Graphene/silicone/carbon nano tube composite material and preparation method and application thereof

A technology of carbon nanotube composite and silicon-carbon composite materials, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems that hinder industrialization, low intrinsic conductivity, poor cycle stability, etc. problem, to achieve the effect of improving conductivity, high capacity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

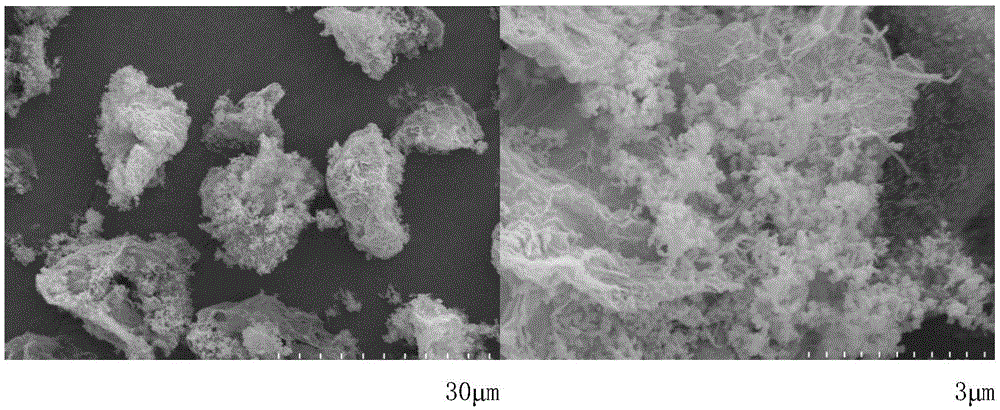

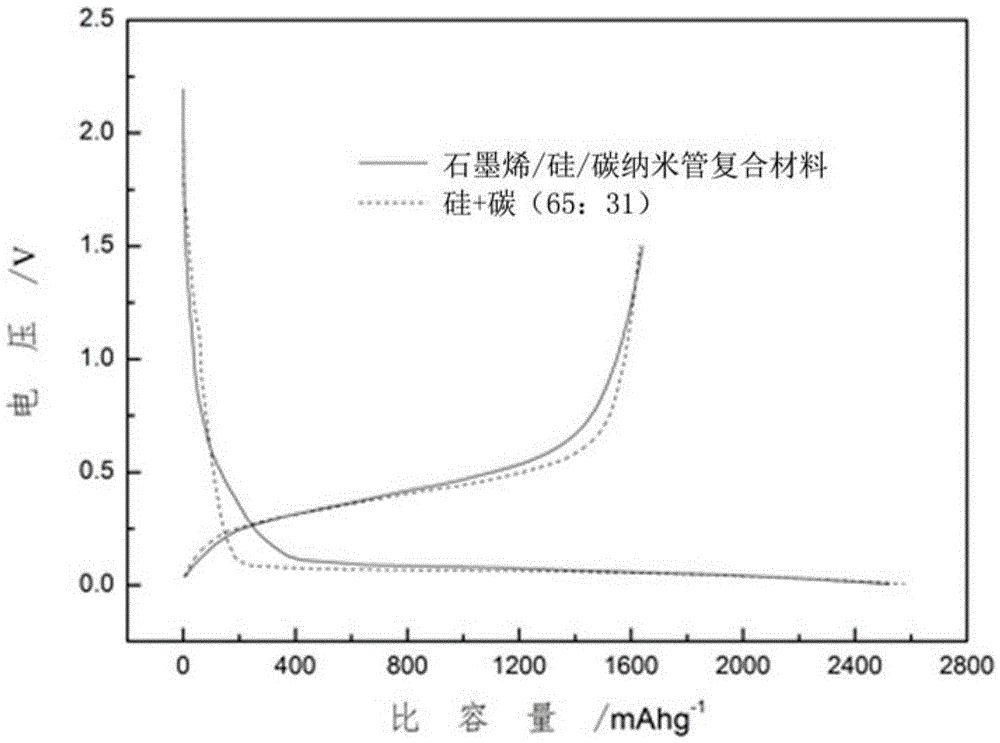

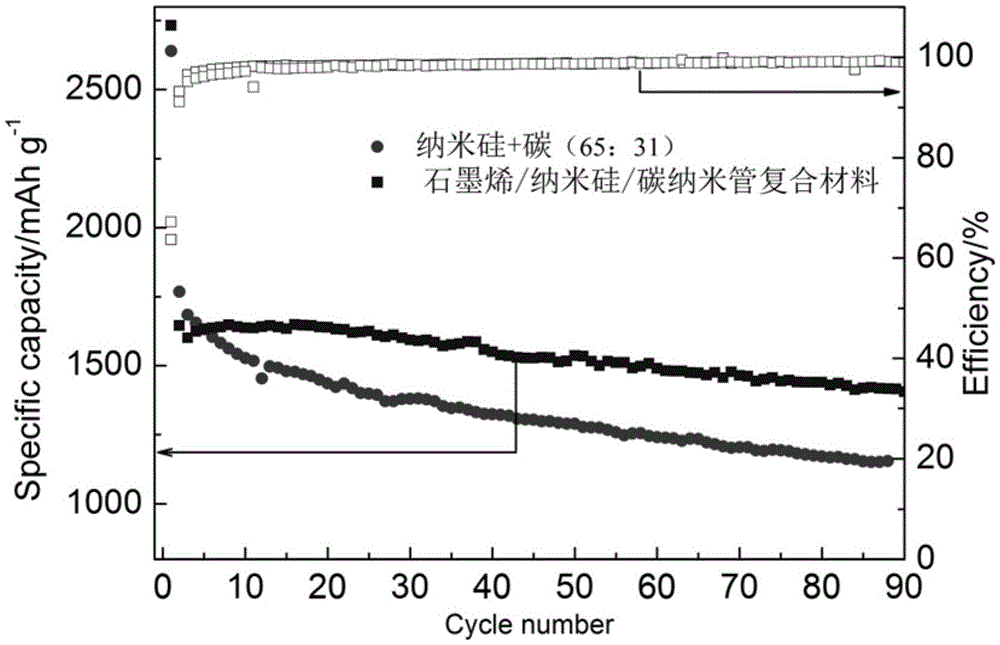

[0024] Add 0.15g of graphene and 0.45g of carbon nanotube powder into 300ml of NMP solution, and ultrasonically vibrate for 1h until the dispersion is uniform. Add 2.4g of nano-silica powder into the above solution, and ultrasonically stir to disperse evenly. Then the mixed solution was spray-dried by a spray-drying method, and moved to a vacuum oven at 100° C. for drying and grinding to obtain a graphene / silicon / carbon nanotube (carbon fiber) composite negative electrode material.

[0025] The anode material prepared above, the binder CMC, and the conductive agent acetylene black were mixed in a ratio of 70:15:15 and ball-milled, evenly coated on the surface of copper foil, and dried at 80°C to obtain an electrode sheet. The above-mentioned electrode sheet is made of a lithium sheet as a counter electrode, ethyl carbonate (EC) and dimethyl carbonate (DMC) are dissolved in 1mol / LLiPF6 with a volume ratio of 1:1, and 10% FEC is added as an electrolyte to make a button battery. ...

Embodiment 2

