Patents

Literature

441results about How to "The post-processing process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

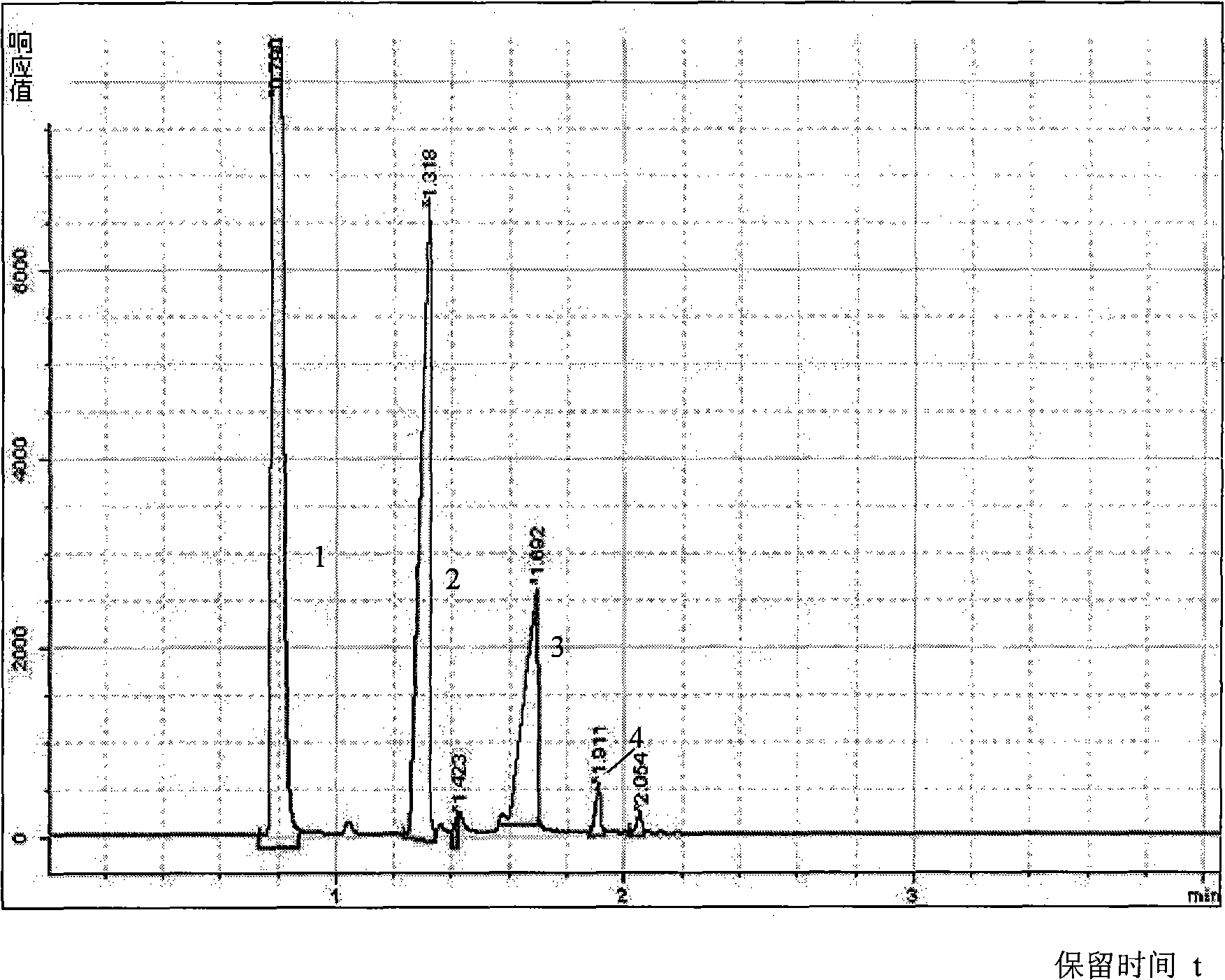

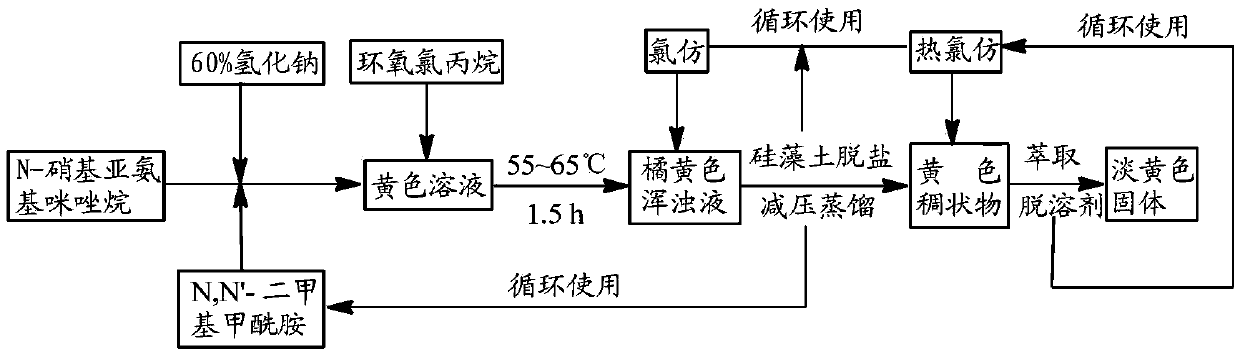

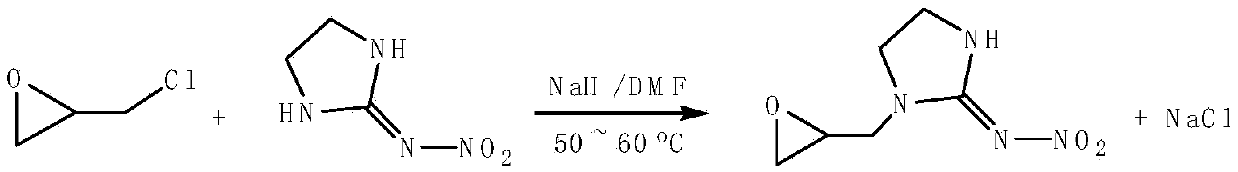

Method for preparing cycloxylidin

The invention discloses a method for preparing cycloxylidin, which belongs to the technical field of pesticides preparation. The method comprises the following steps: under nitrogen protection, N-nitroiminoimidazolidine and an organic solvent are added in a reactor, then sodium hydride is added in batches, and the material is heated to the temperature of 50-60 DEG C, chloropropylene oxide is added drop by drop in the reactor, after the reaction product is cooled, chloroform is added, and the product is filtered by diatomite, then evaporative crystallization is carried out, and the crystals can be precipitated, vacuum distillation is carried out on a processed filtrate to obtain a light yellow dense solid, then heat chloroform is used for extraction, and finally heat ethanol or acetone is used for recrystallization to obtain cycloxylidin: 1-(2,3-glycidyl)-N-nitroimidazoline-2-ylamine, wherein the yield is about 83%. The method has the advantages of short reaction time, high yield and green environmental protection, and is more suitable for large-scale industrial production.

Owner:山东聚强绿洲生物科技有限公司

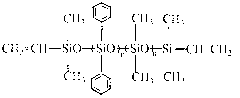

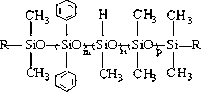

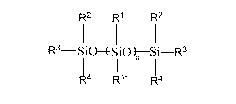

Silicon rubber with high refractive index and high transparency for optical encapsulation and preparation method thereof

ActiveCN103122149AHigh refractive indexImprove mechanical propertiesSemiconductor devicesHydrogenPolymer science

The invention relates to silicon rubber with high refractive index and high transparency for optical encapsulation and a preparation method thereof. The silicon rubber is prepared from a phenyl vinyl polysiloxane component A, a silicon resin component B containing phenyl vinyl, a phenyl component C containing hydrogen polyoxyalkylene, a platinum catalyst component D, a catalytic inhibitor component E, a modified polysiloxane component F, and a water remover component G in a mixing manner. The silicon rubber not only has over 1.50 of refractive index, but also is good in transparency, excellent in adhesion, and stable in performance, can resist heat and ultraviolet radiation for a long period of time, can meet various requirements of LED (light-emitting diode) encapsulation, and is an ideal encapsulation material of the LED. The silicon rubber can be packaged into a bi-component product; the product has good storage stability; and high transparency is still kept after the product is stored for over 6 months.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Method for preparing polyol ester lubricating oil by using composite solid acid catalyst

InactiveCN102887825AHigh esterification rateHigh purityOrganic compound preparationCarboxylic acid esters preparationDistillationAcid value

The invention relates to a method for preparing polyol ester lubricating oil by using a composite solid acid catalyst. The method comprises the following steps of: adding a water carrying agent into polyol ester and monobasic fatty acid, performing esterification reaction under the action of the composite solid acid catalyst, and dehydrating and esterfying to obtain raw ester; performing filter pressing on the raw ester to separate the raw ester from the solid acid catalyst, wherein the catalyst can be recycled; and performing reduced pressure distillation on the raw ester to remove the residual fatty acid, and then deacidifying and decolorizing to refine with heating by using a refining adsorption bed layer respectively to obtain low-acid value polyol ester lubricating oil. The method has the advantages that the catalyst can be recycled, the esterification rate is high, an aftertreatment process is simple, and a product is low in acid value, high in purity, environment-friendly and suitable to be produced industrially. The reaction esterification rate can reach over 99 percent, and the acid value of the ester product obtained through refining can be controlled to be less than 0.01mg KOH / g. The product is excellent in visco-temperature performance, high in lubricity and thermal stability, strong in hydrolytic stability, low in volatility and excellent in electrical insulation property.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

