Patents

Literature

107results about How to "High Capacity Features" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

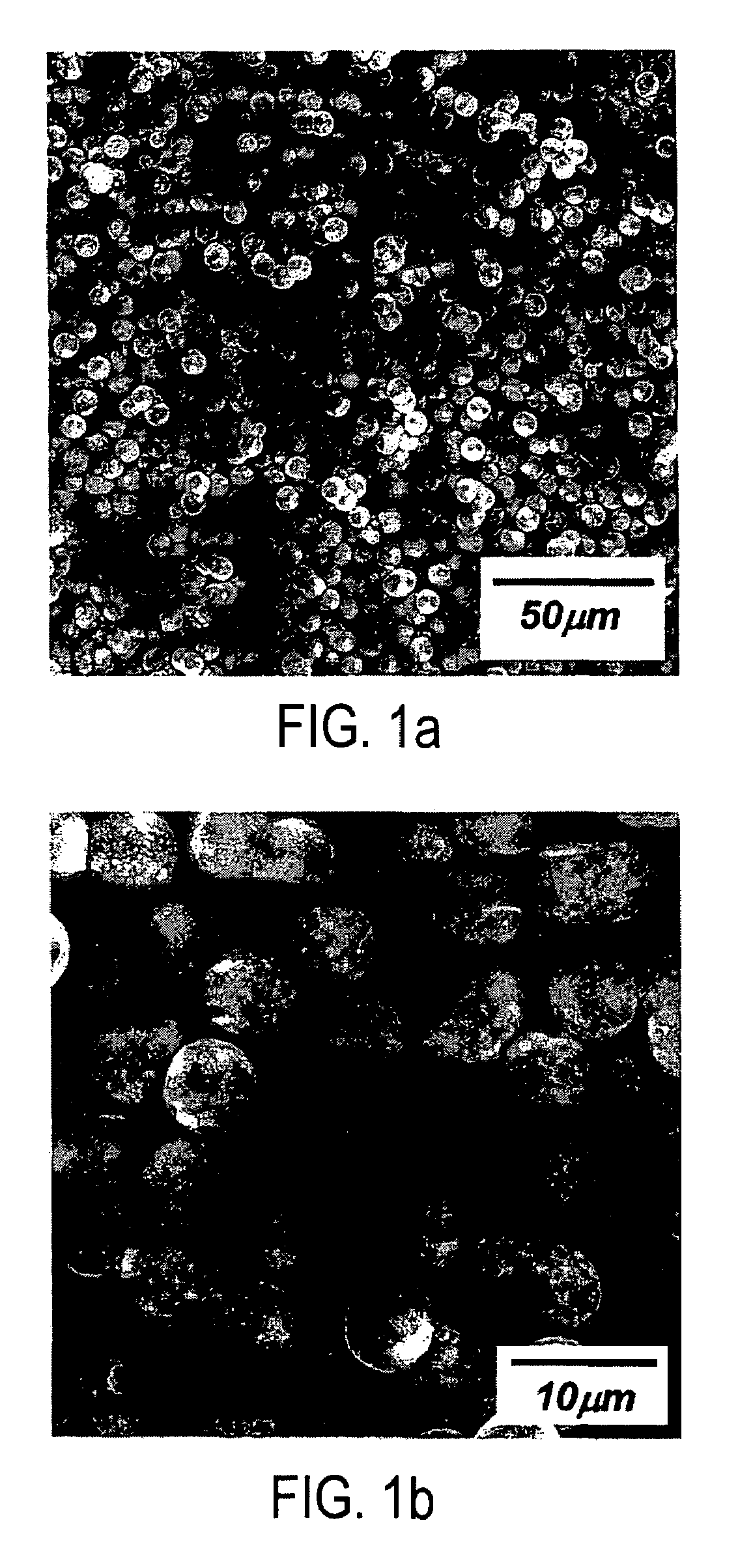

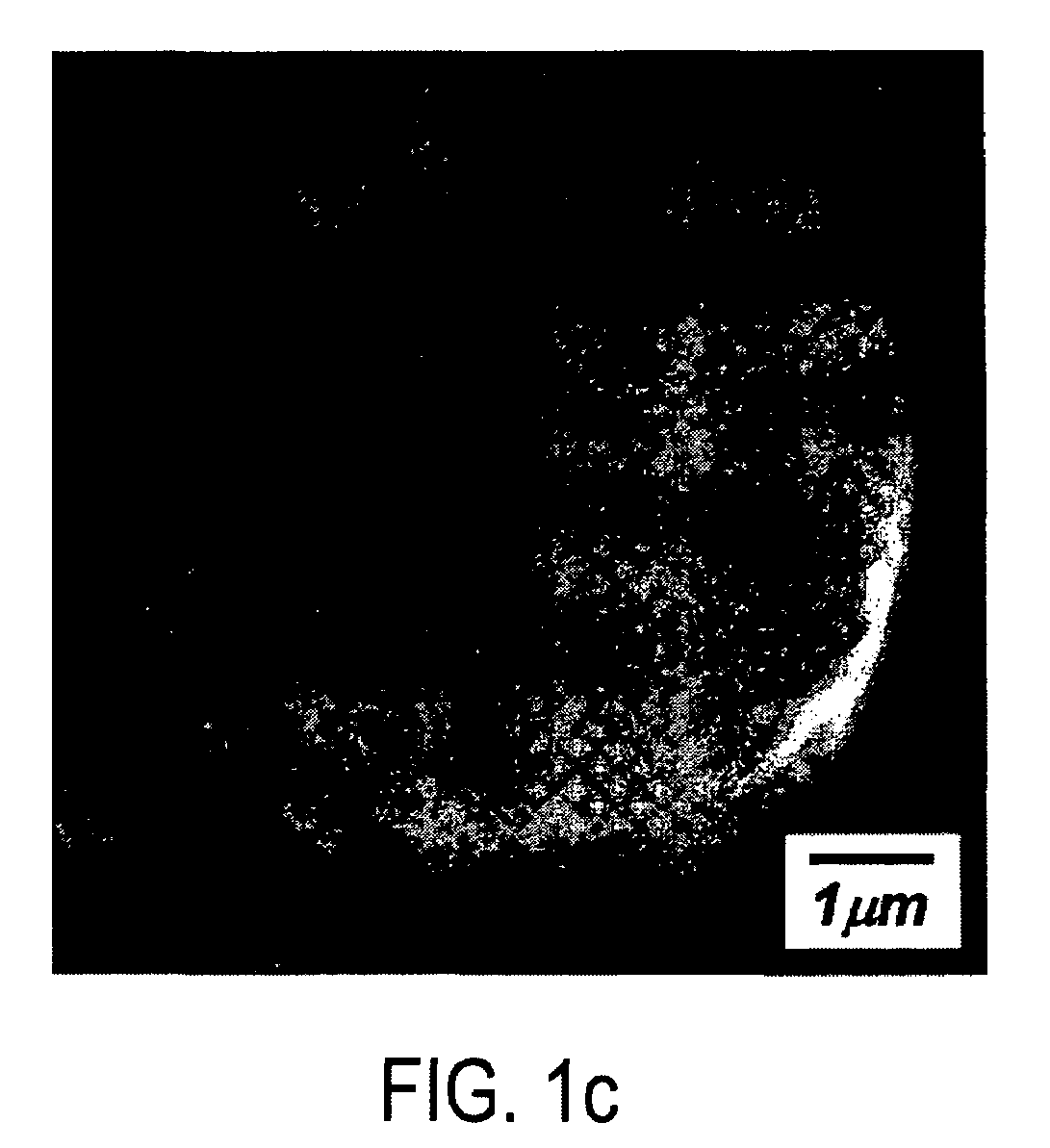

Method and apparatus for preparation of spherical metal carbonates and lithium metal oxides for lithium rechargeable batteries

ActiveUS7435402B2Improve impedance characteristicsImproved stability of the layered oxide structureConductive materialOxide conductorsDopantLithium metal

A number of materials with the composition Li1+xNiαMnβCoγM′δO2−zFz (M′=Mg,Zn,Al,Ga,B,Zr,Ti) for use with rechargeable batteries, wherein x is between about 0 and 0.3, α is between about 0.2 and 0.6, β is between about 0.2 and 0.6, γ is between about 0 and 0.3, δ is between about 0 and 0.15, and z is between about 0 and 0.2. Adding the above metal and fluorine dopants affects capacity, impedance, and stability of the layered oxide structure during electrochemical cycling. Another aspect of the invention includes materials with the composition Li1+xNiαCoβMnγM′δOyFz (M′=Mg,Zn,Al,Ga,B,Zr,Ti), where the x is between 0 and 0.2, the α between 0 and 1, the β between 0 and 1, the γ between 0 and 2, the δ between about 0 and about 0.2, the y is between 2 and 4, and the z is between 0 and 0.5.

Owner:UCHICAGO ARGONNE LLC

Method and apparatus for preparation of spherical metal carbonates and lithium metal oxides for lithium rechargeable batteries

ActiveUS20050058588A1Improve impedance characteristicsImprove stabilityConductive materialOxide conductorsDopantLithium metal

A number of materials with the composition Li1+xNiαMnβCoγM′δO2−zFz (M′=Mg,Zn,Al,Ga,B,Zr,Ti) for use with rechargeable batteries, wherein x is between about 0 and 0.3, α is between about 0.2 and 0.6, β is between about 0.2 and 0.6, γ is between about 0 and 0.3, δ is between about 0 and 0.15, and z is between about 0 and 0.2. Adding the above metal and fluorine dopants affects capacity, impedance, and stability of the layered oxide structure during electrochemical cycling. Another aspect of the invention includes materials with the composition Li1+xNiαCoβMnγM′δOyFz (M′=Mg,Zn,Al,Ga,B,Zr,Ti), where the x is between 0 and 0.2, the α between 0 and 1, the β between 0 and 1, the γ between 0 and 2, the δ between about 0 and about 0.2, the y is between 2 and 4, and the z is between 0 and 0.5.

Owner:UCHICAGO ARGONNE LLC

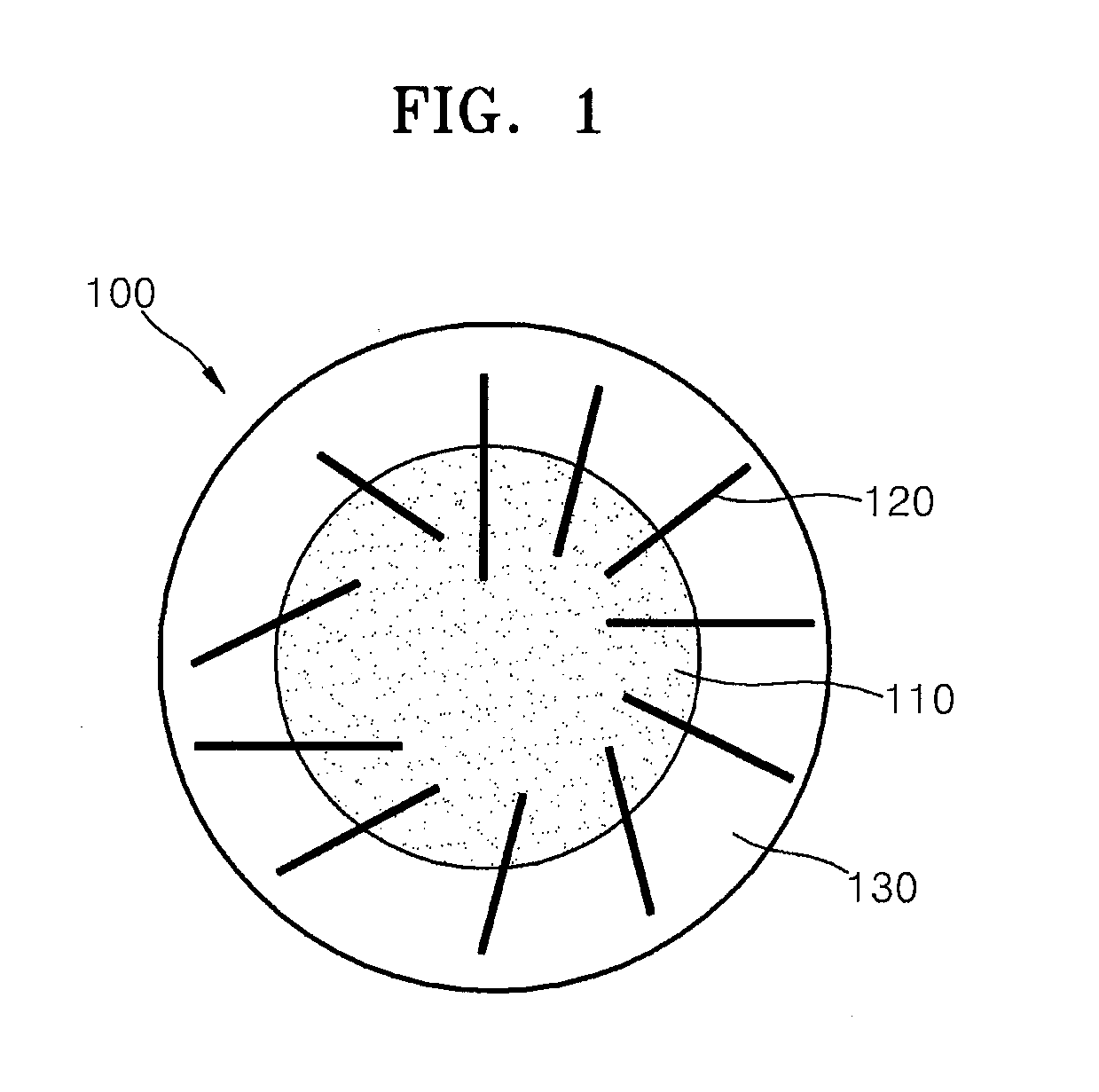

Negative active material and lithium battery containing the negative active material

InactiveUS20130089784A1Excellent capacity characteristicsHigh Capacity FeaturesSilver accumulatorsMaterial nanotechnologyDischarge efficiencyNanowire

A negative active material and a lithium battery including the negative active material. The negative active material includes primary particles, each including: a crystalline carbonaceous core having a surface on which silicon-based nanowires are disposed; and an amorphous carbonaceous coating layer that is coated on the crystalline carbonaceous core so as not to expose at least a portion of the silicon-based nanowires. Due to the inclusion of the primary particles, an expansion ratio is controlled and conductivity is provided and thus, a formed lithium battery including the negative active material may have improved charge-discharge efficiency and cycle lifespan characteristics.

