Patents

Literature

65 results about "Intrinsic conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intrinsic conductivity. The conductivity of a semiconductor or metal in which impurities and structural defects are absent or have a very low concentration.

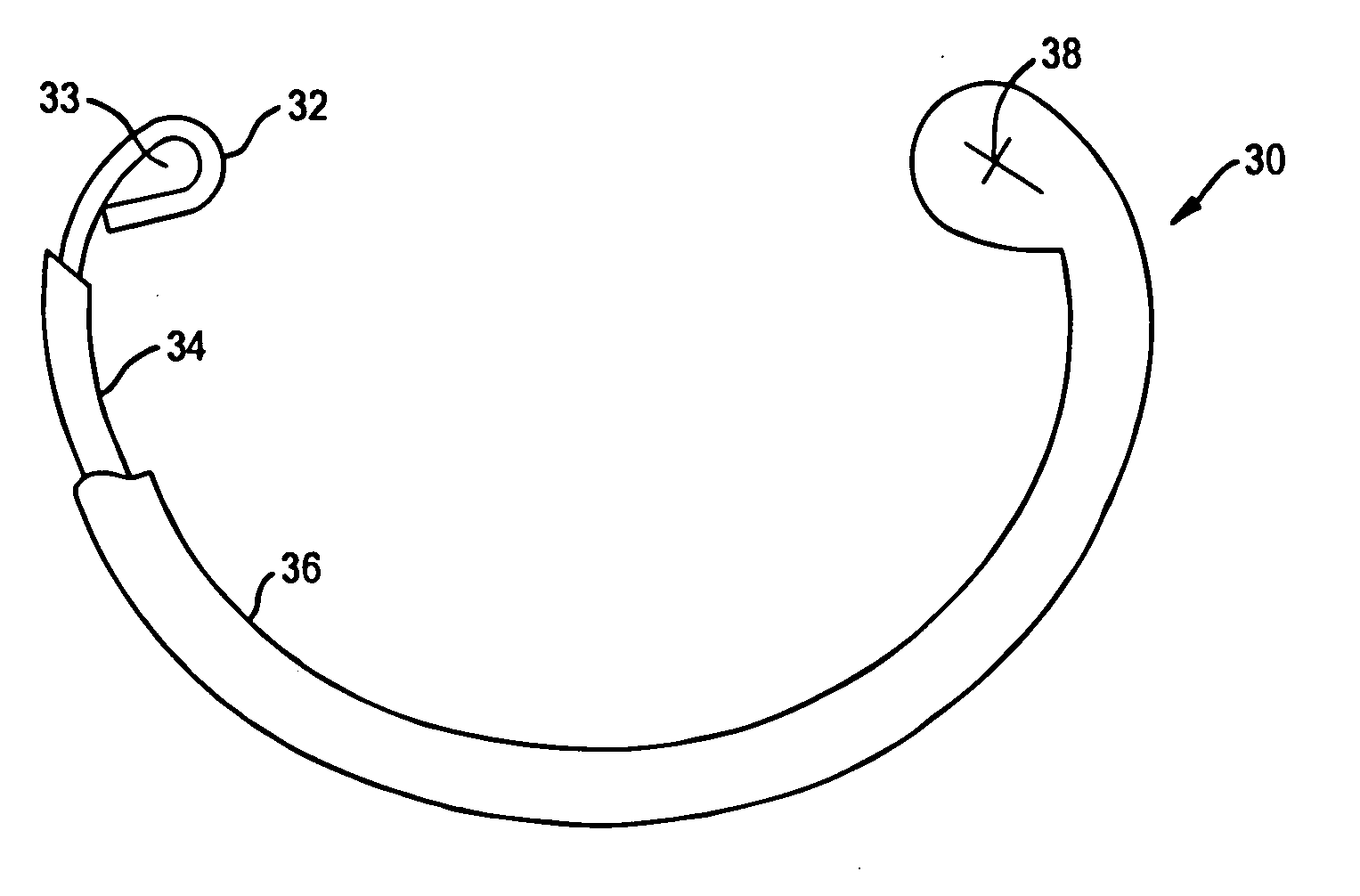

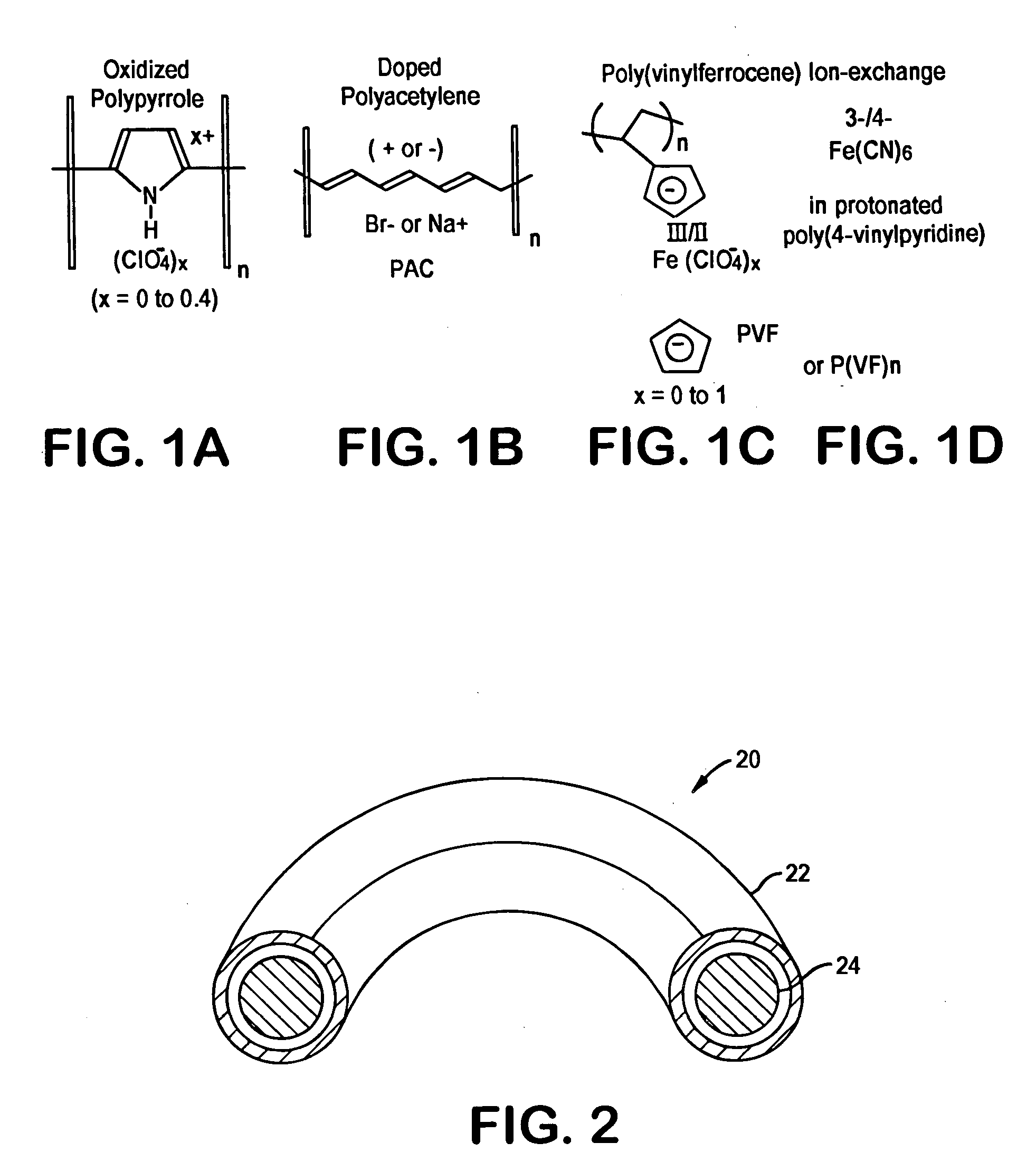

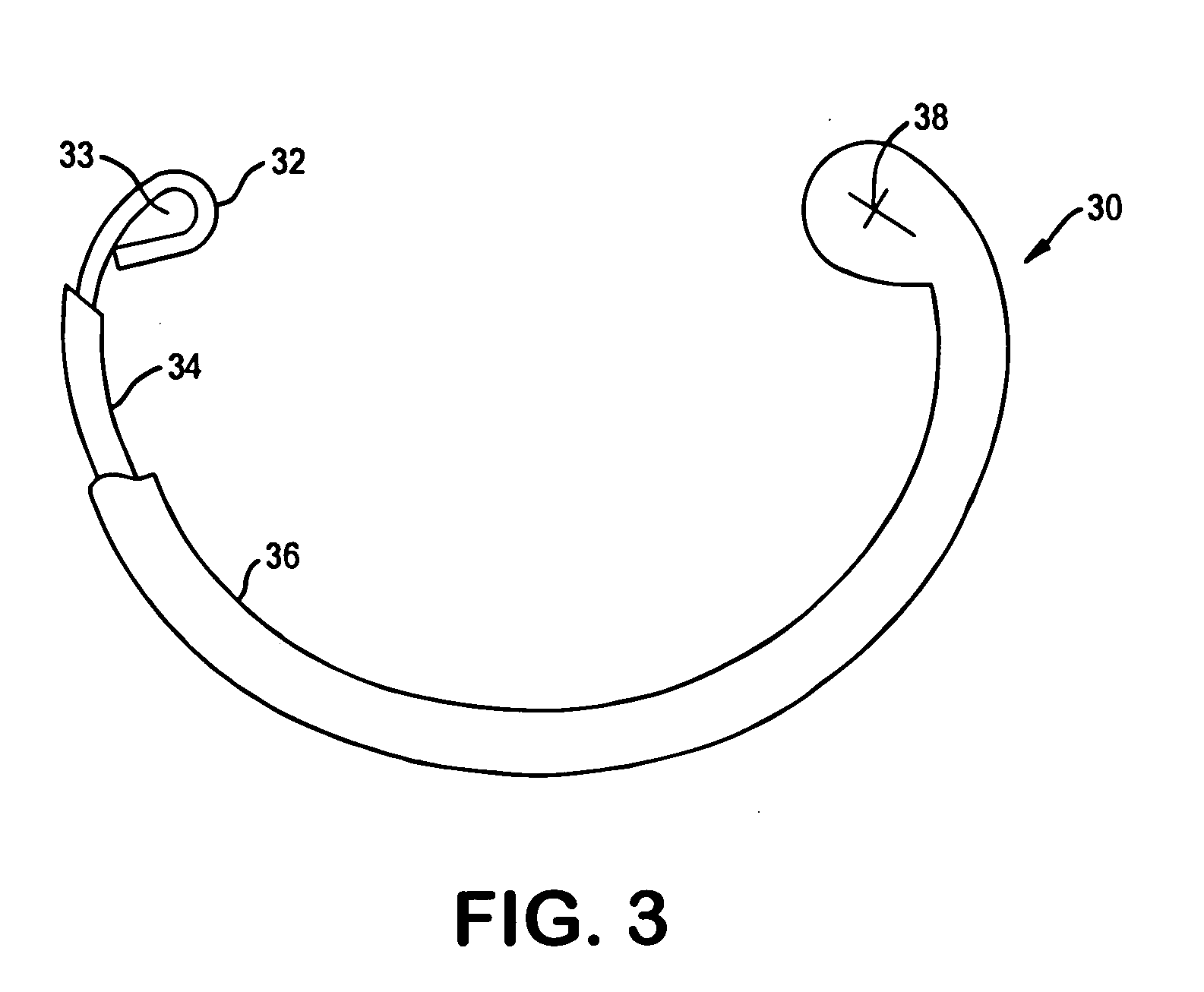

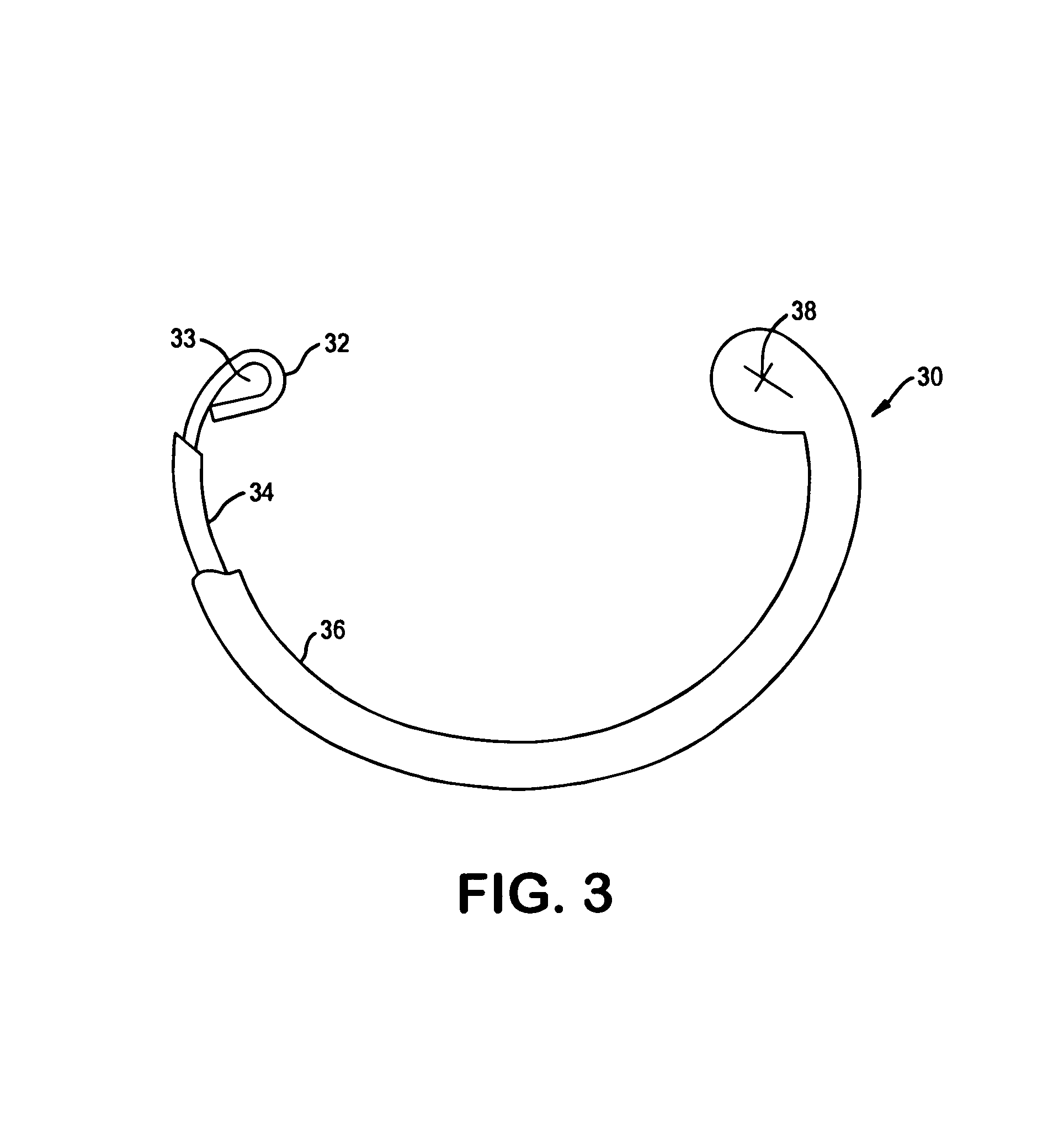

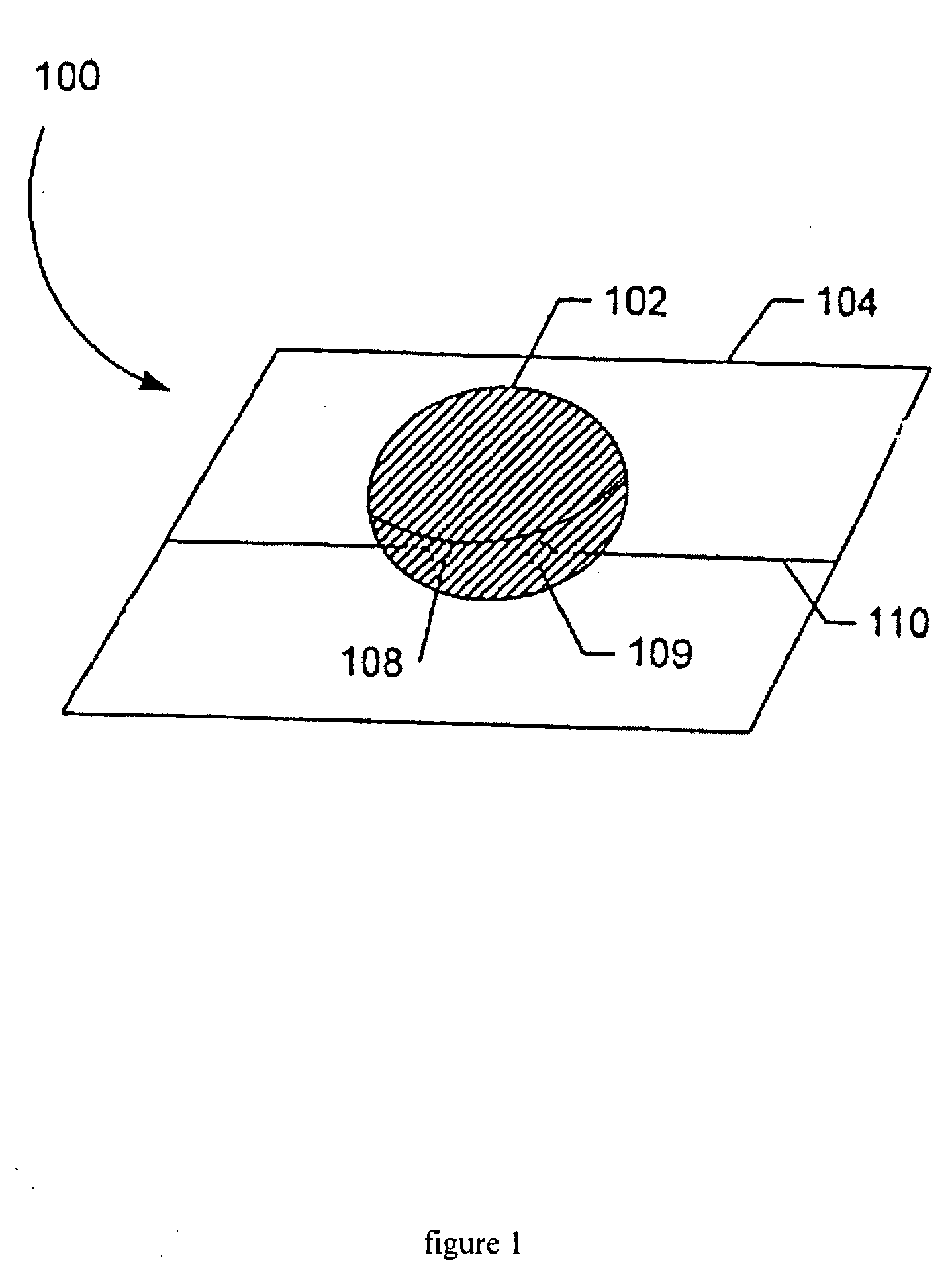

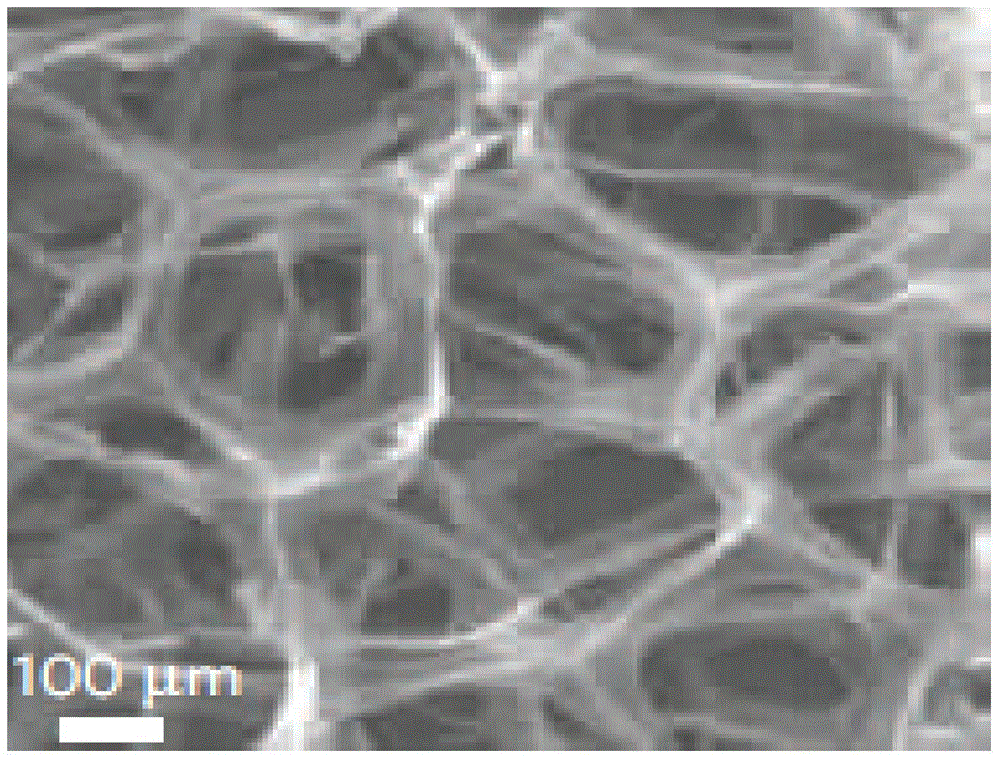

Implantable heart valve prosthetic devices having intrinsically conductive polymers

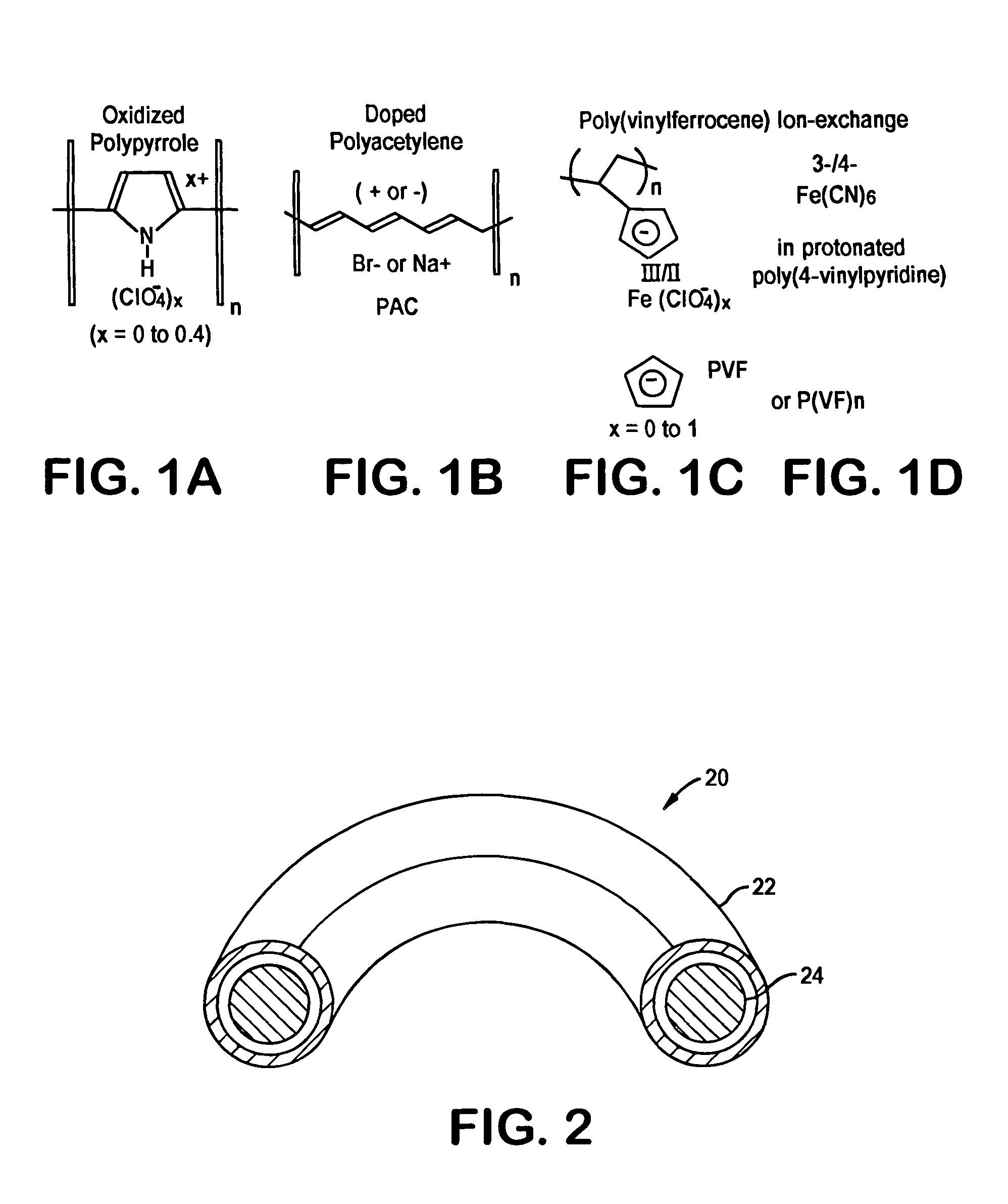

A heart valve sewing prosthesis including an intrinsically conductive polymer. The invention includes annuloplasty rings and bands, and sewing rings or cuffs for prosthetic heart valves. Some annuloplasty rings and sewing rings include fabric that is coated with an intrinsically conductive polymer. The coating can be formed over individual filaments or fibers, or on the fabric surface as a surface layer. One intrinsically conductive polymer is polypyrrole. The intrinsically conductive polymer can be doped to facilitate the intrinsic conductivity. Some devices have a polypyrrole surface layer doped with dialkyl-napthalene sulfonate. The intrinsically conductive polymer can be deposited on a fabric using in-situ polymerization of monomeric or oligomeric species, together with a dopant. Animal studies using implanted annuloplasty rings having an intrinsically conductive polymer coating have demonstrated a substantial reduction in pannus formation and inflammatory response.

