Patents

Literature

153results about How to "Improve electrochemical cycle performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

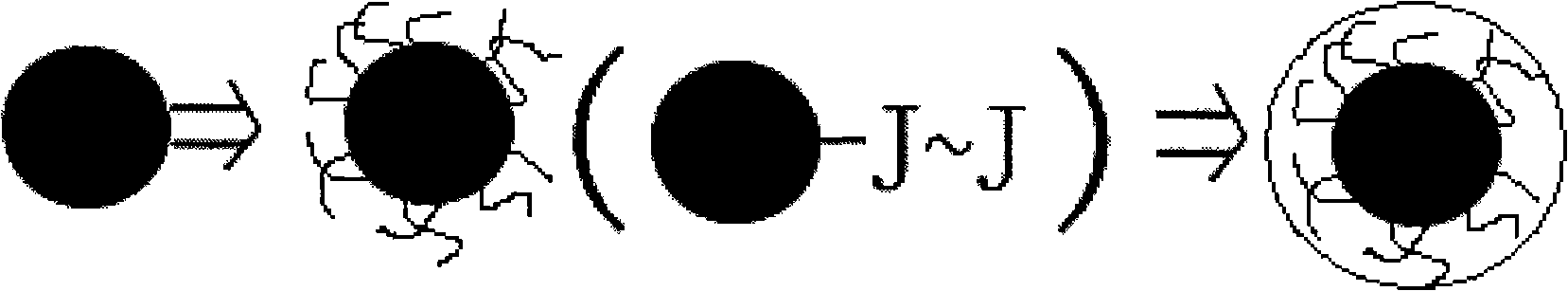

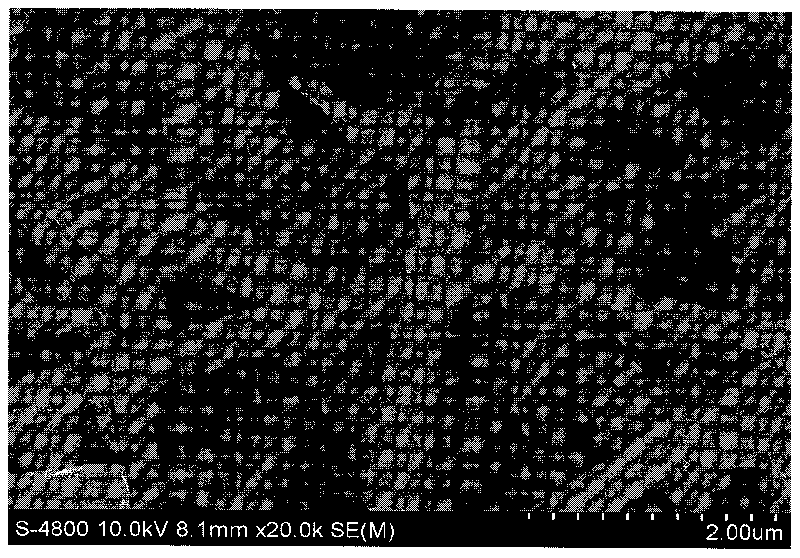

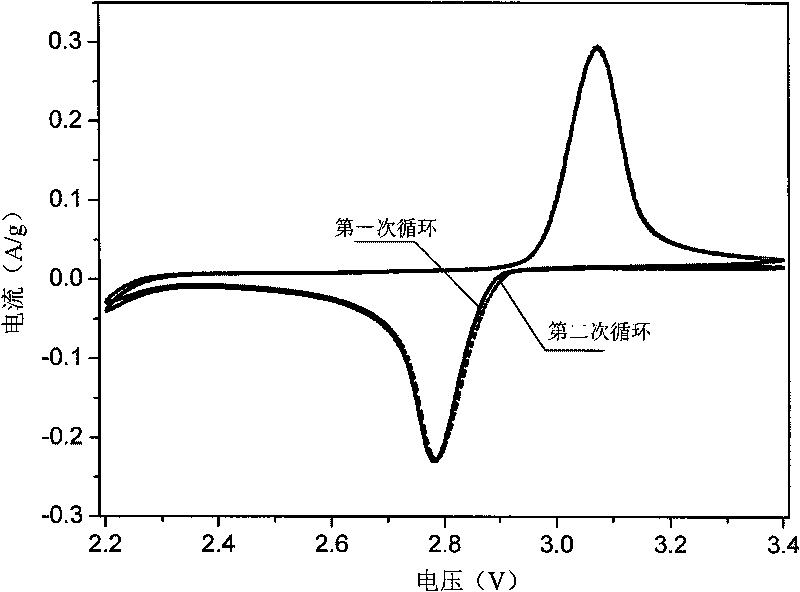

Nano carbon sulfur composite material with network structure and preparation method of nano carbon composite material

InactiveCN102142554AImprove conductivityImprove electrochemical performanceMaterial nanotechnologyCell electrodesCross-linkPorosity

The invention relates to a nano carbon material with a network structure consisting of polymer chains, in particular to a nano carbon sulfur composite material with a network structure suitable to be used in a secondary lithium sulfur battery anode and a preparation method thereof. The carbon sulfur composite material is formed by adopting the following steps of: introducing functional groups onto carbon particles by adopting the electric conductivity and the porosity of a carbon material and the reaction capacity of similar condensed aromatics of the carbon material and by means of an irreversible chemical reaction; introducing the polymer chains, wherein the polymer chains are stretched, bent and cross-linked on the surfaces of the carbon particles to form a cross-linked network structure; and compounding a sulfur element or a polysulfide (m is more than 2) containing -Sm- structure into the network structure to form the nano carbon sulfur composite material with the network structure. The carbon sulfur composite material has a rich cross-linked network structure, nano-scale network pores constrain the sulfur element or the polysulfide (m is more than 2) containing the -Sm- structure in the network, and the active substances are limited in a certain region to react, so that the composite material has predominant electrochemical performance.

Owner:NO 63971 TROOPS PLA

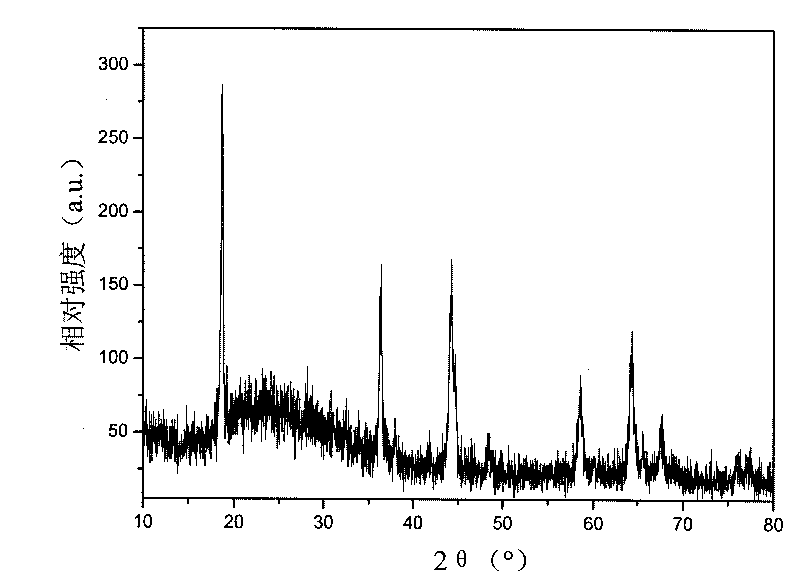

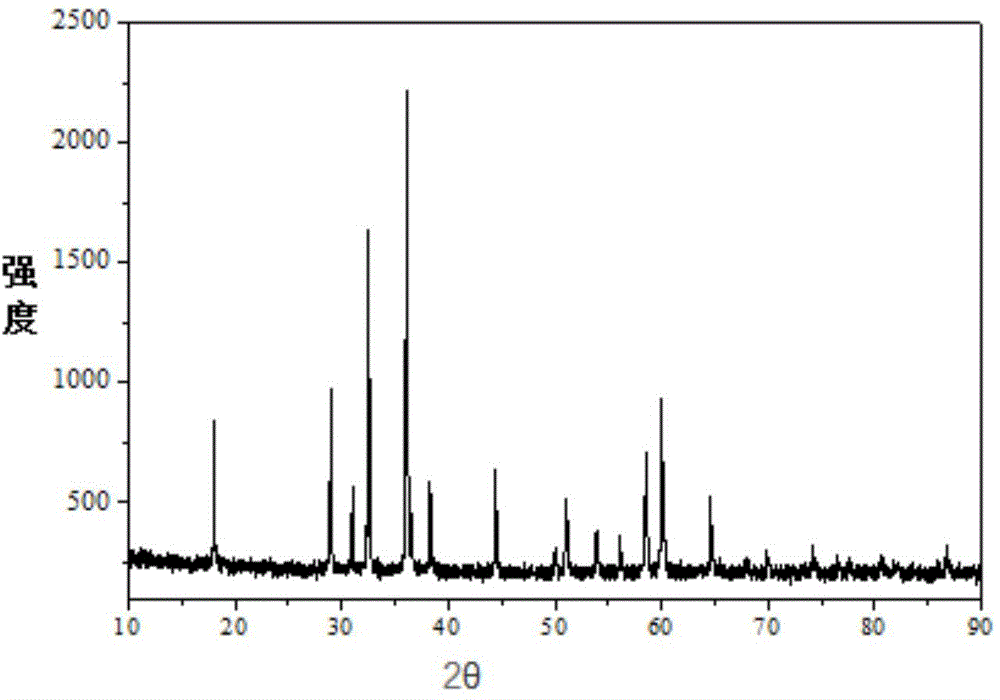

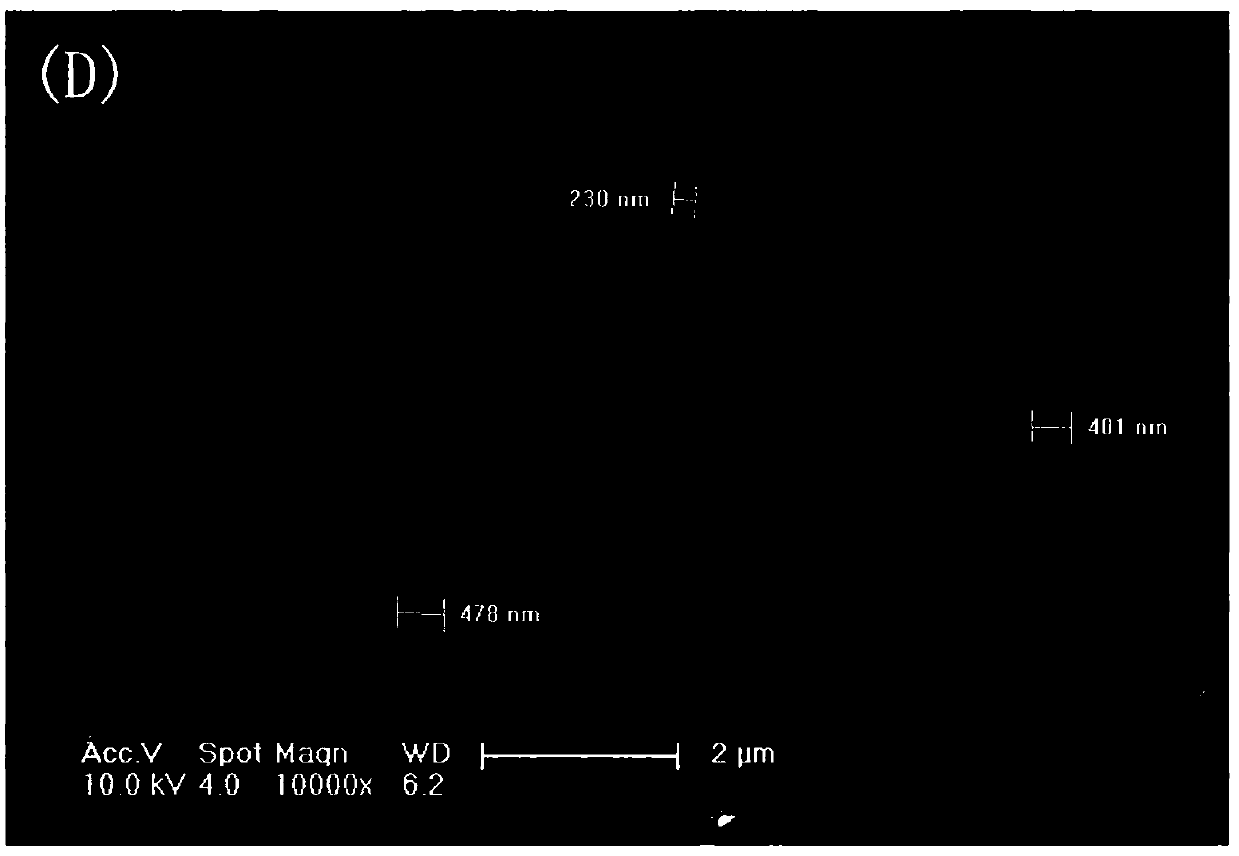

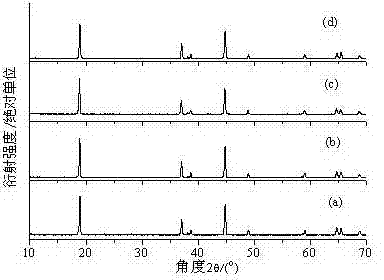

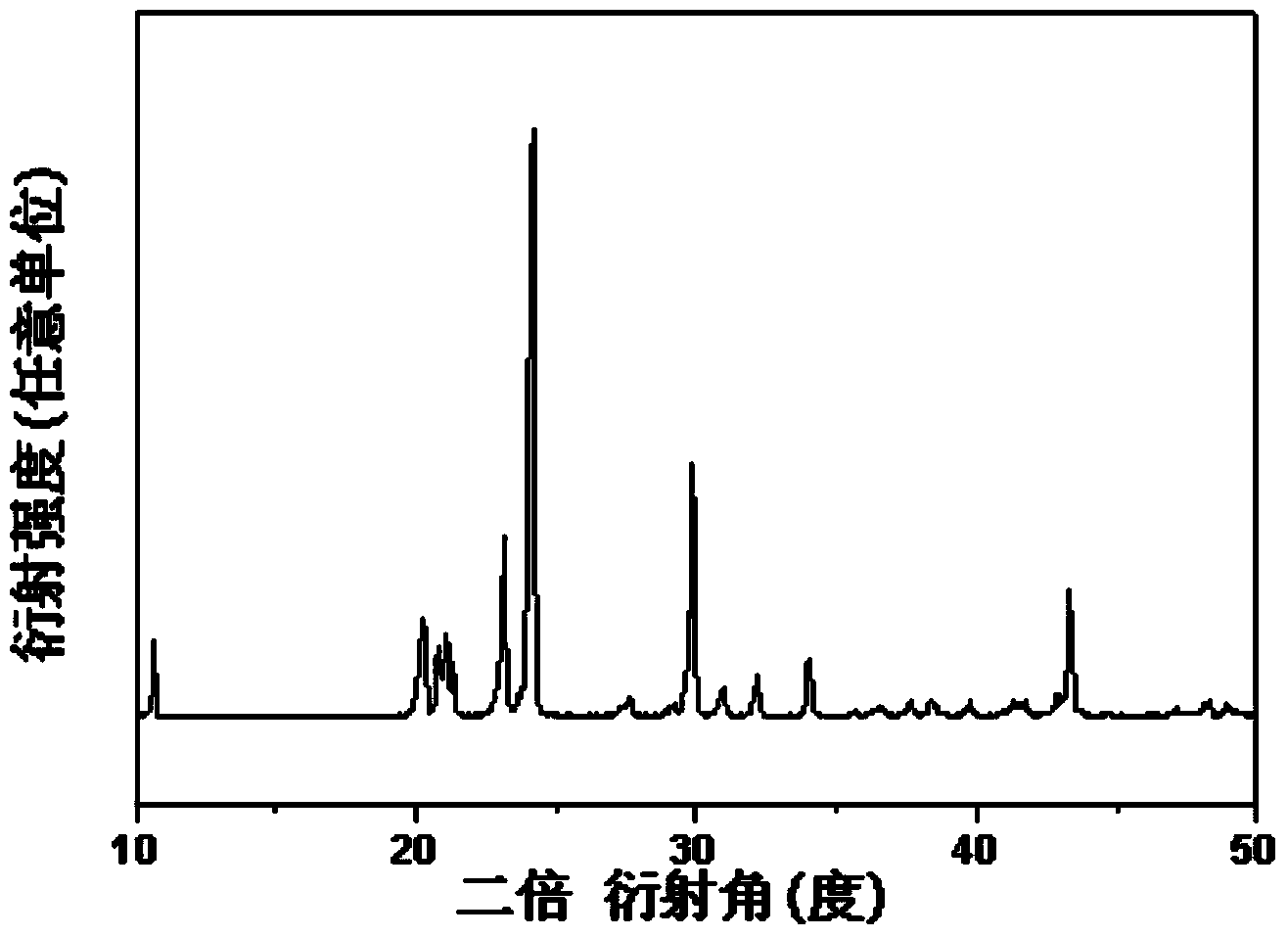

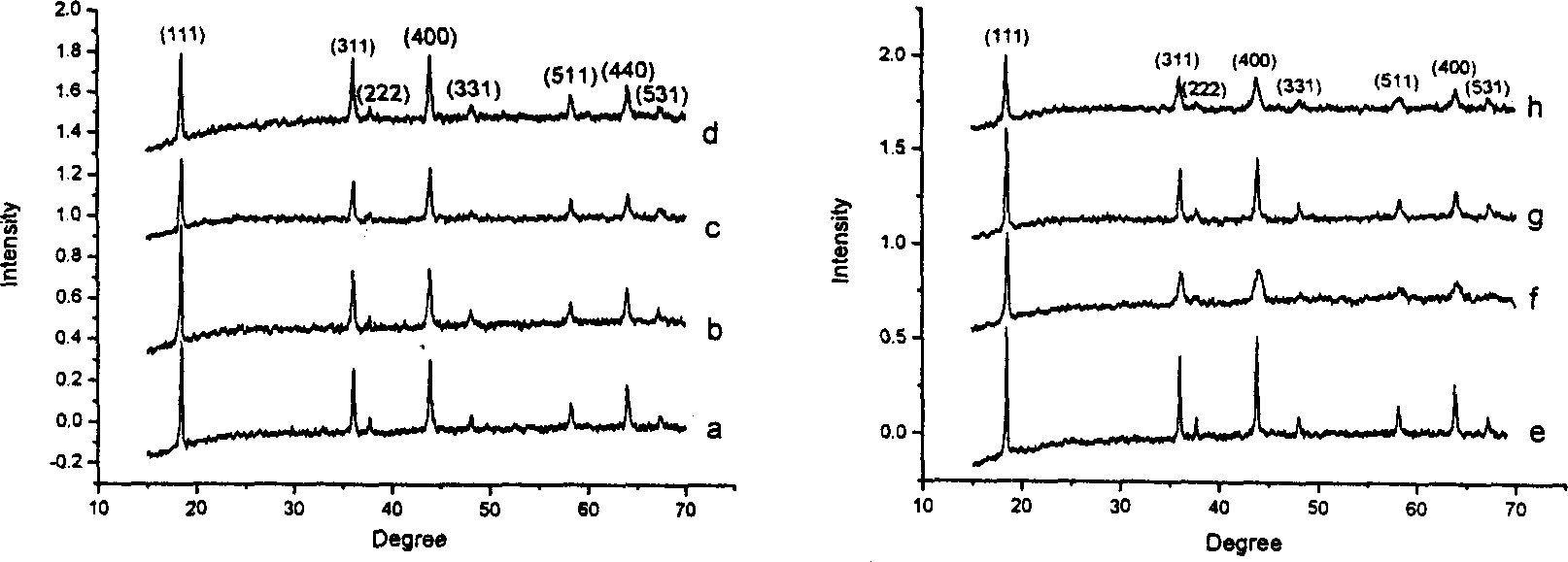

Method for synthesizing Li4Mn5O12 sub-micrometer rod

InactiveCN101764224AGood repeatabilityEasy to operateCell electrodesManganates/permanganatesIonSub micrometer

The invention discloses a method for synthesizing a Li4Mn5O12 sub-micrometer rod, belonging to the technical field of synthesis of active material of a lithium ion battery. The method includes the following steps: firstly, synthesizing a MnOOH sub-micrometer rod through hydrothemal method and secondly preparing Li4Mn5O12 through solid phase technique, wherein the MnOOH sub-micrometer rod is synthesized by taking MnSO4.H2O, KMnO4 and CTAB as raw materials through the steps of keeping the materials warm for 12h-30h under 140 DEG C to 180 DEG C, washing through alcohol and deionized water, and drying; and the Li4Mn5O12 is prepared by taking MnOOH and LiOH.H2O as raw materials through the step of keeping the materials warm for 10h-24h under 500 DEG C-900 DEG C. The method has the advantages of easy implementation, good repeatability and low material cost, and the product of Li4Mn5O12 is of one-dimensional structure which facilitates the transfer of the Li + / charges in the one-dimensional direction when the Li4Mn5O12 sub-micrometer rod is applied on the lithium ion battery and is good for improving the performance of the lithium ion battery.

