Patents

Literature

239results about "Natural fibres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

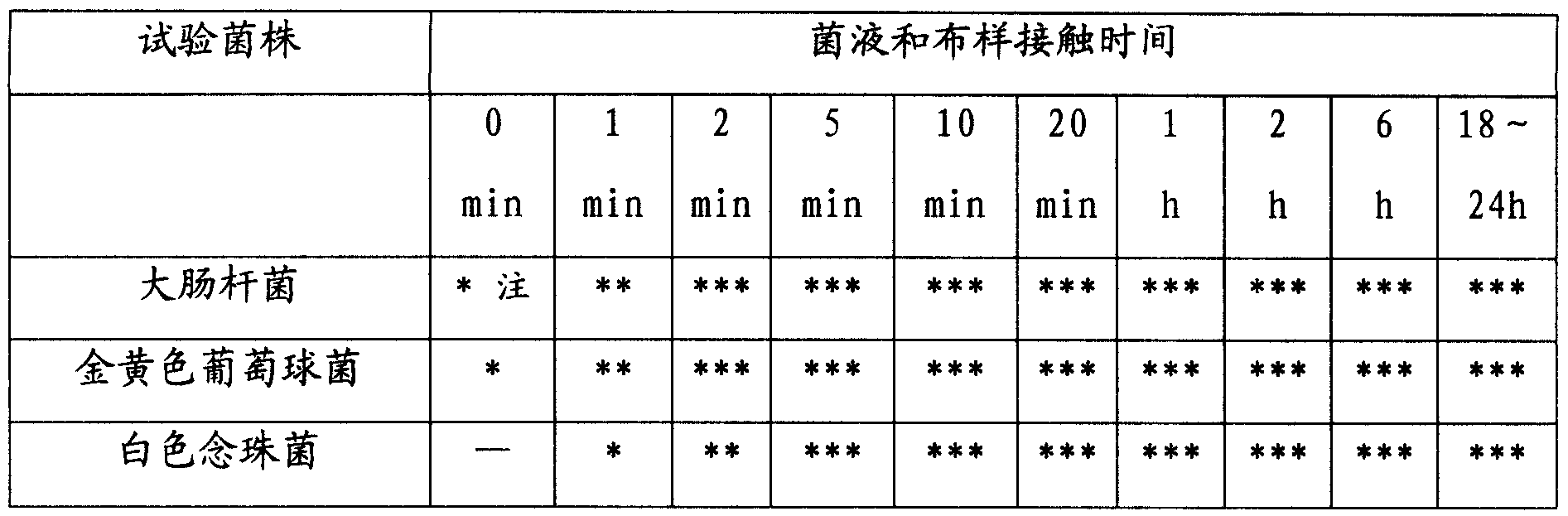

Inorganic/organic nano composite antibacterial agent and its fabric product application

The invention relates to an inorganic / organic nano-composite antibacterial and application of fiber product thereof. 0.01-20 proportions of inorganic antibacterial, 0.01-35 proportions of organic antibacterial, 0.0001-0.4 proportion of inorganic / organic antibacterial compatibility finishing agent, 0.05-40 proportions of macromolecule bond, 0.0001-0.4 proportion of stabilizer that prevents color change of the inorganic antibacterial, 0.1-30 proportions of high efficiency emulsifying agent and 100 proportions of distilled water are added in sequence by weight proportion, wetted, dispersed, ground, dispersed at high-speed, stirred, etc., so as to acquire the nano-composite antibacterial. The antibacterial can process the fiber product by a dip-dye method, a roll-dye method, a spray method, etc. Dresses, socks and socks, blankets, beddings, gowns, patient wears, masks, medicinal gauzes, air filtering nettings, etc., made from the inorganic / organic nano-composite antibacterial of the invention are characterized by high antibacterial efficiency, rapid antibacterial function, long lasting antibacterial performance, laundering durability, etc., and the inorganic / organic nano-composite antibacterial of the invention is applicable to life, medical care, etc., and has the functions of preventing the occurrence and transmission of diseases, protecting the health of people and improving life quality.

Owner:BEIJING CHAMGO NANO TECH

Low-temperature scouring and bleaching agent and preparation method thereof and preprocessing technique

InactiveCN101037842AReduce the bleaching temperatureThe effect of the pretreatment process is obviousBleaching apparatusTextile treatment by spraying/projectingTextile printerBenzene

The present invention realtes to a low temperature scouring and bleaching agent belonging to the pretreatment process technology field of the textile printing and dyeing industry, a manufacturing method thereof and a pretreatment process. Said low temperature scouring and bleaching agent consists of promoter QR2010 consisting of carbon tetrachloride, acetic acid esters, alkyl benzenes, emulsifying agents and scouring agents; promoter QR2011 consisting of potassium hydroxide, carbonates and penetrating agents; and promoter QR2020 consisting of acyls and nitriles activating agents and builders. Said three promoters are prepared using routine methods and are deposited solely. When used, the three promoters, together with hydrogen peroxide, are mixed according to different proportions to prepare solutions. Said low temperature scouring and bleaching agent is capable of annealing, boiling and bleaching a variety of cotton as well as cotton blending textiles at any temperature ranging from 40 DEG C to 80 DEG C, and being processed at different scouring and bleaching equipments, with a whiteness of higher than 80% and a capillary effect of 10-20 cm. Compared with the process in existing, the amount used of hydrogen peroxide activating agent is 1 / 7 to 1 / 5 of that originally used, the total energy consumption is reduced, the tonnage of used water is decreased, and billet flaws such as holes bleached by oxygen and lycra folded crepes sourced and bleached are avoided.

Owner:SHANGHAI QIRUI TEXTILE CHEM

Manufacturing process of antibacterial fiber

Tea polyphenol obtained by the extraction from tea has an antibacterial effect. In methods for producing an antibacterial fiber by fixing the tea polyphenol to fiber, the object of the present invention is to provide a process for manufacturing an antibacterial fiber capable of exerting an excellent antibacterial performance without the use of metal chelates potentially causing metal allergy and environmental problems. In order to achieve the above object, the present invention manufactures an antibacterial fiber by a process comprising the steps of contacting fiber with or immersing fiber in an aqueous solution in which a cationic surfactant with a quaternary ammonium salt group, a water-soluble protein, and an alkaline compound are dissolved; and separating said fiber from the aqueous solution, to immerse the fiber in another aqueous solution containing tea polyphenol.

Owner:SHOKUHIN SANGYO HIGH SEP

Non-fluorinated urethane based coatings

ActiveUS20160090508A1Imparting durable water repellencyIncreased durable water repellencyWater-repelling agents additionSynthetic fibresSaccharic acidPolymer science

The present invention is an aqueous composition comprising at least one hydrophobic compound having at least one linkage of Formula I:—NHC(O)—X— (I)wherein X is the residue of a cyclic or acyclic sugar alcohol which is substituted with at least one —R1; —C(O)R1; —(CH2CH2O)n(CH(CH3)CH2O)mR2; —(CH2CH2O)n(CH(CH3)CH2O)mC(O)R1; or mixtures thereof; where the cyclic or acyclic sugar alcohol is selected from a saccharide, reduced sugar, aminosaccharide, aldonic acid, or aldonic acid lactone; wherein each n is independently 0 to 20; each m is independently 0 to 20; m+n is greater than 0; each R1 is independently a linear or branched alkyl group having 5 to 29 carbons optionally comprising at least 1 unsaturated bond; each R2 is independently —H, a linear or branched alkyl group having 6 to 30 carbons optionally comprising at least 1 unsaturated bond, or mixtures thereof.