Owner:MEDTRONIC INC

Composite materials comprising polar polymers and single-wall carbon nanotubes

InactiveUS6936653B2Improve conductivityMaterial nanotechnologyIndividual molecule manipulationPolyesterPolymer science

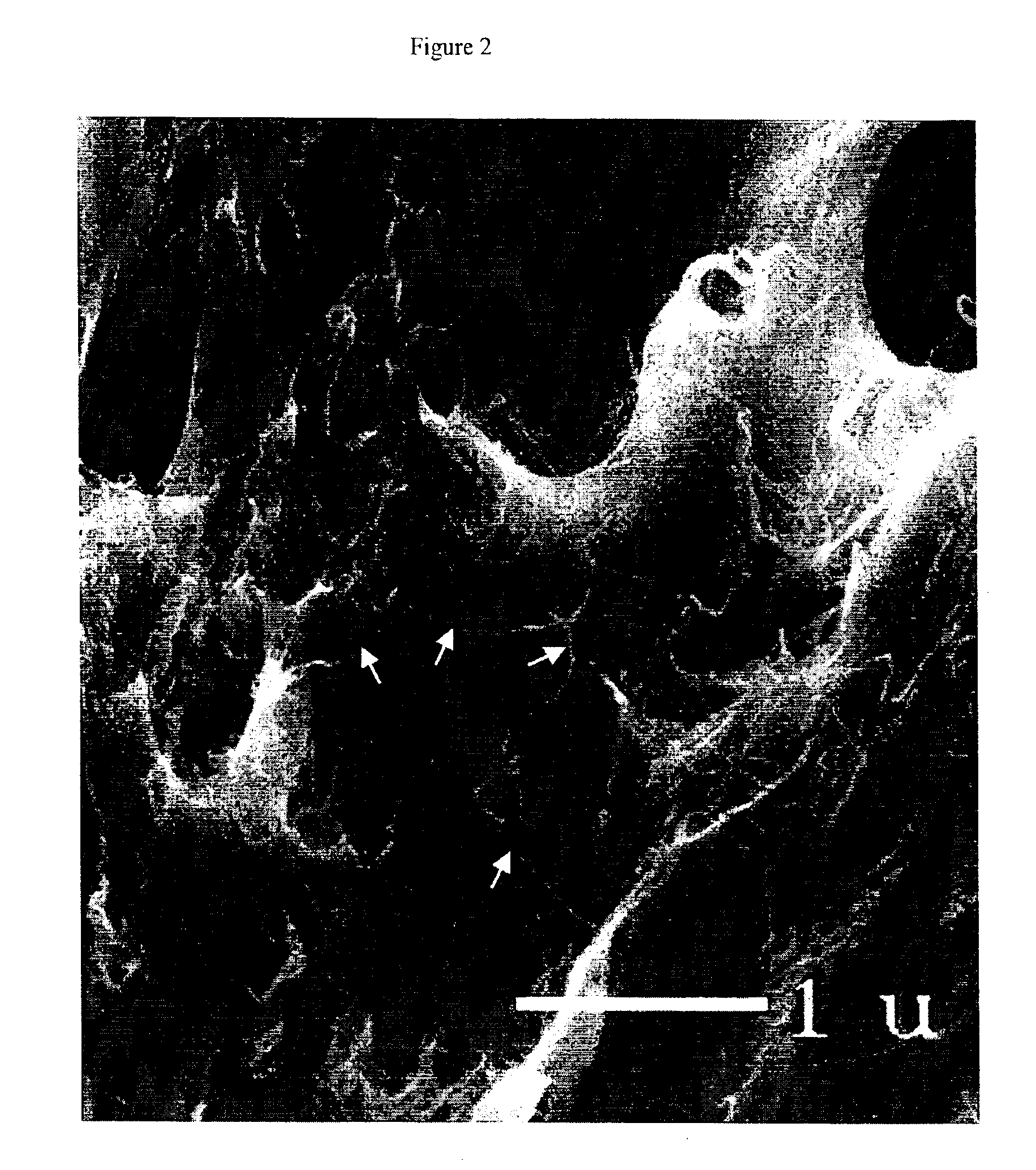

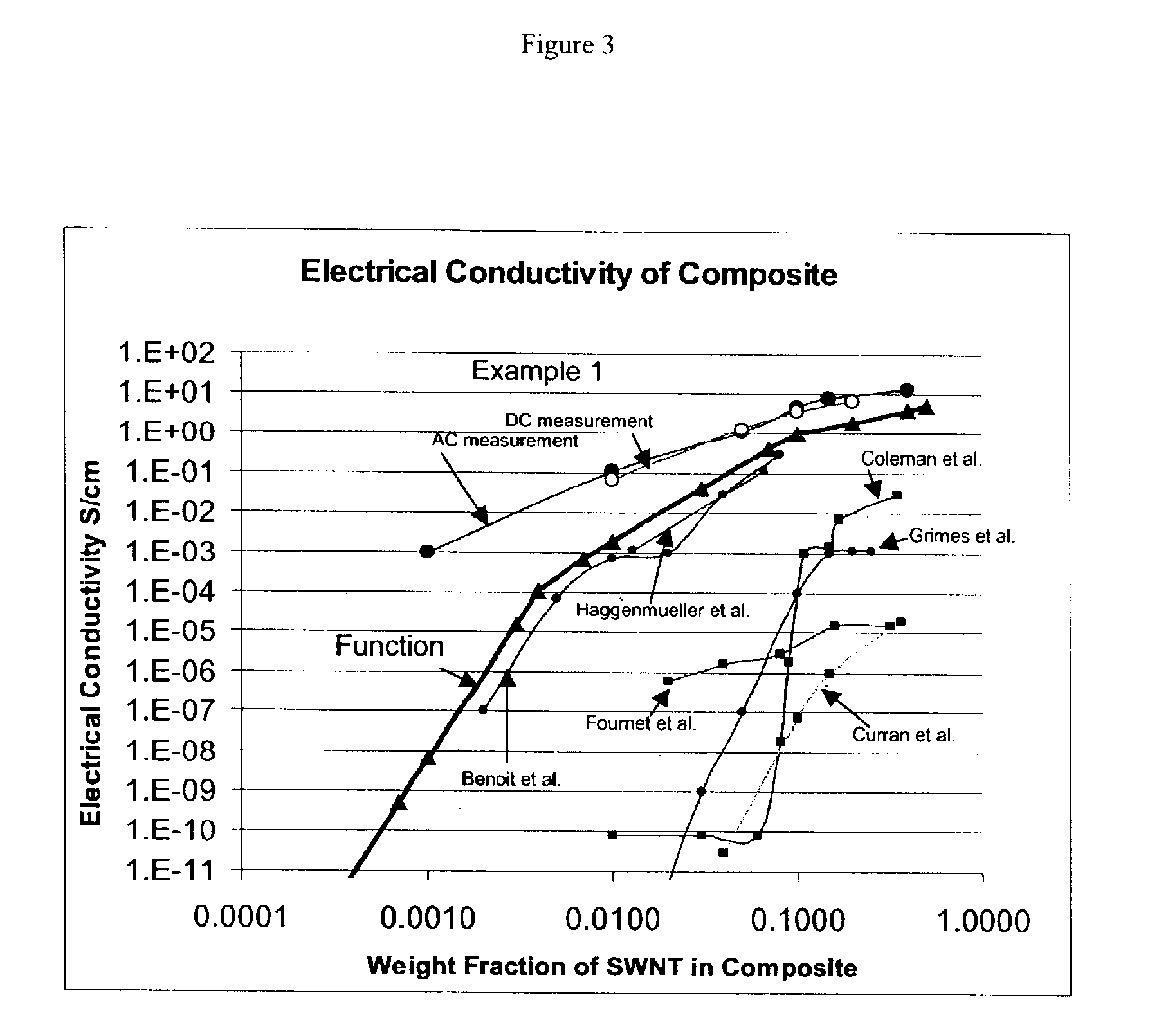

The invention relates to a composite comprising a weight fraction of single-wall carbon nanotubes and at least one polar polymer wherein the composite has an electrical and / or thermal conductivity enhanced over that of the polymer alone. The invention also comprises a method for making this polymer composition. The present application provides composite compositions that, over a wide range of single-wall carbon nanotube loading, have electrical conductivities exceeding those known in the art by more than one order of magnitude. The electrical conductivity enhancement depends on the weight fraction (F) of the single-wall carbon nanotubes in the composite. The electrical conductivity of the composite of this invention is at least 5 Siemens per centimeter (S / cm) at (F) of 0.5 (i.e. where single-wall carbon nanotube loading weight represents half of the total composite weight), at least 1 S / cm at a F of 0.1, at least 1×10−4 S / cm at (F) of 0.004, at least 6×10−9 S / cm at (F) of 0.001 and at least 3×10−16 S / cm (F) plus the intrinsic conductivity of the polymer matrix material at of 0.0001. The thermal conductivity enhancement is in excess of 1 Watt / m-° K. The polar polymer can be polycarbonate, poly(acrylic acid), poly(acrylic acid), poly(methacrylic acid), polyoxide, polysulfide, polysulfone, polyamides, polyester, polyurethane, polyimide, poly(vinyl acetate), poly(vinyl alcohol), poly(vinyl chloride), poly(vinyl pyridine), poly(vinyl pyrrolidone), copolymers thereof and combinations thereof. The composite can further comprise a nonpolar polymer, such as, a polyolefin polymer, polyethylene, polypropylene, polybutene, polyisobutene, polyisoprene, polystyrene, copolymers thereof and combinations thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

Implantable heart valve prosthetic devices having intrinsically conductive polymers

A heart valve sewing prosthesis including an intrinsically conductive polymer. The invention includes annuloplasty rings and bands, and sewing rings or cuffs for prosthetic heart valves. Some annuloplasty rings and sewing rings include fabric that is coated with an intrinsically conductive polymer. The coating can be formed over individual filaments or fibers, or on the fabric surface as a surface layer. One intrinsically conductive polymer is polypyrrole. The intrinsically conductive polymer can be doped to facilitate the intrinsic conductivity. Some devices have a polypyrrole surface layer doped with dialkyl-napthalene sulfonate. The intrinsically conductive polymer can be deposited on a fabric using in-situ polymerization of monomeric or oligomeric species, together with a dopant. Animal studies using implanted annuloplasty rings having an intrinsically conductive polymer coating have demonstrated a substantial reduction in pannus formation and inflammatory response.

Owner:MEDTRONIC INC

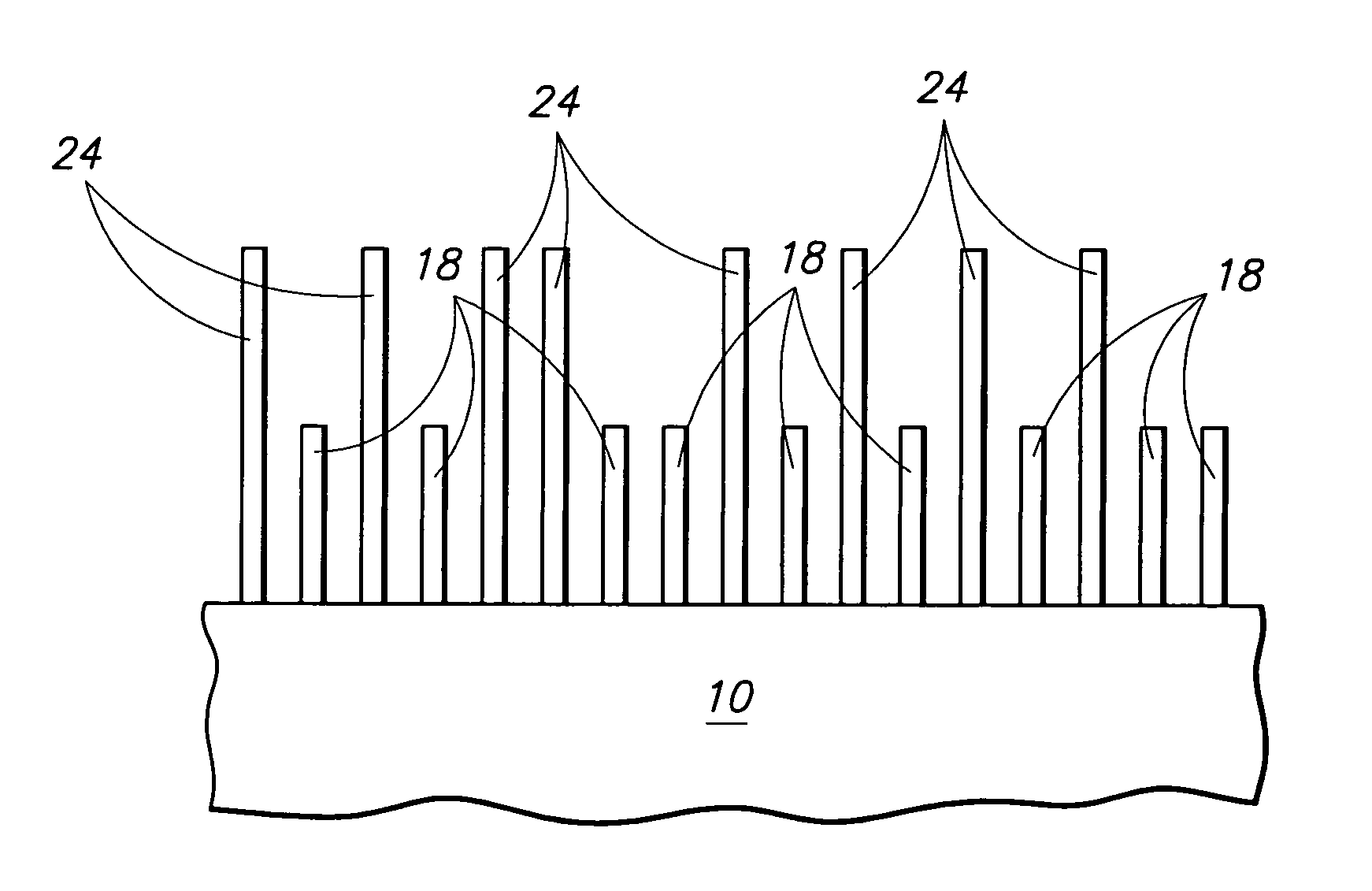

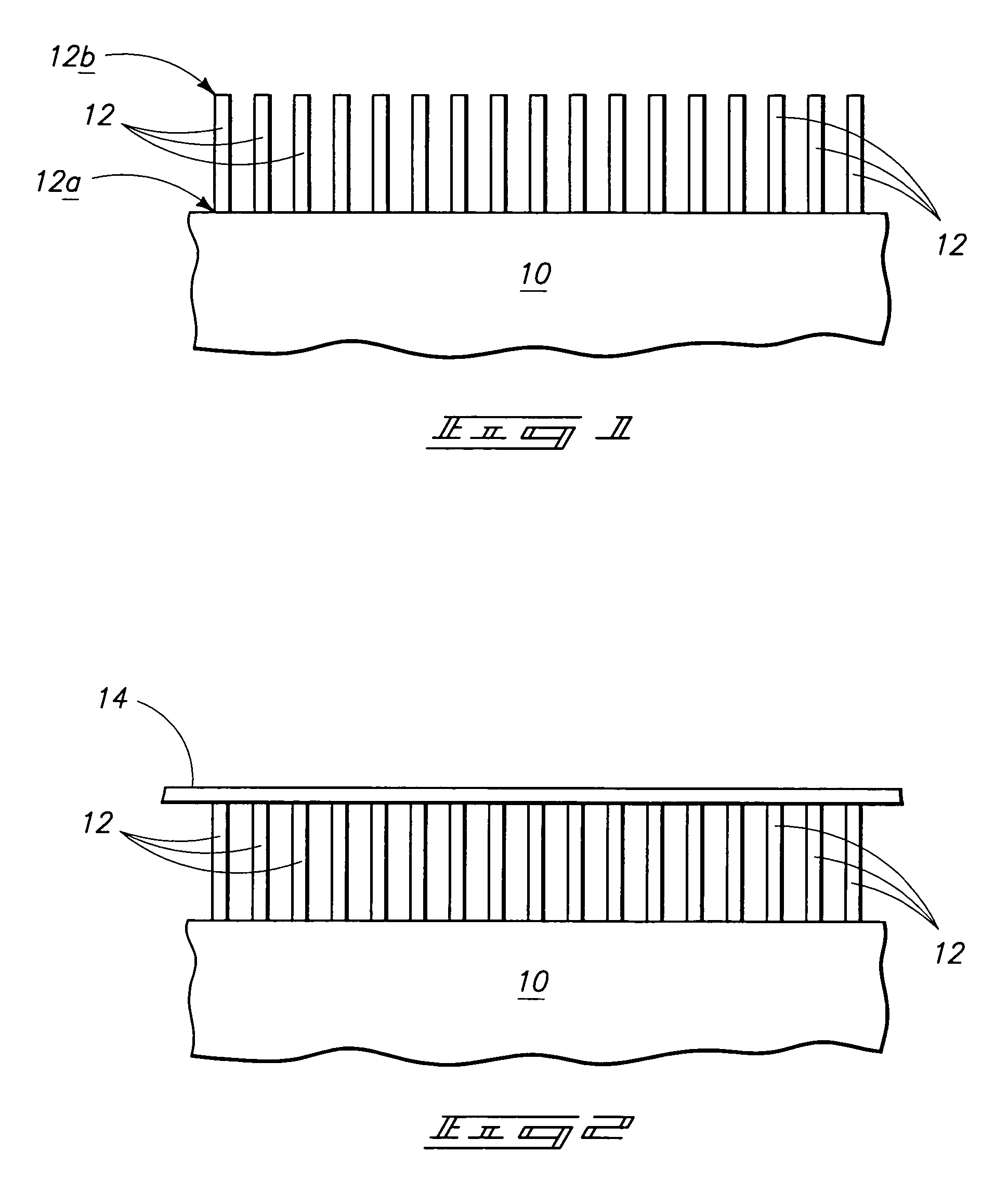

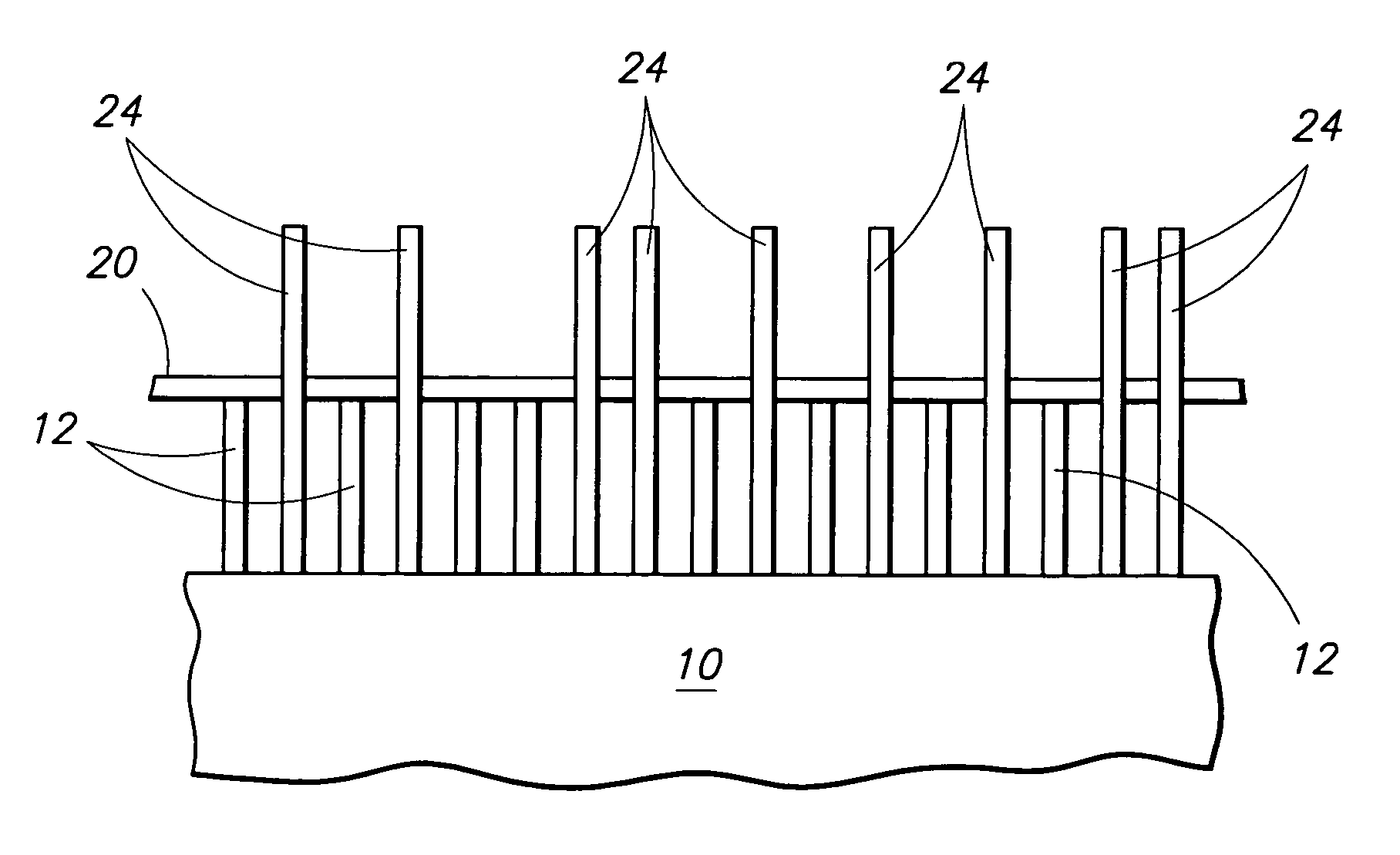

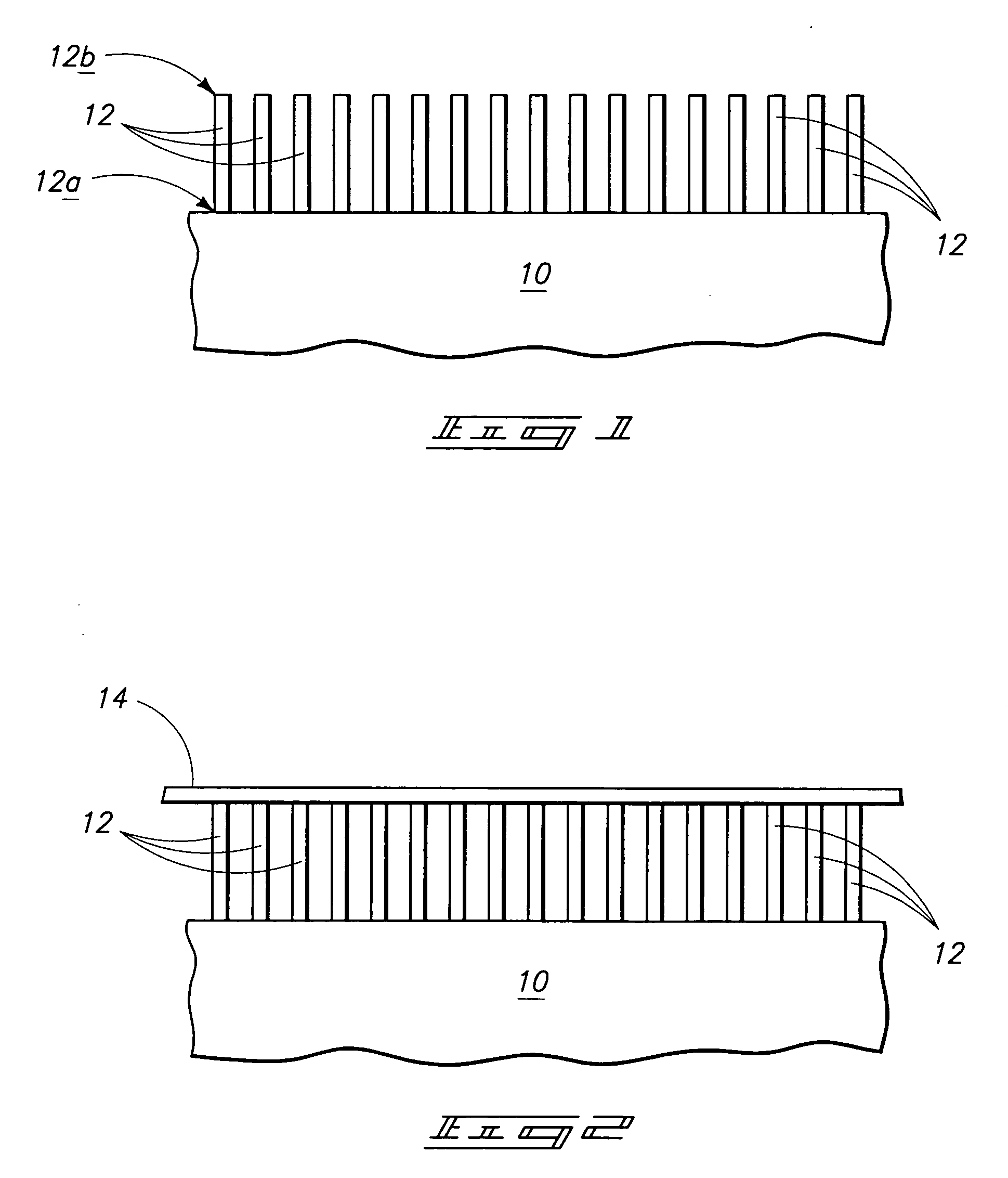

Nanotube forming methods

InactiveUS7553472B2Material nanotechnologyIndividual molecule manipulationIntrinsic conductivityNanotube

A nanotube forming method includes growing a plurality of nanotubes to an intermediate length that is deterministic of nanotube intrinsic conductivity. Individual nanotubes exhibit an effective conductivity, which varies among the plurality of nanotubes. The method includes completing growth of nanotubes exhibiting effective conductivities inside a selected range without completing growth of nanotubes exhibiting effective conductivities outside the selected range. Before completing nanotube growth, the method may further include stopping nanotube growth and screening out nanotubes exhibiting conductivities outside the selected range. The screening out of nanotubes may include deforming or masking nanotubes exhibiting conductivities outside the selected range. Deforming nanotubes may include applying a potential.

Owner:MICRON TECH INC

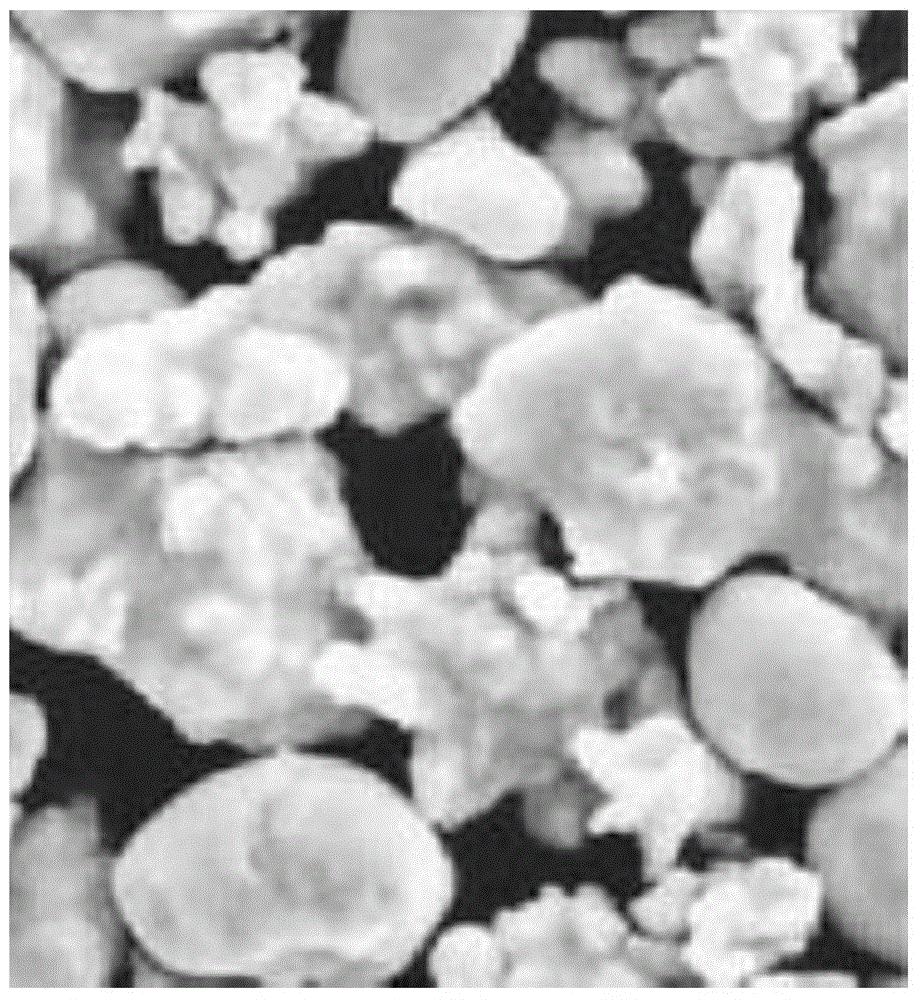

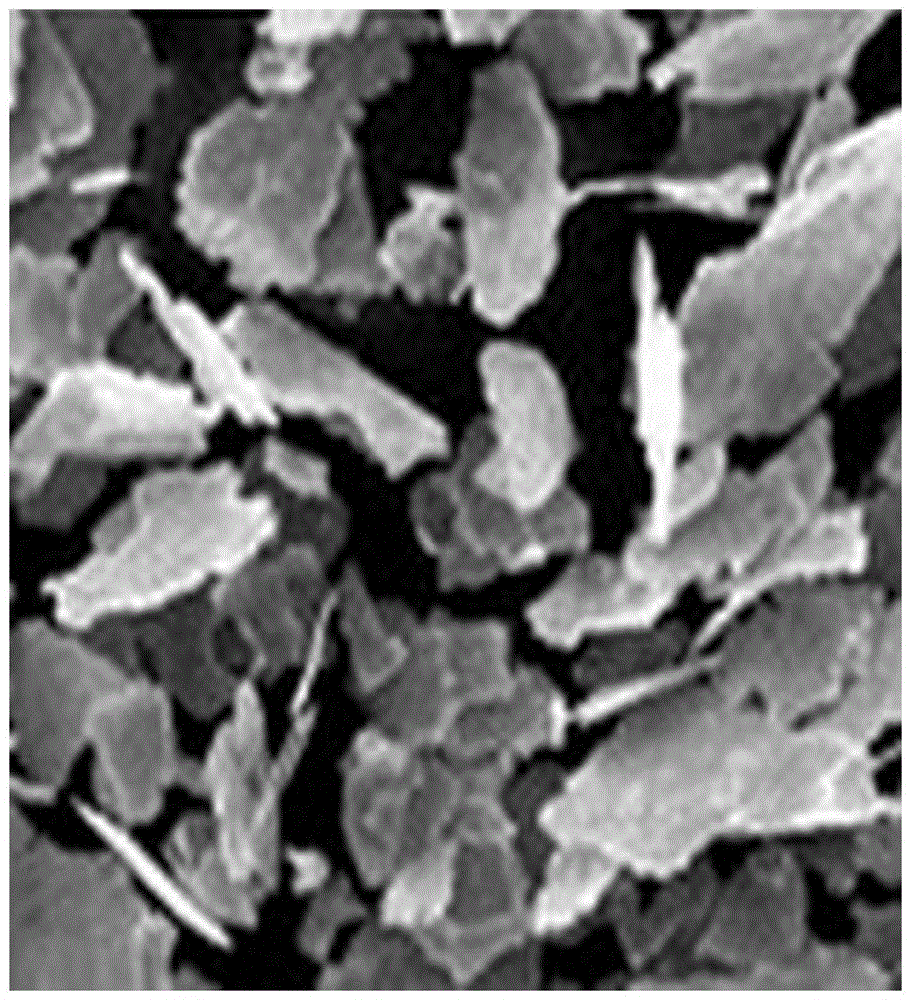

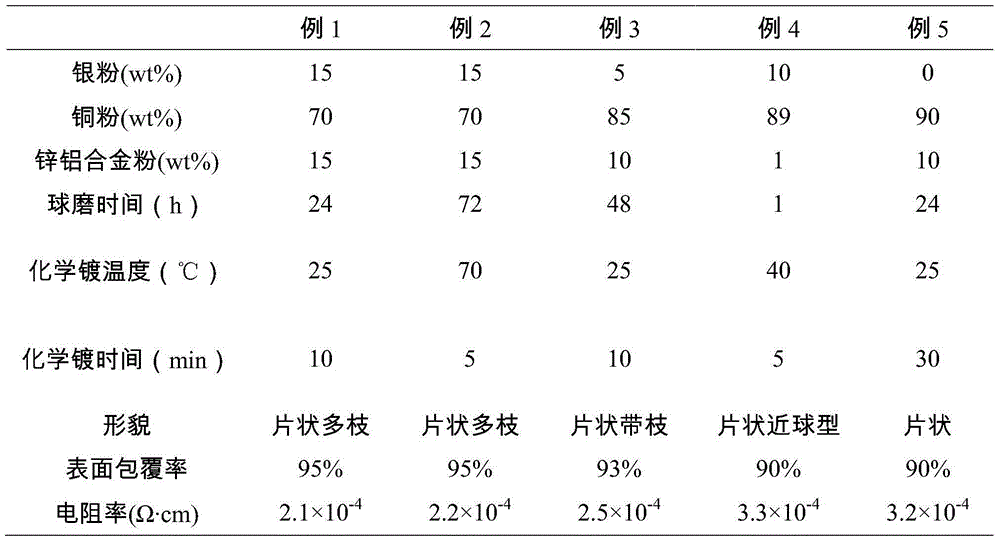

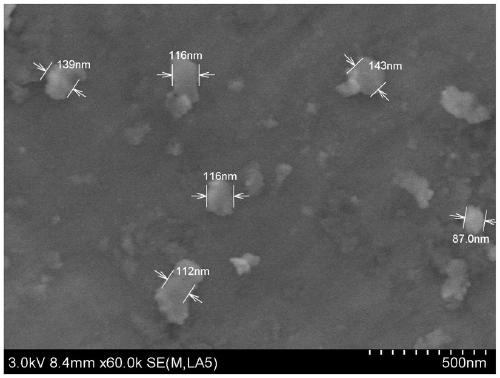

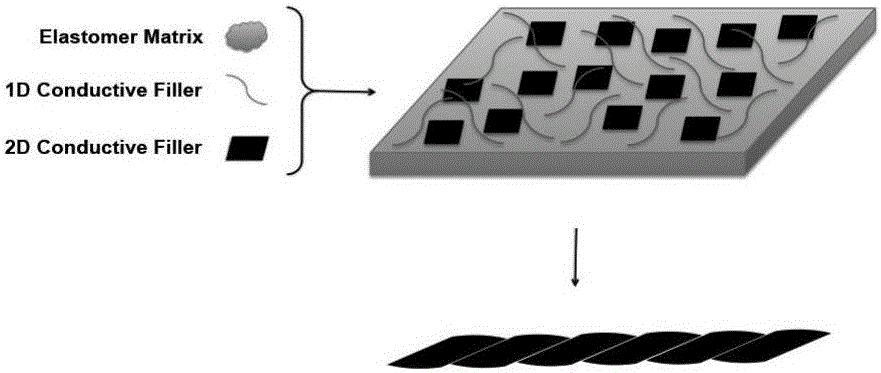

Sheet/branch silver-coated copper powder and green halogen-free low-silver-content economical electrically conductive adhesive capable of replacing traditional electrically conductive adhesives with high silver contents

