Reverse osmosis membrane comprising silver nanowire layer, and preparation method thereof

一种反渗透膜、银纳米线的技术,应用在逆渗透、半透膜分离、化学仪器和方法等方向,能够解决很难获得银本征效应等问题,达到脱盐率和渗透流率优异、改善表面特征、优异防污性和耐氯性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

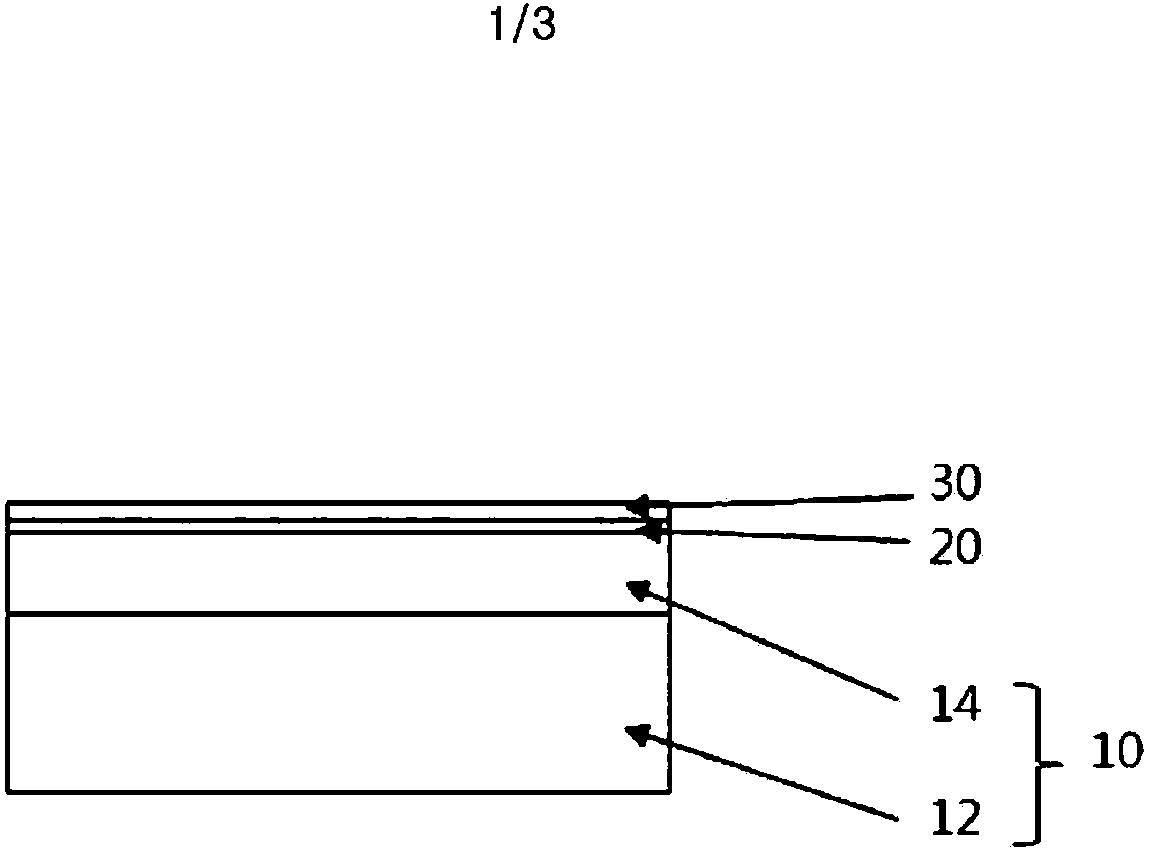

[0052] Polysulfone having a solid content of 18 wt % was put into a DMF (N,N-dimethylformamide) solution and dissolved at a temperature equal to 80° C. for 12 hours or more to obtain a uniform liquid phase. The solution was cast on a nonwoven fabric made of polyester material with a thickness of 95 μm to 100 μm to have a thickness of 45 μm to 50 μm to form a porous polysulfone support.

[0053] Immerse the porous polysulfone support body formed according to the aforementioned method in an aqueous solution containing 2wt% m-phenylenediamine and 0.001wt% silver nanowires for 2 minutes, take it out, and use a 25psi rolling machine to remove excess aqueous solution on the support body, And dry the support at room temperature for 1 minute.

[0054] Afterwards, the support was immersed in a 0.1 wt% organic trimesoyl chloride solution using ISOL-C (SK Chem.) solvent for 1 minute, taken out, and dried in an oven at a temperature of 60° C. for 10 minutes. Thereafter, the support was w...

Embodiment 2

[0056] A reverse osmosis membrane was prepared in the same manner as in Example 1 except that the content of silver nanowires was 0.005 wt%.

Embodiment 3

[0058] A reverse osmosis membrane was prepared in the same manner as in Example 1 except that the content of silver nanowires was 0.01 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| desalination ratio | aaaaa | aaaaa |

| desalination ratio | aaaaa | aaaaa |

| desalination ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com