Patents

Literature

315 results about "Ethyleneglycol monobutyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous acrylic acid-modified alkyd resin and preparation method thereof

ActiveCN103554379AImprove water resistanceImprove aging resistanceCoatingsBenzoic acidPolymer science

The invention discloses aqueous acrylic acid-modified alkyd resin and a preparation method thereof. Basic alkyd resin of the aqueous acrylic acid-modified alkyd resin is prepared from an unsaturated fatty acid, benzoic acid, trimethylolpropane, pentaerythritol, maleic anhydride, isophthalic acid, ethylene glycol monobutyl ether and butanol. The aqueous acrylic acid-modified alkyd resin is prepared by adding styrene, methyl methacrylate, butyl acrylate, acrylic acid, a silane coupling agent, benzoyl peroxide, tert-butyl hydroperoxide, ethylene glycol monobutyl ether and a mixing neutralizer into the basic alkyd resin. According to the aqueous acrylic acid-modified alkyd resin and the preparation method thereof, the advantages of alkyd resin and acrylic resin are integrated, and a product has high gloss retention, color retention and weather resistance; a production process is simple, the raw materials are readily available, and the production cost is low; a paint production process is simple, water is used as a diluting agent, and safety and convenience in construction are ensured.

Owner:西北永新涂料有限公司

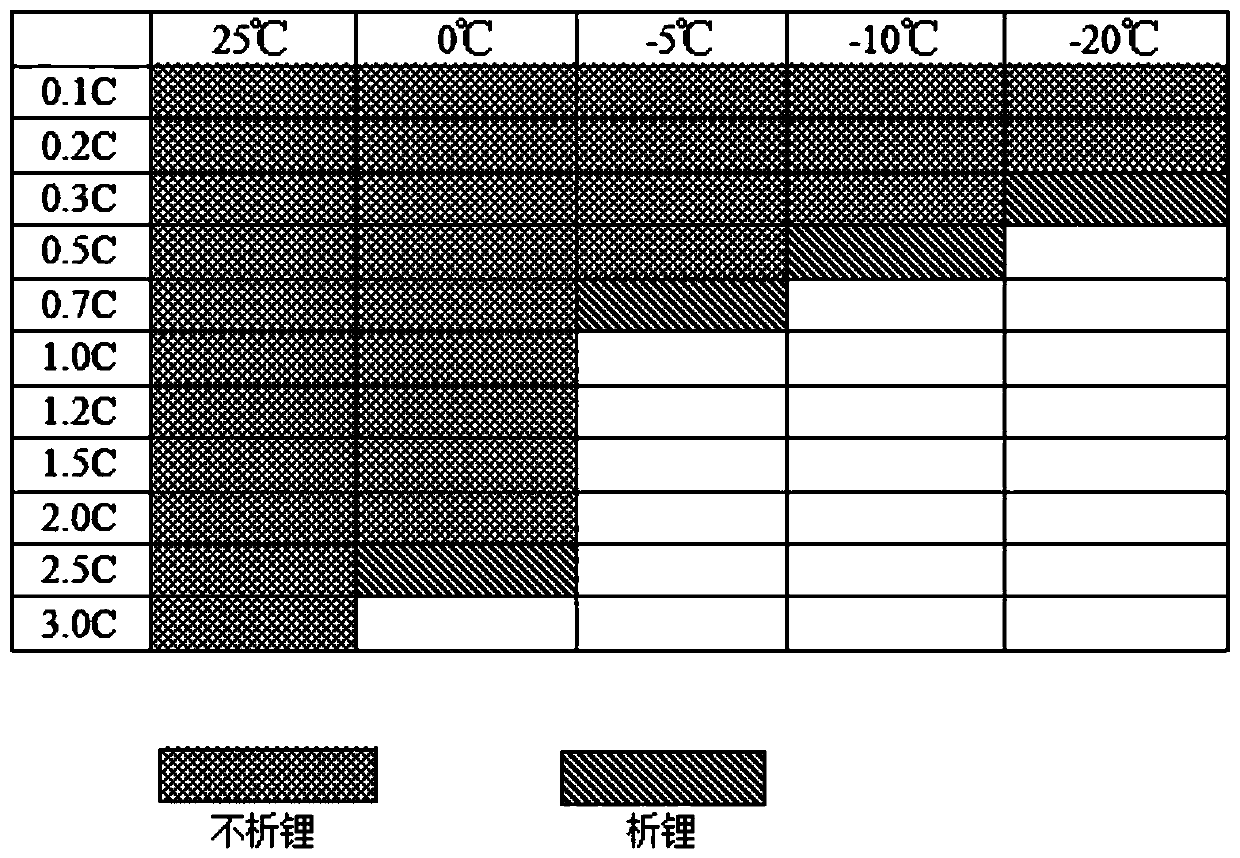

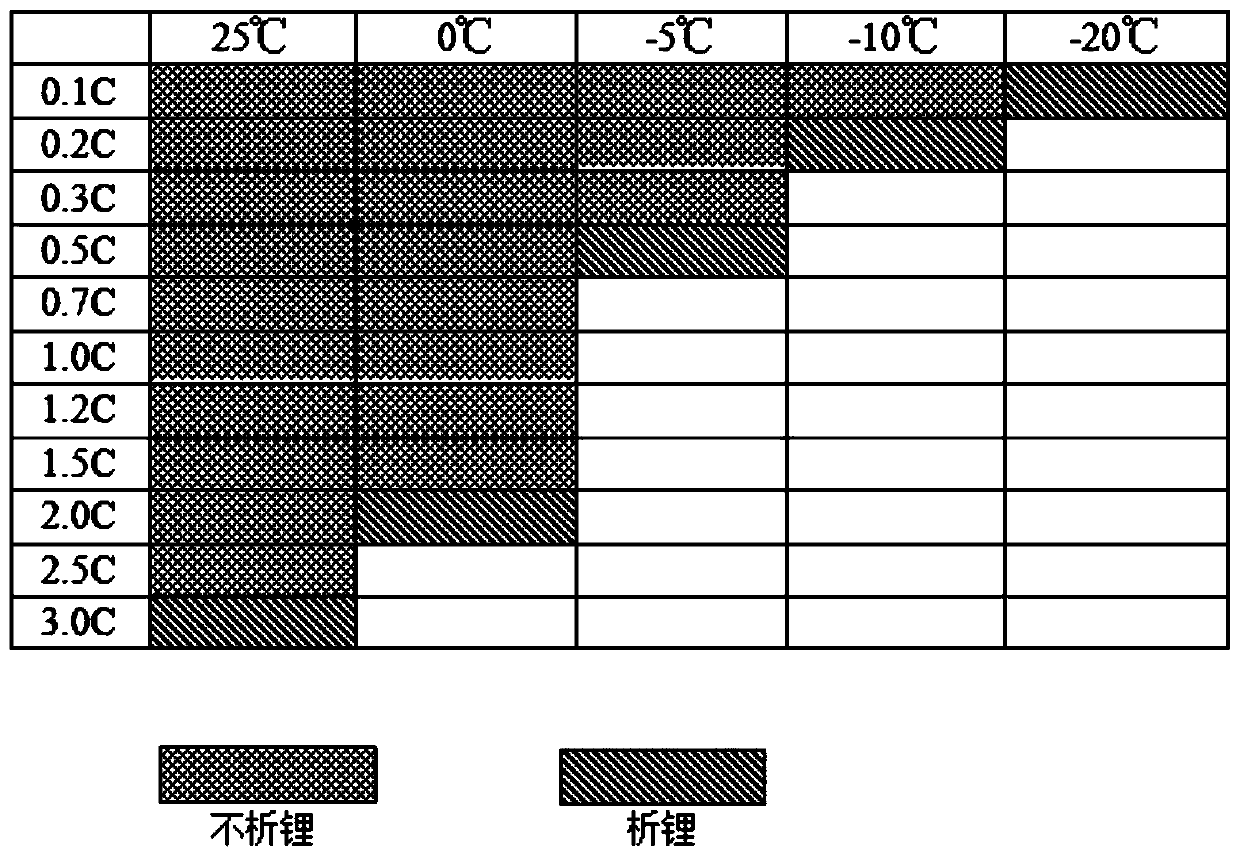

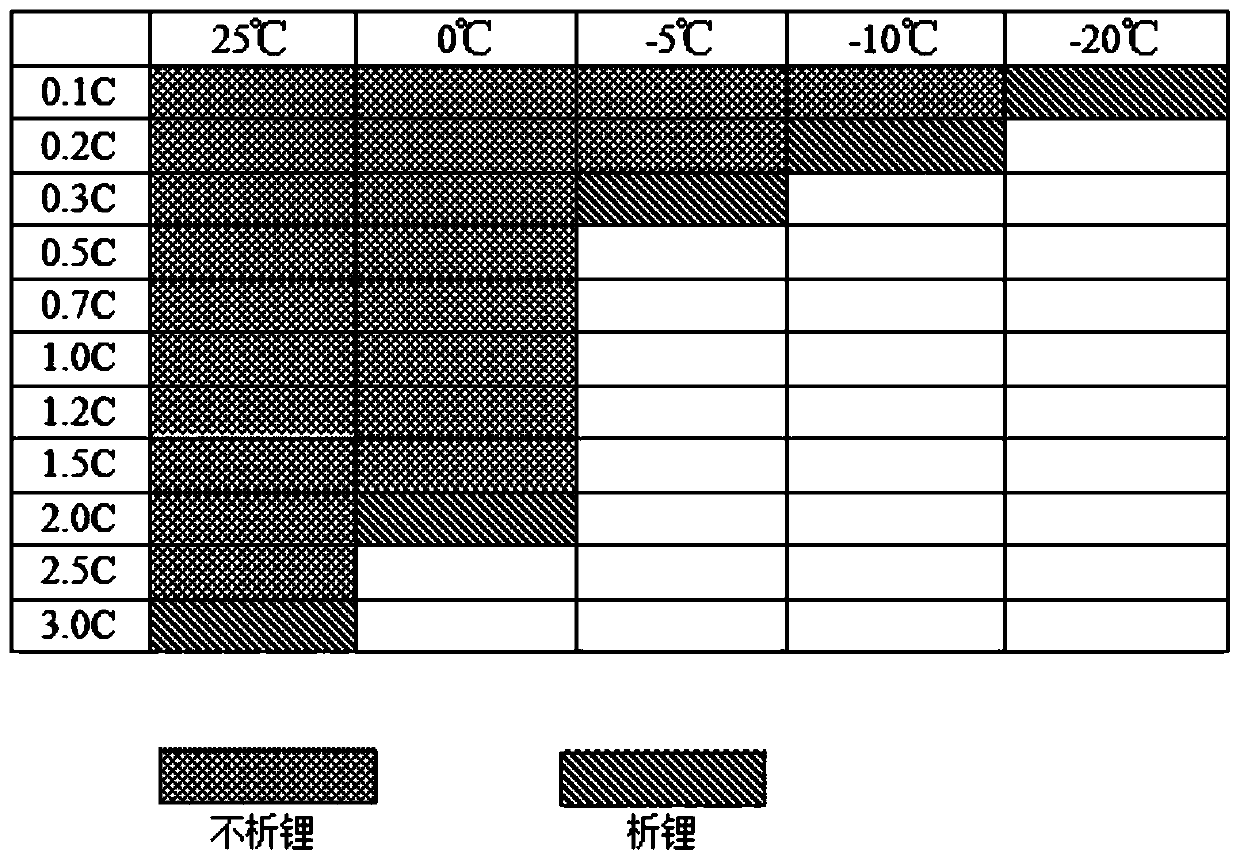

Low-temperature lithium ion battery

InactiveCN110739485AReduce DC internal resistanceImprove low temperature performanceCell electrodesSecondary cellsElectrolytic agentPropanoic acid

