Patents

Literature

70results about How to "Reduce DC internal resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature lithium ion battery

InactiveCN110739485AReduce DC internal resistanceImprove low temperature performanceCell electrodesSecondary cellsElectrolytic agentPropanoic acid

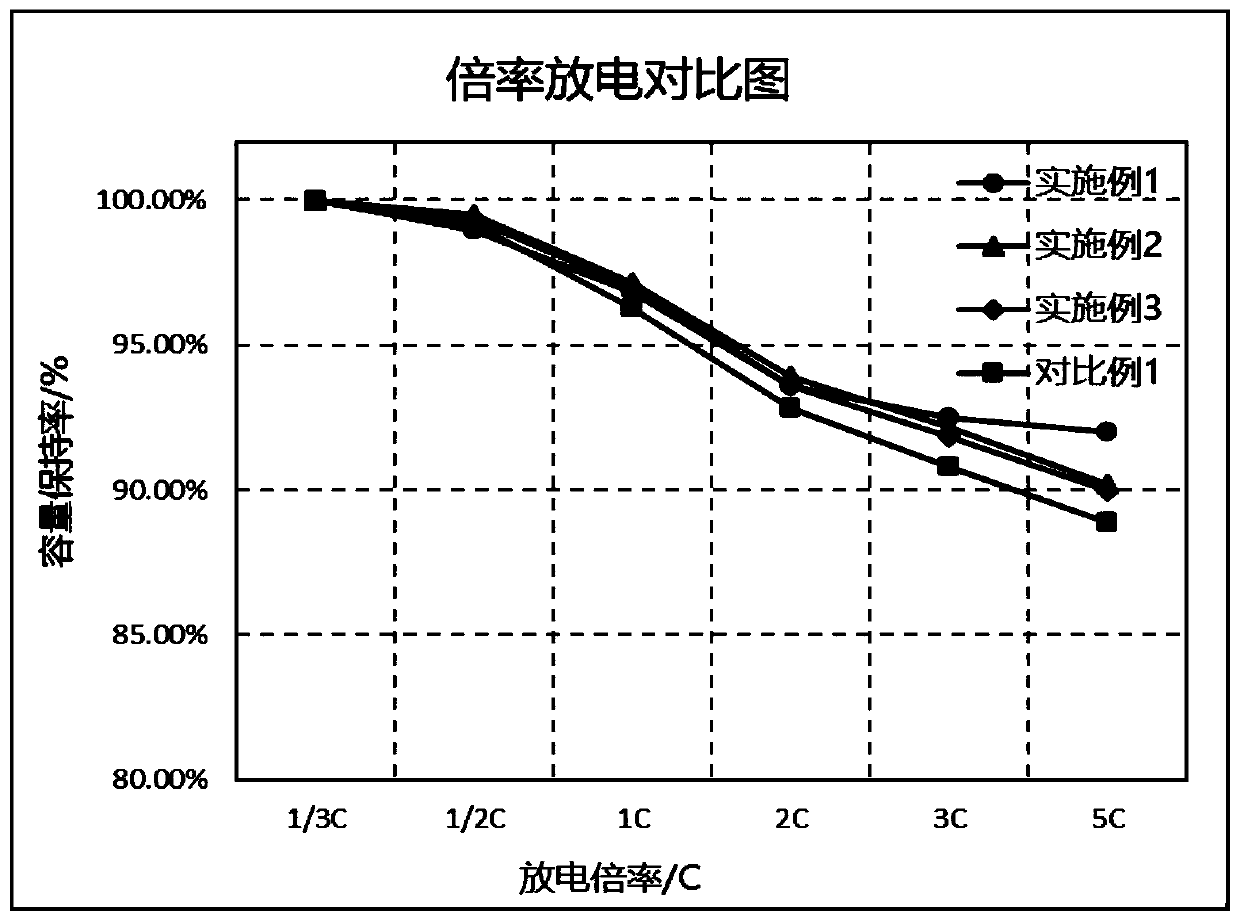

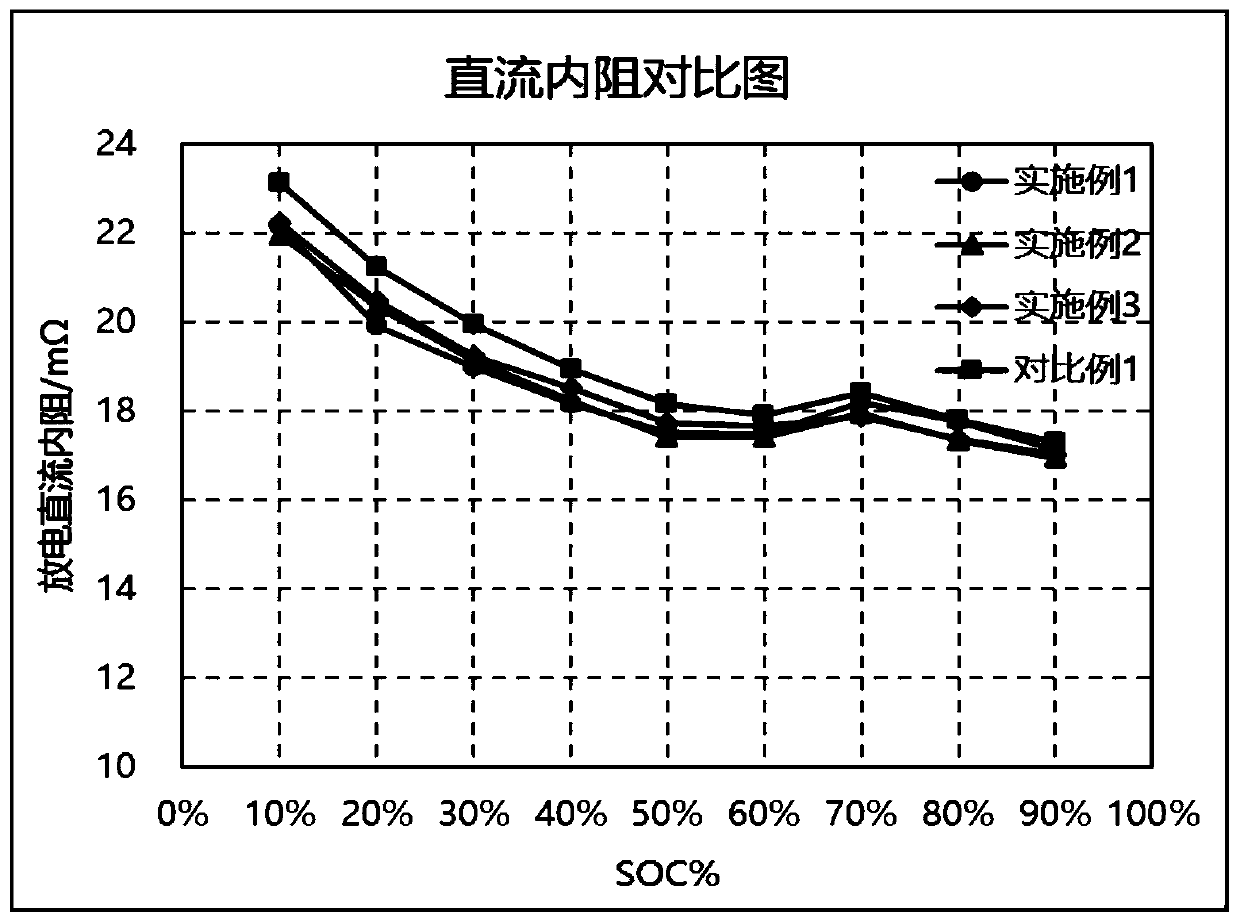

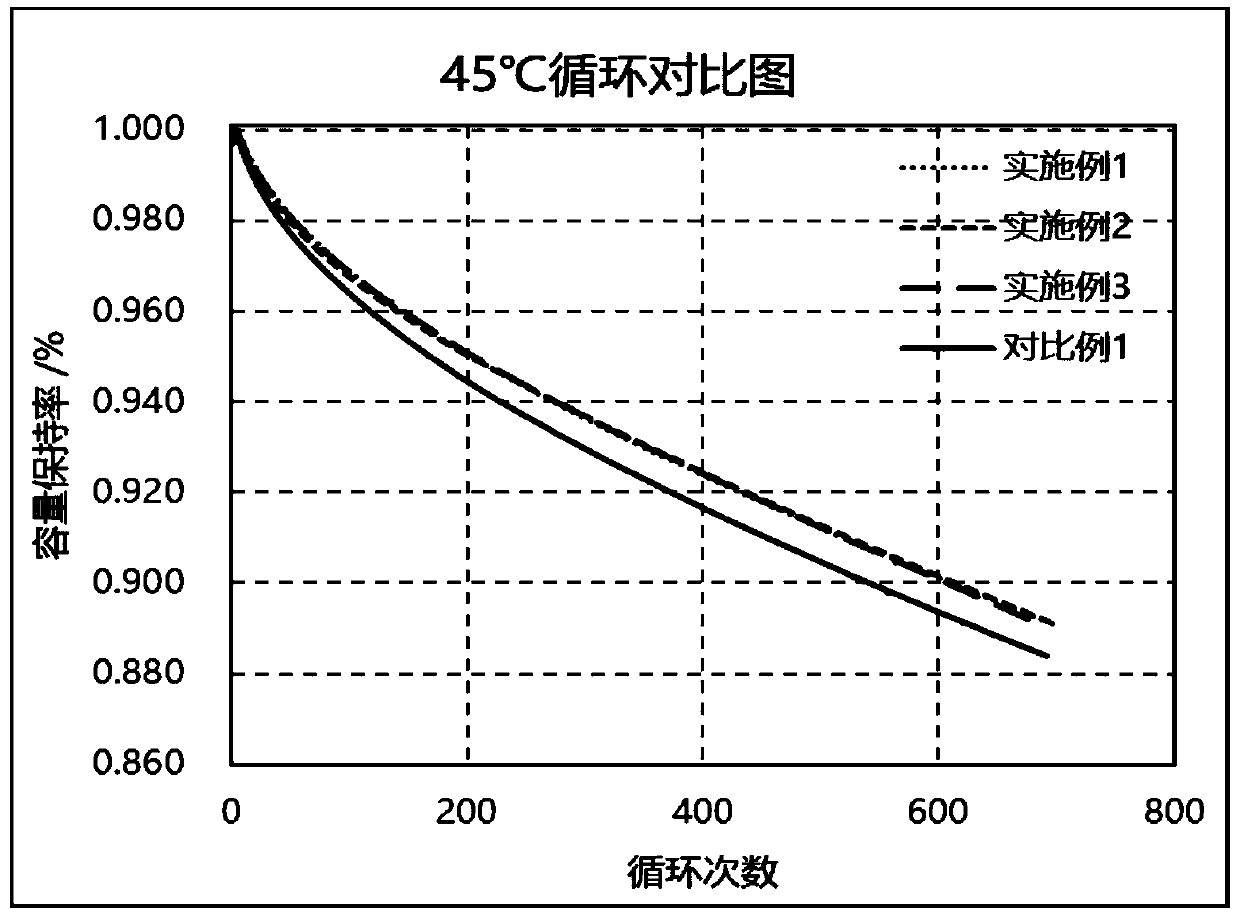

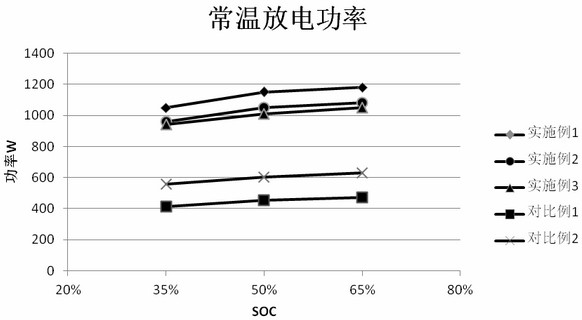

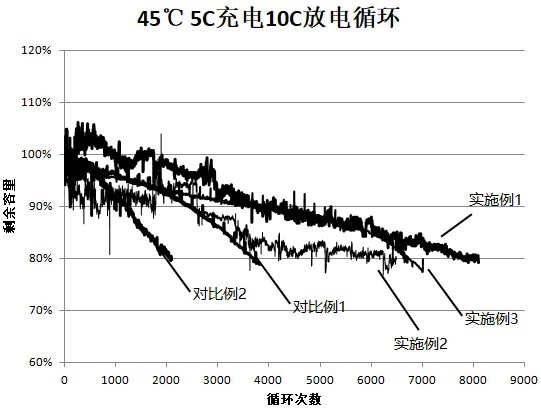

The invention belongs to the field of lithium batteries, in particular to a low-temperature lithium ion battery. The positive electrode sheet comprises a positive electrode current collector and a positive electrode active material layer. The positive electrode active material layer comprises 4.4 V lithium cobaltate material, a positive electrode conductive agent and a positive electrode binder. The negative electrode sheet comprises a negative electrode current collector and a negative electrode active material layer. The negative electrode active material layer comprises a hard carbon coatedsecondary particle artificial graphite material, a negative electrode conductive agent, a dispersant and a negative electrode binder. The electrolyte comprises 10-20% of lithium hexafluorophosphate,10-20% of ethyl propionate, 10-20% of diethyl carbonate, 15-30% of vinyl carbonate, 15-30% of propyl propionate, 3-10% of fluorovinyl carbonate, 2-3% of propylene sulfite, 0.5-2.5% of ethylene glycolmonobutyl ether and 0.5-2.5% of 2, 2'-dithiopyridine. Compared with the batteries in the prior art, the lithium ion battery has good charging and discharging performance and higher energy density under low temperature condition.

Owner:东莞维科电池有限公司

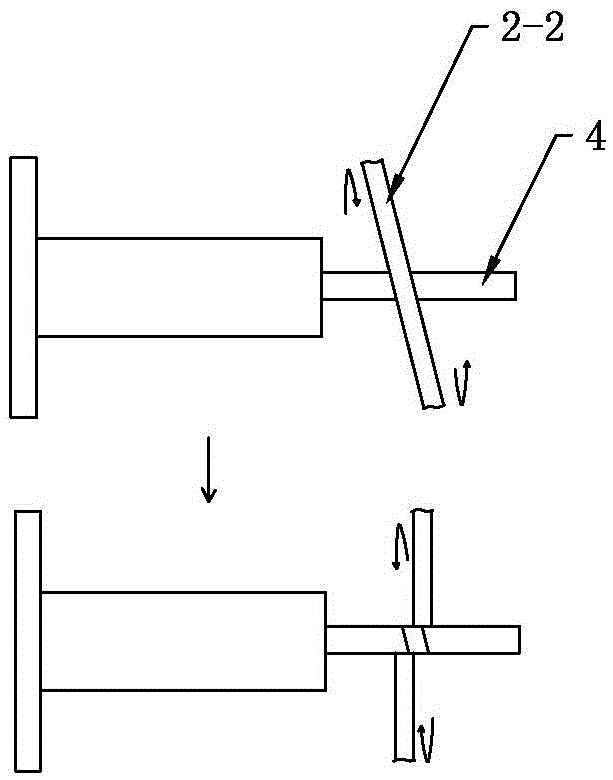

Formation and lamination method for flexible package lithium ion power battery

ActiveCN107403945ALarge fluid lossAvoid lostFinal product manufactureSecondary cells manufactureInternal resistancePre-charge

The invention relates to the technical field of lithium ion batteries and discloses a formation and lamination method for a flexible package lithium ion power battery. The method comprises the following steps: (a) carrying out hot pressing on a battery before pre-charging; (b) carrying out cold pressing on the battery before pre-charging; (c) pre-charging; (d) carrying out hot pressing on the battery after pre-charging; (e) carrying out cold pressing on the battery after pre-charging; (f) carrying out capacity grading; and (g) carrying out cold pressing on the battery after the capacity grading. The liquid maintaining amount of electrolyte processed by virtue of the formation and lamination method is high, the battery is rarely polarized, and the direct current internal resistance of the battery is low; and meanwhile, an anode group and a cathode group in the battery are in tight contact, so that the production of lithium dendrites in charging and discharging processes is avoided, the safety risk of the battery is reduced, meanwhile, the capacity expression of the battery is improved, and the cycle life of the battery is effectively prolonged.

