Patents

Literature

780results about "Stain/soil resistant fibres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorochemical composition comprising a fluorinated polymer and treatment of a fibrous substrate therewith

InactiveUS7094829B2Easy to oilGood water repellency propertyStain/soil resistant fibresLiquid repellent fibresFiberOrganic solvent

A fluorochemical composition for rendering fibrous substrates oil repellent, water repellent, and / or stain repellent and comprising a fluorinated polymer dispersed in water or dissolved or dispersed in an organic solvent, the fluorinated polymer comprising units derived from (i) a mixture of two or more fluorinated polyether monomers that differ in at least their molecular weight, the fluorinated polyether monomers having an ethylenically unsaturated group and a perfluorinated polyether group and wherein at least 90% by weight of the mixture consists of fluorinated polyether monomers that have a perfluorinated polyether group having a molecular weight of at least 750 g / mol and (ii) one or more units derived from one or more co-monomers other than a fluorinated polyether monomer and wherein the co-monomers comprise at least one non-fluorinated monomer. Also, method for treating fibrous substrate with such composition, fluorinated polyether monomers, and fluorinated polymers derived from such monomers.

Owner:3M INNOVATIVE PROPERTIES CO

Fabric care formulations and methods

InactiveUS20120077725A1Improve antifouling performanceStain/soil resistant fibresOrganic detergent compounding agentsMedicineParticulate material

Fabric care compositions for providing improved stain repellency are described. The fabric care composition includes a mixture including a hydrophobic fluid, a particulate material and an amphoteric or cationic oligomeric / polymeric deposition aid. Methods for providing improved stain repellency for a textile by treating the textile with the fabric care composition are also described.

Owner:THE PROCTER & GAMBLE COMPANY

Low temperature high elastic type waterproof antifouling water-based polyurethane finishing agent preparing method and product

ActiveCN103497308AGood flexibilityImprove low temperature resistanceStain/soil resistant fibresLiquid repellent fibresWater basedEnd-group

The invention relates to a low temperature high elastic type waterproof antifouling water-based polyurethane finishing agent preparing method and product. The method comprises the steps of preparing raw materials, and dewatering polyether triol and polyether diol; enabling the polyether triol and the polyether diol to be in performed reaction with end hydroxyl polysiloxane linear bodies and diisocyanate under catalysis of polymerization catalyst so as to obtain performed polymers; conducting chain extension on the performed polymers and chain extenders with the existence of diluents to obtain intermediates; conducting end capping on the intermediates and fluorine alkyl alcohol, and then adding reaction termination agents to end reaction; adding neutralizing agents, diluents, and water and emulsifying so as to obtain the low temperature high elastic type waterproof antifouling water-based polyurethane finishing agent emulsion product which is a main chain end hydroxyl polysiloxane modified ionic water-based polyurethane polymer material containing perfluorinated alkyl end groups, is used for processing of various textile coating and artificial leather dry coating, and can endow products with good waterproof antifouling performance, low-temperature high elastic characteristic and bending resistant performance.

Owner:河北多维康助剂有限公司

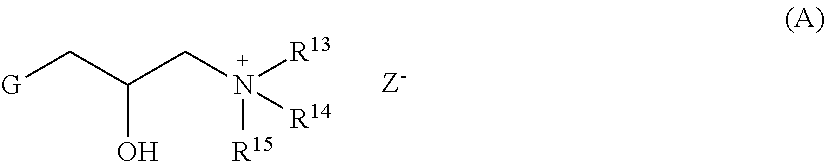

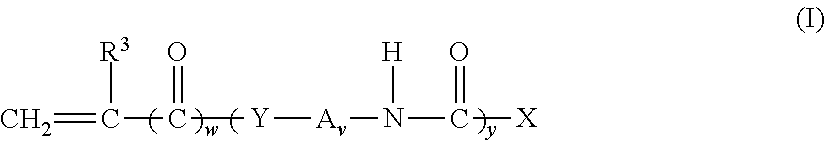

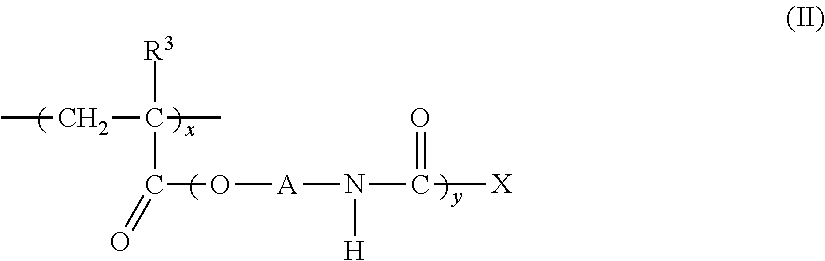

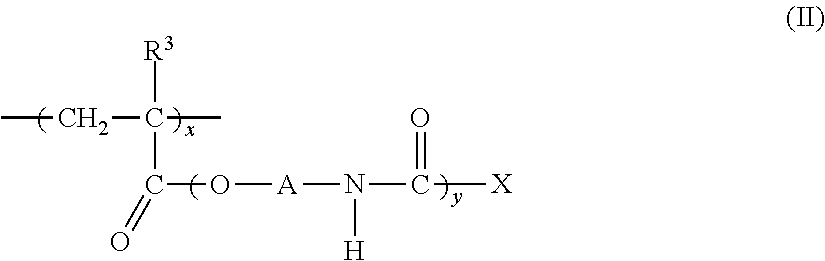

Non-fluorinated monomers and polymers for surface effect compositions

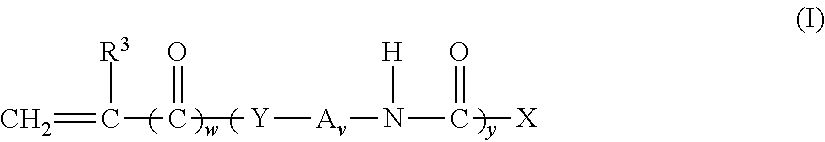

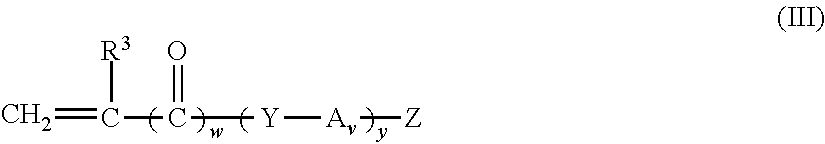

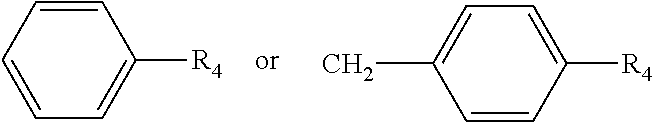

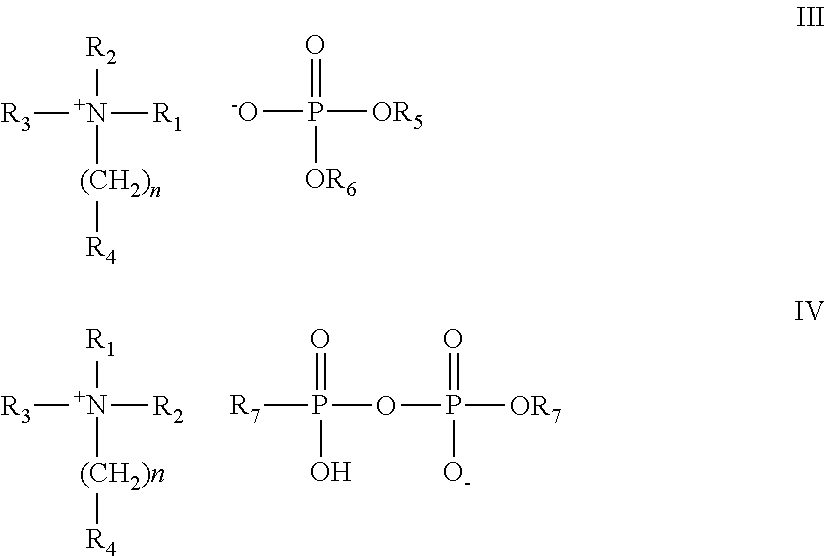

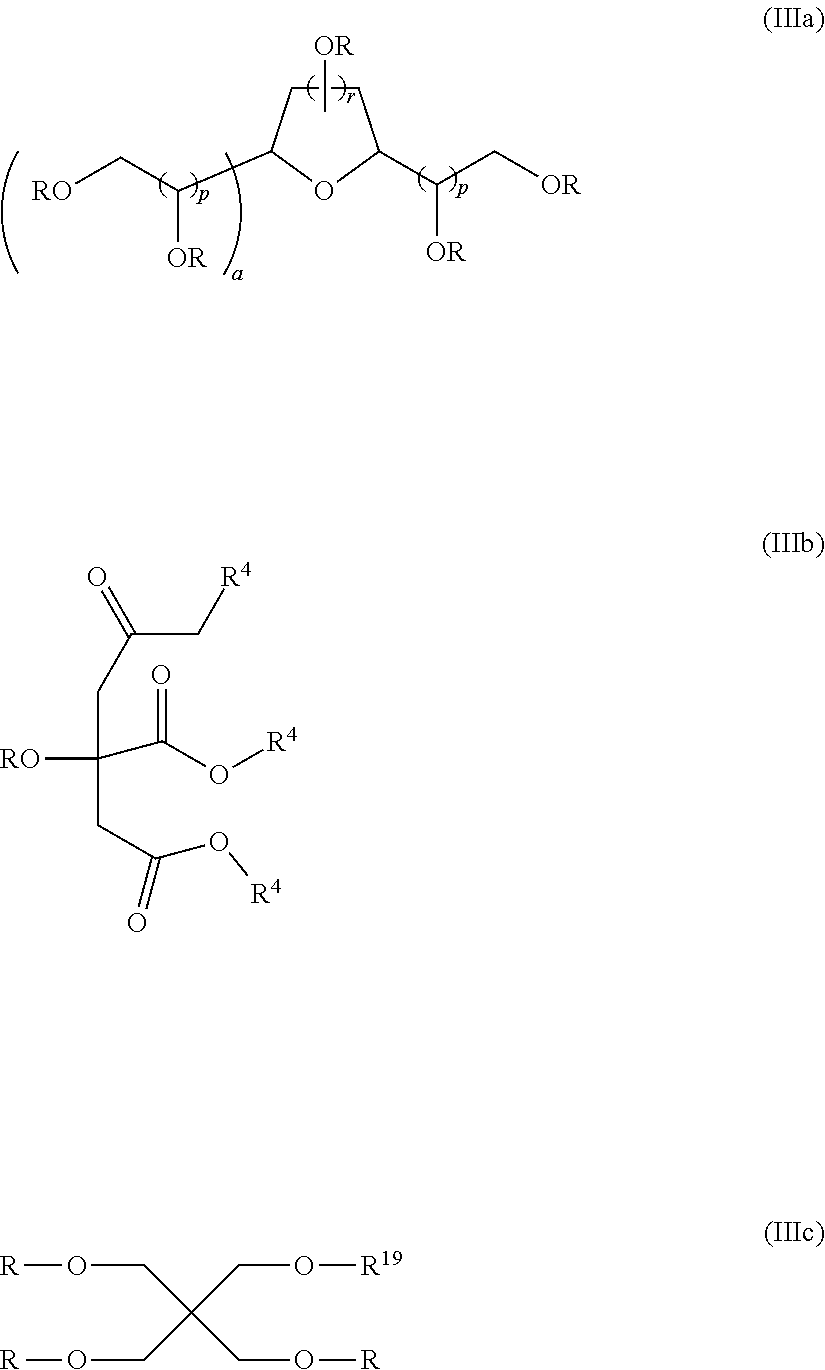

The present invention relates to monomers and polymers of Formula (I):where R3 is selected from H or a C1 to C4 alkyl group; Y is selected from O or a substituted or unsubstituted arylene group; A is a linear or branched C1 to C10 alkylene group; w is 0 or 1; v is 0 or 1; y is 0 or 1; X is the residue of a cyclic or acyclic sugar alcohol which is substituted with at least one —R1; —C(O)R1; —(CH2CH2O)n(CH(CH3)CH2O)mR2; —(CH2CH2O)n(CH(CH3)CH2O)mC(O)R1; each n is independently 0 to 20; each m is independently 0 to 20; each R1 is independently a linear or branched alkyl group having 9 to 29 carbons optionally comprising at least 1 unsaturated bond; and each R2 is independently —H, a linear or branched alkyl group having 6 to 30 carbons optionally comprising at least 1 unsaturated bond, or mixtures thereof.

