Patents

Literature

2071results about How to "Improve antifouling performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Selective membrane having a high fouling resistance

InactiveUS6913694B2Improve antifouling performanceImprove the immunitySemi-permeable membranesSynthetic resin layered productsEpoxyCross-link

Owner:SAEHAN INDS CO LTD

Fabric care formulations and methods

InactiveUS20120077725A1Improve antifouling performanceStain/soil resistant fibresOrganic detergent compounding agentsMedicineParticulate material

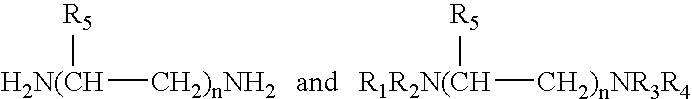

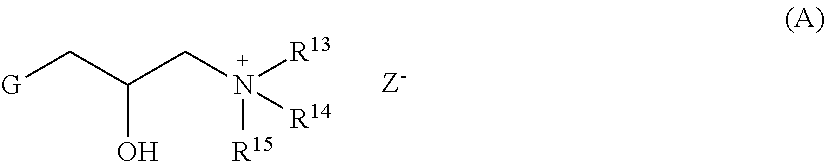

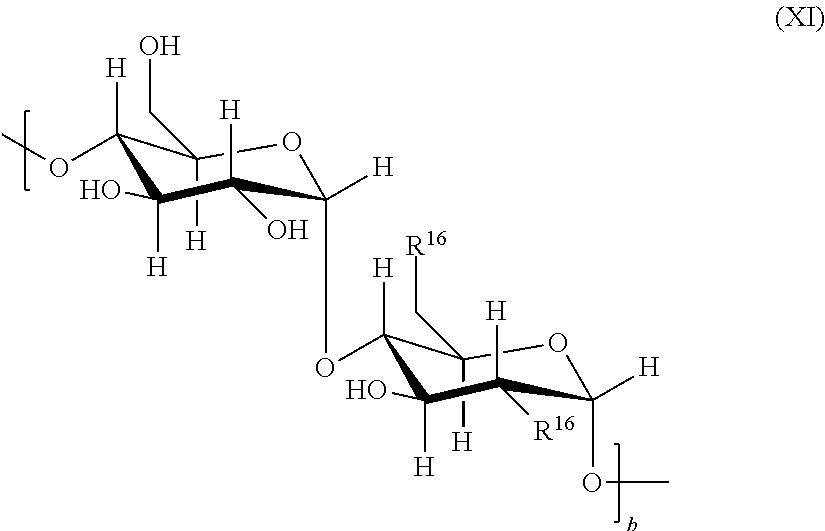

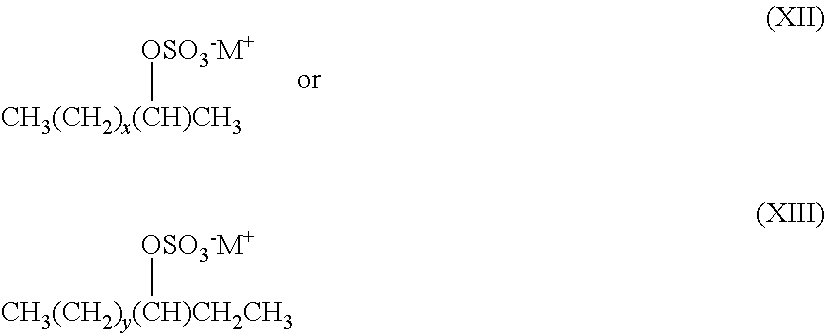

Fabric care compositions for providing improved stain repellency are described. The fabric care composition includes a mixture including a hydrophobic fluid, a particulate material and an amphoteric or cationic oligomeric / polymeric deposition aid. Methods for providing improved stain repellency for a textile by treating the textile with the fabric care composition are also described.

Owner:THE PROCTER & GAMBLE COMPANY

Curable composition, coating composition, paint, antifouling paint, cured product thereof and method of rendering base material antifouling

InactiveUS20020197490A1Shorten the running cycleExcellent in uniformity of coating film surfaceAntifouling/underwater paintsLayered productsHydrophobic silicaHardness

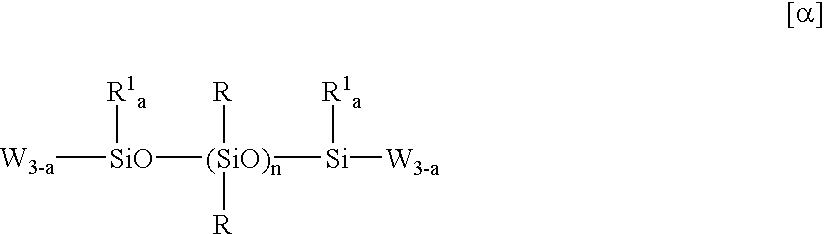

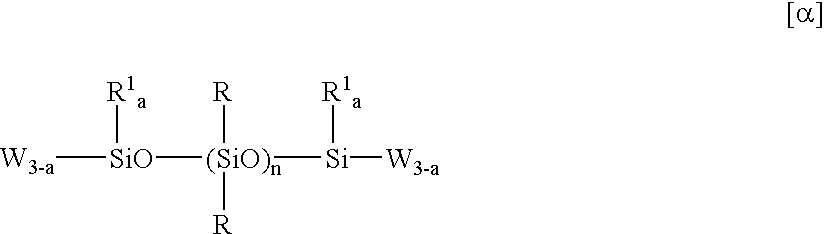

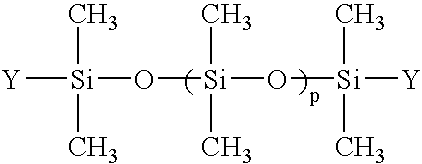

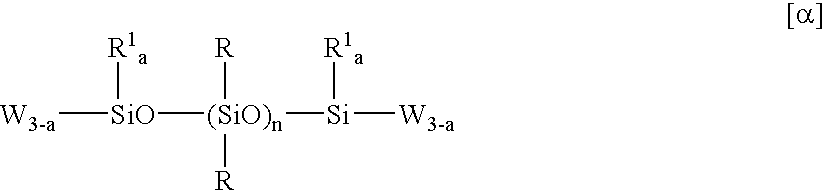

A curable composition comprising (A) an organopolysiloxane having functional groups capable of condensation reaction at both molecular terminals thereof and (B-1) a hydrophobic silica and a hydrophilic silica. A curable composition comprising (A) an organopolysiloxane having functional groups capable of condensation reaction at both molecular terminals thereof and (B-2) a hydrophobic silica, wherein the hydrophobic silica (B-2) is thermally treated together with the organopolysiloxane (A). The organopolysiloxane (A) is preferably represented by the formula: W3-a(R1a)Si(R2)O-(Si(R2)O)n-Si(R1a)W3-a [alpha] (wherein W represents a hydroxyl group or a hydrolyzable group; each of R1 and R independently represents an unsubstituted or substituted monovalent hydrocarbon group having 1 to 12 carbon atoms, provided that the hydrocarbon groups R1 as well as the hydrocarbon groups R may be identical with or different from each other; n is an integer of 5 or greater; and a is 0, 1 or 2). When, in the formula [alpha], W represents a hydroxyl group and a is 2, the curable composition preferably comprises, in addition to the components (A) and either (B-1) or (B-2), (C) an organosilane represented by the formula: R1bSiX4-b [I] (wherein R1 represents an unsubstituted or substituted monovalent hydrocarbon group having 1 to 8 carbon atoms; X represents a hydrolyzable group; and b is 0 or 1), or a partial hydrolyzate of the organosilane. Thus, a curable composition, especially a curable paint composition and an antifouling paint composition, and an antifouling coating film of the following characteristics can be provided. The curable composition, in particular when used as a coating material or a paint, is excellent in sprayability and enables forming a thick coating film by one-time application. The curable composition enables shortening the operating period for coating, and a coating film of uniform thickness can be obtained by the application thereof. The obtained coating film is excellent in film strength and film hardness and, when used for antifouling purposes, exerts excellent antifouling capability for a prolonged period of time. Further, the curable composition ensures excellent storage stability before application thereof.

Owner:CHUGOKU MARINE PAINTS +1

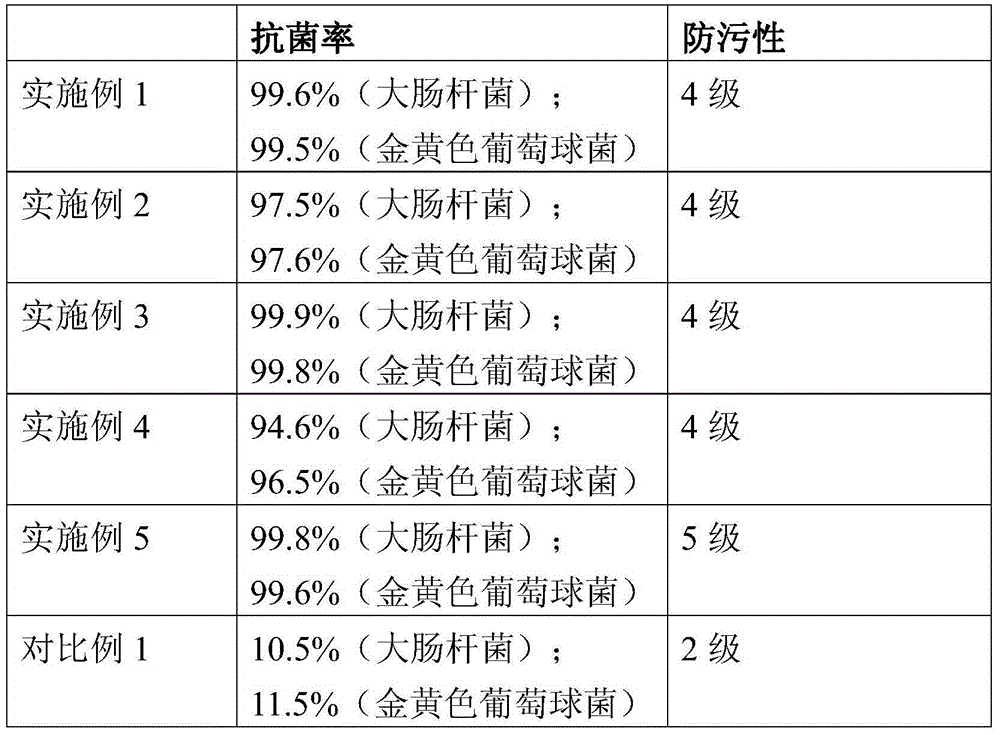

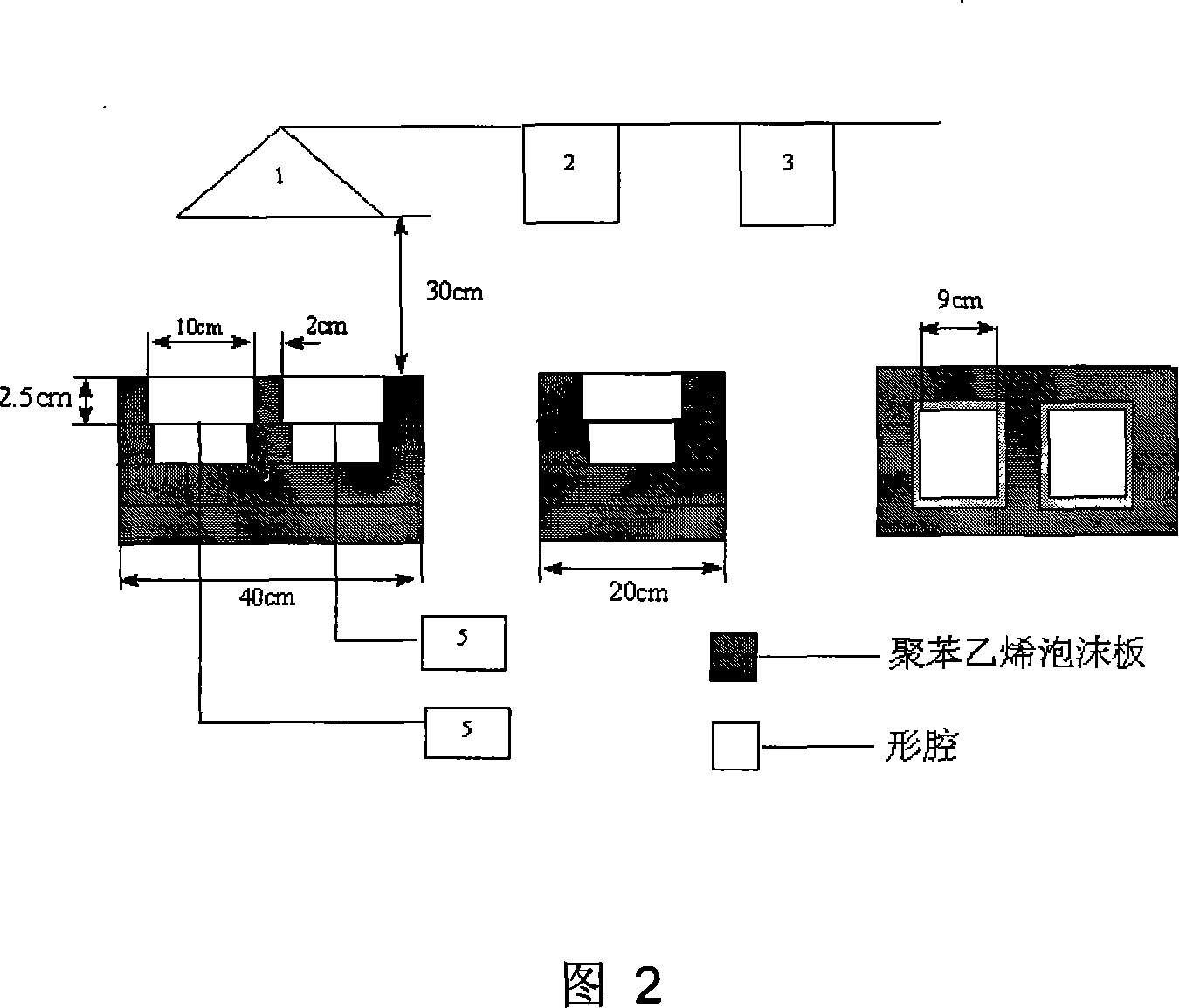

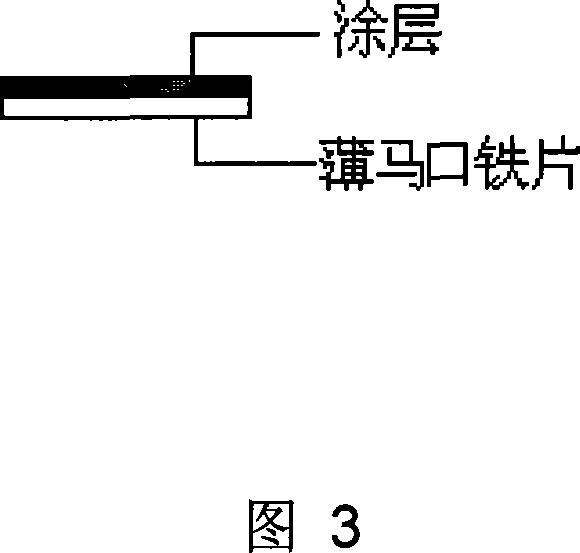

3D printing material having self-cleaning antibacterial function as well as preparation method and application of 3D printing material

The invention discloses a 3D printing material having a self-cleaning antibacterial function as well as a preparation method and an application of the 3D printing material. The 3D printing material consists of the following components: 70-85 parts of a high-molecular polymer, 1-5 parts of pigment powder, 1-5 parts of inorganic filler, 0.5-1.5 parts of a nanometer antibacterial agent and 10-20 parts of a binding material. The 3D printing material having the self-cleaning antibacterial function is prepared by the following steps: uniformly mixing the components; adding the uniformly mixed materials to a single-screw plastic extruder, extruding, cooling and shaping, drying, drawing and winding. The 3D printing material disclosed by the invention is excellent in toughness and mechanical property, and furthermore the 3D printing material is good in self-cleaning and antifouling properties; and the 3D printing material has high application potential.

