Manufacturing method for safe lithium ion power battery positive plate

A power battery and manufacturing method technology, applied to battery electrodes, circuits, electrical components, etc., can solve problems such as increasing the cost of material manufacturing technology and raw material manufacturing costs, changing the inherent advantages of lithium-ion batteries, and having no feasibility or applicable value. Achieve the effects of reducing the possibility of oxidation-reduction reactions, good high-rate charge-discharge performance, and excellent electrochemical cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

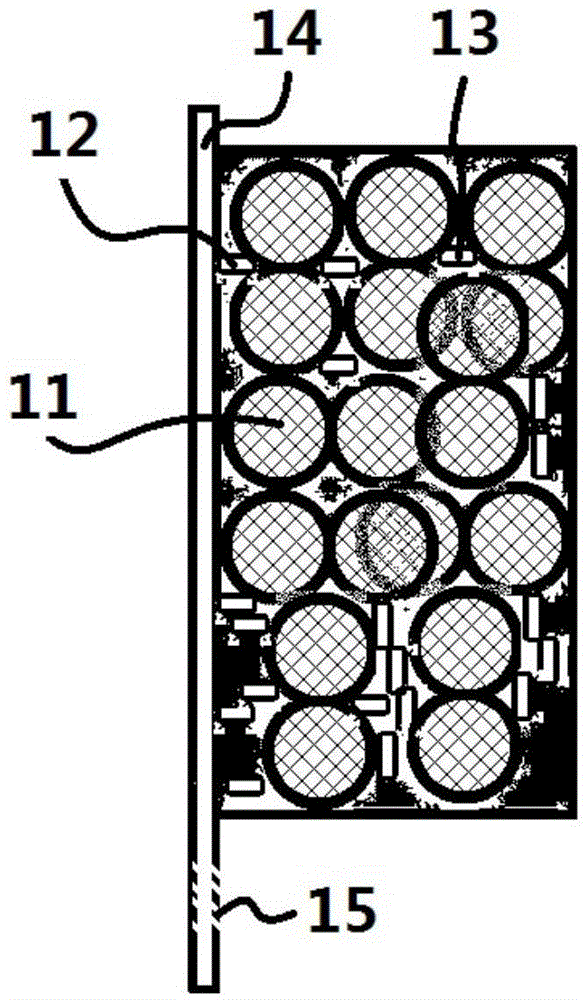

[0055] A method for manufacturing a positive pole piece of a safe lithium-ion power battery, the steps of which are:

[0056] In the first step, the Al-coated double spherical positive electrode active material and the SPS conductive agent with a mass ratio of 100:0.1 (that is, the mass ratio of Super-P to SWCNT, the same below, omitted) are respectively 75% and 20% by mass. % ratio ball milled for 4 hours and mixed evenly to make positive electrode powder positive electrode powder mixture A;

[0057] In the second step, 5% PVdF, which accounts for 5% by mass of the positive electrode active material positive electrode powder mixture A obtained in the first step, is added to the NMP solvent, and stirred for 120 minutes at a temperature of 80°C to form a rubber material B;

[0058] The third step is to add the positive electrode powder mixture A obtained in the first step to the rubber material B in 3 to 5 times, control the mass ratio of the solid amount of the positive electr...

Embodiment 2

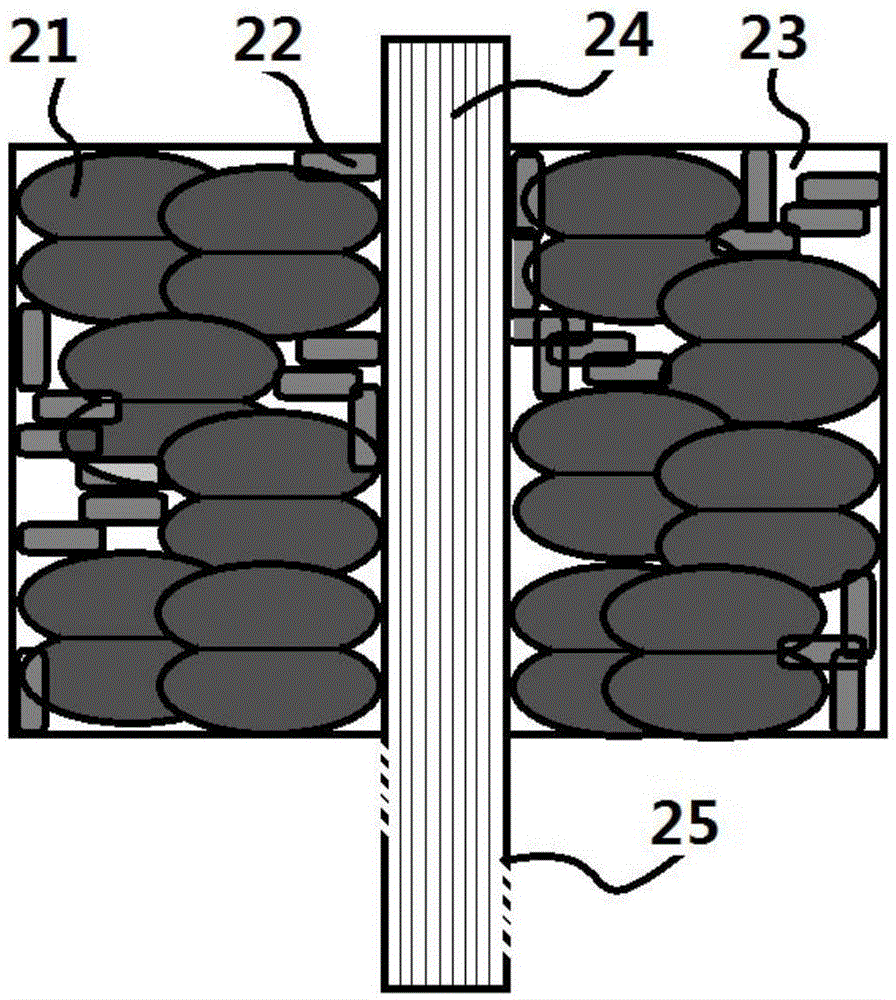

[0062] A method for manufacturing a positive pole piece of a safe lithium-ion power battery, the steps of which are:

