Patents

Literature

146results about How to "Extended gel time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods of plugging a permeable zone downhole using a sealant composition comprising a crosslinkable material and a reduced amount of cement

Owner:HALLIBURTON ENERGY SERVICES INC +1

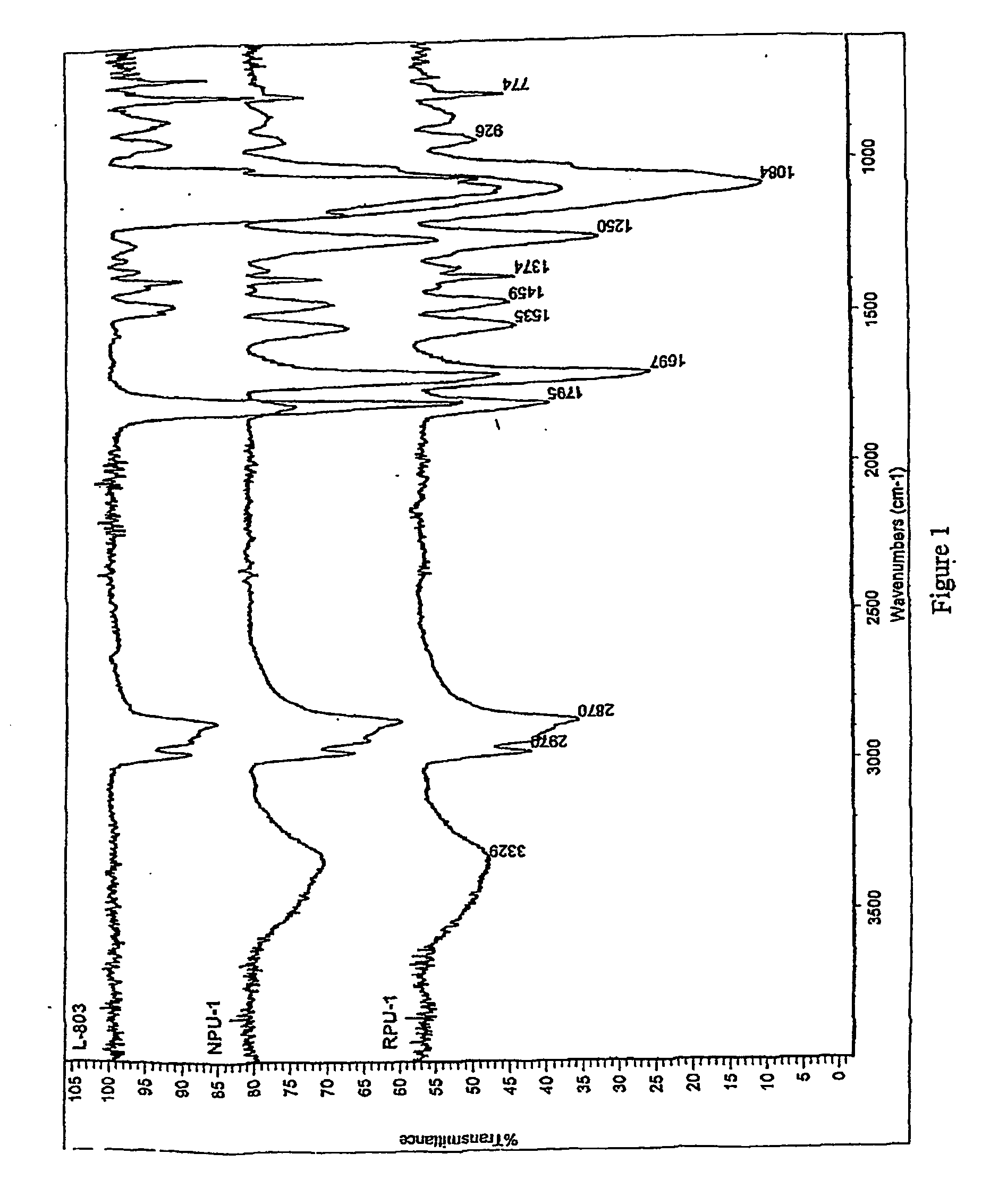

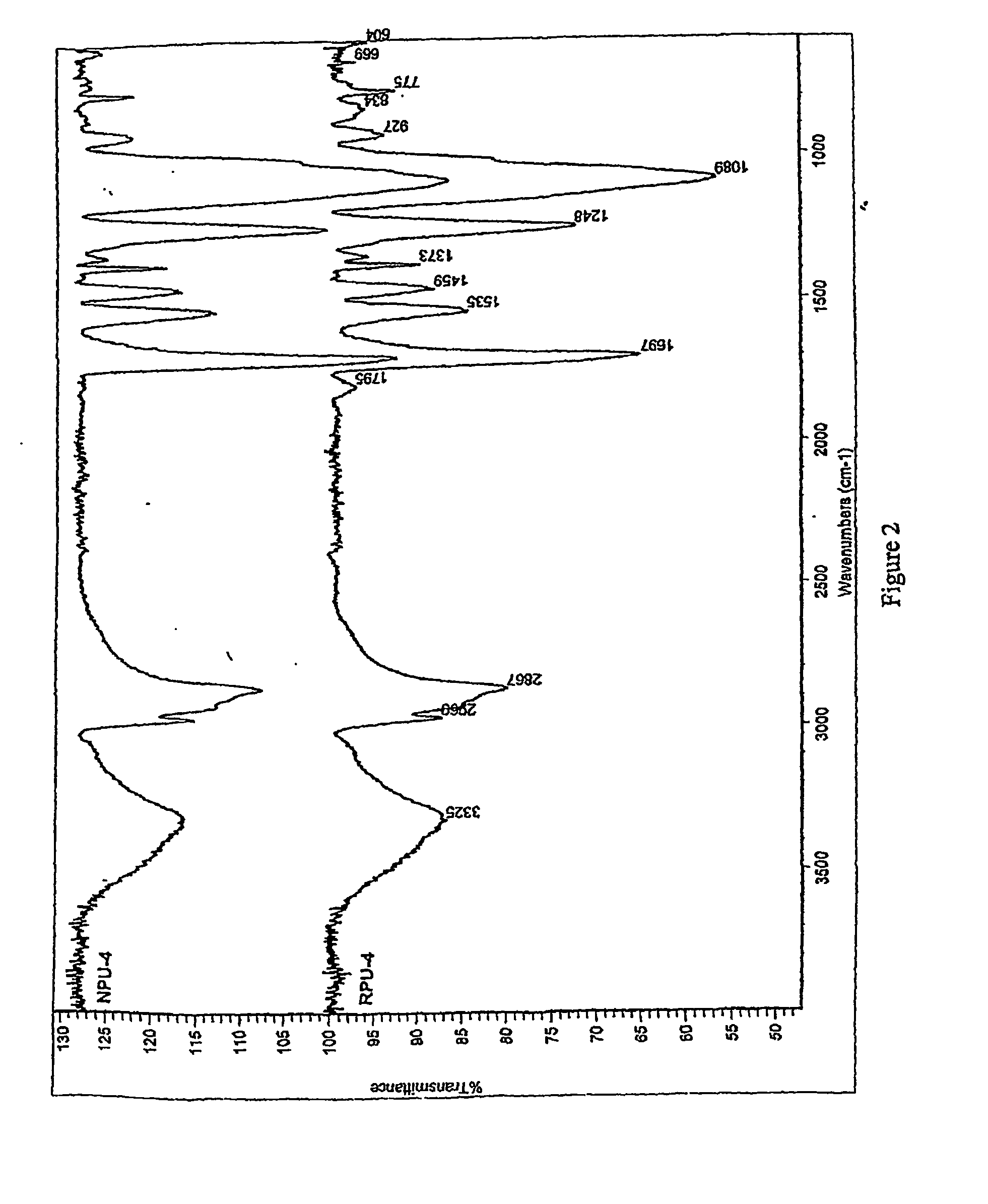

Nanocomposites based on polyurethane or polyurethane-epoxy hybrid resins prepared avoiding isocyanates

ActiveUS20070135588A1Beneficial physicochemical and mechanical propertyAvoid damageMaterial nanotechnologySynthetic resin layered productsNanometreAspect ratio

A fast curable non-isocyanate-based polyurethane- and polyurethane-epoxy network nanocomposite polymeric compositions are derived upon crosslinking a mixture comprising of natural or modified nano-clay [ionic phyllosilicate] with platelet thickness in the scale of A (˜1 nm) and aspect ratio (length / thickness) higher than 10 (nm)] preferably natural or modified montmorillonite with either a monomer(s) or oligomer(s) bearing at least one cyclocarbonate group or a mixture of the latter with an epoxy resin, with a hardener, which is a monomer or oligomer or mixtures therefrom, bearing primary and / or secondary amino groups. The use of the nanoclays reduces the gel time and increases the adhesion of the cured polyurethane and polyurethane / epoxy hybrid and also reduces its water absorption.

Owner:HUNTSMAN ADVANCED MATERIALS AMERICAS INC

Method for preparing a hydrogel adhesive having extended gelation time and decreased degradation time