Owner:GUANGZHOU FEISHENG HIGH POLYMER MATERIAL CO LTD +1

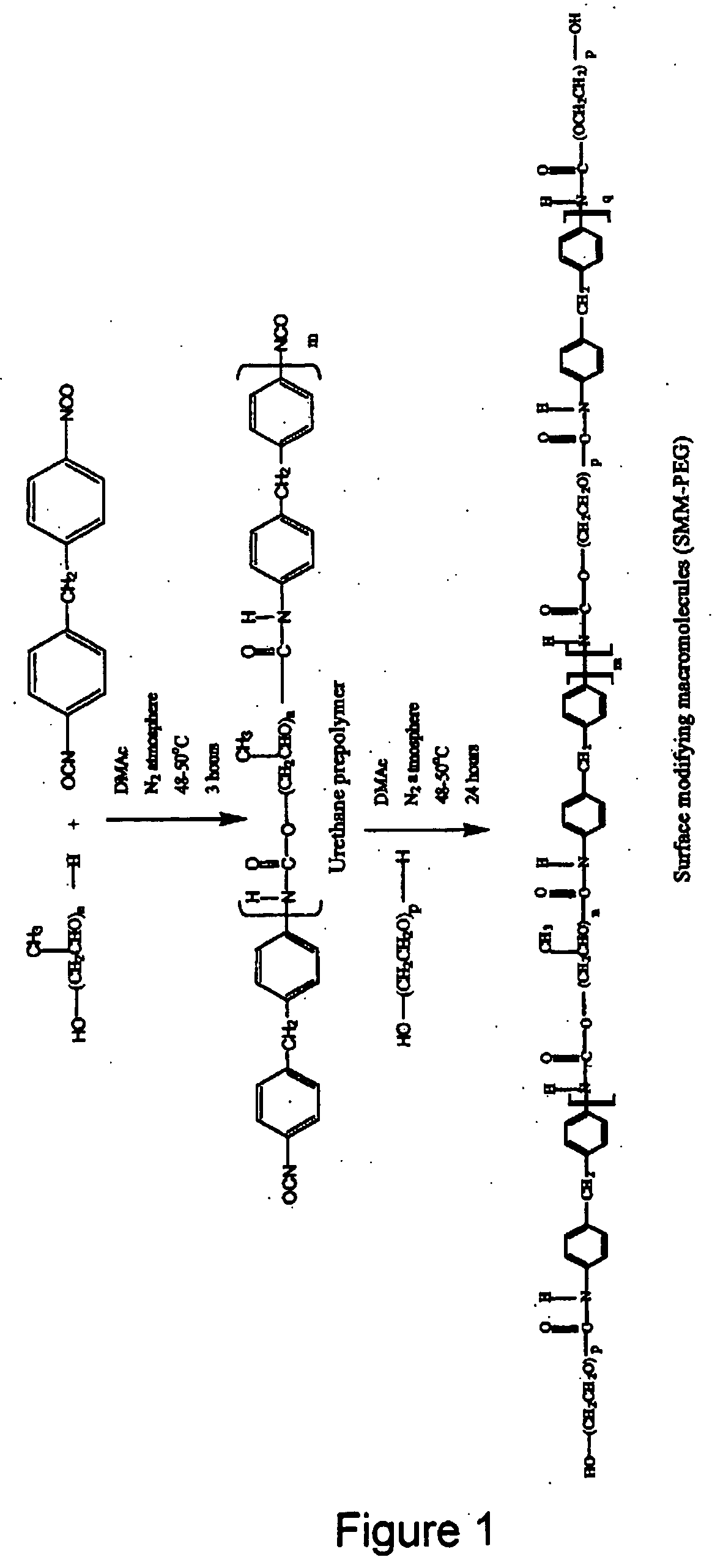

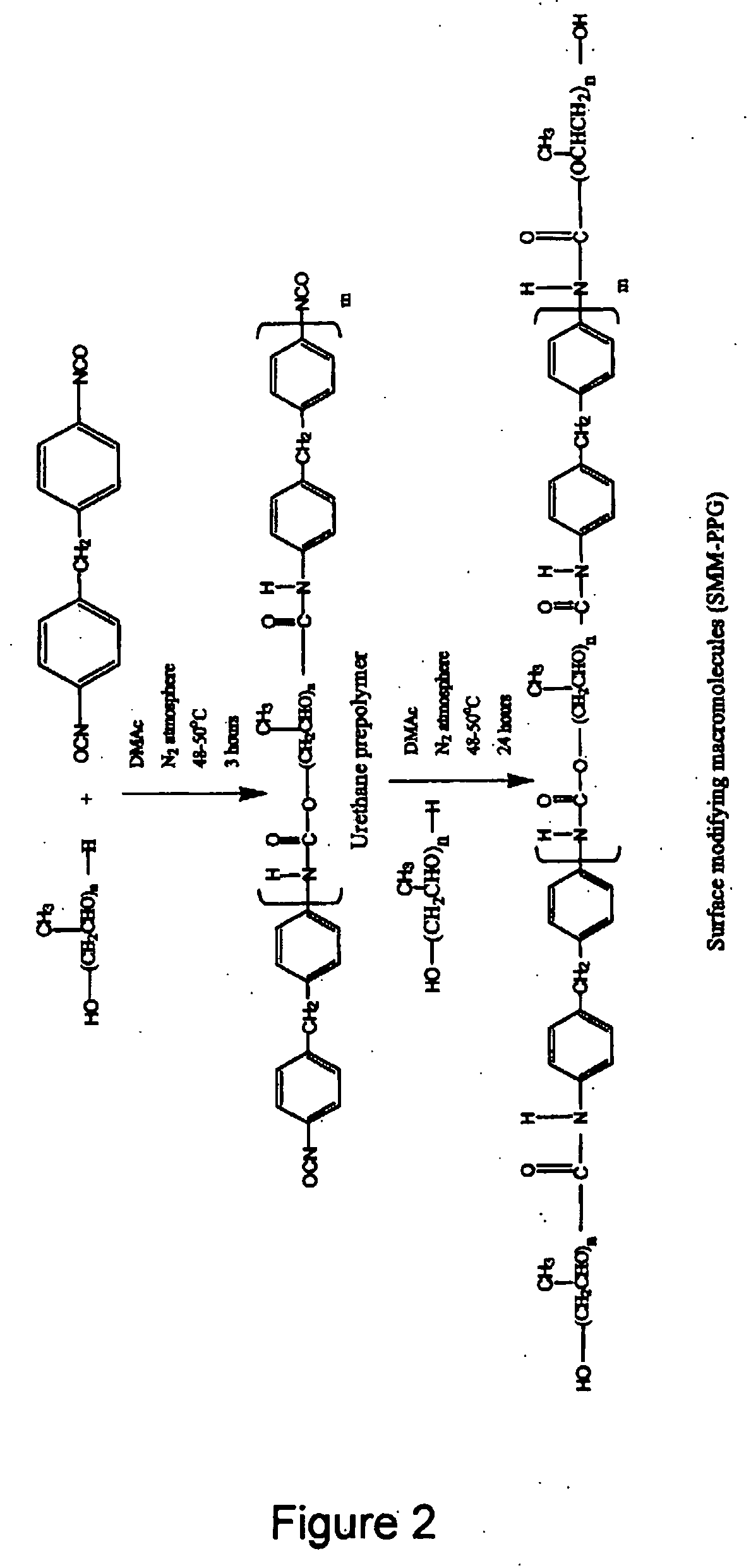

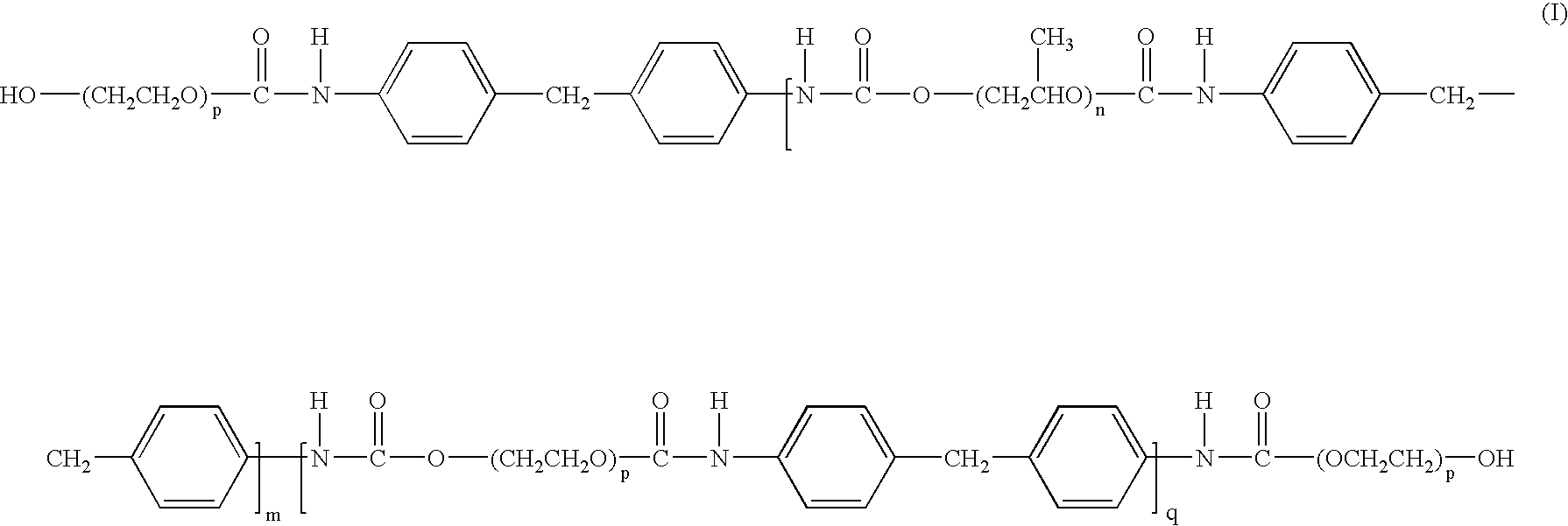

Hydrophilic surface modifying macromolecules (H-phil SMM) and H-phil SMM blended membranes

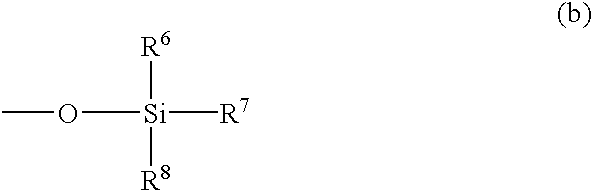

InactiveUS20050176893A1Simple and inexpensiveSurface stabilizationVolatile organic compoundSurface modified

The present invention provides hydrophilic surface modifying macromolecules (H-phil SMM) and H-phil SMM and blended membranes produced incorporating the hydrophilic surface modifying macromolecules. The membranes include a hydrophilic base polymer, and the hydrophilic surface modifying macromolecules (H-phil SMM) which impart surface hydrophilic properties to the membrane. The membranes produced with the surface modifying macromolecules give polymer membranes useful in the separation of water from a solution containing volatile organic compounds and water.

Owner:UNIVERSITY OF OTTAWA

Ultraviolet-cured hard coating and application thereof

ActiveCN102236113AImprove wear resistanceImprove antifouling performanceLayered productsPolyurea/polyurethane coatingsUltravioletPliability

The invention discloses an ultraviolet-cured hard coating and an application thereof. The ultraviolet-cured hard coating comprises a transparent supporting body and a scratch-proof coating coated on the transparent supporting body; the scratch-proof coating comprises the following components in part by weight: 5 to 90 parts of light-cured prepolymer, 5 to 90 parts of thinning agent, 1 to 10 parts of photoinitiator, 0 to 80 parts of active thinning agent, 0 to 20 parts of inorganic nanopadding and 0 to 18 parts of aid. By the invention, the defects that the conventional hard coating is not hard enough, the scratch resistance and the wear resistance are limited, the flexibility is relatively low and the like are overcome; and the ultraviolet-cured hard coating has relatively low surface energy, relatively good antifouling effect, high strength, relatively good scratch resistance and wear resistance, and excellent adhesion, flexibility and transparence.

Owner:中国航天科技集团公司第四研究院第四十二所

Thermal-insulating external-wall coating of nano-composite water and its production

InactiveCN101029206AImprove insulation performanceGood weather resistanceFireproof paintsEmulsion paintsRefractive indexSlurry

A water nan-composite thermal-insulating coating for external wall and its production are disclosed. The coating consists of water, polymer emulsion, high-refractive index pigment, filler, nano-tin-antimony oxide slurry, nano-SiO2, wet dispersant, filming accessory, pH adjuster, thickener, de-foaming agent, anti-freezing agent and mildew-proof bactericide. It's cheap and simple, has excellent wash and weather resistances, better thermal-insulating performance, safe storage and no environmental pollution. It can be used for apparatus surface and architecture external wall.

Owner:SOUTH CHINA UNIV OF TECH +1

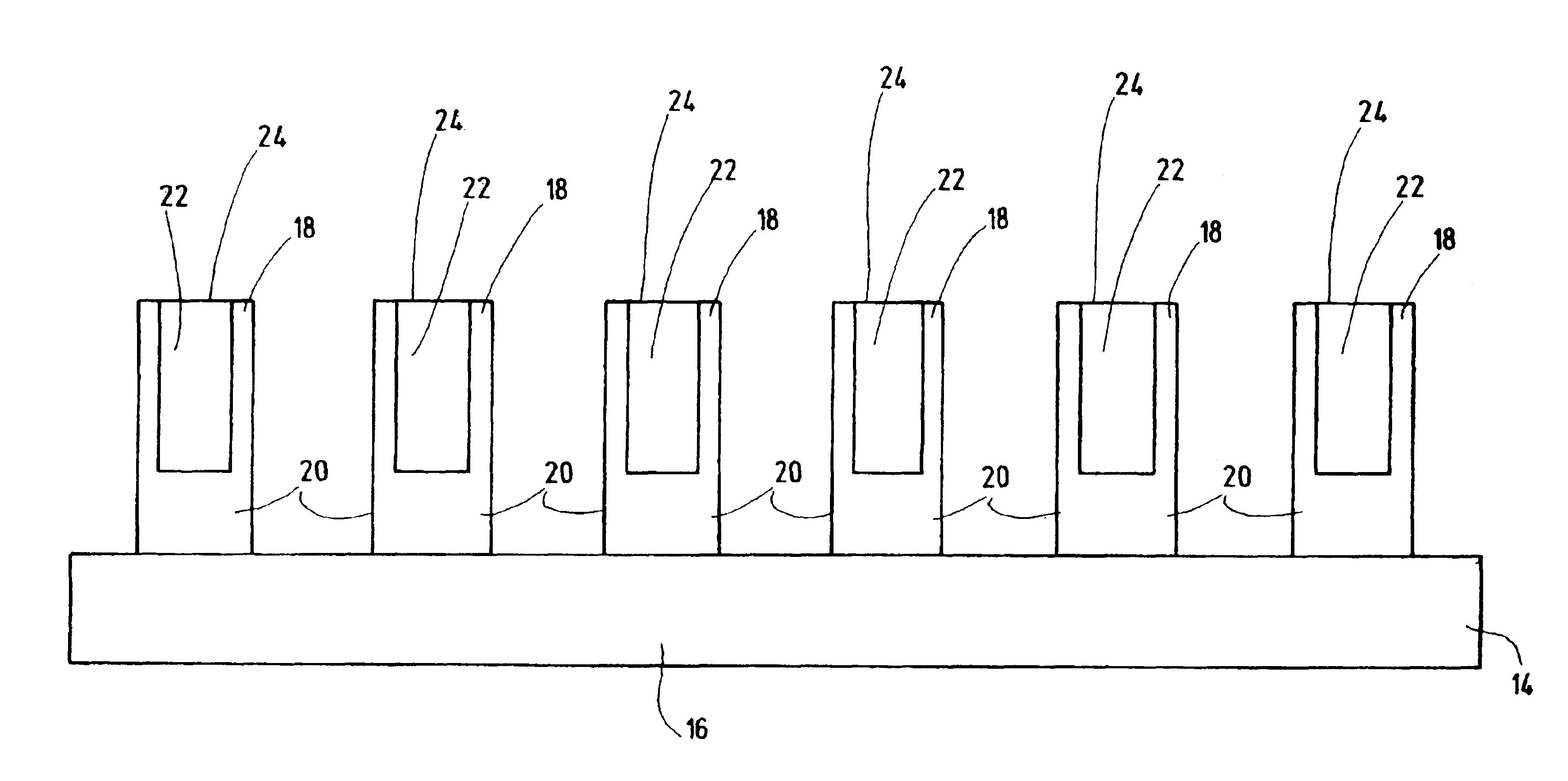

Self-cleaning display device

InactiveUS6946170B2Improve cleanlinessRemove dirtPicture framesLayered productsDisplay deviceBiomedical engineering

A device displays information in identification areas of traffic signs, signposts, billboards, license plates, etc. The identification area is provided with a surface having an artificially producible base structure and other structures or itself forms such a surface having a self-cleaning effect. The base structure has or develops a capillary effect in which the quotient of capillary work and adhesion work is greater than 1. The capillaries have a negative rise, that is, liquid is pressed form the capillaries, providing the self-cleaning effect.