Owner:THE CHEMOURS CO FC LLC

Soil repellency aqueous dispersions, soil repellant soft articles, and methods of making the same

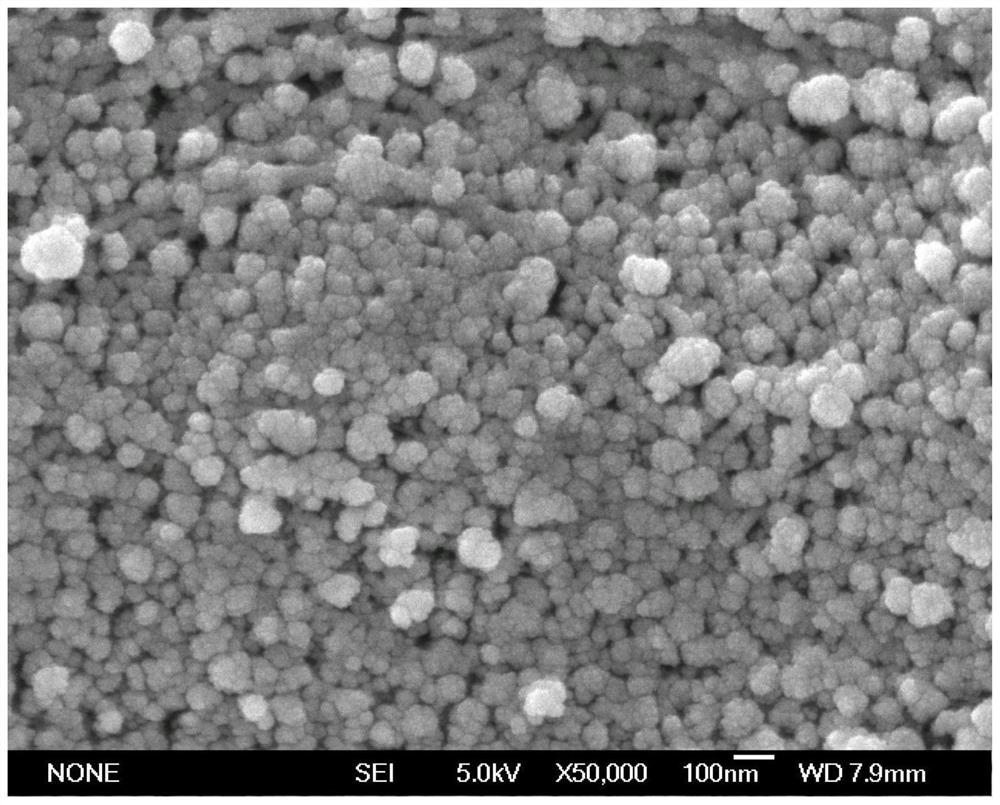

ActiveUS20110311757A1Improve efficiencySoftMaterial nanotechnologyStain/soil resistant fibresFiberYarn

A soil repellency aqueous dispersion for treating various fibers, yarns, and textiles is disclosed. The dispersion provides superior soil resistance when compared to known fluorochemical and silicone fiber treatments. The dispersion comprises clay nanoparticle components and fluorochemicals that can be applied to the fibers, yarns, and textiles using known methods.

Owner:INV PERFORMANCE SURFACES LLC

Double-surface filling composite film containing fluorine and chlorine conductive macromolecules and preparation method thereof

ActiveCN106968110AHigh physical and mechanical strengthImprove antifouling performanceStain/soil resistant fibresCarbon fibresComposite filmMoisture

The invention discloses a double-surface filling composite film containing fluorine and chlorine conductive macromolecules and a preparation method thereof. The double-surface filling composite film containing the fluorine and chlorine conductive macromolecules comprises a micropore film framework and fluorine and chlorine containing conductive macromolecules, more than 60% of double surfaces of the micropore film framework are filled with fluorine and chlorine containing conductive macromolecule resin, the mechanical strength is high, the waterproofness, the oil resistance and the pollution resistance are relatively high, and the film can meet the requirements of higher water resistance and poisonous and harmful chemical invasion resistance and higher moisture-penetrability; the film has convenience and high water and poisonous and harmful chemical resistance, is comfortable, keeps warm and can improve the fighting capacity of soldiers greatly when applied to biochemical protective clothing; when the film is applied to fuel cells, the electric conductivity is high so that better electrical performance is obtained, and the fuels such as hydrogen or ethyl alcohol can be burnt and utilized relatively thoroughly.

Owner:ZHEJIANG HYPROOF TECH CO LTD +1

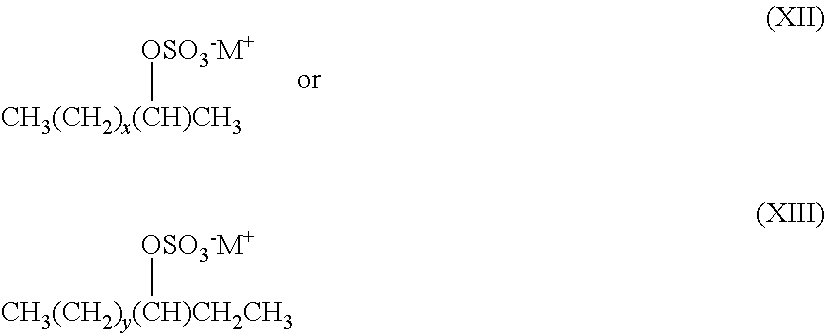

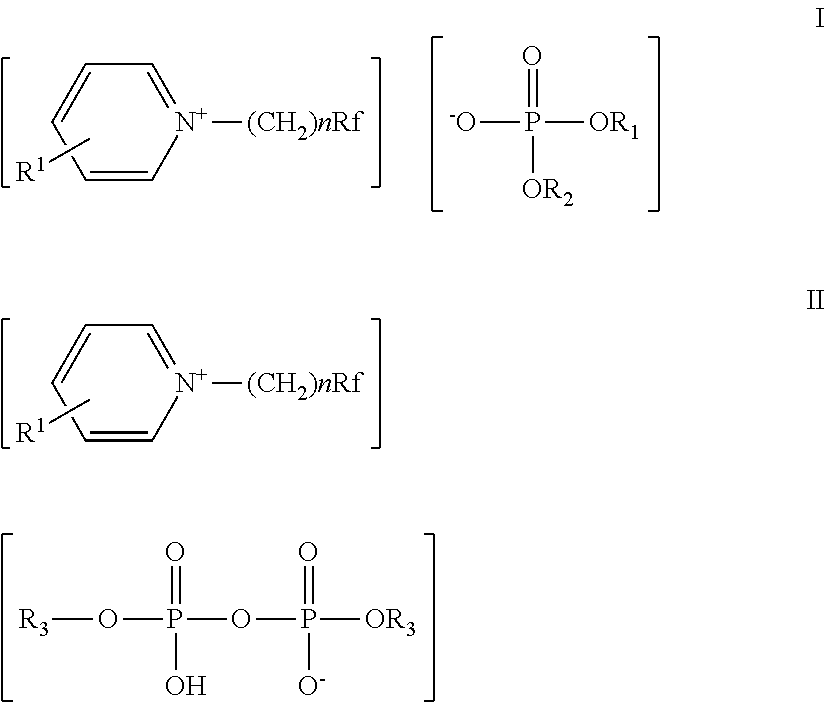

Cleaning compositions and methods comprising a hydrofluoro-olefin or hydrochlorofluoro-olefin solvent

The invention provides solvent and cleaning compositions comprising an ionic surfactant, which preferably has a fluorinated portion thereof, and a solvent selected from hydrofluoro- and / or hydrochlorofluoro-olefins. Additionally, the invention provides drying, dry cleaning, and soil repellency compositions containing a hydrofluoro- or hydrochlorofluoro-olefin and said surfactant. Additionally, the invention provides drying compositions containing a hydrofluoro-olefin or hydrochlorofluoro-olefin and an alcohol such as methanol, ethanol or isopropanol.

Owner:HONEYWELL INT INC

Anti-algae anti-aging fishing net

InactiveCN105442086ASimple processing technologyImprove toughnessStain/soil resistant fibresConjugated synthetic polymer artificial filamentsEpoxyPolystyrene

The invention discloses an anti-algae anti-aging fishing net prepared from the following components: polystyrene, polyethylene fibers, nylon fibers, MBS resin, an epoxy resin adhesive film, ethylene glycol dimethacrylate, a calcium carbonate powder, an attapulgite powder, dibutyl phthalate and calcium stearate. The prepared fishing net has simple processing technology; ultraviolet intermittent irradiation treatment is carried out in a process of polyethylene fiber treatment, and the prepared fishing net can be allowed to have extremely strong performance of preventing algae attachment; the nylon fibers have the defects that the nylon fibers have poor optical rotation resistance, are prone to yellowing and have the strength decreased when illuminated for a long time by the sun outdoor, so a hexamethylene diamine and maleic anhydride mixture is adopted for treating the nylon fibers, the problems are solved, and the anti-aging ability of the prepared fishing net is greatly improved; and through addition of the treated attapulgite powder, mechanical properties of the fishing net are improved, and the toughness is enhanced.