Owner:SAMSUNG SDI CO LTD

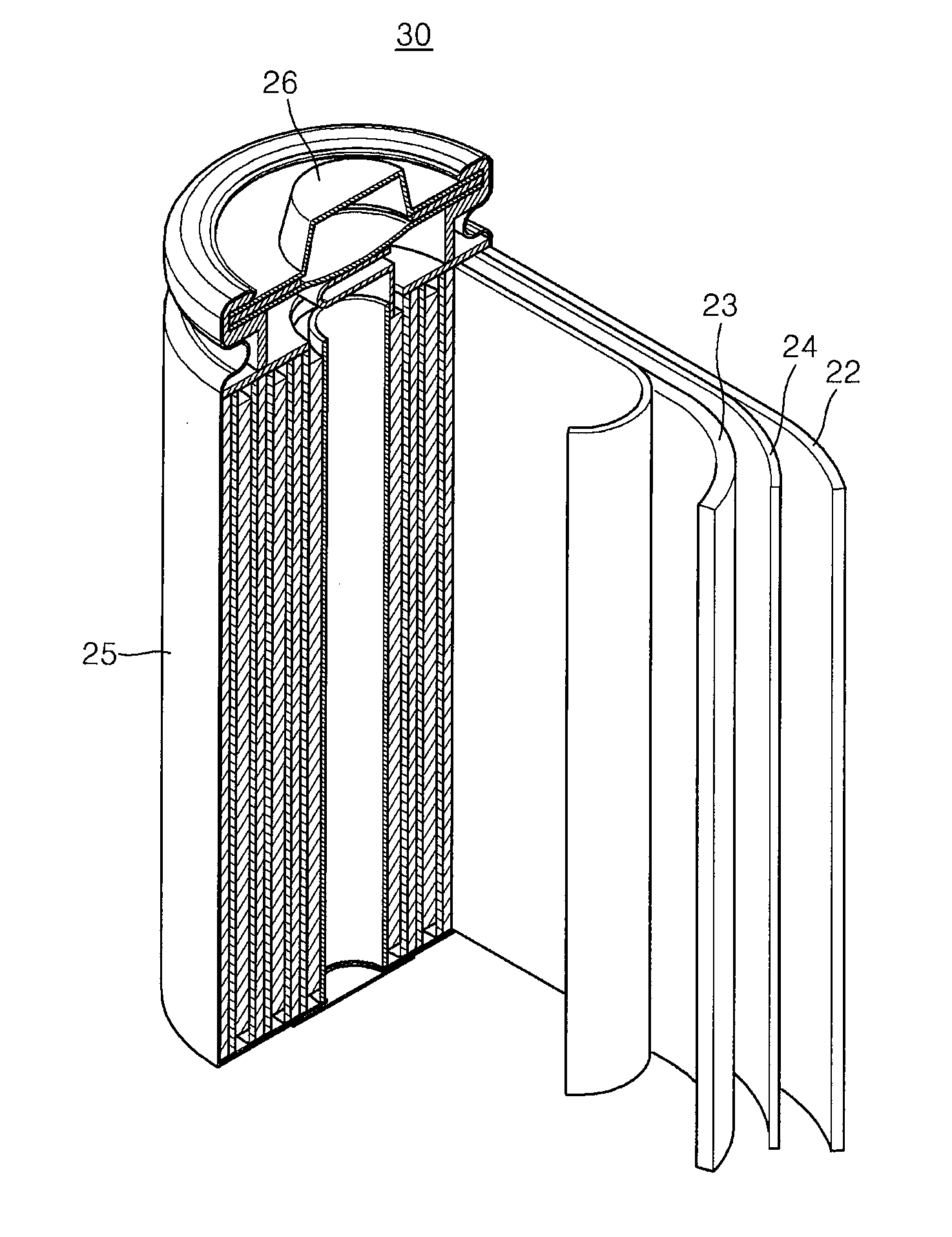

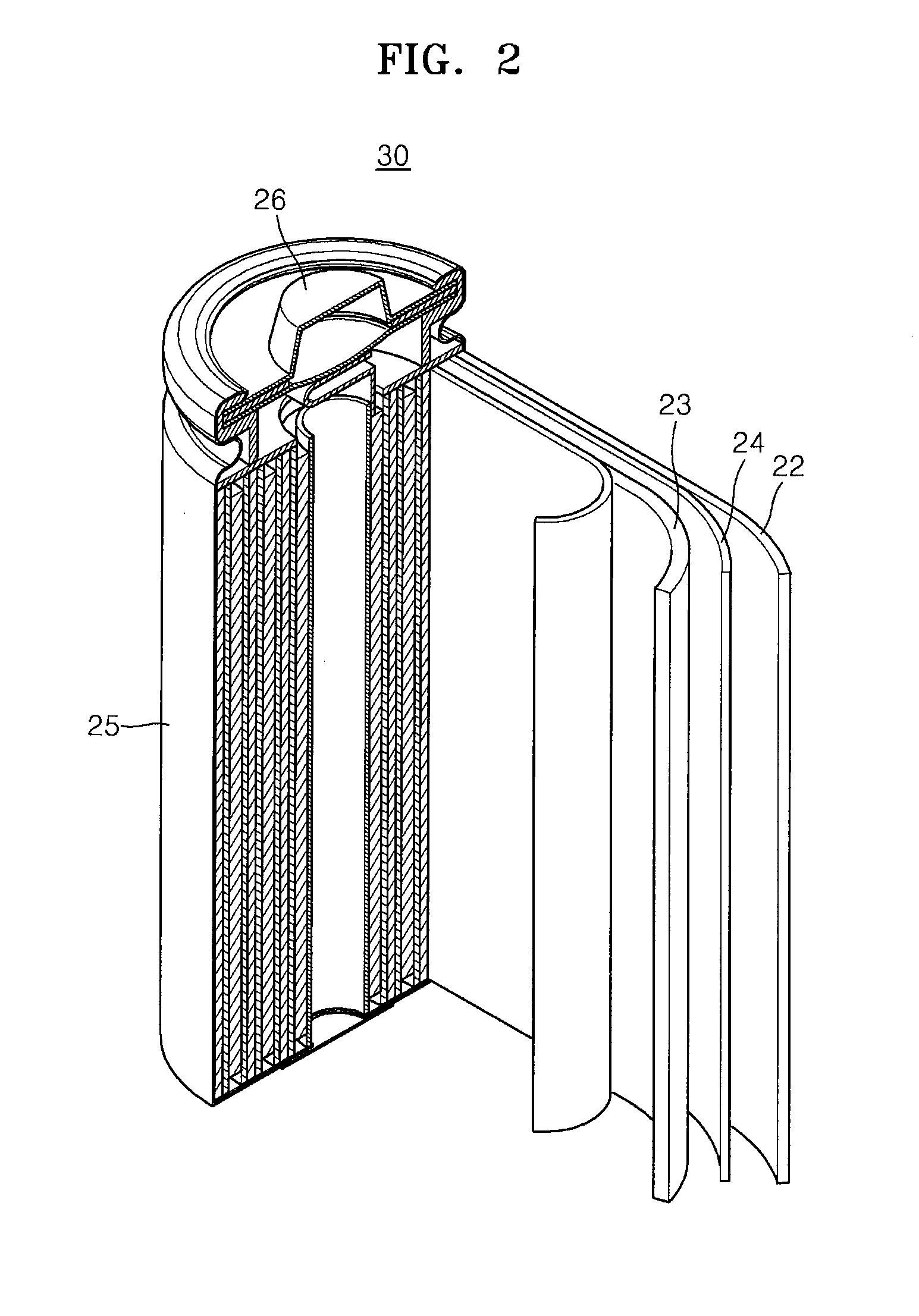

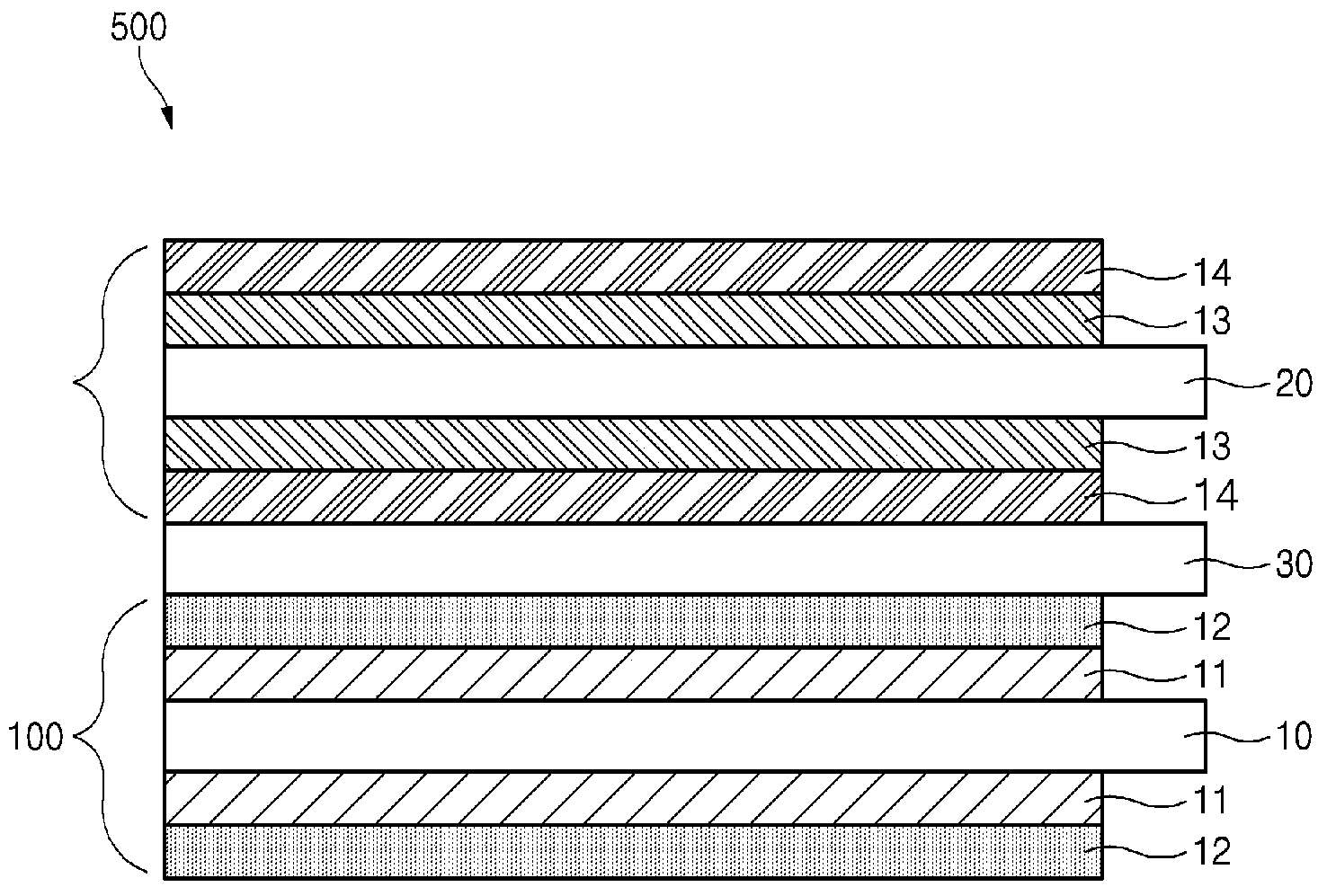

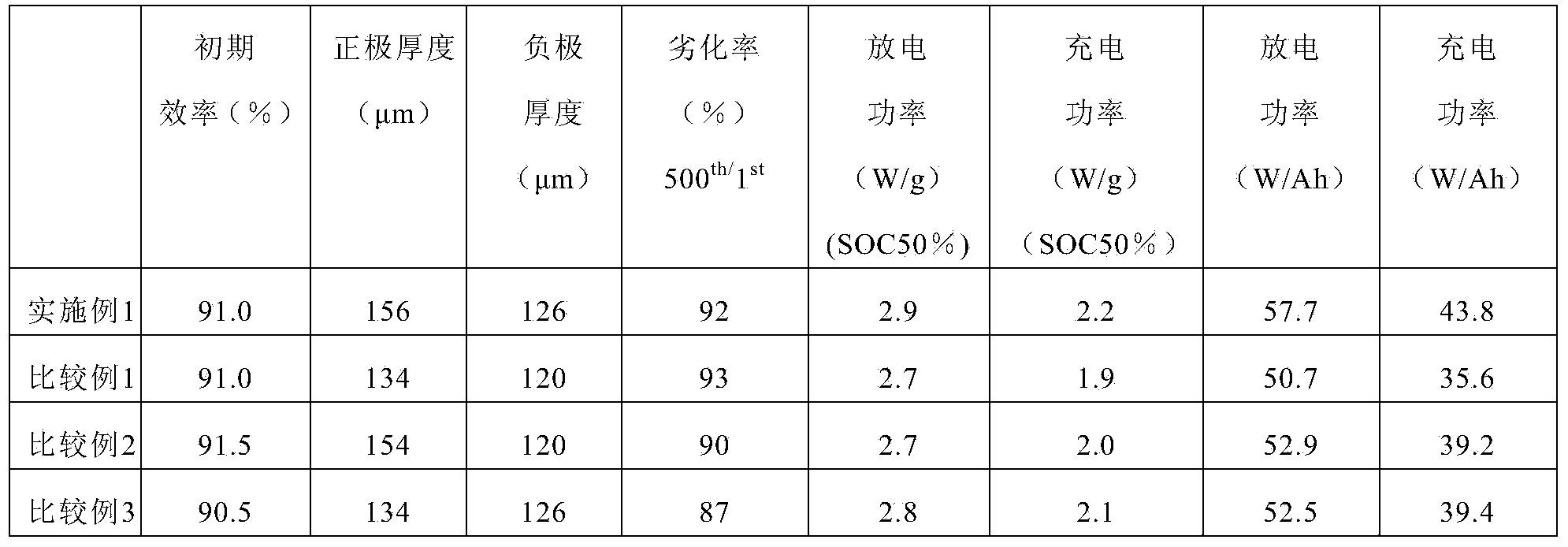

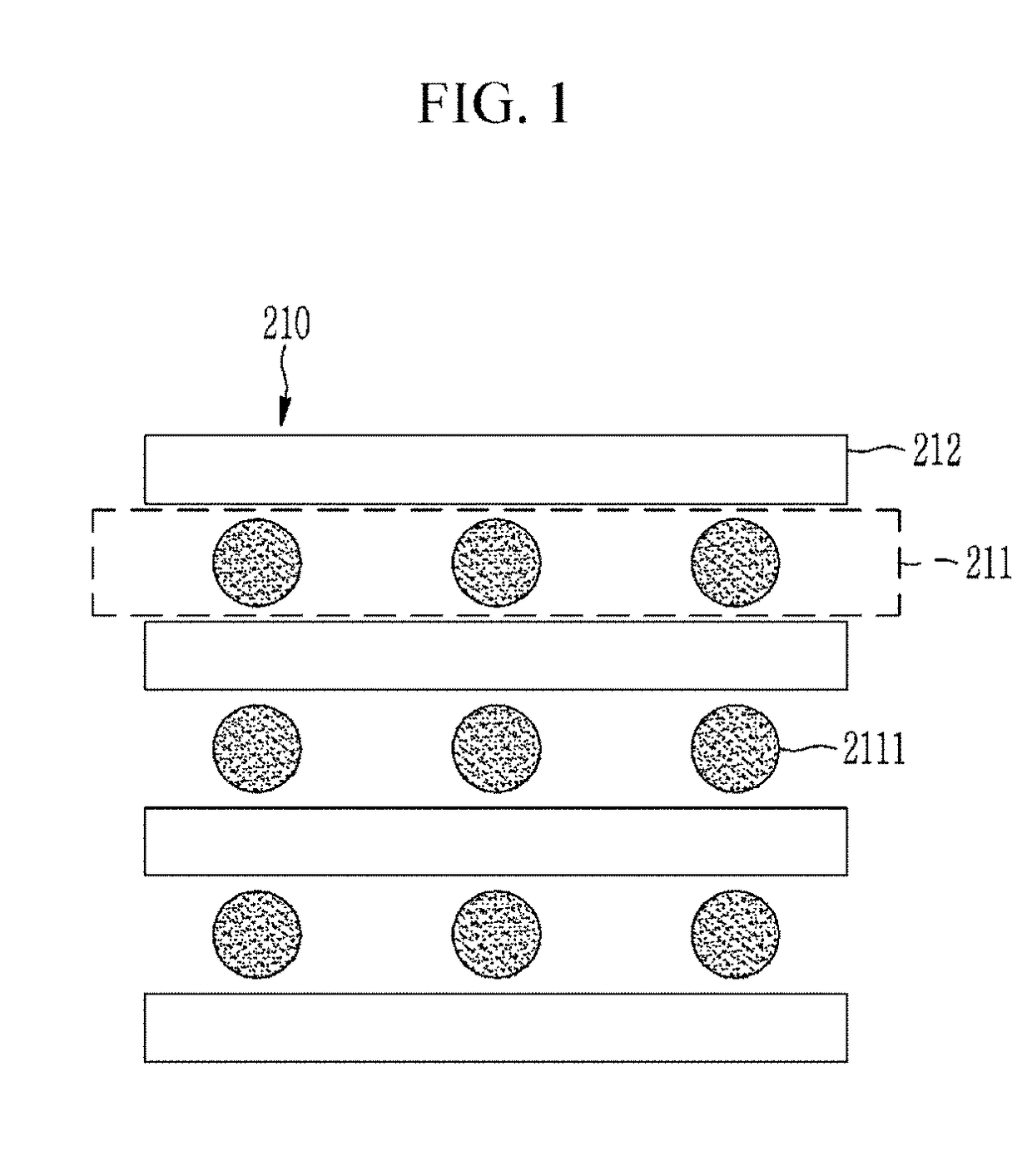

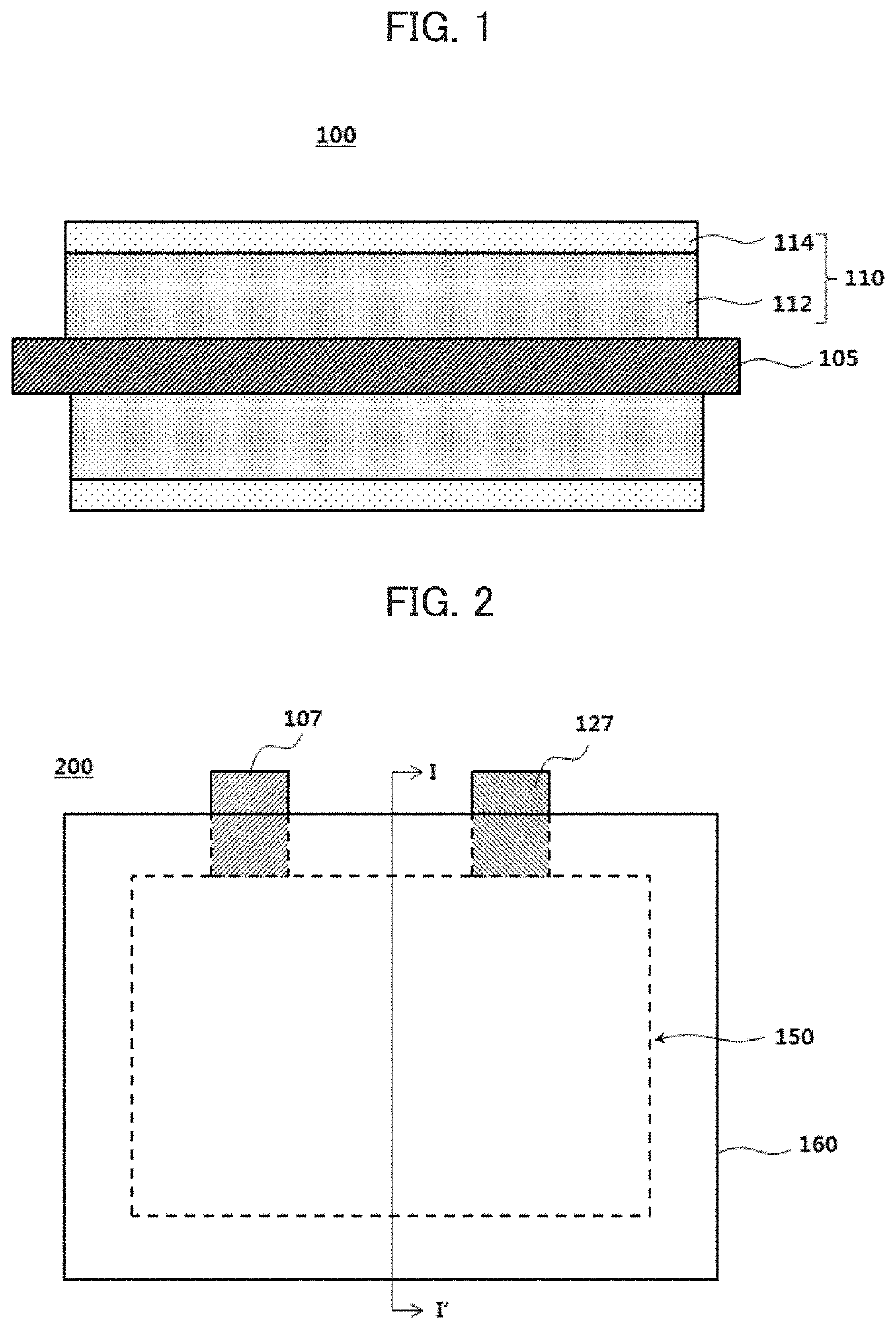

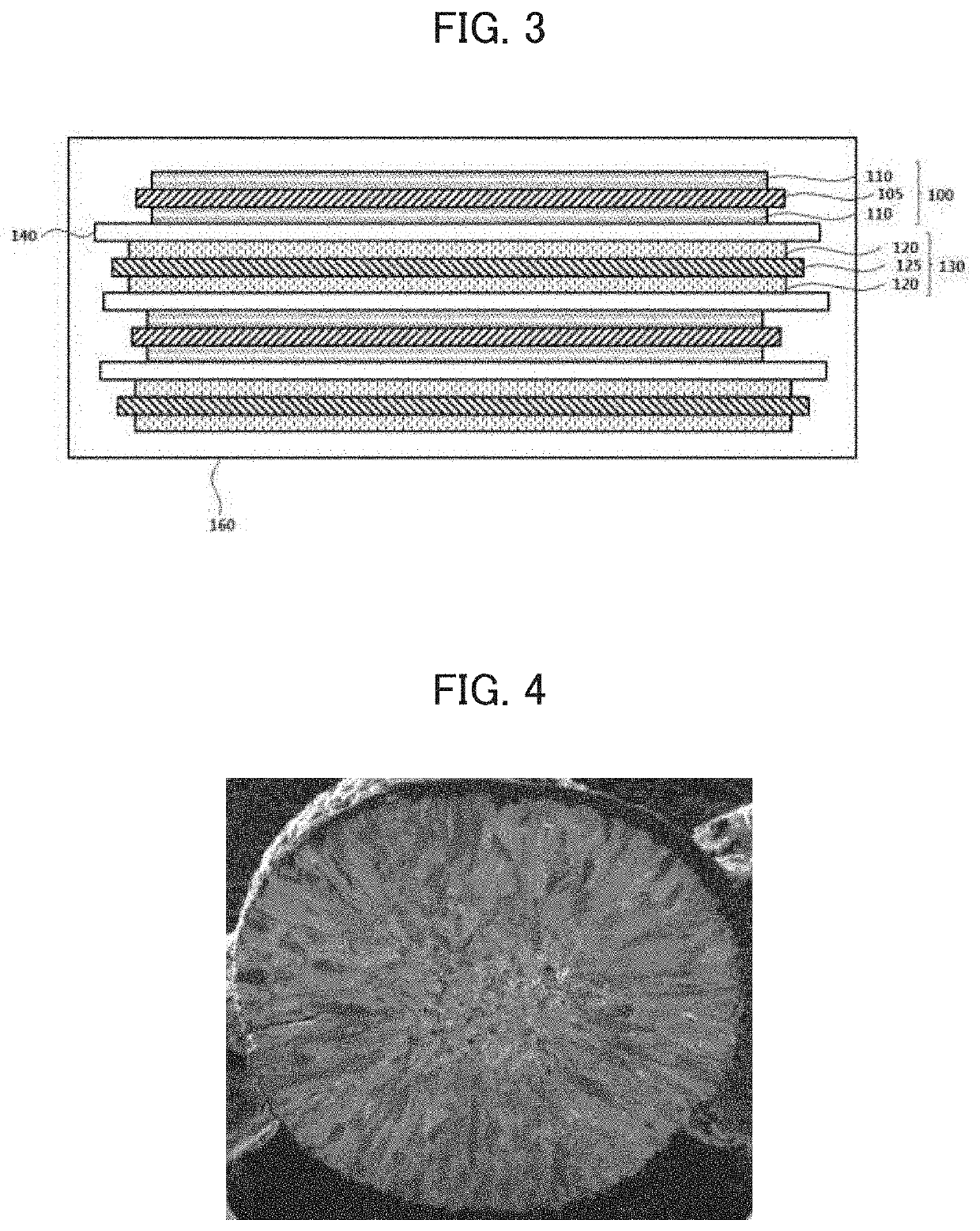

Lithium secondary battery comprising multilayered active material layer

ActiveCN104321912AIncrease powerImprove power characteristicsNon-aqueous electrolyte accumulator electrodesLi-accumulatorsLithiumEngineering

A lithium secondary battery of the present invention may simultaneously improve high output and high capacity characteristics by including a first active material layer having high output characteristics and a second active material layer having high capacity characteristics respectively on a cathode collector and an anode collector.

Owner:LG ENERGY SOLUTION LTD

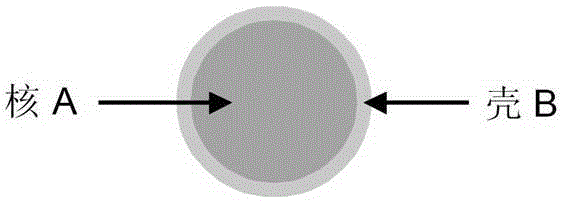

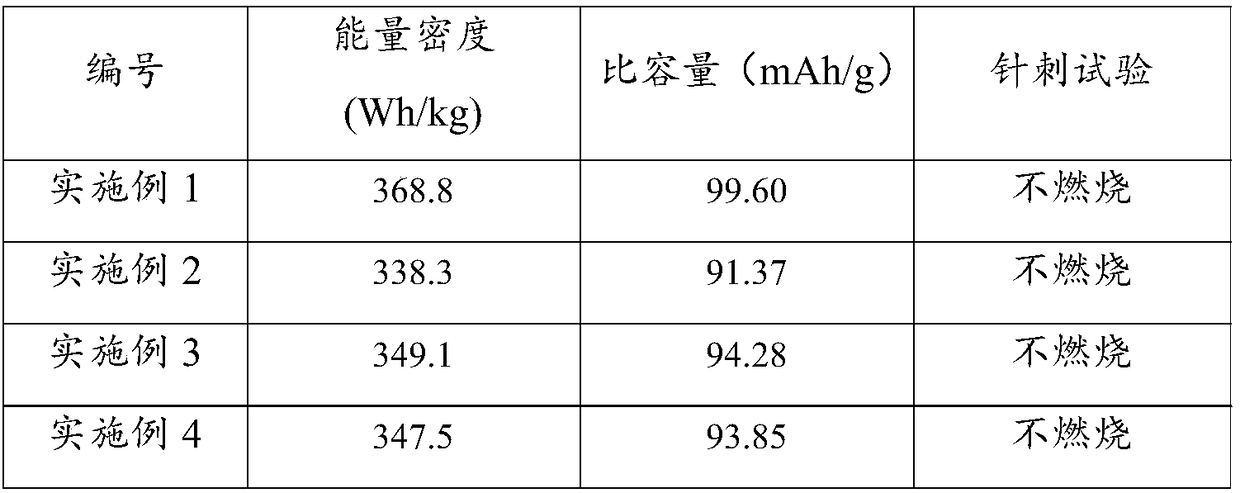

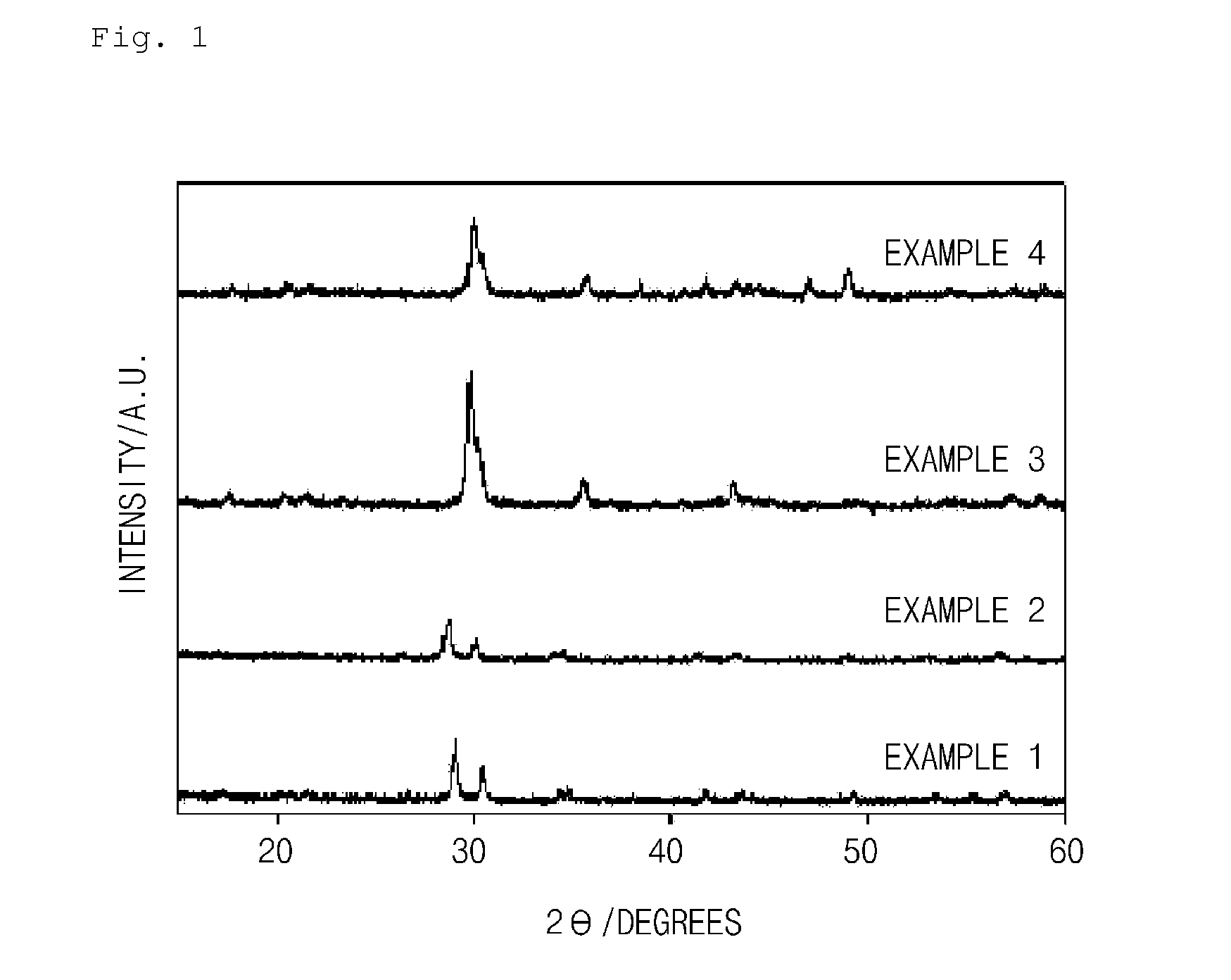

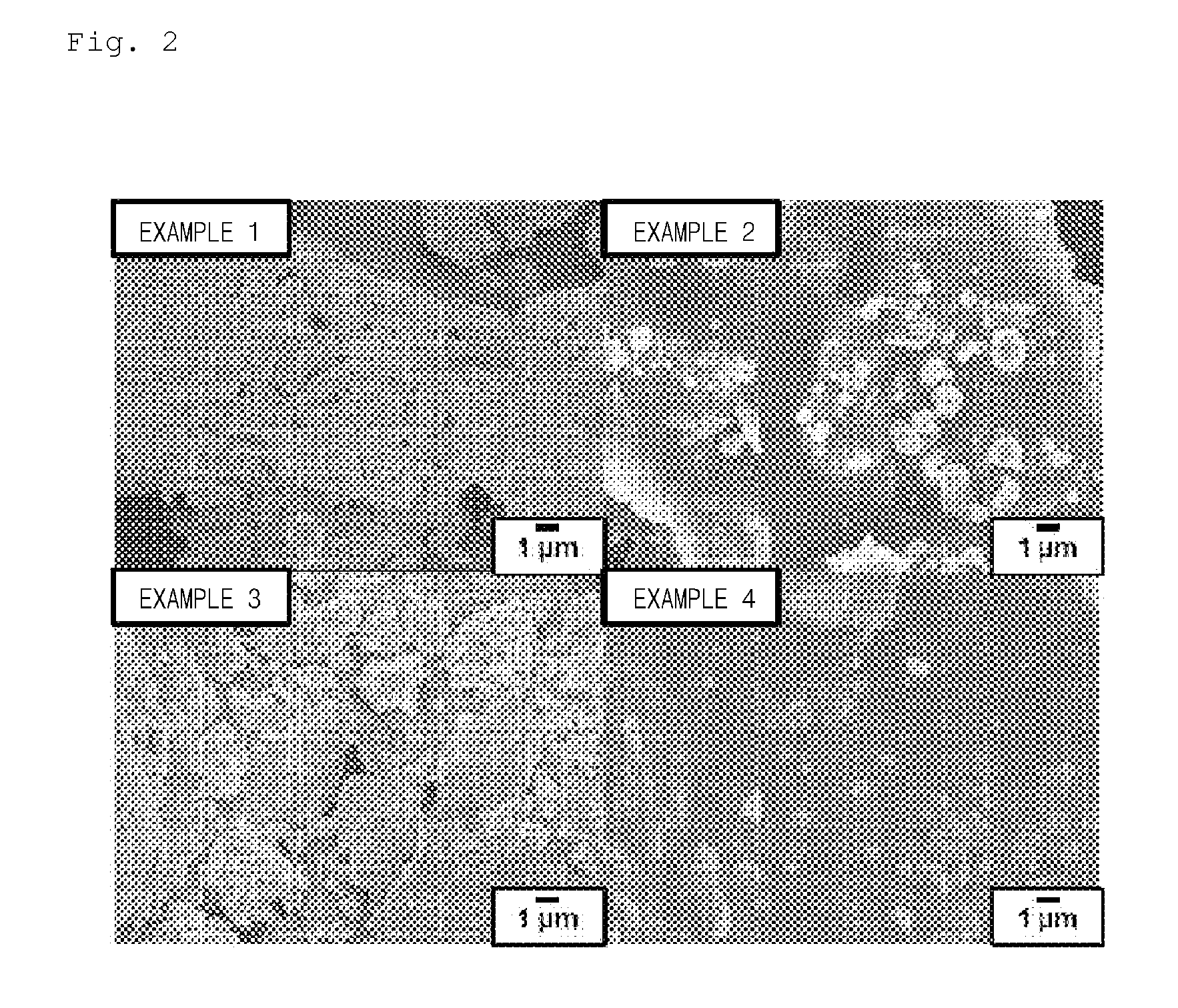

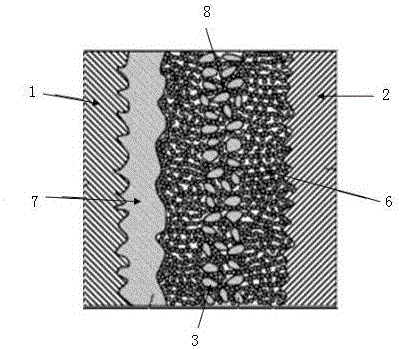

Lithium-rich cathode material and preparation method and application thereof

ActiveCN105161679AFunctionalWith charge and discharge cycle capacityCell electrodesSecondary cellsPhysical chemistryLithium-ion battery

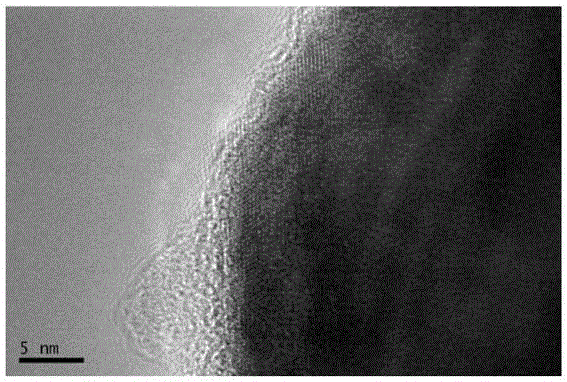

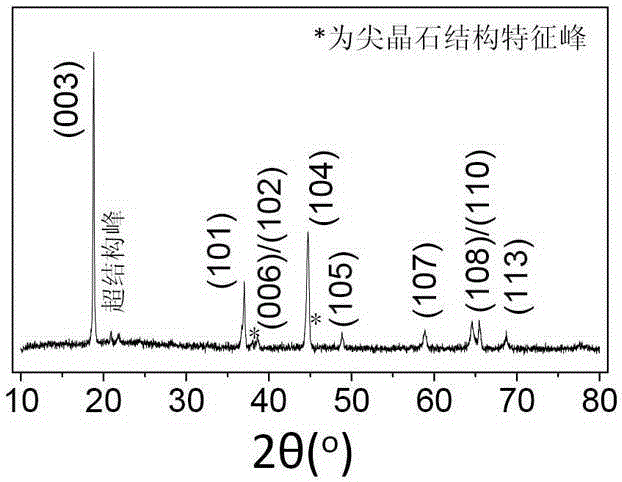

The invention discloses a lithium-rich cathode material and a preparation method and an application thereof. The lithium-rich cathode material has a core-shell structure, and is composed of a core material lithium-rich solid solution and a shell material of one of layered ternary material and spinel structure material with lithium ionic conductivity; the preparation method I comprises the following steps: preparation of the core material, preparation of the core material coated with a shell material precursor, presintering treatment of a core-shell structure material and high-temperature sintering treatment; and the method II comprises the following steps: preparation of the core-material precursor, preparation of a gradient structure precursor material, presintering treatment of the core-shell structure material, and high-temperature sintering treatment. The preparation method disclosed by the invention has the advantages of being simple in technical process, nontoxic, harmless, simple in raw materials, few in byproducts, suitable for large-scale production and the like; the prepared lithium-rich cathode material has a gradient structure; the functional effect is materialized by the structure; the core has high capacity characteristic; the cycling stability of the material can be improved by the surface; and the lithium-rich cathode material can be widely applied to a lithium-ion battery.

Owner:NAT UNIV OF DEFENSE TECH

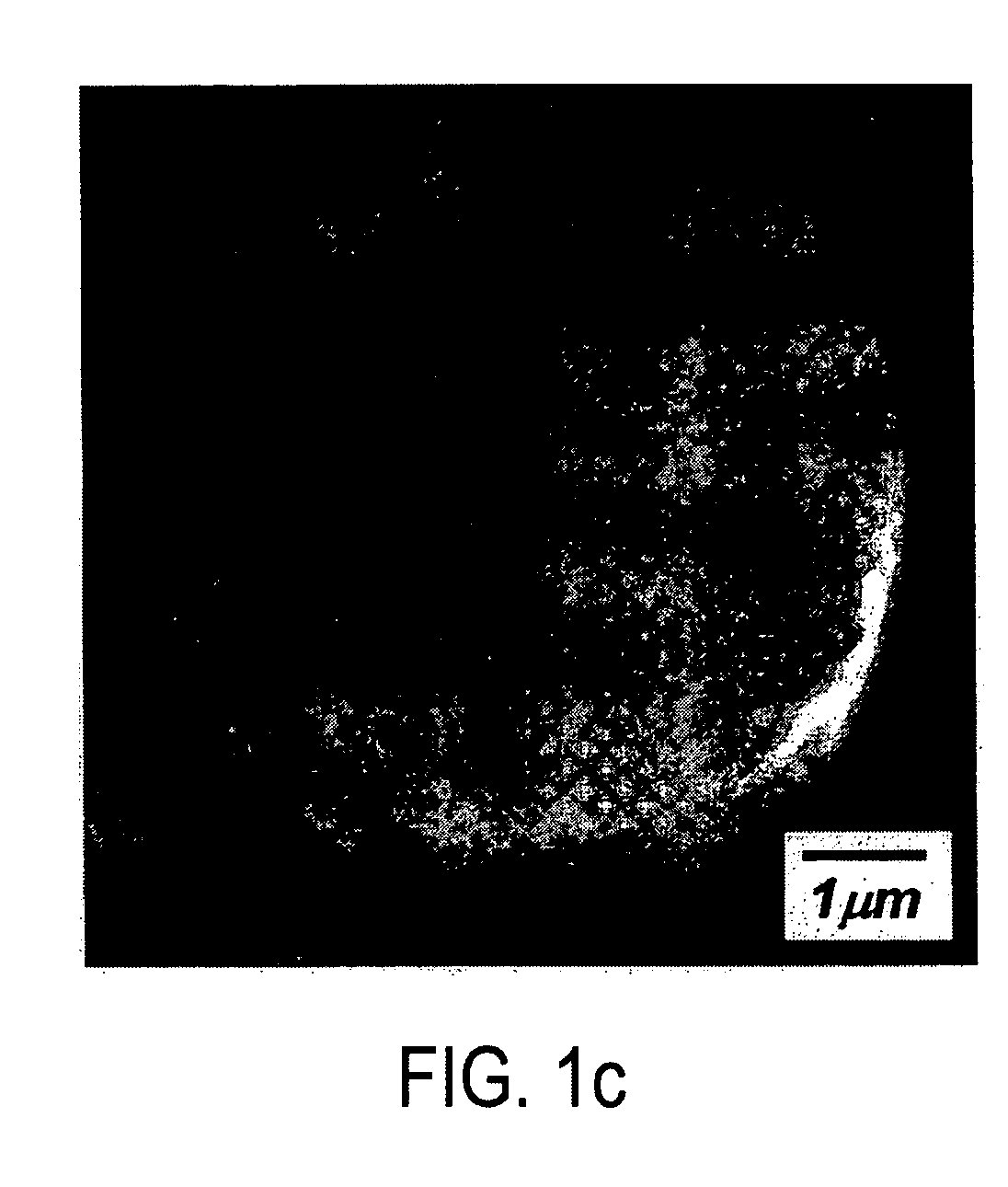

Spherical Metal Carbonates and Lithium Metal Oxides for Lithium Rechargeable Batteries

InactiveUS20090087746A1Improve impedance characteristicsImproved stability of the layered oxide structureSilver accumulatorsAlkaline accumulator electrodesDopantLithium metal

A number of materials with the composition Li1+xNiαMnβCoγM′δO2−zFz (M′=Mg, Zn, Al, Ga, B, Zr, Ti) for use with rechargeable batteries, wherein x is between about 0 and 0.3, α is between about 0.2 and 0.6, β is between about 0.2 and 0.6, γ is between about 0 and 0.3, δ is between about 0 and 0.15, and z is between about 0 and 0.2. Adding the above metal and fluorine dopants affects capacity, impedance, and stability of the layered oxide structure during electrochemical cycling. Another aspect of the invention includes materials with the composition Li1+xNiαCoβMnγM′δOyFz (M′=Mg, Zn, Al, Ga, B, Zr, Ti), where the x is between 0 and 0.2, the α between 0 and 1, the β between 0 and 1, the γ between 0 and 2, the δ between about 0 and about 0.2, the y is between 2 and 4, and the z is between 0 and 0.5.

