Super-hydrophobic material with hierarchical coarse structure and preparation method and application thereof

A rough structure, super-hydrophobic technology, applied in separation methods, chemical instruments and methods, textiles and papermaking, etc., can solve the problems of poor bonding and stability between nanoparticles and substrates, easy aggregation of nanoparticles, poor repeatability, etc., to achieve saving The effect of reaction time, fast reaction rate and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044](1) 1.0 ml of titanium sulfate was added dropwise to 150 mL of continuously stirred deionized water, while slowly dropped the sulfuric acid to adjust the pH to 3;

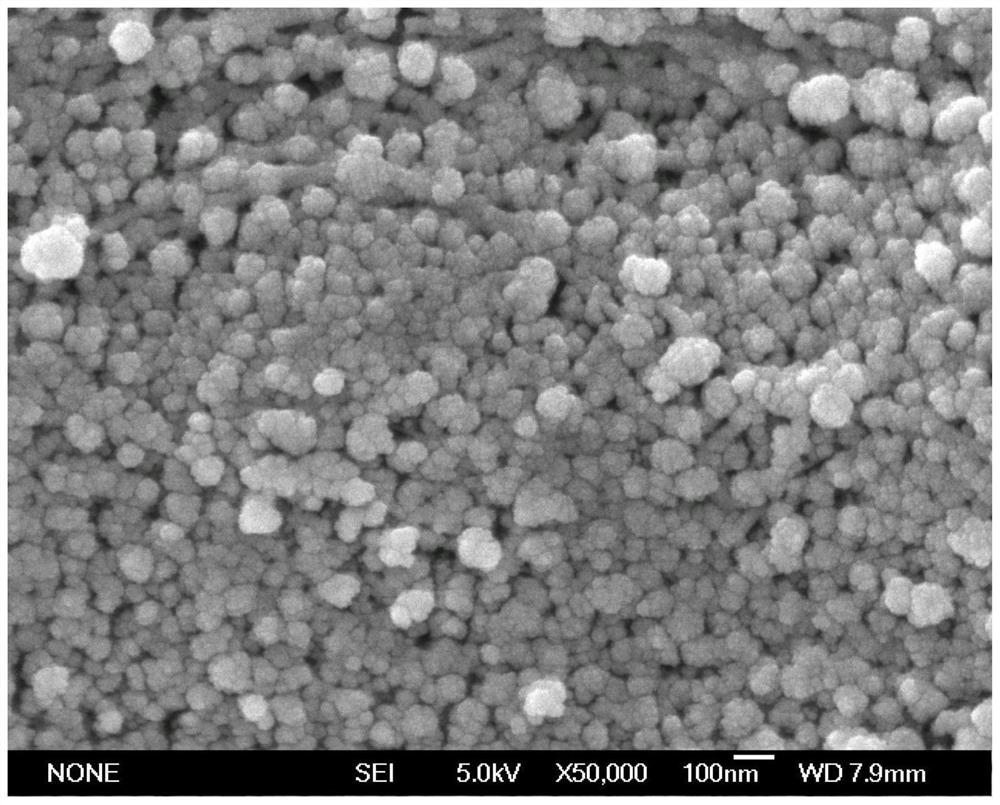

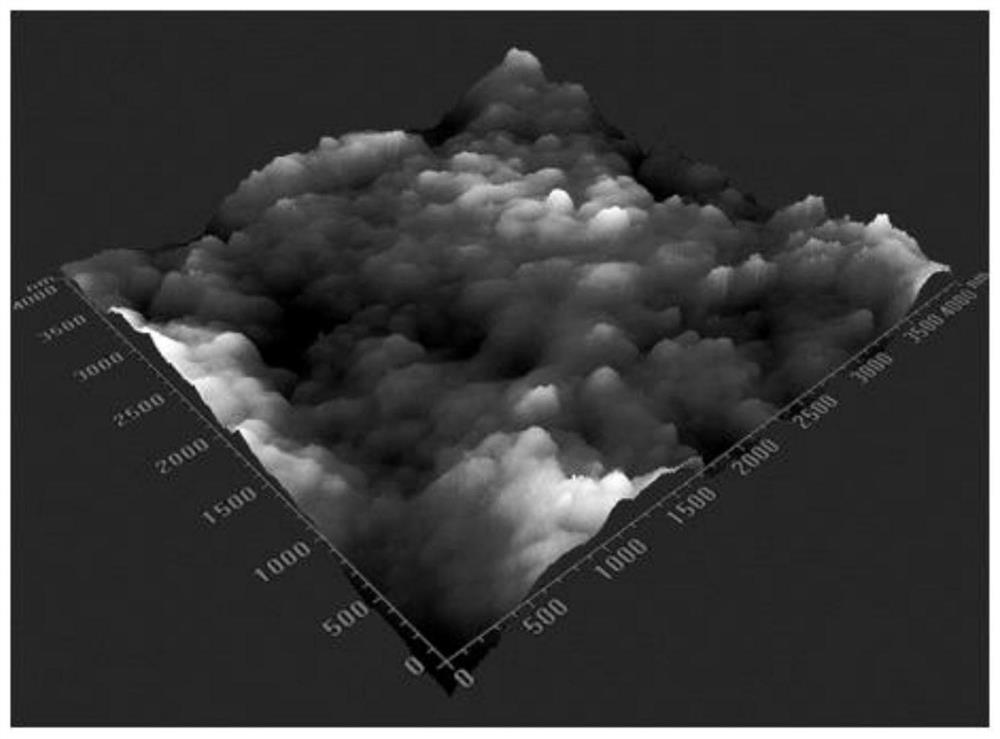

[0045](2) Add a cotton fabric (2 cm x 2 cm) to the above mixture, at normal pressure, microwave irradiation in the microwave reactor, the reaction temperature is 70 ° C, the reaction power is 150W, the reaction time is 45 min, the reaction is completed, Cool to room temperature, remove, remove water wash (100 ml * 3), 30 degrees vacuum dry for 48 hours, obtained TiO2- cotton fabric.