The invention belongs to the field of lithium batteries, in particular to a low-temperature lithium ion battery. The positive electrode sheet comprises a positive electrode current collector and a positive electrode active material layer. The positive electrode active material layer comprises 4.4 V lithium cobaltate material, a positive electrode conductive agent and a positive electrode binder. The negative electrode sheet comprises a negative electrode current collector and a negative electrode active material layer. The negative electrode active material layer comprises a hard carbon coatedsecondary particle artificial graphite material, a negative electrode conductive agent, a dispersant and a negative electrode binder. The electrolyte comprises 10-20% of lithium hexafluorophosphate,10-20% of ethyl propionate, 10-20% of diethyl carbonate, 15-30% of vinyl carbonate, 15-30% of propyl propionate, 3-10% of fluorovinyl carbonate, 2-3% of propylene sulfite, 0.5-2.5% of ethylene glycolmonobutyl ether and 0.5-2.5% of 2, 2'-dithiopyridine. Compared with the batteries in the prior art, the lithium ion battery has good charging and discharging performance and higher energy density under low temperature condition.

Owner:东莞维科电池有限公司

Aqueous automobile framework and automobile motorcycle wheel surface protection coating

ActiveCN101139499AGood car frameFunction increaseLiquid surface applicatorsPolyester coatingsPolyesterEthyleneglycol monobutyl ether

The invention discloses a water protection coating for automobile skeletons and automobile and motorcycles wheels, which essentially comprises by weight the following components: acrylic acid modified polyester 20-55 portions, methylated amino resin 4-20 portions, colorant 2.5-30 portions, dispersing agent 1-9 portions, flatting agent 0.2-1 portions, defoaming agent 0.01-0.5 portions, solving assistant 1-5 portions, pure water 10-30 portions, ethyleneglycol monobutyl ether 5-12 portions, and thixotropic agent 1-3 portions. The film of the coating is of excellent weatherability, resistance to salt fog, resistance to acid and alkaline, resistance to water, resistance to scrubbing by solvent, excellent stiffness, high hardness and resistance to scratching, is of excellent protective and decorative role for automobile skeletons and automobile and motorcycles wheels.

Owner:仙居县鸿润涂料有限公司

Quaternary cationic polymers

ActiveUS20180163020A1Avoid corrosionBiocideScale removal and water softeningIsobutanolEthyleneglycol monobutyl ether

A cationic polymer salt composition is provided that includes a reaction product derived from reaction of a polyamine or a polyalkyleneimine and a substituted alkyl trialkyl quaternary ammonium salt. Also provided are surfactant compositions. The compositions may also include carriers, such as water, methanol, ethanol, propanol, isopropanol, butanol, isobutanol, monoethyleneglycol, an ethyleneglycol monobutyl ether, and hexylene glycol.

Owner:ECOLAB USA INC

Modified waterborne alkyd resin of organic acid salt and preparation method thereof

The invention relates to a modified waterborne alkyd resin of organic acid salt and a preparation method thereof. The modified waterborne alkyd resin of organic acid salt is prepared by adopting the following materials: 4 to 9 portions of dihydric alcohol, 10 to 17 portions of polyhydric alcohol, 11 to 23 portions of dibasic acid or anhydride A, 5 to 10 portions of organic acid, 5 to 10 portions of unsaturated acid B, 0.03 to 0.1 portion of esterification catalyst, 3 to 8 portions of trimellitic anhydride, 10 to 20 portions of xylene and 25 to 35 portions of ethylene glycol monobutyl ether; all the portions are weight portions. The modified waterborne alkyd resin of organic acid salt can be dissolved in water directly by neutralization with little alkali; the prepared paint has good storing stability, and is not easy to form flash stain when being used for painting the metal surface; the painted film has fast drying and high hardness; the production technique is simple and the cost is low.

Owner:湘江涂料科技有限公司

Oil removal cleaning agent for metal surfaces

ActiveCN103334112AGood degreasing effectImprove solubilityDiethylene glycol monobutyl etherEthyleneglycol monobutyl ether

The invention provides an oil removal cleaning agent for metal surfaces. The oil removal cleaning agent is prepared from the following raw materials according to mass proportions: 4-10 of potassium hydroxide, 20-30 of sodium sulfate, 10-20 of trisodium phosphate, 10-15 of sodium carbonate, 5-10 of sodium tripolyphosphate, 1-4 of penetrating agent JFC-M, 6-10 of emulsifier FMES, 3-5 of emulsifier OP-10 and 2-6 of diethylene glycol monobutyl ether. The oil removal cleaning agent can be used at a normal temperature, has good dispersing performance and good cleaning and oil fouling removal effects, is short in oil removal time and does not cause abnomal adhesion pollution.

Owner:LIAONING TIANLONG CHEM

High-temperature-resistant and wear-resistant lubricating oil for drilling fluid and preparation method of lubricating oil

InactiveCN104087269AImprove the lubrication effectImprove high temperature resistanceDrilling compositionPhosphoric Acid EstersEthyleneglycol monobutyl ether

The invention relates to high-temperature-resistant and wear-resistant lubricating oil for a drilling fluid. The lubricating oil is prepared from the following raw materials in parts by mass: 30-48 parts of palm oil, 11-14 parts of sulfurized isobutylene, 5-8 parts of fatty alcohol-polyoxyethylene ether, 6-9 parts of nano graphite powder, 4-9 parts of zinc dialkyl dithiophosphate, 8-12 parts of molybdenum oxygen dialkyldithiophosphate, 1-3 parts of 3, 4, 5-trimethoxyl cinnamic acid, 10-14 parts of lauric acid monoethanolamide phosphate, 16-19 parts of glycerine, 10-13 parts of ethylene glycol monobutyl ether and 20-30 parts of pentaerythritol. By reasonably compounding the palm oil and other additives, the lubricating performance, high-temperature resistance and wear resistance of the lubricating oil are effectively improved. Meanwhile, 3, 4, 5-trimethoxyl cinnamic acid and lauric acid monoethanolamide phosphate are added, so that the high-temperature resistance, the wear resistance and the antirust time of the lubricating oil are effectively improved under the joint effect of 3, 4, 5-trimethoxyl cinnamic acid, lauric acid monoethanolamide phosphate and other components, and the friction coefficient is greatly lowered.