Owner:UCHICAGO ARGONNE LLC

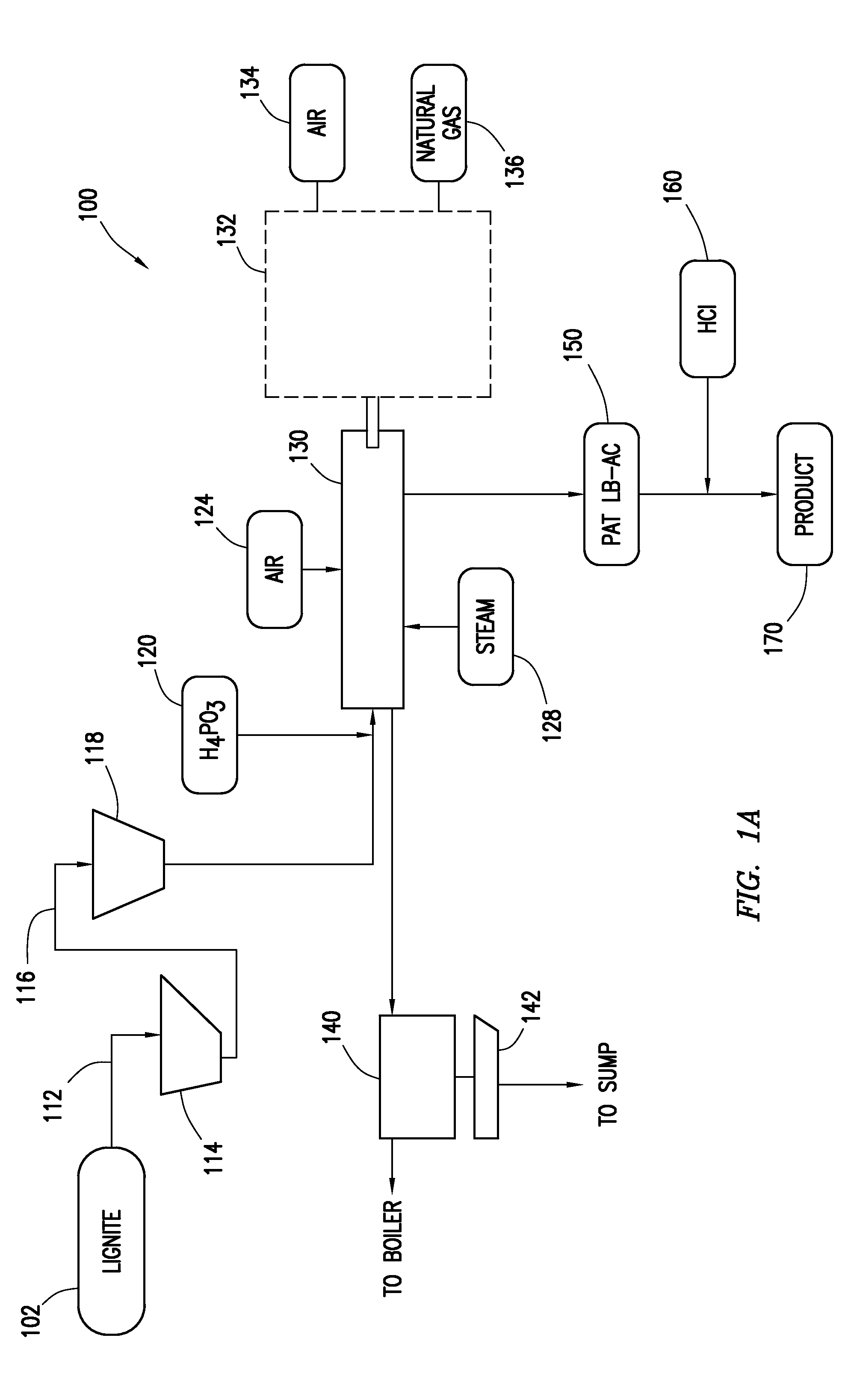

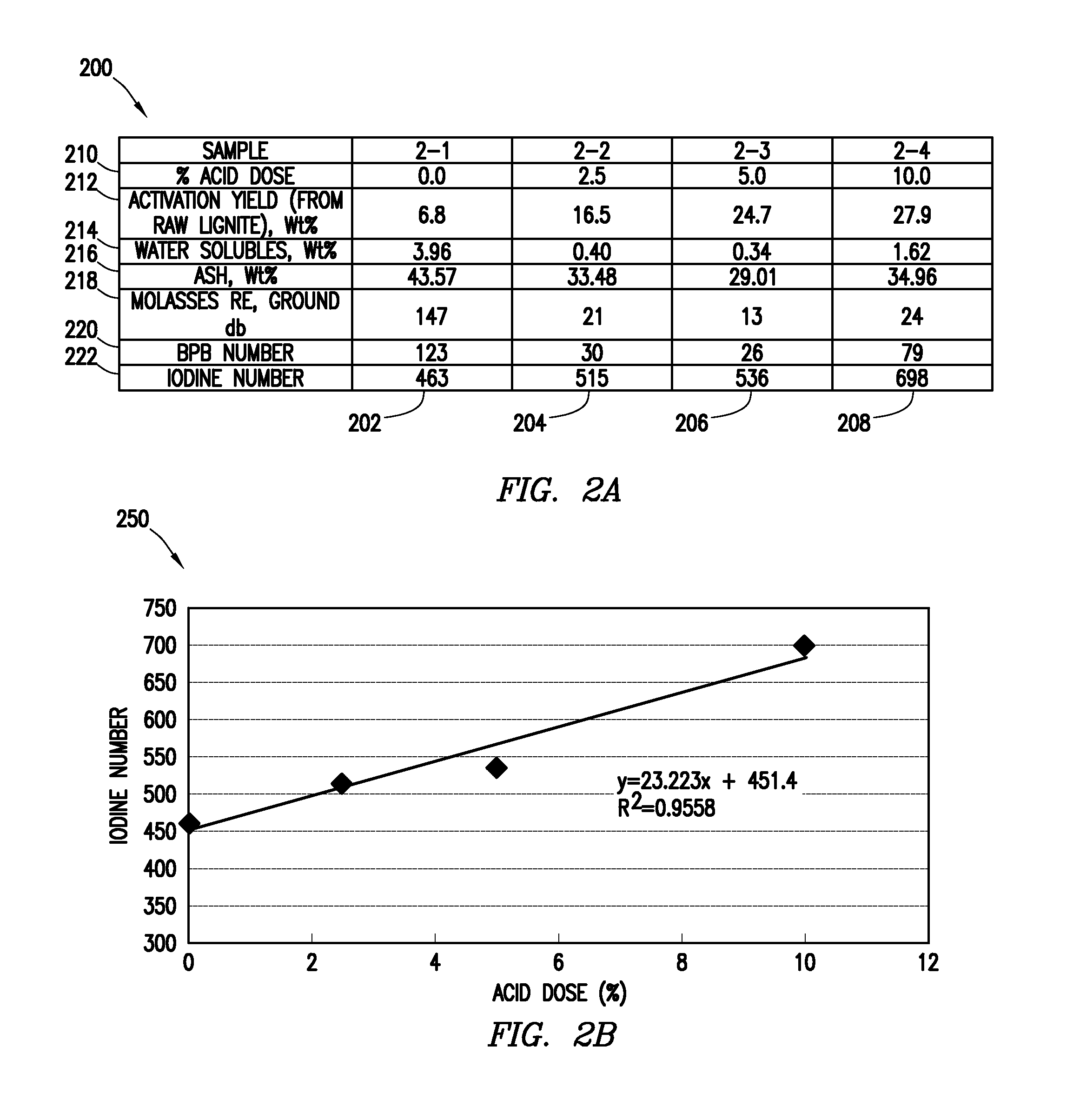

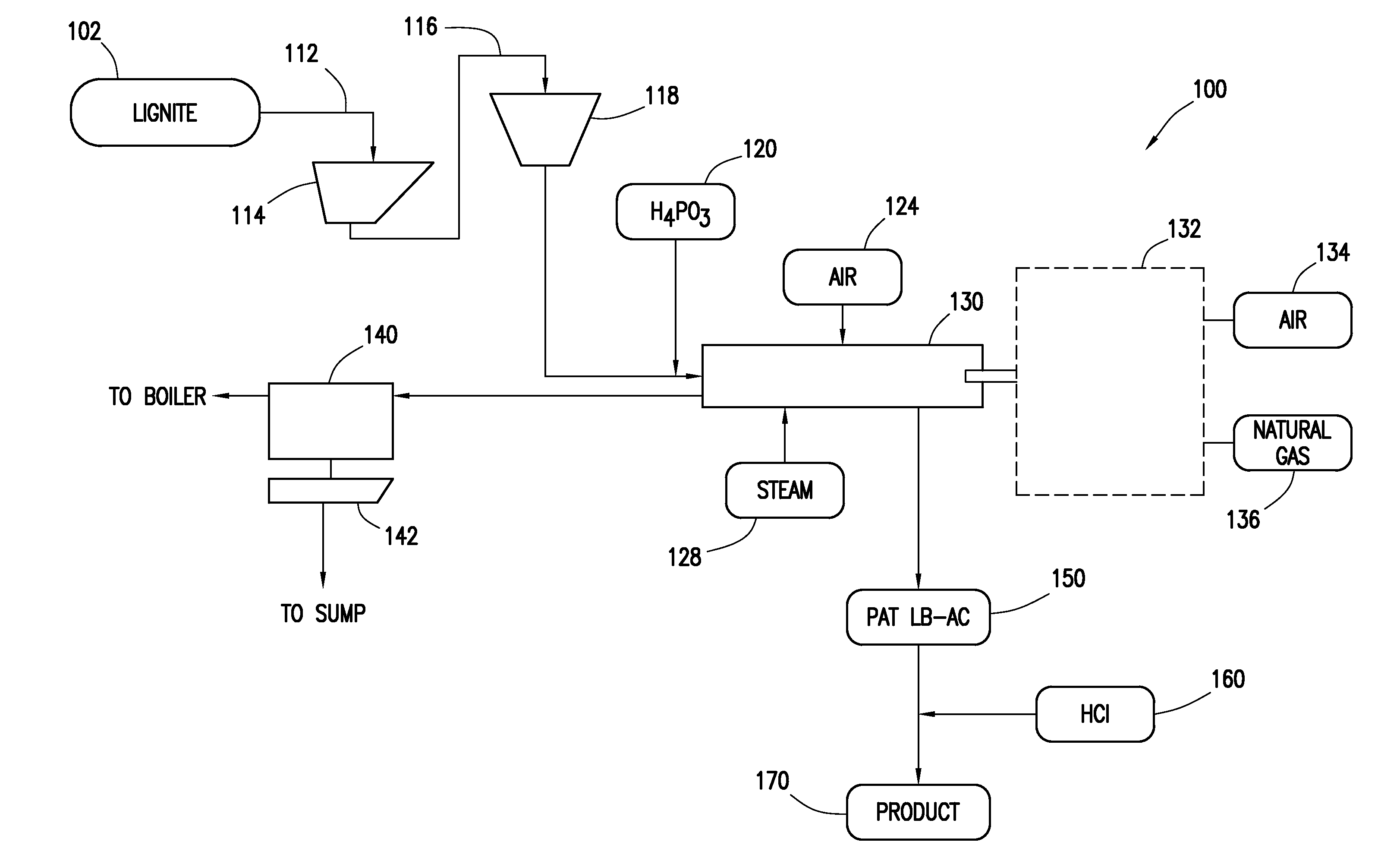

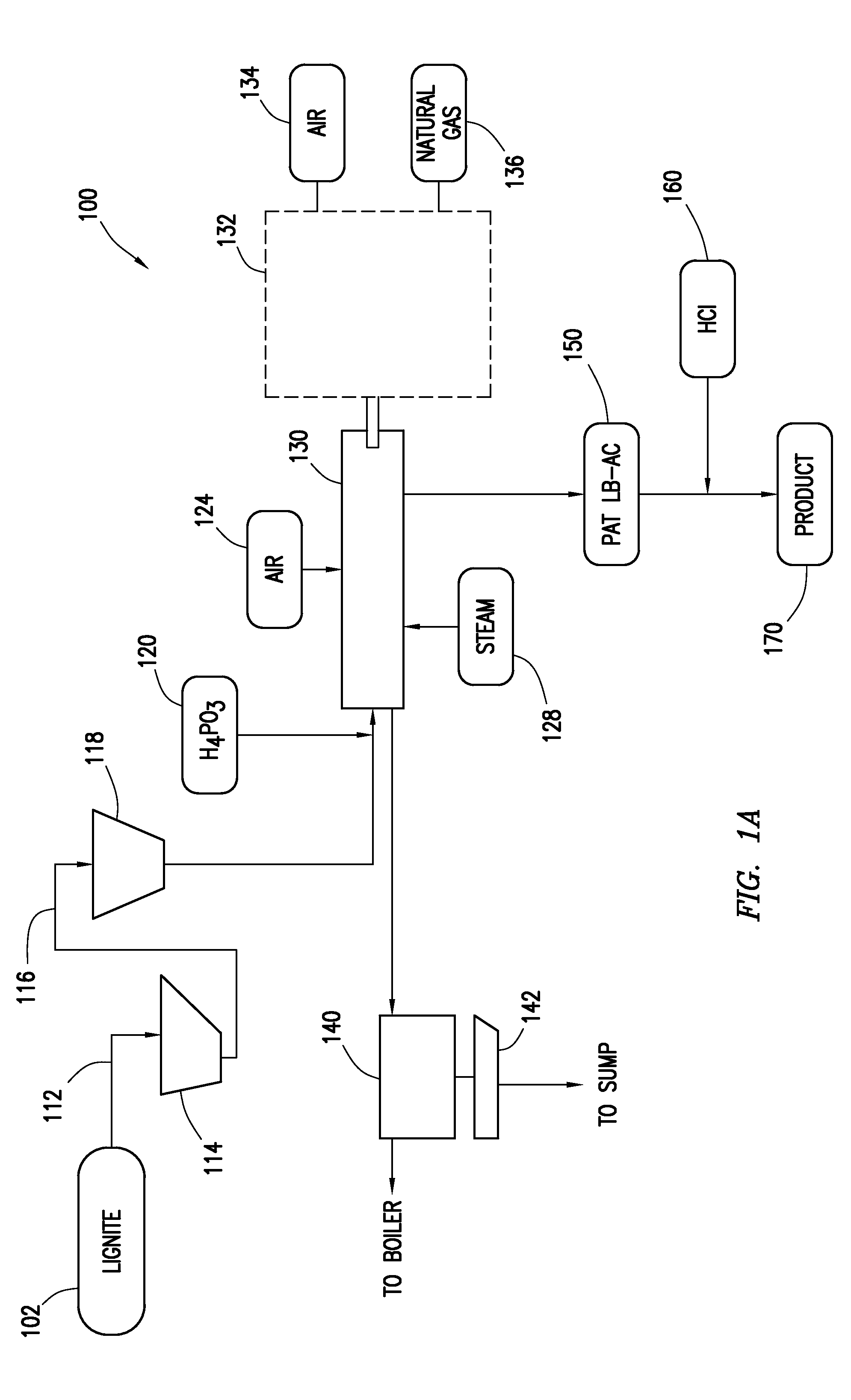

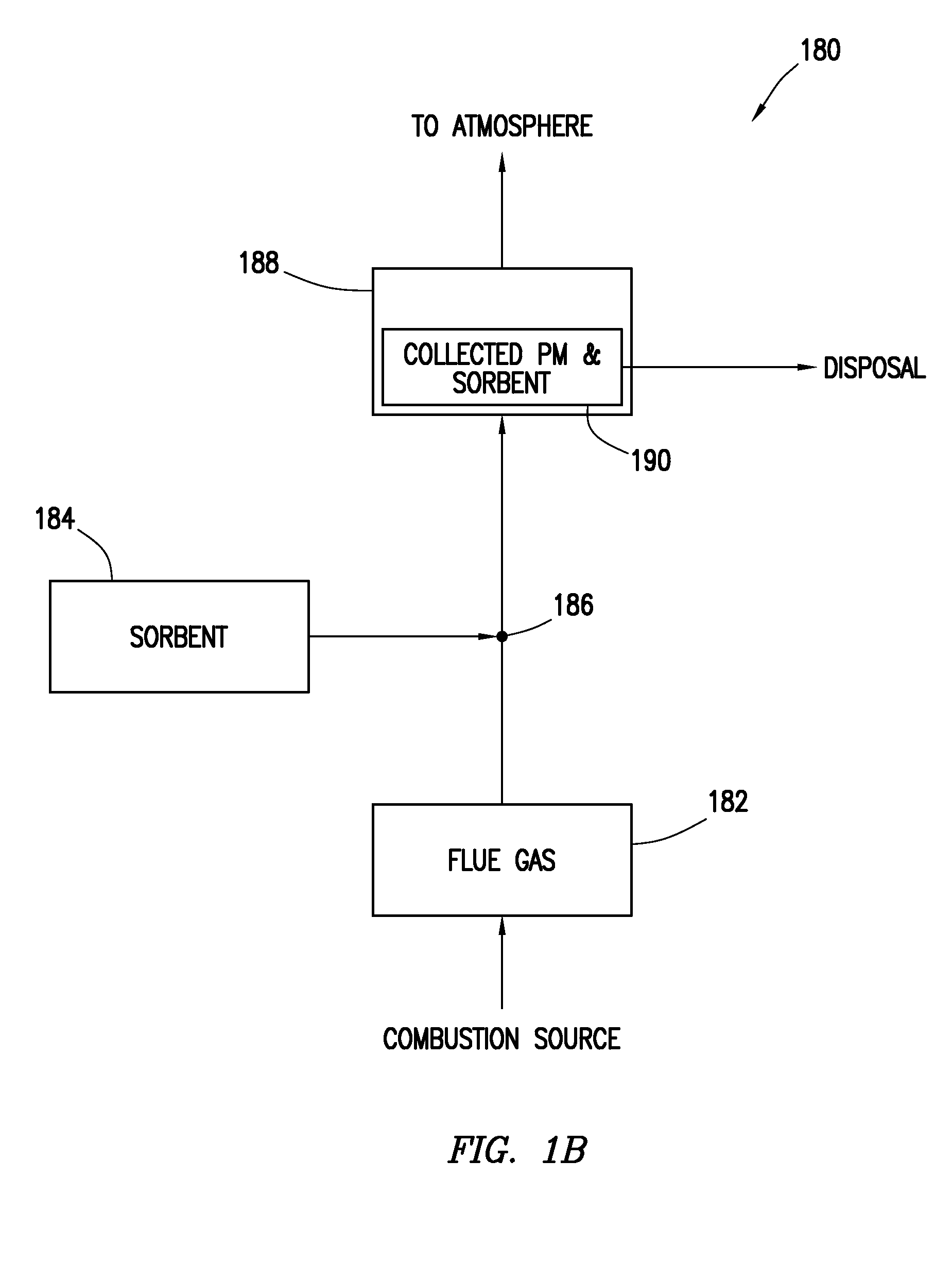

Phosphoric acid treatment of carbonaceous material prior to activation

InactiveUS20140208945A1Disadvantages can be reduced eliminatedProblems can be reduced eliminatedCarbon compoundsOther chemical processesActivated carbonPhosphoric acid

A method of producing an activated carbon, comprising selecting a raw material for direct-activation, applying a solution of at least 50% phosphoric acid by weight at a ratio of from 0.01 pounds to 0.3 pounds of phosphoric acid solution per pound to the raw material selected for direct activation to produce a phosphoric acid treated raw material, and direct-activating the phosphoric acid treated raw material via a gas activation process to produce an activated carbon.

Owner:CABOT CORP

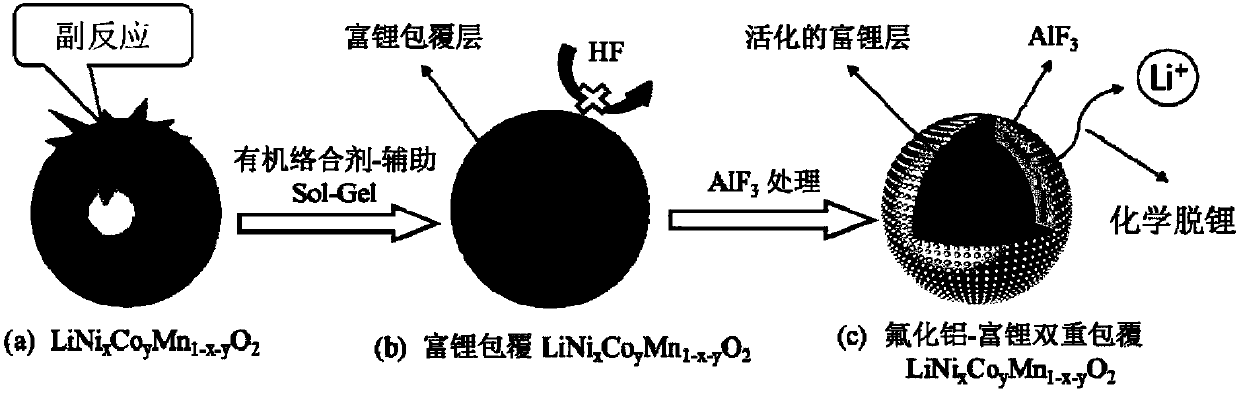

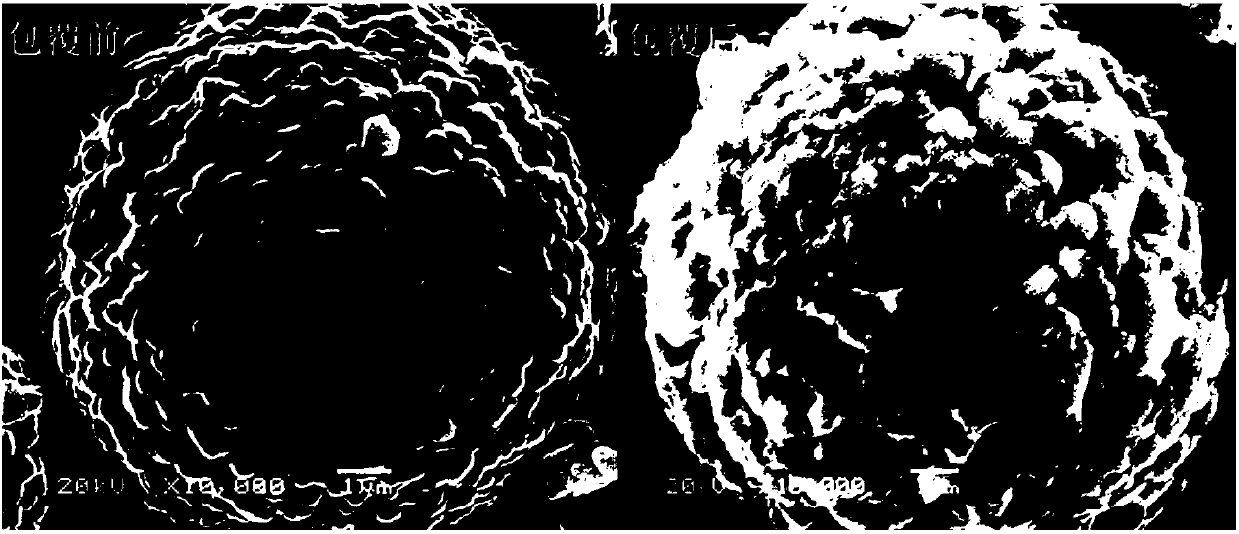

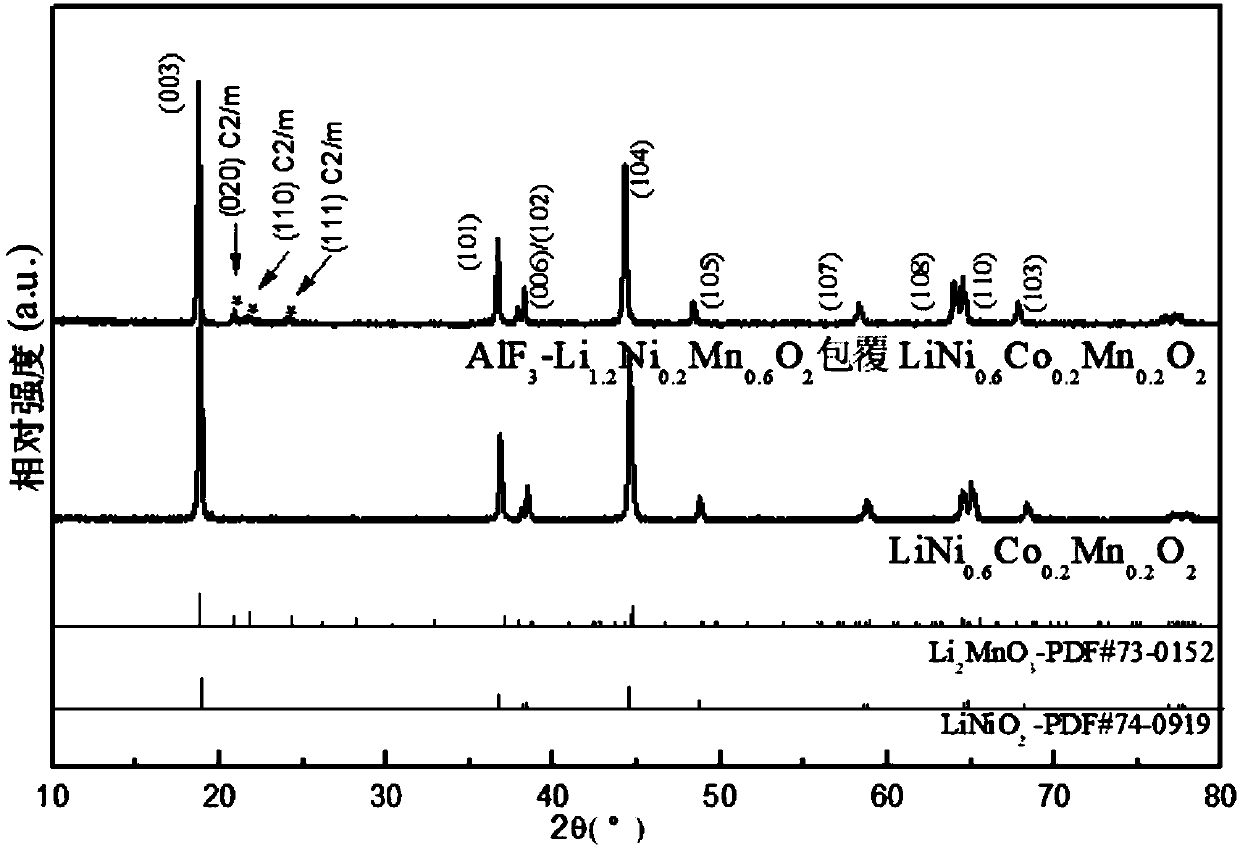

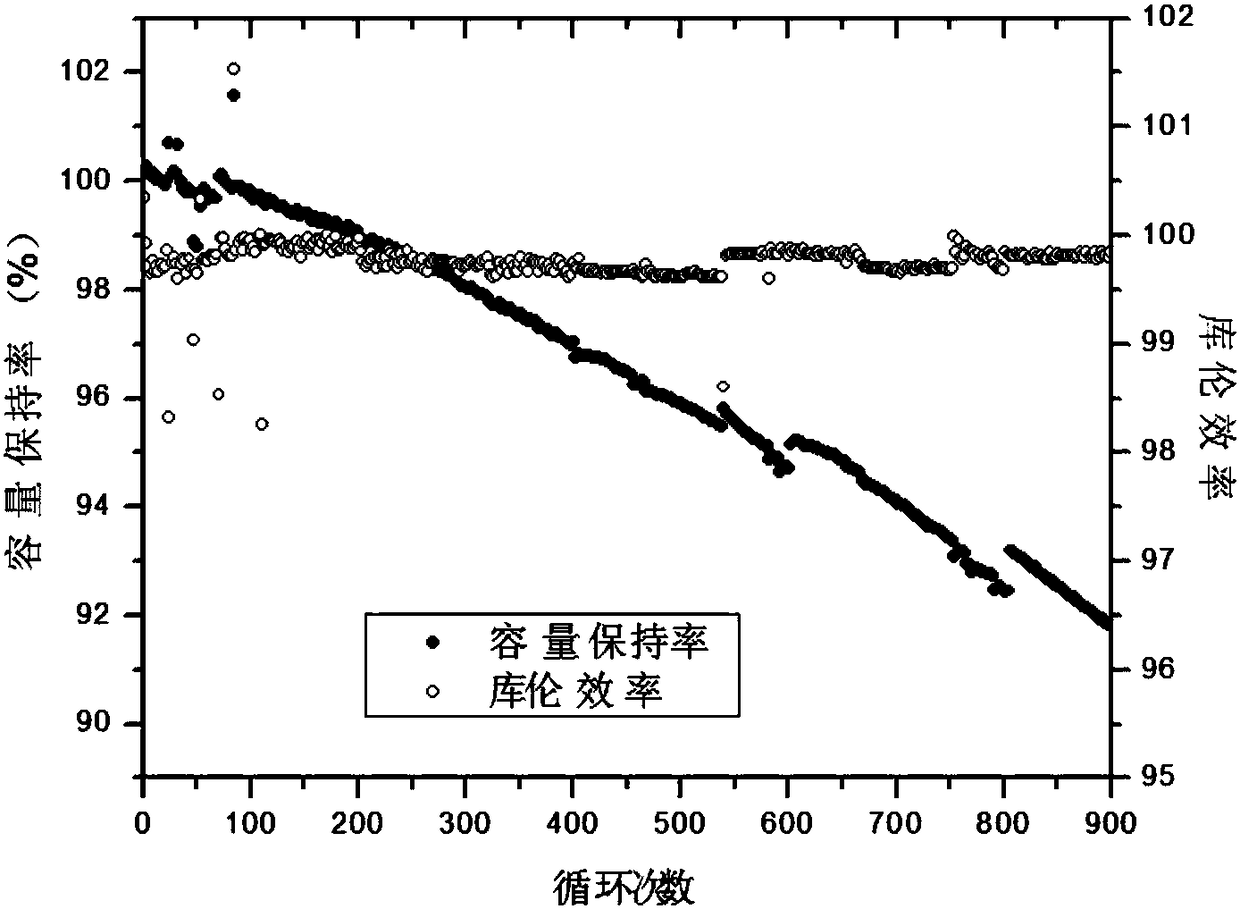

Lithium ion battery ternary material with double-coated surface and preparation method thereof

InactiveCN107768642AHigh Capacity FeaturesImprove protectionCell electrodesSecondary cellsManganeseCobalt

The invention discloses a lithium ion battery ternary material with a double-coated surface. The lithium ion battery ternary material with the double-coated surface comprises a nickel-cobalt-manganeseternary material, wherein a lithium-rich layered oxide coating layer is covered on a surface of the nickel-cobalt-manganese ternary material; an aluminum fluoride coating layer is covered on a surface of the lithium-rich layered oxide coating layer; the lithium ion battery ternary material with the double-coated surface is not easy to fall off, and has good chemical stability and high capacity. The invention also discloses a preparation method of the lithium ion battery ternary material. The method comprises the steps of firstly adopting an organic complexing agent-auxiliary sol-gel method for covering lithium-rich layered oxide on the surface of the ternary material so as to form the lithium-rich coating layer; then using a liquid phase method for coating aluminum fluoride on the surfaceof the lithium-rich layered oxide coating layer, and obtaining the double-coated lithium ion battery ternary material. The preparation method is simple in process, high in operation feasibility, andhigh in element utilization rate.

Owner:CENT SOUTH UNIV

Lithium-rich manganese material, positive electrode material for lithium-ion battery, positive plate for lithium-ion battery, lithium-ion battery and preparation method of lithium-ion battery

ActiveCN108172823AIncrease capacityHigh Capacity FeaturesFinal product manufacturePositive electrodesElectrical batteryLithium-ion battery

The invention discloses a lithium-rich manganese material, a positive electrode material for a lithium-ion battery, a positive plate for the lithium-ion battery, the lithium-ion battery and a preparation method of the lithium-ion battery and relates to the technical field of lithium-ion batteries. The molecular formula of the lithium-rich manganese material is aLi2MnO3.(1-a)LiNi0.5Mn1.5O4.(1-a)LiNi0.5Mn0.5O2, wherein a is smaller than or equal to 0.3 and greater than or equal to 0.01. The positive electrode material comprises the lithium-rich manganese material; the positive plate is coated with the positive electrode material; an active material of the positive electrode material for the lithium-ion battery is the lithium-rich manganese material; and the active material of a negative electrode material is a SiO / C composite material. According to the lithium-rich manganese material, the defects that an existing positive electrode material is in low specific capacity and low in initialefficiency and an existing negative electrode material is low in coulombic efficiency and poor in cycle performance are relieved. Through the cooperation of the positive electrode material and the negative electrode material, the obtained lithium-ion battery has high specific energy and high security, and the energy density of the battery is greater than 320Wh / kg.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

