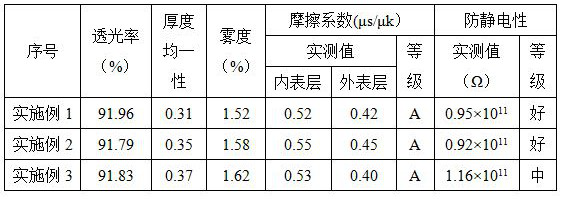

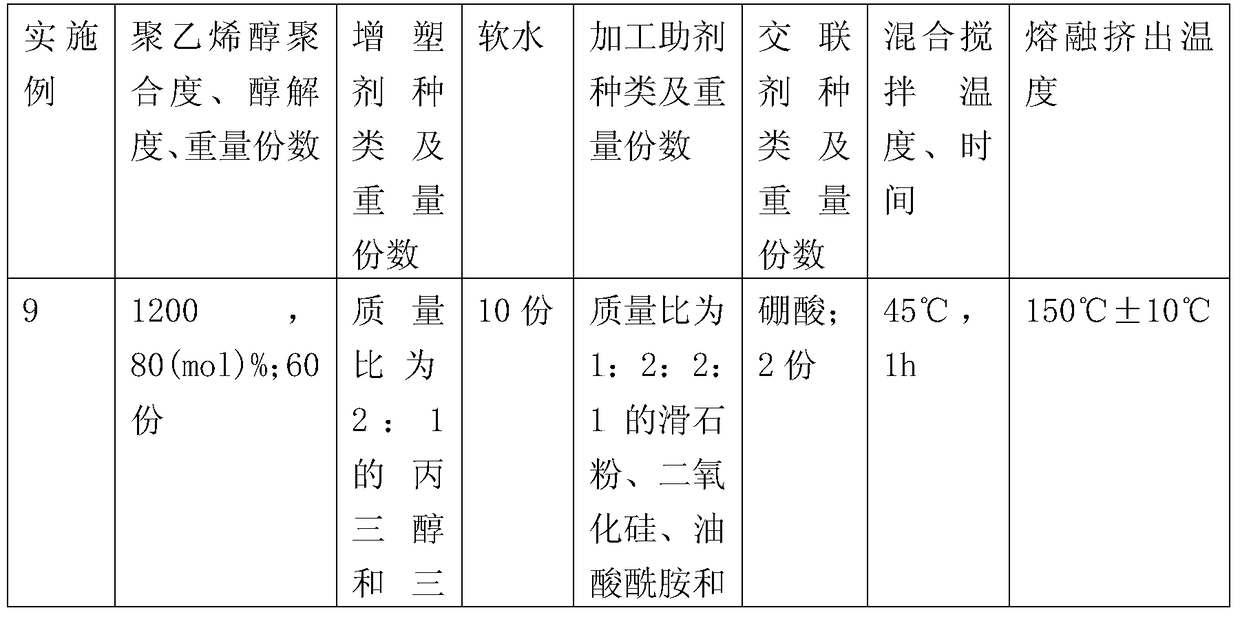

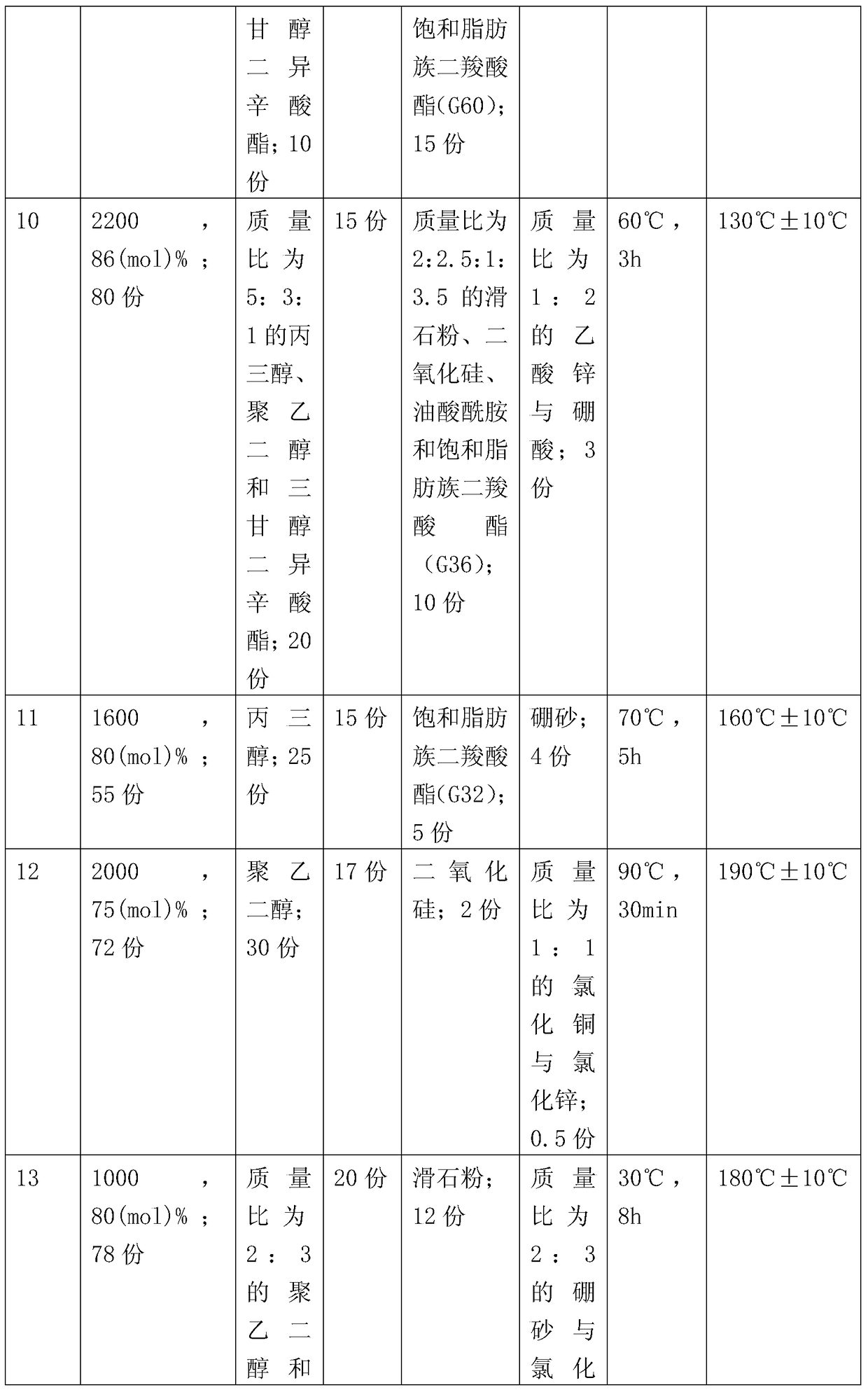

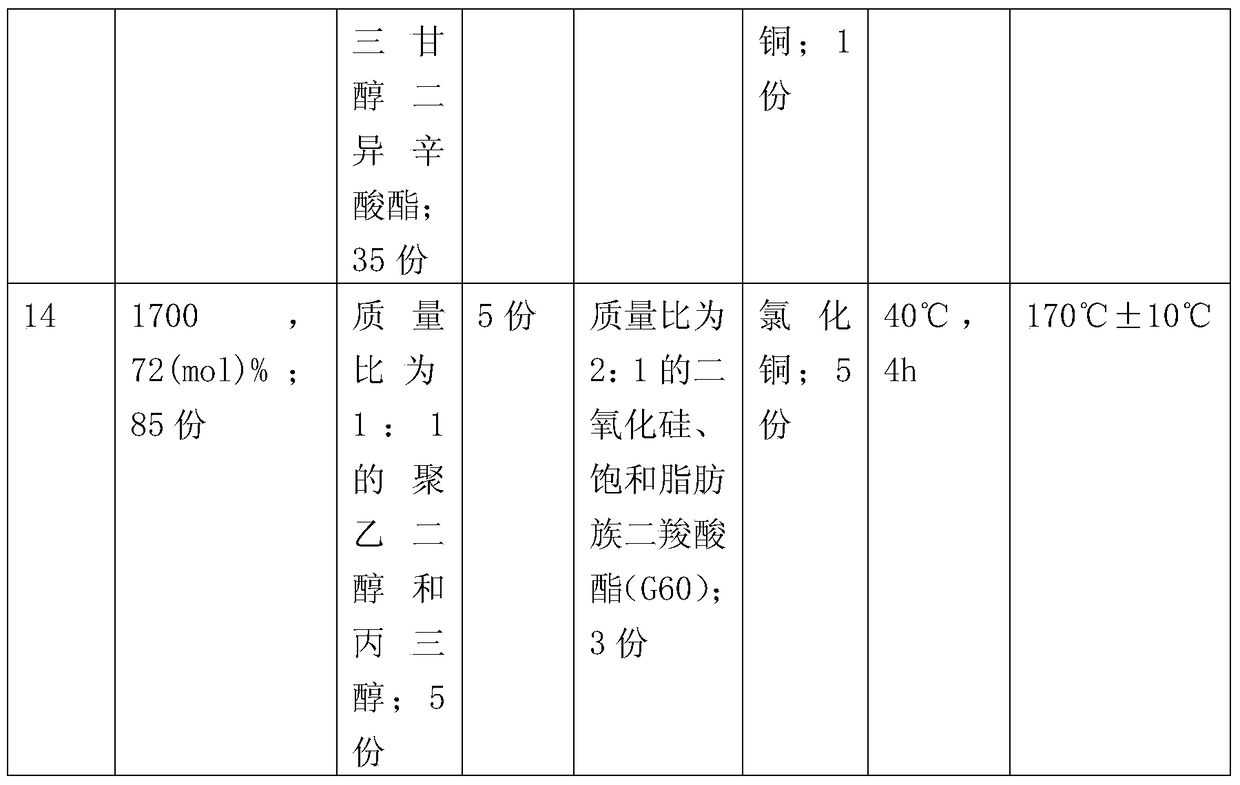

The invention provides a polyvinyl alcohol membrane. The polyvinyl alcohol membrane is produced through blow molding of melt-processible polyvinyl alcohol resin, the tensile strength of the polyvinyl alcohol membrane is not lower than 20 MPa, the melt-processible polyvinyl alcohol resin comprises effective amounts of polyvinyl alcohol, a plasticizer, soft water and a processing assistant, the degree of polymerization (DP) of the polyvinyl alcohol is 1000-3500, the degree of hydrolysis (DH) of the polyvinyl alcohol is greater than 72 (mol)% and is smaller than 99.9 (mol)%, the plasticizer is at least one of glycerol, polyethylene glycol and triethylene glycol di-2-ethylhexoate, and the processing assistant is at least one of talcum powder, silica, oleamide and saturated aliphatic dicarboxylate. The method has the advantages of simple process, less device investment, small occupied area, and realization of blow molding of normal-temperature, medium-temperature and high-temperature water soluble membranes. The method is mainly used for producing double-layer membranes, and the membranes can be directly processed to produce various water-soluble bags, and the water-soluble bags are used in the field of medium and low end packaging application, and can be used as a pesticide and chemical engineering product inner packaging liner bag, a hospital washing packaging bag and a refuse bag.

Owner:CHINA PETROCHEMICAL CORP +2

Plastic pencil and preparation method thereof

The present invention relates to a plastic pencil, which comprises a pencil rod, a pencil core and a pencil skin, wherein the components of the pencil rod comprise 30-50 wt% of polystyrene (PS), 10-30 wt% of a synthetic rubber, 2-8 wt% of a nucleating agent, 30-50 wt% of talc powder, and 5-10 wt% of calcium stearate, and are added with polyethylene (PE), the components of the pencil core comprise 20-50 wt% of polystyrene (PS), 2-10 wt% of an organosilicon polymer, 30-60 wt% of graphite powder, 2-10 wt% of hydrogenated palm oil, 2-10 wt% of oleic acid amide, and 5-10 wt% of a synthetic rubber, and the components of the pencil skin comprise 70-90 wt% of polystyrene (PS), 5-20 wt% of color master batch, and 2-10 wt% of hydrogenated palm oil. According to the present invention, the pencil rod and the pencil core are not easily broken, the pencil core has characteristics of good striking degree, good brightness and dreg falling resistance, and the manufacturing cost is low.