Owner:BEIHANG UNIV

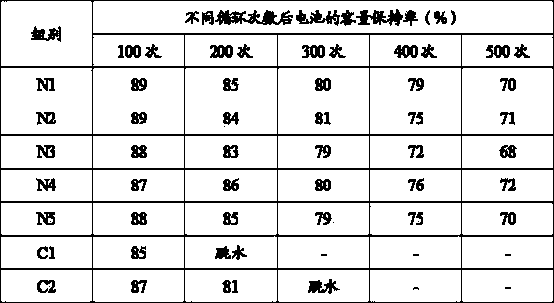

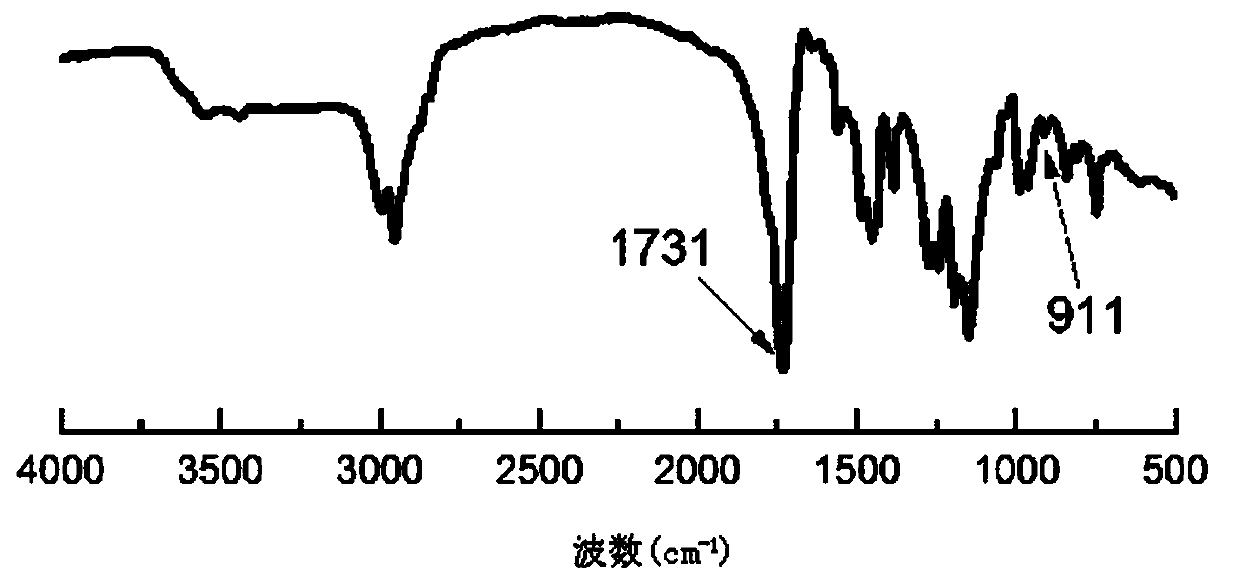

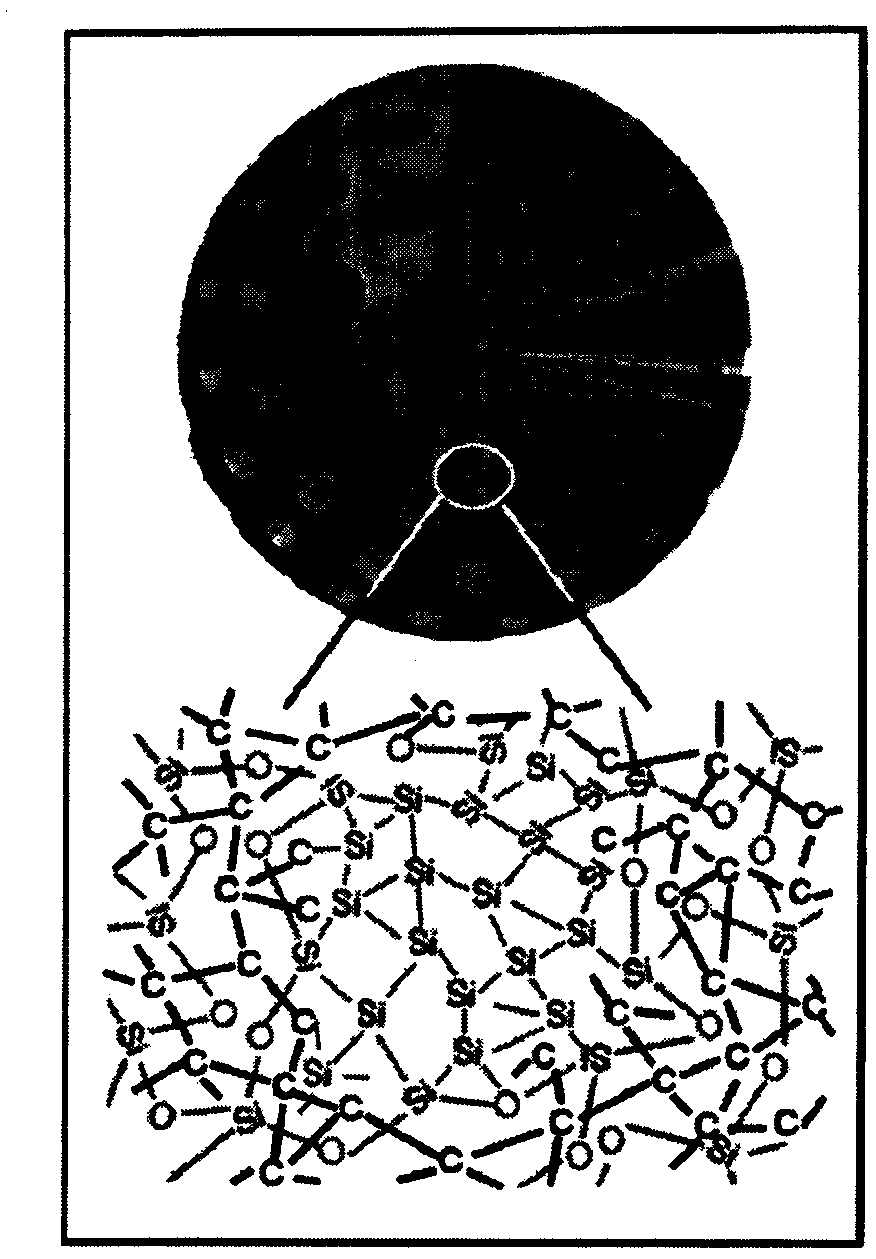

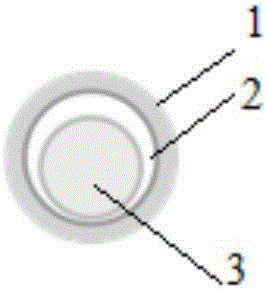

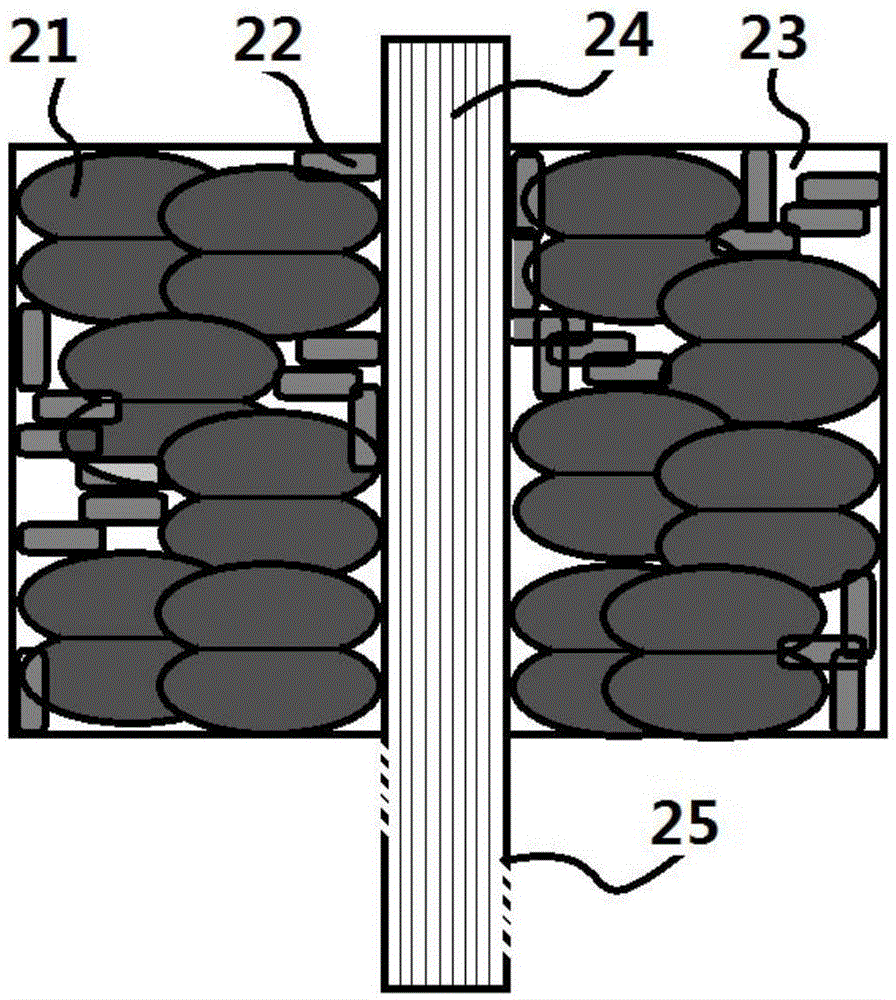

Composite anode material for lithium ion battery and preparation method thereof

ActiveCN103456928AAchieve cross-linkingIntegrity guaranteedManufacture by sprayingSilicon alloySodium-ion battery

The invention belongs to the technical field of lithium ion batteries, in particular relates to a composite anode material for the lithium ion battery. The composite anode material comprises an anode active substance and a coating layer coated on the surface of the anode active substance, wherein the anode active substance can be Si, SiOx or silicon alloy, the coating layer is polymer which is of a reticular structure, and the mass percent of the coating layer accounts for 1-20% of the anode material. Compared with the prior art, the composite anode material has the advantages that the polymer which is of the reticular structure and used as the coating layer is coated on the surface of the active substance in a cross-linking manner, the coating layer has the electron conduction property and the ion conduction property, so that the situation that the lithium ions can be inserted into and separated from the anode active substance particles smoothly is ensured; furthermore, the coating layer is of the reticular structure and has good mechanical strength, and therefore, the integrality of the anode active substance particles can be kept in the electrochemical cycle process, the deformation of an anode strip is relieved, the electrochemical cycle performance of the lithium ion battery is improved and the service life of the lithium ion battery is prolonged.

Owner:DONGGUAN AMPEREX TECH +1

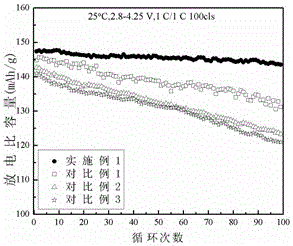

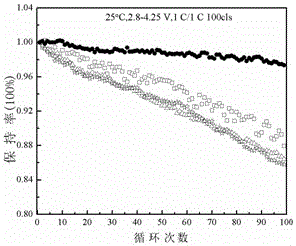

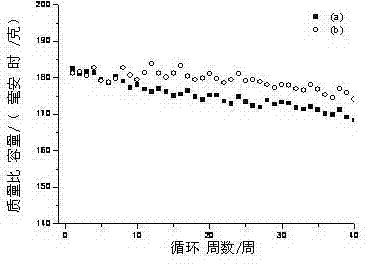

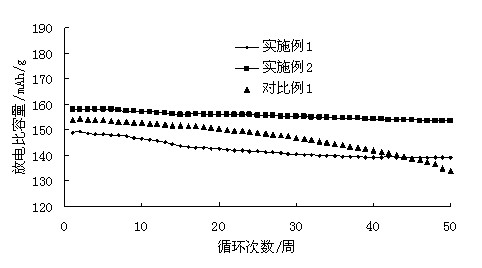

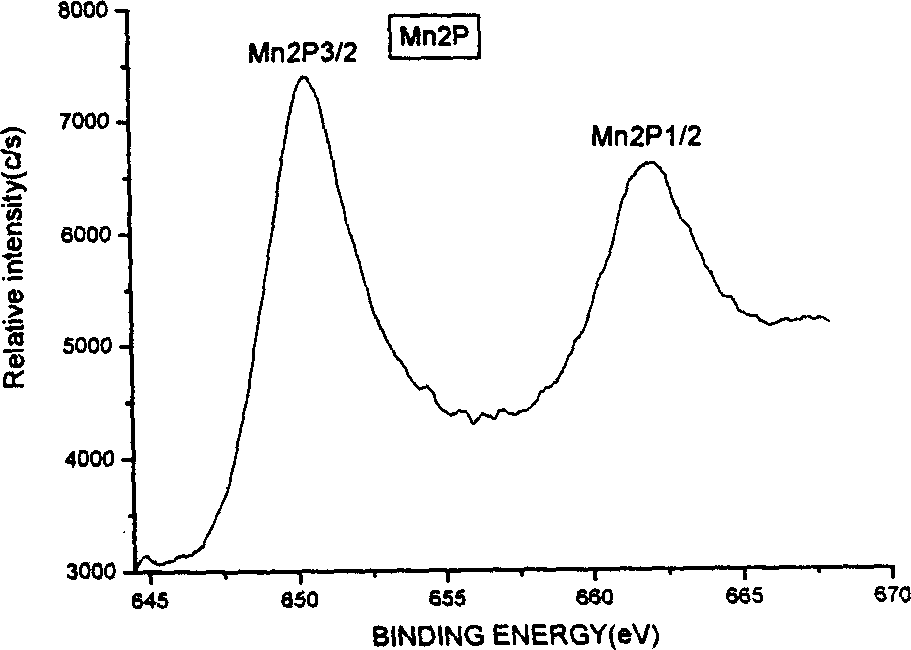

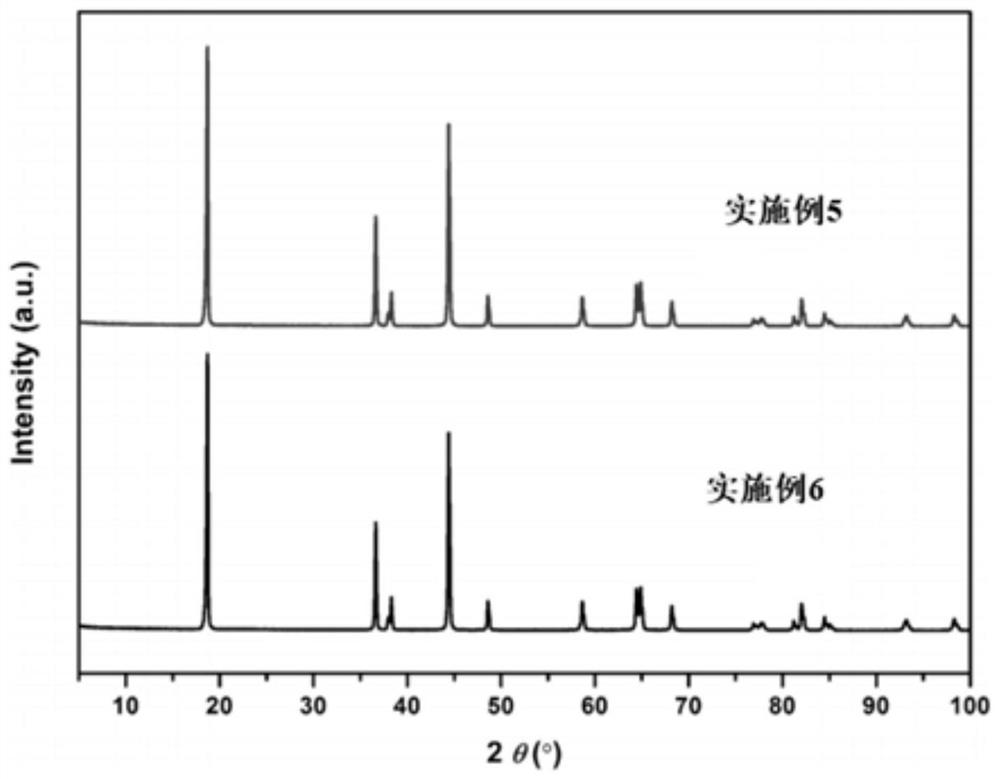

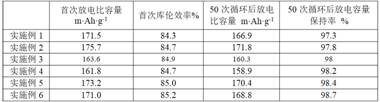

Element co-doping modified ternary lithium ion battery cathode material, and preparation method thereof

ActiveCN106395920AImprove electrochemical cycle performanceHigh magnificationCell electrodesSecondary cellsManganesePhysical chemistry

The invention discloses an element co-doping modified ternary lithium ion battery cathode material, and a preparation method thereof. According to the preparation method, compounds of two kinds of metals Me<1> and Me<2> are respectively selected based on the difference of ion radiuses of lithium ion and transition metal ions in the lithium nickel cobalt manganese ternary material, and are subjected to high temperature sintering with a nickel cobalt manganese precursor, wherein the ion radius of the metal Me<1> ion is close to that of lithium ion, and the metal Me<1> ion is one or a mixture of ions selected from Zn2+ and Zr4+, the radius of the metal Me<2> ion is close to that of transition metal ion Co3+ or Mn4+, and the metal Me<2> is one or a mixture of ions selected from Al3+, V5+, and Ge4+; and then a primary product obtained via high temperature sintering is subjected to second cladding so as to obtain the element co-doping modified ternary lithium ion battery cathode material. The element co-doping modified ternary lithium ion battery cathode material is capable of achieving synergistic effects of two metal elements fully, and improving cycle performance of lithium ion batteries effectively.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

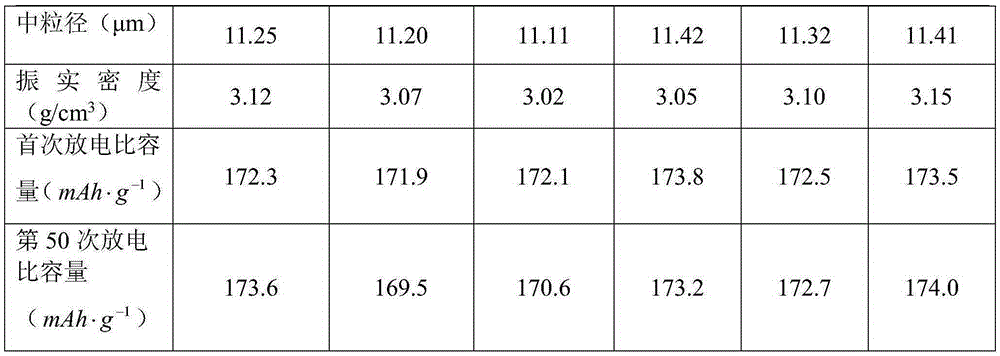

High-temperature type lithium manganate anode material for power lithium ion battery and preparation method of high-temperature type lithium manganate anode material

ActiveCN104485452AImprove high temperature resistanceExcellent discharge specific capacityCell electrodesCobalt(II,III) oxideManganate

The invention discloses a high-temperature type lithium manganate anode material for a power lithium ion battery. The high-temperature type lithium manganate anode material consists of a core material as shown in a formula Li1+xMn2-y-zAyQzO4, and a coating layer on the surface of the core material, wherein the coating layer is one or more of cobaltosic oxide, aluminum oxide and nickel protoxide. The anode material is excellent in high-temperature property, and is good in specific discharge capacity, capacity retention ratio and electrochemical circulation property at high temperature. In addition, the preparation method of the anode material disclosed by the invention is simple in production process, easy to achieve and low in cost, and can be applied to large-scale industrialization production.

Owner:北京盟固利新材料科技有限公司

Composite membrane, preparation method of composite membrane, and lithium-ion battery

InactiveCN103474601AEvenly dispersedImprove electrochemical cycle performanceSecondary cellsCell component detailsPolyolefinHexafluoropropylene

The invention relates to a method for preparing a composite membrane. The method comprises the following steps: a solution with nano sol is prepared, and the nano sol is selected from at least one of titanium sol, alumina sol, silica sol and zirconium sol; a silane coupling agent and methyl methacrylate are added to the solution; the solution is uniformly mixed to form a first mixture; an initiator is added to the mixture to polymerize the methyl methacrylate and the silane coupling agent while the silane coupling agent and the nano sol-gel generates condensation reaction, therefore the nano sol is grafted on a polymethyl methacrylate substrate to form an inorganic-organic grafted hybrid polymer; the inorganic-organic grafted hybrid polymer is mixed with a copolymer of vinylidene fluoride and hexafluoropropylene in an organic solvent to form a uniform second mixture; the second mixture is spread onto the surface of a porous polyolefin membrane; the porous polyolefin membrane coated with the second mixture is dried. The invention further relates to the composite membrane and a lithium-ion battery.

Owner:JIANGSU HUADONG INST OF LI ION BATTERY +1

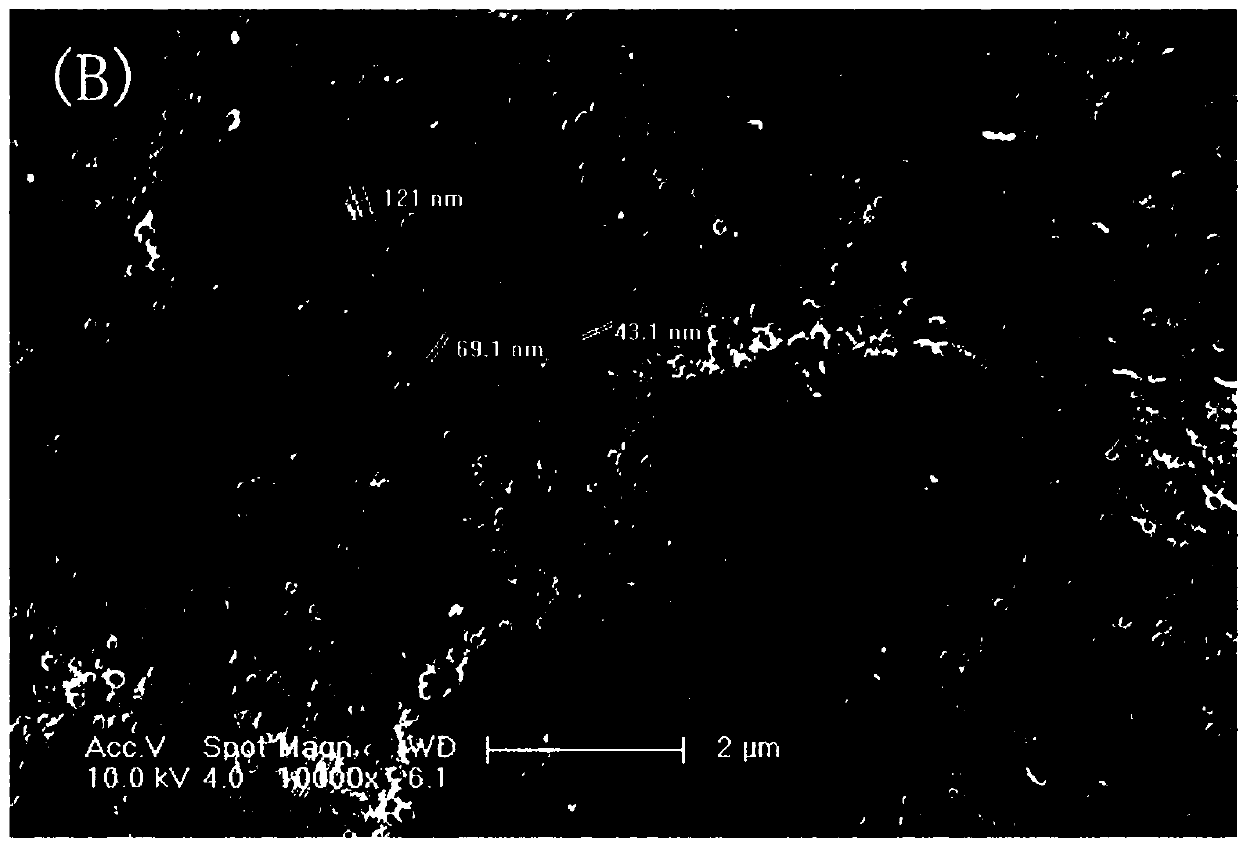

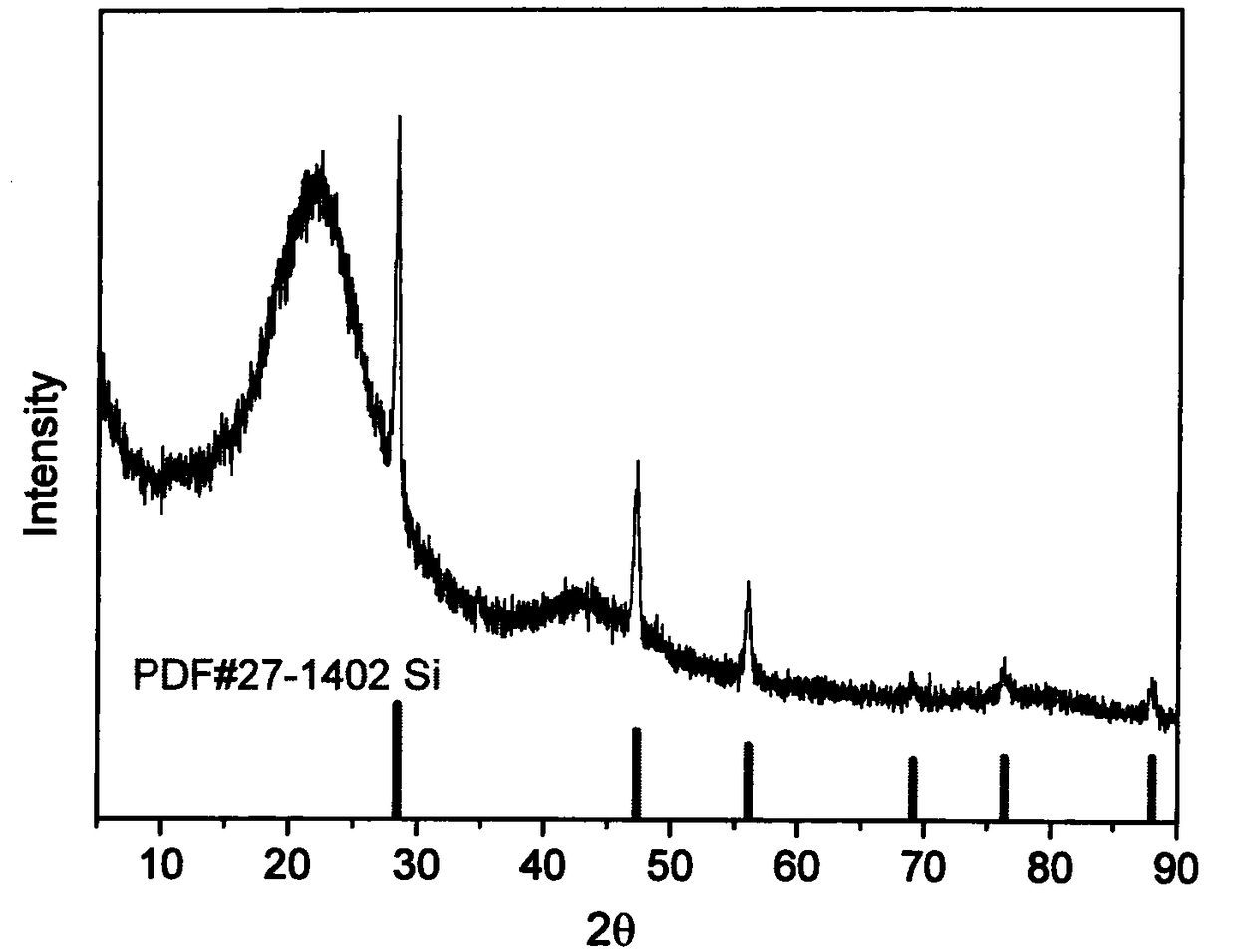

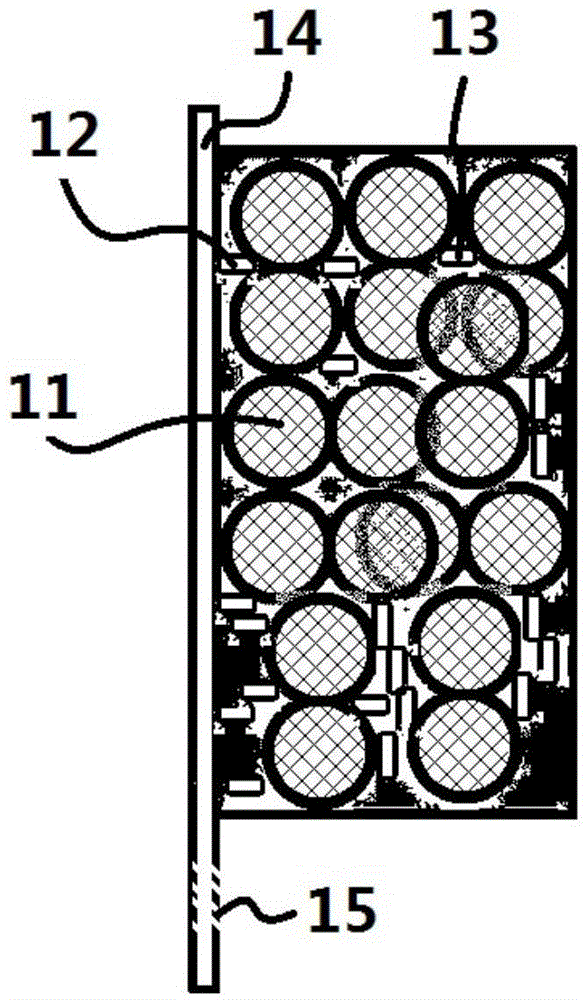

High-performance silicon/carbon anode nanocomposite and preparation method thereof

ActiveCN108428876ARich varietyGuaranteed stabilityMaterial nanotechnologyCell electrodesLithiumCarbon nanosphere

The invention provides a high-performance silicon / carbon anode nanocomposite and a preparation method thereof. The high-performance silicon / carbon anode nanocomposite is characterized by containing carbon nano-spherical particles with mesoporous channels, and the spherical particles and / or the mesoporous channels are filled with elementary silicon particles. The prepared silicon / carbon anode nanocomposite is of a porous structure, the elementary silicon particles are dispersed in a carbon skeleton and the mesoporous channels, the volume expansion effect during lithium-ion charge and dischargeis low, and electrochemical cycle performance is stable.

