Patents

Literature

259results about How to "The reaction conditions are mild and easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

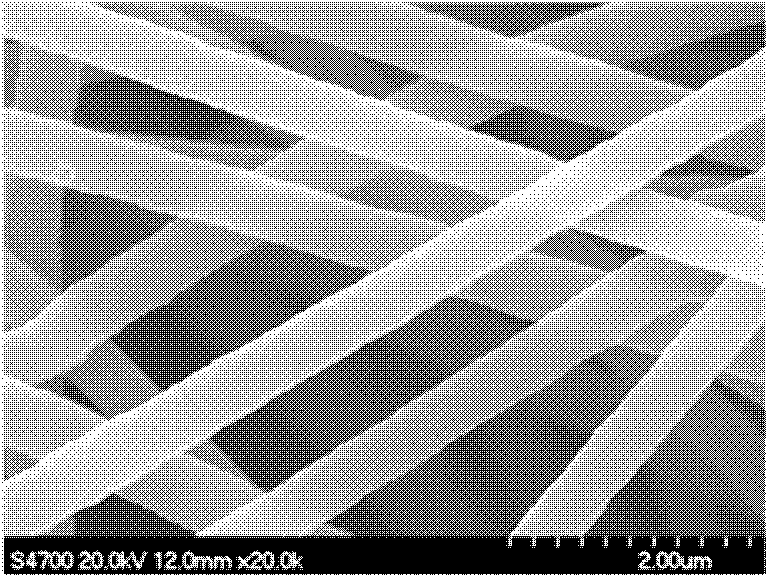

Method for modifying surface of ultrafiltration membrane

InactiveCN102029117AThe reaction conditions are mild and easy to controlSimple and safe operationUltrafiltrationUltrafiltrationChemistry

The invention relates to a novel method for modifying the surface of a polysulfone ultrafiltration membrane, used for improving the pollution resistance of a separation membrane. In the invention, by using polysulfone as a surface modification basement membrane, a living radical is generated on the membrane surface with an ultraviolet initiator or a thermal initiator to further graft a hydrophilic monomer on the surface of the membrane, thereby finishing grafting modification to a polysulfone ultrafiltration membrane. The method is convenient to operate, efficiently inhibits generation of polysulfone main chain fracture and also keeps the interception performance of the ultrafiltration membrane. In the prepared ultrafiltration membrane, the hydrophilicity is obviously improved, and the pollution resistance is remarkably enhanced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

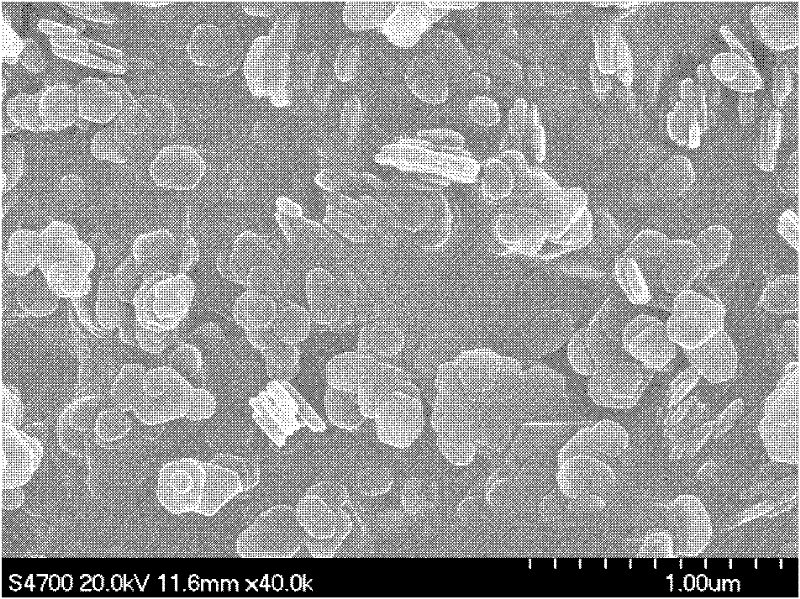

Preparation method of phenolic resin matrix nano activated carbon fiber material

InactiveCN102677193AIncrease flexibilityGood fiber diameterCarbon fibresHeating/cooling textile fabricsFiberCarbon fibers

The invention provides a preparation method of a phenolic resin matrix nano activated carbon fiber material. The preparation method is characterized in that the method specifically comprises the steps of: dissolving benzoxazine monomers and curing catalysts in solvent, adding blending polymers for electrostatic spinning, putting the obtained benzoxazine composite nano fiber membrane in a drying oven for curing, placing the cured benzoxazine composite nano fiber membrane in potassium hydroxide solution for soaking, taking out the benzoxazine composite nano fiber membrane and drying the benzoxazine composite nano fiber membrane in a drying oven to obtain the pretreated benzoxazine composite nano fiber membrane; and placing the pretreated benzoxazine composite nano fiber membrane in a vacuum tube furnace, heating for carbonization under the protection of nitrogen, cooling to room temperature after the carbonization process is ended, acidizing and drying to obtain the phenolic resin matrix nano activated carbon fiber material. The preparation method has a wide application prospect in fields such as activated adsorption, high-temperature catalysis, energy storage and hydrogen storage.

Owner:DONGHUA UNIV

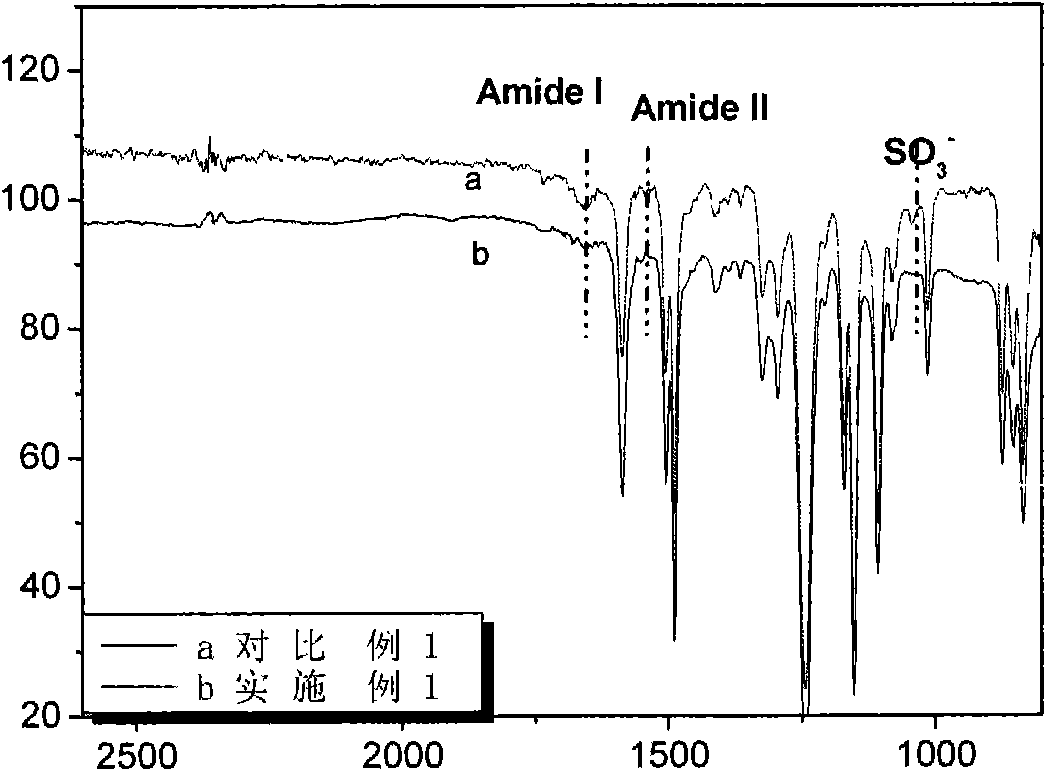

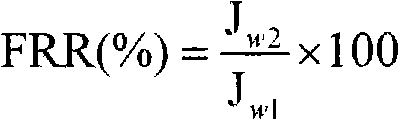

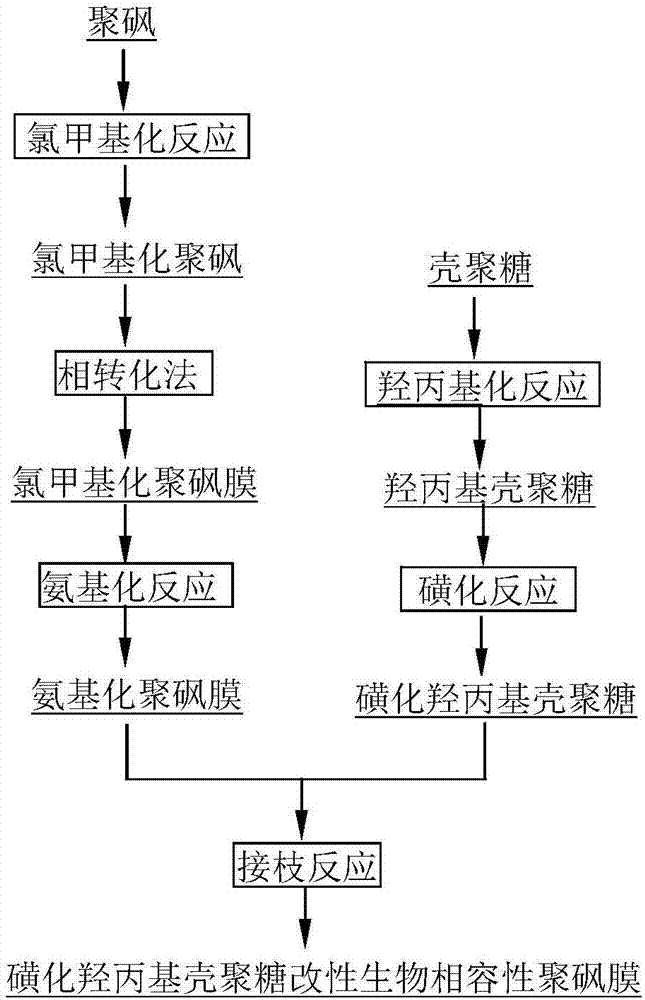

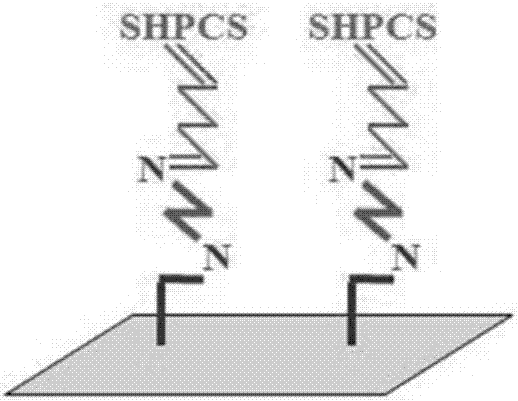

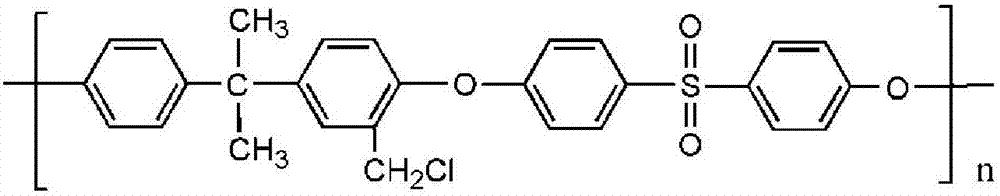

Sulfonated hydroxypropyl chitosan modified biocompatible polysulfone membrane and preparation method thereof

InactiveCN106943901AGood biocompatibilityTo achieve the purpose of anticoagulationSemi-permeable membranesPhase conversionSide chain

The invention relates to a sulfonated hydroxypropyl chitosan modified biocompatible polysulfone membrane and a preparation method thereof. The preparation method comprises the steps of chloromethylating polysulfone firstly so as to obtain chloromethylated polysulfone, and preparing a chloromethylated polysulfone membrane through a phase conversion method; using the chloromethylated polysulfone membrane as a base membrane and performing amination treatment on the chloromethylated polysulfone membrane, so as to obtain an aminated polysulfone membrane; and sulfonating chitosan so as to obtain sulfonated hydroxypropyl chitosan, and grafting a sulfonated hydroxypropyl chitosan hydrophilic side chain on the surface of the aminated polysulfone membrane through Schiff base reaction, so as to obtain the sulfonated hydroxypropyl chitosan modified biocompatible polysulfone membrane. The outstanding feature of the preparation method is to directly bond the sulfonated hydroxypropyl chitosan with a heparitin structure on the surface of the polysulfone membrane, so that the hydrophilicity, anticoagulation and anti-bacterial property are greatly enhanced. The preparation method is easy, the reaction conditions are mild and easy to control, and the preparation cost is low.

