Patents

Literature

1572results about How to "High tap density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphite composite lithium ion battery anode material lithium iron phosphate and preparation method thereof

ActiveCN101562248AImprove electronic conductivityImprove tap densityElectrode manufacturing processesPower batteryChemical Linkage

The invention relates to a graphene composite lithium ion battery anode material lithium iron phosphate and a preparation method thereof. The composite material of lithium iron phosphate and graphene is connected by interface of chemical bonding. The invention also provides the method for preparing the graphene composite lithium ion battery anode material lithium iron phosphate in an in-situ symbiosis reaction mode, and the obtained anode material has high tap density and good magnifying performance, and is suitable to be used as a anode material of a lithium ion power battery.

Owner:龚思源

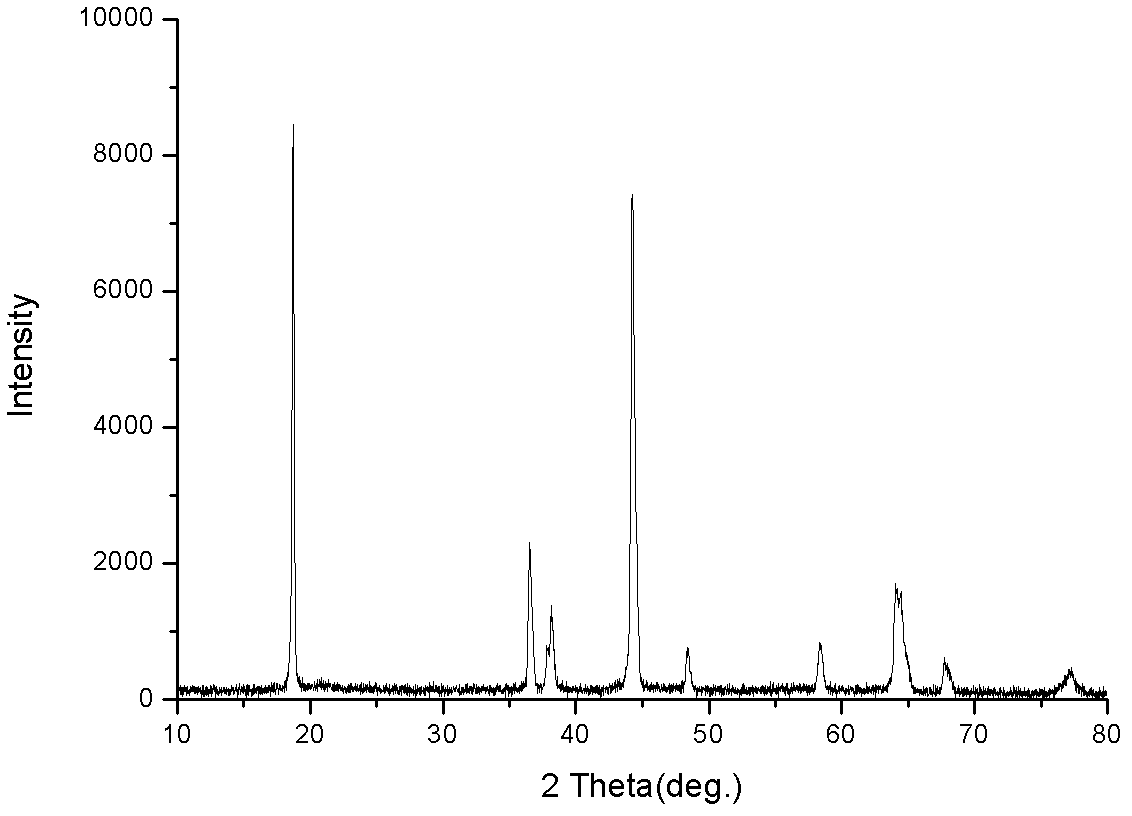

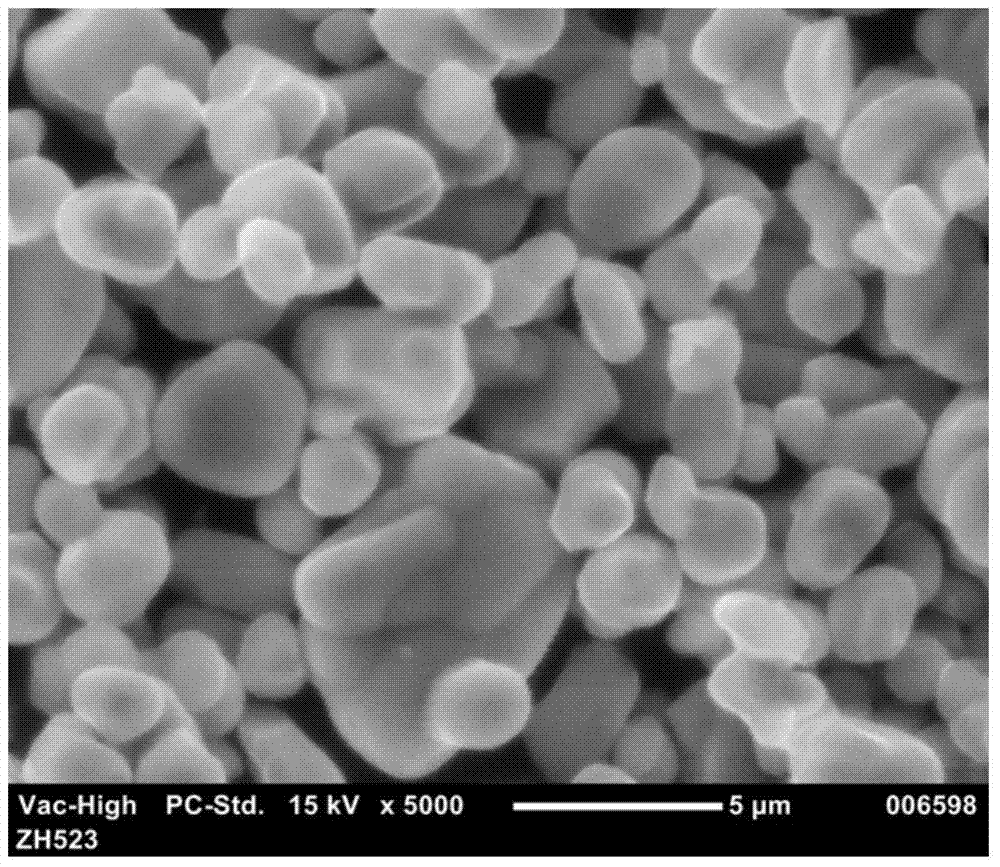

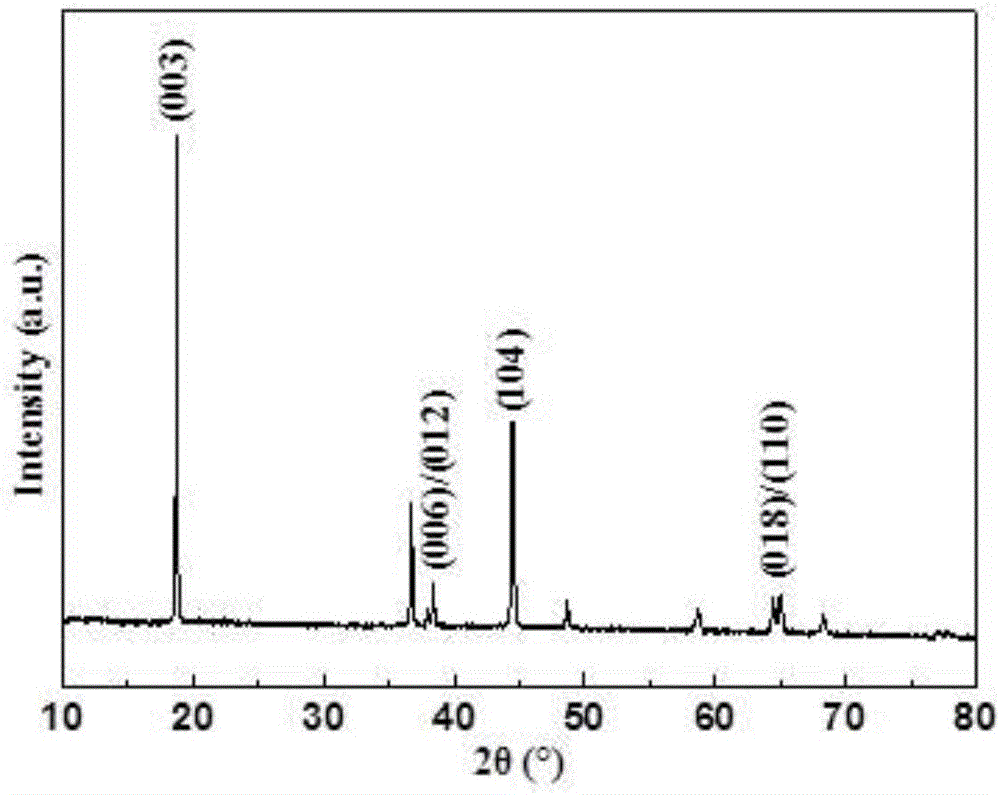

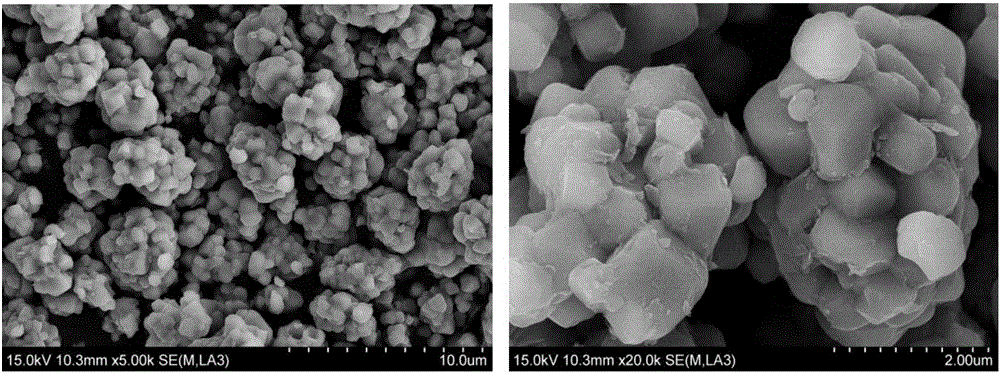

Lithium ion battery positive pole material cobalt nickel oxide manganses lithium and method for making same

ActiveCN101202343AHigh specific capacityExcellent cycle characteristicsElectrode manufacturing processesLithium compoundsLithium oxideAntioxidant

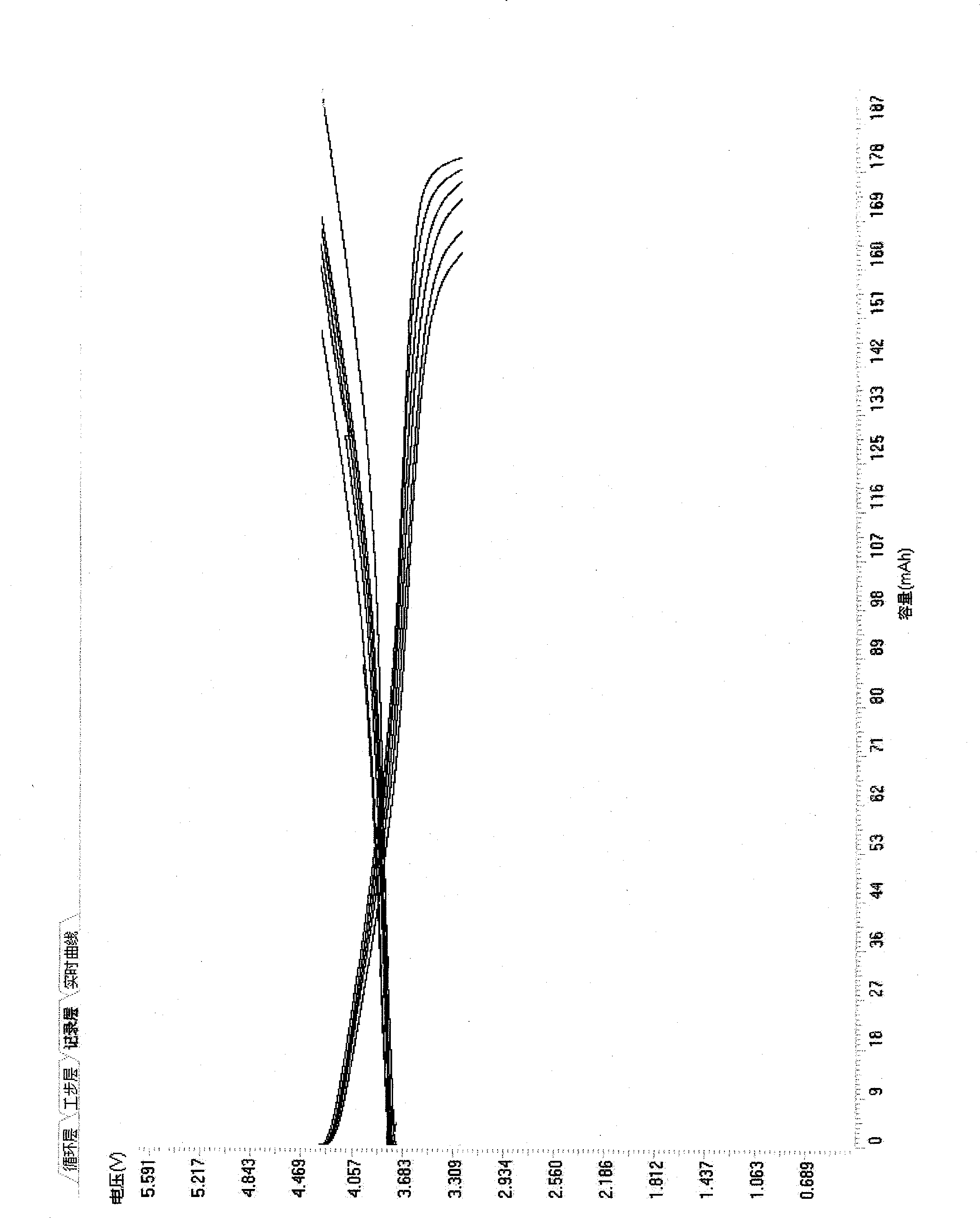

The invention relates to a nickel cobalt manganese lithium oxide material used for an anode of a li-ion battery and a preparation method. The invention belongs to the li-ion battery technical field. The nickel cobalt manganese lithium oxide material used for the anode of the li-ion battery is a li-rich laminated structure with the chemical component of Li1+zM1-x-yNixCoyO2; wherein, z is less than or equal to 0.2 and more than or equal to 0.05, x is less than or equal to 0.8 and more than 0.1, and y is less than or equal to 0.5 and more than 0.1. The preparation method of the invention is that dissoluble salt of the nickel, cobalt and manganese is taken as the raw material; ammonia or ammonium salt is taken as complexing agent; sodium hydroxide is taken as precipitator; water-dissoluble dispersant and water-dissoluble antioxidant or inert gas are added for control and protection; in a cocurrent flow type the solution is added to a reaction vessel for reaction; after alkalescence disposal, aging procedure, solid-liquid separation and washing and drying, the nickel cobalt manganese oxide is uniformly mixed with the lithium raw material; the nickel cobalt manganese lithium oxide powder is obtained by sintering the mixed powder which is divided into three temperature areas. The invention has the advantages of high specific capacity, good circulation performance, ideal crystal texture, short production period, low power loss, and being suitable for industrial production, etc.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST +1

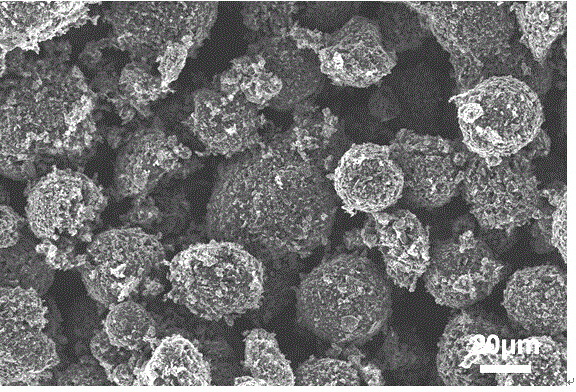

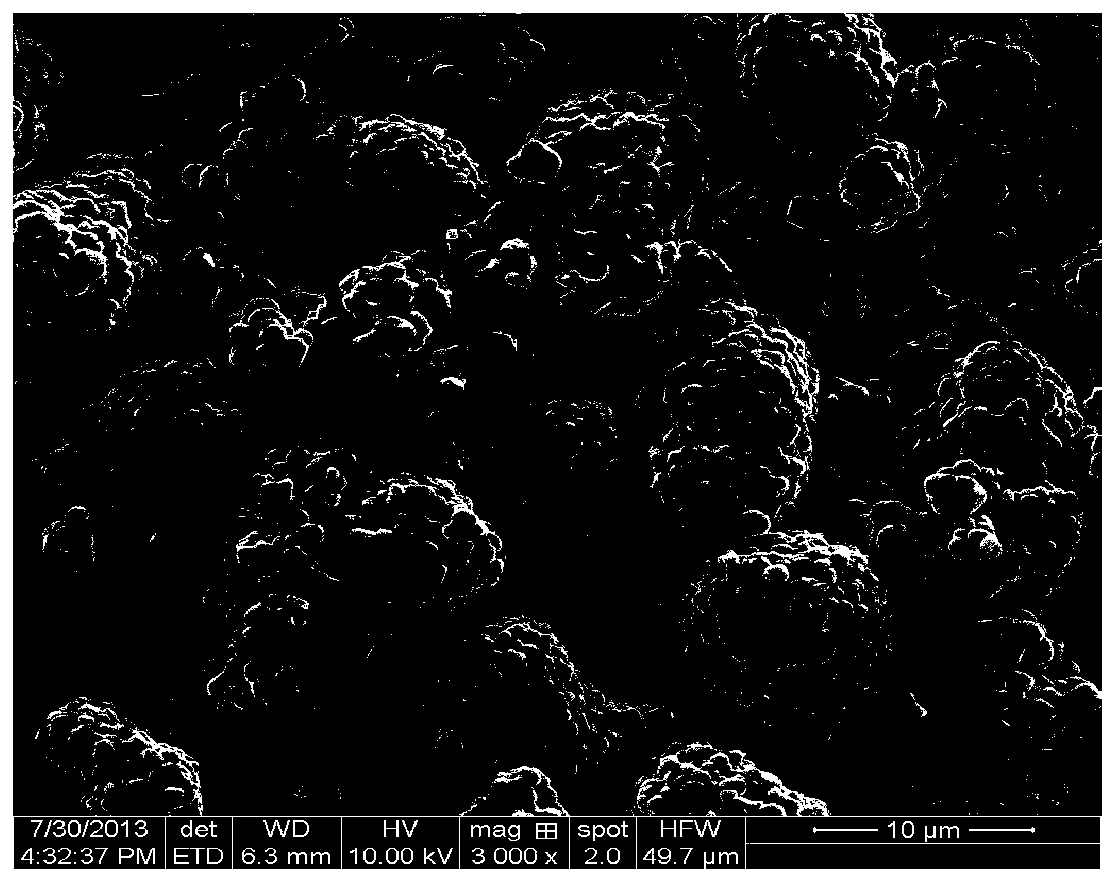

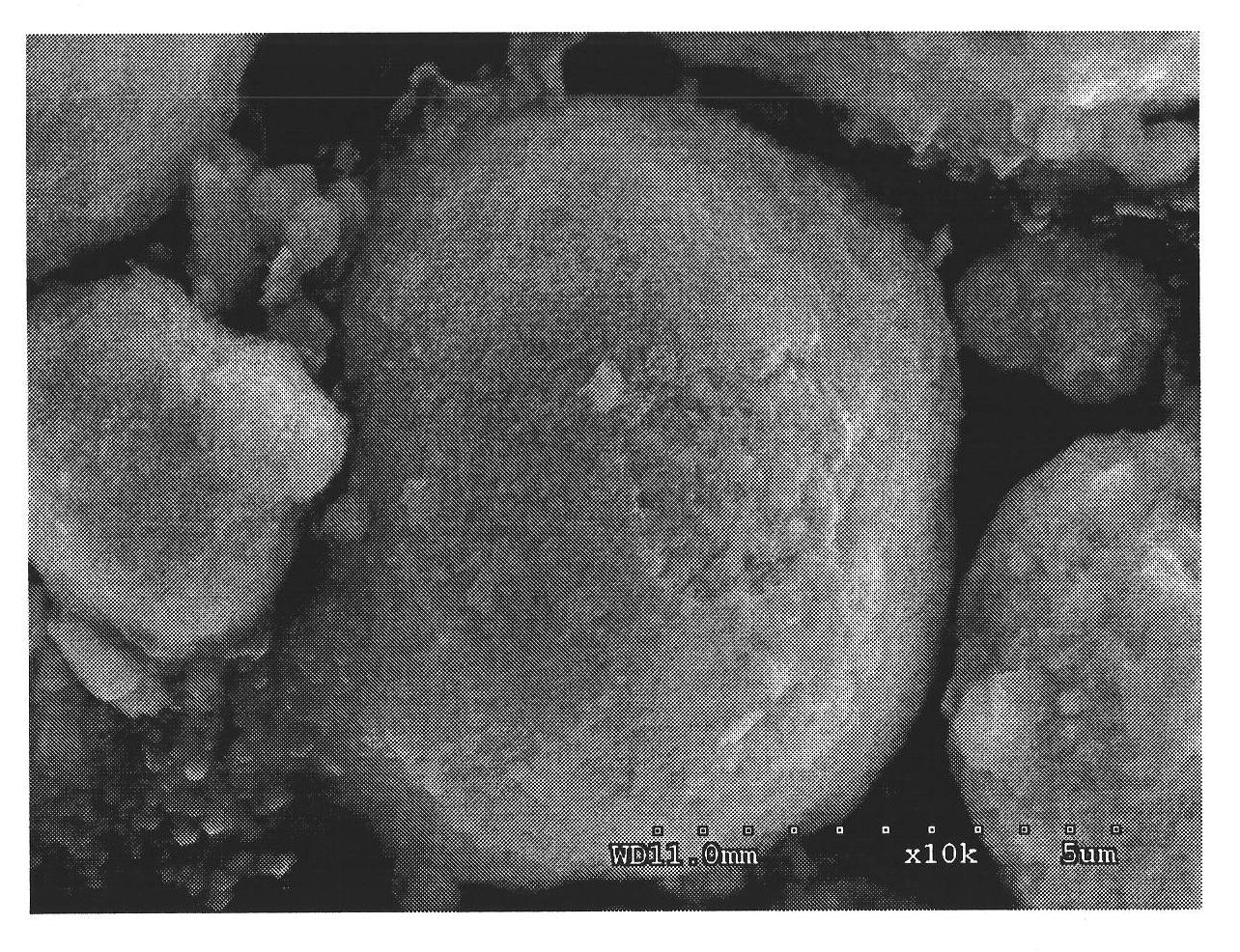

Preparation method for nickel-manganese-cobalt anode material of lithium ion battery

InactiveCN102306765AImprove discharge capacityImprove cycle performanceCell electrodesManganeseLithium compound

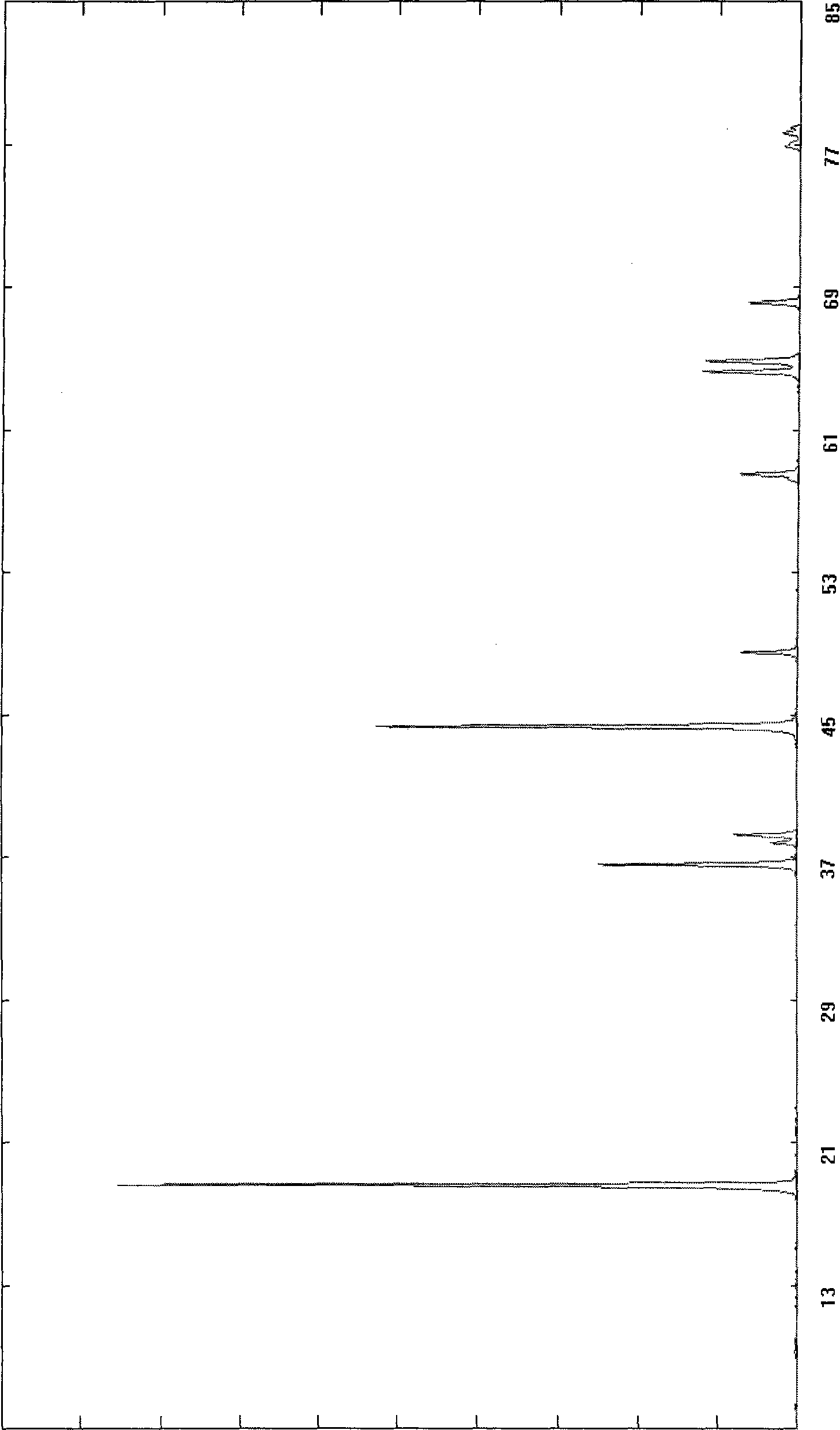

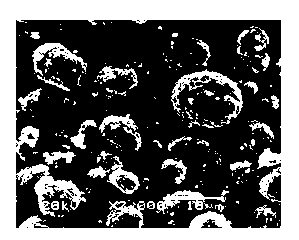

The present invention relates to a preparation method for a nickel-manganese-cobalt anode material of a lithium ion battery. According to the present invention, in the presence of nitrogen atmosphere, a mixed solution containing nickel iron, manganese iron and cobalt ion reacts with a precipitating agent, then processes of aging, washing, drying and the like are performed to obtain a nickel-manganese-cobalt hydroxide precursor, the synthesized precursor material has spherical morphology, ideal particle size distribution and high tap density; the precursor, a lithium compound and a doped compound are mixed, then the sintering processing is performed for twice to prepare the nickel-manganese-cobalt three-element composite anode material. The method has characteristics of simple synthesis process, easy process controlling, low energy consumption, high efficiency and low cost, and is applicable for the industrial production; the prepared precursor material has characteristics of spherical morphology, uniform particle distribution and high tap density; the discharge capacity of the battery is improved through doping the metals; the cycle performance of the battery is stable.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