Owner:青岛蓬勃石油技术服务有限公司

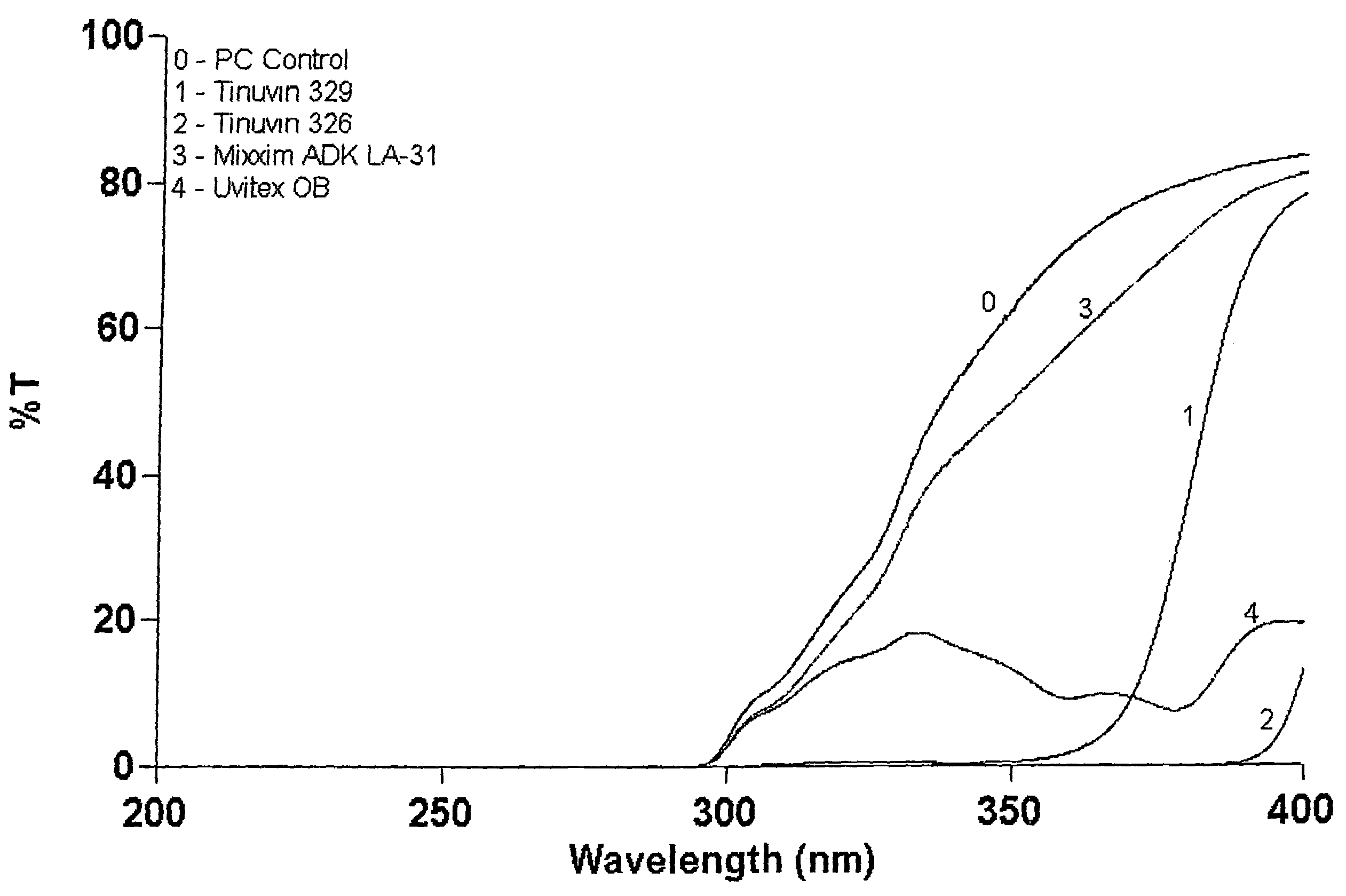

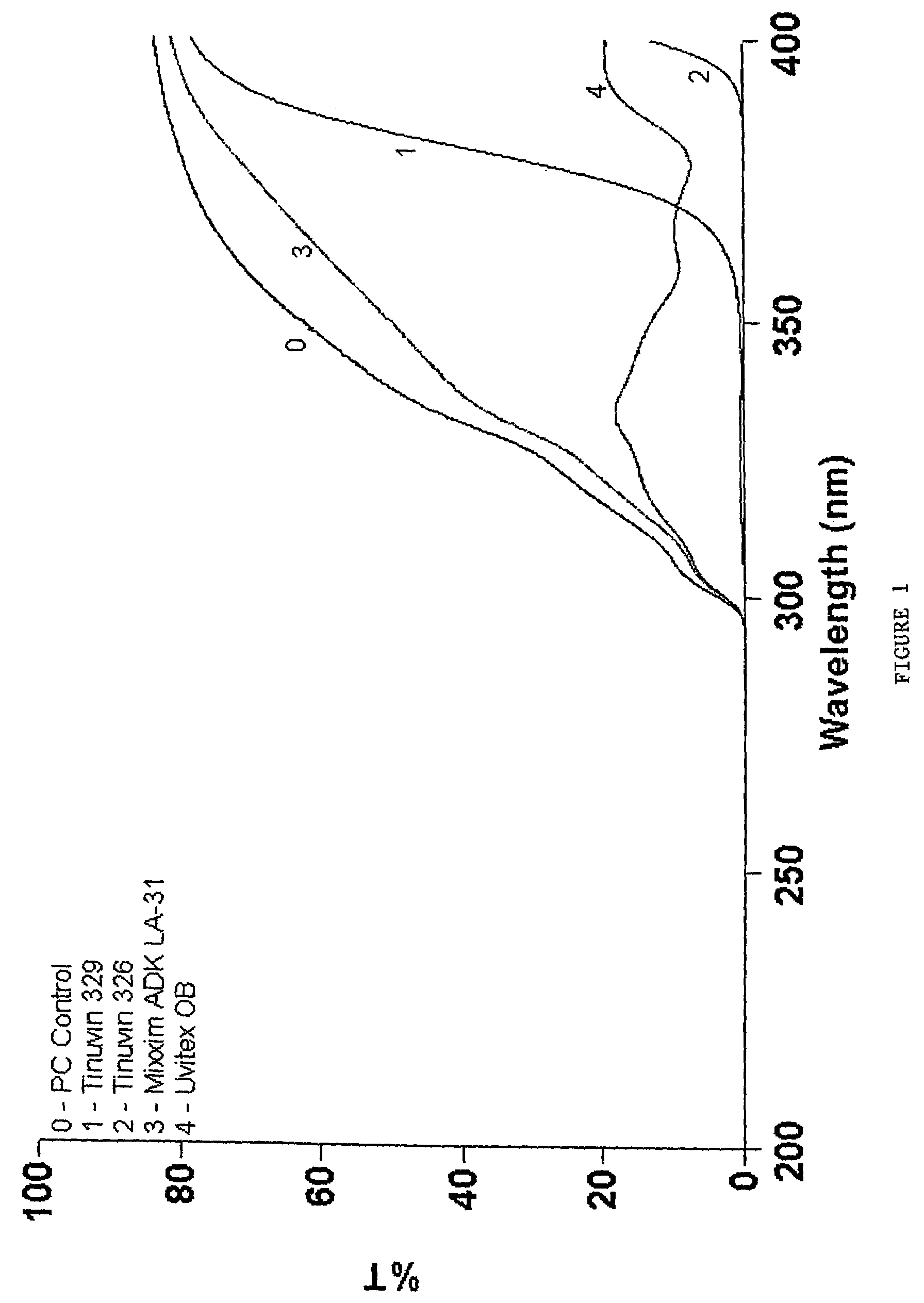

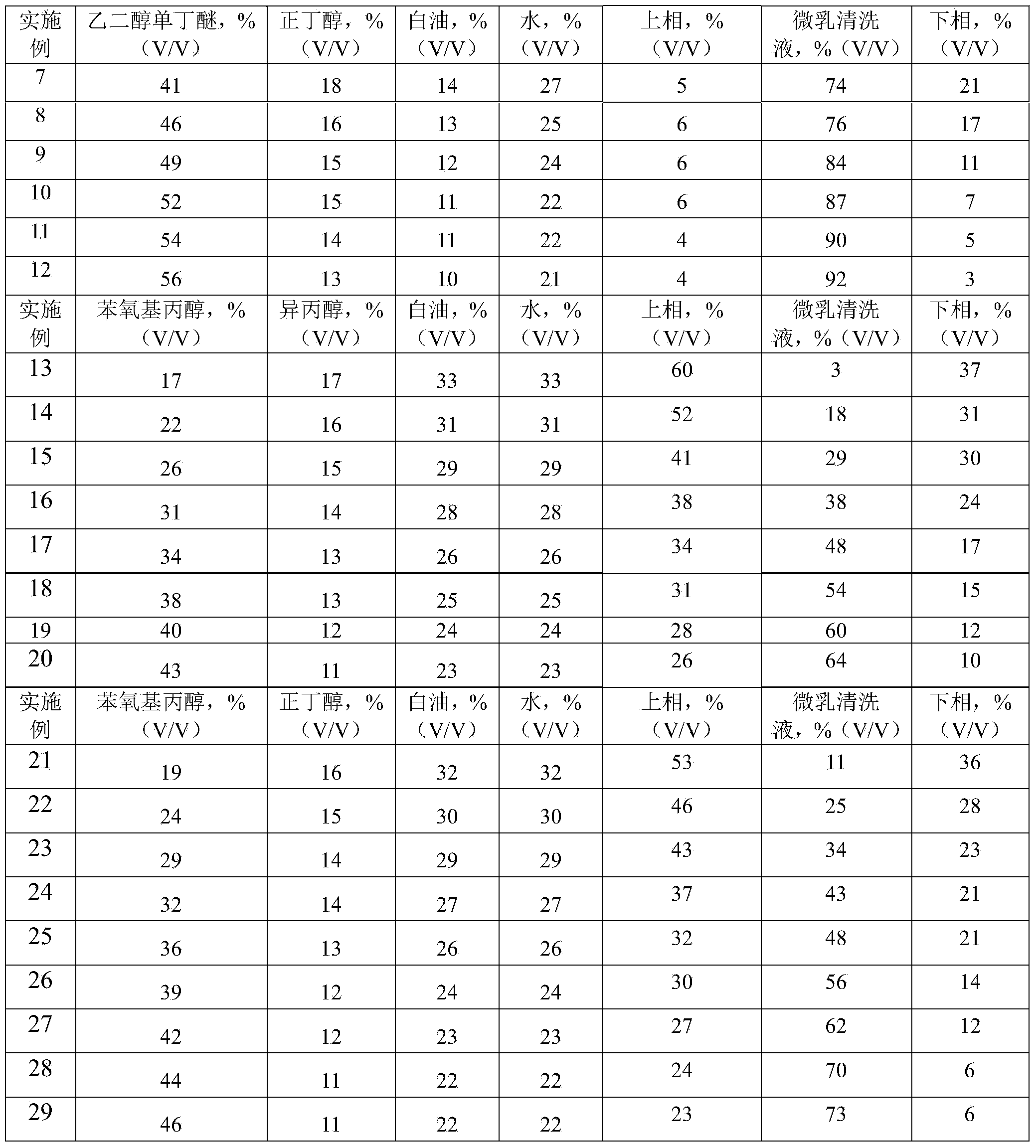

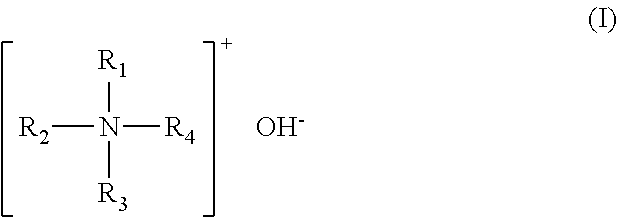

Method of treating a plastic article

In the method of the present invention at least a portion of the surface of a plastic article (e.g., a molded article of thermoplastic polycarbonate) is contacted with (e.g., immersed in) a treatment composition which includes one or more performance additives. The treatment composition contains: (i) at least one performance additive (e.g., an ultraviolet light absorber); (ii) water; (iii) at least one carrier represented by the following general formula I,wherein R1 is a radical selected from the group consisting of linear or branched C1-C18 alkyl, benzyl, benzoyl and phenyl, R2 is a radical selected from the group consisting of linear or branched C1-C18 alkyl, benzyl, benzoyl, phenyl and H, n is 2, 3 or 4, and m is 1 to 35; and (iv) a diol selected from at least one of linear or branched C2-C20 aliphatic diols, poly(C2-C4 alkylene glycol), cycloaliphatic diols having from 5 to 8 carbon atoms in the cyclic ring, monocyclic aromatic diols, bisphenols and hydrogenated bisphenols. In an embodiment of the present invention, the carrier is ethyleneglycol monobutyl ether, and the diol is diethylene glycol.

Owner:COVESTRO LLC

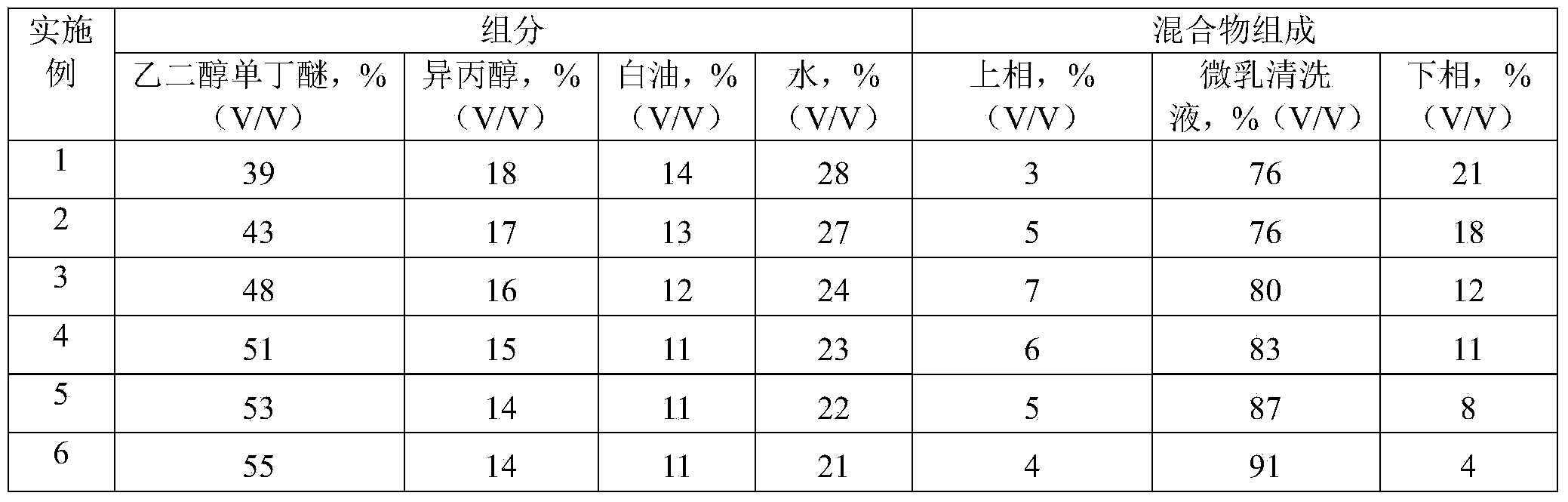

Oil based drilling cutting microemulsion cleaning solution and cleaning method thereof