Owner:CHAOHU TIANYU FISHING TACKLE CO LTD

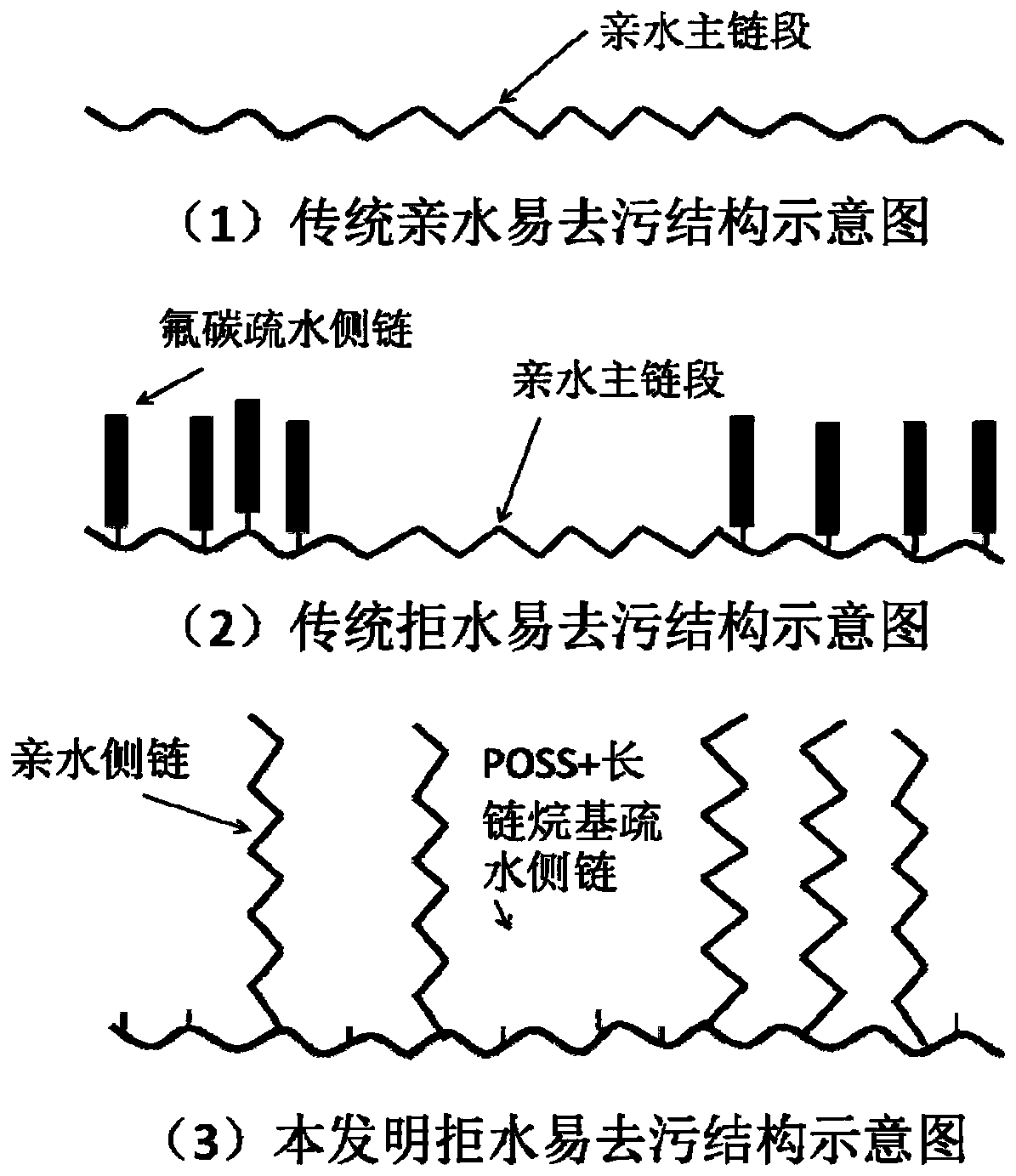

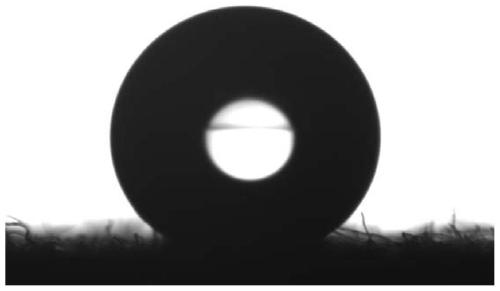

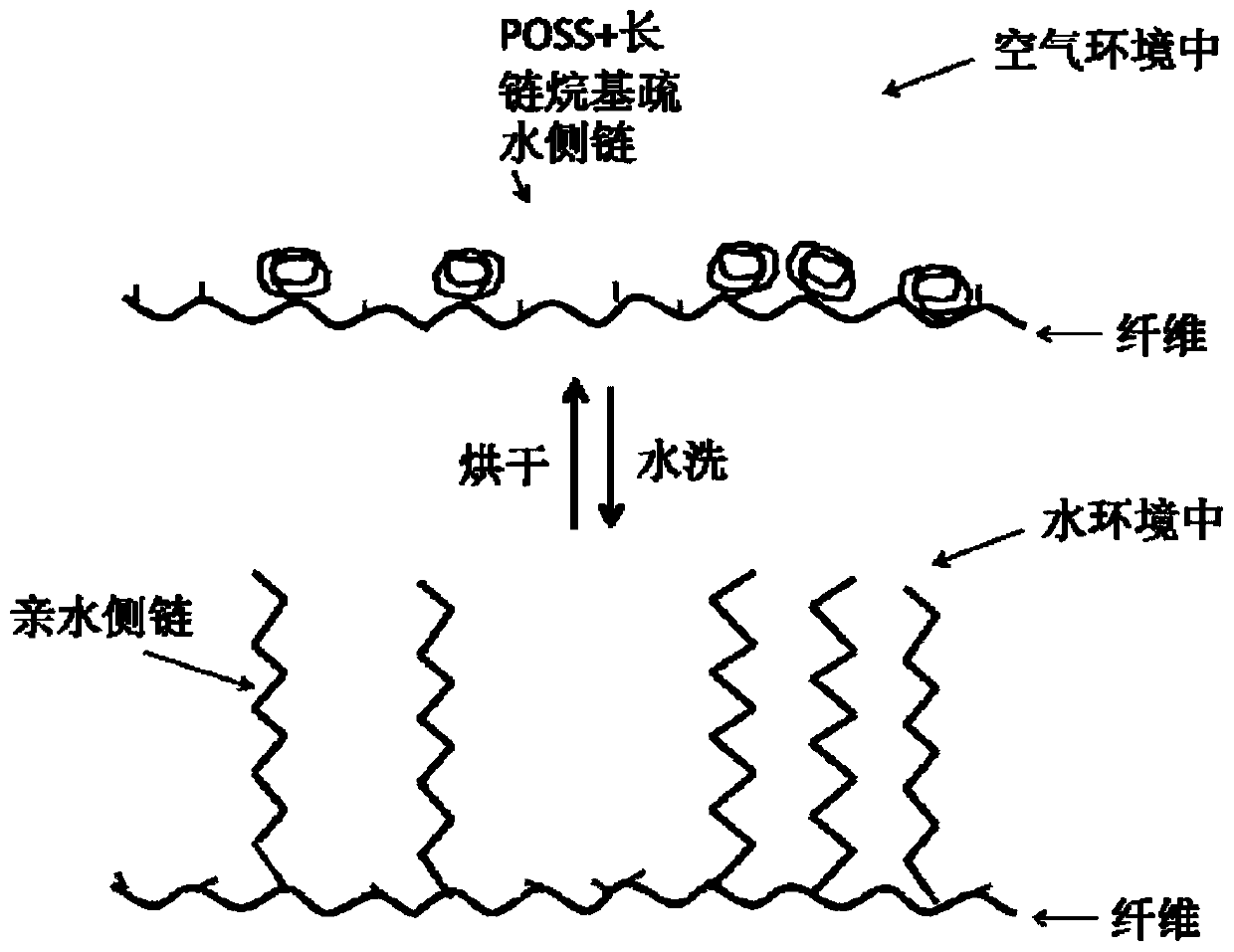

Fluoride-free water-repellency stain-release multifunctional finishing agent and preparation method and application thereof

InactiveCN110317307AFacilitate strippingIncrease the speed of diffusionStain/soil resistant fibresLiquid repellent fibresMethacrylatePolymer science

The invention discloses a fluoride-free water-repellency stain-release multifunctional finishing agent and a preparation method and application thereof. The fluoride-free water-repellency stain-release multifunctional finishing agent is a waterborne emulsion or waterborne solution of a polymer shown in a formula I. The structural formula of the polymer is shown in the formula I, and in the formulaI, R1 is a long-chain acrylate or long-chain methacrylate structure chain segment; R2 is a cage type silsesquioxane structure chain segment containing a mono-acrylate group or a mono-methacrylate group; R3 is a polyethylene glycol methanal structure chain segment containing a mono-methacrylate structure or a mono-acrylate structure; R4 is a structure chain segment of a functional monomer and is selected from an acrylate or methacrylate monomer containing at least one of hydroxyl, an epoxy group, an amide group, dimethylamino, carboxyl, an ester group, an alkoxy, a blocked isocyanate group anda halogen end group, and a, b, c and d represent the degrees of polymerization. The finishing agent is environmentally friendly, capable of removing stains easily, free of biologic toxin and not degradable; preparation is easy, and conditions are mild.

Owner:BEIJING CTA TEX CHEM

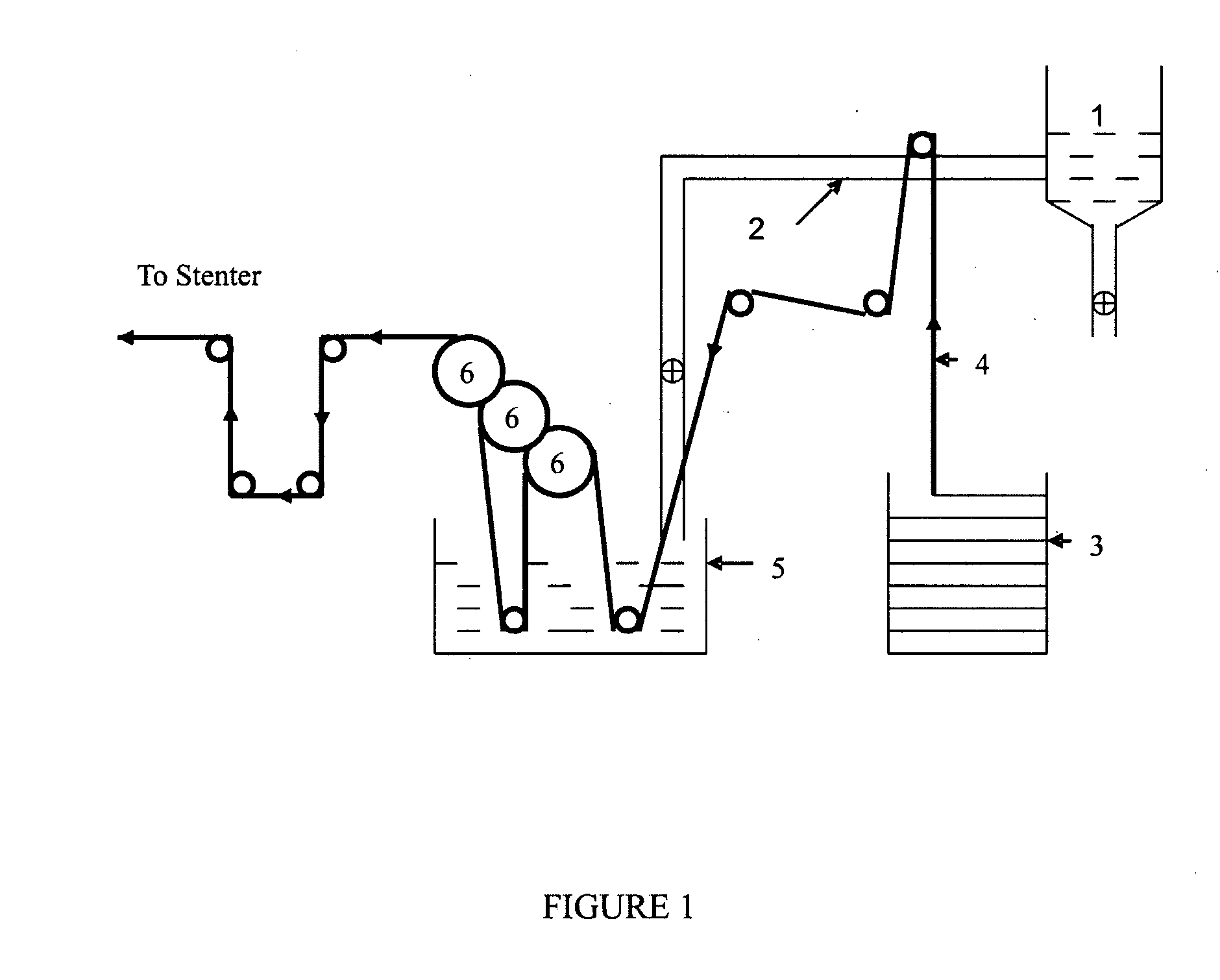

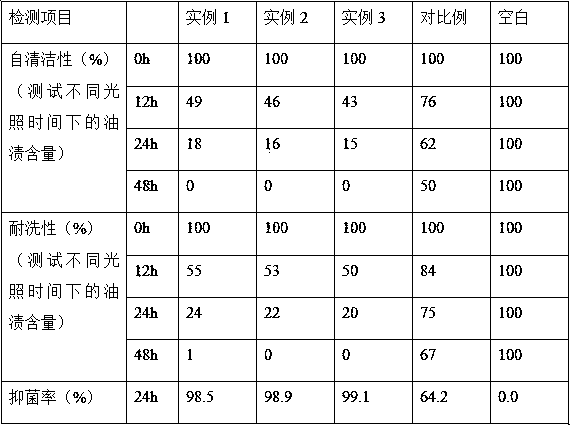

Preparation method of washable three-proofing and easy-decontamination antibacterial fabric

InactiveCN111535026AMeet environmental protection requirementsImprove washing resistanceStain/soil resistant fibresBiochemical fibre treatmentProcess engineeringCross linker

The invention discloses a preparation method of a washable three-proofing and easy-decontamination antibacterial fabric. The preparation method is characterized by comprising the following steps of: soaping, to be specific, after desizing, scouring, bleaching and mercerizing the fabric in advance, removing impurities on the cloth cover by a soaping process, and then drying; and performing one-bathprocess washable three-proofing and easy-decontamination antibacterial finishing, to be specific, shaping and processing the soaped and dried fabric on a shaping machine, drying, baking and finishing, thereby obtaining the washable three-proofing and easy-decontamination antibacterial fabric. A working solution which simultaneously contains a C6 durable three-proofing finishing agent, a purifiedcotton durable fluorine-free waterproof agent, a durable crosslinking agent, an antibacterial agent and a special waterproof penetrant is contained in a rolling groove of the shaping machine, and thefabric is subjected to padding, then is dried and baked to obtain the washable three-proofing and easy-decontamination antibacterial fabric. The preparation method solves the contradiction between thethree-proofing and the easy decontamination, and also solves the problems between the three-proofing and the bacteria prevention; and meanwhile the fabric is endowed with the function of washing resistance, and can meet the overall actual needs for functional fabrics in actual situations.

