Patents

Literature

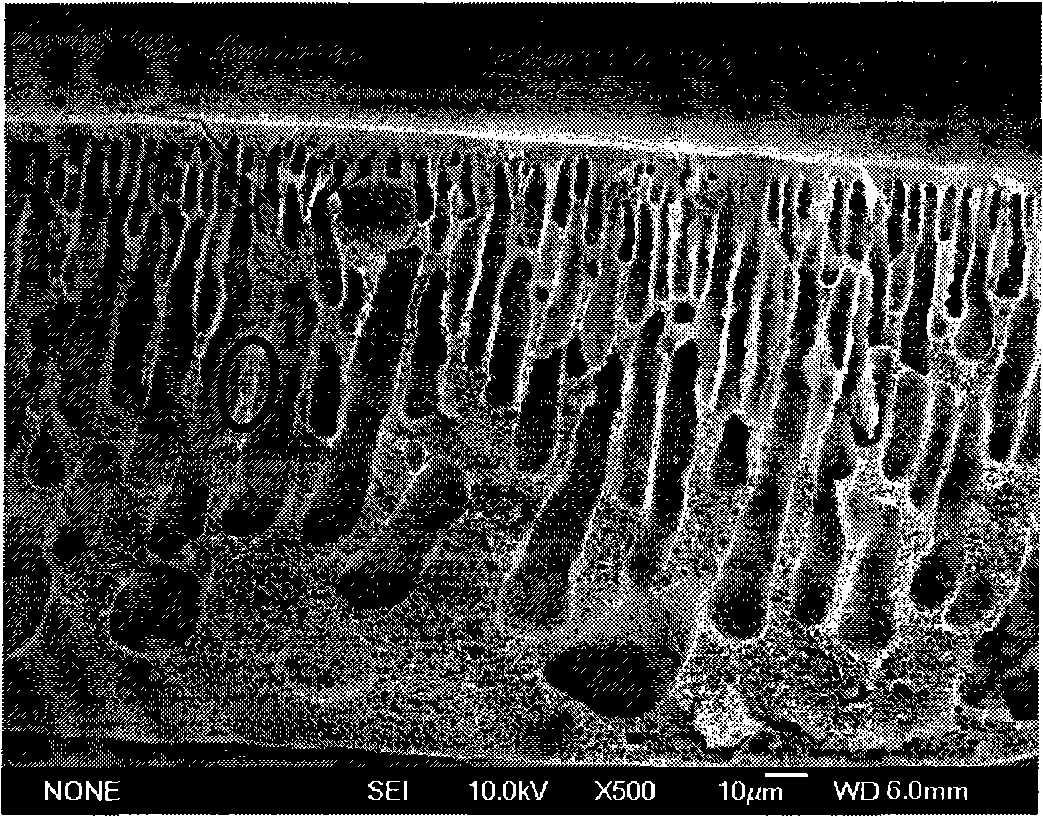

198 results about "Polysulfone membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

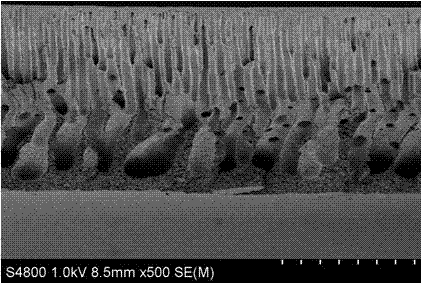

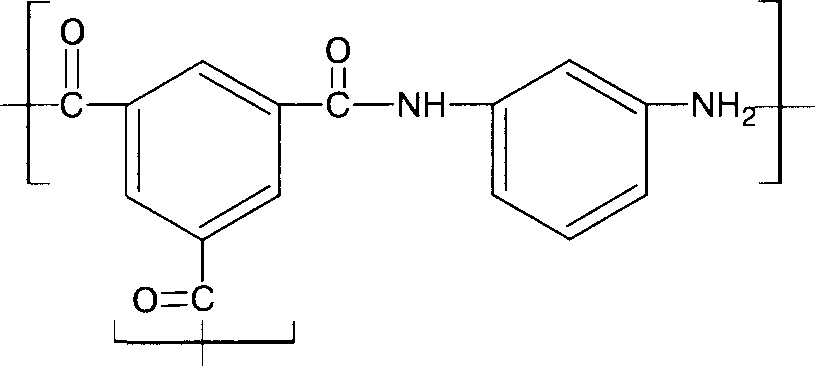

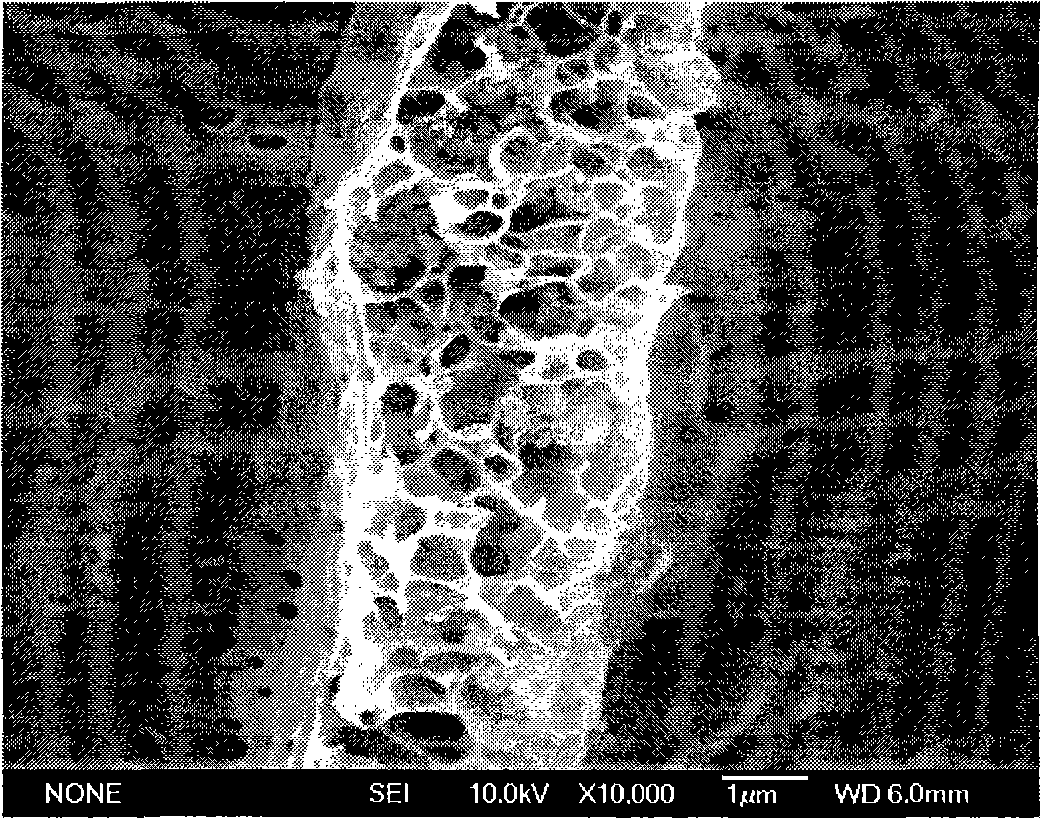

Polysulfone Membrane (PS) with Asymmetric Cross-Section. Unique Structure. Pacific Membranes polysulfone membranes possess a unique asymmetric structure. A high degree of asymmetry provides built-in prefiltration through the depth of the membrane and results in exceptionally high throughput and dirt holding capacity (DHC).

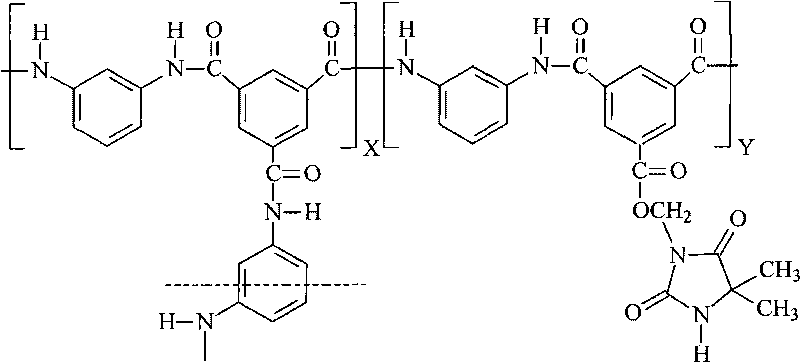

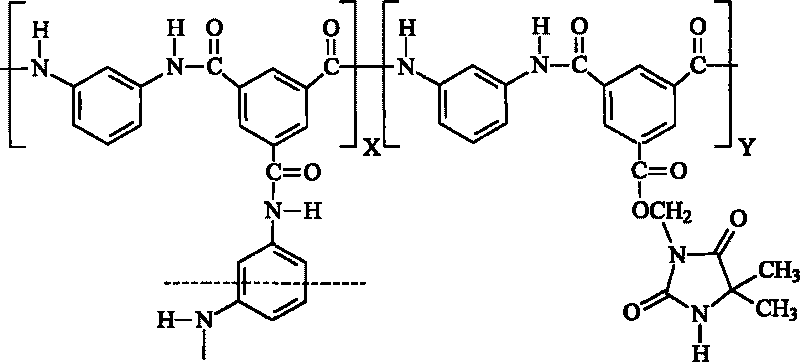

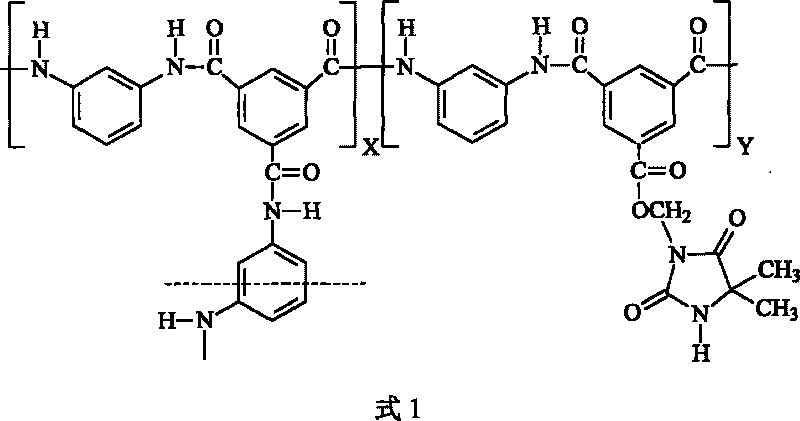

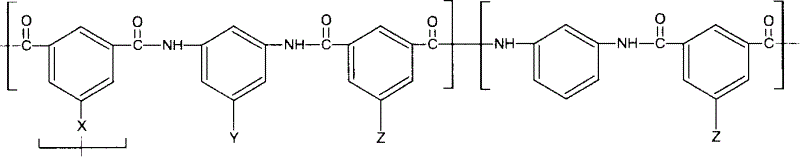

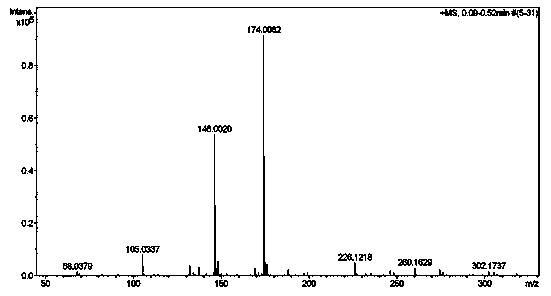

Grafted modified aromatic polyamide composite reverse osmosis membrane and preparation method thereof

ActiveCN101695636AImprove chlorine resistanceSimple methodSemi-permeable membranesHydantoin derivativesPolysulfone membrane

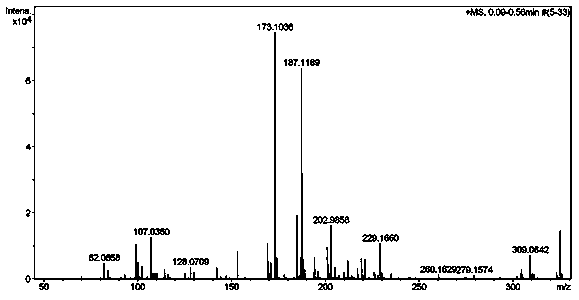

The invention discloses a grafted modified aromatic polyamide composite reverse osmosis membrane and a preparation method thereof, belonging to preparation technology of composite reverse osmosis membranes. The structural formula of the membrane is shown as follow. The preparation process comprises the following steps: taking a polysulphone membrane as a support membrane, preparing an aromatic polyamide composite reverse osmosis membrane to be grafted by an interfacial polymerization; enabling a graft modified solution containing 3-hydroxymethyl-5,5-dimethylhydantoin to contact the surface of the membrane to be grafted quickly for reacting, and conducting heat treatment to obtain the modified aromatic polyamide composite reverse osmosis membrane grafted with hydantoin derivatives. The invention has simple process, and the prepared membrane has the characteristics of good chlorine resistance and good microbial contamination resistance.

Owner:TIANJIN UNIV

High-water-flux forward-osmosis composite membrane and preparation method thereof

ActiveCN103977718AHigh selectivityImprove hydrophilicitySemi-permeable membranesConcentration polarizationPolysulfone membrane

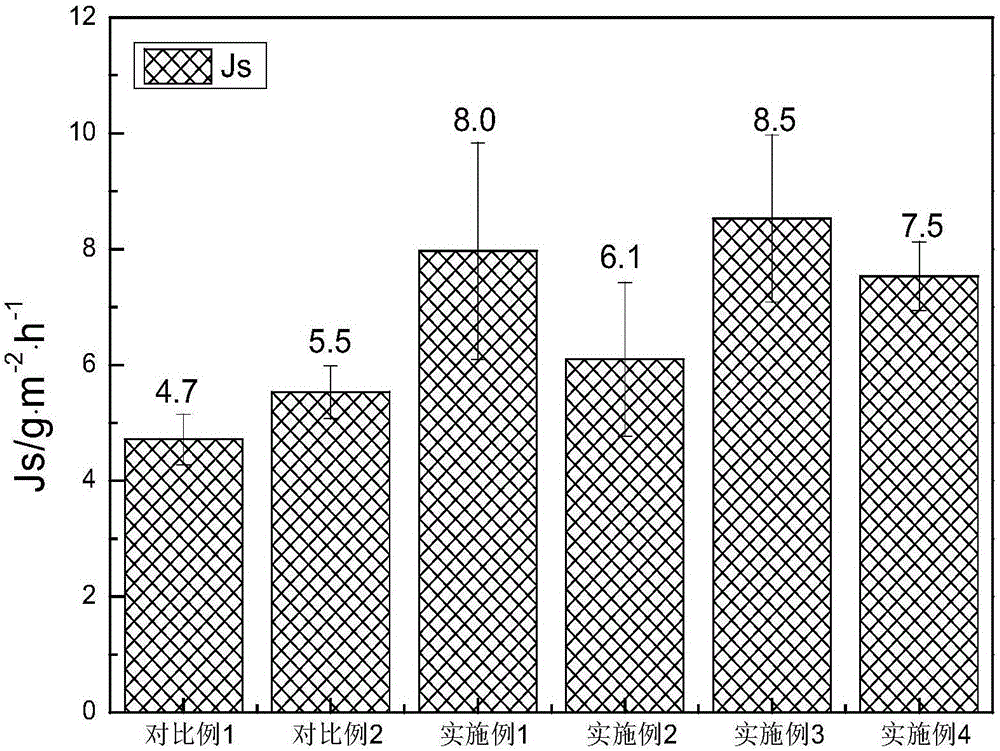

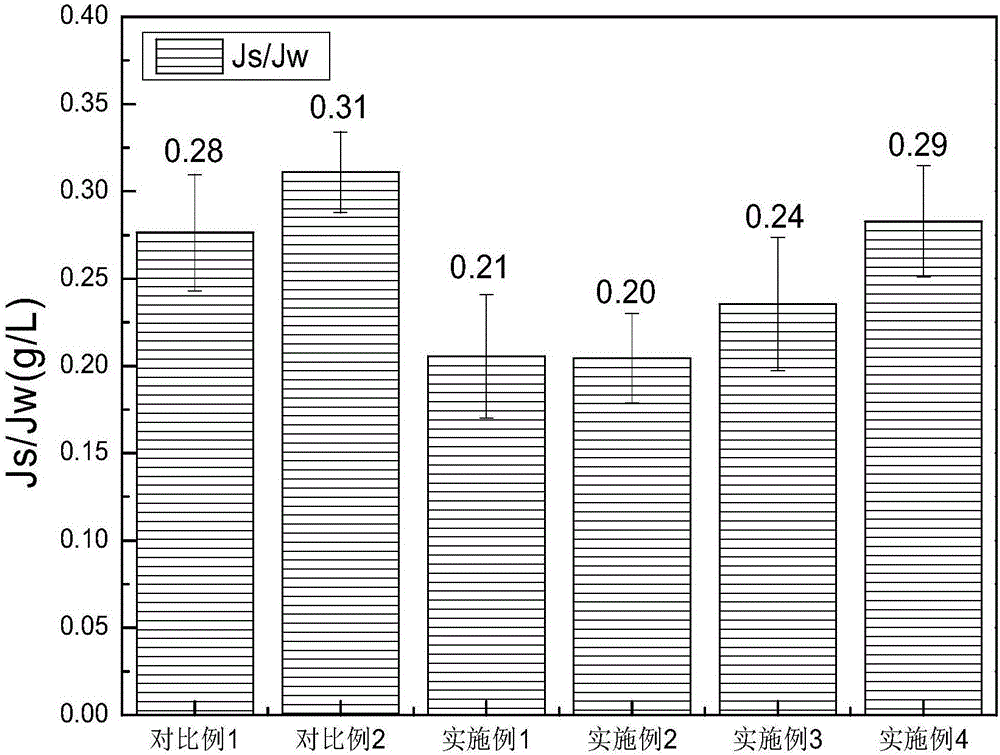

The invention relates to a high-water-flux forward-osmosis composite membrane and a preparation method thereof. The forward-osmosis composite membrane is a polysulfone-sulfonated polysulfone-inorganic filler blended / polyamide composite membrane. A traditional osmosis membrane is generally applied to a reverse-osmosis system, and if the traditional osmosis membrane is used in a forward-osmosis process, the water flux of osmosis is far lower than a theoretical value since the traditional osmosis composite membrane is large in thickness, the hydrophilicity of a supporting layer of a polyamide layer is poor so as to cause serious inner concentration polarization. The preparation method comprises the following steps: blending a polymer with a modifier to form film casting liquid; after scraping or leveling, performing non-solvent coagulating bath with water; by a phase-inversion method, preparing a polysulfone ultrafiltration membrane with good hydrophilicity, high porosity, uniform surface pore structure and narrow pore diameter distribution; and in a clean environment and at room temperature, airing the polysulfone membrane till the surface is dry, and growing a polyamide active layer on the surface of the polysulfone membrane by an interfacial polymerization method, thereby obtaining the forward-osmosis composite membrane with good hydrophilicity, high porosity, low thickness and high mechanical strength. The high-water-flux forward-osmosis composite membrane disclosed by the invention has the advantages that not only the osmosis flux is high, but also the reverse leakage of an extraction medium is low, and the selective permeability is good.