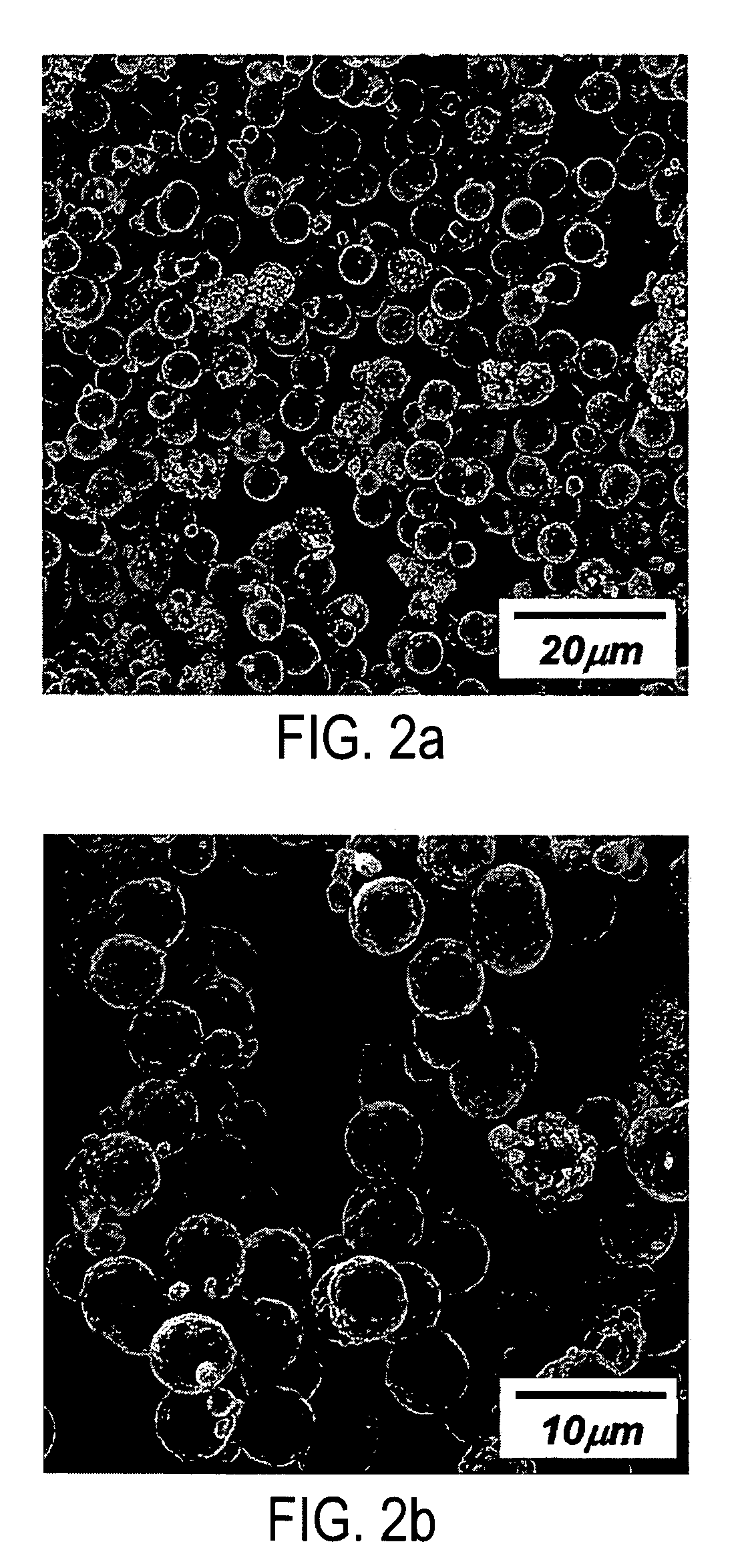

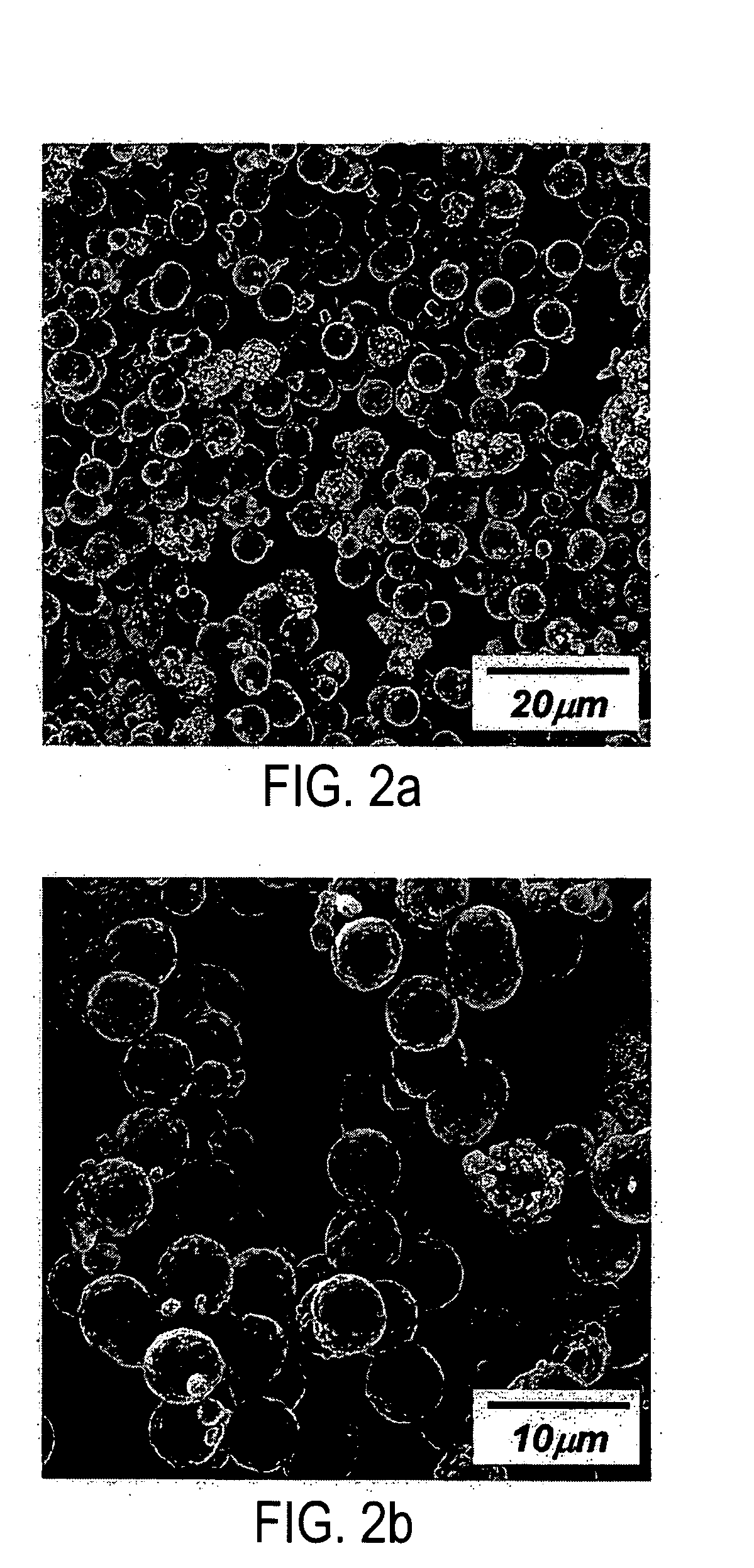

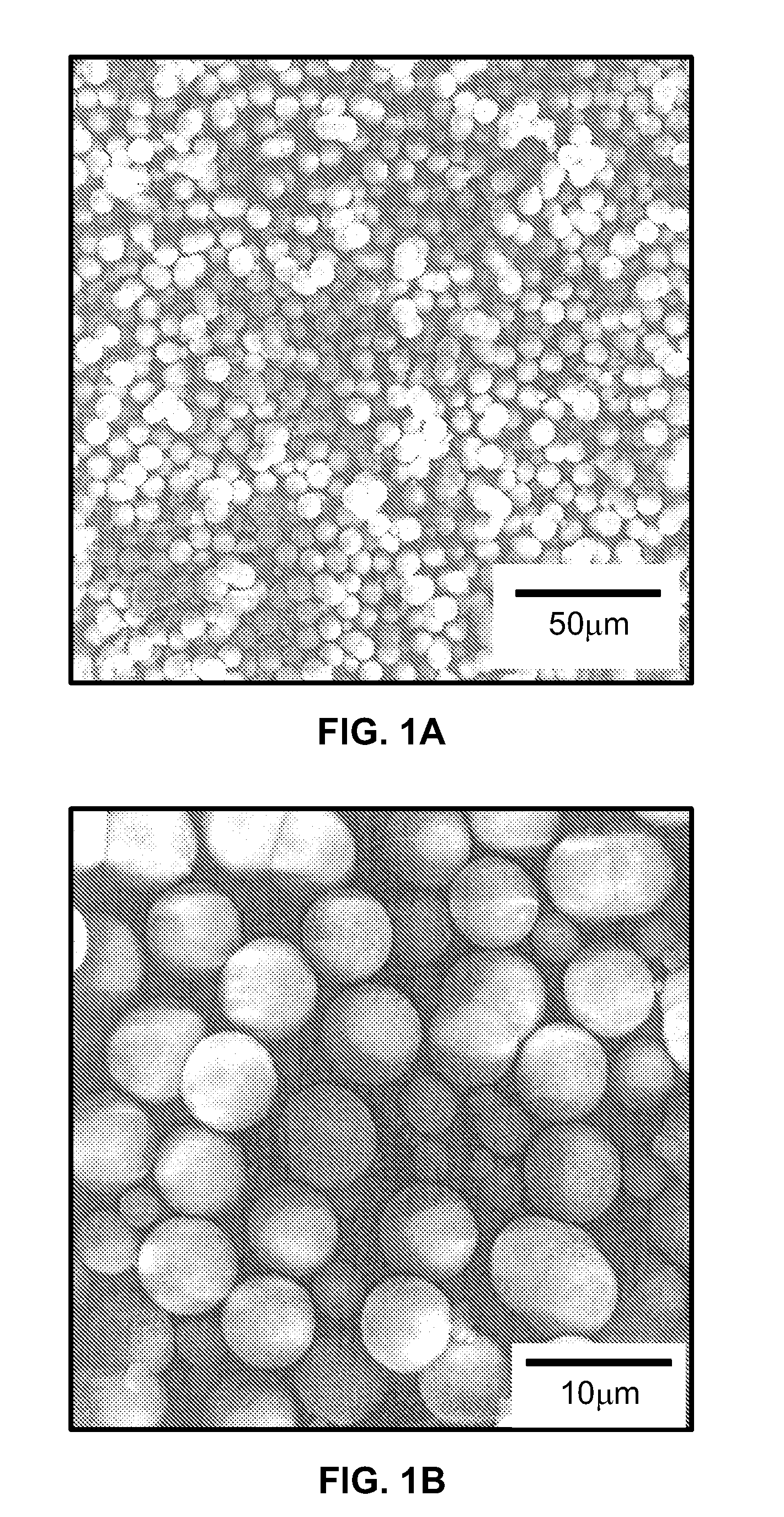

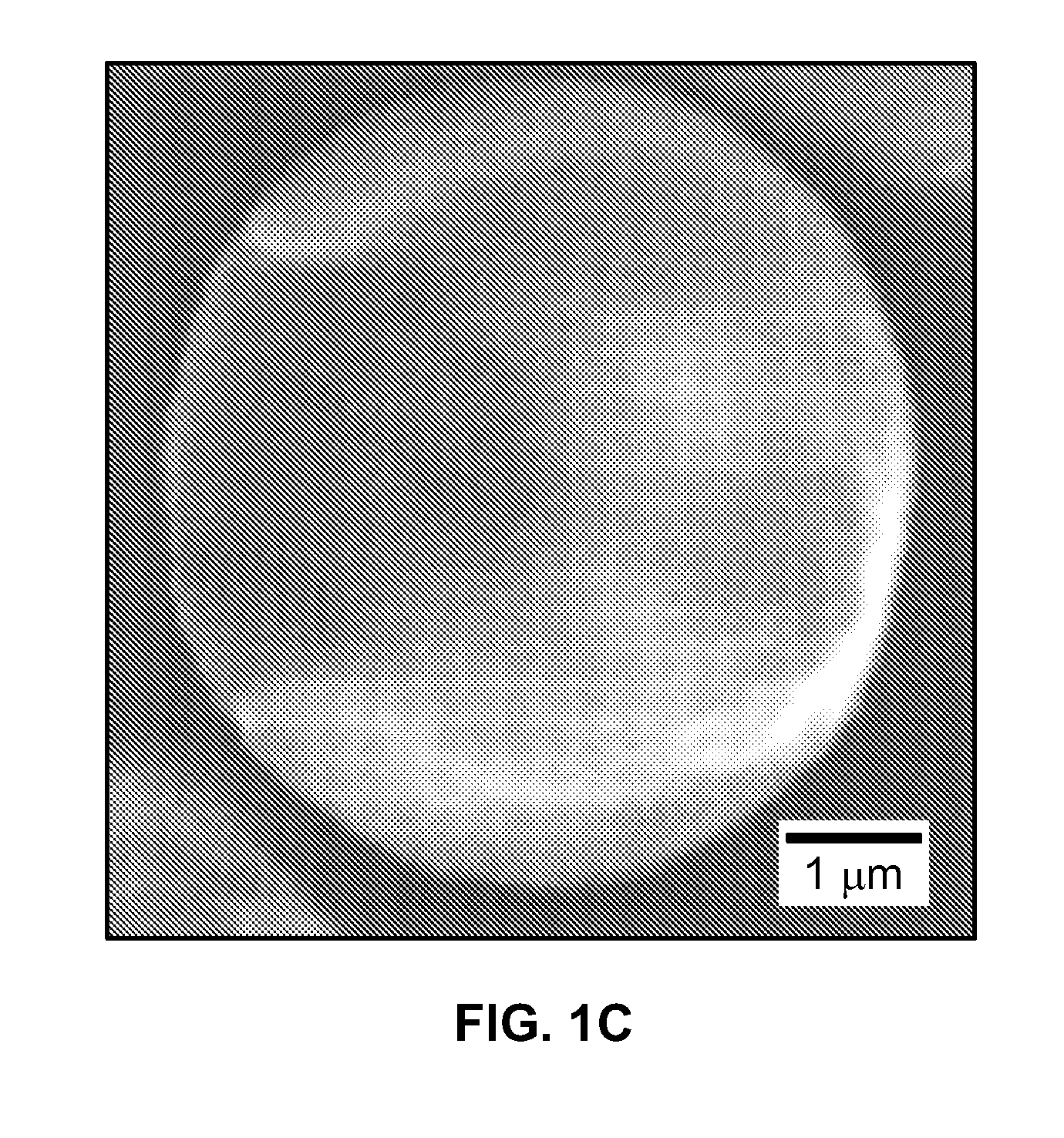

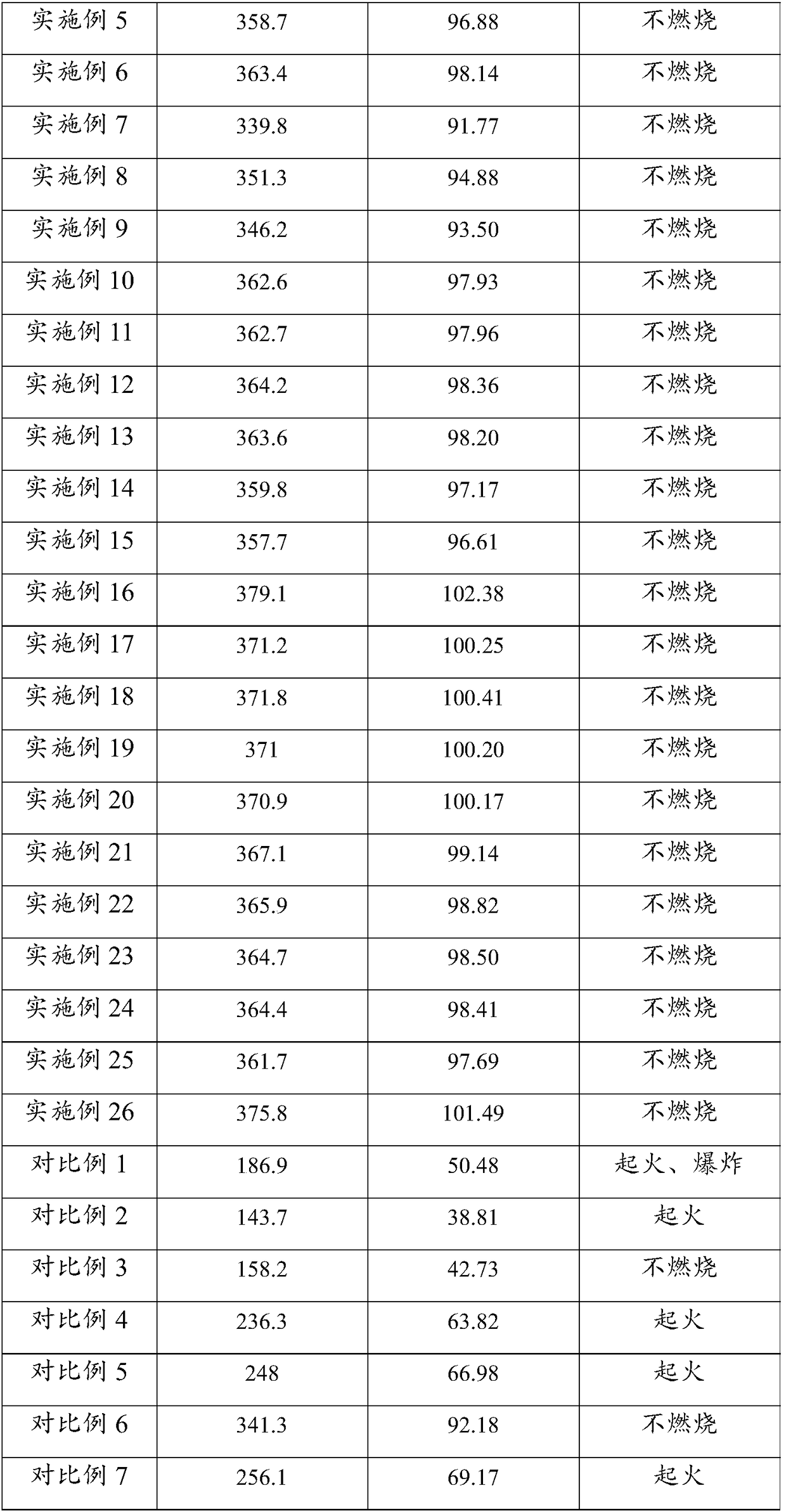

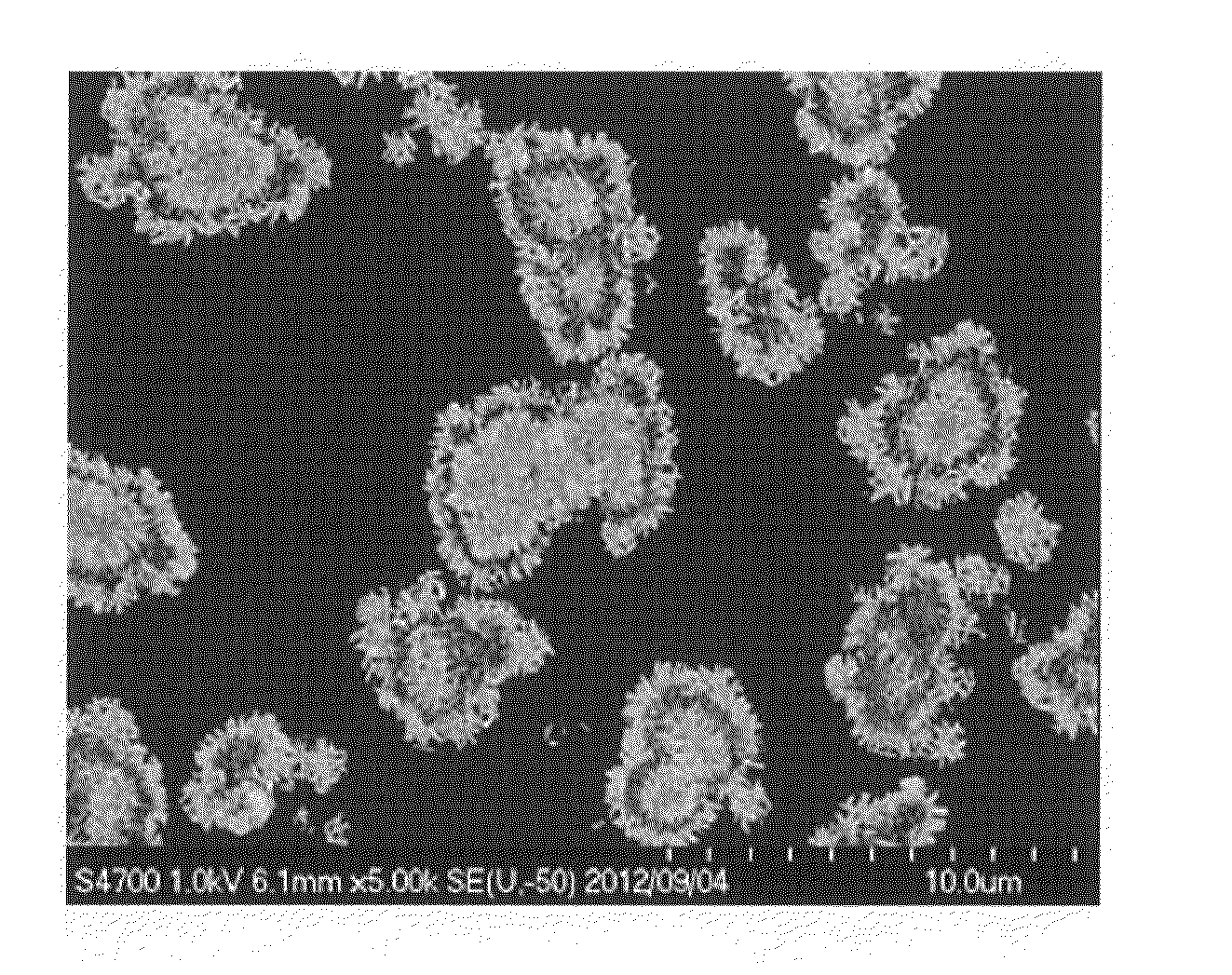

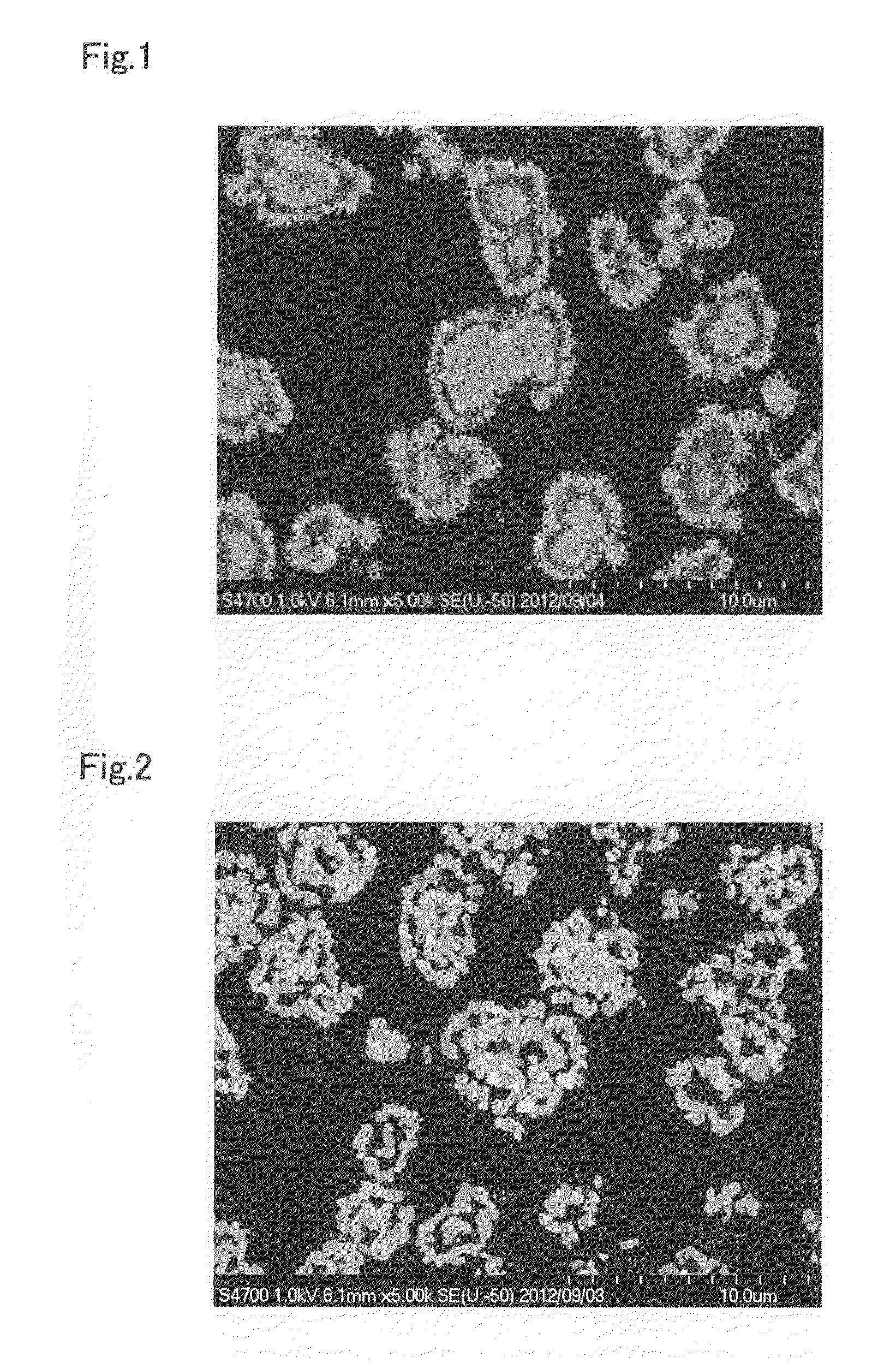

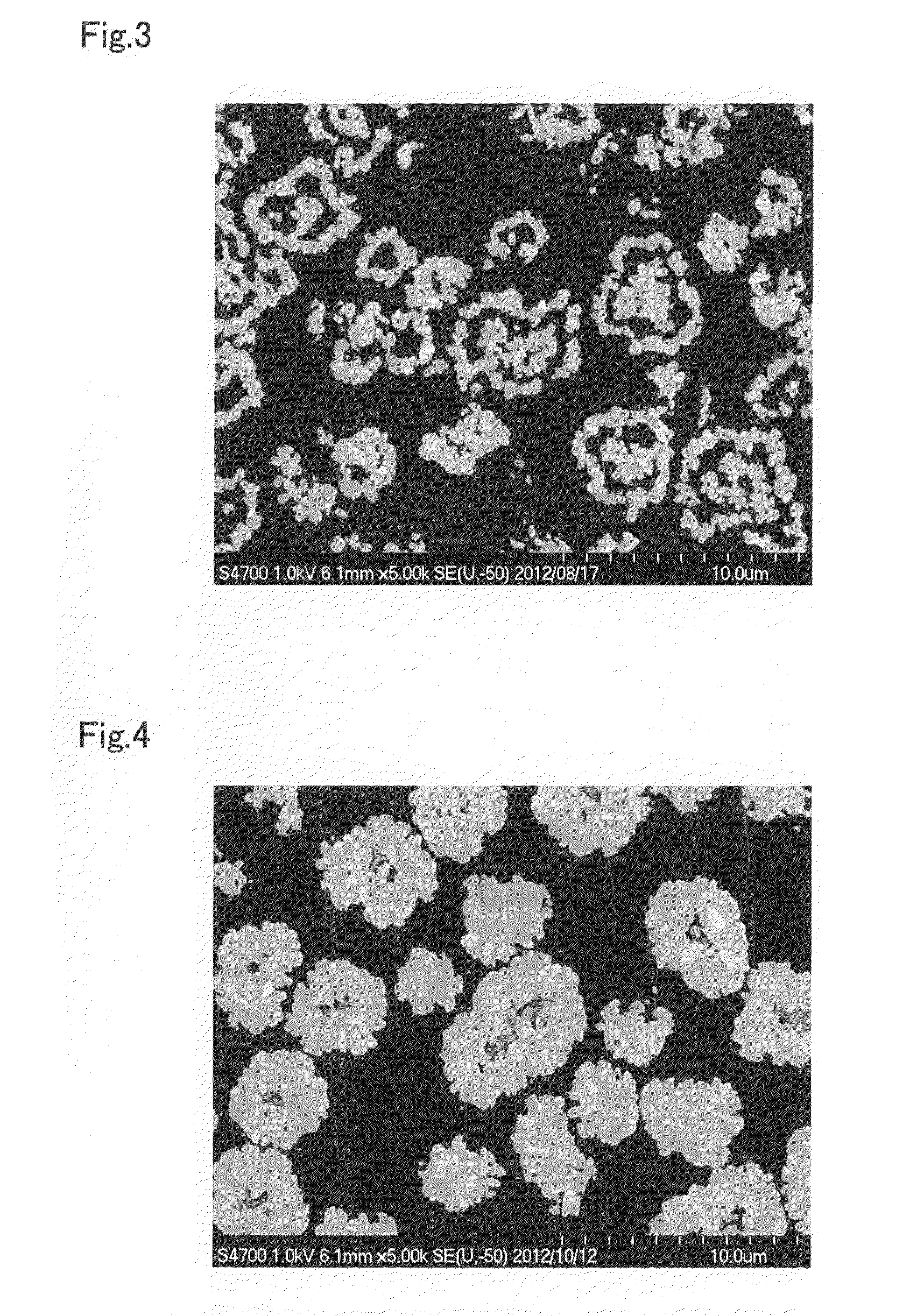

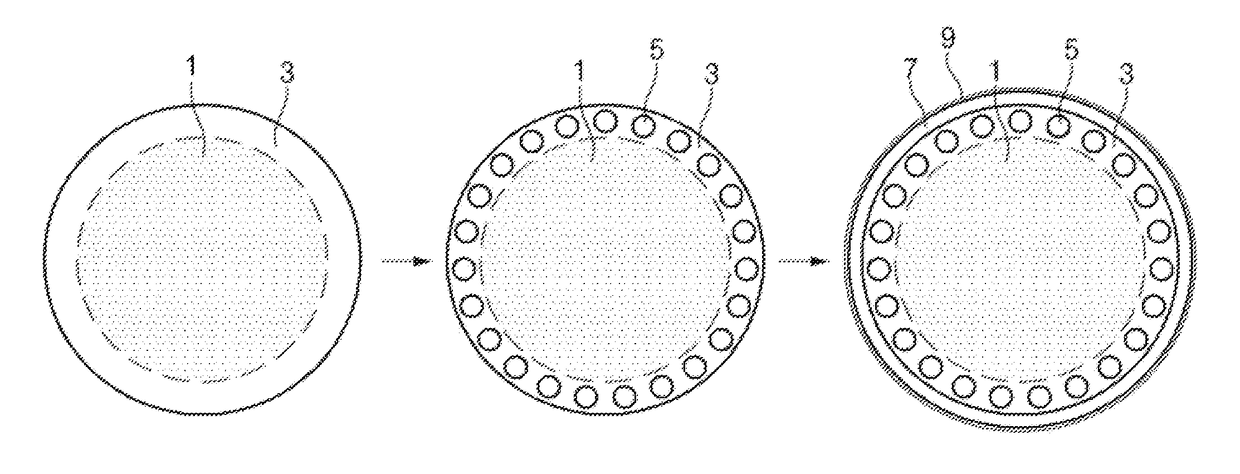

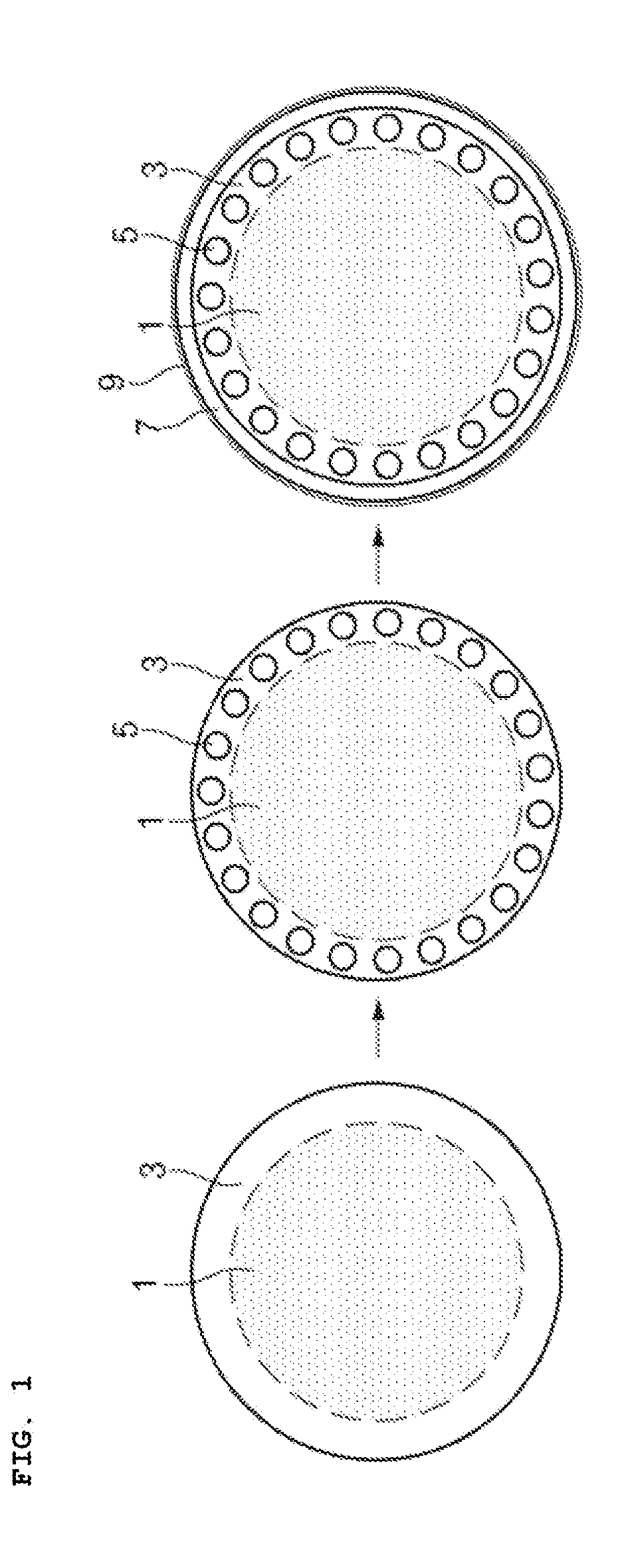

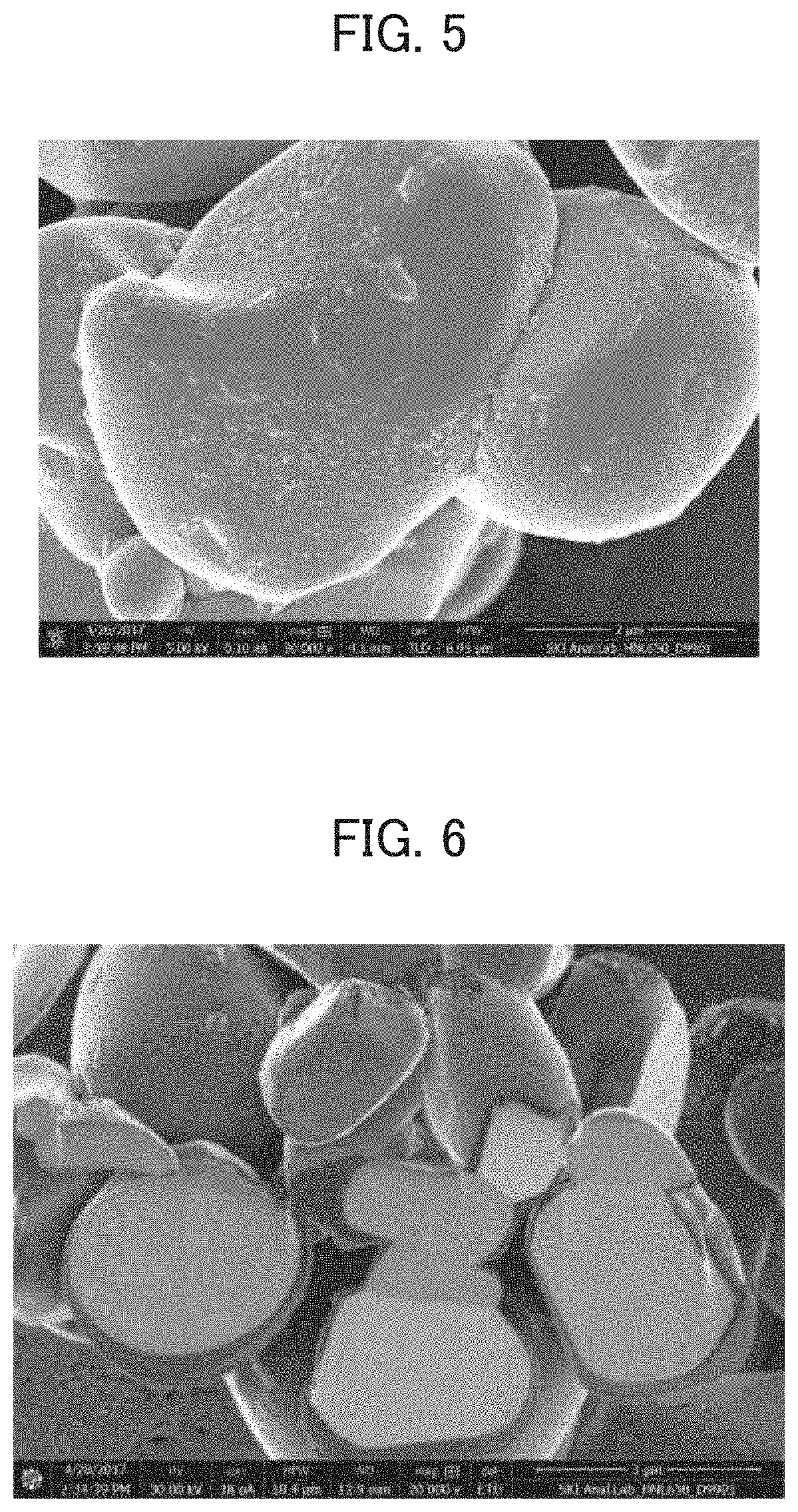

Transition metal composite hydroxide particles and production method thereof, cathode active material for non-aqueous electrolyte rechargeable battery and production method thereof, and nonaqueous electrolyte rechargeable battery

ActiveUS20160093885A1Excellent capacity characteristicsImprove output characteristicsFrom gel stateFrom normal temperature solutionsNon aqueous electrolytesIon

Provided is a cathode active material that can simultaneously improve the capacity characteristics, output characteristics, and cycling characteristics of a rechargeable battery when used as cathode material for a non-aqueous electrolyte rechargeable battery. After performing nucleation by controlling an aqueous solution for nucleation that includes a metal compound that includes at least a transition metal and an ammonium ion donor so that the pH value becomes 12.0 to 14.0 (nucleation process), nuclei are caused to grow by controlling aqueous solution for particle growth that includes the nuclei so that the pH value is less than in the nucleation process and is 10.5 to 12.0 (particle growth process). When doing this, the reaction atmosphere in the nucleation process and at the beginning of the particle growth process is a non-oxidizing atmosphere, and in the particle growth process, atmosphere control by which the reaction atmosphere is switched from this non-oxidizing atmosphere to an oxidizing atmosphere, and is then switched again to a non-oxidizing atmosphere is performed at least one time. Cathode active material is obtained with the composite hydroxide particles that are obtained by this kind of crystallization reaction as a precursor.