Owner:江苏康乃馨纺织科技有限公司

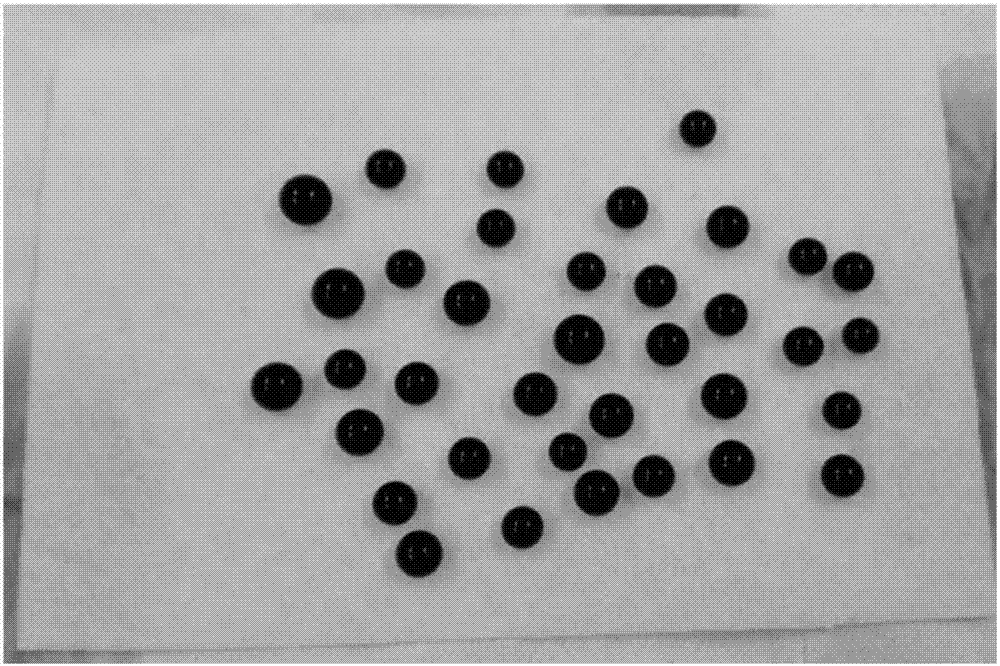

Multifunctional super-amphiphobic fabric and preparation method thereof and application thereof

ActiveCN109610161AImprove mechanical propertiesGood chemical resistanceStain/soil resistant fibresLiquid repellent fibresDouble bondTetrahydrofuran

The invention discloses a multifunctional super-amphiphobic fabric and a preparation method thereof and application thereof. The preparation method of the multifunctional super-amphiphobic fabric comprises the steps of firstly, washing the fabric by using deionized water and ethanol, preparing an ethanol mixed solution of thiol siloxane and tetraethoxysilane, and putting a clean woven fabric intothe mixed solution to be soaked; and secondly, enabling the fabric to react for 5-120 min in the atmosphere containing ammonia, and putting the dried fabric into a tetrahydrofuran solution containinga photoinitiator and a fluorine-containing double-bond compound to perform click reaction. The preparation method of the multifunctional super-amphiphobic fabric, disclosed by the invention, has the advantages of short reaction time, low raw material consumption and simple operation; and the obtained fabric also has a self-cleaning function, an anti-fouling function and a function of separating oil and water of light and heavy oil.

Owner:SOUTH CHINA UNIV OF TECH

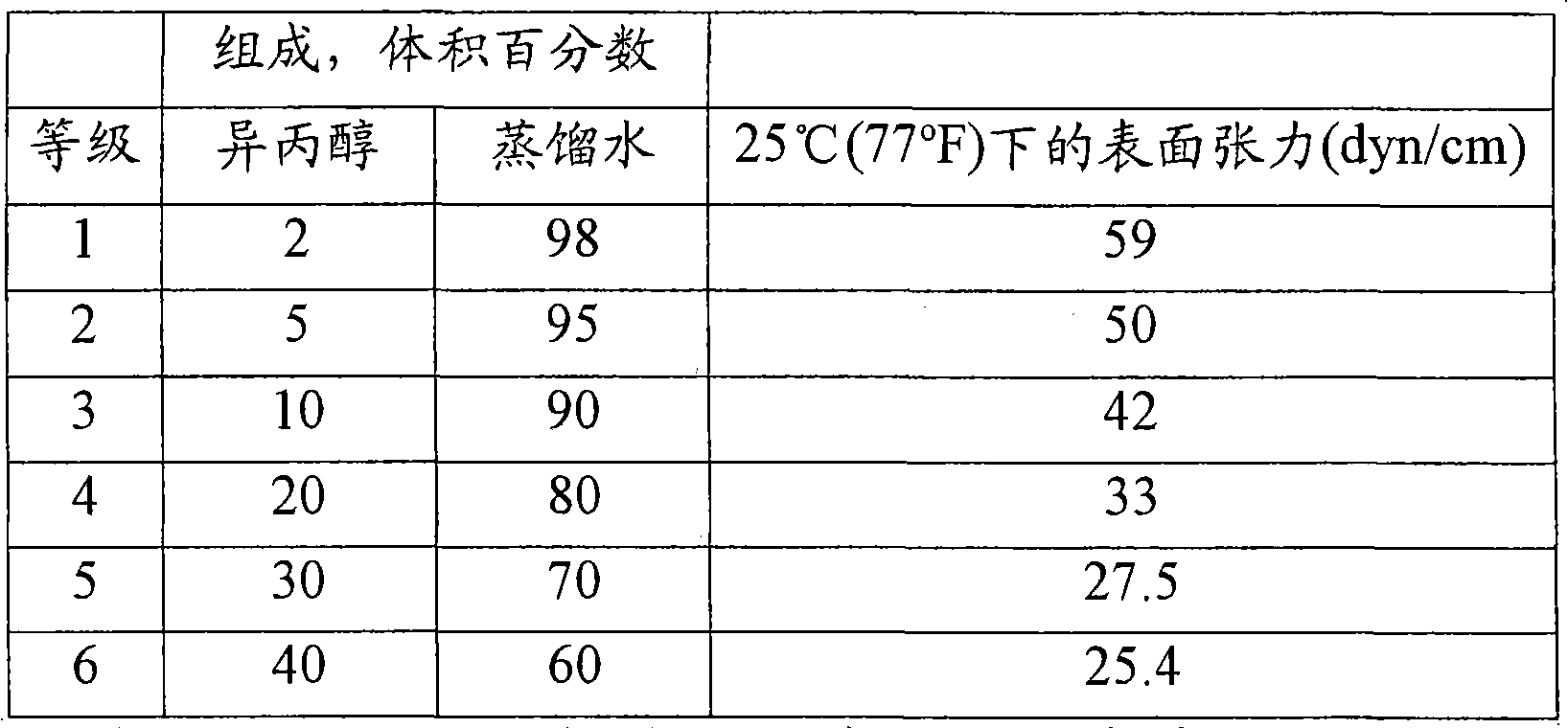

Antimicrobial finish on fabrics

A formulation is provided which comprises at least one phenolic compound in an amount of about 0.5 to about 1.2% of the mass of the formulation; at least one fragrance in an amount of about 0.3 to about 1.0% of the mass of the formulation; and at least one alcohol in an amount of about 90 to about 99% of the mass of the formulation. Said formulation is surfactant free and being capable of rendering anti-microbial finish to fabrics. And also, a process for preparing a fabric with anti-microbial finish is provided.

Owner:RELIANCE INDUSTRIES LIMITED

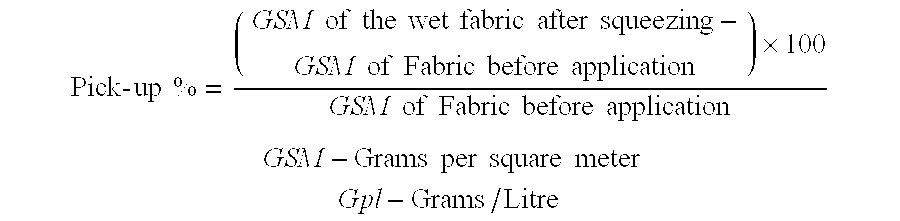

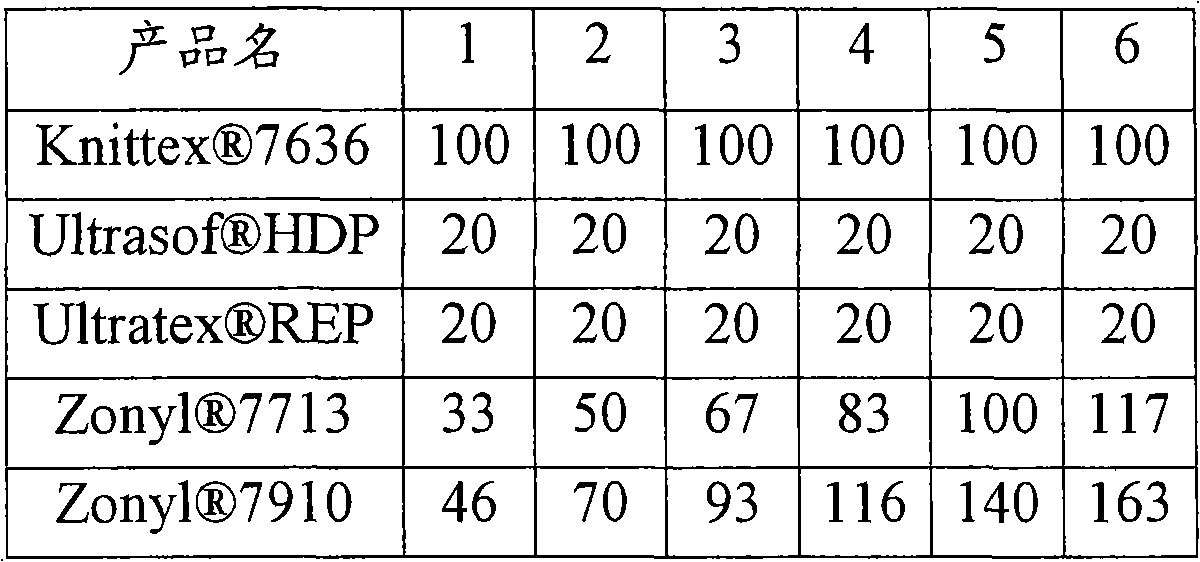

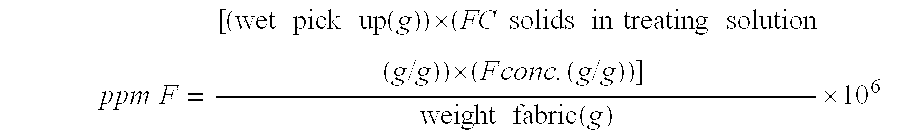

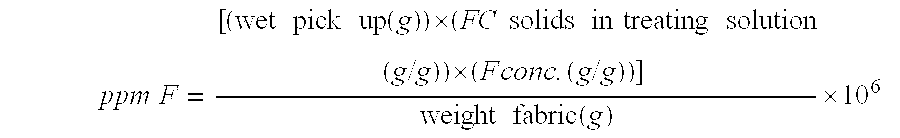

Fabric treated with durable stain repel and stain release finish and method of industrial laundering to maintain durability of finish

The invention provides a fabric comprising one or more polyesters optionally with other fibers which is treated with a finish comprising at least one fluorochemical stain repellent agent and at least one fluorochemical stain release agent, wherein the fabric maintains oil repellency and stain release capability after at least five industrial launderings at about 55 DEG C to about 65 DEG C. The invention also provides a method of treating a fabric with a finish to impart oil repellency, water repellency, and stain release which is durable to repeated industrial laundering. The invention further provides textile articles comprising the treated fabric, and a method for industrial laundering of such treated fabric and textile articles.