Owner:GOTTLIEB BINDER

Antifouling waterproof sheet

InactiveUS20050106967A1Improve antifouling performanceImprove adhesionSynthetic resin layered productsWoven fabricsPlasticizerPolymer chemistry

A stainproof, waterproof sheet with excellent waterproofing property, rain streaking-preventing property, hot melt bonding property is obtained by forming a water proof resin layer comprising a synthetic resin containing no plasticizer, or a synthetic resin containing a plasticizer and / or a softener, on at least one surface of a base fabric, and then forming thereover a stainproof layer comprising a synthetic resin and fine amorphous silica particles, either with or without an intervening additive migration-preventing layer, and with optional addition of a flame retardant agent to at least one member of the waterproof resin layer, additive migration-preventing layer and stainproof layer.

Owner:HIRAOKA & CO LTD

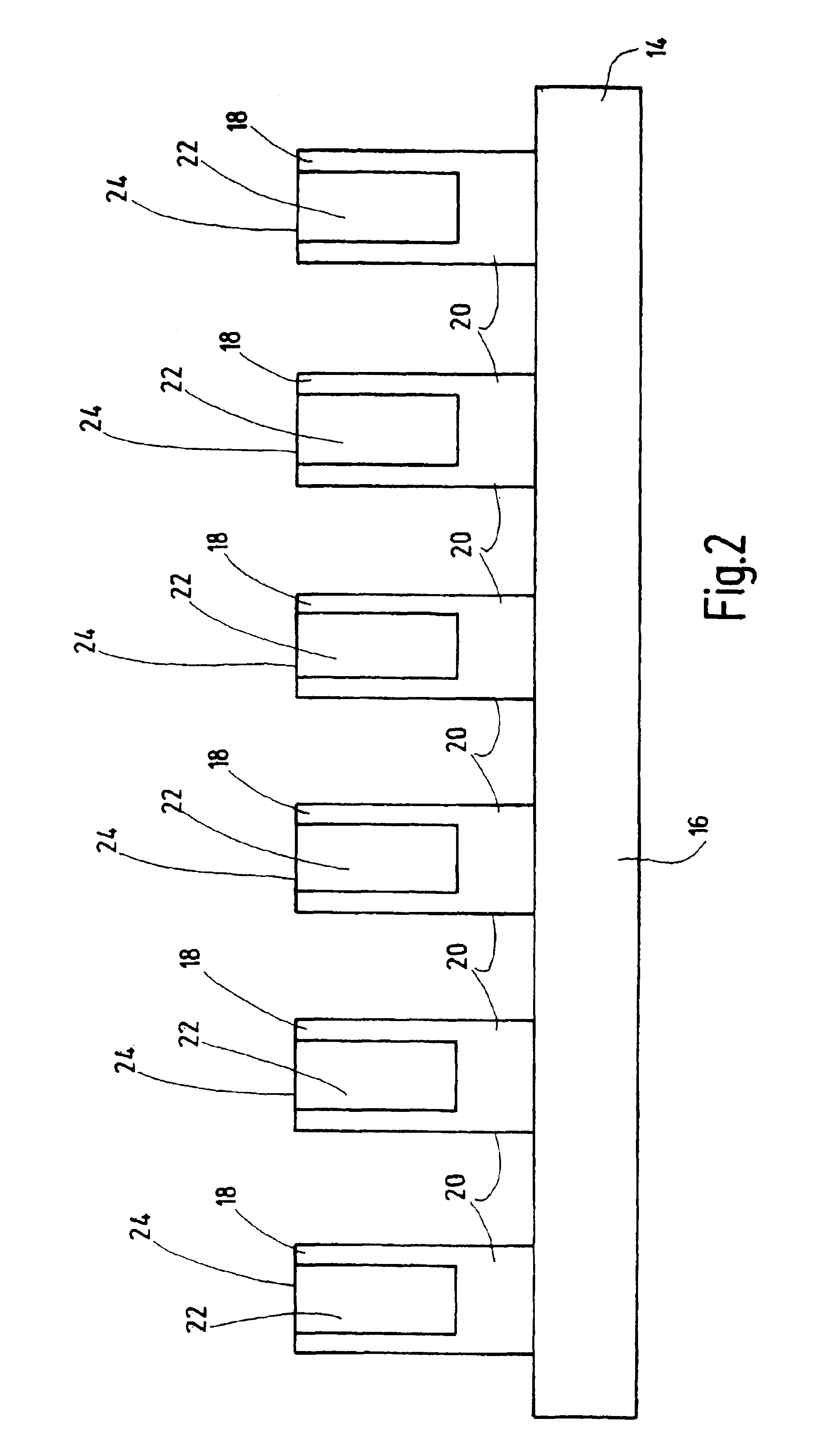

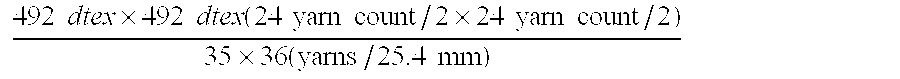

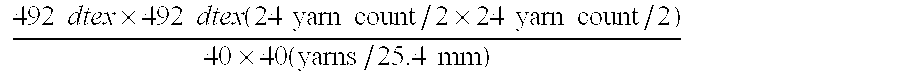

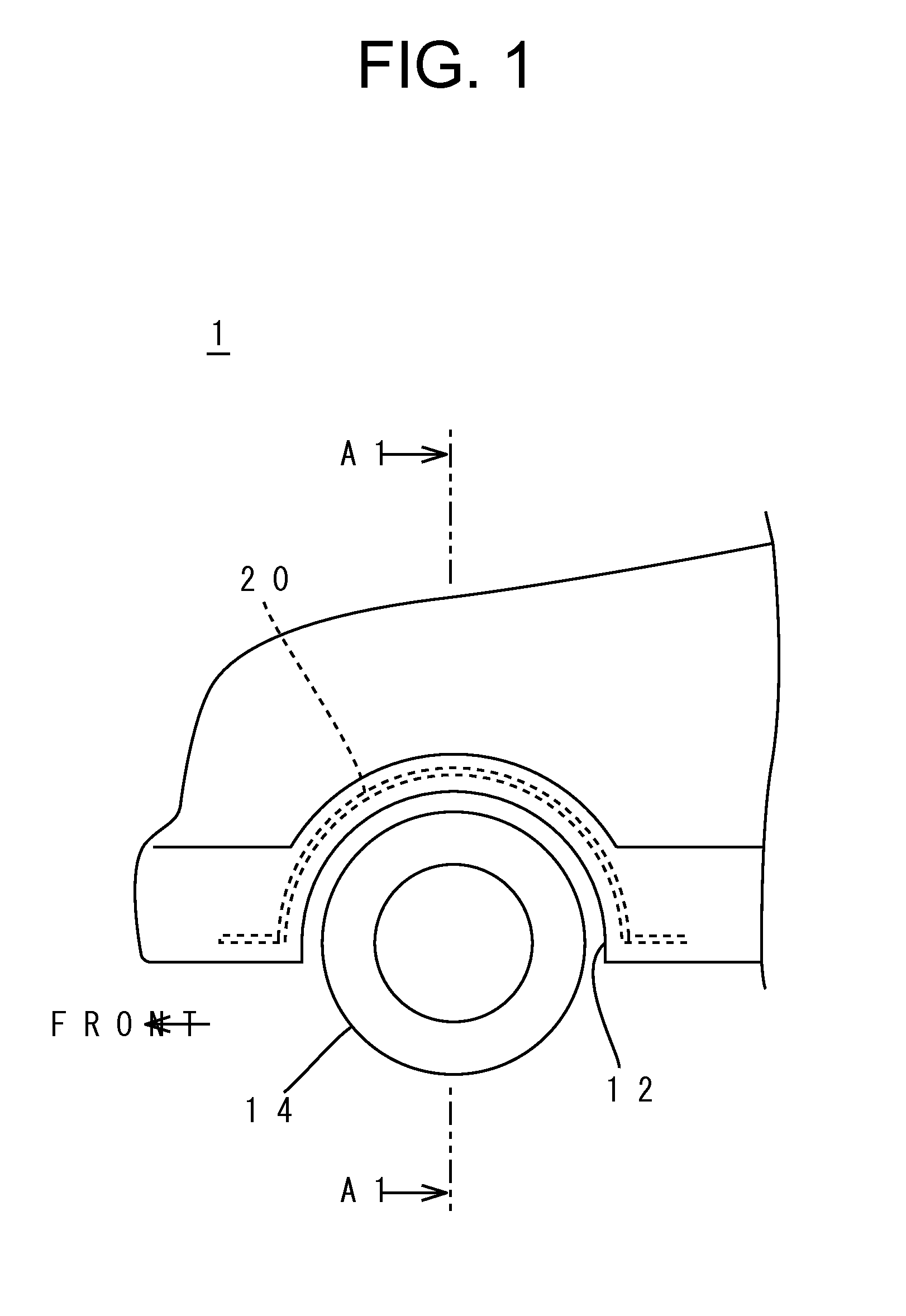

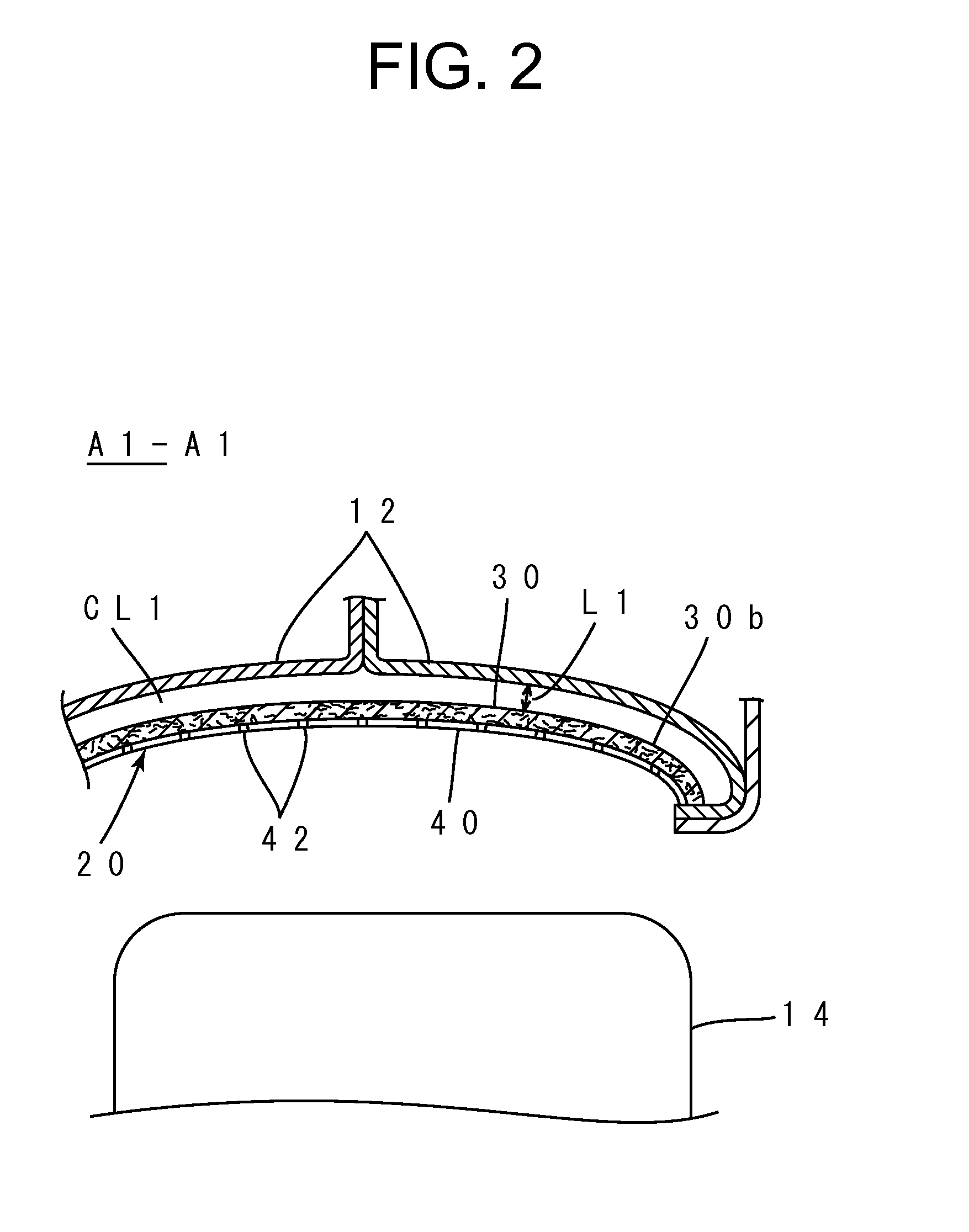

Fender liner and process for producing the same

InactiveUS20100078927A1Lower performance requirementsImprove antifouling performanceButtonsLamination ancillary operationsFiberEngineering

The present invention discloses a fender liner attached to a motor vehicle wheel house. The fender liner includes a breathable base material layer produced by forming a fiber assembly into a shape along the wheel house and a protective layer made of waterproof material. The protective layer is superimposed on a surface of the base material layer that is opposite to a side facing the wheel house. The protective layer is provided with a plurality of through-holes that allow air to flow through the protective layer to the surface of the base material layer on which the protective layer is superimposed.