Owner:THE CHEMOURS CO FC LLC

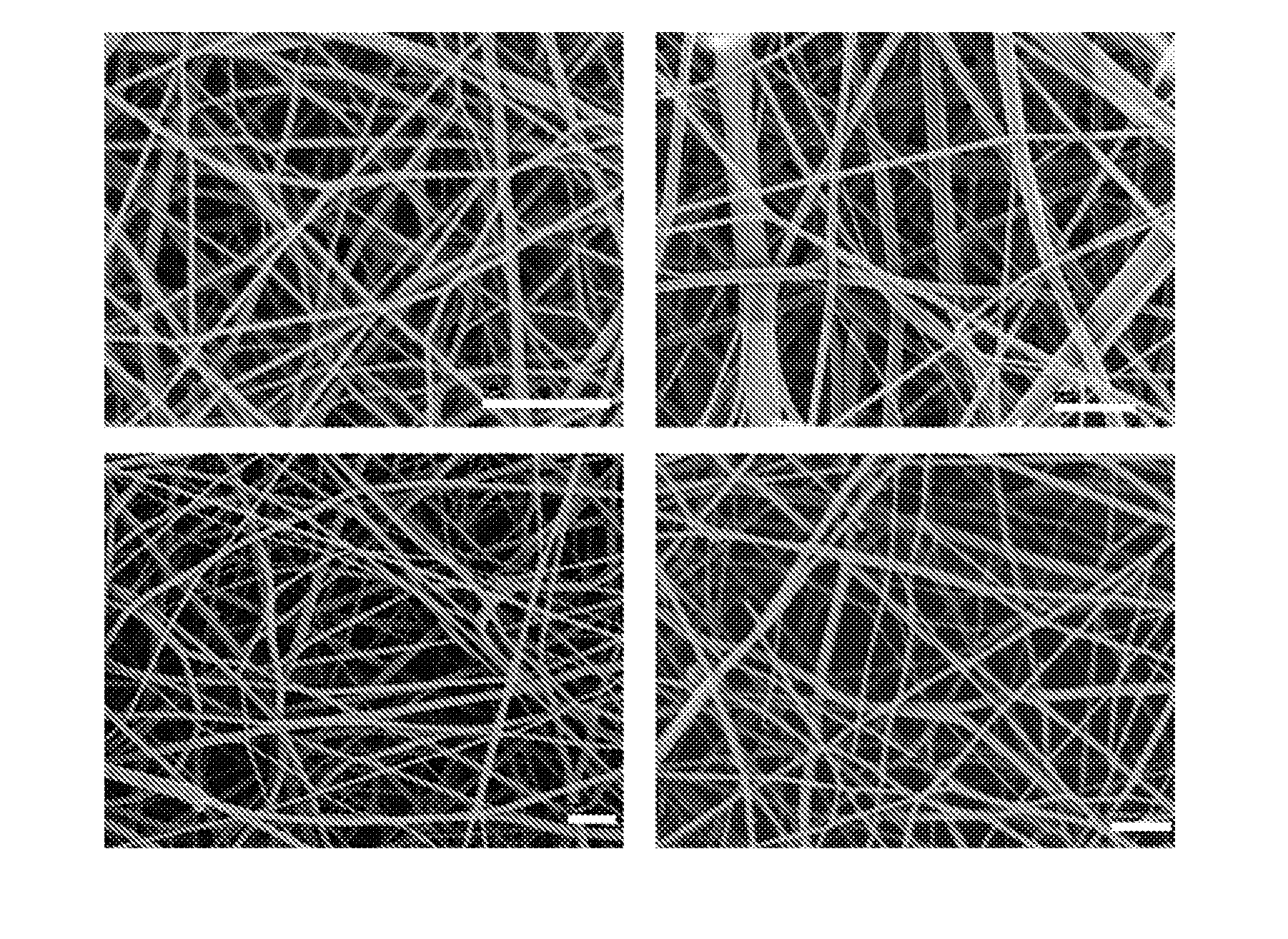

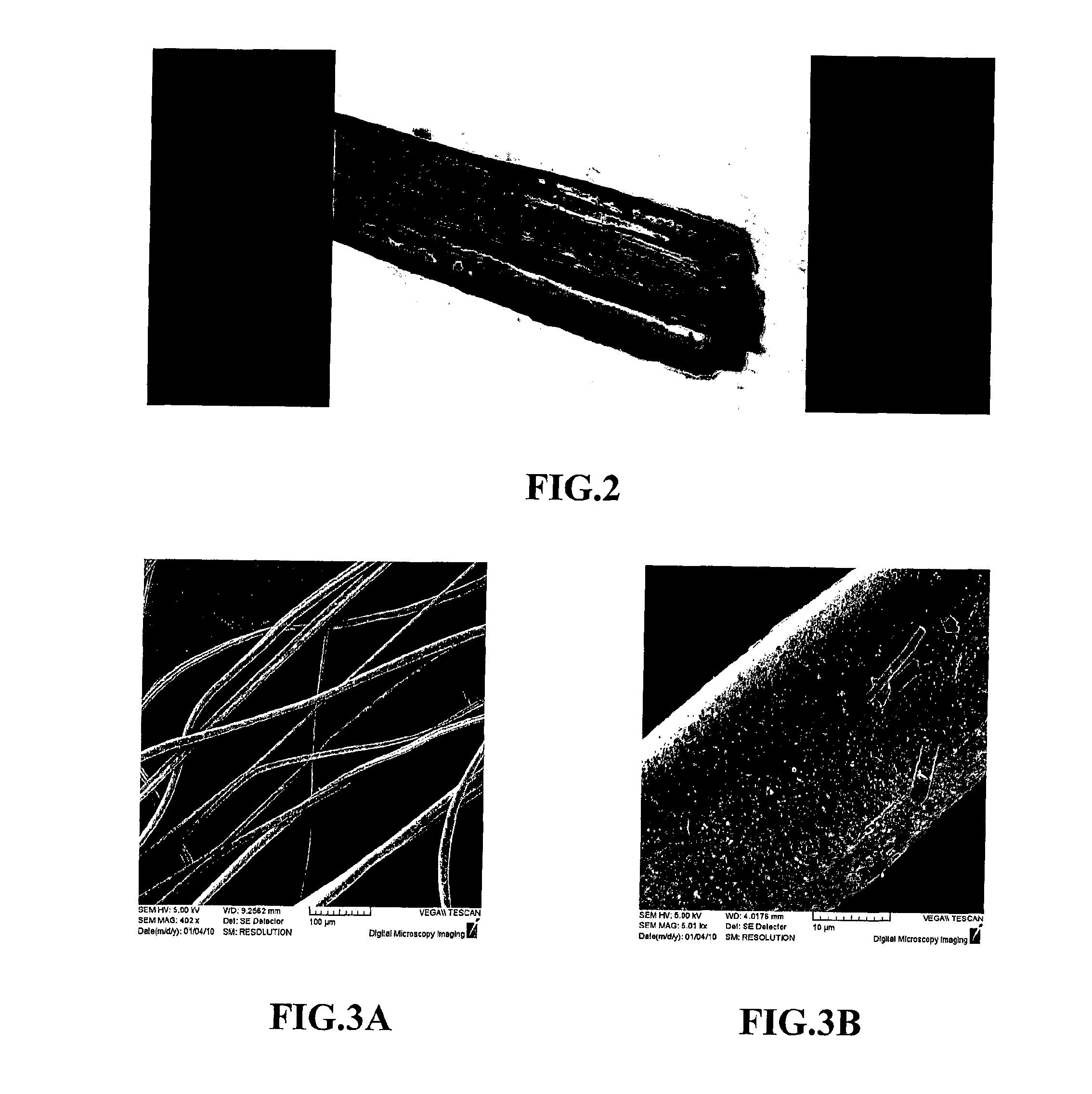

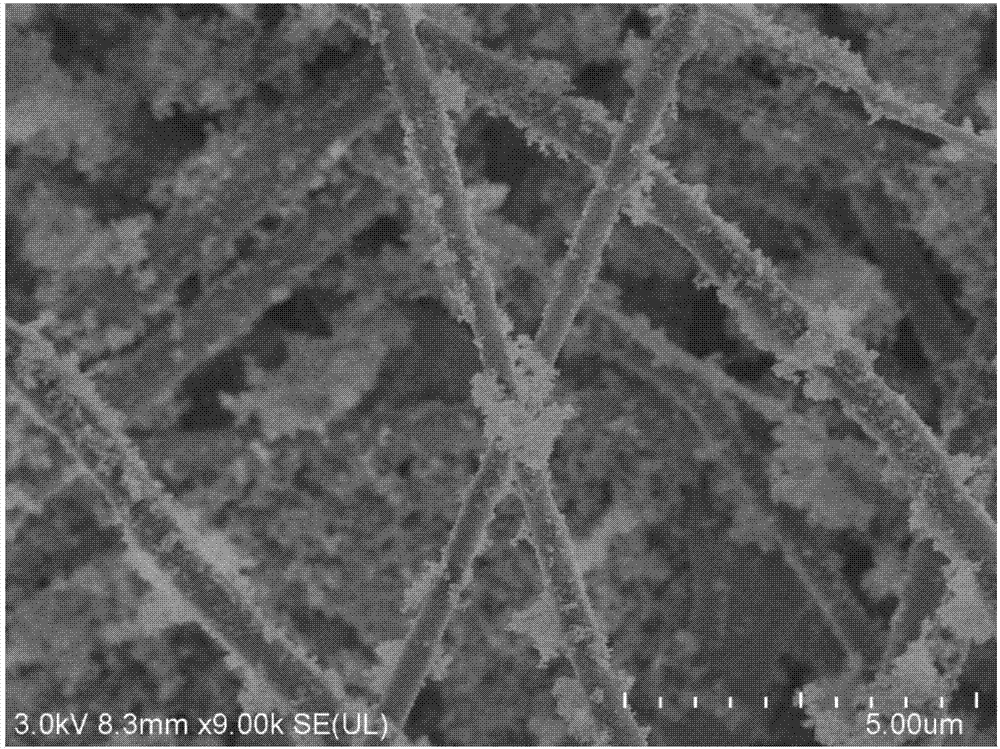

Preparation method of bacterial cellulose based carbon nanofibers

ActiveCN103820883AGood thermal stabilityImprove conductivityArtificial filament chemical after-treatmentNatural fibresFiberCarbon fibers

The invention discloses a preparation method of bacterial cellulose based carbon nanofibers and relates to a preparation technology of a carbon fiber material. The preparation method comprises the following steps: carrying out purification treatment on bacterial cellulose obtained by bacterial fermentation and carrying out freeze drying, carrying out carbonization treatment by putting the dried bacterial cellulose material into an atmosphere furnace and heating to 600-1200 DEG C, further heating the processed material to graphitize the material, and cooling to obtain the bacterial cellulose based carbon nanofiber material having a three-dimensional net structure. The preparation technology is simple and easy to carry out, is convenient to operate and has low cost. The obtained bacterial cellulose based carbon nanofiber has a good spatial net structure, has excellent mechanical property, thermal stability and conductivity, and can be applied in fields of electron devices, special composite materials, high efficient catalytic materials, biological materials and the like.

Owner:钟春燕

Temperature-sensitive hydrophilic cross-linking crystal type polyurethane coating agent, preparation method thereof and application thereof

InactiveCN101709197AGood waterproof and moisture permeabilityHigh precisionSynthetic fibresPolyurea/polyurethane coatingsPolyesterCross-link

The invention discloses a temperature-sensitive hydrophilic cross-linking crystal type polyurethane coating agent, a preparation method thereof and application thereof, and belongs to the technical field of textile chemical engineering. The preparation thereof comprises the following steps of: using a prepolymer method, taking 4,4'-diphenylmethane diisocyanate (pure MDI) as a hard segment, taking polyester polyol or polyether polyol as a soft segment, adding micromolecular diol chain-extension into the segments, and performing self-emulsification to obtain the polyurethane coating agent. After textile is coated by adopting a proper process, the capability of hydrostatic pressure and moisture permeability of the textile is greatly improved, and the moisture permeability of the textile represents higher response accuracy and sensitivity to environmental temperature changes. The response range of the moisture permeability of the finished coated textile to the environmental temperature changes is between about 17.0 and 28.0 DEG C so as to furthest meet the requirement of a human body on comfort.

Owner:广东广纺检测技术股份有限公司

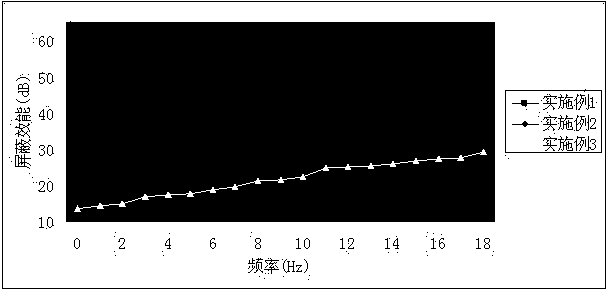

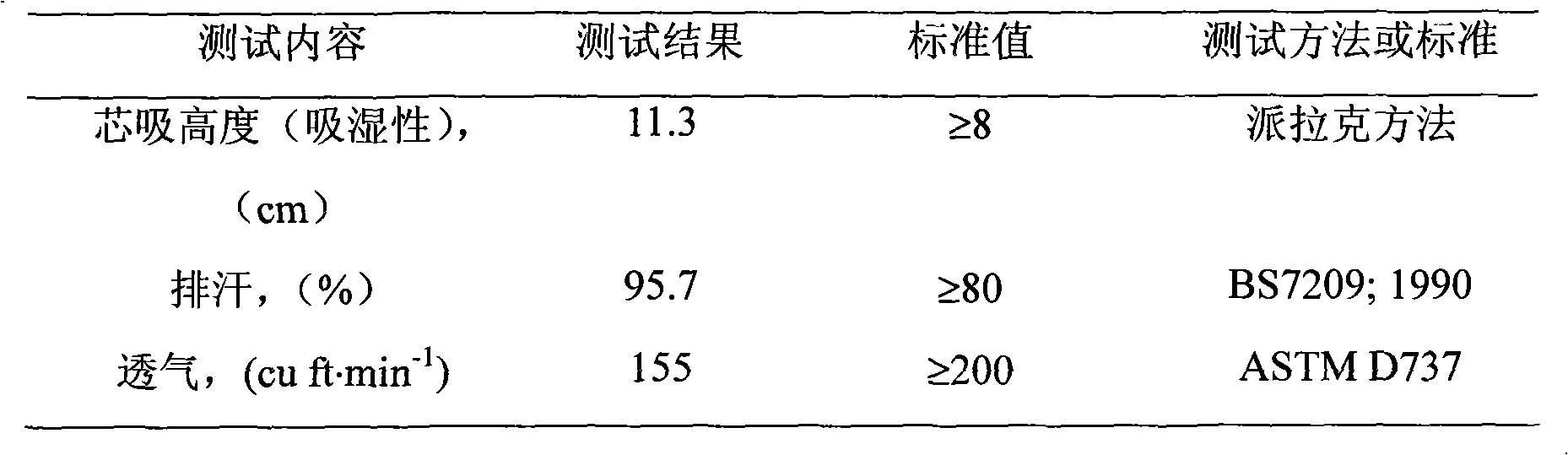

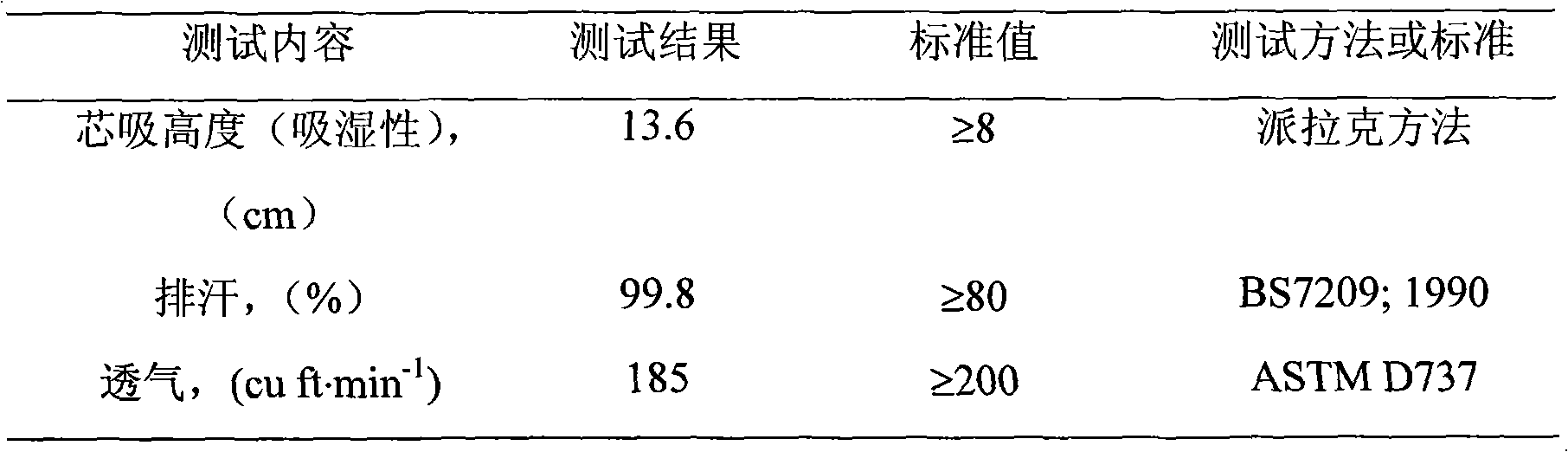

Finishing method of dry-touch and cool knitted underwear or fabric

InactiveCN101353864AFast water absorptionFast water deliveryNatural fibresBiomedical engineeringTemperature sensitive

The invention relates to a method for sorting dry and cool knitted underwear or shell fabrics, comprising the steps of: (1) preliminary treatment according to a conventional method of the enterprise; (2) washing with water; (3) the sorting of a temperature-sensitive type micro-capsule with hydrophobic core material; and (4) post-processing by using a hydrophilic agent. The underwear produced by using the method of the invention has good wet permeability and drying functions, can not only absorb the sudor perspired from the skin of a human body, but also drain the water in the clothes, thus causing the human body to be dry, cool and comfortable.