Owner:EI DU PONT DE NEMOURS & CO +1

Fabric treated with durable stain repel and stain release finish and method of industrial laundering to maintain durability of finish

The invention provides a fabric comprising one or more polyesters optionally with other fibers which is treated with a finish comprising at least one fluorochemical stain repellent agent and at least one fluorochemical stain release agent, wherein the fabric maintains oil repellency and stain release capability after at least five industrial launderings at about 55° C. to about 65° C. The invention also provides a method of treating a fabric with a finish to impart oil repellency, water repellency, and stain release which is durable to repeated industrial laundering. The invention further provides textile articles comprising the treated fabric, and a method for industrial laundering of such treated fabric and textile articles.

Owner:EI DU PONT DE NEMOURS & CO +1

Stain and soil resistant textile article

ActiveUS7879743B2Enhances the water and oil repellencyNegative impactMaterial nanotechnologyStain/soil resistant fibresMedicineStain

Disclosed in this specification is an aqueous dispersion for treating a textile. The dispersion generally includes surface-functionalized inorganic oxides in combination with a fluorochemical. Significantly lower concentrations of fluorochemicals are present in comparison to prior art dispersions.

Owner:BIGSKY TECH

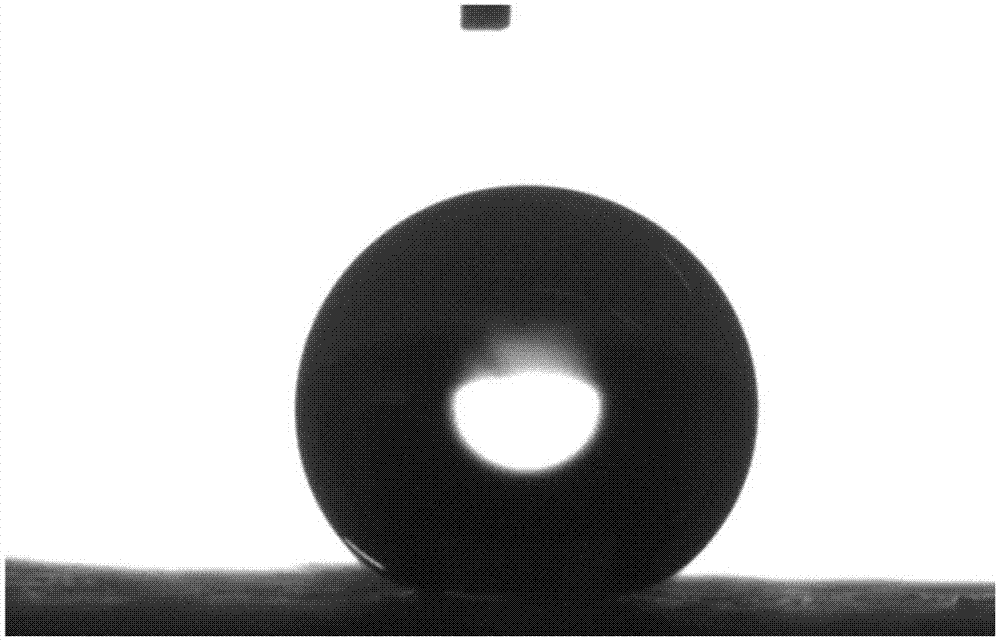

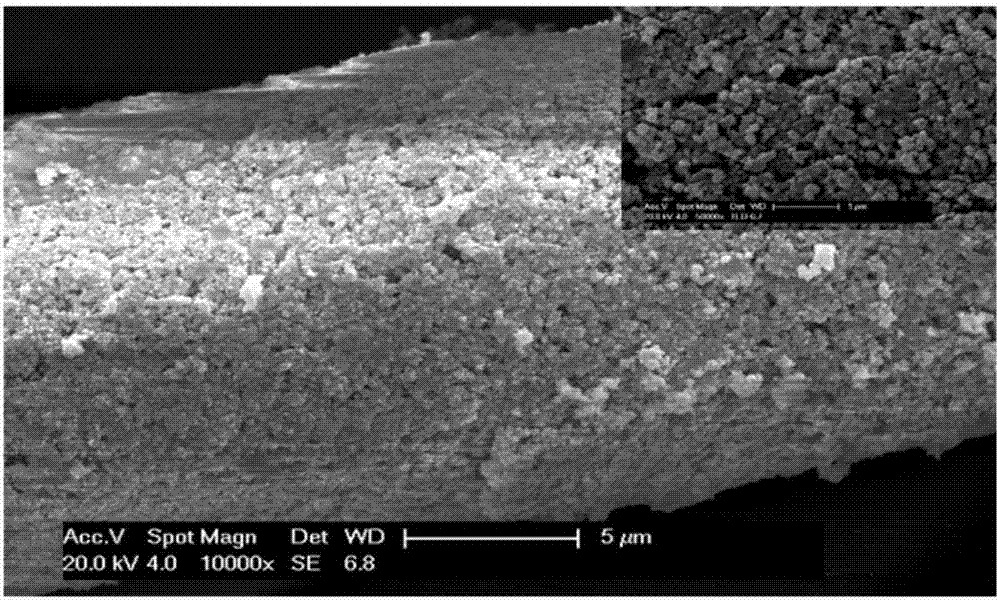

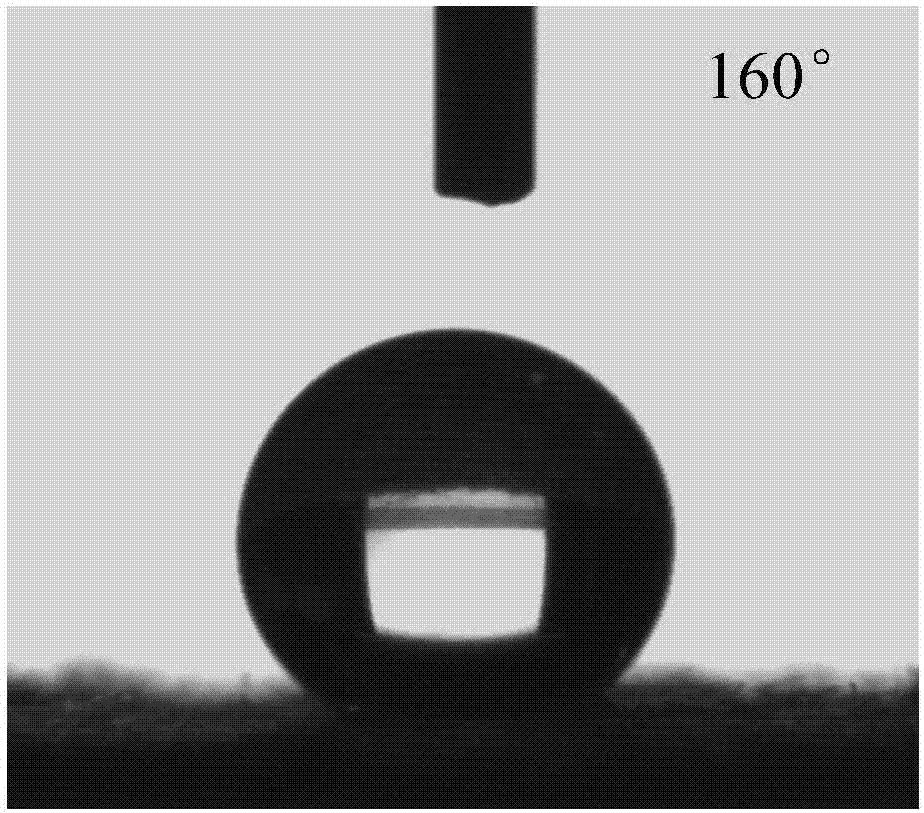

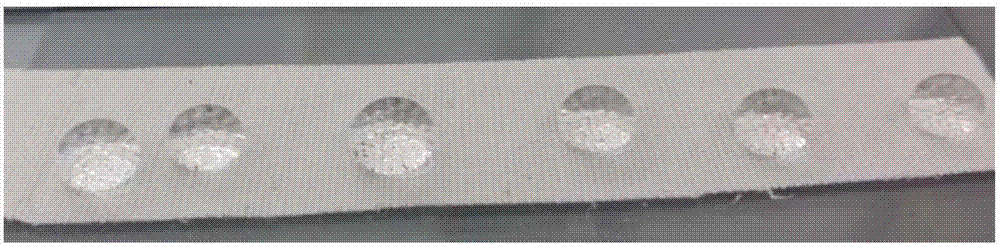

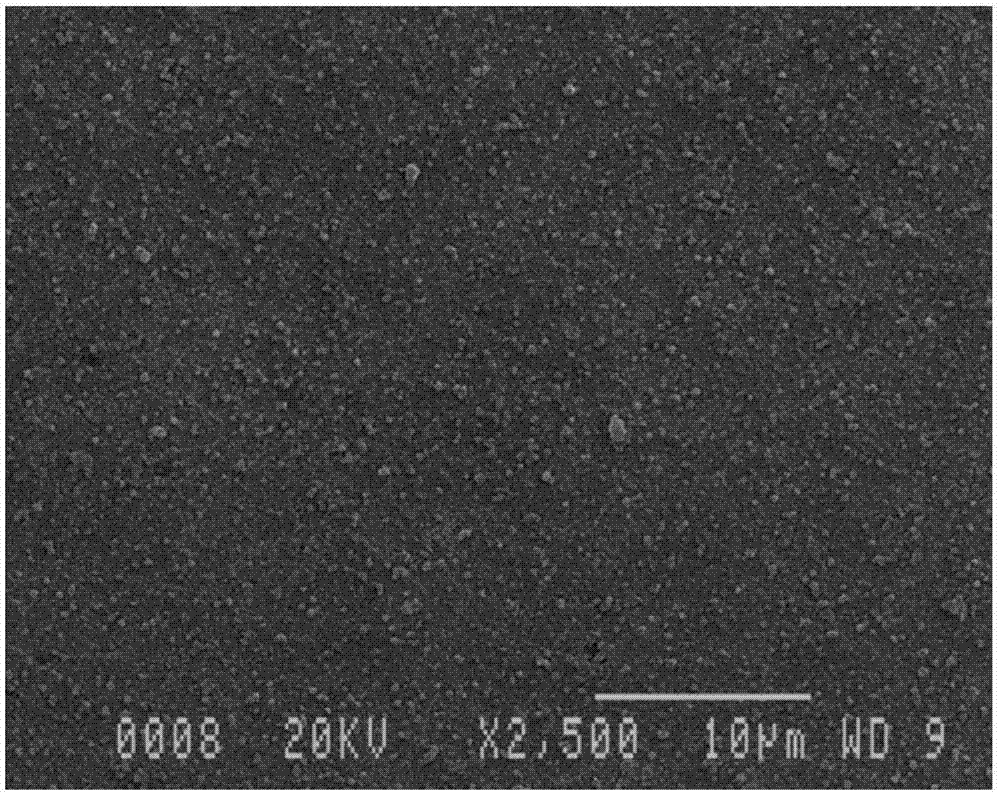

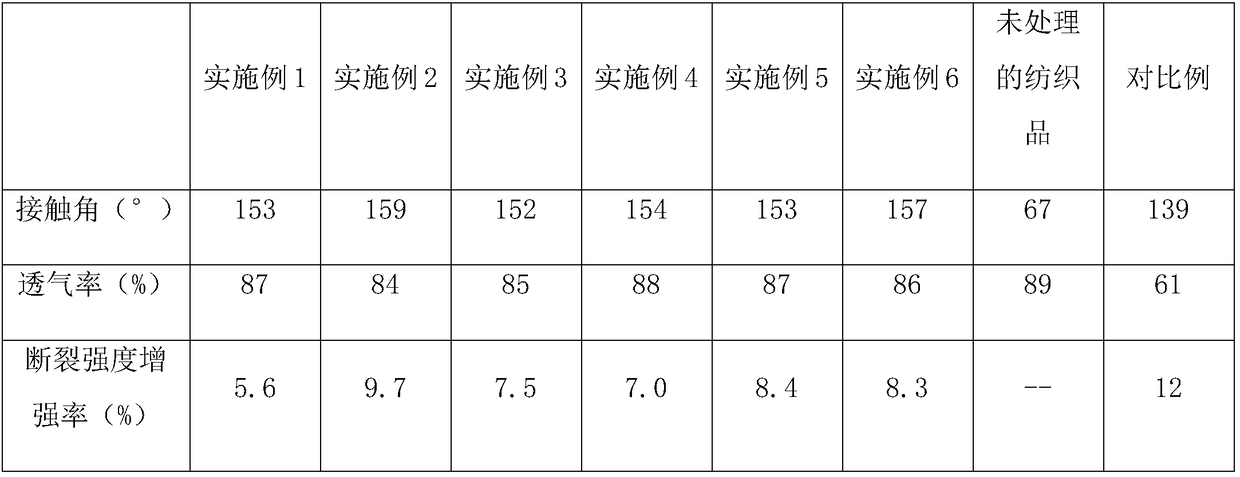

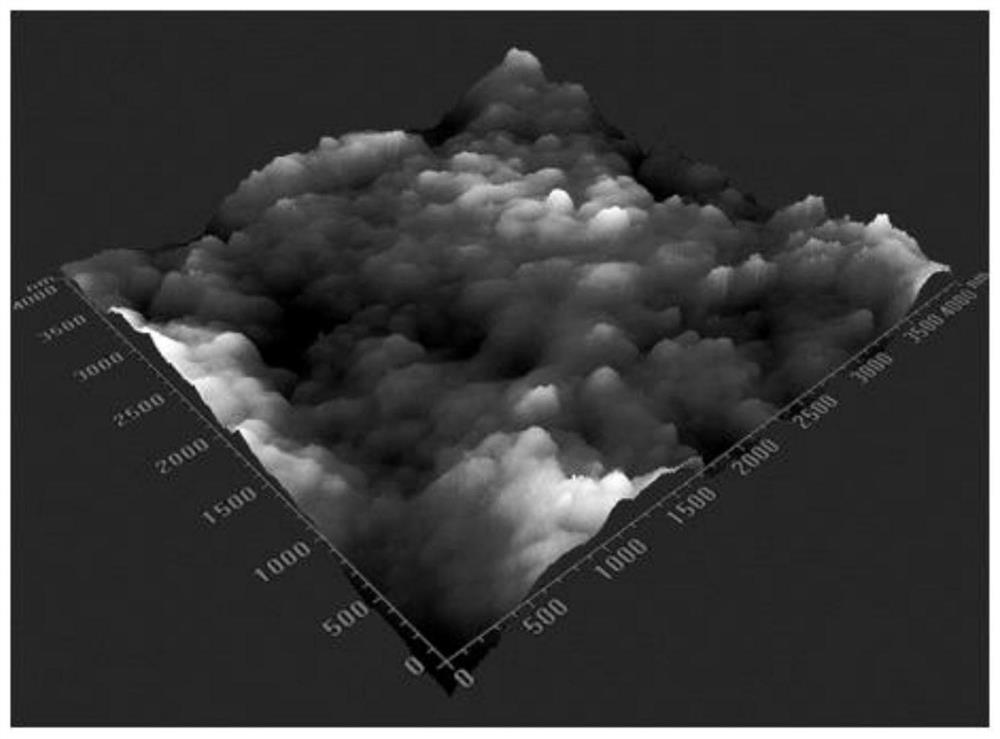

Superhydrophobic fibrofelt and its preparation method

ActiveCN107419534AGuaranteed breathabilityReduce adsorptionStain/soil resistant fibresDispersed particle filtrationFiberSilica nanoparticles

The invention provides a superhydrophobic fibrofelt and a preparation method thereof. The preparation method comprises the following steps: ultrasonically cleaning the fibrofelt in acetone, absolute ethanol and deionized water successively, and then drying the fibrofelt; adding room-temperature-cured fluorocarbon resin (FEVE) and two-component rigid polyurethane resin (SRP-FC) into an organic solvent, and carrying out uniform mixing under stirring so as to form a stable resin solution; directly adding hydrophobic fumed silica nanoparticles and fluorosilane into ethanol, and carrying out ultrasonic dispersion so as to prepare a superhydrophobic finish solution; and putting the cleaned fibrofelt in the