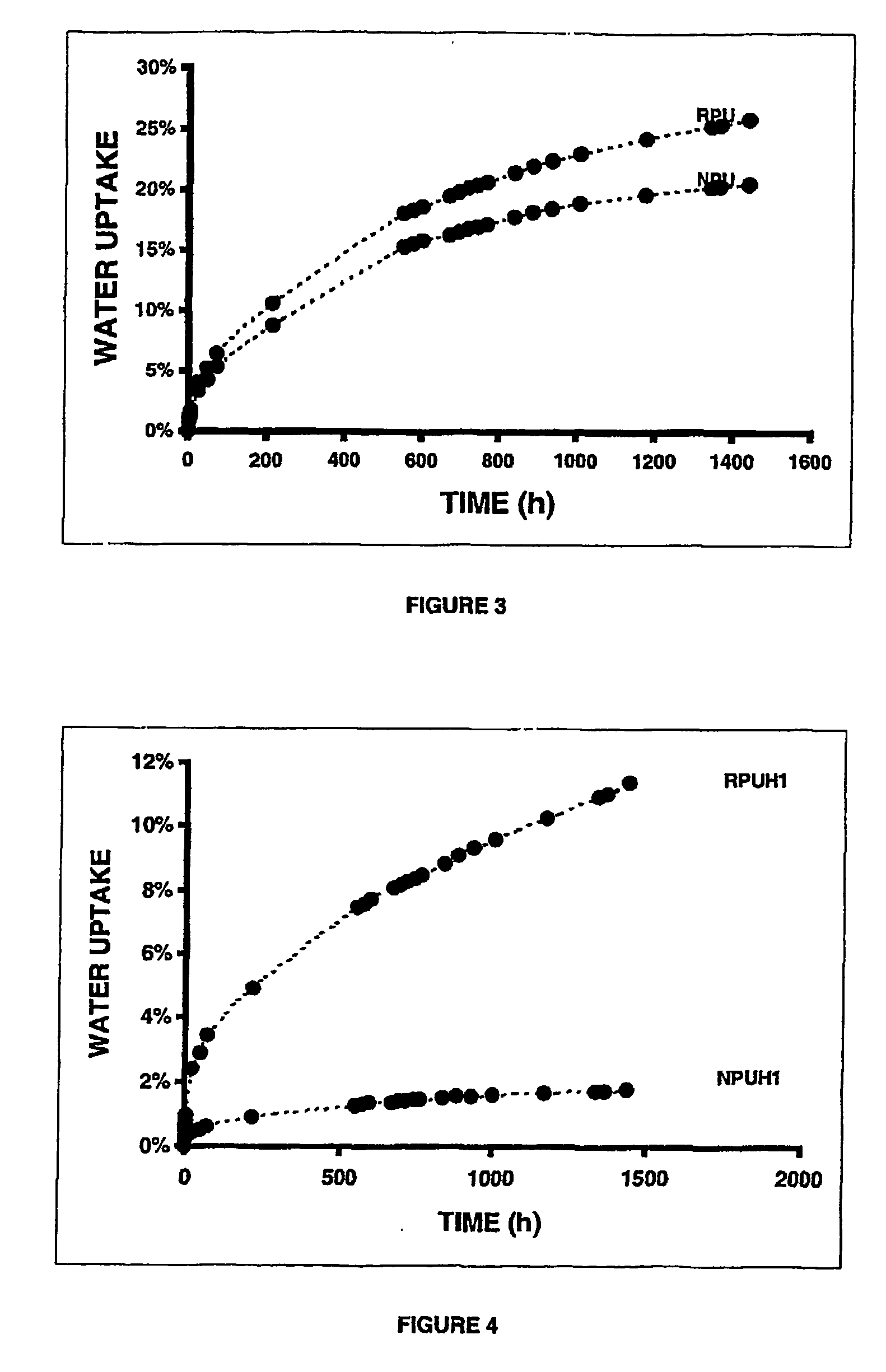

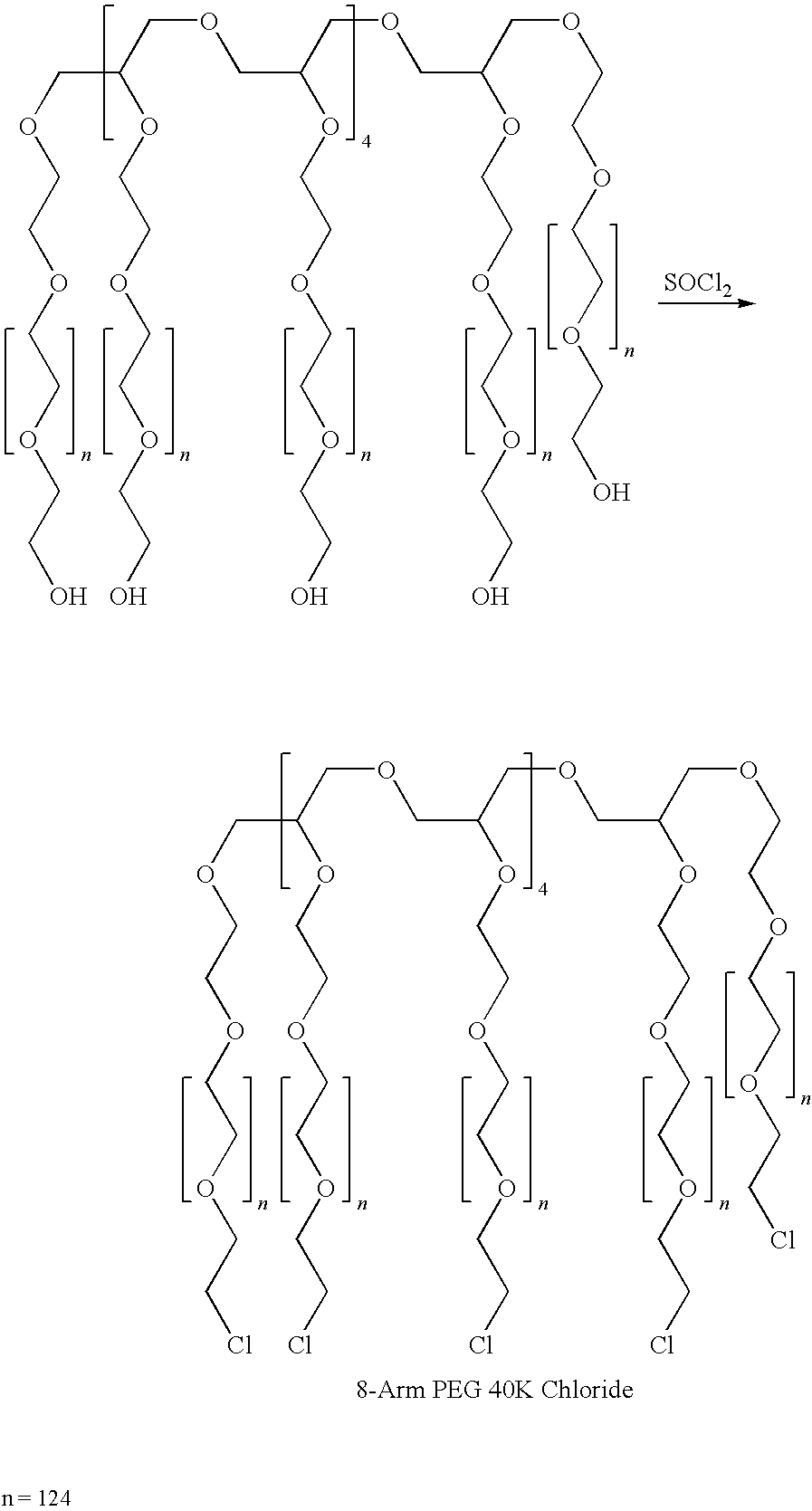

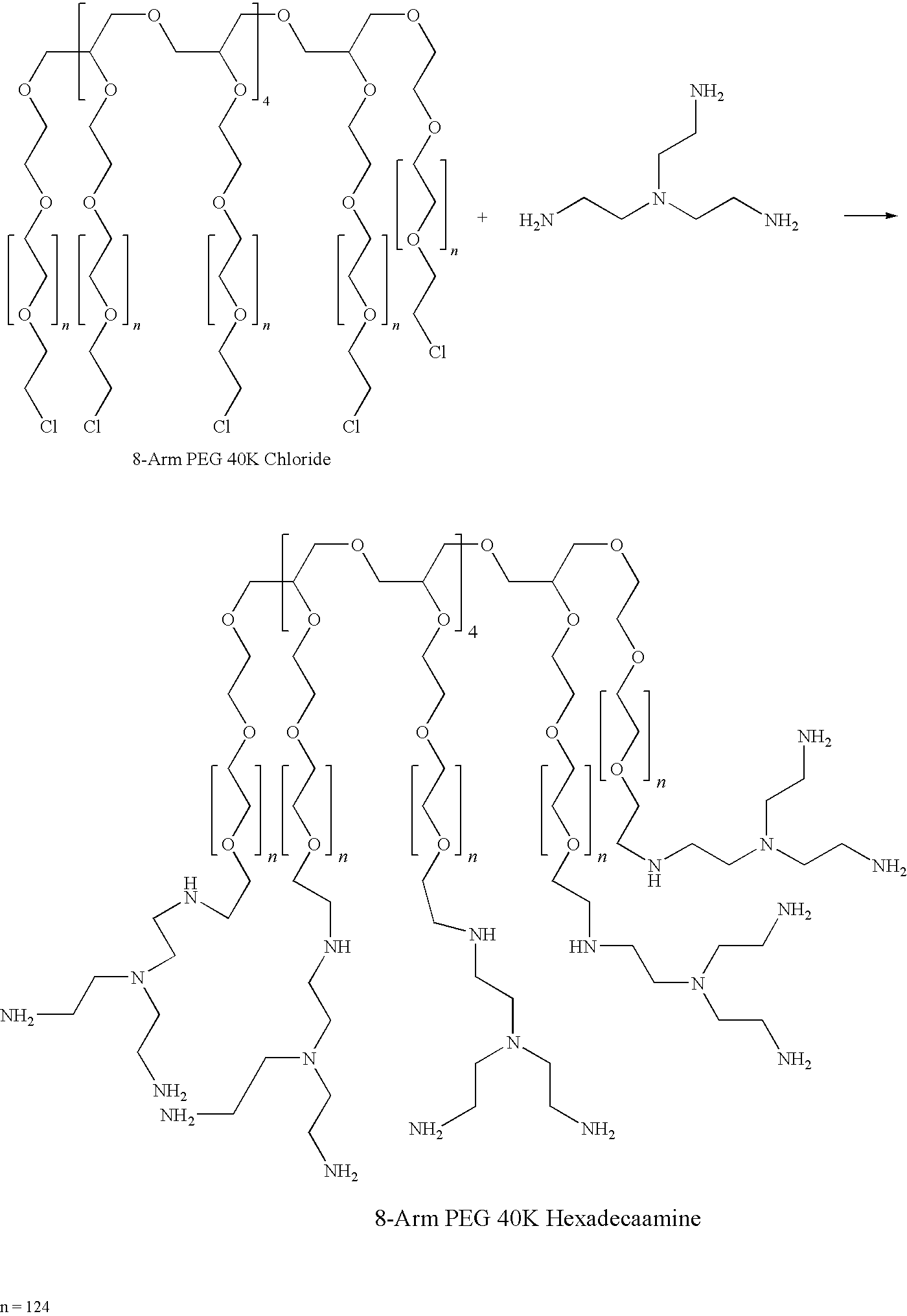

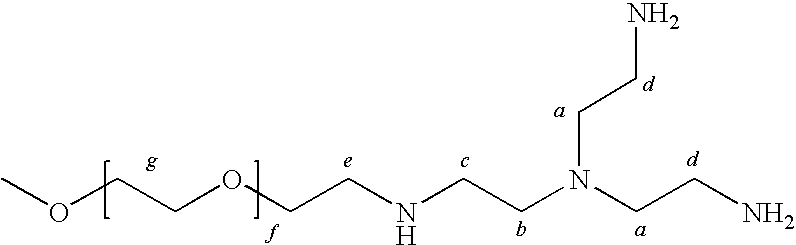

InactiveUS20100112063A1Extended gel timeShorten degradation timePowder deliveryOrganic active ingredientsWater dispersibleAdhesive

A method for extending the gelation time of an oxidized polysaccharide to react with a water-dispersible, multi-arm amine to form a hydrogel is disclosed. The extension of the gelation time is accomplished by using a chemical additive. The method also extends the time for the hydrogel to become tack-free, and may also be used to decrease the degradation time of the hydrogel. The chemical additive reacts with the functional groups of the oxidized polysaccharide or the water-dispersible, multi-arm amine, thereby reducing the number of groups available for crosslinking. The use of the resulting hydrogel for medical and veterinary applications is described.

Owner:ACTAMAX SURGICAL MATERIALS

Methods of plugging a permeable zone downhole using a sealant composition comprising a crosslinkable material and a reduced amount of cement

A method of servicing a wellbore, comprising preparing a sealant composition comprising a crosslinkable material, a crosslinking agent, a fluid loss control additive, and water, placing the sealant composition in a permeable zone in the wellbore, and allowing the sealant composition to set. A method of servicing a wellbore, comprising preparing a sealant composition by combining a crosslinkable material, a crosslinking agent, a fluid loss control additive, water, and a cement, wherein an amount of the cement is reduced to an effective amount to increase a gel time of the sealant composition to greater than or equal to about 4 hours when the sealant composition is exposed to ambient temperatures in the wellbore, placing the sealant composition in a permeable zone in the wellbore, and allowing the sealant composition to gel.

Owner:HALLIBURTON ENERGY SERVICES INC +1

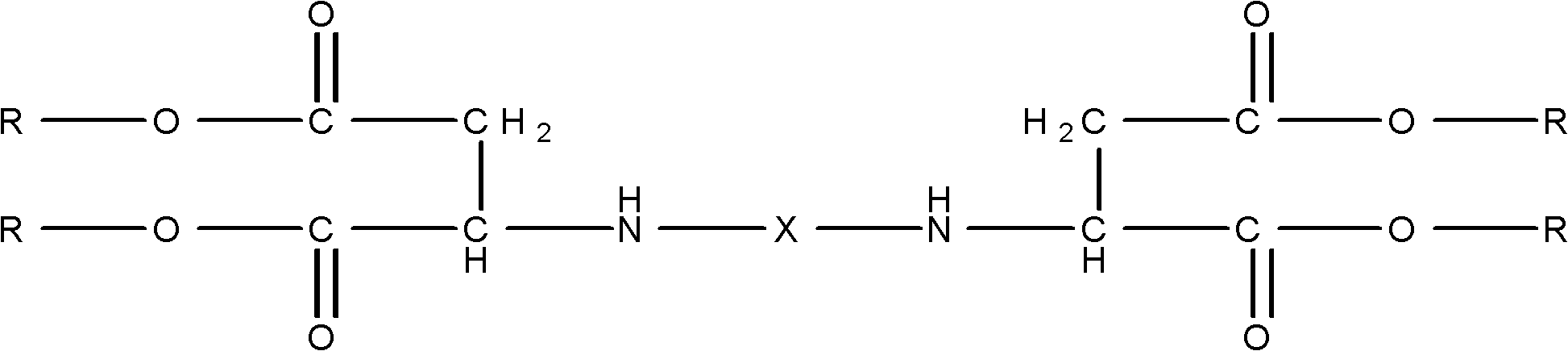

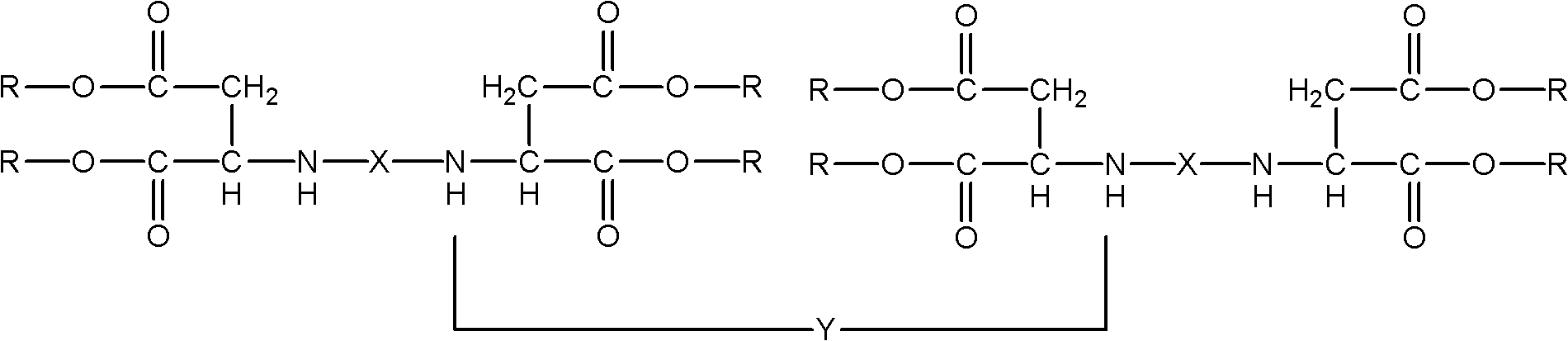

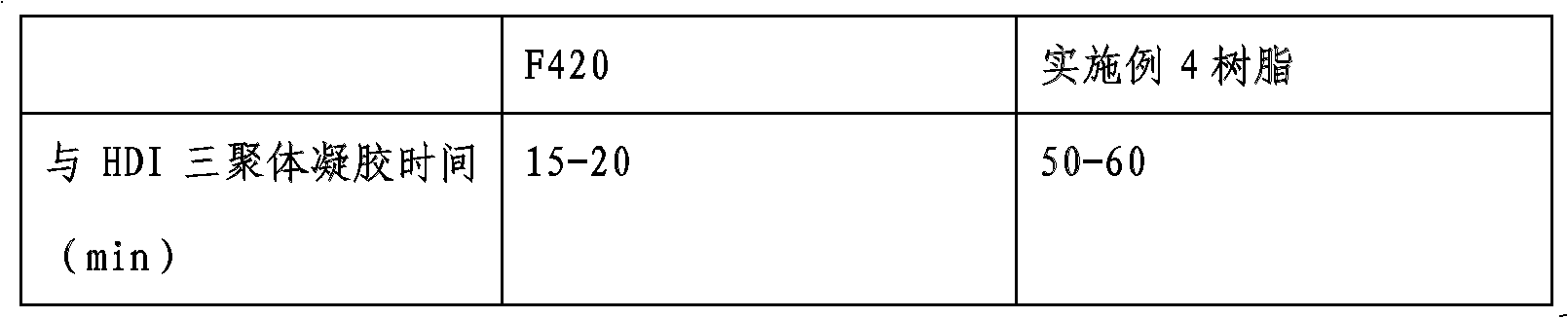

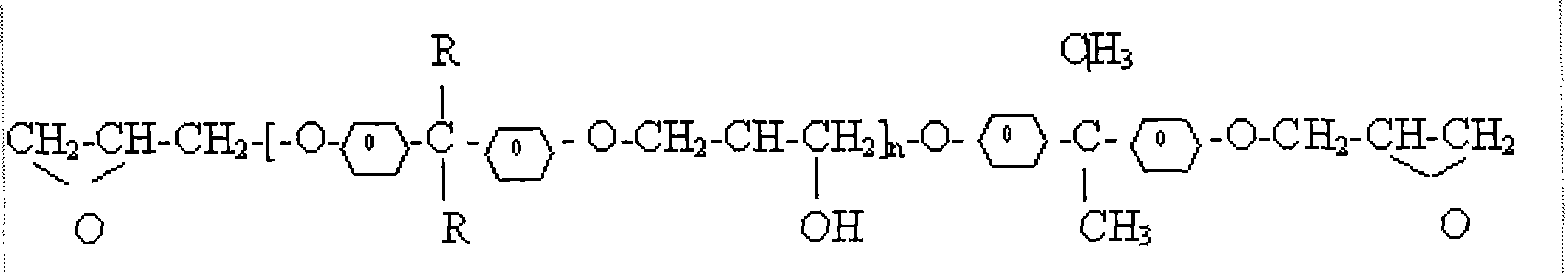

Polymerized modified polyaspartic acid ester compound and preparation method thereof

