Patents

Literature

1375results about How to "Prevent discoloration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing a polymer having a 2,5-furandicarboxylate moiety within the polymer backbone and such (CO)polymers

A process for preparing a polymer having a 2,5-furandicarboxylate moiety within the polymer backbone and having a number average molecular weight of at least 10,000 (as determined by GPC based on polystyrene standards) includes a first step where a prepolymer is made having the 2,5-furandicarboxylate moiety within the polymer backbone, followed in a second step by a polycondensation reaction. In the first step a 2,5-furandicarboxylate ester is transesterified with a compound or mixture of compounds containing two or more hydroxyl groups, in the presence of a tin(IV) based transesterification catalyst. In the second step at reduced pressure and under melt conditions the prepolymer prepared in the first step is polycondensed in the presence of a tin (II) based polycondensation catalyst until the polymer is obtained. This polymer may then be subjected to Solid State Polycondensation. Polymers so produced may have a 2,5-furandicarboxylate moiety within the polymer backbone, and having a number average molecular weight of at least 20,000 (as determined by GPC based on styrene standards), and an absorbance as a 5 mg / mL solution in a dichloromethane:hexafluoroisopropanol 8:2 at 400 nm of below 0.05.

Owner:FURANIX TECH BV

Inherently antimicrobial quaternary amine hydrogel wound dressings

InactiveUS6039940APrevent discolorationAvoid hydrolysisBiocideConductive materialSterile environmentAryl

A composition and method for treating a wound with an inherently antimicrobial dressing. The dressing is a hydrogel containing from about 15 to 95 percent, and preferably from about 61 to 90 percent, by weight of a cationic quaternary amine acrylate polymer prepared by the polymerization of acryloyloxyethyl(or propyl)-trialkyl(or aryl)-substituted ammonium salts or acrylamidoethyl(or propyl)-trialkyl(or aryl)-substituted ammonium salts. The antimicrobial hydrogels are non-irritating to the wound, absorb wound exudate, and, due to the inherently antimicrobial properties, enhance the sterile environment around the wound. The hydrogels have sufficient adhesive properties that loose contact with the wound is assured but can also be removed without leaving any gel residue on the wound. The wound dressings are preferably formed on a substrate, such as a web or patch, for ease in application to and removal from the wound. If desired, additional antimicrobial or other pharmaceutically active agents can also be incorporated into the hydrogel structure.

Owner:AVENT INC

Heavy polymer coated slow-release fertilizer with sulfide as bottom coat

InactiveCN1569774AStrong impact resistanceImprove wear resistanceFertiliser formsUrea compound fertilisersControl releaseCoated urea

The invention relates to an enveloped controlled release fertilizer and method for preparation which consists of, preheating the urea particles to a predetermined temperature, spraying the molten liquid state sulfur to the urea particles, forming a layer of smooth and compact sulfur-coated urea, charging hot-curing resin component on the sulfur-coated urea for even distribution onto the urea particle surface and fast formation.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