Owner:HAYASHI TELEMPU CO LTD

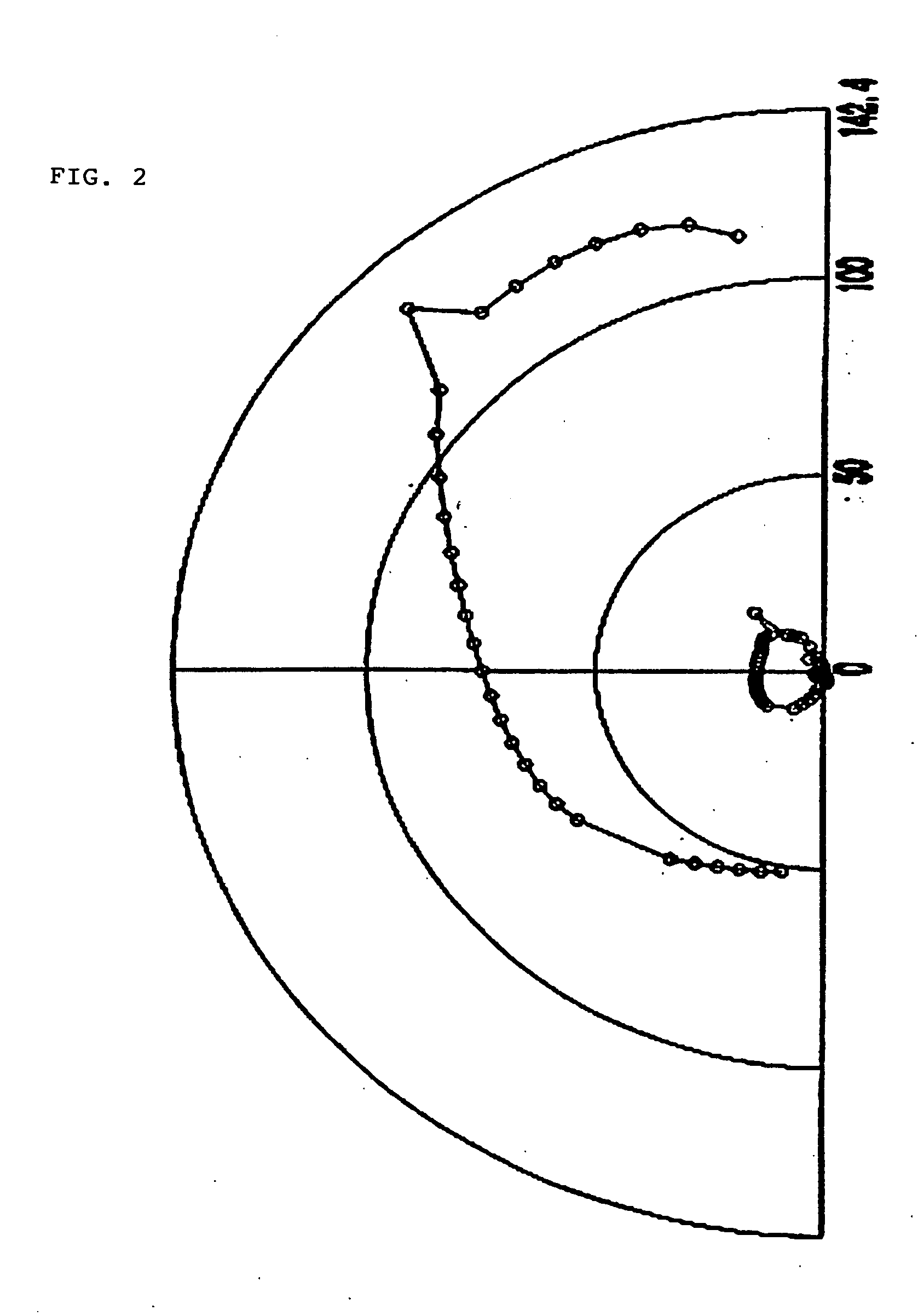

Surface-finishing agent and finished material and method of surface finishing

InactiveUS20060266258A1Developing surfaceHigh water slipping propertyOther chemical processesFibre treatmentSoil propertiesSlurry

The present invention provides a surface-treating agent to form fine roughness on the surface of a material and more specifically a surface treating-agent which forms fine roughness on the surface of a material and is easy to process, thereby being useful for materials for highly water-repellent glass, lenses and fabric, materials with an excellent anti-soiling property, panels having an excellent light scattering property, illumination of optical fiber and the like, materials and coatings to prevent accumulation and adhesion of snow or icicle formation on antennas, wires and steel towers, and roughness formation on the surface of semiconductor substrates; the treated materials; and a method of surface treatment to develop the roughness. The surface-treating agent of the present invention has an average primary particle diameter in the range of 1-50 nm, contains fine particles in the range of 5-60% by mass of the total amount of the surface-treating agent in a slurry of nanoparticles which are treated for water repellency and mechanically dispersed in a solvent containing a volatile solvent, and forms a roughness structure with upward protrusions having a spatial periodicity of 0.1-50 μm on the surface of a material by volatilizing the solvent or dipping repeatedly in water upon treating the surface of the material.

Owner:KEIO UNIV

Water fluorine-carbon nanapaint and producing process thereof

A water F-C nano paint is prepared from aqueous vinyl F-C emulsion as filming liquid, nano material as modifier, pigment, filler, assistant and water. Its advantages are smooth surface, high weatherability, self-cleaning power, chemical resistance and durability, and low cost.

Owner:上海开来湿克威防水材料有限公司 +1

Ultraviolet-cured anti-dazzle hard film and application thereof

InactiveCN103205190AGood anti-glare effectGood compatibilityPolyurea/polyurethane coatingsPolyester coatingsUltravioletReactive diluent

The invention provides an ultraviolet-cured anti-dazzle hard film and application thereof. The ultraviolet-cured anti-dazzle hard film comprises a transparent supporter and an anti-dazzle hard film coating coated on at least one surface of the transparent supporter. A formula for the coating comprises, by weight, 5 to 90 parts of an ultraviolet-cured resin, 5 to 90 parts of a solvent, 1 to 10 parts of a photoinitiator, 0 to 80 parts of a reactive diluents, 1 to 40 parts of an anti-dazzle particle and 0 to 6 parts of an auxiliary agent. Compared with the prior art, the invention has the following advantages: the ultraviolet-cured resin contains a certain amount of an organic silicon resin, which enables the antifouling property of the surface of the anti-dazzle hard film to be improved; and the selected organic particle has good compatibility with the ultraviolet-cured resin, so transmission loss of light is reduced, which enables clarity of displaying by the anti-dazzle hard film to be improved. The ultraviolet-cured anti-dazzle hard film has good anti-dazzling performance, a good antifouling effect, high hardness, good scratch resistance, excellent flexibility and high resolution.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

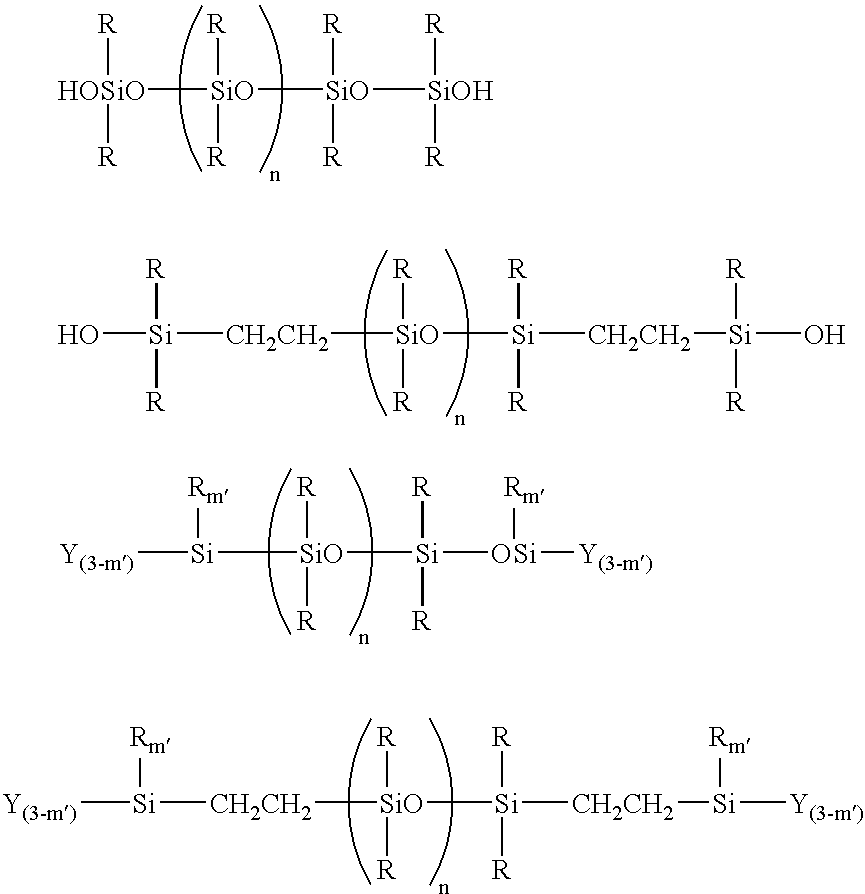

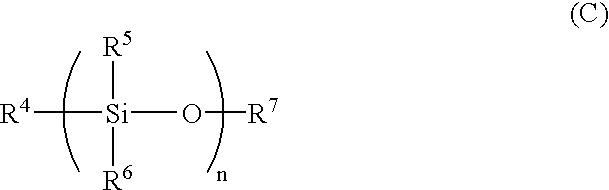

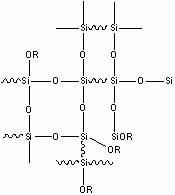

Room-temperature curable organopolysiloxane composition

InactiveUS6906161B2Superior long-term endurance of antifoulingPrevent adhesionAntifouling/underwater paintsPaints with biocidesPartial hydrolysisLong term durability

A room-temperature curable organopolysiloxane composition is provided, which includes (A) an organopolysiloxane with the terminals blocked with a hydroxyl group, a hydrolysable group, or both these types of groups, and (B) an organosilicon compound containing a hydrolysable group, a partial hydrolysis-condensation product thereof, or a mixture of the two, and (C) a polysiloxane containing an oxyalkylene group bonded to a silicon atom via, for example, a C—C—Si linkage. Application of this composition to an underwater structure is able to generate an antifouling coating that is effective in preventing the adhesion and growth of aquatic organisms on the surface of the underwater structure, and displays superior long term endurance of this antifouling effect.

Owner:SHIN ETSU CHEM IND CO LTD

Anti-fouling coating material with excellent compatibility and use thereof

InactiveCN102558989AGood compatibilityImprove antifouling performanceAntifouling/underwater paintsPaints with biocidesAcrylic resinSolvent

The invention relates to the field of anti-fouling coating materials, in particular to an anti-fouling coating material with excellent compatibility. The anti-fouling coating material with excellent compatibility contains liquid bisphenol A epoxy resin, polished acrylic resin, at least two thermoplastic resins for a coating film-forming material, at least two antifouling agents, at least two pigments and fillers, at least two solvents and at least two additives. With the adoption of the anti-fouling coating material with excellent compatibility, the excellent compatibility between a new / old anti-corrosion coating layer and an old antifouling coating layer can be provided, a connecting layer cannot be a coating layer necessary to be coated any more, the processes of coating are reduced, and excellent attachment and antifouling performances are shown after the long-term application of the anti-fouling coating material.

Owner:MARINE CHEM RES INST

Antifouling coating composition, coating film therefrom, base material covered with the coating film and antifouling method

InactiveUS20030207962A1Less peeling tendencyImprove adhesionFireproof paintsVessel cleaningSilyleneCarboxylic acid

An antifouling coating composition comprising (A) a silyl ester copolymer containing constituent units derived from a polymerizable unsaturated carboxylic acid silyl ester; (B) a carboxylic acid; (C) a bivalent or trivalent metal compound; and (D) a dehydrating agent. It is preferred that the component (C) be contained in an amount of 1.2 equivalents or more, in terms of the number of equivalents of metal as a constituent of the component (C), per equivalent of carboxyl group of the carboxylic acid (B); that the component (C) be a bivalent metal compound; and that the component (C) be a compound of at least one metal selected from the group consisting of zinc, copper, magnesium, calcium and barium. From the antifouling coating composition, there can be obtained an antifouling coating film which exhibits less cracking tendency, excellent adherence so as to ensure less peeling tendency and desirably controlled hydrolysis rate so as to be excellent in antifouling performance, in particular, antifouling properties in highly fouling environment and long-term antifouling properties. With respect to the provided antifouling coating composition, its storage stability is high, its concentration can be increased, the amount of solvent used therefor can be reduced, and its applicability is high.

Owner:CHUGOKU MARINE PAINTS

Hard coating article, curing composition, and information recording media

InactiveUS20070048531A1High surface hardnessGood scratch resistanceRecord carriersLayered product treatmentSilicone resinChemistry

To provide a curing composition suitable for forming an antifouling hard coat layer having high surface hardness, excellent in scratch resistance, and having an antifouling property lasting long; and to provide an optical information recording media having scratch resisting and antifouling properties, and persistent reading characteristics of records, the curing composition includes an actinic energy-curing resin, wherein the actinic energy-curing resin hass a silicone resin having a silicon content of from 23 to 32 weight %; and the optical information recording material has a light-transmitting layer formed by coating and curing the curing composition, wherein a coating amount of the silicone resin is from 0.4 to 45 mg / n2.

Owner:FUJIFILM CORP

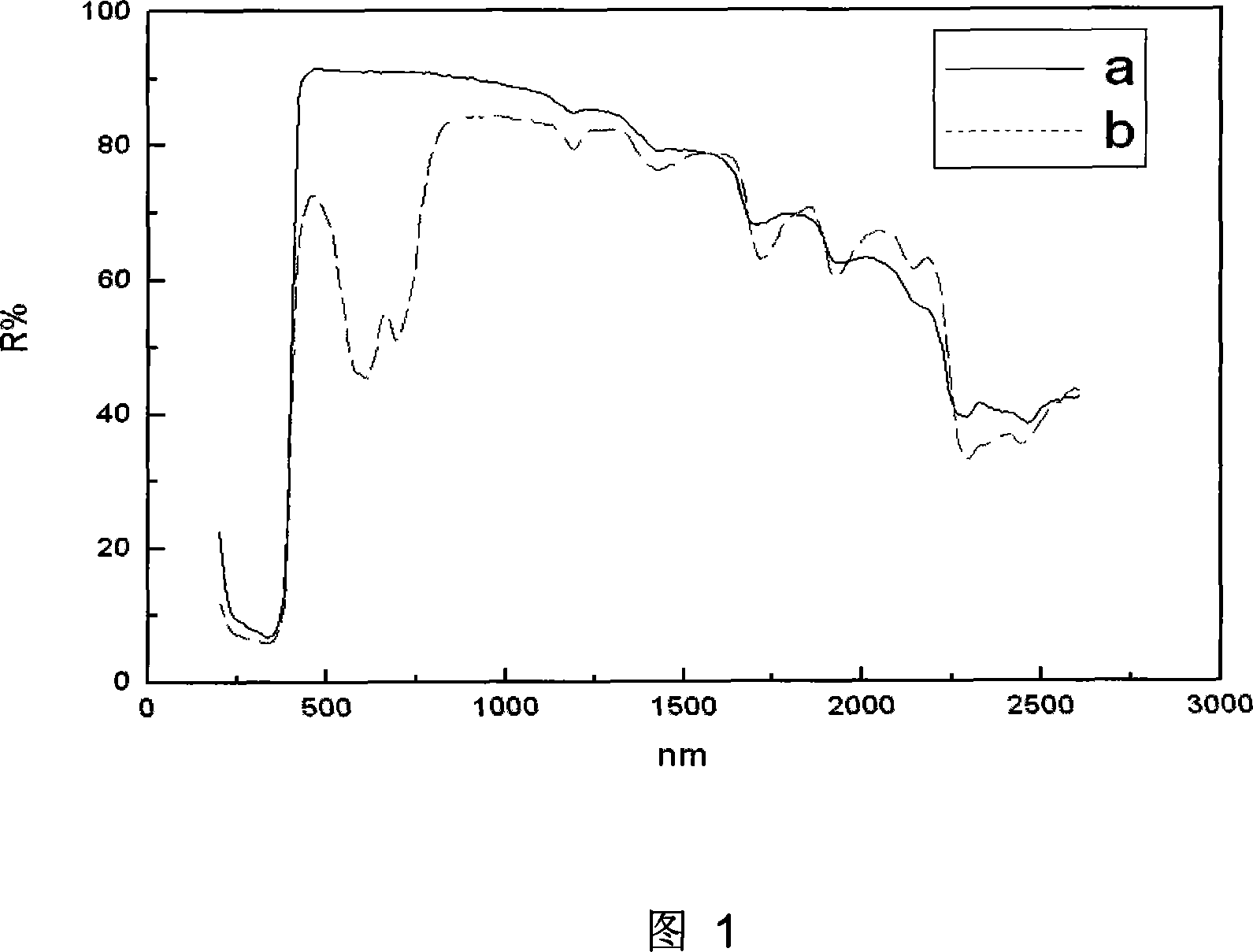

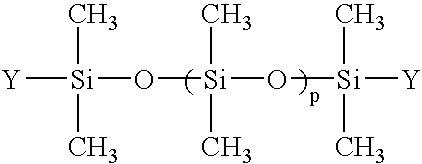

Quaternary ammonium salt modified organosilicon polyurethane ocean antifouling paint and preparation method and application thereof

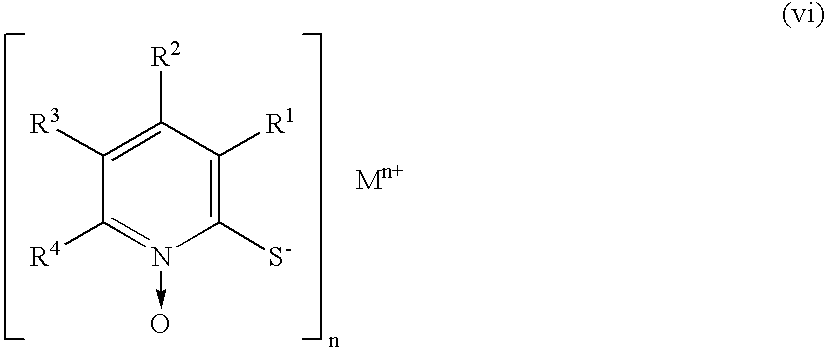

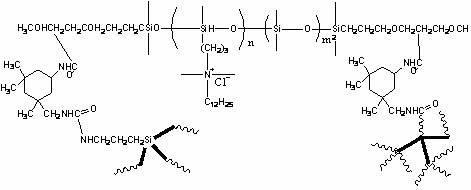

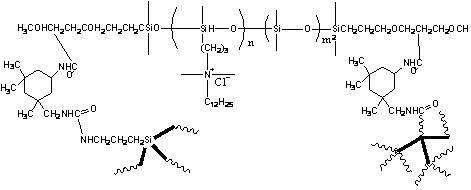

ActiveCN102220080AInhibition of adsorptionReduce usageAntifouling/underwater paintsPaints with biocidesDisiloxaneQuaternary ammonium cation