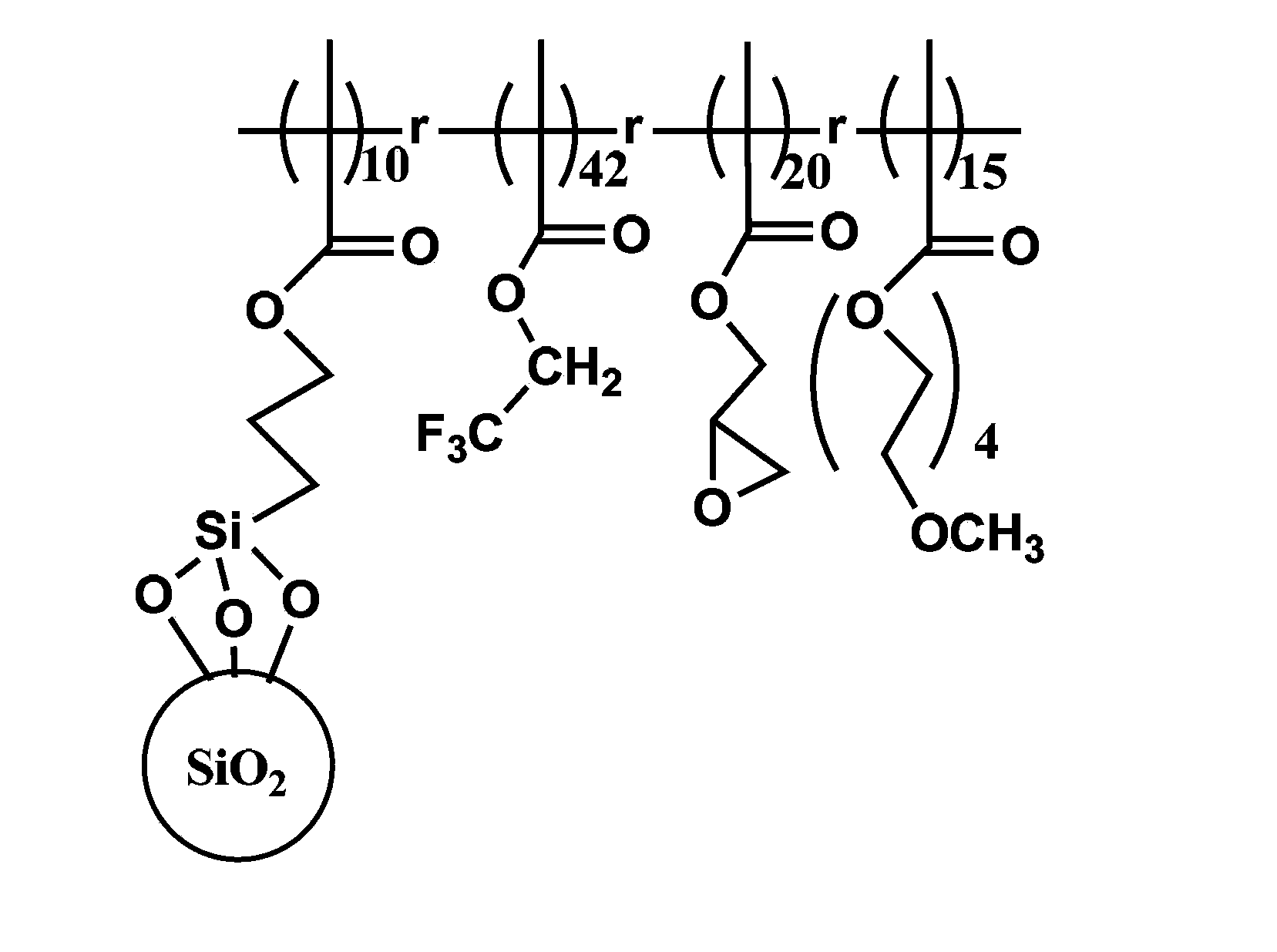

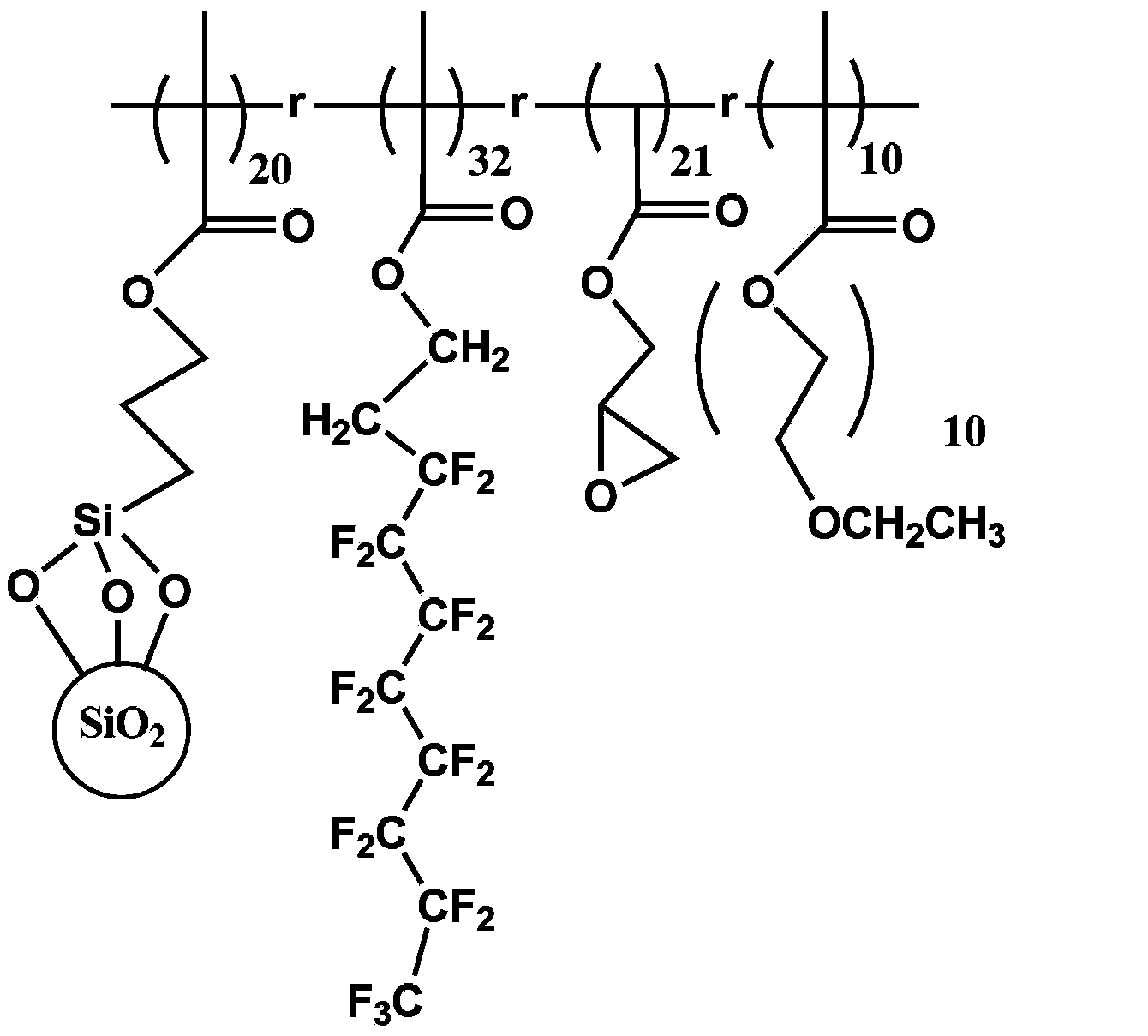

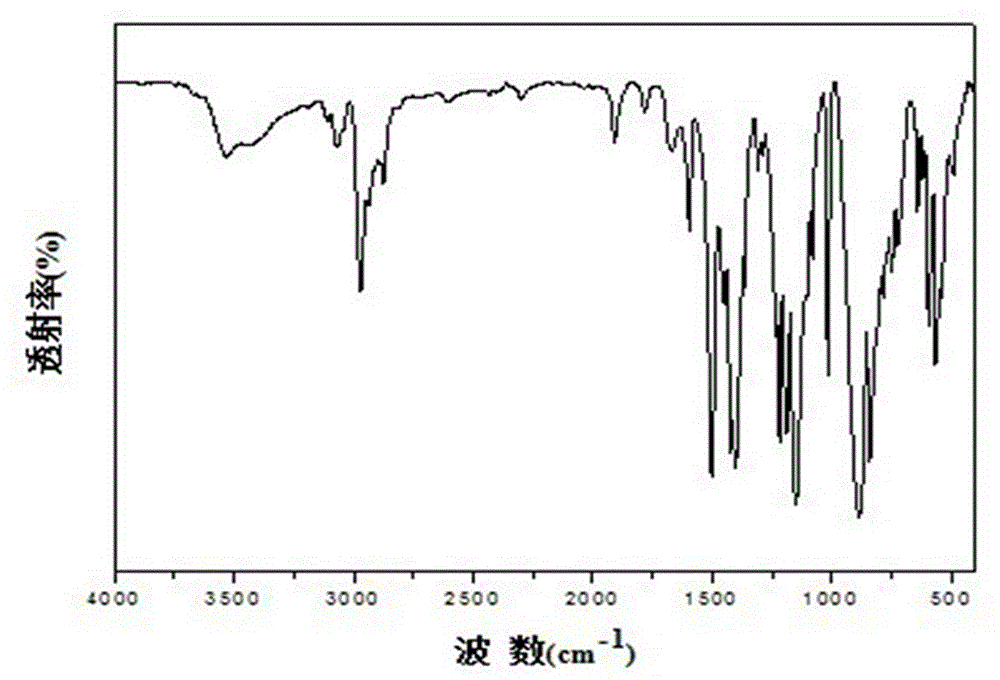

Water-based fluoropolymer and silicon dioxide hybrid material and transparent super-amphiphobic coating prepared from same

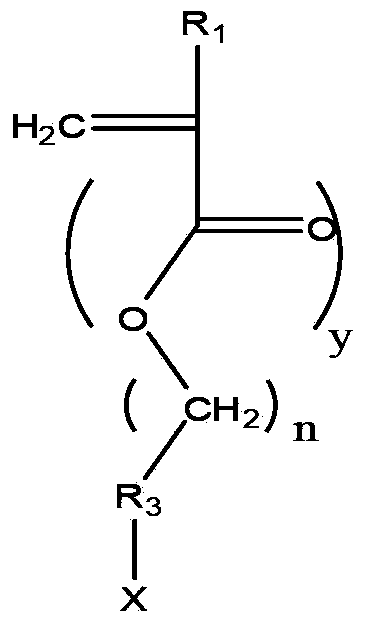

ActiveCN103408709AThe synthesis method is simpleThe post-processing process is simpleCoatingsDouble bondEpoxide

The invention belongs to the field of super-amphiphobic materials and discloses a water-based fluoropolymer and silicon dioxide hybrid material and a transparent super-amphiphobic coating prepared from the same. The water-based fluoropolymer and silicon dioxide hybrid material is a hybrid material with the structural formula of P(A-r-B-r-C)-g-D; the hybrid material is prepared by polymerization reaction of water-soluble monomers A, monomers B, fluorine-containing monomers C and inorganic nano particles D at the mass ratio of 1:(0.2-20):(0.1-20):(0.1-5), wherein the end groups of the monomers B are epoxide groups, and double bonds are grafted on the surfaces of the inorganic nano particles D. The super-amphiphobic material provided by the invention can perform cross-linking reaction with the surface of a substrate in water; compared with the construction methods of traditional super-amphiphobic materials, a method provided by the invention is cheaper and more environment-friendly; besides, a super-amphiphobic interface prepared by the method has excellent super-hydrophobic and super-oleophobic properties and can meet the requirement in industrial application.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

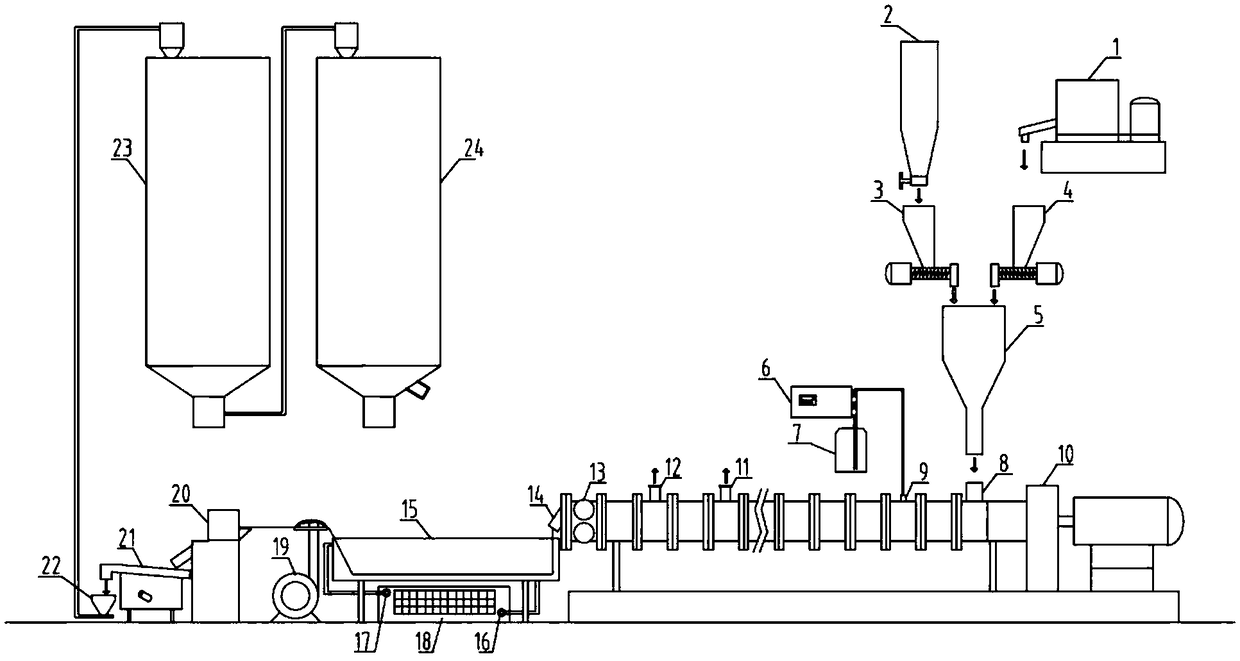

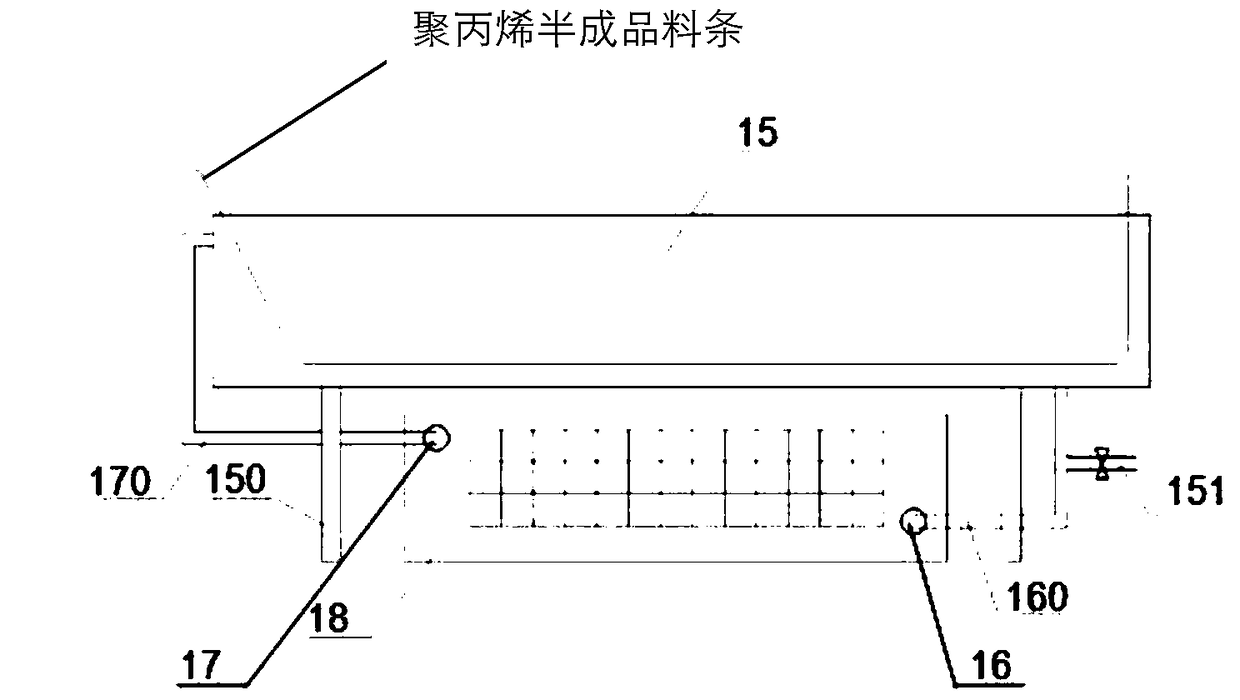

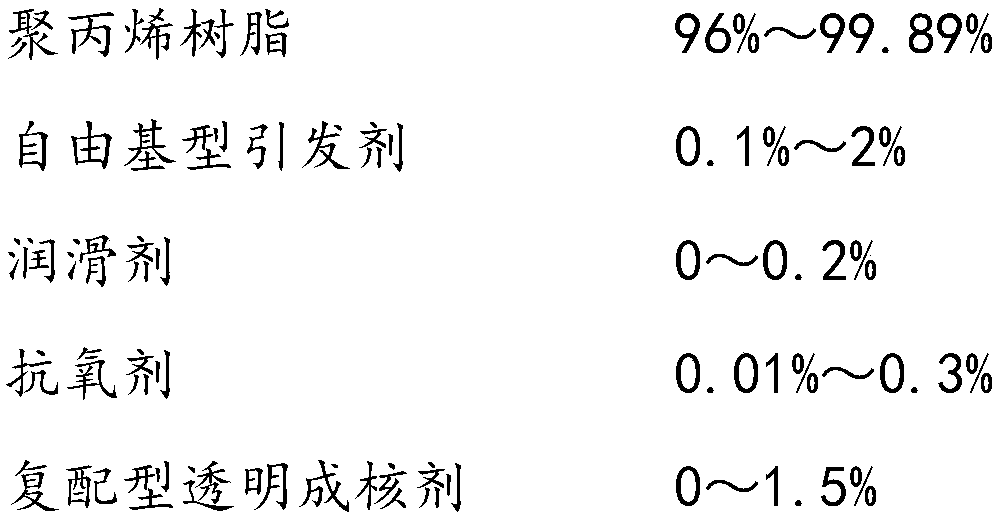

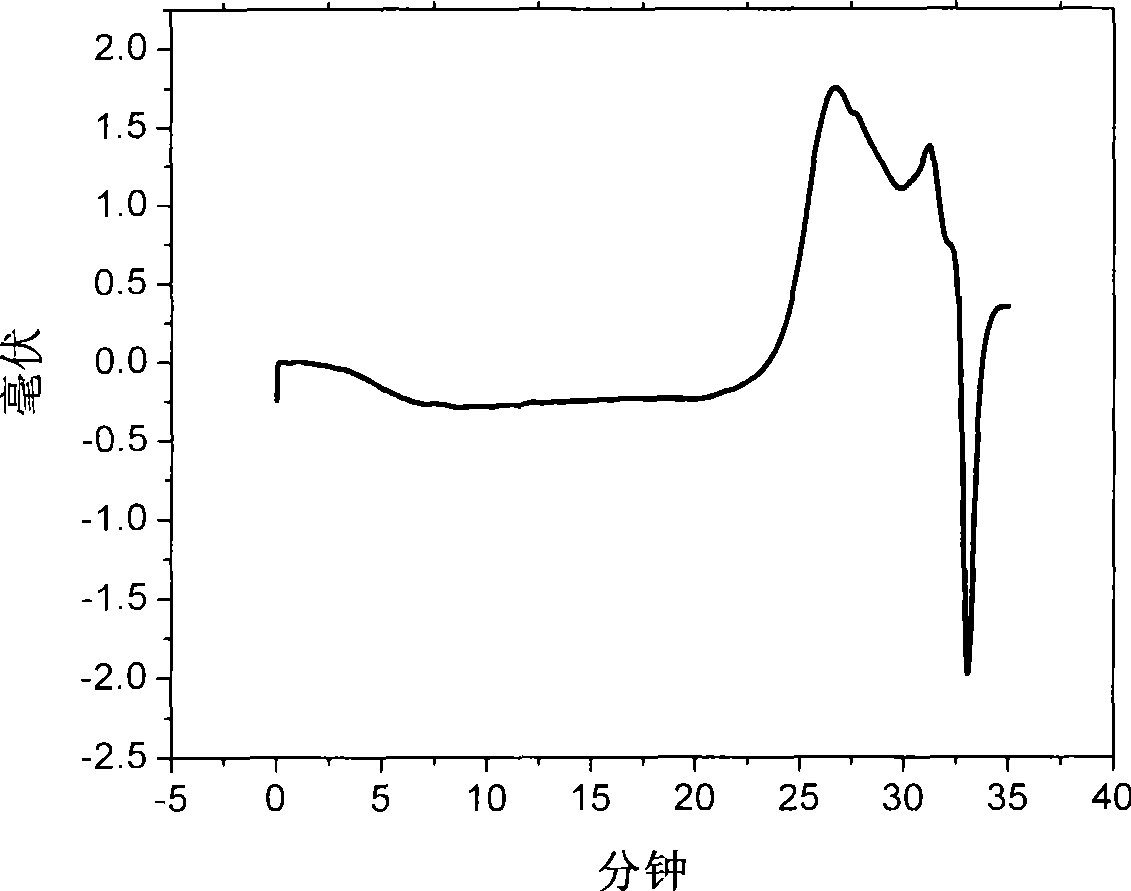

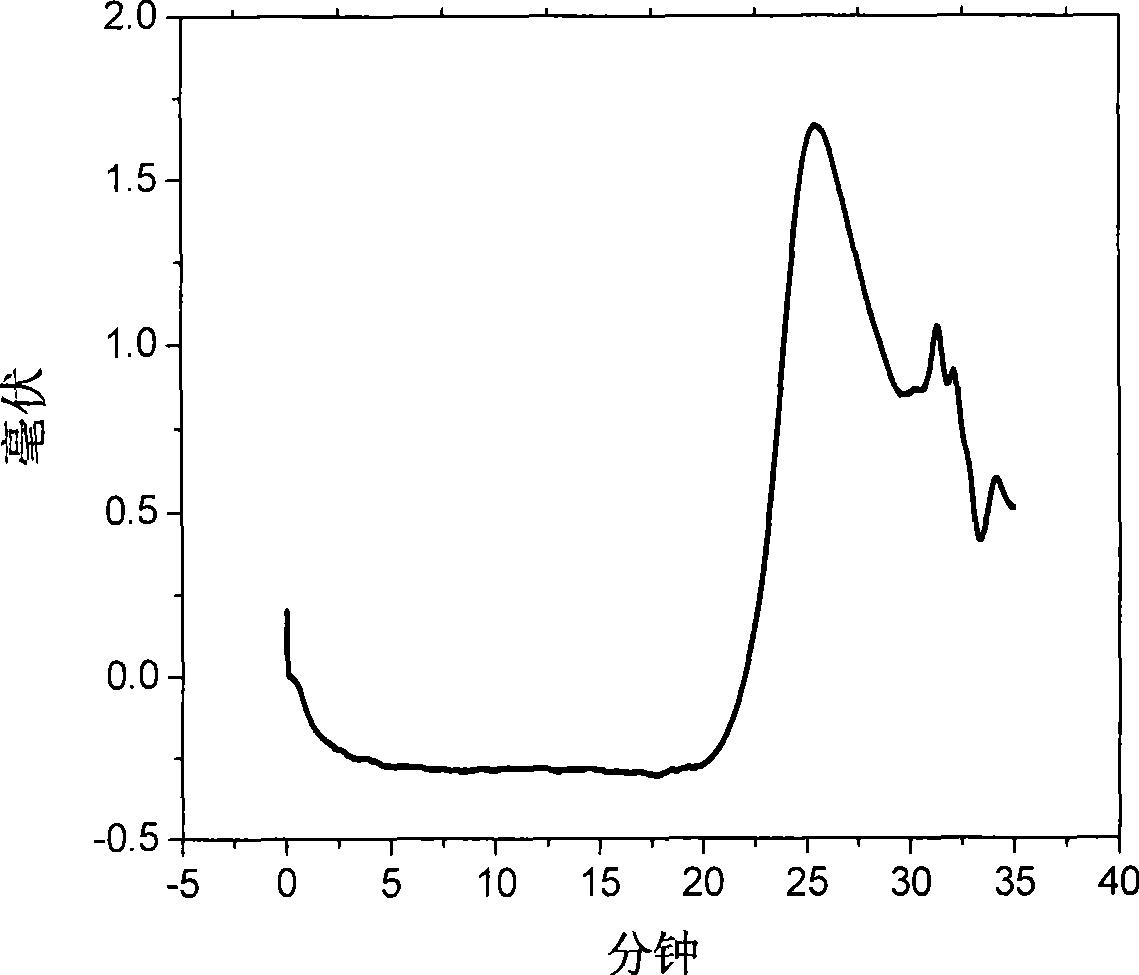

Low-odor high-transparency ultrahigh flowability polypropylene as well as preparation device and method thereof