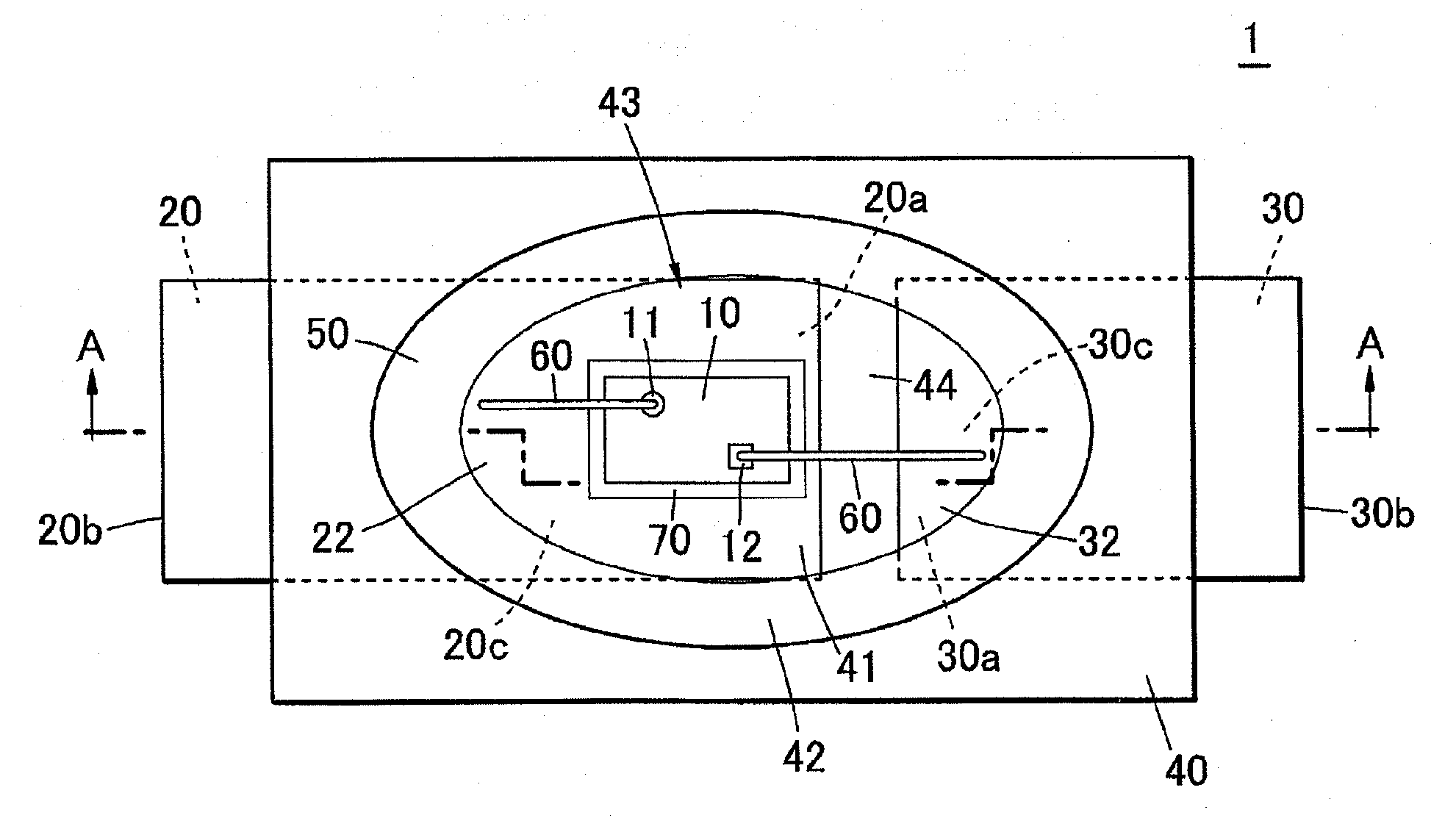

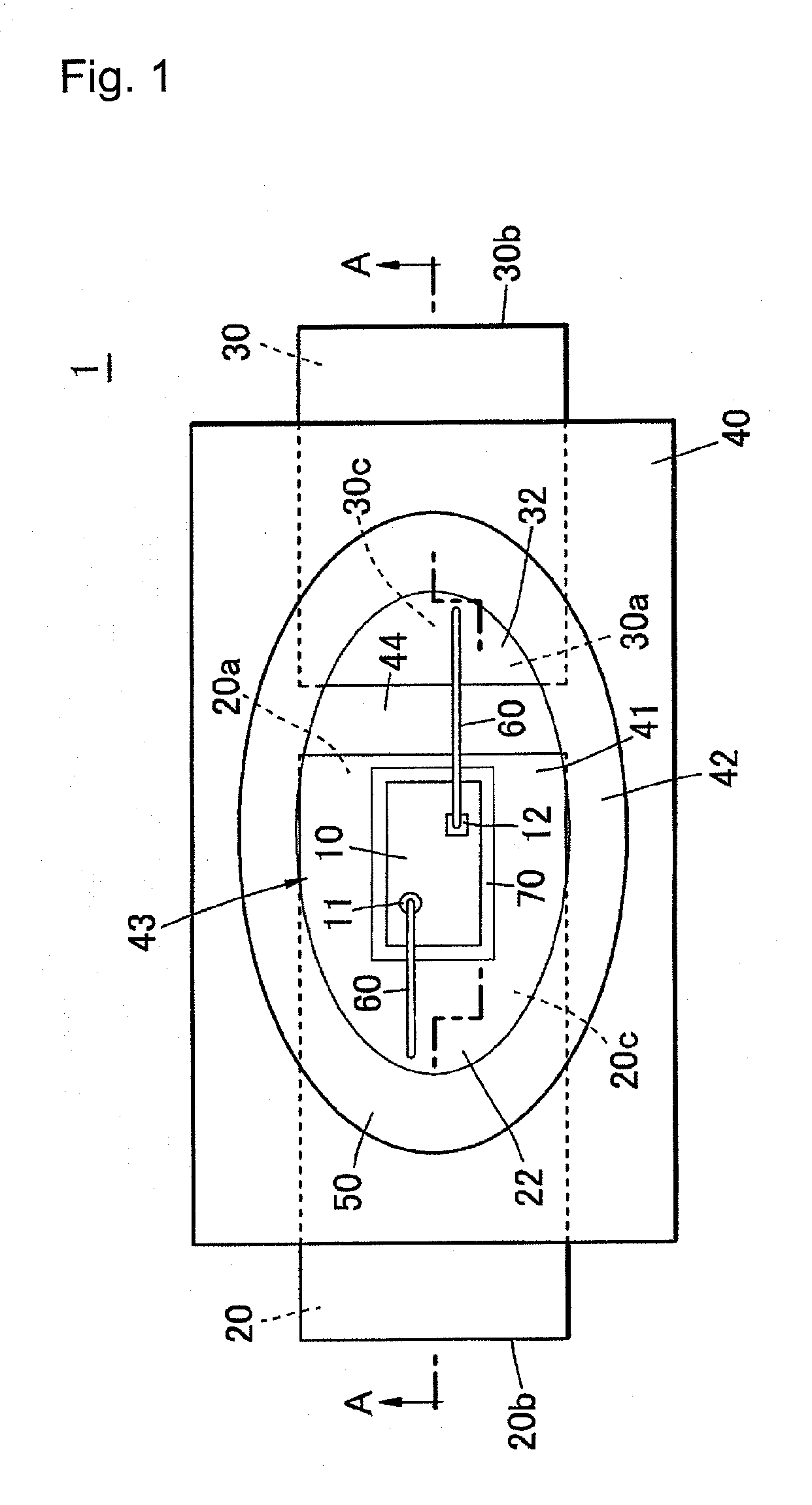

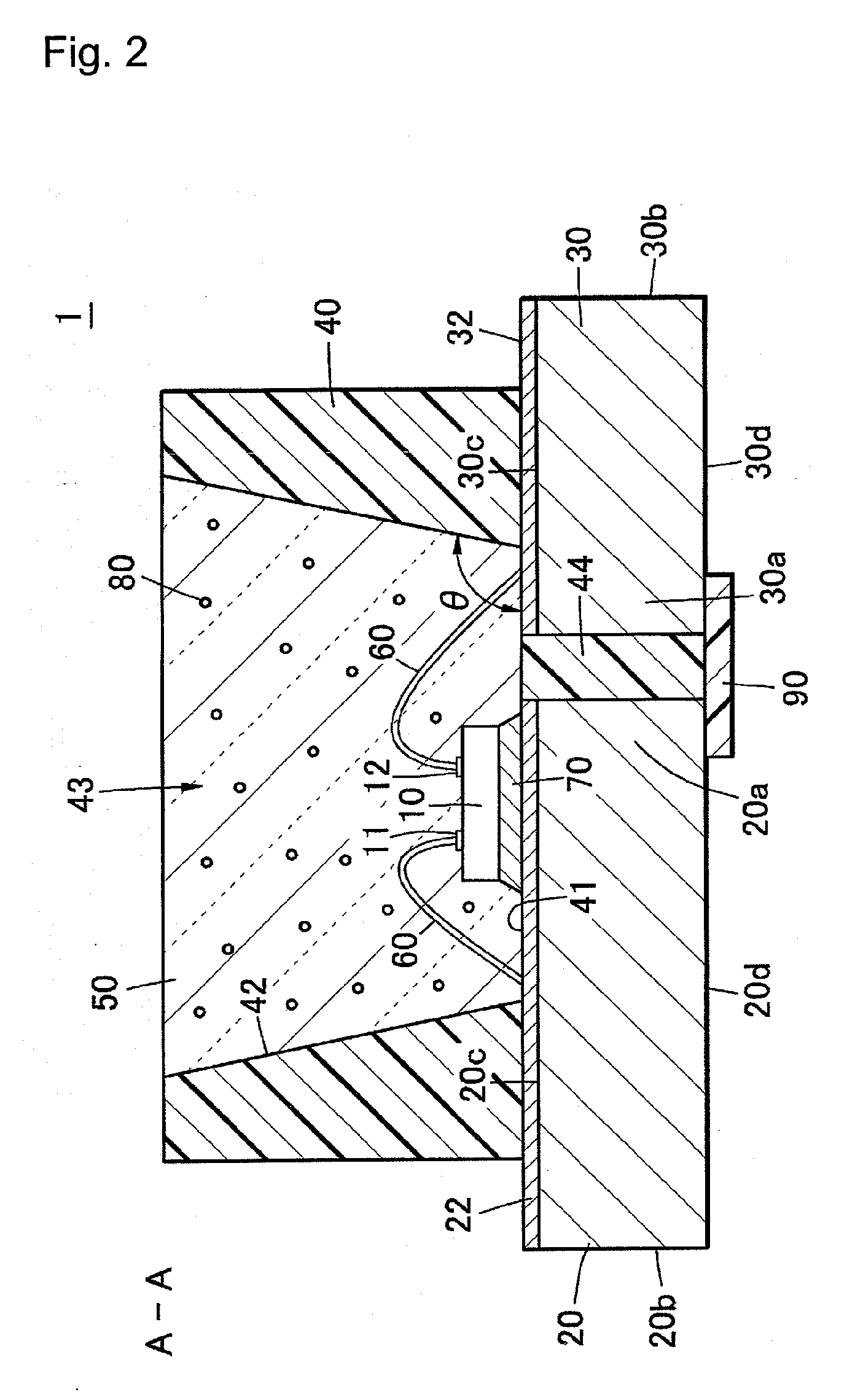

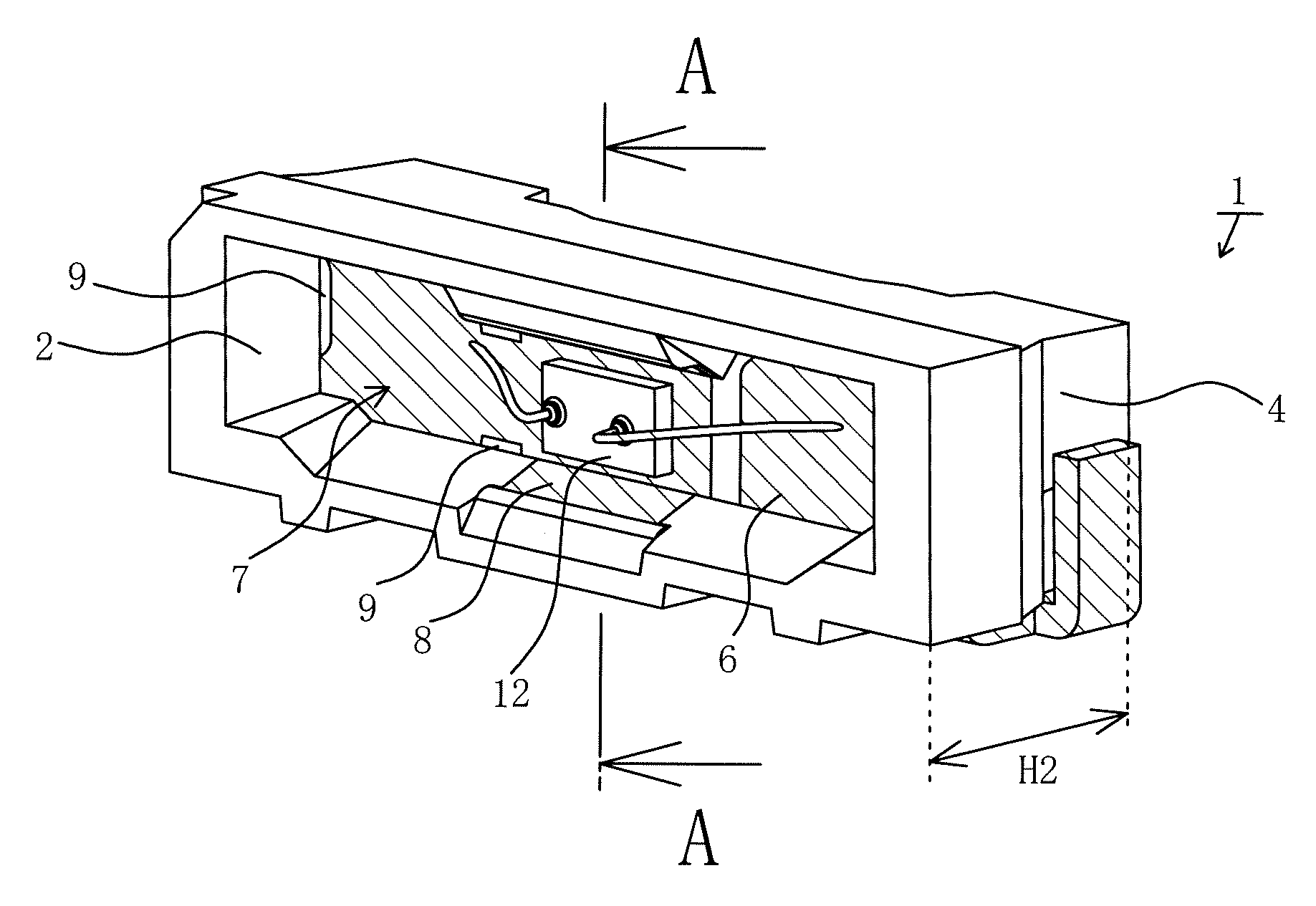

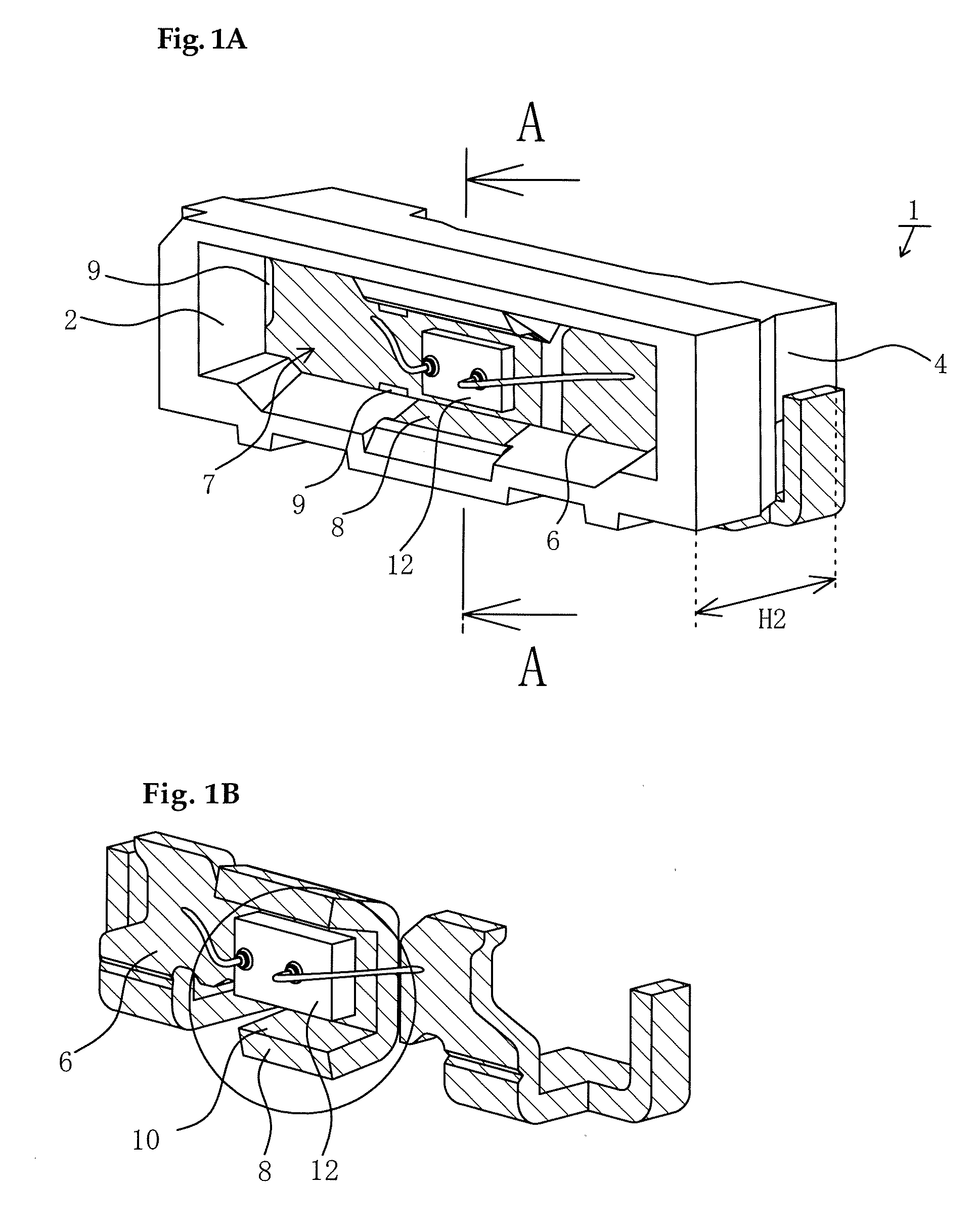

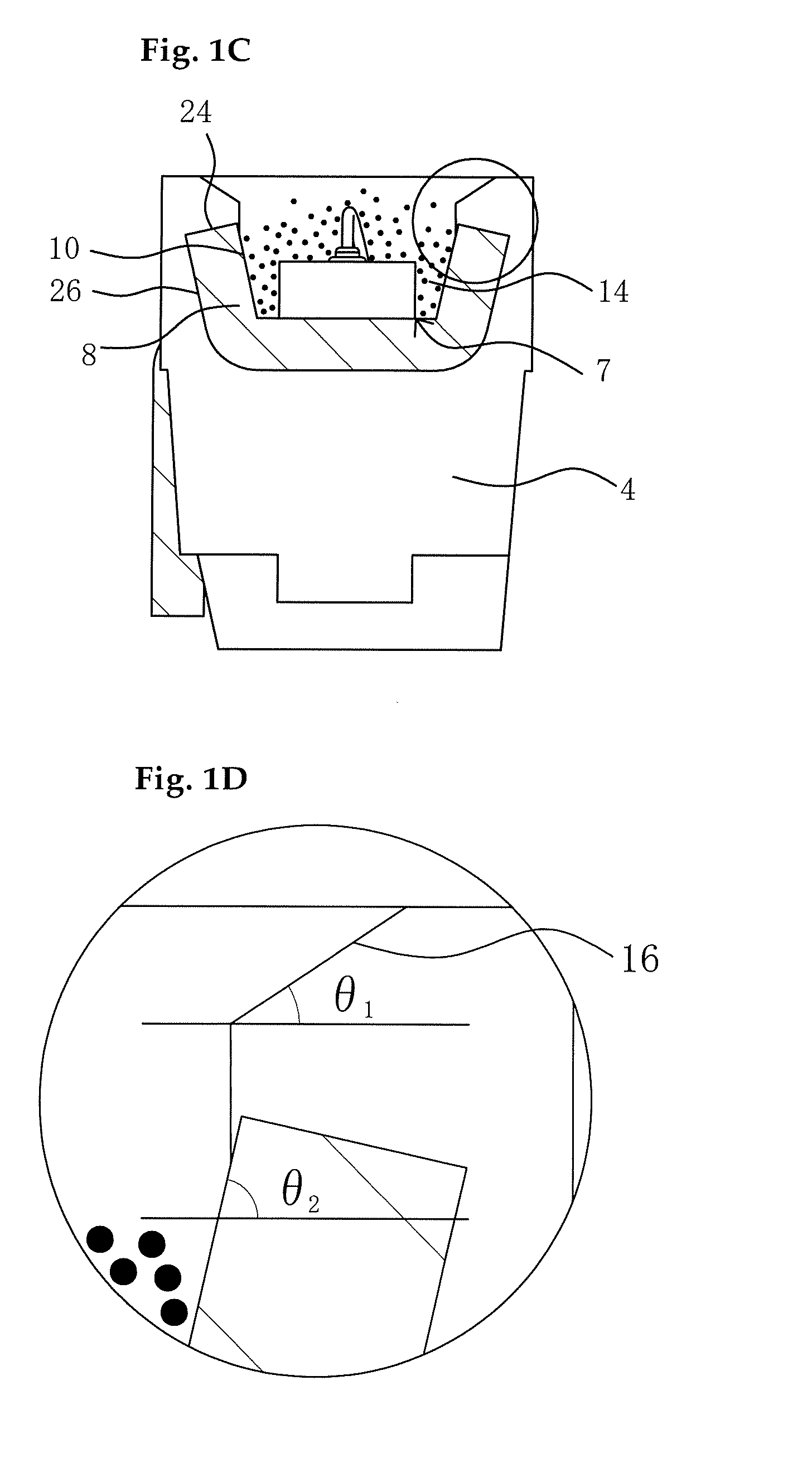

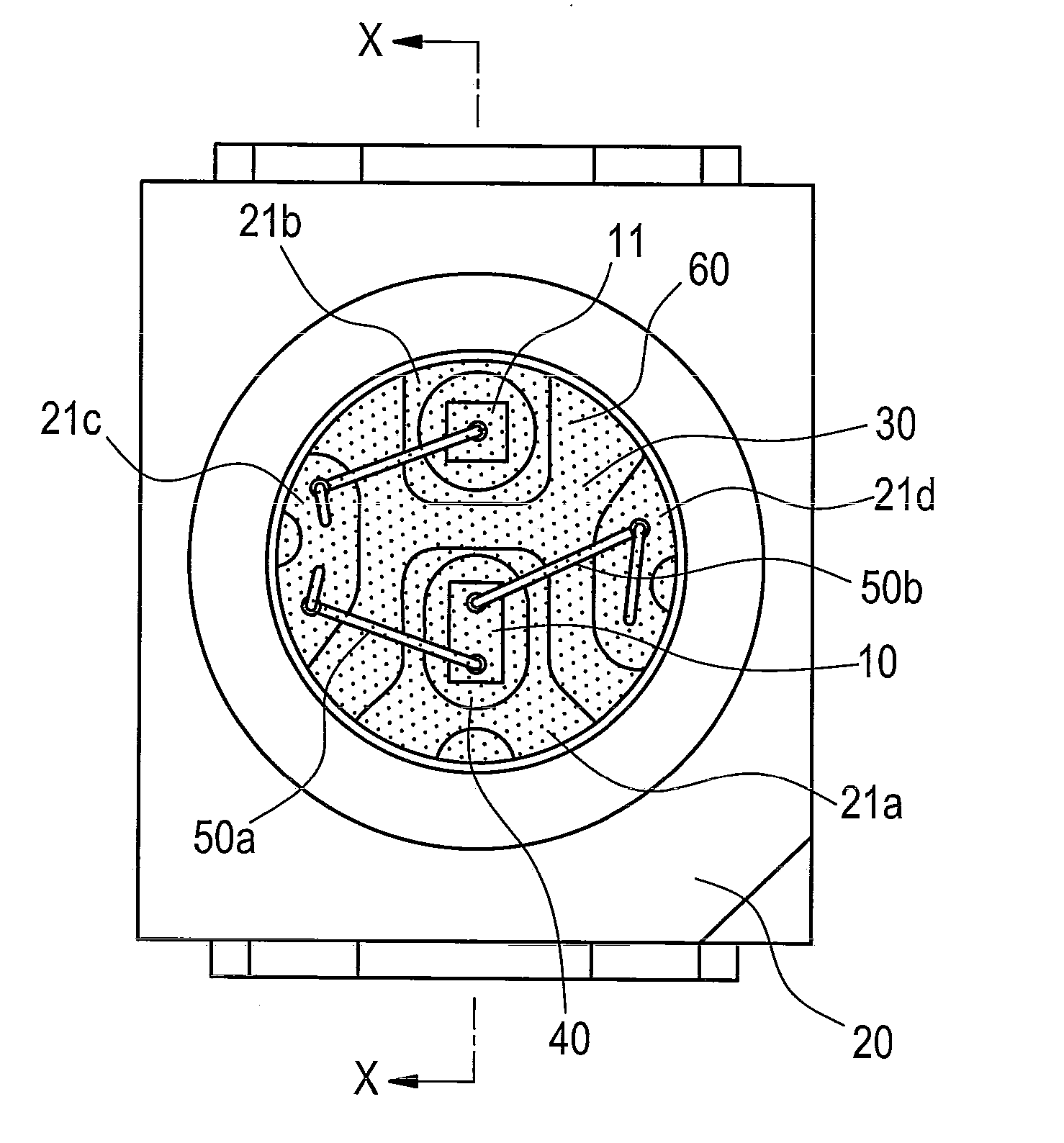

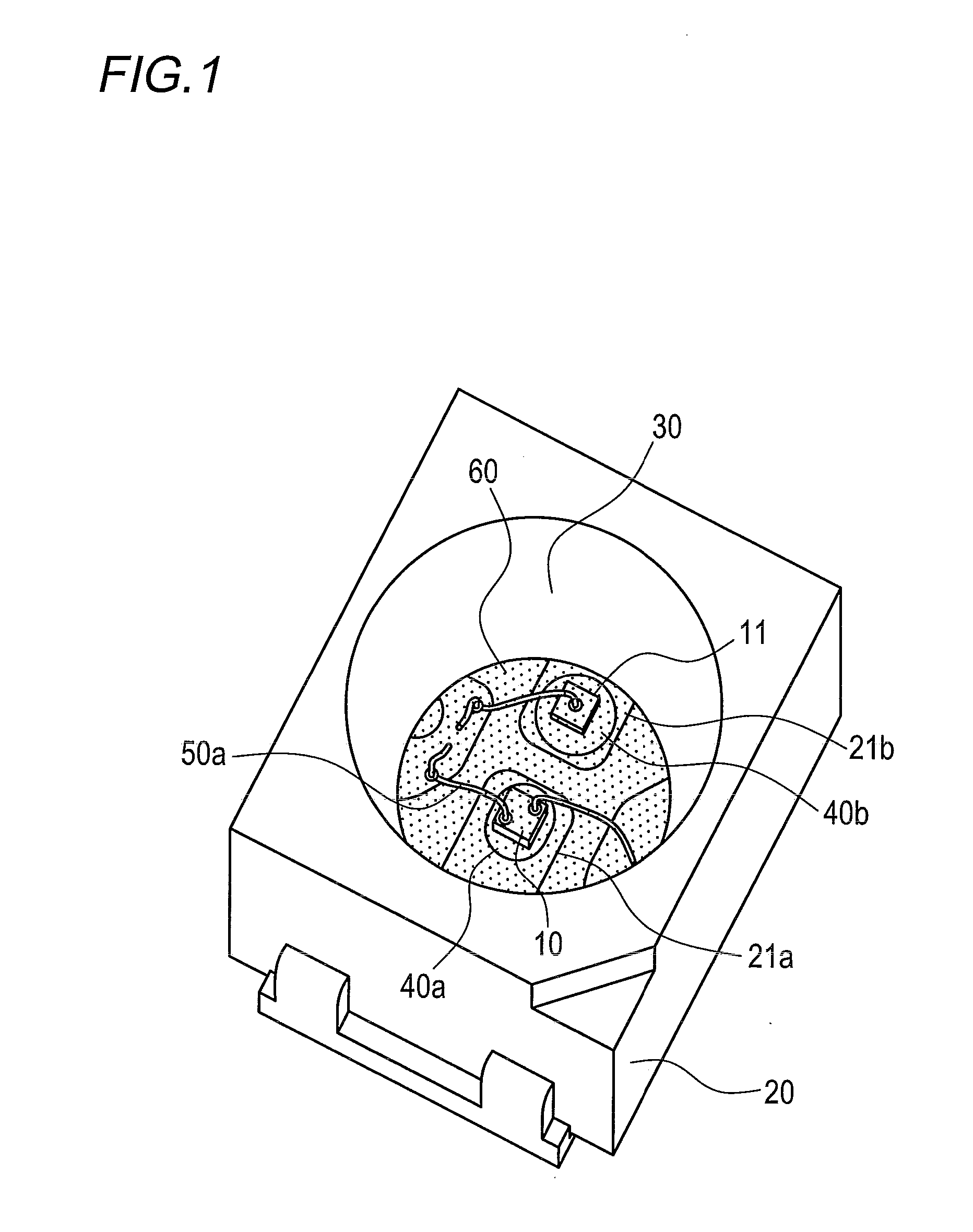

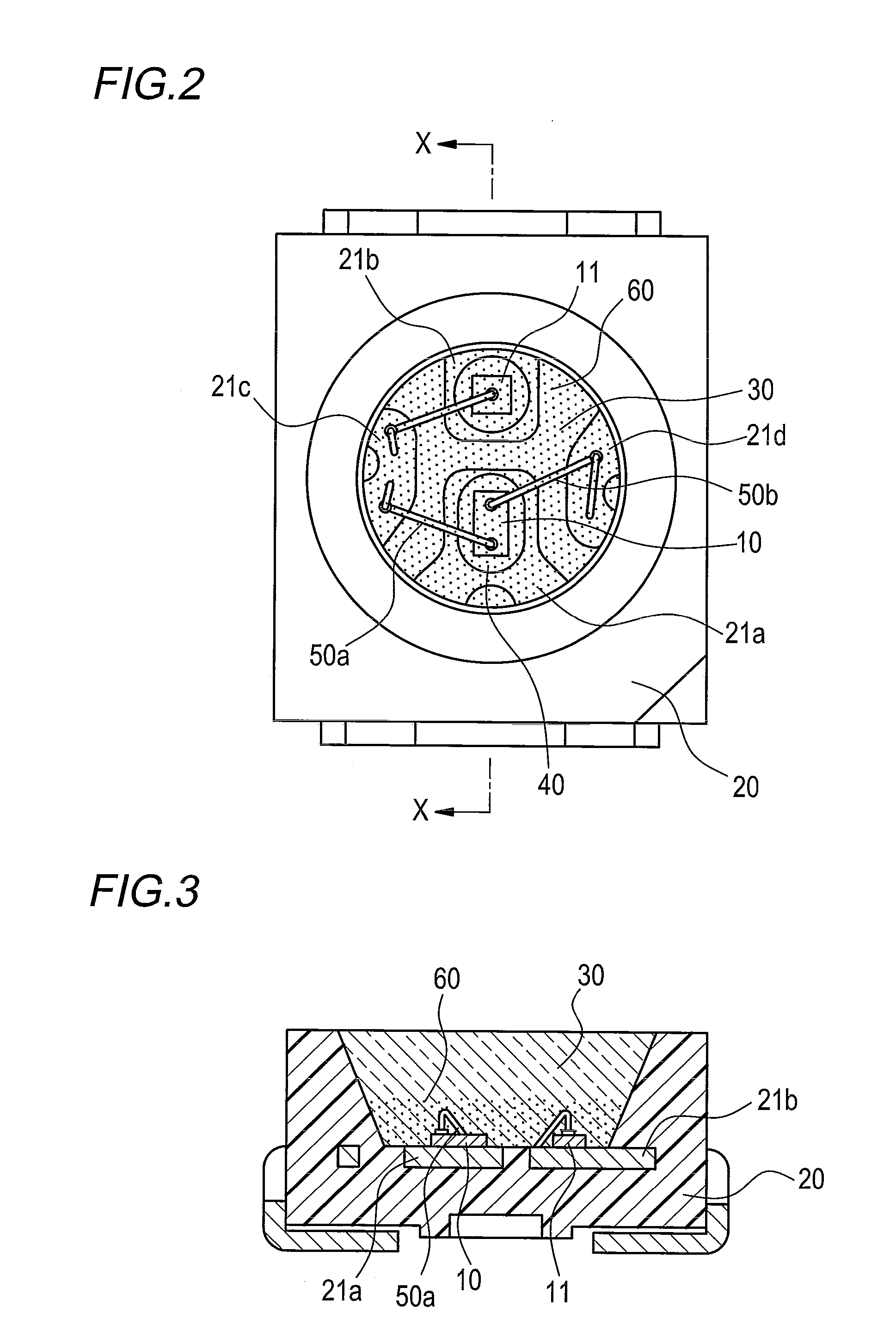

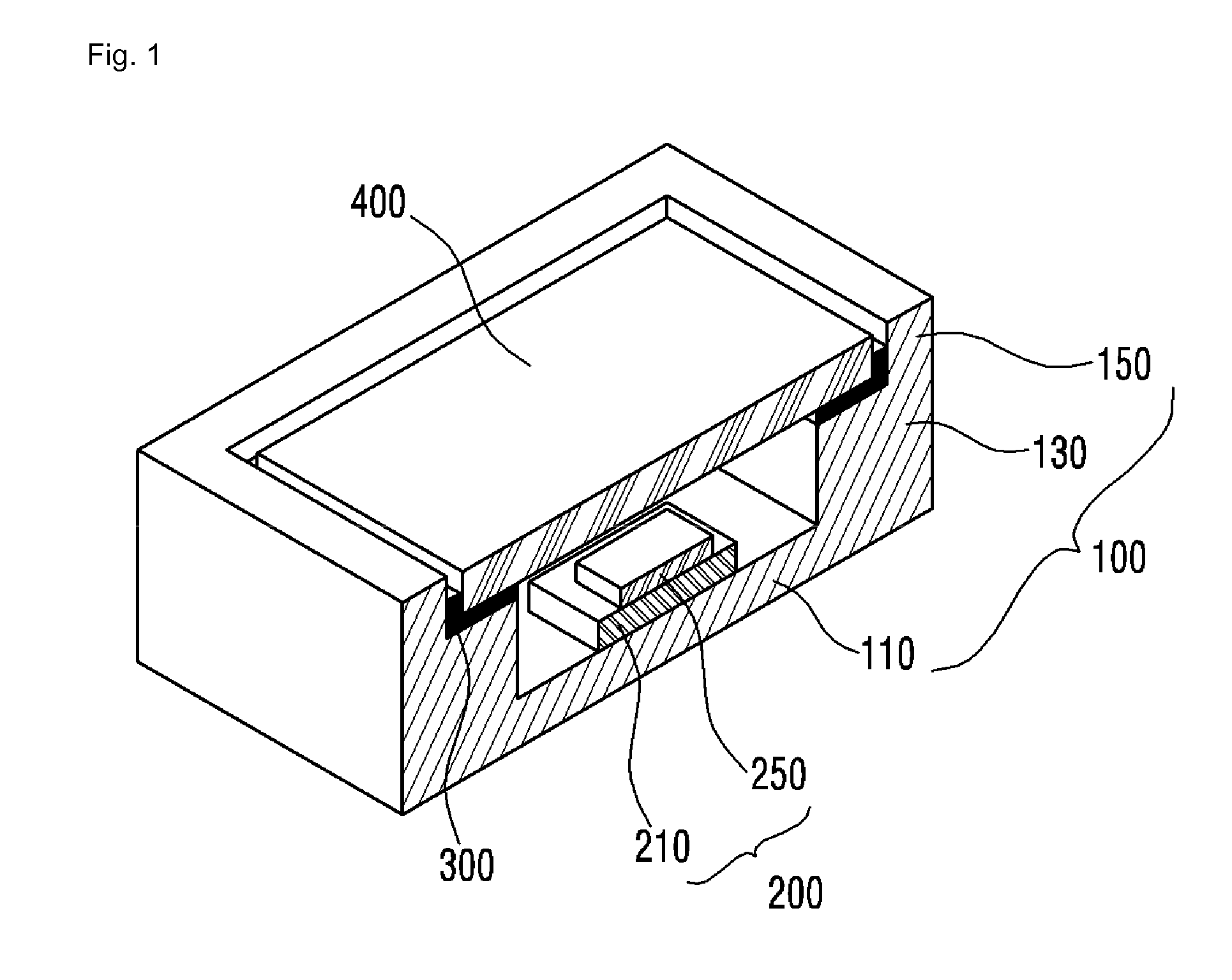

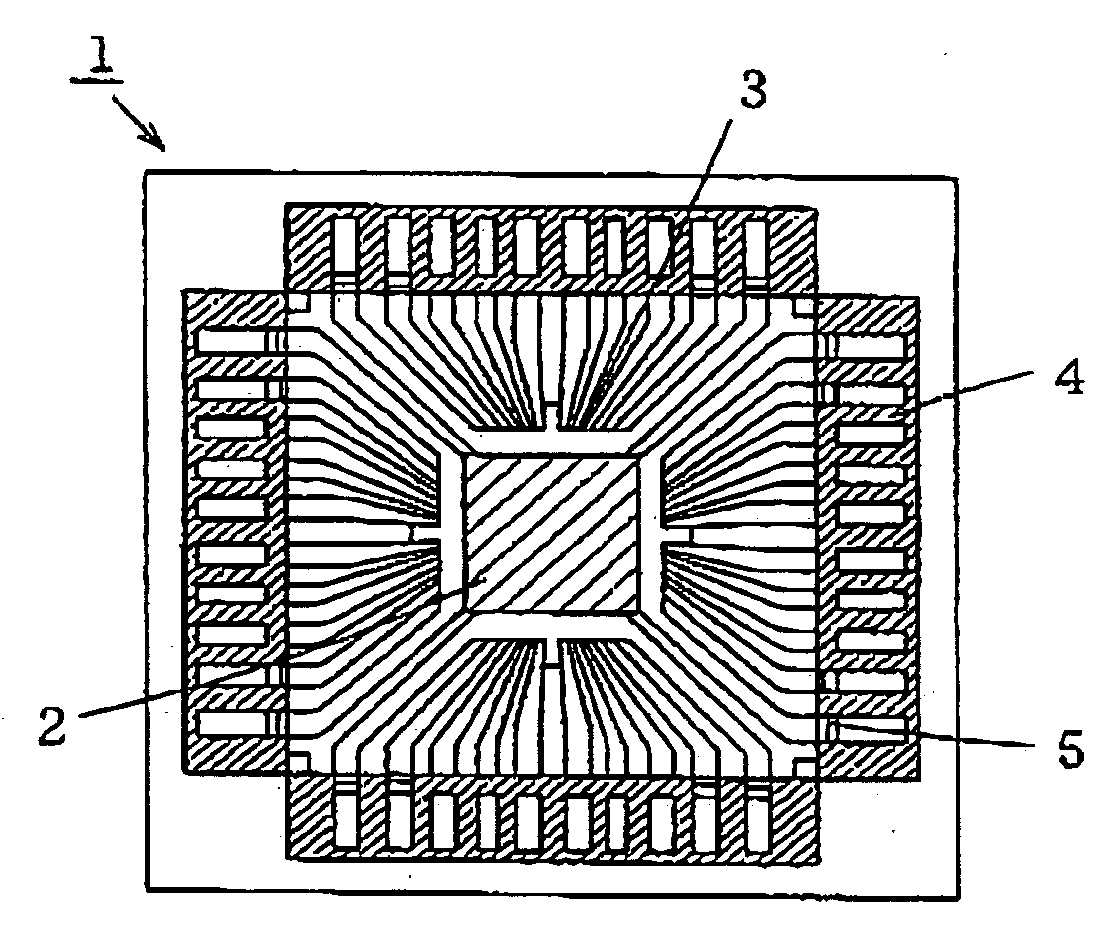

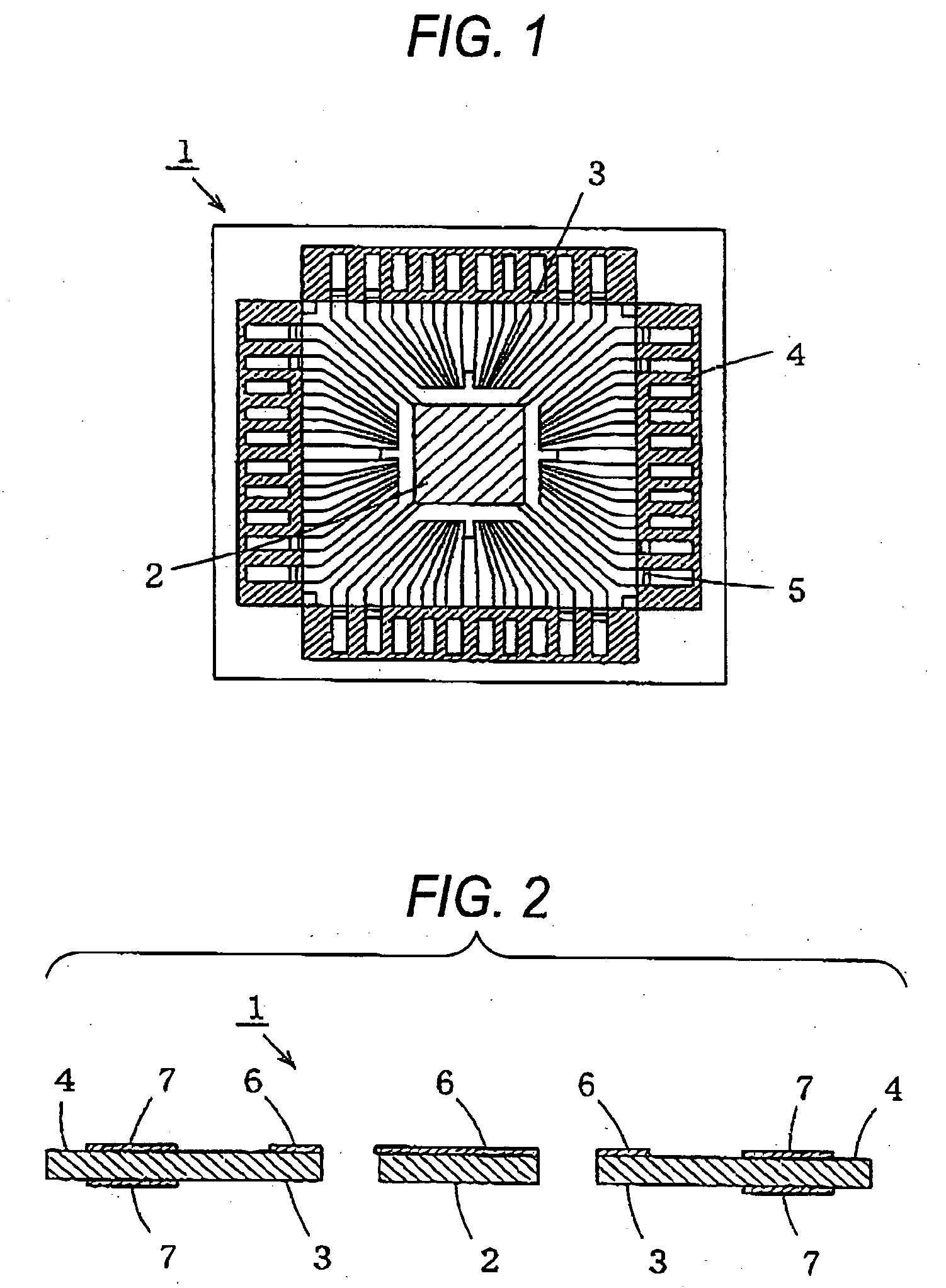

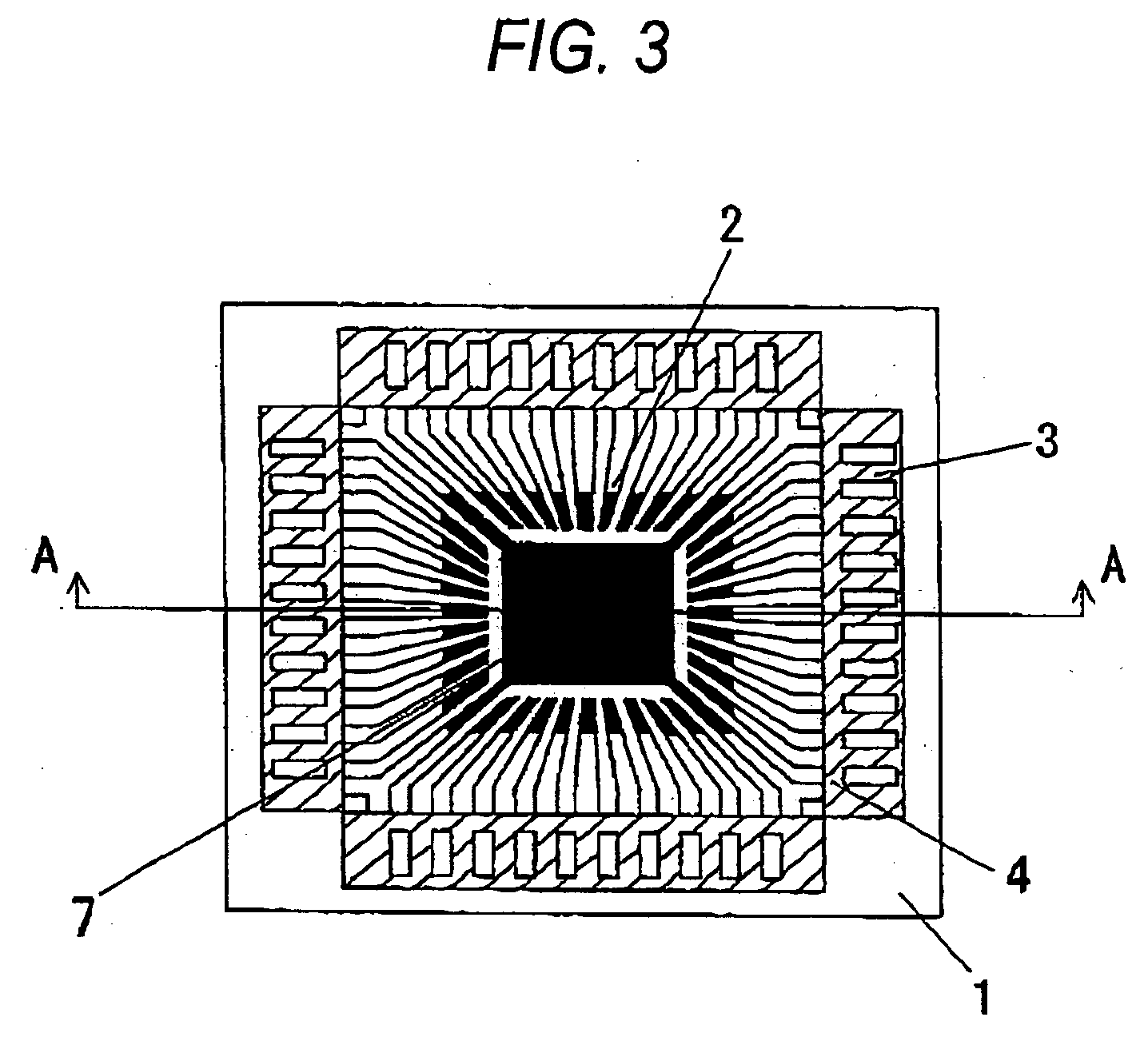

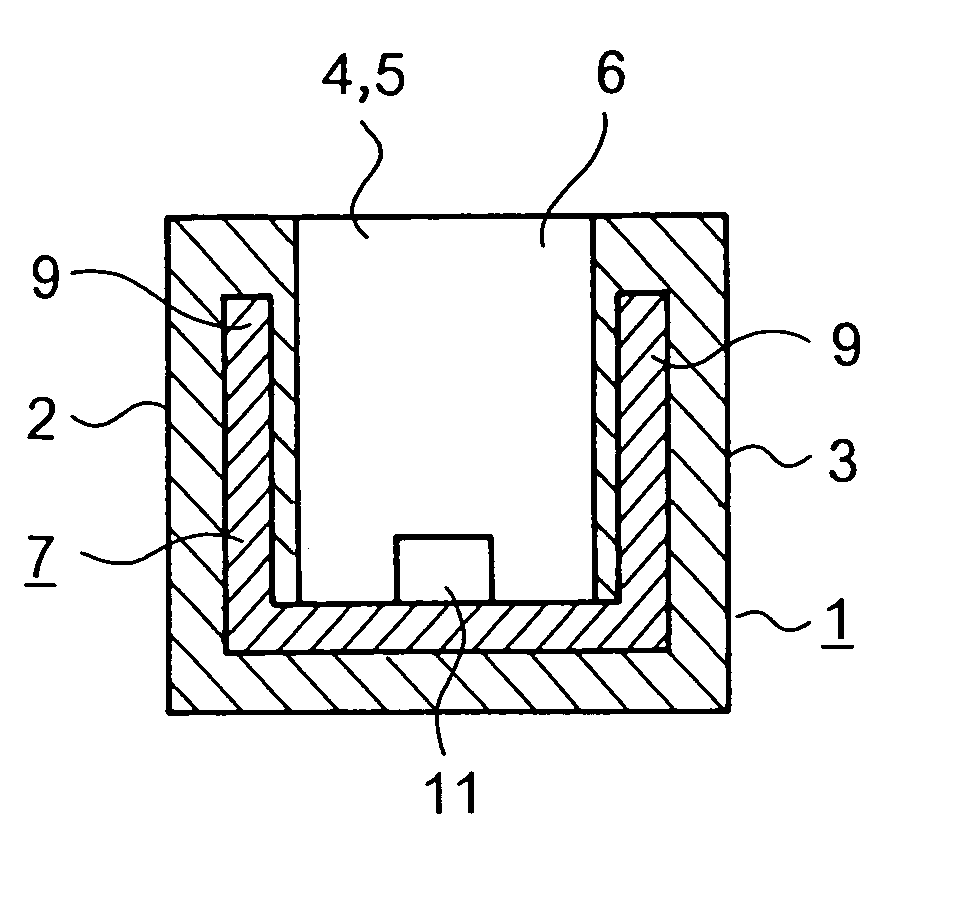

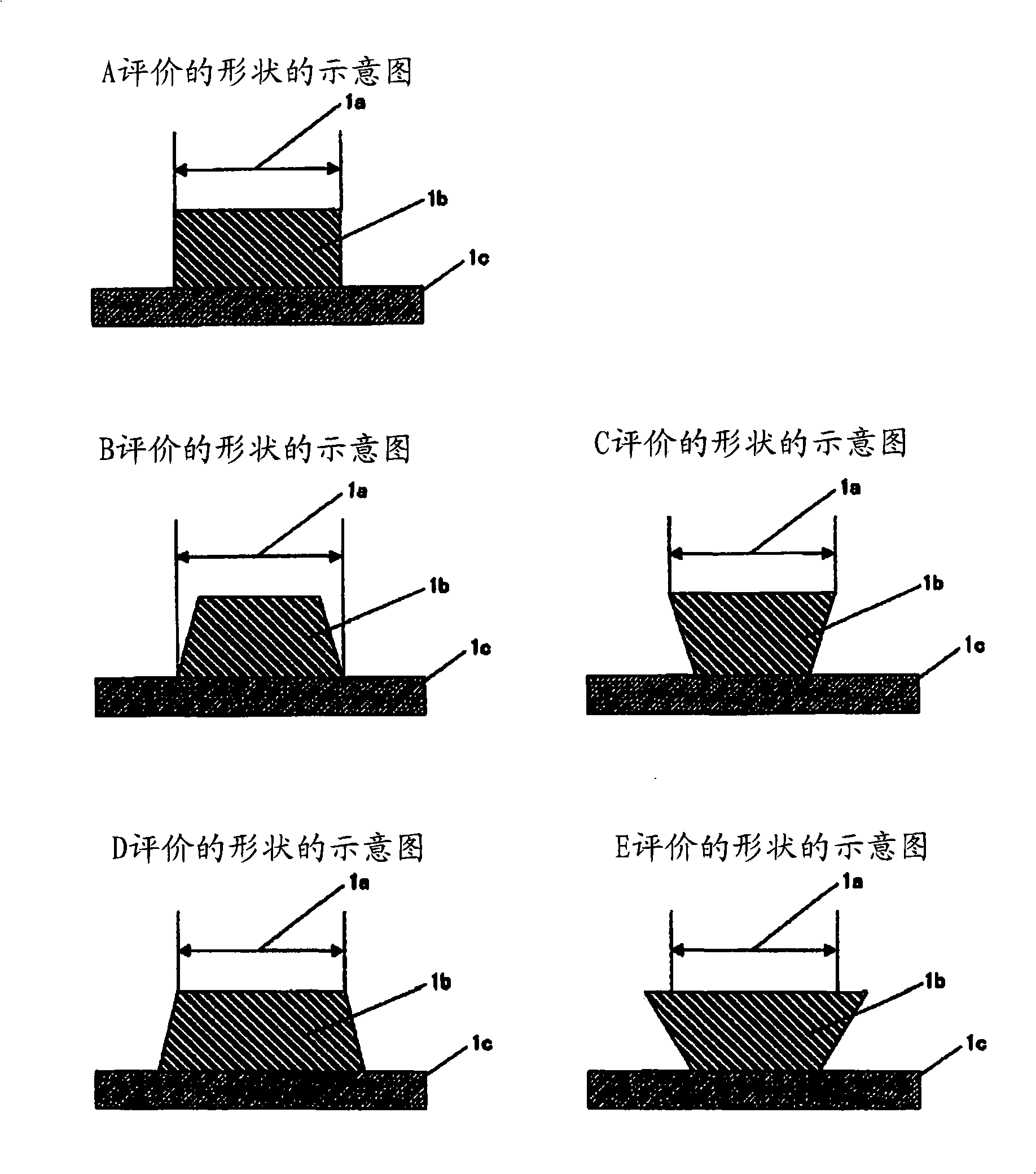

High output power light emitting device and packaged used therefor

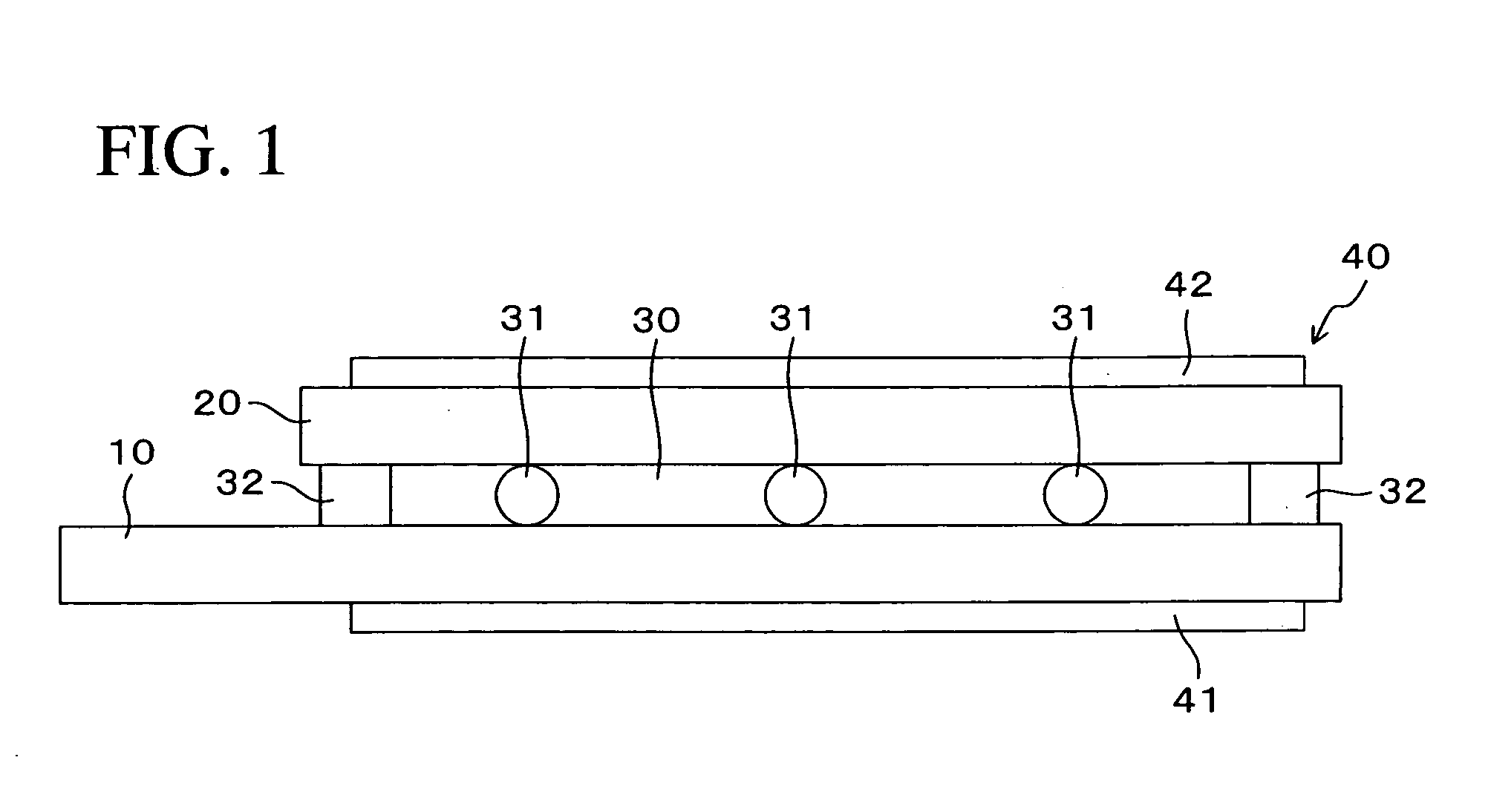

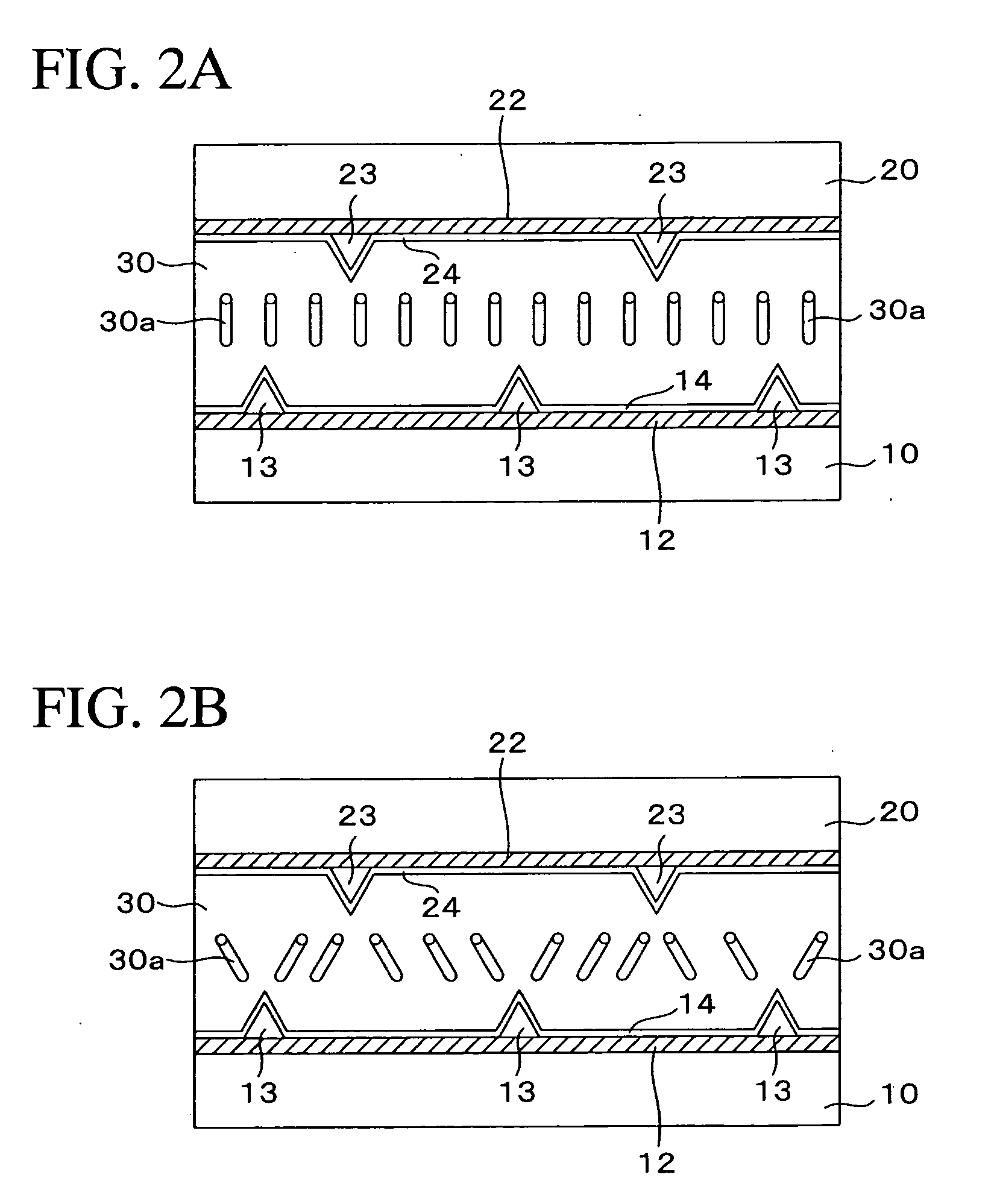

ActiveUS20090261374A1Increase output powerEasy to useSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLight emitting device

An object of the present invention is to provide a light emitting device that has high output power and long service life where a package is suppressed from discoloring due to heat generation. The light emitting device 1 of the present invention contains a light emitting element 10, a package 40 formed of a thermosetting resin, the package having a recess 43 wherein the light emitting element 10 is mounted, a first lead electrode 20 which is exposed at the bottom of the recess 43 of the package 40 and whereon the light emitting element 10 is mounted, and a second lead electrode 30 which is exposed at the bottom of the recess 43 of the package 40 and is electrically connected to the light emitting element 10. The light emitting element 10 is bonded to the first lead electrode 20 through a eutectic layer 70, and at least a surface of the first electrode 20 is coated with an Ag film 22, a thickness of the Ag film 22 being in the range from 0.5 μm to 20 μm.