Owner:CENT SOUTH UNIV

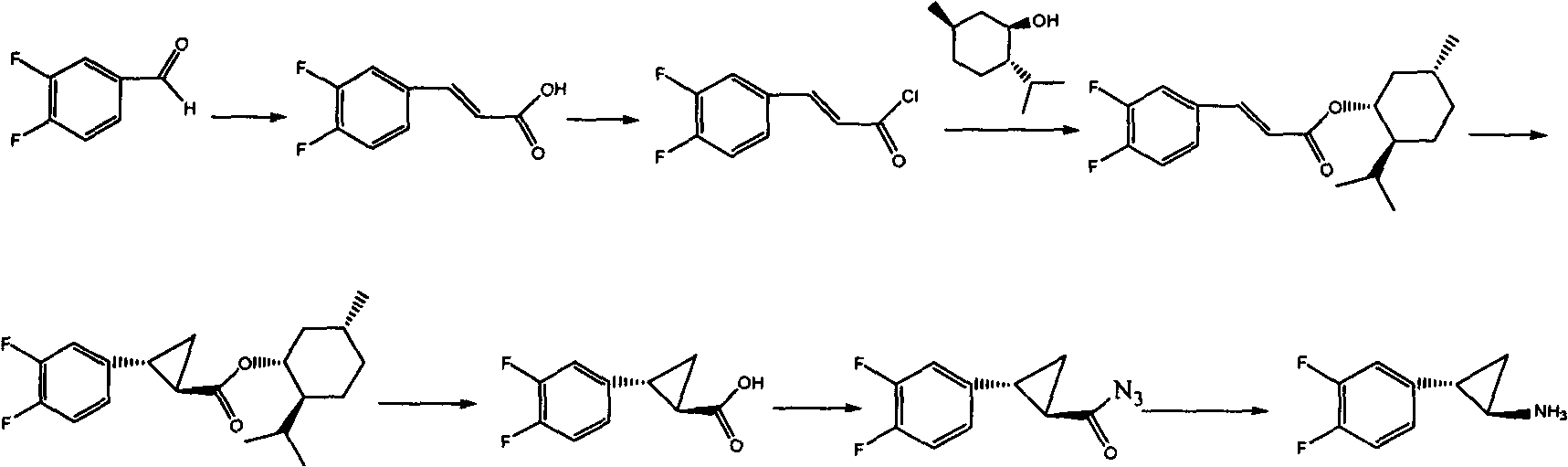

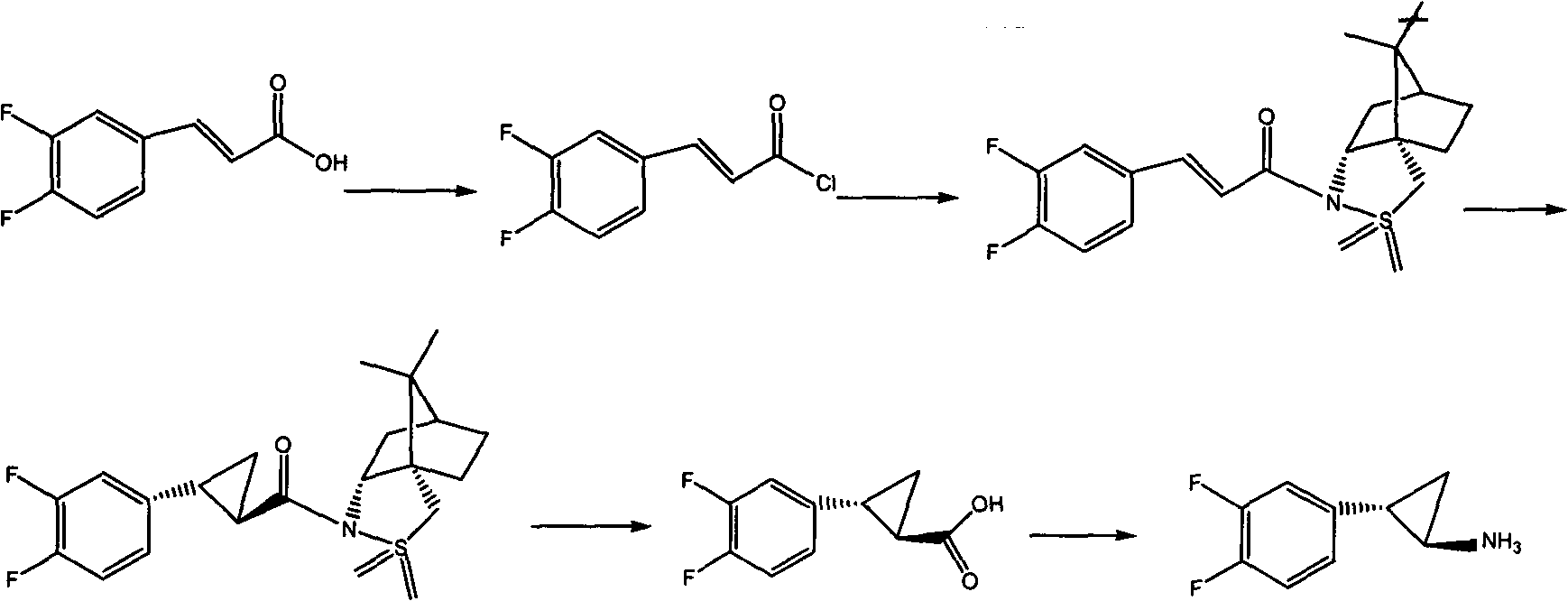

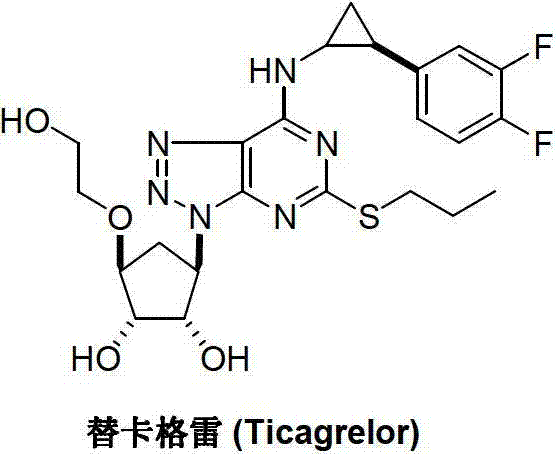

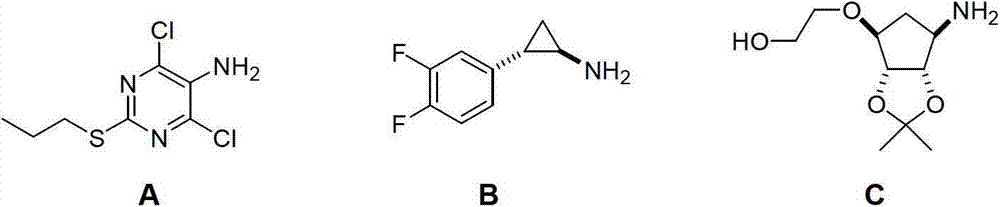

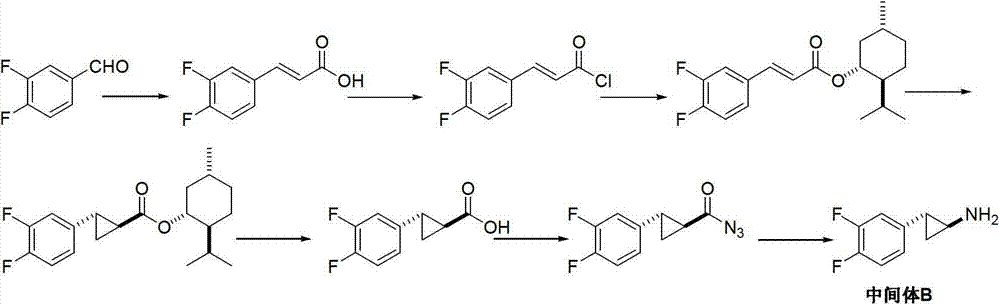

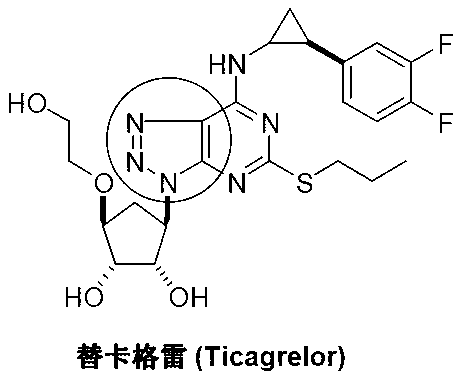

Preparation method of Ticagrelor intermediate

ActiveCN102796007AEasy to prepareEasy to operatePreparation by rearrangement reactionsChemical synthesisTicagrelor

The invention relates to the medicine chemical synthesis field, and especially discloses a preparation method of a Ticagrelor intermediate. The preparation method comprises the following steps: 1) taking 3,4-difluorobenzaldehyde (I) as an initial raw material, reacting with a phosphorus ylide material liquid to obtain (E)-3-(3,4-difluorophenyl)-2-acrylic acid ester (II); 2) performing a Simons-Smith asymmetric cyproteronethe reaction on the (E)-3-(3,4-difluorophenyl)-2-acrylic acid ester (II) to obtain trans-(1R,2R)-2-(3,4-difluorophenyl) cyclopropanecarboxylic acid ester (III); 3) performing aminolysis on the trans-(1R,2R)-2-(3,4-difluorophenyl) cyclopropanecarboxylic acid ester to obtain trans-(1R,2R)-2-(3,4-difluorophenyl)cyclopropanecarboxamide (IV); and 4) performing a Huffman rearrangement reaction on the trans-(1R,2R)-2-(3,4-difluorophenyl)cyclopropanecarboxamide (IV) to obatain the Ticagrelor intermediate (V). The method of the invention has the advantages of simple process, convenient operation, mild reaction condition and easy control, low cost and easy acquisition of raw material, high product yield and product purity, and is adapted to large scale industrial production.

Owner:JINAN RUIFENG PHARMA +2

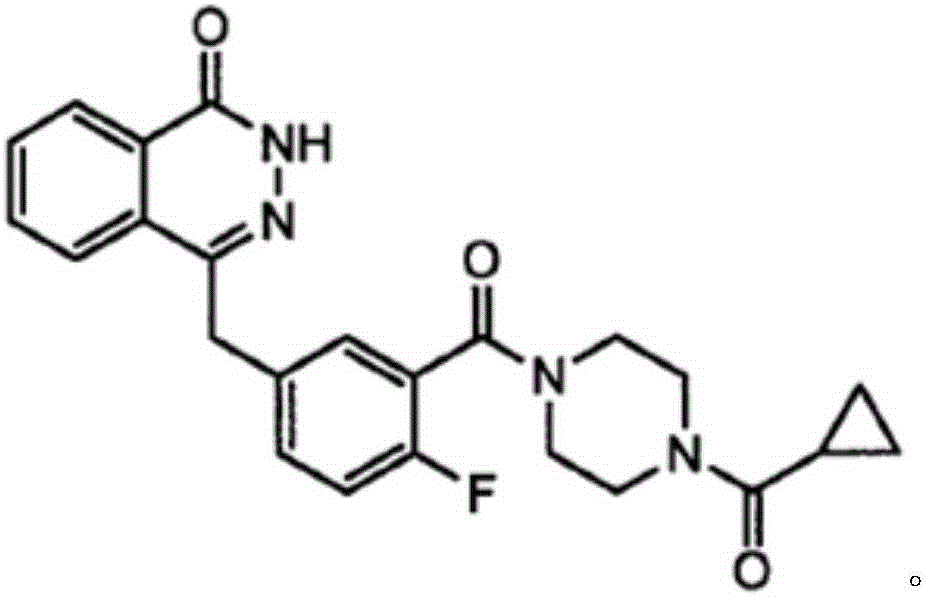

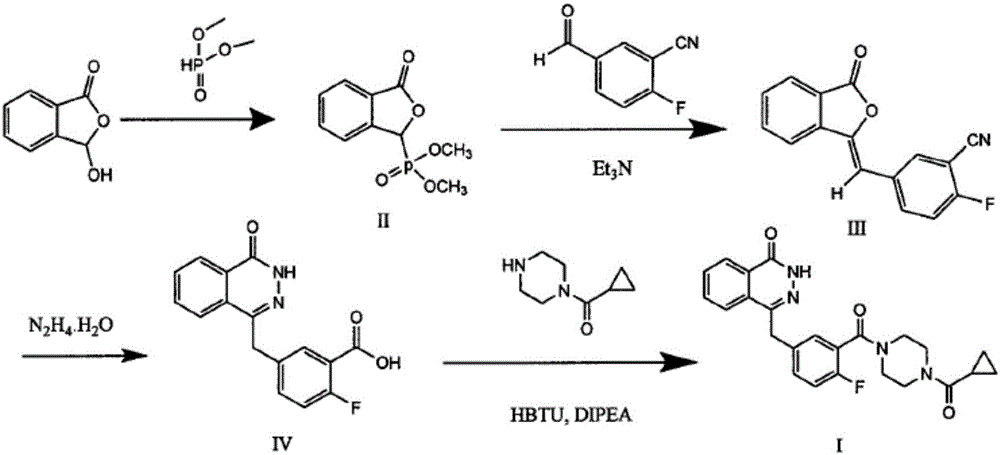

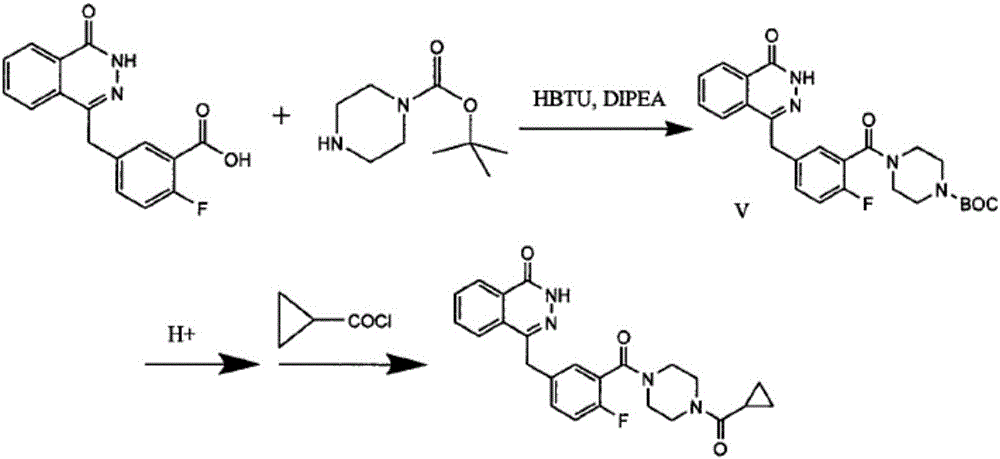

Preparing method for Olaparib

ActiveCN105820126AEasy to operateSimple processing capacityOrganic chemistryCatecholboraneBoric acid

The invention discloses a preparing method for Olaparib. 5-bromomethyl-2-fluorobenzaote serves as a raw material and is subjected to a boric acid reaction with catecholborane, and a compound 3 is obtained; the compound 3 is subjected to a Suzuki coupling reaction, and a compound 5 is obtained; the compound 5 is subjected to a hydrolysis reaction, and a compound 6 is obtained; the compound 6 reacts with a compound 7 under the action of a CDI catalyst, and Olaparib is obtained. According to the preparing method, the raw material is easy to obtain, the course is short, operation and posttreatment are simple, the reaction conditions in all the steps are mild, the reaction yields of all the steps reach 90% or above, the total yield is increased to 82.3% from 49% achieved in the prior art, and the preparing method is environmentally friendly and suitable for industrial production.