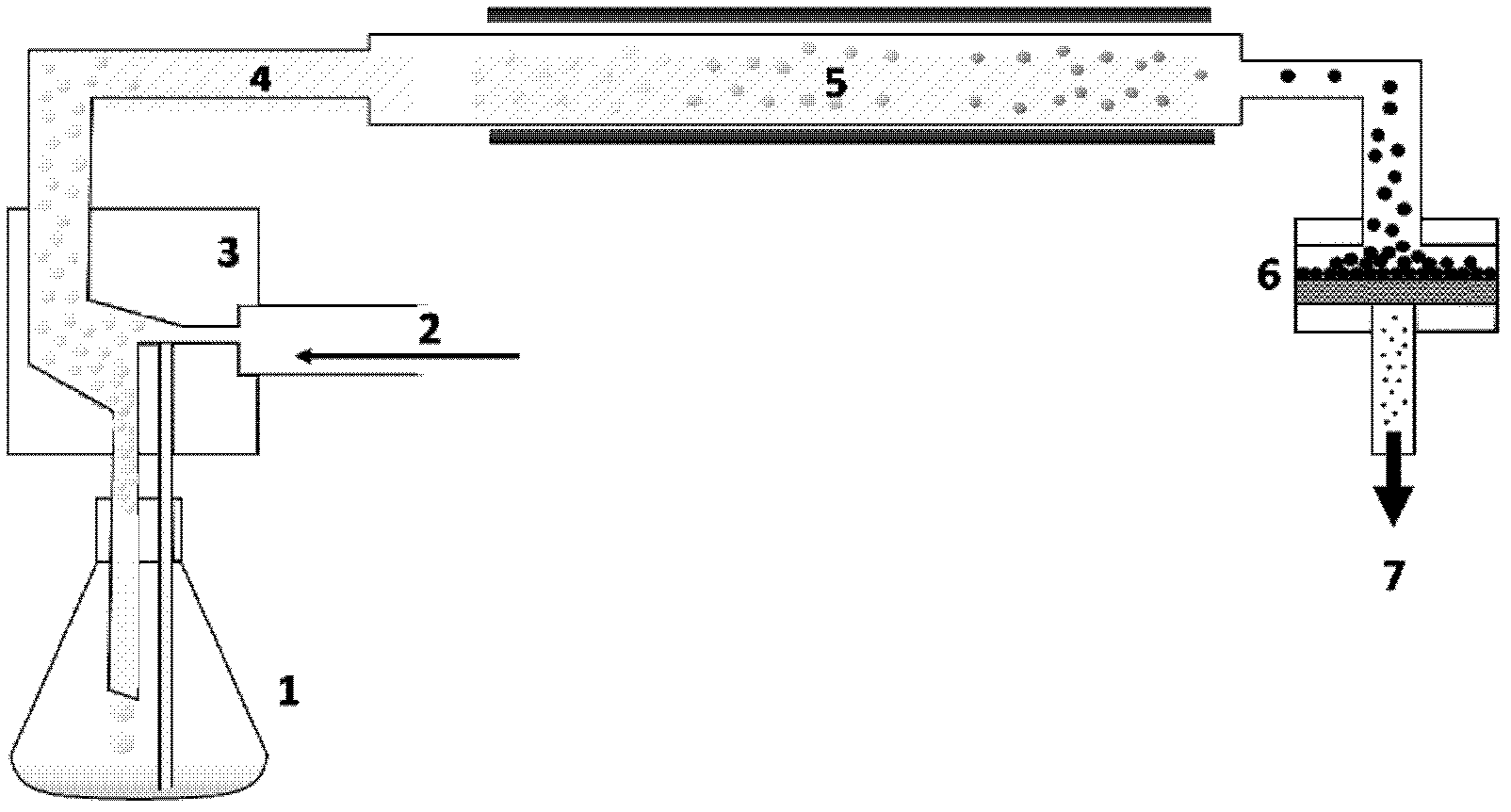

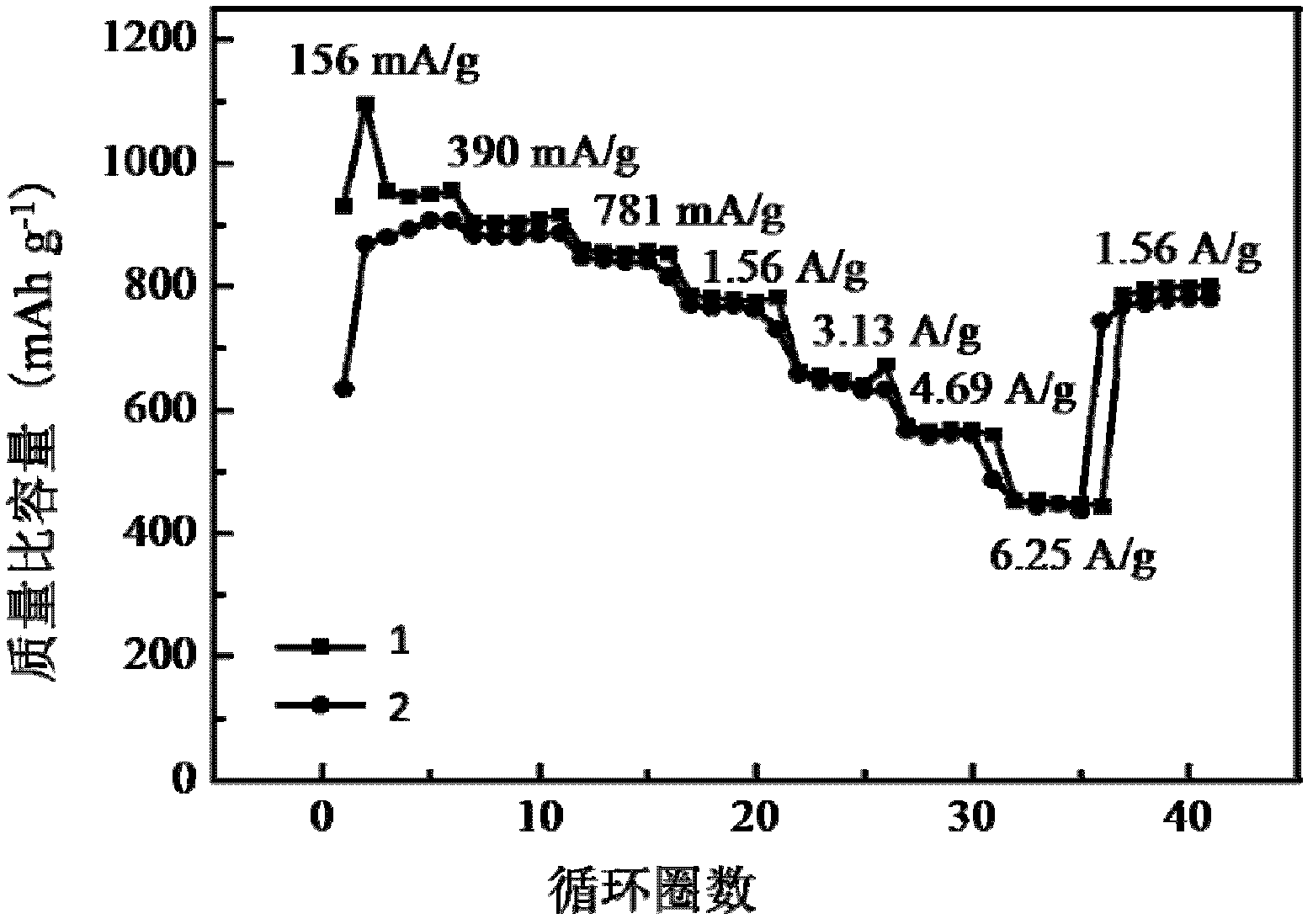

Preparation method of silicon and carbon-coated graphene composite cathode material

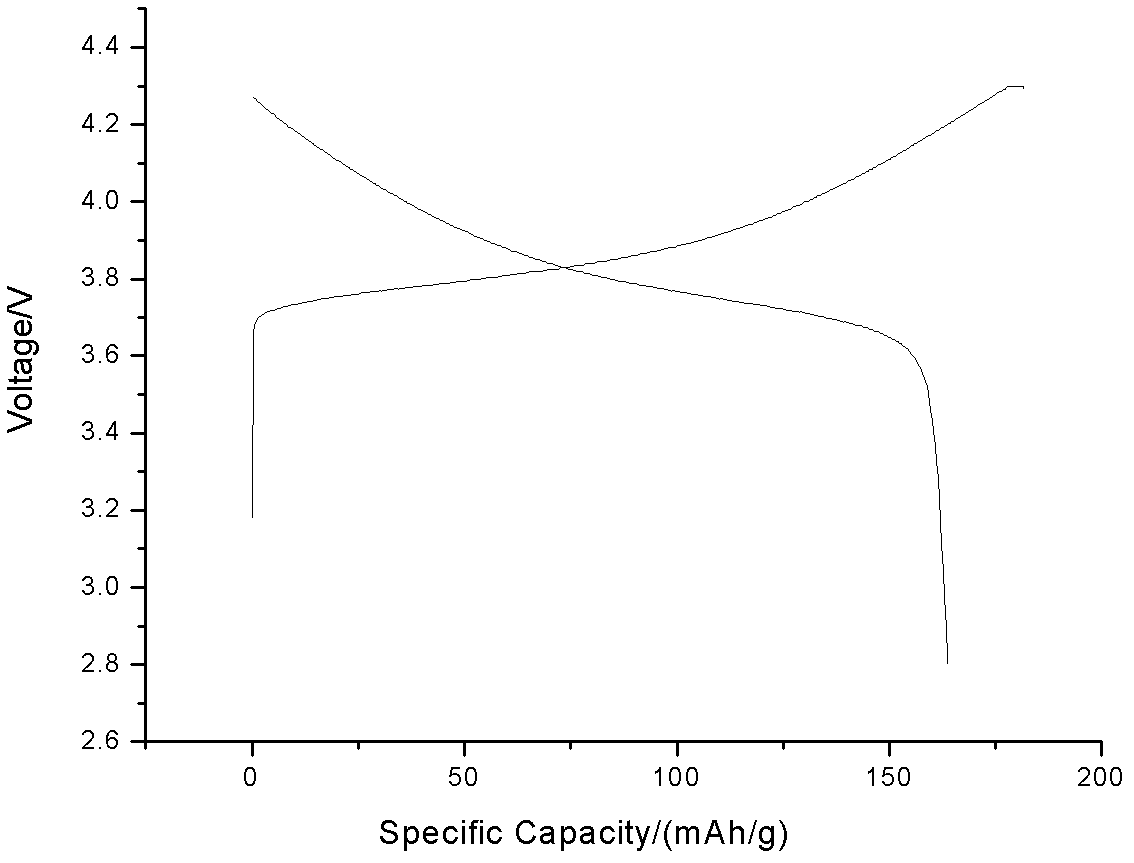

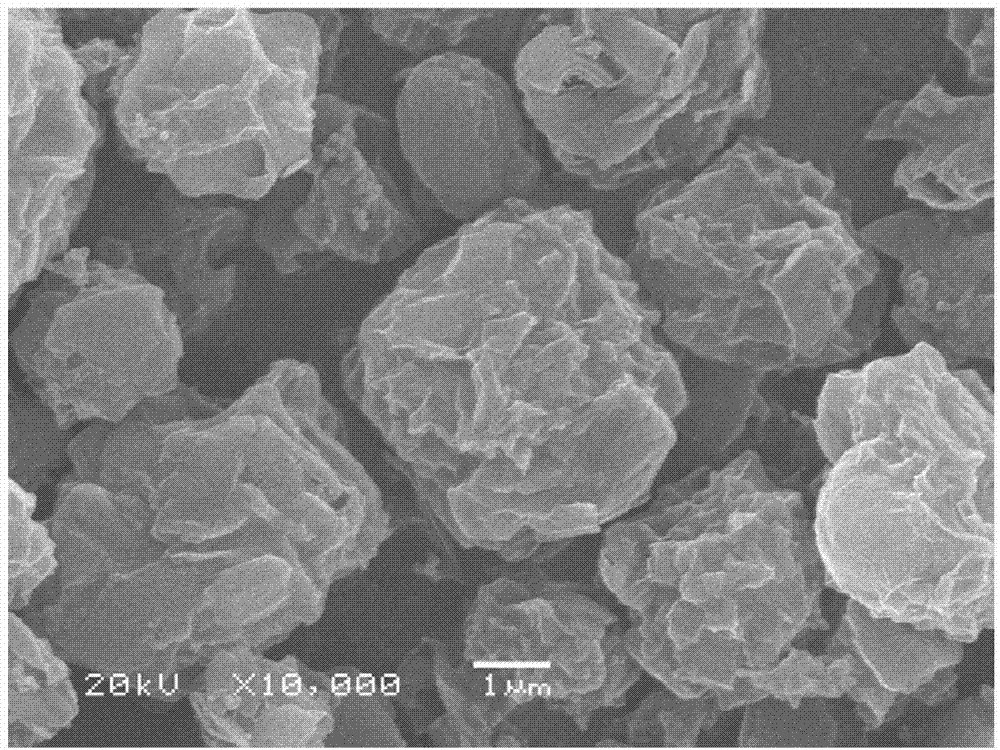

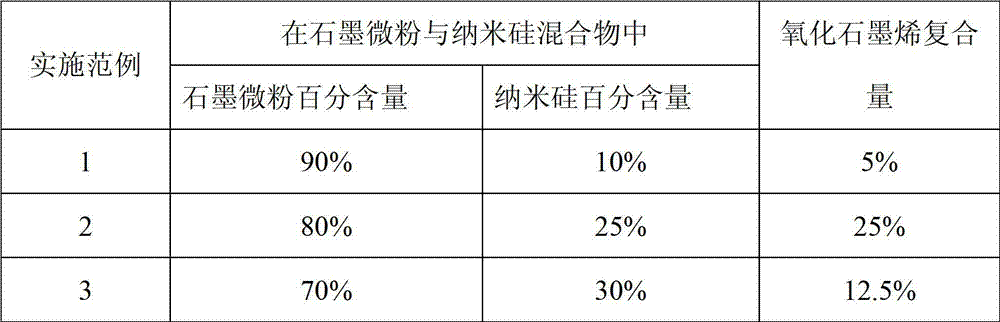

ActiveCN103050666ARealize in situ restorationThe preparation process is simple, convenient and practicalMaterial nanotechnologyCell electrodesCarbon coatedStructural stability

The invention discloses a preparation method of a silicon and carbon-coated graphene composite cathode material. The technical problem to be solved is to enhance the electronic conductivity of the silicon-based cathode material, buffer the volume effect produced in the process of deintercalation of the lithium in the silicon-based cathode material and enhance the structure stability in the circulation process of the material at the same time. The material is prepared by using a spray drying-thermally decomposing treatment process in the invention. The preparation method comprises the following steps of: evenly dispersing nano silicon and graphite micro powder in a dispersion solution of oxidized graphene, carrying out thermal treatment under an inert protection atmosphere after spray drying, subsequently cooling along a furnace to obtain the silicon and carbon-coated graphene composite cathode material. The extra binder does not need to add in the process of manufacturing balls in the invention and the outer oxidized graphene is thermally reduced in situ to graphene in the thermal treatment process of the composite precursor, so that the process is simple and easy to operate; and the practical degree is high. The prepared composite material has the advantages of great reversible capacity, designable capacity, good cycling performance and high-current discharging performance, high tap density and the like.

Owner:CENT SOUTH UNIV

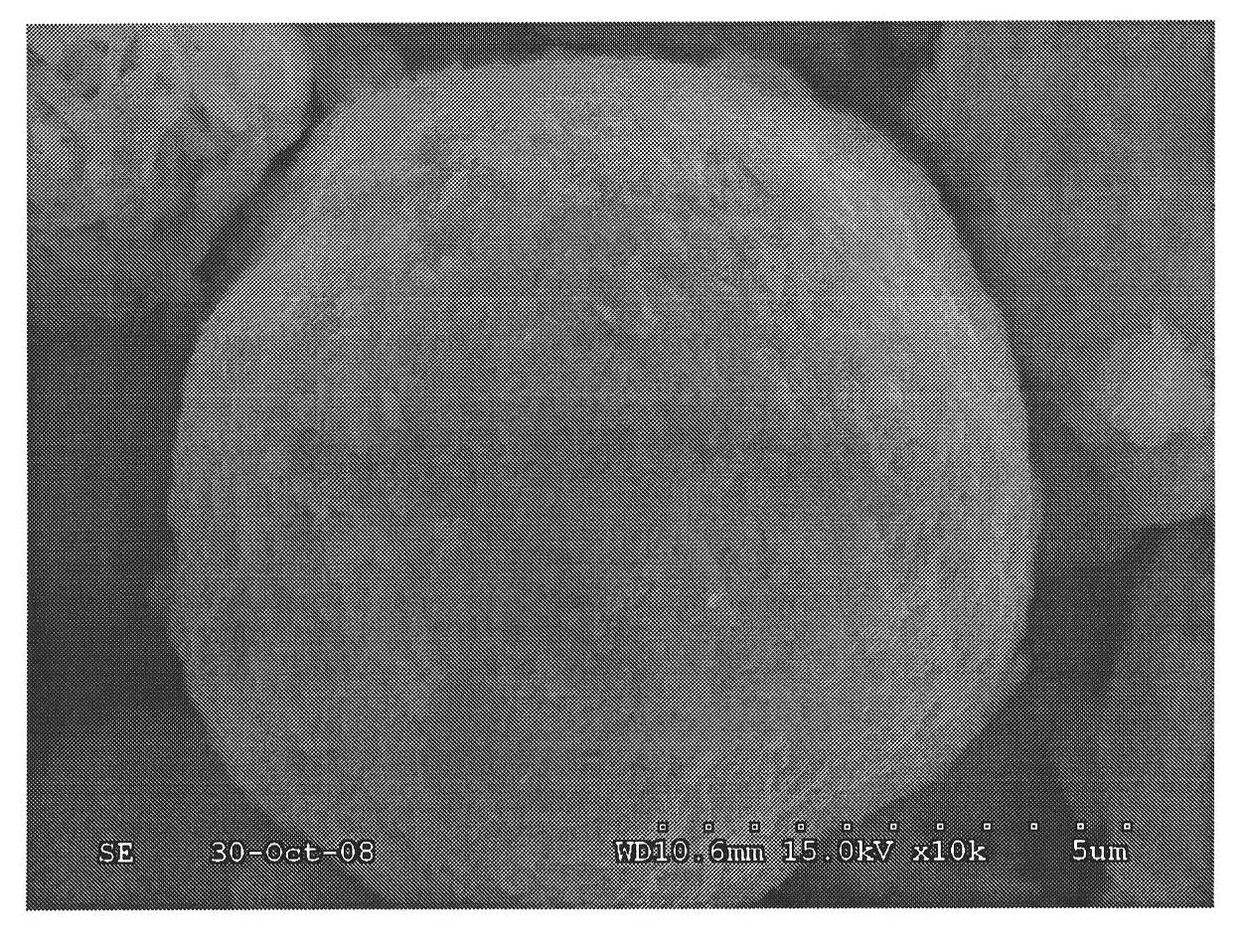

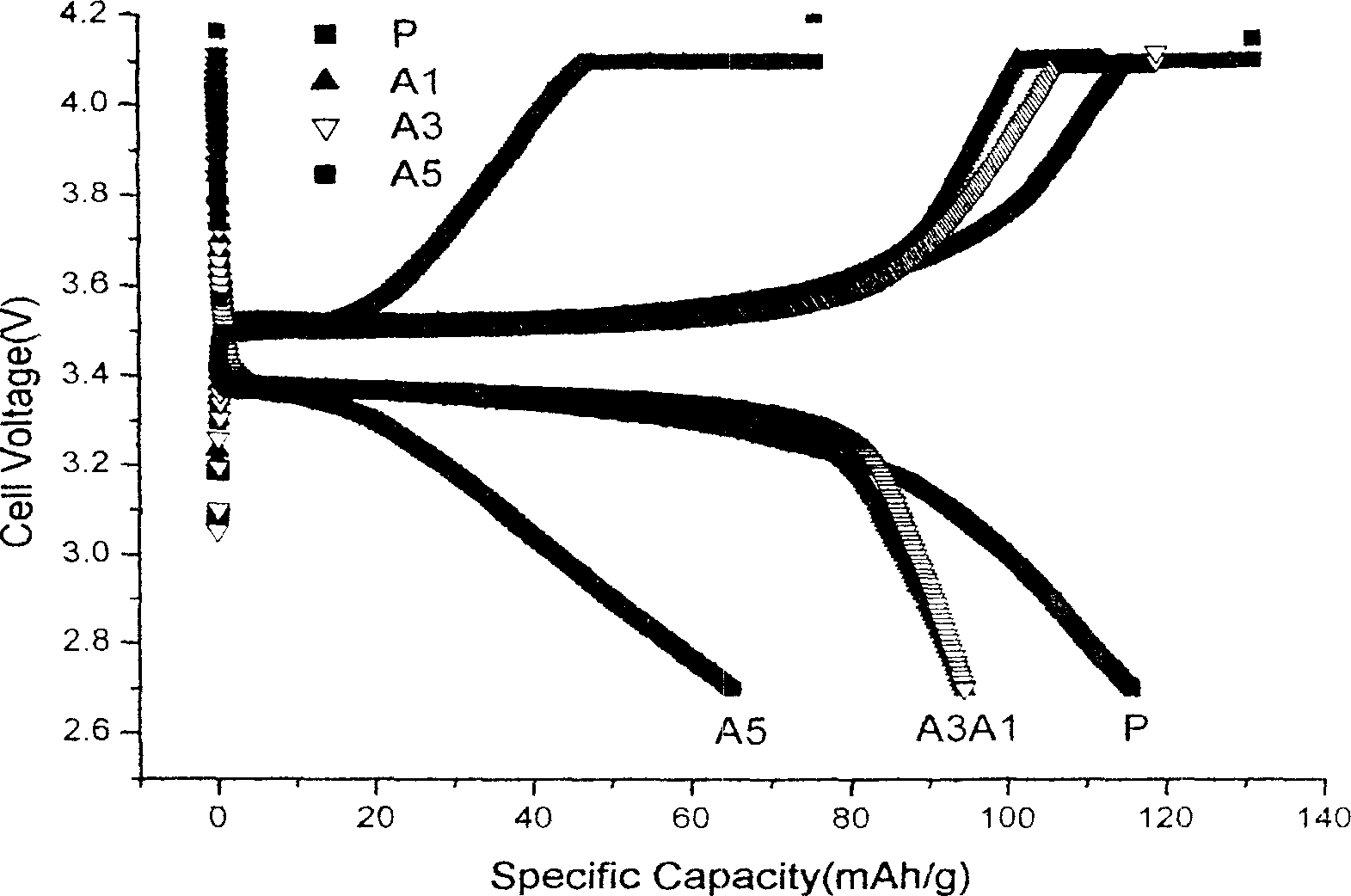

Ferric phosphate lithium material for lithium ion powder cell and preparation method thereof