Owner:SUMITOMO METAL MINING CO LTD

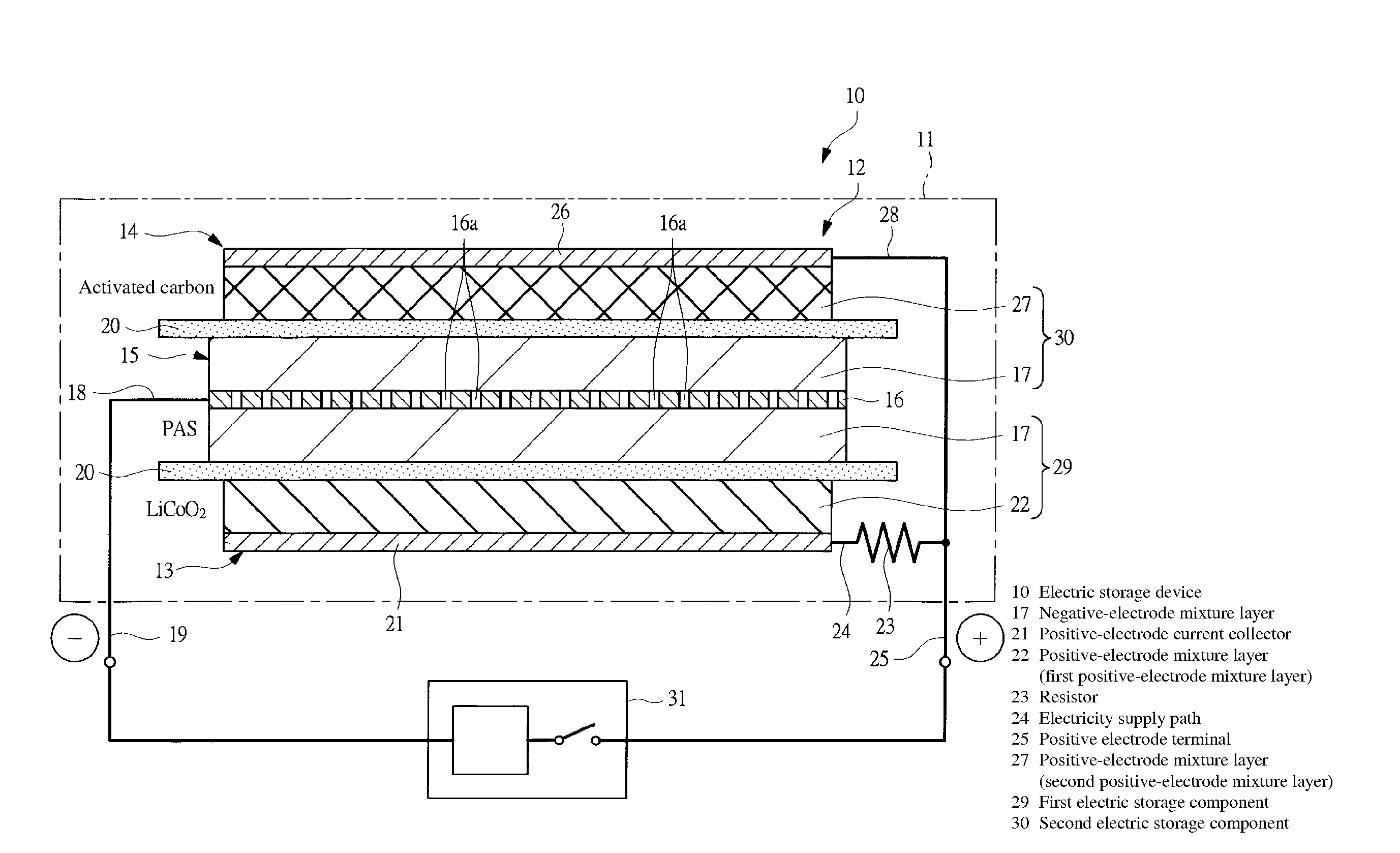

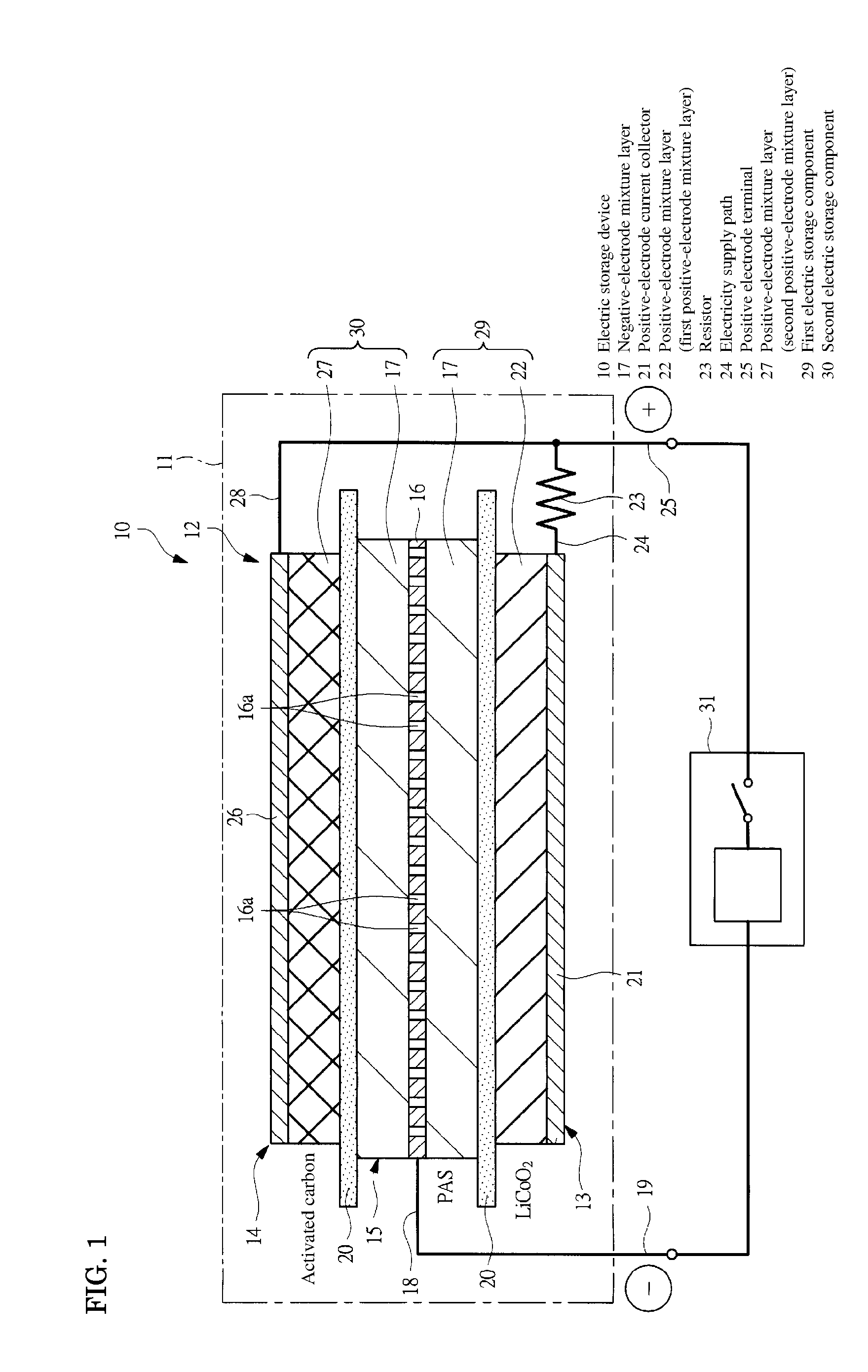

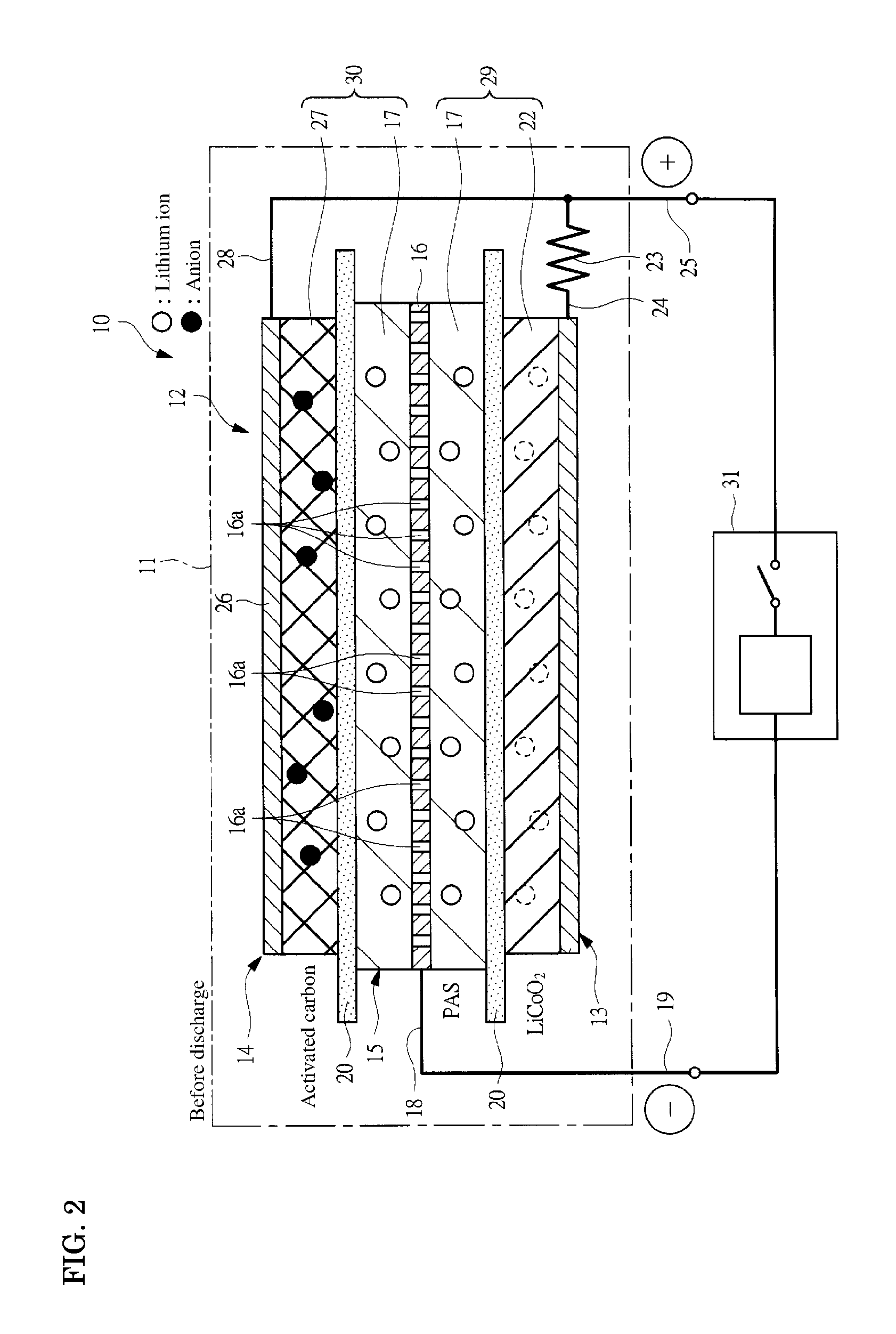

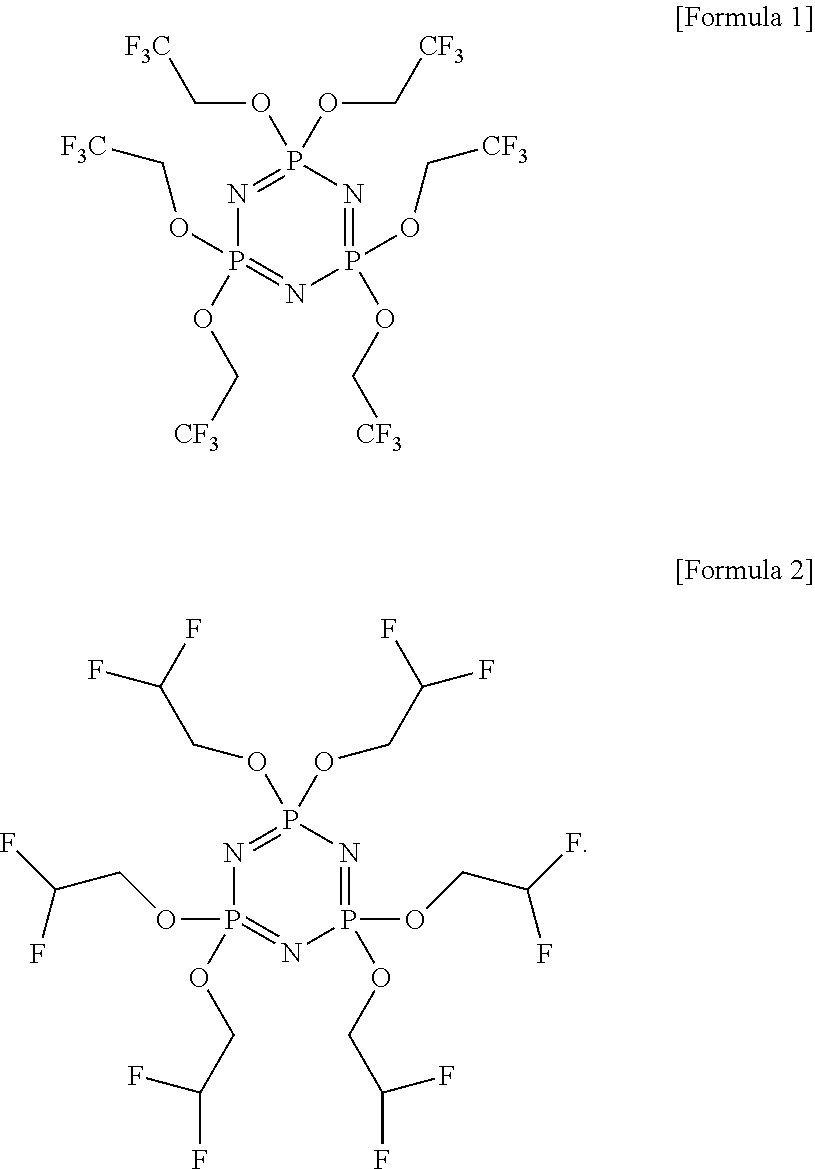

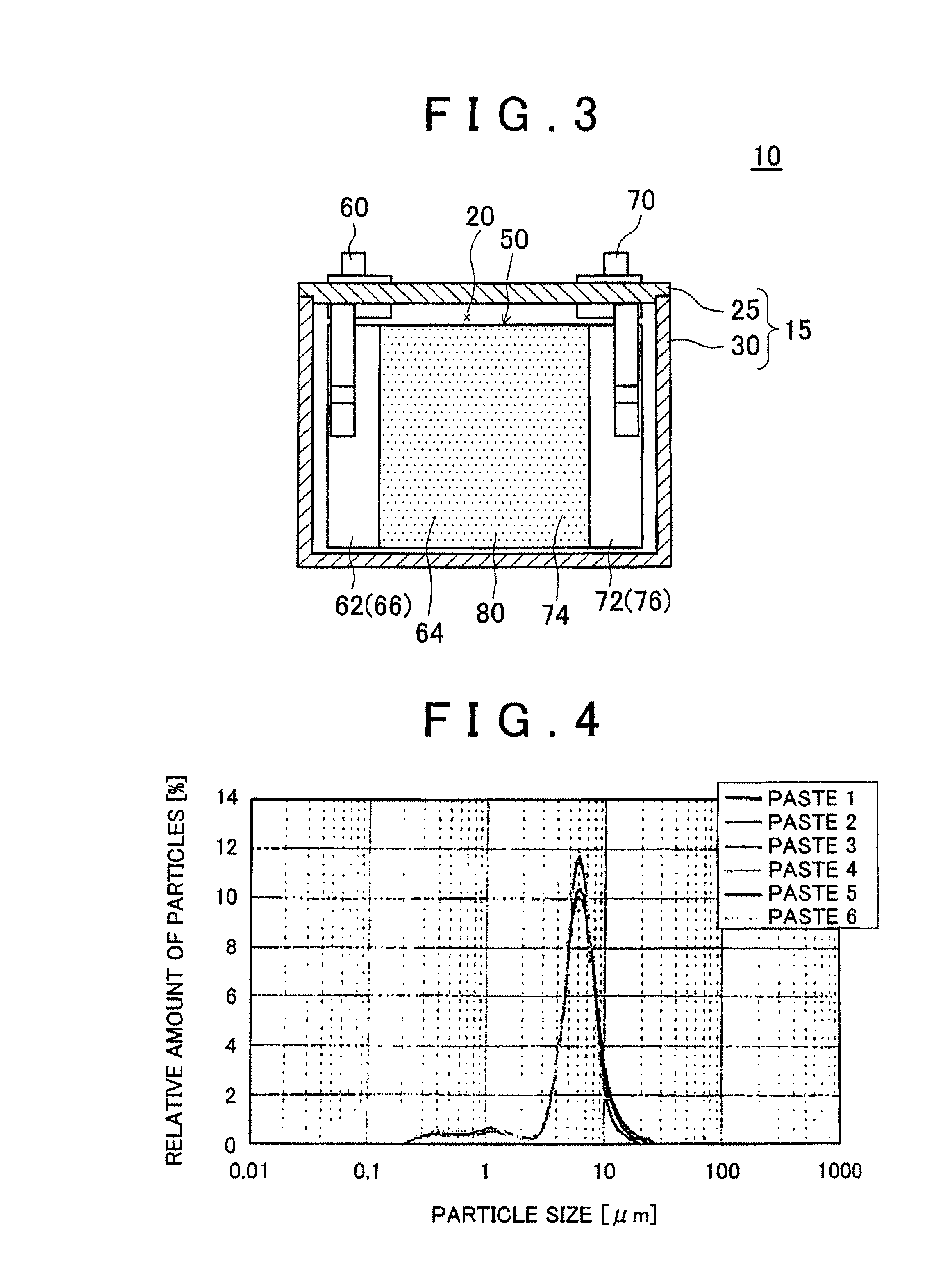

Electric storage device

InactiveUS20090123823A1Increase productionLarge capacityCapacitor and primary/secondary cellsFinal product manufactureLithiumElectricity

An electric storage device 10 has a first electric storage component 29 and a second electric storage component 30. The first component 29 and the second component 30 are connected in parallel. A positive-electrode mixture layer 22 contains a lithium cobaltate to increase a capacity. A positive-electrode mixture layer 27 contains an activated carbon to increase an output. A current collector 16 having through holes 16a is provided between the layers 22 and 27. A positive electrode terminal 25 is connected to a positive-electrode current collector 21 of the first component 29 through an electricity supply path 24 provided with a resistor 23. By this configuration, the electric current flowing through the first electric storage component 29 can be restricted when the device is charged or discharged with high current.