Owner:SHANDONG LUOXIN PHARMA GRP HENGXIN PHARMA CO LTD

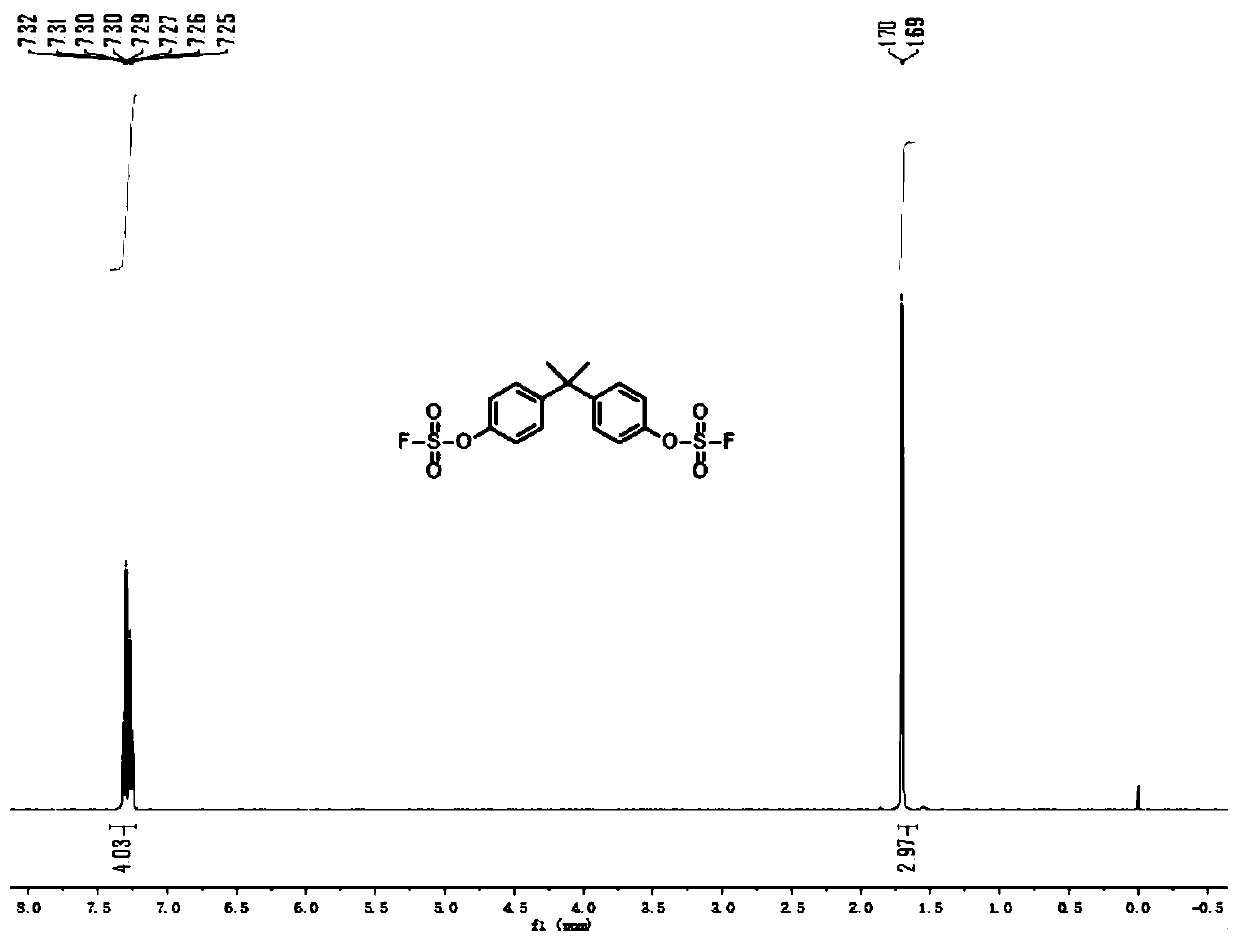

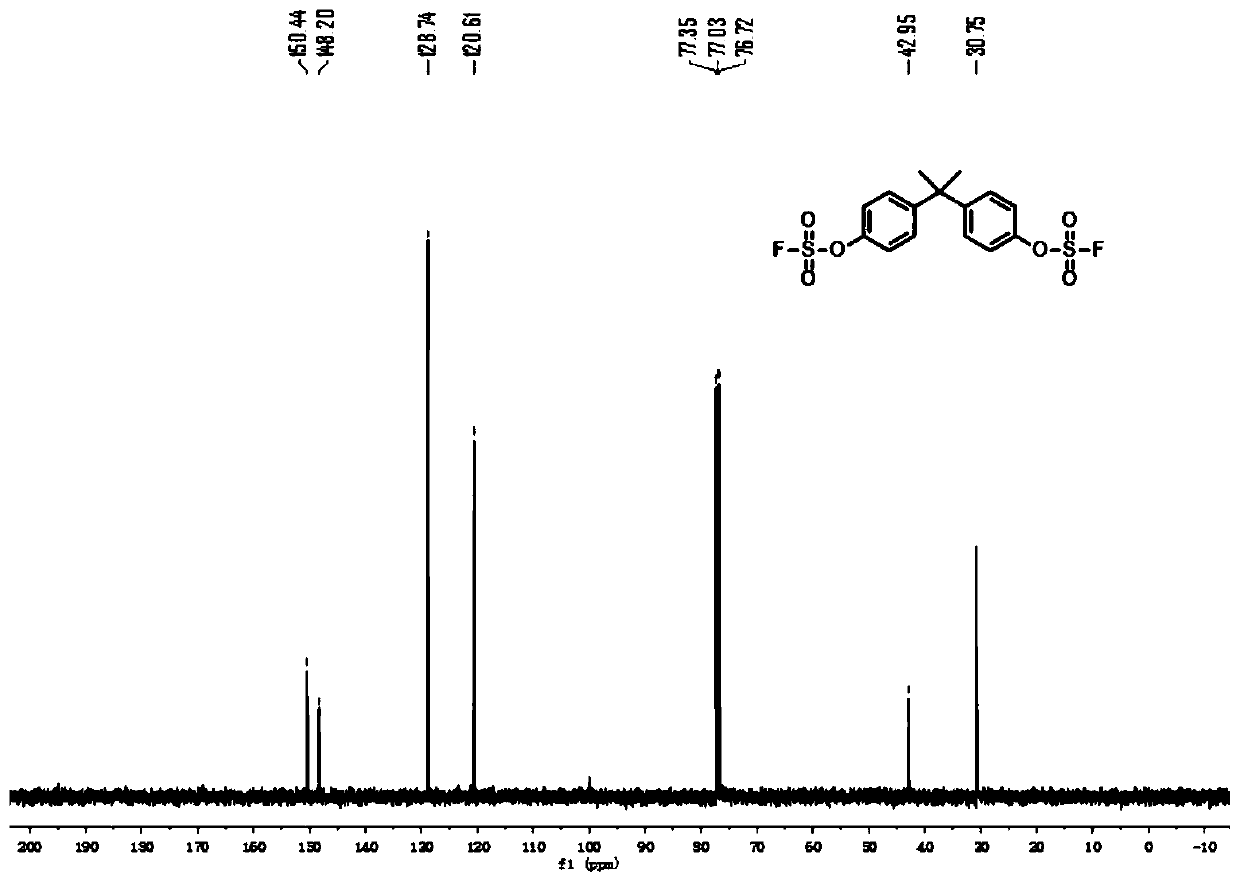

Polymerization method of (ammonium) sulfate connexon polymer

The invention relates to a polymerization method of an (ammonium) sulfate connexon polymer. The polymerization method comprises a step of subjecting a hydroxyl-containing monomer or an amino-containing monomer and a sulfuryl fluoride monomer to condensation polymerization on through a one-pot process under alkaline conditions. Compared with a traditional polyester synthesis method, the method is cost-saving; reaction conditions are mild and easy to control; reaction flow is simple, and operation is easy; and a post-treatment process is simple, environmental pollution is small, and industrial production is facilitated. In addition, a bisphenol type polysulfate compound synthesized in the invention has excellent mechanical properties, dielectric properties, tolerance and wear resistance.

Owner:内蒙古图微新材料科技有限公司

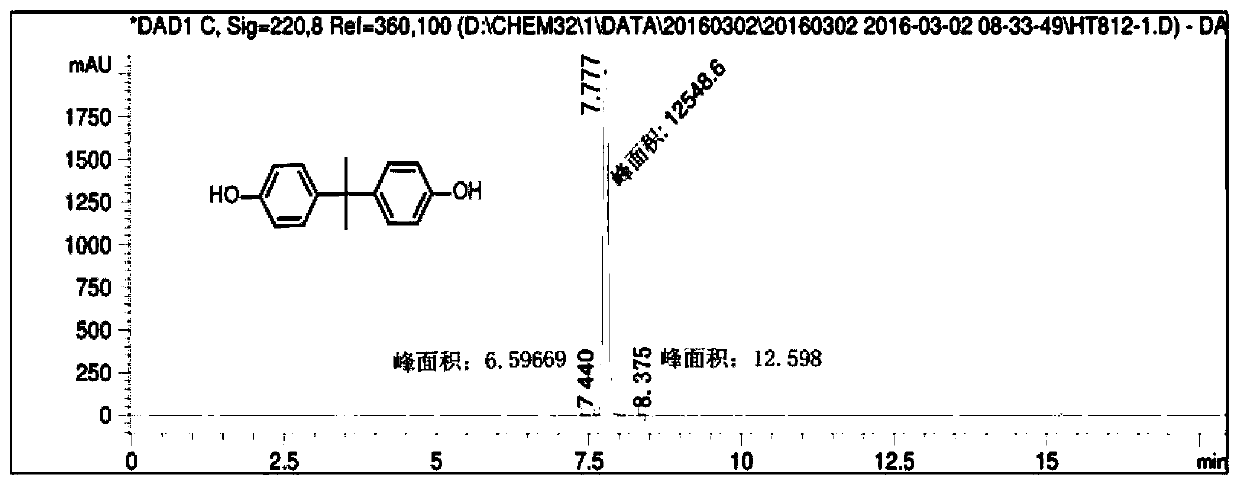

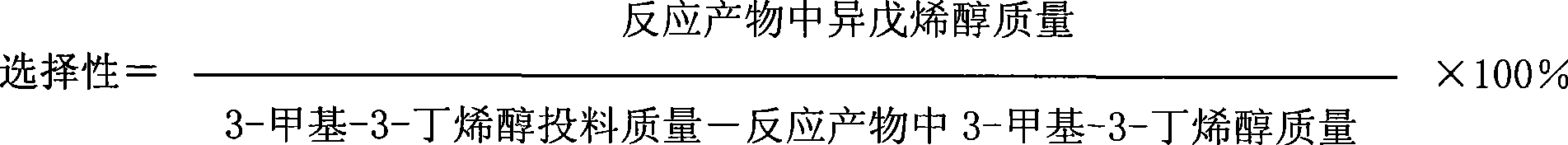

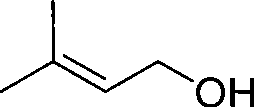

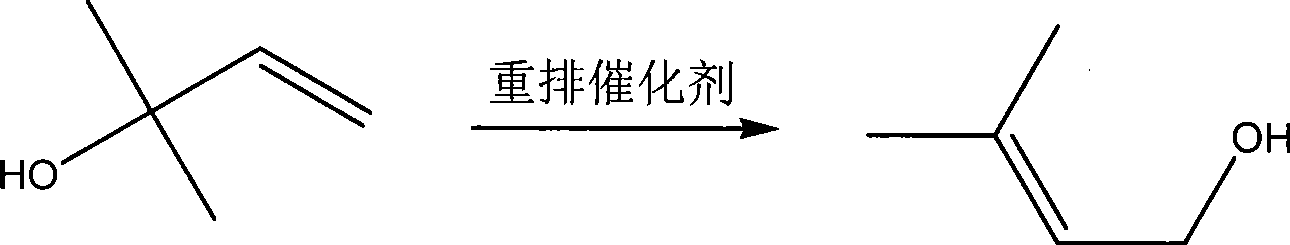

Method for preparing isopentenol from 3-methyl-3-butenol

ActiveCN101544538ALow content of active ingredientsReduce manufacturing costPreparation by isomerisationIsomerizationHydrogen

The invention relates to a method for preparing isopentenol from 3-methyl-3-butenol, which performs isomerization reaction on a raw material of 3-methyl-3-butenol to generate the isopentenol in the presence of a catalyst in an atmosphere containing hydrogen, wherein the reaction pressure is normal pressure, the reaction temperature is between 50 and 90 DEG C, the reaction time is between 25 and 40 minutes, the catalyst uses Al2O3 as a carrier, a load active component is metal Pd, the content of the Pd in the catalyst in percentage by weight is between 0.1 and 2.0 percent, the particle size of the catalyst is between 80 and 200 meshes, and the weight ratio of the raw material to the catalyst is 30-100:1. Compared with the prior art, the method has obvious improvement, the catalyst is simpler, and the content of the active component is lower, thus the preparation is easier and the cost is lower; the reaction condition is mild; and on the premise of ensuring the selectivity and the product yield of a perfect product, the reaction time is greatly shortened. The reduction of the preparation cost of the catalyst and shortening of the reaction time finally reduce the overall production cost greatly.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Bisphenol A type poly sulfuric acid (ammonia) ester compound and synthetic method thereof

ActiveCN104059228AImprove mechanical propertiesExcellent dielectric propertiesPolyesterPtru catalyst

The present invention discloses a bisphenol A type poly sulfuric acid (ammonia) ester compound, and belongs to the technical field of polymers. The bisphenol A type poly sulfuric acid (ammonia) ester compound is prepared as follows: using bisphenol A dioxygen sulfonyl fluoride as a raw material for reacting with trialkyl silicon group-protected bisphenol or diamine in the presence of an inert gas for protection and a catalyst at 30-120 DEG C for 3 to 36 hours; and pouring the reaction mixture into water to precipitate a polymerization product, namely the bisphenol A type poly sulfuric acid (ammonia) ester compound. The bisphenol A type poly sulfuric acid (ammonia) ester compound has excellent mechanical properties, dielectric properties, tolerance and wear resistance, and has broad application prospects in aerospace, electronic communications, electromechanical and microelectronic industries. In addition, the high reaction activity bisphenol A type dioxygen sulfonyl fluoride compound is used as a polyester synthetic raw material, and compared with a traditional polyester process, the reaction condition is mild and easy to control, the reaction process is simple and easy to operate; the after treatment process is simple, the environmental pollution is less, and the bisphenol A type poly sulfuric acid (ammonia) ester compound is favorable to industrial production.

Owner:内蒙古图微新材料科技有限公司

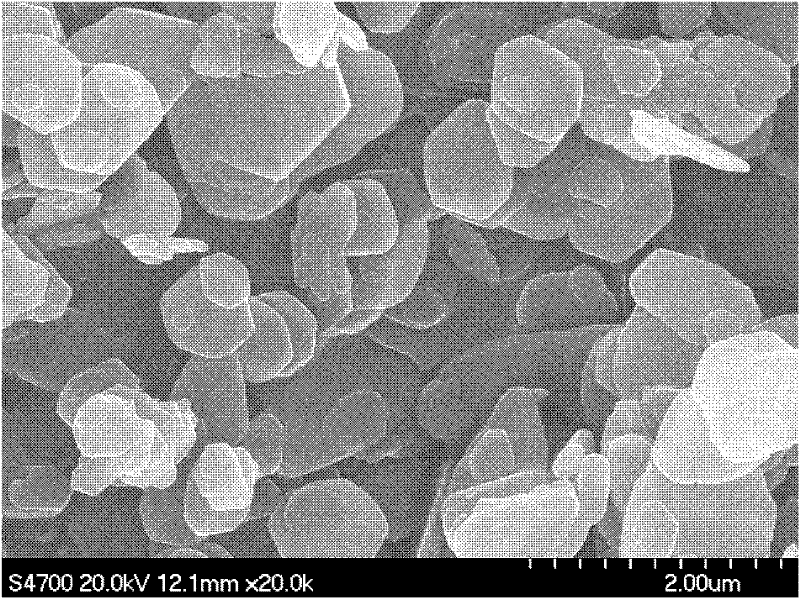

Method for preparing magnetic benzoxazinyl carbon nanofiber material

InactiveCN102653891ASolve the problem that it is difficult to evenly distributeStrong magnetismArtificial filament chemical after-treatmentArtifical filament manufactureFiberCarbon fibers

The invention provides a method for preparing a magnetic benzoxazinyl carbon nanofiber material. The method is characterized by comprising the following specific steps of: dissolving a benzoxazinyl monomer and a solid catalyst in a solvent to obtain a benzoxazinyl solution; adding a blending polymer and an iron-containing compound; carrying out electrostatic spinning and solidification treatment, placing the solidified benzoxazinyl composite nanometer fiber membrane in a potassium hydroxide solution to soak, taking out the solid benzoxazinyl composite nanometer fiber membrane and drying in a vacuum drying box to obtain a pretreated solid benzoxazinyl composite nanometer fiber membrane; placing the pretreated solid benzoxazinyl composite nanometer fiber membrane in a vacuum tube type furnace, heating to carry out carbonization treatment under the protection of nitrogen, cooling down to room temperature after finishing a carbonization process, carrying out acidizing treatment, and drying in the vacuum drying box, thereby obtaining the magnetic benzoxazinyl carbon nanofiber material. According to the method for preparing the magnetic benzoxazinyl carbon nanofiber material, magnetism is endowed to the material based on excellent performances of a carbon fiber so that the method has wider application prospect in the fields, such as solvent recovery, water treatment, gasoline trapping and the like.