InactiveCN104140799AReduce surface tensionReduce processing costsDrilling compositionEnvironmental resistanceOil phase

Belonging to the technical field of environment-friendly application of drilling engineering oilfield chemistry in the petroleum and natural gas field, the invention relates to an oil based drilling cutting microemulsion cleaning solution and a cleaning method thereof. For the oil based drilling cutting microemulsion cleaning solution, a surfactant, a cosurfactant, an oil phase and water are mixed in a volume percentage of (17-56):(11-18):(10-33):(21-33) to form three phases, and the middle phase is the microemulsion cleaning solution. The surfactant is ether alcohol, preferably ethylene glycol monobutyl ether or phenoxy propanol, and the cosurfactant is short chain alcohol, preferably n-butyl alcohol or isopropyl alcohol. The cleaning solution and drilling cuttings are mixed uniformly according to a mass ratio of (0.5:1)-(3:1), then solid-liquid separation is carried out, and the base oil, cleaning solution and drilling cuttings cleaned out from the oil based drilling cuttings are separated into different phases. Compared with other oil based drilling cutting treatment technologies, the process is simple, the base oil recovery rate is greater than 80%, and the residual oil content of the drilling cuttings is less than 2%, thus meeting relevant environmental protection technical standards. Also, the microemulsion cleaning solution can be used repeatedly, and the treatment cost is low.

Owner:CHINA PETROLEUM & CHEM CORP +3

Method of treating a plastic article

InactiveUS20050127570A1Liquid surface applicatorsWood working apparatusThermoplasticEthyleneglycol monobutyl ether

In the method of the present invention at least a portion of the surface of a plastic article (e.g., a molded article of thermoplastic polycarbonate) is contacted with (e.g., immersed in) a treatment composition which includes one or more performance additives. The treatment composition contains: (i) at least one performance additive (e.g., an ultraviolet light absorber); (ii) water; (iii) at least one carrier represented by the following general formula I, wherein R1 is a radical selected from the group consisting of linear or branched C1-C18 alkyl, benzyl, benzoyl and phenyl, R2 is a radical selected from the group consisting of linear or branched C1-C18 alkyl, benzyl, benzoyl, phenyl and H, n is 2, 3 or 4, and m is 1 to 35; and (iv) a diol selected from at least one of linear or branched C2-C20 aliphatic diols, poly(C2-C4 alkylene glycol), cycloaliphatic diols having from 5 to 8 carbon atoms in the cyclic ring, monocyclic aromatic diols, bisphenols and hydrogenated bisphenols. In an embodiment of the present invention, the carrier is ethyleneglycol monobutyl ether, and the diol is diethylene glycol.

Owner:COVESTRO LLC

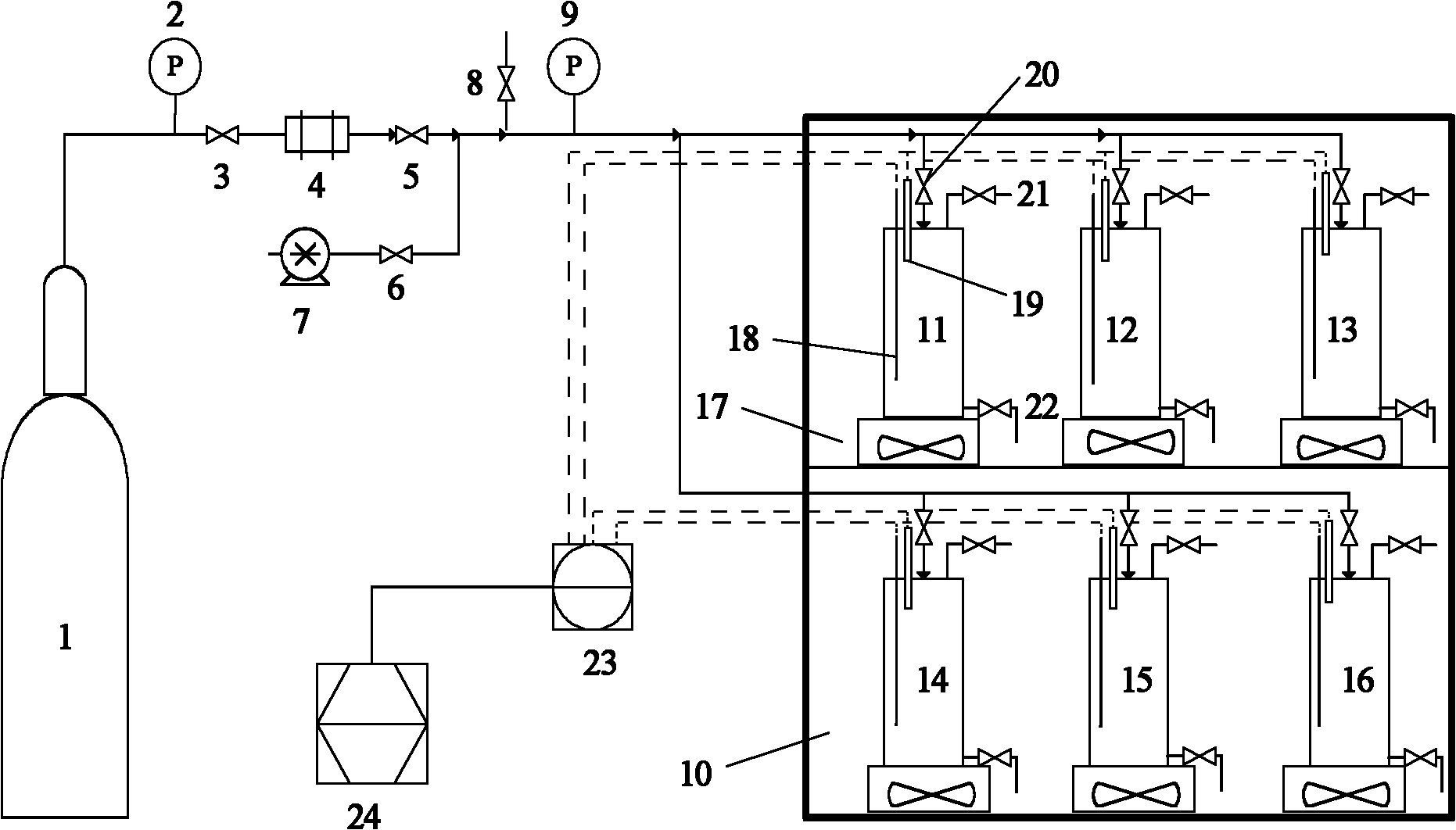

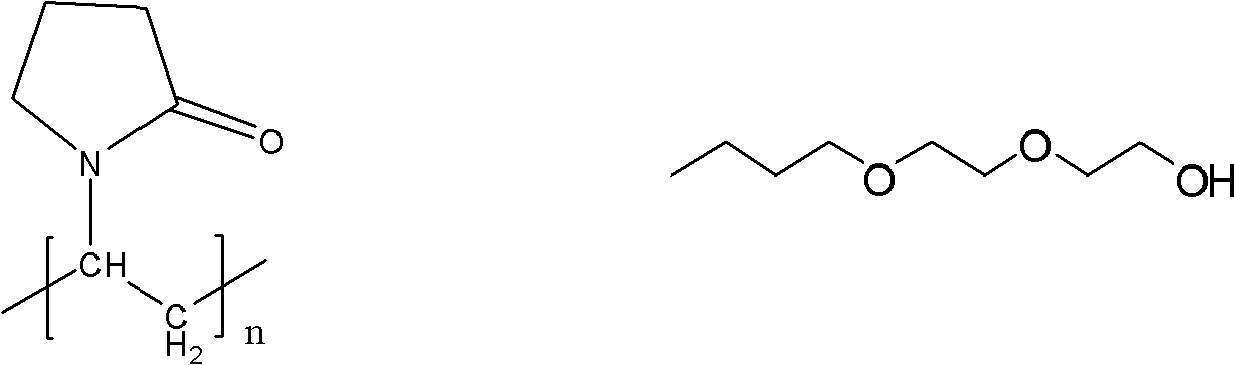

High-efficiency composite hydrate inhibitor as well as preparation method and application thereof

ActiveCN102161720ANo pollutionLow toxicity and good biocompatibilityPipeline systemsPolymer scienceBenzoyl peroxide

The invention discloses a high-efficiency composite hydrate inhibitor as well as a preparation method and an application thereof. The preparation method of the high-efficiency composite hydrate inhibitor comprises the following steps: taking N-vinyl pyrrolidone as a monomer and azodiisobutyronitrile or benzoyl peroxide as an initiator; and carrying out a polymerization reaction of a free-radical solution in a solvent to obtain the composite hydrate inhibitor, wherein the solvent is selected from at least one of the following components: carbinol, ethylene glycol, diethylene glycol, isopropanol, diethylene glycol, ethylene glycol monobutyl ether and Di(ethylene glycol) butyl ether, the volume ratio of the monomer to the solvent is (1:2)-(1:5), and the use amount of the initiator is 0.3-1.5wt% of the monomer. Compared with the method for industrially synthesizing the initiator, the method disclosed by the invention saves energy and is convenient and economic. The inhibitor synthesized by the invention can be applied to hydrate prevention and treatment in the processes of producing and transporting petroleum fluid.

