Preparing method of nanometer silicon particles for lithium battery

A technology of nano-silicon and silicon particles, which is applied in the field of nano-material preparation and new energy, can solve the problems of loss of conductive environment, capacity decay, low conductivity of silicon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

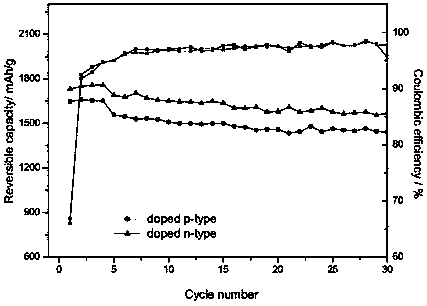

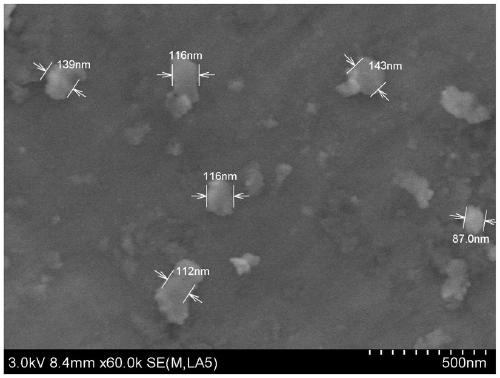

[0019] N-type heavily doped crystalline silicon (0.01 Ω·cm) was selected as the workpiece electrode, a copper tube was used as the tool electrode, and deionized water was selected as the working fluid. The pulse width of the discharge pulse generated by the pulse power supply is 100μs, the duty ratio is 1:4, and the rectangular pulse voltage with an open circuit voltage of 160V is applied between the workpiece electrode and the tool electrode, and ionizes and breaks down the insulating working medium to form a plasma discharge channel. Micron or submicron silicon particles are obtained after the high-temperature melting and gasification workpiece electrodes are condensed. After filtering with a centrifuge, silicon particles with a median particle size of about 3.2 µm were obtained.

[0020] Use high-energy ball milling to further refine the collected micron or submicron silicon particles, use ethanol as a dispersion medium, prepare a silicon slurry with a solid content of 10%,...

Embodiment 2

[0022] N-type heavily doped crystalline silicon (0.01 Ω·cm) was selected as the workpiece electrode, a copper tube was used as the tool electrode, and deionized water was selected as the working fluid. The pulse width of the discharge pulse generated by the pulse power supply is 150μs, the duty ratio is 1:4, and the rectangular pulse voltage with an open circuit voltage of 300V is applied between the workpiece electrode and the tool electrode, and ionizes and breaks down the insulating working medium to form a plasma discharge channel. Micron or submicron silicon particles are obtained after the high-temperature melting and gasification workpiece electrodes are condensed. After filtering with a centrifuge, silicon particles with a median diameter of about 10 µm were obtained.

[0023] The collected micron or submicron silicon particles are further refined by high-energy ball milling, acetone is used as the dispersion medium, and a silicon slurry with a solid content of 25% is ...

Embodiment 3

[0025] P-type heavily doped crystalline silicon (0.01 Ω·cm) was selected as the workpiece electrode, copper tube was used as the tool electrode, and deionized water was selected as the working fluid. The pulse width of the discharge pulse generated by the pulse power supply is 100μs, the duty ratio is 1:4, and the rectangular pulse voltage with an open circuit voltage of 180V is applied between the workpiece electrode and the tool electrode, and ionizes and breaks down the insulating working medium to form a plasma discharge channel, resulting in Micron or submicron silicon particles are obtained after the high-temperature melting and gasification workpiece electrodes are condensed. After filtering with a centrifuge, silicon particles with a median diameter of about 10 µm were obtained.

[0026] The collected micron or submicron silicon particles are further refined by high-energy ball milling, methanol is used as a dispersion medium, and a silicon slurry with a solid content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com