Owner:DONGHUA UNIV

Novel hydrophilic hollow fiber membrane preparation method

The invention discloses a novel hydrophilic hollow fiber membrane preparation method, which comprises the following steps: firstly polyvinylpyrrolidone (PVP) is subjected to hydrolytic treatment to obtain partially hydrolyzed modified PVP; then the obtained modified PVP is blended with a polymer material, and the immersion and sedimentation method is adopted to prepare a hollow fiber membrane; finally a cross-linking agent is adopted to perform cross linking on the hollow fiber membrane after membrane forming so as to obtain a hydrophilic hollow fiber membrane with a cross-linking structure. According to the method, the reaction condition is mild and easy to control, and the operation is simple, convenient and safe; the modified raw materials are convenient and easy to obtain, and are low in cost; the stability of a hydrophilic modifier in the hollow fiber membrane is greatly improved after cross linking, and the hydrophilicity of the hollow fiber membrane is improved.

Owner:DALIAN TINSING TECH

Preparation method of moxifloxacin hydrochloride

The invention discloses a preparation method of moxifloxacin hydrochloride, comprising the steps of: reacting the 1-cyclopropyl-6,7-difluoro-8-methoxy-4-oxo-1,4-dihydro-3-quinoline carboxylic acid and the S,S-2,8-diazabicyclo[4.3.0]nonane to prepare the moxifloxacin in the presence of organic base in organic solvent under the reaction temperature of 60 to 85 DEG C; separating the moxifloxacin, processing the moxifloxacin by concentrated hydrochloric acid in organic solvent under the reaction temperature of 60 to 85 DEG C to obtain the moxifloxacin hydrochloride.

Owner:JIANGSU CHIA TAI FENGHAI PHARMA

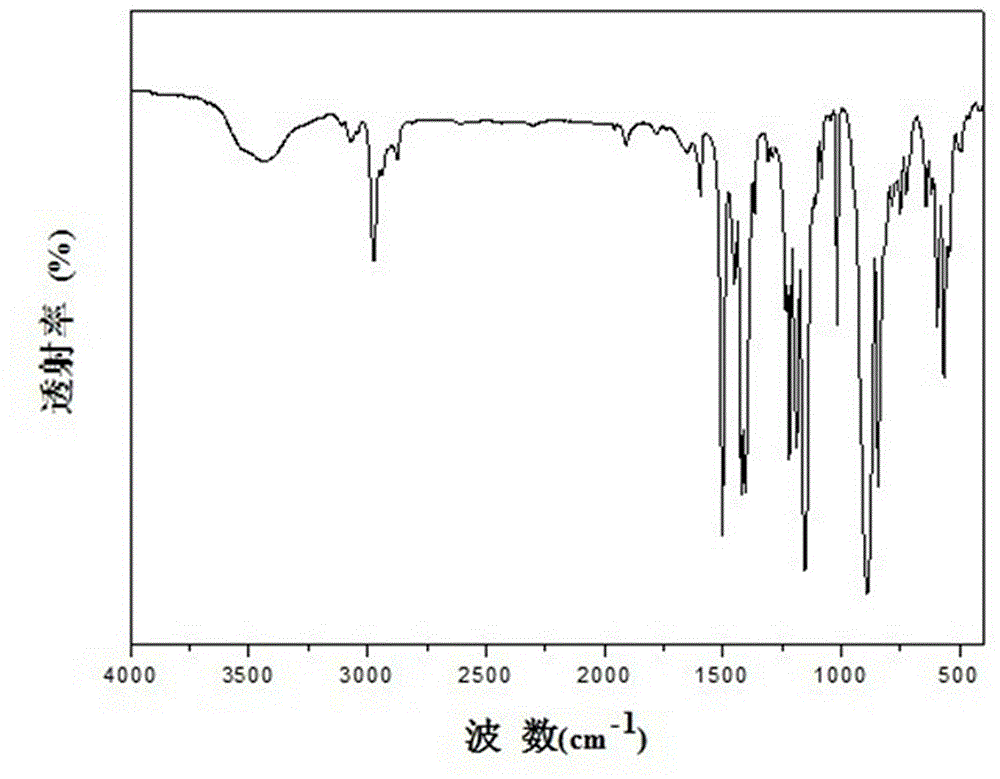

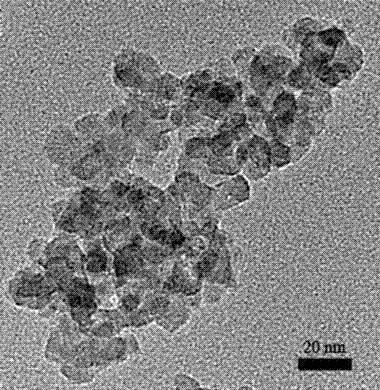

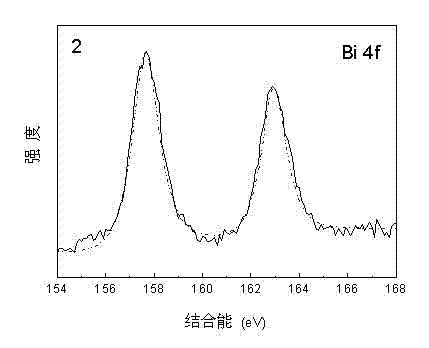

Bismuth and silicon doped nano titanium dioxide photocatalyst, its preparation and its application

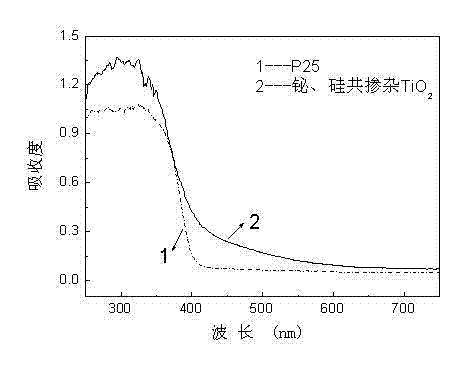

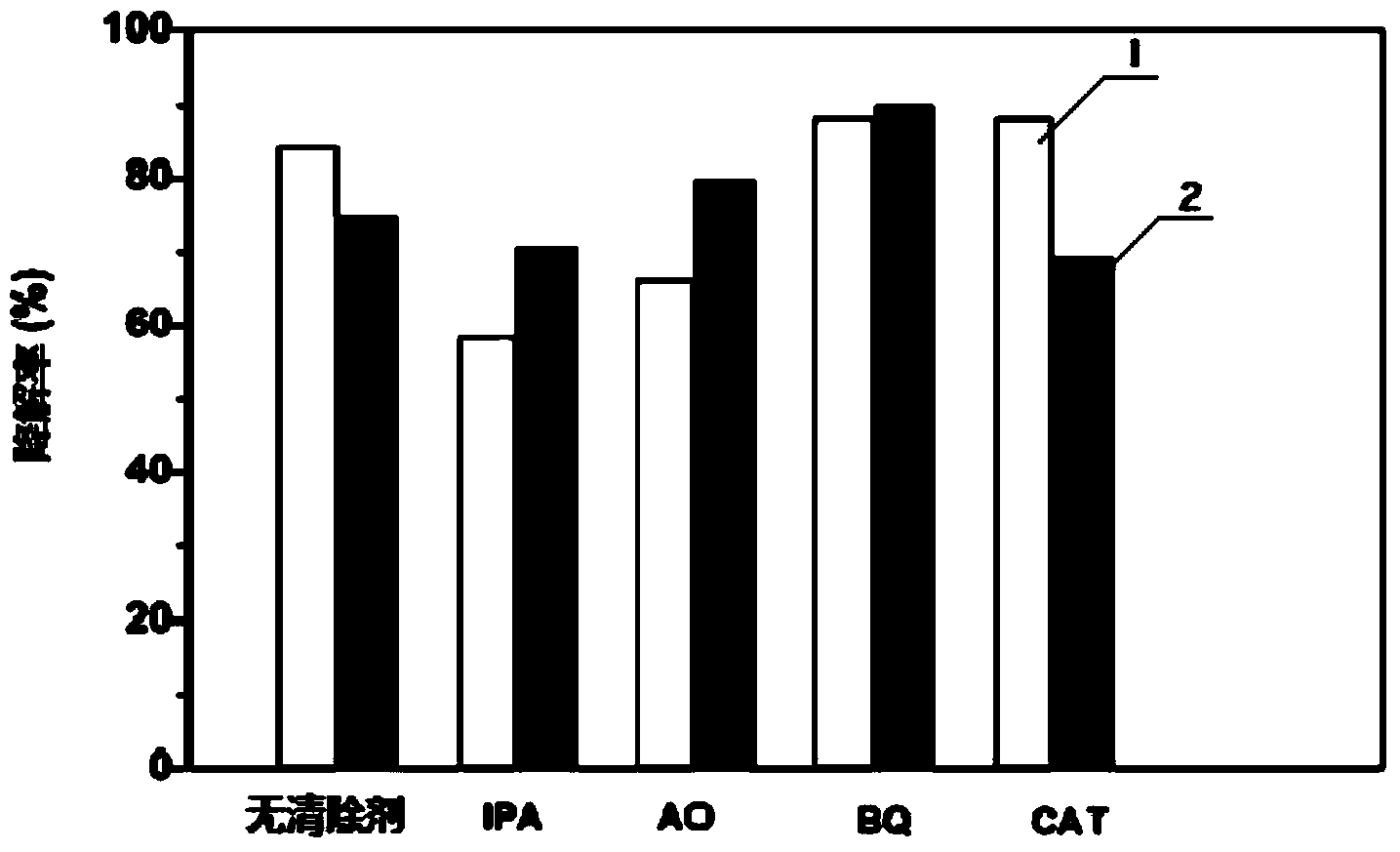

ActiveCN102380366AEasy to modify simultaneouslyFully contactedWater/sewage treatment by irradiationEnergy based wastewater treatmentPtru catalystPhotodegradation

The invention belongs to the nano titanium dioxide catalyst technical field, concretely relates to a bismuth and silicon doped nano titanium dioxide photocatalyst, its preparation and its application. The doping amount of bismuth in the catalyst by mole fraction is 0.2-1.1%, the doping amount of silicon is 4.8-15.6%. The bismuth and silicon doped nano titanium dioxide photocatalyst has the advantages of pure crystalline phase, high specific surface, multiple surface acidity points, visible light response and organic pollutant adsorption. The catalyst of the invention can be rapidly degraded by using visible light and sunshine, so that the catalyst keeps high visible photodegradation efficiency and high photocatalytic activity.

Owner:HENAN POLYTECHNIC UNIV

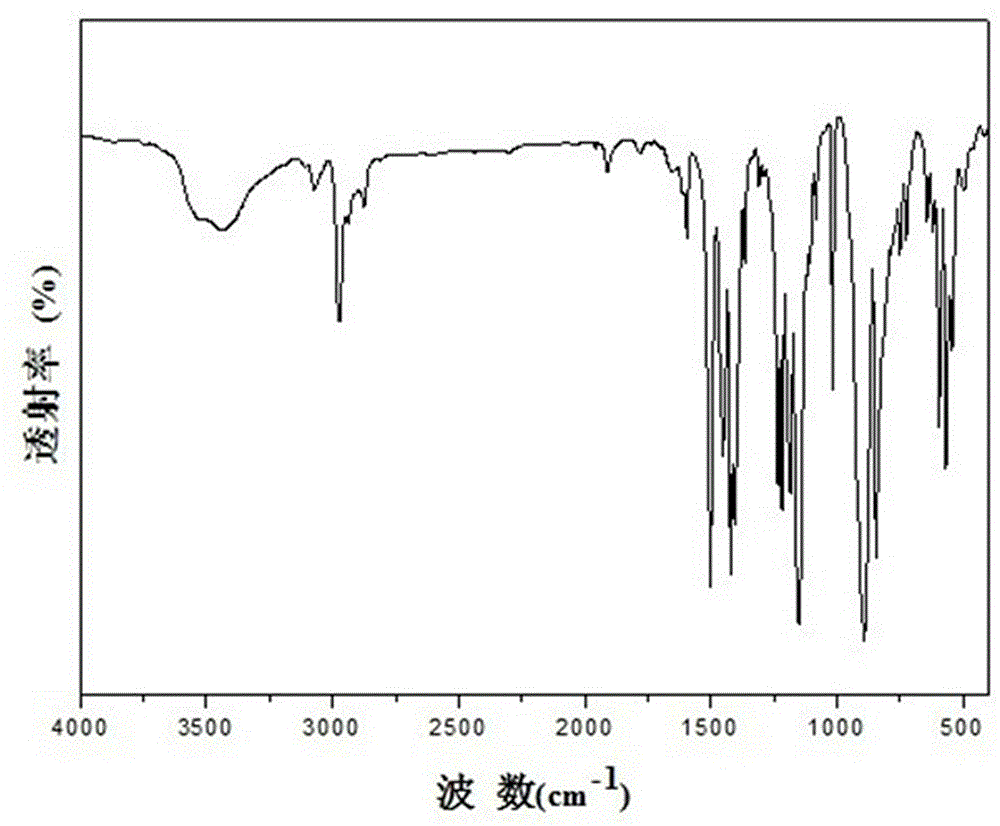

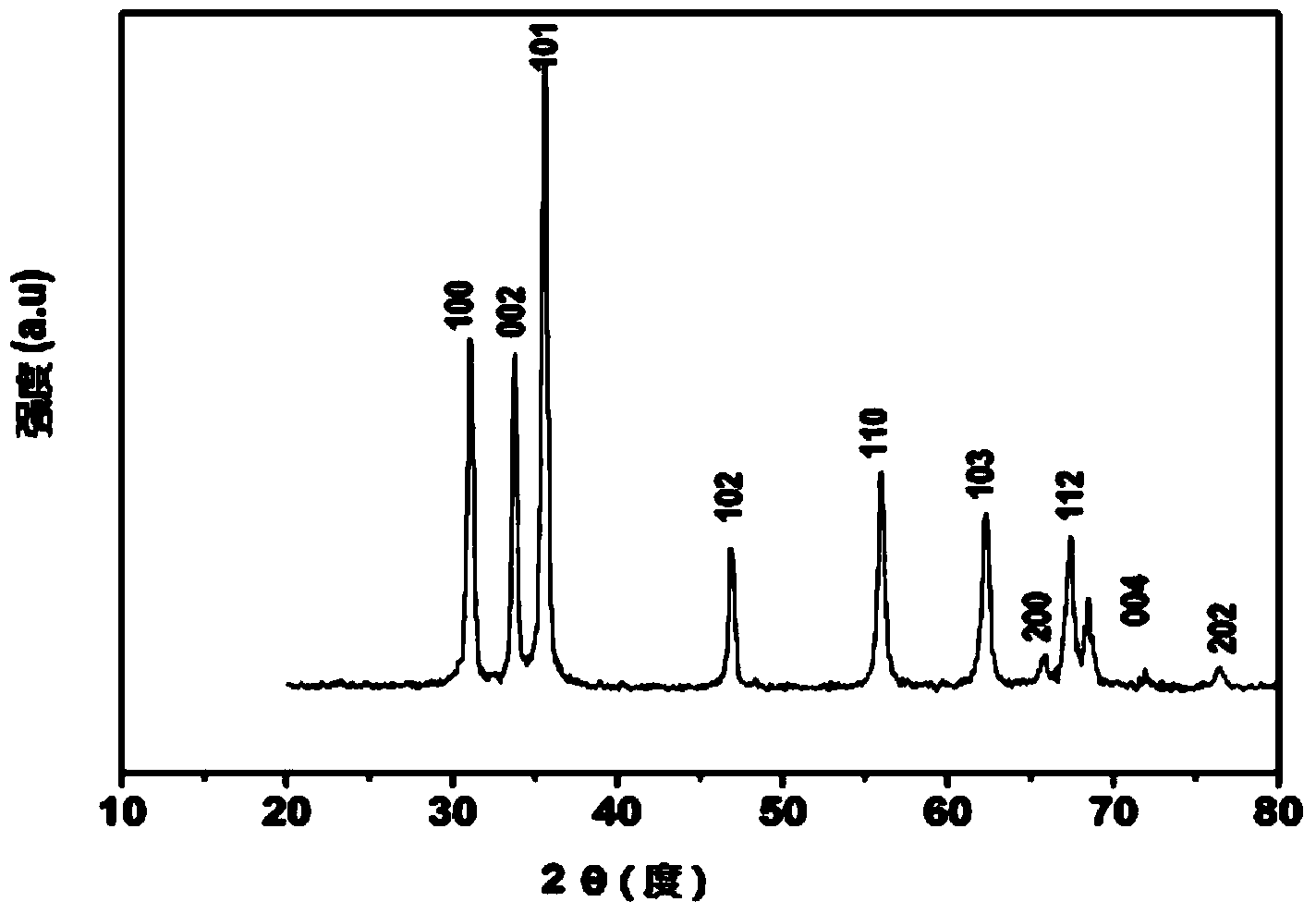

Preparation and application of nano zinc oxide photocatalyst

ActiveCN103816885ASave energyLow costWater/sewage treatment by irradiationEnergy based wastewater treatmentDiethylene glycolLength wave

The invention discloses a preparation method and an application of nano zinc oxide photocatalyst. The method takes zinc acetate dihydrate and diethylene glycol as raw materials and synthesizes the nano zinc oxide (ZnO) photocatalyst by hydrolysis in one step optionally under the presence of water. The method is short in synthetic route, mild in conditions and simple in operations. The prepared nano ZnO photocatalyst has good photocatalytic performance within the range of ultraviolet and visible wavelengths, and has good application prospects particularly in dye sewage treatment.