Owner:NICHIA CORP

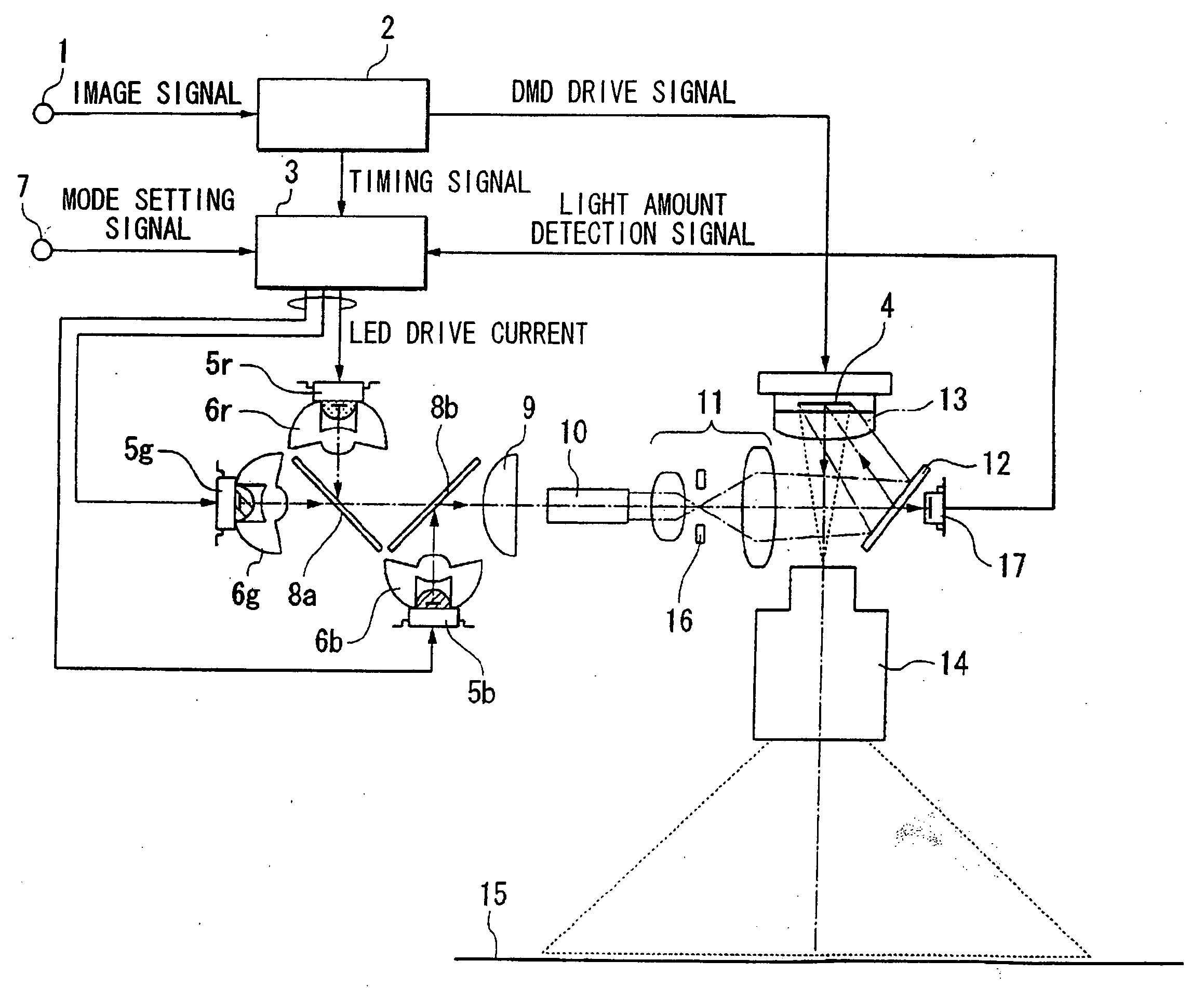

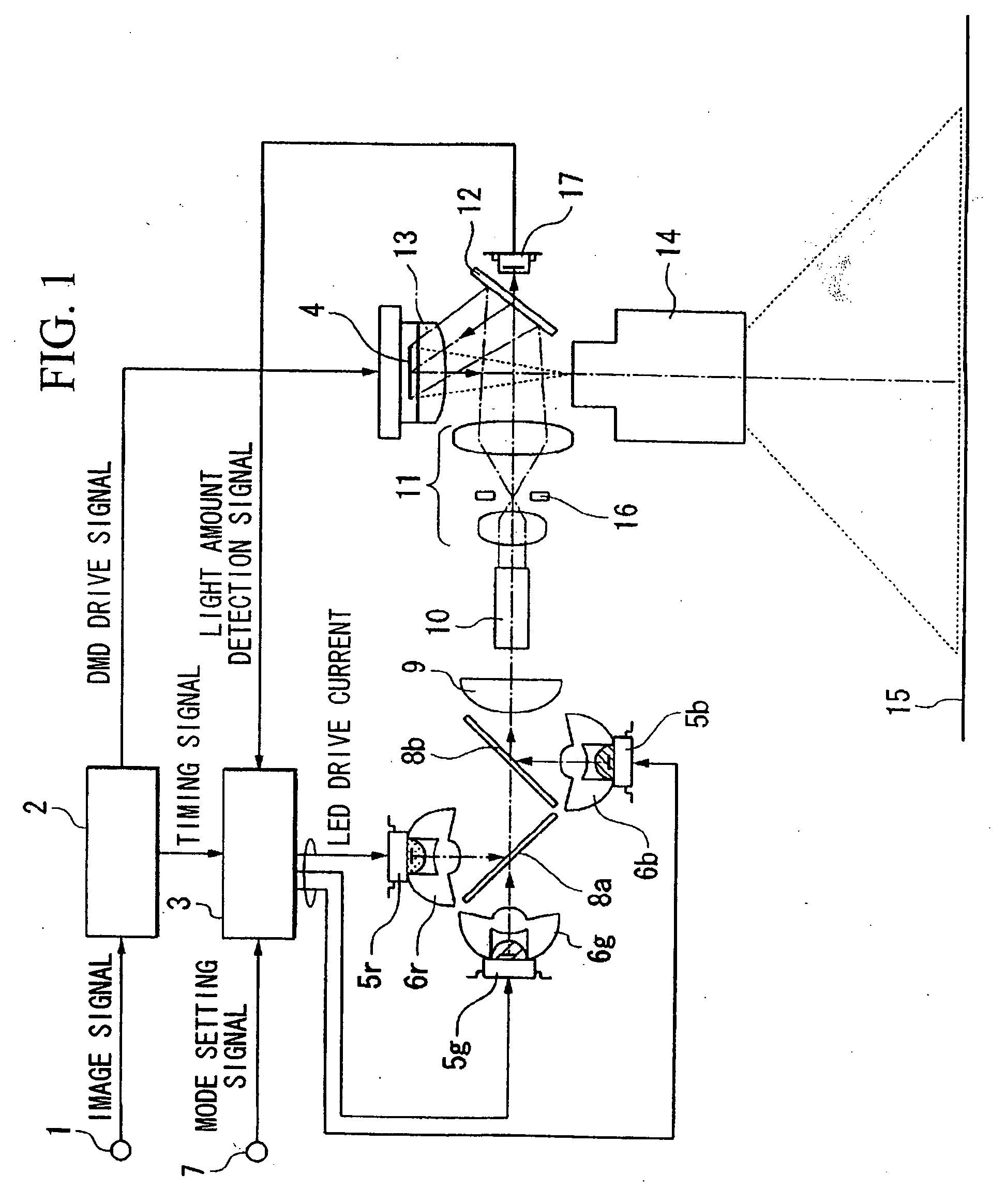

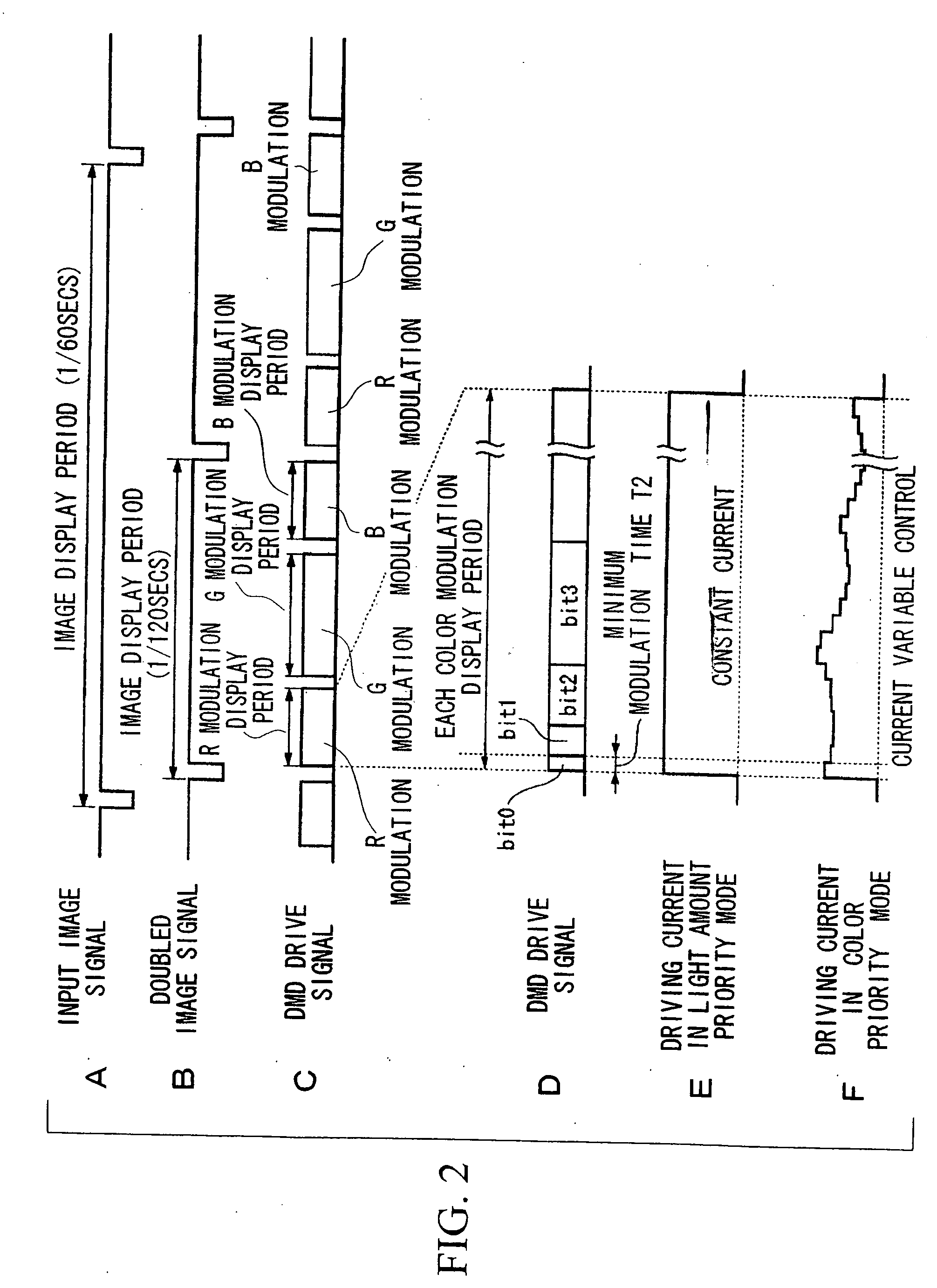

Image projection apparatus

InactiveUS20060279710A1Inhibit deteriorationGood colorTelevision system detailsProjectorsInput controlOptoelectronics

There is provided An image projection apparatus comprising: a spatial light modulation element that modulates illumination light by switching the display and non-display statuses of the respective pixels based on pulse width modulation driving to perform gradation expression for each pixel; a light source section able to increase and decrease the amount of illumination light output according to an input controlled variable; a light source control section that periodically controls the light amount of the illumination light output from the light source section; and a projection optical section that projects images modulated by the spatial light modulation element, wherein the light source control section selectively controls the light amount of the illumination light output from the light source section by either one of a first mode in which the controlled variable is changed in a first control period that is shorter than the display period for the spatial light modulation element to display the input image information, and a second mode in which the controlled variable is changed in a second control period that is longer than the first control period.

Owner:OLYMPUS CORP

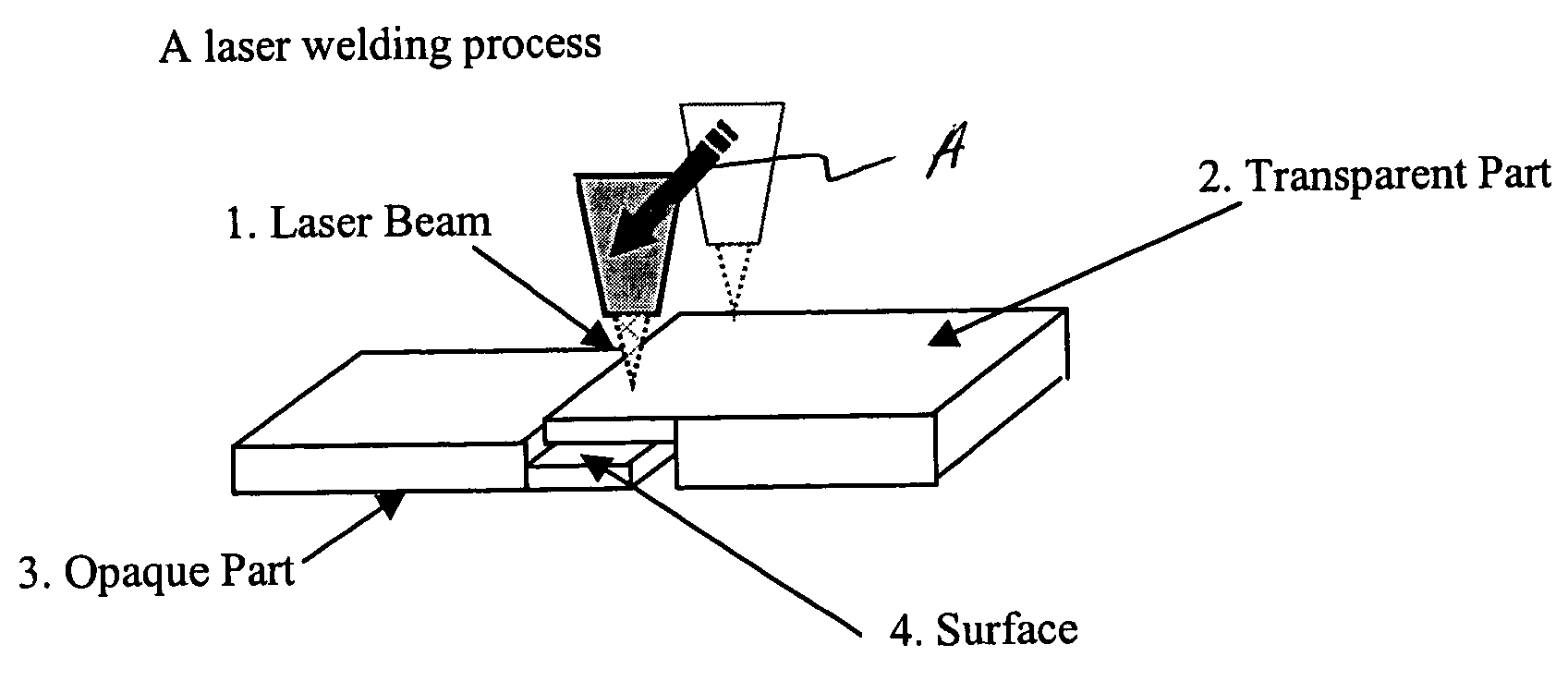

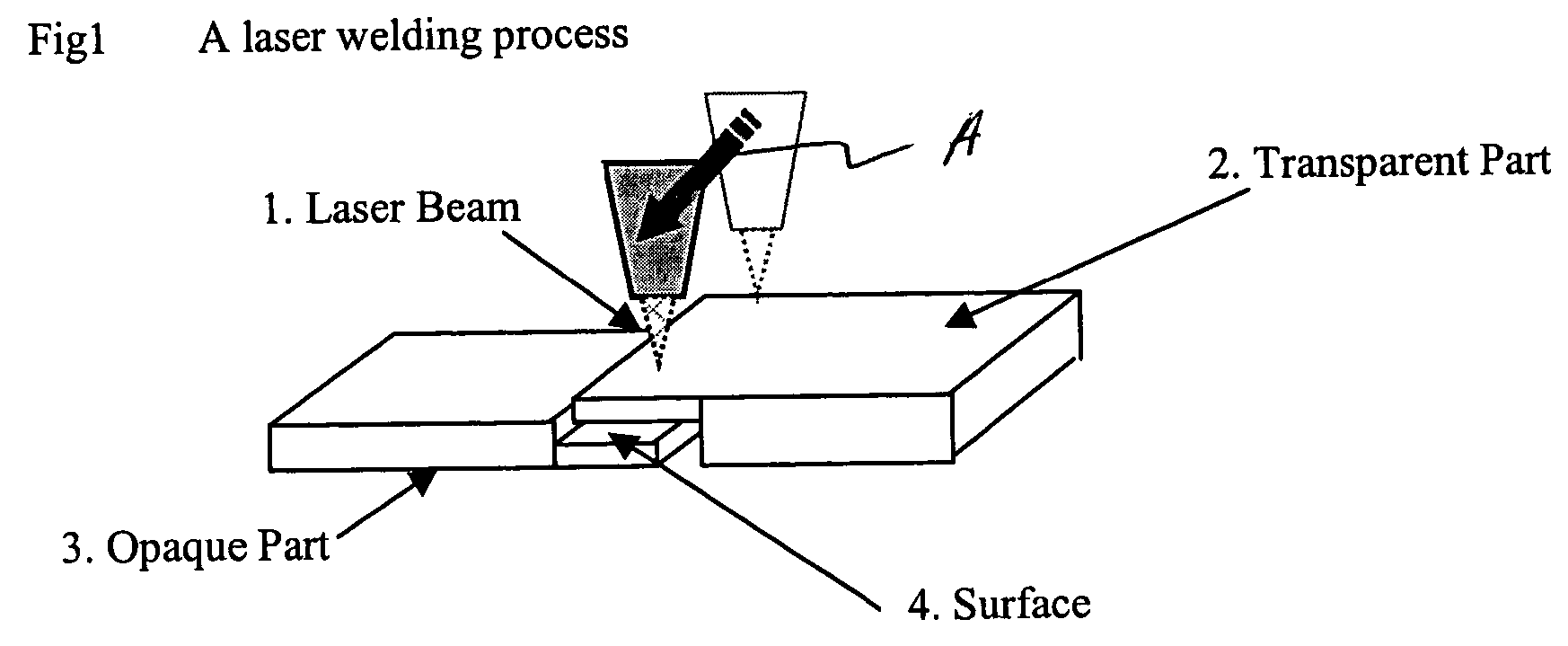

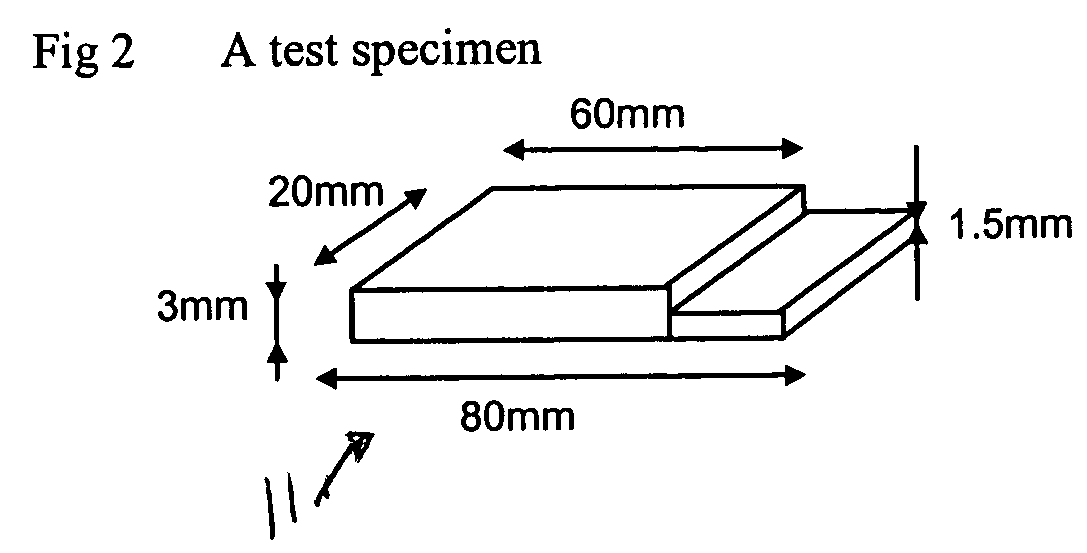

Process for laser welding together articles of polyester resin compositions and related products

InactiveUS20040112519A1Improve flame retardant performanceImprove heat resistanceLamination ancillary operationsLaminationPolyester resinWeld strength

A process for laser welding together a laser beam transparent polyester article and a laser beam opaque polyester article. The method limits the use of a laser beam at an energy level not greater than 100 W at a scanning speed not greater than 1000 cm / min., thus causing the articles to be welded together and maintaining a high weld strength.

Owner:EI DU PONT DE NEMOURS & CO

Heavy polymer coated slow-release fertilizer with sulfide as bottom coat

InactiveCN1246265CStrong impact resistanceImprove wear resistanceFertiliser formsUrea compound fertilisersControl releaseCoated urea

The invention relates to an enveloped controlled release fertilizer and method for preparation which consists of, preheating the urea particles to a predetermined temperature, spraying the molten liquid state sulfur to the urea particles, forming a layer of smooth and compact sulfur-coated urea, charging hot-curing resin component on the sulfur-coated urea for even distribution onto the urea particle surface and fast formation.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Pressure sensitive adhesive composition for optical members, pressure sensitive adhesive layer for optical members, pressure sensitive adhesive optical member and image display

InactiveUS20050014879A1Improve adhesionExcellent in re-releasabilityFilm/foil adhesivesElectroluminescent light sourcesPolymer scienceMeth-

The present invention provides a pressure sensitive adhesive composition for optical members, which is excellent in durability, re-releasability and stress relaxation, as well as a pressure sensitive adhesive composition for optical members, which hardly increases adhesion after storage for a long time and does not leave a residual adhesive on glass upon disposal or repair. The pressure sensitive adhesive composition for optical members according to the present invention comprises 100 parts by weight of an acrylic polymer (A) having a weight-average molecular weight of 500,000 or more, containing at least 50 wt % alkyl (meth)acrylate having an alkyl group with 5 or more carbon atoms and 0.2 to 2 wt % unsaturated carboxylic acid as the monomer unit, 0.1 to 4 parts by weight of an acrylic polymer (B) having a weight-average molecular weight of 2,000 to 50,000, containing at least 70 wt % alkyl(meth)acrylate and 1 to 7 wt % unsaturated carboxylic acid as the monomer unit and having a higher carboxylic acid equivalent than that of the acrylic polymer (A), 0.01 to 1 part by weight of a silane coupling agent, and a crosslinking agent.

