Polymerization method of (ammonium) sulfate connexon polymer

A linker and polymer technology, applied in the field of polymer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Example 1. Synthesis of polysulfate-1 containing 4,4-dihydroxydiphenyl with a degree of polymerization of 5-1000.

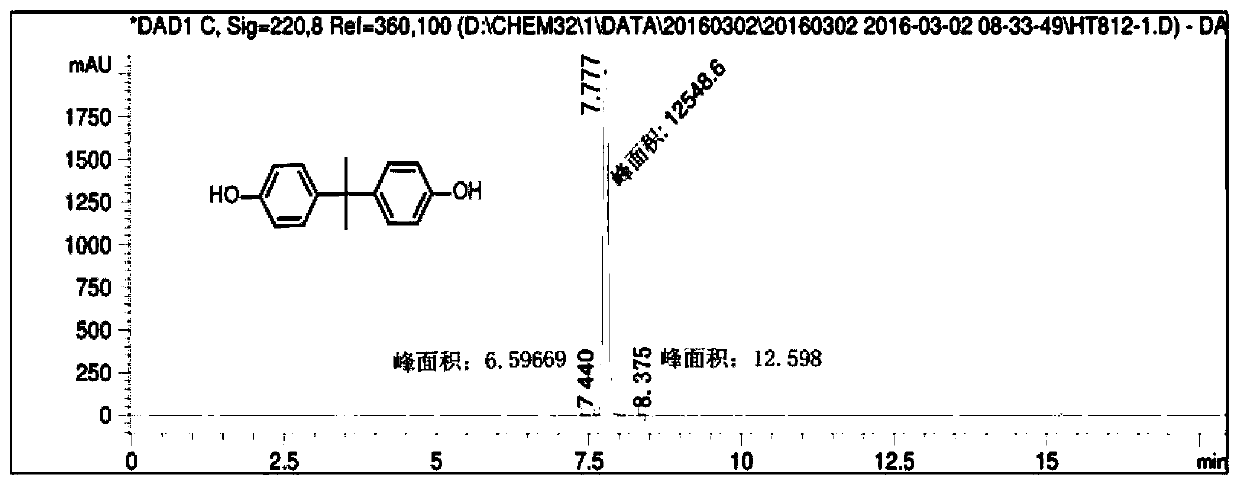

[0095] (1) Synthesis of sulfonyl fluoride-protected bisphenol: Dissolve 228 g (1 mol) of bisphenol A in 100 mL of dichloromethane or chloroform solution, add 24.2 g (2.40 mol) of triethylamine, and then carefully and continuously add Sulfonyl fluoride gas. The reaction was carried out at room temperature for 12 hours. After the reaction was completed, 388 g of sulfonyl fluoride-protected bisphenol A (the full English name of 1,4-phenylene bis(sulfurofluoridate)) was obtained as a dark brown solid after simple concentration, filtration and washing. The yield was : 99%.