ActiveCN104830247AIncrease coverageImprove conductivityNon-macromolecular adhesive additivesRubber derivative adhesivesEpoxyIntrinsic conductivity

The invention relates to sheet / branch silver-coated copper powder, a green halogen-free low-silver-content economical electrically conductive adhesive capable of replacing traditional electrically conductive adhesives with high silver contents, and a preparing method of the electrically conductive adhesive. The morphology of the sheet / branch silver-coated copper powder is in a sheet shape and / or a branch shape. The silver coating area rate on the surface of copper powder is 90-95%. The content of a zinc-aluminum alloy in the silver-coated copper powder is lower than 15 wt%. The electrically conductive adhesive comprises following raw materials by weight: 60-90% of the sheet / branch silver-coated copper powder, 0-30% of micron order silver power, 6-12% of epoxy resin, 1-8% of an active diluting agent, 1-6% of toughening resin, 1-3% of a curing agent, 0-1% of a curing promoter and 0.5-2% of a coupling agent. The sheet / branch silver-coated copper powder is high in silver coating rate on the surface of Cu and excellent in electrically conductive performance, so that the electrically conductive adhesive prepared from the sheet / branch silver-coated copper powder is excellent in performance, low in cost and good in intrinsic conductivity.

Owner:重庆邦锐特新材料有限公司

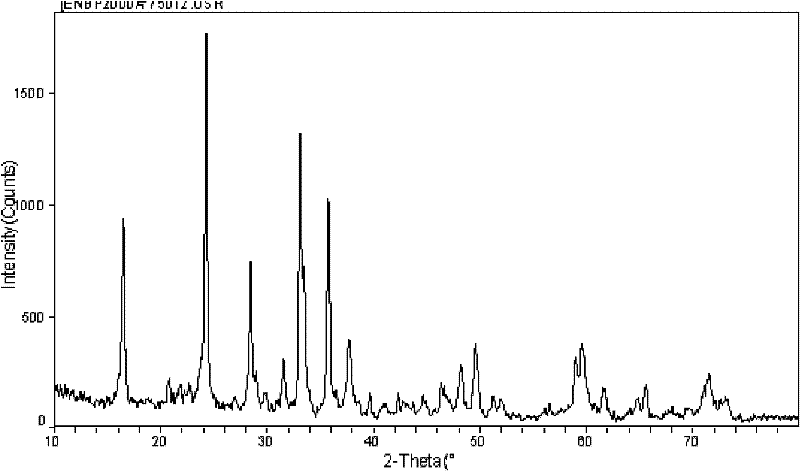

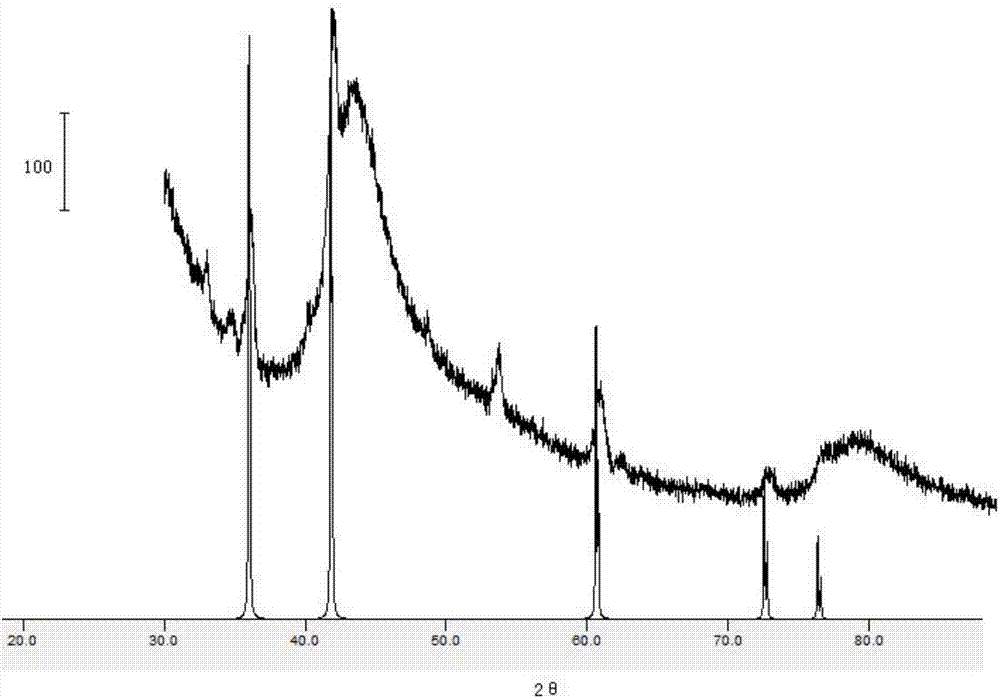

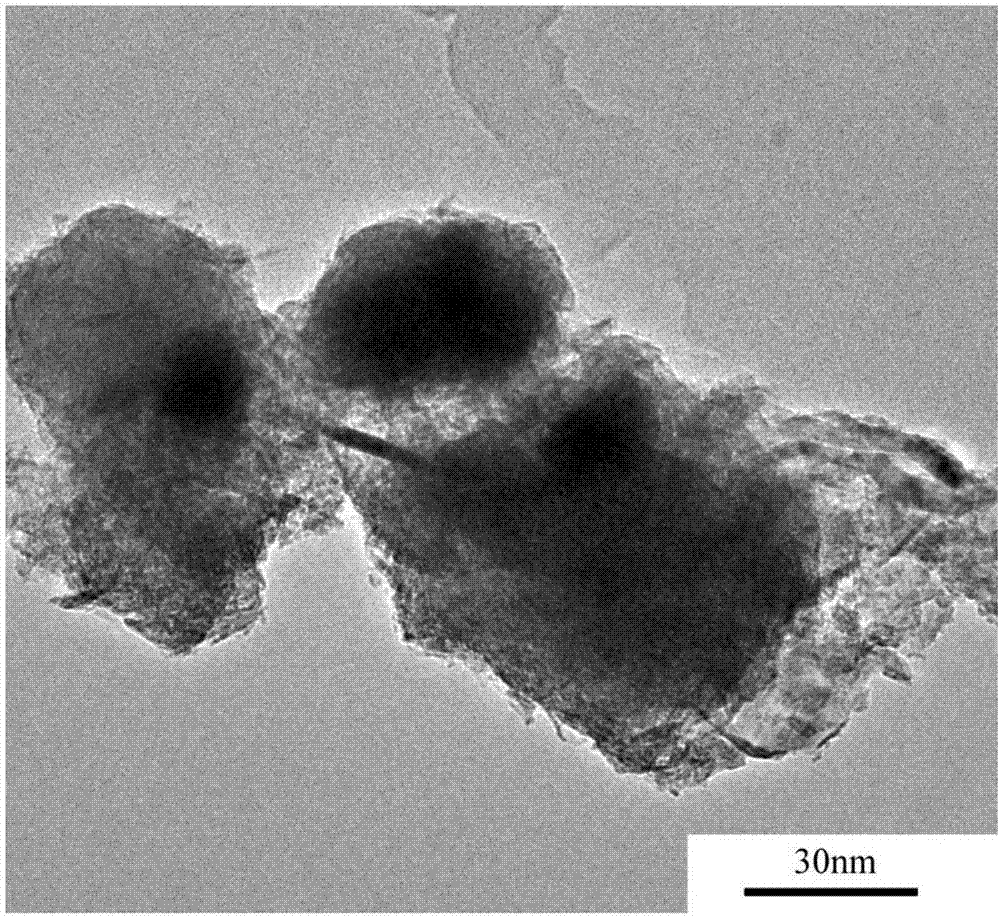

Method for preparing composite thermoelectric material of PPY cladding carbon nano tube

InactiveCN103840074AGood uniformity of component dispersionMild conditionsThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsEnvironmental resistance

The invention relates to a method for preparing a composite thermoelectric material of a PPY cladding carbon nano tube, in particular to a method according to which when ammonium persulfate serves as an oxidizing agent, pyrrole is used for carrying out cladding on the carbon nano tube through in-situ oxidative polymerization to form the composite thermoelectric material. According to the method for preparing the composite thermoelectric material, pyrrole monomers which are low in cost and easy to obtain and the carbon nano tube which is stable in property are used as raw materials, PSSNa serves as a surface activating agent, 1,5-naphthalene disulfonic acid serves as a doping agent, the ammonium persulfate serves as the oxidizing agent and water serves as a solvent, the composite thermoelectric material of the carbon nano tube and the PPY is synthesized with high efficiency by means of in-situ oxidative polymerization of the pyrrole under the room temperature. According to the method for preparing the composite thermoelectric material of the PPY cladding carbon nano tube, the defects of the low intrinsic conductivity of the pure-electricity-conducting macromolecule PPY, the high heat conducting rate of the carbon nano tube and the like are overcome, the features of the low heat conducting rate of the PPY and the high conductivity of the carbon nano tube are made full use of, the PPY and the carbon nano tube are organically combined, and therefore the method for preparing the high-thermoelectric-property composite material of the PPY cladding carbon nano tube is easy to operate, green, environmentally friendly, low in reaction temperature and good in dispersion uniformity of components.

Owner:INST OF CHEM CHINESE ACAD OF SCI

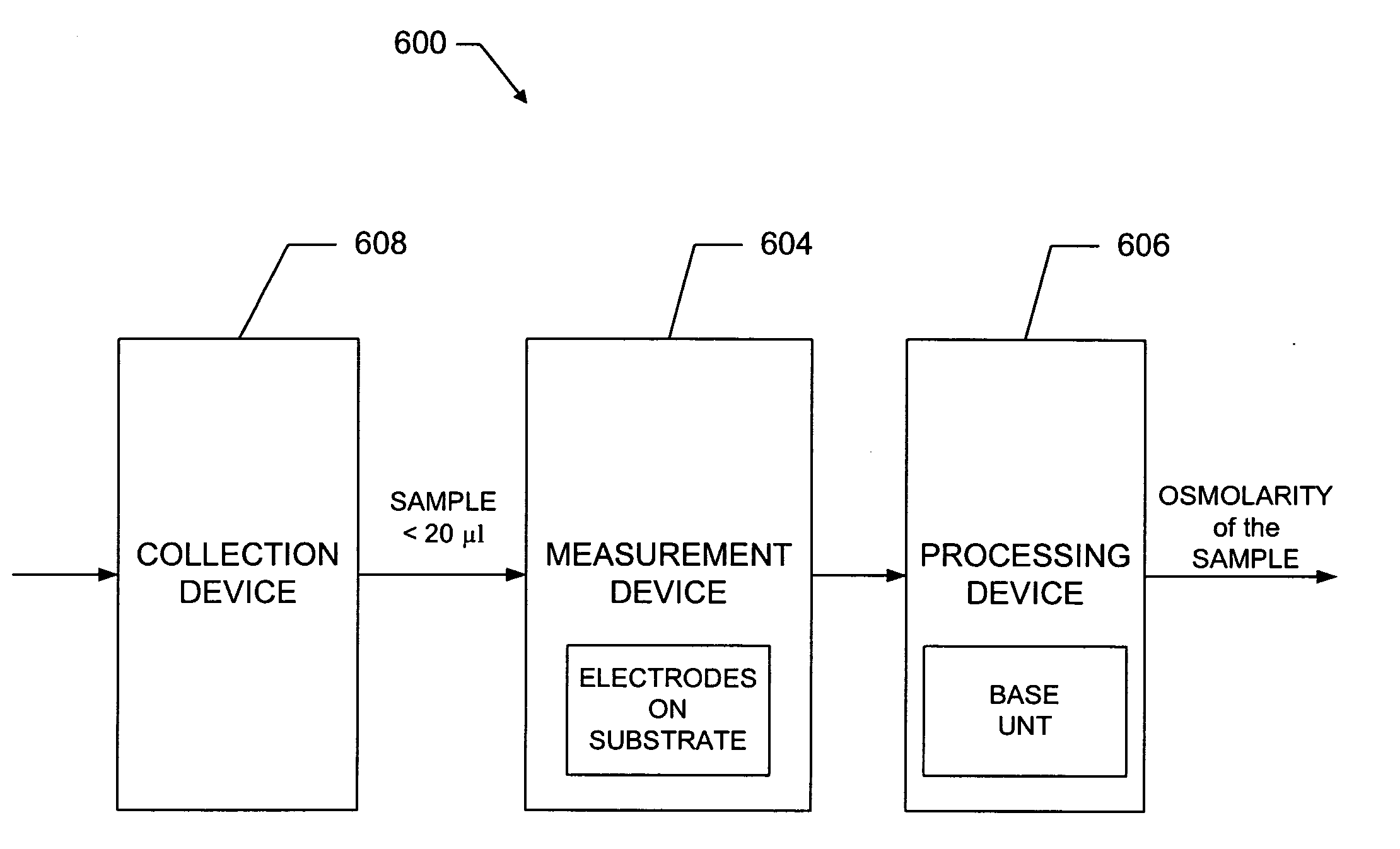

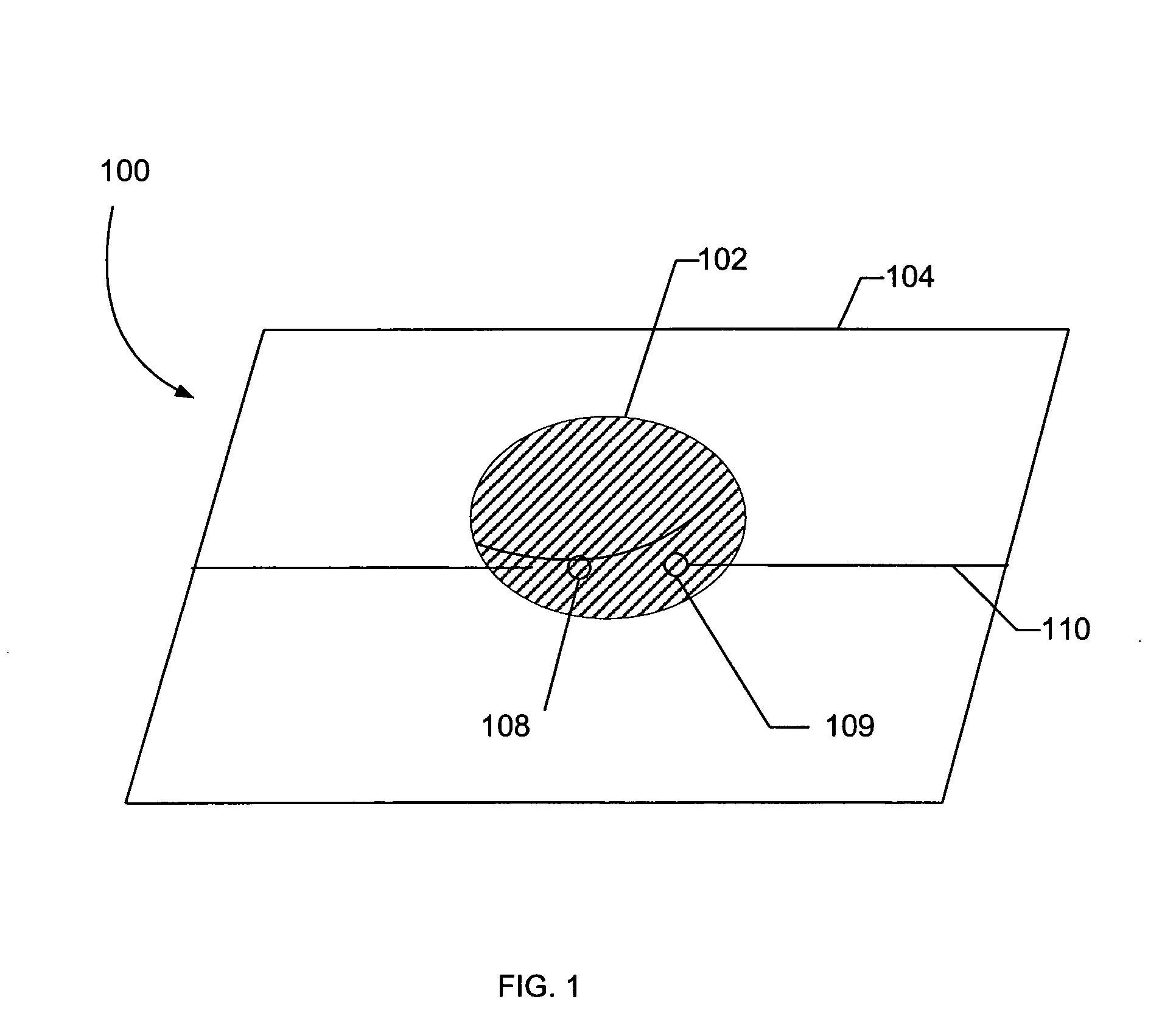

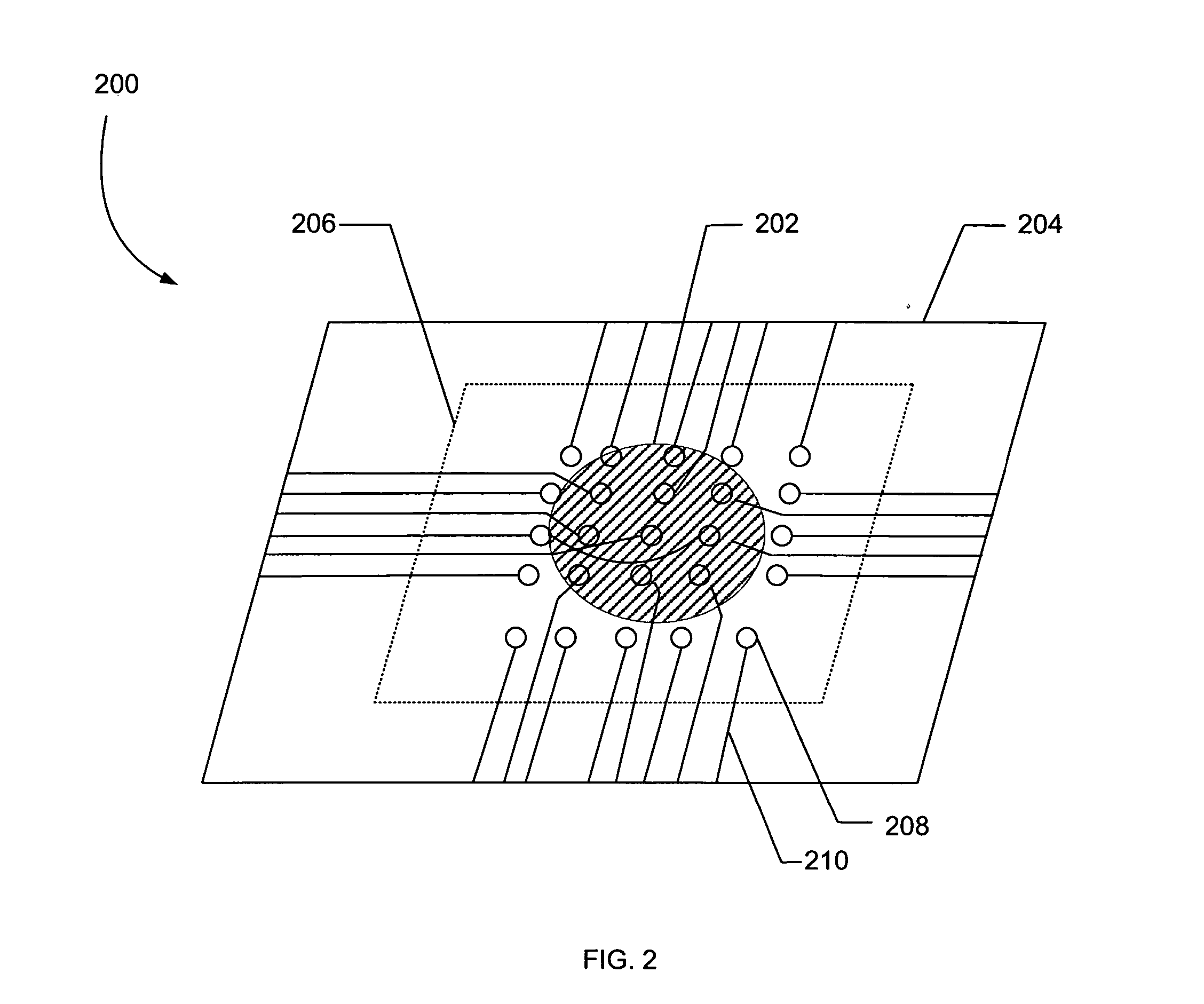

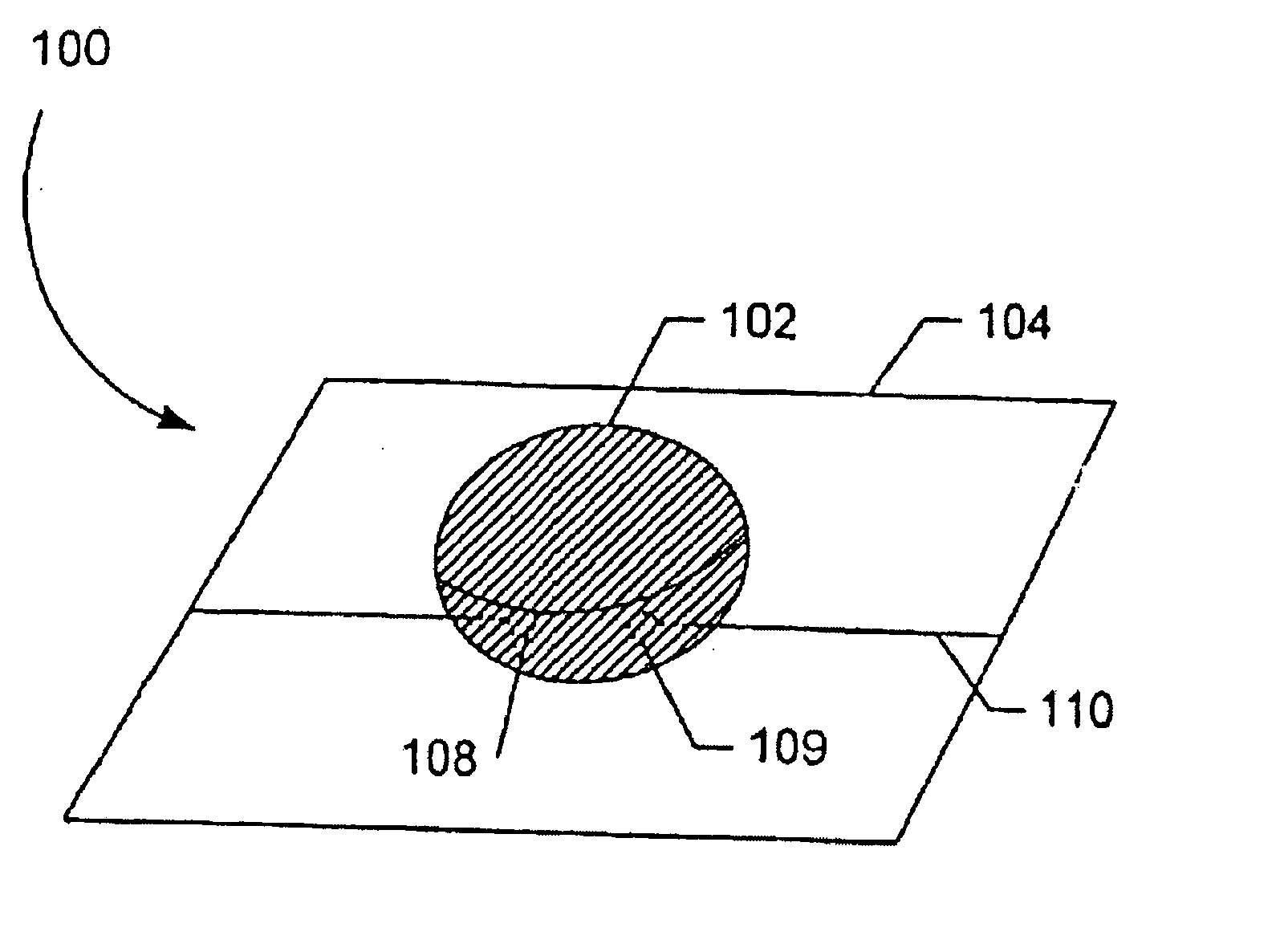

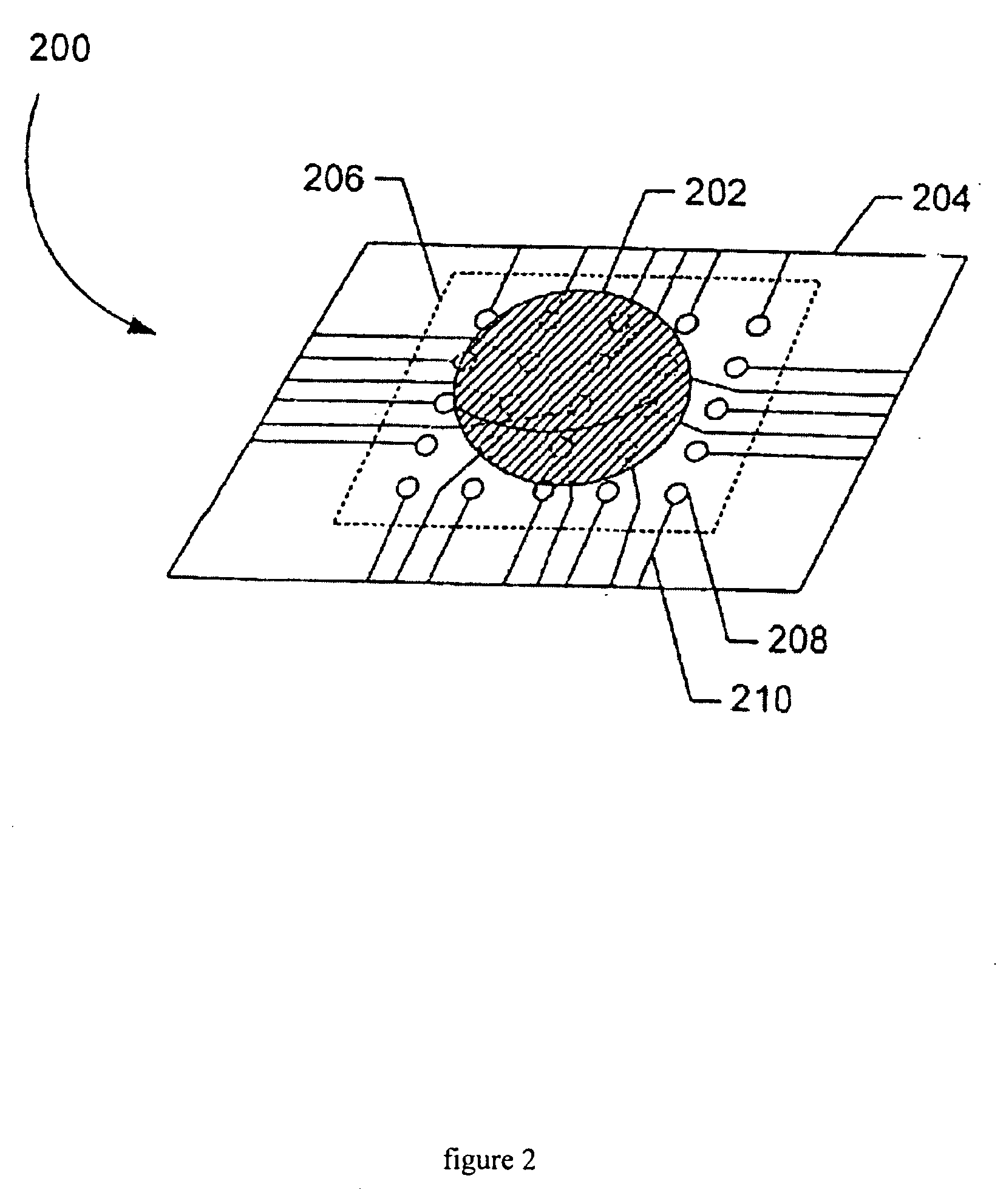

Systems and methods for calibrating osmolarity measuring devices

InactiveUS20060107729A1Surface/boundary effectMaterial analysis by electric/magnetic meansCombined useTiered approach

Owner:RGT UNIV OF CALIFORNIA

Systems and methods for calibrating osmolarity measuring devices

InactiveUS20050120772A1Testing/calibration apparatusResistance/reactance/impedenceMeasurement deviceCombined use

An osmolarity measuring system comprising microscale electrode arrays is configured to account for variations and defects in the arrays using a tiered approach comprising several calibration methods. One method accounts for the intrinsic conductivity of the electrodes and subtracts out the intrinsic conductivity on a pair-wise basis, when determining osmolarity of a sample fluid. Other methods in the tiered approach use standards to determine calibration factors for the electrodes that can then be used to adjust subsequent osmolarity measurements for a sample fluid. The use of a standard can also be combined with a washing step.