Owner:JIANGXI JISHUI GEMSTAR STATIONERY CO LTD

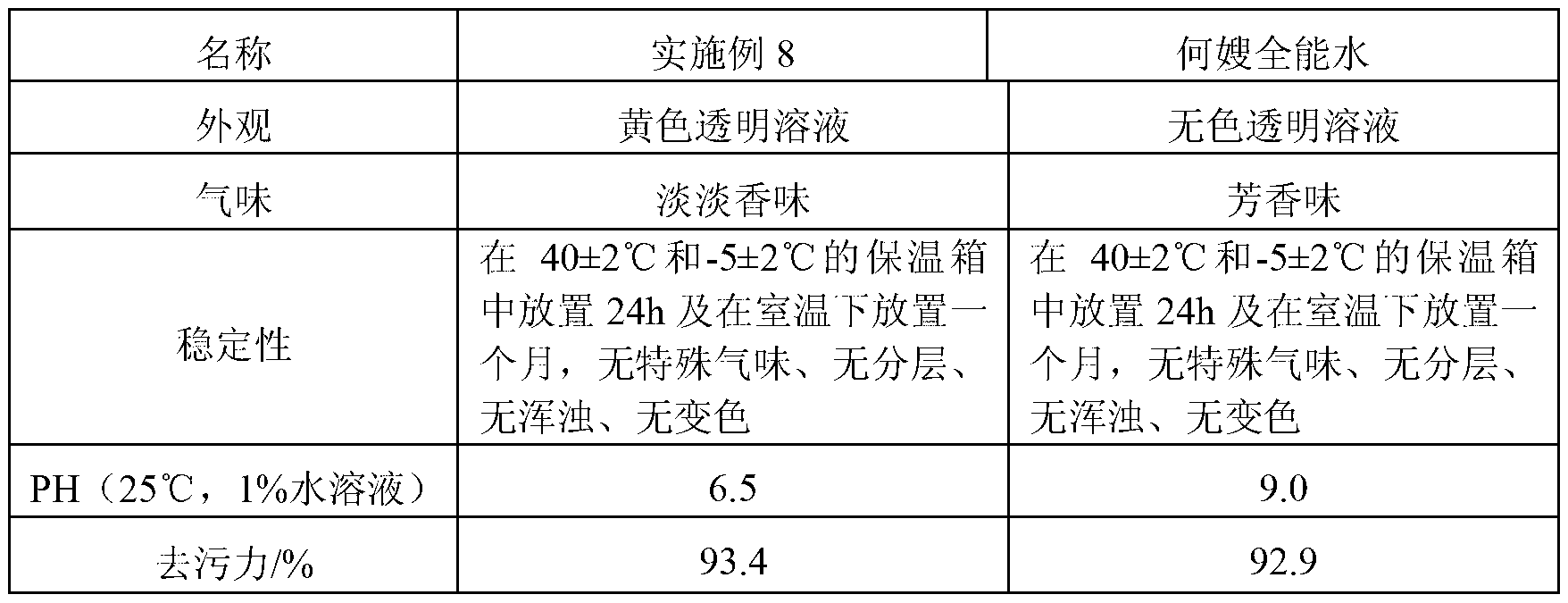

Water-based cleaning agent with weak acidity for removing thick oil dirt, and preparation method thereof

InactiveCN103320238AMild performanceGood compatibilityAmpholytes/electroneutral surface-active compoundsWater basedBetaine

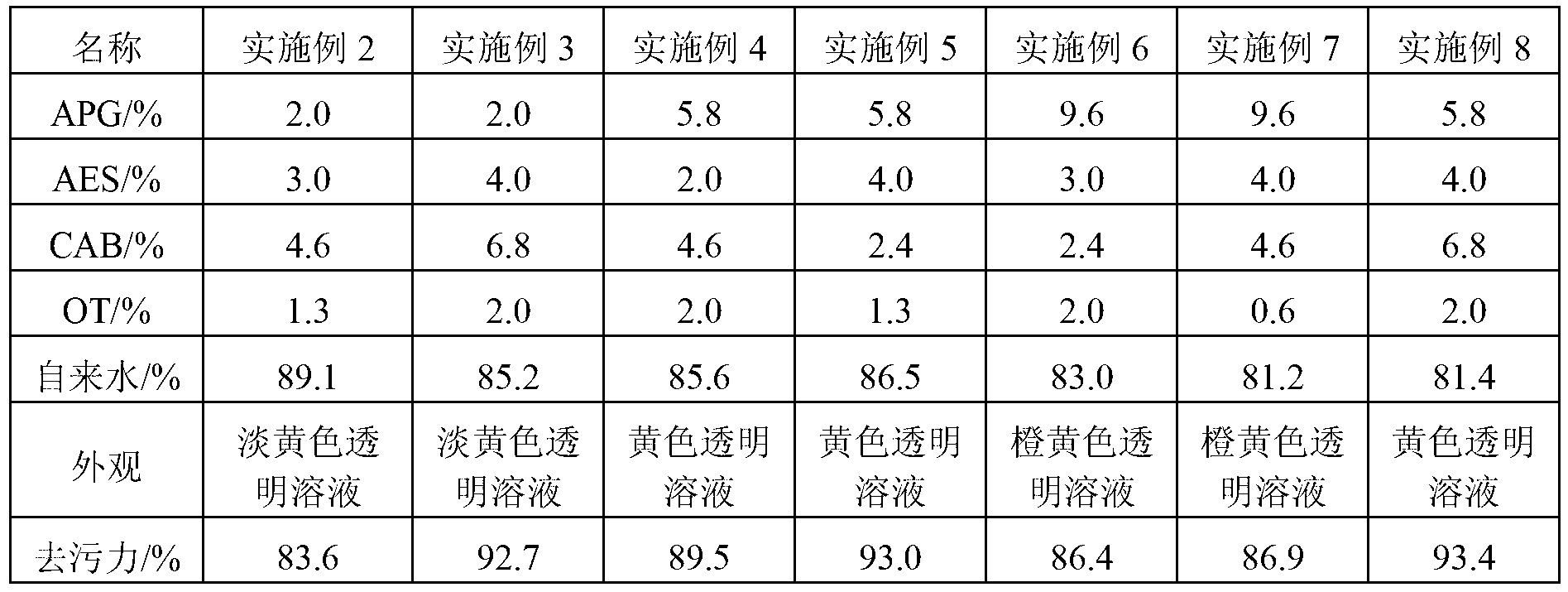

The invention discloses a water-based cleaning agent with weak acidity for removing thick oil dirt, and a preparation method thereof. The water-based cleaning agent is suitable for dinning places of kitchens, restaurants, snack streets and the like. The formula of the water-based cleaning agent is prepared from the following components by weight percent: 2.0-9.6% of alkyl glycoside, 2.0-4.0% of fatty alcohol polyoxyethylene ether sodium sulfate, 2.4-6.8% of coconut oleic acid amide propyl betaine, 0.6-2.0% of sulfonated succinate dioctyl ester sodium salt and the balance of running water. The preparation method of the cleaning agent comprises the following steps of: firstly, weighing the materials according to the ratio, and then putting into a same container to agitate for about 1 hour until a clear transparent solution is formed. The water-based cleaning agent is cheap and available in materials; biodegradation is facilitated; no organic solvent or acid-base is added; the solvent is running water; the formula and the preparation technology are simple; the pH value of the homemade cleaning agent is about 6.5; and the cleaning agent is weak acidic, and is a little different from the traditional mainstream cleaner which is alkaline. Thus, the water-based cleaning agent is an economic and applicable neutral water-based cleaning agent.

Owner:WUHAN UNIV OF TECH

PVC wood plastic composites (WPC) and preparation method thereof

The invention belongs to the technical field of processing for composites, and particularly relates to PVC WPC and a preparation method of PVC WPC. PVC WPC comprises the following components in partsby weight: 50 to 60 parts of PVC, 60 to 70 parts of a plant fiber powder, 5 to 6 parts of glass fibers, 5 to 10 parts of unsaturated polyester resin, 10 to 15 parts of polydimethylsiloxane, 3 to 6 parts of epoxy stearic acid octyl ester, 10 to 15 parts of chlorinated paraffin, 6 to 8 parts of N-methyl pyrrolidone, 2 to 3 parts of oleic acid amide, 1 to 4 parts of a coupling agent, 2 to 3 parts ofan initiator, 2 to 11 parts of an ultraviolet absorbent, and an appropriate amount of a mixed gel solution. The preparation method comprises the following steps: firstly, modifying the plant fiber powder, then mixing with other materials at a high speed, performing plastication and hot-press molding, then impregnating and drawing a coating film to obtain PVC WPC. PVC WPC disclosed by the inventionhas high strength, good stability, strong aging resistance and long service life.