Owner:FUYANG NORMAL UNIVERSITY

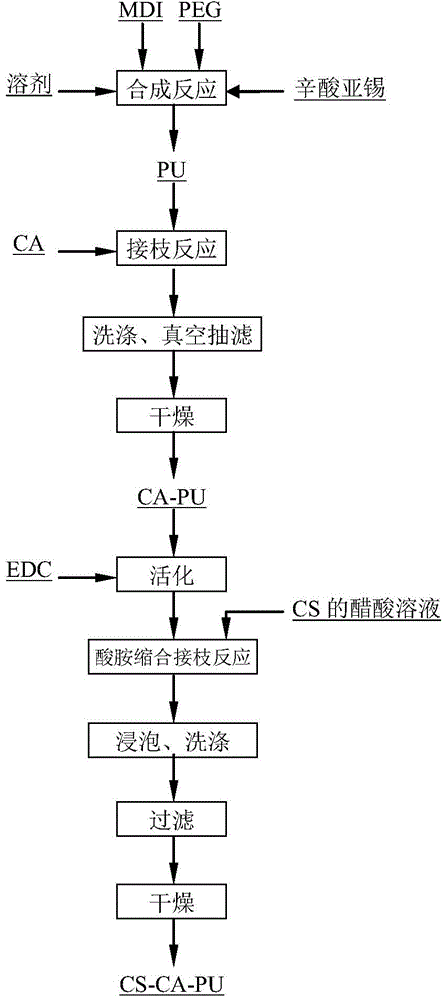

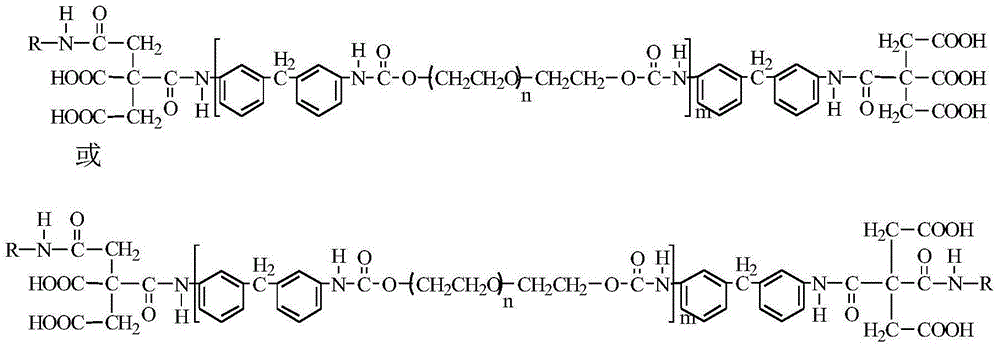

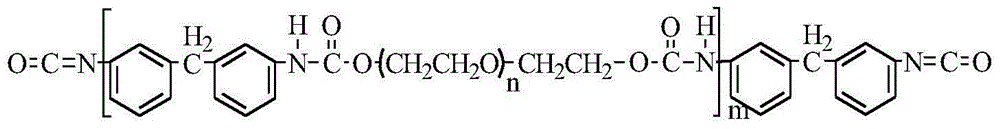

Citric acid and chitosan modified biocompatible polyurethane and preparation method thereof

The invention discloses a citric acid and chitosan modified biocompatible polyurethane and a preparation method thereof. A main chain of the polyurethane disclosed by the invention is a polyurethane long chain, the two ends of the long chain are respectively an anticoagulative citric acid structure covalently grafted with the long chain, and a chitosan structure is selectively grafted on the citric acid structure. The preparation method comprises the following steps: firstly, adding isocyanate, polyethylene glycol and a catalyst into a reactor, and carrying out stirring reaction for 2-5 h in the presence of nitrogen; then, adding a citric acid, and heating for reacting for 12-18 h, so that a citric acid modified polyurethane is obtained; and activating the citric acid modified polyurethane by using carbodiimide, and soaking the obtained object into a chitosan-acetic acid solution to carry out acid-amide condensation reaction, so that the modified biocompatible polyurethane is obtained. According to the citric acid and chitosan modified biocompatible polyurethane disclosed by the invention, the citric acid structures with biocompatibility and the chitosan structure are covalently bonded in the polyurethane long chain, so that the polyurethane has good chemical stability and biocompatibility, and can be used as a biomedical material; and the preparation method has the advantages of simple and easily-controlled process, low cost, and the like.

Owner:CENT SOUTH UNIV

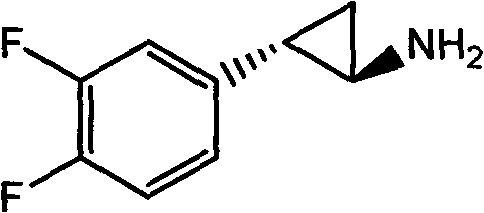

Method for preparing trans-(1R,2S)-2-(3,4-difluorophenyl) cyclopropylamine

InactiveCN103242171AEasy to prepareMild reaction conditionsOrganic compound preparationAmino compound preparationChemistryNitroethylene

The invention discloses a method for preparing ticagrelor intermediate trans-(1R,2S)-2-(3,4-difluorophenyl) cyclopropylamine (intermediate B). The method comprises the following steps of: carrying out condensation reaction between 3,4-difluorobenzaldehyde and nitromethane to obtain trans-beta-(3,4-difluorobenzene)nitroethylene (II); carrying ou cyclopropanation reaction of the compound (II), with zinc iodide and diethyl zinc under catalytic action of chiral ligand, thus generating trans-2-(3,4-difluorophenyl)nitrocyclopropylamine (III), and finally, carrying out nitroreduction reaction of the compound (III), thus obtaining the intermediate B. The preparation method provided by the invention is simple and convenient, economical and environment-friendly, and advantageous for industrial production of the drug; besides, the preparation method is also capable of promoting the development of the economic technology of the crude drug.

Owner:SUZHOU MIRACPHARMA TECH +1

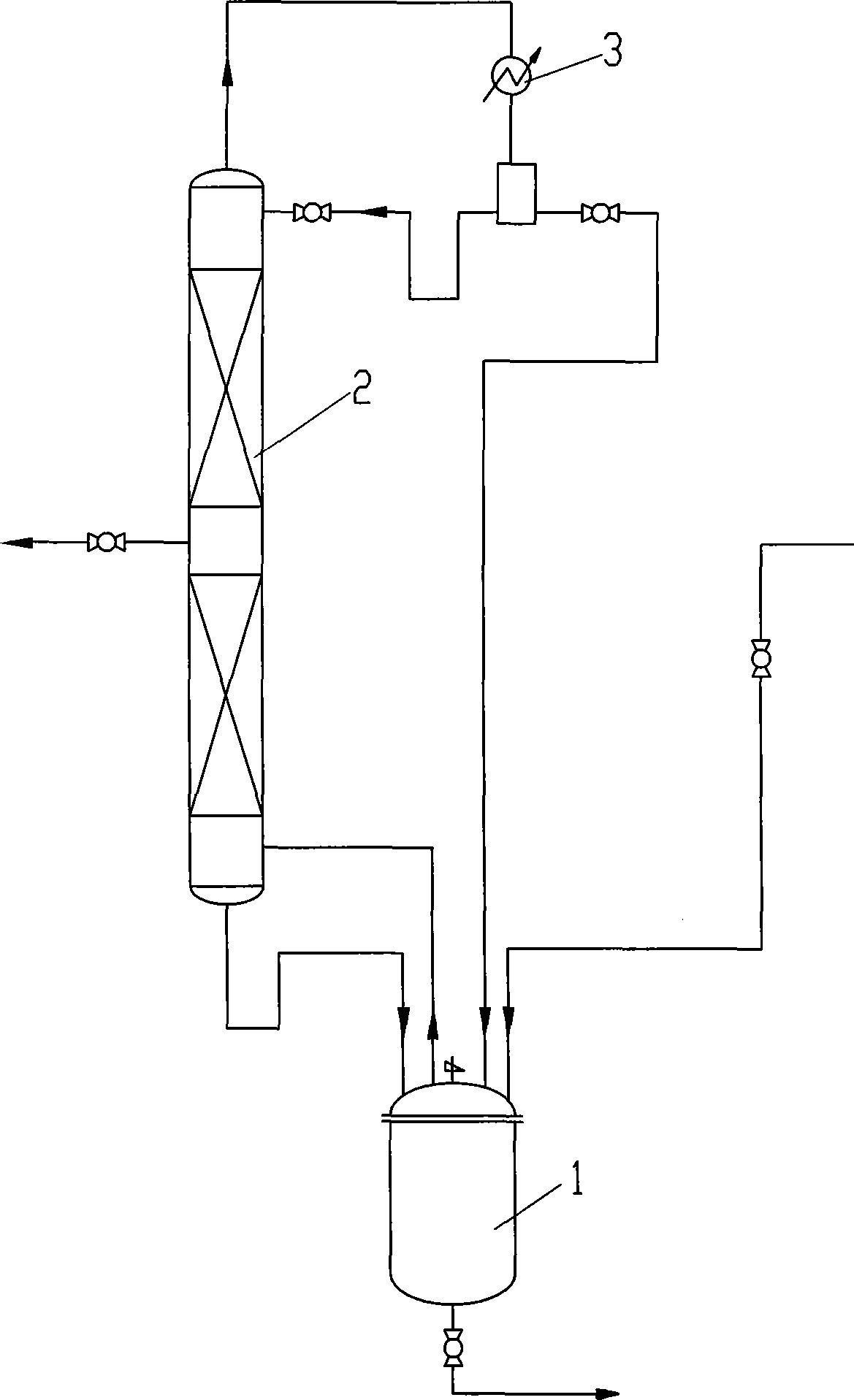

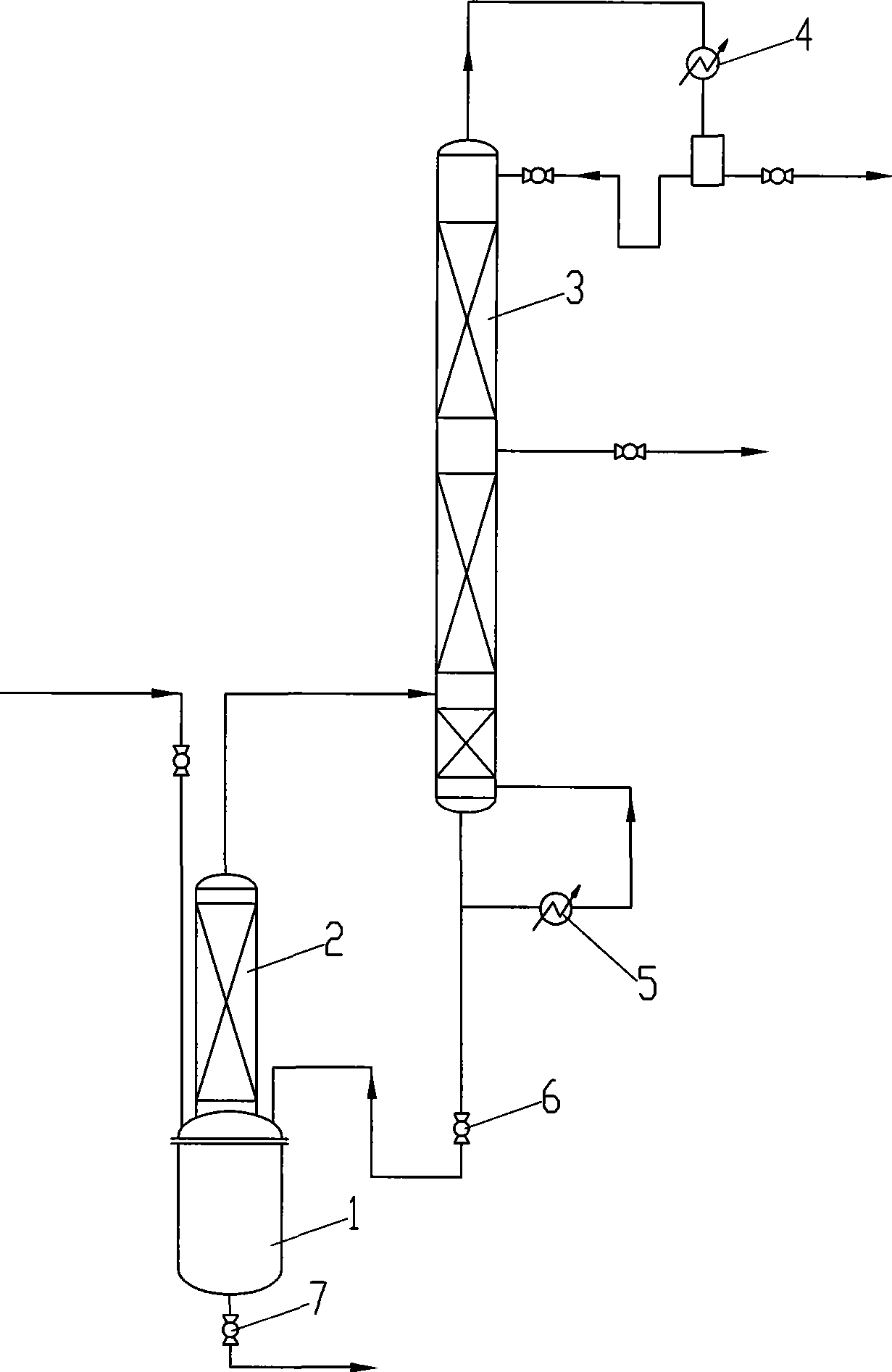

Method for continuously preparing 3-methyl-2-butenol

InactiveCN101381283AOperations that reduce recyclingRaw materials are easy to getPreparation by isomerisationButeneSolvent

The invention discloses a method for preparing intermediate 3-methyl-2-butenol. The prior method has the defects of rigorous conversion reaction condition, low conversion rate, difficult separation, and high technical requirement. The method has the following steps of: putting 2-methyl-3-butene-2-hydrin and rearrangement catalyst into a reaction kettle, and heating the 2-methyl-3-butene-2-hydrin and rearrangement catalyst to undergo a catalytical rearrangement reaction to obtain the mixture of the 2-methyl-3-butene-2-hydrin and the 3-methyl-2-butenol; separating the mixture through a rectification tower, recovering the 2-methyl-3-butene-2-hydrin at the top of the rectification tower and returning the 2-methyl-3-butene-2-hydrin to the reaction kettle for feeding, obtaining the crude product of the 3-methyl-2-butenol through discharging from a lateral line of the rectification tower, and continuously replenishing new 2-methyl-3-butene-2-hydrin into the reaction kettle. The method has the advantages of no use of solvent, mild reaction condition and easy control, and realizes the continuous production based on the continuous feeding and discharging.