Owner:SUBARU CORP

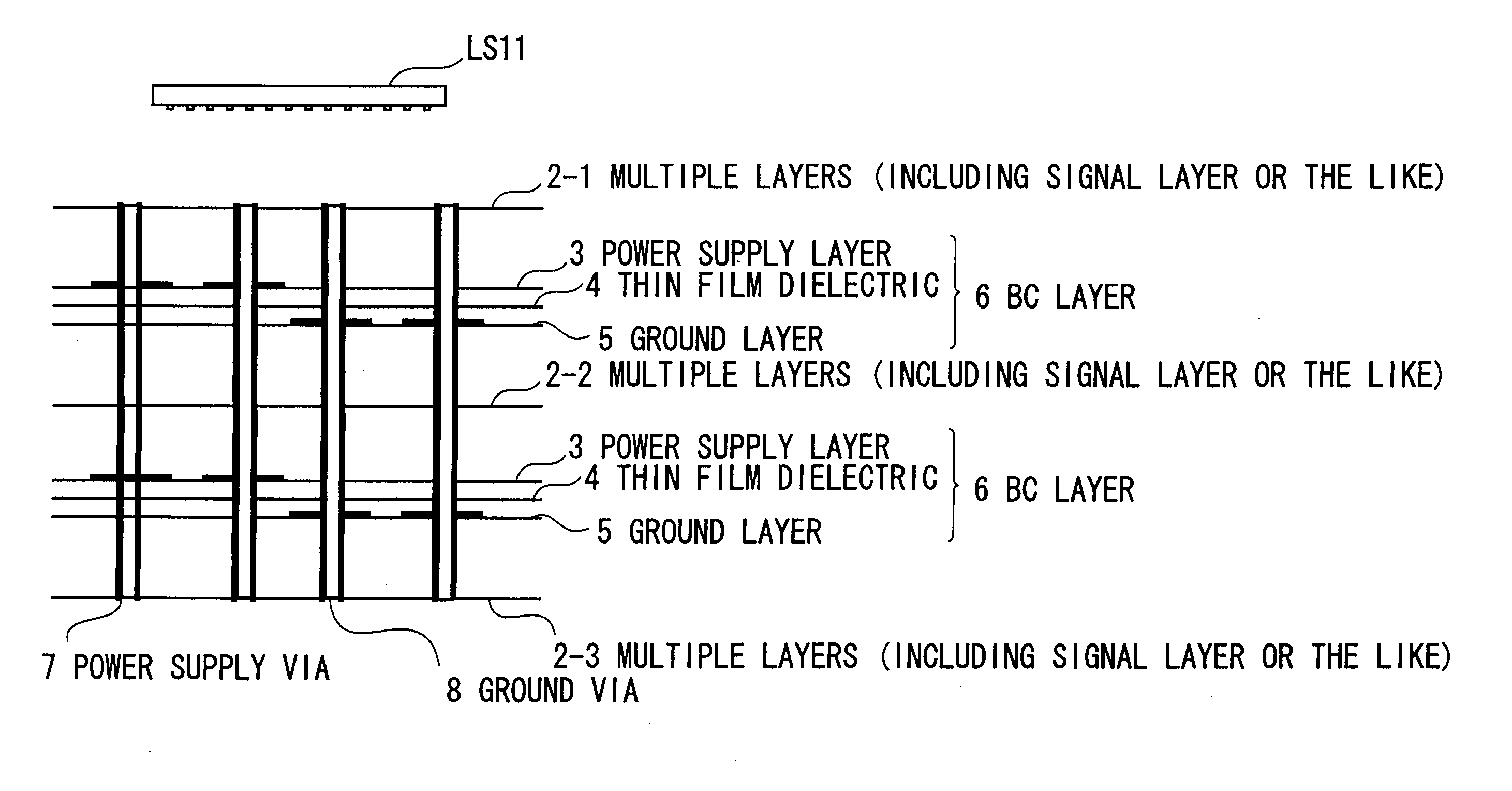

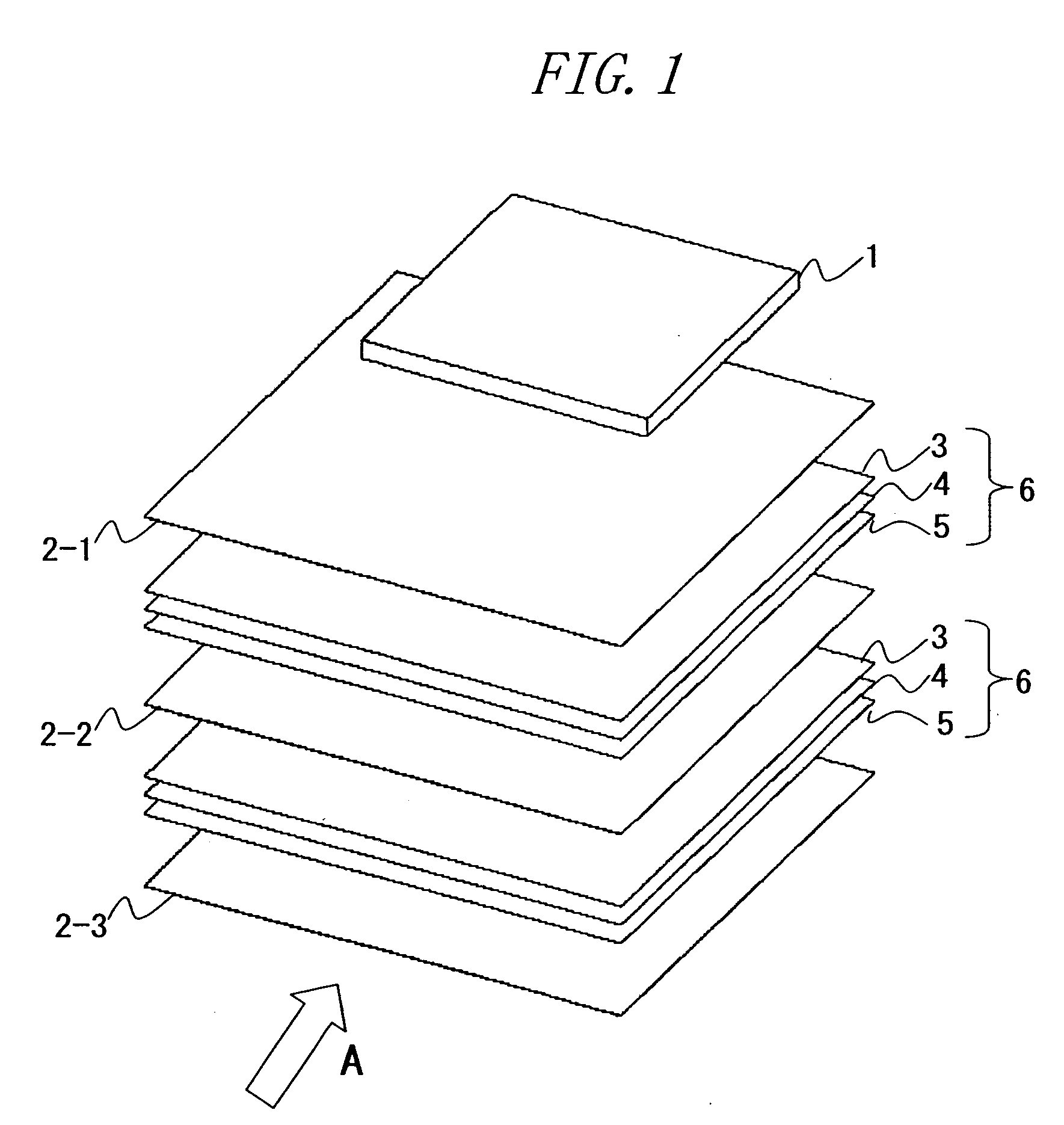

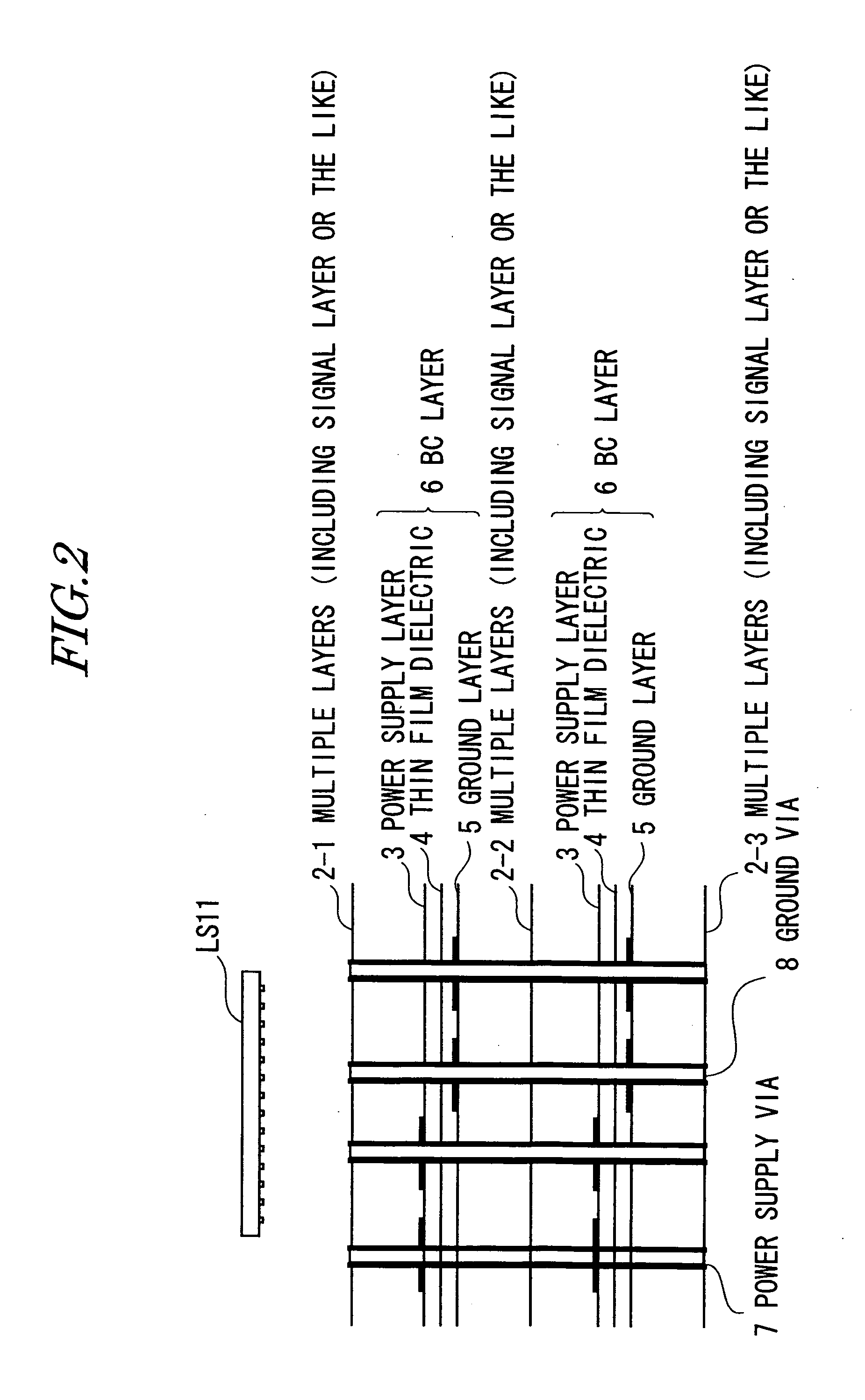

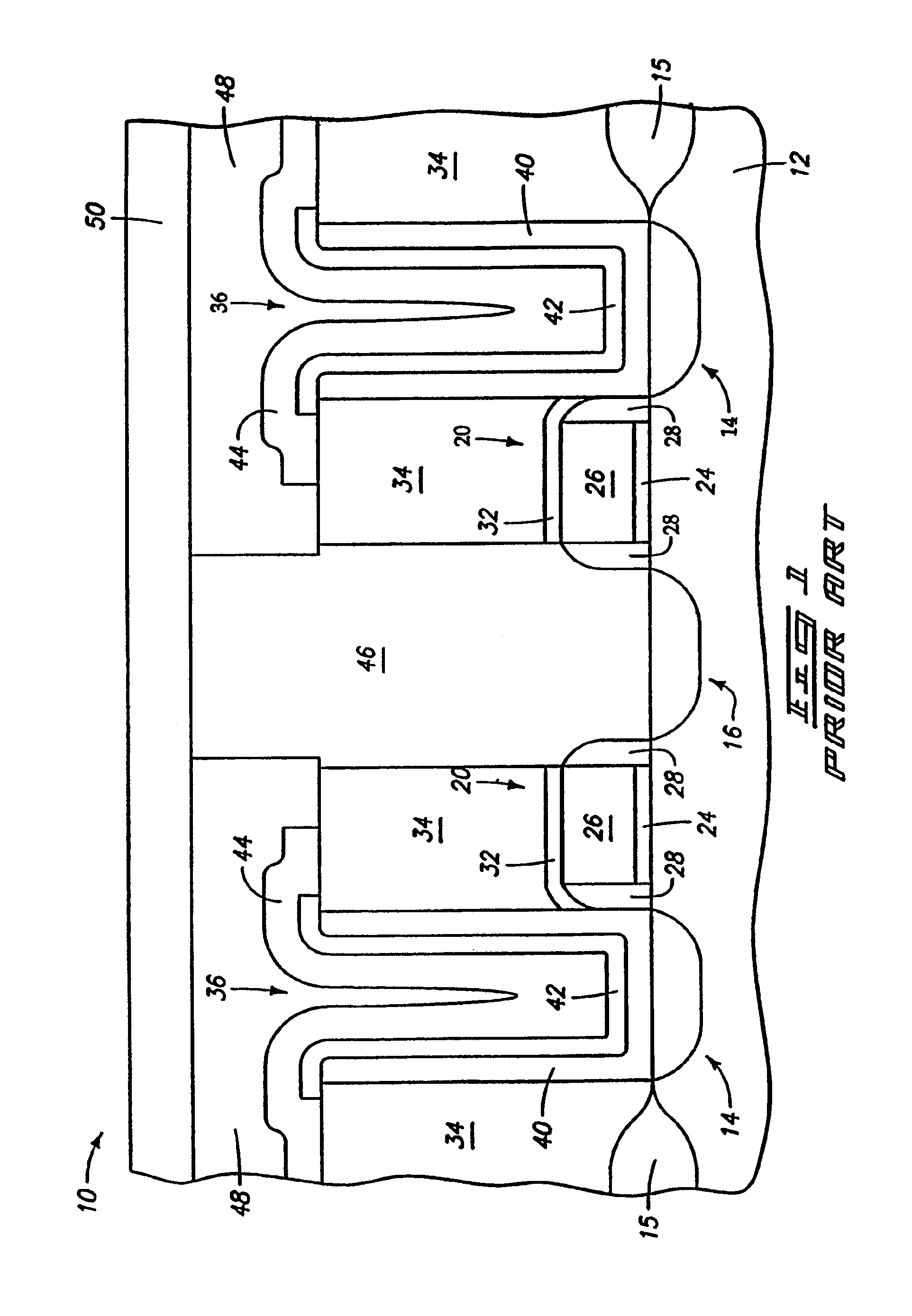

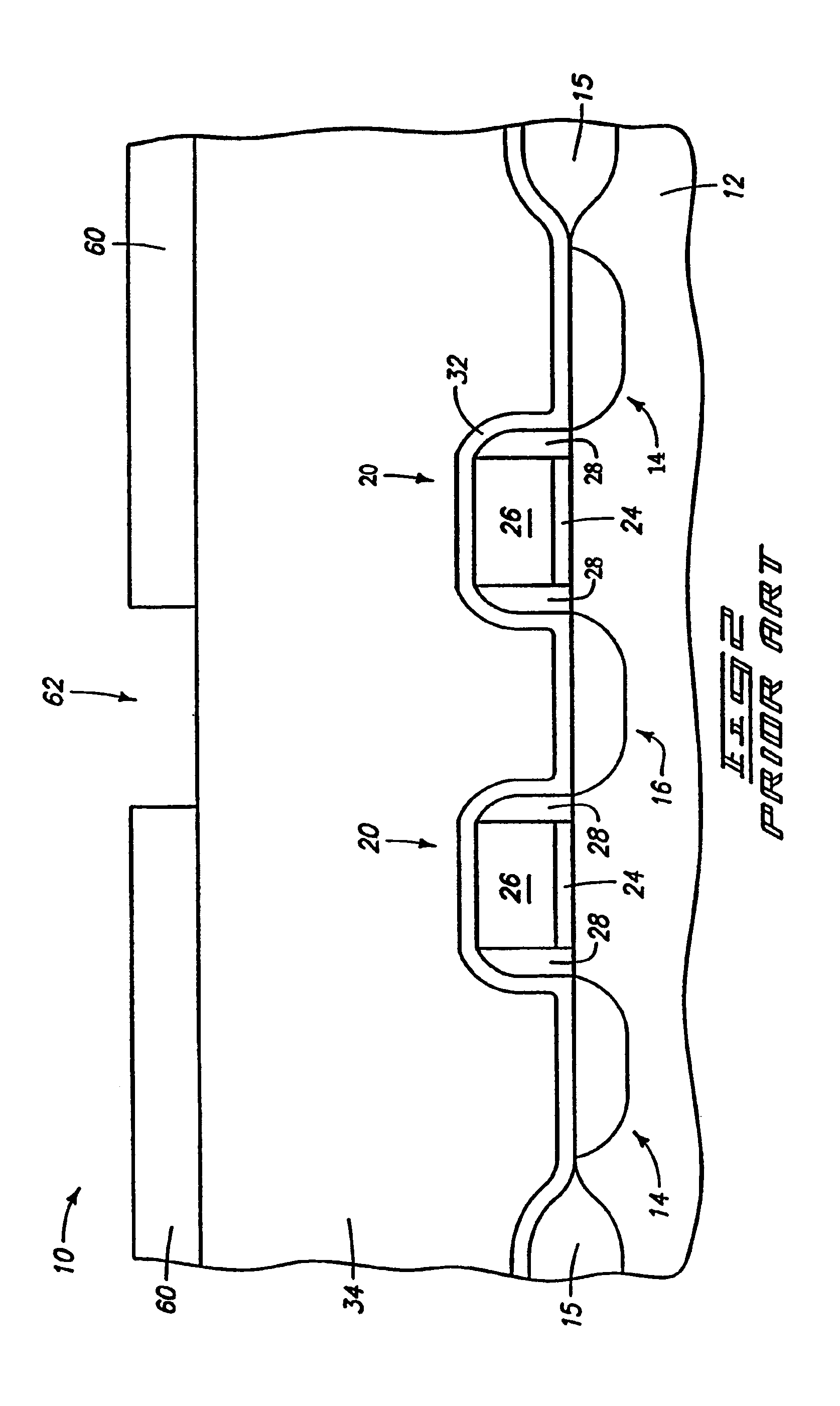

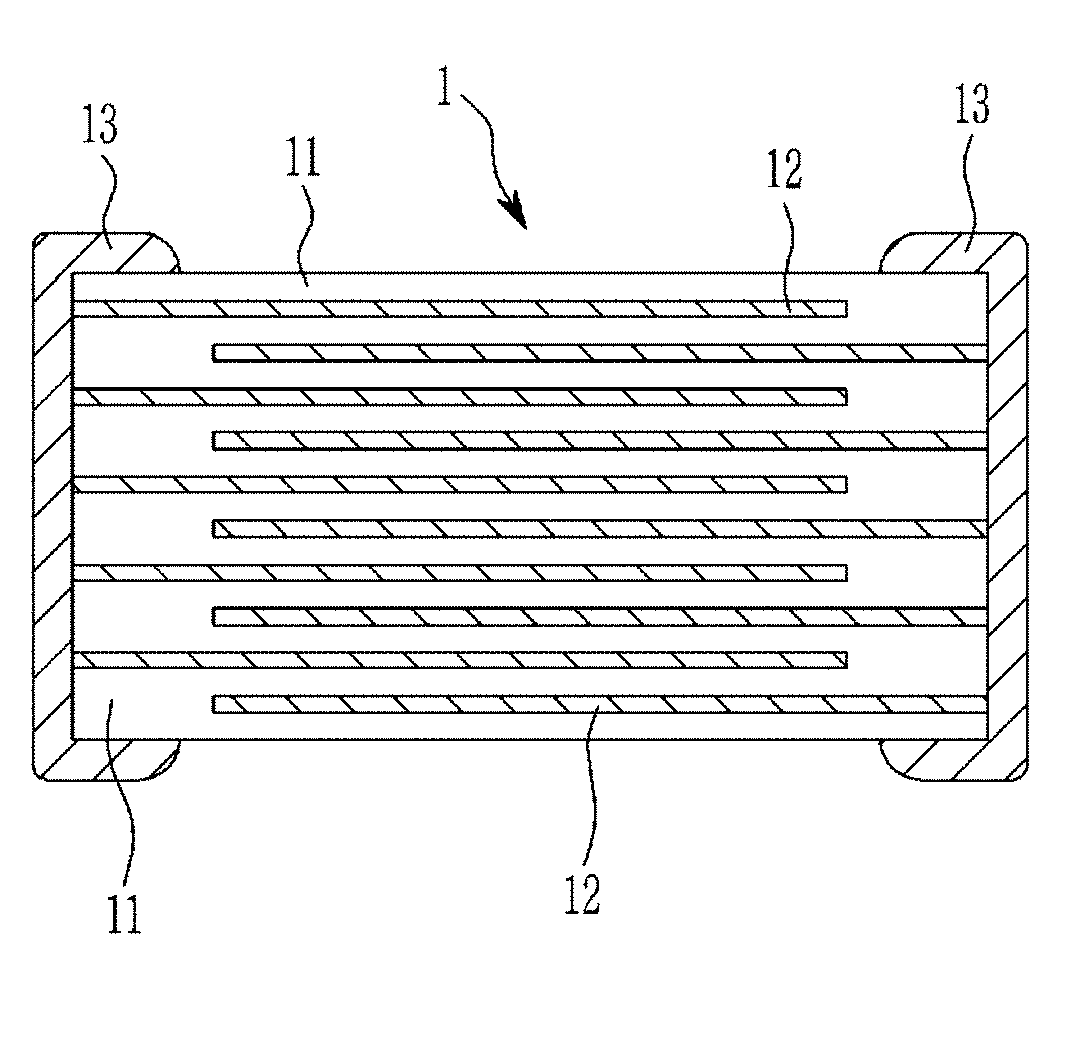

Multilayer printed board, electronic apparatus, and packaging method

InactiveUS20050230146A1High Capacity FeaturesImprove featuresSemiconductor/solid-state device detailsPrinted circuit aspectsCapacitive couplingEngineering

A multilayer printed board comprising a plurality of capacitive coupling layers (6) each consisting of a dielectric layer (4) and a power supply layer (3) and a ground layer (5) facing each other while sandwiching the dielectric layer (4), first vias (7) connecting between the power supply layers (3) included in the plurality of capacitive coupling layers (6), and second vias (8) connecting between the ground layers (5) included in the plurality of capacitive coupling layers (6).

Owner:FUJITSU LTD

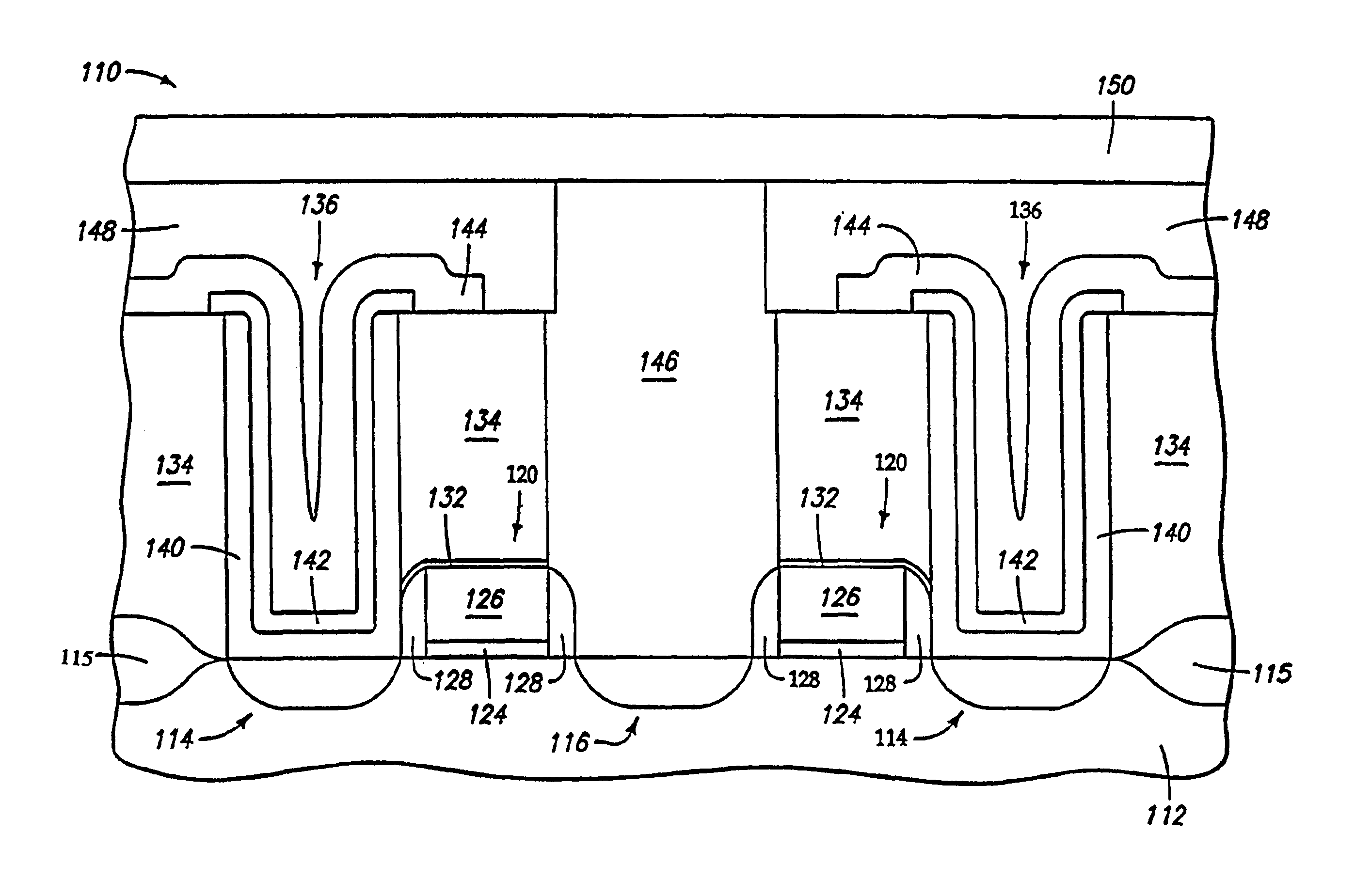

Films doped with carbon for use in integrated circuit technology

InactiveUS6963101B2Low dielectric constantHigh Capacity FeaturesTransistorSolid-state devicesSemiconductor materialsOxygen

The invention pertains to films comprising silicon, oxygen and carbon and the use of the films in integrated circuit technology, such as capacitor constructions, DRAM constructions, semiconductive material assemblies, etching processes, and methods for forming capacitors, DRAMs and semiconductive material assemblies.

Owner:ROUND ROCK RES LLC

Negative electrode active material and lithium secondary battery including the same

ActiveUS20180219216A1Secure physical stabilityImprove life characteristicsNegative electrodesNon-aqueous electrolyte accumulator electrodesLithiumSilicon particle

The present invention relates to a silicon-carbon-based composite negative electrode active material, and a negative electrode for a secondary battery and a lithium secondary battery including the same, and particularly to a silicon-carbon-based composite negative electrode active material, in which physical stability is improved by including a carbon-based core capable of intercalating and deintercalating lithium ions and at least one silicon particle included in the carbon-based core and disposed in the form of being distributed in an outer portion of the carbon-based core, and a negative electrode for a secondary battery and a lithium secondary battery in which life characteristics are improved by including the same.

Owner:LG ENERGY SOLUTION LTD

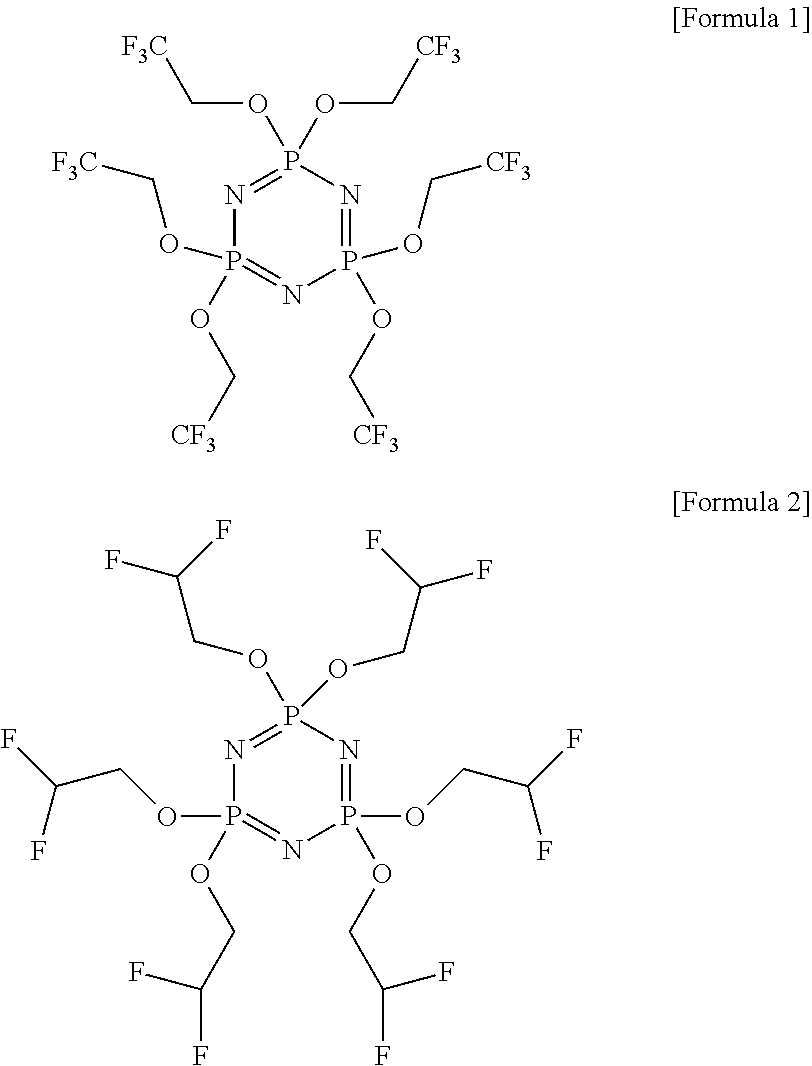

Non-aqueous electrolyte solution and lithium secondary battery comprising the same

ActiveUS20170309960A1Improve output characteristicsHigh Capacity FeaturesSecondary cellsOrganic electrolytesHigh temperature storageImide

Provided are a non-aqueous electrolyte solution, which includes (i) a first lithium salt, (ii) lithium bis(fluorosulfonyl)imide as a second lithium salt, (iii) a phosphazene-based compound as a first additive, and (iv) a non-aqueous organic solvent, and a lithium secondary battery including the non-aqueous electrolyte solution.With respect to a lithium secondary battery including the non-aqueous electrolyte solution of the present invention, since a robust solid electrolyte interface (SEI) may be formed on the surface of a negative electrode during initial charge and flame retardancy in a high-temperature environment may be provided to prevent the decomposition of the surface of a positive electrode and an oxidation reaction of the electrolyte solution, output characteristics and capacity characteristics after high-temperature storage as well as output characteristics may be improved.

Owner:LG ENERGY SOLUTION LTD

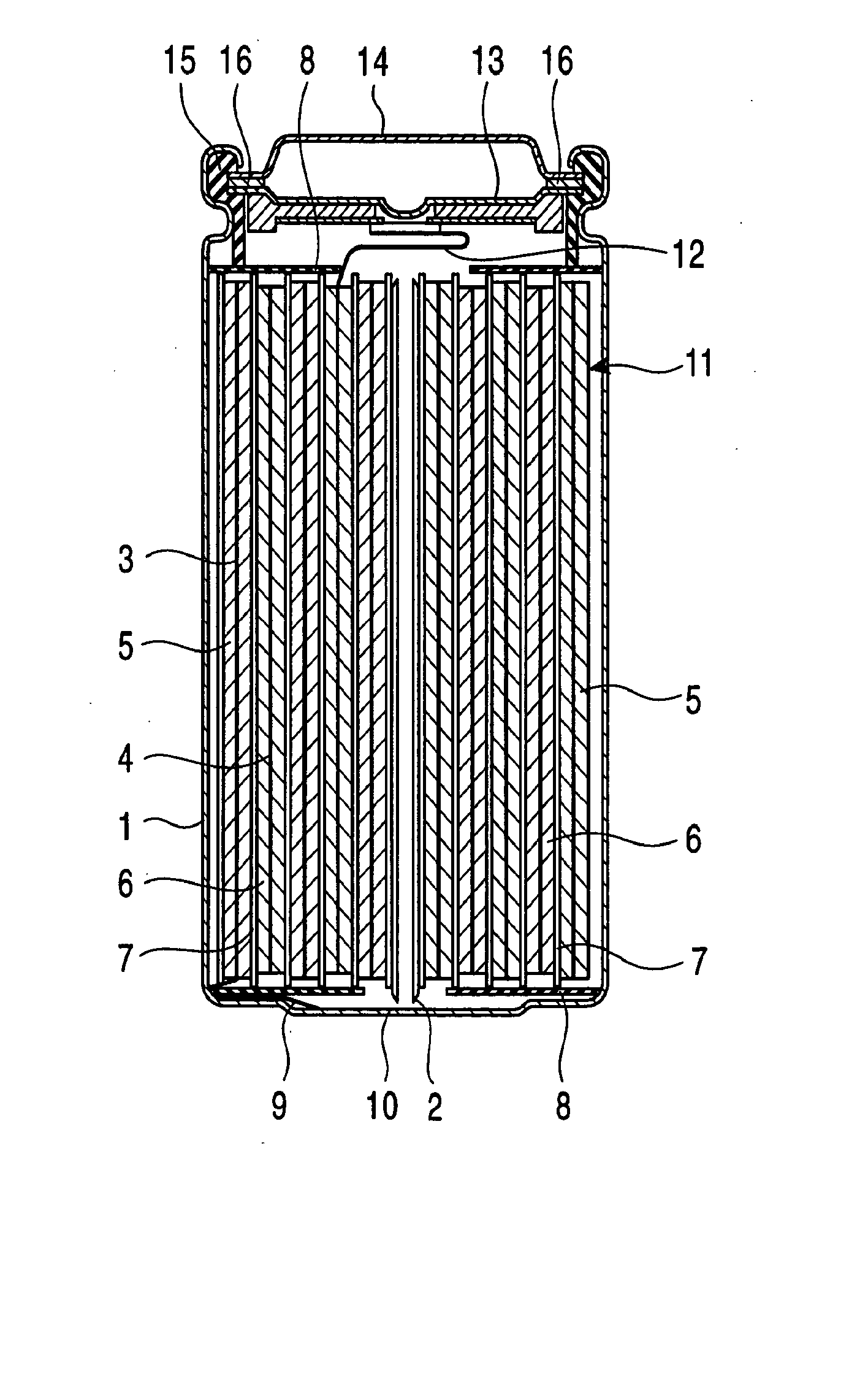

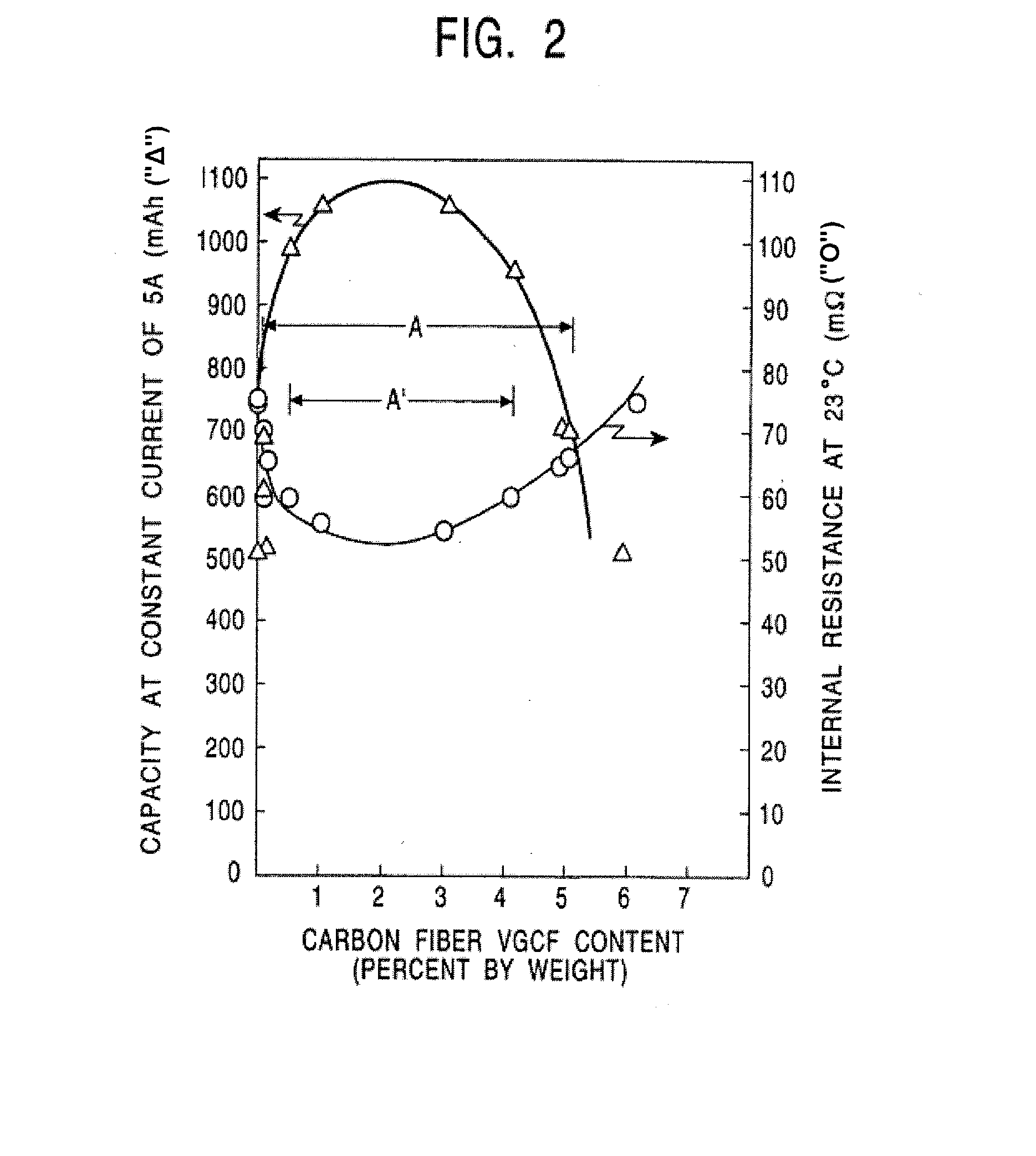

Non-aqueous electrolyte secondary battery having a negative electrode containing carbon fibers and carbon flakes

InactiveUS20070218367A1Satisfactory capacity characteristicHigh Capacity FeaturesNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsFiberCarbon fibers

A nonaqueous electrolyte secondary battery is provided with a positive electrode including a positive-electrode active material, a negative electrode including a negative-electrode active material, and a nonaqueous electrolyte solution. The negative electrode further includes carbon fibers and carbon flakes. The synergistic effects of the improved retention of the electrolyte solution by the carbon fibers and the improved conductivity between the active material particles by the carbon flakes facilitate doping / undoping of lithium in a high-load current mode and increase the capacity of the battery in the high-load current mode.

Owner:MURATA MFG CO LTD

Phosphoric acid treatment of carbonaceous material prior to activation

InactiveUS9108186B2Disadvantages can be reduced eliminatedProblems can be reduced eliminatedCarbon compoundsOther chemical processesActivated carbonPhosphoric acid

A method of producing an activated carbon, comprising selecting a raw material for direct-activation, applying a solution of at least 50% phosphoric acid by weight at a ratio of from 0.01 pounds to 0.3 pounds of phosphoric acid solution per pound to the raw material selected for direct activation to produce a phosphoric acid treated raw material, and direct-activating the phosphoric acid treated raw material via a gas activation process to produce an activated carbon.

Owner:CABOT CORP

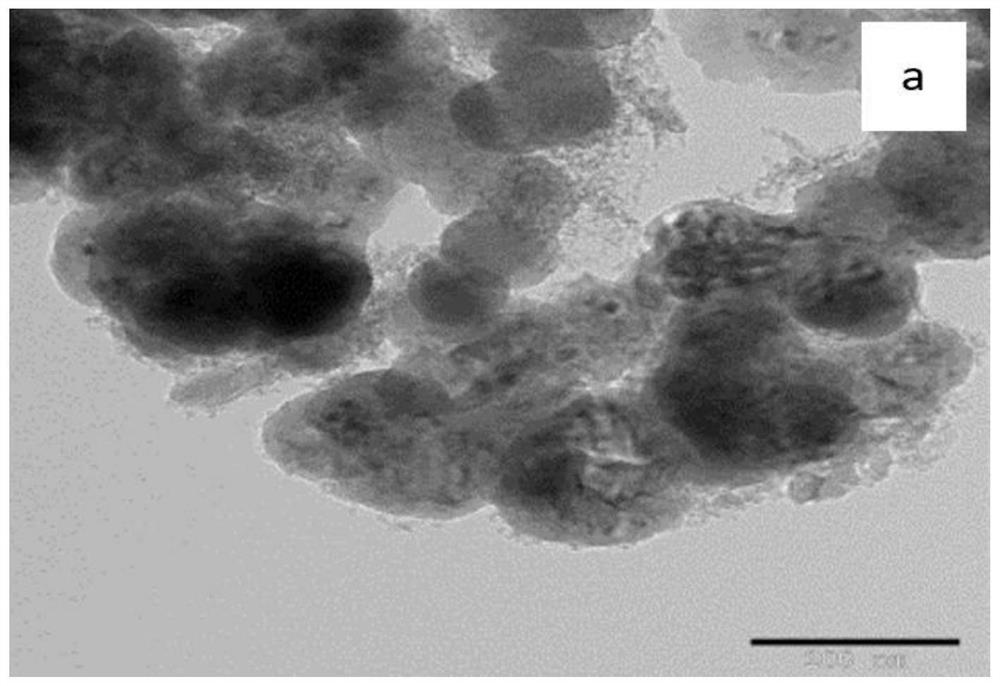

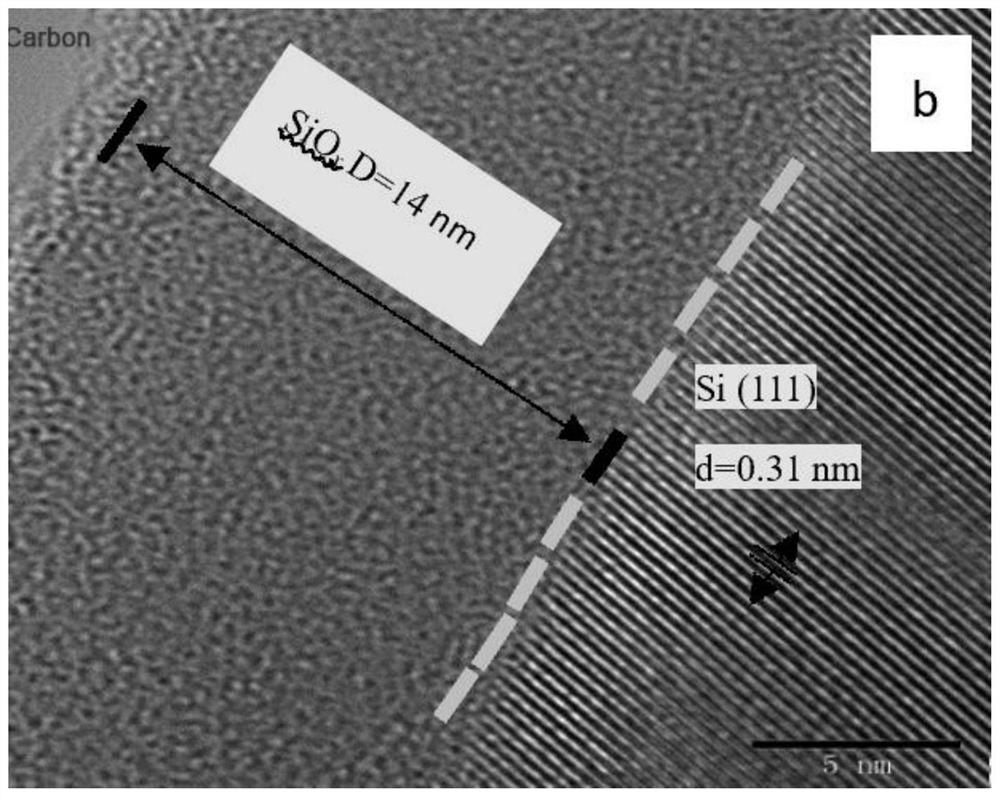

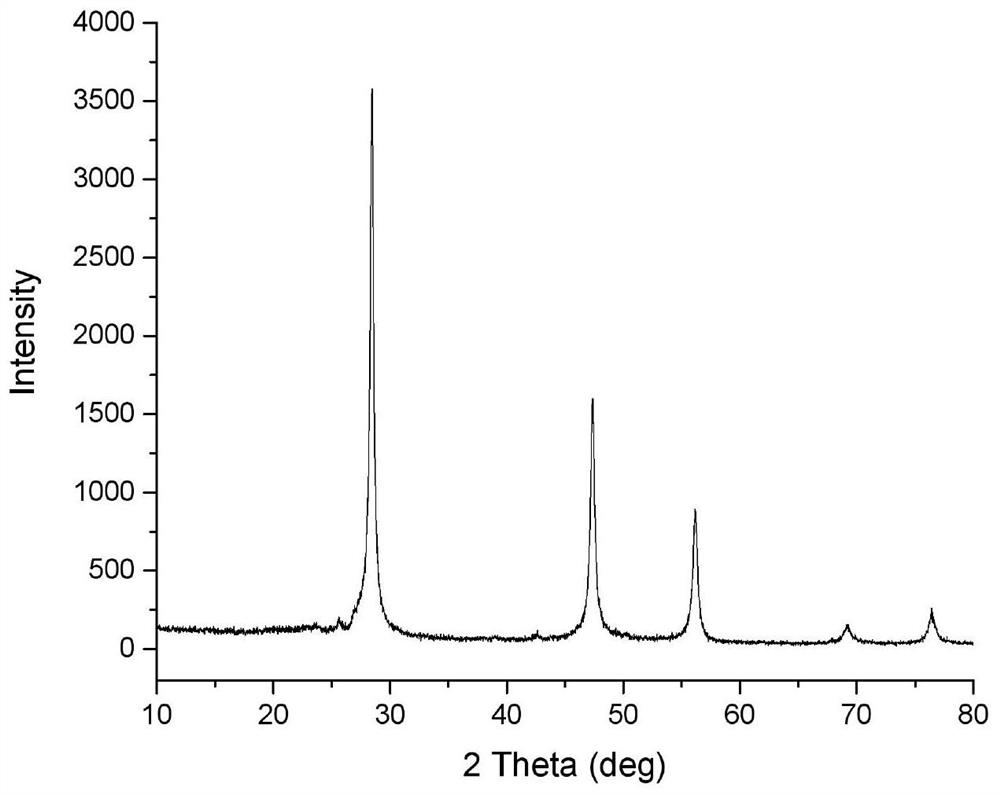

Silicon/silicon oxide/carbon composite negative electrode material for lithium ion battery and preparation method of silicon/silicon oxide/carbon composite negative electrode material

ActiveCN112366301AHigh specific capacityImprove Coulombic efficiencyMaterial nanotechnologyNegative electrodesCarbon compositesSilicon oxide

The invention relates to a negative electrode material for a lithium ion battery, a preparation method of the negative electrode material and the battery, and discloses a preparation method of a silicon / silicon oxide / carbon composite negative electrode material for the lithium ion battery, the silicon / silicon oxide / carbon composite negative electrode material and the battery. The silicon-carbon composite negative electrode material prepared by adopting an in-situ oxidation method and a high-temperature pyrolysis method has a core-shell structure, and the obtained shell structure is stable andfirm in structure. According to the invention, a lithium storage active phase SiOx and an amorphous pyrolytic carbon coating layer are generated on the surface of the nano-silicon through the dual-core shell structure, volume expansion in the charging and discharging process of the nano-silicon can be well buffered on the premise that the capacity is not remarkably reduced, the high conductivity and stability of the pyrolytic carbon coating layer are helpful for enhancing the stability of the Si@SiOx and electrolyte interface SEI film, so that the composite material has high capacity, excellent rate capability and cycle performance.

