Lithium-rich cathode material and preparation method and application thereof

A lithium-rich positive electrode material and lithium-rich technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of complex process, regulation, and distribution of difficult elements in the synthesis of gradient structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] see figure 1 : a lithium-rich cathode material of the present invention, its general formula is expressed as:

[0066] wxya 2 MnO 3 ·yLiNi x1 mn y1 co (1-x1-y1) o 2 ·zLiNi x2 mn y2 co z2 Al x3 o 2 , where x=27 / 100, y=63 / 100, z=1 / 10, x1=1 / 3, y1=1 / 3, x2=1 / 2, y2=3 / 2, z2=0, x3= 0.

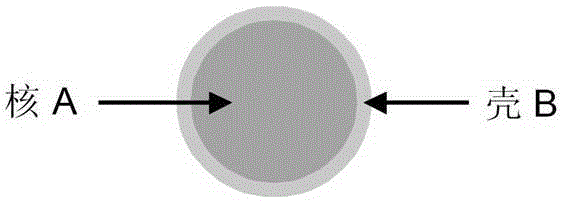

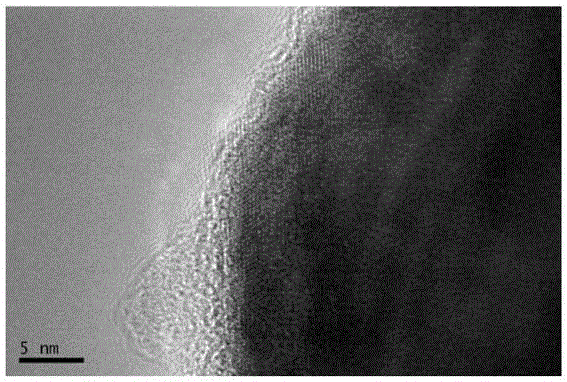

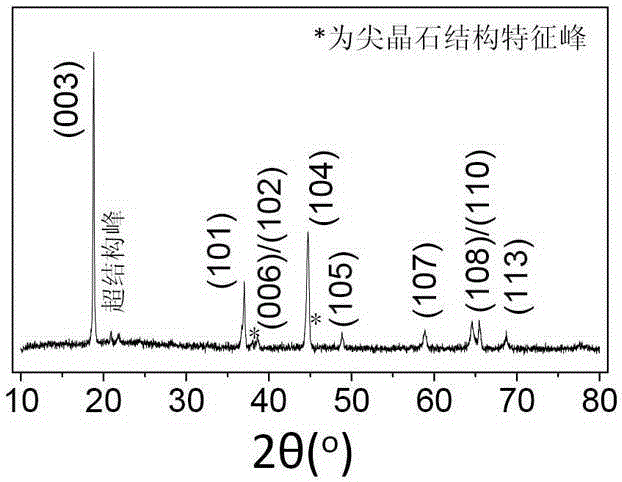

[0067] The lithium-rich positive electrode material includes a lithium-rich solid solution (core A) and a material with lithium ion conductivity (shell B). The material with lithium ion conductivity is coated on the surface of the lithium-rich solid solution to form a core-shell structure; it has lithium ion conductivity The material is a spinel structure material.

[0068] In the lithium-rich positive electrode material of this embodiment, the lithium-rich solid solution (ie, the core material) is granular, and the lithium-rich solid solution is a secondary particle formed by accumulating primary particles, and the particle size of the primary particle is about 0.1 μm to 0.3 μm. I...

Embodiment 2

[0098] A kind of lithium-rich cathode material of the present invention, its general formula is expressed as:

[0099] wxya 2 MnO 3 ·yLiNi x1 mn y1 co (1-x1-y1) o 2 ·zLiNi x2 mn y2 co z2 Al x3 o 2 , where x=27 / 100, y=63 / 100, z=1 / 10, x1=1 / 3, y1=1 / 3, x2=1 / 2, y2=3 / 2, z2=0, x3= 0.

[0100] The lithium-rich positive electrode material includes a lithium-rich solid solution (core A) and a material with lithium ion conductivity (shell B). The material with lithium ion conductivity is coated on the surface of the lithium-rich solid solution to form a core-shell structure; it has lithium ion conductivity The material is a spinel structure material.

[0101] In the lithium-rich positive electrode material of this example, the lithium-rich solid solution is a secondary particle formed by the accumulation of primary particles. The particle size of the primary particle is about 0.1 μm to 0.3 μm. In the range of 4μm ~ 6μm. Its chemical formula is Li 7 / 6 mn 1 / 2 Ni 1 / 6 co 1 / ...

Embodiment 3

[0122] A kind of lithium-rich cathode material of the present invention, its general formula is expressed as:

[0123] wxya 2 MnO 3 ·yLiNi x1 mn y1 co (1-x1-y1) o 2 ·zLiNi x2 mn y2 co z2 Al x3 o 2 , where x=27 / 100, y=63 / 100, z=1 / 10, x1=1 / 3, y1=1 / 3, x2=4 / 5, y2=0, z2=3 / 20, x3= 0.05.

[0124] The lithium-rich positive electrode material includes a lithium-rich solid solution (core A) and a material with lithium ion conductivity (shell B). The material with lithium ion conductivity is coated on the surface of the lithium-rich solid solution to form a core-shell structure; it has lithium ion conductivity The material is a layered ternary material.

[0125] In the lithium-rich positive electrode material of this example, the lithium-rich solid solution is a secondary particle formed by the accumulation of primary particles. The particle size of the primary particle is about 0.1 μm to 0.3 μm. In the range of 4μm ~ 6μm. Its chemical formula is Li 7 / 6 mn 1 / 2 Ni 1 / 6 co ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com