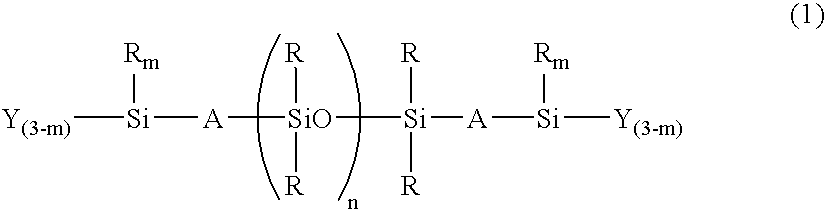

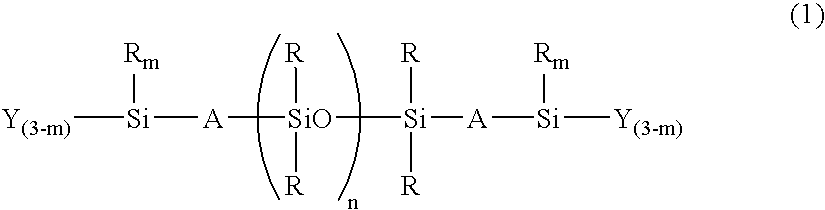

The invention discloses a quaternary ammonium salt modified organosilicon polyurethane ocean antifouling paint, the structure is shown as the formula (1); in the formula, an organosilicon soft segment containing quaternary ammonium salt side chain is an isocyanate hard segment; the quaternary ammonium salt modified organosilicon polyurethane ocean antifouling paint is prepared by the following steps: preparing 2,4,6-tri(3- chlorine propyl group)-2,4,6- trimethyl-ring trisiloxane; preparing 1,3-bi(3-(1-methoxy group-2-hydroxy propyl group) propyl group)-tetramethyl disiloxane; preparing 1,3-bi(3-(1-methoxy group-2-hydroxy propyl group) propyl group)-tetramethyl disiloxane; preparing dihydroxy ended chloropropylated polysiloxane; preparing polysiloxane compound containing the quaternary ammonium salt and hydroxyl; mixing the compound with the isocyanate, and adding gamma-aminopropyl triethoxy silane for chain extension to obtain a prepolymer, and the prepolymer being crosslinked and condensed in air. In the invention, the double effect of low surface energy and poison killing are achieved, so as to suppress the adsorption of marine organisms and kill bacteria adsorbed on the surface of a ship body through the quaternary ammonium salt.

Owner:ZHEJIANG UNIV

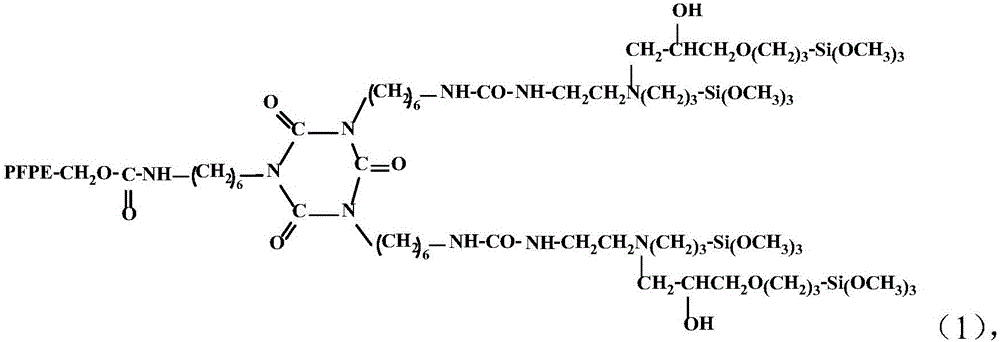

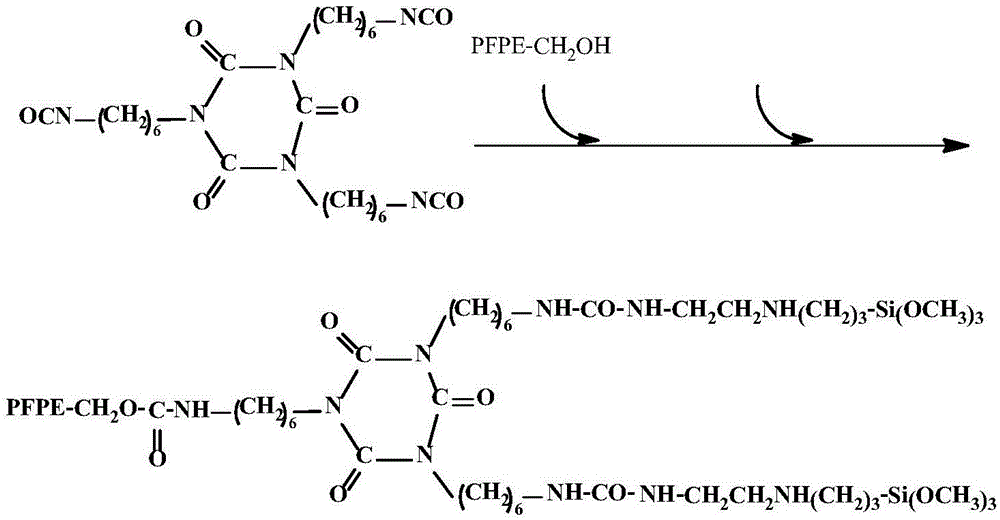

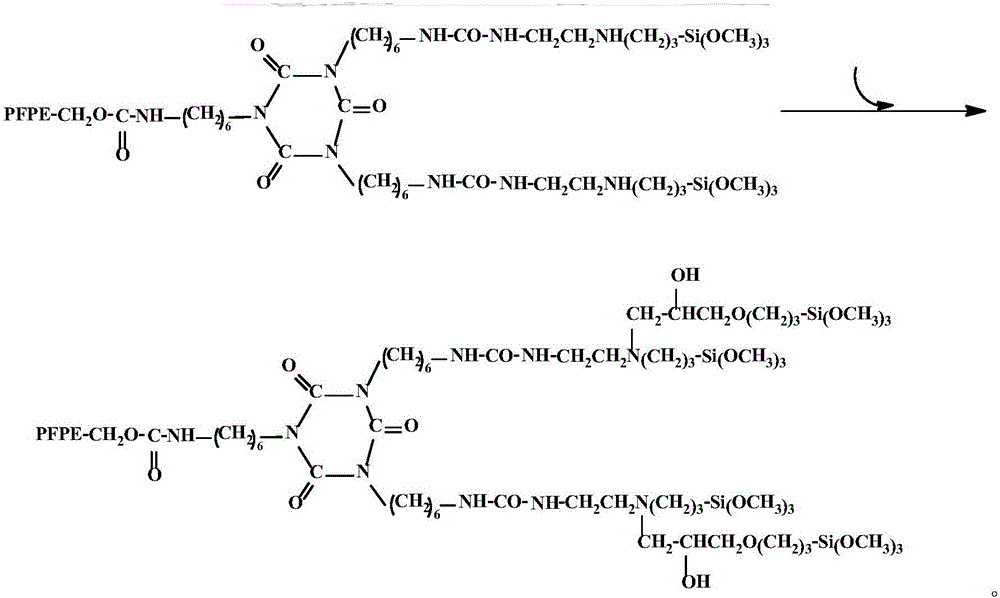

Novel perfluoropolyether alkoxy silane compound and synthesis method thereof

ActiveCN106432686AGood antifoulingGood anti-fingerprint effectAntifouling/underwater paintsPaints with biocidesSilane compoundsPerfluoropolyether

The invention discloses a novel perfluoropolyether alkoxy silane compound and a synthesis method thereof. The structure of the compound is shown as formula (1). The synthesis method includes: reacting hydroxyl terminated perfluoropolyether (PFPE), 3-(2-aminoethyl)aminopropyltrimethoxysilane, 3-(2, 3-epoxypropoxy)propyltrimethoxysilane (KH560), and an HDI trimer in a molar ratio of 1:2:2:1, during reaction, employing a certain amount of a solvent to dilute the mixed hydroxyl terminated perfluoropolyether and 3-(2-aminoethyl)aminopropyltrimethoxysilane, then adding the HDI trimer dropwise, carrying out reaction for 6h at certain temperature, then adding KH560 dropwise, and carrying out reaction for 6h again at certain temperature then reducing pressure and removing the solvent, thus obtaining the perfluoropolyether alkoxy silane compound. The compound can be coated on glass, plastic, film, and other substrate surfaces, and after crosslinking and curing, a layer of solid film can be formed, and the substrate is endowed with excellent anti-fingerprint and antifouling performance and abrasion resistance.

Owner:QUZHOU FLUORIDE & SILICON RES INST +1

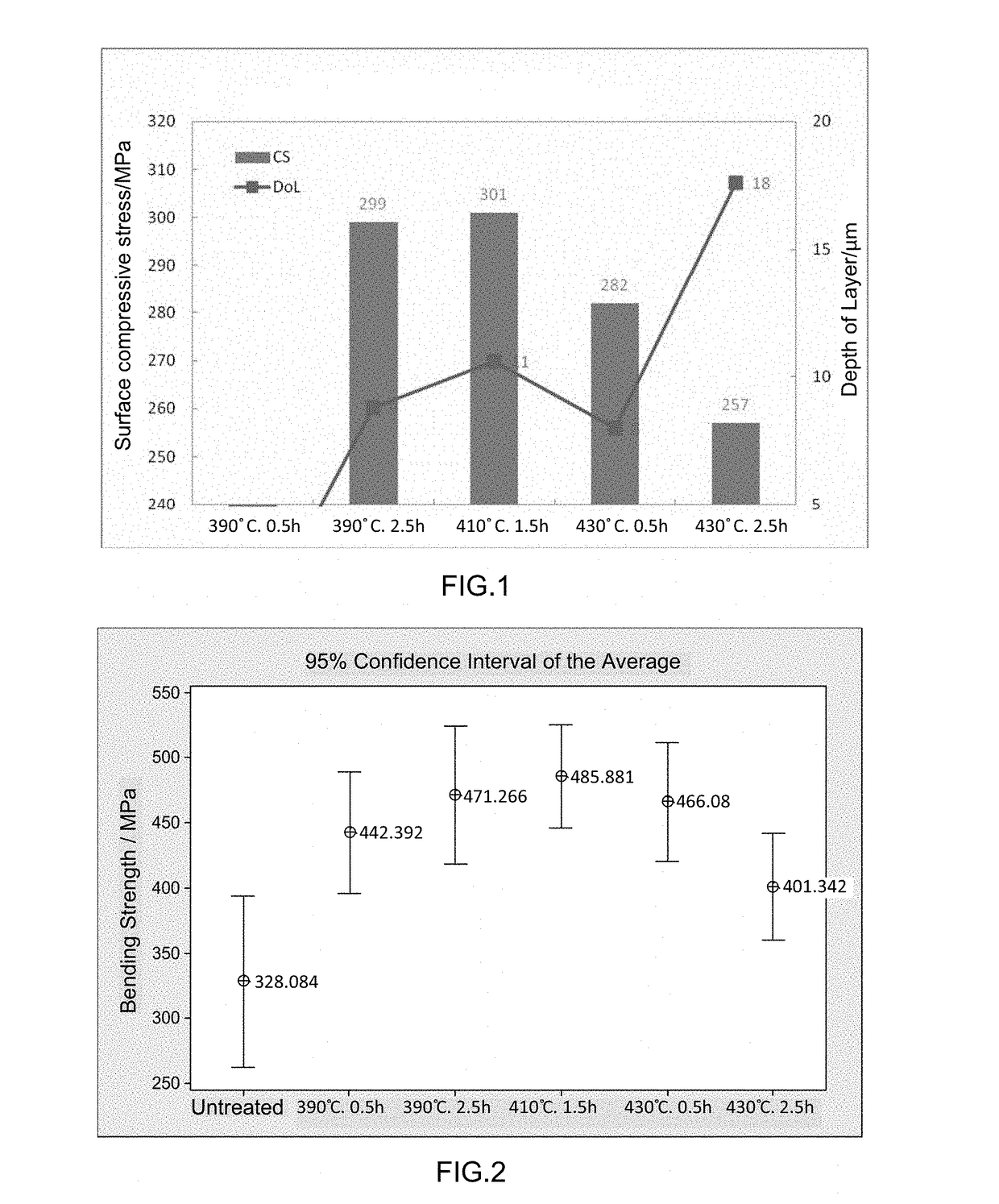

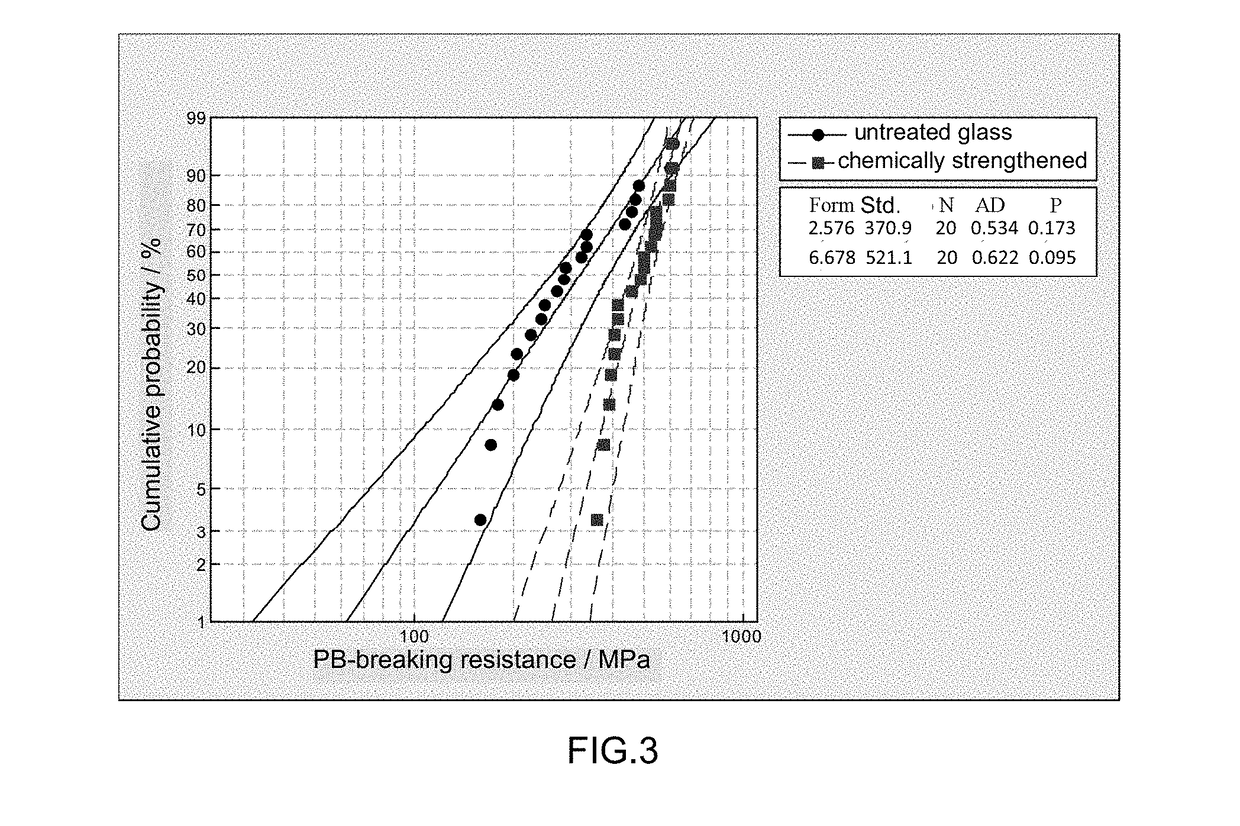

Coated chemically strengthened flexible thin glass

InactiveUS20170183255A1Improve antifouling performanceEasy to cleanGlass forming apparatusPriming paintsNiobiumCerium

A coated chemically strengthened flexible thin glass includes a coating of an adhesive layer in the form of a silicon mixed oxide layer, which contains or consists of a silicon oxide layer in combination with at least one oxide of aluminum, tin, magnesium, phosphorus, cerium, zirconium, titanium, cesium, barium, strontium, niobium, zinc, or boron, and magnesium fluoride, such as at least aluminum oxide.