Owner:WANXIANG 123 CO LTD

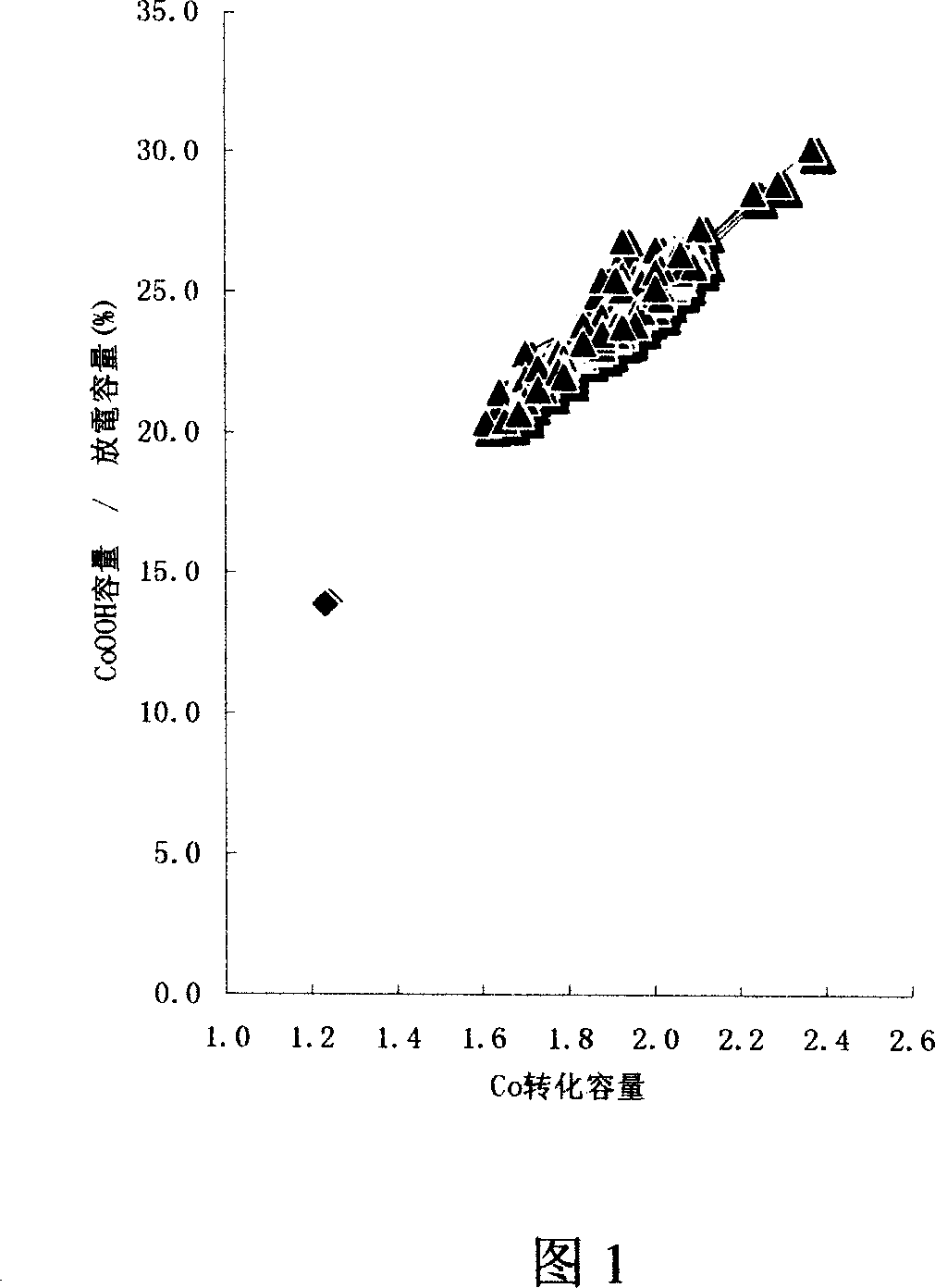

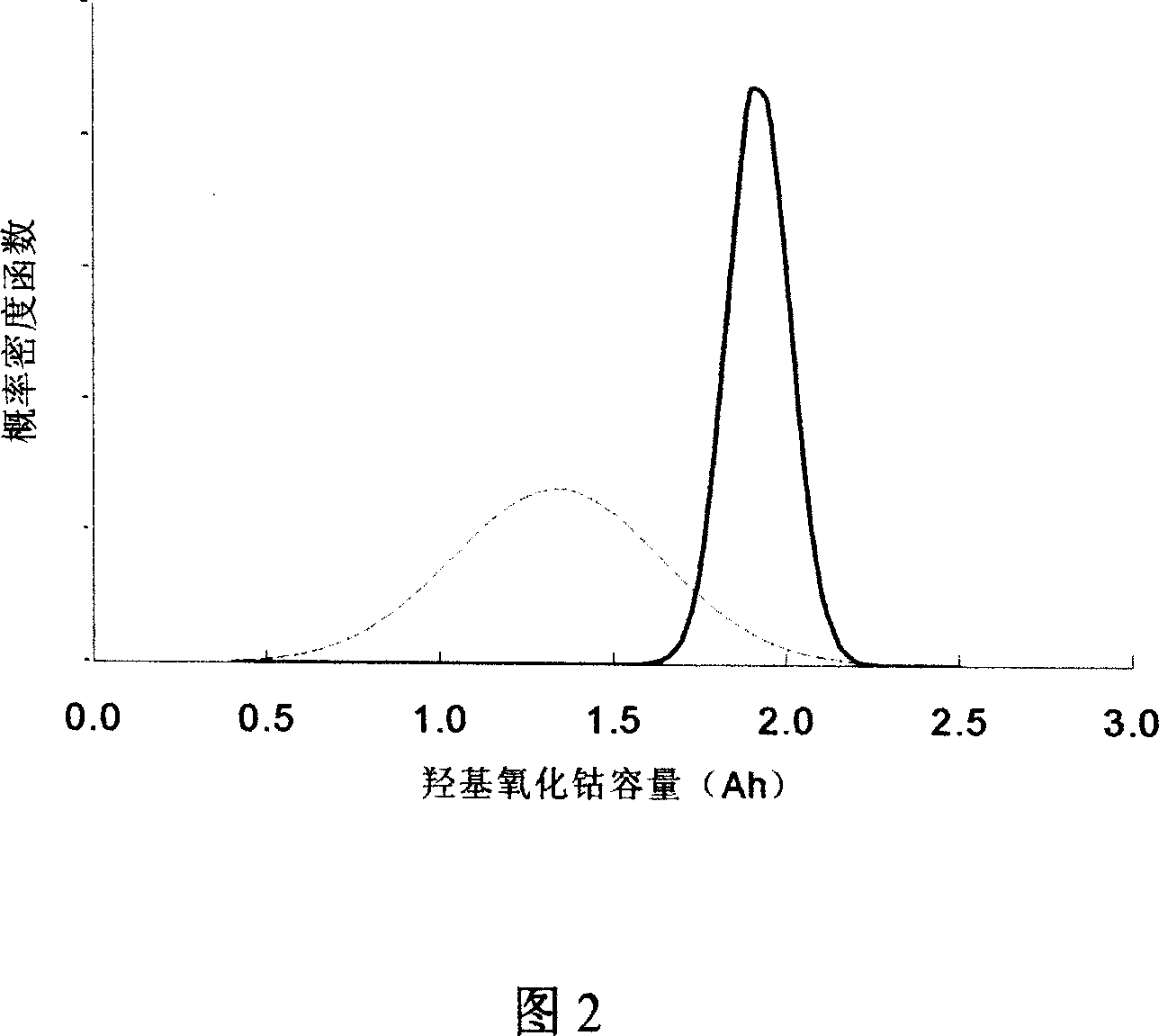

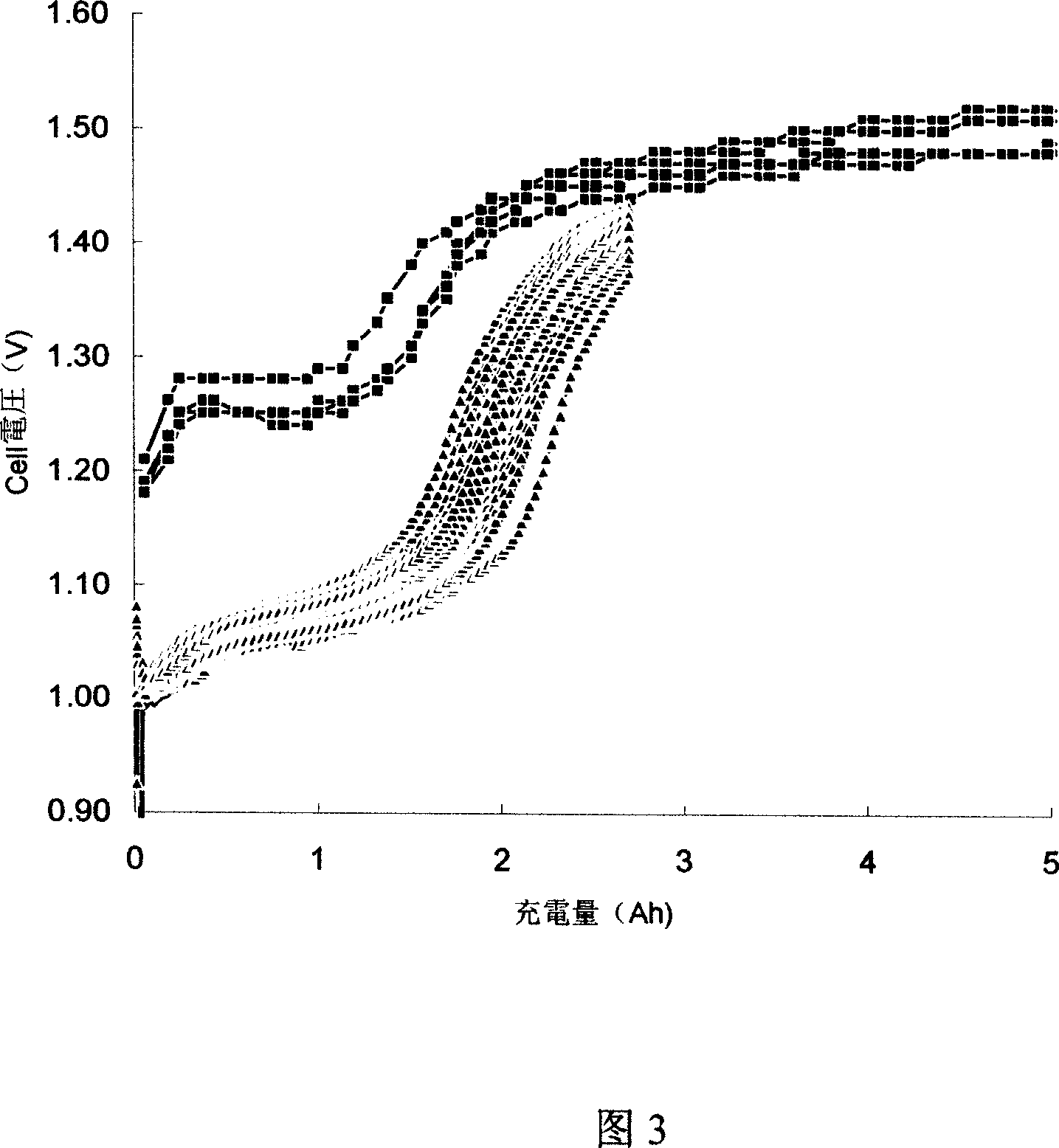

Precharging technique for forming nickel hydrogen battery

InactiveCN1917271AImprove conversion volume consistencyReduce DC internal resistanceFinal product manufactureAlkaline accumulator electrodesUltrasound attenuationInternal resistance

Characters of the invention are as followings: assembled battery includes positive plate composed of compounds Ni(OH)2 and Co(II), and metal Co; in room temperature, or higher than room temperature, batteries are laid aside; next, precharging battery by using current density less than and equal to 20mA / cm2 based on area of positive plate as reference; then, batteries are laid aside in late stage in room temperature, or higher; afterwards, carrying out constant current charge for second time, and then discharging; carrying out constant current charge for second cycle, which includes two segments of constant current charge; finally, carrying out constant current charge for third cycle identical to the said second cycle. The invention raises consistency of quantity of converting cobalt, reduces AC internal resistance and DC internal resistance of battery, delays lowering OCV speed from 15%-20% to 5% of capacity attenuation when battery is laid aside at discharging state.

Owner:INNER MONGOLIA RARE EARTH OVONIC HIGH POWER MH NI BATTERY CO

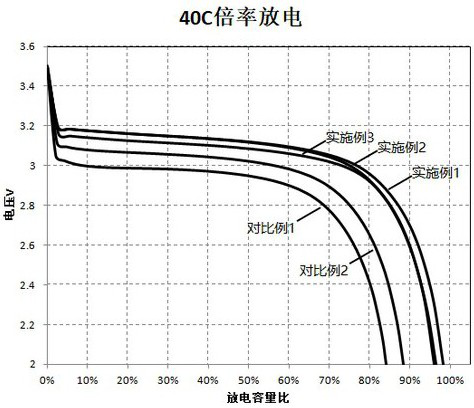

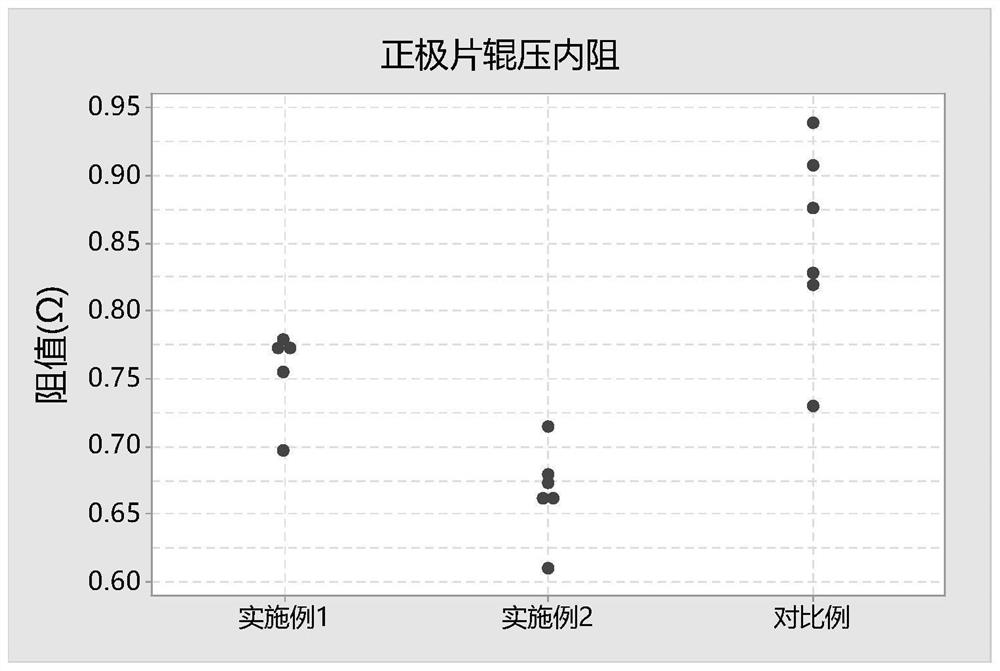

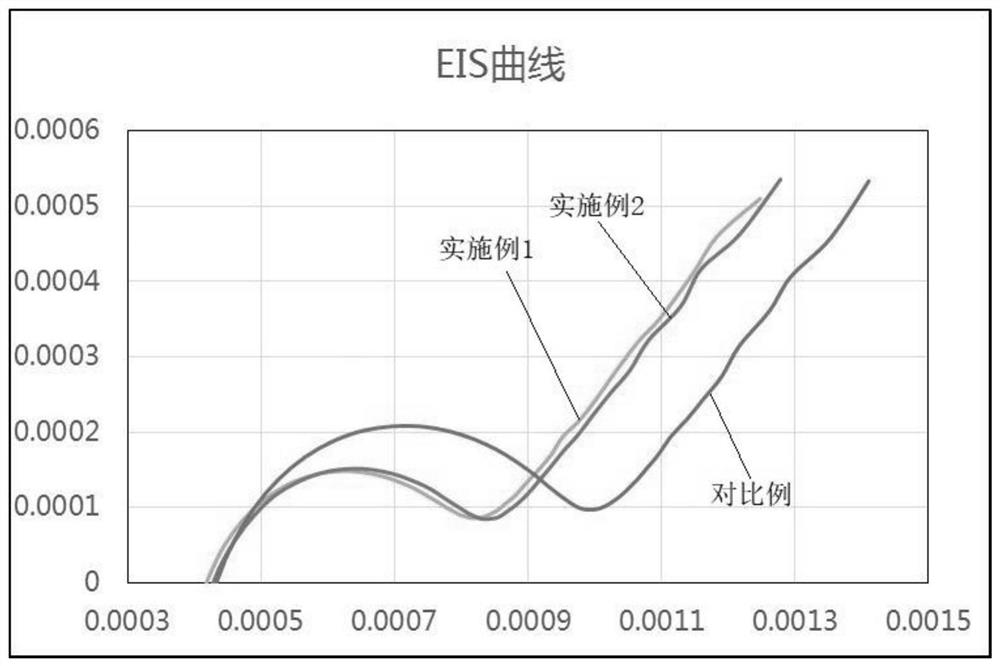

Composite conductive agent, lithium ion battery positive electrode and lithium ion battery

InactiveCN108258245AImprove electrochemical performanceImprove securityElectrode carriers/collectorsSecondary cells servicing/maintenanceElectrical batteryInternal resistance

The invention relates to a composite conductive agent, a lithium ion battery positive electrode and a lithium ion battery. The composite conductive agent consists of conductive carbon black, conductive graphite and a carbon nano tube according to the weight ratio of (1.5-2.0):(1.4-2.0):(0.7-1.0). According to the composite conductive agent provided by the invention, the conductive carbon black isrelatively small in particle size and belongs to a dot-shaped conductive agent; the carbon nano tube is provided with a linear structure and belongs to a linear conductive agent; the conductive graphite is of a laminated structure and belongs to a planar conductive agent; through the organic combination of three different dimensions of conductive agents in a ternary battery, the advantages of allthe conductive agents can be comprehensively utilized, a synergetic coupling effect is fully played, the direct-current internal resistance is reduced in multiple aspects of improving the compaction,promoting the dispersion, constructing a conductive network, improving the ionic and electronic conductivity and the like, and finally, the purpose of optimizing the overcharge performance of the ternary battery is realized.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG +1

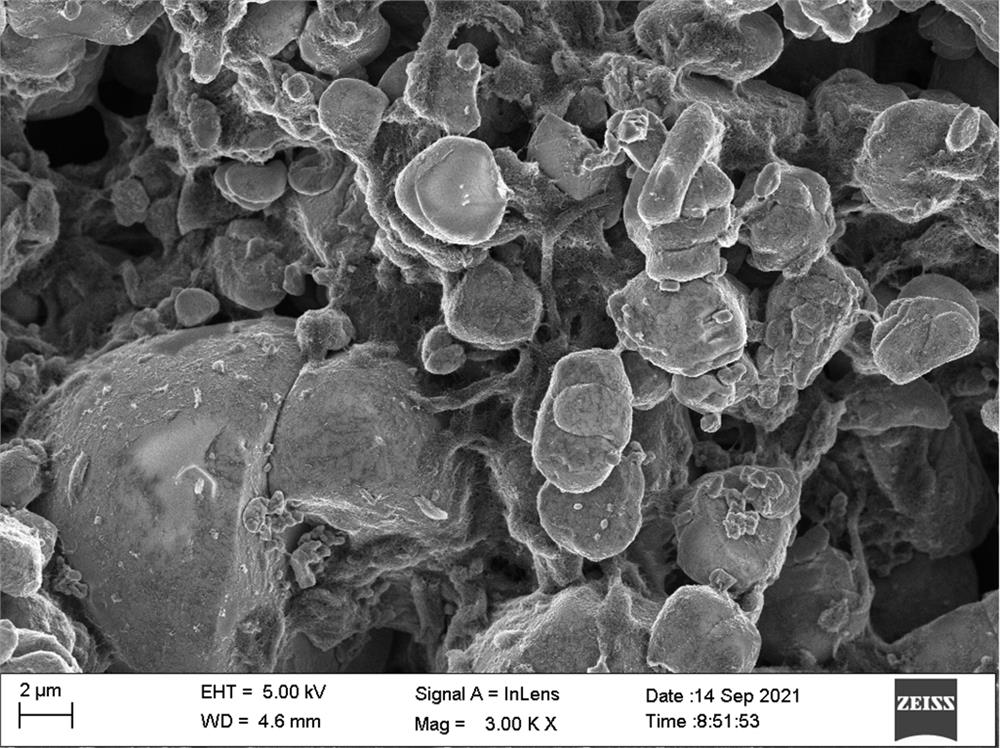

Composite conductive agent and preparation method thereof, and lithium-ion battery positive electrode

InactiveCN109768279AIncrease gram capacityIncrease compaction densitySecondary cellsNon-aqueous electrolyte accumulator electrodesCarbon nanotubeSolvent

The invention discloses a composite conductive agent and a preparation method thereof, and a lithium-ion battery positive electrode. The composite conductive agent comprises following components by weight percentage: 0.5-1.6% of conductive carbon black, 0.28-0.56% of carbon nanotubes, 0.12-0.24% of graphene, 0.5-0.8% of dispersing agent, and 97.5-97.9% of solvent. The preparation method of the composite conductive agent comprises following steps: 1) preparing composite powder according to a formula amount; 2) adding the composite powder into the solvent to obtain a mixture; and 3) performing ultrasonic dispersion on the mixture to obtain the composite conductive agent. The composite conductive agent is advantageous in that the composite conductive agent comprises the conductive carbon black, the carbon nano-tubes and the graphene, the particle size of the conductive carbon black is small, the conductive carbon black is in point-shaped connection, the carbon nanotubes are in linear connection, the graphene is in planar connection, a coupling effect is fully produced among the conductive carbon black, the carbon nanotubes and the graphene, the gram volume of the active substance of the positive electrode is improved, and the rate and the circulation property of the lithium iron phosphate battery are optimized.