Owner:DONGHUA UNIV

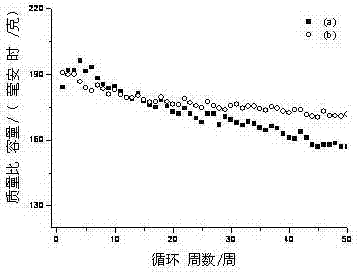

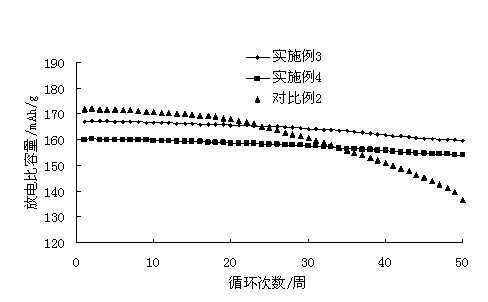

Composite metallic-oxide-cladded lithium nickel cobalt manganese oxide anode material and preparation method thereof

InactiveCN102244260AImprove electrochemical cycle performanceImprove discharge specific capacityCell electrodesHydrotalciteManganese oxide

The invention discloses a composite metallic-oxide-cladded lithium nickel cobalt manganese oxide anode material and a preparation method thereof. One metallic element in the composite metallic oxide in the anode material is Al of which the mass is 0.02%-0.92% of that of the lithium nickel cobalt manganese oxide; and the other metallic element in the composite metallic oxide in the anode material is one selected from transition metal Co or Zn, and the mass of the other metallic element is 0.2%-4.0% of that of the lithium nickel cobalt manganese oxide. The composite metallic-oxide-cladded lithium nickel cobalt manganese oxide anode material can be used to exert the respective advantages of the two metallic oxides and the synergy effect between the two metallic oxides sufficiently, thus improving the electrochemical cycle performance and the specific discharge capacity of the anode material under the condition of higher charge cut-off voltage obviously. The preparation method comprises the following steps: forming a hydrotalcite precursor layer on the surface of the lithium nickel cobalt manganese oxide firstly; and roasting to obtain the composite metallic-oxide-cladded lithium nickel cobalt manganese oxide anode material, thus ensuring the uniform distribution of two kinds of metallic ions in the hydrotalcite precursor and the oxide cladding layer of the final product, thereby exerting the best cladding effect.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

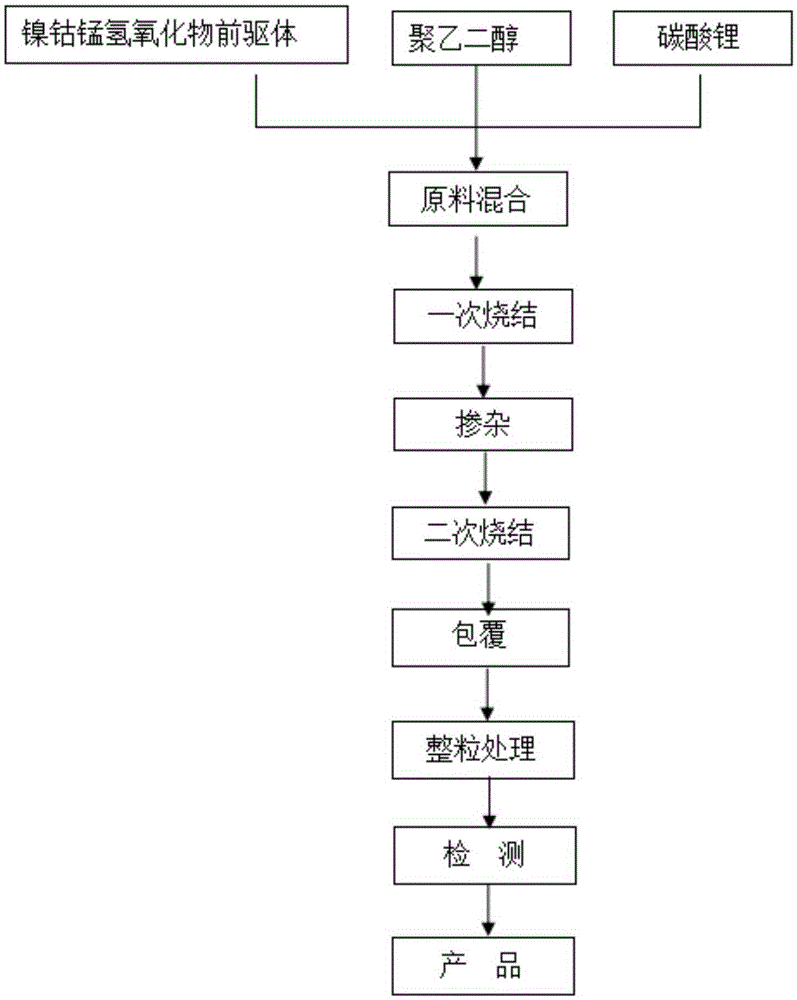

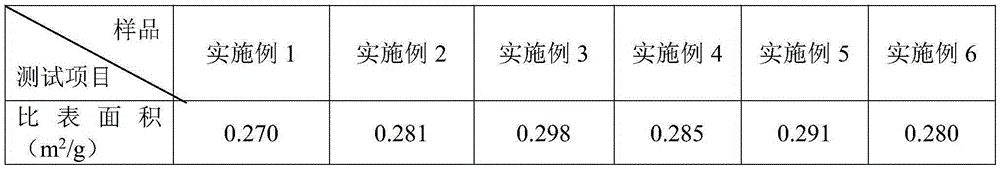

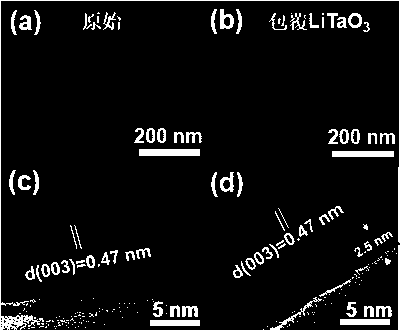

Preparation method of aluminum oxide coated lithium nickel manganese cobalt cathode material

ActiveCN105355911ASimple structureImprove electrochemical cycle performanceCell electrodesSecondary cellsManganesePolyethylene glycol

The invention belongs to the technical field of battery materials, and discloses a preparation method of an aluminum oxide coated lithium nickel manganese cobalt cathode material. The method comprises the steps of raw material mixing, primary sintering, doping, secondary sintering, coating and size stabilization treatment, wherein the step of raw material mixing comprises the steps that a three-dimensional efficient titled mixer is adopted, polyurethane balls serve as a mixing medium, dispersing, even mixing and smashing are conducted on lithium carbonate, a nanometer spherical nickel cobalt manganese hydroxide precursor and polyethylene glycol, and a uniform intermediate mixture is formed. The preparation method of the aluminum oxide coated lithium nickel manganese cobalt cathode material is low in primary sintering temperature, short in sintering time, simple in technology, large in specific capacity and good in cycling performance. The preparation method further has the advantages of being low in investment, reliable in technology, low in operating cost and the like, and the good economic benefit and market promotion value are achieved.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

Spinel type composite metal oxide electrode material and preparing process thereof

InactiveCN1719642AHigh specific capacitanceGood electrochemical cycle performanceElectrode manufacturing processesFinal product manufactureSolid phasesMetal oxide electrode

This invention provides a spinel compound metal oxide electrode material and its preparation method, in which, the composition of the electrode material is Mfe204, M is one element or composition of any two elements in Co, Ni Cu and Fe of +2 valence transition metal elements. Taking compound metal oxide M-Fe2+-Fe3+|-LDHs as the precursor and M is one element or composition of any two elements in Co, Ni, Cu, Fe elements, the electrode material is got by baking them under a certain temperature, compared with carbon materials, said electrode material has higher mass ratio capacity and volume ratio capacity.

Owner:BEIJING UNIV OF CHEM TECH

Lithium ion battery anode material and manufacturing method thereof

InactiveCN102637877AUniform particle sizeHas a layered crystal structureCell electrodesPhosphateManganese

The invention discloses a lithium ion battery anode material and a manufacturing method of the lithium ion battery anode material. The anode material is cobalt nickel oxide manganese with a layer structure and has the chemical composition of LiNil-x-yCoxMnyO2, wherein x is equal to and larger than 0.15 and is equal to and less than 0.3, and y is equal to and larger than 0.2 and is equal to and less than 0.4. The manufacturing method provided by the invention has the following steps: the cobalt nickel oxide manganese powder is manufactured through a coprecipitation method, metal phosphate is adopted as a cladding material with the cladding quantity as 0.5-1.5% of the anode material; and the cobalt nickel oxide manganese is externally cladded by zinc phosphate through fluidization. The cladded battery material after modification with the manufacturing method has high special capacity and has good cycling stability at high temperature.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of alumina coated Li(NixCoyMn1-x-y)O2 lithium ion battery anode material

The invention discloses a preparation method of an alumina coated Li(NixCoyMn1-x-y)O2 lithium ion battery anode material, belonging to the field of application of the lithium ion battery anode material. The preparation method is characterized by comprising the following steps: introducing aluminum isopropoxide during synthesis of Li(NixCoyMn1-x-y)O2 precursor through a hydroxyl coprecipitation method to prepare aluminum hydroxide modified coated Li(NixCoyMn1-x-y)O2 precursor; doping lithium and performing high-temperature calcining to prepare alumina modified coated Li(NixCoyMn1-x-y)O2. According to the preparation method, the problem of oxidation occurring in washing and drying of the synthesis process of the Li(NixCoyMn1-x-y)O2 precursor through the hydroxyl coprecipitation method is solved; the alumina modified coated Li(NixCoyMn1-x-y)O2 obtained by using the method shows superior stability and high-temperature cyclicity.

Owner:QINGDAO GUOXUAN BATTERY CO LTD

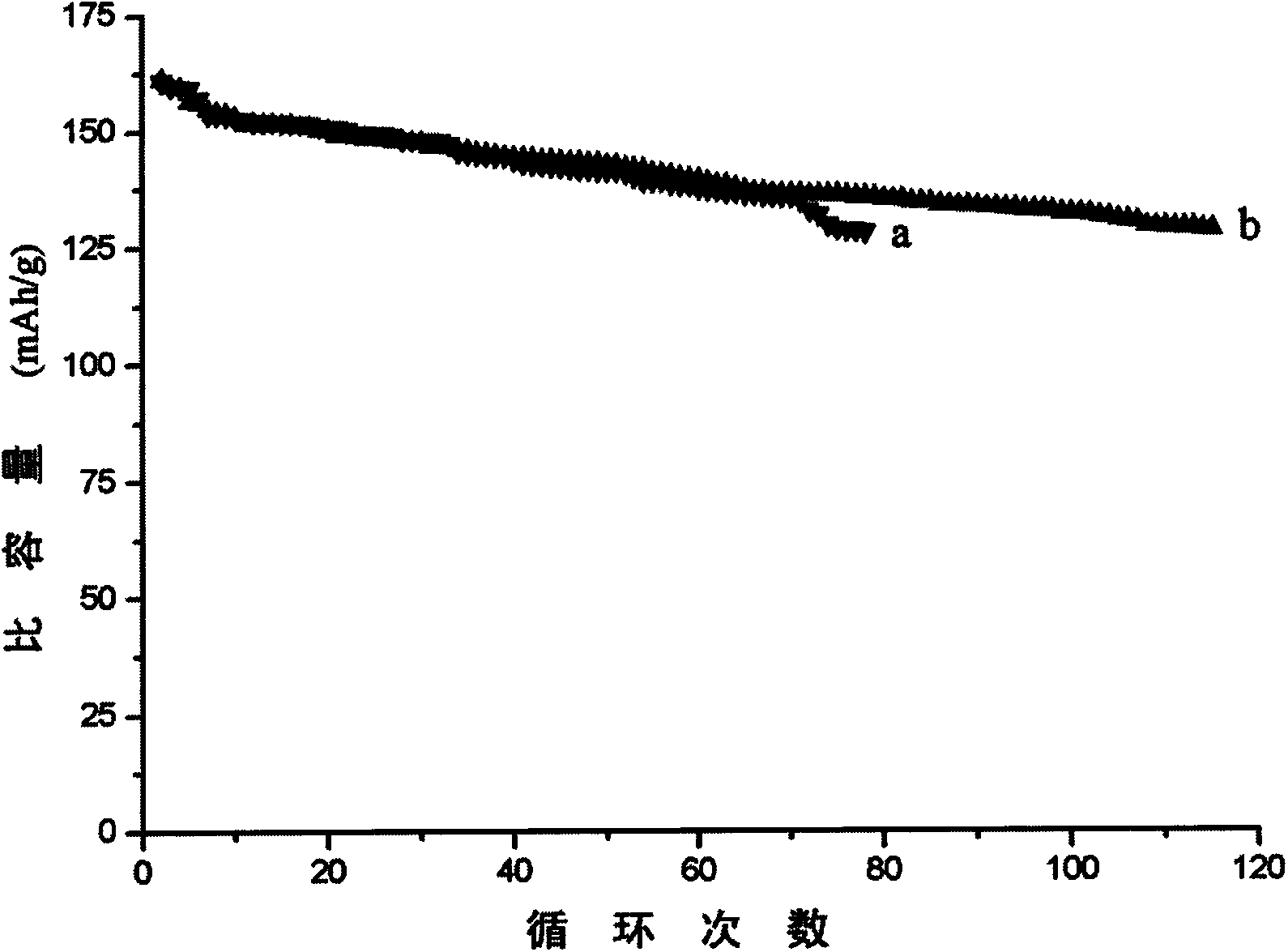

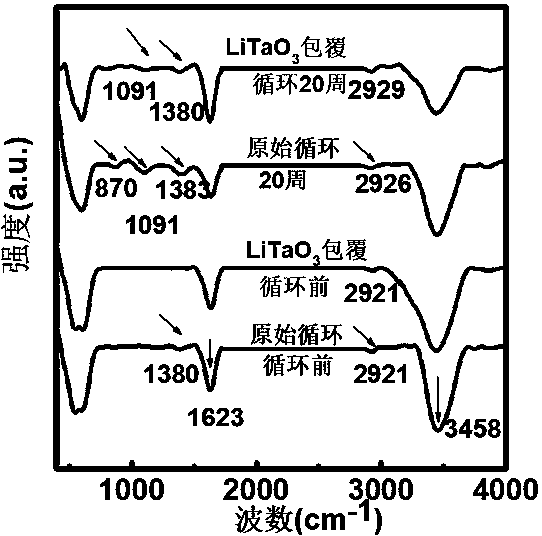

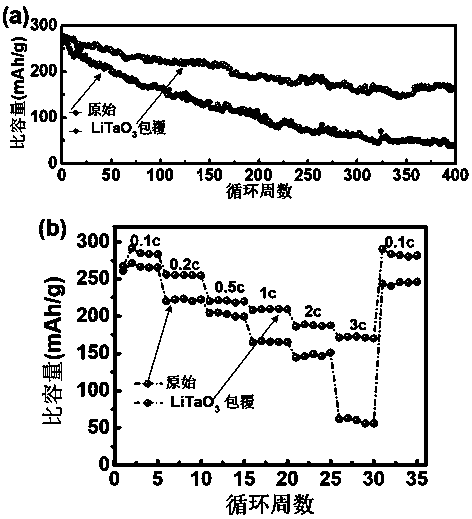

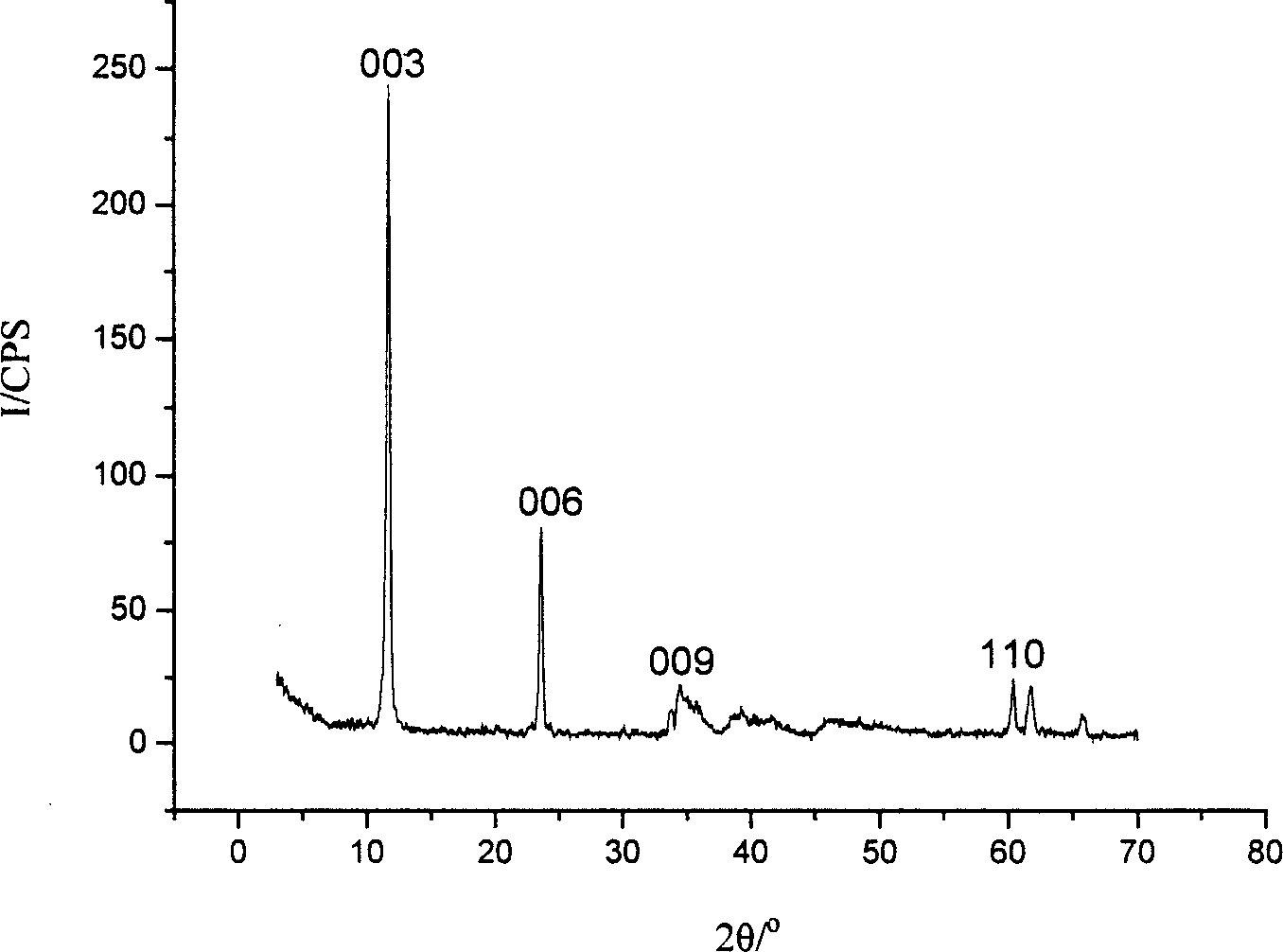

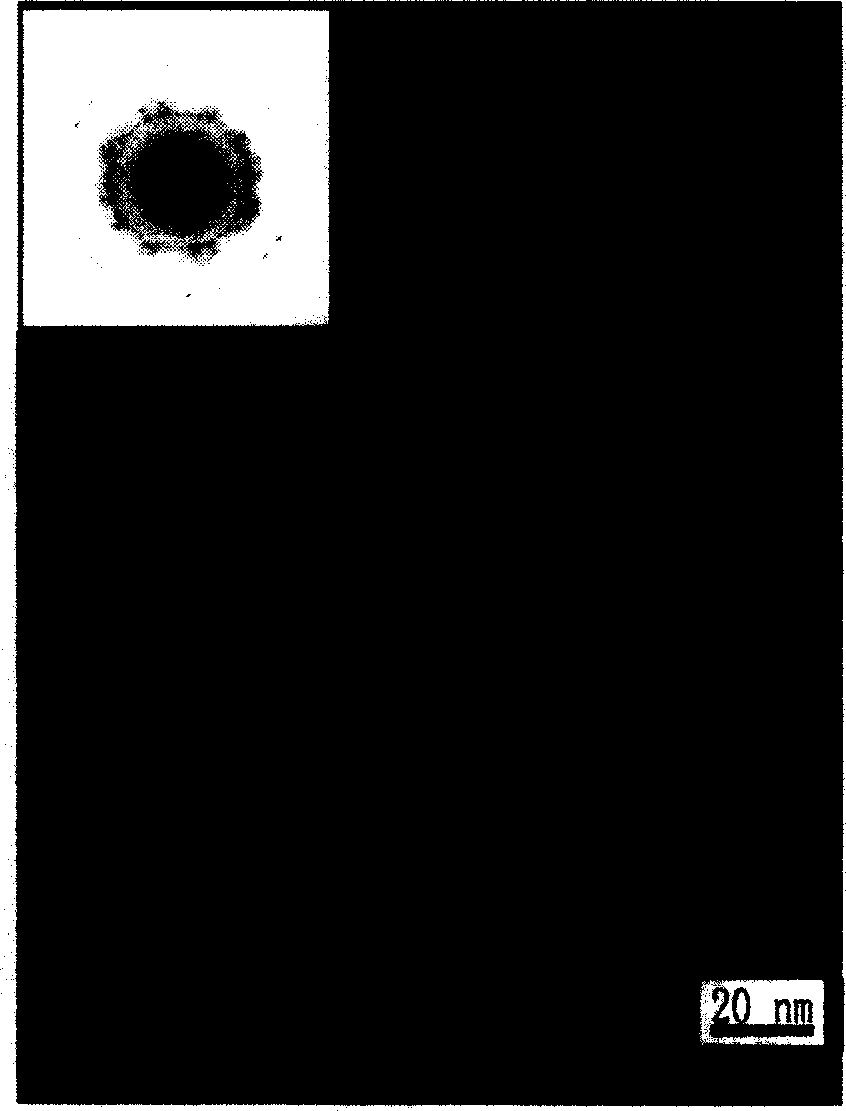

Lithium ion battery anode material coated with piezoelectric material on surface and preparation method thereof

PendingCN109921000AEasy to operateGood repeatabilityCell electrodesSecondary cellsBarium titanatePotassium

The invention provides a lithium ion battery anode material coated with piezoelectric material on the surface and a preparation method thereof. The surface of the battery anode material is coated witha layer of piezoelectric material with piezoelectric effect; the piezoelectric material comprises any one or more of barium titanate, lithium niobate, sodium niobate, lithium tantalite, sodium-potassium metaniobate and barium-strontium metaniobate with piezoelectric effect. The piezoelectric characteristic of the piezoelectric material is utilized to realize a coating modification function for the anode active materials so as to ensure that the volume phase structures of the anode active materials are not influenced and damaged, the growth of solid-electrolyte interface membranes is suppressed, and the diffusion speeds of active material-coating layer interface lithium ions are improved, thereby effectively improving the structure stability and electrochemical cycle performance of the lithium ion battery anode material, improving the pyrolysis temperature of the anode material and then enhancing the safety performance of the lithium ion batteries in the using process.