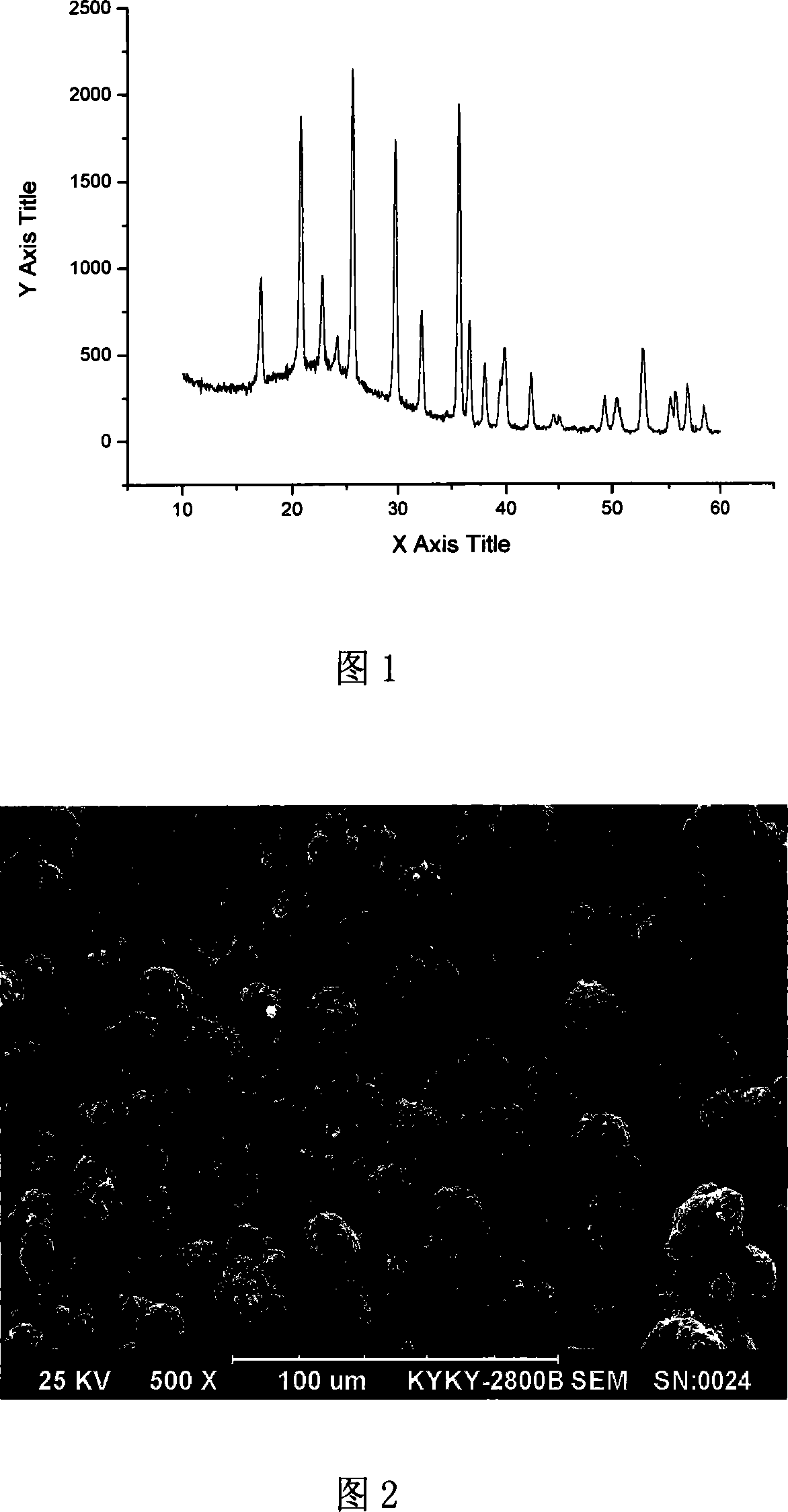

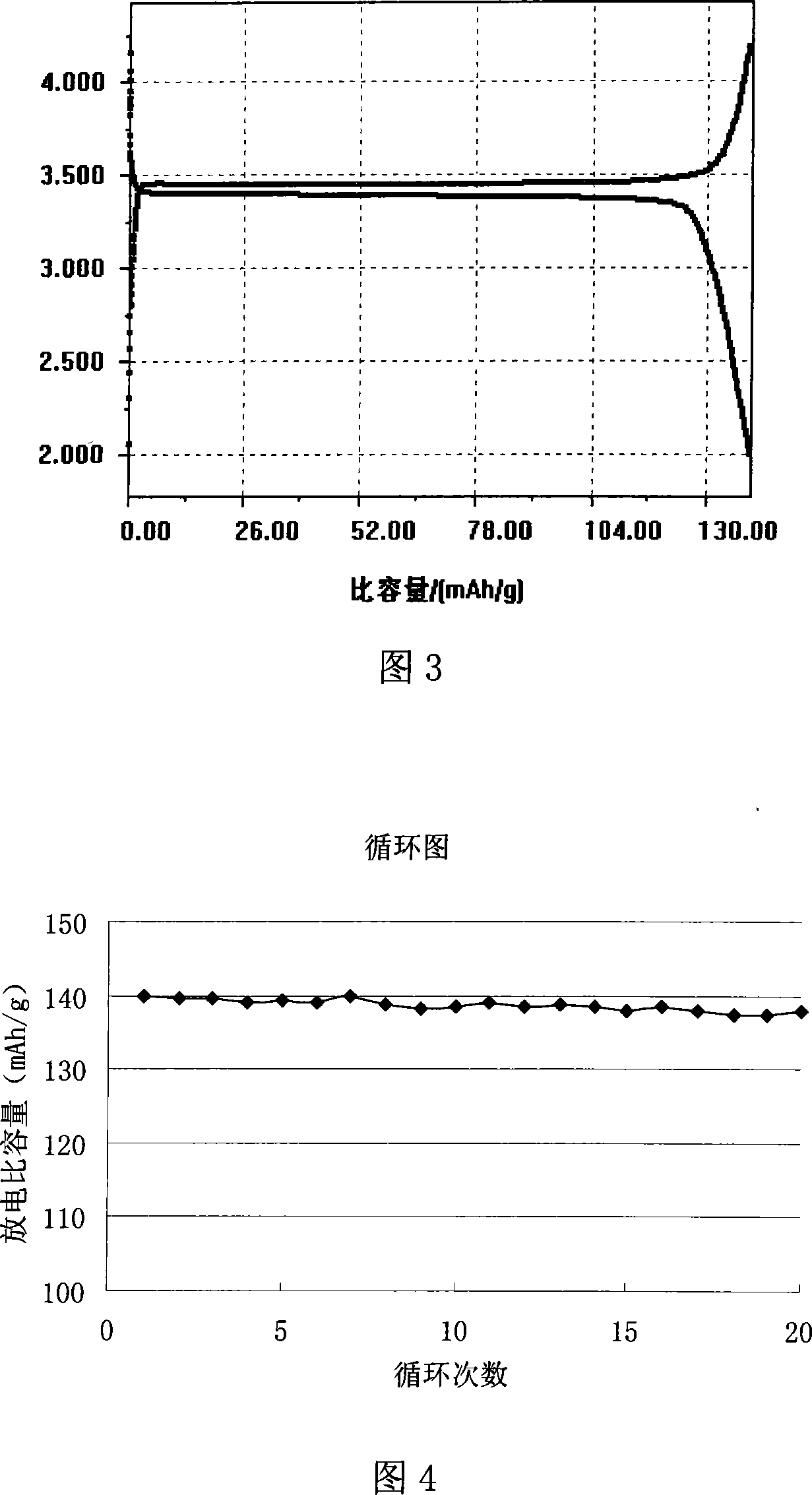

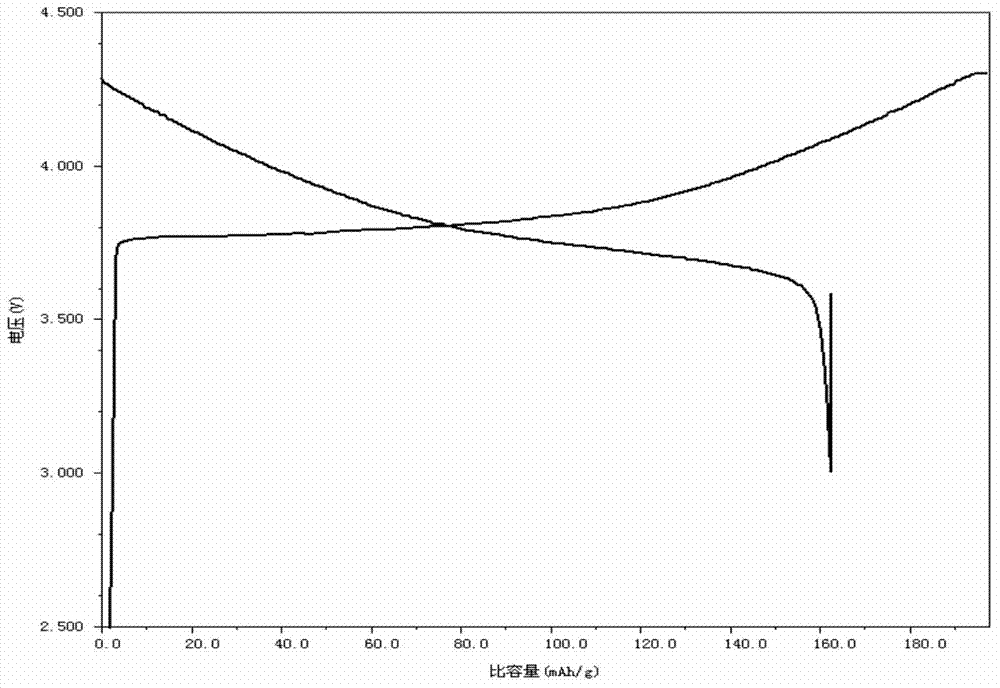

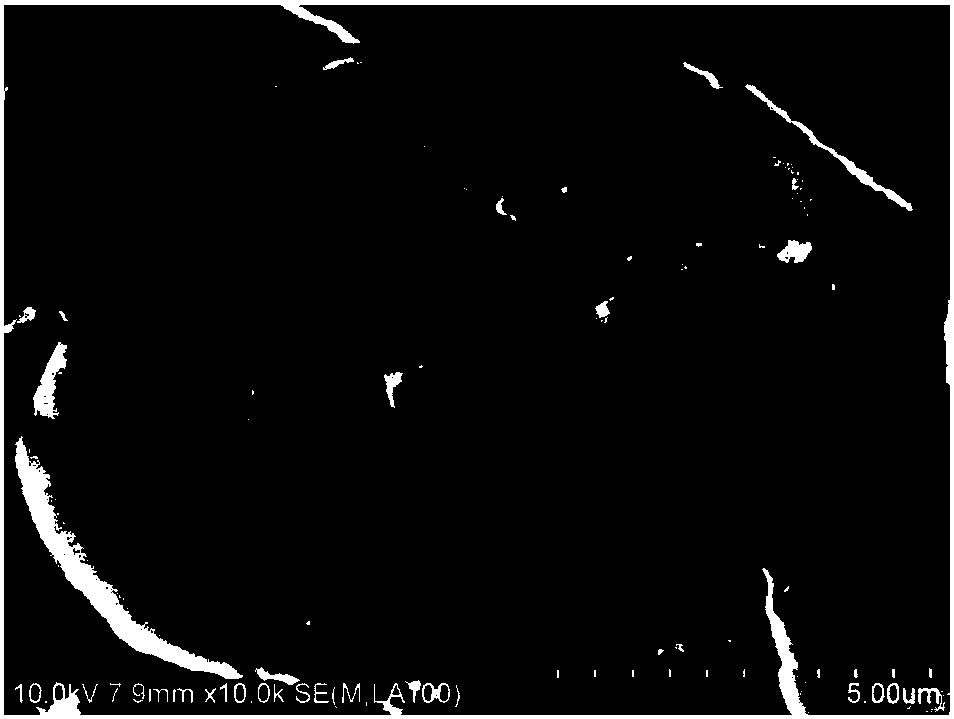

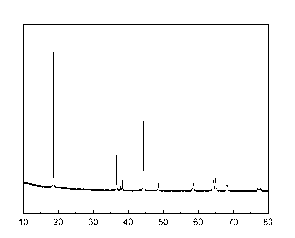

ActiveCN101081696APromote crystallizationSingle structureElectrode manufacturing processesLithium compoundsCarbon layerLithium iron phosphate

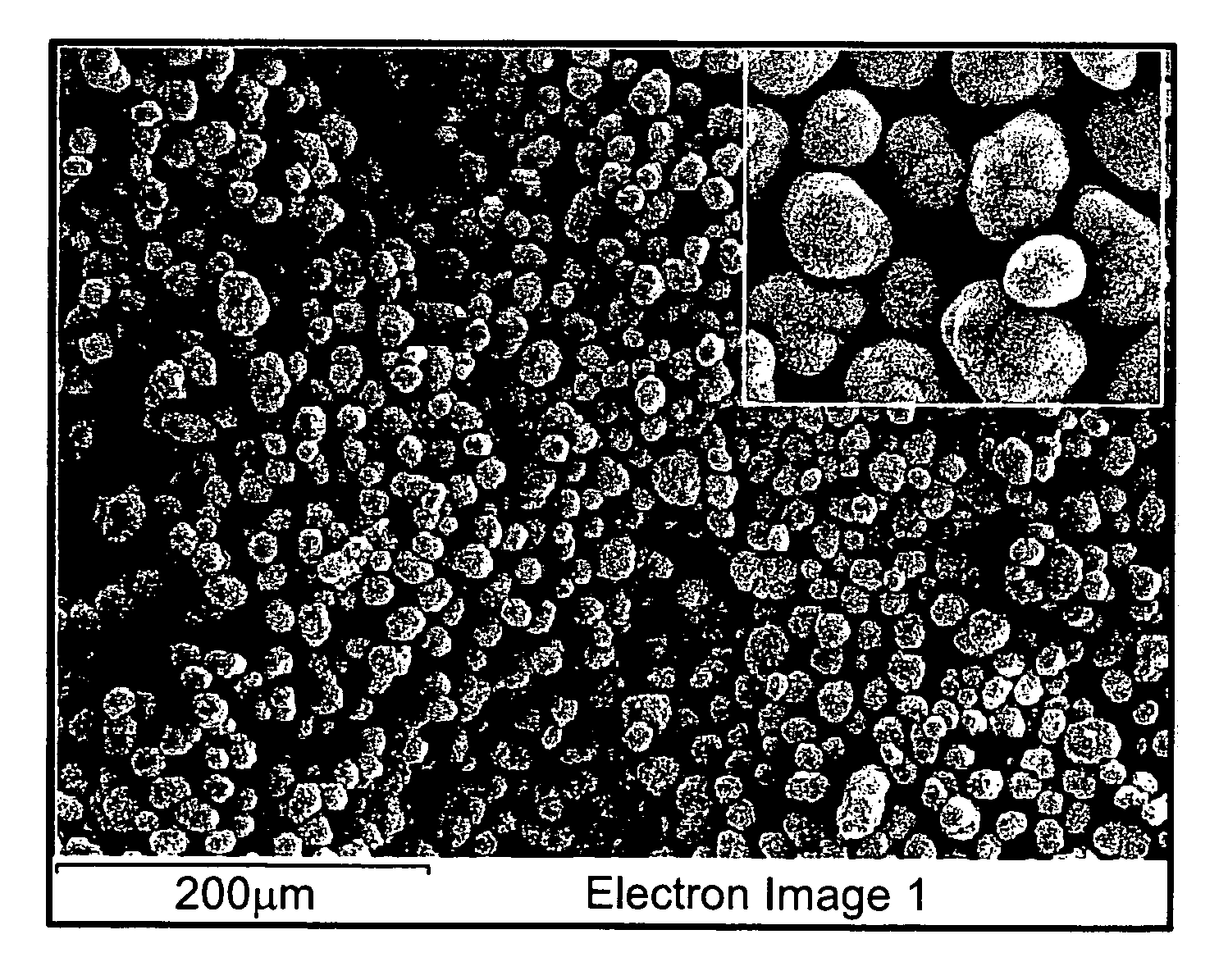

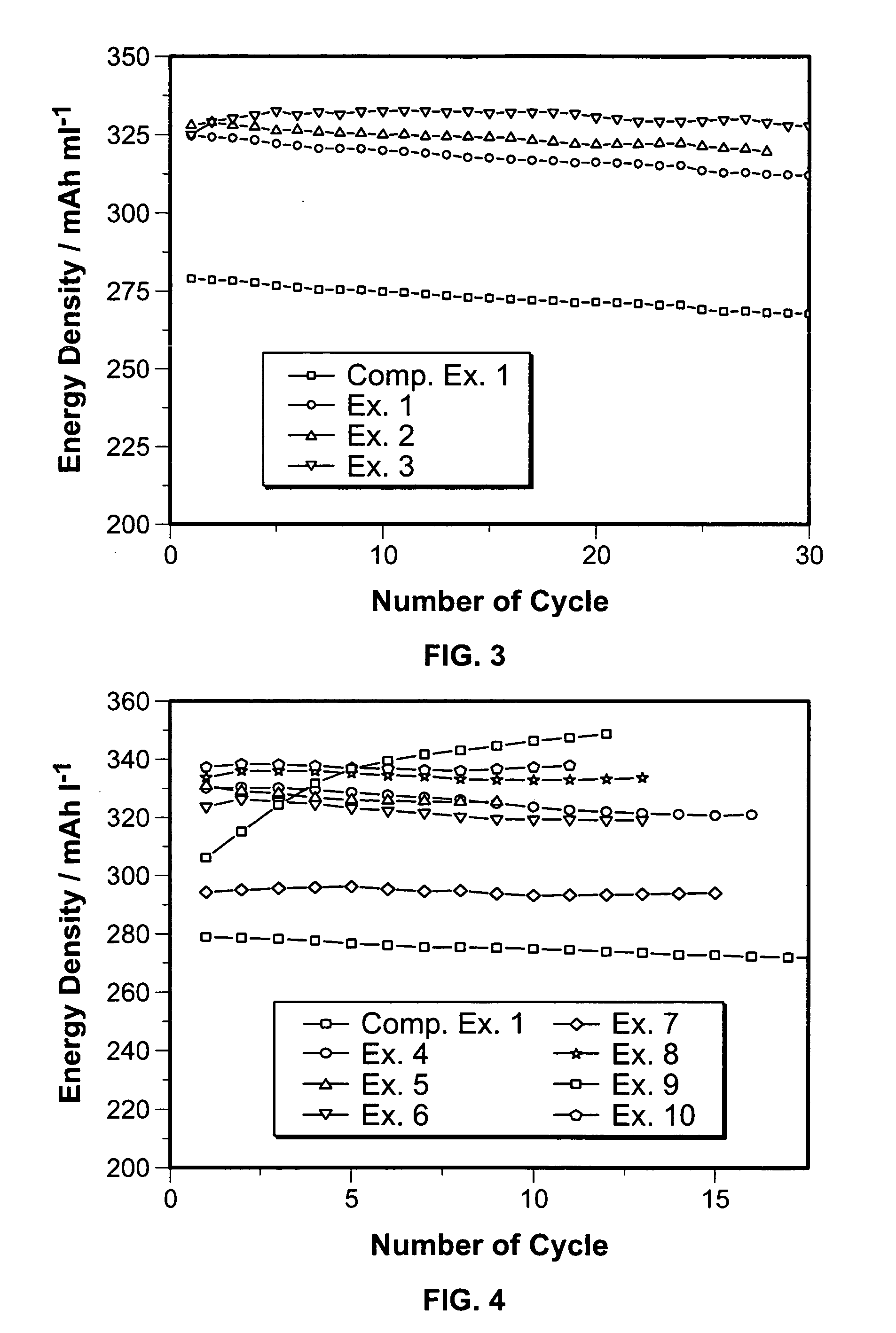

The present invention discloses lithium iron phosphate material for lithium ion power cell and its preparation process, and dissolves the technological problem of raising the discharge power and safety performance. The lithium iron phosphate material is spherical or spheroid composite particle with one base body of lithium iron phosphate and doping and modifying agent and one coating carbon layer. Its preparation process includes wet ball milling the mixture comprising lithium salt, ferric salt, phosphoric acid, doping and modifying agent and dispersant, spraying to pelletize, heating for pre-treatment, maintaining temperature, cooling, pulverizing and shaping. Compared with available technology, the present invention has the features of high crystallization, single structure, average composite particle size of 5-60 microns, specific surface area of 8.0-15.0 sq m / g, bulk density of 1.4-1.7 g / cu cm, high specific capacity, high safety, etc.

Owner:BTR (TIANJIN) NANO MATERIAL MFG CO LTD

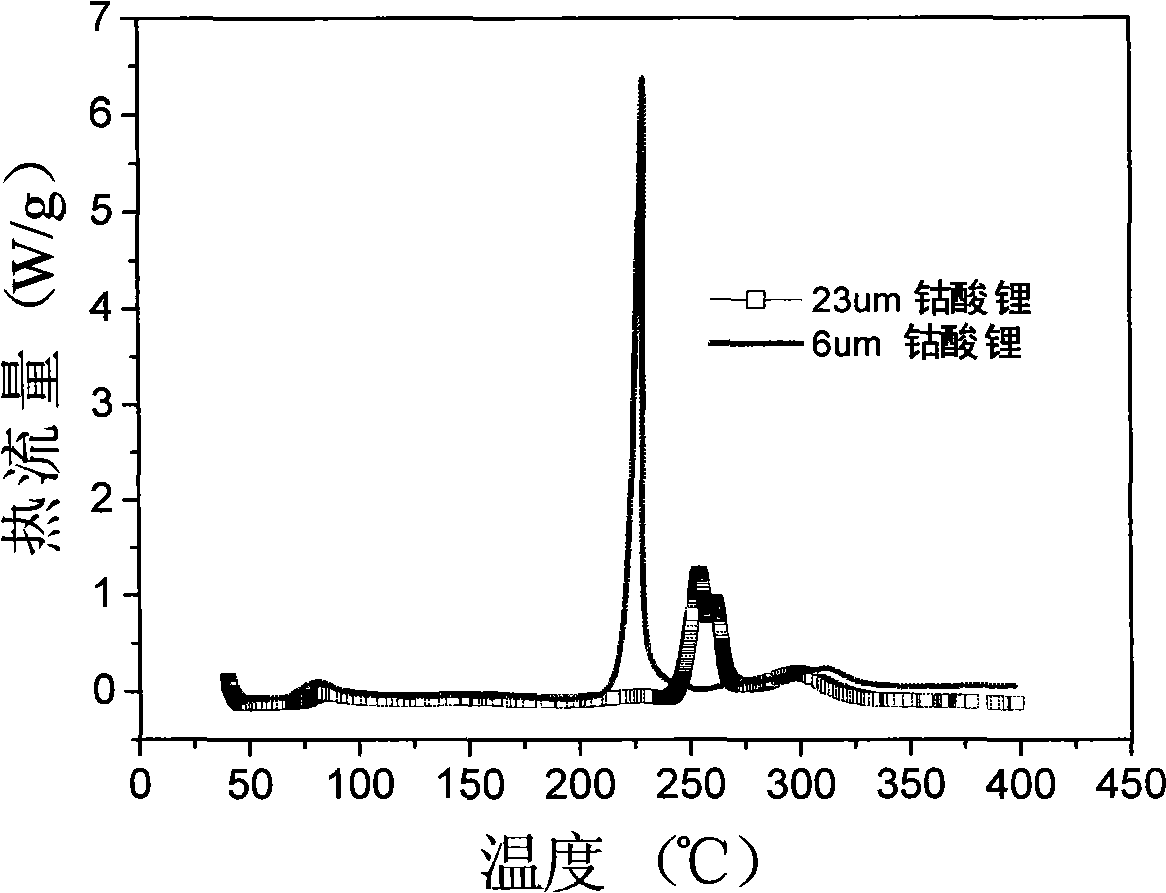

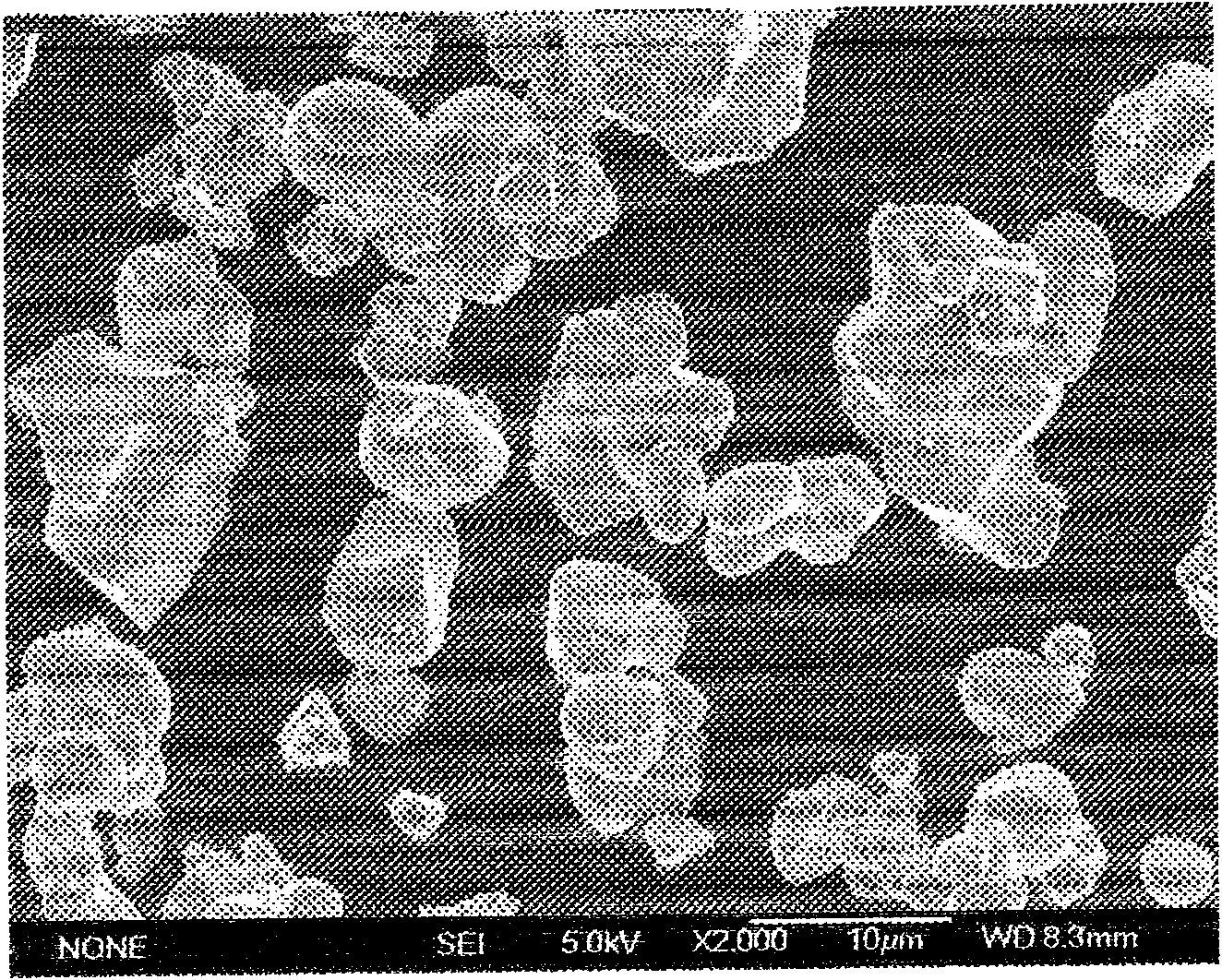

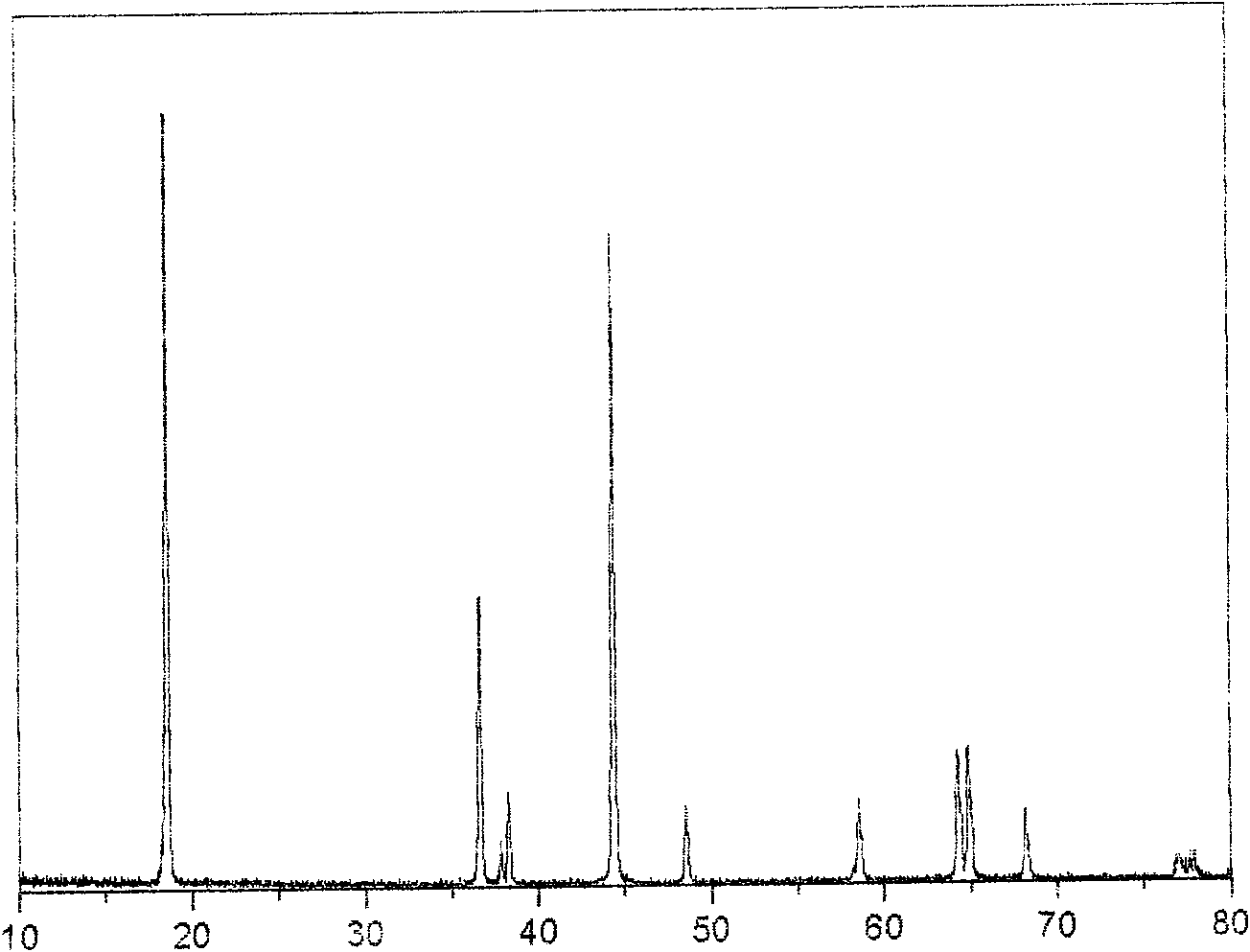

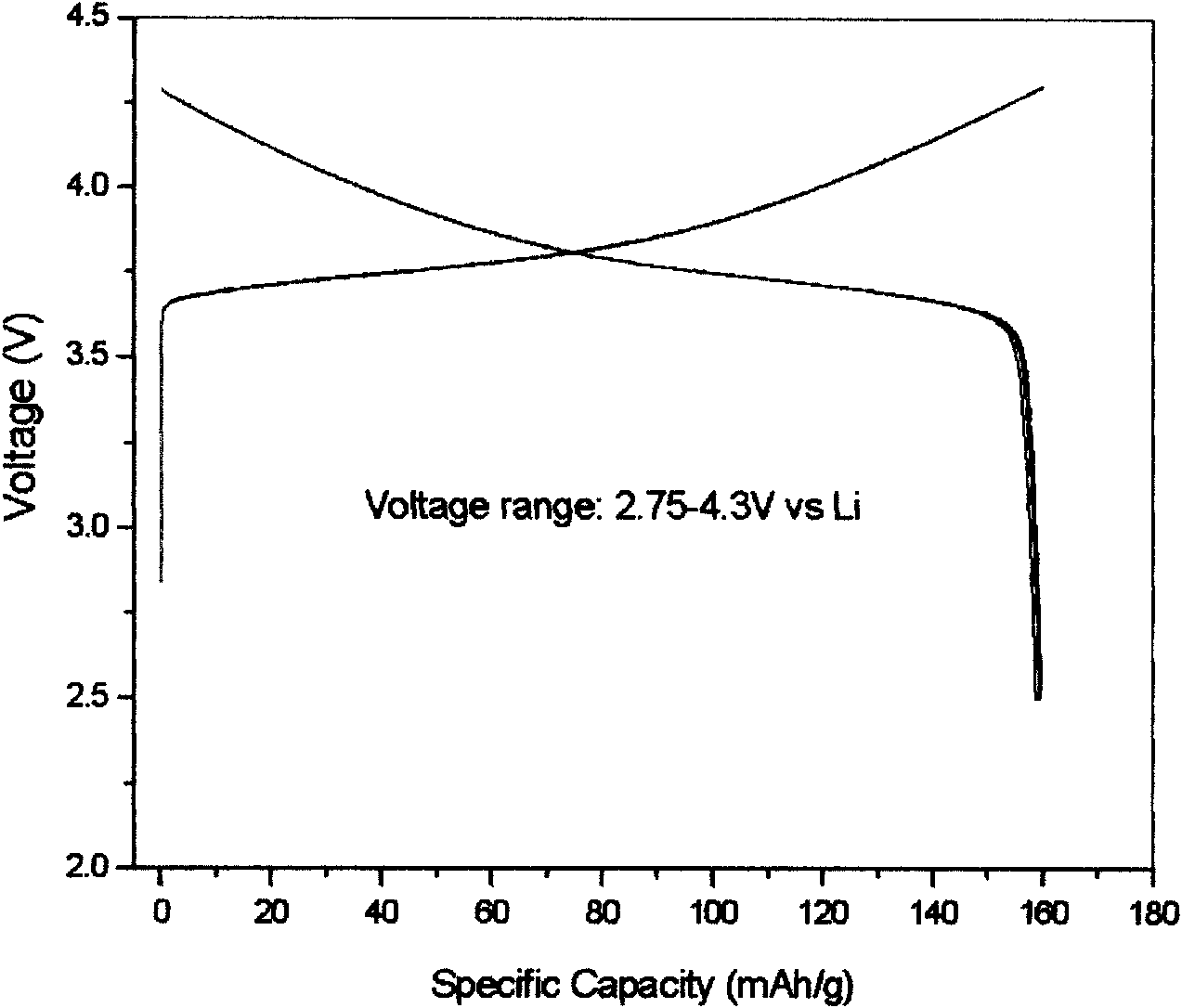

Super-size and high-density lithium cobalt oxide and method for preparing the same

ActiveCN101284681ALarge particle sizeHigh tap densityCell electrodesLithium compoundsHigh densityThermal impact

The invention relates to a high-density lithium cobalt oxide power material with a super-large grain diameter. The method comprises the steps of mixing a cobalt compound, a lithium compound or meanwhile a small amount of doping element compounds; sintering for 3 to 30 hours at the high temperature of 950 to 1,100 DEG C to form a block sintered product; crushing and grading the product to obtain the lithium cobalt oxide power material (molecular formula is LiaCo1-bMbO2), wherein, when b is not equal to 0, the middle diameter of the lithium cobalt oxide containing the doping elements is larger than or equal to 15 Mum, and the tap density is higher than or equal to 2.5g / cm<3>; when b is equal to 0, the middle diameter of the lithium cobalt oxide without the doping elements is larger than 20 Mum, and the tap density is higher than or equal to 2.6g / cm<3>. the 3.6V platform capacity rate of the material as the anode active substance for a lithium battery is higher than or equal to 75%; in the thermal impact test in a 150 DEG C thermotank, the lithium battery with the material is free from leakage and does not catch fire or explode for 60 minutes; the 1C5A specific capacity of the material in the battery is larger than or equal to 135mAh / g.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

Lead-free and cadmium-free electrode silver slurry for piezoelectric ceramics and preparation method thereof

ActiveCN102751000AAchieve lead-freeImprove adhesionNon-conductive material with dispersed conductive materialCable/conductor manufactureAdhesion forceSlurry

The invention discloses a lead-free and cadmium-free electrode silver slurry for piezoelectric ceramics. The lead-free and cadmium-free electrode silver slurry for piezoelectric ceramics is prepared from the following raw materials in percentage by weight: 50 to 75 percent of conducting silver micro powder, 0.5 to 5 percent of inorganic additive, 1 to 15 percent of lead-free glass powder and 15 to 45 percent of organic carrier. The lead-free and cadmium-free electrode silver slurry is technologically advantaged in that a boron-bismuth-silicon-zinc-titanium glass system is designed, the traditional lead-containing glass can be completely substituted, a lead-free product is realized, the system glass can react with a piezoelectric ceramic substrate to form a firm interface between an electrode and the substrate, and the adhesion force of the interface is more than 15N / mm<2>.