Owner:SCHOTT AG

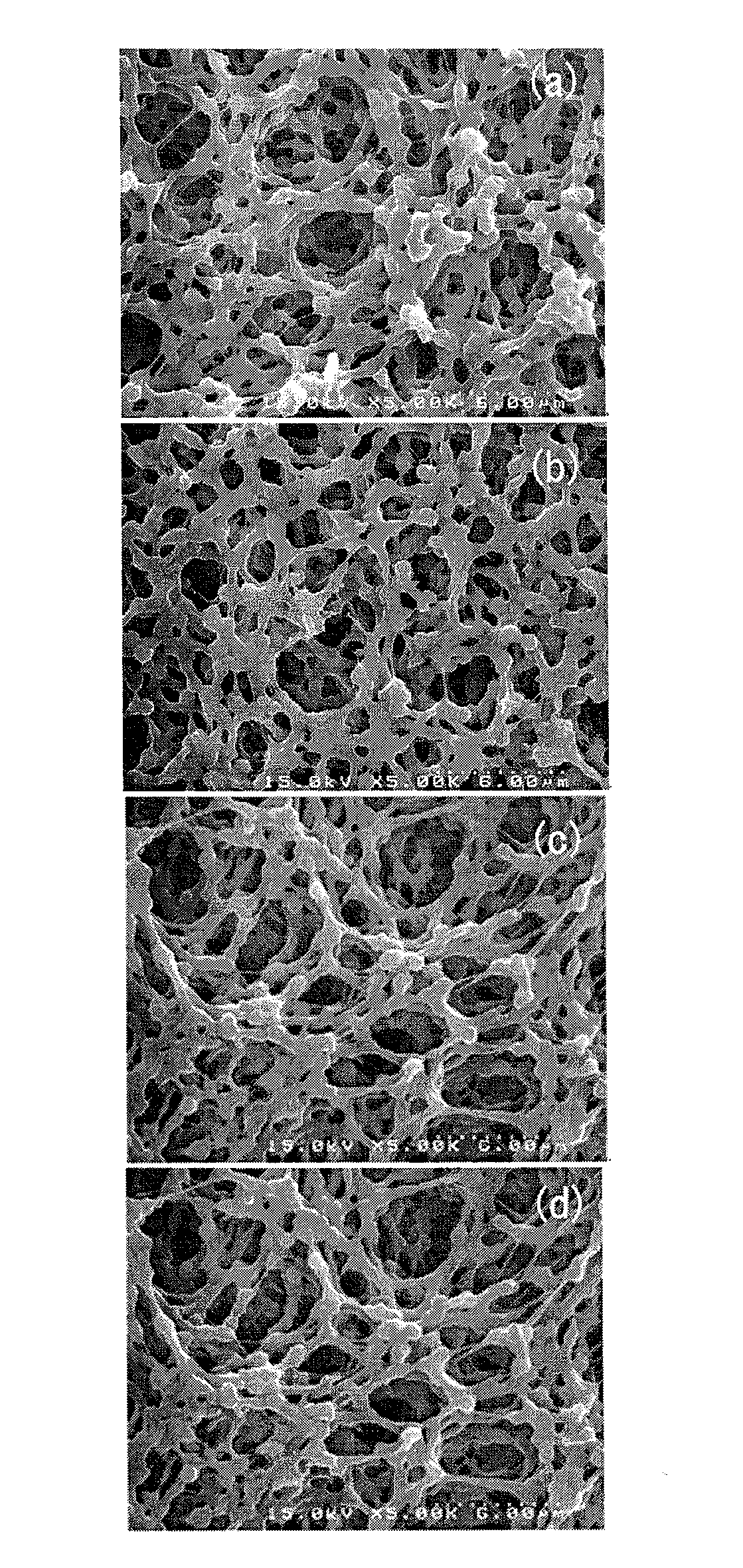

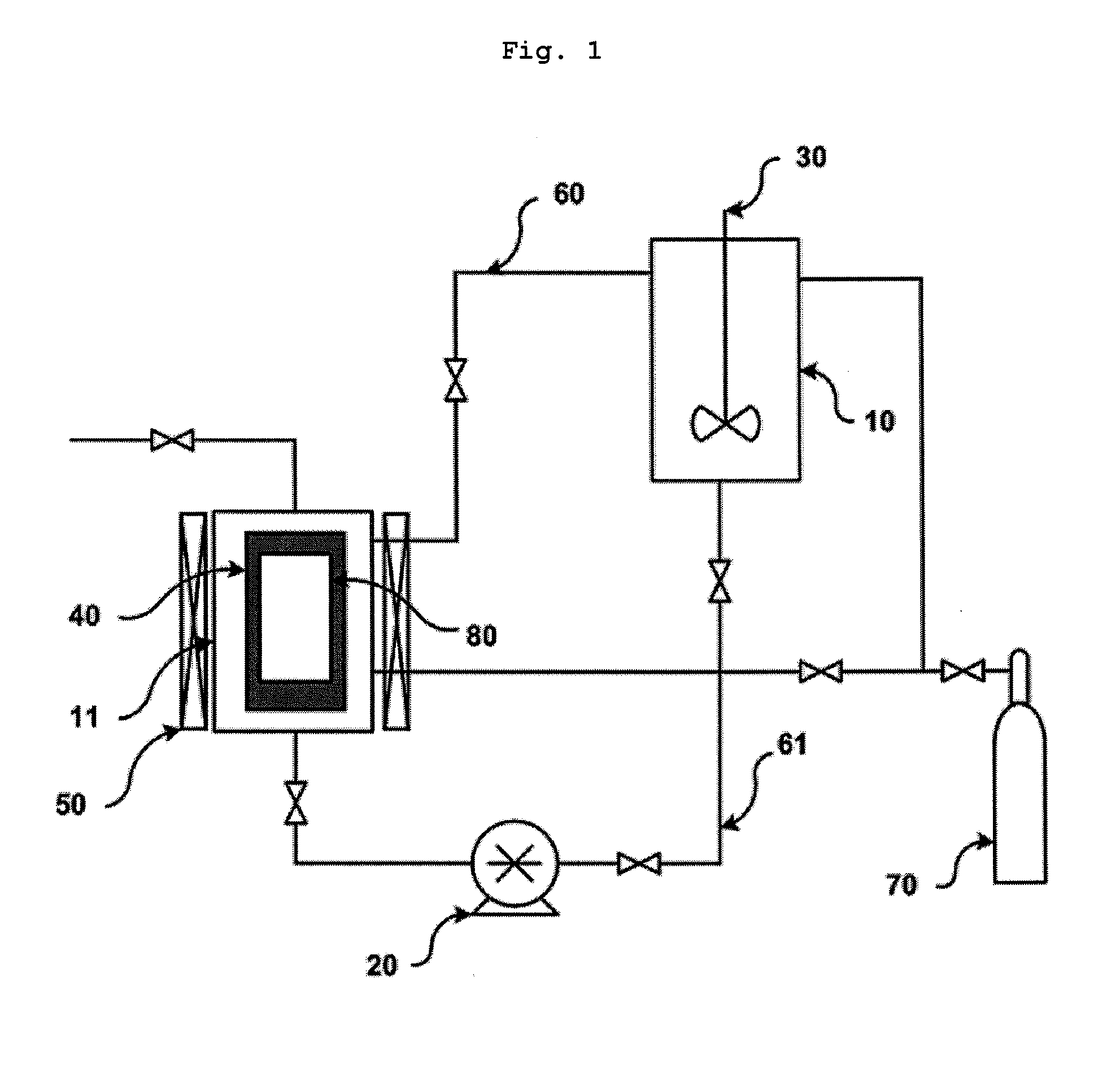

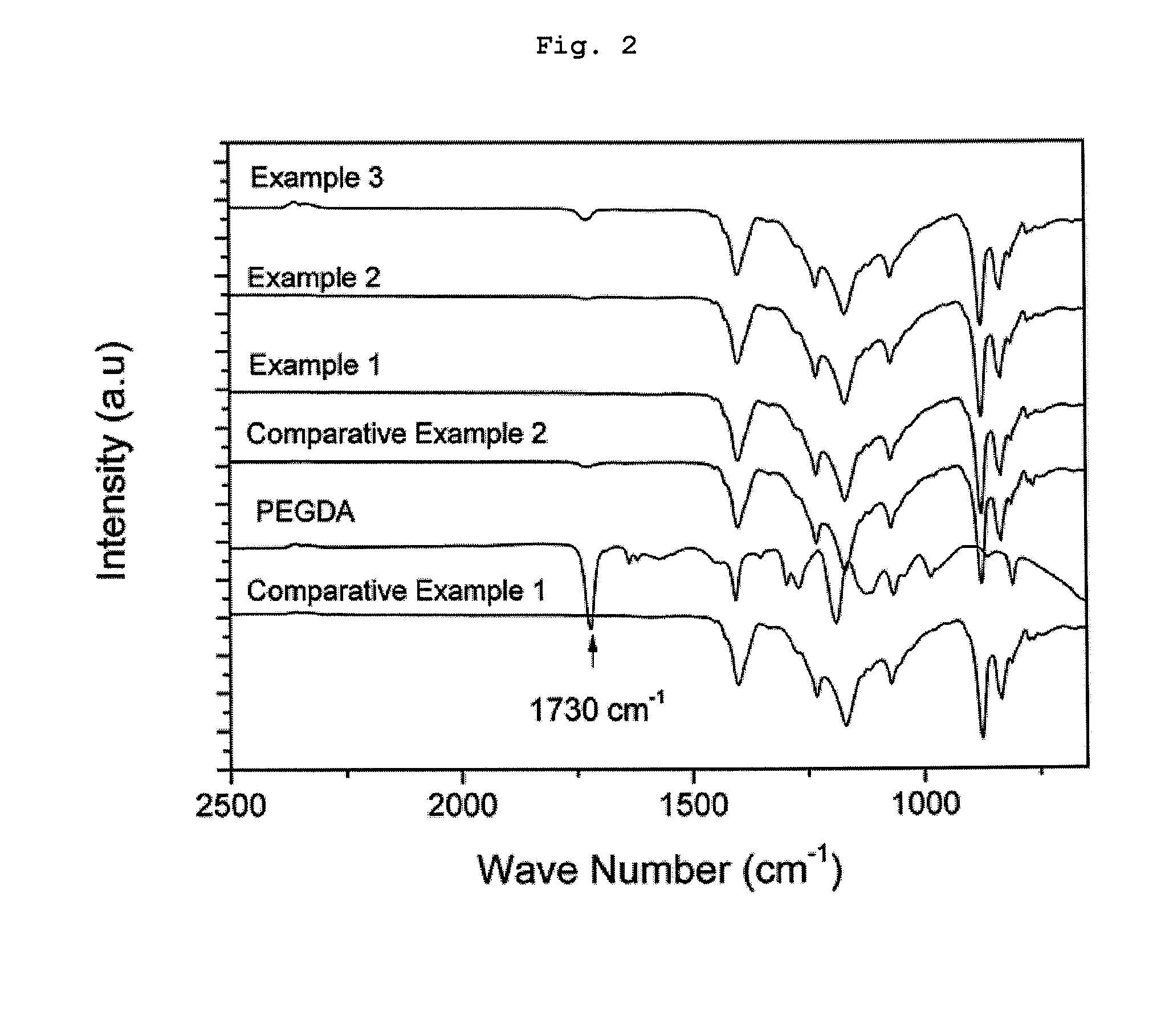

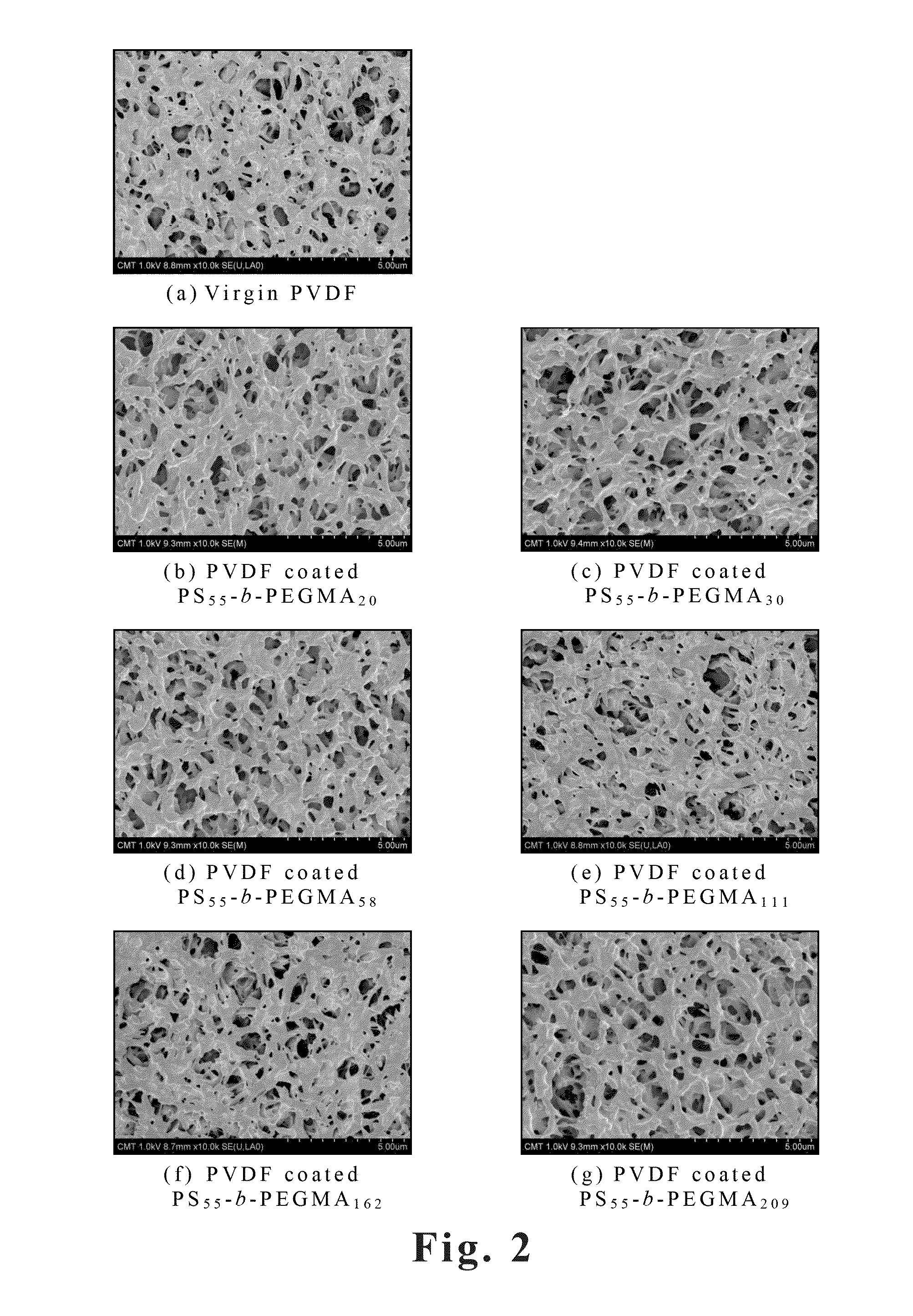

Method of manufacturing hydrophilic membrane having improved antifouling property and hydrophilic membrane manufactured by the method

InactiveUS20110253621A1Maintain good propertiesHigh permeation fluxMembranesSemi-permeable membranesCross-linkHigh pressure

A method of manufacturing a hydrophilic membrane and hydrophilic membranes having improved antifouling property using a supercritical fluid or a subcritical fluid. The method involves combining a coating solution from a hydrophilic group-containing monomer, an initiator, a cross-linking agent and a supercritical fluid or subcritical fluid in a high pressure solution vessel and transferring the coating solution to a membrane in a high pressure coating vessel, coating the surfaces and micropores of the membranes through cross-linking polymerization reactions. Non-reacted coating material is returned to the high pressure solution vessel. The membranes are removed from the coating vessel, cleaned and dried. The hydrophilic membrane manufactured by the present invention is excellent in properties of hydrophobic membranes such as thermal stability, chemical stability and mechanical strength, and surfaces and micropores of the membranes are uniformly coated.