Owner:HENAN UNIVERSITY

Preparation method of layered cobalt aluminium bihydroxy composite metal oxide electrode material

InactiveCN1753115AUniform particle sizeGood dispersionElectrode manufacturing processesHybrid capacitor electrodesCapacitanceAluminium

The invention relates to a method for preparing a sandwich Co-Al-hydroxide composite metal oxide (Co-Al-LDH) electrode material of super capacitor, belonging to the technical field of preparing the electrode material of super capacitor. The invention uses an all-returning mixed solution film reactor to make coprecipitation reaction on Co-Al mixed salt solution and basic solution, making nucleation / crystallization separation, controlling the nucleating and growing conditions of the crystal, respectively, then baking at a certain temperature, and fully exposing the electrochemical active situ of the Co on the basis of keeping the sandwich of Co-Al-LDH. The prepared Co-Al-LDH has the advantages of high specific capacitance, good multiplication property, and excellent electrochemical circulating performance.

Owner:BEIJING UNIV OF CHEM TECH

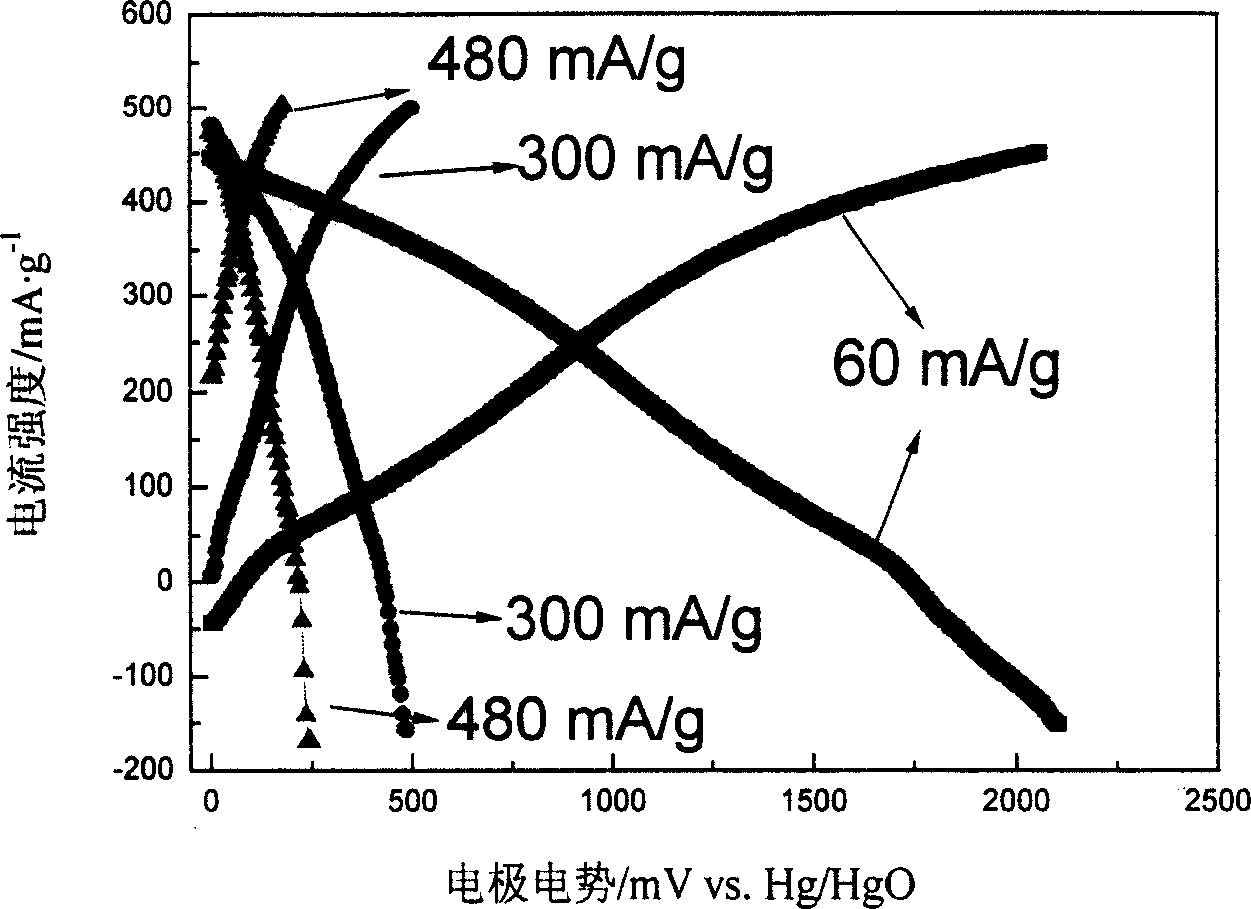

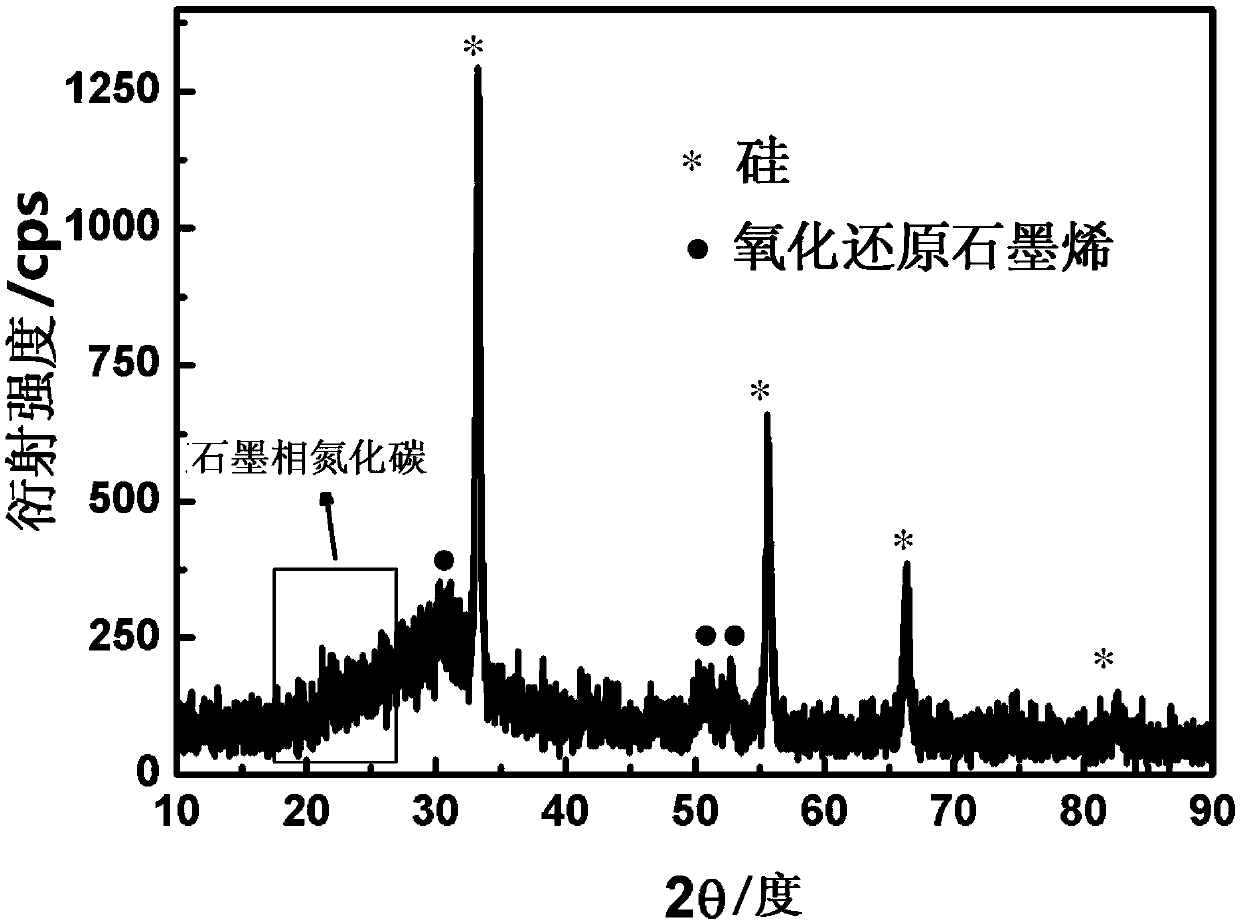

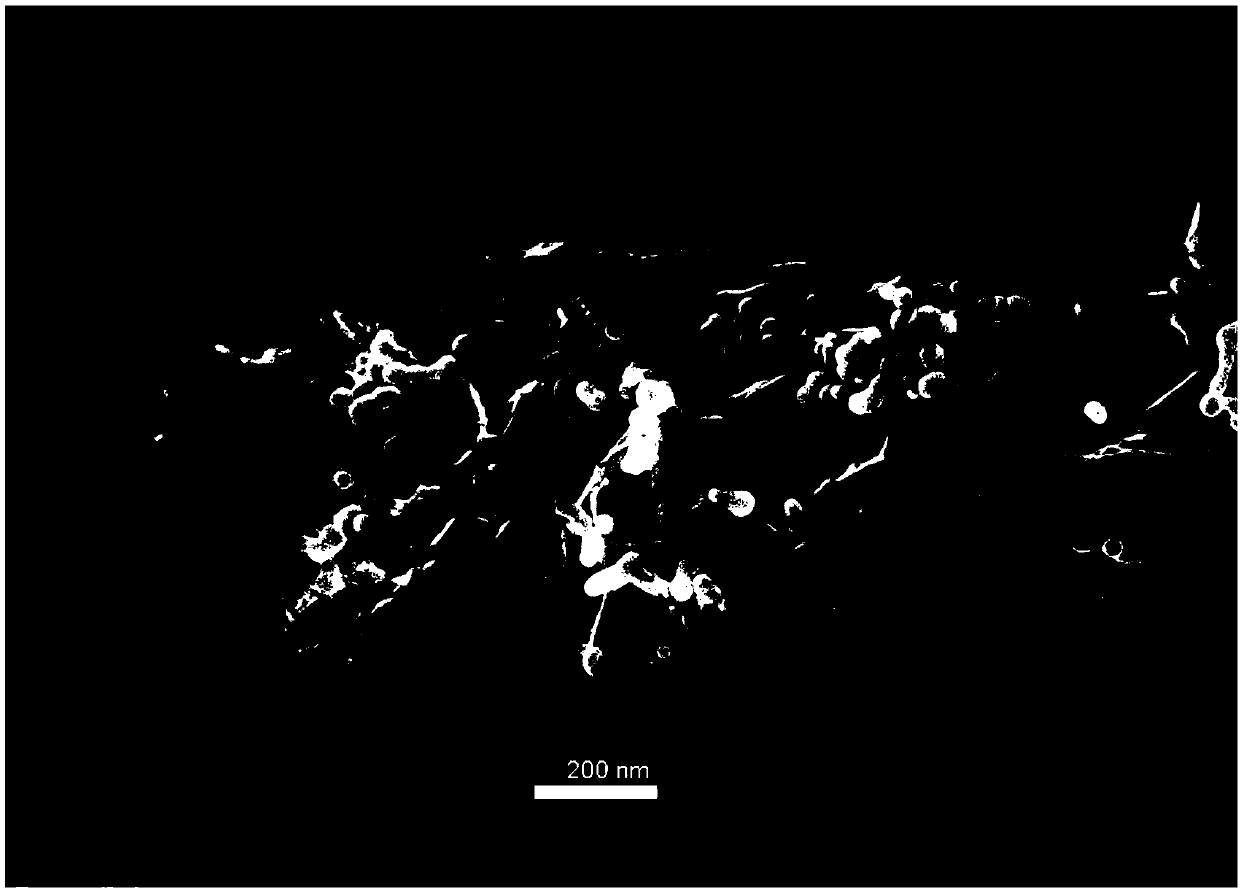

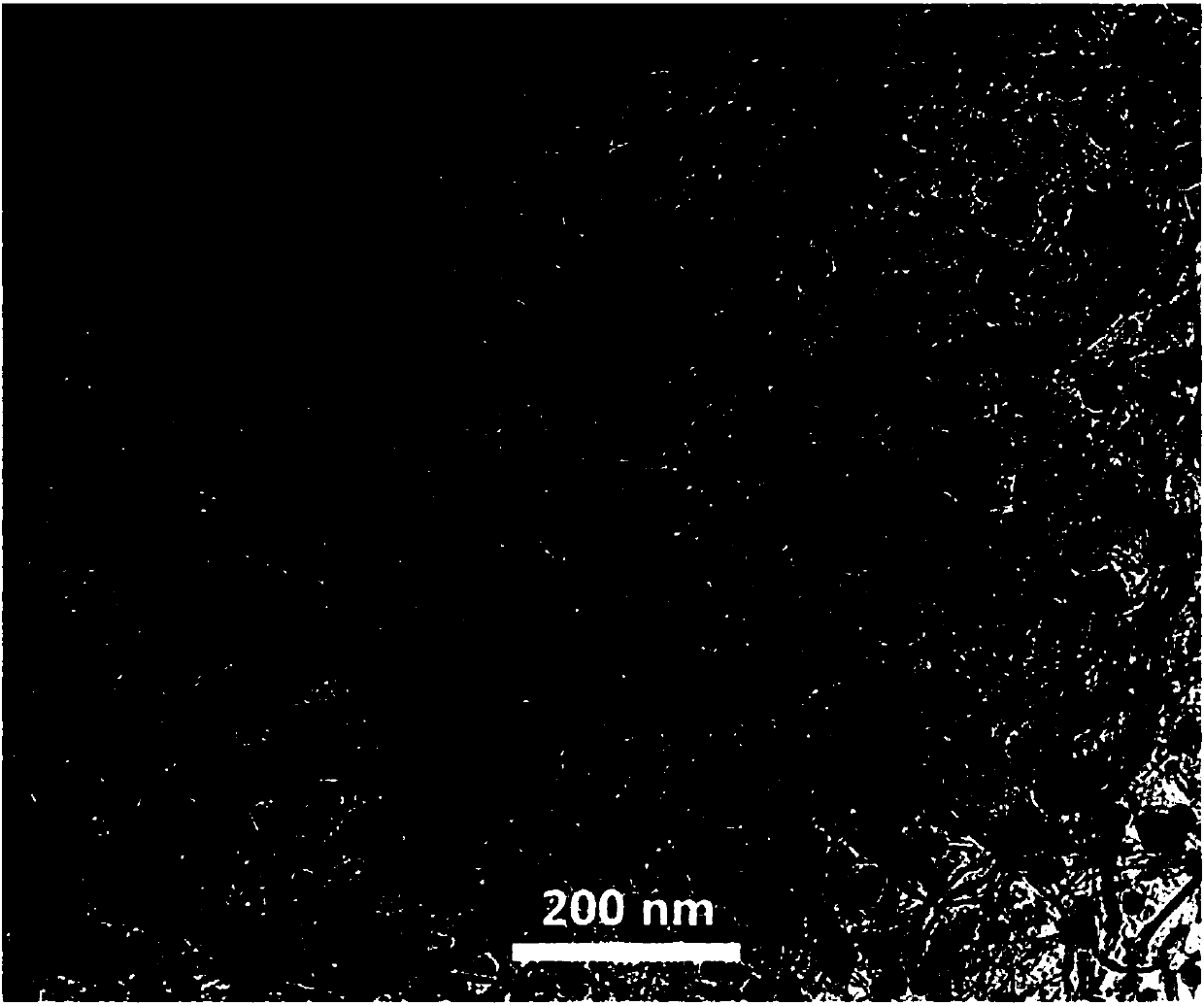

Silicon embedded redox graphene/graphite phase carbon nitride composite material, preparation and application thereof

ActiveCN107634207AReduced responseStable structureMaterial nanotechnologyCell electrodesCarbon compositesCarbon layer

The invention discloses a silicon embedded redox graphene / graphite phase carbon nitride composite material, preparation and application thereof. The silicon embedded redox graphene / graphite phase carbon nitride composite material comprises a redox graphene / graphite phase carbon nitride composite matrix serving as the base material, nano-silicon spheres that act as the active centre and are evenlydispersed and embedded in the lamellar gap of the redox graphene / graphite phase carbon nitride composite matrix, and a carbon layer that is located on the surfaces of the nano-silicon spheres and canstrengthen the chemical bonding force between the active centre and the base material. The silicon embedded redox graphene / graphite phase carbon nitride composite material provided by the invention has good electrochemical cycle performance, excellent compatibility and structural stability, can give play to good synergistic effect between the components, also has high batch stability, and is easyfor large-scale production.