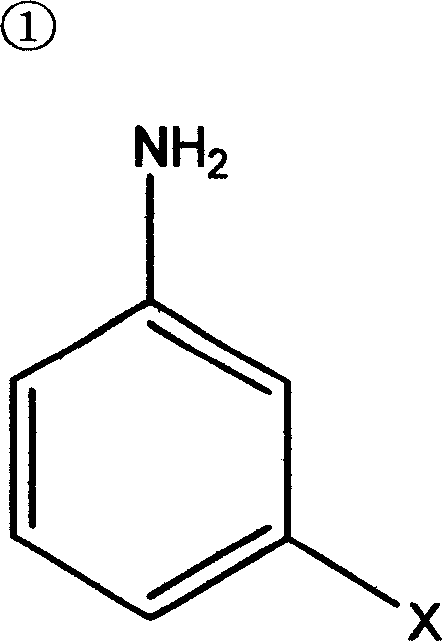

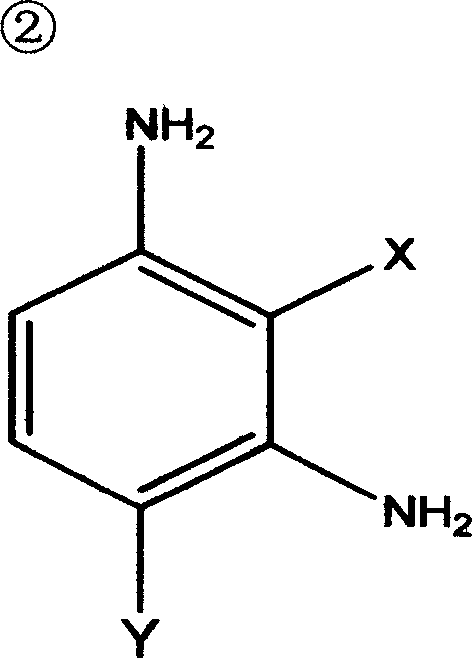

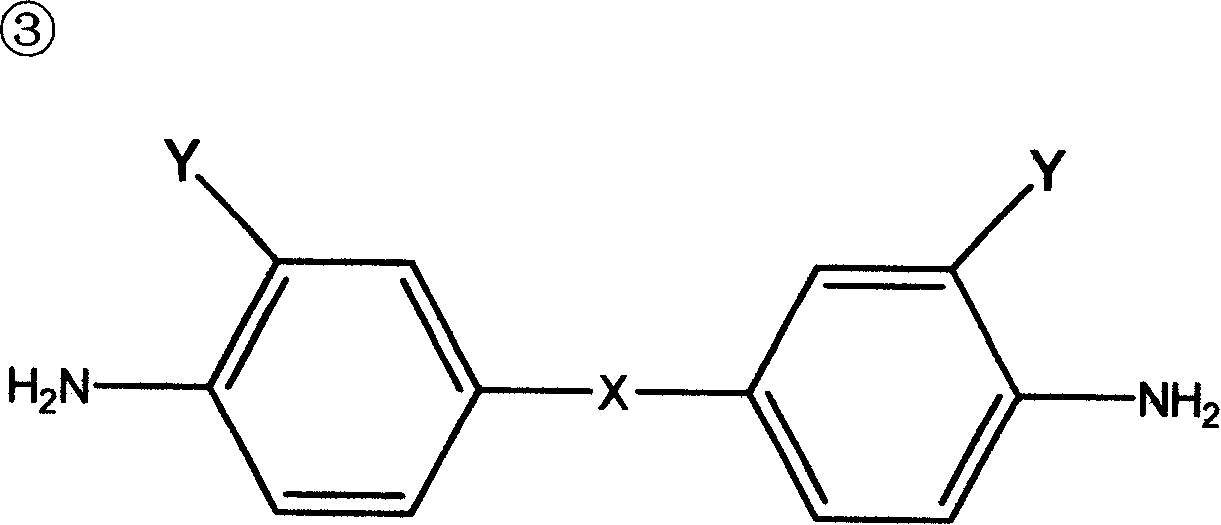

InactiveCN103030773AReduce concentrationImprove performancePolyurea/polyurethane coatingsPolyaspartic acidCarbon chain

The invention relates to a coating raw material and discloses a polymerized modified polyaspartic acid ester compound, which has the following structural general formula shown in the specification, wherein R is alkyl with at most ten carbon atoms, Y is a chain extender, and X is a straight-chain or ring-shaped carbon chain structure. The invention also discloses a preparation method of the compound. Compared with the polyurea paint prepared by the polyaspartic acid ester, the polyurea paint prepared by using the compound disclosed by the invention as the raw material has the advantages of convenience in construction, prolonged gel time, shortened surface drying time, enhanced tensile strength, enhanced elongation at break and improved elastic film coating hardness.

Owner:ZHUHAI FEIYANG NOVEL MATERIALS

Epoxy resin and use thereof

The invention relates to an epoxide resin and the use. The epoxide resin comprises an epoxide, the reacting deflocculating agent and the curing agent, wherein the reacting deflocculating agent is a monomer or oligomer of acrylate and methacrylate with the low viscosity in the ambient temperature and a or a plurality of unsaturated double bond reactive function group, the reacting deflocculating agent is charged in the epoxide resin and is mixed uniformly in order to form the host crystal of the epoxide formulation, the host crystal comprises the reacting deflocculating agent 5-30 parts and agent B which forms epoxy resin formulation comprised by curing agent, the weight percentage of the agent B and the host crystal is 20-50 :100. The invention can improve the gel time, the temperature of exothermic peak and the processing operation characteristic of viscosity in the hardening process of the epoxide, which reduces the mechanical properties of the cured epoxide less, improves the tenacity of the epoxide, is suitable for manufacturing structural element of large scale composite material (air vane, craft, car and aerial craft and the like), and has good operation time, low exothermic peak temperature and fiber immersing property.

Owner:SWANCOR ADVANCED MATERIALS CO LTD

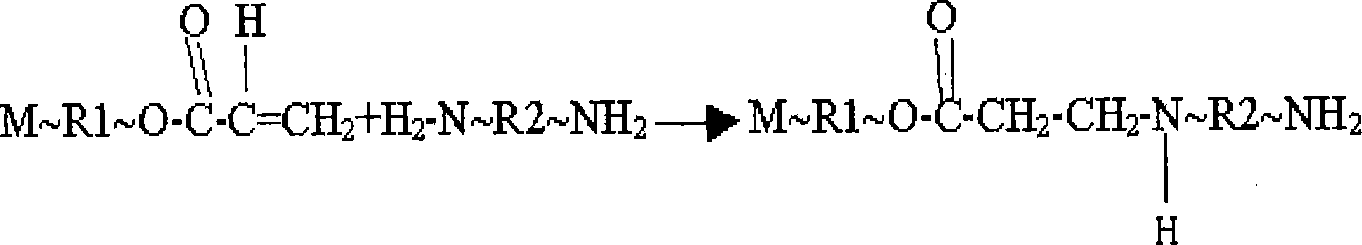

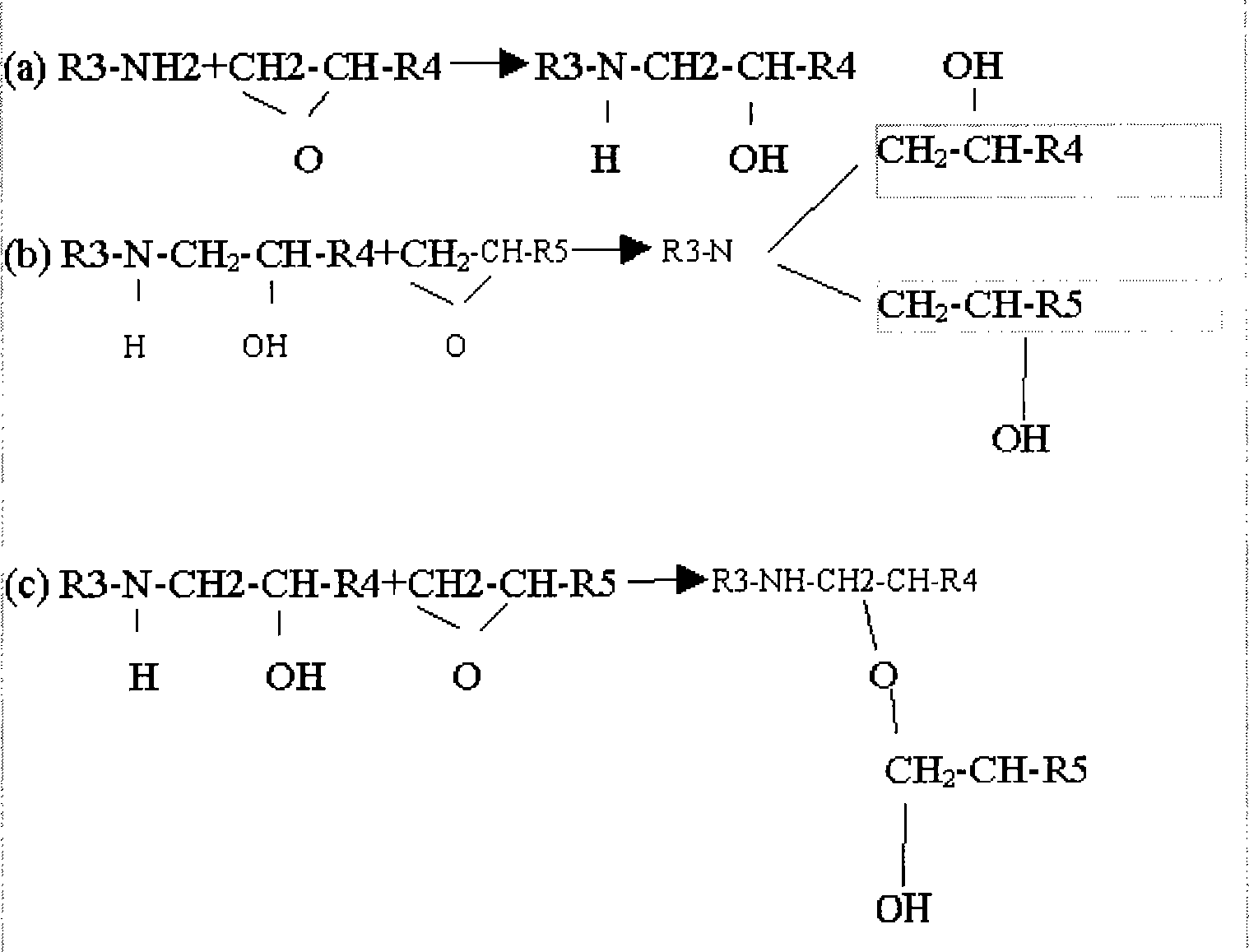

Synthesis of polyaspartate aminoester polyether-amine containing secondary-amine group

InactiveCN101074280AShort reaction timeExtended gel timePolyurea/polyurethane coatingsPolyaspartic acidFumarate Esters

Synthesis of polyaspartic acid ester polyether ammonium containing secondary amine is carried out by taking arylamine compound as active catalyst and Micro-addition reacting for polyether ammonium and maleate or fumarate ester to obtain final product. It has shorter reactive time and delays polyurea coating gel time.

