Patents

Literature

344 results about "Volume effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Volume Effect. The volume effect is seen in normal tissues, where the tolerance dose of a tissue is related to the volume of that tissue irradiated. Tissues may be considered to have functional subunits (FSU), where each subunit performs some of the function of that organ.

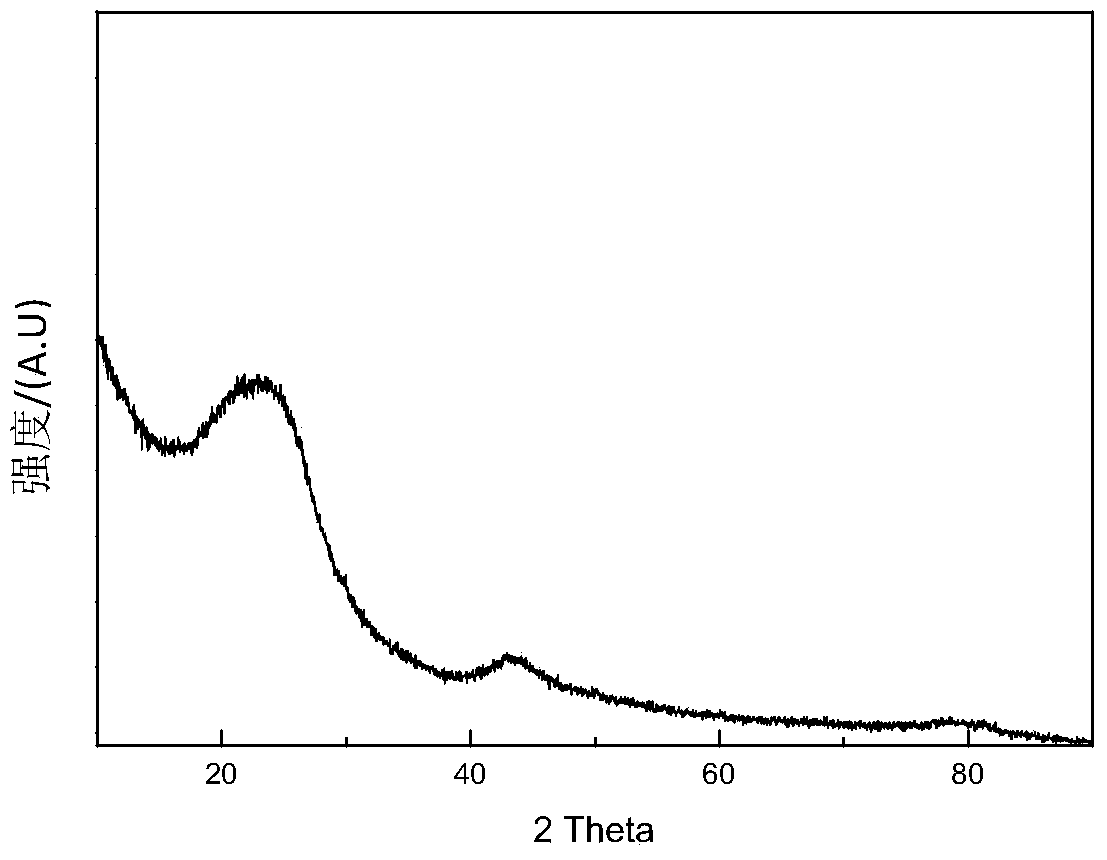

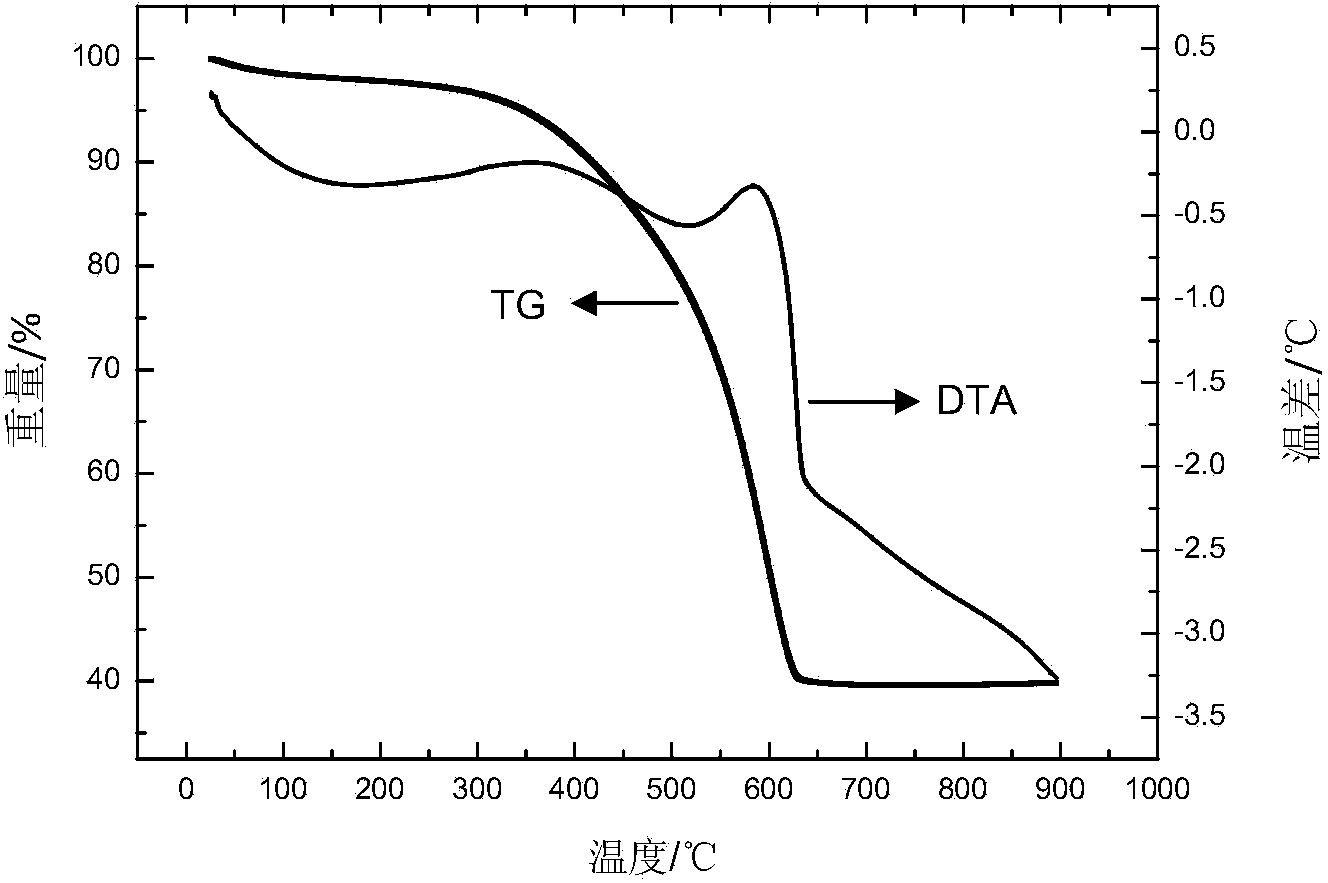

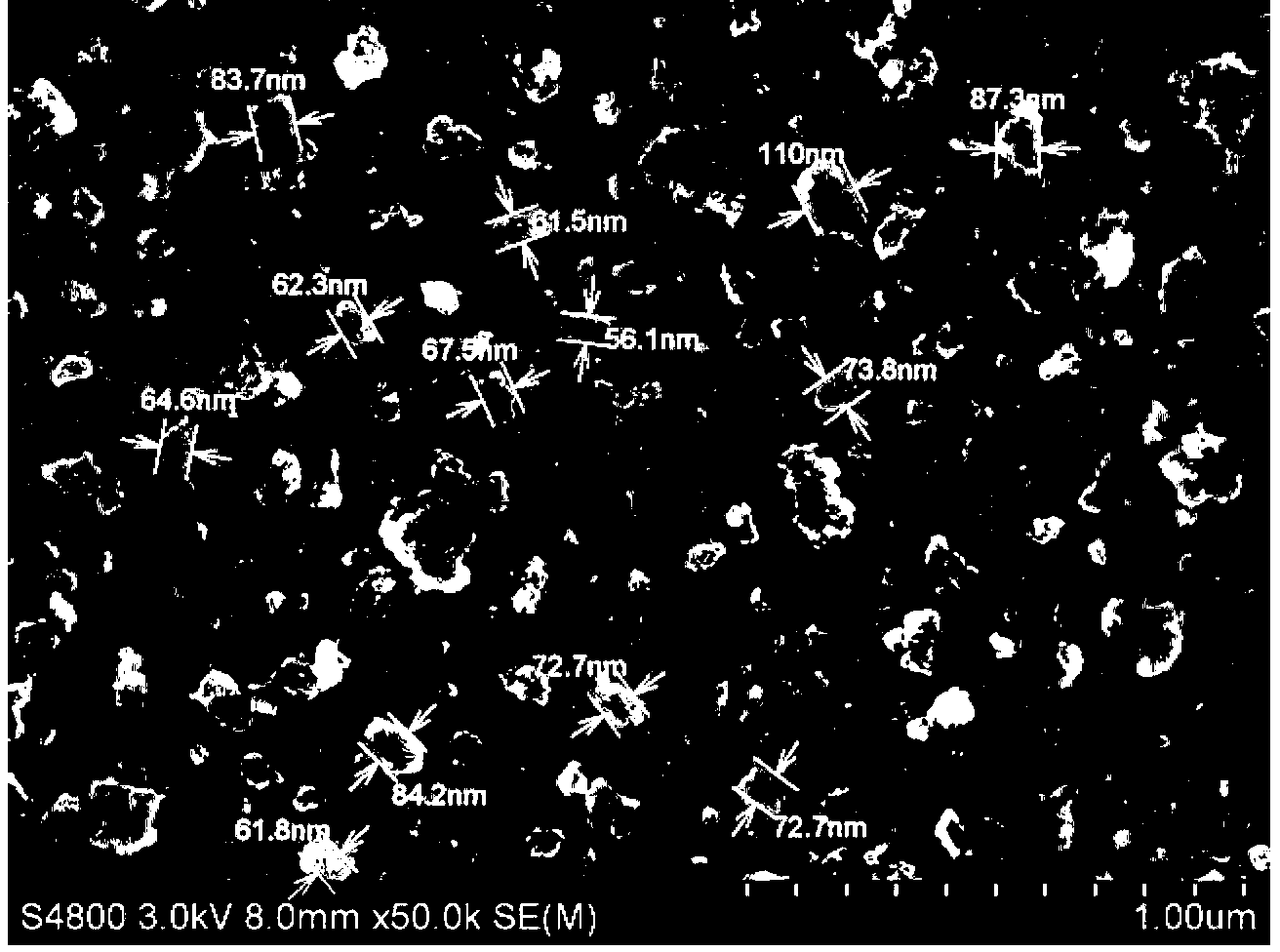

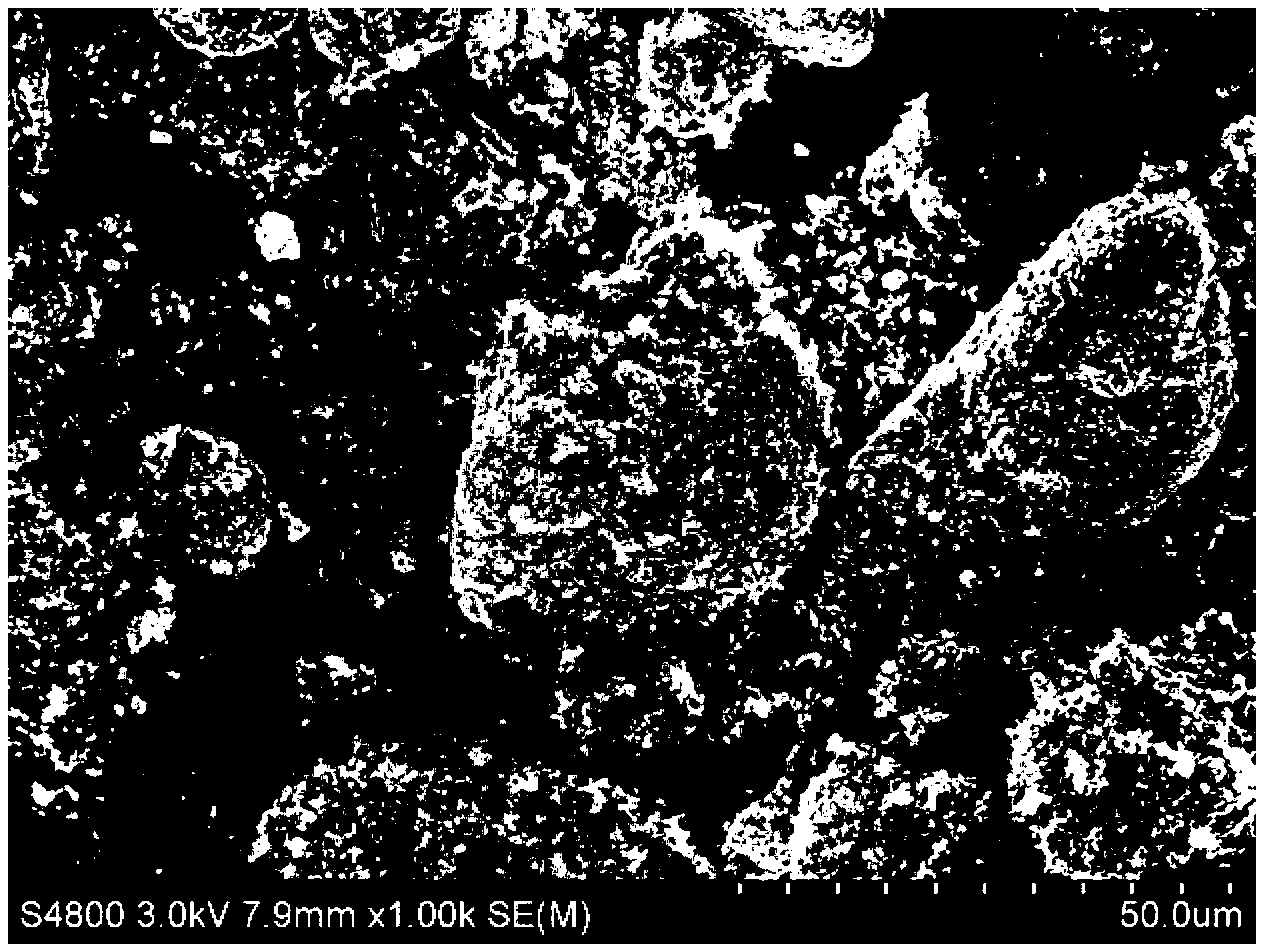

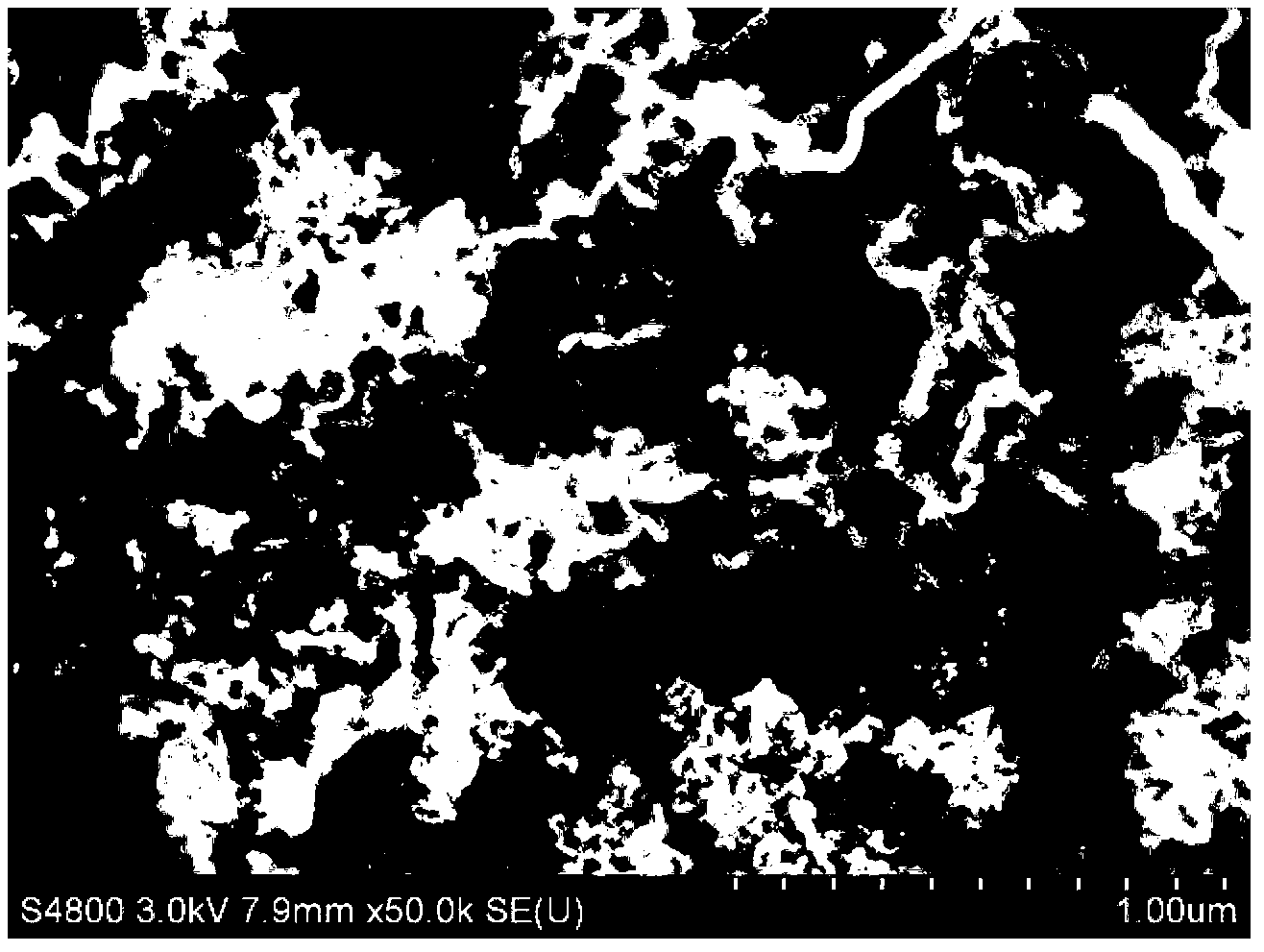

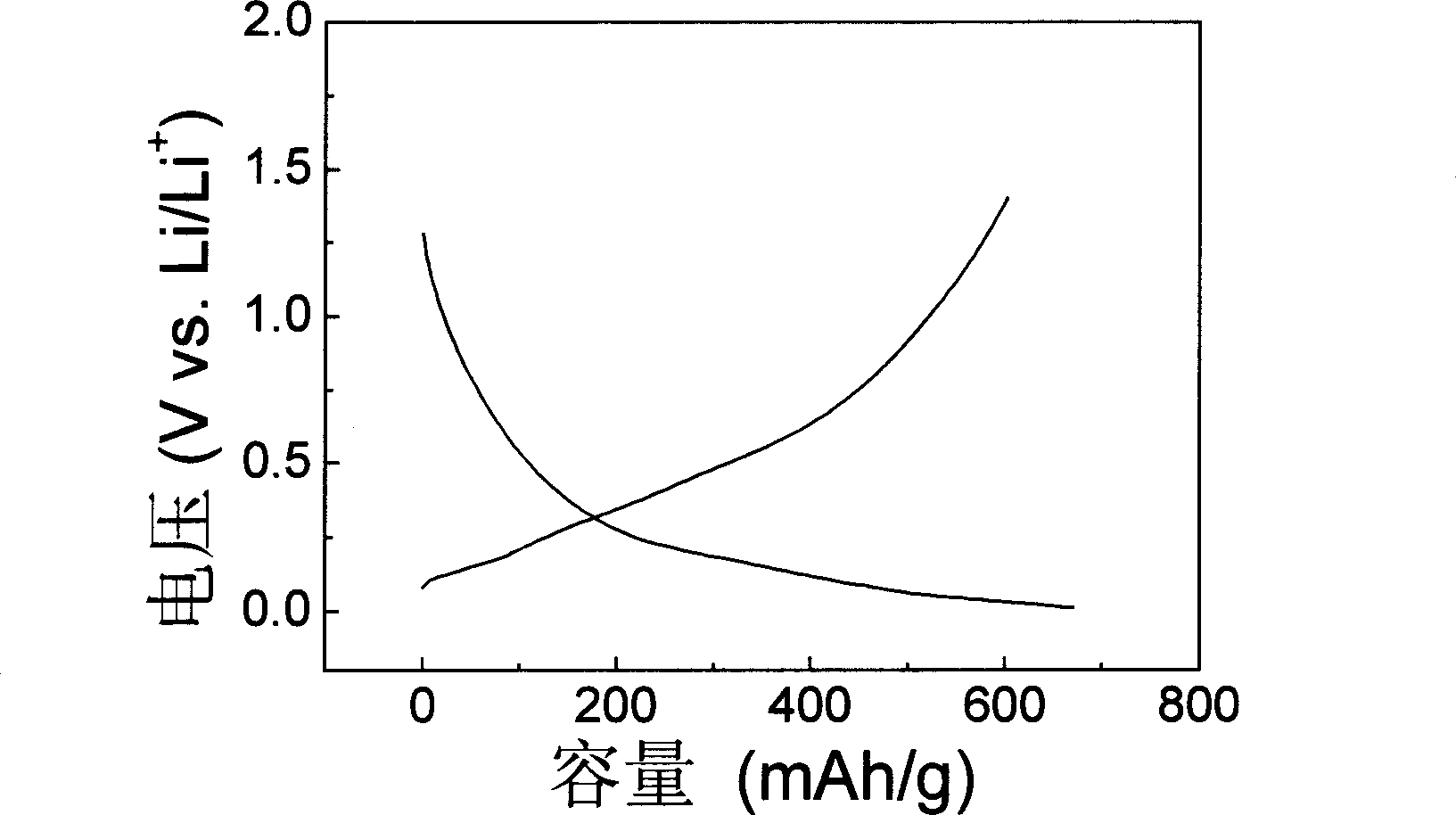

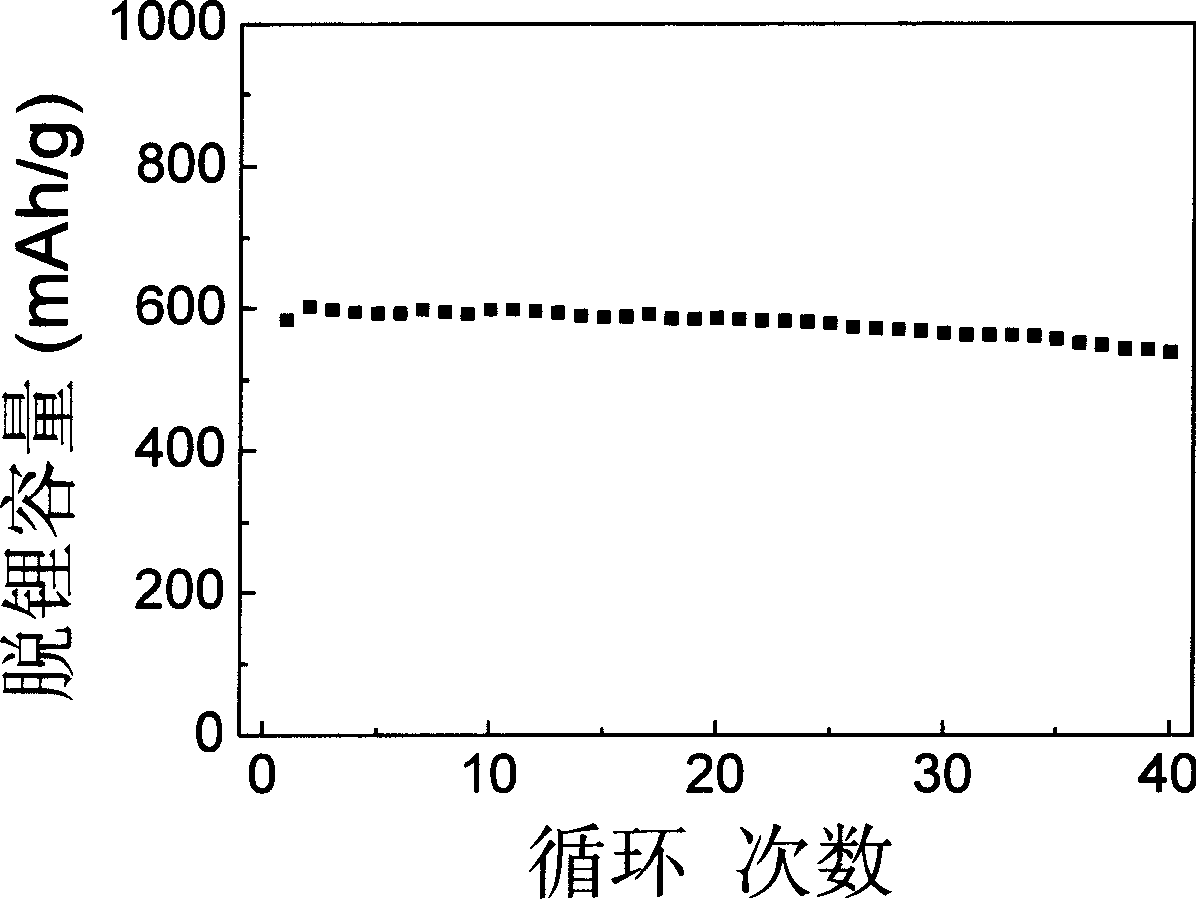

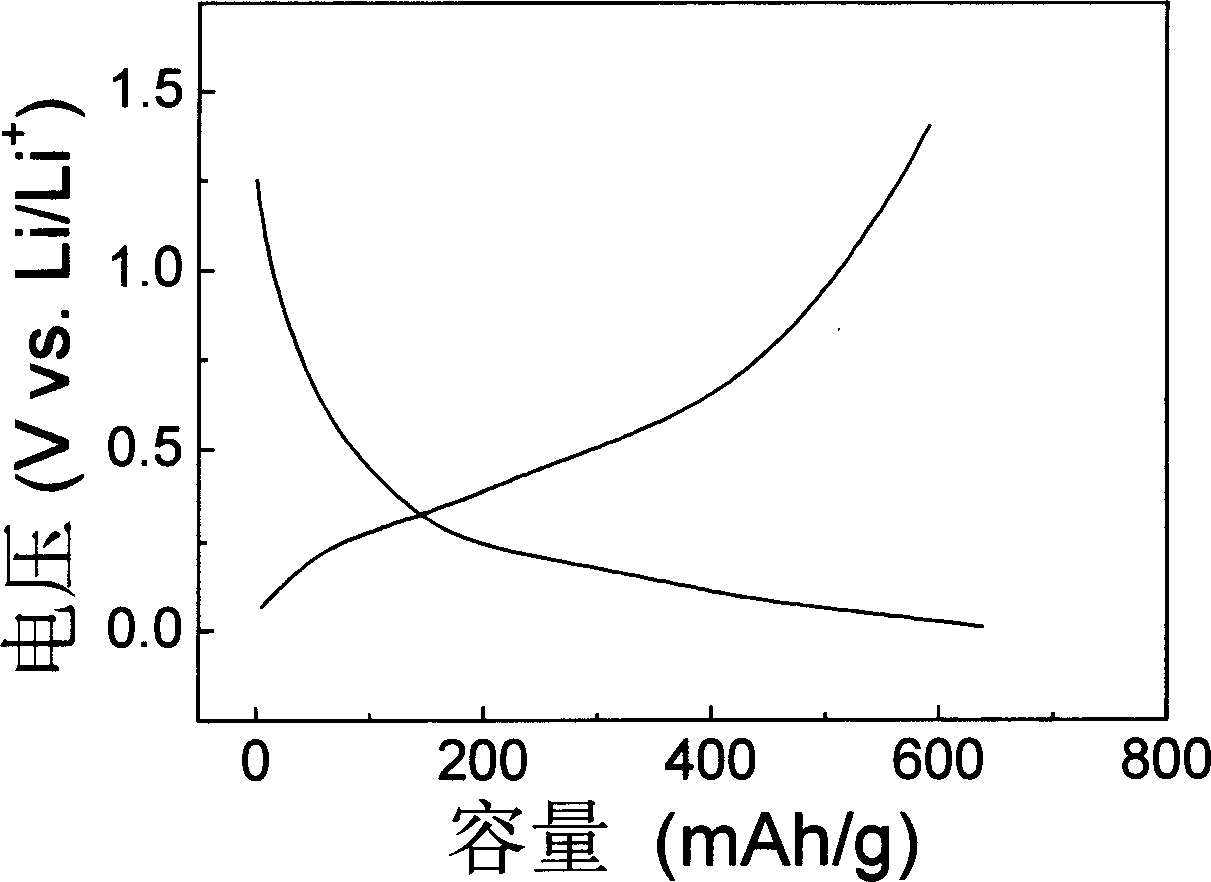

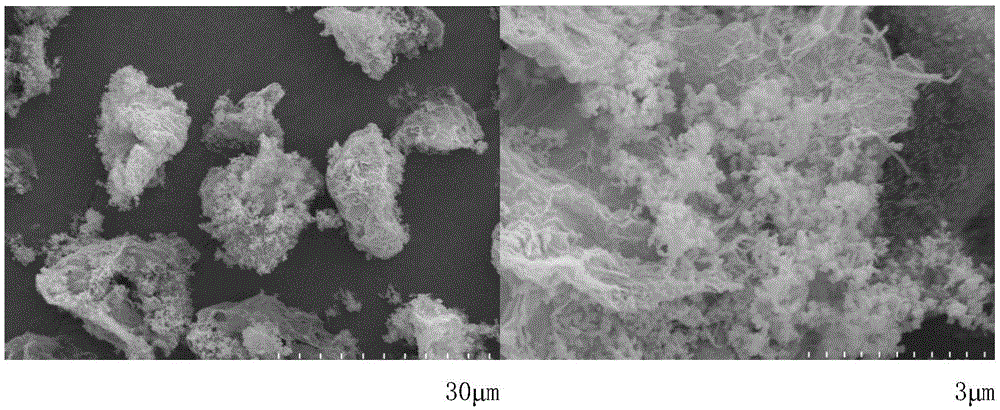

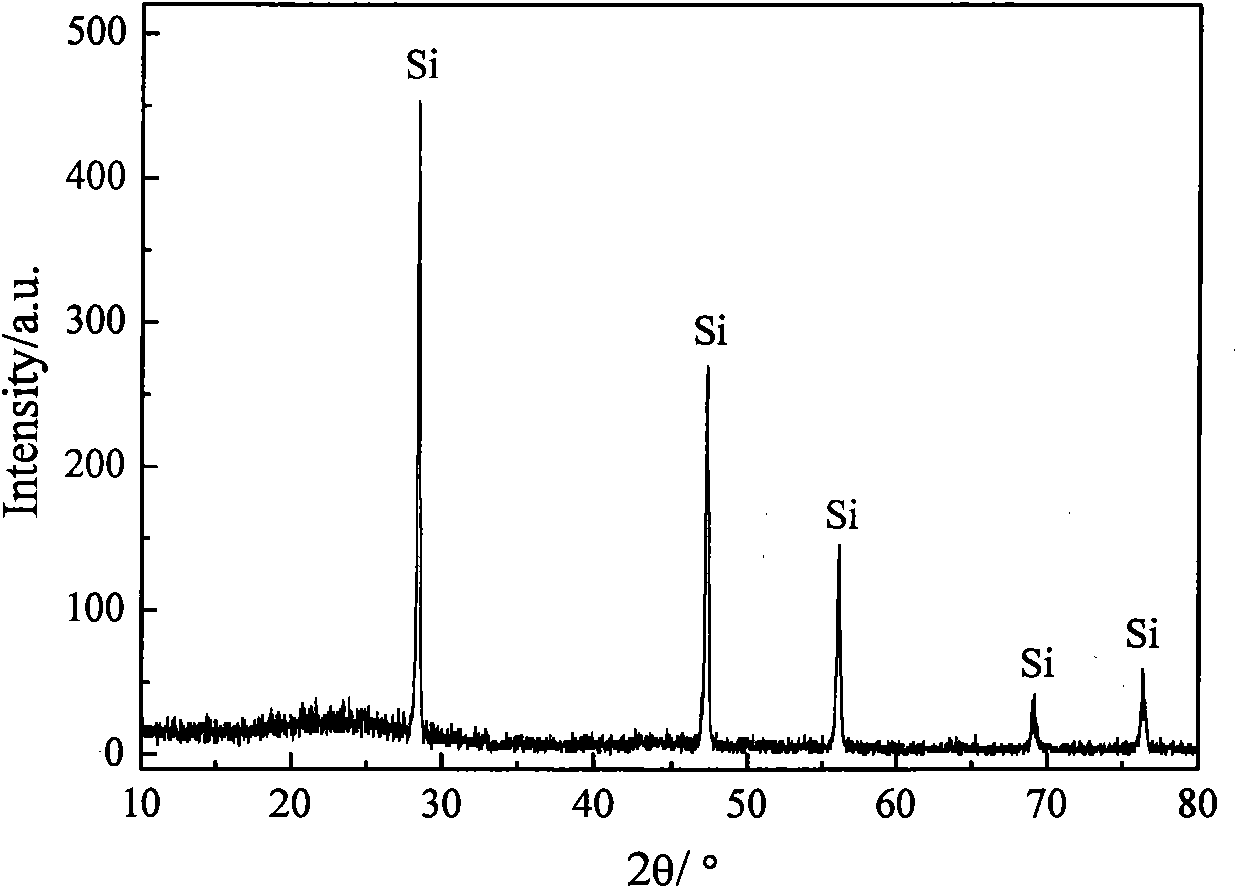

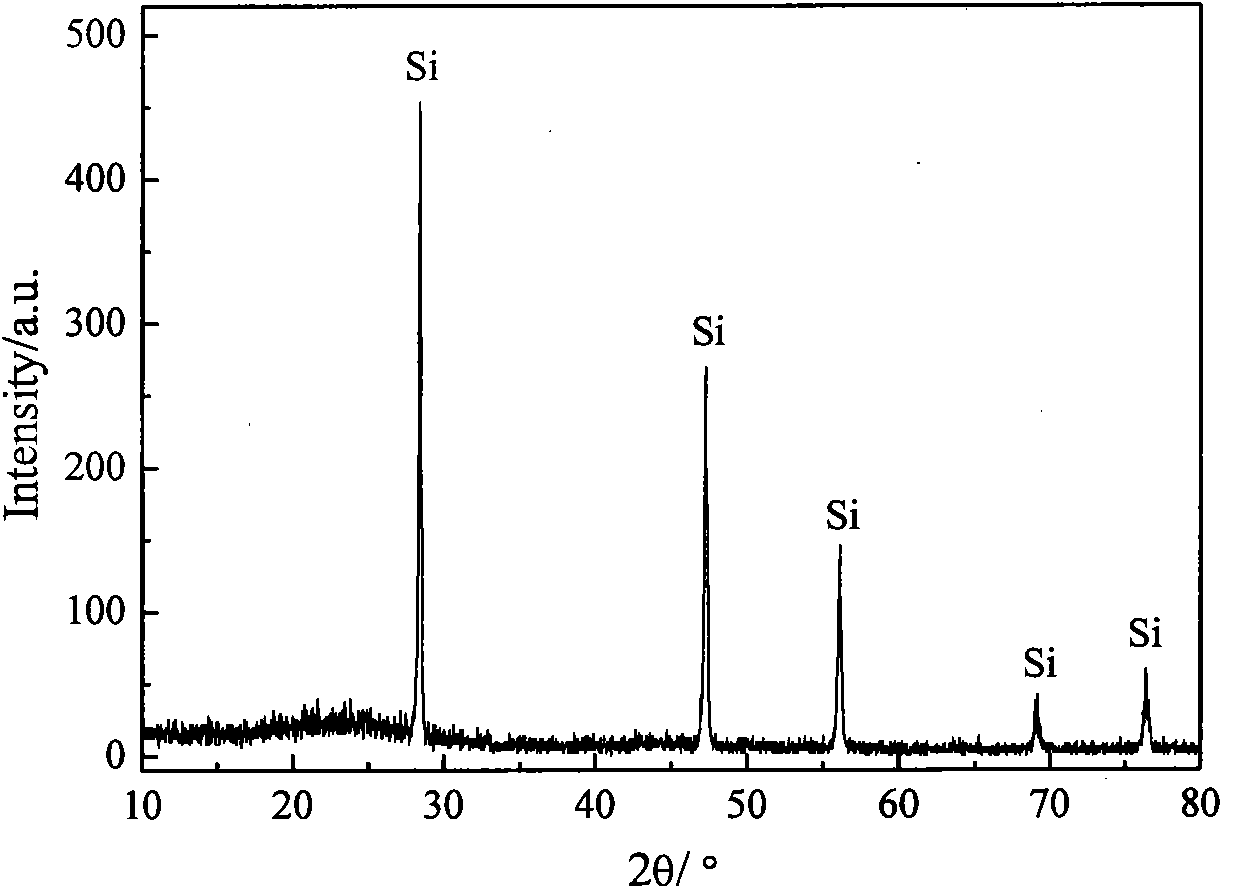

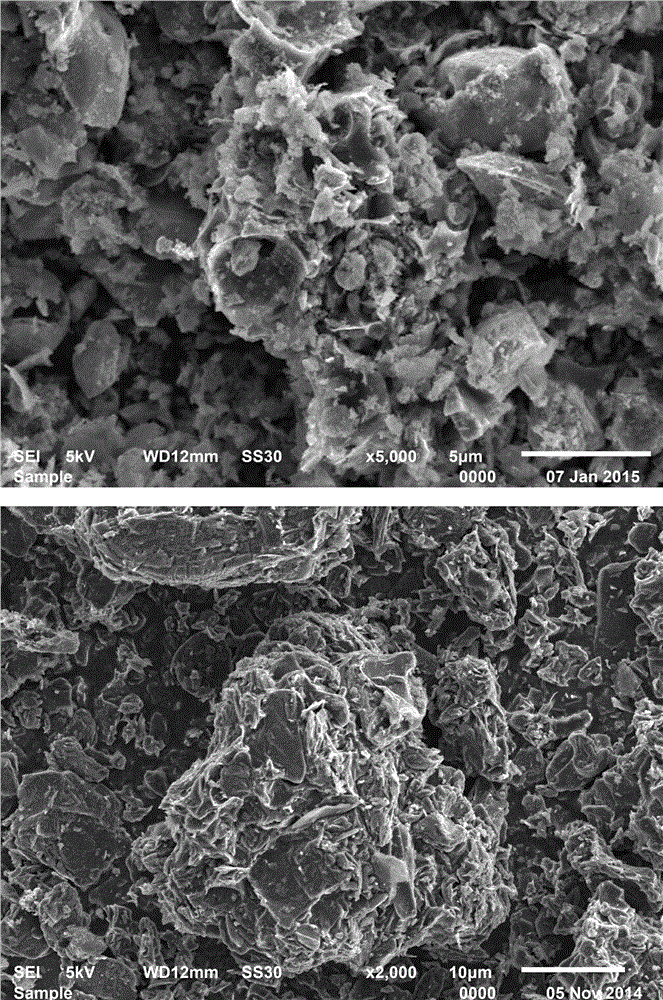

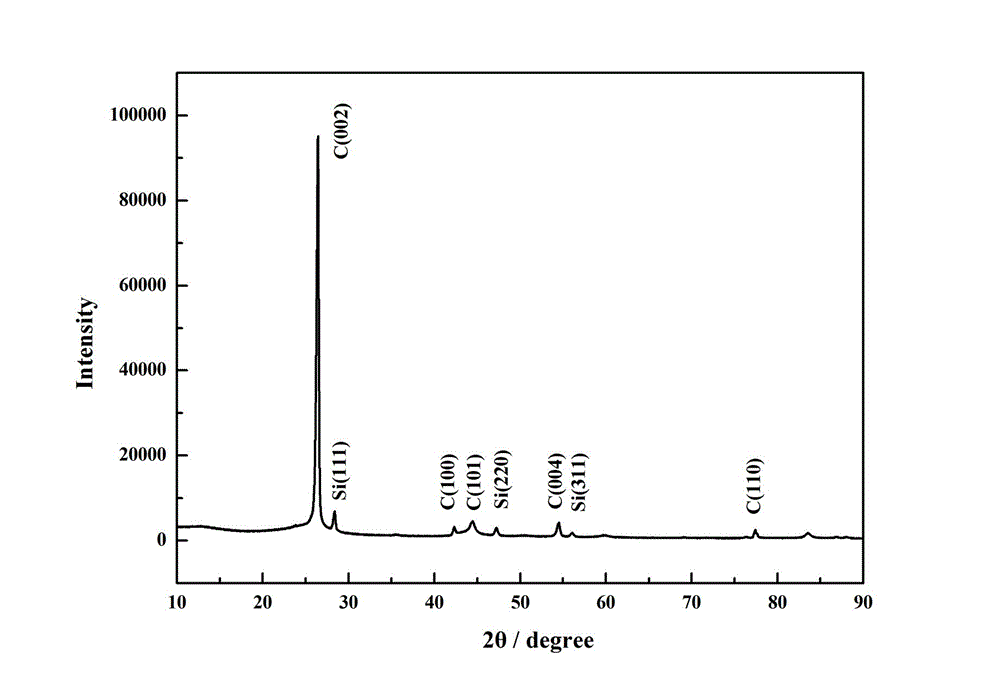

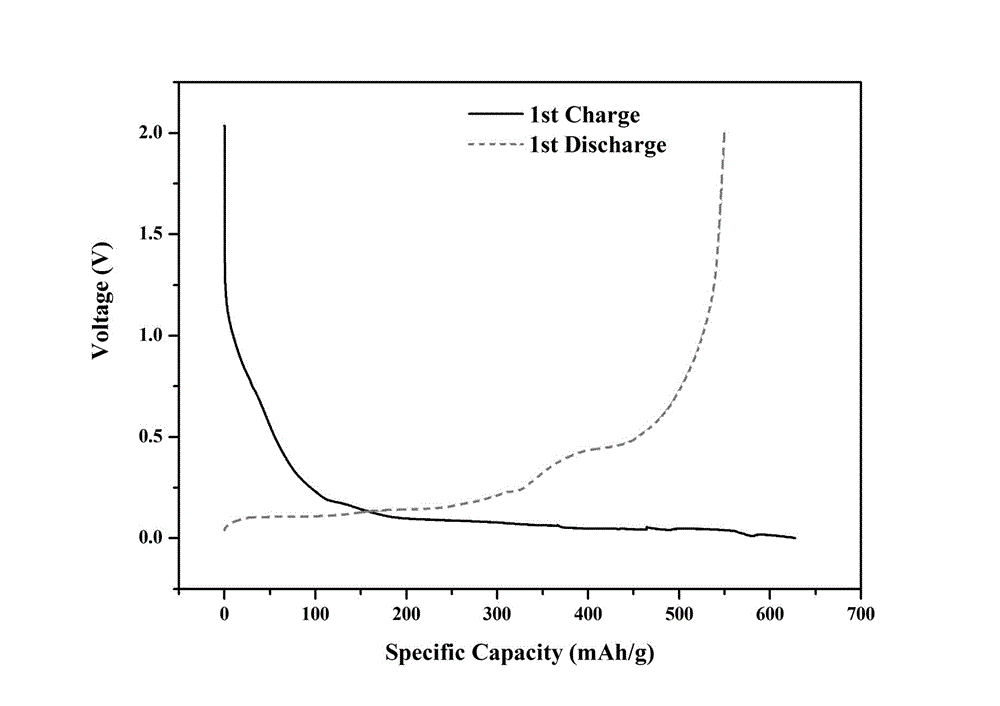

Preparation method of silicon and carbon-coated graphene composite cathode material

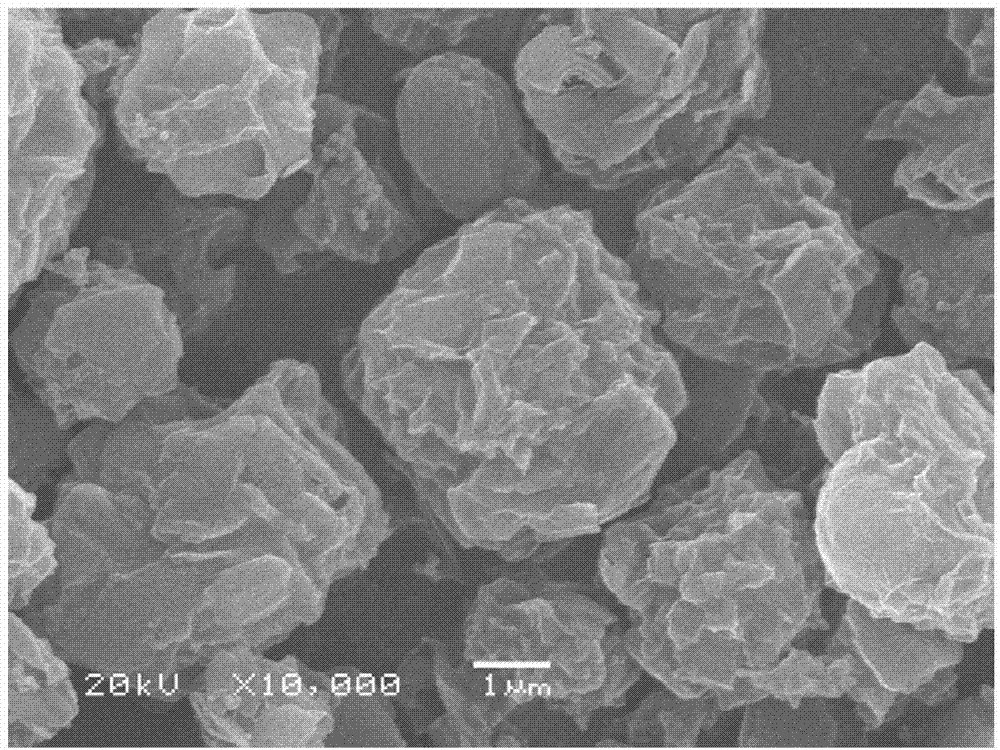

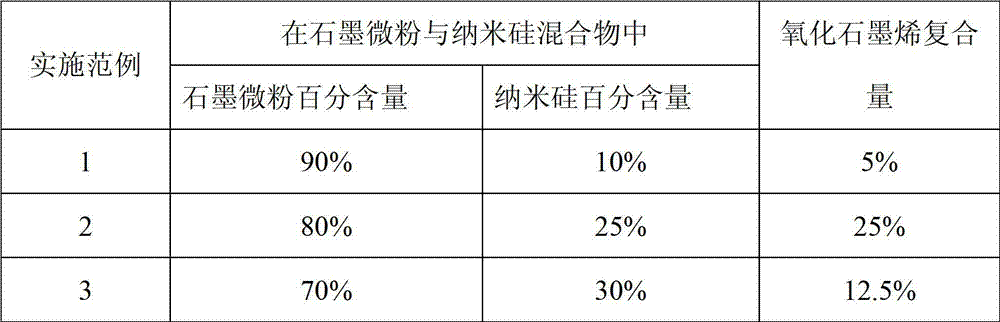

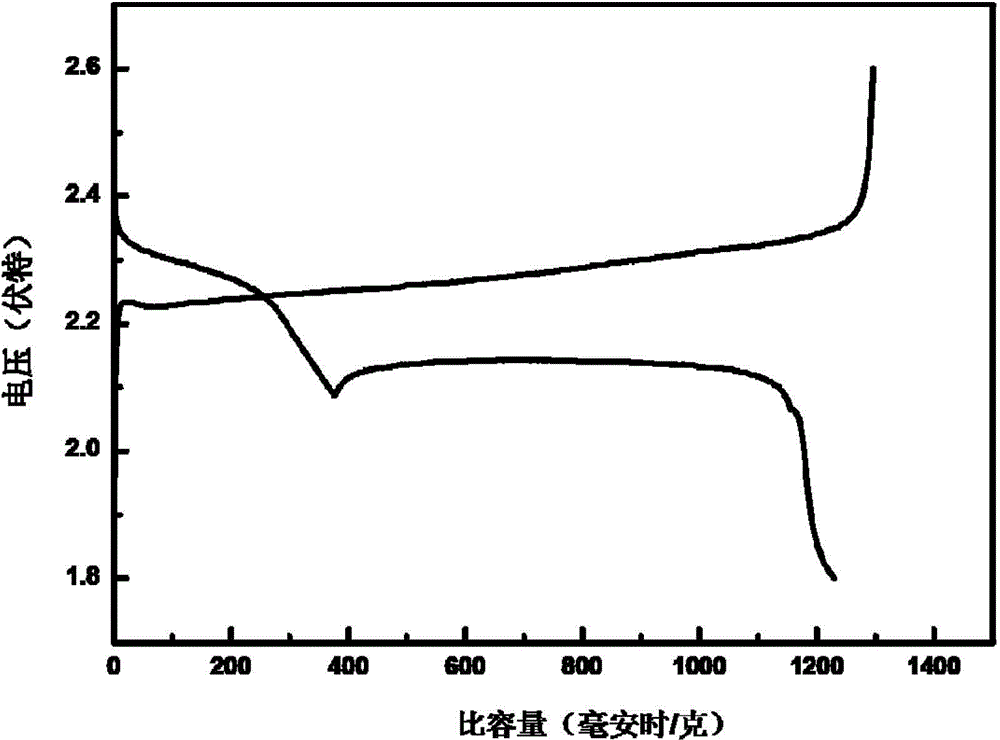

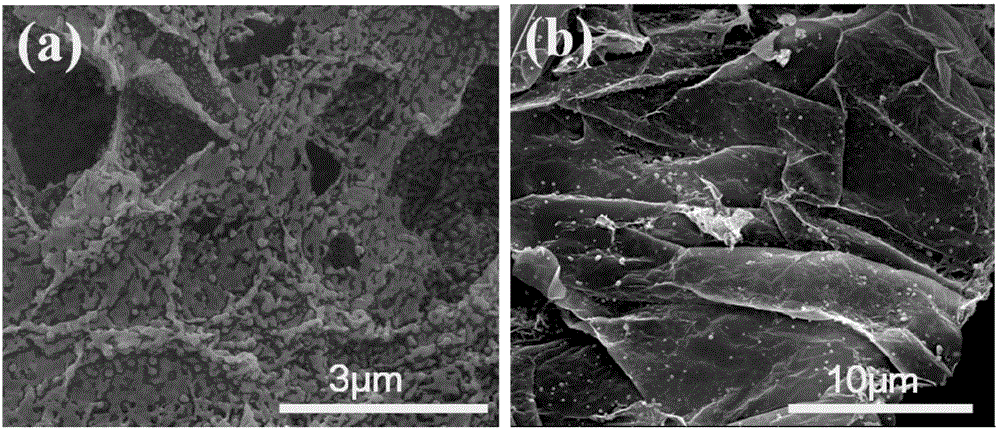

ActiveCN103050666ARealize in situ restorationThe preparation process is simple, convenient and practicalMaterial nanotechnologyCell electrodesCarbon coatedStructural stability

The invention discloses a preparation method of a silicon and carbon-coated graphene composite cathode material. The technical problem to be solved is to enhance the electronic conductivity of the silicon-based cathode material, buffer the volume effect produced in the process of deintercalation of the lithium in the silicon-based cathode material and enhance the structure stability in the circulation process of the material at the same time. The material is prepared by using a spray drying-thermally decomposing treatment process in the invention. The preparation method comprises the following steps of: evenly dispersing nano silicon and graphite micro powder in a dispersion solution of oxidized graphene, carrying out thermal treatment under an inert protection atmosphere after spray drying, subsequently cooling along a furnace to obtain the silicon and carbon-coated graphene composite cathode material. The extra binder does not need to add in the process of manufacturing balls in the invention and the outer oxidized graphene is thermally reduced in situ to graphene in the thermal treatment process of the composite precursor, so that the process is simple and easy to operate; and the practical degree is high. The prepared composite material has the advantages of great reversible capacity, designable capacity, good cycling performance and high-current discharging performance, high tap density and the like.