Owner:广西南宁桂尔创环保科技有限公司

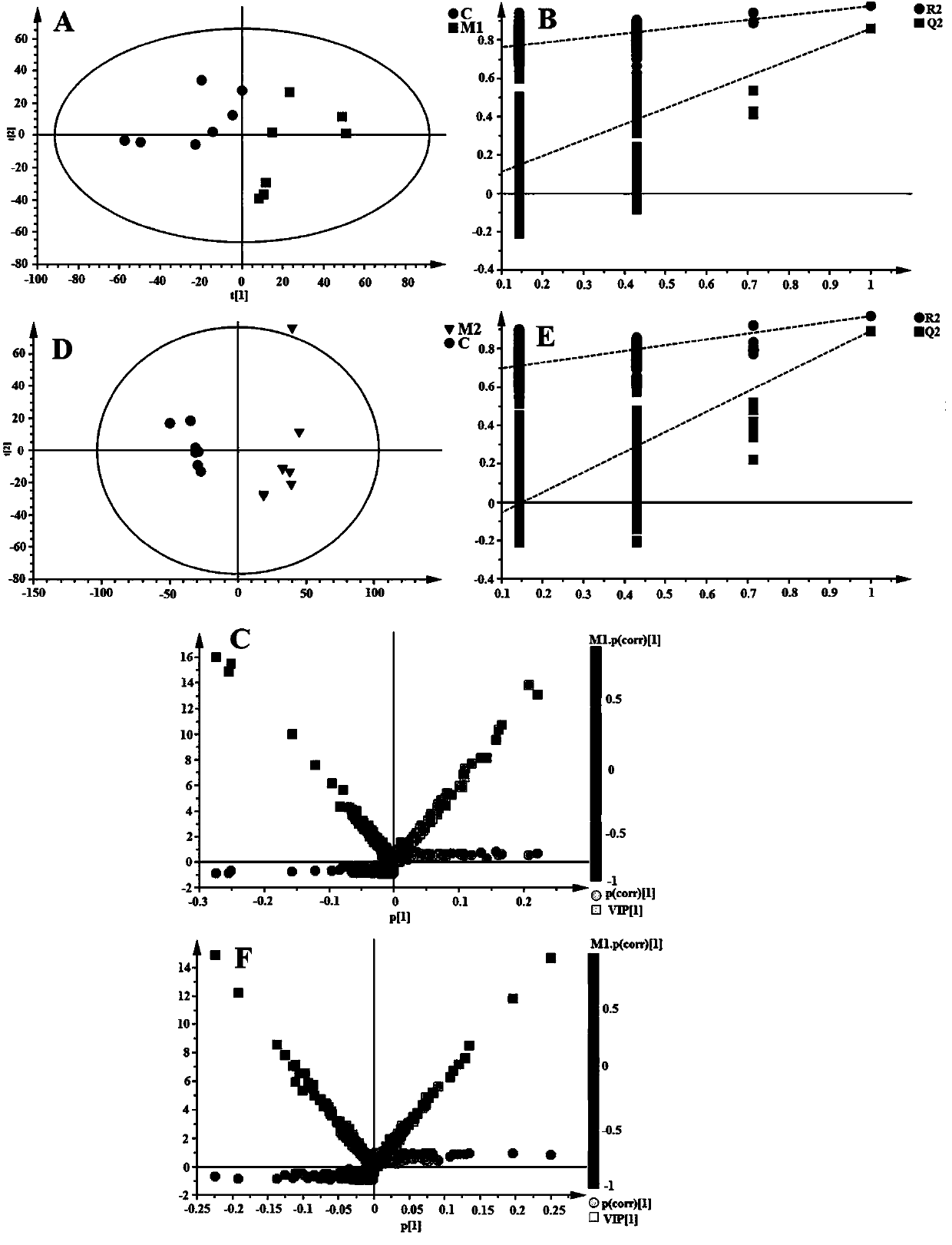

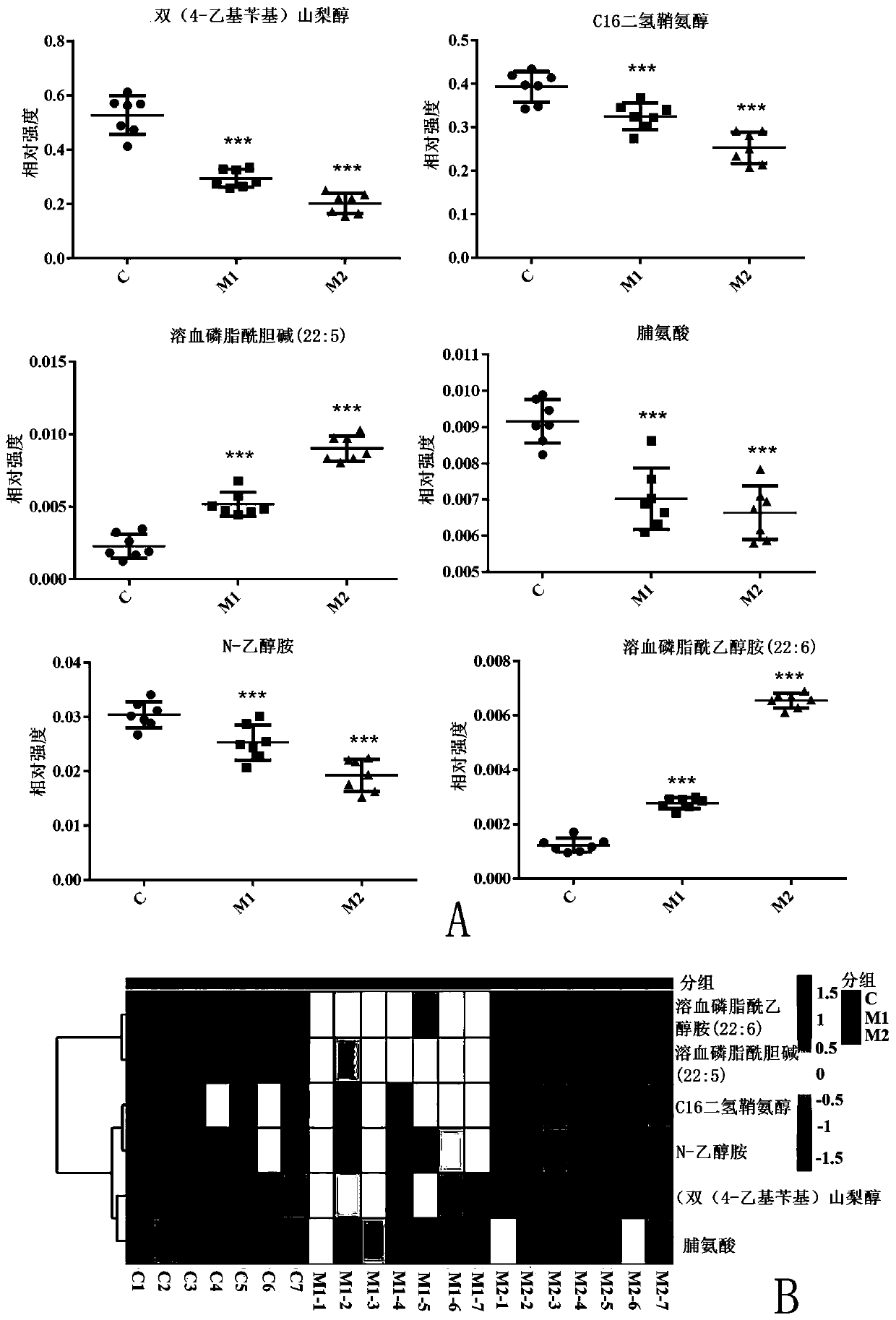

Nephrotic syndrome progression-related metabolic markers and application thereof

ActiveCN110286189AHigh sensitivityStrong specificityComponent separationDisease diagnosisCreatinine risePhosphoric acid

The present invention belongs to the technical field of screening and identification of nephrotic syndrome markers, and provides nephrotic syndrome progression-related metabolic markers and application thereof. Bis(4-ethylbenzyl)sorbitol, C16 d-sphinganine, lysophosphatidylethanolamine (LPE) (22:6), lysophosphatidylcholine (LPC) (22:5), N-ethanolamine and proline are taken as progressive markers; oleic acid amide, docosahexaenoic acid, 14S-hydroxy-docosahexaenoic acid, docosapentaenoic acid, uric acid, and LPC (20:5) and (18:1) are taken as early markers; and acylcarnitine (C18:0), linoleic acid carnitine, LPC (18:3), DL-tryptophan, indoleacrylic acid, p-cresol sulfate, 3-indol sulfate, cytosine, creatinine, sphingosine-1-phosphoric acid, L-aleuritic-dihydrosphingosine and ceramide (d18:0 / 14:0) are taken as late markers. The nephrotic syndrome progression-related metabolic markers provided by the present invention can be quantified, are fast, and have high sensitivity and strong specificity.

Owner:SHANXI UNIV

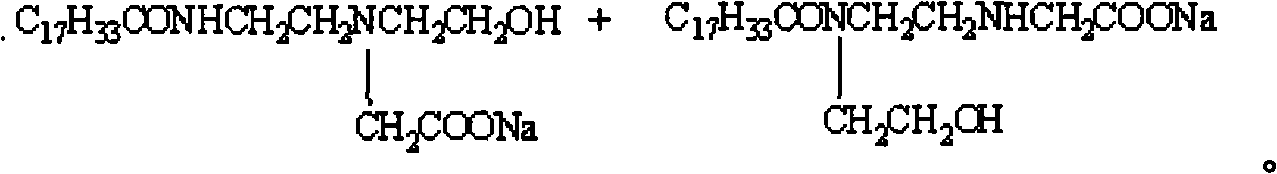

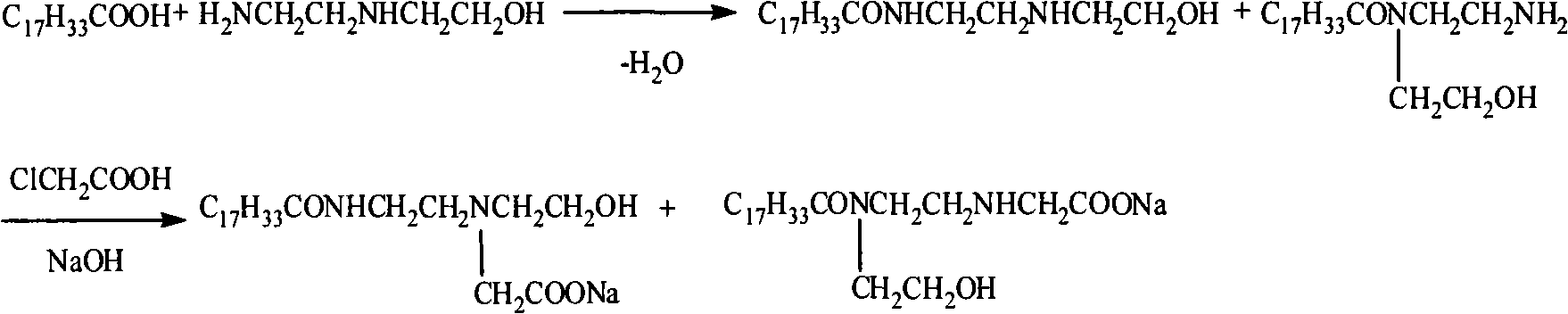

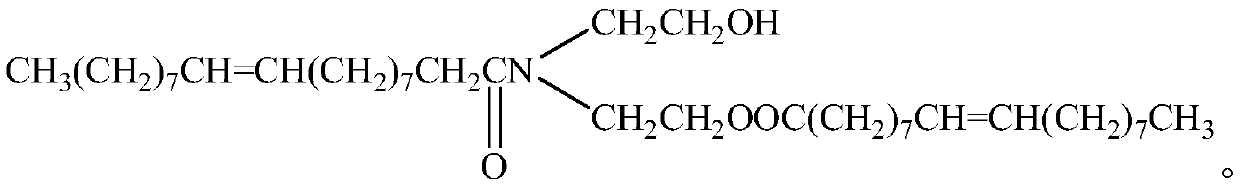

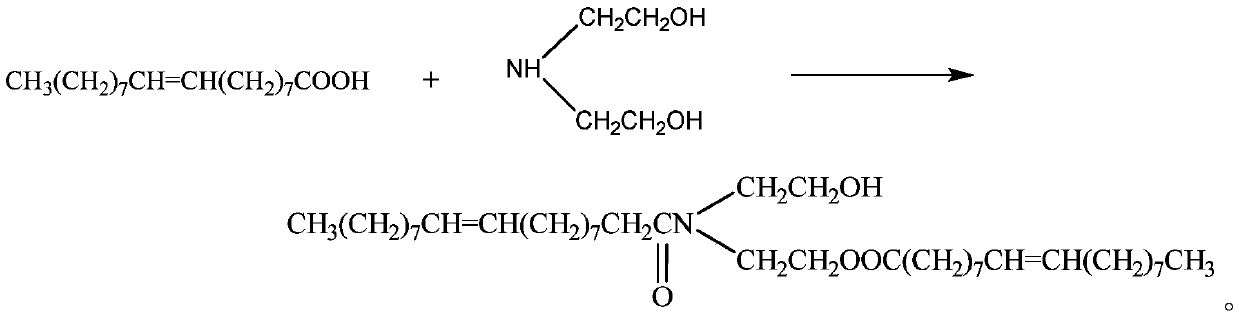

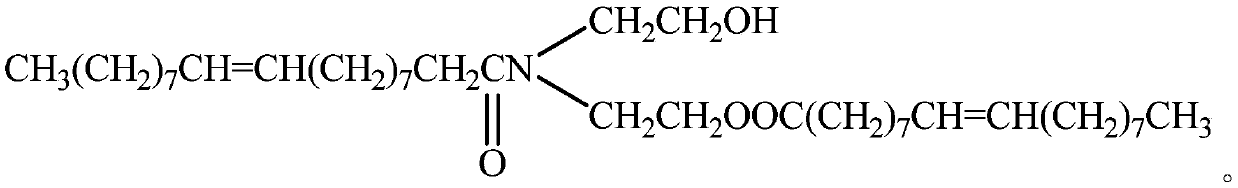

Oleic acid acidamide surfactant and synthetic method

InactiveCN101254437AGood suspensionPrevent redepositionTransportation and packagingMixingVegetable oilActive agent