Owner:上海市涂料研究所有限公司

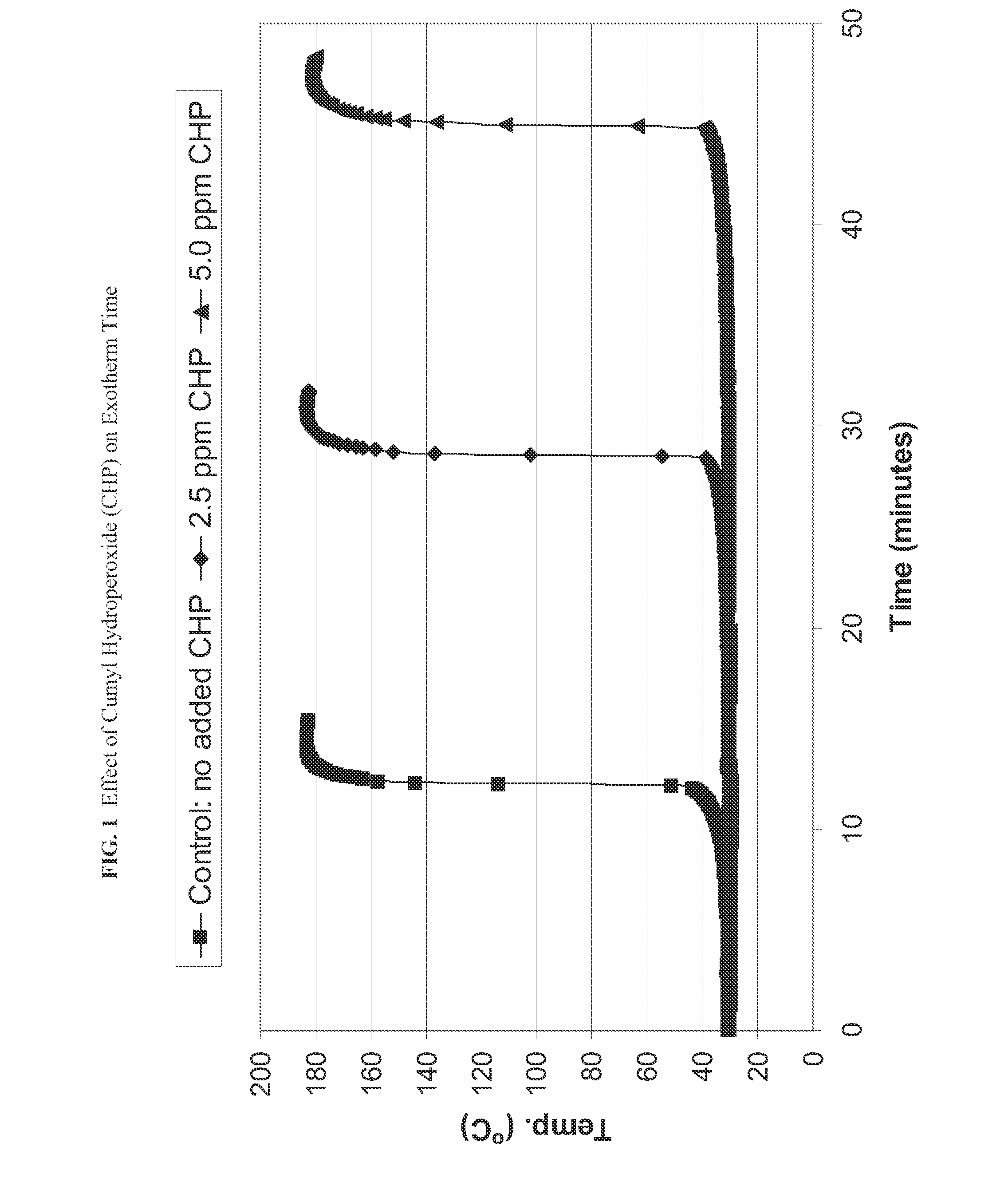

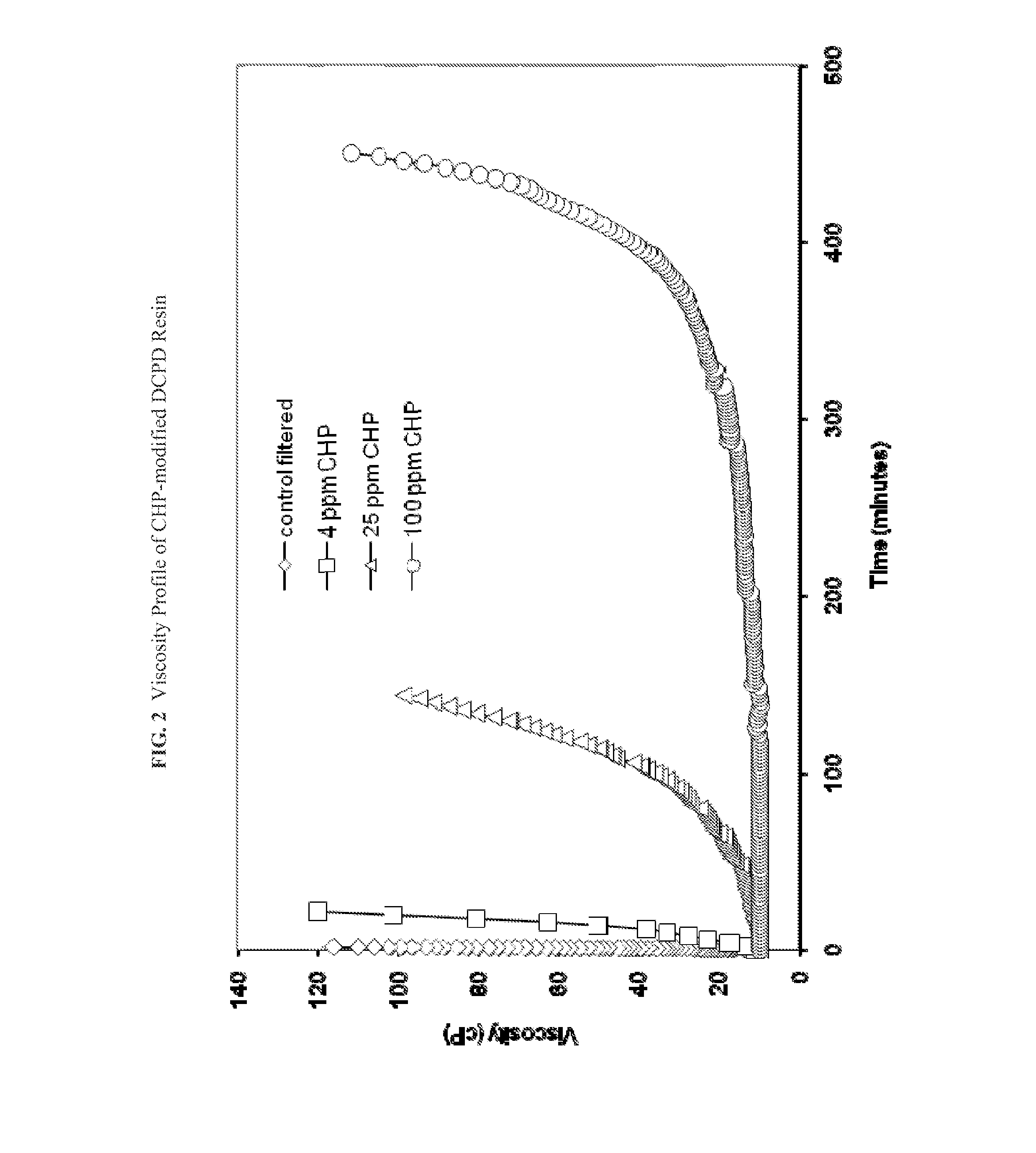

Adhesion promoters and gel-modifiers for olefin metathesis compositions

ActiveUS20140329017A1Simple compositionAffecting mechanical propertyOther chemical processesSynthetic resin layered productsROMPOrganic synthesis

This invention relates to compositions and methods for improving the adhesion of resin compositions to substrate materials, pre-treating substrate materials to improve the adhesion of resin compositions to the substrate materials, and / or controlling gel formation of resin compositions. More particularly, the invention relates to compositions and methods for improving the adhesion of ring opening metathesis polymerization (ROMP) compositions to substrate materials using adhesion promoters containing isocyariate groups in a resin composition. The invention also relates to methods for improving the adhesion of resin compositions to substrate materials by pre-treating substrate materials with adhesion promoters containing isocyanate groups. The invention further relates to a method of providing a gel-modified ROMP composition, in which a hydroperoxide is added to a ROMP polymerizable resin composition in order to control gel formation of the polymerizing resin. An improved ROMP composition is further disclosed, comprising a cyclic olefin, a ROMP metathesis catalyst, an adhesion promoter, and an added hydroperoxide gel modifier. The polymer products produced via ROMP reactions of the invention may be utilized for a wide range of materials and composite applications. The invention has utility in the fields of catalysis, organic synthesis, and polymer and materials chemistry and manufacture.

Owner:MATERIA

Method for preparing silicon dioxide aerogel powder

The invention discloses a method for preparing preparing silicon dioxide aerogel powder, which comprises the following steps: adding acid into sodium silicate solution to make a pH value equal to 3 to 6; adding a chemical drying control agent into mixture and standing to form gel; after the gel is sufficiently aged, adding an azeotropic distillation organic solvent into the gel to distill to form a primary dried product; and drying the primary dried product to form silicon dioxide aerogel powder. The method uses the common commercial sodium silicate as the raw material to prepare the silicon dioxide aerogel powder and has the advantages that the raw material is easily obtained; the normal pressure is used for preparation; the chemical drying control agent is adopted to prolong the gelation time to promote uniformity of the gel structure; an azeotropic distillation drying process is adopted to control a stress level when the solvent is dried; a pore volume and a specific surface area of the silicon dioxide aerogel are controlled; the pore volume reaches 1.2 to 3.0ml / g; the specific surface area reaches 300m2 / g to 800m2 / g; and compared with the normal pressure drying, the drying time is shortened and the like. The organic solvent is easy to realize recycling. And the production process is simple and the production cost is low.

Owner:FUJIAN NORMAL UNIV

Double-component epoxy resin embedding adhesive and its preparation method and can sealing technique

ActiveCN101235269ALow viscositySave operating timeOther chemical processesEpoxy resin adhesivesEpoxyAlcohol

Bi-component epoxy resin pouring sealant and the preparation and the potting technology are disclosed, which comprises an epoxy resin A component and a cursing agent B component, wherein the curing agent B component at least comprises the mixing curing agent of cashew shell oil modified amine curing agent and fatty amine curing agent. The potting technology comprises mixing and stirring evenly the epoxy resin A component and the curing agent B agent to conduct the potting, and spraying a layer of absolute alcohol on the surface of the pouring sealant after 10-15 minutes. The advantages are that gel time is prolonged through adopting the mixing curing agent of cashew shell oil modified amine curing agent and fatty amine curing agent, the requirement of operation time is fulfilled, and the operation time can reach 20-30 minutes, thereby being beneficial for the encapsulation of housing with large capacity, and the pouring sealant of the invention has the effect of fast curing, wherein the curing time is 1-3 hours, and defoaming is accelerated through spraying a layer of absolute alcohol on the surface of colloid after pouring, thereby making the solid gel surface bright and flat after curing.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

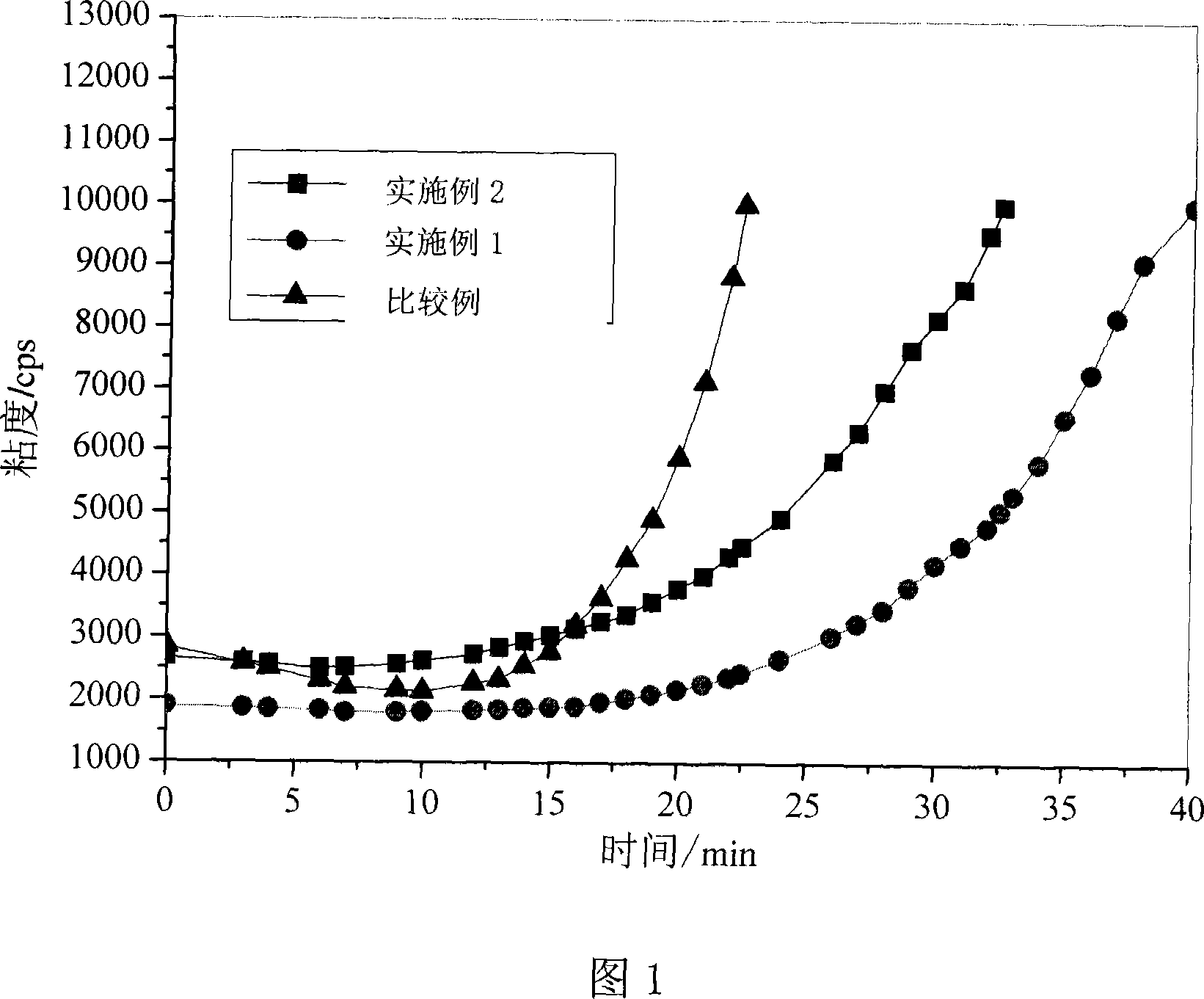

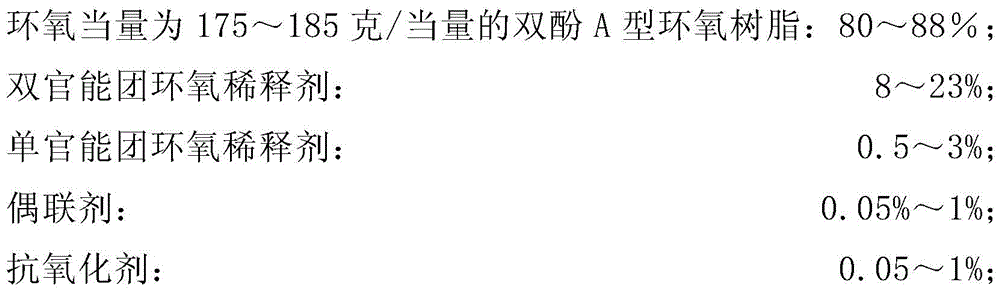

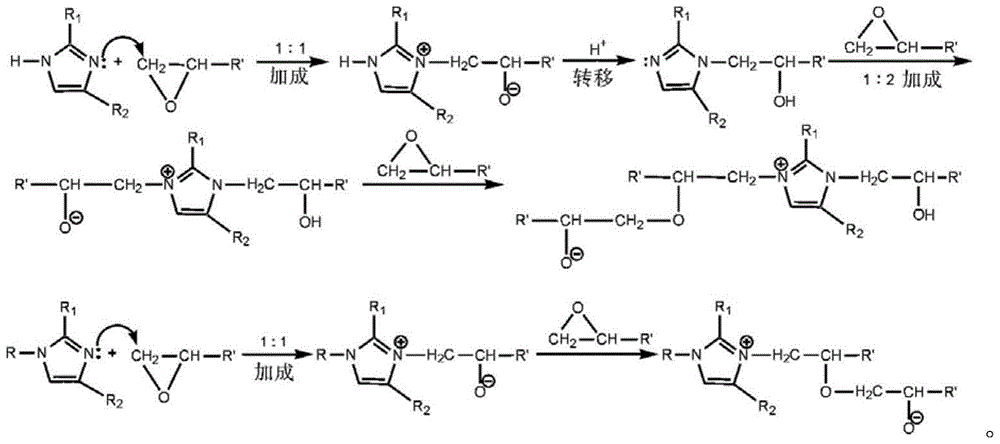

Epoxy resin composition and composite material for wind power generator blade

The invention relates to a composite material for wind power generator blades, wherein the composite material is composed of an epoxy resin composition and a fiber-reinforced fabric accounting for 68-73% by weight of the epoxy resin composition. The epoxy resin composition includes a component A and a component B according to the weight ratio of 100:28-33, wherein the component A is composed of bisphenol-A epoxy resin being 175-185 g / equivalent in epoxy equivalent, a bi-functional-group epoxy diluent, a mono-functional-group epoxy diluent, an epoxy coupling agent and an antioxidant, and the component B is composed of aliphatic polyamine, cycloaliphatic amine and imidazole. The fiber-reinforced fabric is described as the specification. The invention discloses the weight ratio of the raw materials. The composite material, which is prepared through a liquid moulding method, can reach the demand on strength and anti-wind-impact performance of the wind power generator blades.