The invention discloses low-odor high-transparency ultrahigh flowability polypropylene which comprises the following components in percentage by mass: 96-99.89% of a polypropylene resin, 0.1-2% of a free radical form initiator, 0-0.2% of a lubricant, 0.01-0.3% of an antioxidant and 0-1.5% of a compounded transparent nucleating agent. Due to adoption of the compounded transparent nucleating agent which is sufficiently reacted with the polypropylene resin, the initiator, the lubricant and the antioxidant synergistically, the ultrahigh flowability polypropylene which is high in transparency, lowin yellow index and low in haze is prepared. In addition, the invention further discloses a completely novel preparation device and process of the low-odor high-transparency ultrahigh flowability polypropylene. The transparency, the low odor and the low volatilization of the product in the preparation process can be further improved on the basis of a completely novel formula, the product can be prepared by using a one-step method, large-scale popularization and production in factories can be implemented, meanwhile, the problem of small molecule residues in the product is also solved to a largeextent, and aftertreatment processes of non-woven fabric manufacturing companies can be simplified.

Owner:大韩道恩高分子材料(上海)有限公司 +1

Production of feed additive

InactiveCN101028035AReduce manufacturing costLow investment costFood processingAnimal feeding stuffFood additiveAnimal science

An additive of forage for increasing the content of peptide, the utilization rate of protein and the growth speed of animals is prepared from one or more kinds of feed protein through solid fermenting by bacillus and / or bacterium lactis and / or yeast.

Owner:刘唤明

Method for synthesizing low molecular weight phenylethylene / maleic anhydride alternate copolymer

A synthetic method of a styrene / maleic anhydride alternating copolymer with low molecular weight belongs to the field of macromolecular precipitation polymerization. Media and chain transfer agents used in the existing methods for preparing styrene / maleic anhydride copolymers by precipitation polymerization have disadvantages. In the synthetic method, the styrene / maleic anhydride alternating copolymer is prepared by taking a mixed solvent of organic acid alkyl ester and alkane as a reaction medium for the precipitation polymerization, alpha-methylstyrene or vinyl acetate as a molecular weight regulator and organic peroxide or an azo compound as an initiator for initiating a copolymerization reaction between styrene monomers and styrene. The synthetic method has simple process, the synthesized copolymer has good properties, and the method has the advantages of being economical, environment-friendly and the like.

Owner:BEIJING UNIV OF CHEM TECH

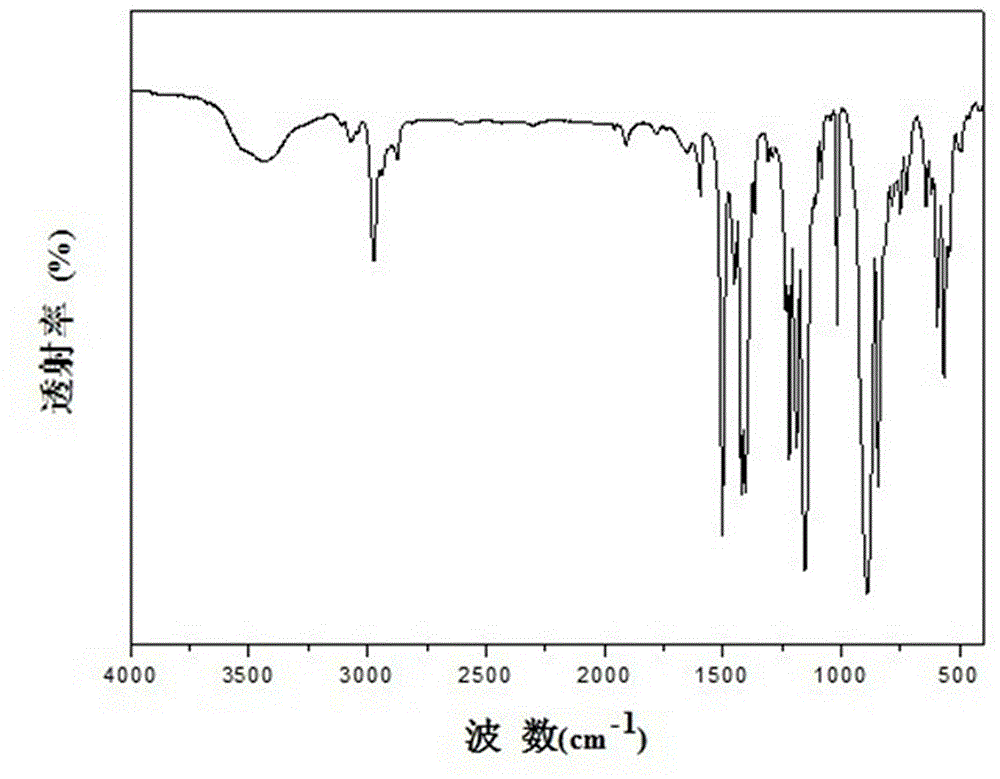

Fluorine-containing anti-fingerprint oil polymer and preparation thereof, and application of polymer in field of super-amphiphobic materials

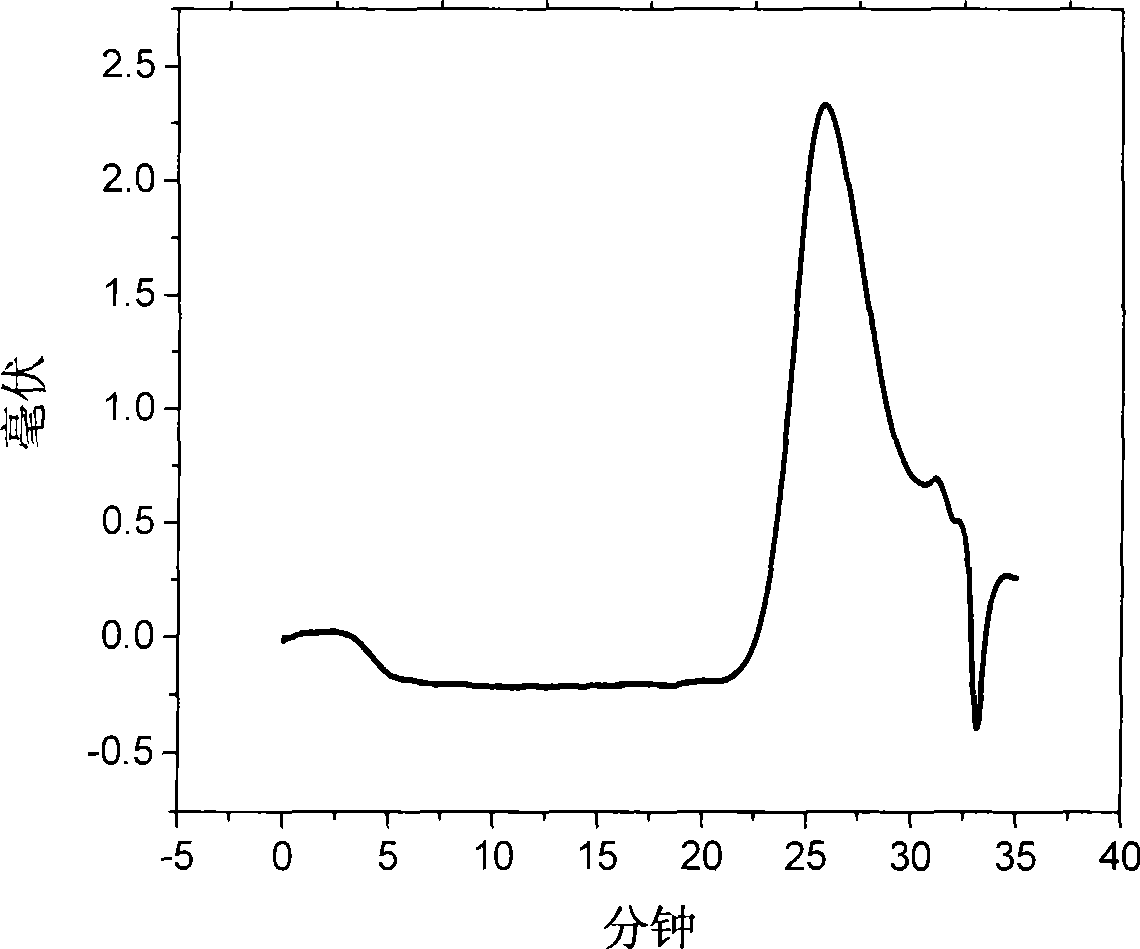

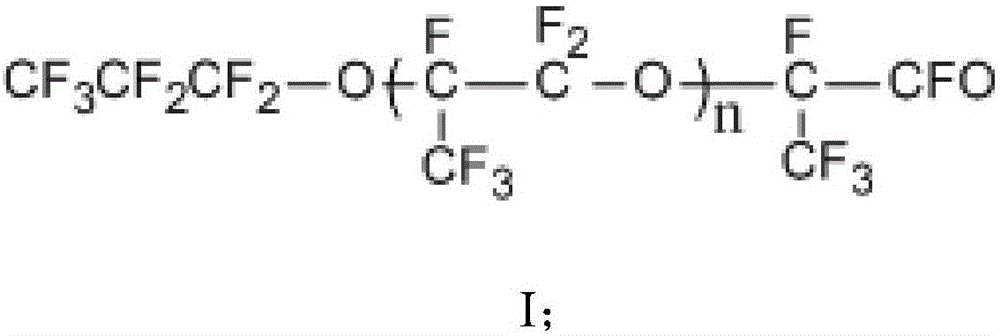

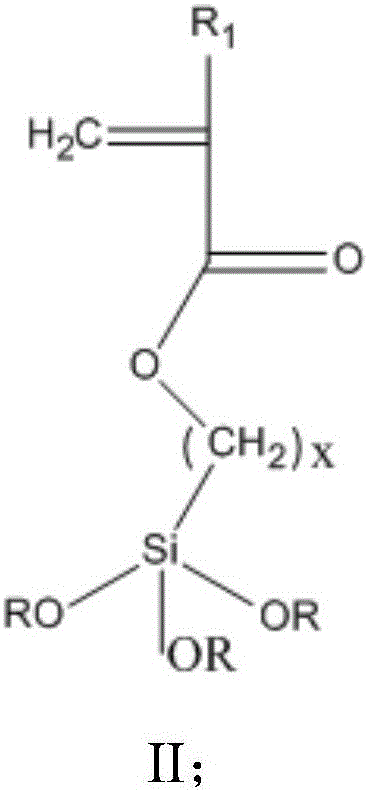

The invention belongs to the field of super-amphiphobic materials, and particularly relates to a fluorine-containing anti-fingerprint oil polymer and preparation thereof, and application of the polymer in the field of super-amphiphobic materials. The preparation method comprises the following steps: carrying out reaction on perfluoropolyether acyl fluorine and a reactant A to obtain a double-bond-containing perfluoropolyether monomer; carrying out copolymerization on the double-bond-containing perfluoropolyether monomer and a silane monomer to obtain the fluorine-containing anti-fingerprint oil polymer, wherein the structures of the perfluoropolyether acyl fluorine and silane monomer are respectively disclosed as Formula I and Formula II. The fluorine-containing anti-fingerprint oil polymer contains siloxy groups, and thus, the copolymer can be bonded with the matrix surface by utilizing the siloxy-hydroxy coupling characteristic, thereby constituting the super-amphiphobic surface. The super-amphiphobic surface prepared from the fluorine-containing polymer has the advantages of high bonding firmness with glass and friction resistance, and is suitable for industrial production and application.