Owner:CENT SOUTH UNIV

Positive electrode of lithium-sulfur battery with multifunctional elastic protection layer

InactiveCN105322132AThere is no effect on the charging and discharging processImprove stabilityNon-aqueous electrolyte accumulator electrodesCapacity lossLithium–sulfur battery

The invention relates to a positive electrode of a lithium-sulfur battery with a multifunctional elastic protection layer. The positive electrode of the lithium-sulfur battery comprises a positive material layer and the multifunctional elastic protection layer, wherein the multifunctional elastic protection layer is formed on the surface of the positive material layer and comprises a polymer and / or a conductive carbon material; and the thickness of the multifunctional elastic protection layer is 0.1-50 microns. The multifunctional elastic protection layer is introduced to the surface of the positive material layer of the lithium-sulfur battery; the multifunctional elastic protection layer has elasticity and conductivity; and has no influence on charge and discharge processes of the positive electrode of the lithium-sulfur battery; compared with the positive electrode of the lithium-sulfur battery without protection from a multifunctional elastic layer structure, the prepared positive electrode of the lithium-sulfur battery with the protection of the multifunctional elastic layer structure has good stability; a structural damage to the positive electrode caused by the volume effect in a charge-discharge cycle process of the battery can be relieved; and meanwhile, the added multifunctional elastic layer structure can ensure that an active material in the positive electrode is not greatly dissolved into an electrolyte to cause the capacity loss.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

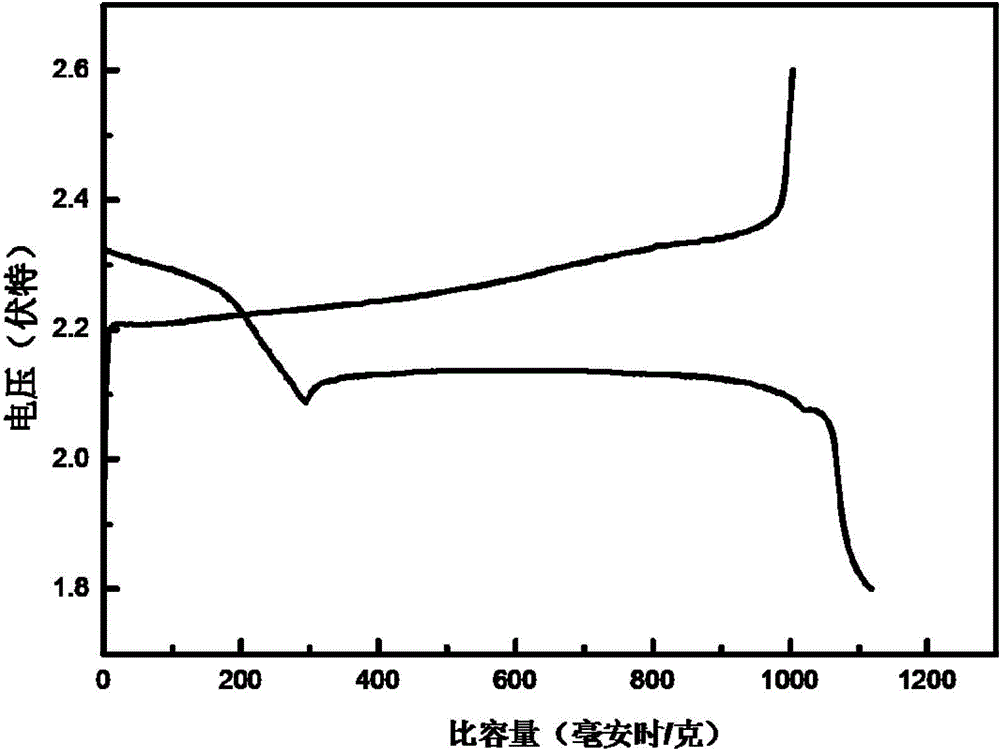

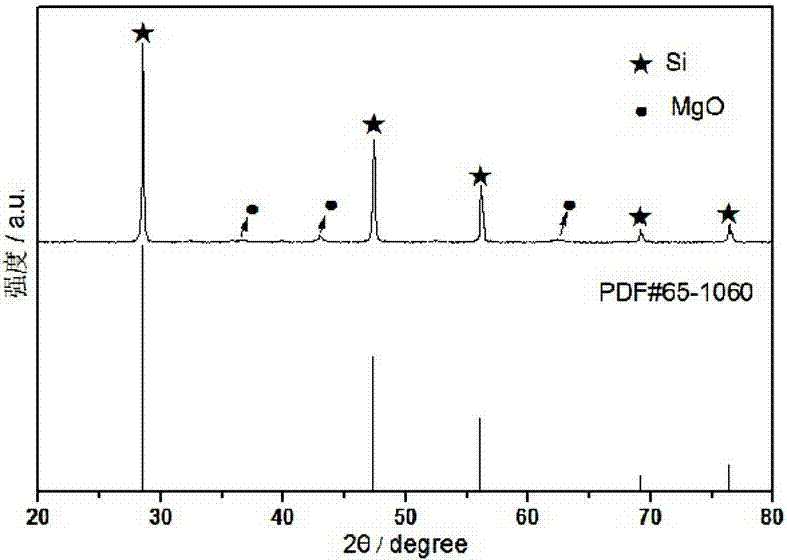

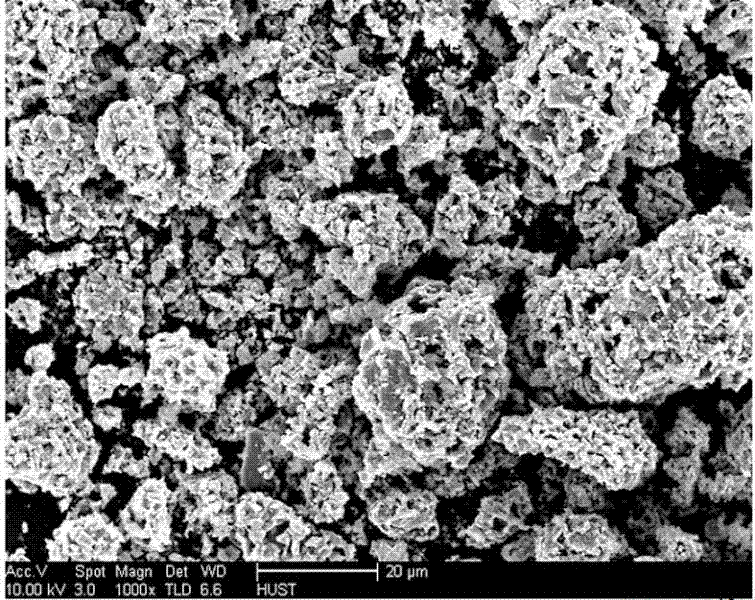

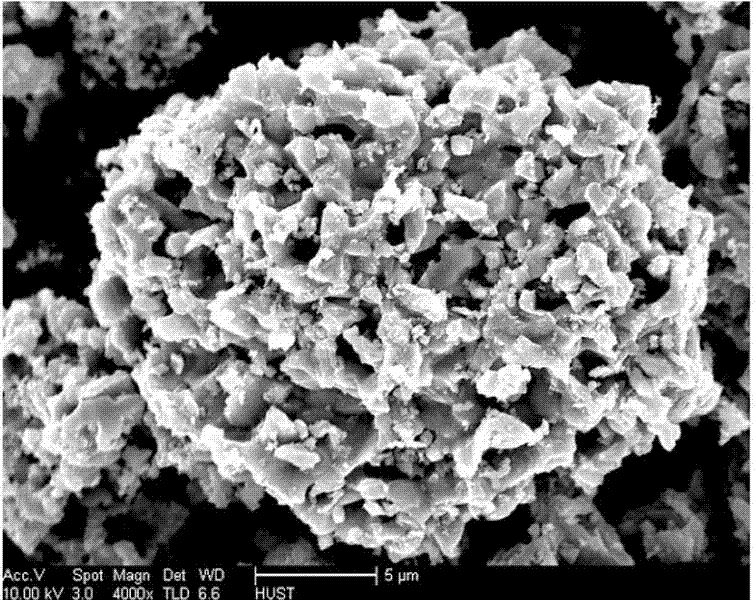

Fluorine-free preparation method for three-dimensional porous silica powder anode material of lithium ion battery

ActiveCN102237519AAvoid pollutionHigh specific capacityCell electrodesSodium-ion batterySilicon particle

The invention discloses a fluorine-free preparation method for a three-dimensional porous silica powder anode material of a lithium ion battery. In the method, combination reaction is performed on ordinary micron-sized silicon and magnesium particles to generate magnesium silicide, and the magnesium silicide is pyrolyzed at high temperature to form magnesium vapor and silica powder with a three-dimensional porous structure. By the fluorine-free preparation method for the three-dimensional porous silica powder anode material of the lithium ion battery, a preparation process is free from fluorine so as to avoid environmental pollutions; the material has the porous structure so as to realize the self-absorption of volume effects of the silicon particles; the specific capacity and recycling stability of the material are improved to a certain extent; and a synthesis process is simple and easy to operate, and the preparation cost of the material is low.

Owner:CHINA THREE GORGES UNIV +1

Negative electrode material, preparation method of material, negative electrode, and battery comprising negative electrode

ActiveCN103682359AImprove volume effectImprove conductivityCell electrodesSecondary cellsIon implantationVolume effect

The invention relates to a negative electrode material which at least comprises SiOx and a carbon material, wherein x is larger than or equal to 1 and is less than or equal to 2. The invention also relates to a negative electrode comprising the negative electrode material, a battery with the negative electrode, and a preparation method of the negative electrode material. The negative electrode with a porous structure can provide a buffer space for a volume effect of the SiOx in charge and discharge processes, SiOx particles with the nano size can enable the volume change during ion implantation and prolapse to be reduced, the volume effect of silicon-based negative electrode material can be reduced, and the cycle performance of the negative electrode material is ensured. The negative electrode material provided by the invention is simple and feasible and has an industrialization prospect.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD +1

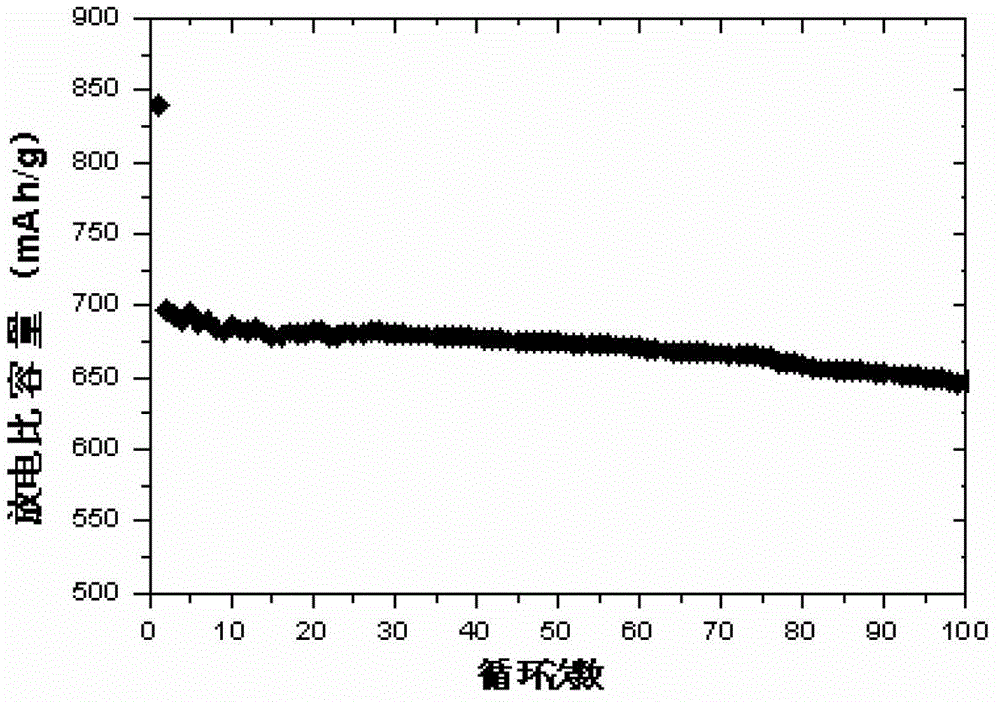

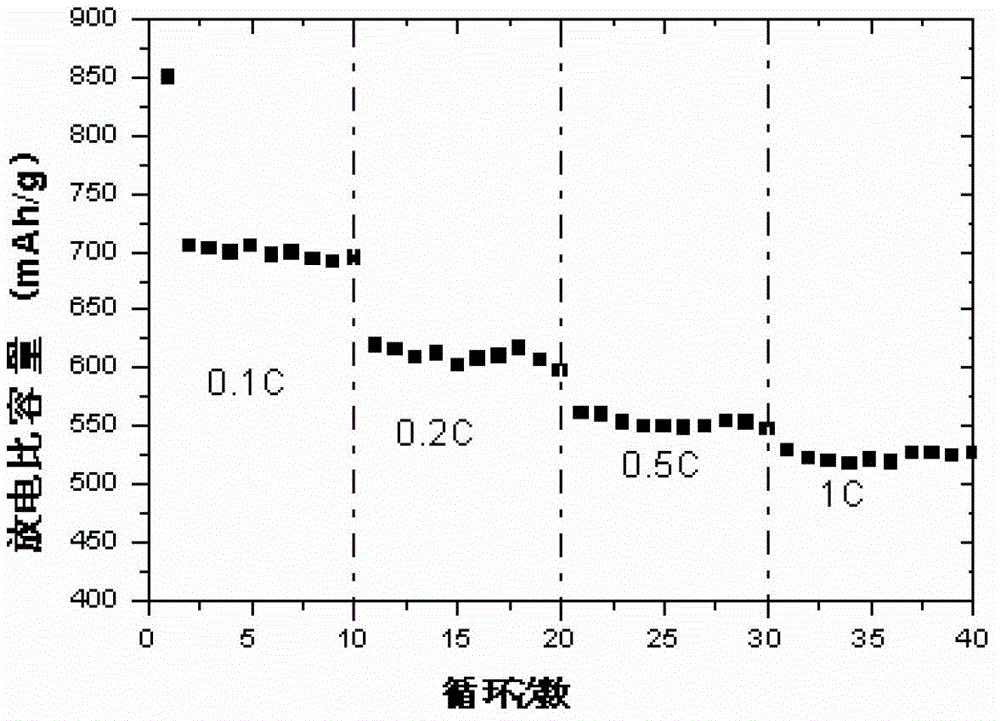

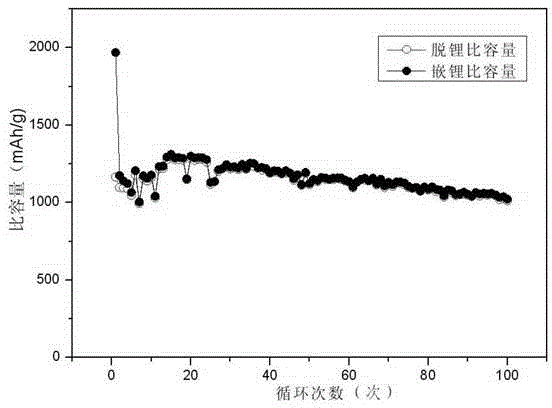

Silicon monoxide composite cathode material for lithium ion battery, and preparation method thereof

The invention discloses a silicon monoxide composite cathode material for a lithium ion battery, and a preparation method of the silicon monoxide composite cathode material, aiming at improving the cycle performance. The composite cathode material comprises the components by mass percent: 10-30% of composite particle material and 70-90% of natural graphite or artificial graphite, wherein the composite particle material is silicon monoxide covered by a carbon nano tube and an amorphous carbon coating layer. The method comprises the following steps of: forming the carbon nano tube and the amorphous carbon coating layer on the surface of silicon monoxide to obtain composite particles, and mixing the composite particles with the graphite. Compared with the prior art, the preparation method enables cracking carbon to be covered on the surfaces of silicon monoxide particles, so that the volume effect of the silicon monoxide particles can be effectively inhibited in the charge-discharge process of a battery, the cycle performance is good, the specific capacity is more than 500mAh / g, and the capacity retention ratio is more than 85% after the circulation is carried out for 100 times; and the preparation method is simple in preparation technology, low in raw material cost and suitable for the cathode material for the high-capacity lithium ion battery.

Owner:BTR NEW MATERIAL GRP CO LTD

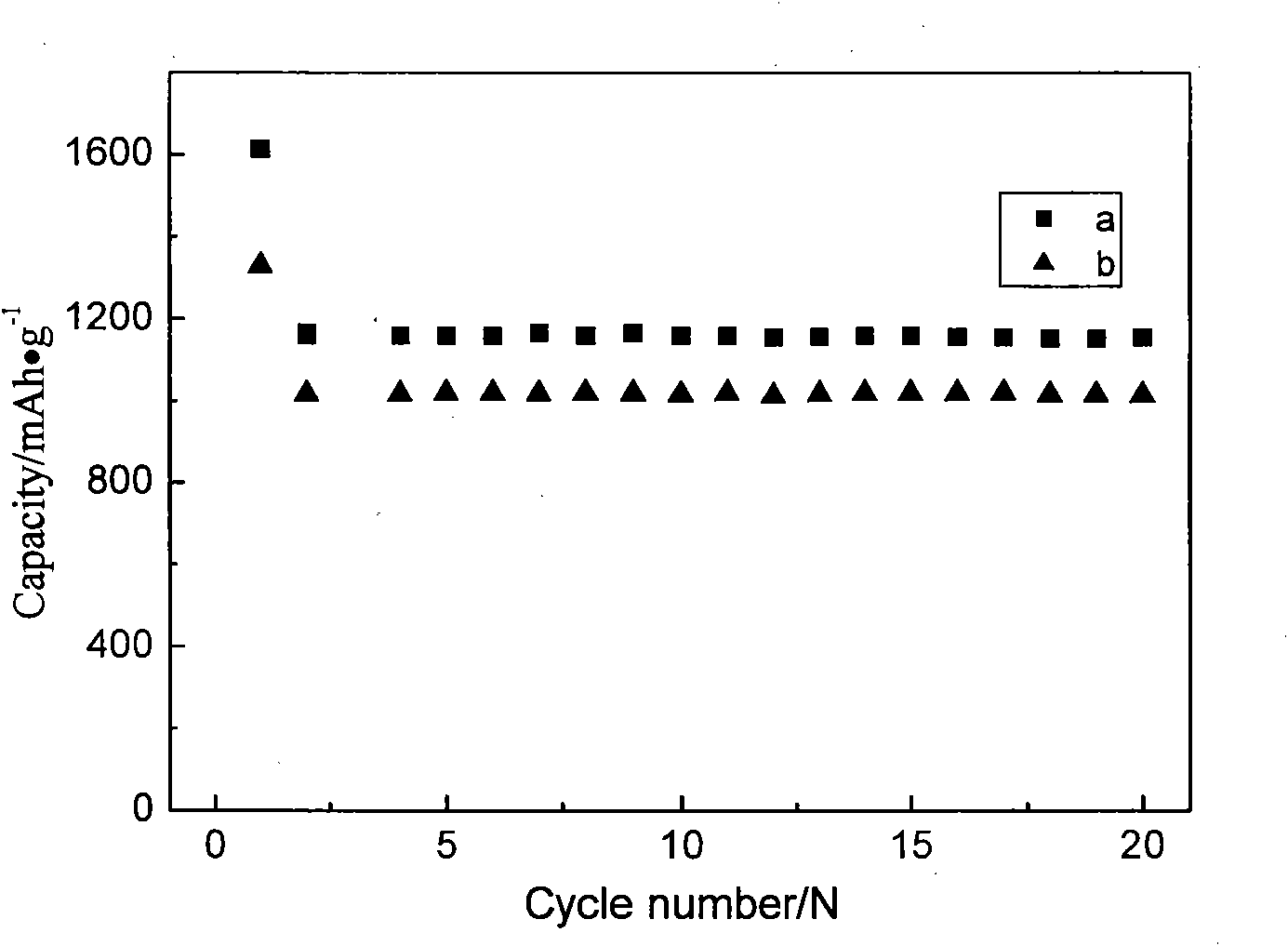

Preparation method for composite negative electrode material of lithium ion battery

InactiveCN1909266AIncrease capacityImprove cycle stabilityNanostructure manufactureElectrode manufacturing processesCarbon compositesHigh energy

The invention relates to a method for preparing the composite cathode of lithium battery, wherein said cathode material is formed by silicon / copper / carbon; said silicon has nanometer porous structure; the nanometer silicon / alumina composite, nanometer silicon / alumina / copper composite, and nanometer silicon / alumina / copper / carbon composite, with high disperse degree, is obtained by high-energy grinding; then adding hydrochloric acid; removing alumina, and over alumina, to obtain said composite cathode. And the inventive method uses hydrochloric acid to remove the inactive alumina and over aluminum, to improve specific capacity of composite; and the treatment of hydrochloric acid makes the silicon with nanometer porous structure, to adsorb the volume change when embedding lithium, to buffer volume effect, improve the structure stability. And the reversible capacity of said cathode material can reach 580mAh .g-1; in the first 35 cycles, the average capacity damage of each cycle is 0.1%.