Owner:上海康达新材料科技有限公司

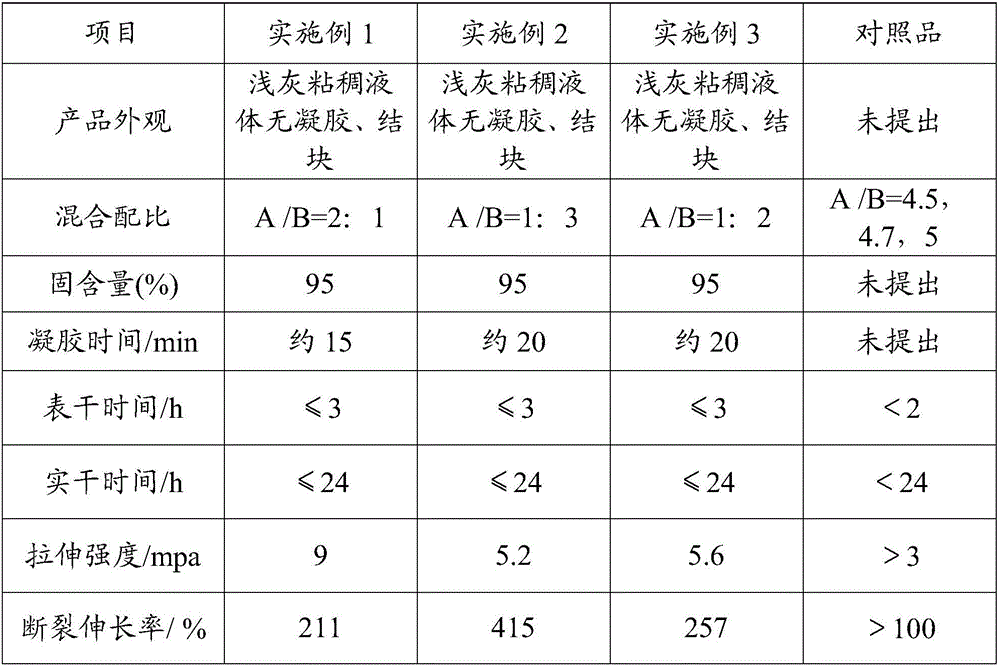

Scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material and preparation method thereof

ActiveCN105802460AHigh mechanical strengthAnti-corrosion and wear-resistantAnti-corrosive paintsPolyurea/polyurethane coatingsElastomerEnd-group

The invention discloses a scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material and a preparation method thereof. The scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material is characterized by comprising an ingredient A and an ingredient B, wherein the ingredient A is prepolymers with NCO end groups obtained through the reaction between 30 to 40 mass percent of polyether polyol and 60 to 70 mass percent of polyisocyanates; the ingredient B is prepared from 30 to 40 mass percent polyaspartic acid ester, 60 to 70 mass percent of filling materials and a small number of auxiliary agents through high-speed dispersion grinding. In the use process, the prepared ingredient A and the prepared ingredient B are weighed according to the weight ratio of 1:4, and are then uniformly mixed; next, scraping coating construction is performed. The material has the characteristics of high mechanical intensity, corrosion resistance, wear resistance, good anti-seeping performance, aging resistance, proper reaction speed, no solvent, convenient construction and the like. The scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material is particularly suitable for industrial and mining enterprise equipment and spare part anti-corrosion wear-resistant liners.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Novel inorganic-organic ternary composite plugging agent for oil extraction and preparation method

The invention relates to a novel inorganic-organic ternary composite plugging agent for oil extraction and a preparation method. The invention adopts the technical scheme that: the plugging agent is prepared by mixing 8 to 12 percent of water glass of which the modulus is 3.3, 0.1 to 0.3 percent of polyacrylamide and 0.3 to 0.8 percent of water-soluble phenolic resin and the balance of phosphoricacid and water, wherein the phosphoric acid is used for adjusting a pH value. Under the condition of overcoming short gelation time and relatively weak gelation intensity of inorganic silicic acid, inorganic-organic plural gel which has the characteristics of relatively long gelation time at the temperature of less than 70 DEG C, high gelation intensity, certain tenacity and difficult cracking isprovided and is suitable for different stratum environments.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Polishing layer of chemical-mechanical polishing pad and application of polishing layer

ActiveCN110977756AImprove mechanical propertiesImprove wear resistanceSemiconductor/solid-state device manufacturingLapping toolsPolymer sciencePolyol

The invention provides a polishing layer of a chemical-mechanical polishing pad and application of the polishing layer. The polishing layer is prepared by the reaction of isocyanate prepolymer, a curing agent and functional filling; the isocyanate prepolymer is prepolymer prepared by the reaction of raw materials including diisocyanate, polyether ester polyol and optional small molecular polyol; the curing agent is dispersion liquid formed in dioctyl adipate by a complex of diamine compound and sodium chloride, wherein concentration of the complex is 40 wt%-50 wt%; and the functional filling is expanded polymer hollow microspheres. The polishing layer has higher mechanical strength and abrasive resistance while having high elasticity and hydrolysis resistance, so that the durability of thepolishing layer is good.

Owner:万华化学集团电子材料有限公司

Gelling agent for water shut-off in oil and gas wells

ActiveUS9074125B1Reduce and eliminate flowDecrease productivityFluid removalDrilling compositionCross linkerPetroleum

The gelling agent for water shut-off in oil and gas wells is a composition that forms a gel to reduce or eliminate the flow of water in a gas or oil well. The composition is formed by mixing polyvinyl alcohol, a polyvinyl alcohol copolymer, or mixtures thereof with an amino-aldehyde oligomer, such as urea formaldehyde or melamine formaldehyde, with or without a cross-linker. The polymer composition can be used to minimize or completely shut off excess water production with insignificant reduction in hydrocarbon productivity.

Owner:KUWAIT INST FOR SCI RES

High-molecular nano polymer electrolyte for lead-acid battery and its compounding method

ActiveCN1978507AIncrease capacityExtended service lifeLead-acid accumulatorsElectrical batterySilicon dioxide

The electrolyte of macromolecule nanometer polymer used in lead acid storage battery and its preparation method were related in this invention. It relates the area of lead acid storage battery. According the weight ratio, the electrolyte is mainly made up of the raw materials as following: ligand agent 0.1-1.5%, complexing agent 2.5-4%, catalytic agent 0.01-0.5%, stabilizing agent 2.3-3.8%, conditioning agent 0.1- 0.5%, antifoam agent 0.01-0.5%, sulfuric acid 36-45%, the others is water. It is characterized in that the content of silicon dioxide is low, the dosage is little and the cost is also low. And in that a steady colloid can be formed in the electrolyte which can elongate the gelatum time. Used in the minitype encapsulation lead acid storage battery, the capacity can increase greatly, the operational life can be elongated and the low temperature resistance can also be enhanced. The gel in the electrolyte can avoid the overflow of acid liquor. Otherwise, the electrolyte also has the merits of little inherent resistance, high capacity, longevity and good thixotropy and so on.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV

Polyaspartatepolyurea coating with moderate surface drying time and adaptability to environmental change and preparation method and use method and application thereof

ActiveCN109354987AAccelerated agingImprove photostabilityAntifouling/underwater paintsPaints with biocidesPolymer sciencePolyol

The invention belongs to the technical field of spraying polyurea elastic materials, and discloses a polyaspartatepolyurea coating witha moderate surface drying time and adaptability to environmentalchanges, which is prepared from a A material and a B material. The mole ratio of NCO in the A material to NH in the B material is 1.05:1.1. The A material is mainly prepared from,by weight,25-44% of polyether polyol, 55-74% of aliphatic polyisocyanate and 1-5% of nanographene oxide; the B material is mainly prepared from, by weight,70-80% of polyaspartate, 10-15% of nano metal oxide filler, 5-10%of pigment and filler, 1-3% of defoaming agent, 1-3% of leveling agent and 2-5% of adhesion promoter. The invention further provides a preparation method and use method and application of the polyaspartatepolyurea coating. The polyaspartatepolyurea coating has the advantages of being easy to brush, moderate in the surface drying time, and capable of adapting to the environmental changes.

Owner:四川嘉宝莉涂料有限公司

Polyurea waterproof and corrosion-resistant coating of graphene modified amine-terminated polyether

InactiveCN110028886APrevent infiltrationAvoid osmosisAnti-corrosive paintsPolyurea/polyurethane coatingsReduction treatmentUltrasonic dispersion

The invention discloses a polyurea waterproof and corrosion-resistant coating of graphene modified amine-terminated polyether. The coating comprises a component A and a component B, wherein the component A is a quasi-prepolymer which is prepared from isocyanate, amine-terminated polyether and a diluent through reactions; the component B is prepared by the following steps: firstly, preparing graphene oxide; secondly, carrying out carboxylation treatment on the graphene oxide; thirdly, carrying out ultrasonic dispersion on the carboxylation graphene oxide into a dimethyl formamide (DMF) solution; under the action of a dehydration agent, modifying the amine-terminated polyether by using the carboxylation graphene oxide; carrying out reduction treatment on the amine-terminated polyether aftercarboxylation graphene oxide modification by using a chemical reduction method; finally, mixing the graphene modified amine-terminated polyether, a chain extender and aids, thereby obtaining the component B. The waterproof and corrosion-resistant coating is simple in process, green and environmentally friendly in process and has the characteristics of being good in waterproof and corrosion-resistant property, good in adhesiveness, slow in reaction speed, controllable in gelation time, and the like.