Owner:DONGHUA UNIV +1

Heat unbinding polyurethane finishing agent resistant to crushing, and production method

InactiveCN101003945AOvercome the disadvantages of reducing fabric strengthImprove wrinkle resistanceNatural fibresAlcoholHydrogen

The present invention relates to a thermal deblocking polyurethane crease-resisting finishing agent. Its composition includes (by wt%) 20-60% of hydroxyl terminated polymer whose average mole mass is 400-6000; 0.1-10% of tribasic alcohol compound; 6-20% of dimethylol carboxylic acid compound; 20-50% of polyisocyanate compound; 6-30% of isocyanate blocking agent and 0.6-6% of ammonia water. Said invention also provides its preparation method and concrete steps.

Owner:LIAONING FIXED STAR FINE CHEM

Pre-treating method for cotton fabric by one bath two-step enzyme method

InactiveCN1944784ANo damageImprove wettabilityBiochemical fibre treatmentNatural fibresChemical treatmentAlpha-amylase

The present invention relates to re-compounded enzyme preparation and its application in cotton fabric treatment, and is especially one bath and two step enzyme process for pre-treating cotton fabric. Alkaline pectase, cellulase, alpha-amylase, PVA degrading enzyme, proteinase, lipase, xylanase and sugar oxidase are first re-compounded, and the re-compounded enzyme preparation is then used in the one bath and two step enzyme process for pre-treating cotton fabric. The process includes the first desizing and boiling off step in the treating bath at 55 deg.c and pH 8.0 for 60-90 min, with the sugar oxidase reacting with the desizing product to produce hydrogen peroxide; and the second fabric bleaching step with the enzyme process generated hydrogen peroxide at 95 deg.c and pH 11.0 for 60-120min. The present invention has low power consumption, short technological process and environment friendship, and may be used to replace chemical process.

Owner:JIANGNAN UNIV

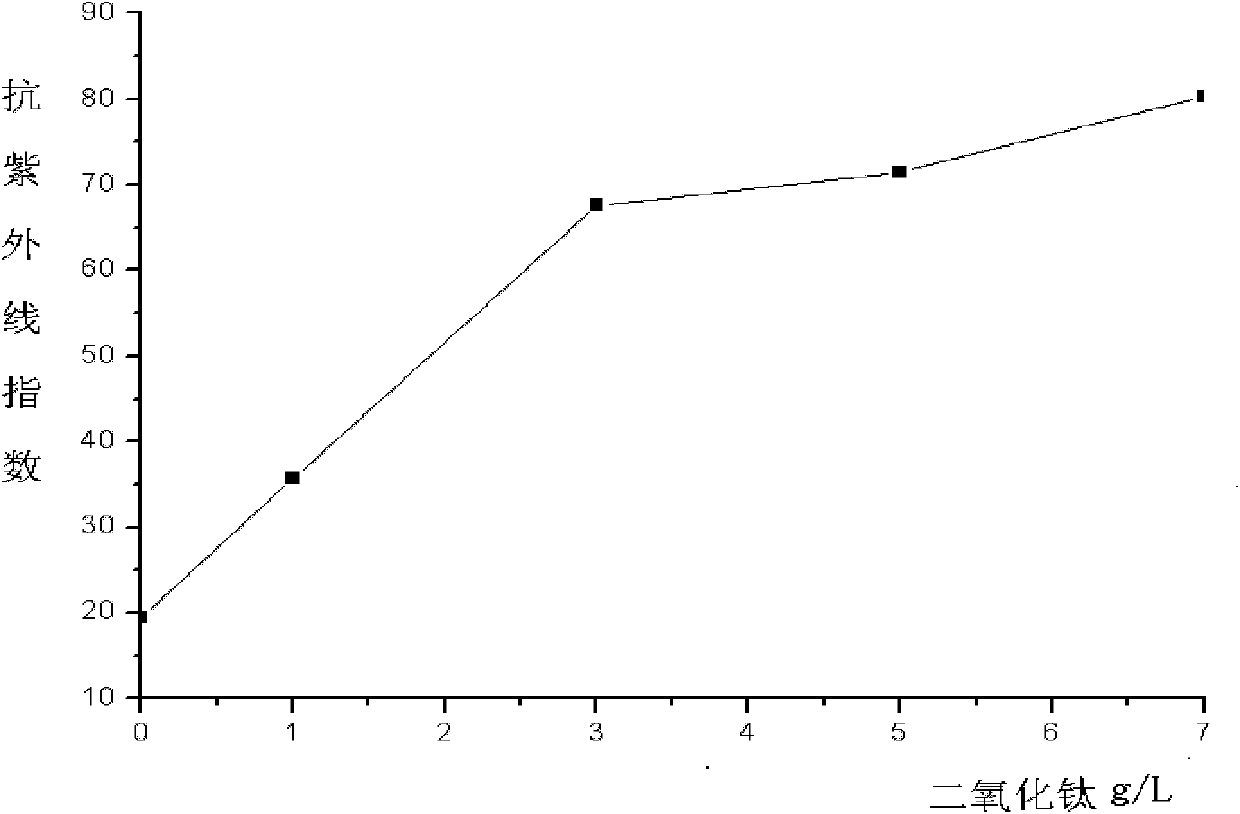

Nano metal titanium dioxide sol negative oxygen ion finishing method for fabric

InactiveCN101481874ASimple operation processLow baking temperatureVegetal fibresAnimal fibresAnhydrous ethanolOxygen ions

The invention relates to a finishing method of fabric by nano-metal titanium dioxide sol negative oxygen ions. The finishing method comprises the following steps: (1) dissolving butyl titanate in 2 / 3 of ethanol, mixing evenly, adding ethanol aqueous solution dropwise, and adjusting pH value to 2 by concentrated inorganic acid after finishing adding dropwise, and continuing to stir for 2h to obtain transparent nano-TiO2 sol, wherein, the butyl titanate, an inhibitor, an anhydrous ethanol and water are at a mol ratio of 1:1:10-30:2-4; and (2) soaking the fabric in the sol finishing agent for 3min, then predrying at the temperature of 80 DEG C, baking at the temperature of 120 DEG C for a plurality of 150s, washing and drying at the temperature of 80 DEG C. The method has simple operation process and low baking temperature of 100-180 DEG C and can help realize industrial production.

Owner:DONGHUA UNIV

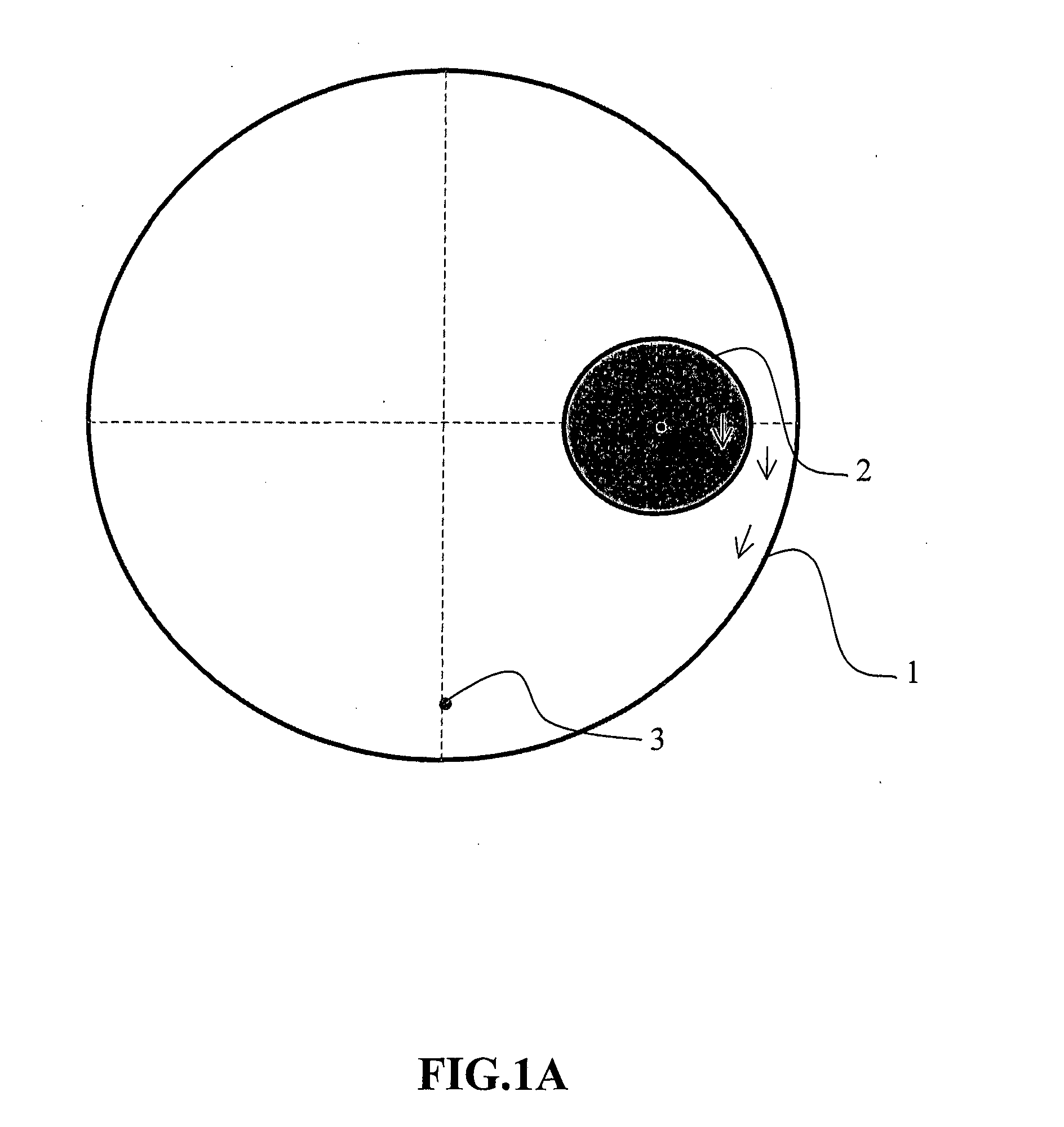

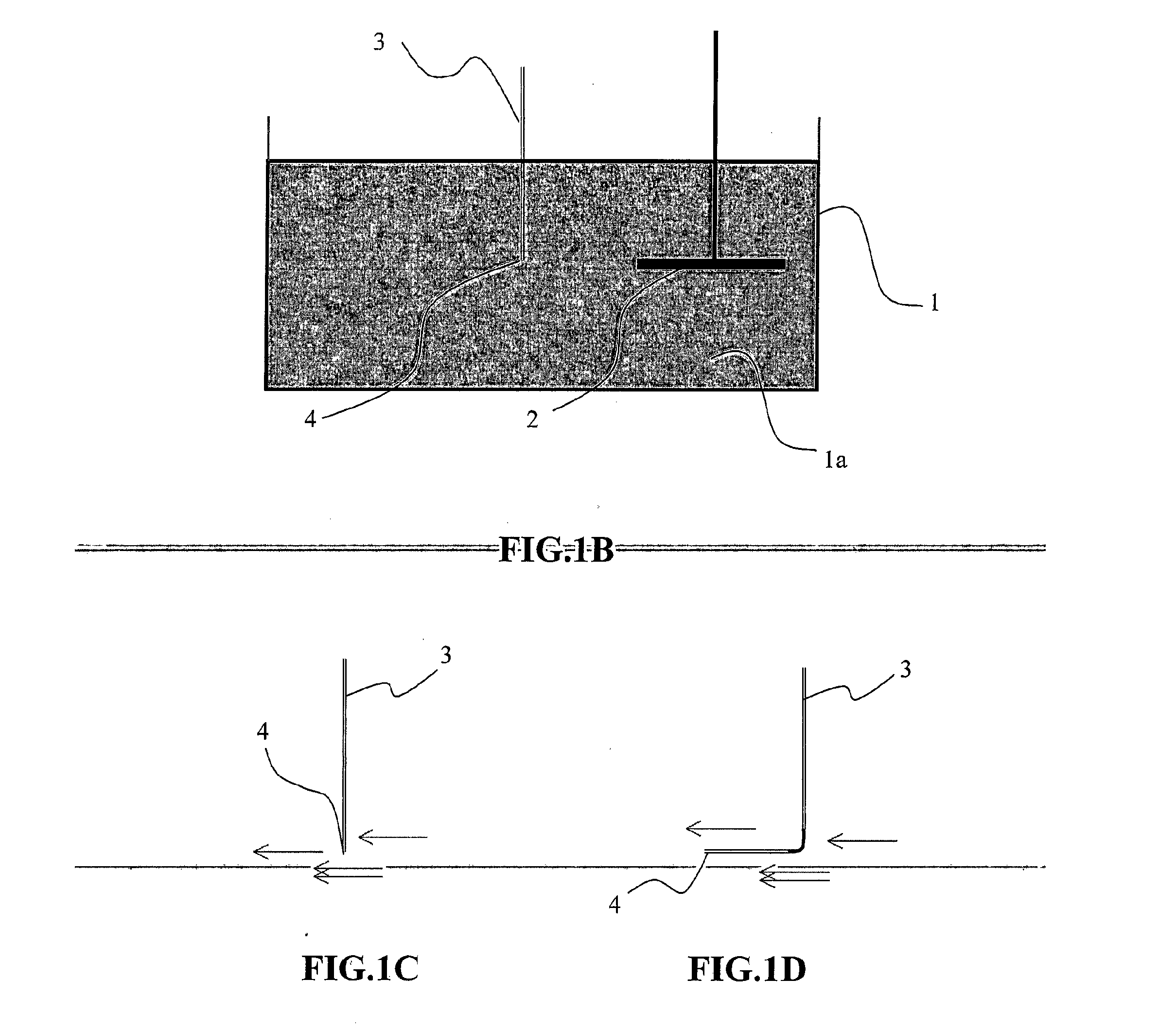

Method of Preparation of Polysaccharide Fibres, Wound Covers that Contain Them, Method of Manufacturing of Wound Covers, and Apparatus for Preparation of Polysaccharide Fibres