Owner:KOREA INST OF SCI & TECH

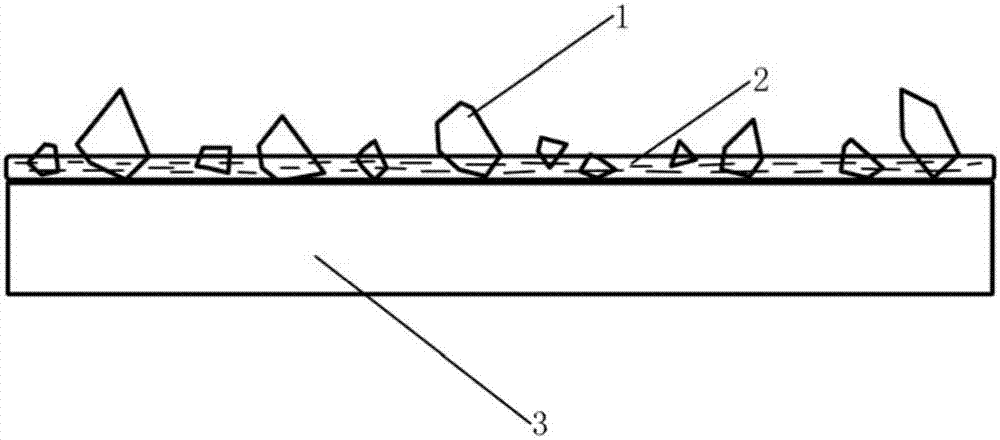

Preparation process of dry-particle tile with strong tile surface stereoscopic sensation

The invention provides a preparation process of a dry-particle tile with strong tile surface stereoscopic sensation. The preparation process comprises the following steps: (1) drying a tile blank to obtain a dried blank; (2) mixing high-temperature dry particles with ceramic glue to obtain dry-particle slurry; (3) coating the dry-particle slurry on the surface of the dried blank to form a dry-particle layer; (4) coating base glaze on the surface of the tile blank with the dry-particle layer to form a base glaze layer, wherein the thickness of the base glaze layer is smaller than the maximum particle diameter of the high-temperature dry particles; and (5) putting the tile blank coated with the base glaze into a kiln and firing to obtain the dry-particle tile. Through the preparation process of the dry-particle tile, the high-temperature dry particles are combined with the ceramic glue to directly coat the dry particles on the surface of the blank body; then through combination of the covering effect of the base glaze, the prepared dry-particle tile is better in tile surface stereoscopic effect, more stable in structure, more abundant, fine and smooth in texture and high in skidding resistance and fouling resistance.

Owner:FOSHAN DONGPENG CERAMIC +2

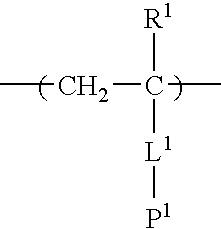

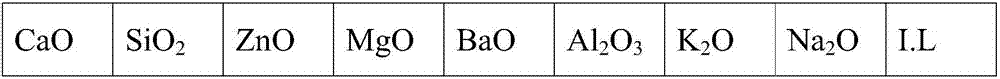

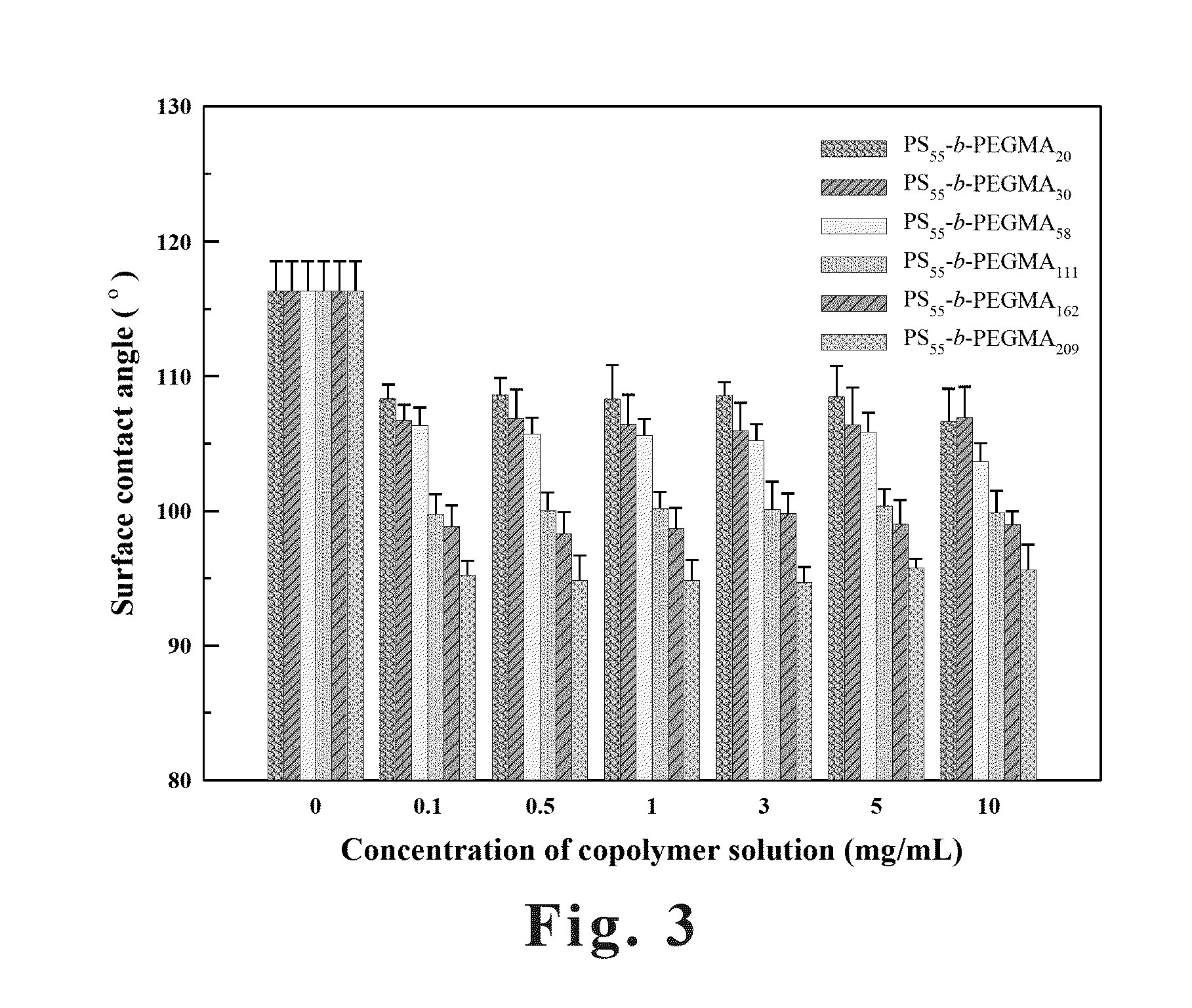

Anti-biofouling Membrane for Water-Treatment

InactiveUS20140083931A1Easy to makeReduce manufacturing costSemi-permeable membranesMembranesBiofoulingOrganic chemistry

This invention discloses an anti-biofouling membrane for water-treatment. The anti-biofouling membrane for water-treatment comprises a substrate, and an anti-biofouling copolymer on the substrate. The anti-biofouling copolymer comprises a plurality of hydrophobic groups and a plurality of hydrophilic groups. The anti-biofouling copolymer can be stably coated on the surface of the substrate by the hydrophobic groups. And the hydrophilic groups can help the anti-biofouling membrane to present excellent anti-biofouling capability. Preferably, the anti-biofouling copolymer coated on the substrate will not decrease the permeability of the substrate. More preferably, the presented capability of the mentioned anti-biofouling membrane for water-treatment can achieve the commercial level filtering membrane.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

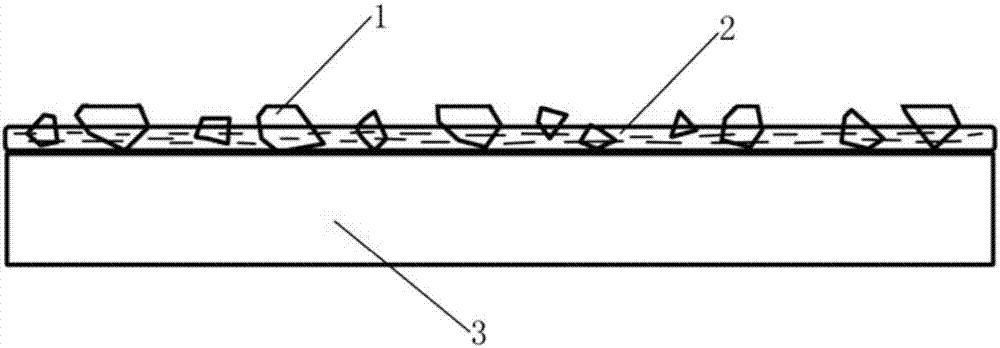

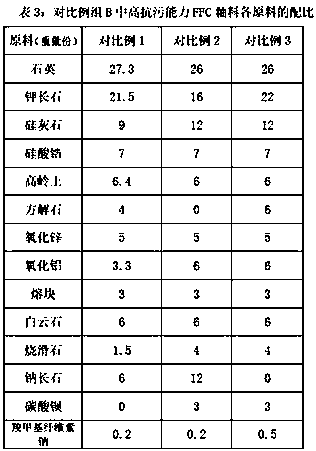

Formula of ceramic for insulator ceramic body and preparation method of the insulator ceramic body

InactiveCN102241506AHigh mechanical strengthImprove electrical performanceCeramicsPotassium dioxideMullite

The invention discloses a formula of a ceramic for an insulator ceramic body and a preparation method of the insulator ceramic body. Beneficial effects of a technical scheme of the invention comprise that the formula contains specific proportions of silicon oxide and alumina and the silicon oxide and the alumina are sintered into mullite to improve a mechanical strength and a hot and cold performance of a ceramic material, and silica can reduce a dry degree, a firing shrinkage degree and a bending deflection degree of a ceramic blank, play a supportive role in a ceramic blank and improve a mechanical strength of a ceramic blank; alumina can improve greatly a mechanical strength of ceramic blank; added potassium dioxide can reduce a sintering temperature, fill gaps of a ceramic blank and improve a compactness of a ceramic material, and a mechanical strength and an electrical performance of a ceramic blank; and through a cooperation with a preparation method, an insulator ceramic body obtains improved greatly hydrophobic properties, anti-fouling properties, insulating properties and mechanical properties.

Owner:SUZHOU AIJIAN ELECTRICAL PORCELAIN

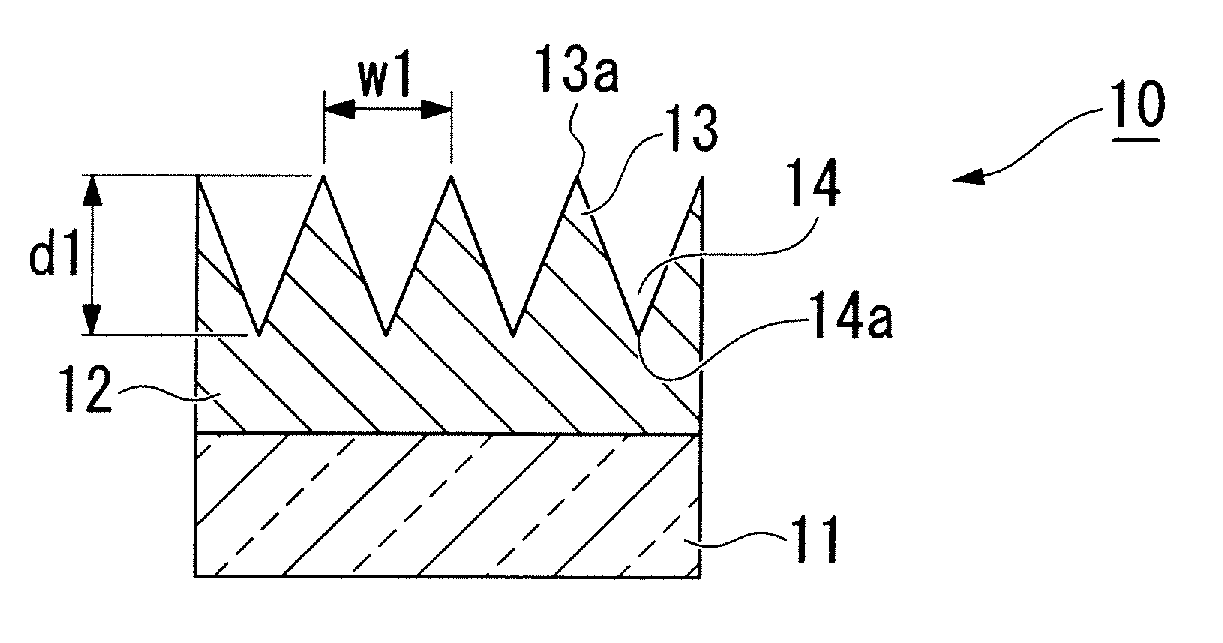

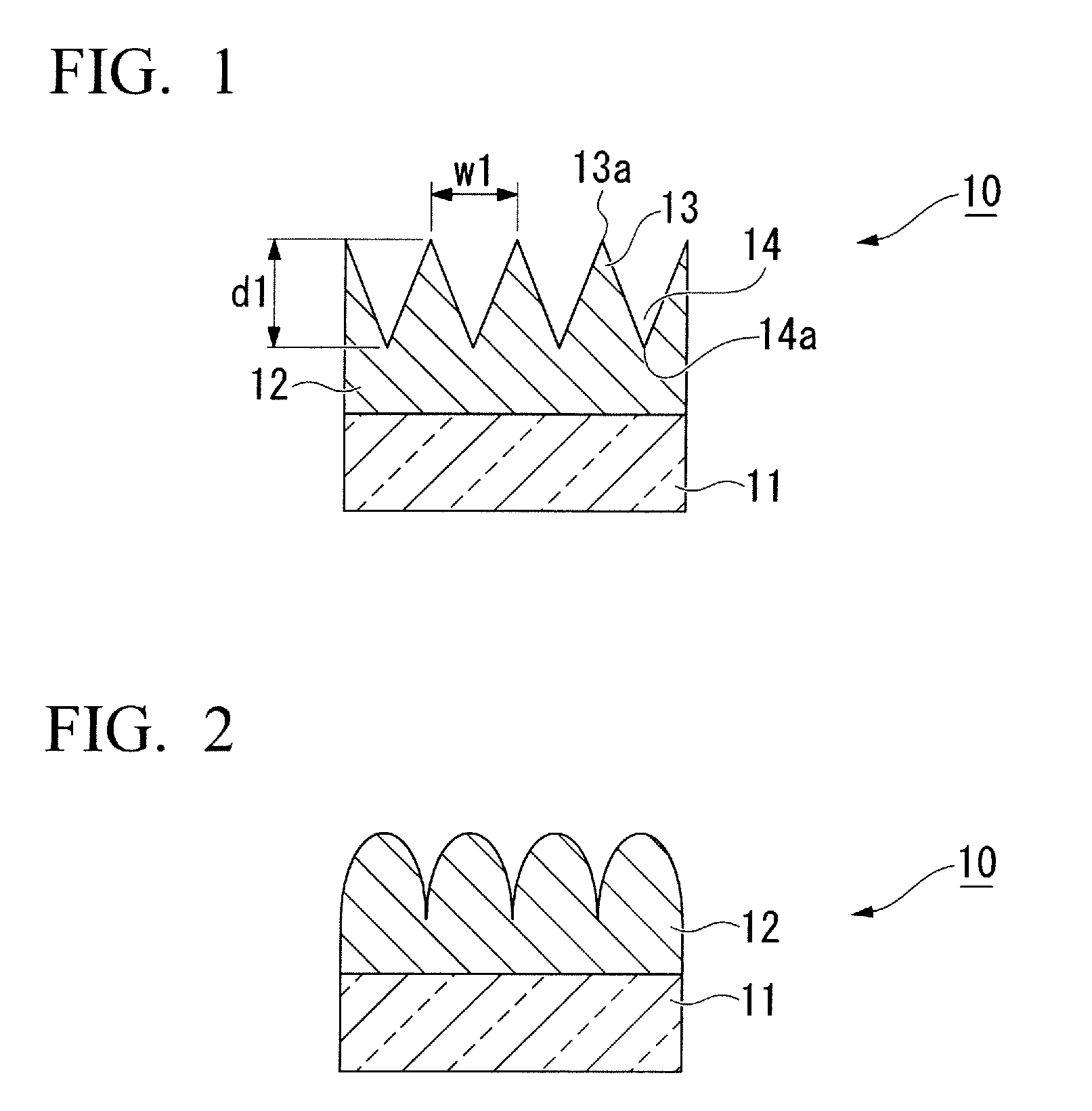

Transparent molded body and antireflective member using the same

ActiveUS20100323165A1Improve antifouling performanceFouling preventionSynthetic resin layered productsWater contactLength wave

The present transparent molded body is a transparent molded body including a transparent substrate and an uneven layer composed of a cured product of an active energy ray-curable composition formed on at least one surface of the transparent substrate, wherein the uneven layer has an uneven structure having a gap between the adjacent convex portions equal to or less than the wavelength of a visible light, the water contact angle of the surface of the uneven layer is equal to or less than 25°, and the modulus of elasticity of the surface of the uneven layer is equal to or more than 200 MPa.