Owner:博尔特新材料(银川)有限公司

Cathode active material, preparation method thereof and lithium battery using same

ActiveCN101740766AAlleviate volume changesHigh Capacity FeaturesElectrode manufacturing processesSecondary cellsFiberCarbon fibers

The invention provides a cathode active material used for a lithium ion battery, which comprises a dispersion carrier and a composite material dispersing in the dispersion carrier. The dispersion carrier comprises silicon fibers and carbon fibers; and the composite material is a silicon / metal alloy. The conventional silica-based material has the problems of serious volume effect, pulverization and shedding during electrochemical lithium extraction, which causes poor cycle performance of the battery. The cathode active material can effectively solve the problems of the volume effect, the pulverization and the shedding so as to improve the cycle performance of the battery. The invention also provides a method for preparing the cathode active material, which comprises the following steps of: ball-milling and mixing the silicon fibers and the carbon fibers, and sintering the mixture at high temperature to prepare silicon-carbon fibers; ball-milling and mixing silicon and a metal, and sintering the mixture at the high temperature to prepare the silicon / metal alloy; mixing the silicon-carbon fibers and the silicon / metal alloy, adding the mixture into a dispersing agent, and dispersing the mixture with ultrasonic waves to obtain slurry; and volatilizing the dispersing agent in the slurry, and processing the slurry under a shielding gas at low temperature.

Owner:BYD CO LTD

Two-dimensional perovskite material, dielectric material and multi-layered capacitor including the same

PendingUS20180286586A1Overcome limitationsHigh Capacity FeaturesOrganic chemistryThin/thick film capacitorTwo dimensional crystalCapacitor

A two-dimensional perovskite material, a dielectric material including the same, and a multi-layered capacitor. The two-dimensional perovskite material includes a layered metal oxide including a first layer having a positive charge and a second layer having a negative charge which are laminated, a monolayer nanosheet exfoliated from the layered metal oxide, a nanosheet laminate of a plurality of the monolayer nanosheets, or a combination thereof, wherein the two-dimensional perovskite material a first phase having a two-dimensional crystal structure is included in an amount of greater than or equal to about 80 volume %, based on 100 volume % of the two-dimensional perovskite material, and the two-dimensional perovskite material is represented by Chemical Formula 1.

Owner:SAMSUNG ELECTRONICS CO LTD

Transition metal- pyrophosphate anode active material, method of preparing the same, and lithium secondary battery or hybrid capacitor including the anode active material

ActiveUS20150072238A1High reactivityHigh Capacity FeaturesSilver accumulatorsPhosphatesPhosphateManganese

Provided is an anode active material including a transition metal-pyrophosphate of Chemical Formula 1 below:M2P2O7 <Chemical Formula 1>where M is any one selected from the group consisting of titanium (Ti), chromium (Cr), manganese (Mn), iron (Fe), cobalt (Co), nickel (Ni), ruthenium (Ru), palladium (Pd), and silver (Ag), or two or more elements thereof.Since the anode active material of the present invention is stable and has excellent conversion reactivity while including only transition metal and phosphate without using lithium in which the price thereof is continuously increased, the anode active material of the present invention may improve capacity characteristics.

Owner:LG ENERGY SOLUTION LTD

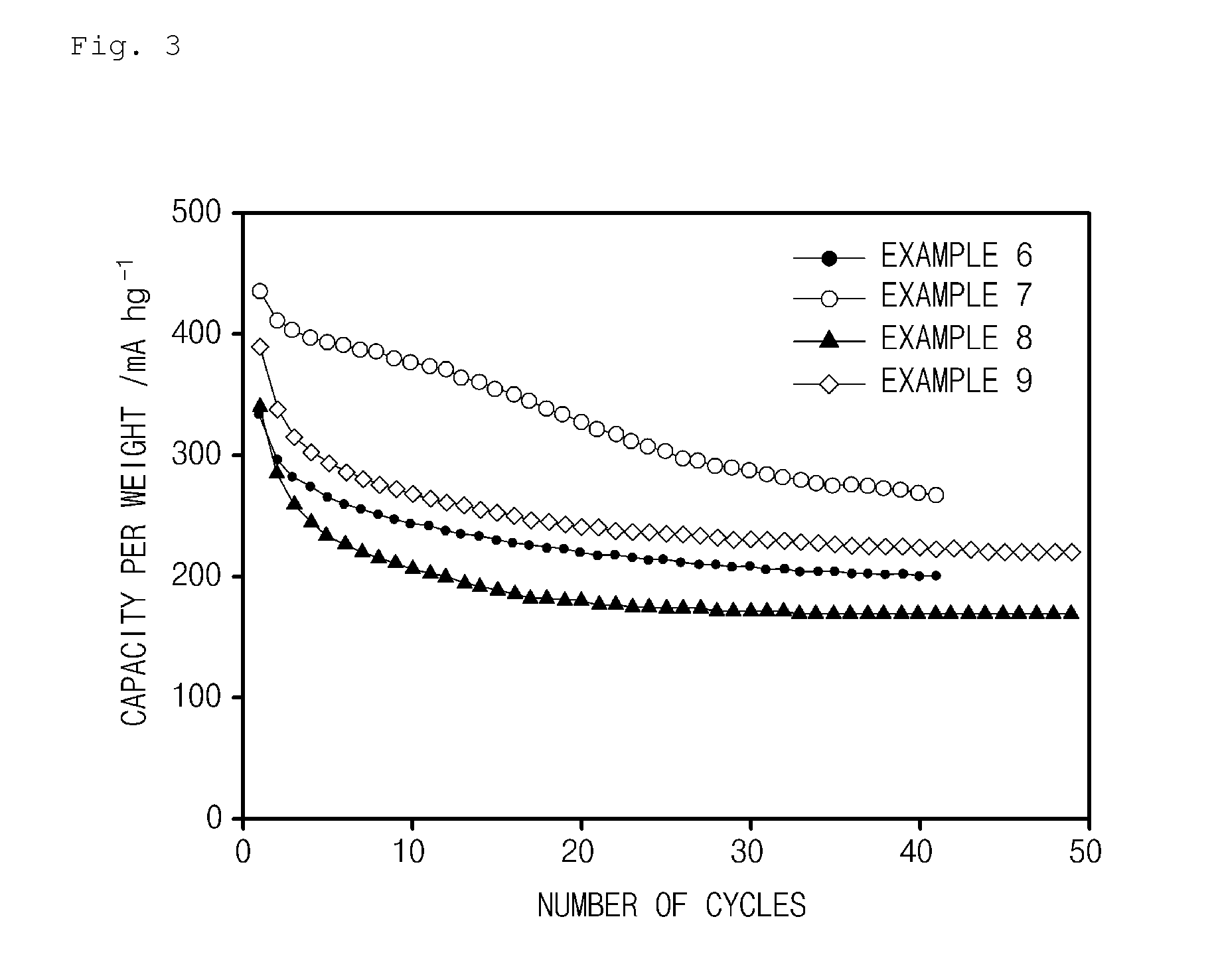

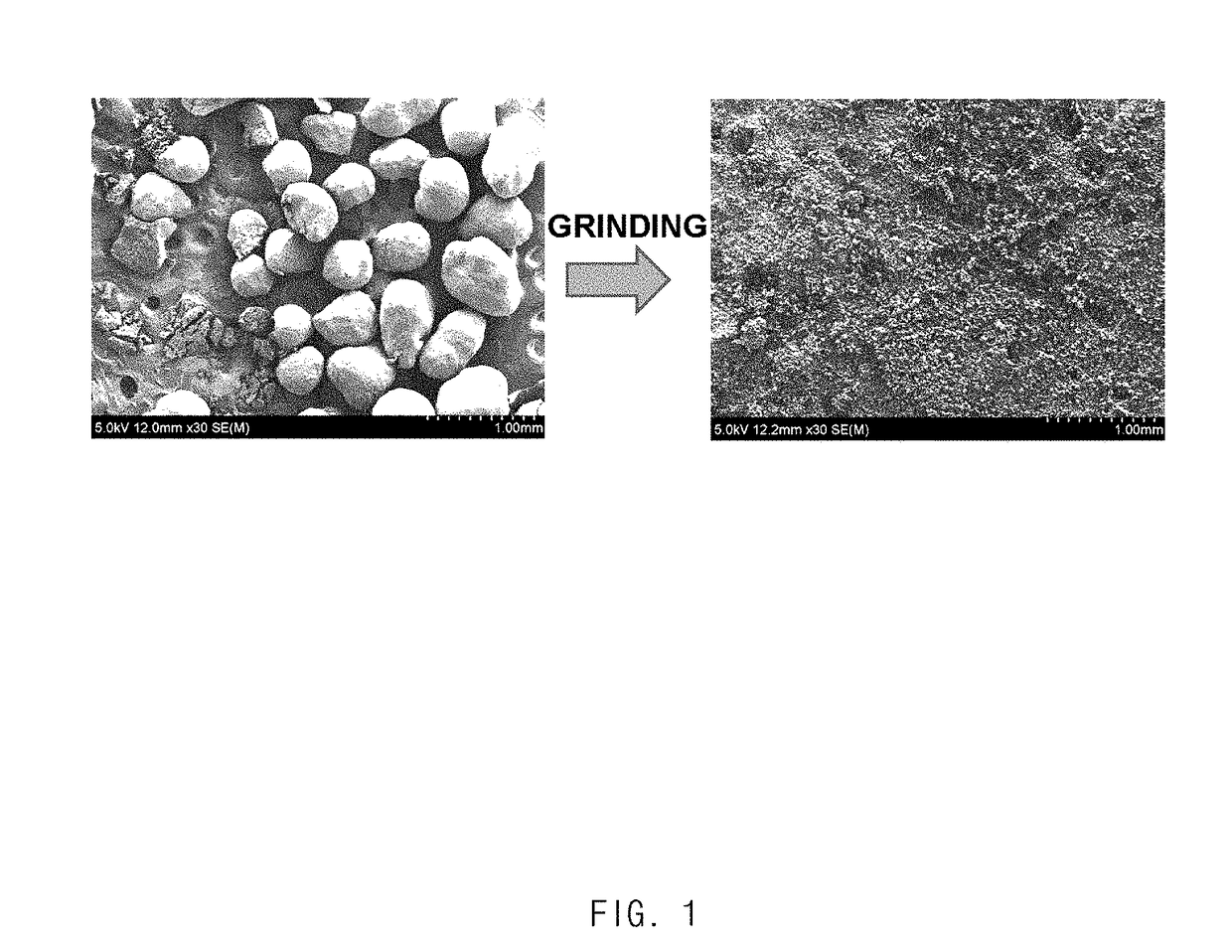

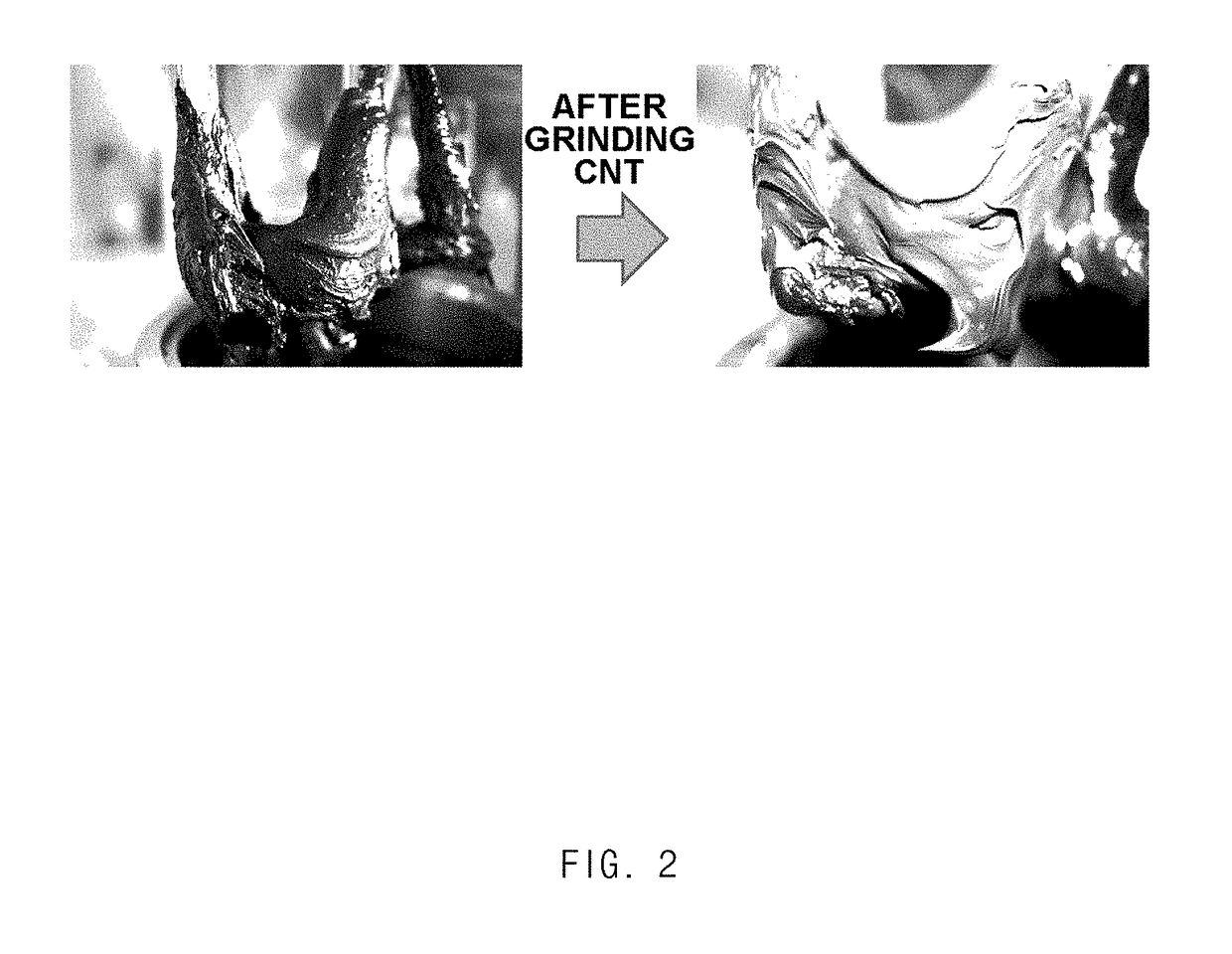

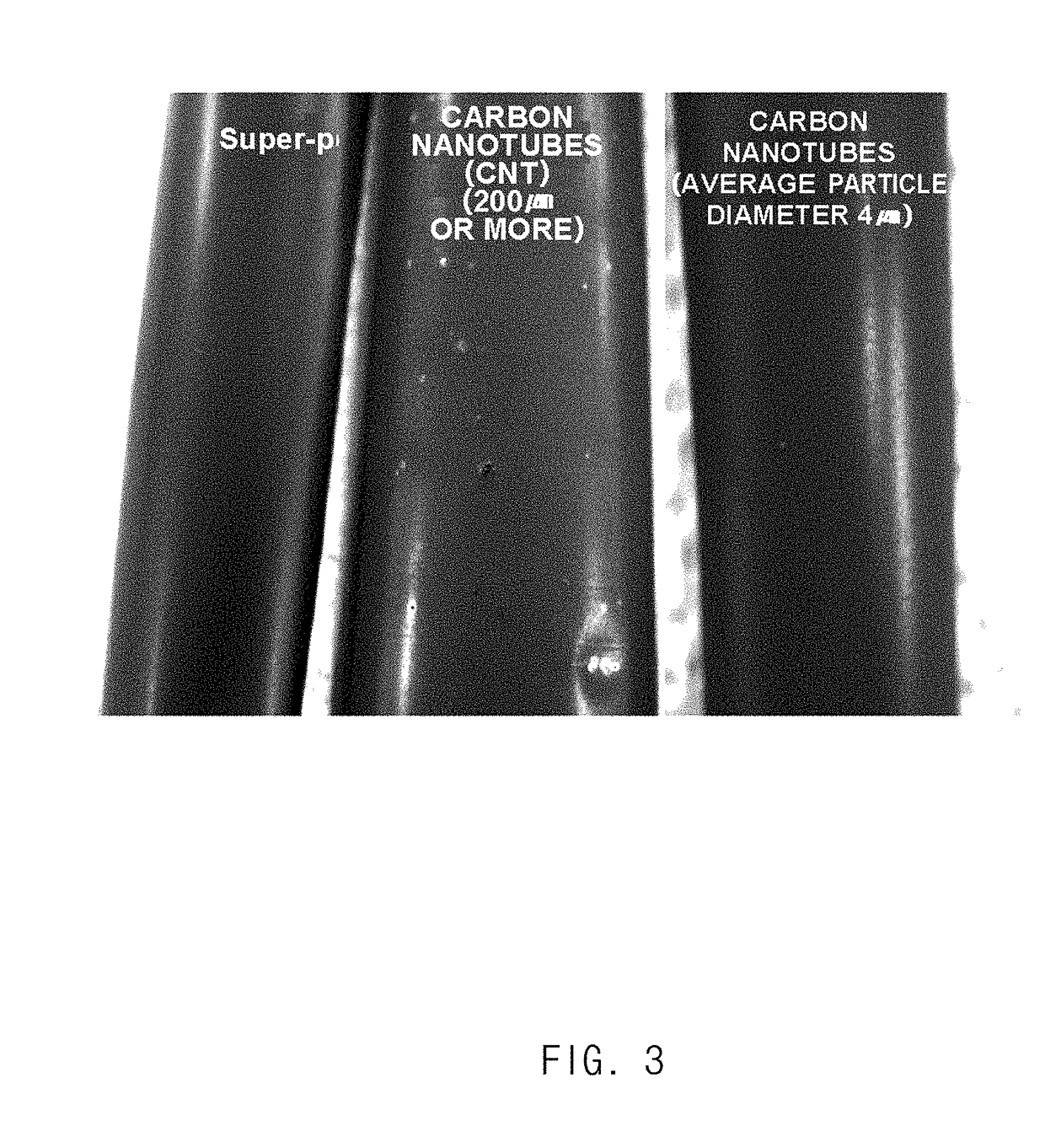

Positive electrode material slurry for lithium secondary battery including at least two conductive materials and lithium secondary battery using the same

ActiveUS20170365858A1Improve conductivityImprove discharge performanceMaterial nanotechnologyPositive electrodesLithiumHigh rate

Provided is a positive electrode material slurry for secondary battery including a positive electrode active material, a conductive agent, a binder, and a solvent, wherein the conductive agent includes a first conductive agent and a second conductive agent having different particle shapes and sizes.Since the conductive agent of the present invention may be uniformly dispersed in the positive electrode active material by including a point-type conductive agent, as the first conductive agent, and carbon nanotubes (CNTs) subjected to a grinding process as the linear second conductive agent, conductivity of an electrode to be prepared may be improved and a secondary battery having improved high-rate discharge capacity characteristics may be provided.

Owner:LG ENERGY SOLUTION LTD

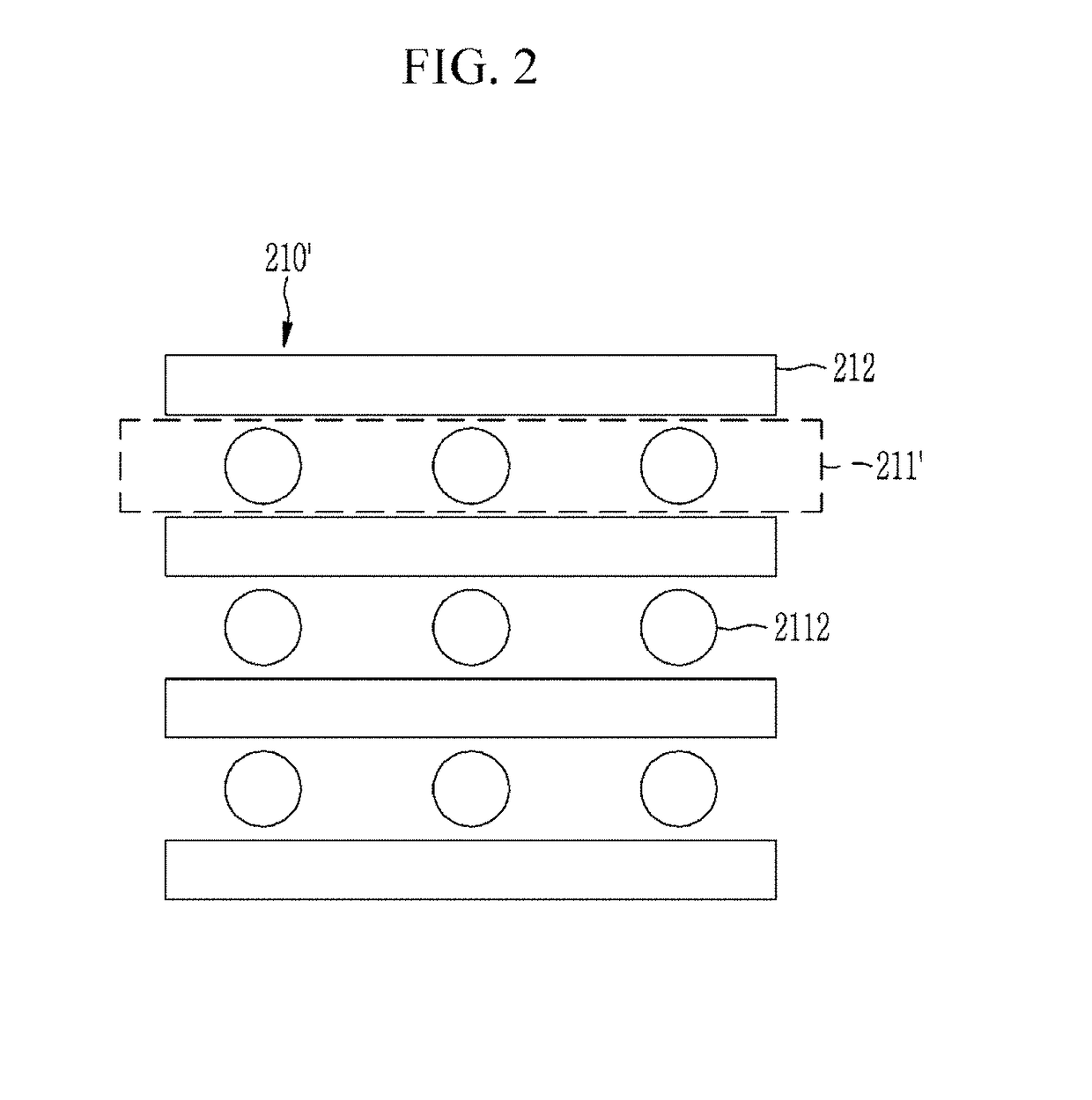

Lithium secondary battery

ActiveUS20200127276A1High power outputImprove permeabilityPositive electrodesLi-accumulatorsChemical physicsLithium metal

A lithium secondary battery includes a cathode including a cathode current collector, and a first cathode active material layer and a second cathode active material layer sequentially formed on the cathode current collector, an anode, and a separation layer interposed between the cathode and the anode. The first cathode active material layer and the second cathode active material layer include a first cathode active material particle and a second cathode active material particle, respectively, which have different compositions or crystalline structures from each other, and the first cathode active material particle and the second cathode active material particle include lithium metal oxides containing nickel. The second cathode active material particle has a single particle structure.

Owner:SK ON CO LTD

Processing liquid and solid-state electrolytic capacitor with same

InactiveCN106548872AHigh voltageIncrease capacitySolid electrolytic capacitorsCapacitor electrolytes/absorbentsBenzoic acidCapacitance

The invention proposes a processing liquid, and relates to the technical field of a solid-state electrolytic capacitor. The processing liquid comprises a solute and a solvent, wherein the solute is an organic or inorganic acid compound, the solvent comprises a water polymer material and an organic solvent, the organic or inorganic acid compound is selected from one or more of phosphoric acid, boric acid, benzoic acid, adipic acid, azelaic acid, sebacic acid, isophthalic acid, phthalic acid, maleic acid, benzene sulfonic acid and citric acid, and the water polymer material is selected one or more of polyethylene alkylene glycol, polyvinyl alcohol, polyethylene glycol glyceryl alcohol ester, polyethylene glycol glyceryl alcohol ester, polyethylene glycol sorbitol ether, polyethylene glycol, polybutylene glycol, polyethylene glycol and polyethylene oxide which has non-volatile characteristic. The processing liquid and a traditional dispersion liquid are used in a matching way, thus, the development of the dispersion liquid is prevented, the production period is shortened, and the cost is reduced.

Owner:CAPXON ELECTRONIC (SHENZHEN) CO LTD

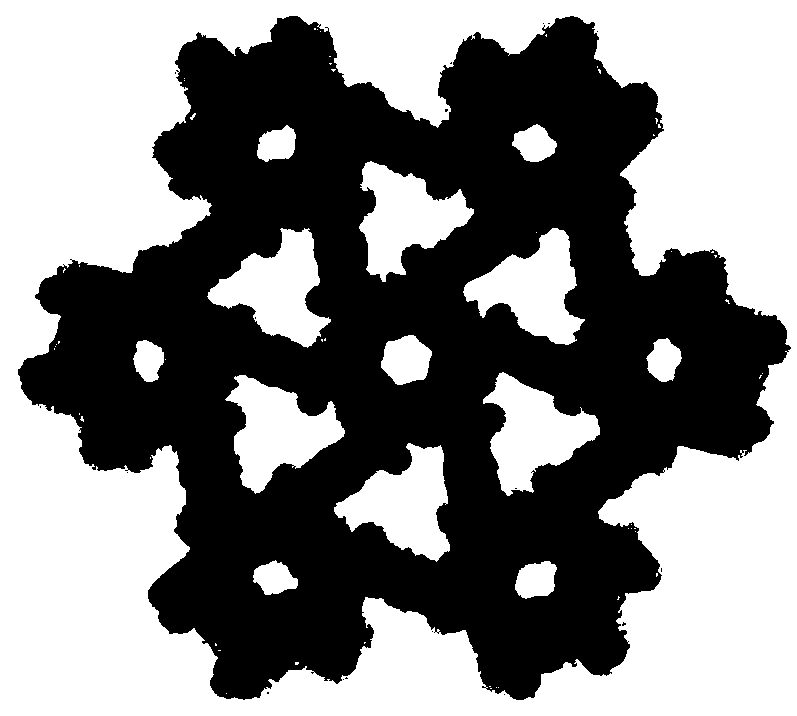

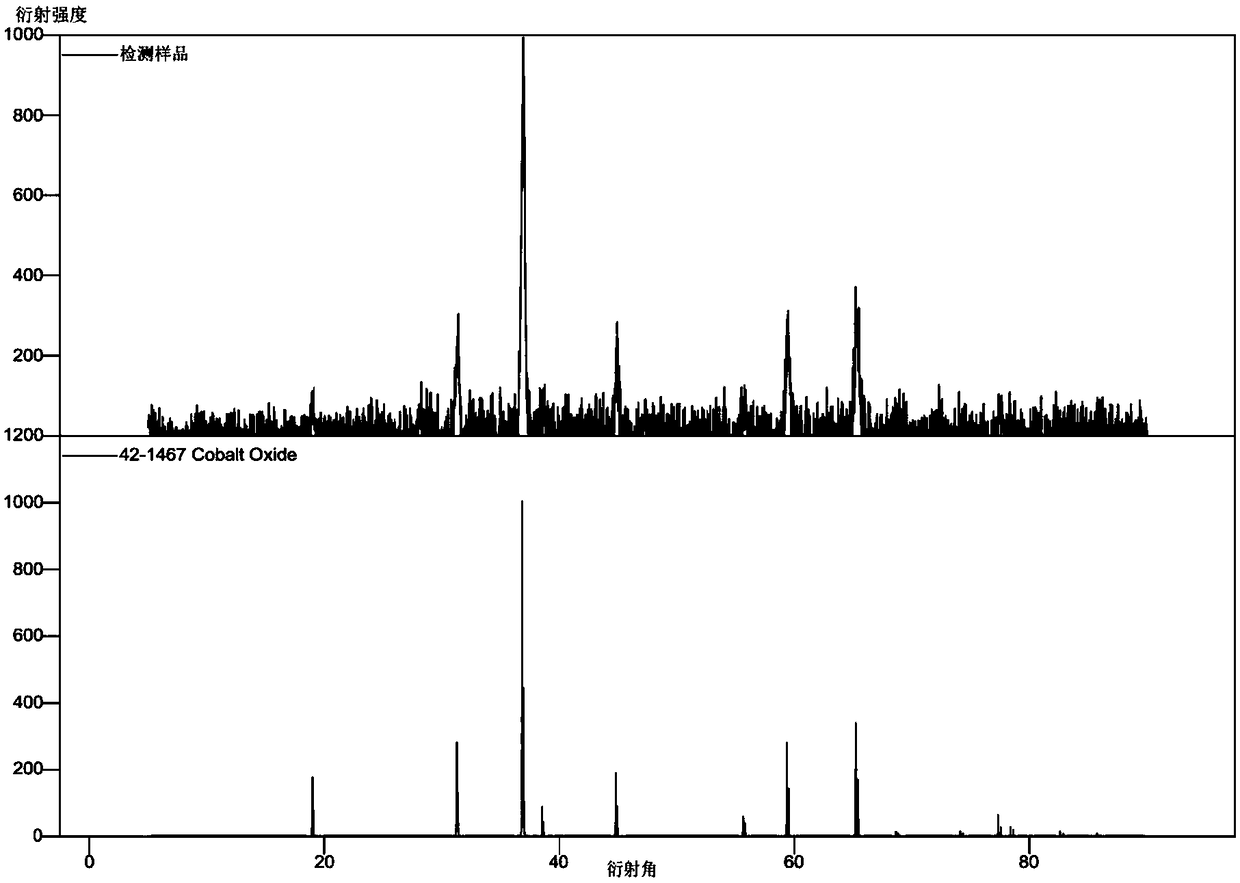

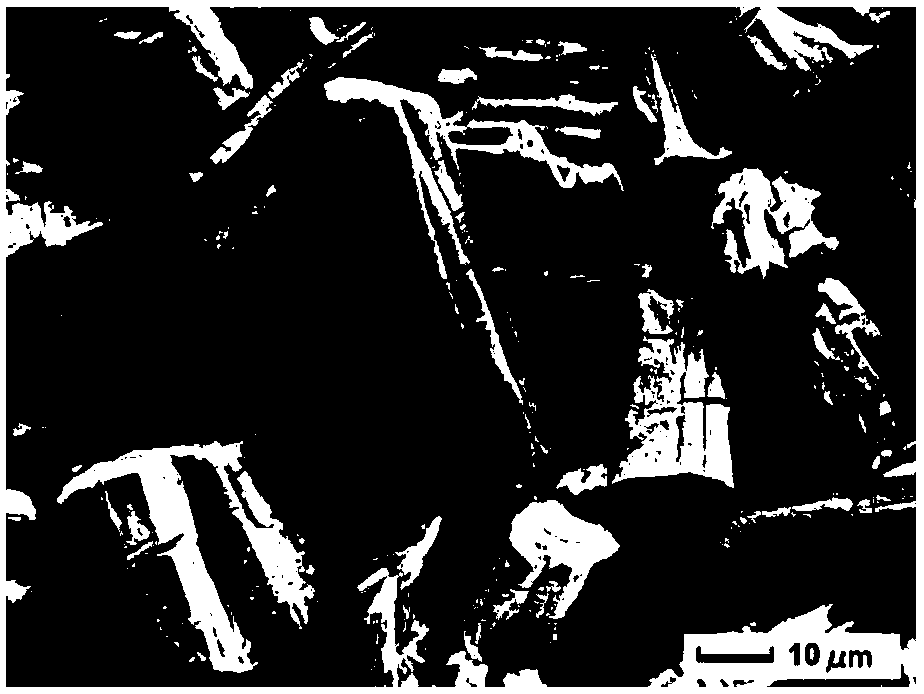

Method of in-situ synthesis of porous nano Co3O4/C anode material

The invention provides a method of in-situ synthesis of a porous nano Co3O4 / C anode material and belongs to the field of electrochemical. The method particularly includes steps of: synthesizing a rod-like porous cobalt-based metal organic framework through a solvothermal method, and washing, soaking and vacuum-drying a product to obtain a precursor; performing high-temperature carbonization decomposition to the precursor in a tubular furnace with an inert gas / oxygen mixture atmosphere, thus preparing a hierarchical porous nano / micro rod-like Co3O4 / C anode material. In the invention, with the porous and large-specific-surface-area cobalt-based metal organic framework, which has periodical network crystal structure, being a self-template precursor, the hierarchical porous nano / micro rod-likeCo3O4 / C anode material is prepared through the in-situ th ermal decomposition. The method has simple process. The anode material has high conductivity and specific capacity, and is excellent in cyclic stability.

