Polyurethane gel coat combination capable of spraying blades of fan conventionally and preparation method of polyurethane gel coat combination

A fan blade, polyurethane technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of contradiction between gel time and sandability and drying degree, labor-intensive, low roller coating construction efficiency, etc. Conflict between glue time and sandability and dryness, saving manpower and material resources, and the effect of good machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

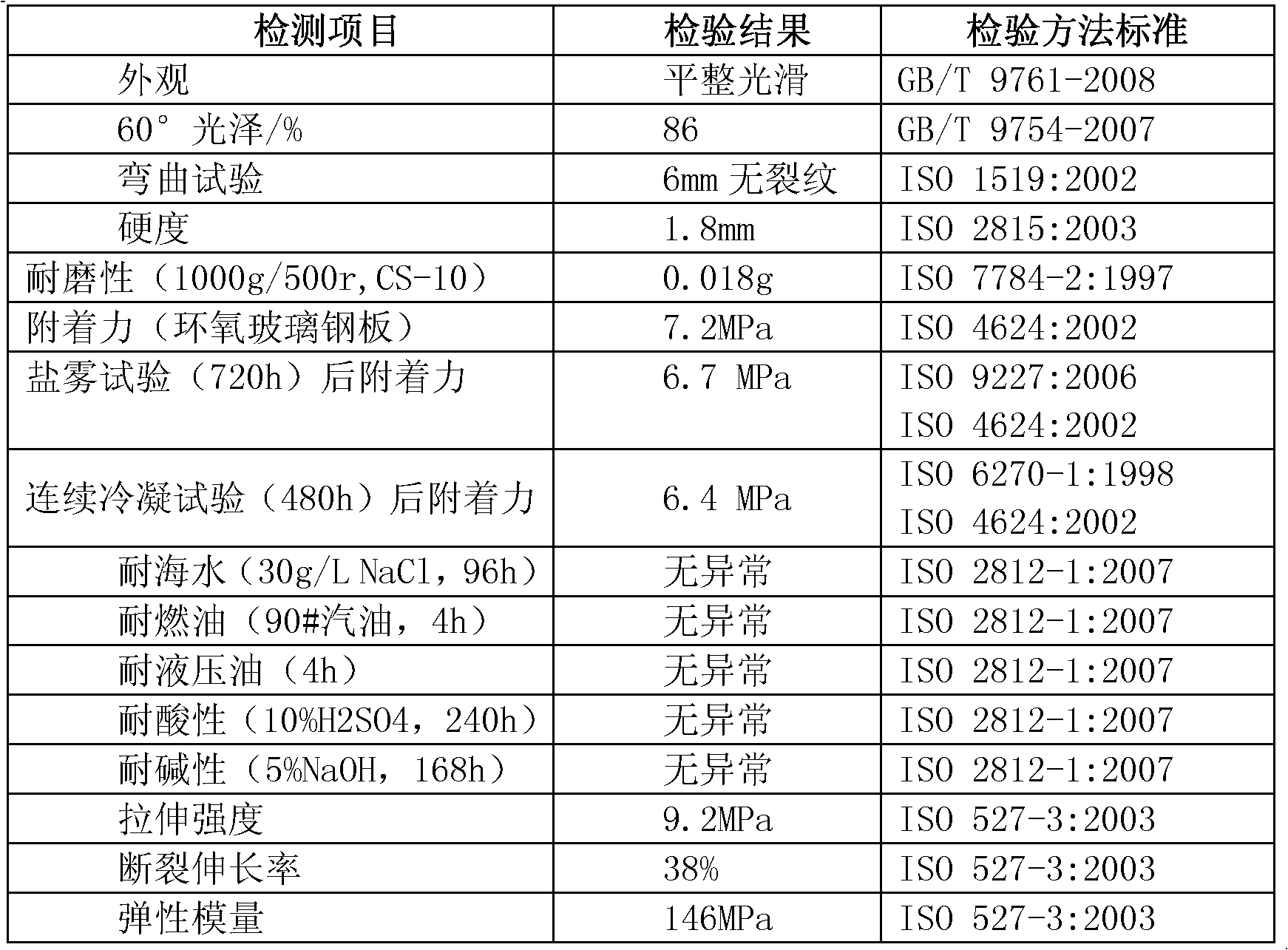

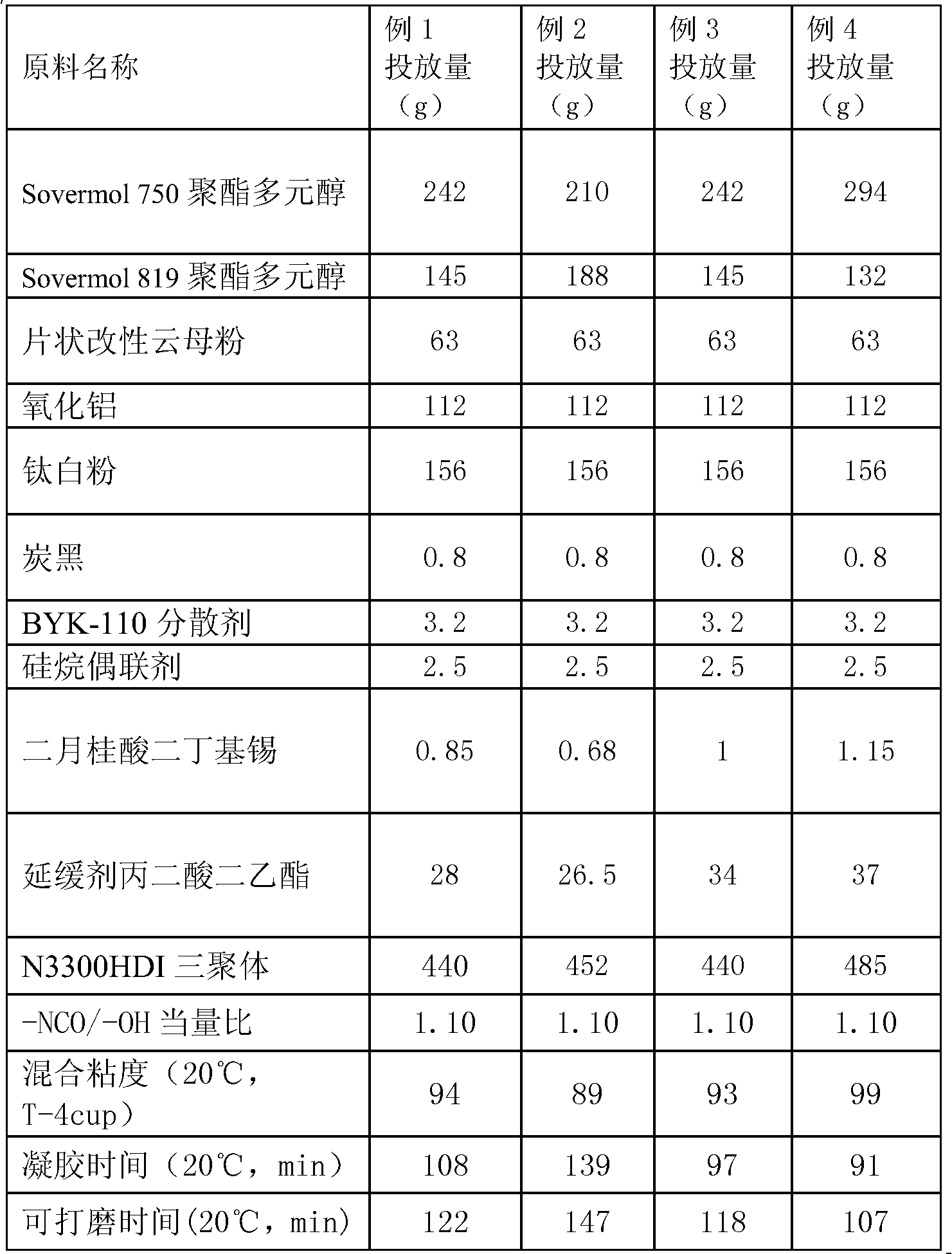

Embodiment 1

[0045] 242g of commercially available Sovermol 750 polyester polyol of Corning Company, 145g of Sovermol 819 polyester polyol of commercially available Corning Company, 3.2g of BYK-110 dispersant, 2.5g of SH-6040 silane coupling agent of Dow Corning Company, dilauric acid Dibutyltin 0.85g, retarder diethyl malonate 28g pre-mixed for 10min until uniform, add 112g of alumina, flake modified mica powder 63g, titanium dioxide 156g, carbon black 0.8g, and act in a high-speed centrifugal disperser Disperse for 45 minutes until the fineness is less than 45 microns to obtain the gel coat main agent. The finished polyurethane gel coat was obtained by mixing the main agent with 440 g of the commercially available Bayer N3300HDI trimer. The viscosity of this system after mixing is 94s (20°C, T-4cup), the gel time after mixing is 108min, and the polishing time is 122min. Spraying is carried out on conventional spraying equipment with a nozzle of 0.23 inches, and the thickness of the coat...

Embodiment 2