Owner:SHANGHAI JIAO TONG UNIV

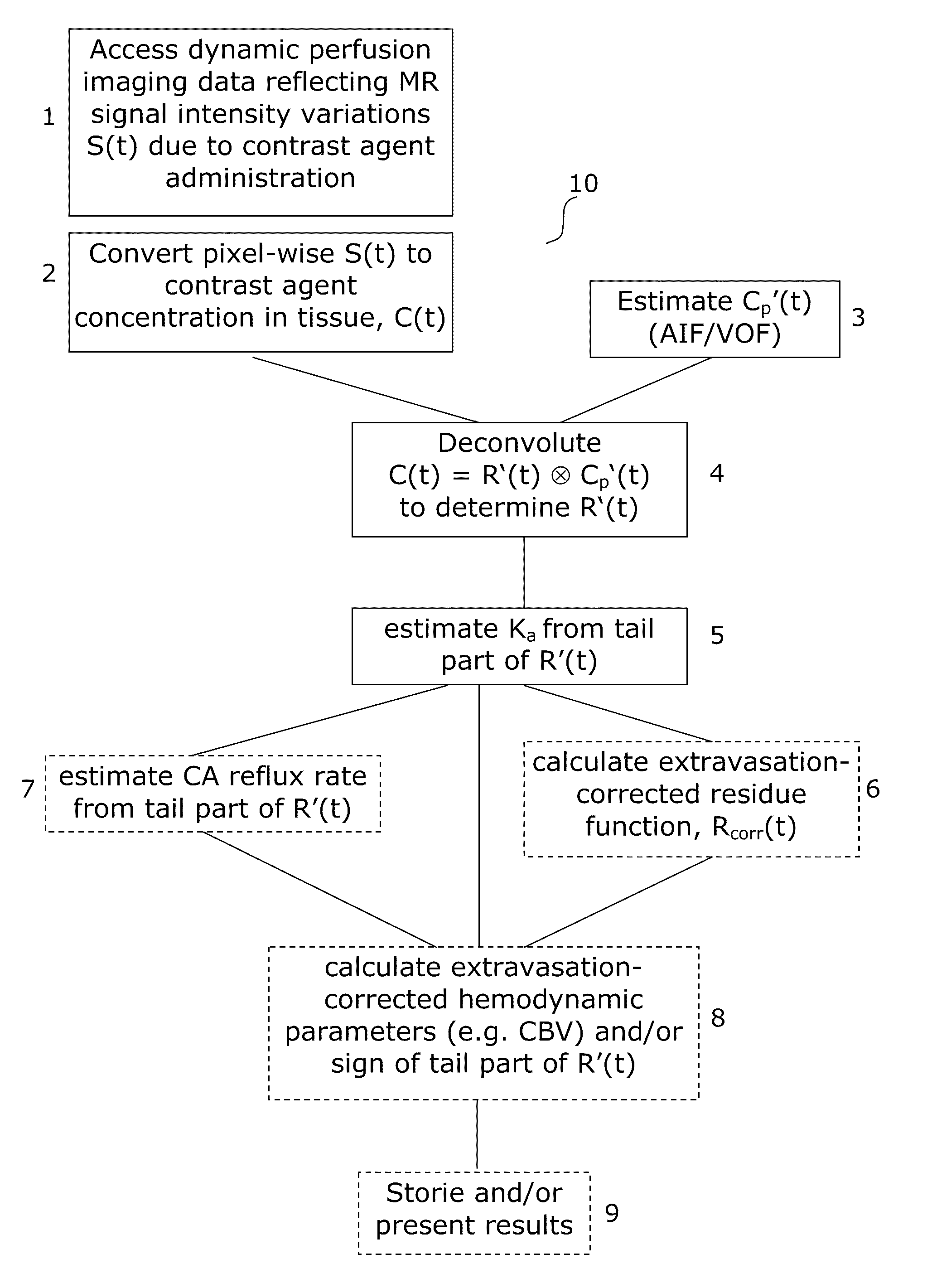

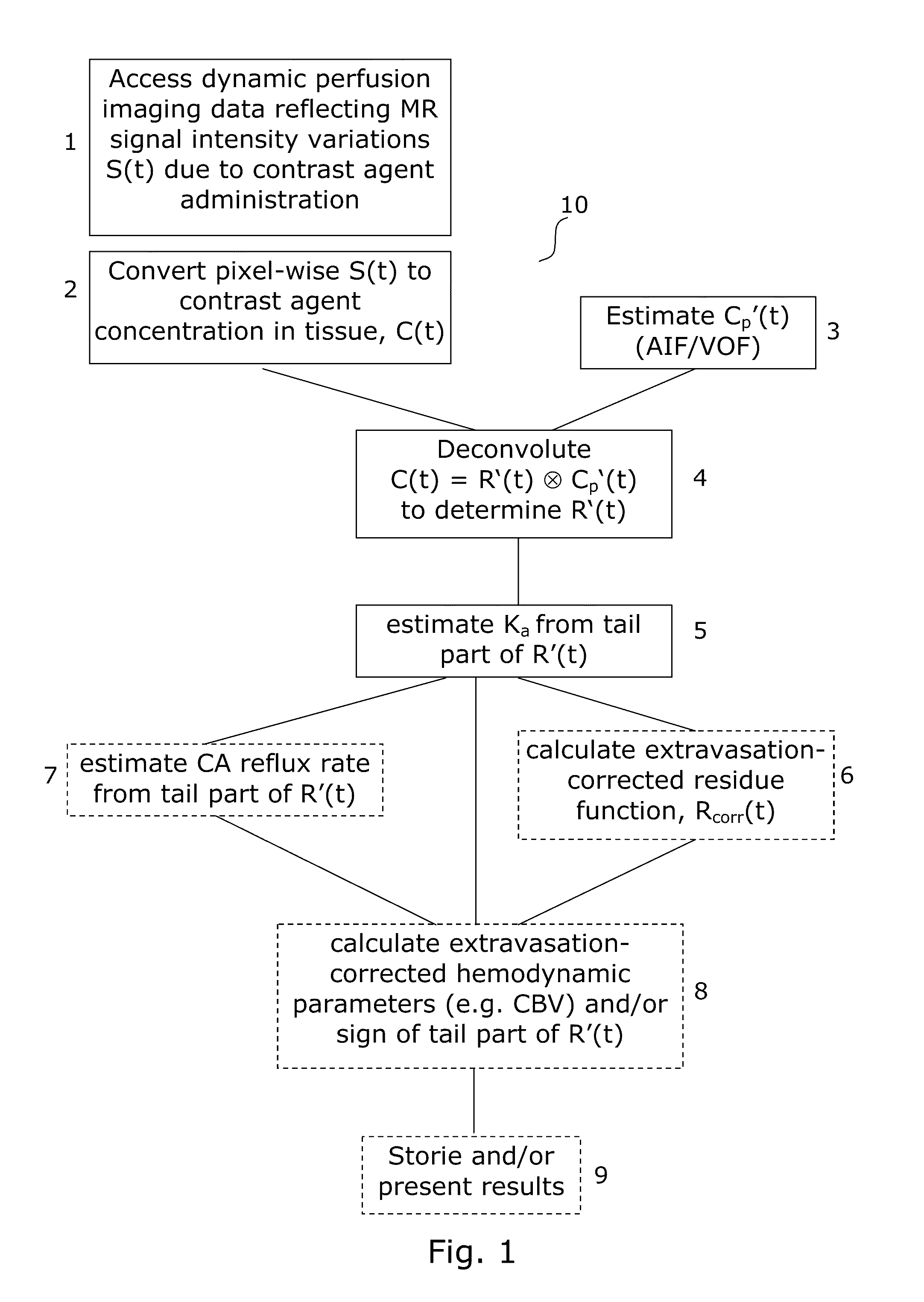

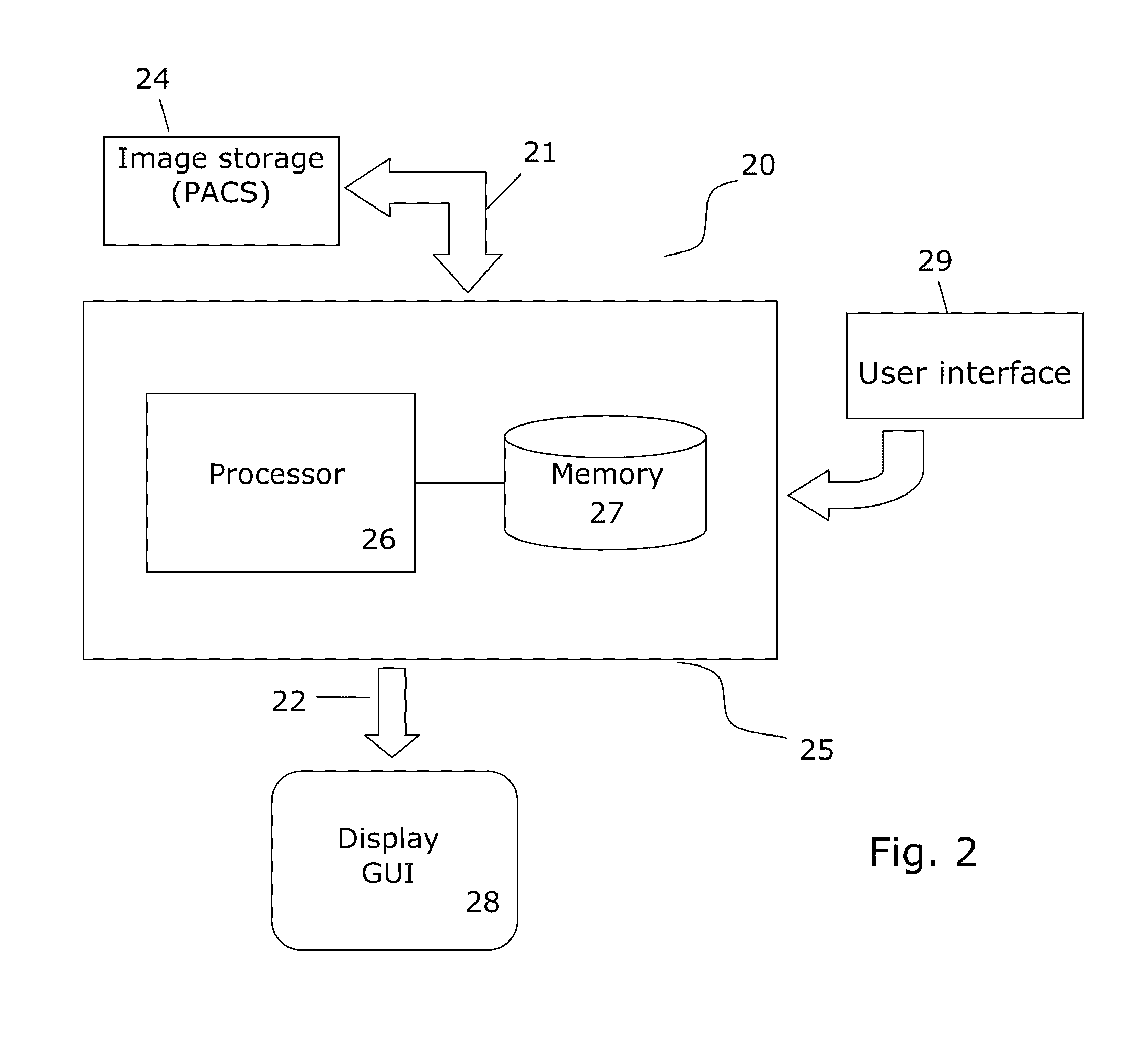

Estimating and correcting for contrast agent extravasation in tissue perfusion imaging

ActiveUS20110257519A1Good estimateRobust estimationImage enhancementImage analysisDynamic contrastArterial input function

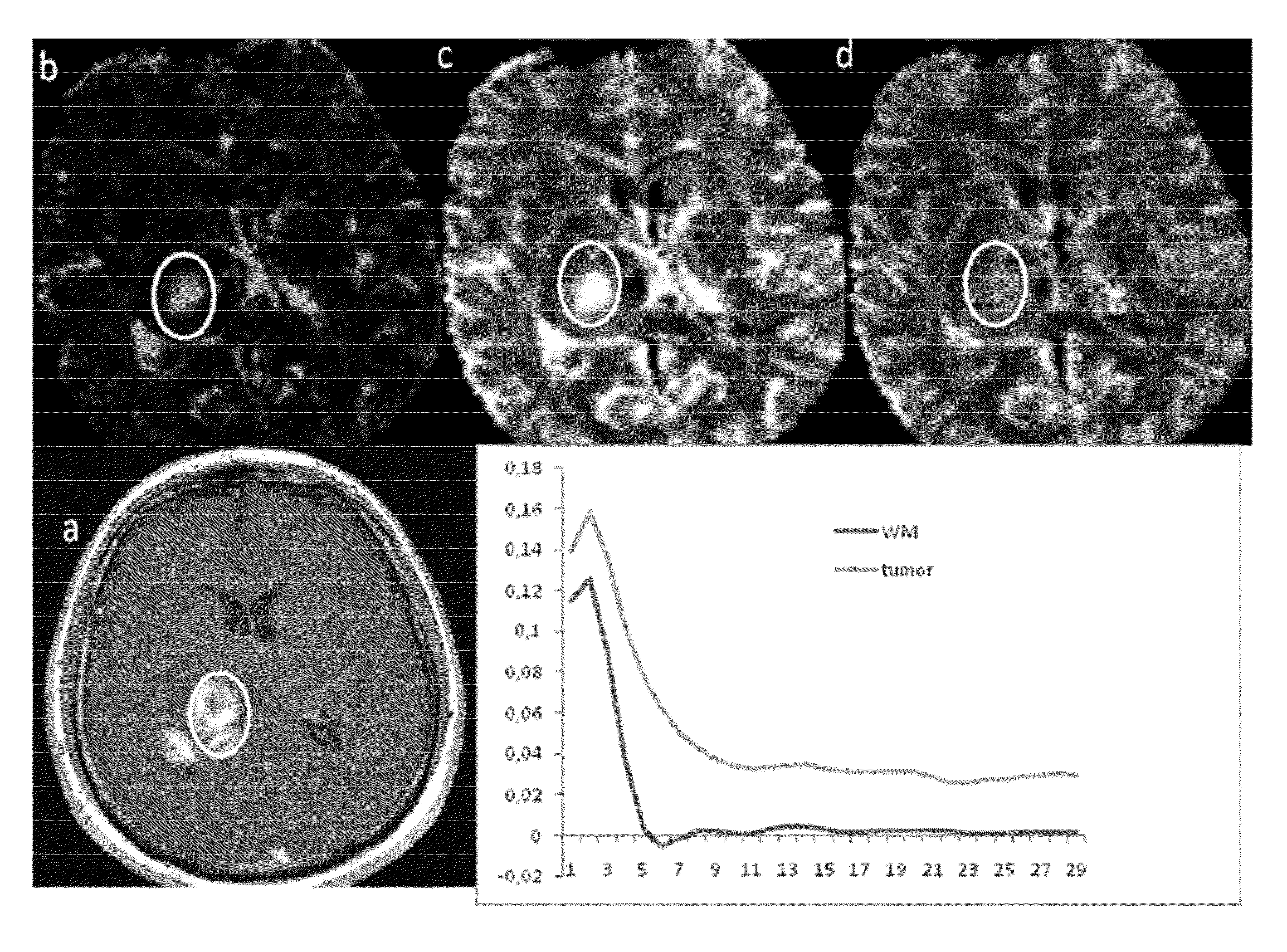

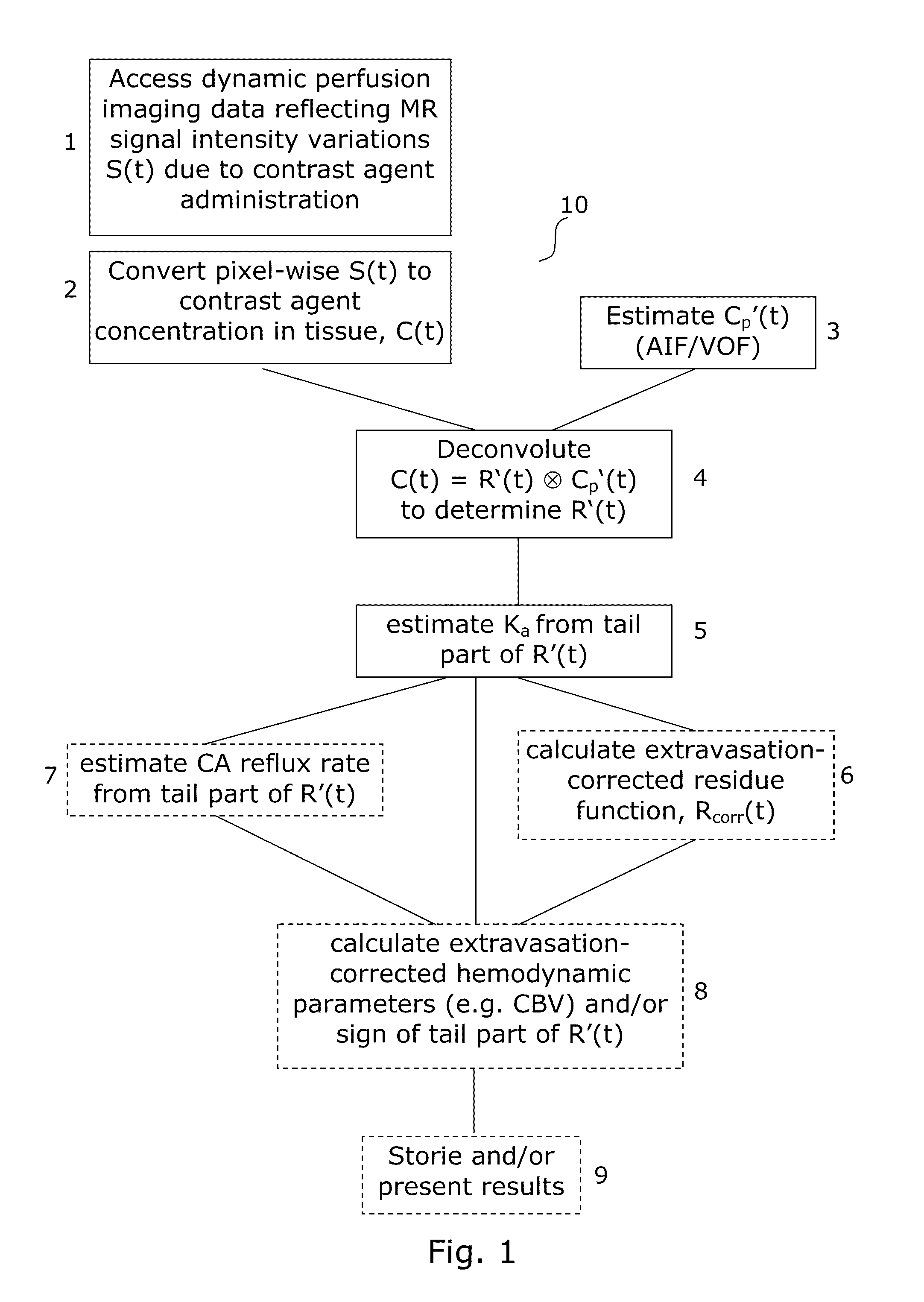

The invention provides a method, an image analysis software product, and a system for medical imaging analysis for estimating contrast agent extravasation in contrast agent based perfusion imaging such as MRI dynamic contrast enhanced (DCE) imaging, and in particular correction, compensation, or visualization of extravascular leakage of contrast agent in tumors. According to the invention, the effect of extravasation is directly manifested in the tail part of an observed, apparent residue function, R′(t), obtained directly by de-convoluting the expression C(t)=R′(t)Cp′(t) with the arterial input function (AIF). A leakage rate or extravasation constant is determined directly from the tail part of the determined apparent residue function. The invention also relates to distinguishing between T1-dominant and T2*-dominant extravasation effects in perfusion imaging to from the sign of the tail part of the determined apparent residue function and to an automated method for DSC-MRI involving correction for contrast agent extravasation and partial volume effects.

Owner:UNIV OSLO HF

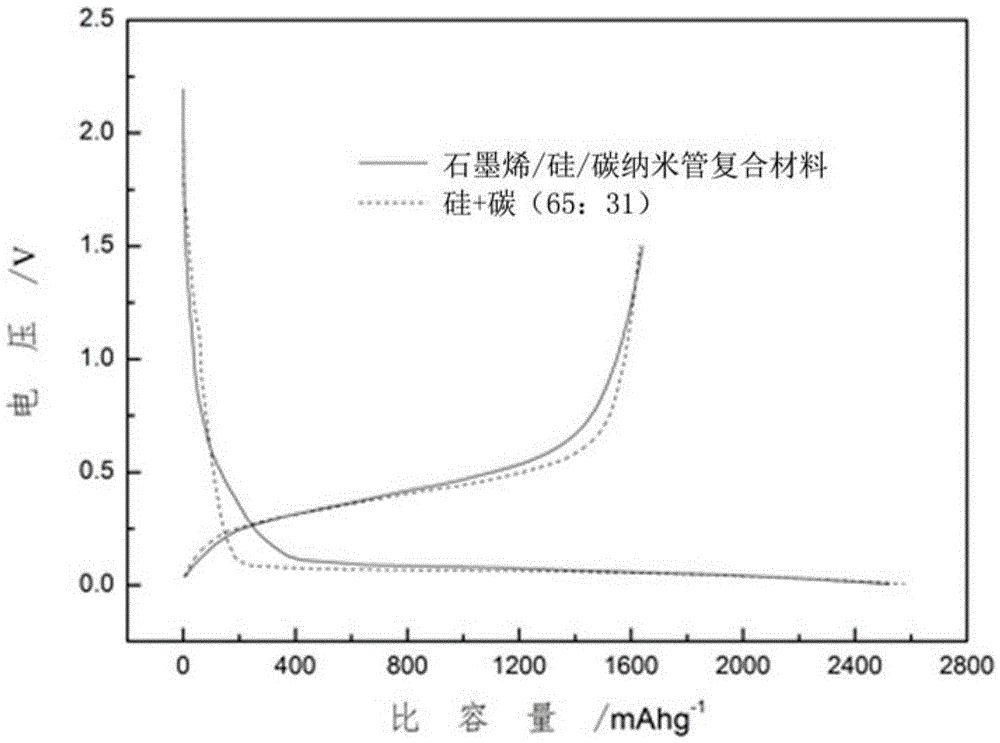

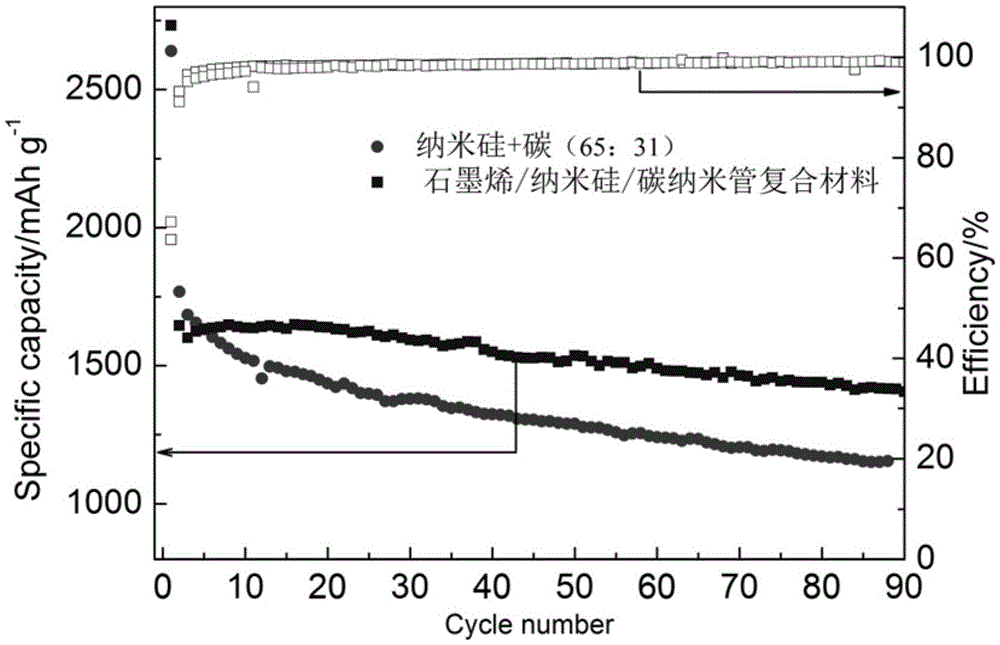

Graphene/silicone/carbon nano tube composite material and preparation method and application thereof

InactiveCN105576203AIncrease capacityImprove efficiencyMaterial nanotechnologyCell electrodesCarbon compositesCarbon nanotube

The invention discloses a graphene / silicone / carbon nano tube composite material and a preparation method and application thereof and relates to lithium ion battery silicone cathode materials. The graphene / silicone / carbon nano tube composite material is a silicone-carbon composite material compositing graphene, a silicone material and carbon nano tubes. The preparation method includes: adding graphene powder and the carbon nano tubes into an NMP solution, adopting ultrasonic oscillation to enable uniform dispersion of the graphene powder and the carbon nano tubes, adding nano silicone powder, and adopting ultrasonic oscillation to enable uniform dispersion; drying, stoving and grinding a mixed solution obtained to obtain the graphene / silicone / carbon nano tube composite material. The graphene / silicone / carbon nano tube composite material can serve as a cathode material to be applied in lithium ion batteries and has characteristics of high capacity, high efficiency and good circulating performance. Graphene, the silicone material and the carbon nano tubes are composited through simple steps, volume effect of the silicone material in the process of charging and discharging is improved through graphene and special structure of a novel material, and electroconductivity of the silicone material is improved.

Owner:XIAMEN UNIV +1

Method for preparing silicon-carbon cathode material of lithium ion battery

The invention provides a method for preparing a silicon-carbon cathode material of a lithium ion battery. The silicon-carbon cathode material prepared by the method has the advantages of high capacity and good cyclical stability. The preparation method of the invention comprises the following steps of: putting phenol monomers and aldehyde monomers into a solvent to carry out hydrolyzation to synthesize a porous precursor with high specific surface, then adding nano silicon powder into the porous precursor and effectively making the nano silicon powder uniformly dispersed in the synthesized porous precursor with high specific surface by using specific cavatition oscillation of ultrasonic to finally synthesize a porous macromolecular resin-coated silicon precursor with high specific surface so as to make the volume effect greatly weakened and make cycle performance excellent; and then drying the obtained precursor and roasting the dried precursor in protective atmosphere at a specific temperature to finally obtain the silicon-carbon cathode material. The preparation method of the invention has the advantages of simple process, short flow and small equipment investment. The prepared silicon-carbon anode material of the lithium ion battery has uniformly distributed particles and excellent electrochemical performance.