Owner:上海力信能源科技有限责任公司

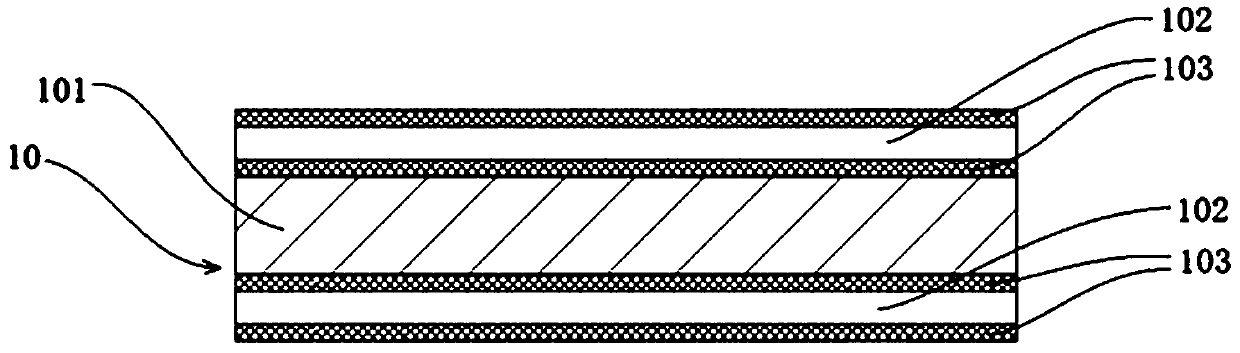

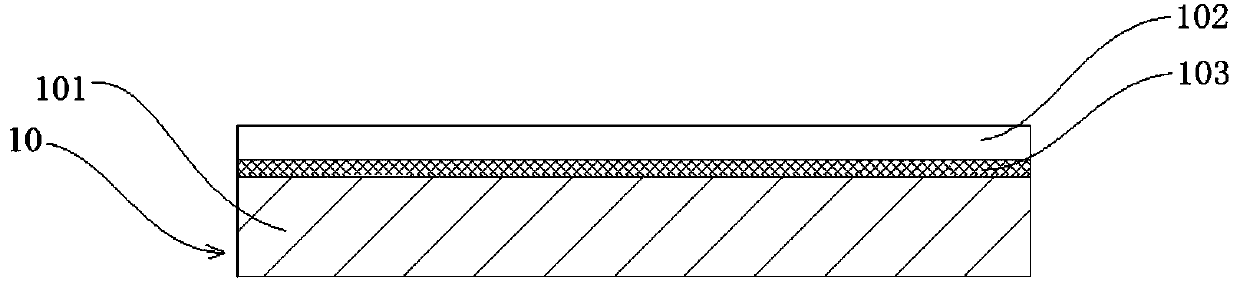

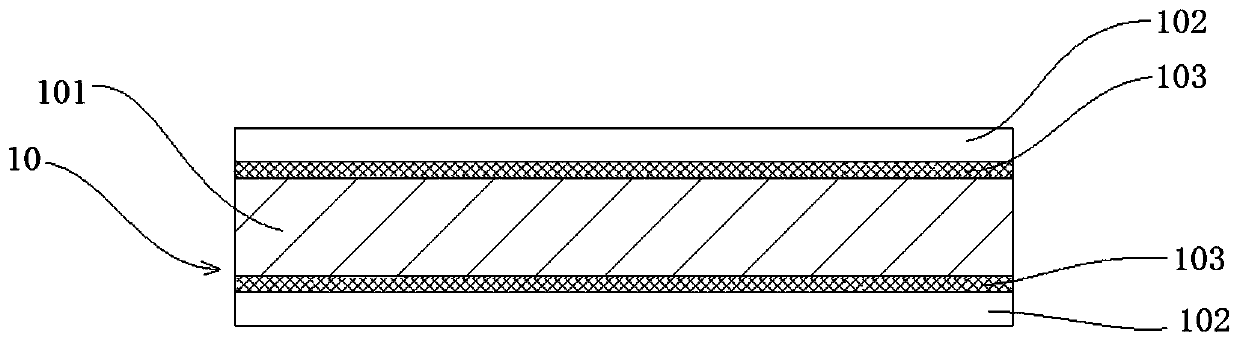

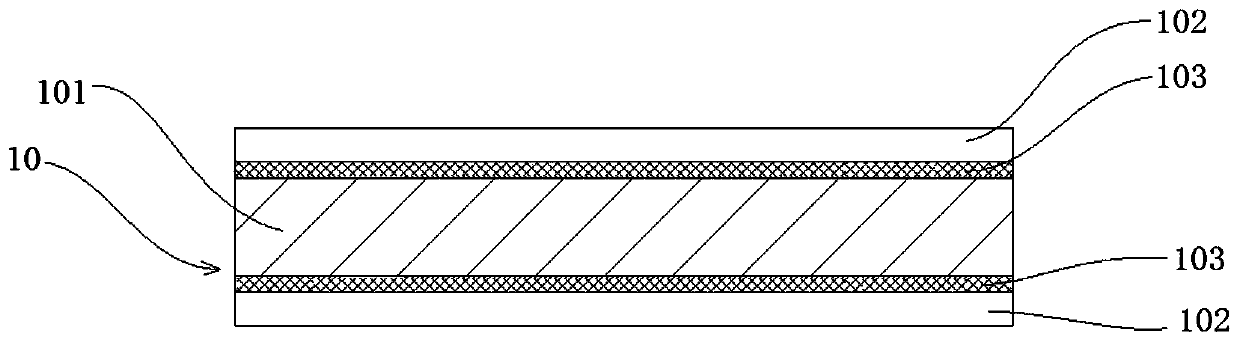

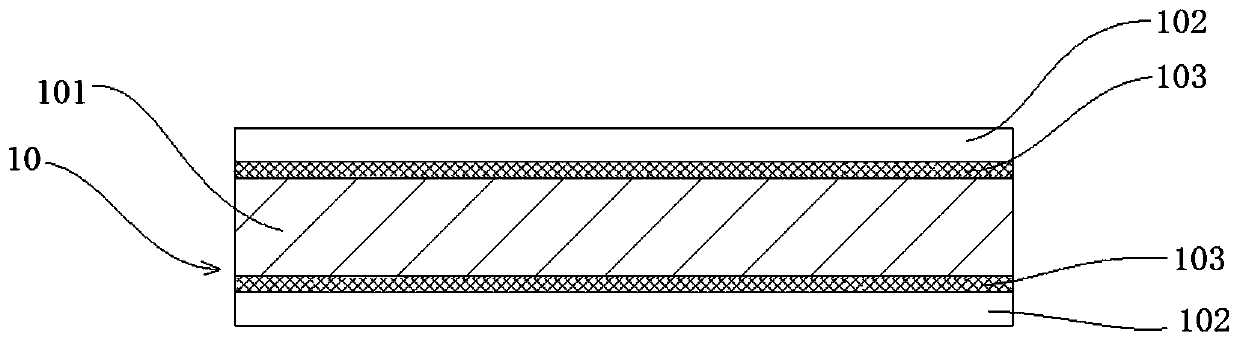

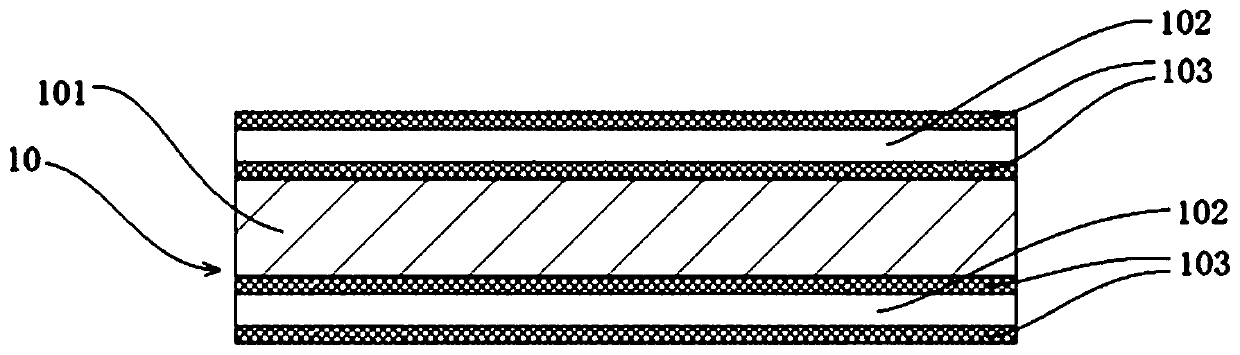

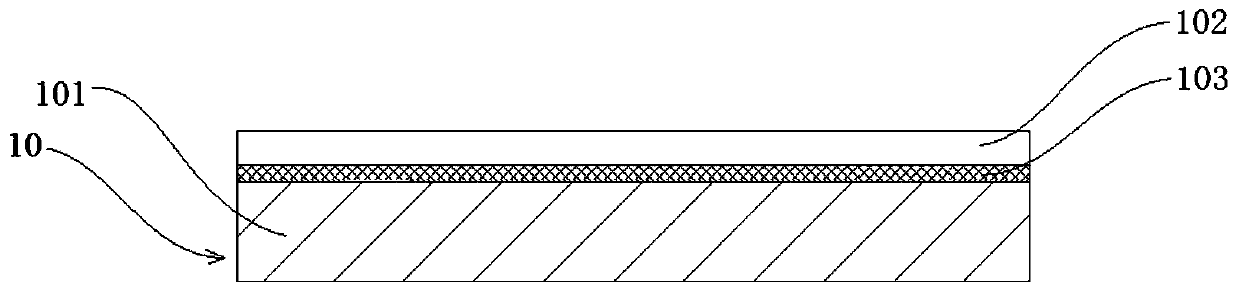

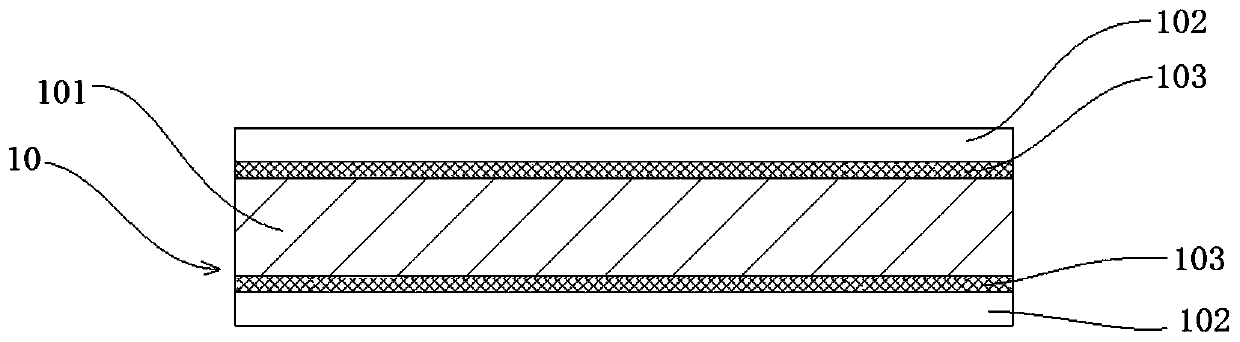

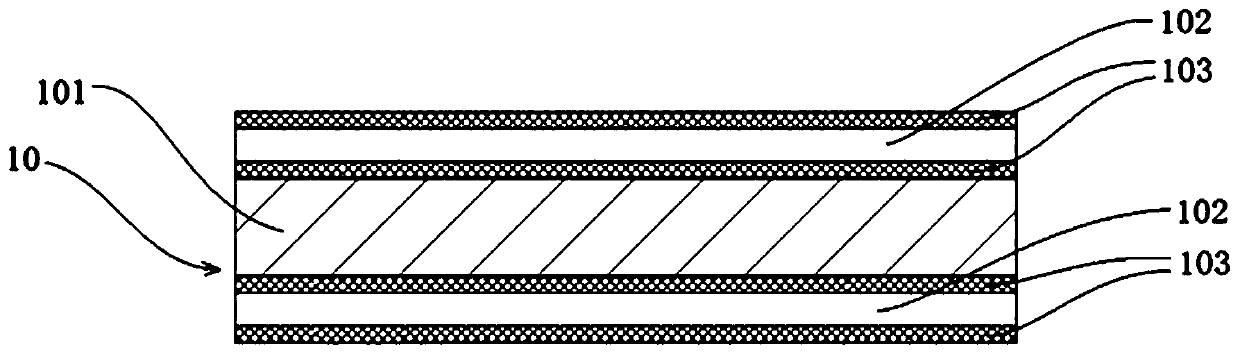

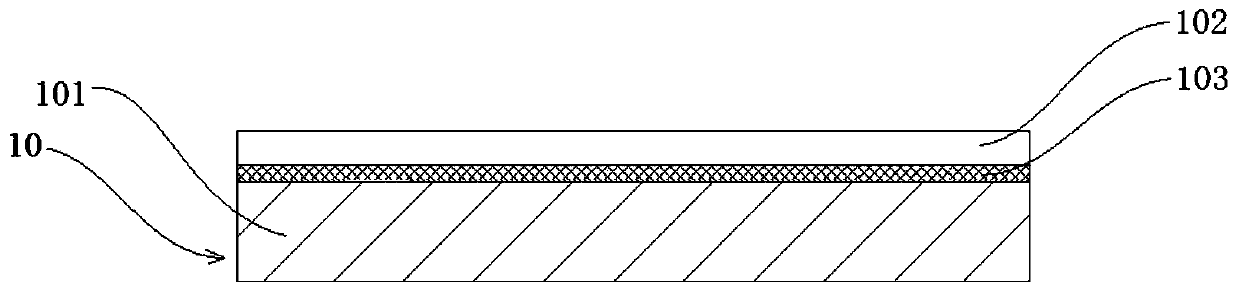

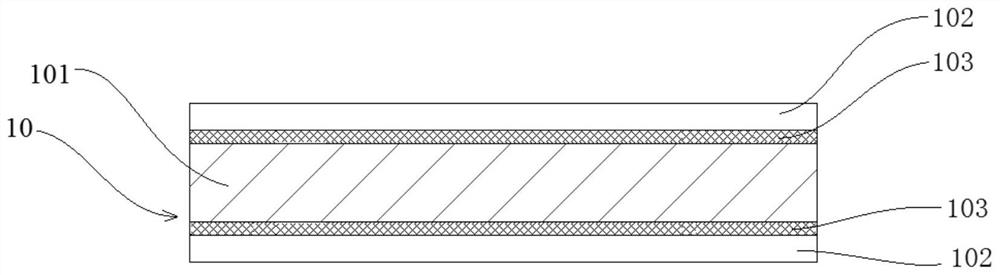

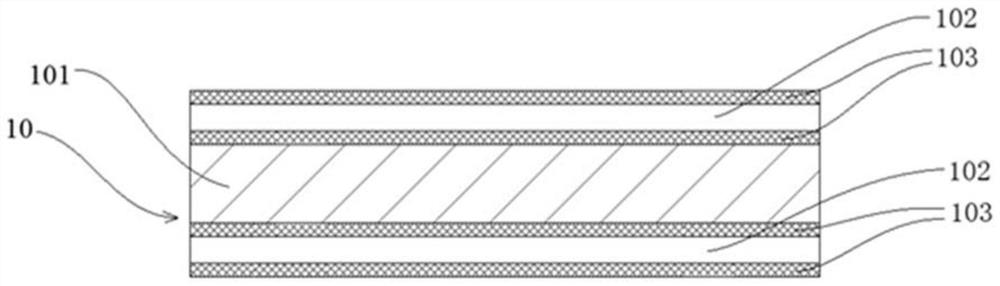

Electrode pole sheet and electrochemical device

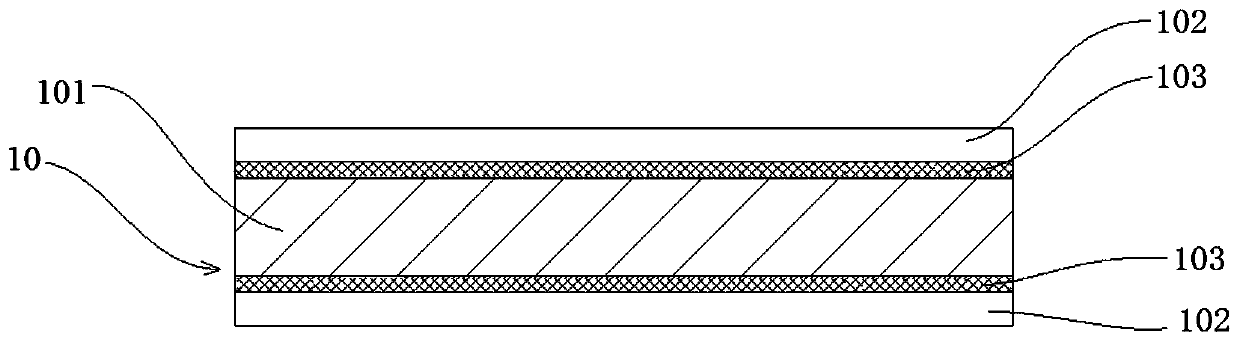

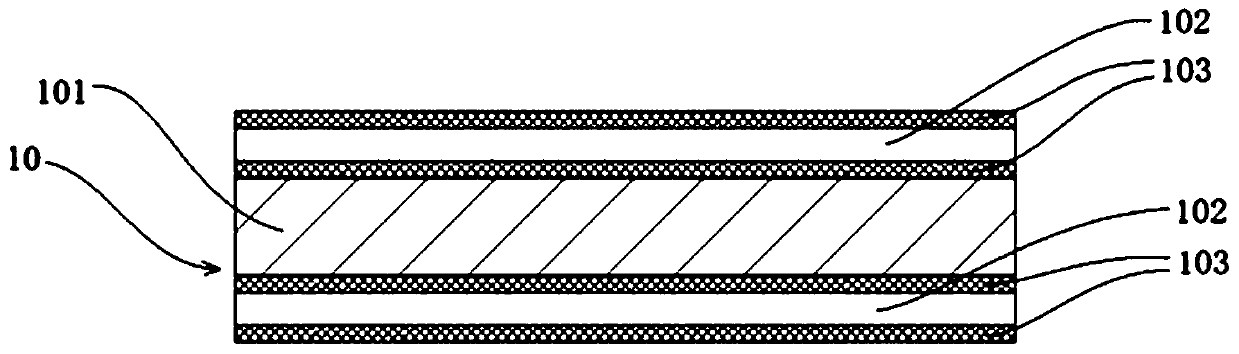

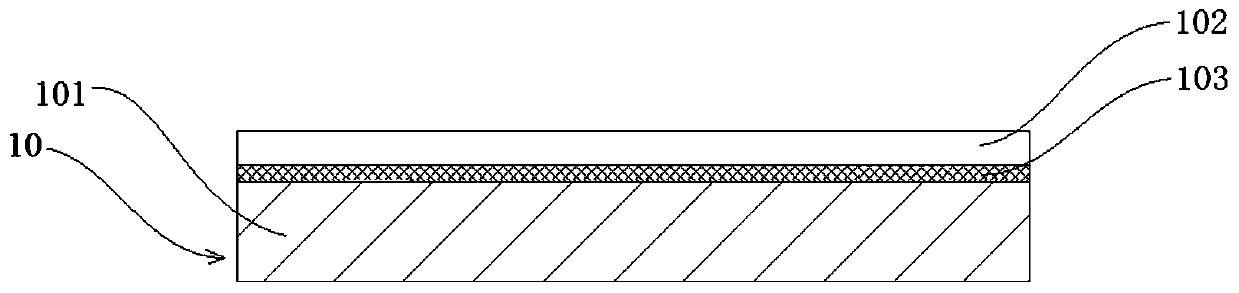

ActiveCN110661003ASet stableSimple interfaceFinal product manufactureElectrode carriers/collectorsPhysicsElectrical battery

The invention belongs to the field of batteries and relates to an electrode pole sheet and an electrochemical device. The electrode pole sheet comprises a current collector and an electrode active material layer arranged on at least one surface of the current collector; the current collector comprises a supporting layer and a conductive layer arranged on at least one surface of the supporting layer; the single-surface thickness D2 of the conductive layer meets a relation that D2 is more than or equal to 30nm and less than or equal to 3 micrometers; the electrode active material layer comprisesan electrode active material, a binder and a conductive agent; the conductive agent in the electrode active material layer is non-uniformly distributed in a thickness direction; and based on the total weight of the electrode active material layer, the weight percentage of the conductive agent in the inner side area of the electrode active material layer is higher than the weight percentage of theconductive agent in the outer side area of the electrode active material layer. The electrode pole sheet has good machinability; and the electrochemical device comprising the electrode pole sheet hashigh energy density, good electrical performance and long-term reliability.