Owner:DALIAN MARITIME UNIVERSITY

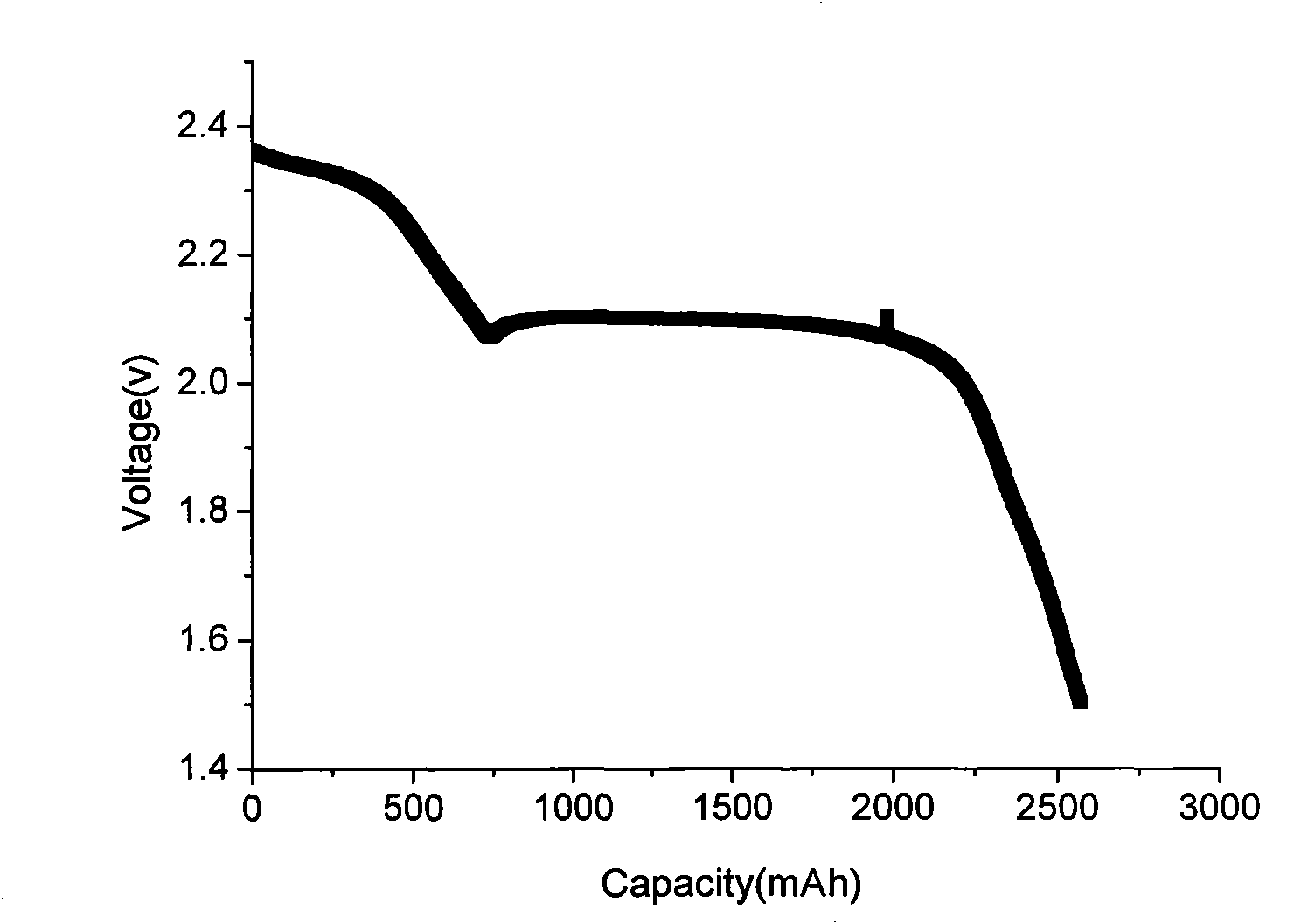

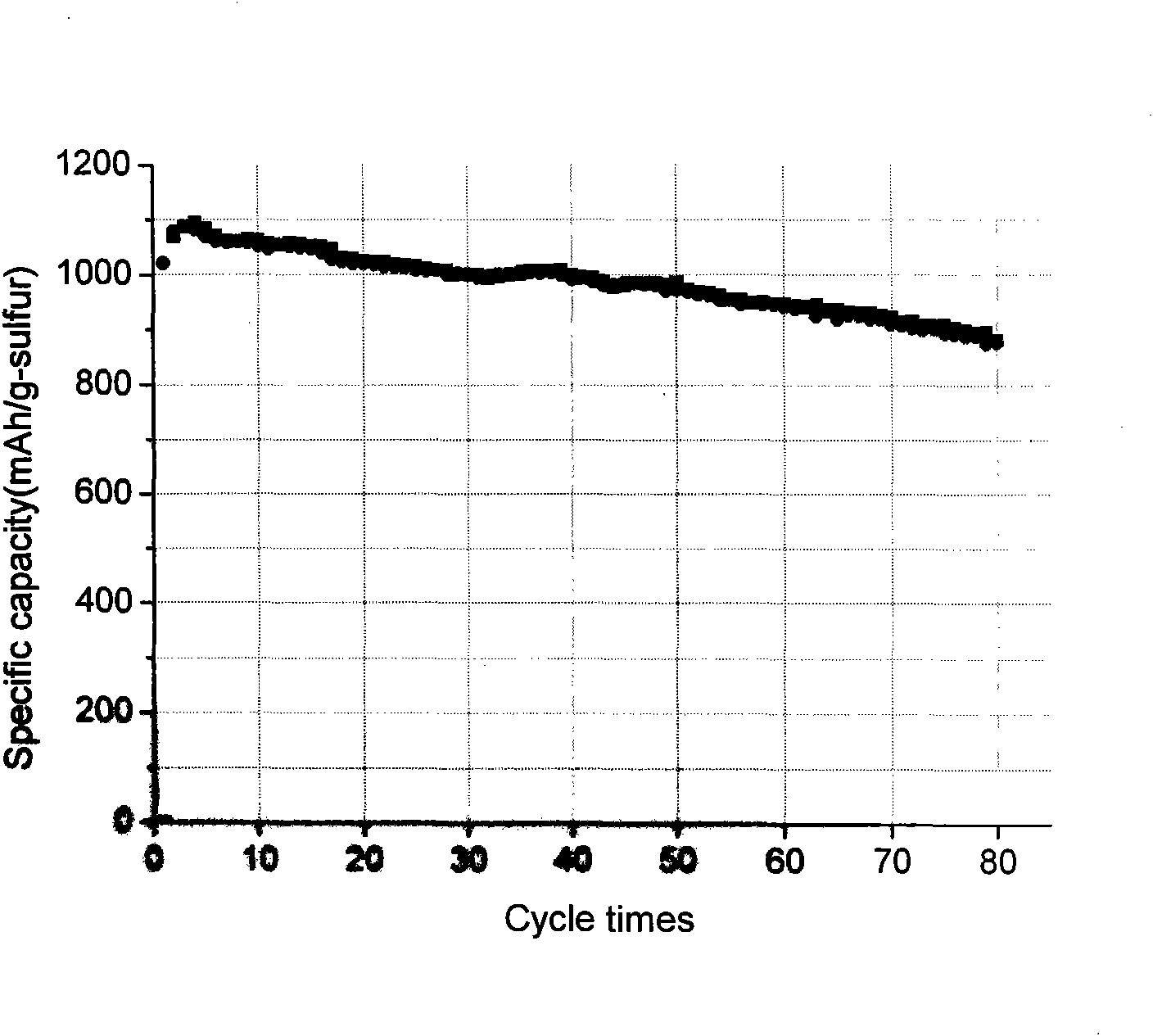

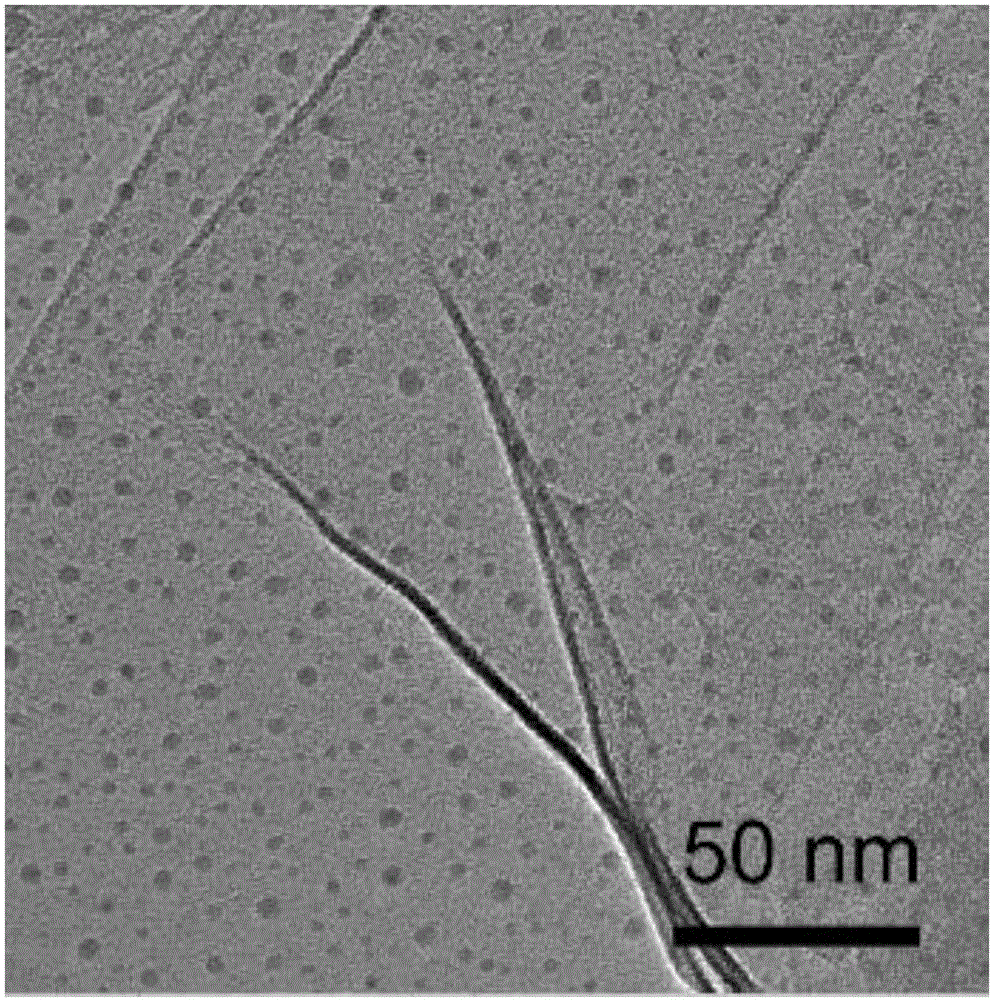

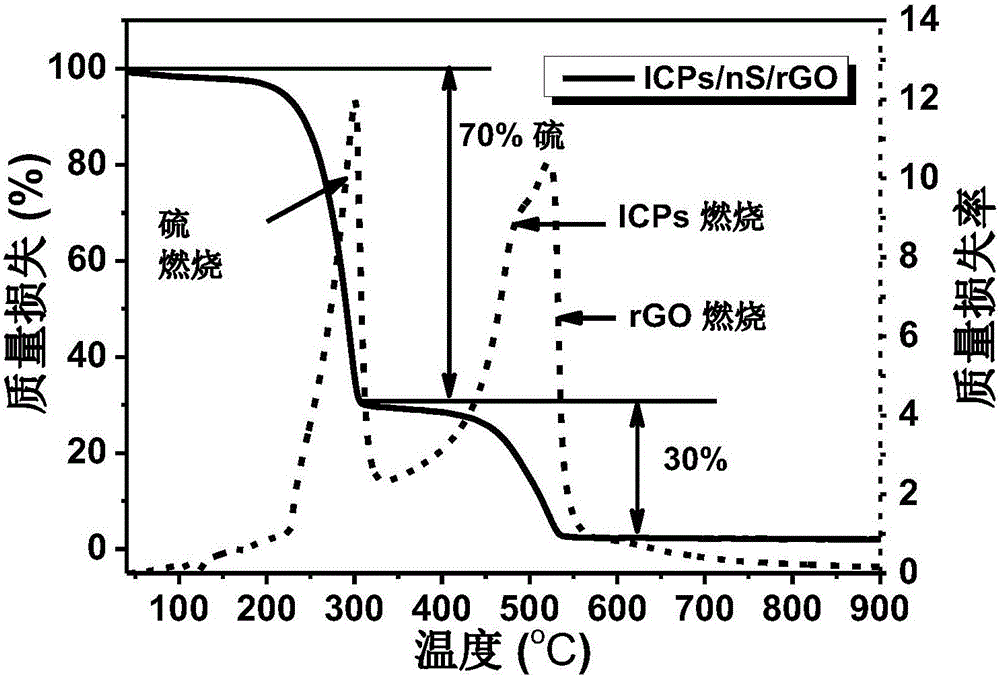

Lithium-sulfur battery positive pole material and preparation method thereof

InactiveCN105826523AImprove conductivityImprove the effect of current collectionMaterial nanotechnologyCell electrodesSingle substanceOxygen

The invention relates to a lithium-sulfur battery positive pole material and a preparation method thereof, and belongs to the technical field of battery materials. The provided positive pole material has abundant micropores and mesopores; porous nano carbon thin sheets with a three-dimensional communicated net structure are taken as the skeleton; nano sulfur dots are filled into the pores of the net structure, and the outer layer of the skeleton is wrapped by reduced oxidized graphene. The preparation method comprises the following steps: mixing porous nano carbon thin sheets with a sulfur single substance, subjecting the mixture to ball milling, carrying out reactions at a temperature of 180 to 200 DEG C in an enclosed environment in the absence of oxygen and water under the protection of inert gas to obtain a porous nano carbon thin sheet / nano sulfur compound; dissolving the compound into an ethanol solution, dispersing the compound by ultrasonic waves, adding oxidized graphene, adjusting the pH to 10.1 by ammonia water, carrying out ultrasonic dispersion, carrying out hydrothermal reactions at a temperature of 80 to 100 DEG C, filtering, washing the reaction product until the reaction product becomes neutral, and drying to obtain the positive pole material. The positive material has the advantages of high specific capacity and stable electrochemical circulation performance, moreover, the preparation method is simple, the price is low, and the positive material is environment-friendly and can be easily produced in batches.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

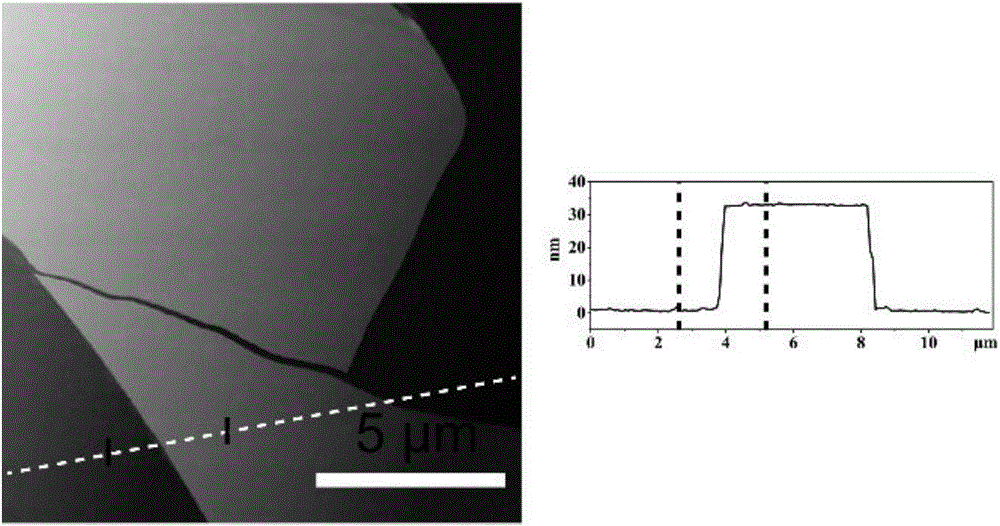

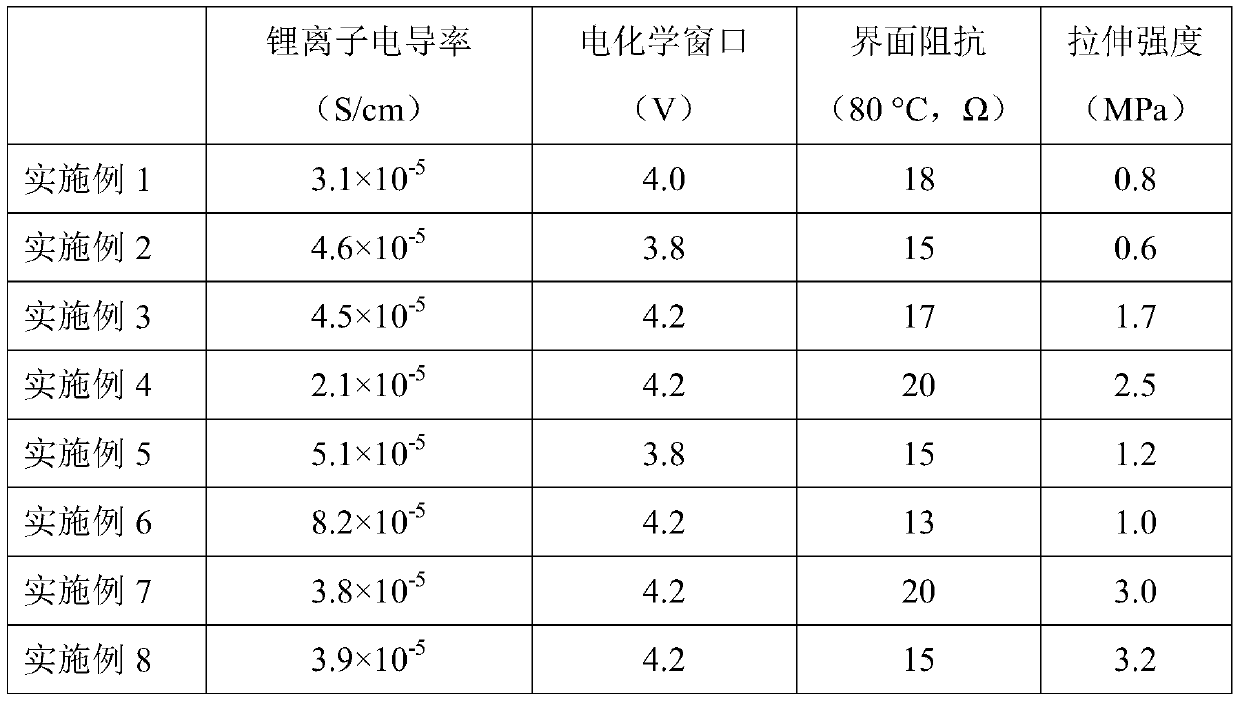

Composite solid polymer electrolyte membrane and preparation method and application thereof

InactiveCN111540948AIncrease energy densityImprove stabilityFinal product manufactureElectrolyte accumulators manufacturePolymer electrolytesPlasticizer

The invention discloses a composite solid polymer electrolyte membrane as well as a preparation method and application thereof. The composite solid polymer electrolyte membrane comprises a polymer component, a lithium salt, 0-25 parts by mass of a plasticizer, and 0-15 parts by mass of inorganic particles, wherein the polymer component comprises 10-30 parts by mass of a thermoplastic polymer and 20-50 parts by mass of a cross-linked network polymer, and the molar ratio of the lithium salt to lithium ion complexing dissociation groups in the polymer component is 1:(1-16). The composite solid polymer electrolyte membrane has high ionic conductivity and good mechanical strength, the preparation process is simple, and the composite solid polymer electrolyte membrane can be applied to large-scale production. In some embodiments of the present invention, the thickness of the composite solid polymer electrolyte membrane is 10-500 [mu]m, the tensile strength is 0.2 MPa or above, the lithium-ion conductivity is 1*10<-5> S / cm or above, and the electrochemical window is 3.8 V or above, so that the composite solid polymer electrolyte membrane can be used in the fields of solid lithium batteries, electrochromic devices and the like, and short circuit is avoided after long-time use at high temperature.

Owner:CHINA LUCKY FILM CORP

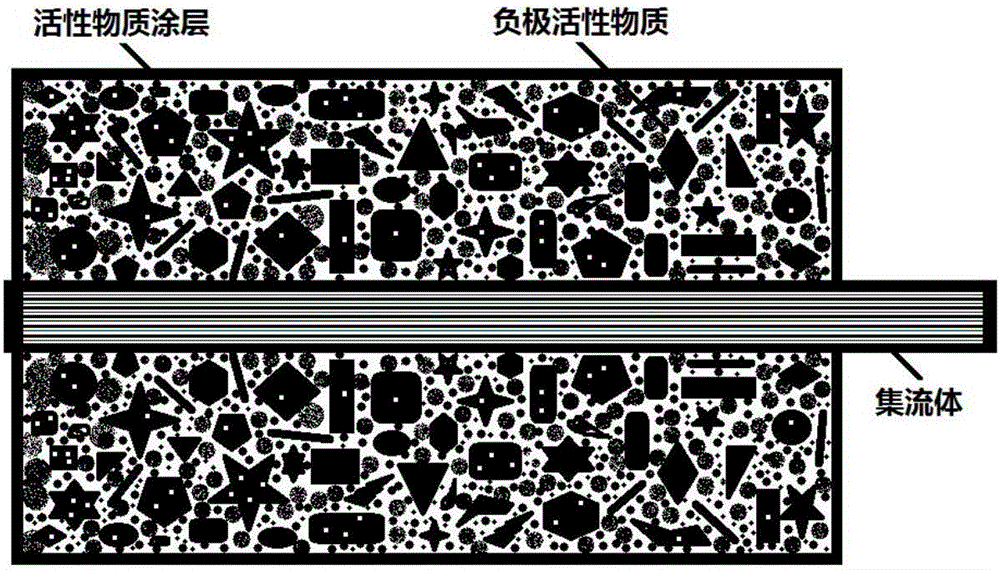

Manufacturing method of negative plate of safety lithium-ion battery

InactiveCN106450169AGood thermal stabilityStable performance during charge and discharge cyclesSecondary cellsElectrode collector coatingCopper foilCurrent collector

The invention discloses a manufacturing method of a negative plate of a safety lithium-ion battery. The method comprises the steps of mixing a negative active material with a conductive agent at a certain mass ratio to obtain a mixture A; carrying out ball-milling and mixing on an additive B and the mixture A at a certain mass ratio to form a mixture C; preparing a certain mass percent of water solution from CMC which accounts for a certain mass ratio of the mixture C, carrying out constant-temperature stirring, adding an SBR which accounts for a certain mass ratio of the mixture C in batches, simultaneously adding an NMP which accounts for a certain ratio of the mixture C and carrying out constant-temperature stirring to form a sizing material D; adding the mixture C to the sizing material D in batches, controlling the solid content of the mixture C and stirring to obtain slurry; adding a proper amount of water, adjusting, controlling the viscosity and stirring to obtain negative slurry E; employing copper foil as a current collector F, intermittently coating a single side or double sides of the current collector F with the negative slurry E, reserving a certain current collector, carrying out drying, controlling the surface density, carrying out rolling and controlling the compactness and the thickness of the negative plate; and dividing, cutting, welding and pasting a tab adhesive tape to obtain the negative plate of the safety lithium-ion battery. The lithium-ion battery assembled by the negative plate has good electric cycle performance and safety performance.

Owner:HUBEI UEE ENERGY TECH CO LTD

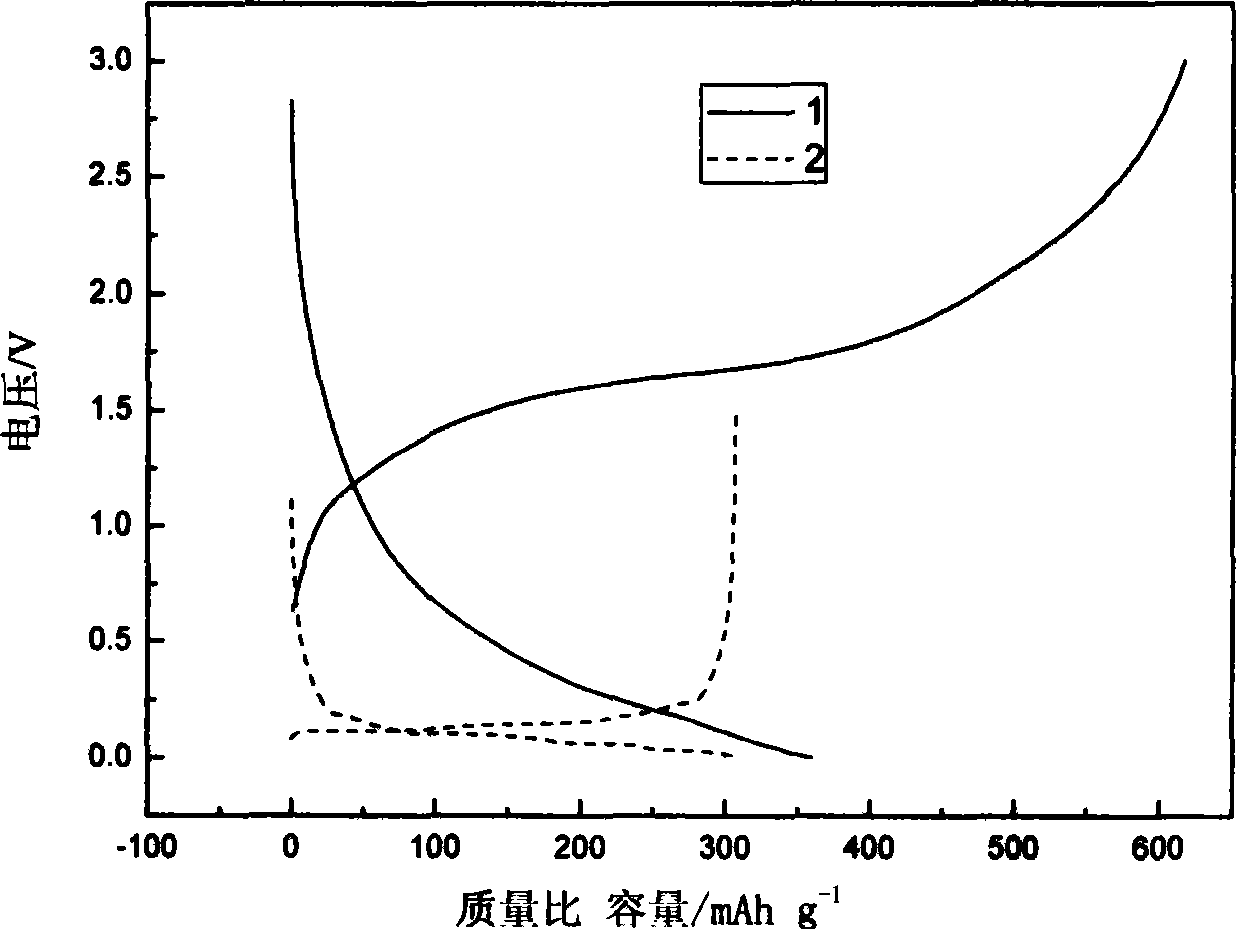

Organic cathode material for sodium ion battery

InactiveCN103456961AThe synthesis method is simpleReduce manufacturing costCell electrodesIonCharge and discharge

The invention discloses an organic cathode material for a sodium ion battery capable of being repeatedly charged and discharged, and belongs to the field of batteries. According to the organic cathode material for the sodium ion battery disclosed by the invention, an active substance of the organic cathode material is para-phthalate or a mixture of different para-phthalates; the chemical composition of the para-phthalate is C8H4O4.Rx, wherein R is Li, K, Rb, Cs, Mg, Ca, Sr, Ba, Ni, Cu, Sn, Fe, Zn, Cr, Al or Mn, and x is equal to 2 / 7, 1 / 3, 2 / 5, 1 / 2, 2 / 3, 1 or 2. The organic cathode material disclosed by the invention has low reaction potential, high quality specific capacity and excellent electrochemical cycle stability, and is simple in synthetic method and good in repeatability; the production cost is reduced, the requirement of sustainable development is met, and the organic cathode material has a wide application prospect in the field of sodium ion batteries.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