InactiveUS20150119783A1Low areal weightEasy to useNon-adhesive dressingsSpinning head liquid feederFiberCarboxymethyl cellulose

The invention relates to the method of the preparation of polysaccharide fibers based on hyaluronic acid, a compound comprising hyaluronic acid and metal ions, schizophylan, chitin / chitosan-glucan complex, a compound comprising chitin / chitosan-glucan complex and metal ions, internal mixture of chitin and chitosan, a compound comprising internal mixture of chitin and metal ions, sodium alginate, potassium alginate, ammonium alginate, xanthane, xanthane sodium salt, xanthane potassium salt, oxycellulose, oxycellulose sodium salt, oxycellulose potassium salt, carboxymethyl cellulose, carboxymethyl cellulose sodium salt, and carboxymethyl cellulose potassium salt, or a mixture of polysaccharides, in a non-stationary coagulation bath. Further the invention relates to covers of internal and external wounds and skin defects based on these fibers, and a method of production thereof, and the apparatus for the preparation of polysaccharide fibers.

Owner:CONTIPRO BIOTECH

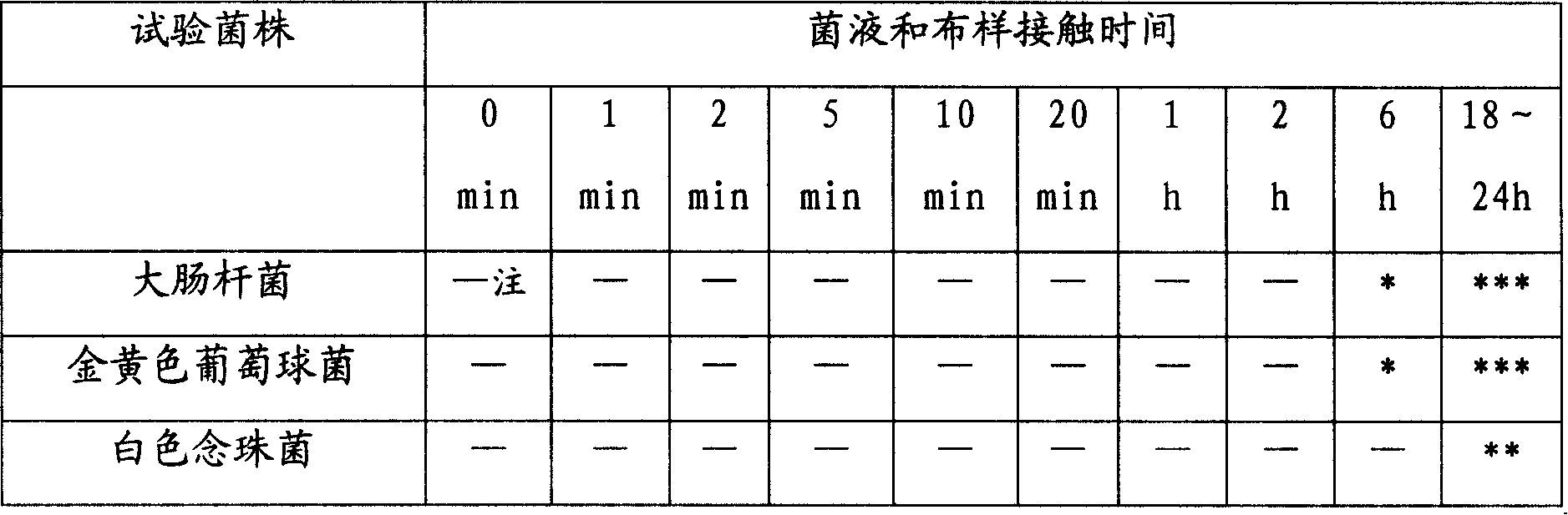

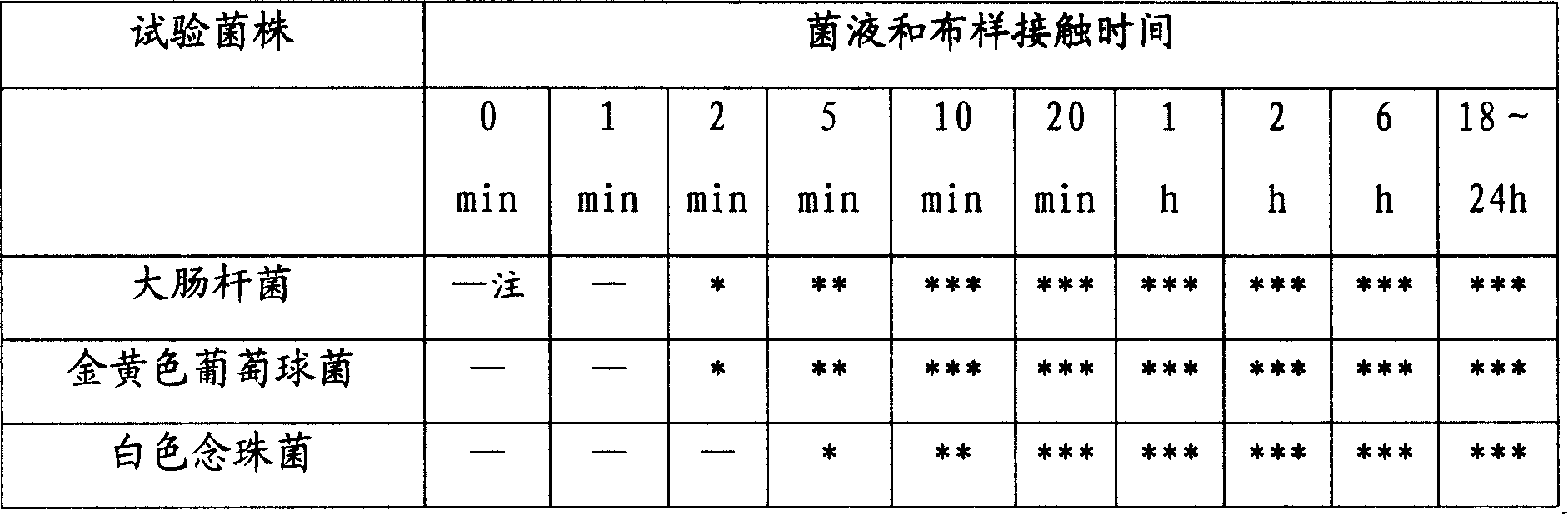

Quaternized chitosan fibers and moisture-absorbing antibacterial wound dressing

The invention belongs to the technical field of medical materials, and discloses a moisture-absorbing antibacterial wound dressing. The dressing comprises quaternized chitosan fiber fabric. The substitution degree of quaternized chitosan fibers is 0.1-1.0. The quaternized chitosan fibers are prepared through the following steps that 1, a quaternization reagent is dissolved in anhydrous alcohol or propyl alcohol to obtain a quaternization solution; 2, chitosan fibers are soaked in the quaternization solution and reacted for 1-10 h at 50-100 DEG C; 3, after the reaction is finished, washing and drying are performed to obtain the quaternized chitosan fibers. According to the moisture-absorbing antibacterial wound dressing, while antibacterial performance is improved, moisture absorption is improved, and high wet strength is maintained.

Owner:FOSHAN UNITED MEDICAL TECH

Filament based on hyaluronic acid in the form of free acid and method for obtaining it

InactiveUS20100310631A1Good biocompatibilityInduce inflammatory reactionAntibacterial agentsAntimycoticsAcetic acidAqueous solution

The present invention relates to a method for preparing by wet spinning a continuous filament based on hyaluronic acid in free acid form, notably soluble in water. The preparation method according to the invention comprises the following steps: a) preparing a spinnable aqueous solution of hyaluronic acid or of a hyaluronic acid salt, preferably a sodium hyaluronate solution; b) extruding said solution to an extrusion die; c) forming the filament by passing the extruded solution into a bath of acetic acid, concentrated to more than 80%, drawing and drying. The invention also relates to a filament based on hyaluronic acid in free acid form, said filament having swelling properties in water and physiological liquids and moreover being solubilizable in water under certain conditions.

Owner:UNIV CLAUDE BERNARD LYON 1 +1

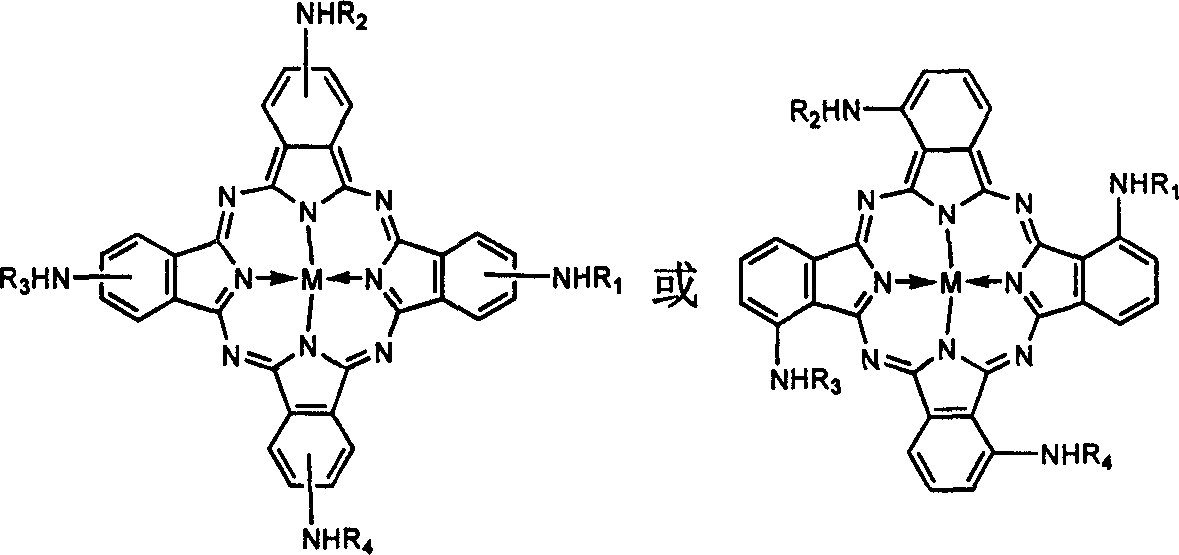

Metal phthalocyanine loaded fiber with catalytic activity and preparing method

InactiveCN1900411AAvoid gatheringGood selective adsorption functionSynthetic fibresCarbon fibresFiberTriazene

The present invention relates to a metal phthalocyanine fiber-supported metal phthalocyanine having catalytic activity and preparation method, said metal phthalocyanine with fiber or fabric through covalent bond conjoint mode combining to form supported fiber having catalytic activity. The used etal phthalocyanine is transition metal ion such as characterized in having the structure of formula 1, in which M is a Fe,Co,Cu,Mn,Rb,Al,Zn and Ni; R1,R2,R3,R4 each can be H, any of the five in formular (1), and others are all H, the construction of the radical R5 can be -NH2, -NHCOCH3, -NHSO3Na, and -NHSO3H. Said preparation method is selecting metal phthalocyanine as reactive group having triazine structure under pH 8- 11 reaction temperature 45 -95 degree centigrade condition, adding fiber or fabric to finite concentration reactivity metal phthalocyanine aqueous solution, continuously stirring, after reaction taking out fiber or fabric and respectively to make caustic washing and water washing, drying to obtain fiber-supported metal phthalocyanine or fabric. Said invention has simple equipment, easy to operate etc advantages.