Owner:CHERY AUTOMOBILE CO LTD

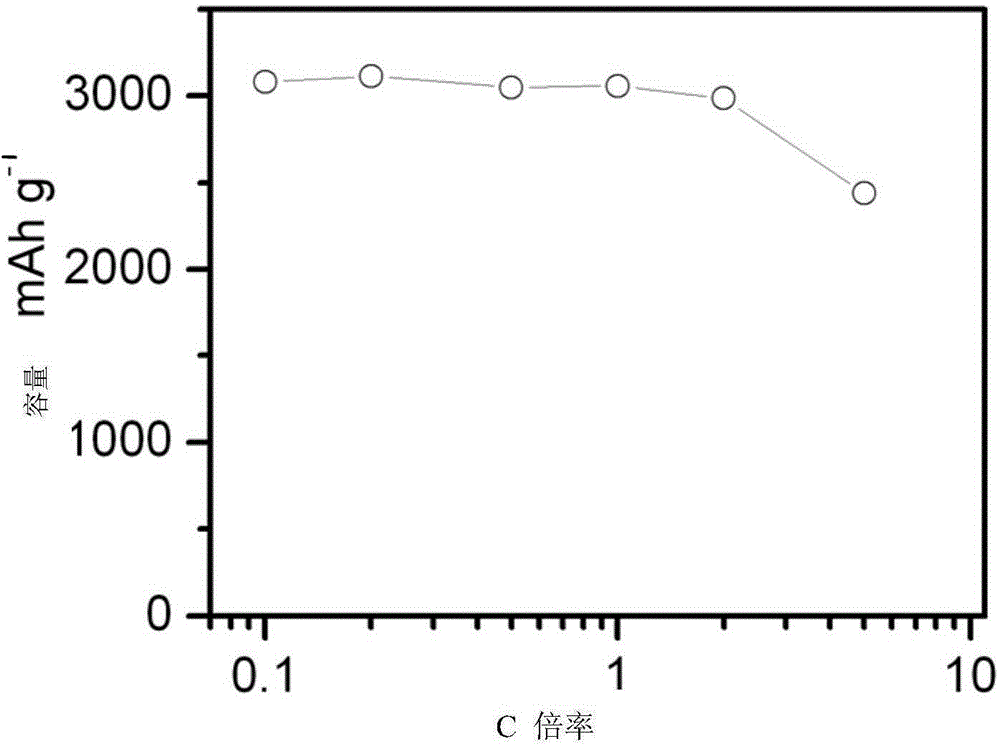

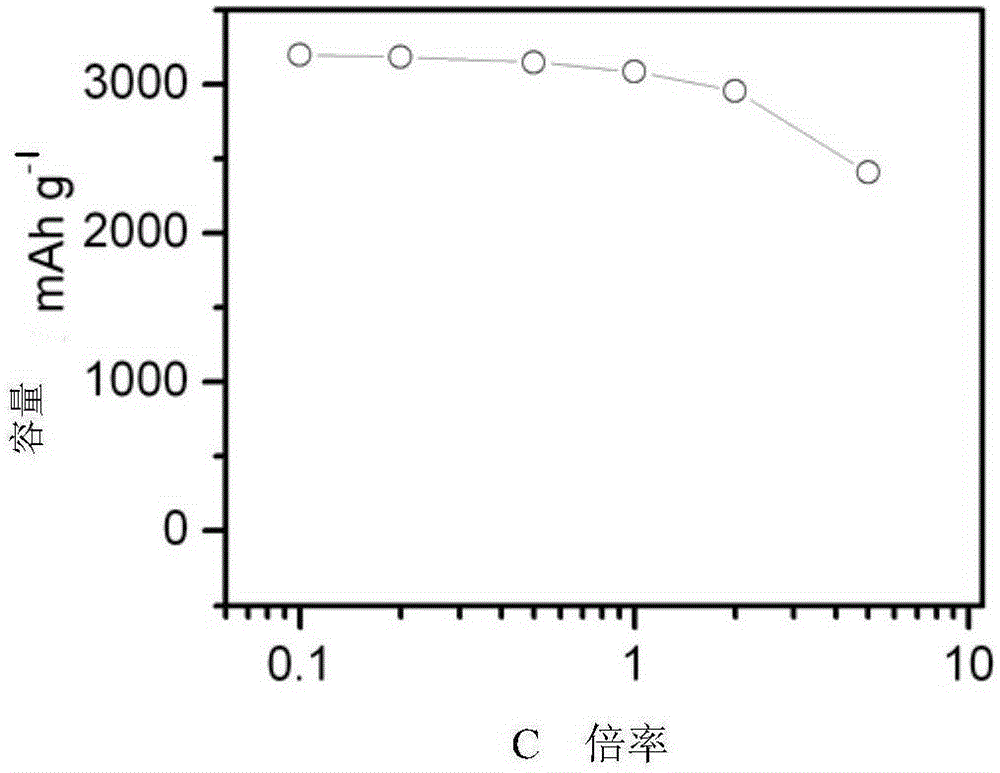

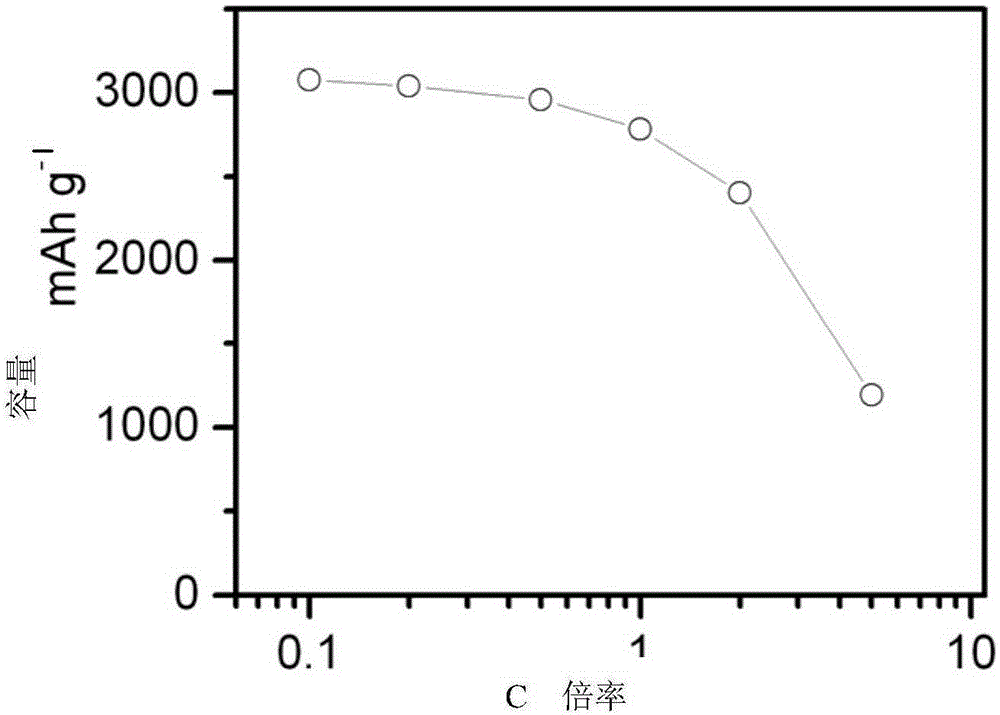

Silicon graphene core-shell material with gaps and preparation and application of silicon graphene core-shell material

InactiveCN105226249AHigh delithiation capacity for the first timeImproved magnification performanceMaterial nanotechnologyCell electrodesHigh rateGraphene

The invention provides a silicon graphene core-shell material with gaps. The silicon graphene core-shell material is a material with a core-shell structure; an inner core is made of silicon particles; a housing is made of graphene; and gaps with the distances of 0.1nm to 10 microns are formed between the inner core and the housing. The invention further provides a preparation method of the silicon graphene core-shell material and an application of the material as a lithium-ion battery anode material. The first lithium deintercalation capacity of the lithium-ion battery employing the silicon material provided by the invention as a negative active material can be up to 3015mA.h / g; the lithium-ion battery prepared from the silicon material as the negative active material has a high rate capability; and the lithium deintercalation capacity at the rate of 5C can be up to 2440mA.h / g. According to the core-shell gap structure of the silicon material provided by the invention, volume expansion and contraction and mechanical stress caused by the volume expansion and contraction in charging and discharging process of the lithium-ion battery can be effectively accommodated and alleviated; the volume effect is removed; and the prepared lithium-ion battery has excellent cycling stability.

Owner:王晓亮

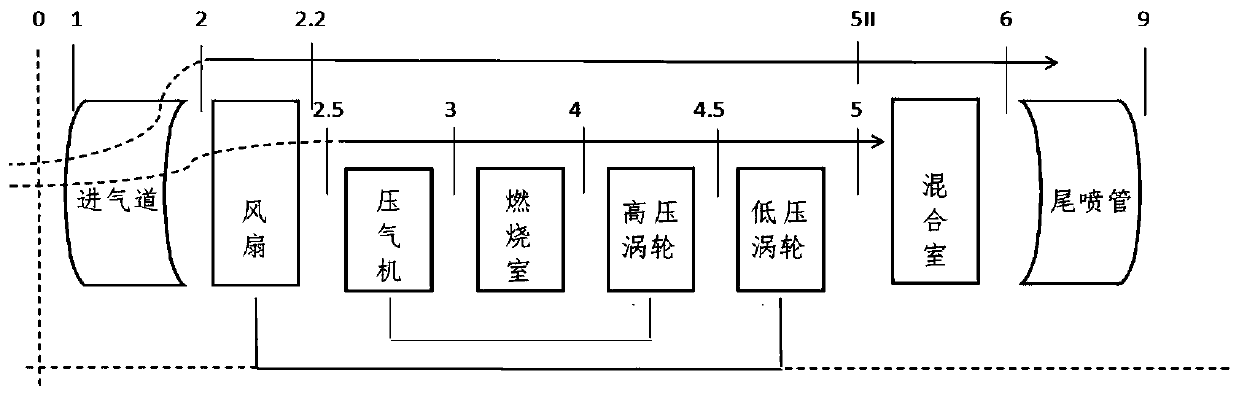

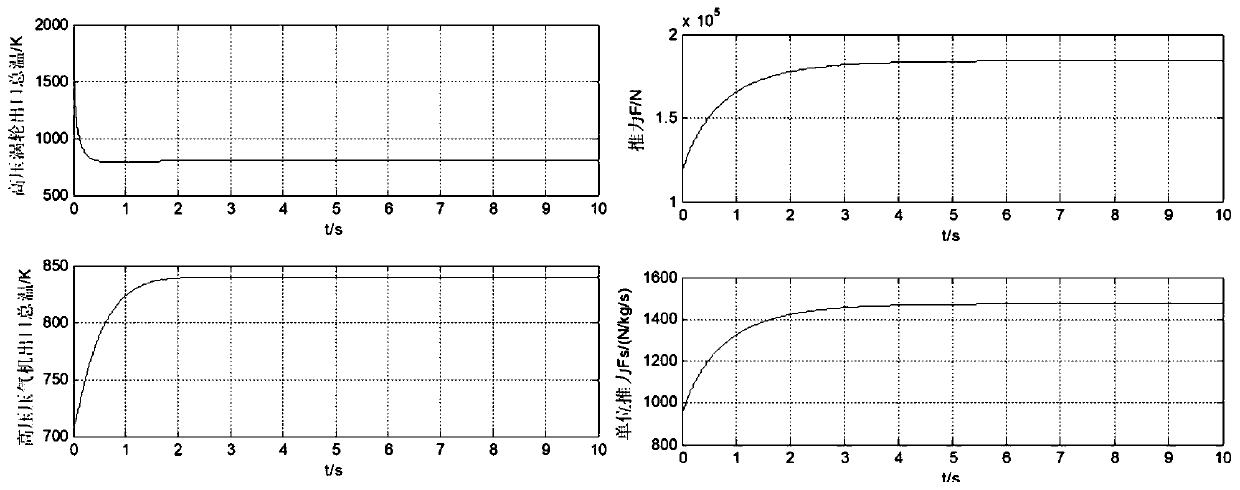

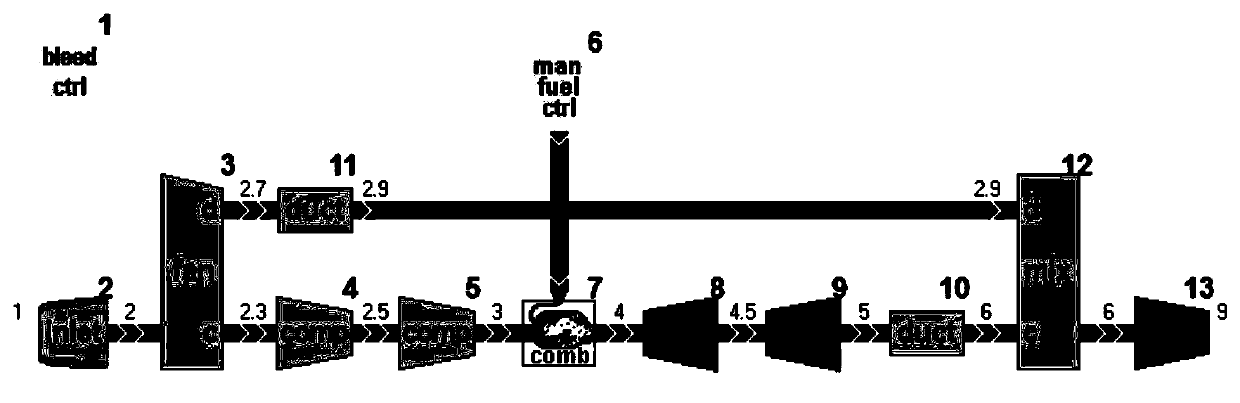

Aero-engine nonlinear model modeling method

The invention belongs to the technical field of aero-engines, and particularly relates to an aero-engine nonlinear model modeling method. The method comprises the following steps: calculating an engine design point nonlinear model, and calculating a transmitter transition state nonlinear model; the method comprises the steps that an engine subsection model is established, and the model is mainly divided into an air inlet channel, a fan, a gas compressor, a combustion chamber, a turbine and an exhaust port according to the structure and function of an aero-engine; describing the aerothermodynamic law obeyed by each component during working by using a nonlinear equation in sequence, and establishing a component-level model of an aeroengine design point; the latter assumes that the characteristics of the parts in the transition state are the same as those in the steady state, and the volume effect of the parts is considered in numerical simulation in the transition state; only the volumetric effect of parts with large volumes is considered in calculation, and meanwhile momentum conservation is simplified to be replaced by the total pressure recovery coefficient of the channel, so thatenough engineering precision can be ensured, and calculation is greatly simplified.

Owner:FUDAN UNIV

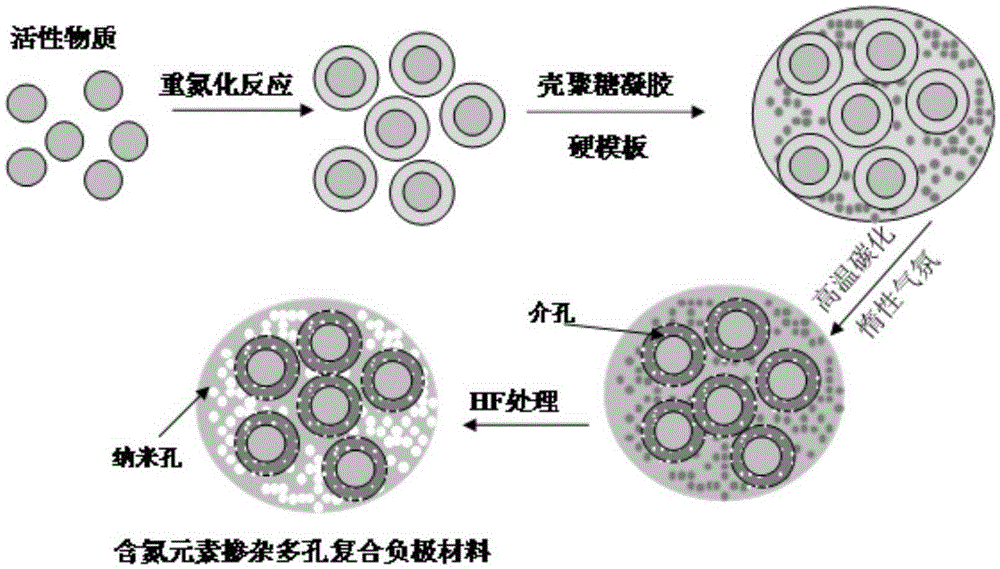

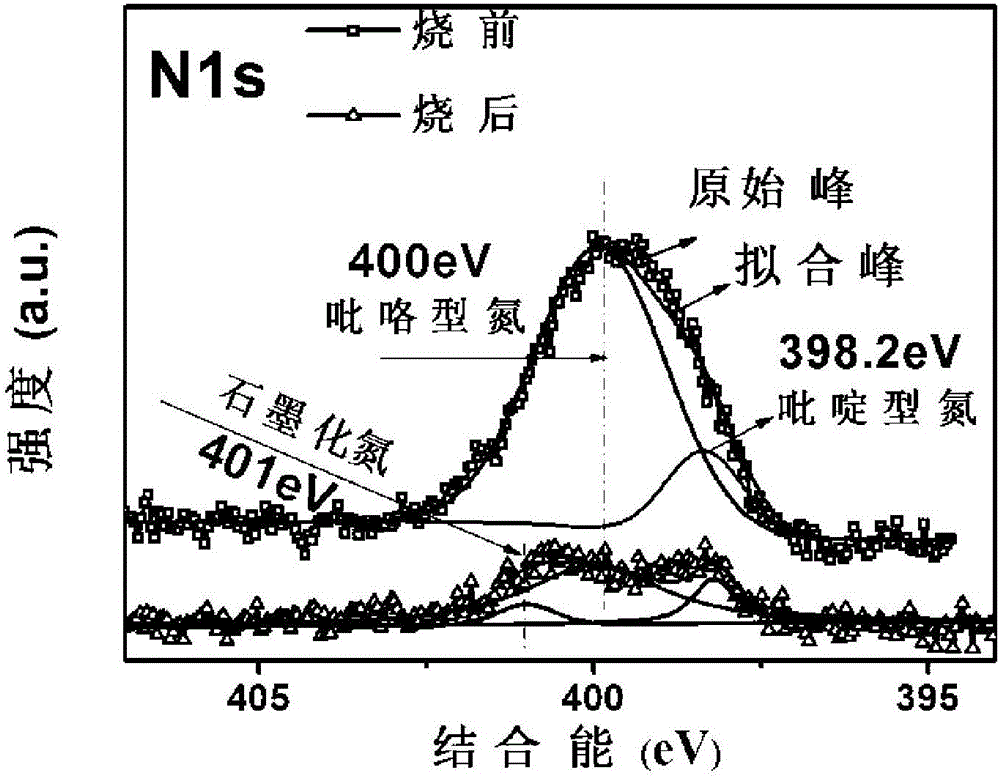

Nitrogen-doped porous composite negative electrode material and preparation method therefor

ActiveCN105428614AControl volume effectFacilitate conductionCell electrodesSecondary cellsPorous carbonNitrogen doped

The invention discloses a nitrogen-doped porous composite negative electrode material and a preparation method therefor. The composite negative electrode material comprises an active substance as a core, a core-shell structure applied to the outer surface of the active substance, and a porous carbon structure applied to the outer surface of the core-shell structure, wherein the core-shell structure is a mesoporous carbon structure formed by nitrogen-doped carbon; and the porous carbon structure is a uniform porous carbon structure coated with nitrogen-doped three-dimensional porous carbon. Compared with the prior art, the composite negative electrode material can better control the volume effect of the active substance, is remarkably improved in conductive performance and electrode cycle performance, is high in repeatability and low in cost, and has relatively high potential of large-scale application.

Owner:合肥龙智机电科技有限公司

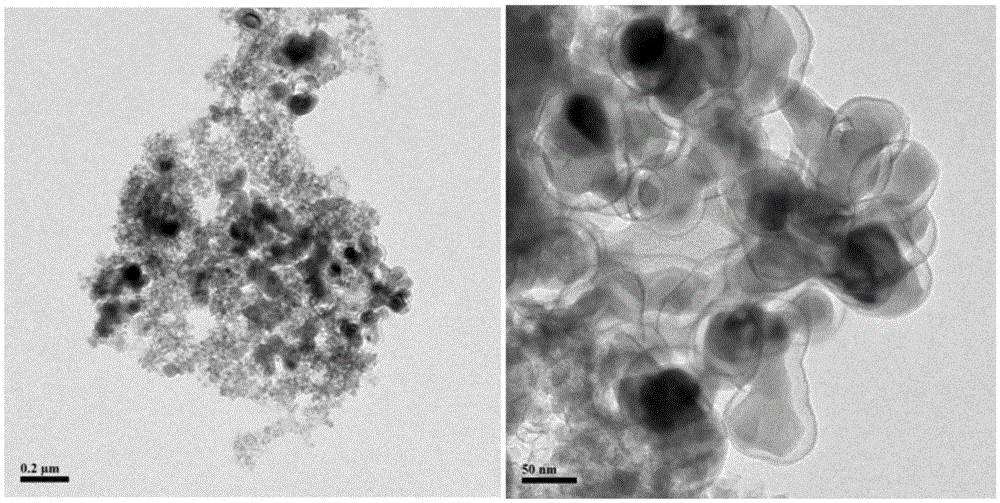

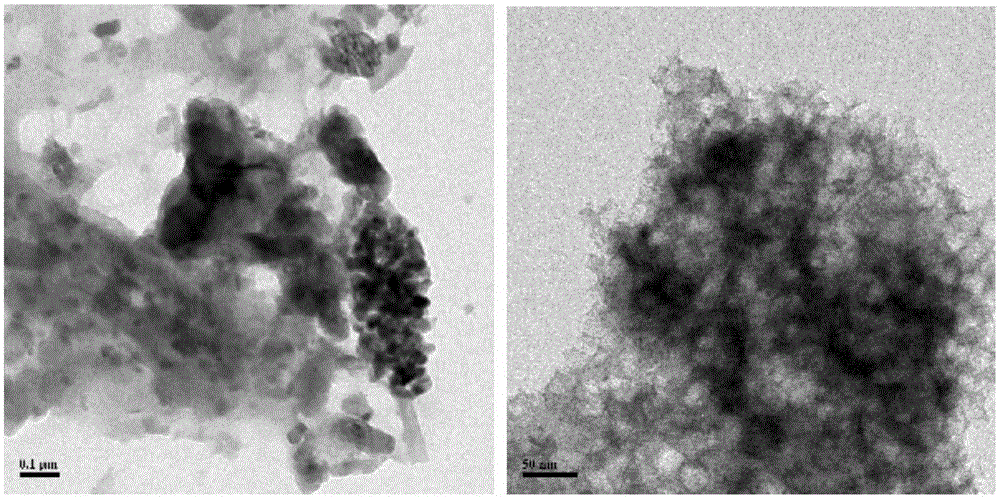

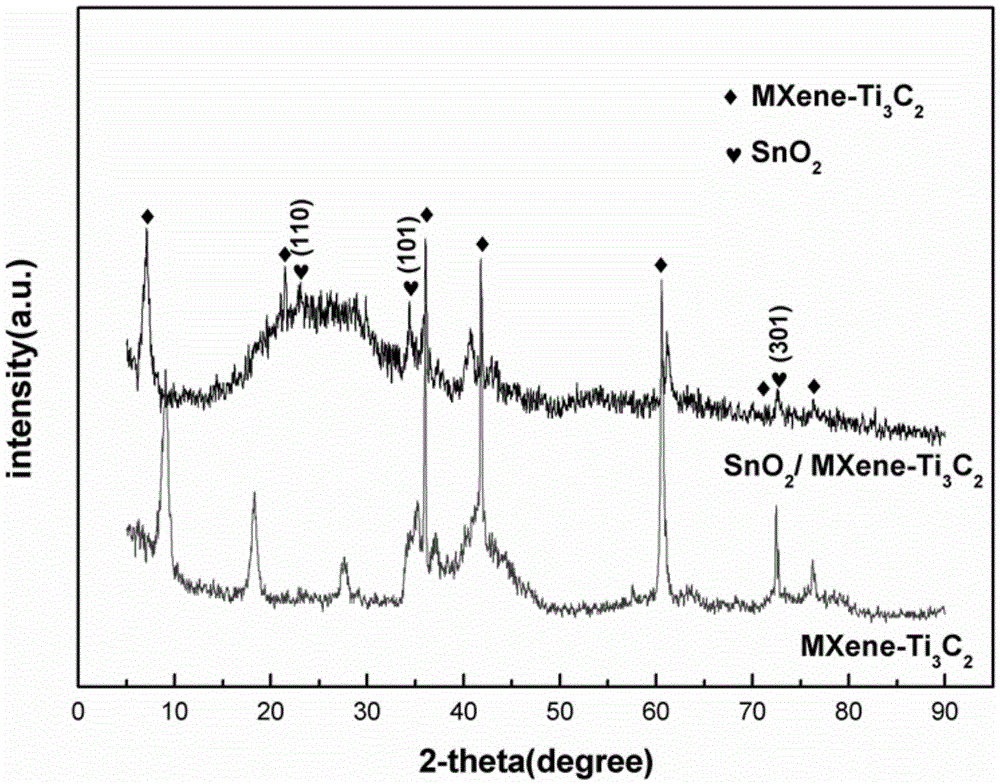

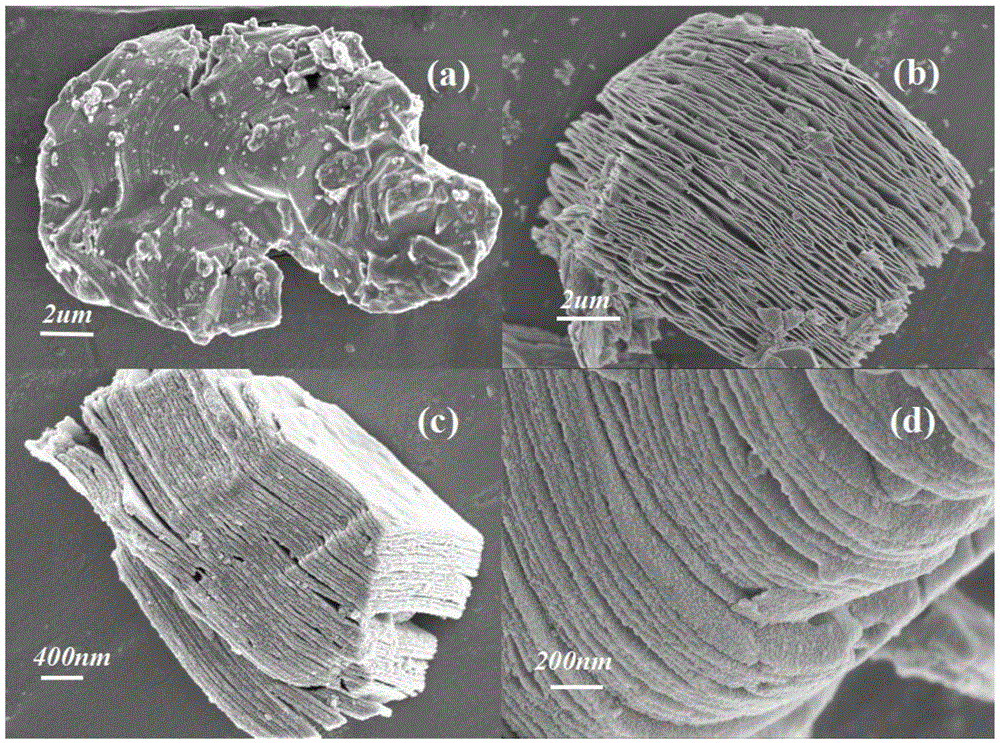

Preparation method of granular tin dioxide/two-dimensional nano titanium carbide composite material

ActiveCN105470486AImprove electrochemical performanceImprove thermal conductivityHybrid capacitor electrodesCell electrodesTin dioxideTitanium carbide

The invention provides a preparation method of a tin dioxide / two-dimensional nano titanium carbide composite material. The preparation method comprises: carrying out ball milling on ternary layered Ti3AlC2 ceramic powder; immersing the obtained product in hydrofluoric acid solution to perform the reaction for 6h to 120h; stirring, centrifugally cleaning a corrosion product by using deionized water, and drying an obtained solid sample to obtain a two-dimensional layered nano material MXene-Ti3C2; and mixing SnCl4.5H2O, glucose and the two-dimensional nano MXene-Ti3C2, using ethanol as a solvent, adjusting PH to 12 to 14, stirring with a magnetic force for 2h, performing the reaction at 120 DEG C for 6h, and after naturally cooling to a room temperature, carrying out centrifuging and drying to obtain a SnO2 / MXene-Ti3C2 composite material. The material obtained by the preparation method can effectively alleviate a volume effect of SnO2 nano particles, and the SnO2 / MXene-Ti3C2 nano composite material has an excellent application prospect in the field of an anode material field of a high storage germanium lithium ion battery.