Owner:CONTEMPORARY AMPEREX TECH CO

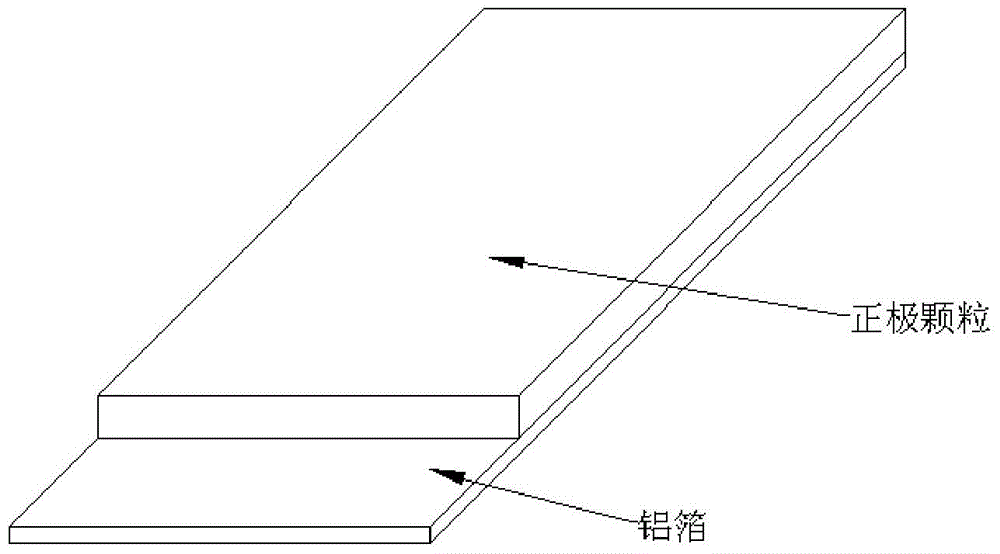

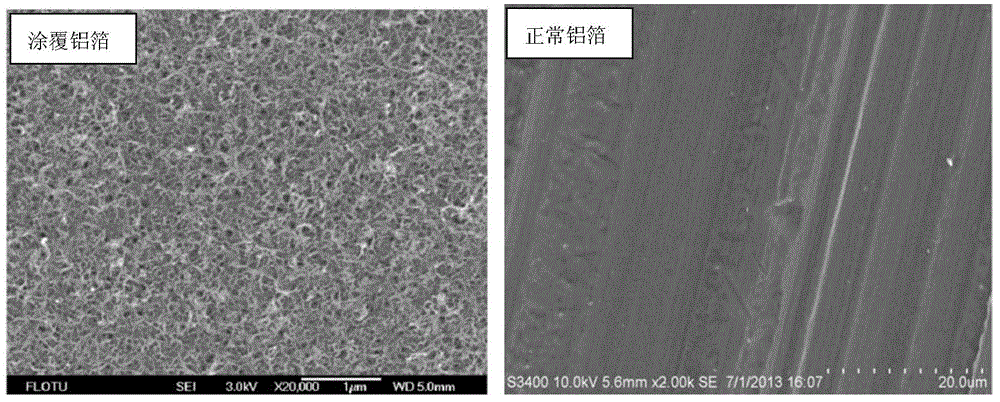

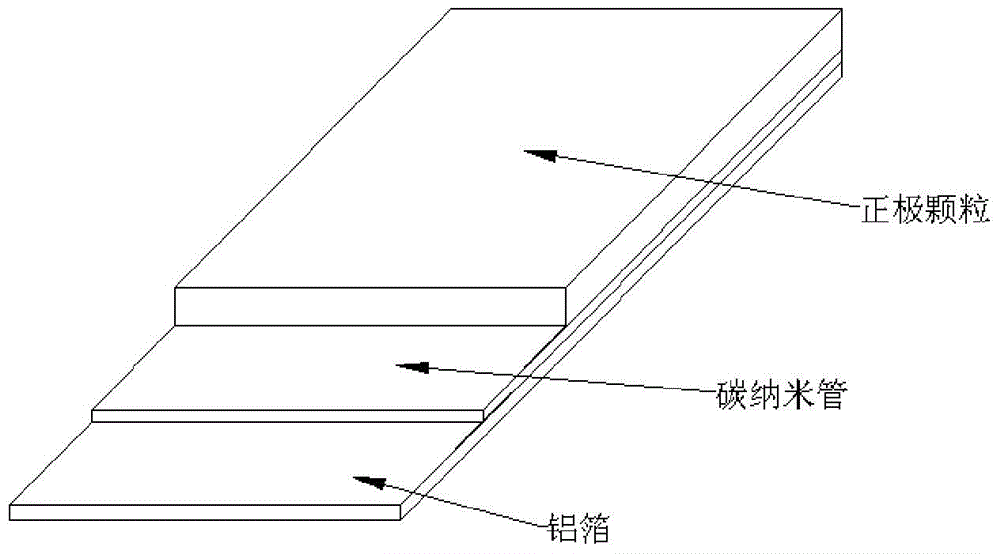

Carbon nanotube coating aluminum foil for power battery and preparation method of carbon nanotube coating aluminum foil

InactiveCN105470524AImprove adhesionReduce DC internal resistanceMaterial nanotechnologyElectrode carriers/collectorsPower batteryInternal resistance

The invention relates to an aluminum film of a power battery, and in particular to a carbon nanotube coating aluminum foil for the power battery and a preparation method of the carbon nanotube coating aluminum foil. In the carbon nanotube coating aluminum foil for the power battery, a carbon nanotube paste is uniformly applied onto the surface of the metal aluminum foil and then dried to obtain a composite aluminum foil serving as a positive electrode current collector for use. Since the surface of the coating aluminum foil is provided with a plurality of conductive carbon nanotubes, the contact area of the carbon nanotube coating aluminum foil with positive electrode particles is larger, a carbon-carbon material is more easy to bond, the conductive passages are abundant, thus, the bonding force between a positive electrode and the current collector is effectively increased, and the internal resistance of the battery is reduced.

Owner:WANXIANG 123 CO LTD +1

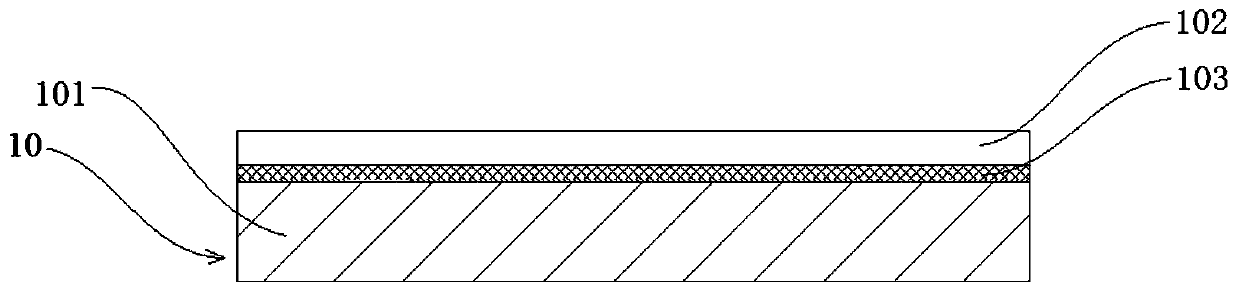

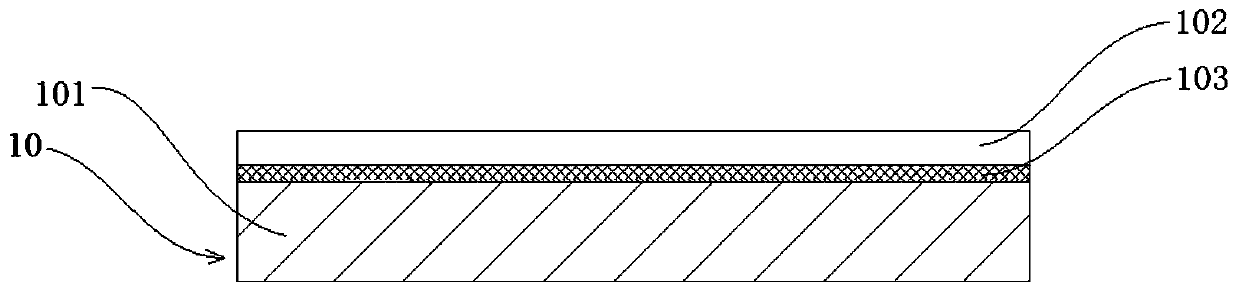

Positive pole piece and electrochemical device

ActiveCN110943201AIncrease energy densityImprove electrochemical performancePositive electrodesLi-accumulatorsElectrical resistance and conductanceElectrical battery

The invention relates to the field of batteries, in particular to a positive pole piece and an electrochemical device. The positive pole piece comprises a current collector and an electrode active material layer arranged on at least one surface of the current collector, wherein the current collector comprises a support layer and a conductive layer arranged on at least one surface of the support layer, the thickness D2 of a single surface of the conductive layer is more than or equal to 30nm and less than or equal to 3mu m, the thickness D1 of the support layer is more than or equal to 1mu m and less than or equal to 30mu m, and the support layer is made of a high polymer material or a high polymer composite material; wherein the electrode active material layer comprises an electrode activematerial, a binder and a conductive agent, the total thickness D of the electrode active material layer is not greater than 170 [mu] m, and the membrane resistance of the electrode active material layer is 0.1 ohm to 10 ohm. The electrochemical device comprising the positive pole piece has high energy density, good safety performance (especially nail penetrating safety performance) and electrochemical performance.

Owner:CONTEMPORARY AMPEREX TECH CO

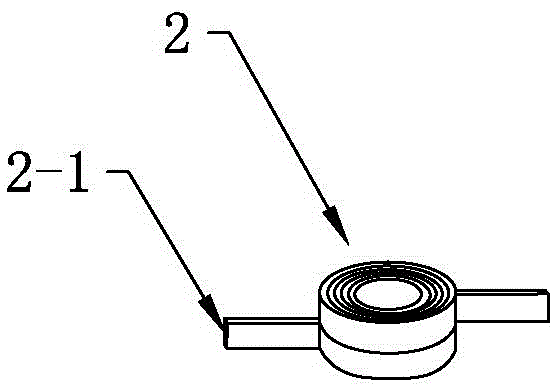

Integrated double-layer vertical wound inductor and manufacturing method thereof

ActiveCN106653307AReduce DC internal resistanceEnhance load capacity protectionTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureInductorWork in process

The invention provides an integrated double-layer vertical wound inductor, which comprises a magnetic body, a hollow coil and a covered electrode, wherein the magnetic body is formed by pressing magnetic powder; the hollow coil is embedded into the magnetic powder and an integrated structure of the hollow coil and the magnetic body is manufactured through high pressure; the end part of the hollow coil is exposed out of the magnetic body; and the surface of one side, out of which the hollow coil is exposed, of the magnetic body is covered with the covered electrode. Compared with the prior art, the integrated double-layer vertical wound inductor has the advantages of being small in volume, good in performance, high in performance-volume ratio and beneficial to high-density installation, and the integration level of a client is improved. A manufacturing method of the integrated double-layer vertical wound inductor comprises the following steps of (1) carrying out compression molding; (2) carrying out multi-stage temperature sintering and solidifying; (3) adding an anti-oxidation coating; (4) grinding the end surfaces of two sides from which a lead of the hollow coil extends outside; (5) forming symmetrical boning pad positions on the upper surface and the lower surface of a semi-finished product; and (6) arranging the covered electrode.

Owner:GUANGDONG DECE TECH LTD

Positive pole piece and electrochemical device

ActiveCN110943223AIncrease energy densityImprove electrochemical performanceElectrode carriers/collectorsSecondary cellsElectrical batteryHigh energy

The invention relates to the field of batteries, in particular to a positive pole piece and an electrochemical device. The positive pole piece comprises a current collector and an electrode active material layer arranged on at least one surface of the current collector, wherein the current collector comprises a support layer and a conductive layer arranged on at least one surface of the support layer, the thickness D2 of a single surface of the conductive layer is more than or equal to 30nm and less than or equal to 3mu m, the thickness D1 of the support layer is more than or equal to 1mu m and less than or equal to 30mu m, and the support layer is made of a high polymer material or a high polymer composite material; the electrode active material layer includes an electrode active material, a binder, and a conductive agent, and the electrode active material includes a small-particle active material having an average particle diameter D50 of 1.0 [mu] m to 7.0 [mu] m and a large-particleactive material having an average particle diameter D50 of 7.1 [mu] m to 20.0 [mu] m. The electrochemical device comprising the positive pole piece has high energy density, good safety performance (especially nail penetrating safety performance) and electrochemical performance.

Owner:CONTEMPORARY AMPEREX TECH CO

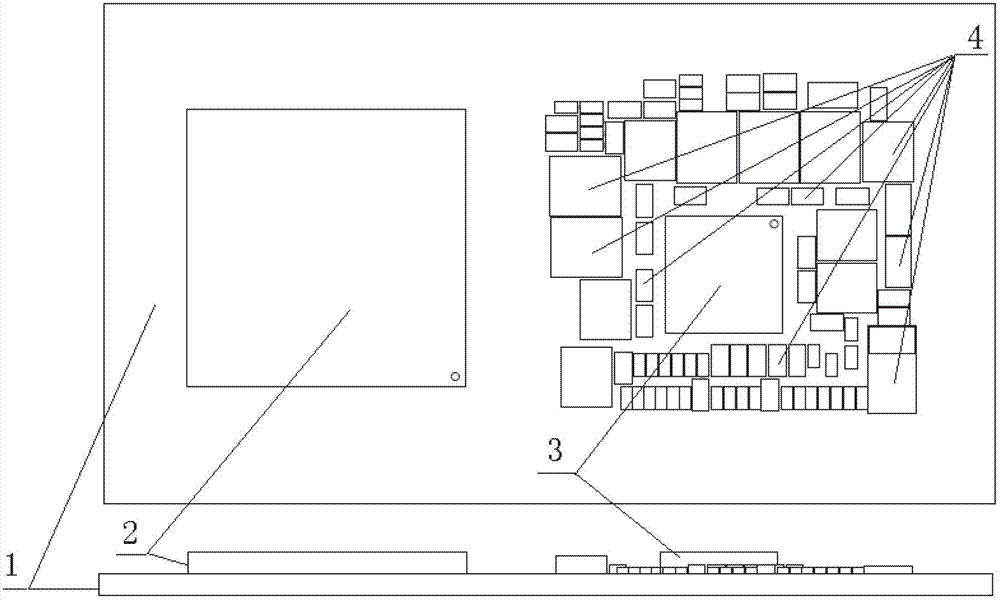

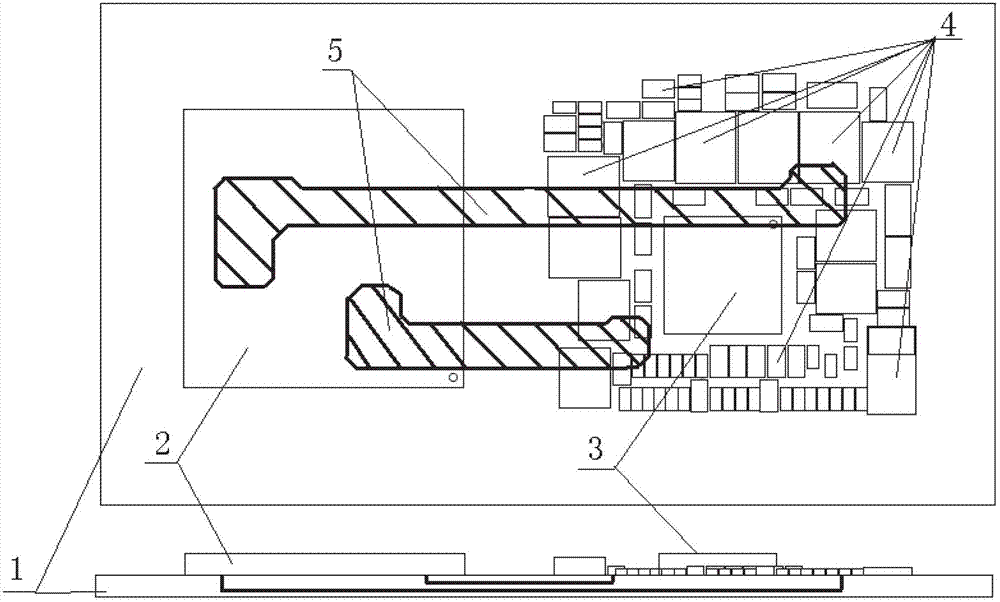

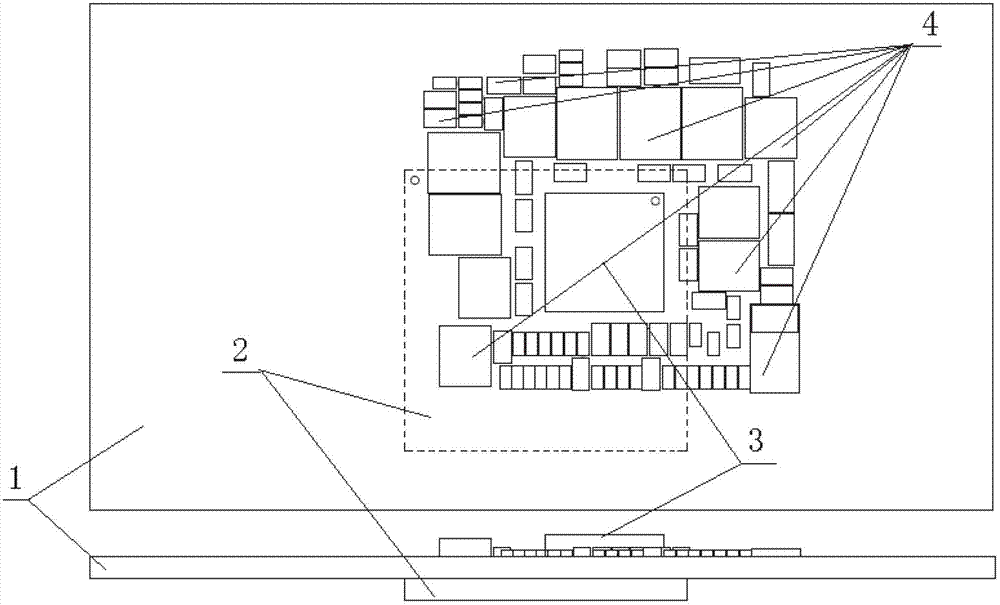

Printed circuit board (PCB) chip layout structure and electronic terminal using the same

InactiveCN103037621AReduce DC internal resistanceReduce AC internal resistancePrinted circuit non-printed electric components associationPower Management UnitEngineering

The invention discloses a printed circuit board (PCB) chip layout structure and an electronic terminal using the PCB chip layout structure. The PCB chip layout structure comprises a PCB, a central processing unit (CPU) and a power management unit (PMU). The CPU and the PMU are respectively arranged at two faces of the PCB. The PMU and projection of the CPU on the PCB are partially or completely overlapped. The electronic terminal using the PCB chip layout structure comprises the PCB chip layout structure consisting of the PCB, the CPU and the PMU. The CPU and the PMU are respectively arranged at two faces of the PCB. The PMU and projection of the CPU on the PCB are partially or completely overlapped.