primer resin solution, carrying out impregnation, then taking the fibrofelt out, removing excess resin and solvents through squeezing, carrying out drying, then subjecting the fibrofelt to dip-coating in the finish solution so as to form a superhydrophobic coating on the resin-treated fibrofelt, and then carrying out drying and curing so as to obtain the anti-fouling anti-moisture anti-mildew superhydrophobic fibrofelt.

Owner:SOUTHEAST UNIV

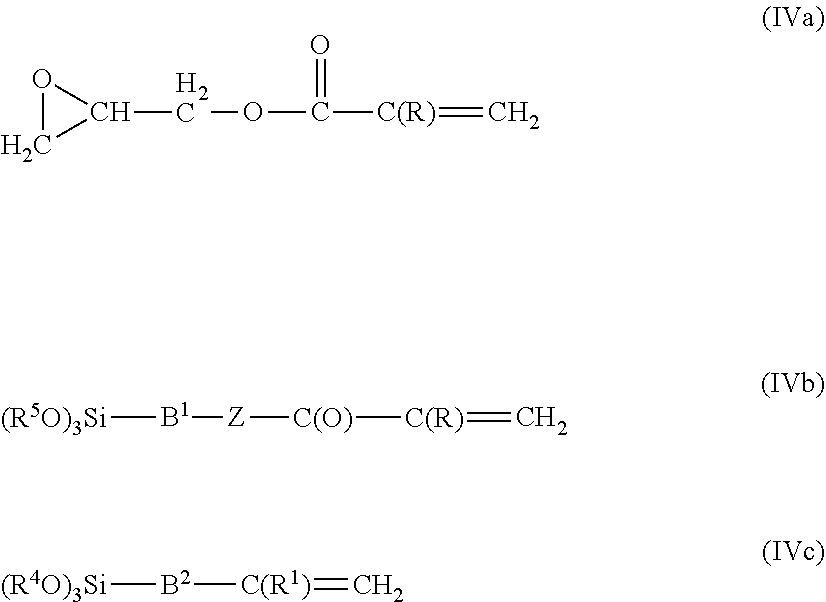

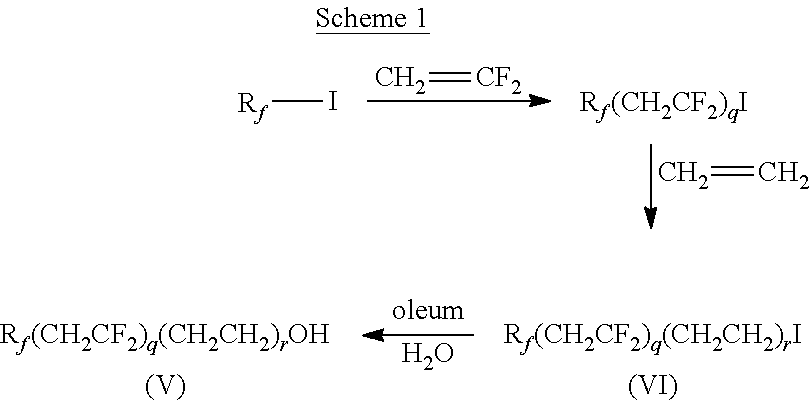

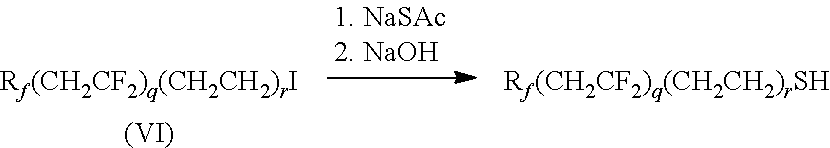

Fluoropolymer compositions and method of use

A composition comprising monomers copolymerized in the following percentages by weight: (a) from about 20% to about 95% of a monomer, or mixture of monomers, of formula (I):Rf—(CH2CF2)q(CH2CH2)r—Z—C(O)—C(R)═CH2 (I)whereinq and r are each independently integers of 1 to 3;Rf is a linear or branched perfluoroalkyl group having 2 to 6 carbon atoms;Z is —O—, —NR1— or —S—;R is hydrogen, Cl, F or CH3;R1 is hydrogen, or a C1 to C4 alkyl; and (b) from about 5% to about 80% of at least one of: (i) an alkyl (meth)acrylate monomer having a linear, branched or cyclic alkyl group of 6 to 18 carbons; or (ii) a monomer of formula (II):(R2)2N—R3—O—C(O)—C(R)═CH2 (II)whereinR is as defined above;each R2 is independently a C1 to C4 alkyl; andR3 is a divalent linear or branched C1 to C4 alkylene; and wherein the nitrogen is from about 40% to 100% salinized; or (iii) a mixture thereof; said composition providing oil repellency, water repellency, and stain resistance to substrates contacted therewith; and a method for treating substrates with such copolymer compositions; are disclosed.

Owner:PENG SHENG +5

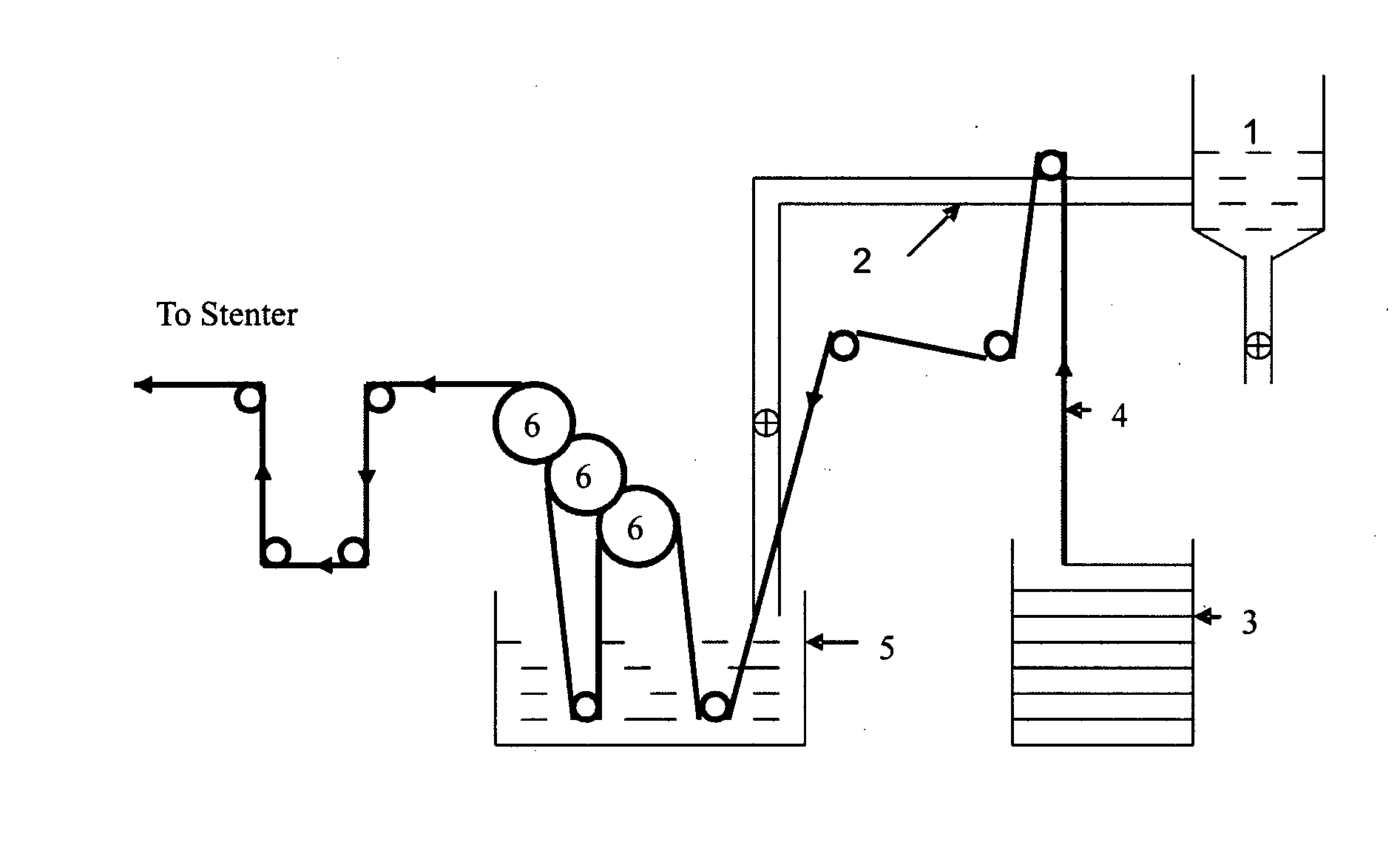

Non-ironing three-proofing finishing process of pure-cotton fabric

InactiveCN105401407AShort processSoft touchStain/soil resistant fibresLiquid repellent fibresMaterials preparationEngineering

The invention relates to a non-ironing three-proofing finishing process of a pure-cotton fabric. The technological process sequentially includes material preparation, liquid ammonia finishing, non-ironing three-proofing finishing, baking, baking and washing, stentering, preshrinking and acceptance check. By the adoption of the non-ironing three-proofing finishing process of the pure-cotton fabric, the technological process is shortened, the cost is reduced, pure cotton is non-ironing and three-proofing and can be produced in a batched mode, the non-ironing level is above Level 3.5, and the pure-cotton fabric is oil-proof, water-proof and anti-stain and meets the AATCC standard.