Owner:MITSUBISHI CHEM CORP

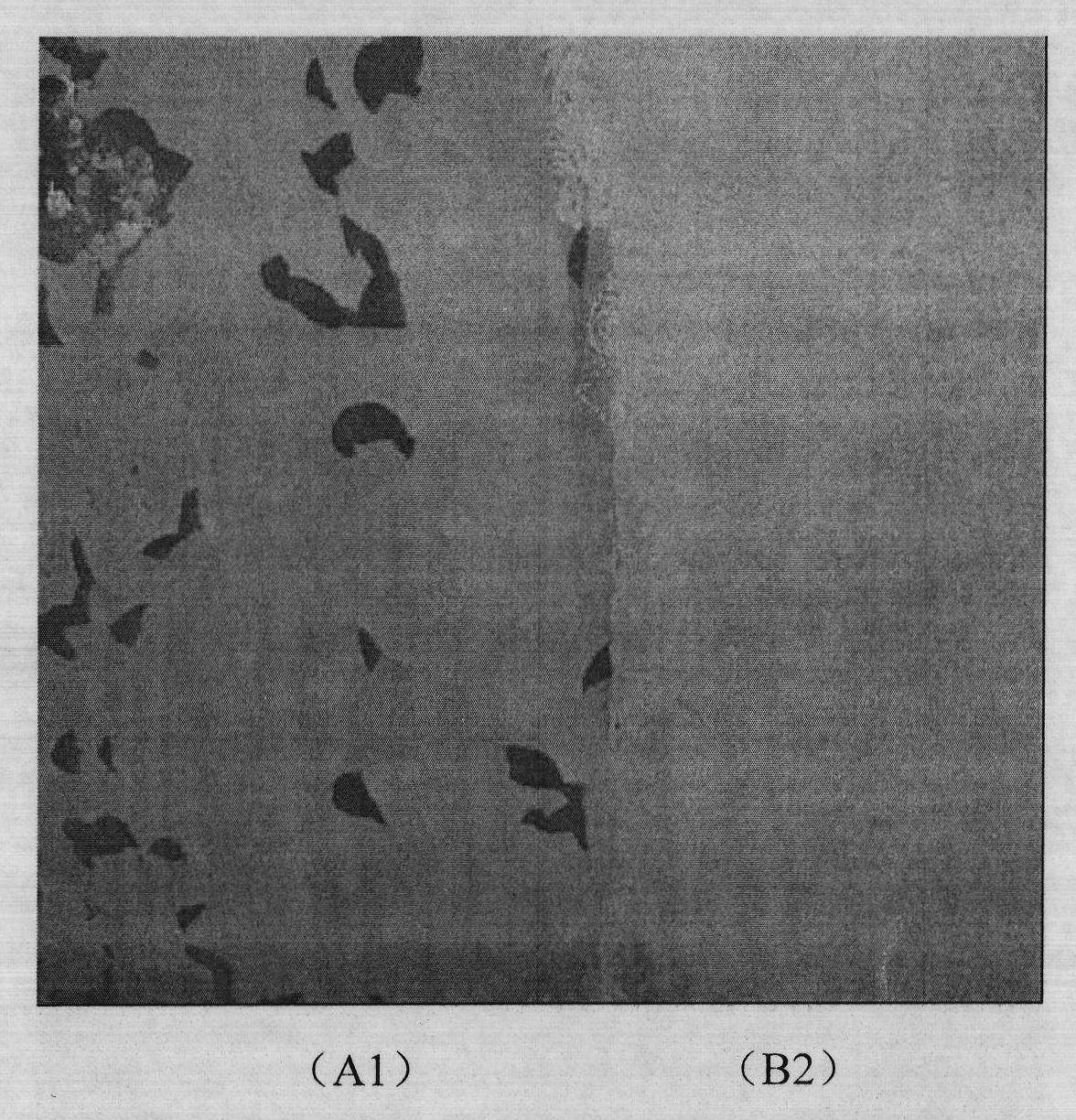

Tei Coat for Organopolysiloxane Antifouling Coat, Composite Coats, and Ships and Underwater Structures Covered with the Composite Coats

InactiveUS20090042042A1Big burden to solveWell formedAntifouling/underwater paintsSynthetic resin layered productsEpoxyBond properties

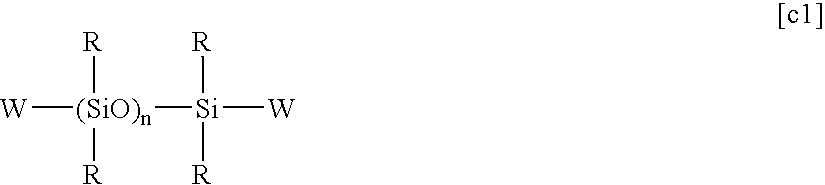

Disclosed is a tie coat which is formed on a surface of a base or an undercoating film prior to formation of an organopolysiloxane-based antifouling coating film and is formed from a moisture-curing organopolysiloxane-based composition comprising (b1) organopolysiloxane having condensing functional groups at both ends of a molecule and / or (b2) a curing composition formed by subjecting the component (b1) and an extender pigment selected from the group consisting of silica, calcium carbonate, talc, mica, clay, kaolin and barium sulfate to contact treatment with heating or without heating. Also disclosed is a composite coating film wherein on a surface of the above tie coat is formed a finish coat formed from a three-pack type organopolysiloxane-based curing composition comprising (c1) a main agent comprising the component (b1), (c2) a curing agent component comprising tetraalkoxysilicate or its condensate and (c3) a curing accelerator component comprising a metallic compound. Further disclosed is a composite coating film wherein an epoxy-based sealer coat, the tie coat and the finish coat are formed in this order on a surface of an old antifouling coating film (G). There is provided by the invention a tie coat capable of forming a composite coating film having excellent interlaminar bond property. The composite coating film is favorably formed on a surface of a base, an undercoating film, an old antifouling coating film or the like, has excellent interlaminar bond strength and antifouling property and is preferably used for coating outer surfaces of ships, submerged parts of marine structures, water supply / drainage channels of atomic power plant, etc.

Owner:CHUGOKU MARINE PAINTS

FFC glaze with high stain resistance, FFC sanitary ceramic and preparation method of FFC sanitary ceramic

ActiveCN111253071AExtended firing temperature rangeReduce glaze porosityPotassium feldsparSodium carboxymethylcellulose

The invention discloses an FFC glaze with high stain resistance, an FFC sanitary ceramic and a preparation method of the FFC sanitary ceramic. The FFC glaze with high stain resistance comprises the following raw materials in parts by weight: 22-29 parts of quartz, 24-28 parts of potassium feldspar, 6-10 parts of wollastonite, 7-8 parts of zirconium silicate, 5-10 parts of kaolin, 0-5 parts of calcite, 5-7 parts of zinc oxide, 5-7 parts of aluminum oxide, 2-3 parts of frit, 4-8 parts of dolomite, 5-8 parts of calcined talc, 1-4 parts of barium carbonate and 0.2-0.5 part of sodium carboxymethylcellulose. According to the FFC glaze with high stain resistance, multi-alkali effect is utilized, barium carbonate is introduced, the use amount of calcined talc is increased, and the use amount of albite is reduced, so venting of a green body is more smooth, the porosity of a glaze surface is reduced, and microcracks of the glaze surface are reduced. Besides, the FFC glaze with high stain resistance also utilizes the principle of like dissolves like to increase the consumption of aluminum oxide and quartz, improve the bonding property of the blank and a glaze, and further reduce the microcracks on the glaze surface of the sanitary ceramic correspondingly.

Owner:江门市东鹏智能家居有限公司

Preparation method of highly-hydrophobic fluorocarbon coating for photovoltaic component back plate

ActiveCN104530852AAvoid stickingReduce transmittancePolyurea/polyurethane coatingsCarbon coatingPtru catalyst

The invention provides a preparation method of a highly-hydrophobic fluorocarbon coating for a photovoltaic component back plate. The preparation method is suitable for outdoor coatings and in particular suitable for coated type photovoltaic back plates. The fluorocarbon coating consists of a component A and a component B in a mass ratio of (1-5):1, wherein the component A comprises fluorocarbon resin, hydrophobic modified nano-particles, a tin type catalyst and an anhydrous diluent A; and the component B comprises an isocyanate curing agent and an anhydrous diluent B. The nano-particles can be uniformly dispersed in main body resin after being subjected to coupling agent hydrophobic modification, is good in compatibility, and can form a micro-nano rough grain structure after being coated on a substrate; and by combining low surface energy of the fluorocarbon resin, the surface of the fluorocarbon coating has high hydrophobicity of a 'lotus leaf effect', has a good antifouling effect, and can greatly reduce influence of water drops on components. Meanwhile, the prepared fluorocarbon coating is excellent in weathering resistance, chemical resistance and salt spray resistance, so that the fluorocarbon coating is suitable for coated type photovoltaic component back plates and is good in performance.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Preparation method for touch screen surface anti-fingerprint film

ActiveCN102808148AHigh light transmittanceImprove antifouling performanceVacuum evaporation coatingSputtering coatingSputteringSilicon dioxide

The invention provides a preparation method for a touch screen surface anti-fingerprint film. The method comprises: under argon gas atmosphere, adopting magnetron sputtering to form an anti-fingerprint film on the surface of a glass substrate, wherein a target material adopted by magnetron sputtering contains silica and a fluorine-containing organic compound. With the preparation method of the present invention, fingerprints can not be stuck on the prepared anti-fingerprint film, an anti-fouling effect is good, adhesion of the film on the surface of the substrate is strong, and the film is suitable for large size touch screens.

Owner:BYD CO LTD

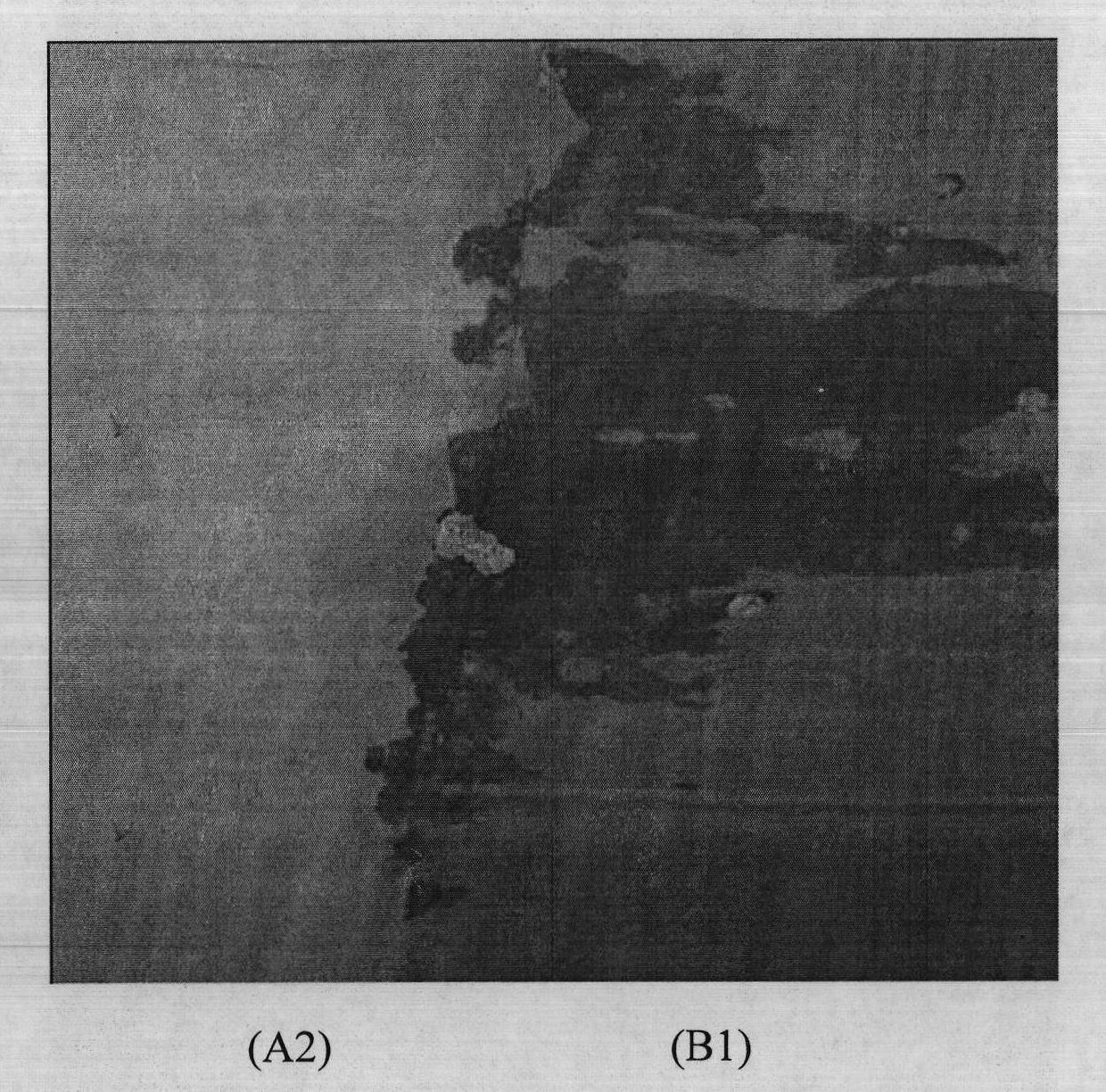

Organosilicon type marine antifouling paint binder and preparation method and application thereof

ActiveCN102212306AInhibition of adsorptionReduce usageAntifouling/underwater paintsPaints with biocidesQuaternary ammonium cationSide chain

The invention discloses organosilicon type marine antifouling paint binder. The structure of the paint binder is shown in the formula (1), wherein the paint binder is an organosilicon-polyurethane compound with bactericide side chain and R represents CH2CH3. The preparation method comprises the following preparation steps: 1) using chloropropylmethyldimethoxysilane and dimethyldimethoxysilicane to react and obtain chloropropyl-containing polysiloxane; 2) using chloropropyl-containing polysiloxane, tertiary amine and hydroxyl-containing tertiary amine to perform reflux reaction and generate polysiloxane with quaternary ammonium salt and hydroxyl; and 3) mixing isocyanate, butyltin dilaurate and polysiloxane with quaternary ammonium salt and hydroxyl with solvent, adding gamma-aminopropyltriethoxysilane to extend the chain and obtain prepolymer with the crosslinked group -Si(OCH2CH3), and using the prepolymer to perform crosslinking and condensation in the air and obtain the finished product. The organosilicon type binder has low surface energy performance and very good hydrophobicity; and the molecular chain has environmentally-friendly bactericide, thus the binder has very good bactericidal effect and marine antifouling effect.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com