Owner:RGT UNIV OF CALIFORNIA

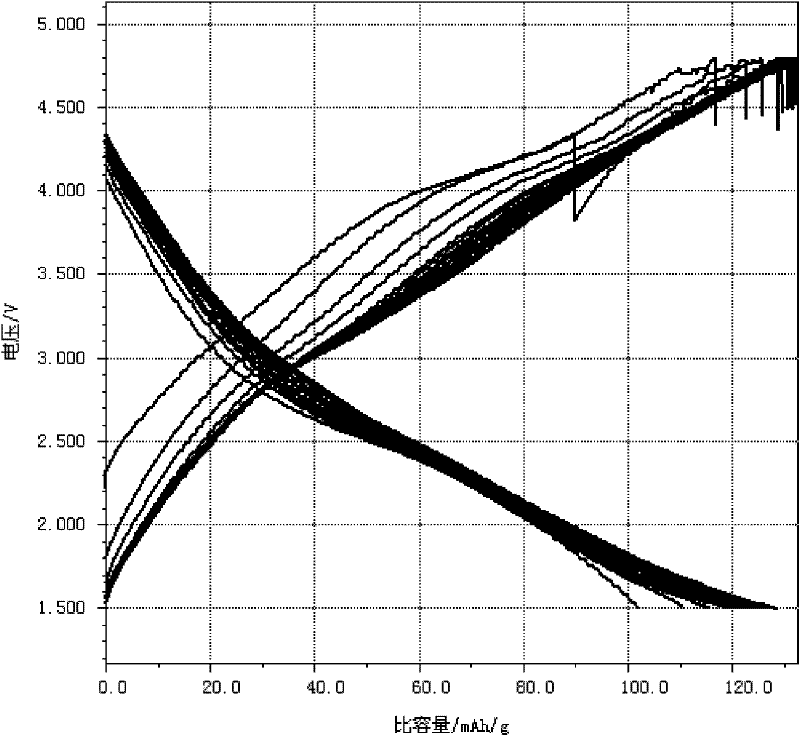

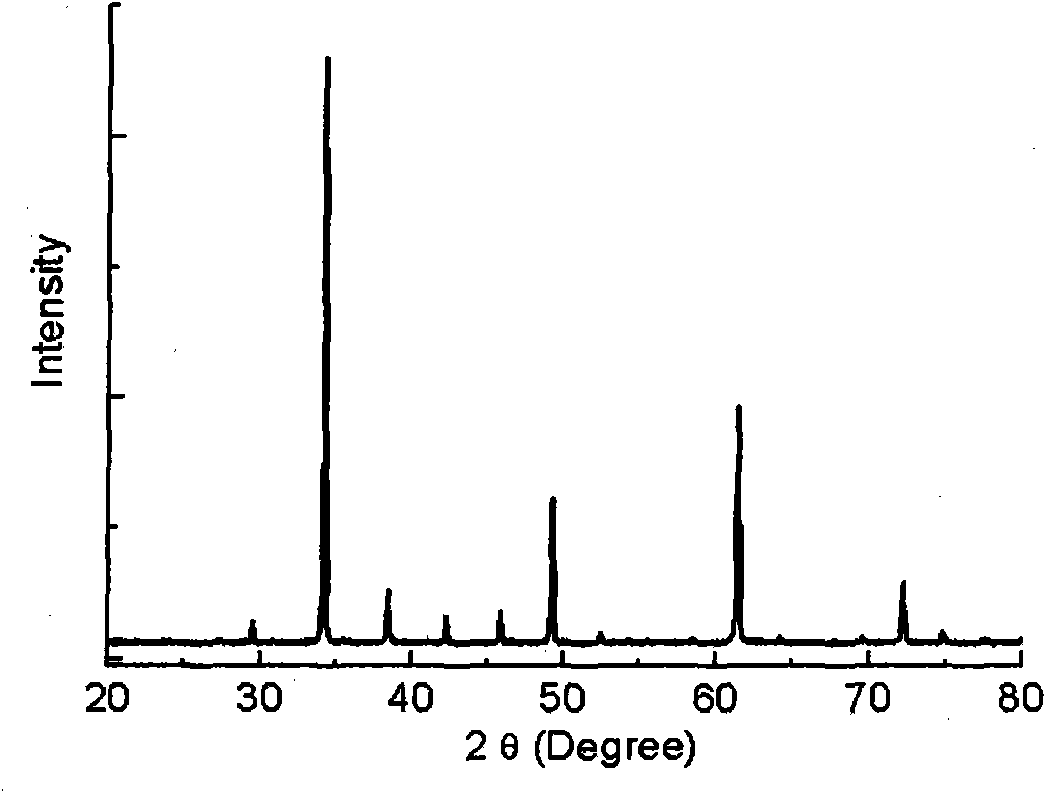

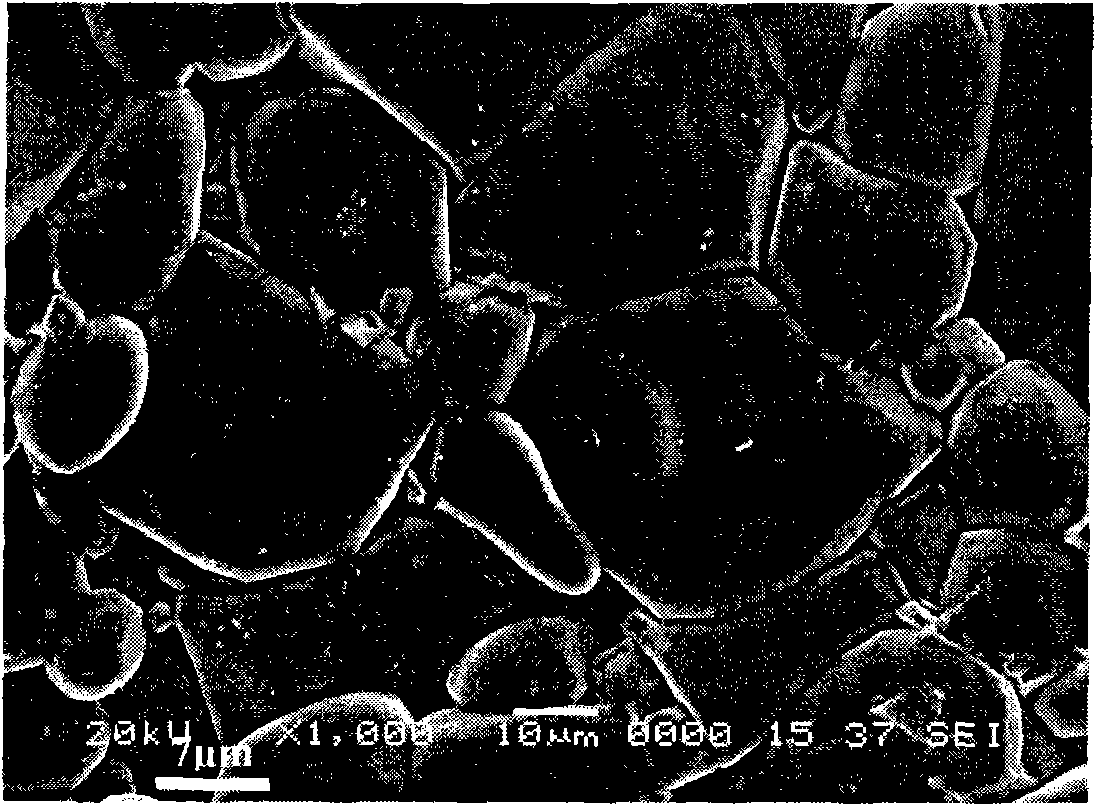

Oxygen-vacancy-containing lithium ferrous silicate and carbon composite anode material and preparation method

The invention relates to a secondary lithium battery anode composite material, in particular to an oxygen-vacancy-containing lithium ferrous silicate and carbon composite material. The chemical formula of the composite material is Li2FeSiO4-xNy / C, wherein x is more than 0 and less than or equal to 1, y is more than 0 and less than or equal to 0.5, the condition that x is more than or equal to 3y / 2 is met, and carbon content is 5-20wt%. The intrinsic conductivity and the lithium ion conductivity inside granules of the composite material are high, and the composite material has excellent performances such as high capacity and high multiplying power. The preparation method of the composite material comprises the steps of: preparing sol from lithium salt, ferrous salt, a silicon source and a carbon source and then carrying out high temperature calcination on the sol twice to obtain granular and oxygen-vacancy-containing lithium ferrous silicate and carbon composite material.

Owner:WUHAN UNIV OF TECH

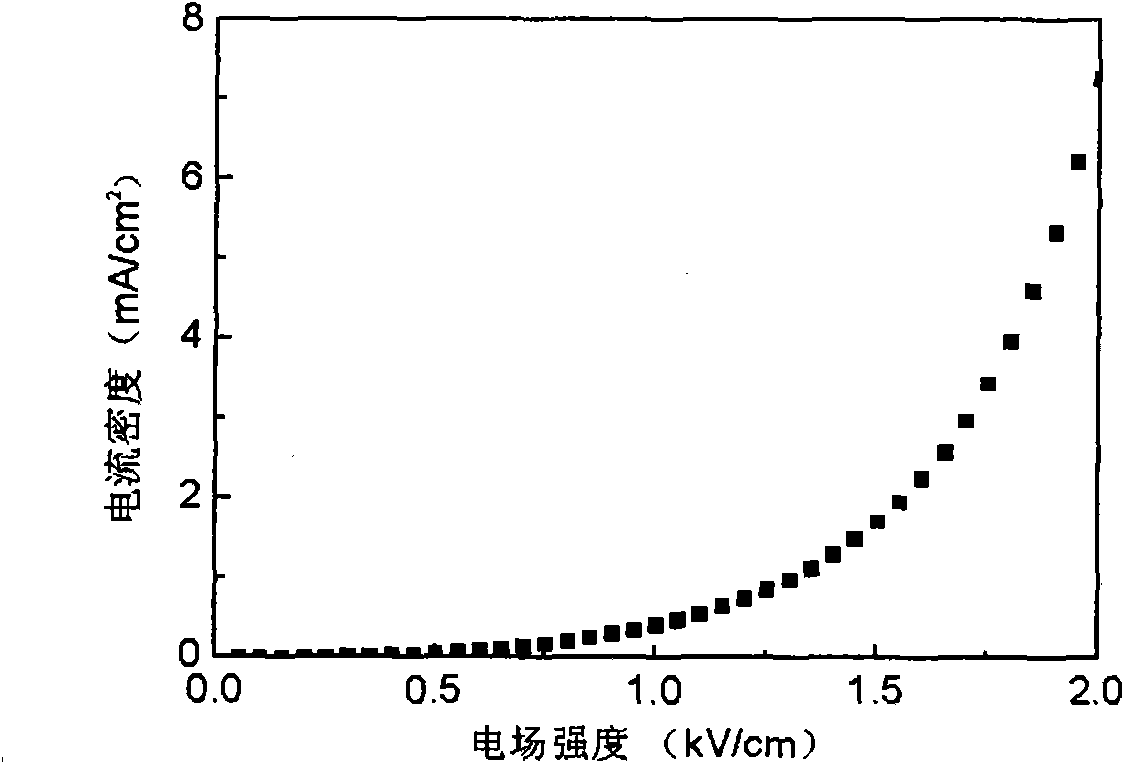

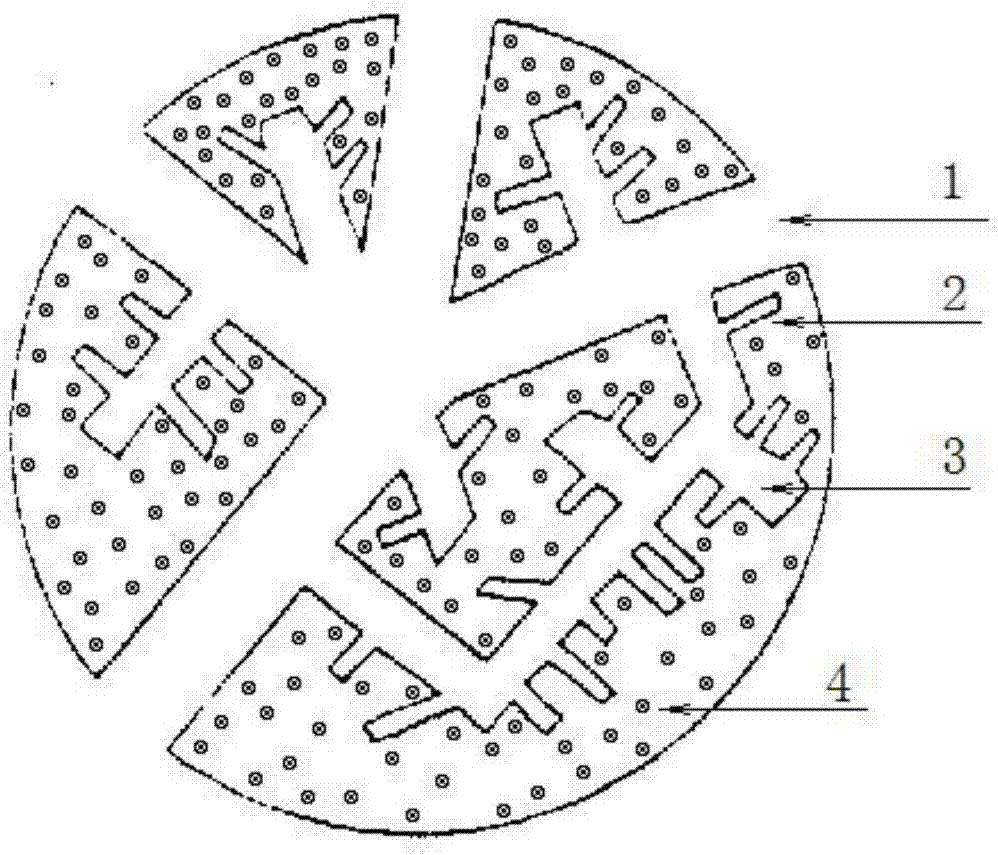

Group VB doping CaCu3Ti4O12 based pressure sensitive material and preparation method

InactiveCN101880159AIncrease intrinsic conductanceReduce the voltage gradientLow voltageChemical element

The invention discloses a group VB doping CaCu3Ti4O12 based pressure sensitive material and a preparation method. The general chemical composition formula of the group VB doping CaCu3Ti4O12 based pressure sensitive materia is CaCu3Ti4-xBxO12, wherein B represents one or combination of group VB elements in the periodic table of chemical elements, and x=0.001-1. The preparation method comprises thefollowing steps of compounding calcium carbonate, copper oxide, vanadium pentoxide, niobium pentaoxide and tantalum pentoxide in accordance with the stoichiometric ratio of CaCu3Ti4-xBxO12 (x=0.001-1, and B represents one or combination of group VB elements in the periodic table of chemical elements), ball milling, calcining, secondary ball milling, pelleting, forming, binder removing, high temperature sintering and the like so that Ca, Cu, Ti-O based ceramics with high permittivity and high pressure sensitive feature can be finally prepared. The invention compensates valence changes of copper ions and titanium ions in the sintering process, which can cause low voltage gradient and large leakage current, by partially replacing a +4 Ti element with a +5 element, thereby reducing the intrinsic conductivity of materials and improving the voltage gradient of the materials.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Carbide doped porous carbon and preparation method thereof

ActiveCN107572498AReduce stickingHigh specific surface areaCarbon preparation/purificationPorous carbonCarbide

The invention provides a carbide doped porous carbon and a preparation method thereof. The carbide doped porous carbon is prepared from porous carbon and a metal carbide embedded into the porous carbon. The obtained carbide doped porous carbon has the advantages that the void of the porous carbon is mostly centralized in micropores and mesopores, so that the specific surface area of the porous carbon is favorably improved; the metal carbide is positioned inside the porous carbon; the intrinsic conductivity of the porous carbon is improved; the condition that the conductivity of the porous carbon is reduced while the specific surface area is increased is avoided. The embodiment result shows that the carbide doped porous carbon provided by the invention has the specific surface area reaching400 to 1700m<2> / g; compared with a porous carbon material obtained by a traditional method, the carbide doped porous carbon has the advantages that under the condition with the equivalent specific surface area, the conductivity is obviously improved; the defect that the specific surface area is improved by using the conductivity reduction as the cost is avoided.

Owner:程杰

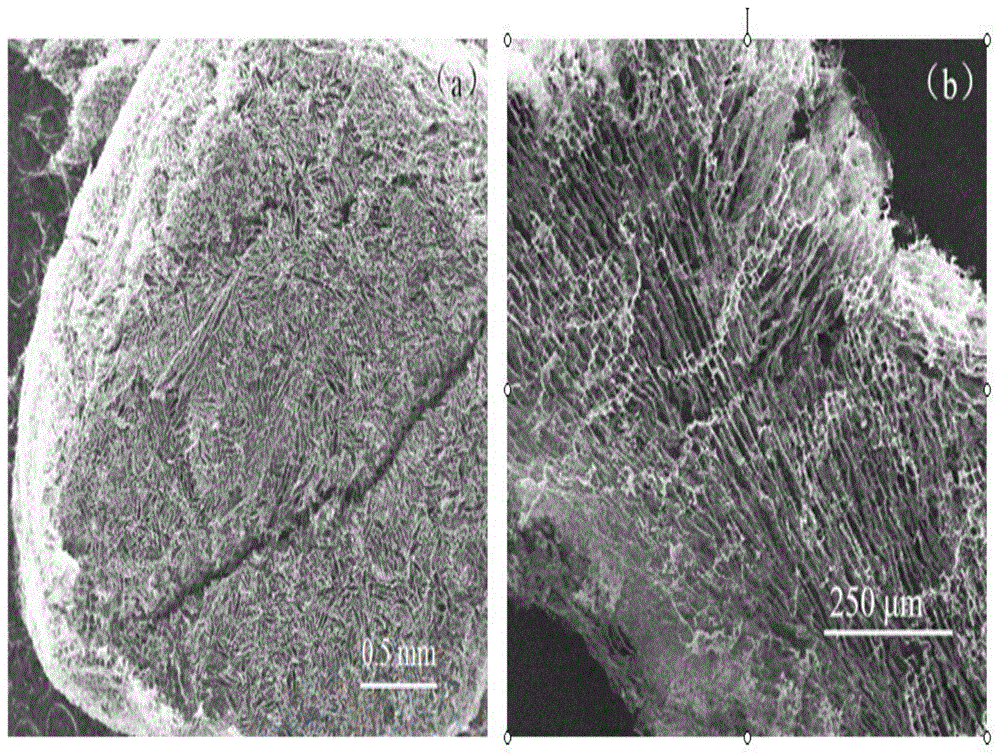

Carbon nanotube three-dimensional network architecture and polymer composite material thereof, and preparation methods thereof

ActiveCN104860293AImprove conductivityImprove thermal conductivityNetwork architectureInterconnection

The invention discloses a carbon nanotube three-dimensional network architecture and a preparation method thereof, and a carbon nanotube / polymer composite material prepared from the carbon nanotube three-dimensional network architecture and having a three-dimensional continuous skeleton structure and a preparation method thereof. The architecture is a three-dimensional network body formed by interconnection of sheet layers composed of carbon nanotubes, and the proportion of the carbon nanotube in the composite material is 0.1 to 10 wt%. The carbon nanotube / polymer composite material with the three-dimensional continuous skeleton structure is constructed by preparing the carbon nanotube architecture with a three-dimensional network by using directional freezing technology, then mixing the carbon nanotube architecture with a polymer and carrying out curing. According to the invention, the carbon nanotube three-dimensional network architecture capable of realizing independent support is used as a conductive additive for a polymer matrix to construct a three-dimensional communicated conductive network in the composite material; and in virtue of good intrinsic conductivity of the carbon nanotube architecture and the characteristics of the inner three-dimensional continuous structure, the conductivity of the polymer composite material is improved.

Owner:DALIAN UNIV OF TECH

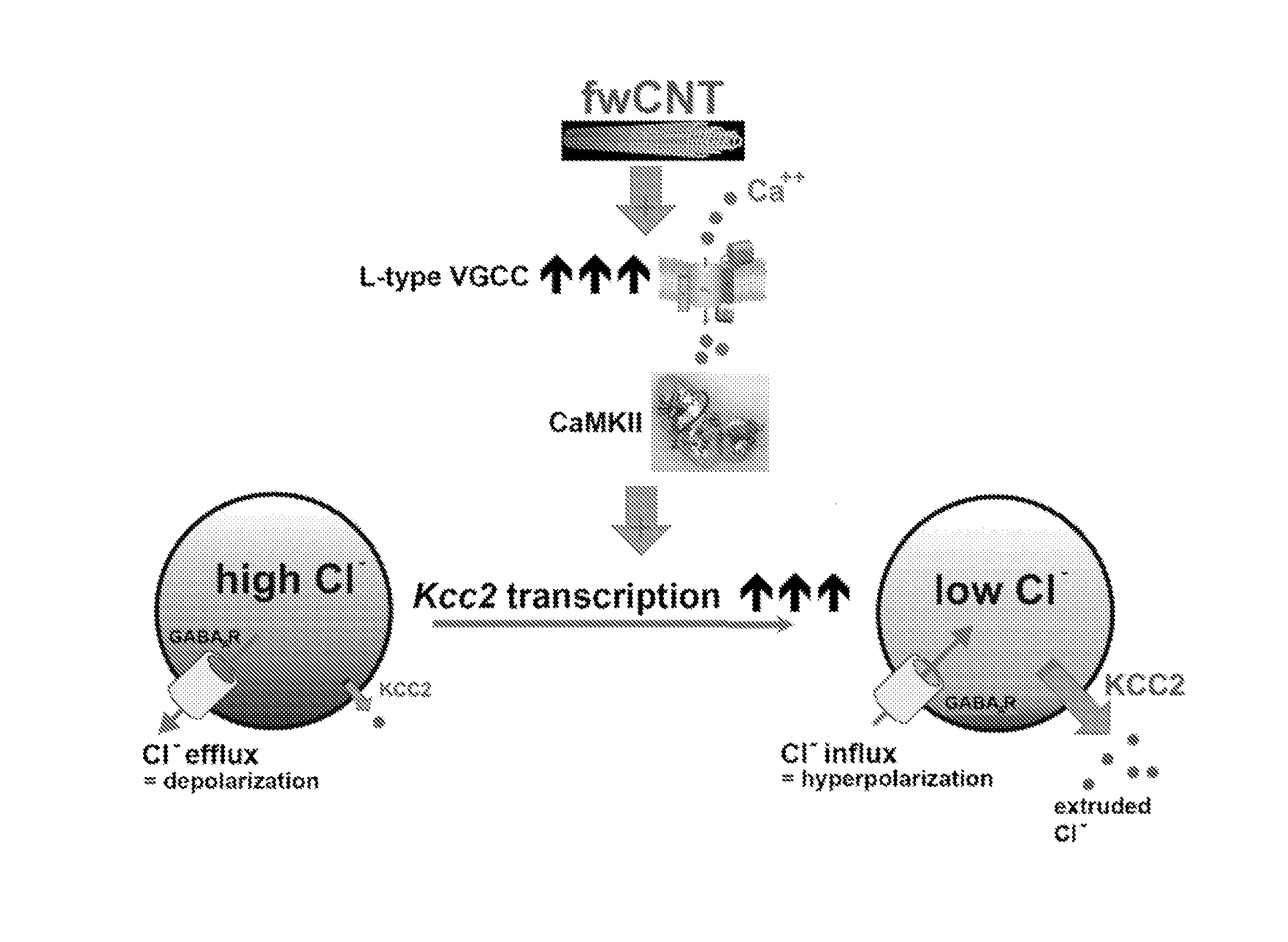

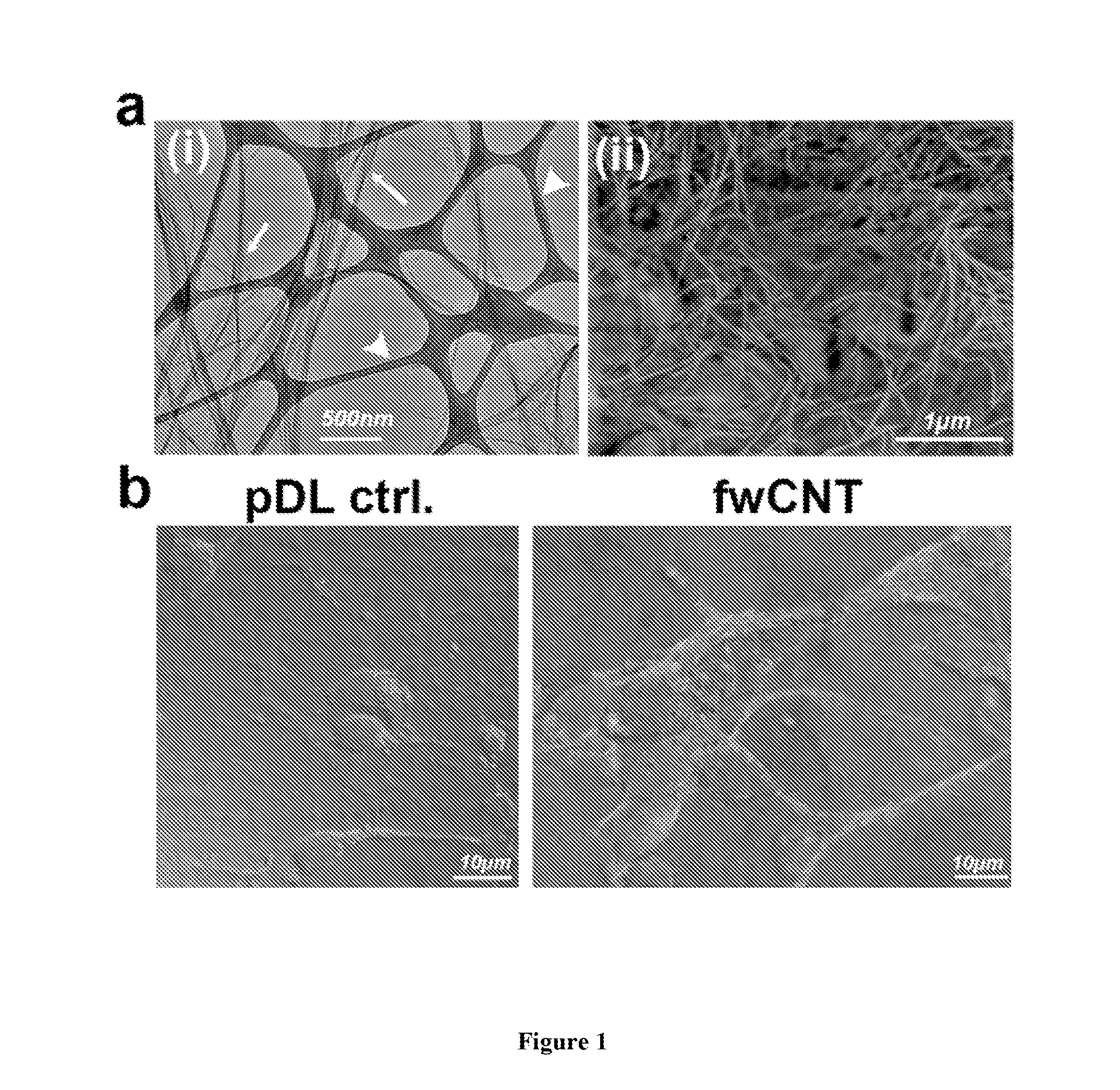

Carbon Nanotubes And Methods Of Use

InactiveUS20150050734A1High expressionNon-metal conductorsInternal electrodesCarbon nanotubeChloride

The present disclosure provides carbon nanotube substrates, and methods of using those substrates, for the treatment and / or amelioration of neurological conditions associated with elevated levels of neural chloride. One aspect of the present disclosure provides a substrate comprising, consisting of or consisting essentially of high-conductivity few-walled CNTs dispersed thereon, wherein the CNTs comprise an intrinsic electrical conductivity of at least 2,500 S / cm. In certain embodiments, the CNTs comprise an intrinsic electrical conductivity in a range of about 1,000 S / cm to about 3,000 S / cm. In an alternative embodiment, the CNTs compromise an intrinsic electrical conductivity in a range of about 1,500 S / cm to about 2,500 S / cm.