Owner:CHINA NAT OFFSHORE OIL CORP +1

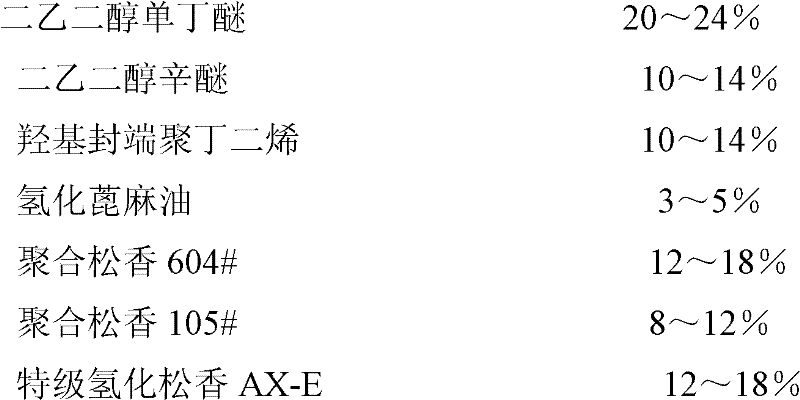

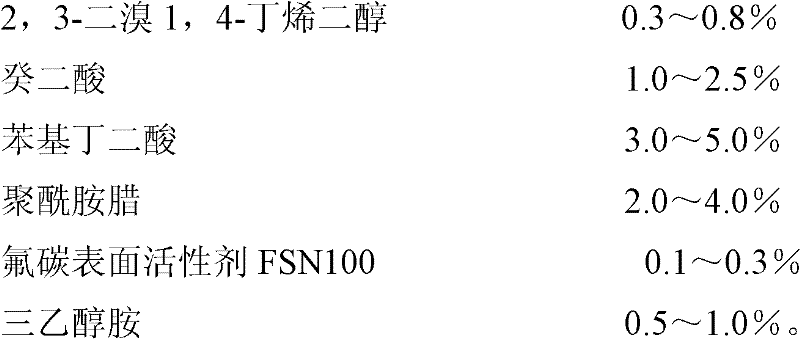

High-temperature lead-free solder paste and preparation method

ActiveCN102528327AImprove adhesionProtects and prevents re-oxidationWelding/cutting media/materialsSoldering mediaDiethylene glycol monobutyl etherButanedioic acid

The invention relates to high-temperature lead-free solder paste and a preparation method. The high-temperature lead-free solder paste comprises lead-free electronic grade tin alloy powder and flux. Diethylene glycol monobutyl ether, diethylene glycol octyl ether and hydroxyl-terminated polybutadiene are added into a temperature control emulsifying machine and are heated and mixed, hydrogenated castor oil, polymerized rosin CLEARON105# and hydrogenated rosin are added into the temperature control emulsifying machine and are mixed to obtain primary mixed liquor, the primary mixed liquor is cooled, 2,3-dibromo 1,4-butylene glycol, sebacic acid and phenyl-butanedioic acid are added into the primary mixed liquor and then are mixed to obtain secondary mixed liquor, the secondary mixed liquor is cooled, polyamide wax is added into the secondary mixed liquor and then is mixed to obtain tertiary mixed liquor, the tertiary mixed liquor is cooled, fluorocarbon surfactant and triethanolamine areadded into the tertiary mixed liquor and then are mixed and vacuumized until the temperature returns to room temperature, the lead-free electronic grade tin alloy powder Sn95Sb5 is added into the prepared flux after standing at the temperature of 22-25 DEG C, and the lead-free electronic grade tin alloy powder and the flux are mixed for 15-20 minutes to obtain the high-temperature lead-free solder paste. The high-temperature lead-free solder paste has the advantages of fine solderability and wettability, high solder joint strength, high reliability and solderability in air and nitrogen protection.

Owner:惠州市斯泰尔科技有限公司

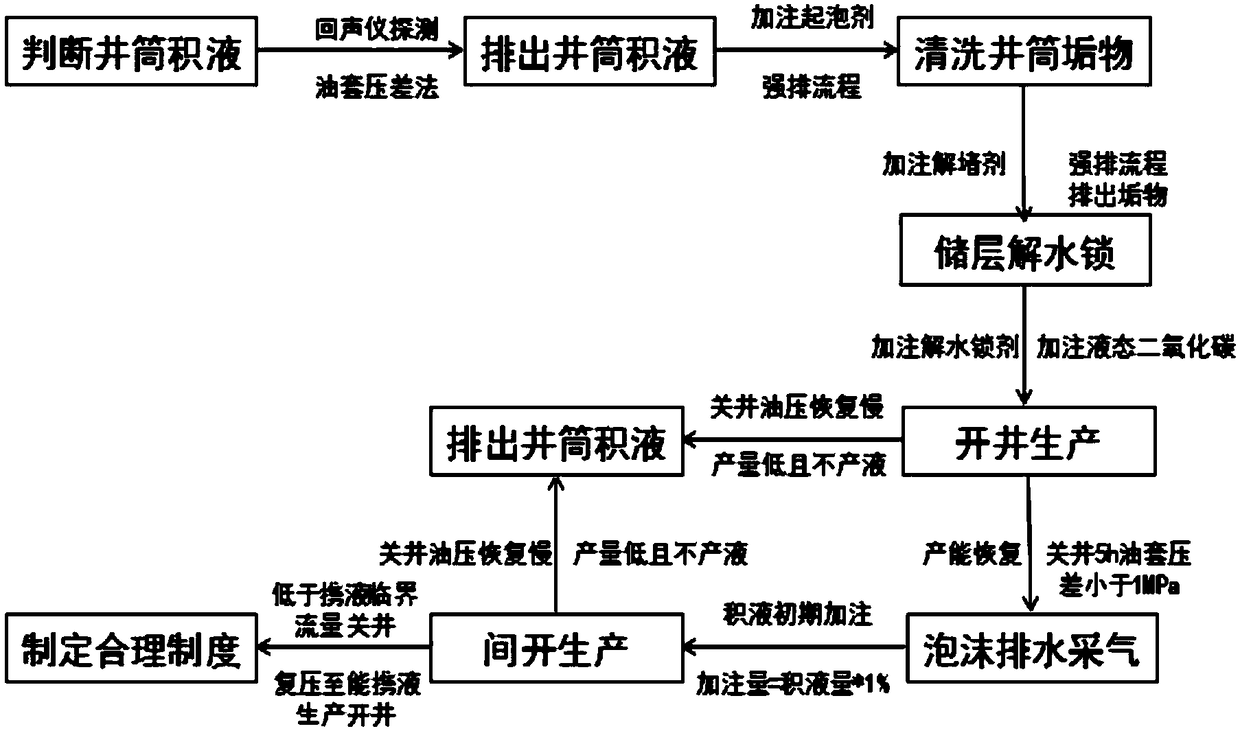

Matching medicament and technology for releasing water lock and blockage of reservoir

The invention relates to the technical field of petrochemical industry, and concretely relates to a matching medicament and a technology for releasing water lock and blockage of a reservoir. The medicament comprises, by mass, 4-15 parts of a cationic surfactant, 3-6 parts of a zwitterionic surfactant, 10-15 parts of ethylene glycol monobutyl ether, 5-15 parts of hydrochloric acid, 4-10 parts of hydrofluoric acid, 1-3 parts of a corrosion inhibitor, 1-2 parts of an iron ion stabilizer, 2-8 parts of a silicone surfactant, 50-70 parts of an alcohol and 5-20 parts of water. The water lock releasing medicament has the advantages of convenience in preparation, strong surface activity, good high temperature resistance, good high salt tolerance, strong rock adsorption property and low cost, and the lock releasing medicament prepared in the invention has strong diffusion ability after entering the reservoir under the technology, has strong adsorption capacity on the rock surface, can effectively release the water lock and blockage of the gas well reservoir, and can effectively improve the effective permeability of gas and liquid in the gas reservoir for a long term.

Owner:陕西新奥石油工程有限公司

Rust remover for ultrasonically cleaning metal mould and preparation method thereof

InactiveCN102337545AIncrease surface tensionOptimum viscosity coefficientMetallic material coating processesO-Phosphoric AcidEthyleneglycol monobutyl ether

The invention discloses non-corroding ultrasonic cleaning equipment. A rust remover for ultrasonically cleaning a metal mould is used for rapidly and completely removing rusts on the surface of the metal mould, generating a dense and complete passivation film at the same time and avoiding a secondary oxidization. The rust remover is prepared from the following raw materials by mass percent: 8-30% of phosphoric acid, 6-25% of room-temperature steel surface conditioning agent, 1-4% of citric acid, 1-5% of tartaric acid, 1-4% of phytic acid, 1-8% of polyethylene glycol, 1-3% of penetrant JFC, 1-6% of ethylene glycol monobutyl ether and the balance of water. A preparation method of the rust remover comprises the following steps of: firstly, adding water with a calculated amount into a stainless steel reaction kettle, starting an agitator and controlling a rotary speed of the agitator to 40-60 r / min; then respectively taking the calculated amount of the phosphoric acid, the room-temperature steel surface conditioning agent, the citric acid, the tartaric acid, the phytic acid, the polyethylene glycol, the JFC and the ethylene glycol monobutyl ether and sequentially and slowly adding the materials into the reaction kettle; and adding the materials while agitating until the solution becomes a light-green transparent liquid.

Owner:DALIAN SANDAAOKE CHEM

Photoresist stripping solution

ActiveUS20100022426A1Improve solubilityAdvantageously usableDetergent mixture composition preparationPhotosensitive material processingDiethylene glycol monobutyl etherTetramethylammonium hydroxide

Owner:TOKYO OHKA KOGYO CO LTD

Red glue cleaning agent

ActiveCN103160398ANo residueGood dispersionSurface-active non-soap compounds and soap mixture detergentsEthyleneglycol monobutyl etherSodium silicate

The invention relates to the technical field of cleaning agents and particularly relates to a red glue cleaning agent. The red glue cleaning agent consists of the following raw materials in percentage by weight: 2-8% of nonionic surfactant TO7, 2-8% of nonionic surfactant FMEE, 1-5% of monoethanolamine, 5-15% of N-methylpyrrolidone, 5-15% of diethylene glycol monobutyl ether, 5-15% of ethyl acetate, 1-5% of sodium silicate and the balance of water. According to the red glue cleaning agent, the nonionic surfactant FMEE and the nonionic surfactant TO7 which have excellent dispersion performance are adopted, all the raw materials of the red glue cleaning agent are thoroughly mixed, and the synergistic action among the materials is exerted, so that the red glue cleaning agent has the characteristics of remarkable cleaning effect, no solid impurity residual, high removal speed and the like. The red glue cleaning agent is environment-friendly, safe, stable, nontoxic and noncorrosive, is good in safety performance and does not pollute environments.