Owner:共青城赛龙通信技术有限责任公司

Electrode pole sheet and electrochemical device

ActiveCN110660963ASet stableSimple interfaceElectrode rolling/calenderingNegative electrodesHigh energyPhysical chemistry

The invention belongs to the field of batteries and relates to an electrode pole sheet and an electrochemical device. The electrode pole sheet comprises a current collector and an electrode active material layer arranged on at least one surface of the current collector; the current collector comprises a supporting layer and a conductive layer arranged on at least one surface of the supporting layer; the single-surface thickness D2 of the conductive layer meets a relation that D2 is more than or equal to 30nm and less than or equal to 3 micrometers; the electrode active material layer comprisesan electrode active material, a binder and a conductive agent; the conductive agent in the electrode active material layer is non-uniformly distributed in a thickness direction; based on the total weight of the electrode active material layer, the weight percentage of the conductive agent in the inner side area of the electrode active material layer is higher than the weight percentage of the conductive agent in the outer side area of the electrode active material layer; and the conductive agent in the inner side area of the electrode active material layer contains an aqueous binder. The electrode pole sheet has good machinability; and the electrochemical device comprising the electrode pole sheet has high energy density, good electrical performance and long-term reliability.

Owner:CONTEMPORARY AMPEREX TECH CO

Secondary battery and electronic device

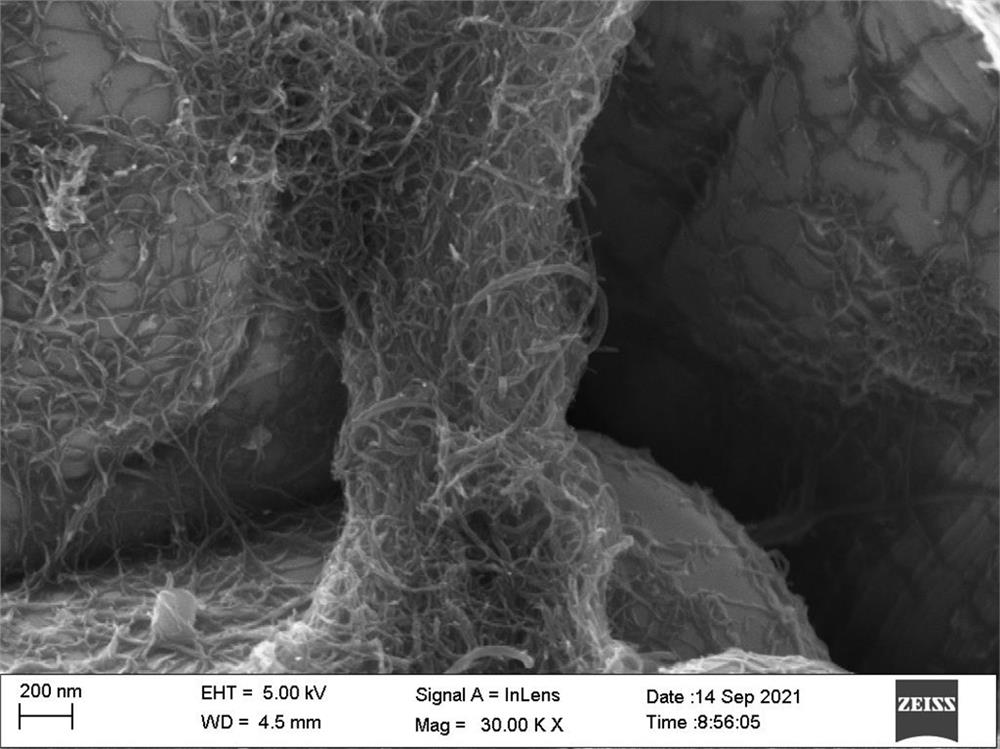

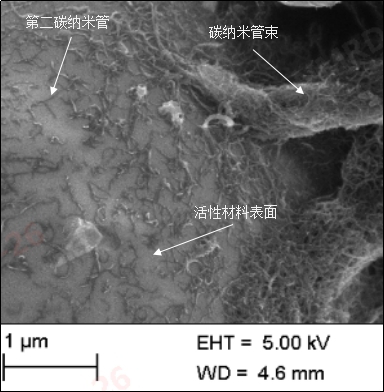

ActiveCN114300686AReduce initial DC internal resistanceGuaranteed to be perfectMaterial nanotechnologyElectrode manufacturing processesInternal resistanceCarbon nanotube

The invention discloses a secondary battery and an electronic device, and belongs to the technical field of batteries. The secondary battery comprises a positive pole piece, wherein the positive pole piece comprises a current collector and a positive active material layer; the positive electrode active material layer comprises a positive electrode active material and a carbon material; the carbon material comprises a carbon nanotube bundle with the length-diameter ratio of 2.5 to 100; the carbon nano tube bundle comprises a plurality of first carbon nano single tubes. The carbon nanotube bundle can reduce the initial internal resistance of the battery, guarantee the improvement of a conductive network in the circulation process, effectively reduce the increase of the internal resistance, and improve the charging speed.

Owner:NINGDE AMPEREX TECH

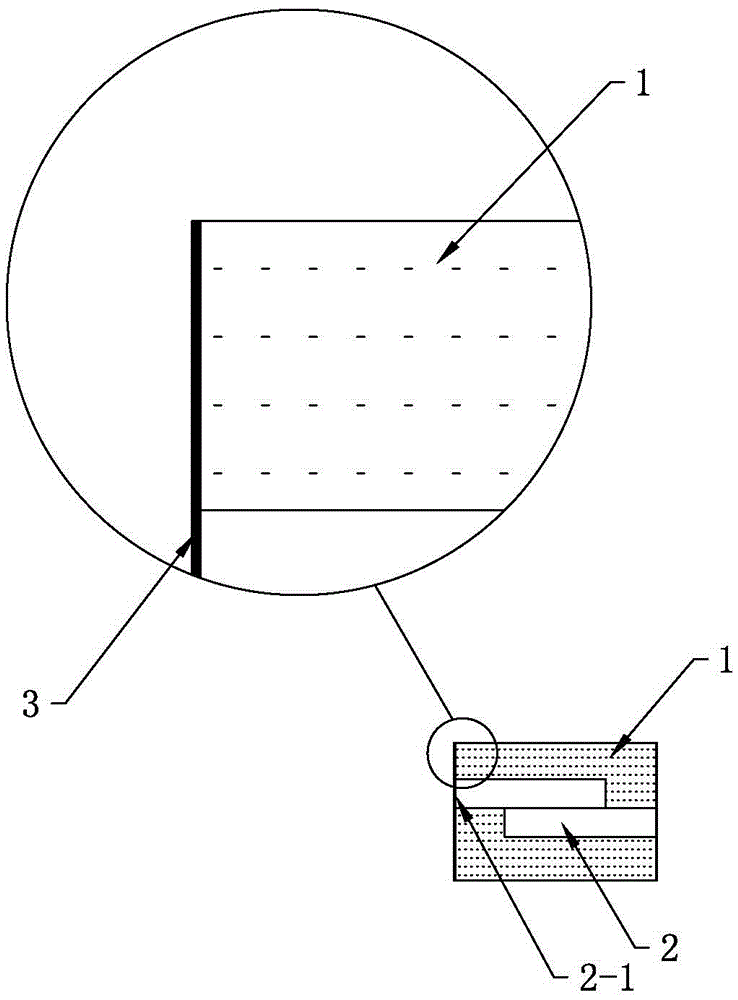

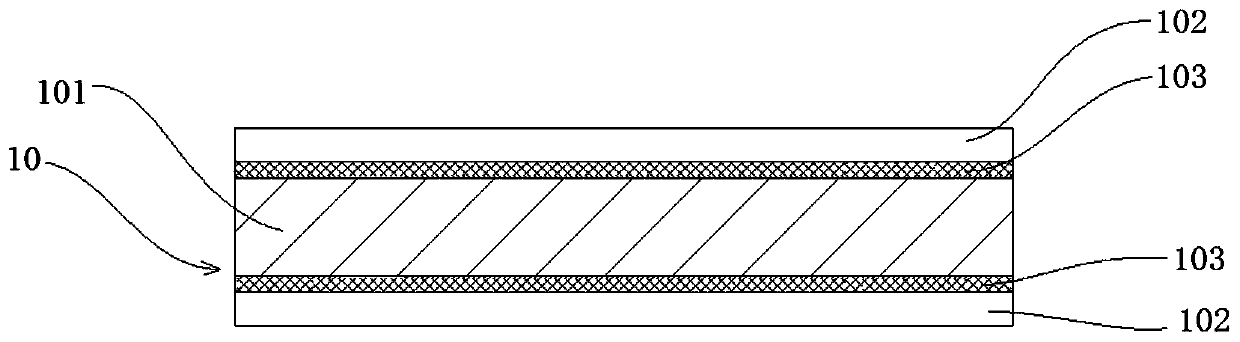

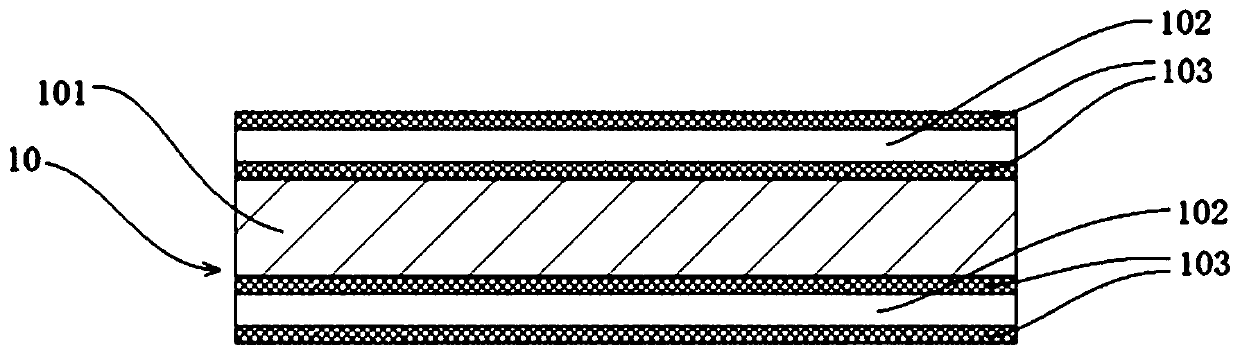

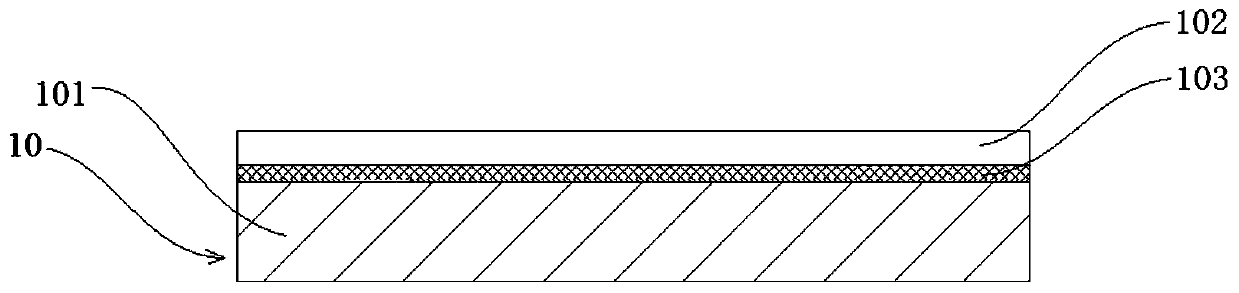

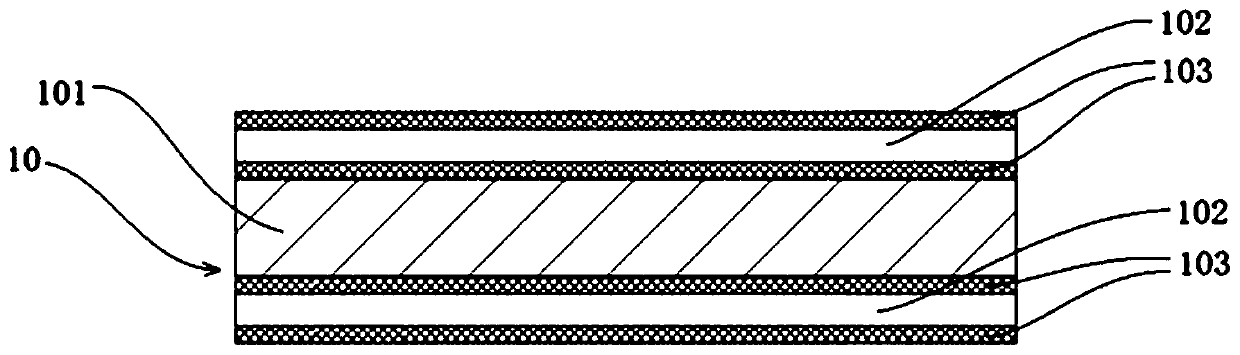

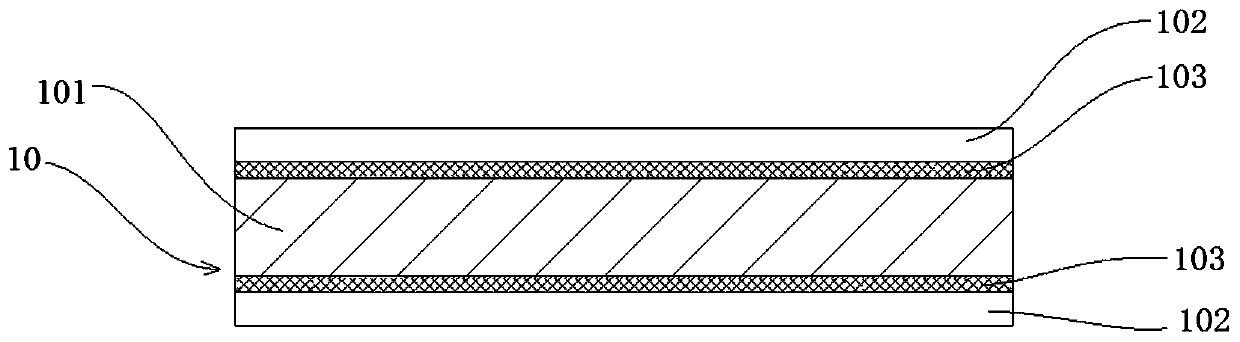

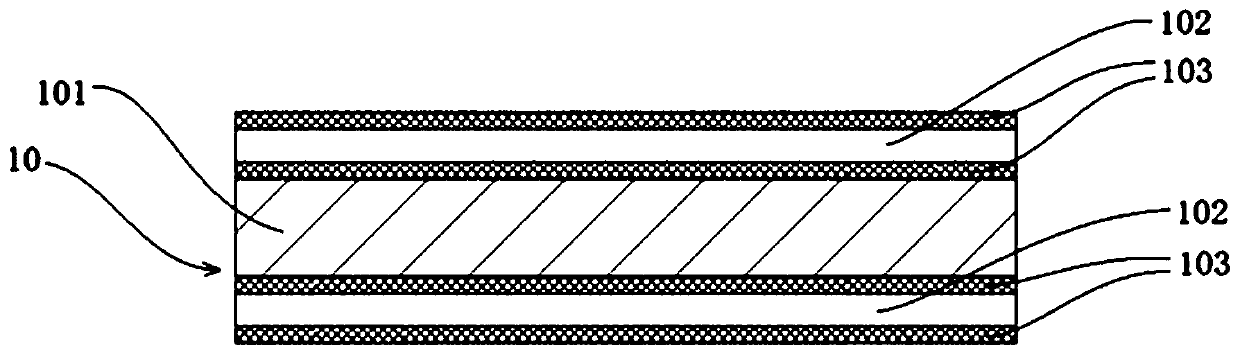

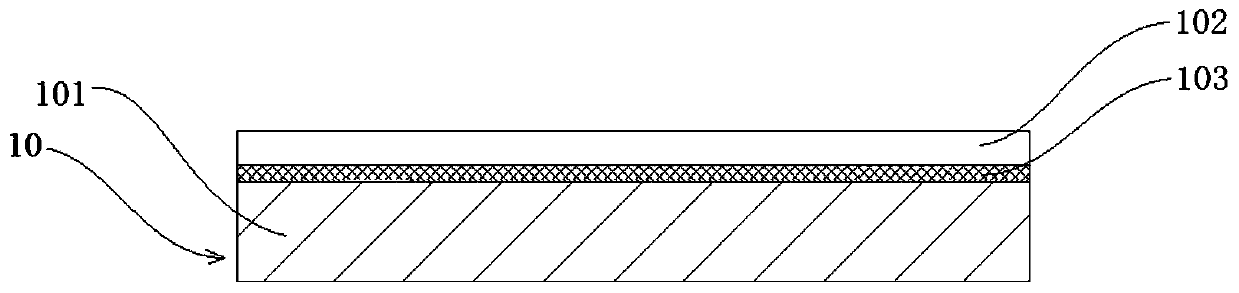

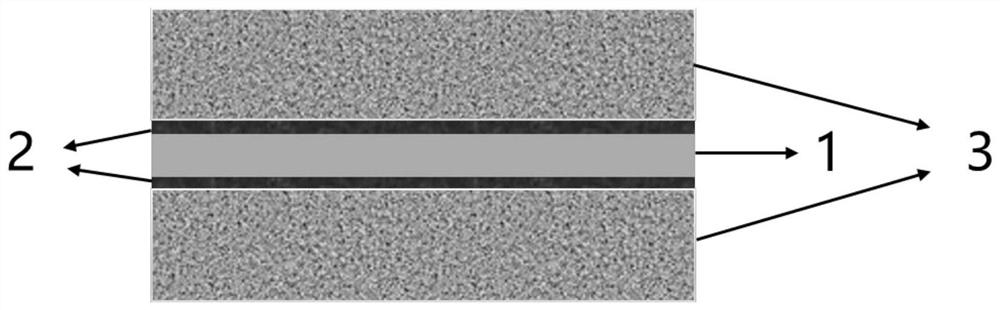

Lithium ion battery diaphragm as well as lithium ion battery

ActiveCN108695475ASatisfy the adhesionReduce DC internal resistanceFinal product manufactureCell component detailsNon symmetricInternal resistance