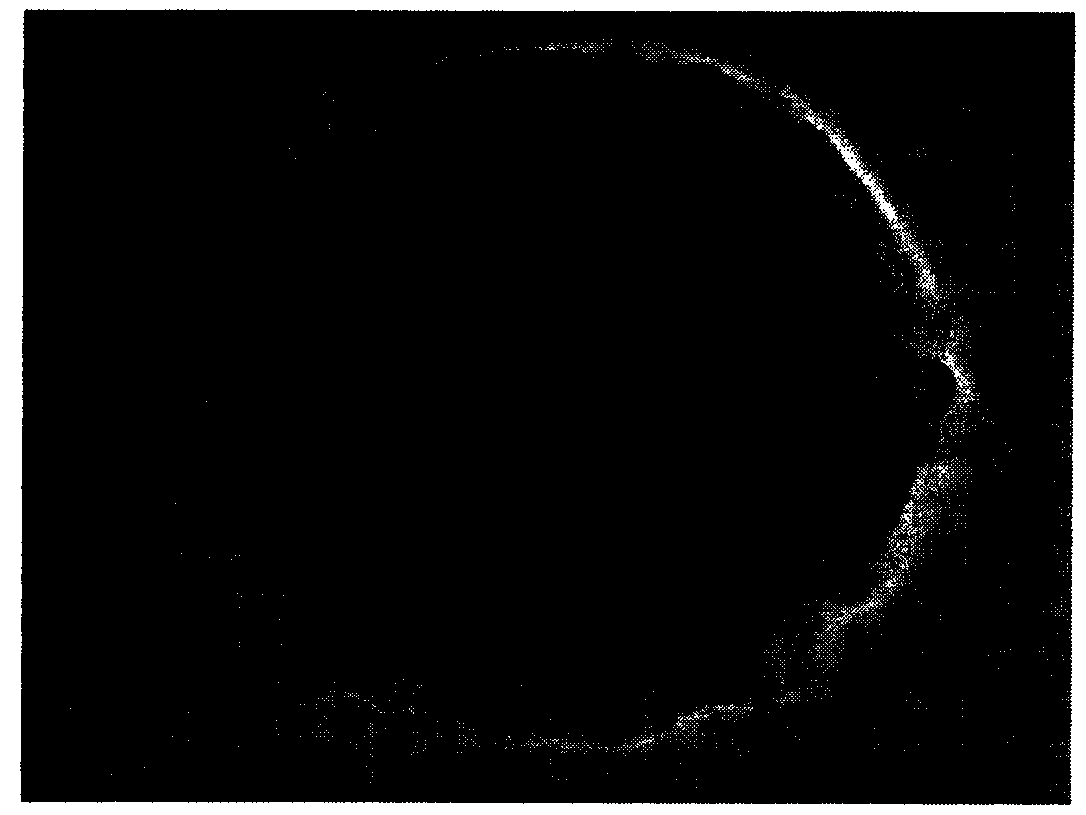

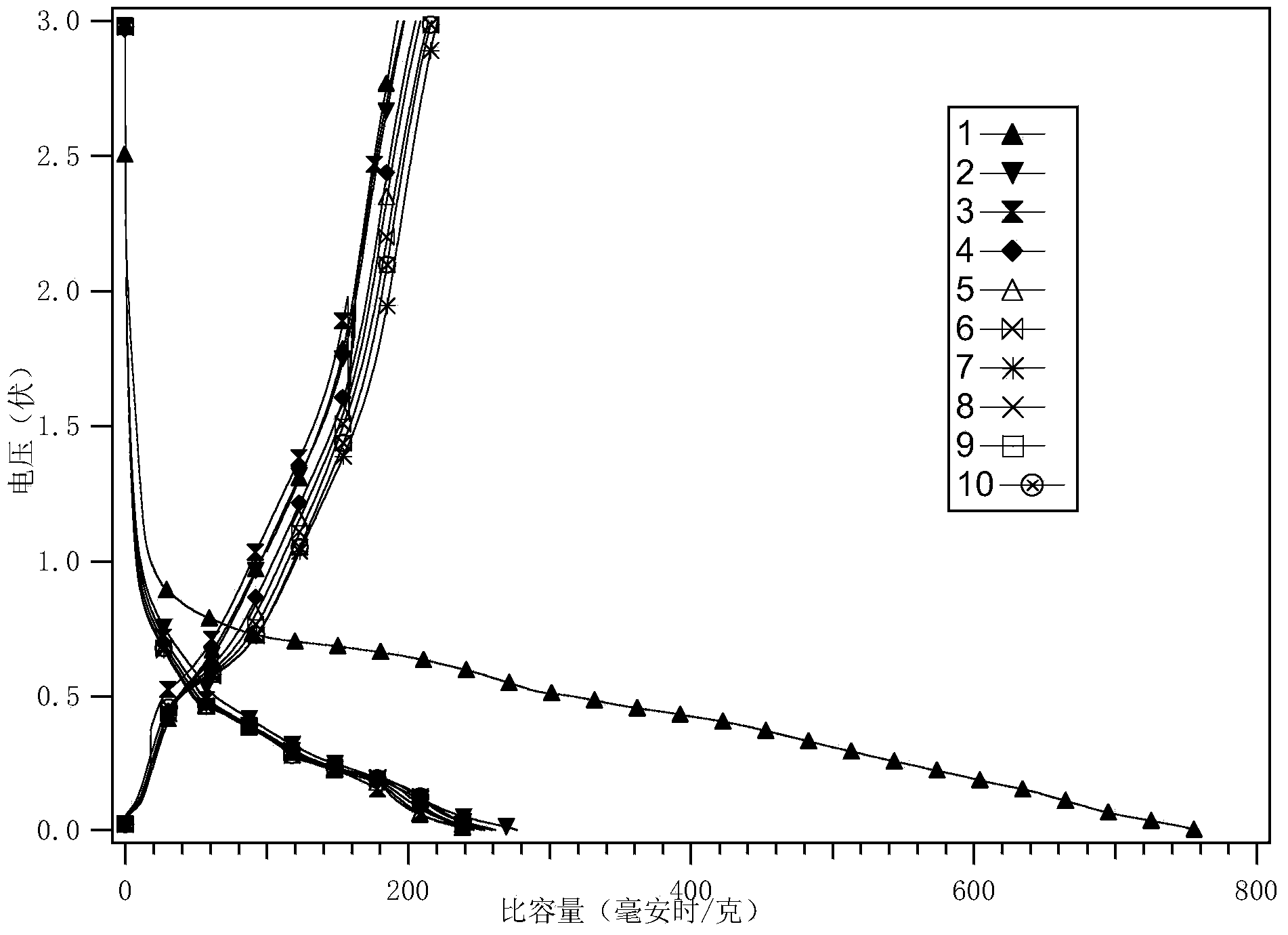

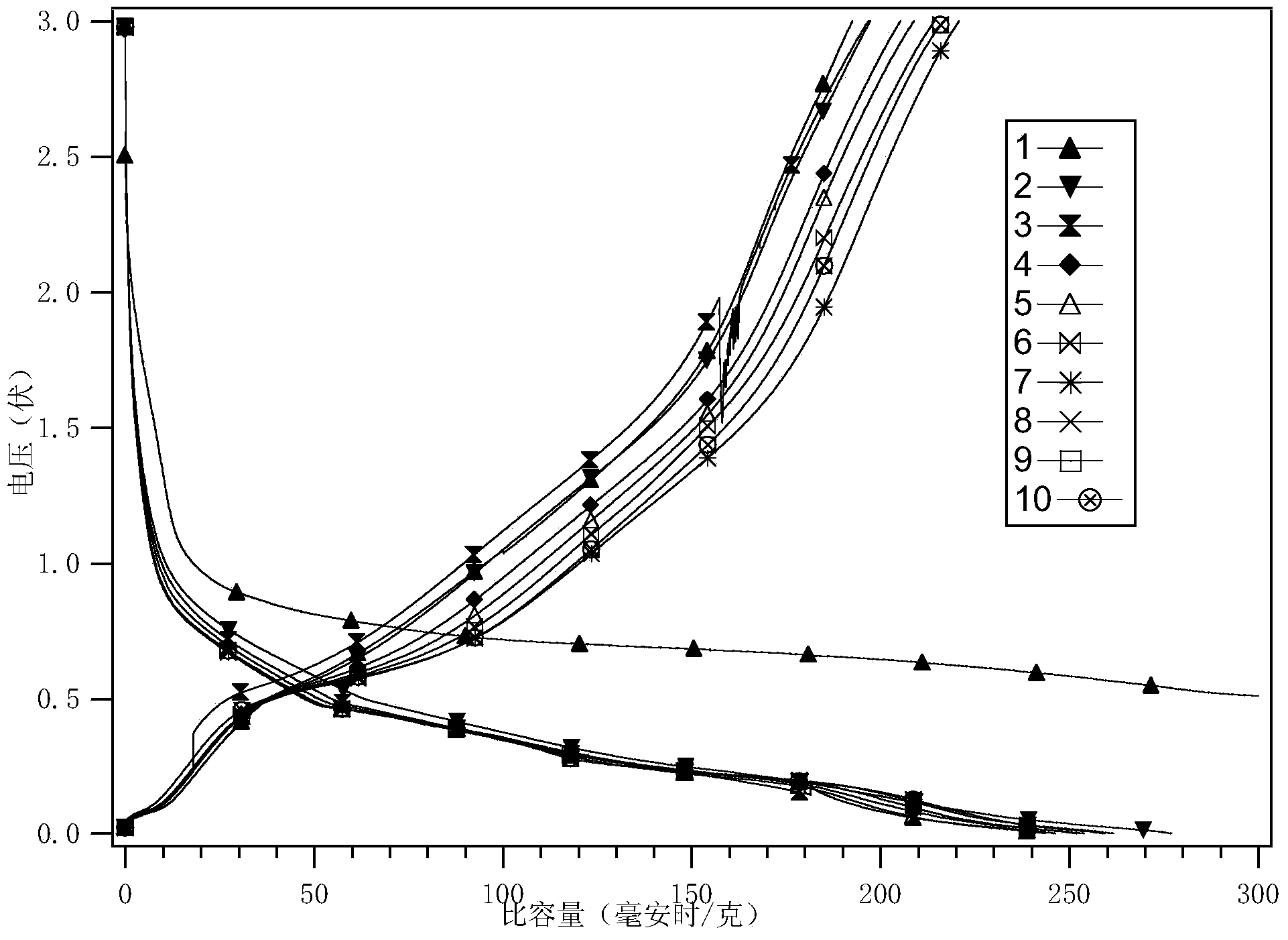

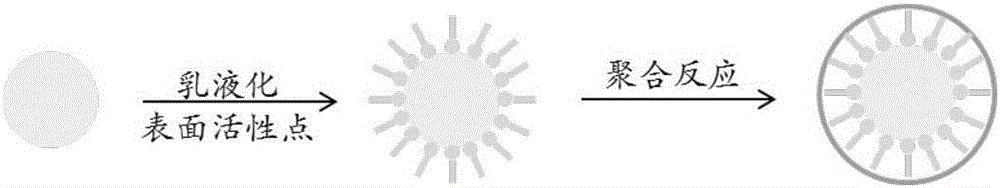

Polymer and nanometer sulfur composite material with shell and egg yolk structure and preparation method

ActiveCN106602019AShorten the transmission distanceAvoid reunionMaterial nanotechnologyCell electrodesLithium–sulfur batterySulfur

The invention relates to a polymer and nanometer sulfur composite material with a shell and egg yolk structure and a preparation method of the composite material. The composite material is provided with the shell and egg yolk double-layer structure, a central nucleus is formed by sulfur particles, an outer shell is formed by a polymer, a gap is preserved between the central nucleus and the shell, so that the double-layer structure like an egg shell and an egg yolk is formed; elemental sulfur is shrunk in the process that the temperature is quickly changed by using the change of crystal form and the change of density in different temperatures, and the elemental sulfur is partially dissolved and separated out by using a solvent, so that the composite material of the shell and egg yolk structure is formed. The composite material of the structure is applicable to cathodes of lithium sulfur batteries, structure collapse caused by volume expansion in the discharge process of the elemental sulfur is relieved, the dissolution and loss of discharge products are inhibited, and the electrical conductivity and circularity of the material are improved.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

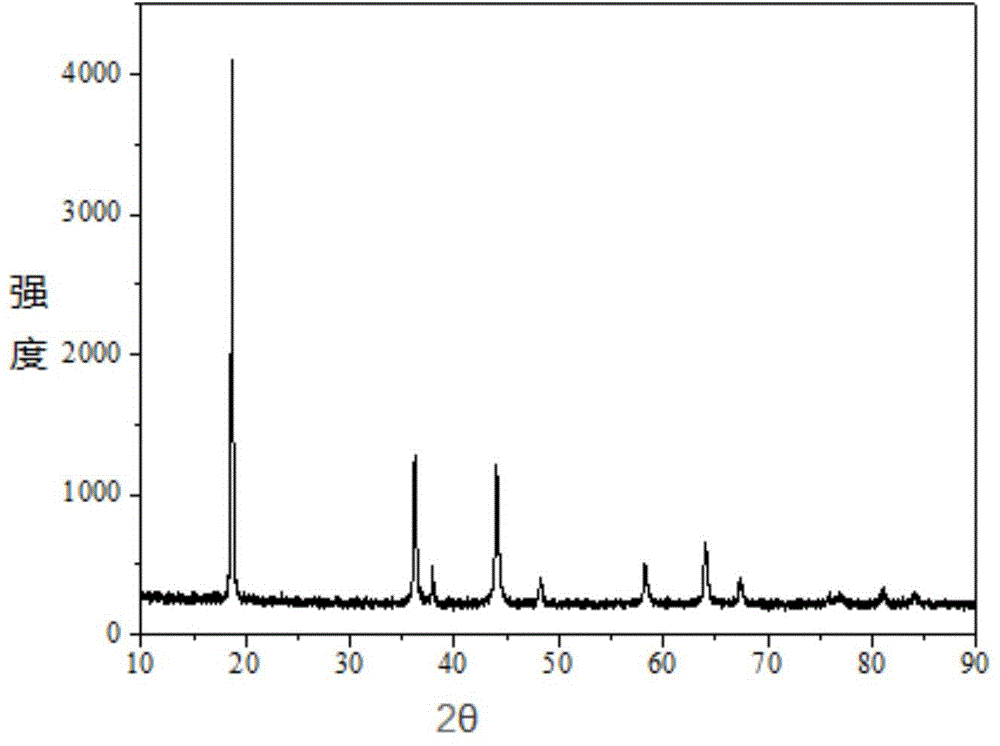

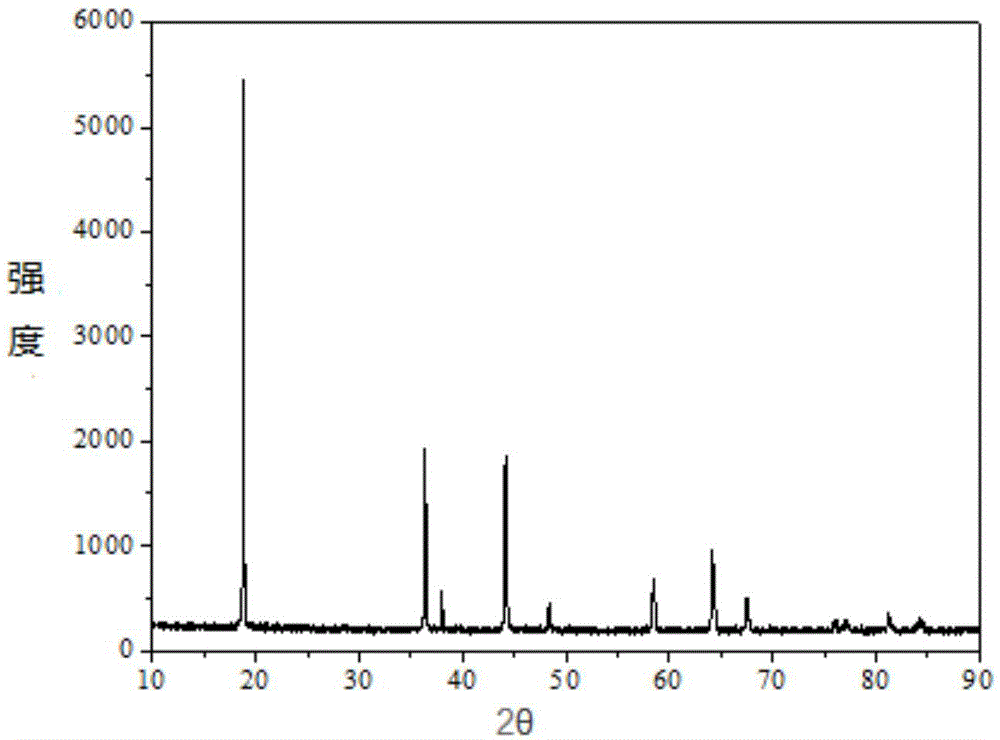

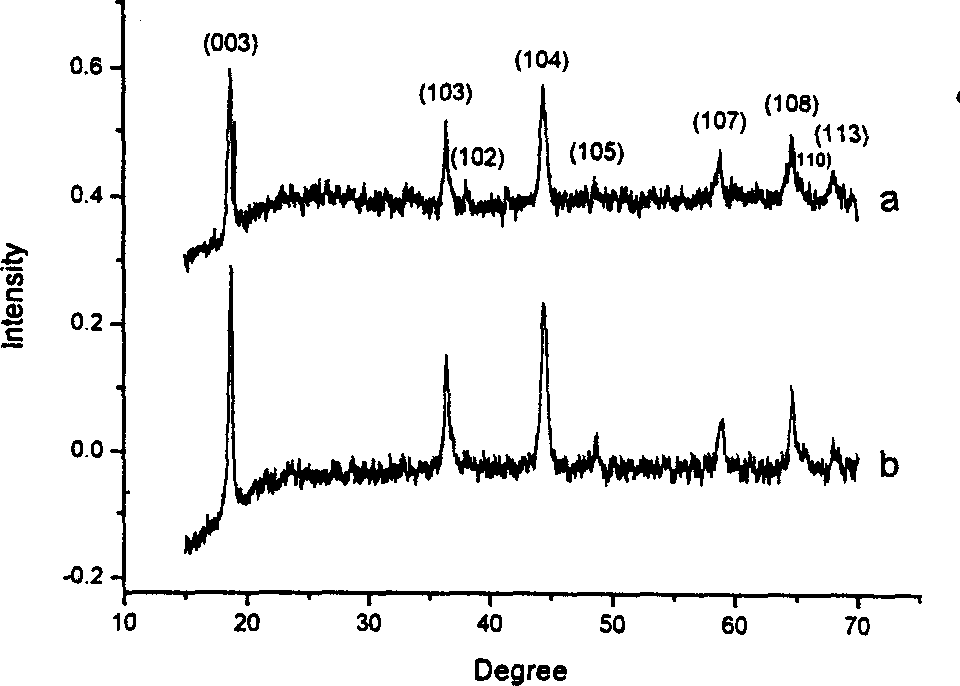

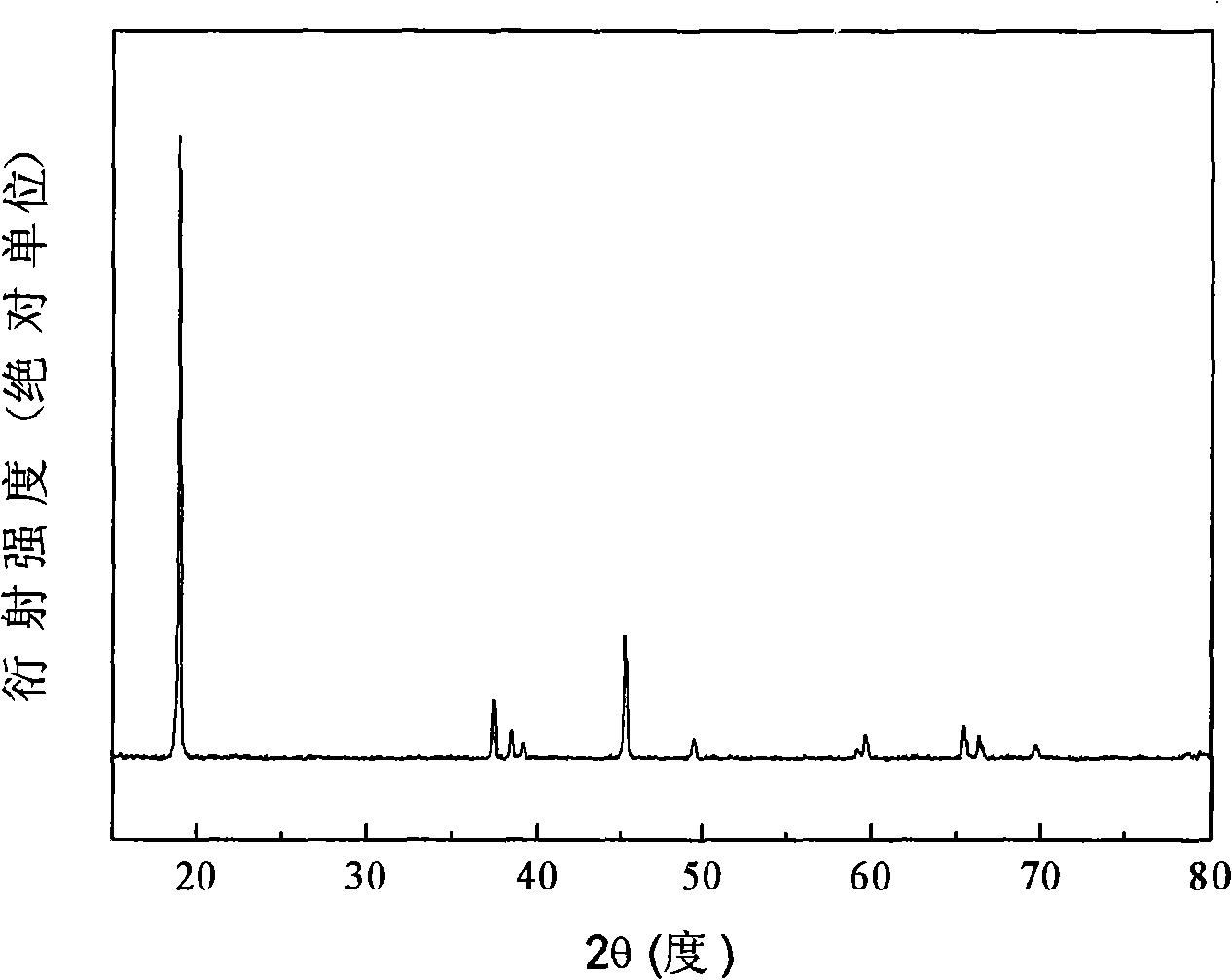

Method for preparing lithium manganese oxide by using low-heat solid phase reaction

InactiveCN1461064ALow priceSimple reaction conditionsElectrode manufacturing processesManganese oxides/hydroxidesMANGANESE ACETATESolvent

The method for preparing lithium-manganese oxide by using low-beat solid phase reaction includes the following steps: according to stoichiometric ratio mixing lithium acetate, manganese acetate and solid phase organic acid or alcohol or sugar or amino acid; grinding at room temp., drying the obtained mixture at 75-85 deg.C and calcining at 350-850 deg.c for 12-18 hr. so as to obtain the invented final product Li1+xMn2O4 or Li1+xMnO2, in which x=-0.1í½+0.2. According to different stoichiometric ratio the spinelle type LiMn2O4 or laminate LiMnO2 can be obtained.

Owner:NANJING UNIV

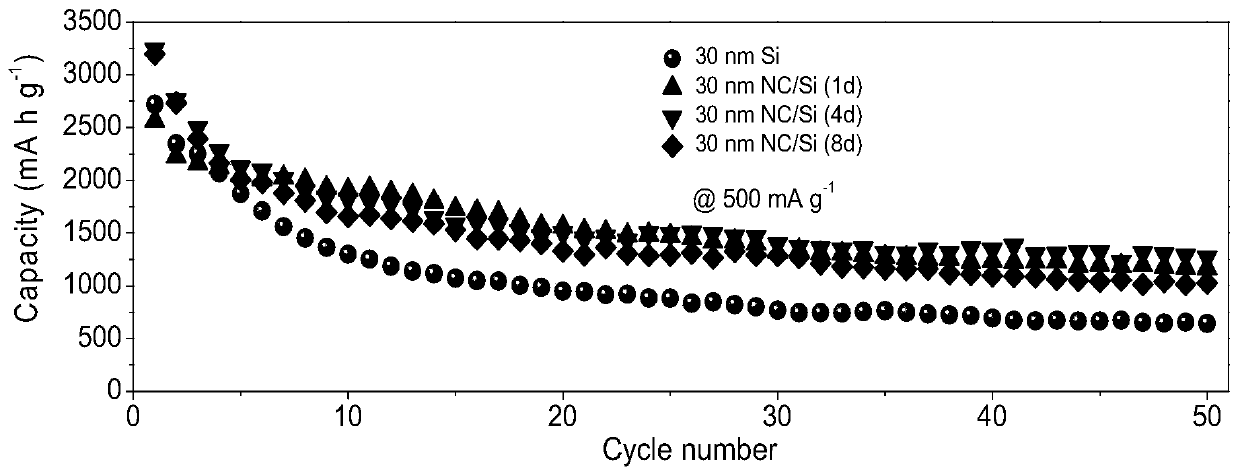

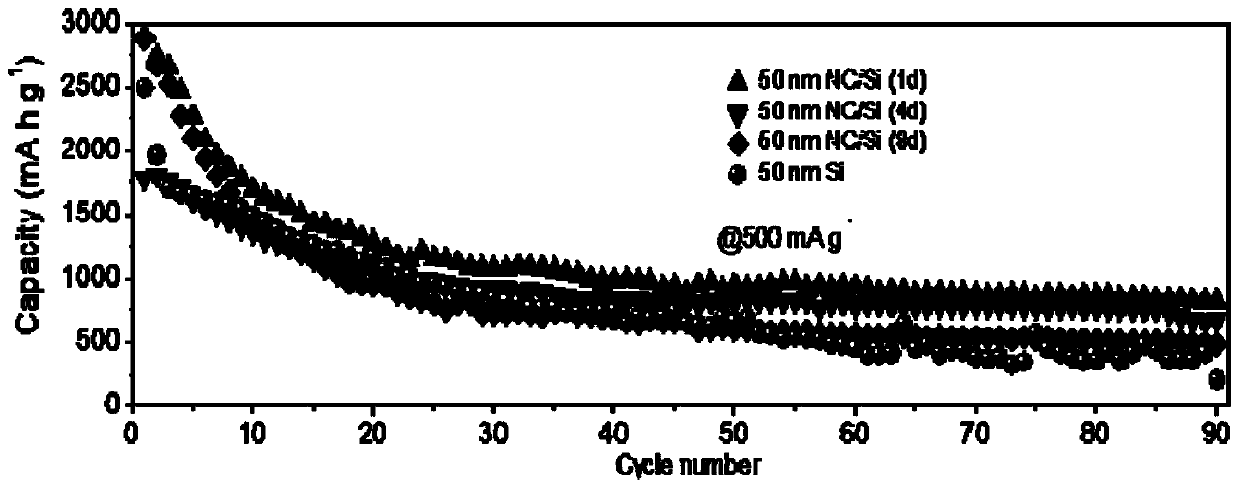

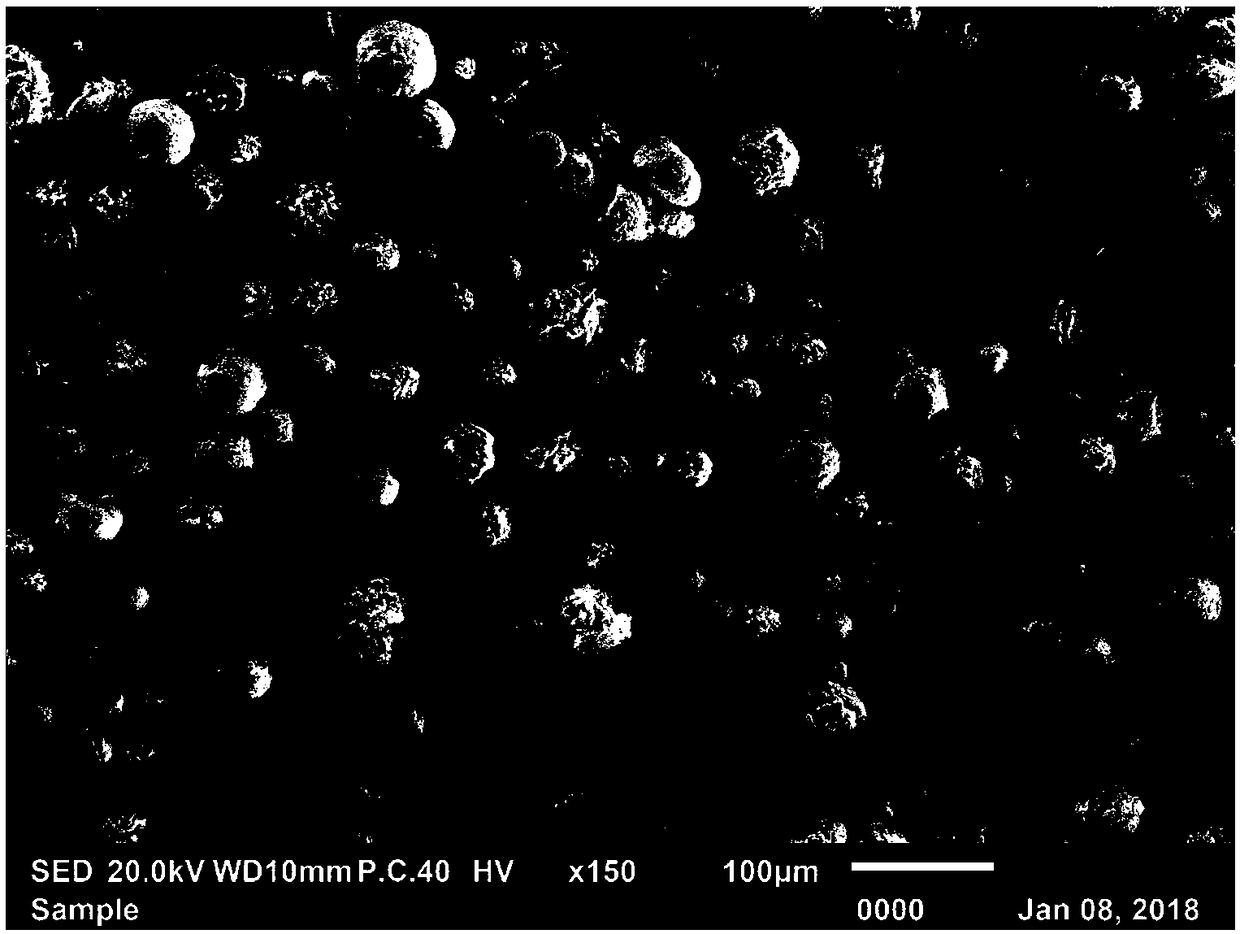

Nitrogen-doped carbon-coated silicon nanoparticle composite material, preparation method and application

InactiveCN109786666AEasy to operateEasy to implementMaterial nanotechnologySiliconCarbon coatedSilicon nanoparticle

The invention discloses a nitrogen-doped carbon-coated silicon nanoparticle composite material and a preparation method thereof. The preparation method comprises the following steps that: S1: puttinga silicon nanoparticle of which the grain diameter is 30-50nm in Tris-HCl buffer solution of which the pH (Potential of Hydrogen) is 7.5, cleaning, and drying to obtain processed silicon nanoparticles; S2: adding dopamine hydrochloride into Tris-HCl buffer solution of which the pH is 8.5, and dissolving to obtain dopamine solution; S3: adding the silicon nanoparticle processed in S1 into the dopamine solution obtained in S2, evenly dispersing, carrying out stirring reaction at the room temperature for 1-8 days, and carrying out separation and drying to obtain reactant; and S4: under an inert atmosphere, calcinating the reactant obtained in S3 at a temperature of 700-900DEG C for 1-2h to obtain a composite material. The invention also discloses the application of the above composite material on a lithium battery negative electrode. The composite material synthesized by the preparation method has excellent cycling stability.