[0046](3) Mix the mercapto-siloxane, deionized water, ethanol according to the ratio of 4: 6: 9, stirred at normal temperature for 1 h, resulting in a mercaptosiloxane solution. Subsequently, the above TIO2- Cotton fabric is immersed in a mercaptosiloxane solution, and the impregnated time is 2 h to give a thiol-TiO2-cotton fabric.

[0047](4) The solution of 5 wt% methacrylate is formulated, 2 wt% restored ether (compared to the quality of th...

Embodiment 2

[0049](1) Treatment of commercially available 2g acrylonitrile fibers with 5 wt% potassium sulfate solution;

[0050](2) 1.0 ml of titanium sulfate was added dropwise to 100 mL of continuously stirred deionized water, while slowly dropping the sulfuric acid to adjust pH to 4;

[0051](3) Immerse the processed acrylonitrile fibers in the mixture, at normal pressure, microwave irradiation, the reaction temperature is 80 ° C, the reaction power is 80W, the reaction time is 10 min, the reaction is completed, cooling To room temperature, deionized water was washed (100 mL * 3), and the dried over 50 degrees was dried for 24 hours.

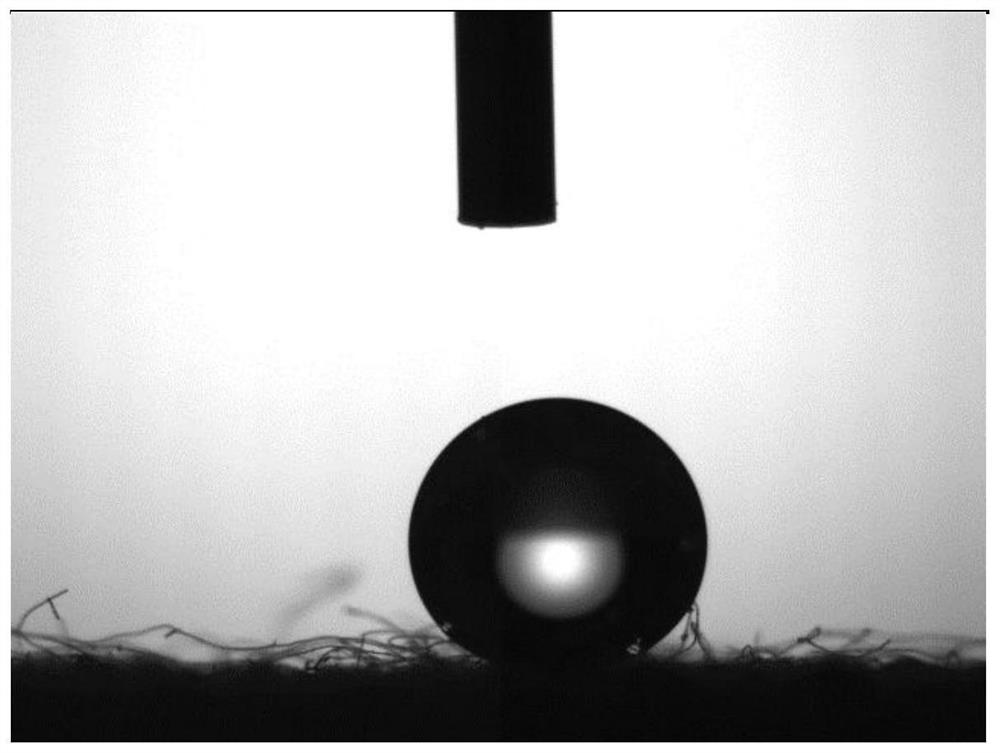

[0052](4) The above-mentioned polyacrylonitrile fibers having a rough structure of TiO2 are placed in a sealed container, and hexafluorobutyltrimethoxysilane is added, and the low surface energy substance is deposited to have a rough structure at 200 degrees. The surface of the polyacrylonitrile fiber, which obtains superhydrophobic polyacrylonitrile fibers. The conta...

Embodiment 3

[0054](1) The commercially available nylon microporous membrane is immersed in a dopamine solution (0.2 g of dicamine, 0.24 g of Tris-HCl and 200 mL water), and the polybicine layer is modified on the surface of the porous filter surface.

[0055](2) 10 ml of titanium tetrachloride was added dropwise to 100 mL of the continuously stirred ethanol and deionized water, wherein the volume ratio of ethanol and deionized water was 1: 5, while slowly dropping citric acid to adjust pH to 4.

[0056](3) Immersion the nylon membrane after (1) is immersed in the mixture, and the microwave irradiation is performed under normal pressure, the reaction temperature is 50 ° C, the reaction power is 240W, the reaction time is 30 min, the reaction is completed Cooled to room temperature, deionized water washed (100 mL * 3), and dried over 80 degrees for 24 hours.

[0057](4) The above-mentioned nylon membrane having a rough structure of TiO2 is placed in a sealed container, and thirteenctyl triethoxysilane is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| oil-water separation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com