Silicon-carbon composite material and preparation method thereof and application thereof in lithium ion battery

A technology of silicon-carbon composite materials and lithium-ion batteries, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unfavorable large-scale industrial production, low initial Coulombic efficiency of batteries, and unstable material structure, etc. Impact, low cost, small expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

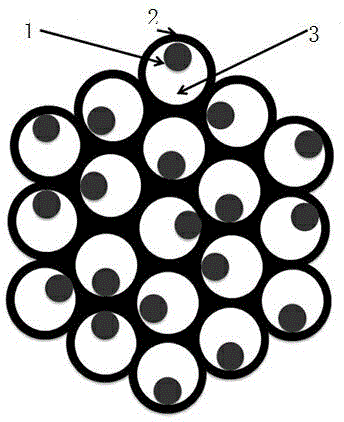

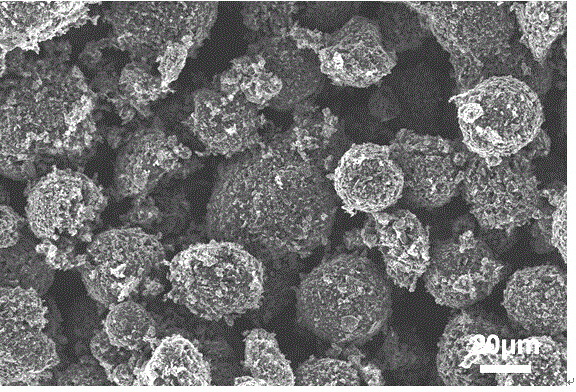

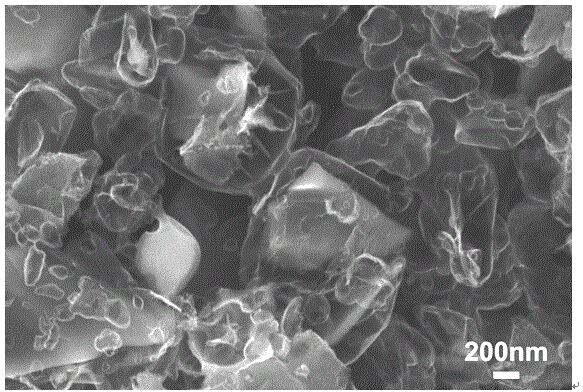

[0053] Take 400g of silicon powder with a D50 of 1.5 μm and put it into a rotary tube furnace, and heat it at 1000°C for 3 hours in a pure oxygen atmosphere to obtain particles whose outer layer is silicon dioxide and the inner core is silicon, and the oxygen content is about 42%. Can be labeled as Si@SiO2. During the oxidation process, the oxygen flow rate is kept at 160ml / min, and the furnace tube keeps rotating to ensure that the silicon powder is in full contact with oxygen and oxidized evenly. Dissolve 240g of sucrose in 2360g of water, take 350g of oxidized silicon powder, slowly add it to the sucrose aqueous solution, and disperse with mechanical stirring at a speed of 1300rpm for 1 hour to obtain a uniform slurry with a solid content of about 20%. The obtained Si@SiO2 sucrose slurry was spray-dried with spray drying equipment, the inlet air temperature was 150°C, the outlet temperature was 105°C, the rotary atomizing nozzle speed was 400Hz, and the feed rate was 120g / m...

Embodiment 2

[0058] Take 200 g of spherical silicon powder with a D50 of 0.05 μm and put it into a rotary tube furnace, and heat it in an air atmosphere at 900 ° C for 2 hours to obtain Si@SiO2 powder with an oxygen content of about 39%. Dissolve 180g of glucose in 1600g of water, take 220g of oxidized silicon powder, slowly add it to the aqueous glucose solution, and disperse for 1 hour at a speed of 1300rpm with mechanical stirring to obtain a uniform slurry with a solid content of about 20%. The obtained Si@SiO2 glucose slurry was spray-dried with spray drying equipment, the inlet air temperature was 210°C, the outlet temperature was 110°C, the rotary atomizing nozzle speed was 400Hz, and the feed rate was 70g / min. Spray drying to obtain spherical glucose-encapsulated Si@SiO2 dry powder is aggregated into secondary particles, and the D50 is about 16 μm. The spray-dried dry powder was heated at 900° C. for 3 hours in an argon inert atmosphere to obtain Si@SiO2@C powder. Take 5g of the a...

Embodiment 3

[0061] Take 4kg of silicon powder with a D50 of 2 μm, mix it with deionized water to make a slurry with a solid content of 50%, and perform wet grinding with a sand mill for 5 hours to obtain a submicron silicon slurry with a D50 of about 0.7 μm. Dilute the silicon slurry obtained by sand grinding to a solid content of about 30%, and stir in a reactor at a constant temperature of 80°C for 36 hours to make the silicon particles react with water and form a silicon dioxide layer on the surface. During the constant temperature oxidation process, add water to the reaction kettle properly to prevent the water from evaporating to dryness. Finally, a Si@SiO2 slurry with a solid content of 32.1% was obtained, and the solid Si@SiO2 oxygen content was about 17%. Take 12.7kg of the above slurry, dissolve 350g of sucrose and 200g of glucose in deionized water and mix evenly, then add deionized water so that the solid content of the final slurry is about 25%. The obtained Si@SiO2, glucose,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com