Positive plate and energy storage device

A technology of positive electrode sheet and positive electrode film, which is applied in the direction of positive electrode, vehicle energy storage, battery electrode, etc., can solve the problem of deteriorating the power performance of lithium-ion batteries, and achieve suitable for large-scale production, excellent high-temperature storage performance, and low DC internal resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

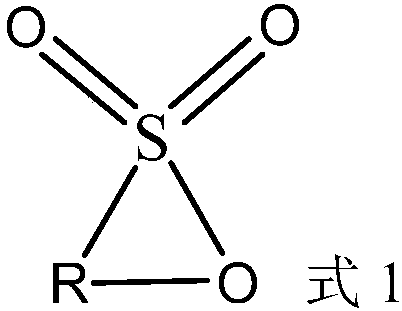

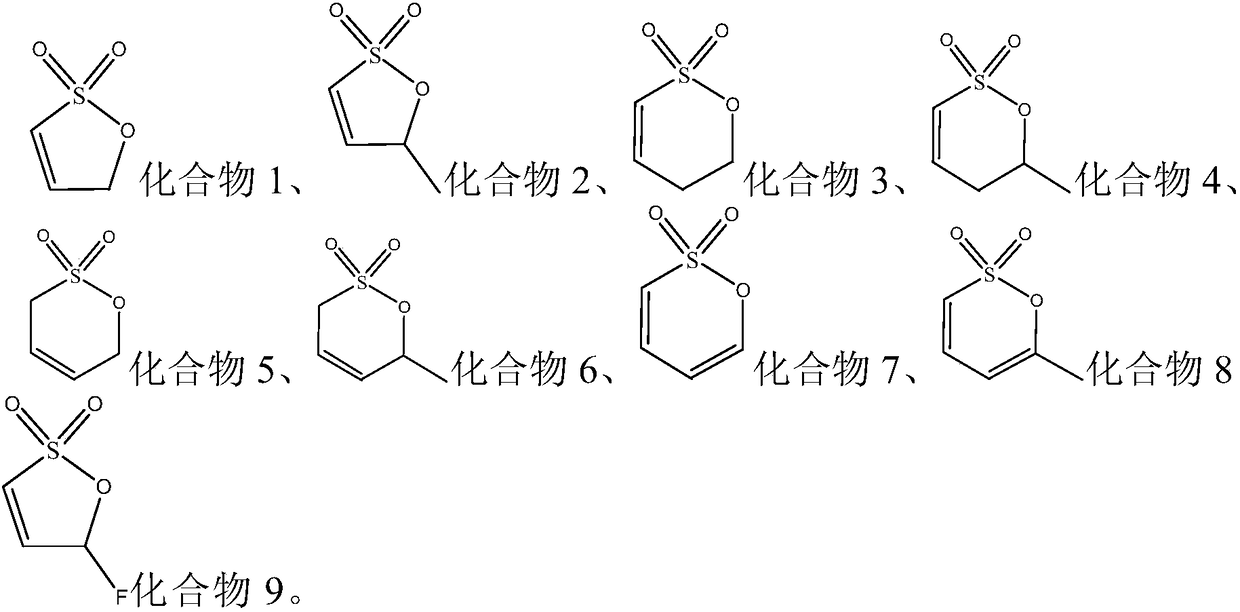

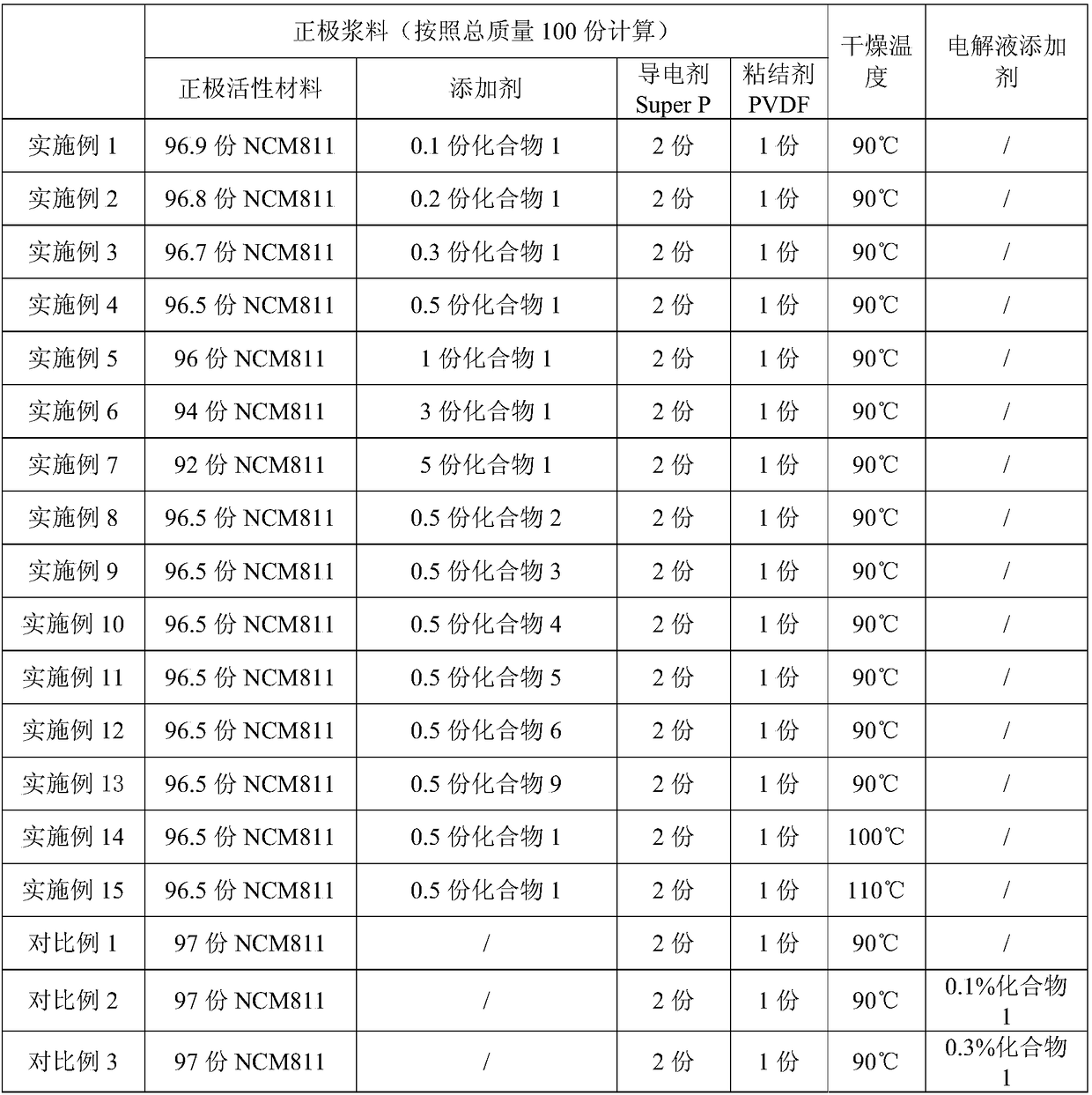

[0030] Secondly, the preparation method of the positive electrode sheet according to the second aspect of the present invention is described, which is used to prepare the positive electrode sheet described in the first aspect of the present invention, including the steps: (1) firstly mix the positive electrode active material, optional conductive agent, optional The binder is mixed evenly, and then a solvent is added for dispersion, and then an additive containing a C=C double bond cyclic sultone compound is added for further mixing and dispersion to obtain a positive electrode slurry; (2) the positive electrode obtained in step (1) The slurry is coated on the surface of the positive electrode current collector, and then dried to form a positive electrode membrane; (3) the positive electrode membrane dried in step (2) is sequentially rolled, slit and sliced to obtain the positive electrode sheet .