The invention discloses a lithium ion battery diaphragm as well as a lithium ion battery. The lithium ion battery diaphragm includes a diaphragm base material and non-symmetric organic coatings comprising a first organic coating and a second organic coating, which are formed by respectively coating both surfaces of the diaphragm base material with organic polymers; herein, the first organic coating and the second organic coating include non-symmetric organic coatings, which are prepared from the same organic polymer but are in different surface densities, or include non-symmetric organic coatings, which are prepared from different organic polymers but are in the same surface densities, or include non-symmetric organic coatings, which are prepared from different organic polymers and are indifferent surface densities. In the invention, by coating the both surface of the diaphragm base material with the non-symmetric organic coatings, direct current internal resistance of the lithium ionbattery is reduced on the basis of satisfying the adhesivity between positive and negative plates of the lithium ion battery, so that the lithium ion battery has better performances.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

High-power lithium ion battery for automobile start-stop power supply

InactiveCN112582667AImprove overcurrent capabilityImprove power performanceSecondary cellsPositive electrodesElectrolytic agentElectrical battery

A high-power lithium ion battery for an automobile start-stop power supply comprises a positive plate and a negative plate, the tab width accounts for more than 50% of the width of the battery; the positive electrode current collector is a conductive coating aluminum foil with the total thickness of 24 microns, the conductive coating is coated on the positive electrode current collector before thepositive electrode active substance is coated, and the total thickness of the conductive coating is 0.5-2 microns; the positive electrode active substance is lithium iron phosphate; the positive electrode conductive agent is a mixture of carbon nanotubes, graphene and carbon black; and the electrolyte contains a lithium salt, an organic solvent and an additive. According to the invention, the overcurrent capacity of the battery can be improved, the power performance is enhanced, the problem of low conductivity of the lithium iron phosphate anode is solved, and the electrode conductivity is improved; particularly, the low-temperature rate discharge capacity is improved by more than 30%; the falling of lithium iron phosphate from the aluminum foil can be slowed down, and the cycle life is prolonged by about 8%; the electrolyte is not easy to vaporize at a high temperature, still has low viscosity at a low temperature of -30 DEG C, and maintains high ionic fluidity.

Owner:CAMEL GRP NEW ENERGY BATTERY CO LTD

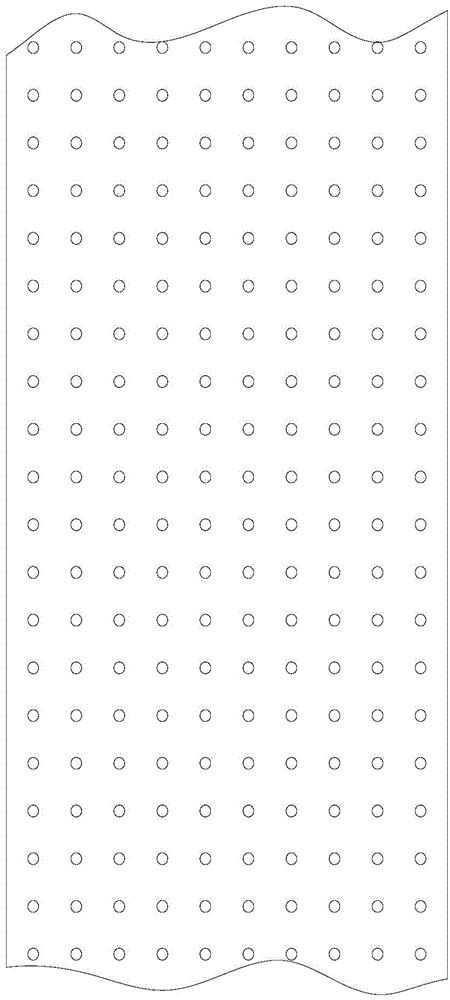

Electrode sheet and manufacturing method thereof

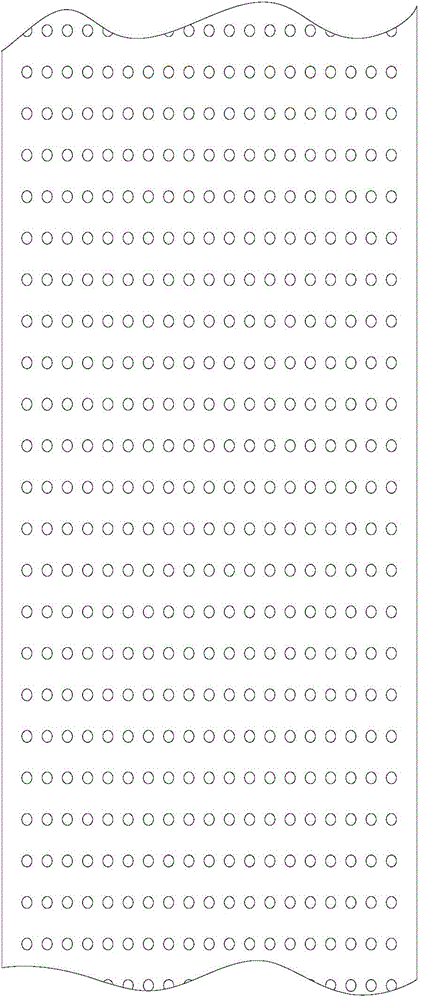

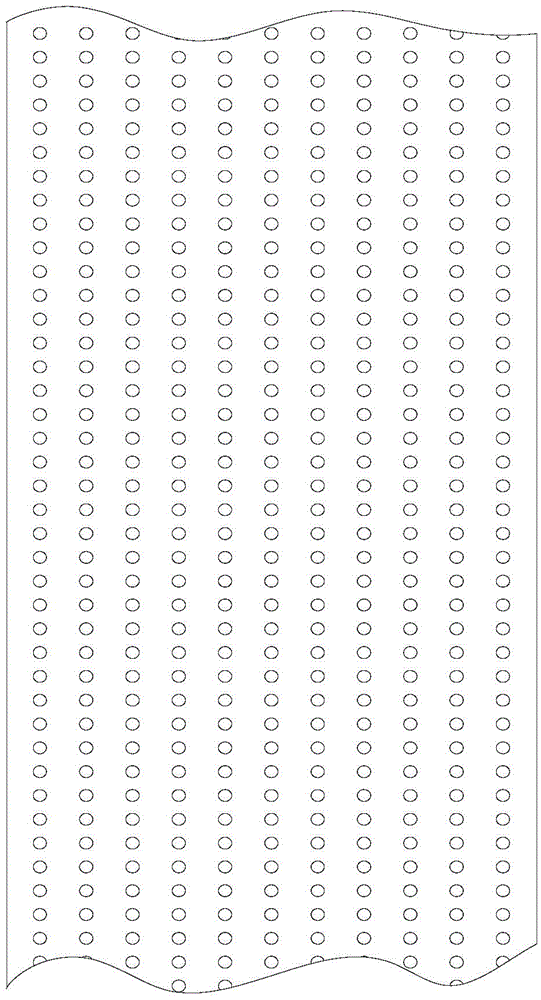

InactiveCN105322130AConvenient shuttleImprove adhesionNon-aqueous electrolyte accumulator electrodesSlurryEngineering

The present invention provides an electrode sheet and a manufacturing method thereof. The electrode sheet comprises a current collector layer and a slurry layer, wherein the slurry layer is coated on the current collector layer, small through holes are distributed on the current collector layer. The electrode sheet is characterized in that the small through holes are arranged into the column parallel to the edge of the current collector layer and the row perpendicular to the edge of the current collector layer, and the centers of the four small through holes distributed on different adjacent three rows and different adjacent three columns are connected to form an equilateral quadrangle. With the technical scheme of the present invention, the uniformity of the slurry on the current collector layer is increased, the active material can be automatically balance through the small holes, the uniformity is improved, and the local excess charge and discharge is avoided so as to improve the safety performance; and the rate performance, the cycle life and the energy conversion efficiency of the battery are improved.

Owner:MICROVAST POWER SYST CO LTD

Electrode pole sheet and electrochemical device

ActiveCN110660995ASet stableSimple interfaceElectrode carriers/collectorsSecondary cellsElectrical batteryHigh energy

The invention belongs to the field of batteries and relates to an electrode pole sheet and an electrochemical device. The electrode pole sheet comprises a current collector and an electrode active material layer arranged on at least one surface of the current collector; the current collector comprises a supporting layer and a conductive layer arranged on at least one surface of the supporting layer; the single-surface thickness D2 of the conductive layer meets a relation that D2 is more than or equal to 30nm and less than or equal to 3 micrometers; the electrode active material layer comprisesan electrode active material, a binder and a conductive agent; the conductive agent in the electrode active material layer is non-uniformly distributed in a thickness direction; based on the total weight of the electrode active material layer, the weight percentage of the conductive agent in the inner side area of the electrode active material layer is higher than the weight percentage of the conductive agent in the outer side area of the electrode active material layer; and the conductive agent in the inner side area of the electrode active material layer contains at least one of a one-dimensional conductive material and a two-dimensional conductive material. The electrode pole sheet has good machinability; and the electrochemical device comprising the electrode pole sheet has high energy density, good electrical performance and long-term reliability.

Owner:CONTEMPORARY AMPEREX TECH CO

Directionally arranged graphene-coated positive electrode material for lithium ion battery

ActiveCN110311137AReduce DC internal resistanceIncrease capacitySecondary cellsPositive electrodesOrganic solventSodium-ion battery

The invention belongs to the field of preparation of positive electrode materials for lithium ion batteries, and in particular relates to a directionally arranged graphene-coated positive electrode material for a lithium ion battery. According to the directionally arranged graphene-coated positive electrode material for the lithium ion battery, the preparation material comprises an A component, aB component and a C component; the A component comprises a fluorine-containing organic substance and an organic solvent; the B component comprises a fluorine-containing organic substance, an organic solvent and graphene; and the C component comprises a positive electrode active material.

Owner:宁夏汉尧富锂科技有限责任公司

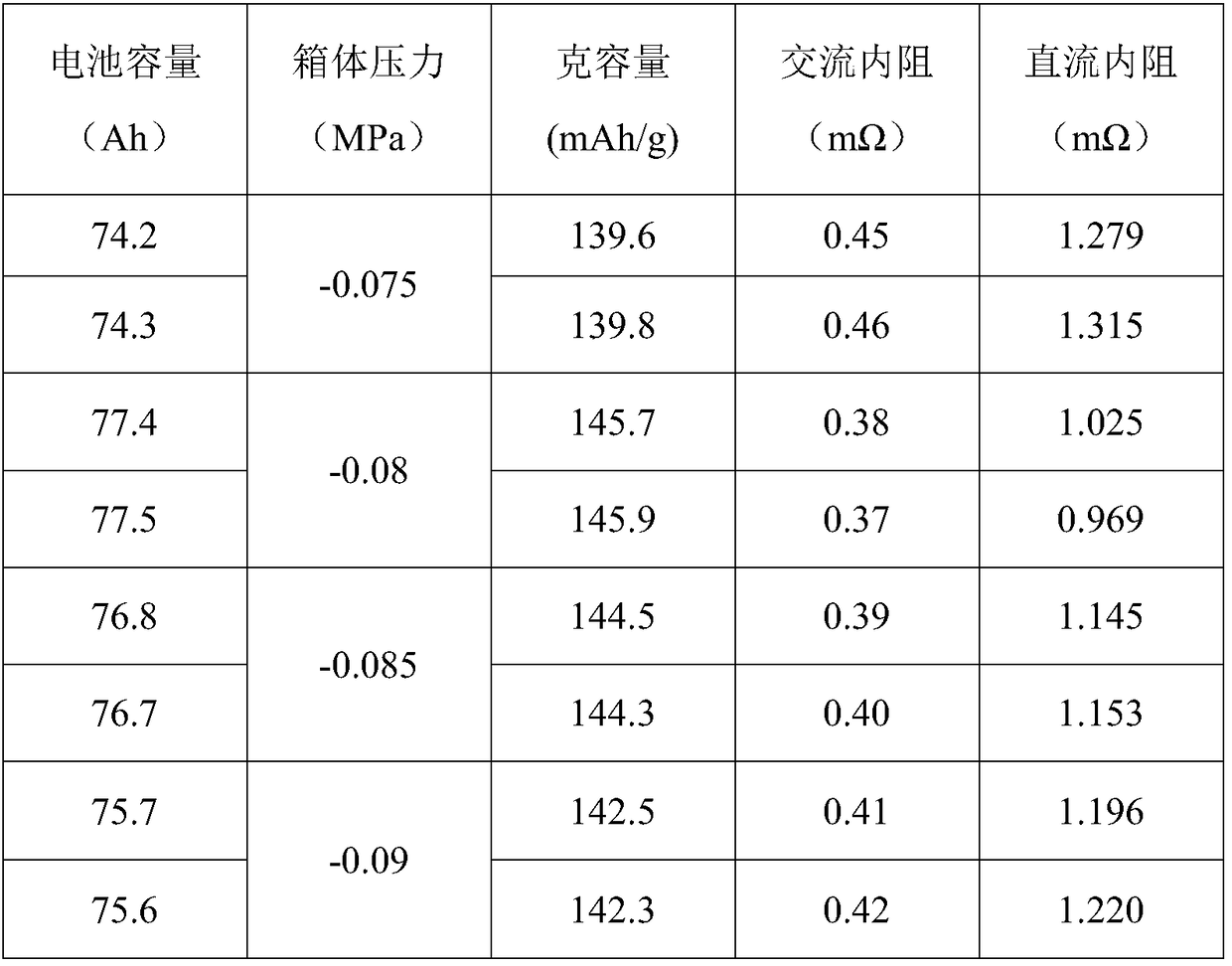

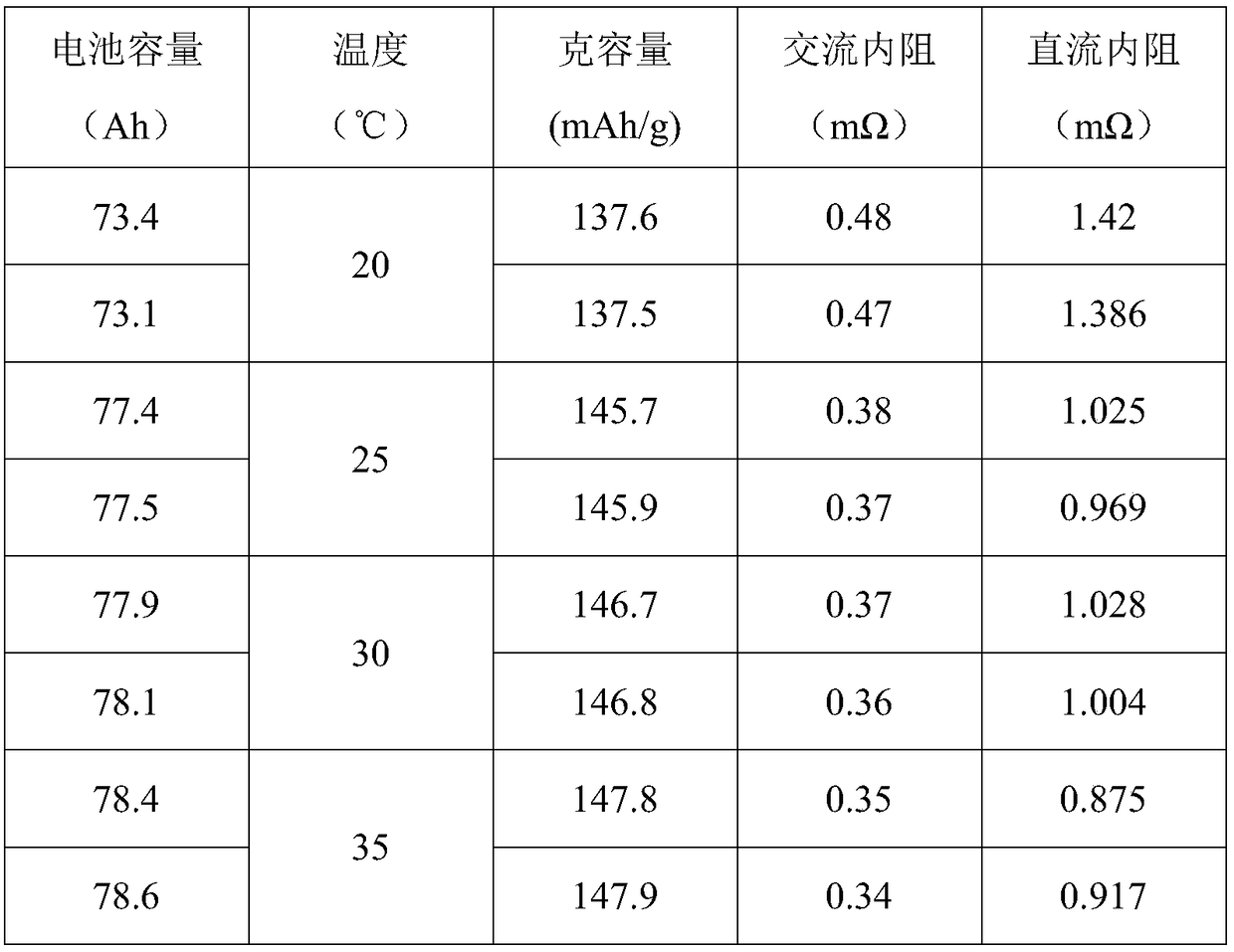

Isobaric formation method for lithium ion battery

InactiveCN108923072AReduce sucking volumeReduce DC internal resistanceFinal product manufactureSecondary cells charging/dischargingInternal resistanceLiquid storage tank

The invention relates to the field of lithium ion battery manufacturing, in particular to an isobaric formation method for a lithium ion battery. The method comprises the following steps that (1) thebattery to be formed is placed into a formation box, inert gas is introduced for 15 minutes, a sealing plug is pulled out, a liquid storage tank is additionally arranged above a liquid injection portof the battery and is open; (2) an inert gas inlet valve is closed, vacuumizing is carried out to reach -0.075 MPa to -0.09 MPa, a vacuum valve is closed, and heating is carried out to increase the temperature in the box to 20-35 DEG C; (3) the formation step is set and started; and (4) after formation is finished, the inert gas is introduced, and the liquid injection port of the battery is plugged with the sealing plug. According to the method, an isobaric formation technology is adopted, so that the sucking-back amount of electrolyte in the formation process can be decreased, in addition, gas generated in a battery cell in the formation process can be removed in time, the periphery of the battery cell is fully filled with the electrolyte, polarization caused by the concentration difference of lithium ions is reduced, so that a thin and dense SEI film is formed on the surface of a negative electrode, the direct current internal resistance and the alternating current internal resistance of the battery are reduced, the discharge capacity is improved, and therefore the capacity per gramme of the battery is improved.