Owner:UNIV OF SCI & TECH OF CHINA

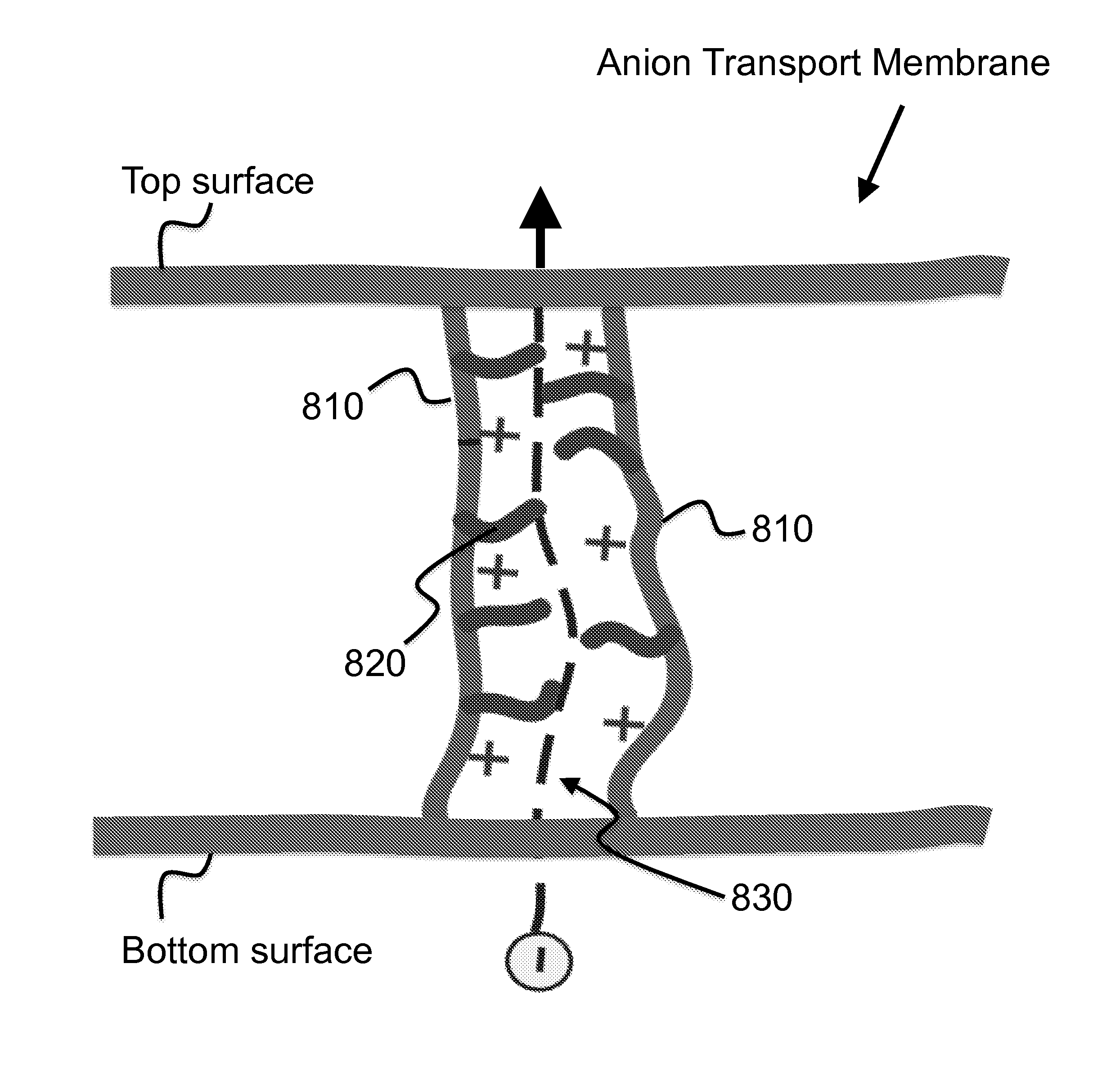

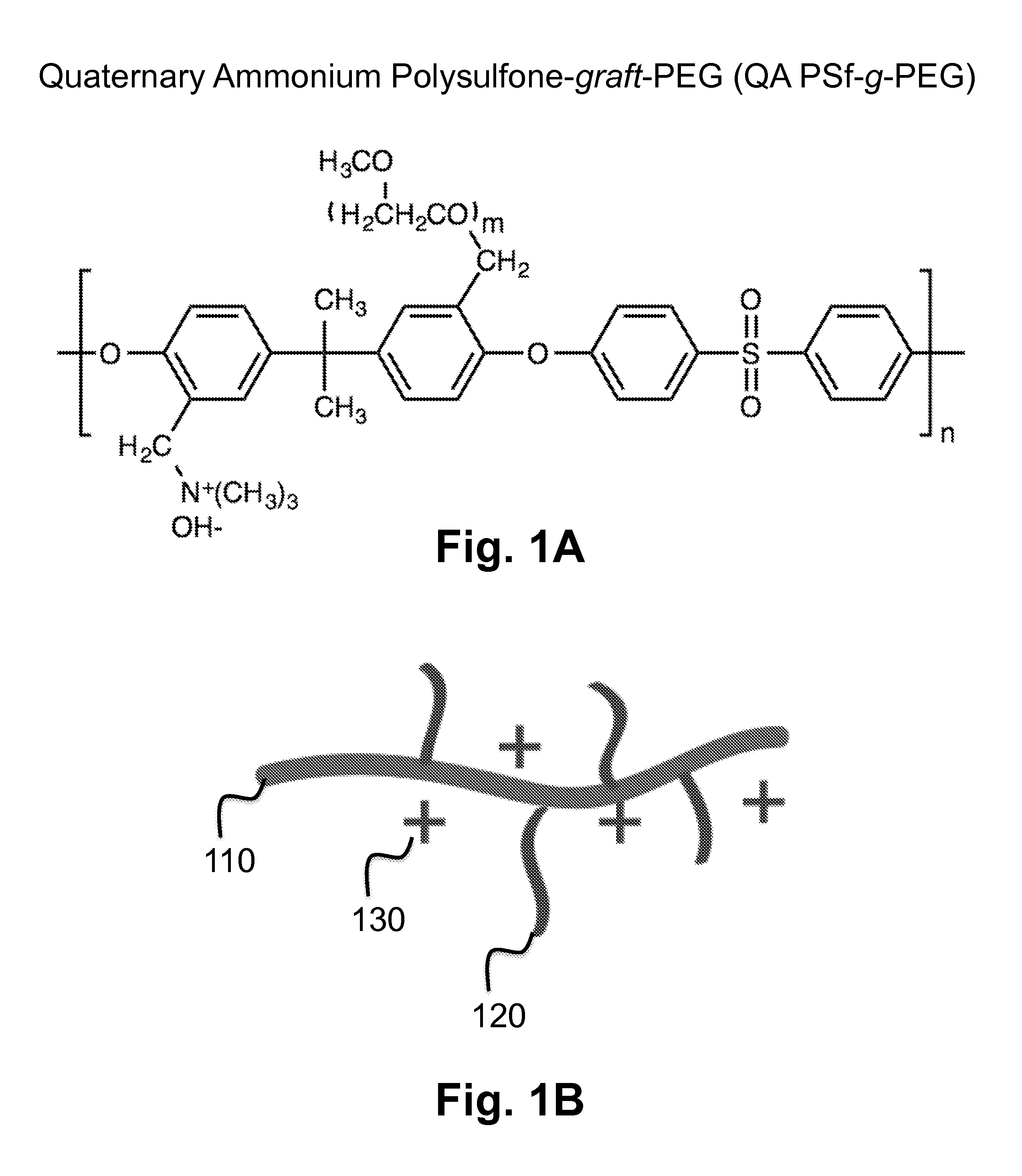

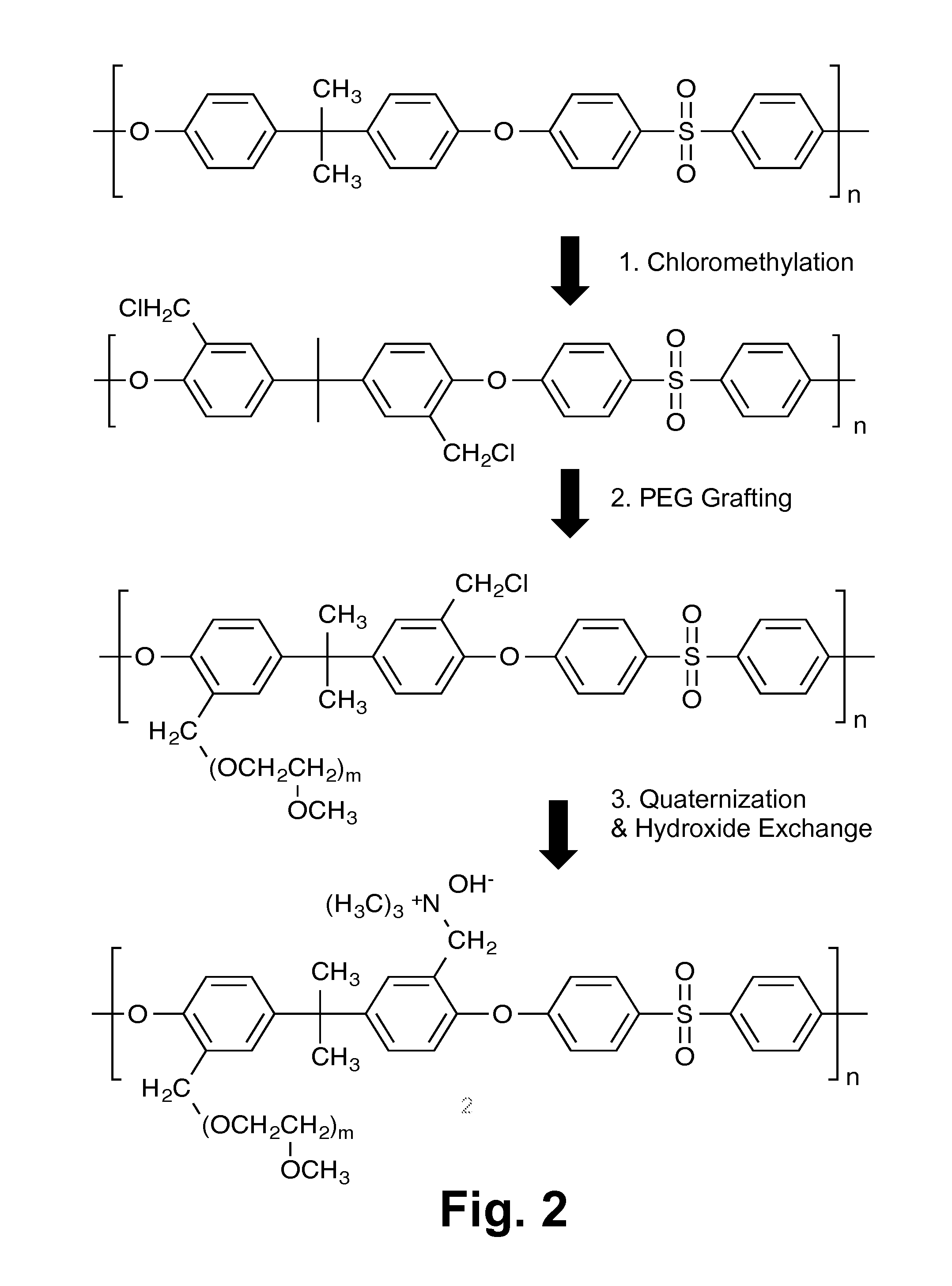

Anion Transport Membrane

ActiveUS20140227627A1Improve conductivityImprove fuel cell performanceSemi-permeable membranesMembranesFuel cellsPolysulfone membrane

An anion transport membrane is provided enabling efficient anion exchange across the membrane, which could be used in applications like fuel cells, water electrolyzers, or water filtration systems. The structural membrane morphology is based on a hydrophobic polysulfone membrane backbone and co-grafted thereon hydrophilic poly(ethylene glycol) grafts and anion conducting quaternary ammonium species. This structure defines a bi-continuous morphology with locally phase-separated hydrophobic-hydrophilic domains, and a co-localization of the anion conducting quaternary ammonium species with respect to the hydrophilic poly(ethylene glycol) grafts enabling efficient and continuous ion transport channels for facilitating anion transport.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Preparation method of anticoagulation polylactic acid hemodialysis membrane

The invention discloses a preparation method of an anticoagulation polylactic acid hemodialysis membrane. Cellulose acetate membranes and polysulfone membranes are widely used in current clinical application. Poly lactic acid has a good membrane-forming property, but is inclined to hydrophobicity, and blood contacting materials are often required to have good hydrophilicity, can reduce the protein adsorption on material surfaces and reduce platelet aggregation. In the preparation method, firstly a polylactic acid hollow fiber membrane with epoxy groups is prepared by a one-step method, then diamine activation of the polylactic acid hollow fiber membrane is carried out, finally heparin is introduced into the activated polylactic acid hollow fiber membrane to obtain the anticoagulation polylactic acid hemodialysis membrane. In the preparation method, the polylactic acid is used as a dialysis membrane material, and the novel dialysis membrane is prepared through use of the wet / dry solution spinning method; and through in-situ polymerization of monomers having double bonds and the epoxy groups, groups of high reaction activity are introduced into a polylactic acid matrix, and reaction conditions of subsequent diamine grafting process and heparin fixing process are mild, so the method is a simple and convenient modification method.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