Owner:HANGZHOU GAOXI TECH CO LTD

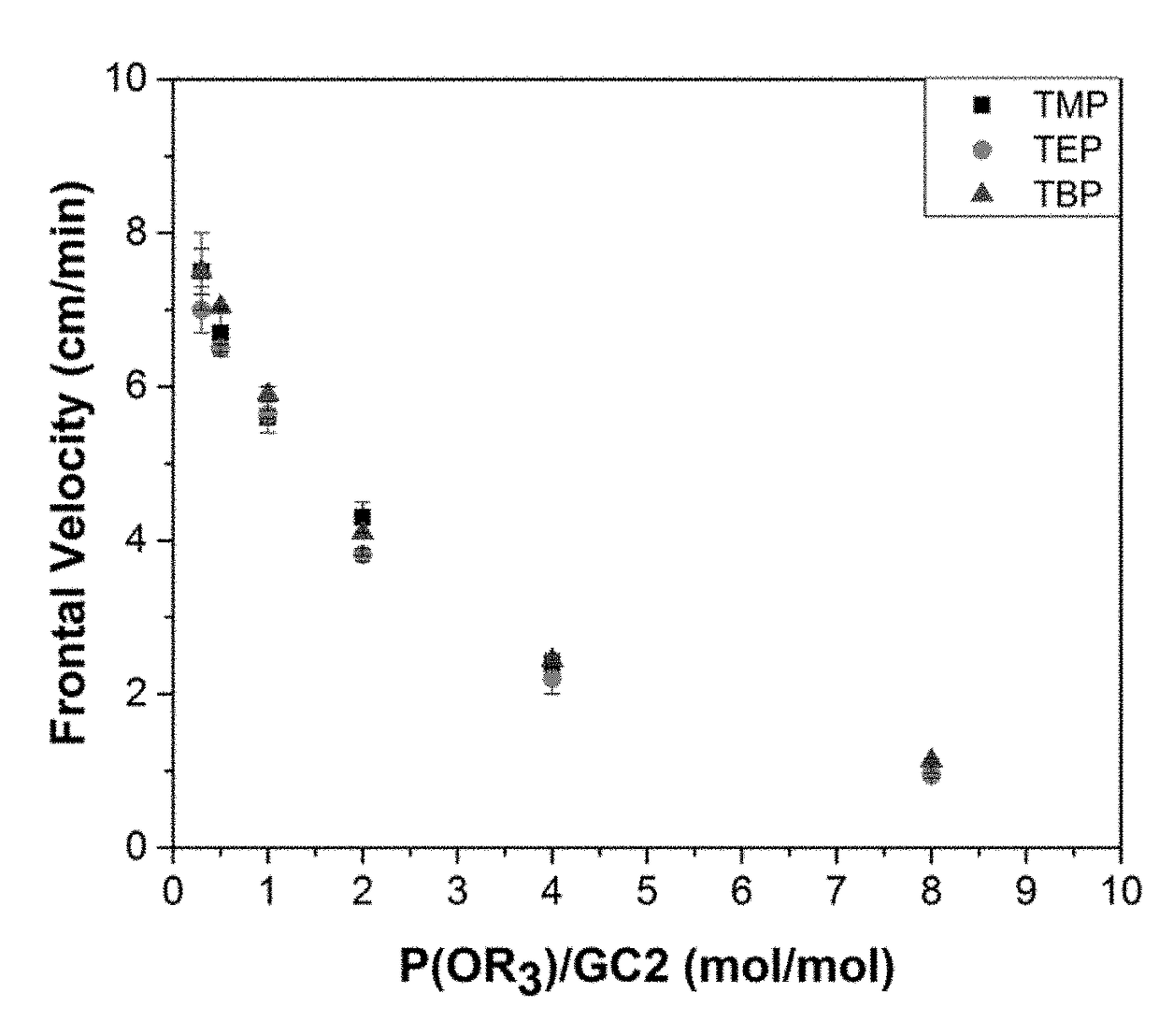

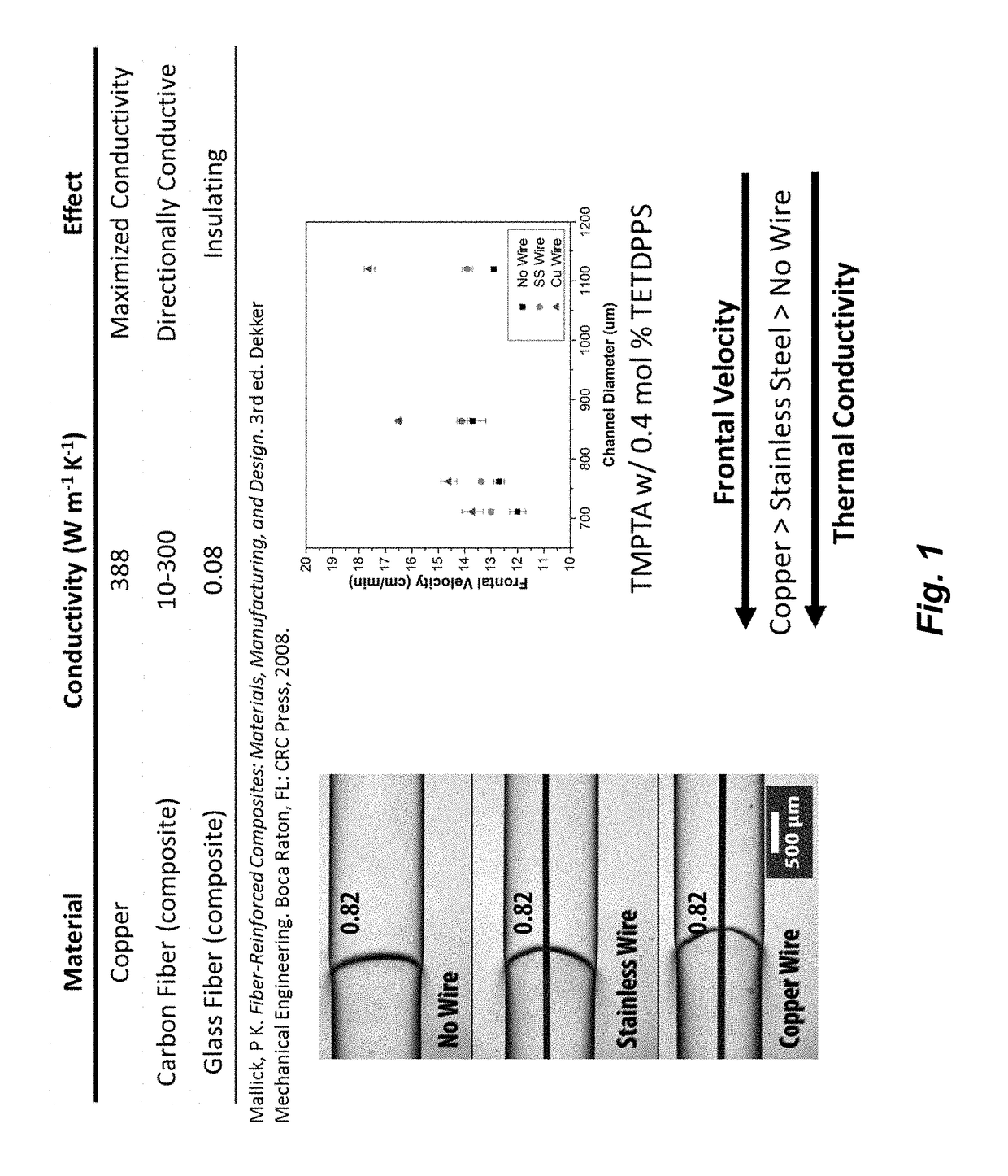

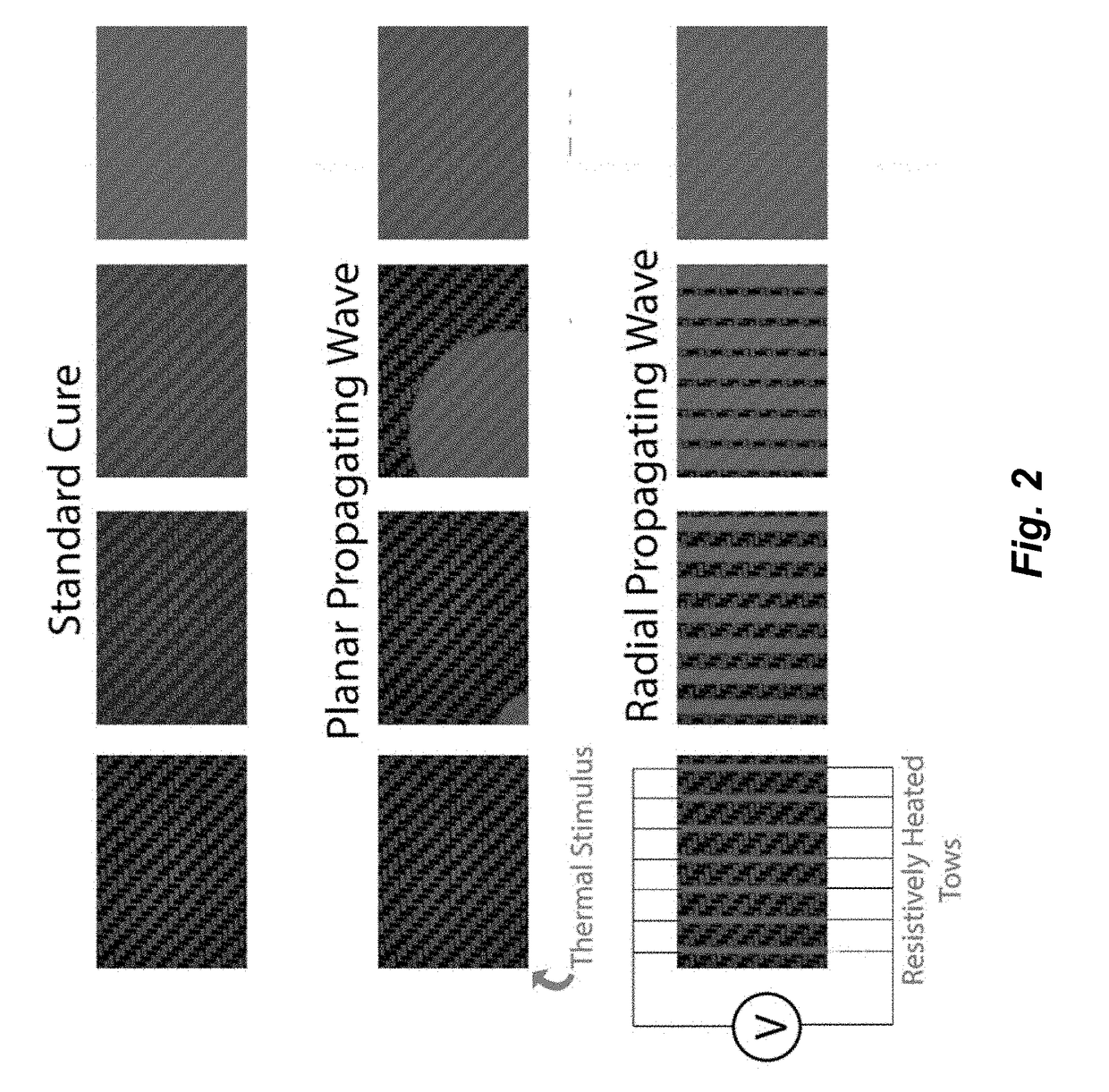

Frontal polymerization for fiber-reinforced composites

ActiveUS20180230642A1Extended validity periodExtended gel timeFibre treatmentWoven fabricsFiber-reinforced compositePolydicyclopentadiene

Polydicyclopentadiene (PDCPD) is a polymer of growing importance in industrial applications. Frontal ring-opening metathesis polymerization (FROMP) offers a means to rapidly cure PDCPD with minimal input energy owing to a propagating reaction wave sustained by the exothermic polymerization. The disclosure provides methods for the rapid fabrication of fiber reinforced composites that is less restrictive and more energy efficient than conventional methods.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

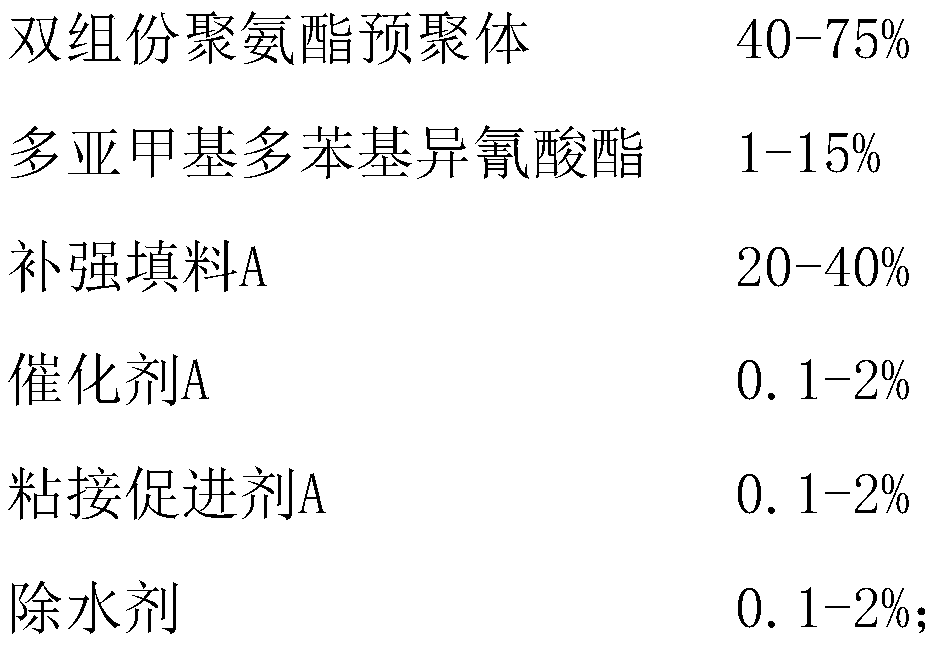

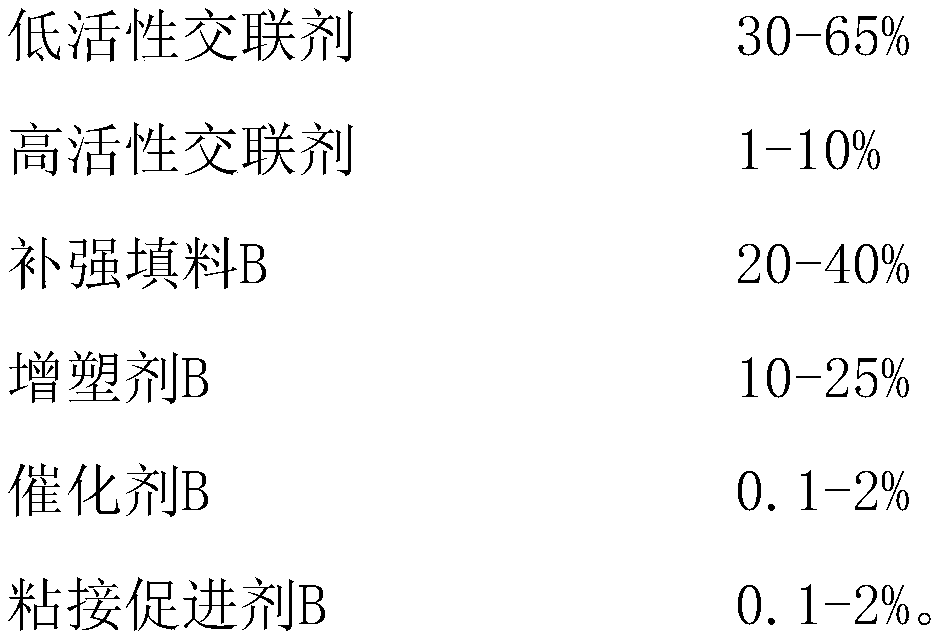

Reaction thickening type two-component polyurethane glass adhesive and preparation method thereof

InactiveCN110093137AEnsure construction mixGuaranteed thicknessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesLow activityPlasticizer

The invention relates to the technical field of adhesives, in particular to a reactive thickening type two-component polyurethane glass adhesive and a preparation method thereof. The preparation method comprises the following steps of: mixing and stirring a component A and a component B in a volume ratio of 1: 0.8-1.2 for 5-20min to prepare the glass adhesive. The component A comprises 40-75% of atwo-component polyurethane prepolymer, 1-15% of polymethylene polyphenyl isocyanate, 20-40% of a reinforcing filler A, 0.1-2% of a catalyst A, 0.1-2% of an adhesion promoter A and 0.1-2% of a water removal agent. The component B comprises 30-65% of a low-activity cross-linking agent, 1-10% of a high-activity cross-linking agent, 20-40% of a reinforcing filler B, 10-25% of a plasticizer B, 0.1-2%of a catalyst B and 0.1-2% of an adhesion promoter B. The preparation method of the invention has simple operation, convenient control, low production cost and high product quality, and can be used for large-scale production.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD +1