Owner:HEFEI SHENGDA ELECTRONIC TECH IND CO LTD

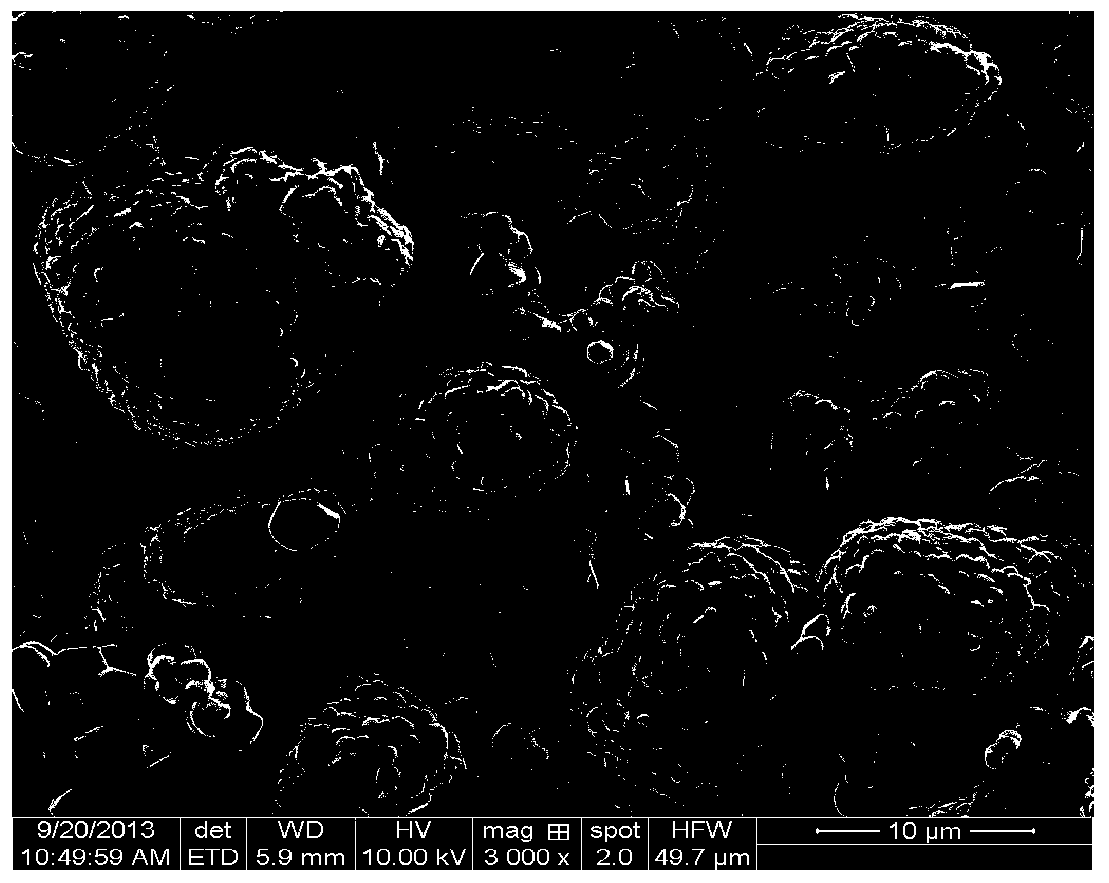

High-performance lithium ion battery cathode material and preparation method thereof

InactiveCN101847722AHigh tap densityImprove electrode processing performanceElectrode manufacturing processesNickel oxides/hydroxidesSingle crystalCobalt

The invention relates to a lithium ion battery cathode material LiNixCoyM1-x-yO2 prepared from micron-sized single crystal particles and a preparation method thereof, wherein x is greater than 0 and is not more than 0.8, y is greater than 0 and is not more than 0.5, and M is one or two of Li, Mn, Al and Mg. The invention is characterized in that (1) composite oxide or hydroxide of transition metal nickel, transition metal cobalt and modified metal M is used as a raw material, the composite oxide or hydroxide is porous aggregate comprising nanocrystals, the average size of the aggregate is 2-50 micrometers, and the specific surface area of the aggregate is greater than 15m<2> / g (measured by BET method); (2) the composite metal oxide or hydroxide and lithium salts are milled in a ball mill, the micron-sized composite metal oxide or hydroxide is converted into nanocrystal particles to obtain a nano-sized mixed precursor of the composite metal oxide or hydroxide and the lithium salts, and the mixed precursor is sintered at uniform temperature to obtain the required lithium ion battery cathode material; and (3) the prepared lithium ion battery cathode material LiNixCoyM1-x-yO2 is basically prepared from micron-sized single crystal particles, and the average size of the single crystal particles is 2-20 micrometers. In addition, the product has excellent physical and electrochemical properties, such as ultra-low specific surface area, reasonable particle size distribution, good electrode processing properties, ultra-long cycle life, excellent rate capability, obvious high and low temperature cycling and storing properties and excellent safety; and the product can be widely used as a high-performance lithium ion battery cathode material. The invention provides the high-performance lithium ion battery cathode material and the preparation method thereof.

Owner:QINGDAO LNCM

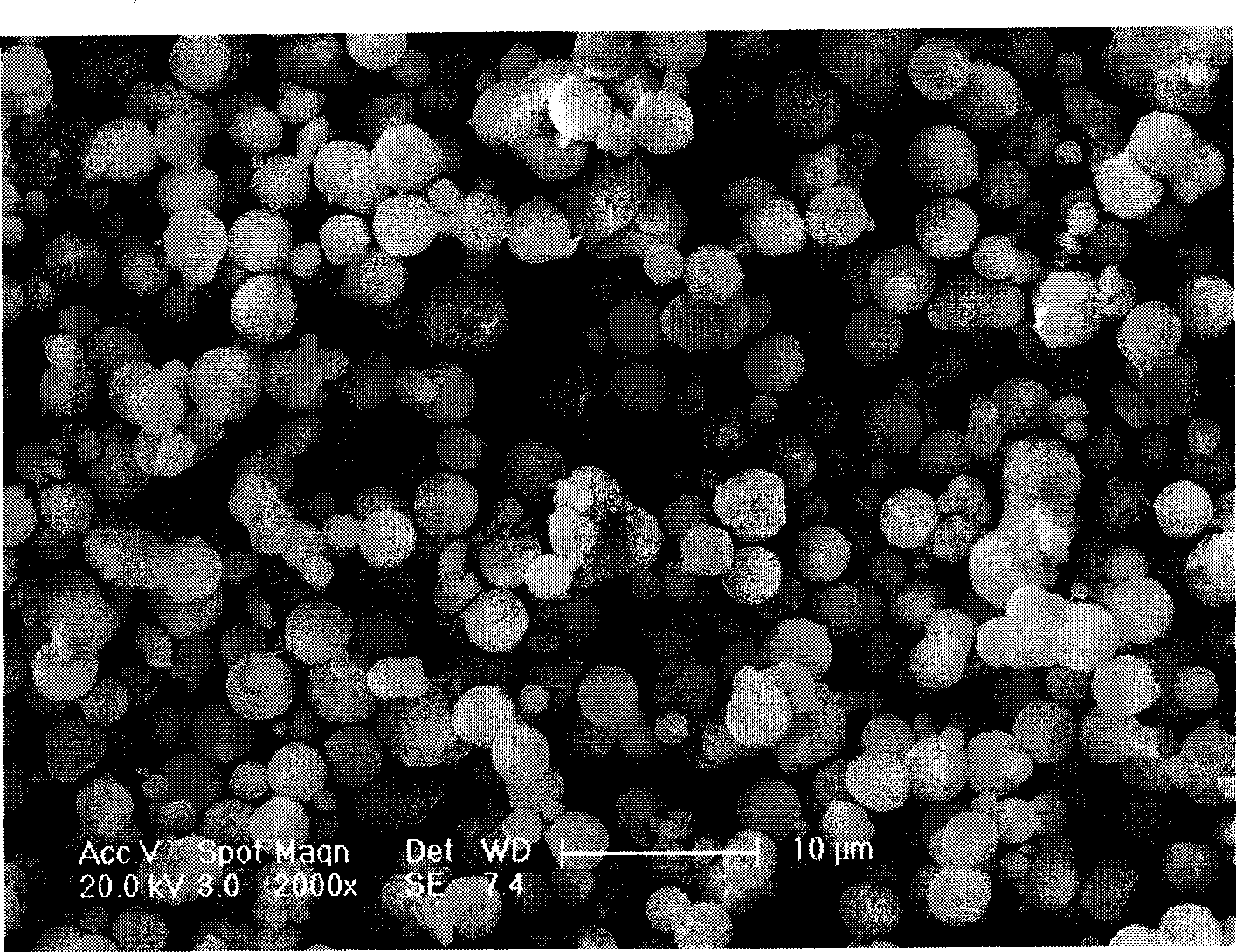

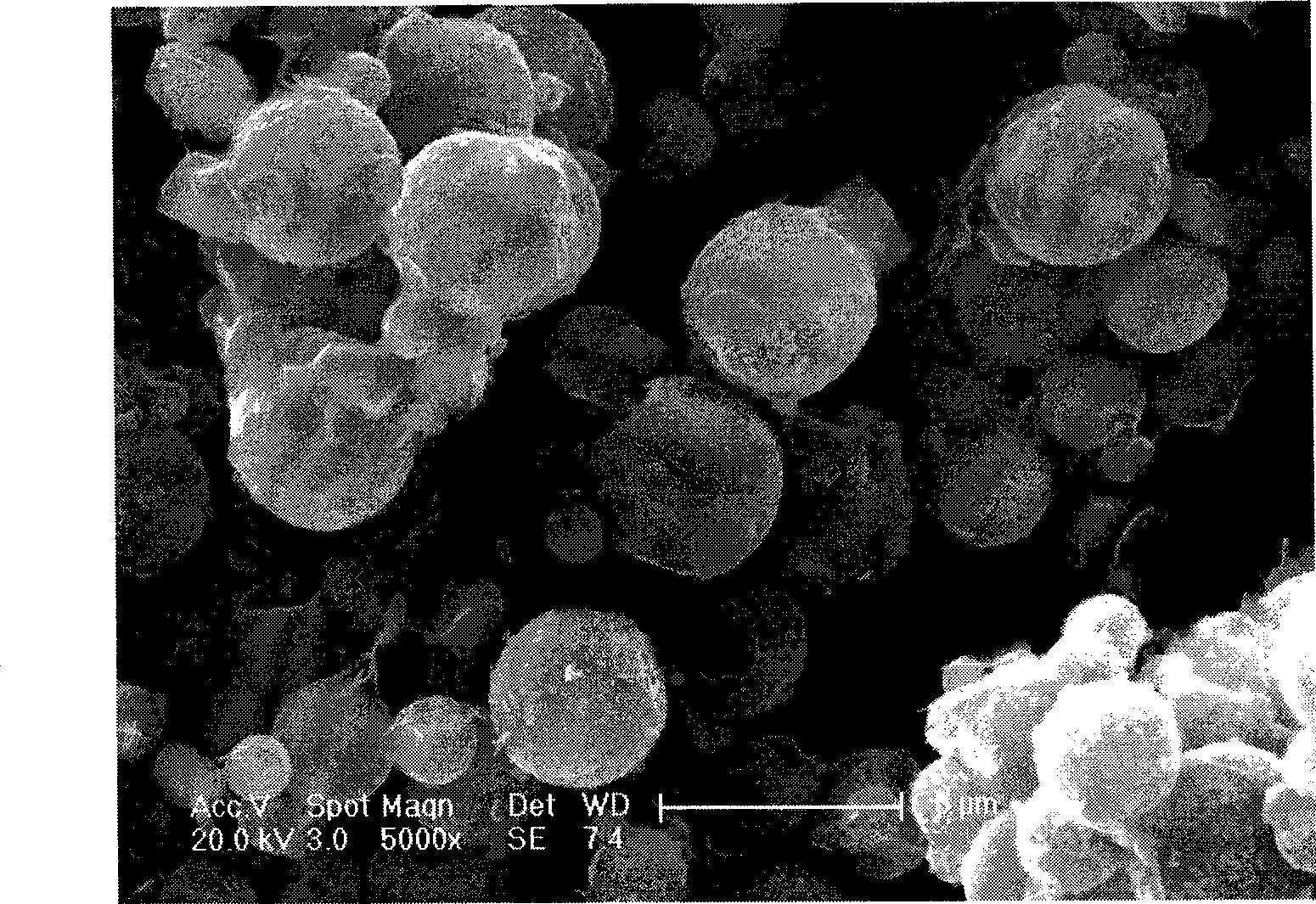

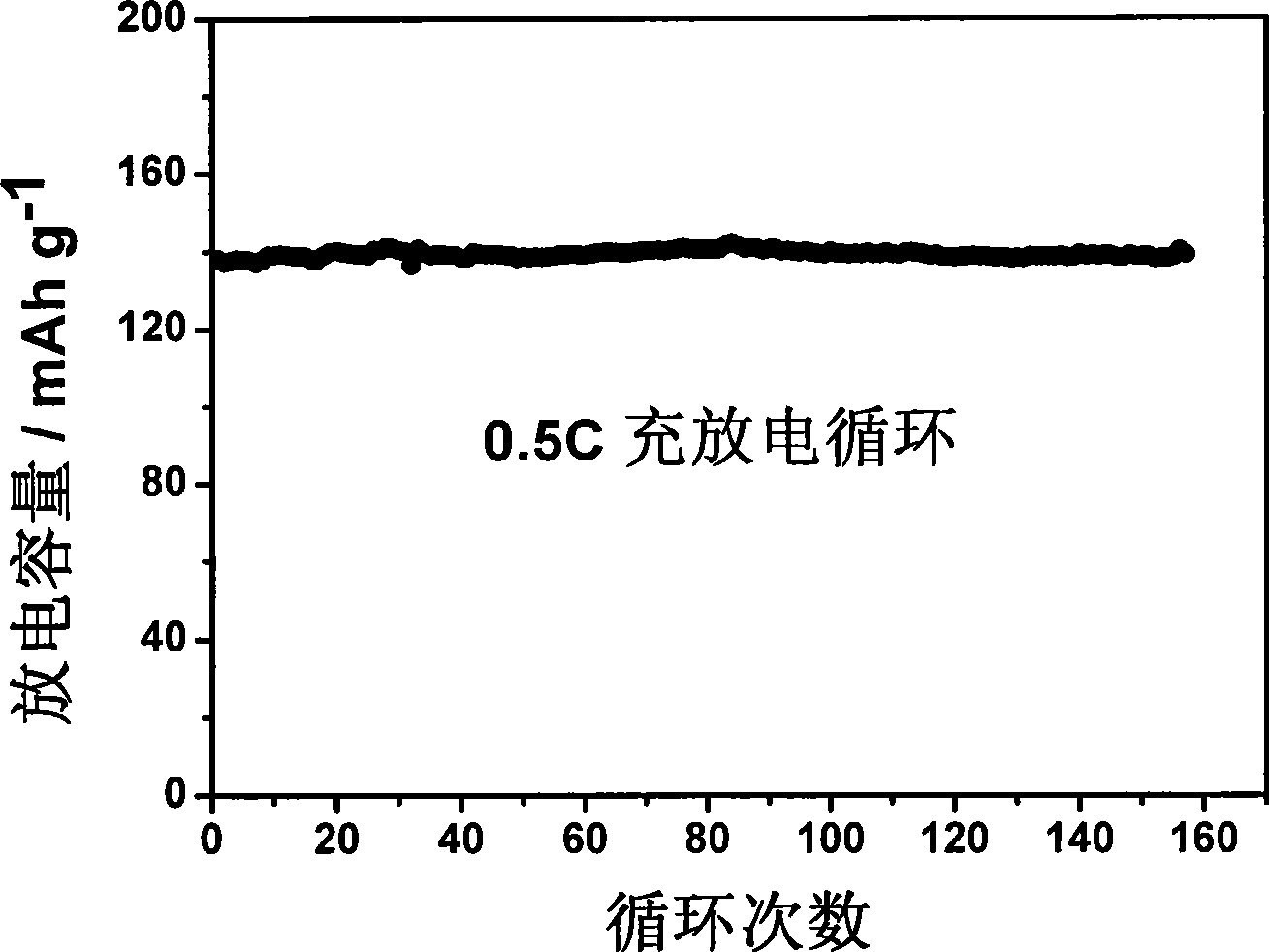

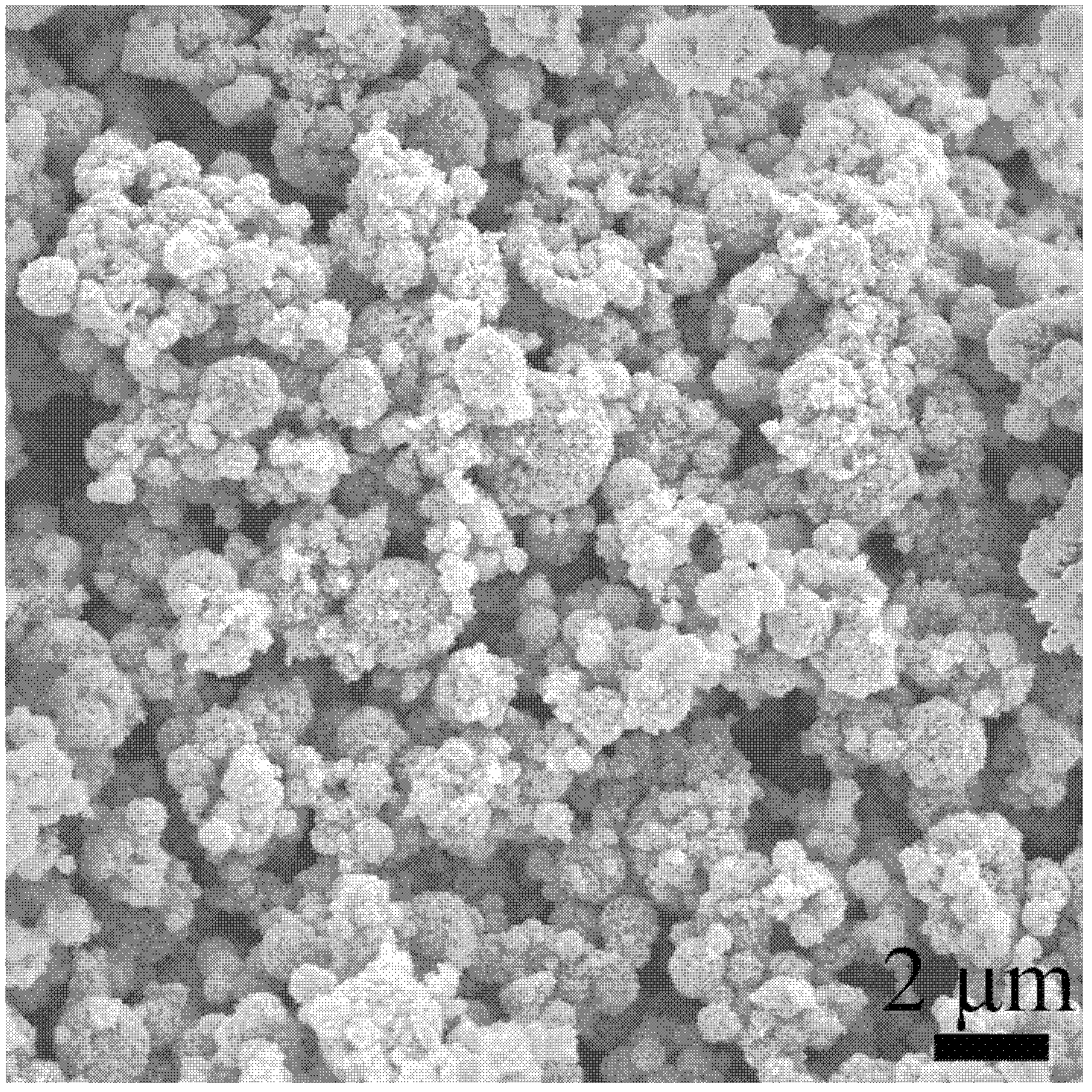

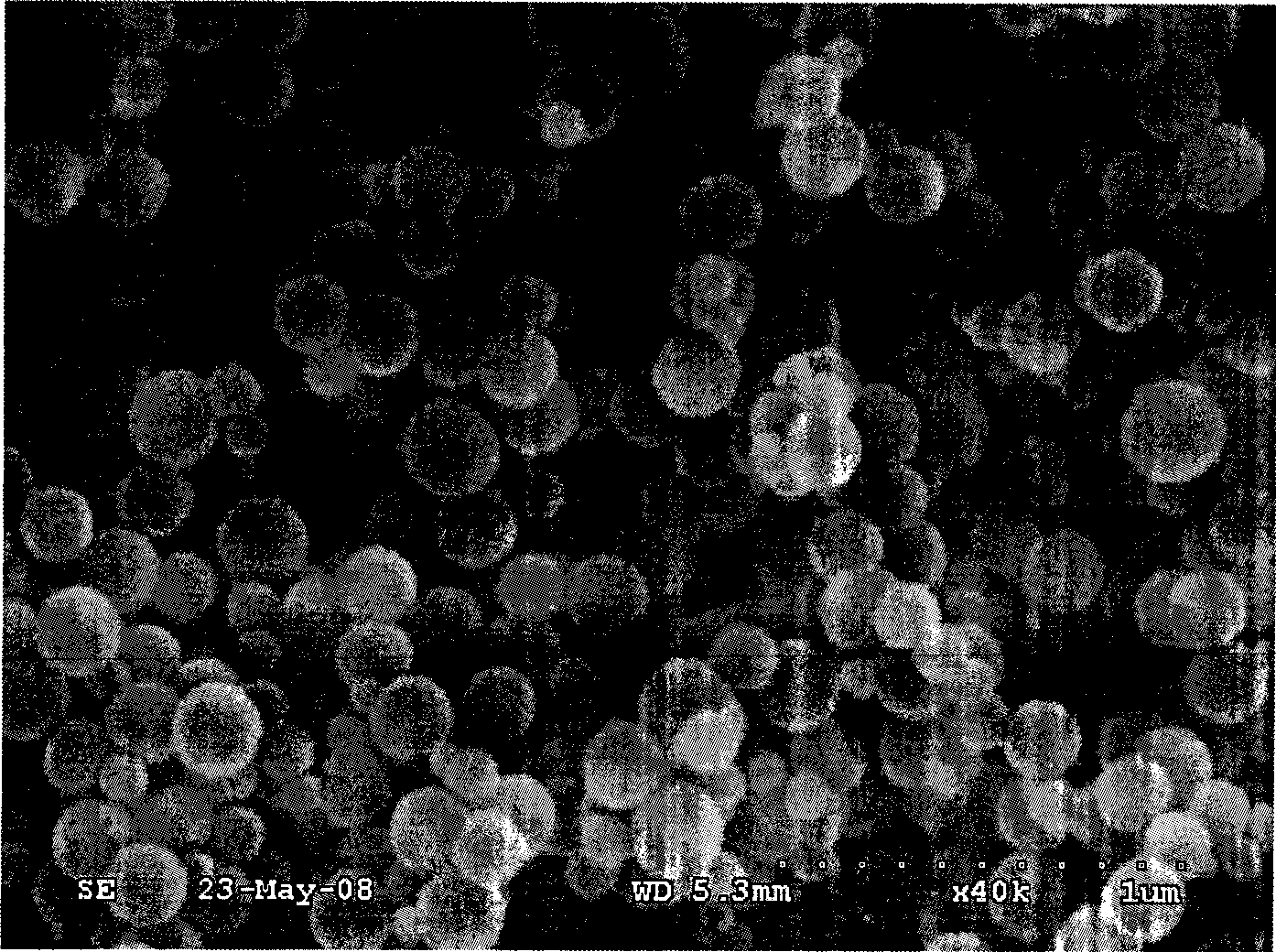

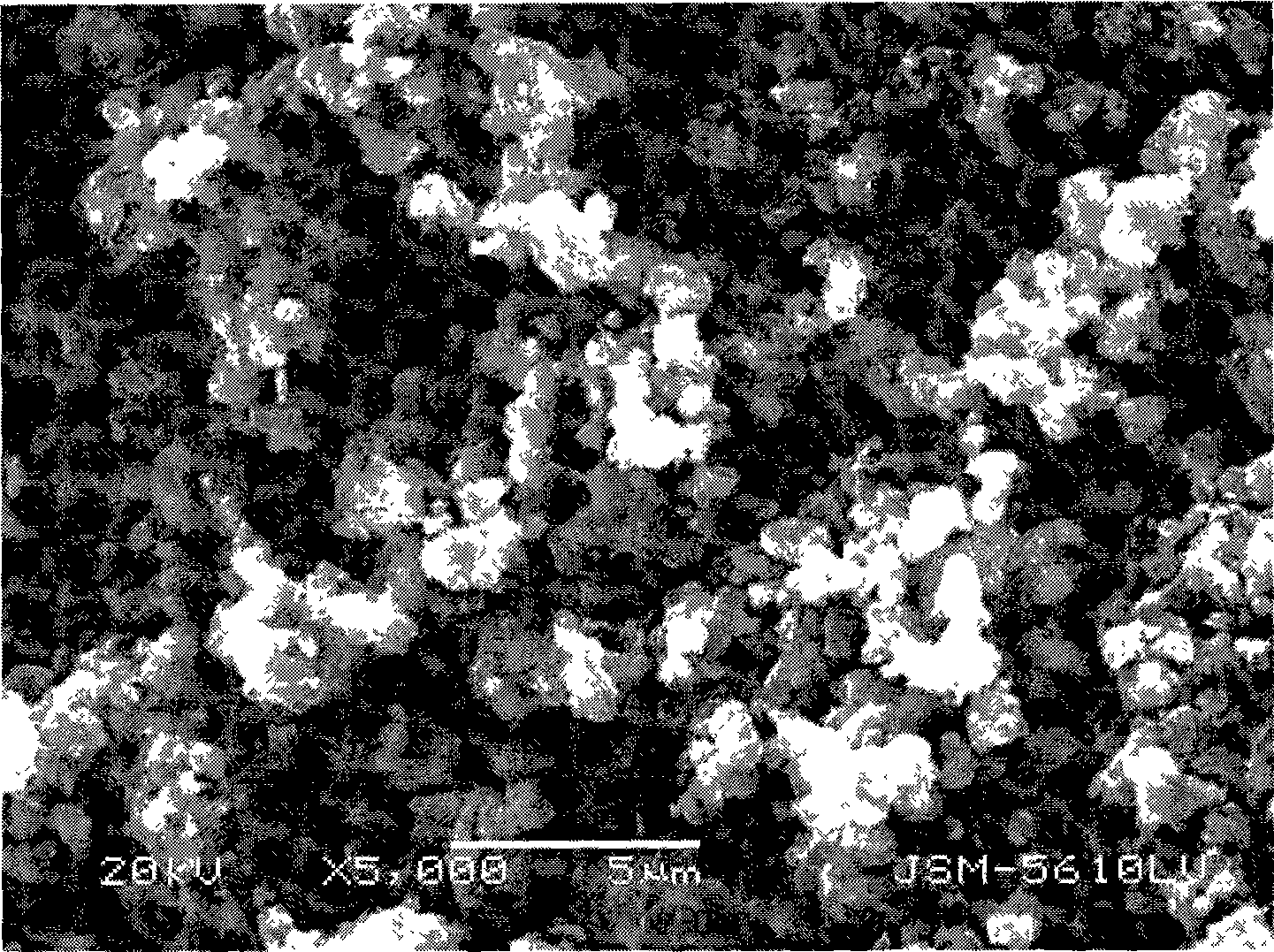

Preparation of lithium iron phosphate nano composite microsphere

ActiveCN101475157AImprove conductivityHigh tap densityElectrode manufacturing processesPhosphorus compoundsMicrospherePhosphoric acid

The invention discloses a method for preparing a lithium iron phosphate nano composite microsphere for a lithium-ion secondary battery anode material by a hydrothermal method, which comprises the following steps: evenly mixing a lithium source, an iron source and a phosphoric acid source according to the stoichiometric ratio of 1-1.05:1:1 to prepare an aqueous solution with certain concentration, adding proper amount of reducing agent, carbonizing agent, ion dopant and the like into the aqueous solution, growing and curing crystals under high-temperature hydrothermal condition, removing a solvent from a hydrothermal product, and burning the hydrothermal product in inert or reducing atmosphere to obtain a final product. The lithium iron phosphate anode material prepared by the method has a regular nano composite microsphere structure, has a particle diameter of between 2 and 4 mu m, even distribution, tap density up to 1.3 to 1.6 g / cm, and has excellent cycle performance and multiplying power performance. The method has simple and easily-controlled process, can use cheap trivalent iron as the iron source, can obtain rich raw materials, and is a practical technique for preparing lithium iron phosphate.