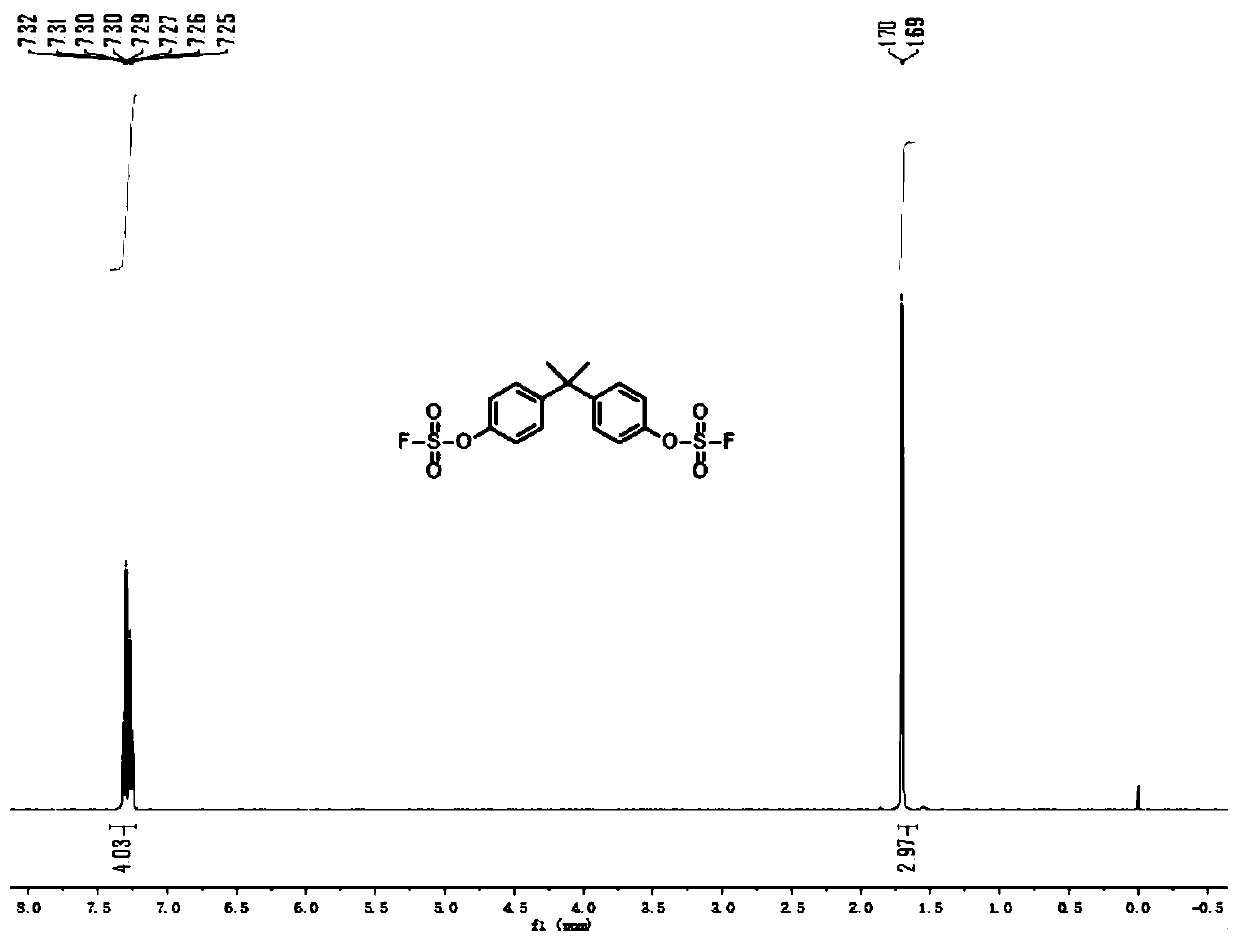

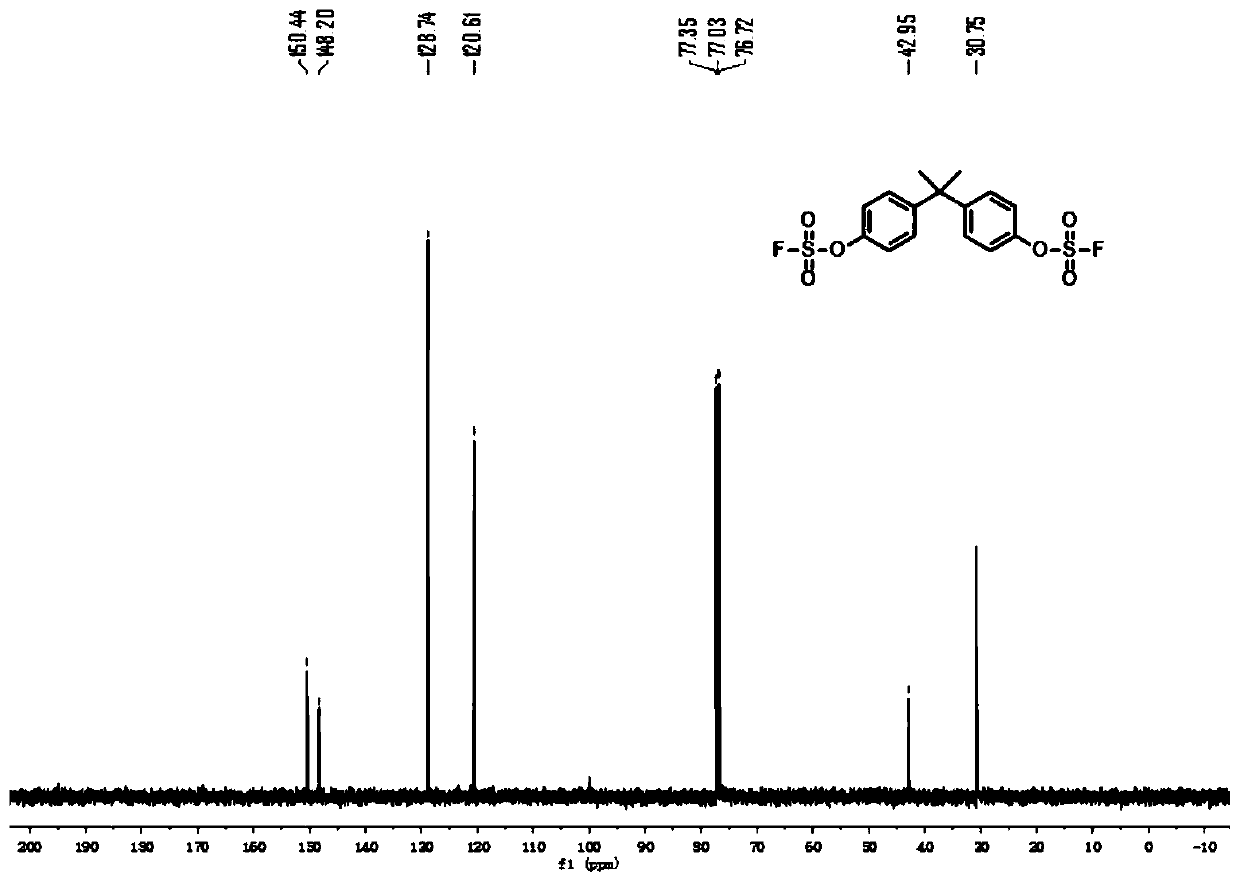

[0096] NMR data of the synthesized product: 1 H NMR (400MHz, CDCl 3 )δ7.36–7.15(m, 8H), 1.69(s, 6H).13C NMR (400MHz, CDCl) 3 )δ150.44, 148.20, 128.74, 120.61, 42.95, 30.75

[0097] The structural formula of the synthesized product is as follows:

[0098]

[0099] Experiments show t...

Embodiment 2

[0113] Example 2. Synthesis of polysulfate PSE-2 (PSE-2) containing 4,4-dihydroxydiphenyl ether with a degree of polymerization of 5 to 500

[0114] (1) Synthesis of bisphenol A protected by sulfonyl fluoride: same as Example 1.

[0115] (2) Synthesis of Bisphenol Polysulfate-2 (PSE-2) with a Degree of Polymerization of 10 to 500

[0116]

[0117] Under nitrogen protection, 392 g (10 mol) of sulfonyl fluoride-protected bisphenol A prepared above and 202 g (10 mol) of 4,4-dihydroxydiphenyl ether in an equal molar amount, 300 g of NMP solvent, and 50 g of xylene were heated. After completely dissolving, add 120% molar weight (1.2mol) of catalyst potassium carbonate, react under mechanical stirring at 130 ° C for 2 hours, heat up to 170 ° C and react for 12 hours, then pour the mixture into water to terminate the reaction, and separate the precipitated polymer product. , extracted with ethanol and dried to obtain 4,4-dihydroxydiphenyl-containing polysulfate PSE-2 as a white sol...

Embodiment 3

[0119] Example 3. Synthesis of polysulfate PSE-3 (PSE-3) containing 4,4-dihydroxydiphenyl sulfide with a degree of polymerization of 5 to 500

[0120] (1) Synthesis of bisphenol A protected by sulfonyl fluoride: same as Example 1.

[0121] (2) Synthesis of Bisphenol Polysulfate-3 (PSE-3) with a Degree of Polymerization of 10 to 500

[0122]

[0123] Under nitrogen protection, 392 g (10 mol) of sulfonyl fluoride-protected bisphenol A prepared above and 218 g (10 mol) of 4,4-dihydroxydiphenyl sulfide in an equal molar amount, 300 g of NMP solvent, and 50 g of xylene were prepared. After heating to dissolve completely, add 120% molar weight (1.2mol) of catalyst potassium carbonate, react at 130 ° C under mechanical stirring for 2 hours, heat up to 170 ° C and react for 12 hours, then pour the mixture into water to terminate the reaction, and separate the precipitated polymerization. The product was extracted with ethanol and dried to obtain 4,4-dihydroxydiphenyl-containing po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com