[0063] In the first step, Al-coated hamburger-shaped positive electrode active material and SPS conductive agent with a mass ratio of 100:0.3 were ball-milled for 6 hours according to the proportions of 80% and 16% by mass and mixed evenly to make a positive electrode powder and a positive electrode powder mixture. A;

[0064] In the second step, PVdF, which accounts for 4% by mass of the positive electrode active material positive electrode powder mixture A obtained in the first step, is added to the NMP solvent, stirred for 100 minutes at a temperature of 80° C., and stirred into a rubber material B;

[0065] The third step is to add the positive electrode powder mixture A obtained in the first step to the rubber material B in 3 to 5 times, control the mass ratio of the solid amount of the positive electrode powder mixture A to NMP between 1350:800, and stir...

Embodiment 3

[0069] A method for manufacturing a positive pole piece of a safe lithium-ion power battery, the steps of which are:

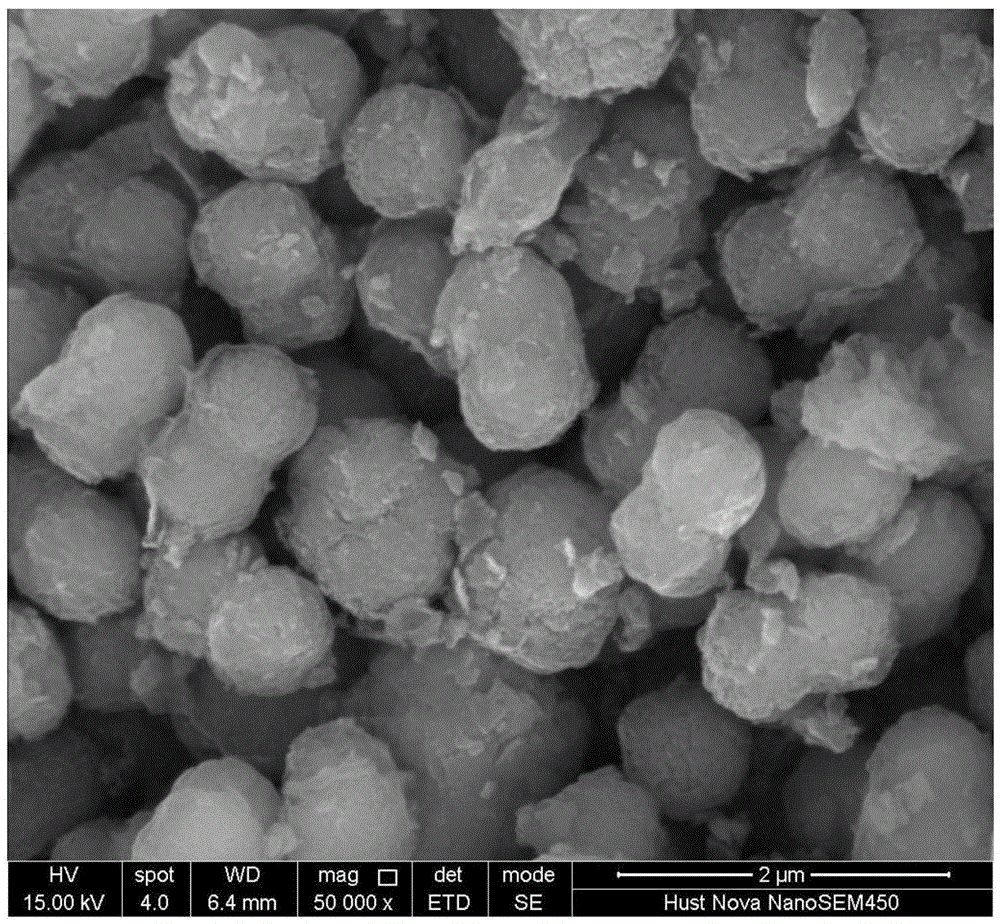

[0070] In the first step, the Si-coated olive body / ellipsoid-shaped positive electrode active material and the SPS conductive agent with a mass ratio of 100:0.5 are ball-milled for 8 hours according to the mass percentages of 85% and 12% respectively, and the positive electrode powder is made. Material positive electrode powder mixture A;

[0071]In the second step, 3% PVdF, which accounts for 3% by mass of the positive electrode active material positive electrode powder mixture A obtained in the first step, is added to the NMP solvent, and stirred for 120 minutes at a temperature of 80°C to form a rubber material B;

[0072] The third step is to add the positive electrode powder mixture A obtained in the first step to the rubber material B in 3 to 5 times, control the mass ratio of the solid amount of the positive electrode powder mixture A to NMP between 145...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com