Fatting agent intermediate and preparation method thereof

An intermediate and fatliquoring agent technology, which is applied in the field of fatliquoring agent intermediates and its preparation, can solve problems such as limiting the application range of long-chain alkanolamides, achieve good softness and natural luster, reduce reaction time, and improve The effect of the composite effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

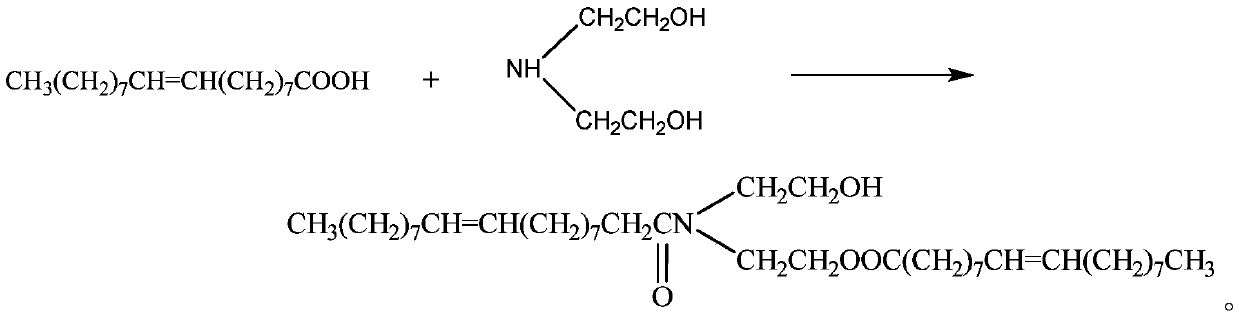

Method used

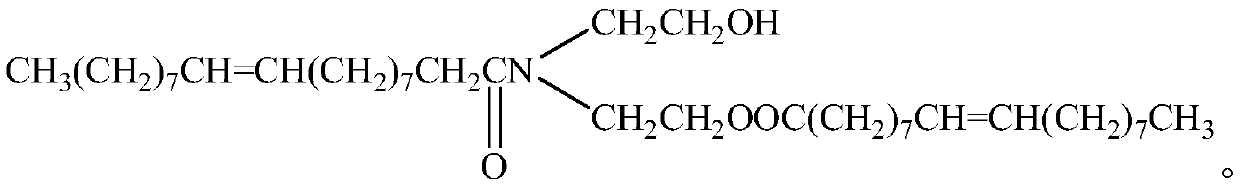

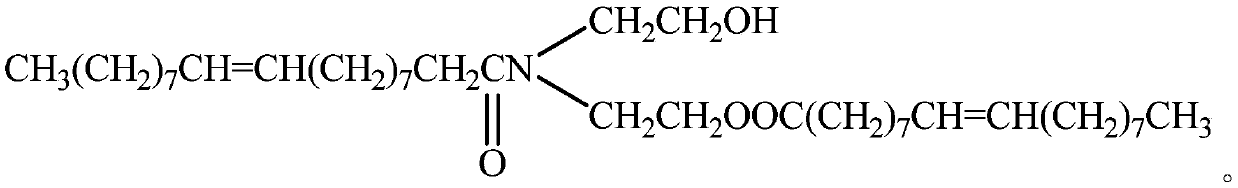

Image

Examples

Embodiment 1

[0025] A preparation method for a fatliquoring agent intermediate, comprising the following steps:

[0026] Step 1: Add 1 mol of diethanolamine and 1 mol of oleic acid into the reaction vessel, stir and mix, and mix well to form the first mixed liquid; then raise the temperature of the first mixed liquid to 130°C and react until the first mixed liquid Medium amine value≤10.0mgKOH / g;

[0027] Step 2: At a temperature of 80°C, add 1 mol of oleic acid and catalyst p-toluenesulfonic acid into the reaction vessel of step 1, stir and mix, and form a second mixed solution after mixing evenly; then raise the temperature of the second mixed solution to After the temperature reaches 130°C, the reaction is carried out until the amine value in the second mixed liquid is ≤5.0mgKOH / g, and the acid value is ≤10.0mgKOH / g; after the reaction is completed, the material is discharged at a temperature of 55°C to obtain fatliquor agent intermediates. (wherein the quality of catalyst in step two ...

Embodiment 2

[0033] A preparation method for a fatliquoring agent intermediate, comprising the following steps:

[0034] Step 1: Add 1 mol of diethanolamine and 0.8 mol of oleic acid into the reaction vessel, stir and mix, and mix well to form the first mixed liquid; then raise the temperature of the first mixed liquid to 120°C and react until the first mixed liquid Amine value in liquid≤10.0mgKOH / g;

[0035] Step 2: At a temperature of 80°C, add 1.2 mol of oleic acid and catalyst p-toluenesulfonic acid into the reaction vessel of step 1, stir and mix, and form the second mixed solution after mixing evenly; then the temperature of the second mixed solution After rising to 120°C, the reaction is carried out until the amine value in the second mixed liquid is ≤5.0mgKOH / g, and the acid value is ≤10.0mgKOH / g; after the reaction, the material is discharged at a temperature of 55°C to obtain Grease intermediates. (wherein the quality of the catalyst in the step two is 0.4% of the quality of th...

Embodiment 3

[0037] A preparation method for a fatliquoring agent intermediate, comprising the following steps:

[0038] Step 1: Add 1 mol of diethanolamine and 0.95 mol of oleic acid into the reaction vessel, stir and mix, and mix uniformly to form the first mixed liquid; then raise the temperature of the first mixed liquid to 140°C and react until the first mixed liquid Amine value in liquid≤10.0mgKOH / g;

[0039] Step 2: At a temperature of 80°C, add 1.05 mol of oleic acid and catalyst p-toluenesulfonic acid into the reaction vessel of Step 1, stir and mix, and form the second mixed solution after mixing evenly; then the temperature of the second mixed solution After rising to 140°C, the reaction is carried out until the amine value in the second mixed liquid is ≤5.0mgKOH / g, and the acid value is ≤10.0mgKOH / g; after the reaction, the material is discharged at a temperature of 55°C to obtain Grease intermediates. (wherein the quality of catalyst in step two is 0.25% of the quality of ol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com