Owner:DUKE UNIV

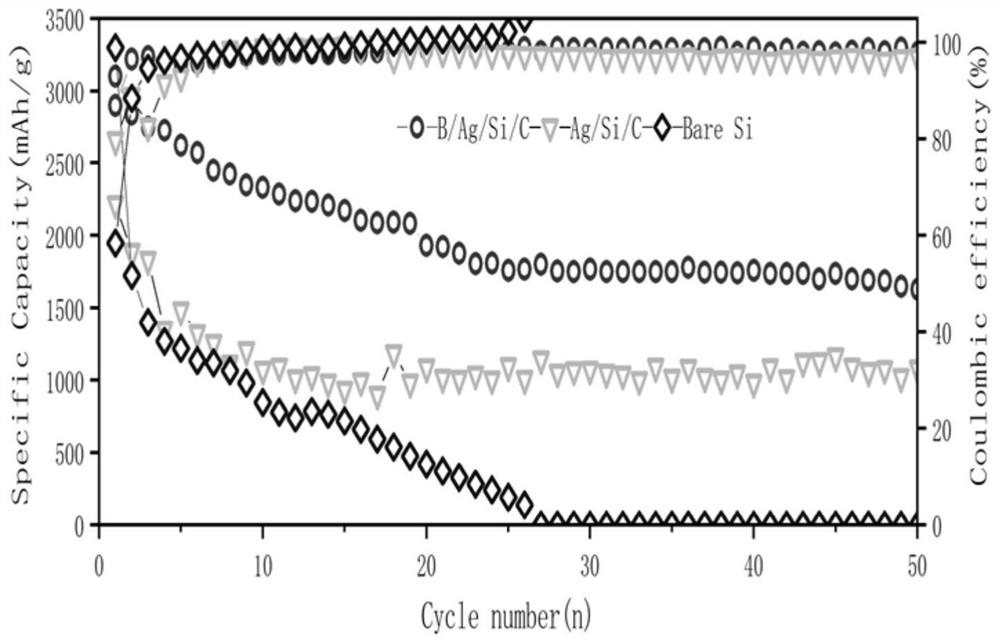

Multilayer silicon/graphene composite lithium battery positive electrode material and preparation method thereof

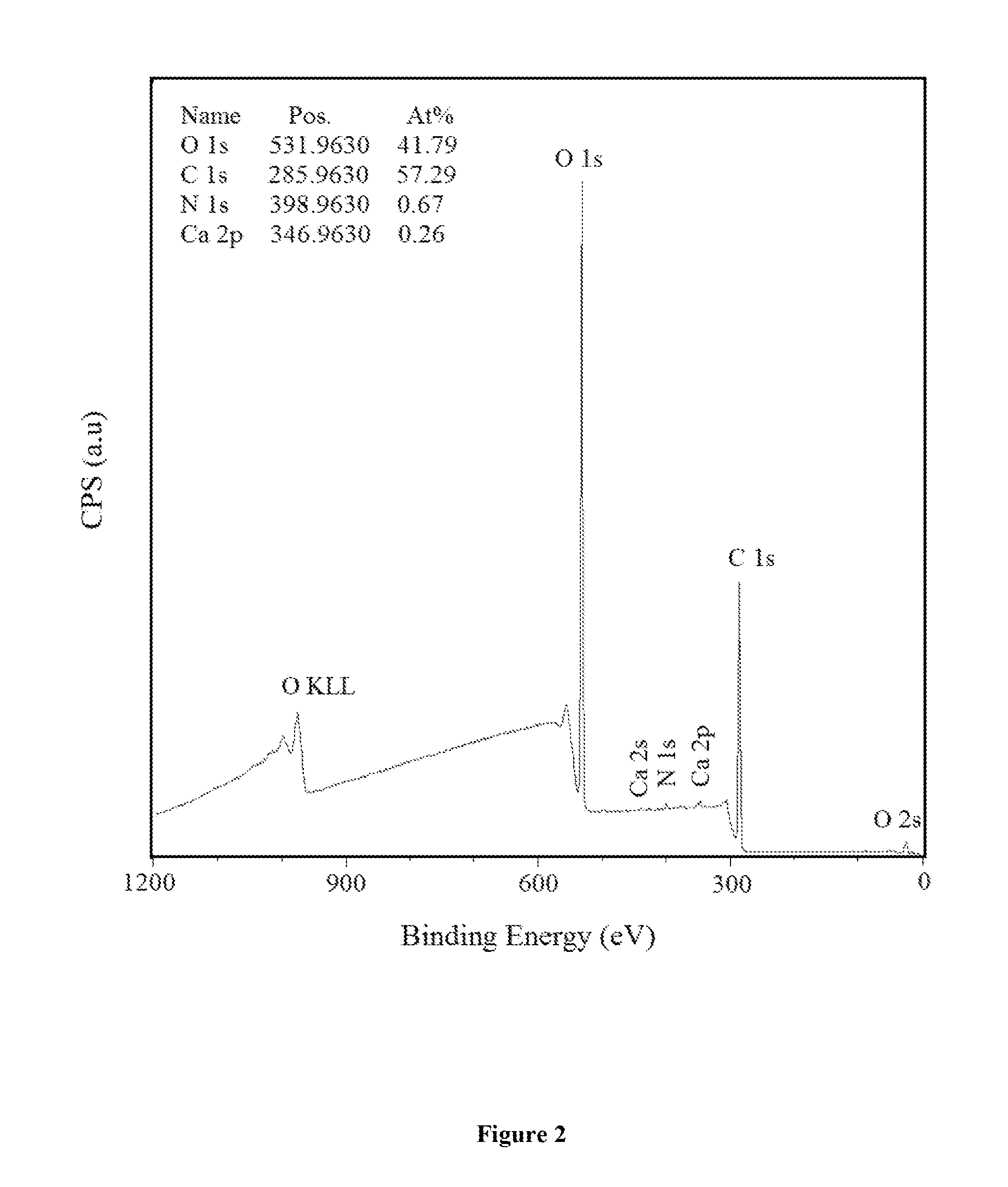

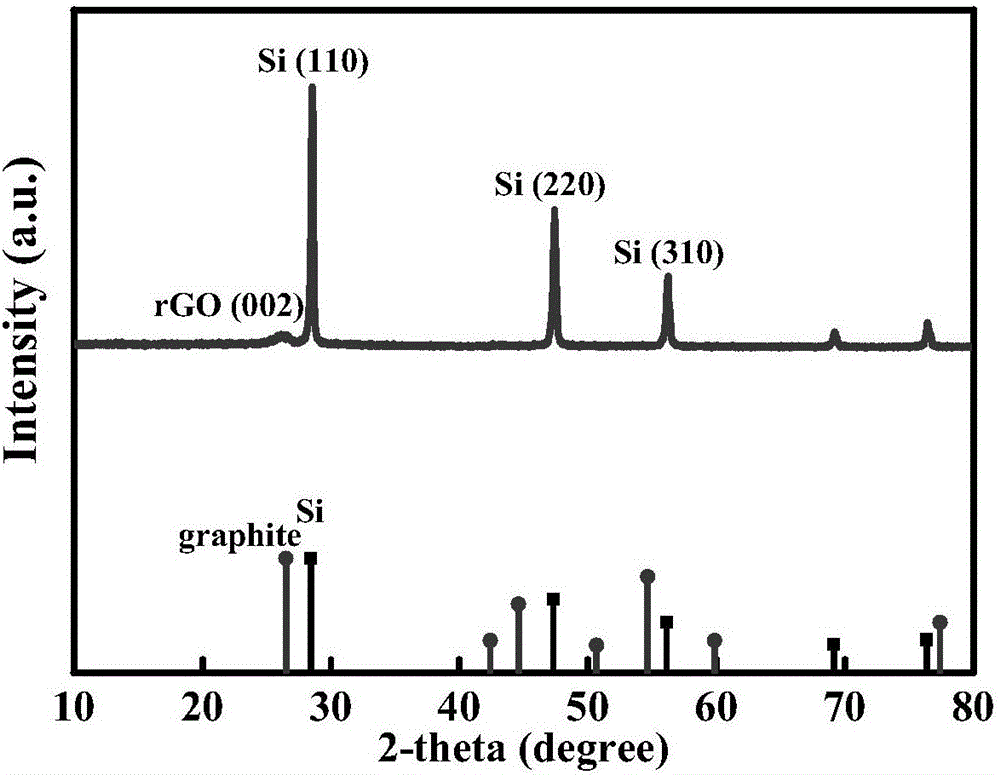

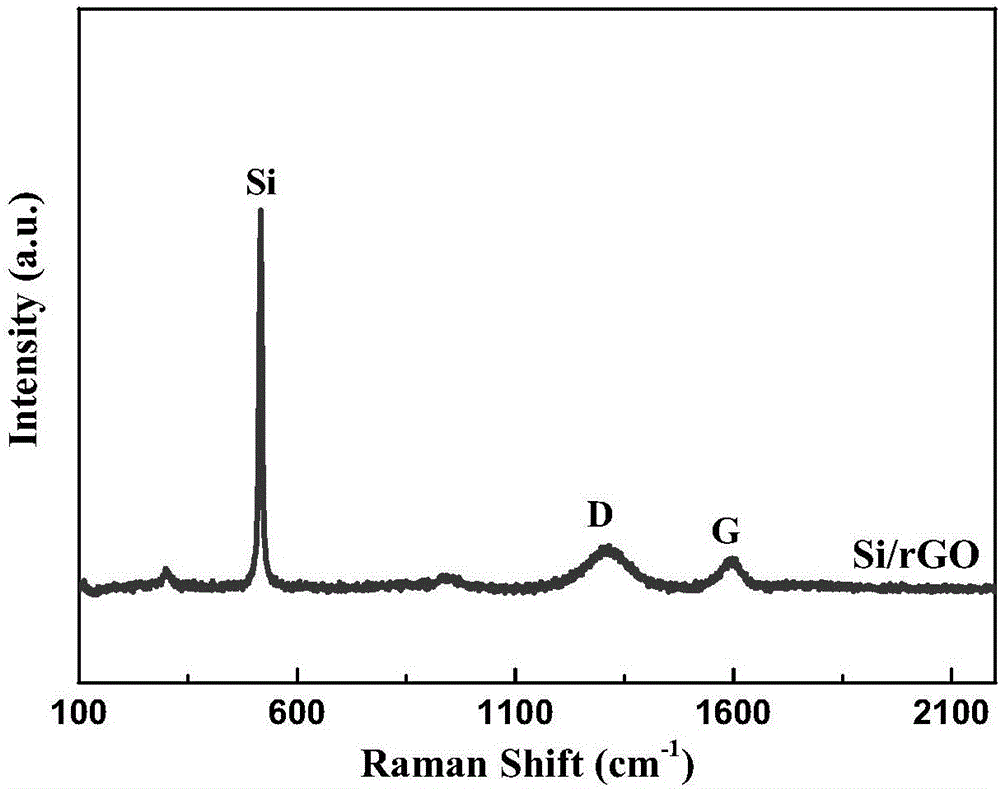

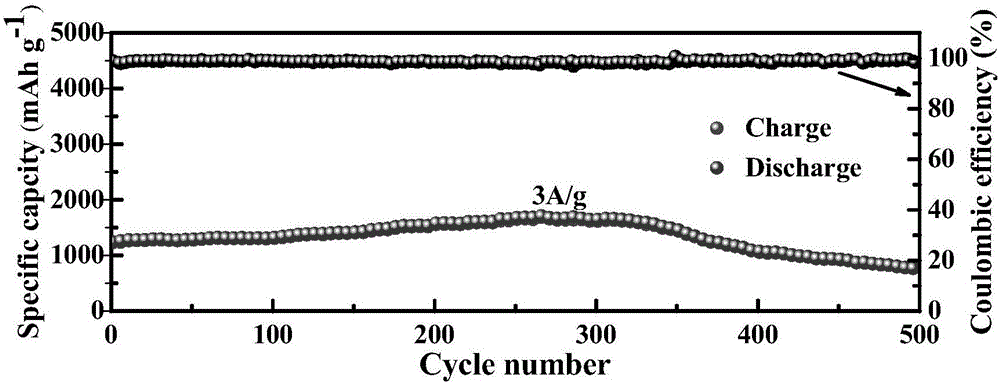

ActiveCN106784700AInhibition of large volume changesGood repeatabilityNegative electrodesSecondary cellsIntrinsic conductivityMechanical property

The invention belongs to the technical field of energy materials, provides a multilayer silicon / graphene composite lithium battery positive electrode material and a preparation method thereof, and aims to overcome the defects that a silicon cathode has an intense volume effect in the electrochemical lithium storage process, a stable surface solid electrolyte membrane is hard to form and the electric circulation performance is poor as the intrinsic conductivity of the silicon cathode self is low. The multilayer silicon / graphene composite lithium battery positive electrode material provided by the invention comprises foamed nickel, graphene layers and silicon layers, wherein the graphene layers and the silicon layers are arranged on the foamed nickel alternatively; the most top layer is a graphene layer. As a multilayer 'graphene / silicon / graphene'sandwich structure is formed, and silicon powder is wrapped in a layer manner by virtue of high mechanical properties and high conductivity of the graphene, great volume change of the silicon powder in the charge / discharge process can be effectively inhibited, a stable SEI (Solid Electrolyte Interface) membrane can be formed, and the multiplying power property and the circulation stability are improved on premise that a high specific capacity of silicon is maintained; meanwhile, the preparation method of the material is simple in process, low in cost and good in repeatability.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

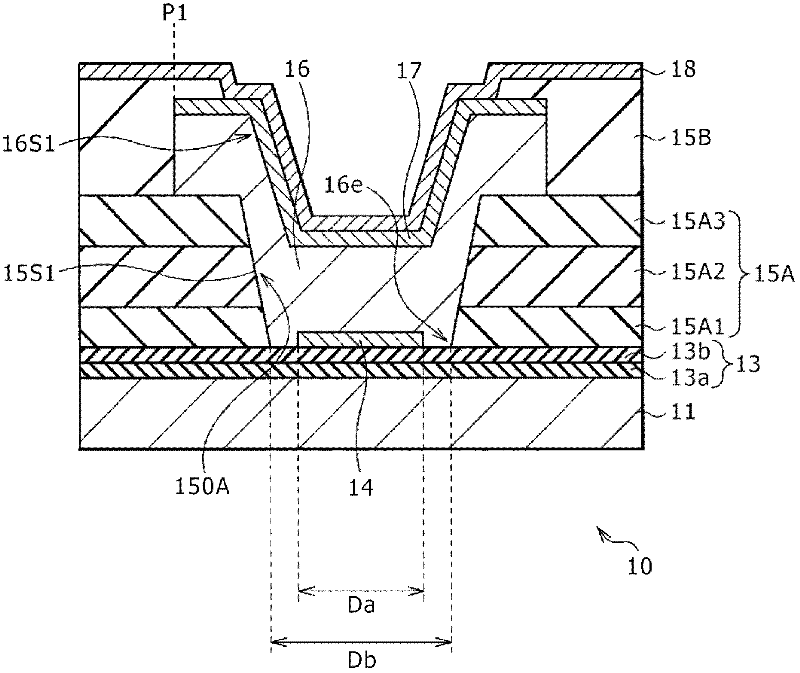

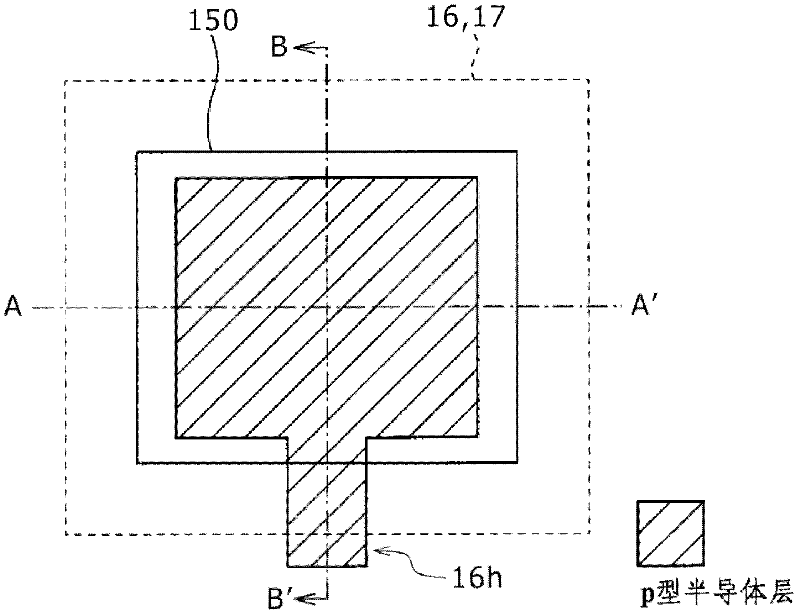

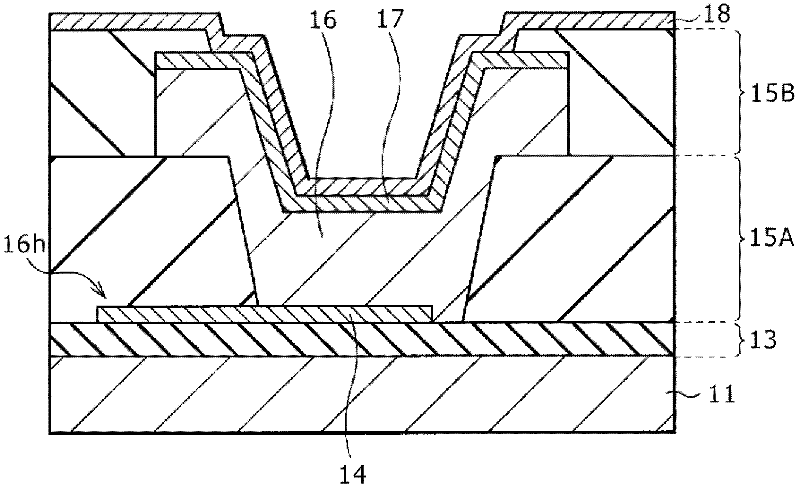

Photoelectric conversion element and method for manufacturing same

InactiveCN102376814ACrack suppressionSuppress dark current increaseSolid-state devicesSemiconductor devicesPower flowElectrical conductor

The invention relates to a photoelectric conversion element and a method for manufacturing the same. The photoelectric conversion element includes a first semiconductor layer that exhibits a first conductivity type and is provided in a selective area over a substrate, a second semiconductor layer that exhibits a second conductivity type and is disposed opposed to the first semiconductor layer, and a third semiconductor layer that is provided between the first and second semiconductor layers and exhibits a substantially intrinsic conductivity type. The third semiconductor layer has at least one corner part that is not in contact with the first semiconductor layer. The invention can suppress increase in the dark current attributed to the crack or the occurrence itself of the crack.

Owner:SONY SEMICON SOLUTIONS CORP

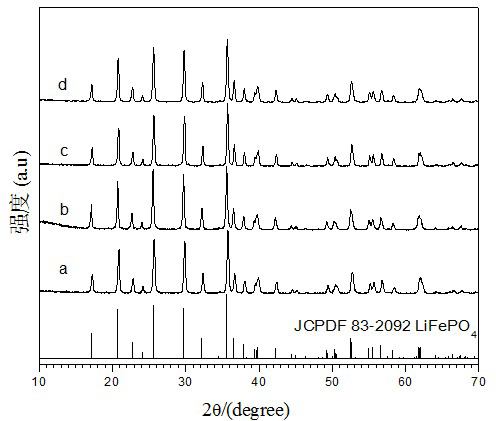

High-conductivity ferrous phosphate lithium cathode material for lithium ion battery and preparation method thereof

The invention provides a high-conductivity ferrous phosphate lithium cathode material for a lithium ion battery and a preparation method thereof. The material is made from a lithium compound, an iron compound, a phosphorous compound, a carbon compound, and a transition metal compound which serves as a graphite catalyst and a doped element, and has a chemical formula of Li(Fe1-xMx)PO4, wherein x is 0 to 0.1; and M may be a transition metal element Fe, Cr, Ni, Co, Mo or Mn. A clad carbon material is catalyzed by adopting the transition metal compound to increase the graphitizing grade of a high-carbon film, thereby improving the conductivity of the material; and the transition metal element can serve as the doped element at the same time to further improve the intrinsic conductivity of the material.

Owner:中国东方电气集团有限公司

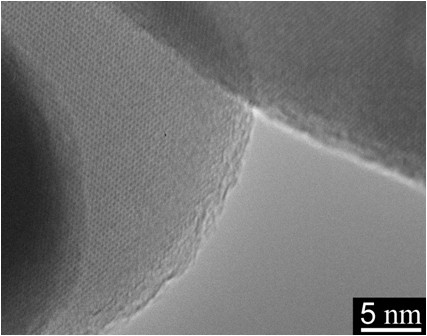

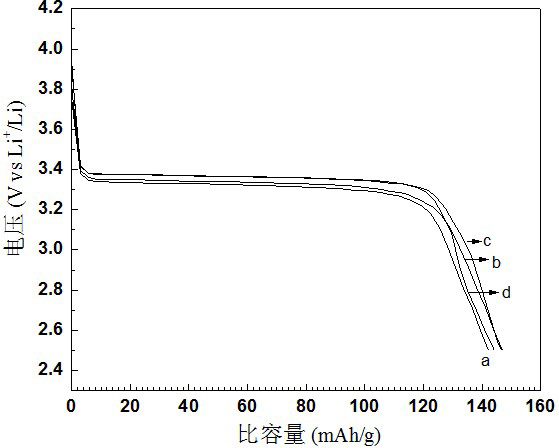

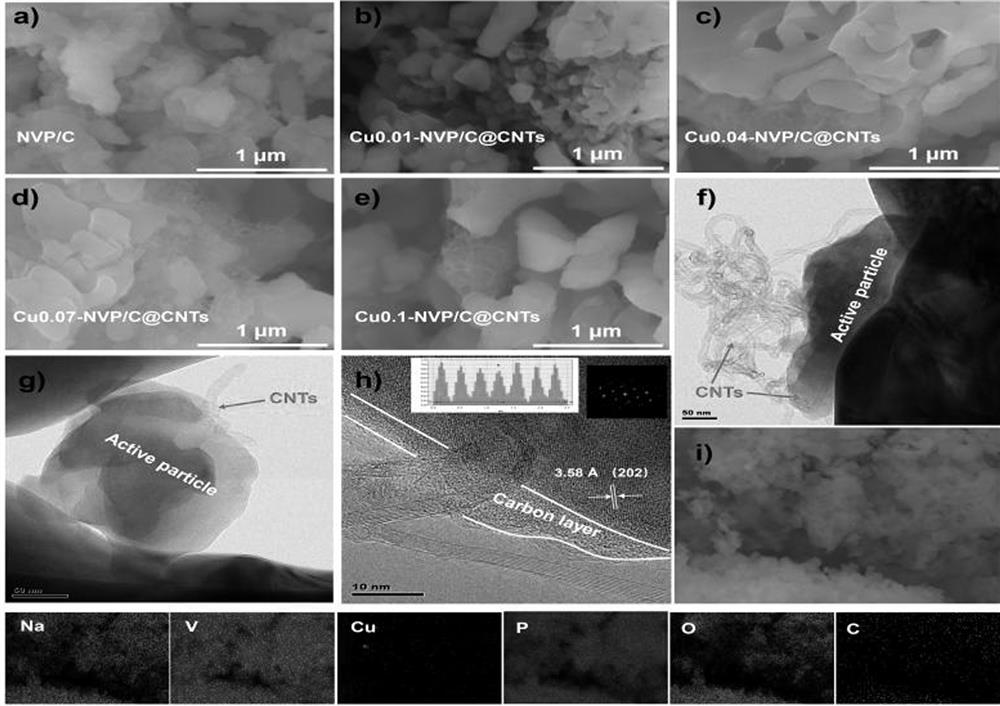

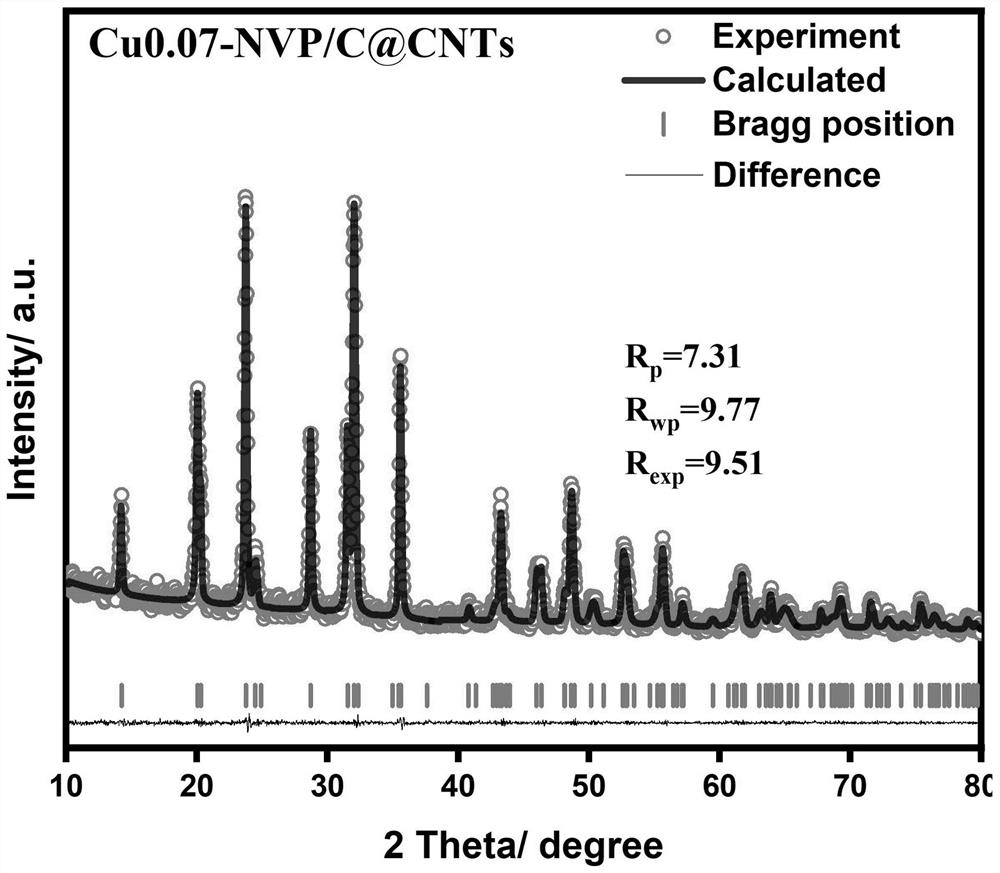

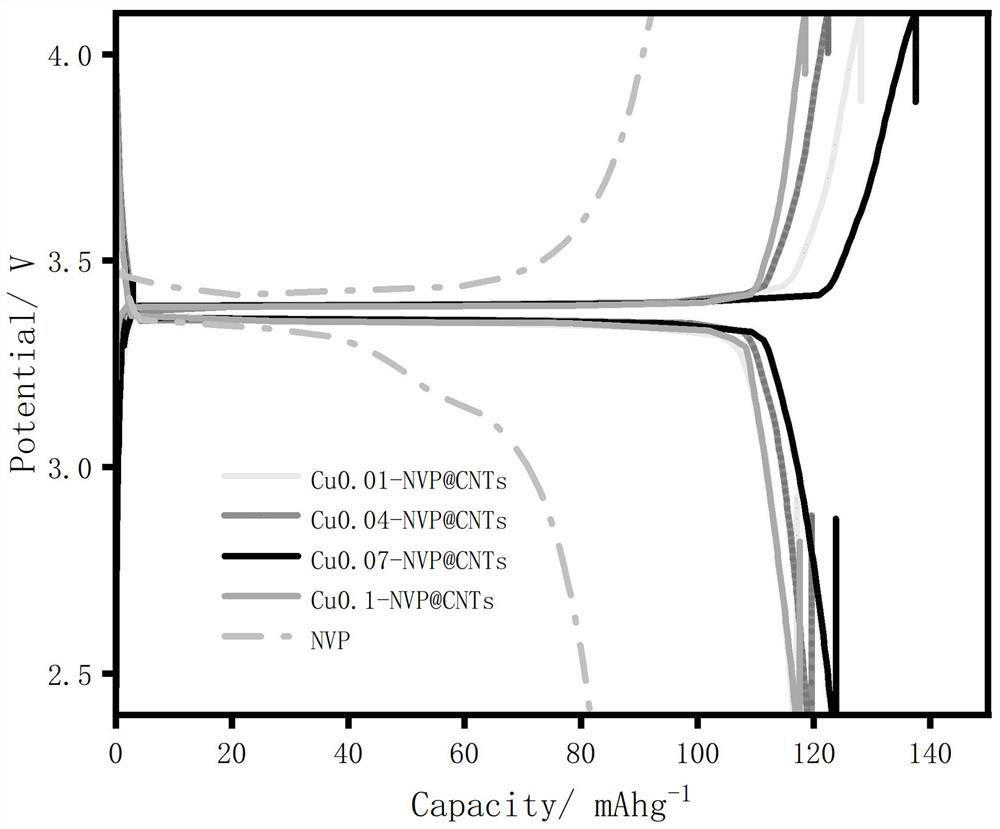

Sodium vanadium phosphate electrode material of vanadium-site copper-doped composite carbon nano tube and preparation method and application of sodium vanadium phosphate electrode material

PendingCN113659139AImprove electrochemical performanceImprove electronic conductivity characteristicsMaterial nanotechnologySecondary cellsCarbon nanotubeSodium-ion battery

The invention belongs to the technical field of new energy materials, and provides a sodium vanadium phosphate electrode material of a vanadium-site copper-doped composite carbon nano tube and a preparation method and application of the sodium vanadium phosphate electrode material. The electrode material is Na<3+x>V<2-x>Cux (PO4)3@5%CNTs, wherein x is equal to 0.01, 0.04, 0.07 or 0.1. Positive bivalent copper ions replace positive trivalent vanadium ions, holes are introduced into NVP unit cells, and the electron conductivity in the material is improved. Meanwhile, an ion transmission channel is widened, the unit cell structure is stabilized, and the ionic conductivity and structural stability of the material are remarkably improved. The carbon nanotubes with high electronic conductivity are compounded to form a layer-by-layer embedded conductive frame, so that the electronic conductivity among the active particles is improved. The intrinsic conductivity and crystal structure stability of the NVP electrode material are comprehensively improved from multiple angles, and the obtained material has excellent rate capability, high rate and long cycle stability when being used as a sodium ion battery positive electrode. The preparation method is simple to operate, easy to control and considerable in yield.