Owner:NITTO DENKO CORP

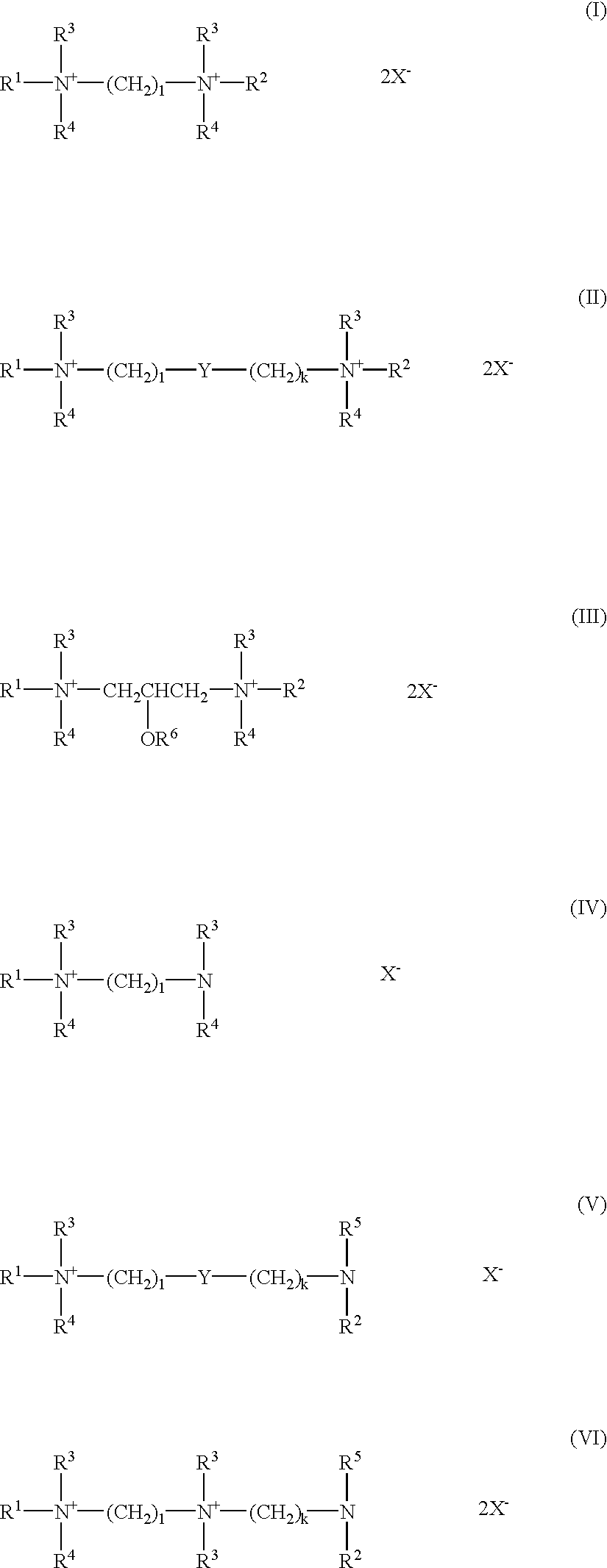

Softener composition

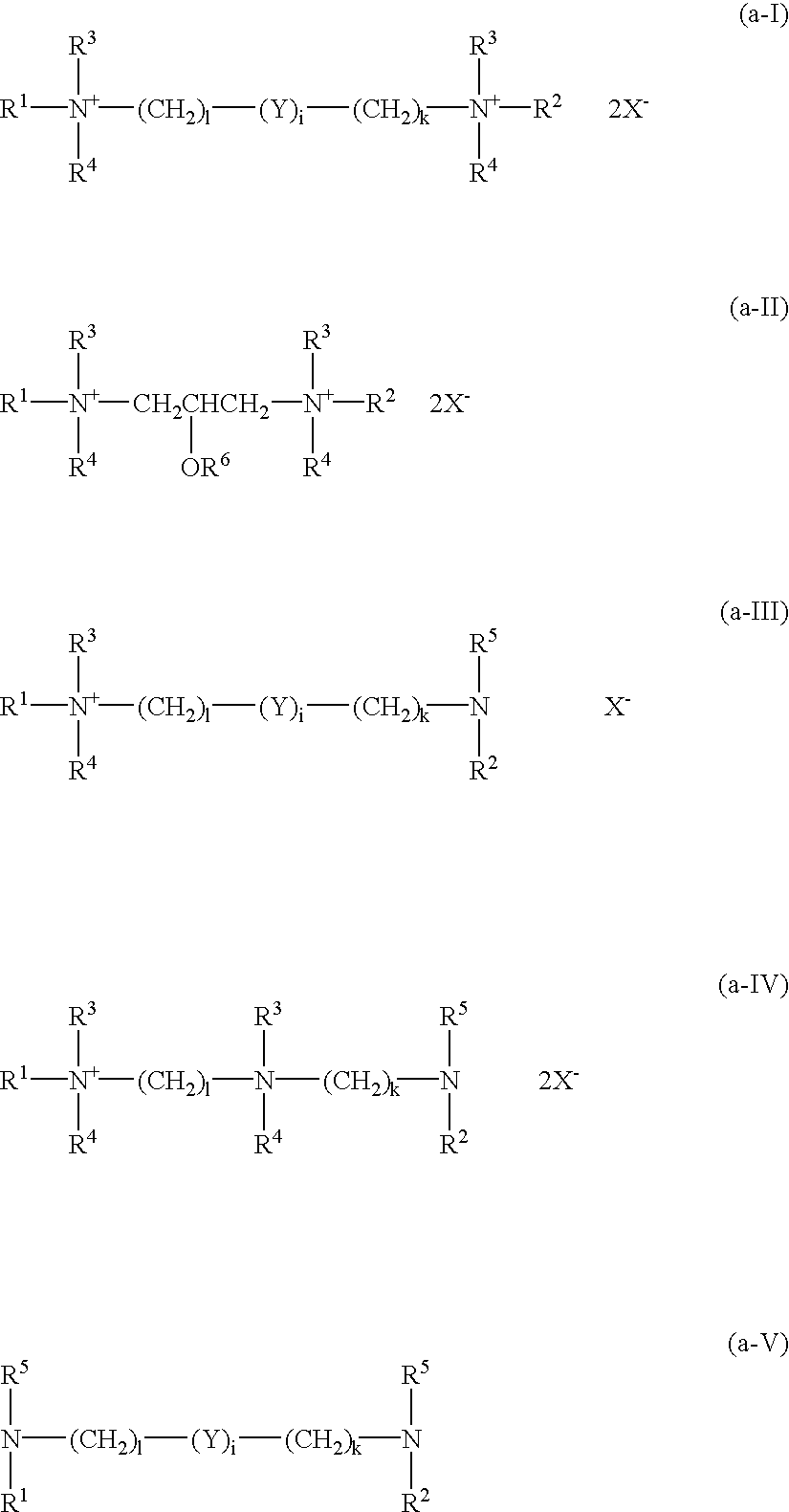

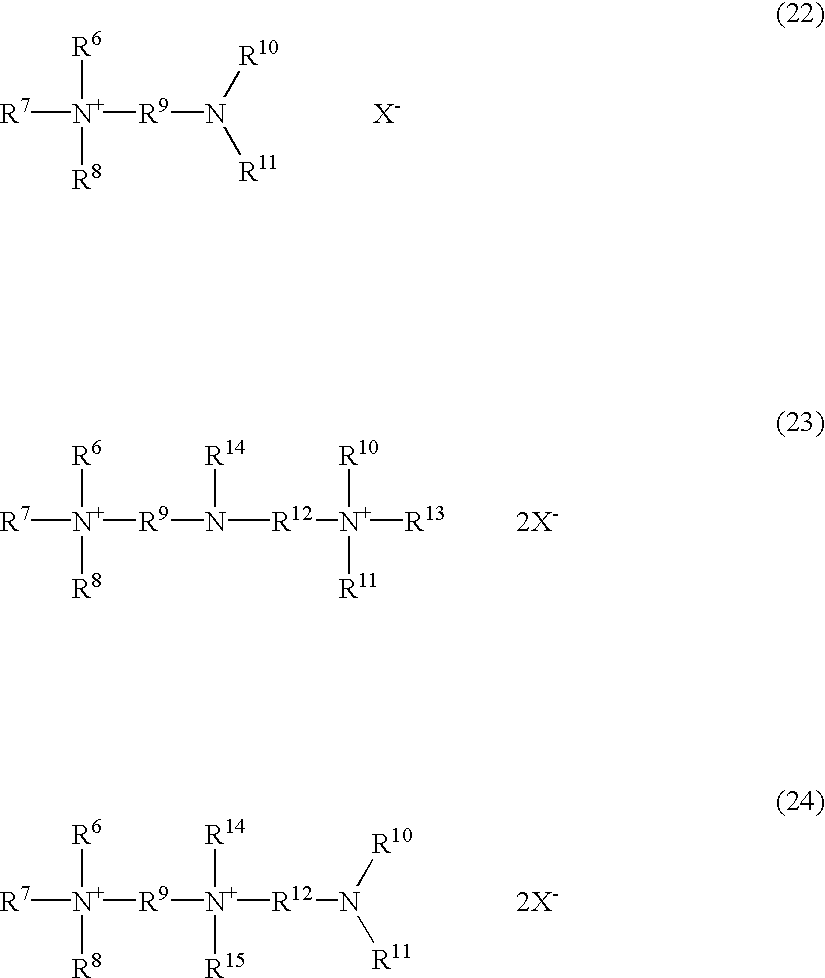

InactiveUS20030004088A1Promote absorptionSufficient softnessCationic surface-active compoundsAnionic surface-active compoundsChemical compoundSURFACTANT BLEND

The softener composition of the present invention comprises a compound having one or more C8-36 hydrocarbon groups and two or more groups selected from an amino group and a quaternary ammonium group in the molecule (component (a)), an anionic surfactant having a C8-36 hydrocarbon group (component (b)) and a nonionic surfactant (component (c)), wherein the molar ratio of the component (a) to the component (b) is from 90 / 10 to 50 / 50. This softener composition can endow cotton and cotton clothes in particular with a preferred softness, elasticity (fluffy feeling) and feeling of dryness with small oiliness.

Owner:KAO CORP

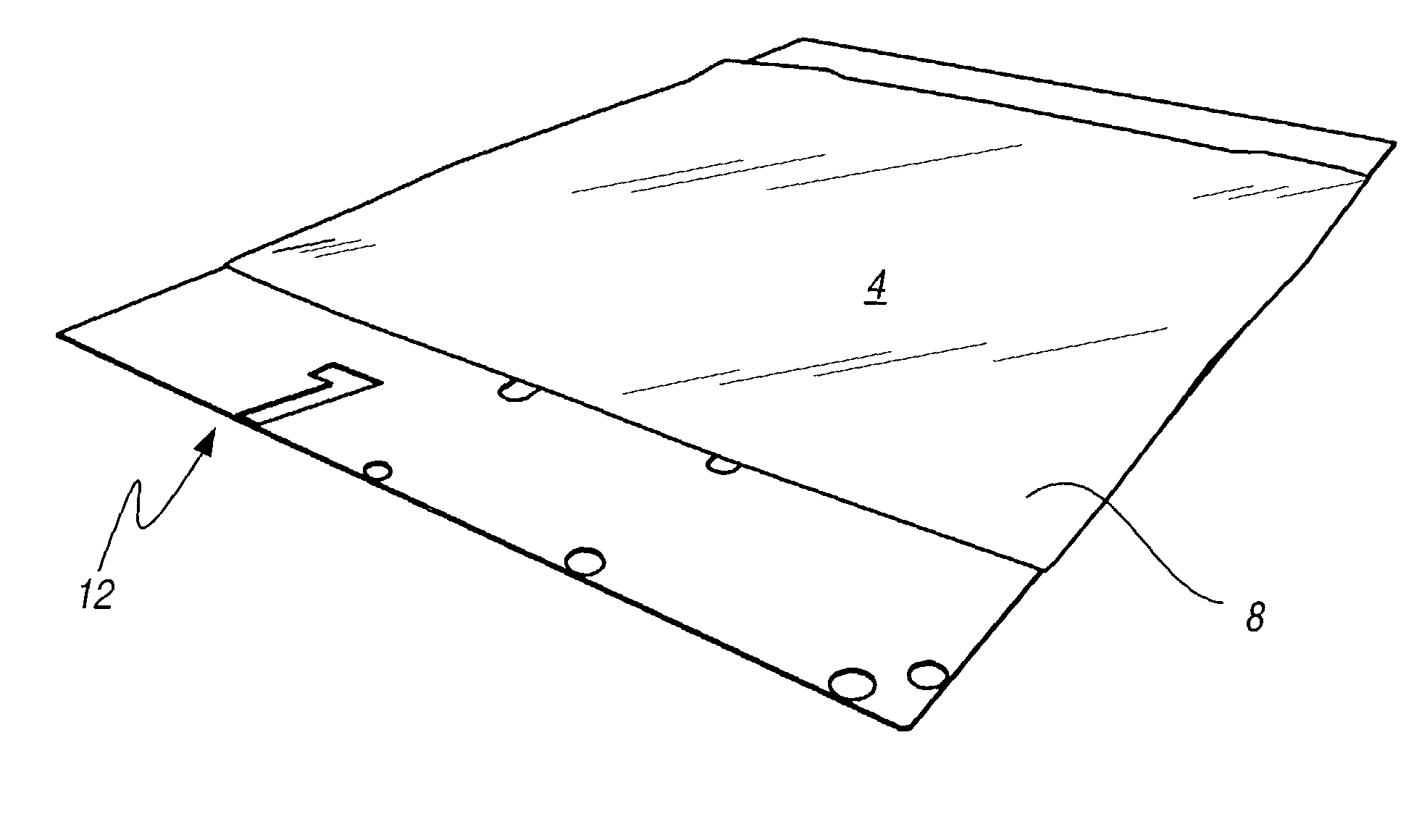

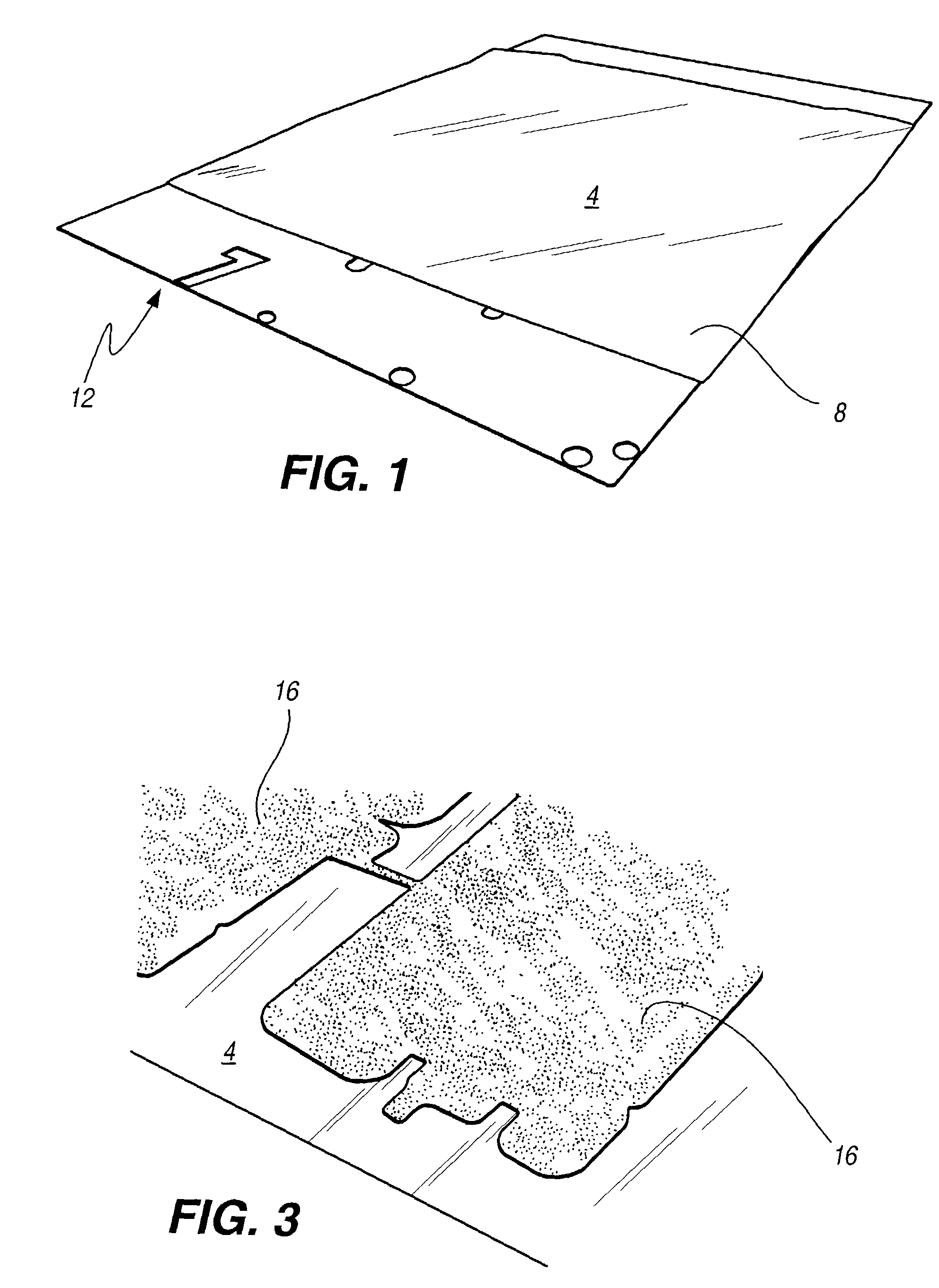

Screen printed resin film applique or transfer made from liquid plastic dispersion

InactiveUS6977023B2Increases viscosity and thicknessPrevent discolorationRadiation applicationsDecorative surface effectsScreen printingFree form

The present invention is directed to the use of a resin dispersion to form a variety of decorative transfers. The transfers can include a decorative medium such as flock. Primary and secondary carriers are used in some embodiments of the invention. The resin dispersion, when gelled and fused, can provide a free-form design article that can be readily applied to any desirable substrate, such as a textile.

Owner:HIGH VOLTAGE GRAPHICS

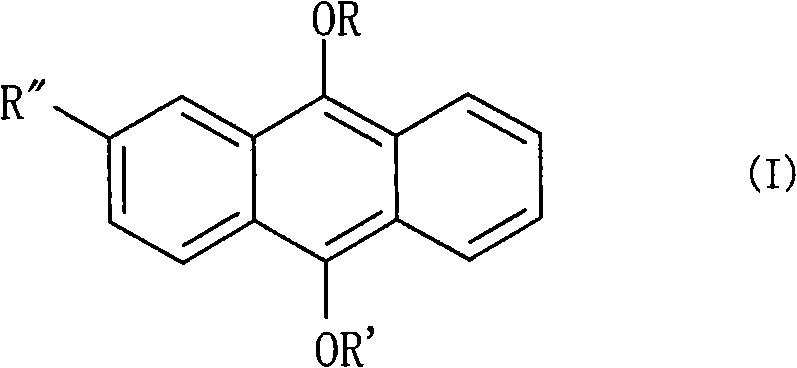

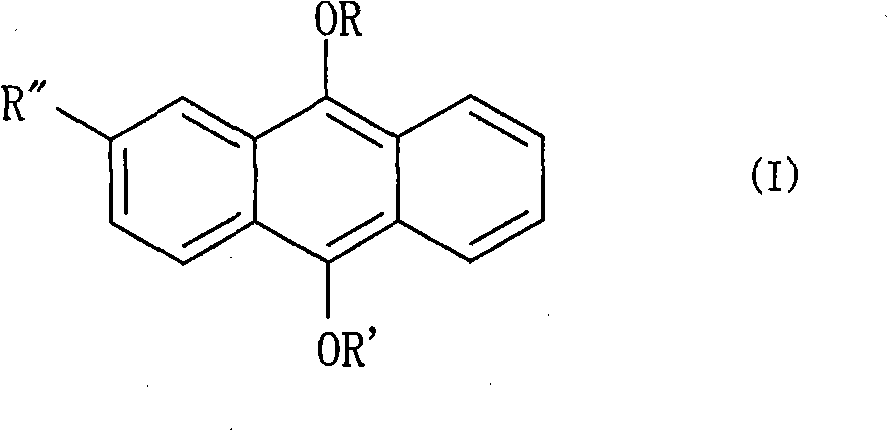

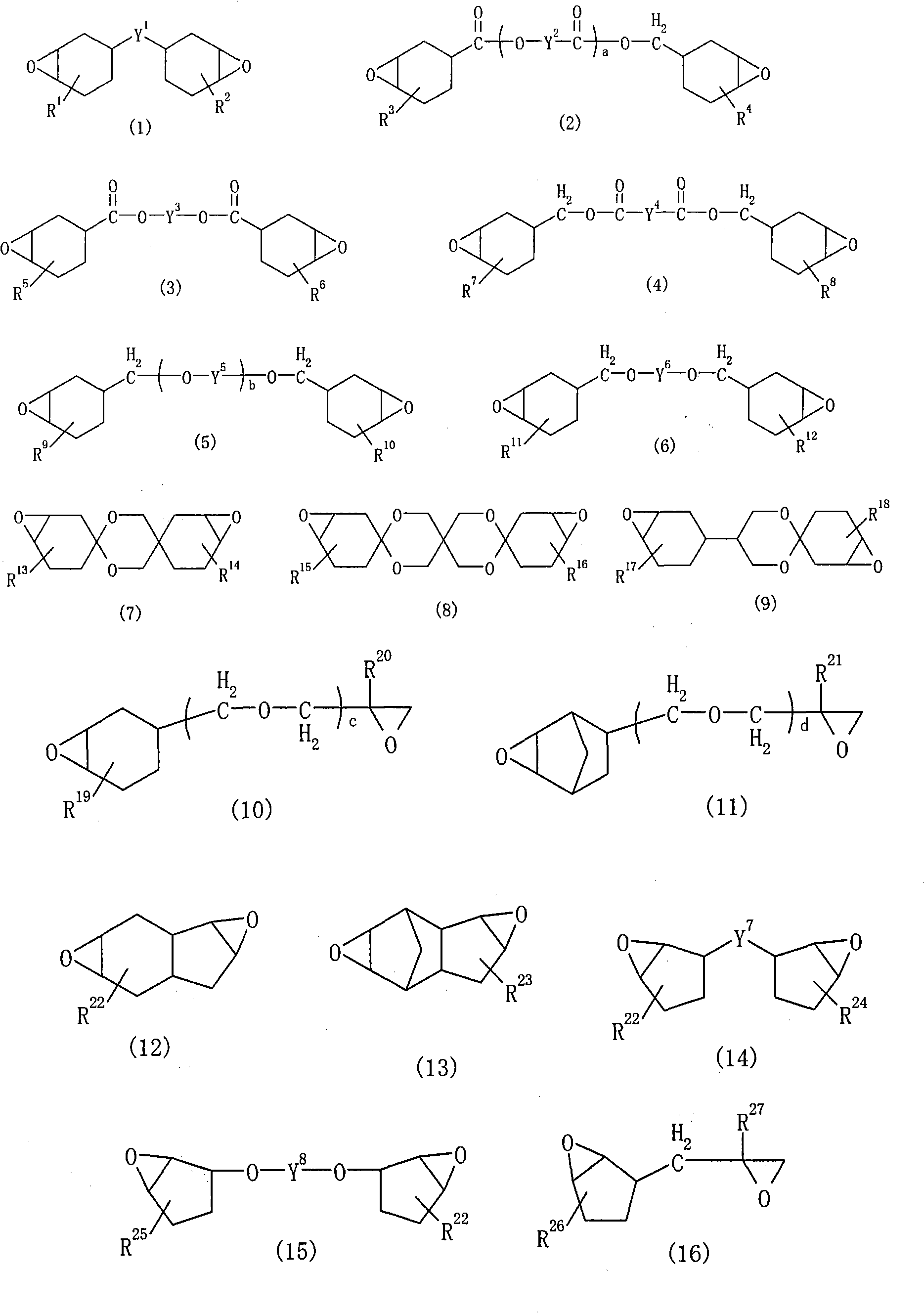

Photocurable adhesive agent, polarizing plate using the photocurable adhesive agent, method for production of the polarizing plate, optical member, and liquid crystal display device

ActiveCN101636672AImprove reliabilityPrevent discolorationNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyTectorial membrane

The invention provides a photocurable adhesive agent which has excellent storage stability, can prevent the discoloration of the adhesive agent itself or a material to be adhered during curing, has a high curing rate, and can provide good adhesion; a polarizing plate using the photocurable adhesive agent; a method for producing the polarizing plate; an optical member; and a liquid crystal displaydevice. Specifically, the invention discloses a photocurable adhesive agent for adhering a protective film to a polarizer comprising a polyvinyl alcohol resin film having iodine or a dichroic dye adsorbed and oriented thereon. The photocurable adhesive agent comprises: 100 parts by mass of an epoxy resin (A) having two or more epoxy groups in the molecule, wherein at least one of the epoxy groupsis an alicyclic epoxy group; 5 to 1000 parts by mass of an epoxy resin (B) having two or more epoxy groups in the molecule and containing substantially no alicyclic epoxy group; and 0.5 to 20 parts by mass of a photo-cationic polymerization initiator (C).