An oleamide surfactant and a synthetic method thereof are provided. The inventive oleic amide surfactant has the structural formula as above. The synthetic method includes the following steps: synthesizing an oleic amide surfactant intermediate from oleic acid and hydroxyethylethylene diamine as raw materials, and then performing amphoteric reaction by 'chloroacetic acid process' to obtain the oleic amide surfactant. Based on the summery of research findings by the predecessors, the invention is novel in direct synthesis of amide surfactants by vacuum-amphoteric method without ring closing reactions. The inventive oleic amide surfactant has good effects of emulsifying, dispersing and suspending greasy dirt in mineral and vegetable oils, helps prevent re-deposition of greasy dirt, and has excellent effect of preventing rust formation on steel, cast iron and other metals. Additionally, the oleic amide surfactant can enhance the stability of anionic and non-ionic emulsions and the lubricating capability of emulsified oils. The oleic amide surfactant is widely used in products such as metal cleaners, drilling oil, machining oil and viscosity reducers in petroleum extraction.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Special aqueous gold ink for tipping paper, preparation method and application thereof

ActiveCN103666088AImprovement of printing fastnessFill in the application gapPaper coatingInksAlcoholSolvent based

The invention relates to the field of tobacco preparation, particularly to a special aqueous gold ink for tipping paper, a preparation method and an application thereof. The special aqueous gold ink comprises the following raw materials, by weight: 25-30 parts of bronze powder, 35-48 parts of alcohol-waterborne polyurethane, 15-25 parts of ethanol, 10-25 parts of water, and 0.5-1.5 parts of coconut oleic acid amide. The present invention further provides a preparation method and an application of the special aqueous gold ink. Compared with the special aqueous gold ink in the prior art, the special aqueous gold ink of the present invention has the following characteristics that: with the special formula and the treatment process, the problem that the aqueous gold ink contacts water to carry out an oxidation reaction so as to change into the aerugo is solved, the printing fastness of the obtained aqueous gold ink is improved, the printing effect of the aqueous gold ink can achieve or exceed the printing effect of the currently-used solvent type gold ink, and great practical application values are provided.

Owner:SHANGHAI DELIN WATER-BASED INK CO LTD

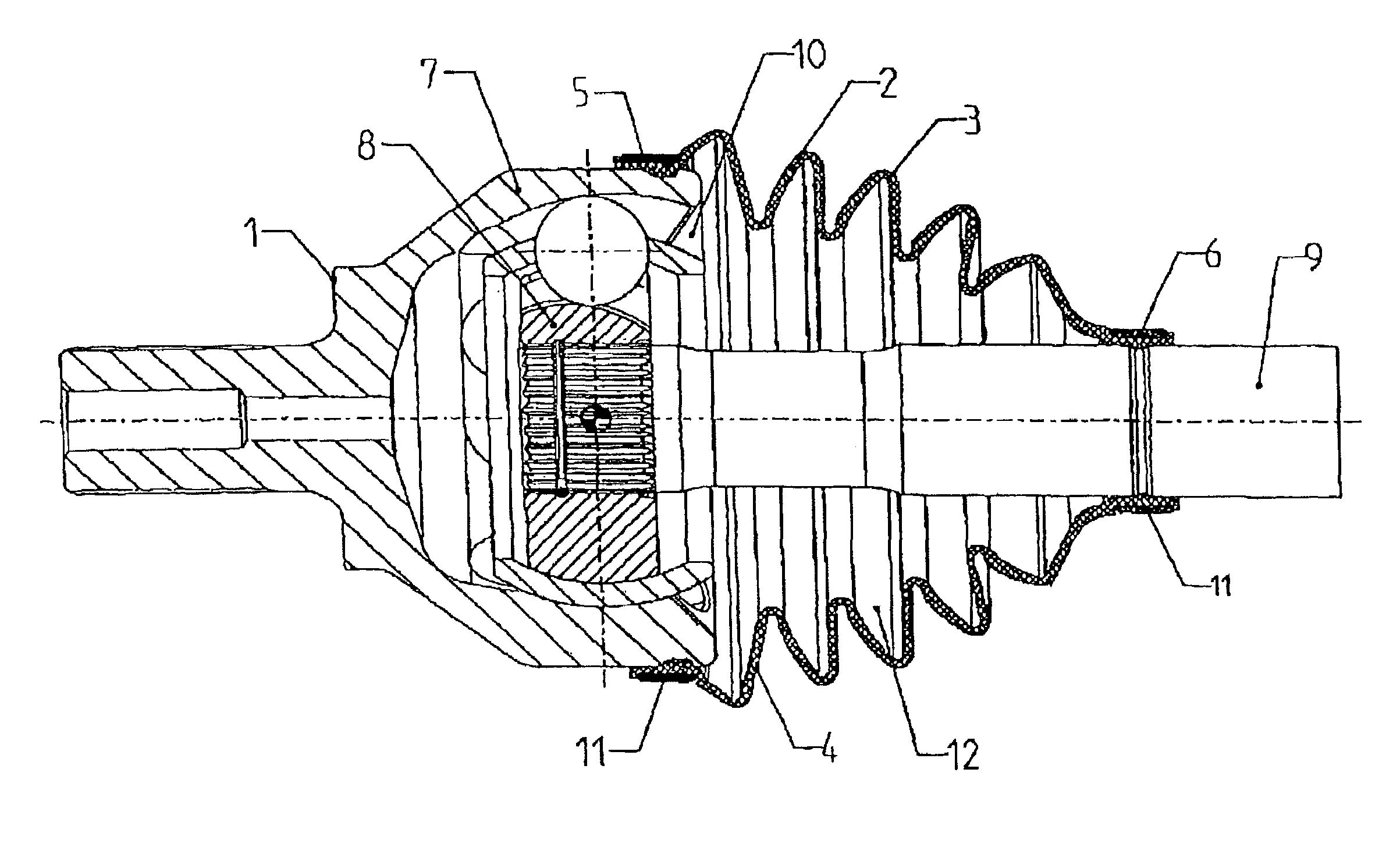

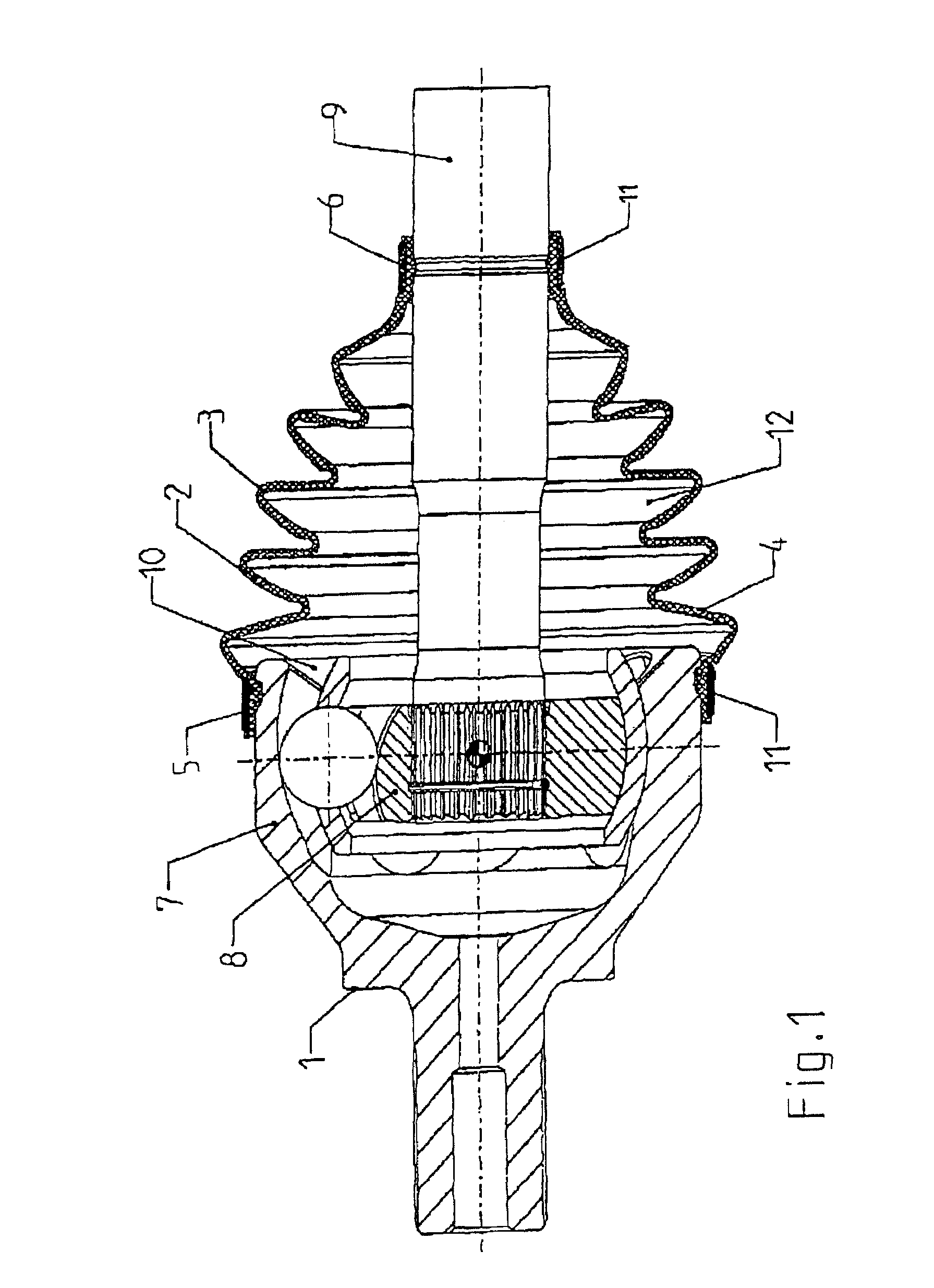

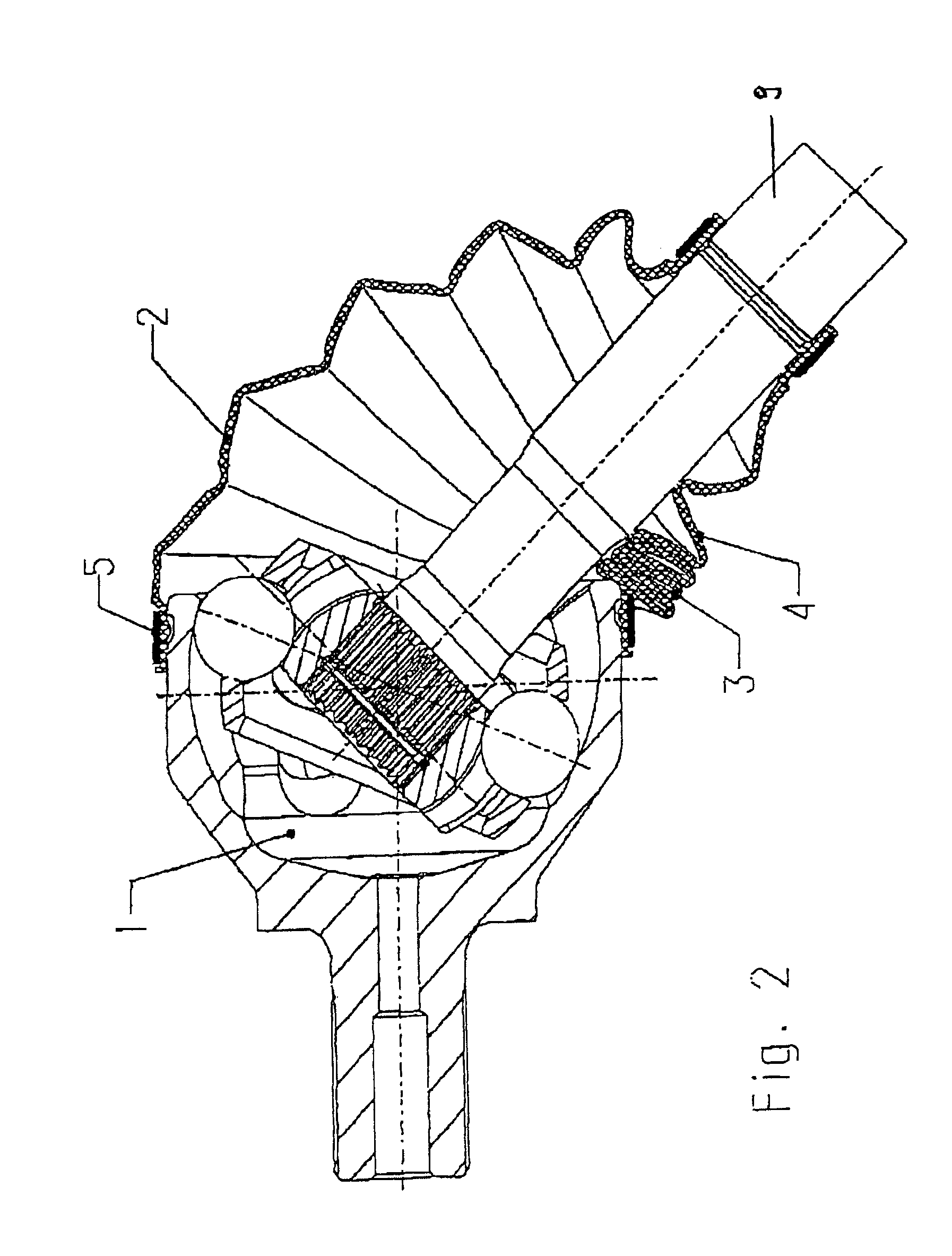

Convoluted boot and constant velocity joint lubricant

ActiveUS7384673B2Avoid vaporisation lossRapid and undisturbed diffusionClutchesEngine sealsWaxEngineering