Owner:HEFEI HENGNENG NEW ENERGY TECH

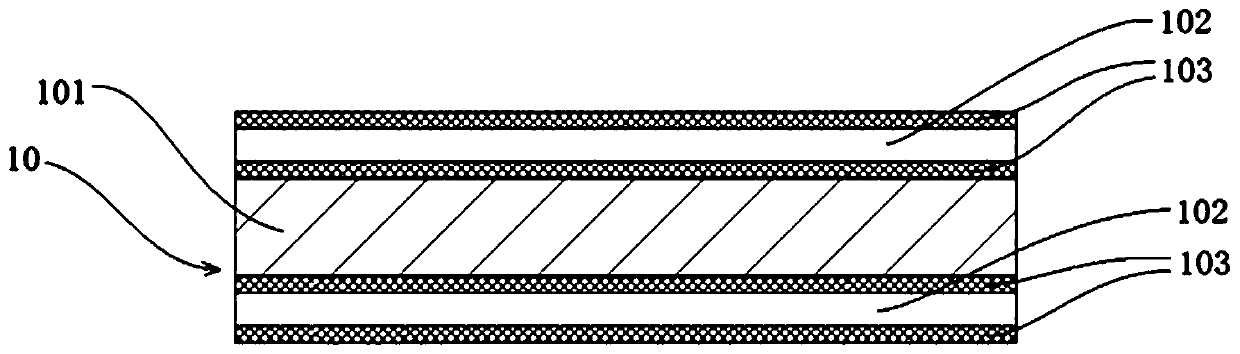

Electrode pole sheet and electrochemical device

ActiveCN110661001ASimple interfaceOvercome the disadvantages of easy breakageElectrode carriers/collectorsNegative electrodesElectrical batteryHigh energy

The invention belongs to the field of batteries and relates to an electrode pole sheet and an electrochemical device. The electrode pole sheet comprises a current collector and an electrode active material layer arranged on at least one surface of the current collector; the current collector comprises a supporting layer and a conductive layer arranged on at least one surface of the supporting layer; the single-surface thickness D2 of the conductive layer meets a relation that D2 is more than or equal to 30nm and less than or equal to 3 micrometers; a conductive priming coat containing a conductive material and a binder is arranged between the current collector and the electrode active material layer; and the conductive material of the conductive priming coat contains at least one materialselected from a one-dimensional conductive material and a two-dimensional conductive material. The electrode pole sheet has good machinability. The electrochemical device comprising the electrode polesheet has high energy density, good electrical performance and long-term reliability.

Owner:CONTEMPORARY AMPEREX TECH CO

Electrode pole sheet and an electrochemical device

ActiveCN110660996ASimple interfaceImprove long-term reliabilityElectrode carriers/collectorsSecondary cellsElectrical batteryHigh energy

The invention belongs to the field of batteries and relates to an electrode pole sheet and an electrochemical device. The electrode pole sheet comprises a current collector and an electrode active material layer arranged on at least one surface of the current collector; the current collector comprises a supporting layer and a conductive layer arranged on at least one surface of the supporting layer; the single-surface thickness D2 of the conductive layer meets a relation that D2 is more than or equal to 30nm and less than or equal to 3 micrometers; the electrode active material layer comprisesan electrode active material, a binder and a conductive agent; the conductive agent in the electrode active material layer is non-uniformly distributed in a thickness direction; based on the total weight of the electrode active material layer, the weight percentage of the conductive agent in the inner side area of the electrode active material layer is higher than the weight percentage of the conductive agent in the outer side area of the electrode active material layer; and the conductive agent in the inner side area of the electrode active material layer contains an acrylic acid group / acrylate group aqueous binder. The electrode pole sheet has good machinability; and the electrochemical device comprising the electrode pole sheet has high energy density, good electrical performance and long-term reliability.

Owner:CONTEMPORARY AMPEREX TECH CO

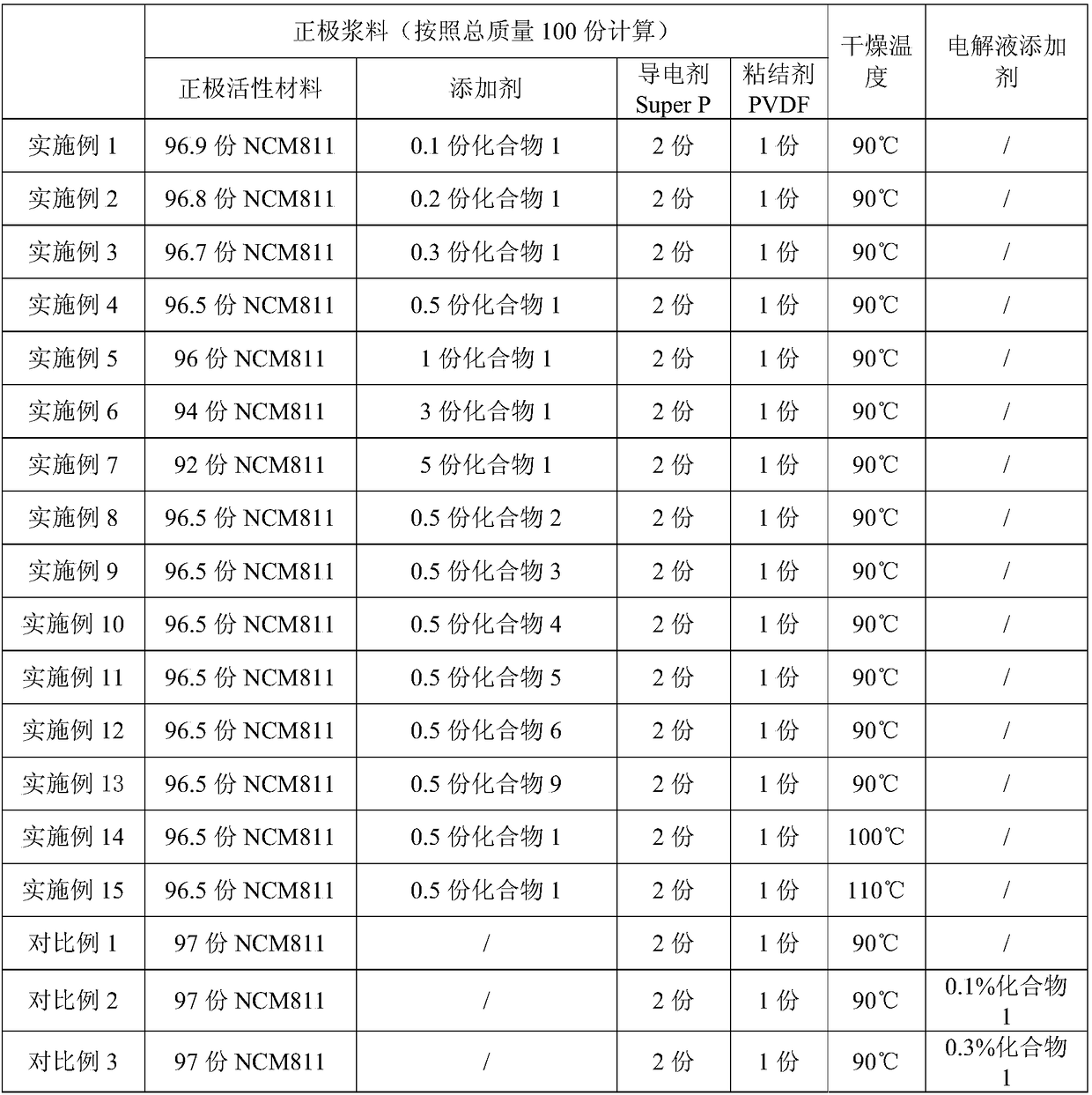

Lithium ion battery positive pole pieceand preparation method thereof

InactiveCN112928240AImprove conductivityEasy to prepareCell electrodesSecondary cellsPolyvinylidene fluorideLithium electrode

The invention provides a lithium ion battery positive pole piece, which comprises a positive current collector, a conductive coating layer and an active slurry layer, wherein the conductive coating layer and the active slurry layer are sequentially coated on the positive current collector, and the active slurry layer comprises, by mass, 95% of a LiFePO4 active substance, 2.8% of a conductive agent and 2.2% of a binder; the conductive coating layer comprises the following components in percentage by mass: 10% of a conductive agent, 2% of a binder, 1% of ethanol, 1% of acetone and 86% of deionized water; the binder is polyvinylidene fluoride, the conductive agent is conductive carbon black, and the positive active substance is LiFePO4. The preparation method is simple, the conductivity of the pole piece can be effectively improved, the lithium ion transfer impedance in the battery is obviously reduced, the direct-current internal resistance of the battery is obviously reduced, and the cycling stability of the battery can be improved.

Owner:江苏中兴派能电池有限公司

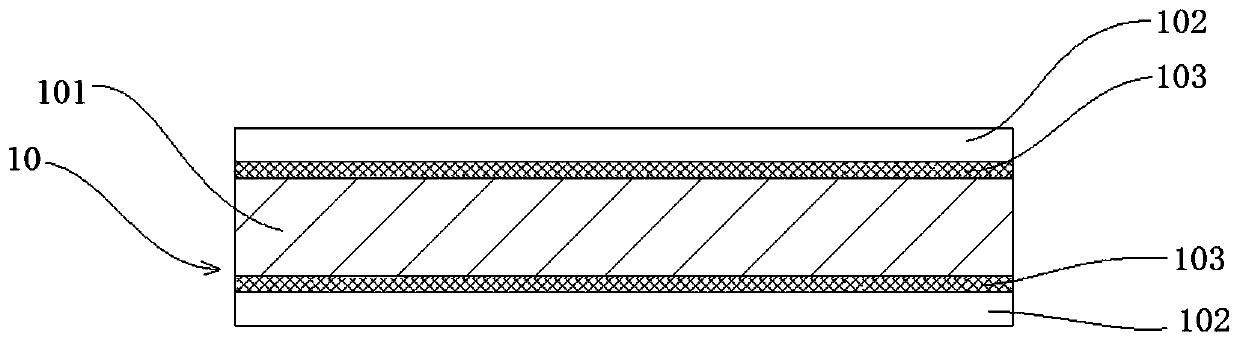

Electrode plate and electrochemical device

ActiveCN110943222AIncrease energy densityImprove nail penetration safety performanceElectrode carriers/collectorsSecondary cellsCoated surfaceElectrical battery

The invention relates to the field of batteries, in particular to an electrode plate and an electrochemical device. The electrode plate comprises a current collector and an electrode active material layer arranged on at least one surface of the current collector, wherein the current collector comprises a supporting layer and a conductive layer arranged on at least one surface of the supporting layer, the thickness D2 of a single surface of the conductive layer is greater than or equal to 30nm and less than or equal to 3mu m, the supporting layer is made of a high polymer material or a high polymer composite material, and the thickness D1 of the supporting layer is greater than or equal to 1mu m and less than or equal to 30mu m; wherein the electrode active material layer includes an electrode active material, a binder, and a conductive agent, and the coated electrode active material layer includes three regions based on a compaction density when viewed from a width direction of a coated surface of the electrode sheet, and a compaction density of a middle region is higher than compaction densities of both side regions. The electrode pole piece and the electrochemical device have high energy density and good electrical performance and safety.

Owner:CONTEMPORARY AMPEREX TECH CO

Preparation method of graphene-coated positive electrode material of lithium ion battery

ActiveCN110165198AEvenly distributedReduce DC internal resistanceSecondary cellsPositive electrodesLithium electrodeGraphene

The invention belongs to the technical field of lithium ion battery positive electrode materials, and particularly provides a preparation method of a graphene-coated positive electrode material of a lithium ion battery. The invention provides the preparation method of a directionally-arranged graphene-coated positive electrode material of the lithium ion battery. The preparation method comprises the following steps: preparing mixed slurry, and performing drying and compounding, wherein the raw materials of the mixed slurry comprise a binder, graphene and a positive electrode active substance;spray drying is utilized in the drying process, wherein the temperature of spray drying is 120-300 DEG C.

Owner:宁夏汉尧富锂科技有限责任公司

Electrolyte and application thereof

InactiveCN112054242AGood high and low temperature performanceImproved magnification performanceSecondary cells servicing/maintenanceComposite electrolytesElectrolytic agentOrganic solvent

Electrolyte and application thereof are disclosed. The invention discloses an electrolyte for a lithium-ion battery and the lithium-ion battery. The electrolyte for the lithium-ion battery comprises amain lithium salt, an auxiliary lithium salt and an organic solvent, wherein the main lithium salt is tris(trifluoromethylsulfonyl) methyl lithium (LiC(SO2CF3)3), and the auxiliary lithium salt comprises lithium oxalyldifluoroborate(LiODFB) and lithium hexafluorophosphate(LiPF6). The electrolyte takes tri(trifluoromethylsulfonyl) methyl lithium as a main lithium salt, so that the high and low temperature performance of the battery can be obviously improved, the rate capability and the cycling stability of the battery are improved, and the direct-current internal resistance of the battery is reduced.

Owner:KUNSHAN BAOTRON NEW ENERGY TECH CO LTD

Preparation method and application of lignin-based hard carbon

ActiveCN111170298AReduce contentStrong pulse discharge abilityHybrid capacitor electrodesCarbon preparation/purificationInternal resistanceNanoparticle

The invention relates to a preparation method and application of lignin-based hard carbon, and belongs to the technical field of energy storage. The preparation method of the lignin-based hard carboncomprises the following steps: pretreating lignin, and dissolving the pretreated lignin in an organic solvent solution to form a lignin nanoparticle precursor solution; drying the lignin nanoparticleprecursor solution to prepare a lignin nanoparticle precursor; and carrying out vacuum carbonization on the lignin nanoparticle precursor to prepare the lignin-based hard carbon. The lignin-based hardcarbon disclosed by the invention is simple in preparation process, strong in pulse discharge capability, good in low-temperature performance and low in direct-current internal resistance when beingused as a negative electrode material of a lithium ion capacitor.

Owner:合盛科技(宁波)有限公司

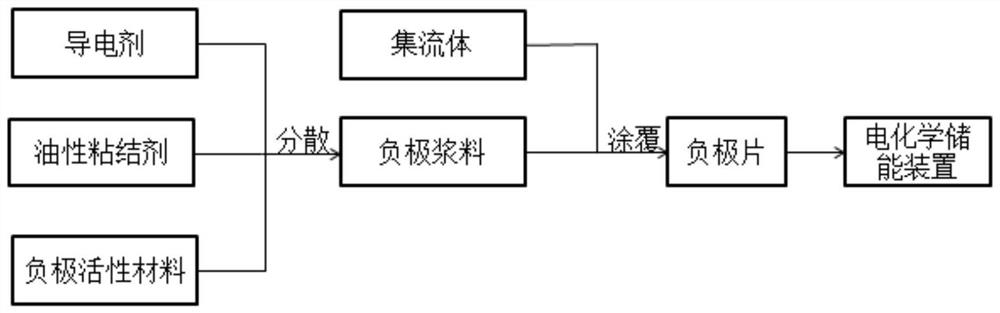

Oily binder and application thereof

The invention relates to an oily binder and application thereof. The oily binder comprises at least one of oily polyacrylic acid, oily polyacrylate, oily styrene acrylate, oily polyacrylonitrile, oilypolyacrylamide, oily polyimide and oily polyamideimide, and the molecular weight of the oily binder is selected from 5W-200W. The oily binder is used for replacing a traditional water-based binder tobe used for negative electrode slurry, and the problems that water-based negative electrode slurry is uneven in dispersion and large in number of coating particles, and the water-based binder floatsupwards and sticks to a roller in a cold pressing mode are effectively solved. Compared with a traditional water-based adhesive, a battery cell obtained by the oily adhesive has the characteristics oflow direct-current internal resistance, good quick-charge performance, small quick-charge temperature rise, few side reactions and long cycle life of the battery cell. Compared with oily polyvinylidene fluoride serving as a binder, the oily binder disclosed by the invention has the advantage that the obtained battery cell has higher energy density.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