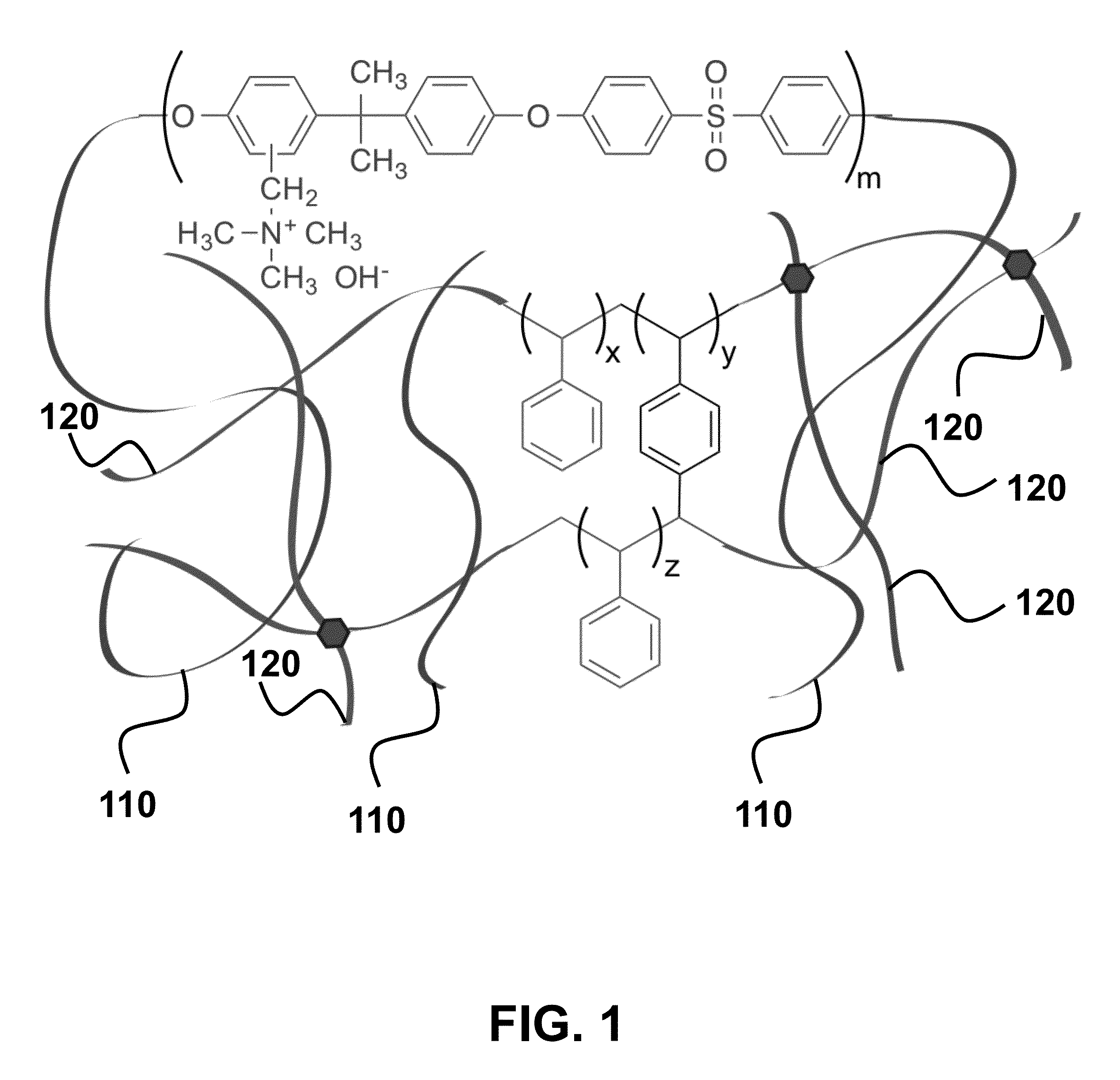

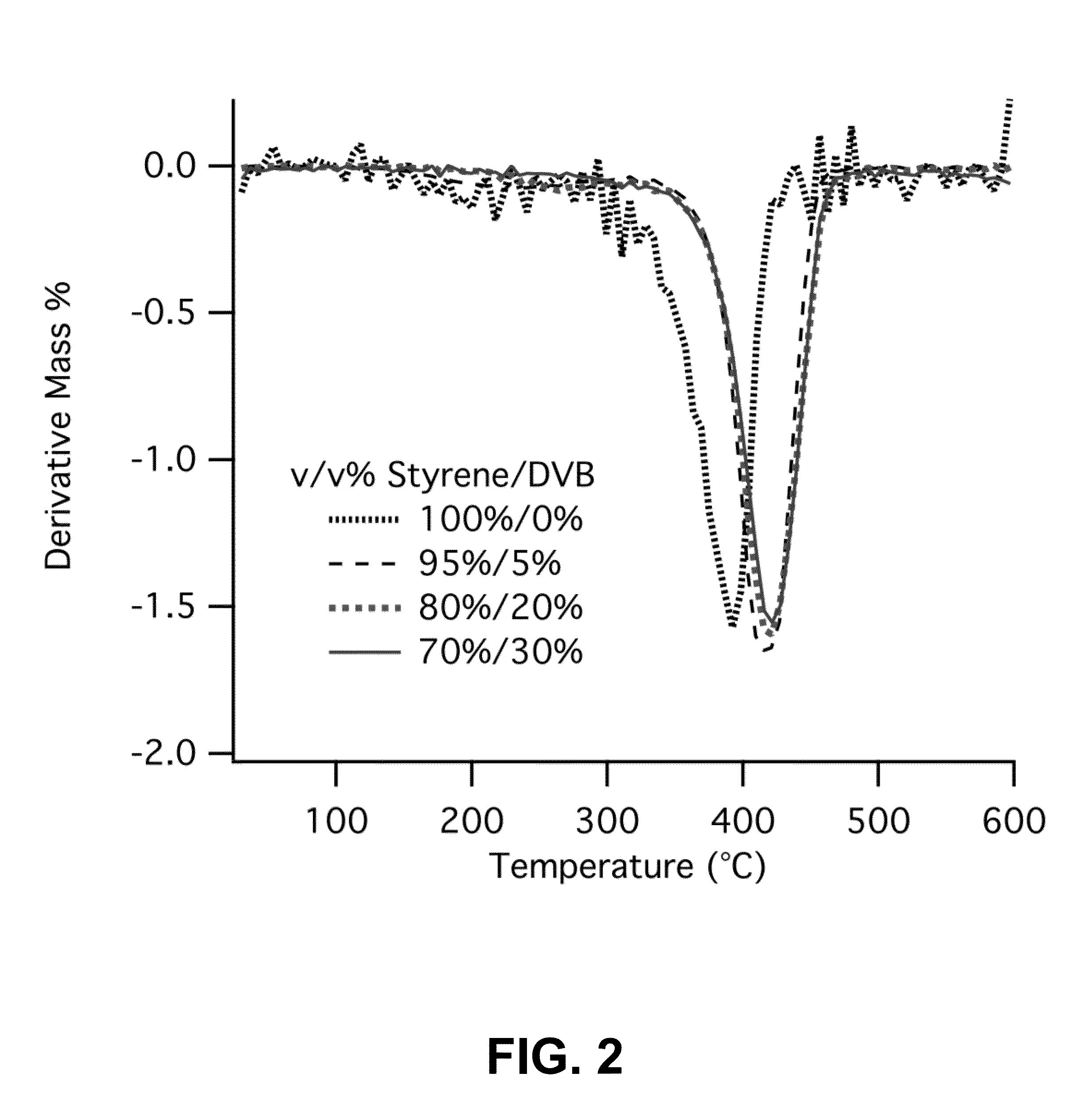

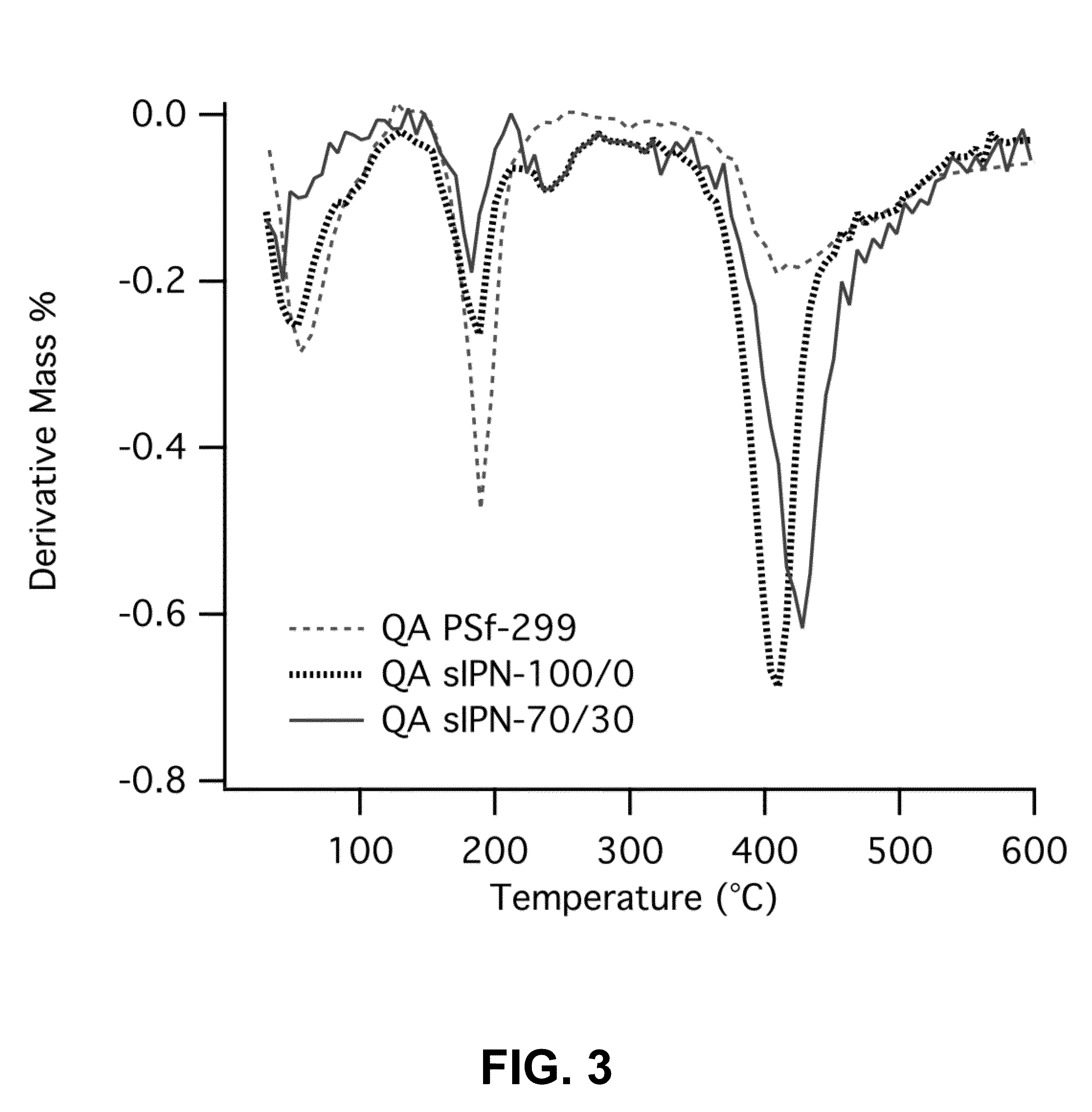

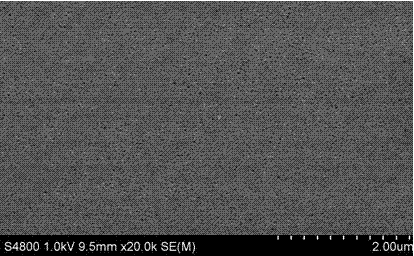

Semi-Interpenetrating Network Method for Dimensionally Stabilizing Highly Charged Polyelectrolyte Membranes

InactiveUS20160248113A1Improve performanceLow dimensional stabilityIon-exchange process apparatusSolid electrolytesCross-linkPolyelectrolyte

An anion transport membrane is provided, which is based on a linear polymer electrolyte with anion-exchange groups that mechanically reinforced by a covalently cross-linked network. The linear polymer electrolyte is partially or fully miscible with the second covalently cross-linked network. In another example, an anion transport membrane is provided, which is based on a linear quaternary ammonium polysulfone membrane backbone mechanically reinforced by a chemically-crosslinked network of poly(styrene-co-divinylbenzene), whereby the reinforcing network has covalent divinylbenzene cross-links.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Preparation method for surface ionization modified polysulfone ultrafiltration membrane

ActiveCN102755844AImprove hydrophilicityLower contact angleSemi-permeable membranesMethacrylatePhase conversion

The invention discloses a preparation method for a surface ionization modified polysulfone ultrafiltration membrane. The preparation method comprises the following steps: 1) dissolving polysulfone, poly-2-(dimethylamino) ethyl methacrylate- polysulfone-2-(dimethylamino) ethyl methacrylate triblock copolymer into a solvent to obtain casting membrane solution; 2) leading the casting membrane solution to flow through a film forming machine, soaking in a coagulating bath to obtain polysulfone membrane; 3) soaking the polysulfone membrane in bromoacrtic solution to carry out surface quaternization treatment; and 4) cleaning and drying to obtain the surface ionization modified polysulfone ultrafiltration membrane. According to the invention, the polysulfone ultrafiltration membrane is prepared by carrying out solution mixing to poly-2-(dimethylamino) ethyl methacrylate-contained amphipathic block copolymer with polysulfone through an immersion sediment phase conversion method, the membrane surface has anion and cation after the surface quaternization treatment is carried out by the bromoacrtic solution, and the hydrophilcity and anti-pollution capability of the membrane are greatly improved. The preparation method is simple and convenient, mild in modification conditions, obvious in effect and the like, and can prepare high-hydrophilcity, large-flux and anti-pollution polysulfone ultrafiltration membrane.

Owner:ZHEJIANG UNIV

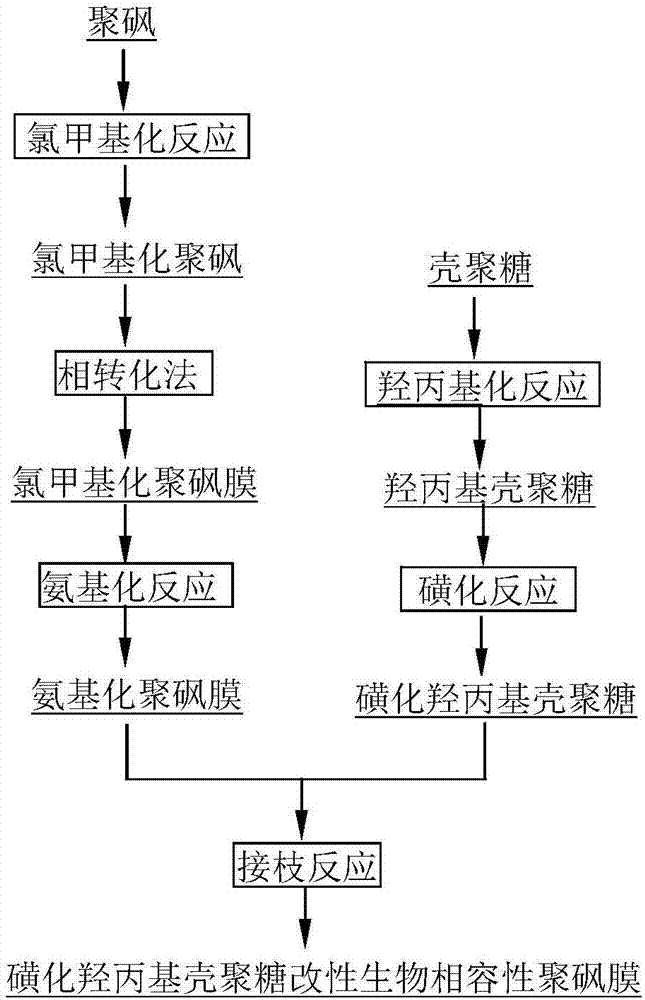

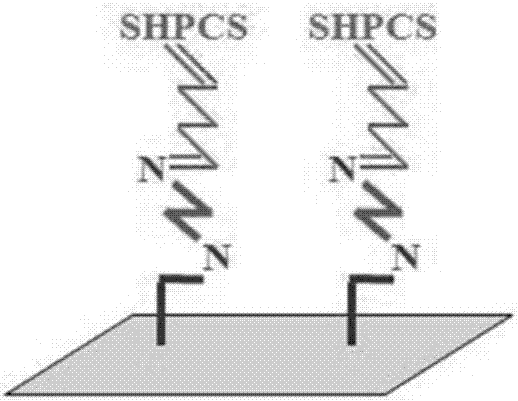

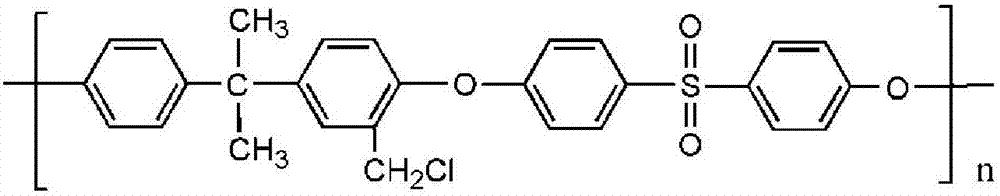

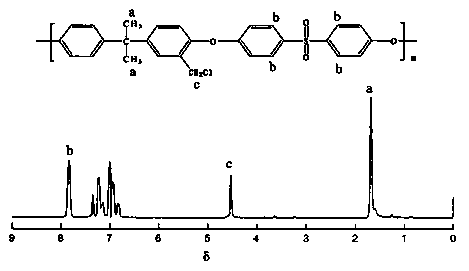

Sulfonated hydroxypropyl chitosan modified biocompatible polysulfone membrane and preparation method thereof

InactiveCN106943901AGood biocompatibilityTo achieve the purpose of anticoagulationSemi-permeable membranesPhase conversionSide chain

The invention relates to a sulfonated hydroxypropyl chitosan modified biocompatible polysulfone membrane and a preparation method thereof. The preparation method comprises the steps of chloromethylating polysulfone firstly so as to obtain chloromethylated polysulfone, and preparing a chloromethylated polysulfone membrane through a phase conversion method; using the chloromethylated polysulfone membrane as a base membrane and performing amination treatment on the chloromethylated polysulfone membrane, so as to obtain an aminated polysulfone membrane; and sulfonating chitosan so as to obtain sulfonated hydroxypropyl chitosan, and grafting a sulfonated hydroxypropyl chitosan hydrophilic side chain on the surface of the aminated polysulfone membrane through Schiff base reaction, so as to obtain the sulfonated hydroxypropyl chitosan modified biocompatible polysulfone membrane. The outstanding feature of the preparation method is to directly bond the sulfonated hydroxypropyl chitosan with a heparitin structure on the surface of the polysulfone membrane, so that the hydrophilicity, anticoagulation and anti-bacterial property are greatly enhanced. The preparation method is easy, the reaction conditions are mild and easy to control, and the preparation cost is low.