Owner:ZHEJIANG NHU CO LTD +1

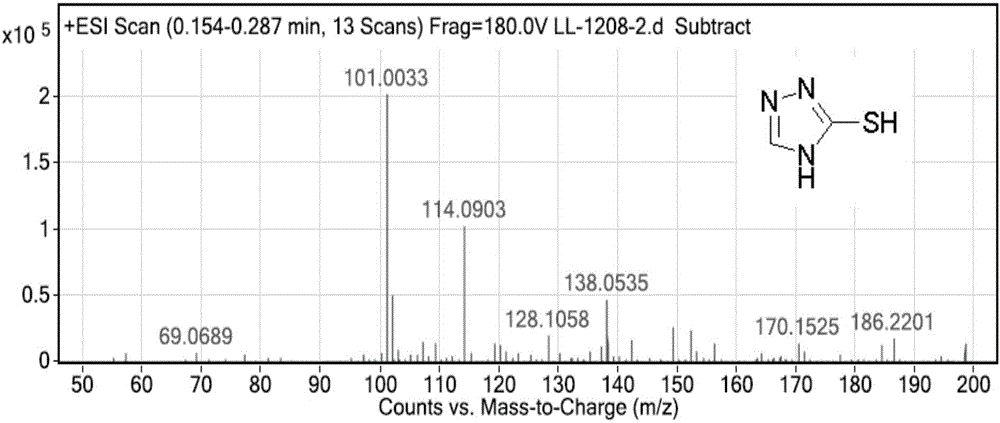

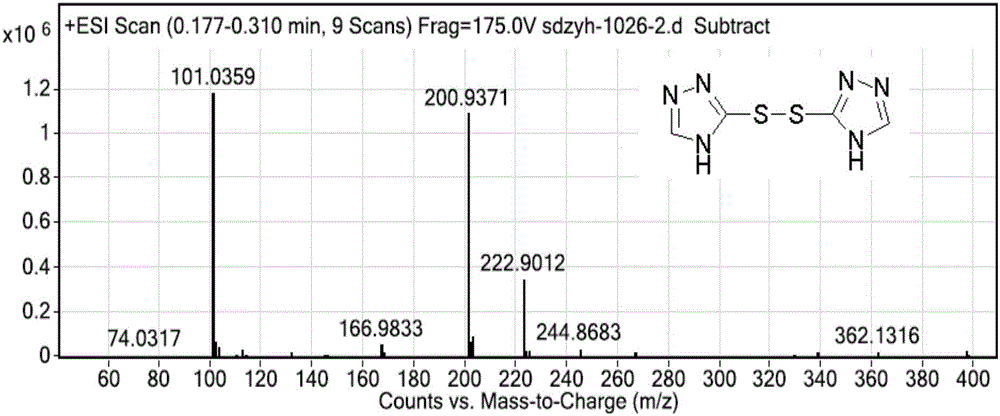

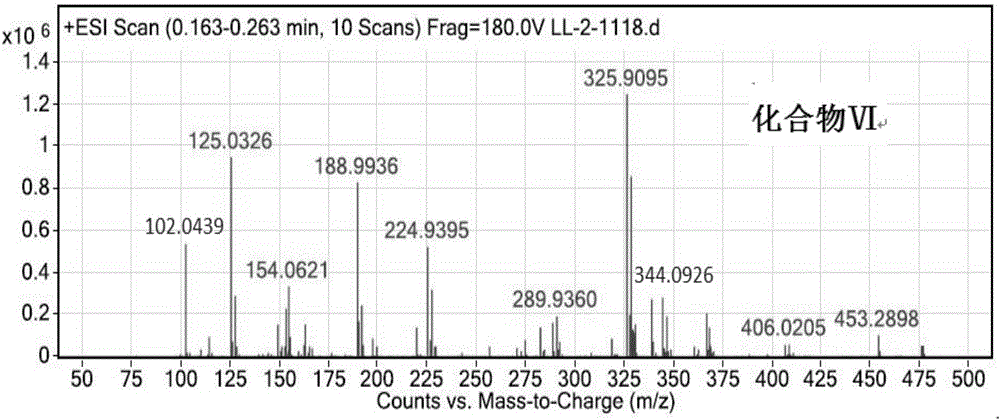

Intermediate compound, and synthetic method of prothioconazole

ActiveCN106749057ASynthetic raw materials are cheap and easy to obtainReduce manufacturing costOrganic chemistryPropanolGreen chemistry

The invention discloses an intermediate compound, and a synthetic method of prothioconazole. The method comprises the following steps: carrying out a substation reaction on 5,5'-dithio-bis(1,2,4-triazole) and 2-(1-chlorocyclopropyl)-3-chloro-1-(2-chlorophenyl)-2-propanol to obtain the key intermediate compound; and reducing the key intermediate compound to obtain the target product prothioconazole. The synthetic method has the advantages of high conversion rate, high selectivity, cheap and easily available synthesis raw materials, reduction of the production cost, mild and easily controlled technologic reaction conditions, simplicity in operation, easiness in product purification, obtaining of the product through direct re-crystallization, simple and accurate control method of intermediates in all steps, high product yield, good atom economy, avoiding of tedious post-treatment, large competition advantages and industrial production utilization values, avoiding of strong alkalis and other raw materials, extremely low three wastes, and according with the green chemistry idea.

Owner:NANJING TECH UNIV

Method for preparing magnesium hydroxide utilizing light-burned dolomite powder

InactiveCN102259898ASave resourcesGood for the environmentMagnesium hydroxideMagnesium carbonate hydroxideEmulsion

The invention discloses a method for preparing magnesium hydroxide utilizing light-burned dolomite powder. The method comprises the following steps: adding the light-burned dolomite powder to enough water for digestion; introducing a carbon dioxide gas to obtained light-burned dolomite emulsion until the pH value of the reaction product is 6.7-7.0, and filtering the product; adding absolute ethanol to filtrate, heating and controlling the temperature to 50-80 DEG C, and after reaction, filtering, wherein the amount of absolute ethanol is controlled to be 30-40% of the volume of the filtrate; adding hydrochloric acid to obtained solid magnesium bicarbonate until bubbles disappear; adding a base liquid to an obtained magnesium chloride solution; and adding polyvinylpyrrolidone or ethylenediamine to obtained magnesium hydroxide slurry, wherein the amount of polyvinylpyrrolidone or ethylenediamine is equal to 2-6% the volume of the slurry; and then adding the slurry into an autoclave, controlling the temperature at 80-200 DEG C and stirring under constant temperature condition for 10-20 hours. Magnesium hydroxide precipitate prepared by the method disclosed by the invention is in a fibrous or flaky crystal shape and has high purity; and the preparation method is simple to operate, and the reaction conditions are mild and easy to control.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

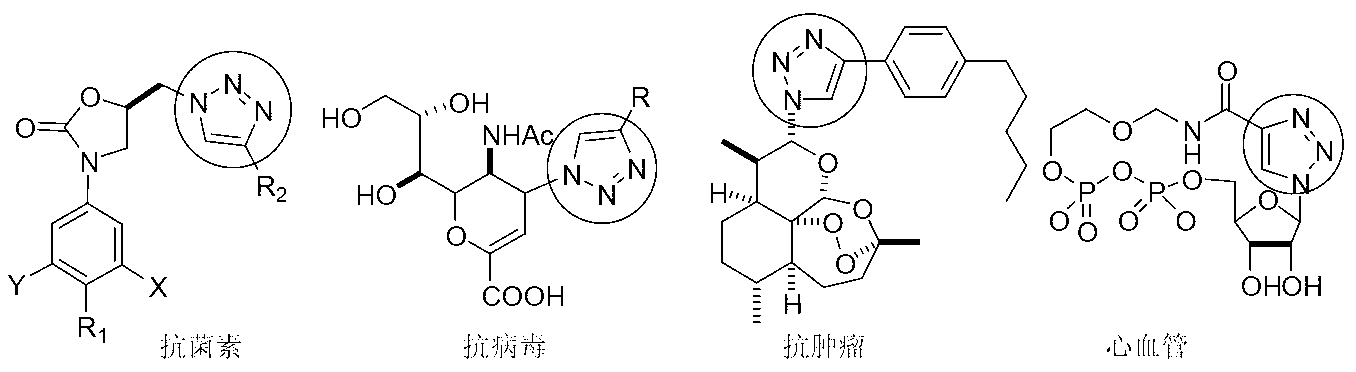

Azide and preparation method thereof

ActiveCN103304535AEasy to prepareThe reaction conditions are mild and easy to controlOrganic chemistryAbsolute configurationAzide

The invention discloses an azide and a preparation method thereof. The azide (I) can be used as a key raw material for preparing medicines with a 1,2,3-triazole structure, such as ticagrelor. The preparation method for the azide comprises the following step of: performing azidation reaction on an amino compound (II) and an azidation reagent (III) to obtain the azide (I). The preparation method is moderate in conditions, safe and environmentally-friendly, high in chemical yield, and especially capable of keeping the original absolute configuration and chiral purity.

Owner:徐州飞云泡沫制品有限责任公司

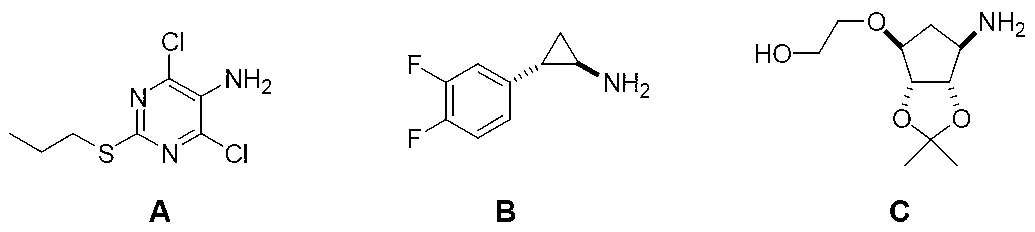

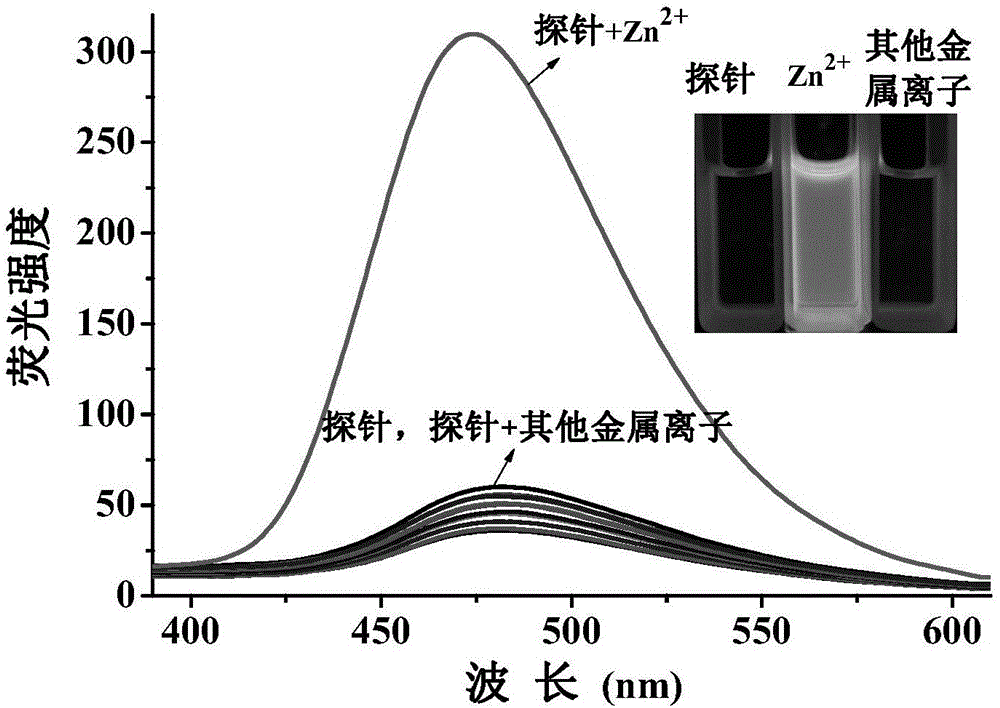

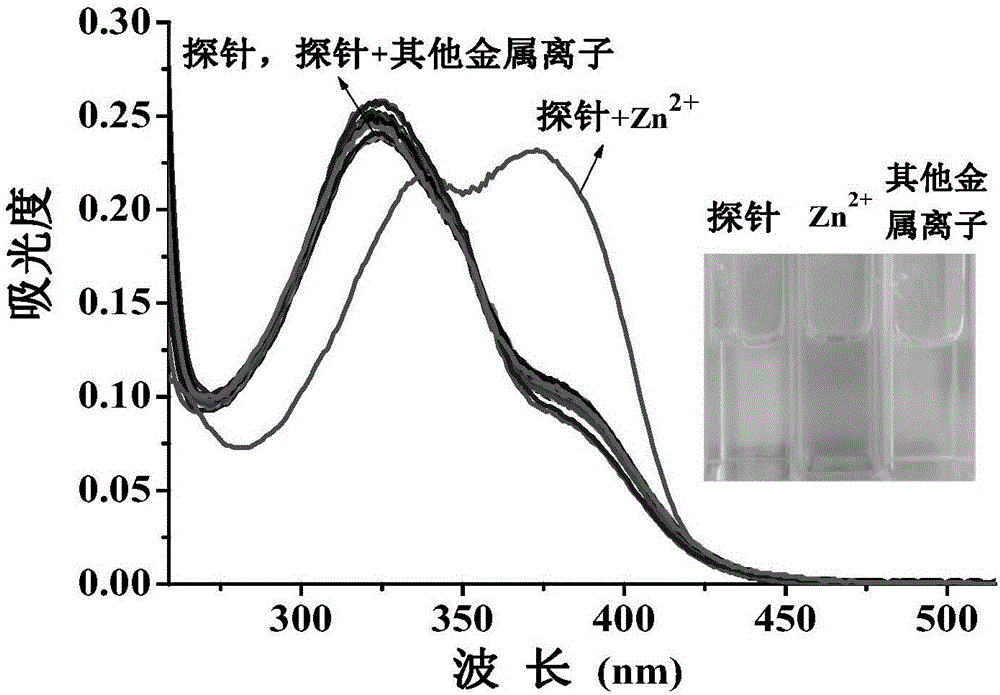

Thiosemicarbazone 7-umbelliferone-8-aldehyde probe reagent as well as preparation and application thereof

InactiveCN105885831AQuick checkLow detection limitOrganic chemistryColor/spectral properties measurementsIonFluorescence

The invention discloses a thiosemicarbazone 7-umbelliferone-8-aldehyde probe reagent which is prepared by enabling 7-hydroxyl-8-aldehyde coumarin and thiosemicarbazone to react. By adopting a probe disclosed by the invention, selective recognition of metal ions and anion can be achieved simultaneously, specific ions can be rapidly detected through visual colorimetric, the probe can be also applied to specific ion imaging detection in living cells, has double-mode detection with fluorescence enhancement and proportioning absorption, is relatively excellent in detection sensitivity and accuracy, has the advantages of high sensitivity, high selectivity, high yield and the like, and moreover is beneficial to quantitative and qualitative analysis on complex micro systems.