Owner:BLUE OCEAN & BLACK STONE TECH CO LTD FUJIAN

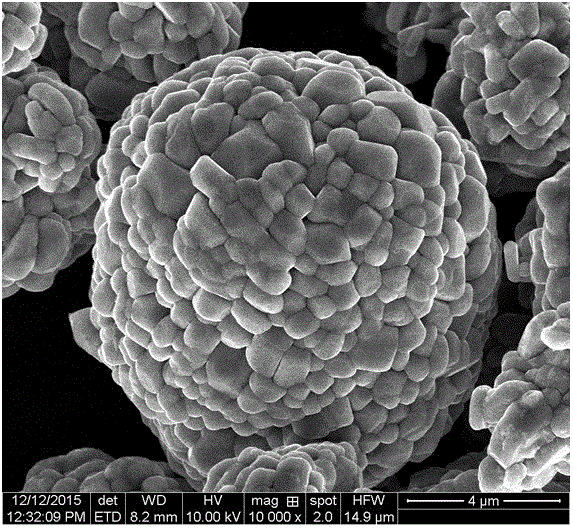

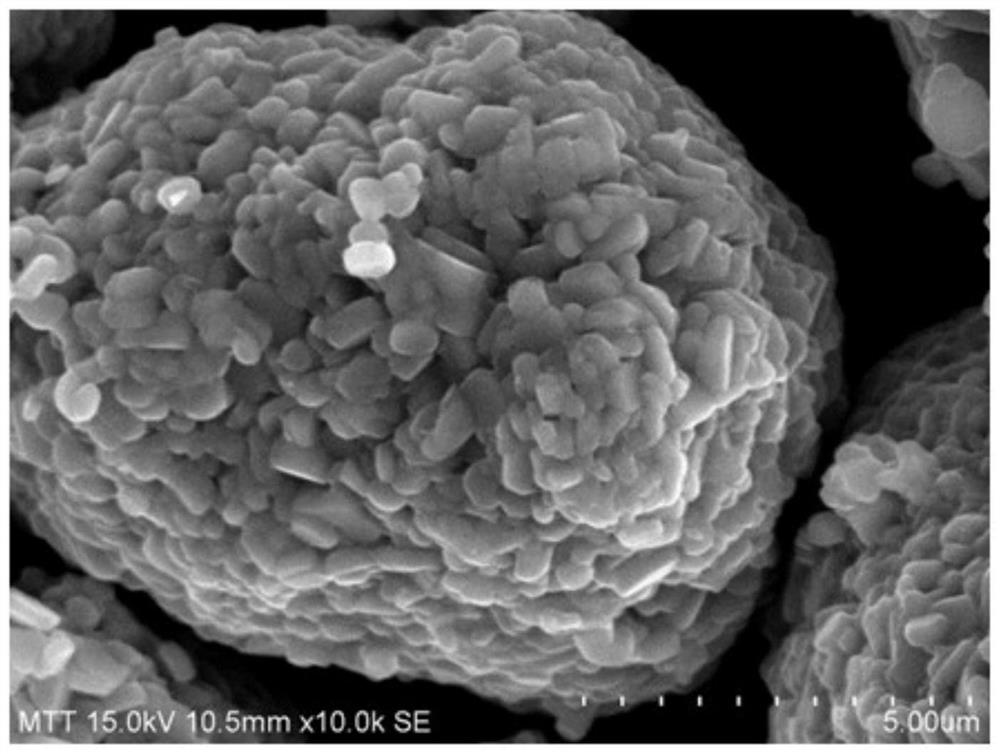

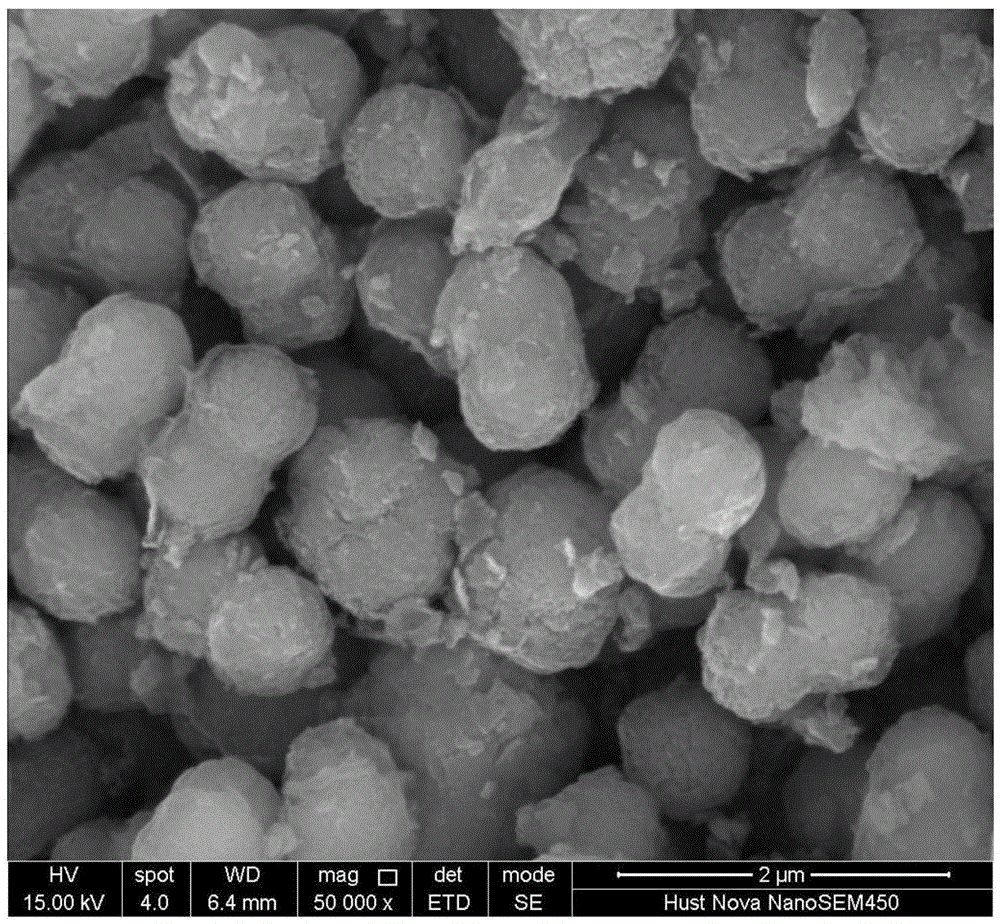

High-sphericility, compact-surface and low-impurity Ni-Co-Mn ternary material precursor and preparation method and application thereof

The invention discloses a high-sphericility, compact-surface and low-impurity Ni-Co-Mn ternary material precursor and preparation method and application thereof, and belongs to the technical field oflithium ion battery preparation. The preparation method comprises the following steps of dissolving a nickel source, a cobalt source and a manganese source compound in deionized water to prepare a solution with certain concentration; mixing the prepared solution and concentrated ammonia water, and combining with a precipitant and an ammonium salt solution to enter a reaction kettle for reaction; washing, re-pulping and re-washing the obtained precursor paste, and adding a certain amount of alkali solution during the re-pulping process; and performing spray drying, thereby obtaining the Ni-Co-Mn ternary material precursor. With the adoption of the method, the prepared Ni-Co-Mn ternary material precursor can be good in crystallinity, high in product sphericility, compact in surface and extremely low in impurity content in a product and can be used for a lithium ion battery positive electrode material-lithium nickel cobalt manganate with more excellent performance.

Owner:安徽同心新材料科技有限公司

Cobalt acid lithium battery material adulterated alkaline-earth metal between layers and its preparing method

InactiveCN1763997AInitial capacity reductionStable structureCell electrodesLithium compoundsAlkaline earth metalCITRATE ESTER

The invention relates to a new anode material with interlaminar doping Li(1-2beta)(AE) (beta)CoO2 (AEú¢Mgú¼Ca) by substituting lithium ion by alkaline-earth metal ion and opposite fused salt ion exchange reaction preparation method. Wherein, the preparation method comprises: preparing layer-shape LiCoO2 predecessor with little and even size with citrate sol-gel method; substituting part lithium ion with Mg2+ or Ca2+ by fused salt ion exchange reaction; baking to distribute lithium ion and alkaline-earth metal ion evenly in main body layer constructed by CoO2. This product has more stable structure, better anti-overcharge performance, higher specific capacity and super electrochemical circulation property.

Owner:BEIJING UNIV OF CHEM TECH

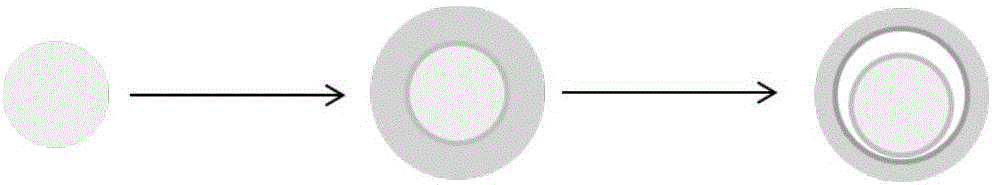

Method for recycling valuable metals of waste lithium ion battery and regenerating ternary positive electrode material

PendingCN112194201AHigh metal ion leaching rateNovel preparation methodMaterial nanotechnologyCell electrodesChemistryElectrically conductive

The invention provides a method for recycling valuable metals of a waste lithium ion battery and regenerating a ternary positive electrode material. The method comprises the following steps of: discharging the waste lithium ion battery, performing disassembling, and removing impurities to obtain a positive plate, and removing a conductive agent and a binder in the positive plate at high temperature to obtain the waste ternary positive electrode material; according to a first regeneration route, valuable metal ions can be leached out from organic acid or a eutectic solvent added with a reducingagent, a sodium alginate solution is adopted to crosslink the metal ions to form an egg box structure gel with a three-dimensional net structure, and the regenerated ternary positive electrode material is obtained after calcination; according to a second regeneration route, ball milling nanocrystallization is beneficial for lithium ions to enter particles to supplement lithium, gel is used for repairing an uneven surface, and the regenerated ternary positive electrode material is obtained after calcination. The two regeneration routes are simple and easy to operate, the steps of separation and purification of valuable metal ions and the like are avoided, the method is novel, low in cost, and easy to realize industrialization, and the prepared material has excellent electrochemical performance.

Owner:江苏载驰科技股份有限公司

Method for preparing lithium cobaltate composite electrode material coated by iron phosphate

InactiveCN101276913AThickness is easy to controlImprove electrochemical cycle performanceElectrode manufacturing processesChemical/physical/physico-chemical processesComposite electrodeFiltration

The invention relates to the preparation method of an iron phosphate coating lithium cobalt oxide composite electrode material, which belongs to the lithium ion battery electrode material and the preparation technology field. The preparation technology of the invention is that: a LiCoO2 is added into a Fe(NO3)3 solution, then an ultrasound dispersive treatment is carried out for the solution, under a mechanical agitation, a (NH4)2HPO4 solution is slowly dropped into the solution, after filtration, wash and heat treatment, the iron phosphate coating lithium cobalt composite electrode material is obtained. The invention has the advantages of having simple preparation process, good coating effect, and having good electrochemistry circulation stability and charge-off-resistant properties under the condition that the composite electrode material obtained does not reduce the specific discharge capacity of the lithium cobalt oxide.