Owner:ZHEJIANG SCI-TECH UNIV

Ultra-high-flux nano-fiber waterproof gas-permeable membrane and preparation method thereof

ActiveCN107326653AAvoid destructionAvoid attenuationLiquid repellent fibresNon-woven fabricsPorosityFiber

The present invention relates to an ultra-high-flux nano-fiber waterproof gas-permeable membrane and a preparation method thereof, and belongs to the field of textile technology material synthesis. The ultra-high-flux nano-fiber waterproof gas-permeable membrane is prepared from the following two components such as bifunctional group-modified nano-silica particles and a polymer nano-fiber membrane, wherein the nano-fiber membrane uses the bifunctional group-modified nano-silica particles as the adhesive between fibers, such that the rub resistance of the membrane material can be enhanced, the nano-fiber surface roughness can be increased, and the water resistance of the fiber membrane can be increased. According to the present invention, the prepared ultra-high-flux nano-fiber waterproof gas-permeable membrane has characteristics of small pore size, high porosity and enhanced adhesion structure, can provide advantages of high water resistance, high moisture permeable flux and high strength in the waterproof and moisture permeation field, has the moisture permeation flux of more than or equal to 18000 g / m<2> / d, has the water resistance of more than or equal to 100 kPa, and has wide practical application prospects.

Owner:温明昊

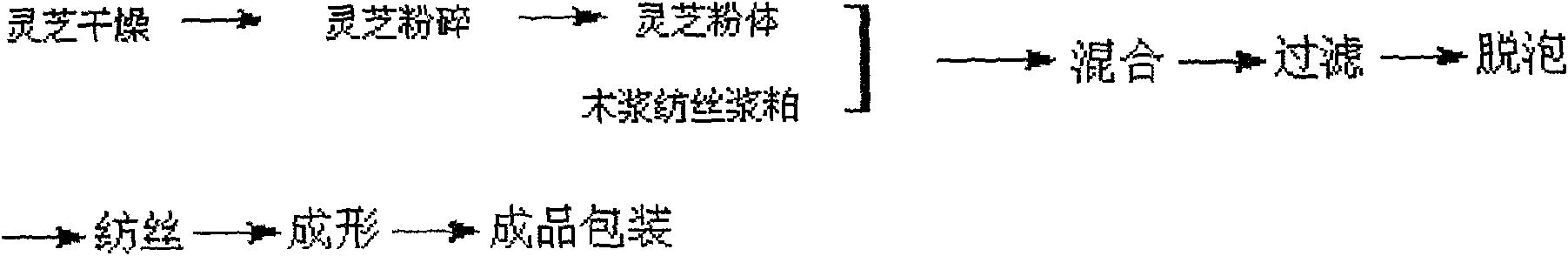

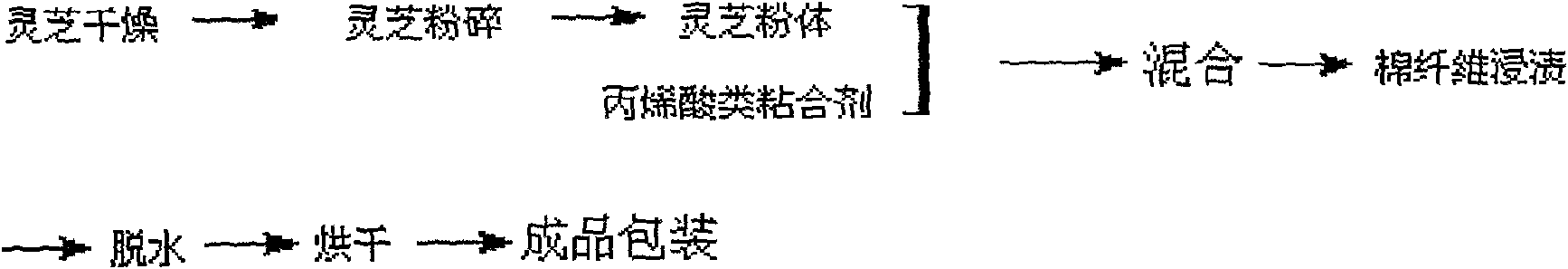

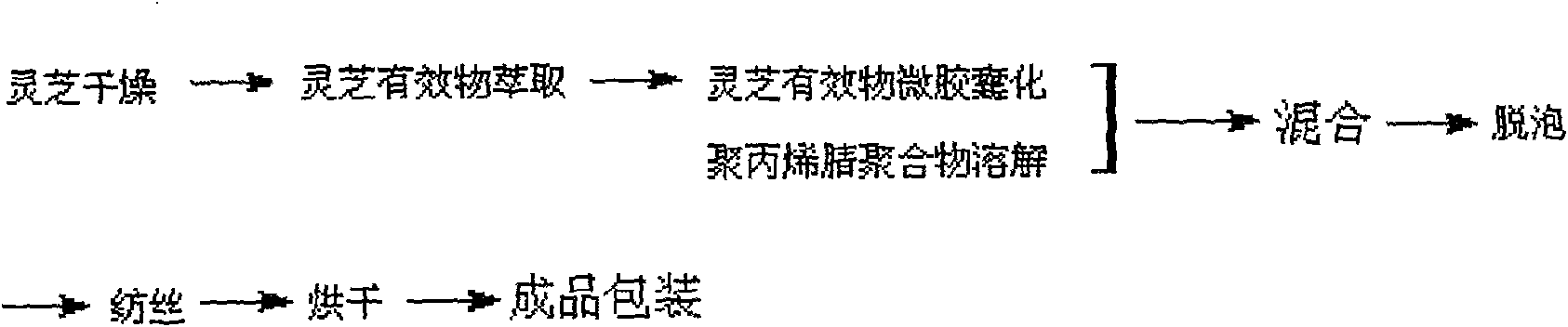

Ganoderma lucidum fibre with function of health care and preparation method thereof

InactiveCN101634055AImprove the immunityImprove immunityMonocomponent protein artificial filamentSynthetic fibresDiseaseNylon 66

The invention relates to ganoderma lucidum fibre with the function of health care and a preparation method thereof. The fibre contains traditional Chinese medicine ganoderma lucidum components; the preparation method comprises the following steps: adding the ganoderma lucidum components into regenerated cellulose fibre spinning liquid, regenerated protein fiber spinning liquid, terylene fibre spinning liquid, orlon fibre spinning liquid and nylon 6 or nylon 66 fibre spinning liquid and adopting conventional spinning to obtain the ganoderma lucidum fibre. The fibre can reinforce the resistance and immunity of an organism, eliminates in-vivo free radicals, resists radiation and has the effects of preventing and treating diseases, building the body, strengthening the body and prolonging the life; the invention has simple preparation method and is suitable for industrialized production.

Owner:陈对范 +1

Flame-proof treatment method for light and thin natural fiber material

ActiveCN101016694AImprove flame retardant performanceMaintain original sexualityHeat resistant fibresNatural fibresUltra fineCleansing Agents

A flameproof treatment method of thin natural fiber material comprises that ultra-fine fiber fabric, poaching treatment or dyeing, low-temperature expansion flameproof treatment, baking crosslink, oxidization, neutralization, washing with water, checking final product, wherein the low-temperature immersion condition comprises 15-30Deg. C and 10-30s, the expansion treatment temperature is 35-60Deg. C for 20-40min, the baking crosslink temperature is 145-185Deg. C for 2-8min. Then the invention uses cleaning agent to process the ultra-fine flameproof fiber, while the cleaning agent is nanometer TiO2 or / and ZnO whose mass ratio is 1-12.0wt%, while the disperser is 0.2-1.5wt% as nanometer composite disperser to be treated in water solution.

Owner:NANTONG JINSHAIDA SPECIAL FAB CO LTD

Ready-made clothes after-finishing process

InactiveCN101265661AImprove waterproof performanceGood oil proofDry-cleaning apparatus for textilesNatural fibresEngineeringSoil resistance

The invention relates to a post-finishing process for ready-made clothes, which adopts the one-step method of one-bath in the following working procedures of desizing, unwatering, soaking in treatment fluid, re-drying, pressing and baking for setting, and cooling. In preparing the treatment fluid, resin 5-10%, OLEOPHOBOL 4-8%, penetrant 0.1-0.25%, and catalyst 1-2.5% are included. After finishing, the ready-made clothes with no ironing and washing for 30 times can achieve the crease shedding of level 4, water resistance of level 5, oil resistance of level 5, and soil resistance of level 5, thereby having excellent water-washing serviceability, durability and shrink resistance. The formaldehyde content is lower than 75ppm. The post-finishing process has the advantages of little pollution, obvious effects of water resistance, oil resistance, soil resistance, and no ironing, good durability and so on, thereby being applied to the ready-made clothes made of natural fibers such as cotton, hemp, tencel and so on.

Owner:翁卫东

Method for surface modification of super-high molecular-weight polyethylene fiber surface

InactiveCN101024919AImprove surface adhesionNo damage to mechanical propertiesNatural fibresFiberPolymer science

The invention relates to an ultrahigh molecular weight polythene fiber surface modifying method, comprising: 1. placing ultrahigh molecular weight polythene fiber in organic iron sulfonate solution to soak for 15-60 min, where the organic iron sulfonate solution is iron trichloride solution with mass concentration of 18-60%, or one of the iron toluenesulfonate solution, ferric tri(dodecanesulfonate), iron 2-acylamido-2-demthyl-1-propanesulfonate, or iron morphine propanesulfonate solution with mass concentration of 5-40%, and the organic iron sulfonate solvent is normal butyl alchohol or water; 2. placing the soaked polythene fiber in vacuum device with vacuum of 650-730mmHg in the proportion of 100-120 ml of intrinsic conducting polymer monomer per kg of fiber to process at 25-85deg.C for 0.5-8 h, and making it, where the intrinsic condcuting polymer monomer is pyrrole or thiophene with purity not lower than 99%. And the method can effectively surface adhesiveness of ultrahigh molecular weight polythene (UHMWPE) fiber and besides, keep the original strength of UHMWPE and the process is simple.

Owner:CHINA PETROLEUM & CHEM CORP +1

Bedding fabric with antibacterial and cool functions and post-finishing process thereof

InactiveCN103132196AGood hygroscopicityRefreshingSolvent-treatmentBiochemical fibre treatmentPolymer scienceSpinning

The invention discloses bedding fabric with antibacterial and cool functions and a post-finishing process thereof. The bedding fabric is formed by weaving blended yarn with antibacterial and cool functions. The blended yarn with antibacterial and cool functions is formed by blending linen fiber, chitin fiber staple and polyester filament yarn according to sirofil spinning technology. In the blended yarn with antibacterial and cool functions, the linen fiber and the chitin fiber staple are both wrapped on the surface of the polyester filament yarn. The post-finishing process includes the following steps: desizing and scouring-singeing-bleaching repeatedly through chlorine oxygen-cellulase washing-dying-washing and gentle stretching-preshrinking-finished products. The fabric finished products has cool touch, excellent antibacterial performance and good crease resistance. Compared with pure linen fabric, the fabric is soft. Simultaneously compared with chitin fabric, the fabric has a certain body and is appropriate for bedding fabric in spring and summer.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