Owner:鲁丰织染有限公司

Multifunctional super-hydrophobic textile finishing agent, and preparation method and applications thereof

ActiveCN107326651AReduce usageSimple manufacturing processStain/soil resistant fibresBiochemical fibre treatmentHydrolysisSkin protection

The invention discloses a multifunctional super-hydrophobic textile finishing agent, and a preparation method and applications thereof. The preparation method comprises following steps: a precursor of an oxide sol and a graphite oxide aqueous dispersion are dispersed in deionized water, an anionic surfactant is added, a catalyst is added for hydrolysis and condensation reaction after uniform dispersion so as to obtain a mixed reaction system, and the mixed reaction system is heated to 30 to 50 DEG C for 3 to 12h of reaction so as to obtain a hydrosol; a functional agent is added into the hydrosol so as to obtain the multifunctional super-hydrophobic textile finishing agent. The multifunctional super-hydrophobic textile finishing agent is safe, is friendly to the environment, is excellent in effect, is used for super hydrophobic and multifunctional finishing of textile, is capable of providing textile with six functions including super-hydrophobic property, flame resistance, antibacterial property, stain resistance, ultraviolet resistance, and skin protection performance, is capable of eliminating adverse effect of the plurality of functions, improving the synergistic effect; the preparation method is simple and convenient, is easy to control, and is suitable for large scale production.

Owner:石狮市杰立纺织科技有限公司

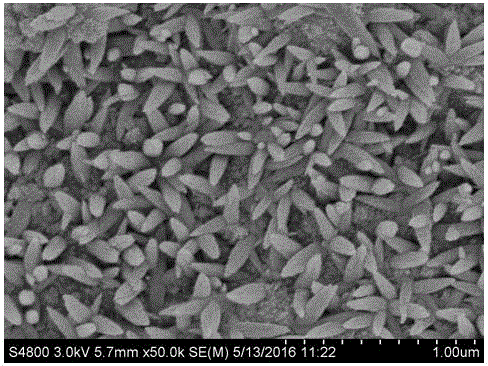

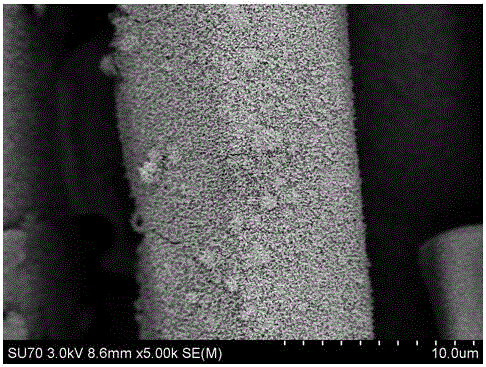

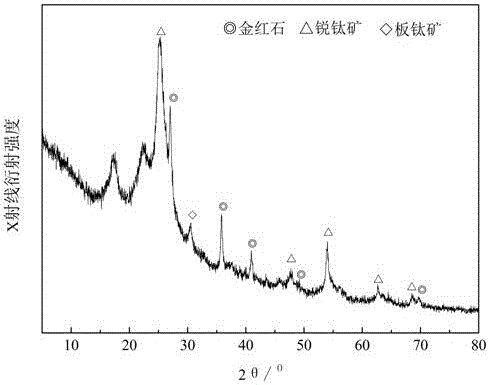

Two-dimensional titanium dioxide/graphene flaky modified self cleaning fabric and preparation method thereof

InactiveCN108301202AEvenly distributedHigh degree of reductionStain/soil resistant fibresGrapheneWater vaporCopolymer

The invention provides a two-dimensional titanium dioxide / graphene flaky modified self cleaning fabric and a preparation method thereof. According to the method, a titanium source and a triblock copolymer F127 are added into a tetrahydrofuran solution; the pH is regulated to an acid state; continuous stirring is performed until the solvent is completely volatilized; titanium source precursor gel is obtained; the titanium source precursor gel is added into a polylol mixed solution; after the uniform mixing, an oxidized graphene solution is dripped; uniform mixing is performed; the materials aretransferred into a hydrothermal reaction kettle; hydrothermal reaction is performed; after the centrifugal separation and cleaning, a graphene modified two-dimensional titanium dioxide flaky materialis obtained; then, the graphene modified two-dimensional titanium dioxide flaky material is dispersed into a flexible substrate solvent; the material is applied or sprayed onto the surface of the fabric; drying is performed; then, through ethanol water vapor treatment, the two-dimensional titanium dioxide / graphene flaky modified self cleaning fabric is obtained. The graphene modified two-dimensional titanium dioxide flaky materials are uniformly distributed in the flexible substrate nanometer layer on the surface of the prepared fabric; the fabric has good ventilation performance, comfort performance and good self cleaning effect.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Liquid and soil repellent compositions for fibers

InactiveUS20150004351A1Good lookingIncreased durabilityStain/soil resistant fibresSynthetic resin layered productsFiberWax

Included are compositions for fibers which include a clay nanoparticle and a wax. The composition provides the fibers with oil and water repellency.

Owner:INVISTA NORTH AMERICA R L

Self-cleaning coating

InactiveCN108410221AImprove performanceExtend your lifeMaterial nanotechnologyStain/soil resistant fibresGas phaseAntistatic Materials

The invention discloses a self-cleaning coating, which is formed by compounding one or various coatings in one time or multiple times. The coating at least comprises the following three substances: a)hydrophilic material, b) hydrophobic material, c) porous material, d) photocatalysis material and e) antistatic material. The self-cleaning coating is a functional material which compounds more thanthree specific physical properties, one-time or multi-time compounding is used for forming a self-cleaning surface so as to form an environment-friendly self-cleaning surface, the surface can be formed by the coating, and the surface also can be constructed by chemical vapor deposition or physical vapor deposition according to a key principle. According to the self-cleaning coating, through an innovative physical chemistry design, various physical chemistry surface characteristics are integrated. According to the construction method, advanced self-cleaning surfaces superior to common self-cleaning coatings and the like sold in the market can be produced.

Owner:刘峰

Stain and soil resistant textile article

ActiveUS20090081440A1Add waterEnhances oil repellencyMaterial nanotechnologyStain/soil resistant fibresMedicineStain

Disclosed in this specification is an aqueous dispersion for treating a textile. The dispersion generally includes surface-functionalized inorganic oxides in combination with a fluorochemical. Significantly lower concentrations of fluorochemicals are present in comparison to prior art dispersions.

Owner:BIGSKY TECH

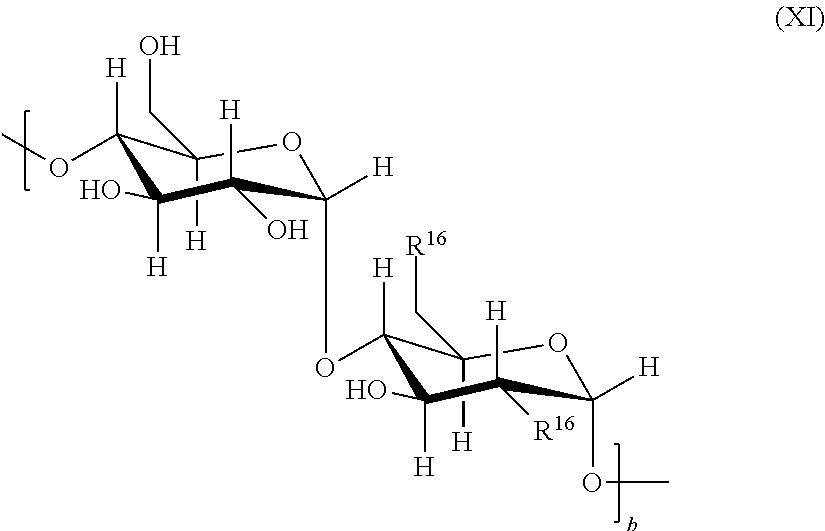

Non-fluorinated and partially fluorinated polymers

InactiveUS20160090505A1Imparting durable water repellencyIncreased durable water repellencyStain/soil resistant fibresLiquid surface applicatorsSaccharic acidPolymer science

A polymer composition with (A) a first poly(meth)acrylate polymer or urethane polymer; and (B) a second poly(meth)acrylate polymer or urethane polymer which has a residue X incorporated therein, where X is the residue of a cyclic or acyclic sugar alcohol which is substituted with at least one —R1; —C(O)R1; —(CH2CH2O)n(CH(CH3)CH2O)mR2; —(CH2CH2O)n(CH(CH3)CH2O)mC(O)R1; or mixtures thereof; where the cyclic or acyclic sugar alcohol is selected from a saccharide, reduced sugar, aminosaccharide, aldonic acid, or aldonic acid lactone; wherein each n is independently 0 to 20; each m is independently 0 to 20; m+n is greater than 0; each R1 is independently a linear or branched alkyl group having 5 to 29 carbons optionally comprising at least 1 unsaturated bond; and each R2 is independently —H, a linear or branched alkyl group having 6 to 30 carbons optionally comprising at least 1 unsaturated bond, or mixtures thereof.