A convoluted boot for constant velocity joints and a constant velocity joint lubricant for use in such a convoluted boot. An additive which is added to the constant velocity joint lubricant and / or to the convoluted boot material is provided. The additive comprises amide waxes and also may include hydrocarbon oils. Use is made, in particular, of monoamides and / or diamides of carboxylic acids with 8 to 50 carbon atoms to form, by diffusion, a lubricating film on the surface of a convoluted boot. Furthermore, oleic acid amide and / or ethylenediamine distearate result in a particularly early formation of a lubricating film on the outer boot surface and thus to a long-term prevention of noise.

Owner:GKN AUTOMOTIVE GMBH

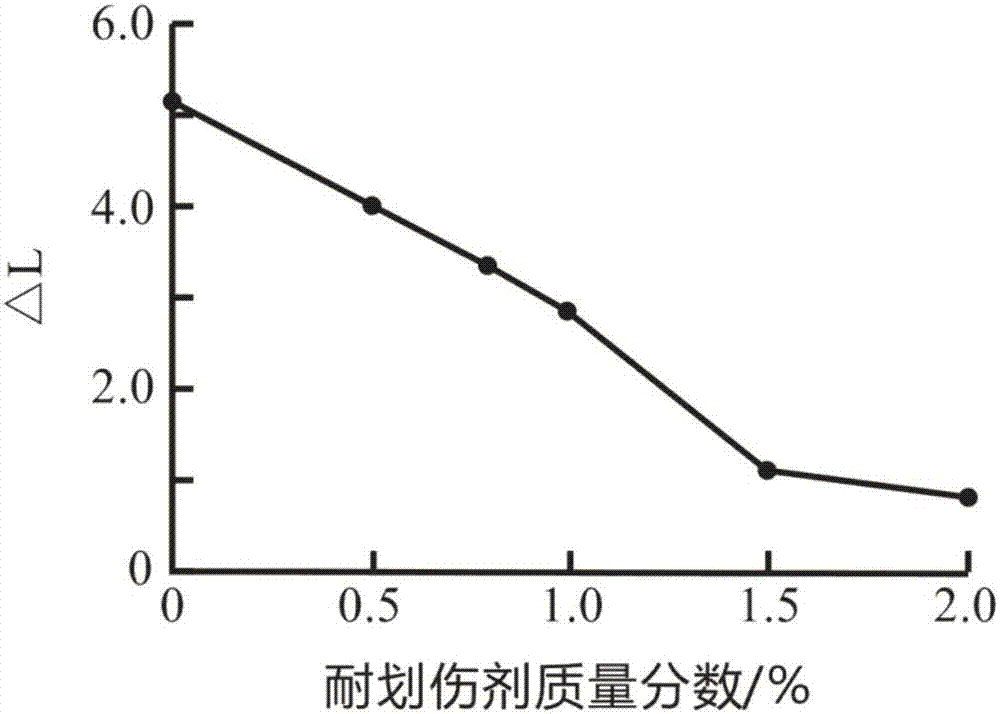

Preparation method of scratch-resistant agent for polypropylene

The present invention relates to the technical field of polymers, particularly to a preparation method of a scratch-resistant agent for polypropylene. According to the preparation method, an ethylene-ethyl acrylate copolymer, oleic acid amide, a hydroxyphenol-based glycidyl ether type epoxy resin, a light stabilizer (UV-770) and a hindered phenol antioxidant are mixed according to a certain weight part ratio, granulation is performed with a two screw extruder under conditions of heating and pressurization by using the characteristics of various components, and a certain post-treatment is performed to obtain the excellent performance scratch-resistant agent. According to the present invention, with the scratch-resistant agent, the good molding effect, the good toughness and the good strength of the polypropylene produced by the using the scratch-resistant agent of the present invention can be provided; by adding the light stabilizer, the service life of the polypropylene product can be prolonged; and the method has advantages of simple process, low cost, low material loss rate, less process step, and strong controllability.

Owner:江门宇度科技有限责任公司

Fluorescently-labeled scale inhibitor and preparation method thereof

InactiveCN106315873AImprove the lubrication effectImprove thermal stabilityScale removal and water softeningPolyethylene glycolStearic acid

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Method for preparing composite modified rubber asphalt mixture

The invention discloses a method for preparing a composite modified rubber asphalt mixture, which comprises the following steps: adding tire rubber powder into road petroleum asphalt to be made into rubber asphalt; adding SIS, coumarone indene resin and oleic acid amide into a screw extruder to carry out bracing and granulating so as to form modifying agent; and adding stone in mineral aggregate after heating into the modifying agent, stirring the mixture evenly and then adding the mixture into the rubber asphalt, and stirring the mixture evenly to obtain a finished product of the composite modified rubber asphalt mixture. The rubber asphalt mixture prepared by the method improves adhesiveness and workability of the product at the same time of ensuring high-temperature and low-temperatureperformances of the mixture.

Owner:广州大象超薄路面技术开发有限公司

Technique for producing N.N-ethylene bisoleamide

InactiveCN101260064ATake advantage ofImprove qualityOrganic compound preparationCarboxylic acid amides preparationEthylene diaminePotassium hydroxide

The invention relates to a production process for N, N-ethylene bis oleamide. Sulfated rapeseed oil is taken as the initial raw material, and is orderly esterified, distilled, amidated, deodorized, bleached and dehydrated, the esterification is to add methanol into the sulfated rapeseed oil with solid acid as the catalyst to react to generate rapeseed oil methyl ester, the rapeseed oil methyl ester is distilled and then is reacted with ethylene diamine with potassium hydroxide as the catalyst to react to generate N, N-ethylene bis oleamide. The production process realizes the full utilization of the renewable resource, reduces the environmental pollution, can produce the N, N-ethylene bis oleamide with higher quality and content, has low production cost, possesses higher economic value, can also reclaim and circularly utilize the castoff at the same time, has smaller pollution produced during the production and easily treated waste water, can achieve the related national standard, and meets the national policy of sustainable development.

Owner:江门市新会区嘉诺合昌油脂有限公司

Antibacterial and antifungal biodegradable plastic and preparation method thereof

The invention discloses an antibacterial antifungal and biodegradable plastic. The plastic is characterized by being prepared from the following materials in parts by weight: 20-30 parts of potato starch, 3-5 parts of cinnamon powder, 10-15 parts of potato stalks and leaves, 3-5 parts of medical stone powder, 0.5-1 part of tannic acid, 0.5-1 part of boric acid, 1-2 parts of glycerol monolaurate, 3-5 parts of stearic acid, 1-2 parts of oleic acid amide, 10-15 parts of acetyl tri-n-butyl citrate, 0.01-0.02 part of propyl p-hydroxybenzoate and 10-15 parts of polypropylene. The biodegradable plastic disclosed by the invention has good antibacterial, antifungal and biodegradable properties, good heat stability, certain water resistance, good use property and low cost, is prepared from easily-available materials according to a simple and feasible process, and is safe and nontoxic.

Owner:ANHUI YUTANG RAIN GEAR

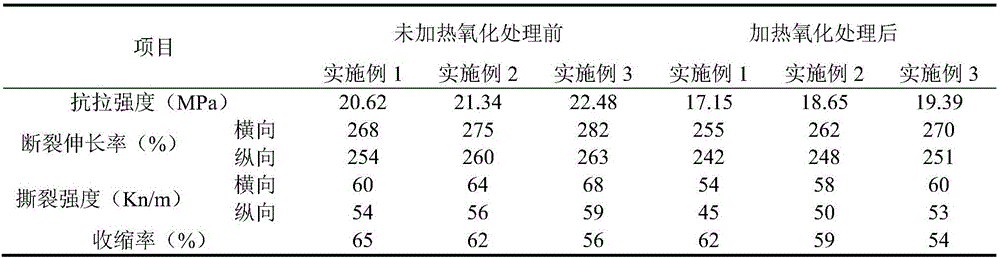

Anti-oxidation polyethylene heat shrinkable film with high tensile strength and preparing method thereof

InactiveCN106317596AGood heat sealing performanceHigh strengthLow-density polyethyleneLinear low-density polyethylene

The invention provides an anti-oxidation polyethylene heat shrinkable film with high tensile strength and preparing method thereof, by weight, comprising 60 - 80 parts of metallocene linear low density polyethylene, 30 - 40 parts of ethylene-octene copolymer, 25- 35 parts of liquorice root, 10 - 20 parts of nano-titanium dioxide, 6- 10 parts of epoxy vegetable oil, 4 - 6 parts of oleic acid amide, 3 - 5 parts of magnesium hydroxide, 2- 3 parts of antioxidant, and 1- 2 parts of heat stabilizer; the invention adopts the metallocene linear low density polyethylene and the ethylene-octene copolymer as the raw materials, which greatly enhances the heat sealability and strength of shrink film, and greatly improves the strength of the prepared film. The film is hard to break and has the outstanding puncture resistance, good age resistance and obvious shrinkage advantages, which can meet the processing performance and the physical and mechanical properties required by the high tensile strength of polyethylene film. And the film is in good shape.

Owner:太仓市鸿运包装材料有限公司

Fatting agent intermediate and preparation method thereof

ActiveCN111118236AImprove compound effectImprove the efficiency of esterificationLeather impregnationPolymer sciencePtru catalyst

The invention discloses a fatting agent intermediate and a preparation method thereof, the fatting agent intermediate is prepared by taking oleic acid and diethanol amine as reactants under the catalytic action of a catalyst p-toluenesulfonic acid; the fatting agent intermediate contains an oleamide structure, an oleate structure and hydroxyl, so that the compounding property of the fatting agentintermediate with other various fatting agents is improved, and the fatting agent intermediate can continuously participate in the reaction. Molecules contain acylamino and ester groups, and the molecules can be used as a raw material to be compounded into various leather fatting agents to improve the compounding effect and fatting performance. Reactive hydroxyl in oleamide ester molecules can also be used as a reaction oil material for preparing phosphorylated fatliquoring agents and sulfosuccinate fatliquoring agents; the leather is endowed with better softness and natural gloss. Other solvents or dispersing agents do not need to be added in the preparation process of the prepared fatting agent intermediate oleamide ester, the fatting agent intermediate oleamide ester is environmentallyfriendly, and the product purity reaches 90% or above through amidation and esterification reactions.