Owner:BEIJING UNIV OF CHEM TECH

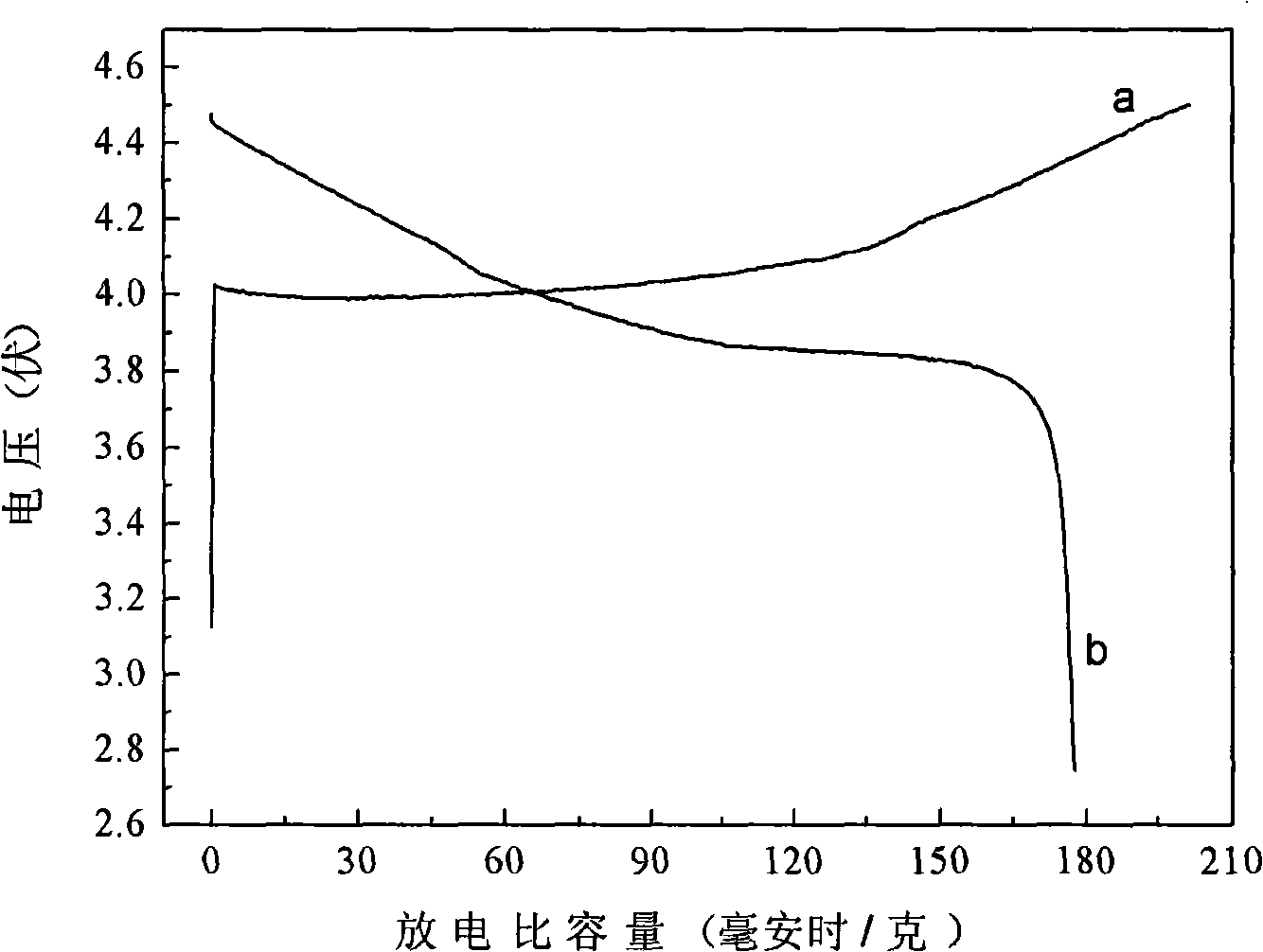

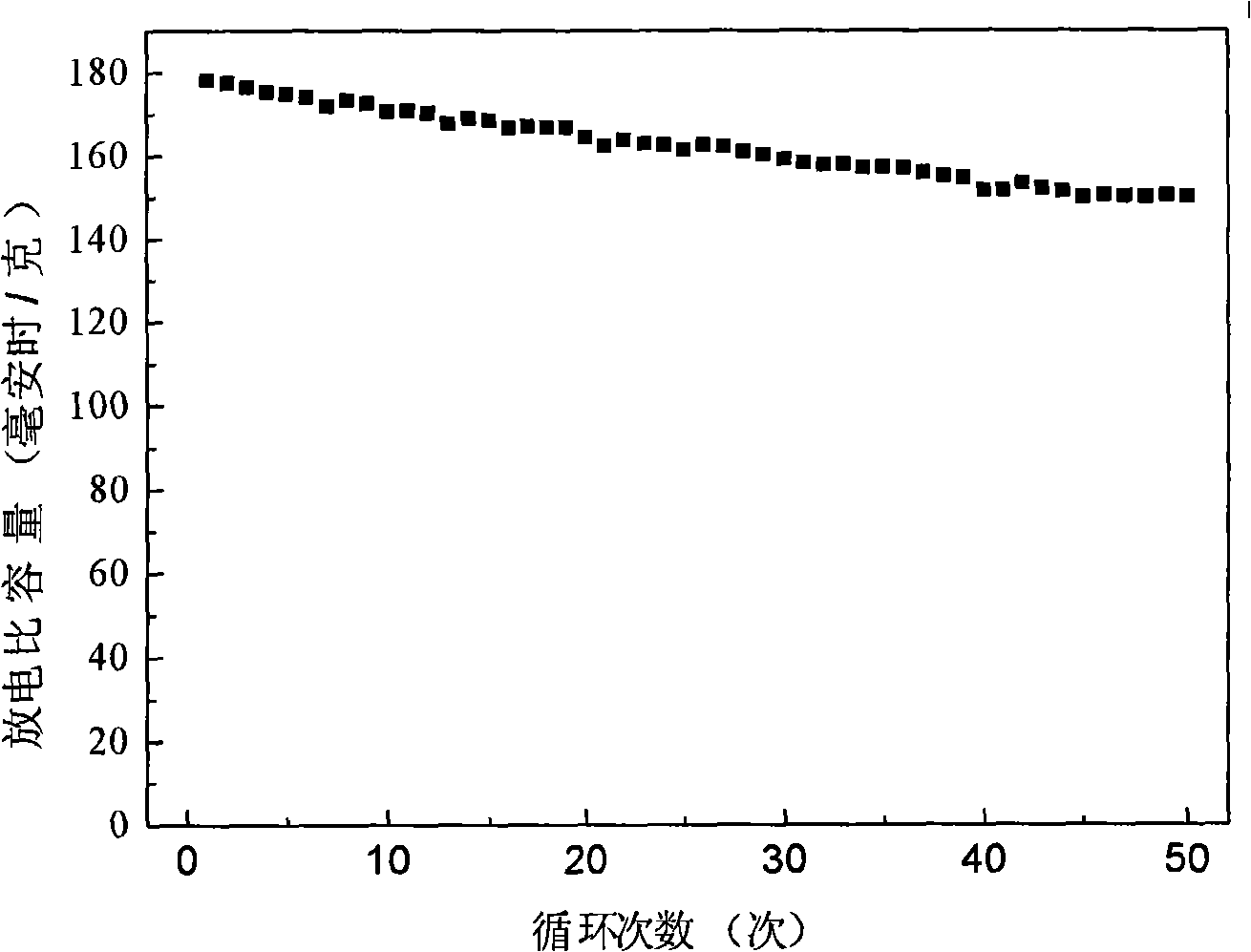

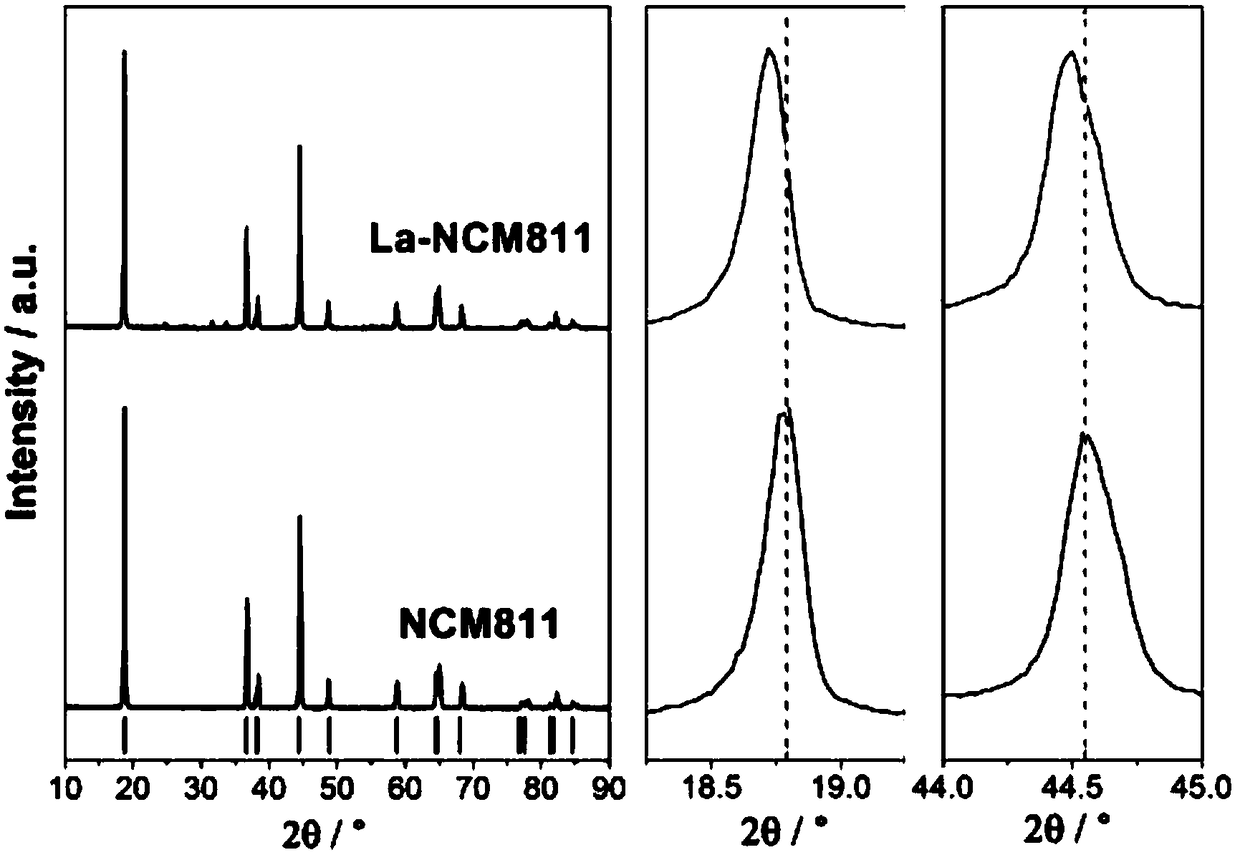

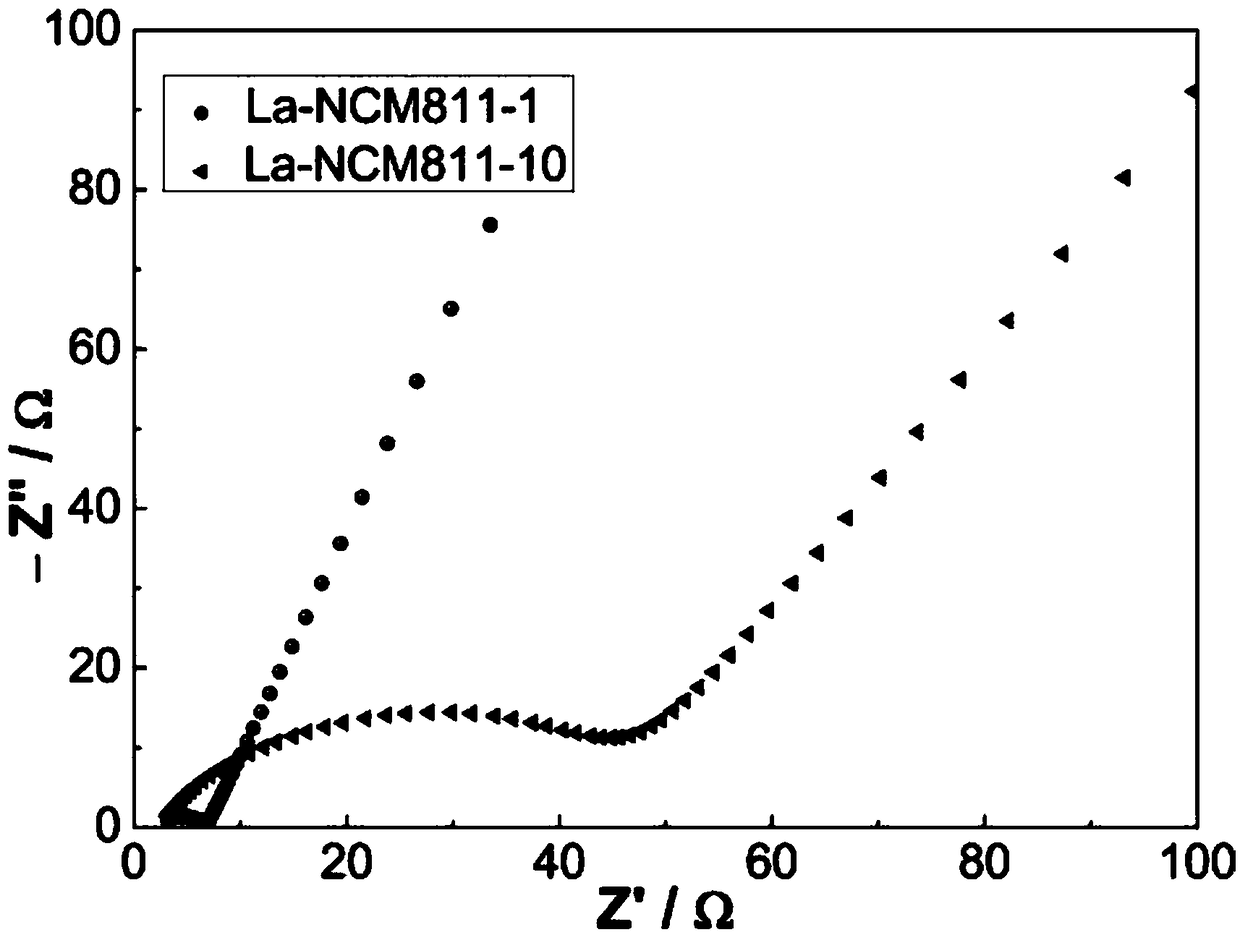

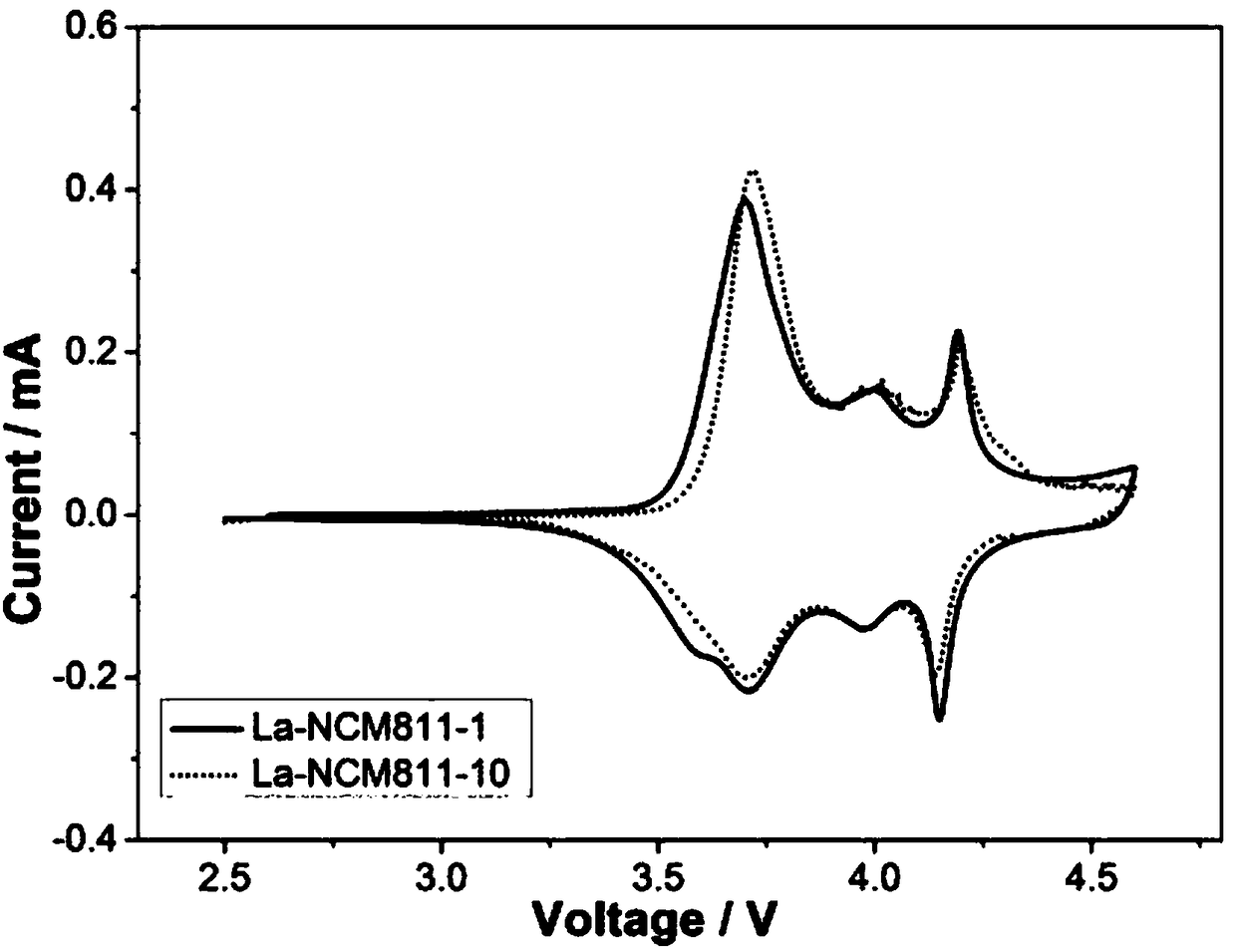

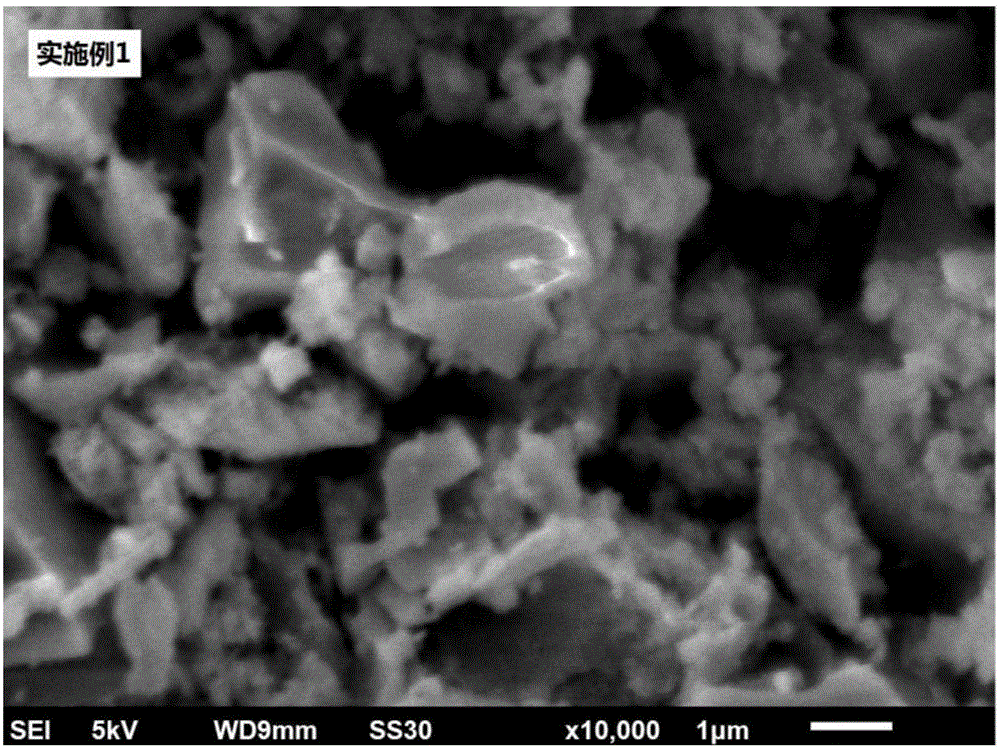

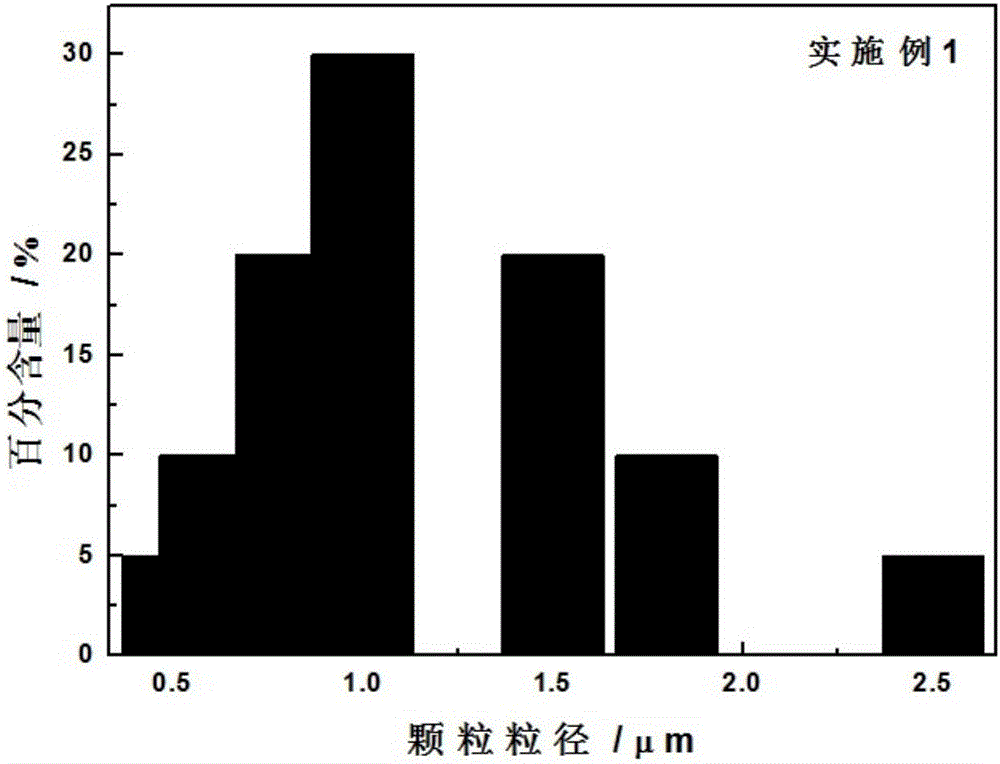

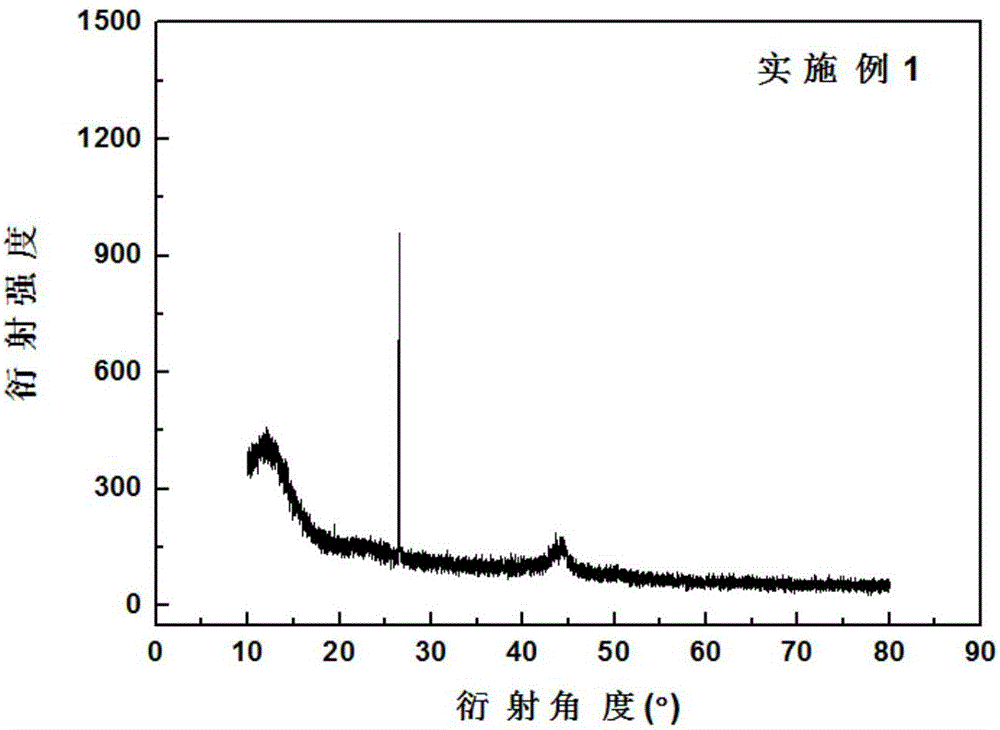

Preparation method of NCM ternary positive electrode material with La3+ doped on surface layer

InactiveCN108134067AInhibition of phase transitionImprove structural stabilityCell electrodesSecondary cellsManganeseCobalt

The invention relates to a preparation method of an NCM ternary positive electrode material with La3+ doped on a surface layer, belonging to the field of chemical energy storage batteries. According to the method of the invention, La3+ is doped in the process of mixing a nickel cobalt manganese hydroxide precursor with the lithium salt, and the doped La3+ enters a transition metal layer of the surface layer to occupy the position of Ni2+ and can play roles in supporting the framework, suppressing the phase change of the surface layer structure and suppressing the mixed arrangement of Li+ / Ni2+;in addition, La3+ has a relatively large ionic radius, and after La3+ is doped to enter the transition metal layer, a channel for embedding and extraction of Li+ can be widened, the transmission rateof Li+ can be improved, and the electrochemical performance of the NCM ternary positive electrode material at high voltage and high magnification (4.5V, greater than or equal to 1C) can be significantly improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation method of battery-grade graphite-activated carbon composite material

InactiveCN106099108AWide particle size distributionHigh porosityCell electrodesSecondary cellsMuffle furnaceActivated carbon

The invention discloses a preparation method of a battery-grade graphite-activated carbon composite material. The preparation method comprises the steps that 1, plant raw materials are washed clean with water and then contained in a metal tank, the metal tank is sealed and put into a muffle furnace, heating is conducted at the constant temperature of 450 DEG C to 650 DEG C, the temperature is naturally decreased to room temperature, and black solid activated carbon is obtained; 2, the obtained black solid activated carbon and graphite are put into a ball milling tank according to the mass ratio of 3:1-1:1, an appropriate amount of hydrochloric acid with the concentration of 0.2 M to1.0 M, an appropriate amount of sulfuric acid with the concentration of 0.1 M to 0.5 M, an appropriate amount of acetic acid with the concentration of 0.5 M to 1.2 M and an appropriate amount of water are sequentially added into the ball milling tank, ball milling is conducted for 0.5 hour to 2 hours under the condition that the ball-material ratio is equal to 1:10-1:20, and then acid washing and water washing are sequentially conducted, wherein sulfuric acid, hydrochloric acid and acetic acid are subjected to ball-milling washing three times to five times separately, and the water is subjected to ball-milling washing until the pH value of eluate is 6.8 to 7.2; 3, the washed graphite-activated carbon mixture is subjected to suction filtration and dried in an atmospheric environment, and the battery-grade graphite-activated carbon composite material is obtained. The preparation method has the advantages of being simple in process, rich in raw materials, short in manufacturing cycle and low in energy consumption and has good economic benefits, environmental benefits and social benefits.

Owner:HUBEI UEE ENERGY TECH CO LTD

Lithium nitride/ceramic base composite material with high activity lithiation/delithiation performance

The invention belongs to the field of lithium ion batteries and super-capacitors, and in particular relates to a lithium nitride / ceramic-based composite anode material and a preparation method thereof, wherein the lithium nitride / ceramic-based composite anode material is prepared by a mechanochemical method and has high specific capacity, electrochemical lithium intercalation-detercalation reversibility and steady cycle performance. The composite material is a composite material which takes lithium nitride as an activity reinforced body and ceramic powder containing silicon element as a matrix; in the composite material, the chemical bonding is taken as a main interfacial bonding mode between the reinforced body and the matrix, the reinforced body and the matrix have good structural stability, and the mol ratio of the reinforcement body to the matrix is 1: 1-9: 1. The material has better electrochemical cycle performance and rate performance; and the material has a wider voltage window, has good ionic conductivity and cyclicity, and has potential application value in novel super-capacitor electrode materials. The preparation method is simple and easy to control, and the needed raw materials do not contain heavy metal elements and have the advantages of environmental protection and low cost.

Owner:DALIAN MARITIME UNIVERSITY

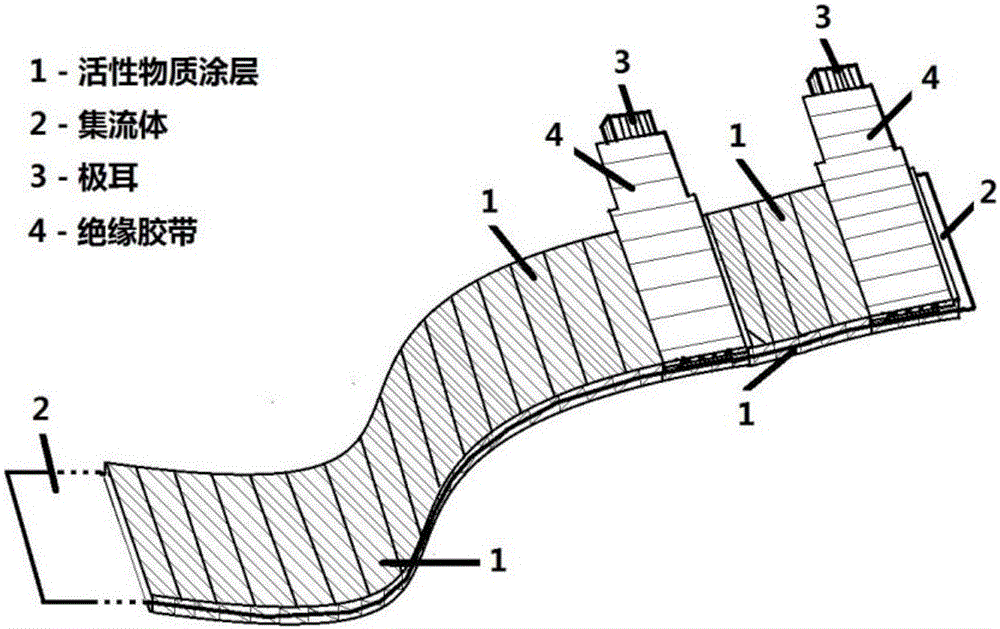

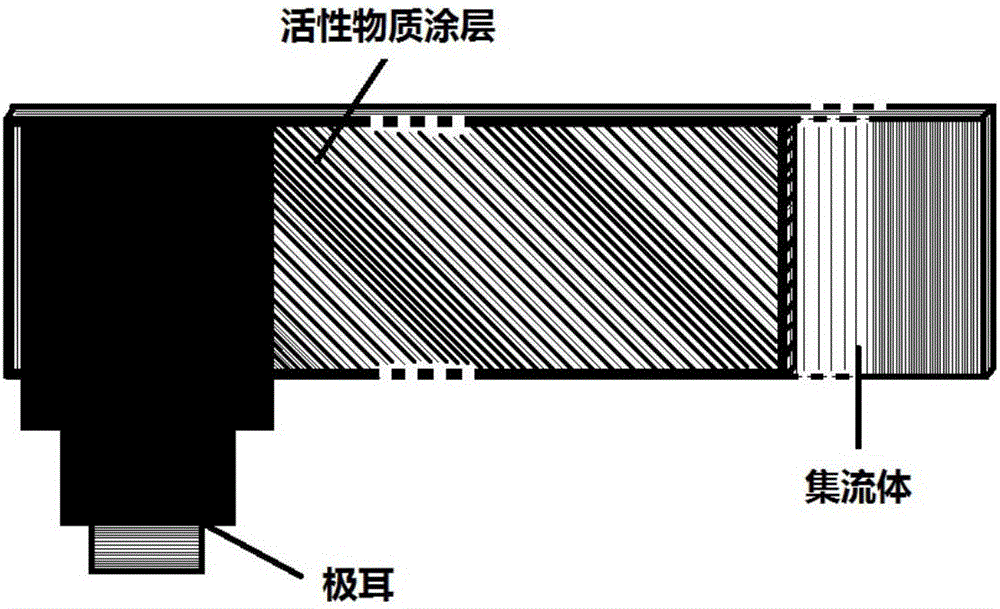

Manufacturing method for safe lithium ion power battery positive plate

InactiveCN105489843AGood thermal stabilityReduces the likelihood of redox reactionsCell electrodesPowder mixtureCurrent collector

The invention discloses a manufacturing method for a safe lithium ion power battery positive plate. The manufacturing method comprises the steps of performing ball milling and mixing on a positive electrode active substance and a conductive agent based on mass percent to obtain a positive electrode powder mixture A; adding the positive electrode powder mixture A into solvent based on a certain proportion, and stirring to obtain a solvent sizing material B; adding the positive electrode powder mixture A into the sizing material B in multiple times, controlling the mass ratio of the solid body quantity of the positive electrode powder mixture A to the solvent, stirring and preparing positive electrode slurry, adjusting and controlling the viscosity of the slurry, and stirring to obtain positive electrode slurry; taking an aluminum foil as a current collector, coating the current collector with the positive electrode slurry in a single-surface coating manner; reserving ML current collector, drying, controlling the surface density, rolling, controlling compaction density and the pole piece thickness; and performing operations of striping, slitting, tab spot welding, and T-shaped tab rubber tape gluing to obtain the safe lithium ion power battery positive plate. The lithium ion battery assembled by the manufactured safe lithium ion power battery positive plate is good in electrical performance and extremely high in safety performance.

Owner:HUBEI UEE ENERGY TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com