Owner:ZHONGBEI UNIV

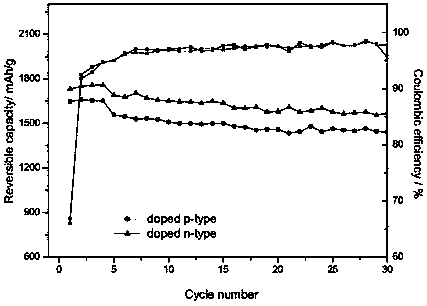

Preparing method of nanometer silicon particles for lithium battery

InactiveCN110065945AImprove conductivityImprove embedding rateCell electrodesNanotechnologyHigh energyTrace element

The invention discloses a preparing method of nanometer silicon particles which are doped with trace elements and used for a lithium battery. The doped trace elements are N-type doped crystalline silicon and P-type doped crystalline silicon. The preparing method comprises the steps that firstly, the N-type doped crystalline silicon and the P-type doped crystalline silicon serve as raw materials, acopper pipe serves as a working electrode, a pulse discharge method is adopted for preparing the micron / sub-micron silicon particles doped with the trace elements, and the intrinsic conductivity of silicon is increased by doping the trace elements. Afterwards, the prepared micron / sub-micron silicon particles doped with the trace elements are further nanocrystallized through a high-energy ball milling method, so that the absolute volume change of the silicon particles is reduced. By means of the method, the circulation performance of the silicon material can be improved. The method is simple in preparing technology, convenient to operate and low in cost, and expanded production is facilitated.

Owner:江苏载驰科技股份有限公司

Nanotube forming methods

InactiveUS20070071668A1Effective conductivityStops growthMaterial nanotechnologyPretreated surfacesIntrinsic conductivityNanotube

A nanotube forming method includes growing a plurality of nanotubes to an intermediate length that is deterministic of nanotube intrinsic conductivity. Individual nanotubes exhibit an effective conductivity, which varies among the plurality of nanotubes. The method includes completing growth of nanotubes exhibiting effective conductivities inside a selected range without completing growth of nanotubes exhibiting effective conductivities outside the selected range. Before completing nanotube growth, the method may further include stopping nanotube growth and screening out nanotubes exhibiting conductivities outside the selected range. The screening out of nanotubes may include deforming or masking nanotubes exhibiting conductivities outside the selected range. Deforming nanotubes may include applying a potential.

Owner:MICRON TECH INC

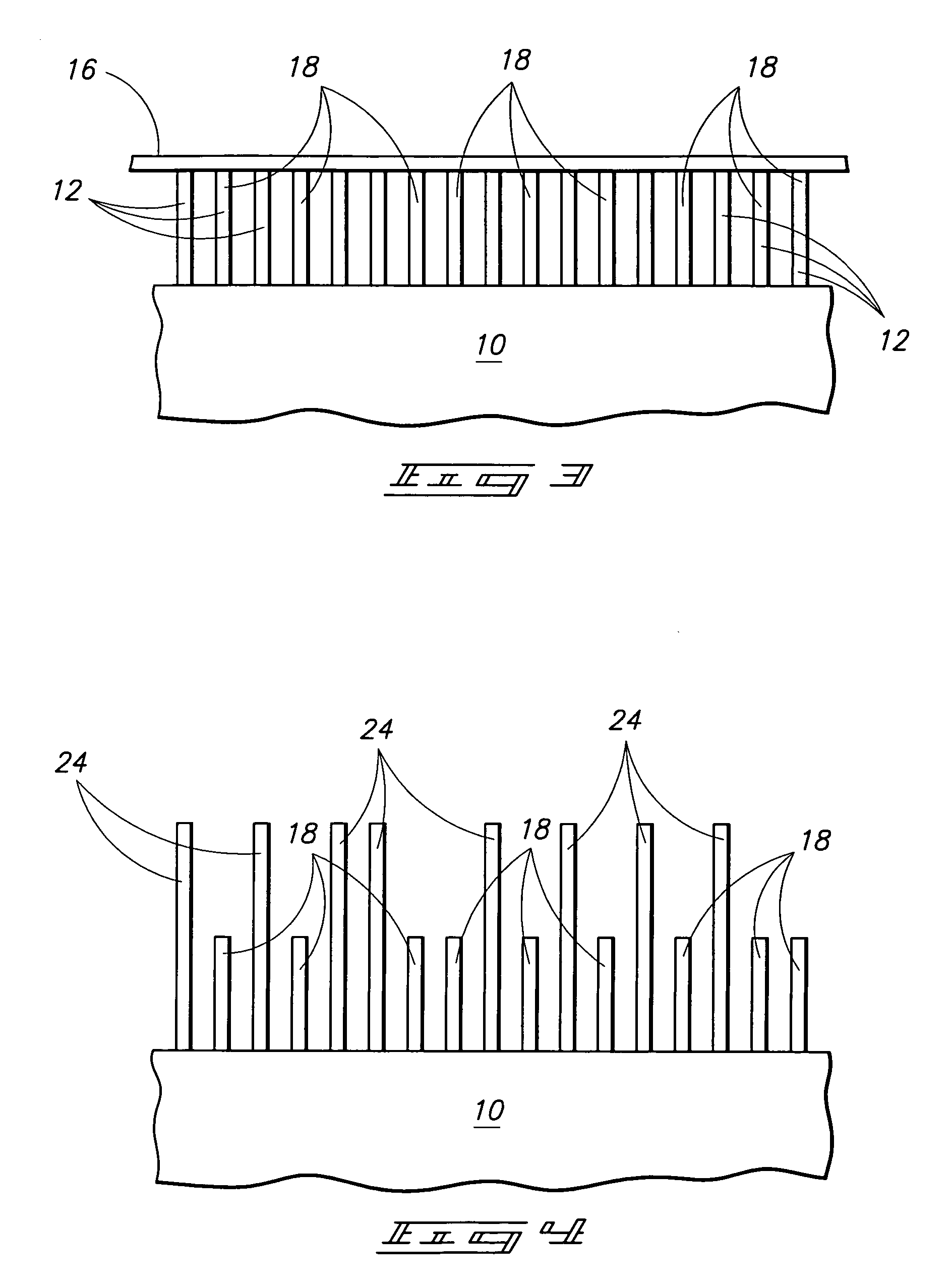

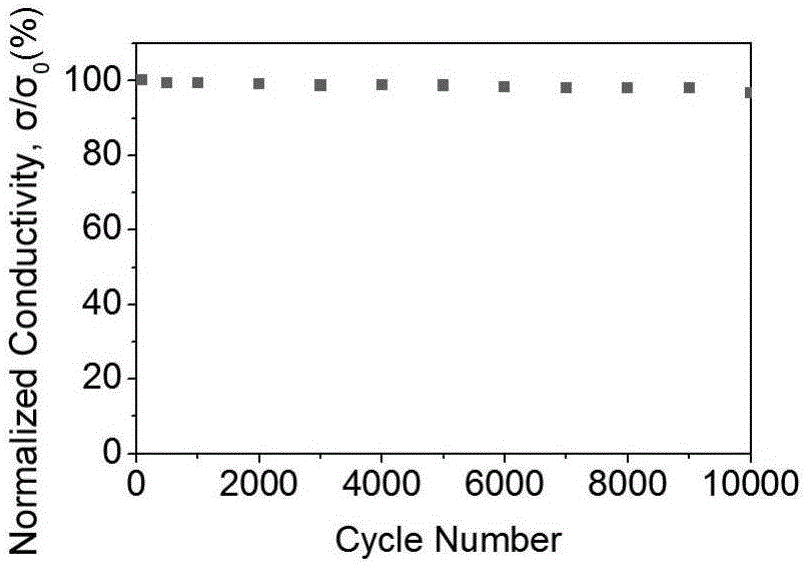

Tensile conductive cable and manufacturing method thereof

InactiveCN106129040AImprove conductivityLow costSemiconductor/solid-state device detailsSolid-state devicesTensile strainElastic matrix

The invention discloses a tensile conductive cable and a manufacturing method thereof, which belong to the field of tensile electronics. An elastic matrix and a conductive filler are composite to form the conductive cable. A thermoplastic elastomer is selected as the matrix, and the filler selects a one-dimensional linear or two-dimensional plate-like nano material with high intrinsic conductivity and a high aspect ratio. The manufacturing process comprises steps: the elastic matrix and the conductive filler are mixed to obtain a master batch; then, the obtained blend master batch is used for manufacturing a conductive composite material thin film; and finally, the obtained conductive composite material thin film is cut into ribbons, the ribbons are then twisted into lines, and the tensile conductive cable is manufactured. The conductive composite material cable can be applied to conductive connection of flexible and tensile electronic devices, has advantages of light weight, low cost and the like, has good comprehensive use performance such as high conductivity and high conductive stability under tensile strain, the manufacturing process is simple and free of pollution.

Owner:UNIV OF SCI & TECH BEIJING

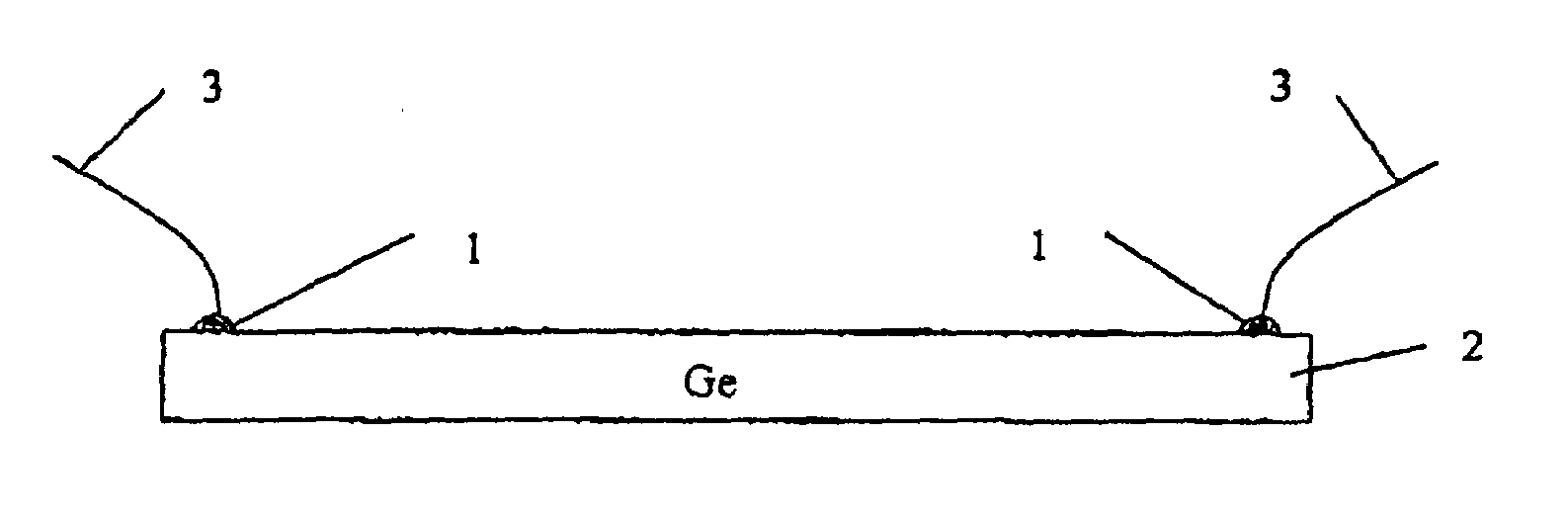

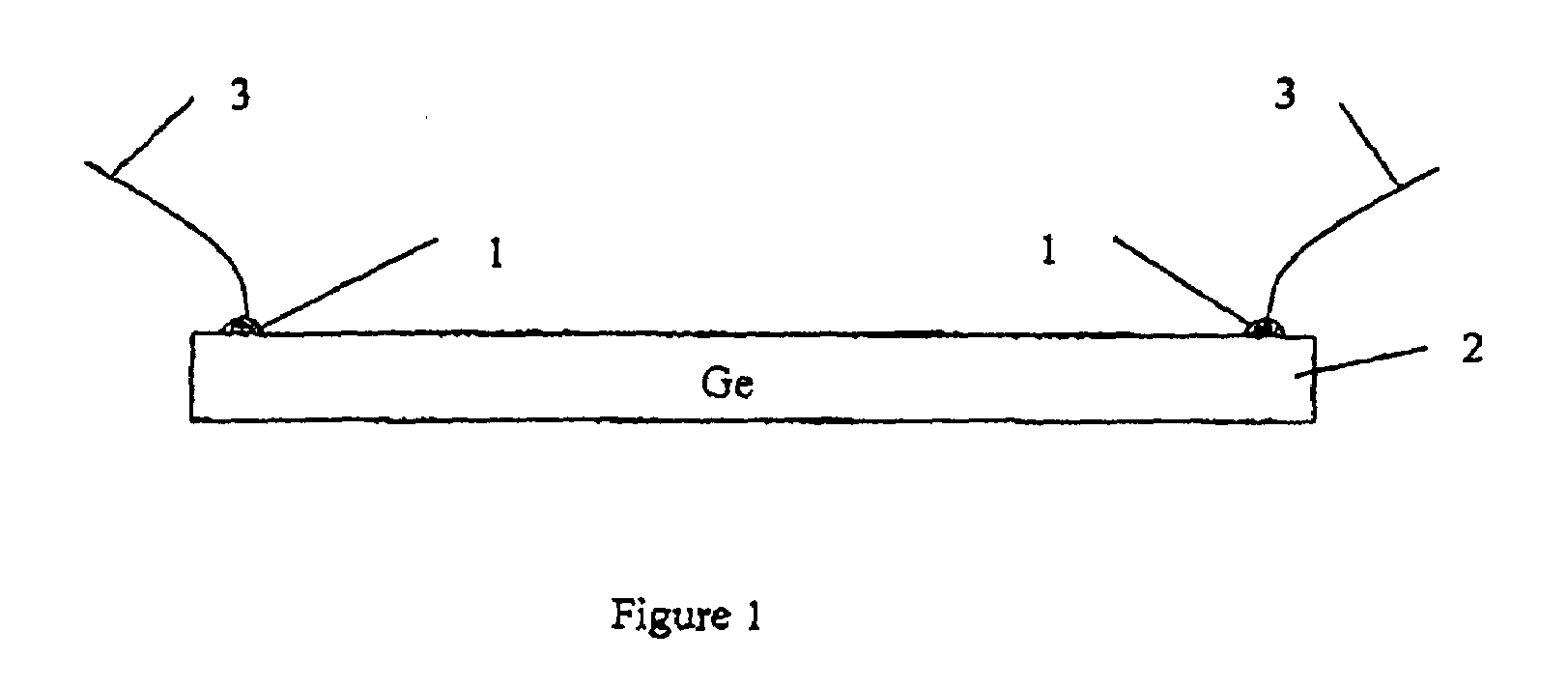

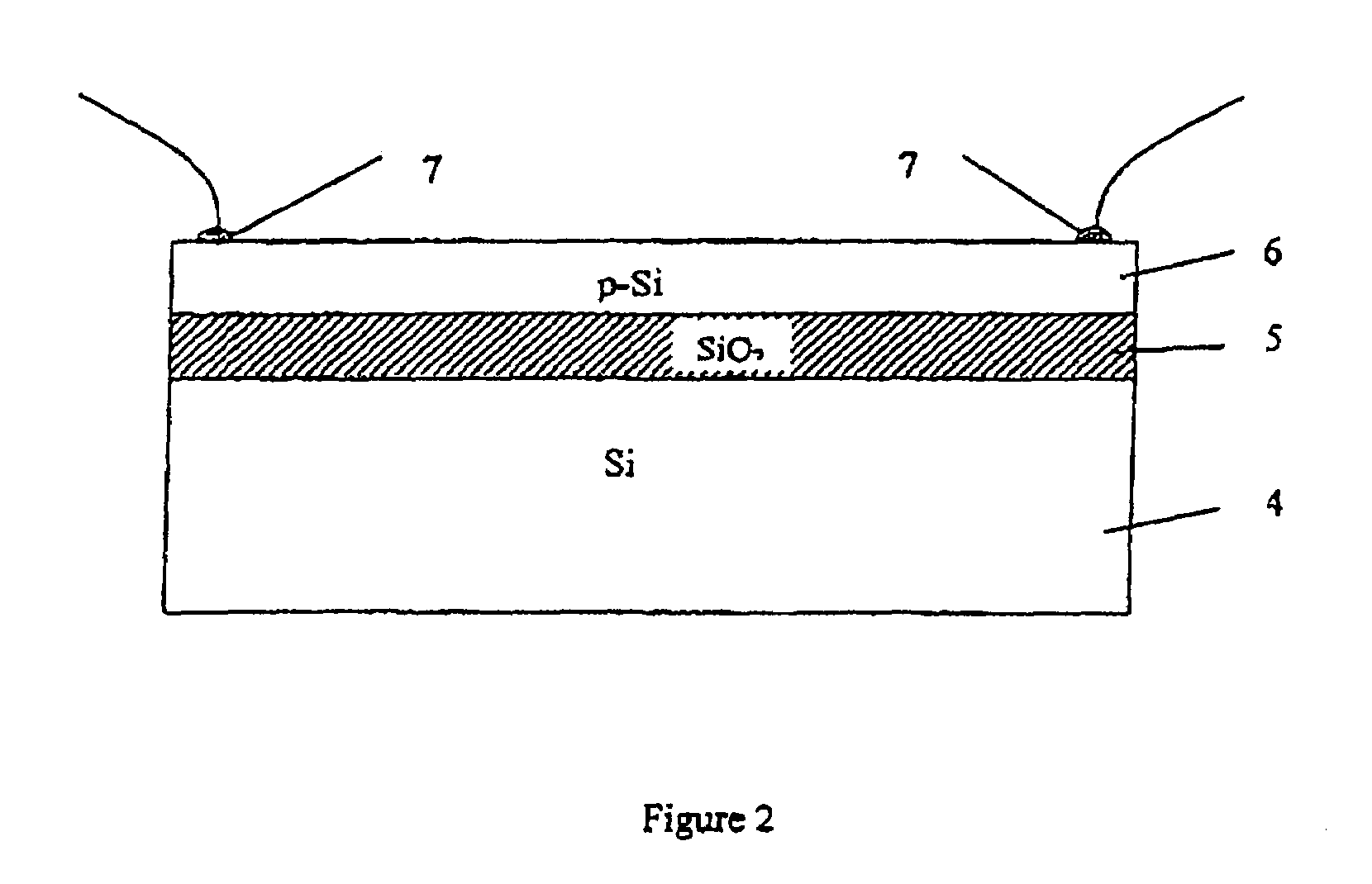

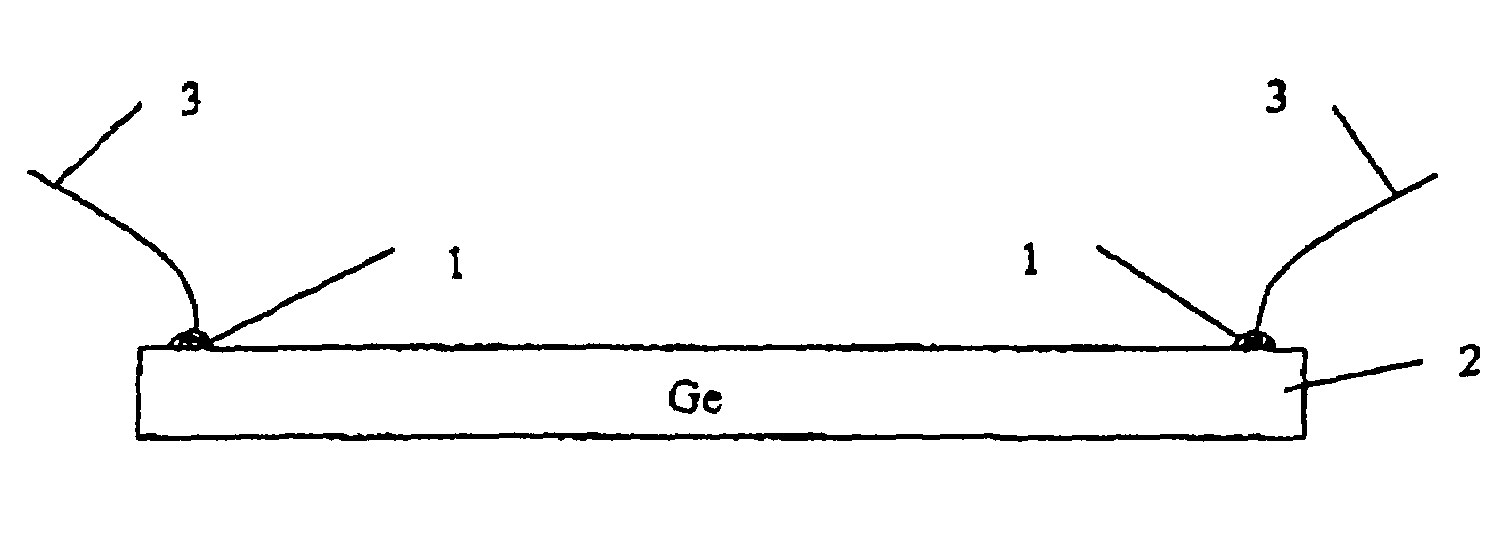

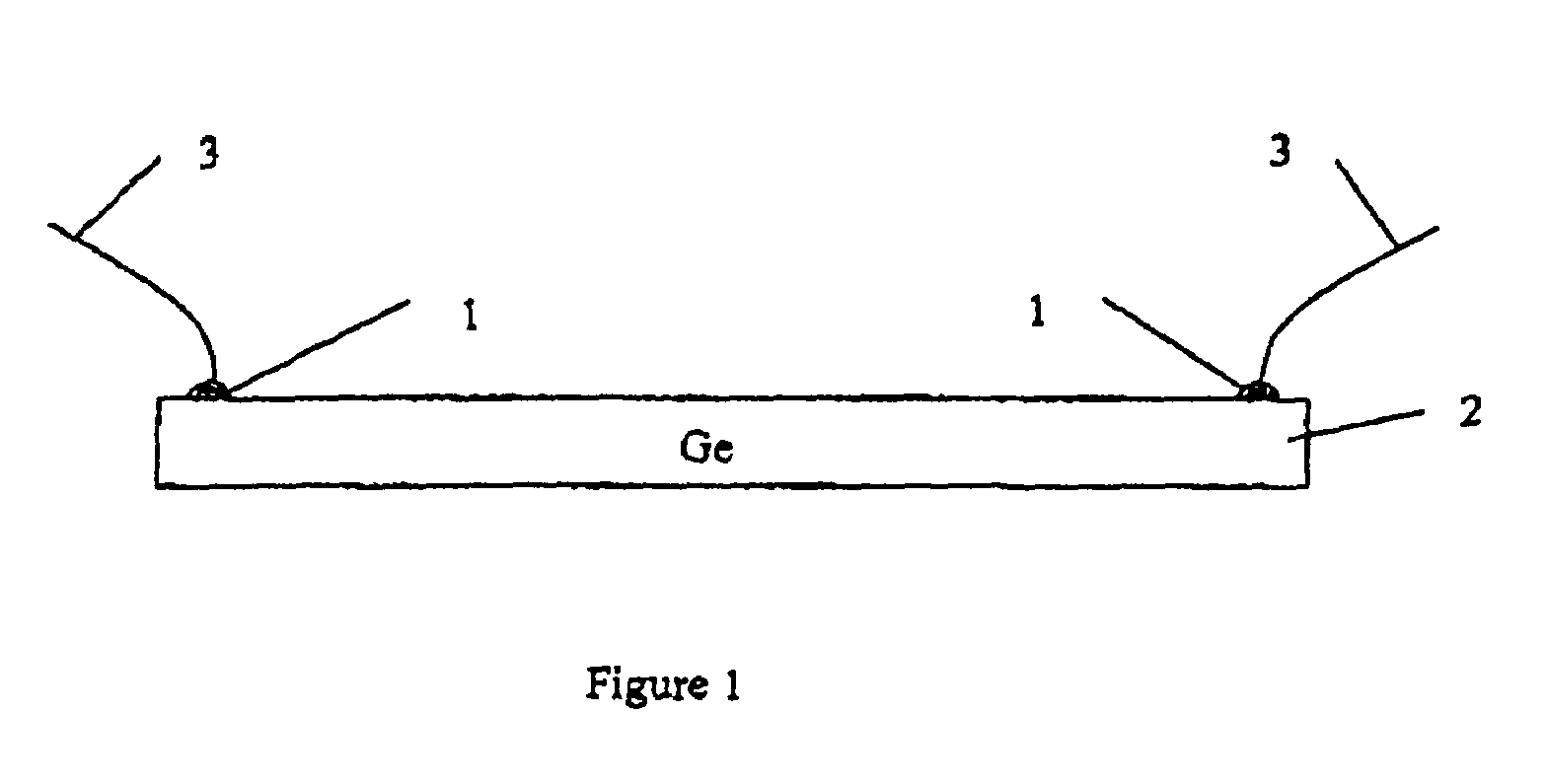

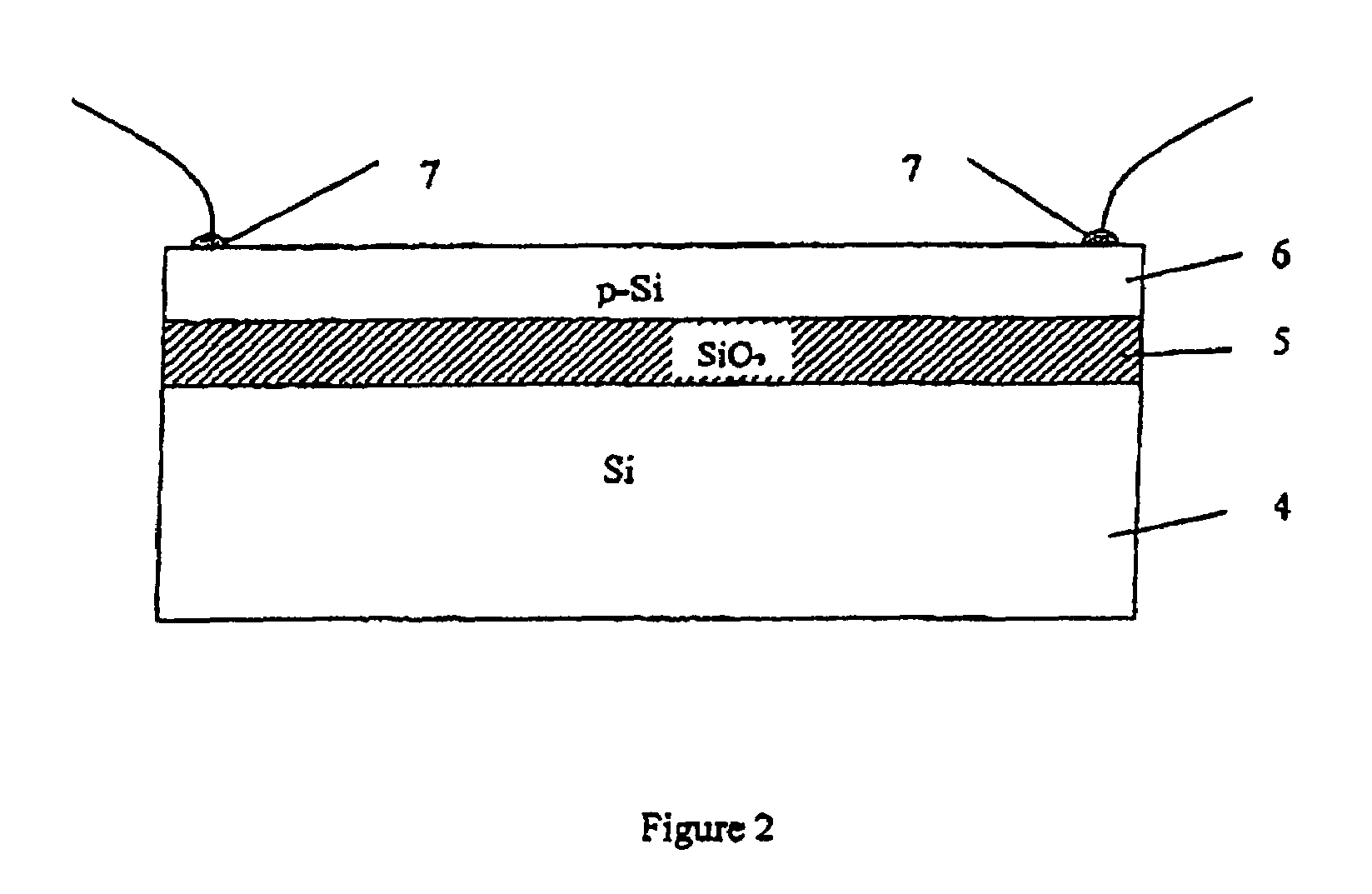

High temperature thermistors

InactiveUS7405457B1Semiconductor/solid-state device manufacturingPhotovoltaicsElectrical resistance and conductanceMetallurgy

A high temperature NTC thermistor includes a polycrystalline thermistor body, selected from a list consisting of polycrystalline Si with intrinsic conductivity and polycrystalline Ge with intrinsic conductivity. At least one ohmic contact is disposed on at least one surface of the polycrystalline thermistor body.