Owner:WENZHOU UNIVERSITY

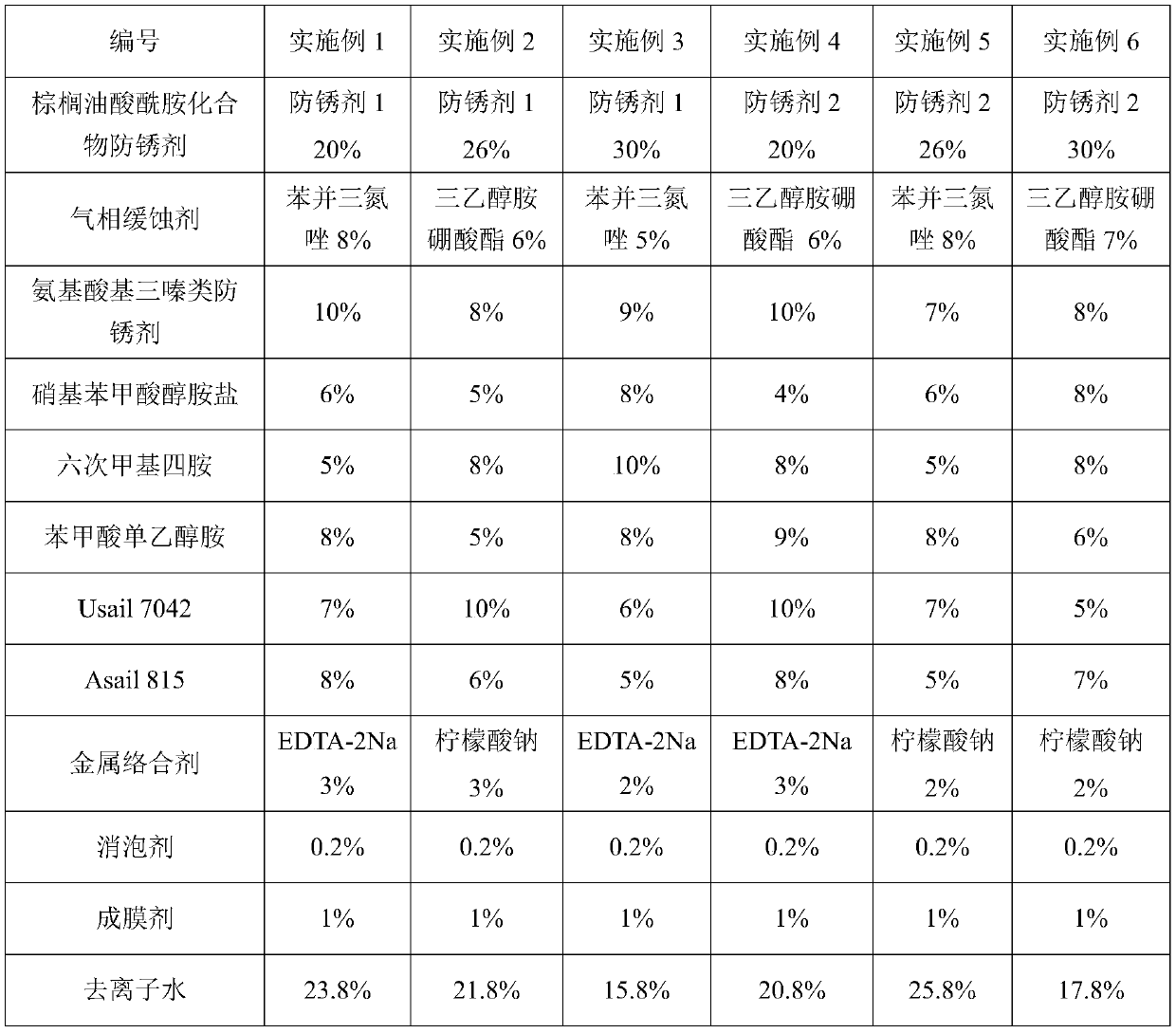

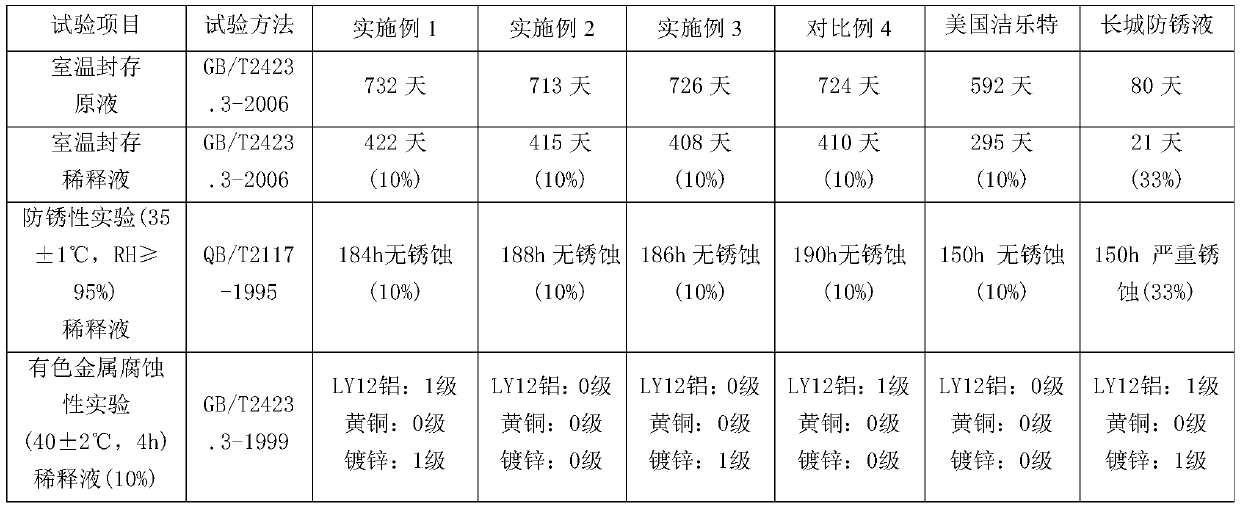

Palmitoleic amide type water-based gas-phase antirust concentrate and preparation and use methods thereof

The invention discloses palmitoleic amide type water-based gas-phase antirust concentrate. The palmitoleic amide type water-based gas-phase antirust concentrate is prepared from the following raw material of: an palmitoleic amide compound antirust agent, a gas-phase corrosion inhibitor, an amino acid-based triazine antirust agent, nitrobenzoate alcohol amine salt, hexamethylenetetramine, monoethanolamine benzoate, a special water-based antirust agent, a metal complexing agent, a defoaming agent and a film-forming agent. According to the palmitoleic amide type water-based gas-phase antirust concentrate, water is used as a carrier, and the green and environment-friendly palmitoleic amide compound antirust agent is a main antirust agent, the antirust concentrate is free of nitrite and other toxic and harmful components to the human body and the environment, and has excellent performance in contact rust prevention, gas phase rust prevention, lubrication, infiltration and chemical adsorption, the antirust concentrate can prevent rust for high precision metal products without damaging the surfaces of the high-precision metal products, and the antirust concentrate facilitates water cleaning, energy-saving and environment-friendly, and can meet the requirements of short-term rust prevention between processes and long-term rust prevention of packaging and sealing of common steel and various non-ferrous metal devices and products .

Owner:QINGDAO UNIV OF SCI & TECH +1

Methanol gasoline additive

InactiveCN107903951AImprove powerImprove combustion performanceLiquid carbonaceous fuelsCyclohexeneCerium

The invention provides a methanol gasoline additive. The methanol gasoline additive comprises, by weight, 20-33 parts of 2,6-di-tert-butyl-p-cresol, 30-35 parts of fatty ether, 5-6 parts of n-octanol,10-11 parts of isopropanol, 12-17 parts of methyl isobutyrate, 6-7 parts of isooctane, 5-6 parts of polyisobutylene amine, 7-8 parts of methyl ethyl ketone, 4-8 parts of di-n-butyl phosphite, 6-7 parts of hexamethylenetetramine, 5-6 parts of cyclohexyl glycidyl ether, 4-8 parts of cyclohexene, 4-8 parts of isopropyl nitrate, 5-6 parts of 4-pentyldicyclohexylanone, 7-8 parts of fatty acid ethyl ester, 4-8 parts of 2-ethylhexanol, 2-6 parts of oleic acid, 5-6 parts of beeswax, 5-6 parts of oleamide, 4-8 parts of p-xylene, 4-8 parts of tetrahydrofuran, 5-7 parts of cerium naphthenate and 4-9 parts of acetylacetone. The methanol gasoline additive can reduce the pollution to the environment and reduce the smoke generation.

Owner:魏崇振

Safe and environment-friendly wooden furniture coating and preparation method thereof

InactiveCN107987694AWill not affect healthMeet the requirements of green environmental protectionEpoxy resin coatingsAlginic acid coatingsPolyesterPropanediol

The invention discloses safe and environment-friendly wooden furniture coating which comprises the following raw materials in parts by weight: 50-55 parts of coconut oil alcohol acid resin, 17-21 parts of methyl methacrylate, 30-35 parts of polyester modified epoxy resin, 28-32 parts of polyvinyl acetate emulsion, 4-8 parts of zinc phosphate, 2-5 parts of isothiazolinone, 1-2 parts of butyl hydroxy anisd, 3-6 parts of propanediol butyl ether, 1-2 parts of a polycarboxylic acid ammonium salt dispersing agent, 7-11 parts of sodium alginate, 2-5 parts of polydimethylsiloxane, 25-30 parts of modified pyrophillite, 21-25 parts of a talcum powder and 2-3 parts of oleic acid amide. The invention also discloses a preparation method of the safe and environment-friendly wooden furniture coating. Theprepared wooden furniture coating has no toxicity or harm, is environmentally friendly and has a wide market prospect.

Owner:GUANGDONG DEXIN TECH INCUBATOR CO LTD

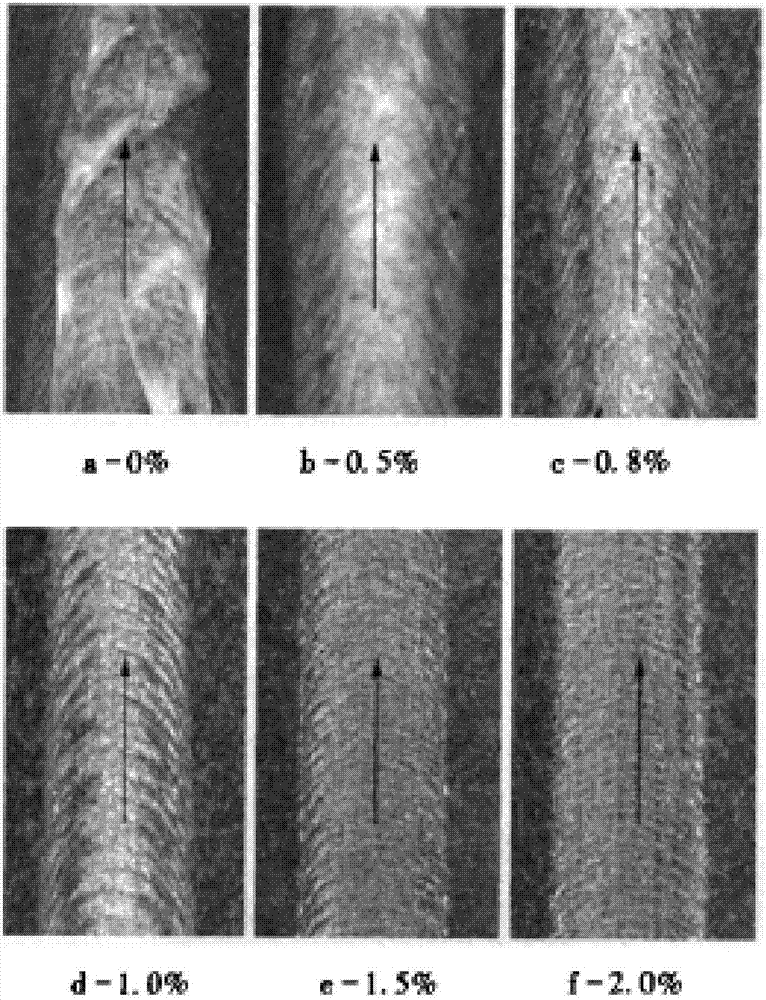

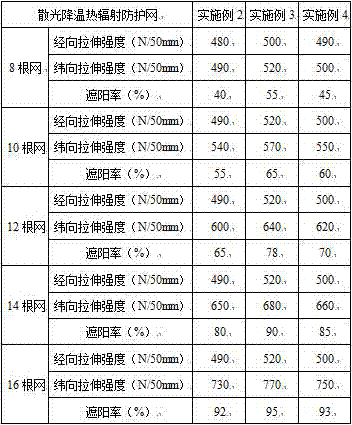

A preparation method of astigmatism cooling thermal radiation protection net

ActiveCN105332091BLower your temperatureReduce the temperatureConjugated synthetic polymer artificial filamentsArtifical filament manufactureFiberMasterbatch

The invention discloses a preparation method of an astigmatism cooling thermal radiation protection net. The preparation method includes the step of preparing a masterbatch, and also includes a fiber preparation step and a drawing molding step. The masterbatch of the protective net includes components: rutile titanium dioxide, LDPE, LLDPE, oleic acid amide, PE wax, far-infrared ceramic powder, and silane coupling agent. The astigmatism cooling thermal radiation protective net prepared by the invention has its own temperature lower by 5-32 DEG C. than that of the commonly used black sunshade net under the condition of full sunshine.