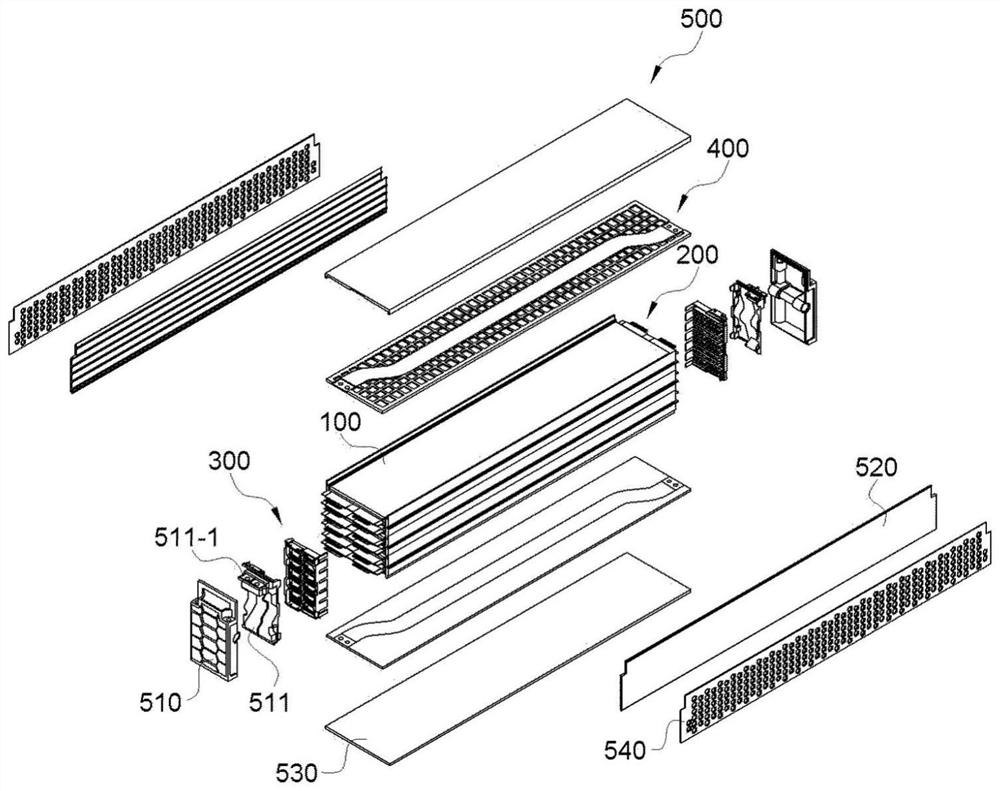

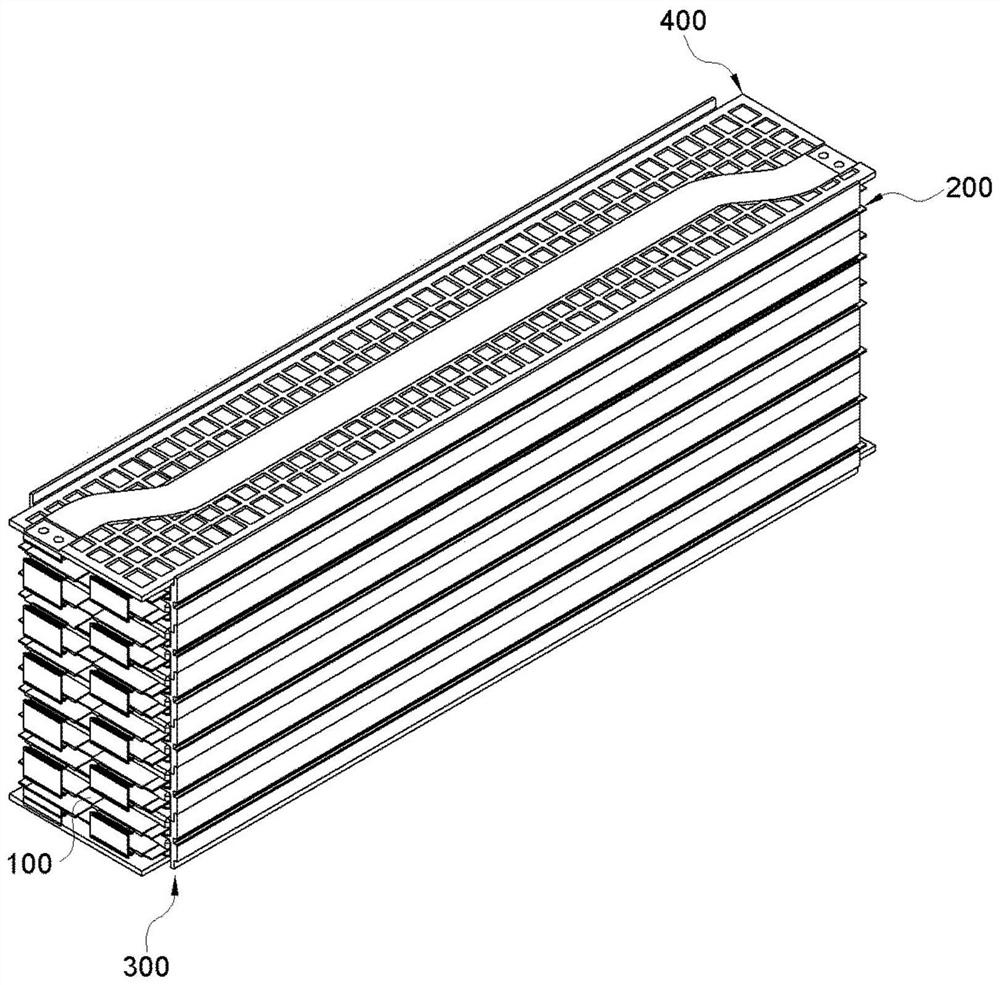

Battery module

PendingCN111834567AReduce DC internal resistanceImprove performance and longevityBattery isolationSecondary cellsPhysicsEngineering

The present invention relates to a battery module including an ultra-long battery cell. The battery module according to the present invention includes: ultra-long battery cells each having opposite ends to which a plurality of electrode tabs are connected; a battery stack formed by stacking the battery cells; end-side bus bar assemblies formed at opposite ends of the battery stack, respectively, and electrically connecting the electrode tabs of the battery cells; transverse bus bar assemblies each electrically connecting electrode tabs connected to opposite ends of an uppermost battery cell ora lowermost battery cell in the battery stack; and a case accommodating the battery stack, the end-side bus bar assemblies, and the transverse bus bar assemblies. With the battery module according tothe present invention, it is possible to suppress an increase in internal resistance of the ultra-long battery cell and heating, and to improve structural stability.

Owner:SK新能源株式会社

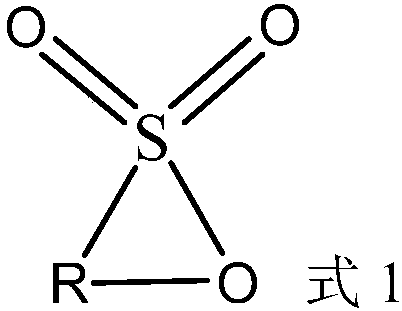

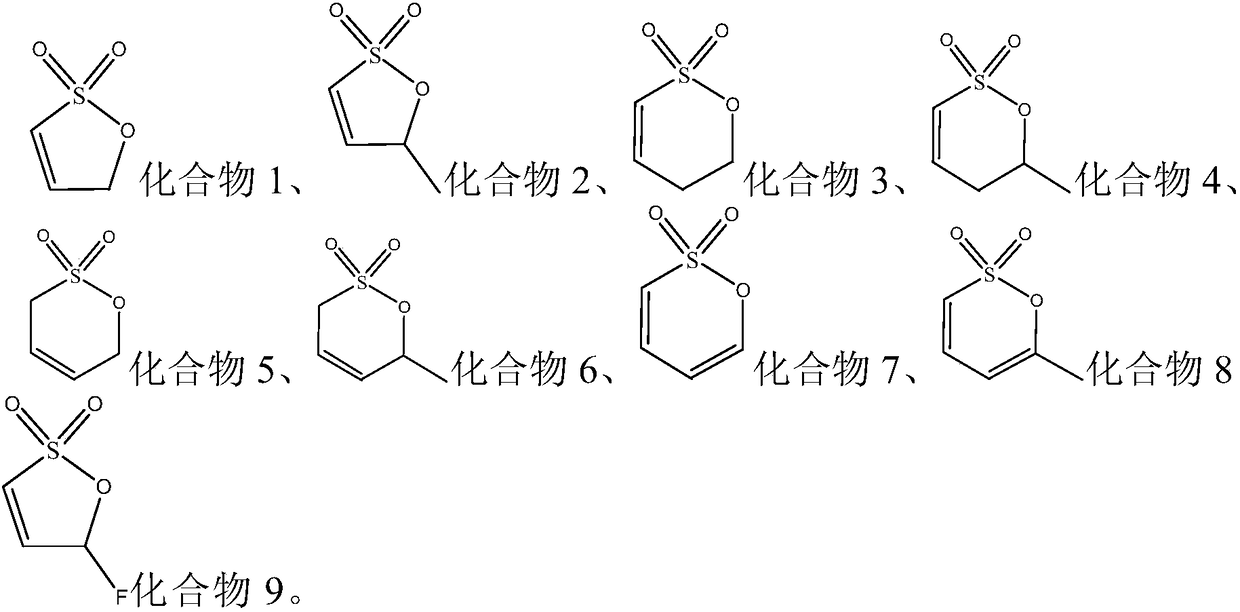

Positive plate and energy storage device

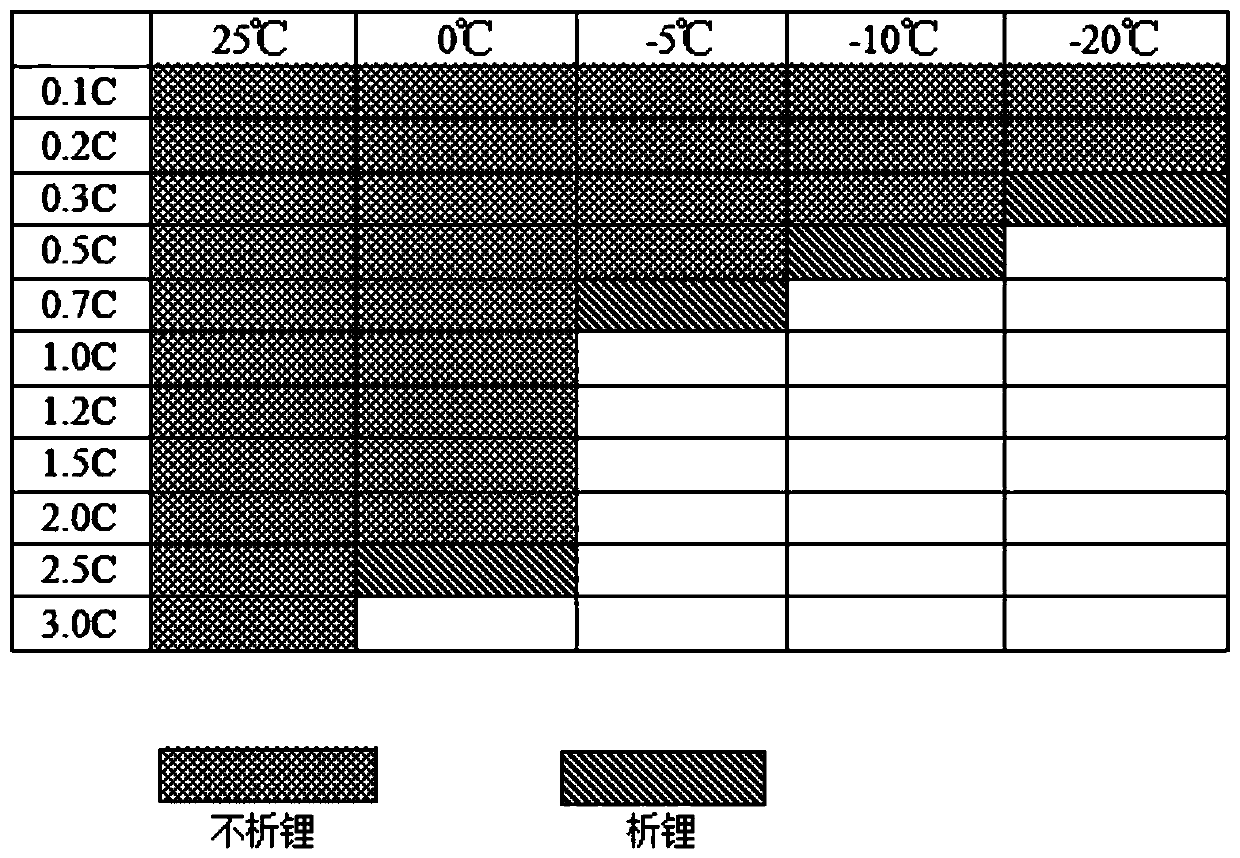

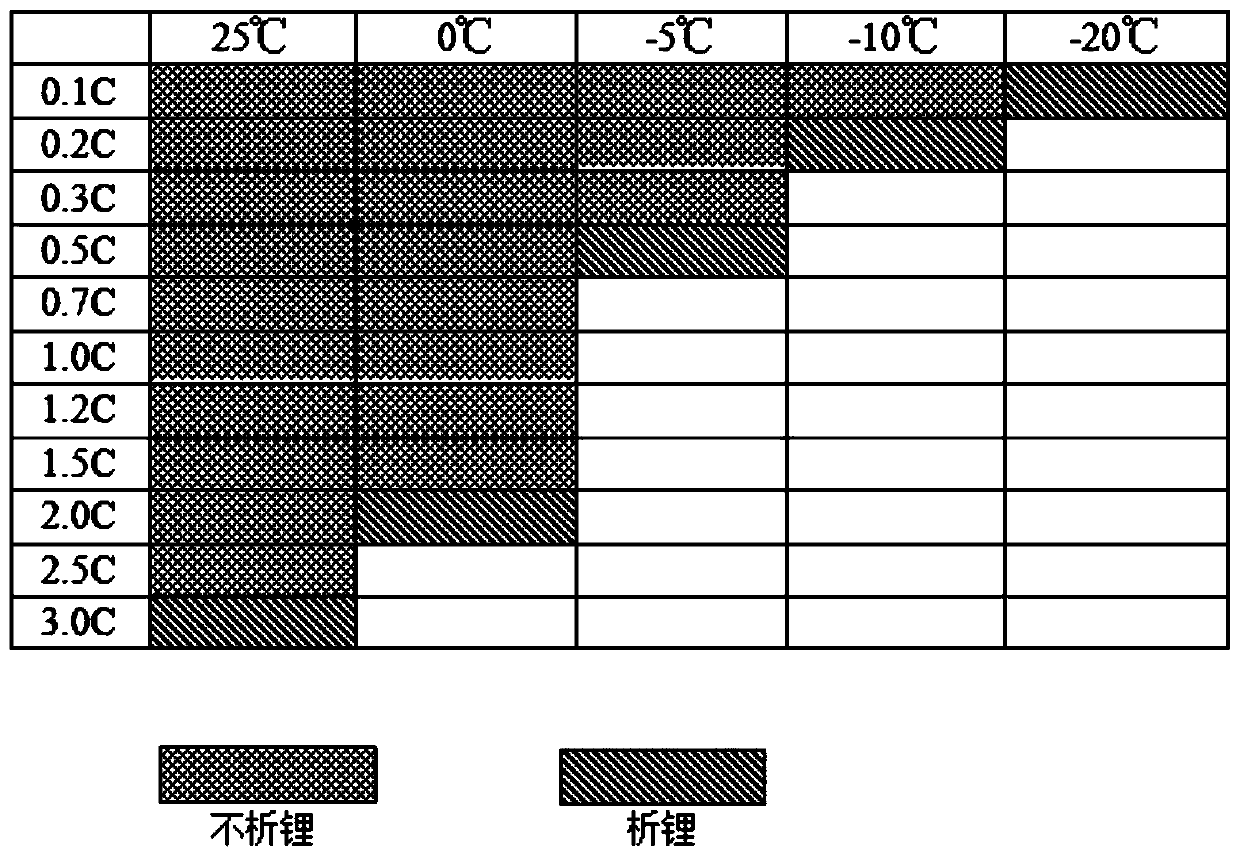

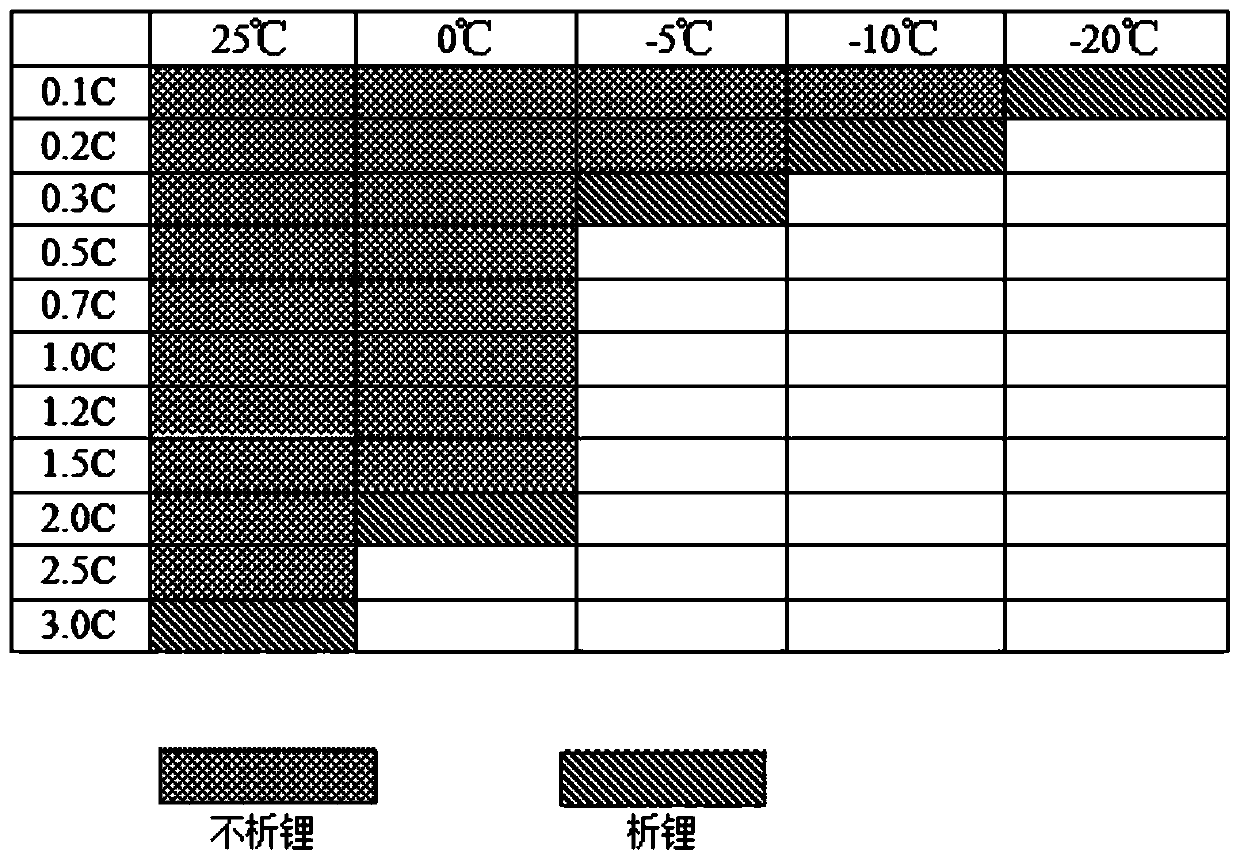

ActiveCN108695487AImprove Interface StabilityReduce DC internal resistancePositive electrodesLi-accumulatorsHigh temperature storageInternal resistance

The invention provides a positive plate and an energy storage device. The positive plate comprises a positive current collector and a positive diaphragm, wherein the positive diaphragm is arranged onthe positive current collector and comprises a positive active material; and the positive diaphragm also comprises an additive which comprises a cyclic sultone compound containing a carbon-carbon double bond. The positive plate provided by the invention has good interface stability and does not significantly increase the interface impedance of a negative pole in the energy storage device when applied to the energy storage device, so the energy storage device has lower direct-current internal resistance, and excellent high-temperature storage performance, high-temperature thermal stability andlow-temperature lithium precipitation performance. The preparation method for the positive plate provided by the invention has the advantages of simple process, easy operation, and applicability to large-scale production.

Owner:CONTEMPORARY AMPEREX TECH CO

An electrode pole piece and an electrochemical device

ActiveCN110661001BSimple interfaceOvercome the disadvantages of easy breakageElectrode carriers/collectorsNegative electrodesElectrical batteryHigh energy

The present application relates to the field of batteries, in particular, to an electrode sheet and an electrochemical device. The electrode sheet of the present application includes a current collector and an electrode active material layer disposed on at least one surface of the current collector, wherein the current collector includes a support layer and a conductive layer disposed on at least one surface of the support layer, the The single-side thickness D2 of the conductive layer satisfies: 30nm≤D2≤3μm, and a conductive primer layer comprising a conductive material and a binder is also provided between the current collector and the electrode active material layer, and the conductive The conductive material of the undercoat layer contains at least one of a one-dimensional conductive material and a two-dimensional conductive material. The electrode pole piece of the present application has good processability, and the electrochemical device including the electrode pole piece has high energy density, good electrical performance and long-term reliability.

Owner:CONTEMPORARY AMPEREX TECH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com