Element co-doping modified ternary lithium ion battery cathode material, and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of element co-doping modified ternary lithium-ion battery positive electrode materials and its preparation, can solve problems such as lattice structure distortion, unproportional changes in unit cell parameters, and influence on material performance. Achieve the effects of inhibiting erosion, synergistic changes in unit cell parameters, and reducing the risk of collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

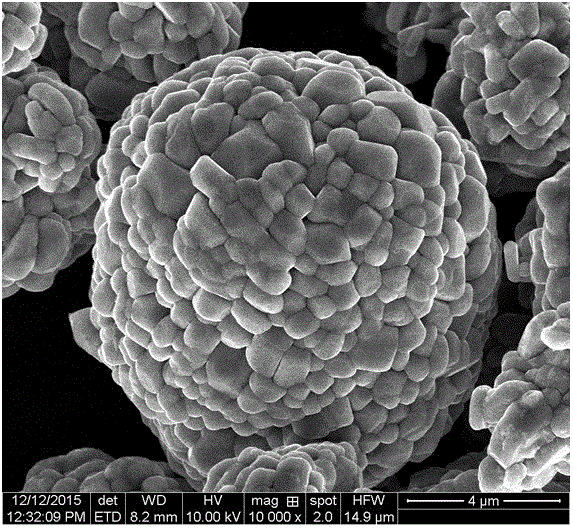

[0019] Weigh 50 g Ni 0.5 co 0.2 mn 0.3 (OH) 2 , 20.9212 g of lithium carbonate, 0.6754 g of zirconium dioxide, and 1.1115 g of boehmite were added together by ball milling in the mixing tank and mixed evenly. Then put the mixed material into the crucible and put it into the muffle furnace for high temperature sintering, using air atmosphere, sintering at 900°C for 10 h. The sintered block is broken to obtain a primary product uniformly doped with Al and Zr.

[0020] Weigh 0.7570g of aluminum isopropoxide and add it to 50mL of absolute ethanol at 60°C and stir at a constant temperature. After the aluminum isopropoxide is completely dissolved, add the primary product obtained in the previous step, continue stirring until the solvent is completely evaporated, and transfer to 110°C Dry in a C oven for 10 h, and then place in a muffle furnace for sintering at 700 ° C for 6 h. After sintering, the material is passed through a 300-mesh sieve to obtain a modified ternary material....

Embodiment 2

[0024] Weigh 50 g Ni 0.35 co 0.35 mn 0.30 (OH) 2 , 20.9212 g lithium carbonate, 1.7532 g zirconium sulfate tetrahydrate, and 1.8526 g aluminum sulfate octadecahydrate were added together by ball milling in the mixing tank and mixed evenly. Then put the mixed material into the crucible and put it into the muffle furnace for high temperature sintering, using air atmosphere, sintering at 1000°C for 10 h. The sintered block is broken to obtain a primary product uniformly doped with Al and Zr.

[0025]Then weigh 0.7099 g of tetrabutyl titanate and add it to 50 mL of absolute ethanol at 60°C and stir for 10 min at a constant temperature, then add the primary product obtained in the previous step, continue stirring until the solvent is completely evaporated to dryness, and transfer to an oven at 110°C Dry for 10 h, then place it in a muffle furnace for sintering at 850°C for 5 h, and pass the sintered material through a 300-mesh sieve to obtain the modified ternary material.

Embodiment 3

[0027] Weigh 0.6309 g of zirconium n-butoxide and 0.3785 g of aluminum isopropoxide into 100 mL of absolute ethanol, heat and stir at 60°C for 20 min, then add 50 g of Ni 0.35 co 0.35 mn 0.30 (OH) 2 , continue to stir and mix at a constant temperature until evaporated to dryness, and then place it in an oven at 100°C for 10 h. Get the dried material and 13.5624 g lithium hydroxide ball mill and mix evenly. After mixing, the above materials were placed in a high-temperature furnace for sintering at 950°C in an air atmosphere for 12 h. The sintered block is broken to obtain a primary product uniformly doped with Al and Zr.

[0028] The primary product obtained in the previous step was mixed with 0.3377 g of zirconia ball mill and placed in a muffle furnace for sintering at a sintering temperature of 900 °C and a sintering time of 4 h. After sintering, the material is passed through a 300-mesh sieve to obtain a modified ternary material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com