Owner:JIANGSU UNIV

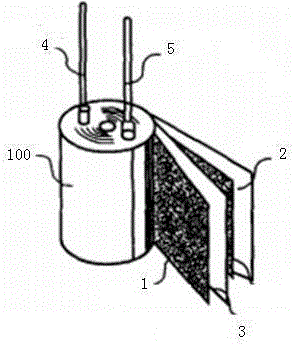

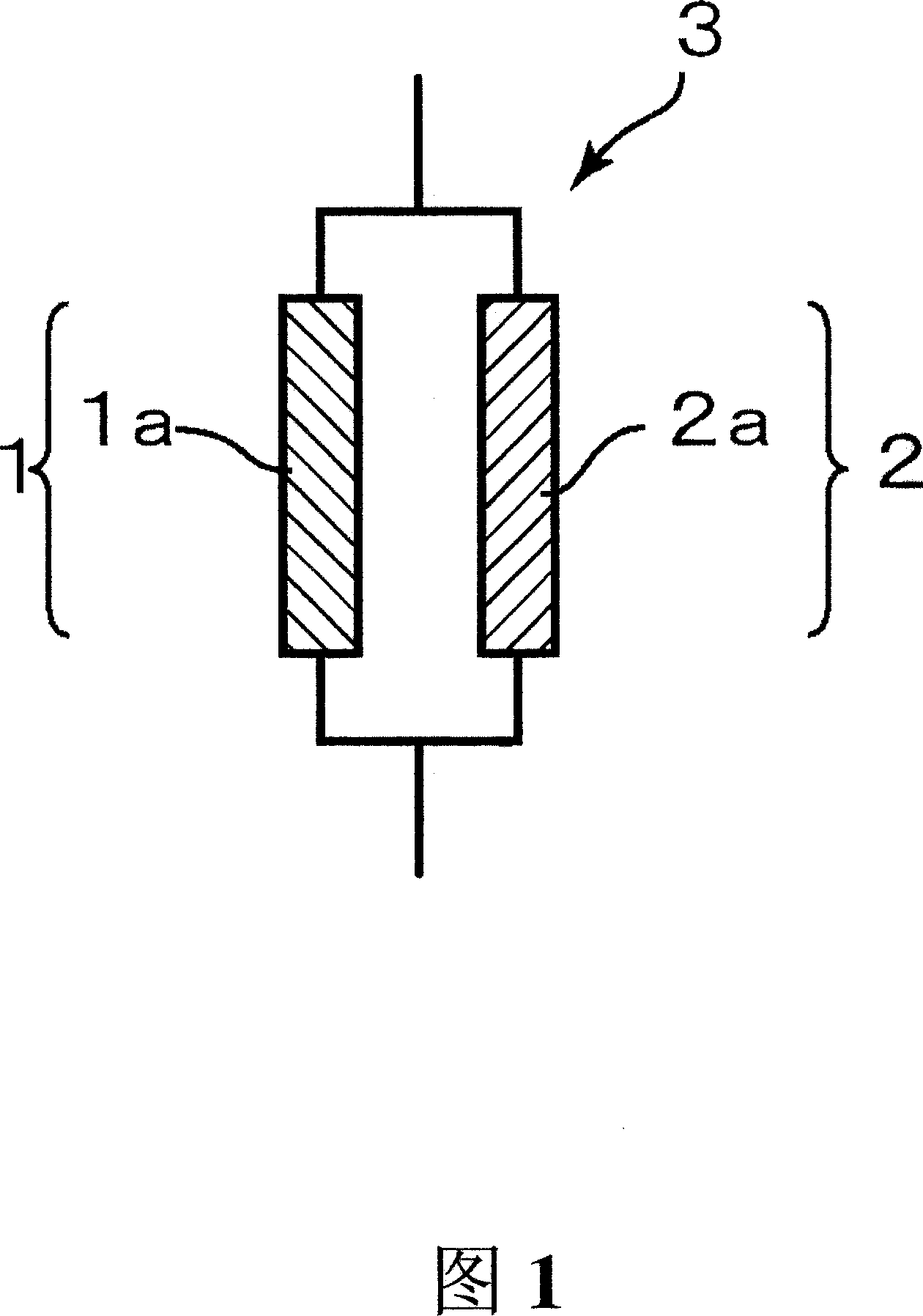

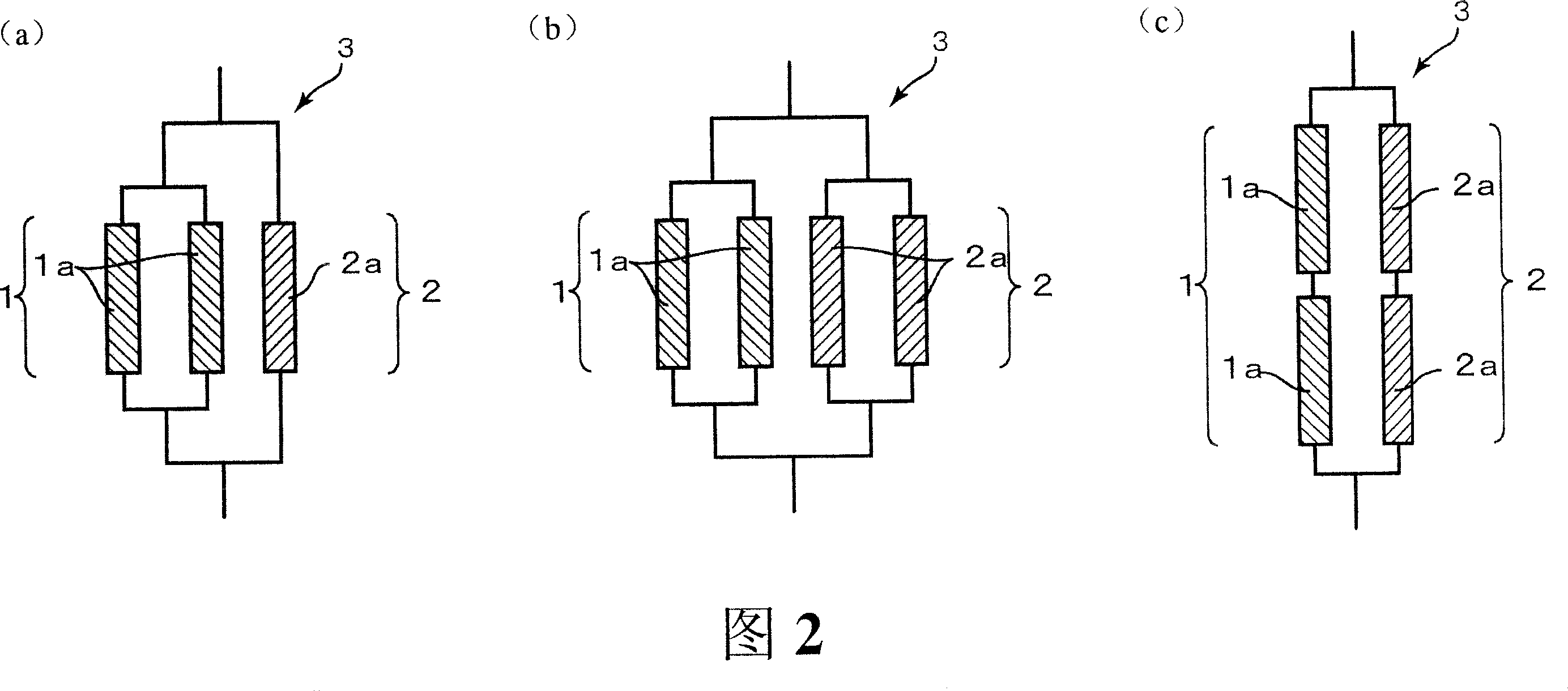

Hybrid power supply unit

InactiveCN101005148AHigh Capacity FeaturesImprove power performanceBatteries circuit arrangementsLarge-sized flat cells/batteriesControl systemNon aqueous electrolytes

The present invention provides a composite power source device which is parallel-connected with a high-capacity non-aqueous electrolyte battery set and a high-power non-aqueous electrolyte battery set which have different discharge properties, wherein: the discharge capacity of each single battery in the high-capacity non-aqueous electrolyte battery set at 0.2C is higher than the discharge capacity of each single battery in the high-power non-aqueous electrolyte battery set at 0.2C; besides the ratio between the discharge capacity of each single battery in the high-power non-aqueous electrolyte battery set at 5C and the discharge capacity at 0.2C is higher than the ratio between the discharge capacity of each single battery in the high-capacity non-aqueous electrolyte battery set at 5C and the discharge capacity at 0.2C. Therefore, the high-capacity property of long-time continuous discharging and the high-capacity property of impulsive discharging with great current can be simultaneously satisfied without the complicated control system.

Owner:PANASONIC CORP

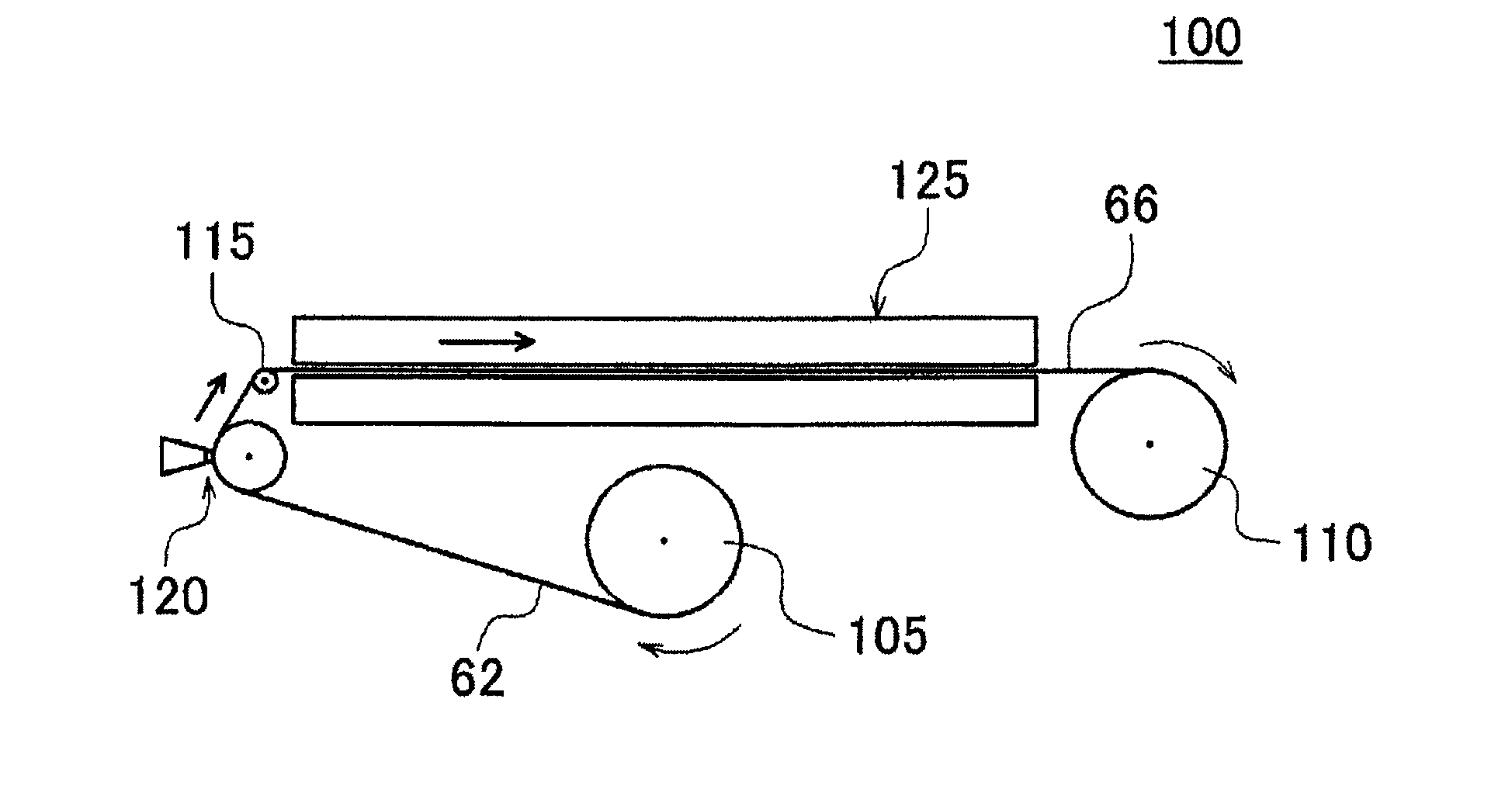

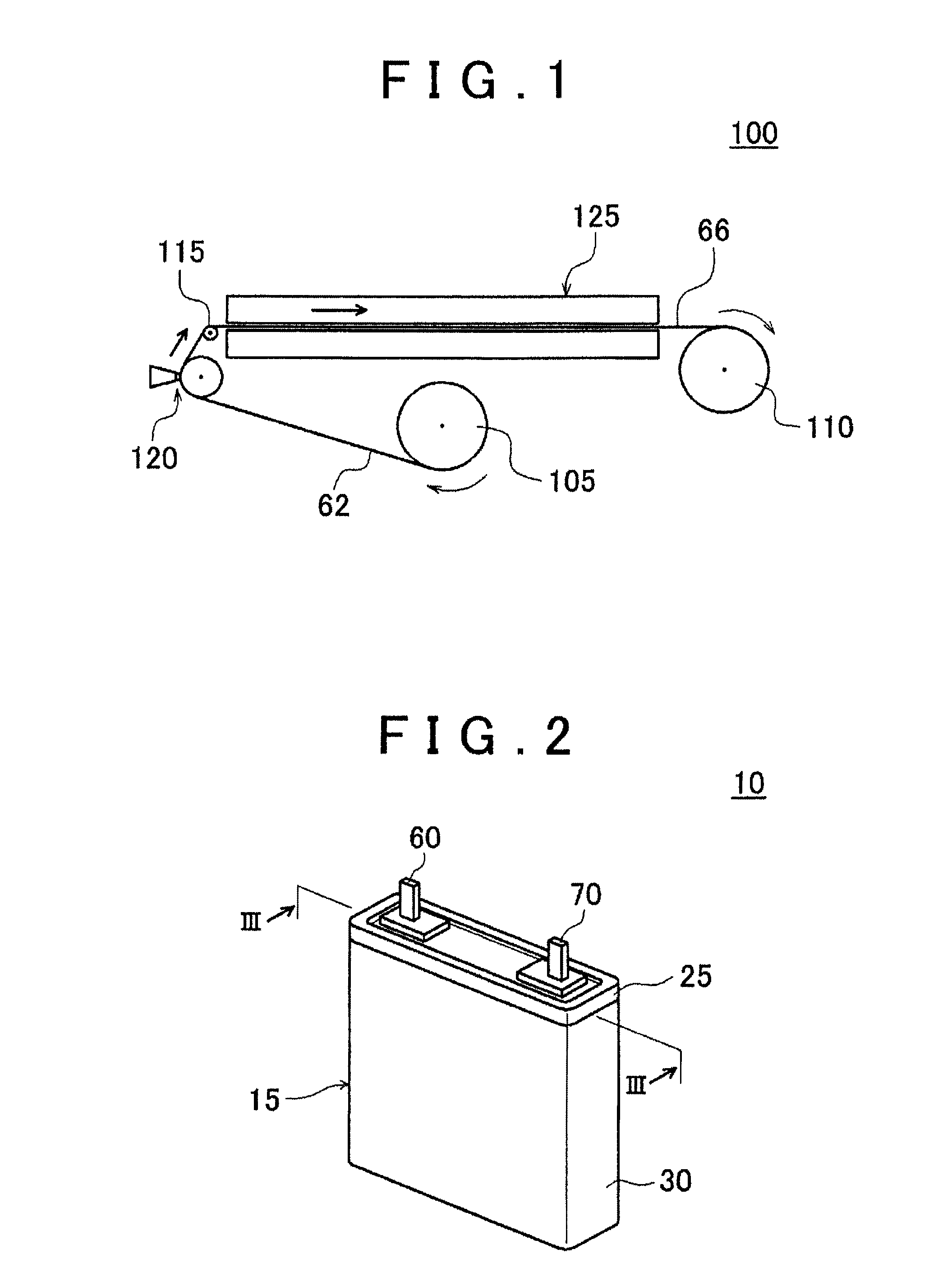

Method of producing electrode for electricity storage device

ActiveUS20130078365A1Highly efficient and low-energy productionImprove performanceSecondary cellsLiquid/solution decomposition chemical coatingElectricityShear rate

A method of producing an electrode for an electricity storage device includes producing a paste to form an electrode active material layer, in which aggregates of a solids fraction material that contains at least an electrode active material and a binder are dispersed in a solvent, coating the paste on a surface of a current collector, and drying the current collector coated with the paste, to form the electrode active material layer formed of the solids fraction material. The paste is produced in such a manner that a content ratio of the solids fraction material in the paste is 60 to 80 mass %, an abundance ratio for the aggregates with a particle size that is equal to or smaller than 20 μm is at least 99%, and a viscosity at 25° C. and a shear rate of 40 s−1 is 200 to 5,000 mPa·s.

Owner:TOYOTA JIDOSHA KK

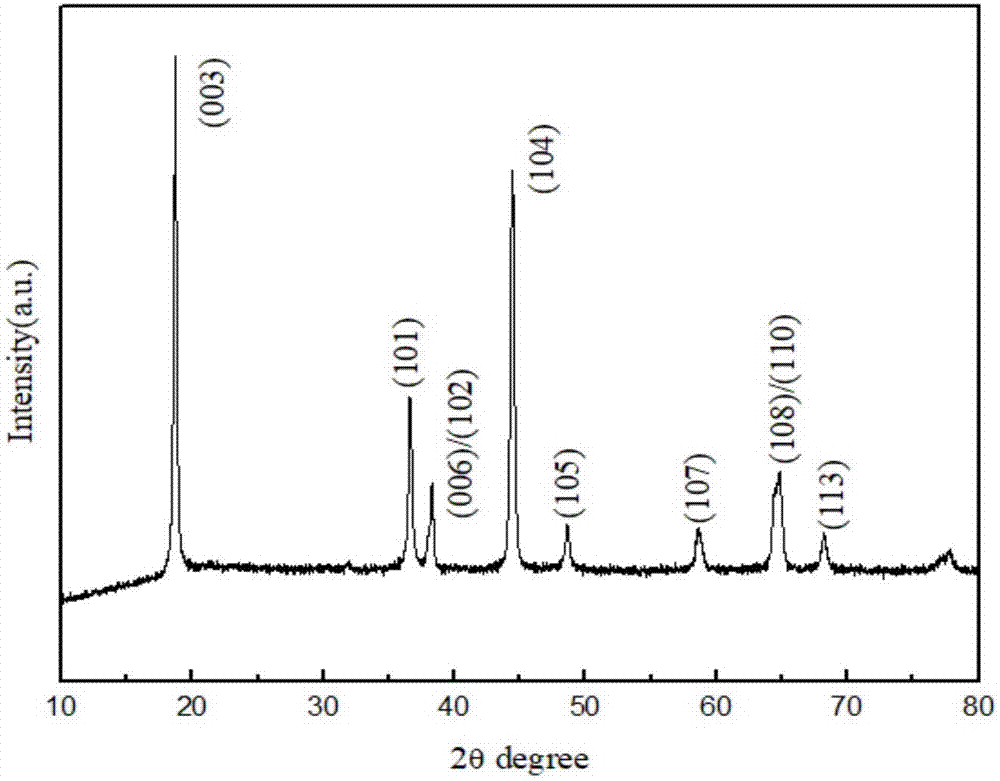

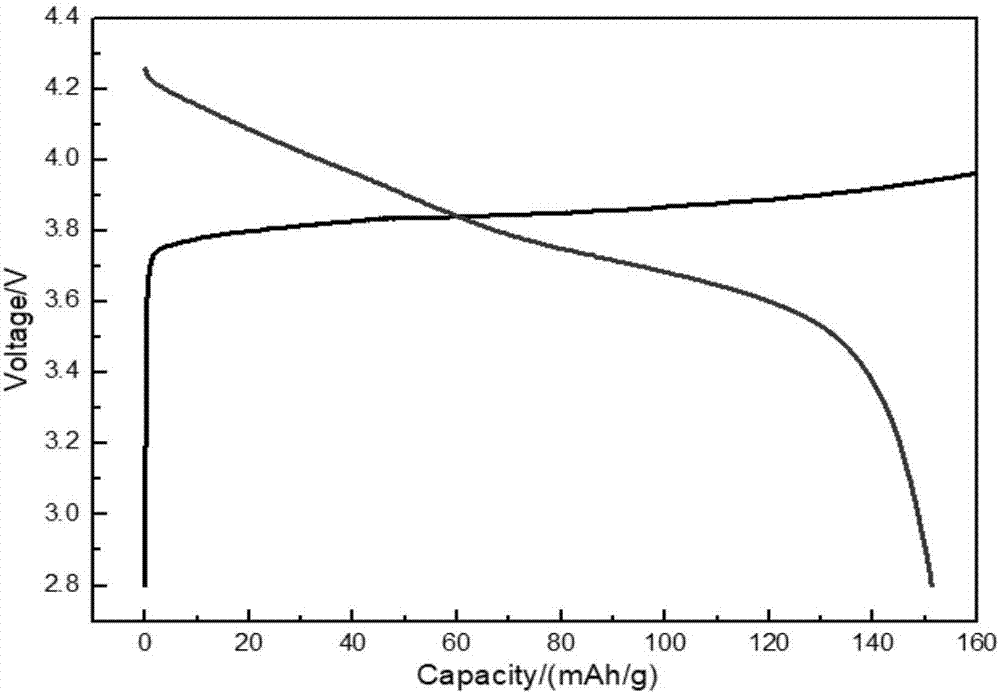

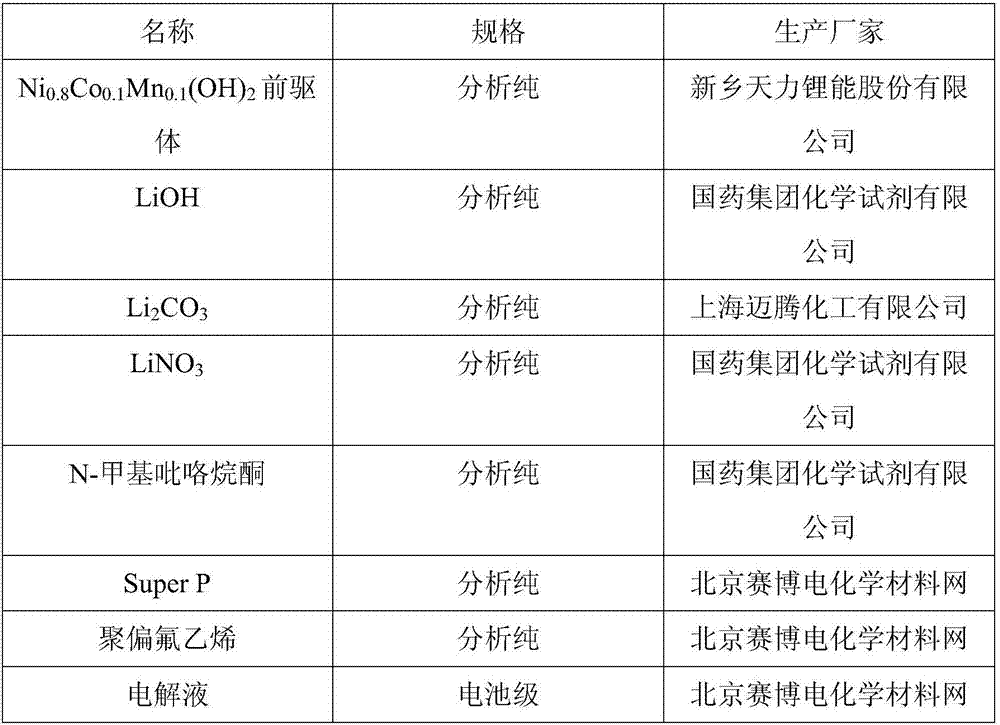

High-nickel positive electrode ternary material for lithium ion battery, and preparation method and application thereof

InactiveCN107364900AObvious ternary synergistic effectIncrease capacitySecondary cellsPositive electrodesAir atmosphereManganese

The invention relates to a high-nickel positive electrode ternary material for a lithium ion battery. The material is composed of elemental lithium, elemental nickel, elemental cobalt, elemental manganese and elemental oxygen, the molecular formula of the material is LiNi0.8Co0.1Mn0.1O2, wherein the existence valence state of the elemental nickel in the material is +2 or +3, the existence valence state of the elemental cobalt in the material is +3, the existence valence state of the elemental manganese in the material is +4, and the high-nickel positive electrode ternary material for the lithium ion battery is a hexagonal a-NaFeO2 layered structure. The invention also provides a preparation method of the ternary material for the lithium ion battery. Ni0.8Co0.1Mn0.1(OH)2 used as a precursor and LiOH / Li2CO3 / LiNO3 used as a lithium source are calcined in an air atmosphere by through a high-temperature solid phase sintering technology to obtain the positive electrode material for the lithium ion battery. The lithium ion battery positive electrode material has the advantages of high capacity, good cycle performances, simple synthesis conditions and low cost.

Owner:SHANGHAI INST OF TECH

Composite nano porous electrode material, process for production thereof, and lithium ion secondary battery

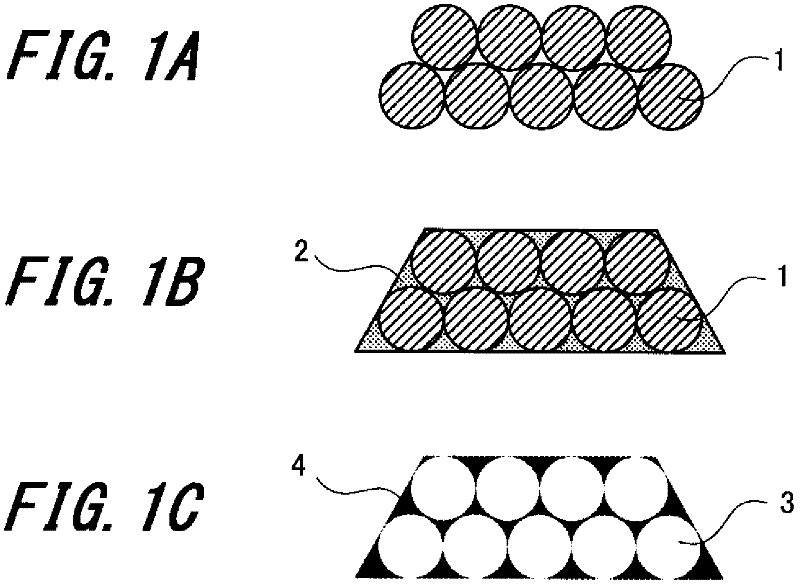

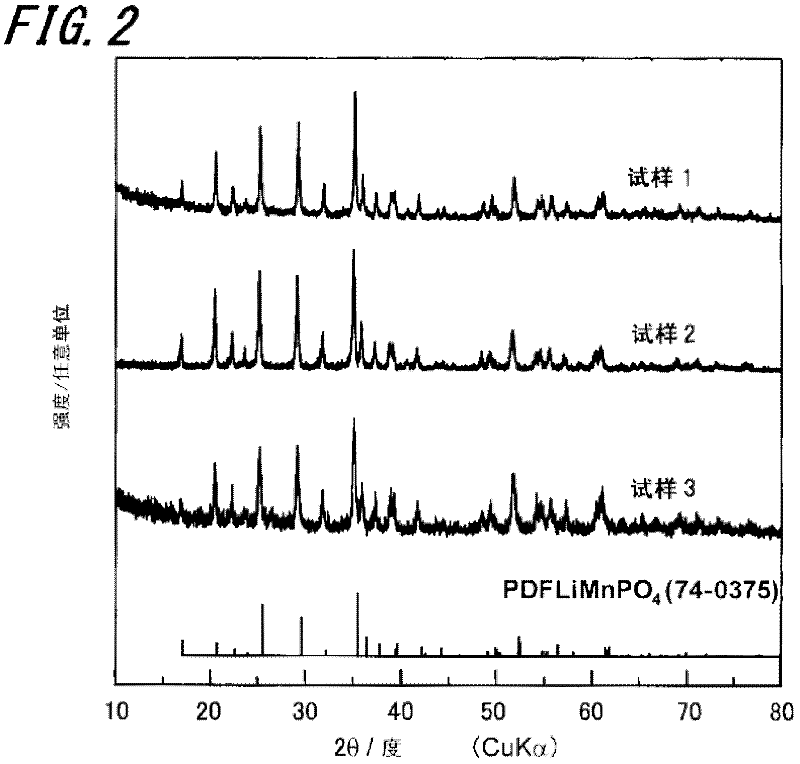

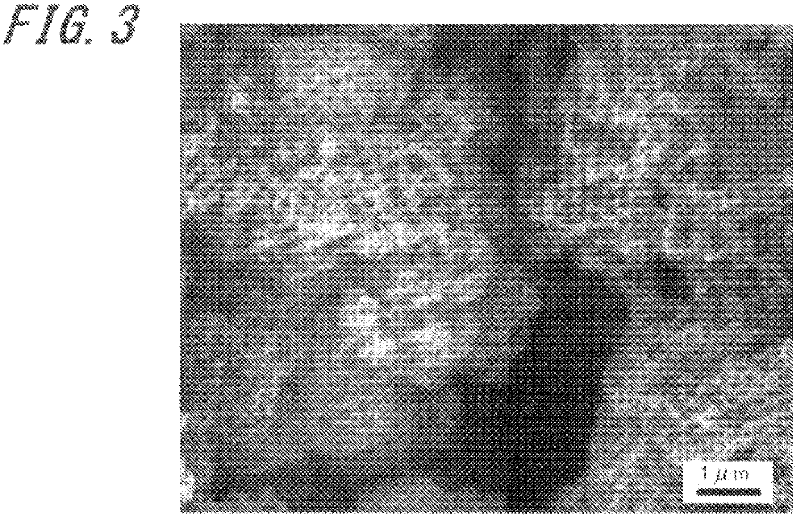

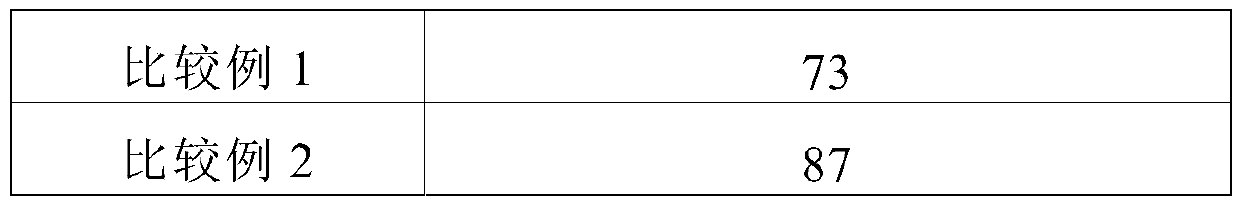

InactiveCN102460786AImprove electron conductivityIncreased insertion and extraction speedMaterial nanotechnologyCell electrodesOlivineCrystallite

Disclosed are: a composite nano porous electrode material having high charge-discharge properties and a high charge / discharge capacity; a process for producing the composite nano porous electrode material; and a lithium ion secondary battery produced utilizing the composite nano porous electrode material. The composite nano porous electrode material has such a porous structure that nano-sized pores are three-dimensionally connected, wherein the wall of each of the pores comprises olivine-type LiMnPO4 and carbon, the specific surface area (Sa) falls within the following range: 55 m2g-1 2g-1, the carbon content (Cc) falls within the following range: 15.5 wt% < Cc < 28 wt%, and the crystallite diameter is smaller than 39 nm. The composite nano porous electrode material can achieve a high charge / discharge capacity and a high-speed charge / discharge properties.

Owner:NAGASAKI UNIVERSITY

Anode for lithium secondary battery, lithium secondary battery comprising same, and manufacturing method therefor

InactiveCN110168783AReduce irreversible capacityHigh Capacity FeaturesFinal product manufactureNegative electrodesLithium metalLithium-ion battery

The present invention relates to: an anode for a lithium secondary battery, comprising an anode active material layer, which is formed on an anode current collector, and a coating layer, which is formed on the anode active material layer and includes lithium metal and metal oxides; a lithium secondary battery comprising the same; and a manufacturing method therefor.

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com