Owner:国科广化(南雄)新材料研究院有限公司 +1

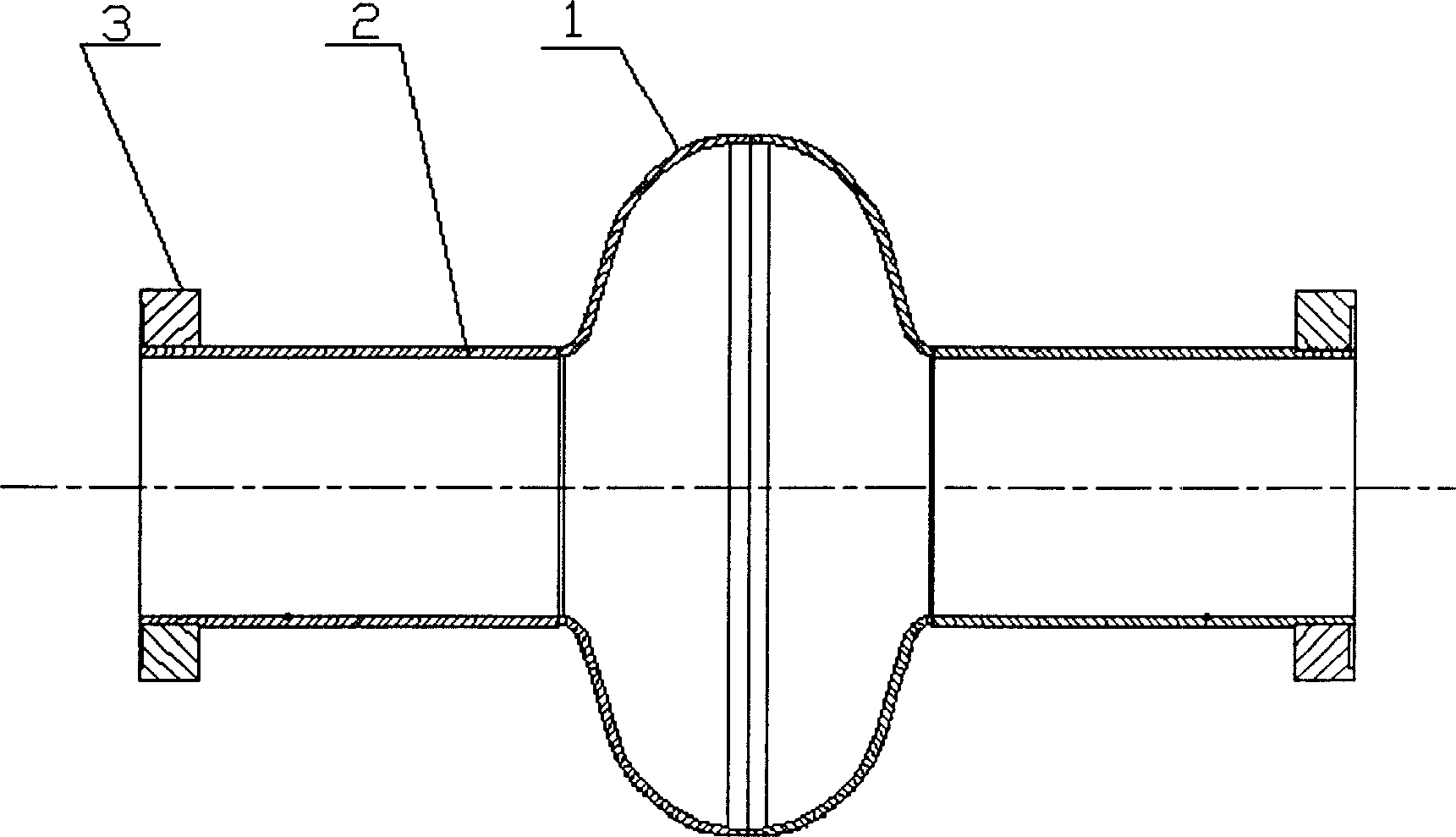

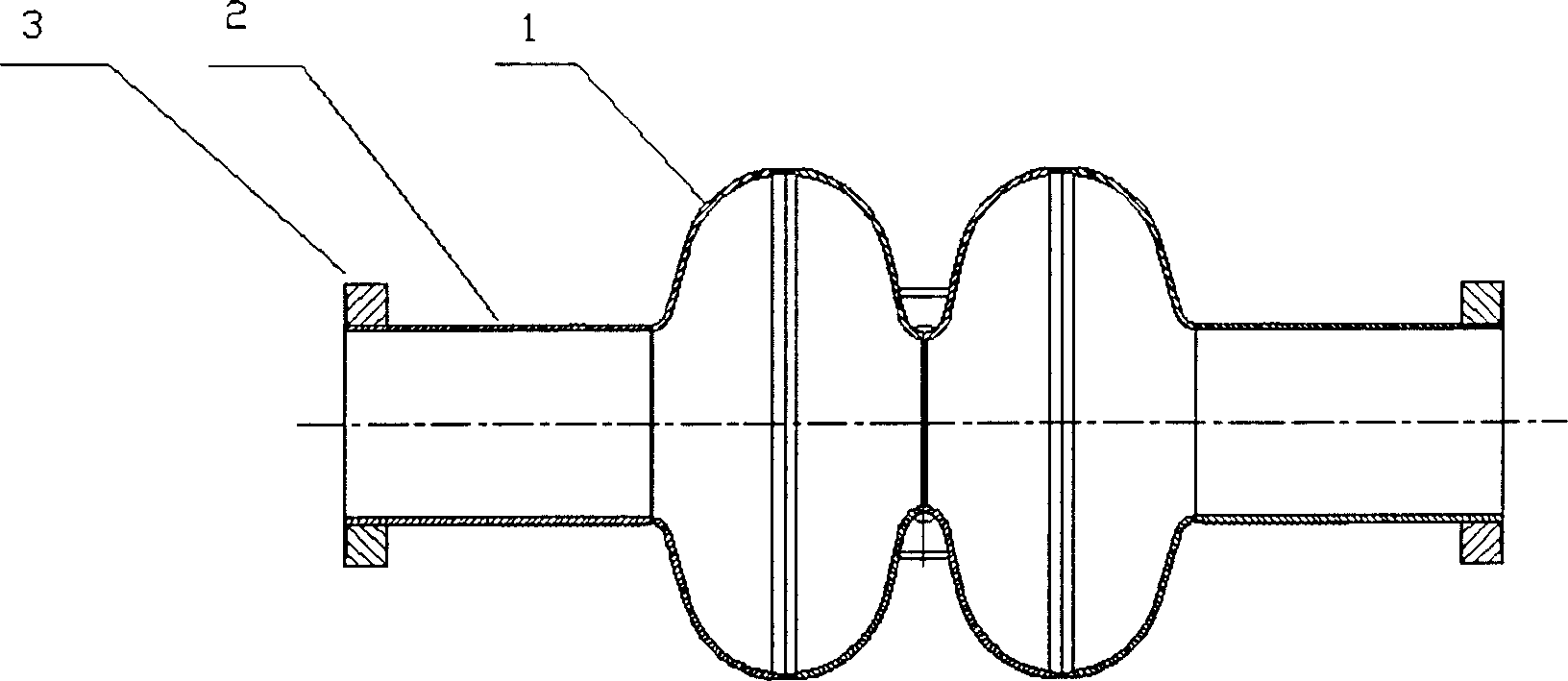

Large crystal grain niobium material superconducting cavity and its manufacturing method

This invention relates to a super-conduction cavity of a large grain Nb material and its manufacturing method, in which, the super-conduction cavity includes an integrated elliptical Nb cavity, beams and flanges and multiple big cm grains are scattered on the wall of the Nb cavity. The method includes: cutting Nb plates from the smelt big grain Nb ingots and cleaning chemically to be punched to the shape of half cavities to connect two or multiple half cavities in series and solder both ends together with the two beams and flange electronic beams of the related aperture to manufacture a complete super-conduction cavity to be cleaned chemically, polished, heat processed, washed in high-pressure super-clean water and installed to greatly increase the quality.

Owner:赵夔 +1

Polymerization method of (ammonium) sulfate connexon polymer

The invention relates to a polymerization method of an (ammonium) sulfate connexon polymer. The polymerization method comprises a step of subjecting a hydroxyl-containing monomer or an amino-containing monomer and a sulfuryl fluoride monomer to condensation polymerization on through a one-pot process under alkaline conditions. Compared with a traditional polyester synthesis method, the method is cost-saving; reaction conditions are mild and easy to control; reaction flow is simple, and operation is easy; and a post-treatment process is simple, environmental pollution is small, and industrial production is facilitated. In addition, a bisphenol type polysulfate compound synthesized in the invention has excellent mechanical properties, dielectric properties, tolerance and wear resistance.

Owner:内蒙古图微新材料科技有限公司

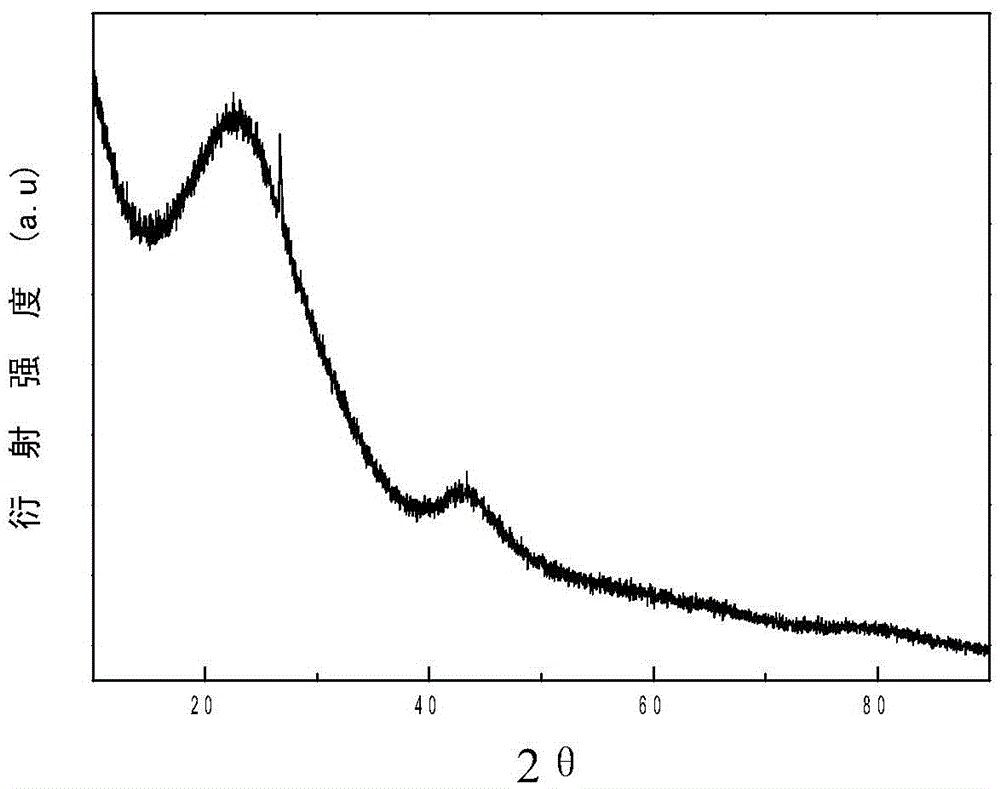

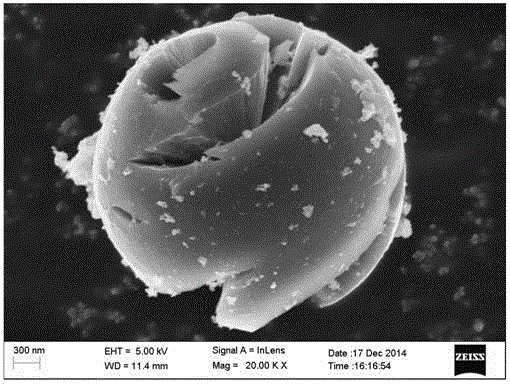

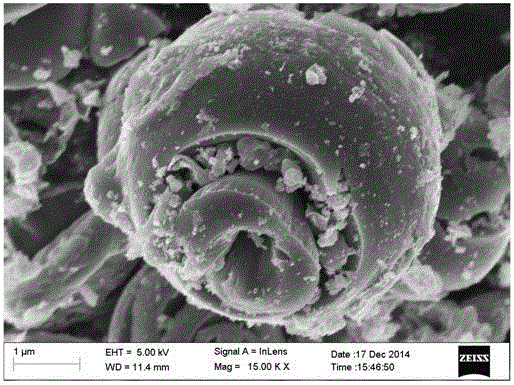

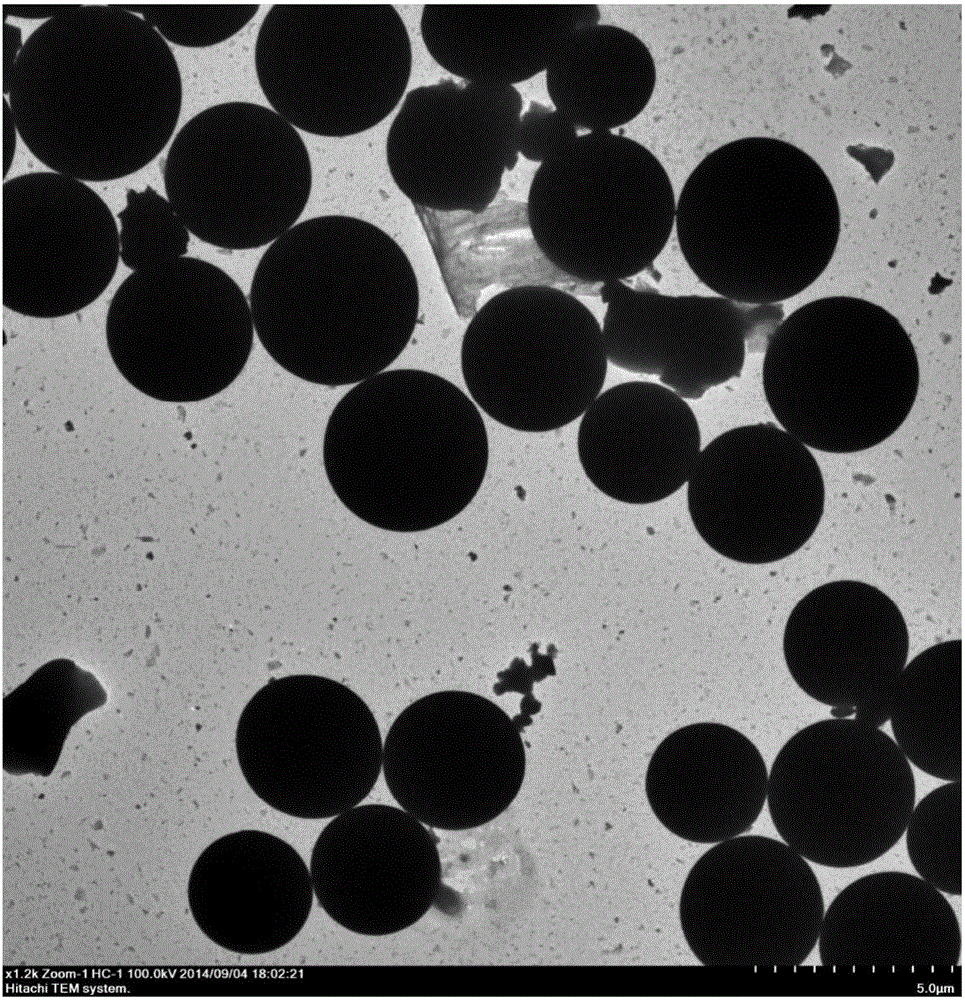

Preparation method of N/S-codoped carbon microspheres with high oxygen reduction catalytic activity

ActiveCN104953133AThe synthesis steps are simpleThe post-processing process is simpleCell electrodesArgon atmosphereMicrosphere

The invention provides a preparation method of N / S-codoped carbon microspheres with high oxygen reduction catalytic activity. The preparation method comprises the following steps: adding a carbon source, a nitrogen source, a sulfur source and an analytically pure surfactant into a stainless steel reaction kettle in sequence under nitrogen protection, stirring, sealing, heating in a crucible furnace, and taking out a mixture when the reaction kettle is cooled naturally to room temperature; washing and filtering the mixture; drying obtained powder in a vacuum drying oven; uniformly mixing an obtained product with analytically pure potassium hydroxide powder, activating in an argon atmosphere; washing with distilled water; and finally, drying in vacuum in the vacuum drying oven. The preparation method has the advantages of simple process, mild reaction condition, high repeatability and low cost; in an alkaline environment, the generated product has excellent oxygen reduction catalytic property, is relatively high in catalytic activity, good in stability and relatively good in tolerance to methyl alcohol and carbon monoxide and has huge application potential on the aspect of fuel cell catalysts.