Owner:SHANDONG WEIFANG ACADEMY OF AGRICULTURAL SCIENCES

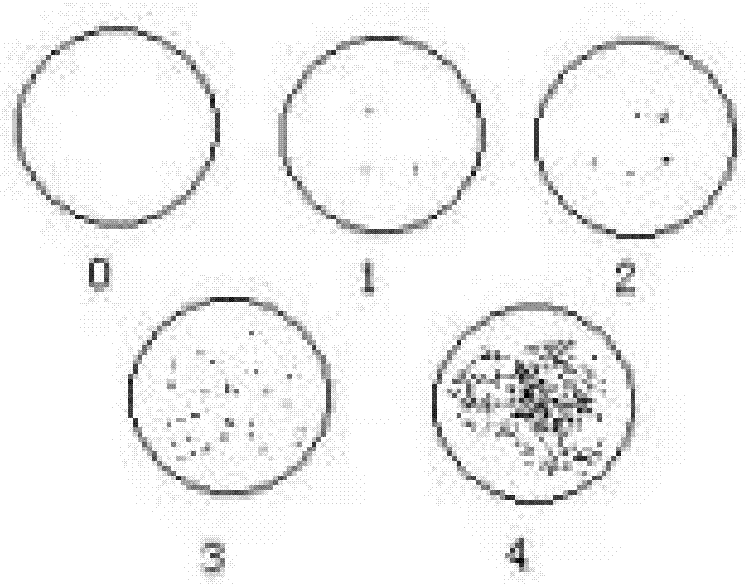

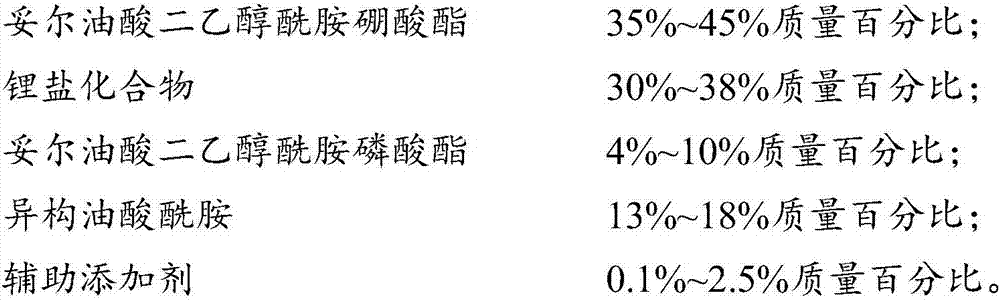

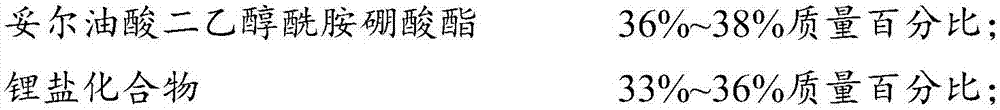

Multifunctional corrosion inhibitor and preparing method thereof

The invention relates to the field of metal machining liquid, in particular to a multifunctional corrosion inhibitor and a preparing method thereof. The multifunctional corrosion inhibitor particularly comprises tall oil acid diethanolamide phosphate, a lithium salt compound, tall oil acid diethanolamide borate, isomeric oleic acid amide and an auxiliary additive; meanwhile, a metal for preparing the above multifunctional corrosion inhibitor is provided. The multifunctional corrosion inhibitor has an excellent corrosion inhibition effect on iron, aluminum, copper and alloys of the iron, the aluminum and the copper; and meanwhile, the good extreme pressure lubricity is achieved, the comprehensive performance is excellent, and the problem that corrosion inhibitor performance is single is solved. The multifunctional corrosion inhibitor can be directly diluted to be used for industrial cutting / grinding liquid and can also serve as a cutting fluid additive, the preparing method is easy to operate and low in cost, and the wide business prospect is achieved.

Owner:德旭新材料(广州)股份有限公司

Degradable plastic

InactiveCN107759988AHigh tensile strengthHigh elongation at breakLow-density polyethyleneLinear low-density polyethylene

The invention discloses a degradable plastic. The degradable plastic comprising the following raw materials: polylactic acid resin, modified poly-beta-hydroxybutyric acid (PHB), diisodecyl phthalate (DINP), unsaturated polyester resin, soybean protein powder, oxidized mung bean starch, alkaline white clay, calcium carbonate, ramie fiber, linear low density polyethylene grafted maleic anhydride, gamma-glycidyloxypropyltrimethoxysilane, a methyl methacrylate-butadiene-styrene copolymer, potassium aluminum sulfate, citrate, an ethylene-vinyl acetate copolymer, ethylene bis(oleamide), diphenylmethane diisocyanate, a mildew-proof antibacterial agent, a degradation agent, an antioxidant and a stabilizer. The degradable plastic of the invention has good tensile strength, good elongation at break,good impact resistance, low water absorption and good light transmission performance, can be completely degraded into carbon dioxide and water in 133 to 136 days, and has no environmental hazards.