Owner:SUMITOMO CHEM CO LTD +1

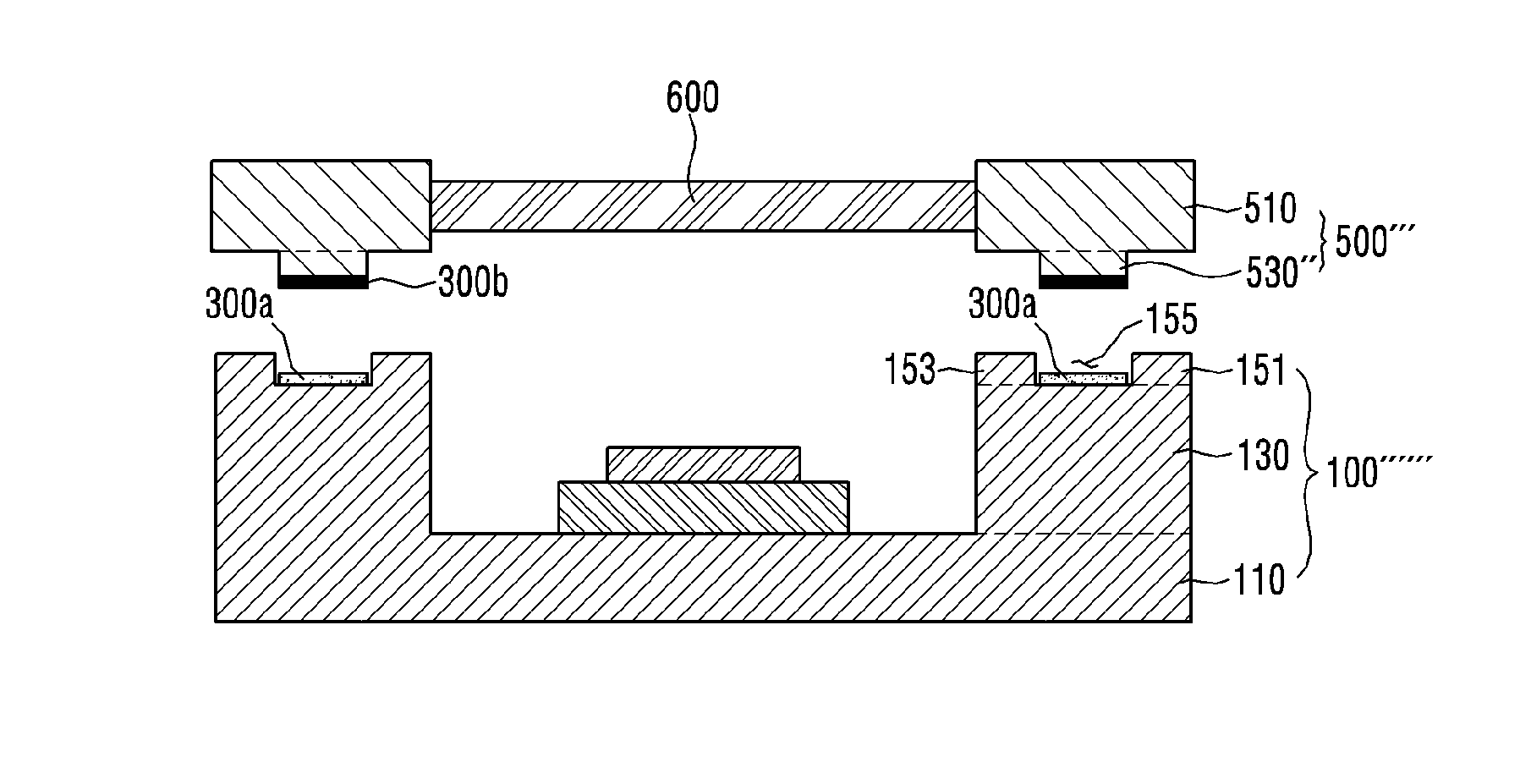

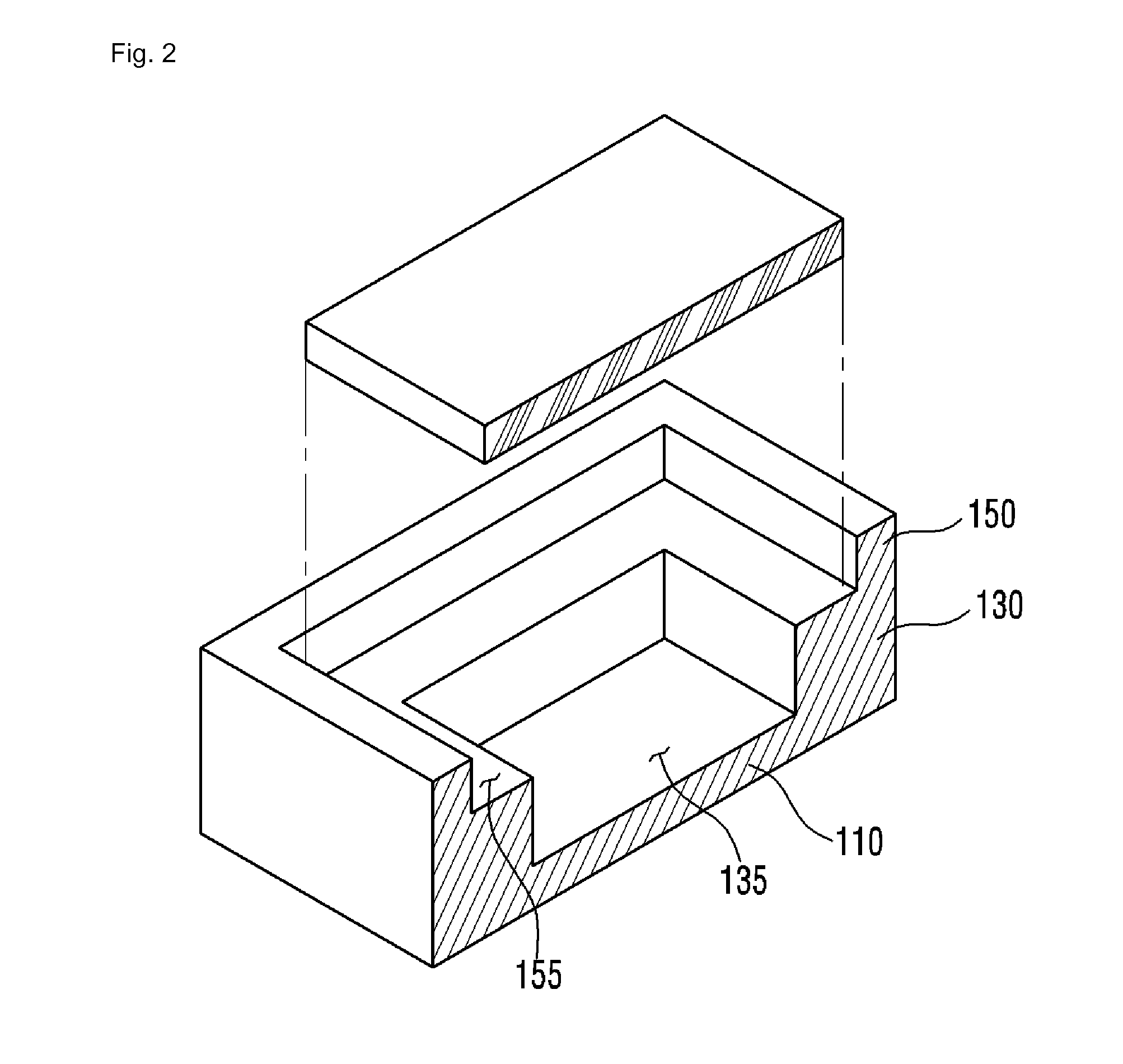

Light emitting device

ActiveUS20110175127A1Improve adhesionPrevent interfacial peelingSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

A light emitting device has a package having an opening provided with a side surface and a bottom surface, and a lead frame exposed to the bottom surface. The lead frame includes a reflection portion bent on the side surface, and a portion of an inner wall surface of the reflection portion is positioned in an inner portion of the package. A light emitting device has a package having a recessed portion on a front surface, a lead frame exposed to a bottom surface of the recessed portion, a light emitting element disposed on the lead frame, and a sealing resin filled into the recessed portion. The lead frame includes a bent portion bent towards the front surface of the package in the recessed portion, and a projecting portion bent to project from the package towards an outer portion, and disposed on a face opposed to the front surface.

Owner:NICHIA CORP

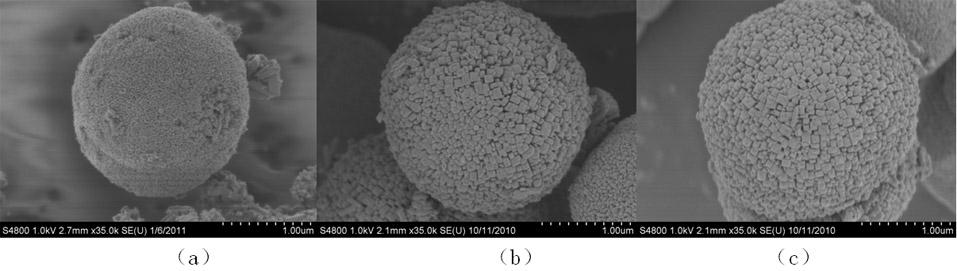

Silver-carrying titanium dioxide anti-bacterial agent and preparation method thereof

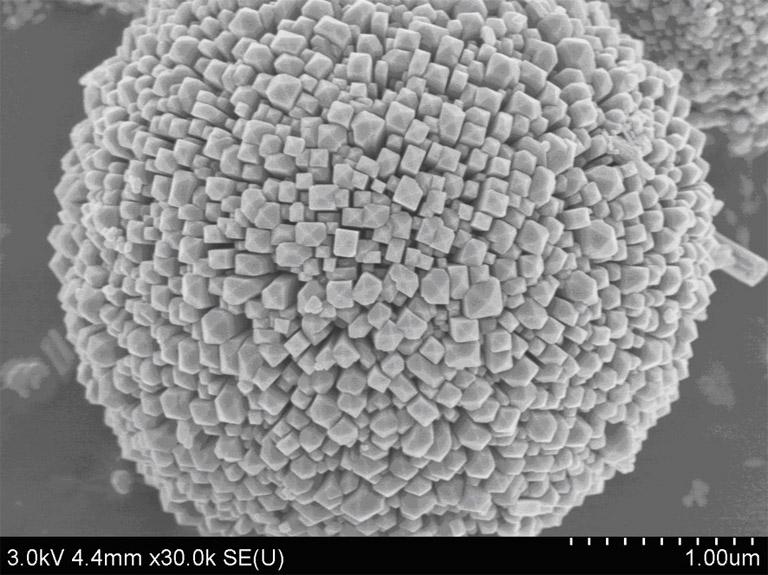

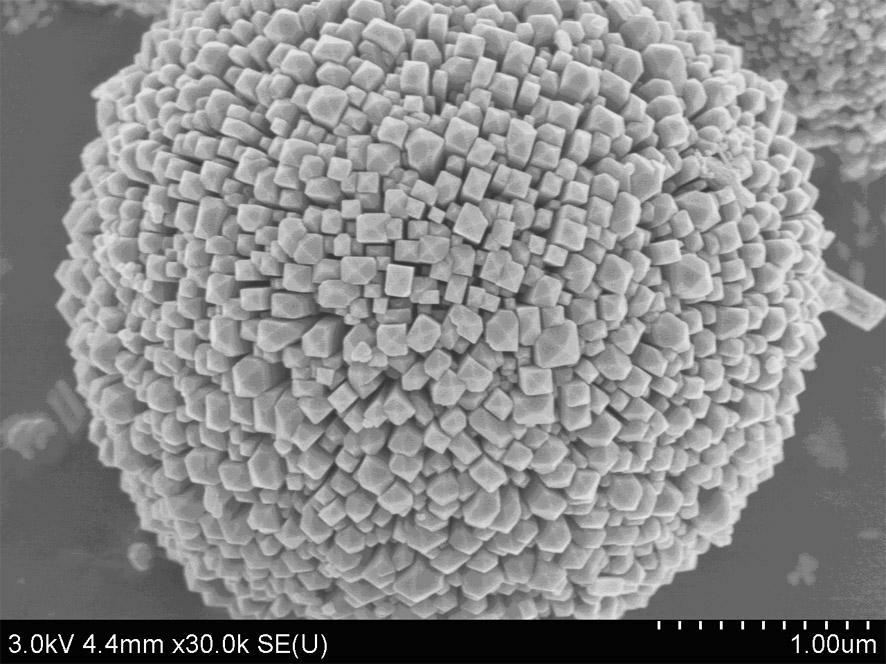

InactiveCN102205244AEnhance photocatalytic antibacterial effectReduce compoundingBiocideFungicidesMicrosphereCombined method

The invention belongs to the technical field of environmental catalytic materials and specifically relates to a preparation method of a silver-carrying titanium dioxide anti-bacterial agent. The anti-bacterial agent comprises titanium dioxide microspheres as carriers with a high length-diameter ratio and silver particles distributed on surfaces or interiors of the titanium dioxide microspheres. The preparation method comprises a titanium dioxide microsphere preparation method and a silver particle carrying method, wherein the silver particle carrying method adopts the following three methods of a complex reaction and photo-reduction combined method, a direct photo-reduction method and an excessive immersion method. The operation of the present preparation method is simple. Titanium dioxide carriers prepared by the present preparation method has a high length-diameter ratio, a high crystallinity and thus can reduce effectively recombination of electrons and holes and enhance titanium dioxide photocatalytical and anti-bacterial effects, and the silver particle carrying method can effectively control a dispersibility of silver and make silver be distributed on surfaces or interiors of titanium dioxide microspheres to realize a slow release of silver, avoid color change, and enhance anti-bacterial effects simultaneously.

Owner:FUDAN UNIV

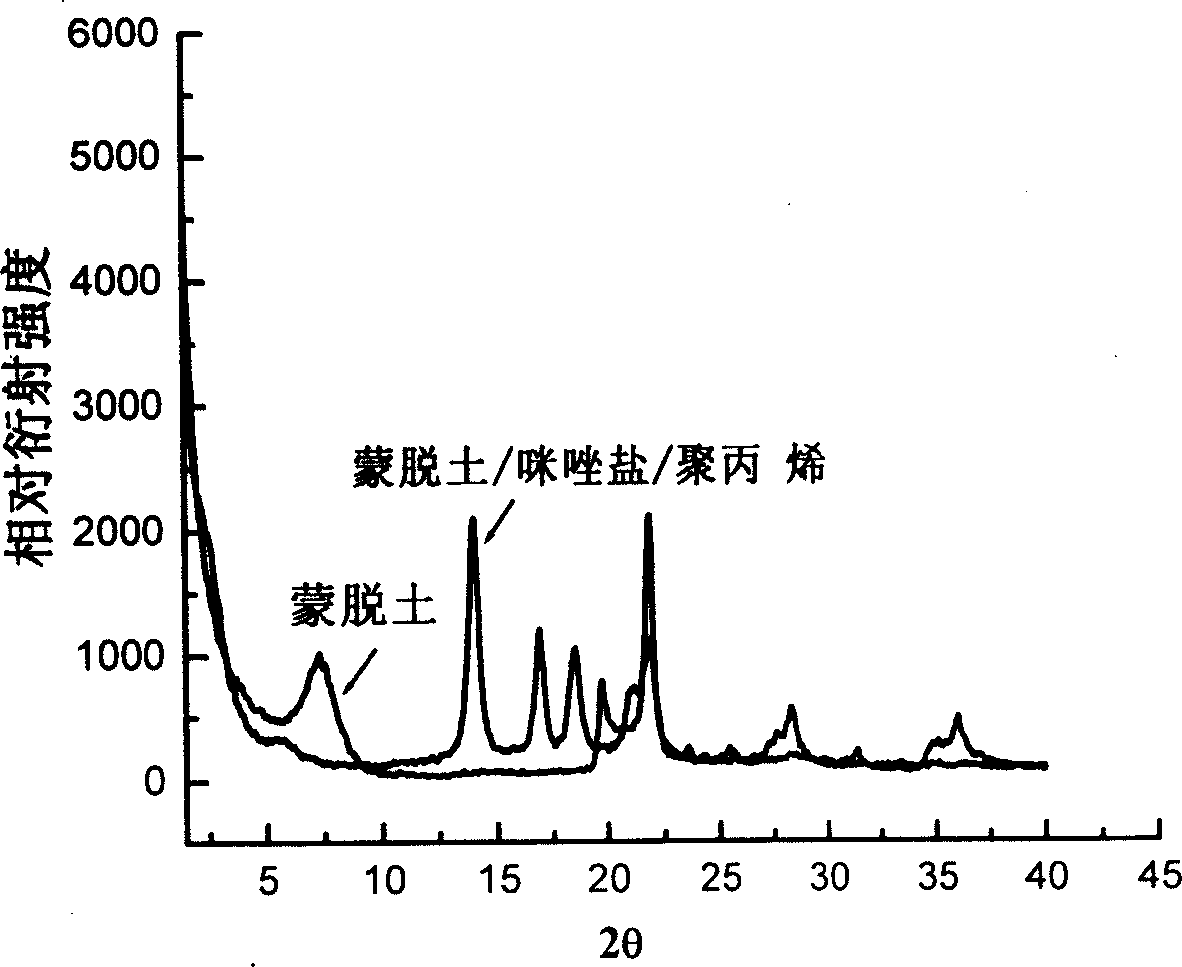

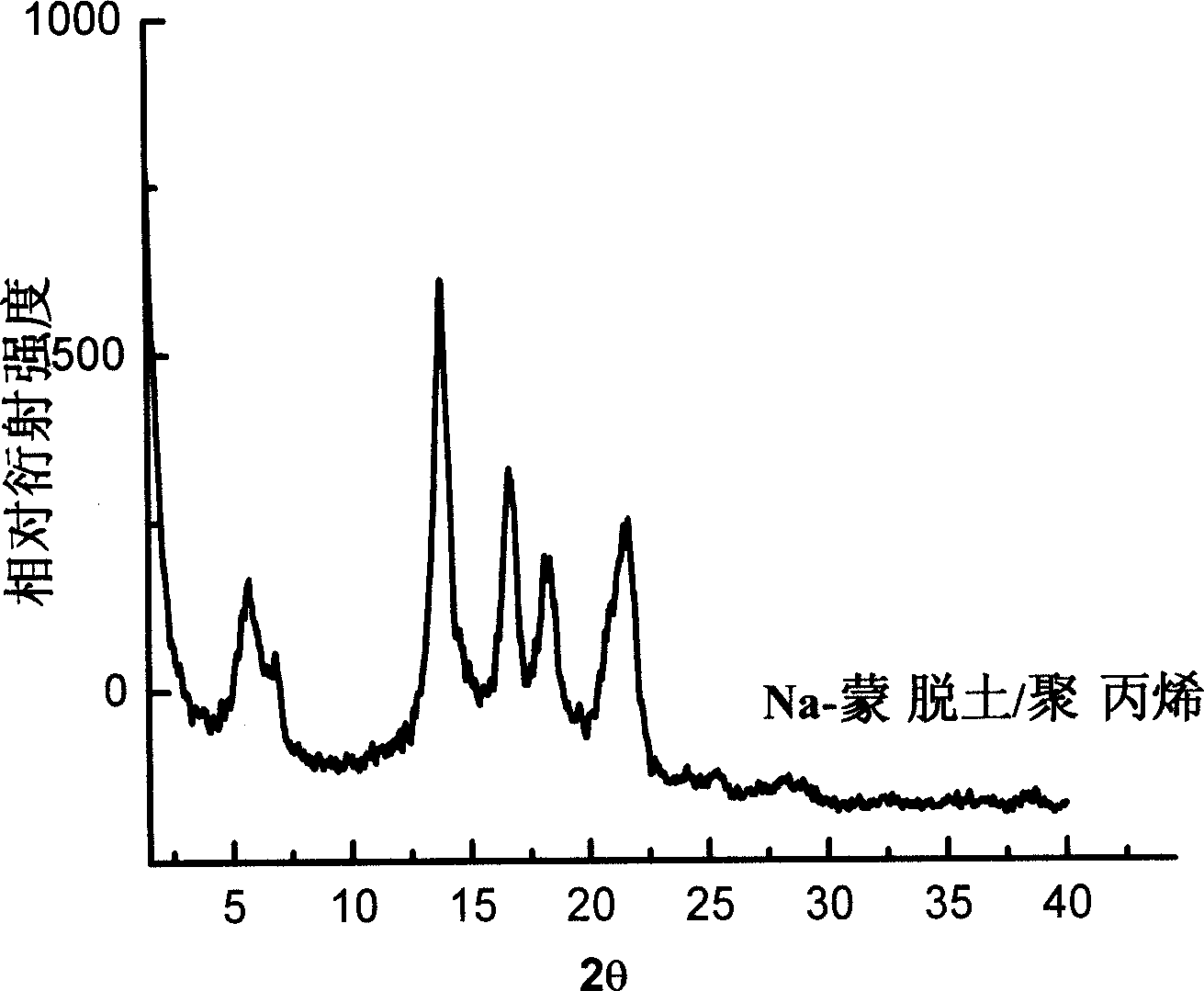

Method of preparing polymer/montmorillonid nano-composite material by montmorillonoid in-situ organization

A process for preparing composite polymer / montmorillonite nanoparticles by in-situ organizing of montmorillonite features that the imidazole-type or pyridine-type organic salt is used in non-water solvent to obtain organic modifier for organizing and dispersing the montmorillonite, resulting in the colloidal solution of its nanoparticles. The solvents with different properties and the organic salts with different molecular structures can be chosen for preparing the nanoparticles with relative performance. Its advantages are high thermal stability and high compatibility.

Owner:INST OF CHEM CHINESE ACAD OF SCI

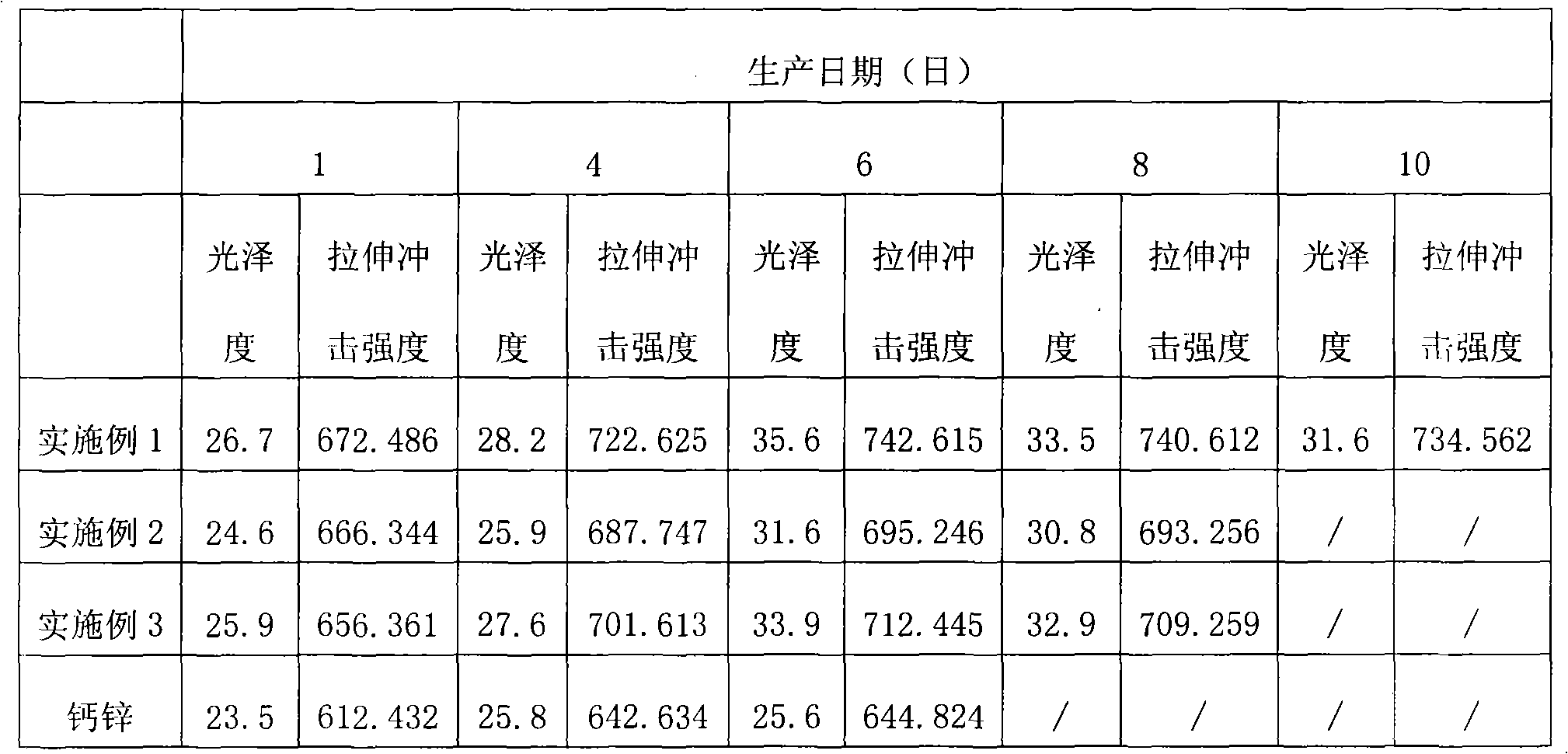

Zn-Ca compound stabilizer

The invention discloses a Zn-Ca compound stabilizer, comprising the following components in parts by weight: 28-35 parts of zinc stearate, 8-11 parts of calcium stearate, 18-32 parts of hydrotalcite, 14-22 parts of polyalcohol, 4.5-10.5 parts of Stearoylbenzoylmethane, 3.6-12 parts of external lubricant, 3.8-9.8 parts of internal lubricant and 1.0-5 parts of antioxidant. Compared with the prior art, the invention has the following characteristics of long continuous production period and good production stability; realization of toxicity and environmental protection without containing heavy metals, such as Ba, Cd, Pb and the like in the components; and avoidance of discoloration at the time of switching mercaptan organic tin without containing heavy metals, such as Ba, Cd, Pb and the like.