Owner:YANSHAN UNIV

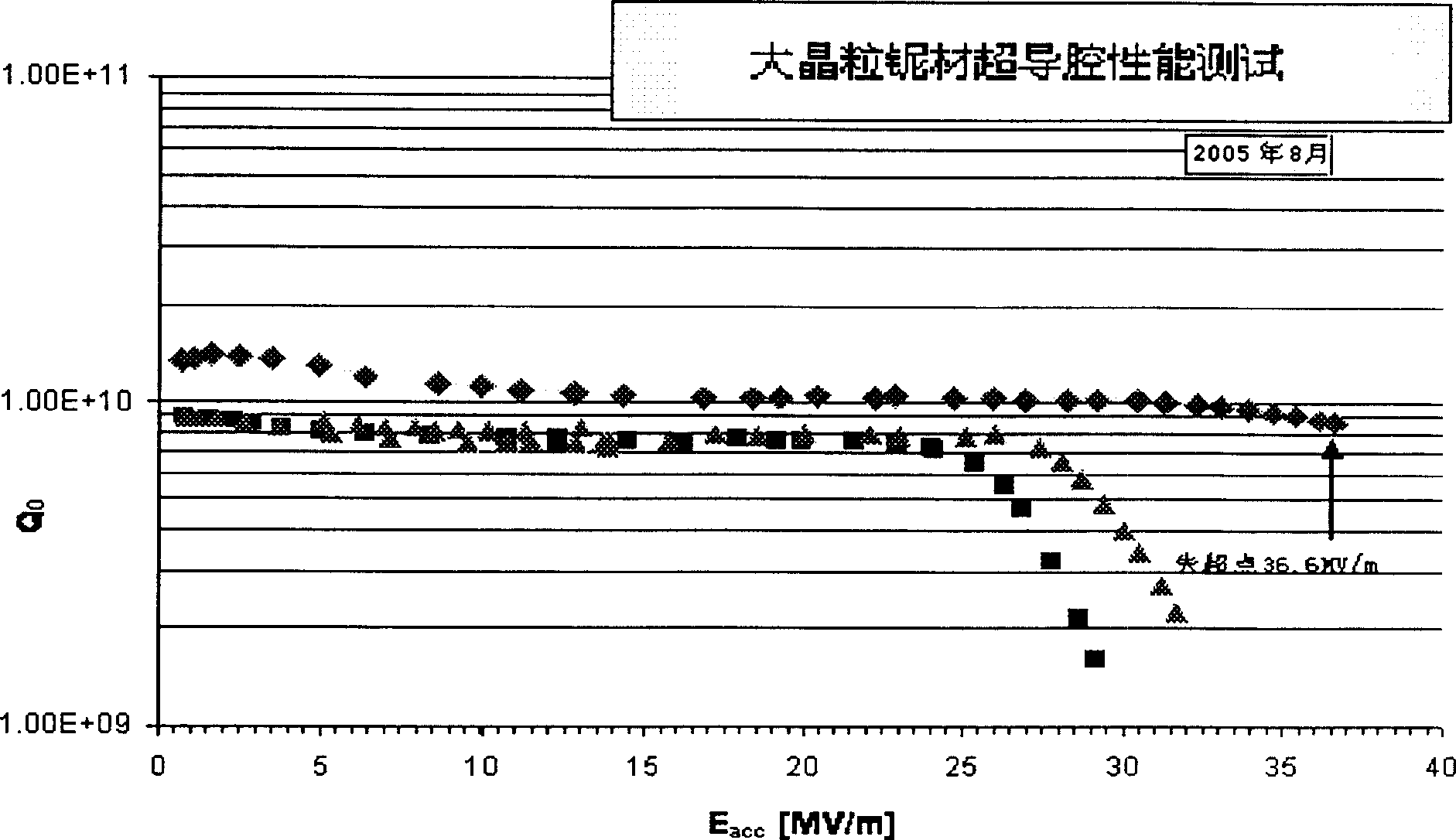

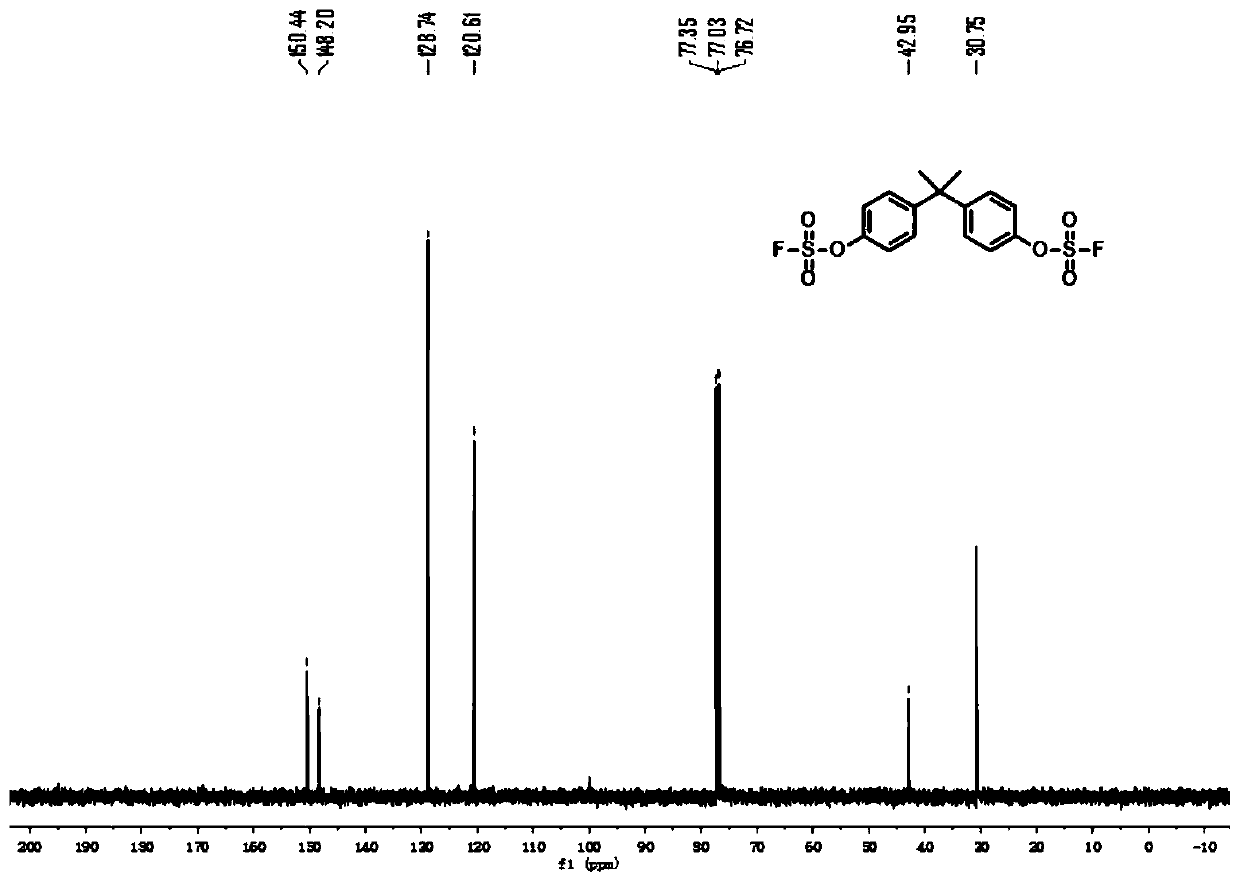

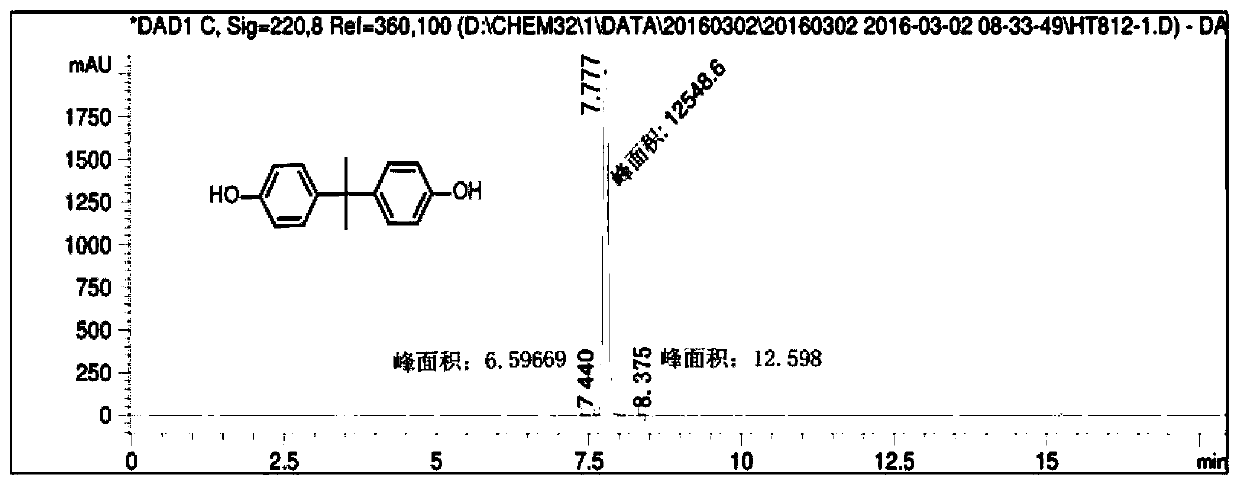

Bisphenol A type poly sulfuric acid (ammonia) ester compound and synthetic method thereof

ActiveCN104059228AImprove mechanical propertiesExcellent dielectric propertiesPolyesterPtru catalyst

The present invention discloses a bisphenol A type poly sulfuric acid (ammonia) ester compound, and belongs to the technical field of polymers. The bisphenol A type poly sulfuric acid (ammonia) ester compound is prepared as follows: using bisphenol A dioxygen sulfonyl fluoride as a raw material for reacting with trialkyl silicon group-protected bisphenol or diamine in the presence of an inert gas for protection and a catalyst at 30-120 DEG C for 3 to 36 hours; and pouring the reaction mixture into water to precipitate a polymerization product, namely the bisphenol A type poly sulfuric acid (ammonia) ester compound. The bisphenol A type poly sulfuric acid (ammonia) ester compound has excellent mechanical properties, dielectric properties, tolerance and wear resistance, and has broad application prospects in aerospace, electronic communications, electromechanical and microelectronic industries. In addition, the high reaction activity bisphenol A type dioxygen sulfonyl fluoride compound is used as a polyester synthetic raw material, and compared with a traditional polyester process, the reaction condition is mild and easy to control, the reaction process is simple and easy to operate; the after treatment process is simple, the environmental pollution is less, and the bisphenol A type poly sulfuric acid (ammonia) ester compound is favorable to industrial production.

Owner:内蒙古图微新材料科技有限公司

Instant-dissolved cationic polyacrylamide capsulation agent and preparing method thereof

The invention belongs to the field of cationic polymer capsulation agents, and relates to an instant-dissolved low-molecular-weight polyacrylamide capsulation agent and a preparing method thereof. The capsulation agent is prepared from three monomers in a copolymerization mode, wherein the first monomer is one of acrylamide and sodium acrylate, the second monomer is one of cationic monomers including dimethyl diallyl ammonium chloride, diethyl diallyl ammonium chloride, acryloxyethyl ethyl dimethyl benzyl ammonium chloride, methacryloyl oxyethyl dimethyl-benzyl ammonium chloride and methacryloyloxyethyl trimethyl ammonium chloride, and the third monomer is one of hydroxyethyl methylacrylate and hydroxypropyl methacrylate. The molecular structures of the monomers contain hydroxyl, the hydroxyl can interact with drilling cuttings, and the capsulation inhibiting performance is improved. According to the capsulation agent, the inverse emulsion polymerization technology is adopted, the aftertreatment technology is simple, the granular product can be conveniently stored for a long time and transported, the dissolving time is short in use, convenience is brought to site utilization, the capsulation inhibiting effect is good, and the performance of a drilling fluid system can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production method for xylose by enzyme process

The technical scheme for xylose preparation with enzyme comprises: using CGMCC1476 as a Aspergillus niger strain to ferment and prepare excision xylanase that has high activity and needs mild reaction condition; enzymolyzing specially corn core and zylan in straw materail; refining to prepare single-xylose with purity more than 90%. This invention has no pollution to environment and conversion more than 80%.

Owner:JINAN GUOLI BIOLOGICAL SCI & TECH

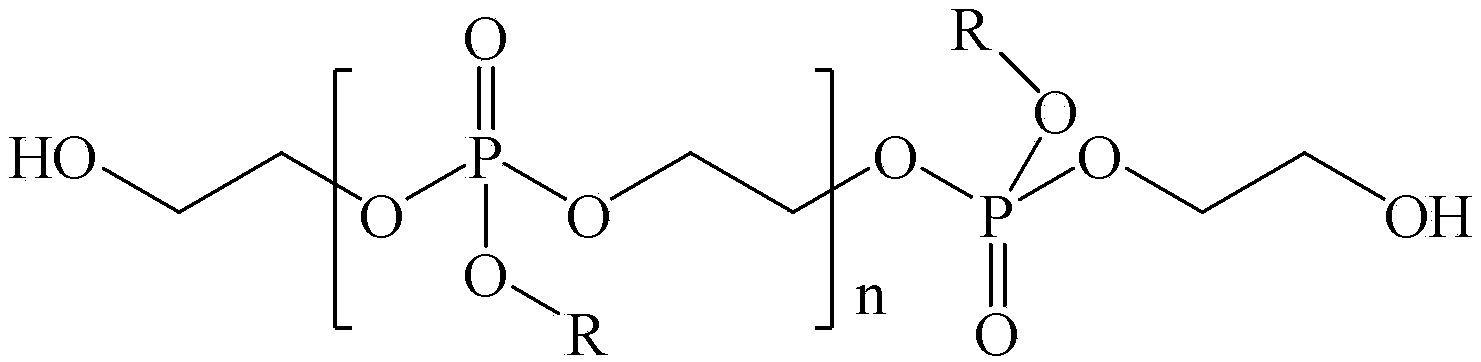

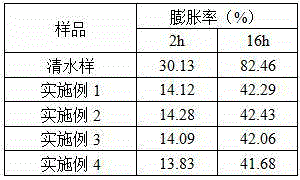

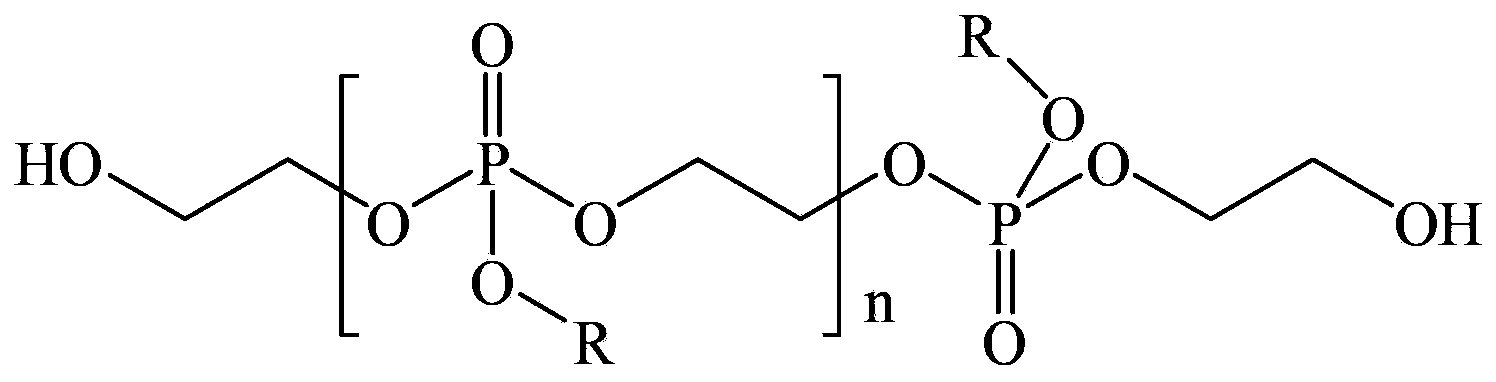

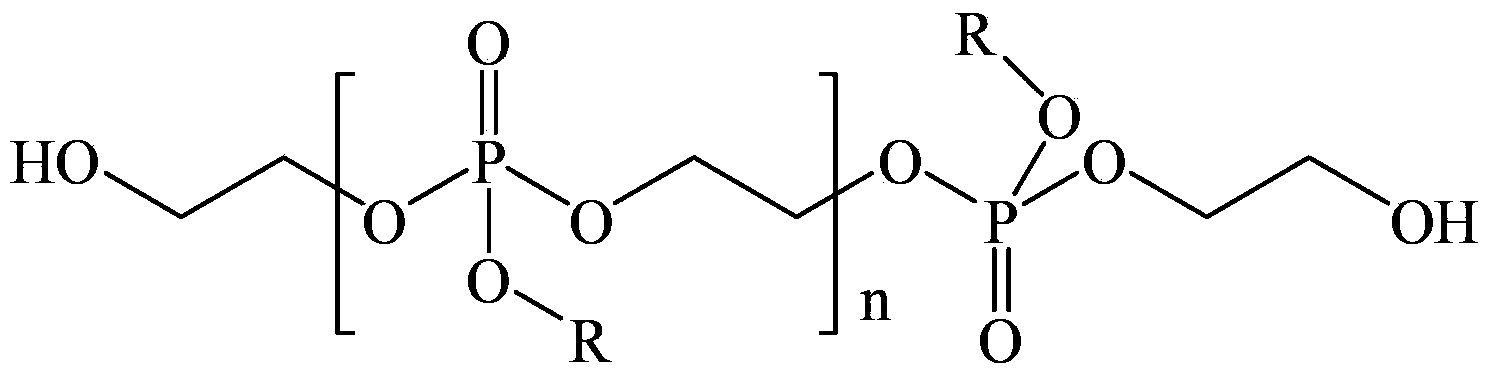

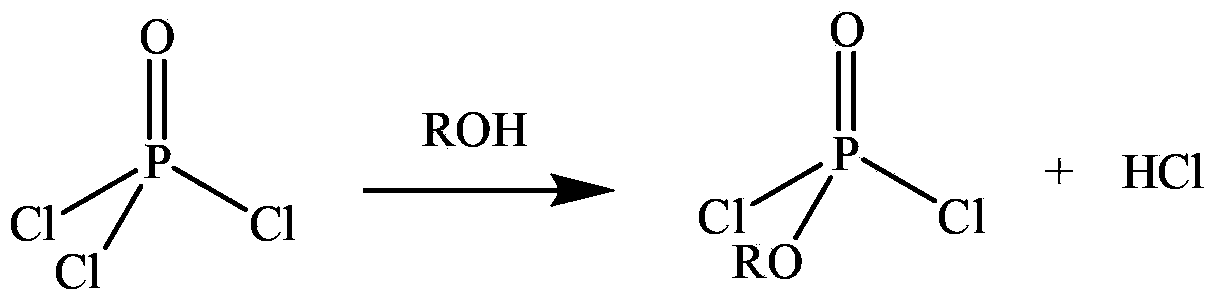

Halogen-free organophosphate fire retardant and its preparation method

ActiveCN103360606ALow costThe post-processing process is simplePhosphorus organic compoundsToxic gasHalogen

The invention relates to a halogen-free organophosphate fire retardant and its preparation method. The fire retardant contains no halogen and will not release corrosive toxic gases when combusted. Through a reaction between polycarbonate polyol and isocyanate, an inflaming retarding element is embedded into a polyurethane foamed material and will not migrate or escape when the material is heated. Thus, the material is permanently endowed with flame resistance.