Owner:广东剑鑫科技股份有限公司

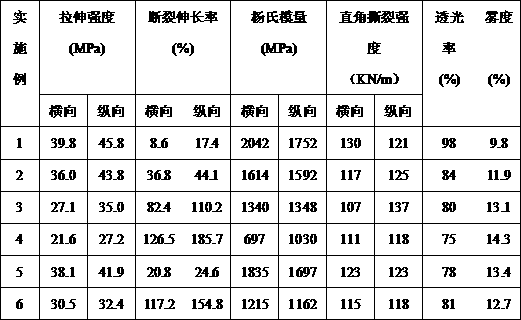

PLA-PBSA blown film and preparation method thereof

InactiveCN108017887AIncreased tensile elongation at breakHigh tear strengthFlat articlesDiethylene glycol monobutyl etherPolymer science

The invention provides a polylactic acid (PLA) / poly(butylene succinate-butylene adipate) (PBSA) blown film and a preparation method thereof. The blown film comprises a mixture of PLA, PBSA, plasticizer diethylene glycol monobutyl ether adipate, a lubricant, a plastic lubricant and an antioxidant. The PLA, the PBSA, the lubricant, the plastic lubricant and the antioxidant are first mechanically mixed into a premix, the premix is added through a feeding port of a twin-screw extruder, meanwhile the plasticizer diethylene glycol monobutyl ether adipate is metered and added in through a liquid feeding port of the twin-screw extruder, modified polylactic acid blown film special resin is prepared by melt-extruding, water-cooling, pelletizing and drying, the modified polylactic acid blown film special resin is blown by a film blowing machine to form a transparent tear-resistant biodegradable film. The PBSA, the plasticizers, the lubricant, the plastic lubricant and the antioxidant can effectively increase the tensile elongation at break and tear strength of polylactic acid films, maintains the transparency of the polylactic acid, and solves the brittleness defects of the polylactic acid films. The polylactic acid (PLA) / poly(butylene succinate-butylene adipate) (PBSA) blown film has good mechanical properties and excellent transparency, and can replace PE, PP, PVC and the like for preparation of films and sheets.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP +1

Starching-free direct injection reactive dye ink

InactiveCN102558959AConserve fresh water resourcesImprove ergonomicsInksDyeing processDiethylene glycol monobutyl etherTextile printer

The invention relates to reactive dye ink, in particular to starching-free direct injection reactive dye ink. The starching-free direct injection reactive dye ink is prepared from a surfactant, glycerol, resin, diglycol, 2-pyrrolidone, ethanol, 1,5 pentanediol, 2-ethylamino diethyl ether, diethylene glycol monobutyl ether, triethylamine alcohol, a reactive dye and deionized water in percentage byweight. When the starching-free direct injection reactive dye ink is used for performing a digital printing process on cotton, silk and wool fabrics which are not subjected to starching by a synthetic sizing agent prepared from sodium alginate or round cardamom, alkali and urea which serve as raw materials, the obtained digital printing cotton, digital printing silk and digital printing wool fabrics have the maximum soaping color fastness and light fastness, fresh water resources can be saved to the maximum degree in the production process, sewage discharge is reduced effectively, and the production efficiency is improved fully.

Owner:GUANGZHOU LIANYIN DIGITAL TECH +1

Preparation method of water-borne acrylic resin

InactiveCN102757529AEasy constructionImprove curing effectElectrophoretic coatingsPaints for electrolytic applicationsPolymer scienceEthyleneglycol monobutyl ether

The invention provides a preparation method of water-borne acrylic resin. The preparation method comprises the following steps of: (1) preparing blocked isocyanate; and (2) synthesizing acrylic resin, i.e., weighing 25-40 g of dimethylaminoethyl methacrylate, 25-40 g of butyl acrylate and 25-40 g of methyl methacrylate and uniformly stirring; adding 0.3-0.8 g of azo-bis-iso-butyrynitrile; adding 40-60 g of blocked isocyanate prepared by the first step and 20-30 g of ethylene glycol monobutyl ether into a flask provided with a stirrer, a thermometer, a condensing pipe and a dropping funnel; introducing nitrogen and stirring; heating to a temperature of 75+ / -1 DEG C; slowly dropwise adding 1 / 4 to all mixed monomer and 1 / 3-3 / 4 initiator azo-bis-iso-butyrynitrile; preserving the heat and reacting for about 1 hour after the dropwise addition is finished; slowly dropwise adding residual monomer for about 2-3 hours; fully dissolving the residual initiator with the ethylene glycol monobutyl ether; slowly dropwise adding into a reaction bottle for several times; controlling the temperature to be kept at a temperature of about 80 DEG C; preserving the heat and reacting for 1 hour; cooling to a temperature of 50 DEG C and discharging to obtain the water-borne acrylic resin. The resin has the advantages of simple preparation process, environmental friendliness, good storage stability and excellent curing performance.

Owner:佛山科富科技有限公司

Aluminum zinc cleaning agent

ActiveCN103160847AGood compatibilityGood decontamination effectXylyleneEthyleneglycol monobutyl ether

The invention relates to the technical field of cleaning agents, and in particular relates to an aluminum zinc cleaning agent. The cleaning agent consists of the following raw materials in percentage by weight: 2 to 7 percent of nonionic surfactant TO7, 5 to 12 percent of nonionic surfactant FMEE (fatty acid methyl ester ethoxylates), 3 to 8 percent of nonionic surfactant TX-10, 1 to 4 percent of nonionic surfactant APG (alkyl polyglucoside), 1 to 7 percent of triethanolamine, 0.5 to 2.5 percent of diethylene glycol butyl ether, 2 to 9 percent of N-methylpyrrolidone, 1 to 8 percent of sodium xylene sulfonate, and the balance of water. According to the cleaning agent, four different nonionic surfactants with high surface activity are mixed with other materials, and the effect of each material can be given a full play by utilizing the synergistic effect of all the materials, so that the final product has strong stain removing capability and a good stain removing effect; the aluminum and zinc materials are bright and not corroded without residuals after being cleaned; and the cleaning agent is environmentally-friendly, good in safety, is not toxic or corrosive, and does not pollute the environment.

Owner:广东剑鑫科技股份有限公司

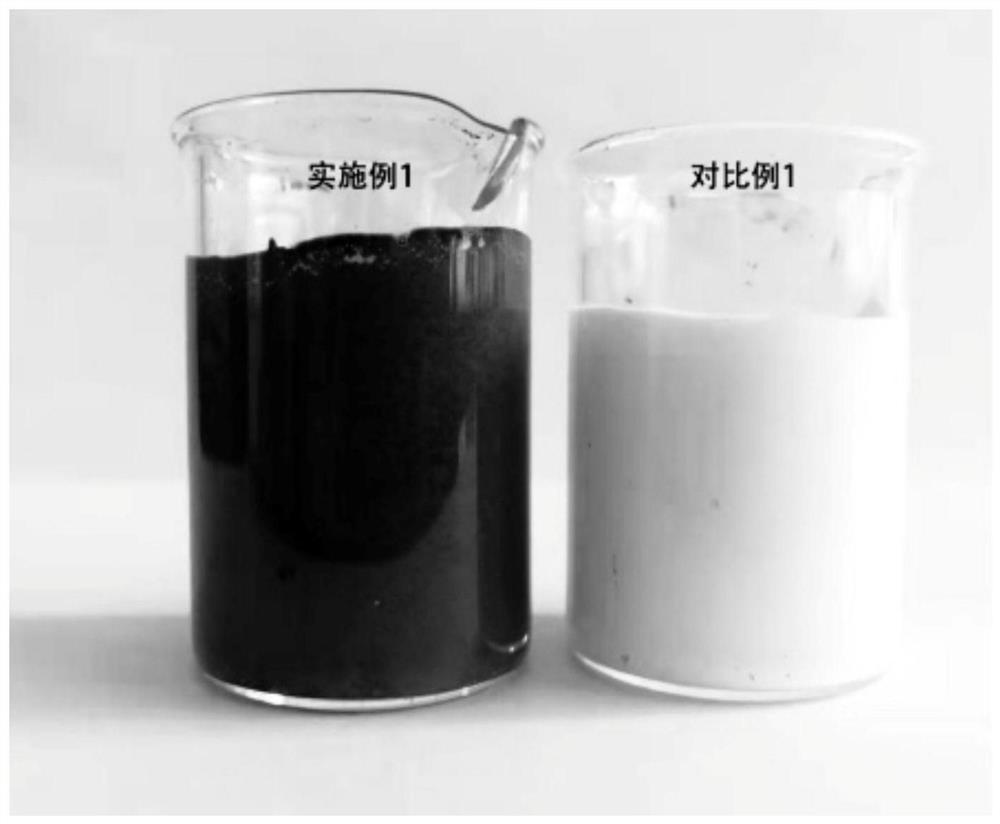

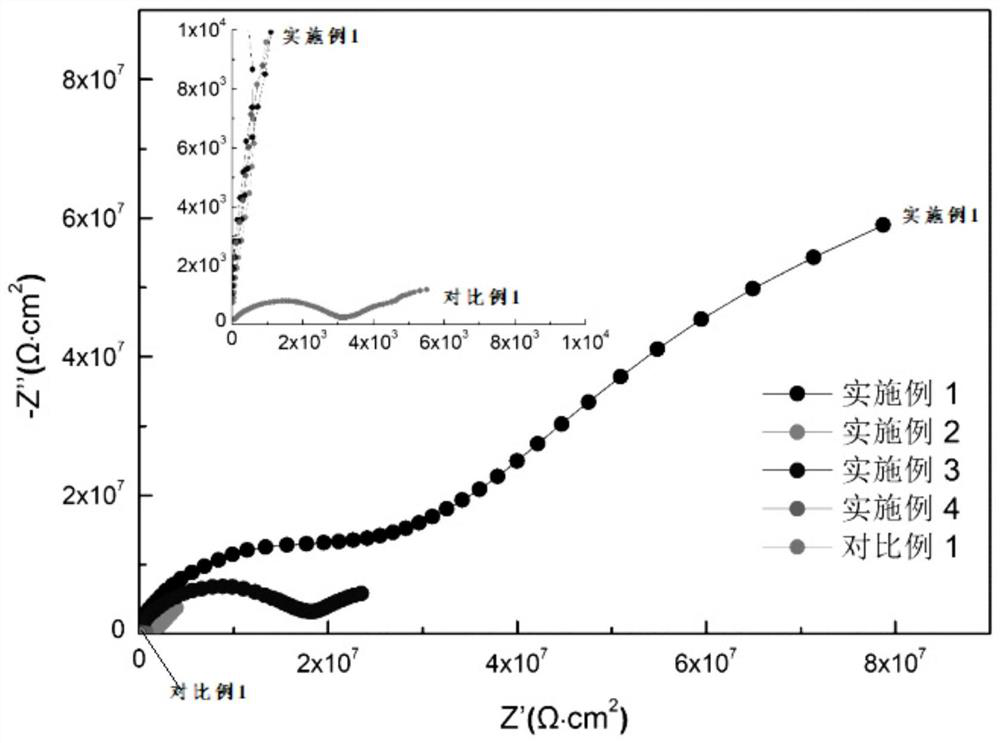

Graphene/waterborne epoxy zinc-rich coating with high corrosion resistance and strong adhesive force and preparation method of graphene/waterborne epoxy zinc-rich coating

ActiveCN112375459AGood compatibilityNo delaminationAnti-corrosive paintsEpoxy resin coatingsPolymer scienceEthyleneglycol monobutyl ether

The invention discloses a graphene / waterborne epoxy zinc-rich coating with high corrosion resistance and strong adhesion. The graphene / waterborne epoxy zinc-rich coating is composed of a component A and a component B. The component A comprises the following components in parts by mass: 0.3-1.5 parts of modified graphene, 5-25 parts of deionized water, 20-75 parts of waterborne epoxy resin and 0.3-1 part of a substrate wetting agent, and the component B comprises the following components in parts by mass: 40-70 parts of zinc powder, 15-30 parts of ethylene glycol monobutyl ether and 10-25 partsof a waterborne epoxy resin curing agent. According to the graphene / waterborne epoxy zinc-rich coating with high corrosion resistance and high adhesive force, graphene oxide is used as a precursor, polyethyleneimine is adopted for graft reduction of graphene oxide, graphene oxide is uniformly inserted and combined into waterborne epoxy resin through stirring and shearing effects, and a uniform system is achieved; and further stirring is conducted with a waterborne epoxy resin curing agent component mixed with zinc powder and ethylene glycol monobutyl ether to obtain the anticorrosive paint with high corrosion resistance and strong adhesive force.

