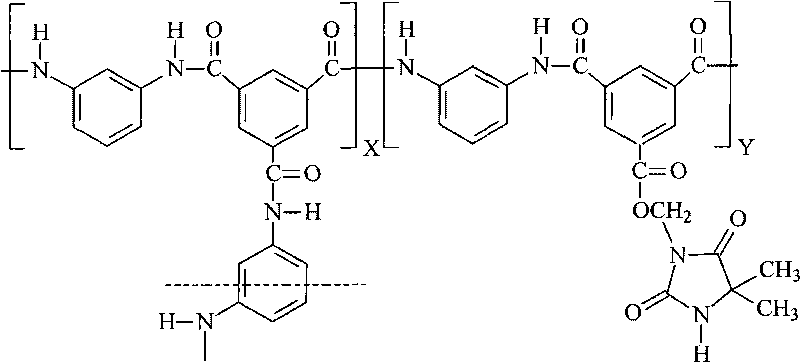

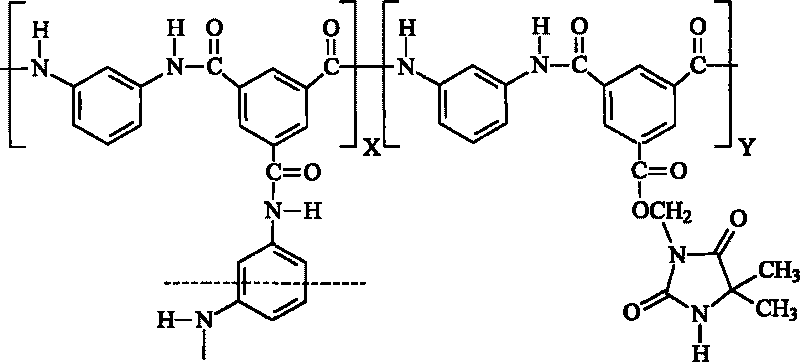

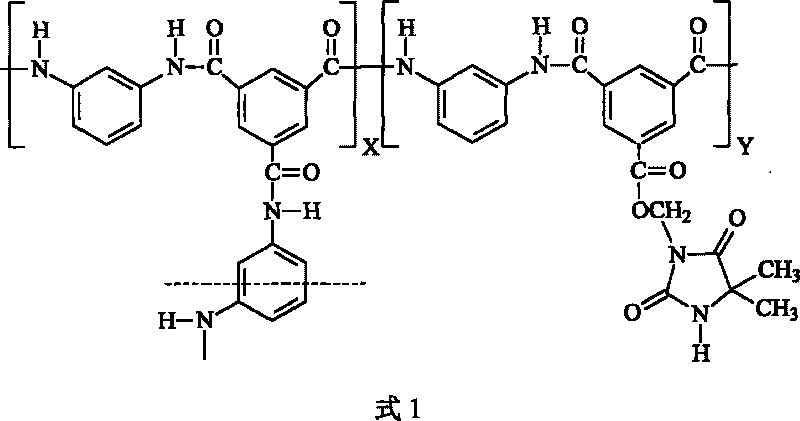

Grafted modified aromatic polyamide composite reverse osmosis membrane and preparation method thereof

A kind of aromatic polyamide, reverse osmosis membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology and other directions, to achieve the effect of easy implementation, good anti-microbial pollution performance, good antibacterial function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A 15×17 cm polysulfone support membrane was fixed in a polytetrafluoroethylene frame, the surface of the support membrane was rinsed repeatedly with deionized water, and the surface of the support membrane was purged with 30kPa nitrogen until dry. Dissolve 5.00 g of m-phenylenediamine, 5.75 g of camphorsulfonic acid, 3.77 mL of triethylamine, 0.375 g of sodium lauryl sulfate and 4.55 mL of dimethyl sulfoxide in 231 mL of deionized water to prepare Obtain an aqueous phase monomer solution; dissolve 0.99 g of trimesoyl chloride in 300 mL of n-hexane solution to prepare an oil phase monomer solution. Pour 50mL of the aqueous monomer solution on the surface of the polysulfone support membrane, and after contacting for 60s, drain the solution, and purge the membrane surface with 30kPa nitrogen to dryness. Then pour 50mL of the oil-phase monomer solution on the surface of the polysulfone support membrane. After the interfacial polymerization reaction for 60s, drain the soluti...

Embodiment 2~5

[0022] First, the same method as in Example 1 is used to prepare the aromatic polyamide composite reverse osmosis membrane to be grafted. The difference from Example 1 is that the MDMH is changed during the preparation of the grafted modified aromatic polyamide composite reverse osmosis membrane. concentration of the aqueous solution.

[0023] Table 1 lists the schedule of the raw materials used in Examples 2-5. The mass concentrations of the substances contained in the prepared aqueous phase monomer solution and the oil phase monomer solution are the same.

[0024] Table 2 lists the chlorine-resistant and anti-microbial fouling properties of the composite reverse osmosis membranes prepared in Examples 2-5 and Comparative Example 1. It can be seen from Table 2 that the water flux and salt rejection rate of the aromatic polyamide composite reverse osmosis membrane modified by MDMH graft modification after chlorination have small changes, indicating that the graft modified arom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com