Owner:常熟国和新材料有限公司

Bacterial strain for producing PMLA [Poly (Beta-L-malic acid)] and method for producing PMLA by fermentation of bacterial strain

InactiveCN102220248AEfficient fermentationThe post-processing process is simpleFungiMicroorganism based processesPullulanMicrobiology

The invention discloses a bacterial strain for producing PMLA [Poly (Beta-L-malic acid)], which is obtained by screening the surface of a plant leaf and can not produce melanin. The classification name is Aureobasidium pullulans, the Latin literature name is Aureobasisdium pullulans ZD-3D, and the preservation number of the bacterial strain is CGMCC No.4605. The method for producing PMLA by the bacterial strain is simple to implement and is beneficial to the separation and purification of PMLA, and the yield can be up to 50-60g / L.

Owner:SHANDONG JINCHENG BIO PHARMA CO LTD

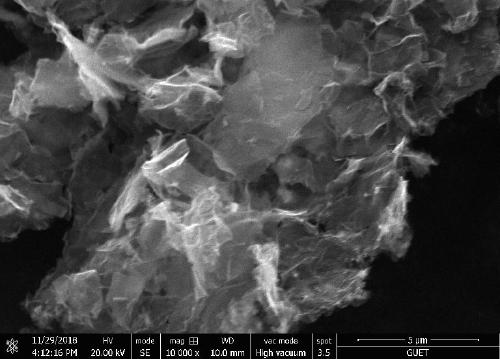

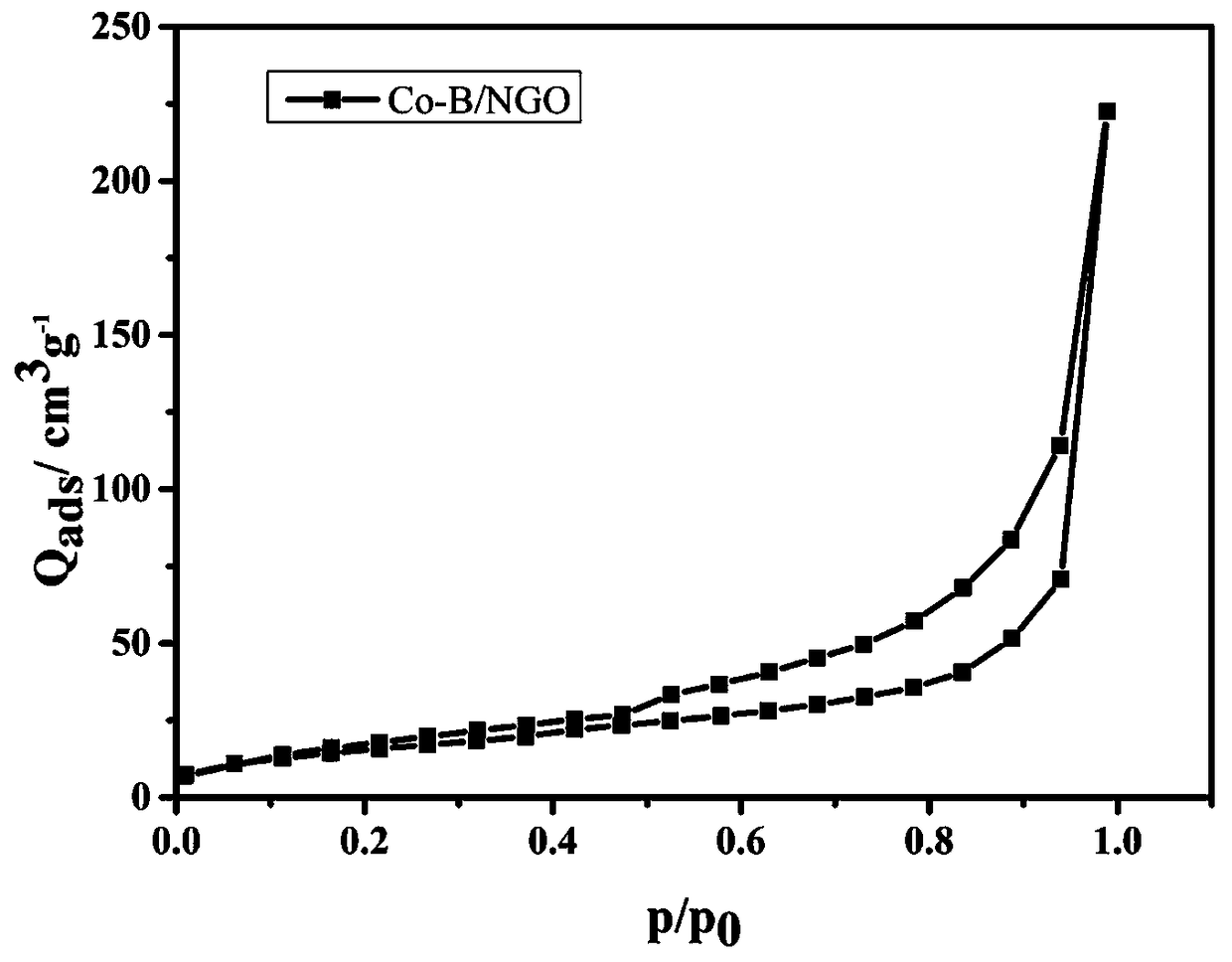

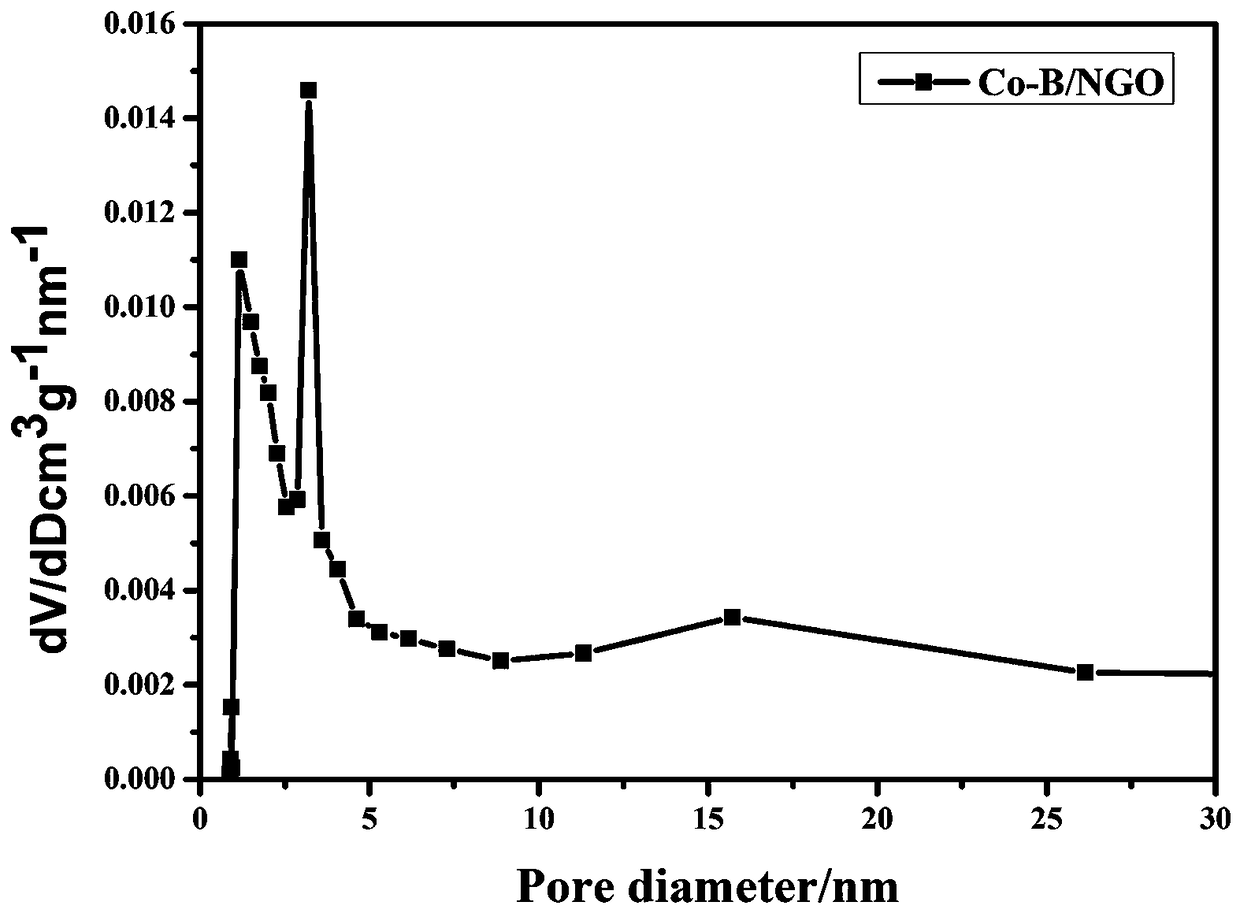

Co-B/NGO composite nanometer material as well as preparation method and application thereof

InactiveCN109499576AChange catalytic performanceLower activation energyMaterial nanotechnologyCatalyst activation/preparationFreeze-dryingHydrogen desorption

The invention discloses a Co-B / NGO composite nanometer material. The Co-B / NGO composite nanometer material is prepared by firstly performing in-site reduction on nitrogen-doped graphene and inorganiccobalt salt through sodium borohydride and then performing freezing-drying, the specific area is 40-100 m<2>g<-1>; the material is magnetic, and can be attracted by a magnet. When the composite nanometer material is used as a catalyst for hydroboron hydrogen generation by hydrolysis, the hydrogen desorption rate is 500-1700mL / min<-1>g<-1>, and the hydrogen production rate is 100%; the material canbe adsorbed and recycled by the magnet, the recycling rate reaches 99.5%, and the hydrogen production rate after being circulated is maintained at 100-1530mL min<-1>g<-1>, namely, maintaining 50-85%of the initial hydrogen production rate. The preparation method comprises the following steps: 1) precursor preparation: adding nitrogen-doped graphene and inorganic cobalt salt in an aqueous solutionfor ultrasonic dispersion mixing, reducing by using sodium borohydride, and finally centrifuging and washing to obtain a precursor; 2) preparation of the Co-B / NGO composite nanometer material: freeze-drying the precursor to obtain the Co-B / NGO composite nanometer material. The Co-B / NGO composite nanometer material disclosed by the invention is simple in preparation, has more excellent catalysis performance, and has an extensive application prospect in the application field of the hydroboron hydrogen generation by hydrolysis.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Method for producing guaiacol with methanol method

InactiveCN101492353AImprove product qualityHigh yieldMolecular sieve catalystsChemical recyclingMethylating AgentGuaiacol

The invention provides a method for preparing guaiacol by a methanol method. Methanol used as a methylating agent and pyrocatechol are used for synthesizing the guaiacol under the action of a solid acid catalyst in a high pressure vessel. The solid acid catalyst used for synthesizing the guaiacol has low price, is friendly to environment and can be recycled. The invention is characterized in that the invention has simple preparation technology, mild reaction condition and short reaction time; the obtained guaiacol is light yellow clear transparent liquid and has good product quality, high yield, high selectivity and few side products; and all side products in reaction liquid can be recycled.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of nanometer silver powder with particles controllable

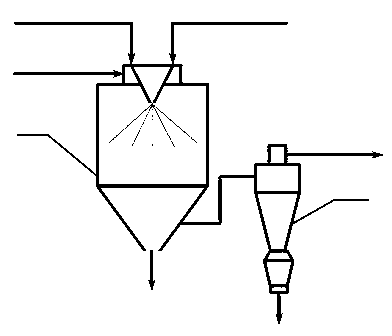

ActiveCN104014804AAvoid cloggingMake up for the lack of concentrationNanotechnologyTowerReducing agent

The invention discloses a preparation method of nanometer silver powder with particles controllable. The method includes the following steps that silver nitrate and dispersants are mixed with water in sequence in proportion so that an oxidizing mixed solution A can be obtained; reducing agents are added into water and stirred to be dissolved, then the pH value of the solution is regulated to range from 7.5 to 13.5 through small molecular amine, and a reducing solution B is obtained after stirring and dissolving; the oxidizing mixed solution A and the reducing solution B are pumped into a spraying nozzle according to the volume ratio ranging from 1:10 to 10:1, the oxidizing mixed solution A and the reducing solution B are sprayed into a spraying drying tower through hot air at the temperature ranging from 35 DEG C to 150 DEG C at the speed ranging from 1 kg / h to 8000 kg / h, and powdery solids are formed and subside to the bottom of the drying tower; powder airflow obtained through the reaction is pumped into a separation tower to be further separated, and finally, silver powder and redundant reducing agents are separated so that the nanometer silver powder can be obtained. The preparation method has the advantages of being simple in process, convenient to operate and capable of achieving mass production fast.

Owner:福建富轩科技有限公司

Production method for solar cell high-density monodisperse silver powder

The invention discloses a production method for solar cell high-density monodisperse silver powder. According to the production method, glyoxal serves as a reducing agent for reducing silver nitrate, and glycolic acid and oxalic acid generated by glyoxal reaction serve as components of silver powder dispersing protective agents. While flow concurrence is performed in a reactor, a glyoxal solution, a sodium hydroxide solution and a silver nitrate solution are added into the reactor, and the molar ratio of the silver nitrate, the glyoxal and sodium hydroxide is controlled to be 1:0.25-0.35:1-1.4, the pH value of a reaction solution is kept at 8-10, the reaction temperature is kept at 20 DEG C-40 DEG C, after feed intake is finished, stirring and reacting are continued for 0.5 hour-1 hour, and therefore reaction is complete, and silver crystal grain crystallization is complete. Silver powder particles are approximately spherical, the surfaces are smooth and glossy, the particle size distribution is narrow, the average particle size is 1.2 micrometers-1.8 micrometers, the apparent density is 2.0 g / cm<3>-2.5 g / cm<3>, the tap density is 4.5 g / cm<3>-5.0 g / cm<3>, and the molar yield is 97-99.5%. The consumption of the reducing agent is small in the process of producing the silver powder, production cost is low, safe and environmentally friendly effects are achieved, the reaction condition is easy to control, product quality is stable, and industrialized application is easy.