Owner:ADSEM

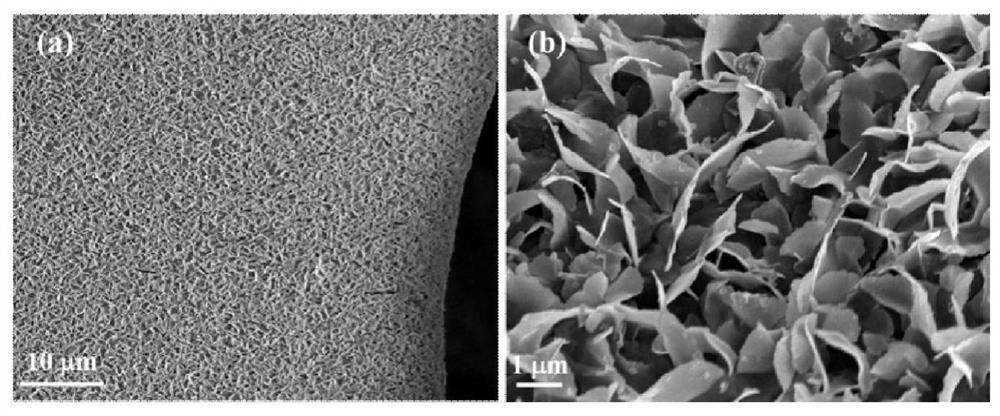

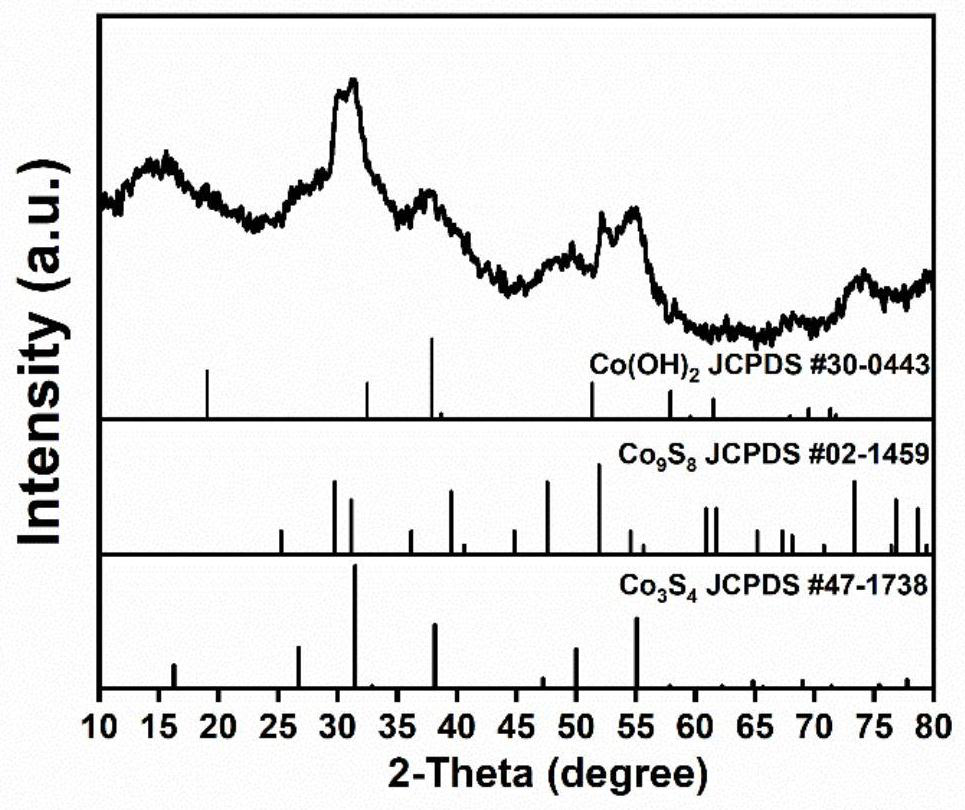

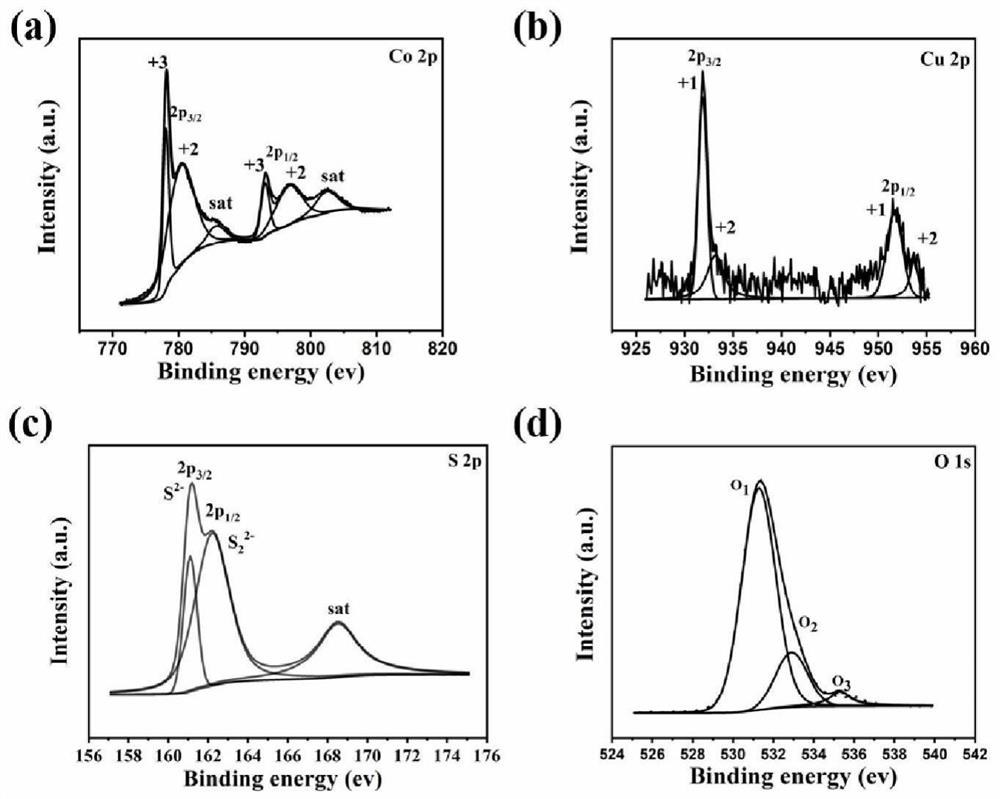

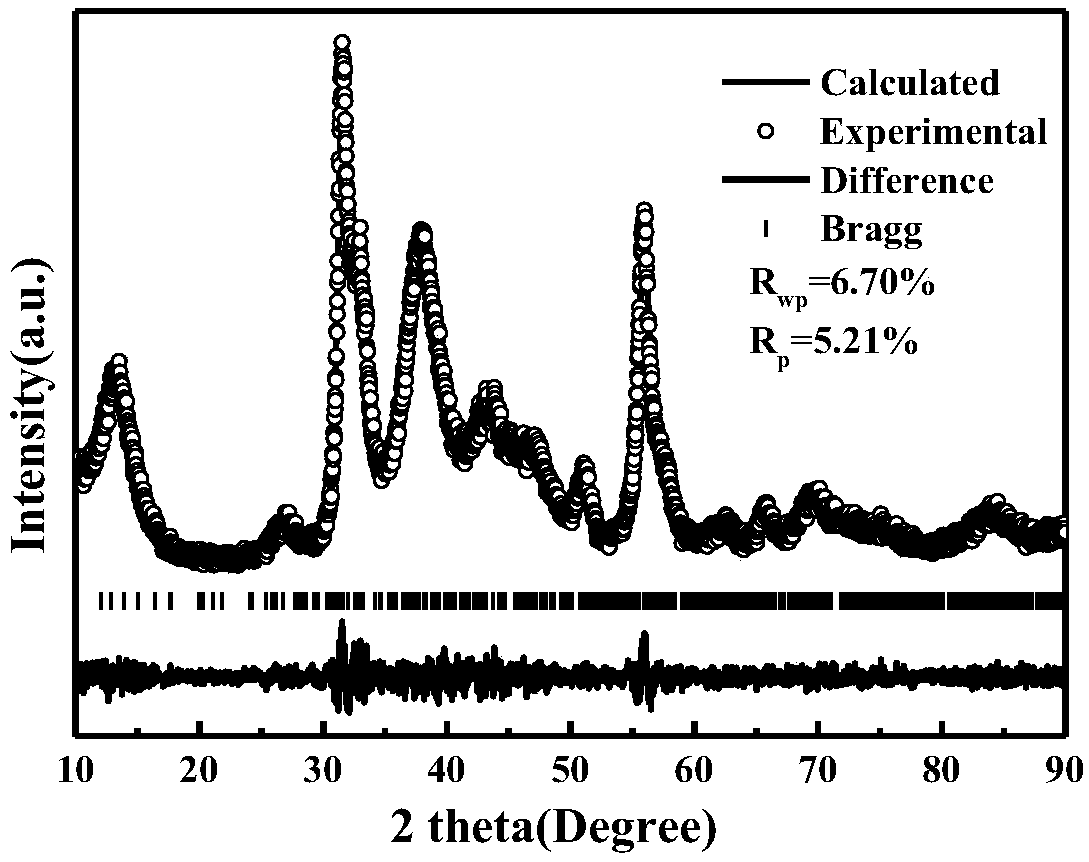

Metal cation doped cobalt polysulfide/cobalt hydroxide composite material and preparation method and application thereof

ActiveCN112103092AHigh specific capacitanceImprove cycle stabilityMaterial nanotechnologyHybrid capacitor electrodesElectrolytic agentInterfacial resistance

The invention provides a metal cation doped cobalt polysulfide / cobalt hydroxide composite material and a preparation method thereof. A solvothermal method is adopted, firstly, metal cations are dopedinto a cobalt precursor growing on foamed nickel in situ, and the precursor is a two-dimensional nanosheet array with a hierarchical porous structure; then a self-supporting M-coated CoSx / Co (OH) 2 nanosheet material is prepared through a liquid phase vulcanization method; the preparation method is simple in process, short in consumed time and low in cost, and the prepared material has a hierarchical and mesoporous structure and a large specific surface area and provides more active sites; meanwhile, the transmission path of ions can be shortened, the interface resistance between the electrodeand an electrolyte is reduced, particularly, due to the doping of metal cations, the electronic structure of the electrode is effectively adjusted, the intrinsic conductivity of the material is optimized, the specific capacitance is as high as 3500 to 4000 F g < 1 >, and the electrode material is a novel high-performance supercapacitor electrode material.

Owner:ZHEJIANG UNIV OF TECH

A prepartion method of a carbon-coated ultrathin FeMoSe4 nanometer potato chip-like potassium ion negative electrode material

ActiveCN109244426AGood lookingSimple methodNegative electrodesSecondary cellsVacuum dryingOleic Acid Triglyceride

The invention relates to a preparation method of carbon-coated ultrathin FeMoSe4 nanometer potato chip-like potassium ion negative electrode material, and belongs to the functional nanometer materialand electrochemical field. The method comprises the following steps: adding ferric chloride hexahydrate and molybdic acid into a single-necked flask filled with oleamine and oleic acid and placing theflask in a heating sleeve for pre-dissolution; after cooling to room temperature, adding selenium powder into the flask and heating the flask to the target temperature for a period of time; cooling that final solution to room temperature, cleaning, centrifuge and vacuum drying to obtain black powder; Finally, the obtained powder is transferred to a crucible and heated in an inert protective atmosphere in a tubular furnace to obtain carbon-coated ultrathin FeMoSe4 nano-potato chip-like potassium ion battery negative electrode material. The potassium ion battery negative electrode material synthesized by the invention has simple process, short production cycle, low cost, strong repeatability, has an important reference to the preparation of selenium-based nanocomposites, and has high intrinsic conductivity and large interlayer spacing, excellent rate performance and cycle performance, but also in the semiconductor, energy storage and catalytic fields have broad application prospects.