[0047] 210g of Sovermol 750 polyester polyol of commercially available Corning Company, 188g of Sovermol 819 polyester polyol of commercially available Corning Company, 3.2g of BYK-110 dispersant, 0.68g of dibutyltin dilaurate, retarder diethylmalonate Premix 26.5g of ester for 10min until uniform, add 112g of alumina, 63g of flaky modified mica powder, 156g of titanium dioxide, and 0.8g of carbon black, and disperse for 45min under the action of a high-speed centrifugal disperser until the fineness is below 45 microns to obtain glue Clothes agent. The finished polyurethane gel coat was obtained by mixing the main agent with 452 g of the commercially available Bayer N3300HDI trimer. The viscosity of this system after mixing is 89s (20°C, T-4cup), the gel time after mixing is 139min, and the polishing time is 147min. Spraying is carried out on conventional spraying equipment with a nozzle of 0.23 inches, and the thickness of the coating film reaches 200 microns at one time, an...

Embodiment 3

[0049] 242g of commercially available Sovermol 750 polyester polyol of Corning Company, 145g of commercially available Sovermol 819 polyester polyol of Corning Company, 3.2g of BYK-110 dispersant, 1.15g of dibutyltin dilaurate, retarder diethylmalonate Premix 34g of ester for 10min until uniform, add 112g of alumina, 63g of flaky modified mica powder, 156g of titanium dioxide, and 0.8g of carbon black, and disperse for 45min under the action of a high-speed centrifugal disperser until the fineness is below 45 microns to obtain a gel coat main agent. The finished polyurethane gel coat was obtained by mixing the main agent with 440 g of the commercially available Bayer N3300HDI trimer. The viscosity of this system after mixing is 93s (20°C, T-4cup), the gel time after mixing is 97min, and the polishing time is 118min. Spraying is carried out on conventional spraying equipment with a nozzle of 0.23 inches, and the thickness of the coating film reaches 200 microns at one time, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com