Owner:WUHU CONCH NEW MATERIAL

Optical semiconductor device encapsulated with silicone resin

ActiveUS20100213502A1Prevent penetrationPrevent discolorationSemiconductor/solid-state device detailsSolid-state devicesDevice materialPhenyl group

An optical semiconductor device encapsulated with a silicone resin that suffers no discoloration of the lead and exhibits excellent thermal shock resistance. The optical semiconductor device includes an optical semiconductor element and a cured product of a silicone resin composition that encapsulates the optical semiconductor element, wherein the amount of (ΦSiO3 / 2) units (wherein Φ represents a phenyl group) within the cured product, determined by solid 29Si-DD / MAS analysis, is within a range from 0.13 mol / 100 g to 0.37 mol / 100 g.

Owner:SHIN ETSU CHEM IND CO LTD

Liquid crystal display device

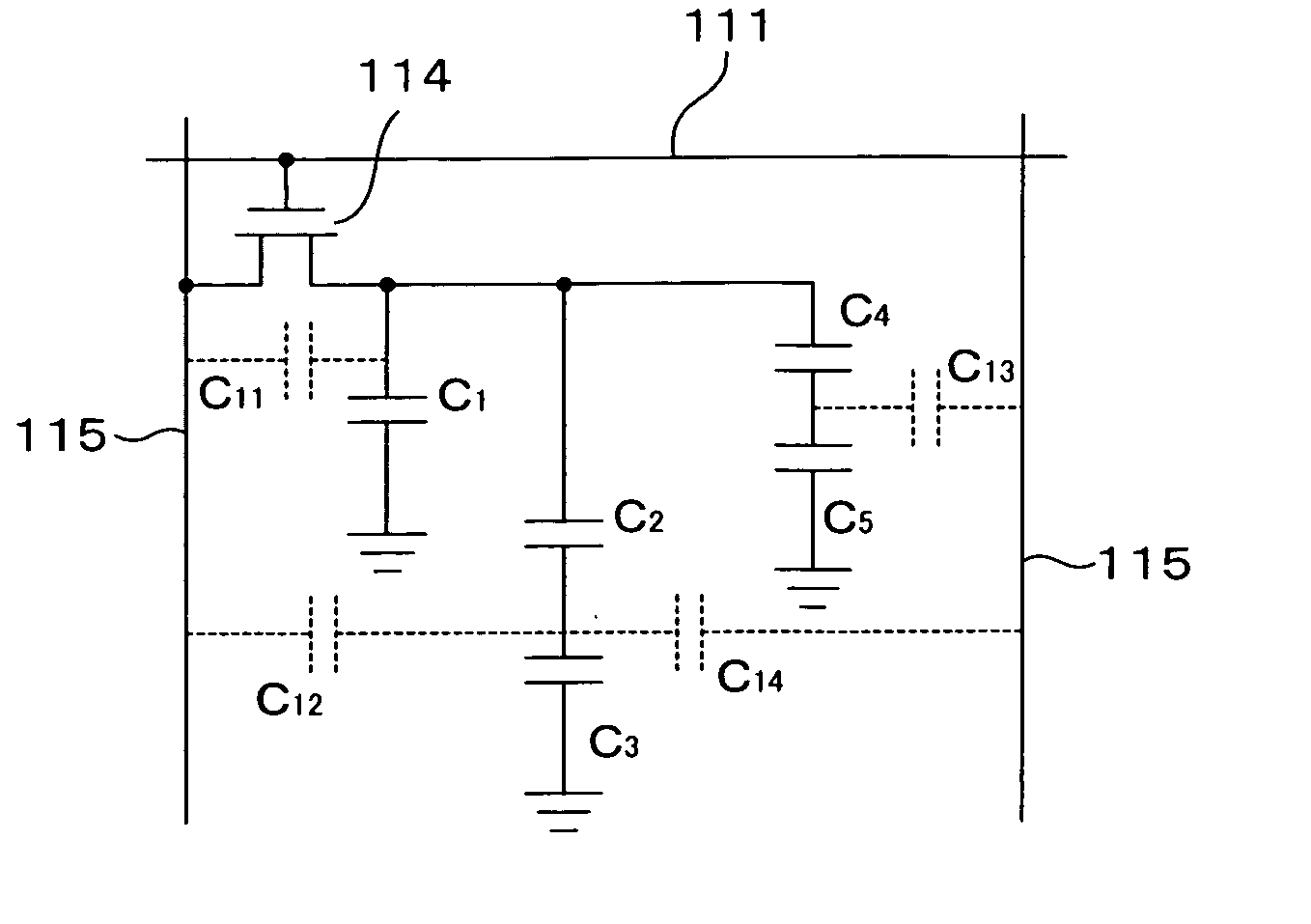

ActiveUS20050219186A1No loss of aperture ratioReliable maintenanceStatic indicating devicesNon-linear opticsCapacitanceLiquid-crystal display

A picture element electrode is divided into sub picture element electrodes by slits extending obliquely. Further, a control electrode is formed over an auxiliary capacitance bus line. Part of the sub picture element electrodes overlaps the control electrode and is capacitively coupled to the control electrode. The control electrode and the source electrode of a TFT are connected through an interconnection. Part of the sub picture element electrodes is electrically connected to the interconnection. Further, part of the sub picture element electrodes is electrically connected to an interconnection extending from the control electrode.

Owner:AU OPTRONICS CORP

Light emitting module

ActiveUS20160126426A1Avoid stickingPrevent discolorationSolid-state devicesSemiconductor devicesLight emitting deviceTransmitted light

An embodiment relates to a light emitting module. A light emitting module according to an embodiment comprises: a light source unit comprising a light emitting device; a body comprising a lower portion on which the light source unit is arranged, a wall portion arranged on the lower portion and configured to surround the light source unit, and an upper portion arranged on the wall portion; an optical member arranged on the light source unit to transmit light from the light emitting device; and an adhesive member arranged between the wall portion of the body and the optical member to couple the body and the optical member, wherein the upper portion of the body is arranged between the light emitting device and the adhesive member.

Owner:SUZHOU LEKIN SEMICON CO LTD

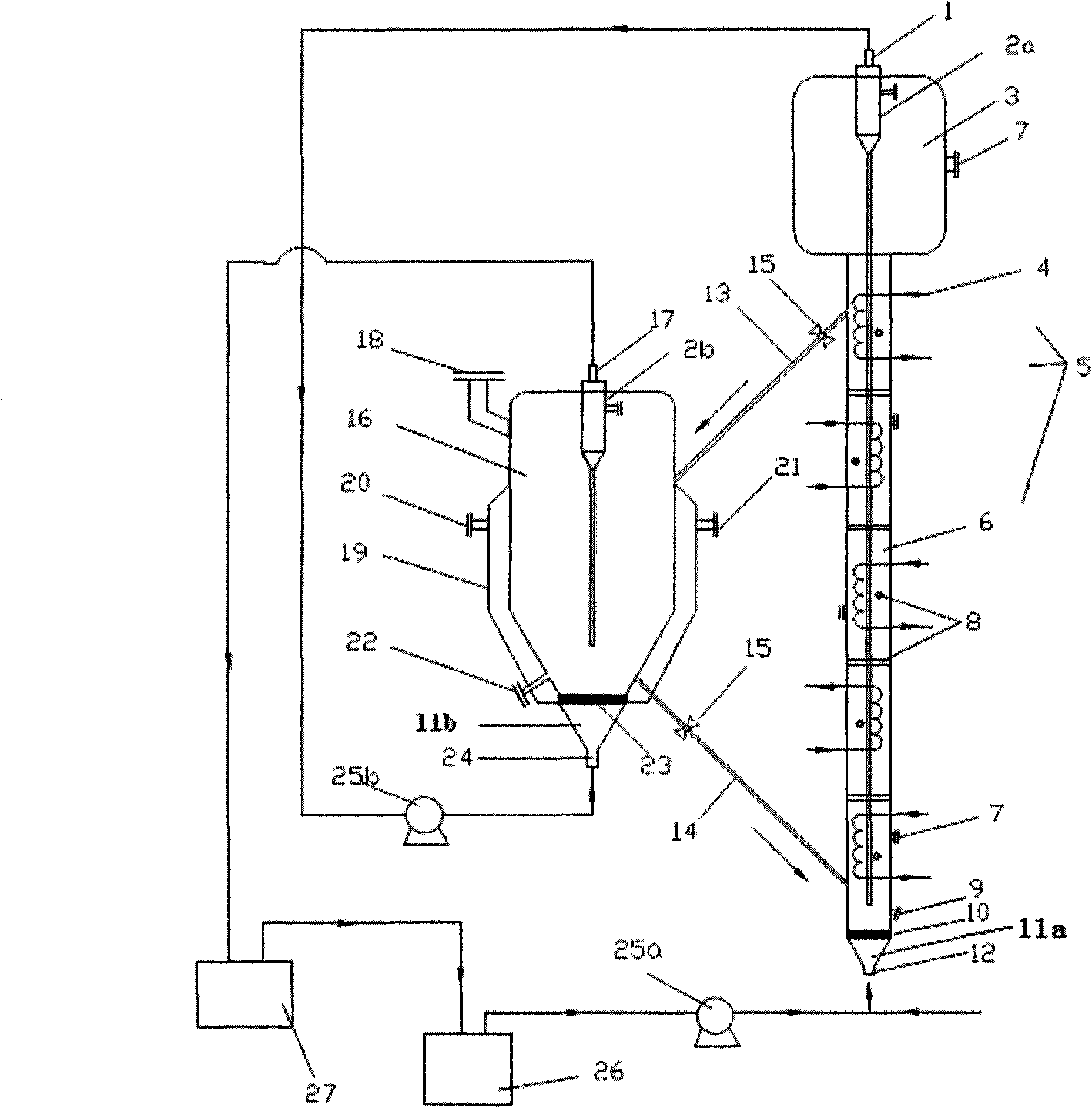

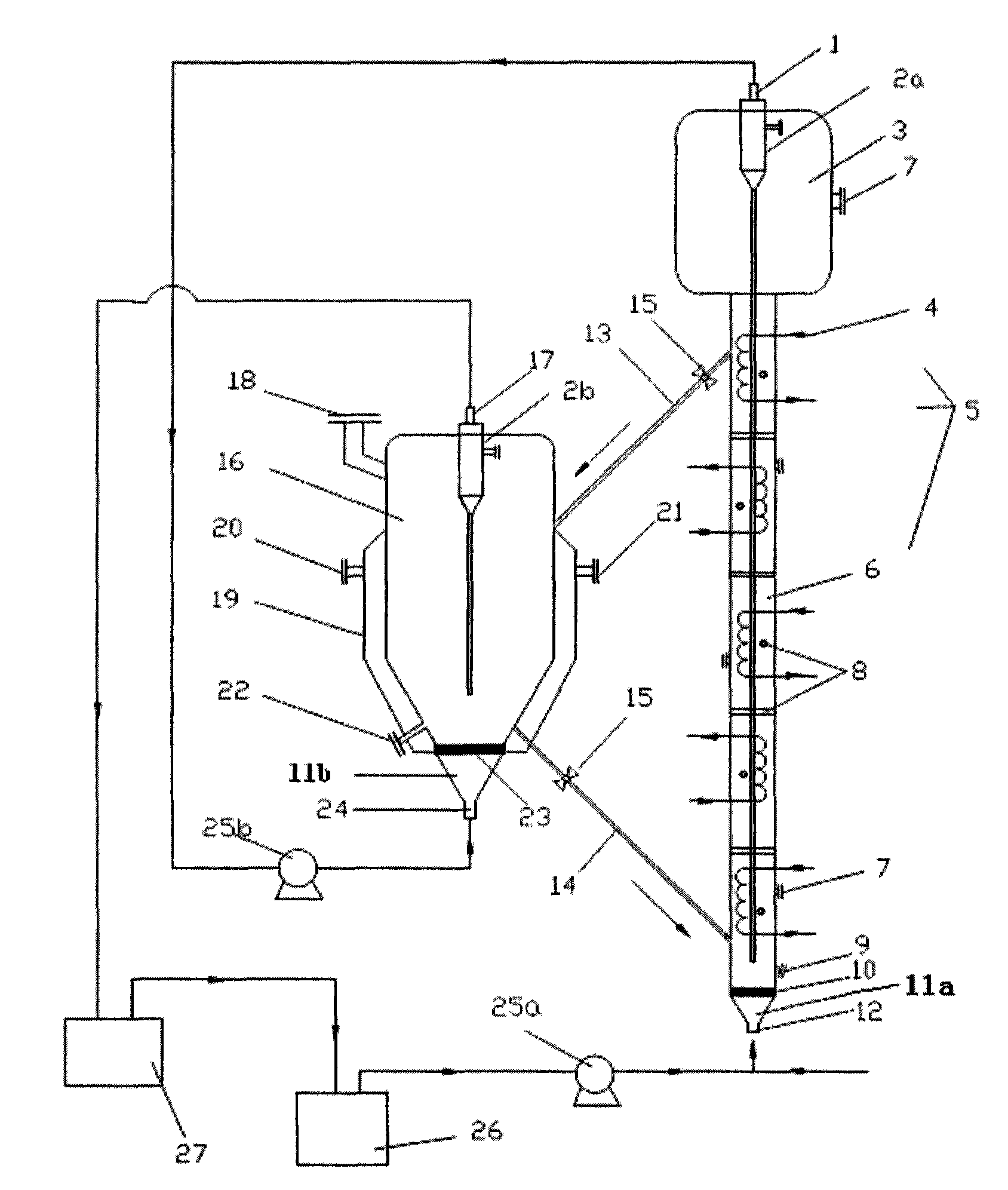

Device for preparing chlorinated polyvinyl chloride by gas-solid phase method and method thereof

InactiveCN101831021APrevents sticking and discolorationReduce energy consumptionChemistryUltraviolet lights

The invention belongs to the technical field of chemical processes and equipment, and relates to a device for preparing chlorinated polyvinyl chloride by a gas-solid phase method and a method thereof. The chlorinated polyvinyl chloride is prepared from polyvinyl chloride (PVC) and chlorine gas serving as raw materials in a dry state. The device comprises a riser reactor, a turbulent fluidized bed reactor, an upper connecting pipe and a lower connecting pipe, wherein the synthesis of the chlorinated polyvinyl chloride is performed in the riser reactor and the turbulent fluidized bed reactor; a chain initiation process is realized and chain transfer is finished by activating the chlorine gas with ultraviolet light, so that the whole process is decoupled into a quick process and a slow process, the chlorination of the materials is uniform, bonding and discoloration can be effectively prevented, the energy consumption is reduced and the operation is simplified; the device has the advantages of compact structure, high practicability and obvious improvement on the efficiency; hydrogen chloride separated from reaction tail gas can be recycled; and the whole process has no waste discharge.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Tin-plated film and method for producing the same

InactiveUS20060016694A1Improve reliabilityHard to generate whiskerSemiconductor/solid-state device detailsSolid-state devicesTin platingThin membrane

The present invention has an object to provide a tin-plated film and a method for producing the same, capable of preventing whiskers from being generated and simultaneously preventing the surface of a substrate to be plated, which is not covered with a tin-plated film, from discoloring due to oxidation, by which prevention of whisker generation, suppression of whisker growth, and prevention of discoloring of a substrate to be plated are compatible with simplified operations ensuring excellent productivity. The method is provided with the steps of removing a part of a tin-plated film formed on copper or copper alloy; processing to prevent discoloring of the copper or copper alloy from which the tin-plated film is removed; and applying heat energy to the tin-plated film of the copper or copper alloy which is processed to prevent discoloring.