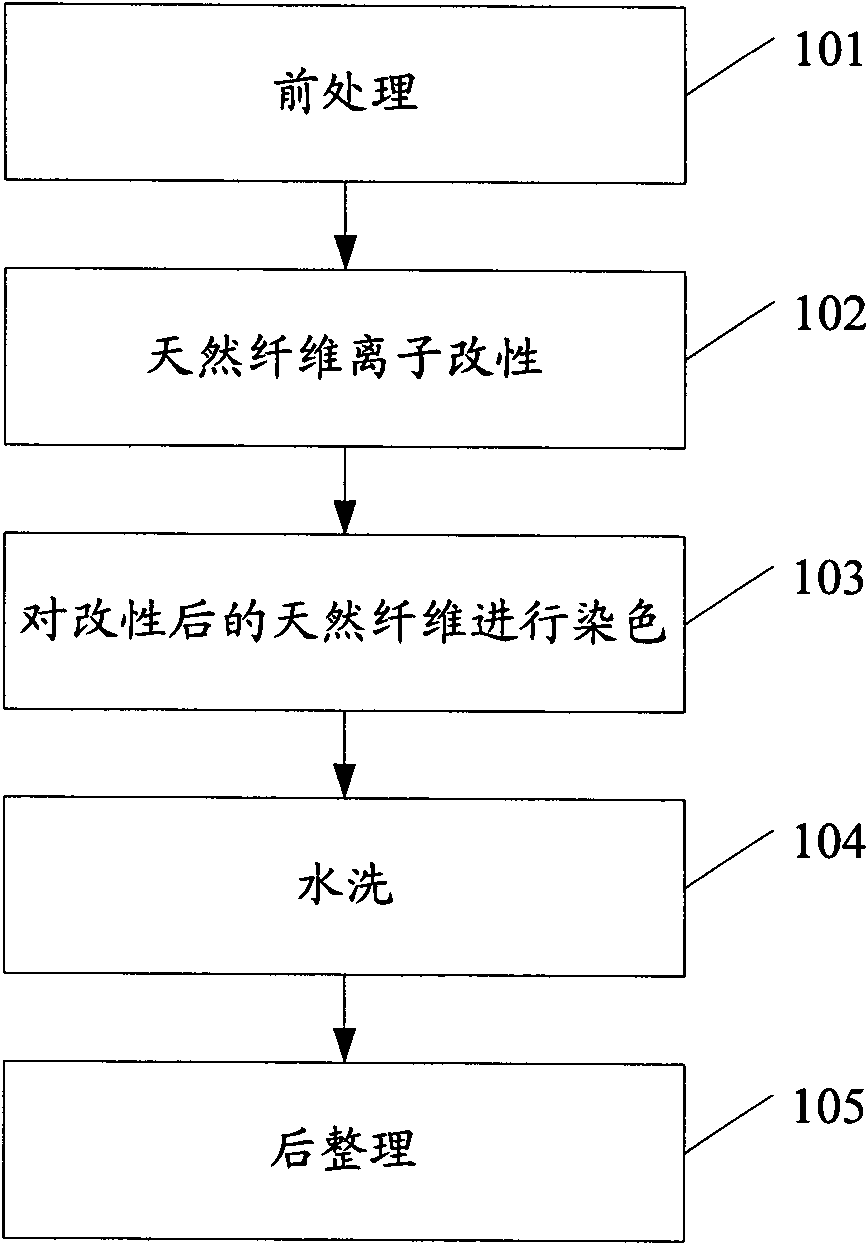

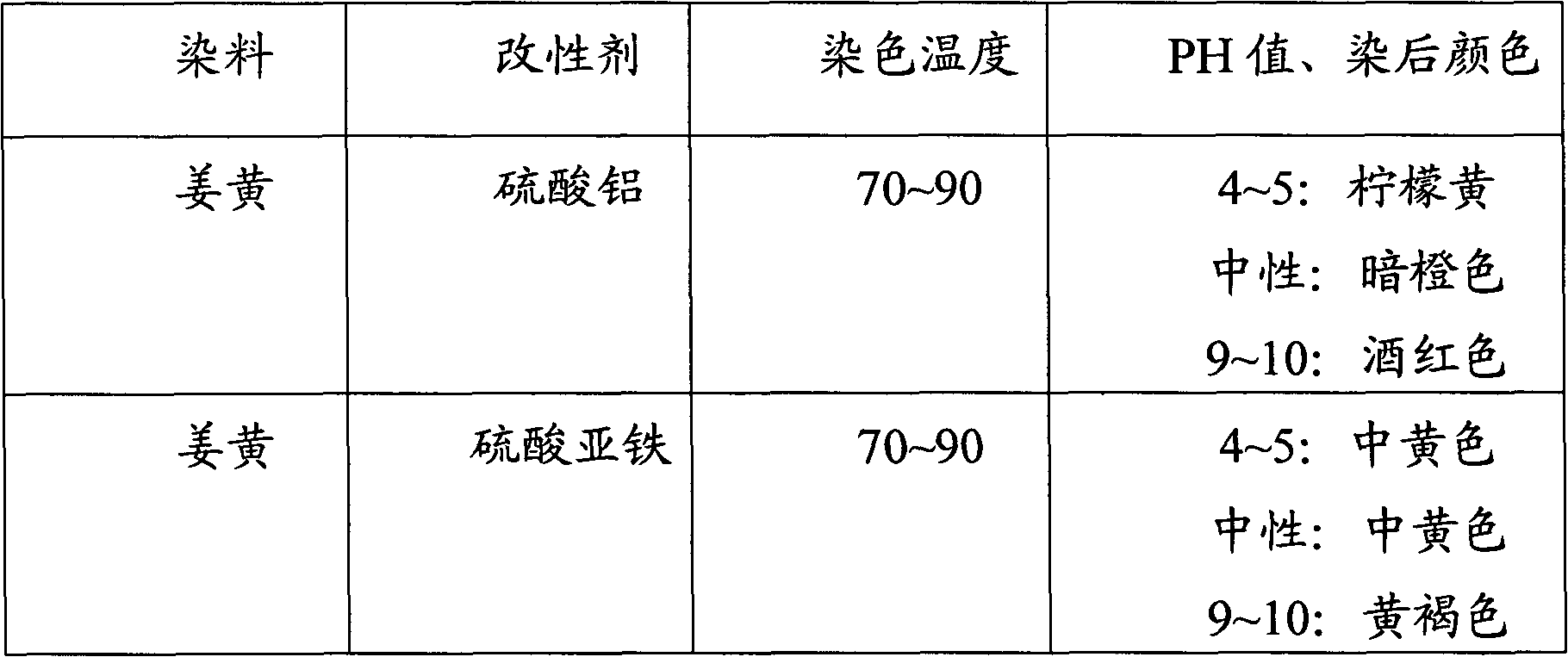

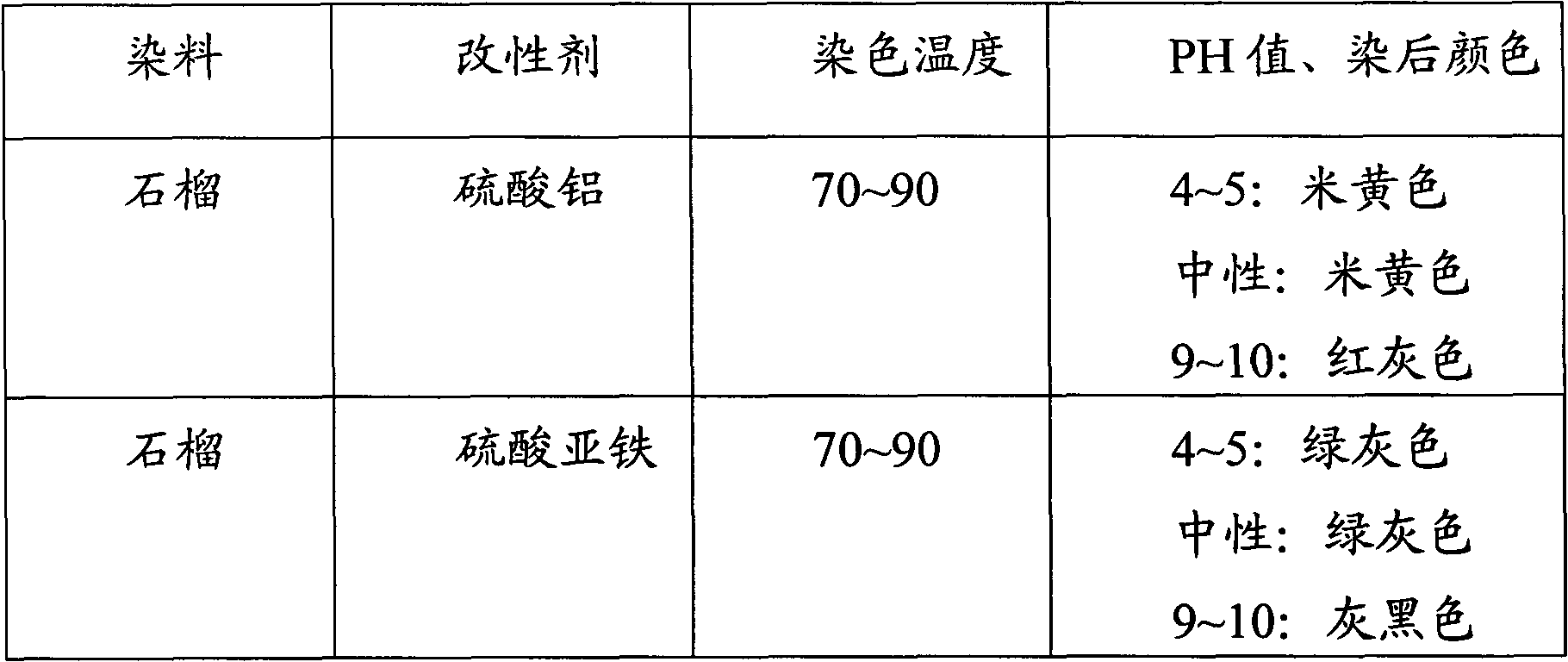

Textile product printing and dyeing method

The invention provides a textile product printing and dyeing method including: subjecting natural fibers to ionic modification; adding aluminum salt or ferric salt modifiers when the water temperature in a dyeing vat is 45-55 DEG C, increasing the temperature to 70-90 DEG C and holding; dyeing the modified natural fibers; and adding natural dye when the water temperature in the dyeing vat is 40-60 DEG C, regulating the pH (potential of hydrogen) to 3-10, increasing the temperature to 70-99 DEG C and holding. Textile products printed and dyed by the textile product printing and dyeing method are environment-friendly and uniform in dyeing without fading.

Owner:河南染匠科技有限公司

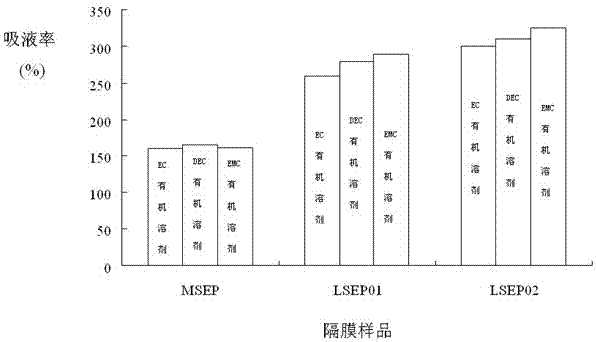

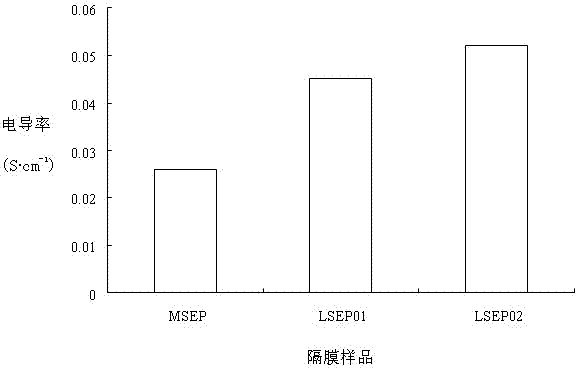

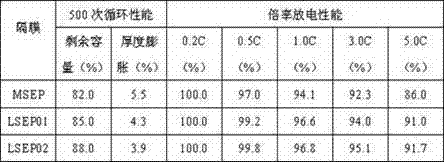

Coating for power lithium battery diaphragm, power lithium battery diaphragm and preparation thereof

ActiveCN102433745AHigh liquid absorptionHigh tensile strengthCell component detailsNatural fibresNano siliconN dimethylformamide

The invention provides a coating for a power lithium battery diaphragm, a power lithium battery diaphragm and preparation thereof. The coating for the power lithium battery diaphragm which takes wet nonwoven cloth as a base material is characterized by comprising 5-20% (wt) chlorinated polyvinylidene fluoride, 10-20% (wt) glycerol, 60-80% (wt) N, N-dimethylformamide, 2.5-5% (wt) sodium hypochlorite and 2.5-5% (wt) nano-silicon carbide whiskers. A method for preparing the coating for the power lithium battery diaphragm which takes the wet nonwoven cloth as the base material is characterized bycomprising the following specific steps of: proportionally dissolving chlorinated polyvinylidene fluoride in the mixed solution of glycerol, sodium hypochlorite and N, N-dimethylformamide to form thick transparent fluid; adding the nano-silicon carbide whiskers to the thick transparent fluid and stirring the same until the whiskers are completely homogenized and dispersed, thereby obtaining the coating for the power lithium battery diaphragm which takes the wet nonwoven cloth as the base material. The coating is capable of obviously improving the absorbency, electrical properties, high temperature shrinkage resistance and tensile strength of the power lithium battery diaphragm.