Owner:CENT SOUTH UNIV

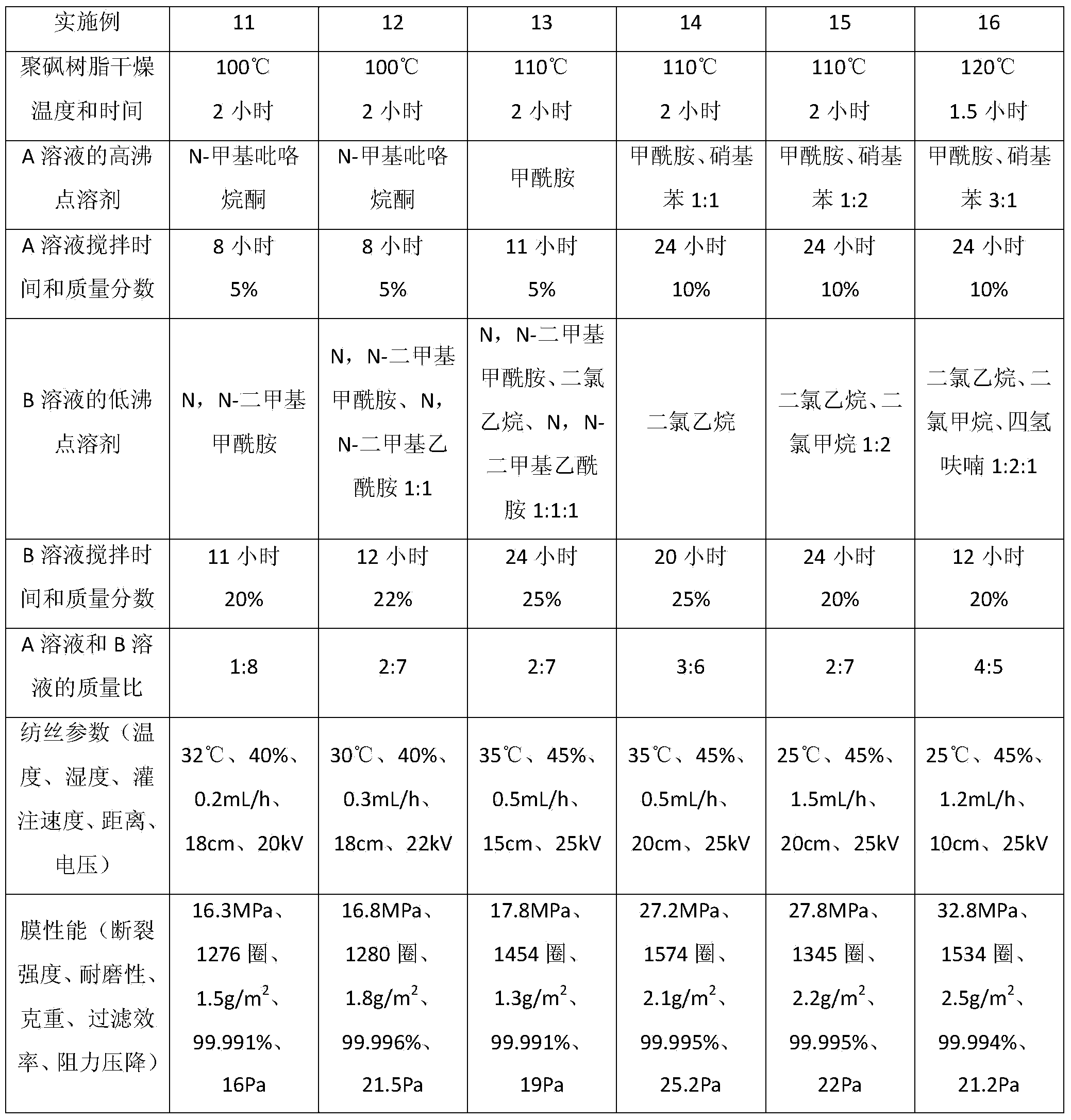

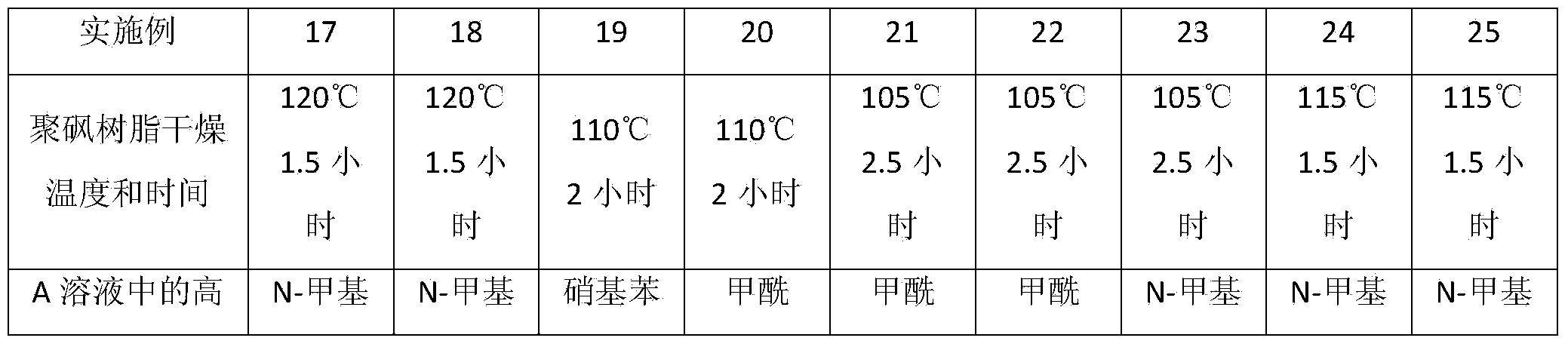

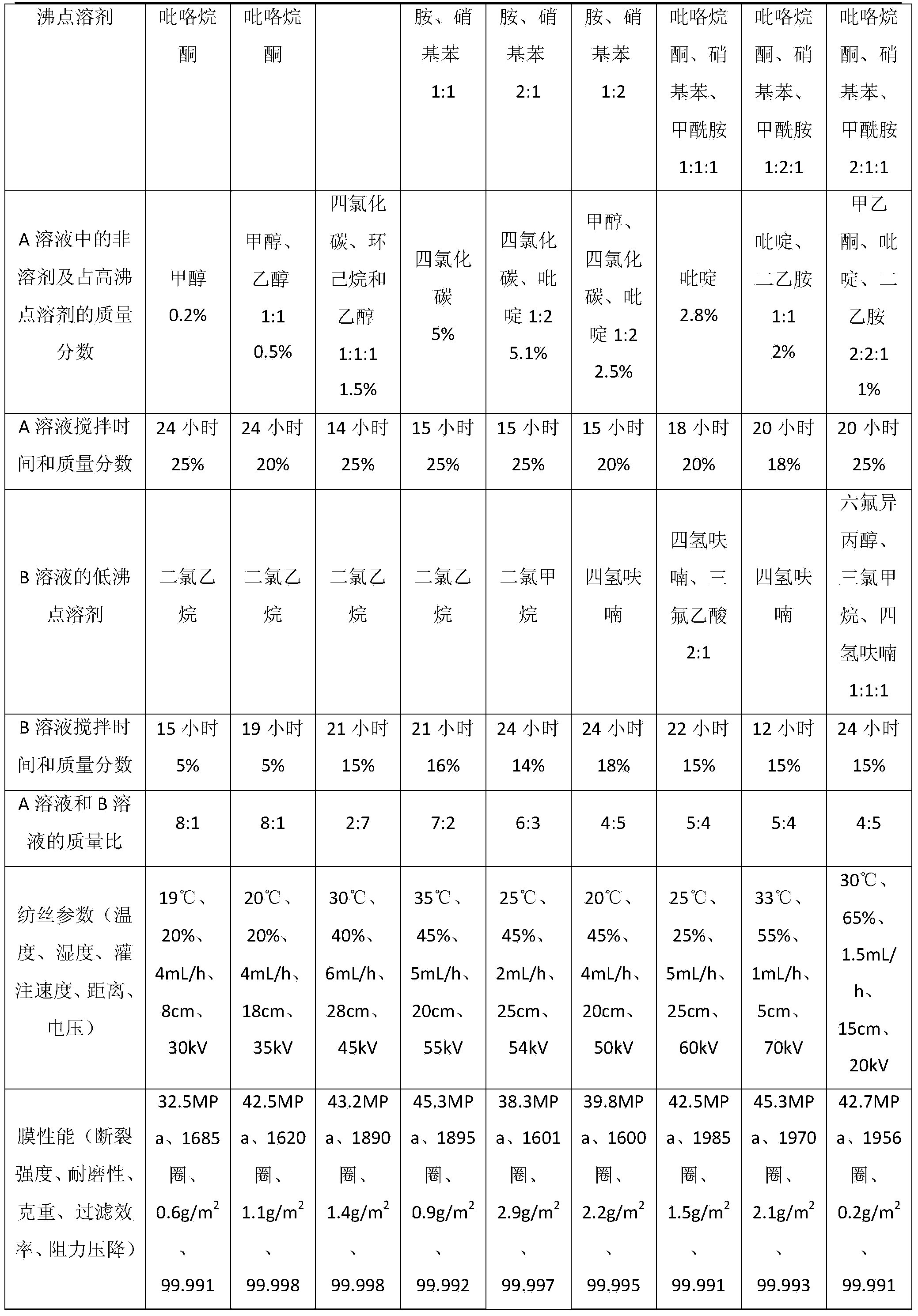

Strengthened polysulfone nano-fiber air filter membrane and electrostatic spinning preparation method thereof

InactiveCN103480285AGood flexibilityGood multi-channel connectivitySemi-permeable membranesDispersed particle separationFiberSolubility

The invention relates to a strengthened polysulfone nano-fiber air filter membrane and an electrostatic spinning preparation method thereof. The preparation method comprises the following steps of firstly, dissolving polysulfone in solvents with different melting points and different solubility parameters to form uniform liquor; and then, carrying out electrostatic spinning on the liquor by a plurality of spray heads to obtain a crossing-point adherent-nonadherent three-dimensional interpenetrating network structure polysulfone membrane. The product is a three-dimensional network shaped material which is formed by interpenetrating and alternating adherent-nonadherent fibers, wherein crossing points in the fibers are interconnected in an adherent manner by virtue of effective non-hydrogen bond bonding effects, wherein gram weight is 0.01g / m<2>-25.5g / m<2>, breaking strength is 16.1 MPa-48.6 MPa, abrasive resistance is 500 rings-2100 rings, filter efficiency for particles of 0.01 micron-5 microns reaches over 99.99%, and resistance drop is below 30Pa. According to the invention, the preparation process is simple, the cost is low, and a fiber membrane product has wide application prospect in the hyperfine filter filed.

Owner:DONGHUA UNIV

Enzymatic extraction method for auricularia auricula polysaccharides

InactiveCN102060934AHigh yieldHigh purityAntibacterial agentsMetabolism disorderAgaricActivated carbon

The invention discloses an enzymatic extraction method for auricularia auricula polysaccharides, which comprises the following steps of: mechanically and coarsely grinding dried auricularia auricula, sieving, mixing according to a material-to-water ratio of 1:(50-200), and extracting at the temperature of between 35 and 50 DEG C and the pH of between 5.0 and 9.0 under the action of chitinase for 60 to 180 minutes, wherein the addition amount of the chitinase is 100 to 600U / g; raising the extraction temperature to be between 80 and 95 DEG C, extracting for 60 to 180 minutes to obtain extract, and centrifuging to obtain supernatant and precipitates; and adding ethanol into the supernatant to precipitate polysaccharides, performing centrifugal separation to obtain precipitates, dissolving the precipitates in water, concentrating to remove residual ethanol, adding a mixture of diatomite and activated carbon into concentrated solution, mixing, fully stirring, filtering, performing membrane filtration on filtrate by using a polysulfone membrane of 30 to 100kD, collecting macromolecular concentrated solution which does not filter through the membrane, and drying the macromolecular concentrated solution to obtain the auricularia auricula polysaccharides. The prepared products have high purity and bioactivity; and the polysaccharide content is over 40 percent.

Owner:CHINA JILIANG UNIV

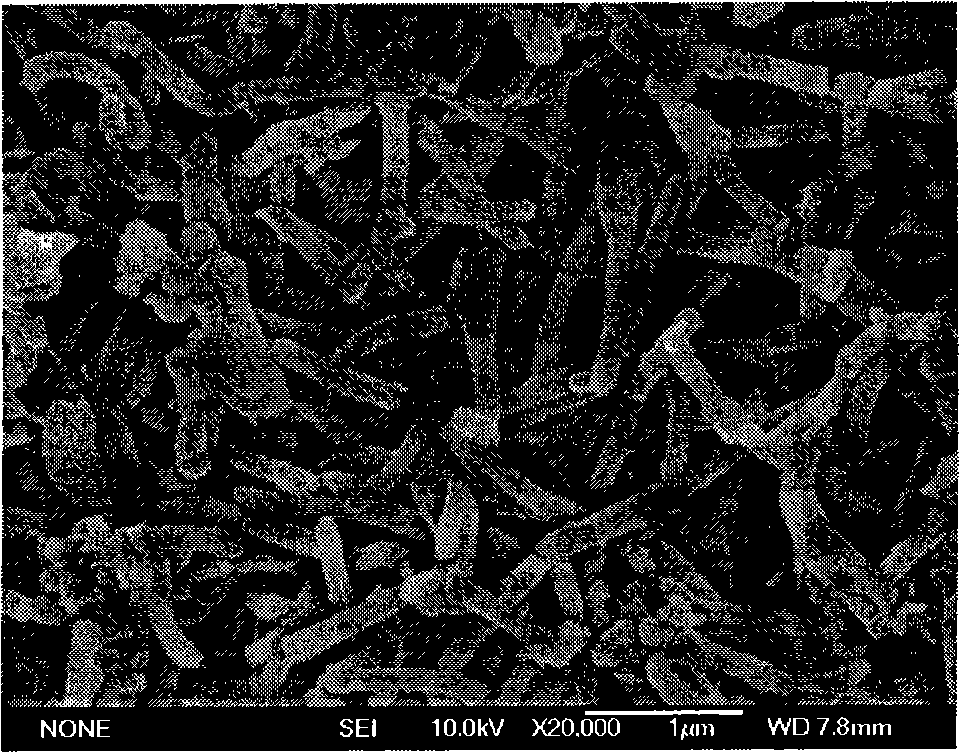

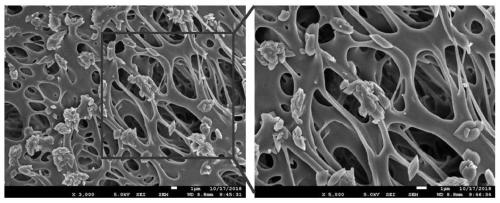

In-situ polymerization process for preparing polyaniline composite hyperfiltration membrane

InactiveCN101274221AImprove interception effectImprove hydrophilicitySemi-permeable membranesComposite filmFiltration

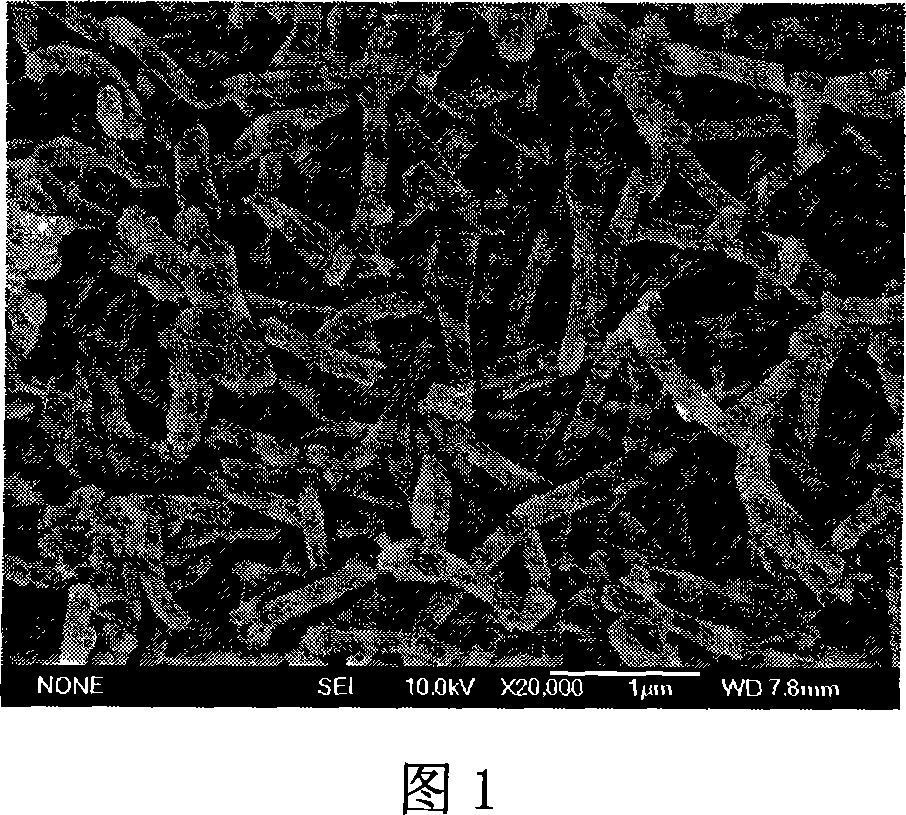

The invention discloses a method for preparing poly-aniline composite ultra-filtration film by in-situ polymerization, belonging to the preparation technique of ultra-filtration composite film. The method process comprises that under the temperature of 20 to 25 DEG C, citric acid, camphor sulfonic acid or hydrochloric acid is added into dodecyl benzene sulfonic acid sodium solution; after the pH value of the solution is adjusted, aniline is added into the solution; after the solution is uniformly mixed, polysulfone membrane is then added into the solution and the solution is then mixed for 4 to 6 hours under the temperature of 20 to 25 DEG C and then for 2 hours under the temperature of 0 to 5 DEG C; water solution of ammonium persulfate with a certain quantity is then added into the solution, and the solution is then mixed for a plurality of minutes under the temperature of 0 to 5 DEG C to complete the reaction. The finished poly-aniline composite ultra-filtration film is gained by a series of cleaning of the prepared poly-aniline composite ultra-filtration film. The method of the invention is simple and has easy operation; the surface of the prepared poly-aniline composite ultra-filtration film is densely and uniformly covered by nano-fibre-shaped polyaniline; the interception performance and the hydrophilicity performance of the poly-aniline composite ultra-filtration film are greatly improved compared with basic films and can be adjusted by controlling the film preparation reaction time.

Owner:TIANJIN UNIV

High-flux and reverse-osmosis composite membrane from eurelon

InactiveCN1778457AImprove hydrophilicityImprove performanceSemi-permeable membranesPolysulfone membraneReverse osmosis

A high-flux composite reverse osmosis polyamide member features that on a supporting polysulfone membrane, there is a functional aromatic polyamide layer which is prepared from aromatic polyamine (the mixture of lentine and 5-sulfonyl lentine) and aromatic polyacyl chloride chosen from sym-phenyltrimethyl acyl chloride, 5-isocyanate-isophthalic chloride, meta-phenyldimethyl acyl chlorid, and their mixture.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

Method for preparing polyaniline and nano-fibre blend composite film

InactiveCN101274220AImprove hydrophilicityImproved ability to resist membrane foulingSemi-permeable membranesProtein solutionComposite film

The invention discloses a preparation method of poly-aniline nano-fibre co-mixing composite film, belonging to the preparation technique of ultra-filter composite film. The method process comprises that poly-aniline nano-fibre is dispersed to one or more out of solvent N, N-dimethylacetamide, dimethylformamide, N-cymene-2-pyrazolidinone or dimethyl sulfoxide; film-forming polymer material polysulfone is uniformly dissolved into the dispersion of the poly-aniline nano-fibre-solvent to gain casting solution; the casting solution is scraped on a glass plate and the film is formed by using water as coagulation bath, so as to gain the poly-aniline nano-fibre co-mixing composite film of the invention with high throughput and high pollution resistance. The preparation method of the poly-aniline nano-fibre co-mixing composite film has simple method, easy operation and low cost; the pure water throughput of the prepared poly-aniline nano-fibre co-mixing composite film is 1.6 to 2.3 times of that of pure polysulfone membrane and the throughput preservation rate of the poly-aniline nano-fibre co-mixing composite film on protein solution is 1.2 to1.5 times of that of the pure polysulfone membrane.