Owner:THE CHEMOURS CO FC LLC

Copolymers for stain resistance

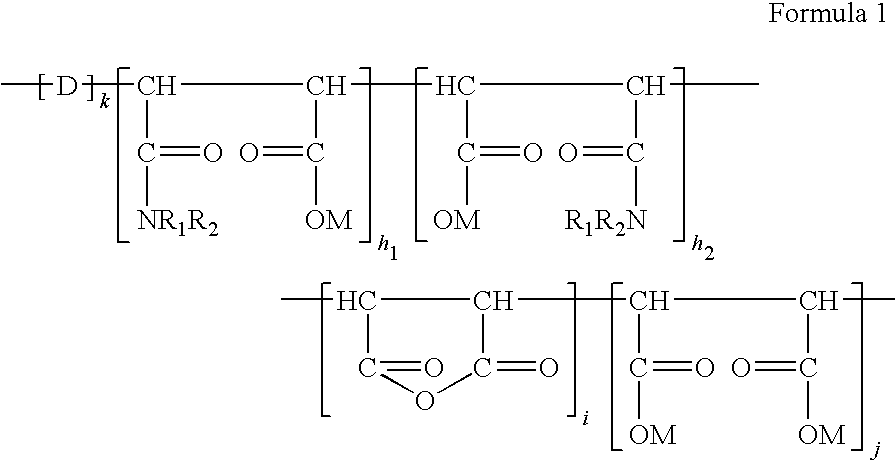

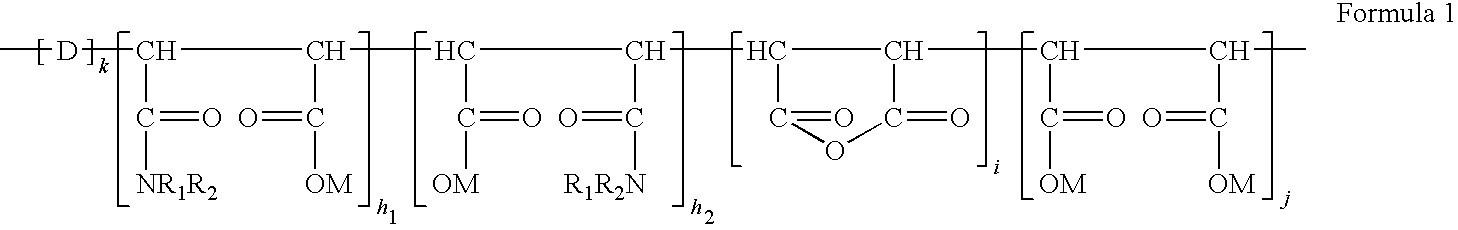

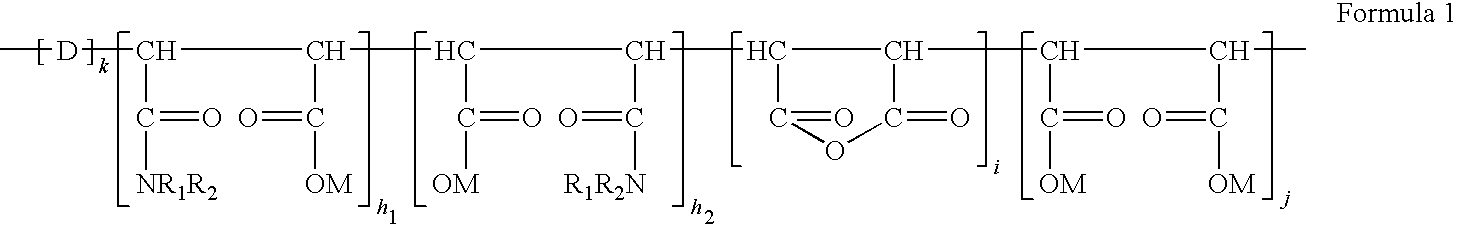

A method for imparting resistance to staining to a substrate comprising contacting the substrate with a copolymer comprising the monomers of FormulawhereinD is at least one vinyl monomer selected from the group consisting of aryl olefin, alpha olefin and diene,each M is independently H, Ca, Mg, Al, Na, or K,each R1 is independently H, C1-C6 alkyl, or C1-C6 hydroxyalkyl,each R2 is independently linear or branched C1-C12 alkyl, C1-C6 hydroxyalkyl, C6F5, arylalkyl, C6H4OH, R3COOH, or R3SO3H,or R1 and R2 are linked together to form a morpholino or pyrrolidino ring,R3 is linear or branched C1-C12 alkyl, CH(COOH)CH2CH2, C6H4, or C6H3(OH),h1+h2 is h, h is a positive integer,k is zero or a positive integer,i and j are each independently zero or a positive integer,provided that the total of 1) h÷(k+h+i+j) is from about 0.005 to about 0.7, 2) k÷(k+h+i+j) is from about 0.3 to about 0.6, 3) [i+j]÷(k+h+i+j) is 0 to about 0.6, and provided that the sum of 1)+2)+3) is 1.0,said monomers occurring in any sequence.

Owner:EI DU PONT DE NEMOURS & CO

Preparation method of super-strong washable polyester fabric moisture absorption and sweat releasing finishing agent

ActiveCN106674507AOvercome the common problem of poor washabilityOvercoming the problem of poor washabilityStain/soil resistant fibresPolyesterDimethyl terephthalate

The invention relates to a preparation method of a super-strong washable polyester fabric moisture absorption and sweat releasing finishing agent. Dimethyl terephthalate, ethylene glycol, one part of polyethylene glycol and a composite catalyst are taken as raw materials, and are polycondensed with polypropylene glycol and the remaining polyethylene glycol to form the polyester-polyether copolymerized moisture absorption and sweat releasing finishing agent after ester-interchange reaction. The method is high in synthesis efficiency, the finished fabric is good in hydrophilicity, high in comfort, excellent in washing resistance, the antistatic property and the decontaminability are obviously improved, and the problem that a traditional moisture absorption and sweat releasing finishing agent is poor in washing resistance generally is solved.

Owner:SHAOXING KEQIAO DEMEI FINE CHEM CO LTD

Super-hydrophobic material with hierarchical coarse structure and preparation method and application thereof

ActiveCN112647287AIncrease surface free energyStain/soil resistant fibresLiquid repellent fibresMicrospherePollution prevention

The invention relates to a super-hydrophobic material with a hierarchical coarse structure. The super-hydrophobic material is characterized in that metal oxide microspheres with a secondary coarse structure are arranged on the surface of a substrate material, and the outer surfaces of the microspheres are modified with a low-surface-energy substance layer. The invention further relates to a preparation method and application of the material. The super-hydrophobic material with the hierarchical coarse structure is simple in preparation process and good in material stability, and has excellent effects in the fields of self-cleaning, water prevention, pollution prevention, drag reduction, noise reduction, oil-water separation and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

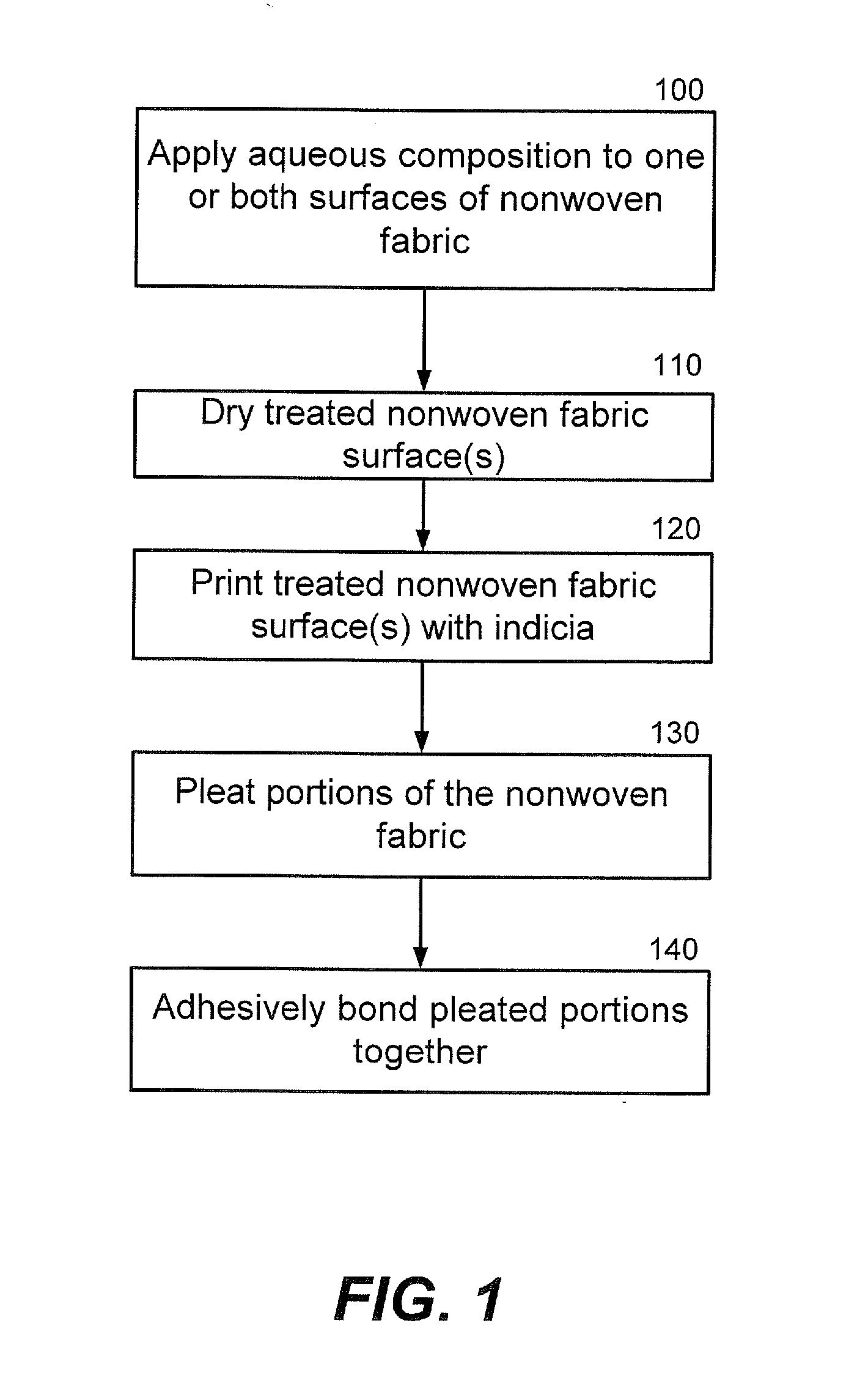

Treated nonwoven fabrics and window shades incorporating same

InactiveUS20080045103A1Stain/soil resistant fibresBiochemical fibre treatmentEngineeringNonwoven fabric

A nonwoven fabric treated to provide pleat retention, static control, stain-resistance, and antimicrobial efficacy for a window shade application. The stain-resistant finish does not significantly interfere with the subsequent printing, as well as the pleating and gluing of the nonwoven fabric into a window shade. A test method to determine the degree of stain resistance to common household products is also described.

Owner:PRECISION FABRICS GROUP

Method for preparing titanium dioxide nanorod/polypyrrole/dacron compound fabric

ActiveCN105970601ASelf-cleaningAntistaticStain/soil resistant fibresPhotocatalytic degradationPyrrole

The invention discloses a method for preparing a titanium dioxide nanorod / polypyrrole / dacron compound fabric. The method comprises the steps of cleaning and drying a dacron fabric, and then placing the dacron fabric in alkali aqueous ammonia for surface roughness treatment; then soaking the dacron fabric in an oxidization bath, and adding pyrrole monomer aqueous solution dropwise so that a polypyrrole layer can be deposited on the surface of the dacron fabric; soaking the dacron fabric with polypyrrole deposited on the surface in prepared titanium dioxide sol, conducting lifting, drying and hydrochloric acid treatment so that a titanium dioxide seed crystal layer can be deposited on the surface of the dacron fabric, and conducting hydrochloric acid treatment and sulfuric acid treatment in sequence; preparing titanium dioxide nanorod growth-promoting media, and adding an excessive amount of titanium source so that titanium dioxide nanorods can be deposited and grown on the surface of the treated dacron fabric. Combination of the one-dimensional titanium dioxide nanorods and polypyrrole on a substrate of a flexible fabric is realized, and the obtained compound fabric has self-cleaning, anti-statistic, photocatalytic degradation and pollutant filtration functions and can be used as a flexible electrode and a flexible supercapacitor.

Owner:ZHEJIANG UNIV

Preparation method of antibacterial self-cleaning fabric

InactiveCN108411615AHigh densityImprove conductivityStain/soil resistant fibresBiochemical fibre treatmentSilicon dioxideMonomer

The invention relates to the technical field of preparation of polymer materials, and in particular relates to a preparation method of an antibacterial self-cleaning fabric. A silver crystal seed solution is prepared from a silver nitrate solution, a trisodium citrate aqueous solution and a sodium borohydride solution, polyvinylpyrrolidone, L-ascorbic acid and the like are added into the silver crystal seed solution, an activated reducing solution is prepared by diluting, a pure cotton fabric is cut and treated as a base fabric to obtain a modified cotton fabric, ethyl orthosilicate and absolute ethanol are mixed, diluted hydrochloric acid is added to obtain a silica sol, absolute ethanol, 5,5-dimethylhydantoin and methacryloyl chloride are mixed and ultrasonically dispersed to obtain an antibacterial monomer suspension, the antibacterial monomer suspension is added to ethyl titanate to obtain a mixed solution, and acetic acid and the silica sol are added dropwise to the mixed solution, ichloromethane is used to dilute to obtain an antibacterial spraying agent, and the antibacterial spraying agent is sprayed by an atomizer to the surface of the modified cotton fabric to obtain theantibacterial self-cleaning fabric, and the application prospect is broad.

Owner:吴刚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com