Owner:SHAANXI UNIV OF SCI & TECH

Estimating and correcting for contrast agent extravasation in tissue perfusion imaging

ActiveUS8718747B2Robust estimationAccurately determineImage enhancementImage analysisDynamic contrastArterial input function

The invention provides a method, an image analysis software product, and a system for medical imaging analysis for estimating contrast agent extravasation in contrast agent based perfusion imaging such as MRI dynamic contrast enhanced (DCE) imaging, and in particular correction, compensation, or visualization of extravascular leakage of contrast agent in tumors. According to the invention, the effect of extravasation is directly manifested in the tail part of an observed, apparent residue function, R′(t), obtained directly by de-convoluting the expression C(t)=R′(t)Cp′(t) with the arterial input function (AIF). A leakage rate or extravasation constant is determined directly from the tail part of the determined apparent residue function. The invention also relates to distinguishing between T1-dominant and T2*-dominant extravasation effects in perfusion imaging to from the sign of the tail part of the determined apparent residue function and to an automated method for DSC-MRI involving correction for contrast agent extravasation and partial volume effects.

Owner:UNIV OSLO HF

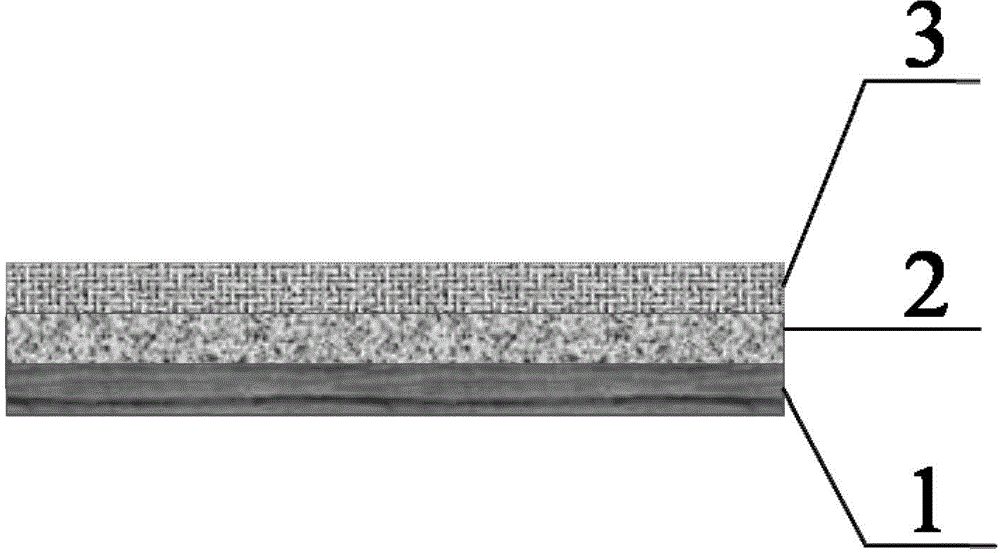

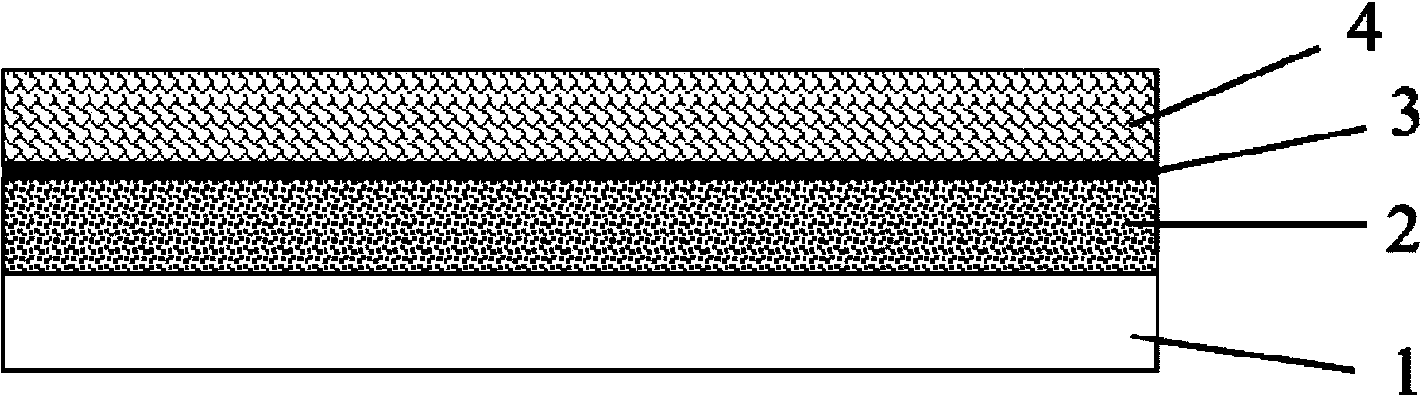

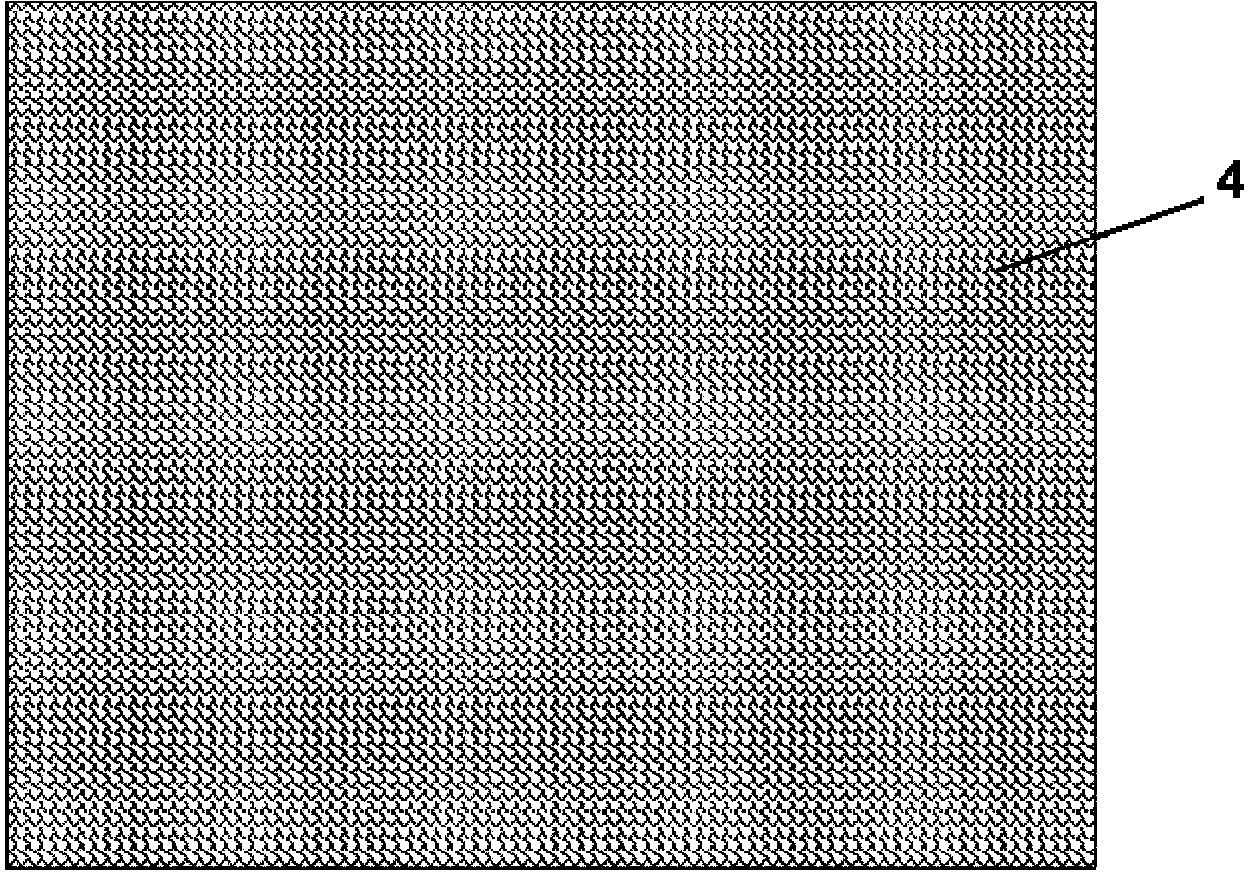

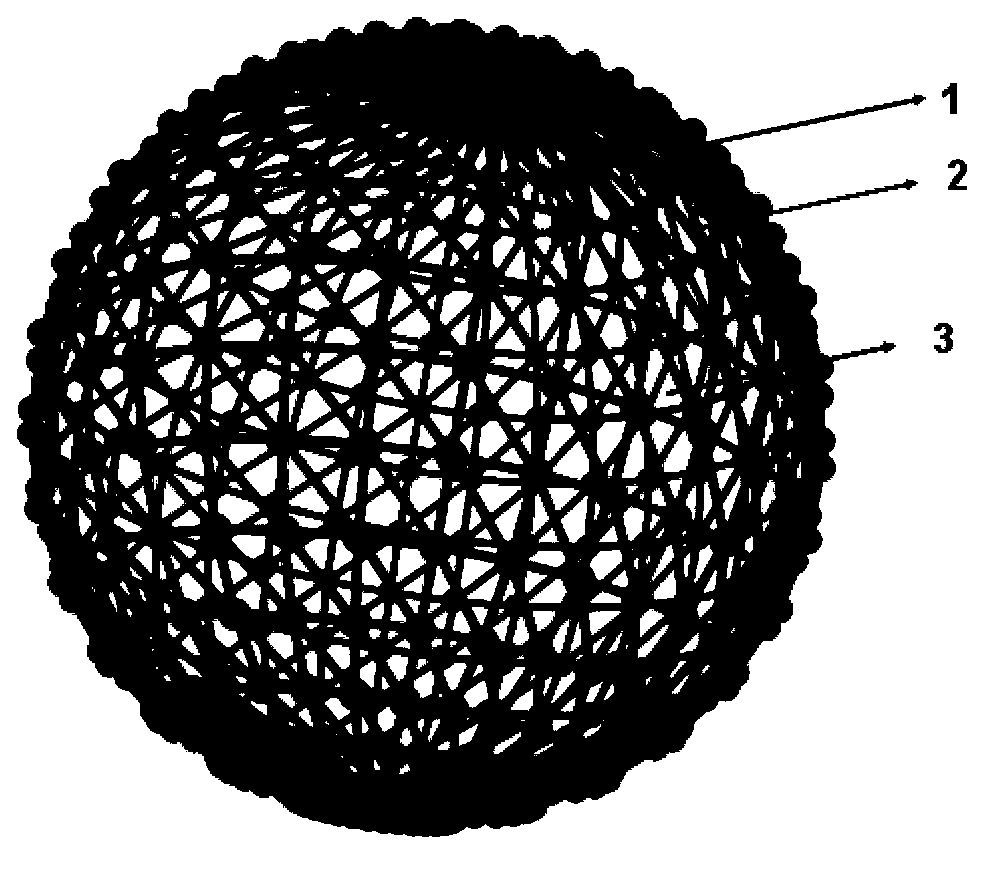

Three-layer electrode structure for alloy anode of lithium ion battery

The invention relates to a three-layer electrode structure for the alloy anode of a lithium ion battery. The three-layer electrode structure comprises a current collector layer, a de-intercalation lithium active material layer and an inert material protecting layer, which are laminated sequentially, wherein the inert material protecting layer is provided with inert protective substances; the inert protective substances are macromolecule polymer fiber which does not perform de-intercalation lithium reaction and have elasticity and electrical conductivity within the circulating voltage range. According to the invention, for the inherent volume expansion effect of the alloy anode, and starting from the design aspect of a process structure, the three-layer electrode structure is adopted, the inert material protecting layer is positioned on the surface of the active material layer, and the fiber network structure of the inert material protecting layer is used, so that inner stress of the de-intercalation lithium alloy anode, which is produced due to the volume effect is effectively relieved, pulverization and crushing of electrode material are prevented, the integrity of the electrode is ensured, electrical contact of active materials and the current collector is maintained, meanwhile, the active material layer is isolated from being in direct contact with an electrolyte through the inert material protecting layer, and corrosion of the electrolyte to active materials is reduced.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

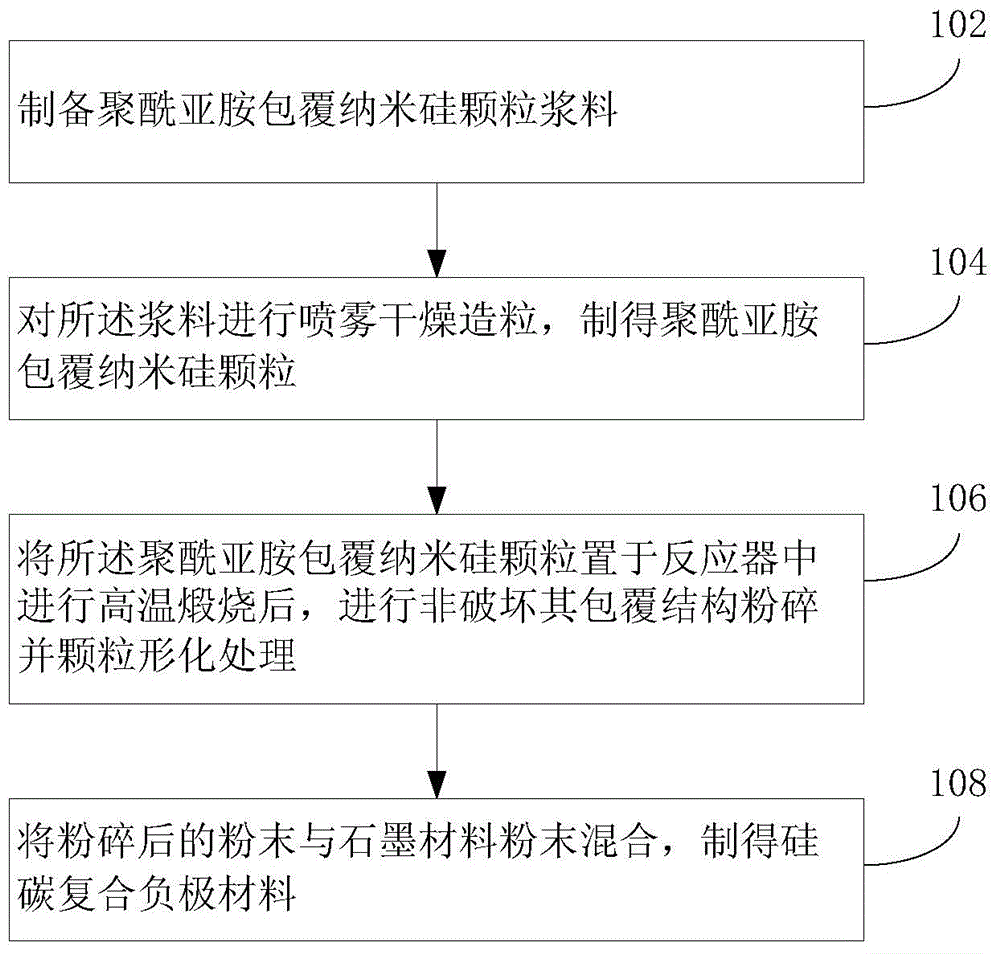

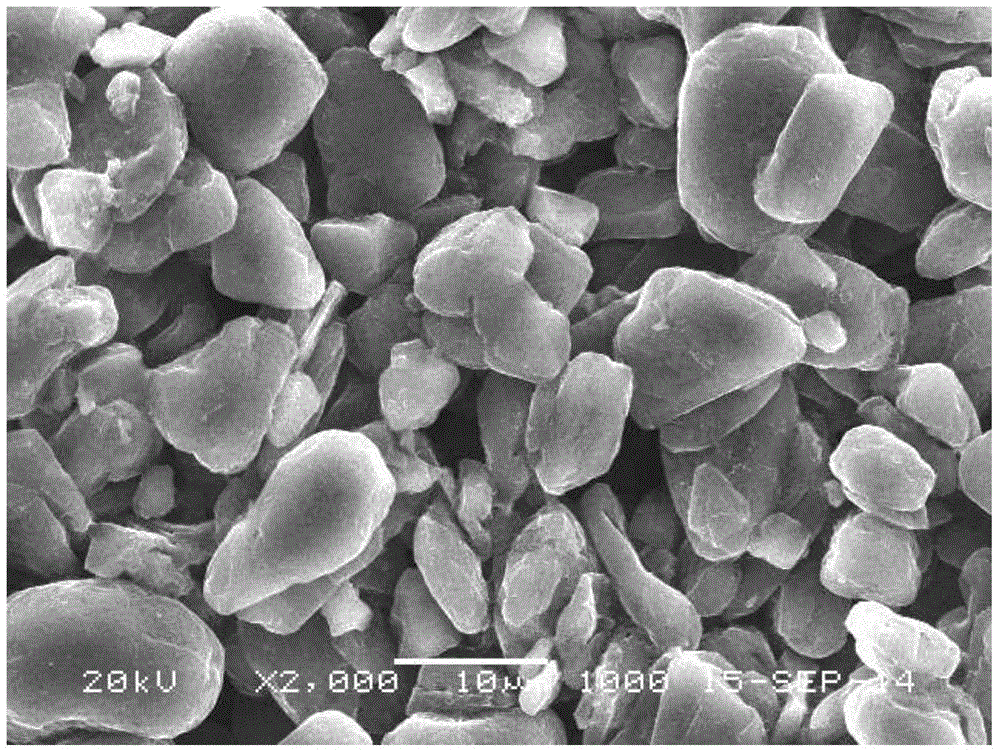

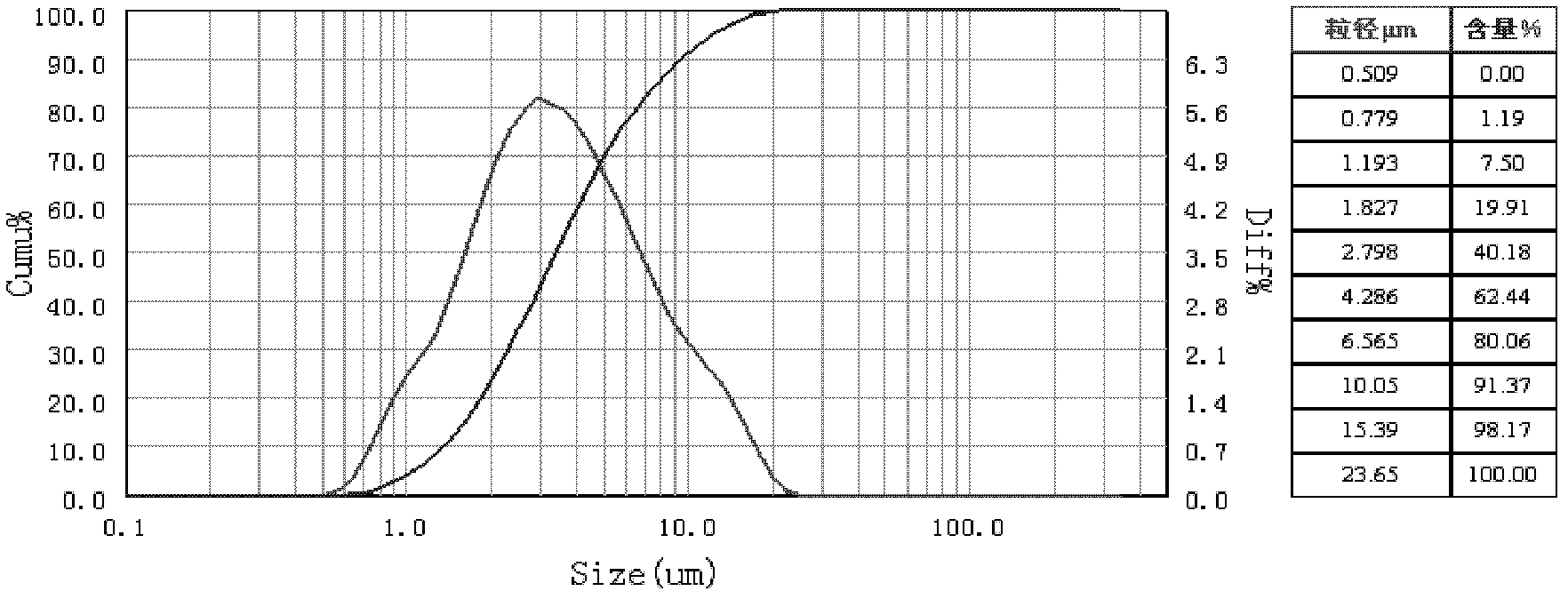

Power lithium ion battery silicon-carbon composite negative electrode material preparation method

PendingCN106207142AAlleviate volume effectInhibition of agglomerationCell electrodesCarbon layerCarbon composites

The invention discloses a power lithium ion battery silicon-carbon composite negative electrode material preparation method. The method comprises the following steps: preparing a polyimide coated nano-silicon particle slurry; carrying out spray drying granulation on the slurry to prepare polyimide coated nano-silicon particle powder; placing the polyimide coated nano-silicon particle powder in a reactor, carrying out high temperature calcining, carrying out non-destructive coating structure crushing, and granulating the crushed powder; and mixing the crushed powder with graphite material powder to prepare a silicon-carbon composite negative electrode material. The surface of silicon nano-particles is uniformly covered with a conductive carbon layer generated by pyrolysis of polyimide polymer, so the volume effect of the silicon particles, appearing in the battery charge and discharge process, is effectively inhibited, and unnecessary side reactions between silicon and an electrolyte are avoided, and a nano-silicon particle dispersion containing the polyimide polymer effectively inhibits the agglomeration phenomenon of the silicon nano-particles in the dispersion and can be used as the adhesive in a next spray drying process.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

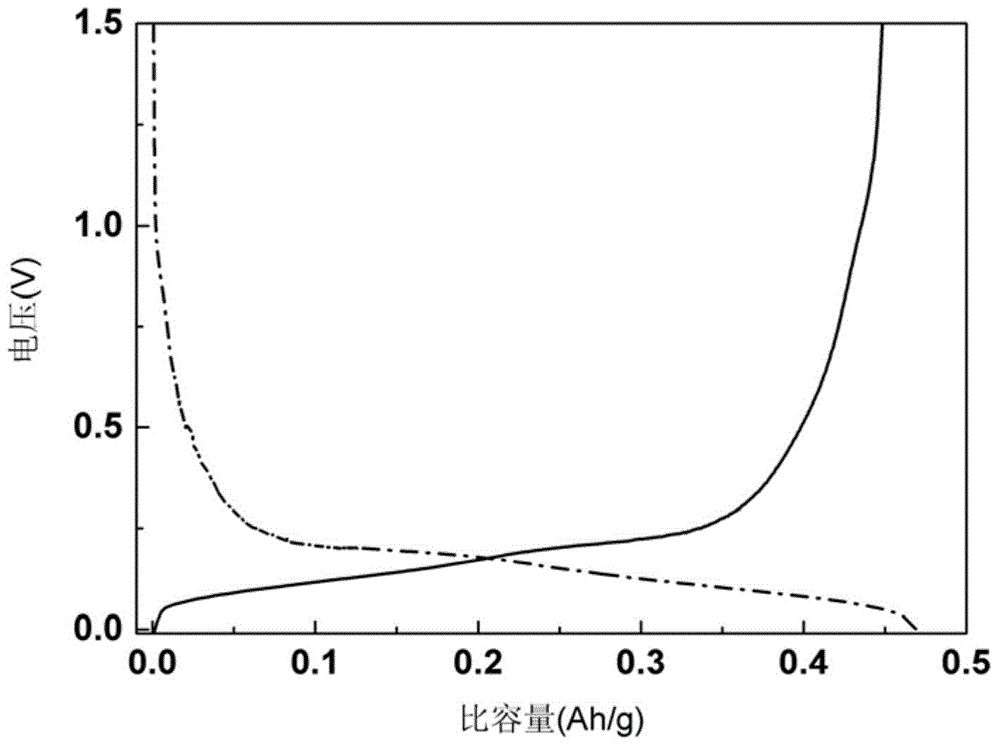

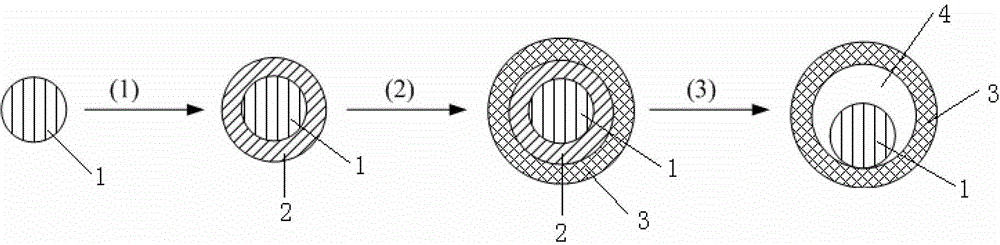

Silicon-carbon composite material and preparation method thereof, and lithium ion battery

ActiveCN103337613ABuffer volume effectImprove conductivityCell electrodesSecondary cellsCarbon compositesLithium-ion battery

The invention discloses a silicon-carbon composite material and a preparation method thereof, and a lithium ion battery. The preparation method comprises following steps: (1) coating a silica-based material with a transition layer to obtain the transition layer-coated silica-based material; (2) coating the transition layer-coated silica-based material with carbon to obtain a carbon-transition layer-silicon based composite material; and (3) removing the transition layer to obtain the silicon-carbon composite material. The silicon-based material is coated with the transition layer, the transition layer is coated with the carbon, and the transition layer between the silicon-based material and the carbon is removed, so that a plurality of pores are formed between the silicon-based material and the carbon of the silicon-carbon composite material. The size of the pores between the silicon-based material and the carbon can be controlled precisely by setting the thickness of the transition layer according to micro-volume expansion theoretical value of the silicon-based material when lithium is embedded, so that volume effect of the silicon-carbon composite material is reduced effectively, and cycling performance of the lithium ion battery is further enhanced. The carbon of the silicon-carbon composite material is capable of increasing conductivity and rate capability of the composite material.