Owner:TIANJIN VOCATIONAL INST

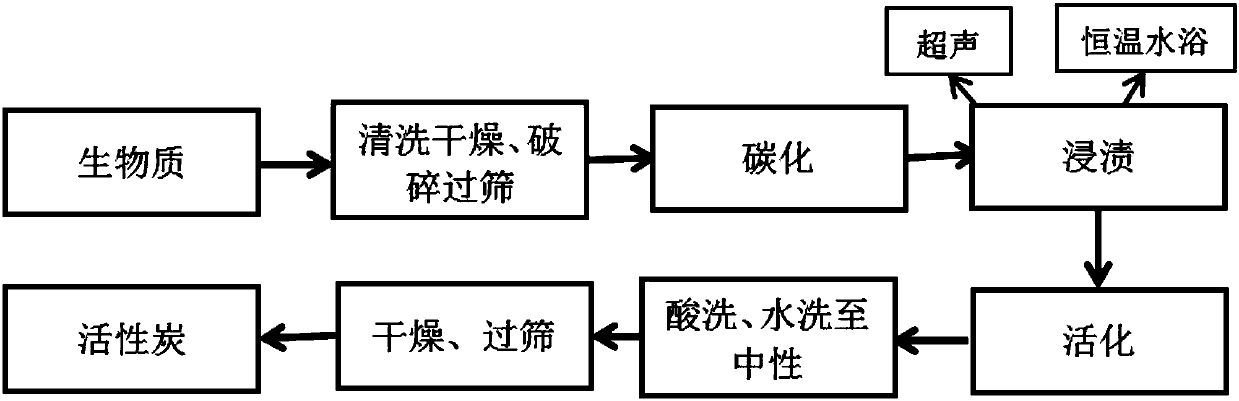

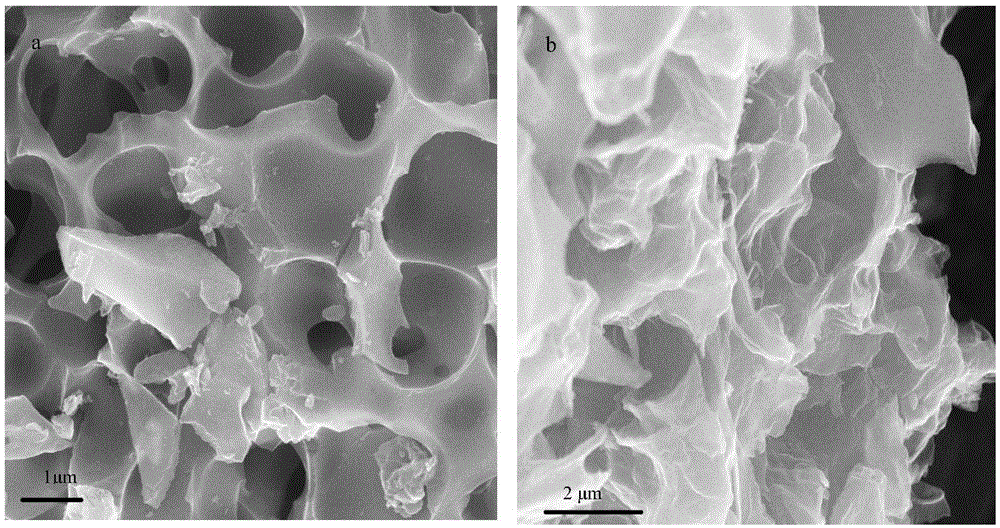

Method for preparing super capacitor based on biogas residue active carbon produced after biomass anaerobic dry fermentation

InactiveCN107644742ARealize high-value utilizationHigh specific capacitanceCarbon compoundsHybrid capacitor electrodesCapacitanceBiological activation

The invention discloses a method for preparing a super capacitor based on biogas residue active carbon produced after biomass anaerobic dry fermentation. The method for preparing the super capacitor based on the biogas residue active carbon after biomass anaerobic dry fermentation performs preprocessing on the biogas residues after biomass anaerobic dry fermentation, then performs high temperaturecarbonization and activation, and immerse an obtained activated product with acid and wash and dry the obtained activated product to obtain an activated carbon as a material of the electrode of the super capacitor. The active carbon prepared through the invention has an aperture structure on which micro holes and middle holes are distributed, has a relatively high specific surface area and has relatively high specific capacitance and cycling stability and is a relatively ideal electrode material of the super capacitor. The method for preparing the super capacitor based on biogas residue active carbon produced after biomass anaerobic dry fermentation uses the biogas to prepare a super capacitor so as to realize high value utilization of the biogas residual and the obtained active carbon isstable in structure and developed in pores, has a relatively high specific capacitance and cycle stability and is a relatively ideal electrode material of the super capacitor.

Owner:HEFEI UNIV OF TECH

Nano-silver inkjet conductive ink subjected to low-temperature post-treatment and stabilization, and preparation method

InactiveCN102504646AIncrease concentrationDoes not affect post-processing temperatureInksAlkyl amineSilver Nano

The invention discloses an inkjet nano-silver conductive ink and a preparation method of the ink. The inkjet nano-silver conductive ink comprises the following components by mass percent (the sum of mass percent of all components is 100%): 5-45% of silver nanoparticle, on the surface of which organic protecting agent with the particle diameter being smaller than 10nm is coated, and 55-95% of ink solvent. The preparation method comprises two steps, including preparation of the silver nanoparticle, on the surface of which organic protecting agent is coated, by taking silver acetate as raw material, and the preparation of nano-silver conductive ink. The method takes a small amount of alkyl hydrosulfide with strong effect on nano-silver and a large amount of alkylamine with weak effect on nano-silver as protecting agent to prepare the silver nanoparticle, so that the inkjet nano-silver conductive ink has the characteristics of high nano-silver concentration, low post-treatment temperatureand good dispersion stabilization, and is particularly suitable for being printed on flexible substrate.

Owner:TIANJIN UNIV

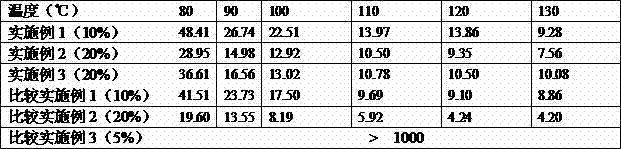

Method for preparing electrode material of supercapacitor from mimosa pudica

ActiveCN105540585AFully preserve the original structureThe synthesis steps are simpleHybrid capacitor electrodesCapacitanceFreeze-drying

The invention relates to a method for preparing an electrode material of a supercapacitor from mimosa pudica. The method mainly includes the steps that mimosa pudica is freeze-dried in vacuum, carbonized at the low temperature of 200 DEG C-400 DEG C and then carbonized at the low temperature of 600 DEG C-800 DEG C in a tube type resistance furnace, biochar and analytically pure potassium hydroxide are mixed uniformly by the mass ratio of 1:0.5-4 and carbonized for 0.5-3 h at the constant temperature ranging from 600 DEG C to 900 DEG C in a box-type atmosphere furnace, and an activated product is subjected to acid treatment, centrifugally washed to be neutral and dried to obtain the electrode material of the supercapacitor. The method is simple in synthesis step, relative moderate in reaction condition, high in repeatability, high in yield and easy to industrialize on a large scale; the specific surface area of the prepared electrode material of the supercapacitor reaches up to 1307 m<2> / g, the measured capacitance reaches up to 250 F / g under the current density of 1A / g in a 6M KOH solution, cycling stability is good, and the electrode material of the supercapacitor is relatively ideal.

Owner:YANSHAN UNIV

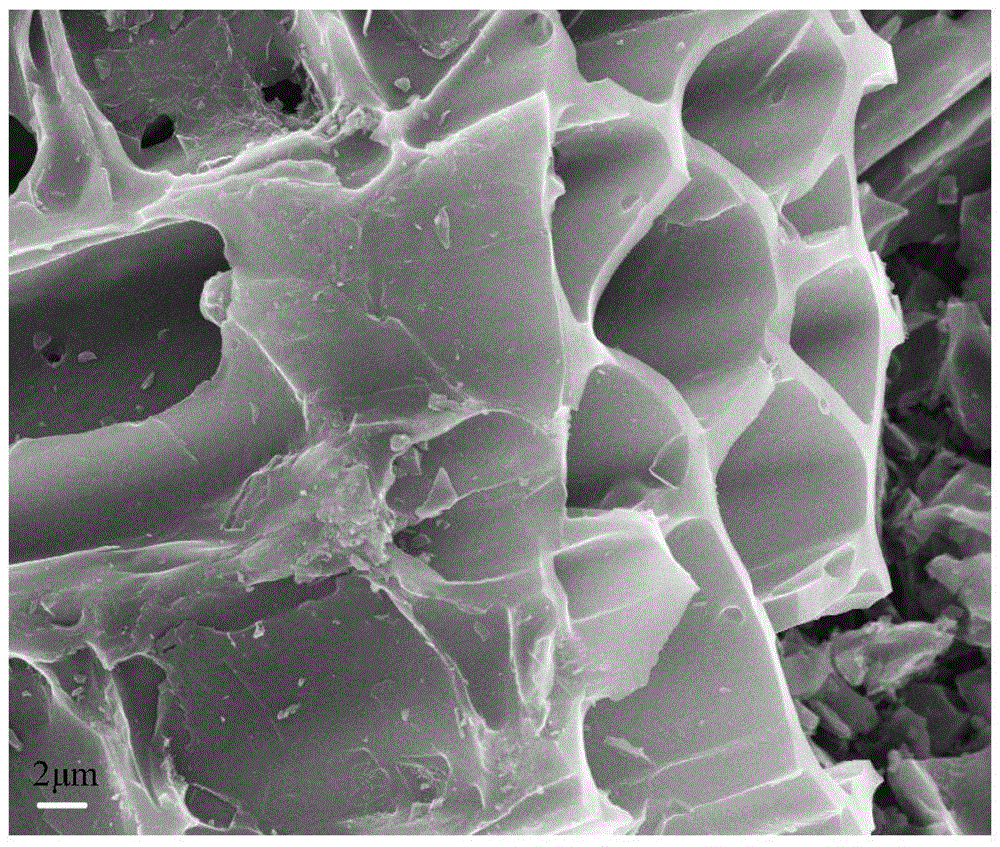

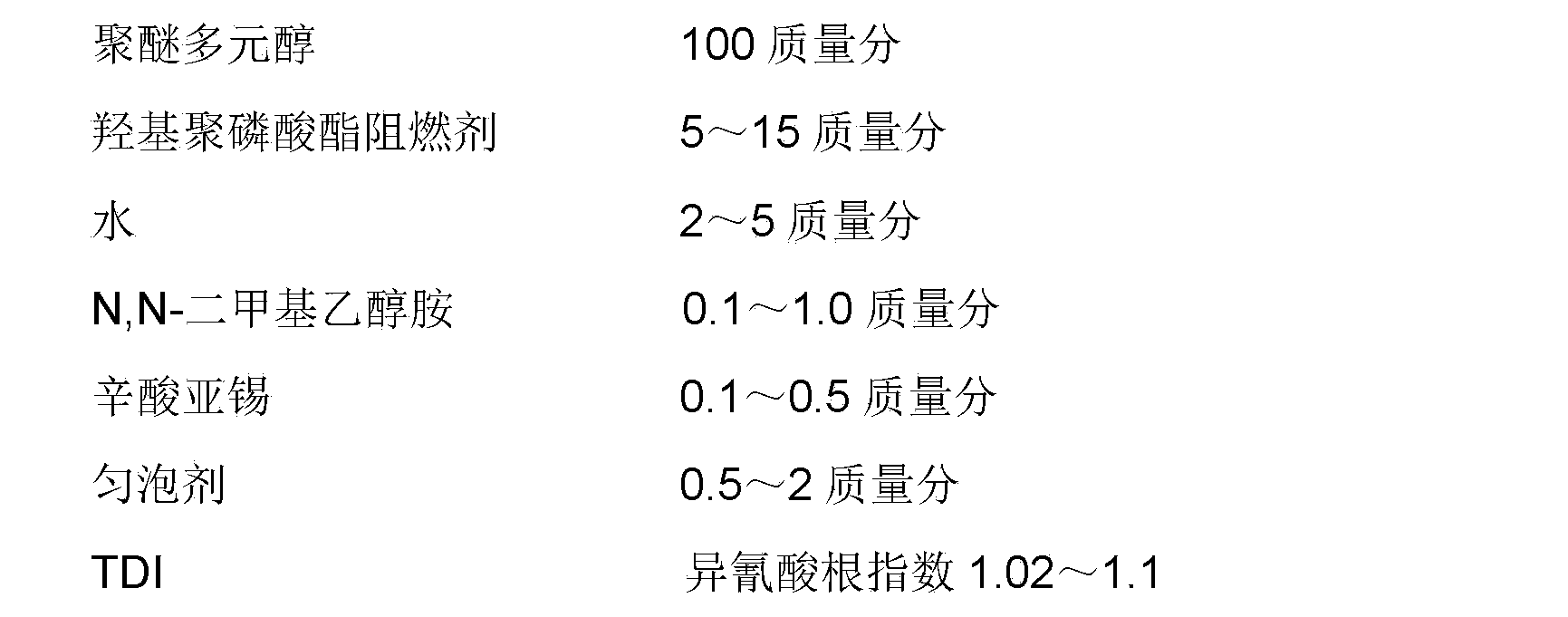

Flame retardant flexible polyurethane foaming plastic

ActiveCN103360567AThe post-processing process is simpleLow costGroup 5/15 element organic compoundsPolymer chemistryFlame resistance

The invention provides flexible polyurethane foaming plastic with flame resistance. A fire retardant used is a hydrophobic polyphosphoester fire retardant. Thus, properties of the product are guaranteed, and requirements on technology simplification, cost reduction and safe and nontoxic product are met.