[0031] The preparation method of the positive electrode sheet of the present...

Embodiment 1

[0051] (1) Preparation of positive electrode sheet

[0052] The cathode active material LiNi 0.8 co 0.1 mn 0.1 o 2 (NCM811), conductive agent Super P, and binder polyvinylidene fluoride (PVDF) were mixed evenly, and then the solvent N-methylpyrrolidone (NMP) was added for dispersion to obtain a dispersion liquid in which each component was uniformly dispersed, and compound 1 Added as an additive to the above dispersion liquid and further mixed and dispersed to obtain positive electrode slurry, wherein the solid content in the positive electrode slurry is 77wt%, and the mass ratio of positive electrode active material, additive, conductive agent, and binder is 96.9:0.1:2 : 1; coating the positive electrode slurry obtained above on both surfaces of a positive electrode current collector aluminum foil with a thickness of 14 μm; then blowing and drying at 90° C., rolling, slitting and slicing to obtain positive electrode sheets.

[0053] (2) Preparation of negative electrode s...

Embodiment 2

[0062] The preparation process of lithium ion battery is the same as embodiment 1, and the difference is that,

[0063] (1) Preparation of positive electrode sheet

[0064] The mass ratio of the positive electrode active material, the additive, the conductive agent, and the binder is 96.8:0.2:2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com