Owner:GUANGXI NANNING ZHICUI SCI TECH CONSULTATION CO LTD

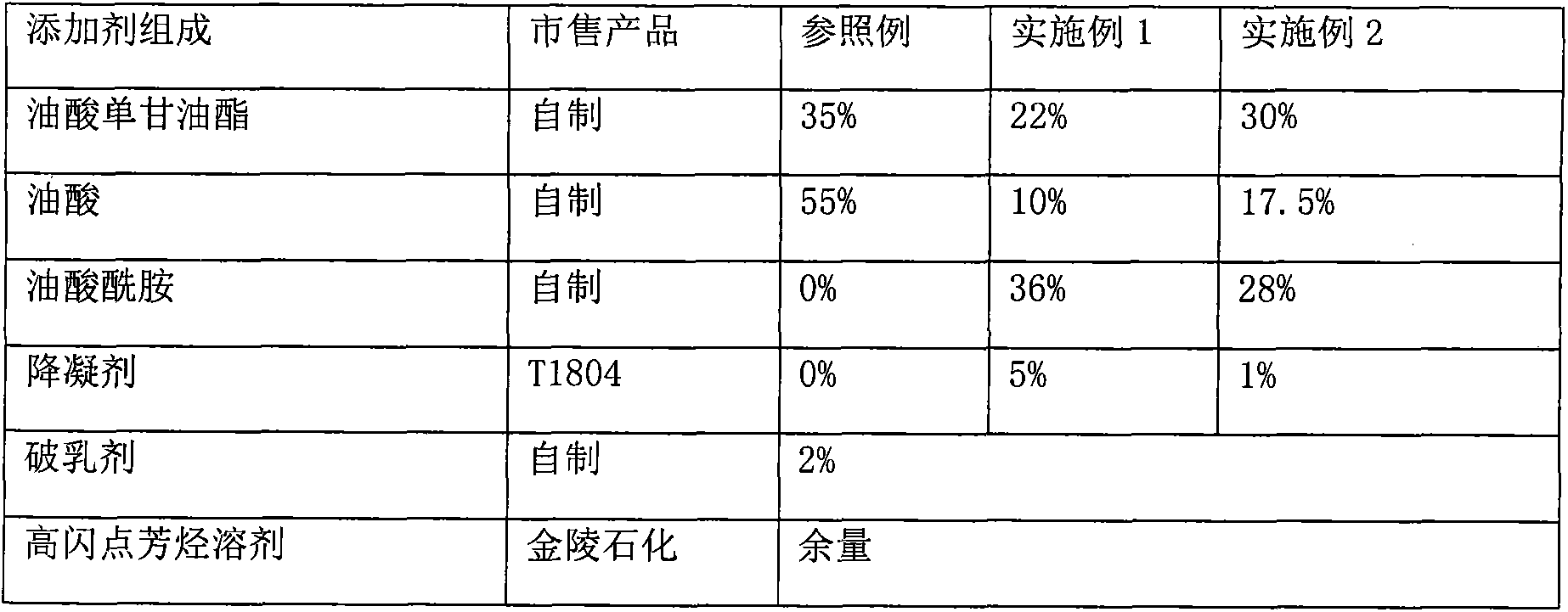

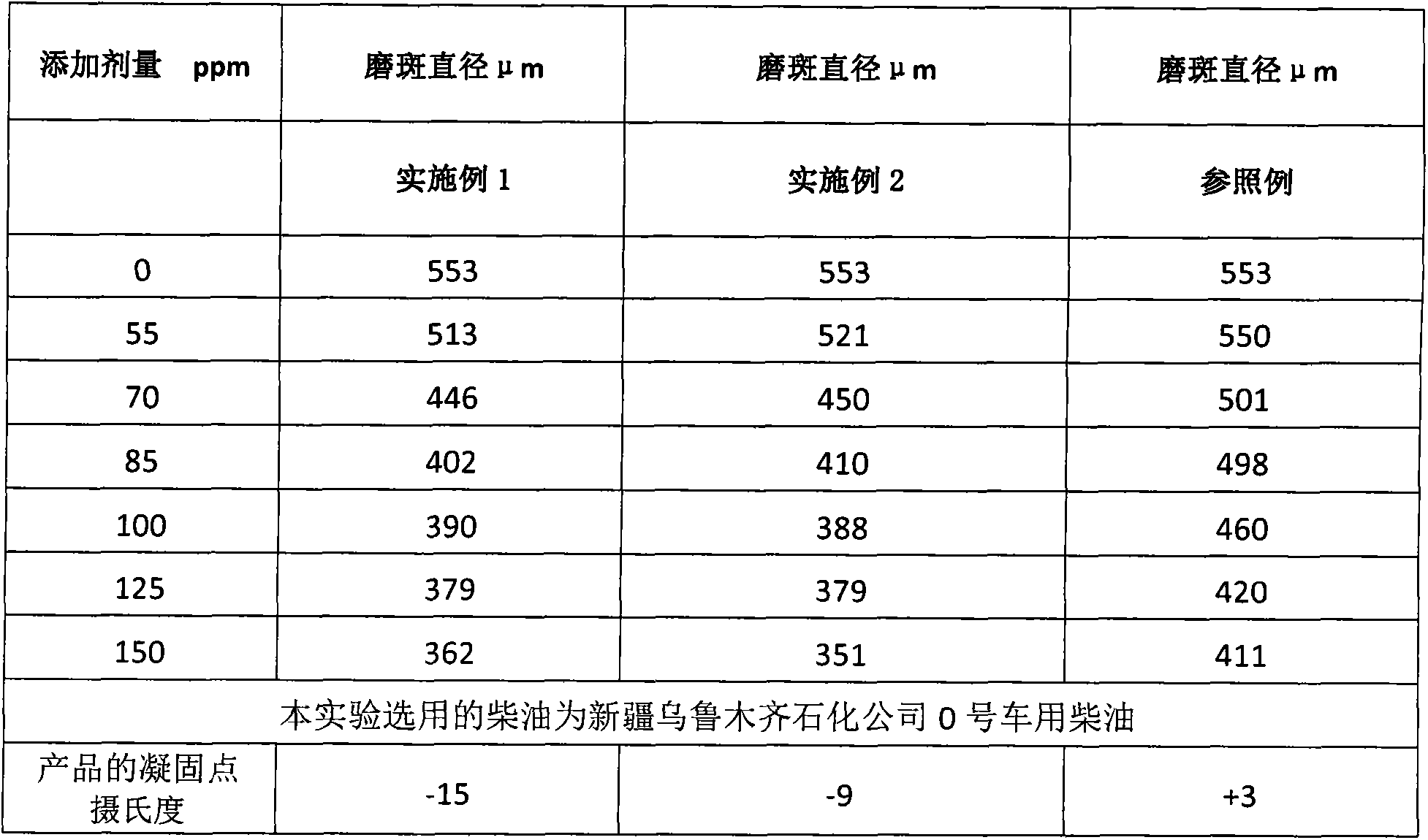

Low pour point diesel fuel lubricity improver composition

The invention discloses a low pour point diesel fuel lubricity improver composition prepared by compounding a pour point reducer with fatty acid, fatty acid ester and oleic acid amide and the like, and the solidifying point of the combination can be obviously reduced.

Owner:ZHONGHAI YABAO BEIJING TECH DEV

Diesel fuel additive

InactiveCN110358590AImprove combustion performanceBoost octaneLiquid carbonaceous fuelsFuel additivesCyclohexeneDiethylenetriamine

The invention provides a diesel fuel additive. The diesel fuel additive is composed of raw materials with the following components by weight: cerium naphthenate, n-butyl acetate, isopropanol, n-caprylic alcohol, isooctane, polyisobutylene amine, methylethyl ketone, ethanol, 3-lauryl thiopropionate, polyethylene glycol ether, ferric sulfate, di-n-butyl phosphite,cyclohexene, diisopropyl ether,npentyldicyclohexylanone, fatty acid polyoxyethylene ester, 2-ethylhexanol, diethylenetriamine, oleic acid amide,p-xylene, cyclohexylglycidyl ether, tetrahydrofuran, acetylacetone, glycol dimethyl ether, castor oil, ethylene glycol butyl ether, methylhydrazine, nitric acid isopropyl ester, phthalimide and polyacrylamide.

Owner:山东纽曼特新材料有限责任公司

A kind of high temperature resistant, low migration organic smooth opening agent and master batch prepared from the opening agent

ActiveCN107501578BImprove smoothnessImprove high temperature resistancePentaerythritolPolymethyl methacrylate

The invention discloses a heat-resistant and low-migrating organic smooth opening agent which is obtained by mixing of, by weight, 25-50wt% of component A, 25-50wt% of component B and 25-50wt% of component C. The component B refers to pentaerythritol fatty acid ester, the component B refers to one or two selected from ethylene bis oleamide and stearyl erucic acid amide, and the component C refers to one or two selected from behenamide and polymethyl methacrylate; ethylene bis oleamide and stearyl erucic acid amide are in the mass ratio of 2:1-1:2 when used simultaneously; behenamide and polymethyl methacrylate are in the mass ratio of 2:1-1:2 when used simultaneously. A carrier-free opening-agent master batch obtained with the above formula has the advantages of smoothness, opening, lubricating, demolding and no folding out of the surface in plastics, and the opening agent is resistant to high temperature to 350DEG C, low in migration and uniform in dispersion and is used for preparing the heat-resistant and smooth plastic master batch.

Owner:禾工(广州)材料科技股份有限公司

Sulfur-phosphor-free oil-soluble organic molybdenum additive

The invention relates to a sulfur-phosphor-free oil-soluble organic molybdenum additive. A technical scheme adopted in the invention is that a preparation method of the additive comprises the following steps: 1, placing castor oil and diethanolamine in a container, reacting for 4-5h under conditions that the temperature is 90-100DEG C and the pressure is a negative pressure, adding oleic acid, and reacting for 2-4h to obtain mixed castor oil amide and oleic acid amide; and 2, mixing the prepared mixed castor oil amide and oleic acid amide with ammonium molybdate, uniformly stirring, adding hydroxyethyl ethylenediamine, reducing the pressure to 13.33-20KPa at 70-80DEG C, reacting for 4-5h, adding polyethylene glycol to wash, separating out a transition layer, cooling the transition layer, and filtering to obtain the brown-red sulfur-phosphor-free oil-soluble organic molybdenum additive. In the additive, the molybdenum content is 7.5%, and the nitrogen content is 3.5%. The production method of the invention has the advantages of simplicity and low cost; and the product (the additive) has the advantages of stable molybdenum structure, good oil solubility, high yield and environmental protection.

Owner:王严绪

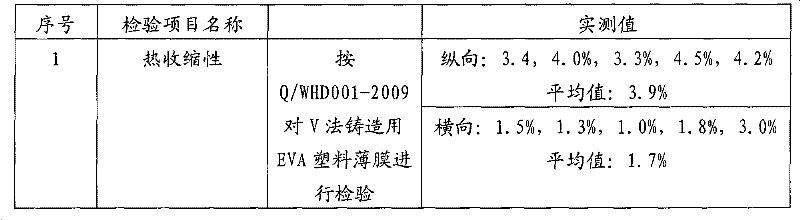

Three-layer ethylene vinyl acetate copolymer negative pressure casting film and preparation method thereof

ActiveCN101722274BMeet extended performance requirementsFoundry moulding apparatusSynthetic resin layered productsLow-density polyethyleneEthylene

The invention relates to an ethylene-vinyl acetate copolymer negative pressure casting film and a preparation method thereof. The content of the ethylene-vinyl acetate copolymer is 79.8-89.8%, the molecular weight of low-density polyethylene is 10-20%, and the oleic acid amide is 0.1-0.2%. The preparation method: The above three materials are respectively added into three mixing bodies according to the upper, middle and lower layer materials, and half of the low-density polyethylene, half of the oleic acid amide and 5-10 % of ethylene-vinyl acetate copolymer, and the remaining ethylene-vinyl acetate copolymer is added to the mixer body of the middle layer material, fully mixed, and then sucked into the discharge port of the extruder through the suction machine, three extruders The extruder moves in the same direction, and gathers at the upper end of the die in three different flow channels to form a three-layer affinity integrated liquefied body, which is blown by air, shaped, cooled, and formed to produce negative pressure ethylene vinyl acetate copolymer. cast film. The film prepared by the invention satisfies the extensibility requirements of the film for V-method casting, and can ensure that the film and the model are not sticky.

Owner:WUHAN HENGDE TECH

A preparation method of modified polyester and its application in polyester film for dry film resist

ActiveCN113861638BImprove antistatic performanceHigh light transmittanceSynthetic resin layered productsPolymer scienceHexamethylphosphoric Triamide

The invention provides a preparation method of modified polyester and its application in polyester film for dry film resist, including the preparation of polyester modified nano silicon dioxide, the preparation and modification of polyester prepolymer Preparation of PET resin chips. Silica powder obtained by reacting titanate coupling agent ZJ-38S in silica sol reacts with phenoxyethanol, hydroxyl-terminated hyperbranched polyester, and p-toluenesulfonic acid to obtain polyester-modified nano-silica; dibutyl Oleic acid amide, hexamethylphosphoric triamide, trimethylolpropane, ethylene glycol, isophorone diisocyanate, butanone oxime, ethylene glycol monoethyl ether solvent and catalyst zinc octanoate react to obtain polyester prepolymer ; Terephthalic acid, ethylene glycol, polyester-modified nano-silica and polyester prepolymers undergo conventional esterification and dehydration reactions to obtain modified polyester chips. The mechanical and optical properties of the modified resin prepared by the invention can meet the application requirements of the polyester film used as a dry film resist.

Owner:WEIFANG FUWEI PLASTIC

A kind of thermoplastic polyvinyl alcohol resin and preparation method thereof

ActiveCN105440522BLower melting temperatureSuccessful realization of thermoplastic processing fieldPolymer sciencePolyvinyl alcohol

A normal temperature water-soluble thermoplastic polyvinyl alcohol resin, which is composed of effective doses of polyvinyl alcohol, plasticizer, soft water and processing aids, the degree of polymerization of the polyvinyl alcohol is 1000-2400, 72 (mol)% ≤ degree of alcoholysis <90 (mol)%, the plasticizer is at least one of glycerol, polyethylene glycol, and triethylene glycol diisocaprylate, and the processing aid is talcum powder, At least one of silicon oxide, oleic acid amide, and saturated aliphatic dicarboxylic acid ester. Thermoplastic polyvinyl alcohol resin has a melting temperature of 120-180°C, dissolves in water at 15-40°C, and has a decomposition temperature above 260°C. It is colorless, transparent, and non-yellowing, with excellent quality.

Owner:CHINA PETROCHEMICAL CORP +1

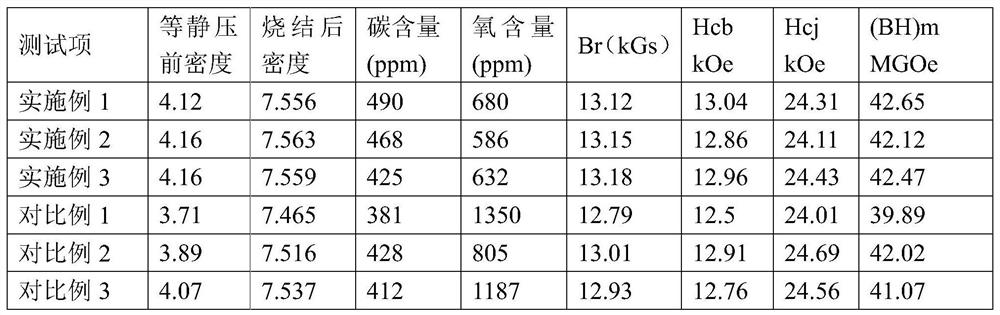

A method and additive for reducing oxygen content of sintered NdFeB material

ActiveCN110444359BHigh carbon contentHas a lubricating effectMagnetic materialsPermanent magnet manufactureCyclohexanoneMetallurgy

The invention relates to the technical field of permanent magnet materials, and discloses a method and additives for reducing the oxygen content of sintered NdFeB materials. The method of the present invention adopts the pre-grinding and post-grinding two-step method to carry out anti-oxidation protection to the magnetic powder, and the pre-milling and post-grinding additives adopt different formulations (Type I and Type II), wherein the Type I additives include BTA, 200# solvent oil , isopropanol and cyclohexanone; Type II additives include stearate and 120# solvent oil, oleic acid amide, terpineol, petroleum ether and stadis (R) 450. In the present invention, the additive is added to the NdFeB powder in the form of continuous spraying, and the particle surface of the NdFeB powder is evenly coated, which improves the anti-oxidation effect of the NdFeB powder. The chain segment of the type I additive is slightly longer, It is convenient to cover the new section produced by jet milling; the chain segment of type II additive is slightly short and contains lubricant and polar group components, which can weaken the static magnetic effect between powder particles and reduce the agglomeration between powder particles, which is beneficial to improve degree of orientation.

Owner:ZHEJIANG DONGYANG DMEGC RARE EARTH MAGNET CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com