Owner:PANASONIC CORP

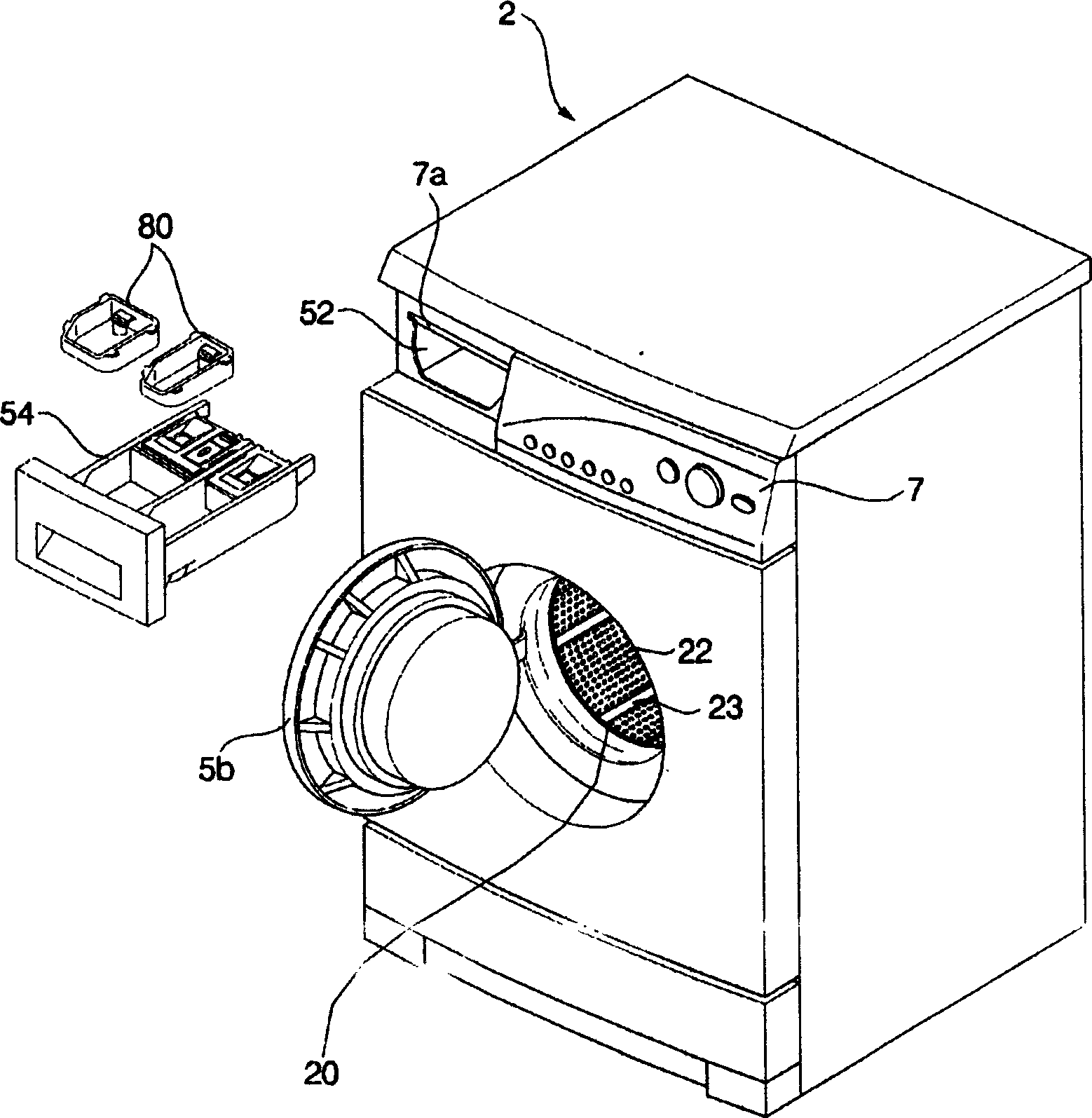

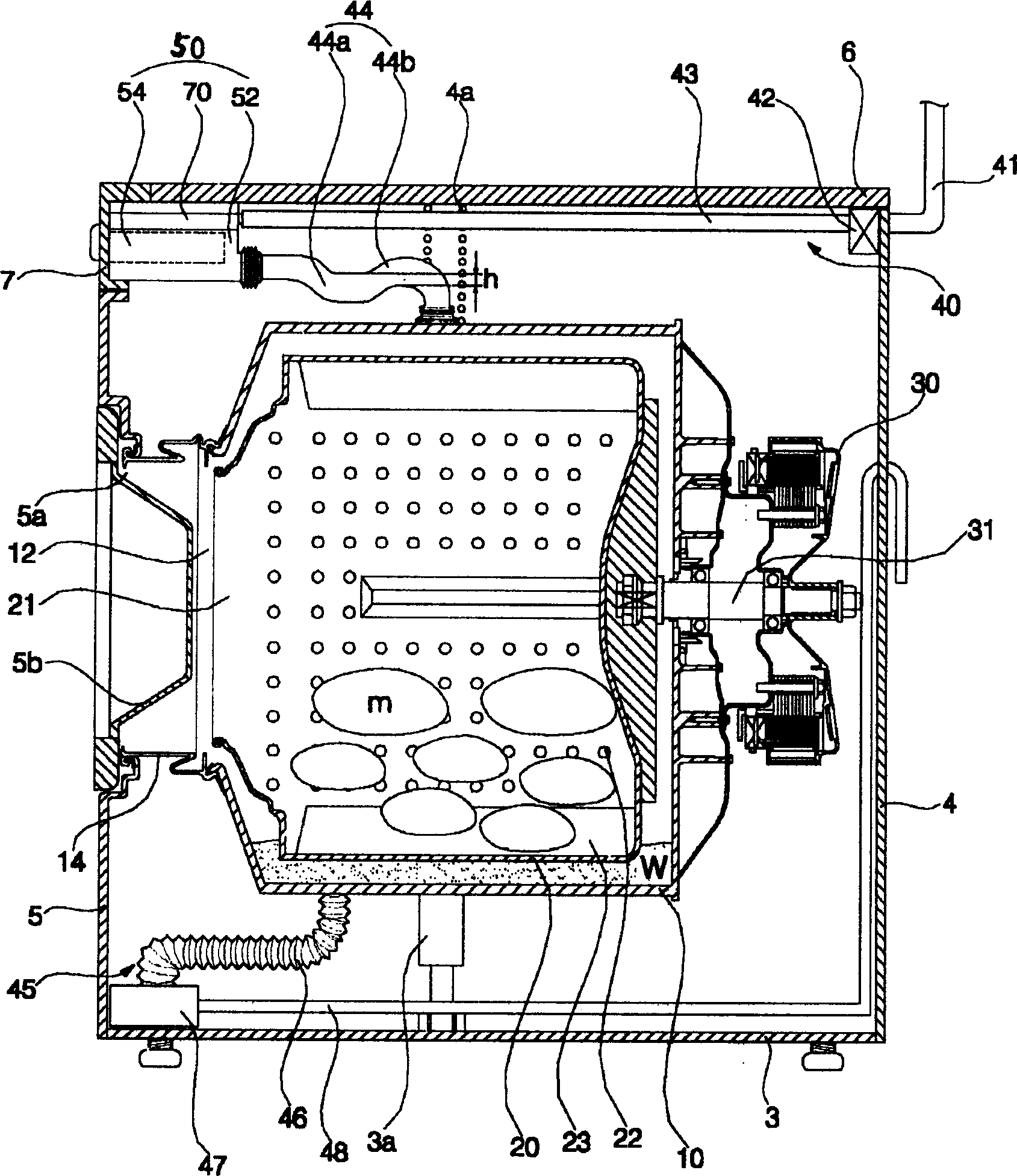

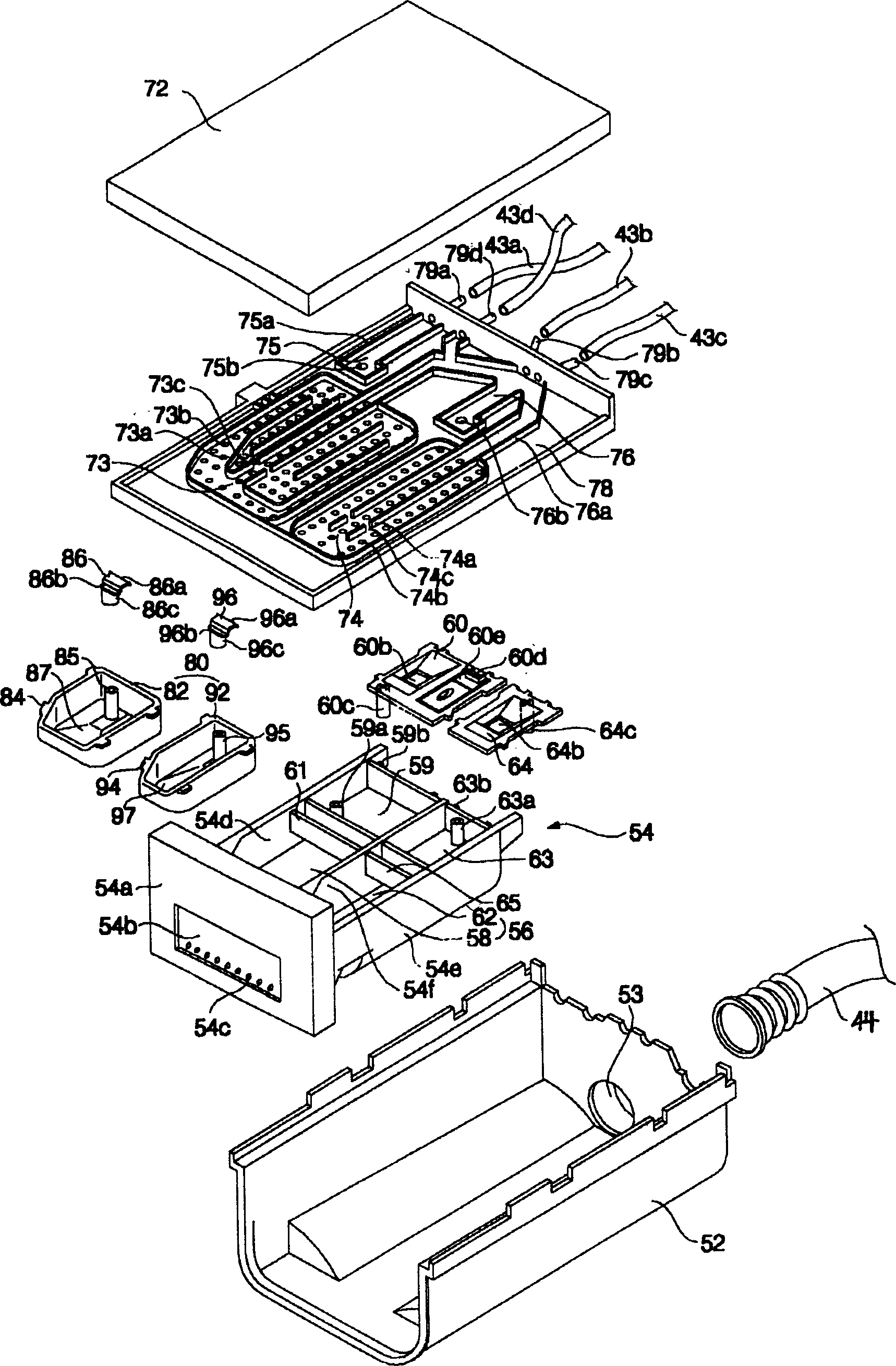

Detergent supplier of washer

InactiveCN1779045APrevent discolorationEasy to put inOther washing machinesTextiles and paperEngineeringScouring agent

The invention opens a scouring agent feed-way for the washer. It is made up of the scour barrel for reserve the powder-scouring agent; the liquid scour box dismounted from the scour barrel. The powder souring agent reserve unit is divided into the main scour reserve unit and the ready scour reserve unit by the scouring barrel. Because of the liquid scouring box, the scour can be supplied conveniently and it can prevent the washings discoloring.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Aldehyde inhibitor composition and polyacetal resin composition

InactiveCN1902279AImprove capture abilityImprove qualityOther chemical processesDeodrantsAlkaline earth metalAntioxidant

Owner:POLYPLASTICS CO LTD

Glass composition

InactiveUS20050209083A1Reducing Pt elutionPreventing loss of glass homogeneityGlass furnace apparatusGlass productionHeliumMaterials science

Owner:NIPPON ELECTRIC GLASS CO LTD

Grey brick mechanically manufactured from lime sludge and construction wastes and method for manufacturing same

The invention discloses a gray brick mechanically manufactured from lime sludge and construction wastes and a method for manufacturing the same. The materials for mechanically manufacturing the gray brick comprise the following raw materials in portion by weight: 1,015 to 1,135 portions of construction waste crushed materials, 240 to 290 portions of cement, 810 to 1,010 portions of lime sludge, 60 to 75 portions of gray lime, and 100 to 125 portions of water, wherein the particle size of the construction waste crushed materials is less than 15 millimeters. If necessary, less than 20 portions of fly ash and proper amount of activating agent can be added to the materials. The method for mechanically manufacturing gray brick comprises the following steps: firstly, crushing the construction wastes; secondly, mixing the construction waste crushed materials with the other materials according to the proportions; and thirdly, pressing the mixture by adopting a mechanical method so as to produce the gray brick of the invention. The gray brick and the method for manufacturing the same recycle the sludge and the construction wastes in a reducing, harmless and resource-utilizing mode, and solve the problem that substituting materials and products are hard to find after clay bricks are forbidden to use and the problem of gray brick sources for civilian constructions.

Owner:梁林华 +1

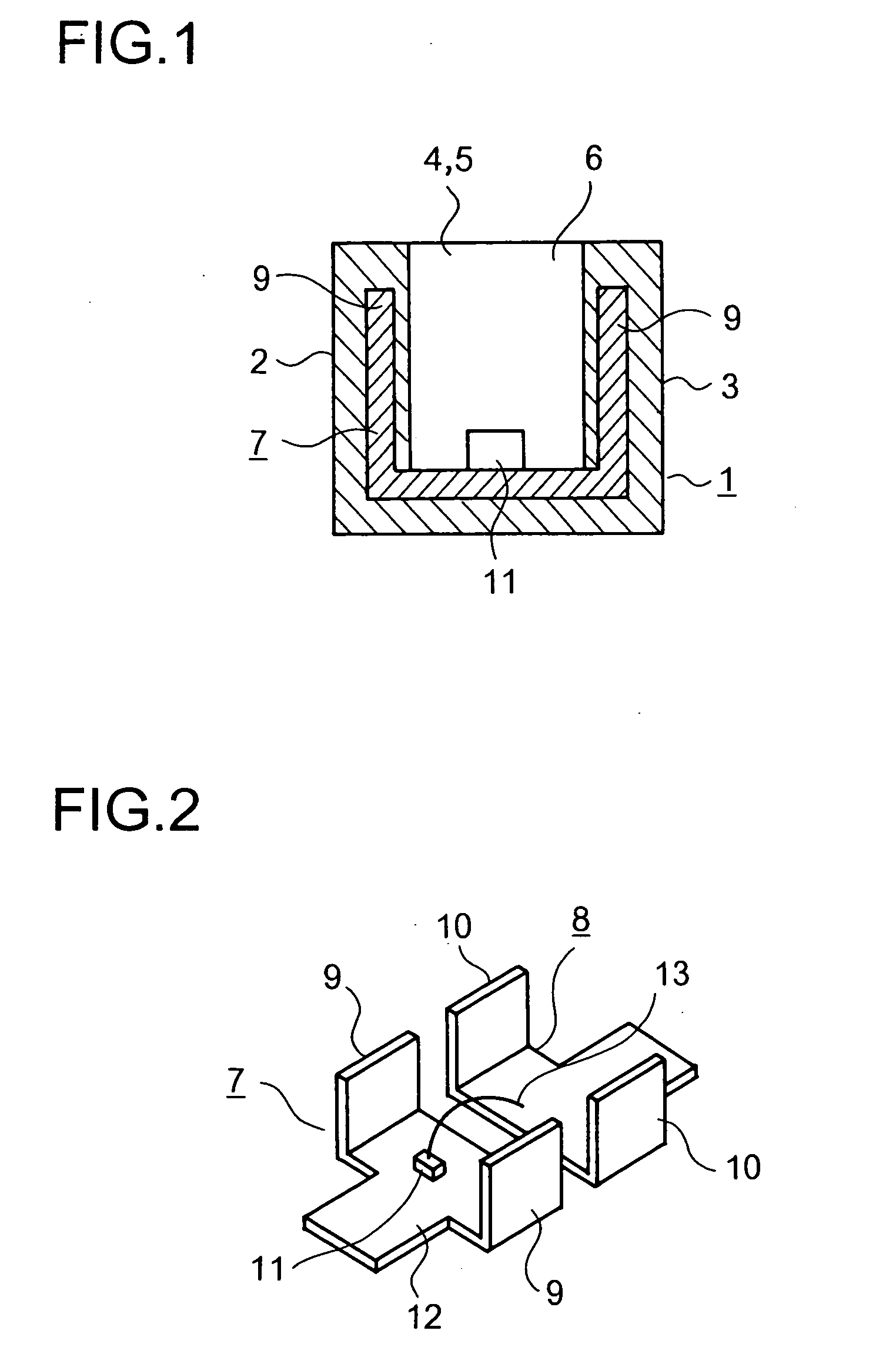

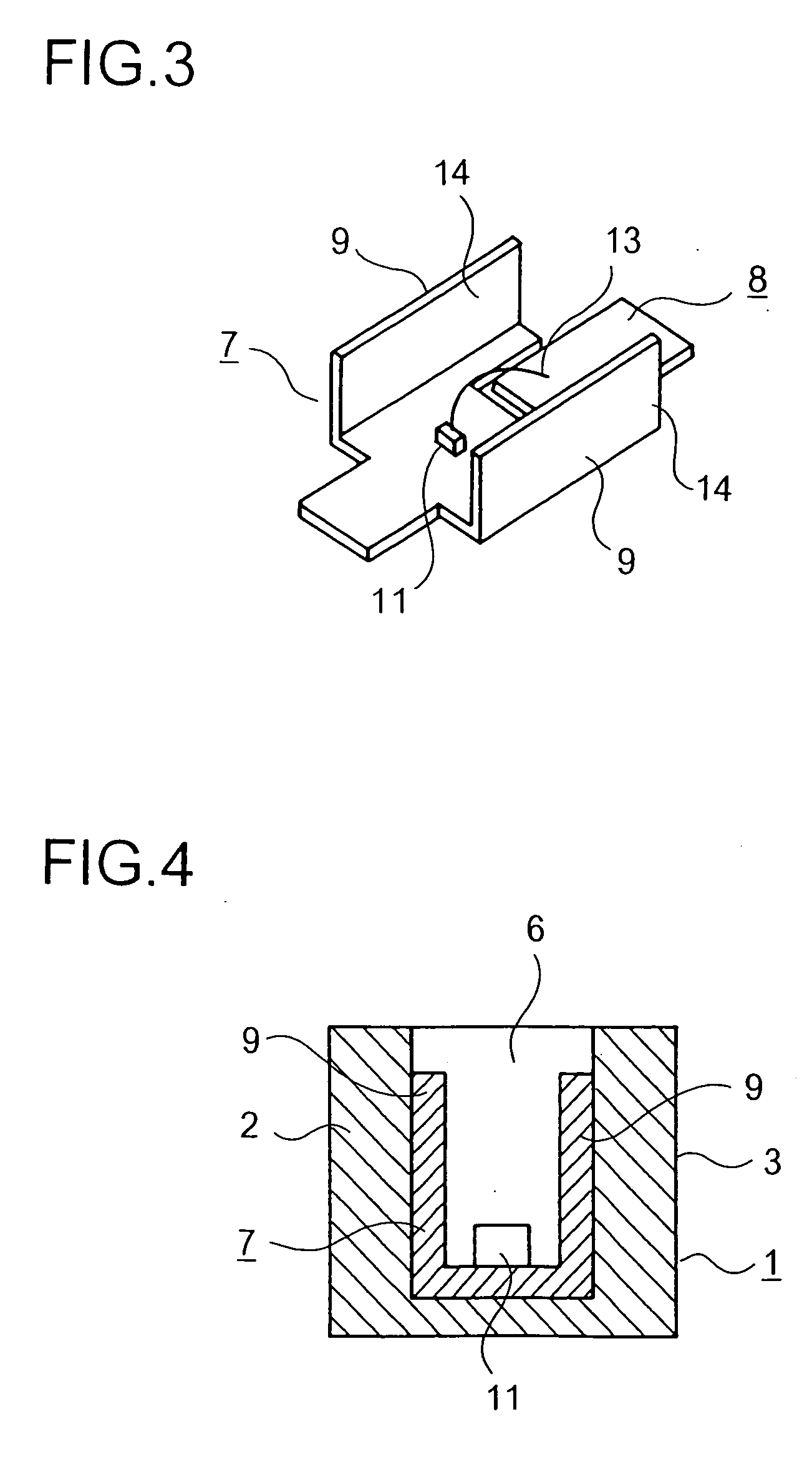

Light emitting element

InactiveUS20060108669A1Less resin leakageEasy to makeLaser detailsSemiconductor/solid-state device detailsConductive materialsEngineering

A light emitting element includes: a box-shaped case formed by an insulation material and having a space inside; a lead frame formed by a conductive material and fixed to the case; and a light emitting chip fixed to the lead frame. On the lead frame, a rise portion is formed in a side wall of the case or along the inner surface of the side wall. The lead frame has a first lead frame fixing the light emitting chip and a second lead frame connected to the light emitting chip by the wire bonding. At least on the first lead frame, a rise portion is formed.

Owner:SANYO ELECTRIC CO LTD +1

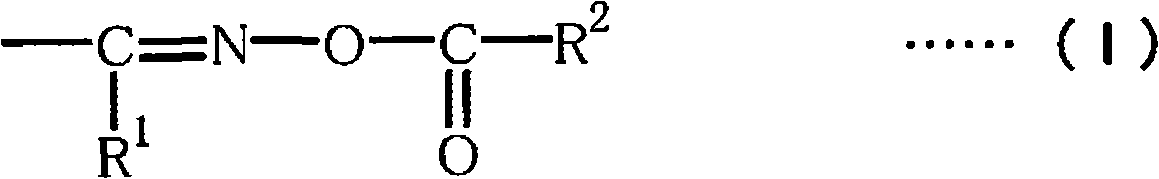

Photocuring resin composition, dry film, curing product and print circuit board

ActiveCN101303527AFull colorIncreased sensitivityOrganic chemistryPhotosensitive materials for photomechanical apparatusUltravioletCarboxylic acid

The invention provides a photocurable resin composition, dry film, cured substance and printed circuit board. The invention provides a photocurable resin composition which is fully coloured, has high photosensitivity under the exposure of ultraviolet ray and laser such that it has good curing depth, in the mean time, adjusting absorption in the ultraviolet region by using red or yellow colorant as well as oxime ester initiators. The photocurable resin composition which may develop through alkaline aqueous solution contains (A) carboxylic acid-containing resins, (B) red colorants, (C) oxime ester initiators and (D) compounds having more than two unsaturated alkene groups in the molecules.

Owner:TAIYO HLDG CO LTD

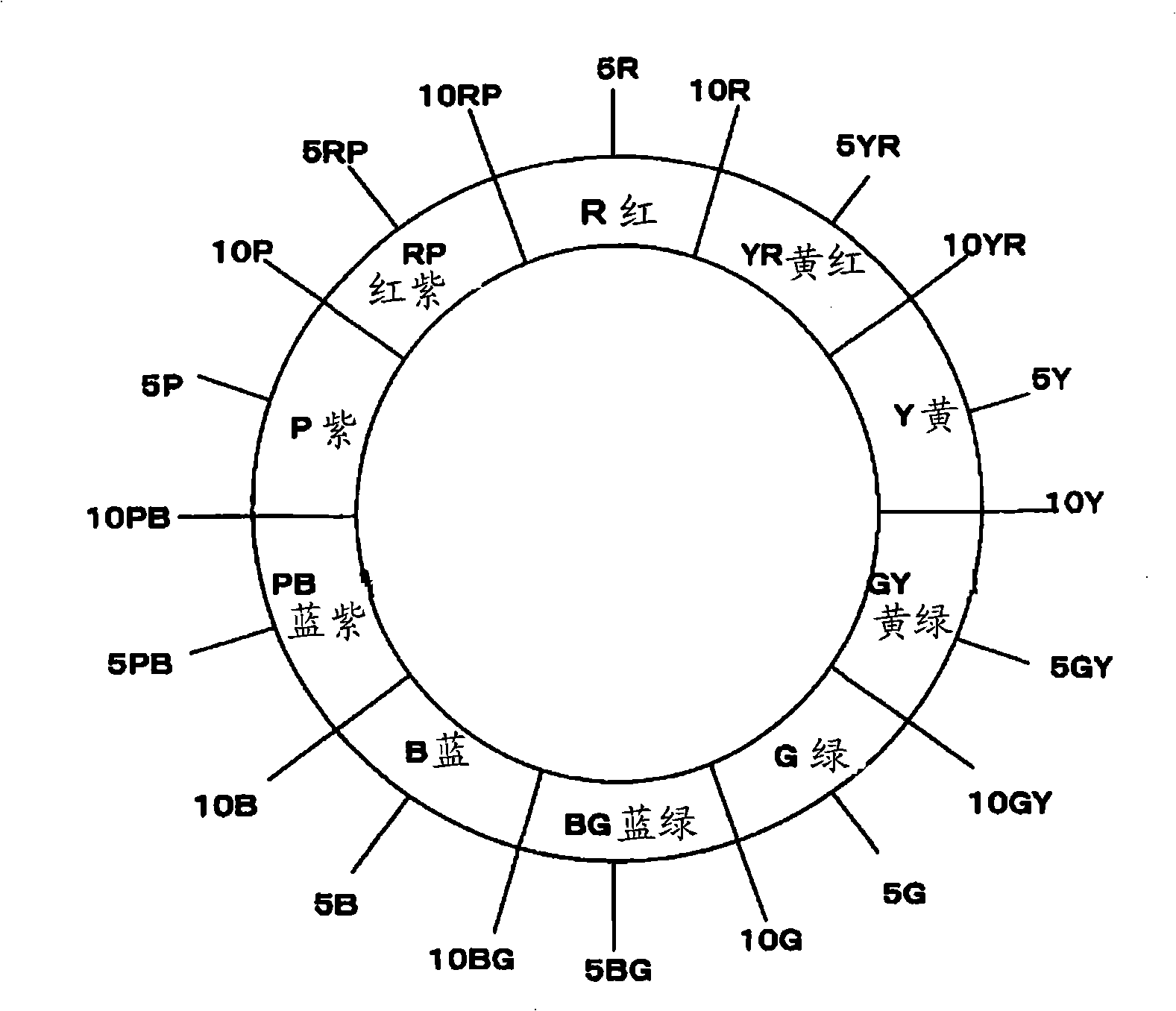

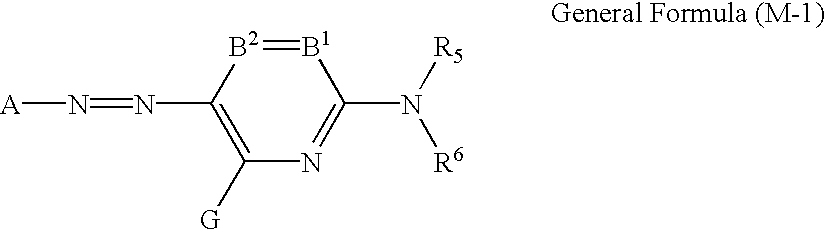

Ink set, container for storing the same, inkjet recording method, and method for preventing discoloration of inkjet-recorded image

InactiveUS6939399B2High fastnessImage can be preventedMeasurement apparatus componentsInksYELLOW DYEMagenta

An ink set having a yellow ink containing at least one yellow dye, a magenta ink containing at least one magenta dye, and a cyan ink containing at least one cyan dye, wherein an oxidation potential of the magenta dye and an oxidation potential of the cyan dye are each higher than 0.8 V (vs SCE), and an inkjet recording method using the ink set.

Owner:FUJIFILM CORP

Low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material and preparation method thereof

ActiveCN102093625AReliable Extrusion PerformanceReliable degree of cross-linkingInsulated cablesInsulated conductorsMasterbatchLow smoke zero halogen

The invention relates to a low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material and the cable material contains the raw materials of flame retardant masterbatch, catalyst masterbatch and crosslinking compounding agent. The preparation method comprises the following steps: mixing flame retardant masterbatch, catalyst masterbatch and crosslinking compounding agent in a sealed mixer for absorption, discharging after 3-5 hours, and packaging to obtain the low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material finished product. Compared with the common low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material, the temperature resistant grade and mechanical properties of the product of the invention can be increased and the problem that the common low smoke non-halogen polyolefin cable material is easy to crack can be eliminated.

Owner:中广核三角洲(江苏)塑化有限公司

Interlayer film for laminated glasses and laminated glass

ActiveUS20070134487A1Prevent discolorationGood effectSynthetic resin layered productsGlass/slag layered productsColor toneLaminated glass

It is the object of the present invention to provide an interlayer for laminated glass having an excellent heat ray shielding property and an excellent transparent property which looks a natural color and laminated glass. The present invention is an interlayer for laminated glass, which is formed by laminating a plurality of layers comprising an adhesive resin, a heat ray shielding resin containing a heat ray shielding fine particle and a color tone compensation resin layer toned to have a color complementary to the color tone of the heat ray shielding fine particle being laminated.

Owner:SEKISUI CHEM CO LTD

Aqueous automobile framework and automobile motorcycle wheel surface protection coating

ActiveCN101139499AGood car frameFunction increaseLiquid surface applicatorsPolyester coatingsPolyesterEthyleneglycol monobutyl ether

The invention discloses a water protection coating for automobile skeletons and automobile and motorcycles wheels, which essentially comprises by weight the following components: acrylic acid modified polyester 20-55 portions, methylated amino resin 4-20 portions, colorant 2.5-30 portions, dispersing agent 1-9 portions, flatting agent 0.2-1 portions, defoaming agent 0.01-0.5 portions, solving assistant 1-5 portions, pure water 10-30 portions, ethyleneglycol monobutyl ether 5-12 portions, and thixotropic agent 1-3 portions. The film of the coating is of excellent weatherability, resistance to salt fog, resistance to acid and alkaline, resistance to water, resistance to scrubbing by solvent, excellent stiffness, high hardness and resistance to scratching, is of excellent protective and decorative role for automobile skeletons and automobile and motorcycles wheels.

Owner:仙居县鸿润涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com