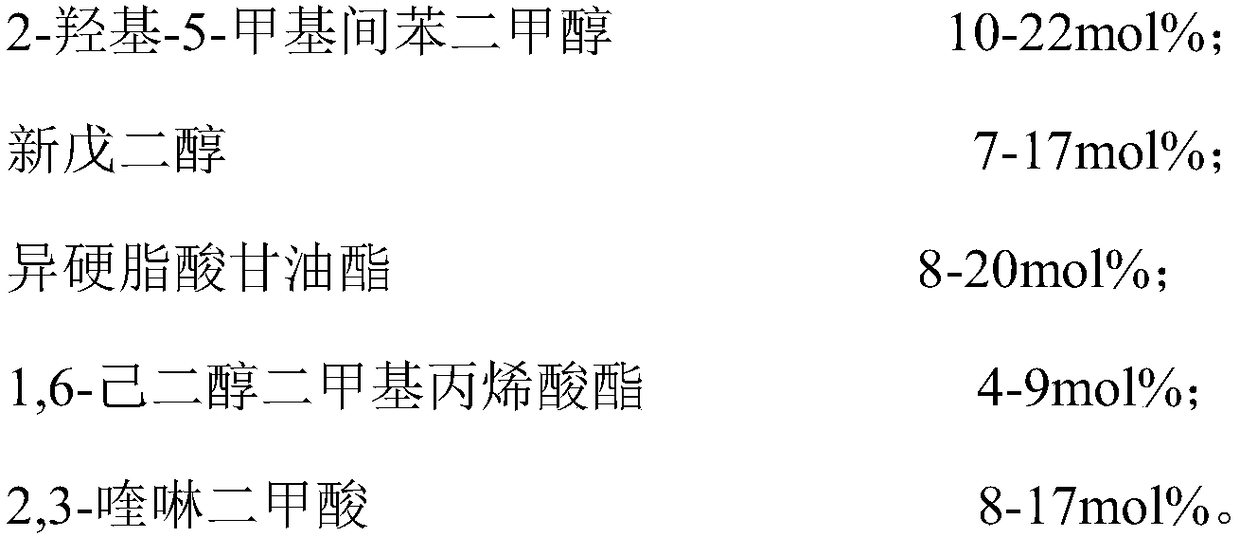

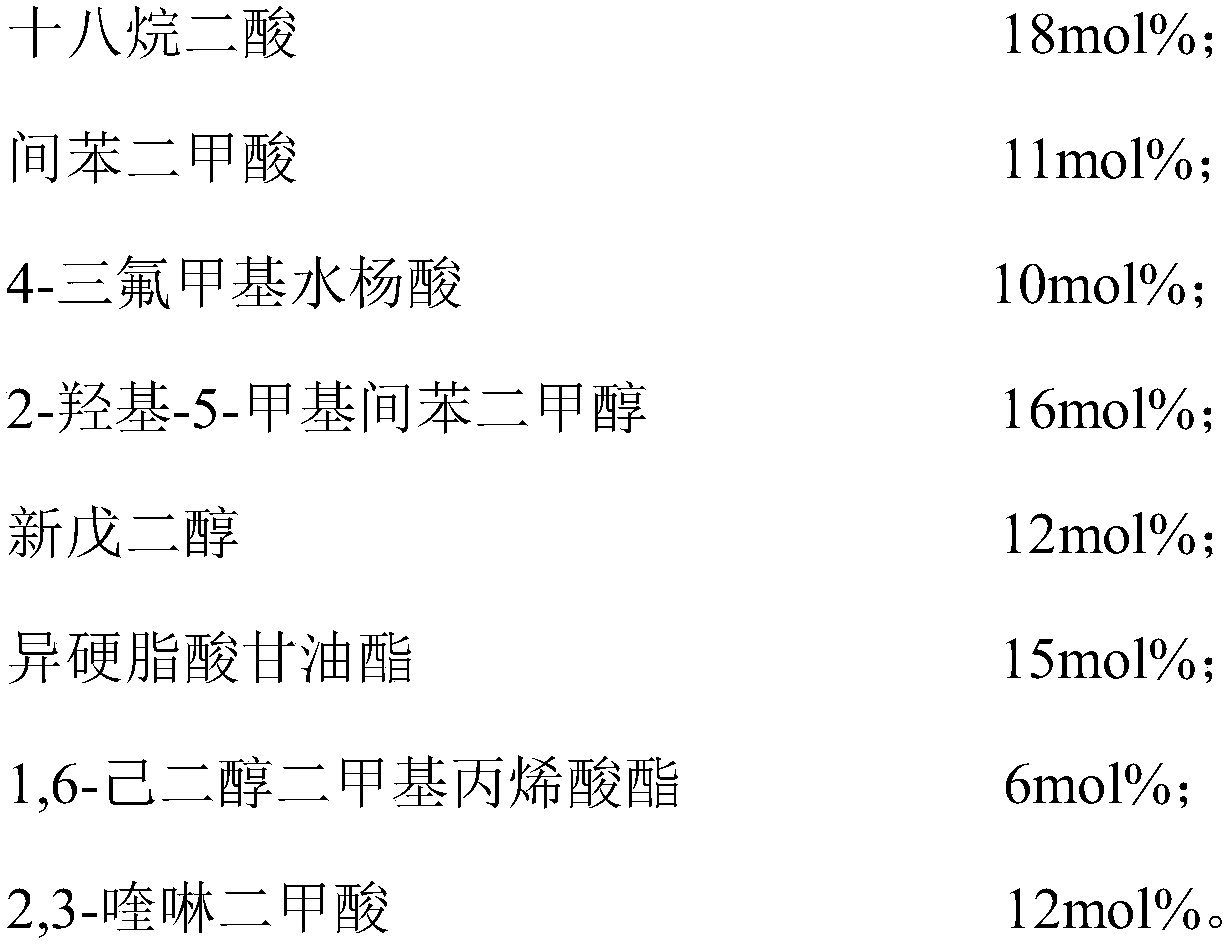

Polyester resin for high gloss powder coating and preparation method and application thereof

ActiveCN109207030AHigh glossHigh surface glossPowdery paintsEpoxy resin coatingsMethacrylateHigh surface

The invention belongs to the technical field of powder coatings, in particular to polyester resin for a high gloss powder coating and a preparation method thereof and application thereof in preparinga 50 / 50 type powder coating. The polyester resin for the high gloss powder coating is prepared by polymerization of octadecanedioic acid, isophthalic acid, 4-trifluoromethylsalicylic acid, 2,6-Bis(hydroxymethyl)-p-cresol, neopentyl glycol, glyceryl isostearate, 1,6-hexanediol dimethacrylate, and 2,3-quinolinedicarboxylic acid as raw materials. The obtained polyester resin product has better structural flexibility and long flow time, has high surface gloss after curing into a film while ensuring mechanical properties, and can be used in the 50 / 50 mixed powder coating for obtaining a high glosscoating board surface.

Owner:安徽恒隆新材料有限公司

Preparation method of silica alumina gel bonding agent for corundum-mullite composite ceramic

The invention discloses a method for producing an alumina silica gel anchoring agent for corundum mullite composite ceramic, which comprises: using silicasol and alumina colloid as raw materials, controlling PH of the alumina colloid, using sol-gel processing to produce the alumina silica gel, controlling the content of alumina silica by dewatering in the alumina silica gel producing process, and controlling the gelling time by adding ammonial solution or acetylacetone, controlling the crystal system of mullite phase produced from burning process of the alumina silica gel by adding the aluminun trifluoride mineralization agent. The alumina silica gel can be used in the ceramic and fire resistive materials producing process as the anchoring agent, also can be used in production of mullite super fine. The crystal form can be controlled by adding the mineralization agent to improve the capacity of the ceramic and fire resistive materials.

Owner:ZHEJIANG UNIV

Colloidal electrolyte for lead-acid storage battery and preparation method of colloidal electrolyte

ActiveCN103280602AExtended gel timeShort gel timeFinal product manufactureLead-acid accumulators constructionGas phaseElectrochemistry

The invention discloses a colloidal electrolyte for a lead-acid storage battery, which relates to the field of storage batteries. The gel strength is an important factor reflecting the performance of a colloidal electrolyte and is mainly influenced by the content of a gelling agent; and with the increment of the content of fumed silica, the gel time of an electrolyte solution is greatly shortened and the difficulty for gel filling is caused. The colloidal electrolyte provided by the invention comprises a gelling agent, sulfuric acid and sodium sulfate, wherein the gelling agent comprises fumed silica and disperse silica gels A and B with different particle sizes. The colloidal electrolyte is prepared from the disperse silica gel with large particle size, the disperse silica gel with small particle size and the fumed silica, and an additive, namely the sodium sulfate, contributing to the improvement of the electrochemical performance of the battery is added at the same time. On the promise of not increasing the content of silicon in the colloidal electrolyte, the key performance of the colloidal electrolyte is broken through on the two aspects that firstly, the gel strength is enhanced, and secondly, the gel time is prolonged. Therefore, the pouring of the storage battery is facilitated, the performance of the colloidal electrolyte is improved, and the service life of the colloidal electrolyte is prolonged.

Owner:CHAOWEI POWER CO LTD

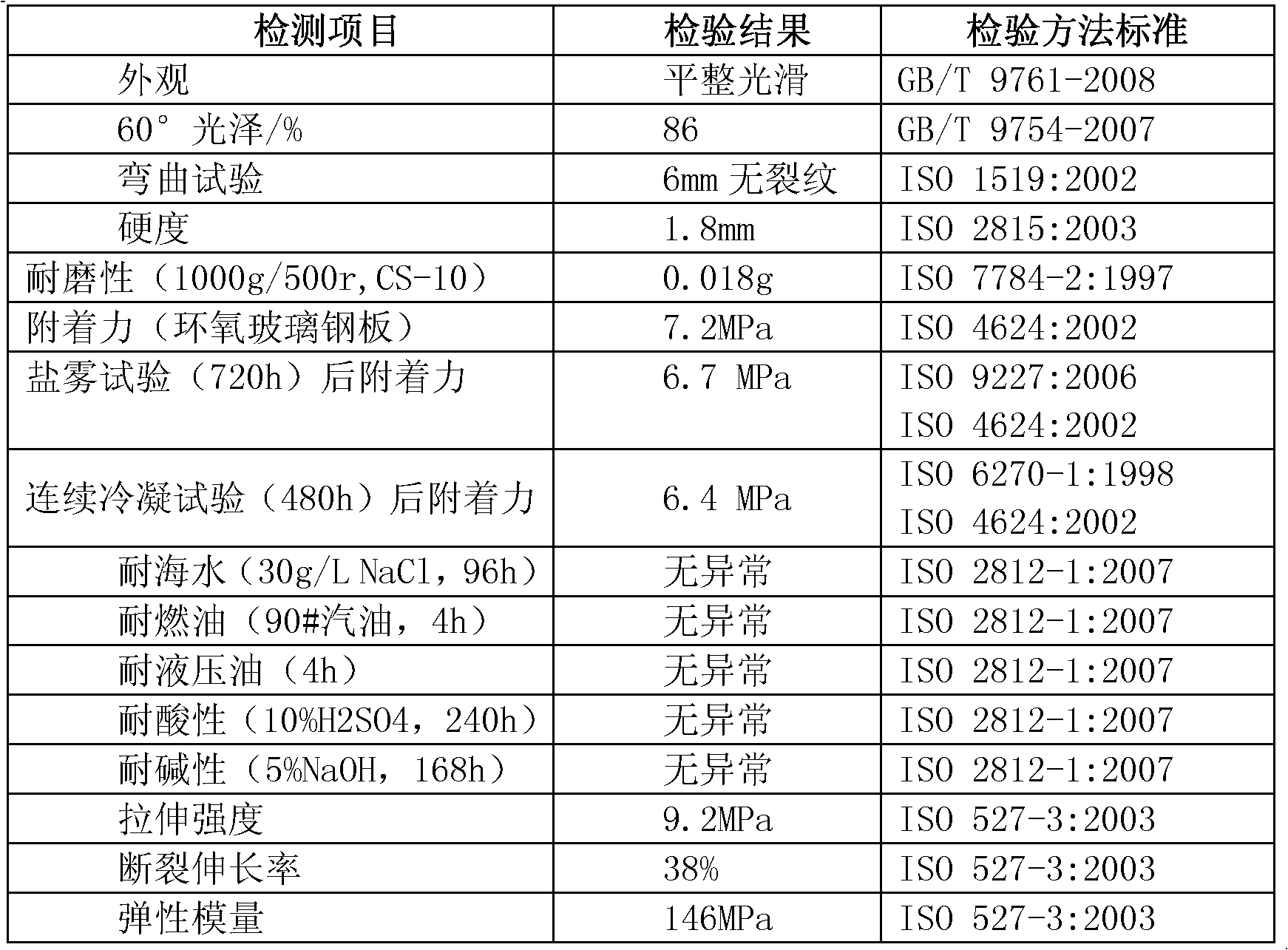

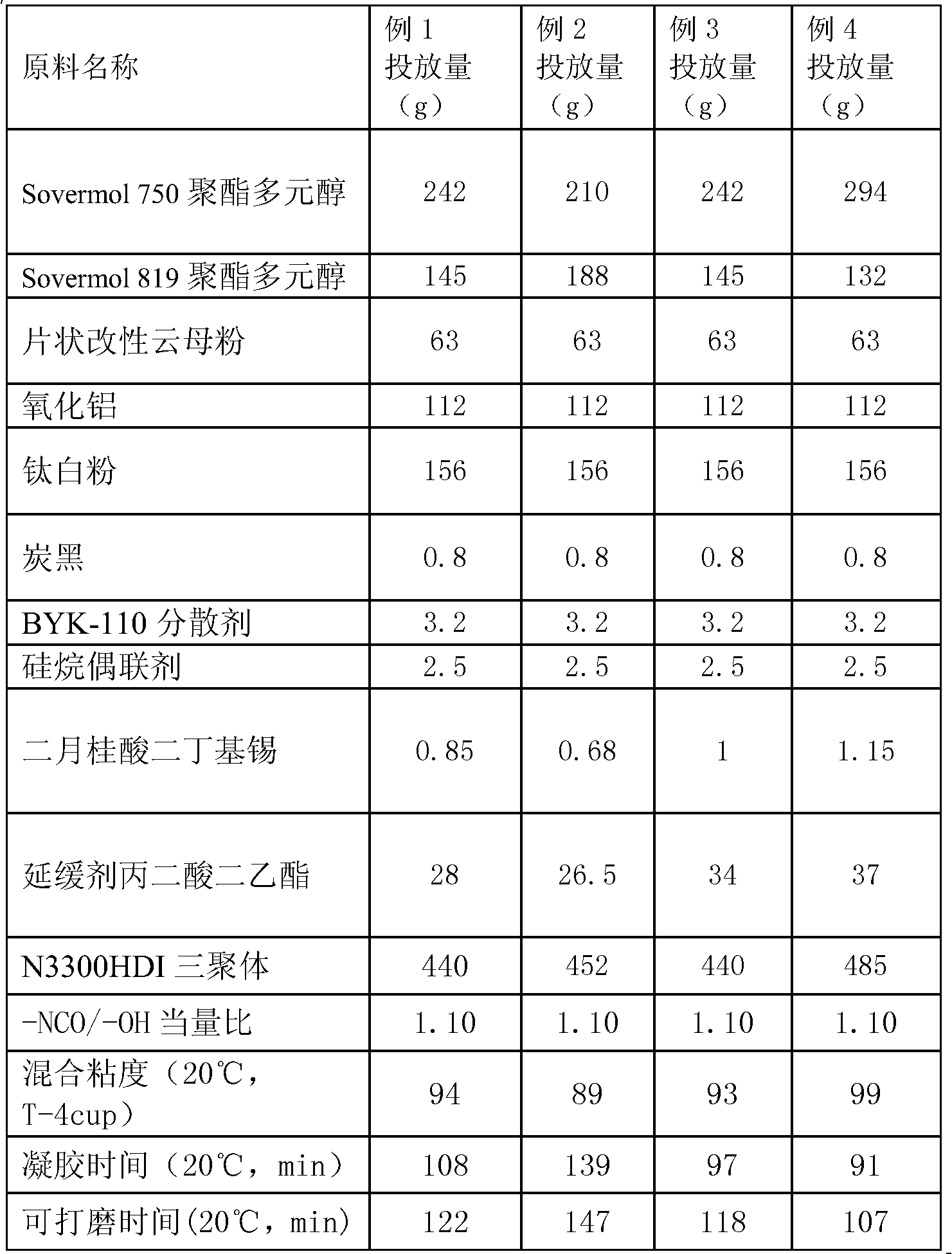

Polyurethane gel coat combination capable of spraying blades of fan conventionally and preparation method of polyurethane gel coat combination

ActiveCN102585684ASolve the contradiction between gel time and sandability and drynessGood protectionPolyurea/polyurethane coatingsSolventPolyester

The invention provides a polyurethane gel coat combination capable of spraying blades of a fan conventionally and a preparation method of the polyurethane gel coat combination. The combination is prepared by the following steps: mixing polyester polyol and an isocyanate curing agent according to a certain proportion to serve as a main film former, and adding a filler, a pigment, auxiliaries and areaction regulator. The reaction regulator includes a drier and a retardant, and the retardant includes one or more Louis acidic compounds having double-teeth ligand structures. Therefore, the gelation time of the polyurethane gel coat is effectively prolonged, the spraying operation can be realized with conventional coating equipment, the current reality that solvent-free gel coats for the blades of a fan can only be coated in a roller coating way or by adopting special equipment is changed, not only is the excellent protecting performance of the solvent-free polyurethane gel coats realized,but also the fine processability of the solvent-free polyurethane gel coats is realized. The invention also provided a preparation method of the polyurethane gel coat combination. The polyurethane gel coat combination prepared according to the invention also has the excellent properties of being tough and tensile, wear-resisting, sand-wind-resisting, ultraviolet-resisting and ageing-resisting andthe like.