Owner:湖北金泉新材料有限公司

Lithium ion battery phosphatic composite cathode material and preparation method thereof

ActiveCN102244263AEasy to processImprove electrochemical performanceCell electrodesMicro structurePhosphoric acid

The invention discloses a lithium ion battery phosphatic composite cathode material and a preparation method thereof. The composite material is a multinuclear core shell structure composed of a plurality of cores and a housing layer, the cores are lithium iron phosphate particles wrapped by lithium vanadium phosphate and the housing layer is amorphous carbon. Preparation of the lithium iron phosphate particles wrapped by lithium vanadium phosphate comprises the following steps: preparing precursor sol with a sol gel method, adding lithium iron phosphate powder to disperse uniformly, carrying out spray drying on the above mixture, calcining the above resultant in inert gas, and followed by cooling and grinding to obtain the lithium iron phosphate particles wrapped by lithium vanadium phosphate. Preparation of the composite cathode material comprises the following steps: dissolving a carbon source compound into deionized water, adding core materials, dispersing the above resultant uniformly, carrying out second spray drying, calcining the above resultant in inert gas, and followed by cooling to obtain the composite cathode material. The composite material prepared in the invention has good electronic conduction performance, good ionic conduction performance and excellent electrochemistry performance. Because of existence of lithium vanadium phosphate, energetic density of a material is raised. Because of the multinuclear core shell structure like nano / micro structures, the composite material has good processing performance, and tap density of the material is greatly raised.

Owner:CENT SOUTH UNIV

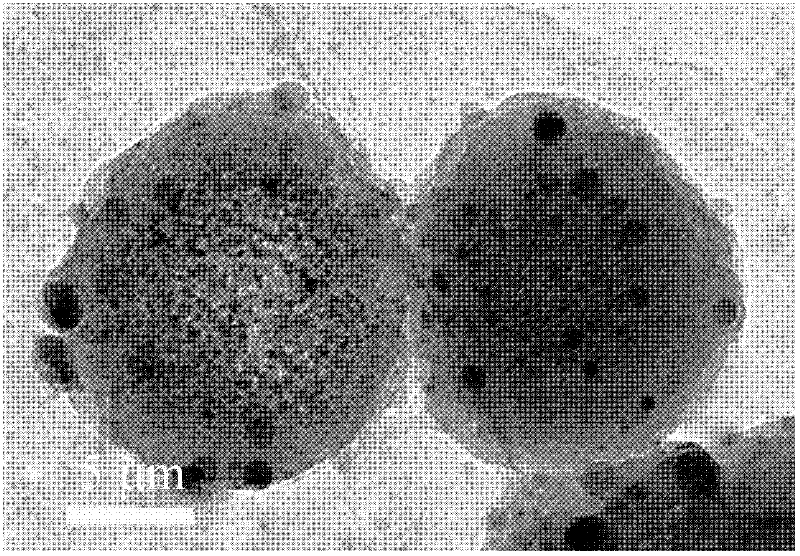

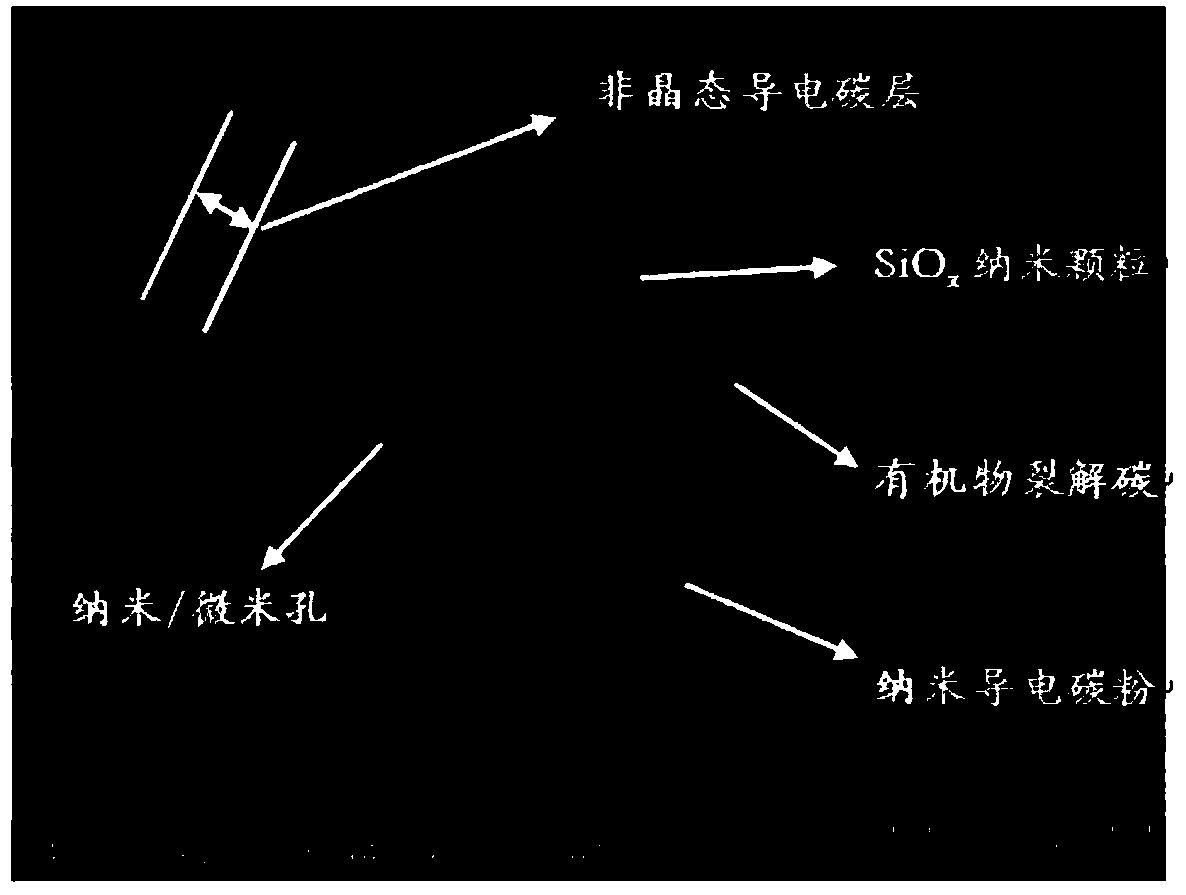

SiOx-based composite material, preparation method and lithium ion battery

ActiveCN103855364AStable structureImprove electronic conductivityMaterial nanotechnologyCell electrodesCarbon layerSpherical shaped

The invention relates to a SiOx-based composite material, a preparation method and a lithium ion battery. The SiOx-based composite material comprises a SiOx / C material, wherein the SiOx / C material comprises SiOx nano particles, organism cracked carbon, nano conductive particles and amorphous conductive carbon layers, the SiOx nano particles, the organism cracked carbon and the nano conductive particles are wrapped in the amorphous conductive carbon layers, the SiOx / C material is in a spherical shape and comprises a porous structure, and x is more than or equal to 0.5 and less than or equal to 1.3. The composite material is used as a negative electrode material of the lithium ion battery, excellent in cycling performance, excellent in rate performance and low in size expansion effect, applicable to the fields such as top-grade digital electrons, electric tools and next-generation vehicle-mounted devices and wide in market prospect.

Owner:BTR NEW MATERIAL GRP CO LTD

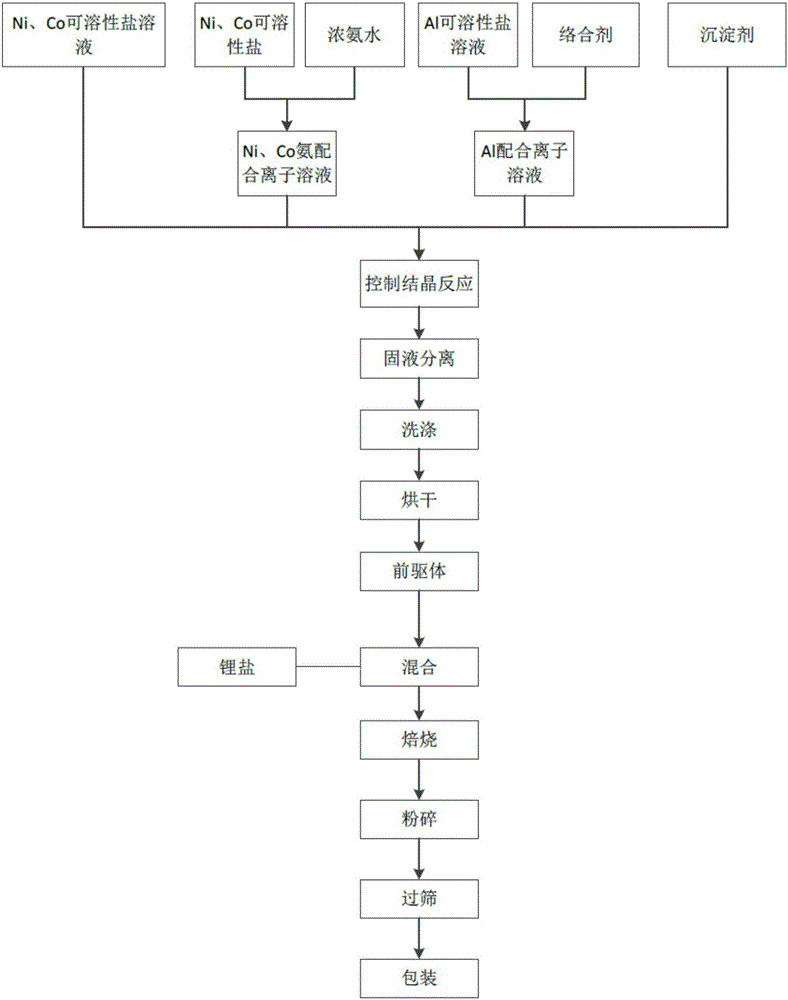

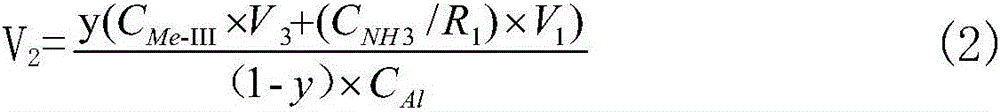

Nickel-cobalt-aluminum ternary precursor as well as preparation method thereof and preparing anode material and method

ActiveCN106299347AImprove mixing uniformityHigh tap densityCell electrodesReaction temperatureSlurry

The invention discloses a nickel-cobalt-aluminum ternary precursor as well as a preparation method thereof and a preparing anode material and a method. The preparation method comprises the following steps: dissolving soluble salts of Ni and Co into ammonia water so as to prepare a Ni and Co ammonia complex ion solution as a complexing agent solution, adding a complexing agent into an aluminum salt solution so as to prepare an Al complex ion solution as an aluminum source solution, combining and adding the Ni and Co soluble salt solution, a precipitant solution, the complexing agent solution and the aluminum source solution into a reaction kettle, controlling a reaction pH value and reaction temperature, controlling the reaction time to be at least greater than 10h, performing solid-liquid separation on slurry obtained through reaction, and washing and drying the obtained solid, thereby obtaining the nickel-cobalt-aluminum ternary precursor. A nickel-cobalt-aluminum ternary anode material can be prepared from a mixture of the precursor and a lithium salt through high-temperature thermal treatment in the presence of air or oxygen. The mixing uniformity of three elements of Ni, Co and Al can be effectively improved, and the tap density of the precursor material can be improved, and the spherical degree of granules can be increased.

Owner:TIANJIN B&M SCI & TECH

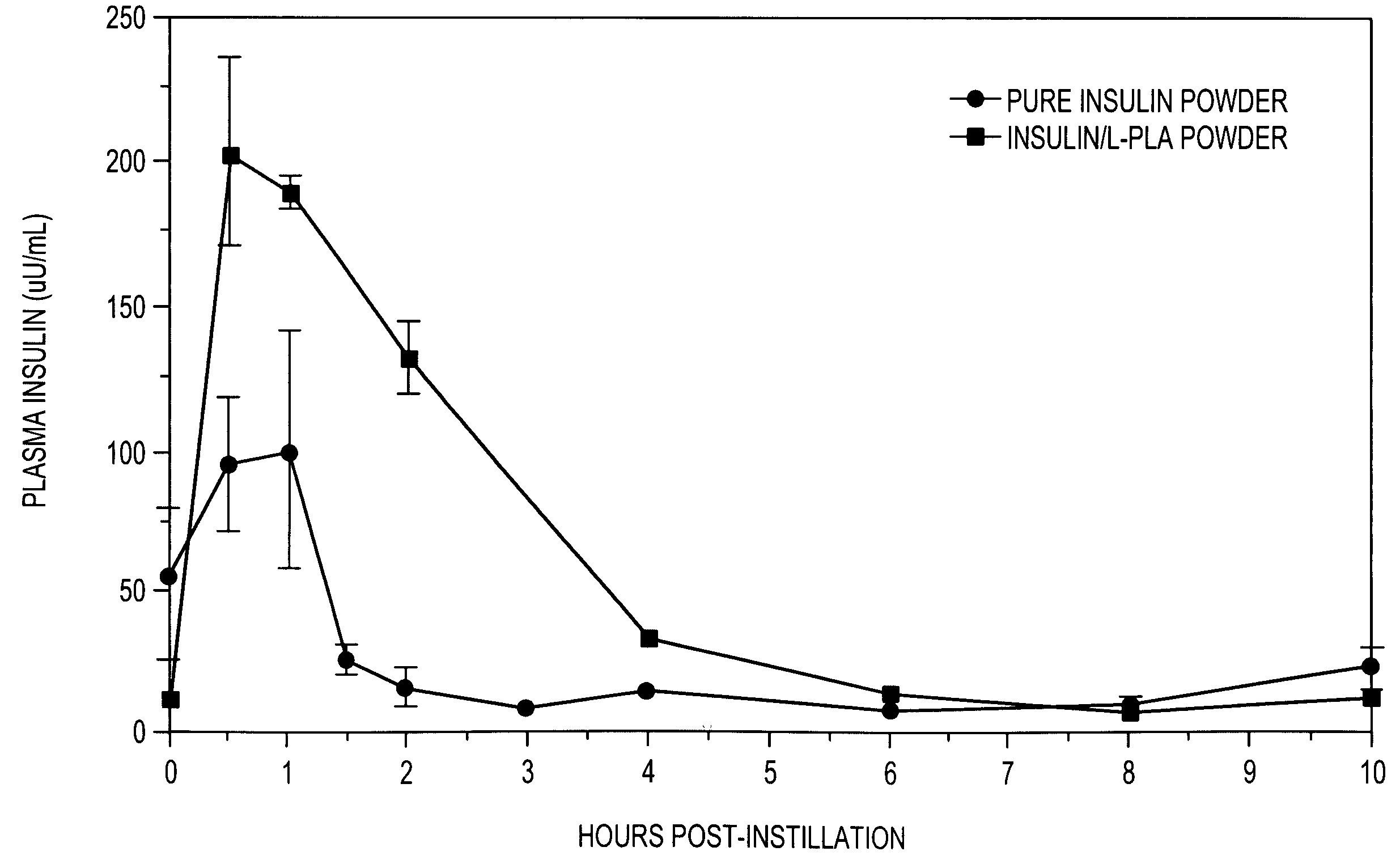

Particulate drug-containing products and method of manufacture

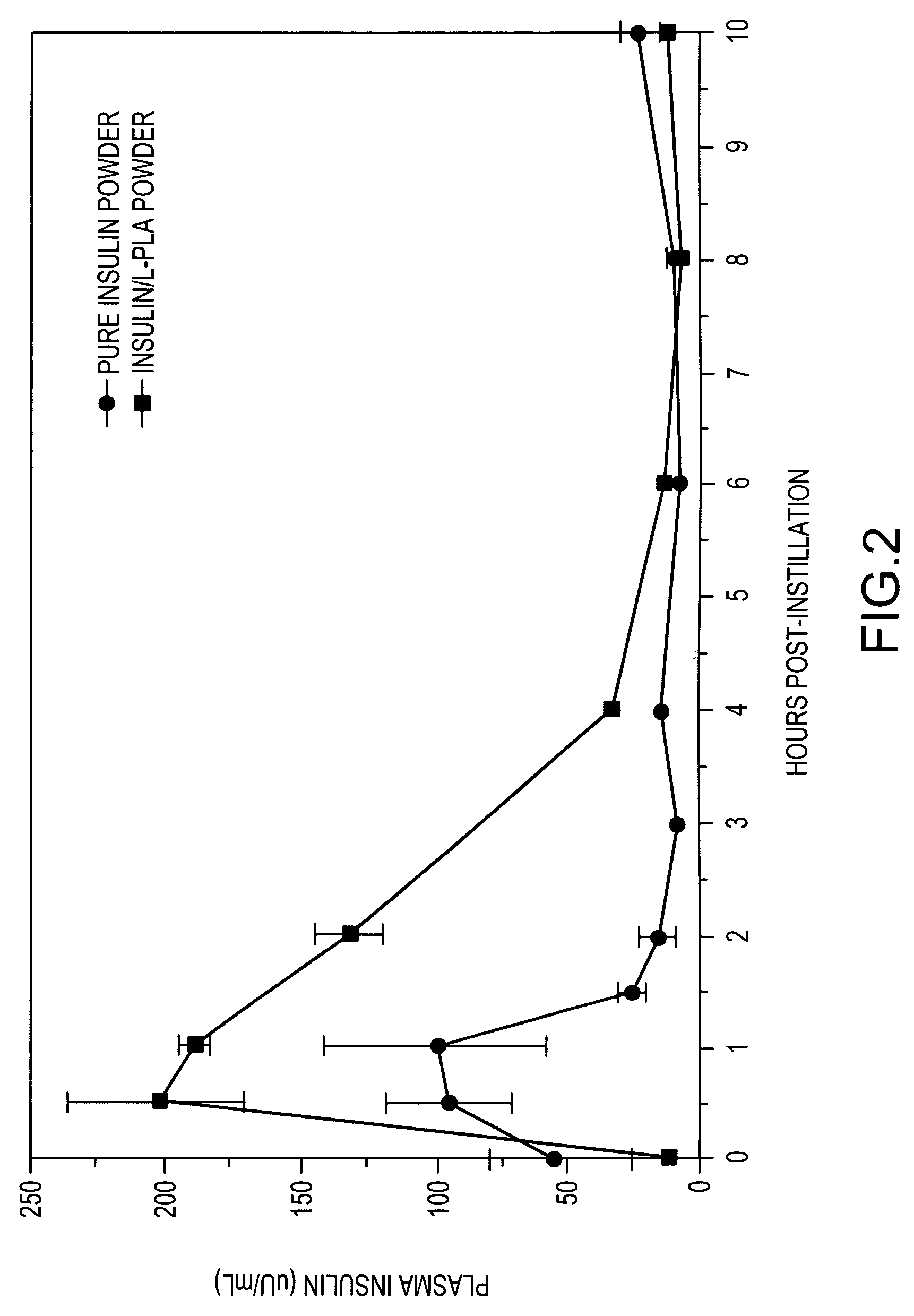

InactiveUS7125566B2Improve featuresEfficiently aerosolizedBiocidePowder deliveryParticulatesOrganic solvent

Provided is a compressed anti-solvent technique for manufacture of drug-containing powders for pulmonary delivery. The drug is processed in a cosolvent system including two or more mutually soluble organic solvents. Also provided are powders manufacturable by the manufacture method, including powders of substantially pure drug and powders including a biocompatible polymer for pulmonary sustained drug release applications. Also provided are packaged products including drug-containing powder in a container that is receivable by and operable with a dry powder inhaler to produce an aerosol including dispersed drug-containing particles when the inhaler is actuated.

Owner:ENDO PHARMA COLORADO

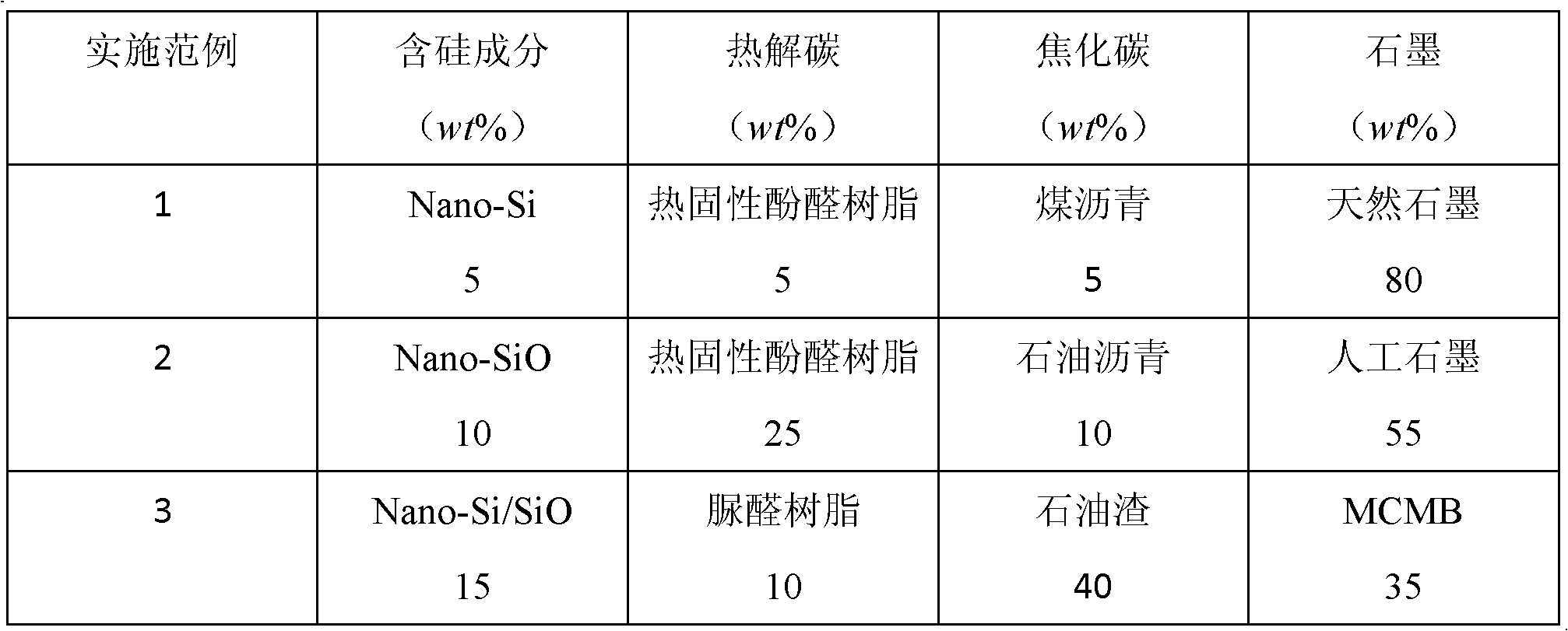

Preparation method for composite cathode material of lithium ion battery

The invention discloses a preparation method for a composite cathode material of a lithium ion battery by means of spray drying pyrolysis treatment. The preparation method includes the steps: dissolving a first type of binder organic carbon source into solvent of a proper quantity, adding a silicon source, a second type of binder and a dispersing agent, dispersing uniformly, adding graphite, dispersing for a certain time, subjecting uniformly dispersed suspension to spray drying, and using the first type of binder organic carbon source to bond the silicon source, the graphite and the second type of binder particles into spherical or spherical-like forms to obtain a composite precursor; and transferring the precursor into a shielding atmosphere for sintering, heating the second type of binder to a certain temperature to be melted into a liquid crystal state, bonding the particle silicon source and the graphite into cores, subjecting the organic carbon source to pyrolysis at the high temperature to form a coating, and furnace cooling to obtain the carbon-silicon composite cathode material of the lithium ion battery. The preparation method is simple, easy in implementation and high in practicality. The carbon-silicon composite prepared by the method has the advantages of high reversible capacity, designable capacity, high circulating performance and high-current discharging performance, high tap density and the like.