Owner:广东豪之盛新材料有限公司

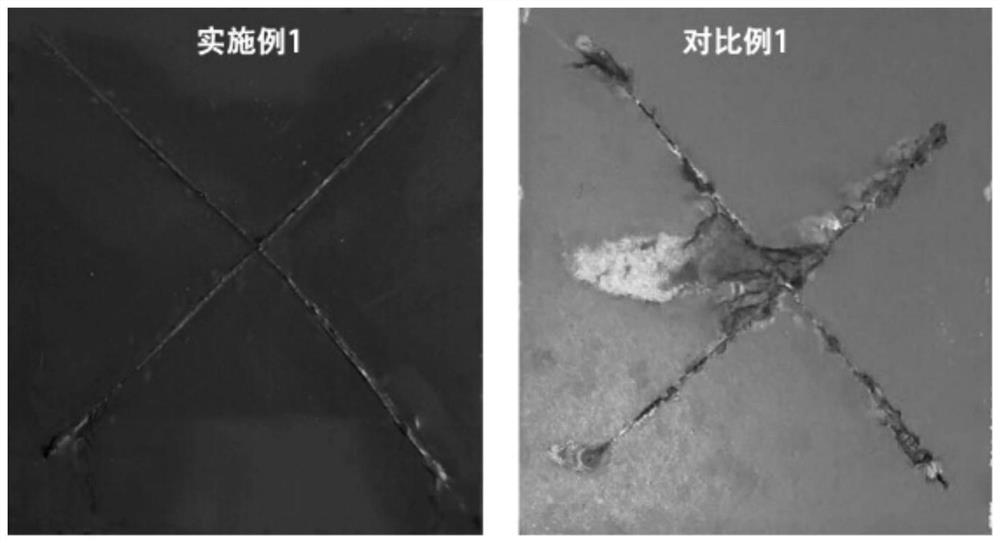

Grinding liquid cleaning agent and preparation method thereof

The invention provides a grinding liquid cleaning agent excellent in cleaning effect on silica sol grinding liquid and free of corrosion effect on aluminum alloys. The grinding liquid cleaning agent comprises the components in parts by weight of 15-25 parts of sulfamic acid, 15-25 parts of surface active agent, 10-15 parts of ethylene glycol monobutyl ether, 2-10 parts of corrosion inhibitor, 10-15 parts of sodium polyacrylate, 3-12 parts of salicylic acid and 20-30 parts of water. The grinding liquid cleaning agent selects high-performance organic amine ester type surface active agents, combined salicylic acid, sulfamic acid, corrosion inhibitors-siloxane ketone, sodium polyacrylate and ethylene glycol monobutyl ether; and through a cooperation effect of the six components, the cleaning performance on silica sol by the cleaning agent is improved, and the excellent cleaning effect is still achieved under acid condition. The grinding liquid cleaning agent is obviously higher in cleaningcapacity for the silica sol at high temperature compared with a conventional weak-acidity grinding liquid cleaning agent, so that higher actual application value is achieved.

Owner:GUANGDONG REDSUNSTAR IND

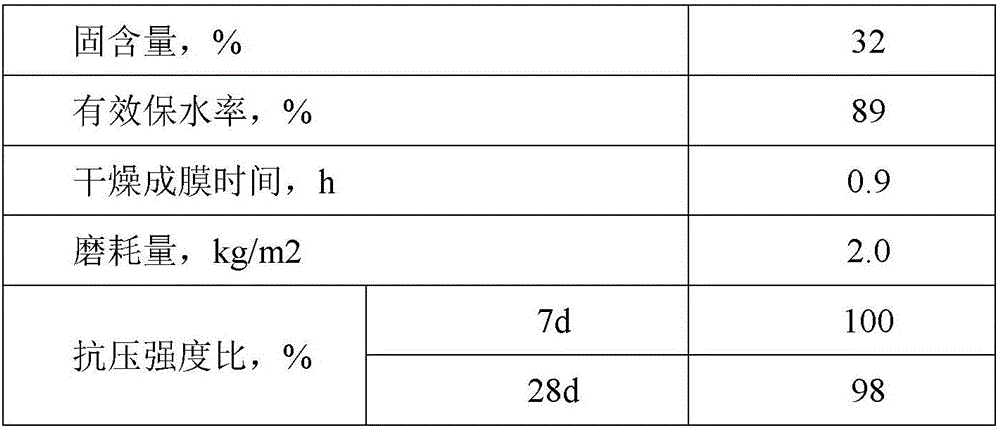

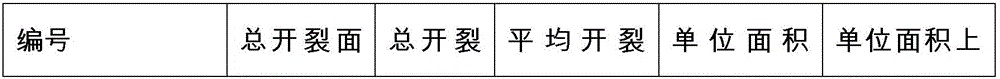

High-efficient curing agent for preventing cracking of concrete, as well as preparation method and application thereof

The invention discloses a high-efficient curing agent for preventing cracking of concrete. The curing agent is prepared by uniformly mixing a polycarboxylic acid copolymer with reduction function, lauryl alcohol ester, a pure acrylic emulsion, hydroxymethyl cellulose, and water; the polycarboxylic acid copolymer with the reduction function is prepared by a copolymerization reaction between triethylene glycol momobutyl ether acrylic acid ester, HPEG, acrylic acid, methyl methacrylate and allyl glycidyl ether which are used as monomers, and an inorganic chain transferring agent and inorganic peroxide which are used as initiators. The high-efficient curing agent for preventing cracking of concrete can be used for solving volatilization of moisture on the surface of concrete completely, and a preparation process of the agent has the advantages of simplicity, and low energy consumption without pollution to environment. In the curing of the concrete, operation is simple, construction is convenient, volatilization of moisture on the surface of concrete is obviously reduced, cracking of concrete is reduced, and strength of concrete is enhanced.

Owner:CCCC FOURTH HARBOR ENG INST +2

Vehicle methanol gasoline composite additive

ActiveCN103695050AImprove the lubrication effectReduce wearLiquid carbonaceous fuelsXylyleneCombustion system

The present invention discloses a vehicle methanol gasoline composite additive. The vehicle methanol gasoline composite additive comprises 2-ethyl hexanol, ethylene glycol butyl ether, lanolin fatty acid isobutyl lanolate, methyl lanolate, polyisobutene amine, an antioxidant, and xylene. The additive does not contain metal compound which is detrimental to engine combustion, and can enhance the stability and cleaning performance of methanol gasoline, effectively inhibit corrosion on an engine combustion system by the methanol gasoline and alleviate swelling of rubber product parts by the methanol gasoline. 0.05-0.20% of the composite additive is added into the vehicle methanol gasoline, and the vehicle methanol gasoline can fully satisfy the use requirements of vehicle engines.

Owner:YANKUANG GRP CO LTD +1

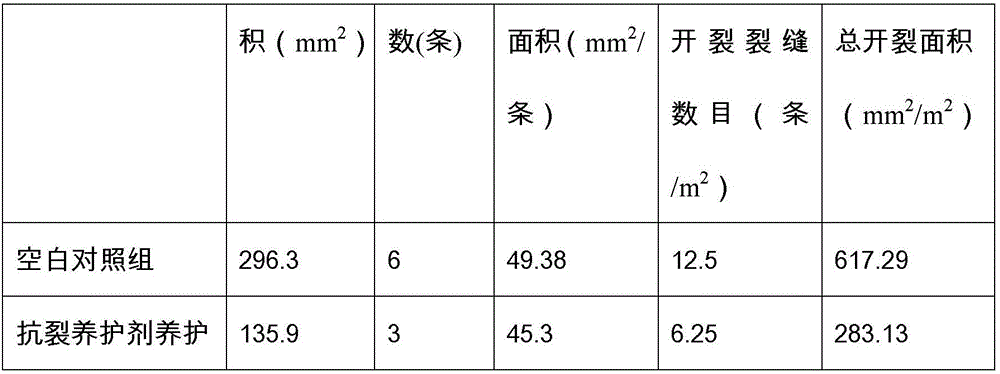

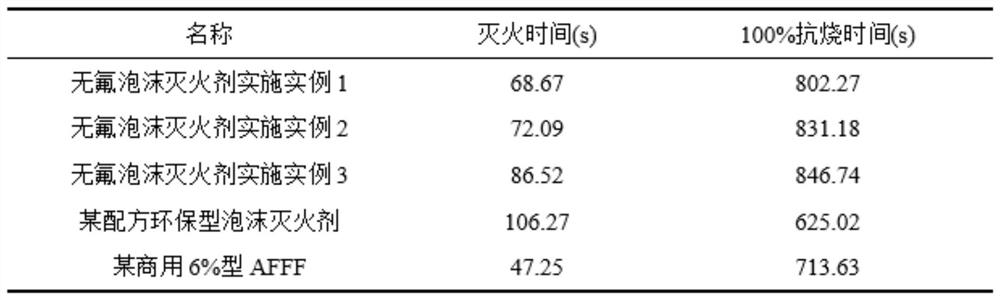

Environment-friendly fluoride-free foam extinguishing agent and preparation method thereof

InactiveCN111991744AImprove stabilityImprove fire extinguishing efficiencyFire extinguisherEthyleneglycol monobutyl etherActive agent

The invention belongs to the technical field of fire extinguishing materials, particularly relates to an environment-friendly fluoride-free foam extinguishing agent and a preparation method thereof, and solves the problems that a traditional extinguishing agent in the prior art is toxic, not environment-friendly and limited in application range, and a fluorocarbon surfactant, a chelating agent andthe like used in an existing foam extinguishing agent are harmful to the environment. The technical scheme of the invention is as follows: the environment-friendly fluoride-free foam extinguishing agent is formed by mixing a foam concentrate liquid and water according to the volume ratio of 6:94; and the foam concentrate liquid includes the following ingredients: a modified organic silicon surfactant, lauryl sodium sulfate, alkyl glycoside, water-soluble imidazoline, dodecyl dimethyl betaine, dodecanol, polyethylene glycol, xanthan gum, sodium carboxymethylcellulose, ethylene glycol, urea, diethylene glycol monobutyl ether and water. According to the product, a traditional fluorocarbon surfactant is replaced with the modified organic silicon surfactant, so that the product is green and pollution-free, and can be widely applied to fire prevention key units such as oil fields, oil depots, ships, submarines, petrochemical plants, hangars, airports and the like.