Owner:CHINA HAISUM ENG

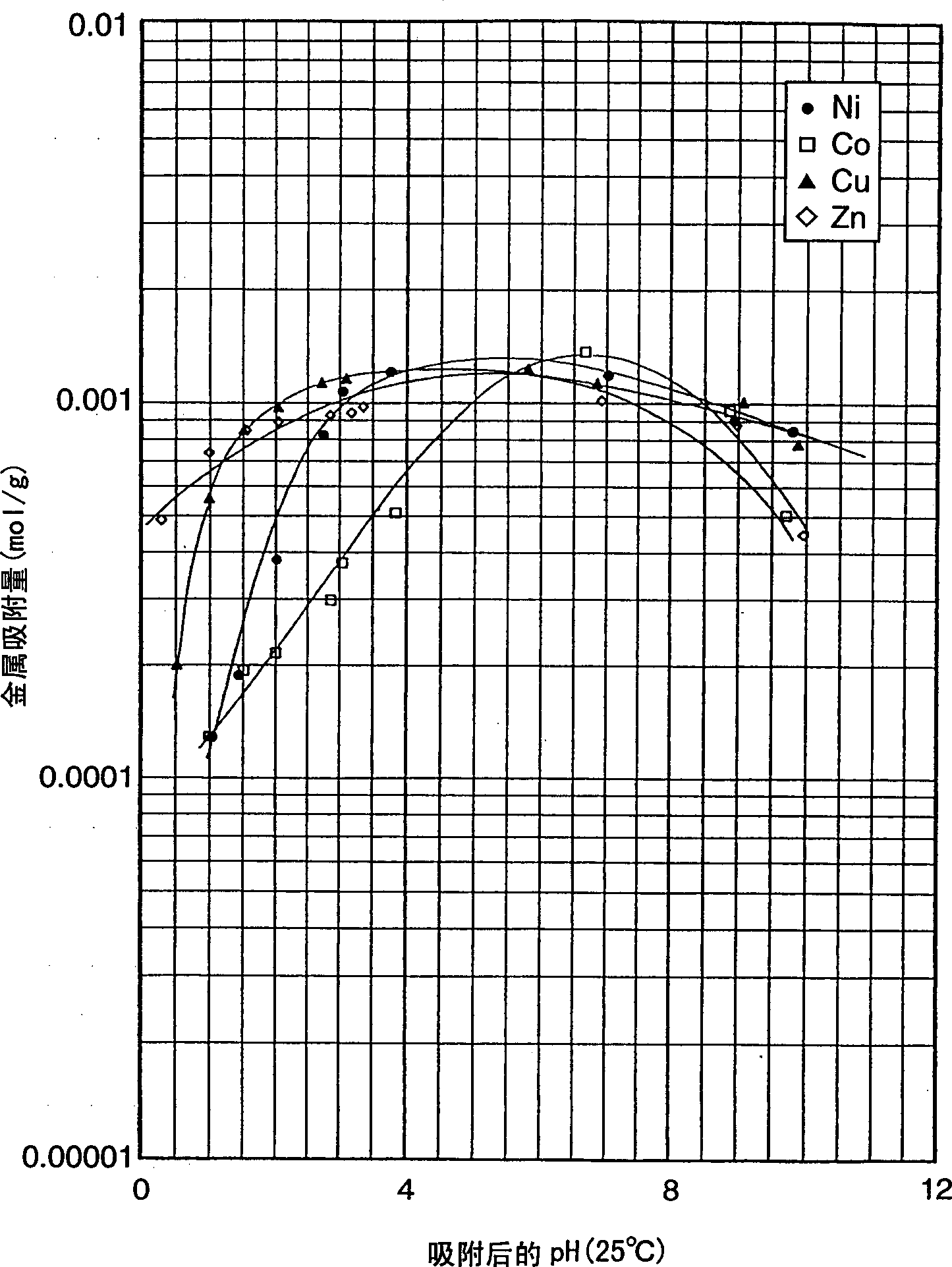

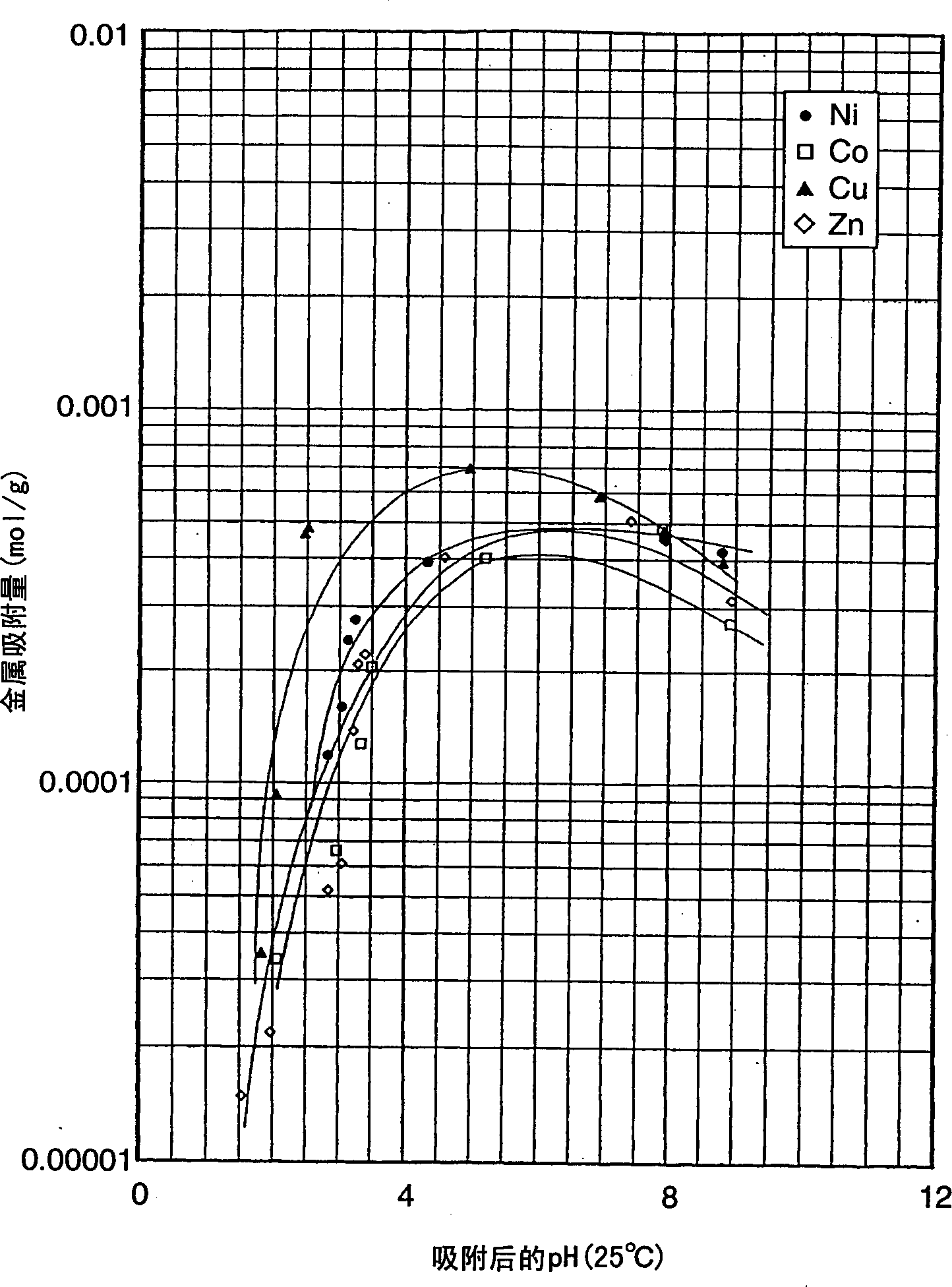

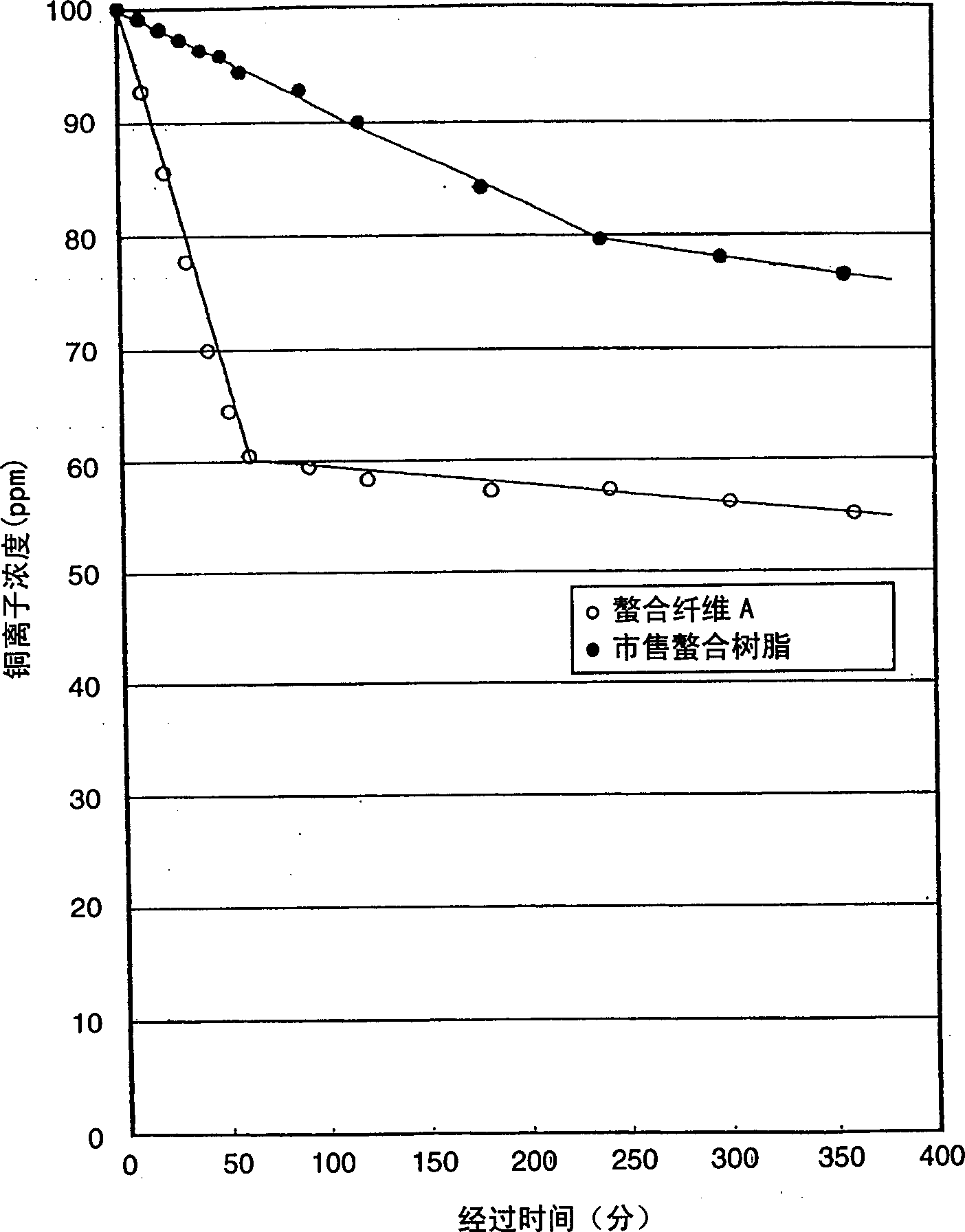

Fiber capable of forming metal chelate process for producing the same, method of trapping metal ion with the fiber, and method chelate fiber

InactiveCN1341176AIon-exchange process apparatusOther chemical processesThiocarboxylic acidRegenerating fibers

A fiber capable of forming a metal chelate and a process for producing the same are disclosed, wherein the fiber is characterized in that at least one metal chelate-forming compound selected from the group consisting of aminodicarboxylic acids, aminocarboxylic acids, thiocarboxylic acids and phosphoric acid, which are reactive with a glycidyl group, is bonded to a molecule of a natural fiber or regenerated fiber through a crosslinkable compound having a reactive double bond and a glycidyl group in its molecule. There are also disclosed a method of capturing metal ions using the fiber and a metal chelate fiber which can effectively make use of the characteristics of the metals and can be easily discarded or incinerated.

Owner:KIRESUTO +1

Textile dyeing and printing method

The invention discloses a textile dyeing and printing method, which comprises the steps of: placing natural fiber in a dye vat with a bath ratio of 3:7, raising the water temperature to 65-75DEG C, adding 5-10g / L ethyl triethoxysilane, 20-25g / L aluminum sulfate and 15-20g / L of ferrous sulfate, raising the temperature to 92-94DEG C, and conducting heat preservation for 1-2 hours to complete modification of natural fiber ions; putting the modified natural fiber into a dye vat with a bath ratio of 2:7, raising the water temperature to 50-55DEG C, adding 5g / L triethanolamine, 30g / L of a natural dye and 10g / L of a salt, adjusting the PH to 2-2.5, raising the temperature to 60-65DEG C at a rate of 15-20DEG C / min, and performing heat preservation for 3-4 hours, thus completing dyeing. The textile printed and dyed by the method provided by the invention has the advantages of environmental protection, uniform dyeing, and color fastness.

Owner:CHANGSHU QINDA KNITTING PRINTING & DYEING

Multi-fibre knitted fabric

InactiveCN102454111ADifferent finenessDifferent lengthWeft knittingBiochemical fibre treatmentEngineeringMilk protein

The invention relates to multi-fibre knitted fabric, which is obtained by taking green multi-fibre spinning, soybean fibre spinning and milk protein fibre spinning as raw materials, adopting one or more tissues of a primary tissue, a variable tissue and knitted dobby, processing shell fabric obtained later by using bio-enzyme, and coating a nano protection solution on the surface. According to the multi-fibre knitted fabric disclosed by the invention, the green raw materials are interweaved, so that advantages of various raw materials are complementary; the multi-fibre knitted fabric corresponds with requirements of comfortableness, functionality, health and green of the new generation of textiles; and the multi-fibre knitted fabric can be widely applied to manufacturing various knitted clothing.