Owner:TIANJIN UNIV

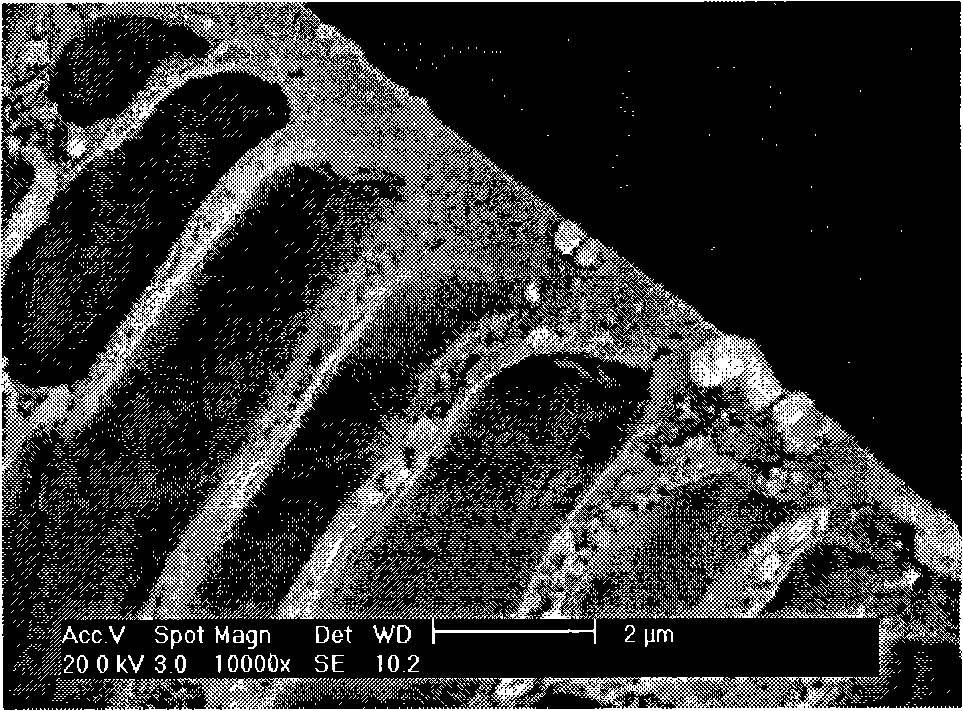

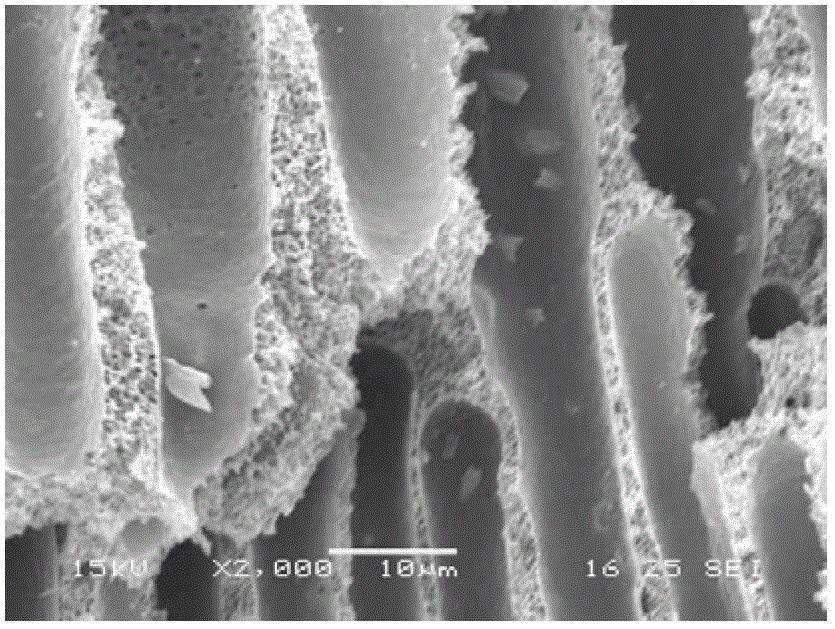

Preparation method of nanocellulose composite polysulfone hollow fiber membrane

InactiveCN105664740AHigh mechanical strengthImprove hydrophilicityMembranesSemi-permeable membranesFiberHollow fibre membrane

The invention provides a preparation method of a nanocellulose composite polysulfone hollow fiber membrane. The preparation method comprises the steps that a membrane casting solution and a core solution are extruded through an annular spinning head of an immersion precipitated phase inversion spinning device at the same time to form a tubular liquid membrane, wherein the membrane casting solution comprises polysulfone, nanocellulose, polyethylene glycol and sulfonated polysulfone; the tubular liquid membrane passes through an air gap to enter a coagulating bath to be solidified, the tubular liquid membrane is placed in water to be soaked and cleaned, and the nanocellulose composite polysulfone hollow fiber membrane is obtained. The nanocellulose is used as a reinforcing agent and a hydrophilic modifying agent, and the mechanical strength and hydrophilism of the polysulfone membrane are improved; the polyethylene glycol is used as a dispersing agent for the nanocellulose and a hydrophilic modifying agent for the polysulfone membrane, the compatibility between the nanocellulose and polysulfone and the hydrophilism of the polysulfone membrane are improved, and therefore the prepared nanocellulose composite polysulfone hollow fiber membrane has the advantages of being high in strength and good in hydrophilism. In addition, the preparation method is simple in technology.

Owner:QINYUAN GRP CO LTD

Preparation method of molecular sieve modified polysulfone ultrafiltration membrane

ActiveCN102512998AIncrease water fluxHigh cut-offSemi-permeable membranesMolecular sievePolysulfone membrane

The invention relates to a preparation method of a molecular sieve modified polysulfone ultrafiltration membrane. Existing methods for improving the permeability of polysulfone membranes cannot give consideration to both water flux and interception performance. The method comprises: first adding an organic additive, a solvent, polysulfone and a molecular sieve into a container in order and conducting stirring for dissolving so as to obtain a preliminarily well dispersed membrane casting solution, which is then leaved to stand for 18-36 hours at a temperature of 30-80DEG C for deaeration; subjecting the deaerated membrane casting solution to 1-5h of action in an ultrasonic field, thus obtaining a molecular sieve uniformly dispersed membrane casting solution; and preparing the molecular sieve uniformly dispersed membrane casting solution into a microporous membrane by a phase inversion method, dipping the microporous membrane in water for at least 24h to remove the solvent, thus obtaining the polysulfone ultrafiltration membrane. The polysulfone ultrafiltration membrane prepared by the method of the invention can has simultaneously improved water flux and interception performance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

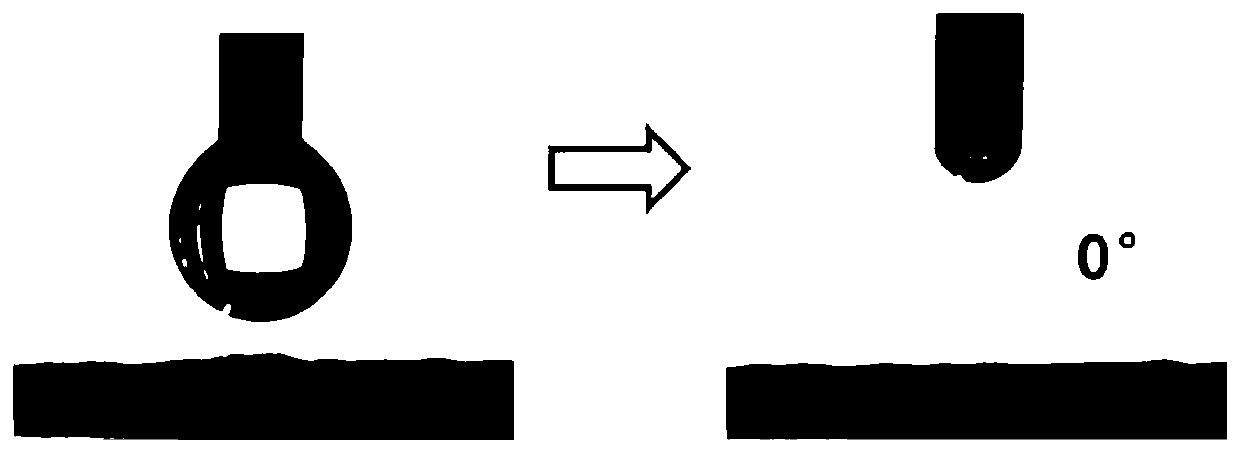

Method for preparing superamphiphobic polysulfone membrane for membrane distillation

ActiveCN110433662AProcess stabilityGood bondingSeawater treatmentWater/sewage treatment bu osmosis/dialysisSilica nanoparticlesSilane compounds

The invention discloses a simple efficient method for preparing a superamphiphobic polysulfone membrane, and relates to the field of membrane separation. Firstly, a polysulfone membrane having an interpenetrating network pore structure is prepared by a conventional solvent-induced phase inversion manner, and interpenetrating network pores form a 'concave angle structure' on the surface of the membrane; then a stepwise sol-gel process is used to generate, in an in-situ manner, uniformly distributed silica nanoparticles on walls of the interpenetrating network pores to provide a certain nano-scale roughened structure for the polysulfone membrane; and finally, the roughened polysulfone membrane surface is coated with a fluorosilane compound film having low surface energy to obtain the superamphiphobic polysulfone membrane. Dual infiltration resistant functions for water droplets and organic liquid droplets are achieved, the contact angle of a water droplet can be 150 degrees or above, andthe contact angle of n-hexane can reach 65 degrees or above. The prepared superamphiphobic polysulfone membrane when applied in a membrane distillation process has a salt interception rate of 99.5% or above and has high anti-wetting stability.

Owner:QINGDAO UNIV OF SCI & TECH

Method for preparing polyaniline conductive composite film by in-situ polymerization

The invention discloses a preparation method for in situ polymerized polyaniline conductive composite membrane, belonging to the technical field of conductive membrane material. The process comprises the following steps: the citric acid, the camphor sulfonic acid or hydrochloric acid are added into the sodium dodecyl benzene sulfonate solution for regulating pH value under twenty to twenty-five DEG C, and then aniline is added into the sodium dodecyl benzene sulfonate solution, polysulfone membrane is added in the sodium dodecyl benzene sulfonate solution after uniform mixing; the solution is agitated for four to six hours under twenty to twenty-five DEG C, and then agitated for two hours under zero to five DEG C; then a plurality of ammonium persulfates are added in the solution to finish the reaction after being agitated for a plurality of minutes under zero to five DEG C; the made polyaniline conductive composite membrane is scoured off the adsorbed impurity through deionized water, then is washed through anhydrous methanol and hydrochloric acid and finally through deionized water, obtaining the finished product of polyaniline conductive composite membrane. The preparation method for in situ polymerized polyaniline conductive composite membrane has the advantages of simple method, easy operation, the conductivity range of the made polyaniline conductive composite membrane is 7.21*10<-4> S / cm to 0.286S / cm.

Owner:TIANJIN UNIV

Preparation method of membrane material used for adsorbing alkaloid

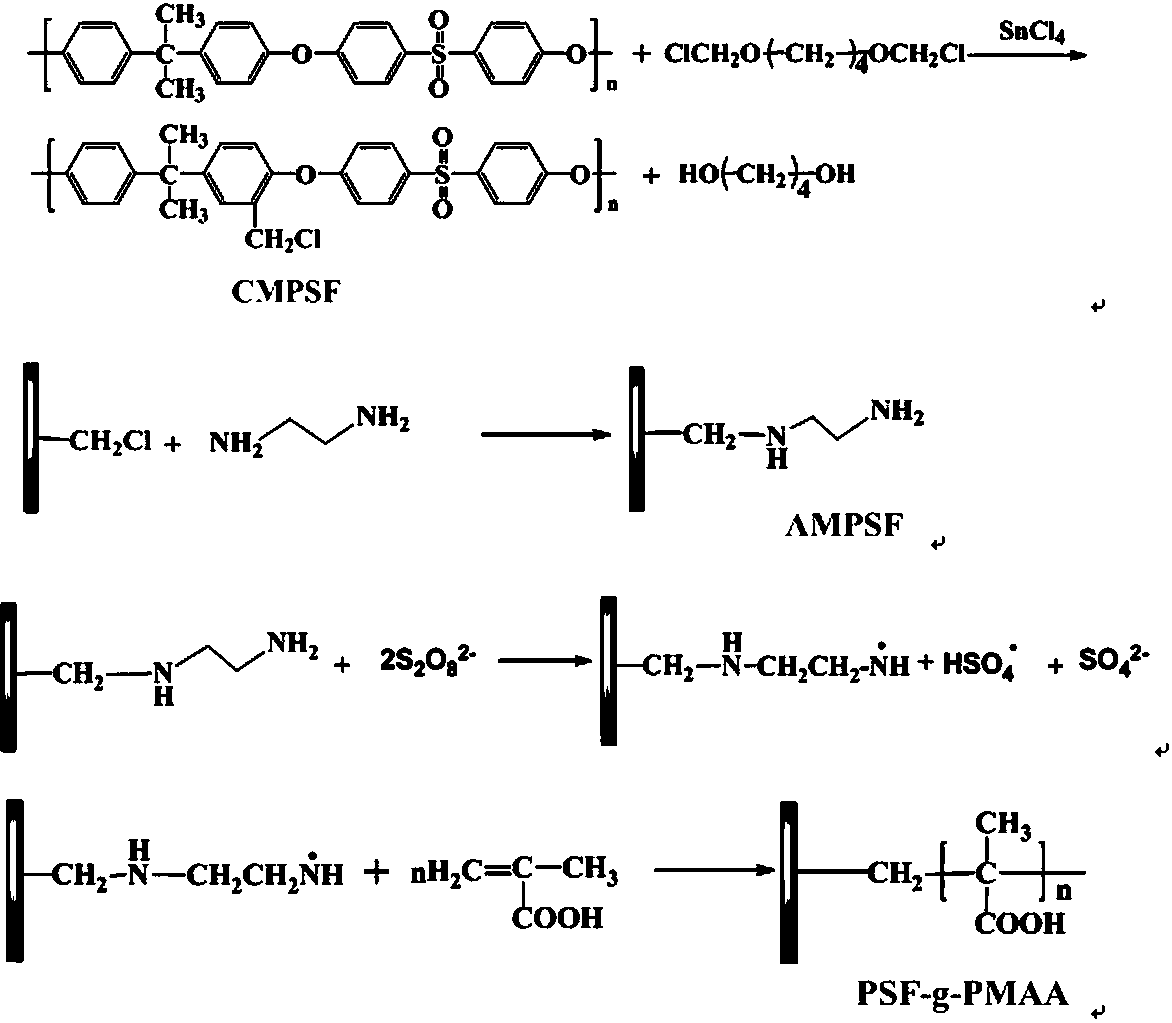

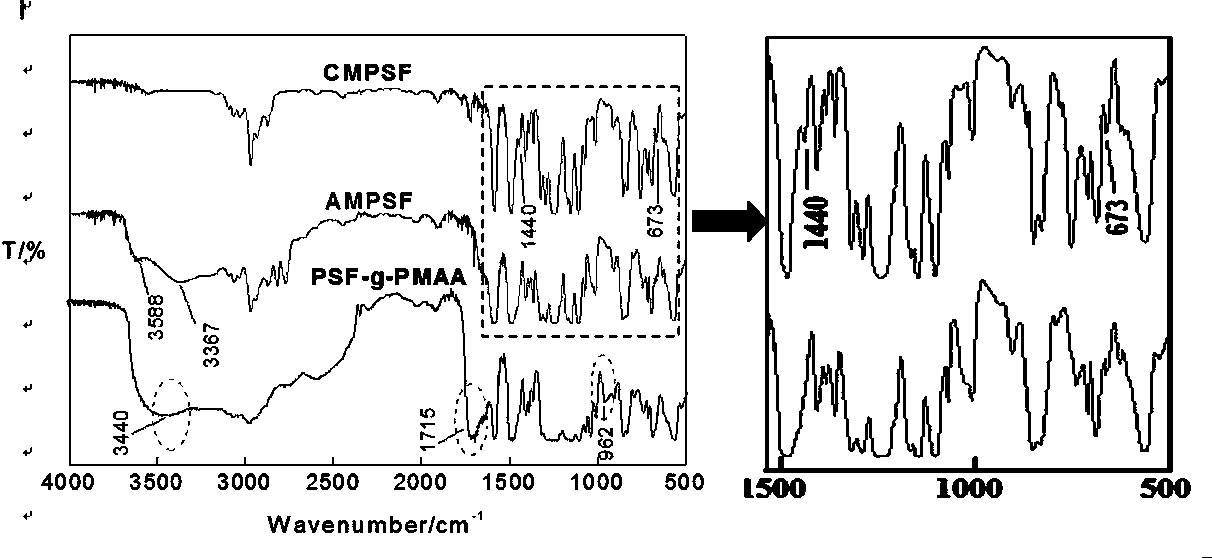

ActiveCN103923336AOther chemical processesAlkali metal oxides/hydroxidesPtru catalystPolysulfone membrane

The invention discloses a preparation method of a membrane material used for adsorbing alkaloid. The preparation method comprises the steps that (1) 2 g of polysulfone are dissolved into 10 mL of dichloromethane, then 2.8 mL of 1,4-dichloro-methoxy butane and 0.26 mL of Lewis acid catalysts SnCl4 are added, the mixture reacts for three hours at the temperature of 25 DEG C to obtain CMPSF, then trichloromethane tape casting membrane forming is conducted, and a CMPSF membrane is obtained; (2) the CMPSF membrane is soaked in ethidene diamine and reacts for four to twenty minutes, and an AMPSF membrane is obtained; (3) 70 mL of mixed liquid containing LDMF and water is added into 0.1-0.15 g of the AMPSF membrane, swelling continues for two hours, 3.3-3.5 mL of single MAA are added, 5 mL of aqueous solution with 0.035-0.040 g of initiator ammonium persulfate dissolved are dissolved into the reaction system, reaction continues for 8-10 hours at the temperature of 50 DEG C on the condition of stirring, and a finished product is obtained. By means of the preparation method, grafting membranes with the PMAA grafting degree being 4.62 mg / cm <2> can be prepared and the finished product has a strong adsorption effect on alkaloid compounds.