Owner:CHERY AUTOMOBILE CO LTD

A tin carbon compound electrode material for lithium ion battery cathode and preparing method

ActiveCN101017893AReduce volume effectHigh reversible specific capacityElectrode manufacturing processesCarbon layerGraphite

The disclosed preparation method for Sn-C composite material for negative electrode of Li-ion cell comprises: (1) ball grinding the graphite and doped stannum salt material together; (2) adding product in (1) into alkali solution for reacting, filtering, and drying; (3) preparing the organic solution for cladding carbon layer, adding the product from last step, and drying for granulation; and (4) taking high-temperature solid phase reaction. The final product comprises the graphite body, cladding carbon layer and Sn-constained Li-storing material between the graphite surface and carbon layer, or in graphite layers, or in carbon layers. This invention can reduce the volume effect of Sn-constained active material, has well reversible specific capacity and cycle life.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

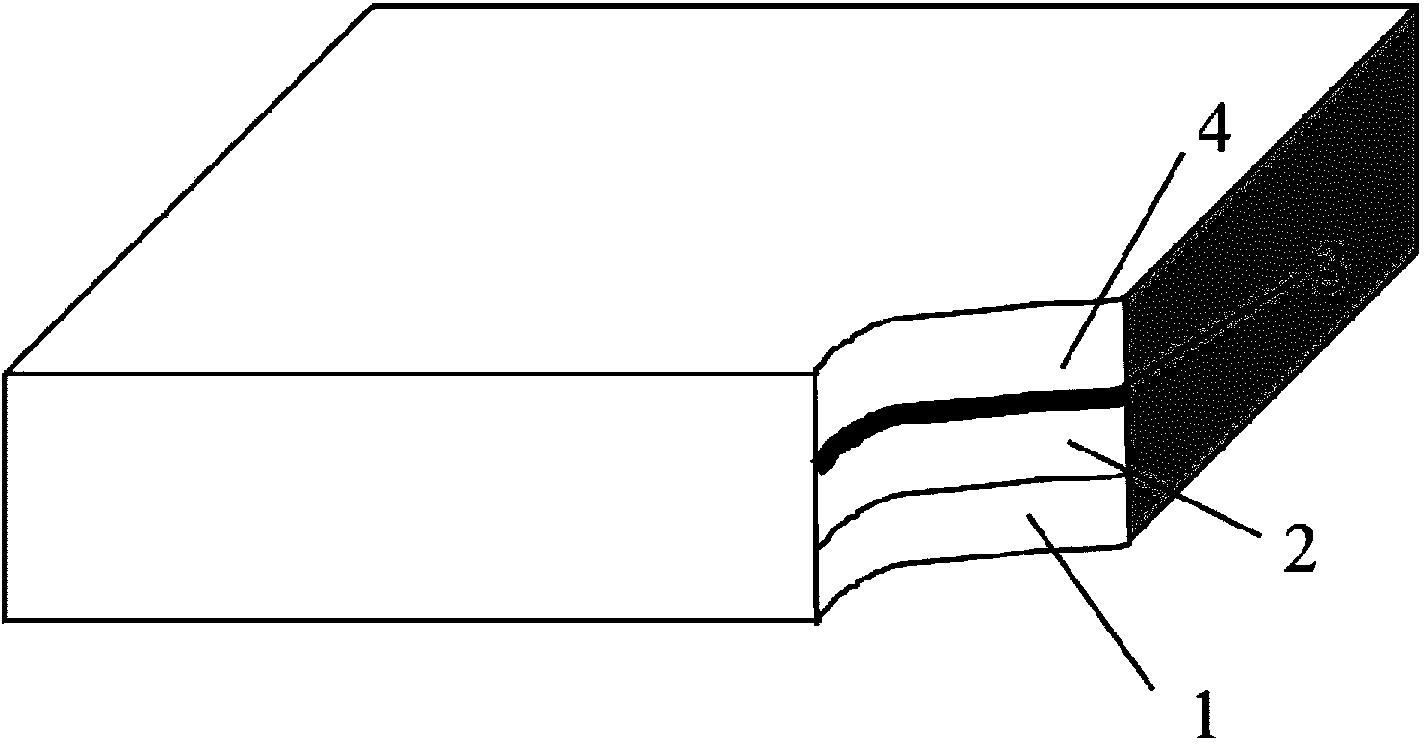

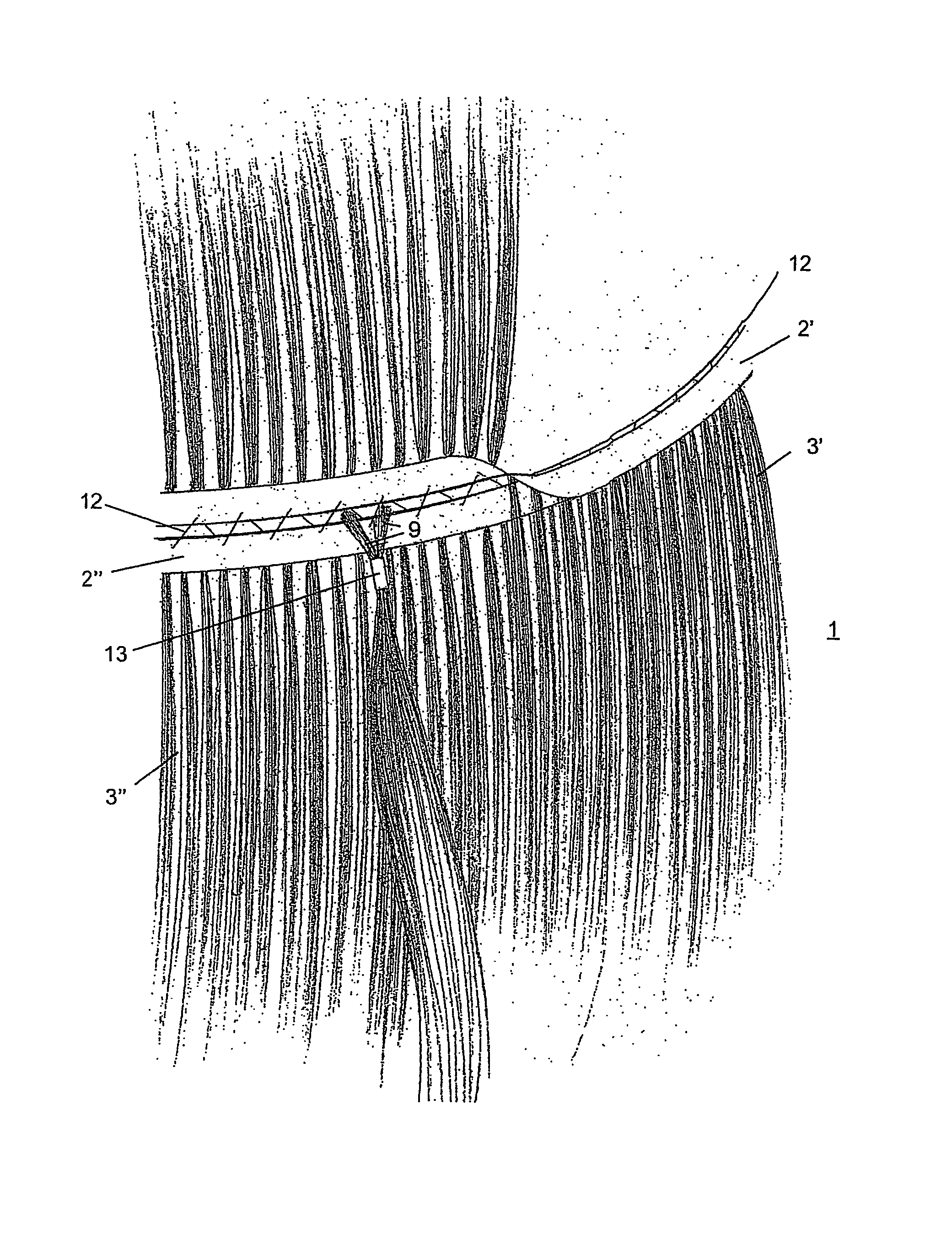

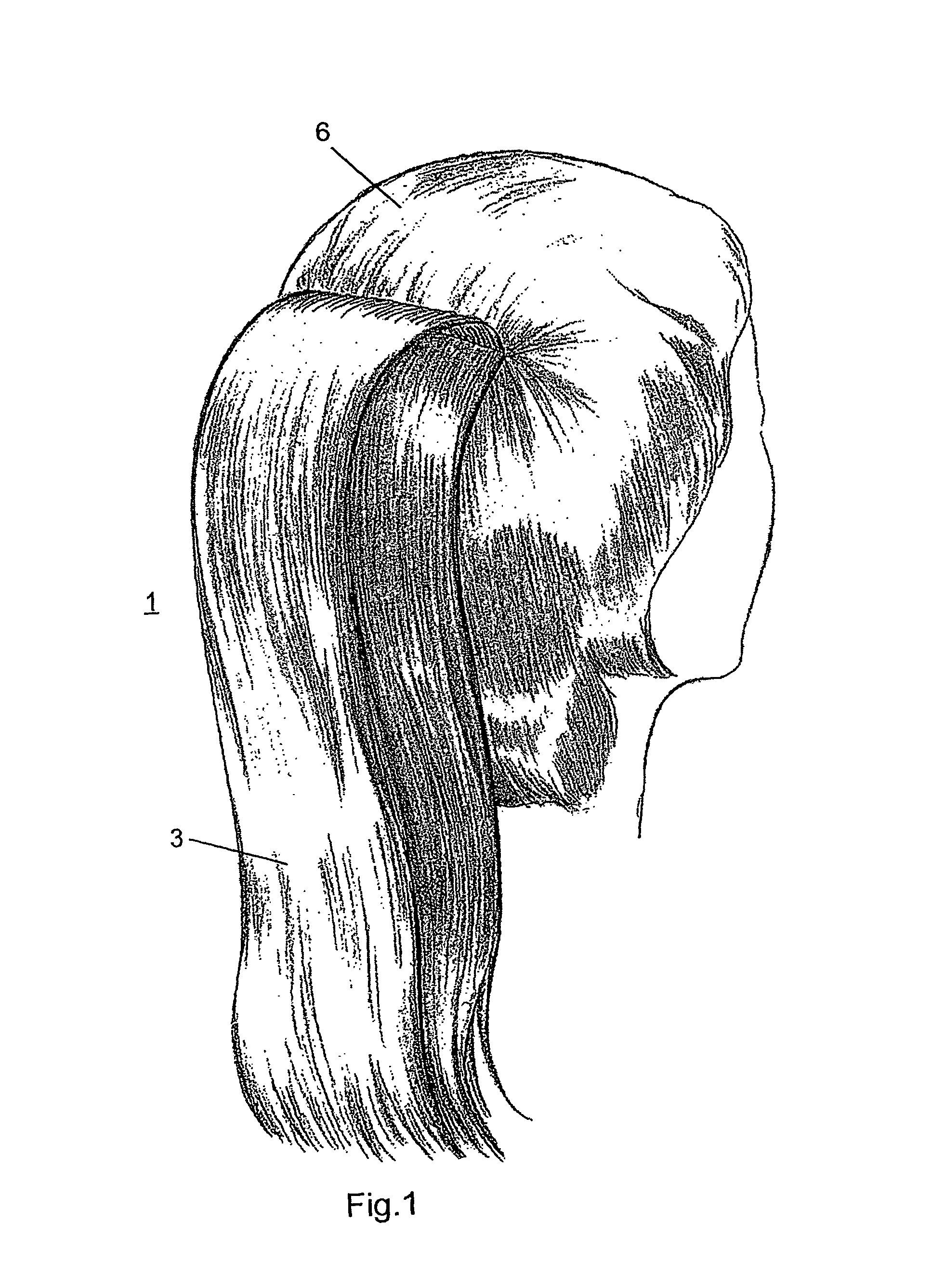

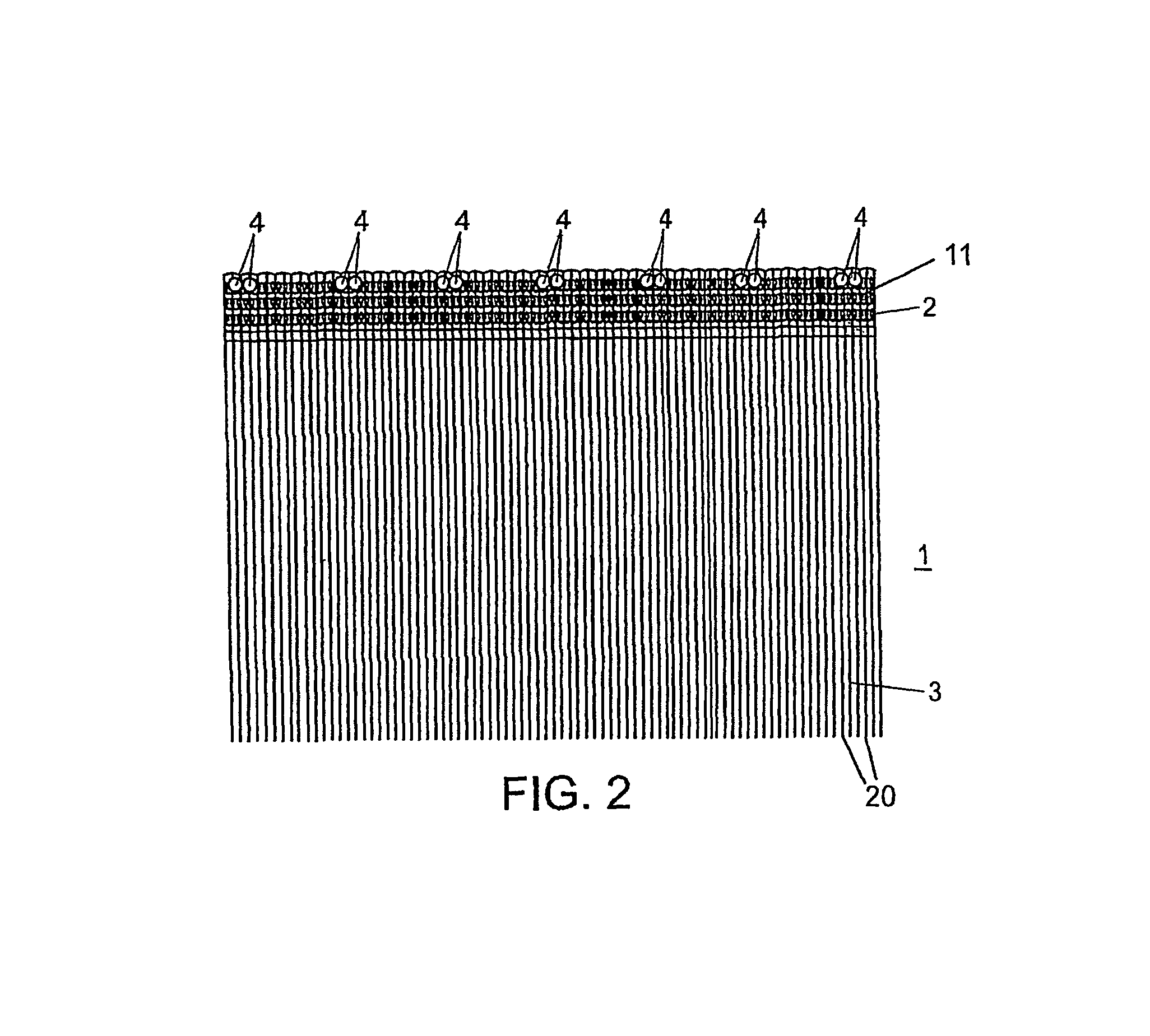

Fast applicable hair piece provided with a weaving band completely integrated with basic hair and method for attaching thereof

ActiveUS8025065B2Easily and reliably and fastly connectableHair accessoriesToupeesSynthetic materialsEngineering

The invention relates to a fast applicable hair piece (1) for obtaining a special esthetical effect like e.g. a colour effect or a hair volume effect having a remarkable high wearing comfort for the user. The hair piece (1) comprises at least one thin, broad and flat hair piece (3) consisting of a number of hairs (20). The hair bundle (3, 3′, 3″) is provided at its free end with a lightweight and thin elongated weaving band (2, 2′, 2″) made from hair or from another suitable material like e.g. cotton or a synthetic material comprising regularly weaving elements (11). This weaving band is characterized by connection opening (4, 4′, 4″, 31) provided at regular mutual distance. A suitable number of basic hairs (9, 9′, 9″) may be passed through said connection openings (4, 4′, 4″, 31). As a result a temporarily, durable however eventually easily removable connection between the hair (1) piece and the basic hair (6) will be formed, in such a way that the hair piece (1) is always reusable. Furthermore the invention relates to a method for attaching a hair piece (1).

Owner:EURO HAIR R&D BV

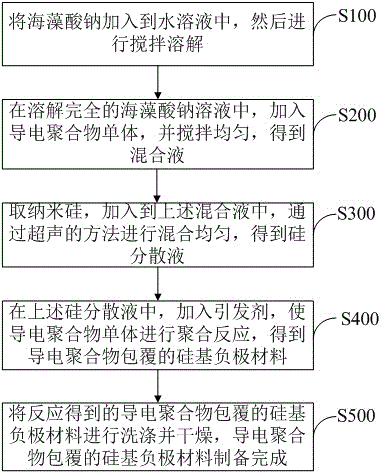

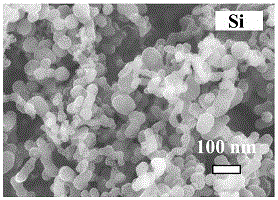

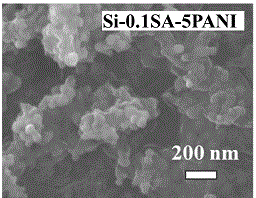

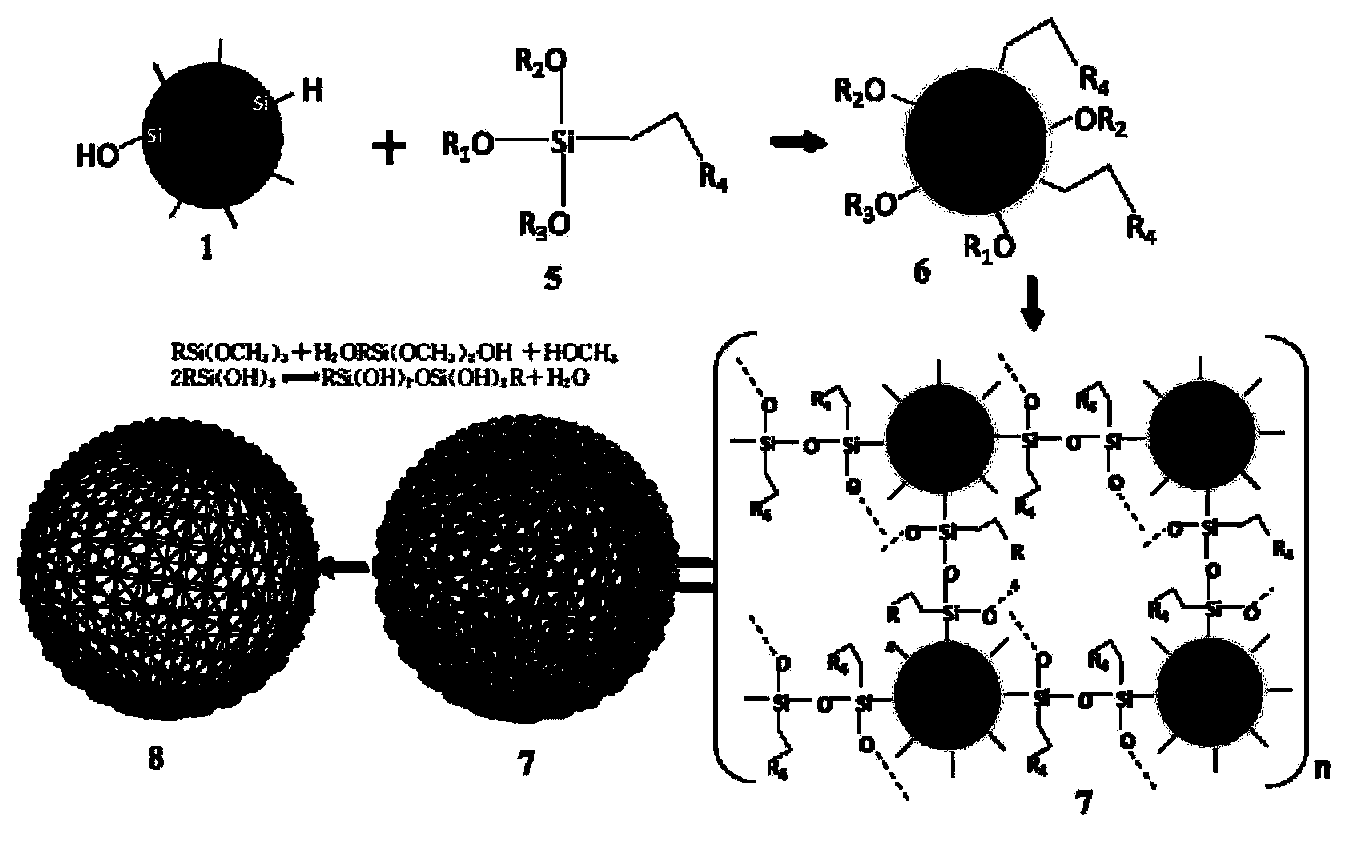

Conductive polymer-coated silicon-based negative electrode material and preparation method thereof

ActiveCN106229495AImprove electrochemical performanceAlleviate volume effectCell electrodesSecondary cellsConductive polymerUltrasound method

The invention discloses a conductive polymer-coated silicon-based negative electrode material and a preparation method thereof. The method comprises the following steps of adding sodium alginate to a water solution, and then stirring and dissolving the sodium alginate; adding a conductive polymer monomer to the completely dissolved sodium alginate solution and stirring evenly; adding taken nanometer silicon to a mixed solution and mixing evenly through an ultrasound method to obtain a silicon dispersion liquid; adding an initiator to the silicon dispersion liquid and carrying out polymerization reaction on the conductive polymer monomer to obtain the conductive polymer-coated silicon-based negative electrode material; and carrying out washing and drying and finishing preparation of a final product. A three-dimensional mesh structure is built by the conductive polymer, so that the conductive polymer-coated silicon-based negative electrode material has conductivity and also provides a certain accommodation space for volume expansion of the silicon; and the silicon is embedded into the mesh structure, so that the volume effect of the silicon is effectively relieved. Furthermore, the hydroxyl-containing sodium alginate is introduced, so that the structure stability of the overall silicon-based negative electrode material is strengthened.