Owner:常熟国和新材料有限公司

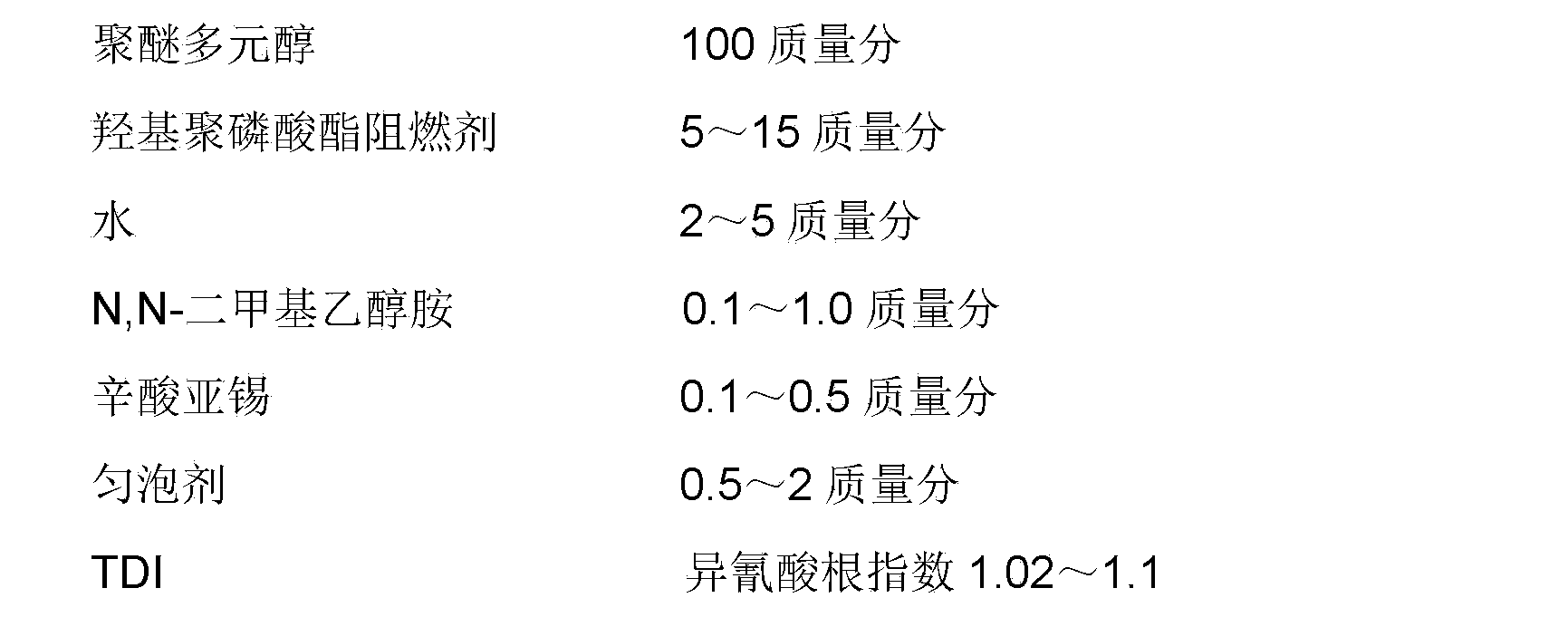

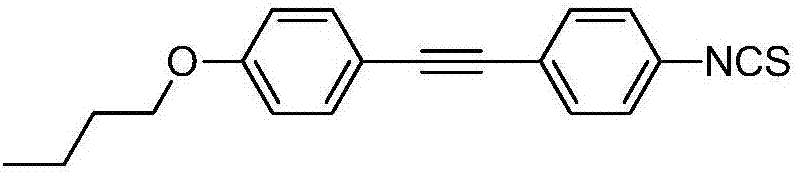

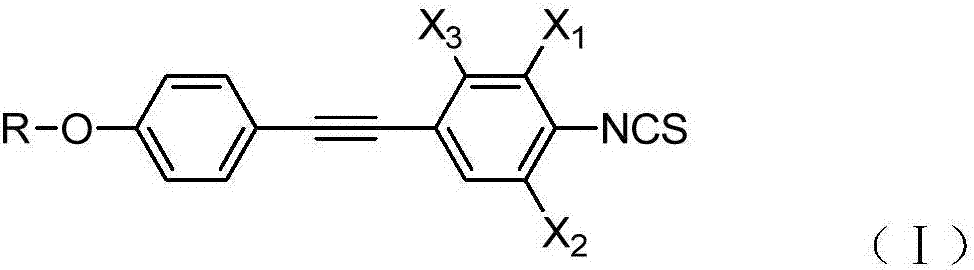

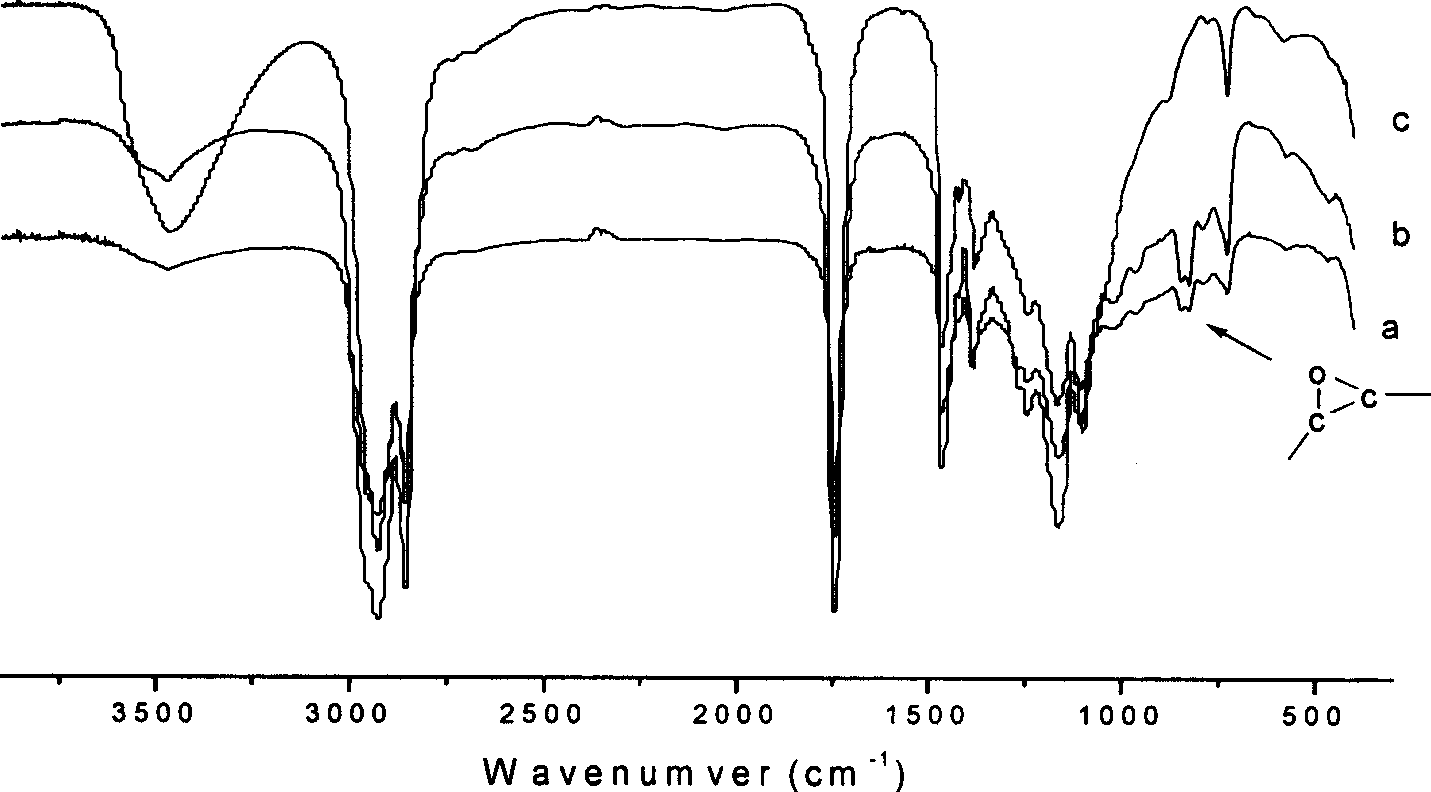

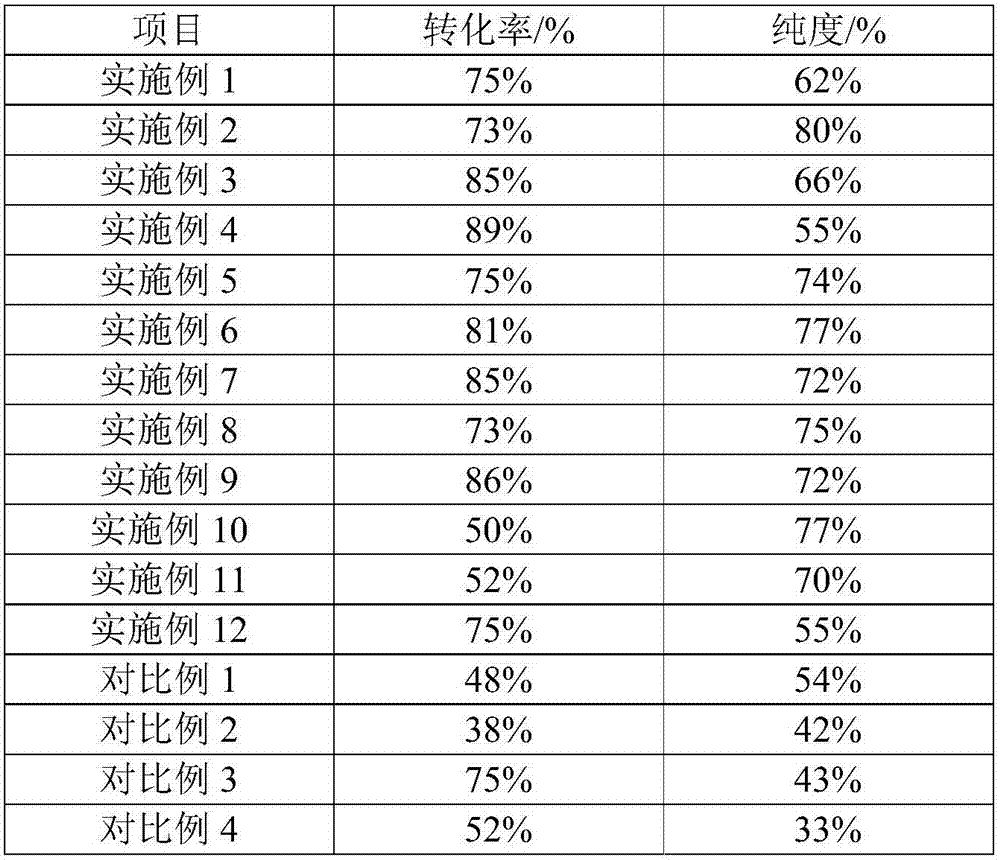

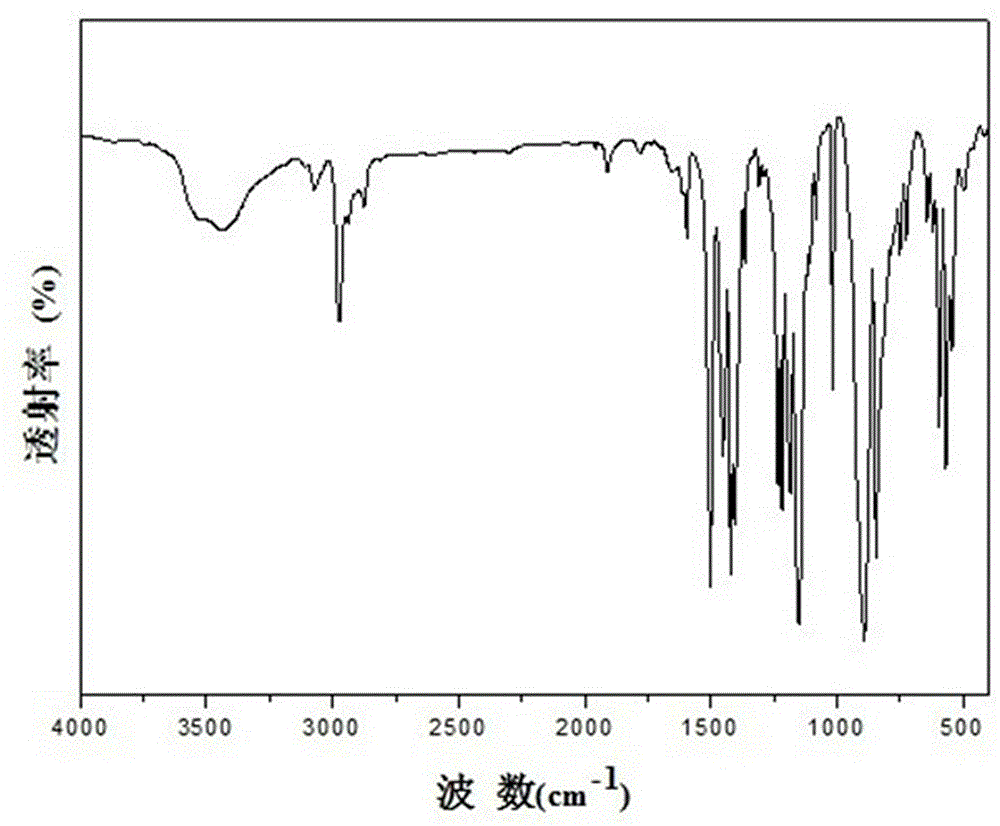

High-birefringence liquid crystal compound, and preparation method and composition thereof

ActiveCN106978192AHigh birefringenceLow melting enthalpyLiquid crystal compositionsSpatial light modulatorAlkoxy group

The invention discloses a high-birefringence liquid crystal compound, a preparation method of the high-birefringence liquid crystal compound and a composition containing the high-birefringence liquid crystal compound. The liquid crystal compound has a structure general formula (I) shown in the description, wherein X1, X2 and X3 is H or F; R is one of straight-chain alkenyl with a carbon atom number being 2 to 5 or fluoro alkenyl with a carbon atom number being 2 to 5. The liquid crystal compound comprises less than or equal to 40 percent (not zero) of compounds shown as the general formula (I), 1 to 40 percent of compounds shown as a general formula (II), 1 to 30 percent of compounds shown as a general formula (III) and 2 to 50 percent of compounds shown as a general formula (IV), wherein the general formulas are shown in the description; R1, R2 and R3 are respectively one of alkyl with a carbon atom number being 1 to 7, alkoxyl with a carbon atom number being 1 to 7 or fluoroalkyl with a carbon atom number being 1 to 5; X4 to X9 are respectively -H or -F. The high-birefringence liquid crystal compound has the advantages of high birefringence and low rotary viscosity, and is applicable to the fields such as space light modulators, laser detectors and 3D (3-dimensional) displays.

Owner:XIAN MODERN CHEM RES INST +1

Process for recovering metallic lead from waste lead-contained glass by adopting mechanical activation reduction method

ActiveCN104120444AThe post-processing process is simpleEasy to operatePhotography auxillary processesProcess efficiency improvementGalvanic depositionGlass ball

The invention discloses a process for recovering metallic lead from waste lead-contained glass by adopting a mechanical activation reduction method. Firstly, the lead-contained glass is crushed into 1-2 mm; the glass, a ball milling medium and a reducing agent are prepared based on the mass ratio of 1: (5-20) of the glass to the ball milling medium and the mass ratio of (0.05-0.3): 1 of the reducing agent to the lead in a raw material; and the ball milling activation is performed for 30-180 minutes at a rotating speed of 300-500 r / min in a planet ball mill; the lead-contained glass powder after the reduction activation is leached through sodium hydroxide solution; after the lead in the lead-contained glass is dissolved, the solid-liquid separation is achieved through filtering; and then, the metallic lead is extracted from the leaching agent by a traditional electrodeposition method. The process realizes the smelting recovery of the metallic lead in the lead-contained glass under the normal pressure by a direct alkaline wet method, is simple in technological flow and low in cost, and achieves the harmless treatment requirement when performing the resource treatment on the waste lead-contained glass.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY +1

Method for synthesizing epoxy soybean oil base polyol under heterogenous catalysis system

InactiveCN101397251AThe post-processing process is simpleGuaranteed purityMolecular sieve catalystsOrganic compound preparationEpoxyDistillation

The invention relates to a method for synthesizing epoxidized soybean oil-based polyol under a heterogeneous catalytic system; the method comprises the steps: epoxidized soybean oil, anhydrous methanol and a catalyst are added in an autoclave, wherein, the weight ratio of the methanol to the epoxidized soybean oil is 1 to 5:1, the weight ratio of the catalyst to the epoxidized soybean oil is 0.005 to 0.25:1, the reaction temperature is 60 DEG C to 160 DEG C, the reaction pressure is the self-pressure, the reaction is started under the action of stirring, the reaction time is 1.5 to 20 hours, the catalyst is filtered out after the completion of the reaction, and the epoxidized soybean oil-based polyol is obtained by distillation under the reduced pressure. The method has the advantages of simplifying the post-treatment process, ensuring the product purity and avoiding the environmental pollution.

Owner:JIANGSU SHUANGBAO TECH

Strain for generating pullulan and method for producing pullulan by fermenting strain

InactiveCN106754410ASimplify the post-processing processSimple methodFungiMicroorganism based processesLaboratory cultureNomenclature

The invention discloses a strain for generating pullulan. The strain is a strain which is obtained from plant leaves and does not generate melanin. The classification and nomenclature of the strain is Aureobasidium pullulans HL-1 as a Latin name. The preservation number of the strain is CGMCC (China General Microbiological Culture Collection Center) No.10772. A method for producing the pullulan by fermenting the strain is simple and feasible; a product is high in conversion rate so as to facilitate later-stage separation and purification.

Owner:SHIHEZI UNIVERSITY

Preparation method of nano-silver particles

InactiveCN106964785AImprove conversion rateHigh purityMaterial nanotechnologyTransportation and packagingPolyolAlcohol

The invention relates to a preparation method of nano-silver particles. The method comprises the steps that silver nitrate is dispersed in polyhydric alcohols to obtain silver nitrate dispersion liquid, and polyvinylpyrrolidone is dispersed in polyhydric alcohols to obtain polyvinylpyrrolidone dispersion liquid; and the obtained silver nitrate dispersion liquid and the obtained polyvinylpyrrolidone dispersion liquid are mixed, have a reaction and are subjected to solid-liquid separation, and the nano-silver particles are obtained. The preparation method is high in yield through one-step reaction preparation, the reaction system is simple and easy to control, and the preparation method can be used for batch production of the nano-silver particles.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

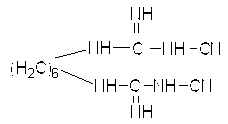

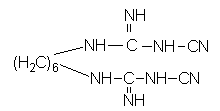

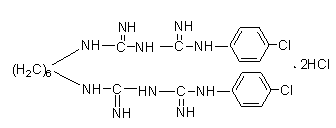

Preparation method of chlorhexidine compound

InactiveCN102993056ASimple processMild reaction conditionsOrganic chemistryOrganic compound preparationP-chloroanilineChemical synthesis

The invention discloses a preparation method of chlorhexidine compound and belongs to the field of organic chemical synthesis. The preparation method comprises the following steps: carrying out a heating reflux reaction on hexamethylene-dicyanoguanidine and chloroaniline hydrochloride as raw materials and glycol ether or normal butanol as a solvent to directly obtain a target compound in a single step. The preparation method is simple in process, mild in reaction condition, short in reaction time, rapid and efficient; as the glycol ether or normal butanol is used as the solvent, the influence of the toxic or side effect of the solvent on a human body is reduced, meanwhile the environmental pollution is reduced; and as a catalyst is not used in the synthesis process, an aftertreatment process is simplified, the synthetic comprehensive cost is effectively reduced, the yield of a final product can reach as high as 84.7%, the purity of the final product can reach as high as 97%, thus the preparation method has a better industrial application prospect.

Owner:GANSU RES INSTION OF CHEM IND GRICI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Bacterial strain for producing PMLA [Poly (Beta-L-malic acid)] and method for producing PMLA by fermentation of bacterial strain Bacterial strain for producing PMLA [Poly (Beta-L-malic acid)] and method for producing PMLA by fermentation of bacterial strain](https://images-eureka.patsnap.com/patent_img/bd7d7ade-f1e4-41b3-8906-fdfc7168172e/110520142403.PNG)