Owner:GUIZHOU UNIV

Surface treatment method for improving adhesive performance of fluorine-containing resin film

ActiveCN102911391AHigh bonding strengthDoes not significantly affect performanceUltravioletWavelength

The invention provides a surface treatment method for improving adhesive performance of fluorine-containing resin film, and relates to the field of surface ultraviolet grafting for the fluorine-containing resin film. In the surface treatment method, reacting liquid containing monomers, photo initiators and solvent is uniformly coated on the surface of the fluorine-containing resin film by the coating quantity of 5-20g / m<2>, then the fluorine-containing resin film is subjected to surface modification under irradiation of an ultraviolet source for 20 seconds to 10 minutes, wherein the irradiation strength of the ultraviolet source is controlled within a scope of 4000-12000 microwatt per square centimeter by referring to the standard of the wavelength lambda equal to 254nm, and the monomers are mixtures of trimethylolpropane triacrylate and n-butyl acrylate. By the surface treatment method, the lamination adhesive performance of the fluorine-containing resin film and EVA (ethylene vinyl acetate) film can be improved, and accordingly problems of low peeling strength and poor durability after adhering of the fluorine-containing resin film and the EVA film are solved. The surface treatment method has a good modification effect to surfaces of the films only and cannot affect performance of the bodies of the films severely, and has the advantages of mild reaction condition, control easiness, simplicity and capability of realizing continuously industrial treatment.

Owner:BEIJING UNIV OF CHEM TECH

Treatment method of organic waste water

InactiveCN102101715AImprove removal efficiencyReduce loadWater contaminantsWater/sewage treatment by oxidationHigh concentrationOxygen

The invention discloses a treatment method of organic waste water. In the treatment method, a supported catalyst made of carbonyl metal is used, so that the chemical oxygen demands (COD) of various high-concentration organic waste waters can be effectively reduced under the mild condition; and the catalyst is convenient for separation and can be recycled, reaction condition is mild, and the treatment method is easy to operate.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

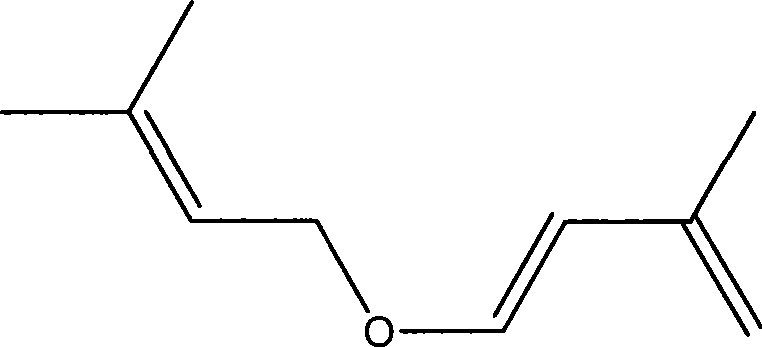

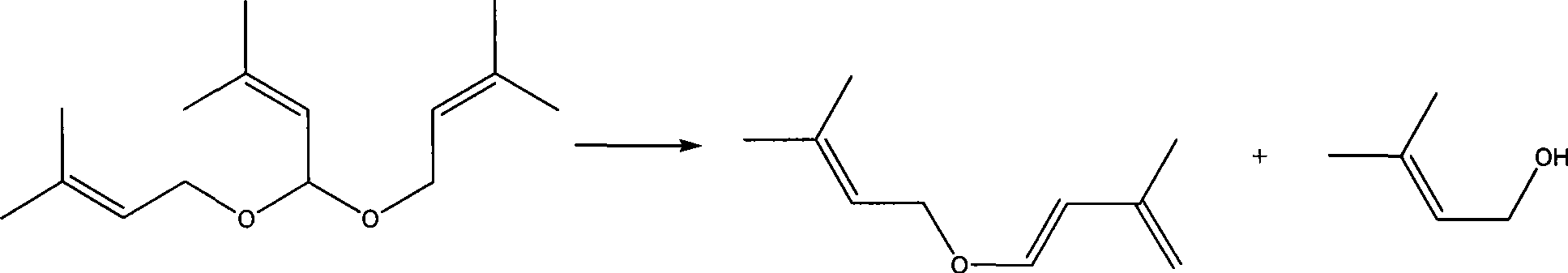

Continuous gas phase reaction method of isoprene-3-methyl butan-2-alkenyl ether

The invention discloses a method for preparing an intermediate prenyl-3-methylbutyl-2-alkenyl ester. The prior methods have high control requirement on the concentration of a phosphoric acid catalyst, which have large difficulty and poor stability, and are hard to carry out in production; and other methods have low yield and conversion ratio. The method has the following steps: feeding 3-methylbutyl-2-olefine aldehyde di-prenyl acetal from a reaction kettle; performing a catalytical elimination reaction in a gas-phase fixed-bed reactor after vaporization to obtain mixed gas; introducing the mixed gas into a rectification tower; recovering the mixture at the top of the rectification tower to obtain 3-methyl-2-butenol; and discharging the material from one side of the rectification tower to obtain the prenyl-3-methylbutyl-2-alkenyl ester, wherein the unreacted raw material 3-methylbutyl-2-olefine aldehyde di-prenyl acetal at the bottom of the rectification tower is refilled into the reaction kettle for vaporization and continuous reaction, and the reaction kettle is replenished with new raw materials continuously. The catalyst used in the method has smaller destructive effect, reduces the quantity of leftover materials after the elimination reaction, and has high selectivity.

Owner:ZHEJIANG UNIV +1

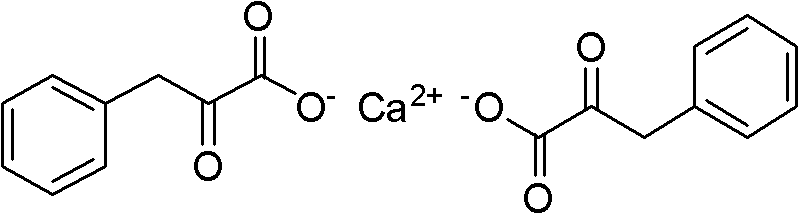

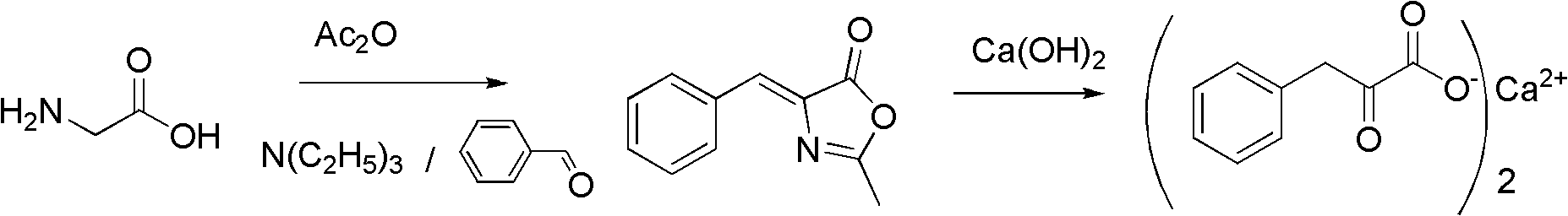

Method for preparing Alpha-keto-phenylalanine calcium

InactiveCN102050725AEasy to produceEasy to buyCarboxylic acid salt preparationChemical recyclingAcetic anhydrideBenzaldehyde

The invention discloses a method for preparing a medical material, namely Alpha-keto-phenylalanine calcium. In the conventional methods, some methods are complicate in operation and has low yield, and oxydol is used in the oxidizing process, which is not favorable for safety production; and some methods have long reaction time, harsh conditions and low hydrolysis yield. The preparation method includes the following steps: glycine, benzaldehyde, acetic anhydride and organic base catalyst are taken as raw materials, and 4-benzal-2-methyl dihydride oxazolone is obtained by adopting one-pot method for catalytic cyclization reaction; and 4-benzal-2-methyl dihydride oxazolone and calcium hydroxide conduct ring-opening and hydrolysis reaction in a pressure kettle to obtain Alpha-keto-phenylalanine calcium. The cyclization reaction adopting the one-pot method has low equipment investment and operating cost; organic amine catalyst is easy for reclamation and indiscriminate use; no waste water generates; and the hydrolysis reaction adopting pressurizing reaction has low possibility of side reaction, and the reaction conditions are mild and are easy to control, so that the reaction yield is improved.

Owner:ZHEJIANG NHU CO LTD

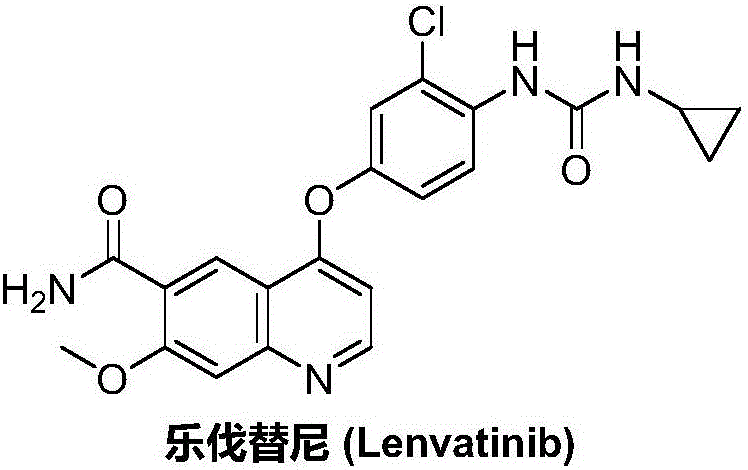

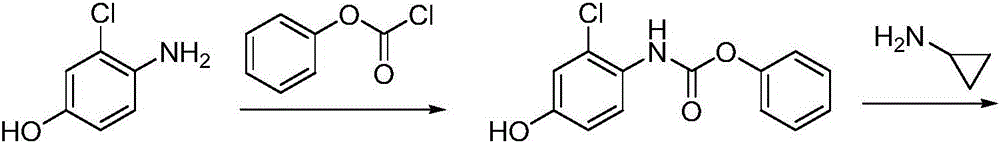

Lenvatinib synthesizing method

InactiveCN105801481AMeet the needs of useMild reaction conditionsOrganic chemistryLenvatinibBenzyl chloroformate

The invention discloses a lenvatinib synthesizing method.The method includes the steps that 4-amino-3-chlorophenol and benzyl chloroformate are subjected to amidation reaction, the obtained 4-(carbobenzoxy)amino-3-chlorophenol and 4-chlorine-7-methoxyquinoline-6-formamide are subjected to condensation reaction, the obtained 4-[3-chlorine-4-(carbobenzoxy)aminophenoxy]-7-methoxyquinoline-6-formamide and cyclopropylamine are subjected to amidation reaction, and the finished product lenvatinib is obtained.The method is short in process route step, operation is simplified, cost is low, and the method is environmentally friendly and suitable for industrial production.

Owner:湖南欧亚药业有限公司

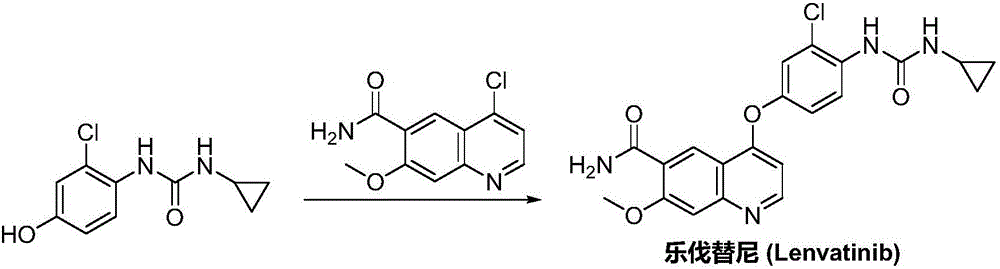

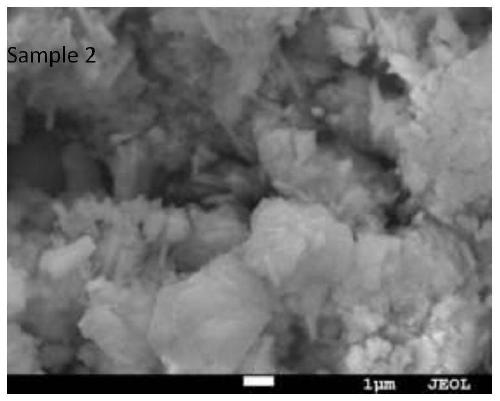

Preparation method of 1D Sb2S3 nanorod/3D ZnIn2S4 composite structure

ActiveCN110124690ARich sourcesSimple preparation processMaterial nanotechnologyWater/sewage treatment by irradiationPtru catalystNanostructure

The invention belongs to the technical field of nano composite materials, and discloses a preparation method and application of a 1D Sb2S3 nanorod / 3D ZnIn2S4 composite structure. The method is as follows: firstly hydrothermally synthesizing 1D Sb2S3 nanorods, then dispersing the 1D Sb2S3 nanorods into deionized water to form a suspension, and finally, using in-situ hydrothermal method to prepare the 1D Sb2S3 nanorod / 3D ZnIn2S4 composite structure. The composite structure prepared by the method can be applied to catalytically degrade 2-thiol benzothiazole under visible light or decompose waterto produce hydrogen under sunlight. The method has rich raw materials, simple operation process and mild reaction conditions, and belongs to a green synthesis method. The 1D Sb2S3 nanorods are combined with 3D ZnIn2S4 nanostructures to make full use of the in-situ growth characteristics, and close contact between the 1D Sb2S3 nanorods and the 3D ZnIn2S4 nanostructures is formed to achieve efficient transmission and separation of photogenerated electrons, improve the electron transport capability in the composite, and broaden the light absorption range of a single photocatalyst, so that the overall photocatalytic activity is enhanced, and the 1D Sb2S3 nanorod / 3D ZnIn2S4 composite structure has important and broad application prospects in environmental management and energy conversion.