[0027] Add 0.3g of graphene and 0.3g of carbon nanotube powder into 300ml of NMP solution, and ultrasonically vibrate for 1h until the dispersion is uniform. Add 2.4g of nano-silica powder into the above solution, and ultrasonically stir to disperse evenly. Then the mixed solution was spray-dried by a spray-drying method, and moved to a vacuum oven at 100° C. for drying and grinding to obtain a graphene / silicon / carbon nanotube (carbon fiber) composite material. Referring to Example 1, lithium-ion battery preparation and electrochemical performance testing were carried out.

Embodiment 3

[0029] Add 0.15g of graphene and 0.15g of carbon nanotube powder into 300ml of NMP solution, and ultrasonically vibrate for 1h until the dispersion is uniform. Add 2.7g of nano-silica powder into the above solution, and ultrasonically stir to disperse evenly. Then the mixed solution was spray-dried by a spray-drying method, and moved to a vacuum oven at 100° C. for drying and grinding to obtain a graphene / silicon / carbon nanotube (carbon fiber) composite material. Referring to Example 1, lithium-ion battery preparation and electrochemical performance testing were carried out.

[0030] The invention uses graphene to compound silicon material, carbon nanotube or carbon fiber. Graphene, carbon nanotubes or carbon fibers and silicon originate from water or organic solution (such as N-methyl dipyrrolidone, NMP) and disperse them evenly with ultrasonic stirring, then carry out spray drying to obtain the described graphene / silicon / carbon nanotubes ( carbon fiber) composite anode mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com