Chlorine-resistant highly permeable water-treatment membrane, and method for preparing same

A water treatment membrane and aqueous solution technology, applied in chemical instruments and methods, reverse osmosis, semi-permeable membrane separation, etc., can solve the problems of reducing the permeation flux of the polyamide layer, increasing the number of processes, etc., achieving excellent chlorine resistance, permeation The effect of excellent flux performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

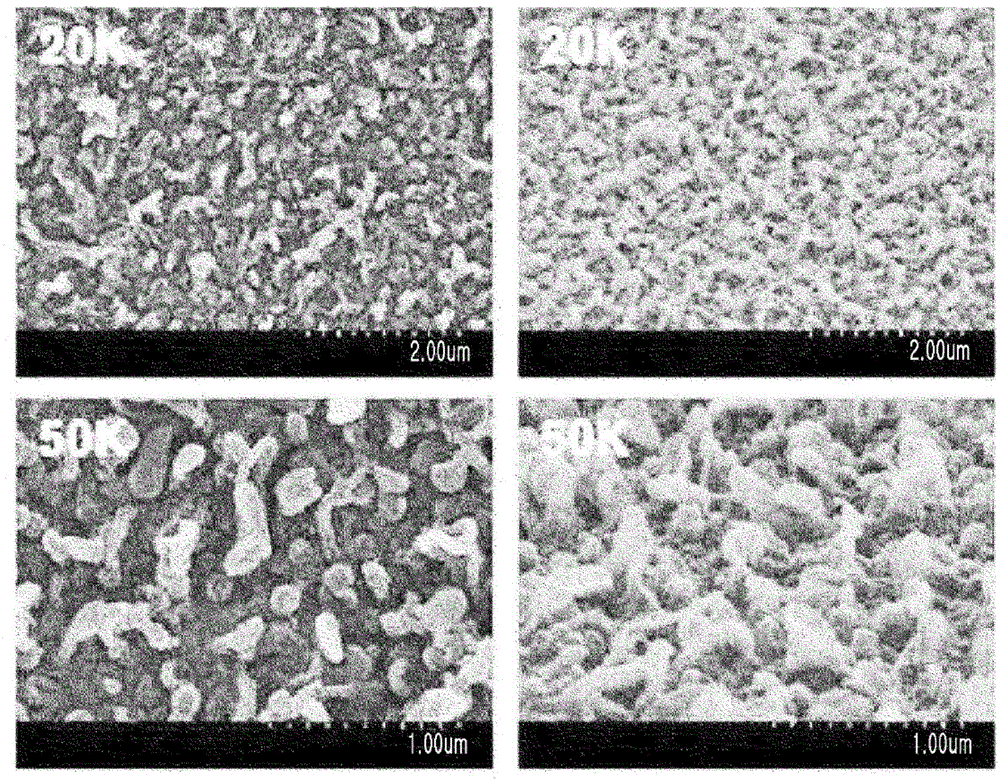

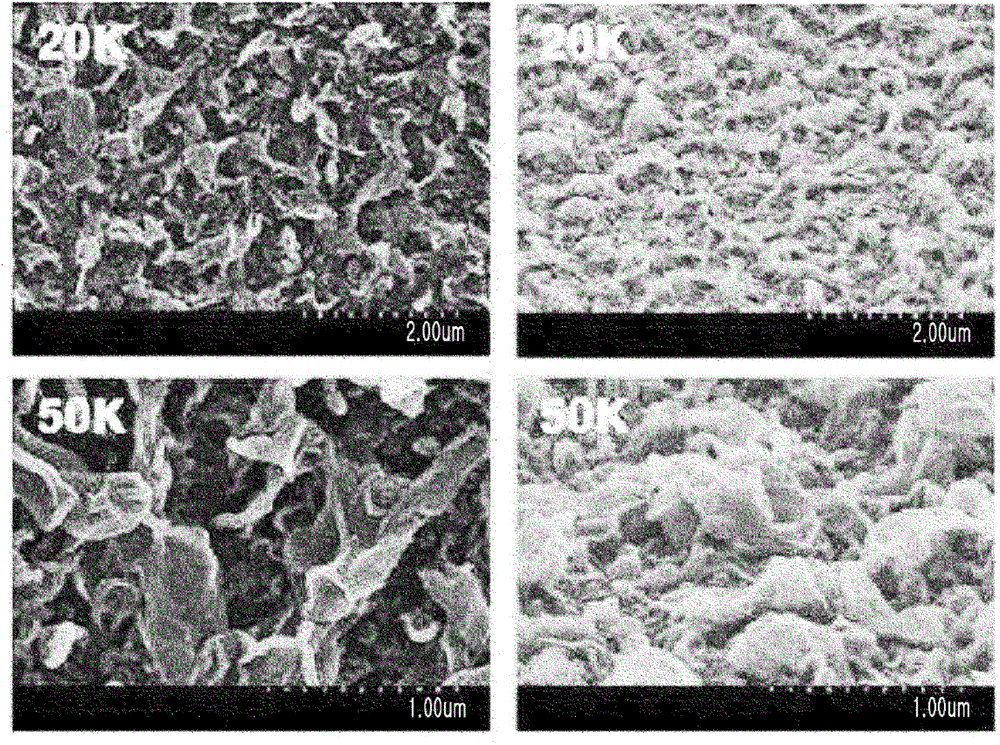

Image

Examples

Embodiment 1

[0059] 18% by weight of polysulfone solid was added to N,N-dimethylformamide (DMF) solution, and dissolved therein at a temperature of 80 to 85° C. for more than 12 hours to obtain a uniform liquid phase. The solution having this uniform liquid phase was casted on a nonwoven fabric formed of a polyester material and having a thickness of 95 to 100 μm, thereby forming a porous polysulfone support.

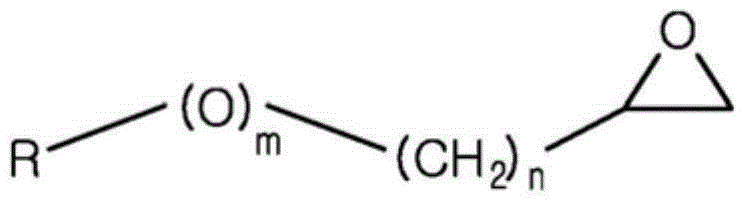

[0060] After impregnating the polysulfone support in an aqueous solution containing 2% by weight of m-phenylenediamine (mPD) and a fluorinated monoglycidyl ether represented by the following chemical formula 3 (the molar ratio of m-phenylenediamine to fluorinated monoglycidyl ether is After 2 minutes in 1000:1), the excess aqueous solution on the support was removed using a roller with 25 psi pressure, and the porous polysulfone support was dried at room temperature for 1 minute.

[0061] [chemical formula 3]

[0062]

[0063] Then, the support body was immersed in a solution of...

Embodiment 2

[0065] A water treatment membrane was prepared using the same method as in Example 1, except that an aqueous solution containing m-phenylenediamine (mPD) and fluorinated monoglycidyl ether in a molar ratio of 500:1 was used.

Embodiment 3

[0067] A water treatment membrane was prepared using the same method as in Example 1, except that an aqueous solution containing m-phenylenediamine (mPD) and fluorinated monoglycidyl ether in a molar ratio of 100:1 was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| desalination ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com