Owner:SOUTHWEST PETROLEUM UNIV

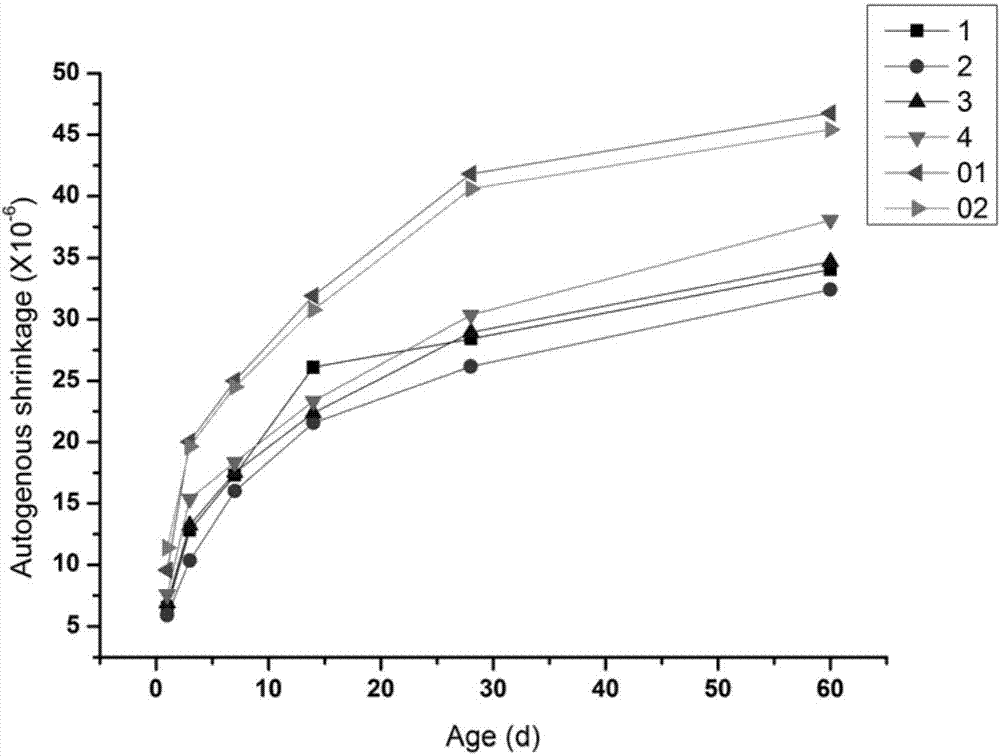

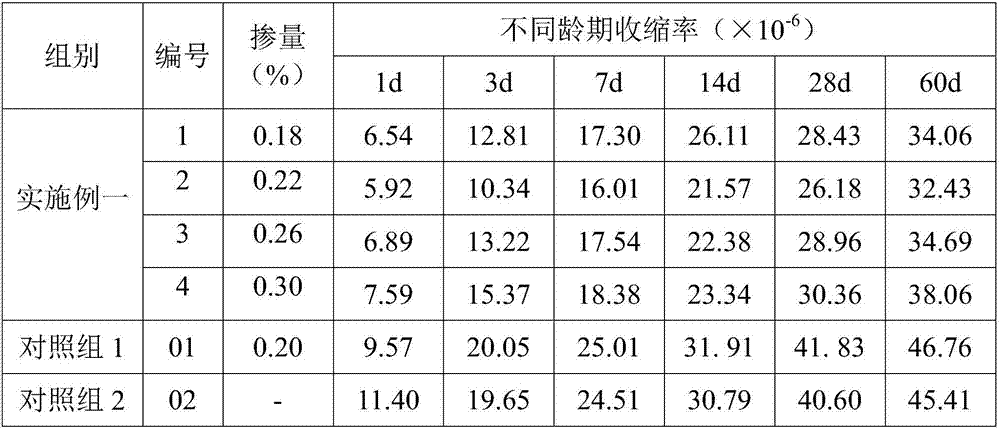

Concrete shrinkage reducing agent and preparation method and application thereof

ActiveCN107033291AGood water reduction effectImprove performanceDiethylene glycol monobutyl etherPhellandrene

The invention relates to a concrete shrinkage reducing agent and a preparation method and application thereof. The preparation method comprises the following steps that acrylic polyether, an initiator and water are mixed to be uniform, a first reactant is obtained, and temperature rise is carried out; crylic acid and water are mixed to be uniform, and a second reactant is obtained; methacrylic acid diethylene glycol monobutyl ether ester and phellandrene are mixed to be uniform, and a third reactant is obtained; a reducing agent, a chain transfer agent and water are mixed to be uniform, and a fourth reactant is obtained; the second reactant, the third reactant and the fourth reactant are dropwise added into the first reactant obtained after temperature rise at the same time; after all the reactants are dropwise added, heat preservation is carried out, and then cooling is carried out; an alkaline solution and water are added into the obtained product, and the concrete shrinkage reducing agent is obtained. According to the prepared concrete shrinkage reducing agent, the water reducing and shrinkage function of the concrete shrinkage reducing agent can be enhanced, the antifreezing capacity, compressive strength and anti-cracking ability of concrete can be improved, and the service life of the concrete can be prolonged; the production cost of the concrete can be reduced, and the application range is wide.

Owner:江苏超力建材科技有限公司

High flow flat imitating steam mold UV curing coating and production method, construction method

ActiveCN101418159AHigh fullnessImprove the level ofPretreated surfacesPaints with free metalsChemistryIsobutyl alcohol

The invention relates to a high-leveling vapor die imitating UV-curing coating, a production method and a construction method thereof. The coating comprises black primer or silver primer, a primer diluent and UV radiation curing varnish, wherein the primer diluent comprises 8 to 15 portions of ethylene glycol monobutyl ether, 5 to 10 portions of diacetone alcohol, 5 to 15 portions of ethylene glycol monoethyl ether, 5 to 15 portions of methylisobutylketone, 25 to 35 portions of ethyl acetate, 10 to 15 portions of isopropyl alcohol and 10 to 15 portions of isobutyl alcohol; and the UV radiation curing varnish comprises 10 to 15 portions of tripropylene glycol diacrylate, 10 to 15 portions of trimethylol-propane trimethacrylate, 20 to 30 portions of amino acrylate resin, 7 to 15 portions of Epocryl, 3 to 6 portions of 1-hydroxyl-cyclohexyl-phenyl ketone, 0.5 to 1 portion of 2, 4, 6(trimethylbenzene formacyl) diphenyl phosphine oxide, 15 to 25 portions of ethyl methyl ketone, 0.5 to 1.5 portions of polyacrylate leveling agent and 0.5 to 1.5 portions of polyether siloxane copolymer. The invention also provides a manufacturing method and a use method for the product. The high-leveling vapor die imitating UV-curing coating, is widely applied to treatment of plastic shells such as TV sets, so that the surface of a treated plastic substrate can achieve the effect of high-leveling vapor die imitating.

Owner:深圳市嘉卓成科技发展有限公司

Heavy greasy dirt mechanical part cleaning agent and preparation method thereof

InactiveCN104450298AStable in natureStrong removal rateOrganic non-surface-active detergent compositionsInorganic non-surface-active detergent compositionsEthyleneglycol monobutyl etherGlycerol

The invention relates to a heavy greasy dirt mechanical part cleaning agent and a preparation method thereof, belonging to the technical field of industrial cleaning agents. The heavy greasy dirt mechanical part cleaning agent comprises the following components in parts by weight: 2-8 parts of castor oil, 5-10 parts of glycerin monostearate, 10-16 parts of polyacrylamide, 10-20 parts of nano silica powder, 5-10 parts of glycerin, 8-16 parts of polydimethylsiloxane, 5-10 parts of potassium hydrogen tartrate, 10-16 parts of sodium alginate, 20-38 parts of ethylene glycol butyl ether and 20-28 parts of ethanol. The cleaning agent disclosed by the invention has high removal rate on oil dirt and impurities deposited on mechanical equipment; the cleaning agent disclosed by the invention is stable in properties, and secondary environmental pollution is avoided; and moreover, the preparation method is simple, feasible and convenient to implement.

Owner:SUZHOU CHANGSHENG ELECTROMECHANICAL

High-temperature-resistant textile dye

InactiveCN104862997AImprove high temperature resistanceImprove dyeing effectDyeing processCellulosePolymer science

High-temperature-resistant textile dye is prepared from raw materials in parts by weight as follows: 6-14 parts of epichlorohydrin, 2-8 parts of acetic acid, 7-9 parts of rosin, 4-10 parts of polyvinyl alcohol, 4-10 parts of an acetic acid aqueous solution, 4-8 parts of methyl silicone oil, 4.2-8 parts of propylene glycol, 5-11 parts of ethylene glycol monobutyl ether, 3-10 parts of ethyl cellulose, 2.5-6 parts of palmitic acid, 5-11 parts of anhydrous sodium sulfite, 4-9 parts of acrylamide and 1-4 parts of an aid. The textile dye has the benefits as follows: the textile dye has the good high temperature resistance and the good dyeing effect and cannot affect hand feeling of cloth.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

Anti-breaking paint for glass and preparation method thereof

InactiveCN104342023AEasy to produceEasy to operateAntifouling/underwater paintsUnspecified rubber coatingsDiethylene glycol monobutyl etherCellulose

The invention discloses an anti-breaking paint for glass. The invention is characterized in that the anti-breaking paint for glass is prepared from the following raw materials in parts by weight: 43-48 parts of methyl organic silicon resin emulsion, 4-6 parts of nitrocellulose, 8-12 parts of modified styrene acrylic emulsion, 15-18 parts of 50% rubber latex, 1-2 parts of alcohol ester 12, 2-3 parts of 1,2-propanediol, 0.3-0.6 part of glycerol, 0.2-0.4 part of sorbitol alcohol, 1-2 parts of diethylene glycol monobutyl ether, 0.3-0.6 part of alkylol amino alkoxy titanate, 0.3-0.5 part of leveling agent BYK-307, 1-2 parts of N-methylpyrrolidone, 0.2-0.4 part of polyethylene wax emulsion, 1-2 parts of wollastonite powder, 1-2 parts of yttrium oxide crystal seed, 0.3-0.5 part of iron powder, 1-3 parts of pigment and 10-15 parts of deionized water. The modified styrene-acrylic emulsion added to the water-based paint has the bactericidal, dust-proof and antistatic actions; the added nitrocellulose and 50% rubber latex can protect the glass and reduce the possibility of breaking of the glass due to heating and pressure, thereby ensuring the personal safety. The paint is simple to produce and convenient to operate, and has the advantages of high drying rate, smooth paint film and excellent properties.

Owner:凤阳徽亨商贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com