Owner:山西铁居环保科技有限公司

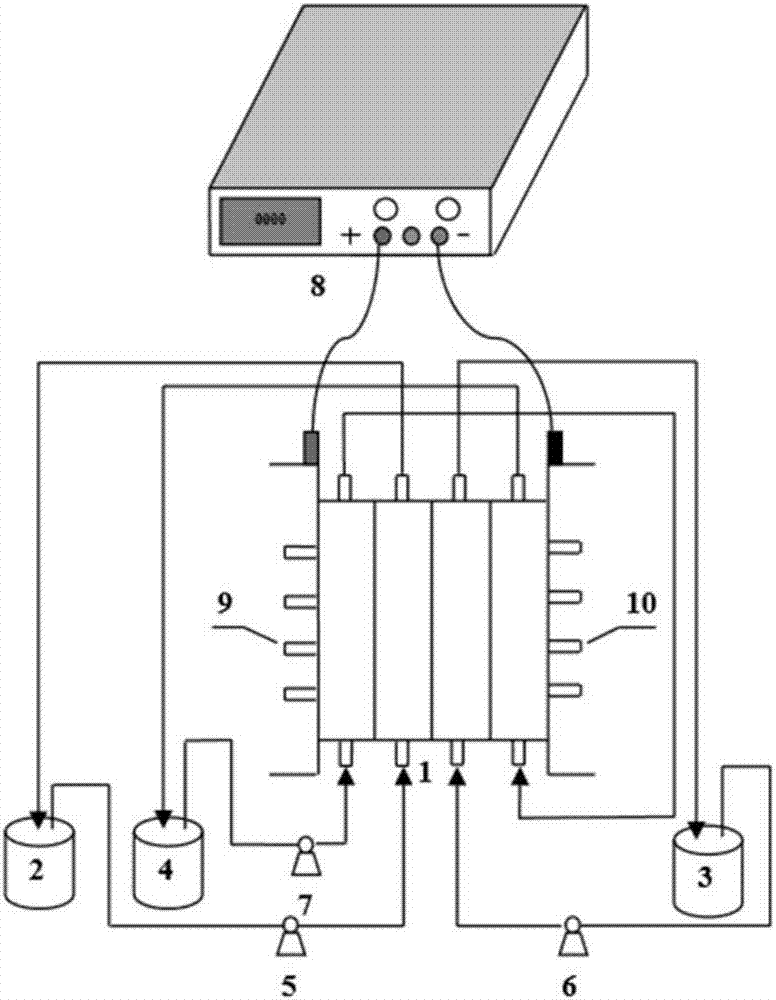

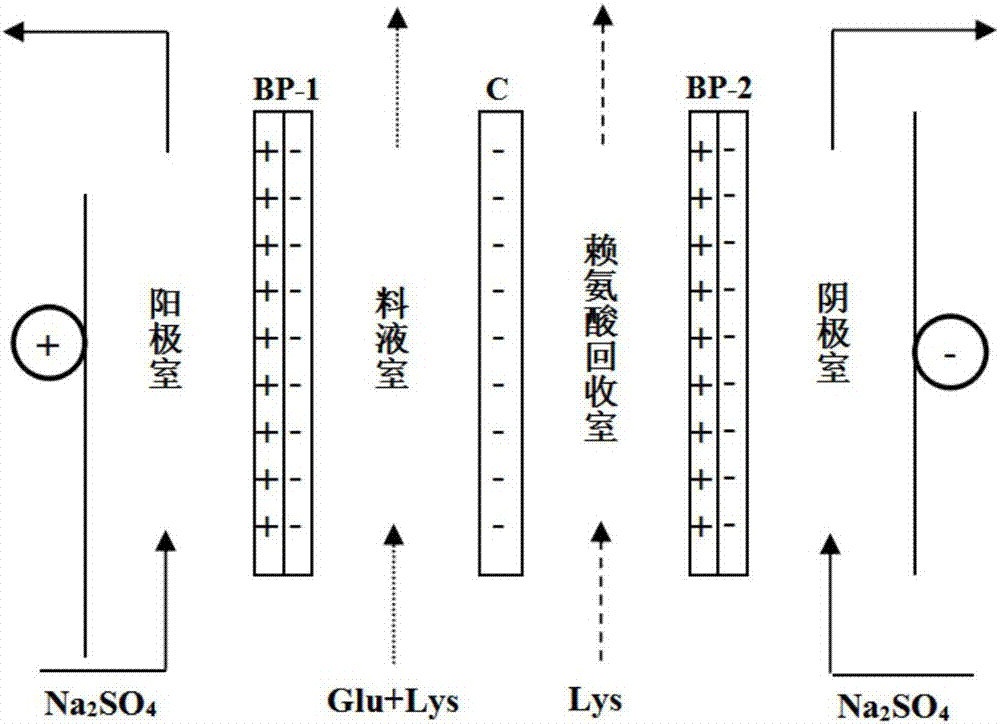

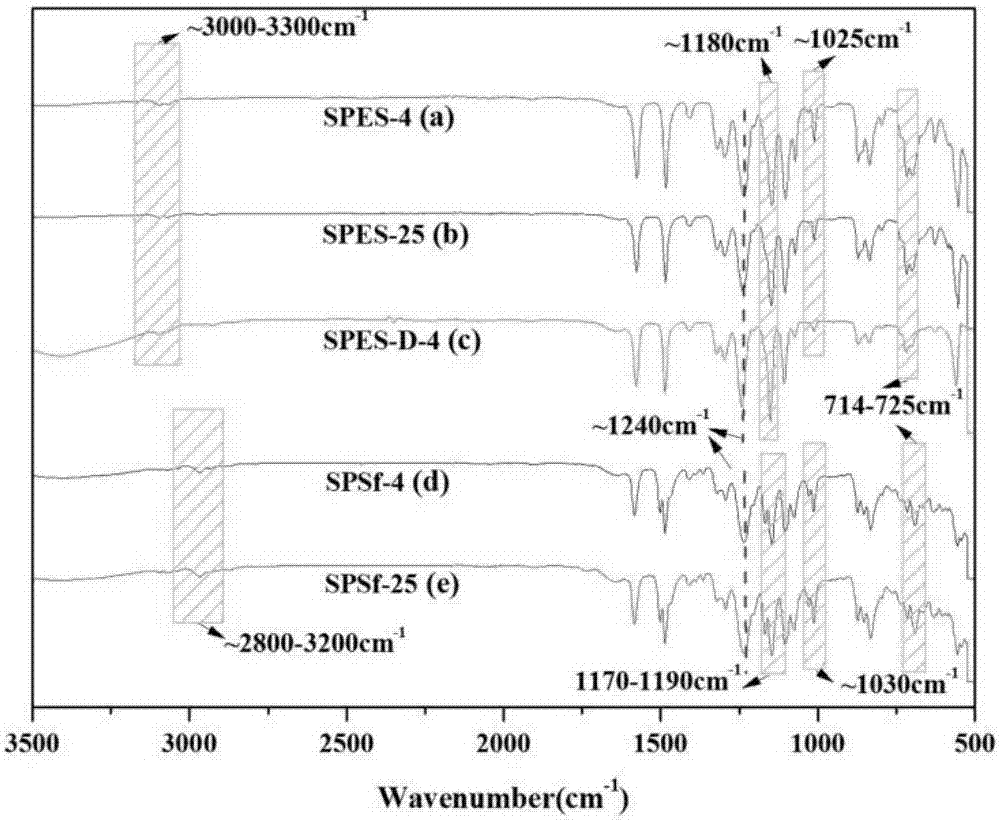

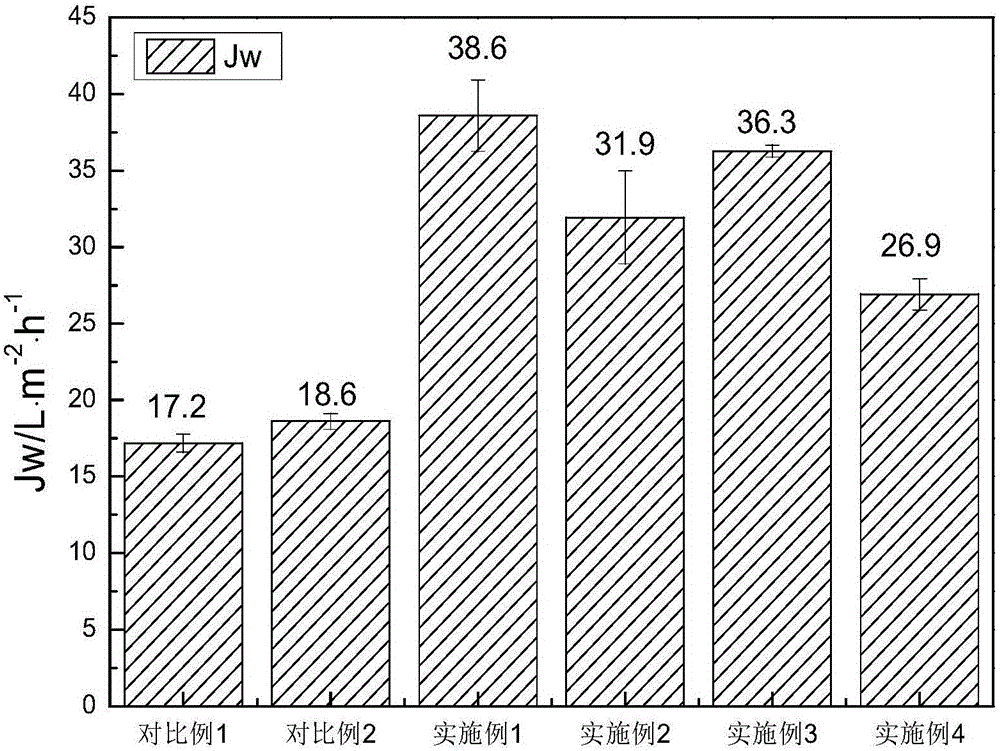

Sulfonated polyethersulfone membrane, preparation method thereof and sulfonated polysulfone membrane as well as preparation method and application thereof

InactiveCN107185417AImprove mechanical propertiesGood electrical propertiesOrganic compound preparationAmino-carboxyl compound preparationPower flowPolysulfone membrane

The invention provides a sulfonated polyethersulfone membrane, a preparation method thereof, a sulfonated polysulfone membrane and a preparation method thereof. The sulfonated polyethersulfone membrane provided by the application is prepared from sulfonated polyethersulfone through a phase inversion method; similarly, the sulfonated polysulfone membrane is prepared from sulfonated polysulfone through the phase inversion method. The application also provides a bipolar membrane electrodialysis device. A cation exchange membrane of the bipolar membrane electrodialysis device adopts the sulfonated polyethersulfone membrane or the sulfonated polysulfone membrane. The application also provides a method for separating an amino acid mixed solution by utilizing the bipolar membrane electrodialysis device. The sulfonated polyethersulfone membrane and the sulfonated polysulfone membrane which are prepared by the preparation methods have excellent mechanical performance, electrical performance and stability, are of porous structures, and are used for a bipolar membrane electrodialysis process to separate the amino acid mixed solution; an amino acid molecule with a positive charge more easily migrates to pass through the membranes; thus, higher recovery rate and current efficiency are obtained.

Owner:HEFEI UNIV OF TECH

Preparation method of polysulfone ultrafiltration membrane

InactiveCN102921317ARaw materials are easy to getEasy to prepareSemi-permeable membranesPolysulfone membraneUltrafiltration

The invention discloses a preparation method of polymeric membrane, in particular to a preparation method of polysulfone ultrafiltration membrane. The preparation method comprises the following steps: a certain concentration of surfactant is dissolved in N-N dimethylacetamide solution at the temperature of 70 DEG C, after the surfactant is completely dissolved, polysulfone with the mass fraction of 18% is added, after the two are completely dissolved, prepared casting membrane solution is used to prepare membrane by a machine membrane scraping method, and the obtained polysulfone membrane is dipped in pure water for a period of time, so that the performance stability of the polysulfone membrane is improved, a hydrophilic modifier is dissolved in water, and the void ratio of the ultrafiltration membrane is improved. The preparation method has the advantages that the selection separation performance is not lower than that of existing ultrafiltration membrane, the materials are easily obtained, the preparation method is simple, and the membrane surface has good hydrophily and good antifouling property.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

Method for preparing high-throughput composite forward osmosis membrane

ActiveCN106215715AFew structural parametersFast exchange rateSemi-permeable membranesConcentration polarizationPolysulfone membrane

The invention discloses a method for preparing a high-throughput composite forward osmosis membrane. The method comprises the following steps: (1) preparing a polysulfone solution, standing and defoaming at room temperature to obtain a uniform membrane casting solution; (2) fixing a filter screen on a membrane forming substrate made of a porous material, coating the polysulfone membrane casting solution to the filter screen, and soaking in a gel bath for phase transformation to obtain a porous supporting layer; (3) soaking the porous supporting layer respectively in MPD and TMC solutions for interface polymerization to generate an active separation layer; and (4) heating to prepare the polysulfone composite forward osmosis membrane. The method has the advantages that due to the porous structure of a membrane forming substrate made of the porous material, water entering the membrane has a higher speed than that of a traditional nonporous substrate in the phase transformation stage, exchange of water and solvent has a high speed, and a perforative finger-like pore structure and an opening bottom structure can be easily formed, so that the membrane structure parameter can be reduced, the concentration polarization in the forward osmosis process can be finally reduced greatly, and the water flux of a composite forward osmosis membrane can be greatly improved.

Owner:OCEAN UNIV OF CHINA

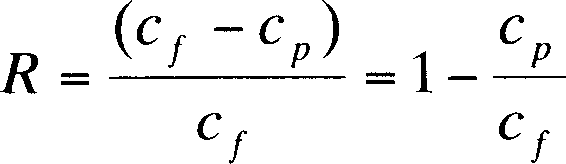

Preparation method of anti-pollution hydrophilic polysulfone membrane modified by amphiphilic amino acid

InactiveCN103877873AImprove pollutionImprove hydrophilicitySemi-permeable membranesOrganic chemistryPolysulfone membraneClick chemistry

The invention discloses a polysulfone membrane modified by amphiphilic amino acid which is expressed by a structure formula (I). An anti-pollution hydrophilic polysulfone membrane modified by amphiphilic amino acid is prepared by modifying the amphiphilic amino acid on the surface of the polysulfone membrane. By clicking chemical, the amphiphilic amino acid is bonded on the surface of the polysulfone membrane; the structure of a matrix membrane is not damaged; the amphiphilic amino acid is connected with the membrane through chemical bonds; the acting force is secure and is not gradually lost along with the extension of service life. The structure formula (I) is as shown in the specification.