Owner:SHENZHEN UNIV

Silicon-carbon composite material and preparation method thereof, and lithium ion battery

ActiveCN102983313ASmall volume effectGood electrical contactMaterial nanotechnologyCell electrodesCarbon compositesElectrical battery

The invention provides a silicon-carbon composite material and a preparation method thereof, and a lithium ion battery containing the material, belongs to the technical field of lithium ion batteries, and can solve the problem of capacity fading caused by a volume effect of the existing silicon-carbon composite material and the lithium ion battery prepared by using the silicon-carbon composite material in the charge and discharge processes. The preparation method of the silicon-carbon composite material, disclosed by the invention, comprises the steps of: mixing silicon dioxide, a conductive carbon material and metal to obtain compound powder, carrying out reduction reaction, and pickling to remove metal oxide. The silicon-carbon composite material with an excellent cycle performance is obtained by selecting proper technological parameters, and the lithium ion battery containing the silicon-carbon composite material is prepared.

Owner:CHERY AUTOMOBILE CO LTD

Anode material of lithium-ion battery and method for preparing anode material

InactiveCN102544461AHigh specific capacityInhibition internal resistanceCell electrodesAdhesiveCrystalline silicon

The invention discloses an anode material of a lithium-ion battery and a method for preparing the anode material, belongs to the technical field of the lithium-ion batteries, and aims to solve the problems of poor volume effect caused in the electrochemical lithium de-insertion process of a high-capacity silicon anode material of the lithium-ion battery and low electric conductivity of the material. The anode material of the lithium-ion battery is high in coulombic efficiency and high in cycle performance. The anode material of the lithium-ion battery is formed by adding a carbon element and an adhesive into N-type or P-type doped crystalline silicon active powder which serves as a main material and then laminating a mixture. By adoption of the anode material of the lithium-ion battery, high capacity can be realized, and the electric contact performance of a microcrystal active lithium insertion center can be improved, so that the volume of a silicon micro crystal is slightly changed, the cycle stability is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Volume measurement method based on industrial CT scanning technology

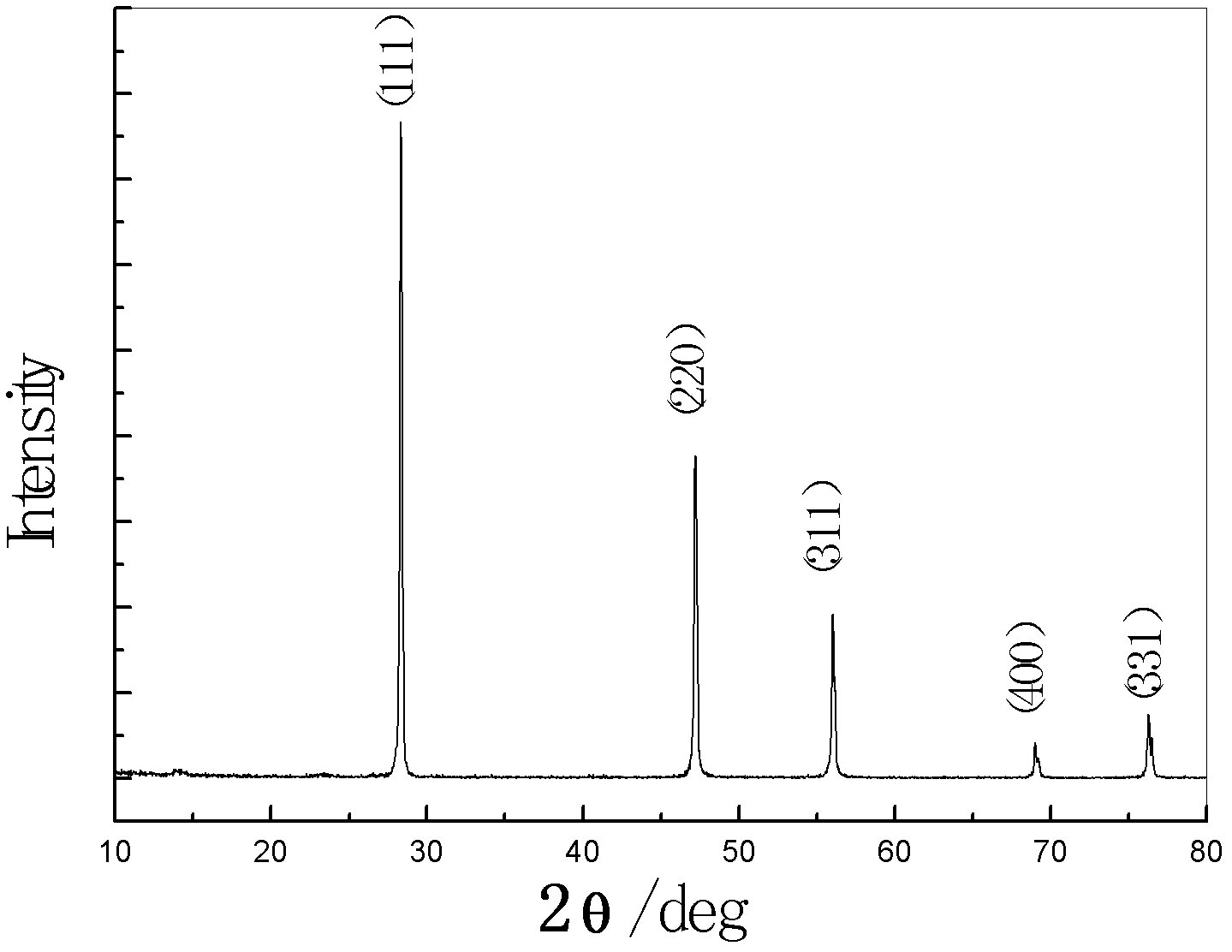

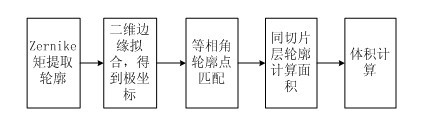

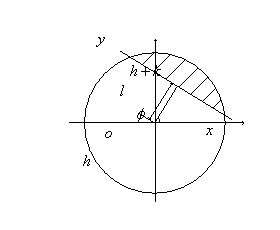

InactiveCN102628682AHigh image resolutionSolve the volume effectImage analysisUsing wave/particle radiation meansPolynomial least squaresComputed tomography

The invention provides a volume measurement method based on industrial CT scanning technologies. The method comprises the following steps: 1) edge extraction: extracting sub-pixel edges of two-dimensional images by using Zernike moments; 2) polynomial fitting: performing polynomial least square fitting on edge points, and transforming fitted point coordinates into polar coordinates; 3) interlayer matching: performing equal phase-angle-interval sampling on fitting function curves in step 2), and establishing a matching relationship between contour points having a same phase angle; 4) interlayer interpolation: acquiring the contour points in an intermediate layer by adopting the interlayer interpolation algorithm; 5) top prediction: estimating a top point of a workpiece by adopting the gray extrapolation method; 6) volume measurement: calculating the volume of the workpiece by using the truncated cone method according to three-dimensional fitting contour data. Based on the Zernike moments and the least square fitting algorithm, the method achieves area and volume measurement precisions which are 5 times or even more than 10 times higher than previous algorithms, and a top absence problem caused by volume effects or incomplete scanning in actual measurement processes is solved.

Owner:CHONGQING UNIV

Silicon-based composite negative electrode material for lithium ion battery

ActiveCN104241621AAlleviate volume changesEvenly dispersedCell electrodesSecondary cellsSodium-ion batteryOxygen

The invention relates to a silicon-based composite negative electrode material for a lithium ion battery, wherein a silicon-containing material with the size of less than 0.3 [mu]m is dispersed uniformly in a porous silicon oxygen carbon skeleton. The invention also provides a method for preparing the composite negative electrode material, wherein the method includes the steps: dispersing the silicon-containing material in a liquid organo-siloxane monomer, successively adding an ethanol-water acidic solution, a curing agent and an amorphous carbon source precursor solution into the dispersion liquid, and carrying out heat preservation to make the mixed solution cured; carrying out high temperature calcination on the precursor after curing in a protective atmosphere, to obtain a bulk silicon-based composite material; and crushing the bulk silicon-based composite material by ball milling to obtain the silicon-based lithium ion battery negative electrode material having various different particle sizes. The silicon-containing material in the silicon-based composite negative electrode material is firmly and evenly distributed in the porous silicon oxygen carbon skeleton, and the structure can effectively bear a volume effect brought by embedding and stripping of lithium and has the characteristics of adjustable charge / discharge specific capacity and high electrochemical cycle stability.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

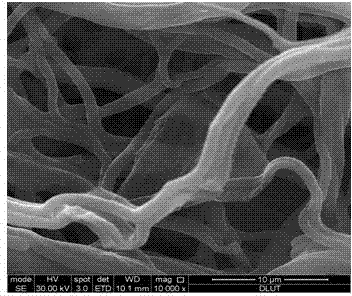

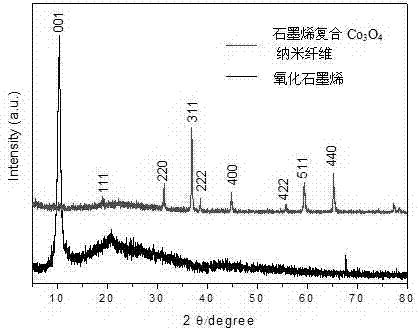

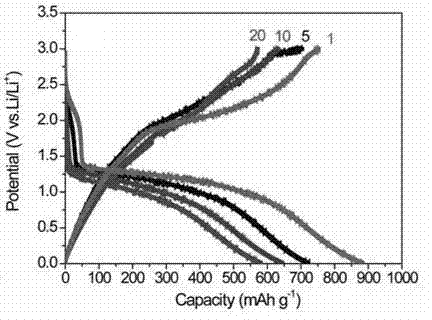

Graphene composite transition metal oxide nanofiber lithium ion battery electrode material and preparation method thereof

InactiveCN102931408AQuick releaseShorten migration distanceMaterial nanotechnologyCell electrodesLithium-ion batteryMaterials science

The invention discloses a graphene composite transition metal oxide nanofiber lithium ion battery electrode material and a preparation method thereof. The composite electrode material combines a function of a graphene laminated structure for embedding and binding transition metal oxide nanoparticles, a function of a micropore tunnel structure interconnected in graphene composite transition metal oxide nanofiber for quickly embedding and taking off lithium ions and a function of three-dimensional space structures wound with each other among nanofibers and used for effectively releasing greatly-changed stress when the volume in an electrode membrane is expanded or contracted. Due to the integration of the three functions, the volume effect of the transition metal oxide material in the process of embedding / taking off the lithium ions can be effectively restrained and buffered, the loss of the irreversible capacity can be reduced, and then, the capacity and the cycling stability performance of a lithium ion battery are further improved.

Owner:DALIAN OCEAN UNIV +1

Method for preparing lithium ion battery silicon carbon composite anode material and product prepared by method

ActiveCN104638240ARelief of mechanical stressEliminate volume effectNegative electrodesCarbon compositesHydrogen fluoride

The invention relates to a method for preparing a lithium ion battery silicon carbon composite anode material and a product prepared by the method and belongs to the technical field of a lithium ion battery anode material. The method comprises the following steps of adding silicon alloy powder into an acid liquor until the alloy is completely dissolved, washing by de-ionized water, placing into a hydrogen fluoride (HF) solution and stirring, again washing by the de-ionized water, performing vacuum drying, and dispersing into a dispersing agent to prepare a silicon powder dispersion liquid; uniformly mixing graphite, a binder and the silicon powder dispersion liquid; performing secondary vacuum drying; carbonizing; placing a carbonized product into the dispersing agent, adding a coating agent and uniformly stirring; performing third vacuum drying; and re-carbonizing. The mechanical stress generated due to volume expansion and shrinkage of silicon in charge and discharge processes can be relieved by a double-layer bonding and cladding model structure, thereby eliminating the volume effect.

Owner:HUZHOU CHUANGYA POWER BATTERY MATERIALS

Lithium ion battery cathode material and preparation method thereof, and lithium ion battery

ActiveCN104701509AMild reaction conditionsThe reaction conditions are safe and controllableCell electrodesSecondary cellsAluminium-ion batteryPotassium

The invention discloses a lithium ion battery cathode material and a preparation method thereof, and a lithium ion battery. The preparation method of the material comprises the following steps: 1)mixing metal and SiOx to obtain a mixture, wherein, metal is one or more from lithium, sodium, potassium, calcium, magnesium and titanium, and x is greater than 0 and less than 2.0; and 2)under inert atmosphere or vacuum condition, roasting the mixture for 0.5-24 hours at 300-1000 DEG C to obtain the cathode material. By reacting the metal and SiOx, active oxygen content in the cathode material is reduced, and the obtained cathode material also comprises the above metal oxide. According to the invention, active oxygen content in the cathode material is reduced, primary efficiency for charge and discharge can be greatly increased, the above metal oxide in the cathode material can alleviate volume expansion of silicon in the cathode material at certain degree, and thereby the volume effect of the whole cathode material is reduced.

Owner:CHERY AUTOMOBILE CO LTD

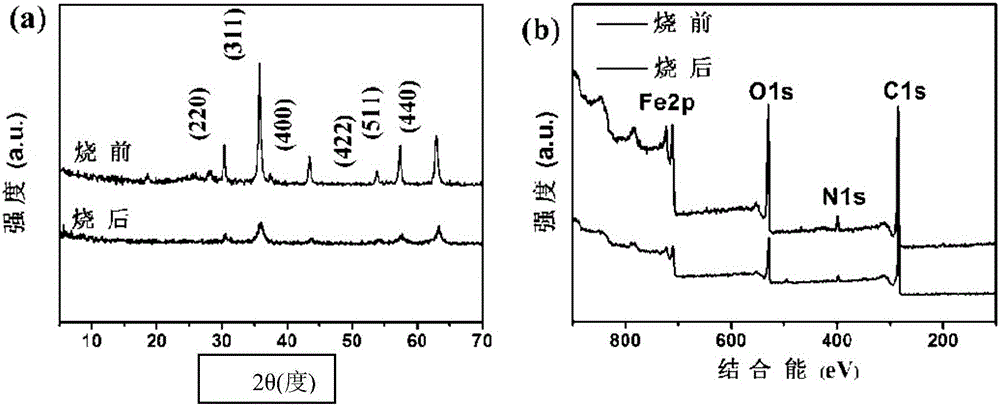

Carbon-coated ferroferric oxide/nitrogen-doped grapheme composite material and preparation method thereof

ActiveCN105762362AIncrease loopImproved magnification performanceCell electrodesSecondary cellsElectrochemical responseNitrogen doped graphene

The invention relates to a composite material and a preparation method thereof, in particular to a carbon-coated ferroferric oxide / nitrogen-doped grapheme composite material and a preparation method thereof, and belongs to the technical fields of material and electrochemistry. The composite material comprises carbon-coated ferroferric oxide and nitrogen-doped grapheme, and in the composite material, ferroferric oxide is uniformly distributed on the surface of a grapheme sheet layer. The composite material comprises carbon-coated ferroferric oxide and nitrogen-doped grapheme, and has excellent cycling performance and rate capability during use as a lithium ion battery cathode material. In addition, the composite material can effectively buffer the volume effect of ferroferric oxide in electrochemical reaction, meanwhile further improves the electrical conductivity, and greatly reduces the impedance of a battery, thereby effectively improving the electrochemical performance.

Owner:SICHUAN UNIV

Silicon-based composite material and preparation method thereof, silicon-carbon composite material and lithium ion battery

The invention provides a silicon-based composite material and a preparation method thereof, a silicon-carbon composite material, and a lithium ion battery containing the materials, belongs to the technical field of lithium ion batteries, and can solve the problem of capacity fading caused by a volume effect of the existing silicon-based composite material and the lithium ion battery prepared by using the silicon-based composite material in the charge and discharge processes. The preparation method of the silicon-based composite material, disclosed by the invention, comprises the steps of: mixing SiOx (x is smaller than or equal to 1.5 and greater than or equal to 0.5) and a conductive carbon substrate to obtain compound powder of the SiOx ( the x is smaller than or equal to 1.5 and greater than or equal to 0.5); and coating the compound powder by a carbon precursor to obtain a coating and carrying out carbonization reaction on the coating. The silicon-based composite material and the silicon-carbon composite material with an excellent cycle performance are obtained by selecting proper technological parameters, and the lithium ion battery containing the materials is prepared. The composite materials disclosed by the invention are prepared by using the method, and the lithium ion battery disclosed by the invention contains the composite materials.

Owner:CHERY AUTOMOBILE CO LTD

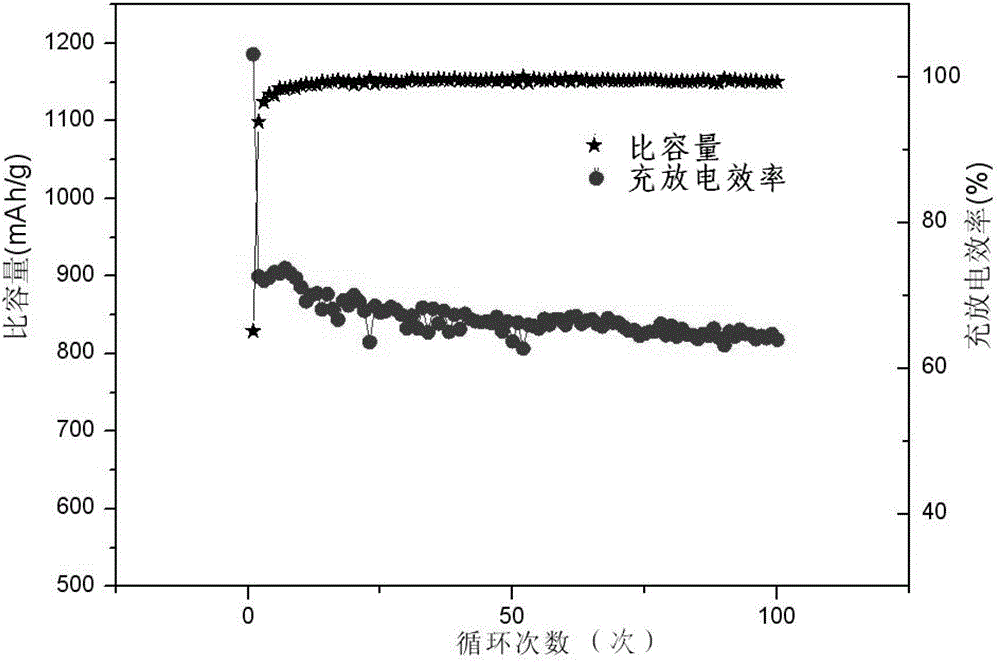

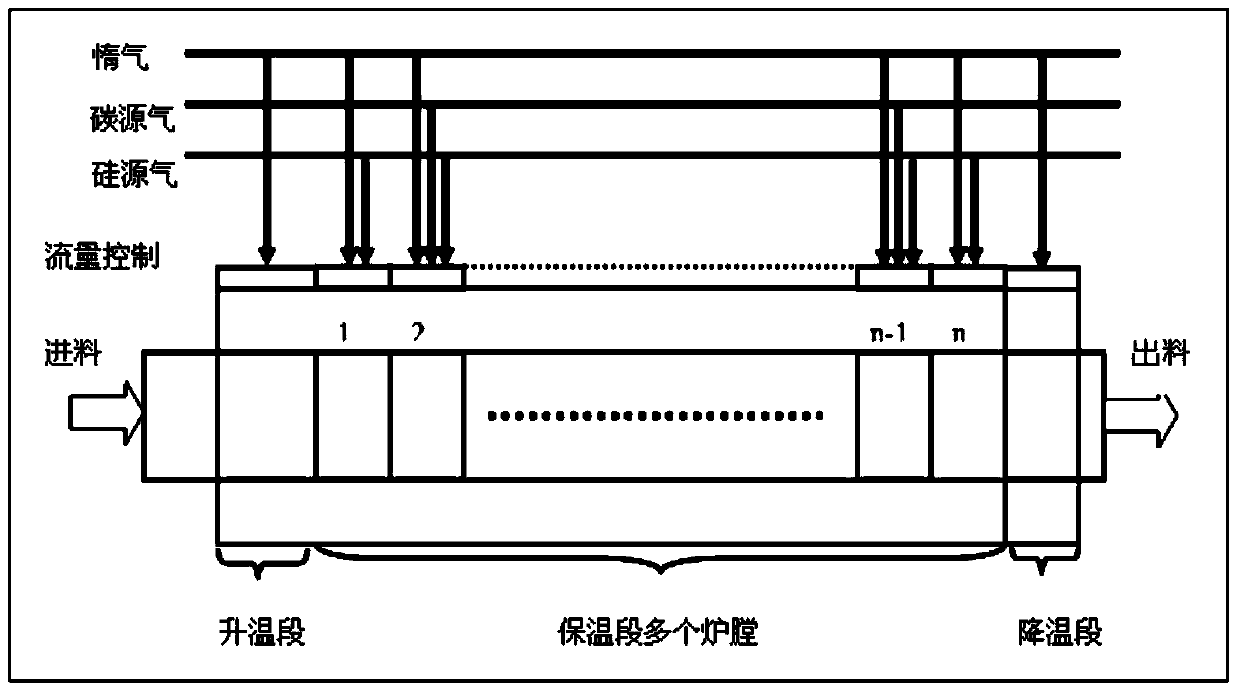

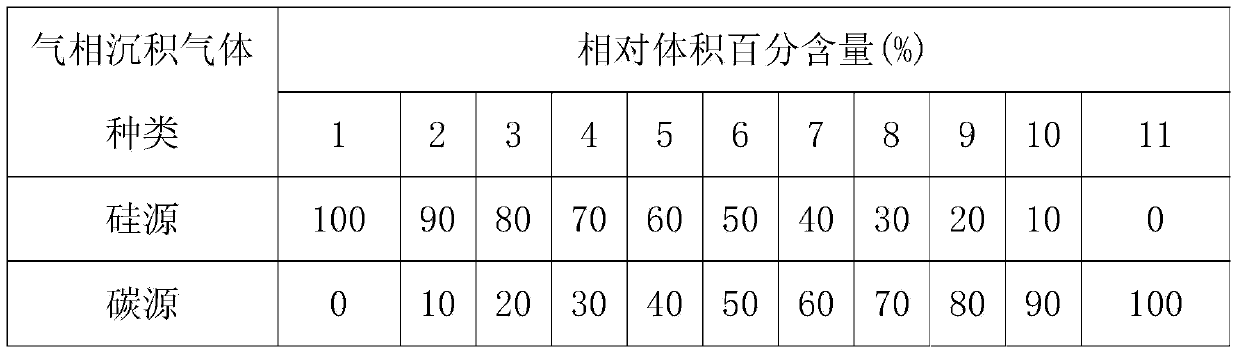

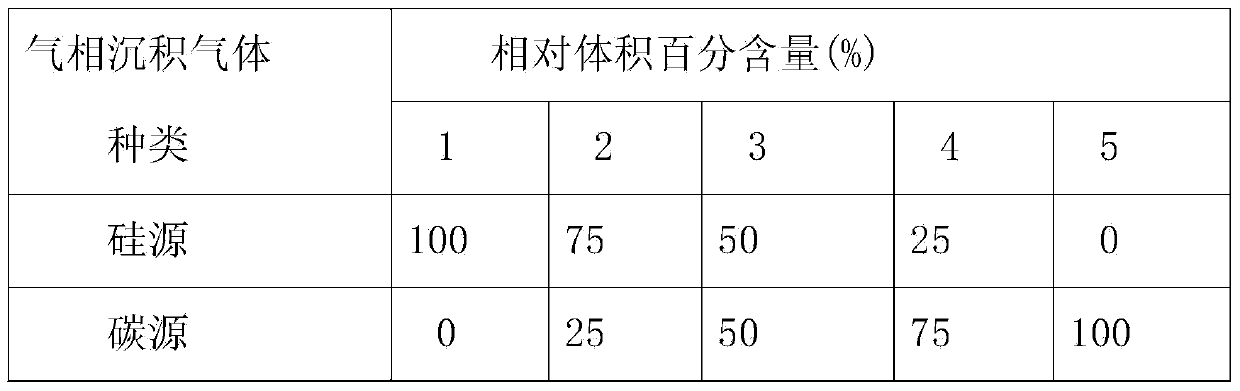

Preparation method of silicon composite anode material provided with gradient change coating layer on surface

ActiveCN103700819AControl heat treatment timeImprove cycle stabilityCell electrodesGas phaseChemical vapor deposition

The invention discloses a preparation method of a silicon composite anode material provided with a gradient change coating layer on the surface, and aims to overcome conventional modification defects of a silicon anode material. According to the preparation method, a porous silicon material is prepared firstly, and on the basis, a chemical vapor deposition method is adopted to uniformly deposit a coating layer on the surface of the porous silicon material, wherein the coating layer adopts an elemental Si-SiC-C transition structure. A test is performed in a vapor deposition reacting furnace provide with segmented temperatures, independently controllable atmosphere and a plurality of furnace chambers. Compared with the prior art, a gradient change process is achieved through the surface coating layer, an obvious interface structure is not formed, the coating layer is tight, so that a volume effect and electric conductivity of the silicon-based anode material in a battery charge-discharge process are inhibited effectively, and the cycling stability of the material is improved greatly. The preparation method is simple in technology and suitable for large-scale industrial production, and has wide application prospect in the field of lithium ion batteries.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com