Owner:JIANGSU UNIV

Planarly chiral ferroceno[1,2-c]-4-quinolinone compound and preparation method thereof

InactiveCN104292275AEasy to operateEasy and efficient to prepareMetallocenesOrganic solventMostly True

The invention discloses a preparation method of a planarly chiral ferroceno[1,2-c]-4-quinolinone compound, which comprises the following steps: mixing a palladium compound, a chiral phosphine ligand, an acid, an alkali and an organic solvent, adding an N-(2-halogenophenyl)-N-substituted formamide ferrocene compound, heating and stirring to react, concentrating, and purifying to obtain the planarly chiral ferroceno[1,2-c]-4-quinolinone compound. The planarly chiral ferroceno[1,2-c]-4-quinolinone compound is disclosed as general formula I. The planarly chiral ferroceno[1,2-c]-4-quinolinone compound has the advantages of high yield and favorable antipode selectivity, and the antipode selectivity is greater than 90% in most cases. The planarly chiral ferroceno[1,2-c]-4-quinolinone compound can also be used for preparing a chiral ligand, and has very wide application range in metal catalytic asymmetric reaction.

Owner:SHANGQIU NORMAL UNIVERSITY

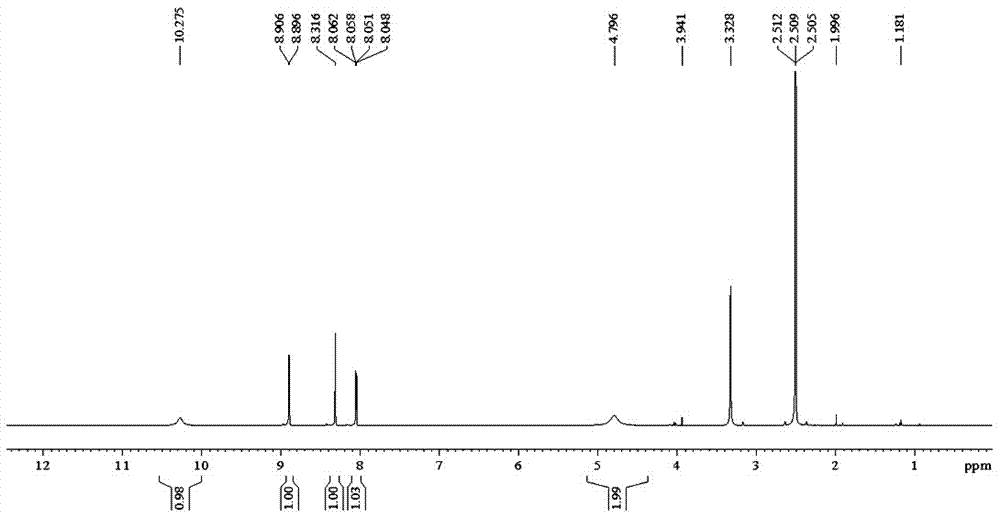

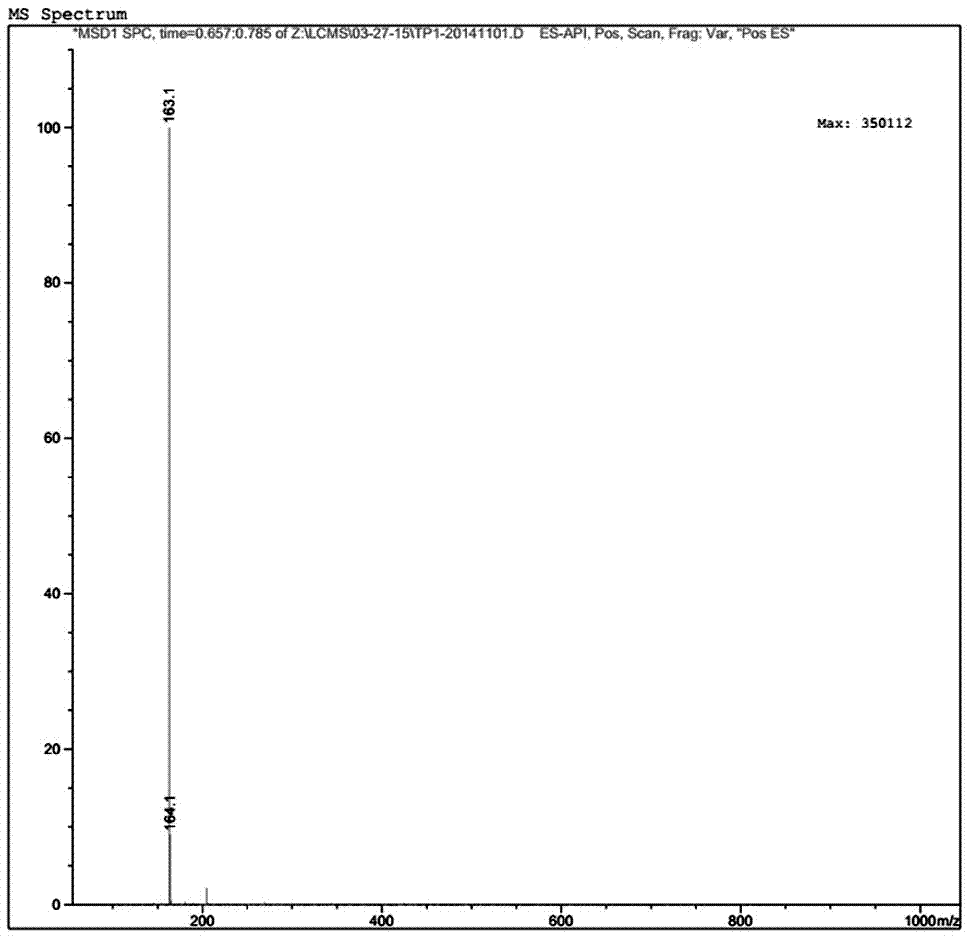

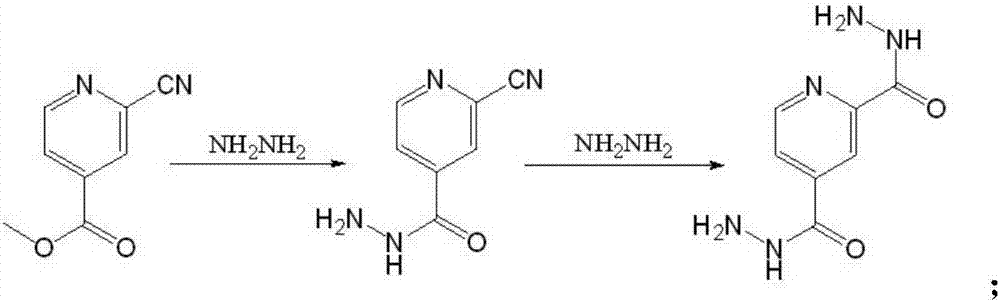

Preparation method of topiroxostat

ActiveCN107573330AReaction raw materials are readily availableThe reaction conditions are mild and easy to controlOrganic chemistryLoop closingTopiroxostat

The invention provides a preparation method of topiroxostat. The preparation method comprises the steps that 2-cyano methyl isonicotinate is used as raw materials; hydrazinolysis is performed at -10 DEG C to -20 DEG C to obtain an intermediate; the intermediate and 4-cyanopyridine react under the conditions with sodium ethoxide and the pH being 4 to 6 to obtain the topiroxostat. The preparation method has the advantages that the 2-cyano methyl isonicotinate is used as a starting material; the 2-cyano methyl isonicotinate and hydrazine hydrate take condensation reaction at low temperature to prepare the intermediate; the intermediate and the 4-cyanopyridine are subjected to condensation and loop closing under the acid condition with sodium ethoxide to prepare the topiroxostat. The raw materials can be easily obtained; the reaction conditions are mild and are easy to control; a reagent with high toxicity is not used in the reaction process; the released toxic substances are few; the sidereaction products are few; the reaction safety is high; the pollution is small; the obtained purity is high; the preparation method is suitable for industrial production.

Owner:HEBEI UNIV OF CHINESE MEDICINE +1

High-strength and wear-resisting liteglow glass product and preparation method thereof

The invention discloses a high-strength and wear-resisting liteglow glass product and a preparation method thereof. The glass product is prepared from the following components: silicon dioxide, aluminum oxide, calcium oxide, magnesium oxide, graphene, titanium dioxide, diboron trioxide, sodium silicate, potassium oxide, antimony oxide, arsenic oxide and noctilucent powder. The preparation method comprises the following steps: firstly, carrying out mixed melting on all the components to obtain a molten mass; secondly, raising the temperature of the molten mass to 1400 to 1500DEG C and performing thermal insulation for 12 to 14 hours; thirdly, feeding a glass molten mass into a forming machine to obtain glass products with different shapes and sizes; fourthly, carrying out annealing treatment on the glass products to obtain a finished product. The glass product prepared by the preparation method disclosed by the invention has better strength and wear resistance; the fragile degree of the product can be greatly reduced, the service life of the product is prolonged, and the use cost of the product is reduced.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

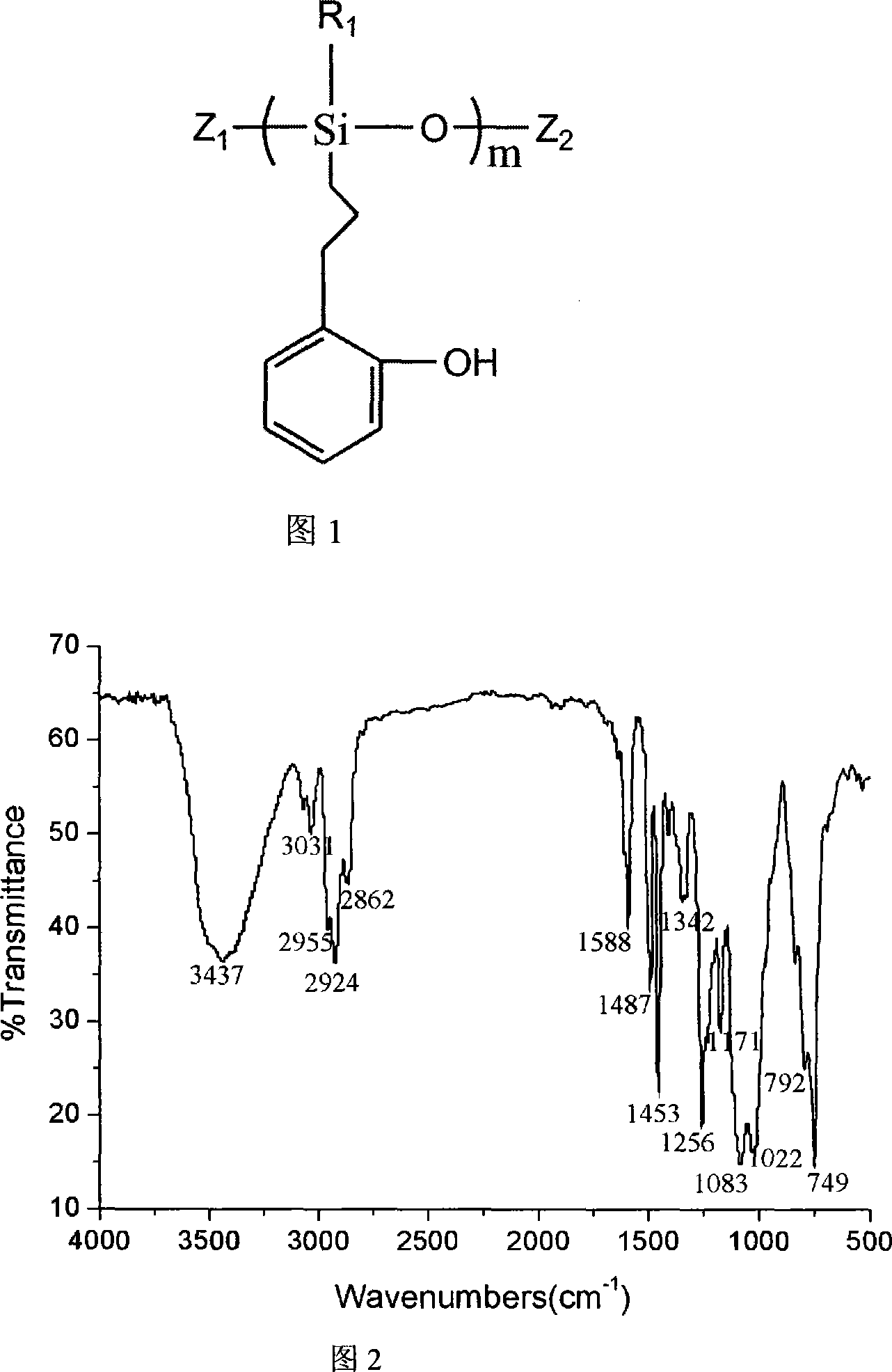

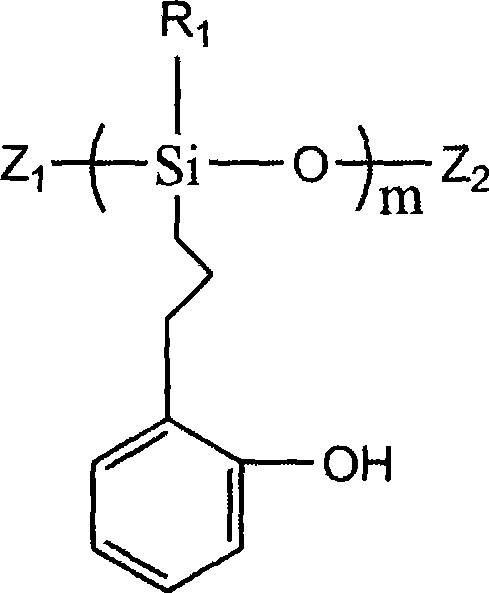

Polysiloxane organic phosphine poison sensitive material and preparation method thereof

InactiveCN101186700AImprove sensitivityQuick responseChemical methods analysisActivated carbon filtrationPhenol

The invention discloses a polysiloxane organo-phosphines toxic sensitive material, which regards polysiloxane as the skeleton and is an organic material with oxybenzene as the functional group. The process for preparation comprises the following procedures: (1) charging hydrogenous silicon oil and platinum catalyst in toluene, mixing uniformly; (2) dropping allyl phenol in the mixed solution of the procedure (1) slowly; (3) heating and reacting, heating the mixed solution of procedure (2) to 80-120 DEG C and mixing 2-6 hours in the temperature; (4) filtering, filtering the reacting liquid of the procedure (3) with activated carbon in order to remove the platinum complex charged in the procedure (1); (5) evaporating, removing toluene of the filtering liquid of the procedure (4) with vacuum distillation. The material responses quickly for the organo-phosphines toxic, and has good selectivity and reversibility, reduces the toxic owing to the material and the intermediate product without halogen, which has simple preparing method, mild and easy control reaction condition, easy operation, few reaction procedures and low cost, and is a nerve toxic sensitive material with good appliance future.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Planarly chiral ferroceno[1,2-c]-4-quinolinone compound and preparation method thereof Planarly chiral ferroceno[1,2-c]-4-quinolinone compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/482998c3-72bc-4a6c-8ac7-05495d75469c/BDA0000574918340000021.PNG)

![Planarly chiral ferroceno[1,2-c]-4-quinolinone compound and preparation method thereof Planarly chiral ferroceno[1,2-c]-4-quinolinone compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/482998c3-72bc-4a6c-8ac7-05495d75469c/BDA0000574918340000022.PNG)

![Planarly chiral ferroceno[1,2-c]-4-quinolinone compound and preparation method thereof Planarly chiral ferroceno[1,2-c]-4-quinolinone compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/482998c3-72bc-4a6c-8ac7-05495d75469c/BDA0000574918340000031.PNG)