Owner:CENT SOUTH UNIV

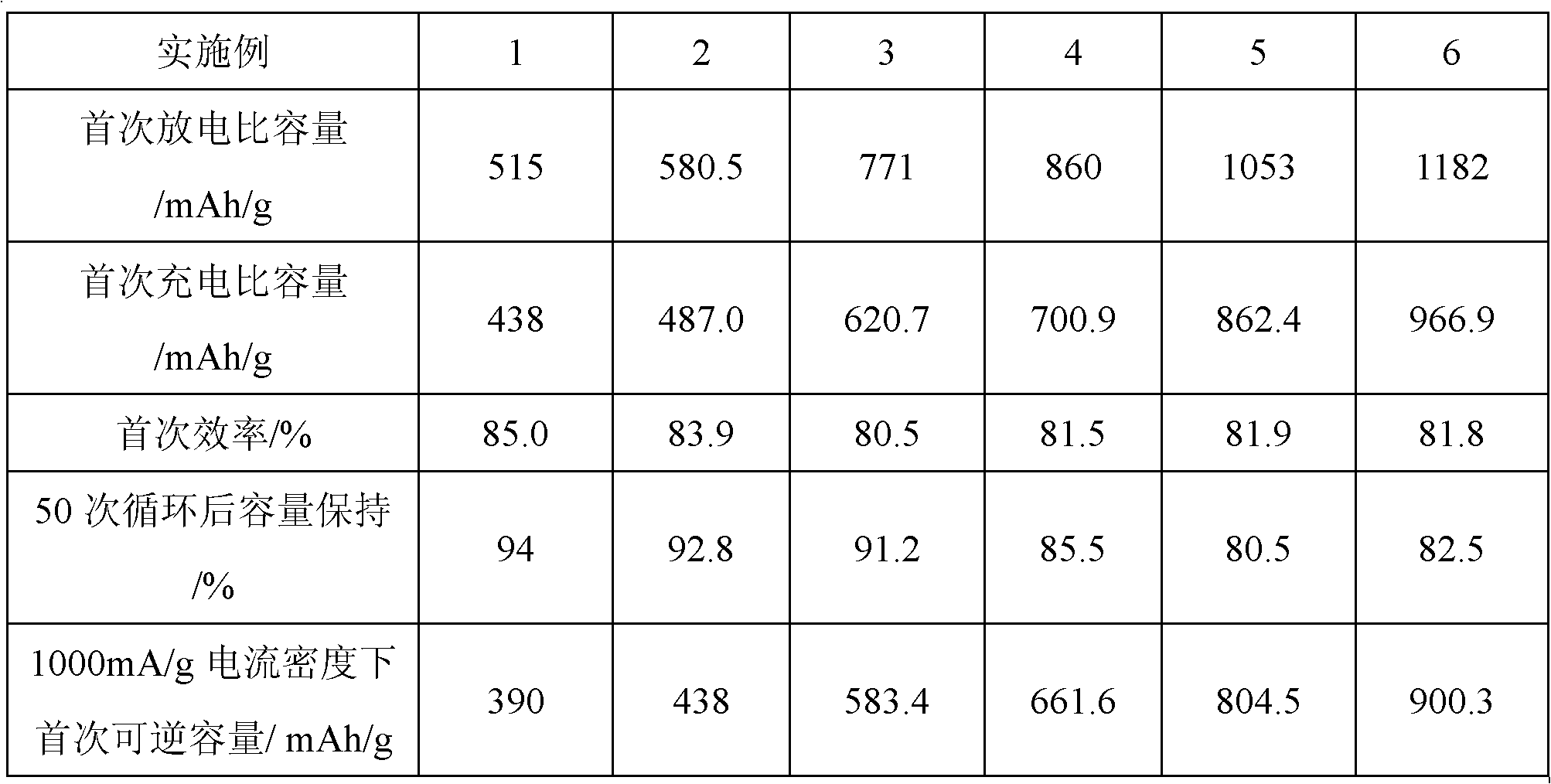

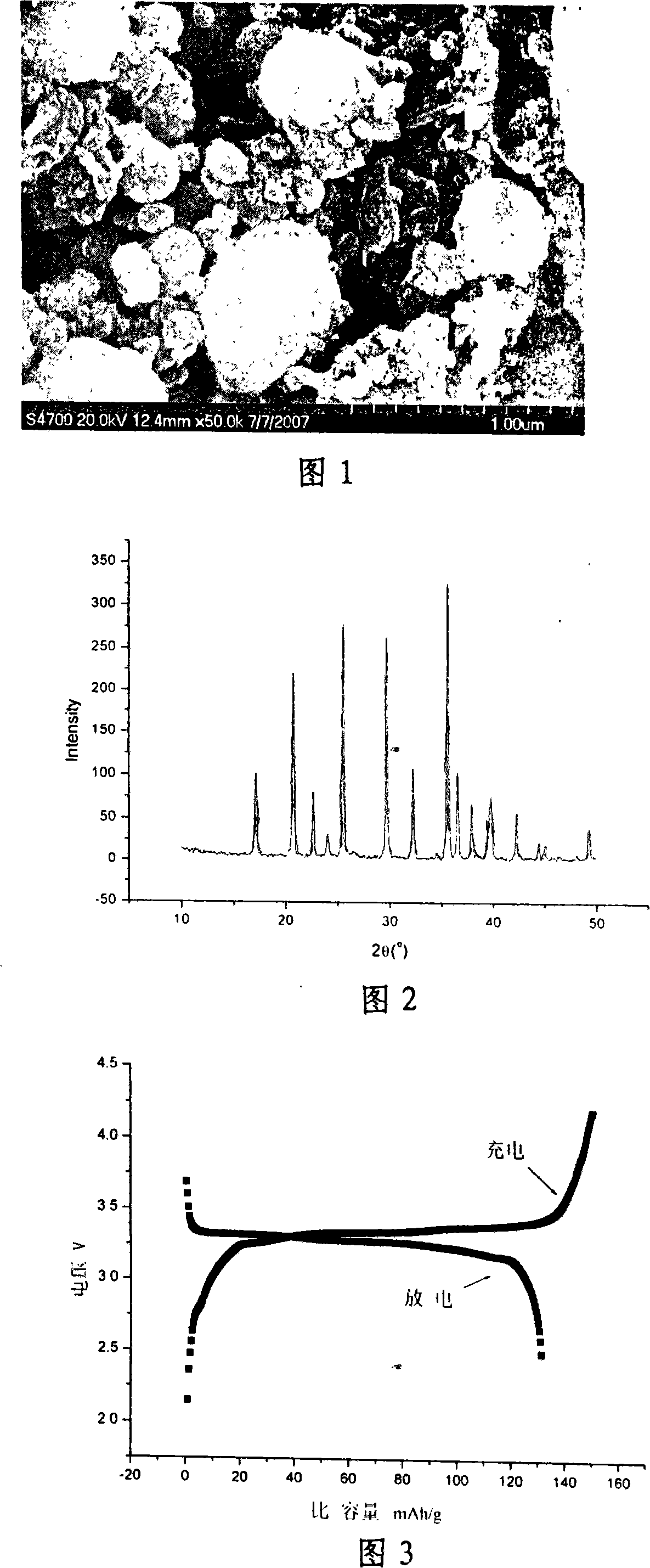

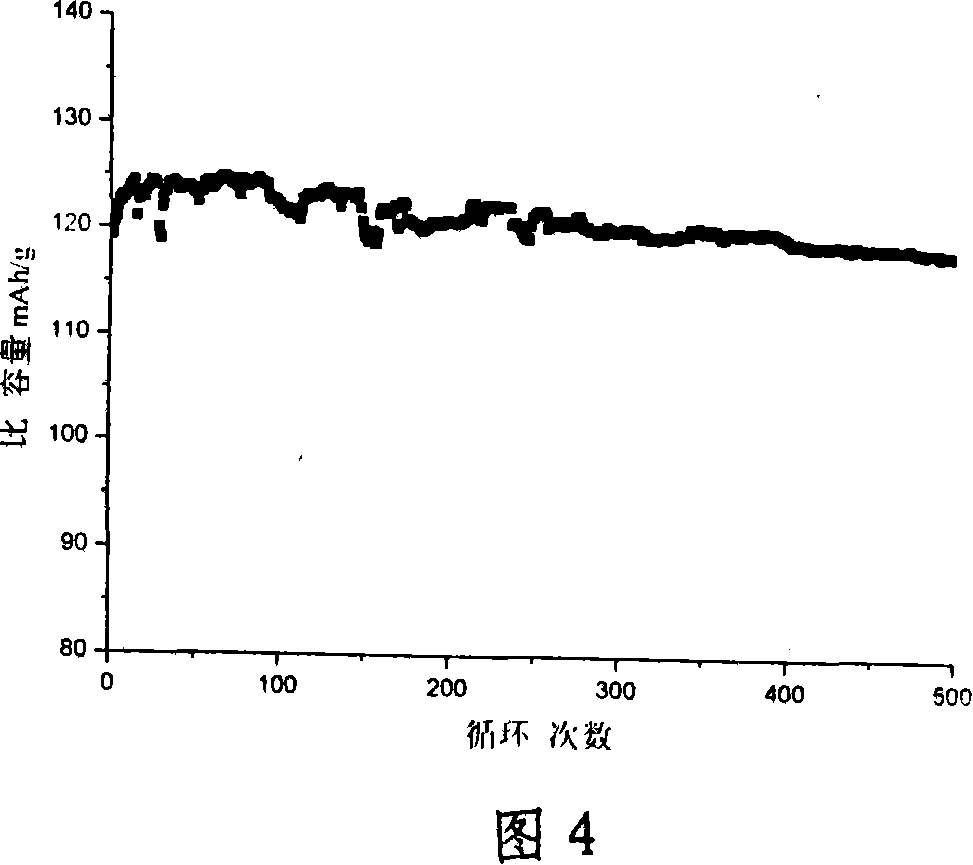

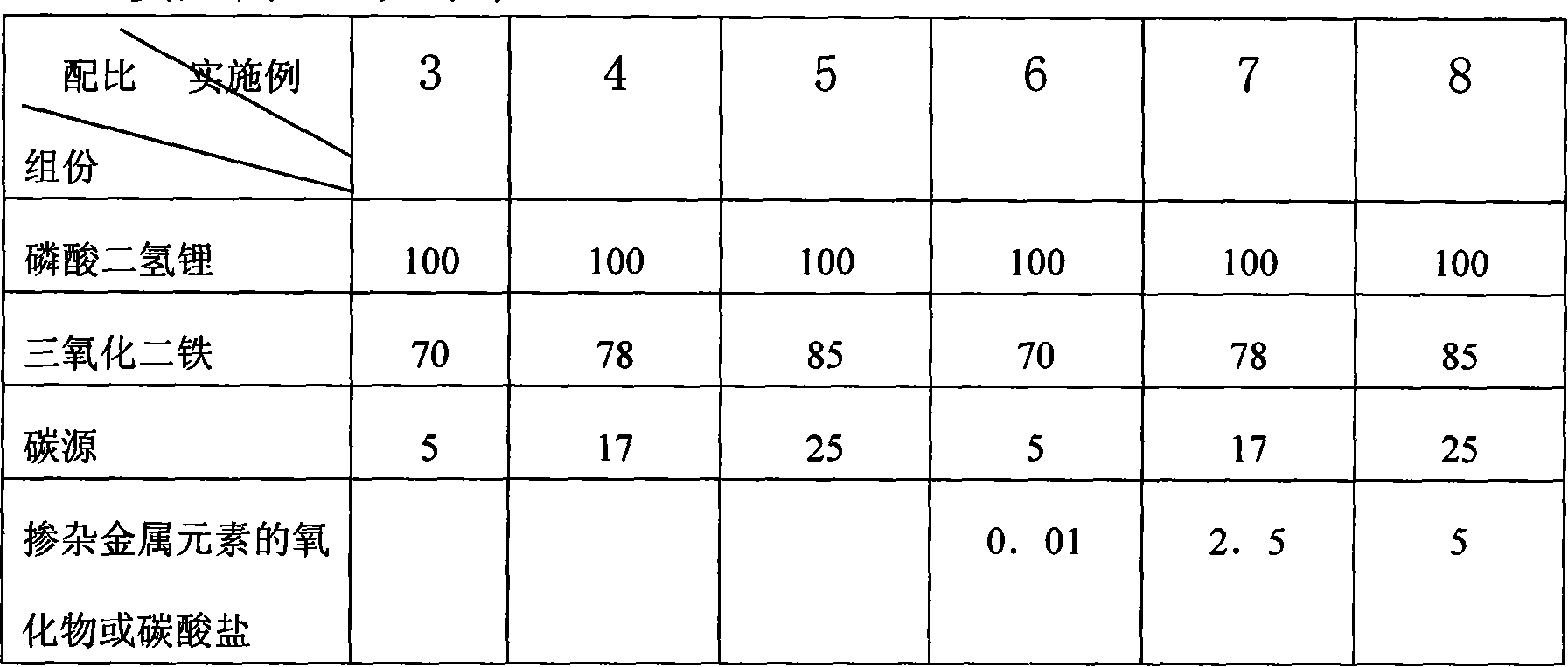

Method of producing lithium iron phosphate with high compacted density and excellent adhesive property

InactiveCN101152961AGood winding performanceGood bonding performanceCell electrodesPhosphorus compoundsNitrogen atmosphereOxide

The present invention relates to a method preparing phosphate iron lithium with high compacted density and good cohesiveness. The technical points are as follows: firstly, ferric oxide, phosphate dihydrogen lithium, oxide or carbonate doping metal elements and carbon source are ball-milled evenly in an aqueous solution and are then sprayed and dried so that a spherical powder is obtained; the spherical powder is secondly mixed with carbon source; after ball-milling and in nitrogen atmosphere protection, the mixture is presintered for 4 hours to 48 hours in 300 DEG C to 400 DEG C; after breaking, the mixture is heat treated for 4 hours to 48 hours in a high temperature of 600 DEG C to 800 DEG C so the phosphate iron lithium with high compacted density and good cohesiveness is obtained. The present invention has the advantages that the phosphate iron lithium prepared by the present invention is good in cohesiveness when used as lithium ion battery anode, an anode plate is high in compacted density, softness and winding performance. The preparing method generates no harmful gas, costs little, is simple in process and especially suitable for large-scale industrial production.

Owner:天津科斯特汽车技术有限责任公司

Silicon-carbon composite material and preparation method thereof and application thereof in lithium ion battery

InactiveCN106159213ASimple preparation processLow costCell electrodesSecondary cellsCarbon compositesSodium-ion battery

The invention relates to the battery field, and in particular relates to a silicon-carbon composite material and a preparation method thereof and application thereof in lithium ion battery. The following problems exist in the application of silicon-based materials in the lithium ion battery: 1. first coulombic efficiency of the lithium ion battery is low; 2, cycle life of the lithium ion battery is short; 3, the rate performance is poor; 4, the materials are low in production efficiency, and not conducive to large-scale industrial production. In order to solve the problems, the silicon-carbon composite material is provided, secondary-particles comprise a plurality of first particles containing core-shell structures, the core-shell structure comprises a carbon shell layer and silicon core particles which are completely wrapped by the carbon shell layer, and a gap is between the carbon shell layer and the silicon core particles. The preparation method of the silicon-carbon composite material and the application of the silicon-carbon composite material in the lithium ion battery are also provided.

Owner:BERZELIUS (NANJING) CO LTD

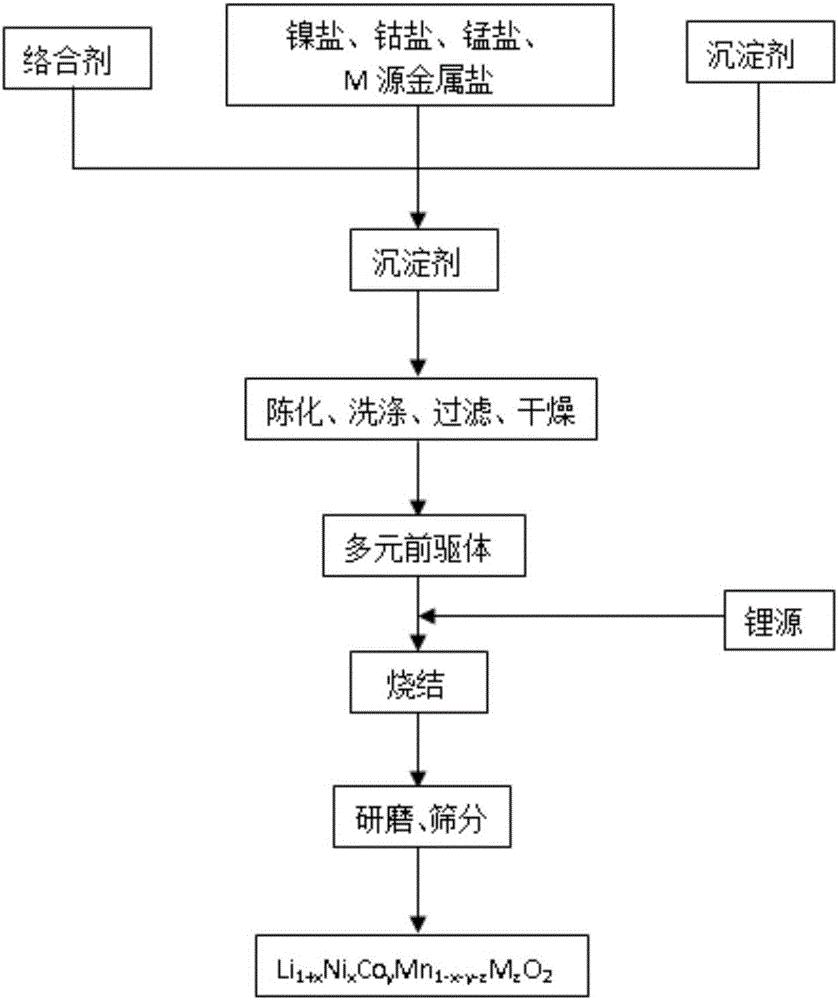

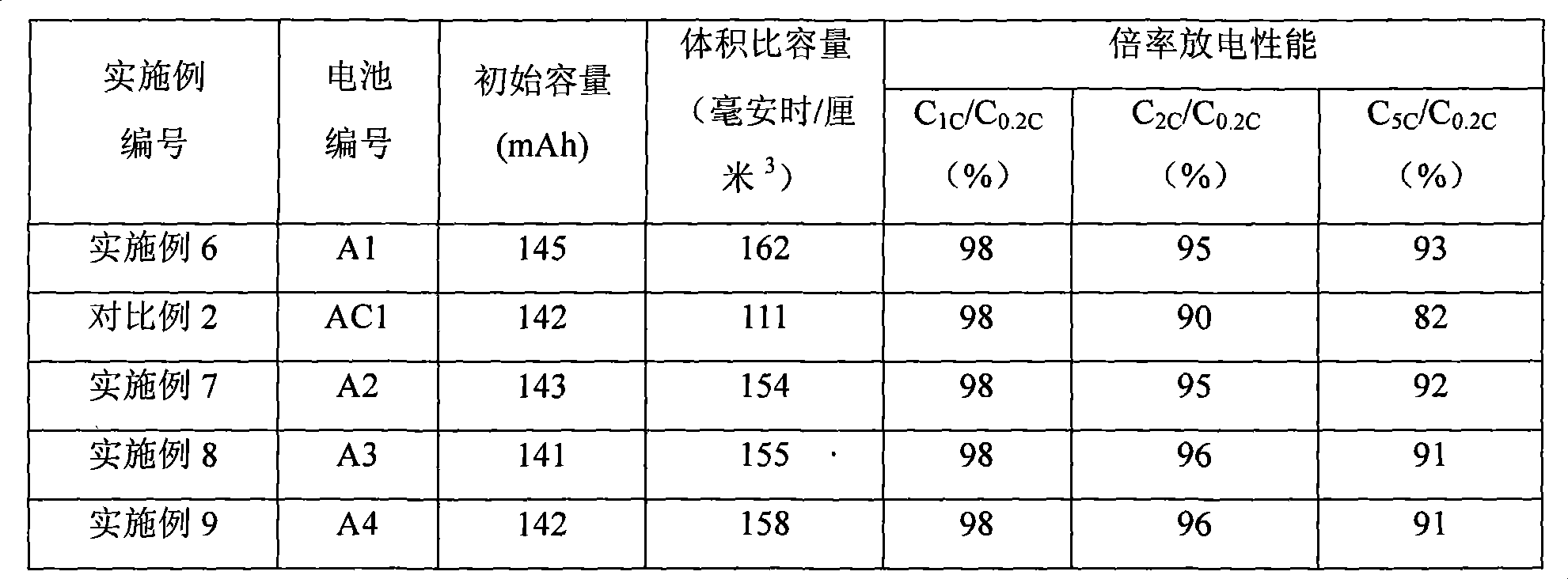

Preparation method of high density nickel cobalt lithium manganate positive electrode material

The invention discloses a preparation method of a high density nickel cobalt lithium manganate positive electrode material, LiNixCoyMnzO2. The preparation method comprises the following steps: firstly, mixing a nickel salt solution, a cobalt salt solution and a manganese salt solution according to a certain mol ratio, adding the mixed solution, a complexing agent solution and a precipitant solution together to a stirring reaction kettle with a base solution, fully reacting, carrying out solid-liquid separation, and washing and drying to obtain a globular nickel cobalt manganese oxyhydroxide precursor; calcining the precursor at the temperature of 350-900 DEG C for 2-20 hours to obtain a globular nickel cobalt manganese oxide precursor, and smashing the globular nickel cobalt manganese oxide precursor at high speed to obtain a mono-crystalline nickel cobalt manganese oxide precursor; mixing a lithium source and the mono-crystalline precursor according to a certain mol ratio, calcining at the temperature of 700-980 DEG C for 2-20 hours, and smashing and classing to obtain the mono-crystalline nickel cobalt lithium manganate positive electrode material. The preparation method provided by the invention has the advantages that the compacted density of the prepared nickel cobalt lithium manganate material is large, the specific capacity is high, the rate property and consistency are good, the preparation method is simple, and the preparation process is easy to control and operate.

Owner:HUNAN SOUNDDON NEW ENERGY

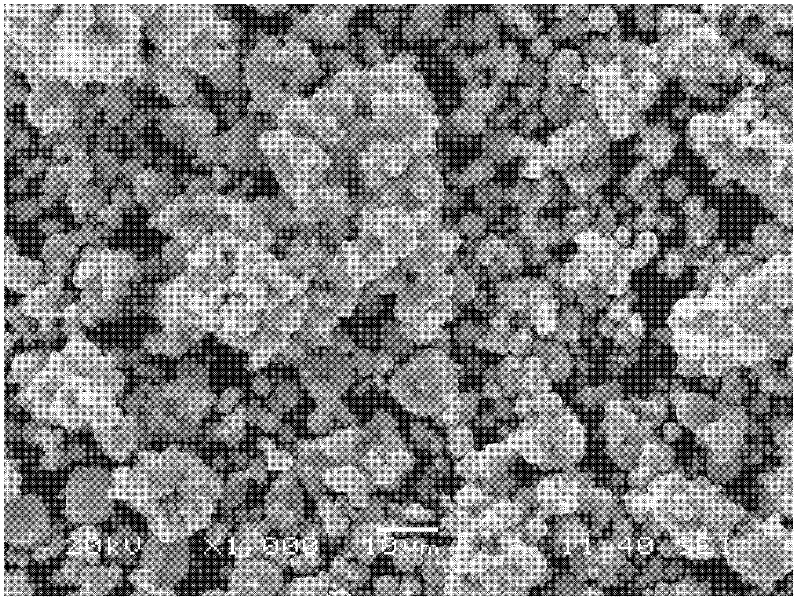

Method for preparing active electrode material of lithium ion battery

InactiveCN102593446AHigh tap densityIncrease energy densityCell electrodesSodium-ion batterySurface-active agents

The invention discloses a method for preparing an active electrode material of a lithium ion battery. The method comprises the following steps of: preparing a nano-crystal with electrochemical activity into an aqueous solution, and adding a carbon source and a surface active agent into the aqueous solution to form a uniform and stable mixture solution; and preparing the mixture solution into spherical particles under the condition that the temperature is between 200 and 900 DEG C through a spray granulation method, and performing heat treatment on the spherical particles in 400-900 DEG nitrogen gas so as to form the active electrode material of the lithium ion battery. Conductive networks are distributed in the active electrode material, and the active electrode material has a porous structure, so that the active electrode material has good lithium ion and electron transmission channels; and the lithium ion battery prepared from the active electrode material has high specific capacity, high-current charging and discharging and high cyclical stability. The method for preparing the electrode material of the lithium ion battery through a spraying method can be easily applied to mass production, and is generally used for preparing various high-performance electrode materials of the lithium ion battery.

Owner:TSINGHUA UNIV

Method for preparing ternary positive electrode material of lithium ion battery

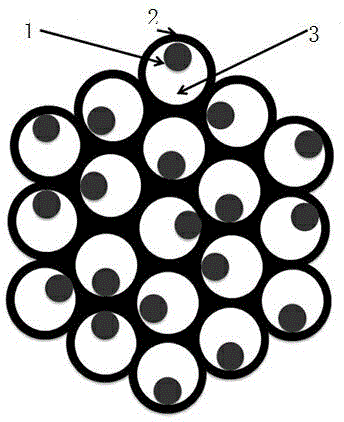

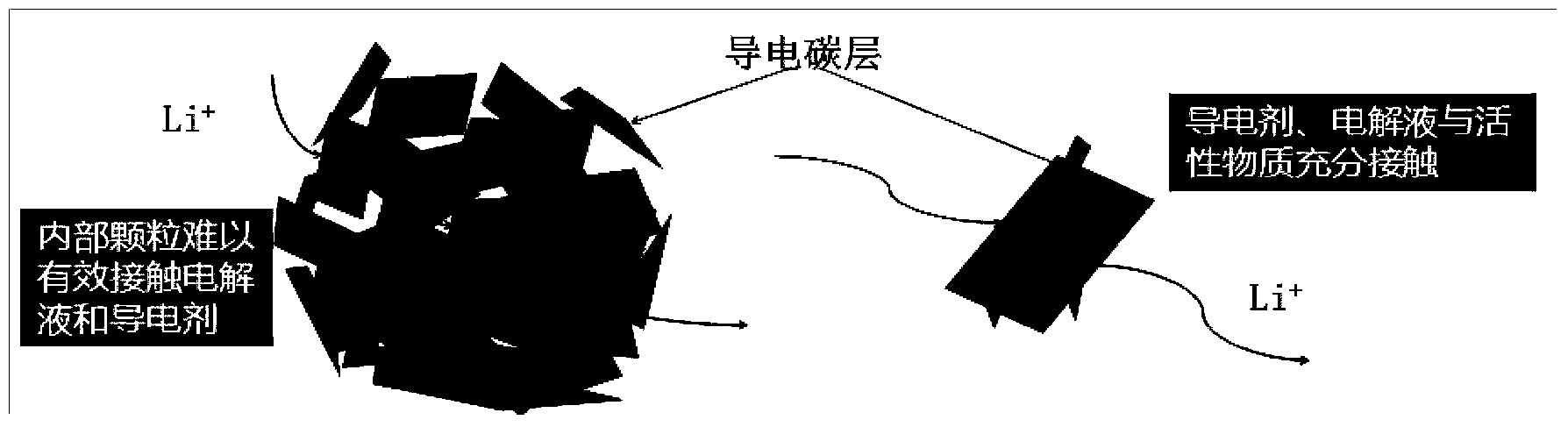

ActiveCN103811744AImprove space utilizationIncrease volumetric energy densityCell electrodesSecondary cellsEnergy densityLithium electrode

The invention relates to a method for preparing a ternary positive electrode material of a lithium ion battery. The method comprises the following steps: preparing an aggregate material A from a lithium source and a precursor, preparing a single-crystal or single crystal-like material B from a lithium source and a precursor, uniformly mixing the aggregate material A and the single-crystal or single crystal-like material B, sintering to form a material C, and coating powder of the material C with a coating, thereby obtaining the lithium-ion ternary positive electrode material. The aggregates with different granularity and shapes and the single-crystal or single crystal-like ternary material are mixed, and single-crystal particles can be effectively arranged among aggregate particles, so that the graded material is in full contact with a conductive agent and an adhesive, the space utilization rate and the compaction density of the material can be improved, the volume energy density of the material is improved, the electrical property of the material is fully exerted, the effect of heat stability of the material is improved, and the safety of the battery is improved.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

Method for synthesizing spherical gradient lithium-rich anode material

The invention discloses a method for synthesizing a spherical gradient lithium-rich anode material, which comprises the following steps of: adding deionized water into MnSO4 and [Ni0.4Co0.2Mn0.4](OH)2 in a molar ratio of x:1-x to form suspension, and dripping 0.025 to 0.1mol / L NaCO3 solution into the suspension in a 60 DEG C water bath to form a compact manganese carbonate precipitate layer; filtering, washing, and drying at the temperature of between 80 and 120 DEG C; and uniformly mixing precursor particles and lithium hydroxide in a molar ratio of 1:1.15-1.45, performing heat treatment in air at the temperature of between 400 and 500 DEG C for 3 to 5 hours, raising the temperature for 22 to 32 hours, and sintering at the temperature of between 750 and 900 DEG C for 12 to 15 hours. The material synthesized by the method has certain Mn concentration gradient, improves the tap density of lithium-rich materials, has high cyclical stability and specific capacity, and keeps high rate performance.