Owner:天津德威涂料化工有限公司

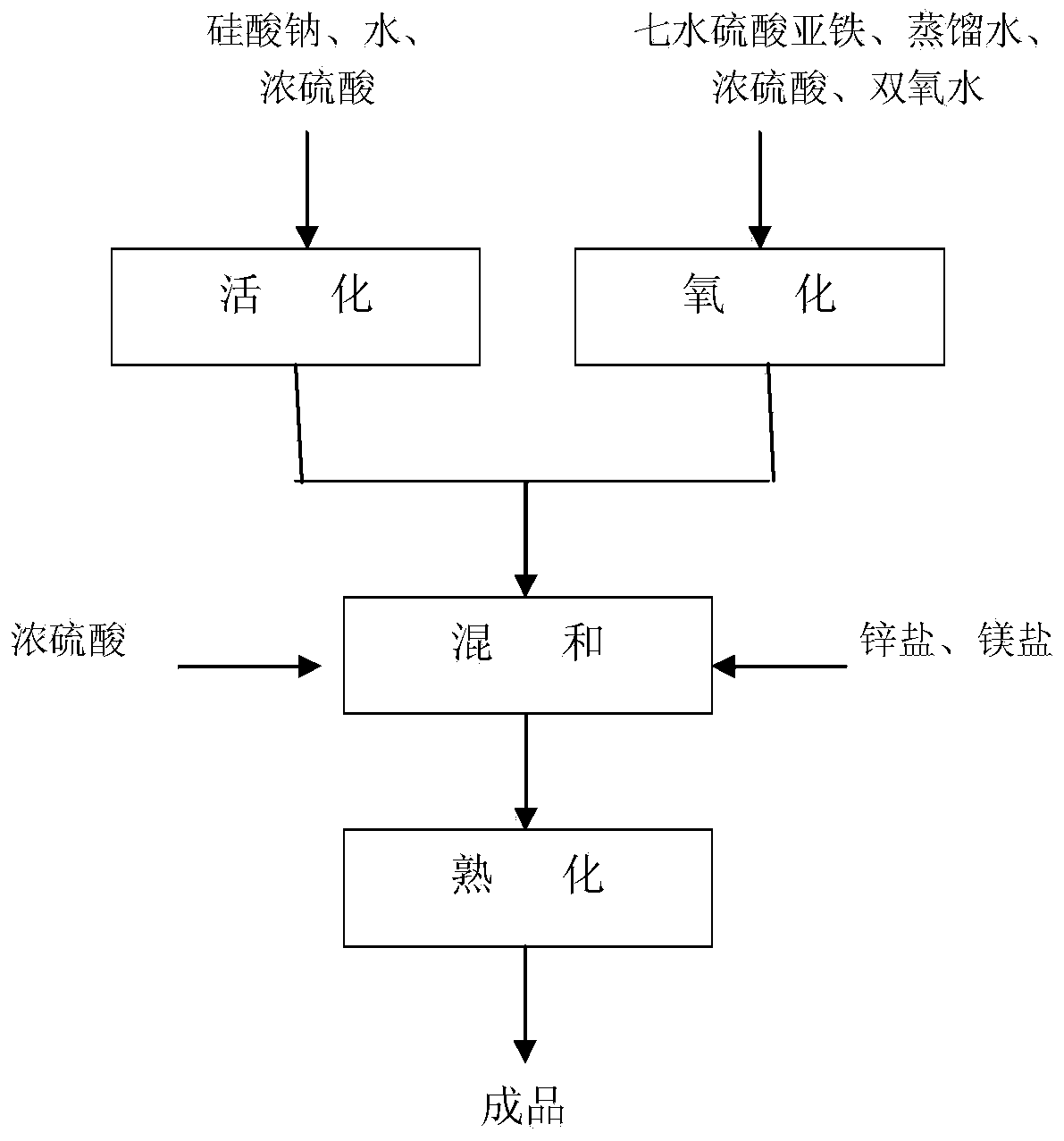

Compound type water treatment flocculating agent and preparation method thereof

InactiveCN103964555AStrengthen the ability of bonding and aggregationMolecular chain lengthWater/sewage treatment by flocculation/precipitationMagnesium saltWater treatment

The invention discloses a compound type water treatment flocculating agent and a preparation method thereof and belongs to the field of waste water treatment. The flocculating agent is prepared from ferrous sulfate, sodium silicate, zinc salt, magnesium salt, hydrogen peroxide, concentrated sulfuric acid, and distilled water and the preparation method comprises the steps of activating, oxidation, mixing, curing and the like. The compound type water treatment flocculating agent disclosed by the invention has the benefits of simple preparation technology, low cost, high convenience in product application and good stability, is suitable for flocculation treatment of sewage and has good effects on sewage in COD reduction, phosphorous removal and de-coloration.

Owner:QINGDAO SHIZHILI CHINESE HERBAL MEDICINE INST

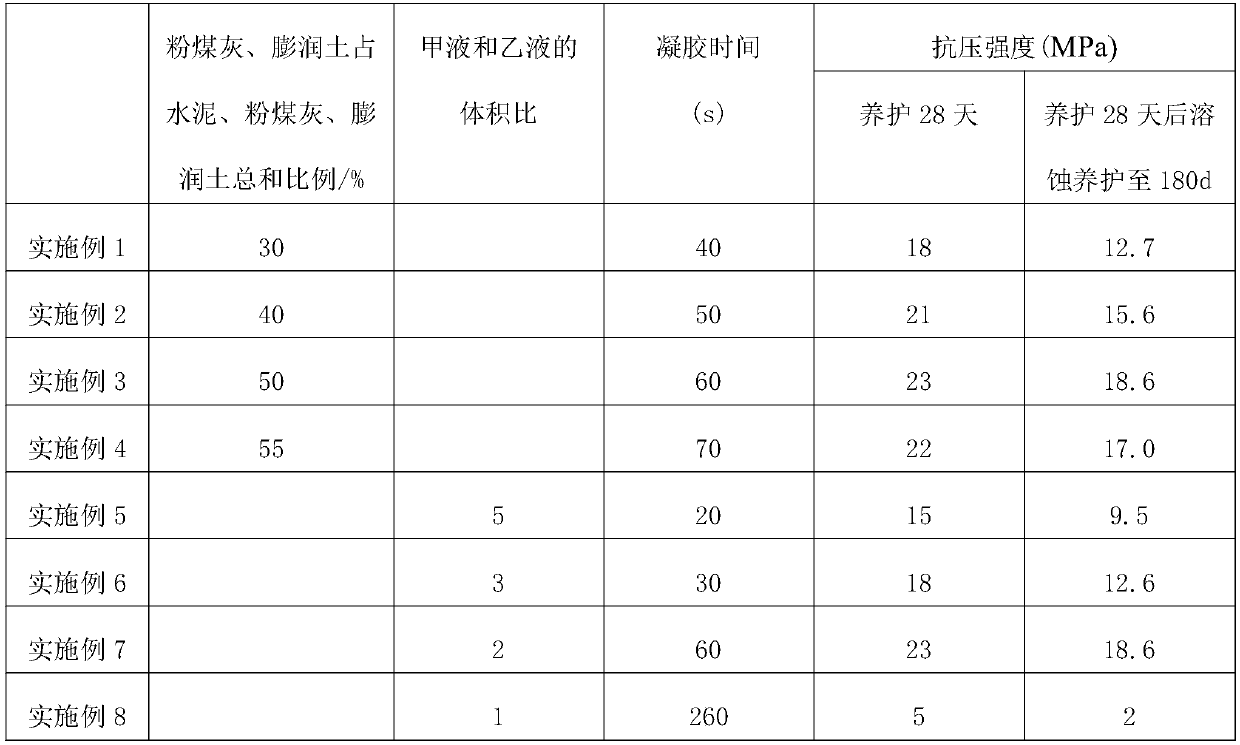

Method for treating tunnel collapse roof fall by using advanced small pipe pre-grouting technology

ActiveCN109578013AExtended gel timeImprove pore structureUnderground chambersTunnel liningSodium BentoniteSlurry

The invention provides a method for treating tunnel collapse roof fall by using an advanced small pipe pre-grouting technology, and relates to the technical field of the tunnel protection. The methodcomprises the following steps: S1, preparing in an early stage; S2, pre-grouting through an advanced small pipe: constructing by using a double-liquid grouting material through adopting the advanced small pipe pre-grouting technology, wherein the double-liquid grouting material comprises liquid A and liquid B, the liquid B is water glass, and the liquid B comprises the following components in parts by weight: cement, coal ash, bentonite, disodium hydrogen phosphate, aluminum oxide, sodium hydroxide, and water; and uniformly mixing the liquid A and the liquid B according to a volume ratio of 1:0.2-1, to obtain the double-liquid grouting material; and S3, monitoring an effect. The method is capable of treating the tunnel collapse roof fall by using the double-liquid grouting material throughadopting the advanced small pipe pre-grouting construction technology, solving a problem that traditional cement-water glass slurry gel is overquick in a certain degree, improving structural stability and durability, and reducing construction cost.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

Polyaspartate polyurea coating and application thereof

ActiveCN106811037AStrong adhesionExtended use timeAnti-corrosive paintsPolyurea/polyurethane coatingsCoating systemPliability

The invention discloses polyaspartate polyurea coating and application thereof; the polyaspartate polyurea coating comprises component A and component B, the component A comprises polyaspartate, a defoaming agent, a dispersant, a thixotropic agent, a filler, and a water absorbent, the component B is polyether-modified polyisocyanate; the mass ratio of the components A and B is 1:3 to 2:1. The polyaspartate polyurea coating of the invention has good softness and waterproofing property, as well as high adhesion; these good features allow the coating of the invention to better act as a buffer layer for a coating system, the ability of a waterproof material to resist environmental changes in actual application is improved greatly, the service life is extended, and maintenance cost is lowered.

Owner:广州嘉睿复合材料有限公司

Method for preparing low-melting-point quarternary BZBS (BaO-ZnO-B2O3-SiO2) glass by virtue of sol-gel method

The invention provides a method for preparing low-melting-point quarternary BZBS (BaO-ZnO-B2O3-SiO2) glass by virtue of a sol-gel method. The method comprises the following steps: 1) preparing ethyl orthosilicate pre-hydrolysate; 2) preparing sol; 3) preparing xerogel; 4) firing glass; and 5) grinding and screening the obtained xerogel to obtain xerogel powder, pretreating the xerogel powder in a muffle furnace, then carrying out firing at a temperature of 950-1050 DEG C for 0.5-1.5 hours, and then rapidly cooling to the room temperature on a steel plate to obtain low-melting-point quarternary borate glass. The method is reasonable in process condition, a gel structure of the glass is a network structure formed by SiO2 and B2O3 together, and the glass is microcrystalline glass, is good in wetting property, good in clarification effect, strong in crystallizing capability and best in comprehensive performance.

Owner:SINOTENG SILICA MATERIALS TECH (JIANGSU) CO LTD

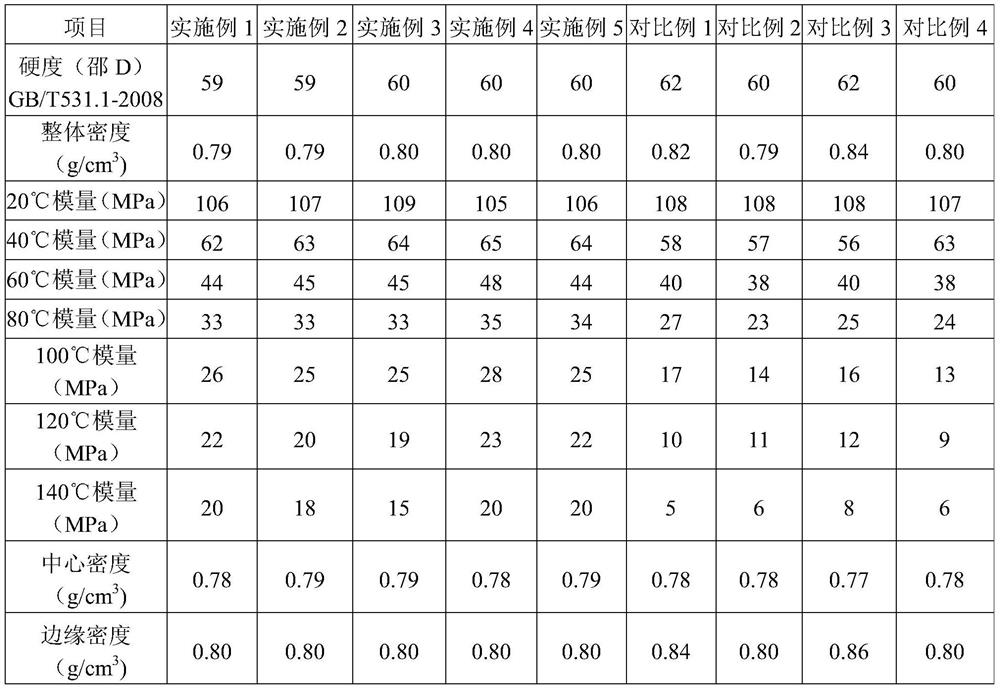

Polishing layer of chemical mechanical polishing pad and preparation method therefor

The invention discloses a polishing layer of a chemical mechanical polishing pad and a preparation method therefor. The polishing layer is prepared from raw materials containing a isocyanate prepolymer, a curing agent and a functional filler; the prepolymer is obtained by two-step reaction of diisocyanate and polytetrahydrofuran polyol; the component of the curing agent is an amine cross-linking agent; and the functional filler is an expanded polymer hollow microsphere. The polishing layer prepared thereby has the advantages that the elastic modulus changes stably along with the temperature, the porosity (the micropore volume fraction is high) is high, and the density is uniform.

Owner:万华化学集团电子材料有限公司

Grouting material, preparation method and application thereof in seepage-proofing and water-plugging construction

PendingCN111892374AImprove permeabilityHigh strengthUnderground chambersDrilling compositionSoil scienceWater flow

The invention provides a grouting material and a preparation method thereof, and belongs to the technical field of underground engineering materials. The grouting material provided by the invention comprises the following raw materials: 760-800 parts of clay, 80-120 parts of cement, 30-70 parts of bentonite, 700-800 parts of water, 5-15 parts of water glass and 1-5 parts of a water reducing agent.According to the invention, bentonite is used for improving the clay basic slurry, and complex reaction with a cement hydration product is carried out, so that the water flushing release resistance,strength and permeation resistance of the slurry are improved, and the product has excellent economical efficiency; the water glass accelerates the gelling time of the material and generates relatively stable micelles with the clay cement slurry; the water reducing agent reduces the porosity of the material and improves the strength and impermeability of the material. The initial setting time of the grouting material is 75min, the final setting time of the grouting material is 135min, and the slurry retention rate reaches 93.82% when the water flow speed is 0.5m / s after grouting.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com