Owner:CHANGSHU XINTEDU GARMENTS

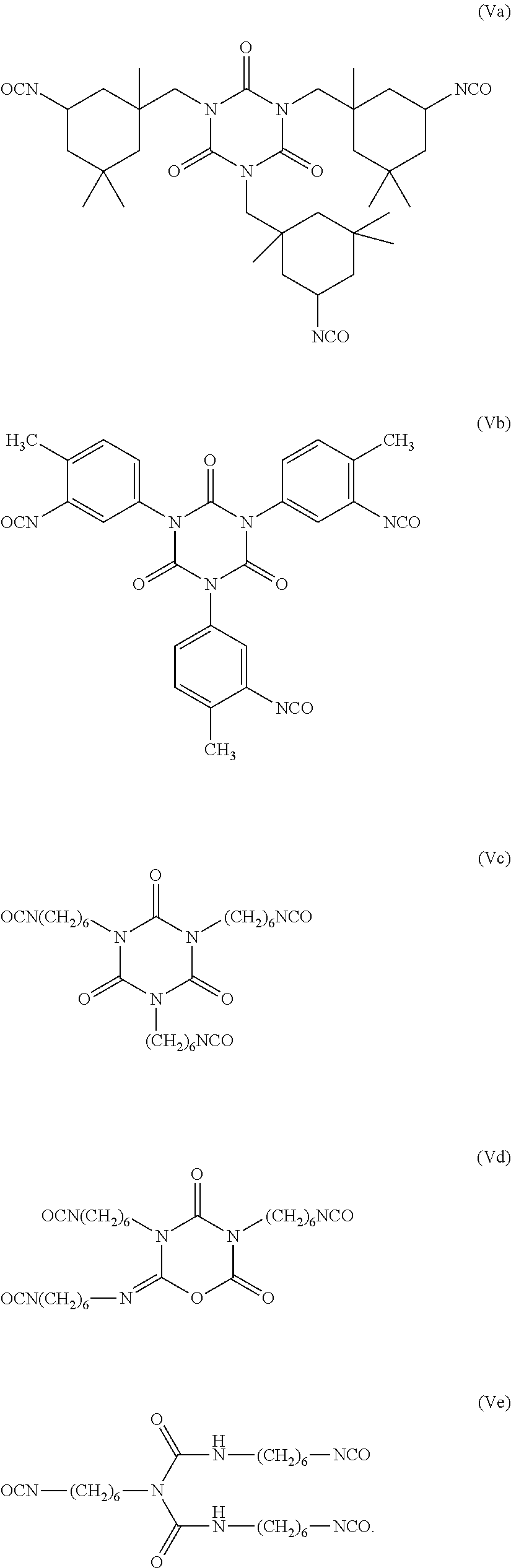

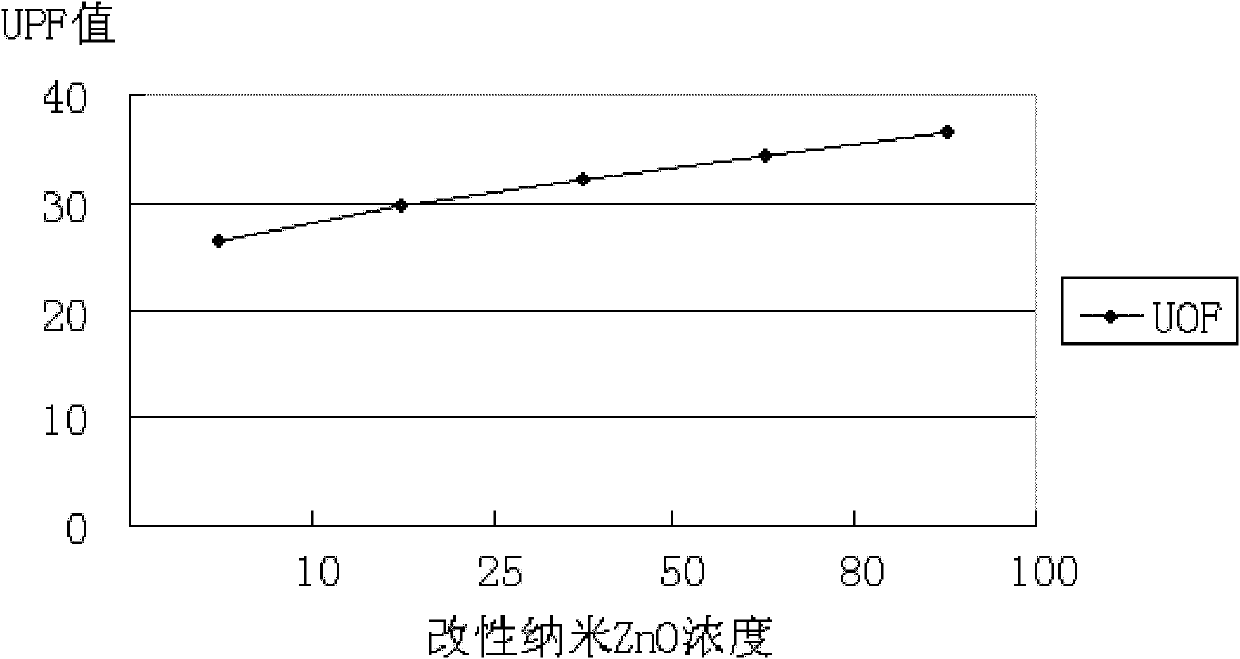

Modified nano oxide, preparation method and application method of self-emulsifying dispersion liquid thereof

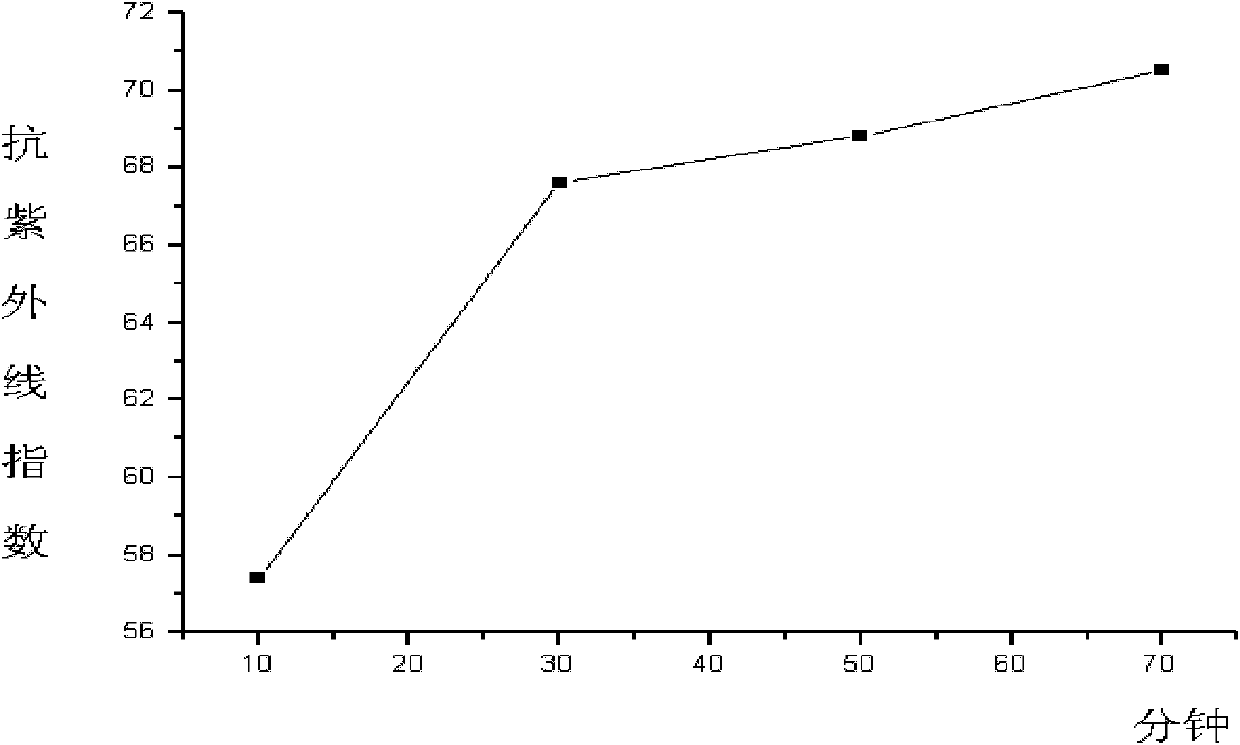

InactiveCN102277722AGive full play to the surface effectStrong and long-lasting UV shielding effectNatural fibresUltravioletNatural fiber

The invention discloses a modified nano-oxide, which is a product with the following structural formula: wherein: A is a nano-oxide, which is nano-titanium dioxide, nano-zinc oxide, silver-doped nano-titanium dioxide, silver-doped nano-zinc oxide, nano-oxide One of silicon, or a compound of two of them; R1 with two isocyanates is a diisocyanate, including TDI, MDI, HDI, NDI, IPDI; Y is a blocking agent, including ethanol, Sodium bisulfite, caprolactam, phenol; n is 10-135. The invention also discloses a preparation method and a use method of the self-emulsifying dispersion liquid of the modified nanometer oxide. The self-emulsifying dispersion of modified nano-oxides prepared by the above technical scheme can be used for functional finishing of textiles, so that natural fiber textiles have anti-ultraviolet, infrared absorption and antibacterial properties after finishing.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Ultra-thin ultra-dryness nanometer fiber mask paper and preparation method

PendingCN109853130AReduce thicknessReduce usageFilament/thread formingNon-woven fabricsWater basedFiber

The invention discloses ultra-thin ultra-dryness nanometer fiber mask paper and a preparation method, and relates to the technical field of mask materials and preparation. The ultra-thin ultra-drynessnanometer fiber mask paper is mask paper with the thickness being 0.04-0.12 mm and the water content being 4-6%. The paper is prepared from, by weight, a nanometer fiber skeleton made of a polymer carrier including a non-water-soluble polymer, and a gel substrate and functional substances attached to the nanometer fiber skeleton. The mask paper is similar to paper in appearance, the water contentis quite low, no corrosion remover needs to be added, the phenomenon that skin irritation, sensitivity and other adverse effects are caused by corrosion removers is avoided, and the safety is bettercompared with a traditional water-base mask. The non-water-soluble or unstable functional ingredients are attached to the nanometer fiber adopting the macromolecular polymer as the carrier, the functional ingredient stability is greatly improved, and the problems that the ingredients are compatible difficultly, easy to degrade and not high in bioavailability are solved.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Hydrogel type alginate fiber film cloth and production method thereof

ActiveCN108998858AEffective control of calcium contentEffective control of sodium contentBiochemical fibre treatmentAlginate artificial filamentsFiberCalcium alginate

The invention relates to a hydrogel type alginate fiber film cloth, and also relates to a production method of the hydrogel type alginate fiber film cloth. The production method of the hydrogel type alginate fiber film cloth comprises the following steps: (1) preparing a sodium alginate spinning solution; (2) performing wet spinning on the spinning solution in a coagulation bath; (3) preparing anaqueous sodium alginate solution having a mass fraction of 20-30%; (4) immersing calcium alginate nascent fibers in the aqueous sodium alginate solution having the mass fraction of 20-30%; (5) squeezing out water, immersing the nascent fibers in an ethanol-water solution, and squeezing out water; (6) preparing a chitosan solution having a mass fraction of 2%; (7) immersing the hydrogel type seaweed fibers obtained in step (5) in the chitosan solution; and (8) squeezing out water, and performing dying and winding processes to obtain the hydrogel type alginate fiber film cloth. The hydrogel typealginate fiber film cloth has a high strength, can be rapidly aggregated when meeting water, and can be applied to the field of hydrogel masks.

Owner:青岛海赛尔新材料科技有限公司

Anti-ultraviolet swimsuit fabric

The invention discloses an anti-ultraviolet swimsuit fabric. According to the formula, the swimsuit fabric consists of the following components: cotton fibers, chitin viscose fibers, polyvinyl alcohol fibers, nano bamboo charcoal fibers, spandex fibers, polyester drawn textured yarns and an anti-ultraviolet finishing agent. The swimsuit fabric, which is made in accordance with the formula, is good in elasticity, high in air permeability, antibacterial, radiation-resistant, soft, wear-resistant and acid and alkali-resistant, sweat-resistant, seawater-resistant, dry-cleaning resistant, smooth and anti-static; a swimsuit, which is made from the swimsuit fabric, is comfortable to wear, breathable, and is capable of killing bacteria and resisting ultraviolet rays; and meanwhile, the swimsuit is excellent in slimming and shaping performances.

Owner:NANTONG JIANWEI YARN DYED CLOTHING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com