Owner:BEIJING UNIV OF TECH

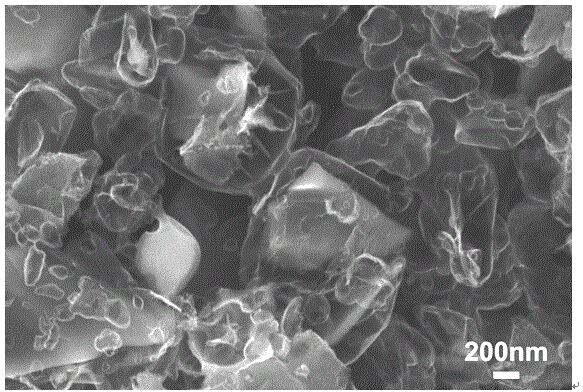

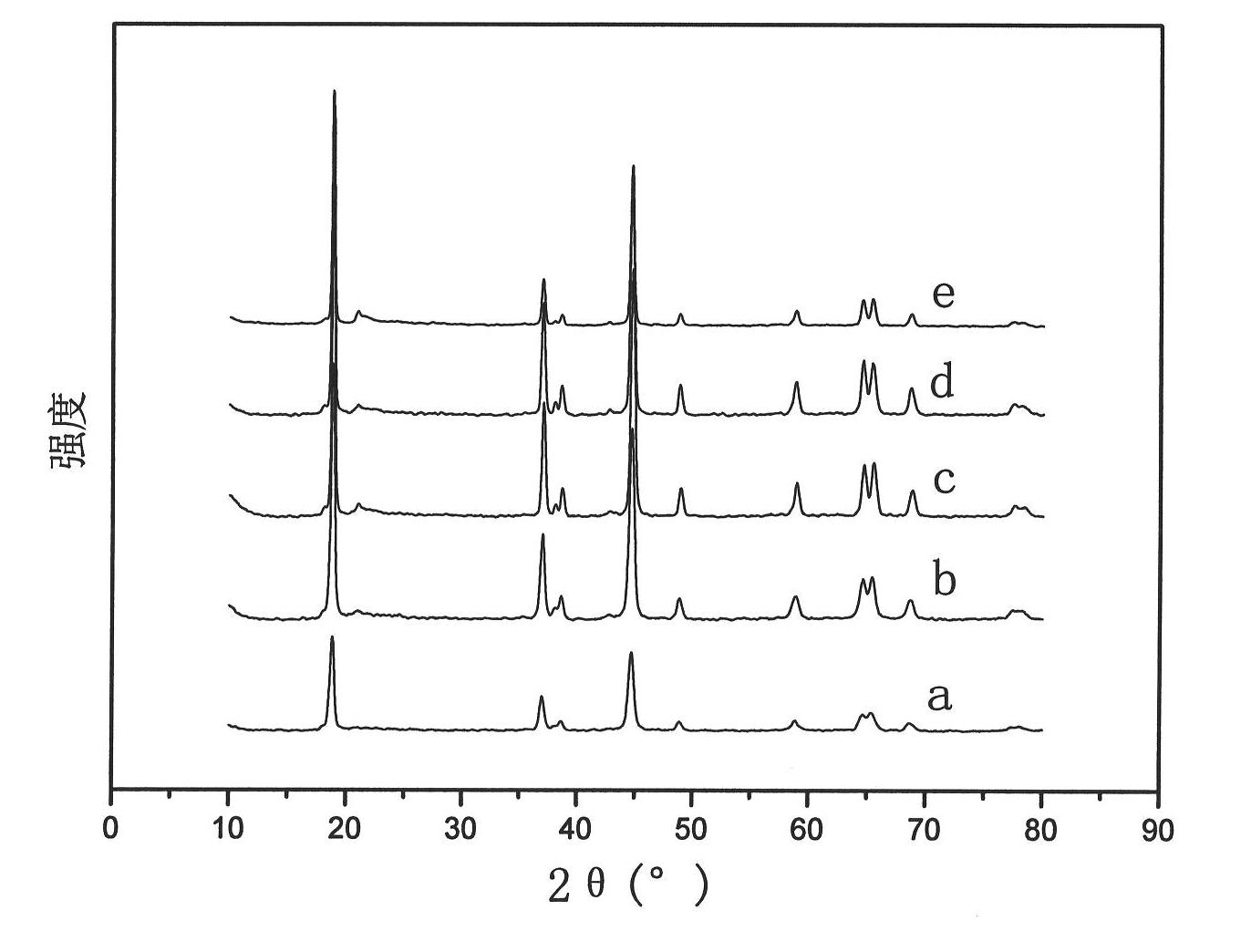

Doped monocrystal multi-component material for lithium ion batteries and preparation method of such doped monocrystal multi-component material

InactiveCN106784686AIncrease energy densityHigh tap densityHybrid capacitor electrodesCell electrodesManganeseCharge discharge

The invention belongs to the technical field of anode materials for lithium ion batteries and particularly discloses a doped monocrystal multi-component material for lithium ion batteries and a preparation method of such doped monocrystal multi-component material. The doped monocrystal multi-component material and the preparation method thereof have the advantages that nickel-cobalt-manganese ternary materials are modified, and M-source metals are doped when a precursor is prepared to decrease the material sintering temperature and improve material tapping density, so that the mixed arrangement degree of Ni<2+> in a Li<+> layer is weakened obviously; through high-temperature sintering and tempering processes, the precursor of the multi-composite material, prepared through a coprecipitation method, is more stable in crystal structure, metal ions in the material are inhibited from dissolving through surface coating, side reaction between the metal ions and electrolyte is inhibited, and stability and electrochemical performance of an active material are further enhanced; a doped monocrystal multi-component material finished product is stable in crystal structure, high in safety and compaction density and excellent in rate capability and cycle performance, so that specific capacity and charge-discharge voltage of the material are further enhanced; the preparation method is small in doping quantity, simple to operate, easy to control, widely applicable and suitable for large-scale production.

Owner:烟台卓能锂电池有限公司

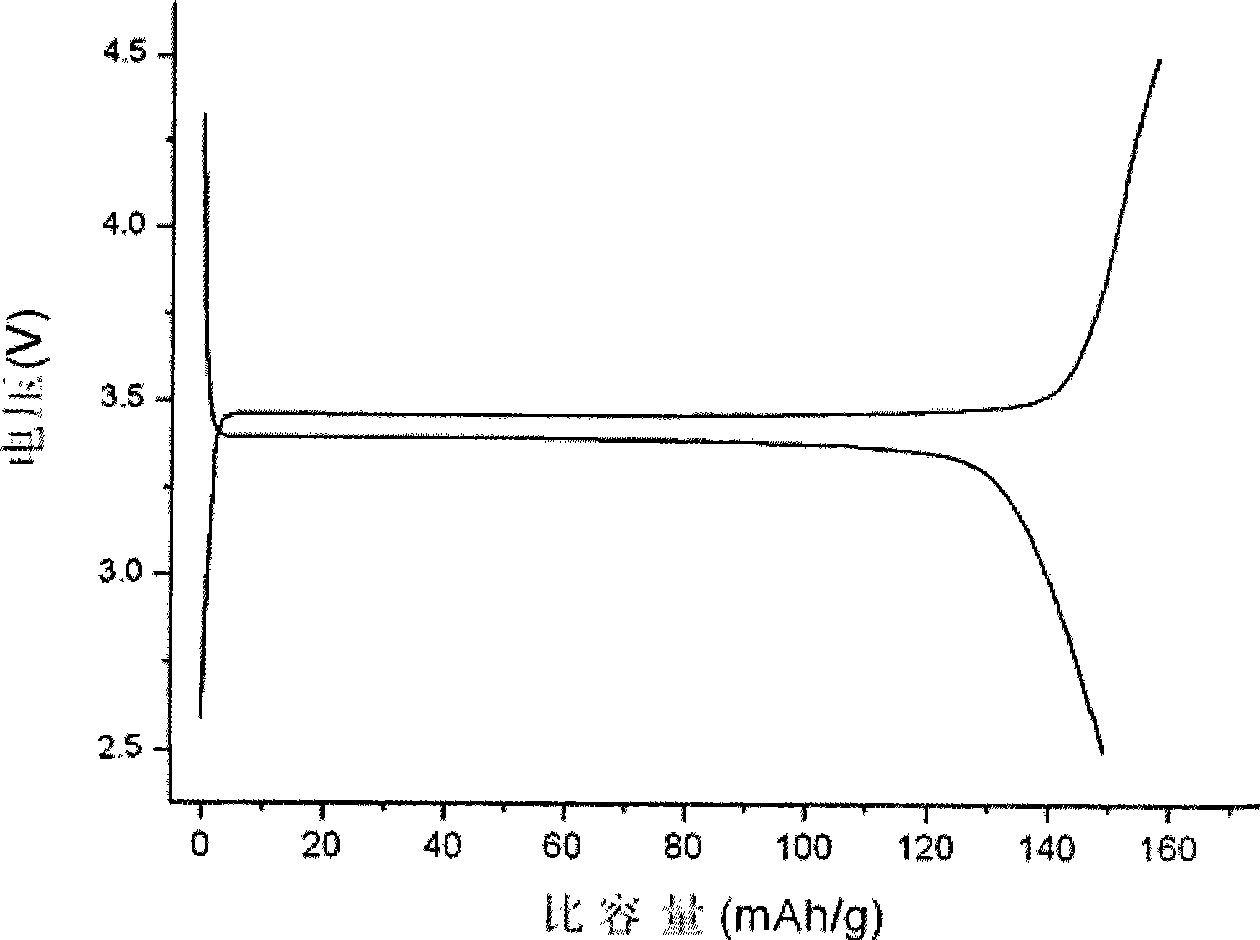

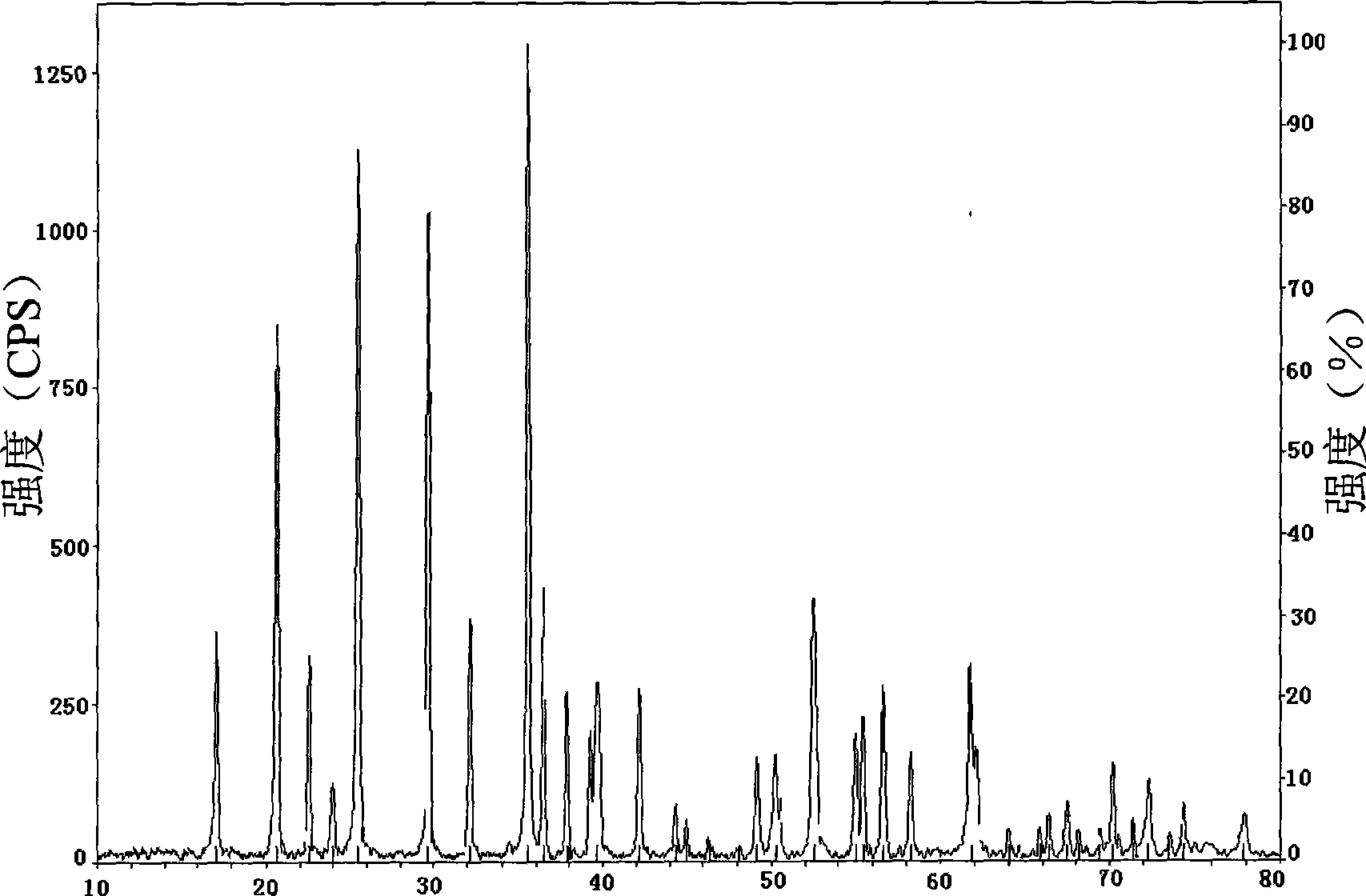

Lithium iron phosphate anode material and its preparing method

InactiveCN1767238AImprove conductivityHigh tap densityElectrode manufacturing processesCalcium/strontium/barium compoundsBorideAlcohol

The invention relates to ferric phosphate lithium anode material and its preparing method, which relates to a cell anode material, especially to a ferric phosphate lithium anode material used in lithium ion cell second time. It provides a cell anode material and ití»s preparing method which can elevate the LiFePO4 conductivity and tap density at the same time. It is formed by ferric phosphate lithium and calcium boride (by weight rate): ferric phosphate lithium: calcium boride=100í† (1.01- 5.26). It first syntheses pure ferric phosphate lithium: it balls the ferrous salt, microcosmic salt and lithium salt by alcohol grease, heats the mixed material and uses inactive gas as preserving gas. It balls the synthesis ferric phosphate lithium anode and calcium boride, burns the mixed material and adds inactive gas as preserving gas to obtain the object product.

Owner:河南天科科技有限公司

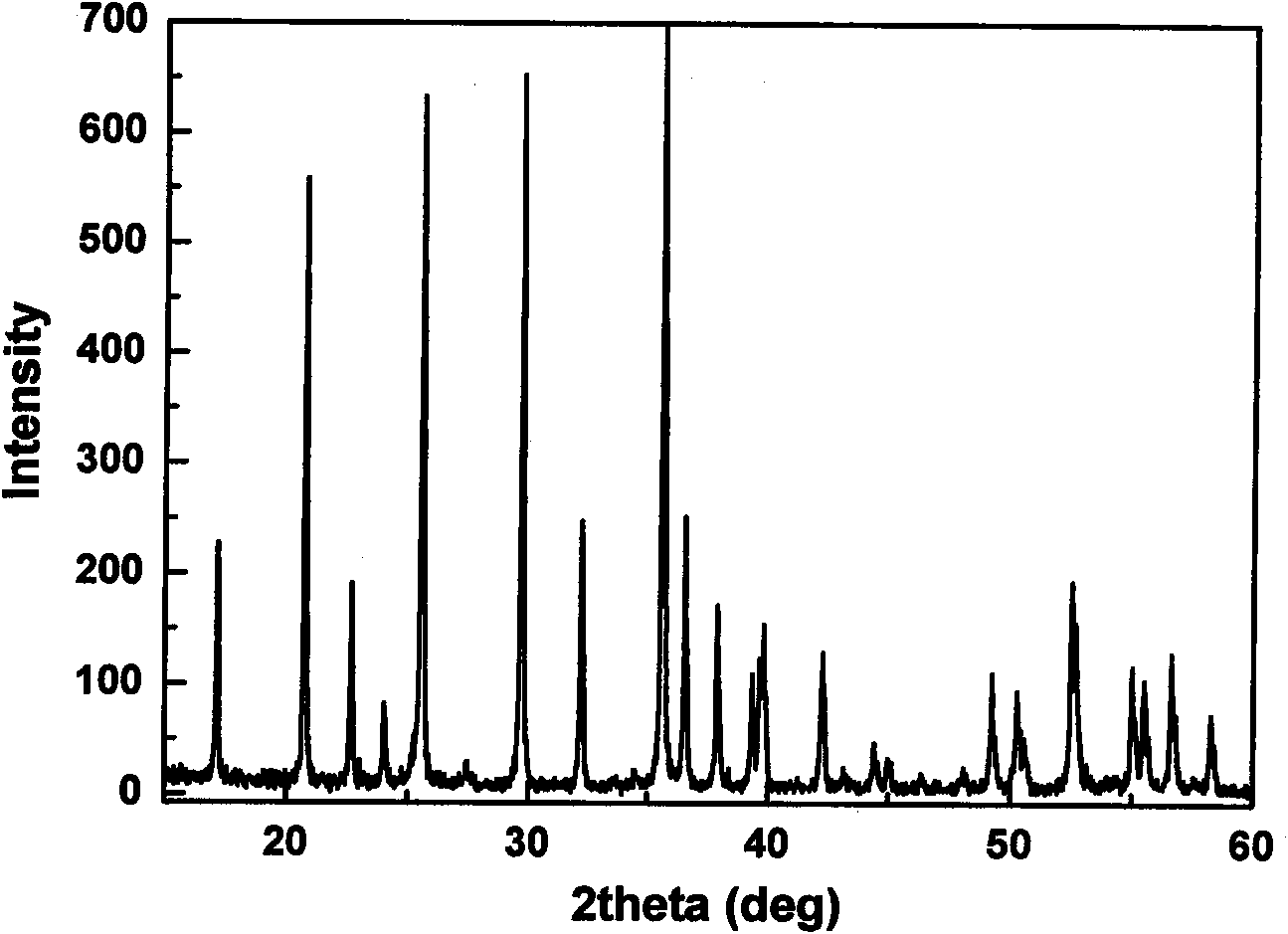

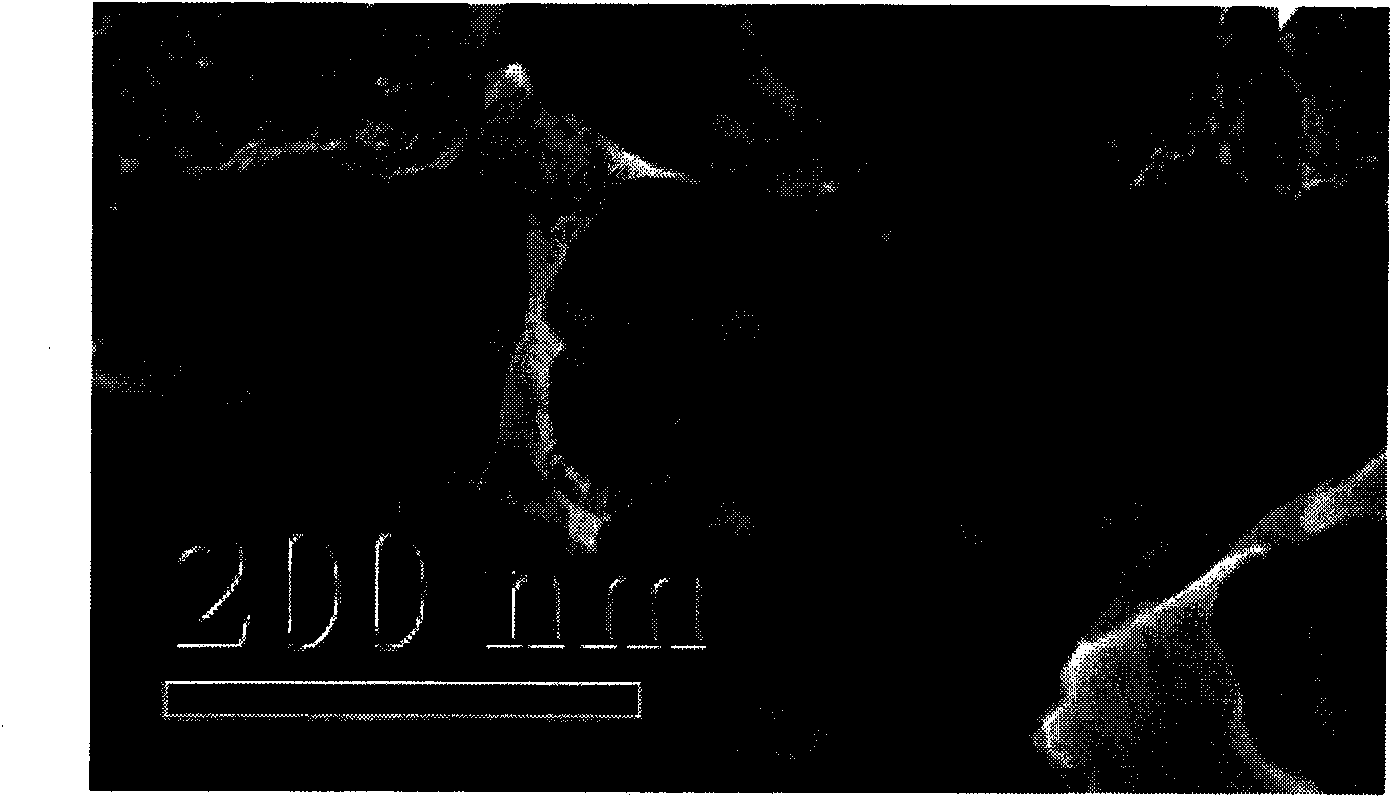

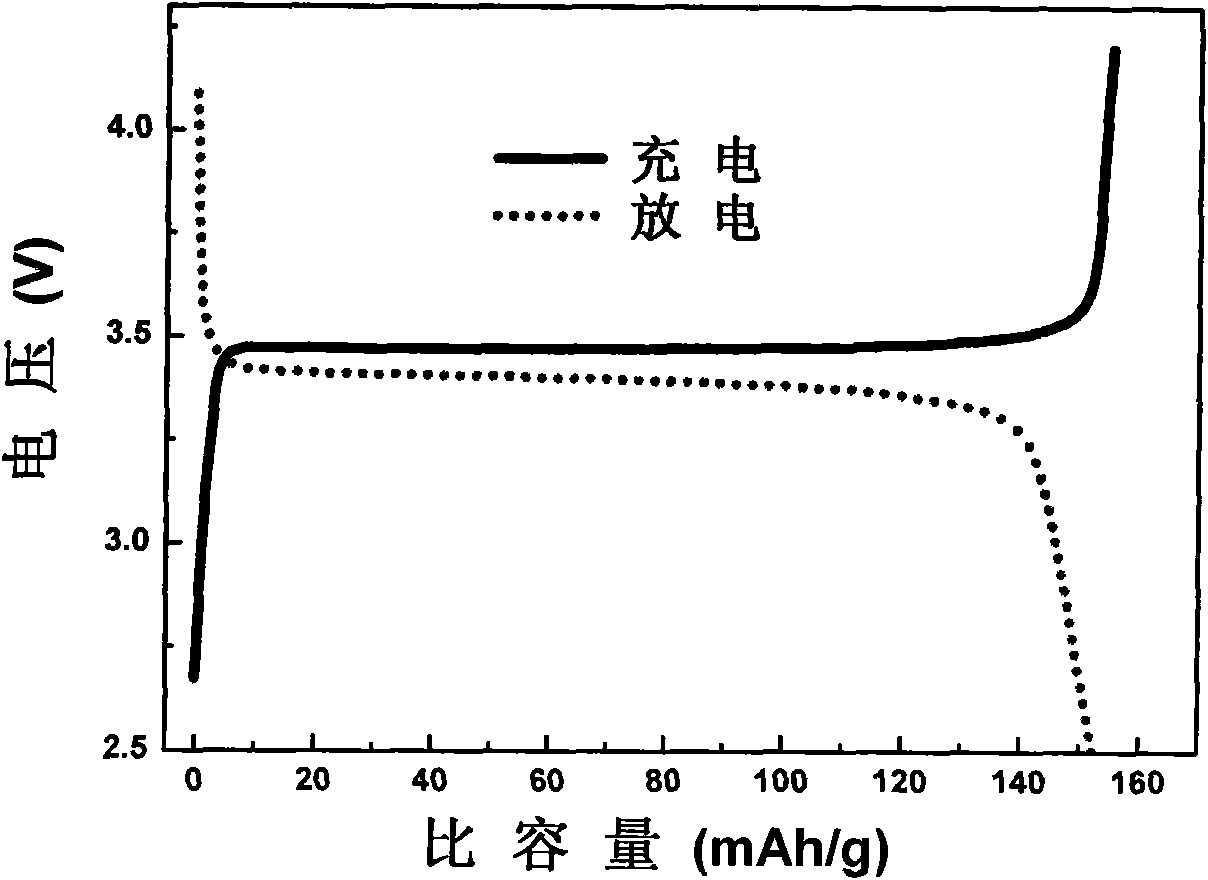

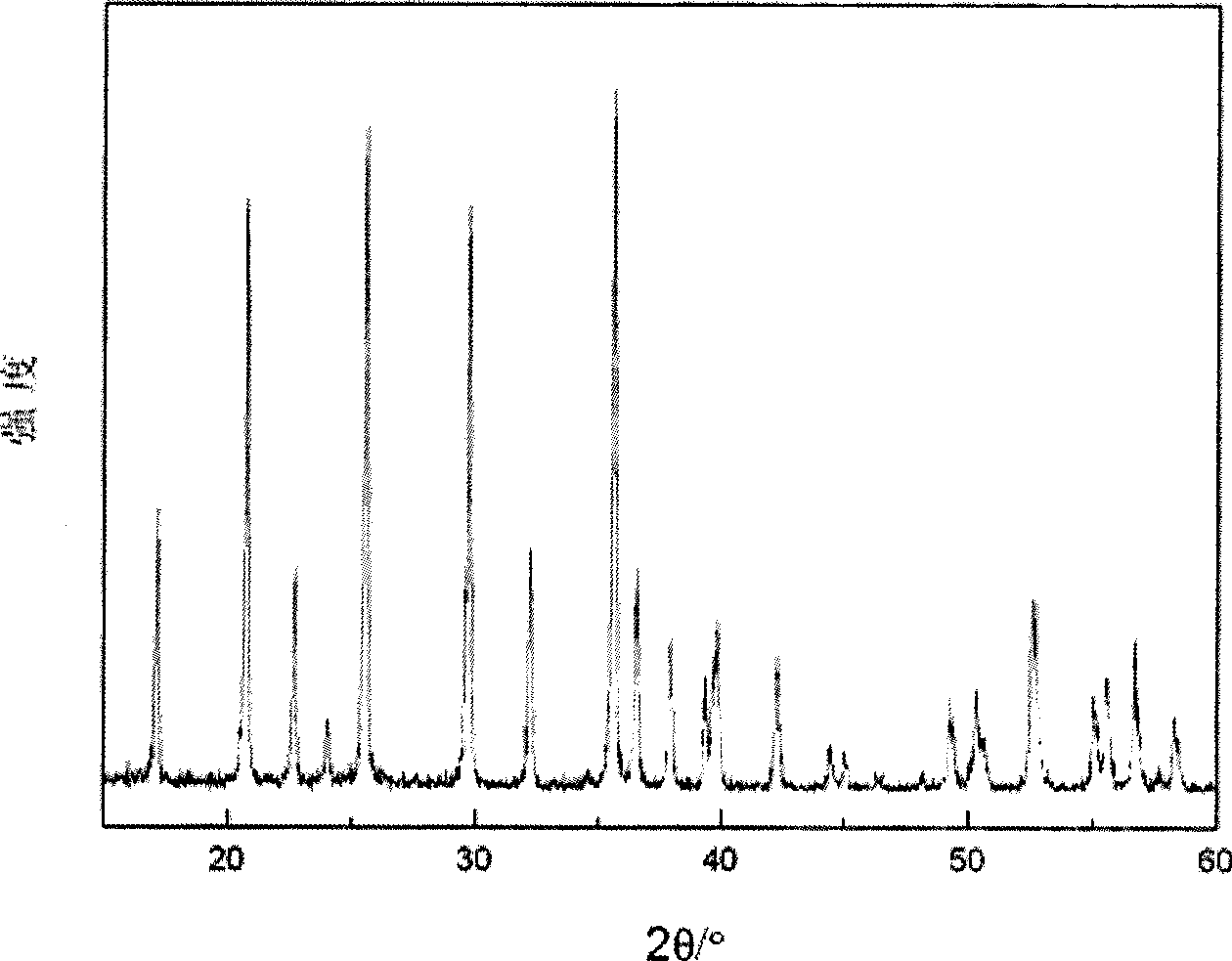

Process for producing homodisperse spherical iron lithium phosphate

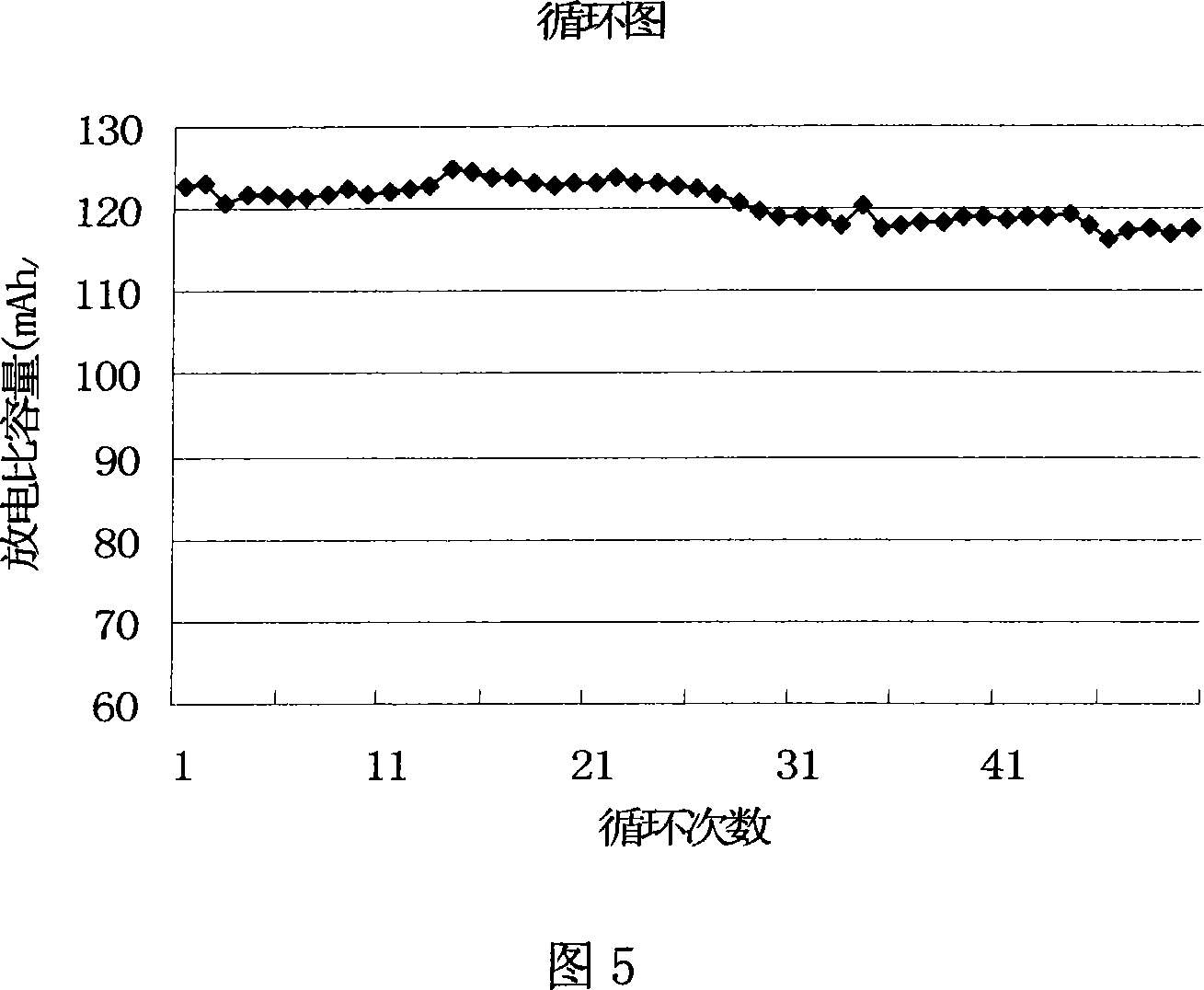

InactiveCN101508431ALow costSimple process controlCell electrodesPhosphorus compoundsLithium iron phosphateRoom temperature