Owner:NORTHWEST UNIV

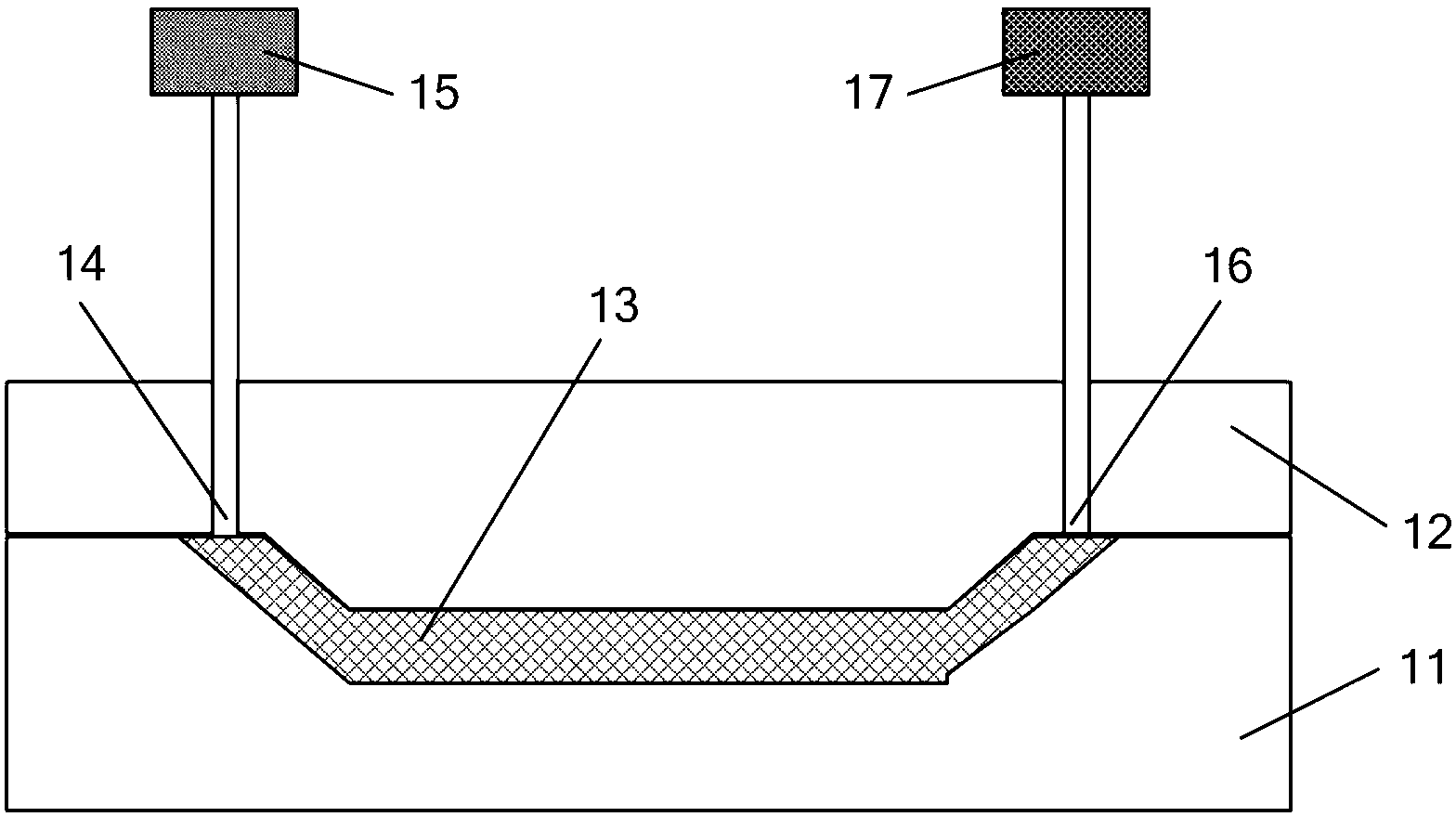

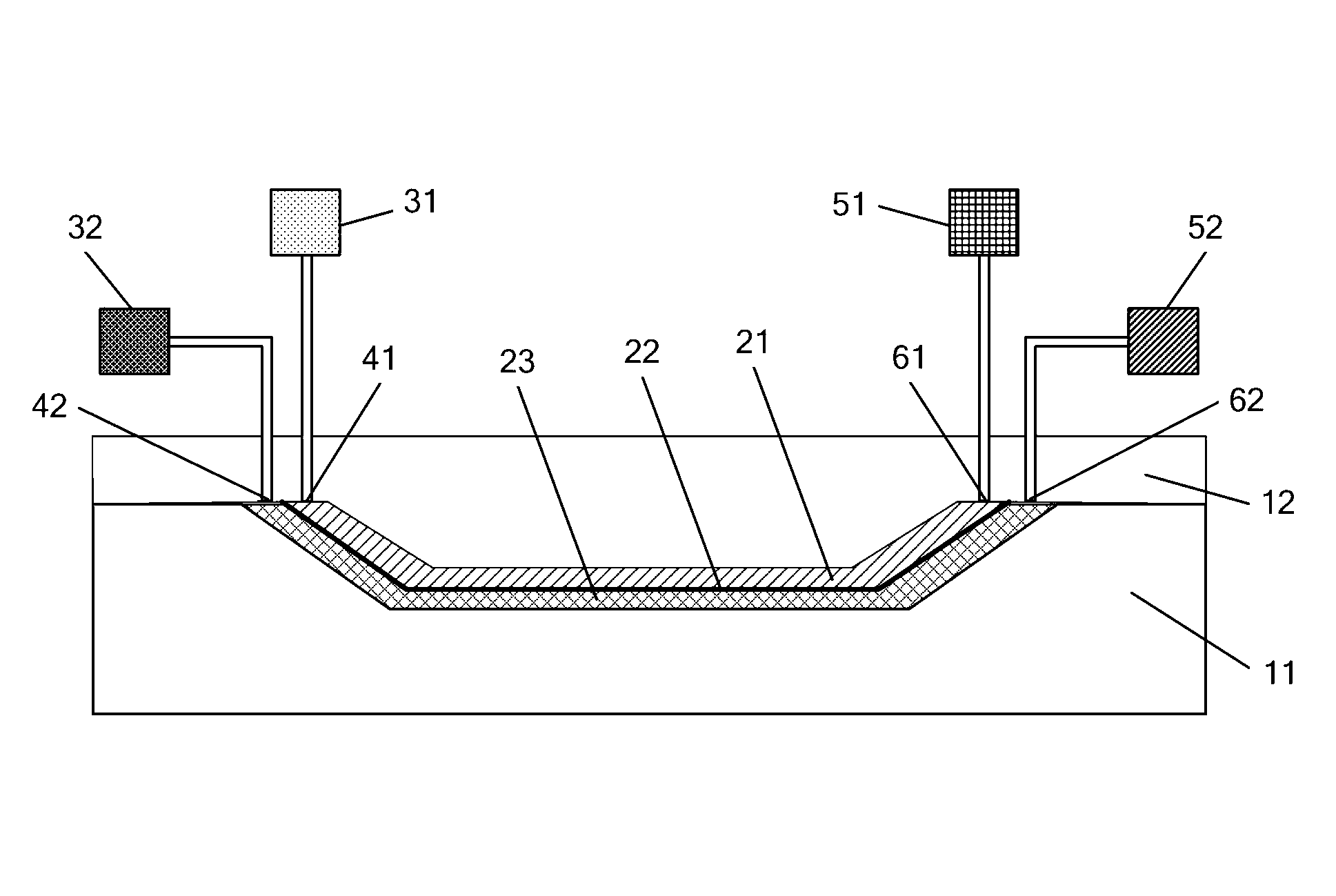

Spacecraft shell material as well as RTM (Resin Transfer Molding) molding technology and injection molding system thereof

InactiveCN102935754ASimultaneous injectionRealize simultaneous curingSynthetic resin layered productsFiberVacuum pumping

The invention discloses a spacecraft shell material which mainly consists of an inner composite material and an outer composite material, wherein the inner composite material takes an epoxy resin and aromatic amine curing agent system as matrix; the outer composite material takes benzoxazine resin as matrix; the transition between the inner and outer composite materials is realized through a polysulfone membrane; and the shell material is prepared by carrying out simultaneous injection and synchronous curing through an RTM (Resin Transfer Molding) technology: an injection molding system is prepared, then an overlapped fiber pre-molding body is prepared, preheating is carried out on the resin in two injection systems, and simultaneous injection, synchronous curing, demolding and finishing are carried out to obtain the spacecraft shell material. The injection molding system comprises a die, a first injection system, a second injection system, a first vacuum pumping system and a second vacuum pumping system; and a polysulfone membrane is arranged in a die cavity to divide the die cavity into an inner die cavity and an outer die cavity. The spacecraft shell material has the advantages of few technology steps, low equipment investment, low cost, high efficiency, benefit to integral molding and the like.

Owner:NAT UNIV OF DEFENSE TECH

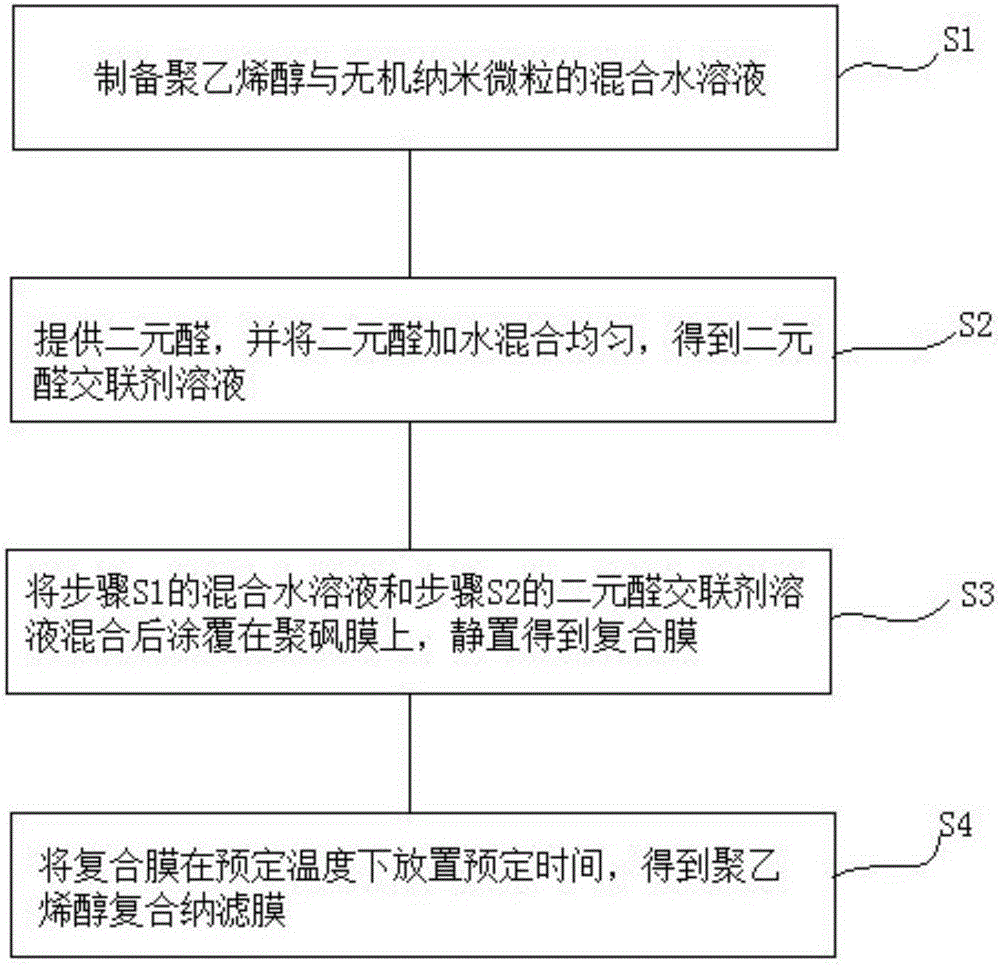

Polyvinyl alcohol composite nanofiltration membrane preparation method

The invention discloses a polyvinyl alcohol composite nanofiltration membrane preparation method. The method includes the following steps that S1, a mixed aqueous solution of polyvinyl alcohol and inorganic nanoparticles is prepared; S2, dialdehyde is provided, added into water and evenly mixed, and a dialdehyde cross-linking agent solution is prepared; S3, the mixed aqueous solution in the first step and the dialdehyde cross-linking agent solution in the second step are mixed and are coated on a polysulfone membrane, and still standing is carried out to obtain a composite membrane; S4, the composite membrane is placed for a preset period of time at a preset temperature to obtain a polyvinyl alcohol composite nanofiltration membrane. The polyvinyl alcohol composite nanofiltration membrane preparation method is simple in process and low in cost, and facilitates industrial production. Besides, the polyvinyl alcohol composite nanofiltration membrane prepared through the method can intercept small molecular substances of organic matter with the molecular weight being 400, almost all univalent and divalent inorganic salt can pass the membrane, and the membrane has high water flux.

Owner:BEIJING ORIGIN WATER FILM TECH

Polysulfone dialysis membrane as well as preparation method and application thereof

InactiveCN107174983AReduce the amount of adsorptionWill not cause deteriorationSemi-permeable membranesDialysis membranesPolysulfone membrane

The invention provides a polysulfone dialysis membrane as well as a preparation method and application thereof. The polysulfone dialysis membrane is formed by connecting a bioactive molecule onto a polydopamine surface modified polysulfone membrane, wherein the bioactive molecule is any one or a combination of at least two of human serum albumin, bovine serum albumin, natto kinase, lumbrokinase, thrombomodulin and hirudin. The polysulfone dialysis membrane provided by the invention can guarantee the activity of the bioactive molecule and has a good anticoagulation function; the pure water flux is 65L / m<2>.h.bar to 140L / m<2>.h.bar, the retention rate on BSA (Bull Serum Albumin) is 95 percent or above and the retention rate on lysozyme is 25 percent to 35 percent; compared with an unmodified polysulfone membrane, the adsorption amount on the BSA, fibrinogen and blood platelets is remarkably reduced. The method provided by the invention has moderate conditions and a simple preparation process; the deterioration of membrane structure and performance and the inactivation or denaturation of bioactive macromolecules are not caused; the polysulfone dialysis membrane has a wide application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

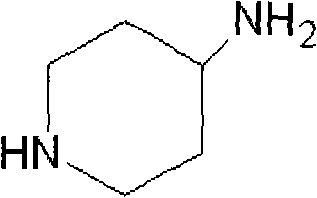

Preparation method for heterocyclic amine composite nanofiltration membrane

InactiveCN101695629AHigh selectivityImprove throughputSemi-permeable membranesSodium phosphatesPolysulfone membrane

The invention discloses a preparation method for a polymer composite membrane, in particular a preparation method for a polypiperidinyl amide nanofiltration membrane, which comprises the following steps of: firstly, preparing a polysulfone support membrane; secondly, putting the polysulfone support membrane into an aqueous solution of 4-aminopiperidine, wherein the aqueous solution of 4-aminopiperidine contains a mixture of a sodium phosphate and a dibastic sodium phosphate, which serves as an acid-acceptor, and the polysulfone support membrane soaked by the aqueous solution of 4-aminopiperidine is rolled by a rubber roll to remove the redundant aqueous solution of 4-aminopiperidine; thirdly, contacting the polysulfone support membrane with a trimesoyl chloride containing organic solution; and finally, putting the polysulfone membrane in a vacuum oven to dry, and washing the membrane with water to obtain the polypiperidinyl amide nanofiltration membrane. The preparation method has the advantages of good permselectivity for the removal rate of the sodium chloride and the sodium sulphate, and relatively high flux, and is widely applied to specialized separation fields.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

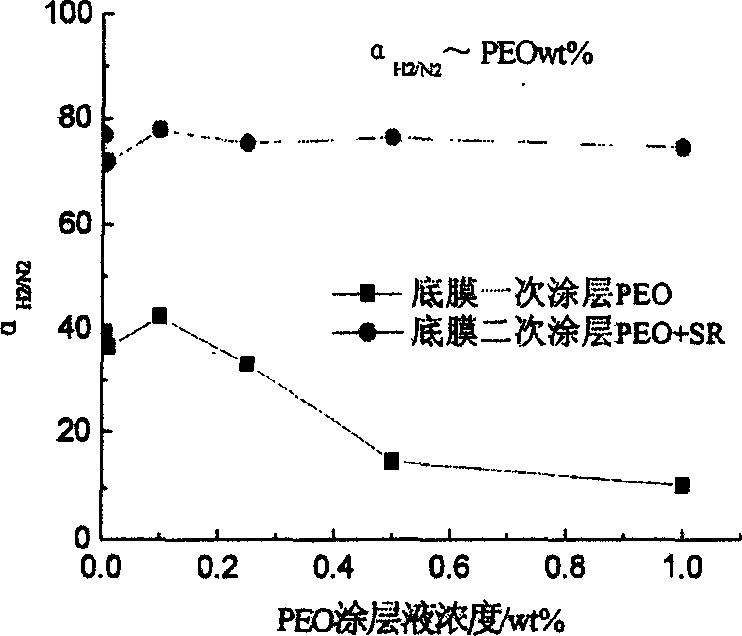

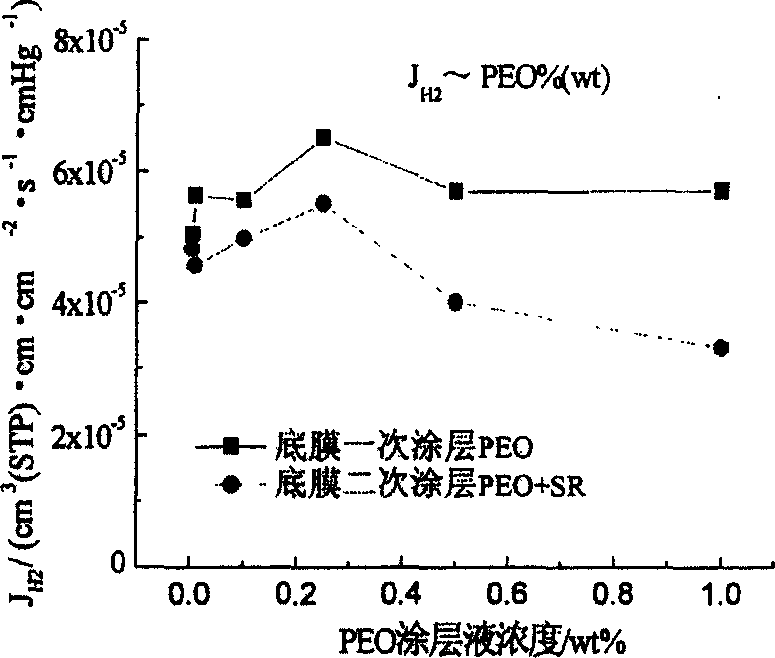

Composite hollow fiber membrane and its preparation and application

InactiveCN1657144AImprove selective separation performanceImprove the ideal separation factor of pure gasSemi-permeable membranesHollow fibrePolymer science

A composite hollow fibre membrane based on the composite resistance Henis membrane model (silica rubber / polysulfone membrane) for separating H2 or N2 with high effect is composed of basic membrane, water-soluble high-molecular layer in rubber state at ordinary temp and silica rubber layer. It can be used for the ammonia synthesizing plant or oil refinary to recover N2 or H2. Its preparing process is also disclosed.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