Owner:UNIV OF SCI & TECH BEIJING

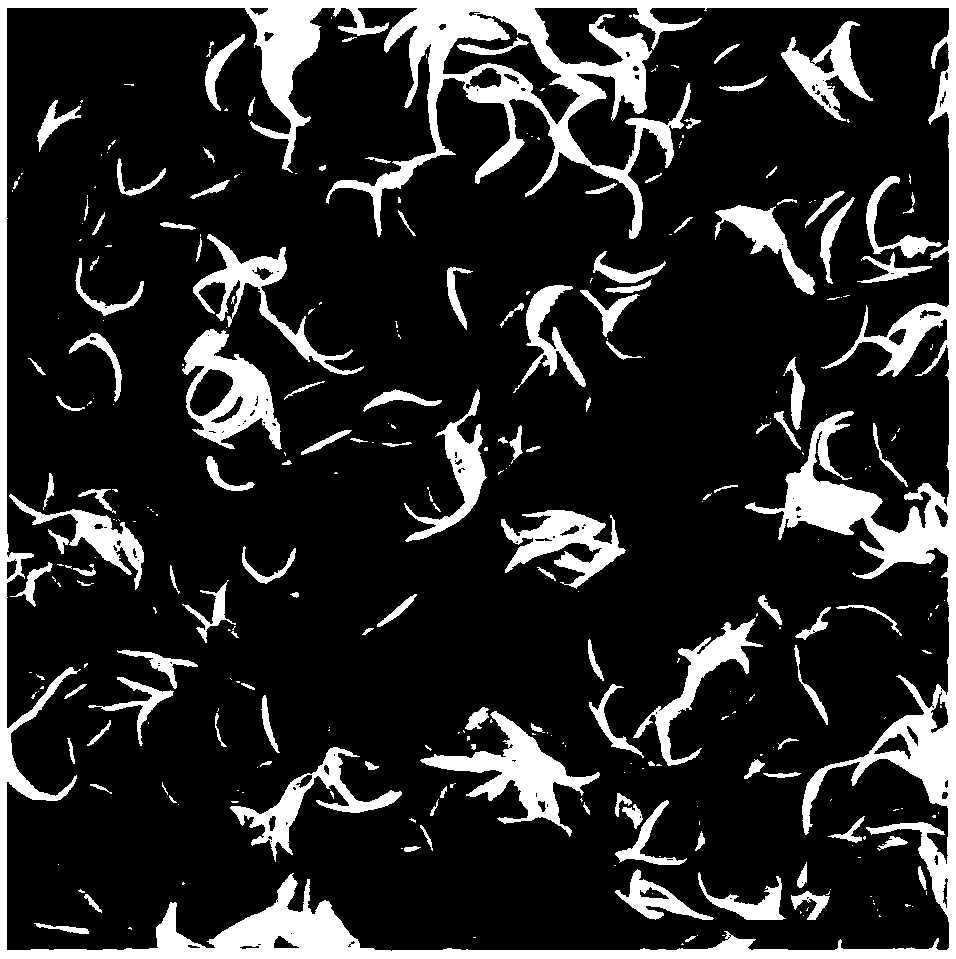

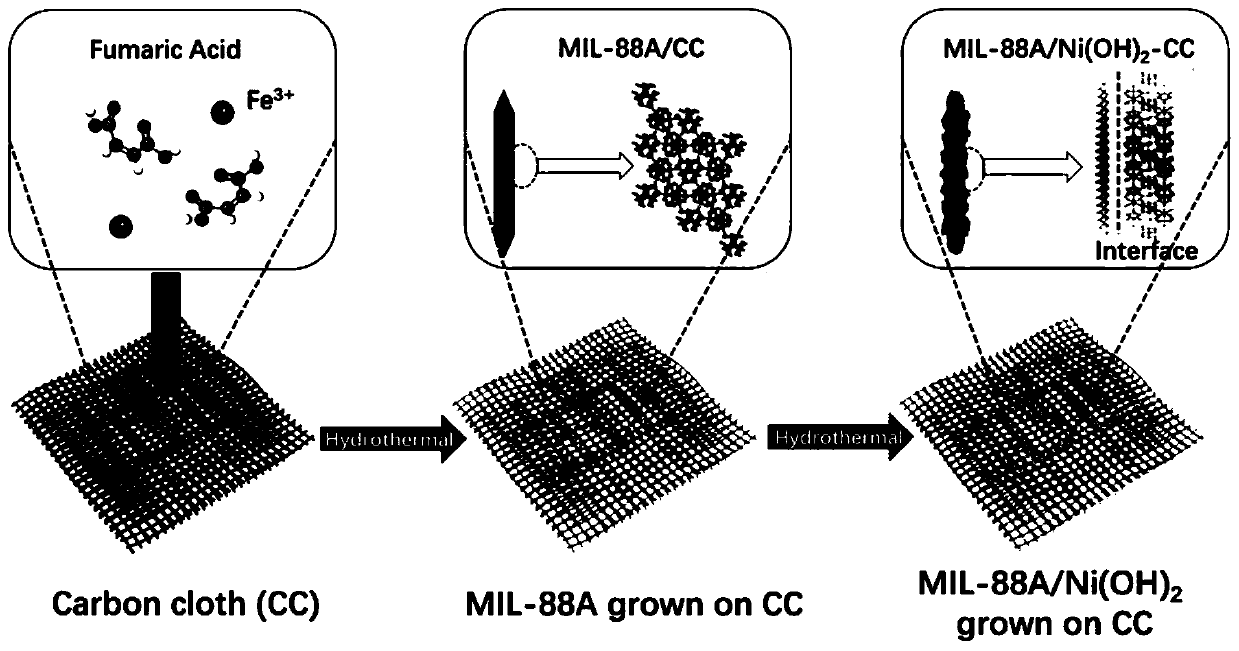

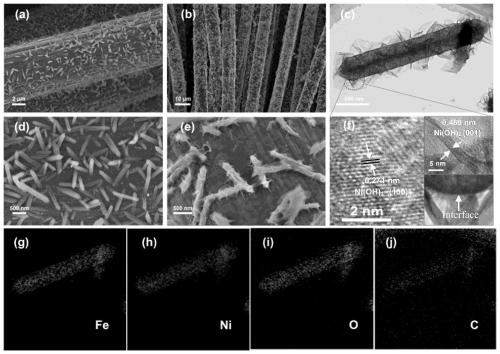

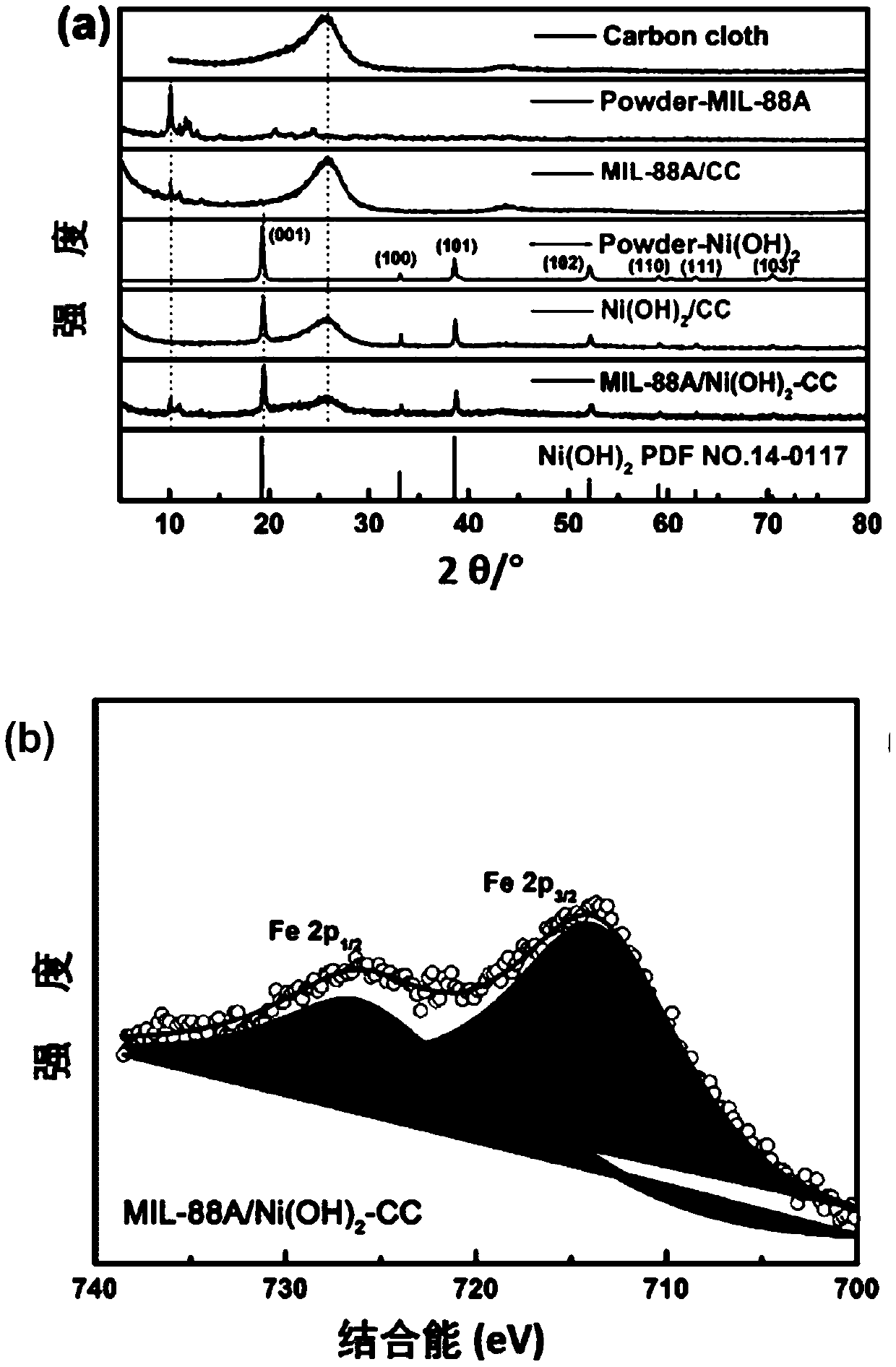

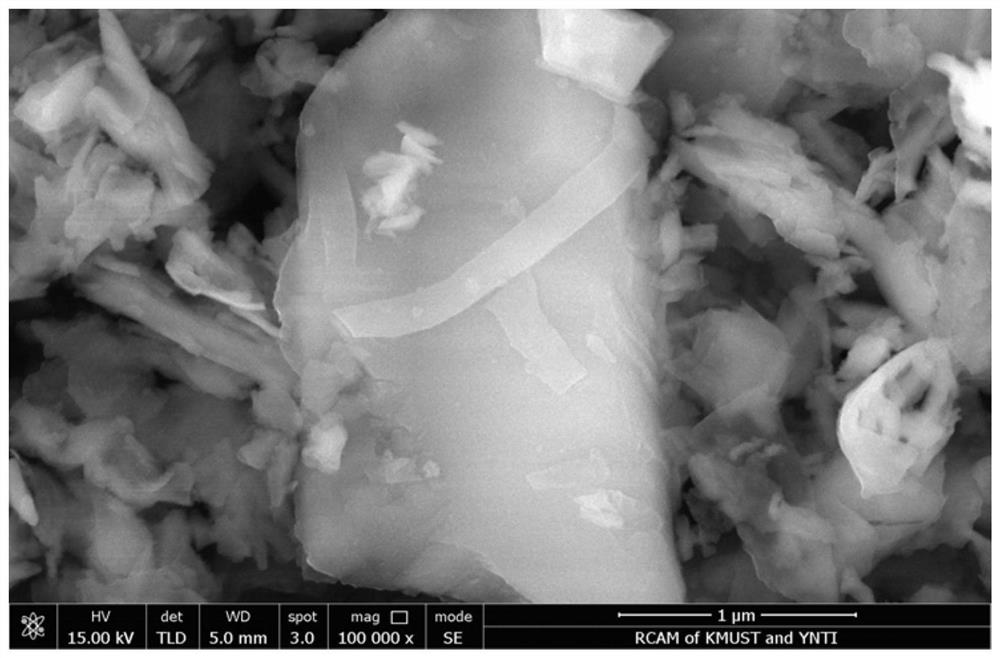

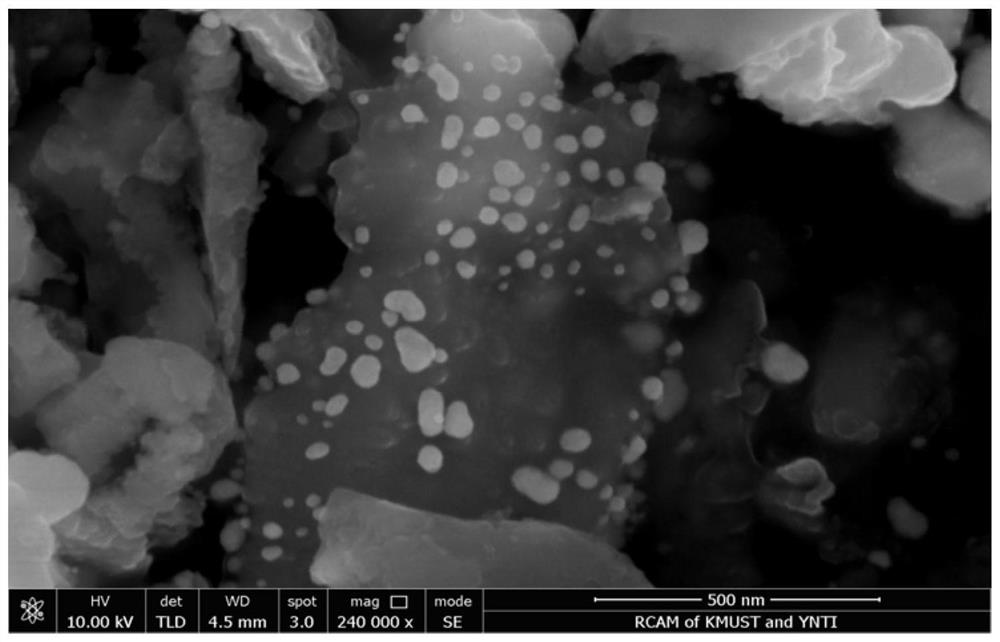

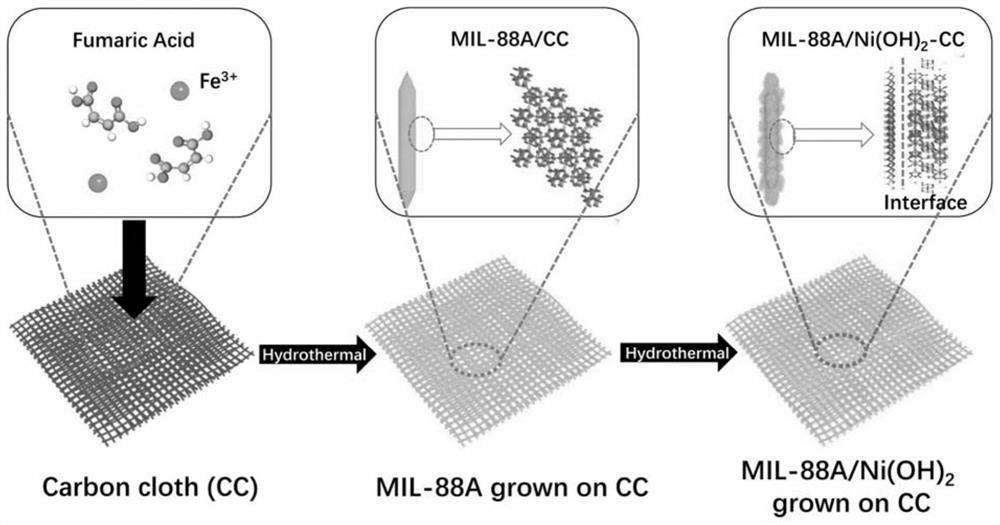

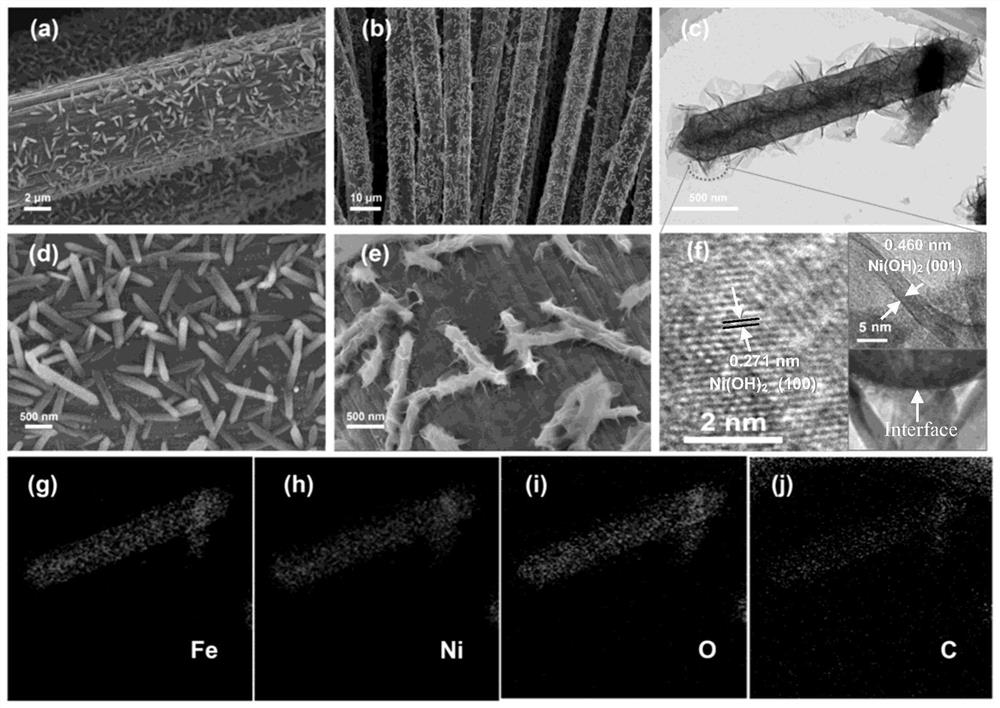

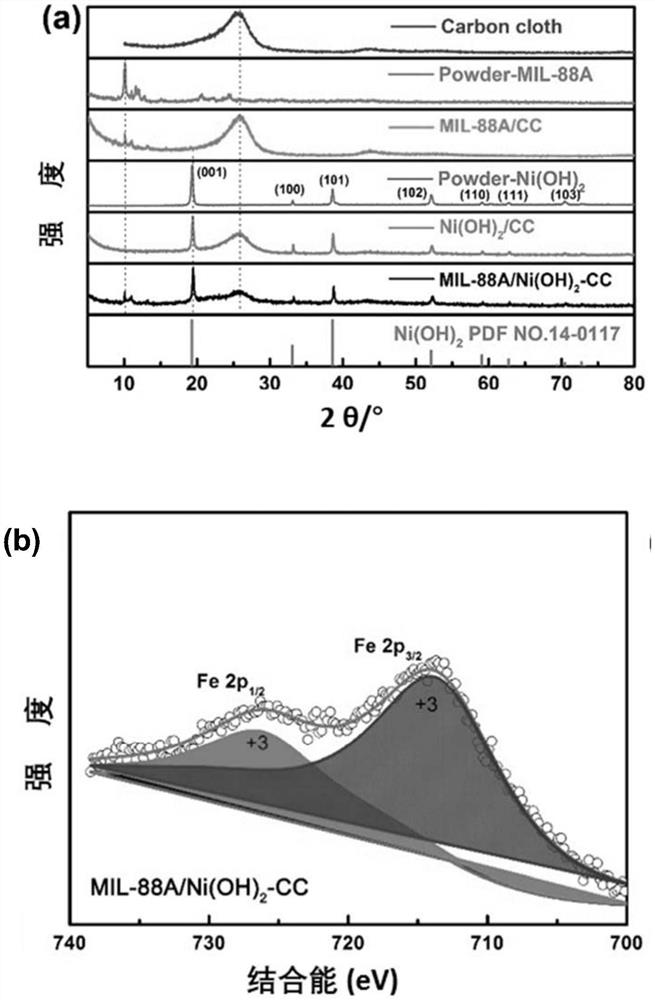

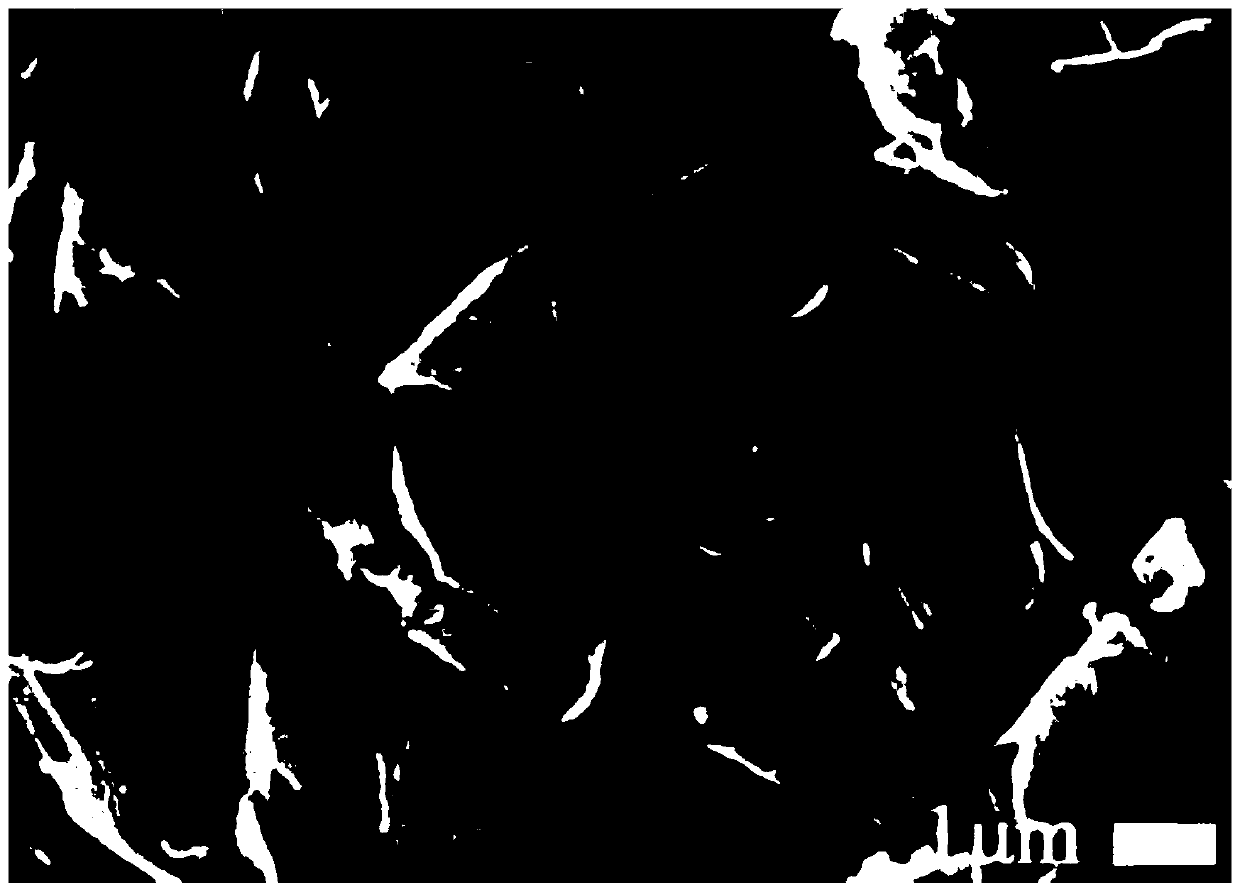

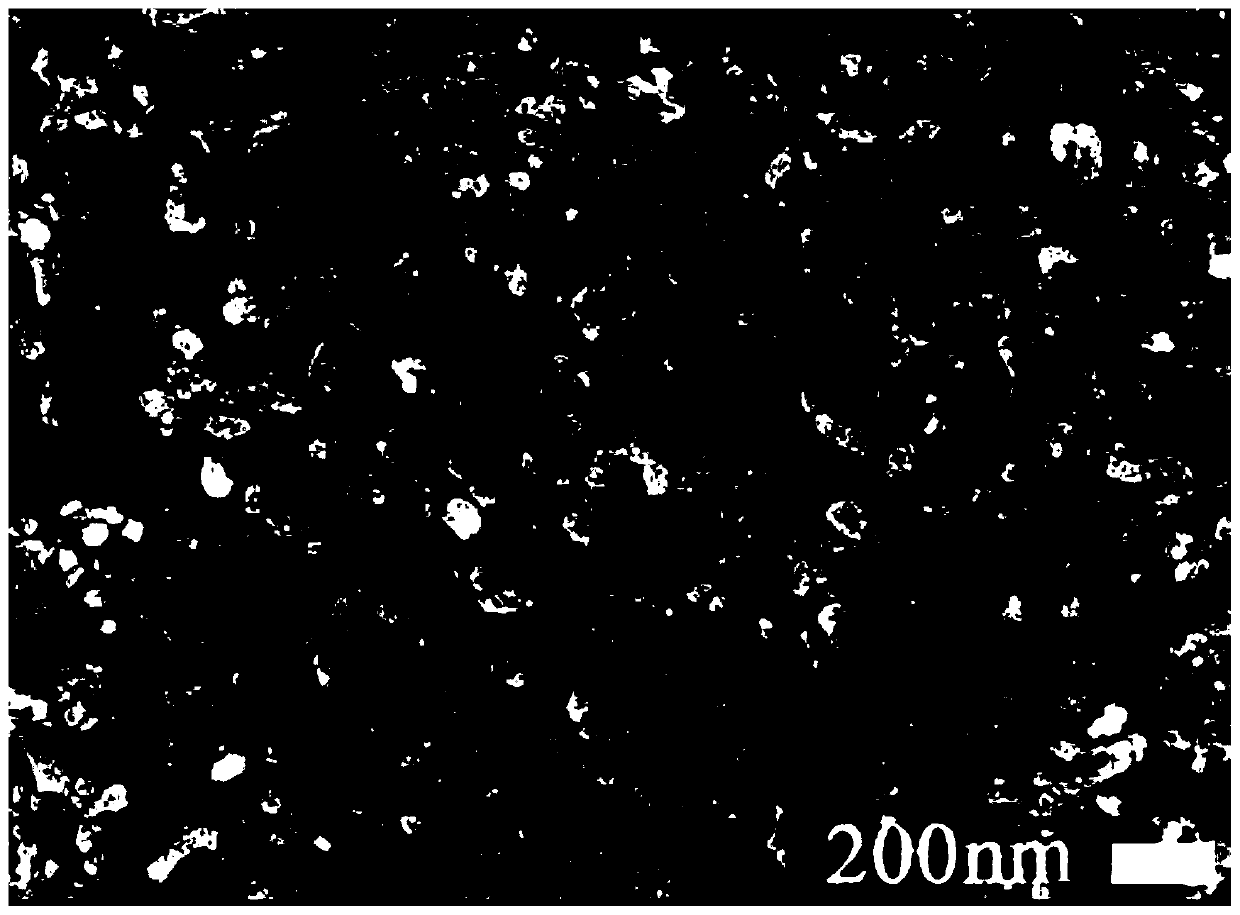

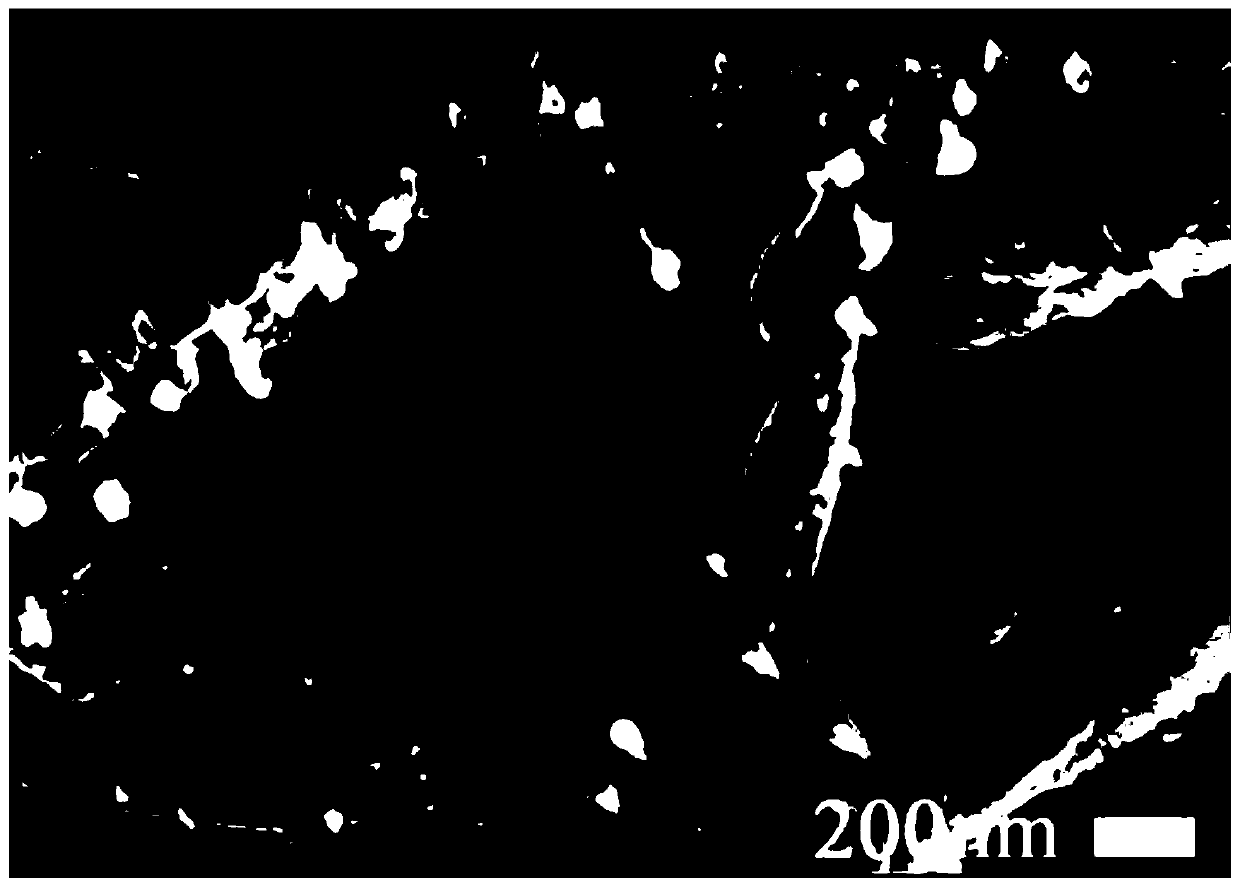

Heterostructure self-supporting electrode material and preparation method and application thereof

ActiveCN111129515AReduce manufacturing costIncrease intrinsic activityFuel and secondary cellsCell electrodesHeterojunctionMetal framework

The invention belongs to the technical field of energy materials, and discloses preparation of a heterostructure self-supporting electrode material and an application. The method comprises the following steps: (1) firstly enabling MIL-88A to grow on the surface of carbon cloth through a hydrothermal reaction; (2) then enabling Ni (OH) 2 to grow on the surface of MIL-88A through a secondary hydrothermal reaction, so as to finish the preparation of the heterostructure self-supporting electrode. The method is simple and low in cost; the prepared composite material has excellent oxygen productionperformance and excellent long-term stability. The carbon cloth is used as a self-supporting electrode, so the defect of poor intrinsic conductivity of MIL-88A is overcome, and the organic metal framework plays the maximum catalytic performance. The preparation method is free of a high-temperature calcination process, energy is saved while an organic metal framework structure is not damaged, and the method is environmentally friendly and has industrial prospects.

Owner:SOUTH CHINA UNIV OF TECH

Methods of manufacturing high temperature thermistors

InactiveUS7432123B1Current responsive resistorsSemiconductor/solid-state device manufacturingOhmic contactMetallurgy

A method of manufacturing high temperature thermistors. A polycrystalline thermistor body is formed from a material selected from a list consisting of bulk polycrystalline Si with intrinsic conductivity and bulk polycrystalline Ge with intrinsic conductivity. At least one ohmic contact is formed on at least one surface of the polycrystalline thermistor body.

Owner:ADSEM

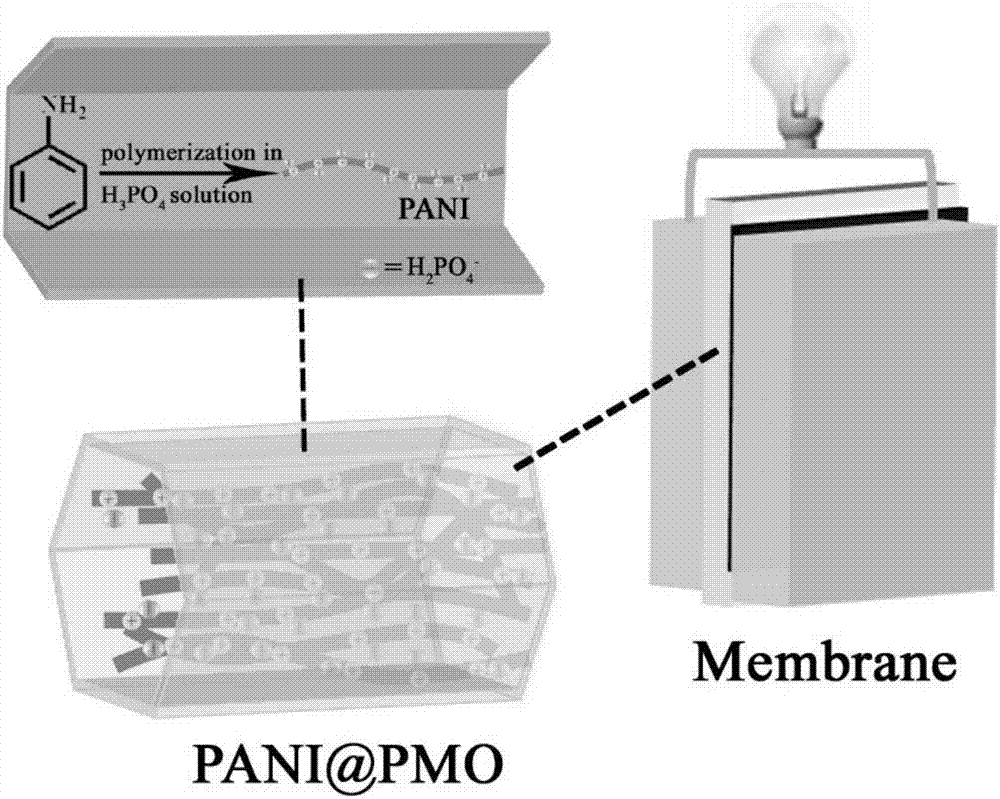

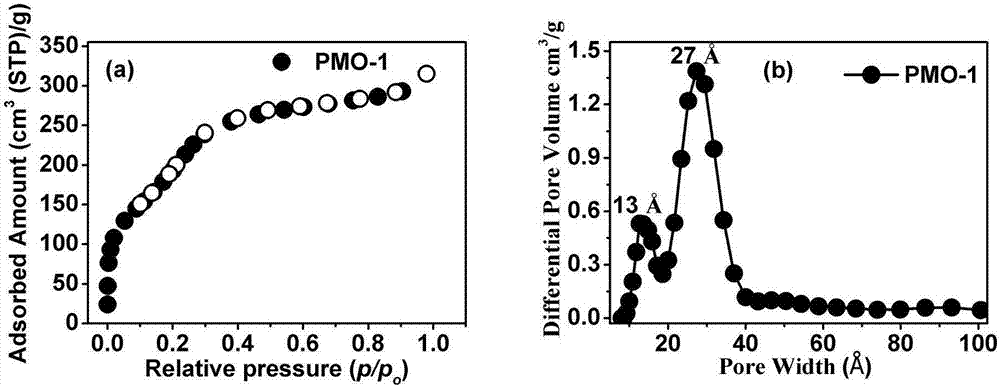

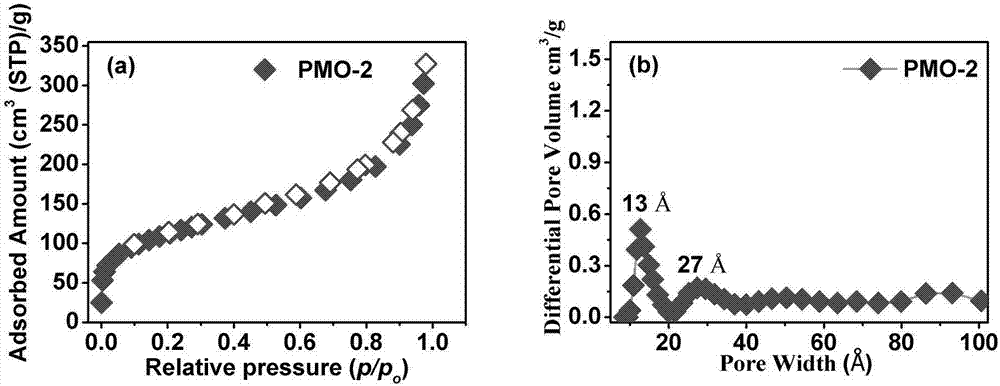

Periodic mesoporous organosilicon material and preparation method of polymer composite material thereof

InactiveCN107369842AImprove proton conductivityResolve dependenciesFuel cellsIntrinsic conductivityNitrogen gas

The invention discloses a periodic mesoporous organosilicon material and a preparation method of a polymer composite material thereof. The method comprises the following steps: preparing periodic mesoporous organosilicon with different pore sizes by using organosilicate ester under the regulation and control of a pore former; and importing monomer micromolecules into PMO pores, and performing limited range polymerization to prepare a nonporous high proton conducting material with wide temperature domain and low humidity dependence. The nonporous material can effectively solve the problematic issues of high humidity dependence, fuel penetration and catalyst poisoning and the like can be effectively solved. The material prepared under the regulation and control can maintain the high proton conductivity of 10-2S cm-1 at the relative humidity (RH) 35% and 95%RH, and the intrinsic conductivity has high proton conducting behaviors exceeding 10-3S cm-1 within a temperature range of -40 DEG C to 130 DEG C, and the maximum value reaches 10-2S cm-1, and meanwhile, 77K nitrogen adsorption data show that the nonporous material with a specific surface area of 15.9m2g-1 can be prepared by the regulation and control method.

Owner:FUJIAN NORMAL UNIV

Method for preparing boron-doped nano-metal/porous silicon-carbon composite negative electrode based on cut silicon wastes

ActiveCN111799460AWide variety of sourcesLow priceMaterial nanotechnologyCarbon compoundsCarbon compositesIntrinsic conductivity

The invention relates to a method for preparing a boron-doped nano-metal / porous silicon-carbon composite negative electrode based on cut silicon wastes. The method comprises the following steps: removing impurities from cut silicon wastes, and carrying out metal-assisted etching treatment to obtain a nano-metal / porous silicon composite material; mixing the nano-metal / porous silicon composite material with a boron source, and carrying out high-temperature treatment to form substitution doping of silicon by boron; compounding with a carbon material to obtain the boron-doped nano-metal / porous silicon-carbon composite negative electrode. By adding the porous structure of silicon and the carbon material, the volume expansion of silicon can be relieved and cycling stability is increased; the metal particles are physically compounded with silicon on the surface of the silicon substrate, and the boron has the chemical doping synergistic effect of silicon on the atomic scale, so that the intrinsic conductivity of the silicon-based composite material and the electrochemical activity are finally improved, and the boron-doped nano-metal / silicon-carbon composite negative electrode material withhigh charge-discharge specific capacity and long cycle life is prepared.

Owner:KUNMING UNIV OF SCI & TECH

A kind of heterostructure self-supporting electrode material and its preparation method and application

ActiveCN111129515BReduce manufacturing costIncrease intrinsic activityFuel and secondary cellsCell electrodesHeterojunctionMetal framework

The invention belongs to the technical field of energy materials, and discloses preparation of a heterostructure self-supporting electrode material and an application. The method comprises the following steps: (1) firstly enabling MIL-88A to grow on the surface of carbon cloth through a hydrothermal reaction; (2) then enabling Ni (OH) 2 to grow on the surface of MIL-88A through a secondary hydrothermal reaction, so as to finish the preparation of the heterostructure self-supporting electrode. The method is simple and low in cost; the prepared composite material has excellent oxygen productionperformance and excellent long-term stability. The carbon cloth is used as a self-supporting electrode, so the defect of poor intrinsic conductivity of MIL-88A is overcome, and the organic metal framework plays the maximum catalytic performance. The preparation method is free of a high-temperature calcination process, energy is saved while an organic metal framework structure is not damaged, and the method is environmentally friendly and has industrial prospects.

Owner:SOUTH CHINA UNIV OF TECH

High-performance polypyrrole-based ternary composite thermoelectric material and preparation method thereof

The invention discloses a high-performance polypyrrole-based ternary composite thermoelectric material and a preparation method thereof. The ternary composite material takes polypyrrole as a matrix and enables a pyrrole monomer to be doped with a graphene nanosheet and then carry out the adsorption and polymerization along the surface of graphene, thereby promoting the adsorption growth of polypyrrole on the surface of graphene as a template, and then the compound and polyaniline are compounded into a polypyrrole / graphene / polyaniline ternary composite thermoelectric material. By adopting the method and the material, the dispersity and compatibility of the composite material can be improved, a special conductive path is formed between the ternary composite materials, the thermoelectric property of the composite material is improved, the defects of low intrinsic conductivity of polypyrrole, high thermal conductivity of graphene and the like are overcome, and by compounding polypyrrole, graphene and polyaniline, the novel preparation method of the polypyrrole-based high-thermoelectric composite material which is simple to operate, environmentally friendly and good in component dispersion uniformity is provided.

Owner:SICHUAN UNIV

Open-Shell Conjugated Polymer Conductors, Composites, and Compositions

PendingUS20200362098A1Increase intrinsic conductivityWide-range tunabilityConductive materialNon-conductive material with dispersed conductive materialDopantPolymer science

The invention provides for polymer structures and their preparation and resulting novel functionalities including open-shell character and high intrinsic conductivity with wide-range tenability. Electrical conductivity can be further modulated by introducing or blending with materials, fillers, dopants, and / or additives. The materials or resultant composites of the invention can be processed by various techniques into different forms to realize multiple applications.

Owner:AZOULAY JASON D +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com