The invention relates to a method for preparing uniformly dispersed spherical lithium iron phosphate-an anode material for a lithium ion battery, and belongs to the field of green energy materials. The method comprises the following steps: firstly, preparing a spherical iron phosphate precursor through liquid-phase homogeneous precipitation; secondly, performing predecomposition on the spherical iron phosphate precursor at a temperature of between 350 and 450 DEG C for 2 to 8 hours under the protection of inert gas; and thirdly, performing reaction at the temperature of between 550 and 800 DEG C for 2 to 24 hours to obtain the uniformly dispersed spherical lithium iron phosphate. The particle diameter of the product is between 100 and 200 nanometers, the tap density is between 1.6 and 2.0 g / cm, and the specific capacity of initial discharge at the room temperature reaches 140 to 160 mAh / g. The method utilizes a liquid-phase spheroidization process to prepare the uniformly dispersed spherical lithium iron phosphate, has simple process, and is easy to realize industrialized production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

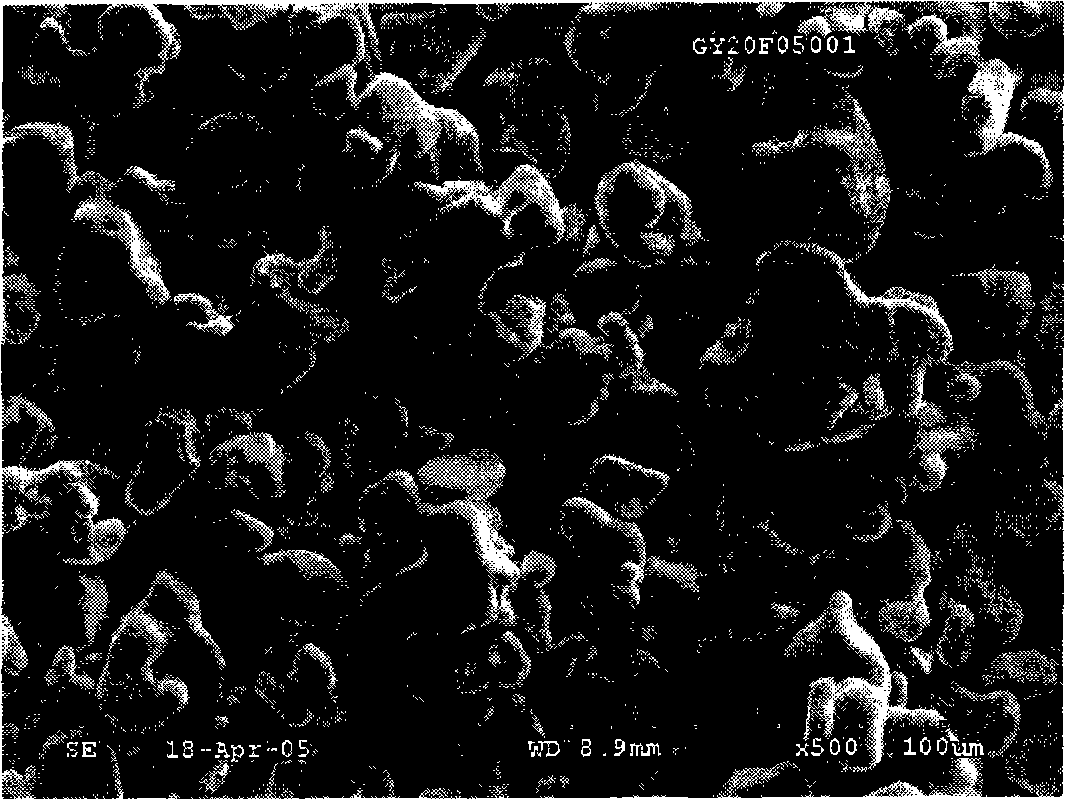

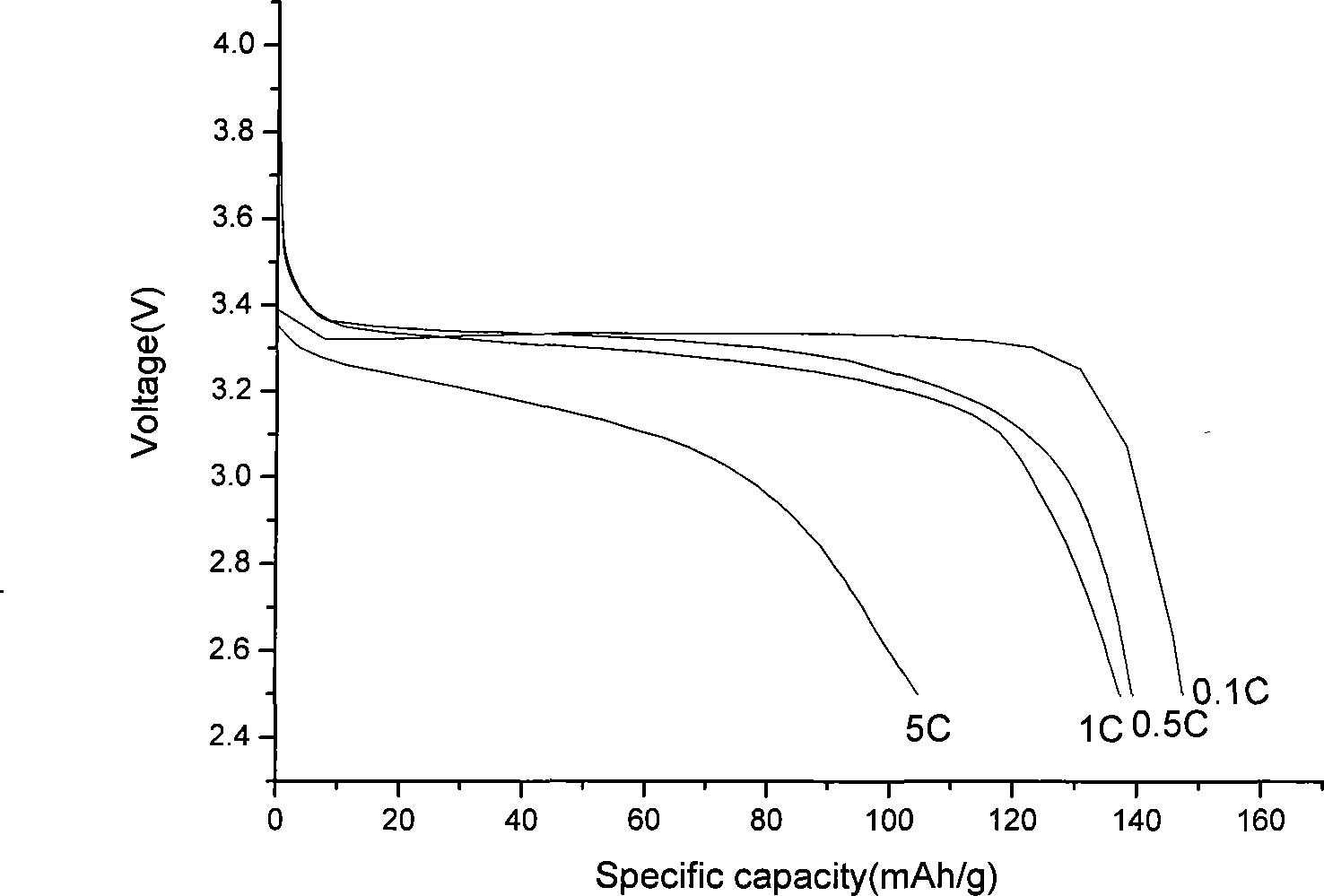

Method for making ferrous lithium phosphate/carbon compound material of high active disorderly ferric phosphate

InactiveCN101237043AHigh activitySmall particle sizeElectrode manufacturing processesPhosphorus compoundsCarbon compositesPhosphate

The present invention belongs to energy material, and in particular relates to a method of using high-activity disordered iron phosphate to prepare ferrous phosphate lithium / carbon composite material. A ferrous iron source is mixed with phosphorus source solution according to stoichiometric ratio, has hydrogen peroxide added in, has pH value controlled and is stirred so as to prepare high-activity disordered iron phosphate. iron phosphate, a lithium source and a carbon source are mixed pro rata, ball-milled uniformly, spray-dried and treated via high temperature under protective atmosphere, so as to obtain high specific capacity ferrous phosphate lithium / carbon composite material of which the average particle diameter is 200-500nm, 0.25C rate specific discharge capacity reaches 145-150mAh / g, 1C rate specific discharge capacity reaches 130-140mAh / g, and 5C rate specific discharge capacity reaches 105-110mAh / g. The method is low in cost and simple in process. Prepared material is good in electrochemical performance and especially excellent in rate performance, which is applicable to battery anode material of electric vehicles and other large-scale mobile devices.

Owner:NORTHEAST NORMAL UNIVERSITY

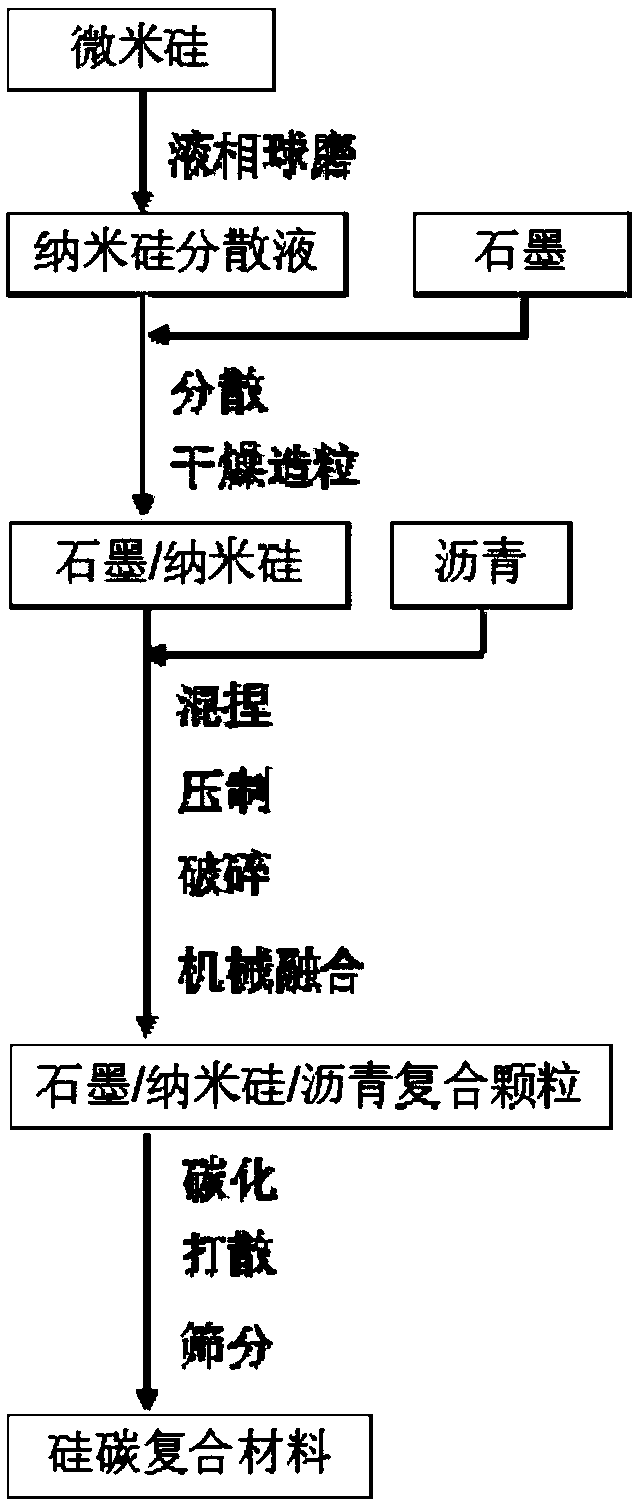

High-performance silicon-carbon cathode material and preparation method thereof

ActiveCN107785560ACover tightlyCoated evenlyNegative electrodesSecondary cellsNano siliconCarbonization

The invention relates to a high-performance silicon-carbon cathode material and a preparation method thereof. The preparation method comprises the following steps: (1) dispersing silicon into a solvent, carrying out liquid-phase ball-milling, so as to obtain nano-silicon dispersion liquid, adding graphite, and carrying out liquid-phase ball milling so as to uniformly mix nano-silicon with graphite; (2) carrying out granulation on slurry obtained the step (1), so as to obtain graphite / nano-silicon composite particles; (3) carrying out granulation on the product of the step (2) and asphalt by virtue of a mixed kneading-pressing-crushing method, so as to obtain graphite / nano-silicon / asphalt composite particles, and carrying out mechanical fusion so as to realize spheroidization and uniform coating of the graphite / nano-silicon / asphalt composite particles in one step; and (4) carrying out carbonization, scattering and sieving, so as to obtain the high-performance silicon-carbon cathode material. The preparation method is simple and low in cost and can be used for easily producing the high-performance silicon-carbon cathode material in large scale.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Preparing method of anode active material lithium iron phosphate for lithium ionic secondary cell

ActiveCN101399343AEasy to crushImprove high current charge and discharge performanceElectrode manufacturing processesSecondary cellsLithium iron phosphateBall mill

The invention provides a preparation method of lithium iron phosphate of a lithium-ion secondary battery positive electrode active material, the method comprises: a ferrous source compound, a phosphorus source compound, a lithium source compound and a carbon source compound are mixed, the first sintering is carried out on the obtained mixture under the protection atmosphere, products in the first sintering are ball-milled and dried, the second sintering is further carried out to obtain the lithium iron phosphate, wherein, the method further comprises the heating of the mixture at the temperature of 60-250 DEG C under the oxidation atmosphere before the first sintering or after the first sintering. The lithium iron phosphate which is obtained by adopting the method can have both high volume specific capacity and excellent high-current discharge performance.

Owner:TAICANG RONGCHI MOTOR

Preparation of lithium iron phosphate positive electrode material for lithium ion power cell

InactiveCN101339995ANo danger of flammabilityImprove securityElectrode manufacturing processesPhosphorus compoundsWater wetPhosphate

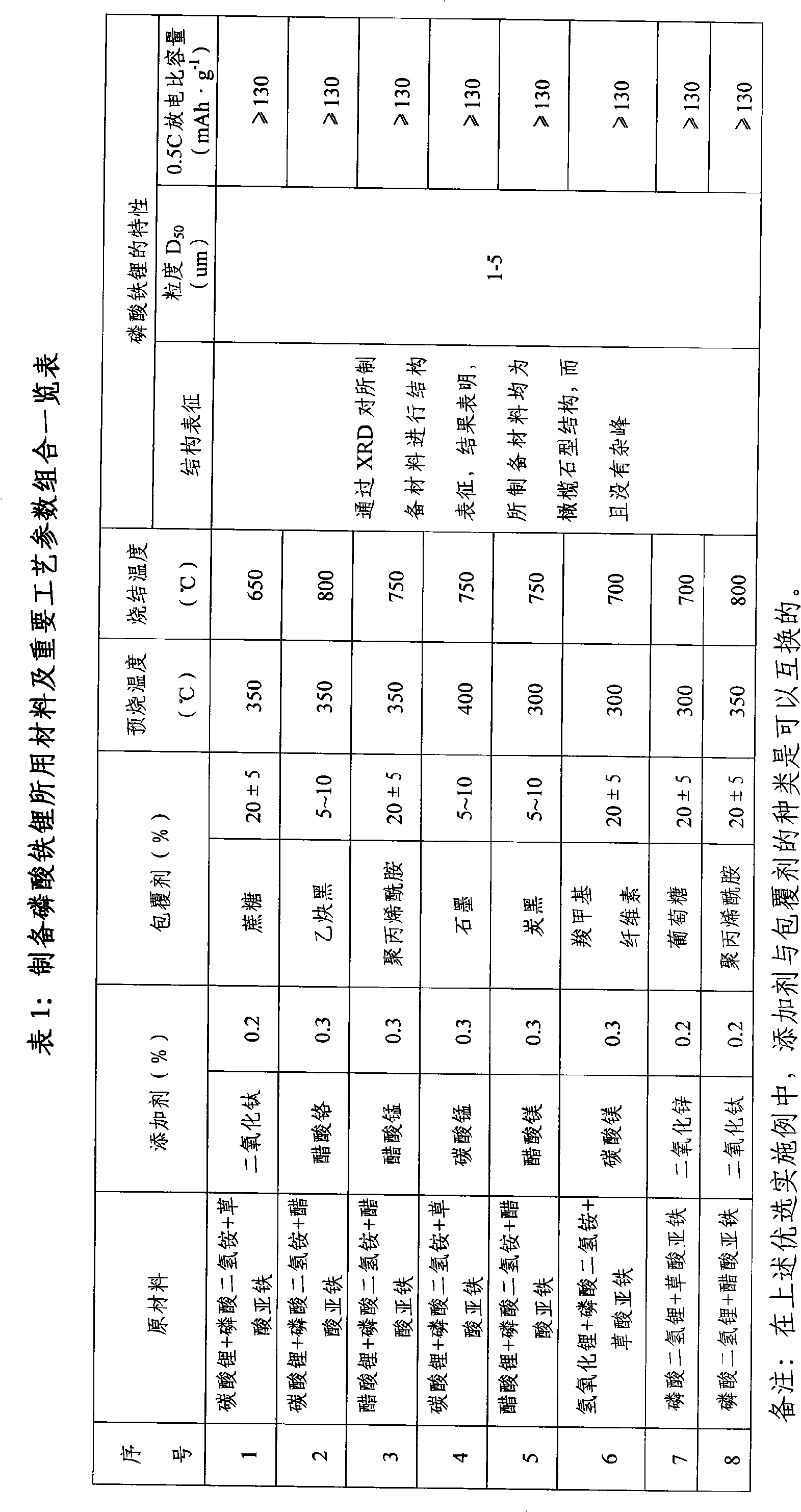

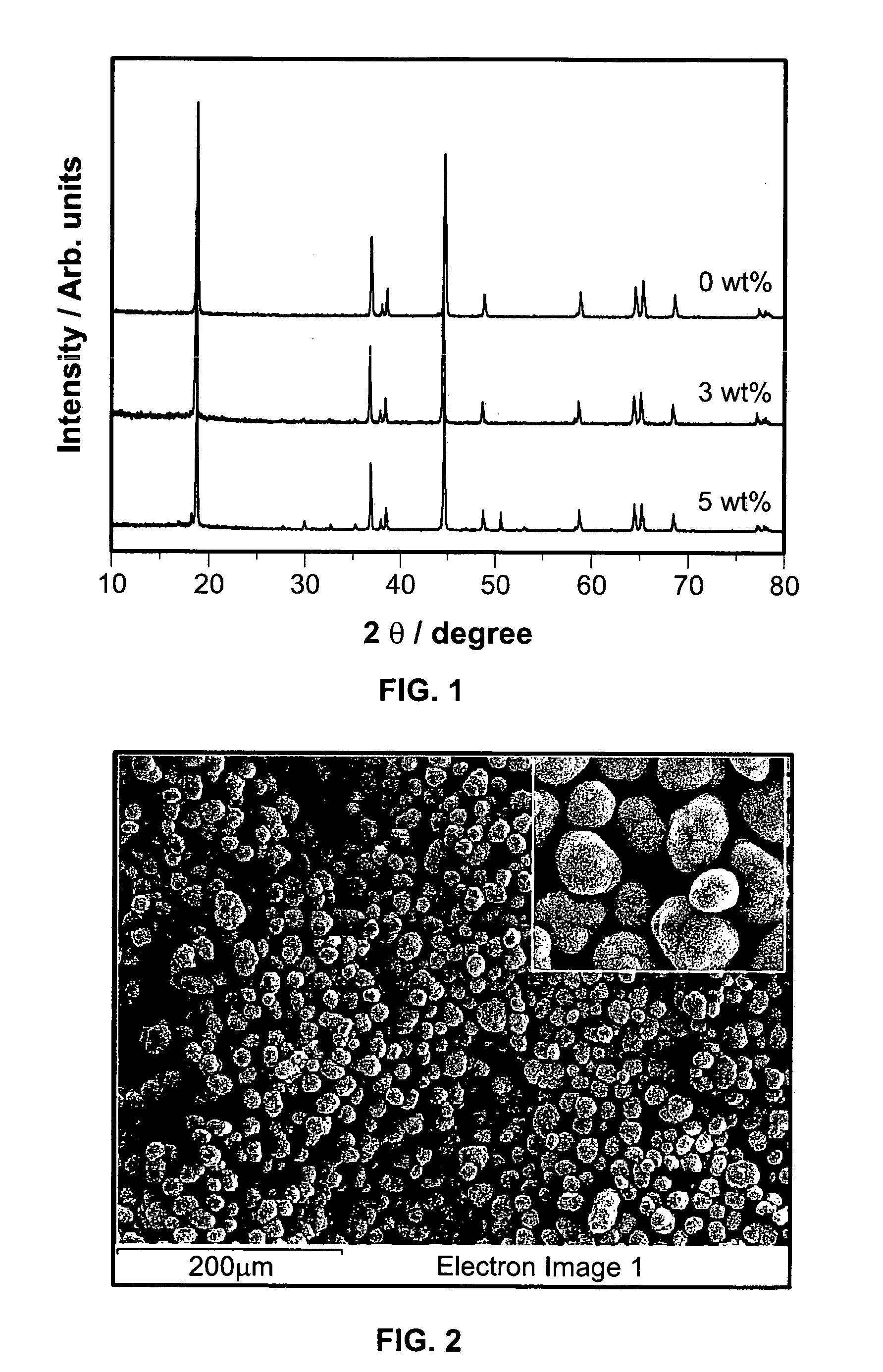

The invention discloses a preparation method of a lithium iron phosphate anode material used in a lithium-ion power battery. The preparation method takes ammonium dihydrogen phosphate and lithium carbonate or lithium hydroxide or lithium acetate and ferrous oxalate or ferrous acetate or takes the lithium dihydrogen phosphate and the ferrous oxalate or ferrous acetate as raw materials, the raw materials are prepared according to the ratio of Li, P and Fe of 1:1:1 or the ratio of LiH2PO4 to Fe of 1:1, and is added with micro amount of nano-metallic oxide or metal salt. After the process of mixing by a water wet method, spraying, drying, rolling and prilling, the mixture is pre-sintered for 10 minus or plus 2 hours at the constant temperature of 300-400 DEG C and is clad with carbon for prilling after being cooled; and then after the process of mixing by the water wet method, spraying, drying, rolling and prilling, the mixture is sintered for 10 minus or plus 2 hours at the temperature of 650-800 DEG C and then is cooled to obtain the lithium iron phosphate which is made after being crashed by gas stream and being compacted. The preparation method has the prominent advantages of safe preparation process, simple operation procedure, easy realization of industrialization and stable material performance of the product.

Owner:中国兵器工业第二一三研究所

Cathode material for lithium batteries

ActiveUS20070292763A1High tap densityIncrease energy densityAlkali metal oxidesCobalt compoundsOxide cathodeMaterials science

A method of manufacture an article of a cathode (positive electrode) material for lithium batteries. The cathode material is a lithium molybdenum composite transition metal oxide material and is prepared by mixing in a solid state an intermediate molybdenum composite transition metal oxide and a lithium source. The mixture is thermally treated to obtain the lithium molybdenum composite transition metal oxide cathode material.

Owner:UCHICAGO ARGONNE LLC

Method for preparation of multi-element composite lithium ion battery anode material by secondary sintering

InactiveCN103840148AImprove cycle performanceImprove securityCell electrodesSecondary cellsManganateCobalt

The invention relates to a preparation method of a multi-element composite material mainly used as a lithium ion battery anode material, and also relates to a preparation method for a precursor of the multi-element composite material. The material belongs to nickel-cobalt lithium manganate anode materials, and can be represented by the chemical formula Lia(NixCoyMnz)NbO2 / M, wherein a is greater than or equal to 1 and is smaller than or equal to 1.2, b is greater than or equal to 0 and is smaller than or equal to 0.1, (x + y + z) is greater than or equal to 0.9 and is smaller than or equal to 1, N is a doping element and is one or more of Mg, Al, Ti, Cr, Zr, La, Nb and other elements, M is a cladding element and is one or more of Li, B, C, Al, Si, Ti, Co, Zr and other elements. By full mixing of the precursor and a lithium salt, the method provided by the invention improves the reaction activity, and strictly controls the sintering temperature so as to obtain the multi-element anode material with regular shape and uniform particle size.

Owner:GUANGRAO GELIN NEW ENERGY

Nickel cobalt lithium manganate composite cathode material and preparation method of nickel cobalt lithium manganate composite cathode material

The invention relates to a nickel cobalt lithium manganate composite cathode material and a preparation method of the nickel cobalt lithium manganate composite cathode material. The nickel cobalt lithium manganate composite cathode material has the chemical formula of Li(NixCoyMn<1-x-y>)O2. The preparation method comprises the steps that after soluble nickel salts, cobalt salts, manganese salts and complexing agents are uniformly mixed, sodium hydroxide precipitating agents are added, the reaction is carried out in a stirring reactor with an ultrasonic device, composite hydroxides of nickel cobalt manganate are obtained, then, the composite hydroxides, water soluble macromolecular compounds and lithium source compounds are placed in the stirring reactor with the ultrasonic device, the spray drying is carried out in the ultrasonic reinforced stirring mixing process, and nickel cobalt lithium manganate precursors are obtained, the precursors are subjected to primary sintering under the certain atmosphere protection, and nickel cobalt lithium manganate products are obtained. When the nickel cobalt lithium manganate composite cathode material and the preparation method are adopted, the prepared product particles are uniform, the morphology is regular, the specific surface area is small, the tap density is high, the electrochemical performance is excellent, the processing performance is good, the cost is low, the environment-friendly effect is realized, and the environment pollution is avoided.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com