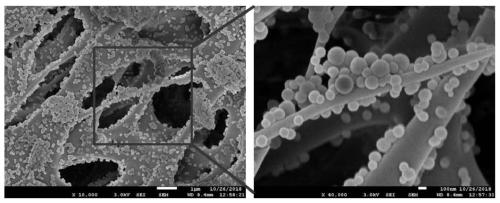

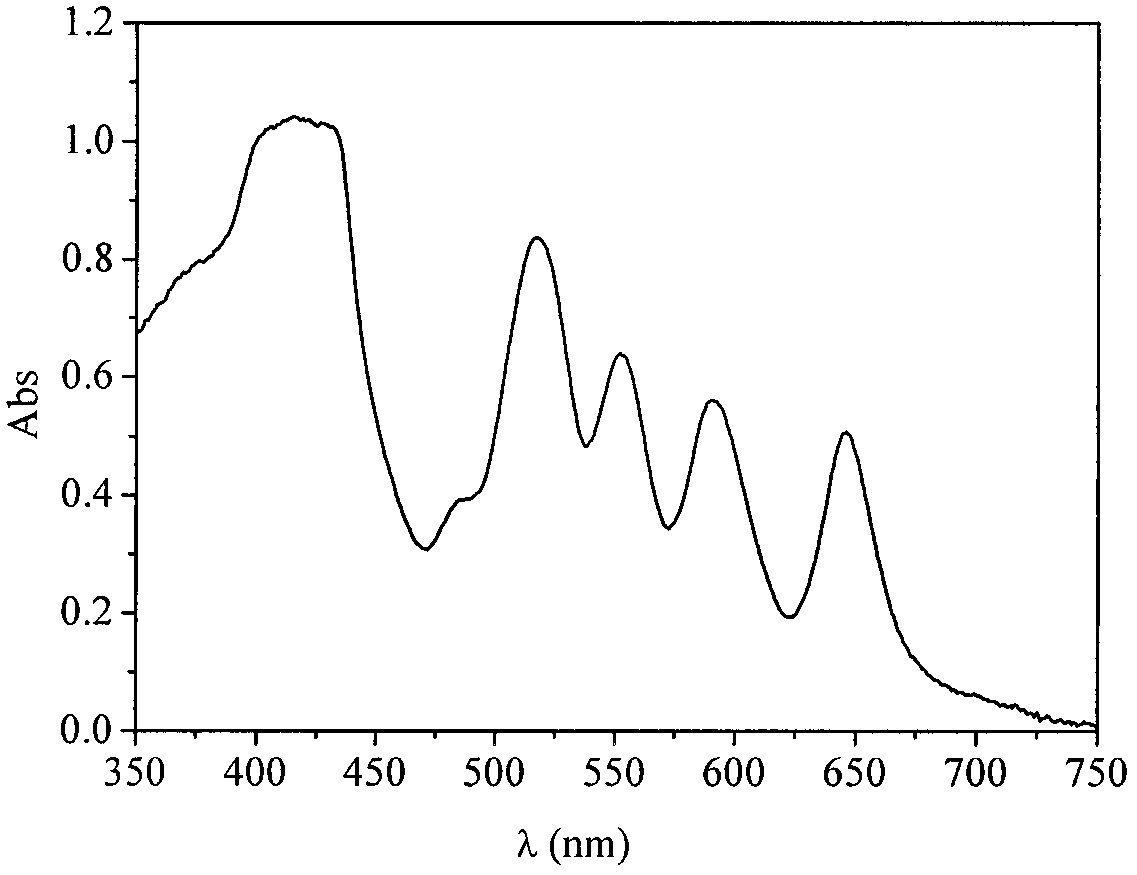

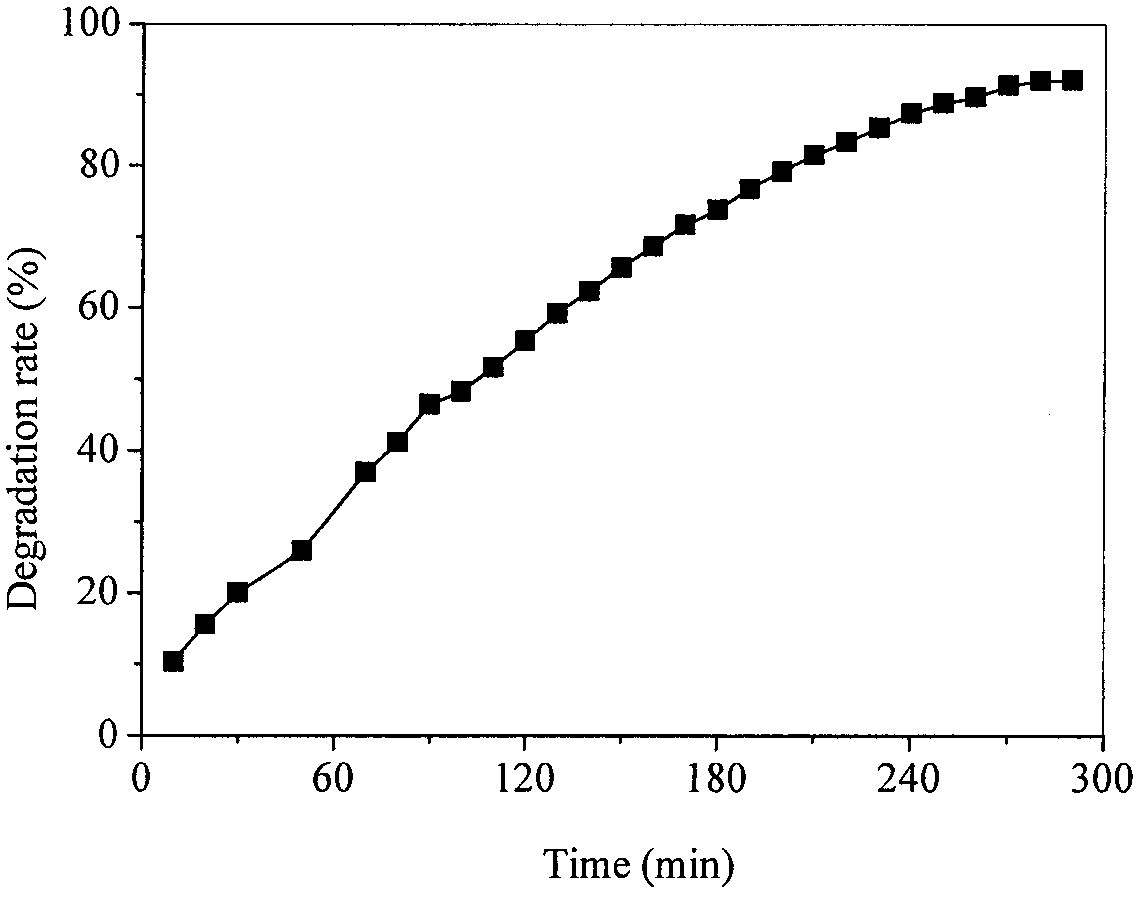

Porous membrane matrix-based monodisperse porphyrin visible-light-driven photocatalyst and preparation method thereof

InactiveCN107930692AWater/sewage treatment by irradiationWater treatment compoundsPolysulfone membraneOrganic dye

The invention discloses a preparation method of a porous membrane matrix-based monodisperse porphyrin visible-light-driven photocatalyst. A macromolecule porous membrane is an electropositive quaternized polysulfone membrane, a quaternized polyether sulfone membrane or a quaternized polysulfone / quaternized polyether sulfone blended membrane; porphyrin is meso-tetra(4-sulfonatophenyl)porphyrin (TPPS), meso-tetra(4-carboxylphenyl)porphyrin (TCPP) a mixture thereof. A monodisperse porphyrin functional membrane is prepared by immersing an electropositive porous membrane into a porphyrin solution,and performing electrostatic assembly for 1 to 10h. The functional membrane can be used for photocatalytically degrading organic dyes. The method has the advantages that the operation is simple, the period is short, the catalyst is easy to recover and reuse, the degradation efficiency is high, environment friendliness is realized, and the like.

Owner:TIANJIN POLYTECHNIC UNIV

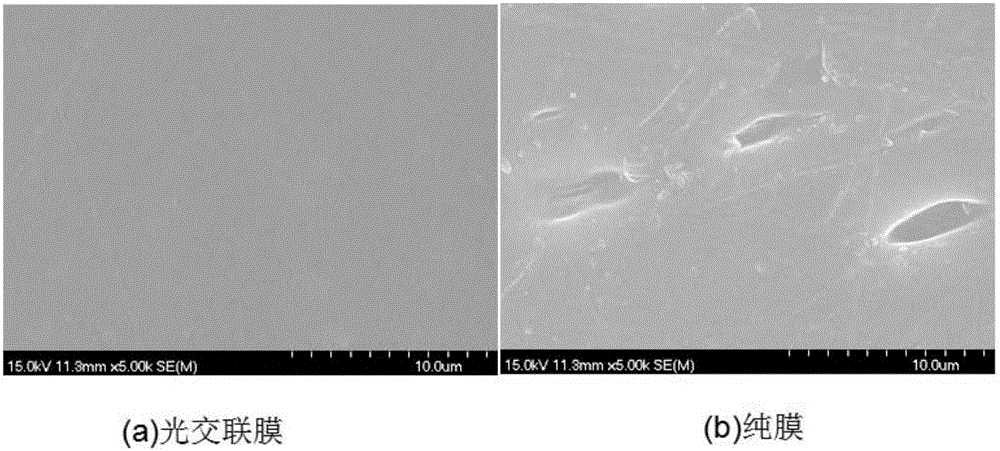

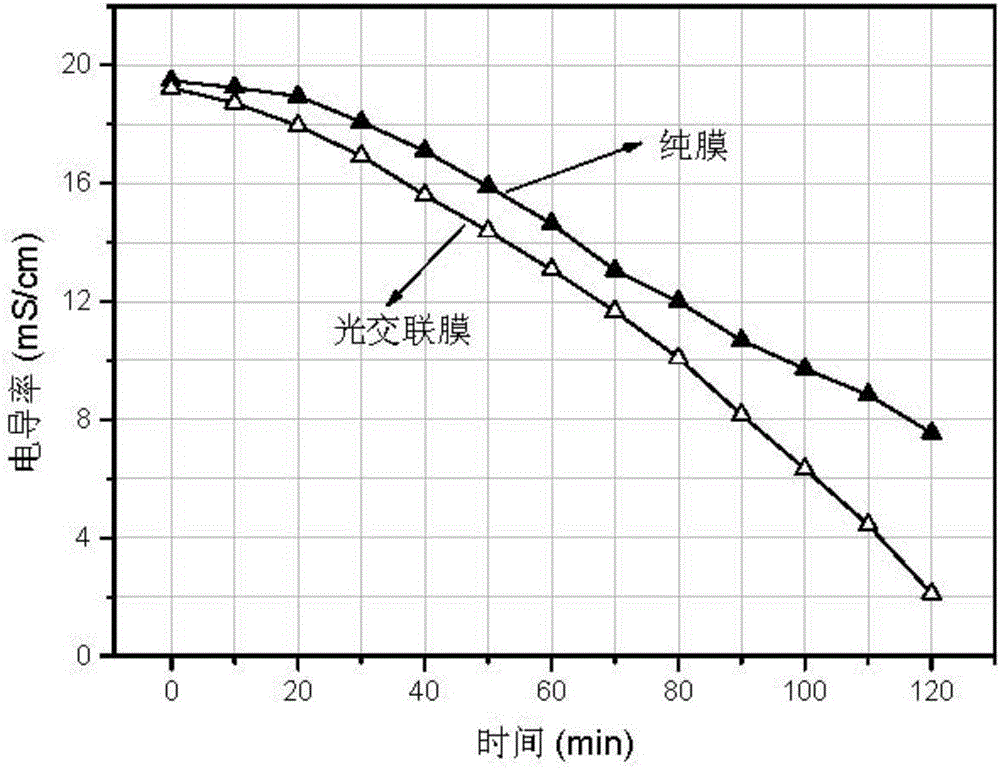

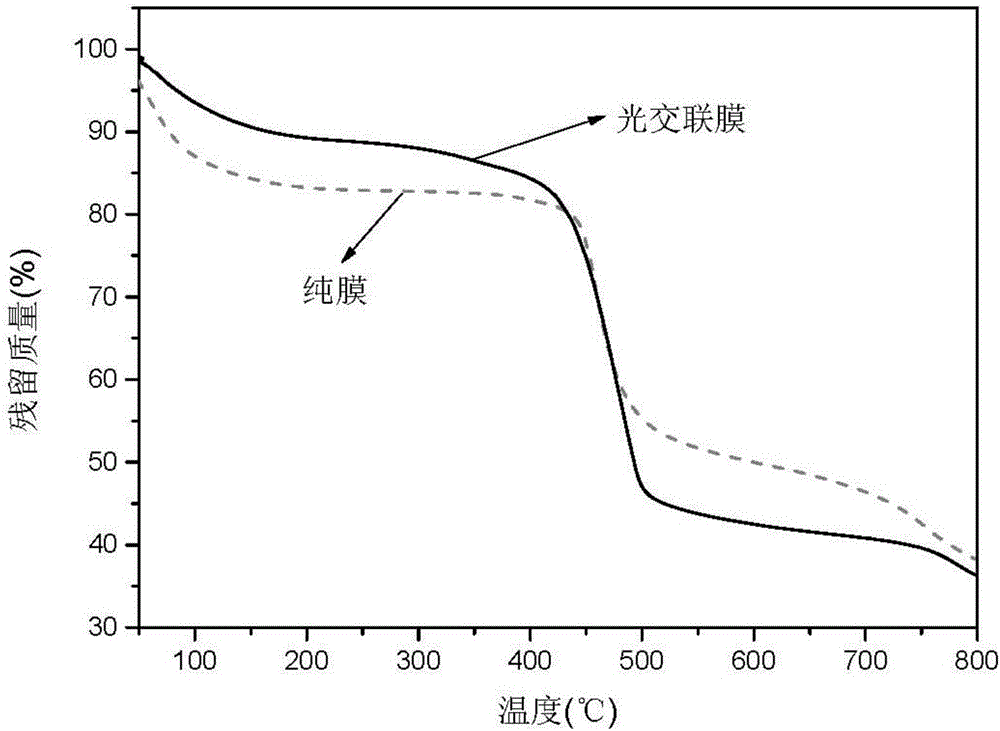

Preparation method of photo-crosslinked sulphonated polysulfone ion exchange membrane

ActiveCN106188591AHigh ion exchange capacityImprove mechanical propertiesCation exchangersN dimethylformamidePolysulfone membrane

The invention discloses a preparation method of a photo-crosslinked sulphonated polysulfone ion exchange membrane. The method comprises the following steps that 1, sulphonated polysulfone with a certain sulfonation degree is dissolved in a solution prepared from N,N-dimethylformamide (DMF), stirring is conducted, and standing and cooling are conducted at room temperature; 2, a photoinitiator and a cross-linking agent are added in the solution obtained in the first step, stirring is conducted, a uniform solution is obtained, standing is conducted, and a membrane casting solution is obtained; 3, the membrane casting solution obtained in the second step is poured on a glass plate, an automatic membrane scraper is used for rapid scraping in the mode of being perpendicular to the glass plate, and a membrane is formed; 4, the membrane obtained through scraping in the third step is rapidly subjected to ultraviolet irradiation, the membrane is rapidly put in vacuum of 50 DEG C to 80 DEG C to be dried, and the photo-crosslinked sulphonated polysulfone membrane is obtained. The exchange membrane obtained through the method is good in chemical stability, low in swelling degree and high in ion exchange capacity.

Owner:YIWU SCI & TECH INST CO LTD OF ZHEJIANG UNIV OF TECH +1

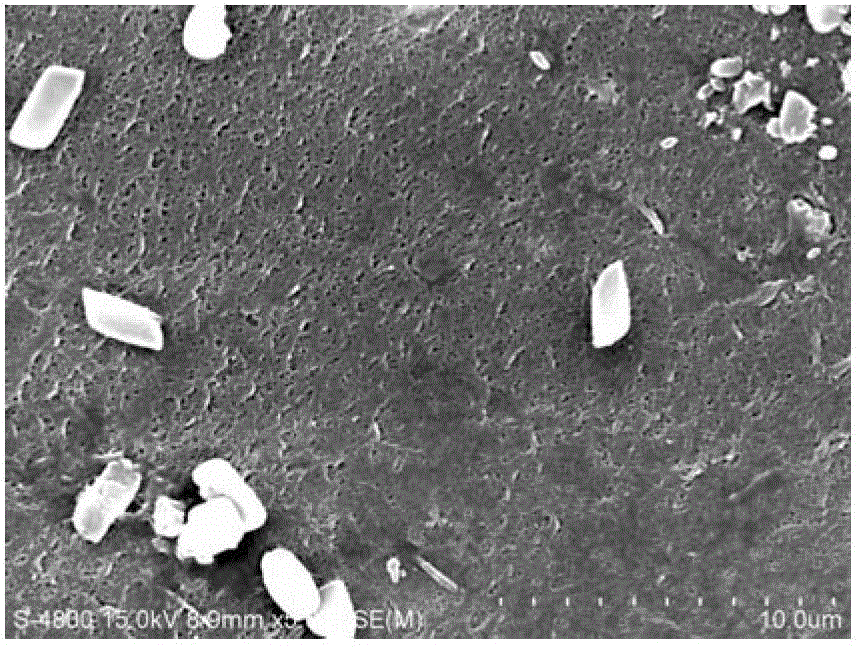

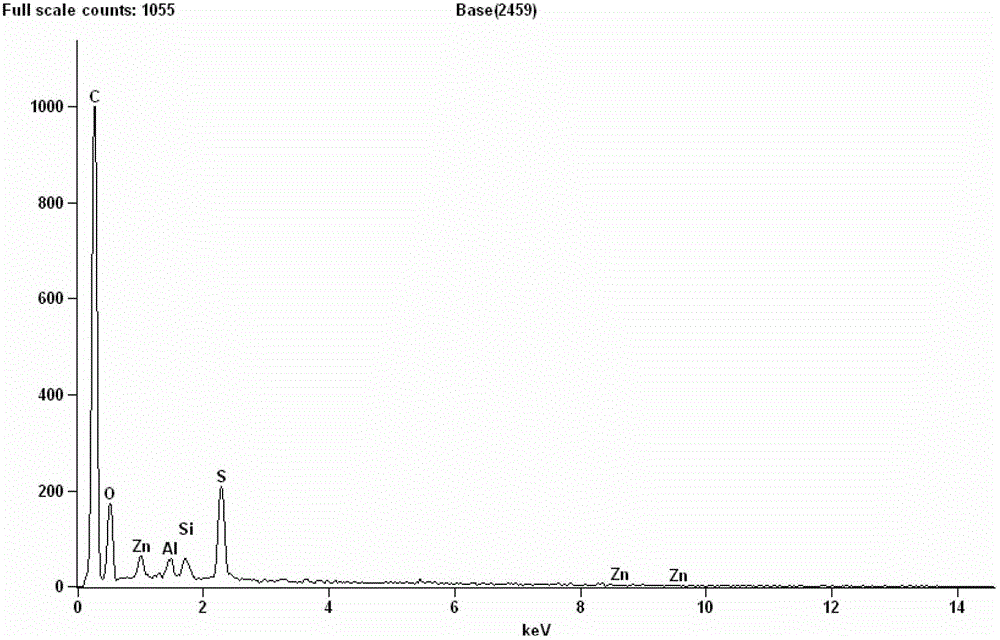

Composite flat-sheet polysulfone membrane doped with active carbon and nanometer zinc oxide and preparation method thereof

InactiveCN102974236AImprove hydrophilicityIncrease water fluxSemi-permeable membranesPolymer scienceMeth-

The invention discloses a composite flat-sheet polysulfone membrane doped with active carbon and nanometer zinc oxide and a preparation method. The preparation steps are as follows: mixing nanometer zinc oxide, active carbon particles, polysulfone and 1-methyl-2-pyrrolidone in a mass ratio of (0.5-1) to 5 to 20 to 100; ultrasonically oscillating and dispersing the components; stirring the mixture until the components are completely dissolved, de-foamed and membrane-pushed; standing the pushed membrane in the air for 15-20 seconds, then soaking the membrane to a water coagulating bath for 20 minutes, putting the soaked membrane to deionized water to soak for 3 days and then taking out the soaked membrane. The composite flat-sheet polysulfone membrane provided by the invention can improve anti-pollution and adsorption performances of the membrane, and further can carry out photocatalysis under ultraviolet irradiation to effectively remove degradation-resistant pollutants in the water.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com